Patents

Literature

255 results about "Jarosite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Jarosite is a basic hydrous sulfate of potassium and iron with a chemical formula of KFe³⁺₃(OH)₆(SO₄)₂. This sulfate mineral is formed in ore deposits by the oxidation of iron sulfides. Jarosite is often produced as a byproduct during the purification and refining of zinc and is also commonly associated with acid mine drainage and acid sulfate soil environments.

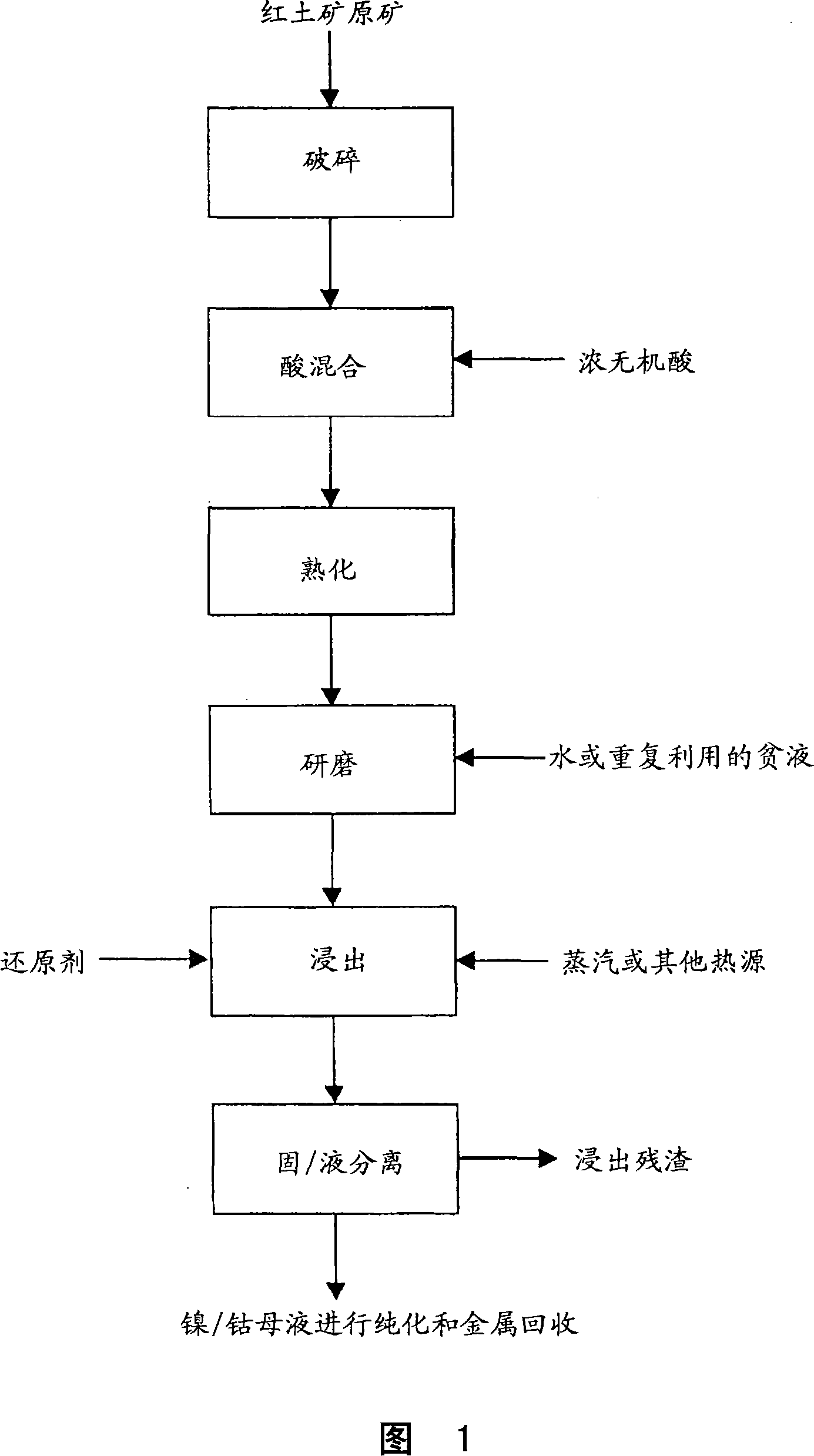

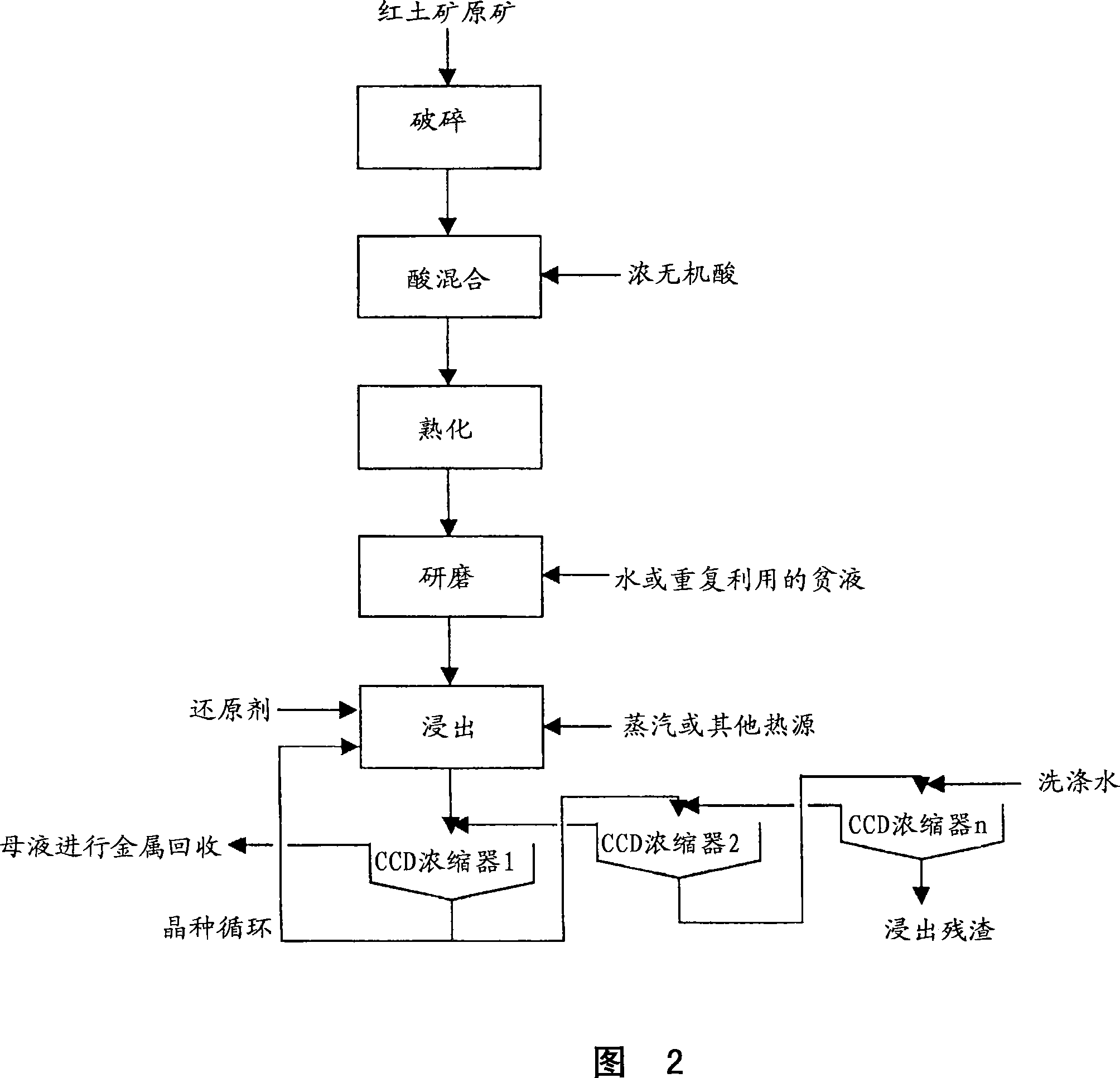

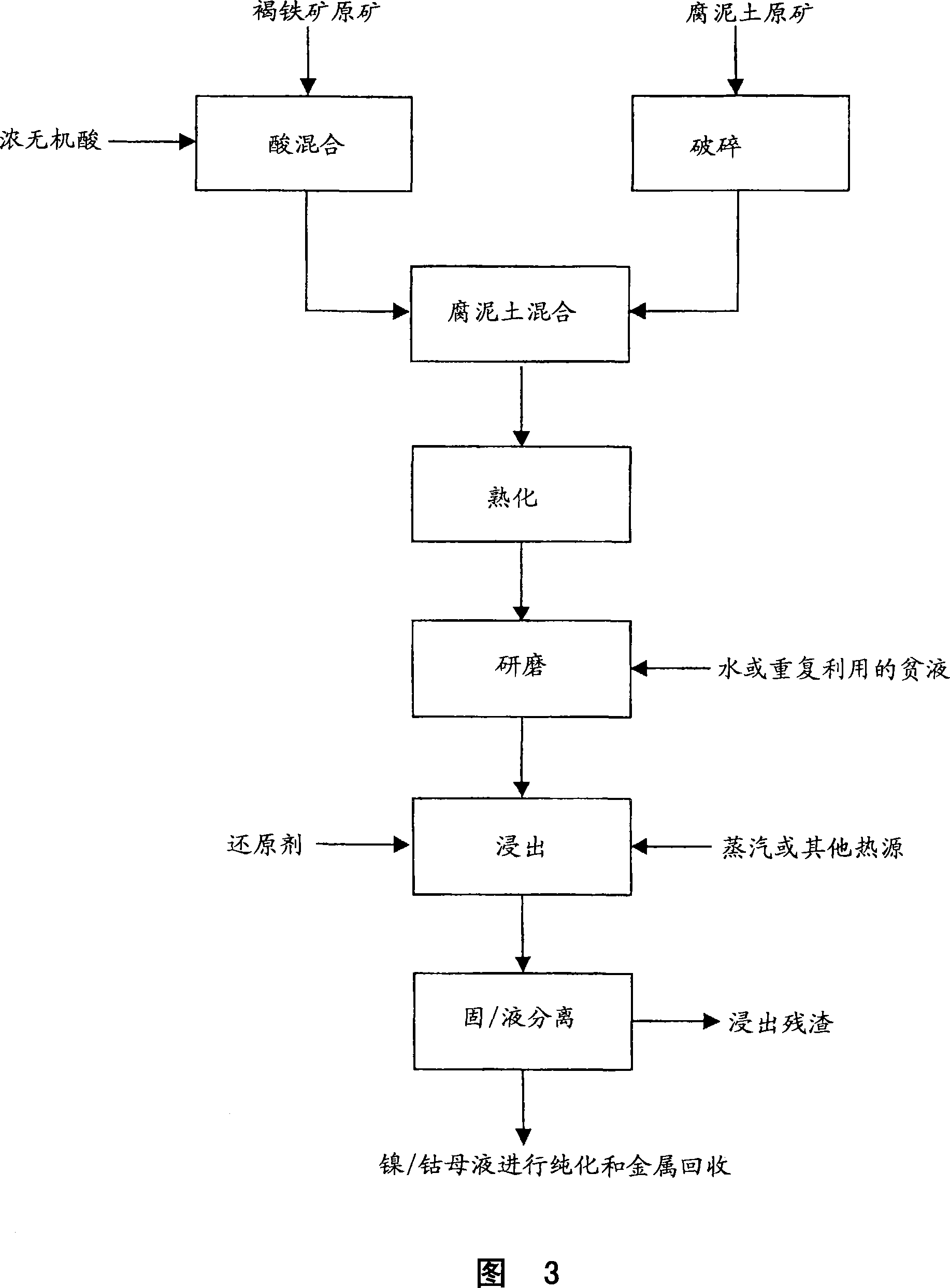

Method for nickel and cobalt recovery from laterite ores by reaction with concentrated acid and water leaching

InactiveCN101006190AHigh extraction rateLow extraction rateProcess efficiency improvementPotassiumSlurry

A process for leaching laterite ores containing limonite and saprolite in a two stage process. The first stage consisting of mixing and reacting the ore with concentrated mineral acid, and the second stage consisting of preparing a slurry of the acid / ore mixture in water and leaching the mixture to dissolve nickel and cobalt. Iron is efficiently separated from nickel and cobalt in the solid leach residue primarily as an oxide or hydroxide of ferric iron other than jarosite.

Owner:SKYE RESOURCES

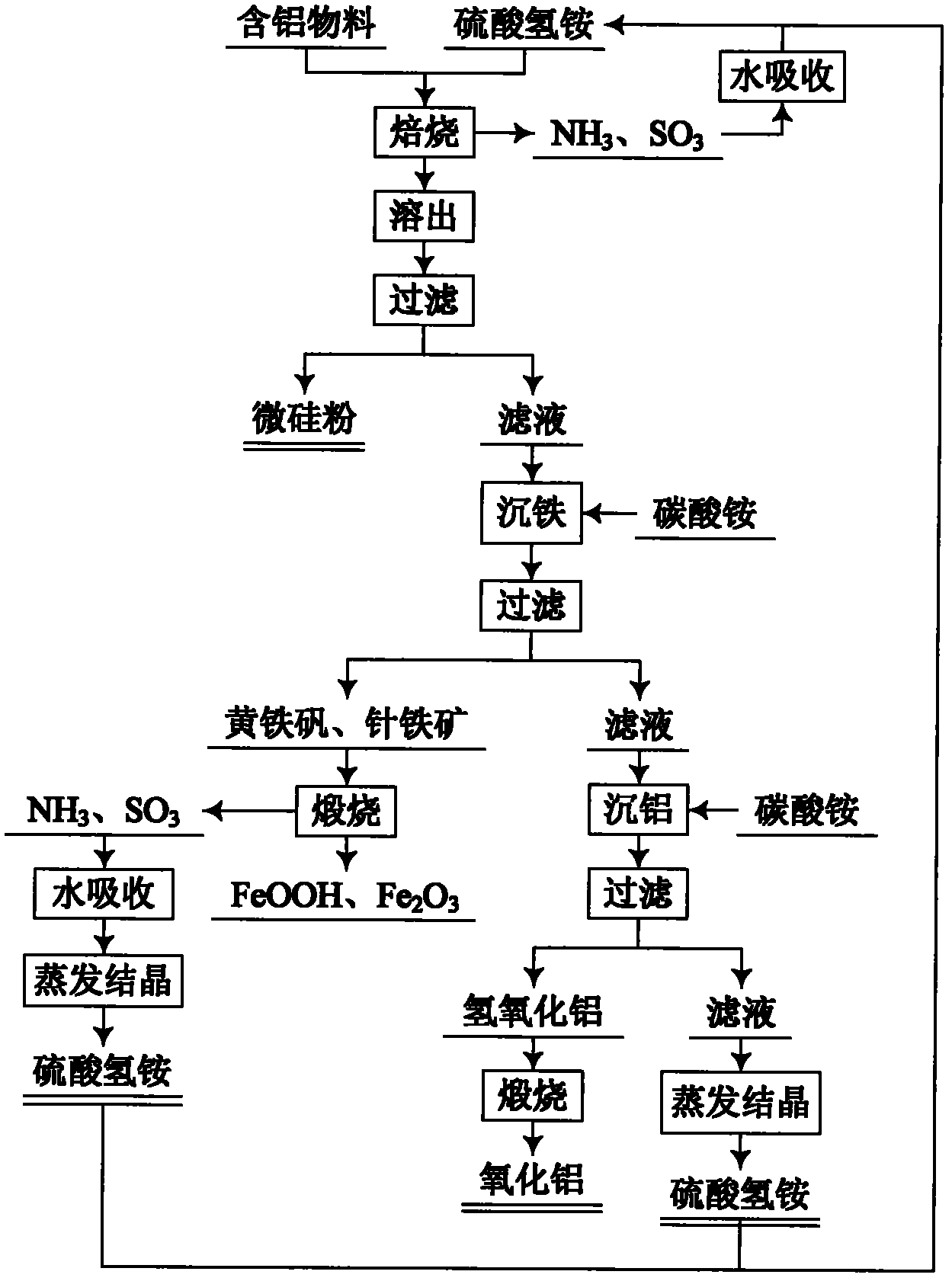

Method for comprehensive utilization of aluminum-containing material

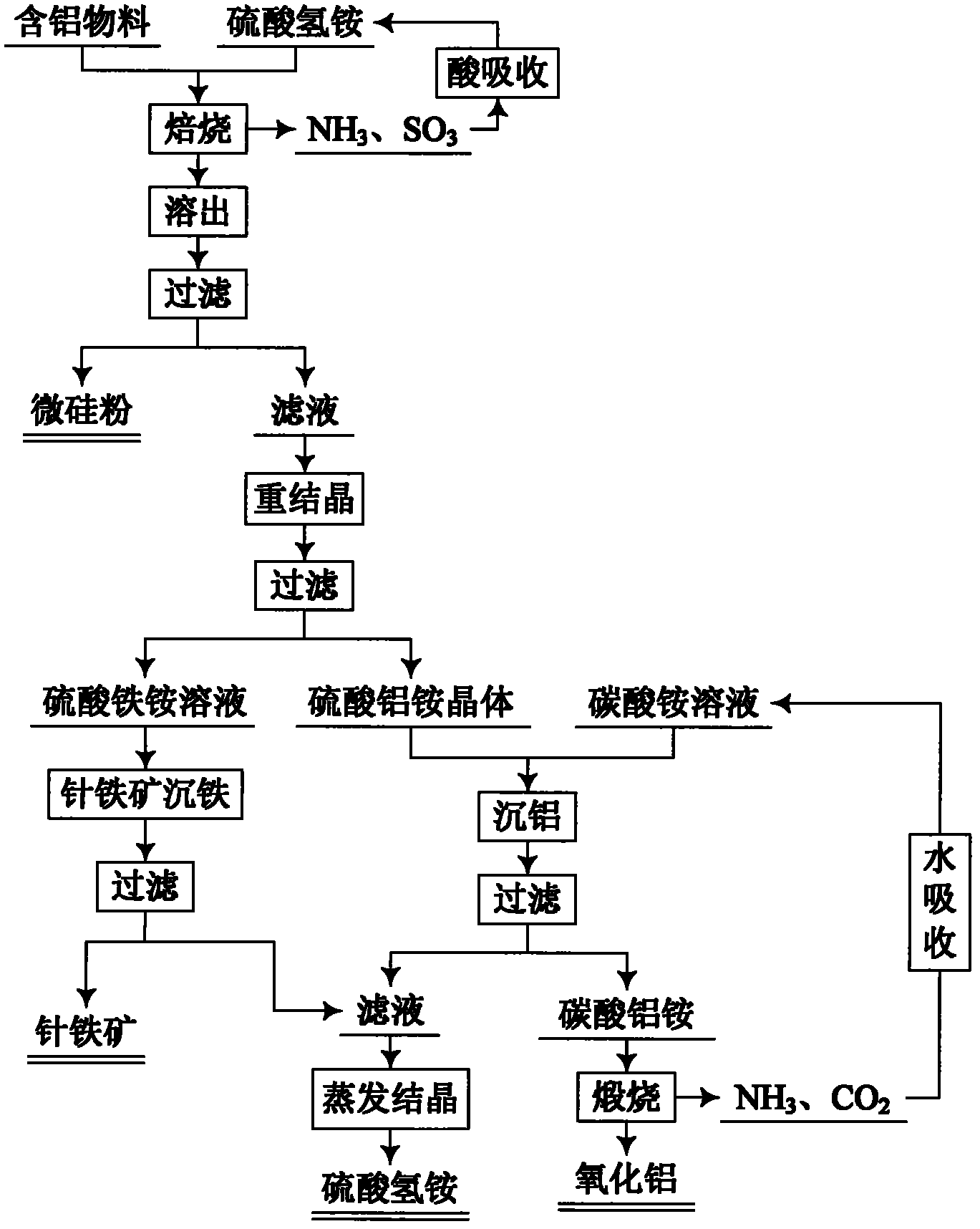

The invention relates to a method for preparing aluminum oxide and other products by aluminum-containing materials of bauxite, alunite, nepheline, fly ash, kaolin, coal gangue and clay. The method comprises the following steps: (1) crushing and grinding an aluminum-containing material, carrying out mixing and baking for the treated aluminum-containing material and ammonium bisulfate; (2) carryingout dissolution and filtering for the baked clinker to obtain a crude ammonium aluminum sulfate solution and aluminum extracting residue; (3) carrying out an iron precipitating treatment for the ammonium aluminum sulfate solution with the concentration more than 1 g / L by adopting a jarosite method, then carrying out an iron precipitating treatment by a goethite method, carrying out an aluminum precipitating treatment for the resulting solution, carrying out calcination for the resulting aluminium hydroxide to prepare aluminum oxide; (4) carrying out an iron precipitating treatment for the ammonium aluminum sulfate solution with the concentration less than 1 g / L by adopting the goethite method, and carrying out an aluminum precipitating treatment to prepare aluminum oxide, or adopting a recrystallization method to carry out purification, adopting a reaction of the ammonium aluminum sulfate crystal and a ammonium carbonate solution to precipitate the aluminum to obtain ammonium aluminumcarbonate, carrying out calcination for the ammonium aluminum carbonate, and adopting a Bayer method to treat the calcined ammonium aluminum carbonate to prepare sandy aluminum oxide; (5) washing anddrying the aluminum extracting residue, wherein the dried aluminum extracting residue is adopted as the silicon dioxide product.

Owner:NORTHEASTERN UNIV

Comprehensive recovery method for extracting ferrovanadium from stone coal acid immersion liquid

InactiveCN102127657AEasy to separateEasy to recycleProcess efficiency improvementRecovery methodSlag

The invention relates to a comprehensive recovery method for extracting ferrovanadium from stone coal acid leaching liquid. The process mainly comprises the following steps of: crystallizing a stone coal sulfuric acid leaching liquid into ammonium aluminum alum sulfate and adding a pH value regulator to the crystallized liquid at a room temperature; oxidizing, precipitating and separating out crystallized liquid into a mixture containing ammonium jarosite and ammoniojarosite, leaching the vanadium-contained mixture separated from the precipitate in alkaline to obtain alkaline leaching liquid and alkaline leaching slag; adding sulphuric acid to the alkaline leaching liquid to acidify and precipitate vanadium pentoxide, calcining, washing and drying the vanadium pentoxide to obtain a refined vanadium product, calcining the alkaline leaching slag to obtain ferric oxide or adding sulphuric acid to dissolve, concentrate and crystallize to obtain polymerase ferric sulfate; and transforming the ammonium aluminum alum sulfate and regenerating vanadium precipitation mother liquor alkali, and the like. The invention has the advantages of good product quality, less reagent amount, low production cost, environmental protection, and the like.

Owner:CENT SOUTH UNIV

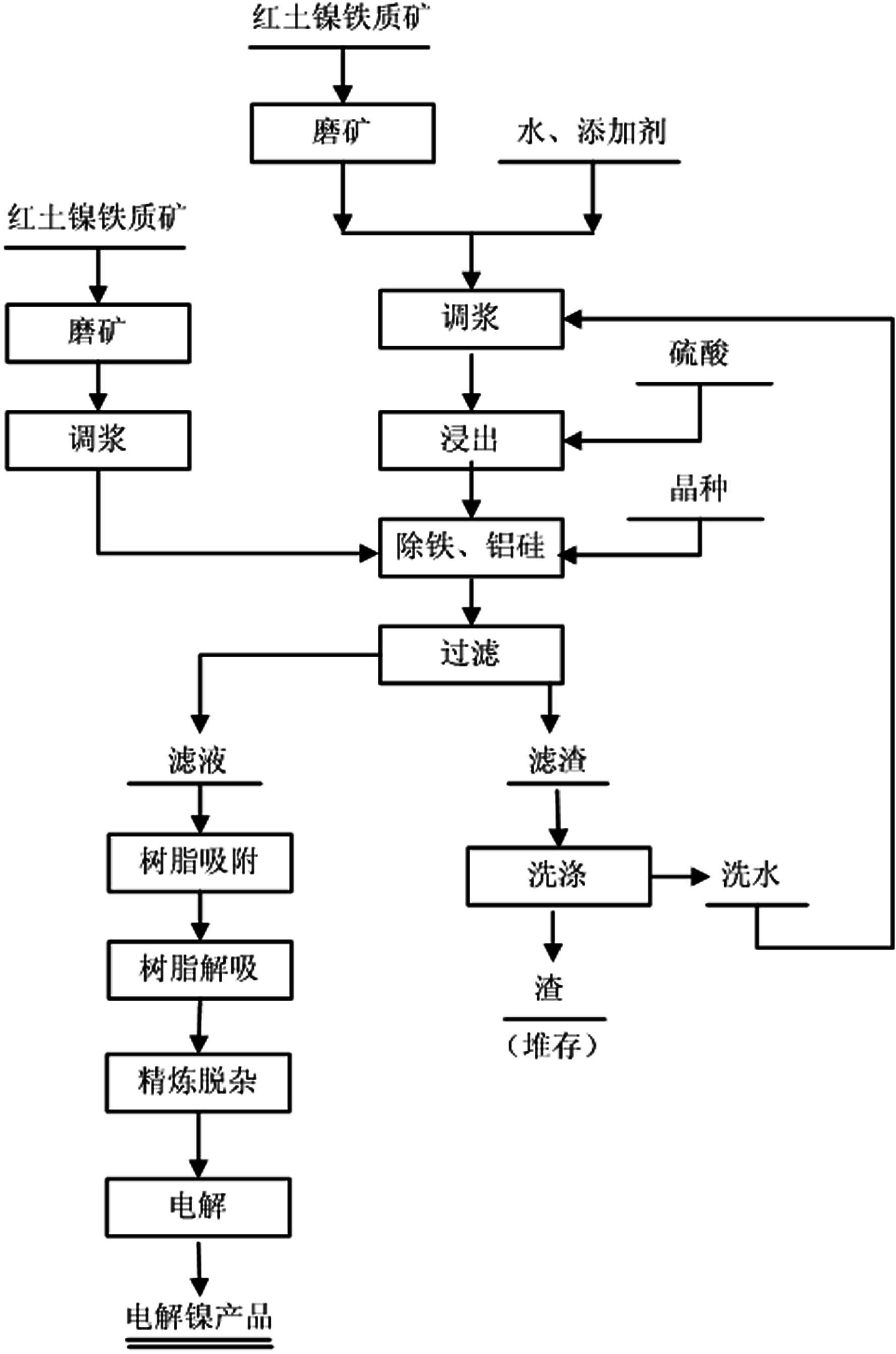

A kind of method of direct electrolysis of sulfuric acid leaching of laterite nickel ore

InactiveCN102286661AFully oxidizedEasy to leachPhotography auxillary processesProcess efficiency improvementElectrolysisIon exchange

A method for directly electrolyzing laterite nickel ore with sulfuric acid leaching, the invention relates to a method for leaching low-grade laterite nickel ore with sulfuric acid at normal pressure, and belongs to the technical field of hydrometallurgy. The steps of the method are: separately grinding and pulping the iron ore and magnesia ore in the laterite nickel ore, leaching the iron ore with sulfuric acid under high acidity and high acid ore ratio, adding magnesia ore slurry to adjust the pH value to precipitate jarosite Alkaline neutralizer is added to the mother liquor to remove aluminum and silicon. The filtered leachate is used to absorb nickel ions with ion exchange resin. The electrolytic nickel product is produced by electrolysis, and the magnesium sulfate-containing solution after the ion exchange resin is added with calcium hydroxide to precipitate, and the magnesium and calcium are separated by carbonization to obtain magnesium carbonate. The present invention solves the disadvantages of long process flow, large amount of magnesium-containing wastewater and difficult treatment, and makes the magnesium open to become a product, and the wastewater can be directly discharged or reused, and at the same time, part of the recovered magnesium can be returned to the process for recycling. agent.

Owner:YUNNAN TIN GROUP HLDG

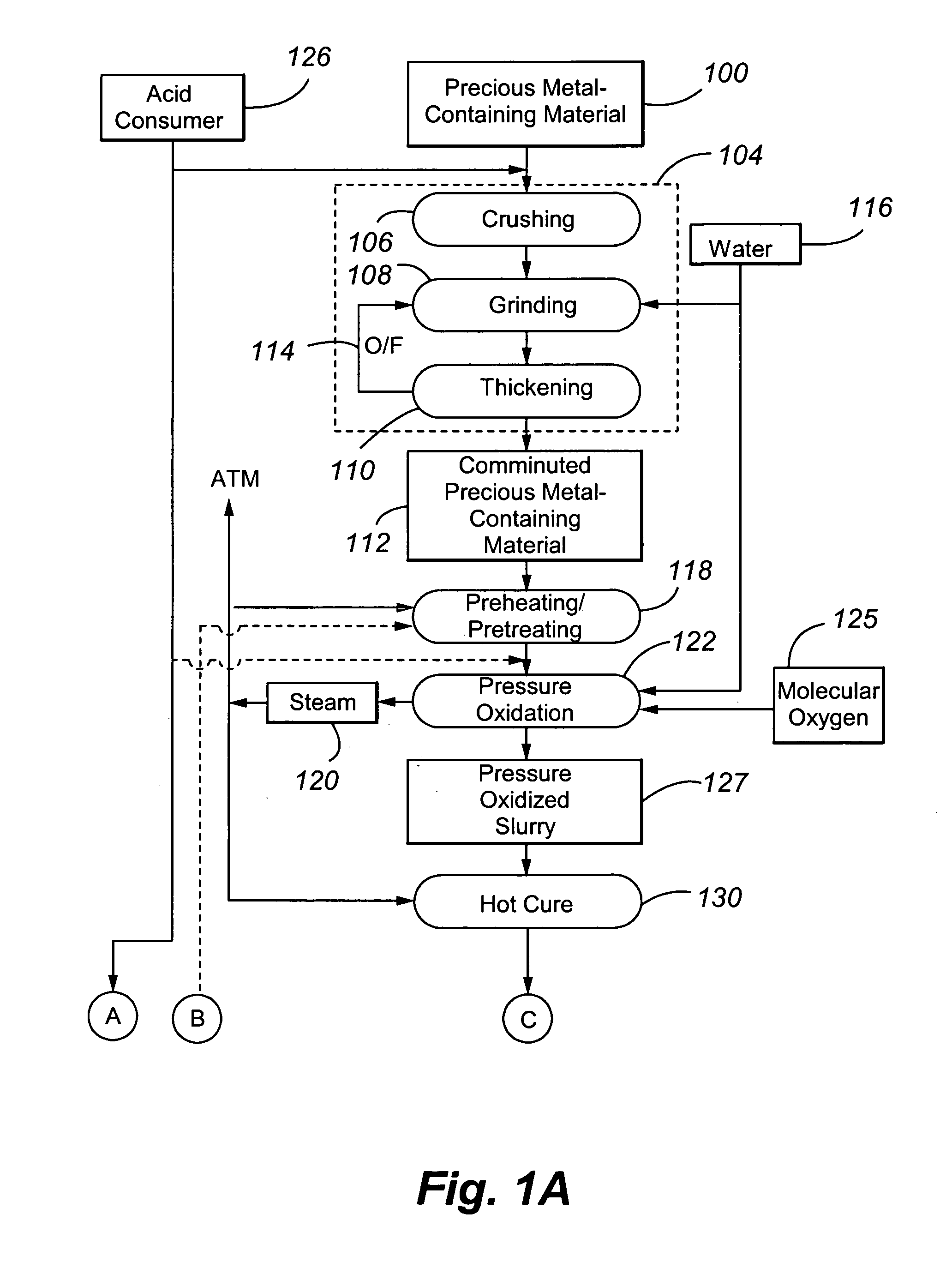

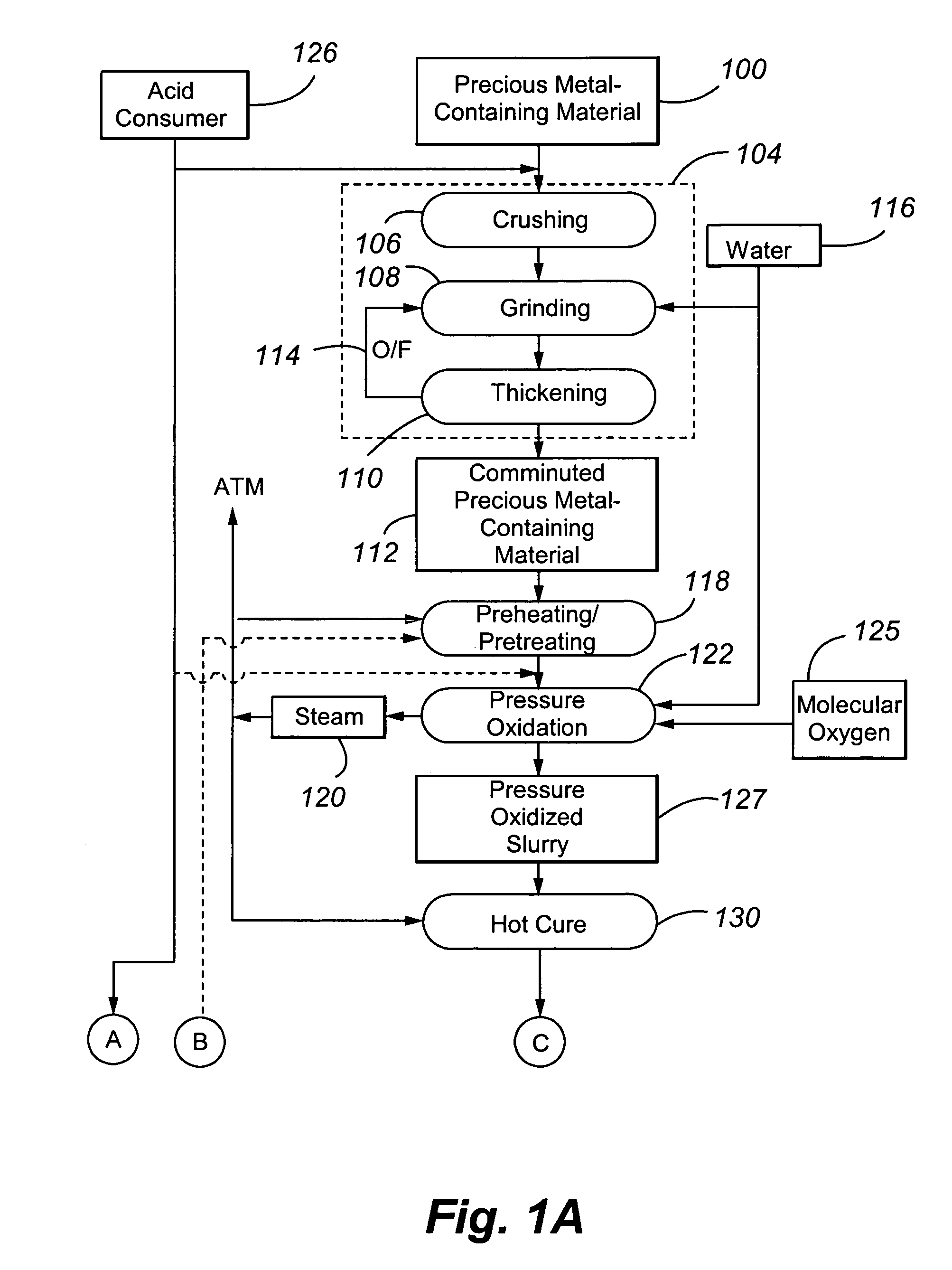

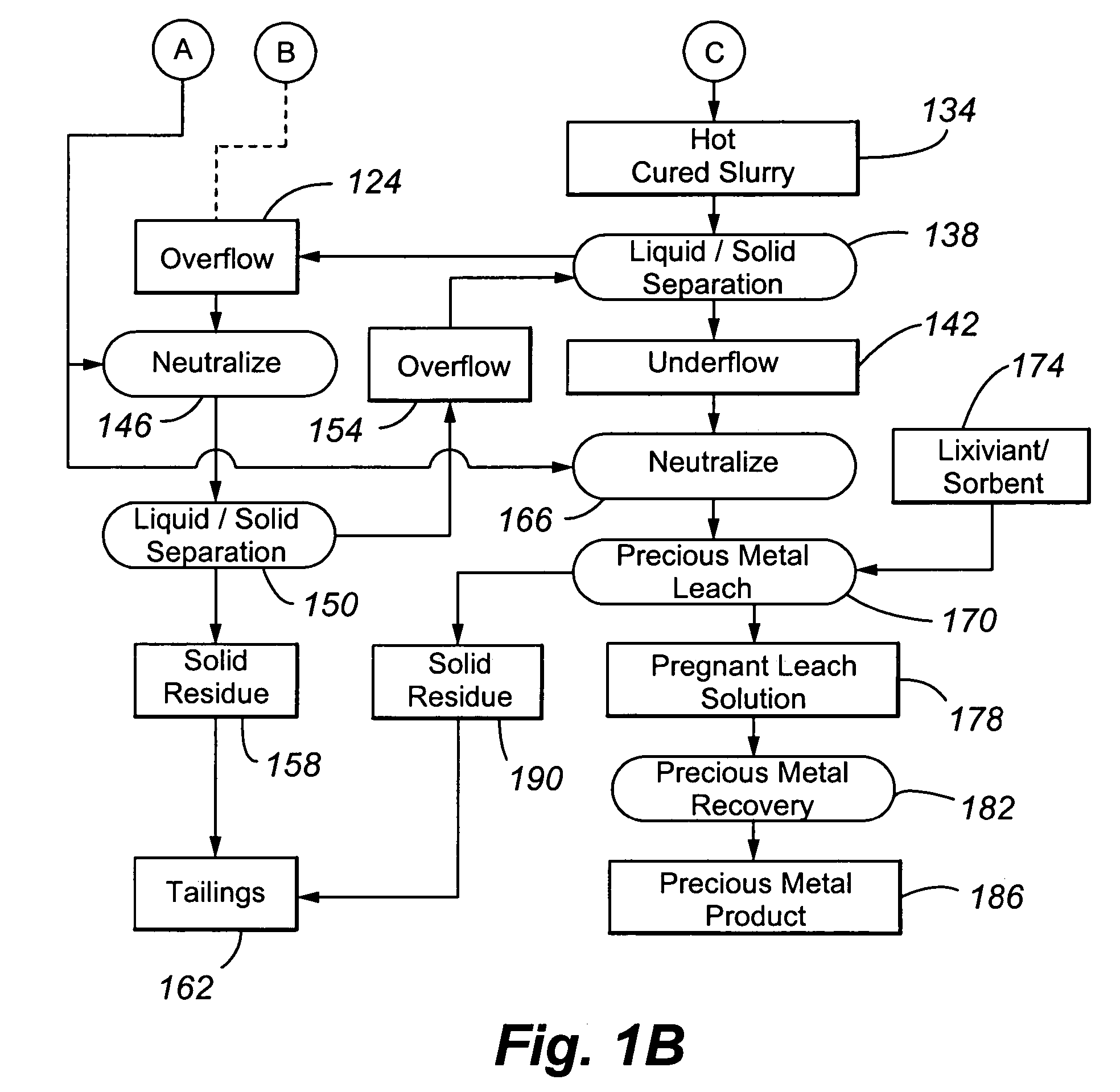

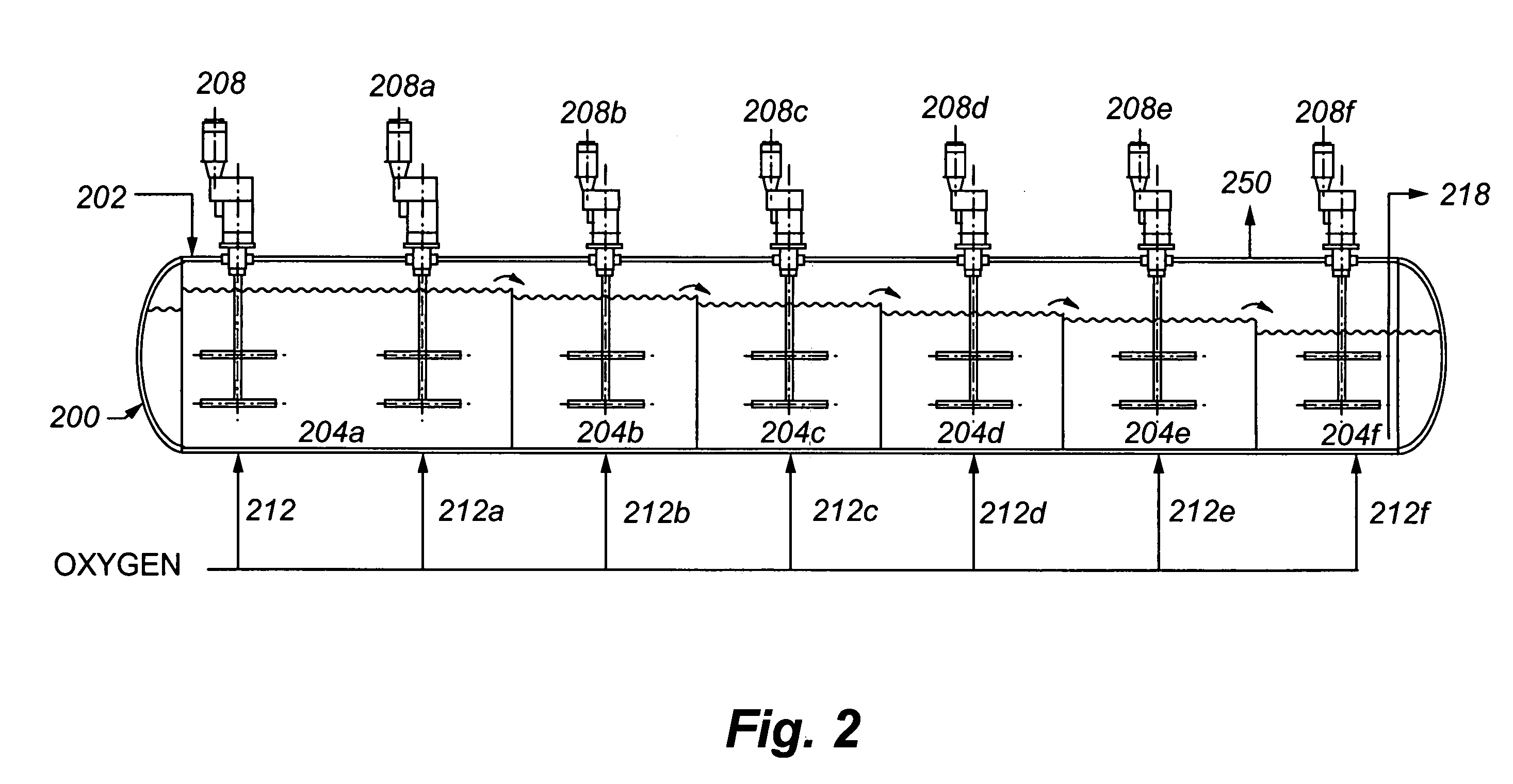

Reduction of lime consumption when treating refractory gold ores or concentrates

ActiveUS20060133974A1Improve the level ofReduce operating costsSolvent extractionGold compoundsSlurryGold ore

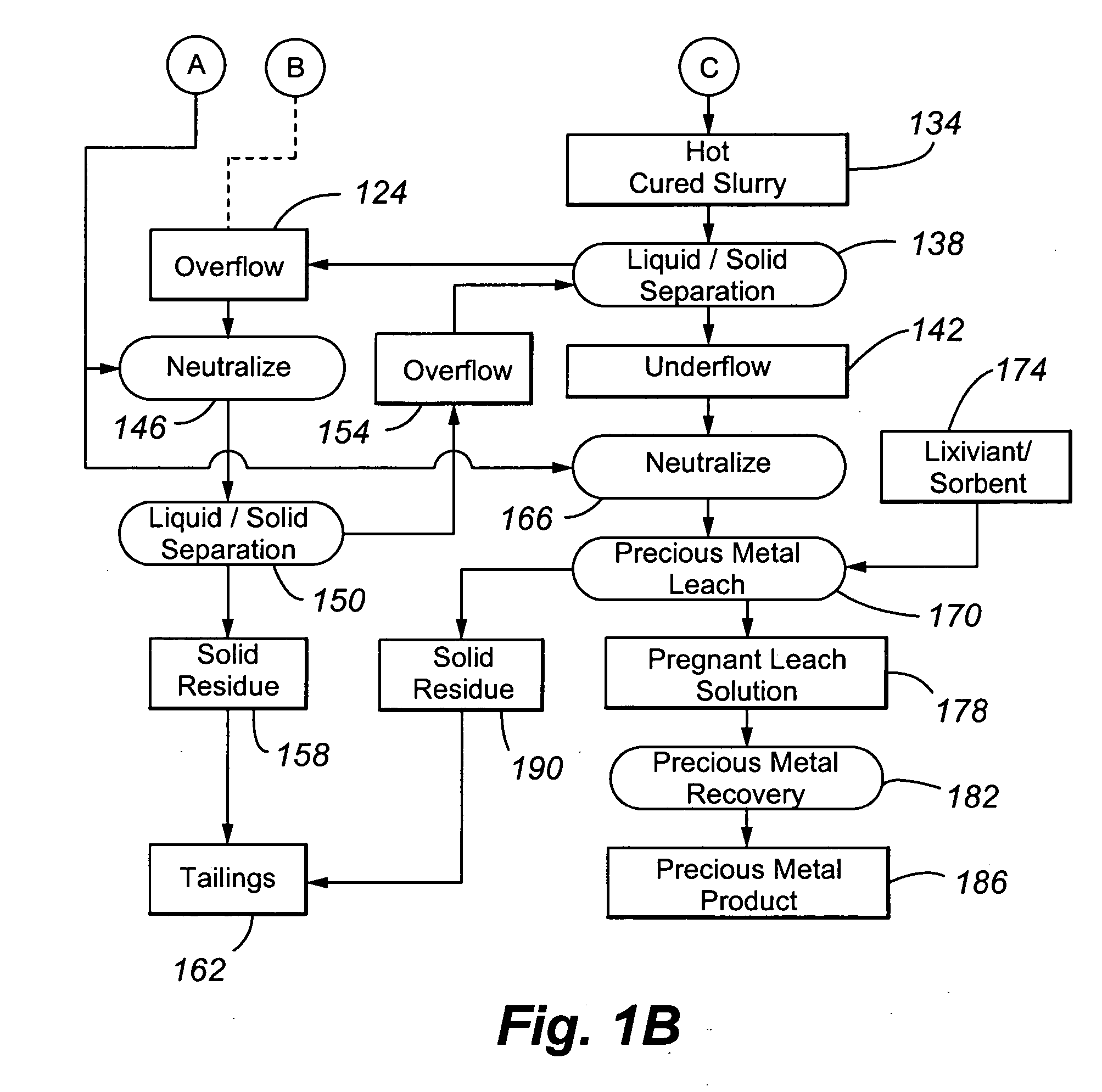

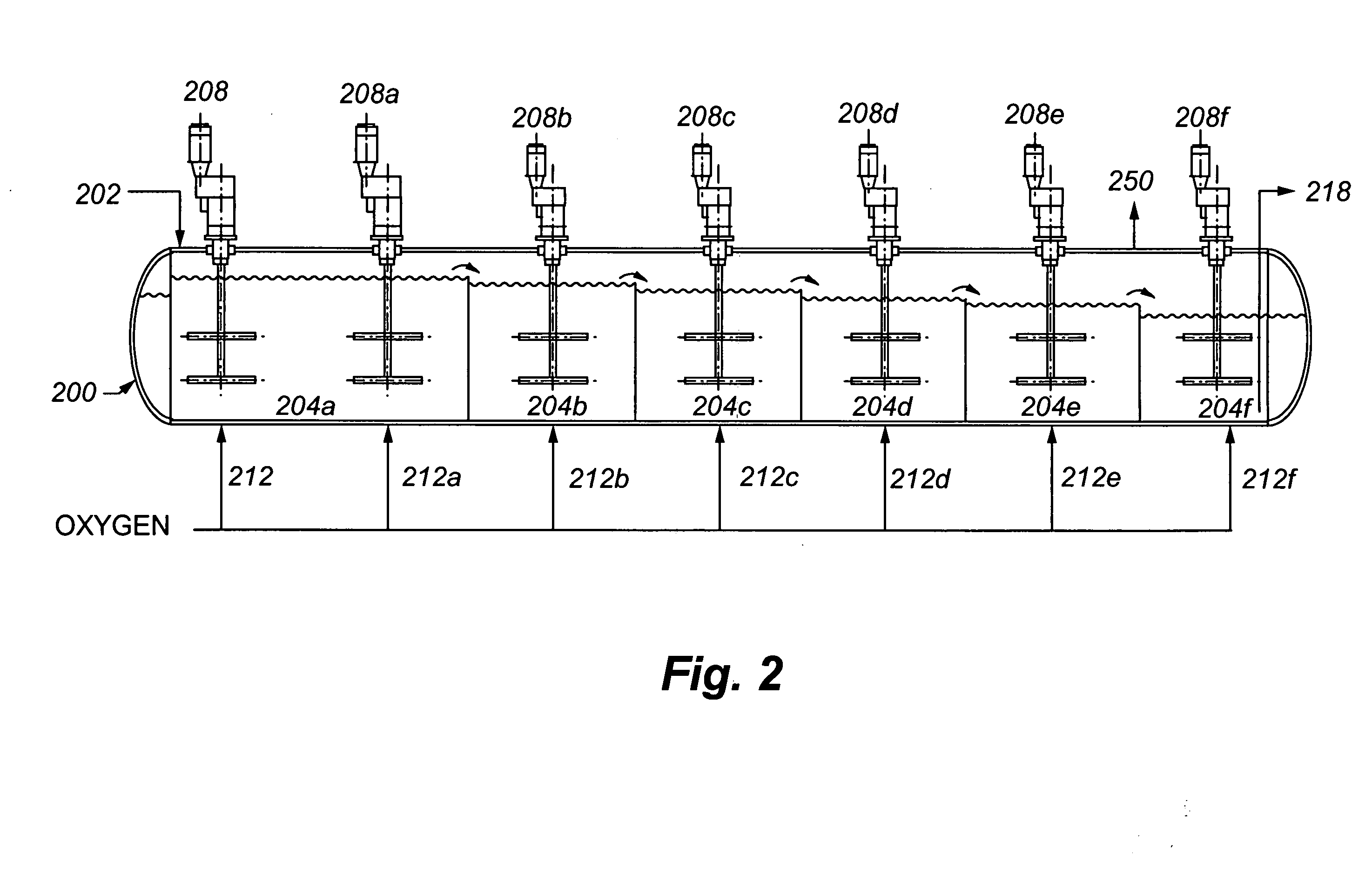

The present invention is directed to a precious metal recovery process in which basic ferric sulphates and / or jarosites are controlled by a number of mechanisms, including control of the oxidation reaction conditions in the first autoclave compartment, hot curing of the autoclave discharge slurry, and / or contacting of the autoclave feed slurry with the hot cured discharge liquid.

Owner:PLACER DOME TECHN SERVICES

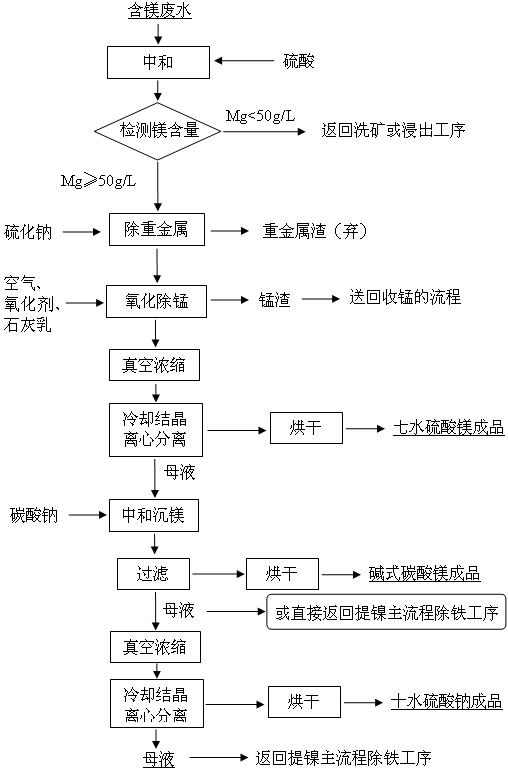

A comprehensive treatment method for laterite nickel ore hydrometallurgy wastewater

ActiveCN102276099ASolve the emission problemReduce manufacturing costMagnesium carbonatesMagnesium sulfatesManganeseEvaporation

The invention discloses a comprehensive treatment method of waste water from laterite-nickel ore wet smelting, which comprises the following steps: adjusting magnesium-containing waste water to be neutral so as to return the waste water to the ore-washing or leaching procedure for a process purpose, increasing the magnesium concentration of the waste water to above 50 g / L, performing heavy metal removal and manganese removal, performing negative pressure evaporation concentration, cooling crystallization, centrifugation separation, and drying to obtain magnesium sulfate heptahydrate, performing magnesium precipitation of the mother liquor after crystallization by sodium carbonate, separating basic magnesium carbonate, performing negative pressure evaporation concentration, cooling crystallization, centrifugation separation, and drying of the mother liquor after magnesium precipitation to obtain sodium sulfate decahydrate, or returning the mother liquor after magnesium precipitation directly to the iron-removing procedure of the nickel-extraction flow and to be used as a sodium source for iron removal by a sodium jarosite method. The method of the invention is simple and practical,has low cost, does not generate waste by-products, can both produce salable chemical products and reduce the production cost of the main flow for nickel recovery, and also prevents environment pollution.

Owner:广西银亿新材料有限公司

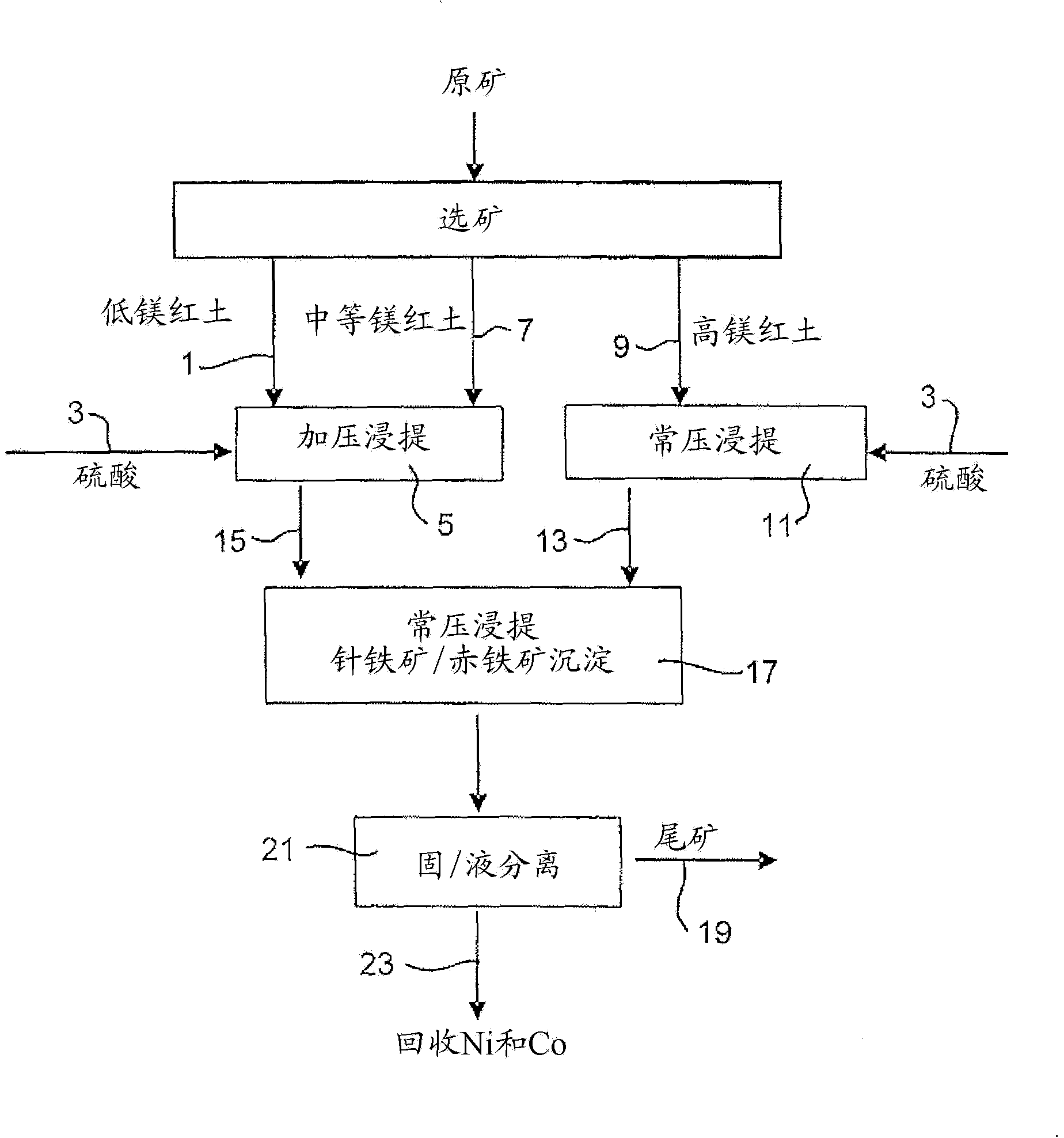

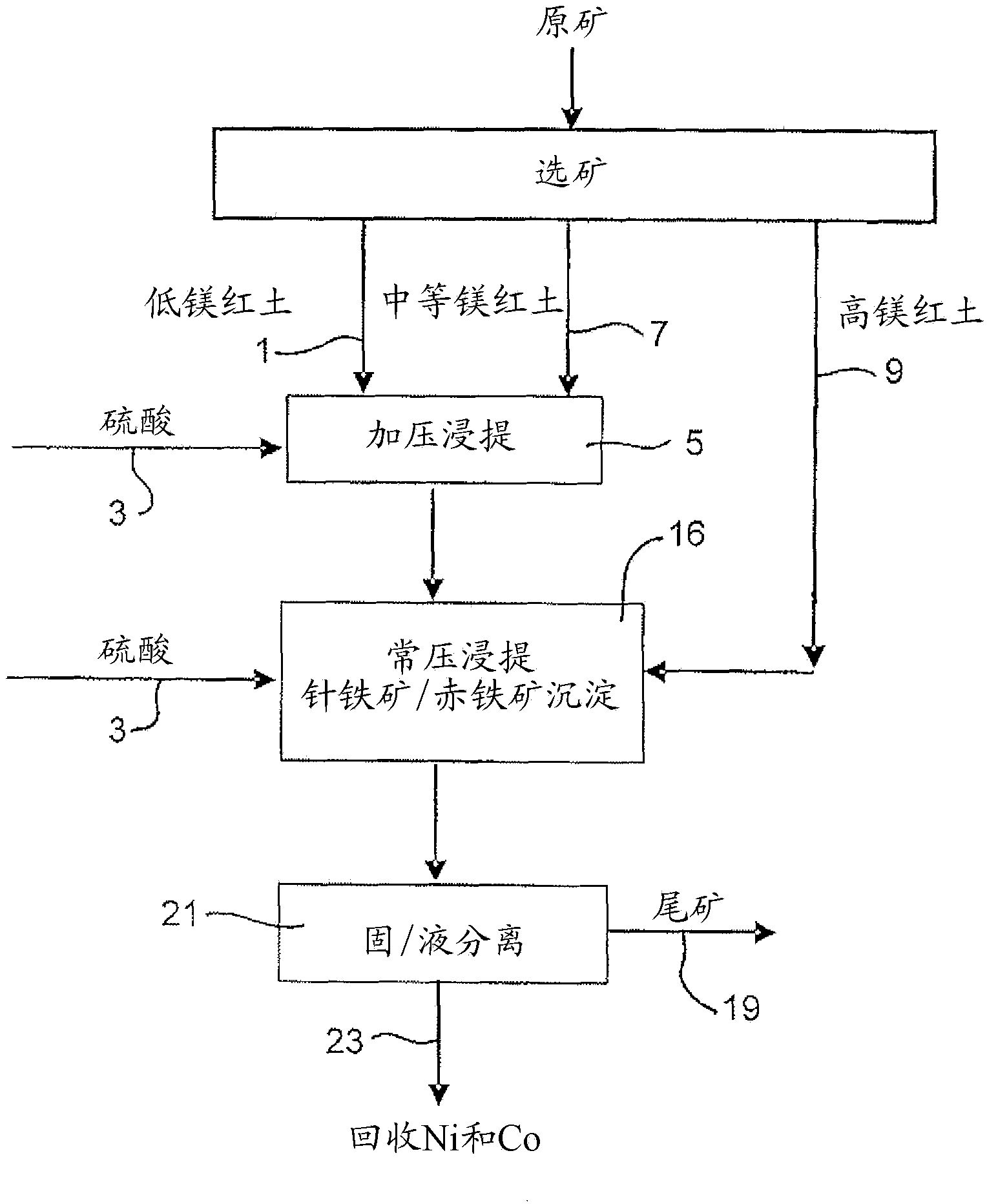

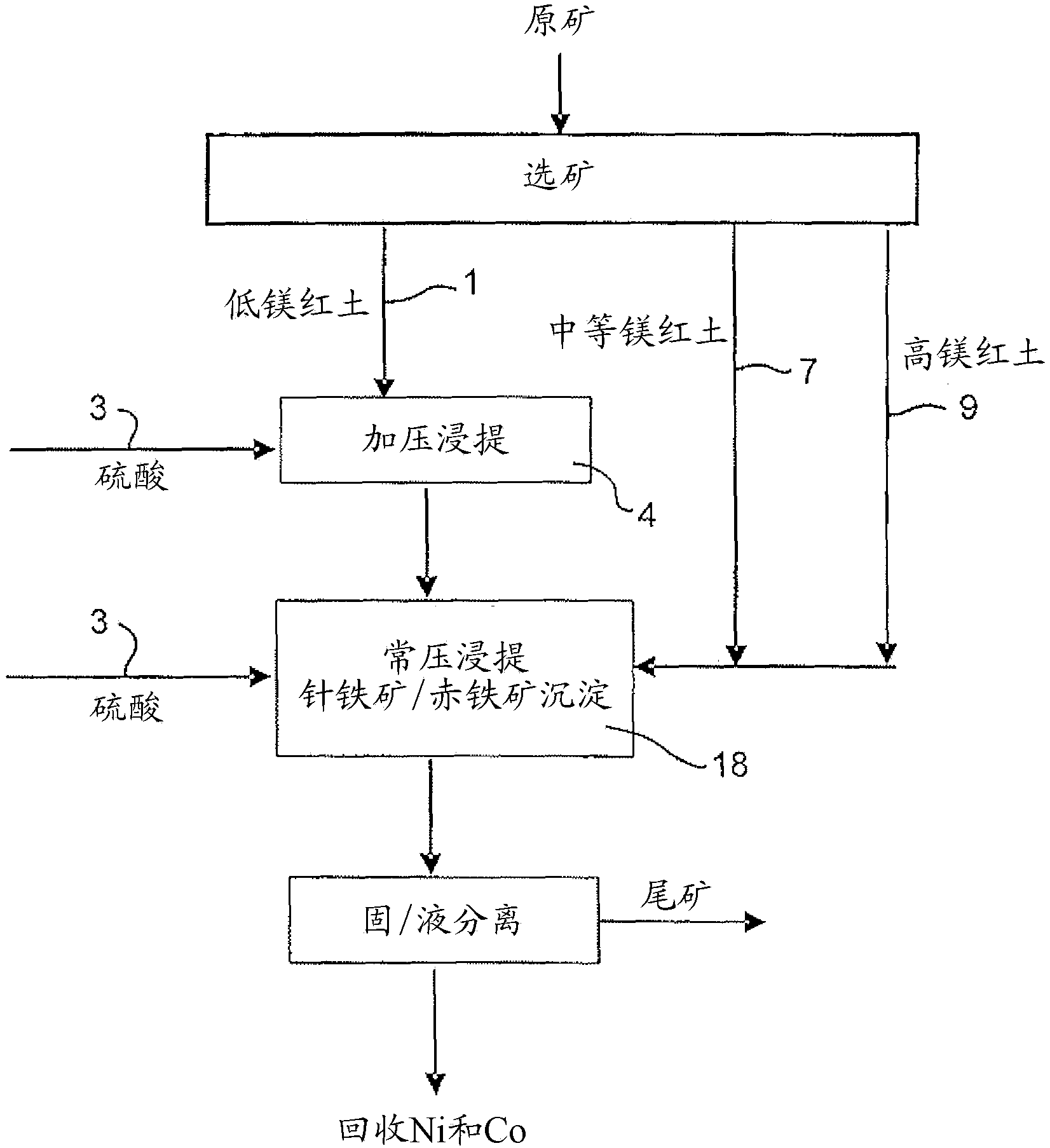

Process for enhanced acid leaching of laterite ores

A process is described for the recovery of nickel and cobalt from a nickeliferous laterite ore including the steps of: a) providing a nickeliferous laterite ore and separating that ore into its low magnesium limonite fraction and high magnesium saprolite fraction; b) treating the limonite fraction in acid solution in a primary high pressure leach step to produce a primary leach slurry; c) adding the saprolite fraction to the primary leach slurry to initiate precipitation of iron as goethite and / or hematite, while simultaneously releasing further acid from the iron precipitation, to effect a secondary atmospheric leach step, producing a secondary leach slurry; wherein all water used to prepare the ore slurries and / or acid solutions has an ionic composition that substantially avoids jarosite formation.

Owner:BHP BILLITON SSM TECH PTY LTD

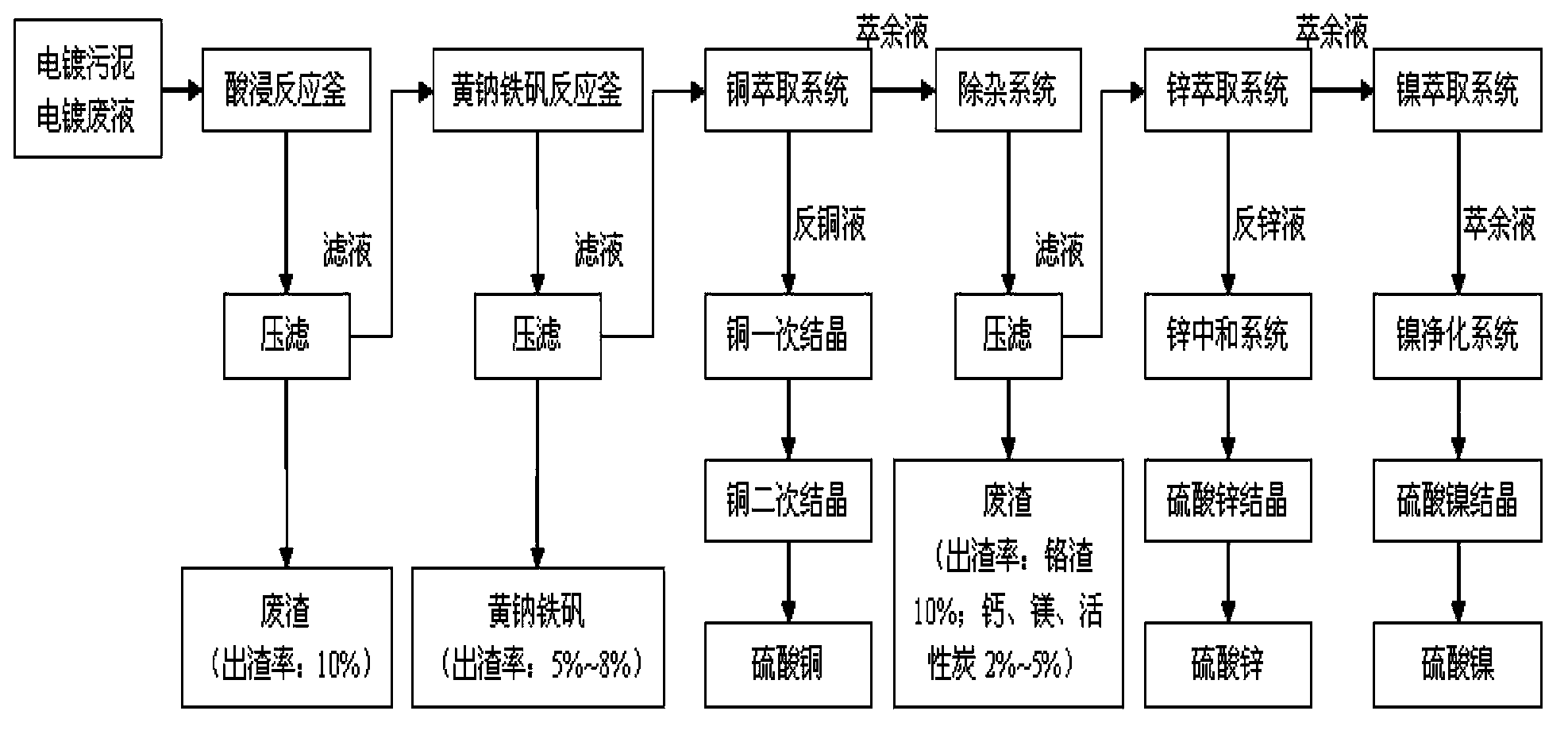

Electroplating sludge recycling technology

InactiveCN104099474AReduce dosageGuaranteed leaching rateZinc sulatesSludge treatmentLiquid wasteSludge

The invention discloses an electroplating sludge recycling technology. The technology comprises the steps of acid dipping, iron removal, copper extraction, impurity removal, zinc extraction, nickel extraction, low acid leaching and high acid leaching, tailings are washed with water, the iron removal step is carried out through a sodium jarosite process, copper extraction adopts two stage extraction, two stage water washing, four stage back extraction, and second stage extraction is carried out after first stage extraction, precipitation, washing and acid dissolution. The technology has the advantages of technological period shortening, guarantee of the product purity through multiple stage extraction, effective use of the waste resource, and reduction of the emission of a waste liquid.

Owner:ZHENJIANG HUAKE ENVIRONMENTAL PROTECTION TECH

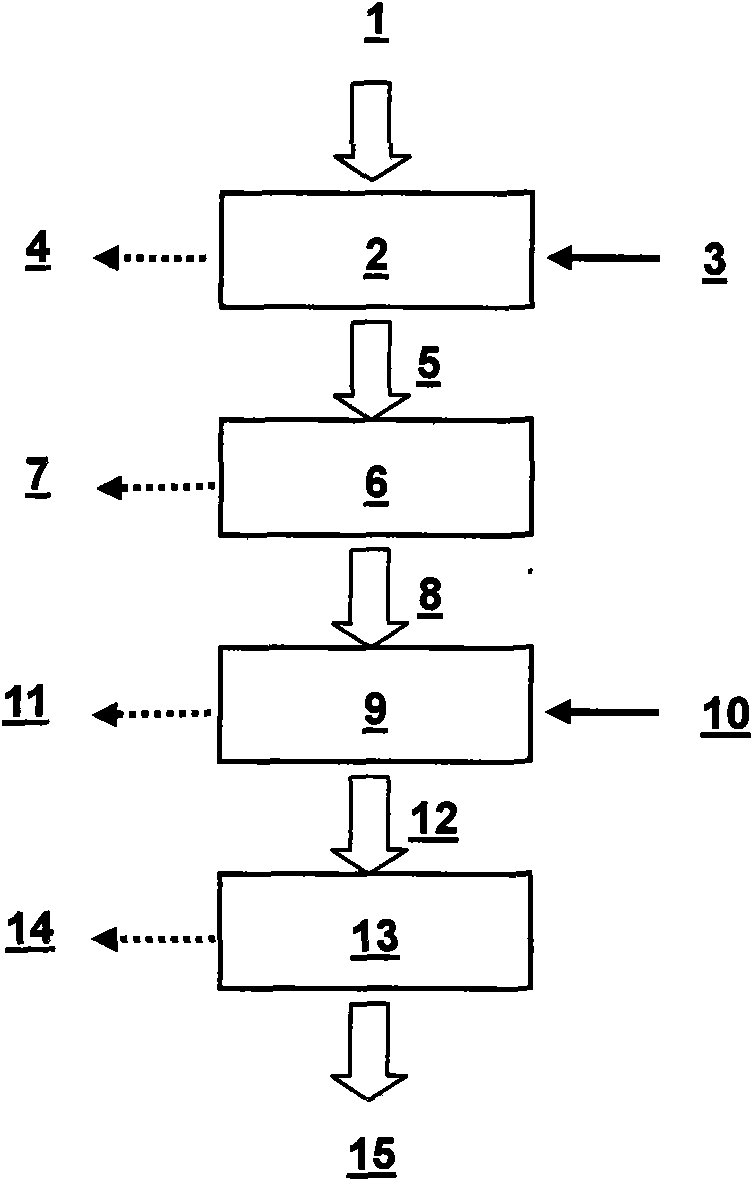

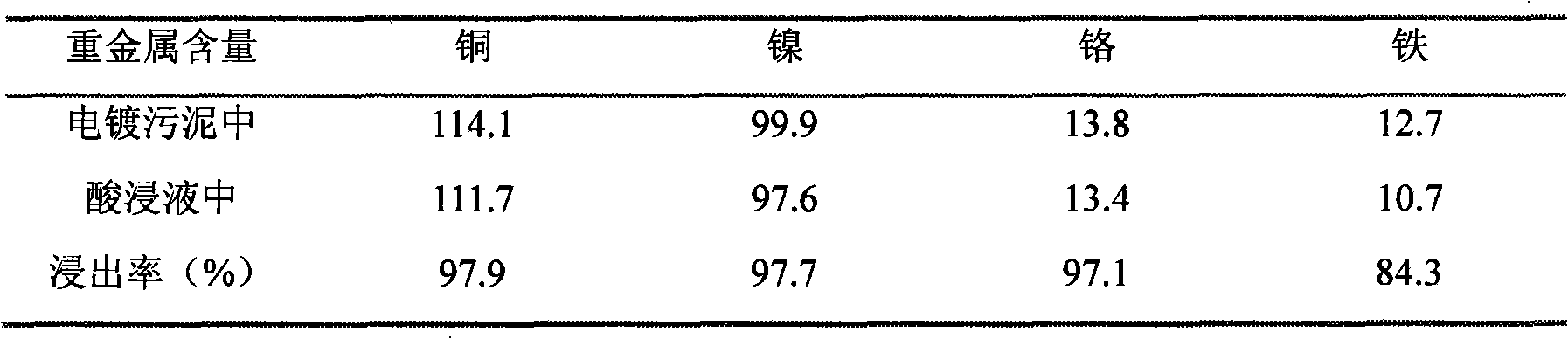

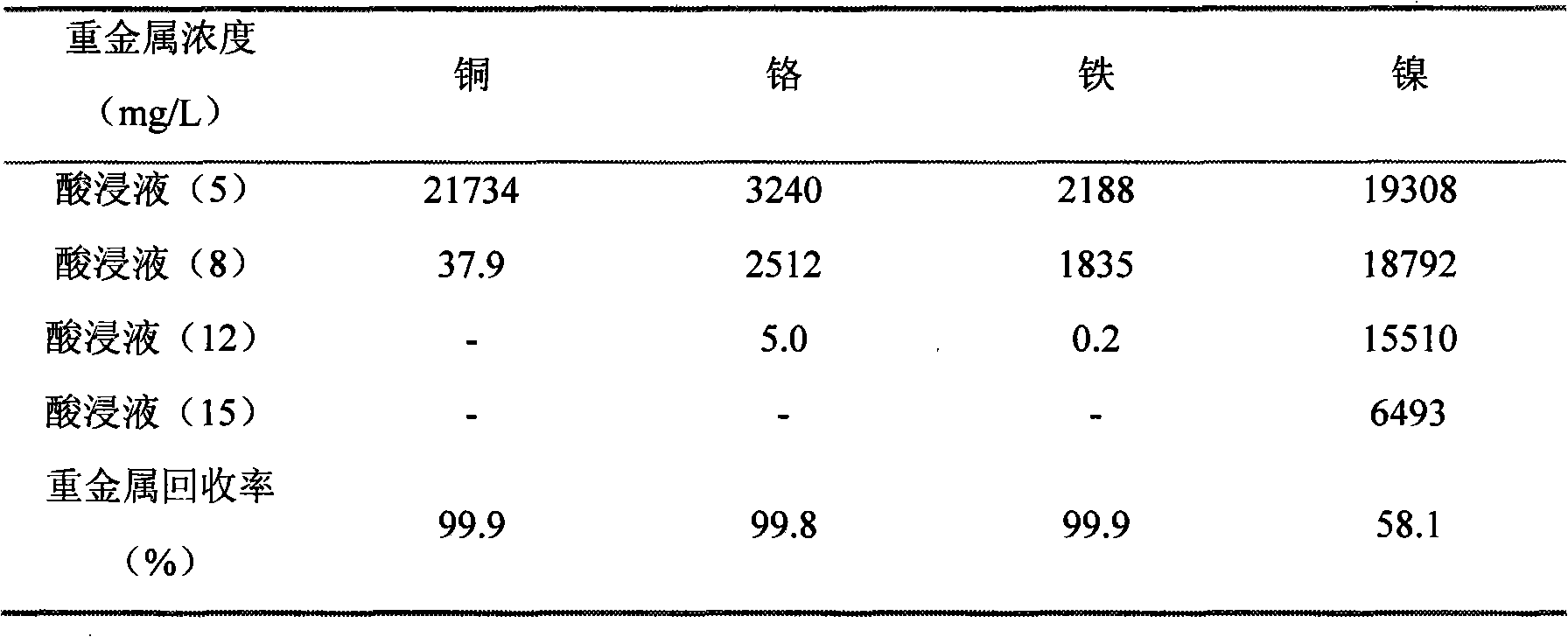

Method for realizing resource recovery of electroplating sludge

The invention relates to a treatment method for realizing resource recovery of electroplating sludge, which comprises the following steps: firstly, valuable metals in electroplating sludge are leached out by acid at normal temperature; secondly, filtered acid immersion liquid is poured into a copper electrolytic bath to recover and obtain electrolytic copper; thirdly, ferrum and chromium in copper acid immersion liquid are removed by ammonium jarosite through sedimentation, and iron-chromium residue and acid immersion liquid containing nickel are separated through filtration; and finally, the acid immersion liquid containing nickel is poured into an electrolytic bath of nickel to recover part of electrolytic nickel, and the rest nickel vitriol solution is taken as material for plating solution to be reused by a plating workshop. The method adopts a step-processing technique of acid dipping, electrolysis, sedimentation and electrolysis, so that electrolytic copper with high purity, iron-chromium residue and electrolytic nickel can be obtained. In addition, the method has simple process, low investment and operation cost, and higher economic benefit and environmental benefit.

Owner:OCEAN UNIV OF CHINA

Reduction of lime consumption when treating refractory gold ores or concentrates

The present invention is directed to a precious metal recovery process in which basic ferric sulphates and / or jarosites are controlled by a number of mechanisms, including control of the oxidation reaction conditions in the first autoclave compartment, hot curing of the autoclave discharge slurry, and / or contacting of the autoclave feed slurry with the hot cured discharge liquid.

Owner:PLACER DOME TECHN SERVICES

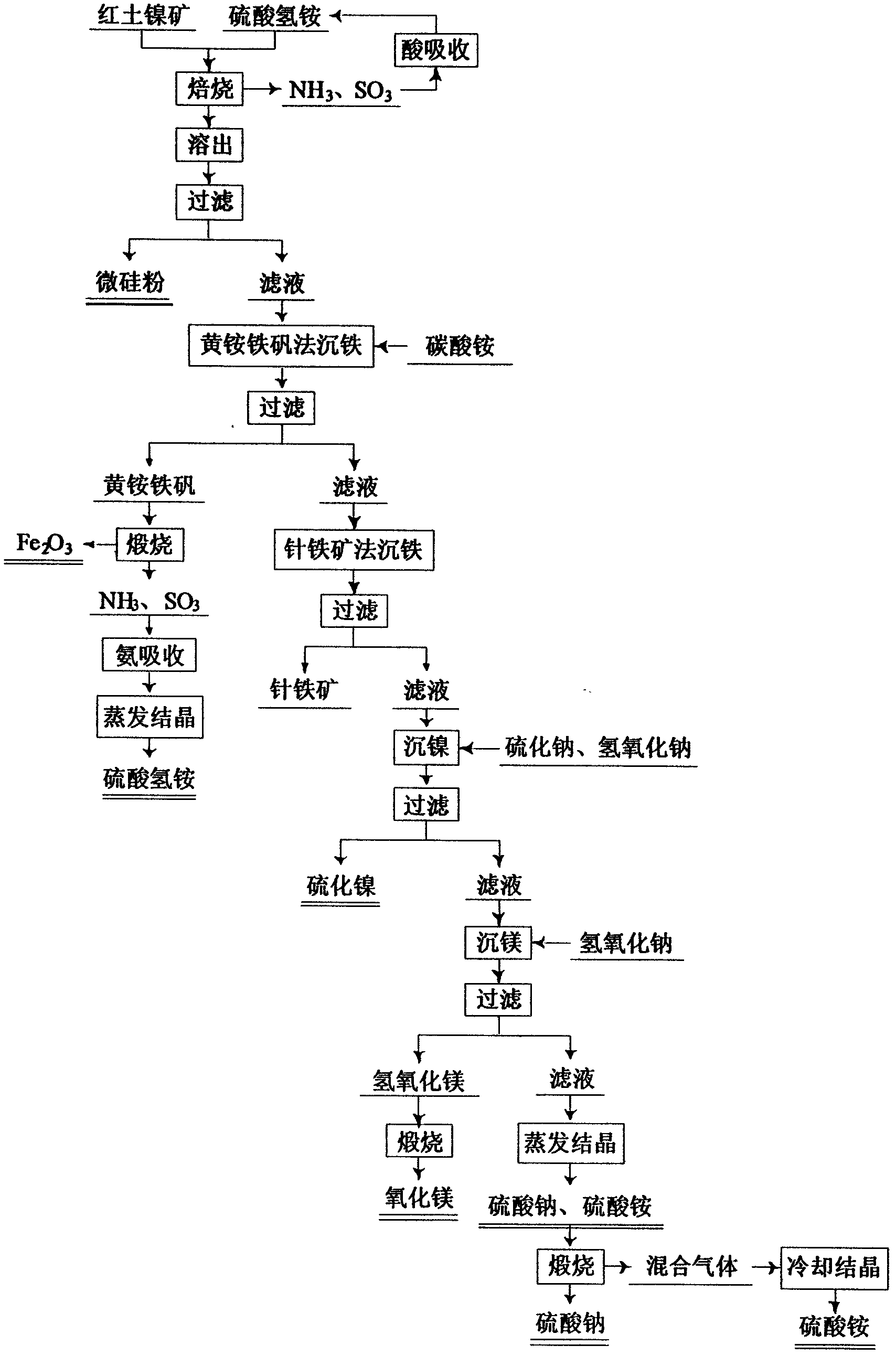

Method for comprehensive utilization of laterite nickel ore

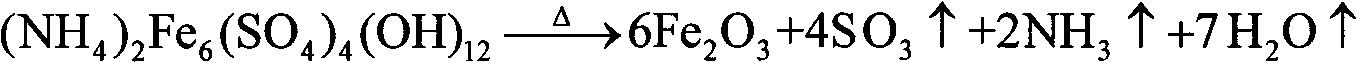

A method for comprehensive utilization of laterite nickel ore comprises the following steps: (1) pulverizing laterite nickel ore, grinding, mixing with ammonium bisulfate, and roasting; (2) dissolving and filtering the roasted clinker to obtain a filtrate, depositing iron by an ihleite method, and depositing iron by a goethite method; (3) performing nickel deposition of the filtrate obtained after iron deposition by sodium sulfide, preparing a nickel sulfide product; (4) performing magnesium deposition of the filtrate obtained after nickel deposition by sodium hydroxide to obtain magnesium hydroxide; (5) washing, drying and calcining magnesium hydroxide to prepare a magnesium oxide product; (6) using the roasted clinker dissolved slag as a microsilica fume product directly, wherein the main component of the slag is silica; (7) calcining ammonium jarosite to obtain an iron oxide product.

Owner:NORTHEASTERN UNIV

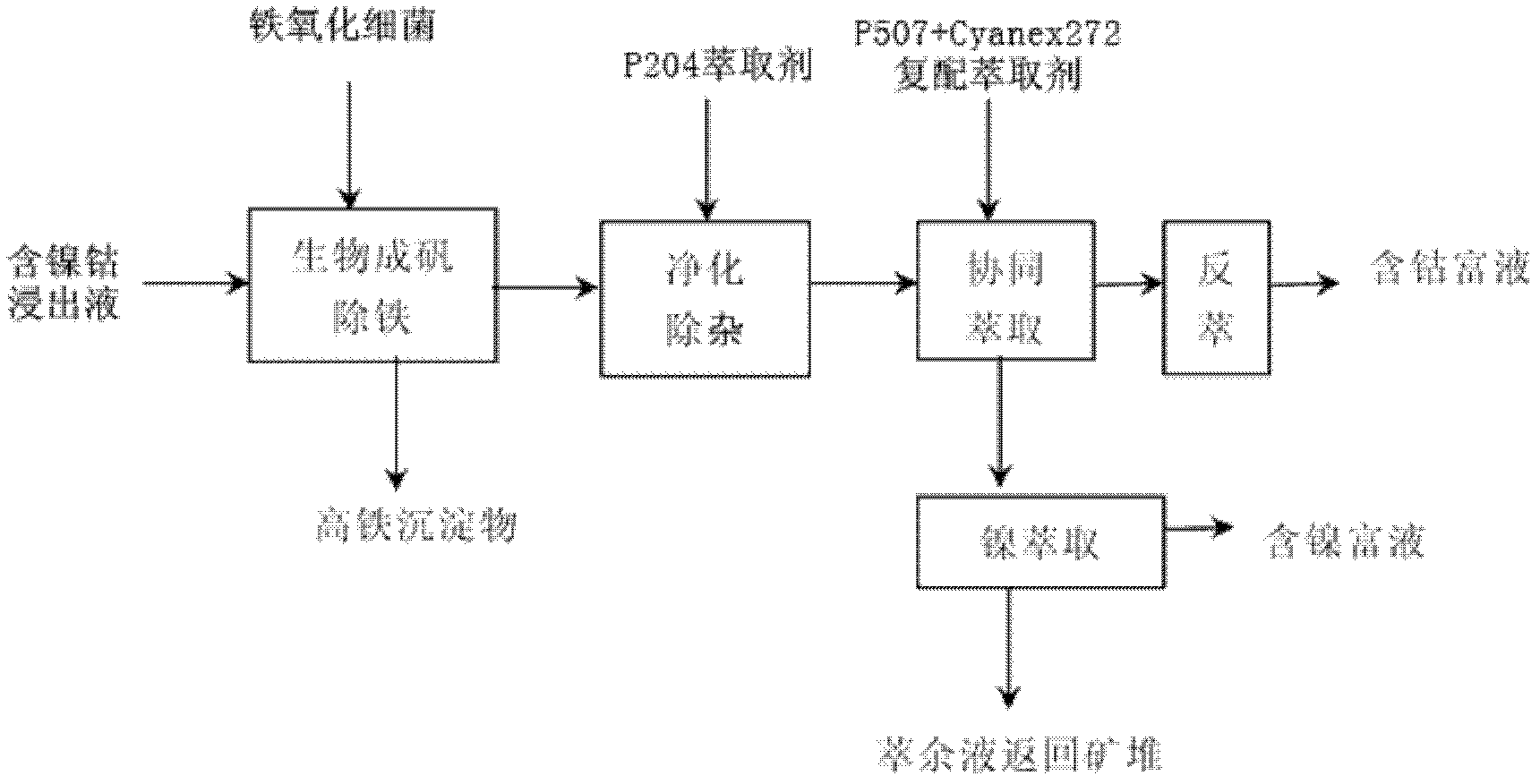

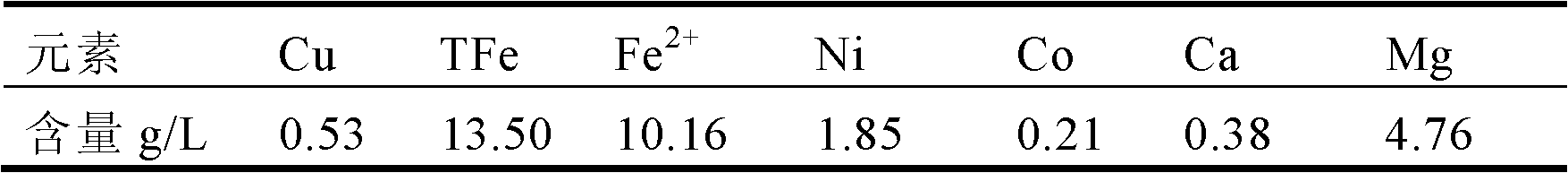

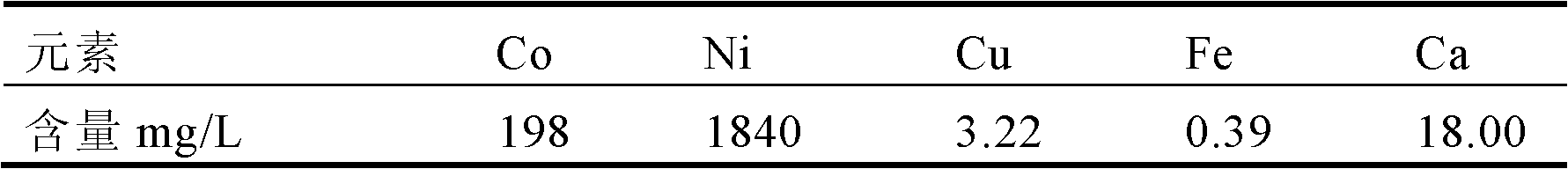

Separation and extraction method for nickel and cobalt in low-grade sulfide mineral bioleaching agent through synergistic extraction

InactiveCN103184337ARealization of iron removalReduce entrainment lossProcess efficiency improvementSulfide mineralsCobalt

The invention provides a separation and extraction method for nickel and cobalt in a low-grade sulfide mineral bioleaching agent through synergistic extraction. The separation and extraction method comprises the following steps: adopting a biological alum precipitation method to perform iron removing on the nickel-cobalt-containing leaching agent, adding iron-oxidizing bacteria under the condition that the pH is 1.8 to 2.0, utilizing oxidation of the bacteria to oxidize ferrous ions in the leaching agent into ferric ions, and enabling the ferric iron to form jarosite-class precipitation; adopting the extraction agent P204 to perform impurity removing on the residual impurities in the leaching agent after iron removing to remove impurities including calcium, magnesium and the like; and using the compound extraction agent containing extraction agent P507 and Cynaex 272 to perform synergistic extraction on the leaching agent after impurity removing, standing for phase splitting for 30 min after extraction, and adding sulfuric acid into the organic phase and performing reverse extraction to extract out cobalt, so as to realize separation of nickel and cobalt through synergistic extraction. The method provided by the invention can reduce neutralization cost of pH value adjustment before extraction of the leaching agent, and omits the pH adjusting procedure when subsequent extraction raffinate returns back to the mineral pile, so as to simplify the technological process, and reduce the neutralization cost and nickel and cobalt entrainment losses caused in the neutralization process.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

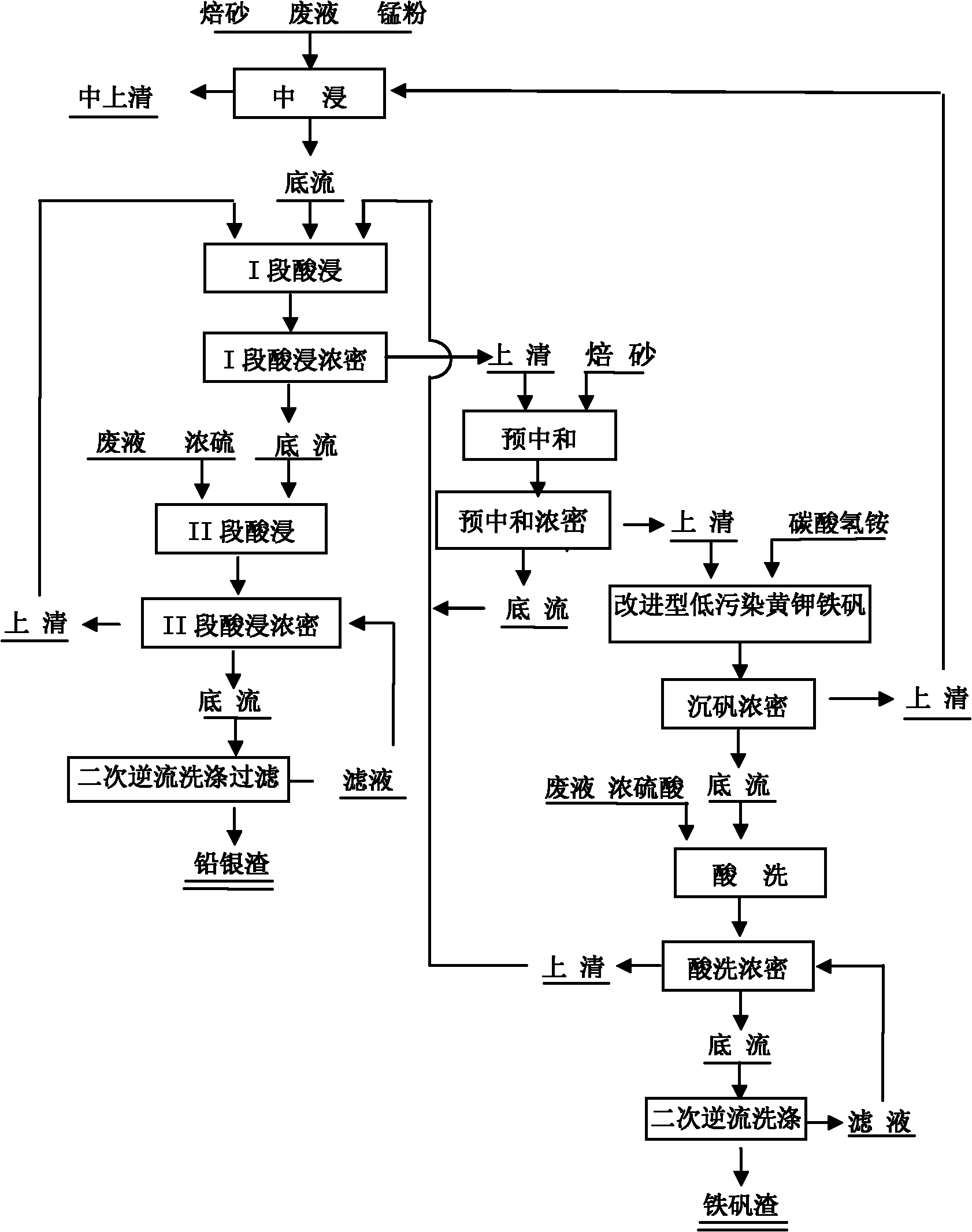

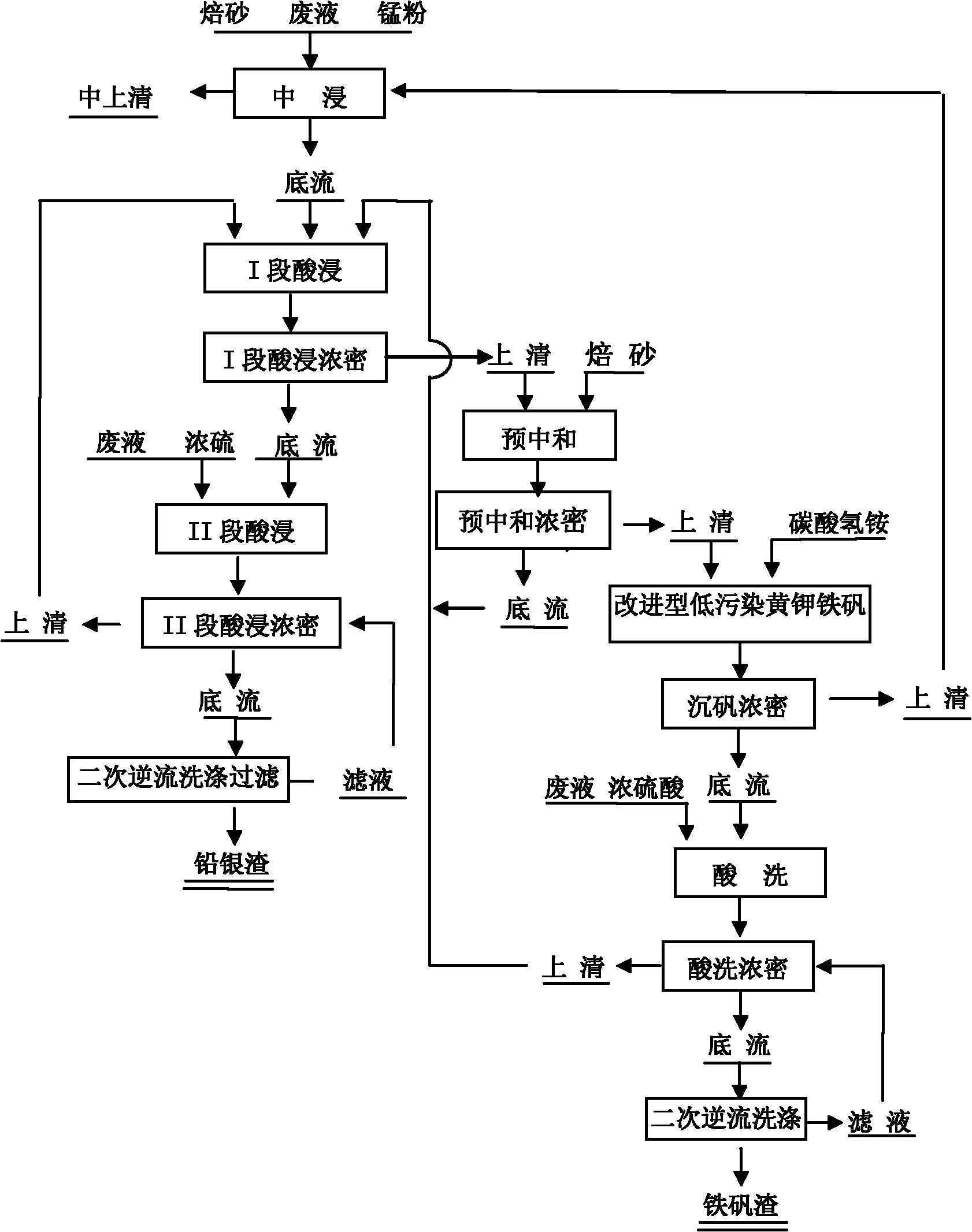

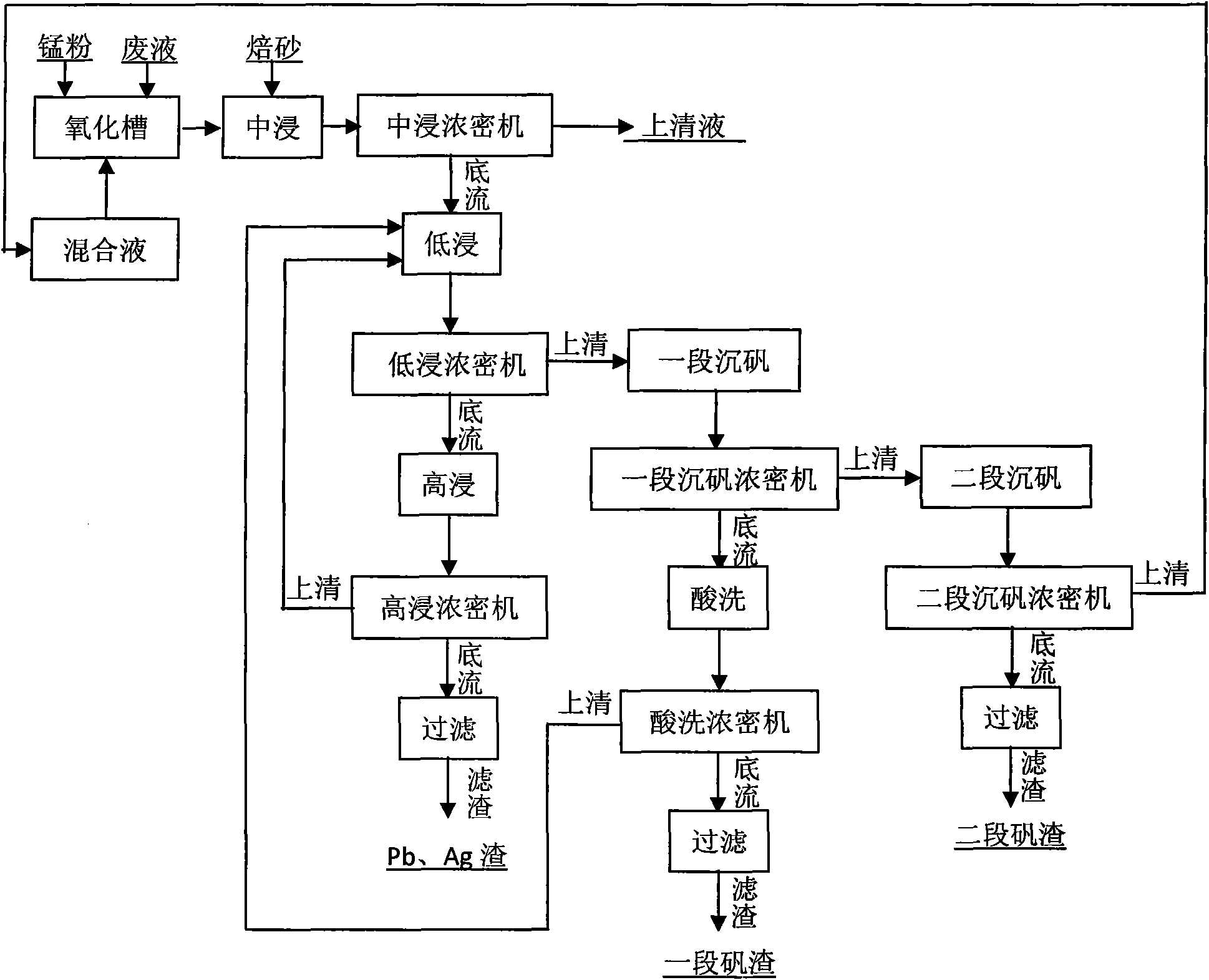

Process for smelting zinc with wet method of high temperature and high acid-jarosite iron removing-iron vitriol slag pickling by two stages

InactiveCN102094126AImprove leaching rateHigh recovery rateProcess efficiency improvementSlagZinc metal

The invention provides a process for smelting zinc with a wet method of high temperature and high acid-jarosite iron removing-iron vitriol slag pickling at two stages, belonging to the technical field of non-ferrous metal smelting. The process comprises the following steps of neutral leaching, acid leaching at the first stage, acid leaching at the second stage, pre-neutralizing, settling vitriol and pickling to obtain zinc metal with a high recovery rate. The total recovery rate of zinc metal is 94.45%. The loss of valuable metal in iron vitriol slag is less, the recovery rate of metal is high, and the pollution of vitriol slag to the environment is improved.

Owner:BAIYIN NONFERROUS GROUP

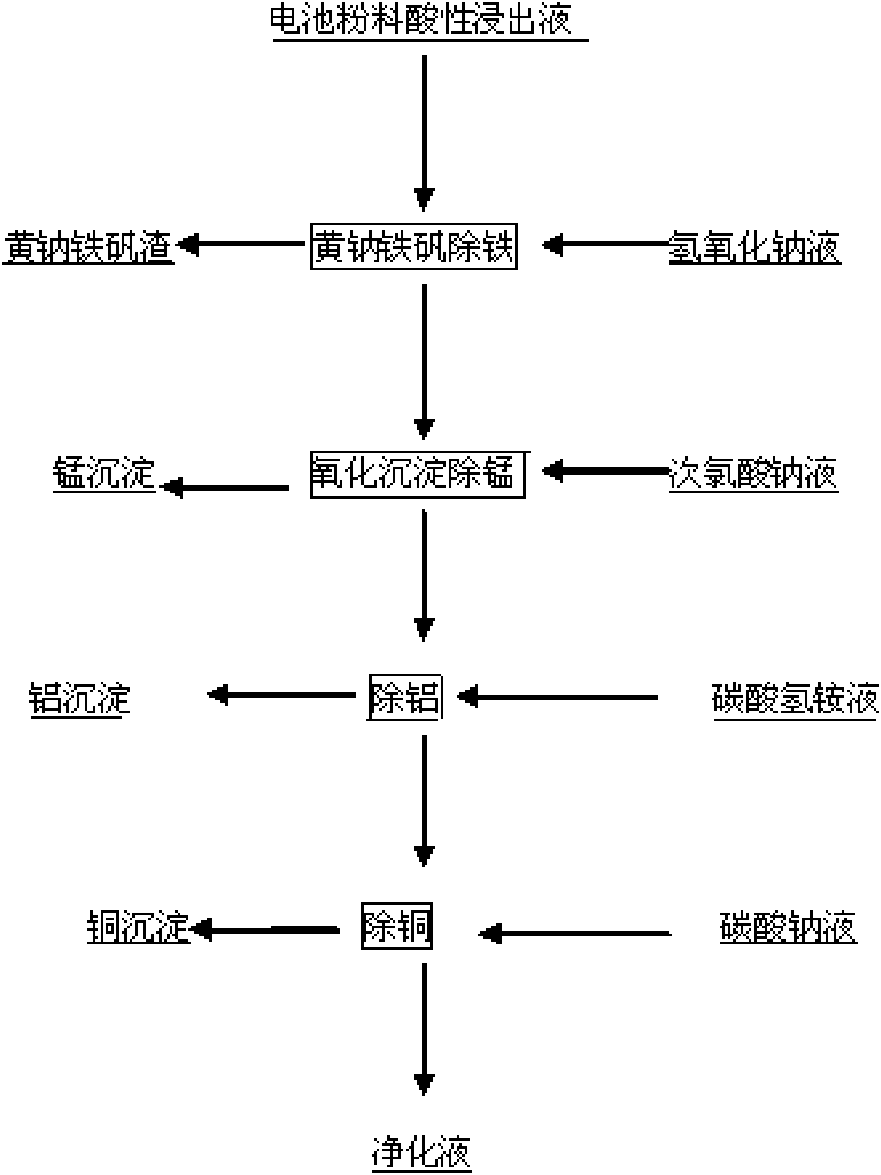

High-efficiency purification process for acid leaching solutions of active substances in waste lithium batteries

InactiveCN101597689ASolve the disadvantages of not being able to comprehensively recover valuable metalsReduce lossesProcess efficiency improvementManganeseTotal recovery

The invention discloses a high-efficiency purification process for acid leaching solutions of active substances in waste lithium batteries. The process comprises working procedures of the purification of the acid leaching solutions of the active materials of positive poles in the waste lithium batteries. The process is mainly characterized by adopting an improved hydrolysis precipitation method and an improved oxidation precipitation method to remove impurity ions in the acid leaching solutions. The process comprises four steps of removing iron by a sodium jarosite method; removing manganese by the oxidation precipitation method; removing aluminum by ammonium bicarbonate; and removing copper by sodium carbonate. A method used by the invention has the advantages of low cost, large operation flexibility, and high cobalt recovery rate, can comprehensively recover valuable metals such as the aluminum, the copper, the manganese and the like, and is suitable for lithium cobalt oxide battery materials which are widely used at present and heavily doped battery materials which may be used in the future. The use of the method can ensure that the total recovery rate of cobalt in waste lithium ion batteries is about 98 percent, and the content of impurities is lower than 2 percent.

Owner:CENT SOUTH UNIV

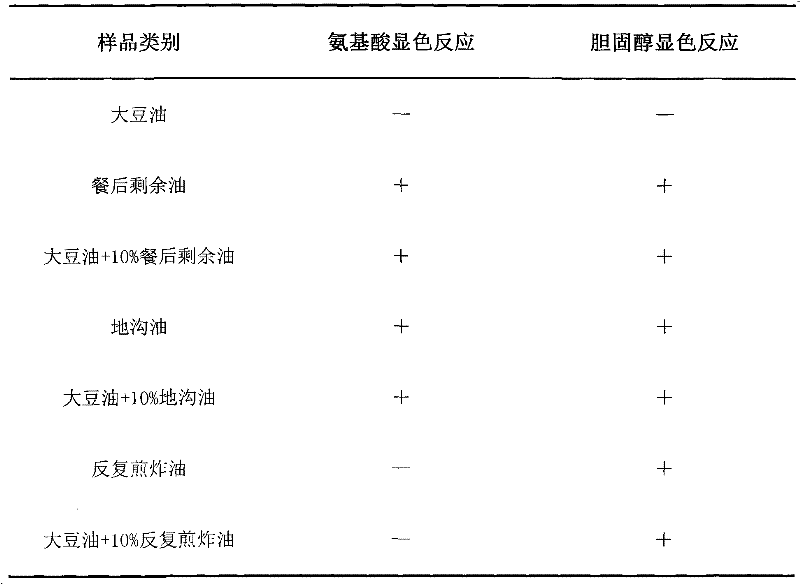

Method for rapidly identifying inferior edible oil

InactiveCN102519953ARapid identificationEasy to detectMaterial analysis by observing effect on chemical indicatorCholesterolPotassium hydroxide

The invention relates to a method for rapidly identifying inferior edible oil. According to the method, whether an edible oil sample contains cholesterol and amino acid impurities is determined to visually, accurately and rapidly identify inferior edible oil. The method contains the following steps of: firstly adding potassium hydroxide and ethanol into the edible oil sample for saponification, adding petroleum ether and sodium chloride solution for centrifugal extraction, respectively adding a jarosite reagent and a ninhydrin reagent into an upper layered extract and a lower layered extract for color development reaction, determining whether the edible oil sample contains corresponding exogenous substances through observation of color change and simultaneously carrying out quality identification. The method provided by the invention is applicable to the detection of inferior edible oil in food hygiene and safety supervision and inspection.

Owner:黄耀江 +2

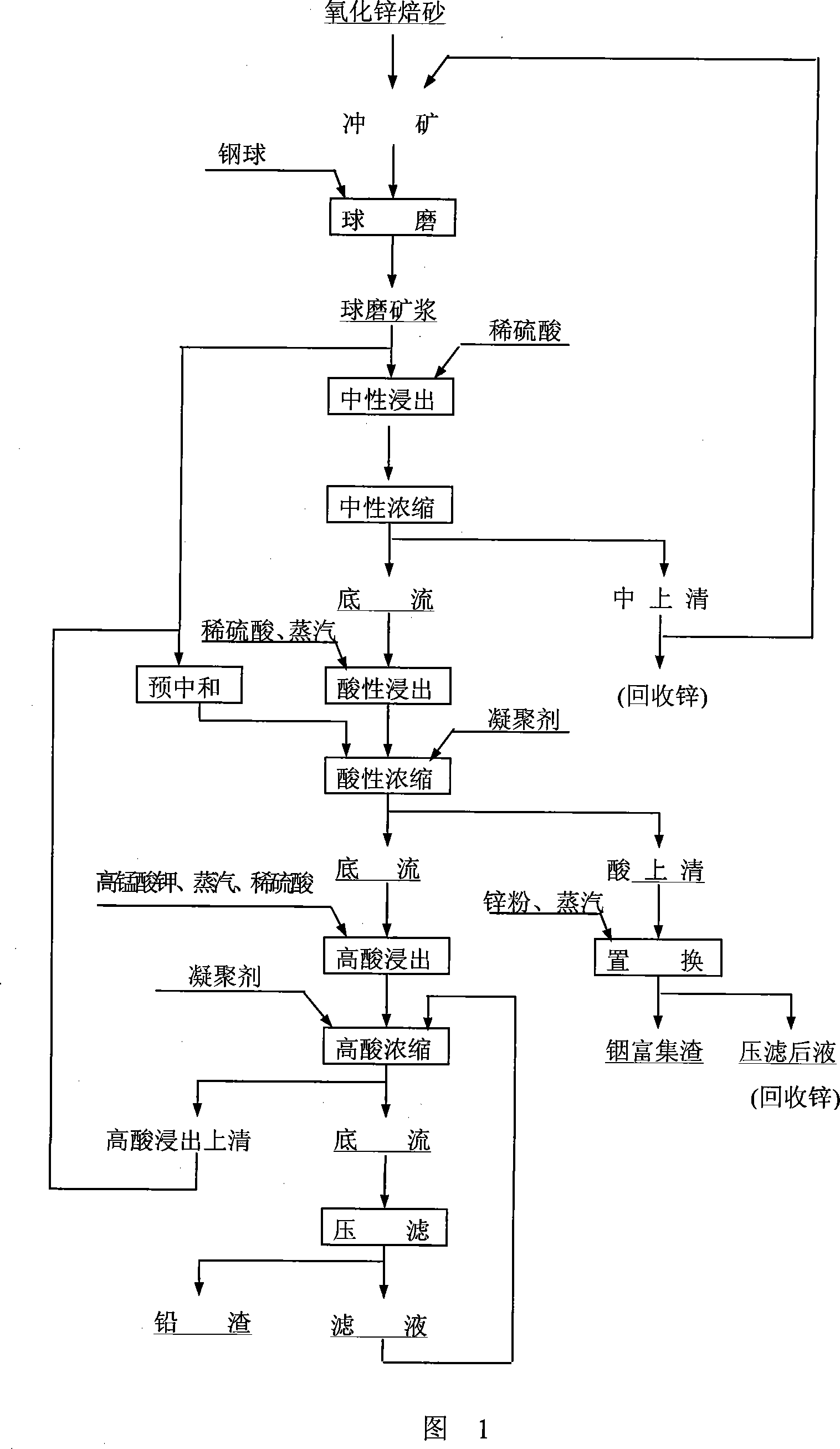

Method for leaching, enriching and reclaiming indium from lead-zinc smelting by-product zinc oxide

ActiveCN101104884ASolve liquidity problemsSolve the low leaching rateProcess efficiency improvementIndiumStrong acids

The invention discloses a method for leaching, enriching and recovering indium from zinc oxide byproduct in the lead and zinc smelting process. The invention is implemented by the following technical proposal: by using three-step leaching process and adding oxidizing agent in the leached slurry, the problem of low indium leaching rate is solved; intermittent slag feeding mode is used to prevent the over-high acidity due to the leached strong acids and the excessive iron production and thus to avoid the production of indium-conjugated jarosite in the next preneutralization process, which may influence the recovery of indium; the high-acidity solution is neutralized with a neutralizer such as zinc oxide or zinc calcine, so that the problem of high-acidity solution disposal is solved; when the low-acidity and high-acidity leach slurry are fed into the concentration machine, the compound flocculant is added to solve the technical problems of difficulty in settlement clarification of ore slurry, poor fluidity of thickened underflow and serious hardening. With this method, the indium leaching rate is increased up to 70-80 percent and the recovery rates of indium and zinc are also increased. Additionally, the method allows the disposal of lead-containing materials (lead slag) in the lead system and helps to reduce the discharge of waste slag, gas and water, protecting the environment.

Owner:ZHUZHOU SMELTER GRP

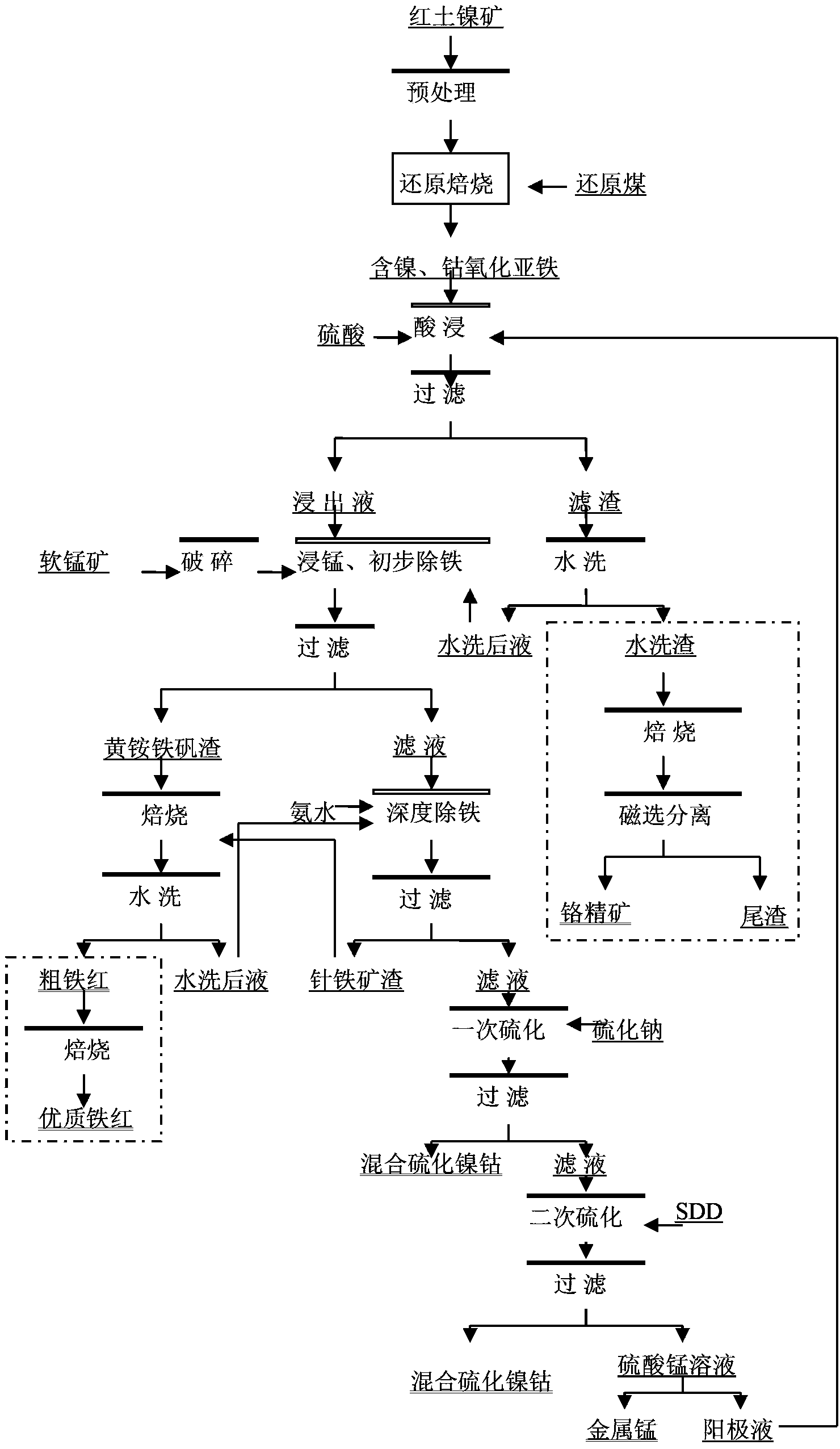

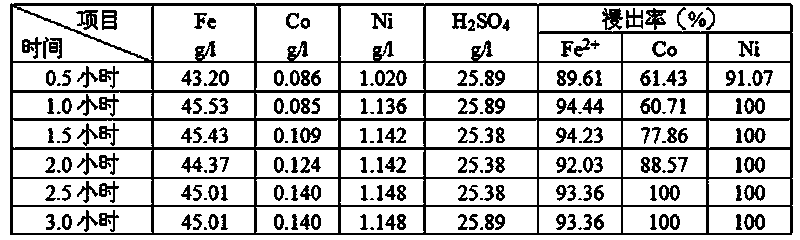

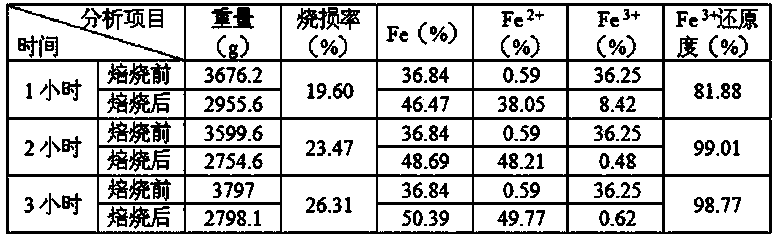

Two ore combined process for treatment of laterite nickel ore and pyrolusite

The invention relates to a two ore combined process for treatment of laterite nickel ore and pyrolusite. The process includes the following steps: mixing laterite nickel ore with coal and roasting to obtain a ferrous oxide powder containing nickel and cobalt; leaching the ferrous oxide powder containing nickel and cobalt with concentrated sulfuric acid; after filtering, adding ammonium sulfate to the solution, controlling the concentration of H2SO4, adding pyrolusite to oxidize Fe<2+> into Fe<3+> and reduce Mn<4+> into Mn<2+>, and filtering to obtain a MnSO4-containing solution and an ammonium jarosite precipitate; adding a vulcanizing agent to the MnSO4-containing solution to produce sulfide nickel and cobalt sulfide precipitates, drying the precipitates to obtain a mixed powder of sulfide nickel and cobalt sulfide; and roasting the obtained ammonium jarosite precipitate, washing by water and drying to obtain crude iron red. The process can extract valuable metallic elements nickel, cobalt, iron and manganese from the two ores; and compared to respective treatment on the laterite nickel ore and manganese ore, the process saves production cost and improves production efficiency.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

Method for extracting aluminum oxide from fly ash by one-step process

ActiveCN102351227AFully recycleReduce energy consumptionSolid waste disposalAluminium oxides/hydroxidesEngineeringSulfur trioxide

The invention relates to a method for extracting aluminum oxide from fly ash by a one-step process. The technique for extracting aluminum oxide from fly ash by an acid-process / alkali-process has the defects of long technological procedure, complex equipment and poor economic performance, and restricts the large-scale application. The method comprises the following steps: mixing fly ash and potassium sulfate in concentrated sulfuric acid to carry out granulation; roasting for activation at certain temperature; dissolving out the solid in water or sulfuric acid to remove solid residues; removing the impurity iron from the solution by a jarosite process; crystallizing the solution to obtain solid potassium aluminum sulfate dodecahydrate; roasting the potassium aluminum sulfate dodecahydrate to obtain aluminum oxide, potassium sulfate solid and sulfur trioxide gas; and washing the solid phase, and filtering to obtain the aluminum oxide product. The potassium aluminum sulfate solid is obtained by cooling crystallization, thereby lowering the energy consumption; the impurities can be effectively removed in the crystallization process, thereby reducing the investment for the impurity removal system; and the potassium sulfate and sulfuric acid can be recycled, so the economic benefit of industrial production is high.

Owner:西安航天华威化工生物工程有限公司 +1

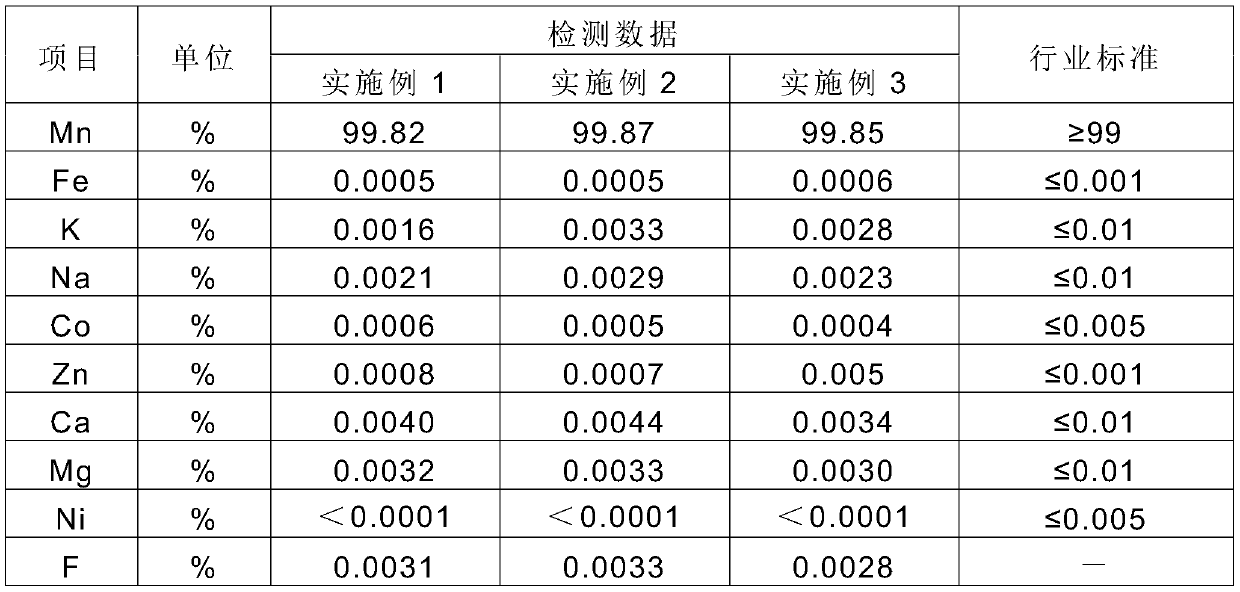

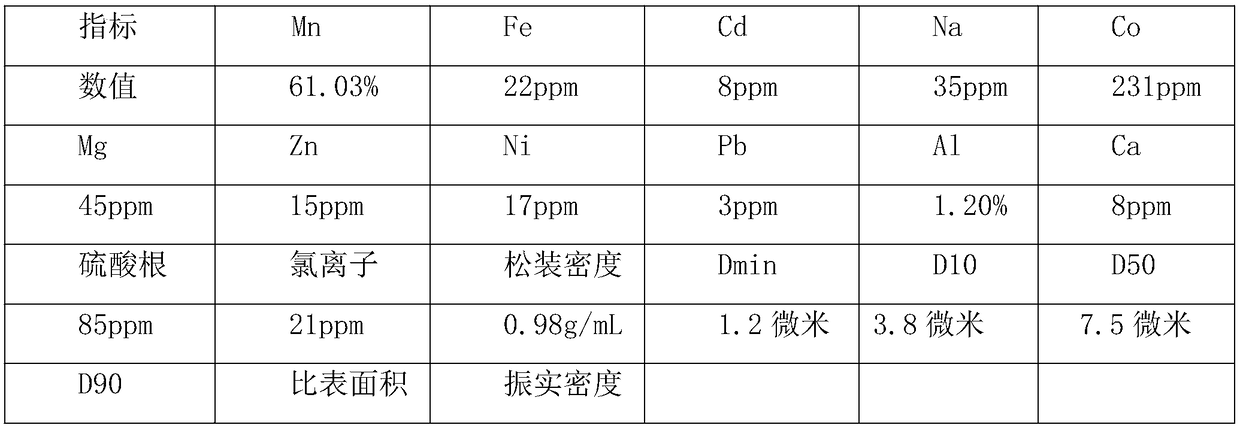

Production method of battery-grade high-purity manganese sulfate

InactiveCN109704408AImprove controllabilityGood reproducibilityManganese sulfatesManganeseControllability

The invention belongs to the technical field of chemical production, and discloses a production method of battery-grade high-purity manganese sulfate. Impurities of manganese sulfate are removed by adopting a chemical precipitation method. The production method comprises the following steps: step one, adding a ferric salt for generating jarosite and sodium jarosite to remove potassium-sodium impurities, and meanwhile, adding a vulcanizing agent to remove heavy metal ions; step two, adding a fluorinating agent for generating calcium fluoride and magnesium fluoride precipitates to remove calcium-magnesium impurities; step three, carrying out concentrating crystallization to obtain a high-fluorine manganese sulfate crystal; step four, adding a fluorine removal agent into the high-fluorine manganese sulfate to remove fluorine ions, and then carrying out filtering to obtain a high-purity manganese sulfate clear solution; and step five, carrying out concentrating crystallization on the high-purity manganese sulfate clear solution, and carrying out drying to obtain the high-purity manganese sulfate crystal. The high-purity manganese sulfate is produced by the production method, and a proper amount of chemical reagents are added to remove the impurities in the production process. The operation is convenient, controllability and reproducibility of quality are high, and product quality is guaranteed.

Owner:赵永阳 +2

Method for purifying zinc hydrometallurgy leaching solution

ActiveCN106191463ARealize enrichment recoveryHigh affinityProcess efficiency improvementSludgeHydrometallurgy

The invention discloses a method for purifying a zinc hydrometallurgy leaching solution. The method is particularly suitable for a zinc sulfate solution or zinc oxide soot sulfate leaching solution obtained after high acid leaching-jarosite (ammonium alum) process iron removal. The method includes the steps that ferroporphyrin in an oxidation solution or a supplement iron source is used for guaranteeing the ferric iron concentration of the solution at first; then seed crystal-lepidocrocite (gamma-FeOOH) slurry is added into a reaction still; afterwards, a zinc sulfate leaching solution with impurities to be removed is added slowly; and meanwhile, a neutralizer is added, the reaction pH value and temperature are controlled, most of ions of ferric iron, arsenic, germanium, fluorine and the like in the solution or all the ions are precipitated, and obtained precipitation sludge is easy to filter and wash. The technological process is simple, and cost is low. Detrimental impurities (like iron, arsenic, fluorine and germanium) generated in the zinc electroanalysis process can be removed, and meanwhile effective enrichment of the germanium is realized, so that the method is suitable for industrialized application.

Owner:SHENZHEN SHENTOU ENVIRONMENT TECH CO LTD

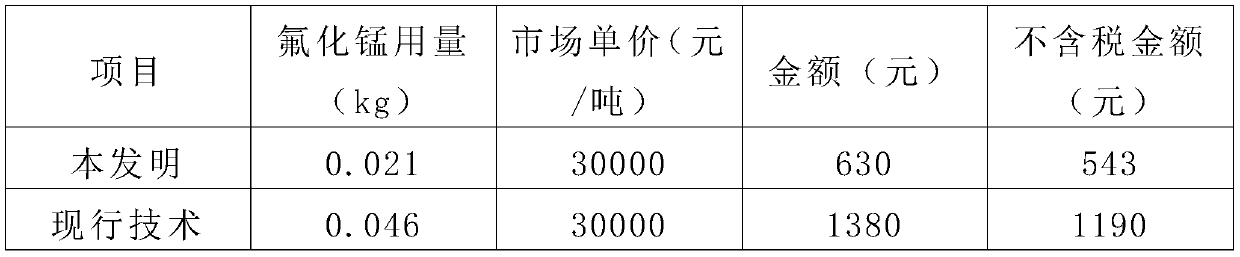

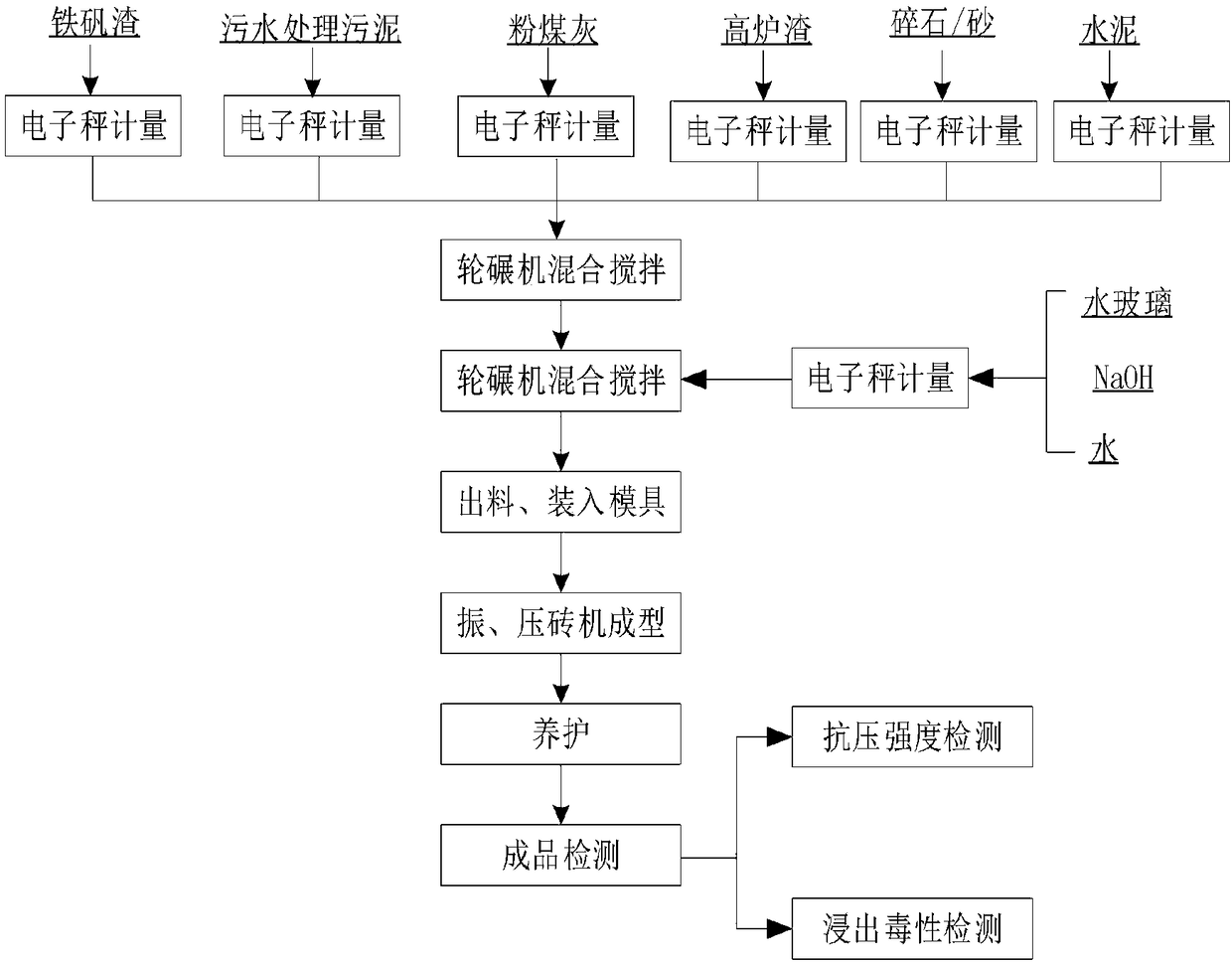

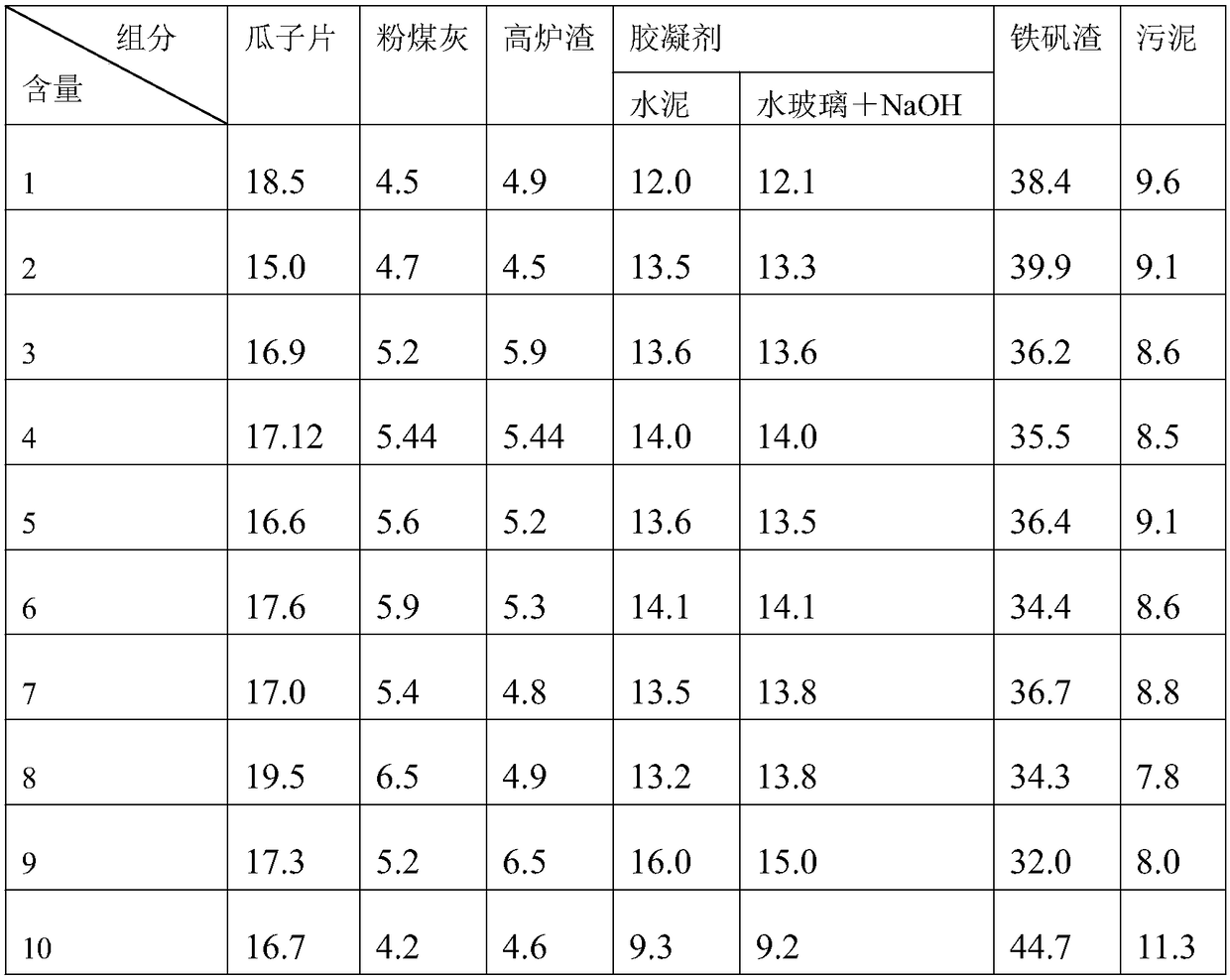

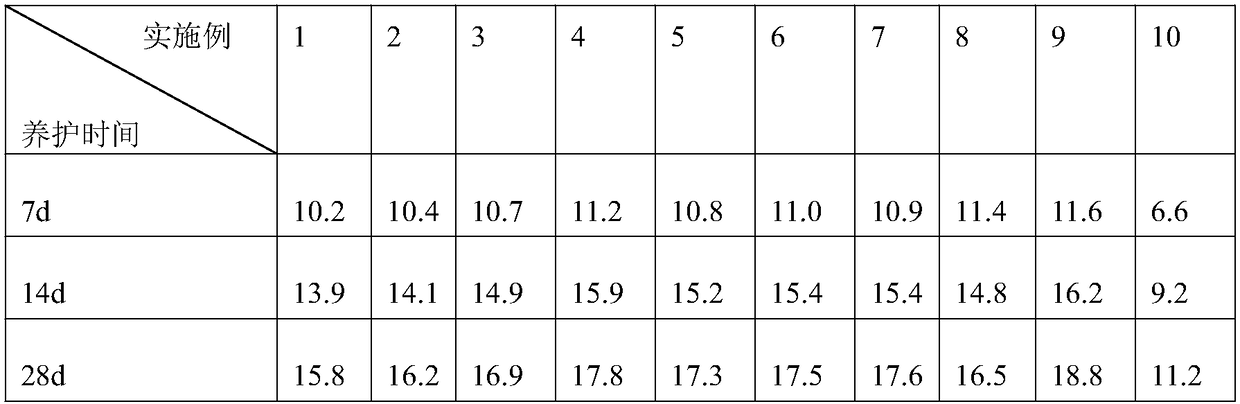

Resource utilization method for zinc hydrometallurgy jarosite residue and sewage treatment sludge

The invention discloses a resource utilization method for zinc hydrometallurgy jarosite residue and sewage treatment sludge. The zinc hydrometallurgy jarosite residue and the sewage treatment sludge are taken as main raw materials, and the concrete solid brick is prepared. The raw materials comprise the following raw materials in percentage by mass: 15.0%-19.5% of crude sand / gravel, 4.5%-6.5% of fly ash, 4.5%-6.5% of blast furnace slag, 24.1% to 31.0% of a gelling agent, 40.0% to 49.0% of the zinc hydrometallurgy jarosite residue and the zinc hydrometallurgy jarosite sewage treatment sludge, wherein the mass ratio of the zinc hydrometallurgy jarosite residue to the zinc hydrometallurgy jarosite sewage treatment sludge is 4:1-5:1. According to the invention, the waste is used for treating waste, and the zinc hydrometallurgy jarosite residue and the sewage treatment sludge are subjected to whole, large-scale tretment and utilization, the zero emission of zinc hydrometallurgy jarosite residue and sewage treatment sludge can be realized, and the purposes of quantization reducing, harmlessness and recycling of the zinc hydrometallurgy jarosite residue and the sewage treatment sludge areachieved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +2

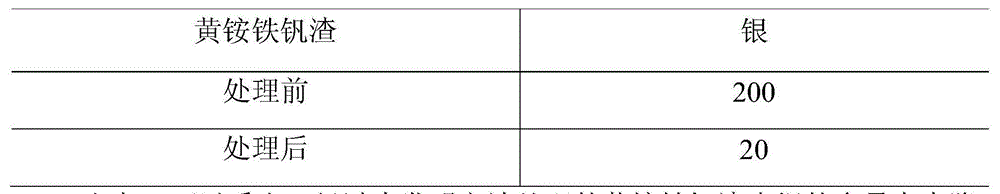

Method for recycling silver from jarosite residue

The invention relates to a method for recycling silver from jarosite residue. The method for recycling silver from the jarosite residue comprises the following steps: mixing the jarosite residue with pulverized coal and a desulphurizing agent, and briquetting, thus obtaining mixed spheres, then putting the mixed spheres into a vacuum distillation furnace, and heating at the temperature of 1100-1300 DEG C, thus silver in the jarosite residue is separated, wherein the molar weight ratio of the added pulverized coal to the desulphurizing agent to silver in jarosite residue is 1 to (2-10) to (0.1-10). The method for recycling silver from the jarosite residue has the advantages that the ratio of the pulverized coal to the desulphurizing agent to the jarosite residue is reasonably controlled, and the separation of silver from jarosite residue under the vacuum condition of 1100-1300 DEG C is realized; besides, the whole technological process is carried out in a vacuum furnace, influences on personnel and environments are slight, the method and the required equipment are simple, safe and controllable and are easy to operate, and silver can be recycled from the jarosite residue effectively.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

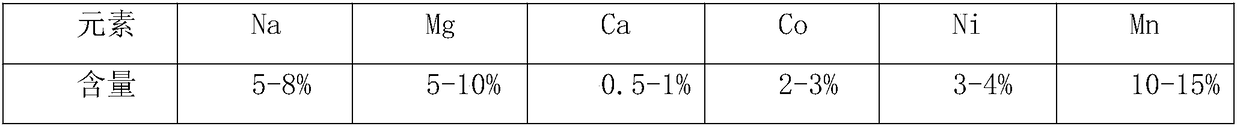

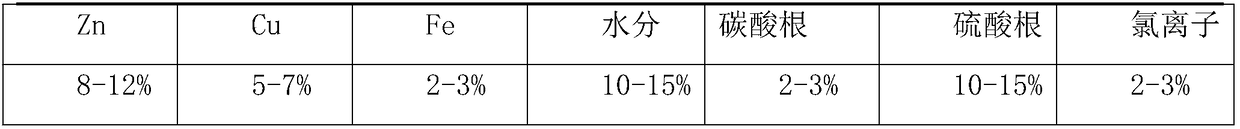

Treatment method for cobalt-nickel metallurgical wastewater slag

The invention discloses a treatment method for cobalt-nickel metallurgical wastewater slag. The treatment method is characterized in that coke is reduced for reducing metal such as zinc, manganese, cobalt, nickel, copper and iron in wastewater slag into elementary substances, calcium, magnesium, sodium and the like cannot be reduced into elementary substances, and washing is adopted for dissolvingcalcium, magnesium and sodium into hot water, so that calcium, magnesium and sodium are separated from other metals; zinc is separated from other metals through alkaline dissolving, properties of copper powder are relatively stable through acid dissolving, and copper powder does not react with acid, so that copper powder is obtained; and after iron of a solution for dissolving is removed througha sodium jarosite process, potassium permanganate is adopted for oxidizing manganese ions into manganese dioxide, and the rest of a cobalt-nickel solution is prepared into nickel-cobalt binary precipitates through homogeneous precipitation. The treatment method is short in flow, is simple in process, can realize separating and recycling of all components, is high in recovery rate; and the finallyobtained product is high in purity and is great in product additional value.

Owner:湖南荣桓科技有限公司

Eosino-thiobacillus and application thereof to copper pyrites leaching

ActiveCN103131650AReduced film surface passivationReduce generationBacteriaMicroorganism based processesPotassiumAntibiotic Y

The invention discloses extreme eosino-thiobacillus which is named Acidithiobacillus sp.ZJJN, and the preservation number of the eosino-thiobacillus is CCTCC NO: M2012104. The eosino-thiobacillus is highly sensitive to a plurality of kinds of antibiotics and highly tolerant to a plurality of types of common metal in a bio-leaching process. Moreover, the eosino-thiobacillus is used for assisting ferrous oxide thiobacillus in a chalcopyrite leaching experiment under an extreme potential of Hydrogen (pH), and a recovery rate of copper is found to be greatly improved compared with a contrasting system. A scanning electron microscope is used for observation of the surfaces of leached chalcopyrite, jarosites are found to be greatly reduced on the surfaces of the chalcopyrites in a system which is added with the strain ZJJN system, and leaching efficiency is greatly improved. The extreme eosino-thiobacillus can endure an environment with a quite low pH value, is quite suitable for a chalcopyrite leaching system, and is applied to industrial chalcopyrite leaching hopefully.

Owner:JIANGNAN UNIV

Technology for performing recycling pretreatment on zinc smelting low-pollution jarosite process jarosite slag

InactiveCN106244817ANo pollution in the processRealize comprehensive utilizationProcess efficiency improvementIndiumMass ratio

A technology for performing recycling pretreatment on zinc smelting low-pollution jarosite process jarosite slag comprises the following steps: evenly mixing low-pollution jarosite process jarosite slag with a bonding agent and broken coal according to mass ratio of 1 to 0.08 to 0.08 and then pelleting; then, entering a calcining kiln and sintering for reduction at 1200 to 1400 DEG C; collecting dust after sintered slag is reduced to be less than 2 percent in sulfur content and produced flue gas is cooled to be not higher than 180 DEG C; then, purifying the flue gas; and finally, entering an acid making system to make acid by gas mixing. According to the technology provided by the invention, the flue gas enters after zinc in the jarosite slag is reduced and volatilized for about 70 percent and lead, cadmium and indium are reduced and volatilized for about 85 percent, and thus, these valuable metals are recycled to produce benefit; the sulfur content of the sintered slag reduced by sintering is less than 2 percent, and thus, heavy metal is further reduced, and the sintered slag is transform into a production raw material that a cement manufacturer likes using; benefit is produced, and the whole process has no environmental pollution; and through the process, hazardous wastes of the jarosite slag are harmlessly and comprehensively utilized.

Owner:HANZHONG ZINC IND

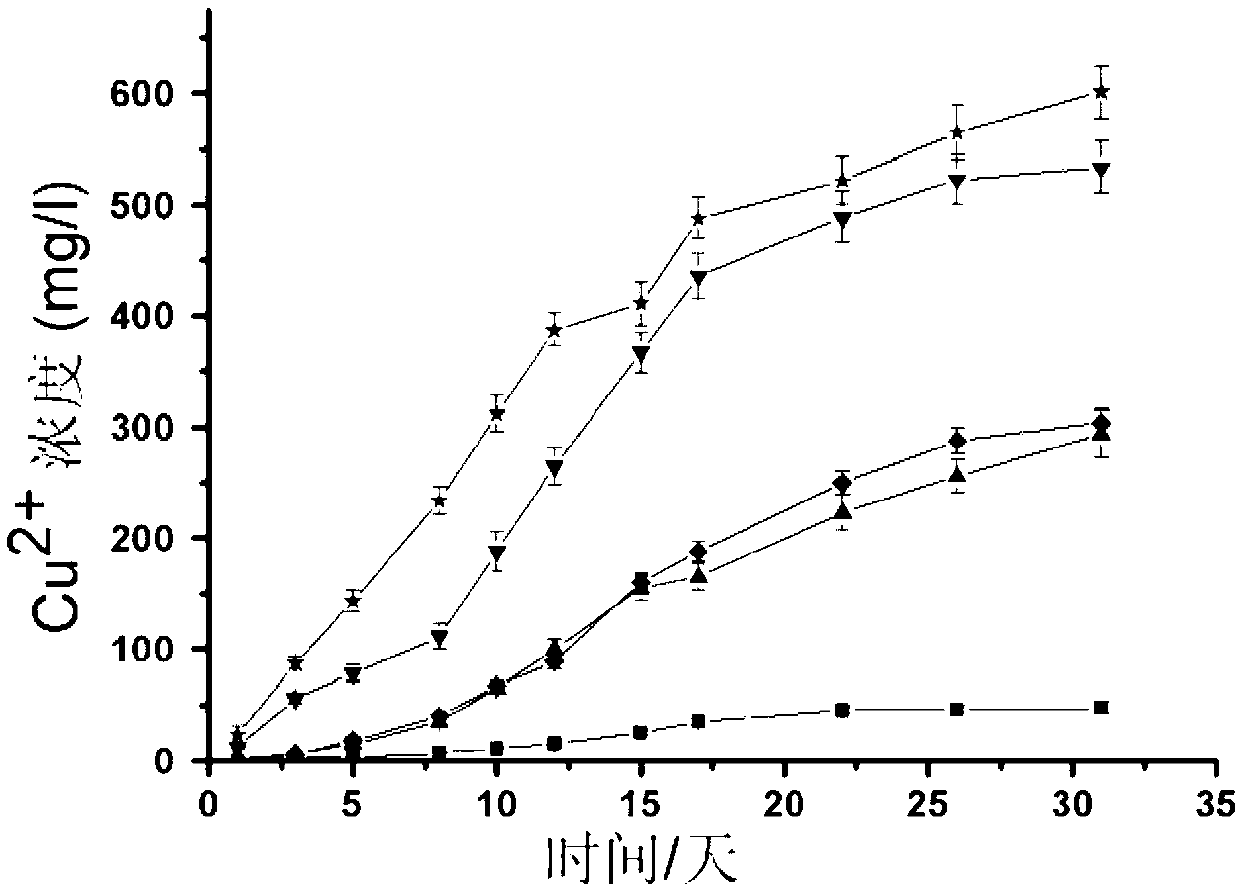

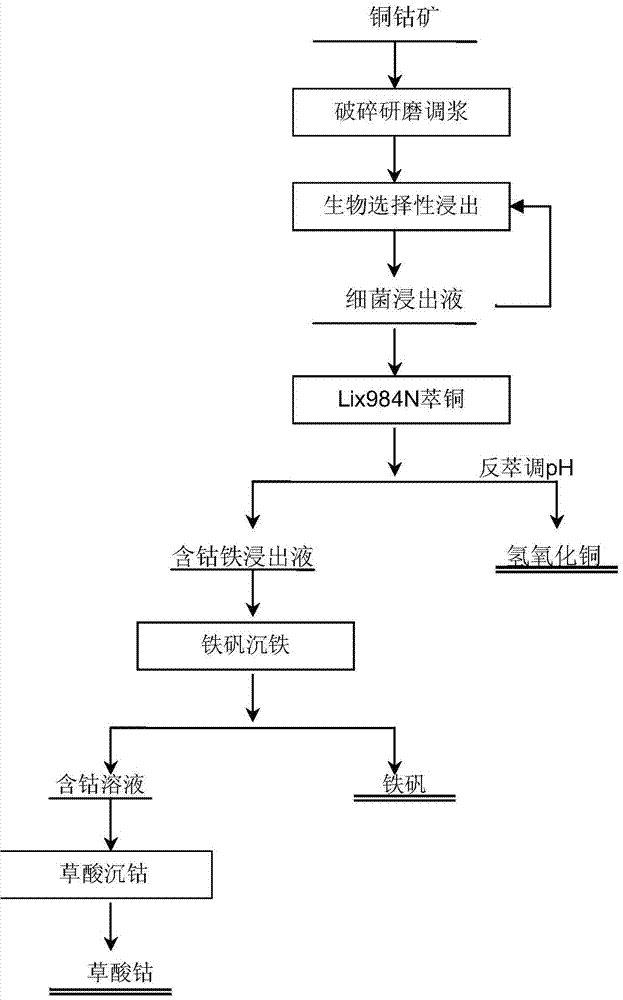

Biological selectivity leaching method of low-grade copper-cobalt ore

ActiveCN103572050AAchieve separationEfficient recyclingProcess efficiency improvementThiobacillus ferrooxidansCobalt

The invention discloses a biological selectivity leaching method of low-grade copper-cobalt ore, and belongs to the field of microbial metallurgy. The biological selectivity leaching method comprises the following steps: the copper-cobalt ore is crushed and grinded; a mixed bacterium liquid containing ferrous oxide micro spirilla, acidophilic thiobacillus ferrooxidans and acidophilic thiobacillus thiooxidans is introduced to a 9 K of culture medium for cultivating to obtain a bacterium culture solution. The copper-cobalt ore is added to the bacterium culture solution to conduct bacterium leaching on the cobalt concentrate; when the leaching rate of cobalt in the bacterium leaching liquid reaches above 97%, the leaching liquid containing valuable metal ions such as cobalt and copper is separated from the leaching residue; then Lix984N extraction agent is adopted to extract copper to obtain a copper product; the raffinate from which the copper is extracted is subjected to precipitation and iron removing treatment by a jarosite process to obtain an iron product; cobalt-containing liquid after being subjected to iron removal is crystallized to obtain a cobalt oxalate product. The biological selectivity leaching method has the advantages of short technique flow, easy operation, simple equipment, low energy consumption, no high-temperature smelting, no emission of pollutant smoke and poisonous gas, and quick achievement of separation and efficient recovery of cobalt and other valuable metals.

Owner:NORTHEASTERN UNIV

Method for enriching germanium from wet process zinc smelting system

ActiveCN102031371AShort processIncrease replacement rateProcess efficiency improvementIron removalZinc smelting

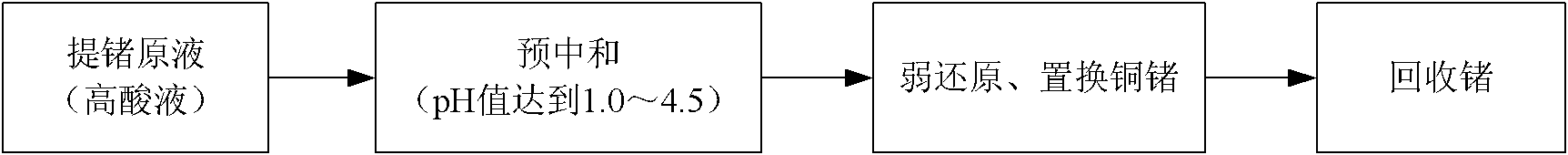

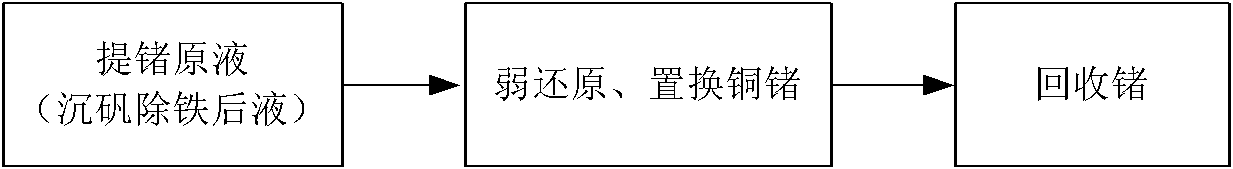

The invention discloses a method for enriching germanium from a wet process zinc smelting system. The method comprises the following process steps of: pre-neutralizing germanium extracting stock solution; weakly reducing; replacing reduced germanium; cleaning replacement residue; extracting germanium; opening a path and removing iron and the like. The method comprises the following specific steps of: firstly, pre-neutralizing pickle liquor (or liquid obtained from iron removal by jarosite process) with high germanium content by using a small amount of neutralizing agent and controlling the pH of a reaction final point to be between 1.0 and 4.5; secondly, adding a slightly excess amount of reducing agent such as zinc powder or scrap iron to replace germanium; and lastly, after reaction, separating excessive zinc powder or the scrap iron, separating solid from liquid to obtain copper germanium residue with high germanium grade and extracting germanium. Germanium replacement rate is high, and germanium residue has high grade and is easy to treat; moreover, the method is easy to operate, has easily-controllable process condition and low cost and is suitable for the requirement of industrial production.

Owner:CENT SOUTH UNIV +1

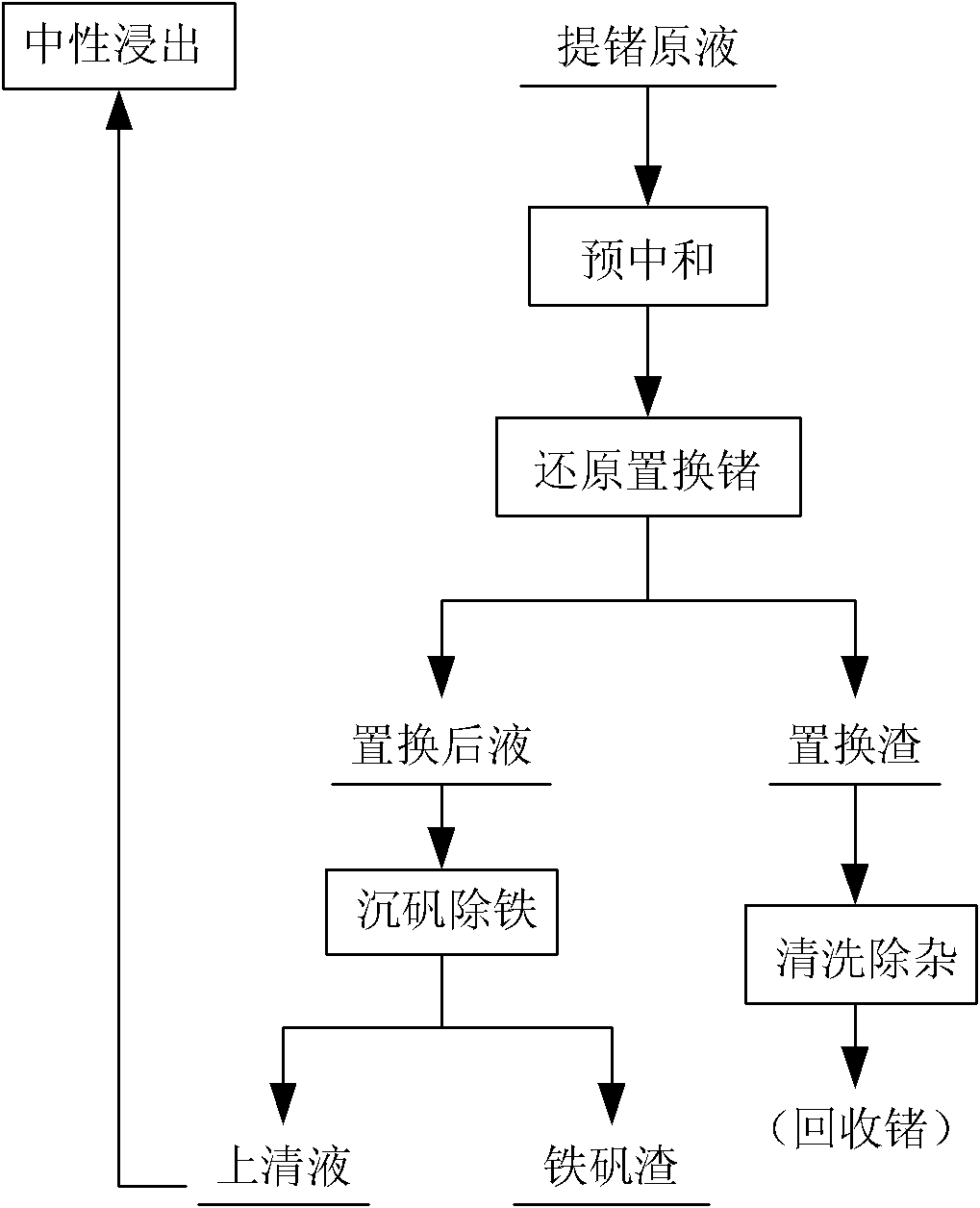

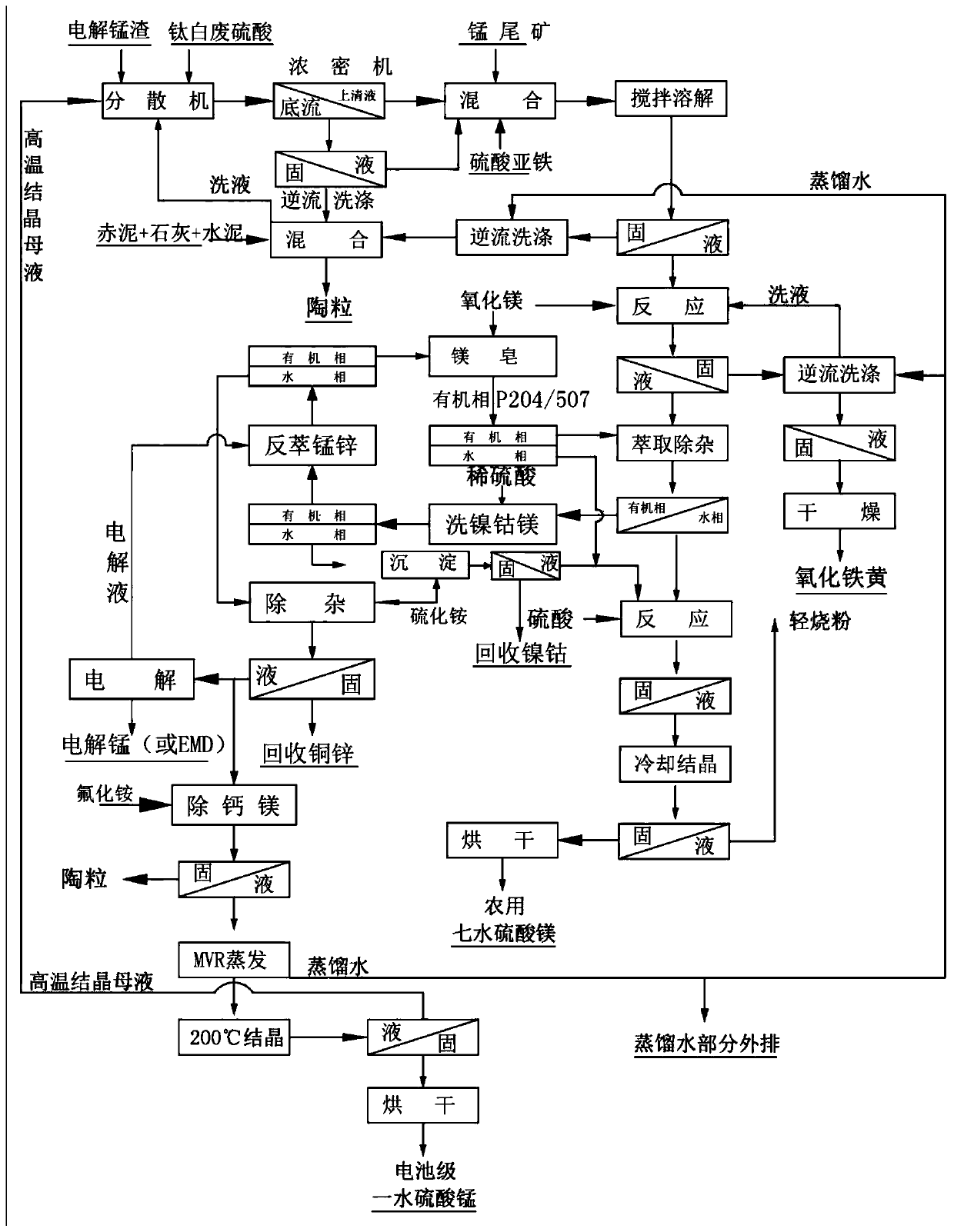

Process for comprehensively recycling electrolytic manganese residues and manganese tailings

InactiveCN110157911ASolve pollutionAddressing Purity IssuesProcess efficiency improvementElectrolysisManganese

The invention discloses a process for comprehensively recycling electrolytic manganese residues and manganese tailings. The process for comprehensively recycling the electrolytic manganese residues and the manganese tailings specifically comprises the following steps that liquid-phase crushing is performed on the electrolytic manganese residues by adopting a dispersion machine so as to obtain leached residues and leachate; a qualified de-ironed precursor solution without solid particles is obtained through filter pressing, and hydration pulping is performed on the magnesium oxide through the dispersion machine. The process for comprehensively recycling the electrolytic manganese residues and the manganese tailings has the advantages that as long as the manganese content of the electrolyticmanganese residues and the manganese tailings is greater than 1%, the manganese can be enriched and recovered, so that a new profitable industrial way is developed for resource comprehensive recoveryof the manganese tailings, the problems that when electrolytic manganese is produced through a traditional process, pollution is caused due to the fact that sodium jarosite and goethite which are generated through purification iron removal cannot be recovered, the purity of the electrolytic manganese is low due to the fact that the leaching solution is not purely purified and the like are solved,and the process is simple, stable and strong in operability.

Owner:张响 +2

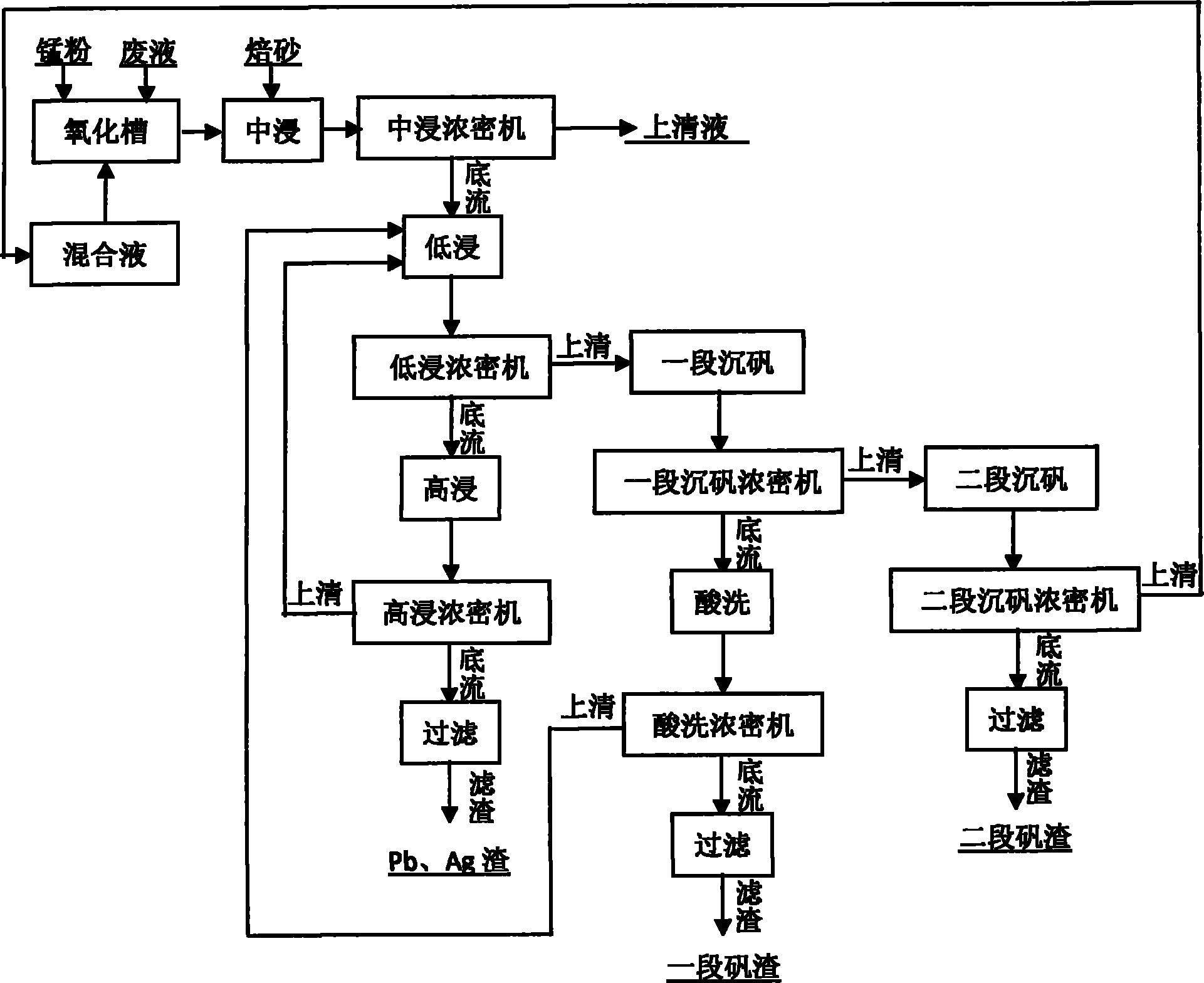

Low grade zinc concentrate associated lead and silver recovery process

ActiveCN102676805ARaise the gradeImprove the level of comprehensive utilizationProcess efficiency improvementSlagAcid washing

The invention discloses a low grade zinc concentrate associated lead and silver recovery process which includes the steps of neutral leaching, low acid leaching, high acid leaching, first step jarosite precipitation, second step jarosite precipitation, and acid-washing of leached slag. The lead and silver slag recovered through the process disclosed by the invention is effectively enriched with the precious metals such as Pb and Ag from raw materials. Waste materials are changed into things of value, thereby creating new economic growth points for the enterprise, reducing the pressure on the environment caused by the stacking and disposal of the leached slag and improving the level of comprehensive use of the resources.

Owner:巴彦淖尔紫金有色金属有限公司

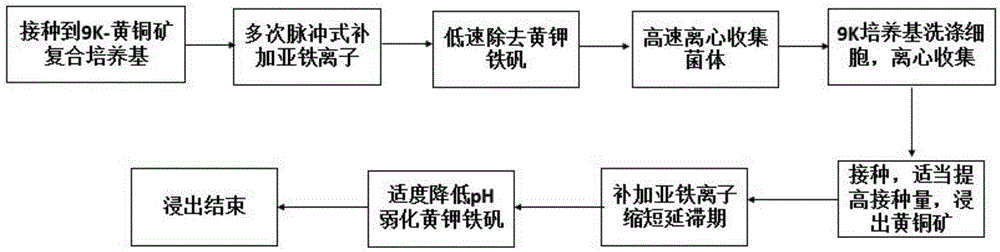

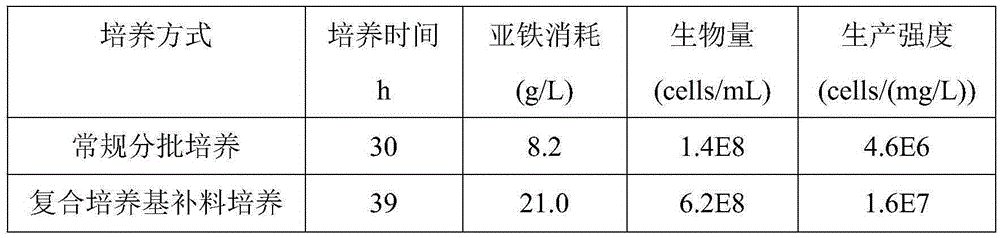

Method for leaching chalcopyrite through reinforced iron oxidized culture

ActiveCN105256133AIncrease cell concentrationImprove leaching efficiencyProcess efficiency improvementChalcopyriteHigh density

The invention discloses a method for leaching chalcopyrite through a reinforced iron oxidized culture and belongs to the technical field of bioleaching. The method includes the steps that on the basis of a 9K-chalcopyrite complex medium, a ferrous energy substrate is added through an impulse type supplementary material in the middle and later periods of cultivation, and ferric oxide thiobacillus is cultured at high density; centrifugal operation and suspended elution cells of the 9K medium are adopted for removing jarosite, the cells not containing jarosite are adopted for inoculation, the inoculation size is increased properly, and meanwhile ferrous ions are supplemented and included to shorten a lag phase; and the pH of lixivium is lowered level by level in the later leaching period, accumulation of the jarosite is reduced, and the leaching effect of the chalcopyrite is improved in the whole process. By the adoption of the method, the iron oxidized culture can be more efficiently cultured, the lag phase can be shortened, the passivation effect caused by accumulation of the jarosite can be weakened, the leaching process of the chalcopyrite is improved while iron metabolism is reinforced, operation is easy and feasible, and the method is suitable for being applied and popularized on a large scale.

Owner:JIANGNAN UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com