Patents

Literature

41results about How to "Shorten electrolysis time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

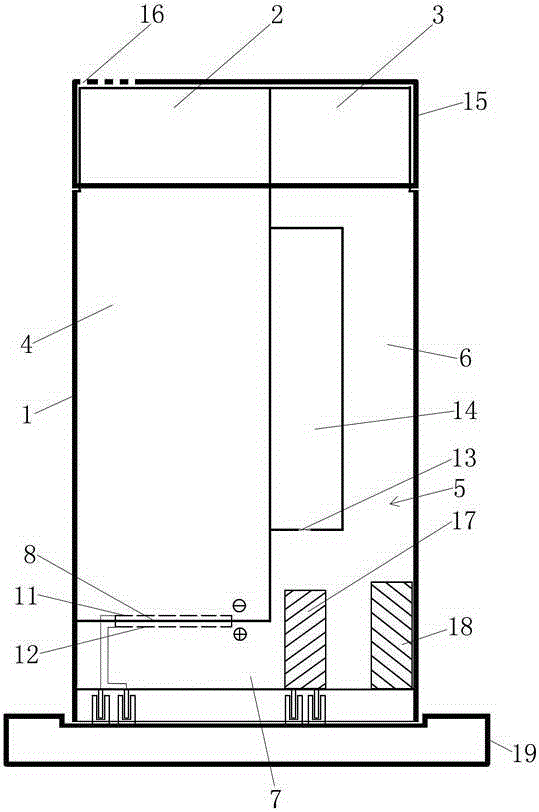

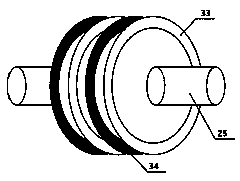

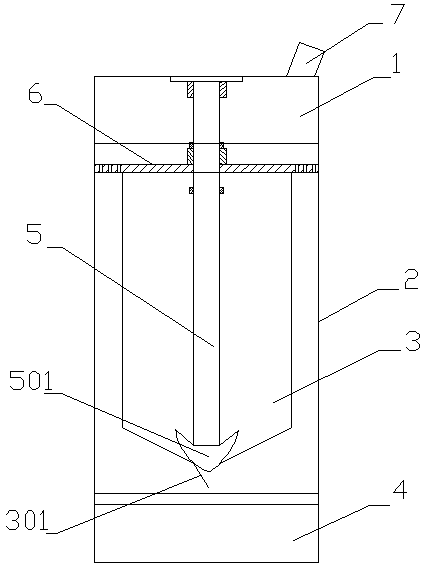

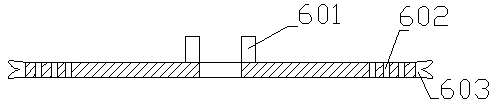

Integrated manufacturing apparatus for hydrogen-enriched water

ActiveCN105174384AExtended service lifeAvoid secondary pollutionWater/sewage treatment by ion-exchangeElectrolysisHydrogen

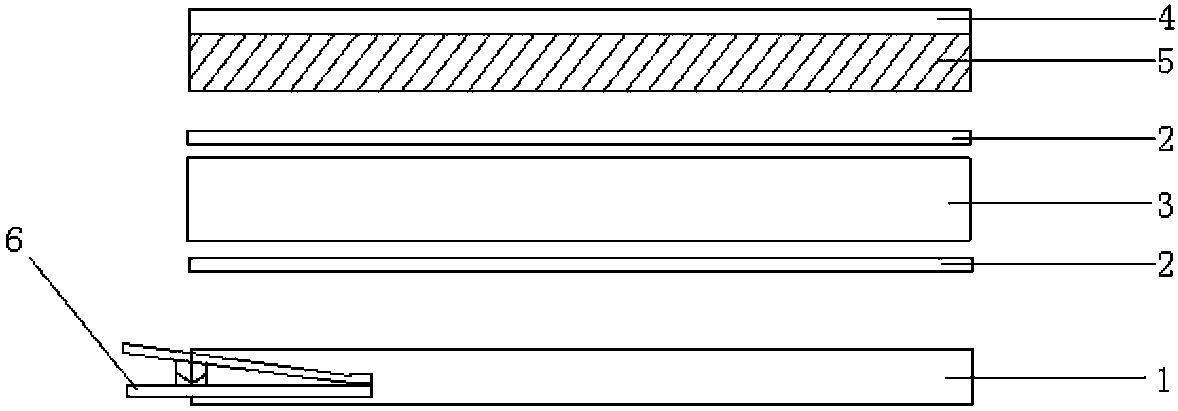

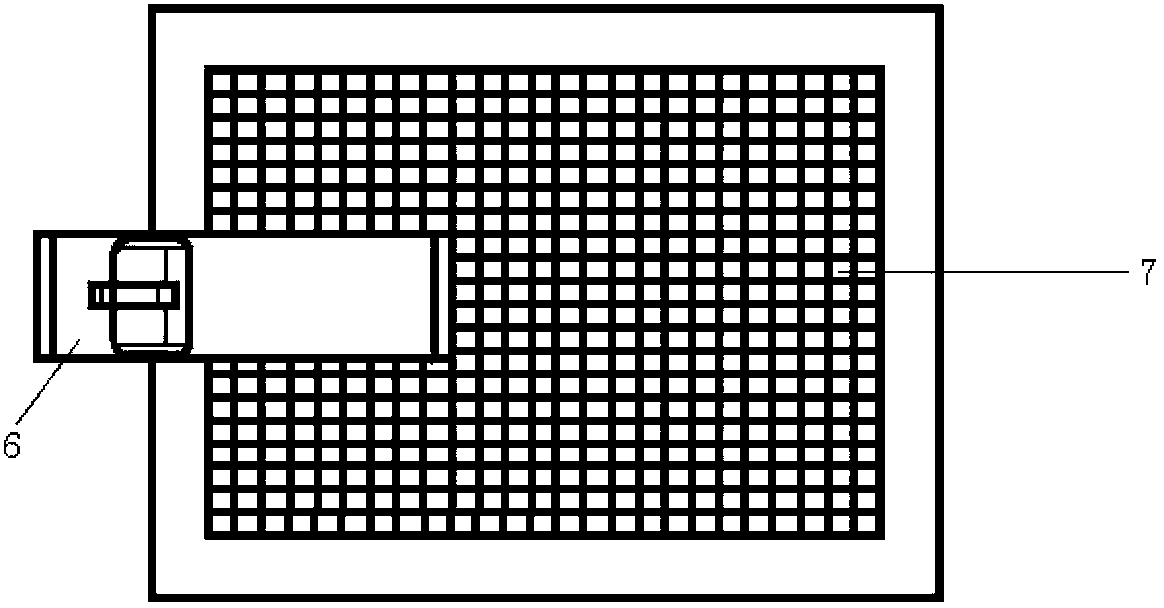

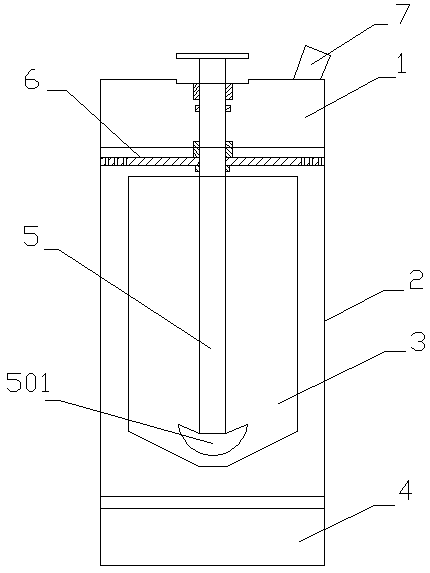

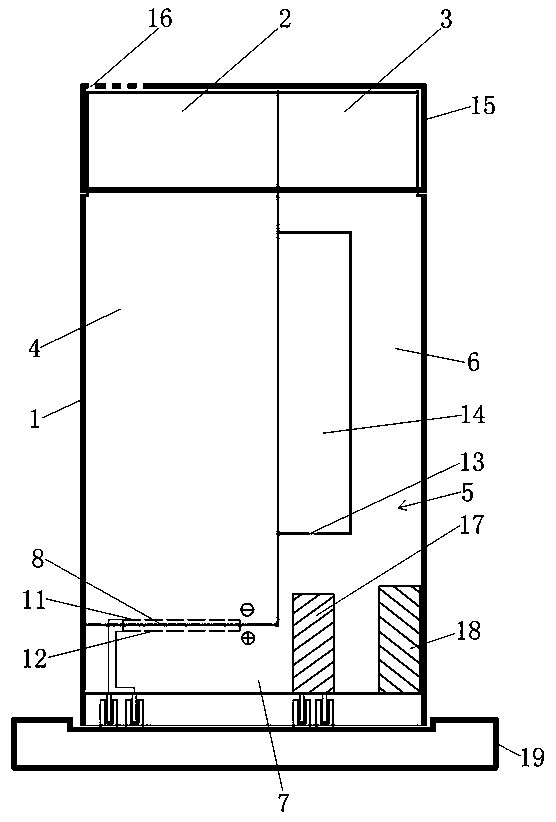

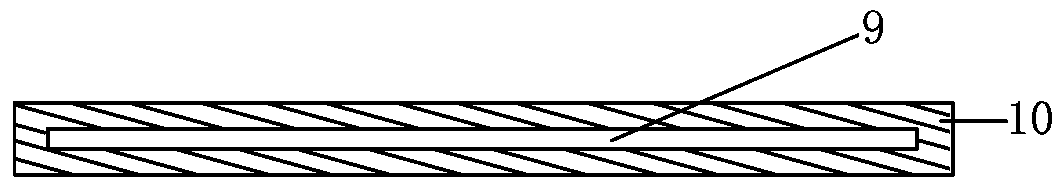

The present invention discloses an integrated manufacturing apparatus for hydrogen-enriched water. The apparatus comprises a drinking cup, wherein a first water filling opening and a second water filling opening are formed at the upper end of the drinking cup, a first water reservoir which is communicated with the first water filling opening and a second second water reservoir which is communicated with the second water filling opening are arranged inside the drinking cup. The second reservoir is an "L"-shaped cavity consisting of a longitudinally extending cavity that extends downwardly from the second water filling opening and a transversely extending cavity that extends transversely from the lower portion of longitudinally extending cavity. The first water reservoir is located at the top of the transversely extending cavity, a cation-exchange membrane is arranged between the first water reservoir and the transversely extending cavity. A cathodic electrolysis plate and an anode electrolysis plate are separately arranged above and under the cation-exchange membrane, and the cathodic electrolysis plate and the anode electrolysis plate are separately located inside the first water reservoir and the transversely extending cavity. In the present invention, the drinking cup is integrally designed internally, so that secondary pollution which may be generated is avoided, the service life of the electrolytic plate is prolonged, and the phenomenon of dripping water is avoided.

Owner:陈志越

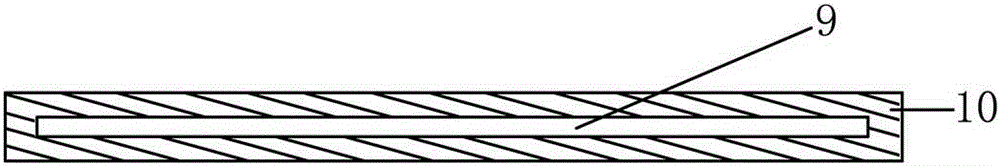

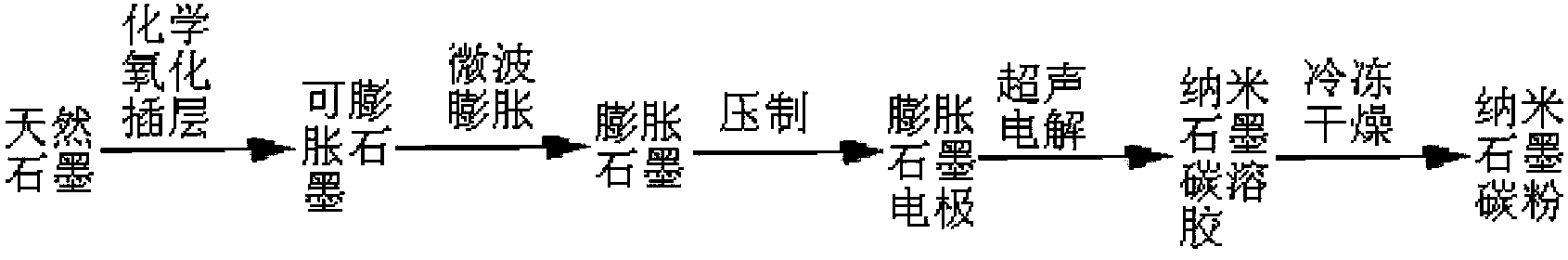

Preparation method of nano-graphite carbon powder

ActiveCN103395777AImprove electrolysis efficiencyShorten electrolysis timeMaterial nanotechnologyGraphiteElectrolysisFreeze-drying

The invention relates to a preparation method of nano-graphite carbon powder. The method comprises the steps of: (1) preparing expansible graphite by a chemical oxidation intercalation process; (2) preparing expanded graphite by a microwave process; (3) pressing the expanded graphite into a expanded graphite sheet, putting it into a microporous filter membrane sieving assembly, conducting pressing and sealing, then placing the assembly at the anode and cathode of an electrolytic bath, taking a chlorate solution as an electrolyte solution, carrying out ultrasonic electrolysis at a temperature below 60DEG C, controlling the electrolytic current at 5-18A / cm<2>, the voltage at 6-20V, the ultrasonic oscillation power at 200-600W, and the frequency at 20-40kHz, inverting the anode and the cathode at an interval of 8-15min, completing electrolysis when the concentration of sol in the electrolytic bath is 2-5%, thus obtaining nano-graphite carbon sol; and (4) adding ammonium sulphate into the nano-graphite carbon sol till the mass concentration of ammonium sulfate reaches 5-8%, stirring them uniformly, then performing freeze drying, thus obtaining the nano-graphite carbon powder. The method has the advantages of mild reaction condition and high speed, thus being suitable for industrialized mass production.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Method for handling organic wastewater based on Fenton reaction

InactiveCN102020384AImprove current efficiencyReduce concentration polarizationMultistage water/sewage treatmentWater/sewage treatment by oxidationFenton reactionDC - Direct current

The invention discloses a method for handling organic wastewater based on Fenton reaction, comprising the following steps of: (1) high-voltage pulse electric coagulating reaction: regulating the pH value of wastewater to be 3-4 so that wastewater performs high-voltage pulse electric coagulating reaction in a high-voltage pulse electric coagulating device at the current intensity of 1-30A, wherein the electric coagulating reaction time ranges from 30-120min, the high-voltage pulse electric coagulating device is input by the 100-400V alternating current which is then converted into direct current after rectification, the pulse voltage of 80V to 350V is formed by utilizing a pulse generator, the anode and cathode plates adopted by the high-voltage pulse electric coagulating device are iron plates with the carbon content above 0.45wt% and the space between the polar plates ranges from 10-30mm; (2) Fenton reaction; and (3) concrete precipitation reaction. Compared with the prior art, the invention reduces the handling cost, shortens the handling time and ensures better handling effect.

Owner:JIANGSU SUJING GROUP +1

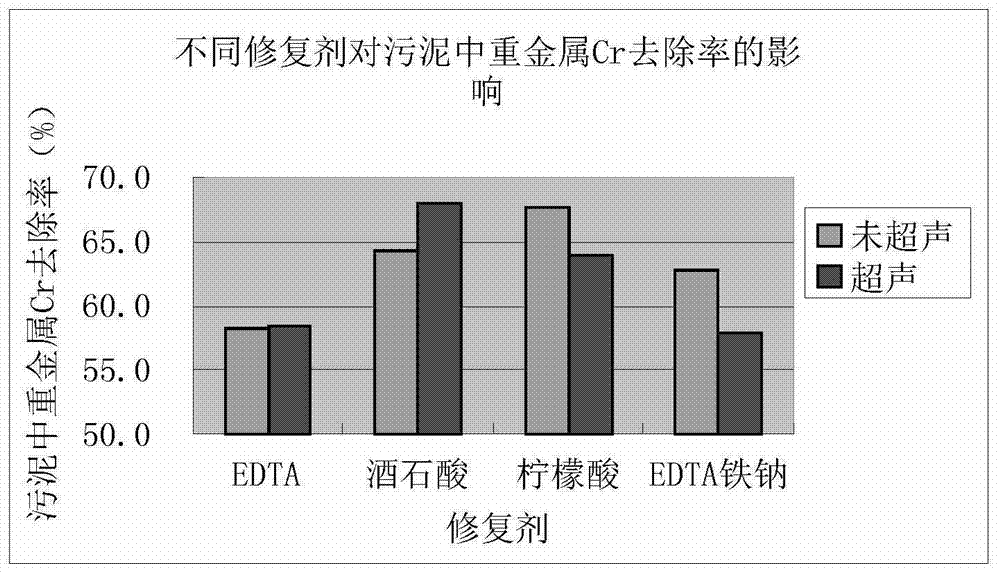

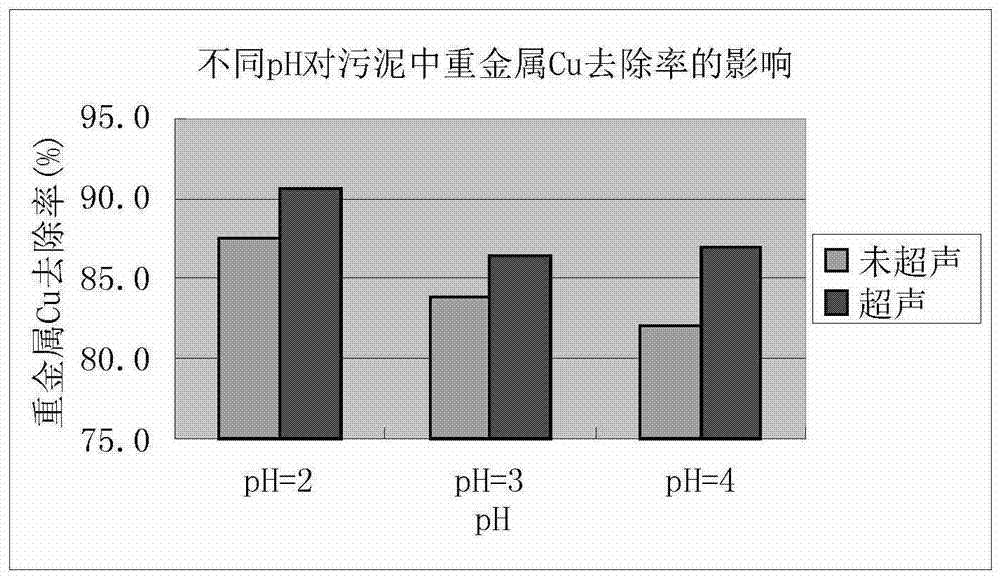

Method and device for removing heavy metals and POPs in organic wastes by electromagnetic reinforcement

The invention discloses a method and a device for removing heavy metals and POPs in organic wastes by electromagnetic reinforcement. The method comprises the following steps of: firstly preparing theorganic wastes into slurry; applying a magnetic field to the slurry to make sure that the heavy metals and the POPs in the slurry are transformed into a water solution state; separating the organic waste slurry into two components; afterwards applying an electric field to the slurry, migrating water molecules and the heavy metals and POPs which are continuously transformed into the water solutionstate to a cathode region of the electric field under the effect of electro-migration, and meanwhile migrating the components of the organic wastes to an anode region of the electric field so as to realize separation of the two components; and filtering and dehydrating the organic waste slurry to finally obtain harmless low-water-content organic wastes. The method and the device disclosed by the invention can be used for efficiently removing large-particle impurities, some heavy metals and the POPs in the organic wastes, can also reduce the water content of the organic wastes to 30% to 50%, thereby overcoming the defects that a traditional organic waste treatment method is low in efficiency, takes effect slowly and has no oneness.

Owner:KUNMING UNIV OF SCI & TECH

Production of metal material by composite compound

InactiveCN1940143AHigh reducing activityAdd channelPhotography auxillary processesProcess efficiency improvementElectrolysisReaction rate

This invention relates to a method of preparing metal material using complex compounds. Electrolysis is carried out in the electrolyte under the protection of inert gas or air containing M3Y with composite compounds of M1M2X combine with the collector as a cathode and carbon, metal or conductive ceramic as anode. Controlling electrolysis voltage, so that M2 reduction reaction is the dominated reaction, and M1 and X is partly or all dissolved in the electrolyte as electrolysis going on. When M1 is H, M1 can be reduced to gas leaving away the cathode. At the end of electrolys, M2 alone or with part of the M1 and X-stay is left on the cathode, which is the corresponding metal. Since M1X part or all leave away cathode in this invention during electrolysis process, the reactivity and ability of cathode is enhanced, the reaction rate and the current efficiency are effectively improved and energy consumption is reduced.

Owner:WUHAN UNIV +1

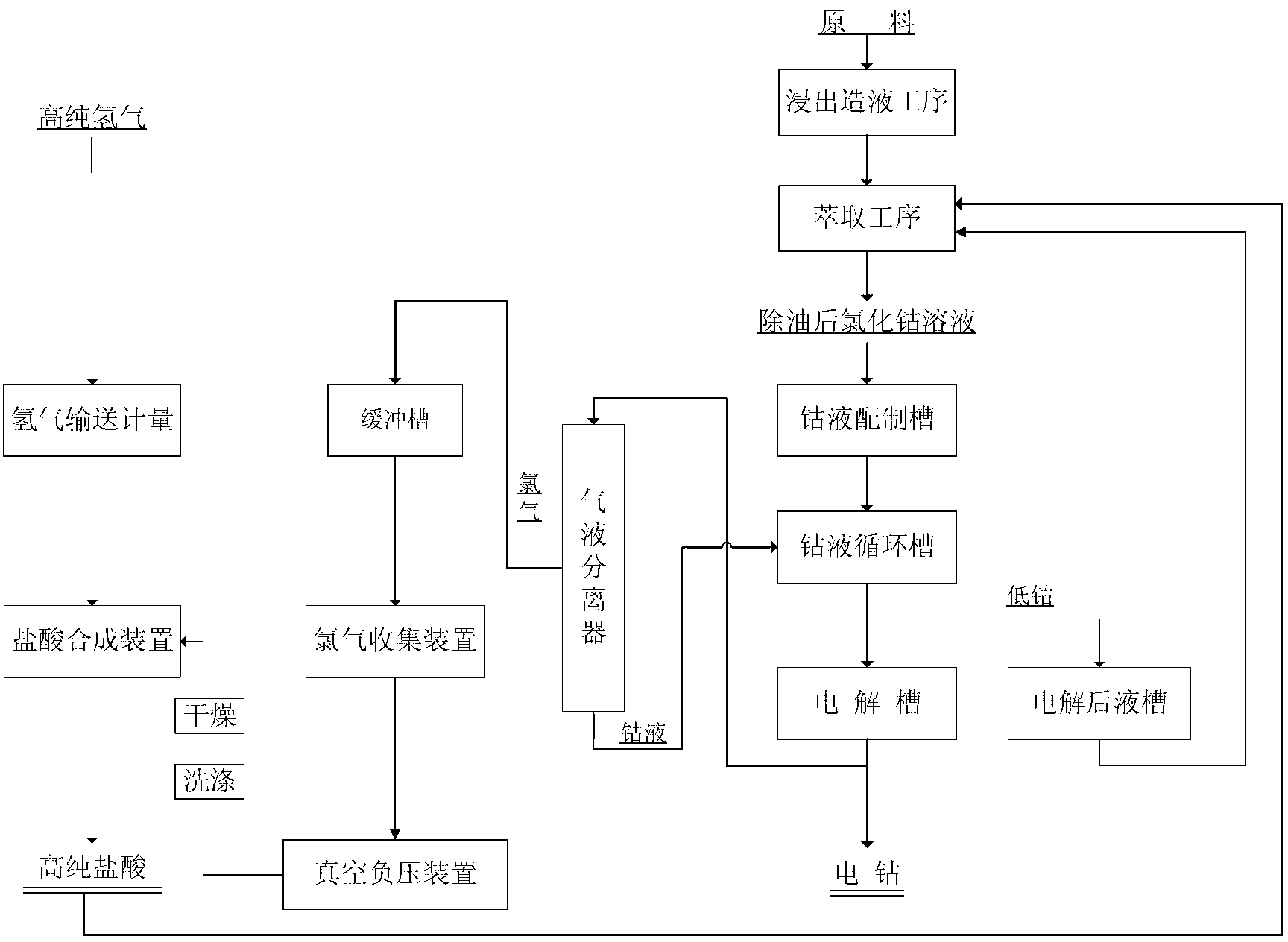

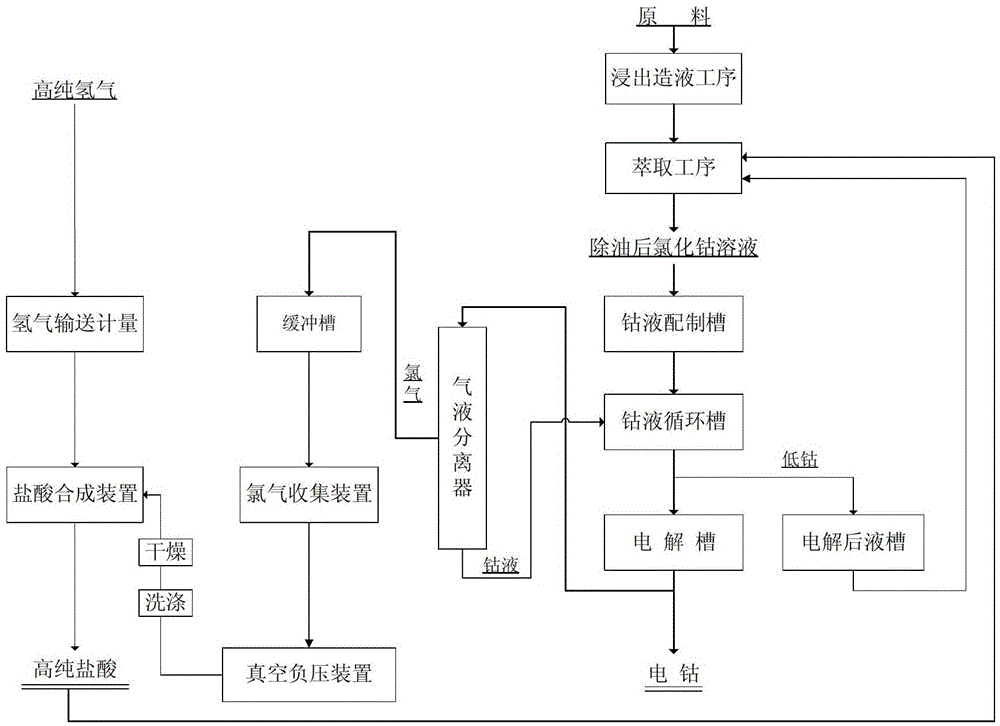

Method for preparing electrodeposited cobalt under large flow

ActiveCN103060842AImprove current efficiencyReduce cathodic polarizationPhotography auxillary processesWater chlorinationHydrometallurgy

The invention discloses a method for preparing electrodeposited cobalt under a large flow. In conventional production methods for electrodeposited cobalt, the process of processing has the disadvantages of low current efficiency and long electrodeposition time, and purity and a recovery rate of produced electrodeposited cobalt hardly reach requirements. A technical scheme employed in the invention is as follows: a deoiled cobalt chloride solution produced in wet metallurgy is used as a raw material and is diluted with pure water so as to allow the concentration of Co<2+> in the cobalt chloride solution to be 30 to 100 g / L, and the diluted cobalt chloride solution is used as electrodeposition pre-liquid; and electrodeposition is carried out on the electrodeposition pre-liquid in an enclosed electrodeposition apparatus under the conditions of a large flow of 5 to 15 m<3> / h.m<2> and a negative pressure. According to the invention, the large flow is employed in the process of preparation of electrodeposited cobalt, so cathodic polarization is reduced, high current efficiency as high as more than 95% is obtained, and direct current consumption is low; utilization of the large flow enables chlorine and oxygen generated by an anode to be taken away in time, and oxidation of the cathode cobalt by chlorine and oxygen is prevented, thereby guaranteeing product quality.

Owner:ZHEJIANG HUAYOU COBALT +1

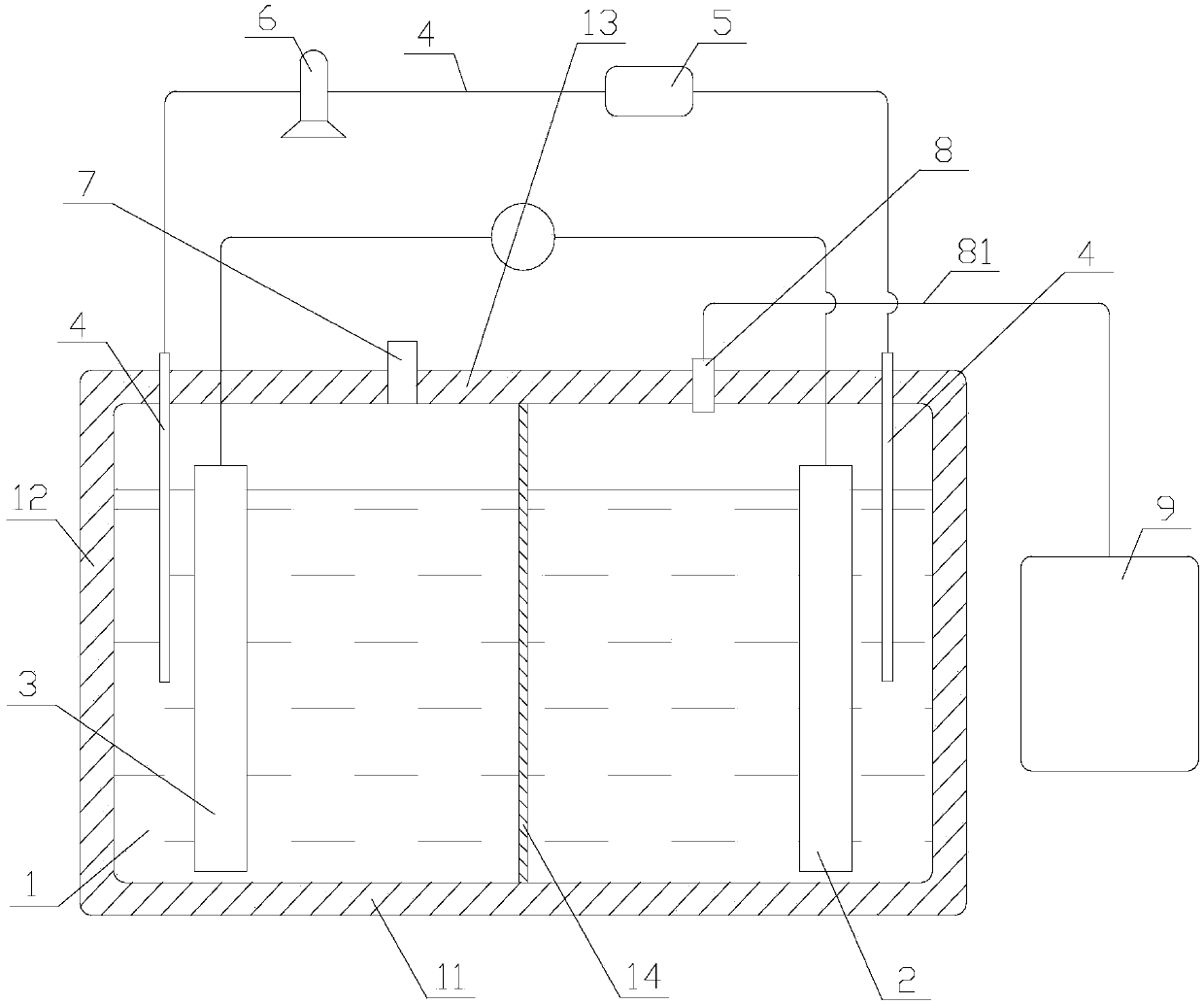

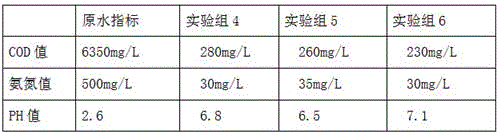

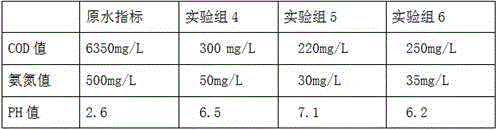

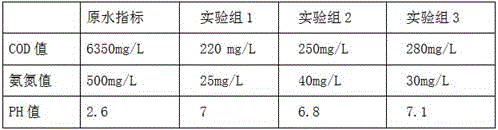

Method for electrolytically treating high ammonia-nitrogen wastewater

InactiveCN109553163ARaise the pHReduce escapeWater contaminantsTreatment involving filtrationChemistryAnode

The invention discloses a method for electrolytically treating high ammonia-nitrogen wastewater. The method comprises the following steps: 1) injecting the high ammonia-nitrogen wastewater into an electrolytic tank, and performing electrolysis; and 2) pumping out a liquid product at the cathode of the electrolytic tank in the process of electrolysis, and adding the liquid product into the anode ofthe electrolytic tank. According to the method disclosed by the invention, the removal rate of ammonia nitrogen in the high ammonia-nitrogen wastewater can be effectively improved by utilizing the method.

Owner:CHENGDU RAISE ENVIRONMENTAL PROTECTION TECH CO LTD

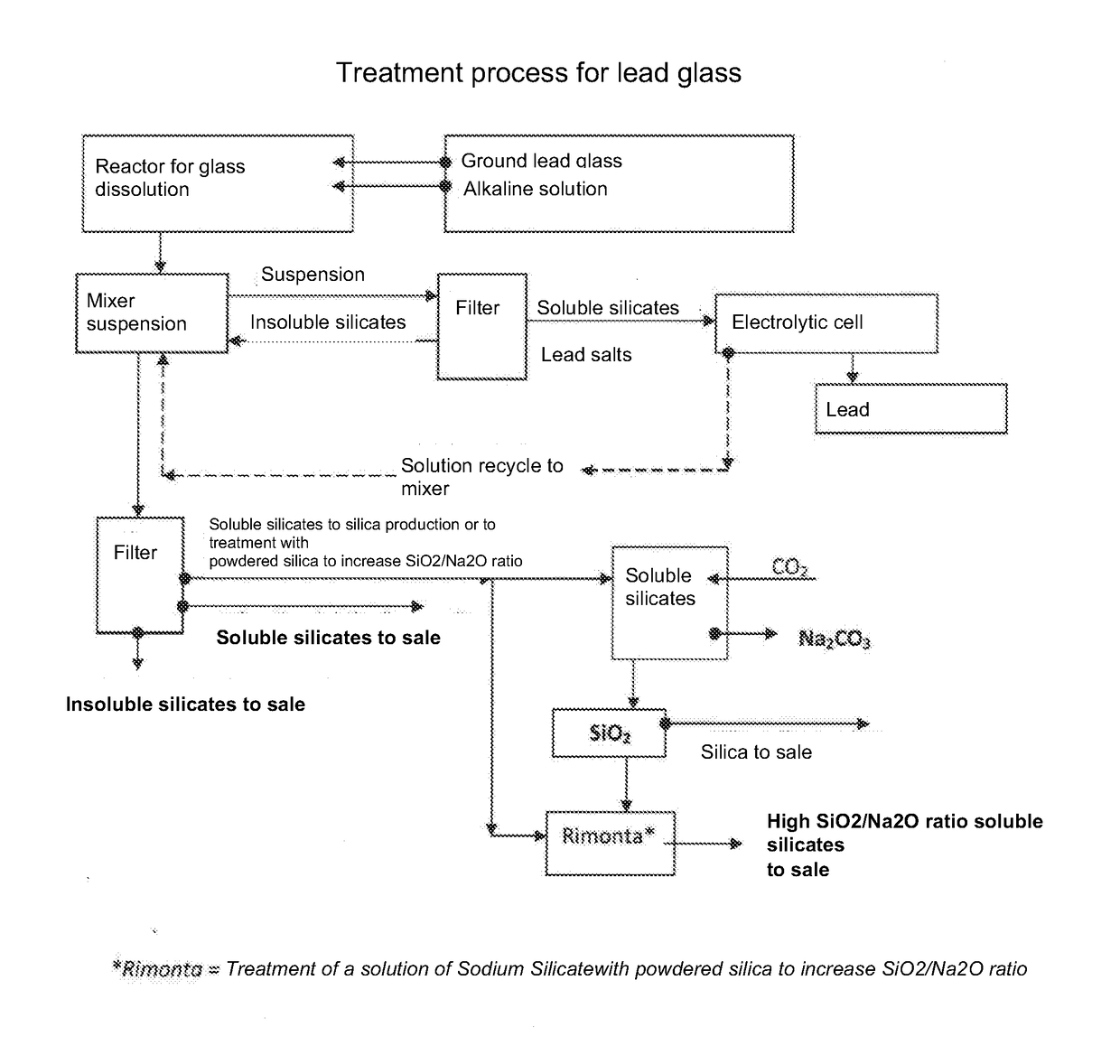

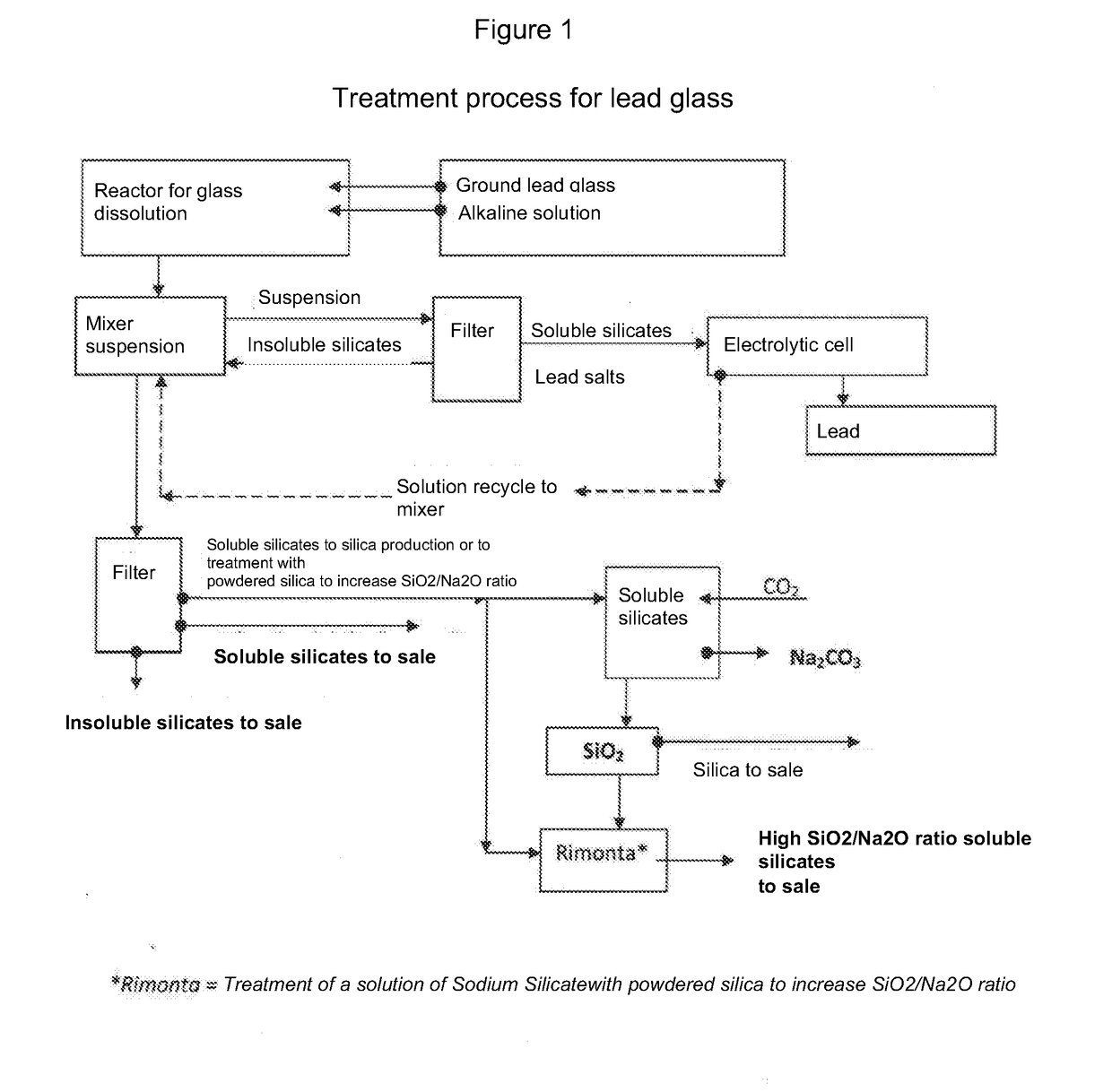

Hydrothermal process for the treatment of lead glass with recovery of lead metal, soluble and insoluble silicates and silica

ActiveUS20170275734A1Reduce electrolysis timeLow yieldProcess efficiency improvementEtchingSodium oxide

There is described a process completely performed in aqueous phase, which provides a heat etching of lead glass with aqueous solutions of strong alkali followed by an electrolytic treatment of the suspension so obtained, in order to recover metallic lead and obtain soluble silicates, separated from insoluble silicates, both lead-free. The process also provides for the production of pure silica, derived from the soluble silicates, and a possible use thereof to increase the ratio between silica and sodium oxide, which characterizes the specifications of the soluble silicates. The electrolysis for the recovery of metallic lead is implemented in a cell in which the polarity of the electrodes is periodically reversed, to obtain the detachment of the metallic lead deposited on the cathodes.

Owner:HELLATRON SPA

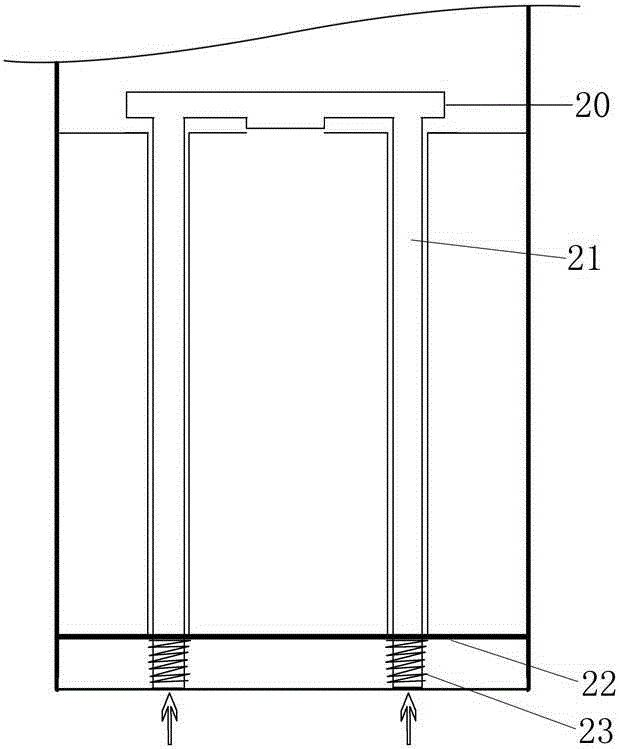

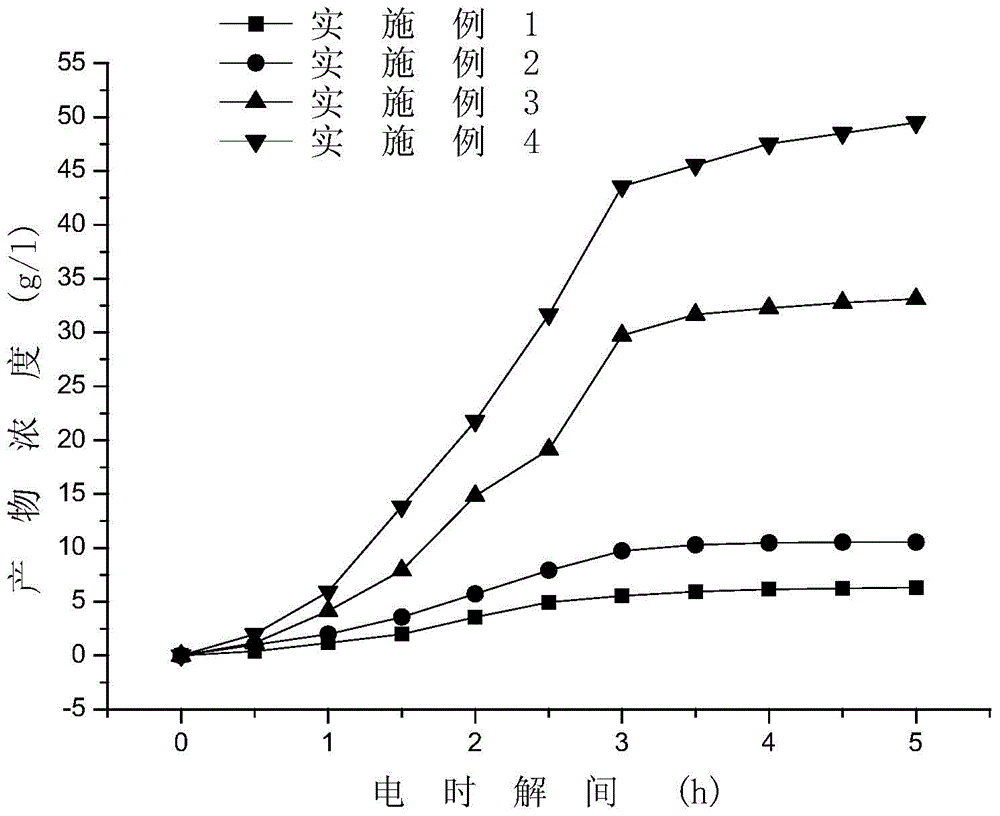

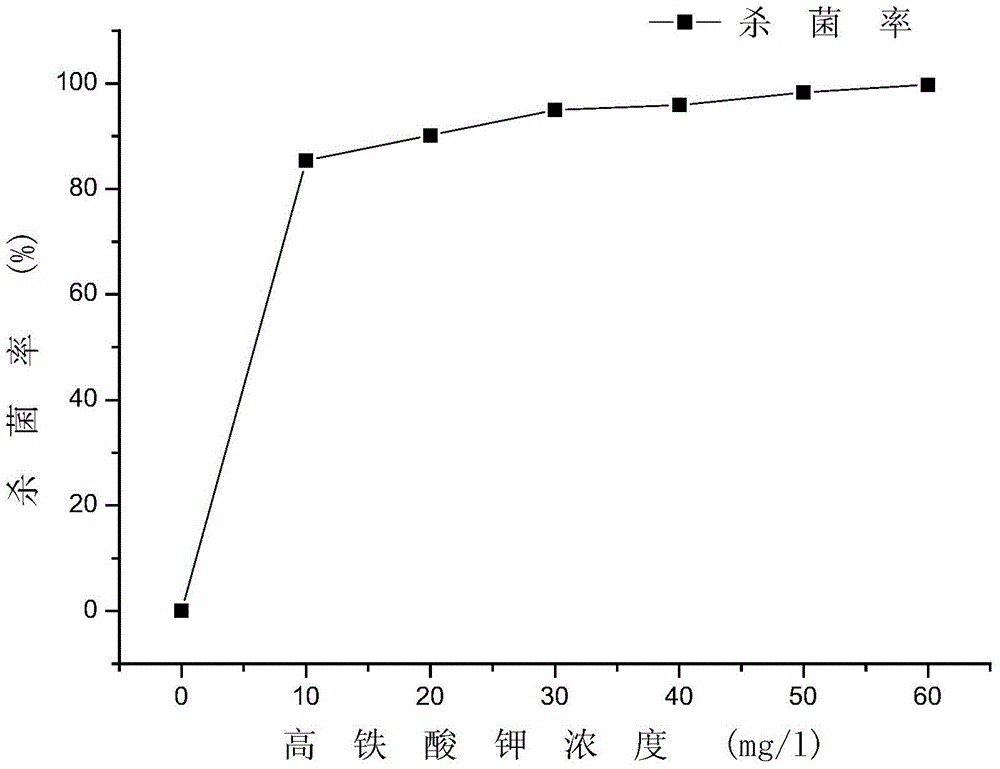

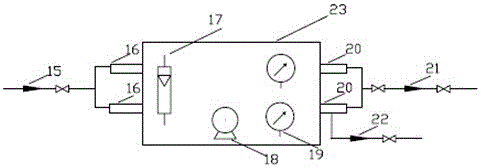

Preparation method of liquid potassium ferrate by utilizing ultrasonic electrolysis

The invention discloses a preparation method of liquid potassium ferrate by utilizing ultrasonic electrolysis. The method adopts an electrolysis device, which comprises an ultrasonic wave generator and an electrolytic tank, wherein the electrolytic tank is arranged in the ultrasonic wave generator and is divided into a cathode chamber and an anode chamber by a perfluorinated ion membrane. The method comprises the following steps: (1) preparing anode electrolyte, wherein the solvent is water, the potassium hydroxide concentration is 14 to 18 mol / L, and the potassium chloride concentration is 0.5 to 2 mol / L; and preparing cathode electrolyte, wherein the solvent is water, the potassium hydroxide concentration is 1 to 3 mol / L, and the potassium chloride concentration is 0.5 to 2 mol / L; (2) starting the ultrasonic wave generator during the electrolysis process, controlling the current density in a range of 50 to 200 mA / cm2 and the temperature in a range of 30 to 40 DEG C, and obtaining liquid perfluorinated ion membrane after electrolysis. The method has the advantages of simple steps, convenient operation, and high product concentration.

Owner:ZHEJIANG UNIV

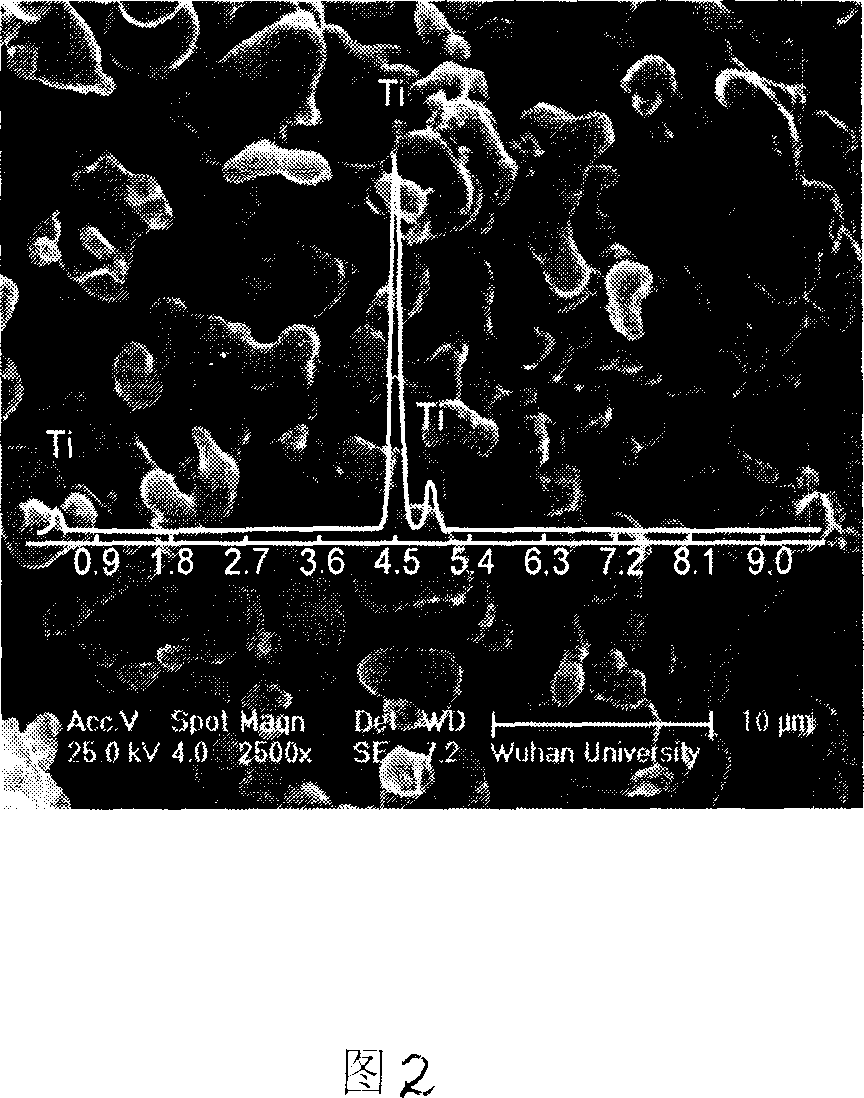

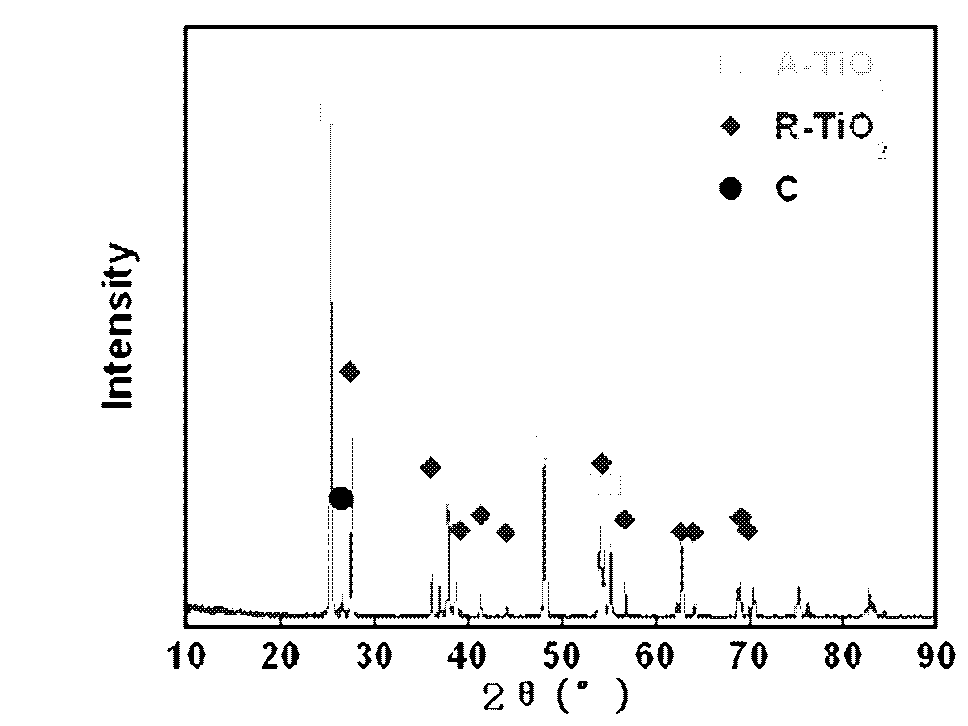

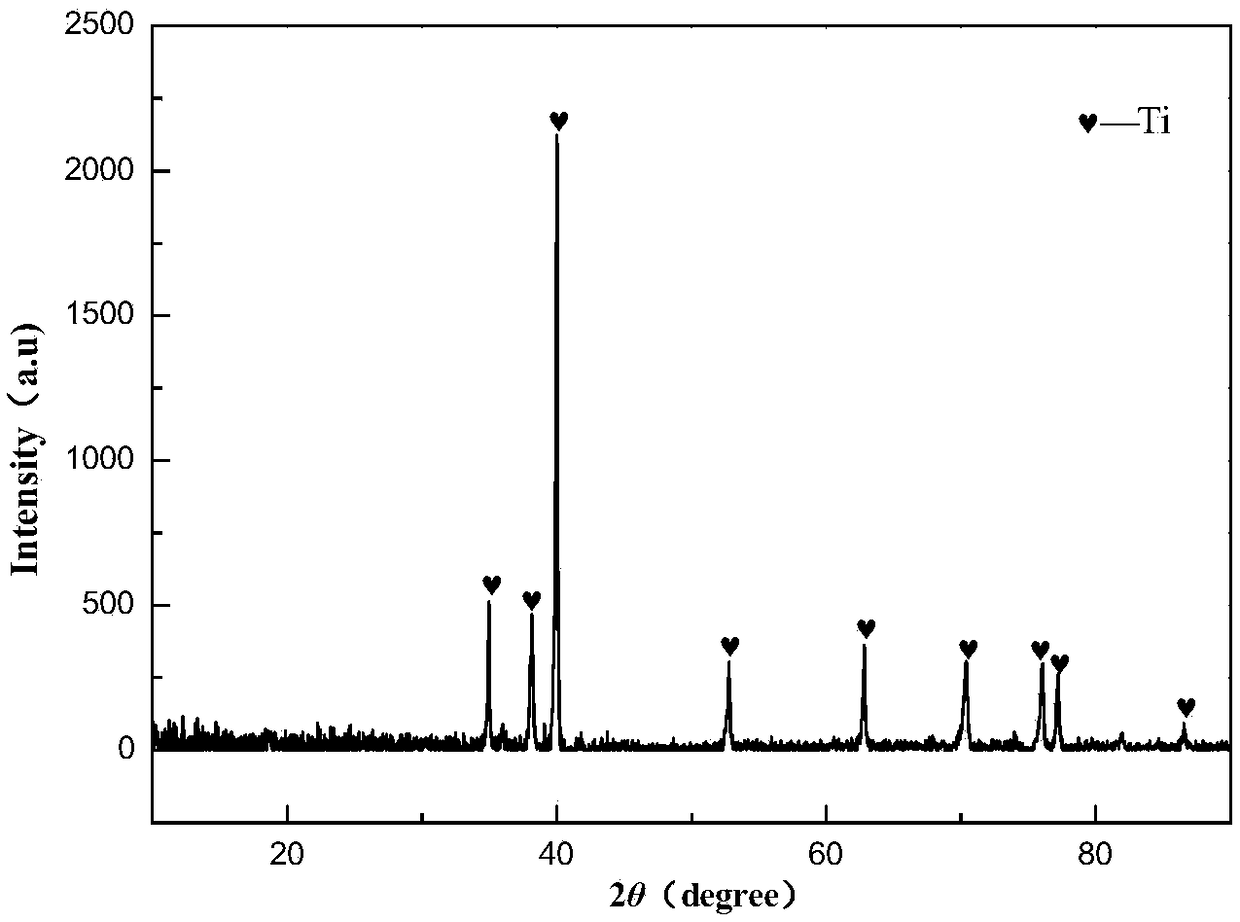

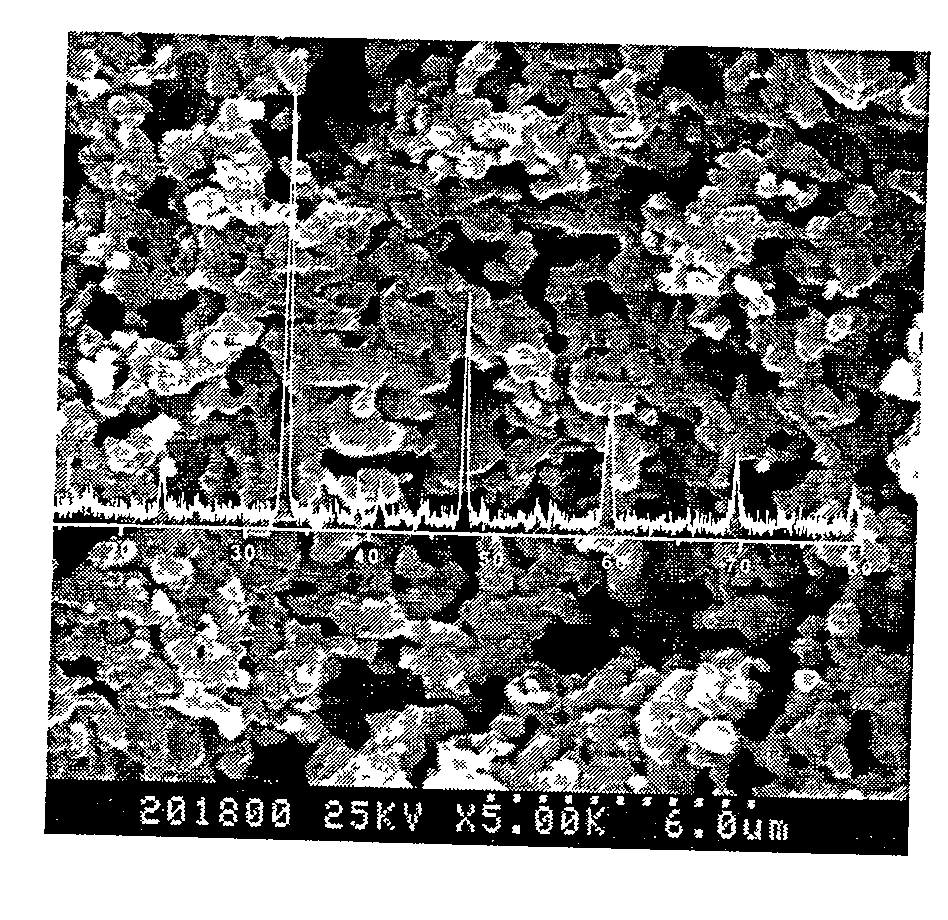

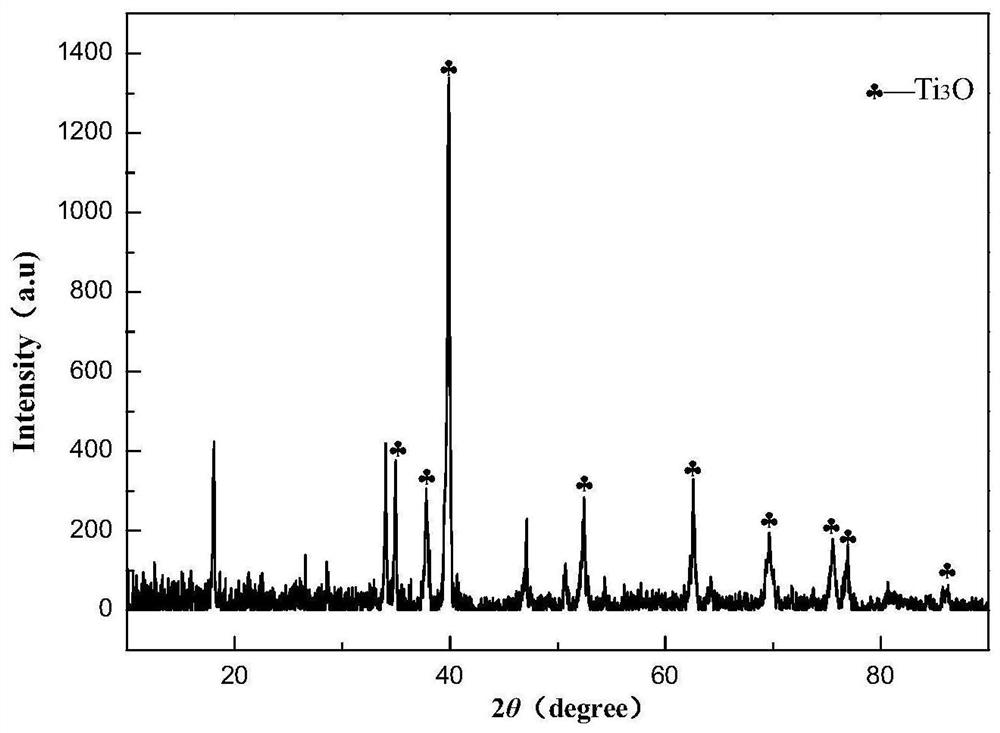

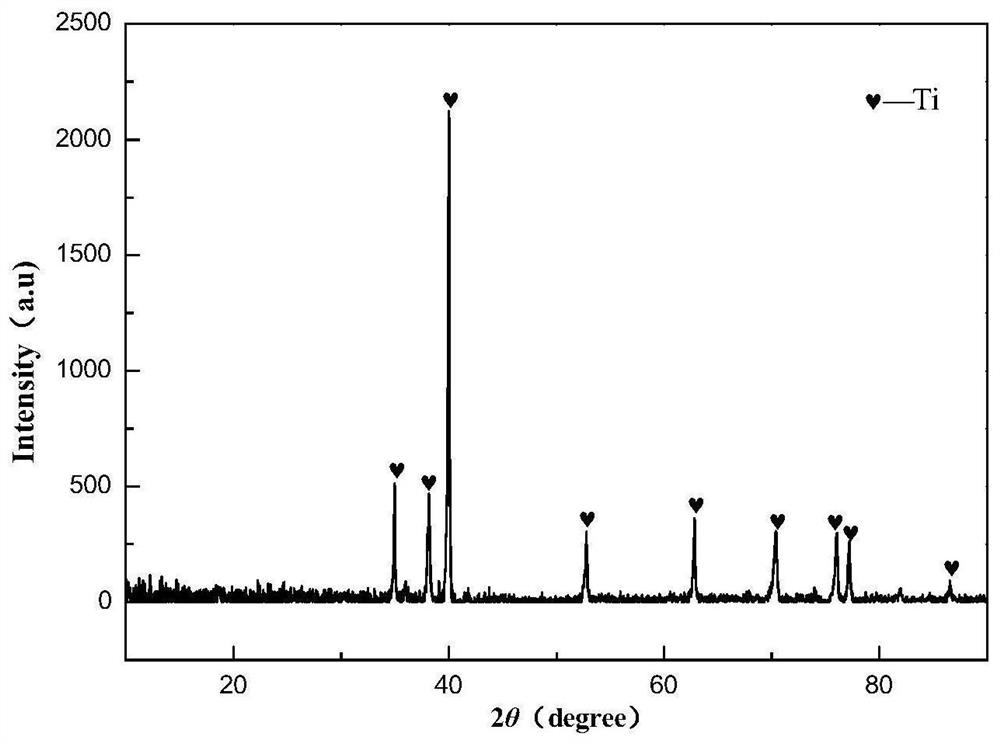

Method for improving TiO2 cathode deoxidizing process by utilizing carbonaceous additive

A method for improving TiO2 cathode deoxidizing process by utilizing a carbonaceous additive specifically comprises the following steps: mixing TiO2 and the carbonaceous additive according to the molar ratio of 2:1-19:1, and pressing a mixture into a block body with diameter of 10mm at the pressure of 1-5 t; performing heat treatment in the Ar protective atmosphere at the temperature of 800-1000 DEG C for 2-8 h to prepare a TiO2 / C composite cathode; using the TiO2 / C composite cathode prepared in the step 1 as a cathode, using a graphite rod as an anode, selecting CaC12 fused salt as an electrolyte system, exerting 2-3 V of bath voltage to perform electrolysis under the temperature condition of 800-950 DEG C for 5-20 h, removing an electrolysis product at the cathode, such asTi and TiCxOy compound at the normal temperature after finishing the electrolysis, and using deionized water and dilute acid to wash and remove chloride from electrolyte for many times. The method for improving the TiO2 cathode deoxidizing process by utilizing the carbonaceous additive has the advantages that the electrolysis time is shortened remarkably, the electrochemical reduction speed of the TiO2 cathode is accelerated accordingly, and a small quantity of added carbon powder enable the electrolysis products to become the compound of metal Ti and metal TiCxOy to be Ti and TiCxOy compound. By means of the method, the electrolytic process can be improved remarkably, remarkable reduction of energy loss is facilitated, and accordingly the production cost of the metal Ti is reduced.

Owner:UNIV OF SCI & TECH BEIJING

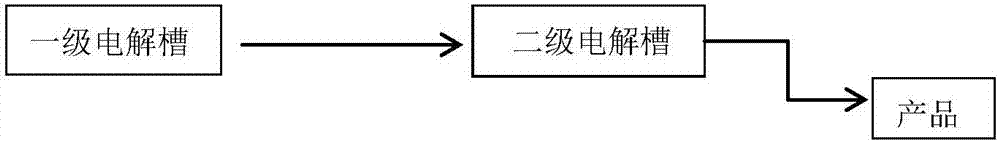

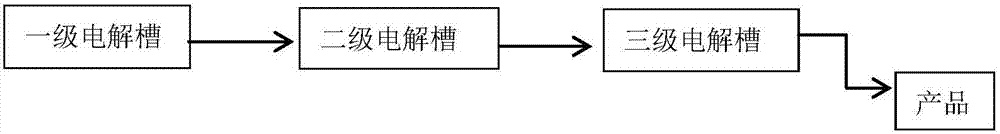

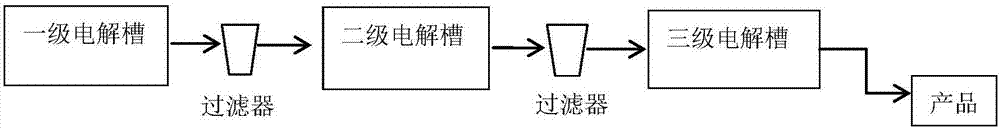

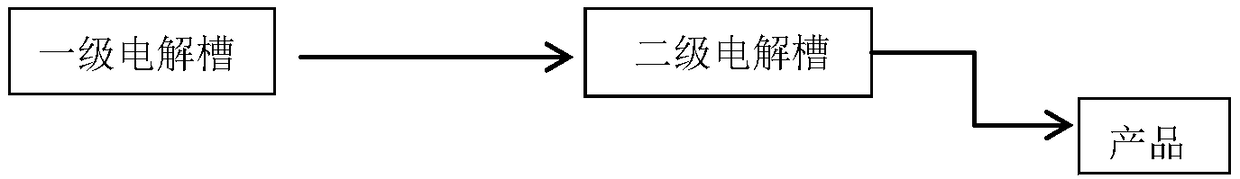

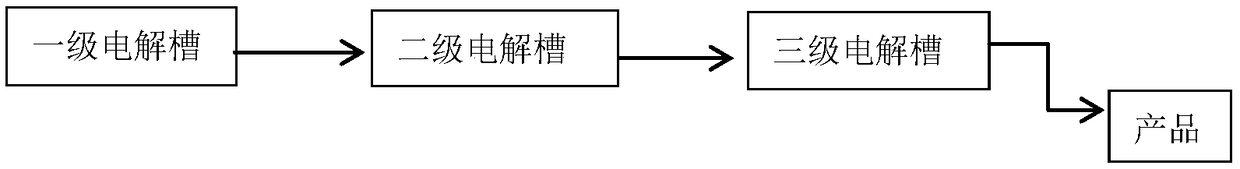

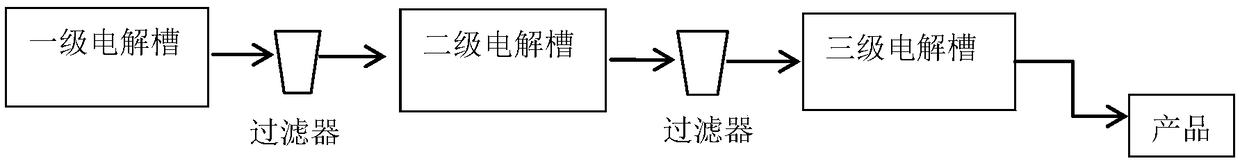

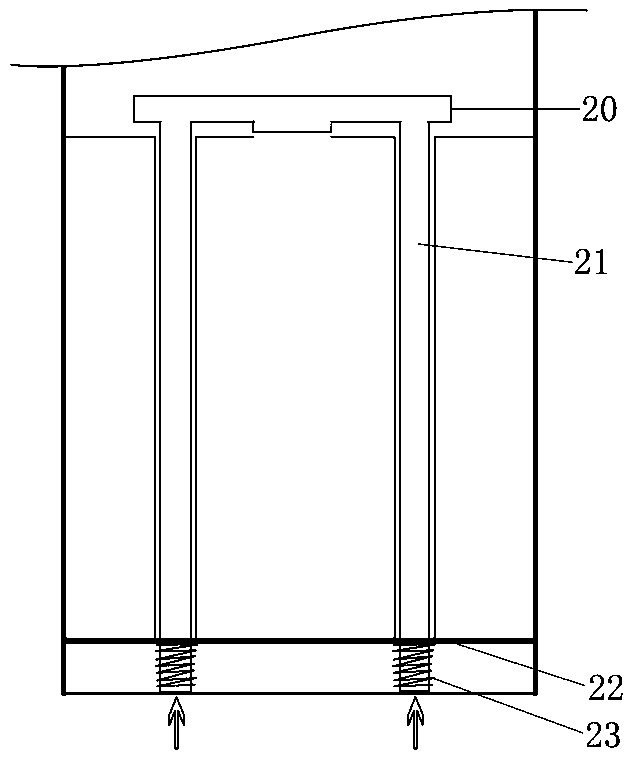

Method for producing high-concentration ferrate through step-by-step electrolytic process

ActiveCN106894037AIncrease concentrationImprove reaction efficiencyCellsHigh concentrationElectrochemistry

The invention discloses a method for producing high-concentration ferrate through a step-by-step electrolytic process, and belongs to the technical field of electrochemistry. Two or more stages of electrolytic baths are adopted. After first-stage electrolytic production is carried out in the first-stage electrolytic bath. Ferrate products in an anode chamber flow into an anode chamber of the second-stage electrolytic bath for second-stage electrolysis, and in this way, more stages of electrolytic baths can be sequentially connected in series for electrolysis. A filtering or cooling device can be added in the middle of each stage of electrolytic bath. Accordingly, ferrate is produced through two or more stages of electrolytic reaction, and the problems that the product concentration is low and production efficiency is low when ferrate is produced through the electrolytic process can be simultaneously solved. The method is efficient, easy and convenient to implement, and capable of being used for producing high-concentration liquid ferrate or producing crystal ferrate.

Owner:NORTHEAST DIANLI UNIVERSITY

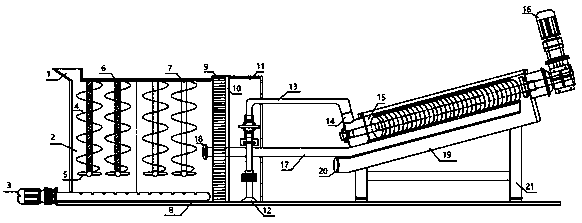

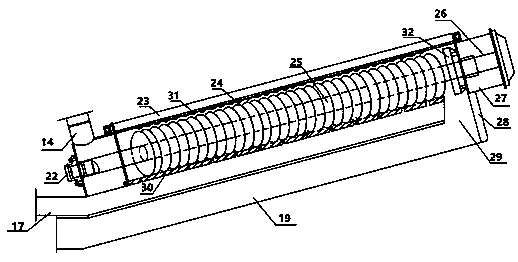

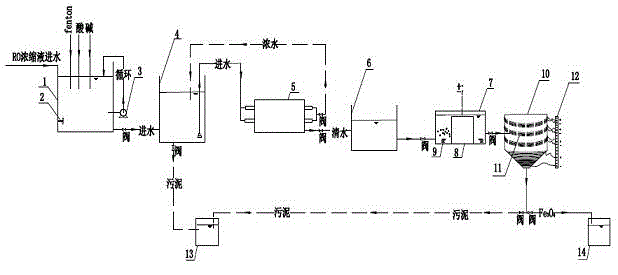

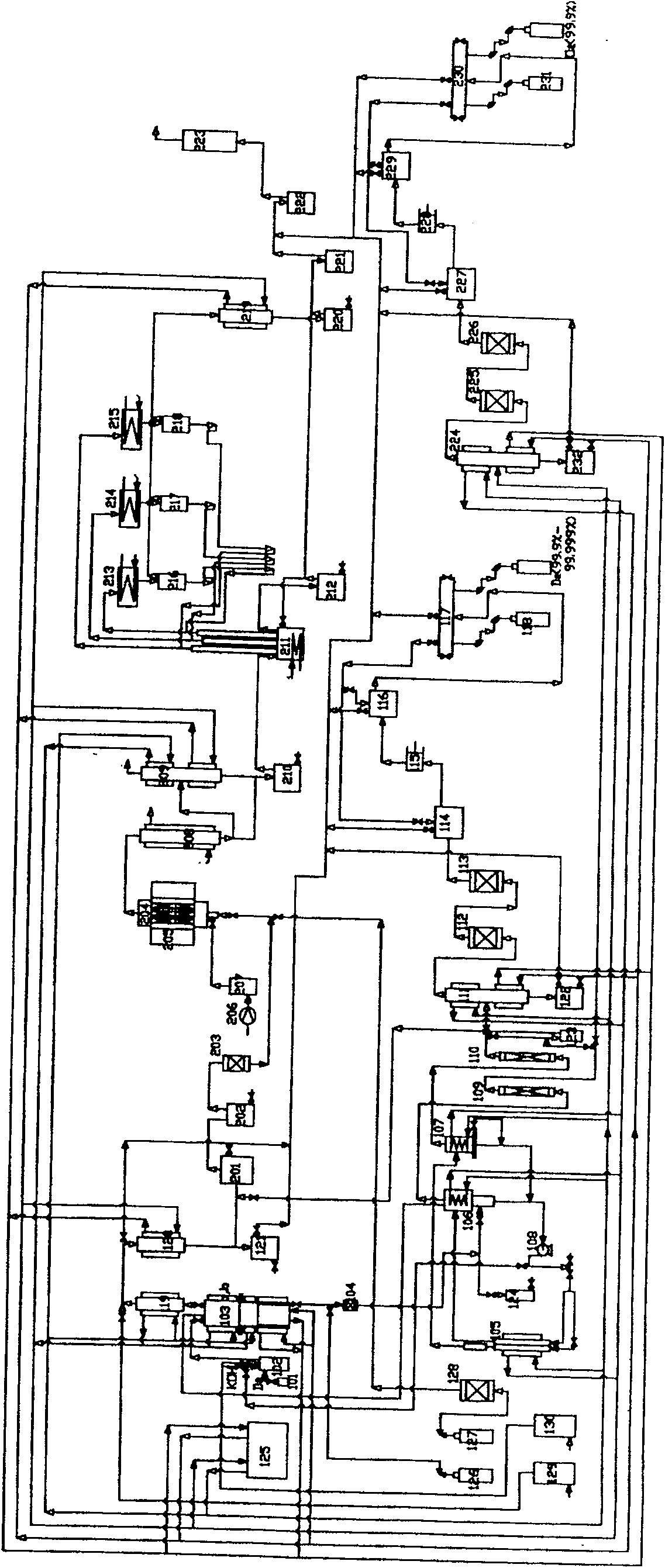

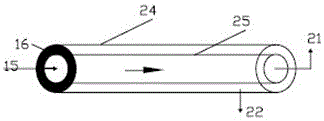

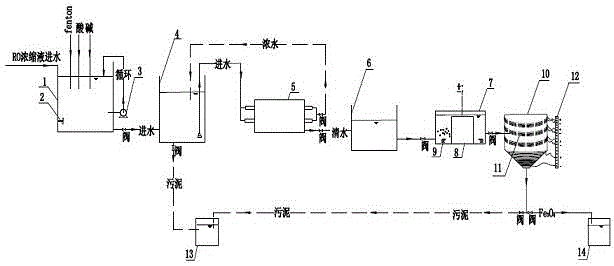

Equipment and combined process for treating RO concentrated solution of high-concentration organic wastewater

ActiveCN104529046AImprove separation efficiencyImprove electrolysis efficiencyMultistage water/sewage treatmentHigh concentrationPre treatment

The invention relates to equipment and a combined process for removing RO concentrated solution in a high-concentration organic wastewater treatment system. The equipment for treating RO concentrated solution of high-concentration organic wastewater comprises a Fenton pretreatment pool 1, membrane system separation equipment 5, a pulsed electrolytic cell 7 and a magnetic settling pond 10 which are sequentially connected by virtue of pipelines, wherein the membrane system separation equipment 5 refers to a tubular coating; the pulsed electrolytic cell 7 is an inverted I-shaped electrolytic cell which consists of two pools 26 and two water tanks 27 and is hollow; and magnets 11 consisting of soft iron and wound coils are arranged on the outer layer of the settling pond wall 28 in a sectional mode. The combined process for treating the RO concentrated solution of high-concentration organic wastewater comprises the following steps: performing chemical Fenton pretreatment; performing membrane separation; forming the pulsed electrolytic cell 7 with the Fe3O4 synergistic effect; forming the magnetic settling pond 10; and performing up-to-standard release on the supernatant. According to the novel equipment and combined process provided by the invention, the equipment is feasible in technology and applicable in economy, and the RO concentrated solution of the high-concentration organic wastewater is efficiently treated.

Owner:中钢集团武汉安全环保研究院有限公司

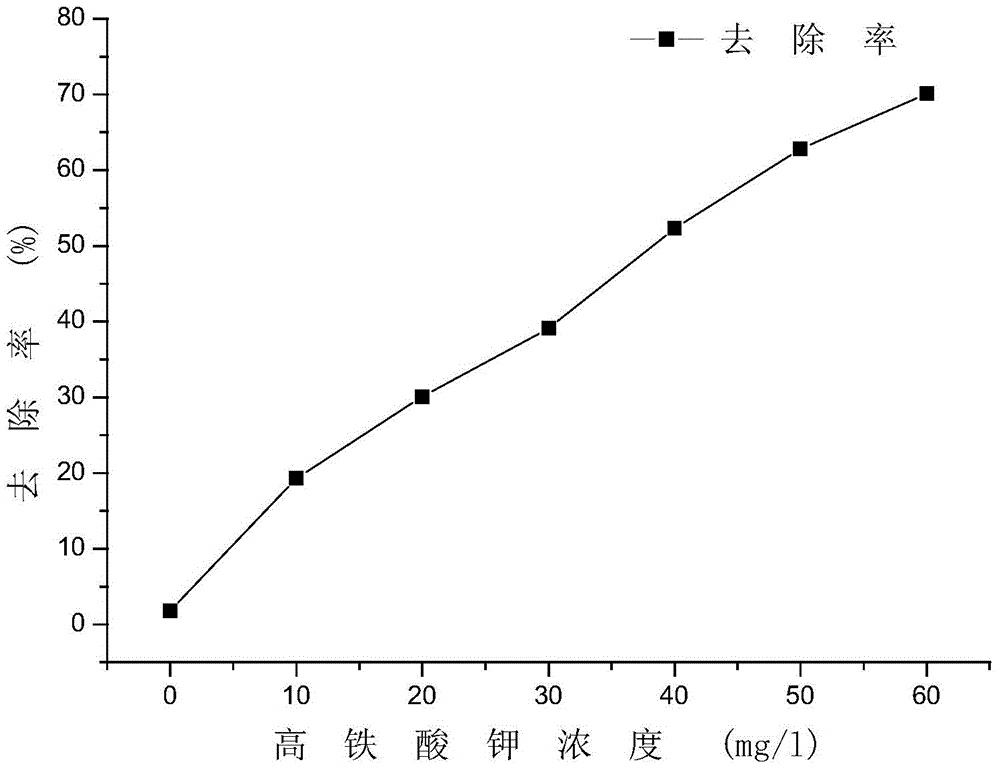

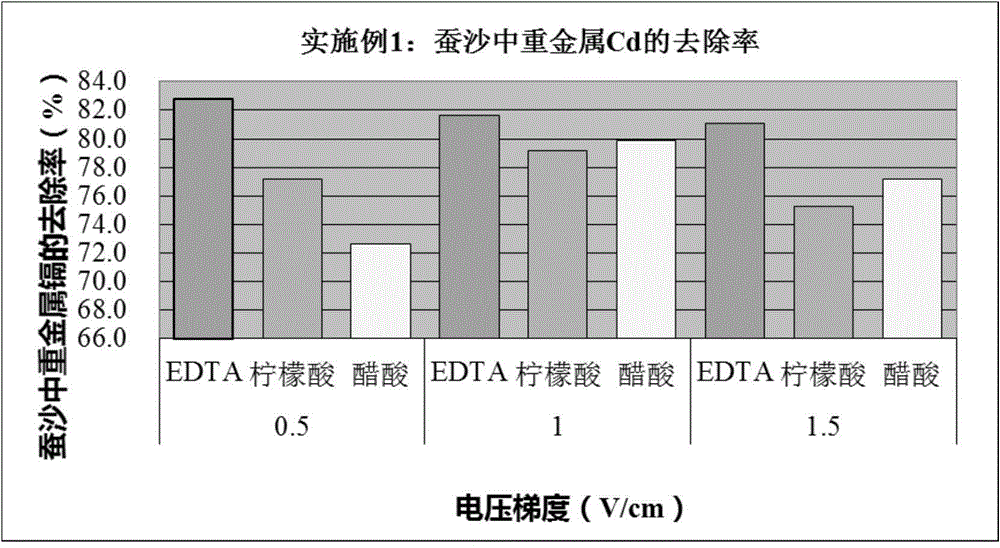

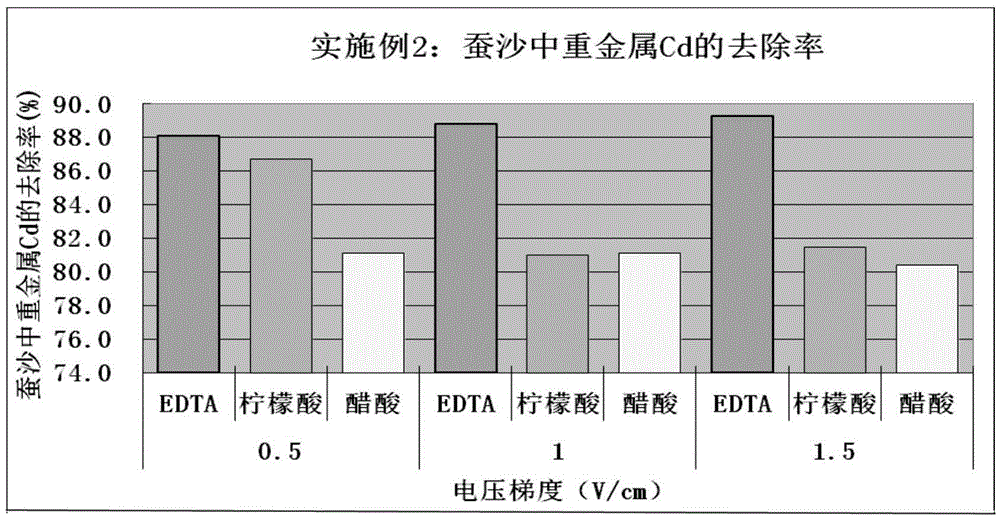

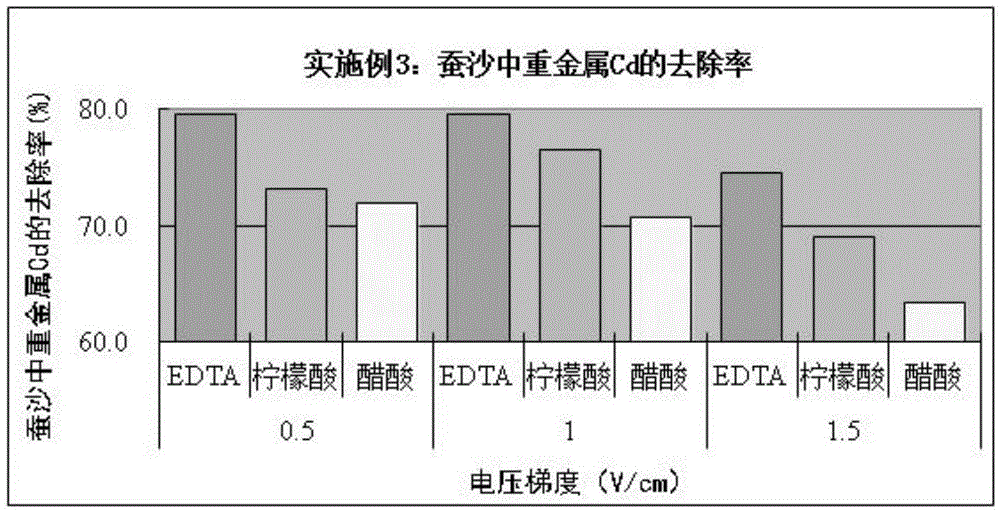

Electrochemical method for removing heavy metal cadmium in silkworm excrement

The invention discloses an electrochemical method for removing heavy metal cadmium in silkworm excrement. The method is characterized by comprising the following steps: weighing the silkworm excrement containing heavy metal cadmium, extracting by adopting 0.1mol / L EDTA, citric acid and acetic acid as extractants, adjusting the pH value to 2-6 by using hydrochloric acid, putting into an electrochemical device taking graphite as an electrode, controlling the electrode plate distance to be 14cm, arranging a layer of cation exchange membrane at a position 10cm away from the anode, controlling the voltage gradient to 0.5V / cm-1.5V / cm and performing electrochemical treatment. According to the method, the electricity consumption is low, the pH range is relatively wide, the electrolysis time is short, the time is shortened, the cation exchange membrane is uniform, the electrode voltage is stable, and the performance is reliable; the removing rate of metal Cd in the silkworm excrement can be up to 63.4 or more. By using the method, the heavy metal Cd is enriched at the cathode, so that the heavy metal Cd is easy to treat, no secondary pollution is generated, no harm factors are generated, and the treated silkworm excrement can be used as drug or can be used as a fertilizer.

Owner:QINGDAO AGRI UNIV

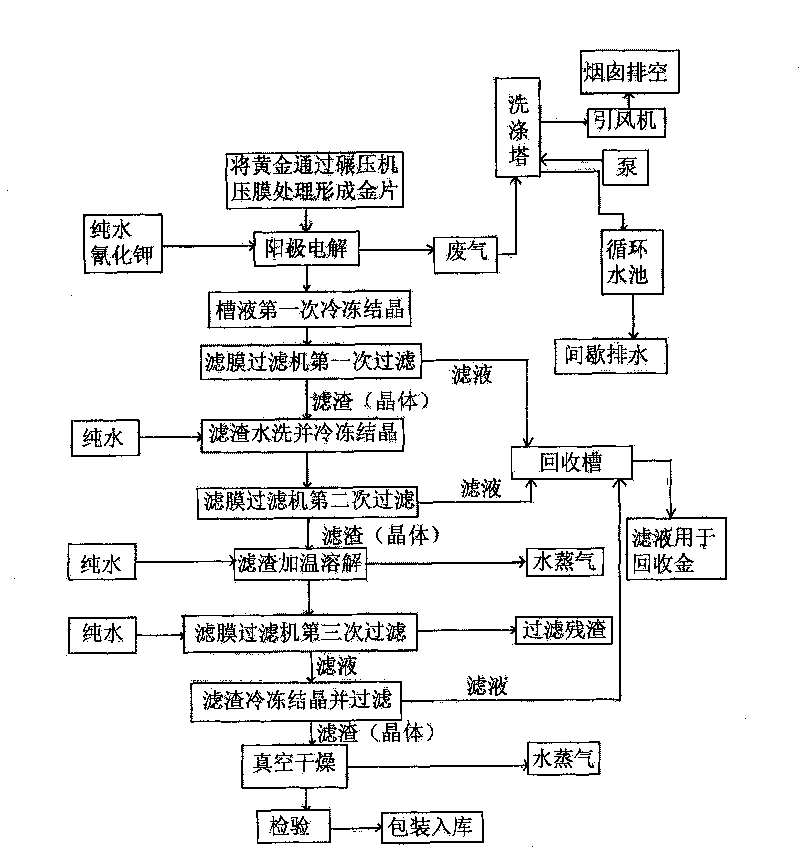

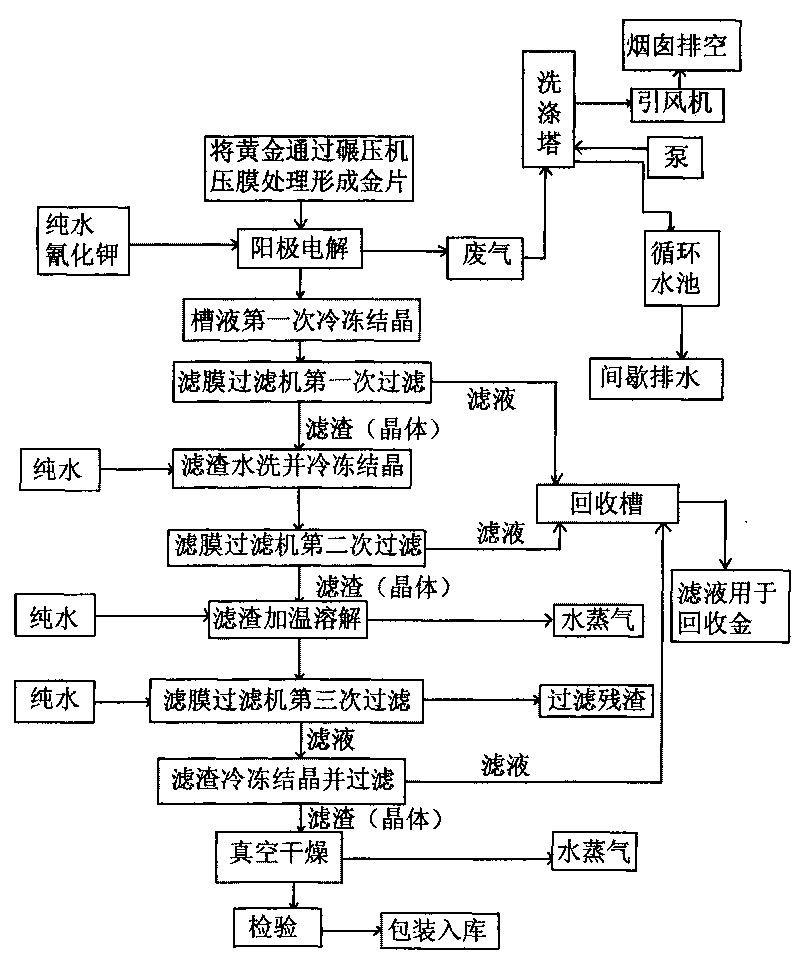

Method for preparing gold salt activator

InactiveCN101717961AReduce lossHigh purityPhotography auxillary processesElectrolysisPotassium cyanide

The invention discloses a method for preparing a gold salt activator, which comprises the following steps: firstly, performing lamination treatment on gold to form a gold sheet; secondly, putting the gold sheet into an electrolytic tank filled with solution of potassuim cyanide for electrolysis, taking the gold sheet as an anode and electrolyzing the anode gold sheet into KAu(CN)2; thirdly, performing freezing crystallization on the electrolyzed solution of KAu(CN)2 in the electrolytic tank to obtain solution containing KAu(CN)2 crystals, filtering through a filter membrane filter, washing the filtered KAu(CN)2 with water, performing the secondary freezing crystallization and secondary filtration, heating and dissolving the filtered KAu(CN)2, performing the third filtration on the dissolved solution with the filter membrane filter, performing the third freezing crystallization on the filtered KAu(CN)2 solution, and filtering to obtain KAu(CN)2 crystals; and finally, directly baking and drying the KAu(CN)2 crystals to obtain KAu(CN)2 particles.

Owner:吴朝勤

Catalyst used for lincomycin production wastewater electrolysis, preparation method and application thereof

ActiveCN106622251AIncreased efficiency in the production of organic wastewaterShorten electrolysis timeHeterogenous catalyst chemical elementsNature of treatment waterElectrolysisRed mud

The invention provides a catalyst used for lincomycin production wastewater electrolysis, a preparation method and application thereof. The catalyst comprises the following components: caustic residues, red mud, manganese, iron compound, coal ash and clay. The preparation method comprises the following steps: solidification and activation, wherein a solidification temperature is 150-200DEG C, solidification time is 2-6 hours, an activation temperature is 500-650DEG C, and activation time is 4-6 hours. According to the catalyst, the efficiency of electrolyzing lincomycin production organic wastewater is obviously improved.

Owner:丁昊怡

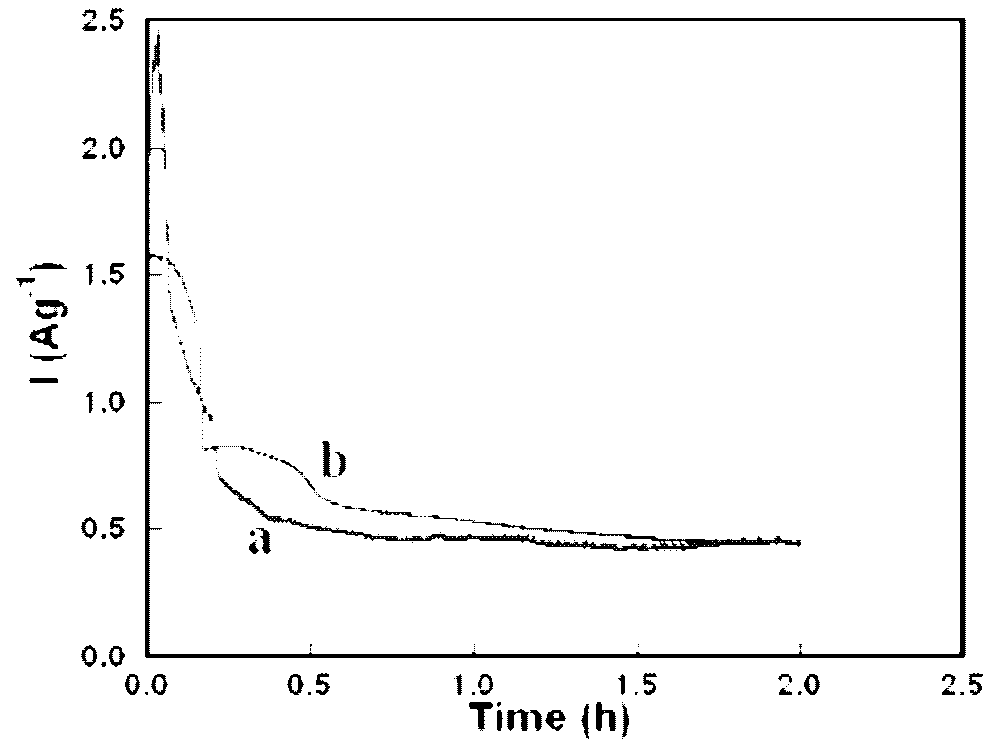

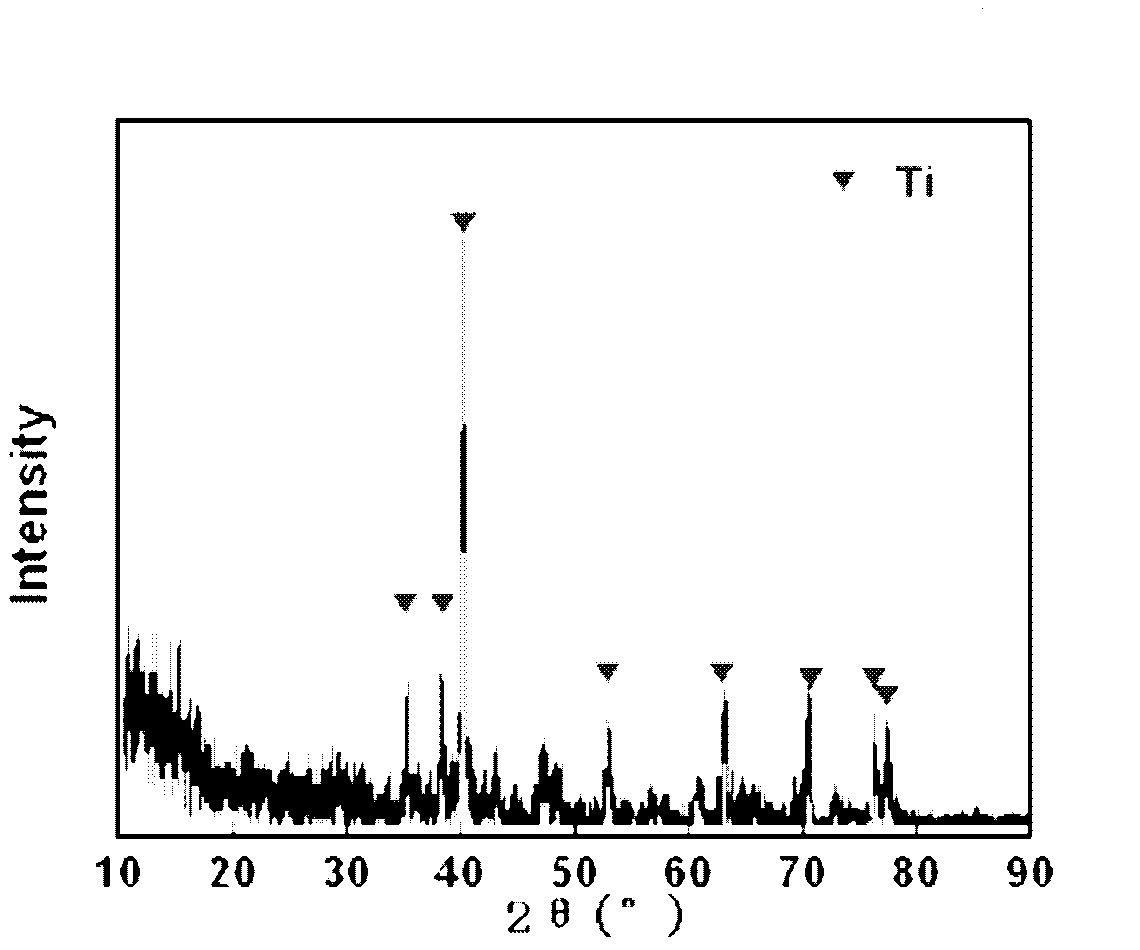

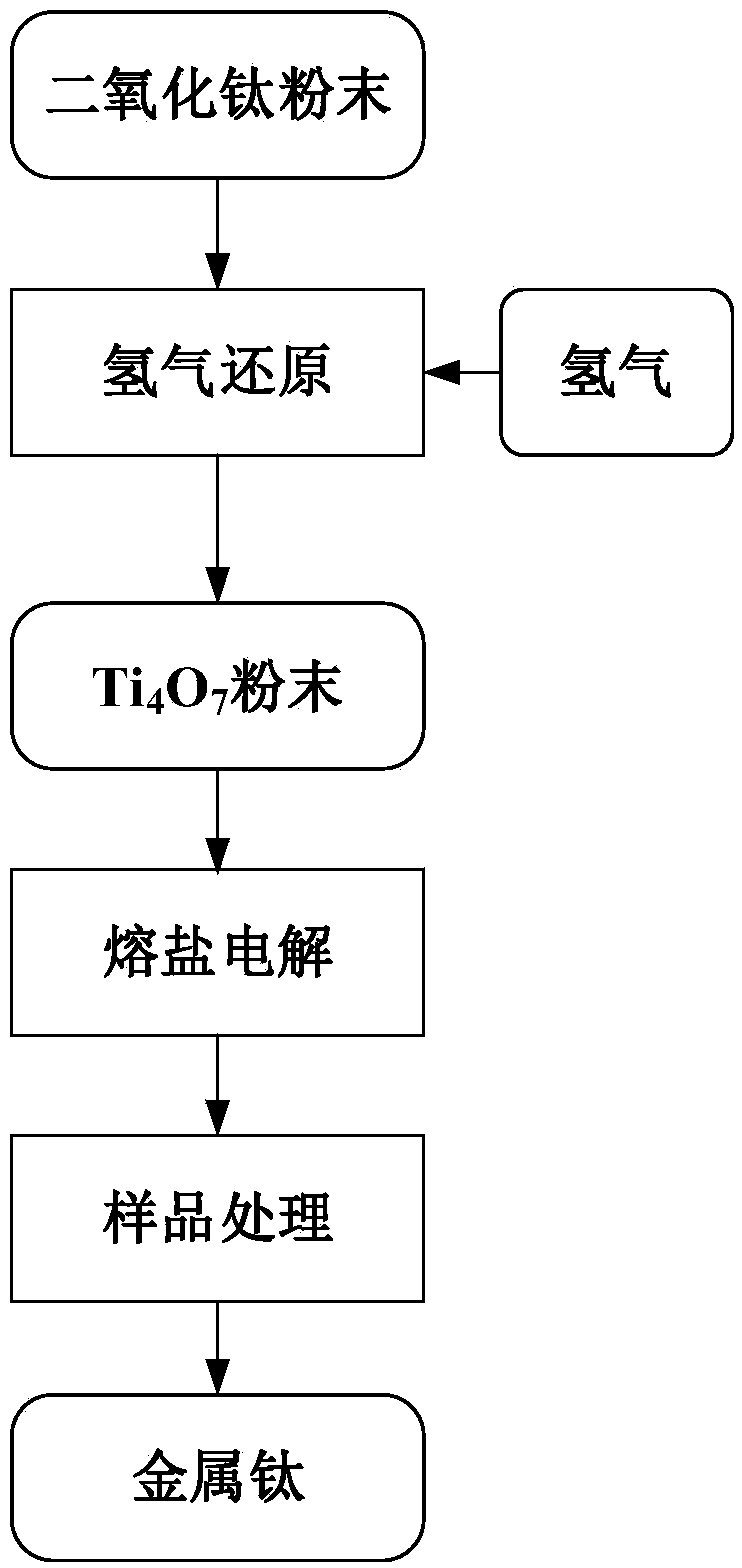

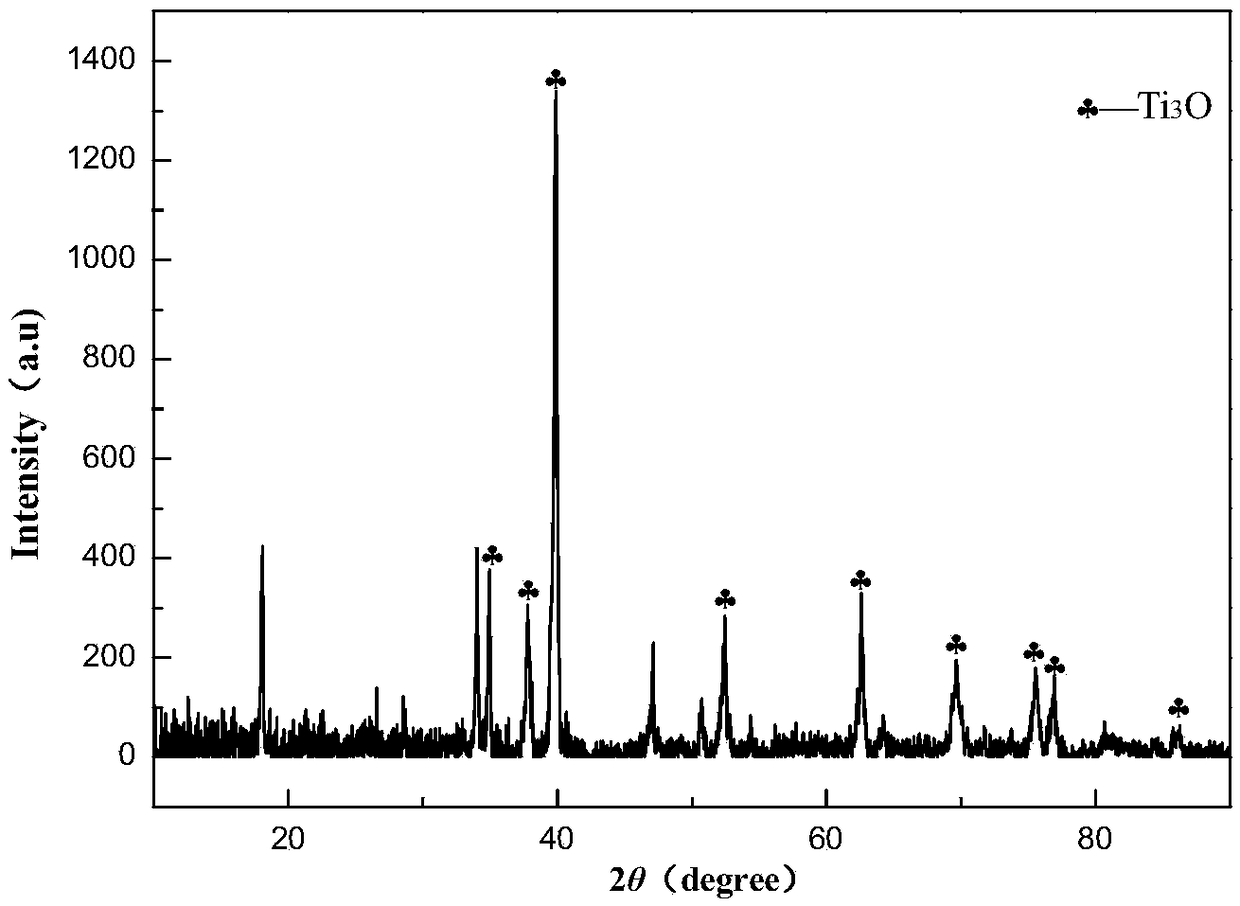

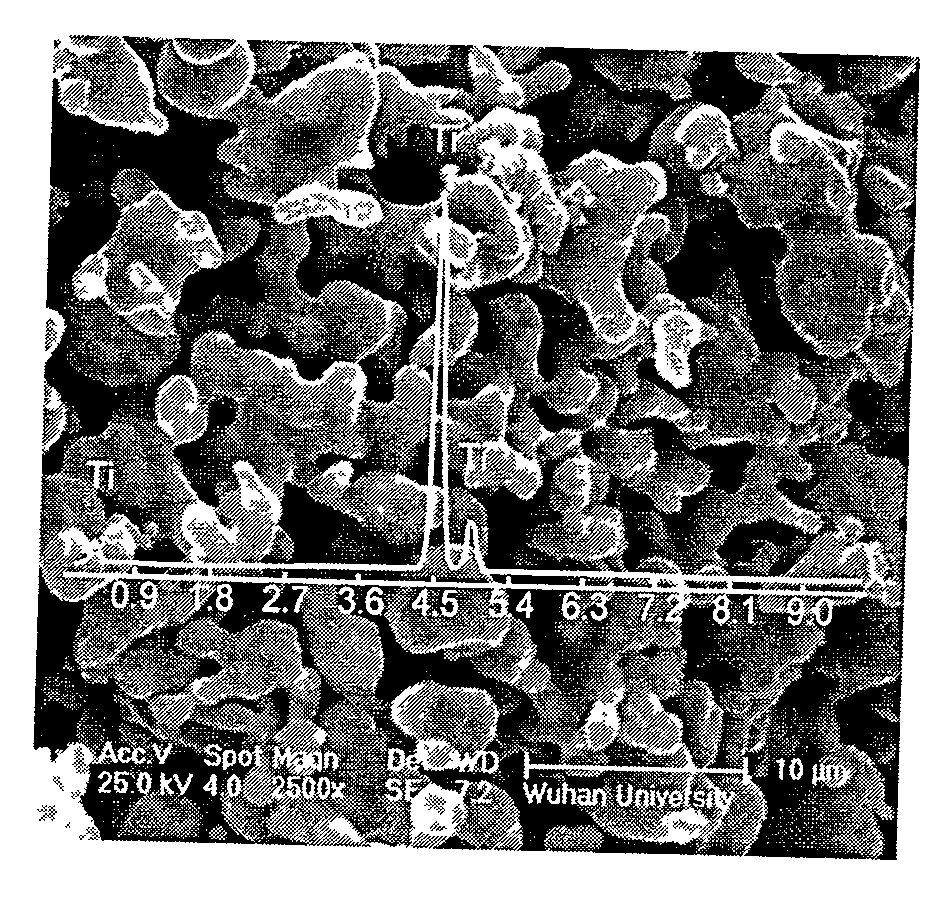

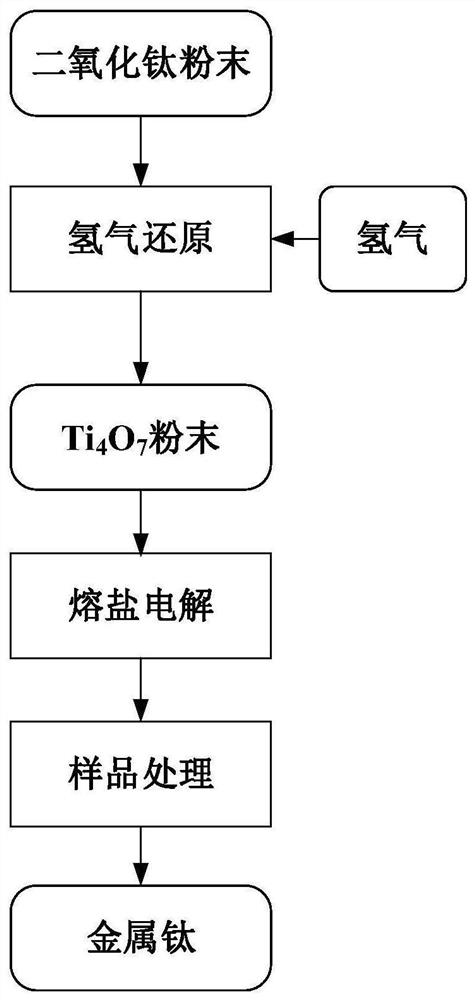

Metal titanium preparation method combining hydrogen reduction of TiO2 and molten salt electrolysis of Ti4O7

The invention discloses a metal titanium preparation method combining hydrogen reduction of TiO2 and molten salt electrolysis of Ti4O7. According to the metal titanium preparation method combining hydrogen reduction of TiO2 and molten salt electrolysis of Ti4O7, the TiO2 is used as the raw material, hydrogen is selected as a reducing agent to perform a gas-solid reduction reaction with the TiO2 raw material at the temperature of 1300-1400 DEG C, and the reduction product is Ti4O7 powder; anhydrous calcium chloride is used as molten salt, graphite is used as an anode, the Ti4O7 obtained throughreduction is used as a cathode, 3.1V direct-current voltage is exerted between the anode and the cathode, electrolysis is conducted for 3 hours in the inert atmosphere of 900 DEG C, and then the metal titanium can be obtained. The metal titanium preparation method combining hydrogen reduction of TiO2 and molten salt electrolysis of Ti4O7 achieves the purpose of electrolysis preparation of the metal titanium within short time, has the advantages of being high in production efficiency, low in energy consumption, environmentally friendly, clean and the like and has the potential to achieve industrialization.

Owner:CHONGQING UNIV +1

Method for handling organic wastewater based on Fenton reaction

InactiveCN102020384BImprove current efficiencyReduce concentration polarizationMultistage water/sewage treatmentWater/sewage treatment by oxidationFenton reactionDC - Direct current

The invention discloses a method for handling organic wastewater based on Fenton reaction, comprising the following steps of: (1) high-voltage pulse electric coagulating reaction: regulating the pH value of wastewater to be 3-4 so that wastewater performs high-voltage pulse electric coagulating reaction in a high-voltage pulse electric coagulating device at the current intensity of 1-30A, whereinthe electric coagulating reaction time ranges from 30-120min, the high-voltage pulse electric coagulating device is input by the 100-400V alternating current which is then converted into direct current after rectification, the pulse voltage of 80V to 350V is formed by utilizing a pulse generator, the anode and cathode plates adopted by the high-voltage pulse electric coagulating device are iron plates with the carbon content above 0.45wt% and the space between the polar plates ranges from 10-30mm; (2) Fenton reaction; and (3) concrete precipitation reaction. Compared with the prior art, the invention reduces the handling cost, shortens the handling time and ensures better handling effect.

Owner:JIANGSU SUJING GROUP +1

Method for producing metal material by composite compound

InactiveCN100570011CHigh reducing activityAdd channelPhotography auxillary processesProcess efficiency improvementElectrolysisReaction rate

This invention relates to a method of preparing metal material using complex compounds. Electrolysis is carried out in the electrolyte under the protection of inert gas or air containing M3Y with composite compounds of M1M2X combine with the collector as a cathode and carbon, metal or conductive ceramic as anode. Controlling electrolysis voltage, so that M2 reduction reaction is the dominated reaction, and M1 and X is partly or all dissolved in the electrolyte as electrolysis going on. When M1 is H, M1 can be reduced to gas leaving away the cathode. At the end of electrolys, M2 alone or with part of the M1 and X-stay is left on the cathode, which is the corresponding metal. Since M1X part or all leave away cathode in this invention during electrolysis process, the reactivity and ability of cathode is enhanced, the reaction rate and the current efficiency are effectively improved and energy consumption is reduced.

Owner:WUHAN UNIV +1

A device for generating high-concentration hydrogen-rich water

ActiveCN106108560BHigh hydrogen contentGood health effectWater/sewage treatmentDrinking vesselsHigh concentrationWater storage

The invention discloses a high-concentration hydrogen-rich water generation device. The device comprises a cup body, wherein the bottom of the cup body is connected with a base provided with an electrolyzer, an inner container is arranged in the center of the cup body to serve as a water storage cavity, a hydrogen-rich water cavity is formed outside the inner container, the bottom of the inner container is provided with a water outlet communicated with the hydrogen-rich water cavity, a bottom cover is rotationally connected to one side of the water outlet, a water-out valve rod is arranged at the center of the inner container, an elastic sealing ball is arranged at the bottom end of the water-out valve rod, the upper end of the water-out valve rod stretches out of the top end of a cup lid, an upper limit ring and a lower limit ring are arranged on a rod body of the water-out valve rod, an inner cover capable of sliding up and down along the rod body is arranged on the portion, between the upper limit ring and the lower limit ring, of the rod body, a contact ring is arranged at the edge of the inner cover, the inner end of the contact ring is fixed to the inner cover, an upper branch and a lower branch which are made of flexible materials are arranged at the outer end of the contact ring, the width of the contact ring is larger than the distance between the edge of the inner cover and the inner wall of the cup body, and the part, covering the hydrogen-rich water cavity, of the inner cover is provided with an annular water-permeable groove surrounding the inner container. Through the device, the hydrogen content in hydrogen-rich water can be greatly increased, and the health care effect is better.

Owner:浙江兆泉智能科技有限公司

A method for producing high-concentration ferrate by step-by-step electrolysis

ActiveCN106894037BIncrease concentrationReduce concentration polarizationCellsHigh concentrationElectrochemistry

The invention discloses a method for producing high-concentration ferrate through a step-by-step electrolytic process, and belongs to the technical field of electrochemistry. Two or more stages of electrolytic baths are adopted. After first-stage electrolytic production is carried out in the first-stage electrolytic bath. Ferrate products in an anode chamber flow into an anode chamber of the second-stage electrolytic bath for second-stage electrolysis, and in this way, more stages of electrolytic baths can be sequentially connected in series for electrolysis. A filtering or cooling device can be added in the middle of each stage of electrolytic bath. Accordingly, ferrate is produced through two or more stages of electrolytic reaction, and the problems that the product concentration is low and production efficiency is low when ferrate is produced through the electrolytic process can be simultaneously solved. The method is efficient, easy and convenient to implement, and capable of being used for producing high-concentration liquid ferrate or producing crystal ferrate.

Owner:NORTHEAST DIANLI UNIVERSITY

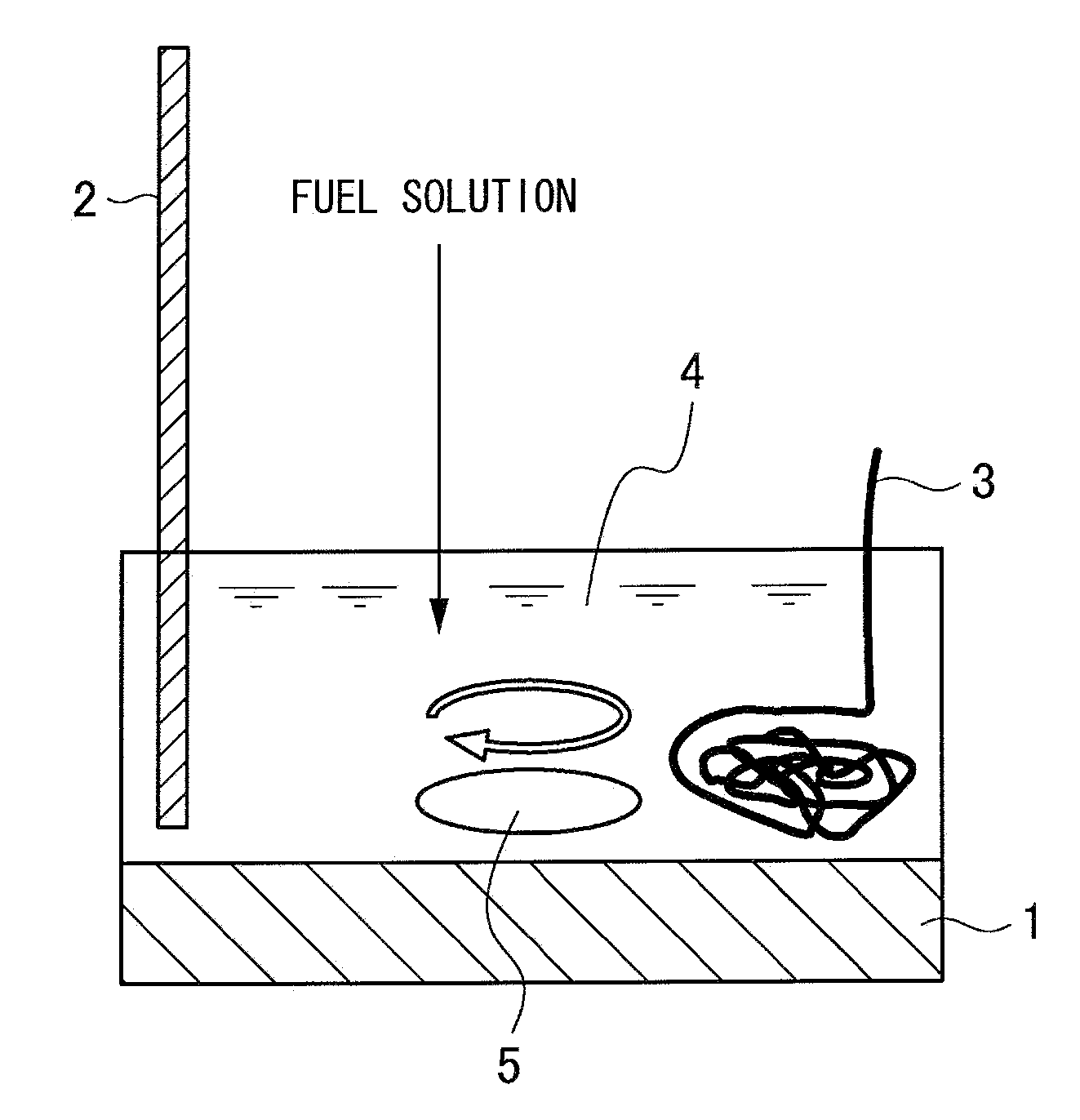

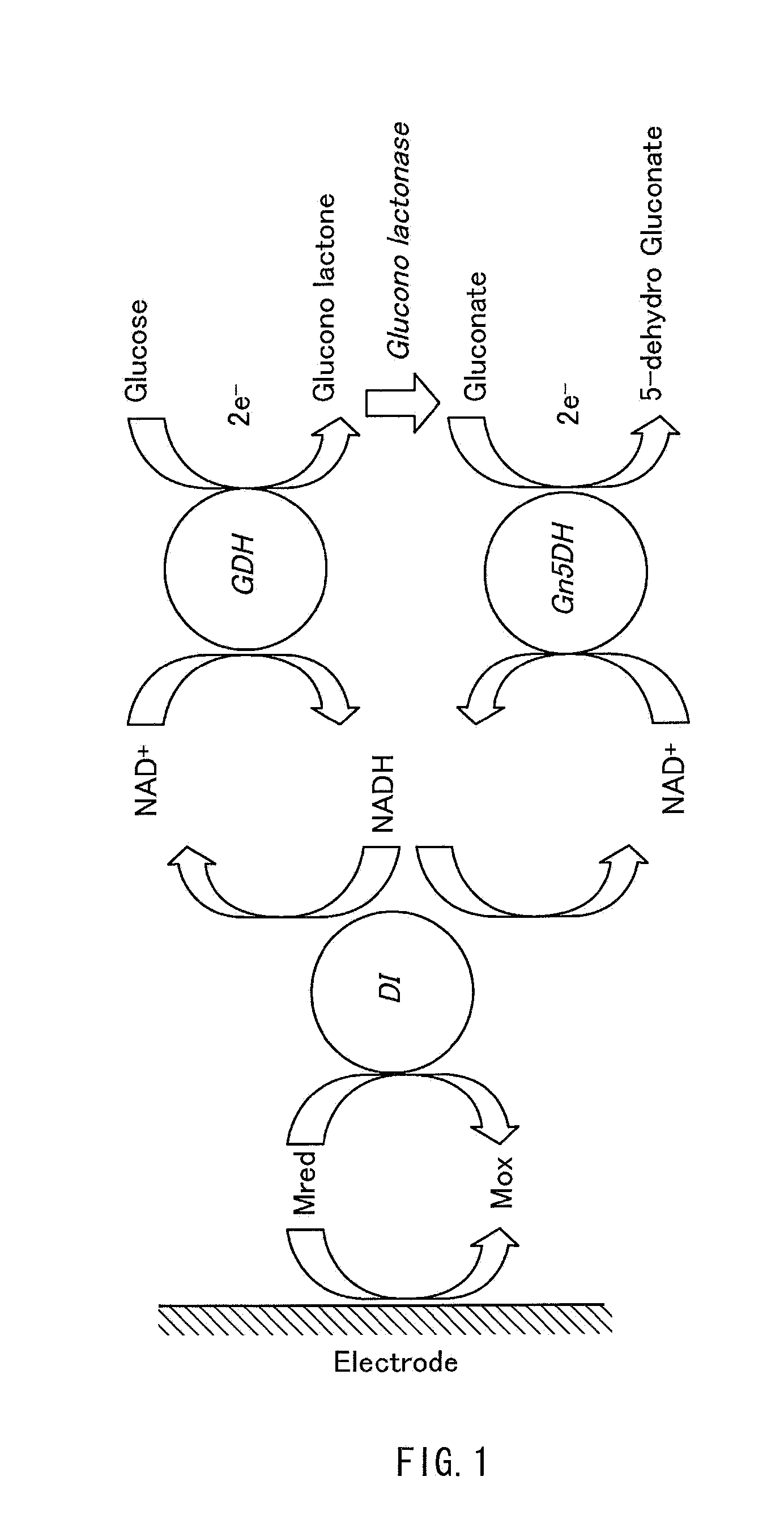

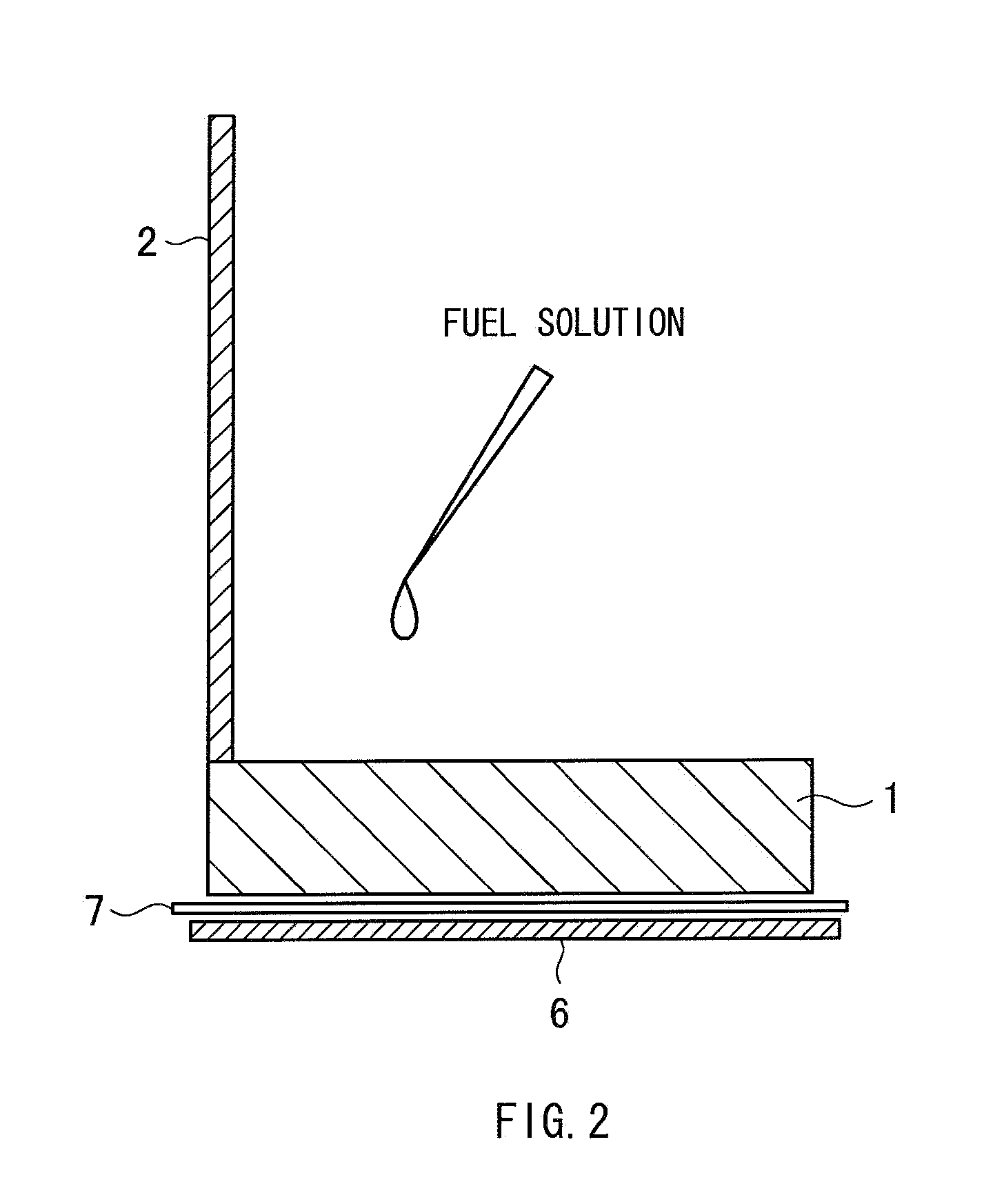

Electrolytic method of fuel

InactiveUS20120000788A1Increase ratingsAvoid the reverse reactionElectrolysis componentsMicrobiological testing/measurementElectrolysisPorous electrode

An electrolytic method of a fuel capable of suppressing reverse reaction of an enzyme and improving electrolytic rate is provided. In electrolyzing a fuel such as glucose by using an enzyme / electron mediator obtained by immobilizing an enzyme such as gluconate-5-dehydrogenase, alcohol dehydrogenase, and malate dehydrogenase and an electron mediator onto a porous electrode made of a carbon material, electrode reaction is generated only in the enzyme / electron mediator electrode.

Owner:SONY CORP

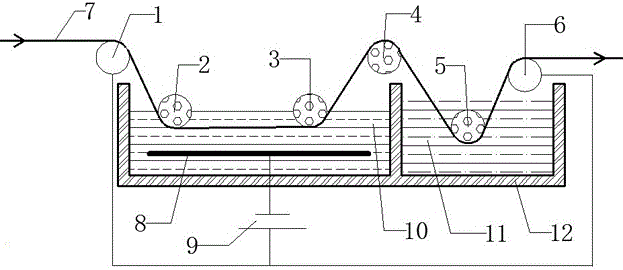

A carbon fiber surface treatment equipment, surface treatment method and application

The invention discloses carbon fiber surface treatment equipment comprising a trough frame, wherein the interior of the trough frame is divided into two independent spaces namely an electrolytic bath for containing electrolyte and a rinsing bath for containing deionized water; a cathode plate is arranged in the electrolytic bath and is connected with the negative electrode of an electrolysis power supply; a first insulating guide roll is arranged above the cathode plate in the electrolytic bath; a second insulating guide roll is arranged in the rinsing bath, and a third insulating guide roll is arranged above the trough frame between the first insulating guide roll in the electrolytic bath and the second insulating guide roll in the rinsing bath; anode guide rolls are respectively arranged above the trough frame on the outer side of the first insulating guide roll and the outer side of the second insulating guide roll, and are connected with the anode of the electrolysis power supply. By adopting the carbon fiber surface treatment equipment disclosed by the invention, the problem that the anode guide roll is oxidized and can not conduct electricity is solved, and meanwhile, by adopting the surface treatment method of the equipment disclosed by the invention, the surface treatment time can be shortened, so that the equipment and the surface treatment method can be applied to the fields of automobiles, medical treatment, food processing industry and chemical industry.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV +1

Additive for regenerating electrolytic copper by using etching waste liquid, preparation method of additive and electrolyte

PendingCN113235132ALow costEasy to usePhotography auxillary processesProcess efficiency improvementElectrolytic agentPhysical chemistry

The invention discloses an additive for regenerating electrolytic copper by using an etching waste liquid, a preparation method of the additive and an electrolyte. The additive for regenerating electrolytic copper by using the etching waste liquid comprises the following components in parts by mass: 500-1000 parts of a copper brightening agent, 300-500 parts of a conductive agent, 1000-1500 parts of a stabilizer, 2000-2500 parts of a wetting agent and 20-100 parts of a complexing agent. According to the technical scheme, the electrolytic density in the electrolytic process can be improved, so that the hardness of an obtained copper plate is enhanced, meanwhile, the electrolytic time is saved, and the electrolytic power consumption is reduced.

Owner:东普瑞环保科技(珠海)有限公司

Method for preparing extra high pure deuterium gas by using heavy water as raw material

ActiveCN100590228CEliminate the production process of distilling and removing alkaliShort processElectrolysis componentsHydrogen isotopesElectrolysisDistillation

This invention relates to a method for preparing ultrahigh-purity deuterium from heavy water. The method comprises: mixing heavy water and KOH at a ratio of 1:(0.01-0.03) to obtain an electrolyte, performing volume reduction electrolysis at (-20)-(-10) deg.C in a diaphragm-free electrolytic tank, stopping electrolysis when the concentration of heavy water is 99.99%, performing volume reduction electrolysis at (-10)-(-5) deg.C in an electrolytic tank with diaphragm, and preparing ultrahigh-purity deuterium (99.99%). Both the diaphragm-free electrolytic tank and the electrolytic tank with diaphragm can utilize KOH electrolyte. The method has such advantages as no need for alkali-removal process by distillation, simple process, low investment and low cost.

Owner:柯香文

A hydrogen reduction tio 2 Combined molten salt electrolysis ti 4 o 7 Method for preparing titanium metal

The invention discloses a metal titanium preparation method combining hydrogen reduction of TiO2 and molten salt electrolysis of Ti4O7. According to the metal titanium preparation method combining hydrogen reduction of TiO2 and molten salt electrolysis of Ti4O7, the TiO2 is used as the raw material, hydrogen is selected as a reducing agent to perform a gas-solid reduction reaction with the TiO2 raw material at the temperature of 1300-1400 DEG C, and the reduction product is Ti4O7 powder; anhydrous calcium chloride is used as molten salt, graphite is used as an anode, the Ti4O7 obtained throughreduction is used as a cathode, 3.1V direct-current voltage is exerted between the anode and the cathode, electrolysis is conducted for 3 hours in the inert atmosphere of 900 DEG C, and then the metal titanium can be obtained. The metal titanium preparation method combining hydrogen reduction of TiO2 and molten salt electrolysis of Ti4O7 achieves the purpose of electrolysis preparation of the metal titanium within short time, has the advantages of being high in production efficiency, low in energy consumption, environmentally friendly, clean and the like and has the potential to achieve industrialization.

Owner:CHONGQING UNIV +1

Integrated hydrogen-rich water manufacturing device

ActiveCN105174384BExtended service lifeAvoid secondary pollutionWater/sewage treatment by ion-exchangeElectrolysisHydrogen

The present invention discloses an integrated manufacturing apparatus for hydrogen-enriched water. The apparatus comprises a drinking cup, wherein a first water filling opening and a second water filling opening are formed at the upper end of the drinking cup, a first water reservoir which is communicated with the first water filling opening and a second second water reservoir which is communicated with the second water filling opening are arranged inside the drinking cup. The second reservoir is an "L"-shaped cavity consisting of a longitudinally extending cavity that extends downwardly from the second water filling opening and a transversely extending cavity that extends transversely from the lower portion of longitudinally extending cavity. The first water reservoir is located at the top of the transversely extending cavity, a cation-exchange membrane is arranged between the first water reservoir and the transversely extending cavity. A cathodic electrolysis plate and an anode electrolysis plate are separately arranged above and under the cation-exchange membrane, and the cathodic electrolysis plate and the anode electrolysis plate are separately located inside the first water reservoir and the transversely extending cavity. In the present invention, the drinking cup is integrally designed internally, so that secondary pollution which may be generated is avoided, the service life of the electrolytic plate is prolonged, and the phenomenon of dripping water is avoided.

Owner:陈志越

Equipment and combined process for treating high-concentration organic wastewater ro concentrate

ActiveCN104529046BImprove separation efficiencyImprove electrolysis efficiencyMultistage water/sewage treatmentHigh concentrationPre treatment

The invention relates to equipment and a combined process for removing RO concentrated solution in a high-concentration organic wastewater treatment system. The equipment for treating RO concentrated solution of high-concentration organic wastewater comprises a Fenton pretreatment pool 1, membrane system separation equipment 5, a pulsed electrolytic cell 7 and a magnetic settling pond 10 which are sequentially connected by virtue of pipelines, wherein the membrane system separation equipment 5 refers to a tubular coating; the pulsed electrolytic cell 7 is an inverted I-shaped electrolytic cell which consists of two pools 26 and two water tanks 27 and is hollow; and magnets 11 consisting of soft iron and wound coils are arranged on the outer layer of the settling pond wall 28 in a sectional mode. The combined process for treating the RO concentrated solution of high-concentration organic wastewater comprises the following steps: performing chemical Fenton pretreatment; performing membrane separation; forming the pulsed electrolytic cell 7 with the Fe3O4 synergistic effect; forming the magnetic settling pond 10; and performing up-to-standard release on the supernatant. According to the novel equipment and combined process provided by the invention, the equipment is feasible in technology and applicable in economy, and the RO concentrated solution of the high-concentration organic wastewater is efficiently treated.

Owner:中钢集团武汉安全环保研究院有限公司

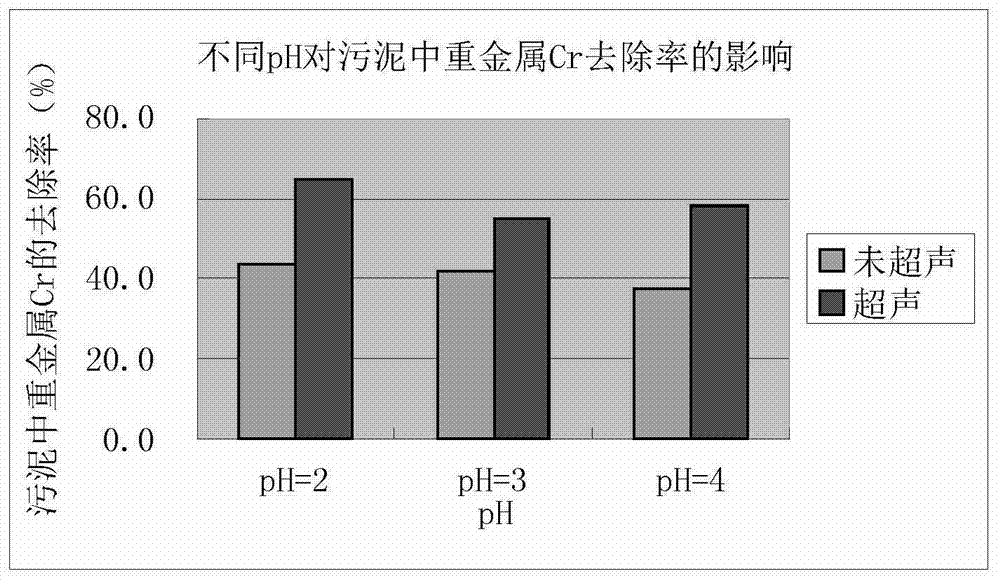

An electrochemical method for removing heavy metals from excess sludge

InactiveCN104986929BEfficient removalImprove removal efficiencySludge treatmentWater contaminantsElectrolysisSludge

Owner:QINGDAO AGRI UNIV

A method for preparing electro-deposited cobalt under a large flow rate

ActiveCN103060842BImprove current efficiencyReduce cathodic polarizationPhotography auxillary processesOxygenCathodic polarization

The invention discloses a method for preparing electrodeposited cobalt under a large flow. In conventional production methods for electrodeposited cobalt, the process of processing has the disadvantages of low current efficiency and long electrodeposition time, and purity and a recovery rate of produced electrodeposited cobalt hardly reach requirements. A technical scheme employed in the invention is as follows: a deoiled cobalt chloride solution produced in wet metallurgy is used as a raw material and is diluted with pure water so as to allow the concentration of Co<2+> in the cobalt chloride solution to be 30 to 100 g / L, and the diluted cobalt chloride solution is used as electrodeposition pre-liquid; and electrodeposition is carried out on the electrodeposition pre-liquid in an enclosed electrodeposition apparatus under the conditions of a large flow of 5 to 15 m<3> / h.m<2> and a negative pressure. According to the invention, the large flow is employed in the process of preparation of electrodeposited cobalt, so cathodic polarization is reduced, high current efficiency as high as more than 95% is obtained, and direct current consumption is low; utilization of the large flow enables chlorine and oxygen generated by an anode to be taken away in time, and oxidation of the cathode cobalt by chlorine and oxygen is prevented, thereby guaranteeing product quality.

Owner:ZHEJIANG HUAYOU COBALT +1

A kind of recovery treatment method of low concentration platinum in organic waste liquid

ActiveCN112342572BSolve recycling difficultiesReduction of recycling energy consumptionPhotography auxillary processesProcess efficiency improvementPlatinumIon exchange

The invention provides a method for recovering and treating low-concentration platinum in organic waste liquid. The method includes the following steps: A. Filling ion exchange resin, inert conductive material, and sacrificial anode metal balls into the electrochemical three-dimensional electrode bed, constructing Three-dimensional electrode system; B. Using the above-mentioned three-dimensional electrode system to carry out electrodeposition recovery of platinum in organic waste liquid. The invention not only solves the problem of difficult recovery of low-concentration platinum, but also has the advantages of simple process and low energy consumption, and is suitable for wide industrial applications.

Owner:WANHUA CHEM GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com