Electrolyte additive for improving low-temperature properties of lithium ion battery and electrolyte

An electrolyte additive and lithium-ion battery technology, applied in the field of lithium-ion batteries, can solve problems such as inability to balance normal temperature and high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

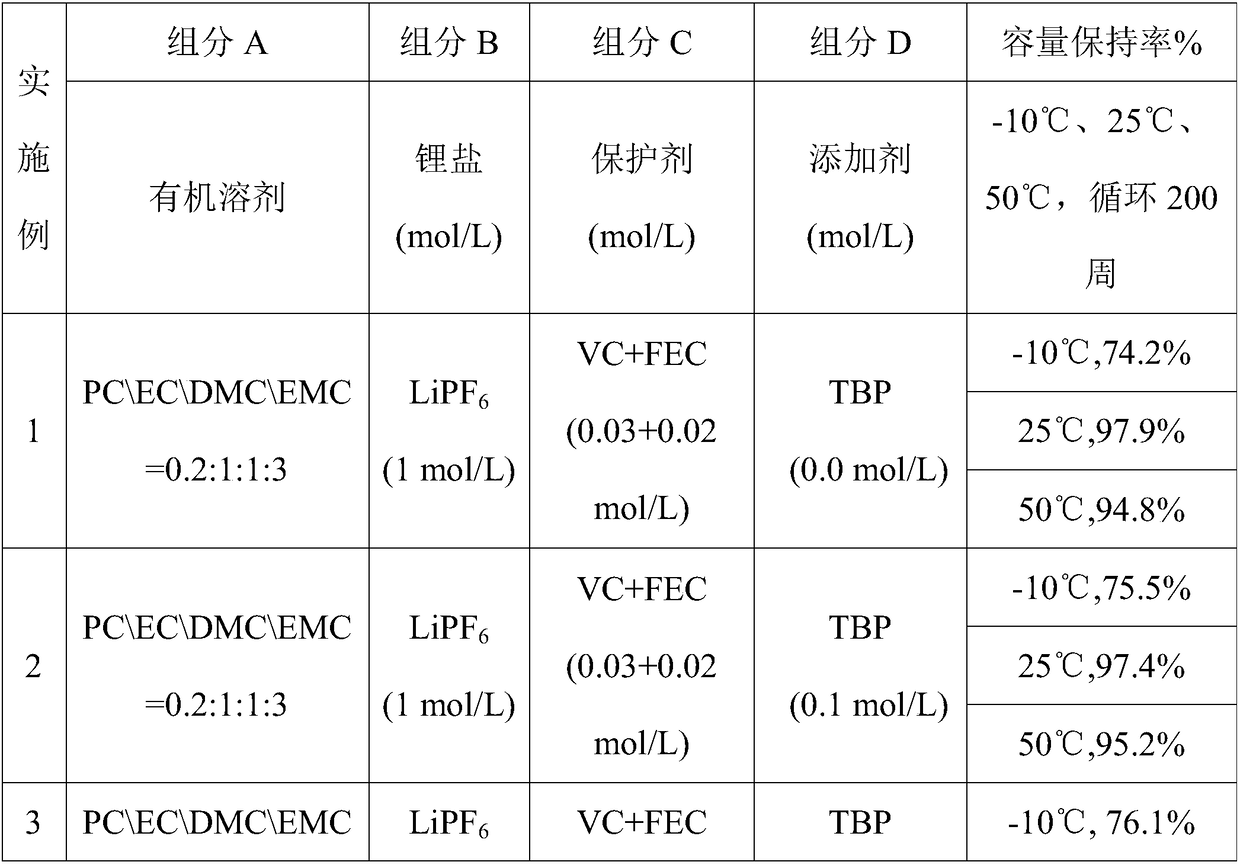

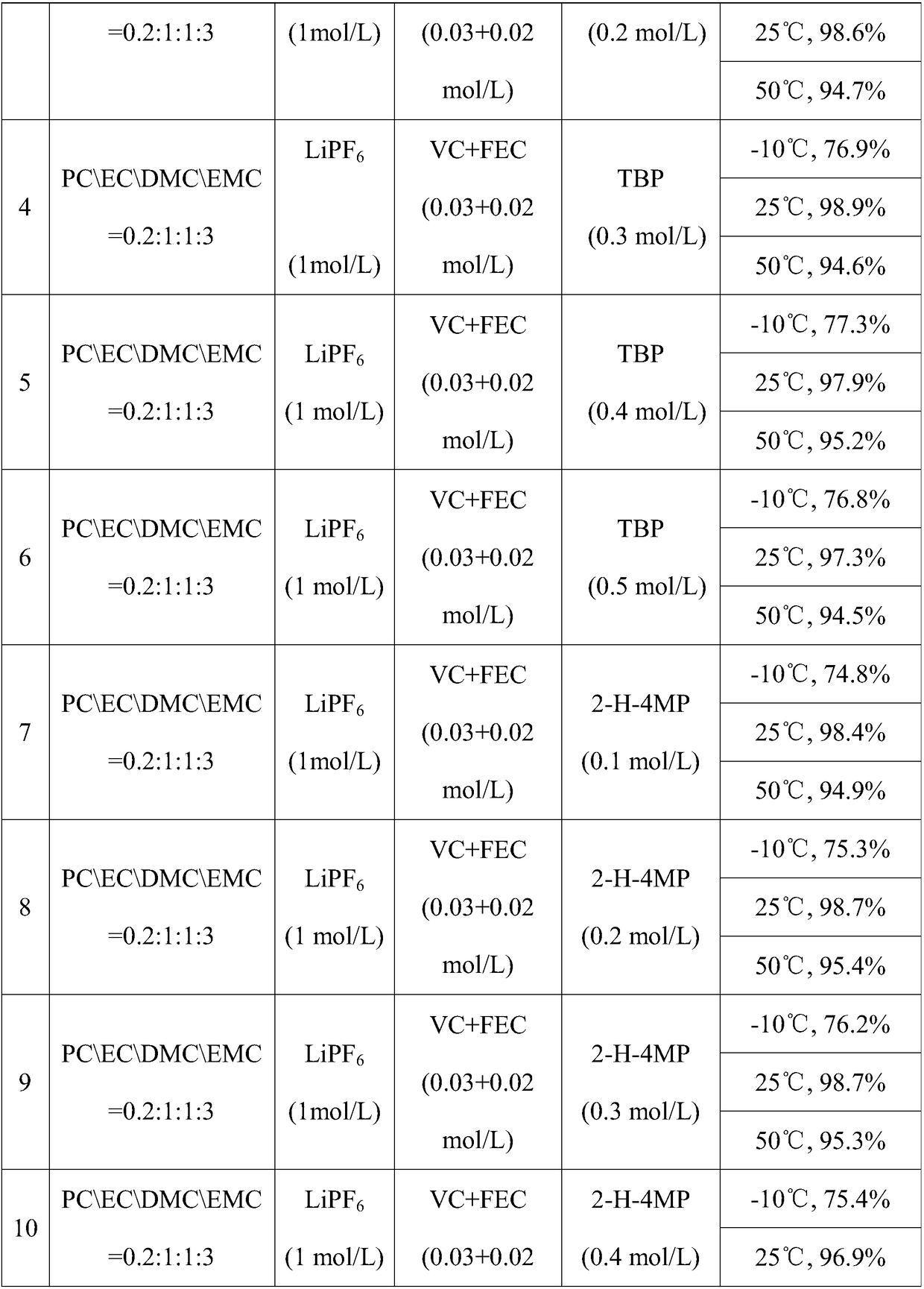

[0019] The composition of the lithium-ion battery electrolyte containing additives is given in Examples 1-10, and the electrolyte is injected into an aluminum shell 38Ah ternary NCM523 lithium-ion battery at -10°C, 25°C and 50°C respectively The capacity retention rate was tested after 200 cycles of down cycle, and the electrolyte composition and capacity retention rate test data are shown in Table 1.

[0020] Electrolyte composition and capacity retention data of table 1 embodiment 1-10

[0021]

[0022]

[0023]

[0024] It can be seen from the above table 1 that the electrolyte prepared by the present invention is injected into the aluminum shell 38Ah ternary NCM523 system lithium-ion battery, and the capacity retention rate is the highest when compared with the battery without additives after 200 cycles at -10°C The growth rate is about 3%, and the performance is not affected at room temperature and high temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com