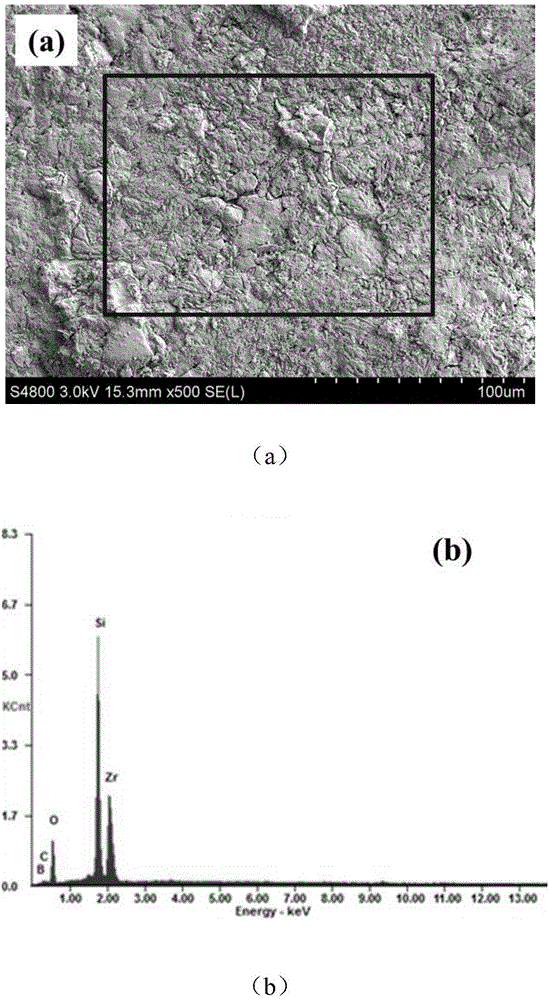

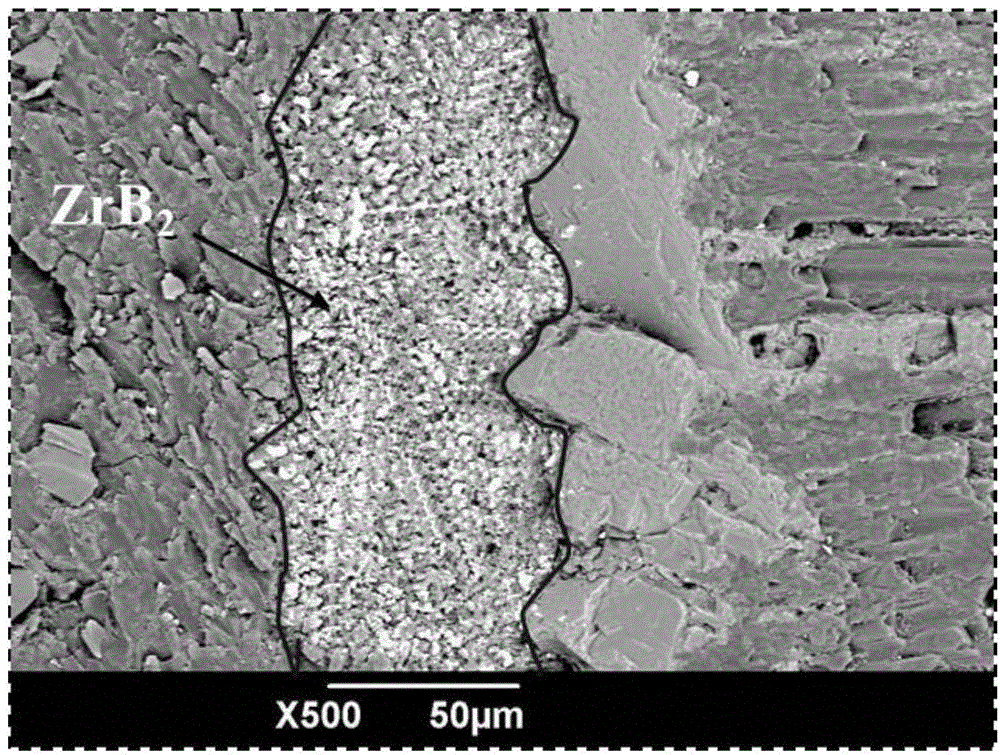

Preparation method for ZrB2-SiO2 composite high-temperature oxidation resistant coating

A high-temperature anti-oxidation and coating technology, which is applied in the preparation of ZrB2–SiO2 composite high-temperature anti-oxidation coatings and the preparation of high-temperature anti-oxidation coatings on the surface of materials, can solve the problem of poor bonding ability between coatings and base materials and long preparation cycles , high sintering temperature and other problems, to achieve the effect of improving anti-oxidation performance, short preparation cycle and good combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] a ZrB 2 – SiO 2 A method for preparing a composite high-temperature anti-oxidation coating, comprising the following steps:

[0027] 1) Use commercially available chemically pure ZrB 2 The powder is subjected to dry ball milling for 6 hours to obtain a powder with an average particle size of 4-5 μm, which is set aside. Select commercially available elemental iodine (purity ≥ 99.7%) and isopropanol (purity ≥ 99.8%) as raw materials.

[0028] 2) Weigh ZrB 2 Powder 1g, pour it into a Erlenmeyer flask, add 45mL isopropanol and stir on a magnetic stirrer for 2h to obtain ZrB 2 Suspension, then add 0.3g of iodine to the suspension, and then put it on a magnetic stirrer and stir for 1h to obtain Suspension A.

[0029] 3) Pour the suspension A into the hydrothermal kettle with a filling degree of 60%; place the SiC–C / C sample on the cathode clamp in the hydrothermal kettle with graphite as the anode, and seal the hydrothermal kettle; The cathode and anode of the hydrother...

Embodiment 2

[0033] a ZrB 2 – SiO 2 A method for preparing a composite high-temperature anti-oxidation coating, comprising the following steps:

[0034] 1) Use commercially available chemically pure ZrB 2 The powder is subjected to dry ball milling for 8 hours to obtain a powder with an average particle size of 3.5-4.5 μm, which is set aside. Select commercially available elemental iodine (purity ≥ 99.7%) and isopropanol (purity ≥ 99.8%) as raw materials.

[0035] 2) Weigh ZrB 2 Powder 2g, pour it into a Erlenmeyer flask, add 300mL isopropanol and stir on a magnetic stirrer for 3h to obtain ZrB 2 Suspension, then add 1g of iodine to the suspension, and then stir on a magnetic stirrer for 2h to obtain suspension A.

[0036] 3) Pour the suspension A into the hydrothermal kettle with a filling degree of 60%; place the SiC–C / C sample on the cathode clamp in the hydrothermal kettle with graphite as the anode, and seal the hydrothermal kettle; The cathode and anode of the hydrothermal kett...

Embodiment 3

[0040] a ZrB 2 – SiO 2 A method for preparing a composite high-temperature anti-oxidation coating, comprising the following steps:

[0041] 1) Use commercially available chemically pure ZrB 2 The powder is subjected to dry ball milling for 10 hours to obtain a powder with an average particle size of 2.5-3.5 μm, which is set aside. Select commercially available elemental iodine (purity ≥ 99.7%) and isopropanol (purity ≥ 99.8%) as raw materials.

[0042] 2) Weigh ZrB 2 Pour 3g of powder into a conical flask, add 190mL of isopropanol and stir on a magnetic stirrer for 4h to obtain ZrB 2 Suspension, then add 2g of iodine to the suspension, and then put it on a magnetic stirrer and stir for 3h to obtain Suspension A.

[0043] 3) Pour the suspension A into the hydrothermal kettle with a filling degree of 60%; place the SiC–C / C sample on the cathode clamp in the hydrothermal kettle with graphite as the anode, and seal the hydrothermal kettle; The cathode and anode of the hydrot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com