Patents

Literature

1565 results about "Nickel ions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel(3+) is a nickel cation in which the nickel carries a triple positive charge. It is a metal cation allergen, a nickel cation and a monoatomic trication.

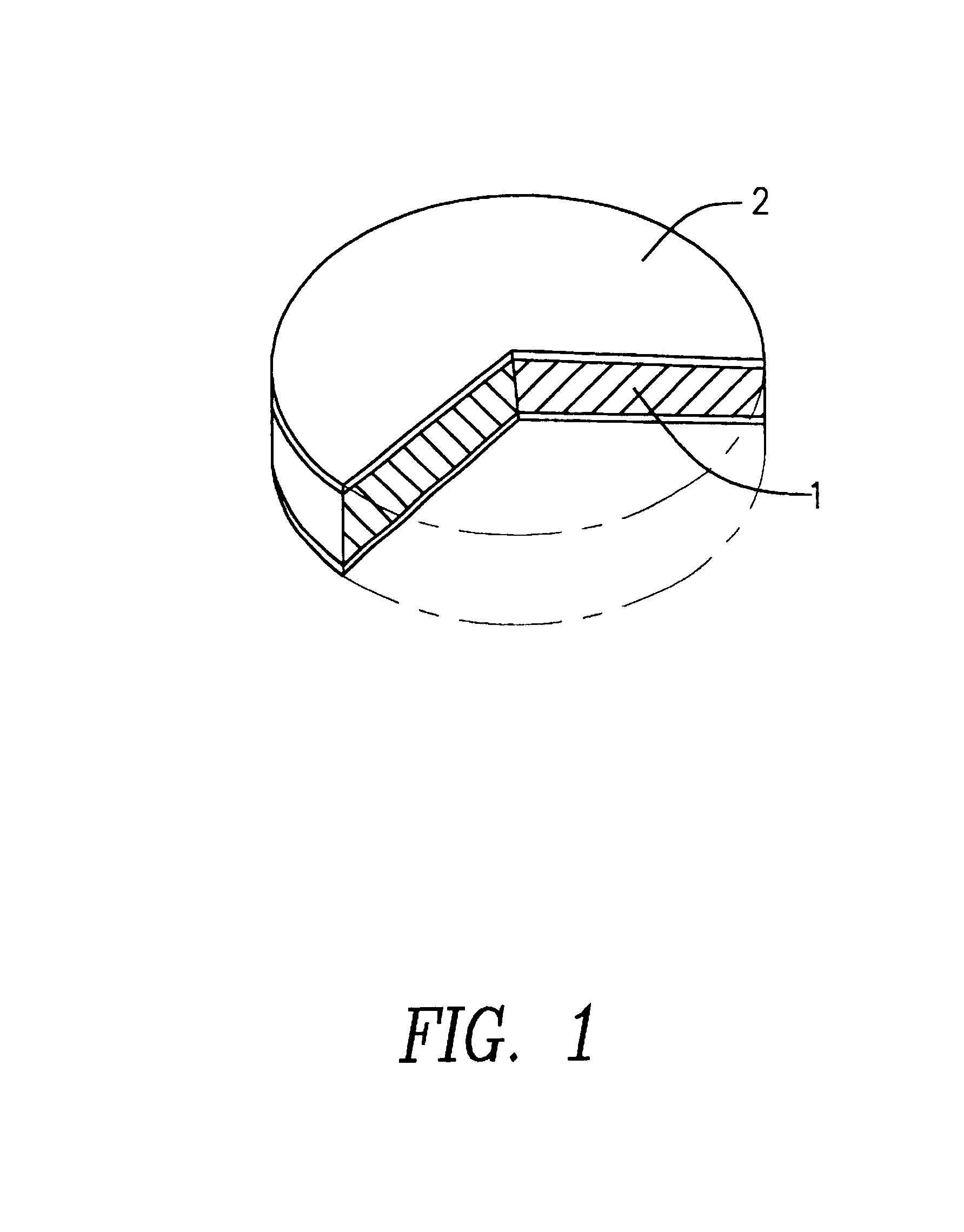

Articles with electroplated zinc-nickel ternary and higher alloys, electroplating baths, processes and systems for electroplating such alloys

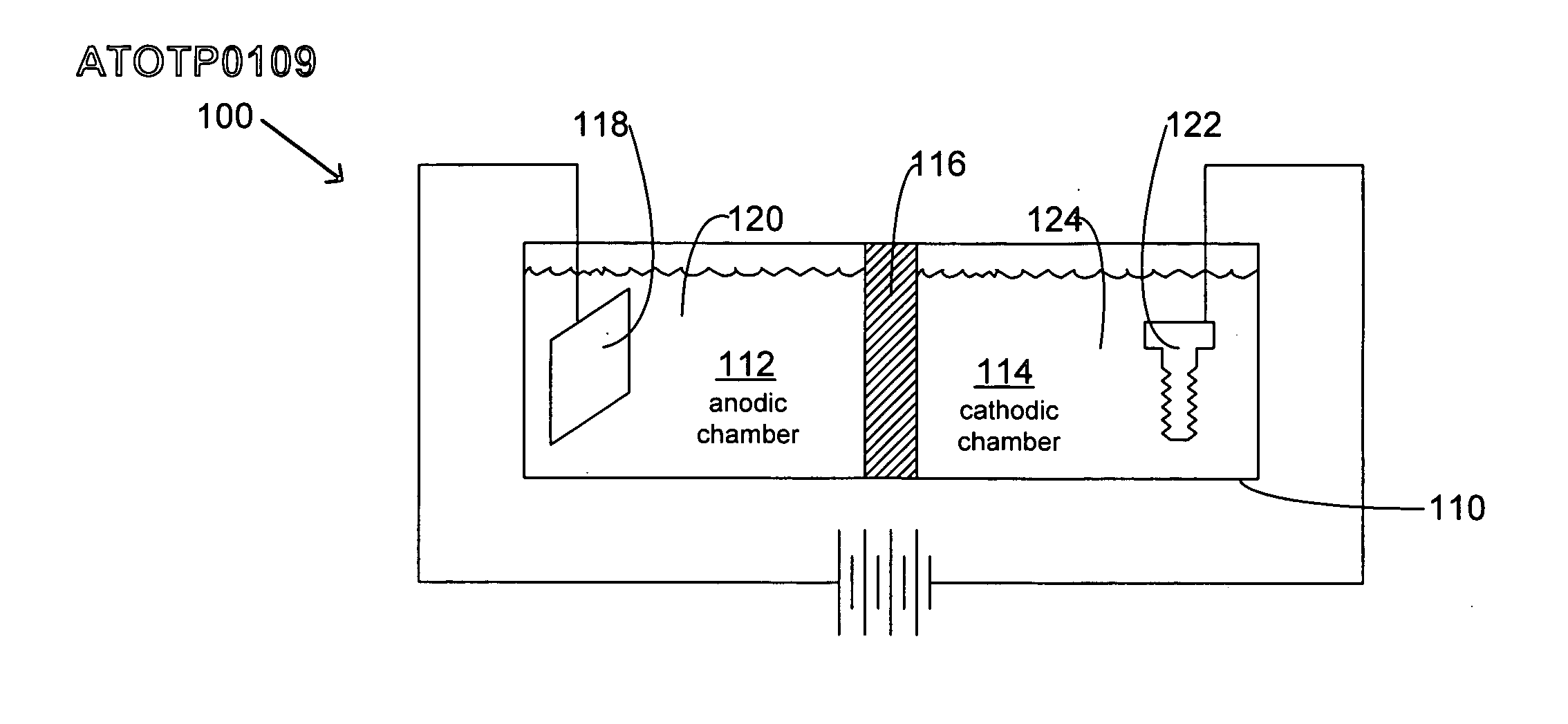

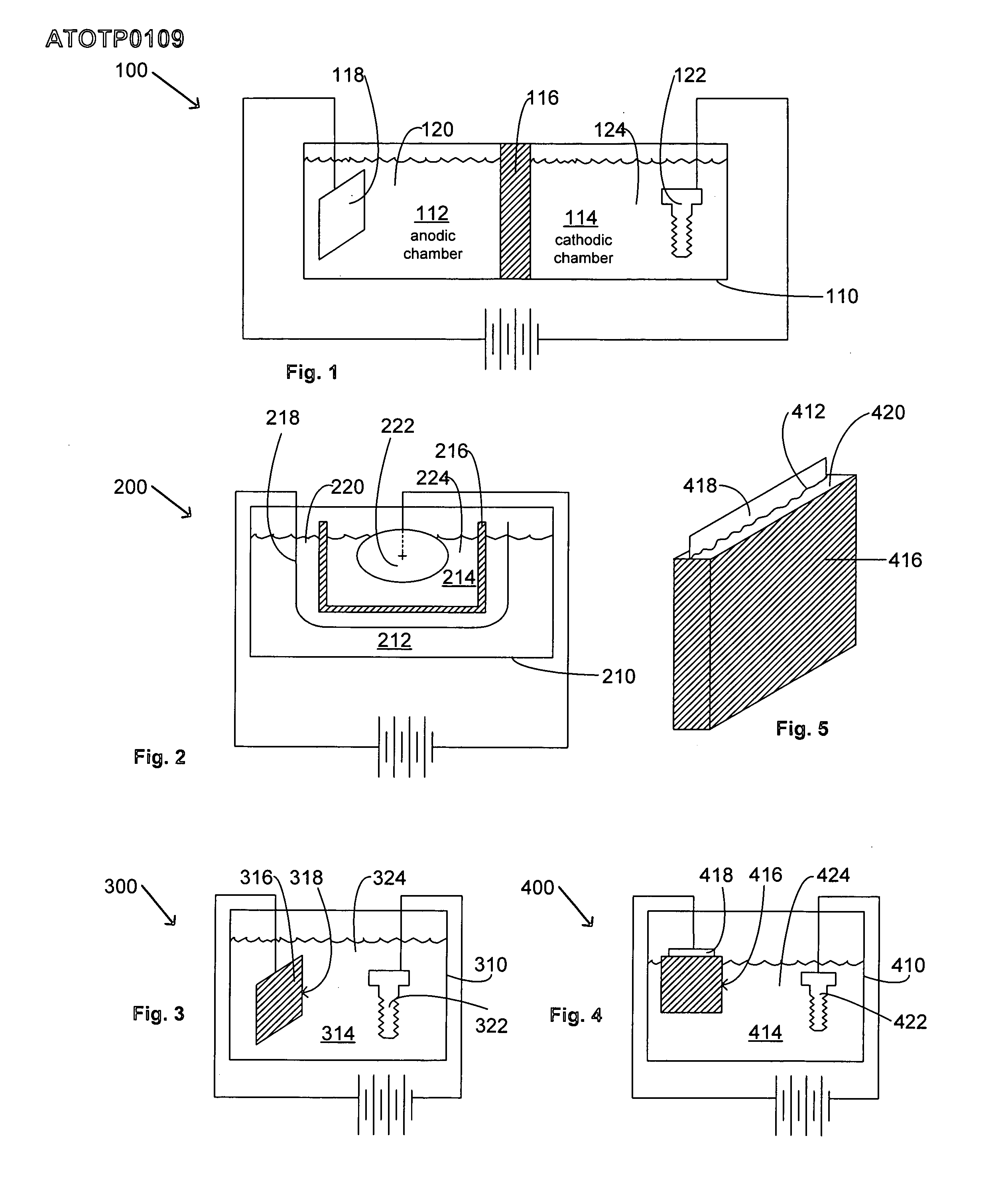

An electroplating bath, a system, a process for, and the article obtained from, depositing a zinc-nickel ternary or higher alloy, a) zinc ions; b) nickel ions; and c) one or more ionic species selected from ions of Te+4, Bi+3 and Sb+3, and in some embodiments, further including one or more additional ionic species selected from ions of Bi+3, Sb+3, Ag+1, Cd+2, Co+2, Cr+3, Cu+2, Fe+2, In+3, Mn+2, Mo+6, P+3, Sn+2 and W+6. In some embodiments, the system includes a divider forming a cathodic chamber and an anodic chamber, with the electroplating bath in the cathodic chamber only. In various embodiments, the zinc-nickel ternary and higher alloys may provide improved properties to the conductive substrates upon which the alloys are deposited.

Owner:ATOTECH DEUT GMBH

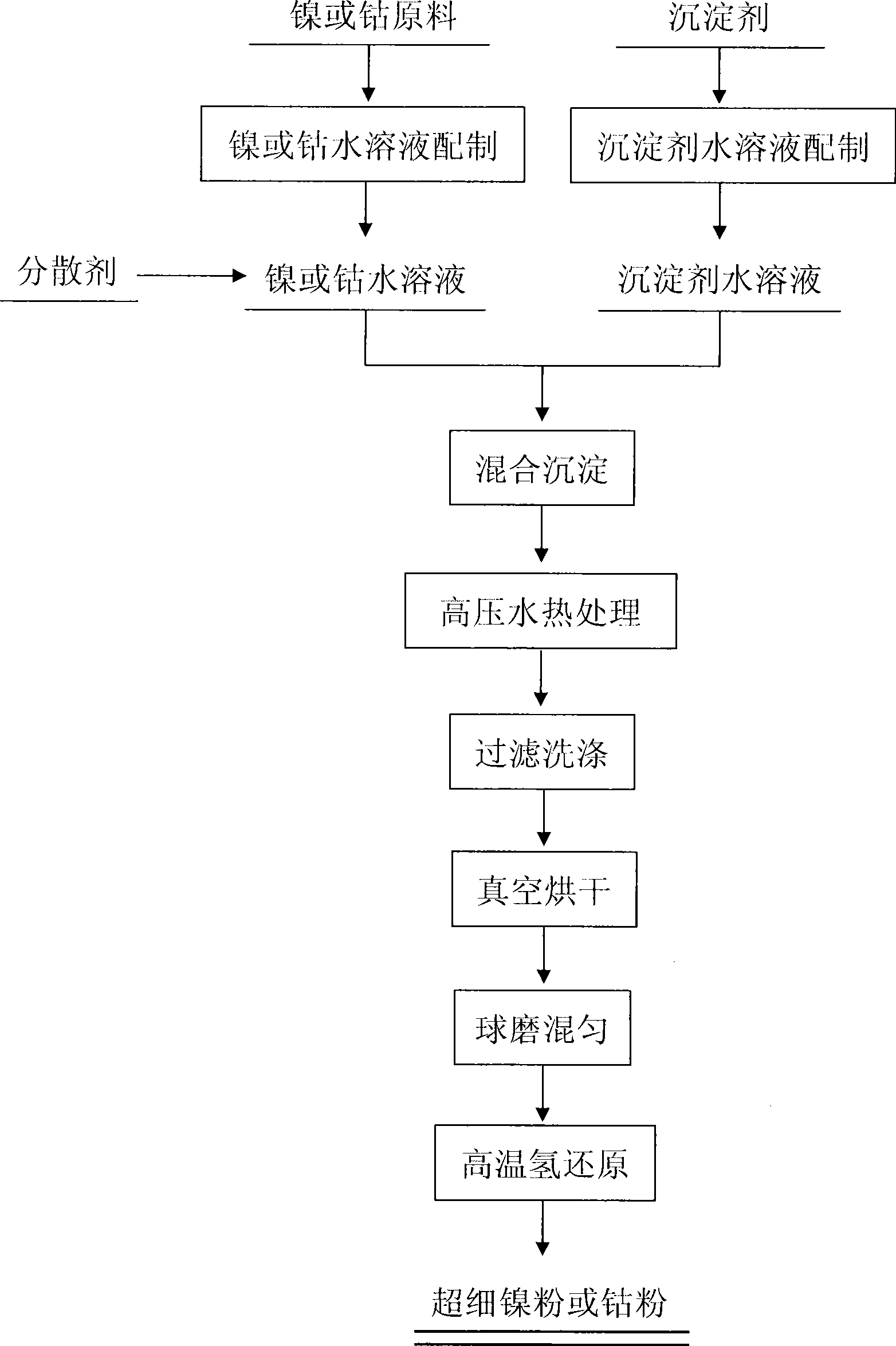

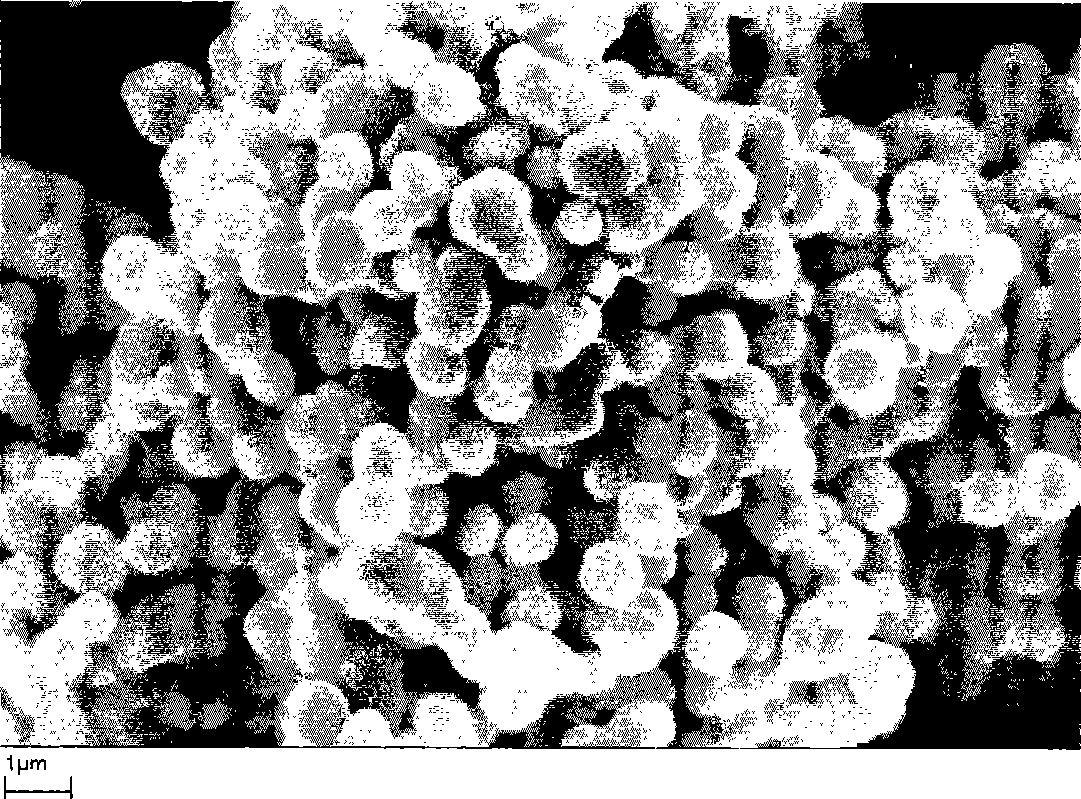

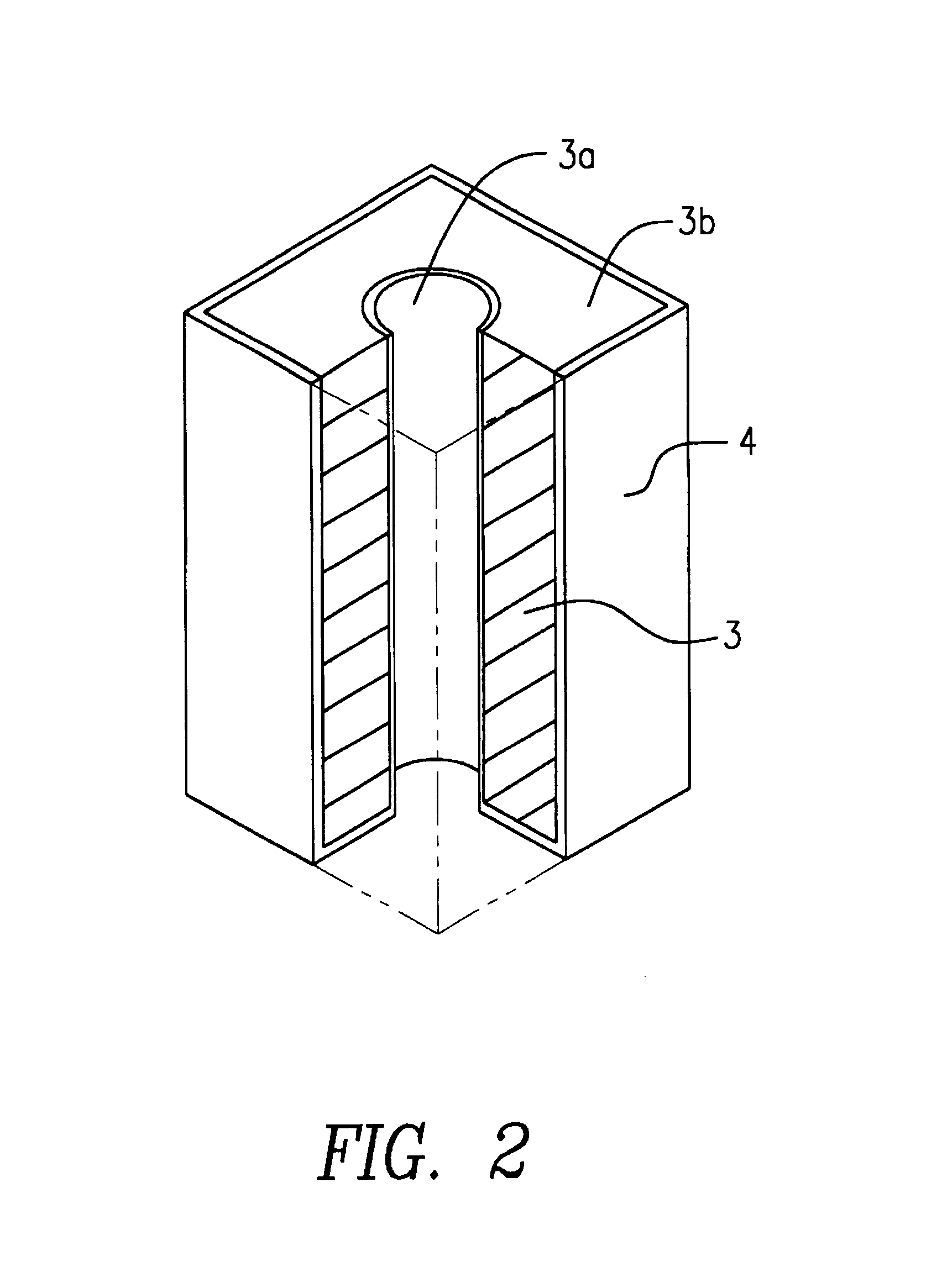

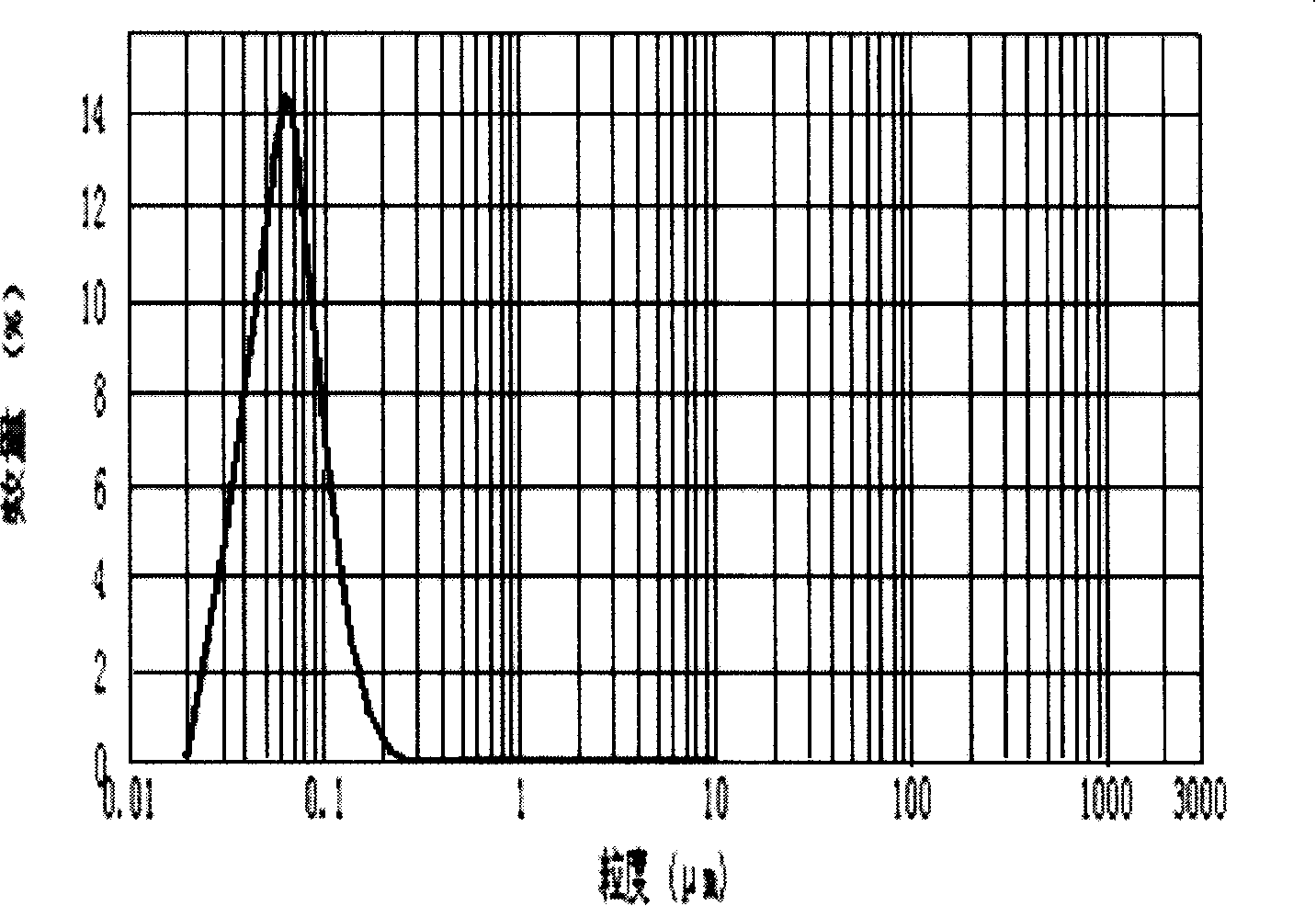

Process for producing spherical submicron metal with hydro-thermal treatment

The invention discloses a technological method for preparation of sphere-shaped ultrafine metallic powders through hydro-thermal treatment, which relates to a technological method for preparation of sphere-shaped ultrafine nickel powders or ultrafine cobalt powders through the procedures such as precipitation, dispersing agent surface finish, high-pressure hydro-thermal treatment, washing, drying and high-temperature hydrogen reduction and the like, and which belongs to the technical field for preparation of metal powder materials. The technological method adopts water soluble salts with nickel and cobalt, cobalt oxide, sub-carbonate, carbonate or hydroxide as raw materials, which are prepared into water solution after processing, the dispersing agent is added, then nickel ion and cobalt ion in the water solution are precipitated through alkali, carbonate, oxalic acid or ammonium oxalate and the like, the hydro-thermal treatment of water pulp of the precipitate is performed in an autoclave, and products of sphere-shaped ultrafine nickel powders or ultrafine cobalt powders with even graininess and good dispersibility can be obtained through washing, drying and high-temperature hydrogen reduction. The technological method is not only suitable for medium- and small-scale discontinuous-type manufacture, but also used for large-scale continuous manufacture, and the manufacturing cost is low.

Owner:张建玲

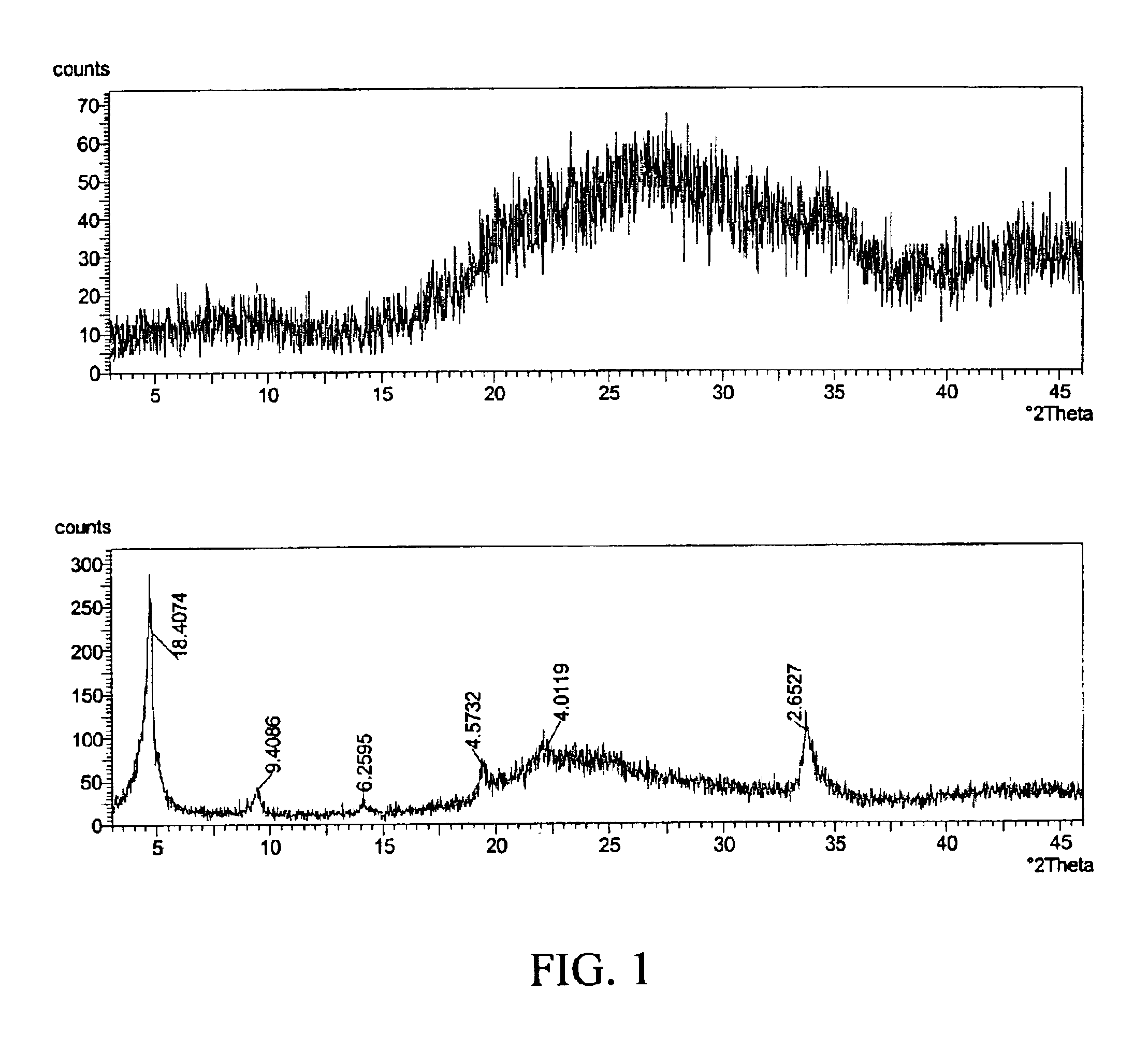

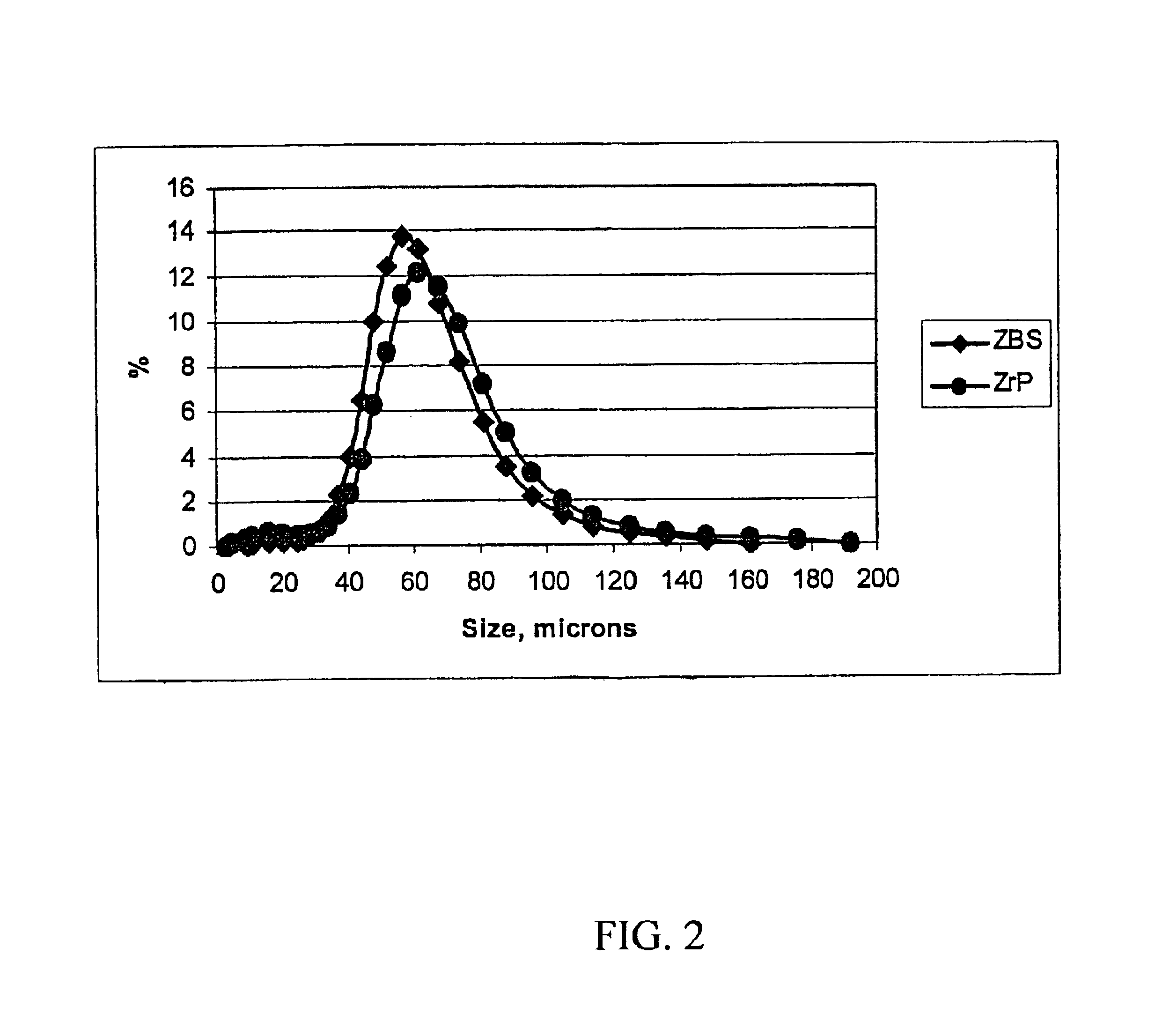

Alkaline zinc-nickel alloy plating compositions, processes and articles therefrom

InactiveUS20050133376A1Easy to handleImprove ductilityAnti-corrosive paintsLiquid/solution decomposition chemical coatingZinc ionNickel alloy

The present invention relates to an aqueous zinc-nickel electroplating bath, including water; nickel ion; zinc ion; at least one complexing agent; and at least one non-ionogenic, surface active polyoxyalkylene compound, wherein the bath has an alkaline pH. In one embodiment, the zinc ion, the nickel ion and the non-ionogenic surface active polyoxyalkylene compound are present at concentrations sufficient to deposit a zinc-nickel alloy comprising a substantially gamma phase.

Owner:ATOTECH DEUT GMBH

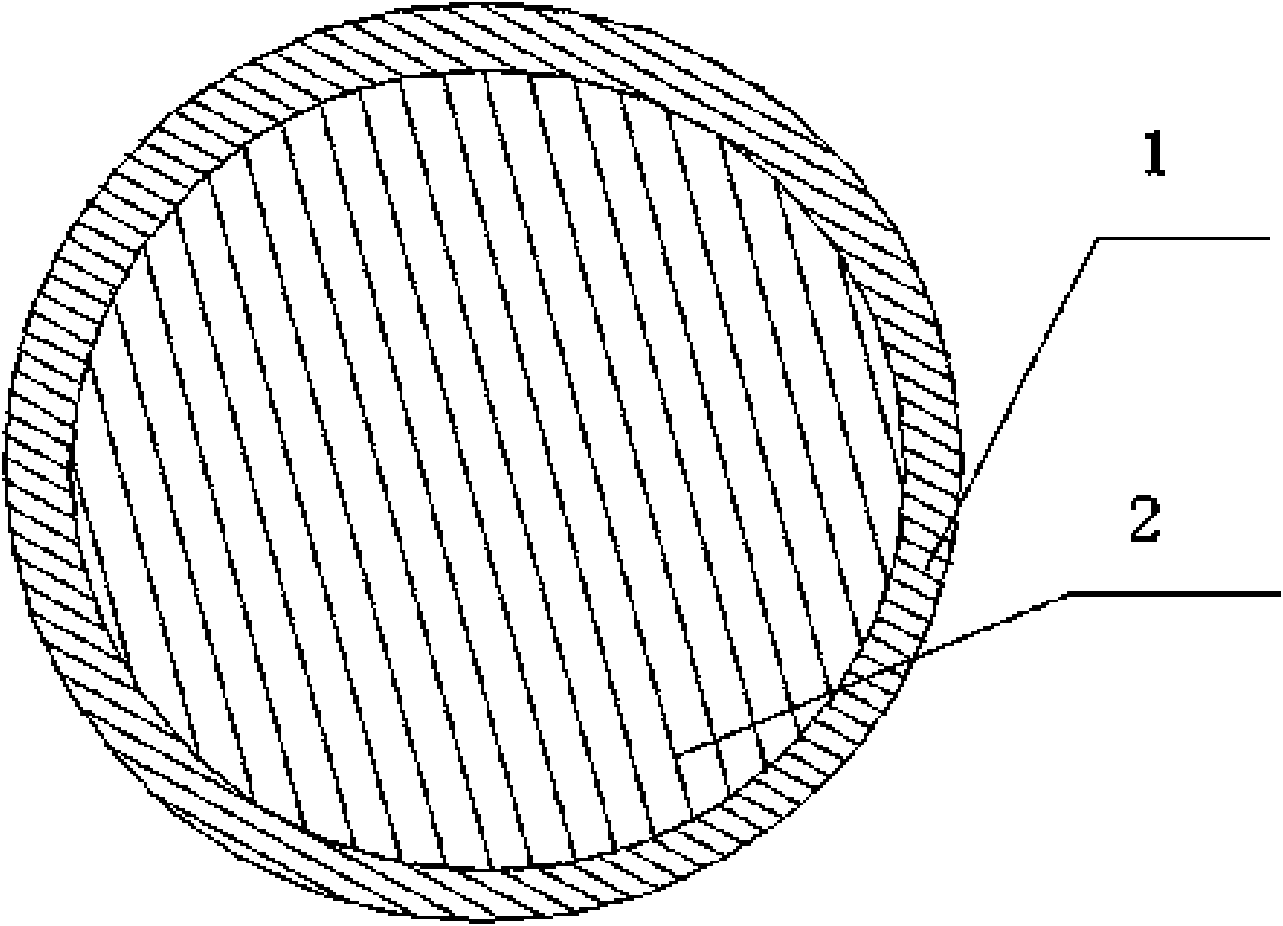

Ceramic cladding powder and preparation method thereof

InactiveCN101423398AThere will be no phenomenon of grain aggregation and growthEvenly distributedCeramic coatingTitanium nitride

The invention relates to ceramic coating powder the ceramic phase of which is coated by a metallic phase cobalt or / and a metallic phase nickel. The metallic phase cobalt and the metallic phase nickel are obtained by means of a liquid phase reduction method; and the ceramic phase is at least one of titanium carbonitride, titanium carbide, titanium nitride, tungsten carbide, silicon carbide, niobium carbide, tantalum carbide, aluminum oxide, zirconium oxide, magnesium oxide, boron nitride and silicon nitride. A method for preparing the ceramic coating powder is the liquid phase reduction method to carry out a reduction reaction between cobalt or / and nickel ions in a plating solution to generate the metallic phase cobalt or / and nickel which is deposited on the surface of a ceramic core to form the ceramic coating powder; and the process steps are as follows: (1) pre-treatment of the ceramic powder; (2) preparation of the plating solution; (3) liquid-phase reduction reaction; and (4) plating post treatment.

Owner:SICHUAN UNIV

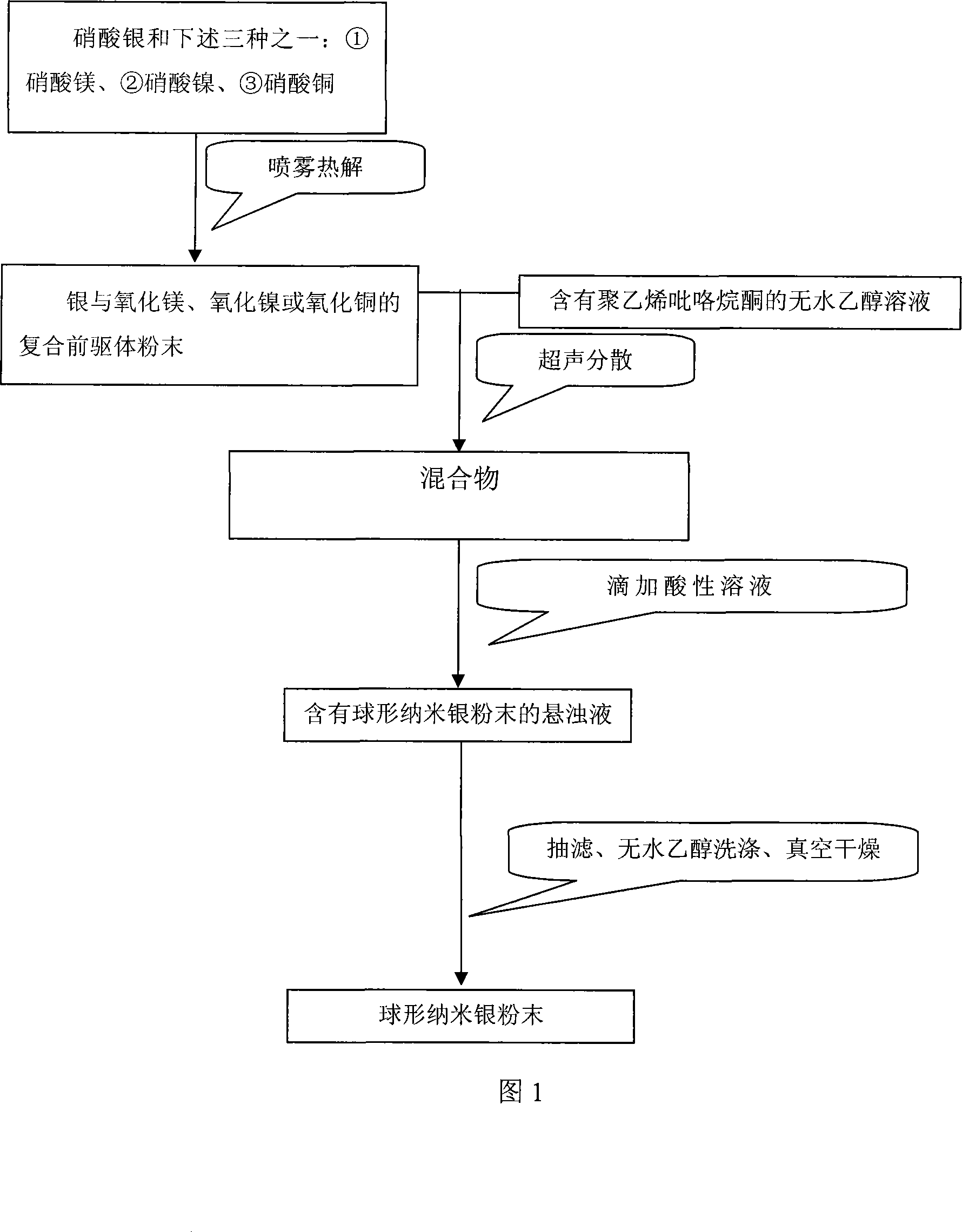

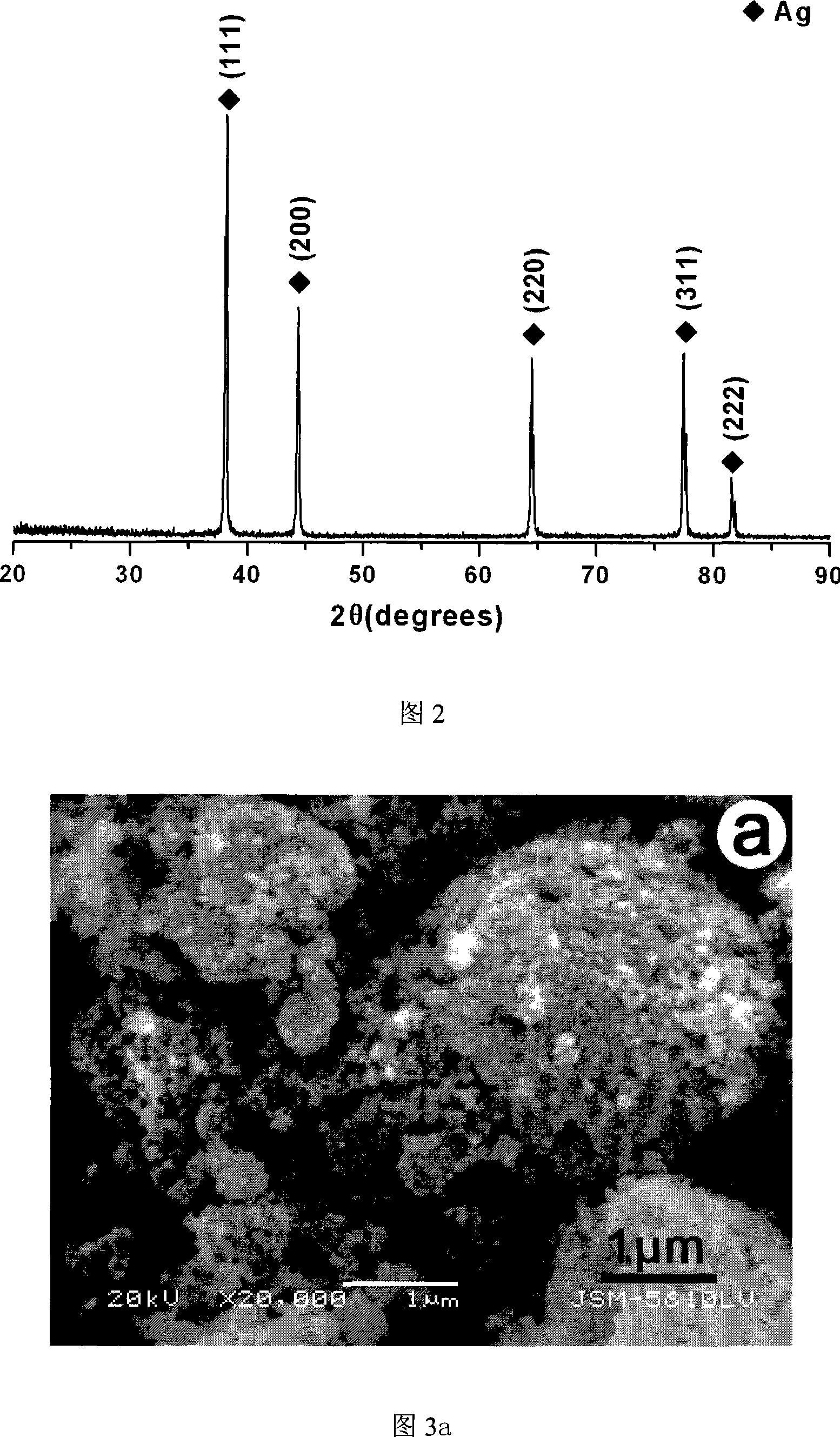

Method for preparing spherical nano silver powder

The invention relates to a method for preparing a spherical nanometer sliver powder. A method for preparing a spherical nanometer sliver powder is characterized in that the invention includes the following steps: 1) spraying and pyrolyzing: a, dissolving silver nitrate with one of the three: {1}magnesium nitrate, {2}nickel nitrate, {3}copper nitrate into water to prepare into a water liquor with a consistency of 10 to 40wt percent; the mol ratio of magnesium ion, nickel ion or copper ion in the liquor is 0.05 to 1 :4; then spraying for pyrogenation; b, under the existence of a dispersant and protecting agent, adding into a non-water ethanol to disperse to acquire a mixture; 2) preparing the spherical nanometer sliver powder: a, dripping acid liquor into the mixture and adjusting a PH value between 3 to 5 to acquire a suspension containing the spherical nanometer sliver powder; b, pumping filtration, washing and drying to acquire the spherical nanometer sliver powder. The preparing method is simple and easy to be controlled, has no pollution and low cost, is suitable for industrialization scale production. The prepared spherical nanometer sliver powder belongs to the nanometer grade and the powder has uniform distribution of the grain diameter, regular shape and high yield.

Owner:WUHAN UNIV OF TECH

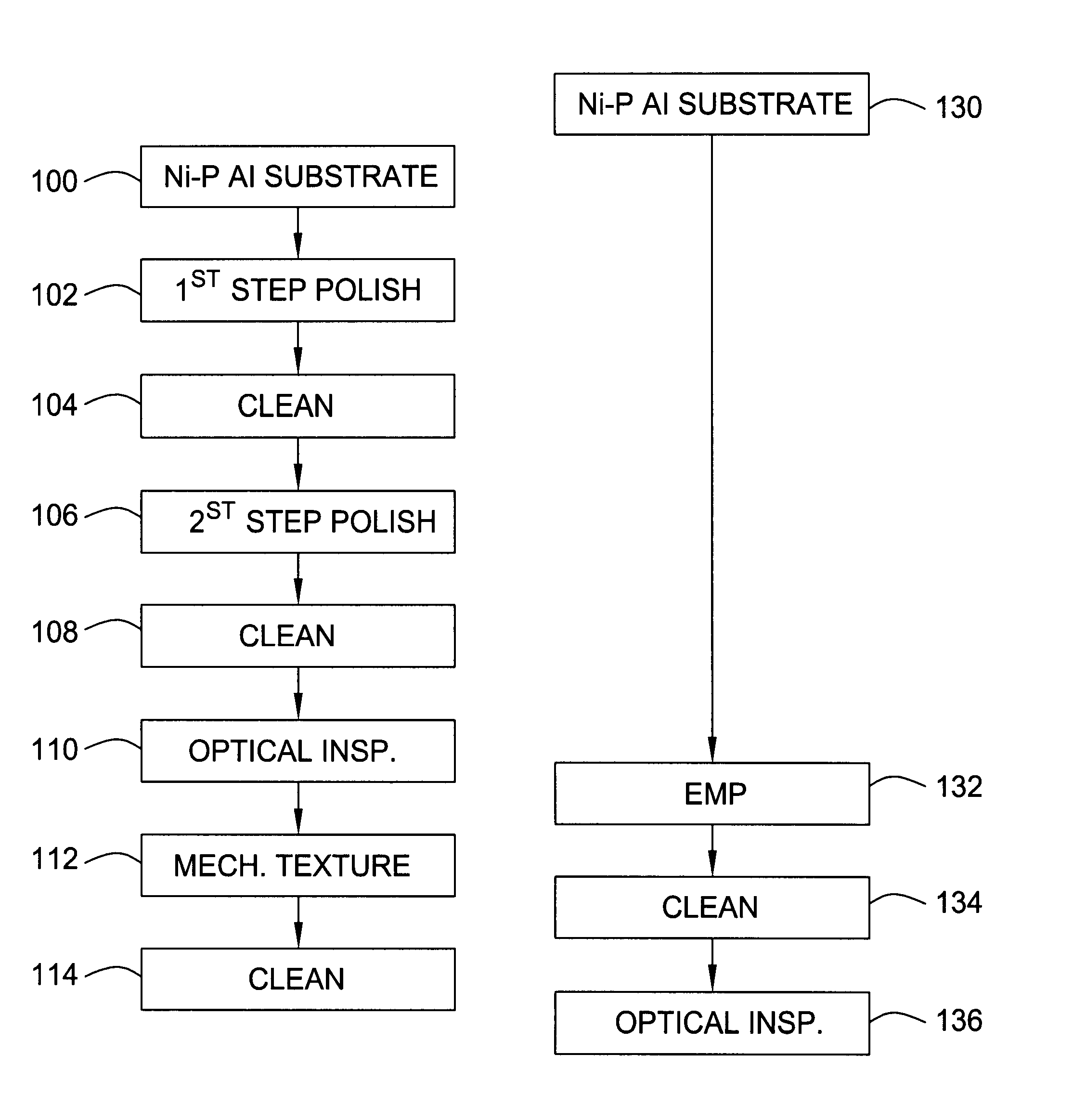

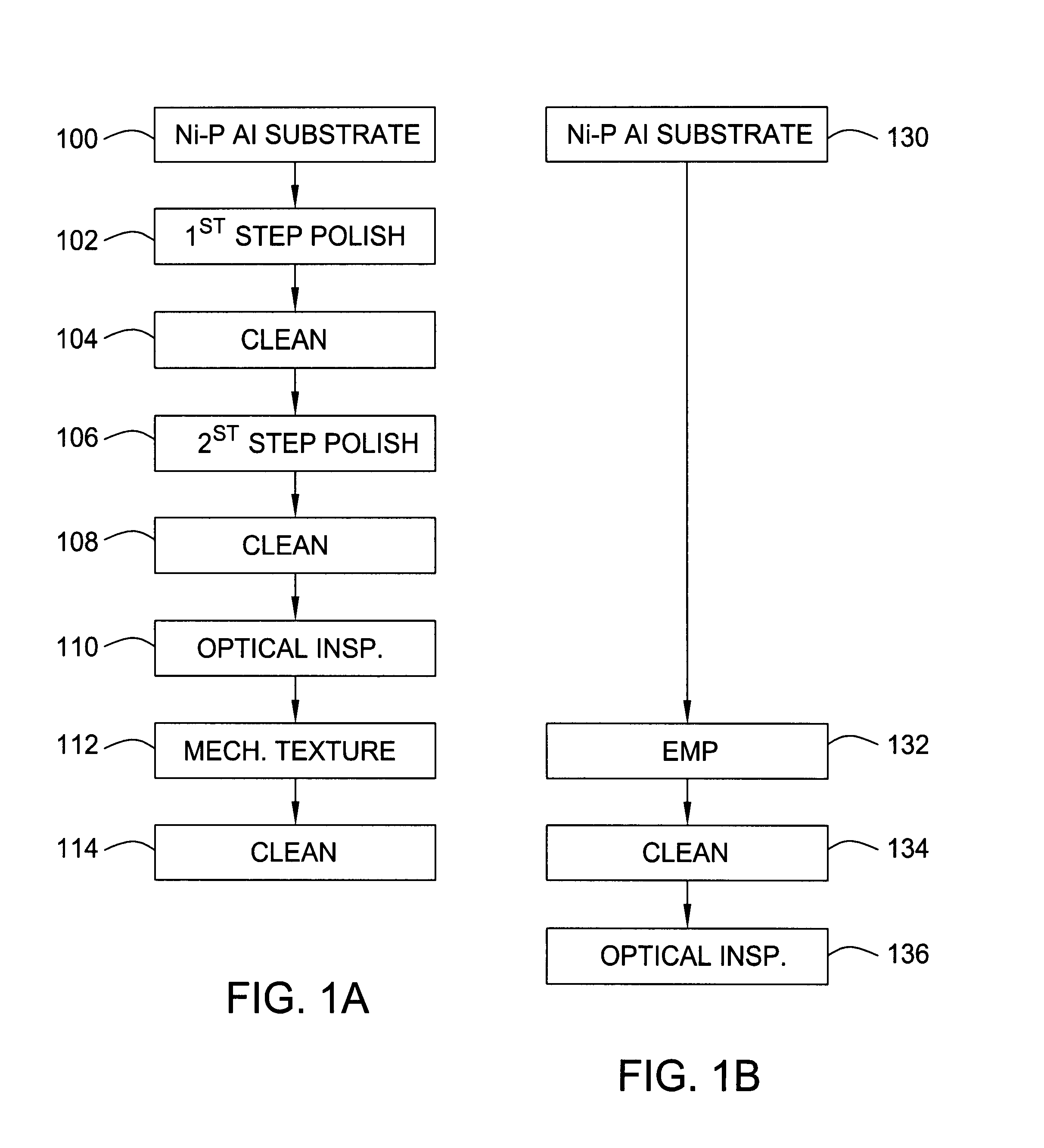

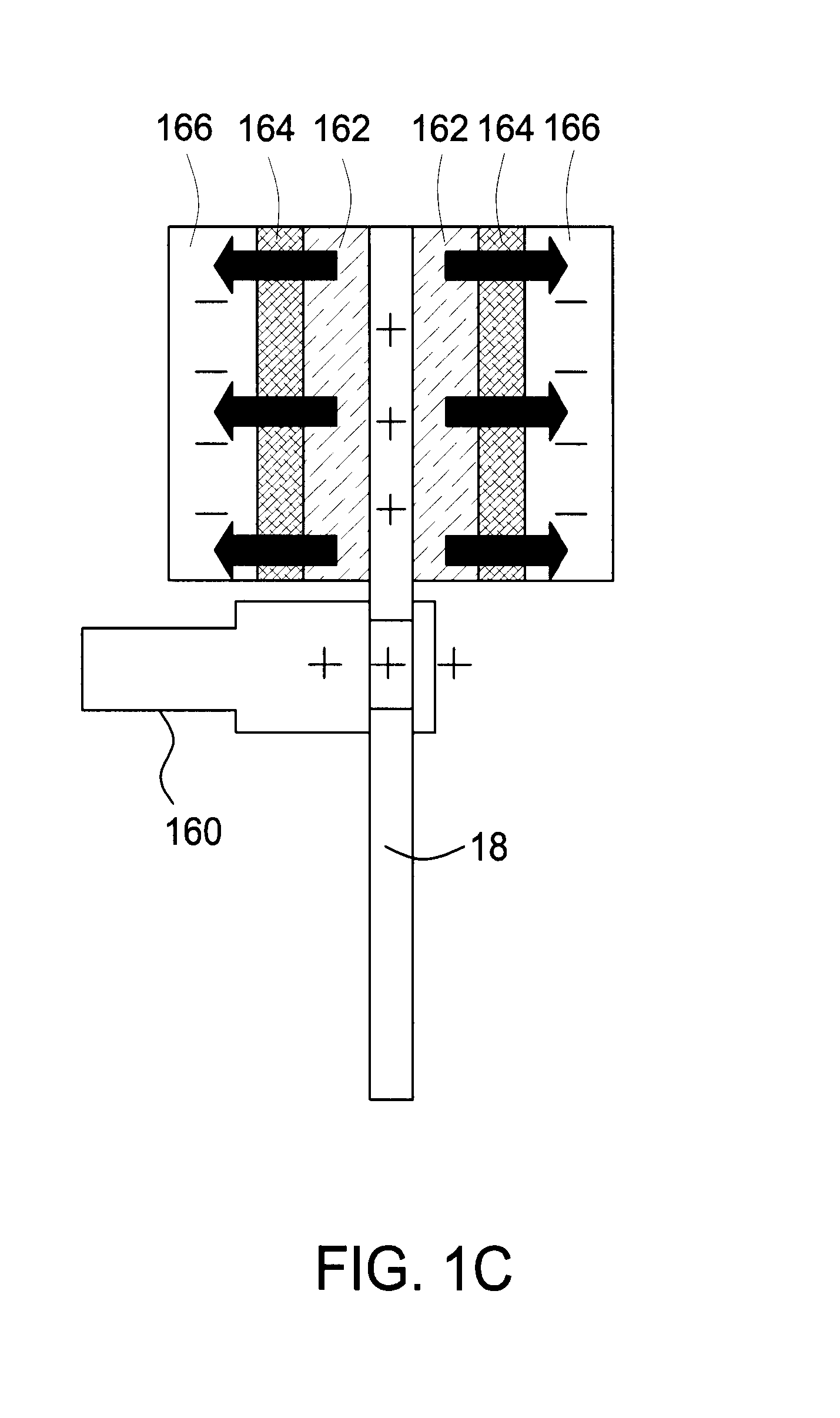

Single-step electromechanical mechanical polishing on Ni-P plated discs

InactiveUS6957511B1Reduce in quantityReduce processing timeBelt grinding machinesLapping machinesElectrical conductorSlurry

Beginning with a smooth ground aluminum blank with a relatively thin layer of leveled Ni—P, circumferential electropolishing / texturing is carried out to achieve a smooth oriented surface. A conductive slurry is provided between the disc and a porous texturing tape which is in contact with a conducting plate or equivalent conductor. The disc serves as the anode, and the conducting plate as the cathode, while the slurry, being conductive, functions as an electrolyte. In the presence of current, a reverse electroplating occurs so that the Ni—P dissolves to form Ni2+, or nickel ions which are carried away by the conductive slurry. The conductive slurry further supports or carries therein abrasive material so that by moving the porous texturing tape past the disc surface, the texturing tape picks up the abrasive material in the slurry and simultaneously with the reverse electroplating, provides the desired mechanical abrasion to achieve texturing of the disc surface. The abrasive material comprises diamond particles. The circumferential electropolishing / texturing polish is achieved by spinning the disc while applying the mechanical-chemical action through the slurry system to the disc surface with electric current passing through the electrically conducting interface during processing.

Owner:SEAGATE TECH LLC

Ternary Zn-Ni-Mn phosphorizing solution

InactiveCN1847455AImprove stabilityExtended service lifeMetallic material coating processesPhosphate ionElectrophoresis

The present invention discloses one kind of ternary Zn-Ni-Mn phosphorizing solution and its preparation process. The ternary Zn-Ni-Mn phosphorizing solution consists of zinc ion, phosphate radical ion, nickel ion, manganese ion, chlorate radical ion, nitrate radical ion, fluorine ion, promoter A, additive B and complexing agent C in certain proportion. The present invention can form compact and homogeneous phosphide film with high base resistance and high corrosion resistance, and is suitable for the phosphorizing treatment of cathode before electrophoresis coating.

Owner:WUHAN UNIV

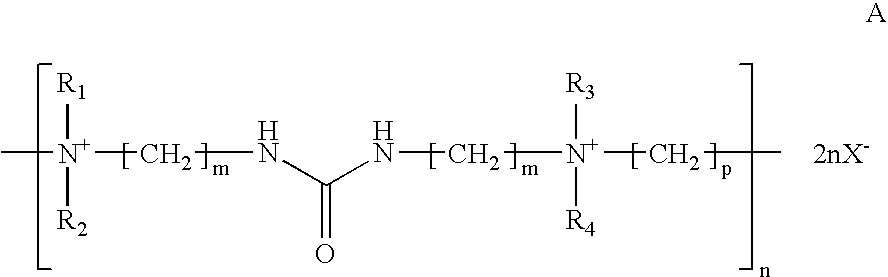

Prepn. method and application of high-dispersion loading type nickel-based catalyst

InactiveCN1751789AImprove activity and stabilityStrong effectHydrogenCatalyst activation/preparationIonAcetylacetone

A high-dispersity carried Ni-base catalyst for reforming, oxidizing, or oxidizing-reforming methane in fluidized bed is prepared by direct dipping to make the Ni ions be carried by microspherical silica gel or alumina. Its advantages are high activity and high stability.

Owner:ZHEJIANG UNIV

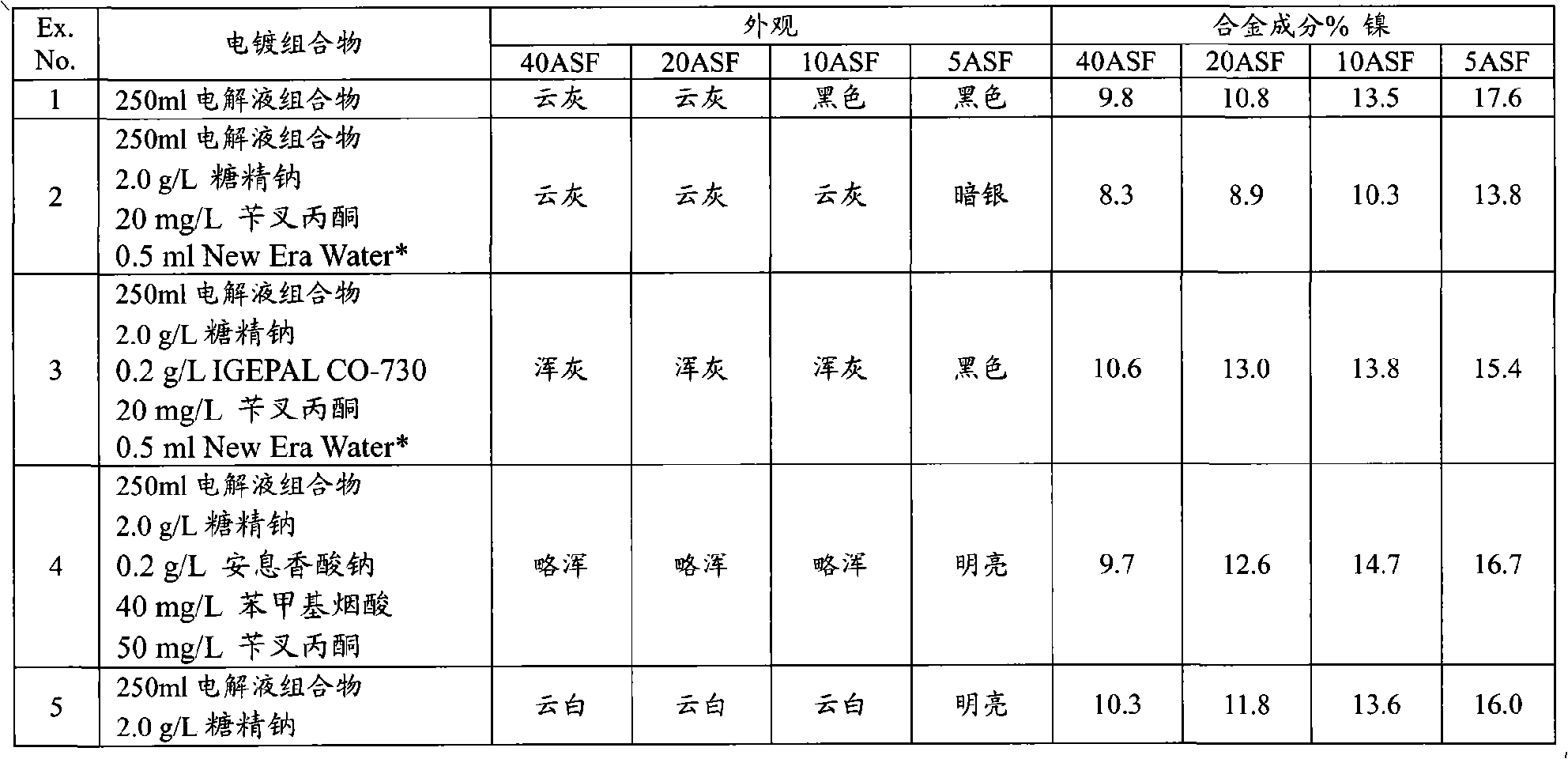

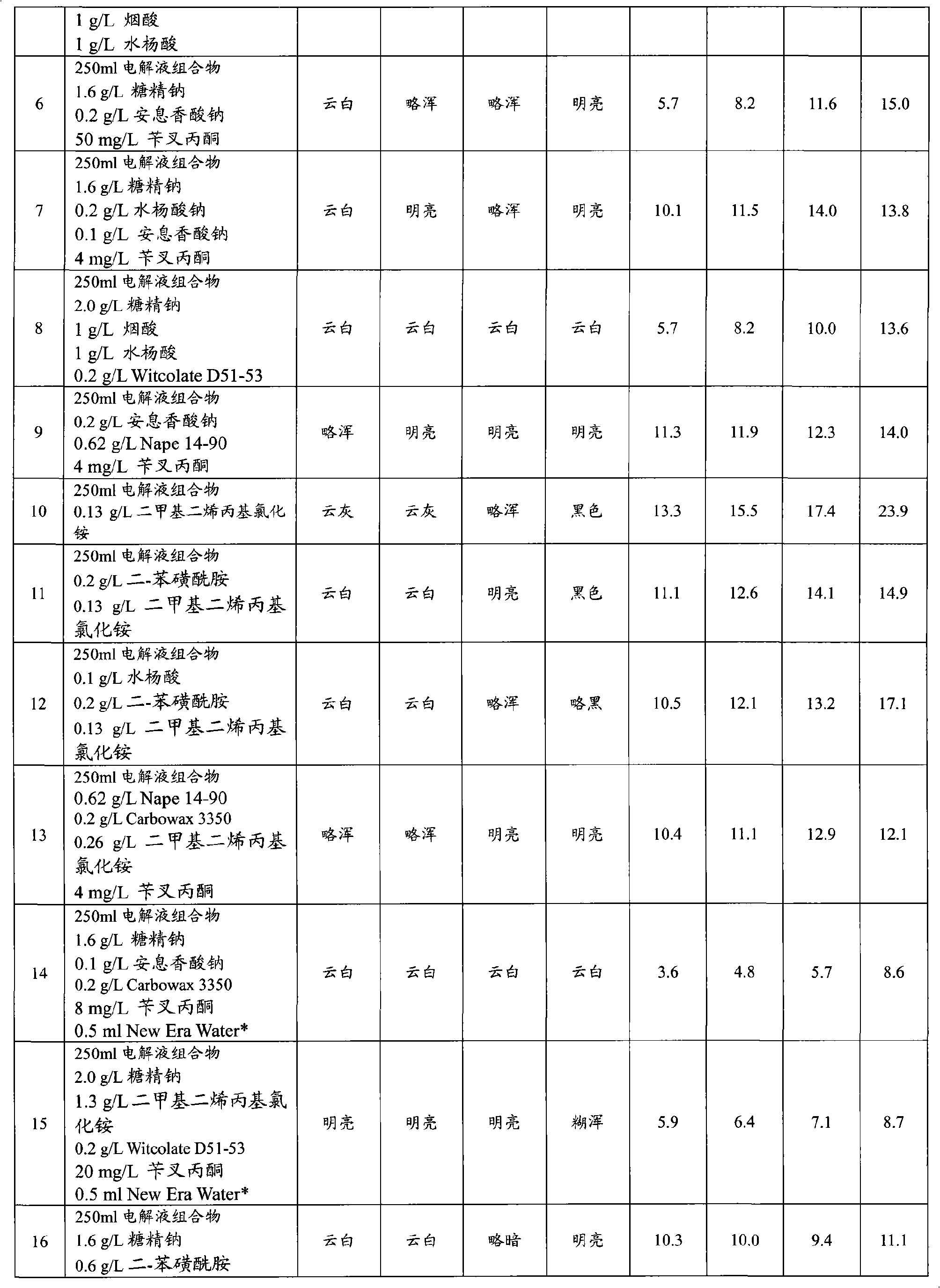

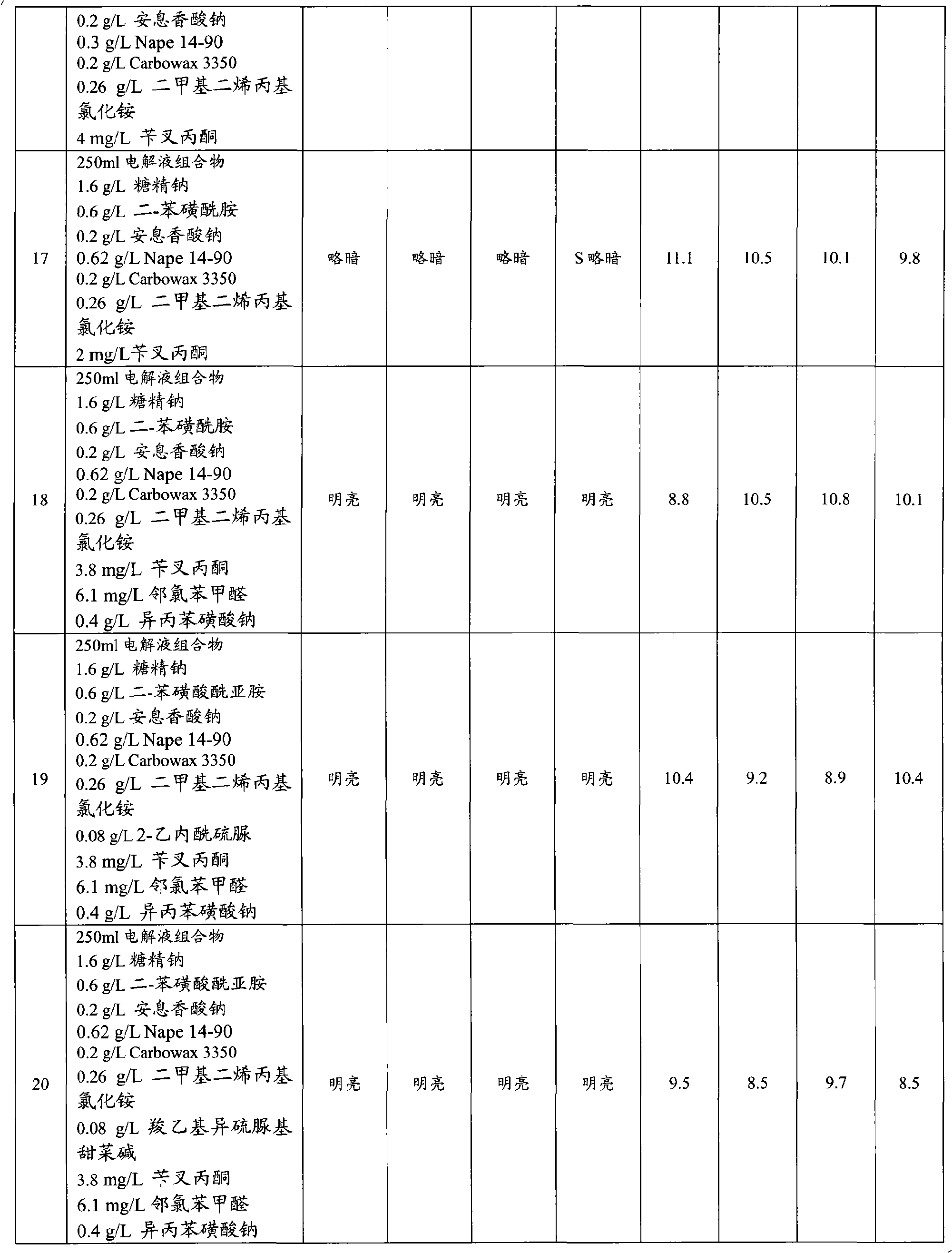

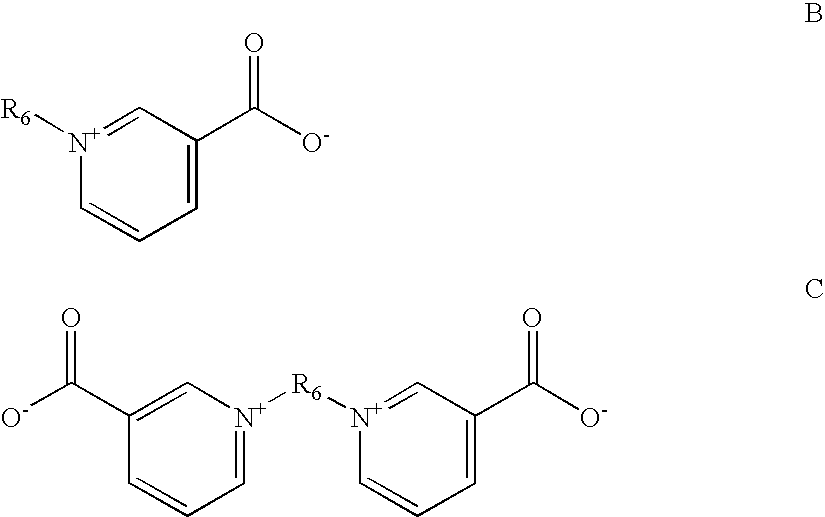

Zinc-nickel alloy electroplating system

The invention provides an aqueous zinc-nickel alloy electroplating composition particularly useful in an electroplating method for depositing a zinc-nickel alloy layer on a substrate, wherein the deposited layer exhibits uniform nickel concentration and good aesthetics across a broad range of current densities. The electroplating composition comprises an electrolyte composition and an organic composition. In one embodiment, the electrolyte composition comprises a zinc ion source, a nickel ion source, a pH buffering agent and at least one additional salt, and the organic composition comprises a Class I nickel brightener, a Class II nickel brightener, an aromatic carboxylic acid, an aldehyde or ketone compound, and a non-ionic or anionic surfactant. The electroplating composition is particularly free of chelators and free ammonium-producing agents.

Owner:PAVCO INC

Method for treating complexed chemical nickel electroplating wastewater

InactiveCN103833123AImprove processing efficiencyGood effectWaste water treatment from metallurgical processWater/sewage treatment by oxidationPotassium ferrateAdsorption effect

The invention provides a method for treating complexed chemical nickel electroplating wastewater and aims at the problem in the existing complexed chemical nickel electroplating wastewater treatment processes that the nickel ion removal efficiency is inadequate. The method comprises the main processes of firstly adding calcium hydroxide into the wastewater, adjusting the pH to 8-9 so as to form calcium phosphate precipitates, adding sulfuric acid into a supernatant liquid so as to adjust the pH of the liquid to 4-5, then, adding a potassium ferrate liquid with strong oxidizing power so as to decomplex in a strong oxidizing manner and change complexed nickel ions into free-state nickel ions, then, adding calcium hydroxide, adjusting the pH to 10-11 so as to enable the free-state nickel ions to form precipitates to be removed from the wastewater, enabling trivalent ferric ions with excellent flocculation function generated after oxidation of ferric acid radical ions to have flocculation with hydroxide precipitates with an adsorption effect, and finally, adding polyacrylamide (PAM) to coagulate and precipitate, thereby removing nickel ions from the electroplating wastewater. The method has the advantages that the condition that the nickel ions obtained after the complexed chemical nickel electroplating wastewater is treated reach the national standards can be effectively guaranteed, the treatment efficiency is high, and the requirements on emission are met.

Owner:陈瀚翔

Zinc-nickel alloy electroplating system

The invention provides an aqueous zinc-nickel alloy electroplating composition particularly useful in an electroplating method for depositing a zinc- nickel alloy layer on a substrate, wherein the deposited layer exhibits uniform nickel concentration and good aesthetics across a broad range of current densities. The electroplating composition comprises an electrolyte composition and an organic composition. In one embodiment, the electrolyte composition comprises a zinc ion source, a nickel ion source, a pH buffering agent and at least one additional salt, and the organic composition comprises a Class I nickel brightener, a Class II nickel brightener, an aromatic carboxylic acid, an aldehyde or ketone compound, and a non- ionic or anionic surfactant. The electroplating composition is particularly free of chelators and free ammonium-producing agents.

Owner:百富可公司

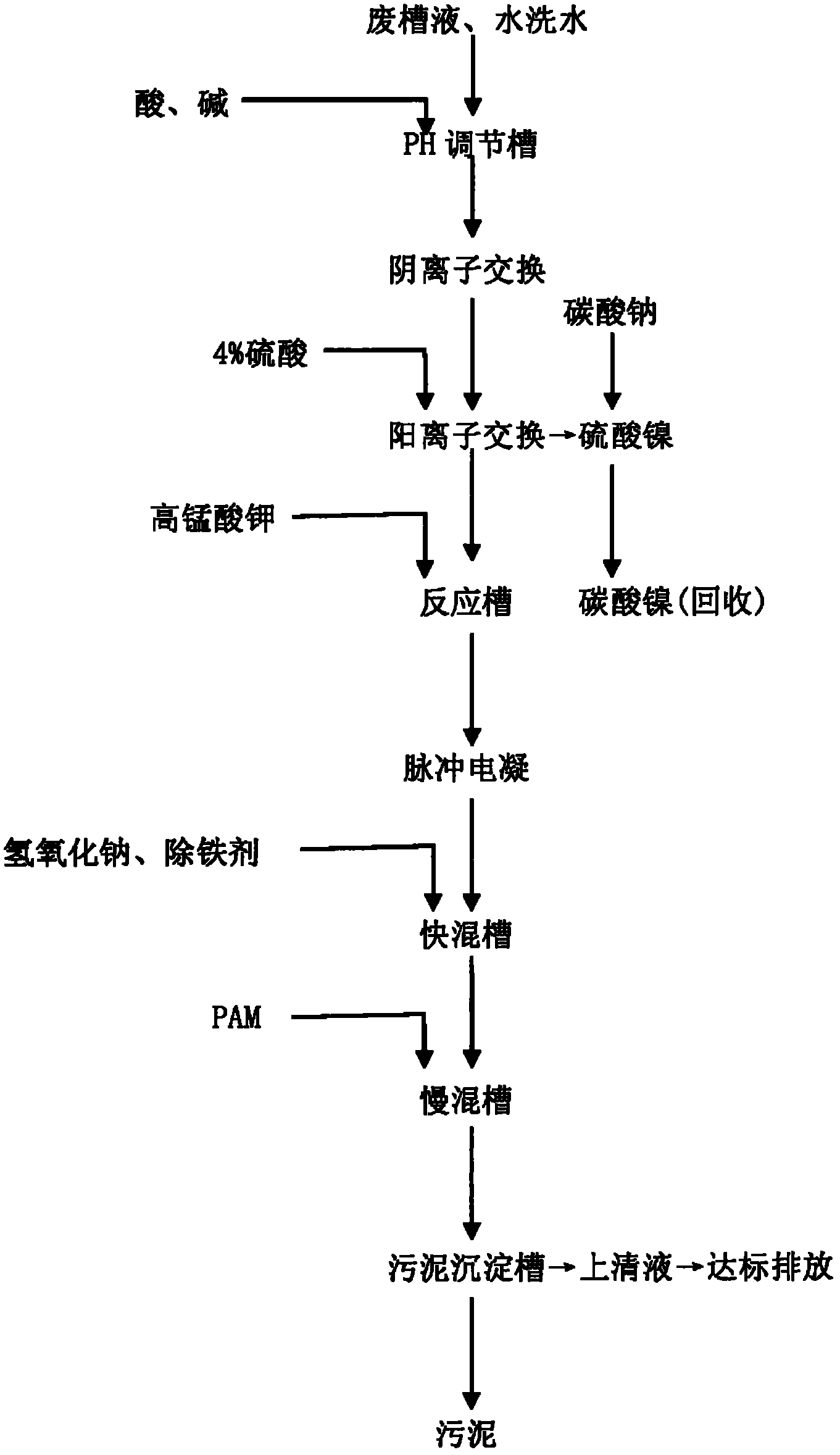

Treatment method of chemical nickel-plating wastewater

ActiveCN102329030AImprove processing economicsAchieve recyclingWaste water treatment from metallurgical processWater/sewage treatment by ion-exchangePhosphateIon-exchange resin

The invention discloses a treatment method of chemical nickel-plating wastewater. The method comprises the following steps: (1) treating nickel-plating wastewater with strongly basic anion-exchange resin so as to destabilize nickel complex; (2) adsorbing nickel ions contained in the nickel-plating wastewater with strongly acidic cation-exchange resin; (3) adding a strong oxidant in the nickel-plating wastewater so that hypophosphite, phosphite and macromolecular organic acid complexing agent which are contained in the wastewater are oxidized so as to form phosphate and organic micromolecules;(4) carrying out pulse electrocoagulation on the nickel-plating wastewater so that the phosphate forms iron phosphate to be precipitated and residual nickel ions are oxidized to form oxidized scale precipitate at the same time; and (5) regulating the wastewater to alkalinity so that iron ions in the wastewater are precipitated, successively adding a deironing agent and a flocculant to remove ferrous ions and suspended matters in the wastewater, and directly discharging supernate. According to the invention, the content of the nickel ions in the wastewater treated by the process is far less than 0.1ppm and meets a national primary standard, the recycle of nickel resources can be realized, and the economic benefits of wastewater treatment are improved.

Owner:中新联科环境科技(安徽)有限公司

Method of manufacturing an aluminum product

InactiveUS6383661B2High densityIncrease line speedLiquid surface applicatorsThin material handlingAlloyPre treatment

The invention relates to a method of manufacturing an Al or Al alloy workpiece, including the steps of (a) providing an Al or Al alloy workpiece, (b) pre-treating of the outersurface of the Al or Al alloy workpiece, and (c) plating a metal layer including nickel onto the outersurface of the pre-treated Al or Al alloy workpiece. During step (c) the metal layer including nickel is deposited by electroplating both nickel and bismuth using an aqueous bath comprising a nickel-ion concentration in a range of 10 to 100 g / l and a bismuth-ion concentration in the range of 0.01 to 10 g / l. The invention further relates to an aqueous plating bath for use in the method of this invention.

Owner:CORUS ALUMINUM WALZPRODUKTE GMBH (DE)

Cyanide-free zinc dipping solution and cyanide-free electroplating method of filter aluminium alloy by using the same

The invention discloses a cyanide-free zinc dipping solution and a cyanide-free electroplating method of filter aluminium alloy by using the cyanide-free zinc dipping solution. The cyanide-free zinc dipping solution, measured as per liter of cyanide-free zinc dipping solution, comprises 450-600 ml of plating bath solution and 400-550 ml of water, wherein the plating bath solution comprises 20-40 g / L zinc ions, 2-10 g / L nickel ions, 0.001-0.400 g / L copper ions, 0.05-1.00 g / L iron ions, 1-4 g / L cobalt ions, 80-200 g / L alkali metal hydroxide, 50-100 g / L main complexing agent, 13-40 g / L auxiliary complexing agent, and 0.07-2.00 g / L crystallization refiner. Zinc dipping and electroplating on materials with high silica content can be carried out by using the cyanide-free zinc dipping solution by just conducting zinc dipping once, the operation is simple, and the control is easy.

Owner:GUANGZHOU HONWAY TECH CORP +1

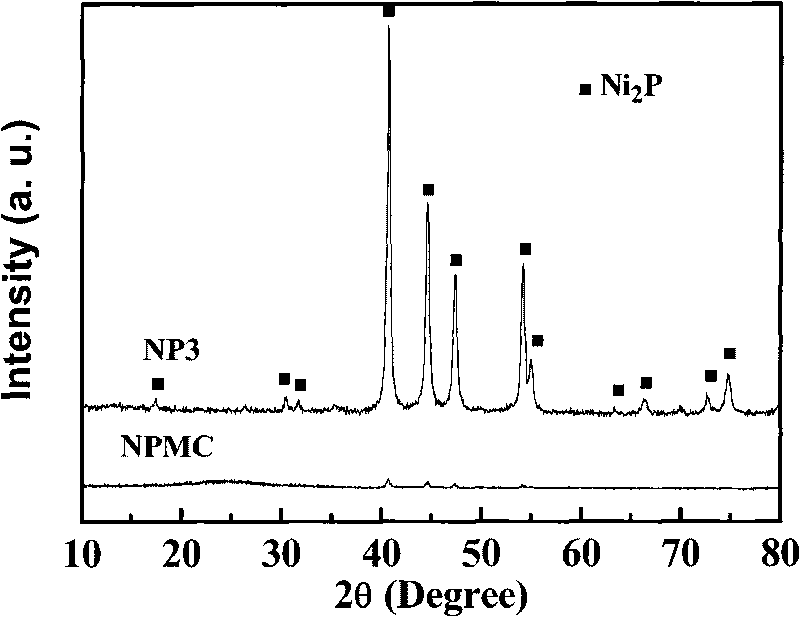

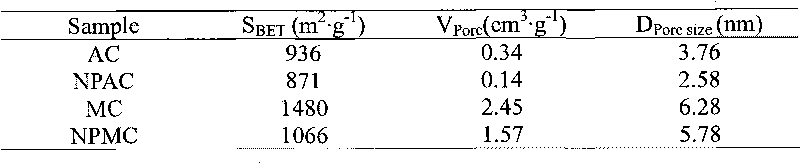

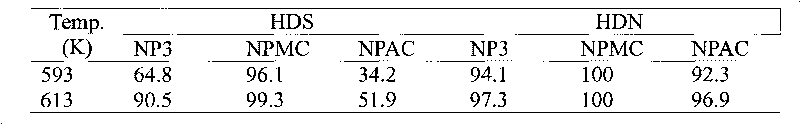

Preparation method of nickel phosphide

InactiveCN101734633ASolve the problem of sulfur poisoningIncrease investmentPhosphidesDispersityPhosphorous acid

On the premise of deep hydrodesulfurization, the main problem in diesel fuel's hydrotreatment is to rid the refractory sulfide and hydrogenate polycyclic aromatic hydrocarbon. Loaded nickel phosphide catalyst demonstrates higher hydrodesulfurization activity and better activity stability. However, the traditional nickel phosphide catalyst is prepared by temperature programming of nickel phosphide, so that dispersion degree of active components is low. In the invention, through solid-phase reaction between phosphorous acid ions and nickel ions, bulk phase and loaded nickel phosphide catalyst with higher active component dispersion degree and fine catalytic activity are obtained at low temperature. The invention is applicable to diesel oil hydroprocessing.

Owner:NANJING UNIV

Electroless copper plating solution and high-frequency electronic component

InactiveUS6743479B2Well formedImprove adhesionFixed capacitor electrodesConductive materialCopper platingElectronic component

An electroless copper plating solution which can ensure superior adhesion of a copper plating film to a flat ceramic surface having low roughness and which can form a high-frequency electronic component having superior high-frequency conductivity and a high Q value is provided. Also provided is a high frequency electronic component formed by using this electroless copper plating solution. The electroless copper plating solution of contains copper ions, nickel ions, formaldehyde or a derivative thereof, and tartaric acid or a salt thereof. The ratio of the content of the nickel ions to that of the copper ions on a molar basis is in the range of about 0.0001 to 0.015.

Owner:MURATA MFG CO LTD

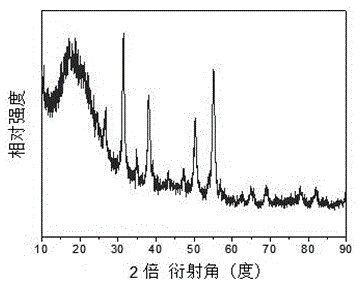

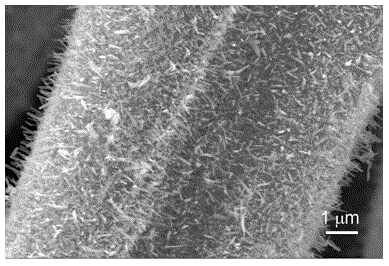

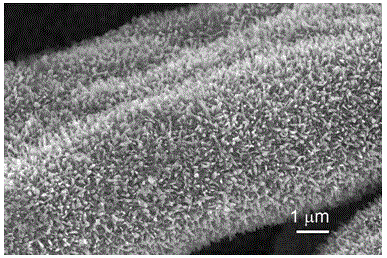

One-dimensional NiCo2S4 crystal array on surface of activated carbon fiber and preparation method of one-dimensional NiCo2S4 crystal array

ActiveCN104088016ALarge specific surface areaFacilitates directional transferPolycrystalline material growthFrom normal temperature solutionsFiberNickel salt

The invention discloses a one-dimensional NiCo2S4 crystal array on the surface of an activated carbon fiber and a preparation method of the one-dimensional NiCo2S4 crystal array. The preparation method comprises the following steps: dissolving soluble nickel salt and soluble cobalt salt in water, wherein the mole number ratio of nickel ions to cobalt ions is 1:2; adding ethylene diamine tetraacetic acid of which the mole number is equal to one half of the total mole number of nickel and cobalt ions and thiourea of which the mole number is equal to 5-10 times of the total mole number of nickel and cobalt ions; immersing an activated carbon fiber in the solution and soaking; then carrying out hydrothermal treatment at the temperature range of 150-260 DEG C; washing hydrothermally treated activated carbon fiber and drying to obtain the one-dimensional NiCo2S4 crystal array growing on the surface of activated carbon fiber. Since the one-dimensional NiCo2S4 crystal array on the surface of the activated carbon fiber obtained by the invention has the directional growth structure, the specific surface area of the activated carbon fiber can be improved, and the one-dimensional NiCo2S4 crystal array is conducive to electronic transport and is an ideal catalyst material and electrode material.

Owner:INNER MONGOLIA PURUIFEN ENVIRONMENTAL SCI ANDTECH

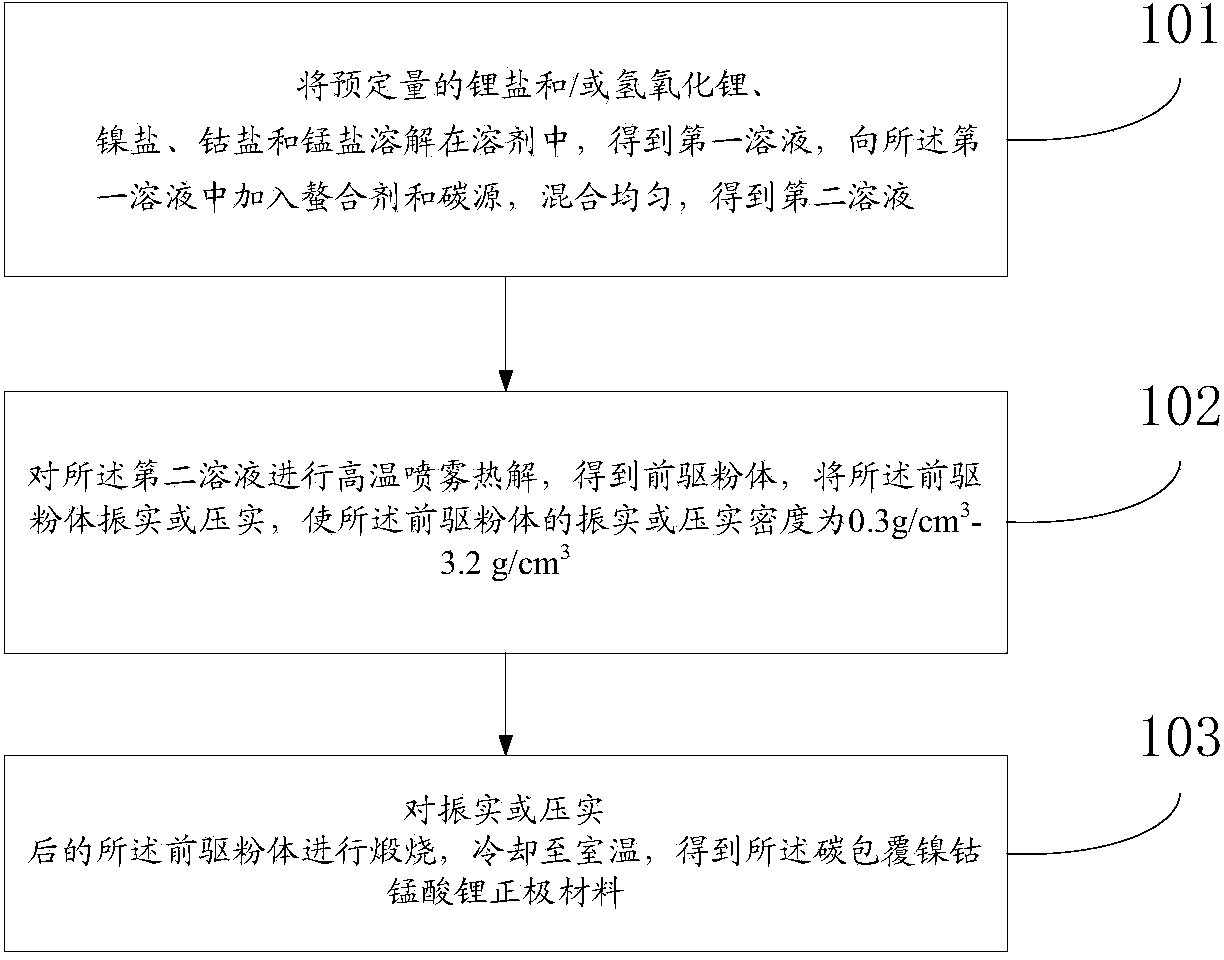

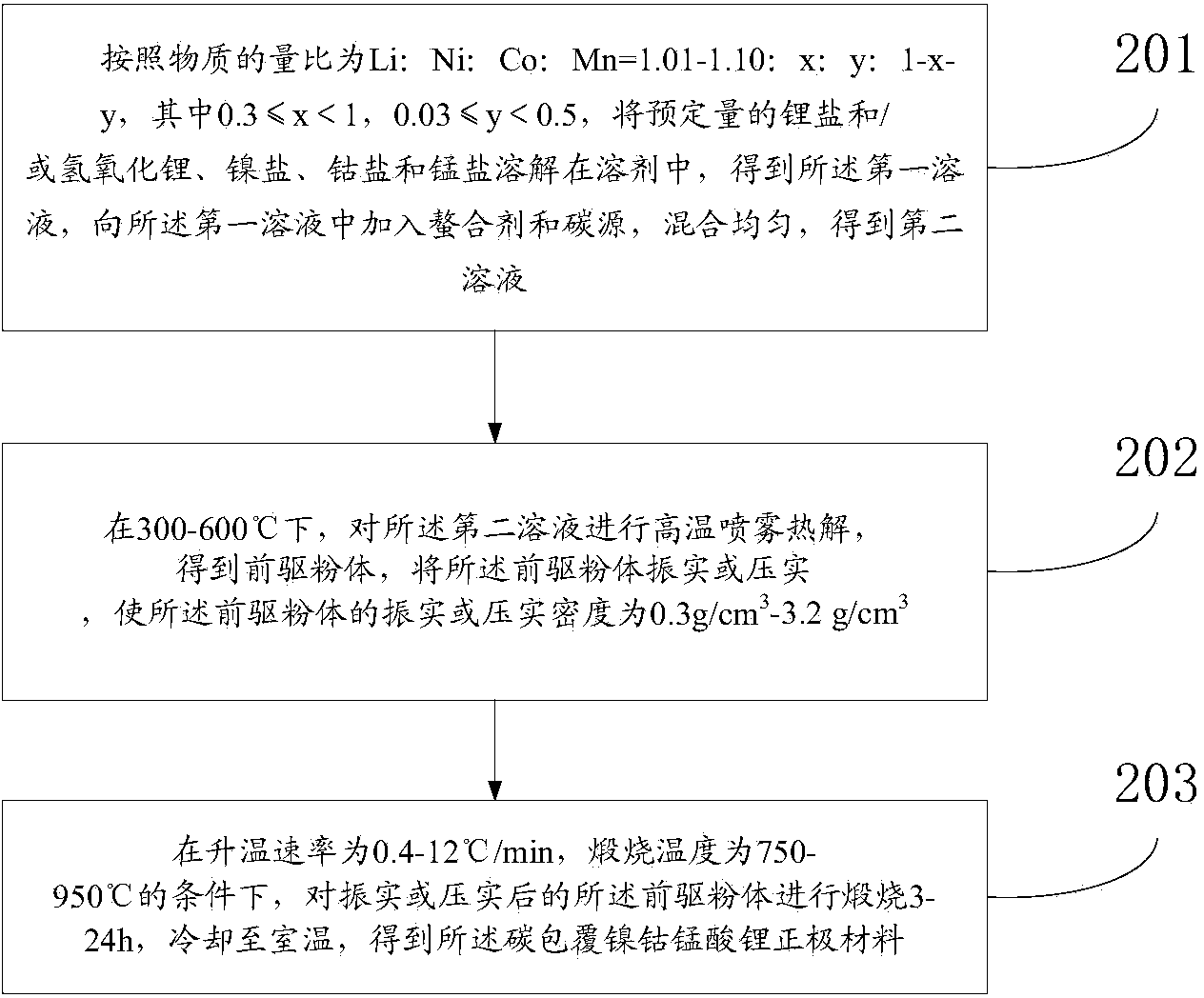

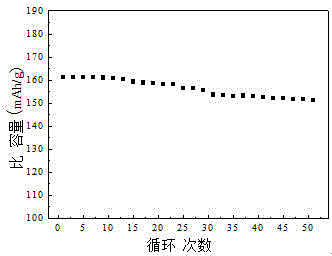

Carbon-coated nickel-cobalt lithium manganate positive electrode material and preparation method thereof

InactiveCN104051724AImprove conductivityImprove cycle stabilityCell electrodesSecondary cellsCarbon coatingNickel salt

The embodiment of the invention discloses a preparation method of a carbon-coated nickel-cobalt lithium manganate positive electrode material, and belongs to the technical field of preparation of a lithium battery positive electrode material. The preparation method comprises the following steps: adding a chelating agent and a carbon source into a solution containing lithium salt, nickel salt, cobalt salt and manganese salt, and performing high-temperature spray pyrolysis to obtain precursor powder; compacting the precursor powder by vibration or pressure, wherein the compaction density by the vibration or the pressure is 0.3-3.2g / cm<3> so that lithium ions, nickel ions, cobalt ions and manganese ions are uniformly dispersed in the powder and are contacted closely; and calcining the precursor powder, and cooling to obtain the carbon-coated nickel-cobalt lithium manganate positive electrode material with the good conductivity and the high cyclic stability. The carbon-coated nickel-cobalt lithium manganate positive electrode material comprises nickel-cobalt lithium manganate and carbon coating the surface of nickel-cobalt lithium manganate. The method disclosed by the embodiment of the invention is easy to operate and easy to control and facilitates the large-scale industrial production.

Owner:CHERY AUTOMOBILE CO LTD

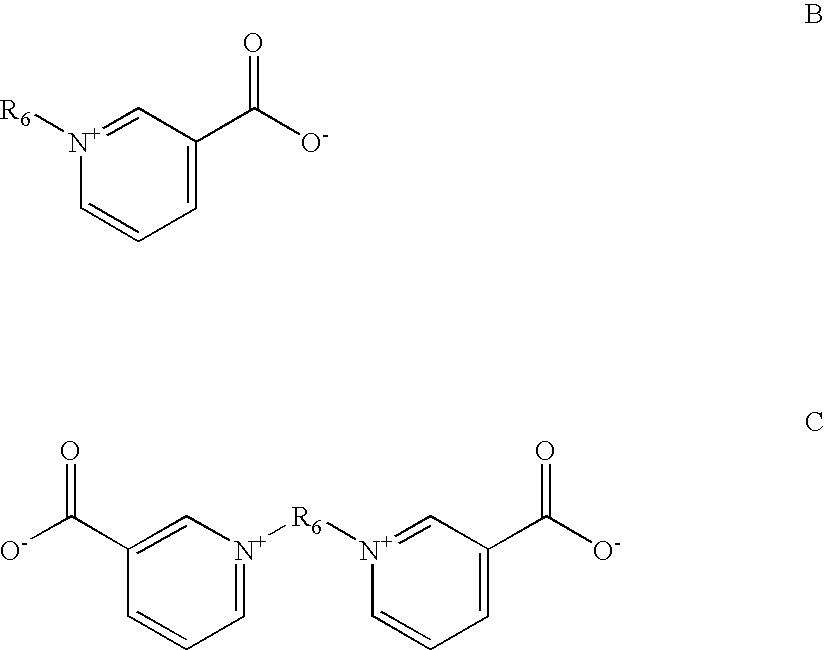

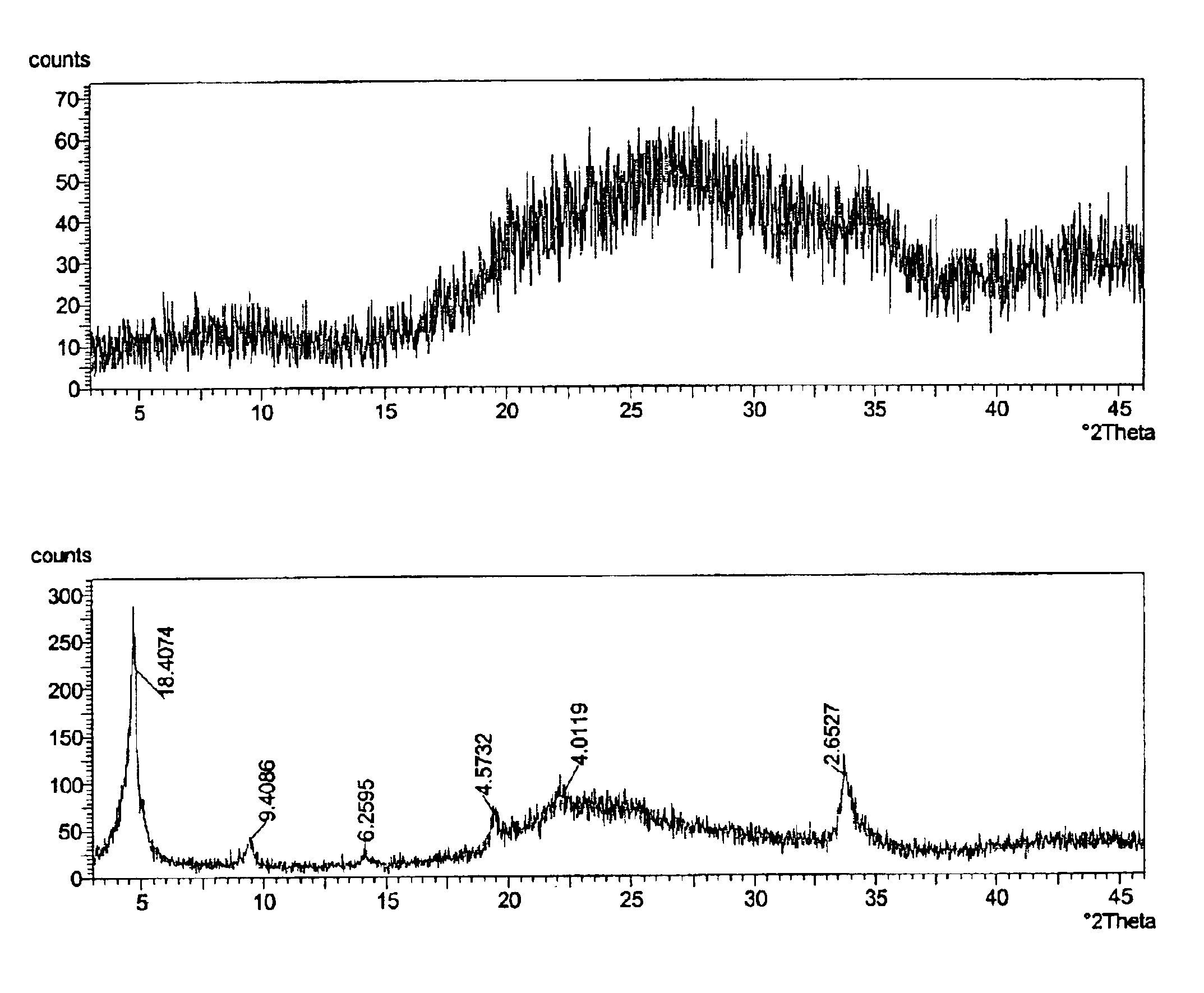

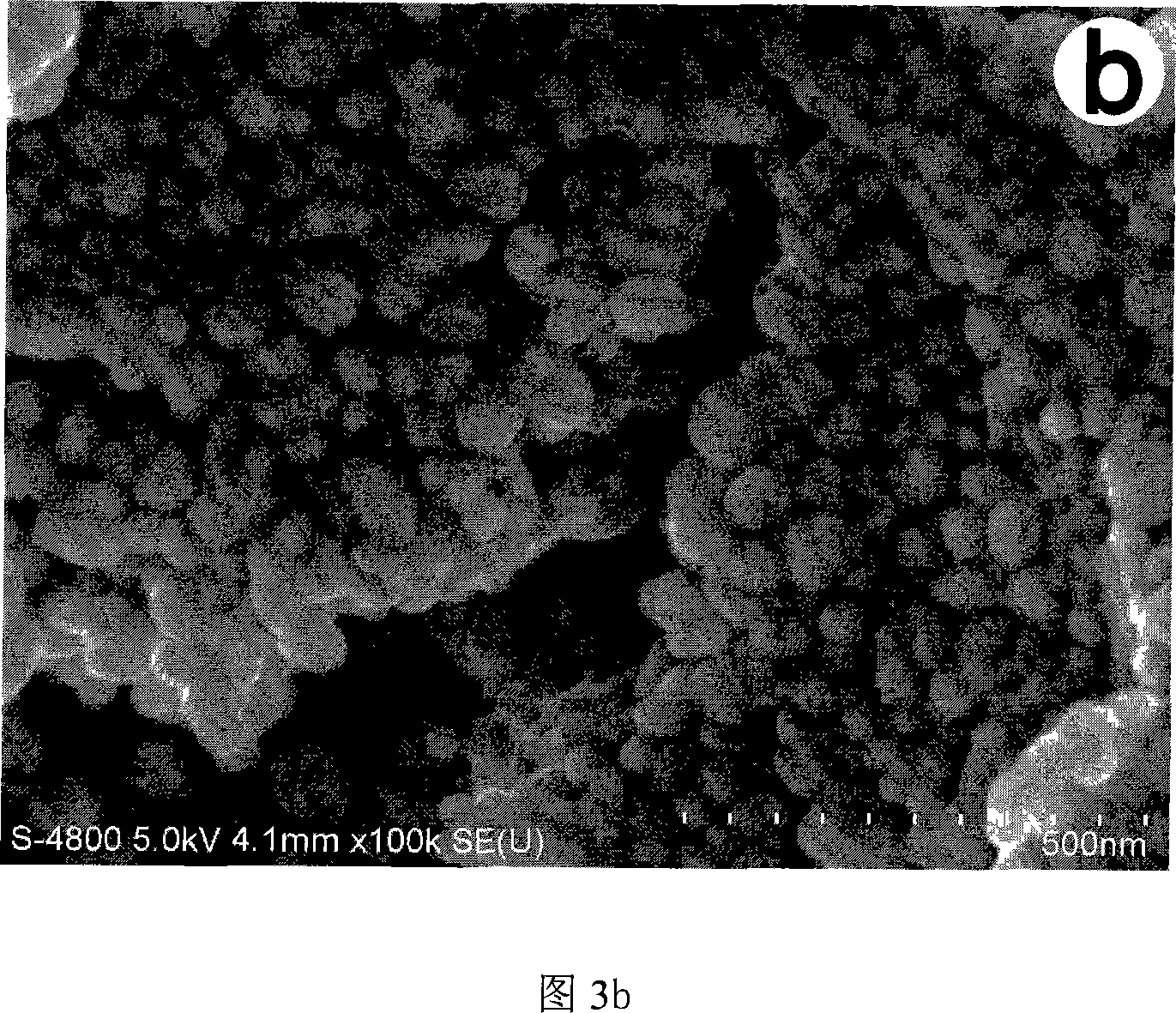

Mixed lithium battery positive material and preparation method thereof

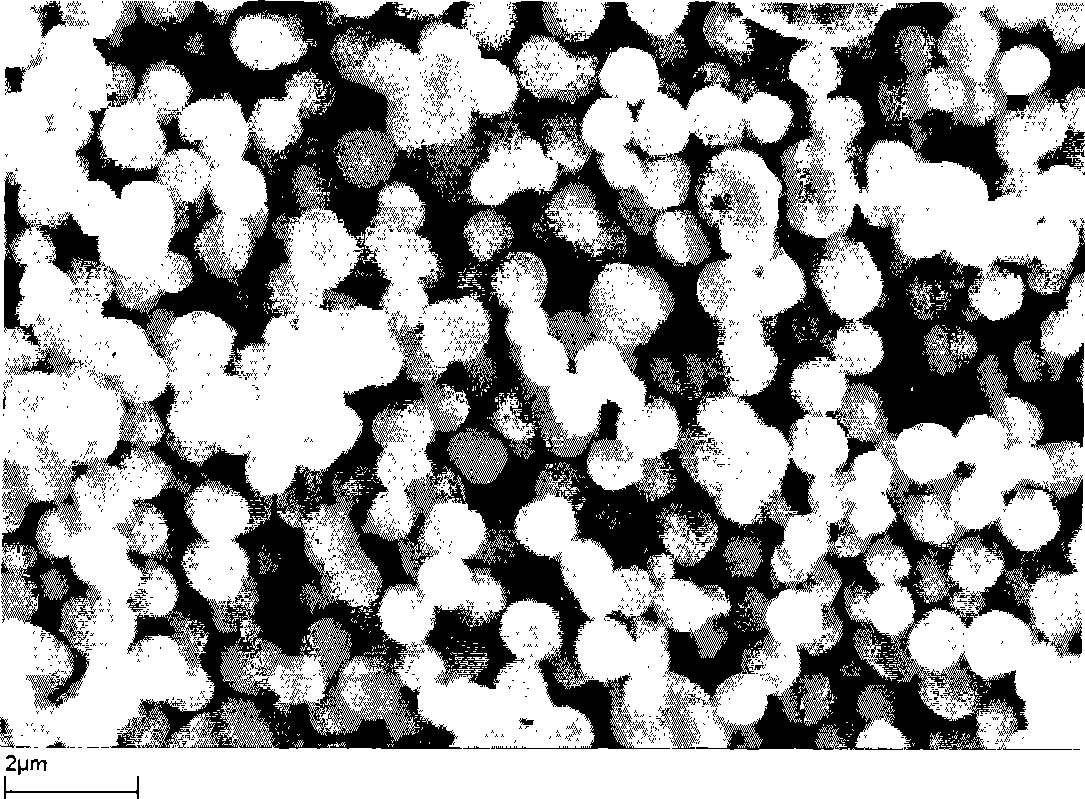

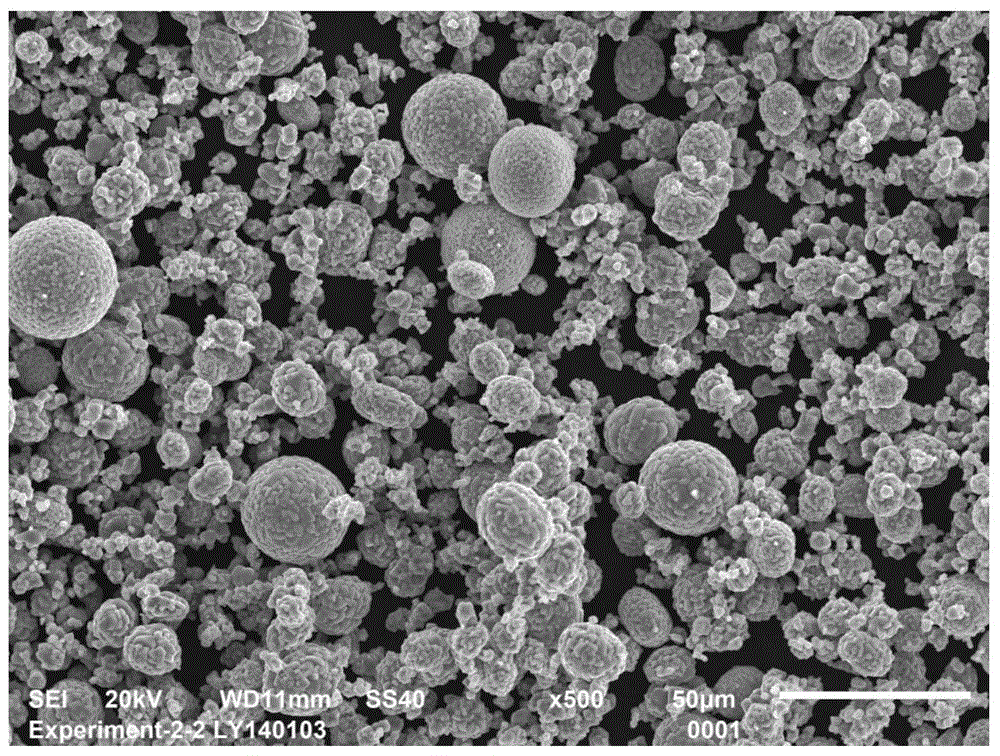

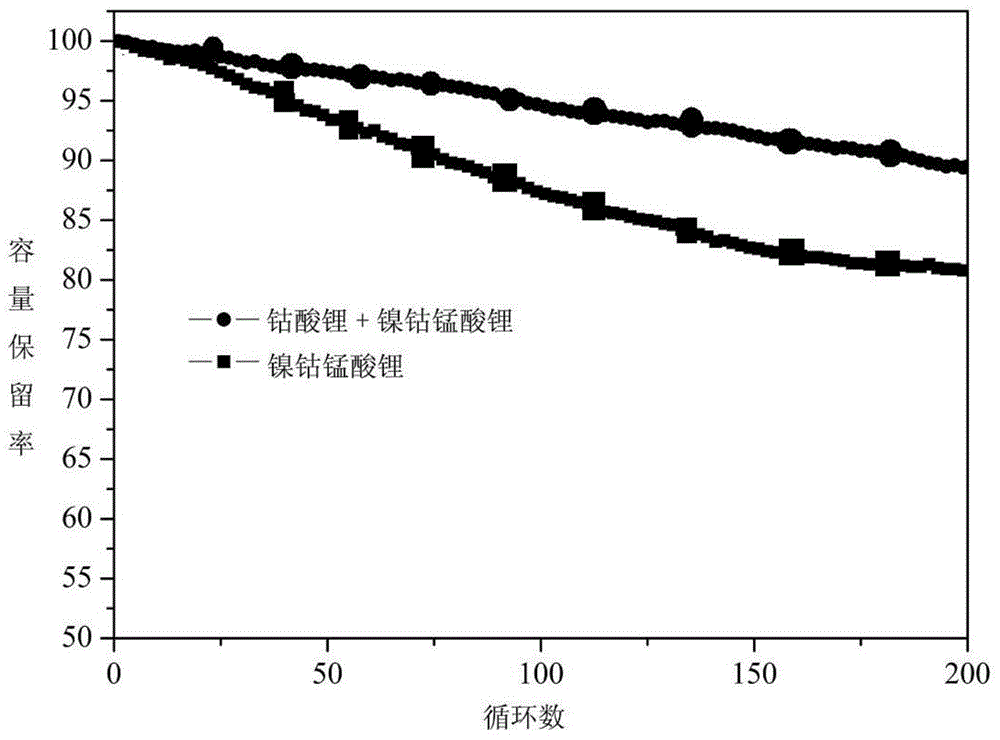

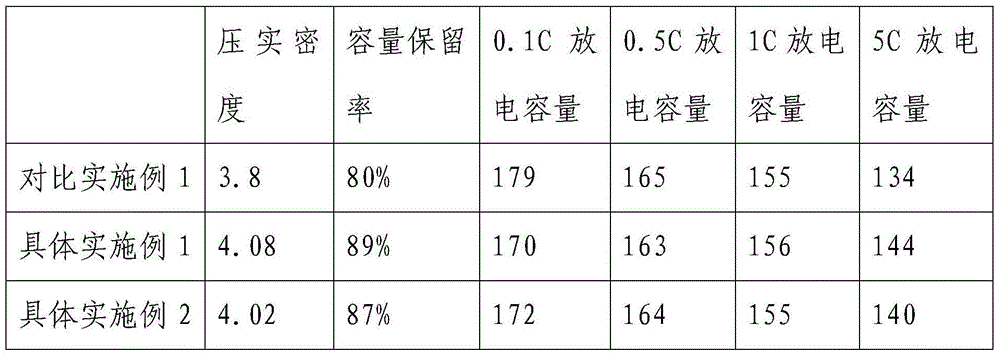

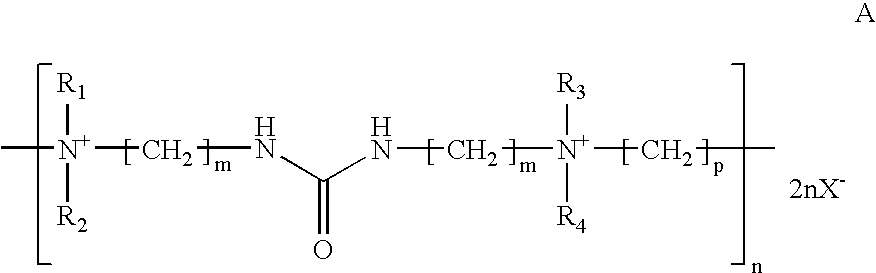

InactiveCN103985857ALarge particlesSmall particlesCell electrodesSecondary cellsDecompositionManganese

The invention belongs to the field of inorganic non-metallic materials and relates to a mixed lithium battery positive material and a preparation method thereof. The preparation method comprises the following steps: mixing cobalt oxide and a nickel-cobalt-manganese ternary material precursor, and performing two-step sintering, thereby directly obtaining a mixed positive material of lithium cobalt oxide and nickel cobalt lithium manganate, wherein a microscopic structure formed by coating nickel cobalt lithium manganate particles with lithium cobalt oxide particles is shown in the figure in the specification, and the diameter of the lithium cobalt oxide particles is less than that of the nickel cobalt lithium manganate particles. According to the structure that large and small spheres of lithium cobalt oxide and nickel cobalt lithium manganate are arranged in a mixed manner, gaps the material can be effectively filled, and the compaction density of the material is improved; the conductivity of the material can be improved after the material is coated with lithium cobalt oxide, dislocation of Li and Ni in a nickel cobalt lithium manganate crystal structure can be effectively alleviated, and decomposition of high-valence nickel ion catalytic electrolyte is inhibited; moreover, the compaction density of nickel cobalt lithium manganate can be improved after being coated with lithium cobalt oxide, so that the capacity, stability, high-current discharge capacity and rate performance of the battery in unit volume can be effectively improved.

Owner:QINGDAO QIANYUN HIGH TECH NEW MATERIAL

Alkaline zinc-nickel alloy plating compositions, processes and articles therefrom

The present invention relates to a process for electroplating a zinc-nickel alloy on a substrate, including electroplating the substrate in an aqueous zinc-nickel electroplating bath, including water; nickel ion; zinc ion; at least one complexing agent; and at least one non-ionogenic, surface active polyoxyalkylene compound, wherein the bath has an alkaline pH. In one embodiment, the zinc ion, the nickel ion and the non-ionogenic surface active polyoxyalkylene compound are present at concentrations sufficient to deposit a zinc-nickel alloy comprising a substantially gamma phase.

Owner:OPASKAR VINCENT C +1

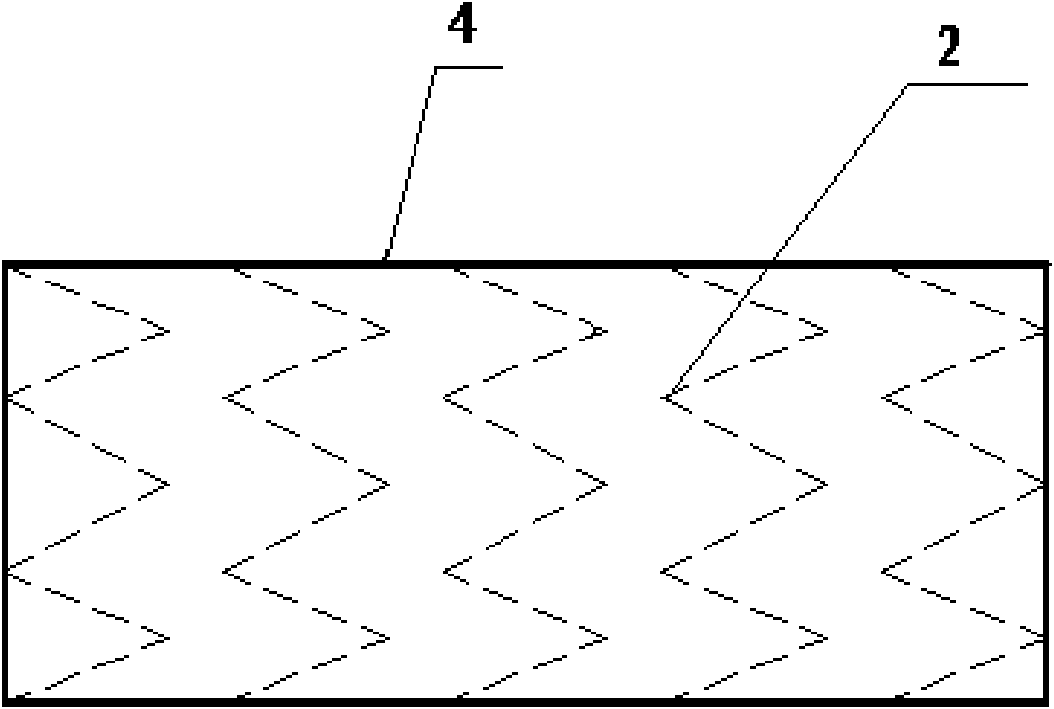

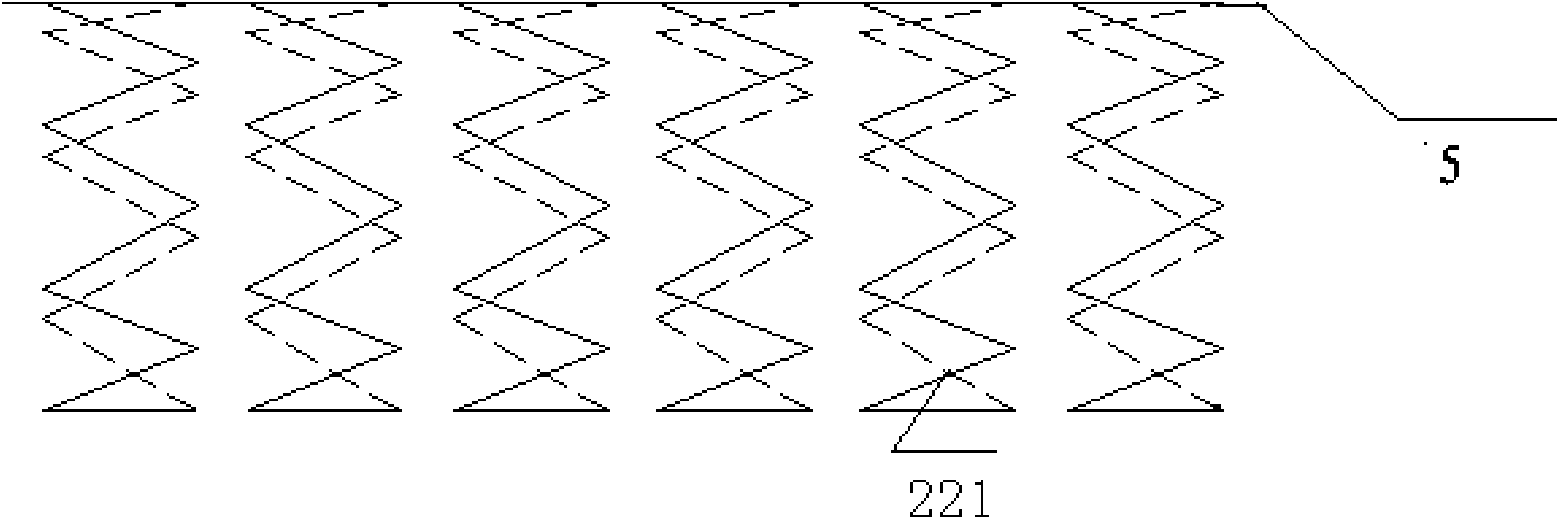

Preparation method of electroplating diamond fret saw

The invention relates to a preparation method of an electroplating diamond fret saw, comprising the following technological processes: 1. roughening processing is carried out to micrometer diamond particles in advance, nanometer diamond powder is added in cationic surface active agents according to the proportion of 1 : 3 by mass ratio, so as to prepare uniform and stable nanometer diamond powder suspending liquid, plating solution is arranged in an electroplating tank, after the weighted nanometer diamond powder suspending liquid is mixed with the micrometer diamond particles according to the proportion of 1 : 3 by mass ratio, and then the mixture is added in the plating solution, the plating solution is circulated continuously, and nickel aminosulfonate is main material in the plating liquid, and boracic acid and nickel chloride are additionally added, and a magnetic stirring device is arranged in the electroplating tank; 2. a steel wire continuously and uniformly passes through the electroplating tank, under the action of electrical current, nickel ions move to cathode from anode, so as to drive the nanometer diamond powder and the micrometer diamond particles to move to the steel wire, so as to lead the steel wire to be plated with the nanometer diamond powder and the micrometer diamond particles, meanwhile, chemical nickel-plating is carried out to the steel wire; 3. after the steel wire is separated from the electroplating tank, wires are wound up after being cleaned and dried. The method can continuously and quickly produce electroplating diamond fret saw, and the production efficiency is high.

Owner:JIANGSU FUNLIN SUPER HARD TOOLS

Method of manufacturing an aluminum product

InactiveUS20020012811A1High densityIncrease line speedLiquid surface applicatorsThin material handlingAlloyPre treatment

Owner:CORUS ALUMINUM WALZPRODUKTE GMBH (DE)

Octanol hydrorefining catalyst and preparation method thereof

InactiveCN101791556AHigh surface active sitesIncreased surface active sitesOrganic compound preparationPreparation by hydrogenationRare-earth elementNickel salt

The invention discloses an octanol hydrorefining catalyst, which belongs to the field of hydrorefining catalytic materials. The prepared catalyst is used for modifying a carrier by using a rare earth element, reducing the amount of an active component of a nickel ion entering a carrier framework and improving the content of surface nickel species; the active component is loaded by adopting a hydrothermal deposition method, the dispersion of nickel salts on the surface of a carrier pore canal by using hydrothermal high-temperature and high-pressure conditions and forming nickel precipitation with proper size at the loading initial period of the active component by using a deposition reaction, so the invention can effectively control the amount of the nickel ions entering the carrier, improve the content of the surface nickel species and simultaneously can avoid the growth of nickel oxide particles; and the catalyst greatly increases the surface nickel active site, effectively improves the utilization rate of the active component of nickel and has higher catalytic reaction activity during hydrorefining the octanol at higher airspeed. The result shows that the hydrogenation rate of an unsaturated substance in crude octanol reaches over 90 percent when the temperature is 120DEG c, the pressure is 2.5MPa, the ratio of hydrogen to liquid for feeding is 8:1 and the airspeed is 30<-1>hour.

Owner:UNIV OF SCI & TECH BEIJING

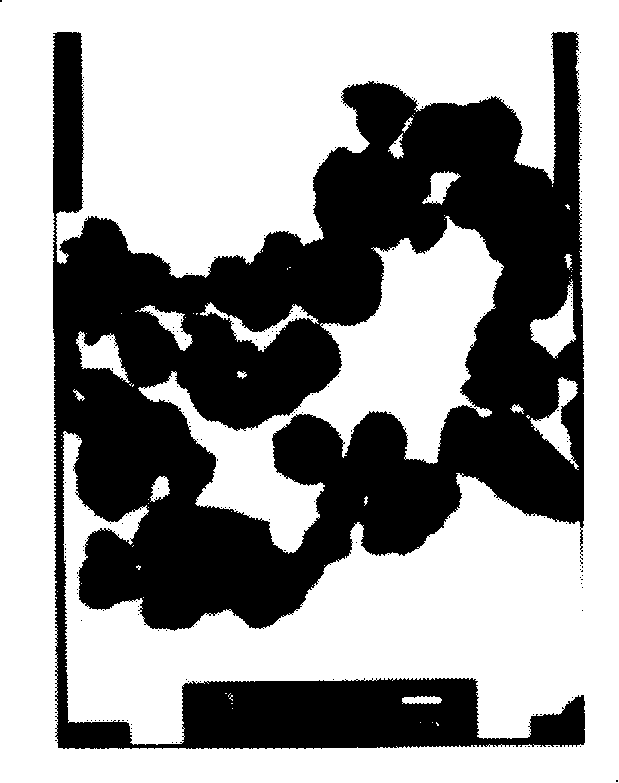

Nano core-shell type copper-nickel bimetal powder body and preparing method and application thereof

ActiveCN101209493AOvercome the disadvantage of easy oxidationMeet the requirement of transparent appearanceCoatingsThioureaConductive materials

The invention relates to a bimetal powder of copper and nickel and a preparation method thereof. The invention solves the defect of easy oxidation of the simple substance nanometer copper powder and improves the use effect of the ordinary copper nickel composite powder. Referring to the prior art, the invention firstly prepares a nanometer copper powder, the copper powder is stirred and dispersed homogeneously in the water, and suspension liquid of the copper powder is prepared; the suspension liquid of the copper powder is blended with the nickel sulfate solution comprising macromolecule protective agent and special copper coordination agent thiourea so as to cause a replacement reaction between nickel ion and the copper; surfaces of the ultrafine copper particles are partly or all coated with the nickel, thus forming the core-shell copper-nickel bimetal nanometer powder. The bimetal powder can be taken as lubricant, lubricating grease extreme pressure-antiwear additives, additives in powder metallurgy, or as porous materials, antibacterial materials, antifouling coatings, conductive materials, magnetic materials, self-lubricating materials, antifriction materials, diamond tools, and raw materials or additives of electrical carbon products.

Owner:HAILIAN INST OF LUBRICATING MATERIALS SHANGHAI

Blood vessel covered stent and manufacturing method thereof

The invention relates to a blood vessel covered stent and a manufacturing method thereof. The blood vessel covered stent comprises a tubular nickel-titanium alloy framework and an isolation membrane; the isolation membrane is arranged on at least most tubular surface of the nickel-titanium alloy framework as a tube wall and used for preventing blood in the blood vessel covered stent from permeating through the tube wall; and a shielding layer for preventing nickel ions from releasing and entering into blood is formed on the surface of the material which forms the nickel-titanium alloy framework. The manufacturing method of the nickel-titanium alloy framework comprises the following steps: manufacturing the tubular nickel-titanium alloy framework with the shielding layer; and arranging the isolation membrane onto the tubular surface of the nickel-titanium alloy framework as the tube wall. In the blood vessel covered stent, the shielding layer is formed on the surface of the material forming the nickel-titanium alloy framework and can prevent the nickel ions from releasing and accumulating in a human body.

Owner:LIFETECH SCIENTIFIC (SHENZHEN) CO LTD

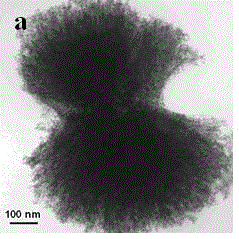

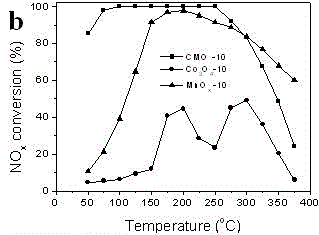

Synthesis method for low-temperature manganese-based compound metal oxide denitration catalysts

InactiveCN104001520AInhibition of agglomerationGood resistance to low temperature freezingDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNickel saltPtru catalyst

The invention belongs to the technical field of material preparation, and particularly relates to a synthesis method for low-temperature manganese-based compound metal oxide denitration catalysts. According to the method, a manganese salt and a salt from a cobalt salt, a ferric salt or a nickel salt are dissolved in ethylene glycol in a mixed manner; a sodium carbonate water solution is dripped at a low temperature, and coprecipitation is carried out; and coprecipitation products are washed by water, are dried, and are calcined in the air, and products can be obtained. The synthesis method provided by the invention adopts a low-temperature artificially induced crystal splitting technology, one kind of ions from cobalt ions, ferric ions and nickel ions are added, and manganese ion precipitate crystals are induced to split in the manganese ion precipitate crystal growth process. The split crystals do not agglomerate during the growing in low-temperature environment. After the crystals after splitting growth are calcined, manganese-based compound metal oxides with high specific surface area can be obtained, and the manganese-based compound metal oxides can show excellent low-temperature catalytic activity when being used for catalyzing a denitration reaction. The synthesis method has the advantages that the operation is simple, the control is easy, and raw materials can be easily obtained, so the synthesis method is suitable for large-scale production, and in addition, the environment pollution is little.

Owner:DALIAN UNIV OF TECH

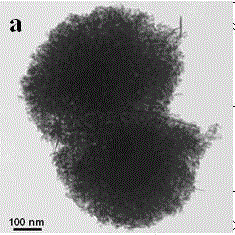

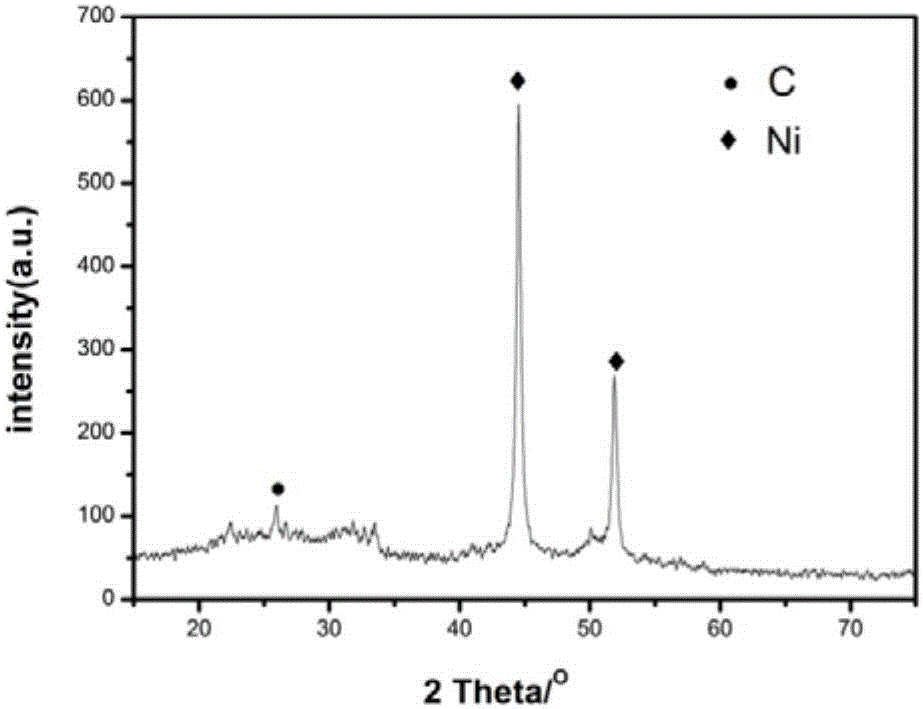

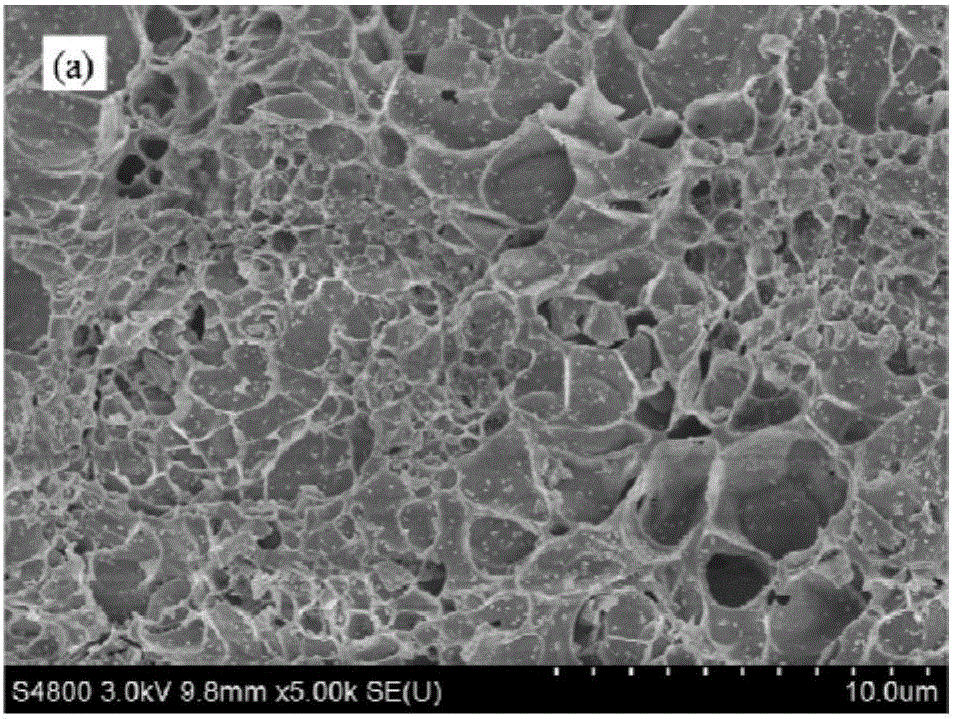

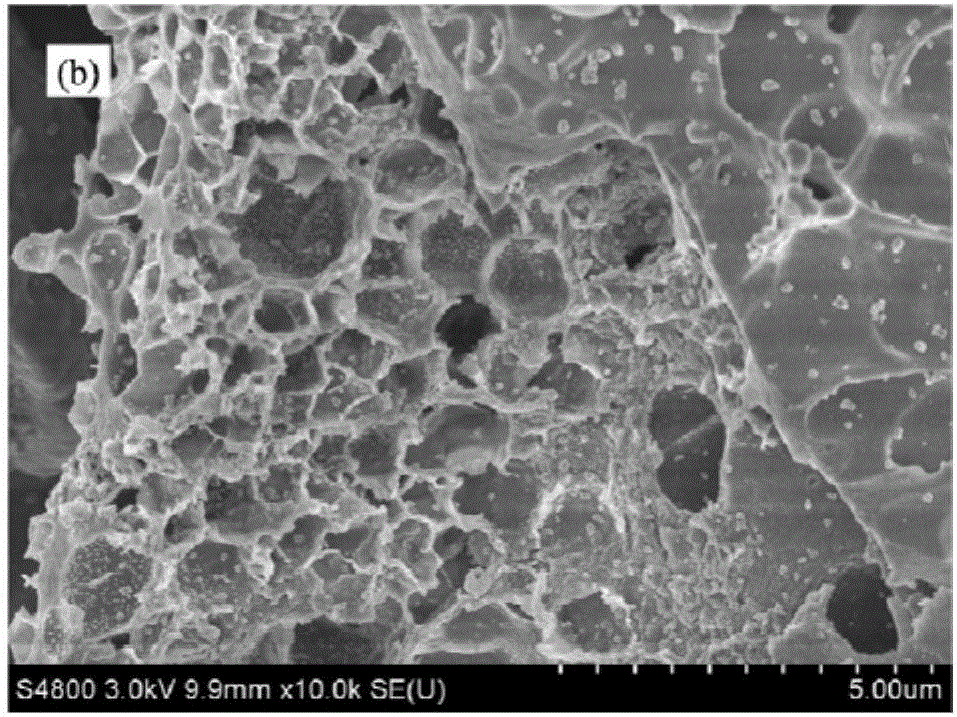

Preparation method of wave absorbing material with nickel nanoparticles wrapped with porous carbon-loaded graphene

ActiveCN106563816ARich pore structureAbundant specific surface areaOther chemical processesTransportation and packagingPorous carbonNickel ions

The invention provides a preparation method of a wave absorbing material with nickel nanoparticles wrapped with porous carbon-loaded graphene. The preparation method of the wave absorbing material with the nickel nanoparticles wrapped with the porous carbon-loaded graphene comprises the steps that alga are used as a carbon source and soaked in a nickel saline solution, and nickel ions are made to enter algal cells; low-temperature heat treatment is conducted on the alga after the alga are frozen and dried, so that the alga are converted into carbon, and metallic nickel slat is oxidized into nickel oxide; and then the temperature is increased to continue to conduct high-temperature heat treatment, so that the nickel oxide is reduced into nickel, the amorphous carbon wrapping the nickel nanoparticles is catalyzed and graphitized in the heat treatment process, and finally the composite material with the nickel nanoparticles wrapped with the porous carbon-loaded graphene is obtained. According to the preparation method of the wave absorbing material with the nickel nanoparticles wrapped with the porous carbon-loaded graphene, the alga are used as the carbon source, and thus the preparation method is economical and practical; nickel is evenly dispersed onto a carbon material by means of the characteristic that holes of natural algal plants are abundant; a porous carbon material of a network structure is obtained after heat treatment, the nickel particles wrapped with the graphene are dispersed on the surface of the porous carbon material, and thus the material has excellent micro-wave absorption performance.

Owner:SHAANXI UNIV OF SCI & TECH

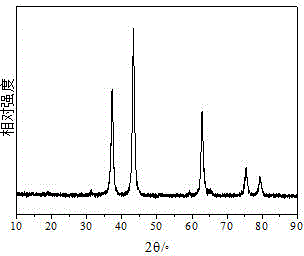

Preparation method of lithium ion battery positive material nickel cobalt aluminum

InactiveCN104466154ALow activity Ni

<sup>2+</sup>

low contentImprove electrochemical performanceCell electrodesElectrochemistryLithium-ion battery

The invention discloses a preparation method of lithium ion battery positive material nickel cobalt aluminum. The preparation method comprises the following steps: mixing nickel, cobalt and aluminum salt solutions, mixing a precipitator, a complexing agent and the mixed solution of the nickel cobalt aluminum to obtain a mixed solution, adding the mixed solution into a reaction kettle to carry out co-precipitation reaction, adjusting the pH value of the system to 10 to 11 at the temperature of 40 to 60 DEG C, stirring at the speed of 500 to 1500 turns / minute, carrying out reaction for 10 to 30 hours, filtering, washing and drying to obtain a hydroxide precursor; pre-sintering the precursor at high temperature to obtain a nickel cobalt aluminum oxide, mixing the nickel cobalt aluminum oxide with a lithium source to obtain a mixture, sintering the mixture at high temperature under an oxygen atmosphere, and crushing and sieving to obtain the nickel cobalt aluminum powder. By calculating the pre-sintering loss rate of the precursor, the content of Ni<2+> and the content of Ni<3+> in the nickel cobalt aluminum oxide at different temperatures are analyzed by utilizing XPS, so that the nickel cobalt aluminum oxide with the highest content of Ni<3+> can be obtained, more nickel ions in the secondary sintering process can be promoted to be converted into Ni<3+>, the mixed arrangement of the Li<+> and the Ni<2+> can be reduced, and the electrochemical performance of the material can be improved.

Owner:HARBIN INST OF TECH AT WEIHAI

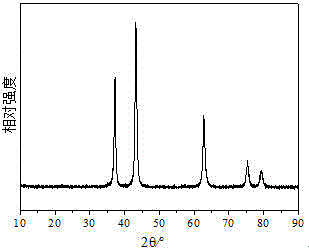

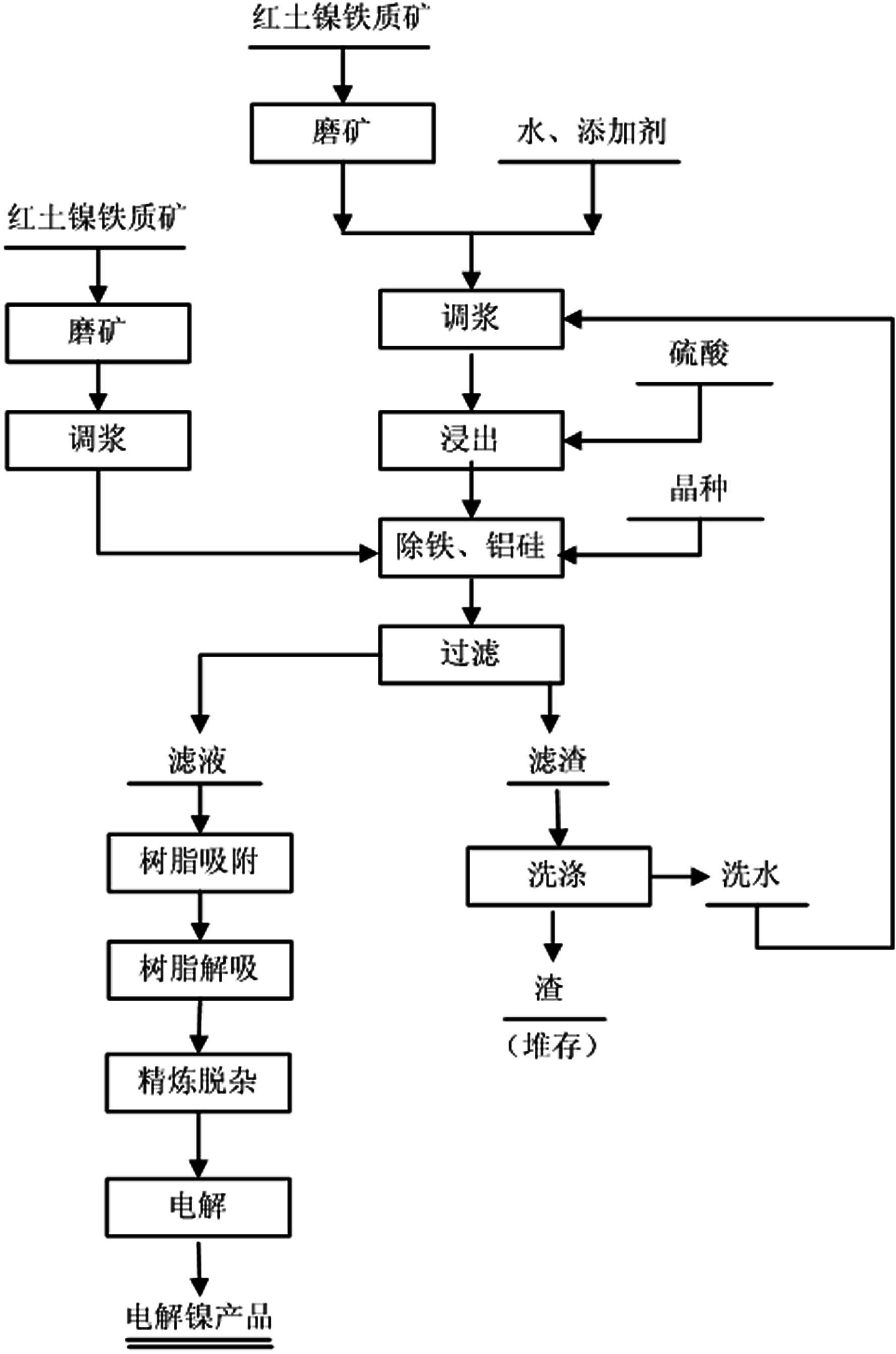

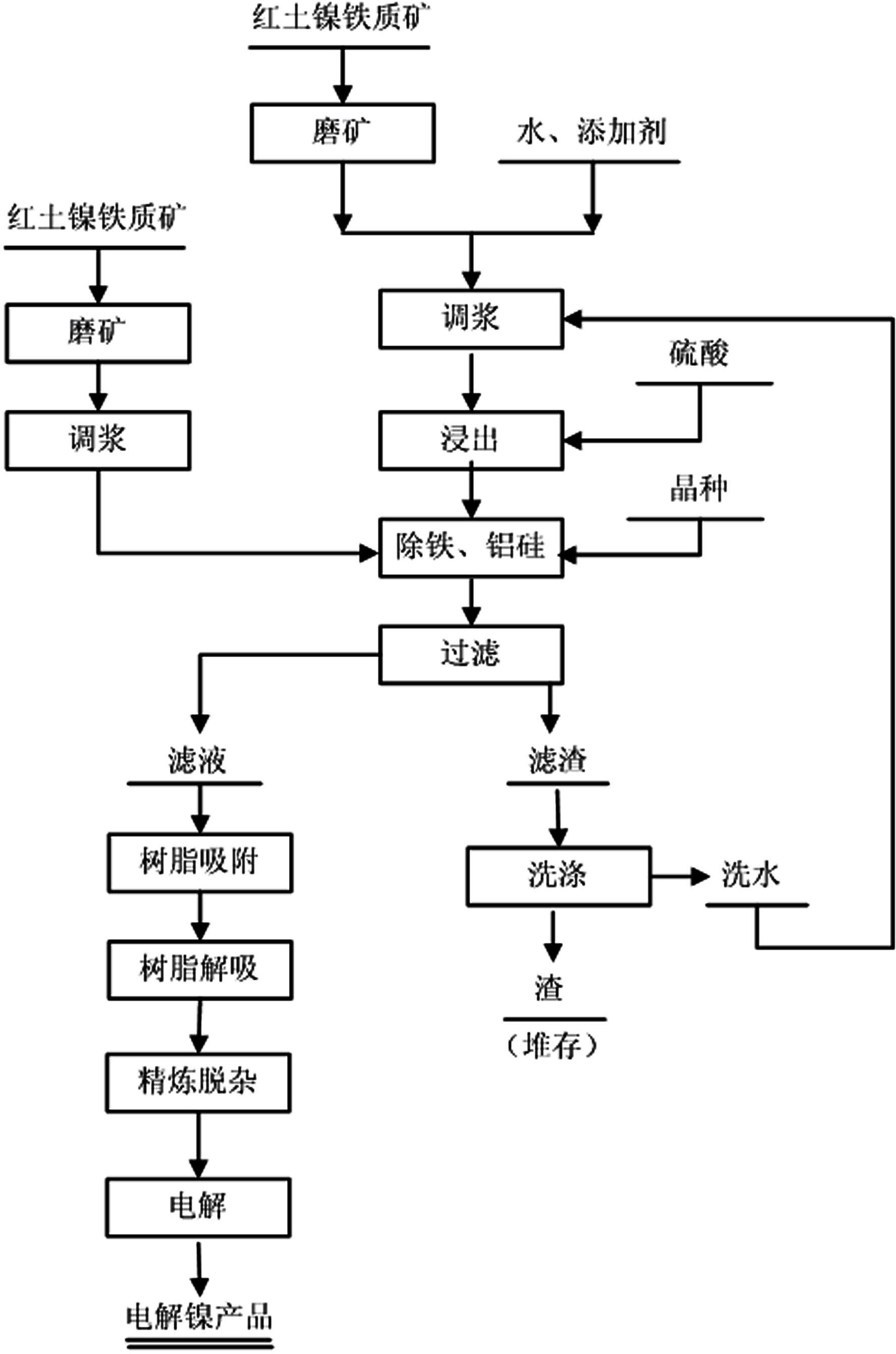

A kind of method of direct electrolysis of sulfuric acid leaching of laterite nickel ore

InactiveCN102286661AFully oxidizedEasy to leachPhotography auxillary processesProcess efficiency improvementElectrolysisIon exchange

A method for directly electrolyzing laterite nickel ore with sulfuric acid leaching, the invention relates to a method for leaching low-grade laterite nickel ore with sulfuric acid at normal pressure, and belongs to the technical field of hydrometallurgy. The steps of the method are: separately grinding and pulping the iron ore and magnesia ore in the laterite nickel ore, leaching the iron ore with sulfuric acid under high acidity and high acid ore ratio, adding magnesia ore slurry to adjust the pH value to precipitate jarosite Alkaline neutralizer is added to the mother liquor to remove aluminum and silicon. The filtered leachate is used to absorb nickel ions with ion exchange resin. The electrolytic nickel product is produced by electrolysis, and the magnesium sulfate-containing solution after the ion exchange resin is added with calcium hydroxide to precipitate, and the magnesium and calcium are separated by carbonization to obtain magnesium carbonate. The present invention solves the disadvantages of long process flow, large amount of magnesium-containing wastewater and difficult treatment, and makes the magnesium open to become a product, and the wastewater can be directly discharged or reused, and at the same time, part of the recovered magnesium can be returned to the process for recycling. agent.

Owner:YUNNAN TIN GROUP HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com