Patents

Literature

2694results about "Vegetable peeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

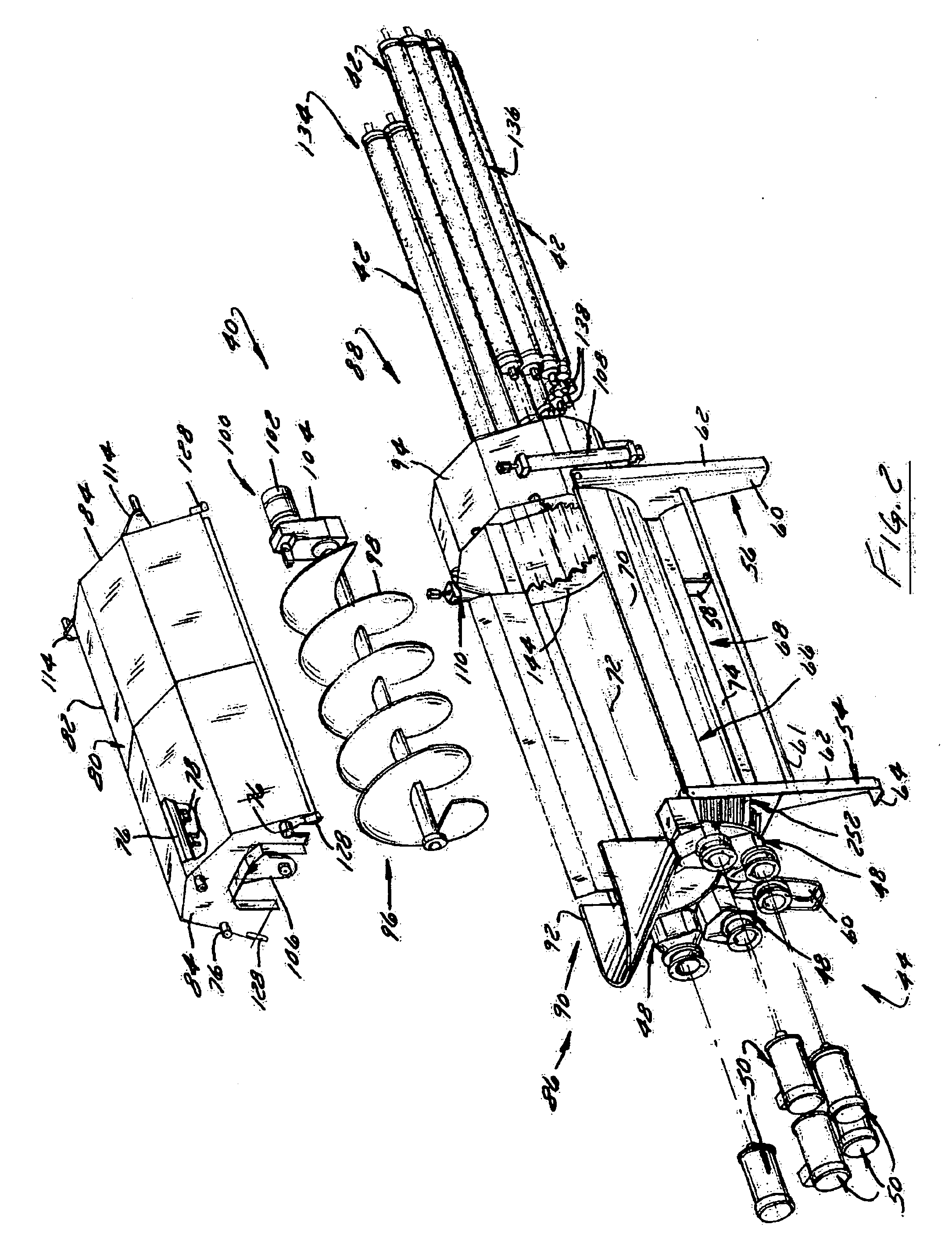

Apple/potato peeler

InactiveUS6854383B2Easy to optimizeEffective peelingFruit coringFruit stoningEngineeringKnife blades

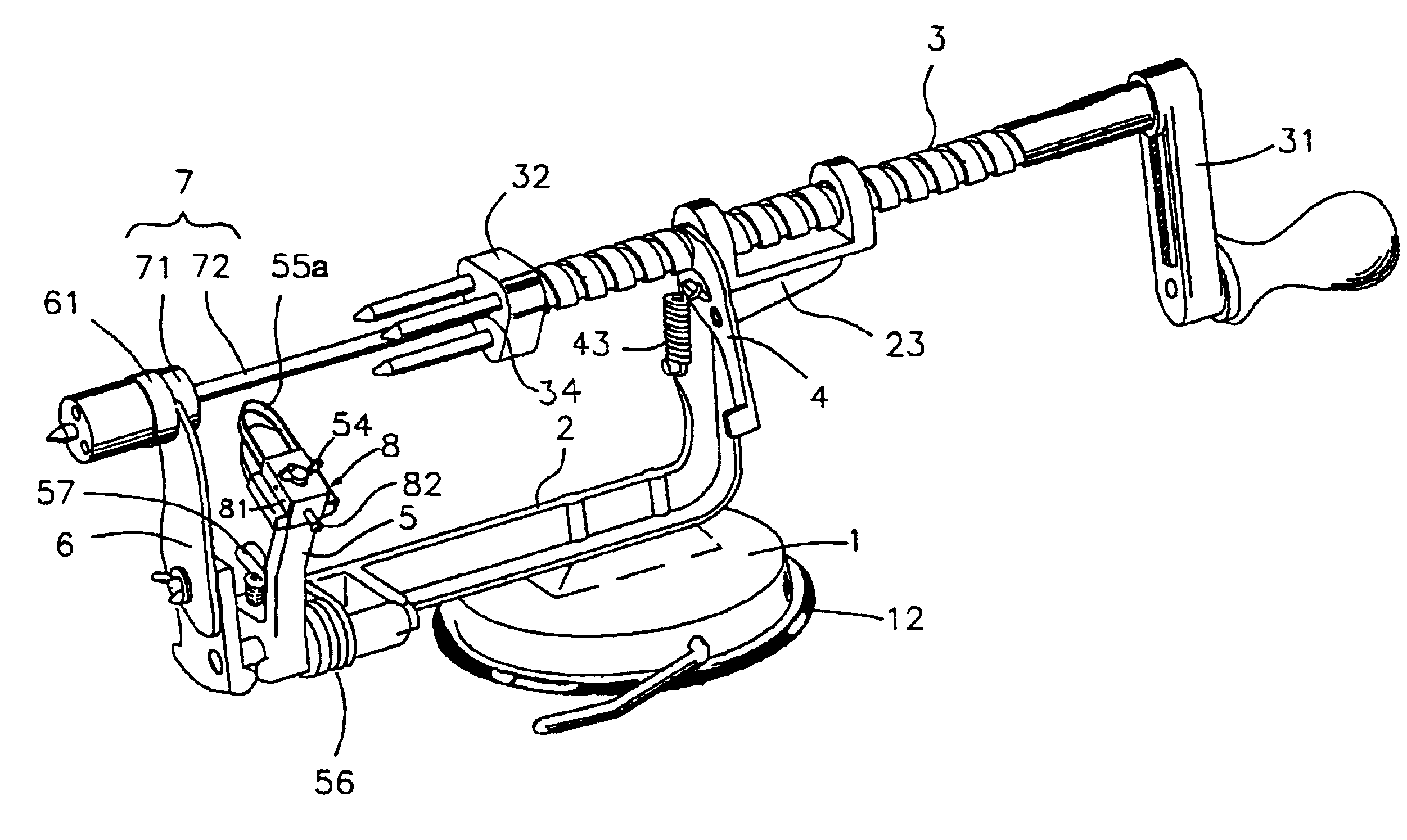

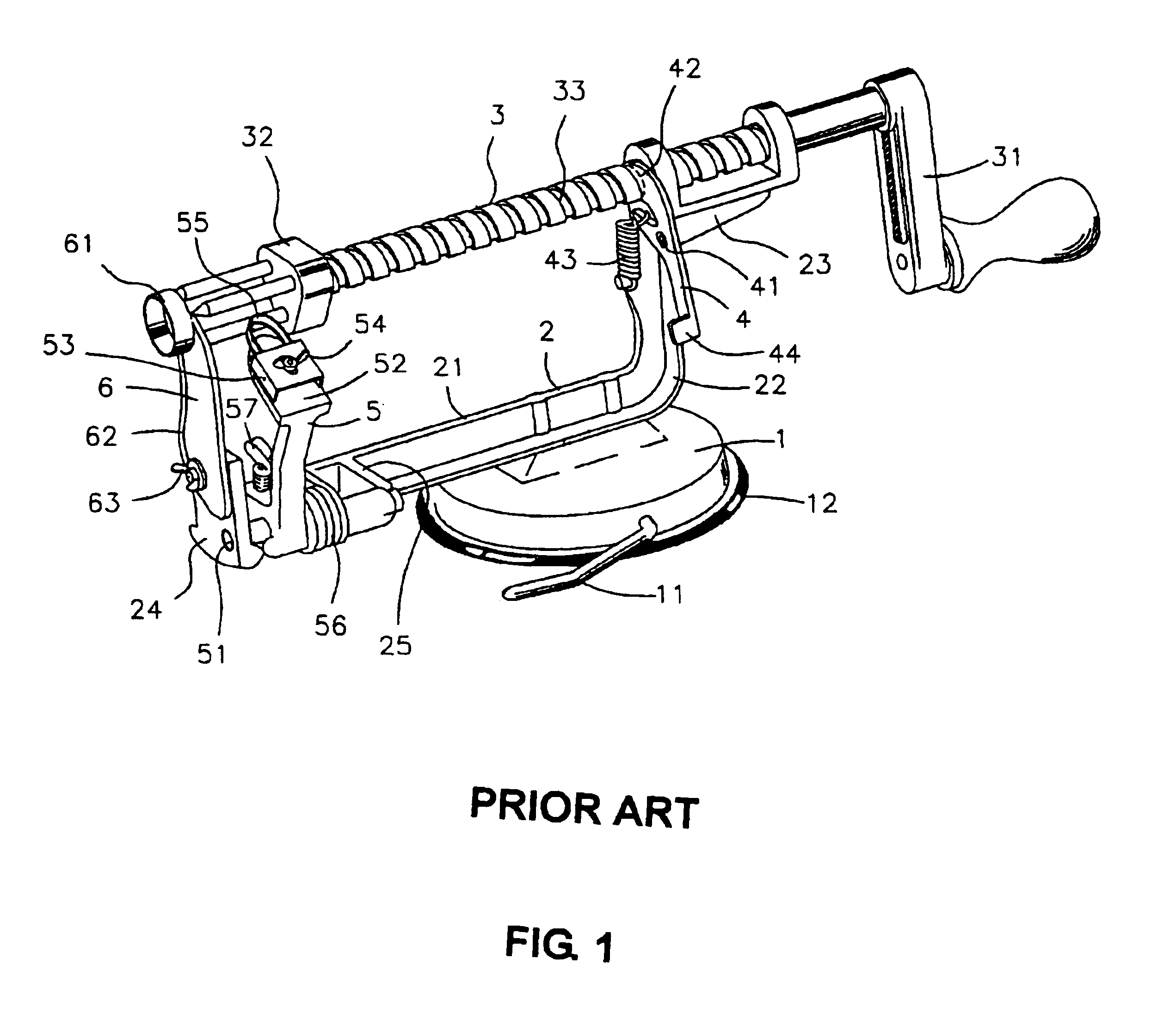

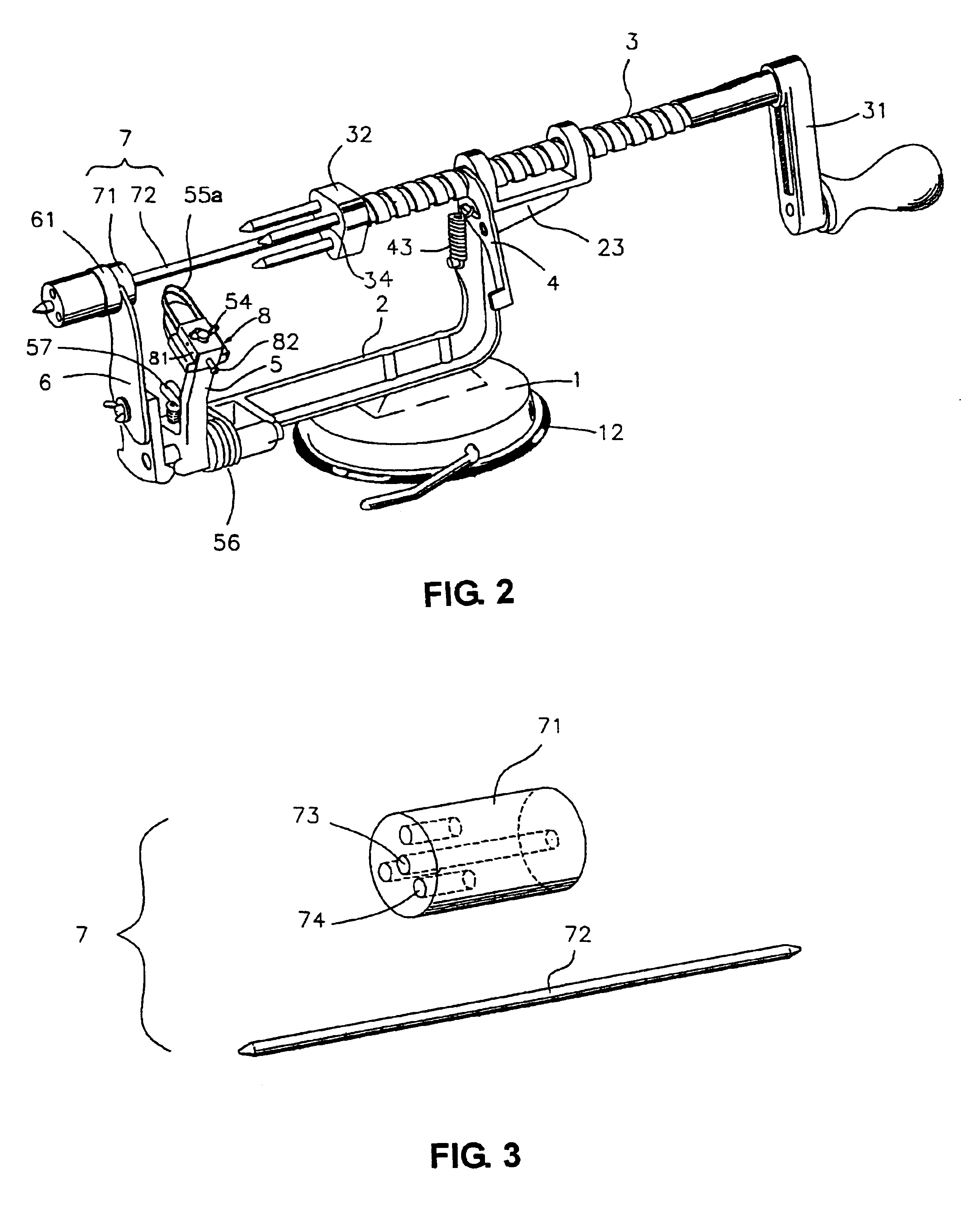

An apple / potato peeler. The peeler includes a base, a main frame mounted to a slightly L-shaped structure on the base, a rotatable and axially movable screw horizontally supported on a screw support member on a vertical frame member disposed at the rear of the main frame, a 3-prong fork fixed to the front end of the screw, a guide piece pivotally mounted on the vertical frame member and being releasably engageable relative to a screw channel of the screw, a resiliently movable peeling arm fore-and aft swingeable pivoted to the front part of the horizontal frame member of the main frame, a U-shaped peeling blade fixed to the upper end of the movable peeling arm by a blade positioning device, and a coring / slicing blade fixed to the front end of the horizontal frame member for cutting flesh of a vegetable fruit held by the 3-prong fork if the screw into continuous spiral slices and for coring fruit.

Owner:WANG PHILIP

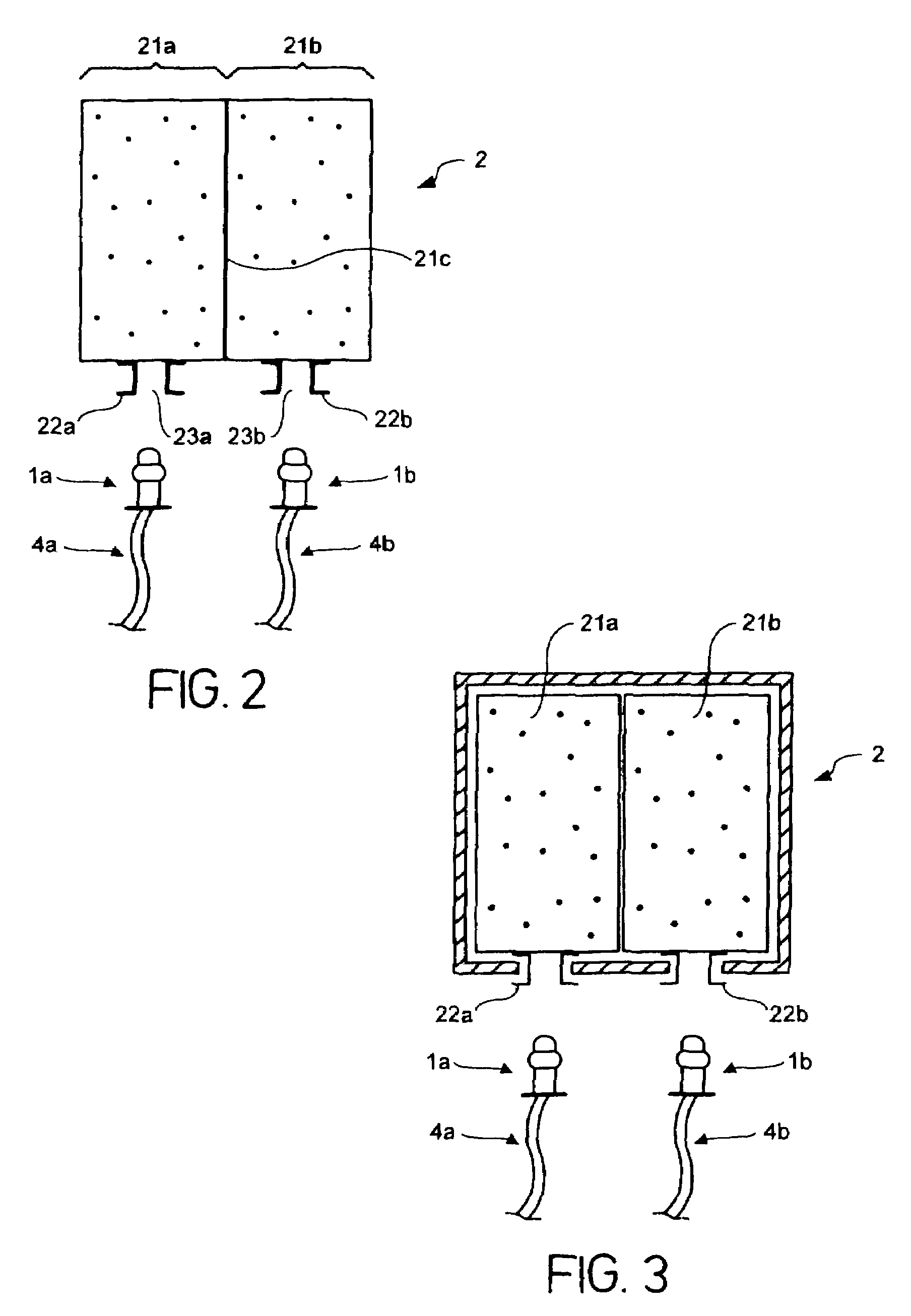

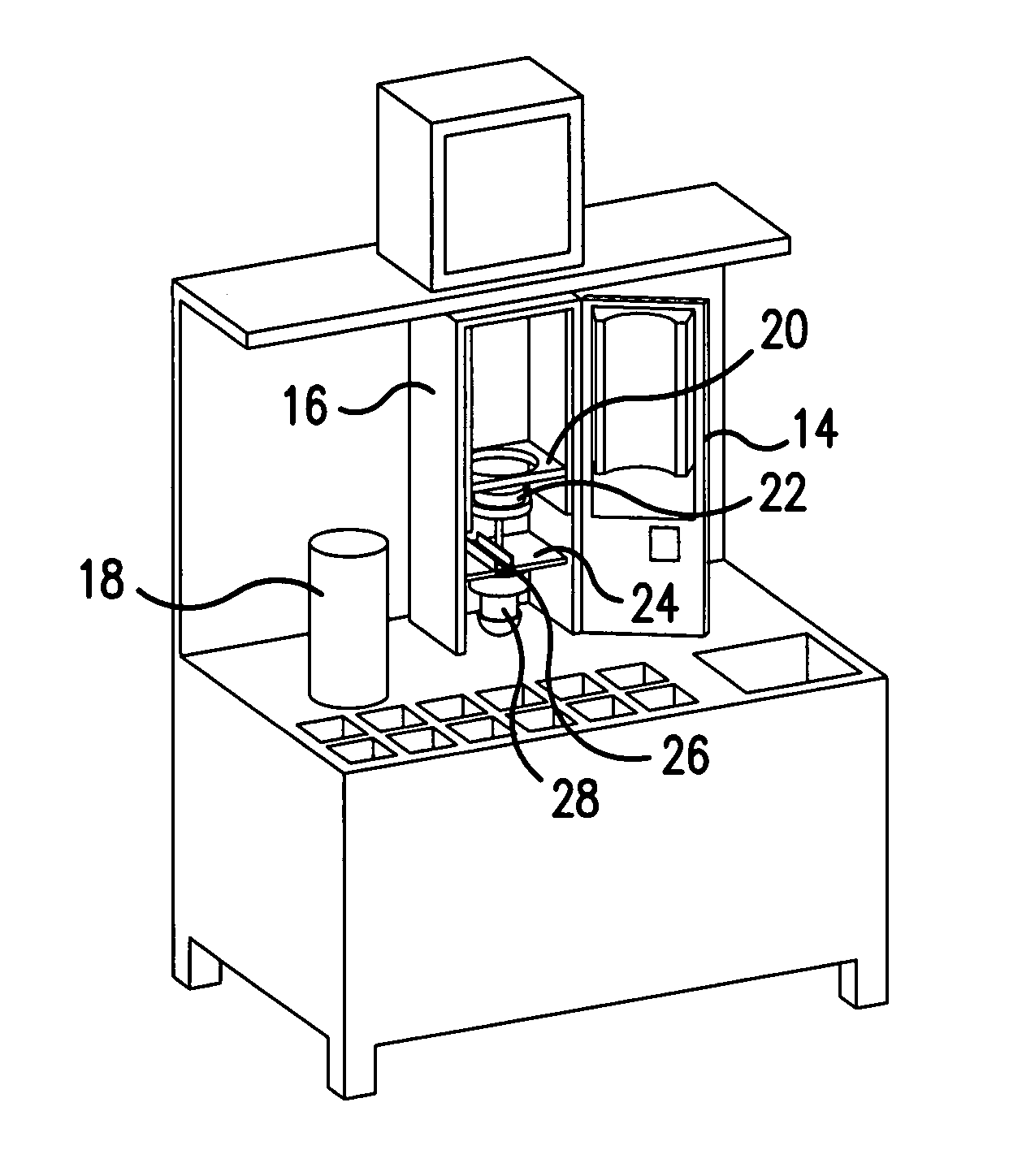

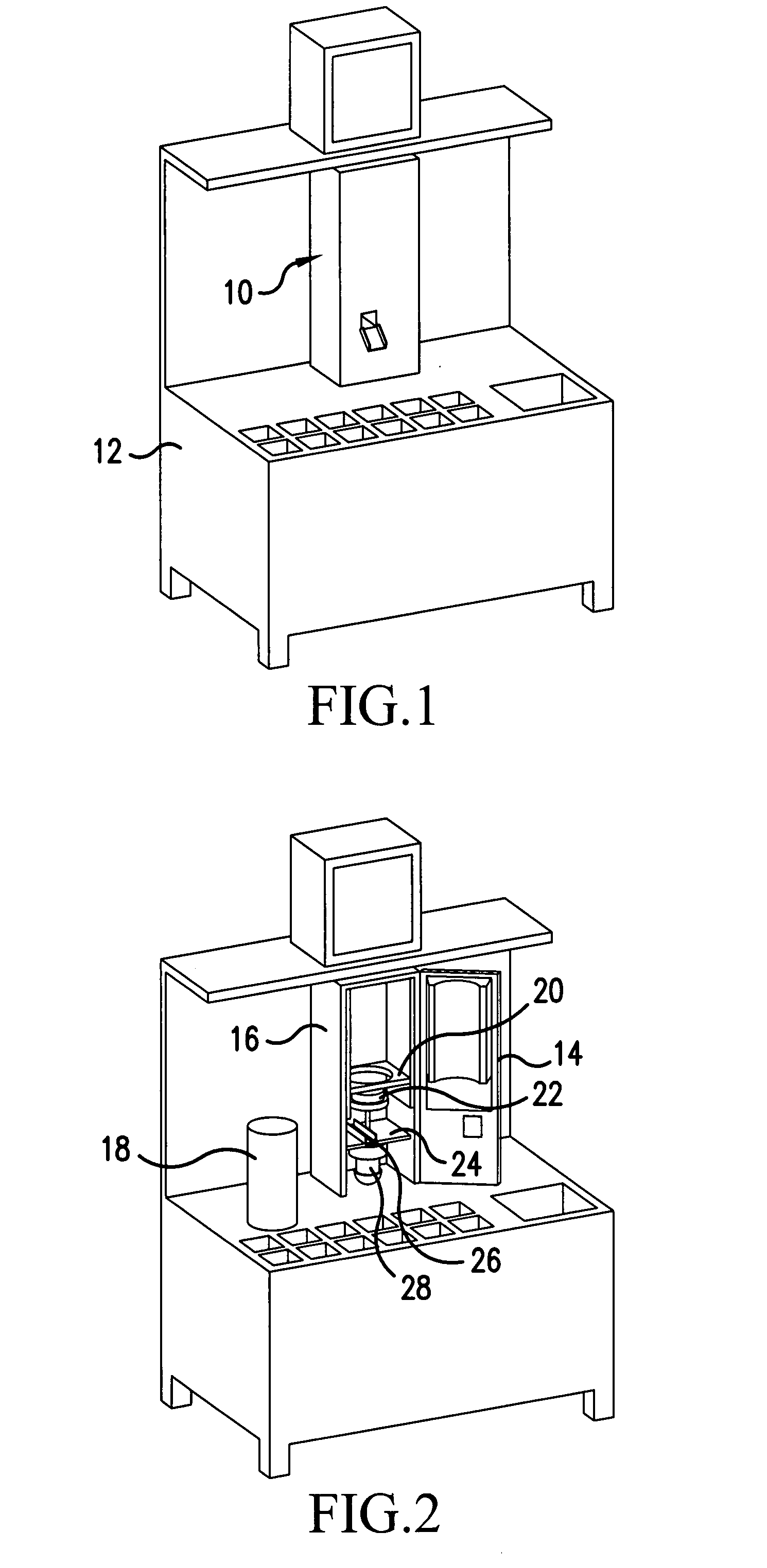

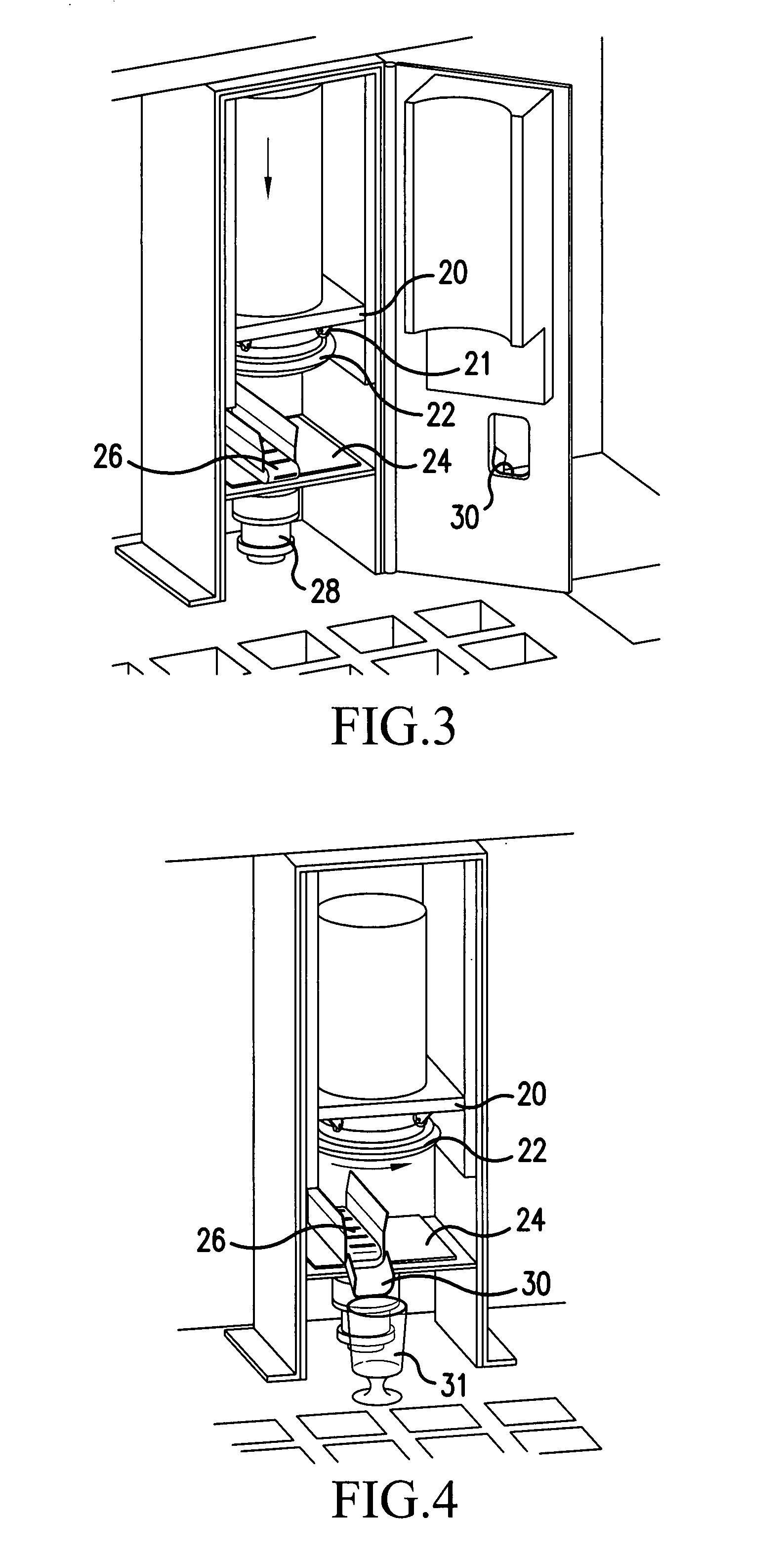

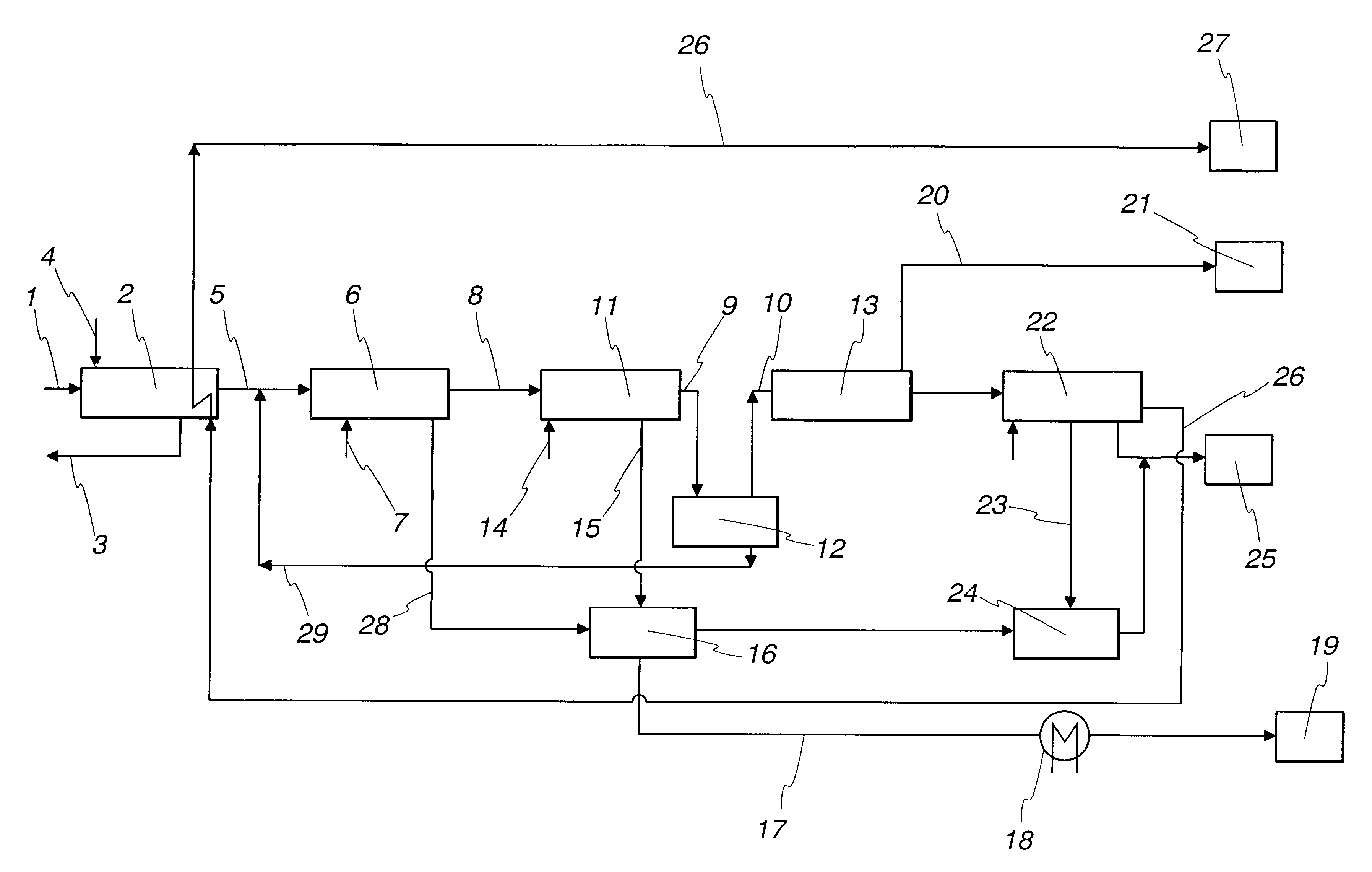

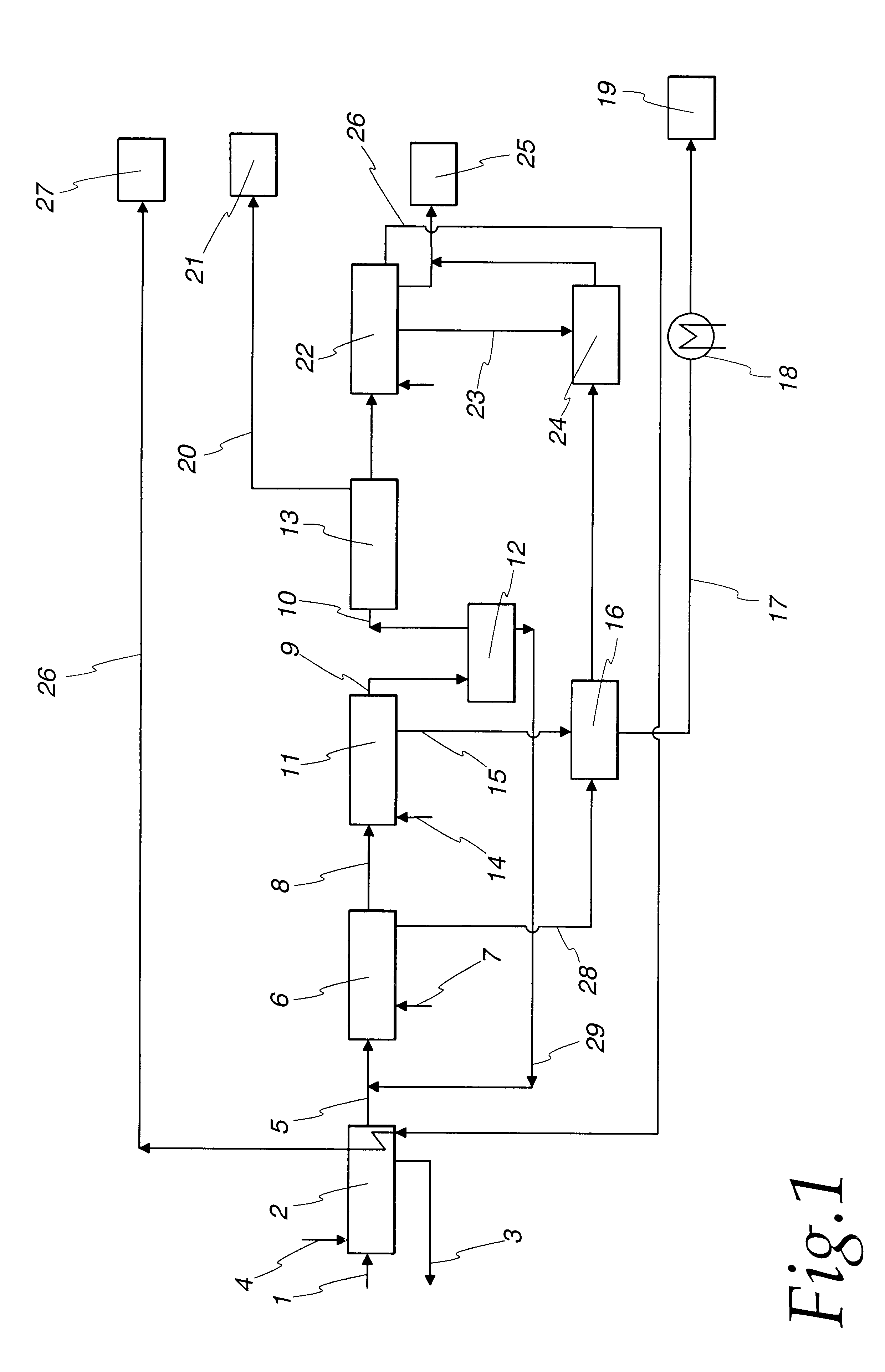

System and method for dispensing a liquid beverage concentrate

InactiveUS7223426B2Quality improvementPower operated devicesOther dairy technologyPeristaltic pumpMoisture

The present invention is related to a device and method for dispensing dual component liquids or concentrates packaged in separate containers to provide protection from effects such as oxidation and moisture loss. The liquids or concentrates can be dispensed through a pumping system, preferably including a peristaltic pump, mixed together, and optionally diluted with another liquid, such as water, to provide a consumable beverage. In addition, the device of the present invention can dispense liquids or concentrates having different viscosities, such that they are mixed together in the proper ratio.

Owner:NESTEC SA

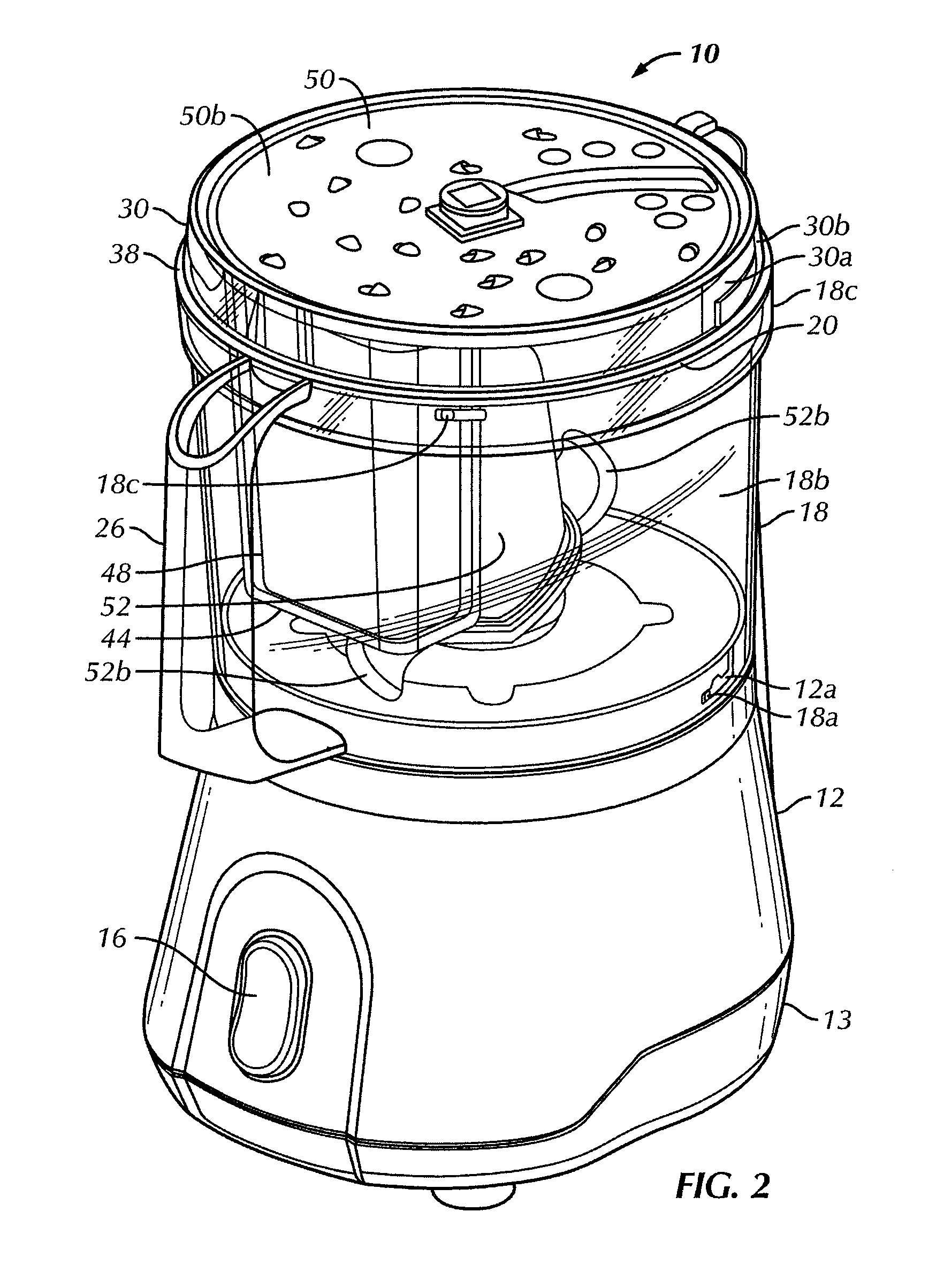

Hand-held food processor

InactiveUS7264189B2Increase torqueLong and high torque rotational forceMetal sawing devicesCoffee millsHand heldEngineering

A hand-held hand-powered food processor having a pull cord motor for rotating a spindle that carries an arm. The arm can be a cutter blade or an elastomeric flexible peeler arm having a durometer of preferable between Shore 80A and Shore 82A. A food processor having a spindle, an elastomeric arm driven by the spindle, a stop block on a sidewall near the end of the arm, and a drive for rotating the spindle to rub against the skin of food in the processor for peeling the food. The cover of the processor has a flat outer periphery so the cover can be used as a storage unit for the contents of the processor.

Owner:CHEFN

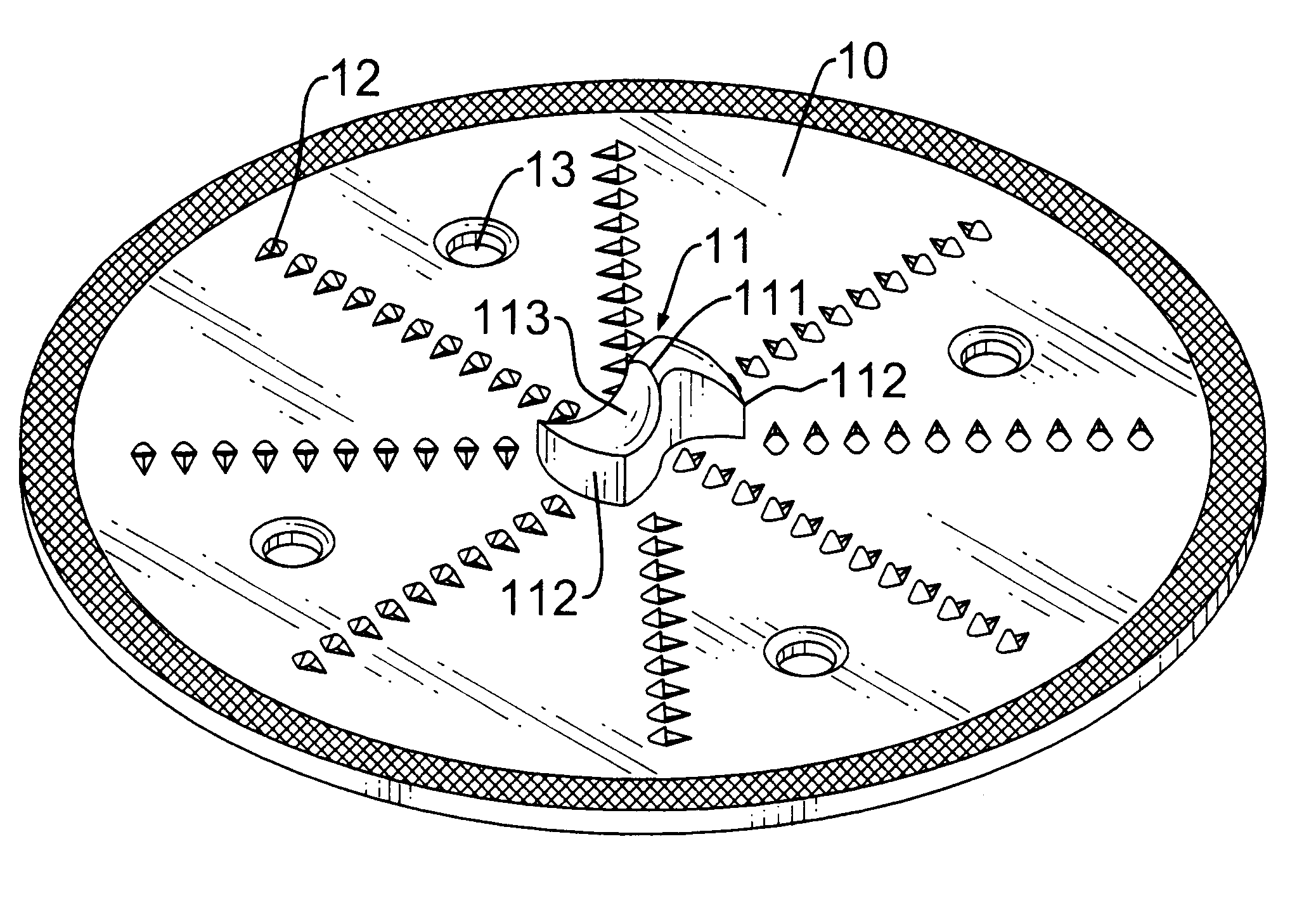

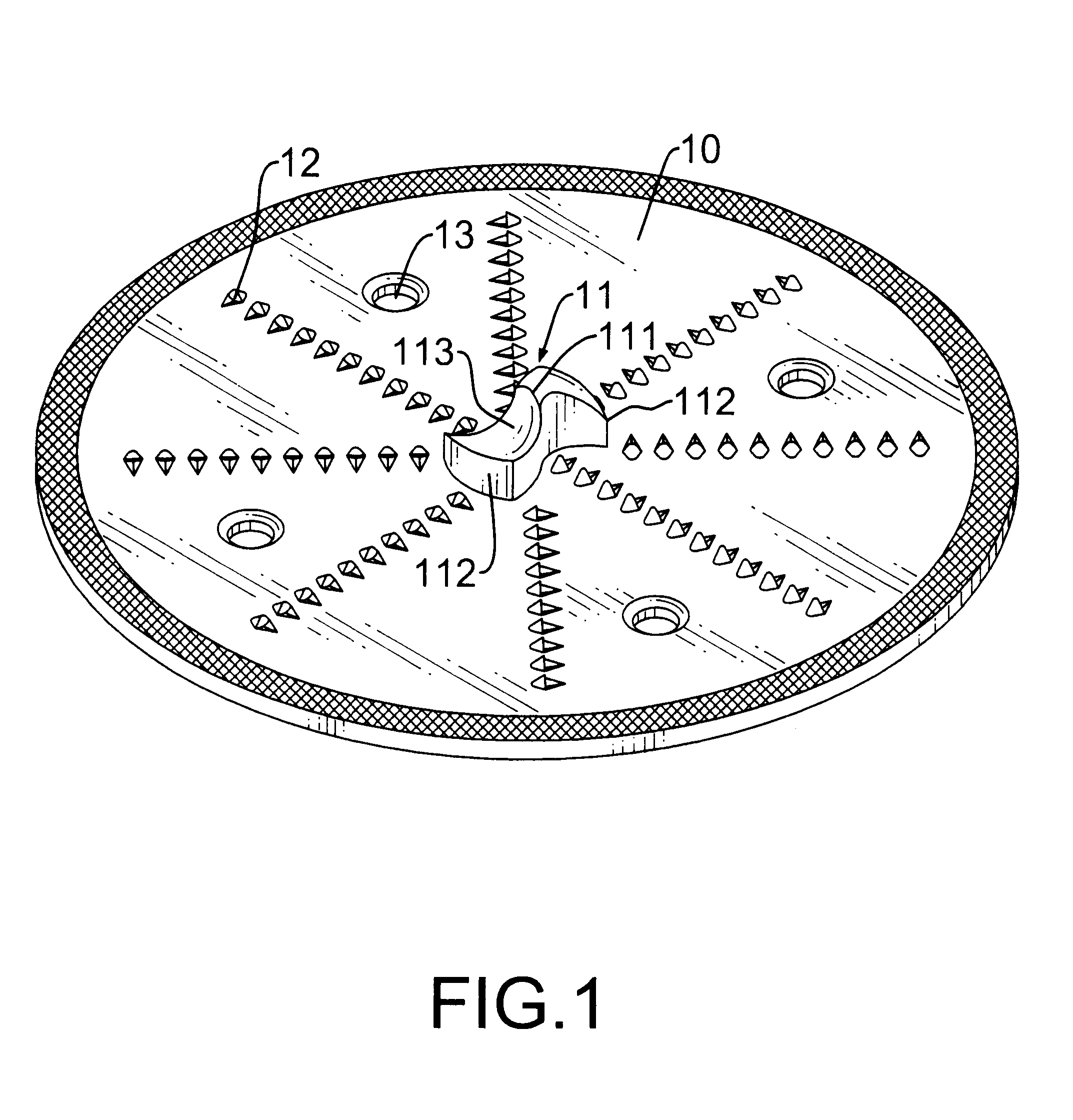

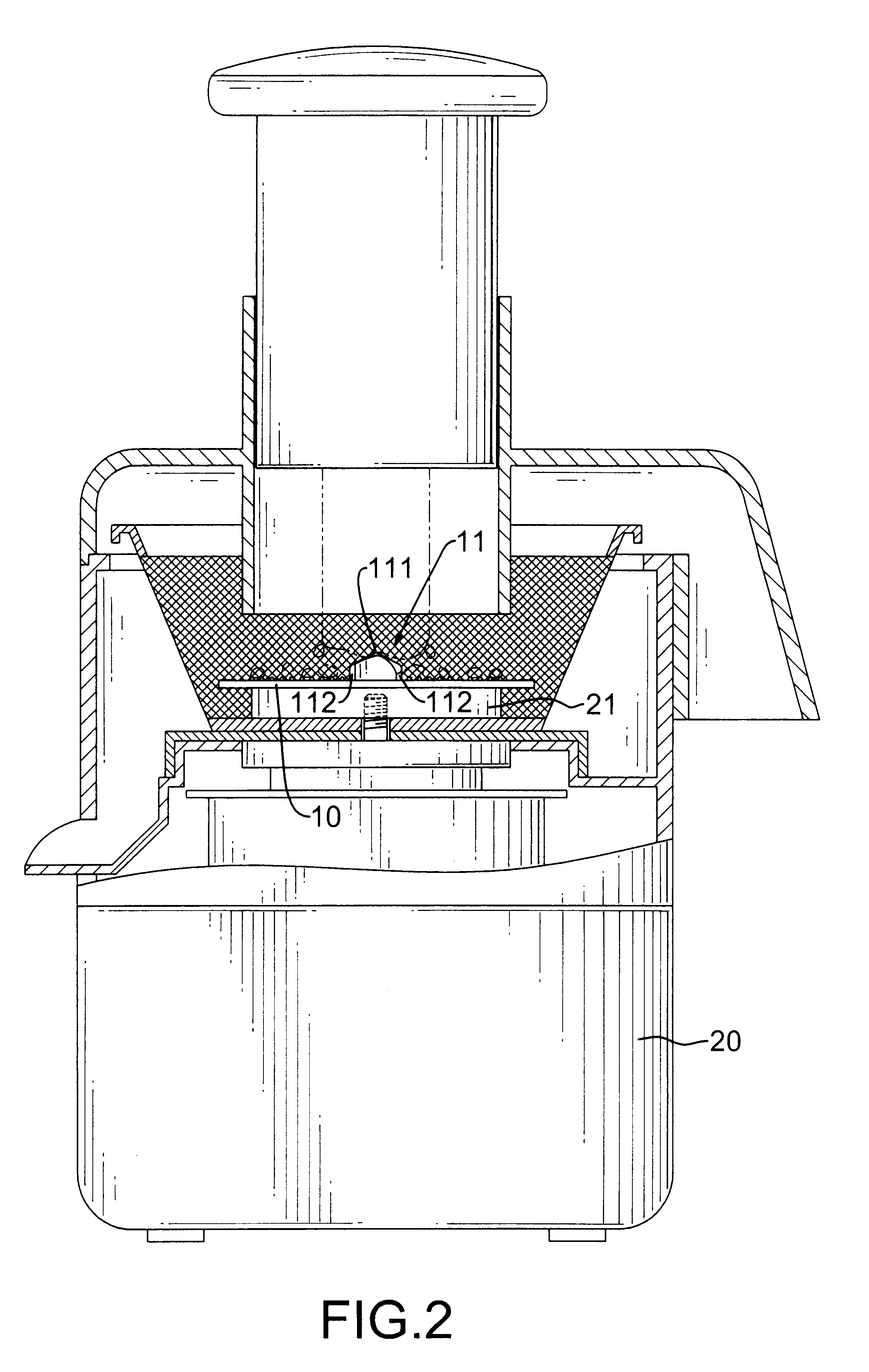

Disc cutter for fruit and vegetable juice extractor

A disc cutter for a fruit and vegetable juice extractor includes a disc body and a food disintegrating device. The disc body is rotatably mounted in the juice extractor has a top, a center and grinding blades. The grinding blades are radially formed in the top of the disc body for grinding food into juice. The food disintegrating device is attached to the top at the center of the disc body and includes a pointed body having a tapered top and two opposite edges. The tapered top has a central tip and a fluted land defined in the tapered top adjacent one of the edges. Therefore, the rotating pointed body will disintegrate efficiently the inserted food into several large pieces for the grinding blades to grind completely into juice without any food remaining on the pointed body.

Owner:CHEN MING SUNG

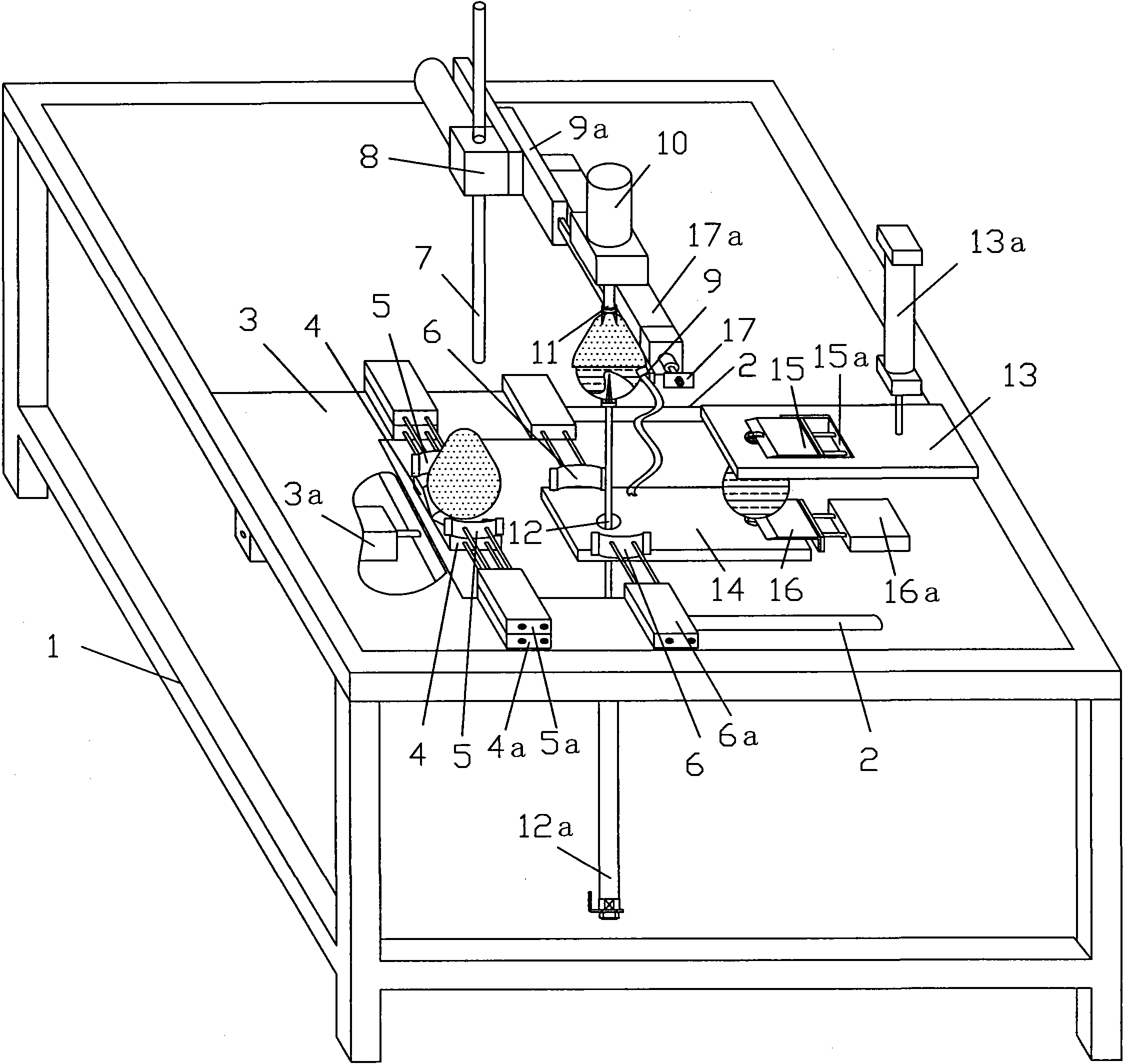

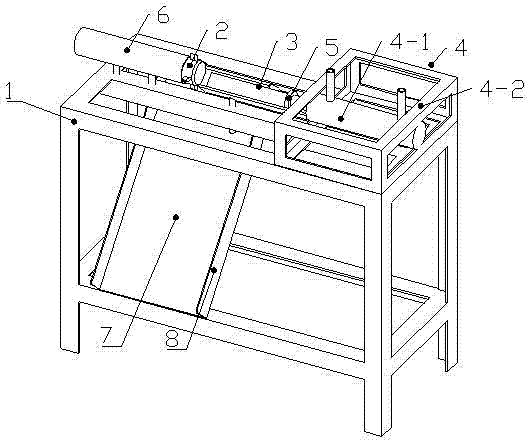

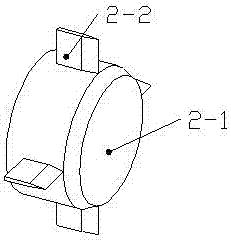

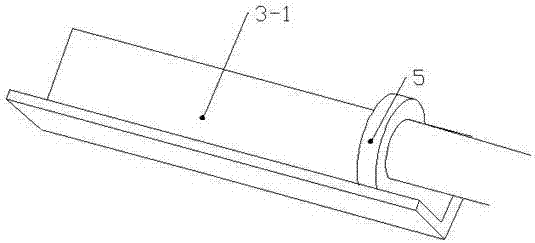

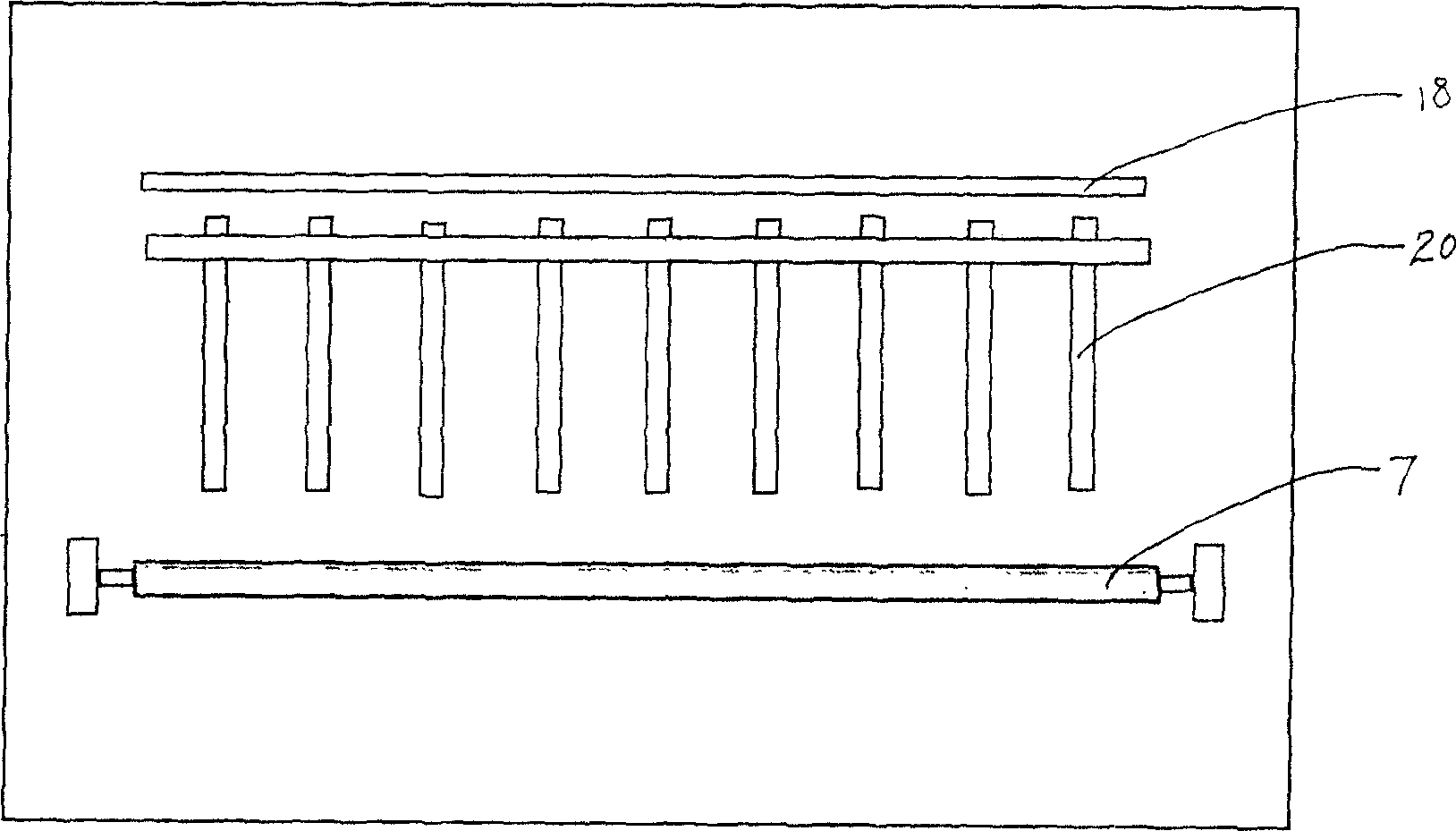

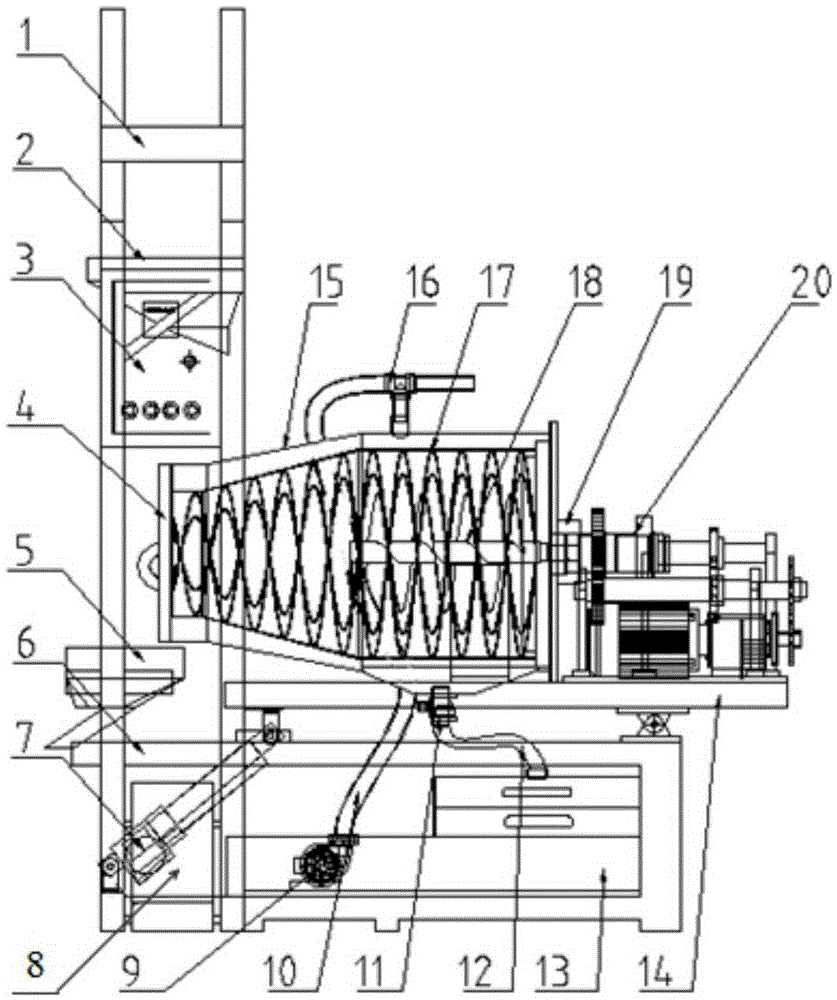

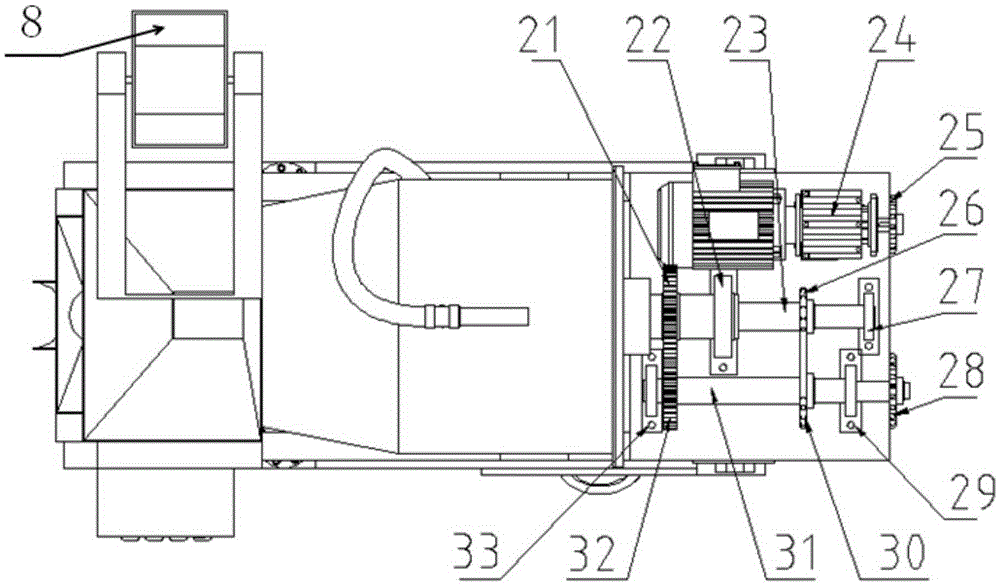

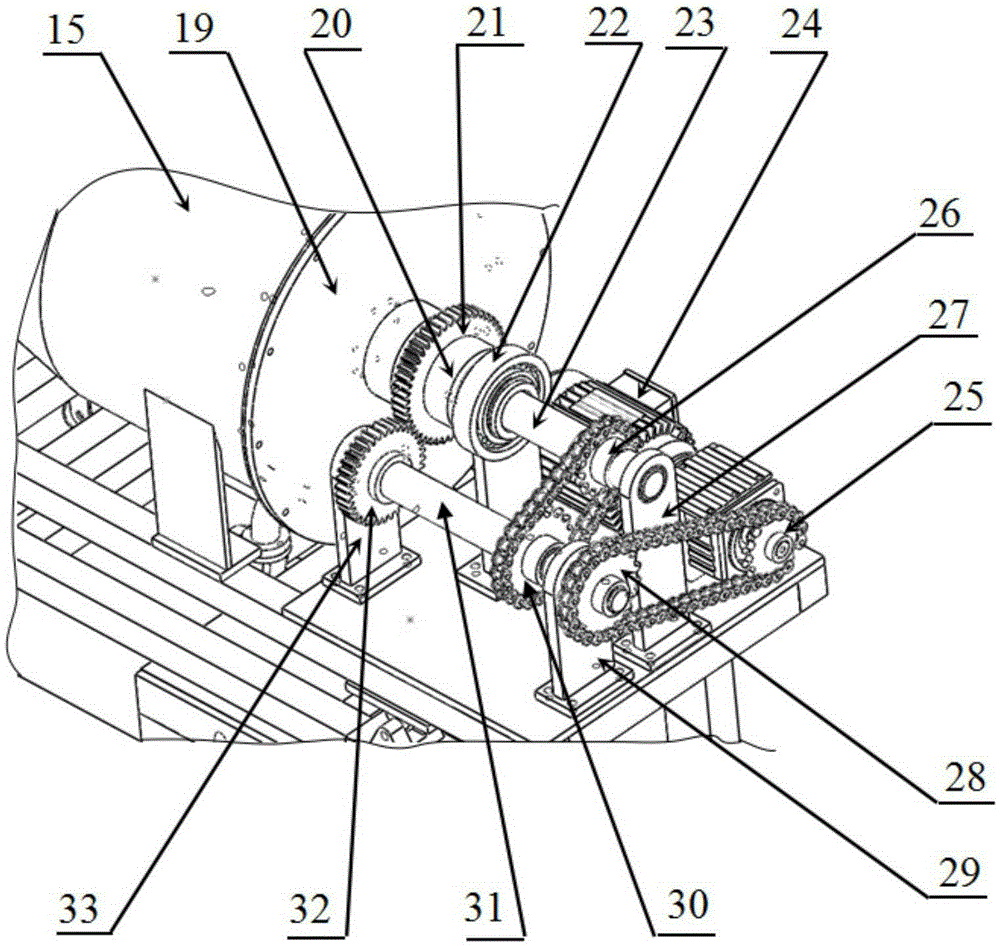

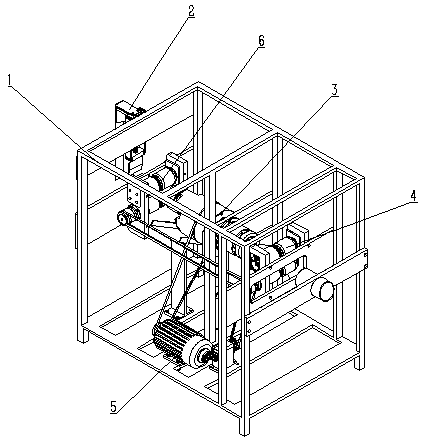

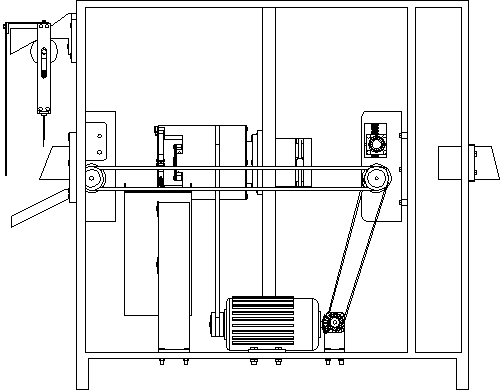

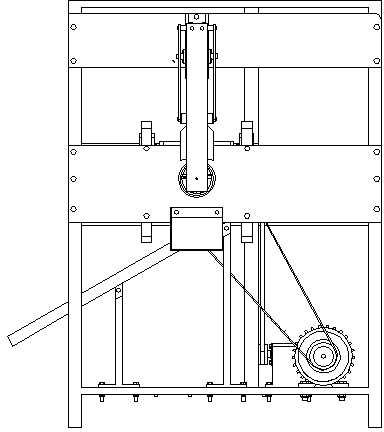

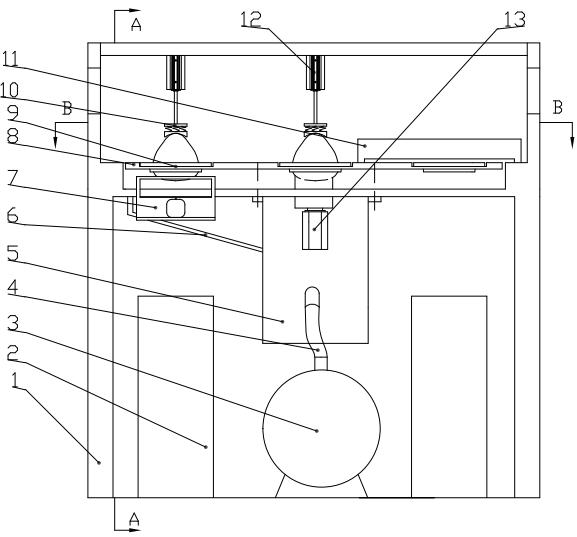

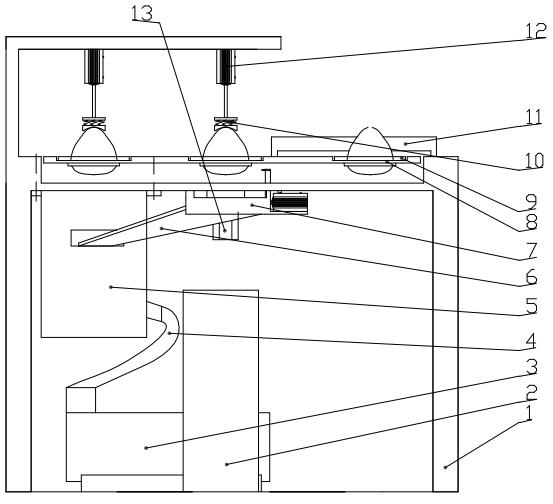

Electromechanical full-automatic peeling machine and peeling method thereof

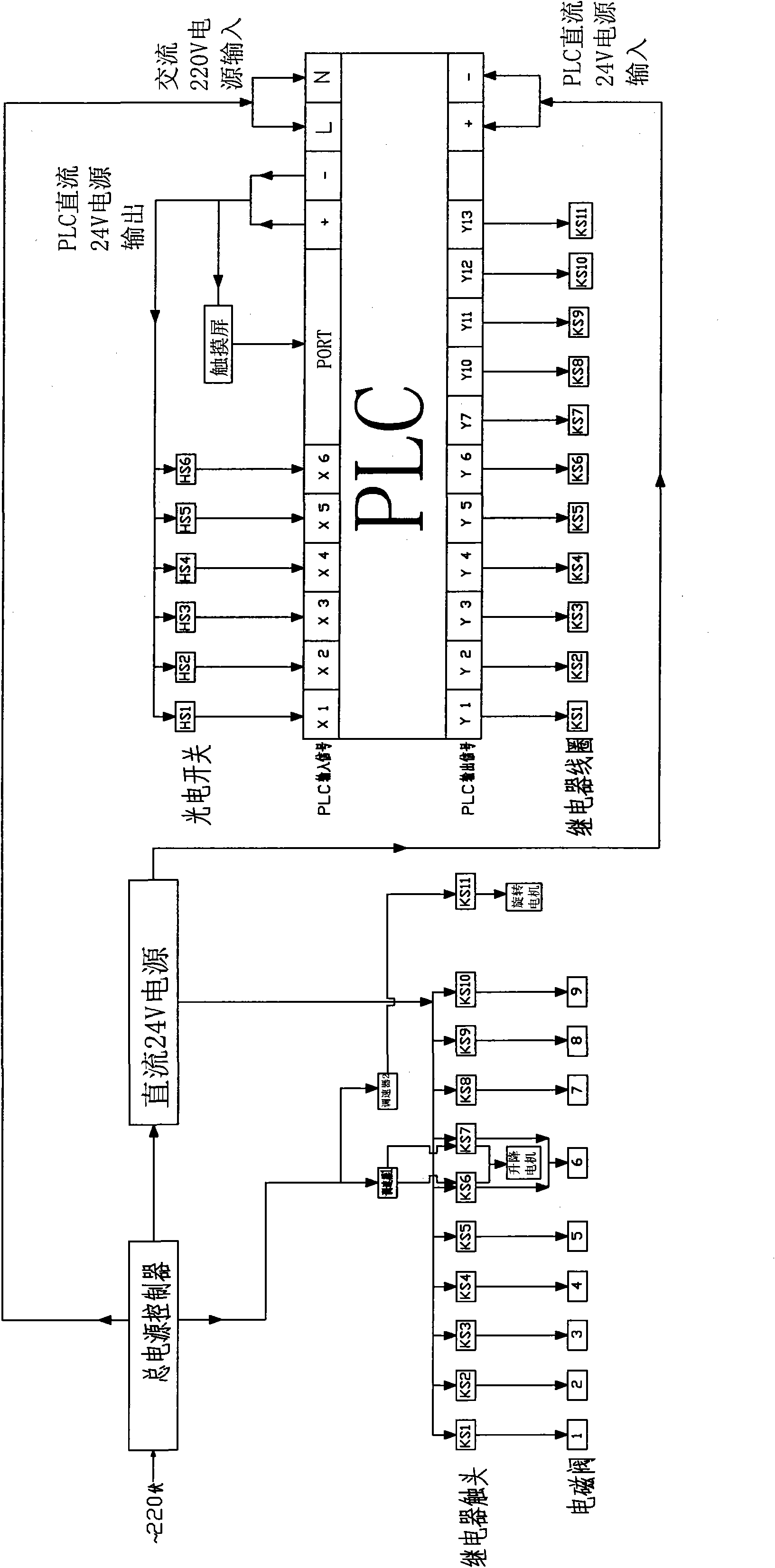

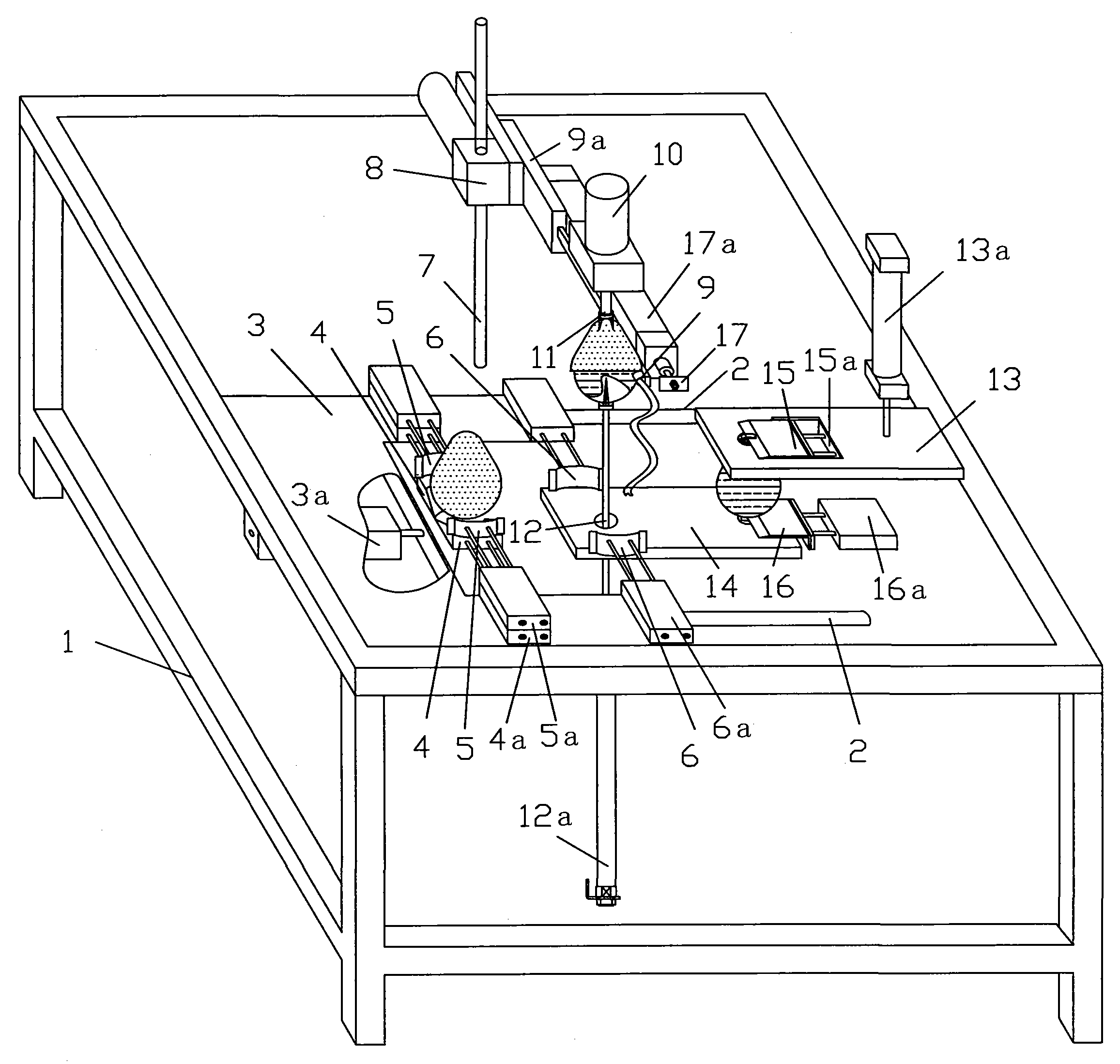

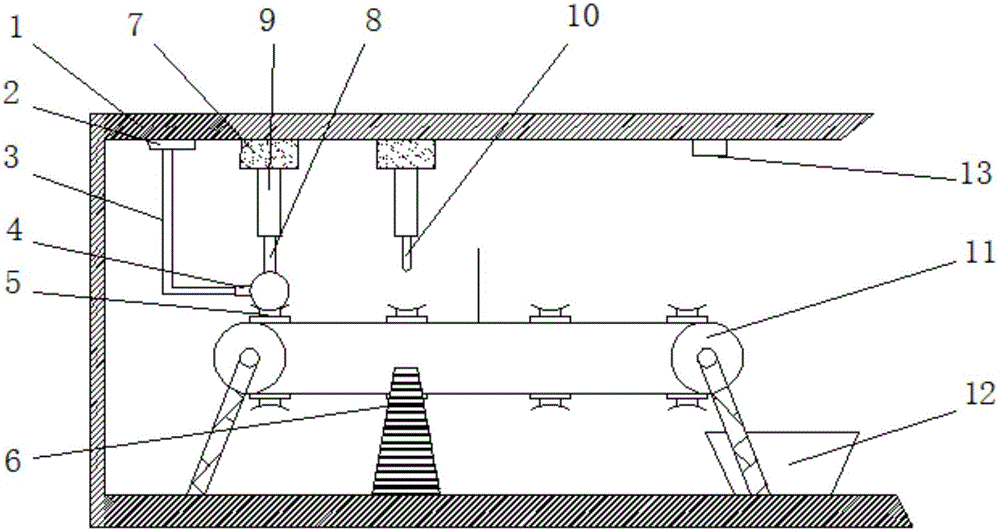

ActiveCN101856139AReduce labor costsMeet the needs of deep processingVegetable peelingProgramme control in sequence/logic controllersControl systemEngineering

The invention discloses an electromechanical full-automatic peeling machine and a peeling method thereof. The electromechanical full-automatic peeling machine comprises a rack, a fruit feeding mechanism, a peeling mechanism, a cutting mechanism and a control system, wherein the fruit feeding mechanism, the peeling mechanism and the cutting mechanism are arranged in the rack; the fruit feeding mechanism is arranged on two lead rails of the rack; the fruit feeding mechanism, the peeling mechanism and the cutting mechanism are arranged in sequence according to processing procedures; and the control system connects and controls the fruit feeding mechanism, the peeling mechanism and the cutting mechanism. The invention also discloses a peeling method of the electromechanical full-automatic peeling machine. The electromechanical full-automatic peeling machine has the advantages of high processing efficiency, safety and health.

Owner:广州达桥食品设备有限公司

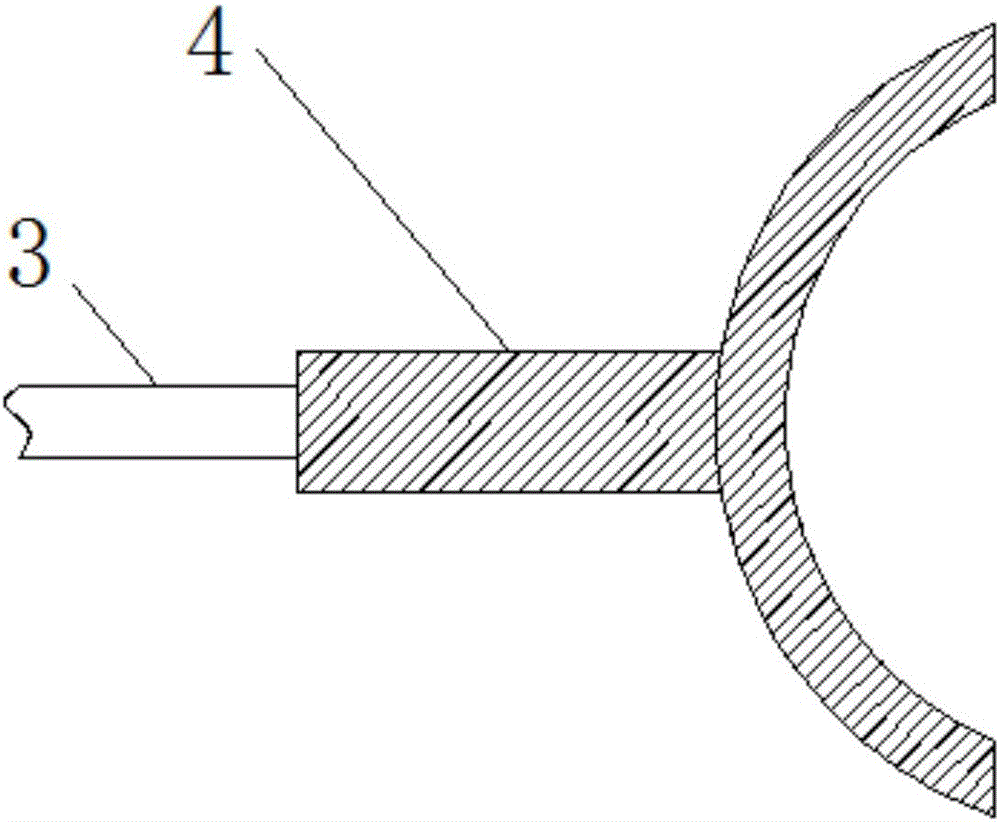

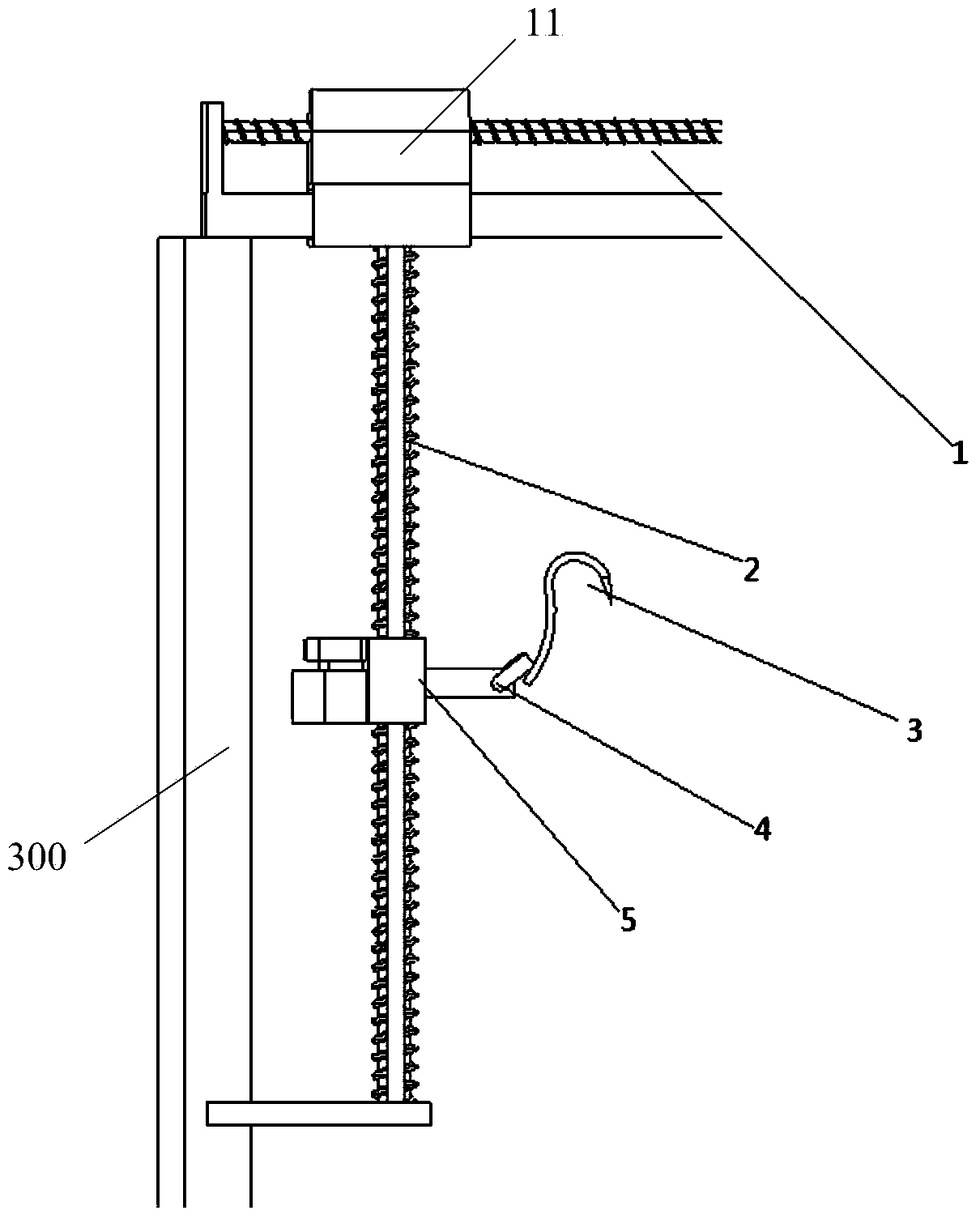

Apple peeling and core removing all-in-one machine

InactiveCN106376939AReasonable structural designSmall footprintFruit stoningVegetable peelingApple peelEngineering

The invention discloses an apple peeling and core removing all-in-one machine, which comprises a machine frame, wherein a pulley rail is arranged under the machine frame; an L-shaped pushing rod is arranged under the pulley rail; the tail end of the pushing rod is provided with a peeling cutter blade; two groups of motors are arranged under the machine frame; rotatable telescopic rods are arranged under the motors; a steel needle used for being inserted into an apple so as to conveniently rotate for peeling is arranged under one group of telescopic rods; a core removing device is arranged under the other group of telescopic rods; a conveying belt is arranged in the machine frame; a circular ring-shaped tray is arranged on the conveying belt; a recovery box used for discharging out apple cores is arranged under the conveying belt; in addition, the recovery box is arranged right under the core removing device; the right end of the conveying belt is provided with a collecting box; a switch is also arranged on the machine frame. The apple peeling and core removing all-in-one machine has the advantages that the structural design is reasonable; the occupied area is small; the peeling and the core removing are integrated; the work efficiency is high; the apple peeling and core removing all-in-one machine is suitable for being generally popularized and used.

Owner:ANHUI RUIZHIXIN INFORMATION TECH CO LTD

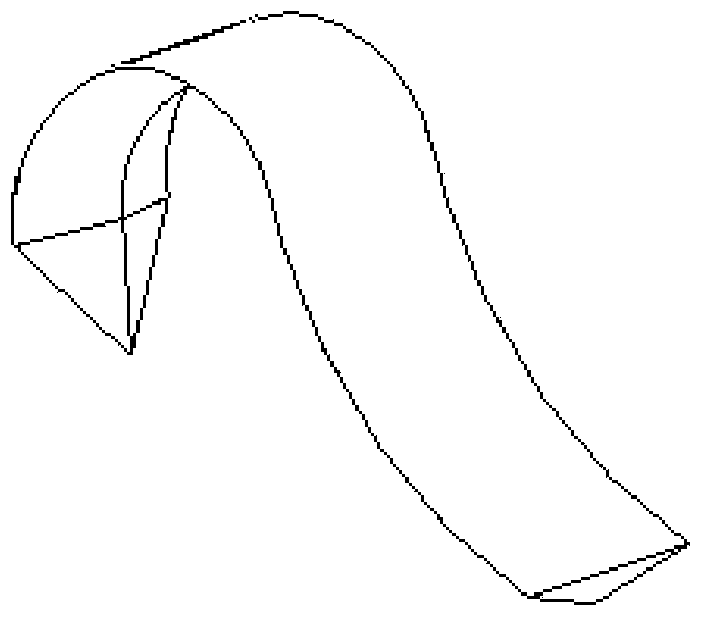

Vegetable cutter

A cutter used to spirally slice a vegetable including a frame; a shaft supported on the frame, the shaft being freely rotatable and movable along an axis; a holder attached at one end of the shaft; a cutting assembly supported opposite the holder having a first annular blade defining a first bore adapted to form a first peel, a cross cutter adapted to break the first peel into a segment, and a second annular blade defining a second bore, wherein the second annular blade is spaced axially outward from the first blade relative to the holder and wherein the second blade has a diameter smaller than a diameter of the first blade and is adapted to cut a second peel from the core left by the first blade.

Owner:PRAGOTRADE +1

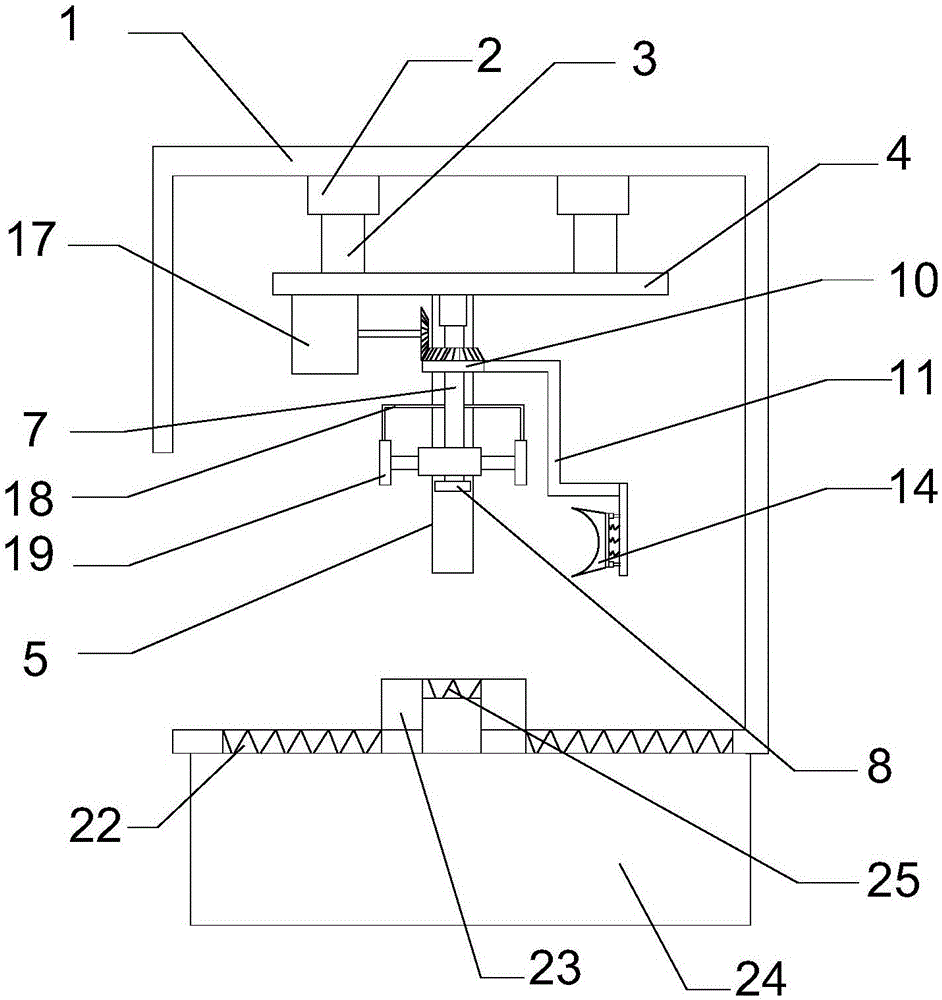

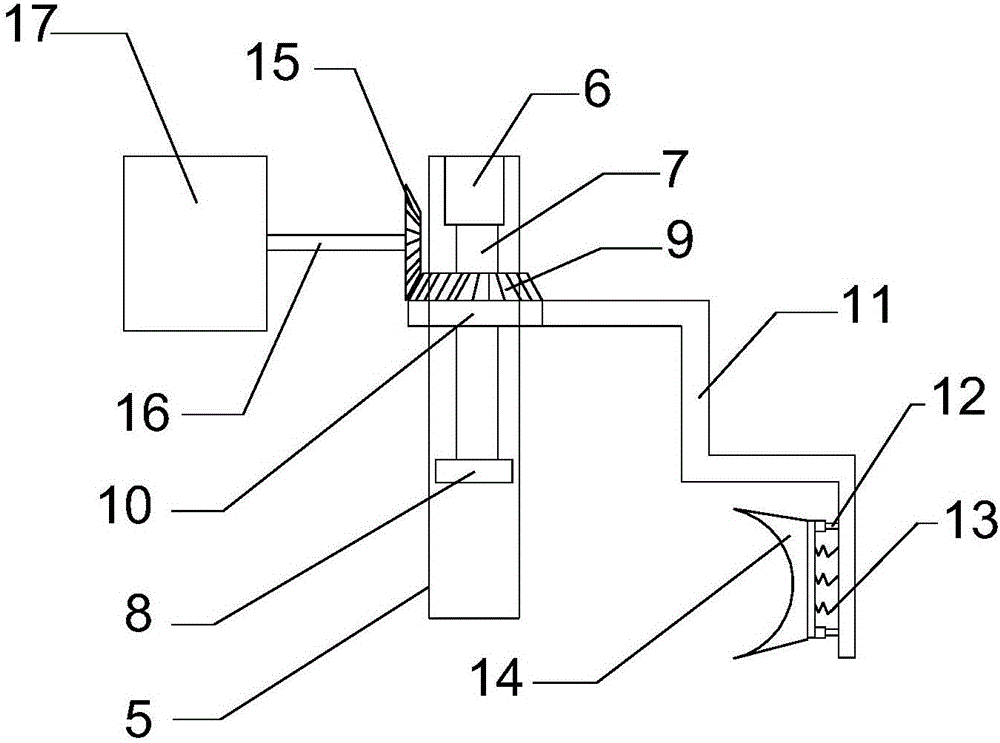

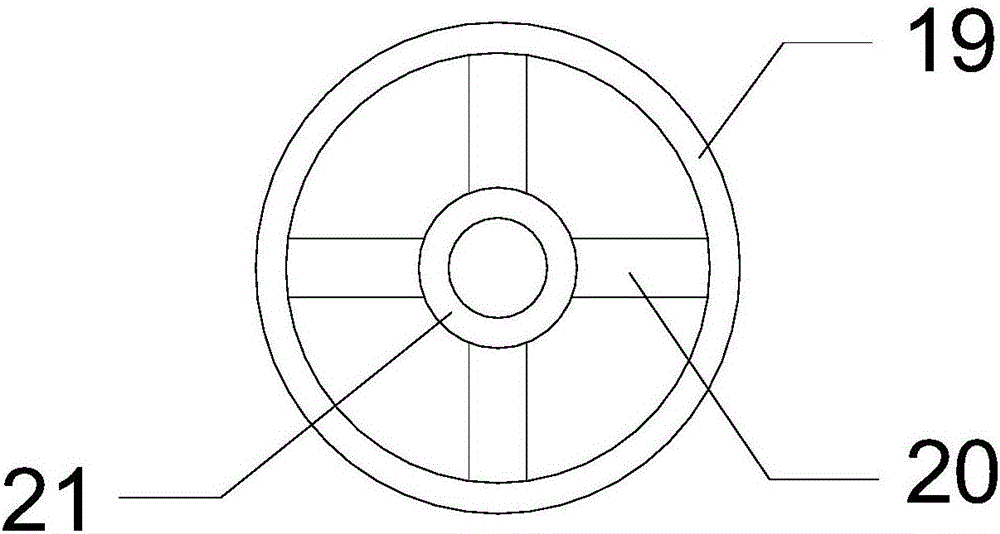

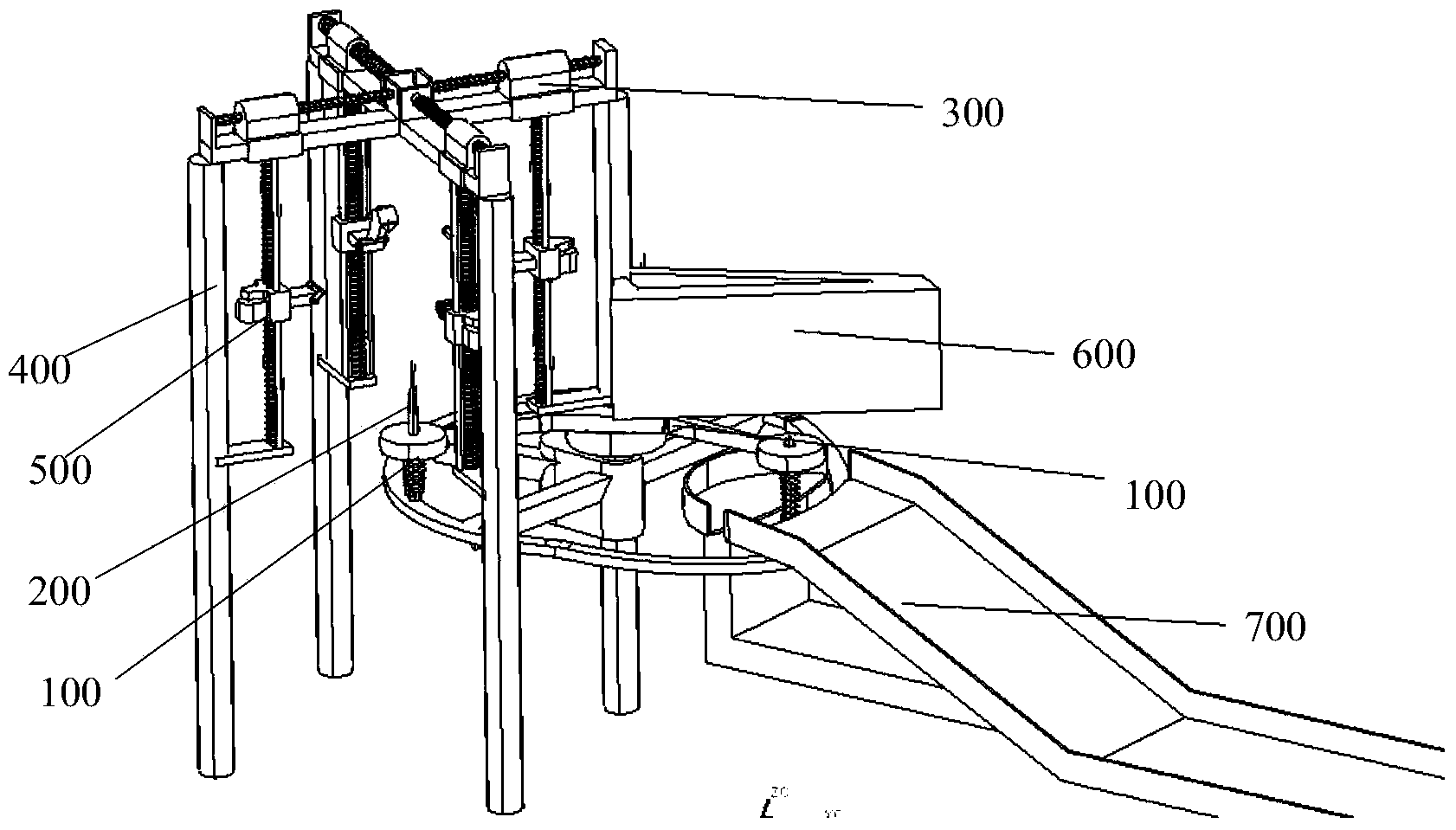

Rotary type fruit peel and pit removing device

PendingCN106805257AComplete denuclearizationKeep clean and tidyFruit stoningVegetable peelingHydraulic cylinderEngineering

The invention discloses a rotary type fruit peel and pit removing device. The rotary type fruit peel and pit removing device comprises a machine body; the top of the machine body is fixedly connected with a first hydraulic cylinder through bolts; the first hydraulic cylinder is provided with a first piston rod; the first piston rod is connected with a moving plate; the lower surface of the moving plate is connected with a sleeve; a second hydraulic cylinder is arranged in the sleeve; the second hydraulic cylinder is provided with a second piston rod; the tail end of the second piston rod is connected with a pushing block; the side wall of the second piston rod is connected with a connecting rod; the connecting rod is connected with a dicing device; a sleeve ring is arranged in the position, above the dicing device, of the sleeve; the side wall of the sleeve ring is connected with a rotating rod; the lower end of the rotating rod is connected with a knife blade through a telescopic rod; a waste peel box is arranged below the machine body. According to the rotary type fruit peel and pit removing device, a peeling operation and a pitting operation of fruit are quickly performed through a rotating arc-shaped knife blade; the peeled fruit is diced quickly through the dicing device; fruit peel is collected in a centralized manner so as to keep a production environment clean and tidy.

Owner:惠安县丽佳智能设备有限公司

Sugarcane peeling and splitting machine

InactiveCN105058487AImprove peeling efficiencySimple structureCleaning using toolsVegetable peelingEngineeringMechanical engineering

The invention relates to a sugarcane peeling and splitting machine which comprises a peeling mechanism. The peeling mechanism comprises a cutting motor, a cutting quantity auxiliary protection plate, a tape spool and a sleeve. The tape spool is located on the sleeve in a rotating mode and in transmission connection with a main motor. A round groove is formed in the spool surface of the tape spool. The cutting motor is matched with the round groove to limit a rotation seat in a movable mode. The output end of the cutting motor is connected with a cutter shaft. The cutting quantity auxiliary protection plate is fixed to the outer side of the cutting motor. Moreover, an arc plate is arranged on the front portion of the cutter shaft and shields a part of the cutter shaft in the direction that sugarcane enters the cutter shaft. The non-shielded part of the cutter shaft is used as a cutting part for cutting the sugarcane, and the arc surface of the arc plate guides the sugarcane to enter the cutter shaft. The end of the cutting quantity auxiliary protection plate is movably connected with a balance block through a tension spring. The balance block is fixed to the tape spool. The cutting surface of the cutter shaft is made to be close to the axis of the sleeve under the effect of the tension spring. The sugarcane peeling and splitting machine is simple in structure, small in size, low in weight, high in peeling efficiency, good in effect and suitable for sugarcane peeling.

Owner:宁波市奉化奇佳机械设备有限公司

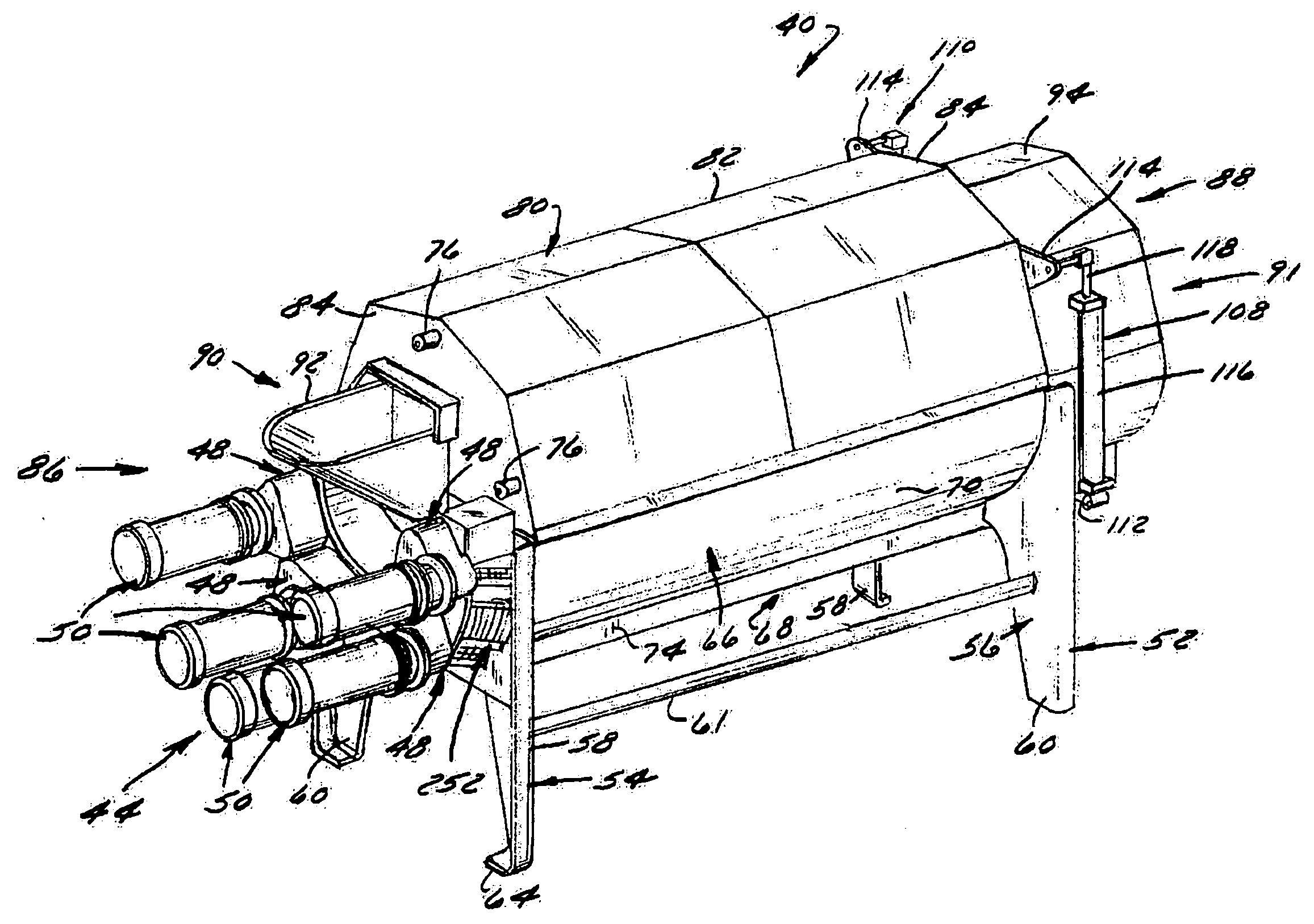

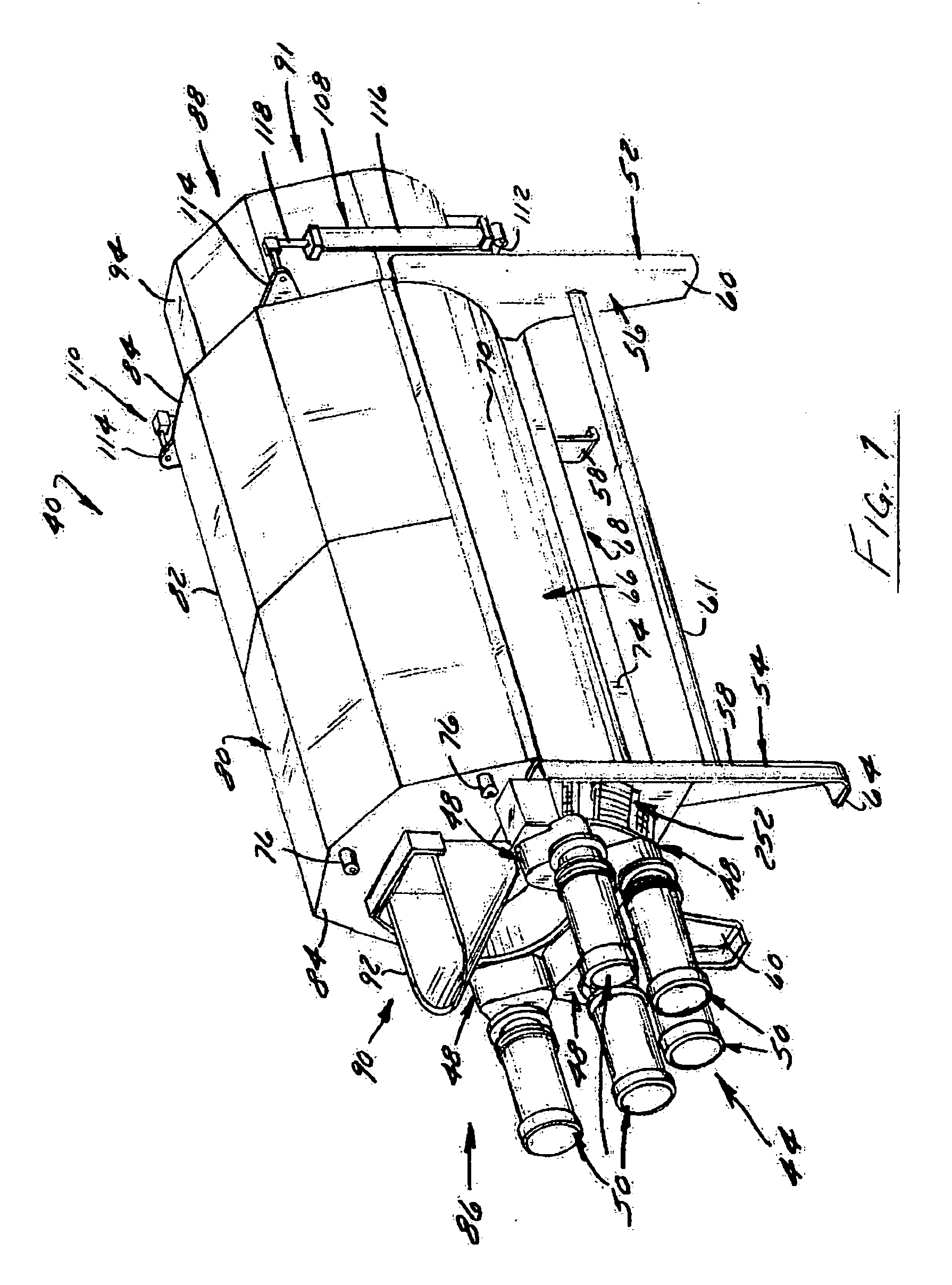

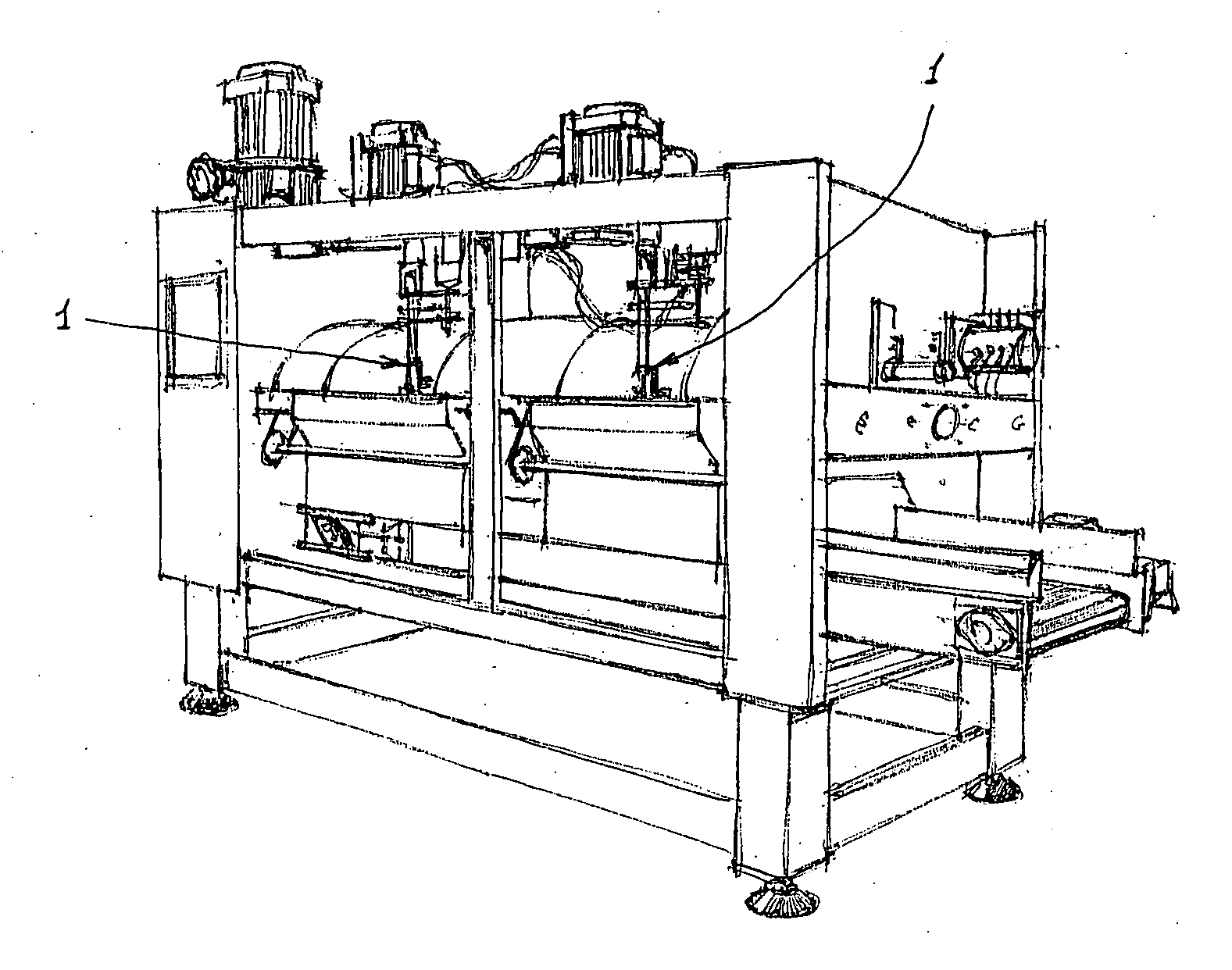

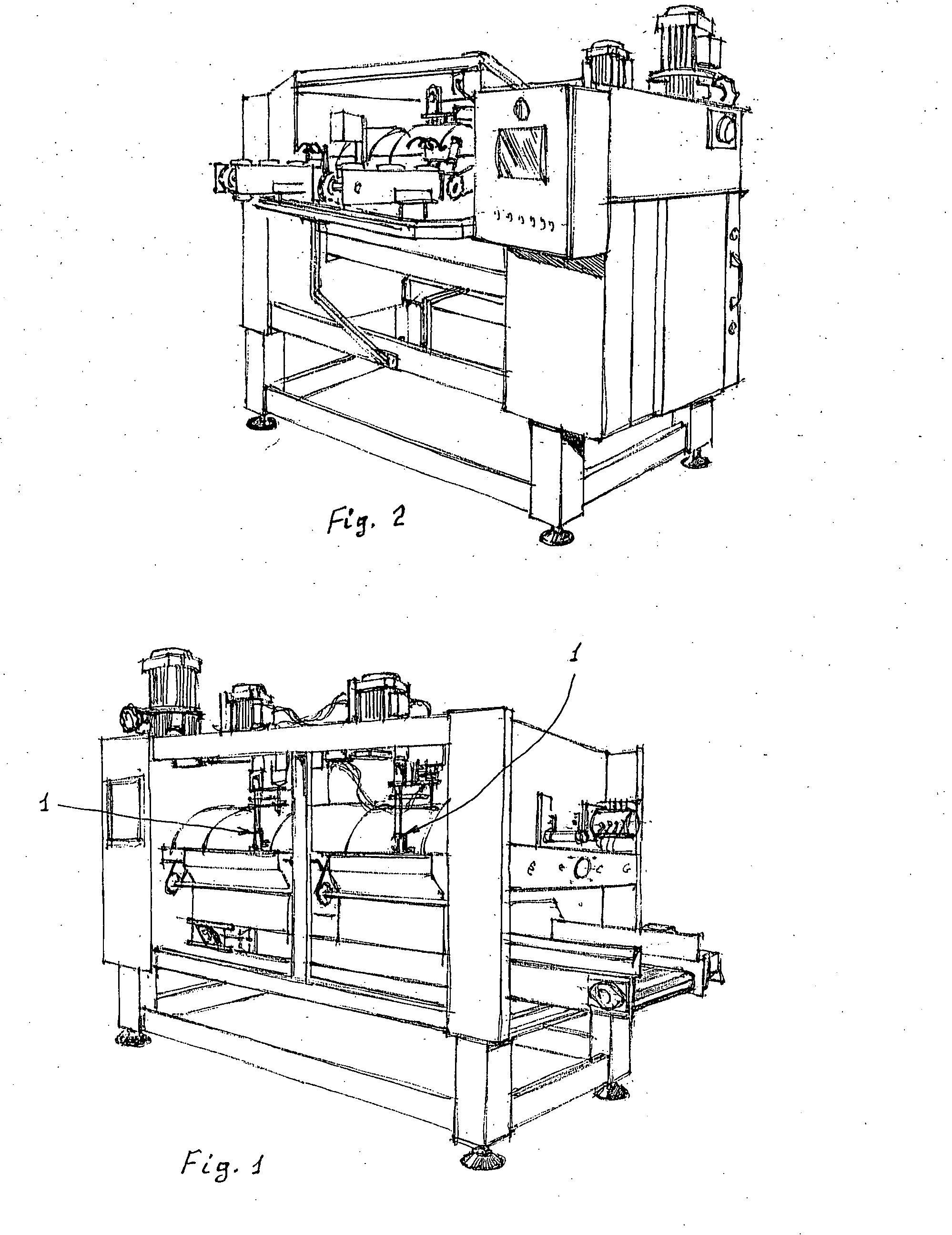

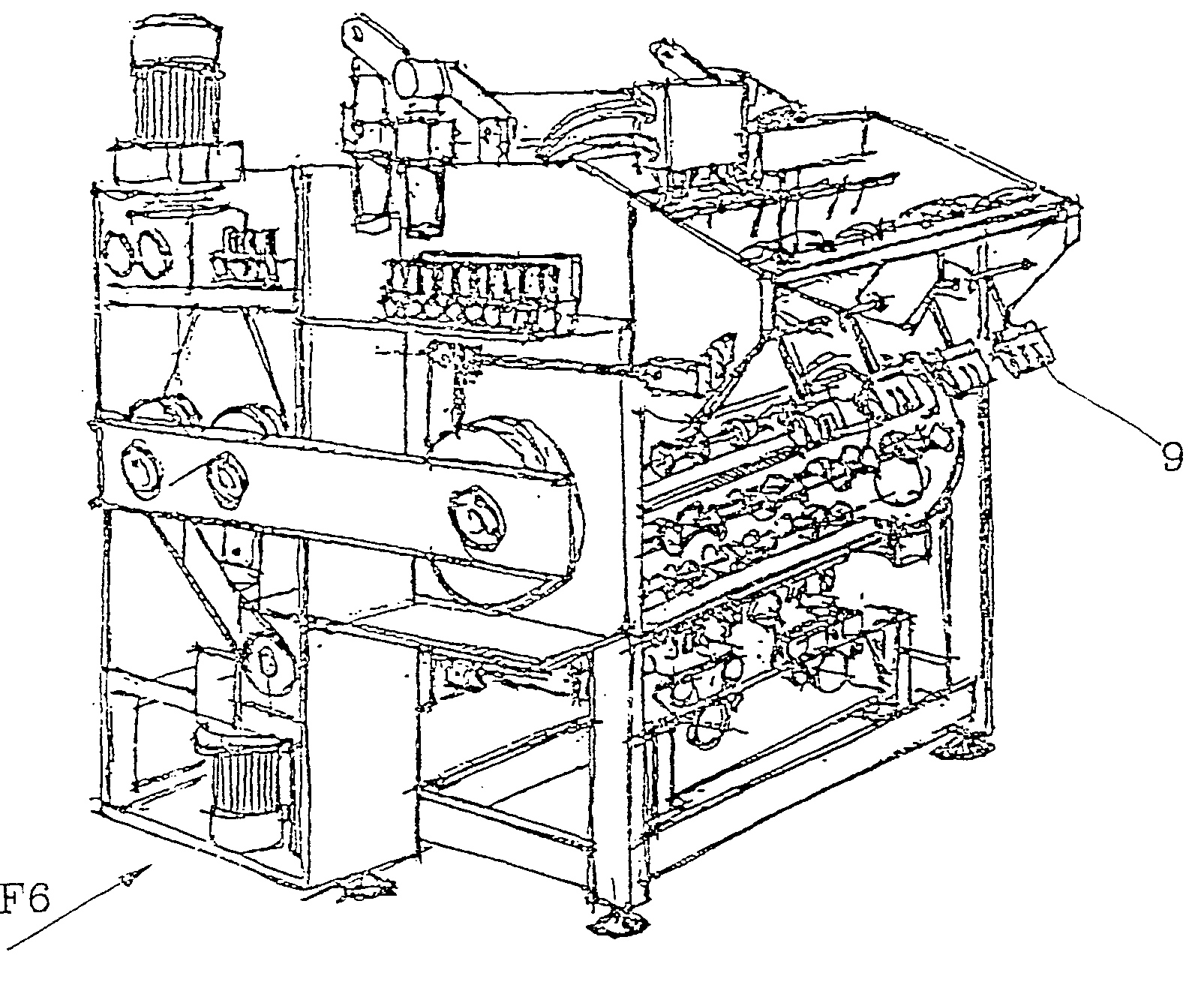

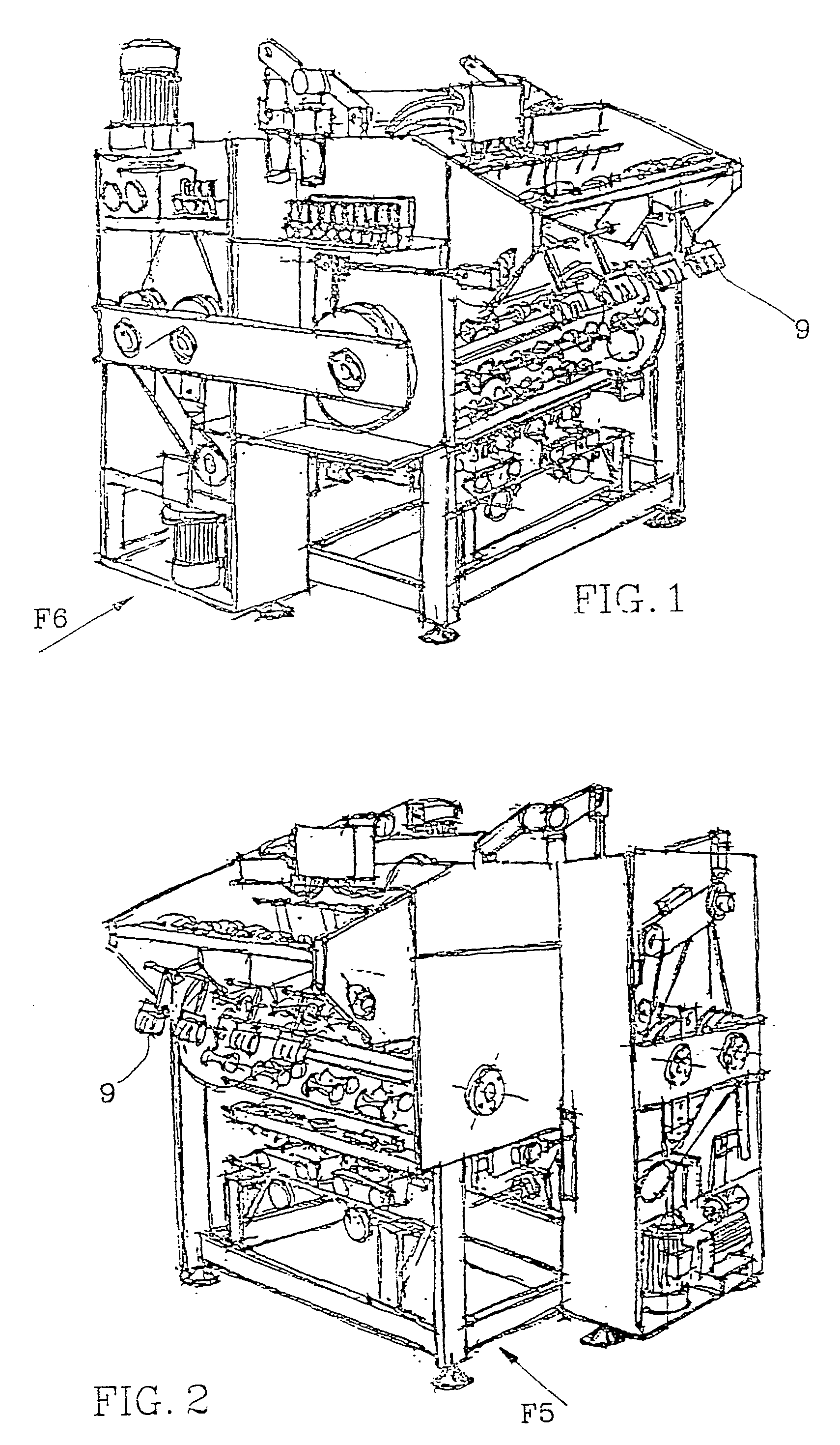

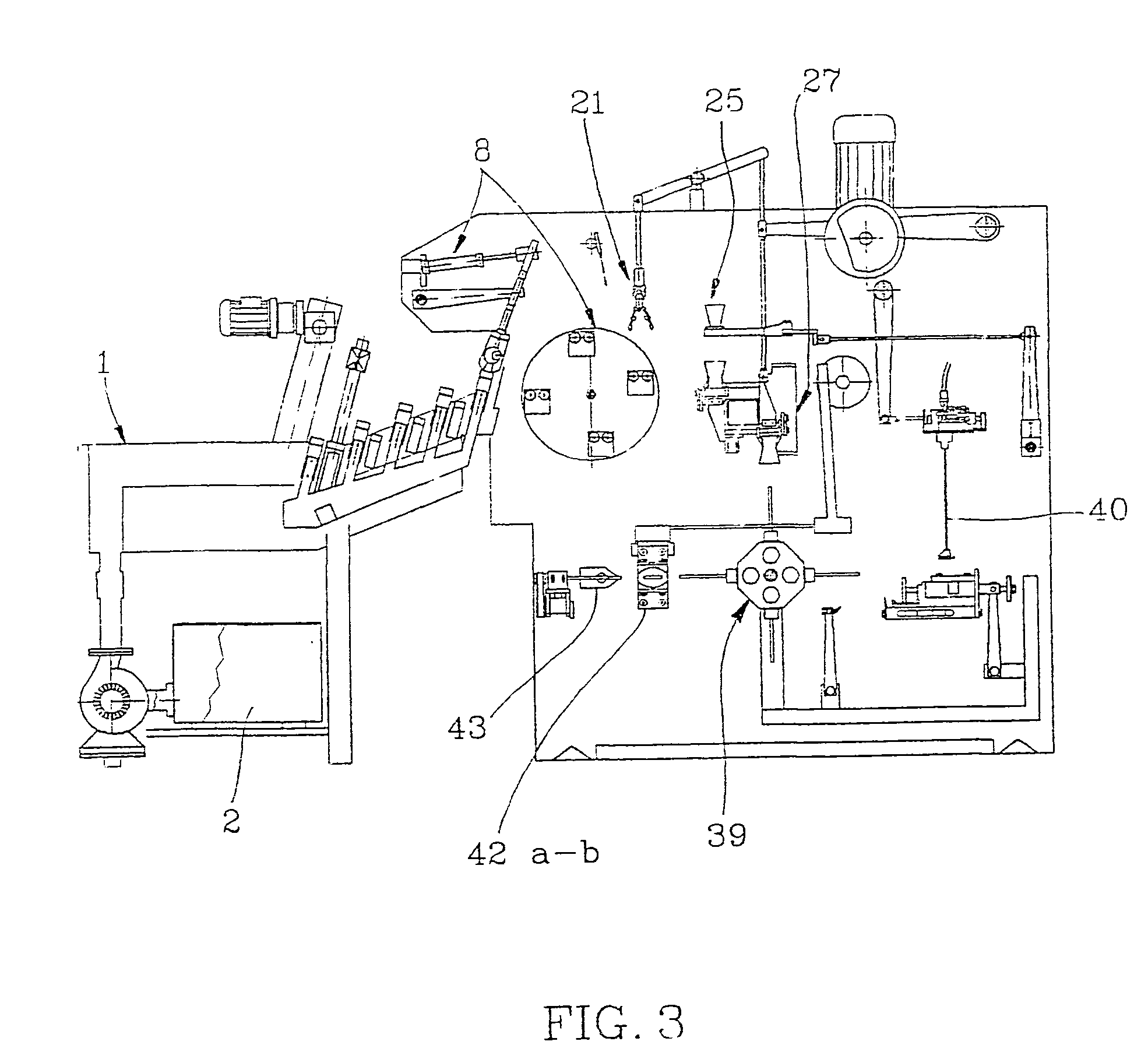

High speed food product peeling or cleaning machine and method

InactiveUS20050082144A1Increase speedReduce maintenancePackagingVegetable peelingCouplingEngineering

An apparatus for peeling or cleaning food product that includes a plurality of rollers each coupled to a drive box, preferably a gear box, by a vibration dampening coupling that preferably is disposed exteriorly of one end of the roller and part of the frame of the machine that supports the roller. A drive that preferably is an electric motor is attached to the drive box such that a plurality of rollers is driven thereby. Such an arrangement enables rollers to be driven at speeds of 600 RPM and preferably 750 RPM or faster, which decreases processing time and increases capacity and throughput. In a method of operation, each roller is driven at a speed of 750 RPM or greater to peel or clean food product before being discharged from the machine. In one preferred method, the rollers are driven at speeds between 900 and 1200 RPM.

Owner:LYCO MFG

Radish peeling forming machine

PendingCN107198257ALabor savingImprove efficiencyVegetable peelingCucumber familyMechanical engineering

The invention relates to a radish peeling forming machine which comprises a machine frame. The radish peeling forming machine is characterized in that the machine frame is sequentially provided with a peeling device, a feeding device and a power device from front to rear, a push plate is slidably arranged on the feeding device, and the output end of the power device is connected with the push plate to push the push plate to move in the direction of the peeling device. Batched radishes are pushed to an annular knife to be peeled and formed under the pushing by a cylinder by adoption of the annular knife, a discharging frame and the push plate on the discharging frame, manual labor is reduced, efficiency is improved, and the radish peeling forming machine is applicable to peeling and forming of rhizome vegetables such as cucumbers, carrots, white radishes, yam and lotus roots.

Owner:NINGBO SHOWCO FOOD

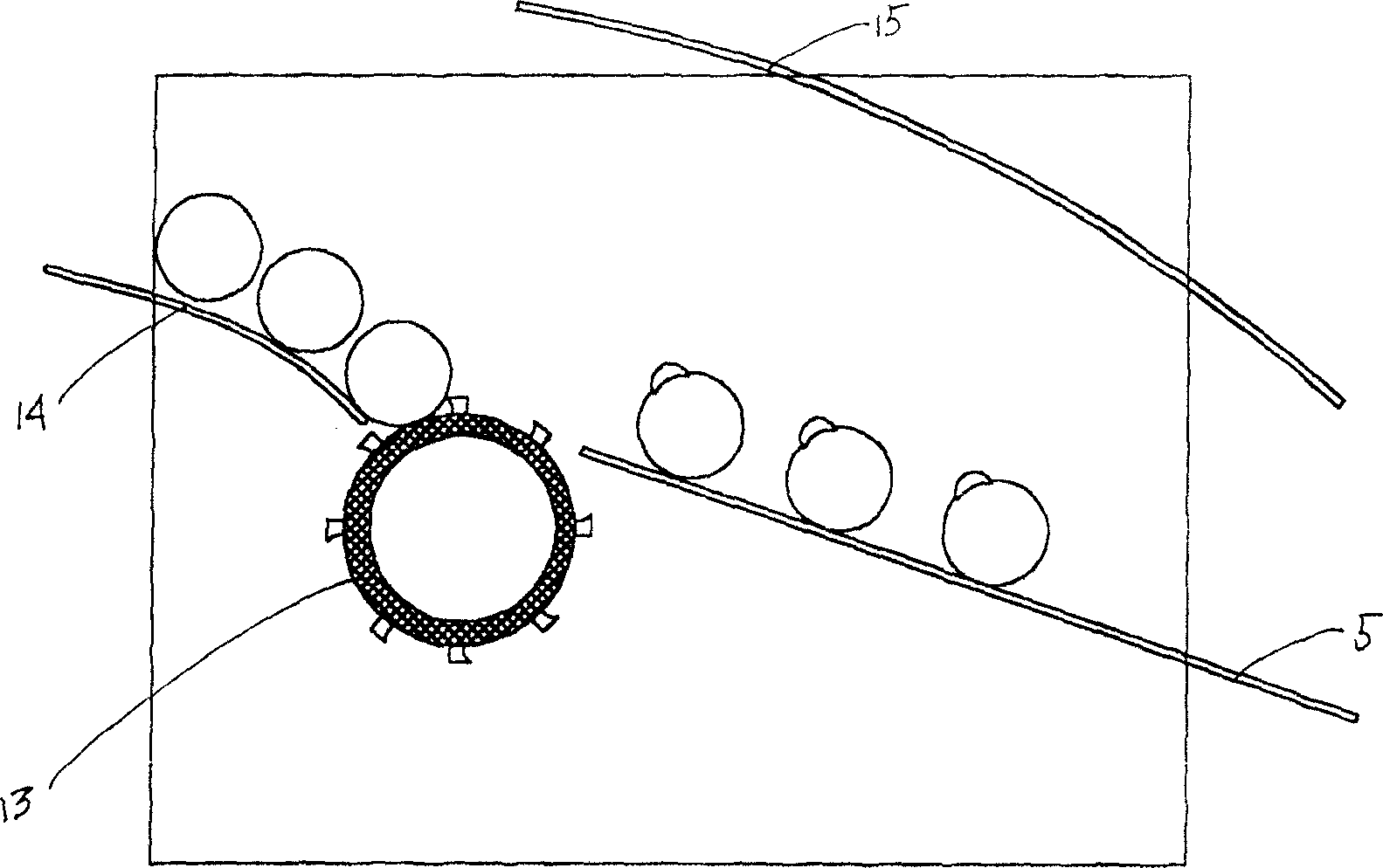

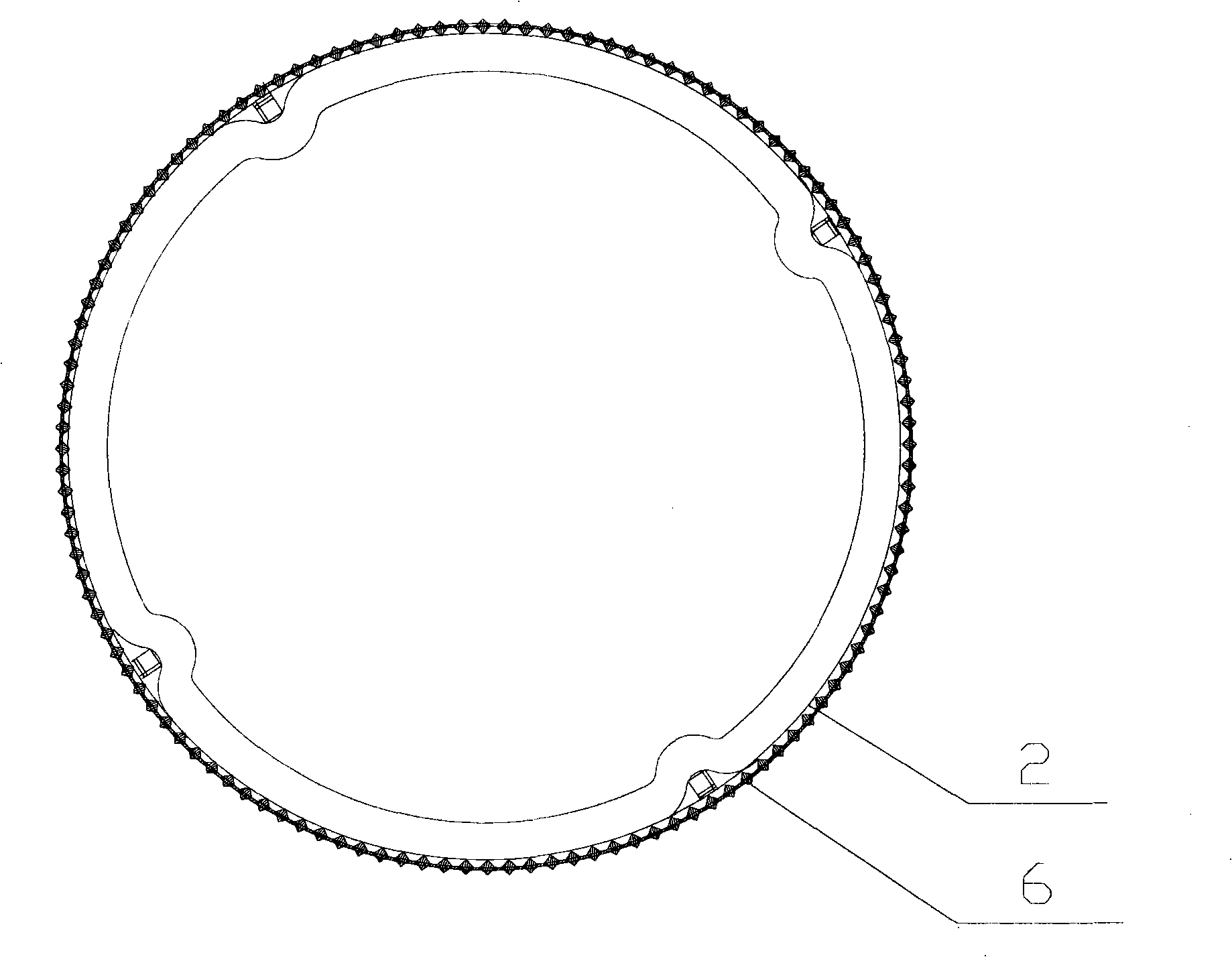

Peeling machine for orange

InactiveCN1631272AHigh success rate of one-time peelingImprove productivityVegetable peelingFood treatmentProduction rateSEMI-CIRCLE

Disclosed is an orange barking machine, which comprises a peel cutting device, a barking device, a transfer arrangement connected therewith, a mated sprinkling arrangement, and an electric controller, the peel cutting device comprises a high speed rotating peel cutting knife roller, an upper guide plate and a lower guide plate, the peel cutting knives on the knife roller are arranged along the single-head spiral lines at equal appearing interval on the roller surface, the barking device comprises bicycle chain conveyor belt and shift rod rows, each husking roll is equipped with even teeth in the shape of semi-circles with coated silicone rubber material.

Owner:象山双鱼轻工机械有限公司

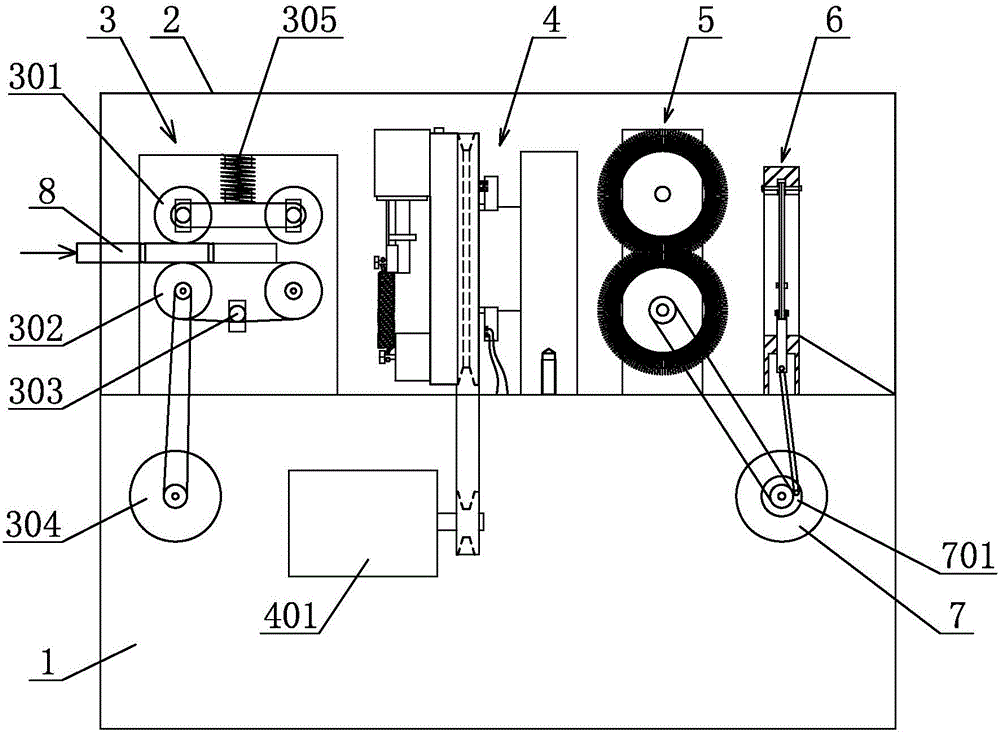

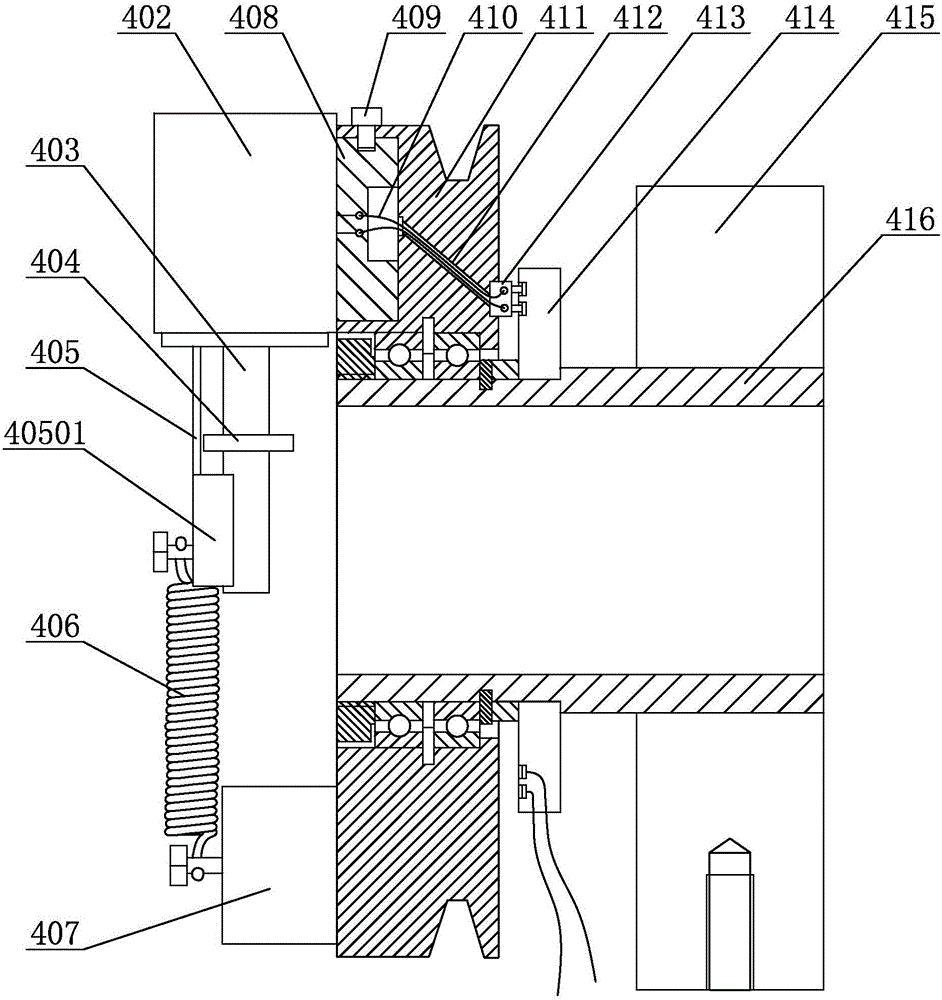

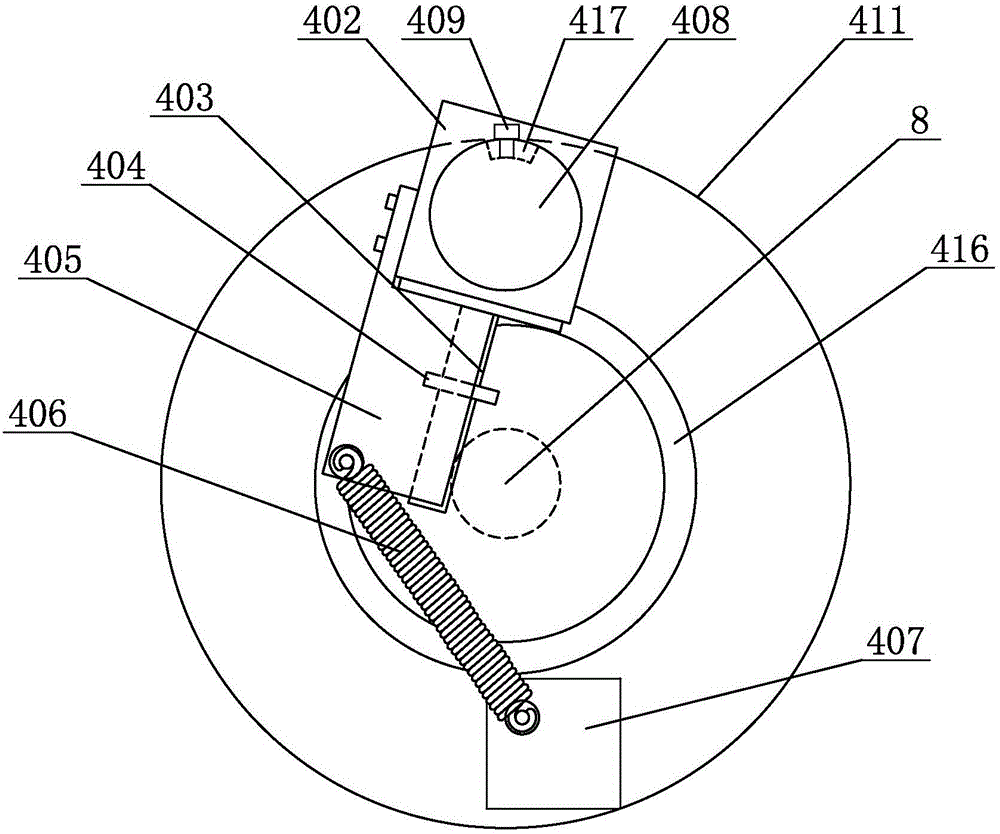

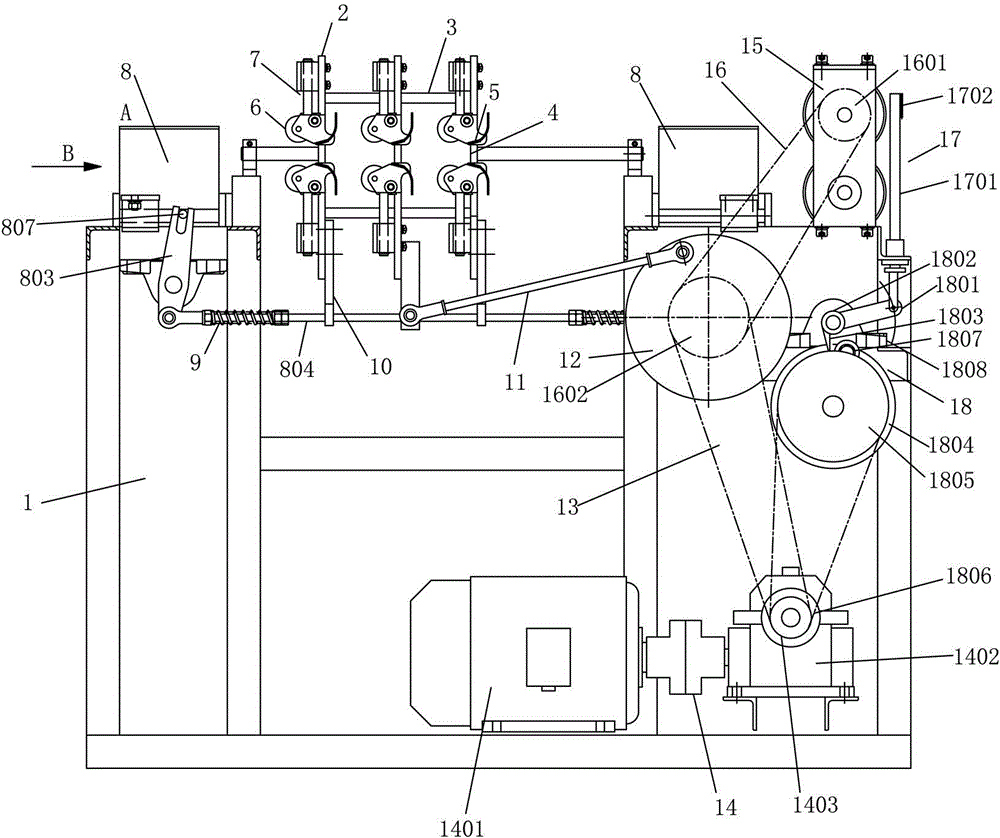

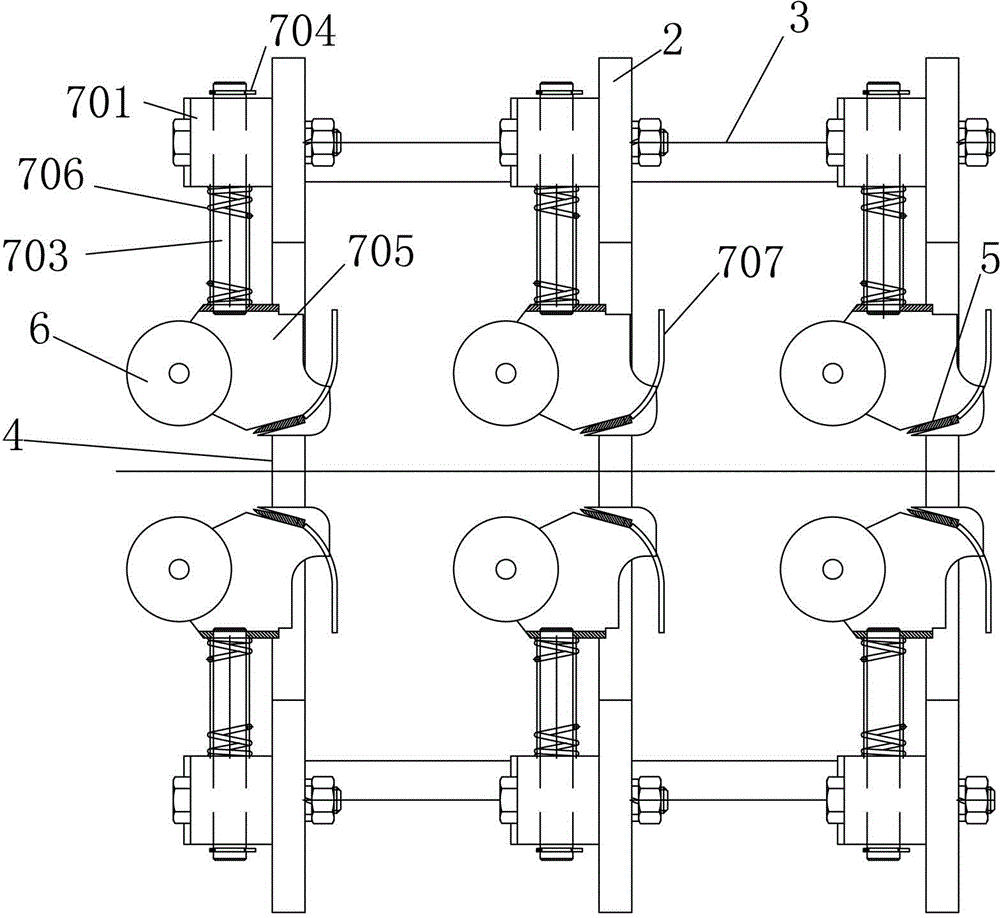

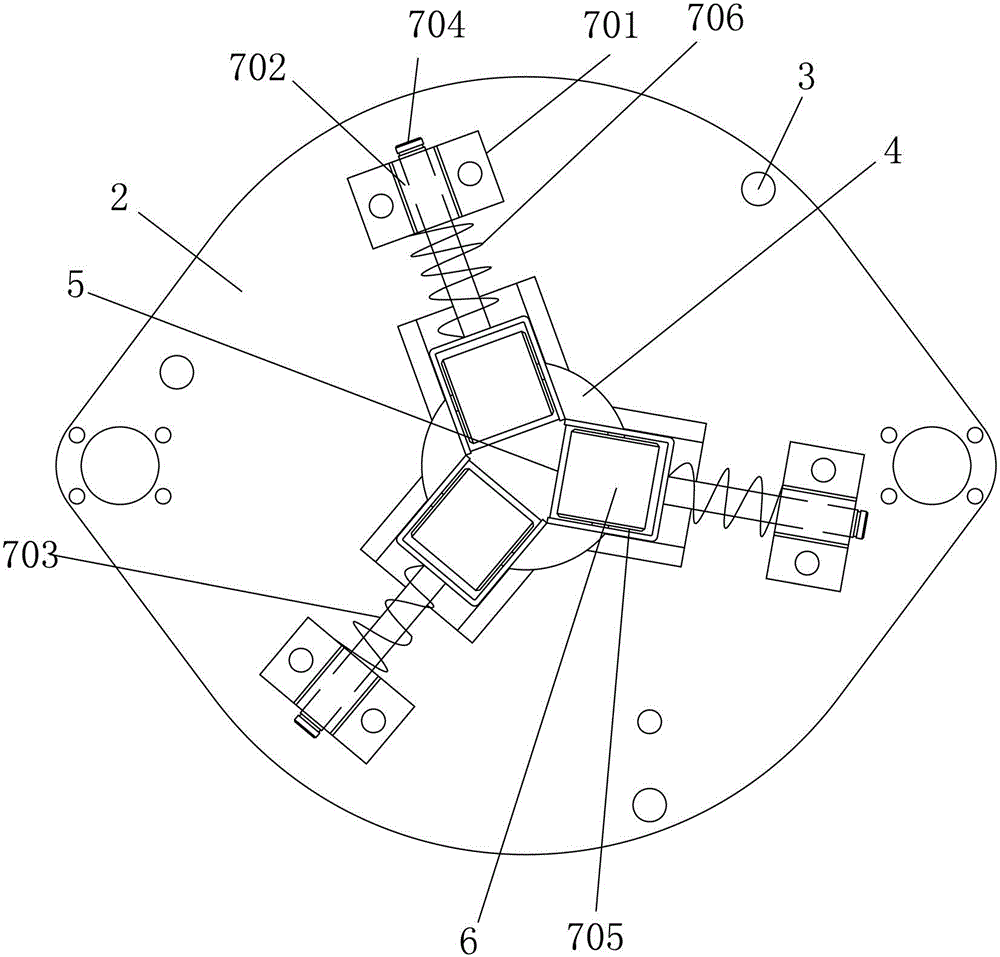

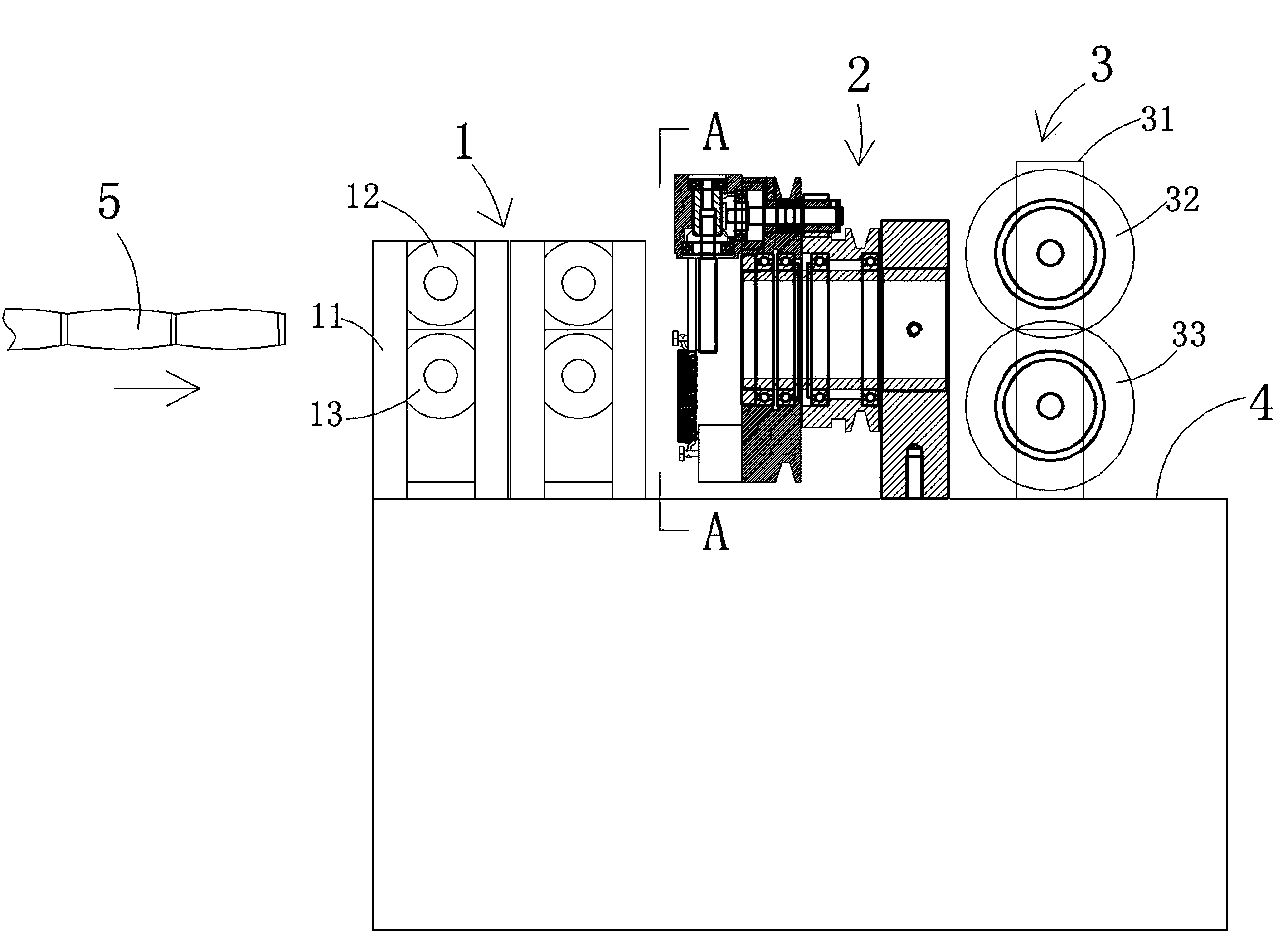

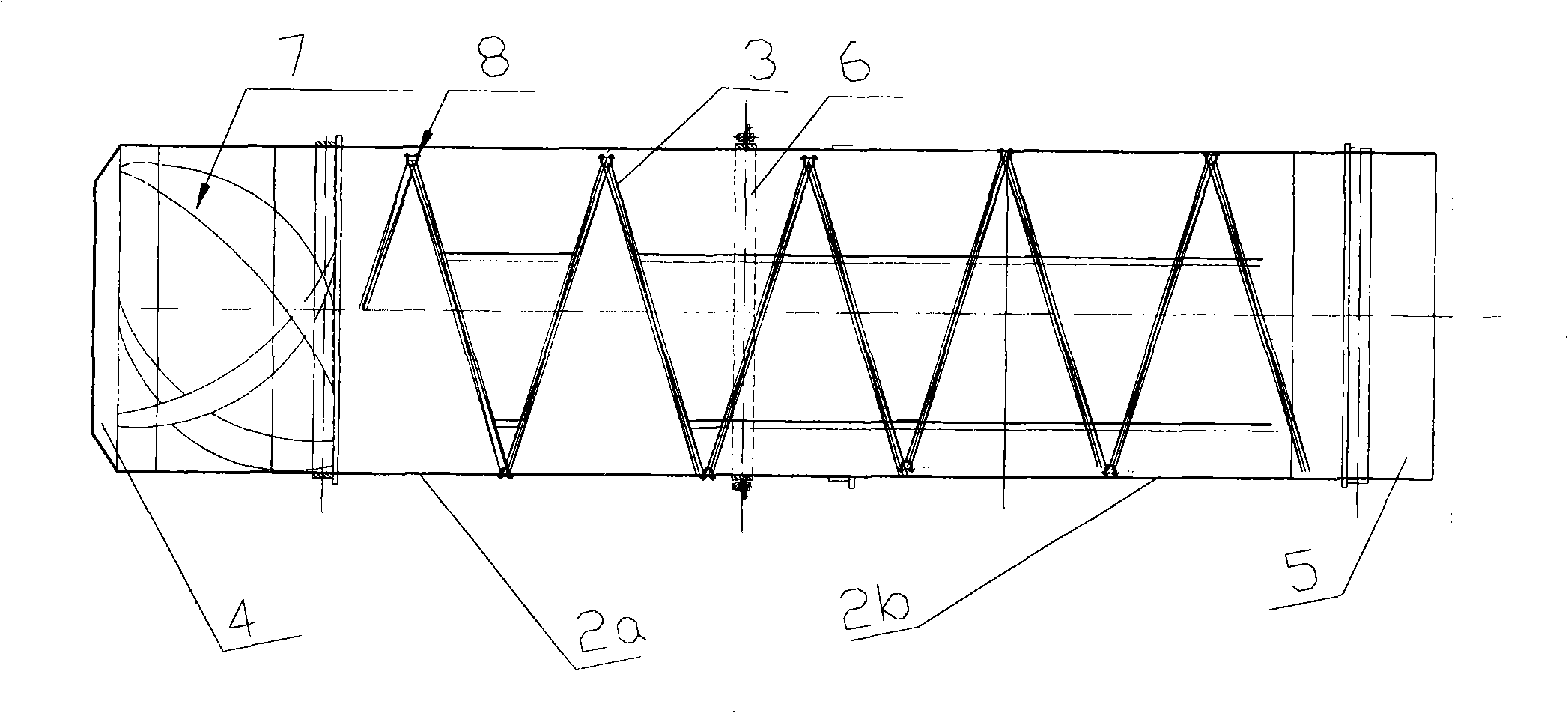

Automatic sugarcane peeling and cutting machine

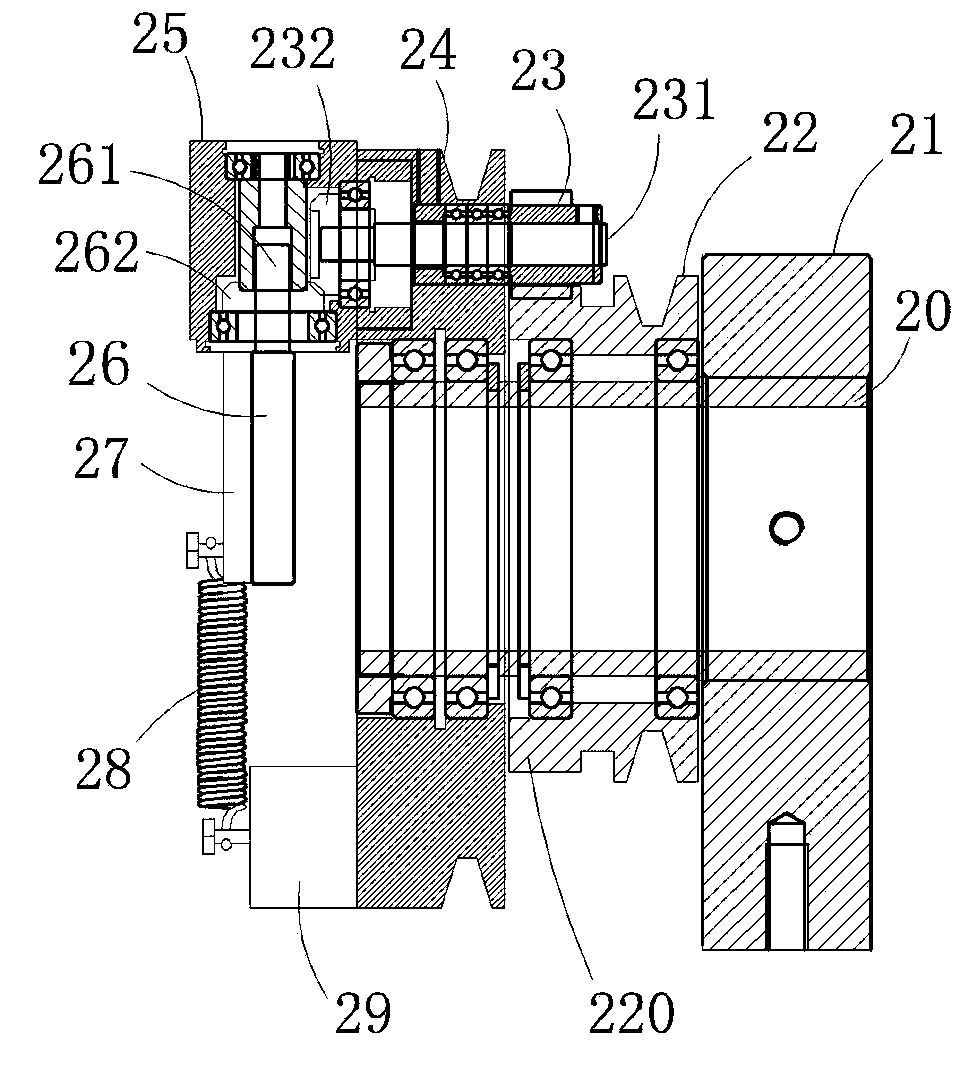

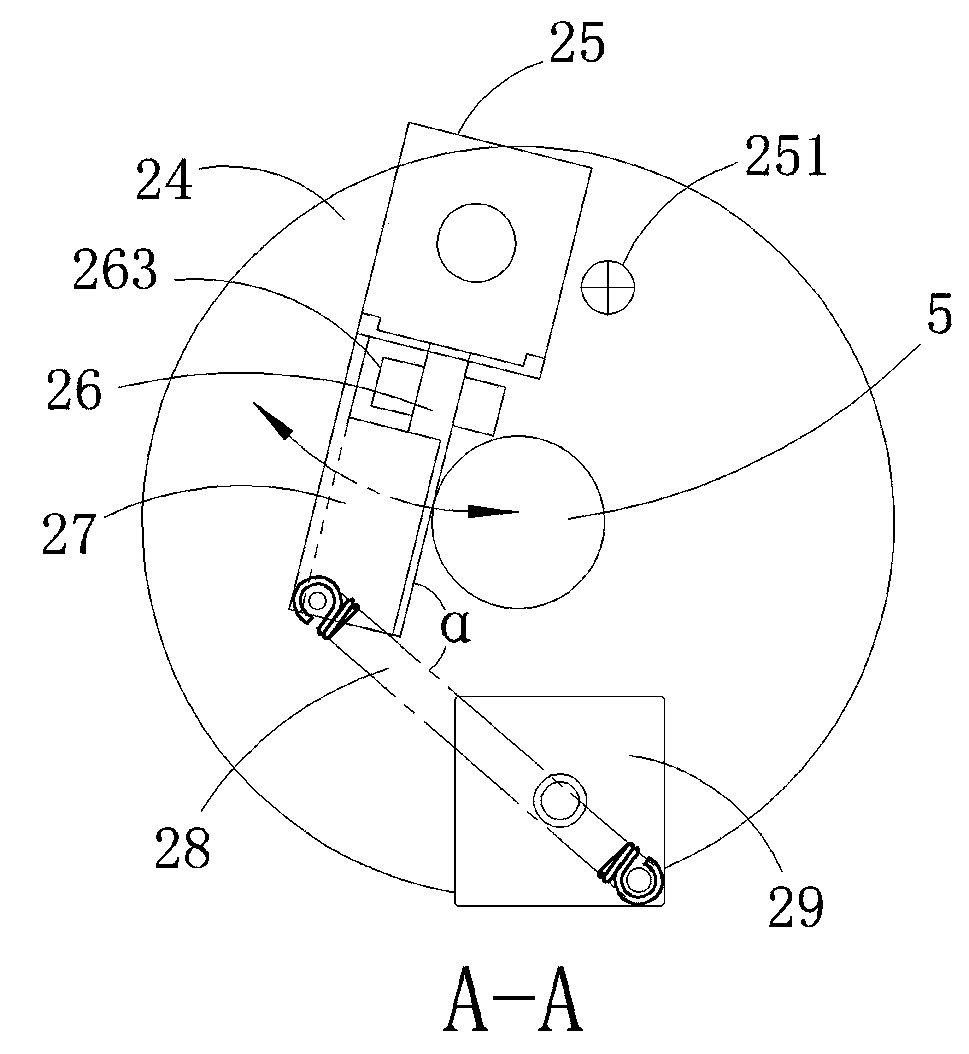

ActiveCN104643268AIn line with expectationsEasy to acceptVegetable peelingMetal working apparatusLinear motionEngineering

The invention relates to an automatic sugarcane peeling and cutting machine. The technical scheme is that the automatic sugarcane peeling and cutting machine comprises a frame, wherein multiple knife rests are arranged transversely on the frame at intervals and are connected with one another by virtue of multiple connecting shafts, a sugarcane passing hole is formed in the center of each knife rest, multiple peeling blades uniformly distributed around the circumference of each sugarcane passing hole are arranged on the knife rests, a guide roller is rotatably arranged on each knife rest at one side, facing a sugarcane inlet, of each peeling blade, an elastic part which is used for limiting each peeling blade at a position for doing linear motion towards the center of each sugarcane passing hole is fixed between each peeling blade and the corresponding knife rest, a holding device is arranged at the outer side of each of the two end knife rests, and a sugarcane traction device is arranged on each holding device in a direction facing a sugarcane outlet. The automatic sugarcane peeling and cutting machine is produced according to a principle of simulating artificial sugarcane peeling, and the appearance of a peeled sugarcane finished product achieves or superior to that obtained by artificial peeling, accords with expectations of people and is beneficial to be accepted by the masses. The automatic sugarcane peeling and cutting machine can well adapt to sugarcanes with different thickness diameters and bending degrees, the complete peeling rate reaches 95% or more than 95%, and the artificial peeling can be completely replaced.

Owner:关永刚

Device for peeling pulpy fruits, having an adjustable cutting depth

ActiveUS20050028686A1High yield percentage valueReduce wasteAutomatic control devicesFeeding apparatusPEARKiwi

A device for peeling pulpy fruits having an adjustable cutting depth The invention relates to a device suited to peel pulpy fruits, like citrus fruits, mango, kiwi, papaya, apples, pears, and particularly oranges and other fruits whose skin has not a uniform thickness. The peeling of fruits whose skin has an uneven thickness is made possible by the fact that the inventive device is equipped with a mechanism capable of varying continuously—according to a program—the amount of projection of the peeling tool relative to the feeler device, in the peeling step. The device is applicable to any kind of peeling machine, or to a machine that foresees a peeling step.

Owner:A B L SRL

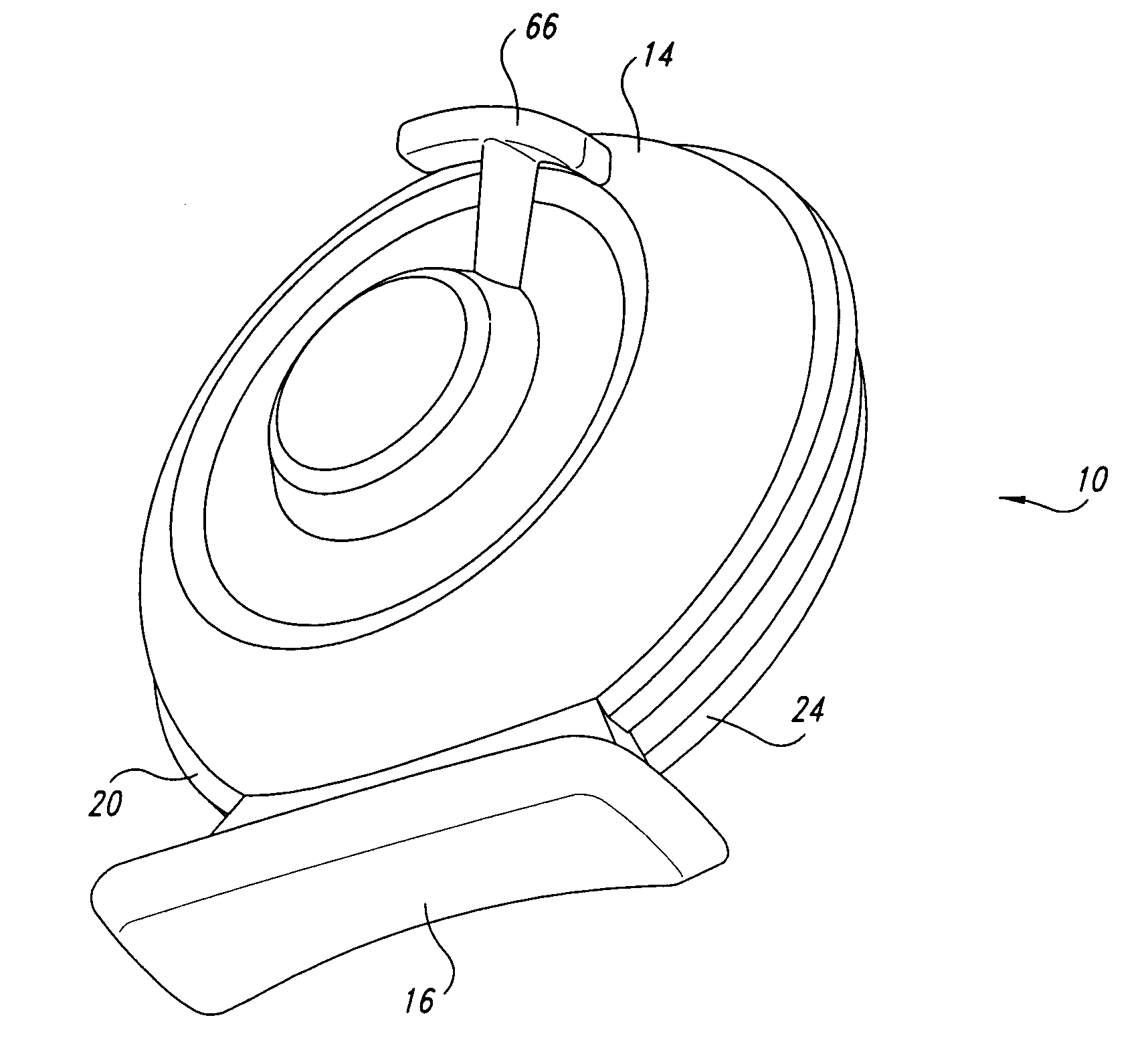

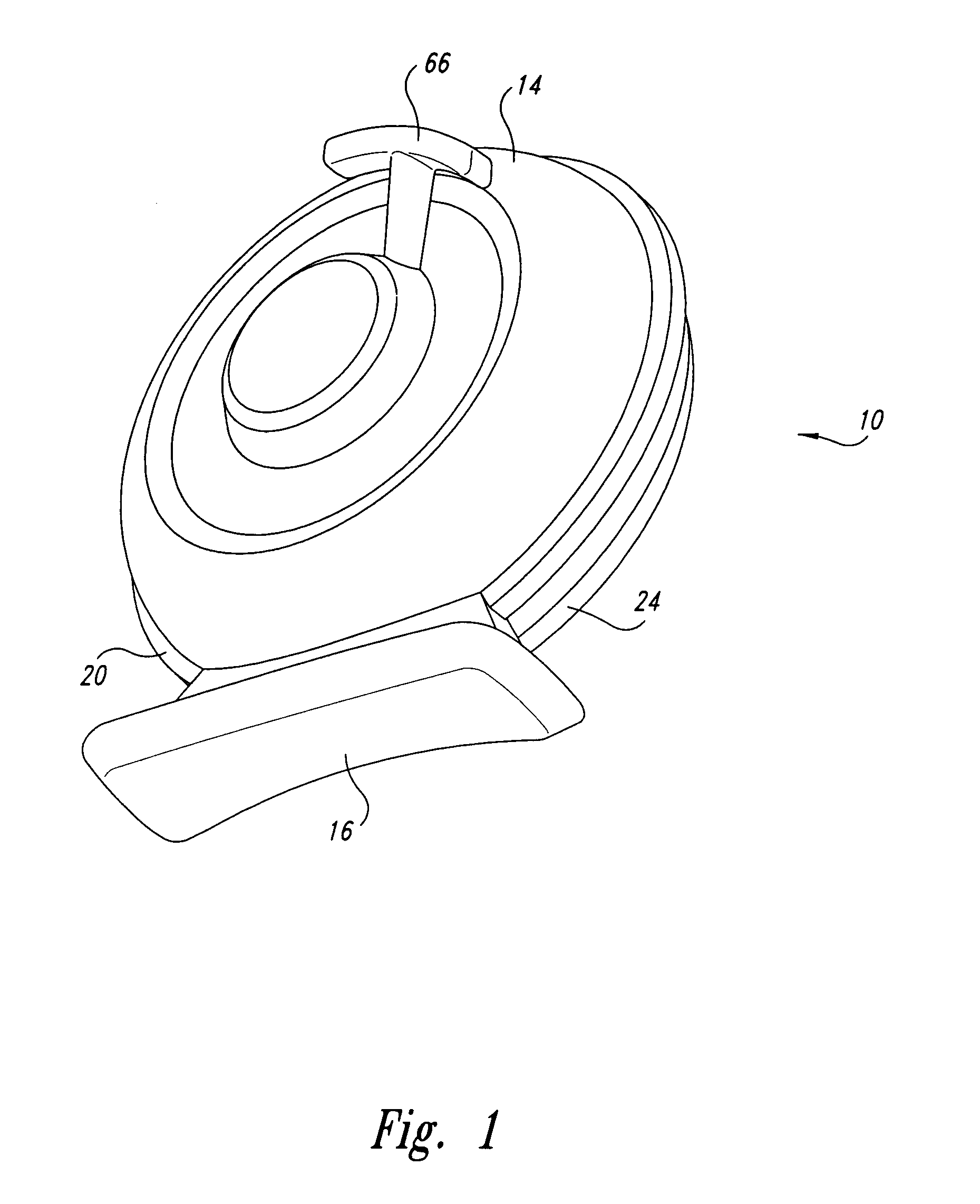

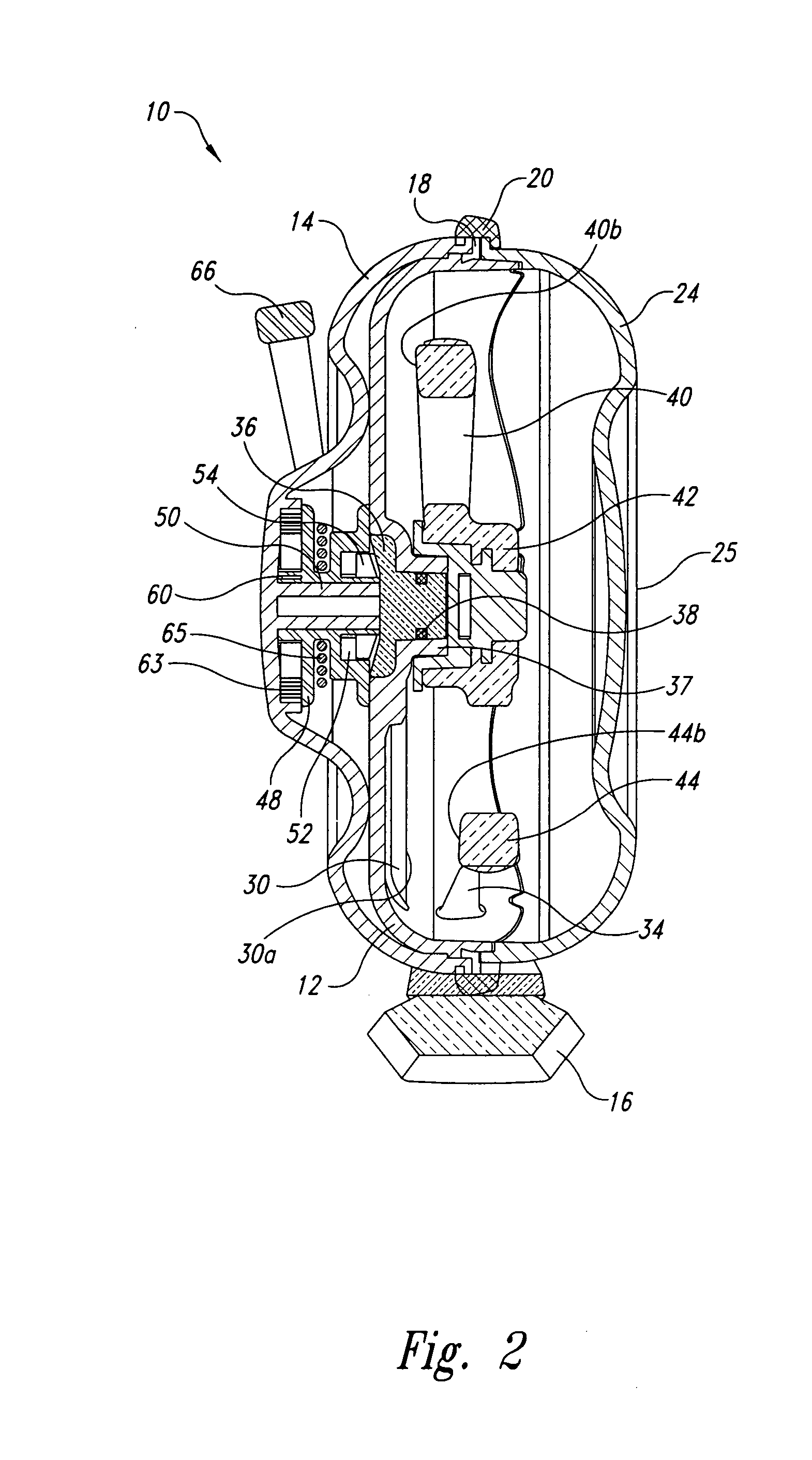

Automatic ice cream scooper

An automatic ice cream scooper. A cylinder of ice cream is placed vertically within a refrigerated container on a slicer having a disc shape. The slicer includes an angled slicing blade for removing ice cream. The slicer is rotated by a motor to remove the ice cream. The slicer has an upstanding edge with the screw thread formed thereon for removing the sidewall of the ice cream container.

Owner:RICHMAN DEBRA S

Whole fruit enzymatic method for peeling coating of tangerine

ActiveCN101095554AIncrease productivityImprove product qualityVegetable peelingProduction rateTangerine Fruit

The invention discloses an excystation method for orange with enzyme, which comprises following steps: selecting orange and cleaning it; piercing orange with needle bed, the needle passes outer layer of orange but not contact orange meat; adding a certain amount of pectic enzyme, cellulose and hemicellulase into water, getting enzymolysis solution, adjusting enzymolysis solution pH with acid or alkali; immersing pierced orange into said enzymolysis solution; vacuuming, keeping 10-120 minutes; heating enzymolysis solution to 35-60 Deg. C, keeping the condition for 0.5-5 hours; barking and splitting orange, and getting excystated orange. The invention is characterized by high production rate, little human influence, stable product quality, reliable product safety and little environmental pollution.

Owner:HUNAN AGRI PRODS PROCESSING INST

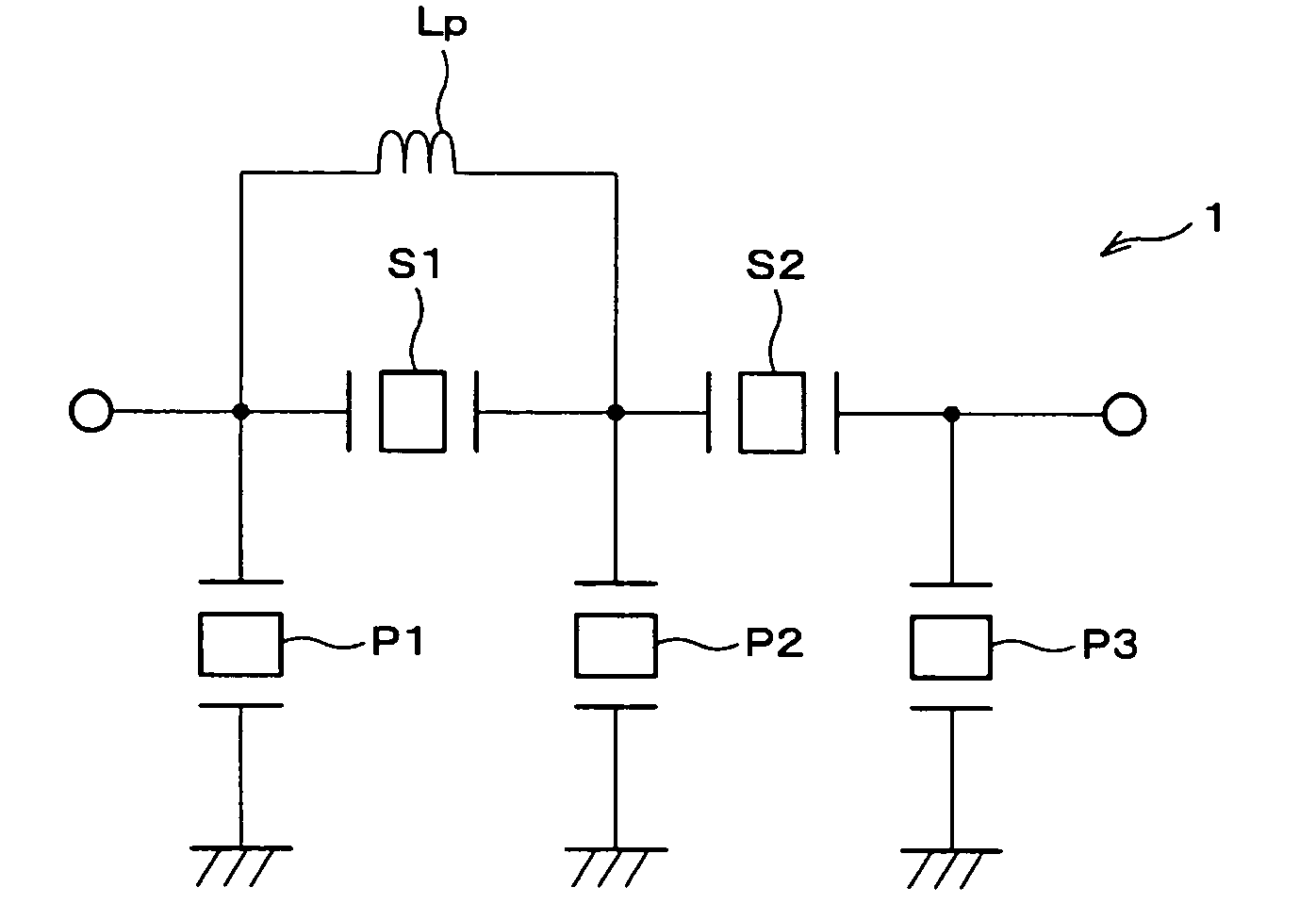

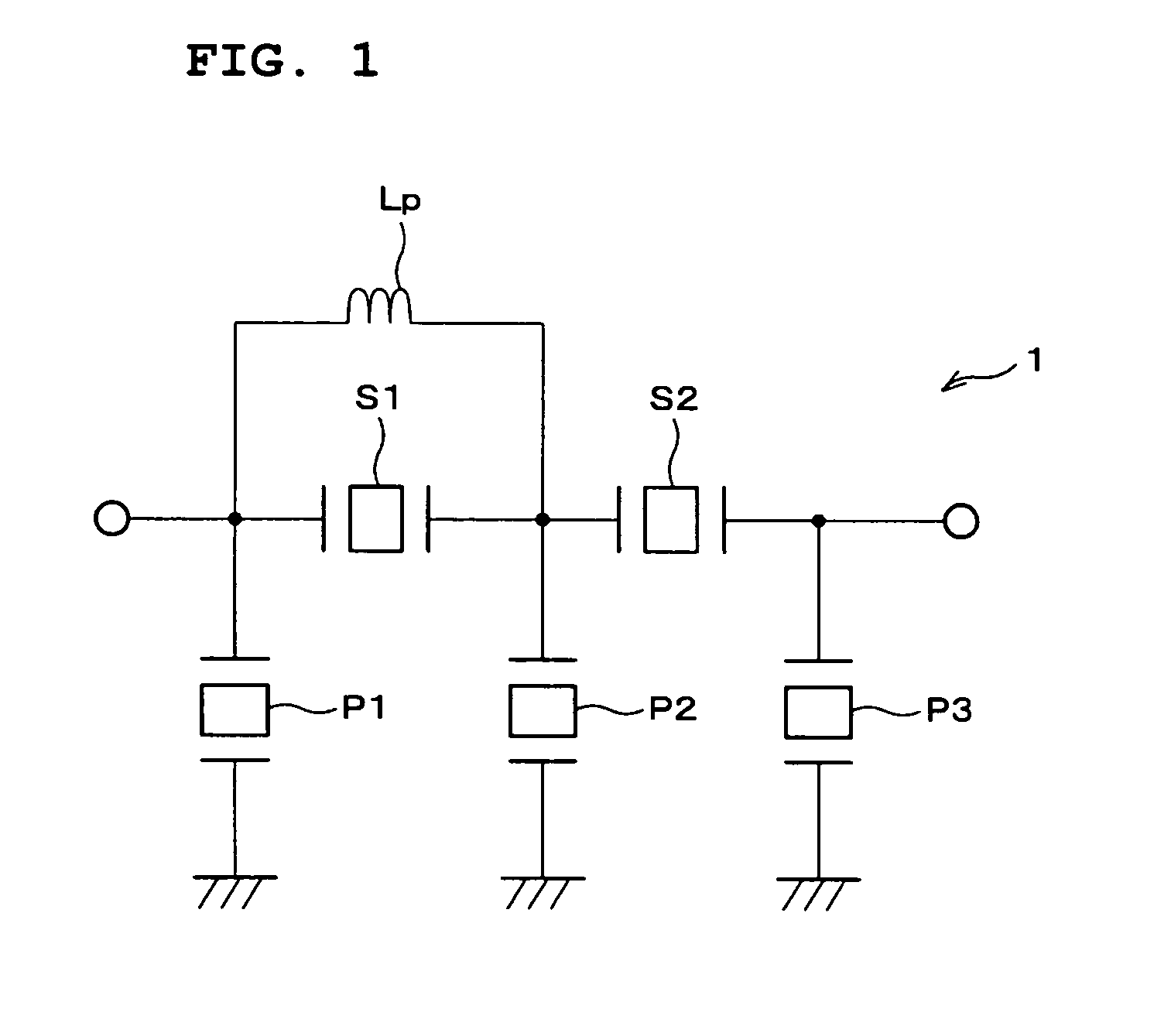

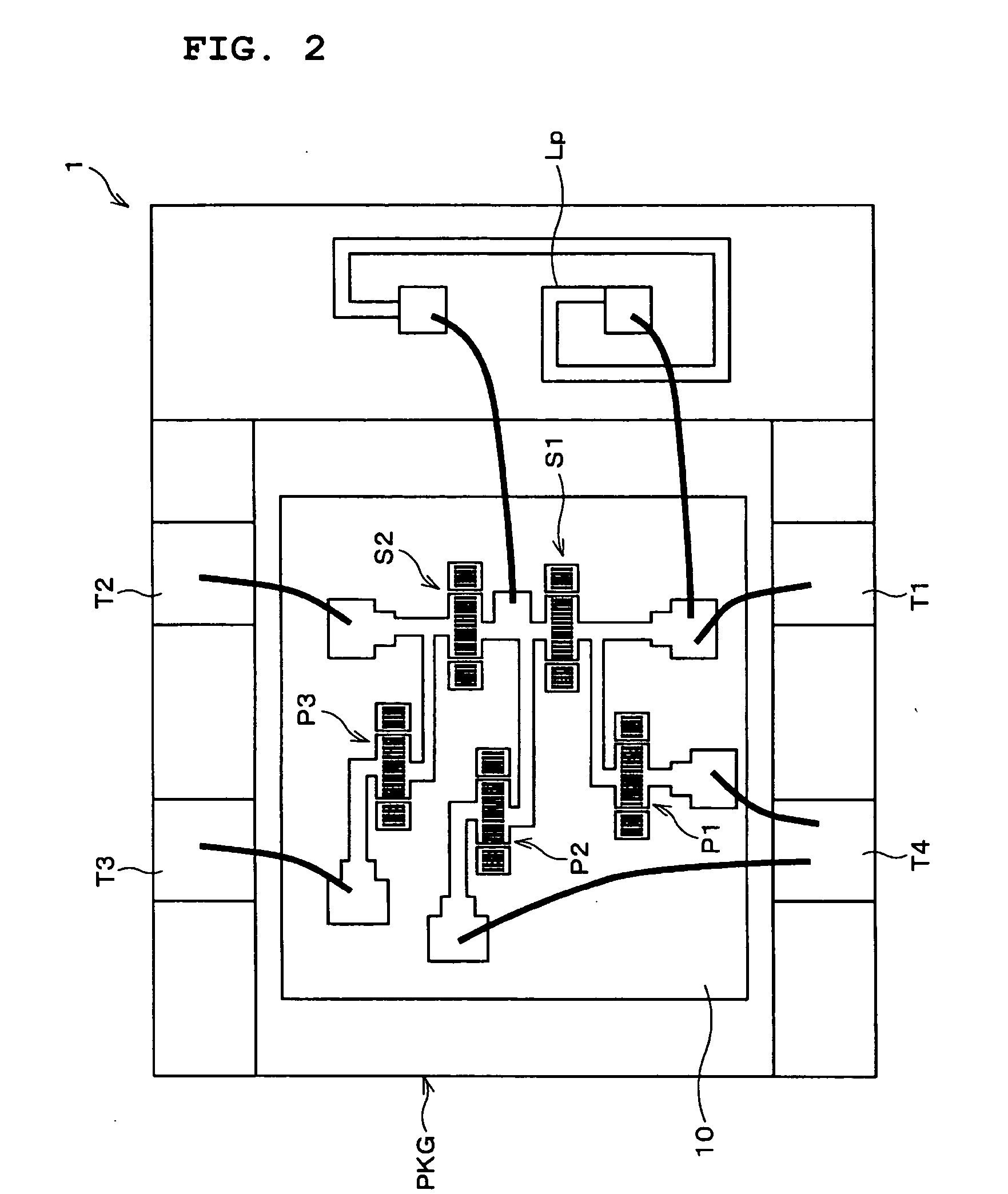

Ladder filter, branching filter, and communication apparatus

ActiveUS20040140866A1Reduced characteristicsLarge band widthMultiple-port networksVegetable peelingInductorResonator

A ladder filter includes series arm resonators and parallel arm resonators which are alternately connected to each other. The series arm resonators include a first series arm resonator connected in parallel with an inductor and a second series arm resonator not connected to the inductor. The ladder filter satisfies the relationship of fsr1<fsr2, where fsr1 represents the resonant frequency of the first series arm resonator and fsr2 represents the resonant frequency of the second series arm resonator.

Owner:MURATA MFG CO LTD

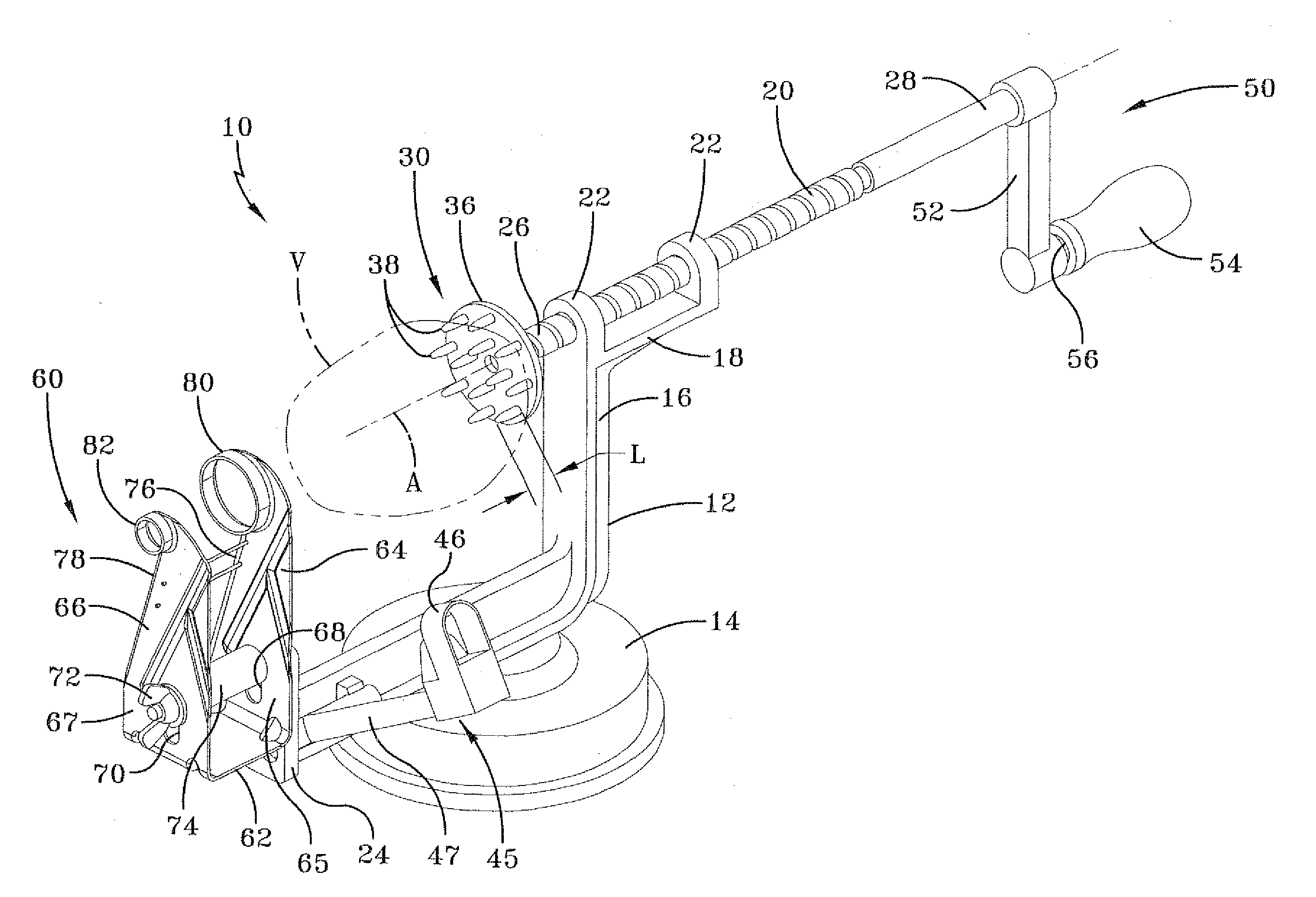

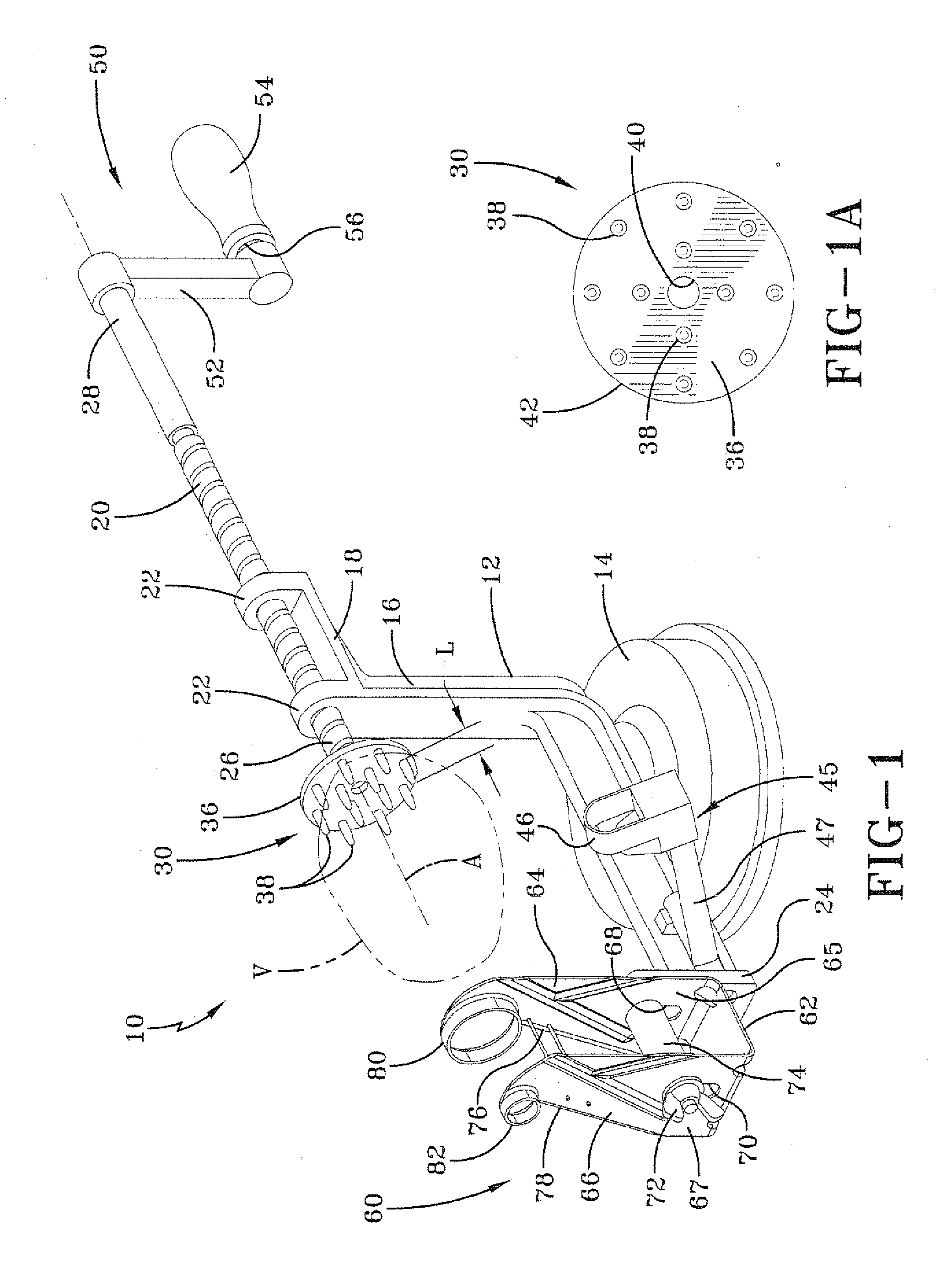

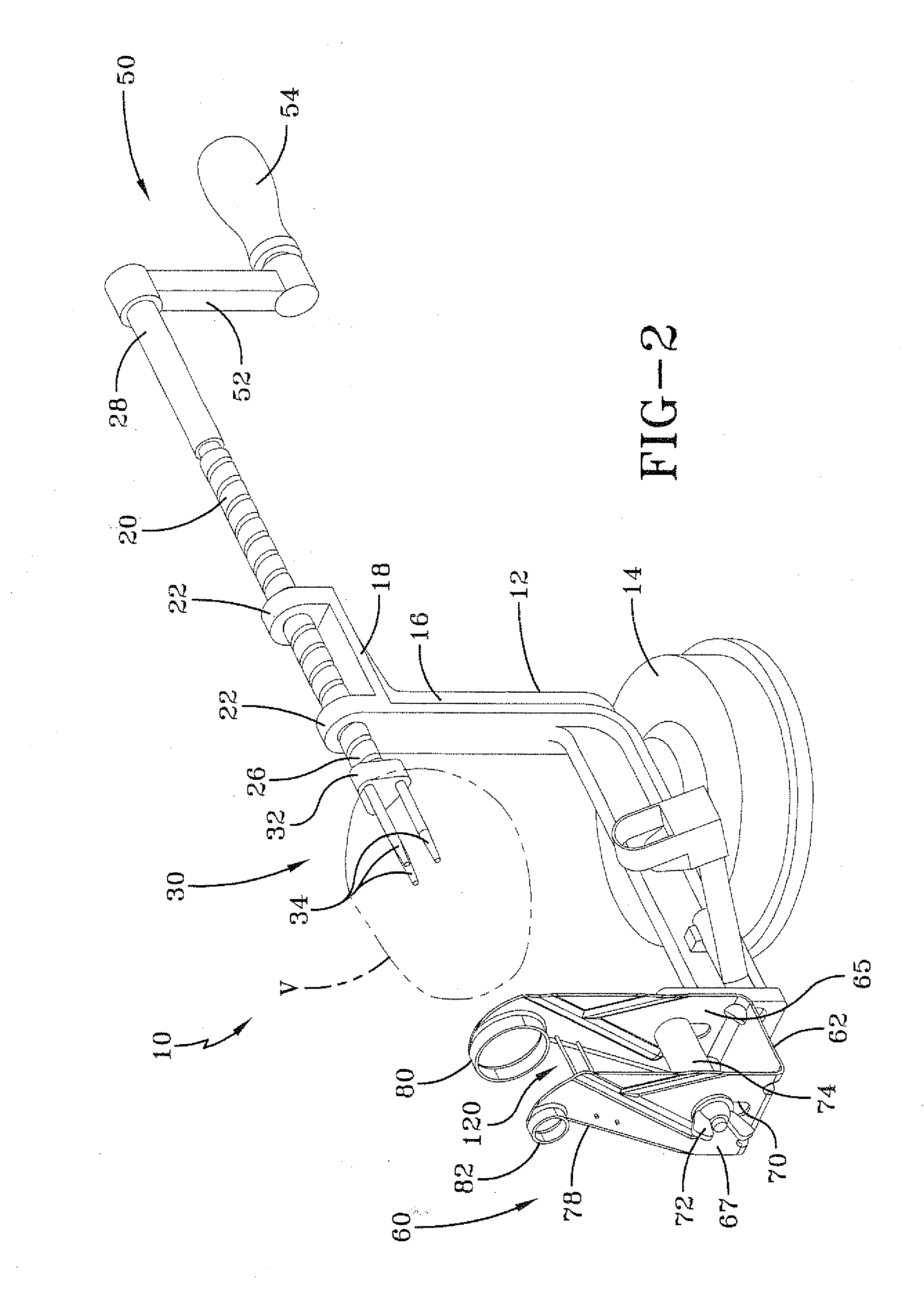

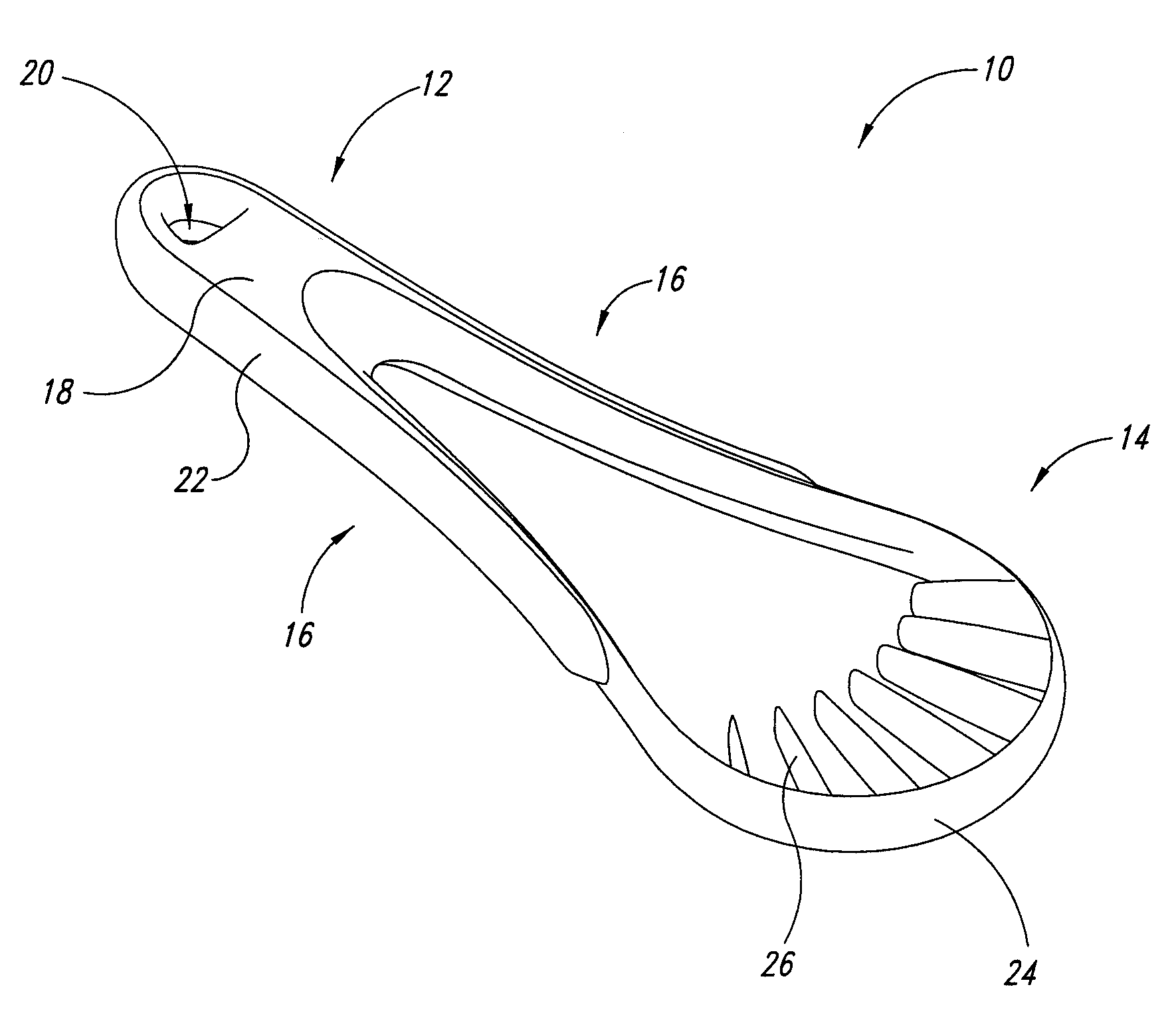

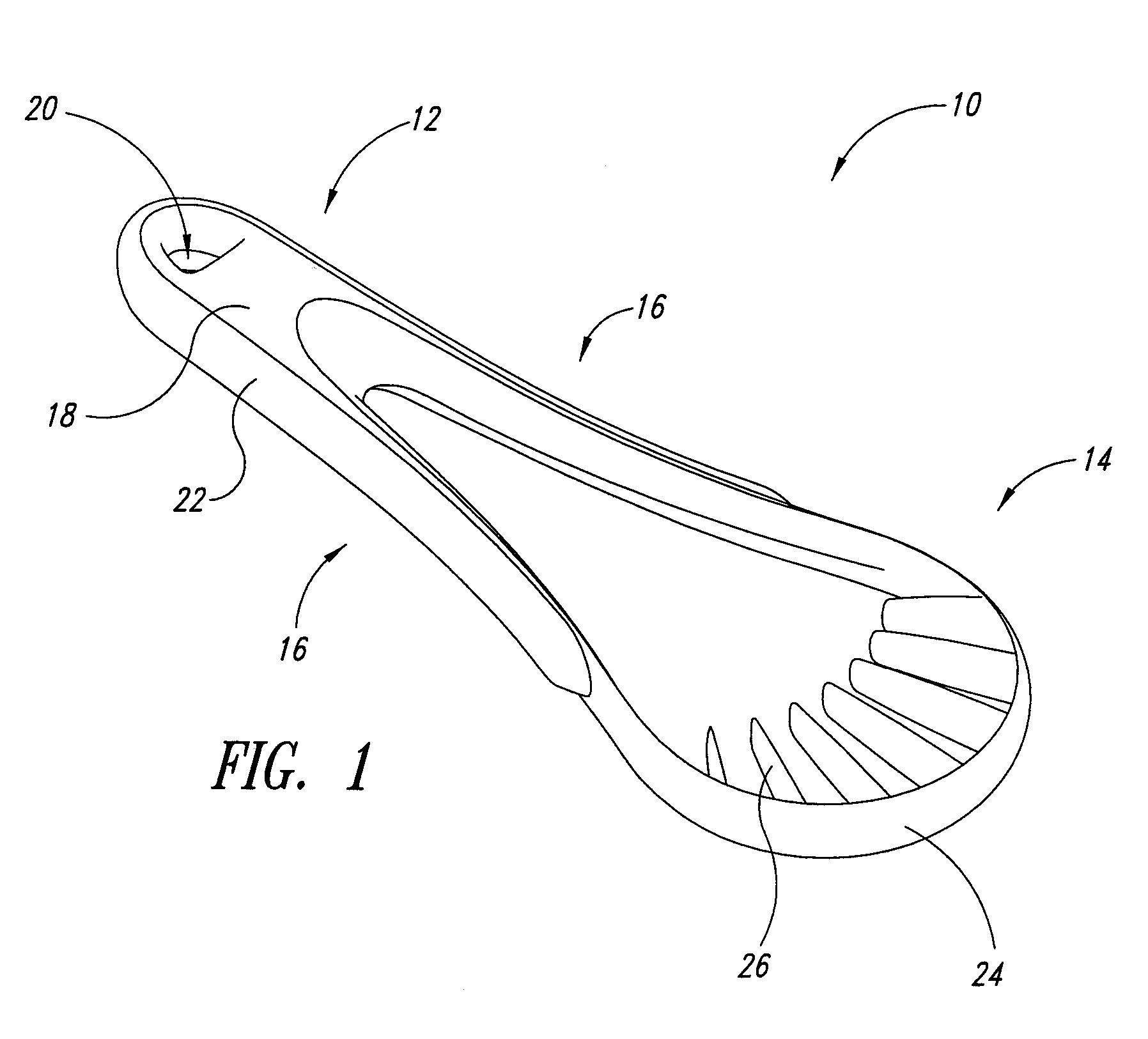

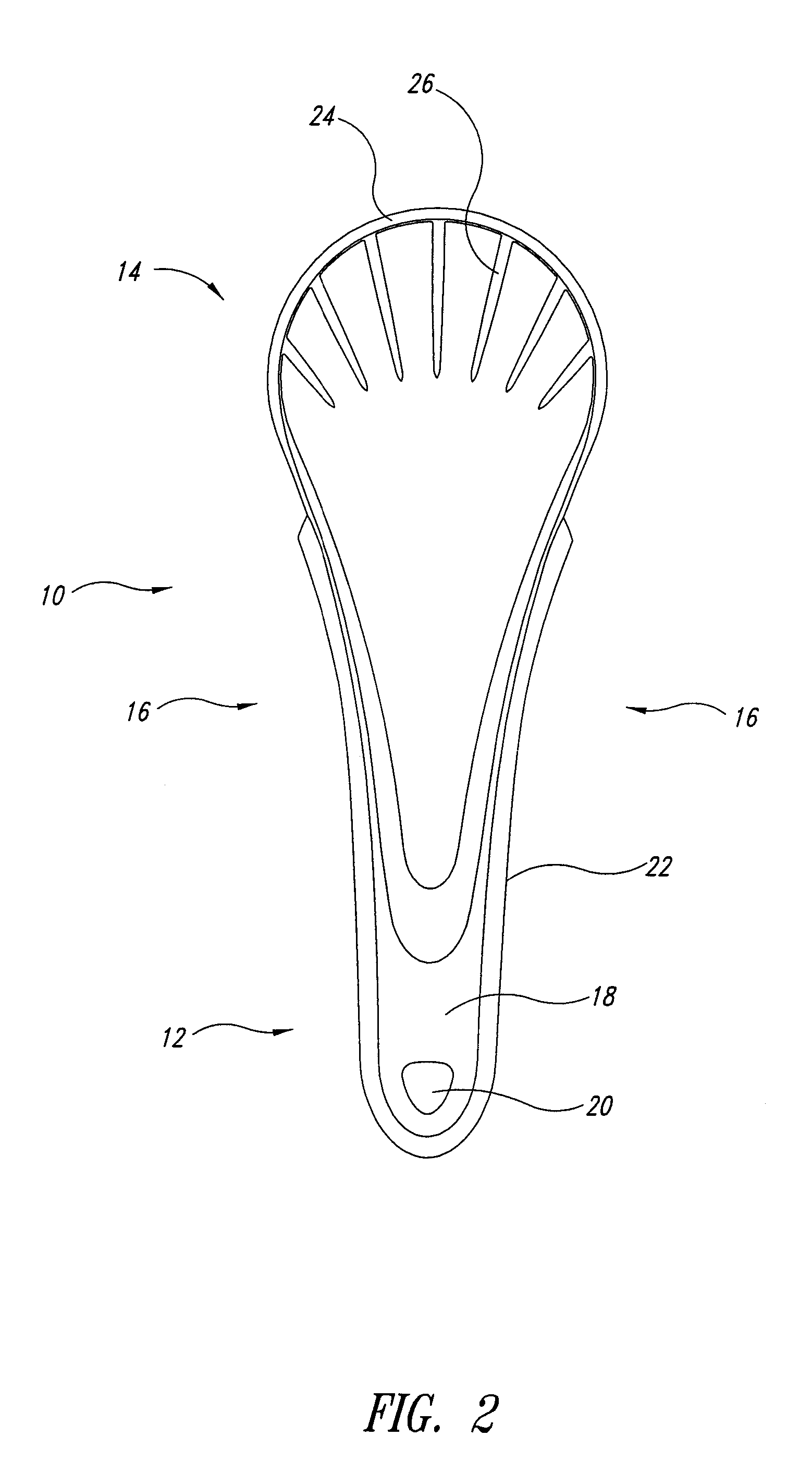

Devices and methods for use in preparing certain fruits for consumption

Devices for removing and / or slicing a meat of fruit are disclosed. In one embodiment, the device has a handle portion and a working portion having an elongated blade and a pair of lateral extensions. The elongated blade has a cross-sectional shape adapted to facilitate movement of the elongated blade through the meat of the fruit. The working portion of the device has a resting configuration in which the elongated blade has a first radius of curvature, and at least one of the lateral extensions is manipulable under a manual force during use to deform the working portion from the resting configuration to a displaced configuration in which the elongated blade has a second radius of curvature, selectively conforming to the curvature of the skin before and as the elongated blade moves through the meat of the fruit.

Owner:CHEFN

Technology for producing citrus juice sac through peeling and capsule dressing removal of whole fruits

InactiveCN102488151AAvoid damageConserve waterVegetable peelingFood preparationLoss rateBreakage rate

The invention discloses a technology for producing a citrus juice sac through the peeling and the capsule dressing removal of whole fruits. The technology comprises the following steps: 1, grinding the fruits or scratching peels; 2, blanching or carrying out compound enzyme processing; 3, carrying out peeling and capsule dressing removal of the whole fruits; 4, carrying out dispersion and impurity removal of the whole fruits; 5, blend-mixing; 6, disinfecting and killing enzymes; and 7, carrying out aseptic loading. According to the invention, fruit grinding or peel scratching preprocessing is adopted, a whole fruit enzyme method is adopted to peel and remove capsule dressings, a whole fruit improvement acid-alkali method is adopted to remove the capsule dressings, and a whole fruit dispersion method is adopted to produce the citrus juice sac which is used as a raw material for a citrus juice with fleshes. The technology of the invention allows labor force to be saved by above 25%, an acid-alkali or enzyme preparation and water for the capsule dressing removal to be saved by about 30%, a raw material loss rate to be reduced by about 15%, and a juice sac breakage rate to be reduced by about 10%, so the production cost can be saved by about 20%, and the juice sac quality can be improved.

Owner:CITRUS RES INST OF CHINESE ACAD OF AGRI SCI

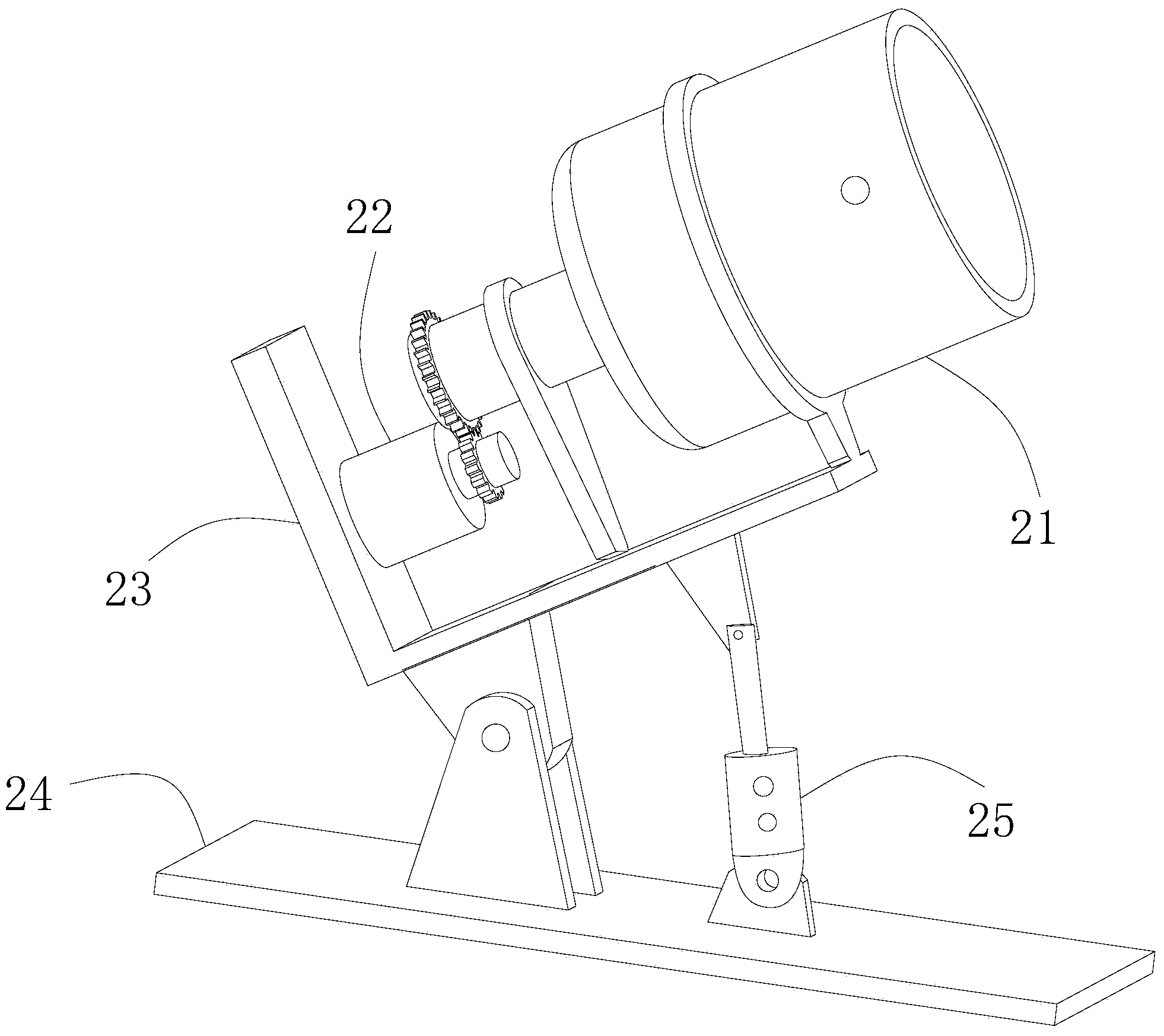

Device for peeling potatoes

InactiveCN103815527AEffective primary peelingImprove processing efficiencyVegetable peelingDevice formEngineering

The invention discloses a device for peeling potatoes. The device comprises a peeling barrel for containing the potatoes to be peeled, the peeling barrel is obliquely arranged and rotationally fixed on a base in the barrel depth direction, the inner barrel face at the bottom of the peeling barrel is composed of cleaning ball wires, and a driving mechanism is arranged at the bottom of a barrel body to drive the peeling device to rotate. According to the peeling device formed according to the scheme, the potatoes are poured into the peeling barrel, the driving mechanism drives the peeling barrel to rotate, the potatoes are rubbed and wiped with the cleaning ball wires on the barrel face at the bottom of the peeling barrel, and therefore the potatoes can be peeled, the rate of peeling can reach to more than 60 percent when the device is used for peeling the potatoes, and the device is suitable for initially and quickly peeling the potatoes.

Owner:LUAN TIANRUN DAIRY IND

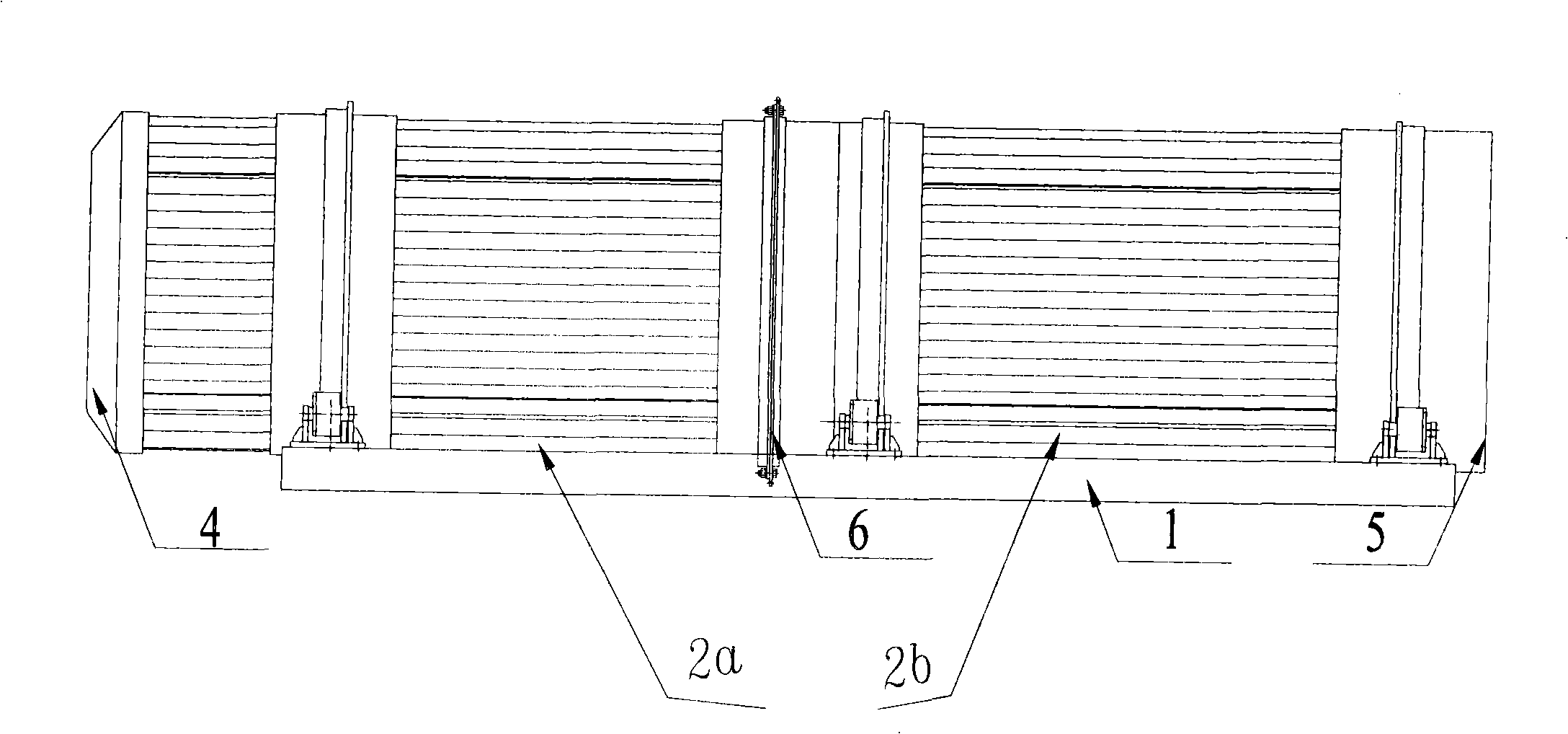

Peeling machine for sugarcanes

The invention relates to a peeling machine for sugarcanes different in thickness. The peeling machine for the sugarcanes comprises a peeling mechanism and is characterized in that the peeling mechanism comprises a cylindrical spiral milling cutter, a cutter base and a main belt plate. The spiral milling cutter is installed on the cutter base through a cutter shaft in a rotatable mode. The cutter base is installed on one side of the main belt plate in a rotatable mode, the main belt plate is installed on a shaft sleeve in a rotatable mode, and the shaft sleeve is fixedly installed on a shaft sleeve base. An auxiliary peeling piece is fixedly connected to the cutter base, the auxiliary peeling piece and the spiral milling cutter are arranged side by side, the milling cutter is used in cooperation with the auxiliary peeling piece for peeling, the cutter base makes the milling cutter close to the shaft center of the shaft sleeve through a torsion component, and the milling cutter and the main belt plate are driven by a power source to rotate. The peeling machine has the advantages of being stable in structure, convenient to use, thorough in peeling and capable of peeling the sugarcanes different in thickness.

Owner:RUIAN RUIHONG AUTOMATION TECH

Method of removing the fibrous shells from cereal grains

InactiveUS6368649B1Risk minimizationNeed for relatively lowGrain huskingGrain polishingFiberPre treatment

The invention relates to a method of removing the fibrous shells from cereal grains. This method according to the invention comprises a pretreatment step, wherein the moisture content of the cereal grains is increased, e.g. in the case of corn grains from 16 to more than 20% by weight, followed by the step of exposure of the pretreated grains to a thermal shock by means of a cryogenic medium and thereafter mechanical treatment step thereof.

Owner:CARGILL AMSTERDAM

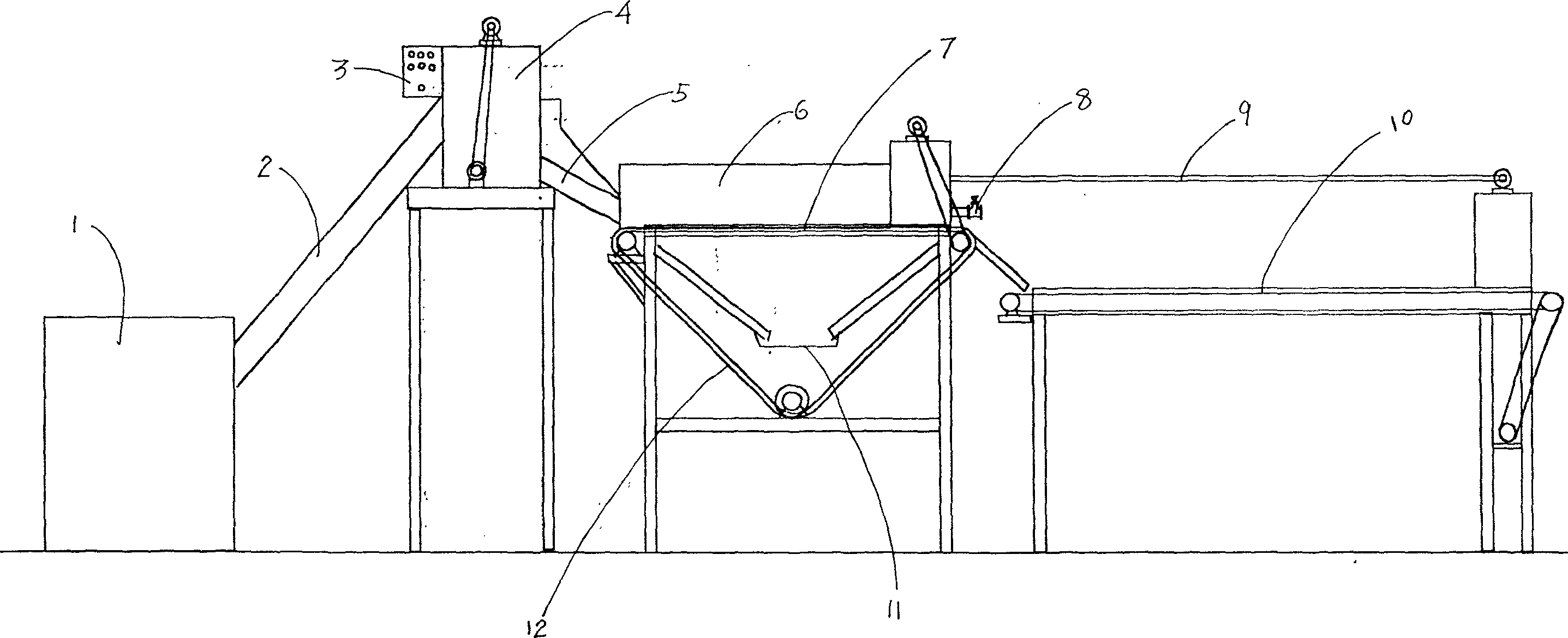

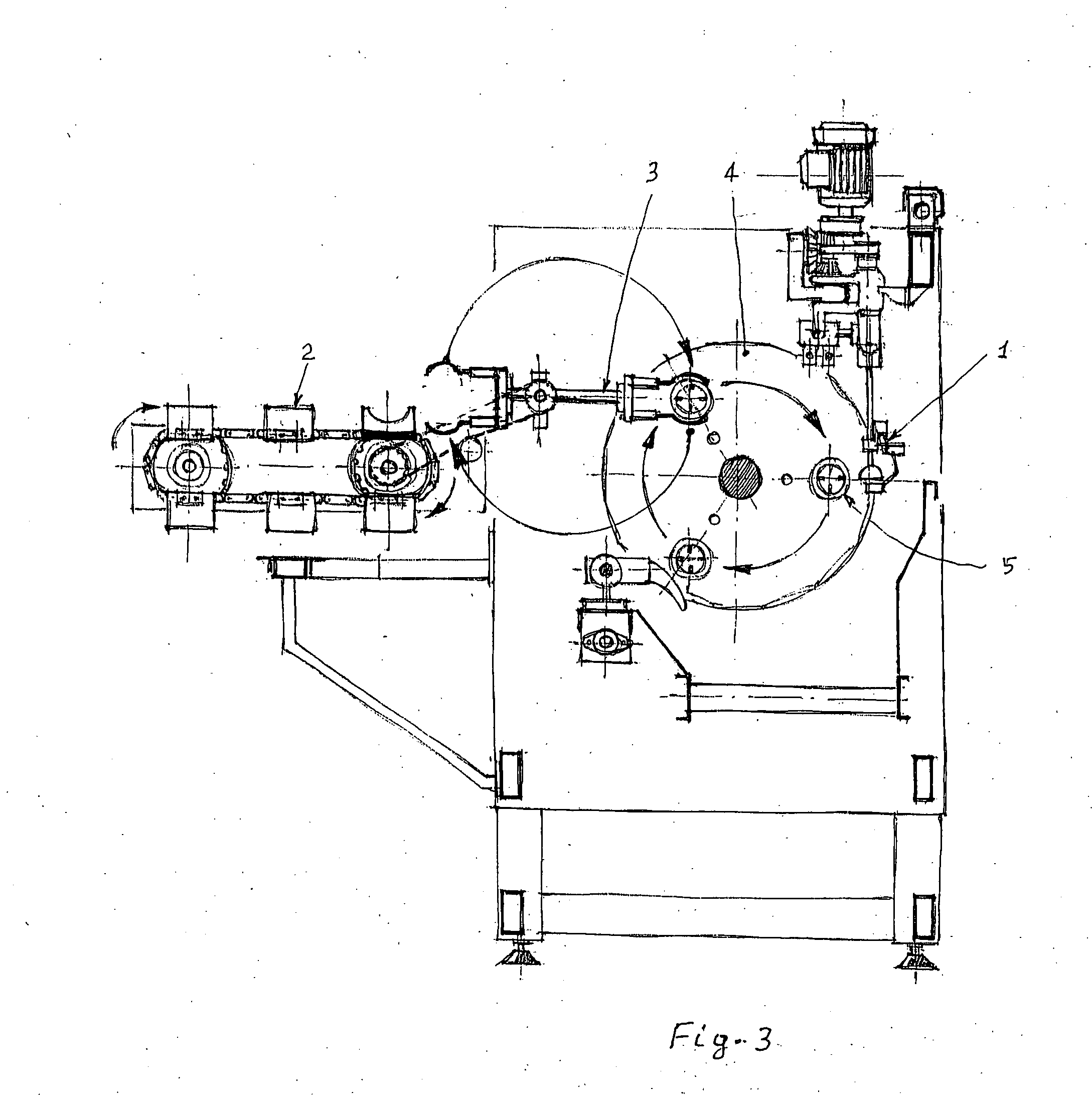

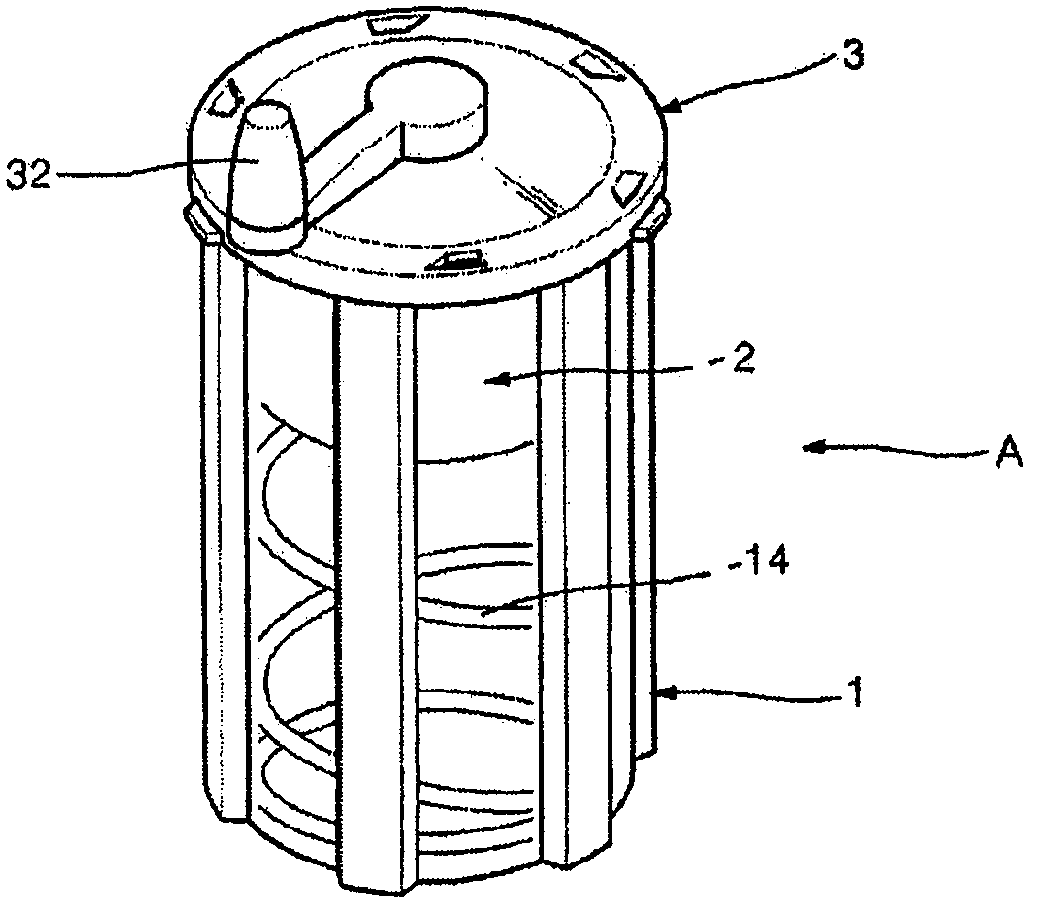

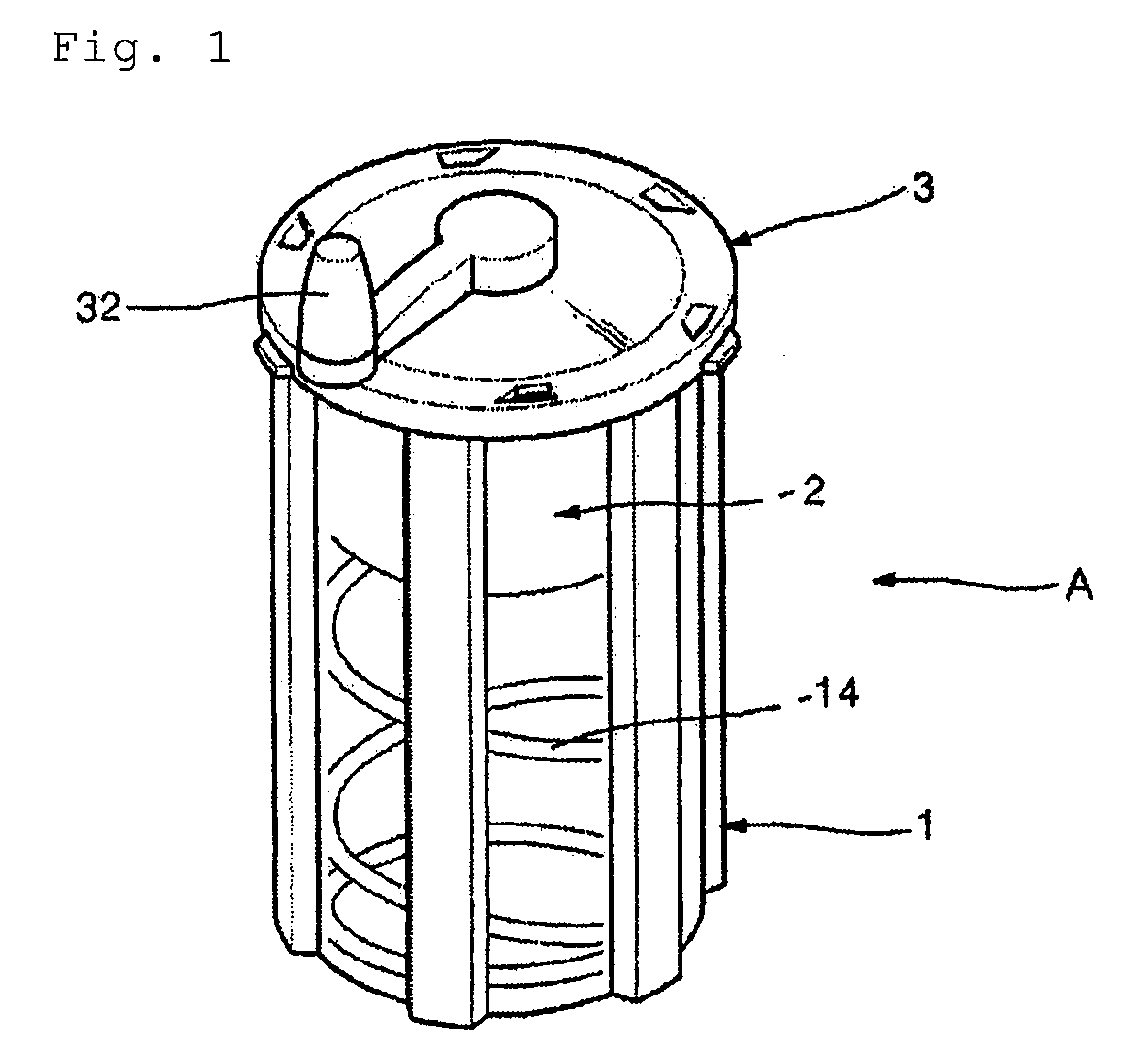

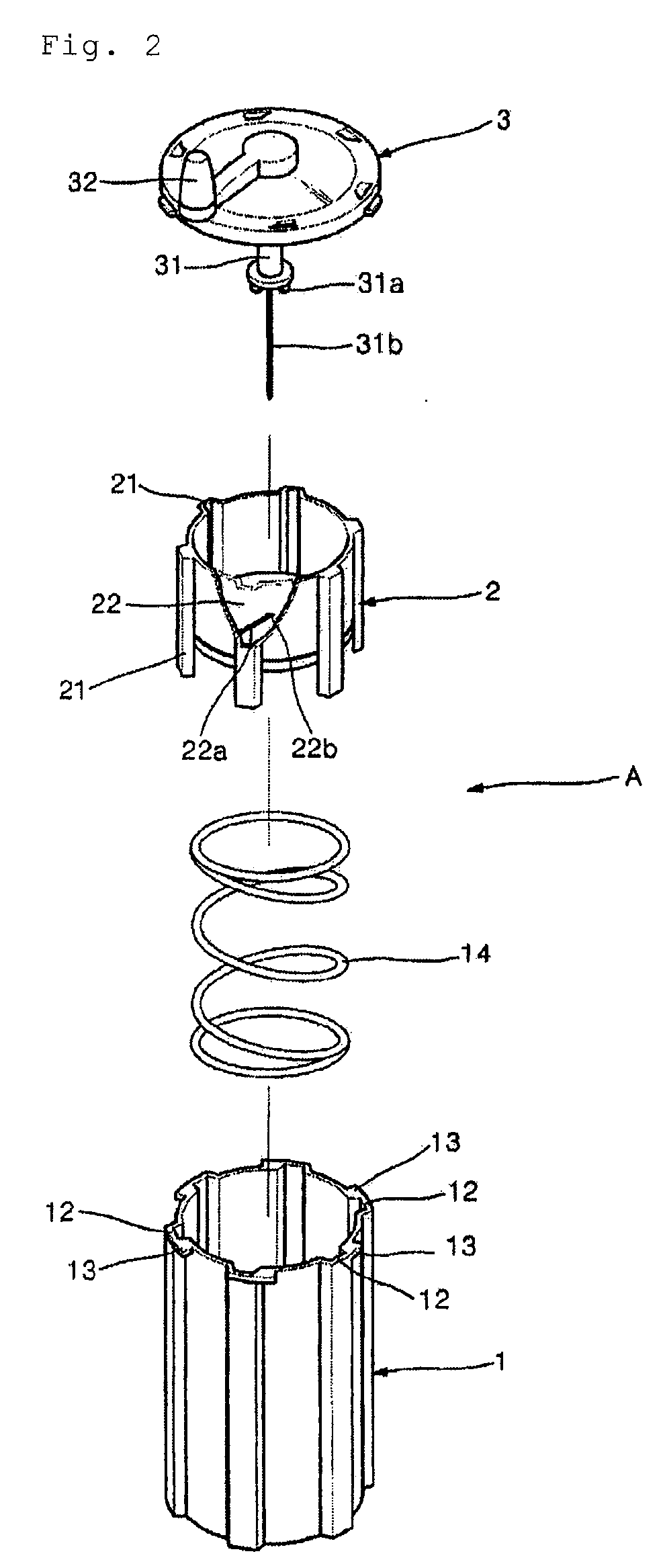

Automatic pear processing machine

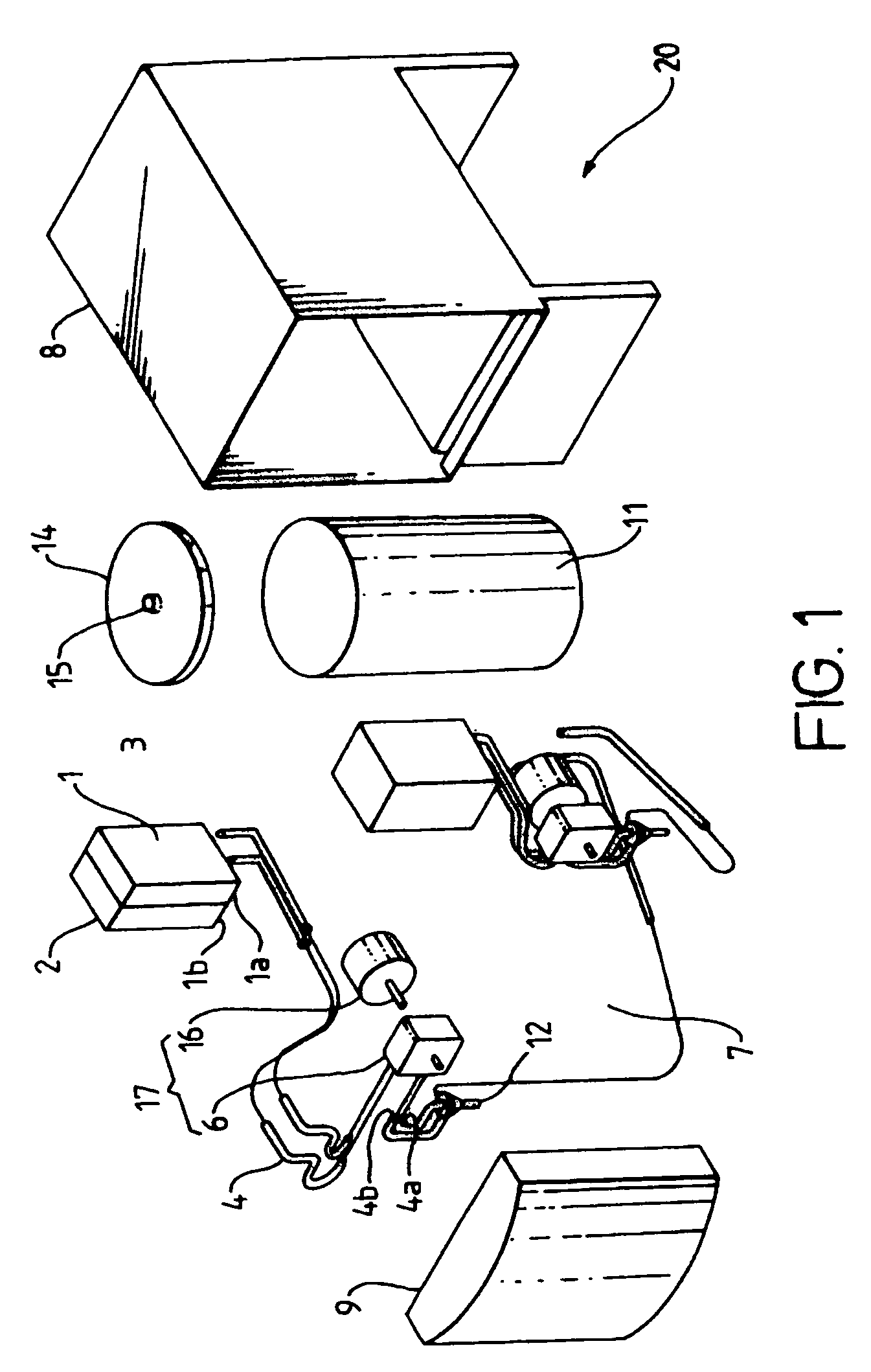

Automatic pear processing machine, performing the operations of singularising the pears, picking them up from a container (2), peeling and coring them, and separating the edible parts, wherein the improvement consists, besides other things, in providing means 14, 15, 16, 17, 20) allowing to immediately reject pears of irregular for, which would necessarily lead to waste material, and moreover, in providing holes (46, 53) of very small diameters, on the blades (44, 45) used for cutting the pears into segments. The holes (46, 53) of very small diameter, or "microholes", allow to inject a fluid, so as to ensure the detachment of the core from both halves of the pears, and the detachment of these parts from the blades (44, 45).

Owner:ABL SA

Grapefruit peeling machine

The invention provides a grapefruit peeling machine which comprises a grapefruit peeling table, a fixing support and a blade set. The grapefruit peeling table is provided with fixing needles used for fixing a grapefruit, a plurality of symmetrically-arranged movement sets are fixed on the fixing support and surround the grapefruit peeling table, and the blade set is arranged on the multiple movement sets. According to the grapefruit peeling machine, a plurality of lead screw motors and a plurality of steering engines are adopted, two lead screw motors and one steering engine in one set are matched to be capable of achieving free translational motion or rotation of a plough-shaped blade in a certain vertical plane, and the operational feasibility is accordingly provided for reasonable and effective peeling of the grapefruit in the irregular shape. Positioning sensors are adopted for the grapefruit peeling machine and allocated on blades respectively, detection positioning on the grapefruit on the grapefruit peeling table is carried out through the positioning sensors, and accurate peeling and cutting on the grapefruit peel is accordingly achieved.

Owner:SHANGHAI DIANJI UNIV

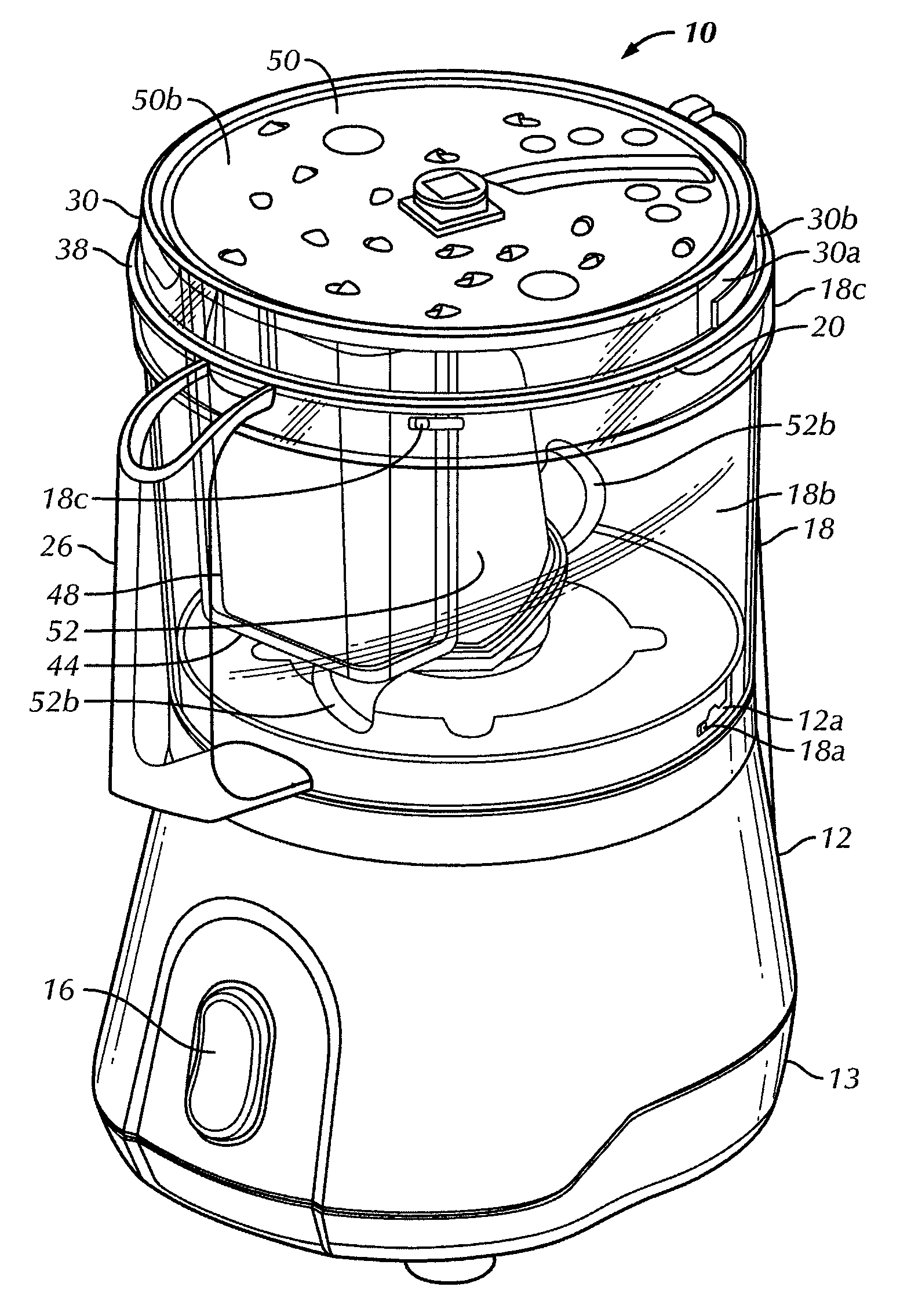

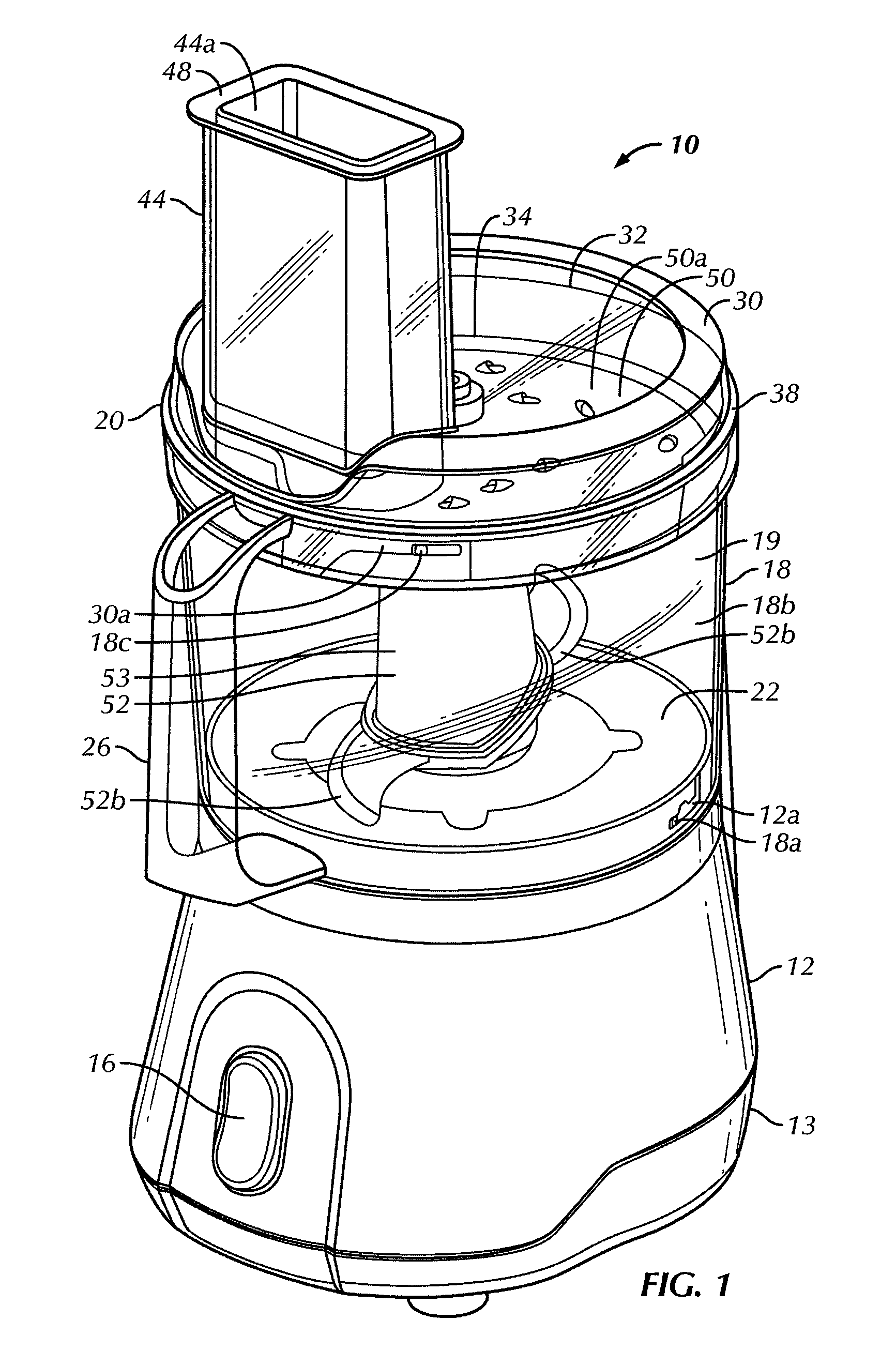

Food processor

Owner:HAMILTON BEACH BRANDS

Roller type washing and peeling machine

InactiveCN105410958AImprove efficiencyImprove sexual functionVegetable peelingFood treatmentSpiral bladePulp and paper industry

The invention discloses a roller type washing and peeling machine. A roller type washing device comprises a roller, wherein the roller is horizontally put on a machine frame, and one end of a feed port of a roller body can be pushed up or put down. The roller comprises a closed outer cylinder and a closed inner cylinder, wherein the closed outer cylinder and the closed inner cylinder are coaxial with each other and separated from each other. Hollow spiral blades axially and spirally extending are arranged on the inner side of the inner cylinder. A spiral blade shaft which is horizontally suspended along the central axis of the roller is arranged at the center of the hollow spiral blades of the inner cylinder. The spiral blade shaft and the hollow spiral blades are opposite in spiral direction and are arranged in the cylinder in a 180-degree staggered mode. The inner cylinder and the spiral blade shaft are both connected with a power device and coaxially rotate in reverse directions. A water circulating system is communicated with the interior of the inner cylinder through a water inlet pipe. The bottom of the inner cylinder is communicated with a filtering device of the water circulating system through a drain outlet. The roller type washing and peeling machine has the advantages of being simple in structure, compact in mechanism, convenient to operate and control, convenient to detach and maintain in the later period and the like; potatoes, sweet potatoes, pinellia ternate and other crops can be effectively washed and peeled in all directions.

Owner:WUHAN UNIV OF SCI & TECH

Process for producing ethanol by using potatoes as raw material

ActiveCN101289674ASmall and uniform particle sizeLarge particle sizeBiofuelsFermentationEnergy consumptionEnzyme

The invention provides a method of using potato raw material to prepare ethanol. The method comprises the steps of crushing peeled potato raw material, and mixing the crushed product with enzyme for enzyme digestion to obtain a zymohydrolysis product, wherein, the crushing method comprises the steps of crushing the peeled potato raw material for one time to obtain a primary crushed product, crushing part of the primary crushed product for the second time to obtain a secondary crushed product, mixing the remaining part of the primary crushed product with the potato raw material peeled but not crashed and crushing once. With the method, water and energy consumption are less and the equipment utilization rate and the crushing efficiency are high; meanwhile, the secondary crushing method can better control the grain diameter of particles of the potato raw materials in the crushed product obtained by crushing, thereby the grain diameter of the particles of the potato raw materials which are finally obtained is small and even..

Owner:COFCO GROUP

Sugarcane peeling and cutting device

InactiveCN104082834AImprove processing efficiencySave spaceVegetable peelingEngineeringMechanical engineering

The invention discloses a sugarcane peeling and cutting device which comprises a rack, a three-phase AC motor, a feeding device, a discharging device, a peeling device and a cutting device. Driven rollers in the feeding device and the discharging device can automatically adjust the distance with driving rollers in the feeding device and the discharging device in real time, and therefore it is guaranteed that sugarcanes with different diameters can pass through the feeding device and the discharging device smoothly. Spike teeth on the surfaces of the rollers can firmly clamp the surfaces of the sugarcanes so that the sugarcanes can acquire enough pushing force in the stable conveying process. Combination of linear cutting and rotatable cutting is used on the peeling device, so that peeling is more complete. The cutting device which is mounted on a discharging opening is used for dividing the sugarcanes into sections with the preset length through the pushing force of the sugarcanes, and the processing efficiency of the sugarcanes is greatly improved.

Owner:XIHUA UNIV

Automatic grapefruit peeling and juicing machine

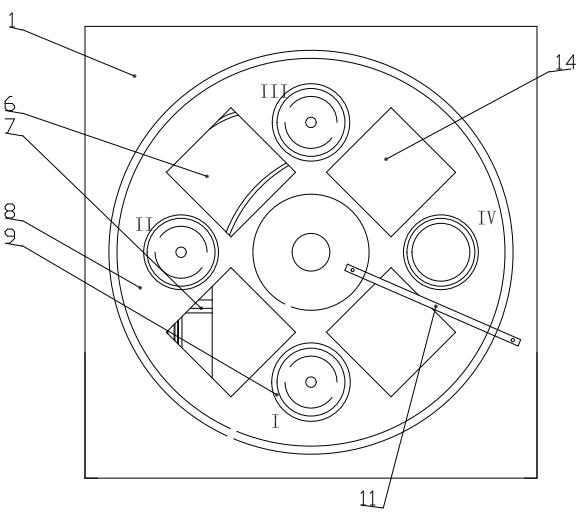

InactiveCN102488294AQuality improvementIntegrity guaranteedJuice extractionVegetable peelingEngineeringReamer

The invention discloses an automatic grapefruit peeling and juicing machine. The upper part of a frame is provided with a turntable; the turntable is driven to rotate by a motor in the center; four stations are arranged on the turntable in turn; and the station I is a feeding station, the station II is a bottom peel cutting station, the station III is a flesh separating station, and the station IV is a peel processing station. The turntable is provided with four processing stations; the peel at the bottom of the grapefruit is cut off, and rotary reamer enters the grapefruit from the bottom ofthe grapefruit and rotates from bottom to top to mince the flesh of the grapefruit, so that the flesh and the peel are separated; the minced flesh enters a spiral juicing machine along a guide tube, and is juiced; and the complete peel is collected in a concentrated way. Therefore, the grapefruit is peeled and juiced automatically and integrally, the flesh is fully utilized, the completeness of the peel of the grapefruit is ensured, the volatilization of essential oil is reduced, and the subsequent processing quality of the peed is improved and the yield of the essential oil is improved.

Owner:JIANGNAN UNIV

Shaping apparatus for fruits and root and tuberous vegetables

ActiveUS20080307980A1Increase valueEasy to implementFruit stoningGang saw millsEngineeringPlant Tubers

An apparatus is disclosed which can shape fruits and root and tuberous vegetables. The shaping apparatus is operated in such a manner that: when root and tuberous vegetable or fruit is placed in a cutting blade case and rotated, the object is spirally tracked and the spirally tracked object is removed from the lower side of the cutting blade case, so that the spirally tracked object is picked up by an additional stick and then ornamented into various forms. The shaping apparatus allows fruits and root and tuberous vegetables to be easily treated in a variety of ways, as per the second process, thereby enhancing the product value of processed foodstuffs produced from the first process.

Owner:LEE BONG GU +6

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com