Process for producing ethanol by using potatoes as raw material

A technology of potatoes and raw materials, applied in the field of ethanol preparation, can solve the problems of low utilization rate of equipment, high utilization rate of equipment, large energy consumption, etc., and achieve high utilization rate of equipment, high crushing efficiency, and water consumption. small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This example is used to illustrate the method for preparing ethanol using cassava raw material of the present invention.

[0051] (1) Peeling and crushing of cassava raw materials

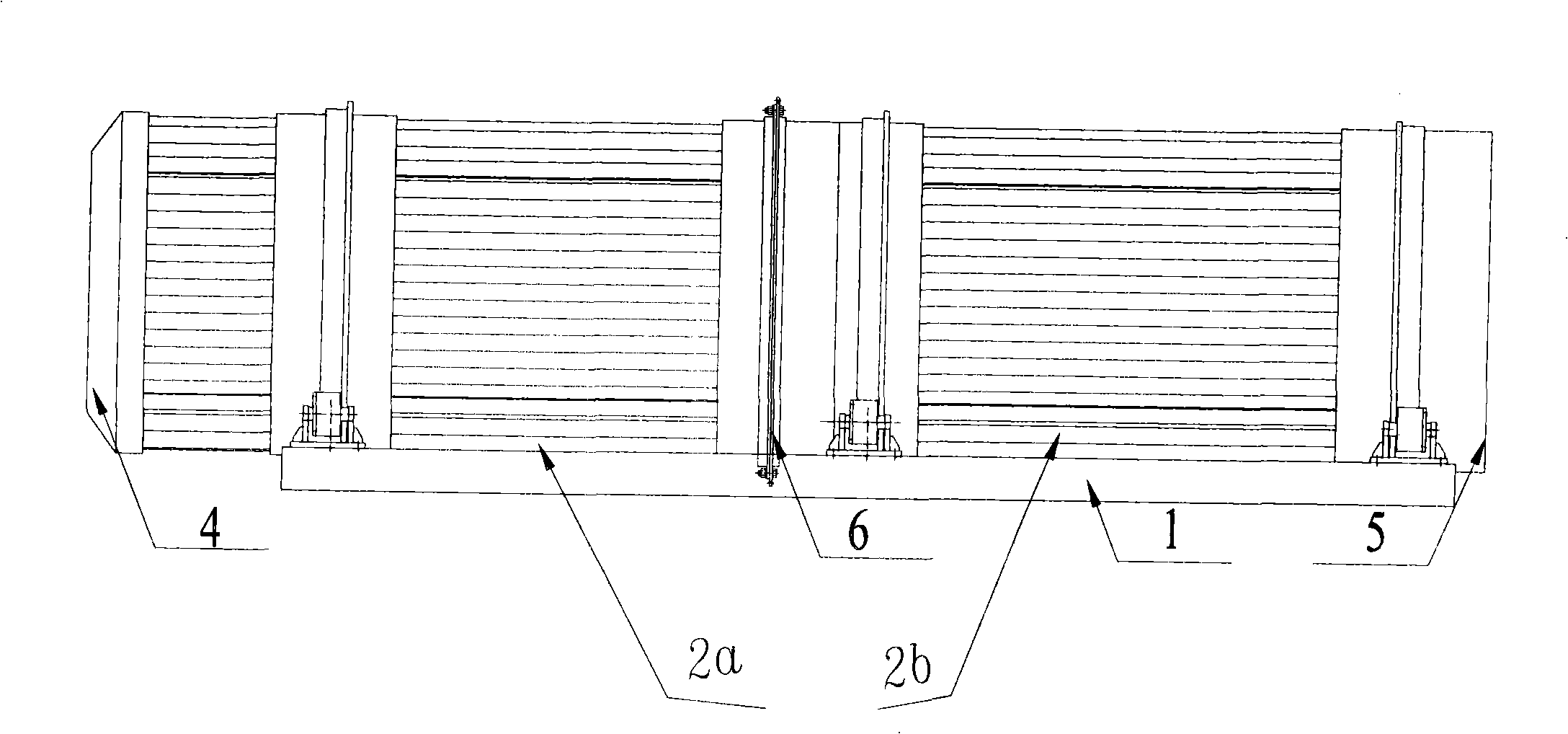

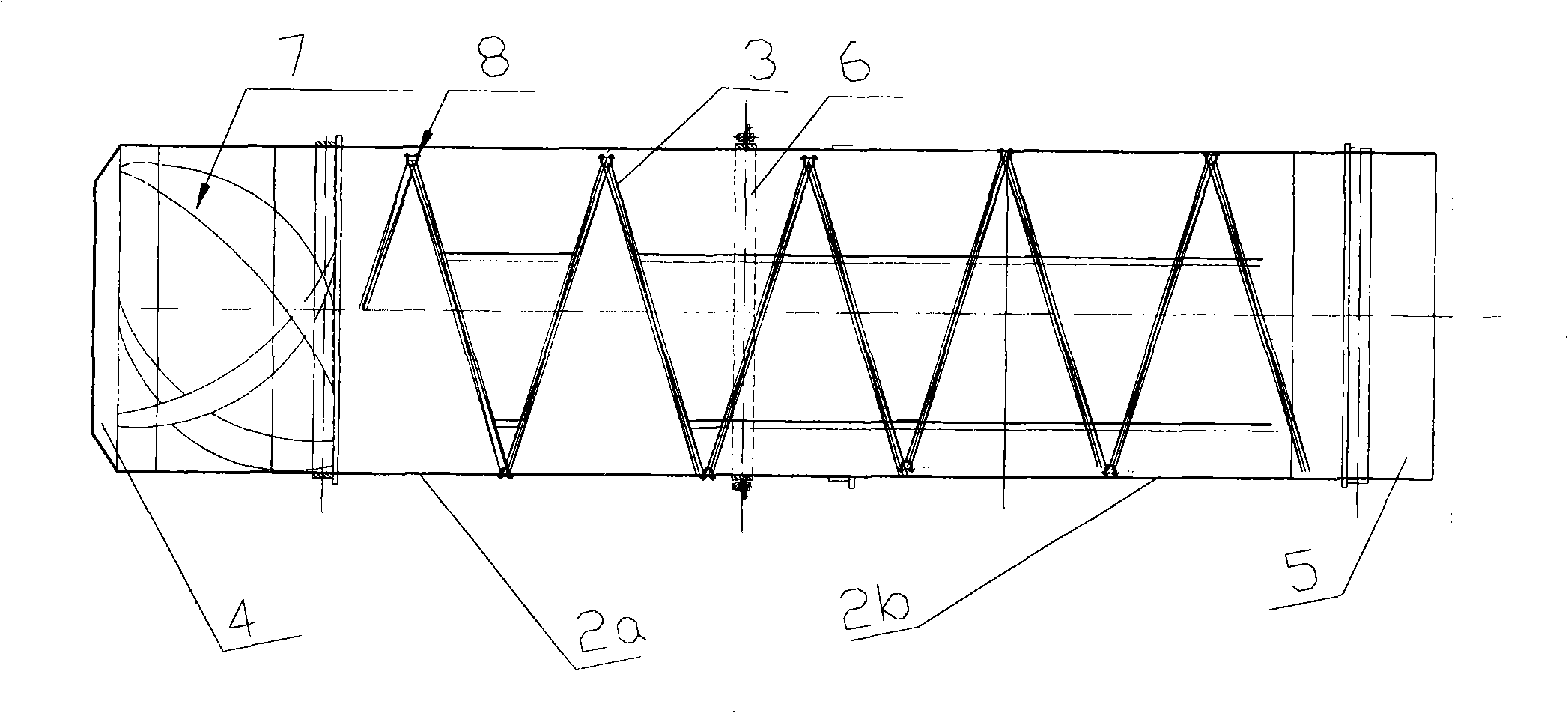

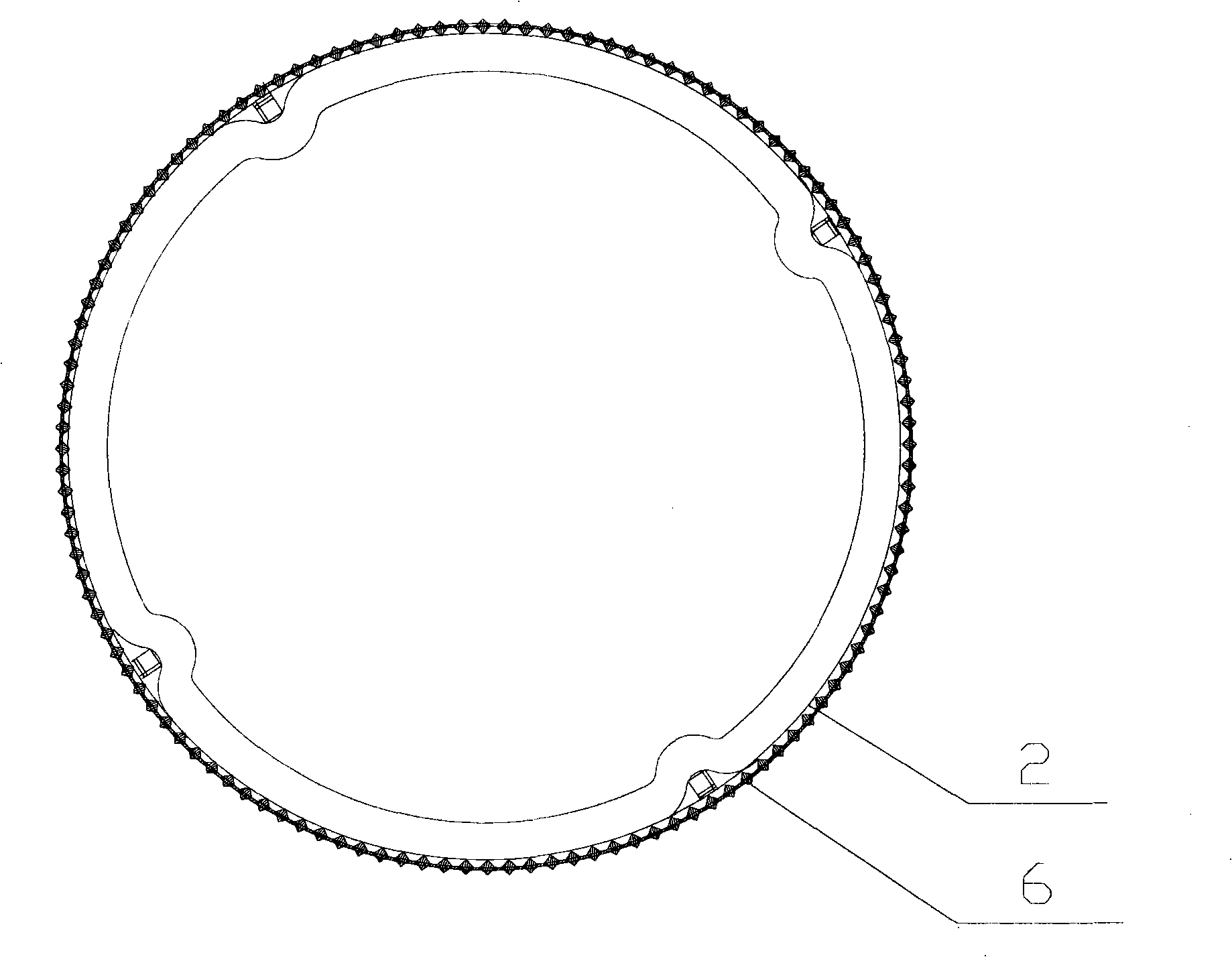

[0052] Prepared as follows figure 1 , 2 and the peeling device shown in 3.

[0053] The drum 2 includes a first segment drum 2a and a second segment drum 2b from top to bottom, the first segment drum 2a and the second segment drum 2b are connected, and the lengths of the first segment drum 2a and the second segment drum 2b are respectively 1.8 meters and 1.6 meters; the drum 2 is made of steel with an inner diameter of 1.6 meters; 40 hot-rolled ribbed steel bars with a length of 1.5 meters are fixed on the inner wall of the first section drum 2a (the brand is HRB335, and the nominal diameter is 12 mm ), each hot-rolled ribbed steel bar is parallel to the central axis of the drum, each hot-rolled ribbed steel bar is distributed at equal intervals along the circumference of the inner wall o...

Embodiment 2

[0065] This example is used to illustrate the method for preparing ethanol using cassava raw material of the present invention.

[0066] Prepare ethanol according to the method for embodiment 1, difference is, adopt the method for manual peeling in step (1) to scrape off the inner epidermis of cassava raw material with a knife, collect and obtain the cassava raw material after 95 kilograms of peeled. The cassava raw material was pulverized according to the method of Example 1 to obtain 95 kg of pulverized product (the particle diameter of the cassava raw material in the pulverized product was about 2 mm). According to the high-efficiency liquid phase conditions described in step (1) of Example 1, it was measured and calculated that the 95 kg pulverized product contained 26.5 kg of starch. According to the conditions of Example 1, the remaining crushed product after the sampling test was enzymatically hydrolyzed, and the enzymolyzed product was fermented to obtain 13.91 kg of e...

Embodiment 3

[0074] This example is used to illustrate the method for preparing ethanol using cassava raw material of the present invention.

[0075] Prepare ethanol according to the method for embodiment 1, and the difference is that the method for pulverizing comprises using SFSP series hammer mill to first pulverize 30 kilograms of fresh cassava raw materials after peeling for 12 minutes to obtain a particle diameter of 5- 30 kilograms of primary pulverized products of 6 mm, then 1.5 kilograms of the primary pulverized products of 5% by weight and remaining 25 kilograms of fresh cassava raw materials that were peeled and not pulverized were mixed and pulverized once again for 10 minutes to obtain a particle diameter of 55 kg of the primary crushed product of 3-4 mm, 2.75 kg of the primary crushed product of 5% by weight and the remaining 40 kg of cassava that has not been crushed through peeling were subjected to primary crushing for 15 minutes to obtain a total of 95 kg of primary crush...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com