Patents

Literature

77results about How to "No sintering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing monodisperse oxide nanoparticles

ActiveCN106348251AWiden the temperature rangeAvoid reunionMaterial nanotechnologyOxide/hydroxide preparationCentrifugationNanoparticle

The invention discloses a method for preparing monodisperse oxide nanoparticles. The method comprises the steps of firstly, preparing hydrosol containing a soluble salt and a nano-oxide precursor, then, mixing the hydrosol with a low-polarity solvent so as to precipitate the soluble salt in a superfine nanoparticle state and co-precipitate the soluble salt with nano-oxide precursor particles, subjecting the co-precipitate to centrifugation, washing and drying, carrying out calcination at a temperature below the boiling point of the salt so as to convert the nano-oxide precursor into a nano oxide, washing off the soluble salt, and carrying out drying, thereby obtaining the monodisperse oxide nanoparticles. During the preparation, the soluble salt exerts an isolating action, and the precursor nanoparticles or oxide nanoparticles can be effectively prevented from agglomeration and sintering in a high-temperature calcination process. According to the method, the temperature range for preparing monodisperse nano-oxides is widened greatly, and the process is simple and convenient and is low in cost.

Owner:SOUTHEAST UNIV

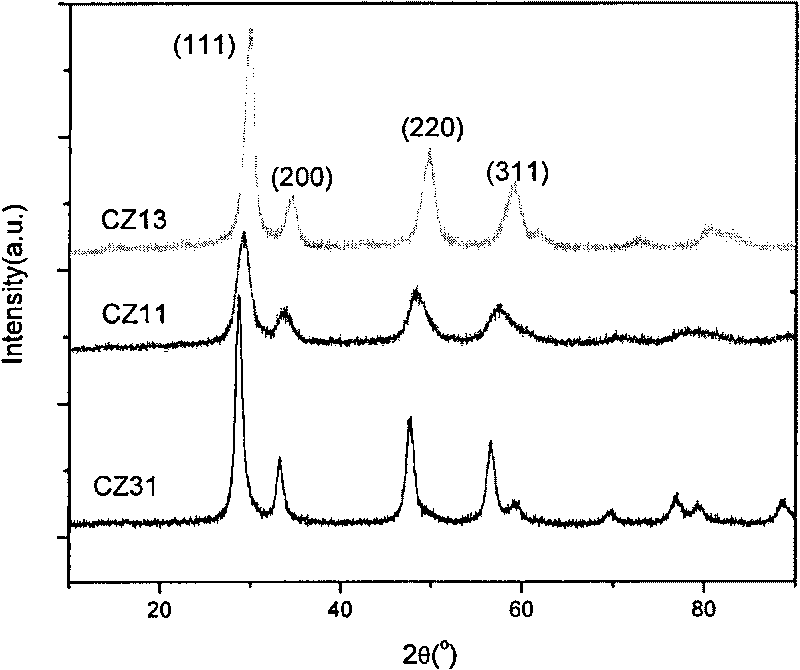

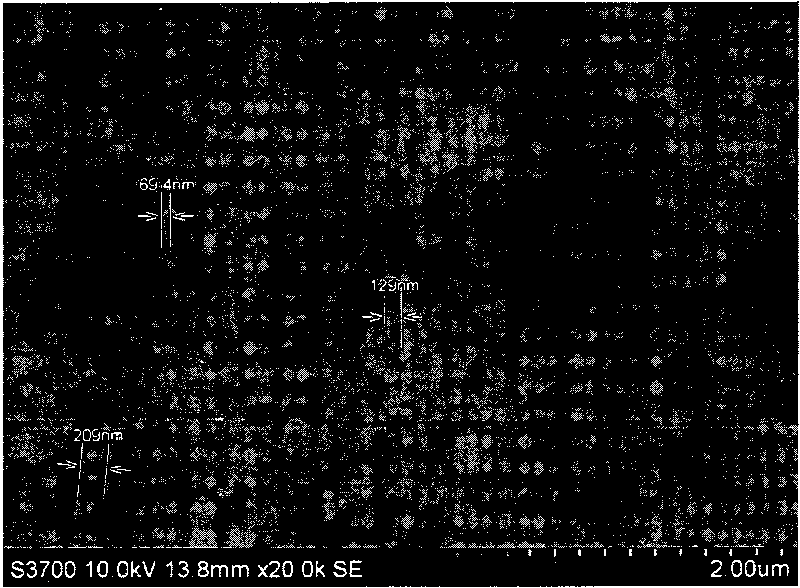

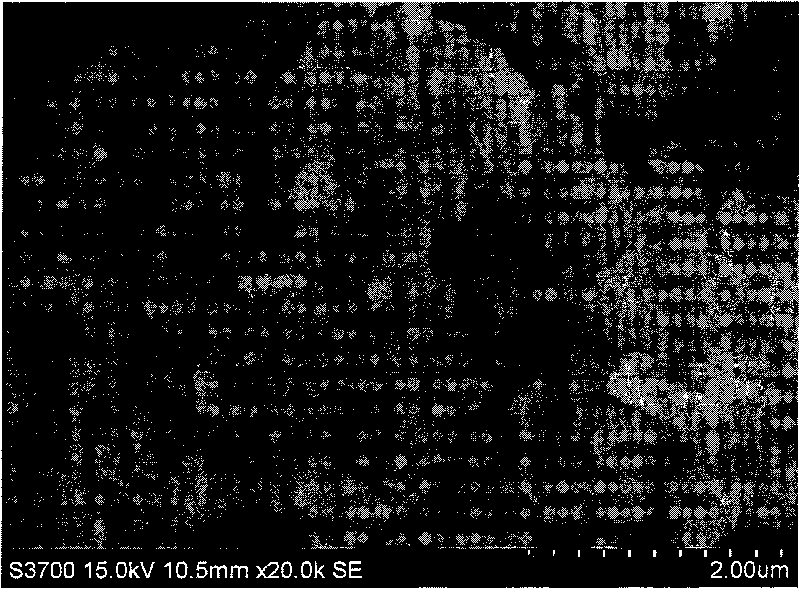

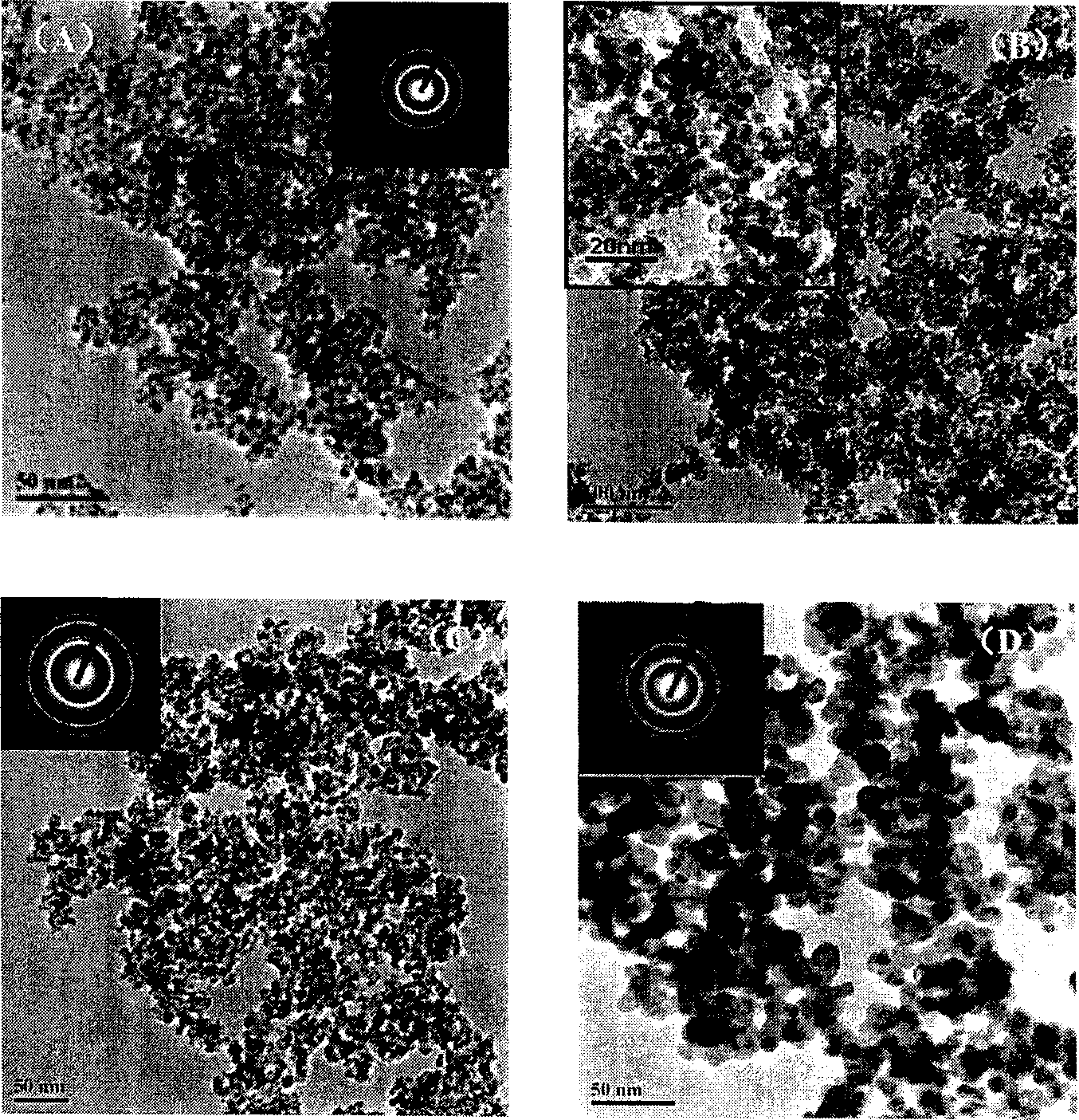

Method for preparing nano-cerium oxide and zirconia solid solution

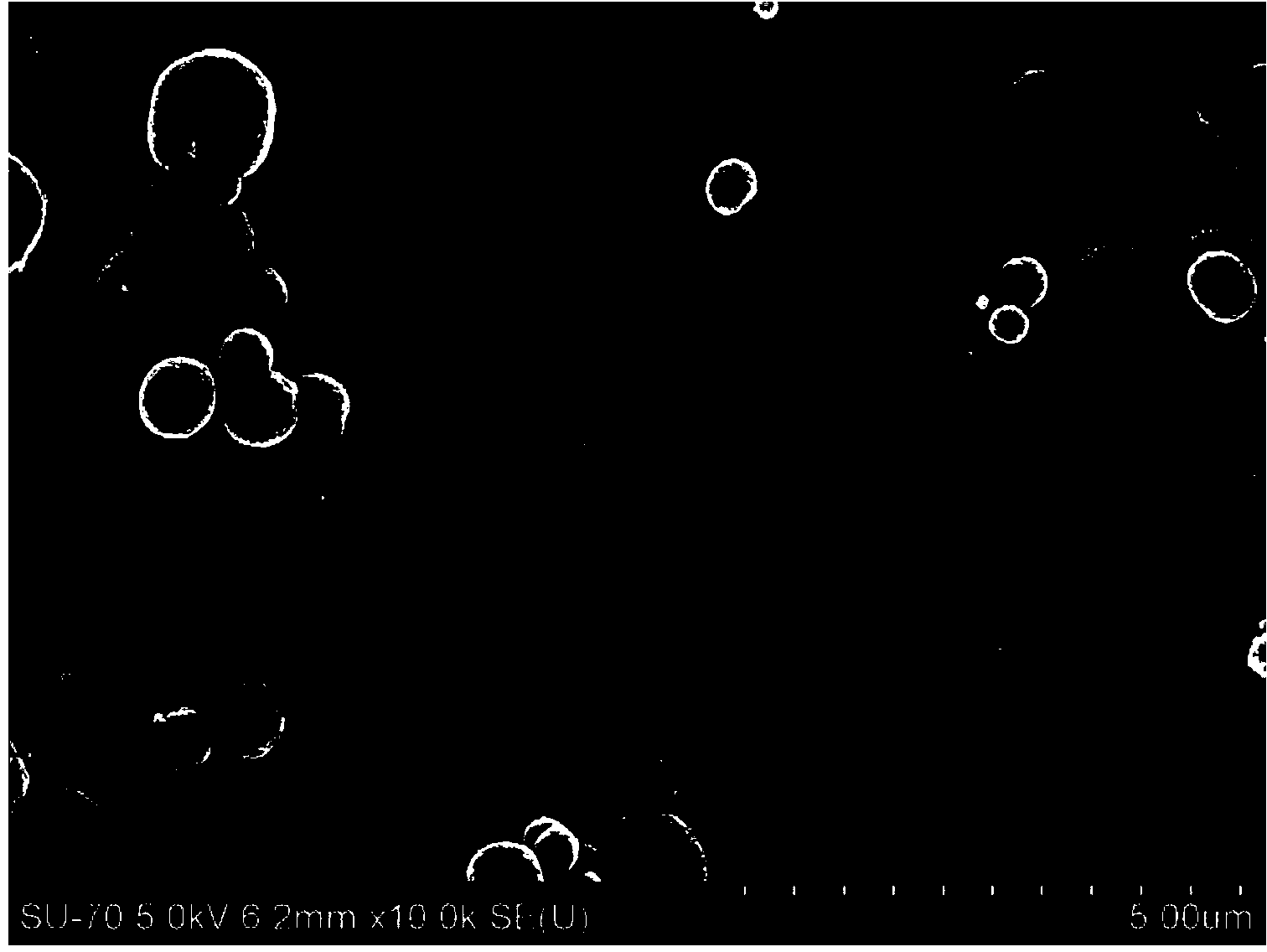

InactiveCN101696034AGain uniformityAchieve precise dopingRare earth metal compoundsMetal/metal-oxides/metal-hydroxide catalystsCeriumComposite oxide

The invention discloses a method for preparing nano-cerium oxide and zirconia solid solutions, which belongs to the field of inorganic catalytic materials. The method comprises: dissolving cerium-containing ionic compound accounting for 10 to 90 percent of the weight of the raw materials and zirconium-containing ionic compound accounting for 10 to 90 percent of the weight of the raw materials in deionized water respectively according to a formulation of raw materials of nano-cerium oxide and zirconia solid solutions, and preparing the two into solutions with the concentration between 1 and 3 M; mixing the two solutions, adding alkaline substances, regulating pH between 7 and 10 to generate precipitate, aging the precipitate through heat treatment, performing washing and centrifugal filtration to obtain a filter cake; dissolving the obtained filter cake in nitric acid, adding surfactant to obtain milky white colloid; and performing calcination to prepare composite oxide of nano-cerium oxide / zirconia. Nano-sized particles prepared by the method improve the microstructure of cerium / zirconium solid solutions, and the prepared nano-composite oxide solid solutions have better thermal stability and larger specific surface area.

Owner:SOUTH CHINA UNIV OF TECH

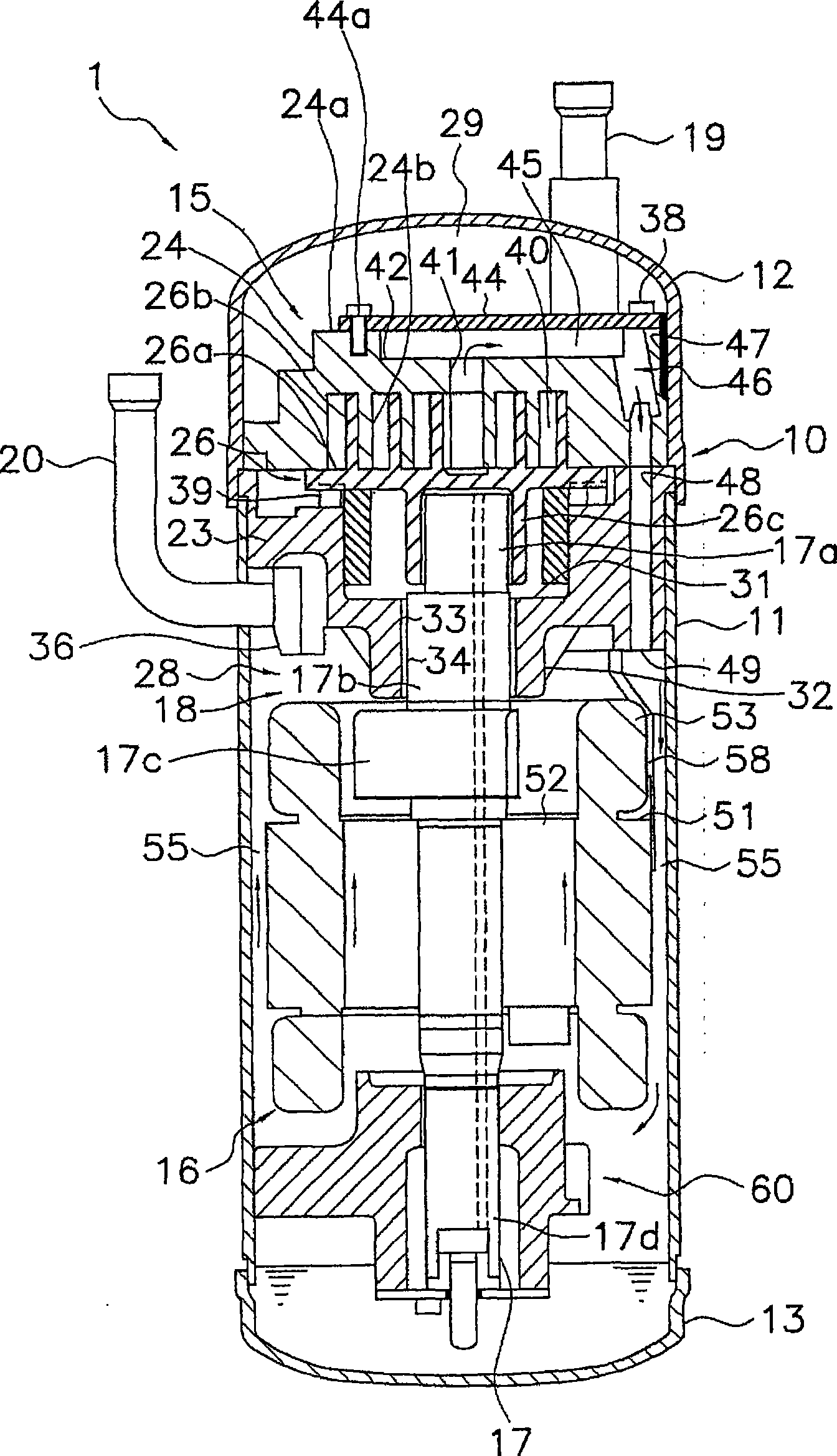

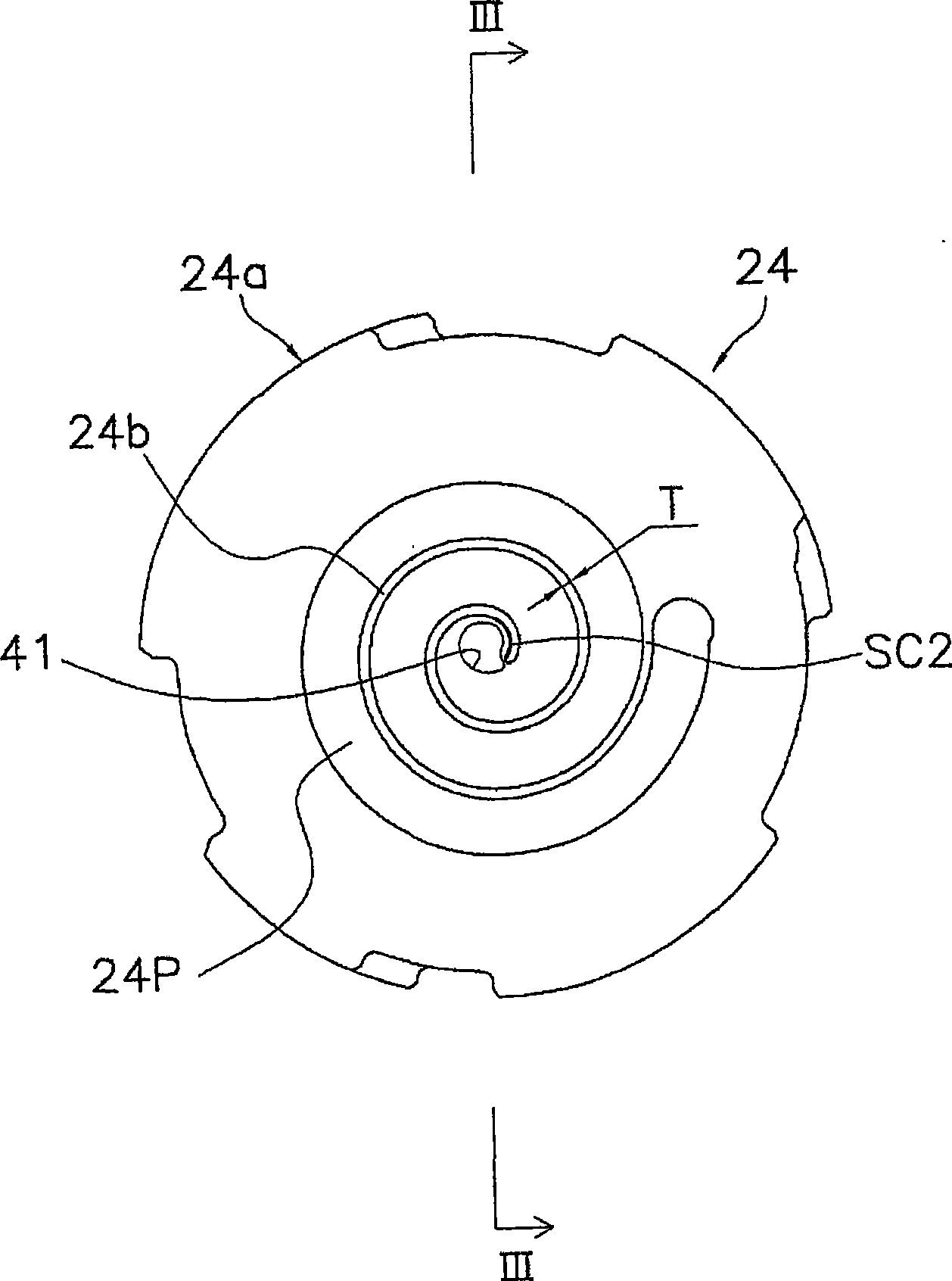

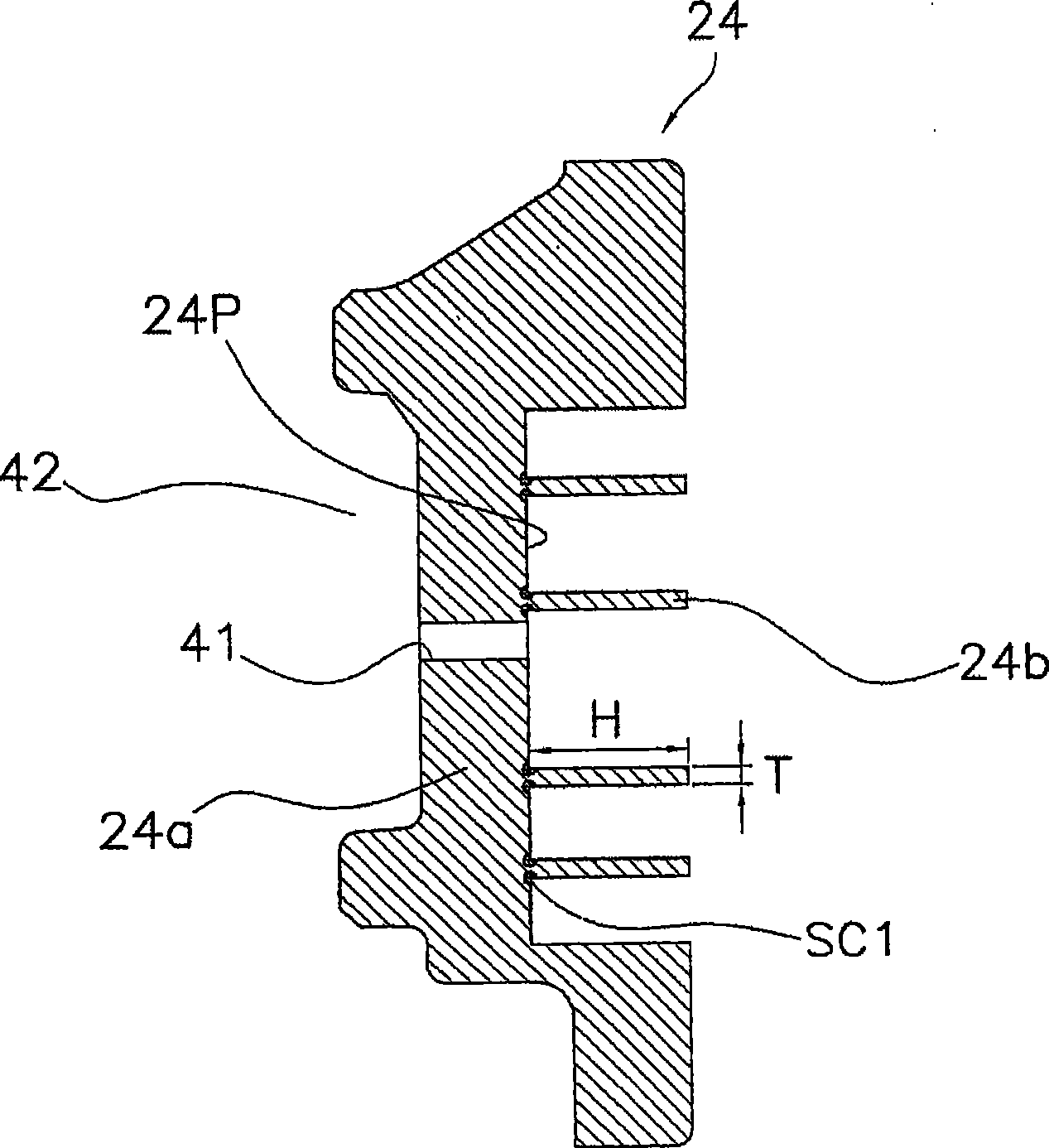

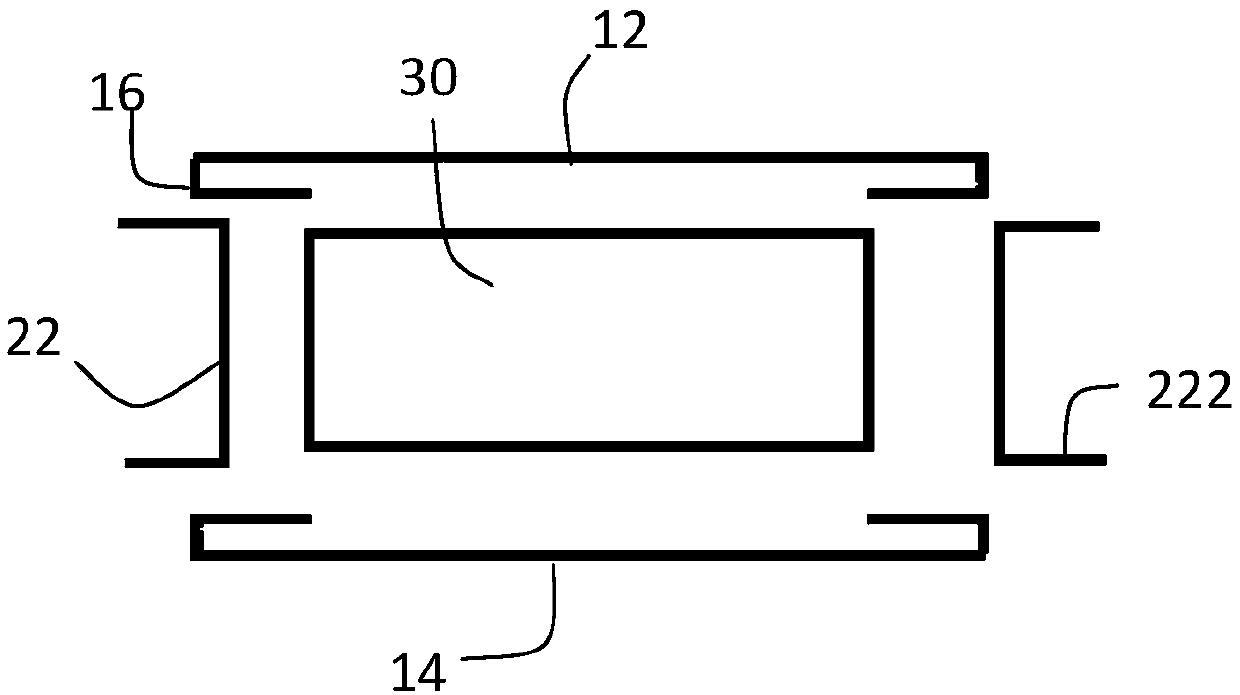

Sliding component of compressor, sliding component base, scroll component, and compressor

ActiveCN101395377AHigh tensile strengthFull durabilityRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsHardnessEngineering

Owner:DAIKIN IND LTD

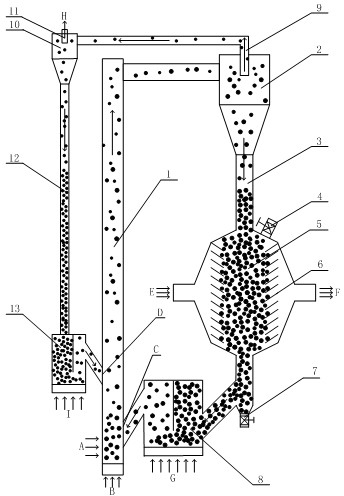

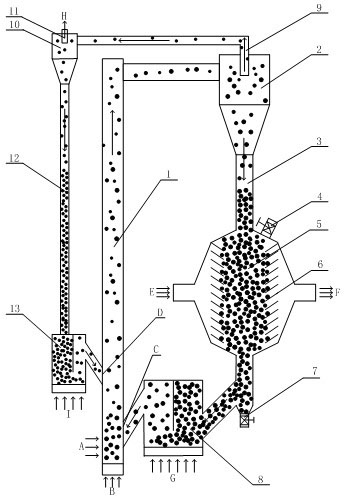

Method for separating CO2 through chemical looping combustion in coal pressure high-density circulating fluidized bed

ActiveCN102183014AIncrease the combustion reaction rateSolving the Response Matching ProblemFluidized bed combustionIndirect carbon-dioxide mitigationCycloneHigh density

The invention provides a method for separating CO2 through chemical looping combustion in a coal pressure high-density circulating fluidized bed, which comprises the following steps: coal particles and a gasifying agent are subjected to gasification reaction in a fuel reactor 1 of the coal pressure high-density circulating fluidized bed, and gasified products and oxygen carriers which return to the fuel reactor are subjected to combustion reaction to produce CO2 and H2O; smoke which is produced during the reaction and carries oxygen-lost oxygen carriers and carbon-containing coal ash enters a primary cyclone separator 2 for separation, and separated oxygen-lost oxygen carriers are in contact with transversely passing air for reaction in an air reactor 5 of a cross flow moving bed to be regenerated and are turned to the combustion reactor through a primary material returning device 8 to continuously participate in the combustion reaction; and separated smoke in the primary cyclone separator 2 further enters a secondary cyclone separator 10 for separation, solid particles secondarily separated are returned to the fuel reactor 1 through a secondary material returning device 13 to continuously participate in the combustion reaction, and H2O is removed from the separated gases through condensation to obtain high-purity CO2.

Owner:SOUTHEAST UNIV

Dye-sensitized solar cell and preparation method of ZnO composite photo-anode of dye-sensitized solar cell

ActiveCN103730260AHigh specific surface areaEase of industrial productionLight-sensitive devicesFinal product manufactureElectronic transmissionElectrical battery

The invention discloses a preparation method of a ZnO composite photo-anode of a dye-sensitized solar cell. The preparation method includes the steps of firstly, growing a ZnO nanometer wire array on a conductive substrate, and then growing and filling ZnO nanometer particles in situ in gaps between nanometer wires. By means of the preparation method, the specific area of the ZnO composite photo-anode is enlarged, and therefore the photovoltaic conversion efficiency of the photo-electrode is remarkably improved; meanwhile, the nanometer wires grow in a specific direction perpendicular to the substrate, and therefore the electronic transmission speed can be increased. In addition, the preparation method is easy to operate, free of sintering, short in response time when the nanometer particles grow in the gaps of the ZnO nanometer wire array, capable of reducing cost and beneficial to industrial production of the photo-anode. Due to the advantages of the photo-anode of the dye-sensitized solar cell, the dye-sensitized solar cell with the ZnO composite photo-anode can be widely applied to the solar cell field.

Owner:SHENZHEN UNIV

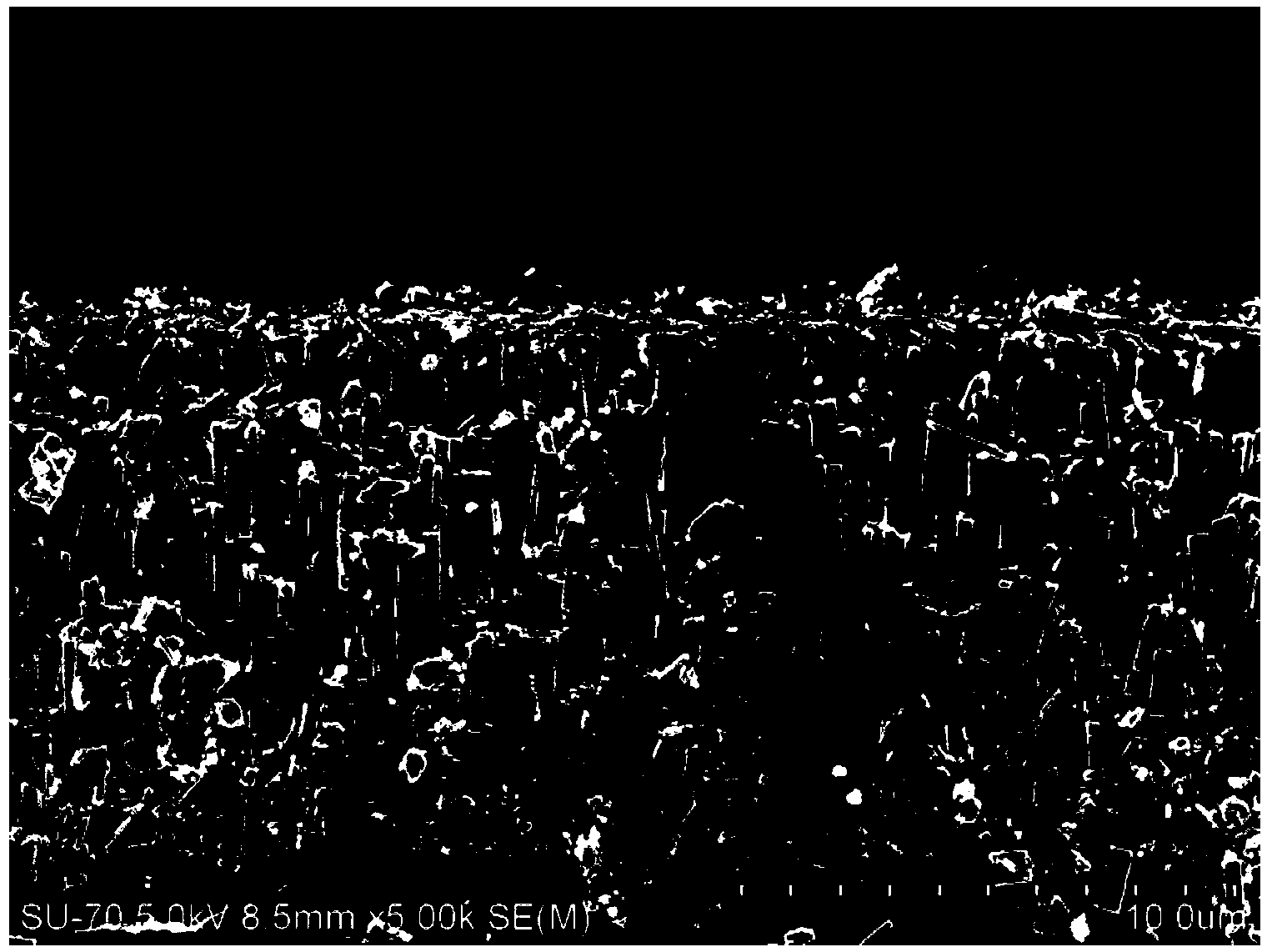

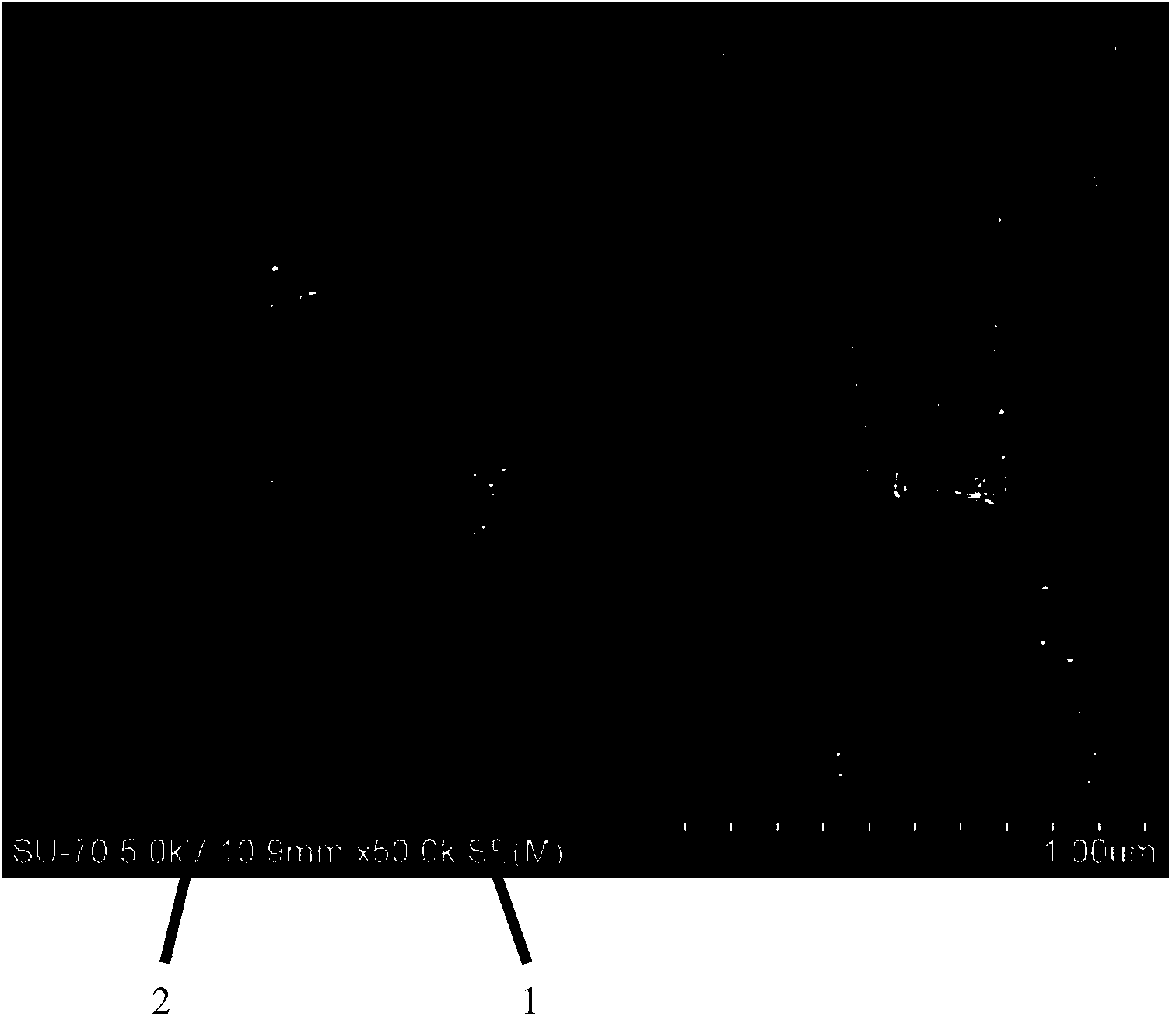

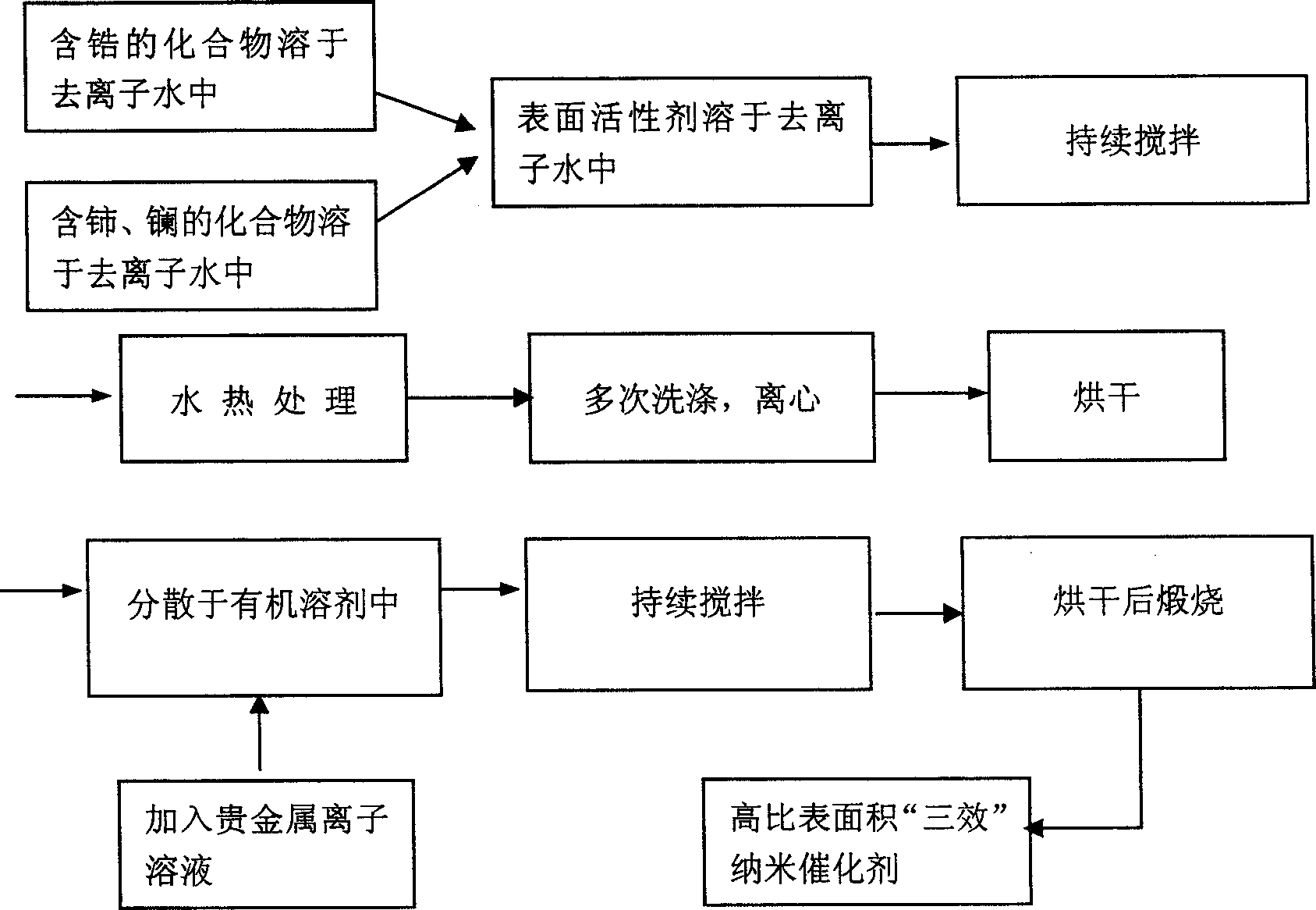

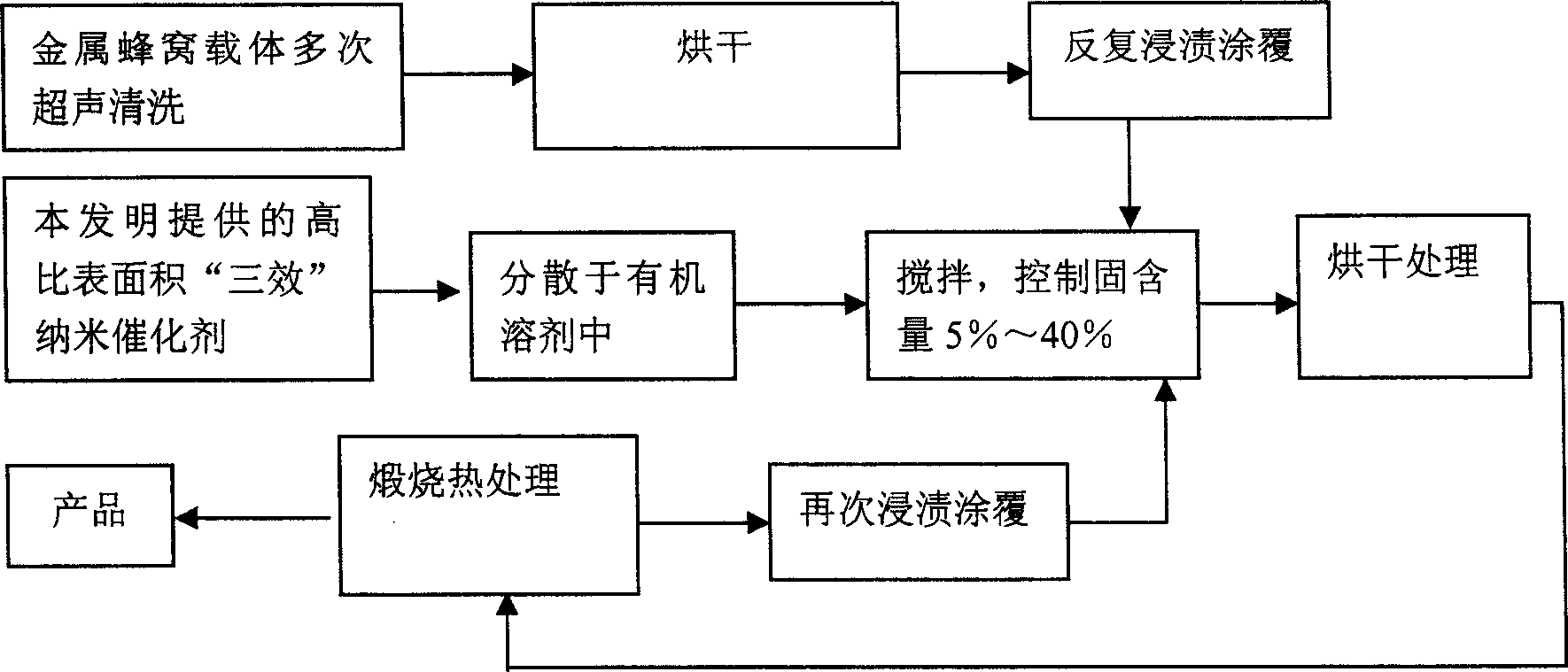

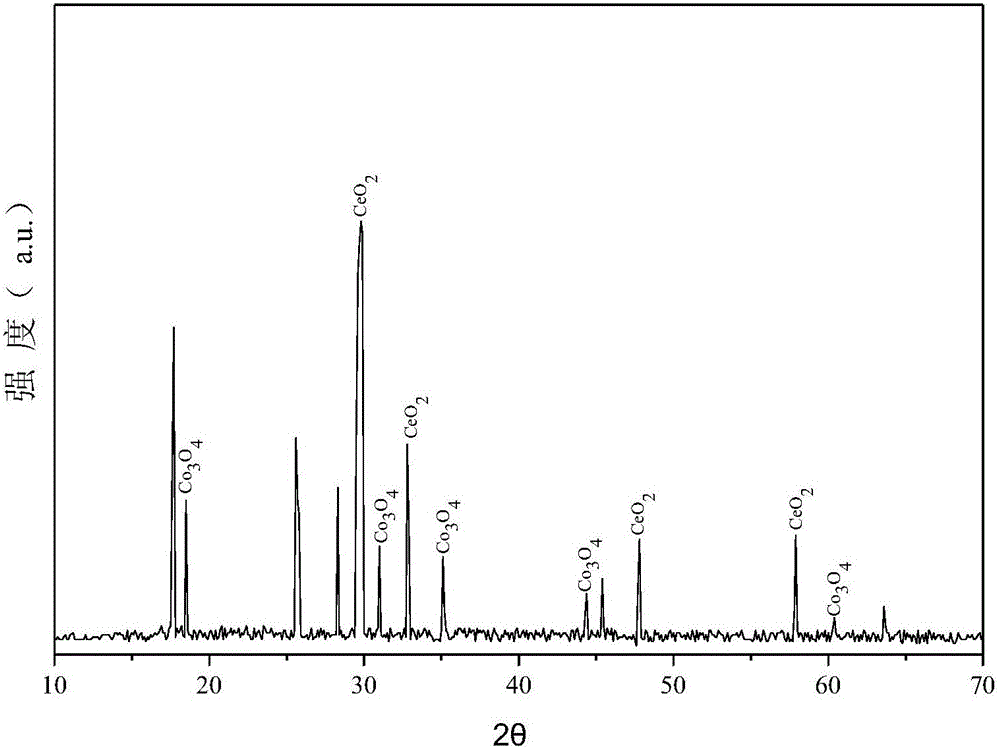

Ternary Nano catalyst in use for cellular carrier of full metal, preparation method and coating process

InactiveCN1915489ACoating Process AdvantagesGood activity at low temperatureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNano catalystOrganic solvent

A three-element nano-catalyst for the metallic cellular carrier used to treat the tail gas of car is proportionally prepared from lanthanum oxide, zirconium oxide and cerium oxide through dissolving them in deionized water, adding surfactant, hydrothermal treating, washing, filtering, dispersing it in organic solvent, adding the solution of noble metal, stirring, baking and calcining. Its coating technology includes such steps as ultrasonic cleaning of metallic cellular carrier multiple times, dispersing said nano-catalyst in organic solvent, stirring, baking, coating and calcining.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

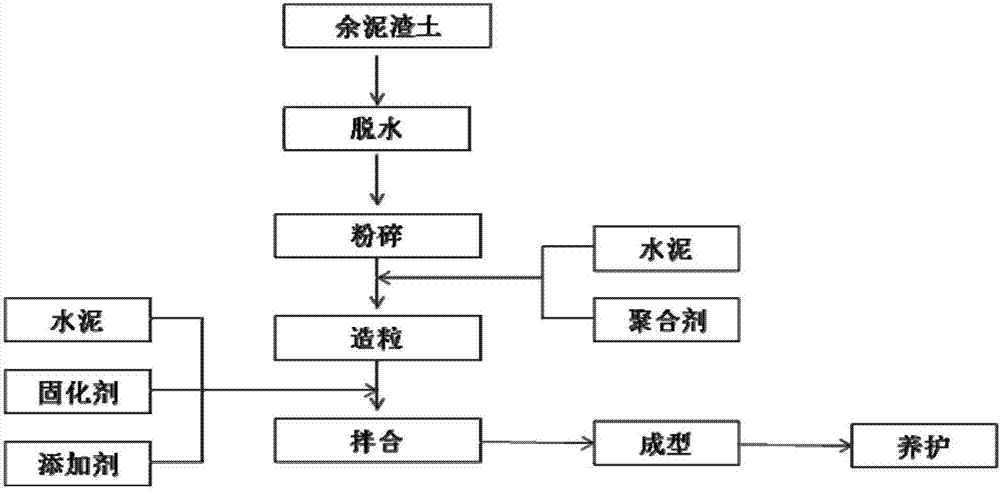

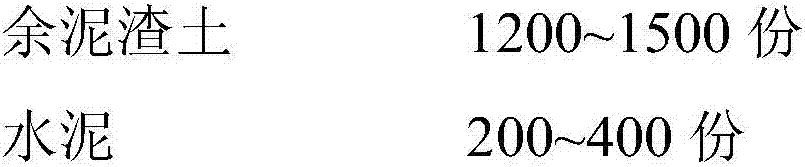

Non-burnt brick prepared from unwanted soil residues and preparation method thereof

ActiveCN107162528AReduce consumption rateSolve a large amount of storageBuilding componentsAbsorption rateNatural resource

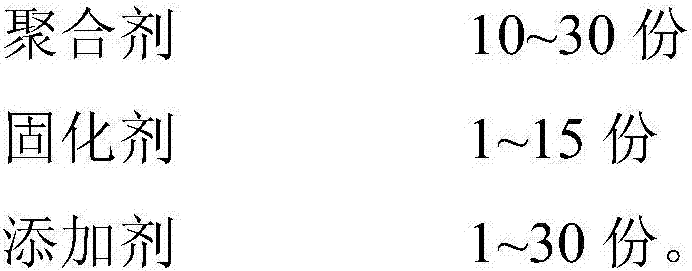

The invention discloses a non-burnt brick prepared from unwanted soil residues and a preparation method thereof. The non-burnt brick comprises, by mass, 1200 to 1500 parts of unwanted soil residues, 200 to 400 parts of cement, 10 to 30 parts of a polymerizer, 1 to 15 parts of a curing agent and 1 to 30 parts of an additive. The preparation method for the non-burnt brick comprises the following steps: drying and crushing the unwanted soil residues, then blending the crushed unwanted soil residues with the cement and the polymerizer and carrying out granulation to form stable soil particles which are used for replacing conventional sand and stone as a framework material for the non-burnt brick; and mixing the stable soil particles with the cement, the curing agent and the additive to prepare the non-burnt brick. The non-burnt brick prepared from unwanted soil residues has a strength grade of Mu5.0 to Mu30 and a softening coefficient of 80 to 98%, and the water absorption rate, durability, radioactivity and the like of the non-burnt brick meet standard requirements. The invention has the beneficial effects that unwanted soil residues are recycled; environmental pollution is reduced; natural resources are saved; production cost for constructional bricks is lowered; the preparation method is simple and convenient; and substantial social benefits and economic benefits are produced.

Owner:深圳市绿志新型建材研究院有限公司

Red-mud-fly-ash high-strength heat-preservation building block based on alkali excitation and preparation method thereof

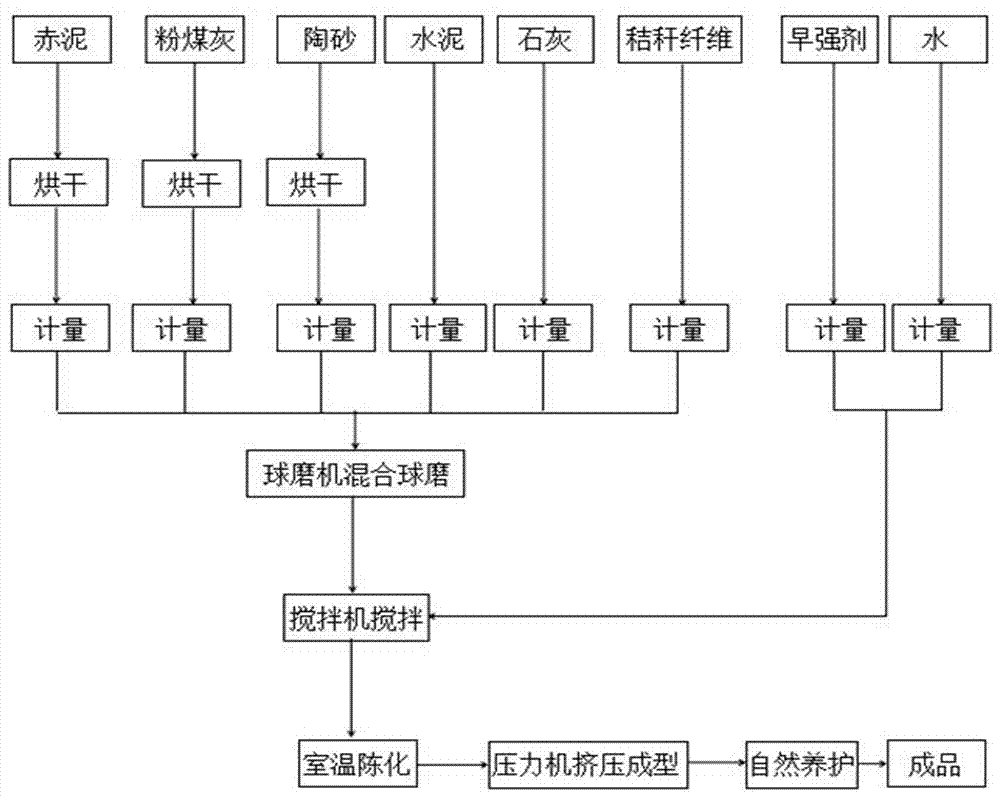

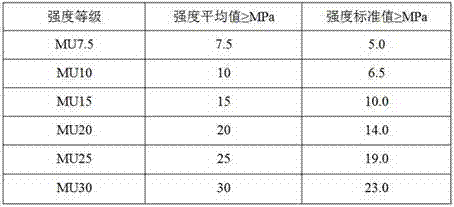

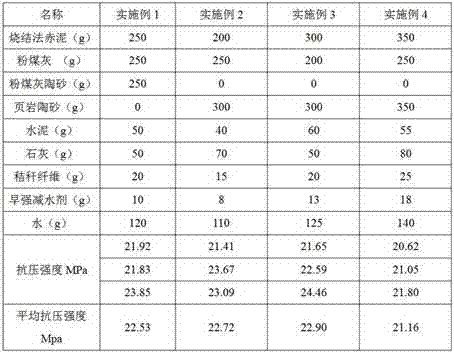

The invention discloses a red-mud-fly-ash high-strength heat-preservation building block based on alkali excitation. Industrial waste fly ash and red mud serve as main raw materials, cement and quicklime serve as auxiliary materials, and fly-ash pottery sand or shale pottery sand serve as heat-preservation materials. The building block is prepared from, by mass, 18-40% of red mud, 18-30% of fly ash, 25-40% of pottery sand, 3-8% of cement, 3-10% of lime, 1-3% of straw fibers and 0.5-2% of early strength agents, the water content is 10-15%, aging is conducted for 8-36 hours, and molding is conducted under the pressure of 40 MPa; the building block is prepared by the steps of drying, grinding, weighing, mixing of the auxiliary materials, compression molding, standard maintenance and natural curing. The red-mud-fly-ash high-strength heat-preservation building block based on the alkali excitation has the advantages of being simple in molding process, capable of having a reaction and being cured quickly at room temperature, and free from sintering and stream-pressure, products of the building block are high in compressive strength and anti-dry-shrinkage performance and good in impermeability, and can be stored for a long time without scumming phenomena. A large amount of industrial waste can be utilized, the energy and resources are saved, and the cost and energy consumption are low.

Owner:HUNAN YUNZHONG REGENERATION TECH CO LTD

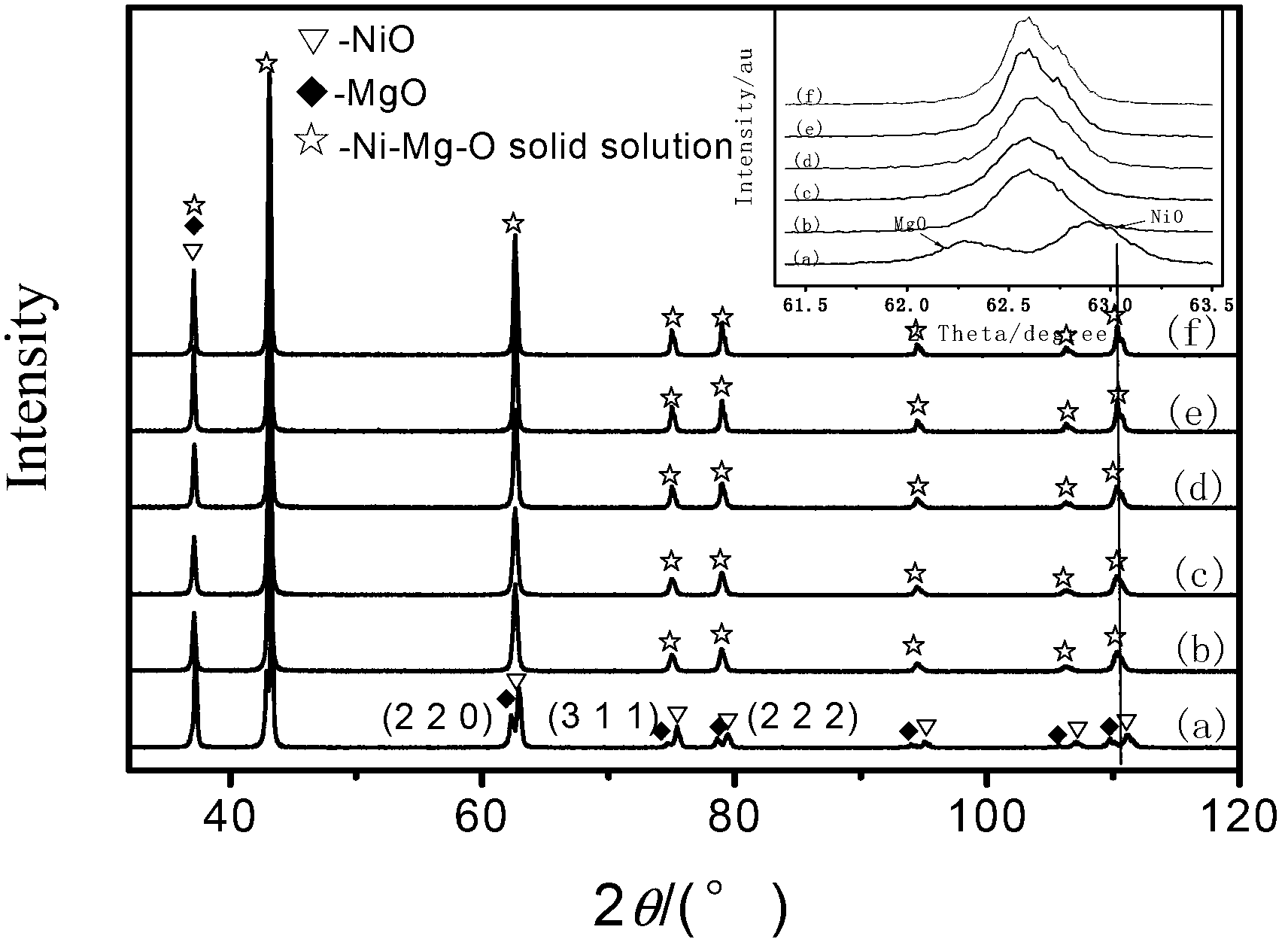

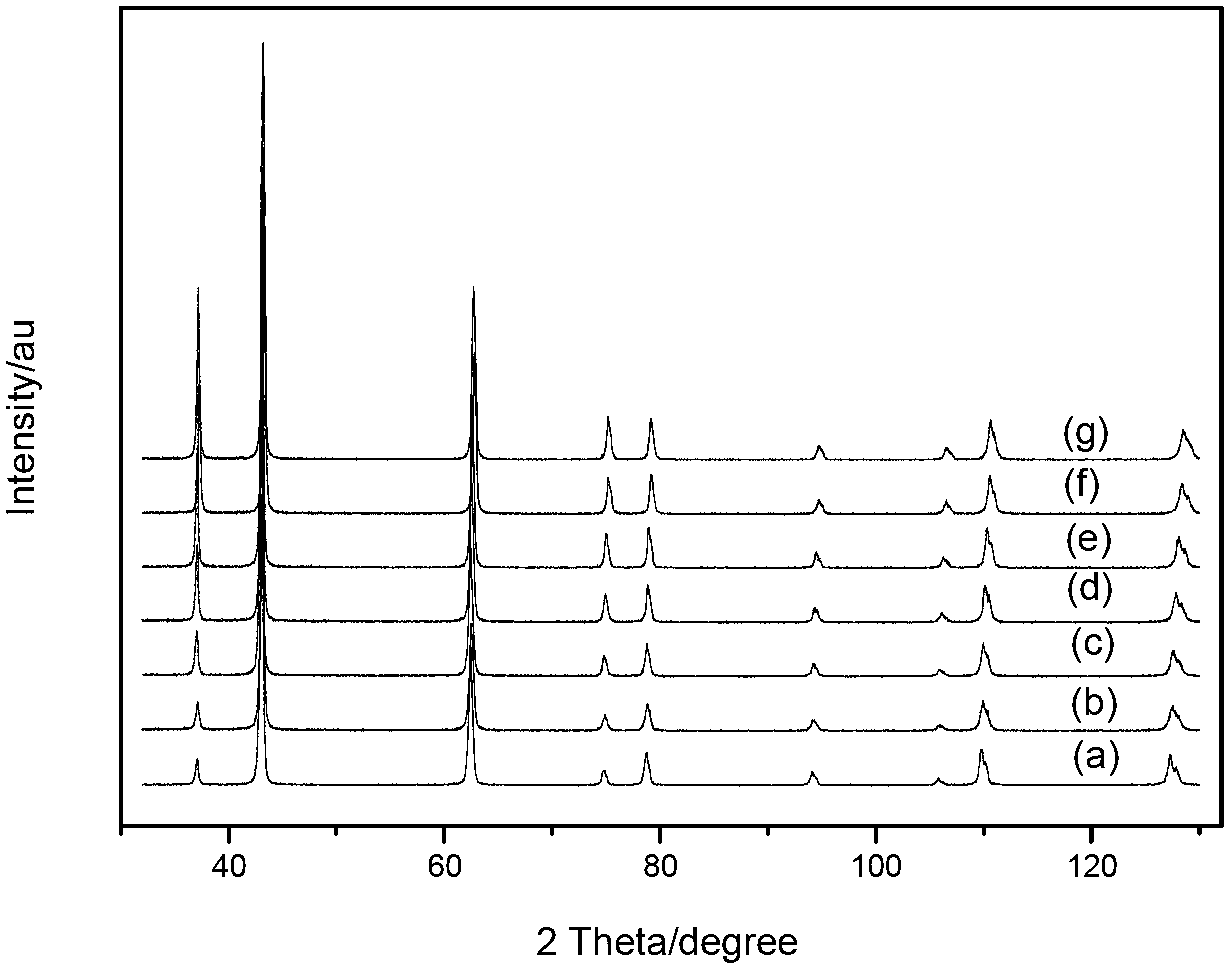

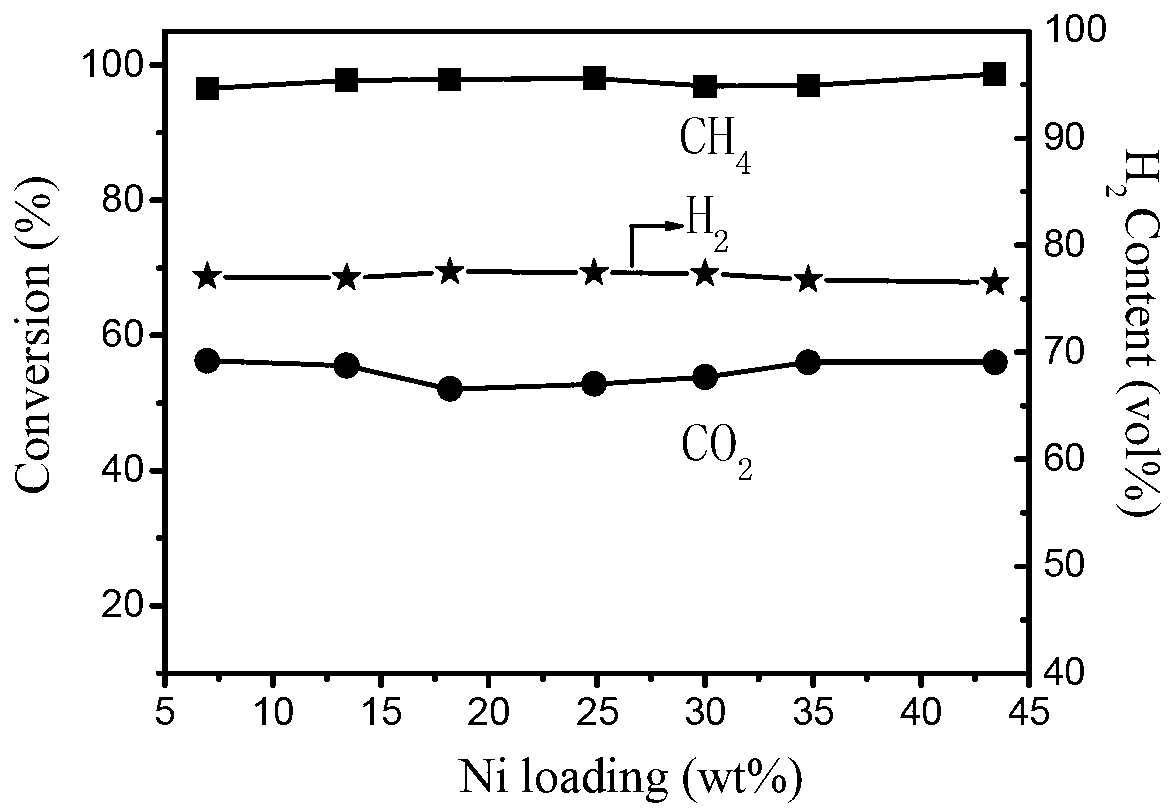

Application of NiO/MgO solid solution catalyst in coke oven coal gas steam reforming hydrogen production method at low water carbon ratio

InactiveCN102935998ANo sinteringNo carbon deposits and obvious sinteringHydrogenMetal/metal-oxides/metal-hydroxide catalystsChemistryCoke oven gas

The present invention relates to an application of a NiO / MgO solid solution catalyst in a coke oven coal gas steam reforming hydrogen production method at a low water carbon ratio, wherein a mass percentage of Ni is 6.9-43%, and the catalyst has characteristics of simple preparation process, high activity at a high temperature and a low water carbon ratio, no carbon deposition and good stability. According to the present invention, during a reforming process at a temperature of 875 DEG C and a H2O / CH4 ratio of 1, a methane conversion rate is maintained to 95-98%, and a carbon dioxide conversion rate is maintained to 52-54%; at a temperature of 875 DEG C and SV of 12600 mL / g.h, when a H2O / CH4 molar ratio is increased to 0.9 from 0.3, a methane conversion rate is correspondingly increased to 98.3% while a carbon dioxide conversion rate is reduced to 67.2% from 88. 4%; and when a reaction temperature is increased to 900 DEG C from 600 DEG C, a methane conversion rate and a carbon dioxide conversion rate are respectively increased to 98.7% and 601%.

Owner:JIANGSU UNIV OF SCI & TECH

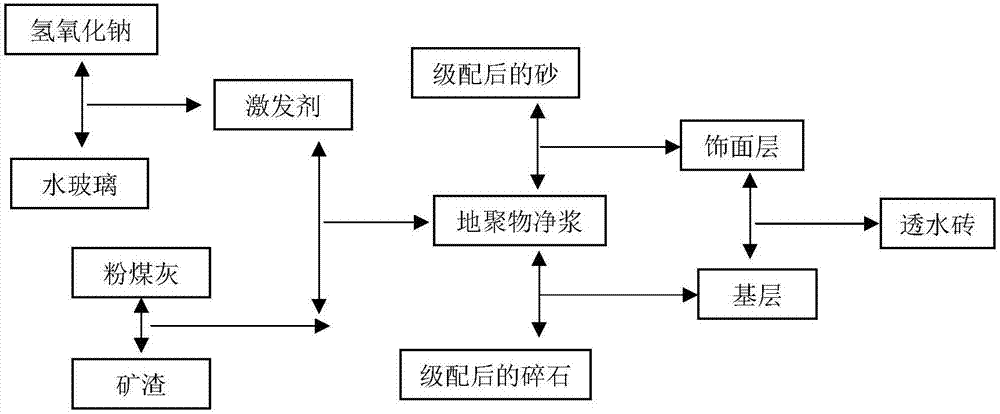

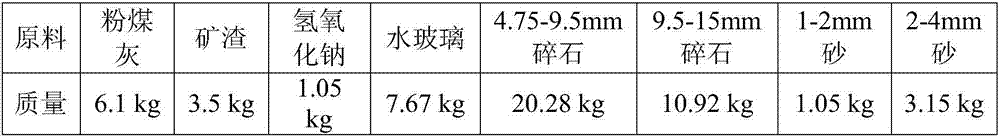

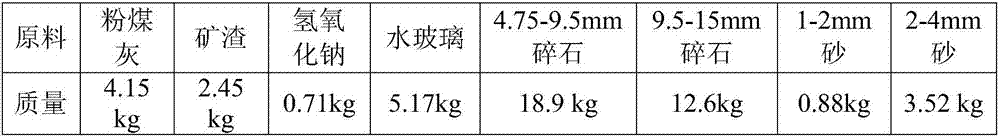

Geopolymer permeable brick and preparation method thereof

ActiveCN107352865AReduce preparation energy consumptionNo pressure formingCement productionPolymer chemistryGeopolymer

The invention discloses a geopolymer permeable brick, which comprises a base layer and a decorative layer. The base layer comprises aggregate A, a gelling material A, and an exciting agent. The decorative layer comprises aggregate B, a gelling material B, and an exciting agent. The invention further provides a preparation method of the geopolymer permeable brick. The provided geopolymer permeable brick has the advantages that the sintering is not needed; the preparation energy consumption is low; the moulding can be carried out without pressure; the technology is simple, and a large amount of solid waste is consumed. The 28d compression strength of the permeable brick is 32.3 MPa or more. The 28d rupture strength is 3.18 MPa or more. The permeation coefficient is 0.028 cm / s or more.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

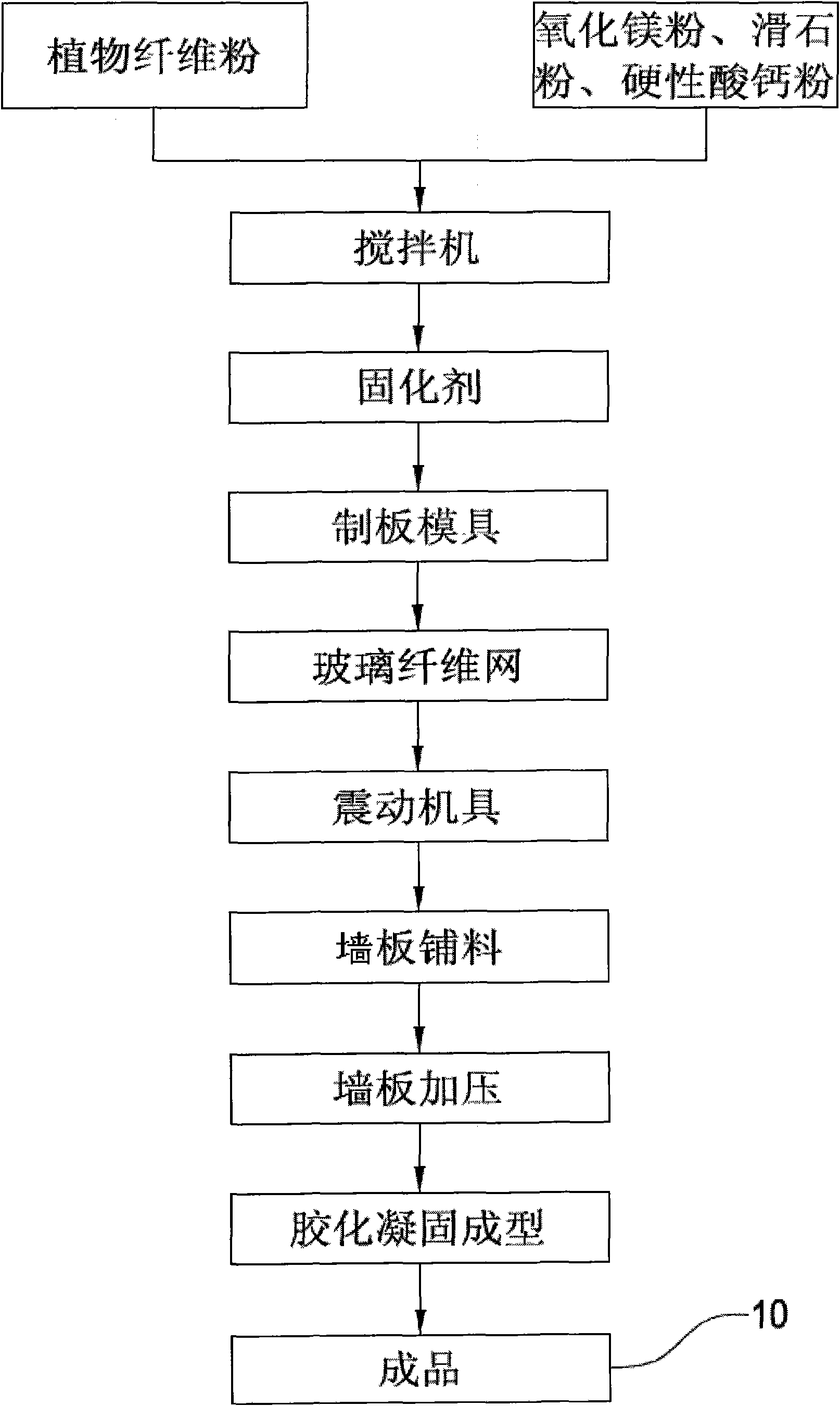

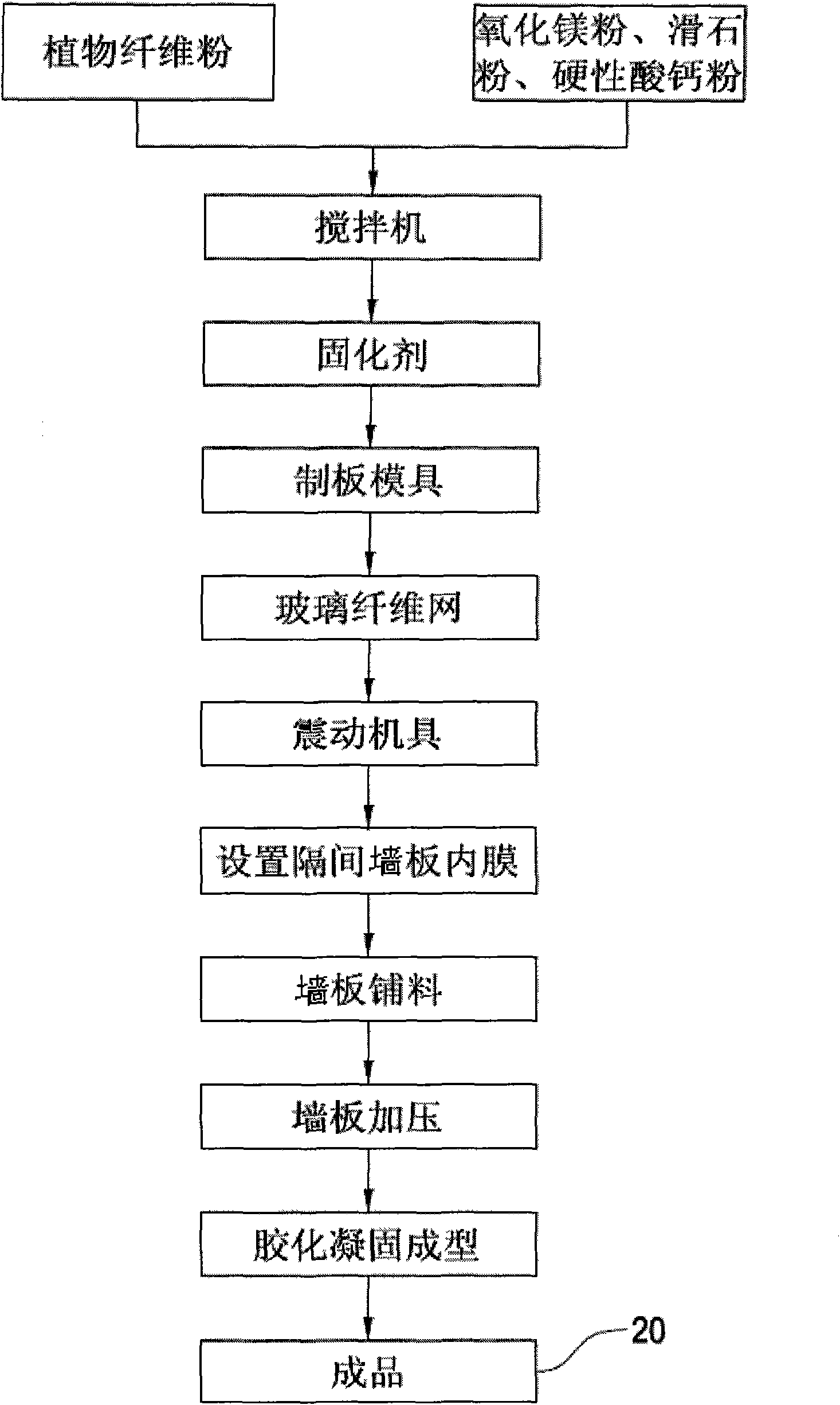

Method for producing environmental-friendly wallboard

ActiveCN101830027AReduce weightEnvironmentally friendlyCeramic shaping apparatusClay processing apparatusFiberResist

The invention discloses a method for producing an environmental-friendly wallboard, mainly comprising the following steps: mixing raw materials including plant fiber powder, magnesium oxide powder, talcum powder and calcium stearate powder according to proportion, stirring the raw materials with a stirrer for a period of time, adding and stirring curing agent to the raw materials, pouring the mixture to a wallboard producing mould, vibrating the mixture with a vibrating mould so as to enable the mixture to be combined more firmly, pressing the wallboard with the vibrating mould, and standing the wallboard for a period of time to enable the wallboard to be gelled and cured to obtain the environmental-friendly wallboard. The method for producing the environmental-friendly wallboard is easy and needs low production cost. The environmental-friendly wallboard produced with the method has the excellent performance of light weight and high strength, is poisonous, odorless and radiationless and can save energy, resist flame, shock and water and insulate sound and heat.

Owner:沛芃工程股份有限公司

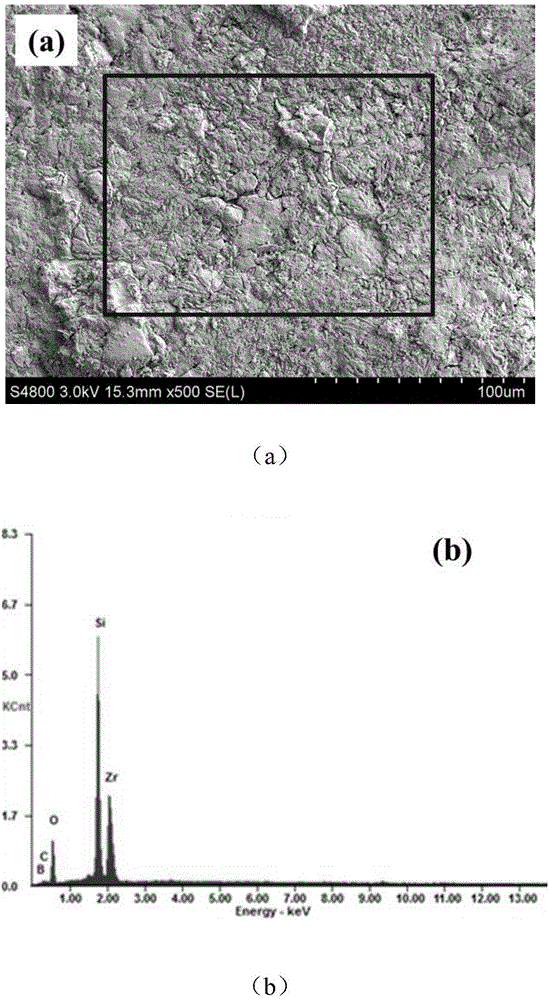

Preparation method for ZrB2-SiO2 composite high-temperature oxidation resistant coating

ActiveCN104150960AImprove antioxidant capacityImprove thermal shock resistanceCeramic coatingOxidation resistant

The invention discloses a ZrB2-SiO2 composite high-temperature oxidation resistant coating, and belongs to the technical field of a ceramic coating. The adopted technical scheme is that ZrB2 powder is added into isopropanol, an iodine is added, and a suspension liquid is obtained through uniformly stirring; the suspension liquid is poured into a hydrothermal kettle, a SiC-C / C sample is placed on a cathode clamp in the hydrothermal kettle to be subjected to the pulsed arc discharge deposition, and a ZrB2 porous skeleton layer is prepared on the surface of the SiC-C / C sample; the SiC-C / C sample with the ZrB2 porous skeleton layer is infiltrated in a silica sol solution and is placed in a drying oven to be dried, so that the ZrB2-SiO2 composite high-temperature oxidation resistant coating is prepared on the surface of the SiC-C / C sample. The preparation method has the advantages that the cost is low, the operation is simple, the preparation cycle is short; in addition, the ZrB2-SiO2 composite coating prepared by the invention has good thermal shock resistance, is compact, can be well bonded with a base body, and is not needed to be sintered.

Owner:SHAANXI UNIV OF SCI & TECH

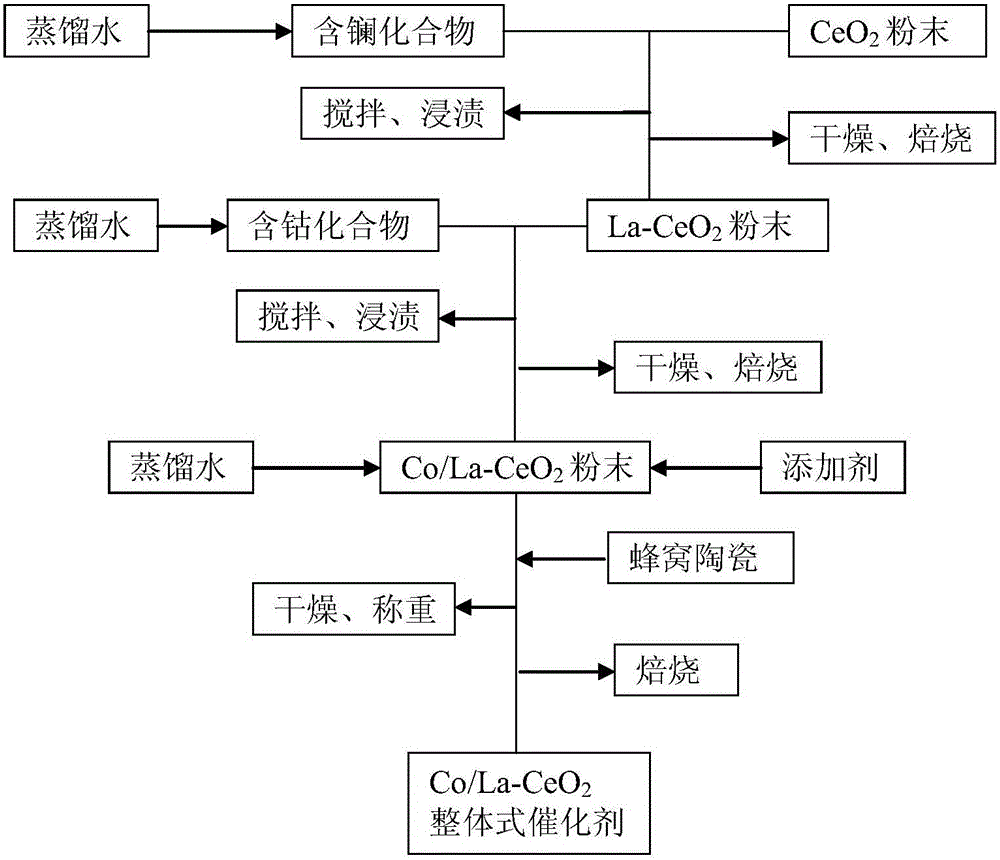

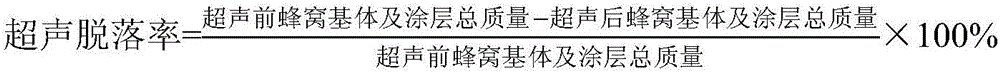

Preparation method of catalyst capable of catalytically combusting VOCs (volatile organic compounds) containing fluorine and chlorine

InactiveCN106140175AStrong adhesionHigh temperature resistantCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPolyvinyl alcoholPolyvinyl chloride

The invention relates to the preparation techniques of catalysts and is intended to provide a preparation method of a catalyst capable of combusting VOCs ((volatile organic compounds) containing fluorine and chlorine. The method includes: preparing La-CeO2 powder from CeO2 and lanthanum-containing compounds by impregnation, and preparing Co / La-CeO2 powdery catalyst with cobalt-containing compounds by impregnation; mixing and stirring with polyvinyl chloride and colloidal alumina into a slurry, soaking a singular honeycomb ceramic carrier in the slurry, impregnating and drying repeatedly until a target value of total carried weight is reached; calcining to obtain the integrated Co / La-CeO2 catalyst. The catalyst is resistant to high temperature and free of deposition when calcined at about 900 DEG C; a coating layer is firmly adhered with ultrasonic peeling rate of 1.6-2.1%; the catalyst has good antitoxic capacity and high catalytic activity for VOCs containing fluorine and chlorine, the materials are easy to obtain, the process is simple, the cost is low, and the catalyst is easy to produce on industrial scale; the catalyst has stable reuse stability, the synthetic process is environment-friendly with no pollution byproducts produced, and the process is widely applicable.

Owner:JIANGSU ANQIER WASTE GAS PURIFICATION

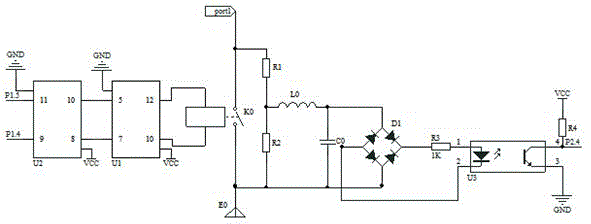

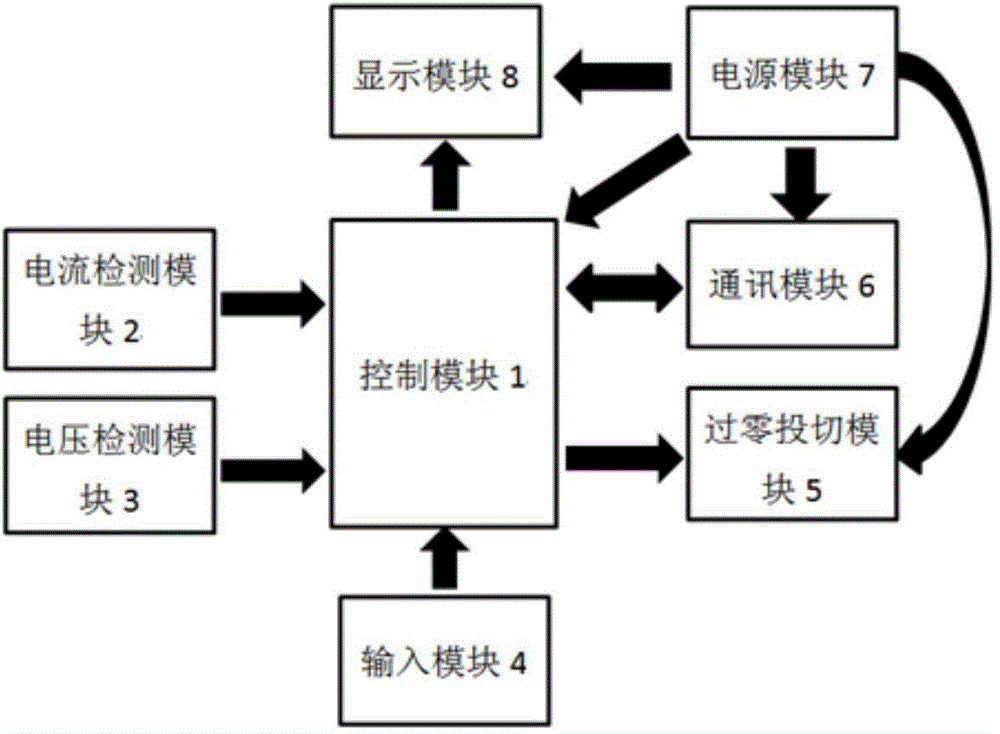

Low-voltage intelligent synchronous switch

ActiveCN104836239AReduce the board area and the number of componentsReduce design costReactive power adjustment/elimination/compensationReactive power compensationAC powerZero crossing

The invention provides a low-voltage intelligent synchronous switch. The switch comprises a control module, a current detection module, a voltage detection module, an input module, a zero-crossing switching module, a communication module, a power module, and a display module. The control module is connected with other seven modules. The power module is connected with the zero-crossing switching module, the communication module, and the display module. Through cooperation of the zero-crossing switching module and the control module, the switch can be switched to a capacitor or an AC power switch on a zero-crossing point, realizing switching-in of the capacitor on a voltage zero-crossing point and switching-off on a current zero-crossing point. In a switching process, the switch has no inrush current, no electric arc, and switch contacts are not damaged. The switch has no inrush current in switching, contacts do not sinter, and the switch is small in volume, low in energy consumption, and does not lead in transient state and harmonic waves. The switch can adapt to various extreme cold extreme hot harsh environment, and can satisfy various occasions of reactive capacity requirements.

Owner:HEBEI UNIV OF TECH

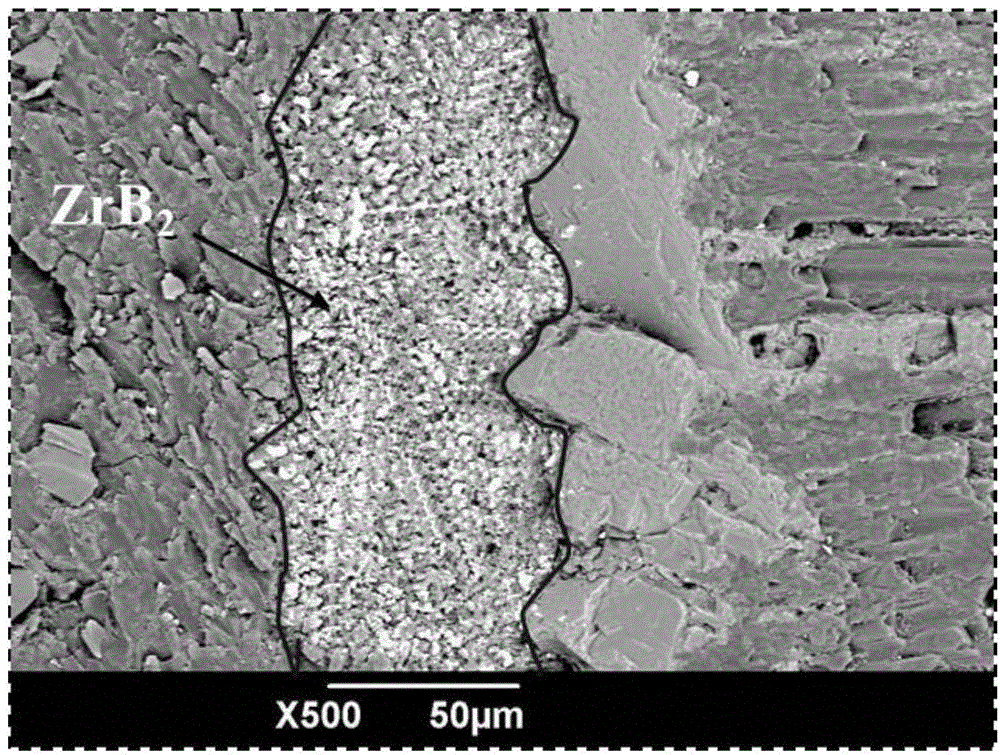

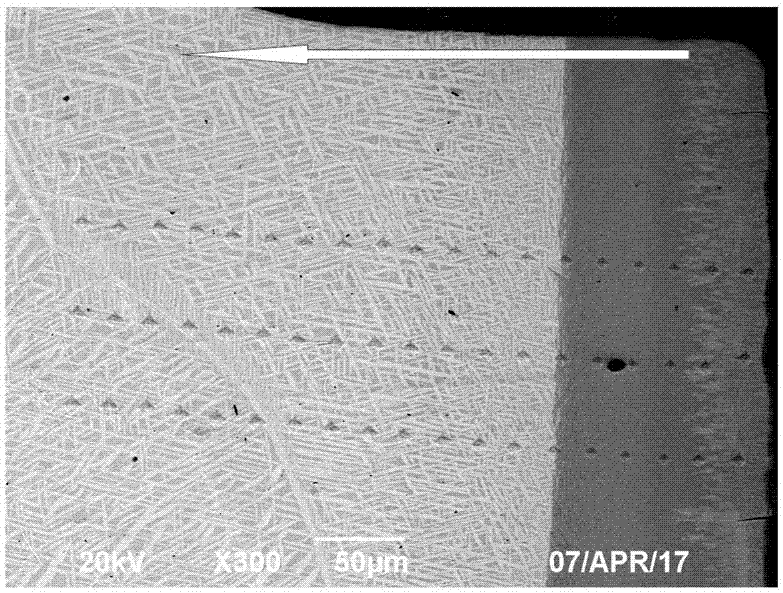

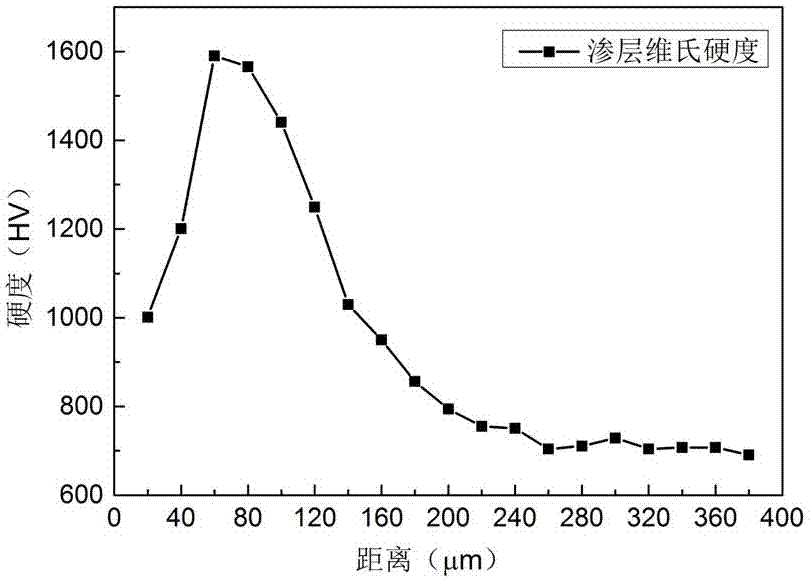

High-entropy alloy surface carburizing modification method

ActiveCN107955928AHigh surface hardnessInterface straightSolid state diffusion coatingActivated carbonAfter treatment

The invention discloses a high-entropy alloy surface carburizing modification method. The method comprises the steps that (1), an HfZrTiTa high-entropy alloy is pre-treated; (2), active carbon is selected as a carburizing agent, a carburizing container is naturally filled with the carburizing agent, and the pre-treated HfZrTiTa high-entropy alloy is buried into the upper middle portion of the carburizing agent; (3), the carburizing container is sealed; and (4), the sealed carburizing container is placed into a heating device, heating is conducted till the temperature is 700-900 DEG C, then heat preservation is conducted for 2-10 h, after treatment is finished, the carburizing container is taken out for air cooling, then a sample subjected to carburizing treatment is taken out to be subjected to ultrasonic washing and drying, and a high-entropy alloy with the surface subjected to carburizing modification is obtained. According to the high-entropy alloy surface carburizing modification method, the surface hardness and the high-temperature oxidation resistance of the HfZrTiTa high-entropy alloy can be effectively improved at the same time.

Owner:NAT UNIV OF DEFENSE TECH

Polystyrene color steel sandwich panel and preparation method thereof

ActiveCN109094175AEasy to prepareReduce investmentNon-macromolecular adhesive additivesSynthetic resin layered productsCombustionAdhesive

The invention discloses a polystyrene color steel sandwich panel. The polystyrene color steel sandwich panel comprises a core board, wherein the core board is a polystyrene fireproof thermal insulation board; two color steel plates respectively bonded to both sides of the polystyrene fireproof thermal insulation board; two side plates and two sealing plates respectively bonded to the two long sides and the two short sides of the polystyrene fireproof thermal insulation board. A fireproof thermal insulation adhesive is used for fireproof coating modification of a polystyrene foam board, so thatthe fireproof thermal insulation adhesive penetrates the polystyrene foam board to prepare the polystyrene fireproof thermal insulation board. The polystyrene color steel sandwich panel prepared by using the polystyrene fireproof thermal insulation board has the advantages of high bending strength, high compressive strength, good endurance, good combustion performance and no collapse in a fire field.

Owner:应急管理部四川消防研究所

Rapid condensation high-strength flame retardant thermal insulation material and preparation method thereof

The invention discloses a rapid condensation high-strength flame retardant thermal insulation material and a preparation method thereof. The rapid condensation high-strength flame retardant thermal insulation material is prepared from the following raw materials in percentage by weight: 5-55% of metallic oxide, 5-55% of phosphate, 1-10% of additive, 0.5-5% of fiber material, 0.5-50 of thermal insulation component and 5-50% of water. The rapid condensation high-strength flame retardant thermal insulation material is high in condensation speed; when the material is placed for 4 hours at a normal temperature, the compression strength of the thermal insulation material can reach 20MPa, and the breaking strength can reach 3.5MPa; and when the material is placed for 8 days at a normal temperature, the compression strength of the thermal insulation material can reach 60MPa, and the breaking strength can reach 10MPa. The thermal insulation material has good compatibility with concrete, cement and the like and high cold resistance and can be used under low temperature conditions of 0-10 DEG C. The rapid condensation high-strength flame retardant thermal insulation material can be directly sprayed to walls, roadway walls, tunnel walls and the like or is poured into a grinding tool with appointed size and shape and is compacted and shaped by vibration.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Burn-free heat-insulation external tile produced from gangue and production method of external tile

The invention discloses a burn-free heat-insulation external tile produced from gangue. The burn-free heat-insulation external tile is produced from the following raw materials in percentage by weight: 40-63 percent of gangue, 2-9 percent of cement, 15-32 percent of a binding agent, 3-9 percent of adhesive, 0.05-1 percent of water reducer, 0.45-3 percent of an initiator, 2-15 percent of foams for foaming and 1.5-4 percent of an accelerant. In addition, the invention also provides a production method of the burn-free heat-insulation external tile produced from gangue. The heat-insulation external tile is free of burning, easily realizes batch production, has excellent safety performance and is environmental friendly, the energy source is saved, the production cost is reduced, the waste gangue is comprehensively utilized, and the land occupied by stacking the gangue is reduced; the produced heat-insulation external tile has the advantages of light weight, high strength, low cost and the like and makes a contribution to the development of building heat-insulation materials in China.

Owner:CHANGAN UNIV

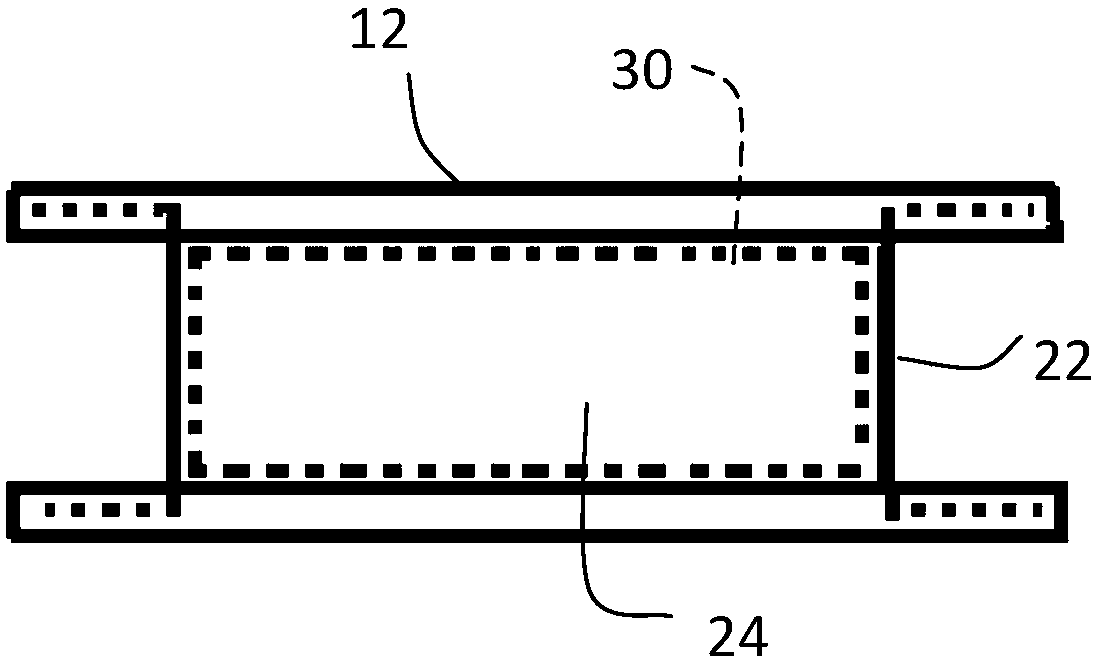

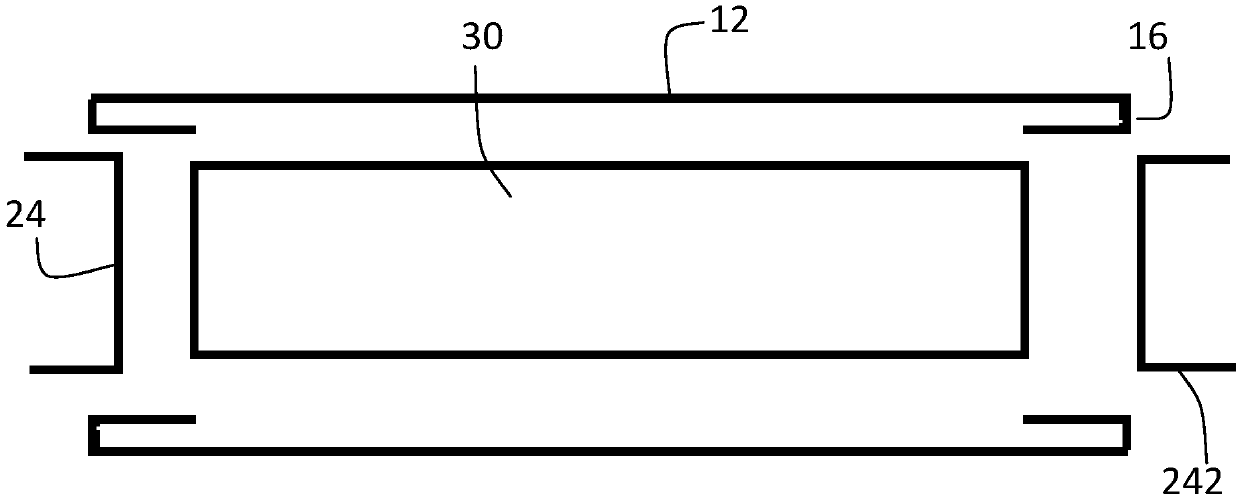

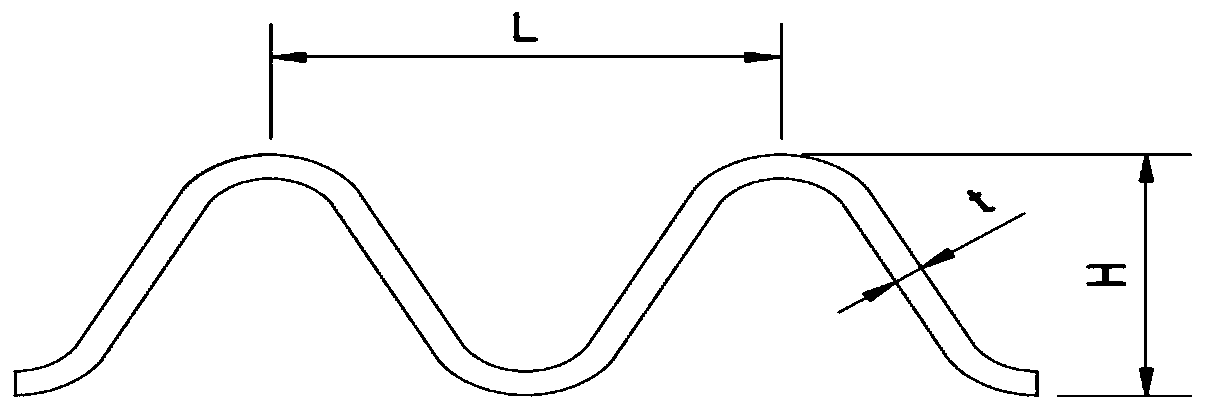

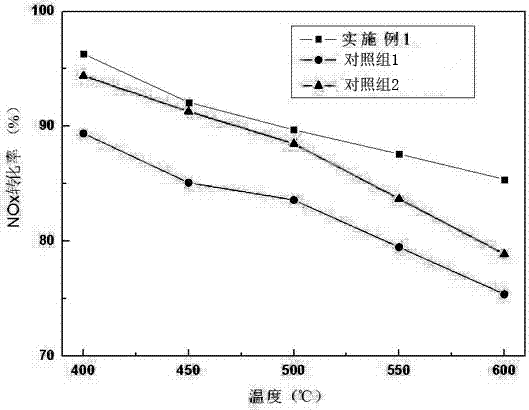

Small-aperture corrugated catalyst for fuel gas denitration, and preparation method thereof

InactiveCN110876942AImprove thermal stabilityNo crystal changeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystIron salts

The invention belongs to the technical field of flue gas denitration, and relates to a small-aperture corrugated catalyst for gas denitration, and a preparation method thereof. The catalyst adopts a glass fiber mat as a skeleton base material, one or two of titanyl sulfate and silicon oxide as a carrier, one or two of ammonium heptamolybdate and cerium salt as an assistant and one or more of a manganese salt, an iron salt and a chromium salt as an active component precursor and deionized water; and the catalyst comprises, by weight, 90 parts of the carrier, 1.6-6.5 parts of an active componentprecursor, 3.8-5.1 parts of the assistant and 120-200 parts of deionized water. The catalyst adopts the titanyl sulfate and silicon oxide as the carrier, so that the catalyst is ensured to have goodthermal stability at a high temperature, and crystal form change and sintering are avoided; the manganese salt, the iron salt and the chromium salt are used as active components, so hole blockage caused by high solution viscosity can be avoided; and the ammonium heptamolybdate and the cerium salt are used as modification aids, so that the catalyst has an extremely high catalytic performance in anSCR reaction.

Owner:QIYUAN XIAN DAE YOUNG ENVIRONMENTAL PROTECTION TECH CO LTD

Method for recycling gold in gold-carrying carbon powder

ActiveCN106498178ANo sinteringComply with process requirementsProcess efficiency improvementSulfite saltImpurity

The present invention relates to a method for recovering gold in gold-carrying carbon powder, which belongs to treatment methods of gold-carrying carbon powder in the gold industry. The method includes ashing the gold-carrying carbon powder at 600 to 650 DEG C; removing impurities in the charcoal ash by nitric acid, filtering and washing to obtain the residue; leaching gold from the residue by the aqua regia method or chlorine salt method, resulting in the liquid-phase gold, filtering and washing to obtain gold leachate; adding sodium sulfite to the gold leachate; reducing the gold leachate, filtering and washing the sponge gold and drying; smelting the sponge gold with 1% to 5% of borax to cast ingot at 1250 DEG C. The method has the advantages that the process is simplified, the labor intensity of the operator is alleviated, the working environment is improved, and the recovery rate of gold-carrying carbon powder is increased.

Owner:CHANGCHUN GOLD RES INST

Antibacterial and thermal insulation foam brick and preparation method thereof

The invention belongs to the field of building materials and discloses an antibacterial and thermal insulation foam brick and a preparation method thereof. The antibacterial and thermal insulation foam brick comprises, by weight, 60 to 80 parts of portland cement, 10 to 16 parts of enteromorpha prolifera, 6 to 10 parts of shells, 8 to 12 parts of luffa vine, 6 to 8 parts of tea meal, 8 to 16 parts of a glass fiber cloth, 10 to 14 parts of expanded perlite, 10 to 20 parts of coal ash, 3 to 5 parts of lanolin, 2 to 3 parts of gelatin, 0.6 to 0.8 parts of coconut fatty acid monoethanolamide, 0.3 to 0.5 parts of disodium ethylenediaminetetraacetate, 9 to 15 parts of lithium silicate, 0.3 to 0.5 parts of sodium lignosulfonate, 0.6 to 0.8 parts of alkylphenol ethoxylates, 1 to 2 parts of an early strength agent, 1 to 2 parts of sodium dehydroacetate and 1 to 2 parts of silicon-containing fluorinated acrylate. The antibacterial and thermal insulation foam brick has the advantages of energy saving, environmental friendliness, good compressive strength, thermal insulation and antibacterial properties.

Owner:QINGDAO HAIZHIXING BIOLOGICAL SCI & TECH

Small-pore catalyst for fuel gas denitration and preparation method

InactiveCN107213906ANo crystal changeNo sinteringHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsNickel saltPhosphate

The invention discloses a small-pore catalyst for fuel gas denitration and a preparation method. The small-pore catalyst is prepared from the following raw materials in parts by weight: 100 parts of a carrier, 2.20-8.21 parts of an active component precursor, 0.45-1.4 parts of aids and 150-250 parts of deionized water, wherein the carrier comprises aluminum titanate, zirconium oxide and tungsten oxide; the active component precursor comprises a nickel salt, a chromium salt and a ruthenium salt; and the aids comprise tetraethoxysilane, hydroxypropyl methyl cellulose, tung oil, aluminum dihydrogen phosphate, graphite and calcined kaolin. The preparation method comprises the following step: 1) performing ball milling; 2) kneading the raw materials; 3) blanking; 4) shaping blanks; and 5) calcining the blanks. The small-pore catalyst is applicable to nitric oxide removal of gas turbine sets, has the advantages of being high in denitration efficiency, small in size, long in service life and the like, has good application prospects, and is suitable for industrial application.

Owner:河南康宁特环保科技股份有限公司

Foaming cement regenerative lightweight concrete and product thereof

The invention discloses a foamed cement recycled lightweight concrete and a product thereof. The foamed cement recycled lightweight concrete is prepared by mixing A material, B material and water; the A material is mainly granules formed by crushing foamed cement waste. ; The B material is composed of cement, yellow sand, melon seed sheet, slag micropowder, polypropylene fiber, redispersible rubber powder, water reducing agent and water. The invention has the advantages of simple and convenient manufacture, environmental protection, waste and energy saving, low cost and convenient construction.

Owner:吴永军

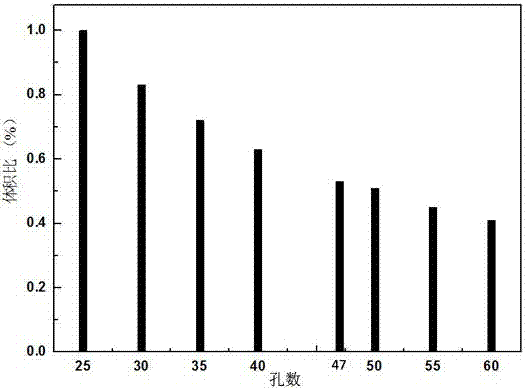

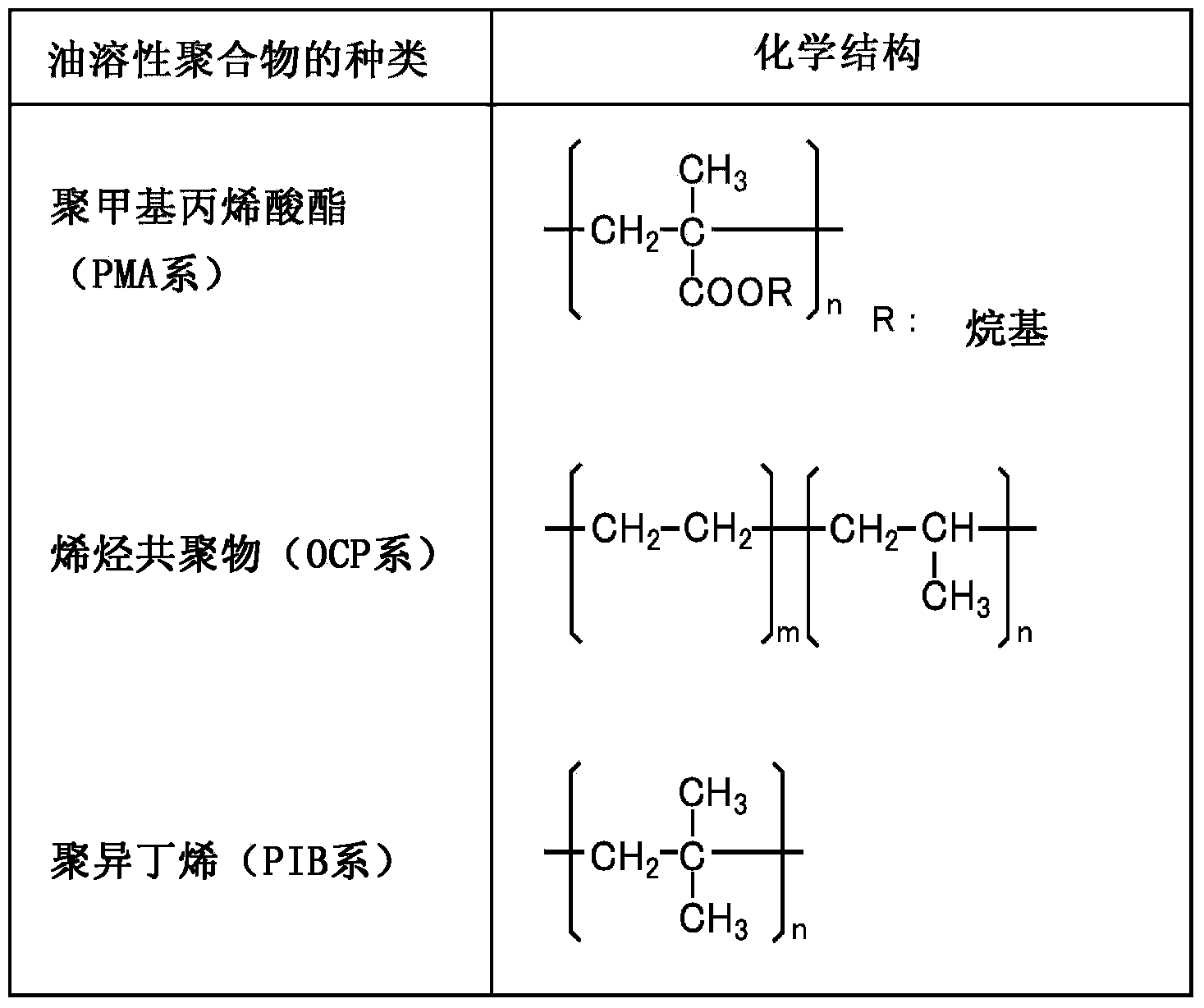

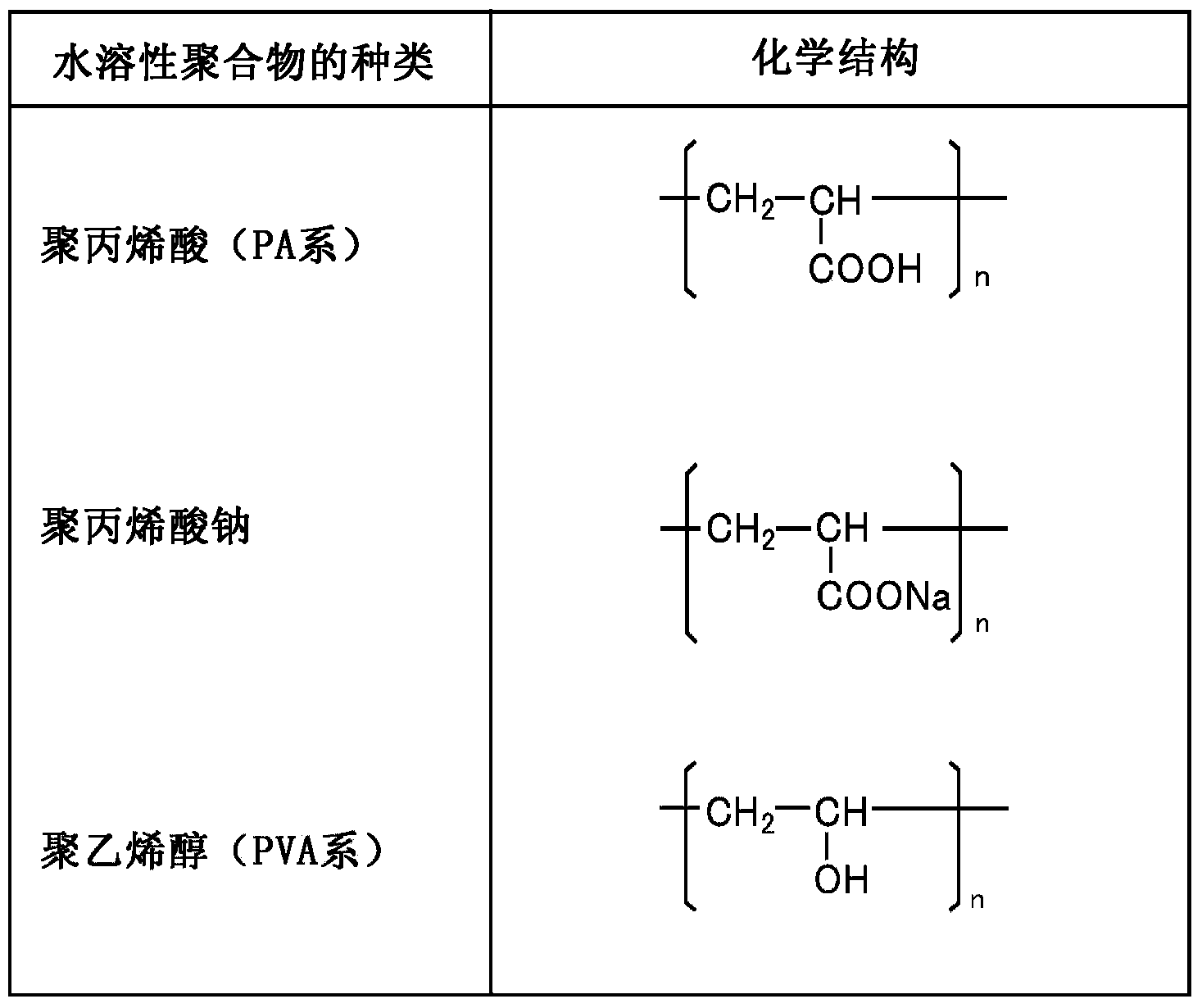

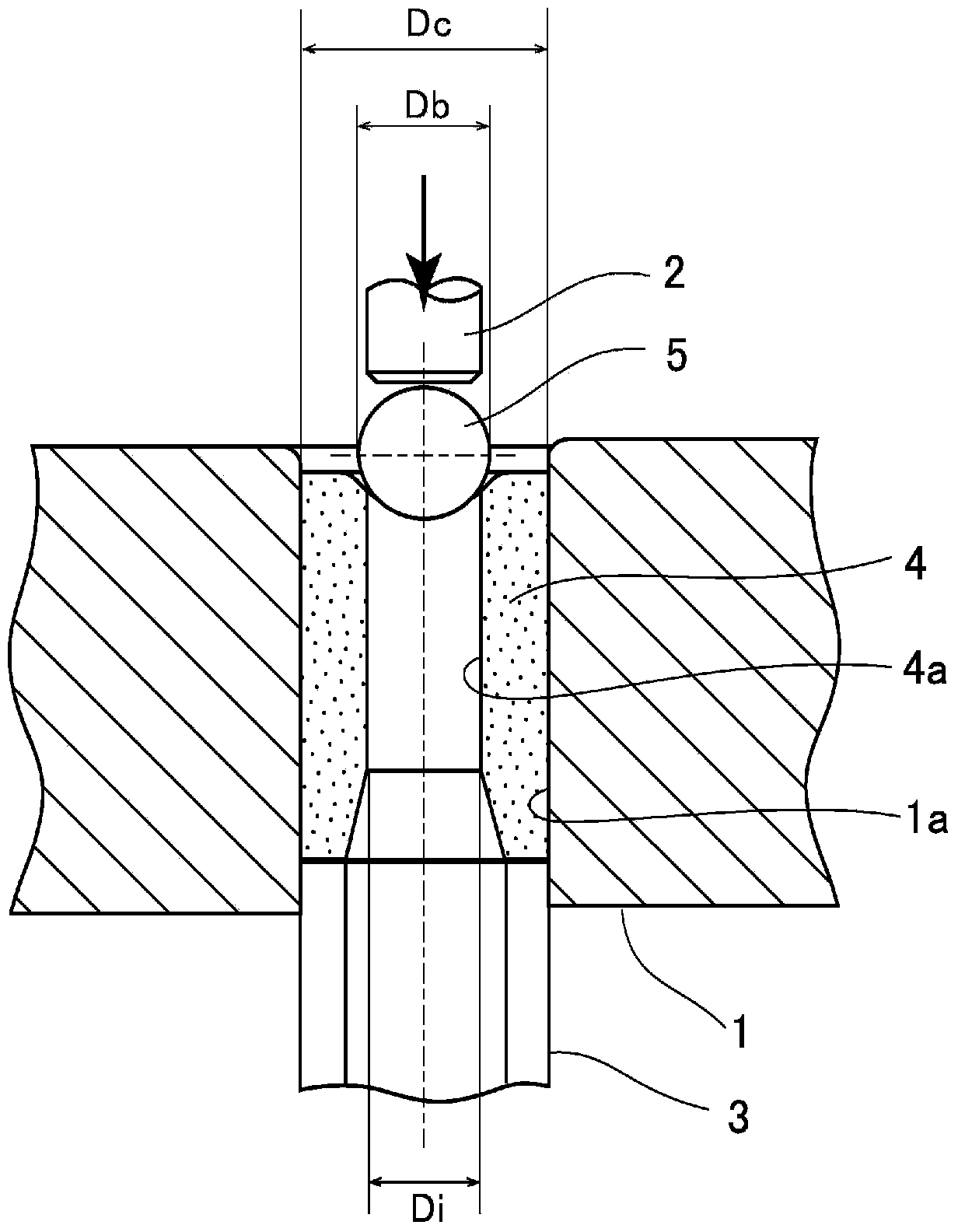

Lubricant for machining, additive for machining, and machining method

Provided is a lubricant for machining aluminum alloys and the like which exhibits superior seizure resistance. The lubricant for machining according to the present invention is interposed between the coated surface of a machining tool coated with an amorphous carbon film and the surface to be machined of a material to be machined which comprises aluminum or an aluminum alloy material and is to be machined by contact with the coated surface. The lubricant for machining is characterized in that 100 mass% of the lubricant comprises 8-50 mass% of a macromolecular compound having a molecular weight of 8,000-1,000,000 and having surface functional groups consisting of at least one type of group among carbonyl groups, amino groups, carboxyl groups and hydroxyl groups. Such a macromolecular compound having a high molecular weight strongly adheres to an amorphous carbon film or the like on a machining tool. As a result, the presence of the lubrication film between the machining surface and the surface to be machined is ensured, thereby inhibiting the direct contact of the surfaces and thus seizing, even when aluminum alloys, which are highly susceptible to seizing, are highly deformed.

Owner:TOYOTA CENT RES & DEV LAB INC

Method for preventing nano-grain from agglomeration and growth under high-temperature environment

InactiveCN101028584AImprove dispersion stabilityImprove thermal stabilitySpecial surfacesCoatingsPhosphateNanoparticle

A method for preventing the nanoparticles from growing and coagulating in high temp environment includes such steps as immersing the nanoparticles in the solution of phosphoric acid or phosphate for a certain time, filtering, washing, baking and calcining at 200-800 deg.C.

Owner:HEBEI NORMAL UNIV

Composite for organic metal catalyst and preparation method thereof

InactiveCN109174205AReduce stickingDense porous structureGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsCross-linkOrganometallic catalysis

The invention discloses a composite for an organic metal catalyst and a preparation method thereof, and relates to the technical field of denitrification catalyst. The composite adopts cross-linked modified carbon nanotubes for being loaded with V2O5-MoO3 / TiO2 having good catalytic oxidation denitrification performance, adopts attapulgite to wrap platinum metal so as to improve the catalytic oxidation activity of the platinum metal, and is prepared from a common organic metal catalyst dioctyl tin dilaurate as a heat stabilizer with a variety of fillers and additives. The preparation method issimple. The composite for the organic metal catalyst has the advantages of large specific surface area, good thermal stability, and good activity and selectivity, and cannot cause alkali metal poisoning, sintering, blockage and erosion phenomena after long-term use.

Owner:广州优润合成材料有限公司

A kind of iron-based soft magnetic composite material and preparation method thereof

ActiveCN104425093BGood compressibilityIncrease green densityInorganic material magnetismCompressibilityMagnetic composite

Owner:NBTM NEW MATERIALS GRP

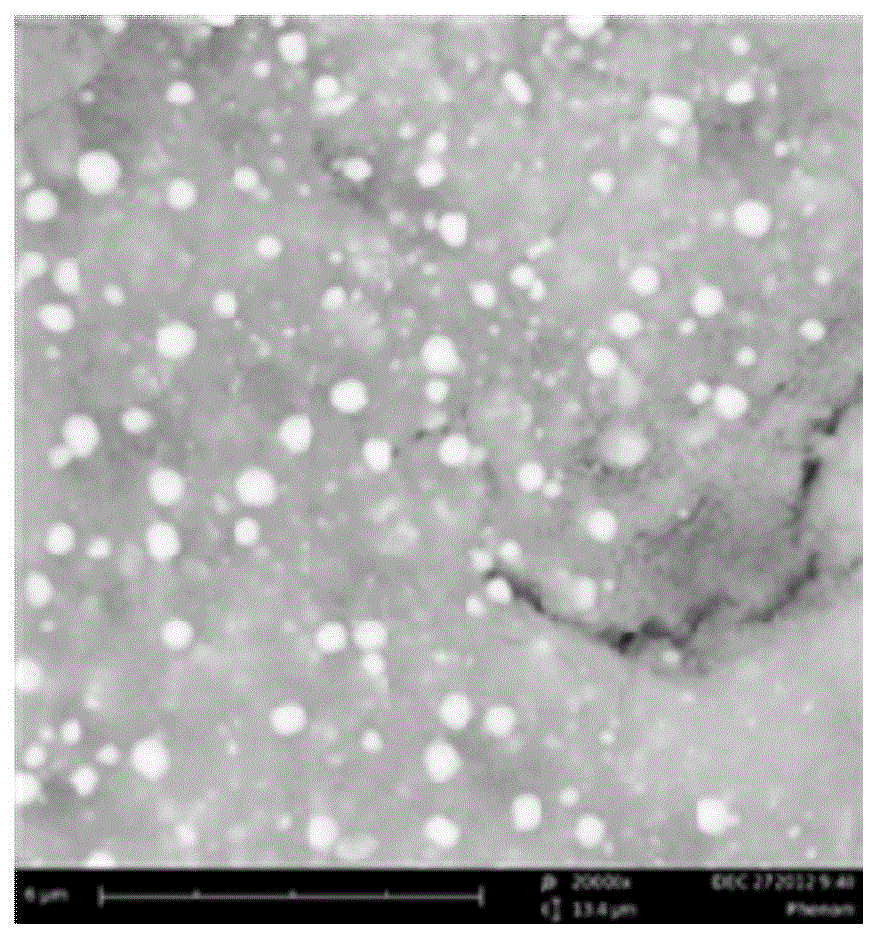

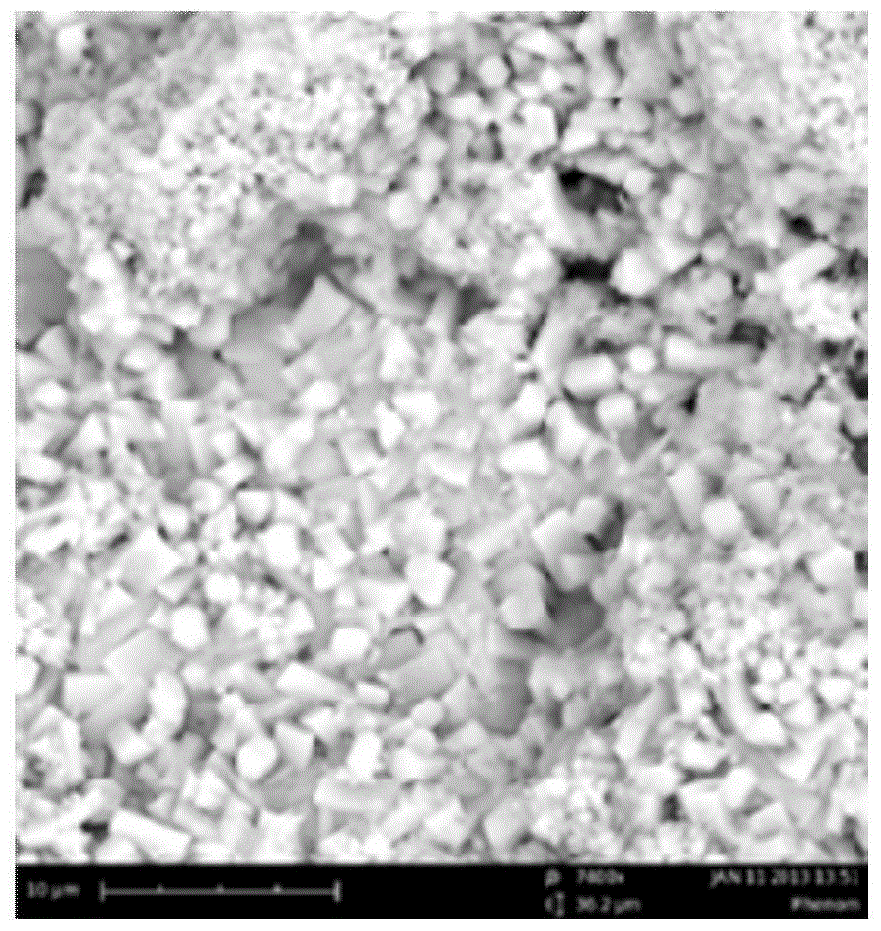

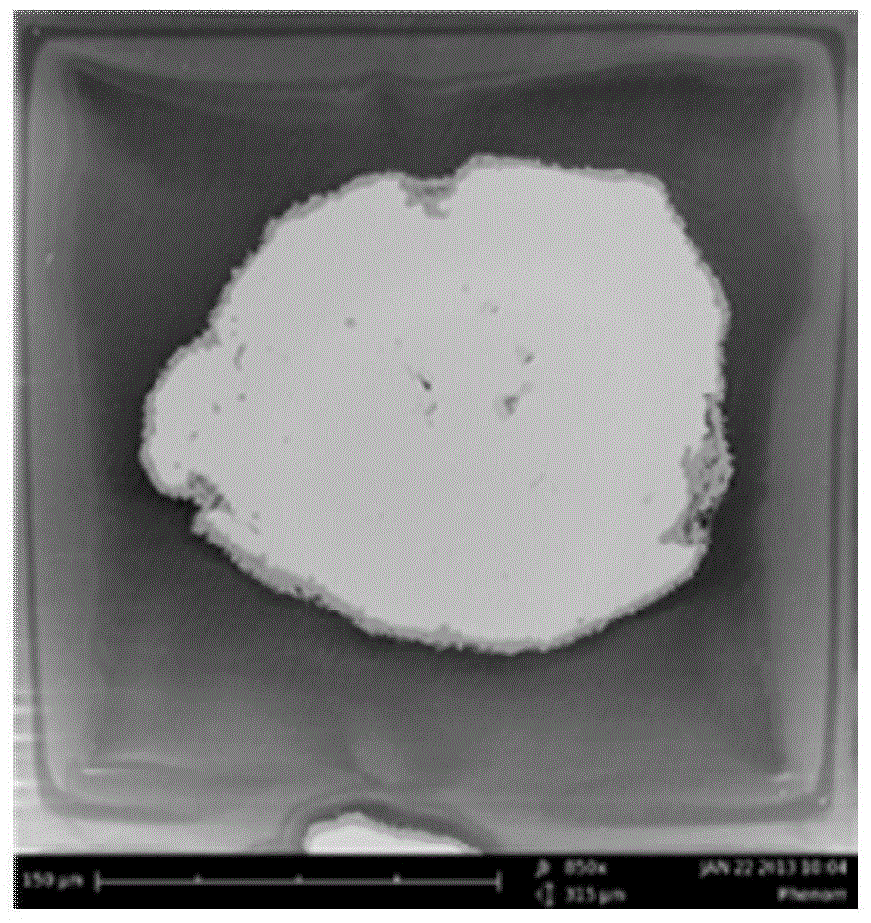

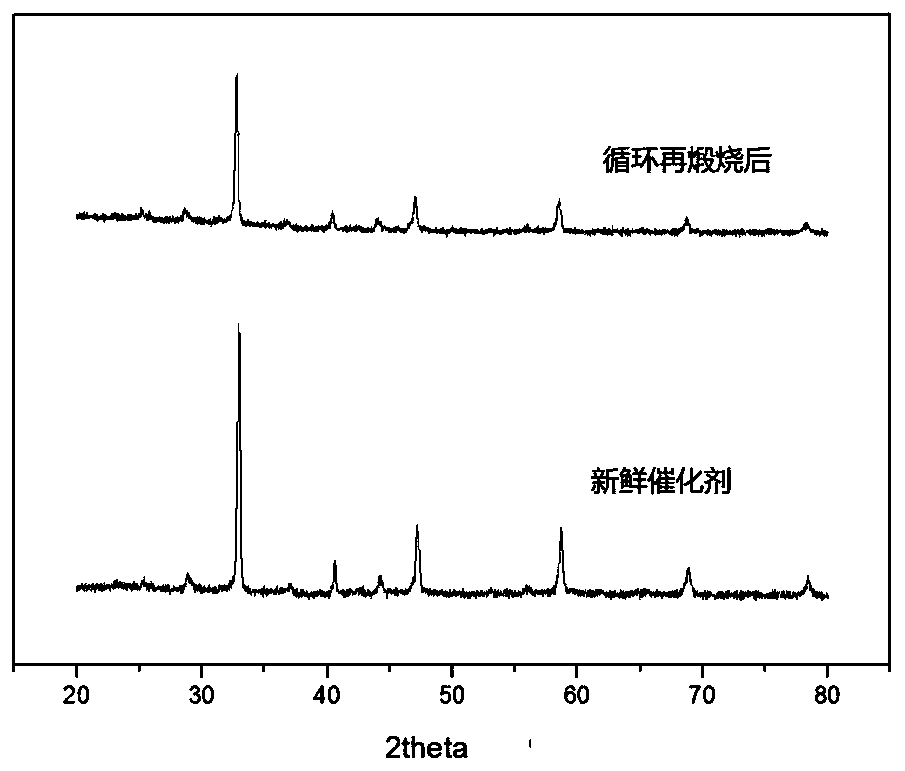

Preparation method and application of composite metal oxide catalysts for coal gasification

InactiveCN109745991AReturn to normal structureNo sinteringChemical recyclingMetal/metal-oxides/metal-hydroxide catalystsWater bathsEthylene diamine

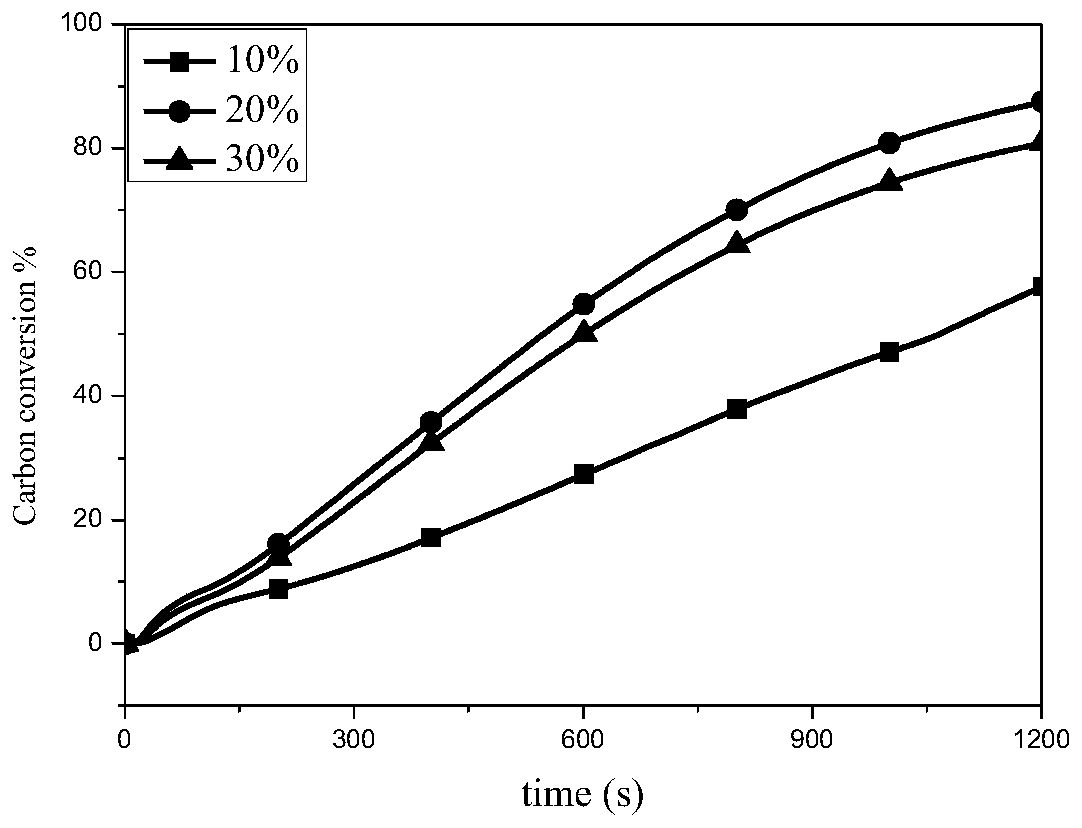

The invention discloses a preparation method and application of a composite metal oxide catalyst for coal gasification. According to the preparation method, lanthanum nitrate, nitrate metal salt A, ferric nitrate and nitrate metal salt B are added into water and mixed evenly to prepare a metal nitrate solution; then EDTA (ethylene diamine tetraacetic acid) and citric acid are mixed evenly, the pHvalue is adjusted to 7-9, and the mixture is stirred evenly in a constant temperature water bath to prepare a precursor solution; the metal nitrate solution is added to the precursor solution, and stirring is performed until a wet gel is formed; and the composite metal oxide catalyst is obtained by drying, calcining and cooling. The composite metal oxide catalyst for coal gasification can not onlyeffectively increase the gasification rate of coal, with the conversion rate reaching 90%; but also maintain the original structure and catalytic activity after the reaction, so that reutilization can be achieved through recycling.

Owner:DALIAN MARITIME UNIVERSITY

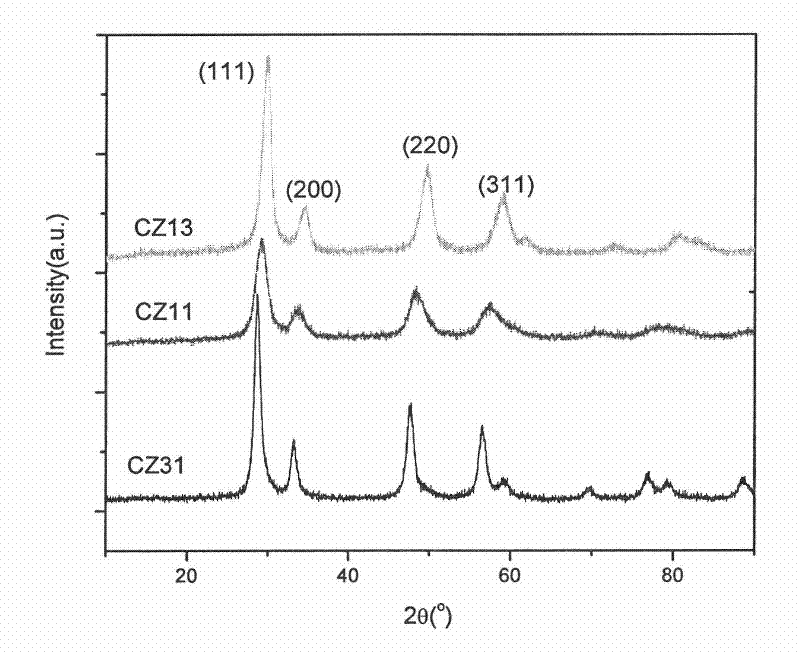

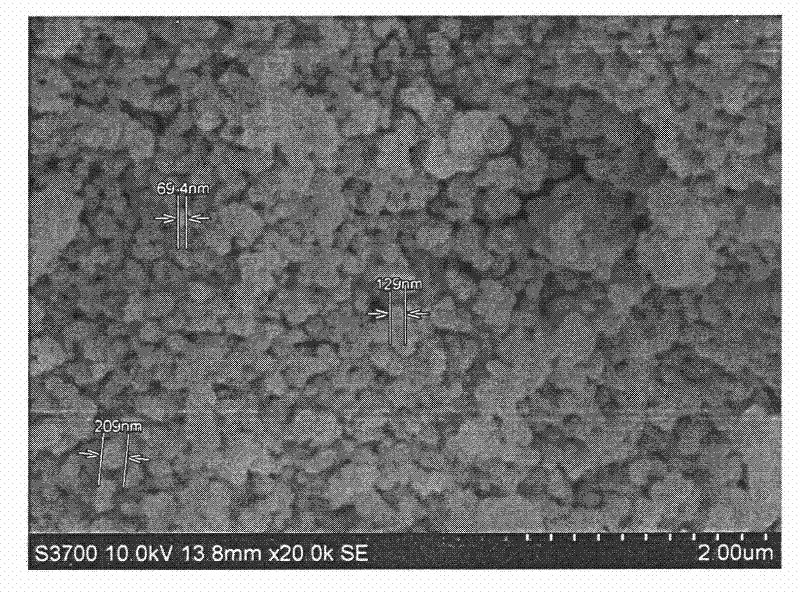

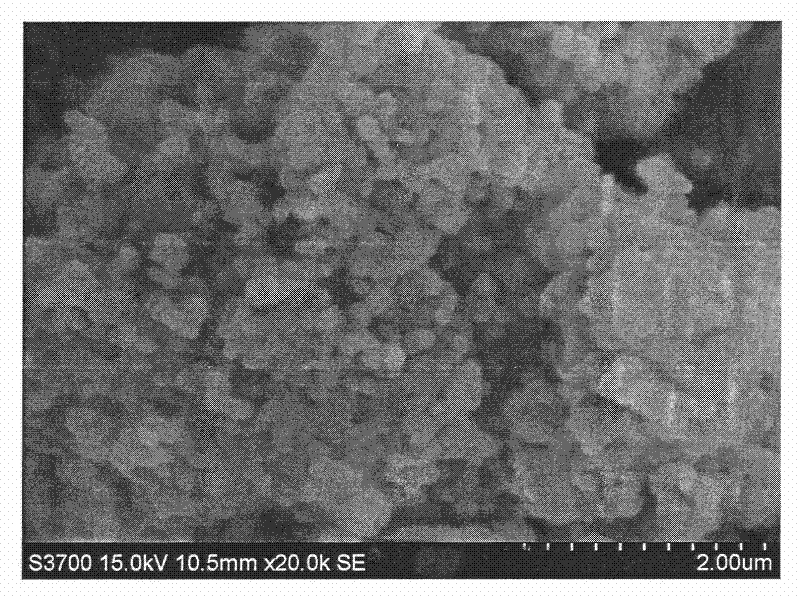

Method for preparing nano-cerium oxide and zirconia solid solution

InactiveCN101696034BGain uniformityAchieve precise dopingRare earth metal compoundsMetal/metal-oxides/metal-hydroxide catalystsActive agentCerium

The invention discloses a method for preparing nano-cerium oxide and zirconia solid solutions, which belongs to the field of inorganic catalytic materials. The method comprises: dissolving cerium-containing ionic compound accounting for 10 to 90 percent of the weight of the raw materials and zirconium-containing ionic compound accounting for 10 to 90 percent of the weight of the raw materials in deionized water respectively according to a formulation of raw materials of nano-cerium oxide and zirconia solid solutions, and preparing the two into solutions with the concentration between 1 and 3 M; mixing the two solutions, adding alkaline substances, regulating pH between 7 and 10 to generate precipitate, aging the precipitate through heat treatment, performing washing and centrifugal filtration to obtain a filter cake; dissolving the obtained filter cake in nitric acid, adding surfactant to obtain milky white colloid; and performing calcination to prepare composite oxide of nano-cerium oxide / zirconia. Nano-sized particles prepared by the method improve the microstructure of cerium / zirconium solid solutions, and the prepared nano-composite oxide solid solutions have better thermal stability and larger specific surface area.

Owner:SOUTH CHINA UNIV OF TECH

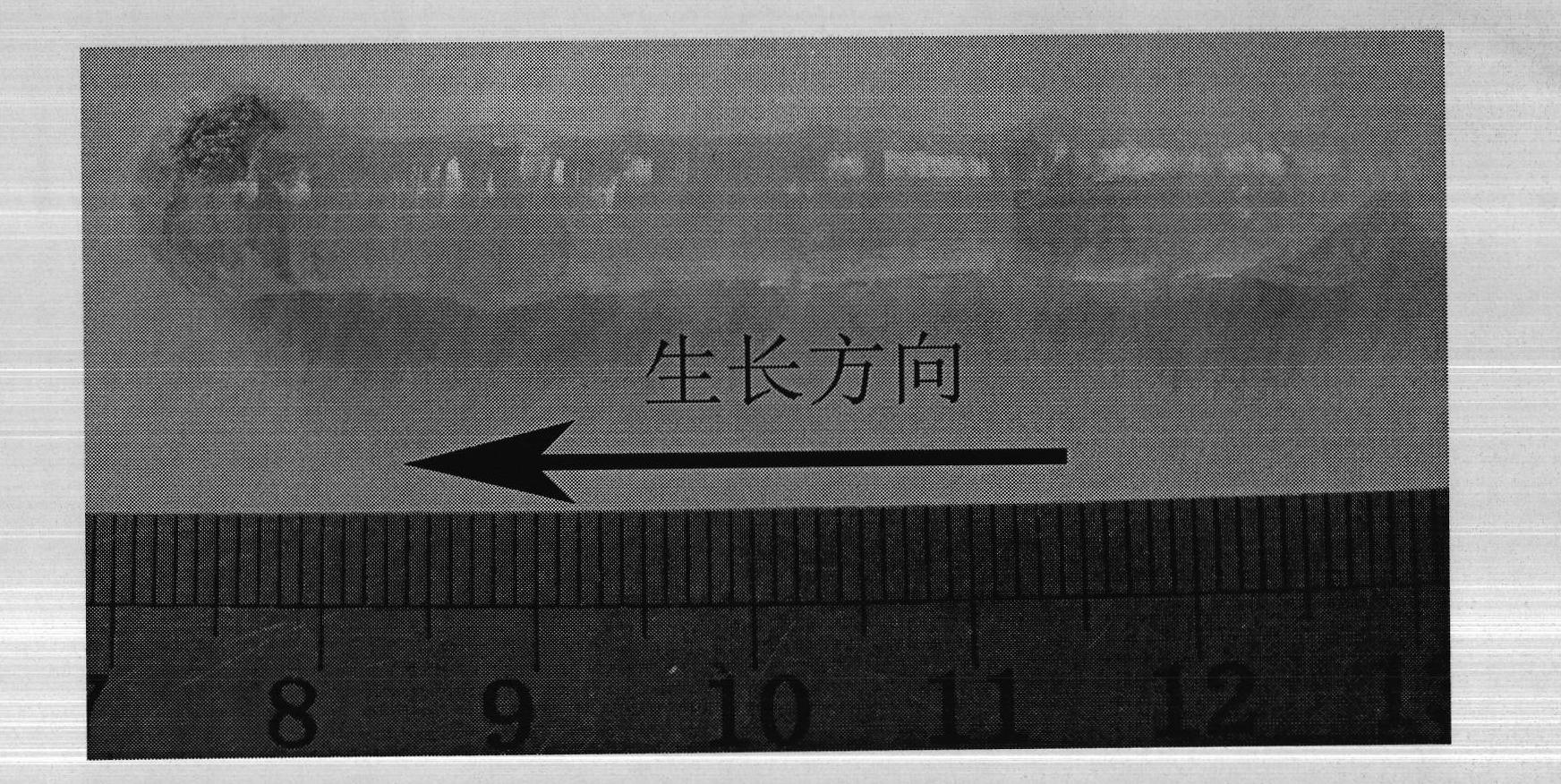

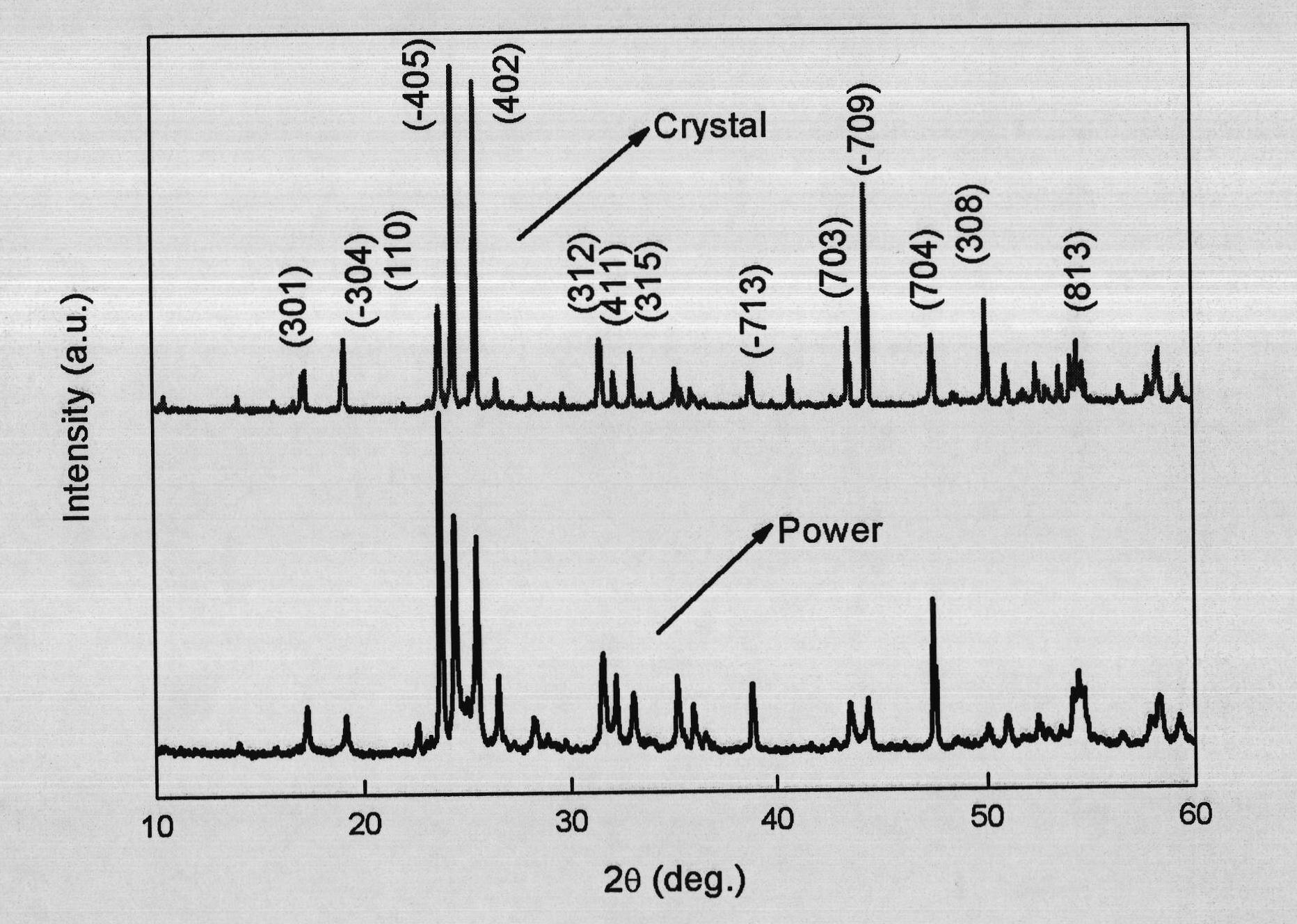

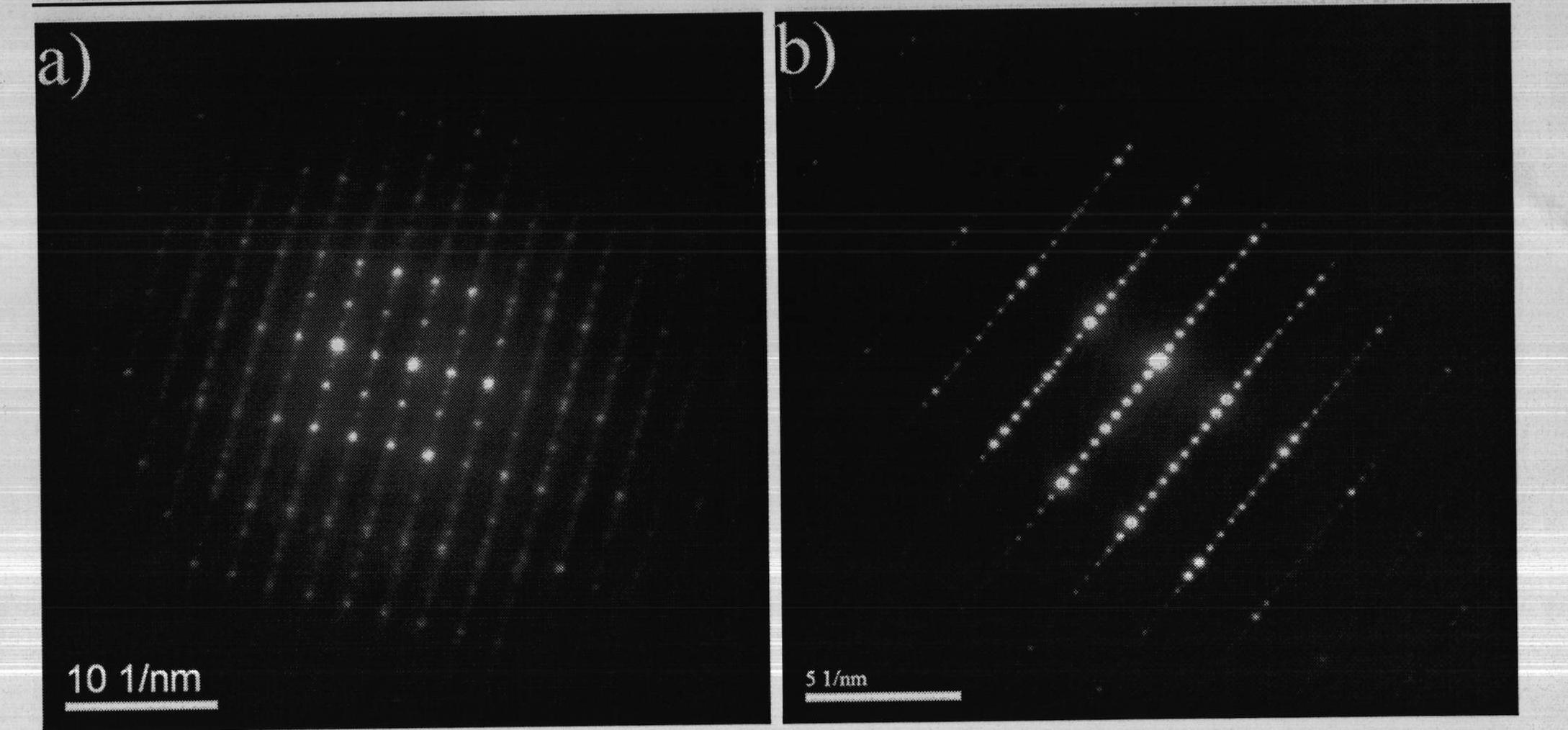

Method for rapidly growing Nb205 crystal

InactiveCN101962801ASmall sizeNo impuritiesPolycrystalline material growthBy zone-melting liquidsAir atmosphereEngineering

The invention discloses a method for rapidly growing Nb205 crystal, belonging to the field of Nb205 crystal growth. The method comprises the following steps: preparing Nb205 powder into biscuit rods; taking one biscuit rod as a seed crystal on a seed rod and hanging the other biscuit rod on a charge bar rod as a charge bar; causing the tail ends of the two charge bars to contact; forming a straight line with a halogen lamp at the contact part in the horizontal direction; causing the two charge bars to form a straight line in the vertical direction; in the air atmosphere, causing the halogen lamp of a single crystal furnace to reach a power output of 1600-1750W / h in 0.2-0.5h; heating to cause the contact part of the two charge bars to be melted so as to form a melting zone; retaining the power output, causing the seed rod and a raw material rod to rotate in the reverse direction at a velocity of 15-20rmp; and causing the raw material and the seed rod to move up and down at a velocity of 8-15mm / h to pass the melting zone to grow the crystal. The product of the invention has the characteristics of no impurities, simple instruments, low cost, fast growth speed and no need of special atmosphere.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com