Patents

Literature

581results about How to "Reduce concentration polarization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Systems and methods for filtration

InactiveUS20120298578A1Reduce foulingImprove water qualityMaterial nanotechnologyGeneral water supply conservationMicroorganismFiltration membrane

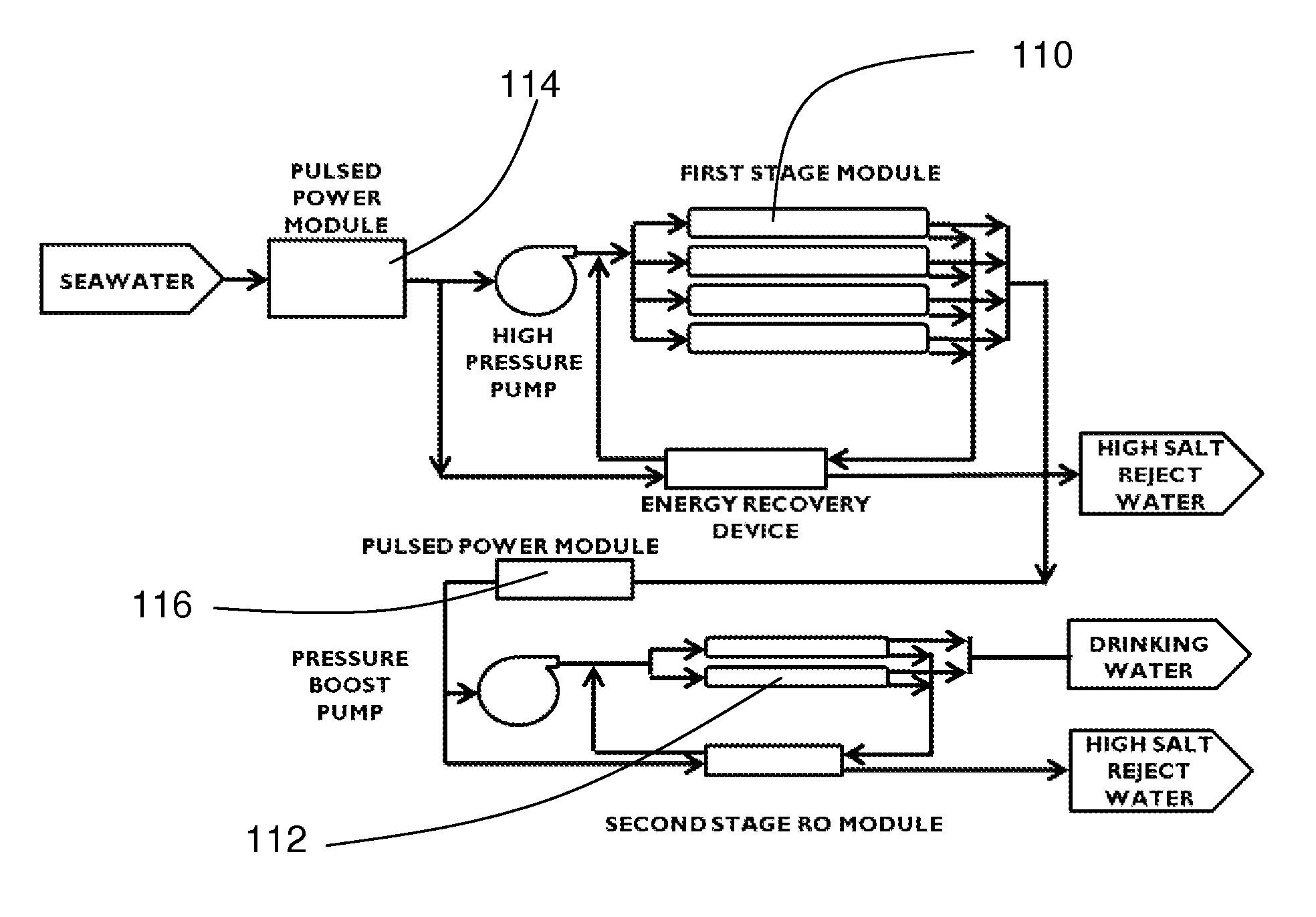

Filtration systems (40) utilize a pre-treatment method to cause scale formation to occur on particles (94) in the fluid stream (96) rather than on the filter surface and may also destroy microorganisms in the fluid stream. More specifically, but not limited to, a filtration device can be a filtration membrane, such as spiral wound filtration membrane (60), that utilizes an open feed spacer (80), such for example an embossed or printed pattern on the membrane, to create a thin feed spacer channel which replaces a conventional feed spacer mesh material. System (40) further utilizes a treatment device (54) to enable a pulsed power, magnetic, electro-magnetic, electro-static, or hydrodynamic fluid treatment scheme to condition particles in the fluid stream (96) such that scale forming elements precipitate (94) on to the particles in the fluid stream rather than on the filtration surfaces.

Owner:AQUA MEMBRANES +1

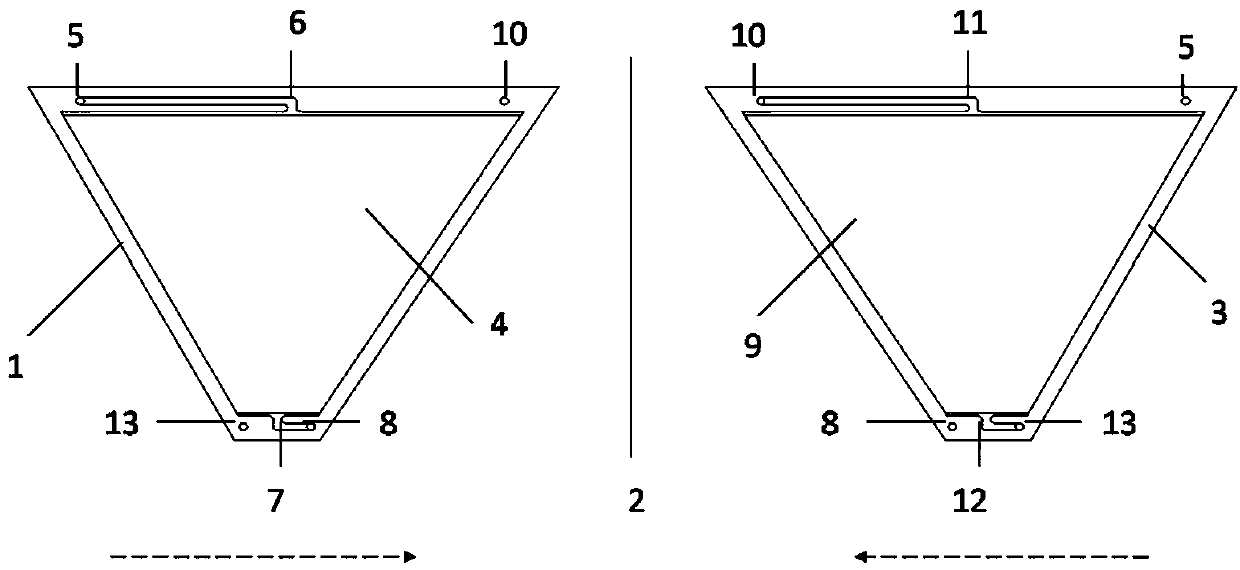

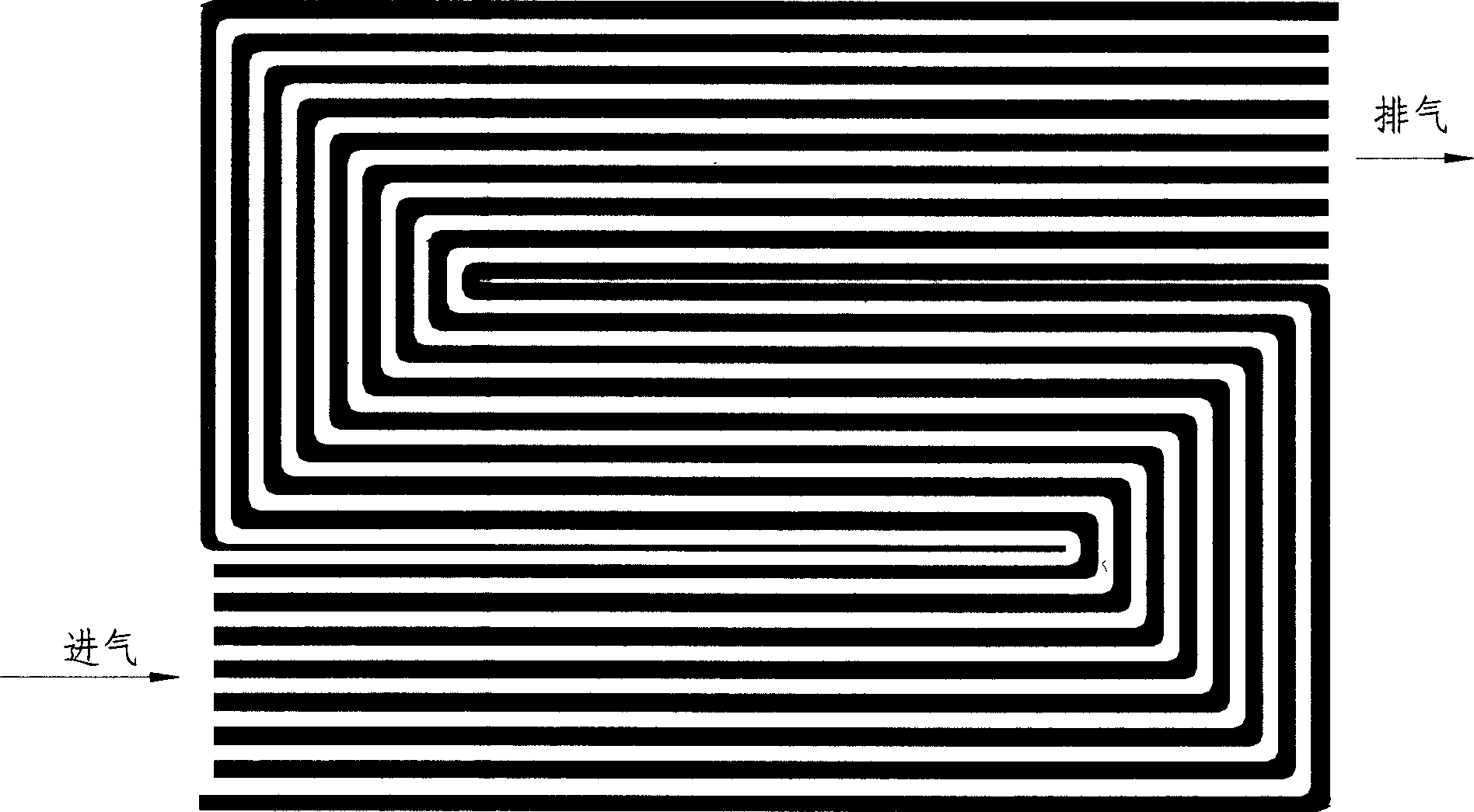

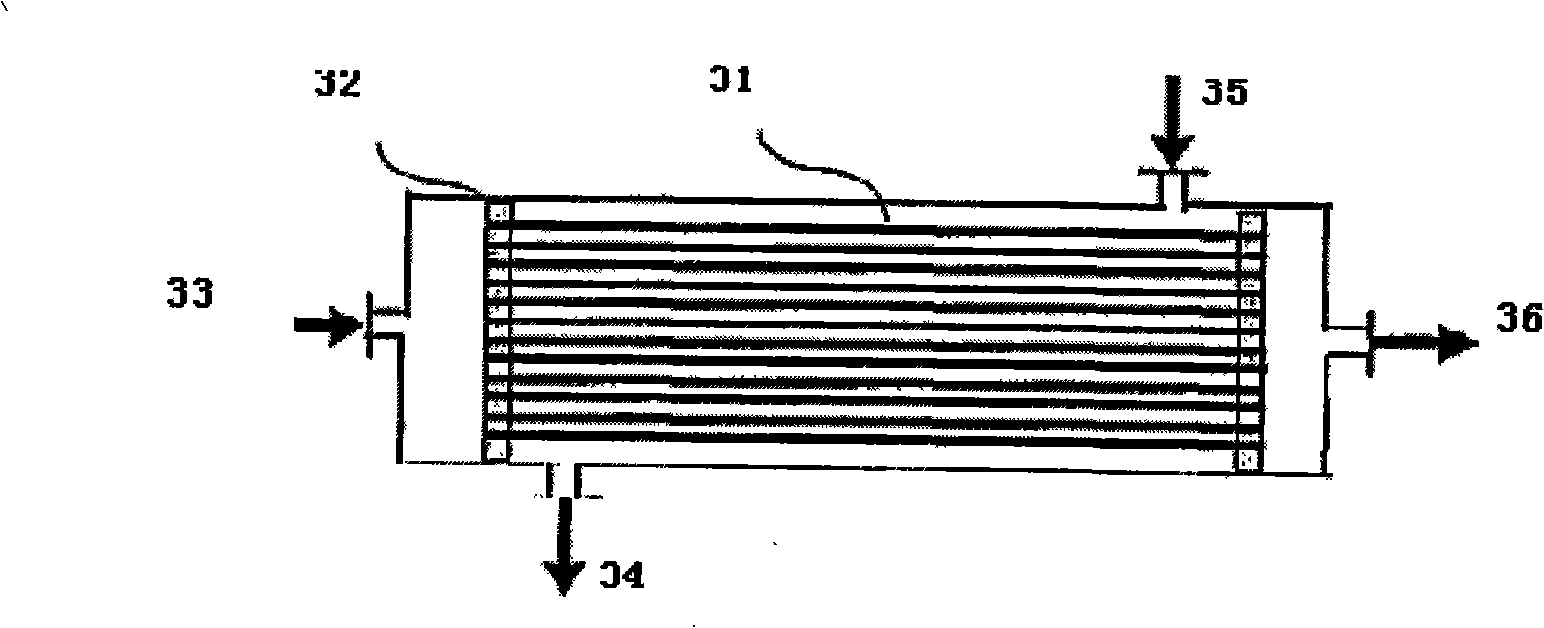

Coiled reverse osmosis membrane element

ActiveCN101708433AReduce pollution rateExtended service lifeSemi-permeable membranesConcentration polarizationWater velocity

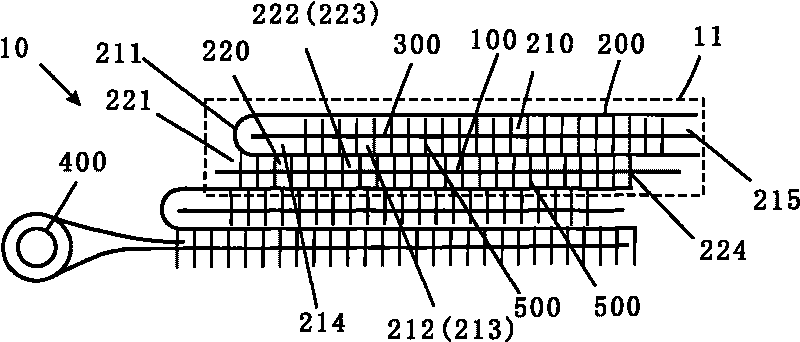

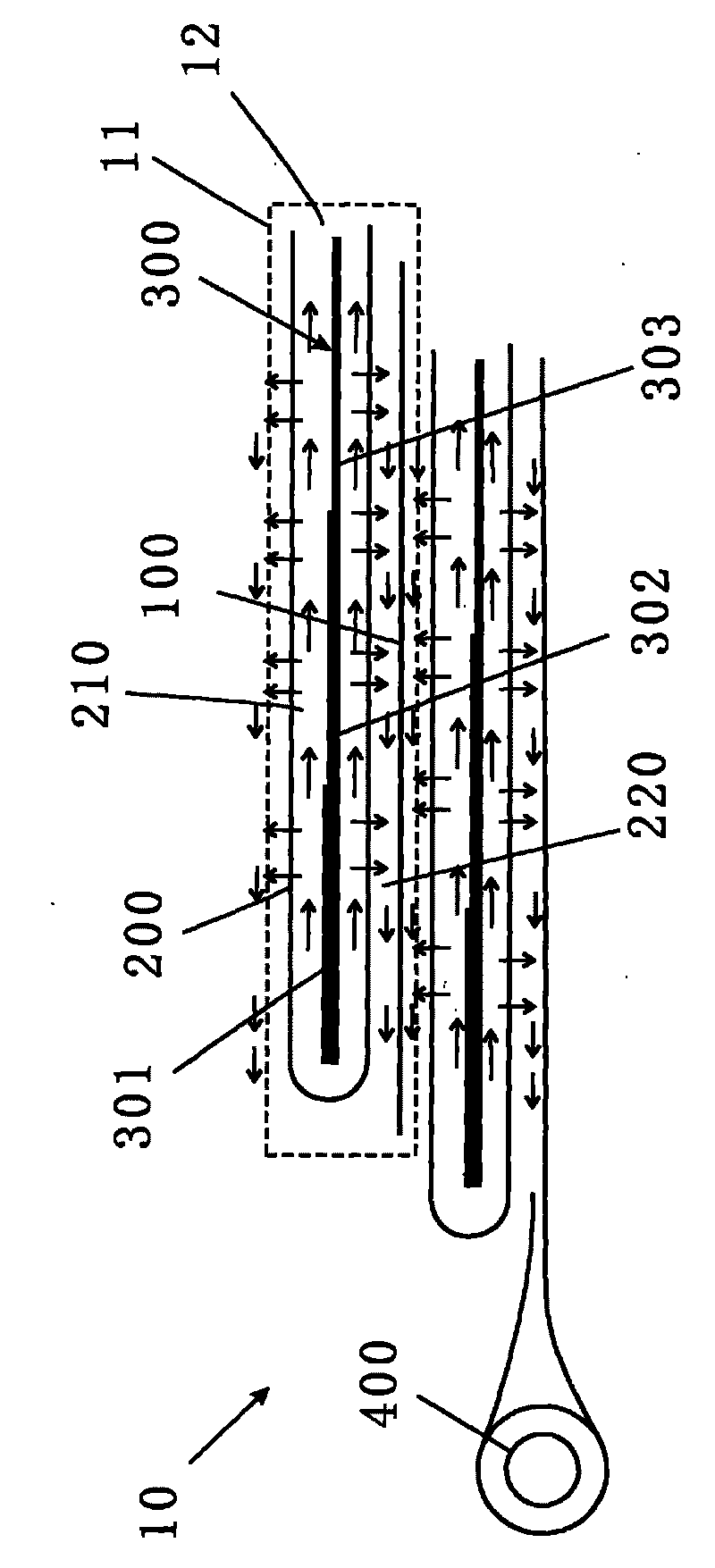

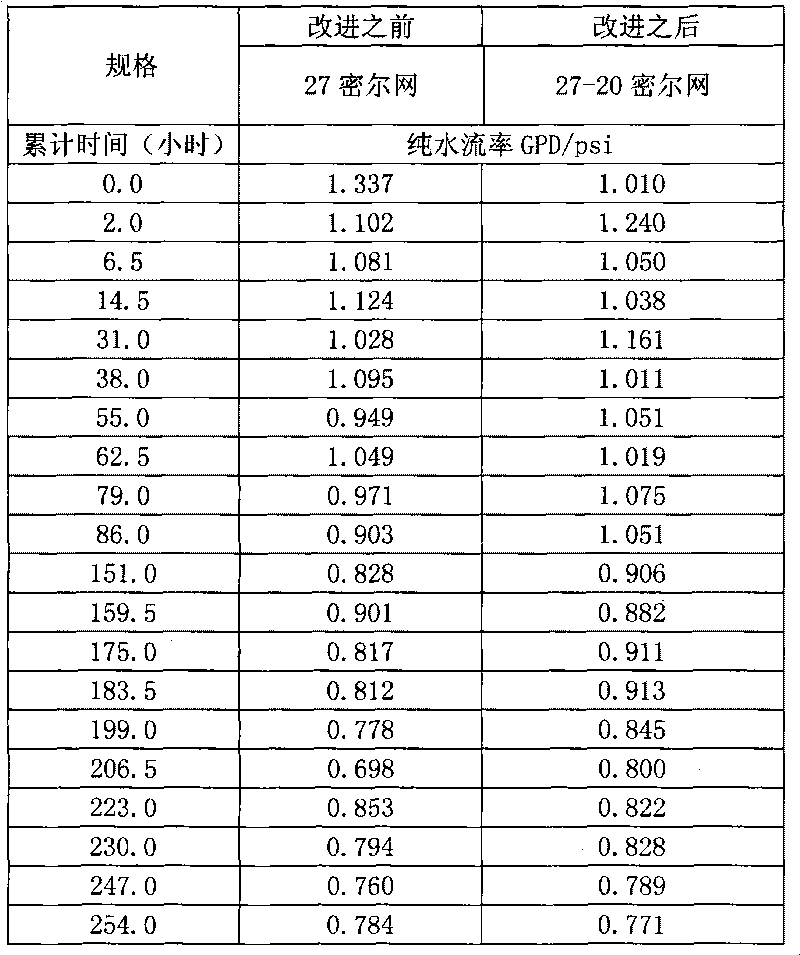

The invention discloses a coiled reverse osmosis membrane element, which is formed by winding at least one group of water purification membranes on a central water yielding pipe, wherein the water purification membrane group consists of a purified water guide net, a reverse osmosis membrane and a water inlet guide net which are overlapped; a water inlet flow channel is formed by folding the inner surface of the reverse osmosis membrane, and a water yielding flow channel is formed between the adjacent outer surfaces; the water inlet guide net is positioned in the water inlet flow channel; the purified water guide net is positioned in the water yielding flow channel; the water yielding flow channel only has a purified water outlet facing the central water yielding pipe, and other three sides of the water yielding flow channel are closed and sealed; the partial zones, far away from the central water yielding pipe, on the two sides, adjacent to a folded side, of the water inlet flow channel which are closed and sealed; so a small section raw water inlet is formed on the two sides close to the central water yielding pipe respectively and a thick water outlet is formed on the side of the water inlet flow channel opposite to the folded side. Through improvement, the reverse osmosis membrane element of the invention increases the water velocity on the surface of the membrane, reduces the concentration polarization on the surface of the membrane, and reduces the pollution speed of the coiled membrane element so as to prolong the service life of the membrane element.

Owner:A O SMITH (CHINA) ENVIRONMENTAL PRODUCTS CO LTD +1

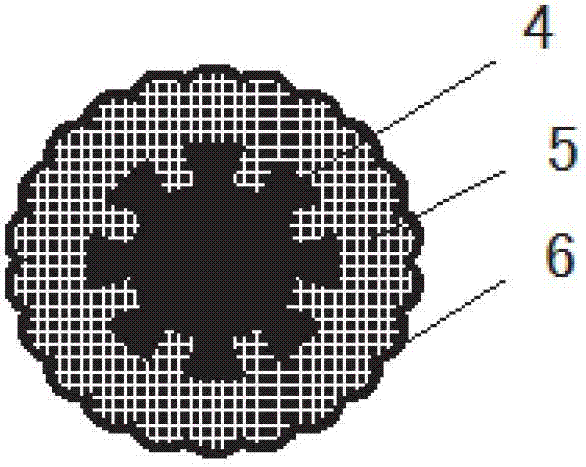

Preparation method of layer-by-layer self-assembled hollow fiber forward osmosis membrane

ActiveCN108325400ALess materialSimple production processSemi-permeable membranesGeneral water supply conservationHollow fibreFiber

The invention discloses a preparation method of a layer-by-layer self-assembled hollow fiber forward osmosis membrane. The preparation method comprises the steps of: preparing hollow fiber forward osmosis base film, modifying hollow fiber ultrafiltration base film, repeating layer-by-layer assembly of polycation and polyanion layers, performing interface cross-linking polymerization for preparinga selective functional layer, conducting moisturizing, and carrying out treatment and storage so as to prepare the layer-by-layer self-assembled hollow fiber forward osmosis membrane. The surface of the hollow fiber self-support base film which is prepared by using a phase conversion method is activated firstly, layer-by-layer assembly of polycation and polyanion is repeated on the surface of thefilm so as to form an functional polarization layer for an electrolyte solution, and the polyamide selective layer is prepared through interfacial chemical cross-linking polymerization. The prepared hollow fiber forward osmosis membrane has a controllable thickness and an internal polarization layer with a high charge capacity, and the internal concentration polarization phenomenon can be alleviated effectively during the forward osmosis process; therefore, the hollow fiber forward osmosis membrane can simultaneously obtain high flux and low reverse salt flux, has high filtration separation efficiency, easy cleaning and a long service life, and can be widely applied to seawater desalination and concentration and desalination of brine.

Owner:西安金藏膜环保科技有限公司

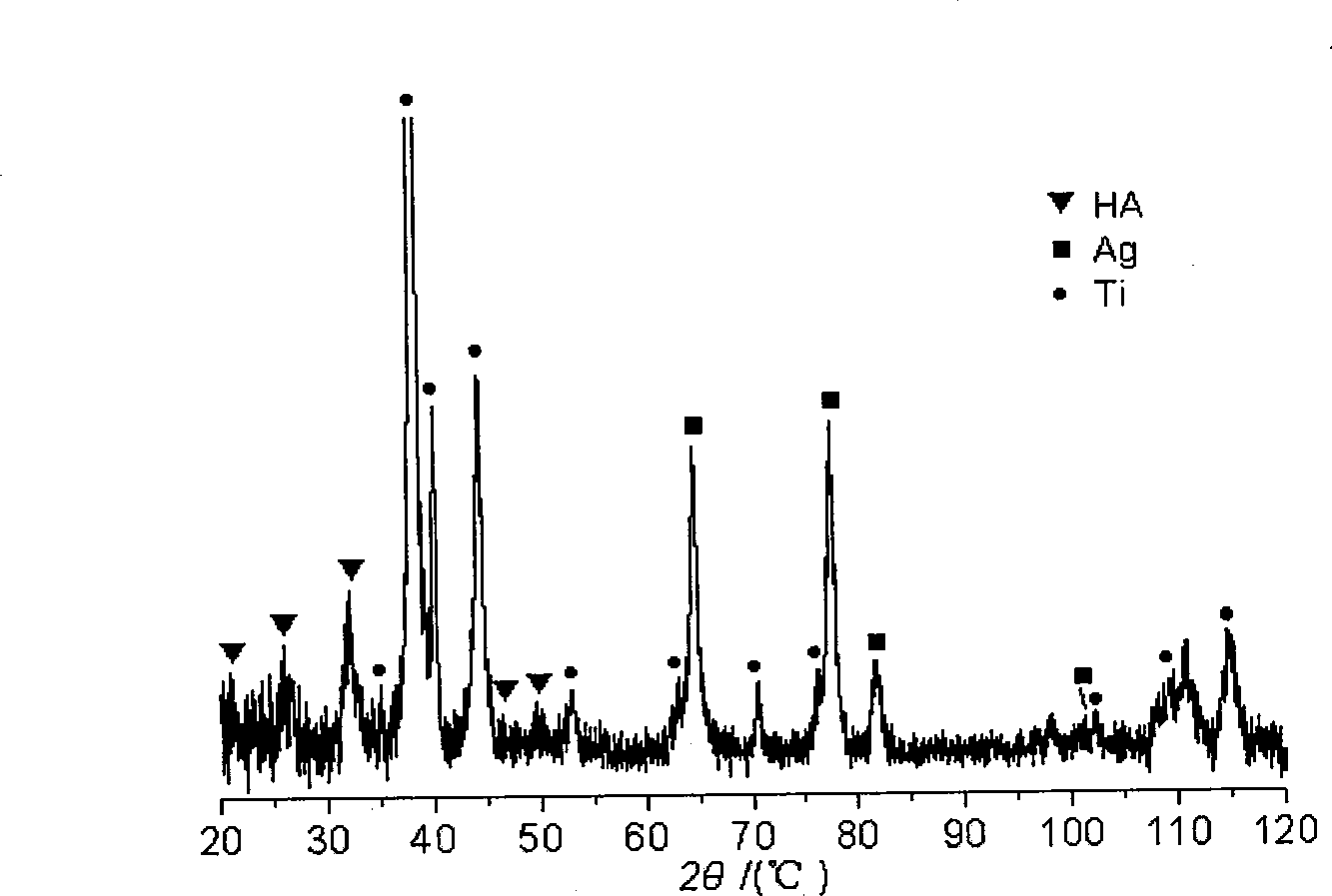

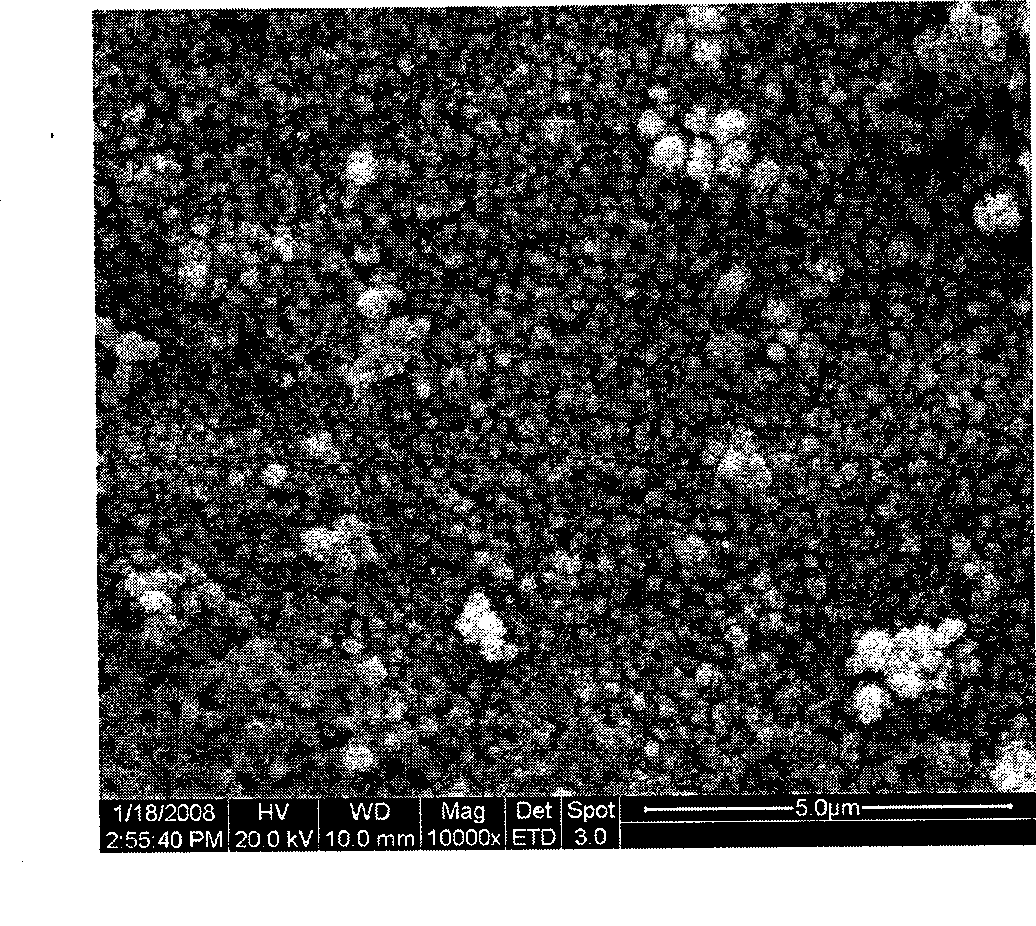

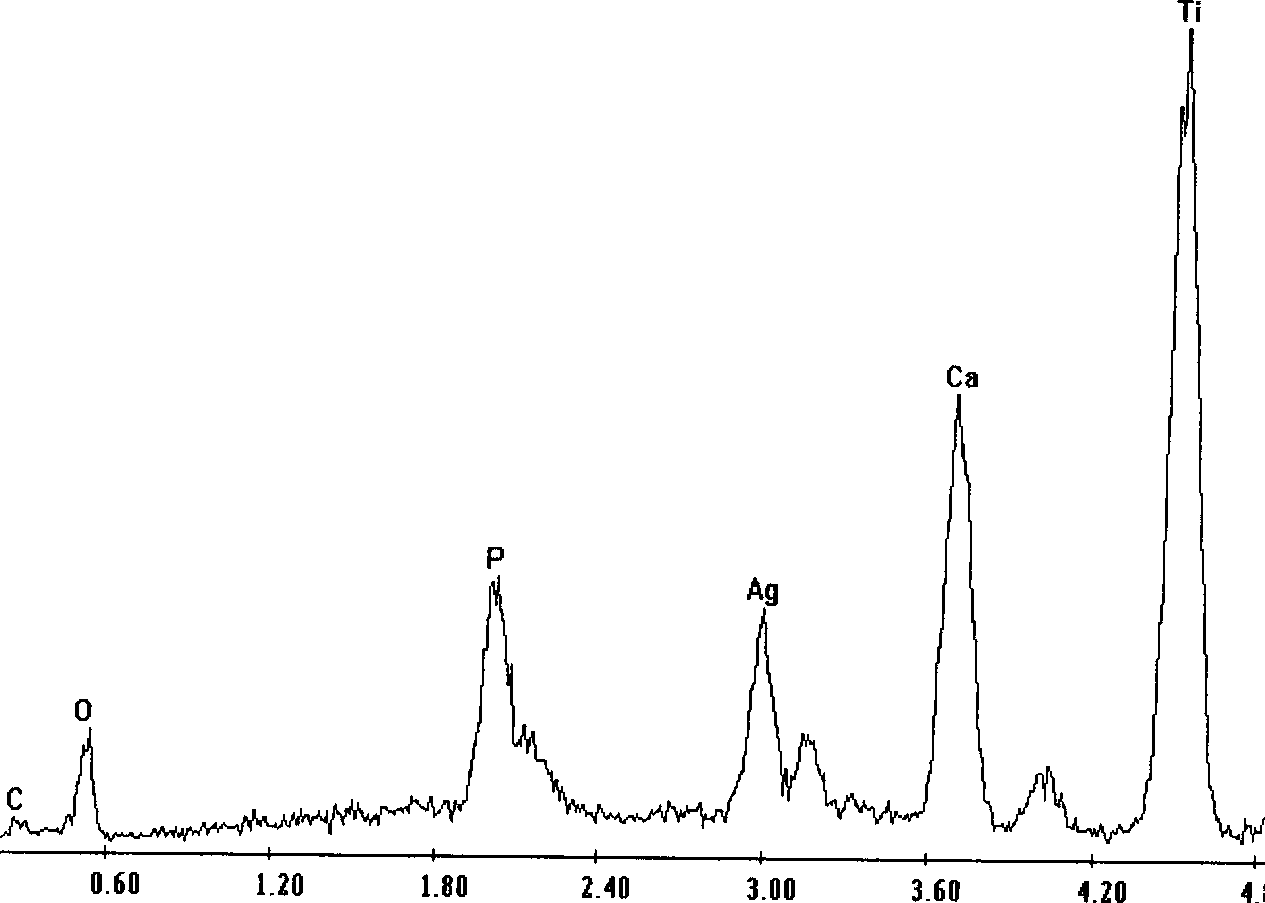

Method for preparing hydroxyapatite/nano silver antimicrobial composite coating by pulse electrochemical deposition

InactiveCN101485901AReduce concentration polarizationCrystal denseCoatingsProsthesisElectrolytic agentPhosphate

The invention discloses a method for preparing a hydroxyapatite / nano silver antibacterial composite coating through pulse electrochemical deposition, which comprises: using a calcium salt, phosphate, silver nitrate and a proper amount of coordination agent to prepare electrolyte with certain concentration and pH value, and performing electrodeposition in a electrolytic cell provided with a three-electrode system; taking a saturated calomel electrode as a reference electrode, a platinum sheet as a counter electrode and biological medical metal to be coated as a working electrode, wherein the pulse high electric potential is 0 volt, the pulse low electric potential is -2.0 volts, the pulse width is 100 seconds, and the deposition time is 2 hours; and depositing compositions in the coating on a base material in a mode of ions, uniformly dispersing nano silver generated during deposition in the composite coating, and finally preparing the hydroxyapatite / nano silver antibacterial compositecoating.

Owner:SOUTHWEST JIAOTONG UNIV

Etching process for aluminum foil for electrolytic capacitor

InactiveCN101275269AGuaranteed mechanical strengthReduce concentration polarizationCapacitor electrodesPre treatmentConcentration polarization

The invention relates to a corrosion process of aluminum foil used in an electrolytic capacitor, which includes six steps: pre-treatment, exchange of pre-corrosion, intermediate processing, post-level AC corrosion, DC corrosion, and after treatment, is characterized in that ultrasound-assisted corrosion is used in the post-level AC corrosion; at the same time, the invention divides the post-level AC corrosion into a plurality of levels, the temperatures are gradually reduced from the first level to the end, but the current densities are increased gradually. The craft of the invention keeps that the etching solution is transferred smoothly in a tank, effectively prevents concentration polarization at the interface of aluminum foil-etching solution, promotes the removing of the corrosion sediments, and greatly enhances the corrosion efficiency.

Owner:日丰(清远)电子有限公司 +1

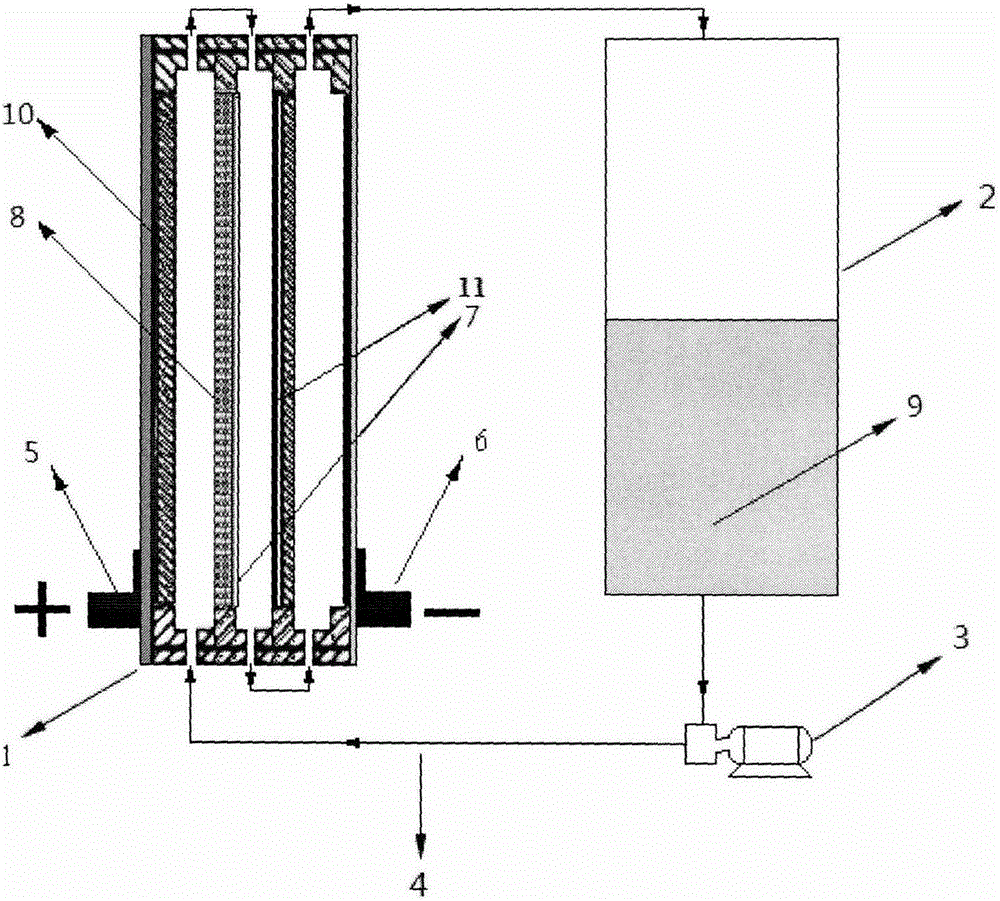

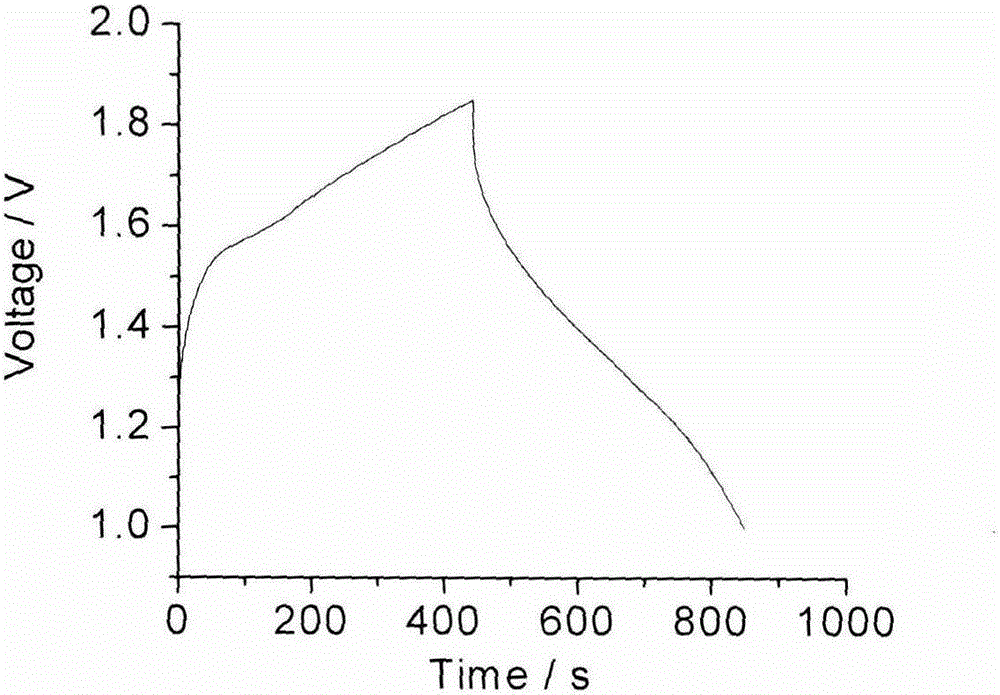

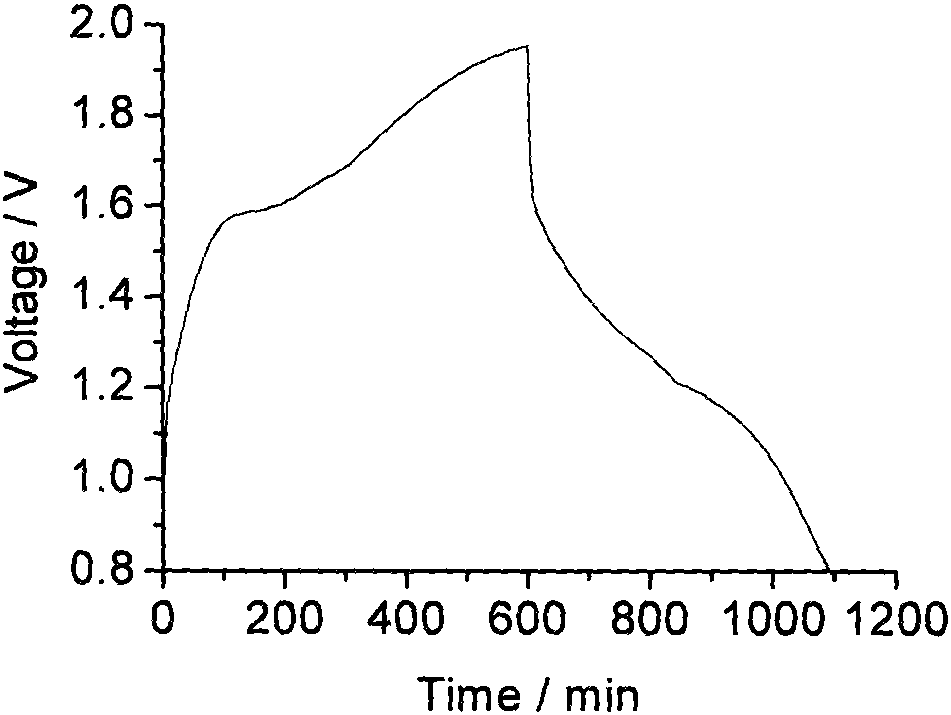

Water-based zinc-manganese single flow battery

ActiveCN105336971AIncrease the speed of mass transferEliminate deformationRegenerative fuel cellsWater basedManganese oxide

The invention relates to a water-based zinc-manganese single flow battery; a positive electrode active material is an oxide of manganese, a metal composite oxide, a metal oxide or a carbon material, a negative electrode is a zinc electrode, an electrolyte solution is a nearly neutral aqueous solution containing a zinc salt and a manganese salt, positive electrode active ions and negative electrode active ions can coexist in one electrolyte solution, and an ion exchange membrane is not required for separating the positive electrode and the negative electrode; in processes of charging and discharging, the electrolyte solution constantly flows between an electrolyte solution storage tank and an electric pile through a pipeline under pushing of a liquid pump. During charging, zinc ions are deposited onto a negative electrode current collector from the electrolyte solution, the zinc ions and manganese ions are co-embedded into the positive electrode active substance at the same time, and the manganese ions are subjected to oxidation deposition; during discharging, the negative electrode deposited zinc is dissolved into the electrolyte solution, and the positive electrode manganese oxide is partially reduced and dissolved and is extricated to the electrolyte solution with the zinc ions simultaneously. The battery has the outstanding characteristics of simple manufacture, relatively high specific energy and specific power, low cost, long cycle life, environmental friendly and the like, and is widely applied in electric power, transportation, electronics and other fields.

Owner:NO 63971 TROOPS PLA

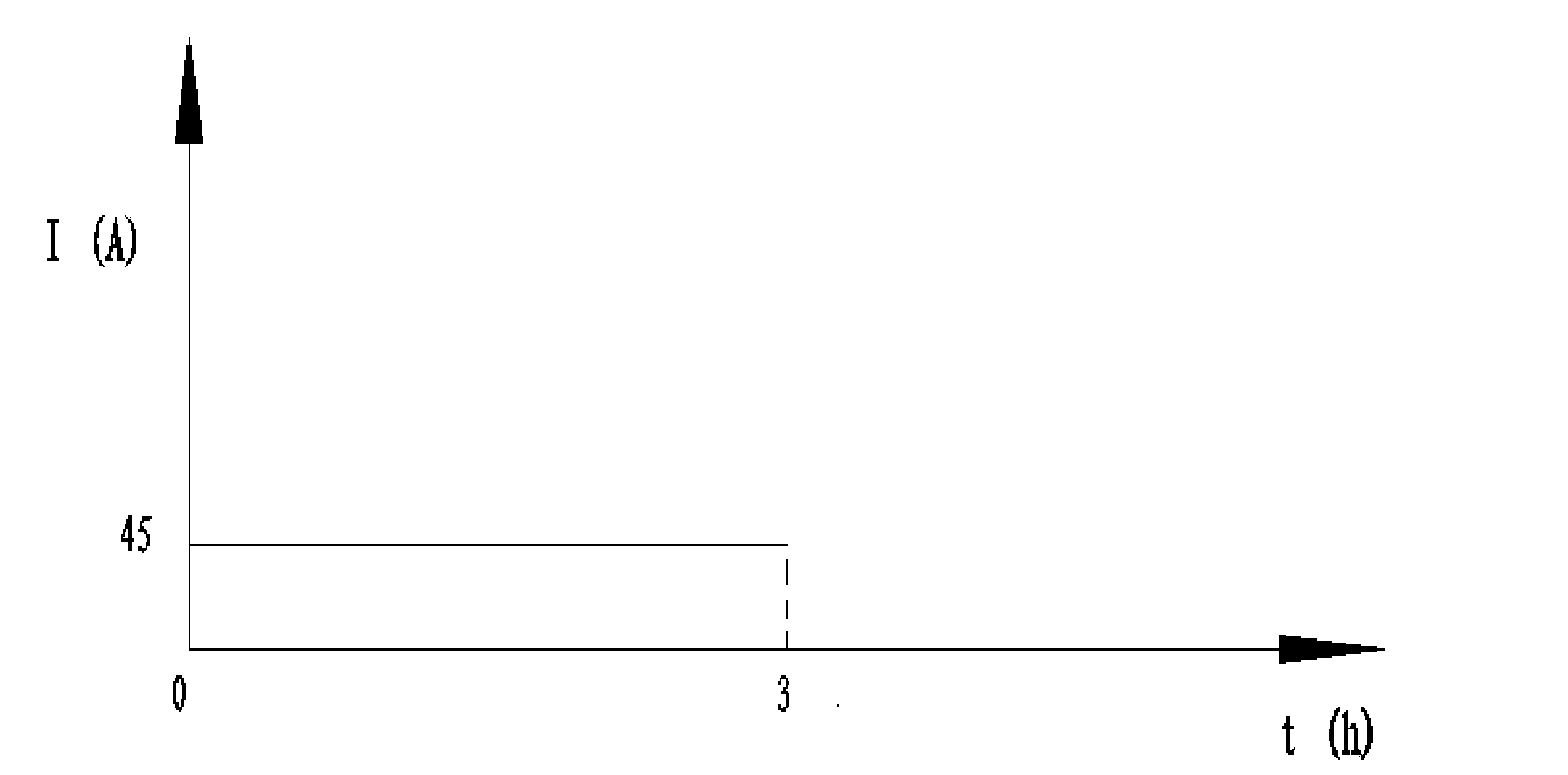

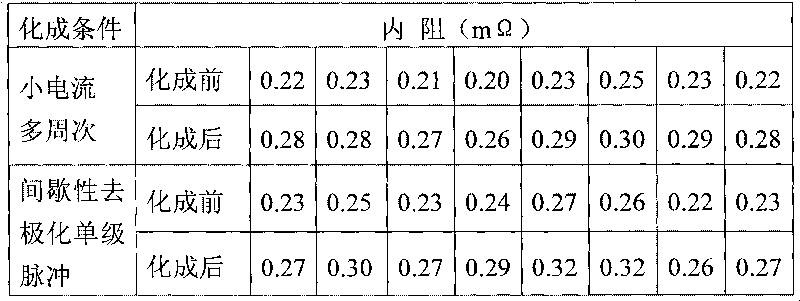

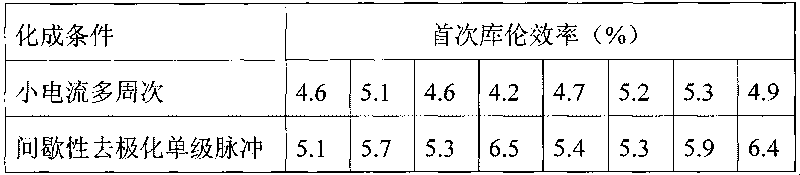

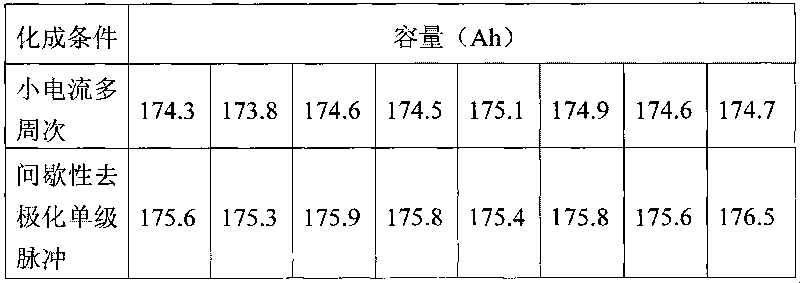

Pulse container formation method for high-capacity lead-acid battery

ActiveCN101877425AReduce shockImprove uniformityFinal product manufactureSecondary cells charging/dischargingEngineeringLow frequency

Owner:HUNAN FENGRI ELECTRIC GROUP

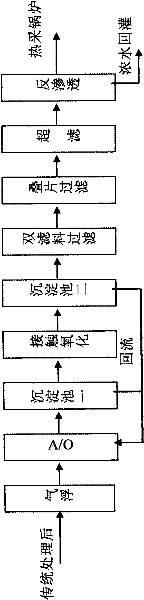

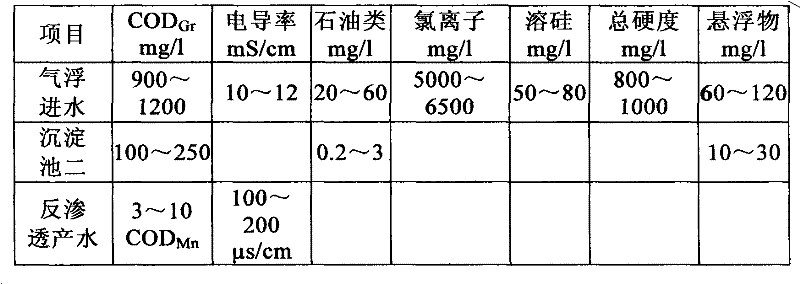

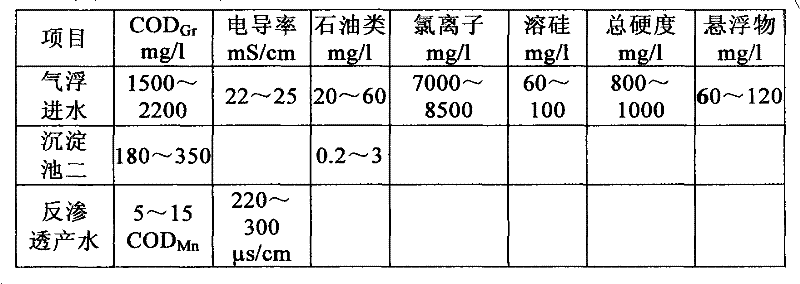

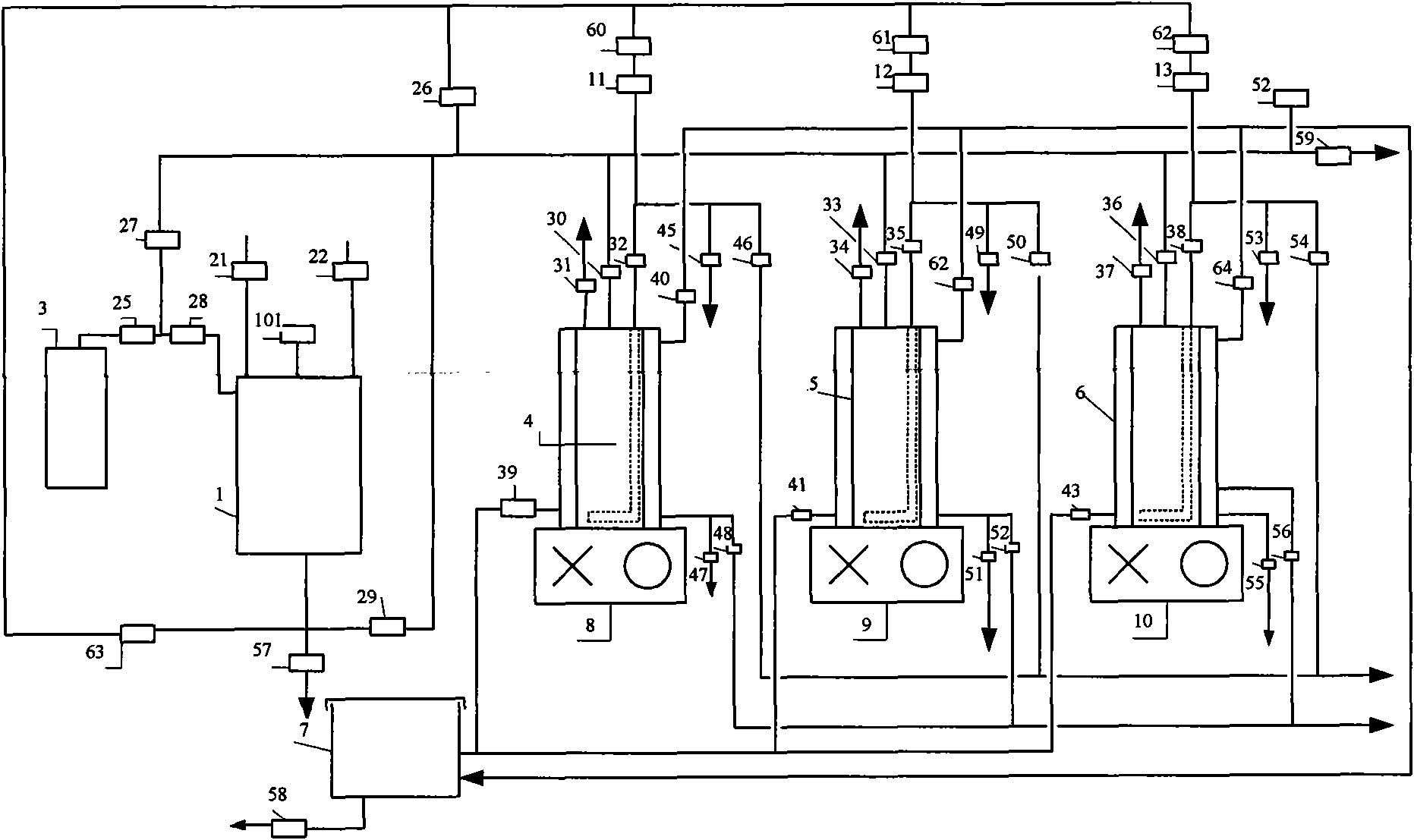

Treatment method for recycle of oil field produced water

ActiveCN102452760AReduce pollutionReduce the impactWater/sewage treatment bu osmosis/dialysisTreatment with aerobic and anaerobic processesChemistryPetroleum

The invention relates to a treatment method for recycle of oil field produced water. The treatment method comprises an air floatation process, a biochemical treatment process, a filtration process, an ultrafiltration process and a reverse osmosis process. Oil field produced water is subjected to the biochemical treatment process so that the content of organic matters, petroleum matters and oligomers in the oil field produced water can be effectively reduced, wherein the organic matters, the petroleum matters and the oligomers can cause membrane pollution easily. The oil field produced water subjected to the biochemical treatment process orderly passes through a double-filter material filter and a disc filter so that a part of suspensions are removed, then enters into an ultrafiltration device and is subjected to designed conventional backwashing and dosing backwashing in a forced circulation-crossflow filtration way. Ultrafiltration produced water enters into a reverse osmosis device and is subjected to designed timed low-voltage positive pulse processing and regular sterilization. Reverse osmosis produced water is recycled and is utilized as high-quality thermal recovery boiler water. Reverse osmosis concentrated water is subjected to recharge processing. Through the air floatation process, the biochemical treatment process, the filtration process and a special membrane operation mode, cleaning periods and service lives of an ultrafilter membrane and a reverse osmosis membrane can be effectively prolonged. The treatment method has the characteristics of high treatment efficiency, good economic effectiveness and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

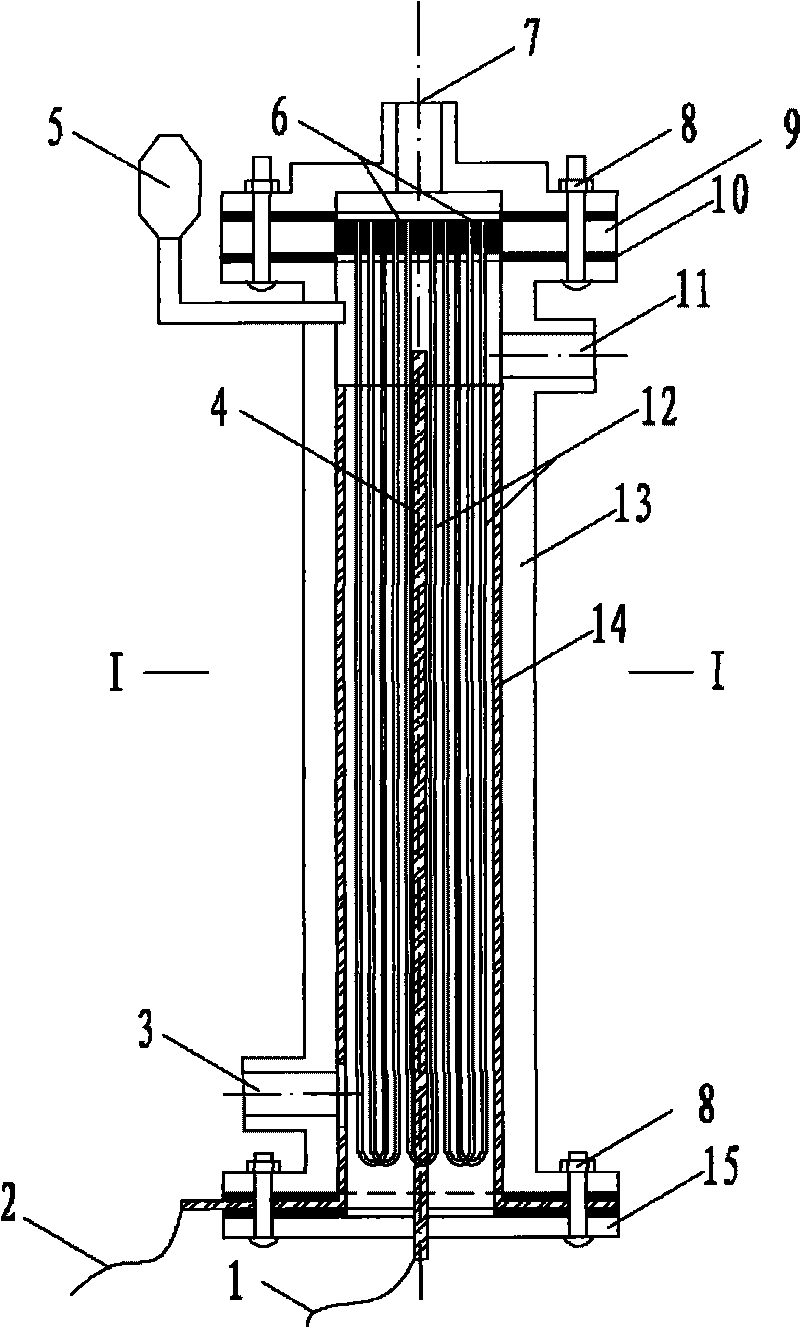

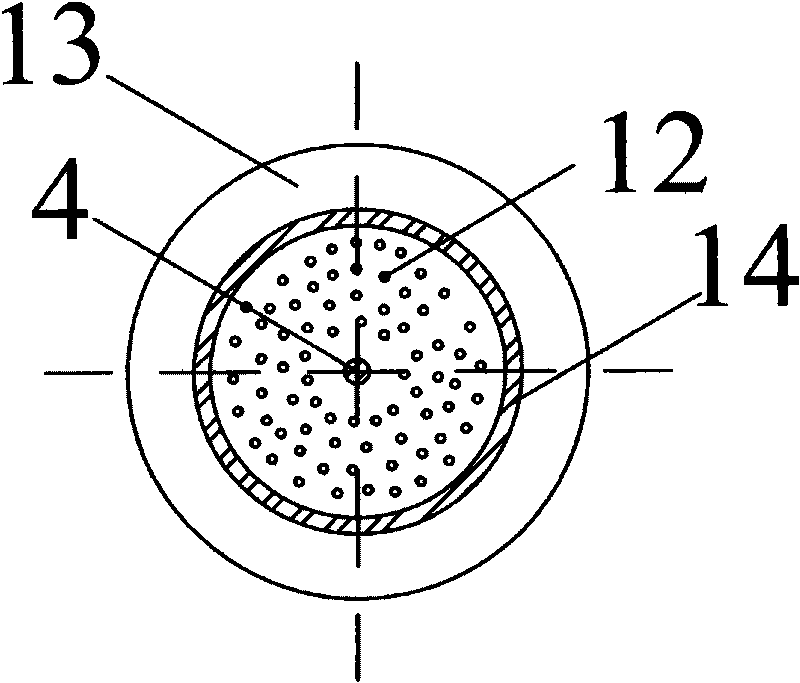

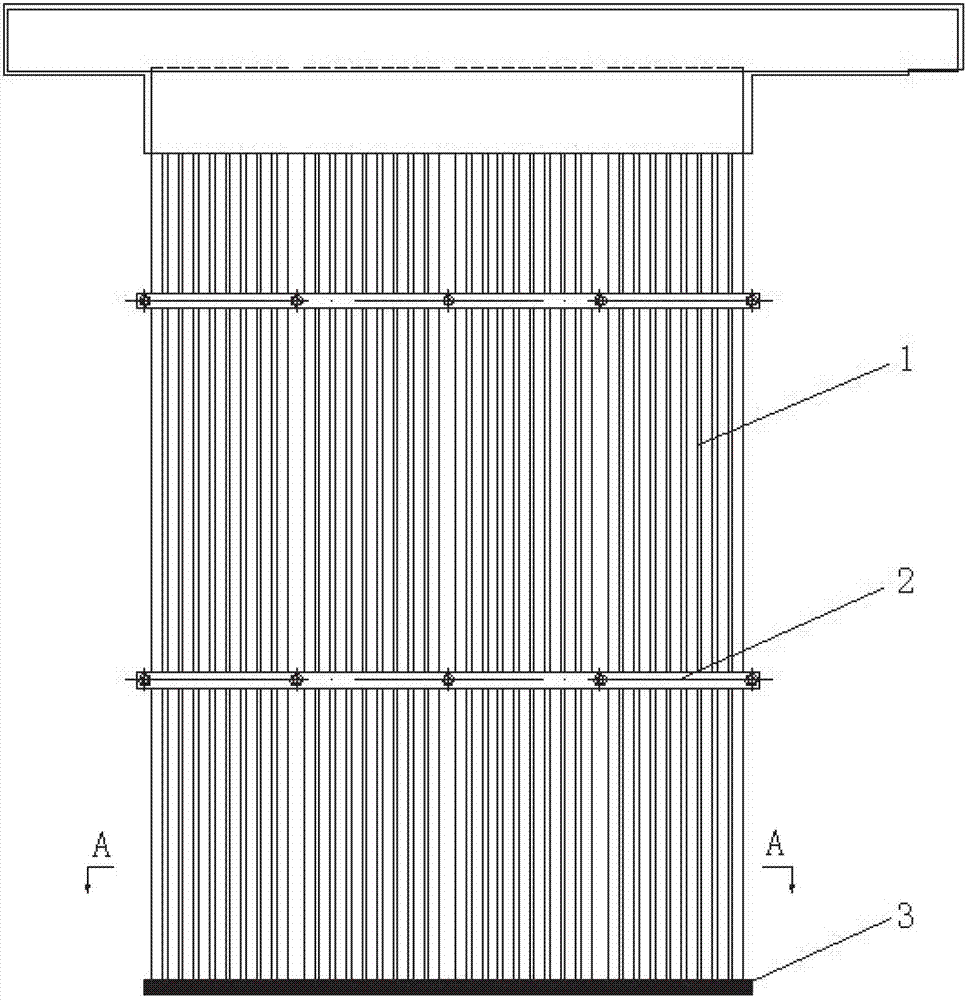

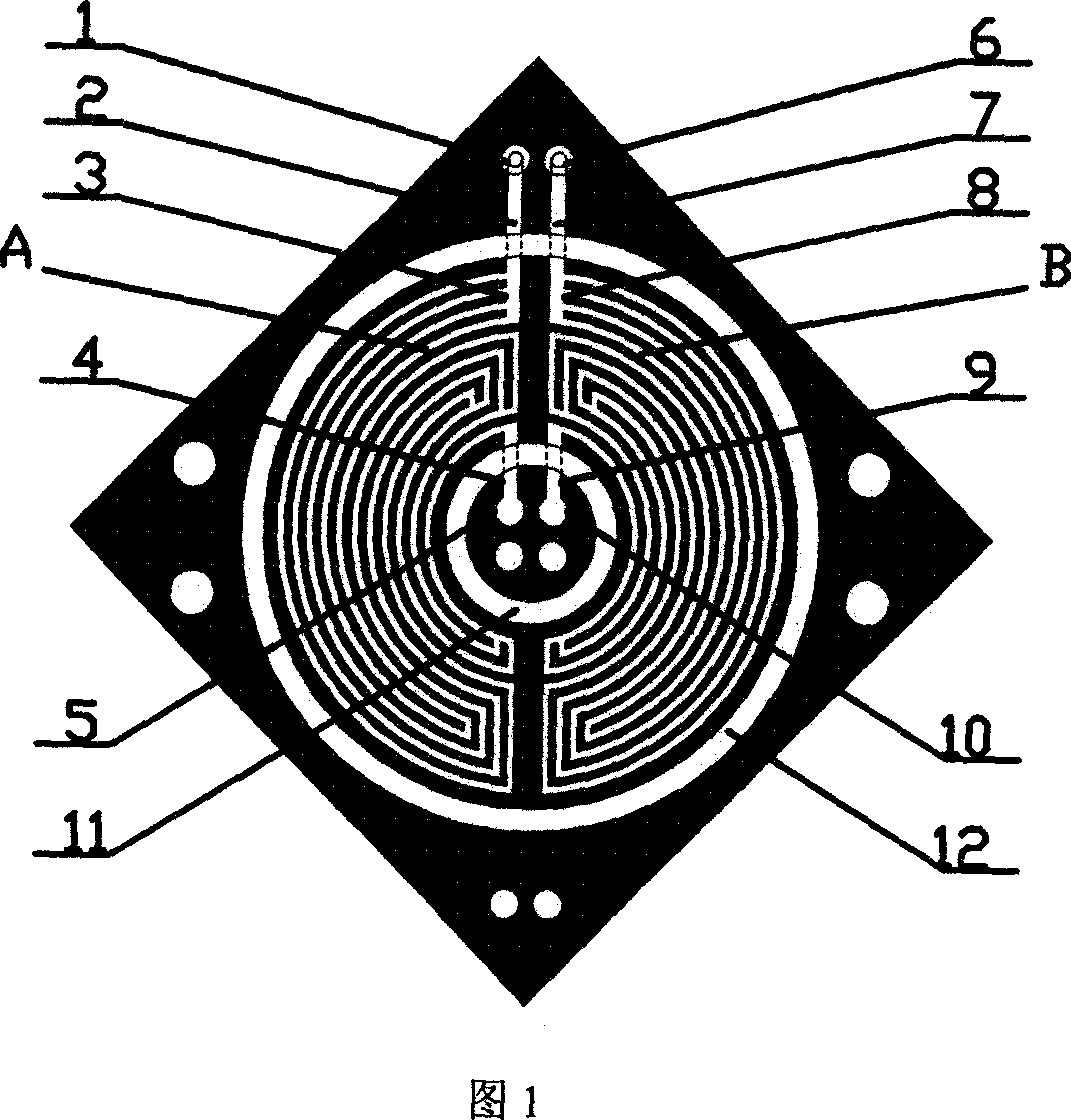

Hollow-fiber membrane module of additional electric field

InactiveCN101721914AImprove filtering effectAchieve separationSemi-permeable membranesFiberConcentration polarization

The invention relates to a hollow-fiber membrane module of an additional electric field, comprising a module casing (13), an anode (4), a cathode (14) and a U-shaped hollow-fiber membrane silk (12), wherein the module casing (13) is provided with a water inlet (3), an air release valve (5) and a cross flow water outlet (11) at the upper casing and the lower casing, the anode (4) is arranged at the central axis of the module casing (13), the cathode (14) is arranged outside the anode (4), the U-shaped hollow-fiber membrane silk (12) is arranged between the anode (4) and the cathode (14). In the process of membrane filtration, under the action of the electric field, charged organics or particles go through electrophoretic migration, electrocoagulation, which can reduce concentration polarization and membrane pollution caused by the charged organics or particles. The module of the invention integrates the electric field with the hollow-fiber membrane, thus giving play to the advantages of the hollow-fiber membrane, such as high filtration and separation efficiency, large membrane filtration area and small occupied space; in addition, multiple modules can be connected in parallel to obtain higher filtration speed and enhance membrane separation efficiency, as a result, the hollow-fiber membrane module enjoys extensive application prospect in the field of deep processing concerning water treatment.

Owner:TONGJI UNIV

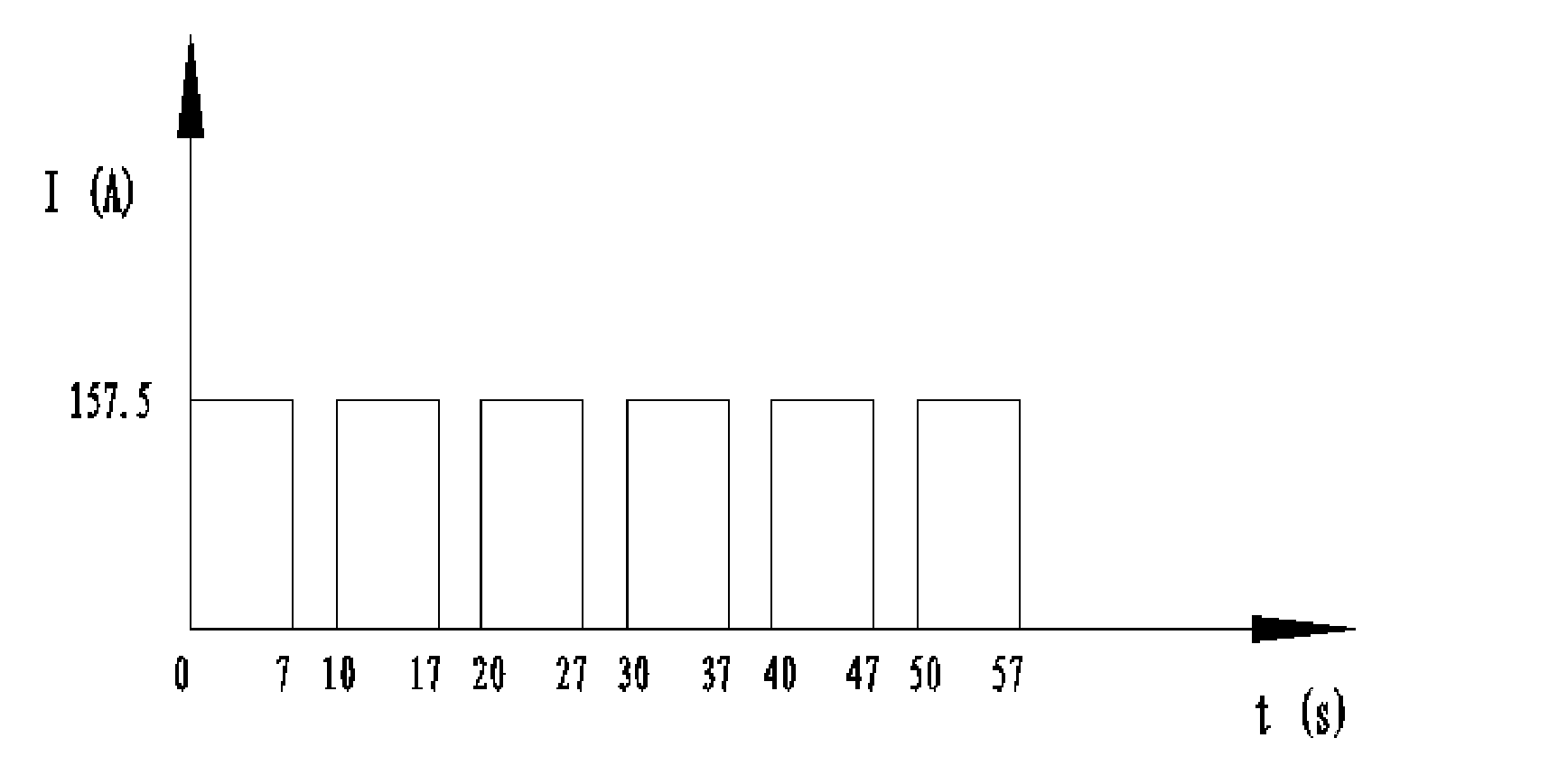

Rapid forming method of lithium ion power battery

InactiveCN101728579ALower impedanceImprove performanceFinal product manufactureSecondary cells charging/dischargingInternal resistanceElectrolyte

The invention discloses a rapid forming method of a lithium ion power battery, which is characterized by comprising the following steps of: 1. precharging; 2. settling and aging; and 3. charging by adopting an intermittent depolarized single-stage impulse charging mode until charge is finished. Because the forming process of the invention adopts the intermittent depolarized single-stage impulse charging mode, the impedance of an SEI (Solid Electrolyte Interface) membrane is lowered, thereby reducing the internal resistance of the battery and improving the rate discharge performance of the lithium ion power battery. Because the forming process of the invention adopts an impulse current with a lower frequency, the battery can be naturally depolarized within the impulse-off time, thereby lowering the polarizing effect, stabilizing the charging voltage, improving the charging efficiency, simultaneously avoiding the high requirement brought by a high frequency impulse current charging mode for equipment, improving the utilization efficiency of electric energy and greatly lowering the production cost. The step of precharge is adopted to facilitate the formation of the stable SEI membrane, thereby improving the performance of the battery.

Owner:SKY ENERGY LUOYANG

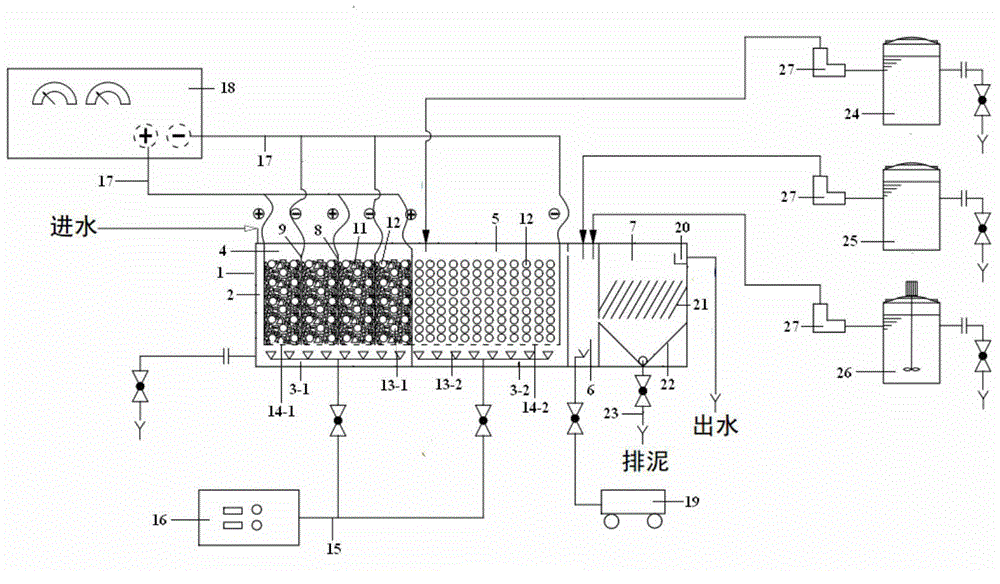

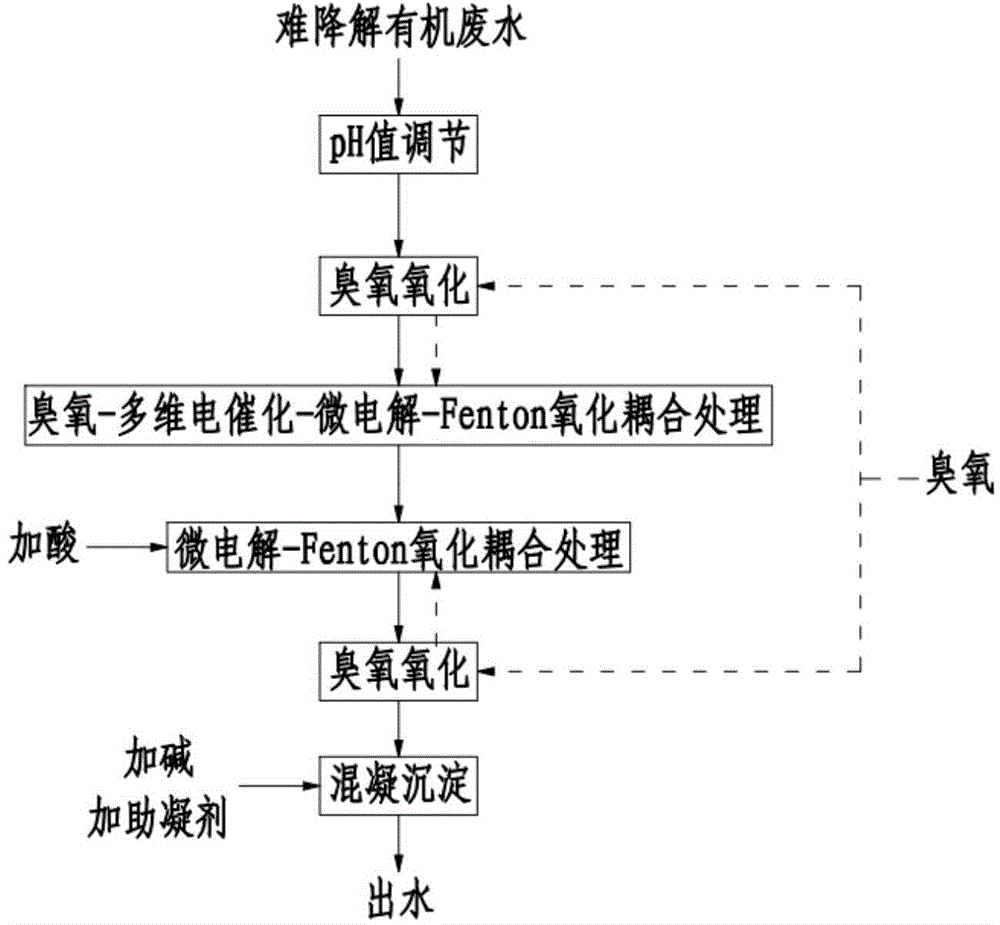

Advanced oxidative coupling device and process for treating organic wastewater difficult to degrade

ActiveCN104787941AImprove removal efficiencyLow running costWater contaminantsWater/sewage treatment by electrochemical methodsElectrolysisMulti dimensional

The invention discloses an advanced oxidative coupling device and process for treating organic wastewater difficult to degrade. A main device body comprises an ozone oxidation-multi-dimensional electro-catalysis / microelectrolysis area, an ozone oxidation-microelectrolysis / Fenton area, a coagulation area and an inclined plate sedimentation area, wherein the ozone oxidation-multi-dimensional electro-catalysis / microelectrolysis area comprises a multi-dimensional electrolysis / microelectrolysis area at the upper part and an ozone oxidation area at the lower part; the ozone oxidation-microelectrolysis / Fenton area comprises a microelectrolysis / Fenton area at the upper part and an ozone oxidation area at the lower part. The device combines four levels of advanced oxidation systems, and electrocatalytic oxidation, ozone oxidation, Fenton oxidation and a microelectrolysis reaction are mutually coupled in function, so that an organic matter difficult to degrade is subjected to multi-level oxidation to realize complete oxidative cracking; when the device is used for treating the organic wastewater difficult to degrade, the yield and the production rate of *OH are increased, the liquid phase transfer process is accelerated, the overall current efficiency of the device is increased, operation expenses are saved, flexible regulation and control of a process unit are realized, and the device can be used for treating various kinds of organic wastewater difficult to degrade.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD +1

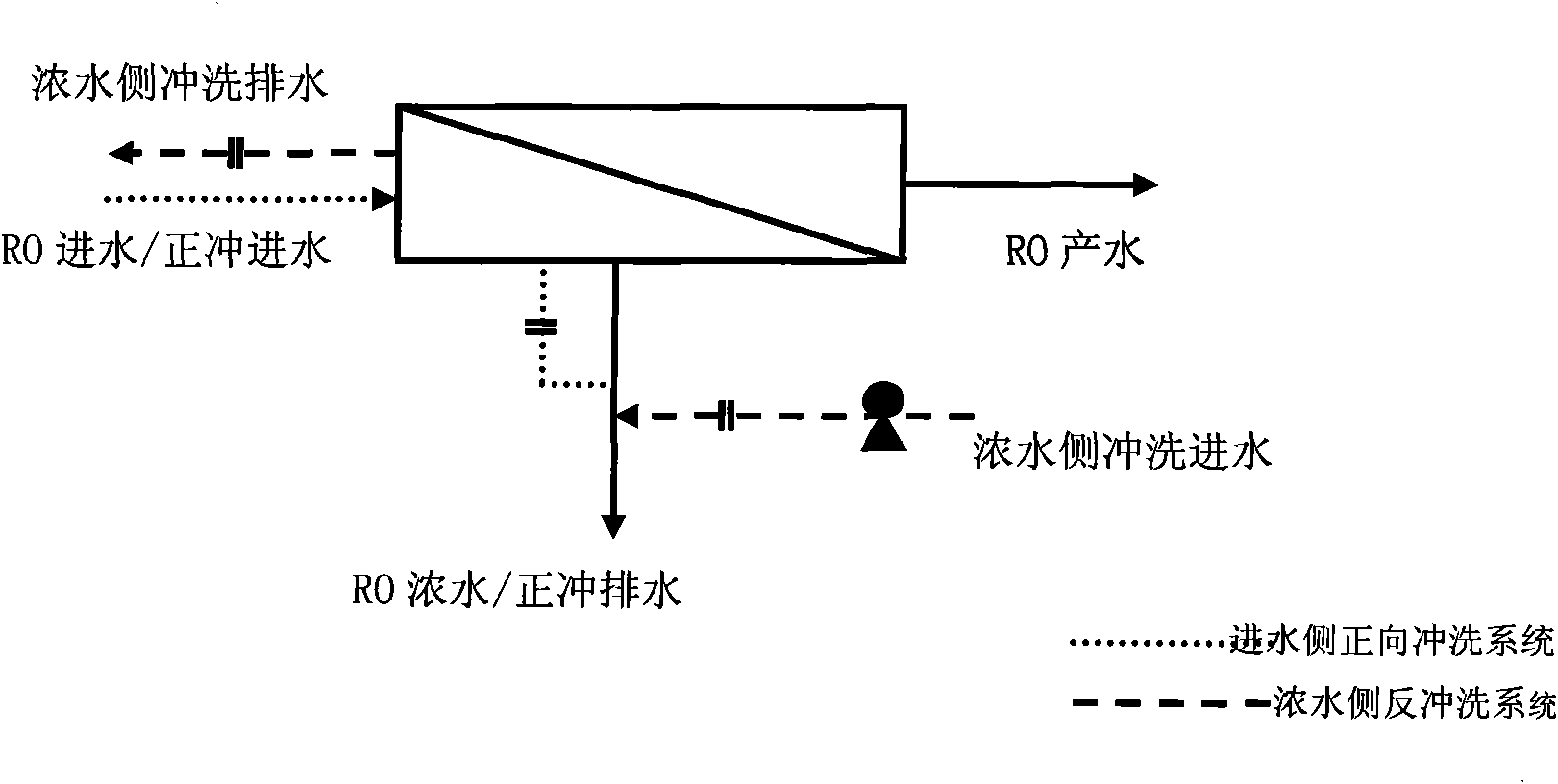

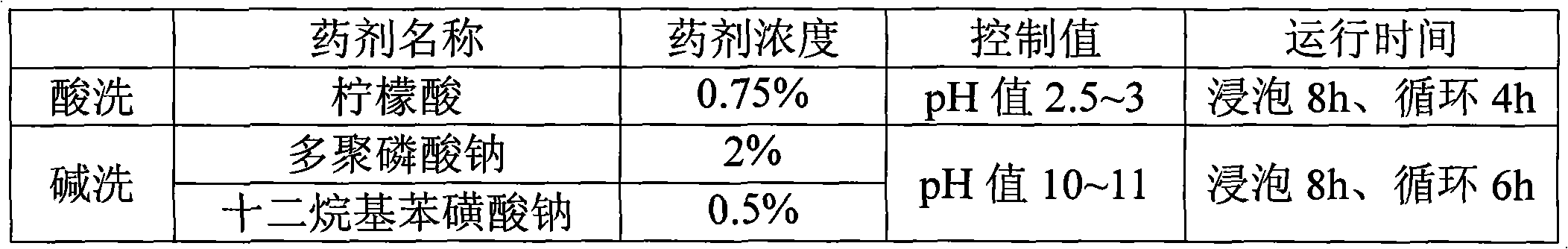

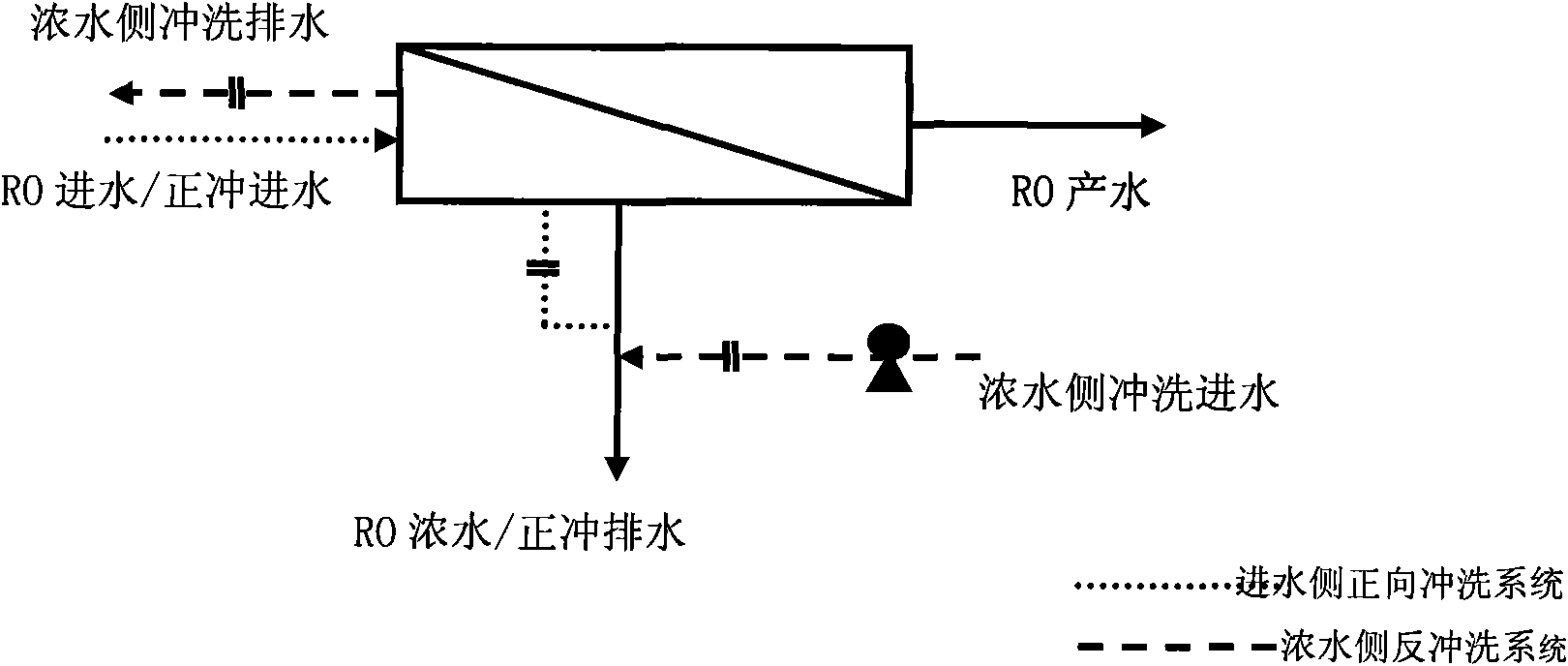

Method for flushing reverse osmosis membrane

ActiveCN102049198AReduce concentration polarizationImprove stabilityReverse osmosisWater/sewage treatment bu osmosis/dialysisColloidal silicaSewerage

The invention provides a method for flushing a reverse osmosis (RS) membrane, which aims at the problems of filtration surface contamination and first-section contamination of a reverse osmosis system membrane caused by high salt, organic colloidal silica, high molecular organic contaminants and microbiological remains during reverse osmosis treatment of olefin production process water, circulating cooling water and sewerage. In the method, positive flushing and concentrated water side reverse flushing are adopted, and agents such as an organic solvent and the like are matched, so hydraulic flushing is formed on the RO membrane filtration surface, blocking contaminants on the membrane surface which cannot be chemically removed are obviously removed, the problem of the first-section contamination of a membrane system is solved, and stable running period of the RO system is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

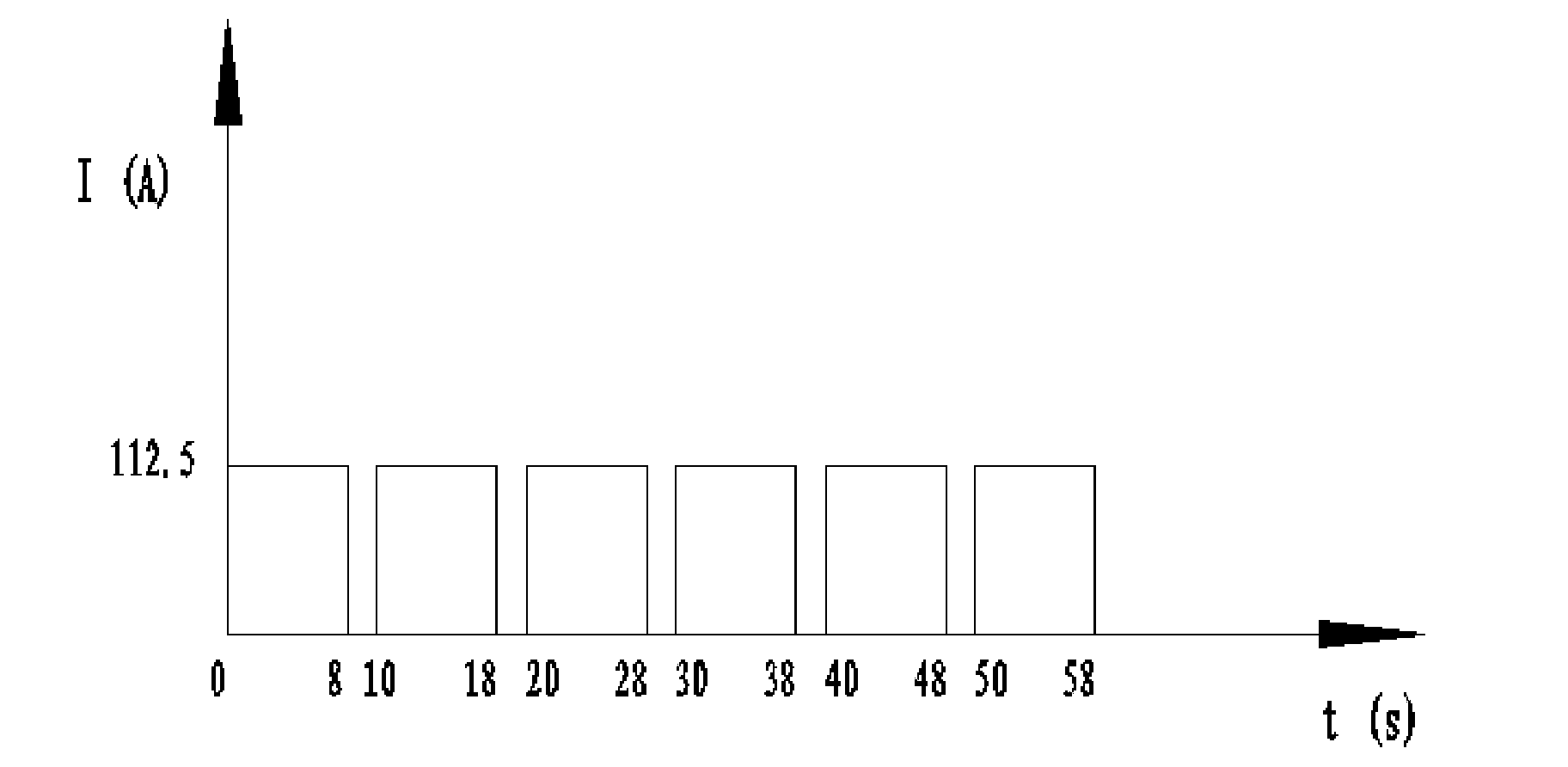

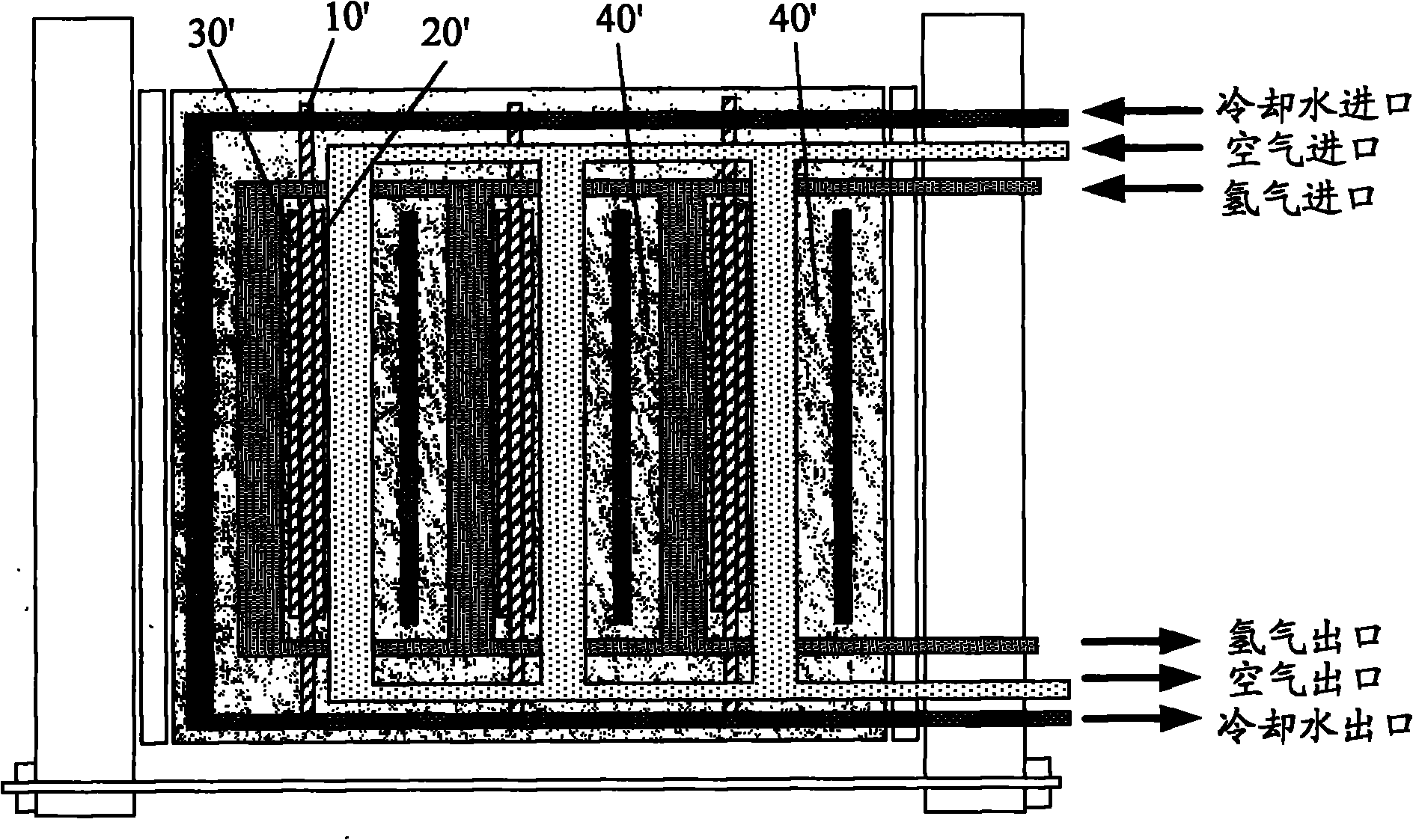

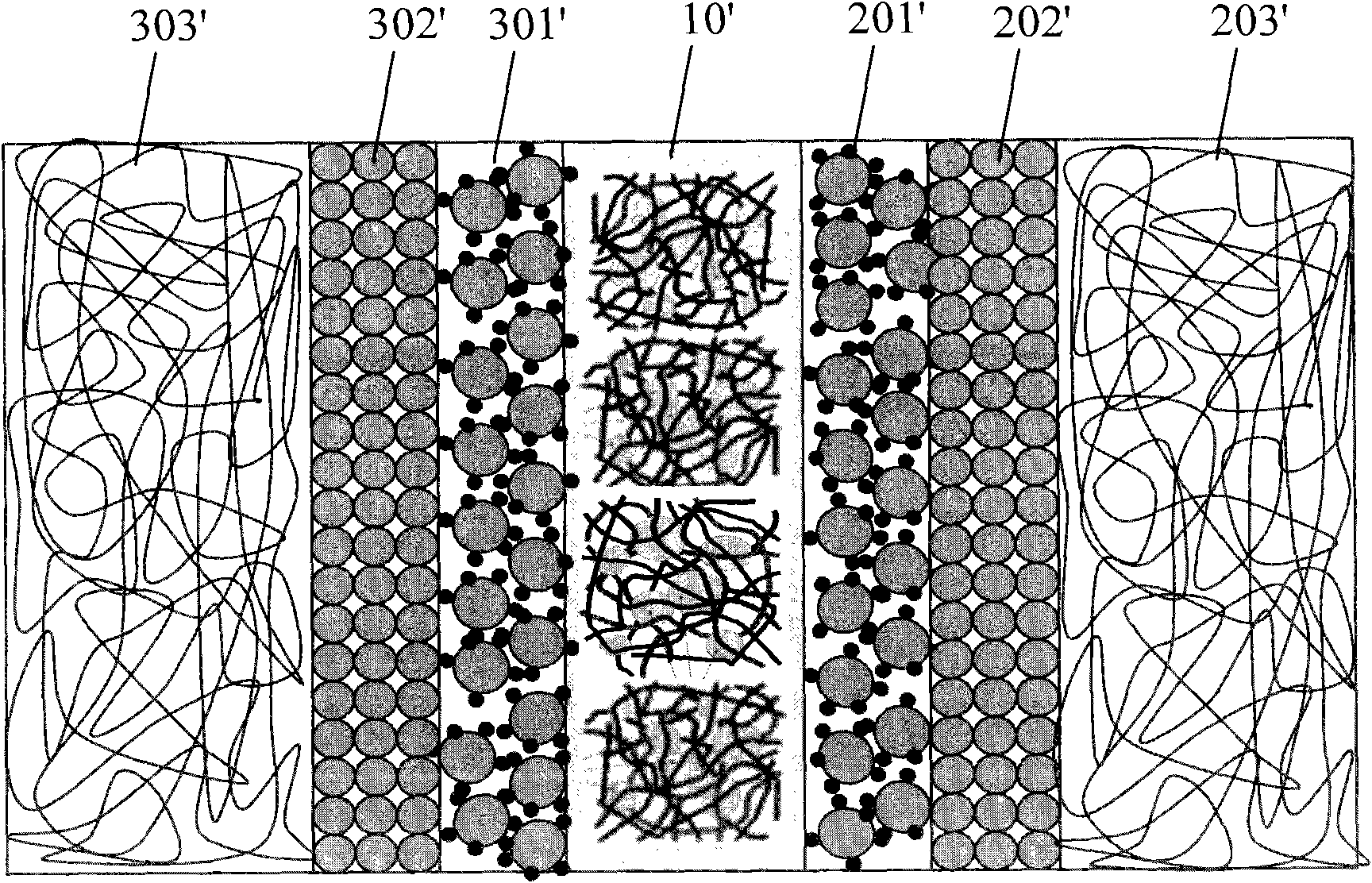

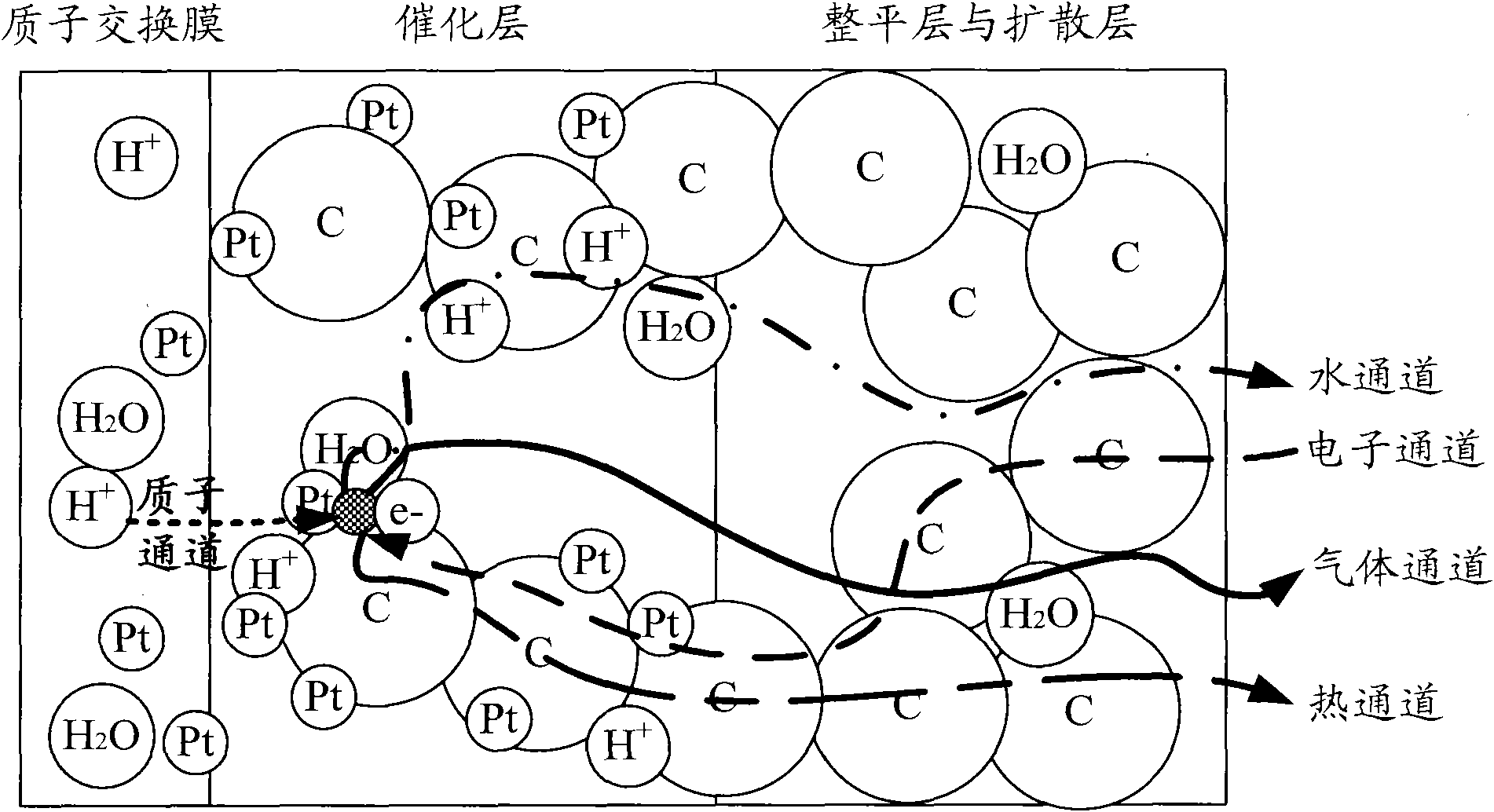

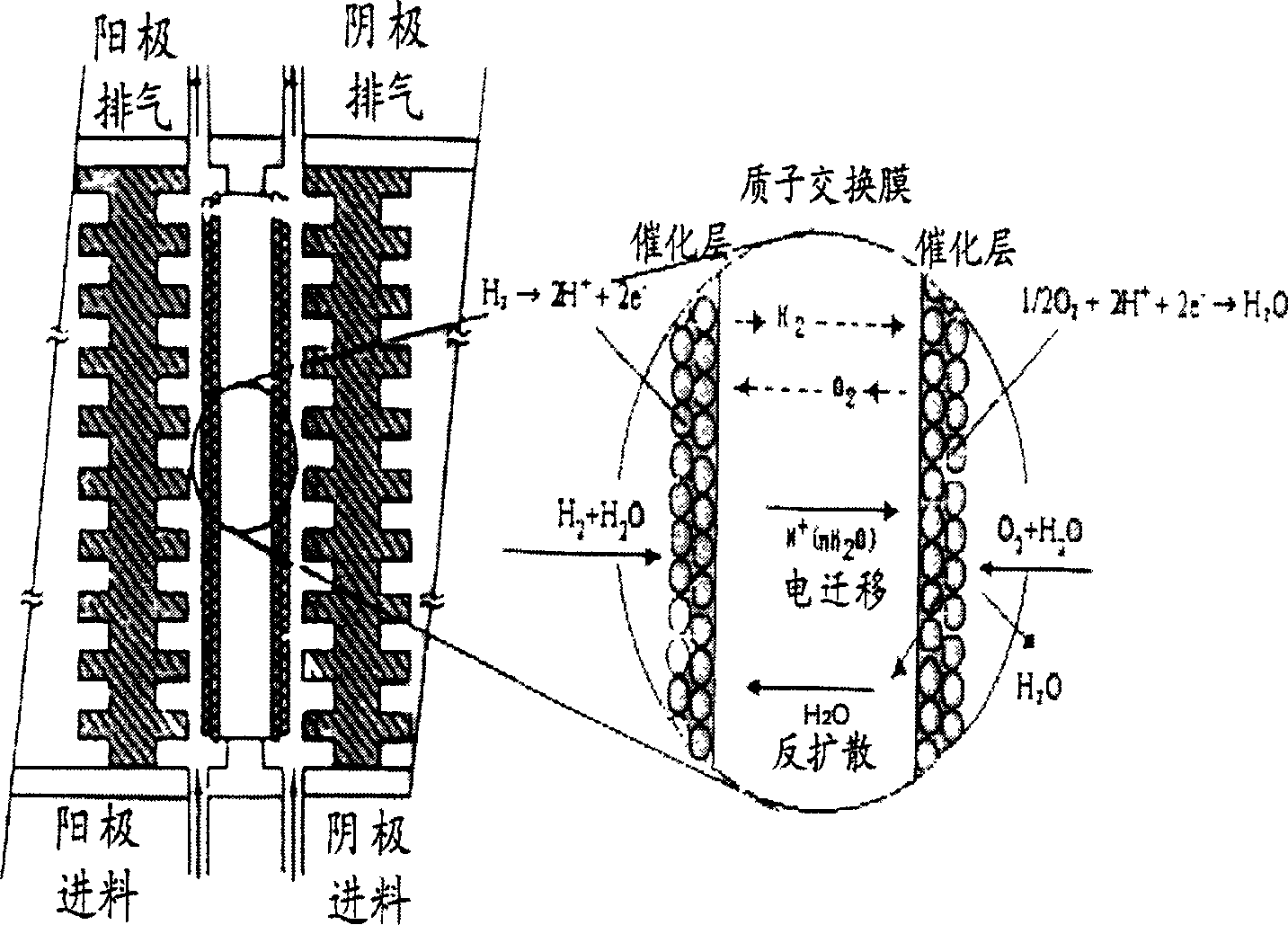

Method and device for activating proton exchange membrane fuel cell

ActiveCN102097631ABest activation rateHigh activation rateFuel cell auxillariesConcentration polarizationPower flow

The embodiment of the invention discloses a method and device for activating a proton exchange membrane fuel cell. The method comprises the following steps of: continuously adding deionized water to a gas channel of the proton exchange membrane fuel cell; adjusting a galvanic pile clamp of the cell according to a preset rule after stopping adding deionized water and removing the deionized water; continuously pumping corresponding reaction gases to the gas channel and adjusting a load so that a current is output according to a preset step gradient until the output voltage of the cell reaches apreset voltage; fully moisturizing a membrane electrode by continuously adding deionized water to the gas channel; decreasing ohmic polarization and concentration polarization to acquire an optimal range between the ohmic polarization and the concentration polarization by adjusting the galvanic pile clamp; and outputting the current by the cell according to the preset step gradient by adjusting the load after pumping the reaction gases so that the transmission channels of water, heat, electrons, protons and gases are internally adjusted, more catalysts become effective reaction points, and the activation effect is better.

Owner:内蒙古快为科技有限公司

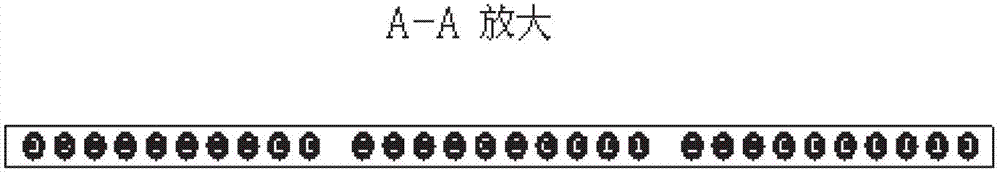

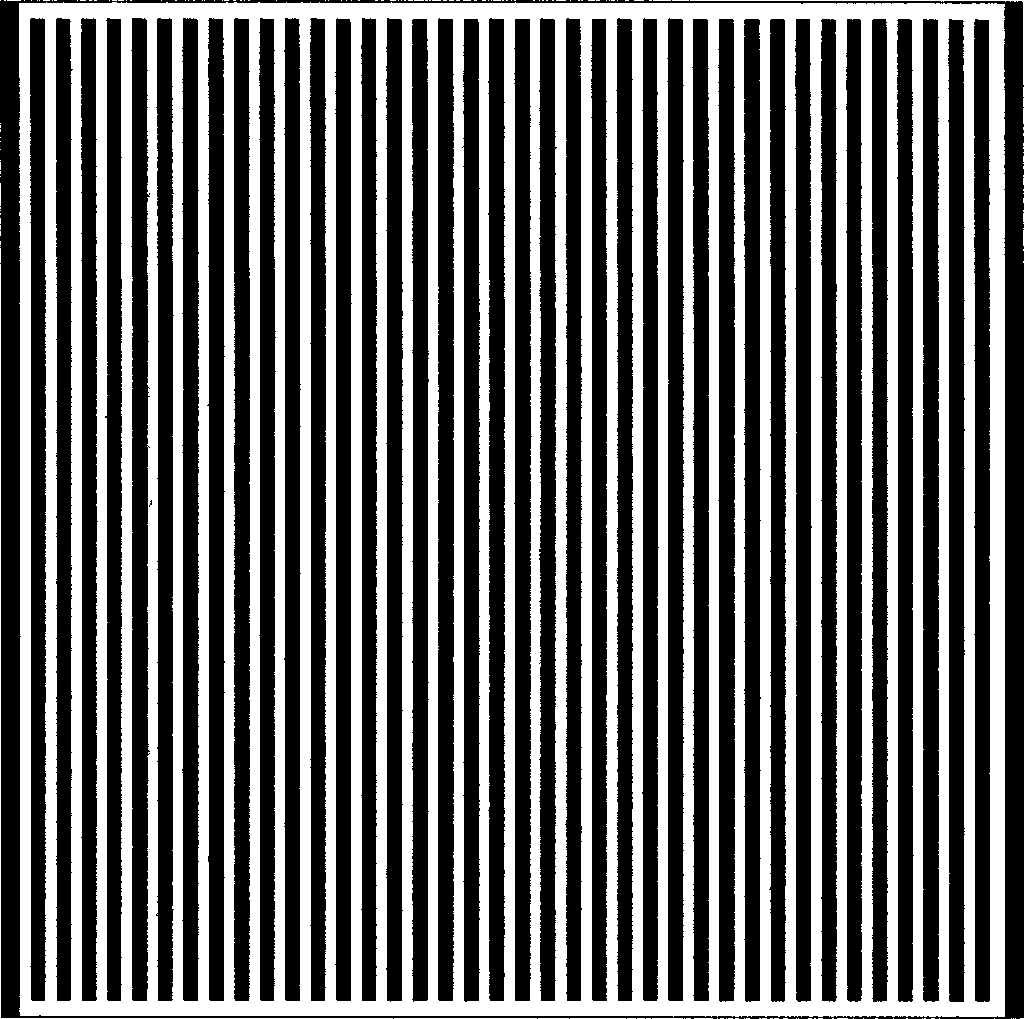

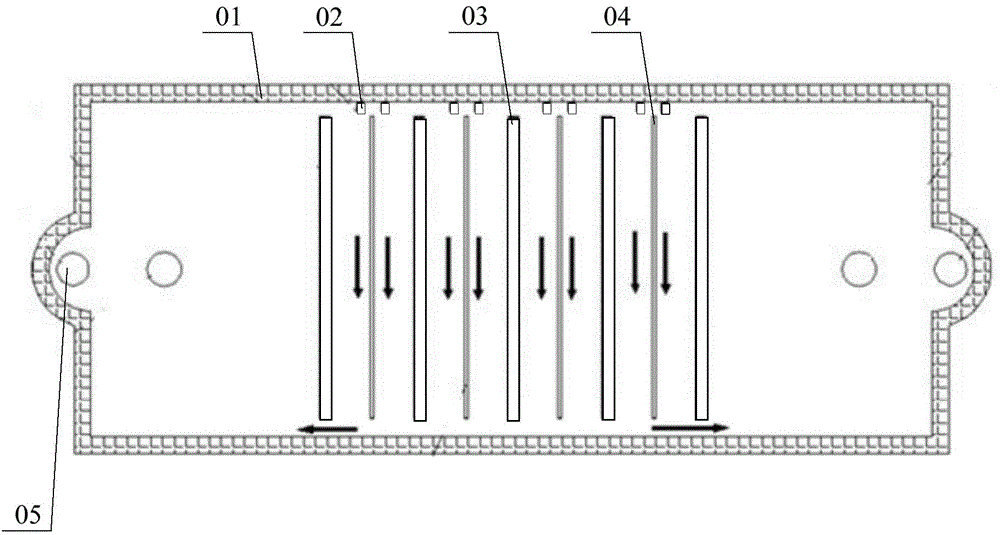

Roll-type reverse-osmosis membrane element with variable-thickness channel net

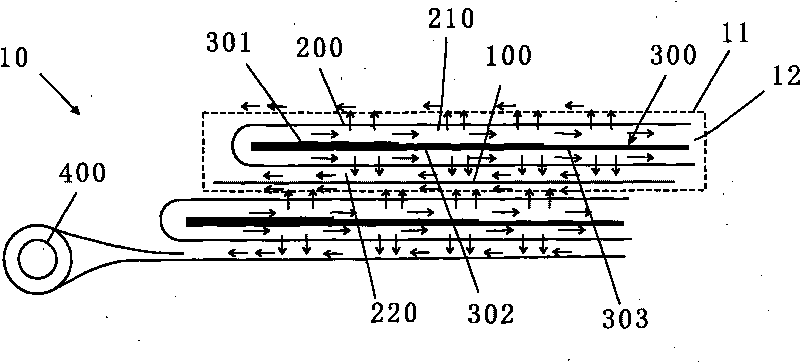

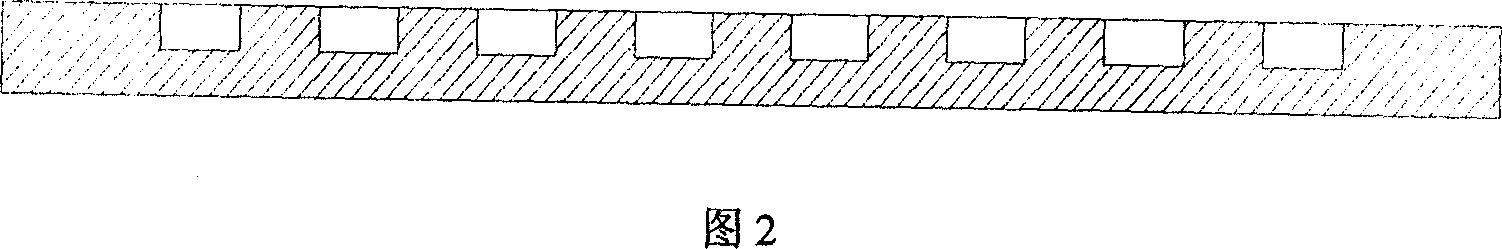

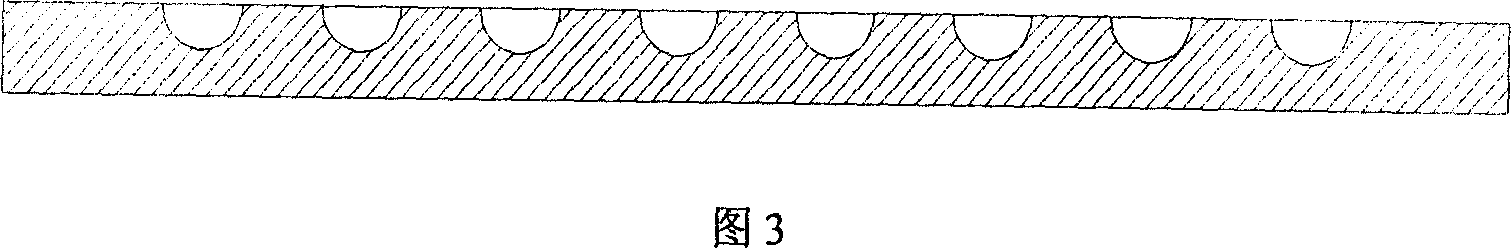

ActiveCN101711948AReduce pollution rateExtended service lifeGeneral water supply conservationReverse osmosisVariable thicknessPolarization phenomenon

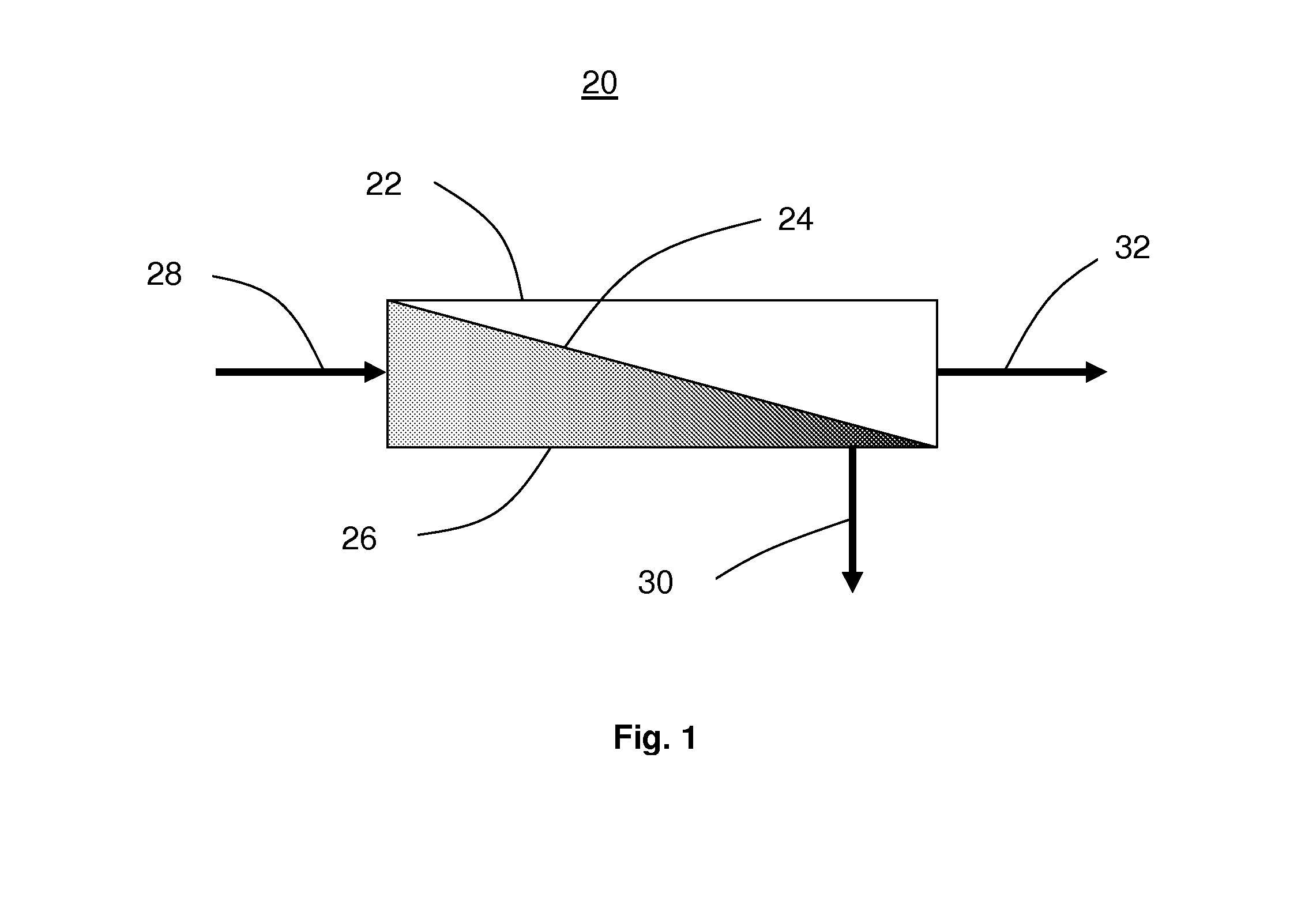

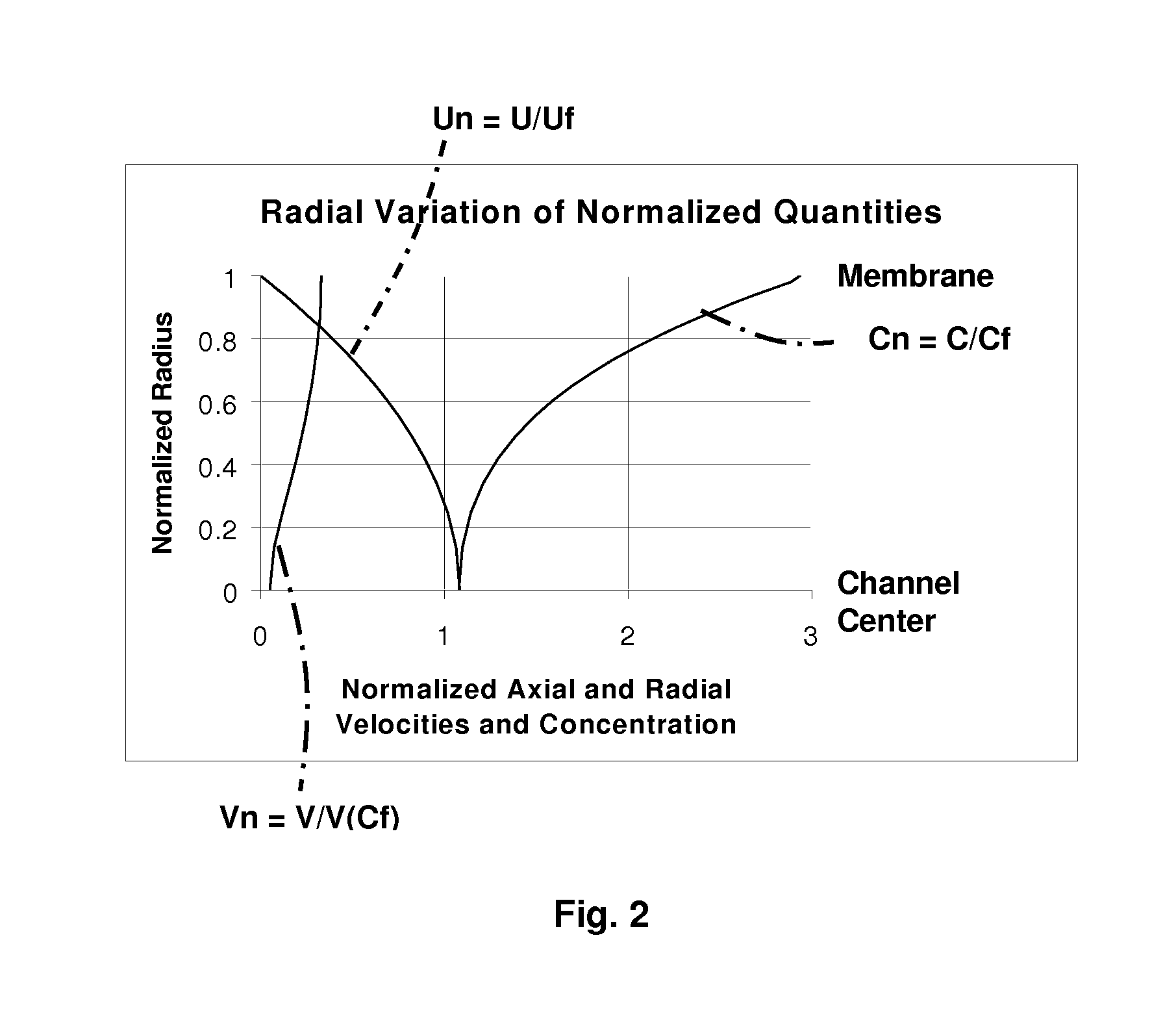

The invention discloses a roll-type reverse-osmosis membrane element with a variable-thickness channel net, formed by overlapping and winding a pure-water diversion net, a reverse-osmosis membrane and an inlet diversion net on a center water-producing pipe. The inlet diversion net and the pure-water diversion net are respectively postioned in an inlet channel formed by the inner surface of the folded reverse-osmosis membrane and a water-producing channel formed by adjacent outer surfaces. The roll-type reverse-osmosis membrane element with the variable-thickness channel net is characterized in that the thickness of the inlet diversion net is gradually reduced along the flowing direction of raw water in the inlet channel. After improvement, when the inlet flow rate and the inlet flow value have constant lengths, the thickness of the inlet channel net is reduced, and the inlet flow rate can increase so that the flow rate of water on the membrane surface is increased, therefore, the invention lessens the concentration difference polarization phenomena of the membrane surface at the water concentrating end of the membrane element, stabilizes the desalting rate and the water-generating amount, decreases the pollution rate of the membrane element and prolongs the service life of the reverse-osmosis membrane.

Owner:A O SMITH (CHINA) ENVIRONMENTAL PRODUCTS CO LTD

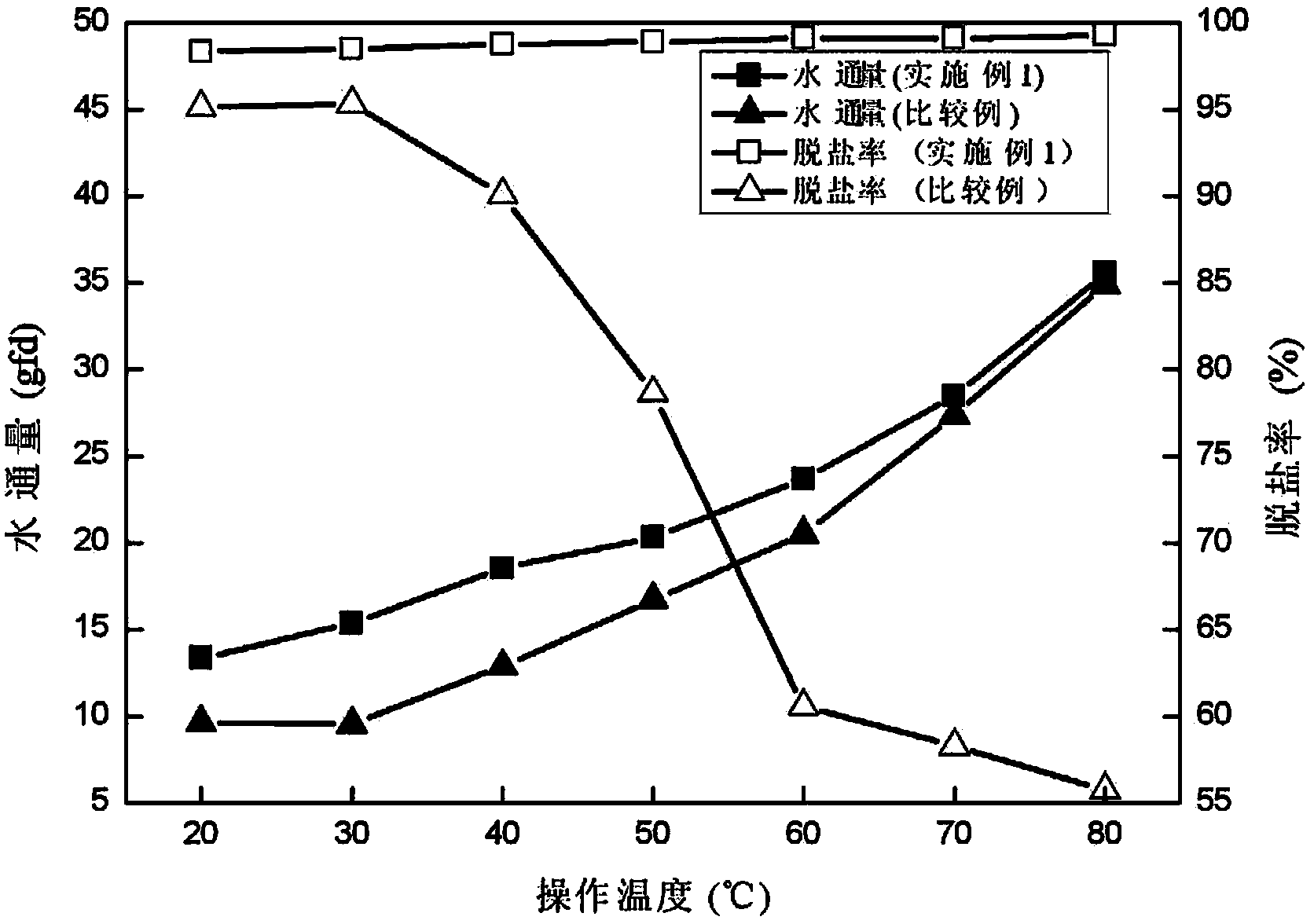

High-temperature resistance double-layer forward osmosis composite film and preparation method thereof

ActiveCN103432913AHigh temperatureReduce concentration polarizationSemi-permeable membranesPolyamideFilm material

The invention discloses a high-temperature resistance double-layer forward osmosis composite film and a preparation method thereof. The forward osmosis composite film comprises a non-woven fabric layer; each of the two surfaces of the non-woven fabric layer is provided with a high-temperature resistance porous supporting film layer; each of the high-temperature resistance porous supporting film layers is provided with a polyamide separation layer; the high-temperature resistance porous supporting film layer is mainly formed by high-temperature resistance polymer. The preparation method comprises the following steps: carrying out blade coating of a casting solution prepared from the high-temperature resistance polymer, a solvent and an additive on both surfaces of the non-woven fabric layer and by phase inversion and heat treatment, and obtaining a supporting film material comprising the non-woven fabric layer and the high-temperature resistance porous supporting film layers; firstly soaking the supporting film material in a water-phase solution and then soaking the supporting film material into an organic-phase solution and forming the polyamide separation layers by reaction so as to obtain the high-temperature resistance double-layer forward osmosis composite film. The forward osmosis composite film disclosed by the invention has high salt rejection, large water flux and high processing efficiency; the preparation method is simple; the process is relatively mature; the forward osmosis composite film is easy for scale production.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

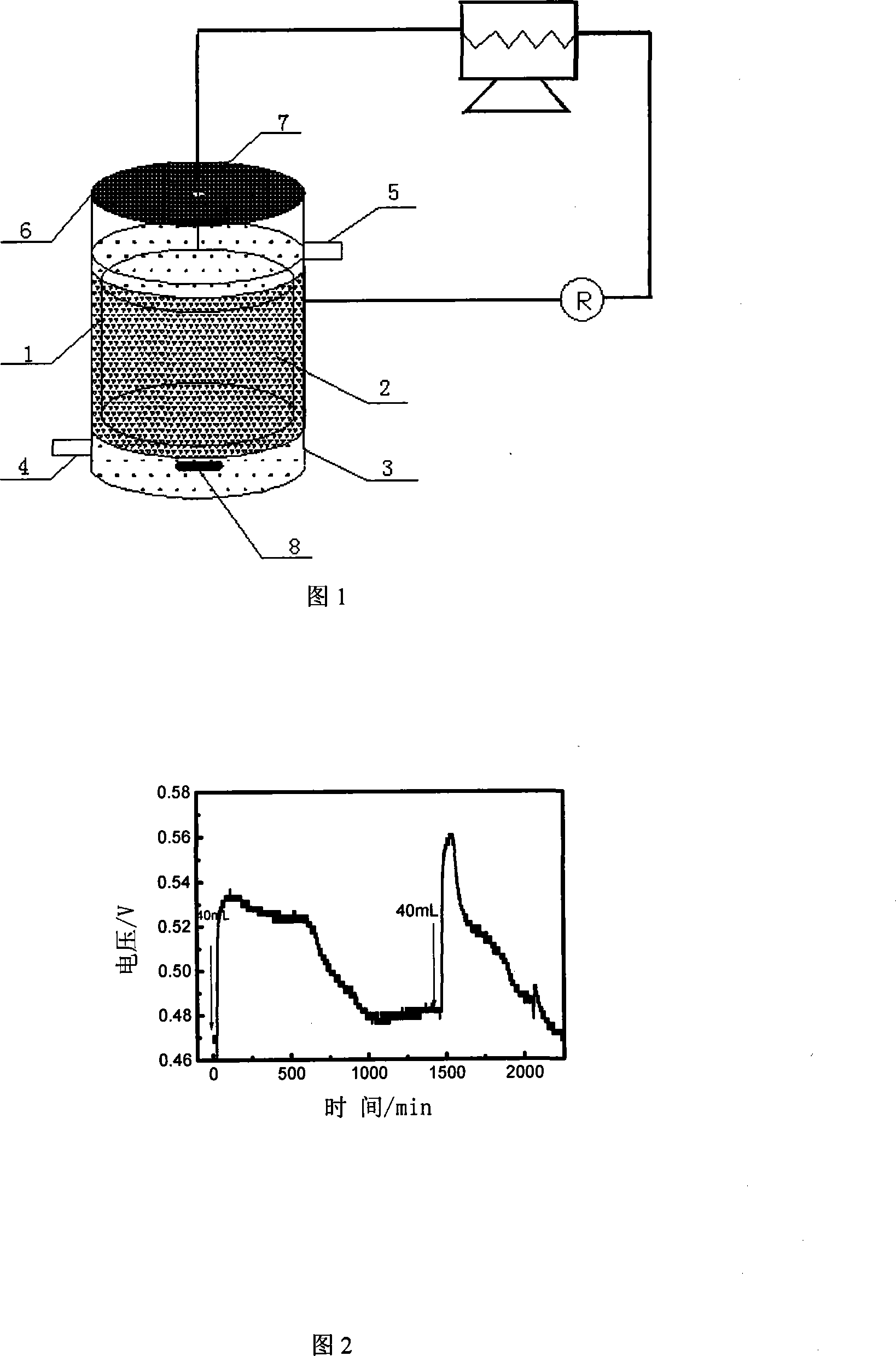

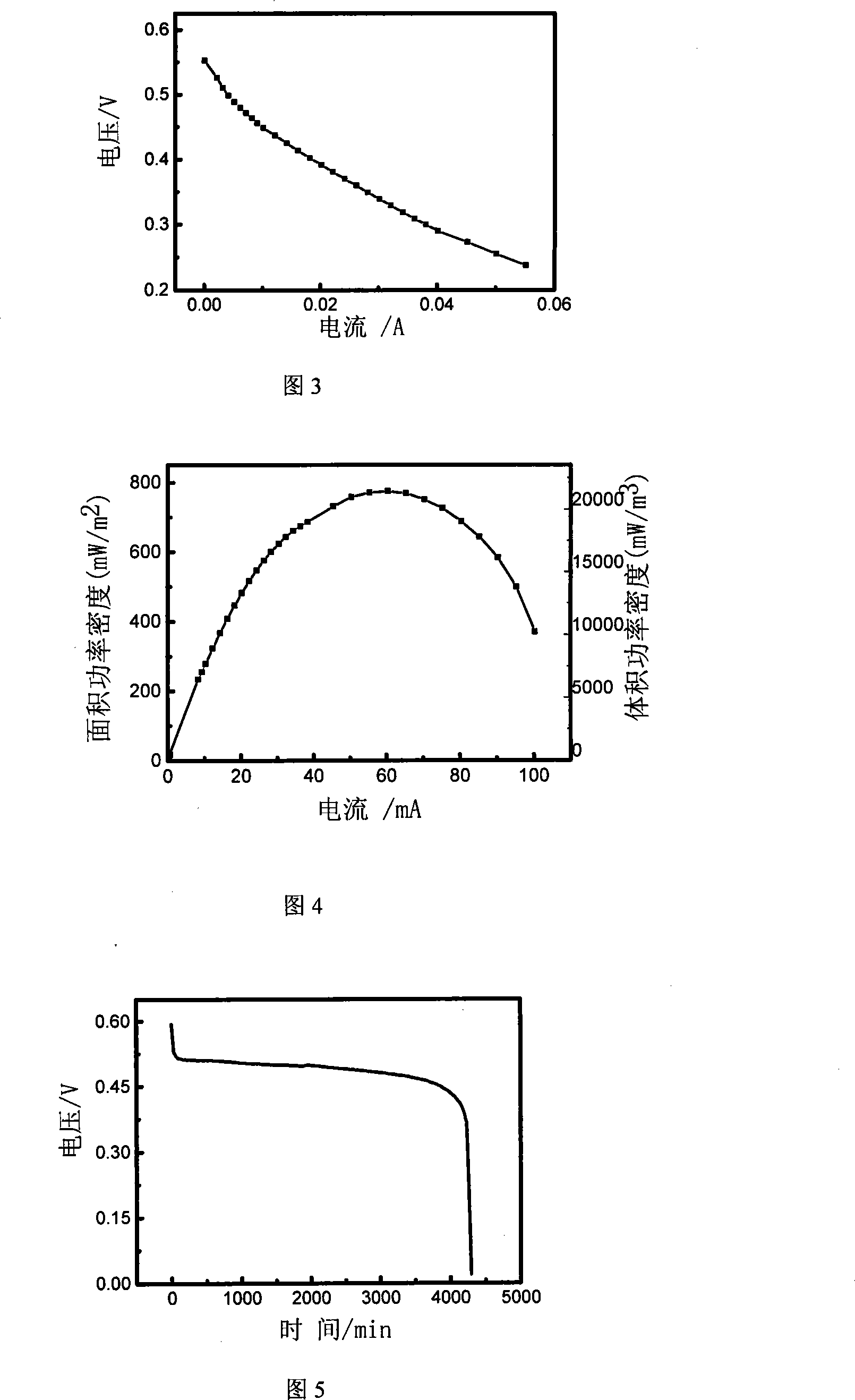

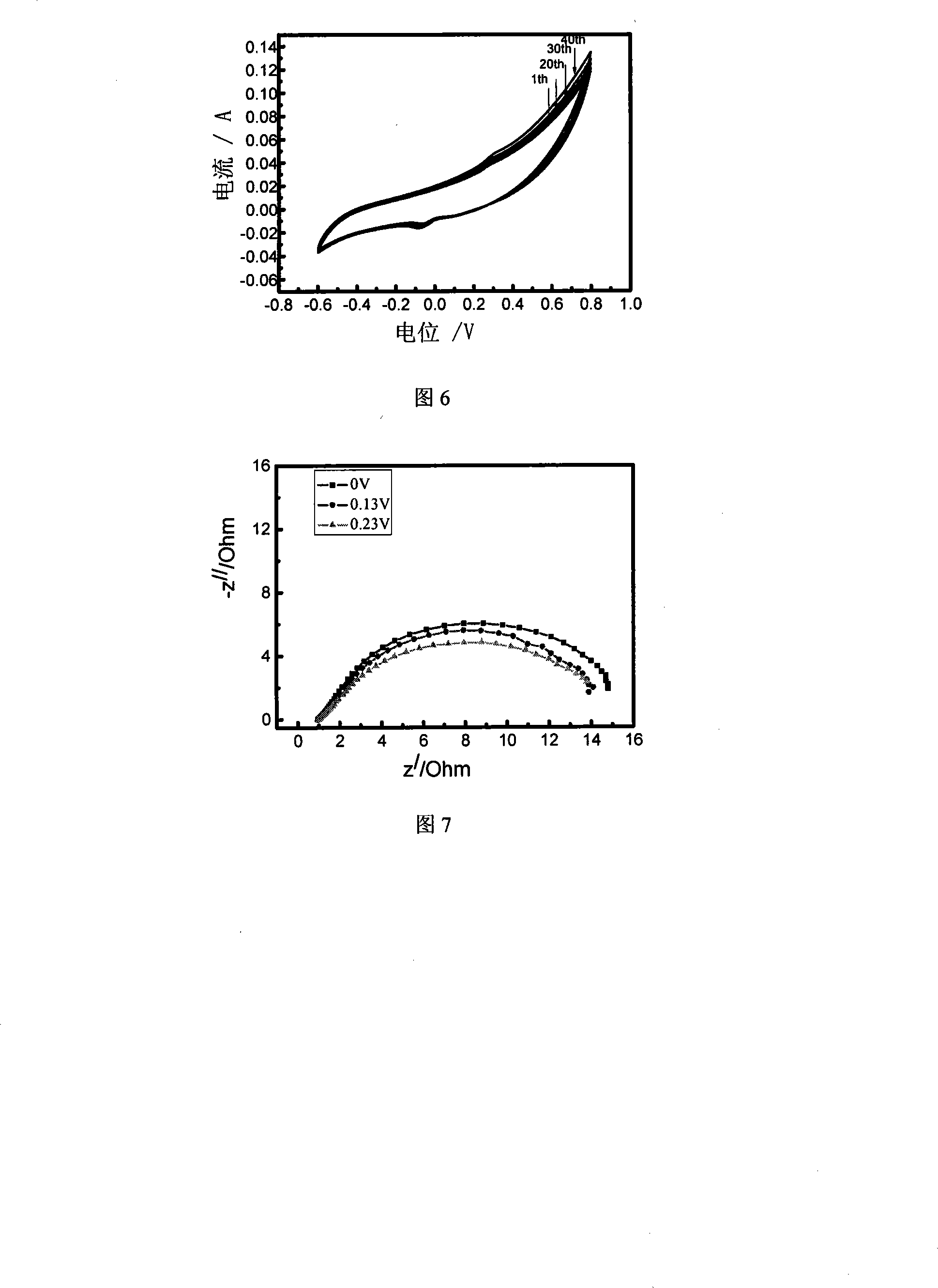

Single microbiological fuel cell with gaseous diffusion electrode as cathode

InactiveCN101207219ALow running costEasy to handleCell electrodesBiochemical fuel cellsCopper conductorClosed loop

The invention provides a single-chamber microbial fuel cell, which takes a gas diffusion electrode as the negative electrode. The invention comprises a container, a positive electrode and a negative electrode; wherein, the positive electrode adopts a foamed metal electrode, the negative electrode adopts a gas diffusion electrode containing metallic catalyst, such as Ag, the container adopts a cylindric glass container, a water inlet opening is arranged at the lower end of the container, a water outlet opening is arranged at the upper end, a sealing cover is arranged at the upper part of the container, a sampling opening is arranged at the middle part of the sealing cover, the positive electrode is positioned at the inner side of the container, the negative electrode is positioned at the outer side of the container, the positive electrode and the negative electrode are arranged along the circumference of the container, copper conductors are connected between the both electrodes, and the both electrodes are connected with a load to form a closed loop. The gas diffusion electrode adopted by the invention exposes in the air, the oxygen gas in the air can be directly utilized as electron acceptors, an extra aerating device is not required; therefore the running cost is reduced. Organism, such as dextrose and discharge water can be used as the fuel of the cell, chemical energy can be effectively converted into electric energy; simultaneously, better discharge water processing effect can be achieved.

Owner:HARBIN ENG UNIV

Wine of low or free alcohol and its brewing method

The invention disclosed the method of brewing the non-low alcohol grape wine, which is enzyme treatment and penetration vaporzatioin method. The characteristics of the invention is the alcohol ranging from 0.5% to 7%, the sugar content which is the glucose below 12g / L in baked mold and below 120g / L in sweet mold, the total acid ranging from 4.5 to 8.0g / L measured by dihydroxysuccinic acid, the extract above 15g / L, free sulfur dioxide below 50mg / L, and total sulfur dioxide below 250mg / L. The said non-low alcohol grape wine is harmonization, delicate fragrance, suitable for the particular group and occasion,

Owner:YANTAI CHANGYU PIONEER WINE CO LTD

Fence type anode plate for electrodeposition of nonferrous metals

The invention discloses a fence type anode plate for electrodeposition of nonferrous metals. The fence type anode plate for electrodeposition of the nonferrous metals is characterized in that lead or lead-based complex alloy with the thickness of 2-10mm is compounded on the surface of a rod core to form a composite rod; a corrugated or sawtooth type pattern is drawn on the surface of the composite rod; a conductive ceramic composite coating layer is coated or electrodeposited on the surface of the composite rod; the fence type anode plate is formed by assembling a plurality of the composite rods; and the composite rods are fixed by insulation edge clamping strips and clamped by insulation rivets. By the fence type anode plate for electrodeposition of the nonferrous metals, fluidity of electrolyte solution is improved, concentration polarization of a cathode area is reduced, and deposition amount of cathode metals is increased, so that cathode current efficiency is improved; the fence type anode plate does not bend and deform, and therefore short circuit phenomenon of anode and cathode plates is prevented; and compared with the conventional lead-based alloy anode plate, the conductivity of the fence type anode plate is obviously improved, the tank voltage is reduced by 10%, the material cost is reduced by 20% and the current efficiency is increased by 2-5%.

Owner:KUNMING HENDERA SCI & TECH

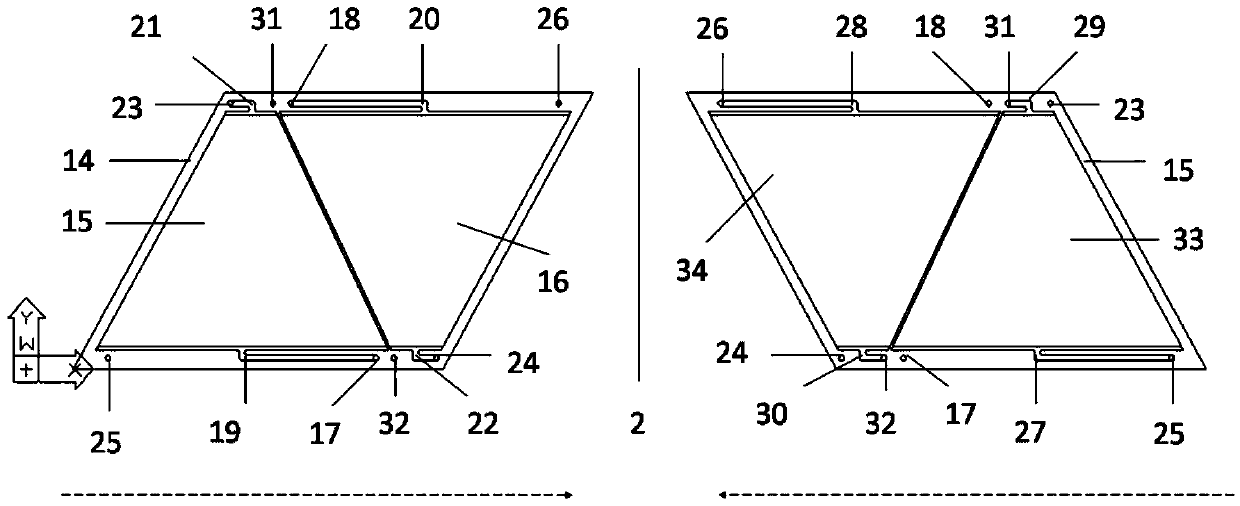

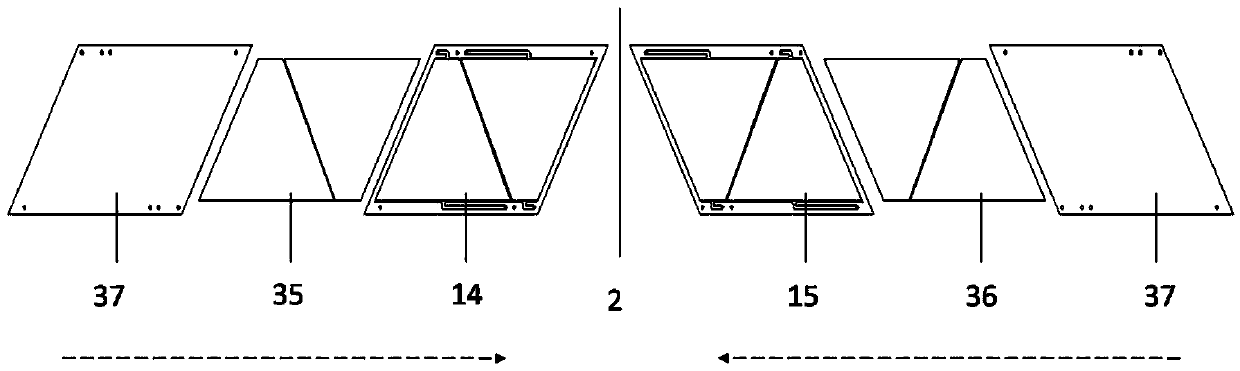

Mono-trapezoid flow battery, poly-trapezoid flow battery and electric pile thereof

ActiveCN105514459AExtend charge and discharge timeIncrease profitFuel cells groupingCell electrodesTotal efficiencyConcentration polarization

The invention provides a mono-trapezoid flow battery, a poly-trapezoid flow battery and an electric pile thereof. Both a cathode porous electrode and an anode porous electrode in the mono-trapezoid flow battery are trapezoidal plate electrodes and are respectively arranged inside a cathode electrolyte flow frame and an anode electrolyte flow frame. On the cathode electrolyte flow frame and the anode electrolyte flow frame, two electrolyte inlet flow paths are arranged nearby the lower bottom edges respectively of the cathode porous electrode and the anode porous electrode, and two electrolyte outlet flow paths are arranged nearby the upper bottom edges respectively of the cathode porous electrode and the anode porous electrode. The electrolyte flows into the cathode porous electrode through the lower bottom edges of the cathode porous electrode and the anode porous electrode and then flows out from the upper bottom edges of the cathode porous electrode and the anode porous electrode. The trapezoid flow battery is reduced in concentration polarization at certain degree and further is reduced in voltage loss, and meanwhile, is improved in utilization efficiency of the electrolyte and is increased in total efficiency.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Mixed gradual conversion field of proton exchange membrane fuel cell

InactiveCN101047252AImprove unevennessEvenly distributedCell electrodesCollectors/separatorsMixed flowProton

A mixed and gradually varied flow field of proton exchange film fuel cell consists of slots at reaction region of mixed flow field, flow guiding slots at inlet and outlet, sealing slots and distribution slots for connecting flow guiding slots to slots at reaction region of mixed flow field. It is featured as setting slots at reaction region of mixed flow field to be multilayer grade slots in arc form and setting center of circle at sealing slots to be with the same central point as center of circle on slots at reaction region of mixed flow field.

Owner:UNIV OF SCI & TECH BEIJING

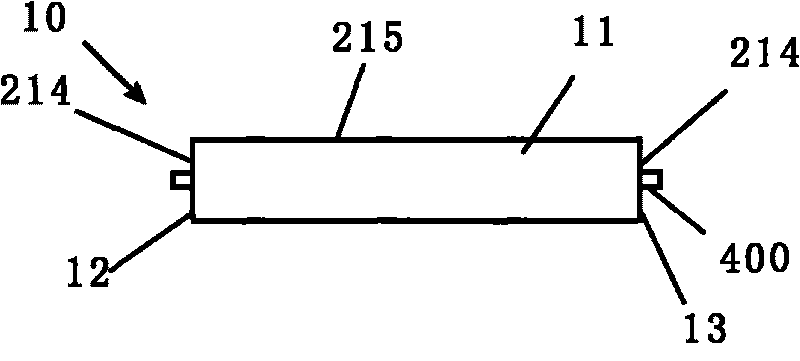

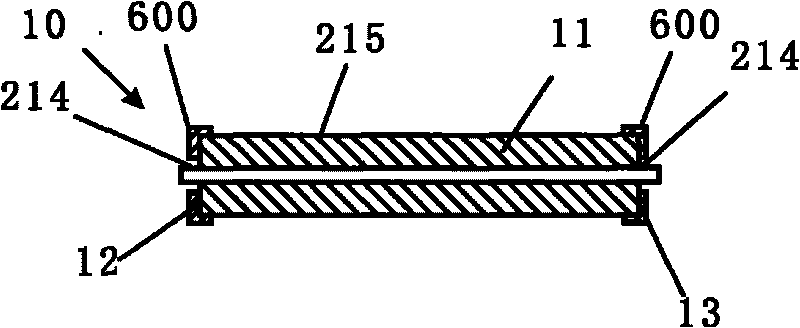

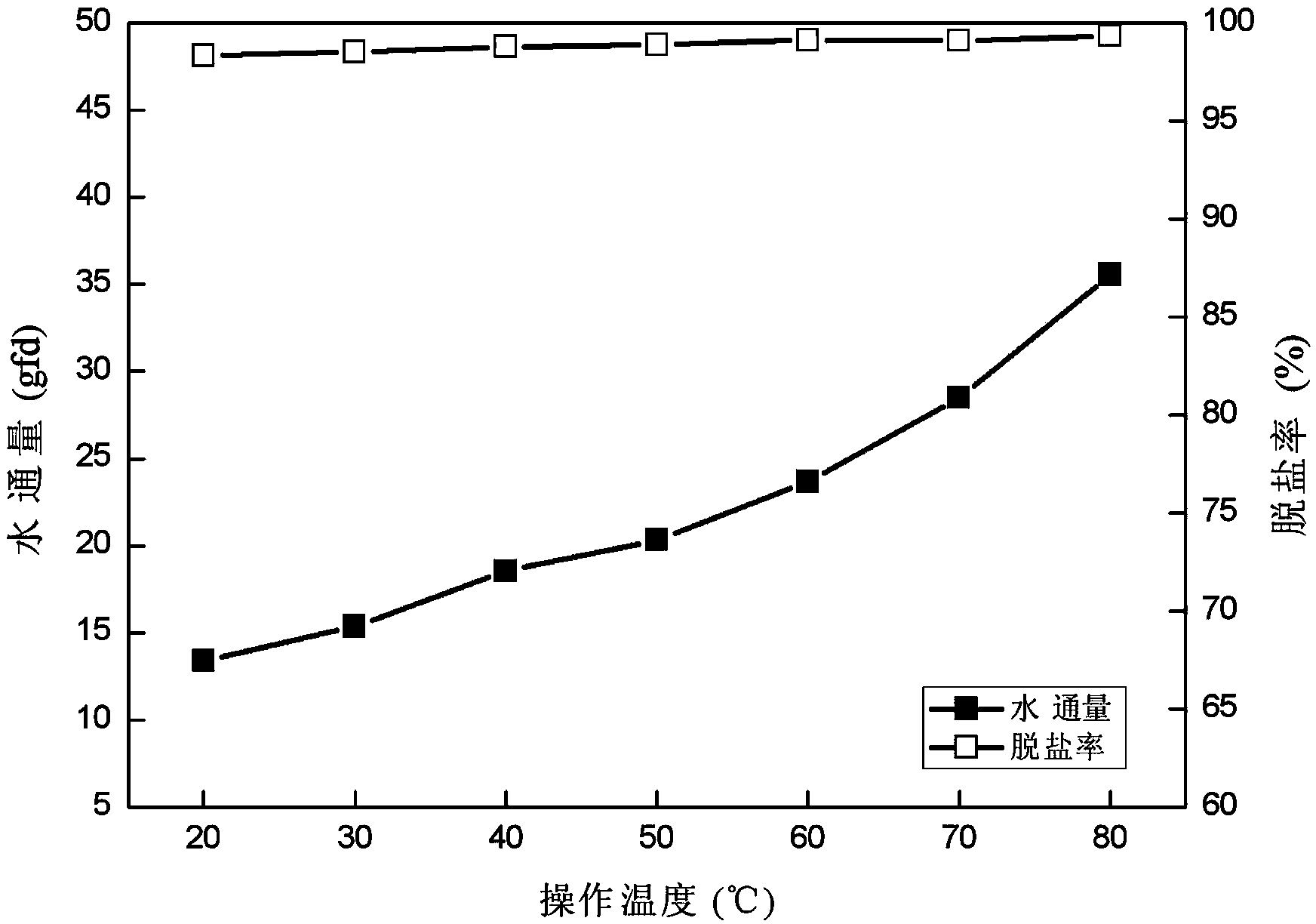

Membrane performance tester and application thereof

ActiveCN102049199AExtended stayStable temperature controlSemi-permeable membranesUltrasound attenuationWater baths

The invention provides a performance tester of a continuous flat ultrafiltration membrane and a reverse osmosis membrane and a use method thereof. The tester comprises a water supply unit, a drainage unit and a plurality of parallel infiltration ponds, wherein each infiltration pond comprises a substrate, a shell, a water inlet, a water outlet, an exhaust port, a bottom inserting tube, a stirrer and a constant-temperature water bath jacket. Produced water penetrating through a separation membrane to be measured is discharged out of the infiltration ponds via the water outlets. The tester can carry out constant-temperature and stable operation at higher temperature and can realize the functions of testing membrane separation performance and membrane flux attenuation, extracting key pollutants of the membrane, cleaning the membrane on line and testing membrane performance restore after cleaning.

Owner:CHINA PETROLEUM & CHEM CORP +1

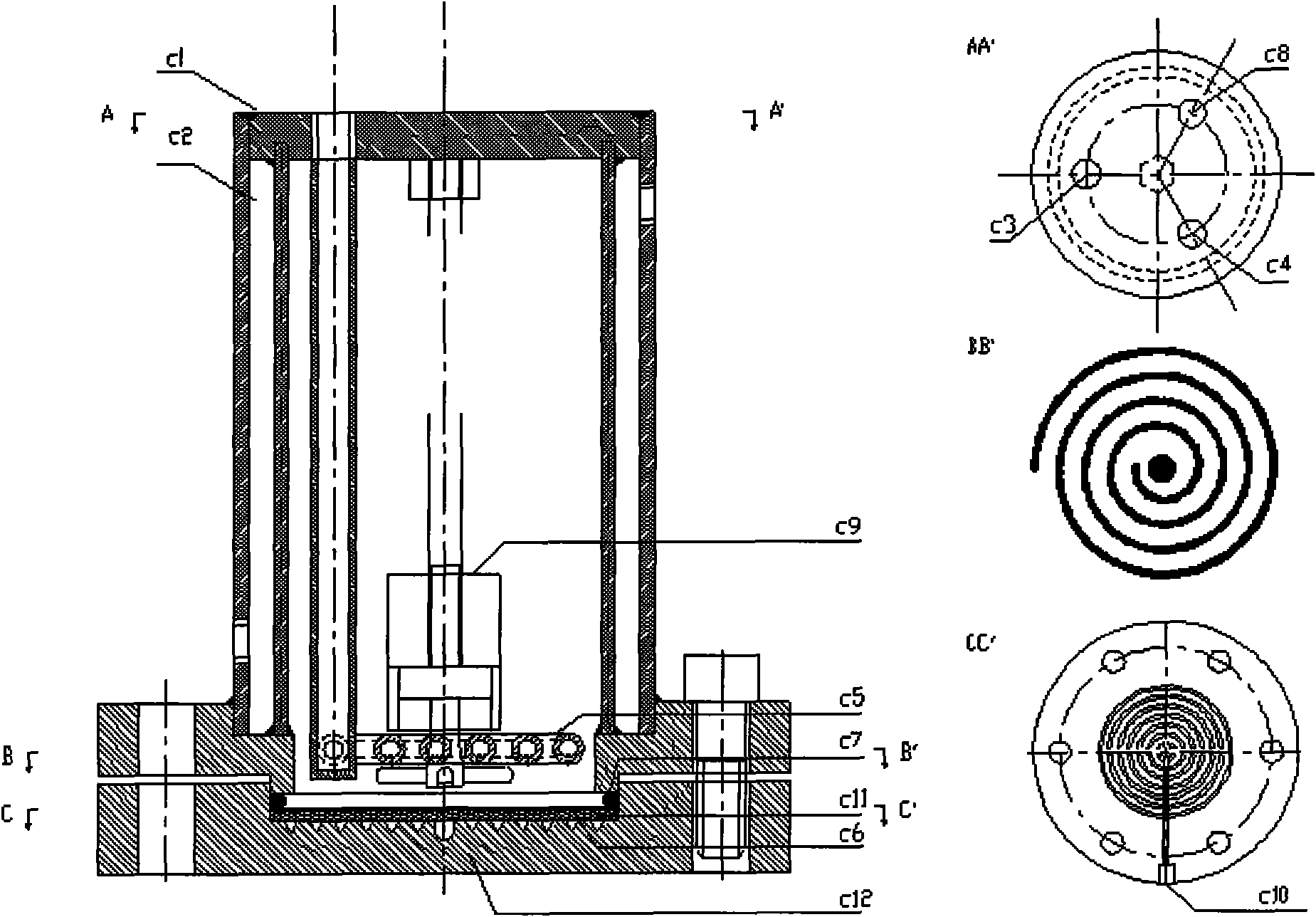

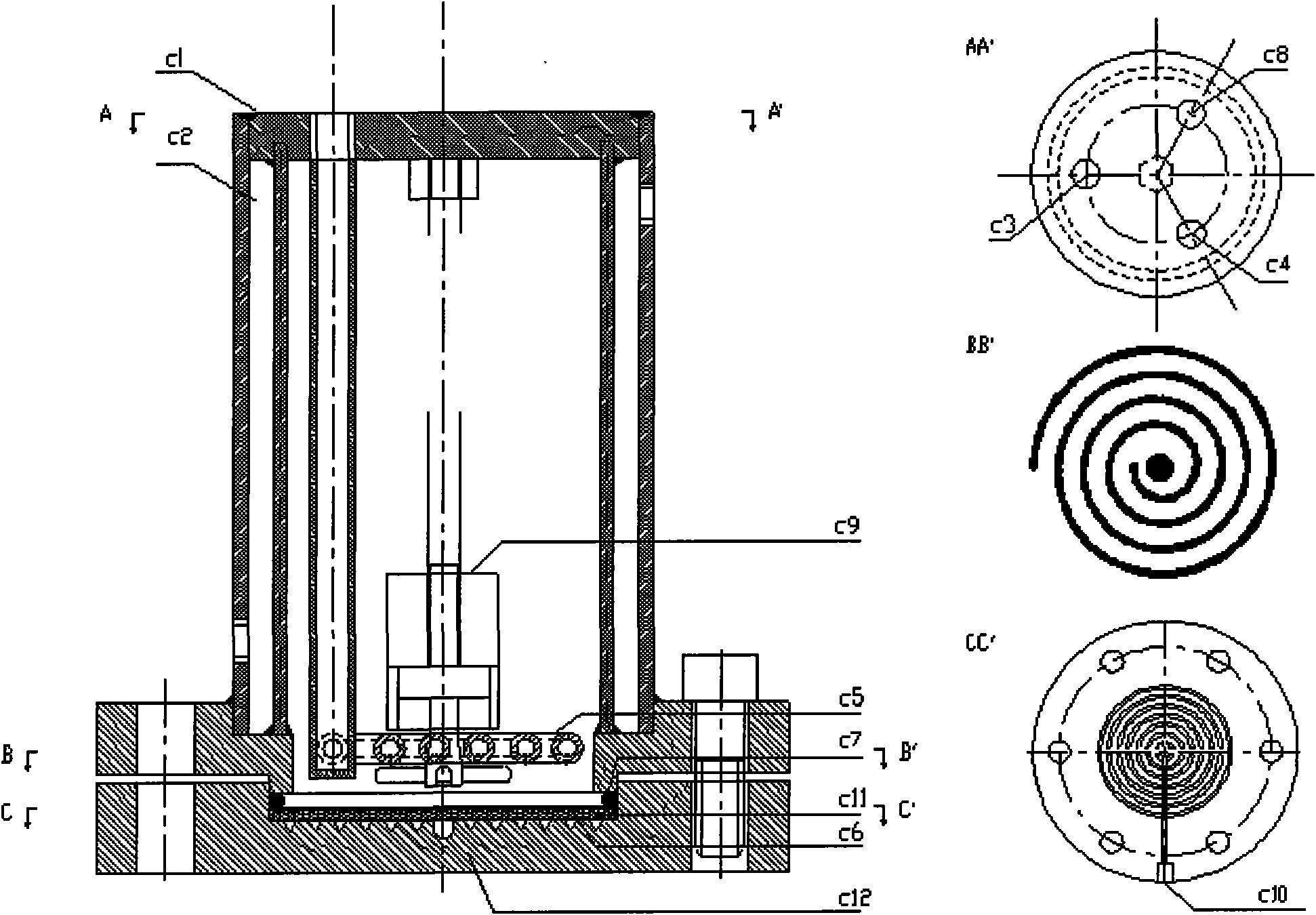

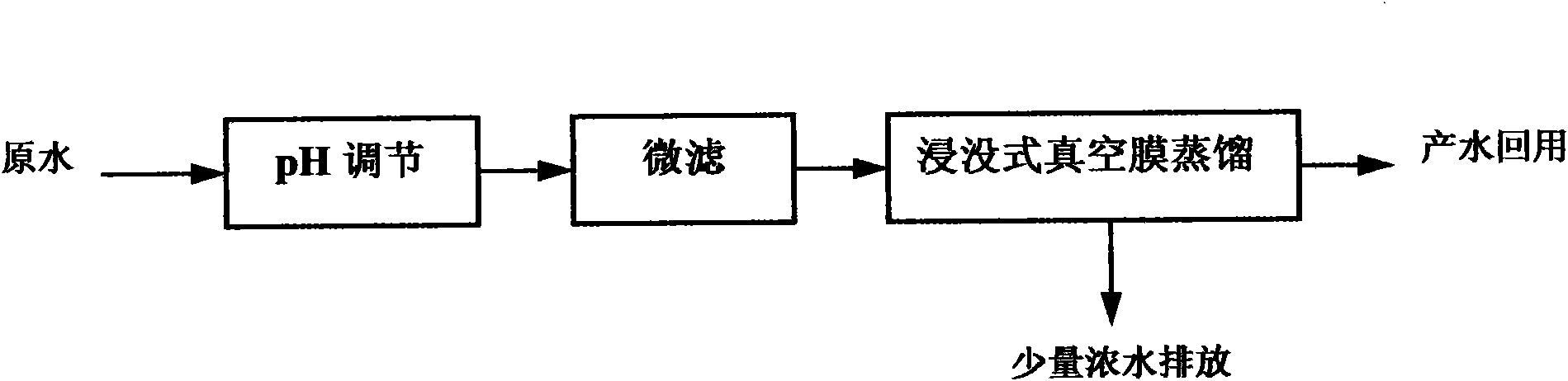

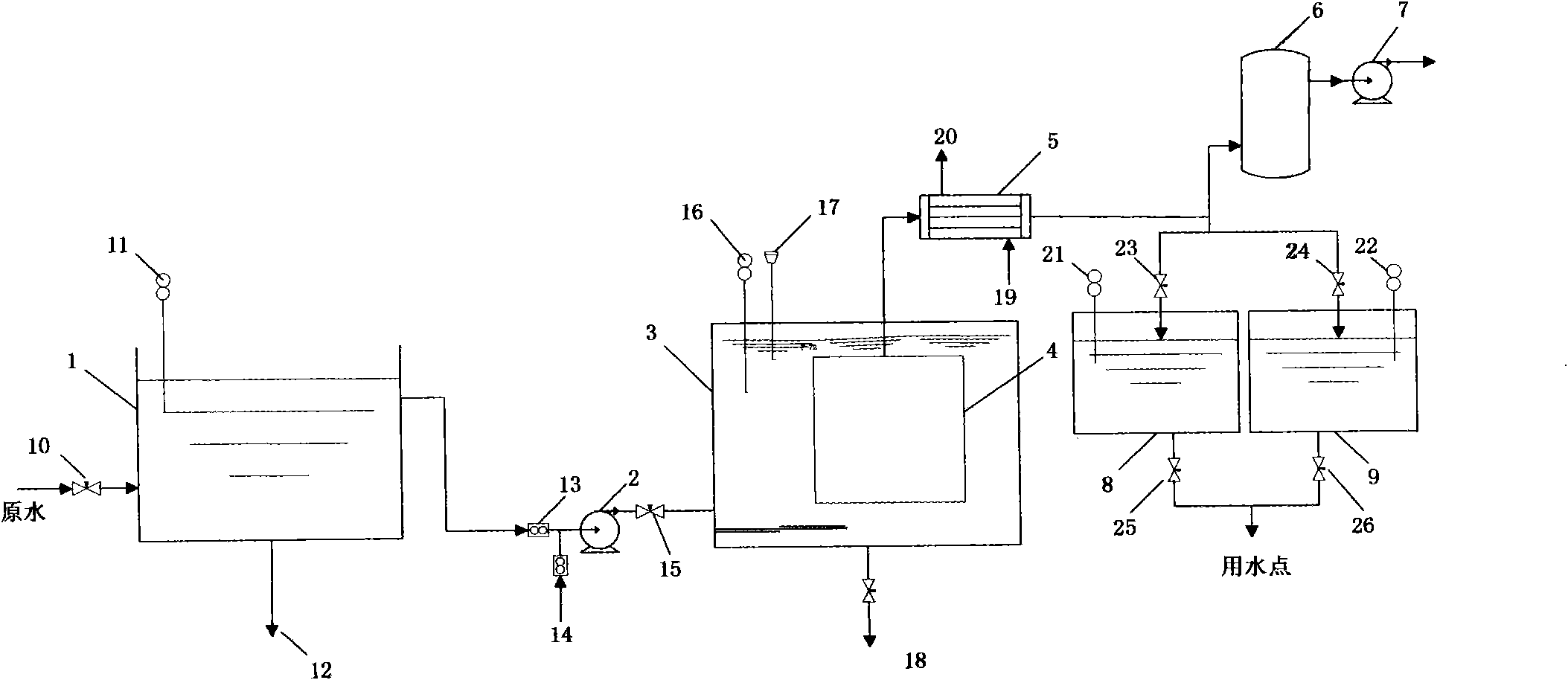

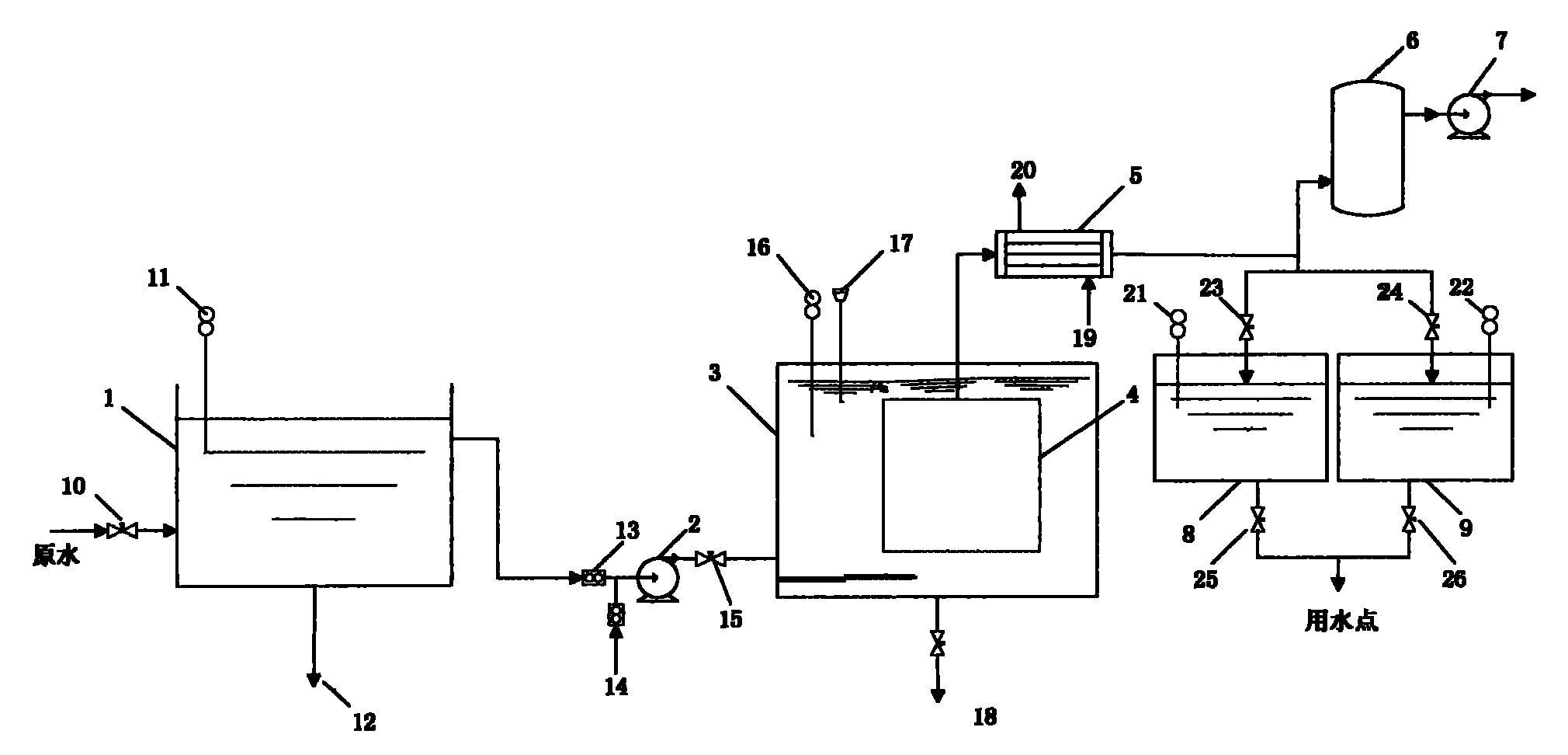

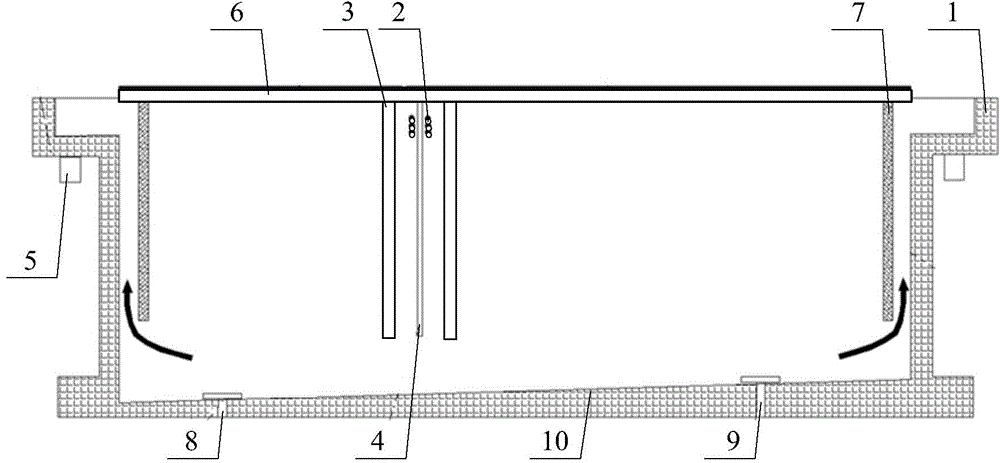

Immersed vacuum membrane distillation plant and sewage treatment technology using the same

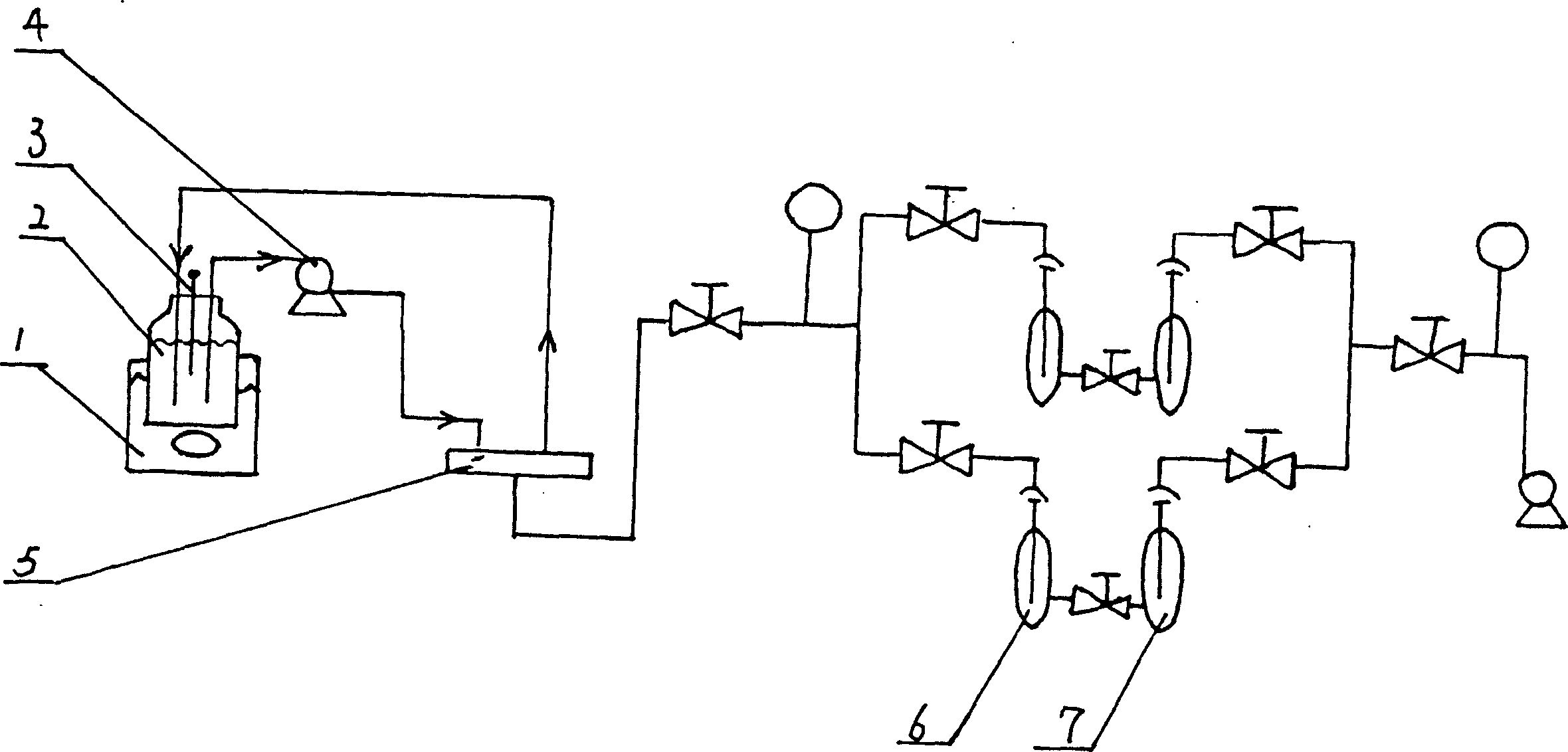

ActiveCN102417210AIncreased distillation throughputReduce pollutionWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentConcentration polarizationMeasuring instrument

The invention relates to an immersed vacuum membrane distillation plant and a sewage treatment technology using the same. The immersed vacuum membrane distillation plant comprises a raw water storage tank, a gas dissolving pump, a raw water heating water tank, a membrane distillation hydrophobic membrane module, a condenser, a vacuum buffer tank, a vacuum pump, a water producing tank, a valve, a measuring instrument, and an automatic controller. The sewage treatment technology is characterized in that: raw water is subject to pH regulation, microfiltration and other pretreatment, then the pretreated raw water enters into the raw water storage tank, the sewage in the raw water storage tank is subject to gas-water mixing through the gas dissolving pump, and then the gas-water mixture enters into the raw water storage tank for heating to a specific temperature, membrane distillation is carried out at the specific temperature, the produced water after membrane distillation is directly reused, and a little thick water is treated concentrately. According to the invention, the use of the plant in sewage treatment reduces the effect of concentration polarization and temperature difference polarization in the sewage, reduces membrane pollution, increases the membrane distillation flux, prolongs the operation period of the membrane module, reduces the heat loss of the pipeline, and increases the heat utilization rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

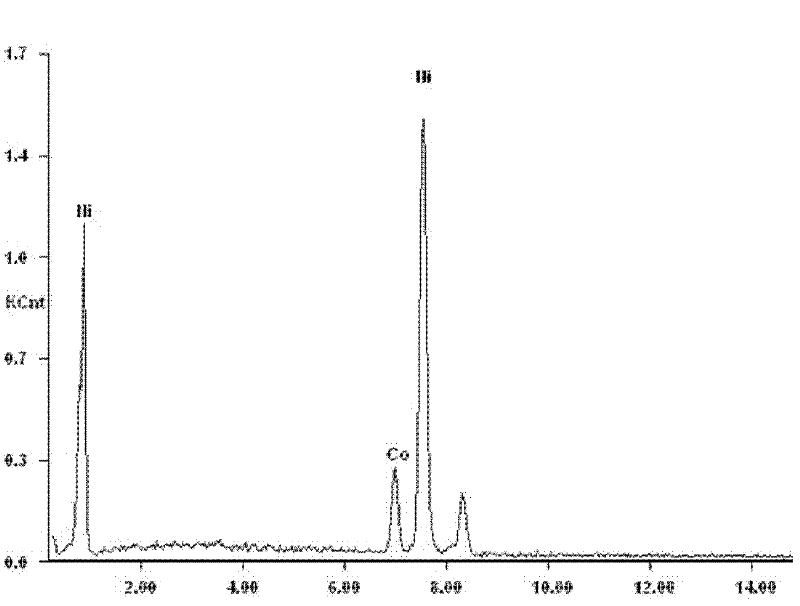

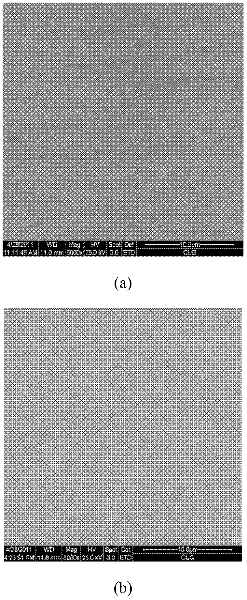

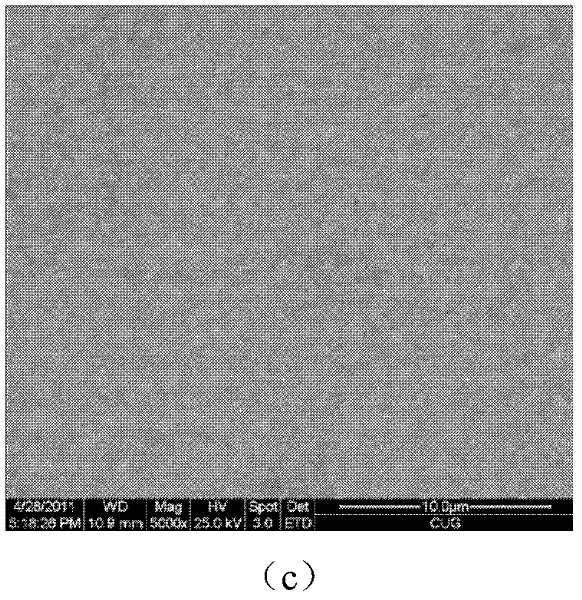

Method for double-pulse electrodeposition of nanocrystalline nickel-cobalt alloy

InactiveCN102260891AUniform crystallizationCrystal fineMaterial nanotechnologyPhotography auxillary processesElectroplatingNickel ions

The invention relates to a method for electrodepositing a nanocrystalline nickel-cobalt alloy by double-pulse. The method for electrodepositing the nanocrystalline nickel-cobalt alloy by double-pulse is characterized by comprising the following processing steps: in a plating solution with a pH value of 5-6, a nickel ion concentration of 0.68-0.95 mol / L and a cobalt ion concentration of 1.9*10<-2>to 3.8*10<-2> mol / L, taking a soluble nickel plate after the soluble nickel plate is subjected to surface treating as a anode, taking an iron sheet after the iron sheet is subjected to surface treating as a cathode and electroplating a nanocrystalline nickel-cobalt alloy layer by using double-pulse electrodepositing technology, wherein the time for electrodepositing is 15-20 min, the positive-going pulse current density is 1.0-2.0 A / dm<2>, the positive-going duty ratio is 60-80%, the working time of the positive-going pulse is 50-100 ms and the positive-going cycle is 40-60 ms; and the negative-going pulse current density is 0.1-0.2 A / dm<2>, the negative-going duty ratio is 60-80%, the working time of the negative-going pulse is 10-20 ms, the negative-going cycle is 1-2 ms and the workingtime of the positive-going pulse is 5-10 times of that of the negative-going pulse. The nickel-cobalt alloy coating prepared by the method has the advantages of smooth surface, compact structure, fine and even crystal, good smoothness, no crack and excellent corrosion resistance.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Proton exchange film fuel cell flow field structure

ActiveCN1622377AEasy to excludePromote accumulationCell electrodesSolid electrolyte fuel cellsProtonEngineering

The present invention relates to proton exchange membrane fuel cell. The flow field structure of proton exchange membrane fuel cell consists of netted flow field and deflecting stripes. The deflecting stripes are set inside the netted flow field and parallel to one group of sealing side walls, and have width equal to the height of the netted flow field. Each of the deflecting stripes has one end connected perpendicularly to the side wall and the other end constituting the gas channel. The gas channel has width not smaller than that of the gas inlet. The present invention has the advantages of high pole area utilization, being favorable to the exhaust of water produced in the electrochemical reaction and the elimination of inertial component, no dead arean of gas flow, and stable operation of the cell under low pressure and normal pressure.

Owner:SUNRISE POWER CO LTD

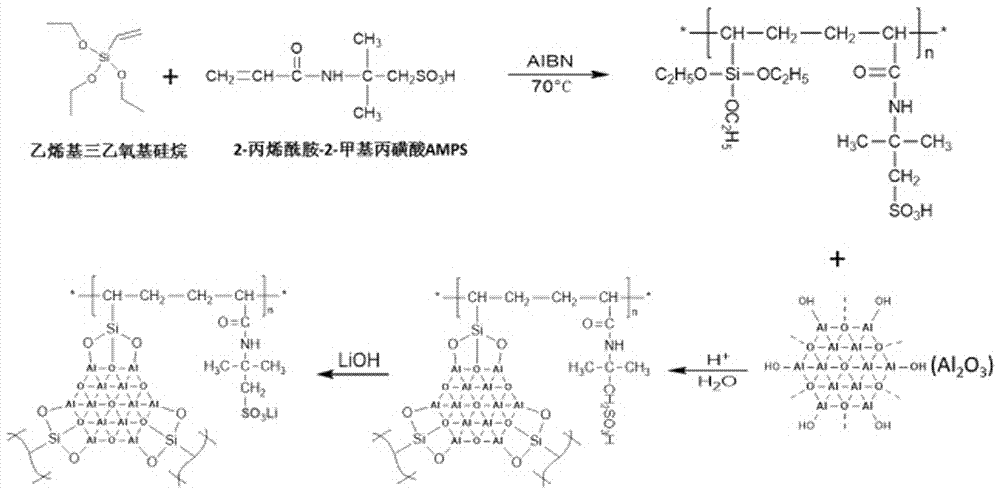

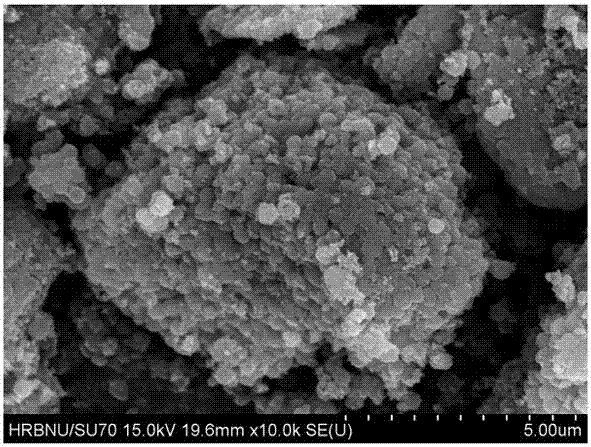

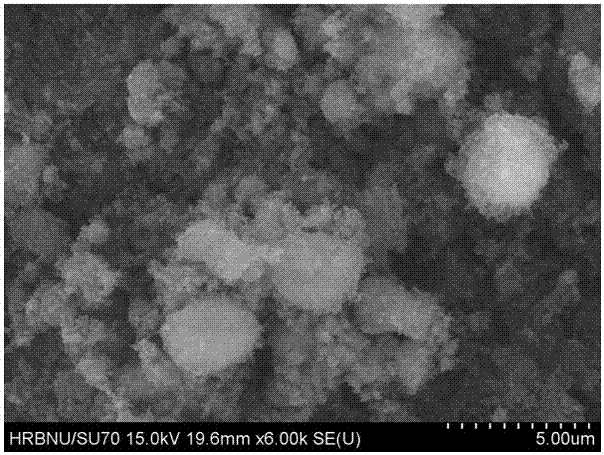

Surface-modified inorganic nanoparticles as well as preparation method and application thereof

ActiveCN107134590AGood dispersionEvenly dispersedMaterial nanotechnologySolid electrolytesDispersityMetal oxide nanoparticles

The invention discloses surface-modified inorganic nanoparticles as well as a preparation method and application thereof. The surface-modified inorganic nanoparticles are composed of a core of inorganic metal oxide nanoparticles and amphipathic organic segments grafted on the surface of the particles, wherein the amphipathic organic segments grafted on the surface of the particles account for 0.1-50% of total mass of the surface-modified inorganic nanoparticles; the inorganic metal oxide nanoparticles refer to one or several in aluminum oxide, silicon dioxide, titanium dioxide, zirconium dioxide and zinc oxide inorganic nanoparticles; and the amphipathic organic segments are produced from a vinyl silicane coupling agent and 2-acrylamido--methylpropane sulfonic acid through solution polymerization. The surface-modified inorganic nanoparticles can be used for preparing polymer electrolyte. Therefore, the inorganic nanoparticles are high in dispersity in a polymer matrix, and the prepared polymer electrolyte is high in lyotropic property, high in ionic conductivity and stable in electrochemical performance.

Owner:浙江久功新能源科技有限公司

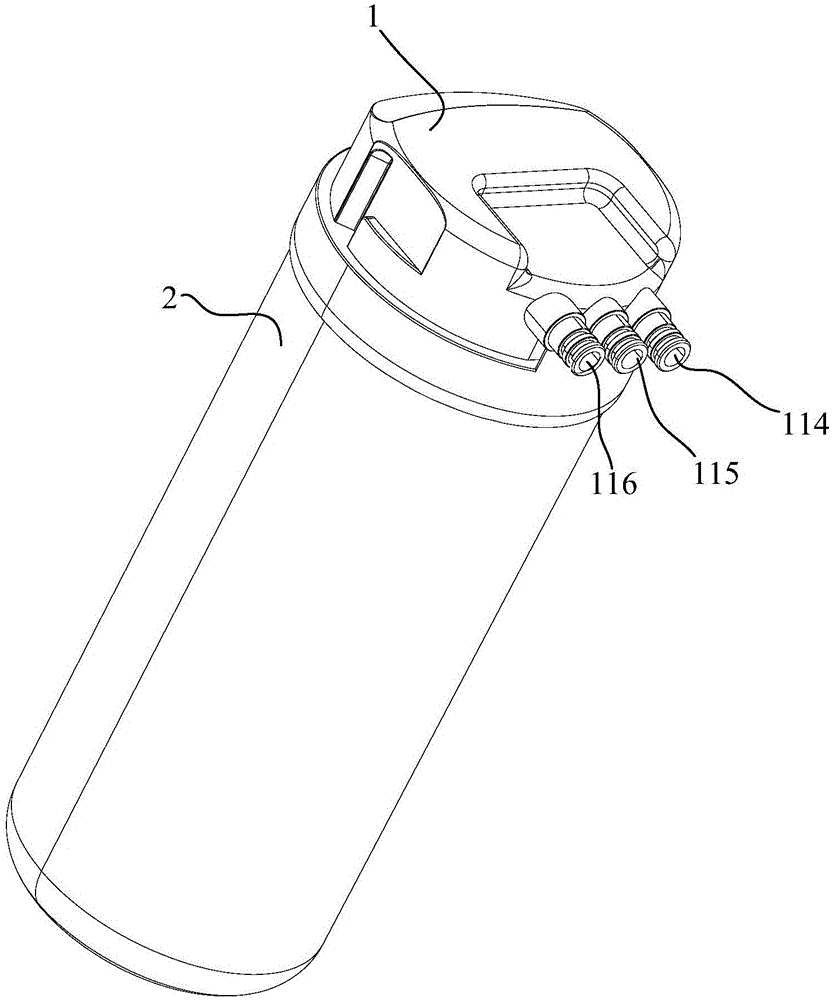

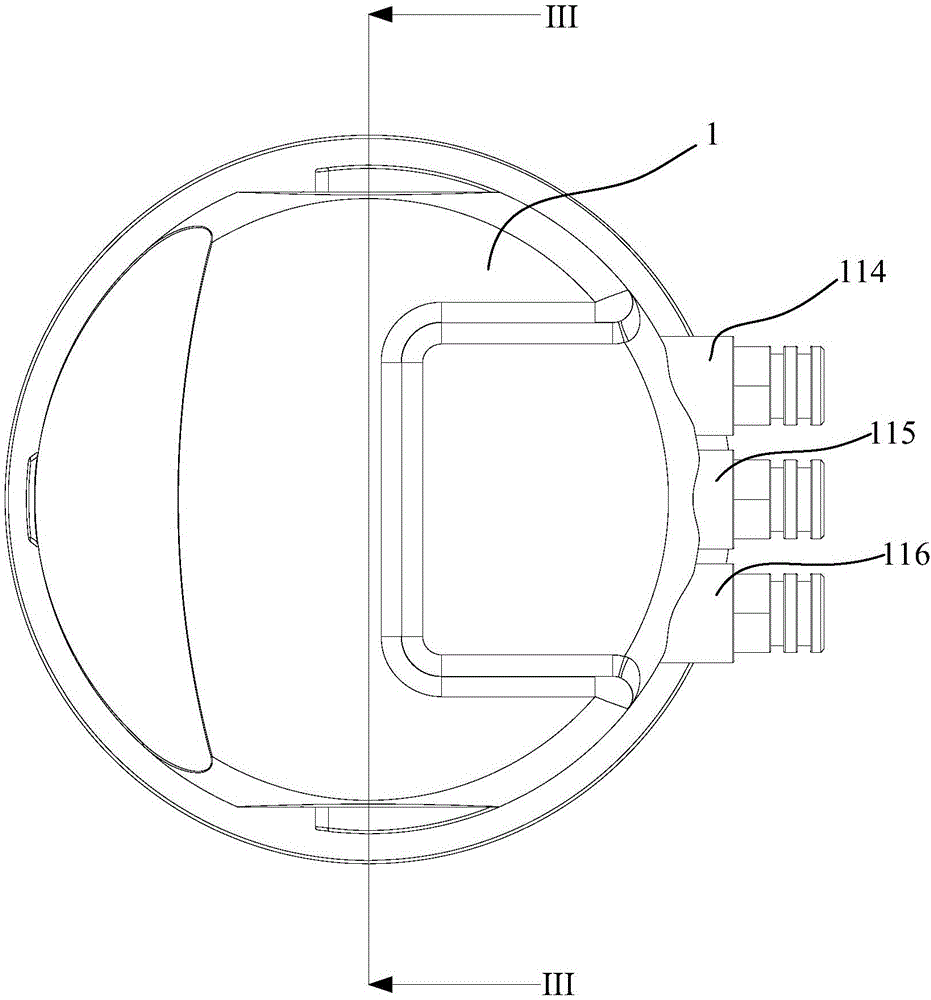

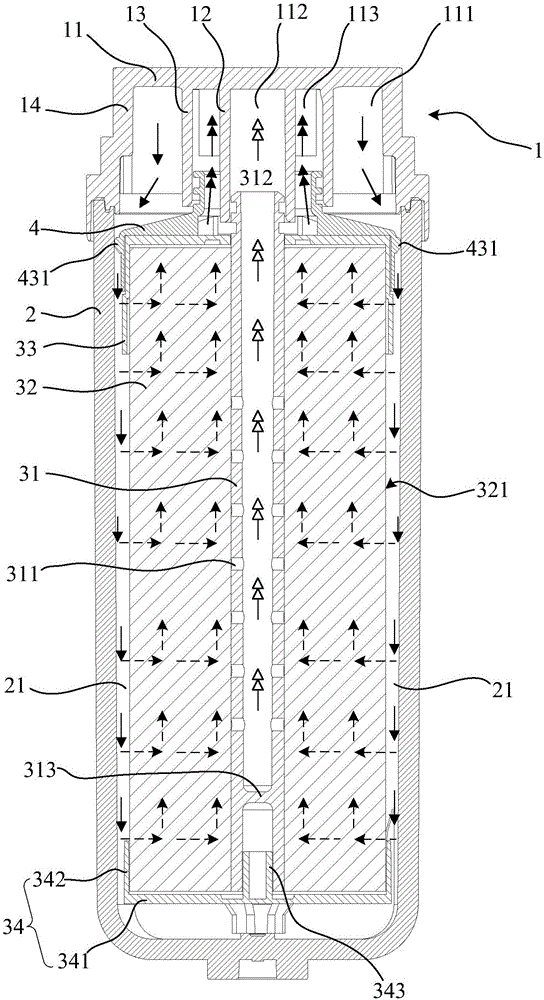

Reverse osmosis membrane assembly, filter element and water purifier

InactiveCN106139904AImprove filtration efficiencyHigh recovery rateMembranesWater/sewage treatment bu osmosis/dialysisWastewaterReverse osmosis

The invention discloses a reverse osmosis membrane assembly, a filter element and a water purifier. The reverse osmosis membrane assembly comprises a central pipe, a reverse osmosis membrane, an upper end cover and a lower end cover, wherein a plurality of water collection holes which are used for clean water to flow in are formed in the central pipe, a pipe orifice which is used for the clean water to flow out is formed in the upper end of the central pipe, and the lower end of the central pipe is closed; the reverse osmosis membrane sleeves the periphery of the central pipe, and the peripheral surface of the reverse osmosis membrane is a raw material infiltration surface which is used for infiltrating raw material; the upper end cover sleeves the upper end of the reverse osmosis membrane, the lower end cover is buckled at the lower end of the reverse osmosis membrane, and both the upper end cover and the lower end cover are matched with the peripheral surface of the reverse osmosis membrane in a sealing manner; and the upper end cover is provided with a through hole matched with the central pipe and a through groove which is disposed on the periphery of the central pipe and used for waste water to flow out. The reverse osmosis membrane is relatively high in filter efficiency and recovery rate.

Owner:FOSHAN MIDEA CHUNGHO WATER PURIFICATION MFG

Two-dimensional/one-dimensional heterogeneous nanochannel film and preparation method and application thereof

ActiveCN110170253AImprove energy conversion effectImprove throughputSemi-permeable membranesComposite filmRoom temperature

The invention provides a preparation method of a two-dimensional / one-dimensional heterogeneous nanochannel film. The method is characterized by comprising the following steps that step 1, graphene oxide is dissolved in an aqueous piperazine solution, and ultrasonic treatment is performed at the room temperature to obtain a uniformly dispersed first solution; step 2, the first solution is added dropwise to the upper layer of a porous aluminum oxide film, and after the solvent is evaporated at the room temperature, a first composite film with a graphene oxide film layer and a porous aluminum oxide film layer is obtained; step 3, a benzenetricarbonyl trichloride solution is added dropwise to the upper surface of the graphene oxide film layer of the first composite film, and drying is carriedout to obtain the two-dimensional / one-dimensional heterogeneous nanochannel film. The invention provides the two-dimensional / one-dimensional heterogeneous nanochannel film prepared by using the methodand application of the two-dimensional / one-dimensional heterogeneous nanochannel film in salt difference energy conversion.

Owner:FUDAN UNIV

Metallic electrolytic cell and metal electrolysis process

ActiveCN104404575AReduce concentration differenceSpeed up the flowPhotography auxillary processesElectrolysis componentsConcentration polarizationMaterials science

The invention discloses a metallic electrolytic cell which comprises a cell body, anode plates, cathode plates and arc-shaped drainage bulges, wherein the arc-shaped drainage bulges are mounted at the two opposite ends of the cell body; the anode plates and the cathode plates are alternatively arranged in the cell body, and liquid inlets and overflow openings are formed in the cell body; the liquid inlets in the two sides of each cathode plate are positioned in the same end of the cathode plate, and the liquid inlets in the two sides of each anode plate are respectively positioned in the two ends of the anode plate; the two ends of each cathode plate are respectively butted with the convex ends of the arc-shaped drainage bulges, and a liquid drainage cavity is formed between the cathode plates and the arc-shaped drainage bulges. Two adjacent cathode plates and one anode plate between the cathode plates form a similar closed space, electrolyte is fast ejected to enter the space through the liquid inlets in one end of one cathode plate and the other end of the adjacent cathode plate, and then the electrolyte flows clockwise and anticlockwise. The kinetic energy of electrolyte is utilized, the concentration difference of metal ions between the two pole plates is greatly reduced, and the concentration polarization is effectively reduced. The invention further discloses a metal electrolysis process.

Owner:YANGGU XIANGGUANG COPPER

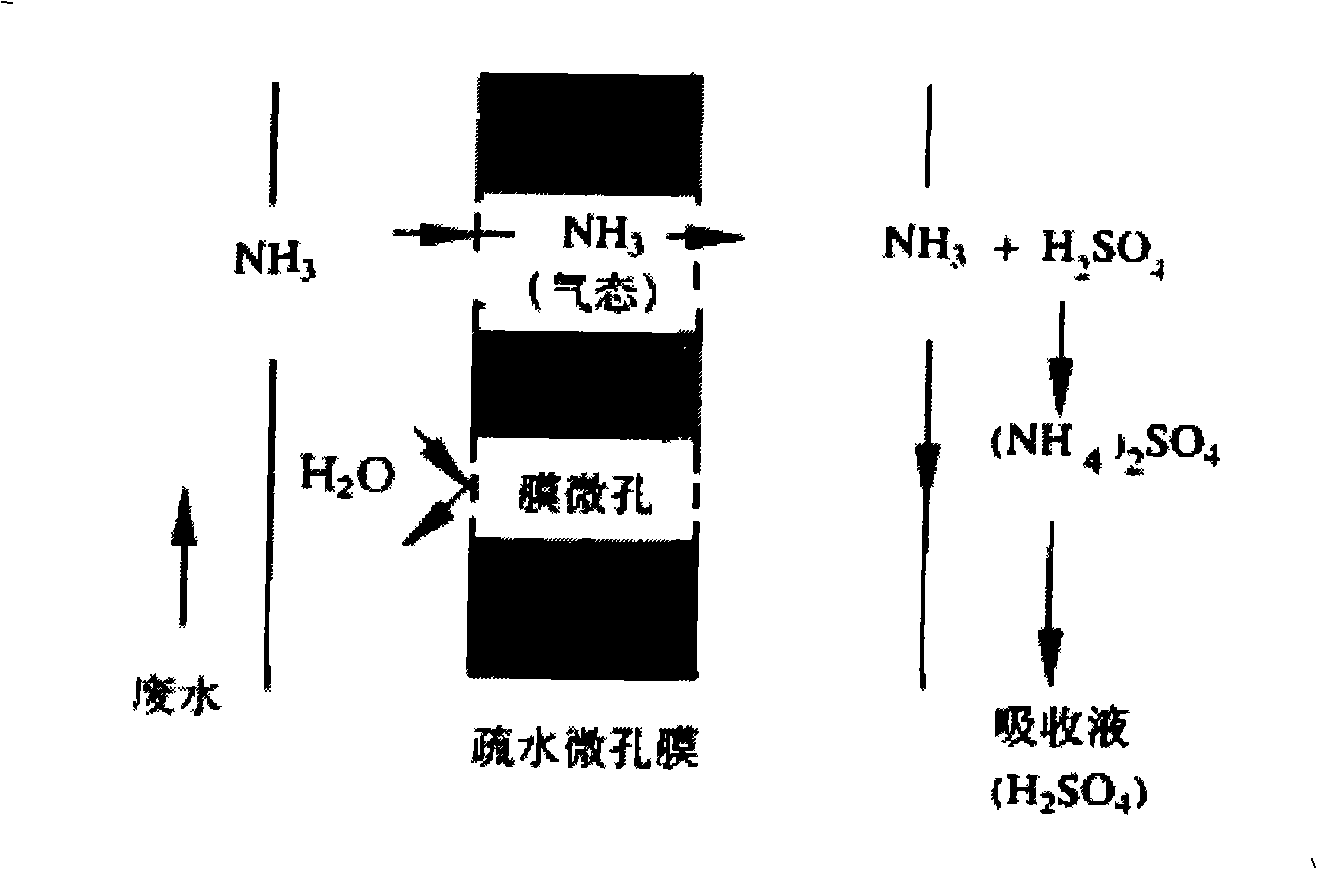

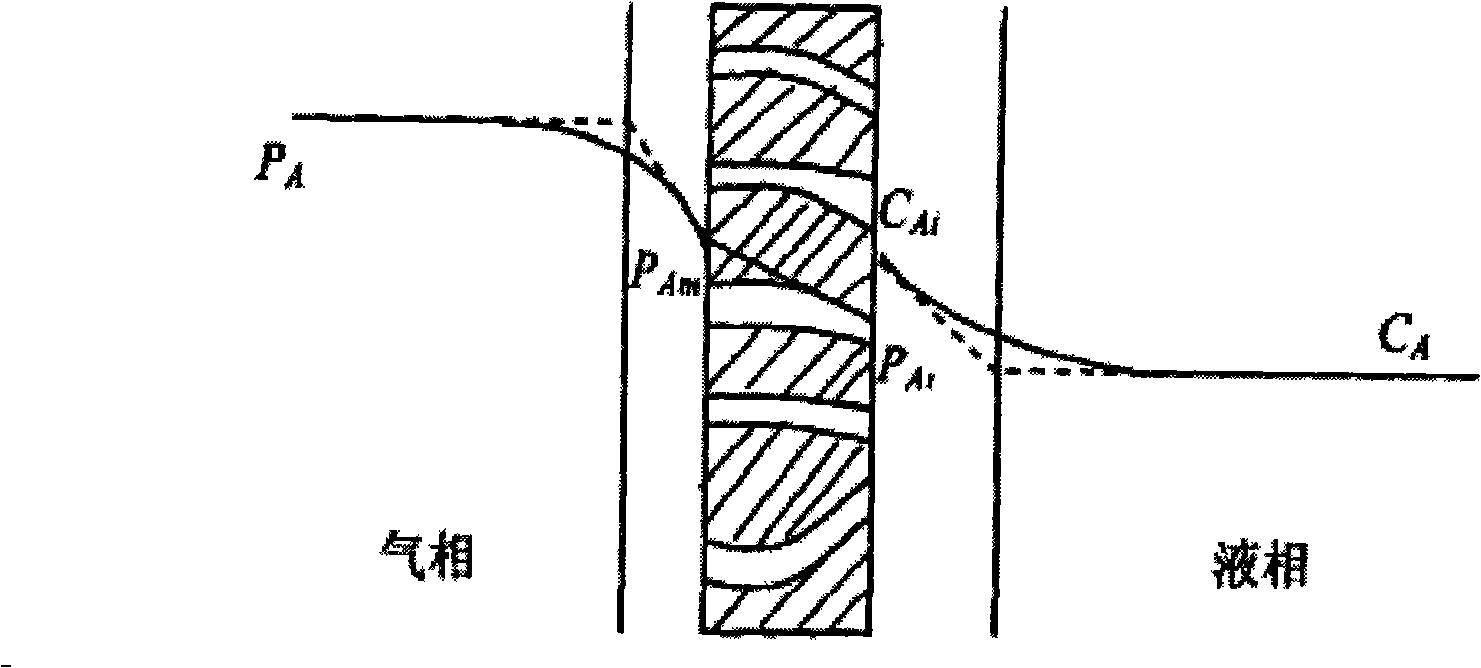

Equipment and method for processing gas absorbed by film

InactiveCN101327393AImprove mass transfer efficiencyLarge membrane contact areaDispersed particle separationDistillationPorous membraneChemistry

The present invention provides a gas absorption-separation membrane device and a method thereof. Stock solution at a given temperature is contacted with a drainage porous membrane; the absorbed gas under the driving of the blew compressed air or the side sub-pressure of the membrane passes through the porous membrane in gas-status way, and is removed and absorbed for collection at the other side of the membrane. An immersion-typed drainage hollow fiber membrane component is adopted. The compressed air is blown in with an aerated conduit, so as to control the membrane pollution, to obtain the stock solution that is contacted with the membrane and has uniform temperature and concentration, and to provide driving pressure for the air transmission. The membrane leakage problem is resolved by adopting a dual-valve mechanism during the membrane absorption process.

Owner:TIANJIN POLYTECHNIC UNIV

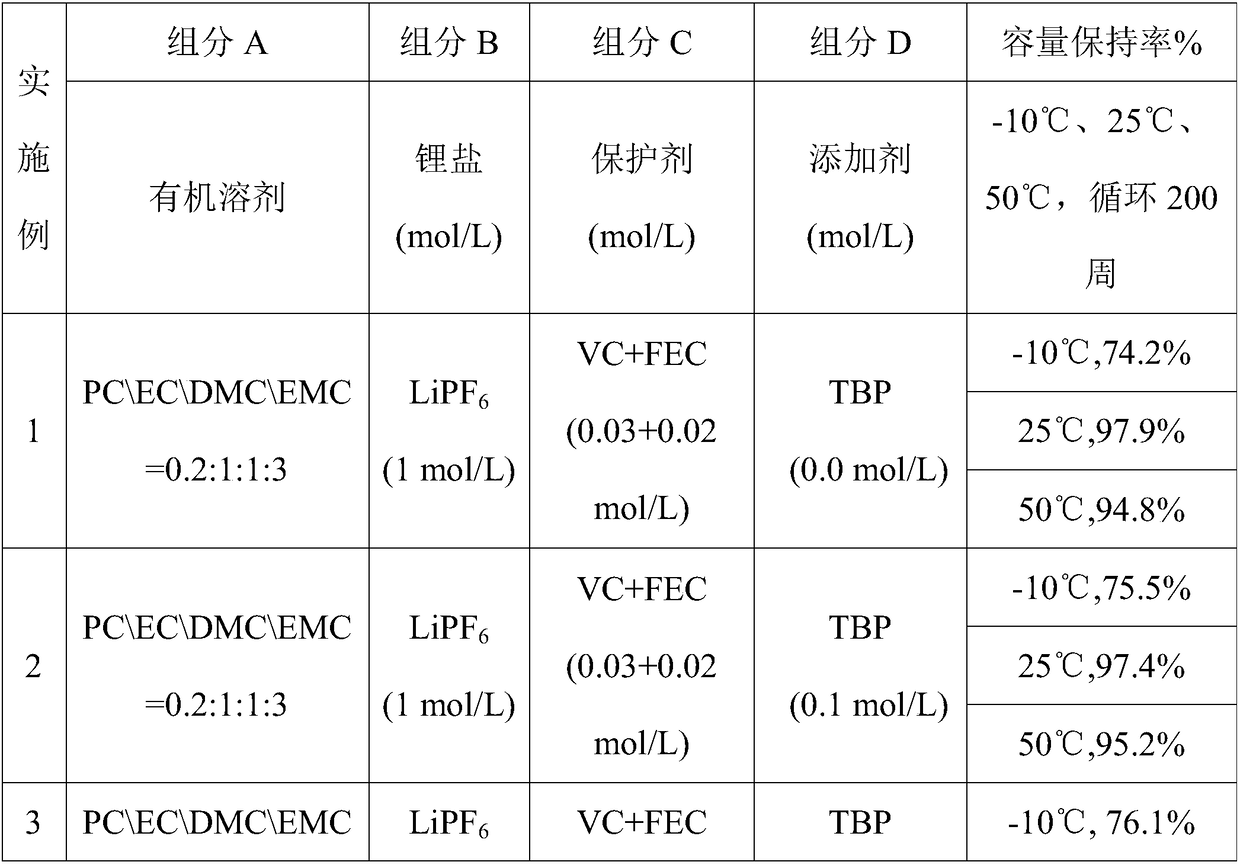

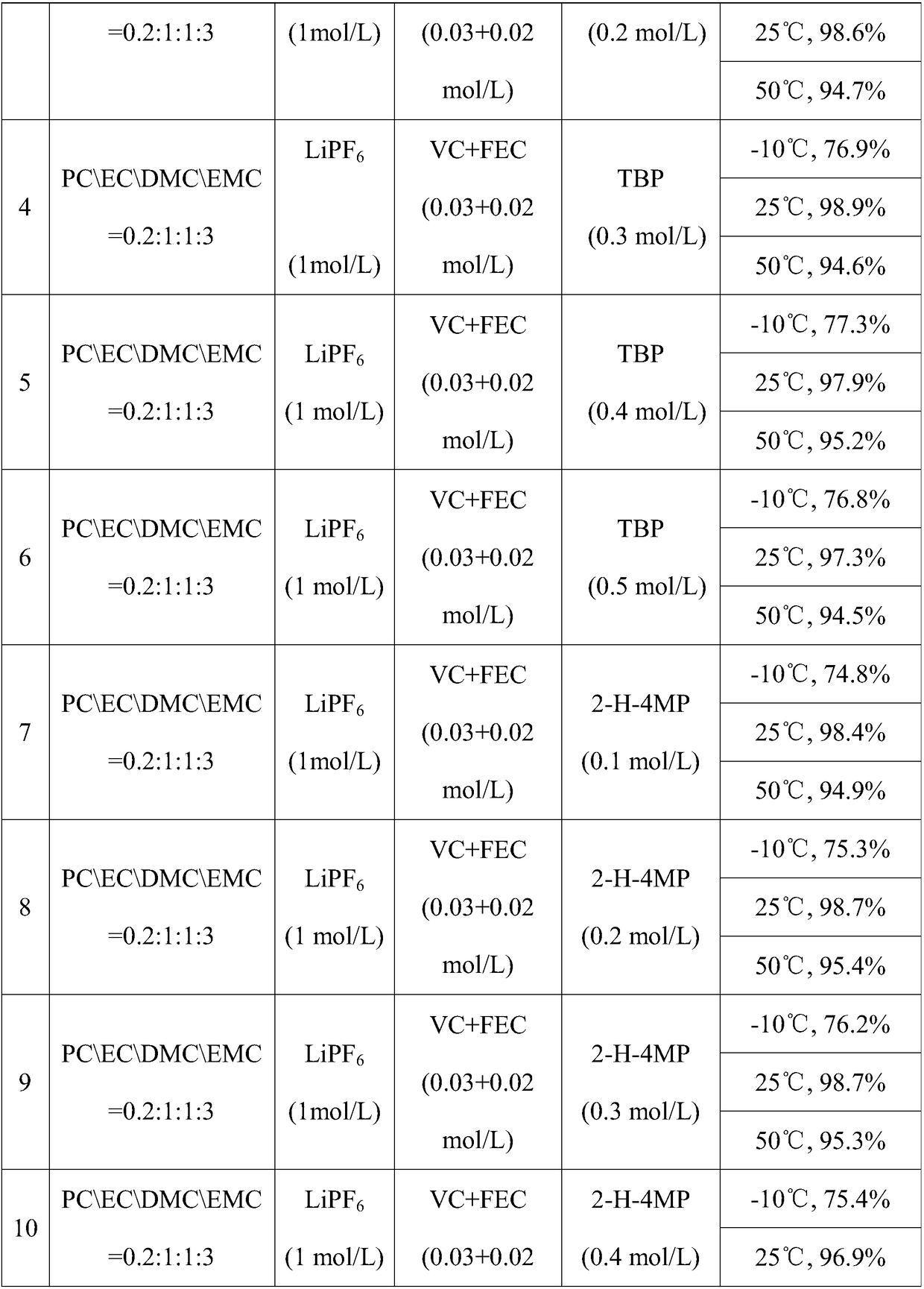

Electrolyte additive for improving low-temperature properties of lithium ion battery and electrolyte

InactiveCN108321433AImprove conductivityHigh freezing pointSecondary cellsOrganic electrolytesChemistryCharge and discharge

The invention discloses an electrolyte additive for improving low-temperature properties of a lithium ion battery and electrolyte and relates to the technical field of lithium ion batteries. The additive is pyridine with an electron donor group substitution group, and in addition, the molecular structure of the additive is free of intense electron withdrawing group substitution group. When the additive is applied to lithium ion battery electrolyte, the ion conduction velocity of the electrolyte under a low-temperature condition can be increased, the curing point of the electrolyte can be reduced, the charge and discharge capacity and the circulation performance of the lithium ion battery at a low temperature can be improved, meanwhile the wettability of an anode piece and a cathode piece can be improved. The additive does not affect the performance of a battery cell at normal temperatures and high temperatures, and is gentle to the environment.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com