Patents

Literature

2281 results about "Isopropanolol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Proteinic drug delivery system using membrane mimetics

A mixed liposome pharmaceutical formulation with multilamellar vesicles, comprises a proteinic pharmaceutical agent, water, an alkali metal lauryl sulphate in a concentration of from 1 to 10 wt. / wt. %, at least one membrane-mimetic amphiphile and at least one phospholipid. The membrane-mimetic amphiphile is hyaluronic acid, pharmaceutically acceptable salts of hyaluronic acid, lauramidopropyl betain, lauramide monoisopropanolamide, sodium cocoamphopropionate, bishydroxypropyl dihydroxypropyl stearammonium chloride, polyoxyethylene dihydroxypropyl stearammonium chloride, dioctadecyldimethylammonium chloride, sulphosuccinates, stearamide DEA, gamma-linoleic acid, borage oil, evening of primrose oil, monoolein, sodium tauro dihydro fusidate, fusidic acid, alkali metal isostearyl lactylates, alkaline earth metal isostearyl lactylates, panthenyl triacetate, cocamidopropyl phosphatidyl PG-diammonium chloride, stearamidopropyl phosphatidyl PG-diammonium chloride, borage amidopropyl phosphatidyl PG-diammonium chloride, borage amidopropyl phosphatidylcholine, polysiloxy pyrrolidone linoleyl phospholipid, trihydroxy-oxo-cholanylglycine and alkali metal salts thereof, and octylphenoxypolythoxyethanol, polydecanol X-lauryl ether, polydecanol X-oleyl ether, wherein X is from 9 to 20, or combinations thereof. The phospholipid is phospolipid GLA, phosphatidyl serine, phosphatidylethanolamine, inositolphosphatides, dioleoylphosphatidylethanolamine, sphingomyelin, ceramides, cephalin, triolein, lecithin, saturated lecithin and lysolecithin, or a combination thereof. The amount of each membrane mimetic amphiphile and phospholipid is present 1 to 10 wt. / wt. % of the total formulation, and the total concentration of membrane mimetic amphiphiles and phospholipids is less than 50 wt. / wt. % of the formulation.

Owner:GENEREX PHARMA

Absorbent article comprising a synthetic polymer derived from a renewable resource and methods of producing said article

An element of an absorbent article is provided. The element has a bio-based content of at least about 50% based on the total weight of the element, and comprises a synthetic polymer derived from a renewable resource via a first intermediate compound selected from the group consisting of crotonic acid, propiolactone, ethylene oxide, i-propanol, butanol, butyric acid, propionic acid, 2-acetoxypropanoic acid, methyl 2-acetoxypropanoate, methyl lactate, ethyl lactate, polyhydroxybutyrate, and a polyhydroxyalkanoate comprising 3-hydroxypropionate monomers. An absorbent article comprising the element and a method of making an element for an absorbent article also are provided.

Owner:THE PROCTER & GAMBLE COMPANY

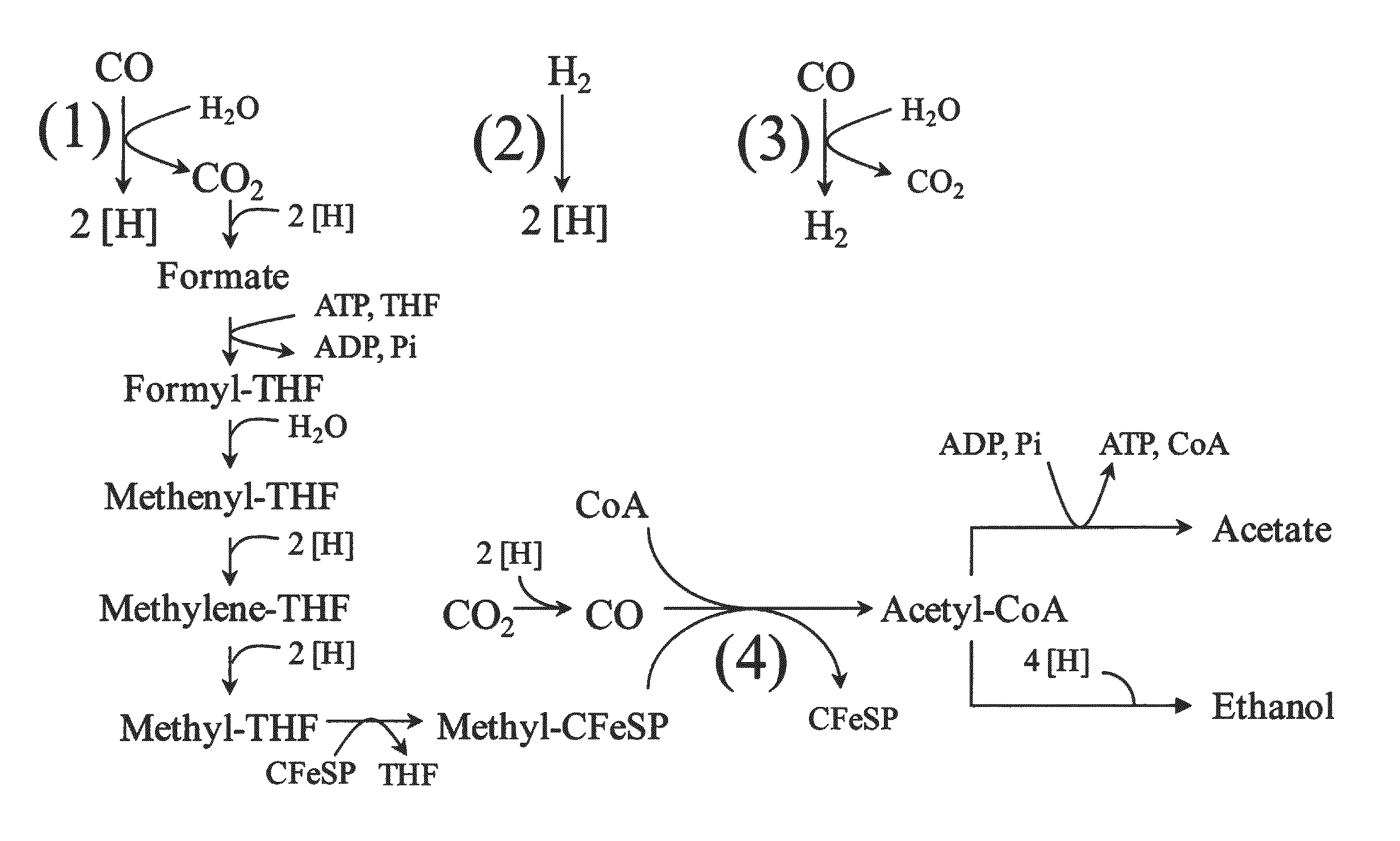

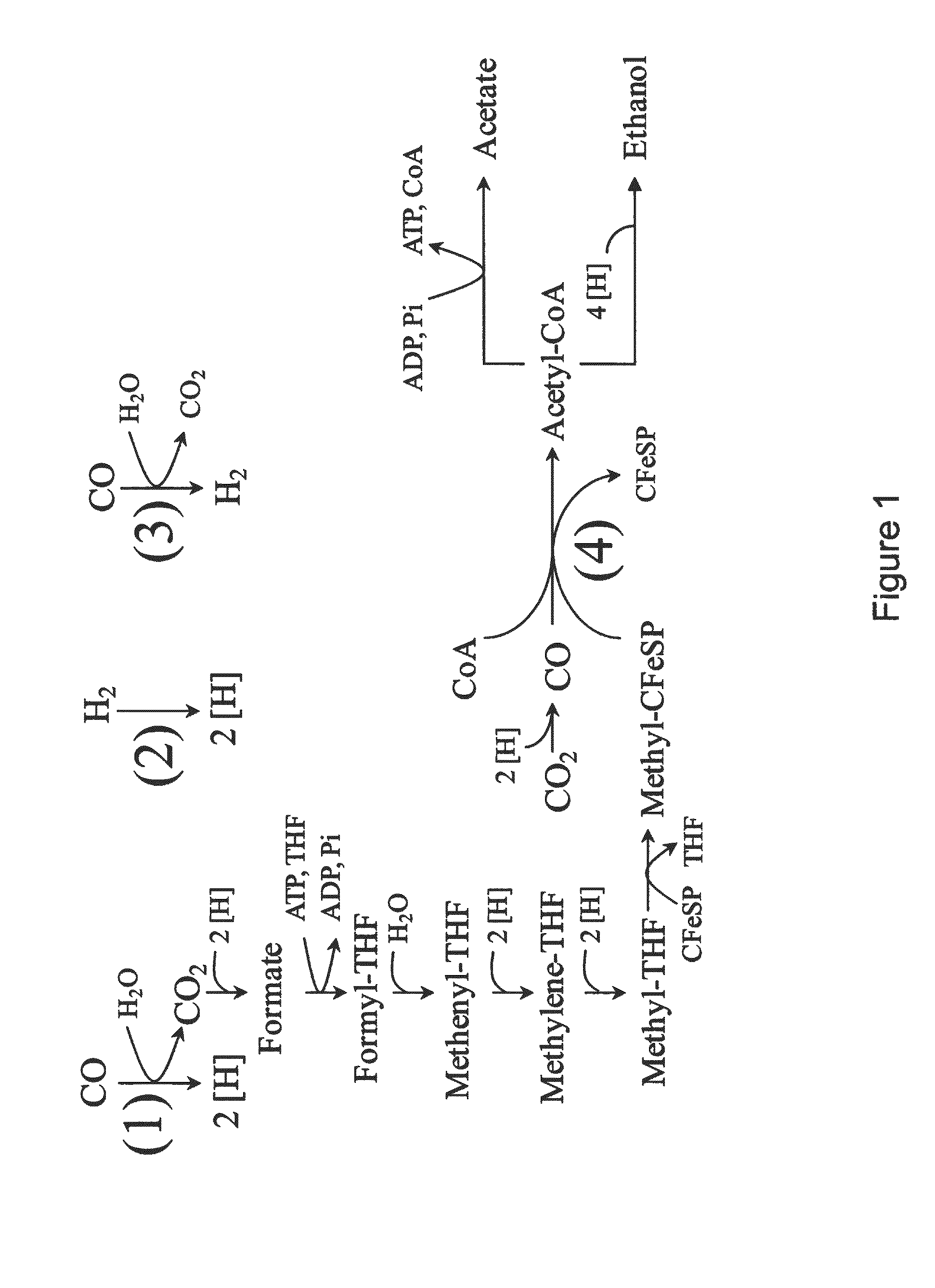

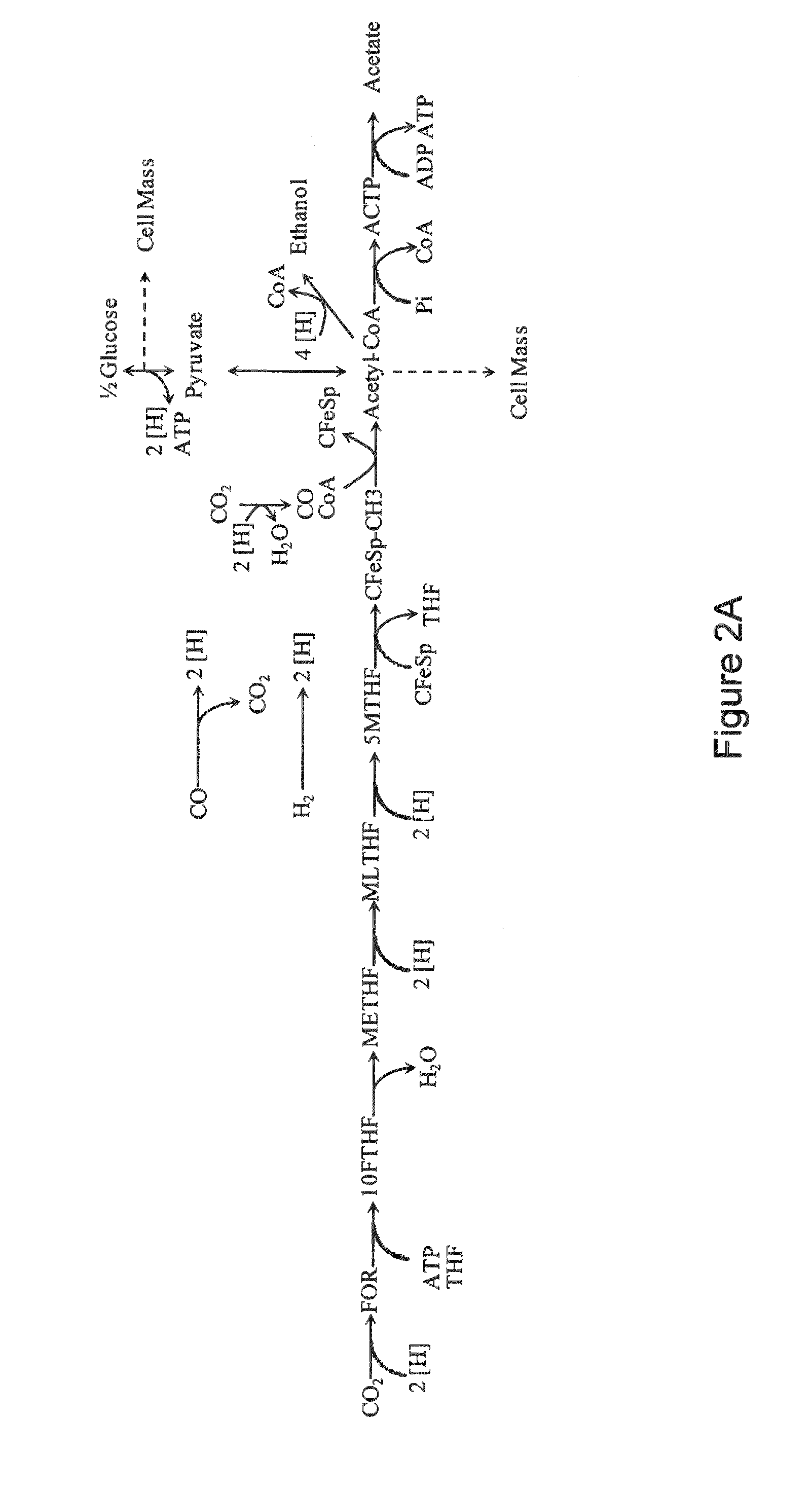

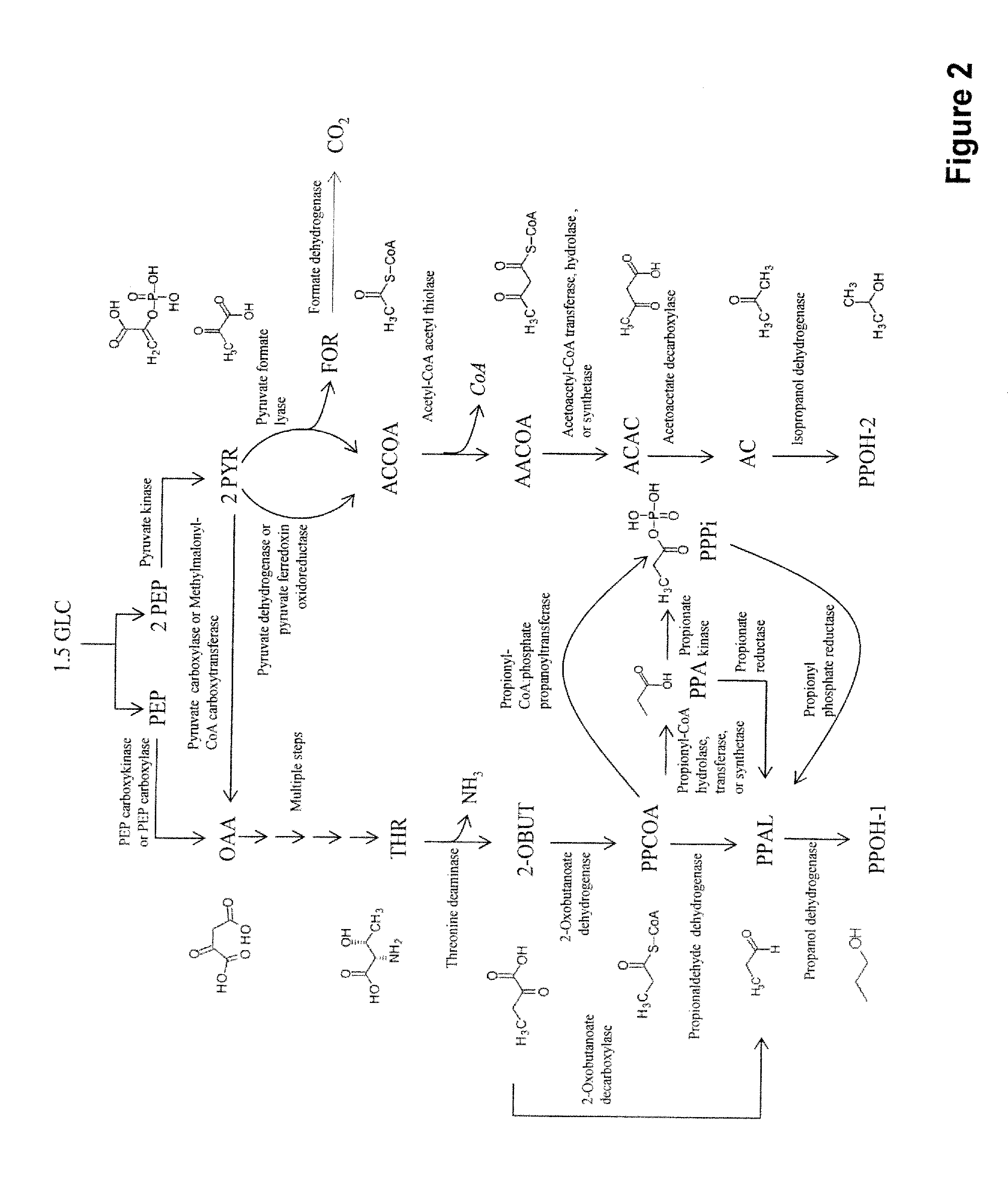

Microorganisms and methods for conversion of syngas and other carbon sources to useful products

A non-naturally occurring microbial organism having an isopropanol, 4-hydroxybutryate, or 1,4-butanediol pathway includes at least one exogenous nucleic acid encoding an isopropanol, 4-hydroxybutryate, or 1,4-butanediol pathway enzyme expressed in a sufficient amount to produce isopropanol, 4-hydroxybutryate, or 1,4-butanediol. The aforementioned organisms are cultured to produce isopropanol, 4-hydroxybutryate, or 1,4-butanediol.

Owner:GENOMATICA INC

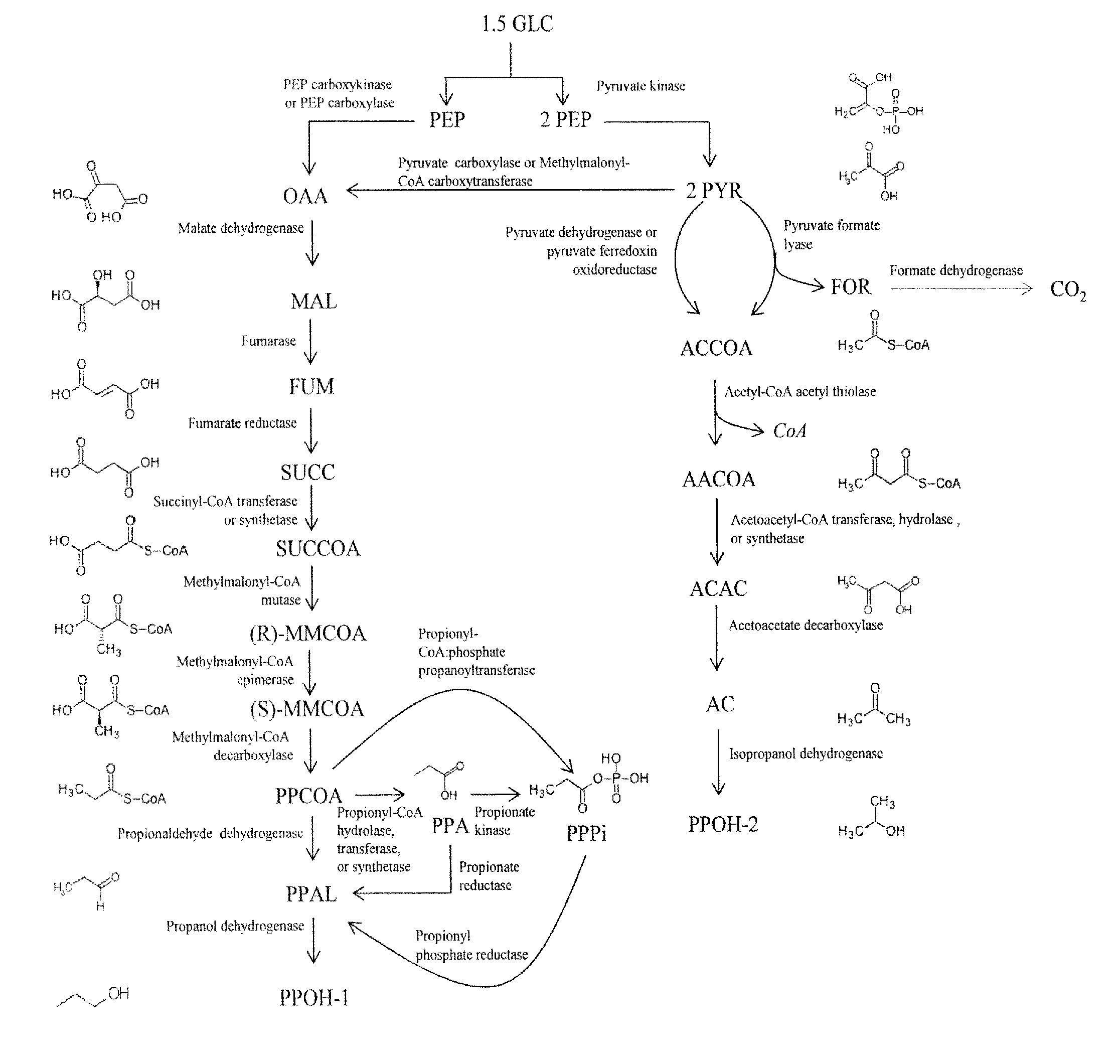

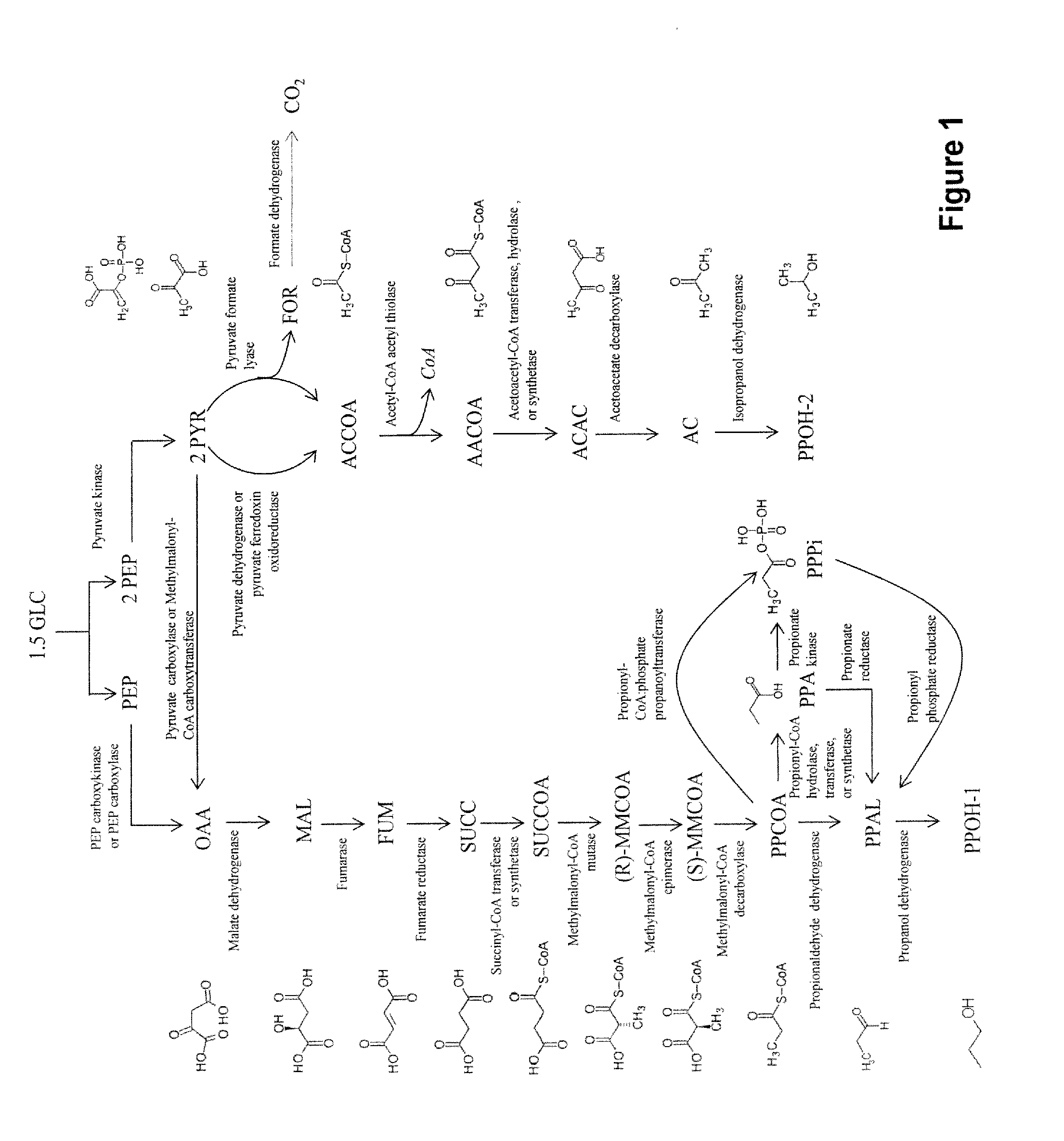

Microorganisms and methods for the co-production of isopropanol with primary alcohols, diols and acids

The invention provides a non-naturally occurring microbial organism having n-propanol and isopropanol pathways, 1,4-butanediol (14-BDO) and isopropanol pathways, 1,3-butanediol (13-BDO) and isopropanol pathways or methylacrylic acid (MAA) and isopropanolpathways. The microbial organism contains at least one exogenous nucleic acid encoding an enzyme in each of the respective n-propanol, 14-BDO, 13-BDO or MAA and isopropanol pathways. The invention additionally provides a method for co-producing n-propanol and isopropanol, 14-BDO and isopropanol, 13-BDO and isopropanol or MAA and isopropanol. The method can include culturing an n-propanol and an isopropanol co-producing microbial organism, where the microbial organism expresses at least one exogenous nucleic acid encoding an n-propanol, an isopropanol, a 14-BDO, a 13-BDO and / or a MAA pathway enzyme in a sufficient amount to produce each of the respective products, under conditions and for a sufficient period of time to produce each of the respective products.

Owner:GENOMATICA INC

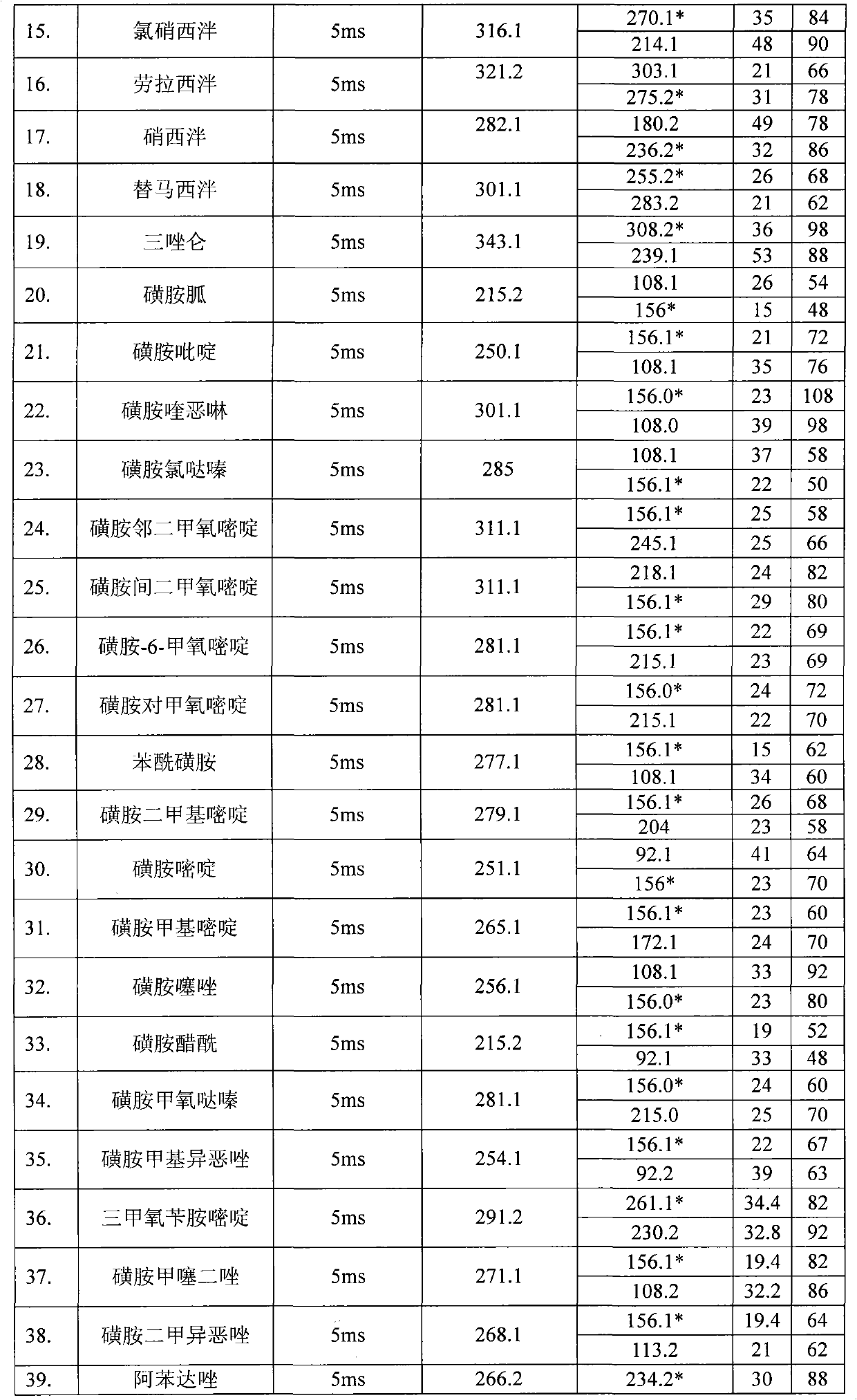

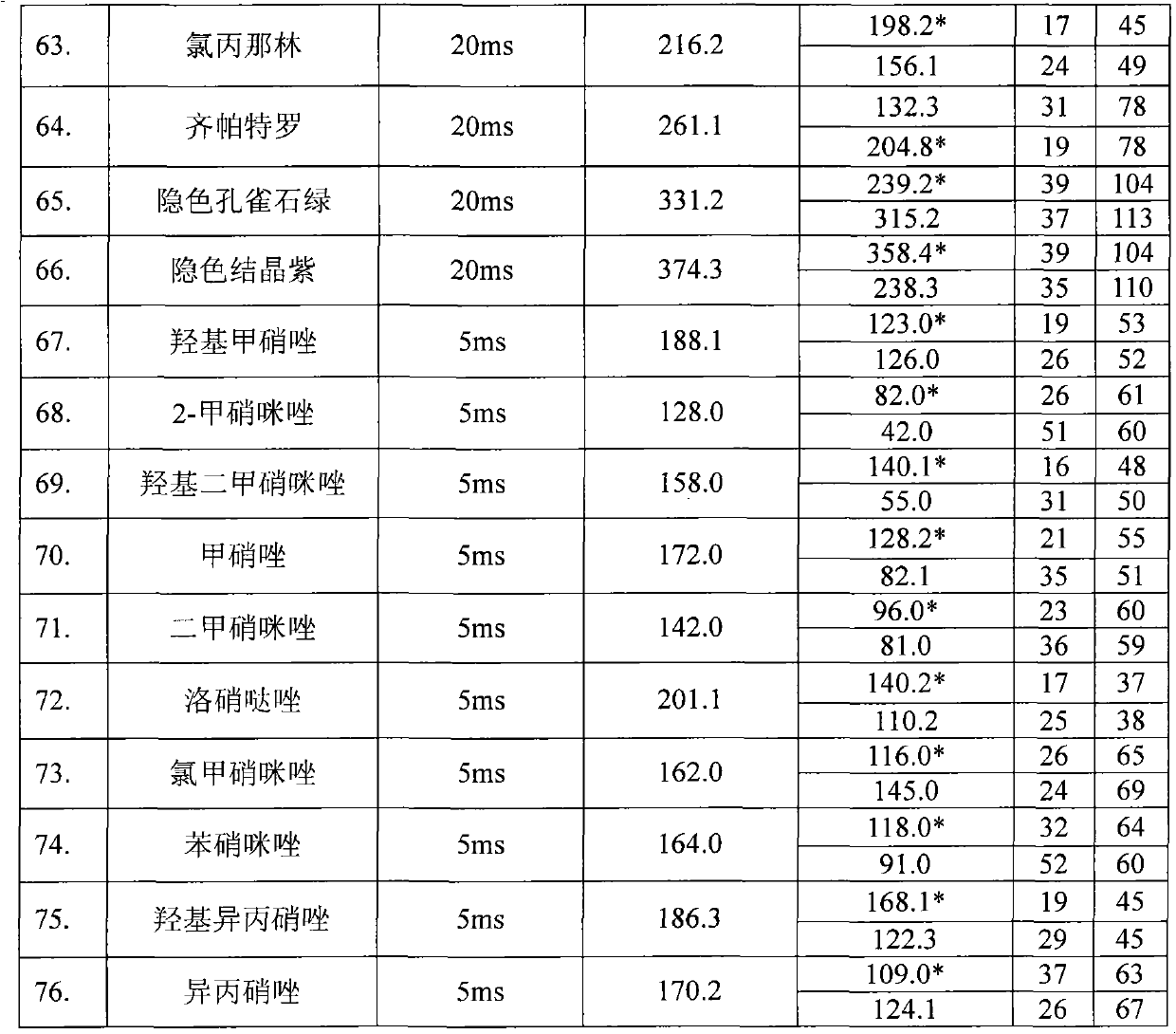

Method for detecting residual quantity of multiple alkaline drugs in animal derived food

The invention relates to the fields of analytical chemistry and food safety, in particular to a method for detecting the residual quantity of multiple alkaline drugs in animal derived food. Based on the vortex mixed extracting of acetonitrile, isopropanol and citric acid buffer solutions, the purification of a hydrophilic polystyrene-divinylbenzene solid phase extraction column and a cation exchange solid phase extraction column and the liquid phase chromatography-mass spectra determination, the method can detect the residual quantity of multiple alkaline drugs in pork, pork liver, eggs, shrimps and milk, such as beta-receptor agonists,sulfonamides, benzodiazepines, nitroimidazoles, benzimidazoles and triphenylmethanes. The method has the advantages of simple operation, fast and accurate detection and high efficiency.

Owner:SHANGHAI ANPEL SCI INSTR +1

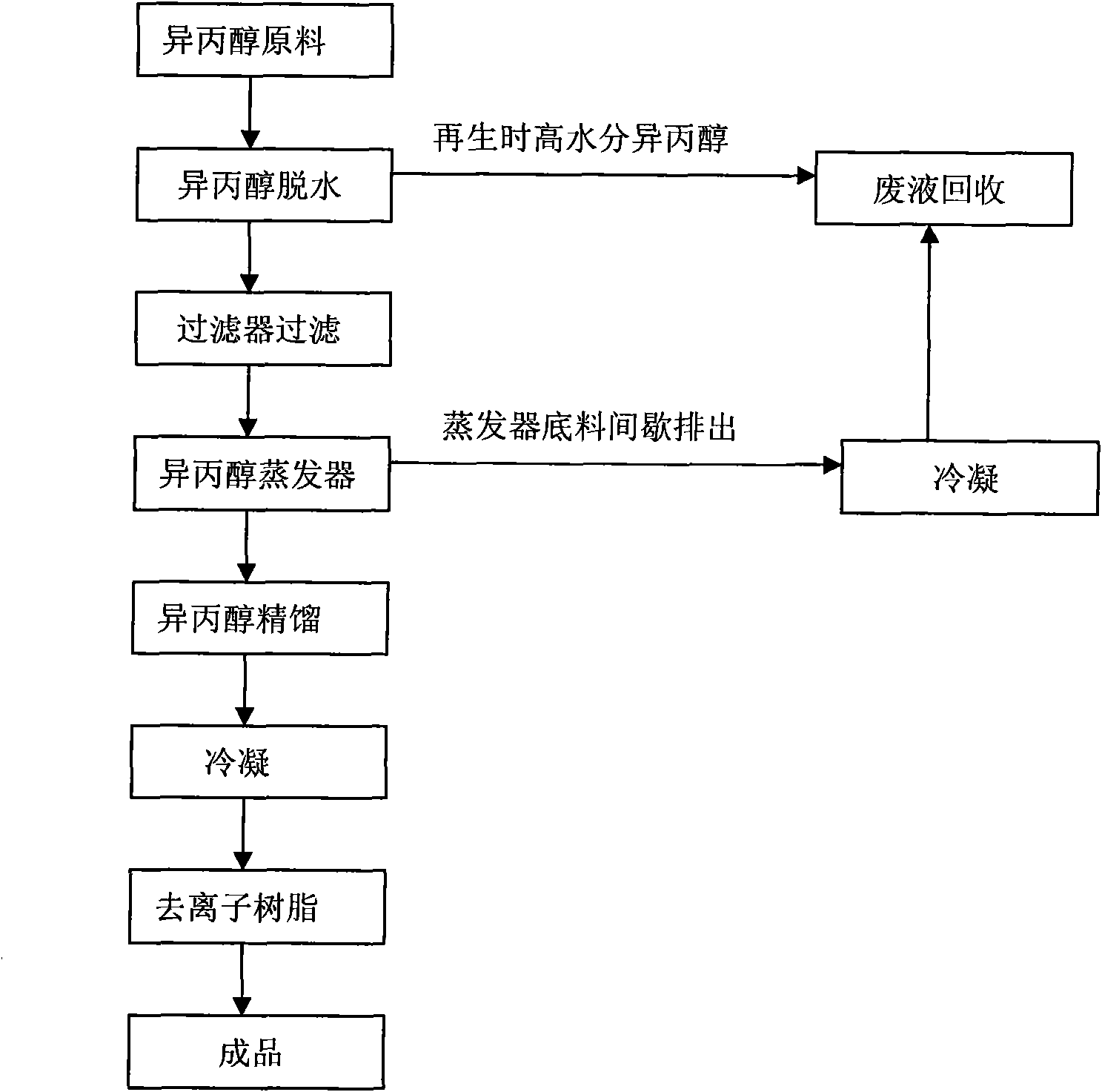

Production process of ultra-high-purity isopropanol

InactiveCN102452897AMild reaction conditionsSimple operation processOrganic compound preparationHydroxy compound separation/purificationMolecular sieveDistillation

The invention discloses a production process of ultra-high-purity isopropanol, which comprises the following process steps of: (1) delivering a feed stream containing at least 98% of industrial grade isopropanol into a molecular sieve adsorption tower from the bottom of the molecular sieve adsorption tower, dehydrating through a molecular sieve, and then flowing out of the top of the tower to obtain high-purity isopropanol of which the moisture content is less than 100ppm; (2) filtering the high-purity isopropanol taken out of the molecular sieve adsorption tower by using a filter so as to remove particles of which the sizes are more than 1mum; and (3) transferring the high-purity isopropanol which is qualified by filtering into a distillation tower and a rectification column for rectifying, then transferring the rectified high-purity isopropanol into a condenser to be condensed into high-purity liquid isopropanol, enabling the condensed high-purity liquid isopropanol after rectifying to pass through a deionized resin tank, and deionizing through ionic resin so as to obtain ultra-high-purity isopropanol of which the metallic impurity is less than 0.1ppb. The production process disclosed by the invention is carried out under the normal pressure, and has the advantages of mild reaction conditions, simple operation processes and good safety performance.

Owner:JIANGSU DENOIR TECH CO LTD

Process for extracting litchi polyphenol from litchi

ActiveCN1733130AFully dissolvedHigh in polyphenolsAntinoxious agentsPlant ingredientsPropanolAlcohol

The invention discloses a process for extracting litchi polyphenol from litchi through dissolvent abstraction, concentrating, separation and purification, and drying, wherein water or low carbon alcohols such as methanol, ethanol, propanol, isopropanol, butanol and amylic alcohol are used as the dissolvent.

Owner:GUILIN NATURAL INGREDIENTS CORP

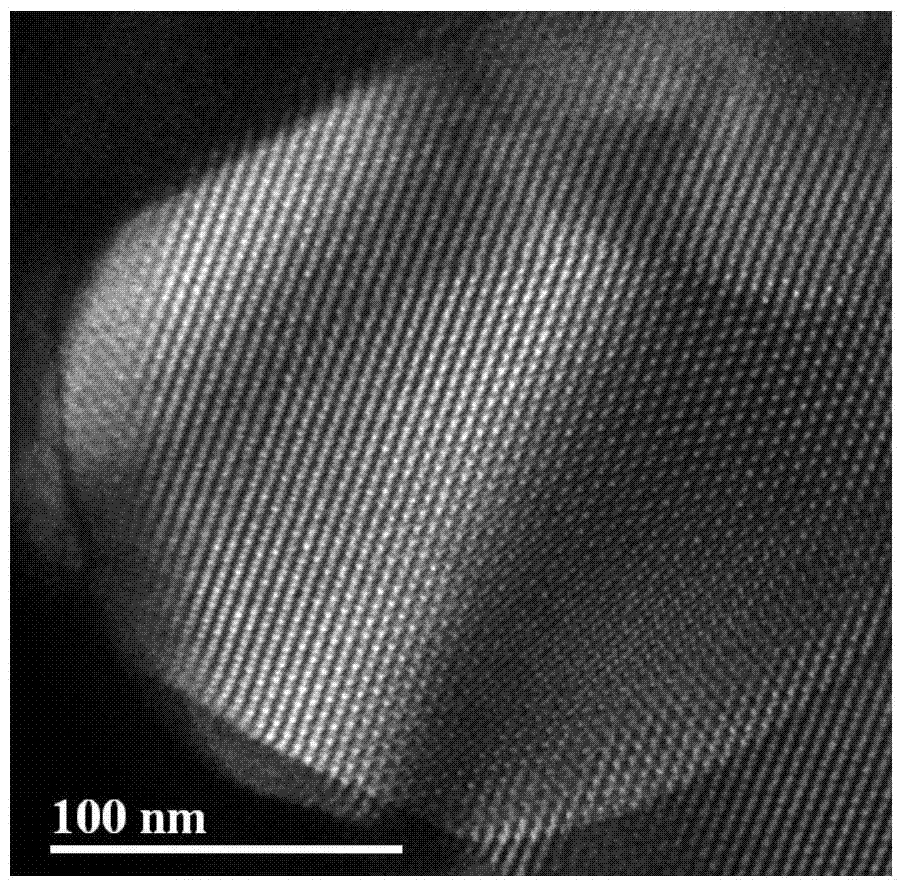

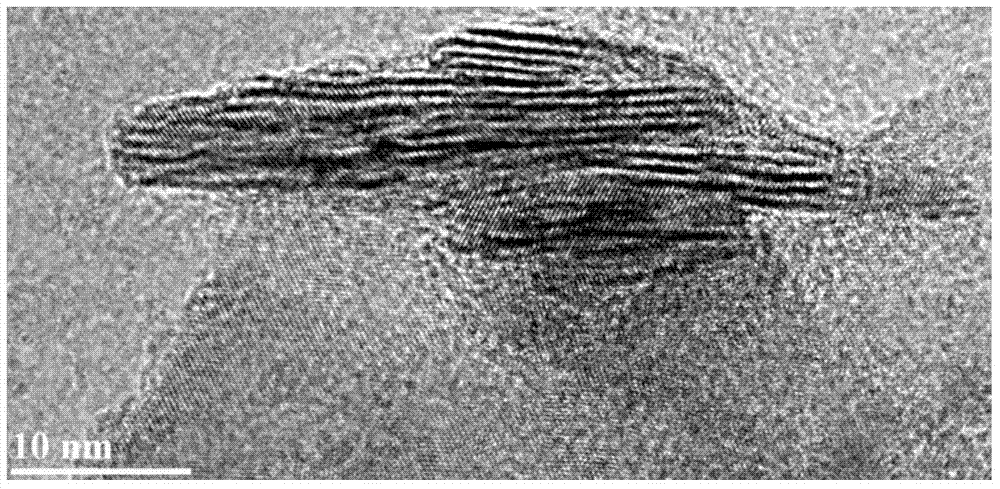

Preparation method of two-dimensional nano-graphene

ActiveCN102910622AConvenient sourceGuaranteed decentralizationGrapheneNanotechnologyPhysical chemistryHydrotalcite

The invention discloses a preparation method of two-dimensional nano-graphene. The method includes: mixing acrylic acid and water according to the volume ratio of 1:1-1:2, adding hydrotalcite particles passing a sieve 20-50 in mesh into acrylic acid solution according to the quantity that each gram of hydrotalcite corresponds to 3-5mmol of the acrylic acid, stirring at the temperature of 60-70 DEG C, ageing, separating particles, adding the particles into isopropanol solution, adding ammonium persulfate, heating to 60-90 DEG C for reaction for 8-10h, drying at the temperature of 70-90 DEG C, grinding, and passing a sieve 20-40 in mesh to obtain powder; heating the power to 600-700 DEG C in vacuum, calcining for 2-4h, adding calcined powder into hydrochloric acid solution 20%-40% in concentration, stirring under the protection of nitrogen, precipitating, separating and drying; and heating an obtained product to 2000-2500 DEG C in vacuum, subjecting the product to heat treatment for 3-6h and cooling so that the two-dimensional nano-graphene is obtained. The method is simple in material sources and simple and mild in process.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

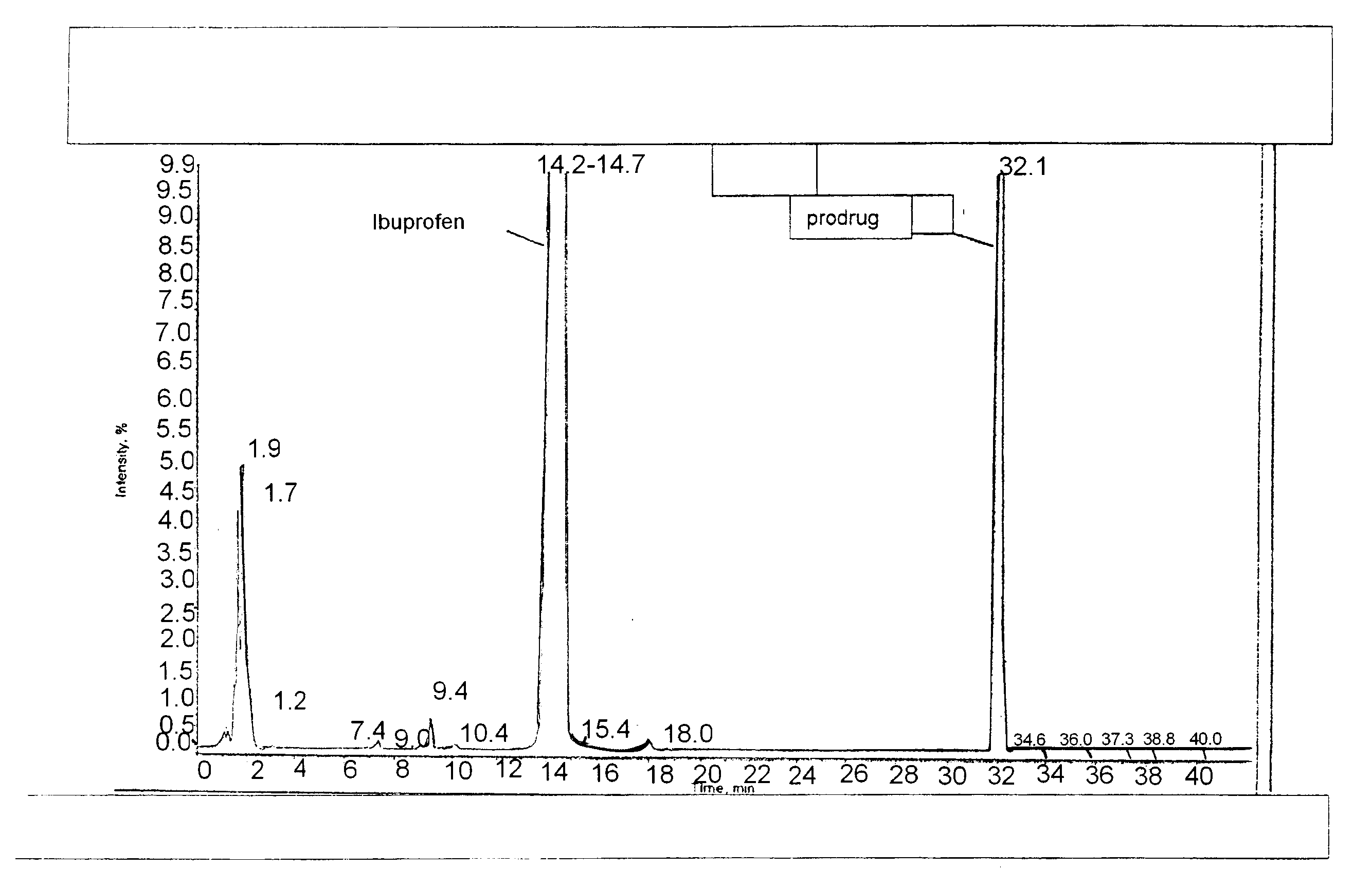

Topical Compositions

InactiveUS20080317684A1Maintain good propertiesAntibacterial agentsBiocidePolyethylene glycolEthanol

Topical compositions are disclosed that are useful for delivering a therapeutic level of an NSAID to a target within a subject having a local inflammatory disorder. A composition of the present invention comprises a Drug and a solvent system, wherein the solvent system comprises at least two solvent alcohols and wherein the solvent system is present in an amount sufficient to solubilize the Drug, the solvent system is a low alkanol system, and the composition is a single phase composition. Exemplary solvent systems are those for which one of the at least two solvent alcohols is polyethylene glycol, glycerin, butylene glycol, dipropylene glycol, propylene glycol, ethanol, isopropanol, or a derivative thereof. Optionally the local inflammatory disorder is pseudofolliculitis barbae, dermatitis, psoriasis, wounds, or sunburn.

Owner:ISW GRP INC

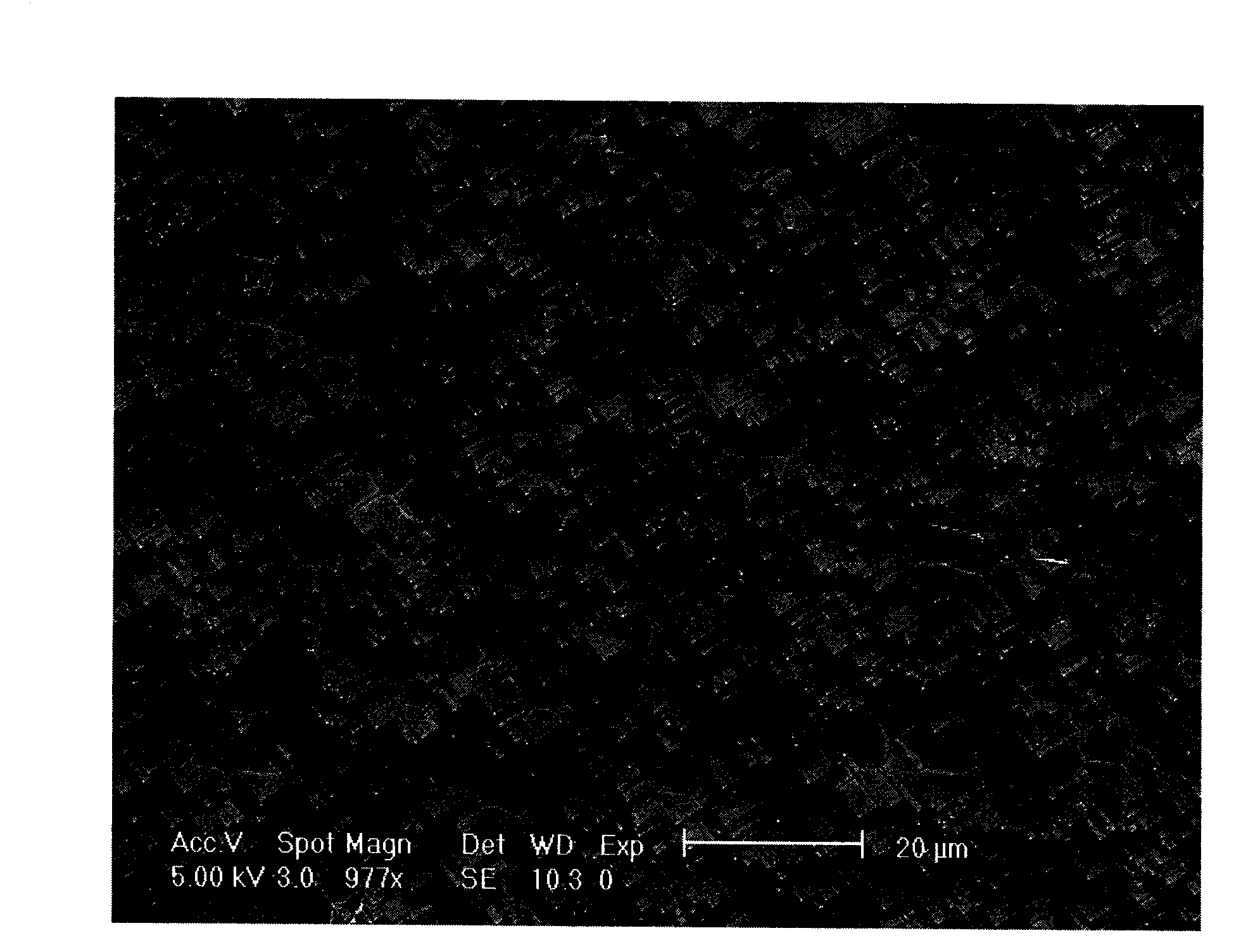

Corrosive liquid for preparing monocrystal silicon textured surface and method thereof

InactiveCN101634026AHigh thermodynamic stabilityGood chemical stabilityAfter-treatment detailsSemiconductor devicesPotassium hydroxidePerfluorooctanoic acid

The invention relates to a corrosive liquid for preparing monocrystal silicon textured surfaces and a method thereof. The corrosive liquid comprises an alkali solution, sodium silicate and isopropanol, and is characterized by also comprising a perfluoro octoate aqueous solution, wherein the perfluoro octoate aqueous solution has the volume percent of 0.2-1 percent and the concentration within a range of 5*10<-5>-5*10<-3>mol / L; the alkali solution has the mass percent of 1-2.5 percent, the sodium silicate has the mass percent of 0.1-2 percent, and the isopropanol has the volume percent of 0.3-2 percent; and the alkali solution is sodium hydroxide or potassium hydroxide or sodium carbonate. The corrosive liquid has low cost, pyramids formed on the prepared monocrystal silicon textured surfaces have small and uniform sizes, and the corrosive liquid is favorable for solar energy absorption and can be widely applied to the field of solar batteries.

Owner:BEIJING SOLAR ENERGY INST +1

Ceramic non-stick coating with bacteriostasis action and coating method thereof

ActiveCN101955697AAchieve bactericidalTo achieve the purpose of food preservationAntifouling/underwater paintsPretreated surfacesAcetic acidPolymer science

The invention belongs to the process technology field of coating liquid or other fluid on the surface, in particular to a ceramic non-stick coating with the bacteriostasis action. The coating is formed by mixing a component (A), a component (B) and a component (C) in a weight ratio of 2 to 0.5-2 to 0.1-2, wherein the component (A) is prepared by dispersing and grinding the following components in percentage by weight: 50-100 percent of silica sol, 0-50 percent of temperature-resisting pigment, 0-20 percent of inert pigment, 0-2 percent of dispersing aid and 0-2 percent of leveling aid for more than 2 h; the component (B) is prepared by mixing the following components in percentage by mass:0.2-1.5 percent of acetic acid and the balance of at least one silane; and the component (C) is prepared by dispersing and dissolving the following components in percent by mass of 1-10 percent of alcohol-soluble acrylic resin, 0-30 percent of non-stick agent and 1-50 percent of antibacterial material in 50-95 percent of isopropanol. Compared with a traditional non-stick coating, the non-stick coating without being added with substances, such as PTFE (Polytetrafluoroethylene), PFOA (Perfluorooctanoic Acid), and the like is environment-friendly and safe and has the bacteriostasis and sterilization functions.

Owner:ZHEJIANG PFLUON TECH CO LTD +1

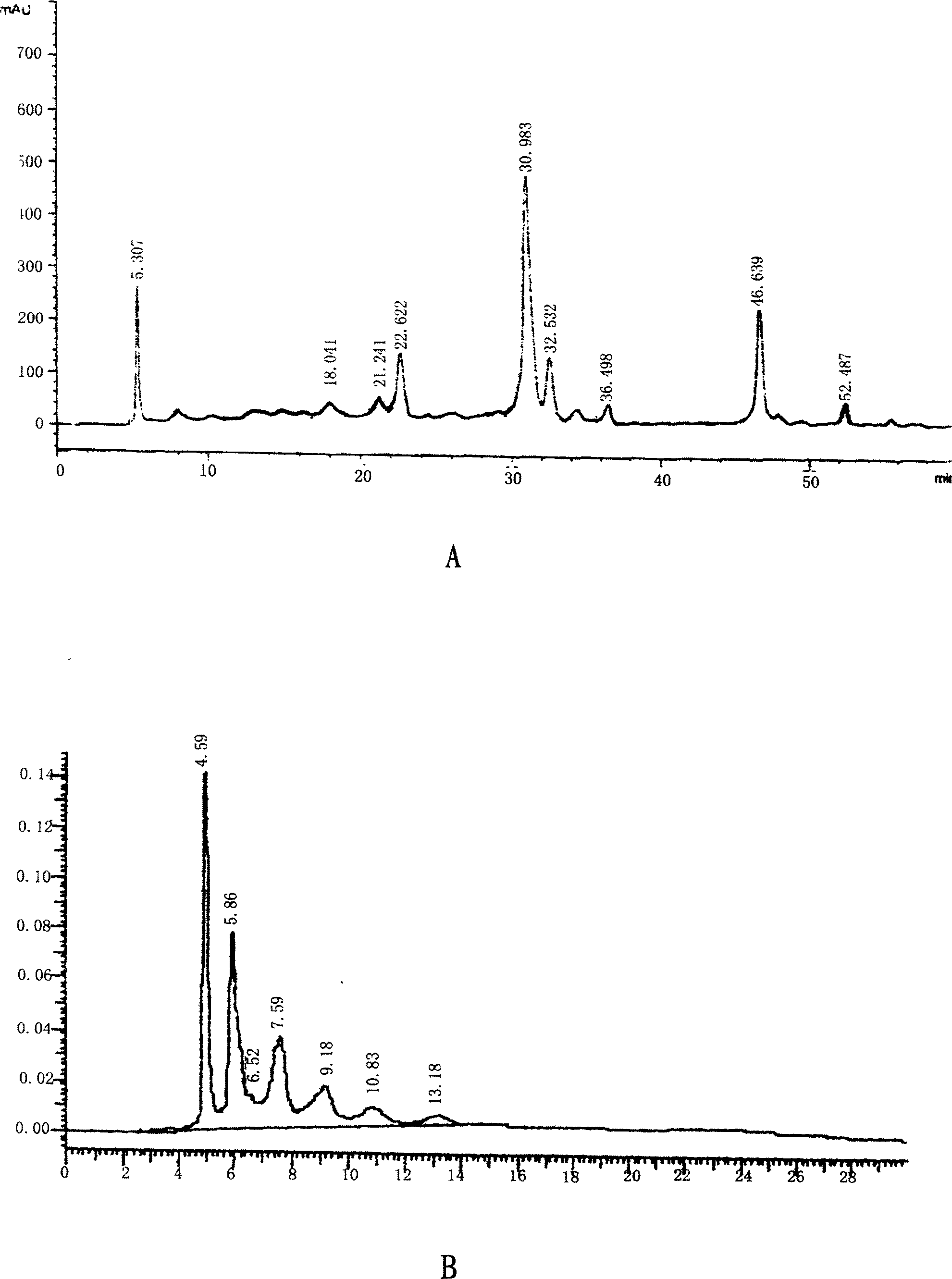

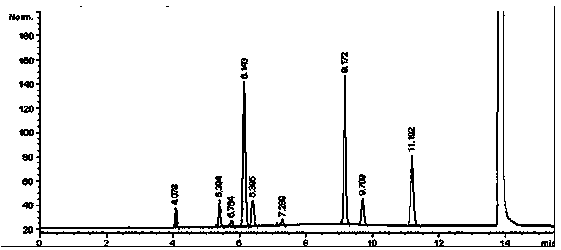

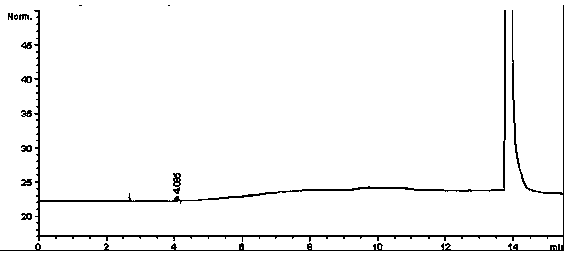

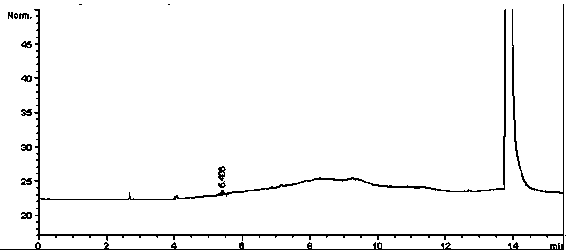

Method for detecting multiple residual solvents in medicament

ActiveCN103487519AHigh sensitivityHigh precisionComponent separationMethylene DichlorideVapor phase chromatography

The invention relates to a method for detecting multiple residual solvents in a medicament. According to the method, by utilizing a gas chromatographic method, nine organic solvents including methanol, ethanol, acetonitrile, acetone, isopropanol, methylene dichloride, ethyl acetate, tetrahydrofuran and triethylamine in the medicament are simultaneously detected, the sensitivity and the precision are high, and the repeatability is good; by utilizing a standard addition method, other standard substances do not need to serve as internal standard substances, only pure substances of to-be-measured components are needed, the accuracy requirement on the sampling volume is low, and the operation is simple; by utilizing a headspace sampling method, a direct solution sample is prevented from interfering the detection and polluting a chromatographic column; by utilizing a temperature programming method, low-boiling-point organic solvents and high-boiling-point organic solvents can be effectively separated.

Owner:SHANGHAI NEW ASIA PHARMA

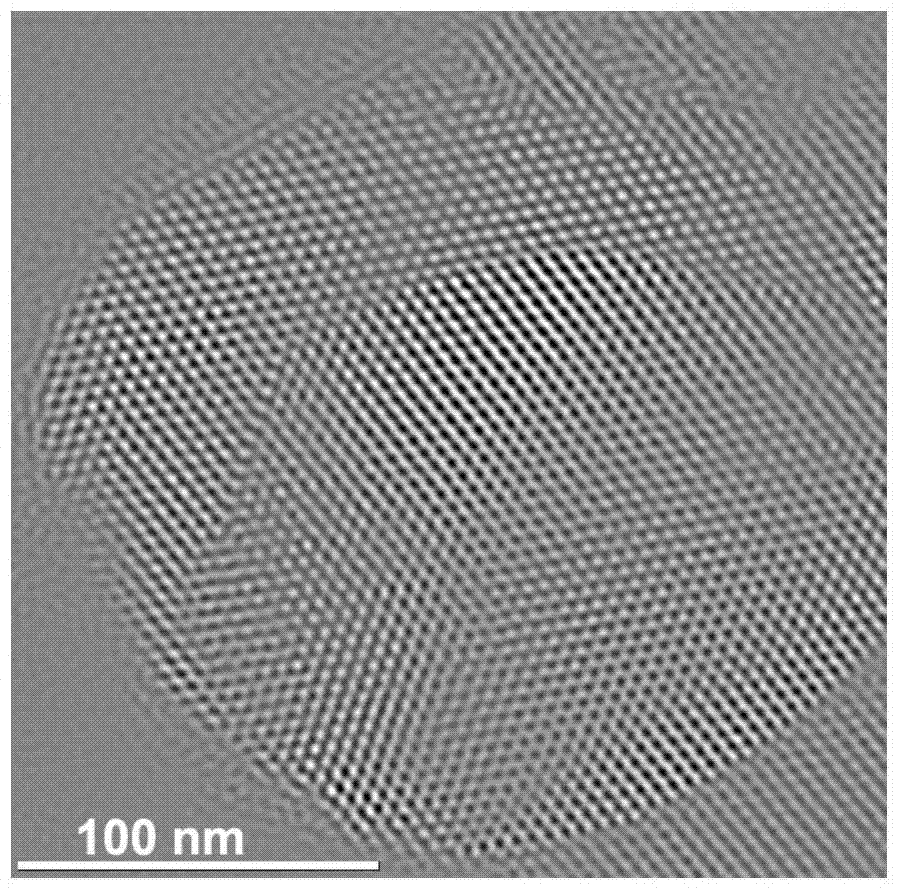

Peeling method of two-dimensional layered nano material

ActiveCN103692763ASimple processEasy to operateLamination ancillary operationsLaminationActive agentSurface-active agents

The invention provides a peeling method of a two-dimensional layered nano material. The peeling method comprises the following steps of: dissolving an amphiphilic surface active agent in an organic solvent, and carrying out ultrasonic water bathing for 0.5-2 hours to obtain mixed solution, wherein the organic solvent is one or more in a mercaptan solvent, octadecylamine, isopropanol, a sulfur solvent, an amino-acid solvent, a polyamino solvent and a polyalcohol solvent; adding a transition metal compound to be peeled into the mixed solution, carrying out 1000-1800w ultrasonic treatment and 1500-5000rpm centrifugal treatment to remove supernatant, collecting precipitates, filtering and drying to obtain solid, i.e., the peeled two-dimensional layered nano material. The peeling method provided by the invention has the advantages that the process is simple, the yield is higher, one-layer, double-layer and multi-layer controllable nano materials with two-dimensional complete crystal surface structures can be obtained, the industrial production with low cost is easily implemented and the problem of secondary pollution to the environment is avoided.

Owner:SHENZHEN INST OF ADVANCED TECH

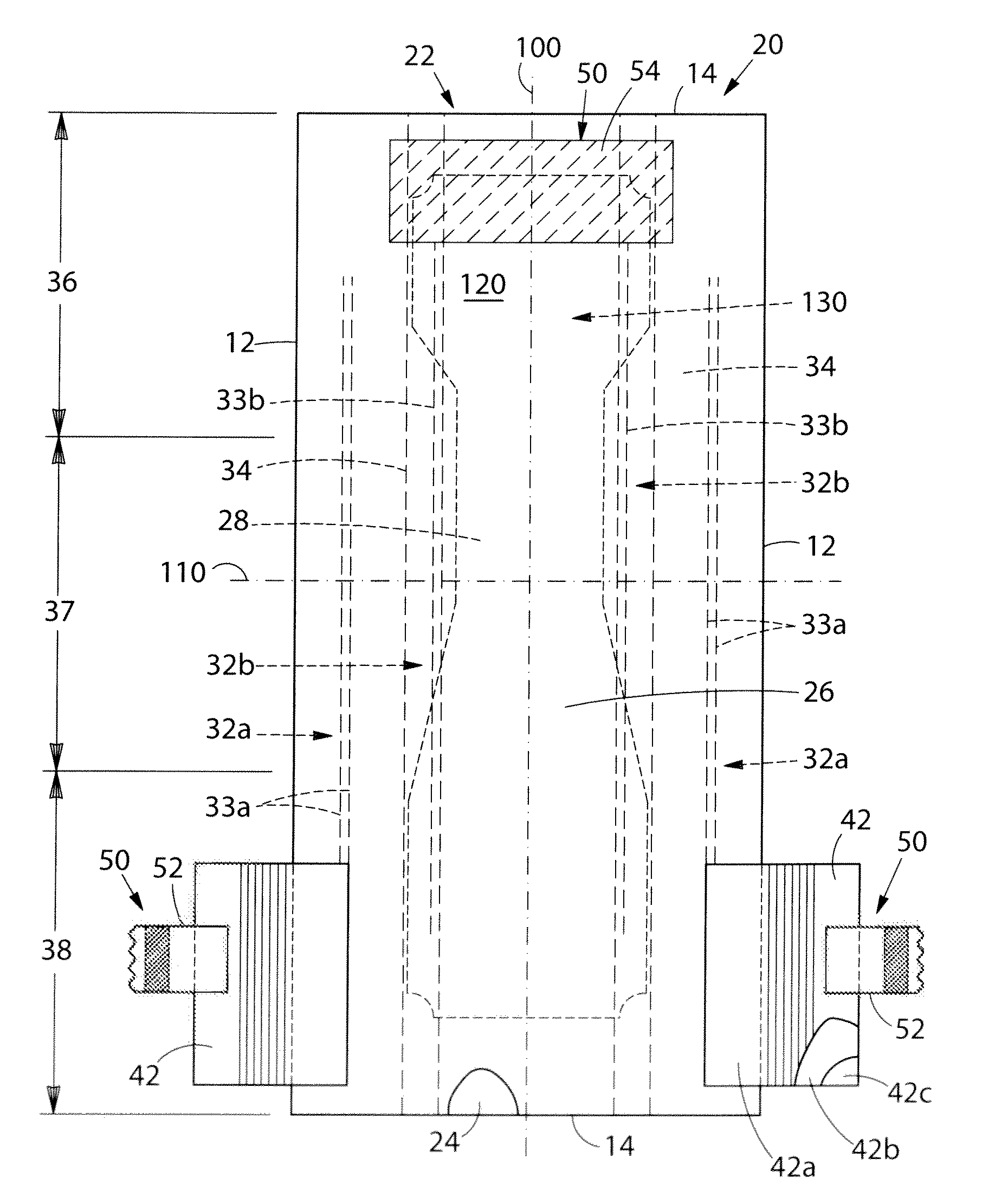

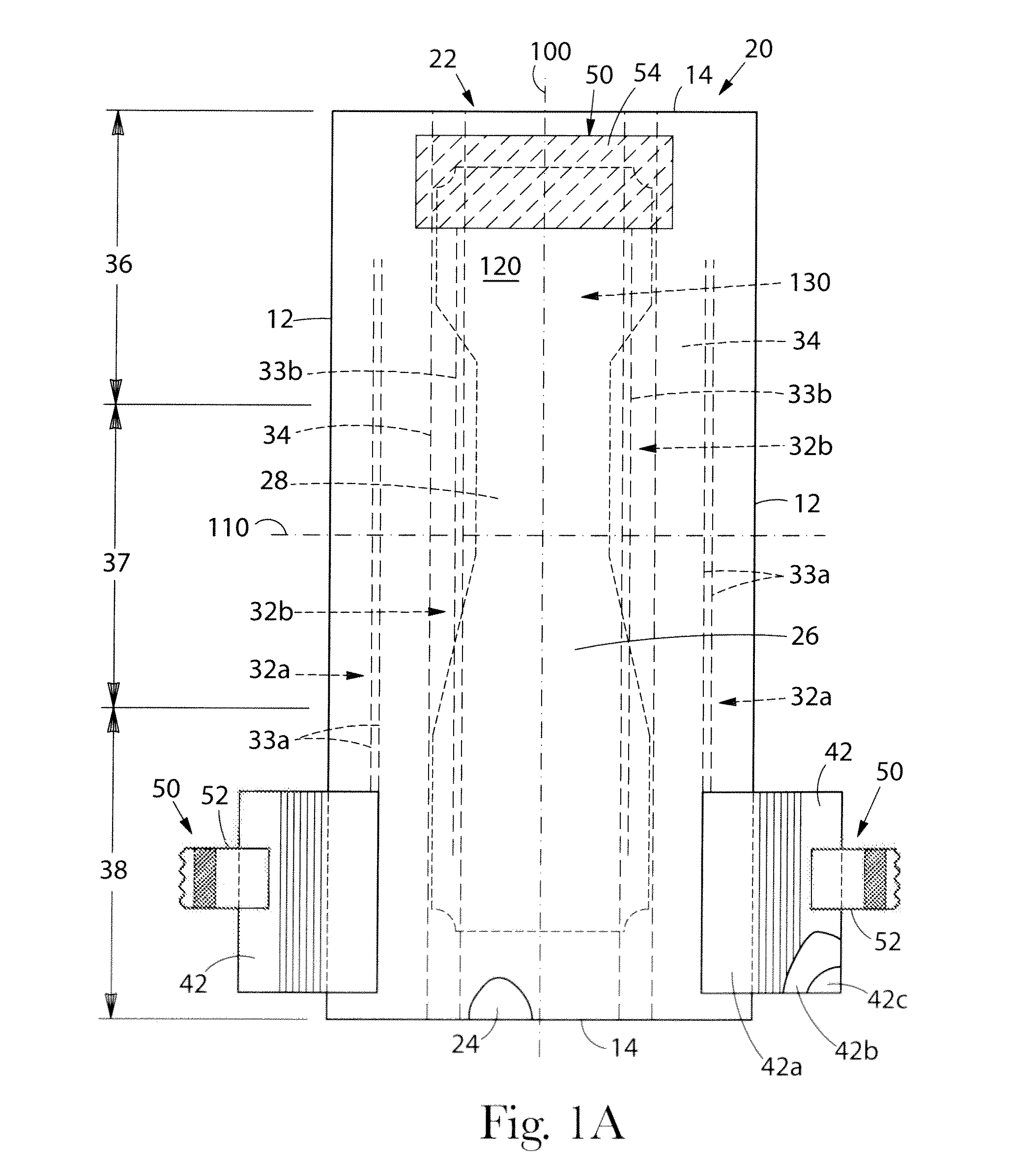

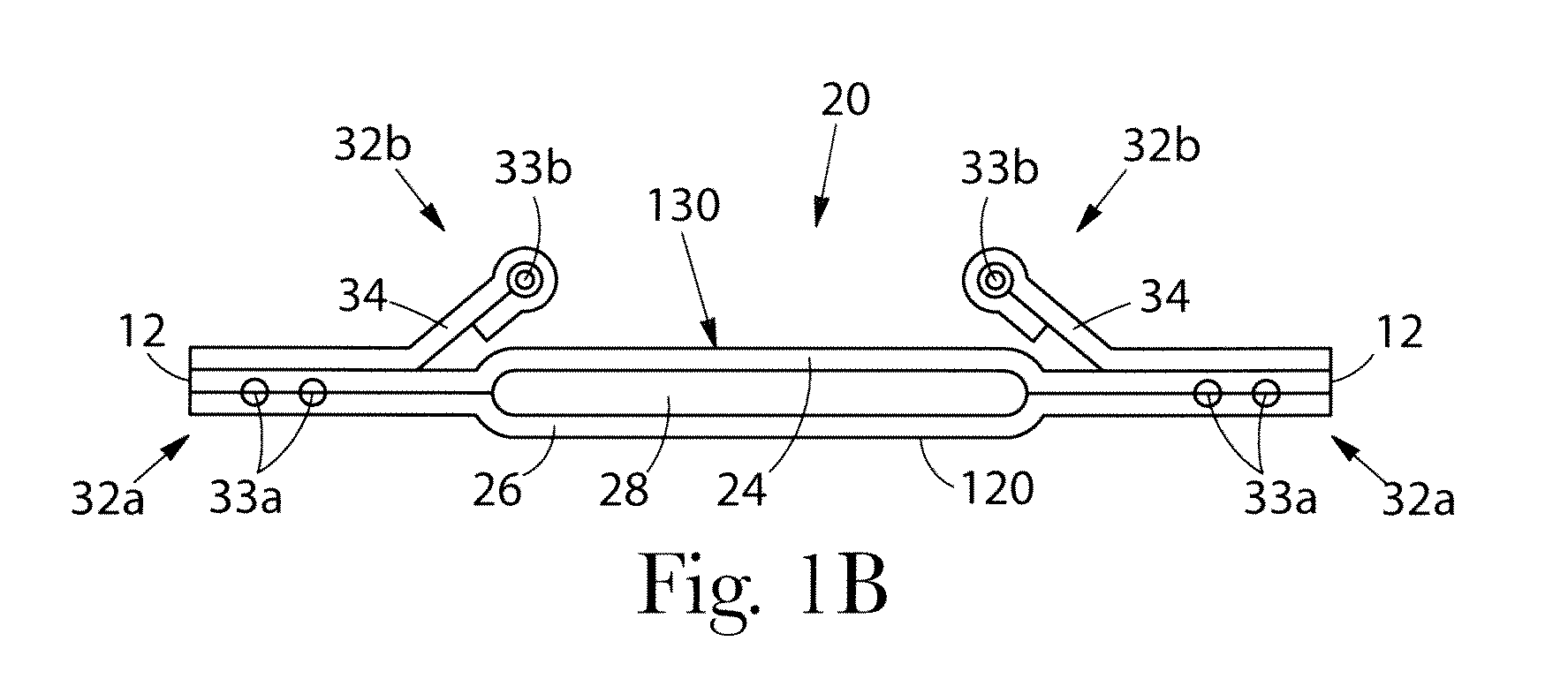

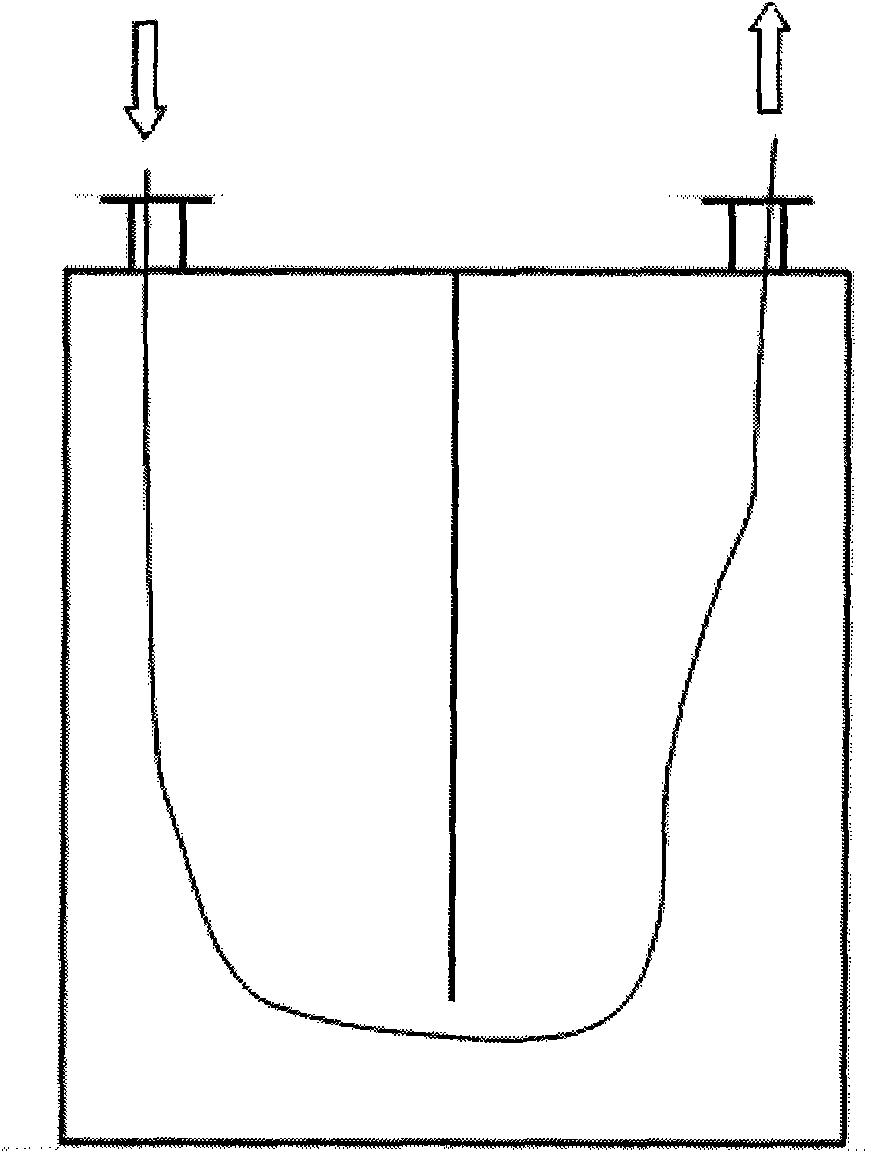

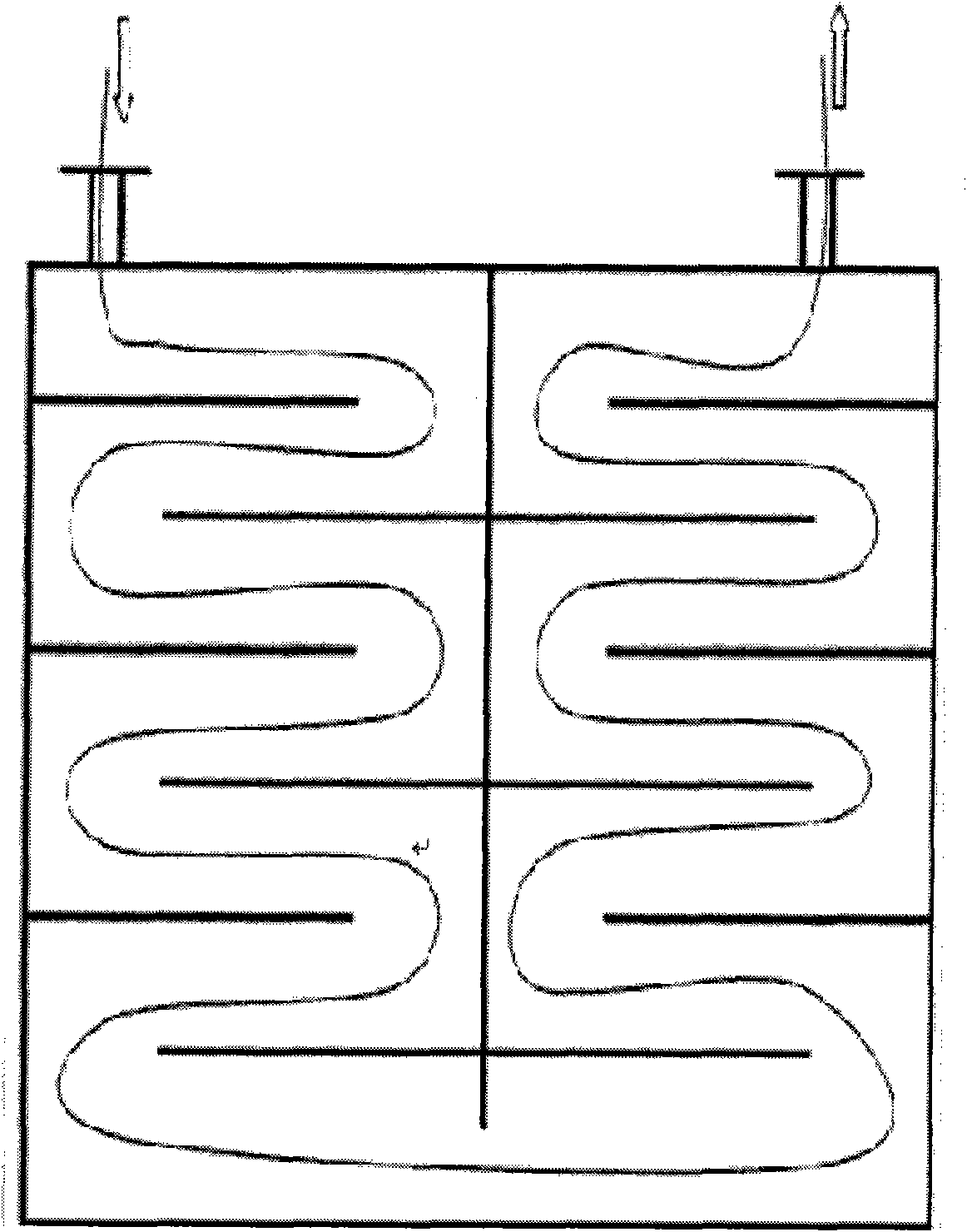

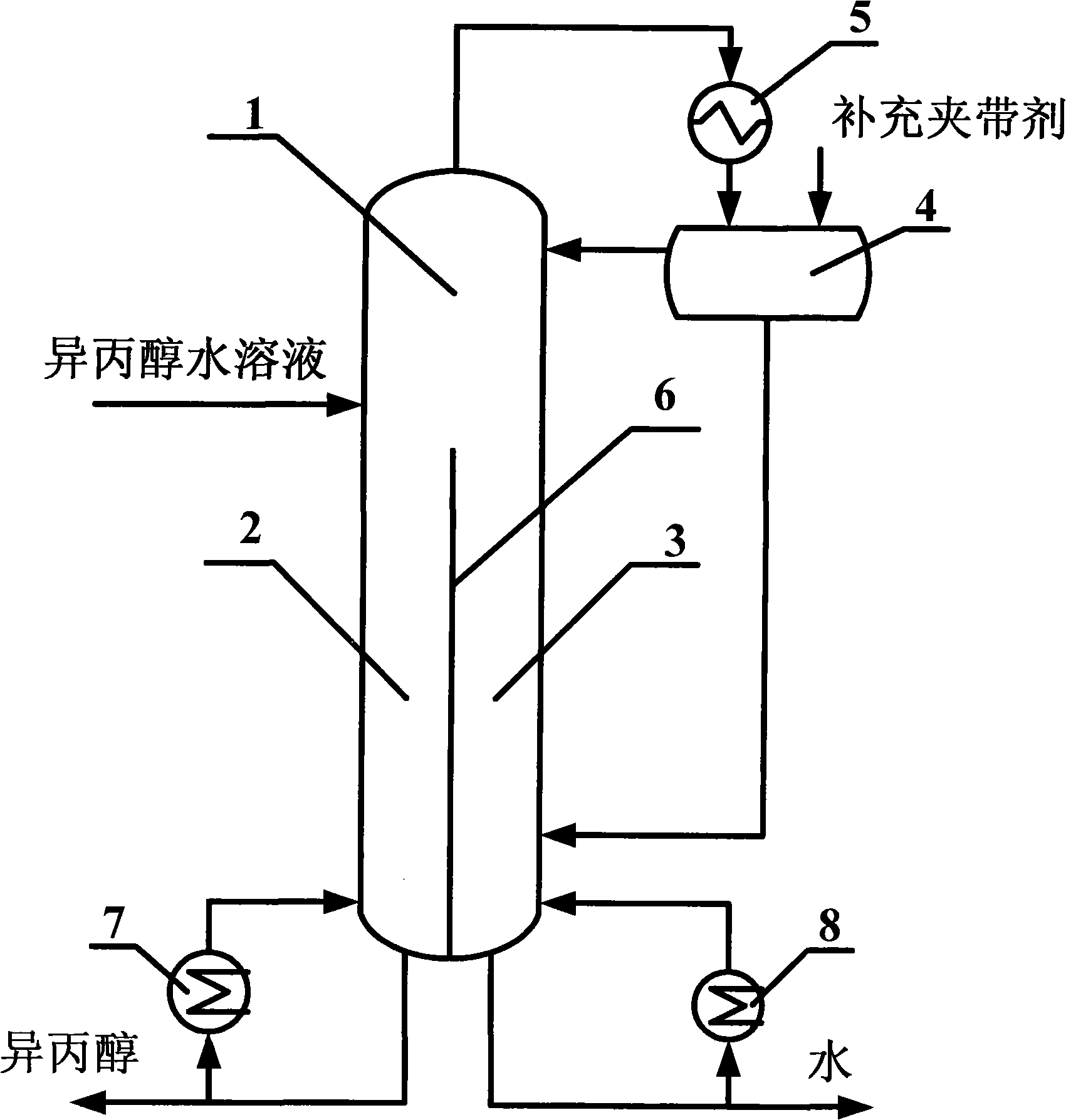

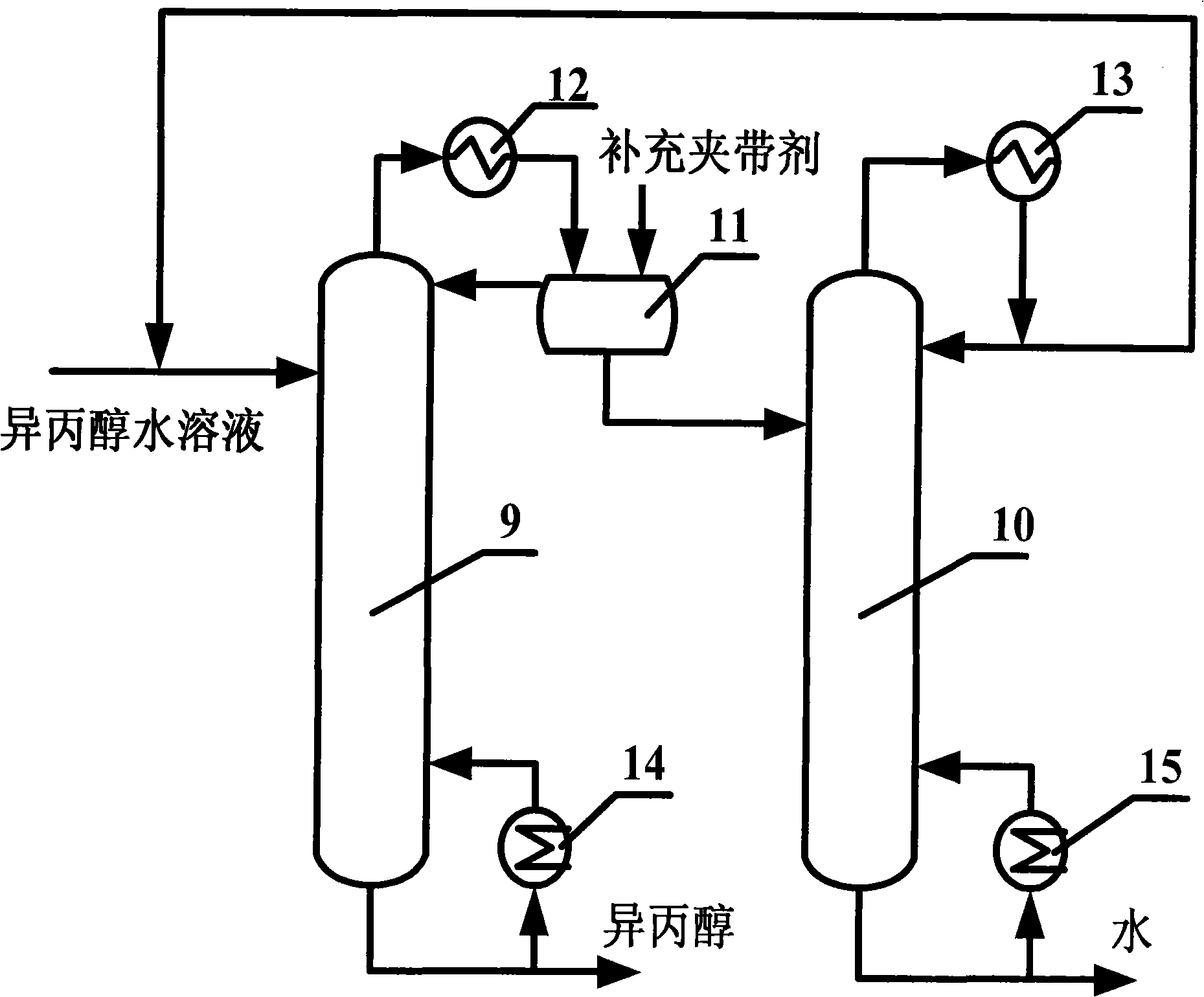

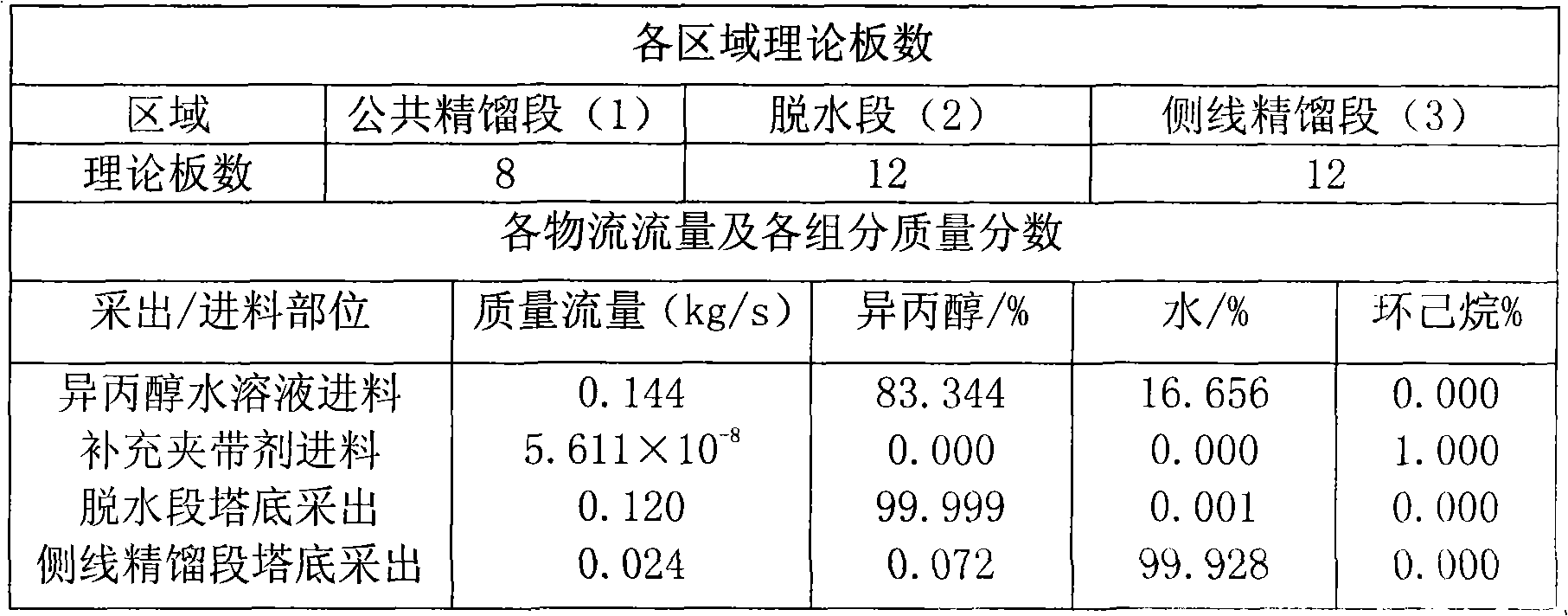

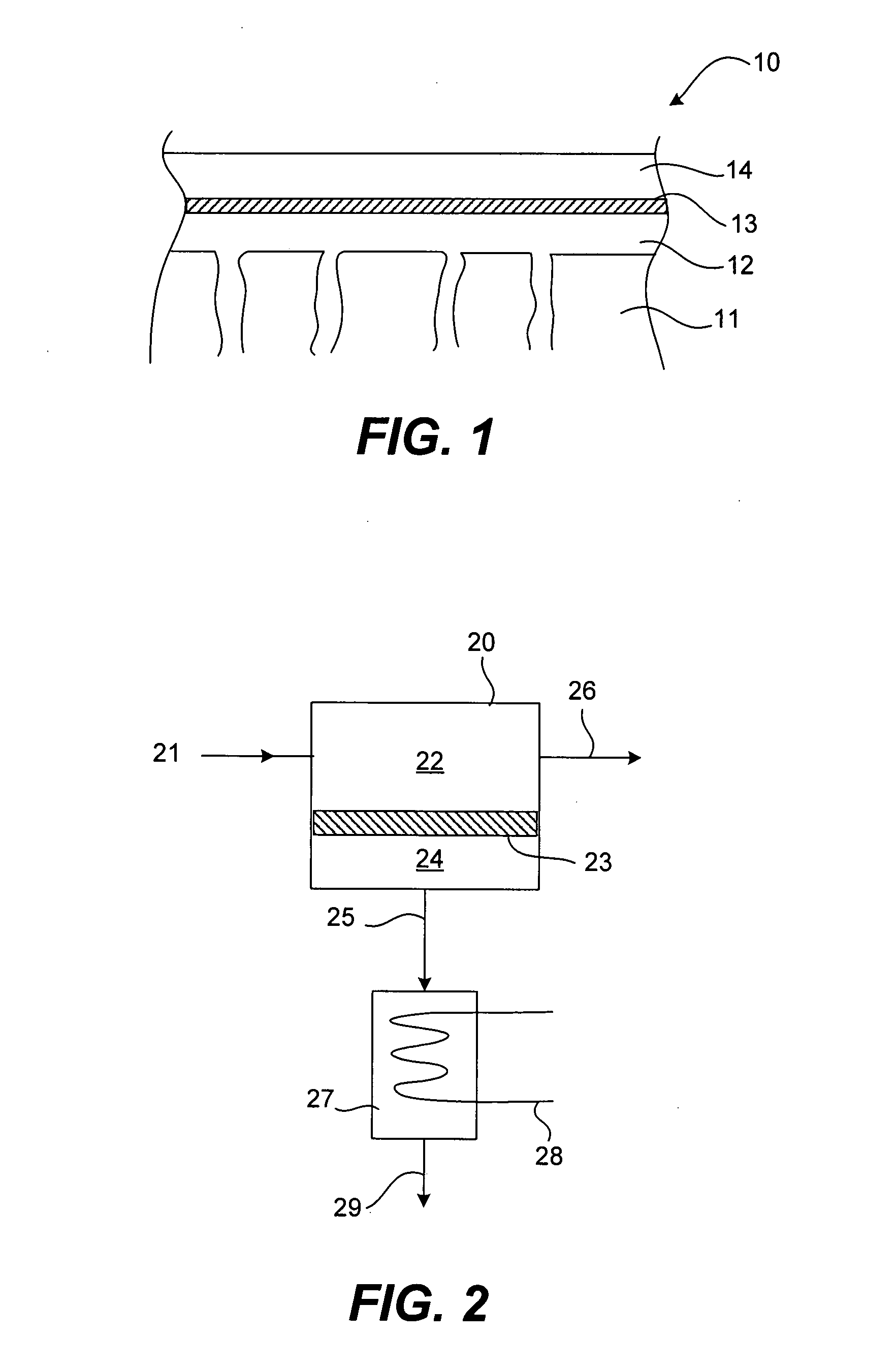

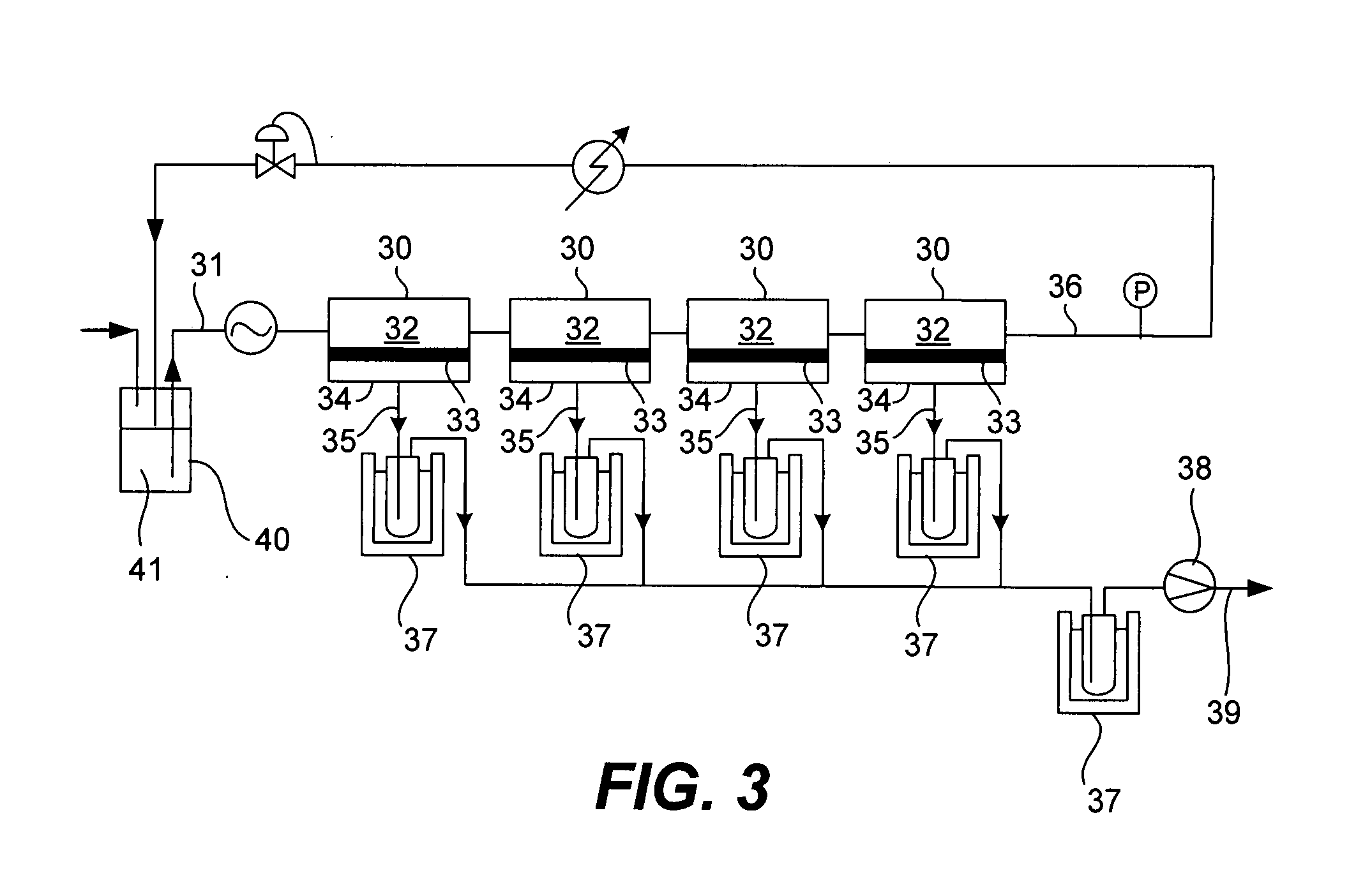

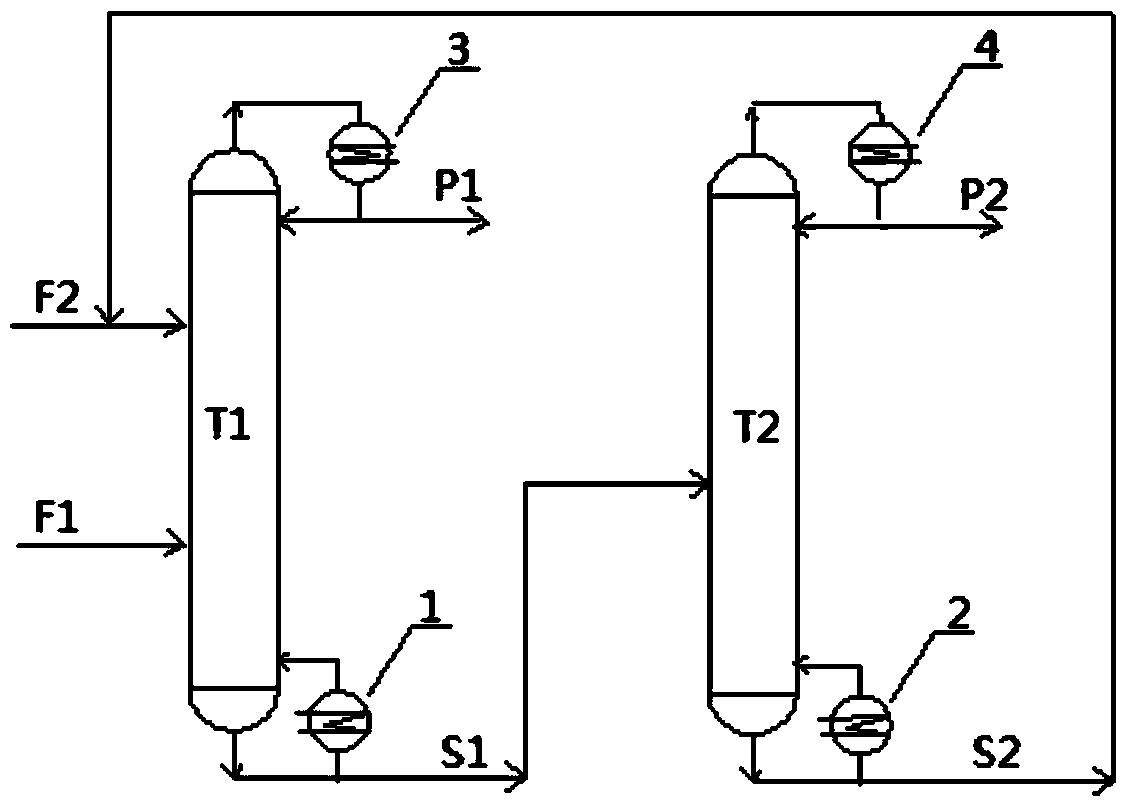

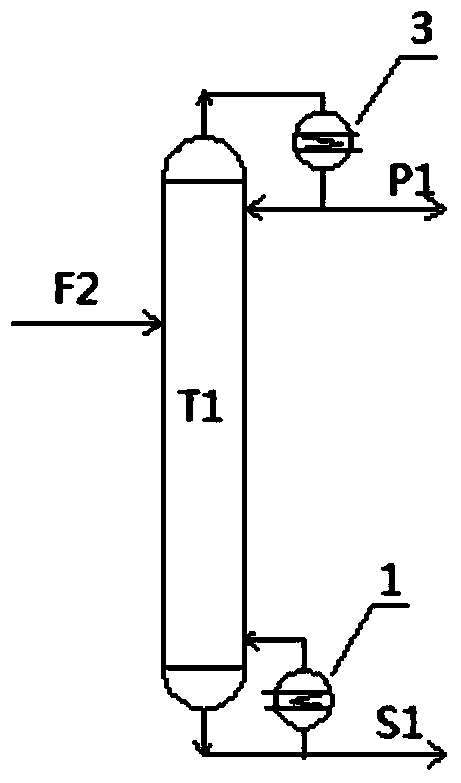

Technological process and device for separating isopropanol water solution

InactiveCN101333150ALess investmentHigh purityOrganic compound preparationHydroxy compound preparationPhase splitterAqueous solution

The invention relates to a novel azeotropic distillation technical method and a device, particularly to a technical method and a device using a bulkhead azeotropic distillation column to produce anhydrous isopropanol. The invention enables the separation between isopropanol and water, as well as the recovery of entrainer to be integrated into the same distillation column. The bulkhead azeotropic distillation column refers to a piece of bulkhead (6) which is arranged in the vertical direction inside the conventional distillation column and extended from the upper part of the distillation column to the bottom part of the distillation column; the total height of the bulkhead (6) is less than that of the distillation column; the bottom of the bulkhead is closed; the bulkhead (6) divides the distillation column into three parts: a public distillation segment (1), a dehydration segment (2) and a lateral line distillation segment (3). The isopropanol aqueous solution which needs to be separated enters into the distillation column from the lower part of the public distillation segment (1) and get the high-purity isopropanol from the bottom of the dehydration segment (2); the , ternary azeotrope is steamed out from the top of the distillation column; the steam at the top of the distillation column is condensed through a condenser (5) and then enters into a phase splitter (4) to be divided into light and heavy two-phase liquid; the light phase (entrainer) flows back, while the heavy phase enters into the lower part of the lateral line distillation segment (3) to get the water containing a small amount of isopropanol at the bottom of the lateral line distillation segment (3).

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

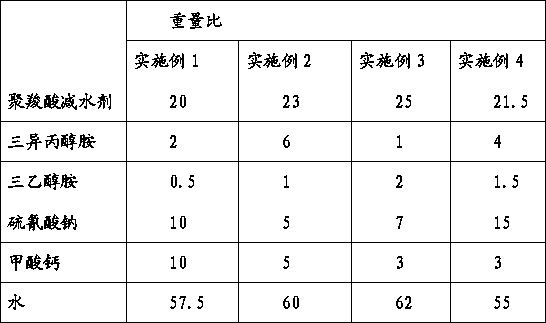

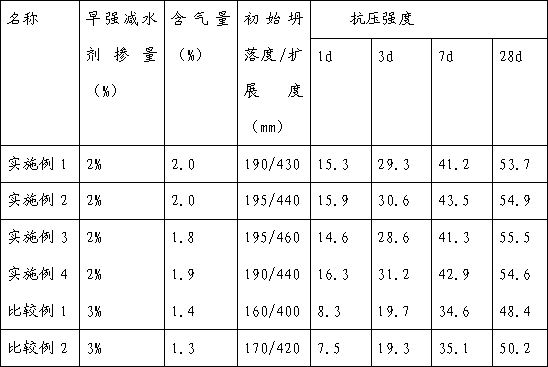

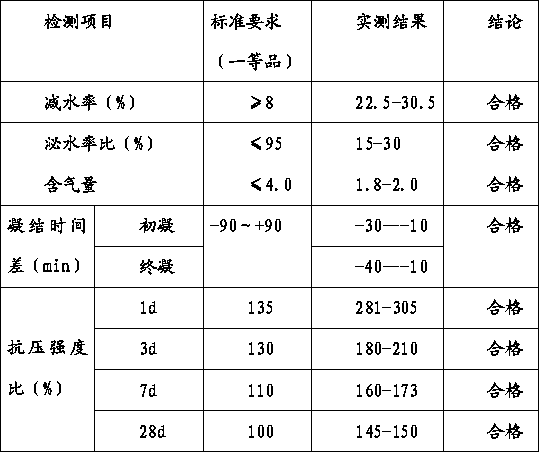

Early-strength water reducer for recycled aggregate concrete

The invention provides an early-strength water reducer for recycled aggregate concrete, which is suitable for the field of building materials. The the early-strength water reducer comprises the following raw materials by weight percent: 20-25% of a polycarboxylic acid water reducer, 1-6% of tri-isopropanolamine, 0.5-2% of triethanolamine, 5-15% of sodium sulfocyanate, 3-10% of calcium formate, and 42-70.5% of water. The early-strength water reducer provided by the invention is low in dosage, good in early-strength effect, free from chloride ions, resistant to the corrosion of steel bars, suitable for recycled concrete, and capable of enhancing the early strength of a recycled concrete product and improving the peaceability of a recycled concrete mixture.

Owner:北京新奥混凝土集团有限公司

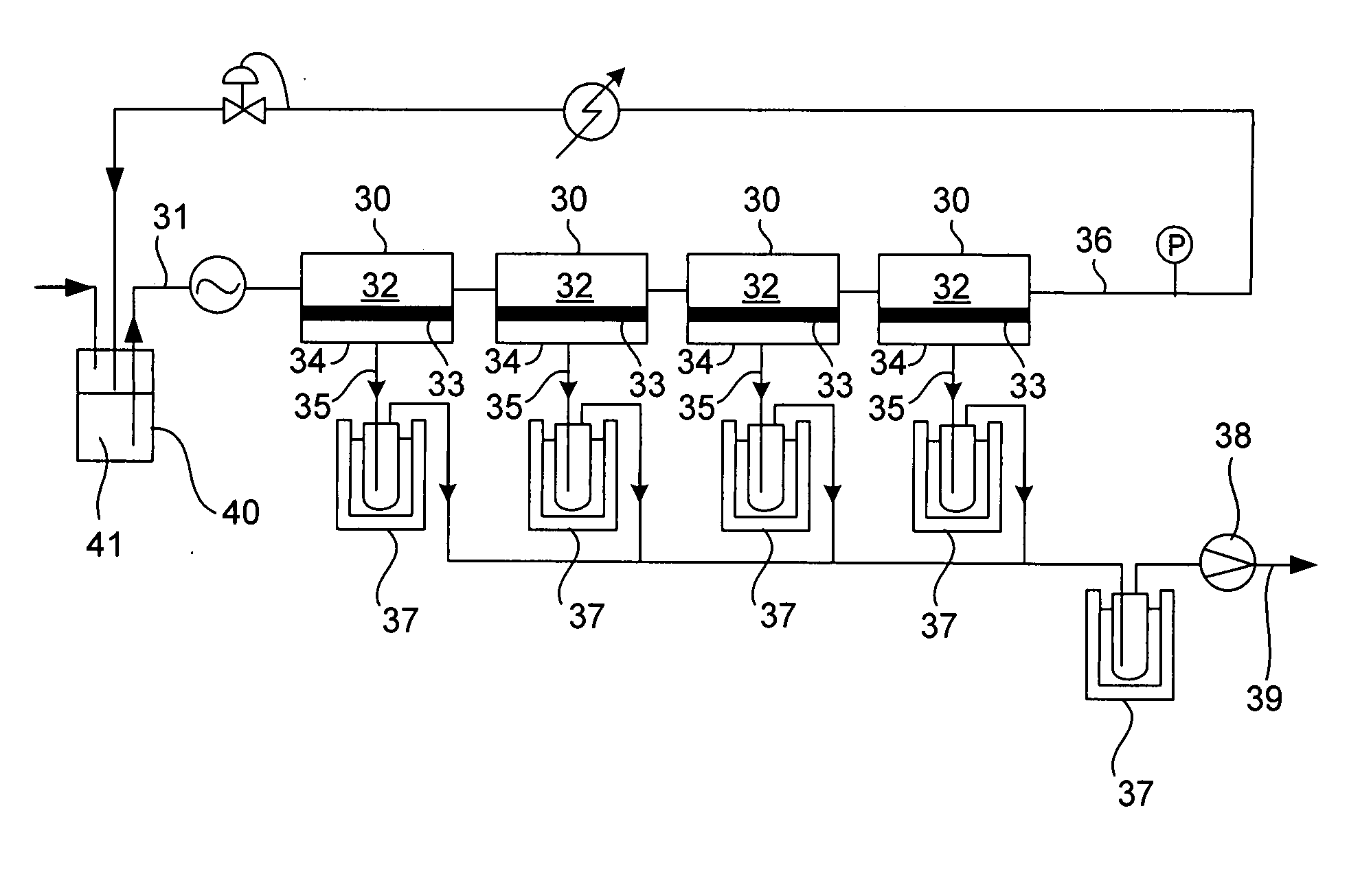

Liquid-phase and vapor-phase dehydration of organic/water solutions

ActiveUS20080216649A1Satisfactory operationDispersed particle separationBiofuelsAcetic acidFluid phase

Processes for dehydrating an organic / water solution by pervaporation or vapor separation using fluorinated membranes. The processes are particularly useful for treating mixtures containing light organic components, such as ethanol, isopropanol or acetic acid.

Owner:MEMBRANE TECH & RES

Extraction method of soil microbe genome DNA and total RNA

The invention provides a method for effectively extracting crop rhizosphere soil microbe genome DNA and total RNA, which comprises the following steps: firstly, removing humus and other impurities which severely disturb nucleic acid extraction in soil samples by aluminum sulfate; further crushing soil microbe cells by glass beads; adding sodium dodecyl sulfonate (SDS) and LiCl solutions for cracking cells and dissociating nucleic acids; adding the mixture of phenol, chloroform and isoamylol for extracting; and then, depositing the extraction solution by isopropanol and sodium acetate to finally acquire the soil microbe metagenome DNA and total RNA. The method is suitable for extraction of the DNA and total RNA of soil in different regions. The invention establishes an extraction technology which has the advantages of simple and easy operation processes and higher purity of the prepared sample, and can provide an important basis for the research of soil metagenomics.

Owner:FUJIAN AGRI & FORESTRY UNIV

Preparation method of Al2O3-SiO2 composite aerogel material by ambient drying

InactiveCN110038493AHigh porosityImprove performanceAerogel preparationColloidal chemistry detailsTrimethylsilyl chlorideSolvent

The invention discloses a preparation method of an Al2O3-SiO2 composite aerogel material by ambient drying, relates to a preparation method of an aerogel material, and aims to solve the problem of poor mechanical properties of pure aluminum aerogel and to lower preparation cost and risk. The preparation method comprises the following steps: 1, mixing silica sol and alumina sol to obtain silicon-aluminum composite sol; 2, performing solvent replacement on the silicon-aluminum composite sol with an ethanol / isopropanol solution in certain proportion; 3, modifying the gel through a mixed solutionof trimethylchlorosilane and n-hexane; 4, adding n-hexane to the modified gel for solvent replacement again; and 5, preparing by ambient drying. According to the preparation method provided by the invention, the ambient drying method is adopted, and the mechanical properties of alumina aerogel is enhanced by composite silica; the morphology of aerogel subjected to calcining at 1,200 DEG C can still be maintained, and the aerogel has good high-temperature resistance.

Owner:QILU UNIV OF TECH

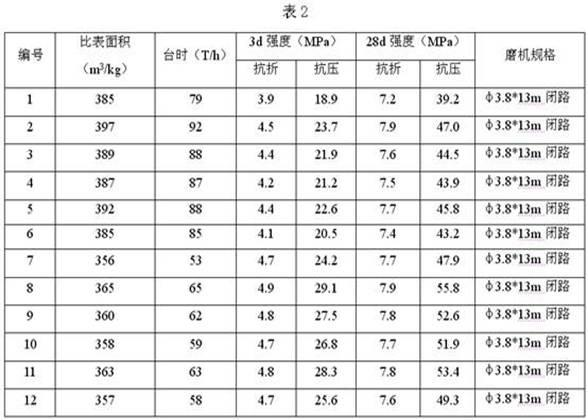

Cement grinding aid and preparation method thereof

ActiveCN102126843AImprove performanceNo adverse side effectsSolid waste managementCelluloseCarbamate

The invention discloses a cement grinding aid. The cement grinding aid comprises the following components in percentage by weight: 8 to 20 percent of triethanolamine, 0 to 10 percent of triisopropanolamine, 8 to 20 percent of diol byproduct, 0 to 10 percent of synthetic glycerine, 0 to 25 percent of molasses, 0 to 5 percent of calcium lignosulfonate, 0 to 15 percent of polyurethane, 0 to 10 percent of cystine, 3 to 5 percent of sorbitol, 5 to 10 percent of sodium carboxymethylcellulose, 0 to 5 percent of citric acid, 0 to 5 percent of silica powder, 0 to 5 percent of fly ash and the balance of water. The invention also discloses a preparation method of the cement grinding aid. The grinding aid can effectively improve the equipment-hour yield of a cement grinding mill, reduce energy consumption and remarkably improve cement performance, does not have adverse side effects on cement, reduces the using amount of cement clinkers by 4 to 10 percent, improves the equipment-hour yield of cement production by 6 to 10 percent, and has a good effect. The method has a unique process, a part of raw materials are treated by ultrasound, and the prepared grinding aid has high performance.

Owner:CHINA UNITED CEMENT LUNAN

Methanol gasoline additive and process for producing methanol gasoline

The invention relates to a preparation method for a methanol oil additive and the methanol oil thereof. The compound additive consists of the components of the following weight percentages; 30 to 50 percent of isopropanol, 10 to 20 percent of tertiary butyl alcohol, 1 to 5 percent of butyl acetate, 1 to 5 percent of methyl ethyl ketone peroxide, 1 to 5 percent of peroxide, 1 to 5 percent of sherwood oil, 5 to 10 percent of dimethylbenzene, 1 to 4 percent of octane enhancing additive, 1 to 5 percent of dimethoxymethane, 0.1 to 0.5 percent of antioxidizing and antigum agent, 0.1 to 0.5 percent of antiseptic, 1 to 8 percent of antiwear agent, 3 to 6 percent of waterproofing agent, 1 to 5 percent of dispersant, 1 to 3 percent of fatty acid amine, 10 to 30 percent of 120# solvent oil as well as 5 to 10 percent of ethanol. The methanol oil consists of the components of the following weight percentages: 10 to 80 percent of methanol, 0 to 85 percent of diesel oil as well as 5 to 20 percent of methanol oil additive. The methanol oil has the advantages of low cost, excellent performance, good environment protection effect, remarkable economic benefit and convenient popularization.

Owner:王宇

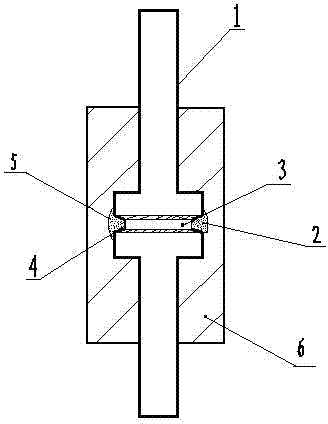

A plastic-encapsulated power diode and its manufacturing process

InactiveCN102263140AAvoid shockRelieve heat stressSemiconductor/solid-state device manufacturingSemiconductor devicesEpoxyManufacturing technology

The invention discloses a plastic-encapsulated power diode and a manufacturing process thereof, and relates to the technical field of semiconductor discrete devices. Its manufacturing process does not adopt the cleaning and dehydration process of organic solvents such as isopropanol and absolute ethanol in the prior art, and the water washing and dehydration process after cleaning with organic solvents is omitted; the chip connected with the wire is put into a heated oven Baking in medium temperature for 4-10 hours, the oven temperature is 200-250°C, and the hydrogen-nitrogen mixed gas or clean air is passed through the oven; put the chip coated with liquid epoxy resin or liquid silicone rubber into the oven at 150±10°C to cure the glue for 10 -60 minutes. Compared with the prior art, the product of the invention has excellent high-temperature characteristics, consistency and reliability.

Owner:SHANDONG YIGUANG ELECTRONICS

Oil-control anti-hair-loss liquid shampoo

InactiveCN105748376AIncrease appetiteBlood normalizationCosmetic preparationsHair cosmeticsAlopecia seborrhoeicaBetaine

The invention provides oil-control anti-hair-loss liquid shampoo and belongs to the technical field of washing and cosmetic products.The oil-control anti-hair-loss liquid shampoo comprises, by percent content, 15-20% of sodium lauryl polyoxyethylene ether sulfate, 5-10% of cocoamidopropyl betaine, 5-10% of sodium lauroyl sarcosine, 1-3% of cocamidopropyl DEA, 1-2% of cocamidopropyl MEA, 1-5% of isopropanol, 1-5% of glossy privet fruit extract, 1-5% of prepared rehmannia roots, 1-5% of ginger extract, 1-5% of cacumen biotae extract, 0.5-1.5% of thickener, 0.1% of bactericide, 0.1% of citric acid and the balance water, wherein the percent content of all components sums up to 100%.According to the oil-control anti-hair-loss liquid shampoo, through mutual compatibility and the synergistic effect of all the components, the oil-control and anti-hair-loss effects can be achieved, oil control time is effectively prolonged, hair can maintain clean and cool for a long time, and thereby the effect of preventing alopecia seborrhoeica is achieved.

Owner:成都彦宁科技有限公司

Method for separating isopropanol-water compound

InactiveCN103467246AIncrease relative volatilityEfficient separationOrganic compound preparationHydroxy compound preparationOrganic solventExtractive distillation

The invention provides a method for separating a isopropanol-water compound, which comprises the following steps: adopting an isopropanol-water compound in any proportion as a raw material, taking ionic liquid or a double solvent composed of ionic liquid and an organic solvent as an extraction agent, and extracting isopropanol and water in sequence after the raw material goes through an extractive distillation stage and an extraction agent recycle stage, wherein the extraction agent is used circularly after being extracted in the recycle stage. The method has the advantages that the energy consumption is low, environment pollution can be avoided, the product purity is high, the industrialization is facilitated, the equipment cost is low, and the economic benefit is good.

Owner:TIANJIN CLEANTECH TECH

Preparation method of ultrahigh-purity and superfine aluminium oxide powder

The invention relates to a preparation method of ultrahigh-purity and superfine alumina powder. The preparation method comprises the following process steps of: (1) injecting a high-purity aluminium sheet, isopropanol and a catalyst into a synthetic reaction tower to generate gaseous aluminium isopropoxide; cooling gaseous aluminium isopropoxide into liquid aluminium isopropoxide by virtue of a condenser; (2) injecting liquid aluminium isopropoxide into a reduced pressure distillation purification tank for evaporating to form steam, injecting the steam to a material receiving tank to become liquid ultrahigh-purity aluminium isopropoxide; (3) adding ultrahigh-purity aluminium isopropoxide into a vacuum stirring and drying machine, injecting high-purity water, and carrying out hydrolysis reaction under the circulating water cooling condition, so as to obtain ultrahigh-purity aluminium hydroxide and isopropanol aqueous solution; and drying in a vacuum stirring and drying machine; and (4) placing ultrahigh-purity aluminium hydroxide powder into a corundum crucible, and calcining in an electrically pushed slab kiln until the aluminium hydroxide powder is changed into alpha-Al2O3 powder, thus preparation is completed.

Owner:DALIAN HILAND PHOTOELECTRIC MATERIAL

High-efficiency environment protection acidic color fixing agent and manufacture method thereof

InactiveCN101245563ARaw material environmental protectionWill not affect healthDyeing processMeth-Hazardous substance

The invention relates to an effective environment protective acid fixing agent that is prepared by a polypropylene acid fixing agent, an addition agent and a solvent which are matched. The polypropylene acid fixing agent is prepared by the following steps: mixing isopropanol, methacrylic acid, 2-acrylamido-2-methylpropane sulfoacid, acrylic acid and sodium persulfate in deionized water to be reacted for 1 to 5 hours at 80 to 90 DEG C and acquiring a reaction product, namely, the polypropylene acid fixing agent by post treatment. The preparation method of the effective environment protective acid fixing agent includes: adding proper water, adding all the materials under the condition of stirring at 40 to 50 DEG C in sequence to be mixed for 2 to 3 hours, uniformly dissolving, filtering, discharging and controlling the pH to be 6 to 7. The materials of the invention are environment-protective, can reduce the treatment cost of waste water and can generate remarkable social and economic benefits.

Owner:杭州下沙恒升化工有限公司

Alkali-free liquid concrete setting accelerator and preparation method thereof

The invention relates to an alkali-free liquid concrete setting accelerator and a preparation method thereof. The alkali-free liquid concrete setting accelerator is prepared from the following components in parts by mass: 30 to 60 parts of polyaluminium sulfate, 5 to 20 parts of magnesium sulfate, 5 to 10 parts of calcium formate, 1.0 to 3.5 parts of methylcellulose, 0.8 to 1.5 parts of polyacrylamide, 0.2 to 1.0 part of organic acid, 1 to 3 parts of triisopropanolamine, 0.15-1.08 parts of defoaming agent, 0.5-2.5 parts of hydrofluoric acid, 2 to 6 parts of aluminum hydroxide, 0.5-1.5 parts of 85%-concentration phosphoric acid and 30 to 50 parts of water. The alkali-free liquid concrete setting accelerator has the beneficial effects that the alkali-free liquid concrete setting accelerator provided by the invention does not contain alkali metal ions, and is free of corrosion and pungent smell, stable in quality, good in adaptability, low in mixing amount, high in condensation speed and high in strength.

Owner:GUANGZHOU DAGUANG EXPRESSWAY CO LTD

Trimethylcyclohexenylcyclopropyl ketones perfume composition

InactiveUS6051548ANeed can be quite largeCosmetic preparationsOrganic compound preparationPropionateAcetic acid

Described are trimethylcyclohexenylcyclopropyl ketones having the structure: wherein one of the dashed lines is a carbon-carbon double bond and the other of the dashed lines is a carbon-carbon single bond, uses thereof in augmenting, enhancing or imparting aromas in or to perfume compositions, colognes and perfumed articles, and mixtures of same with 3-methyl-1-phenylpentanol-5 and / or butanoylcyclohexane derivatives and / or acetic or propionic acid esters of o-methylphenyl isopropanol.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

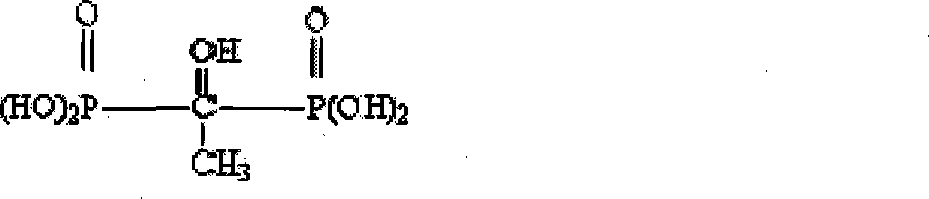

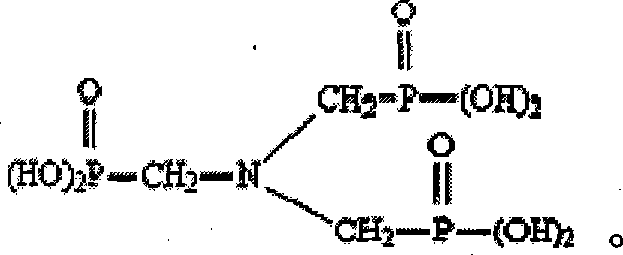

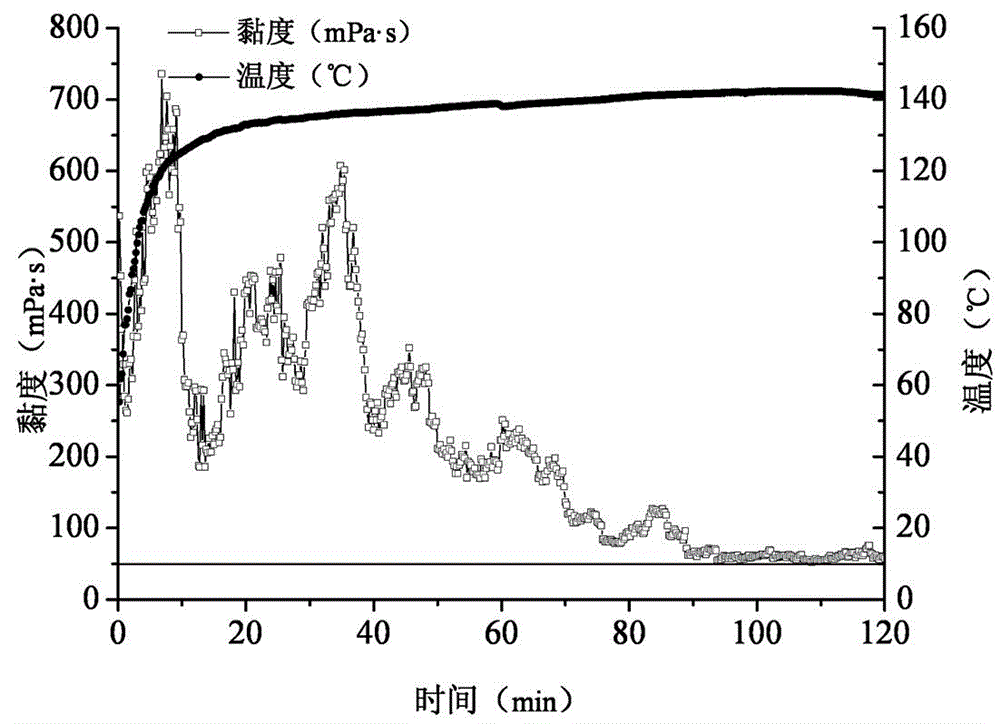

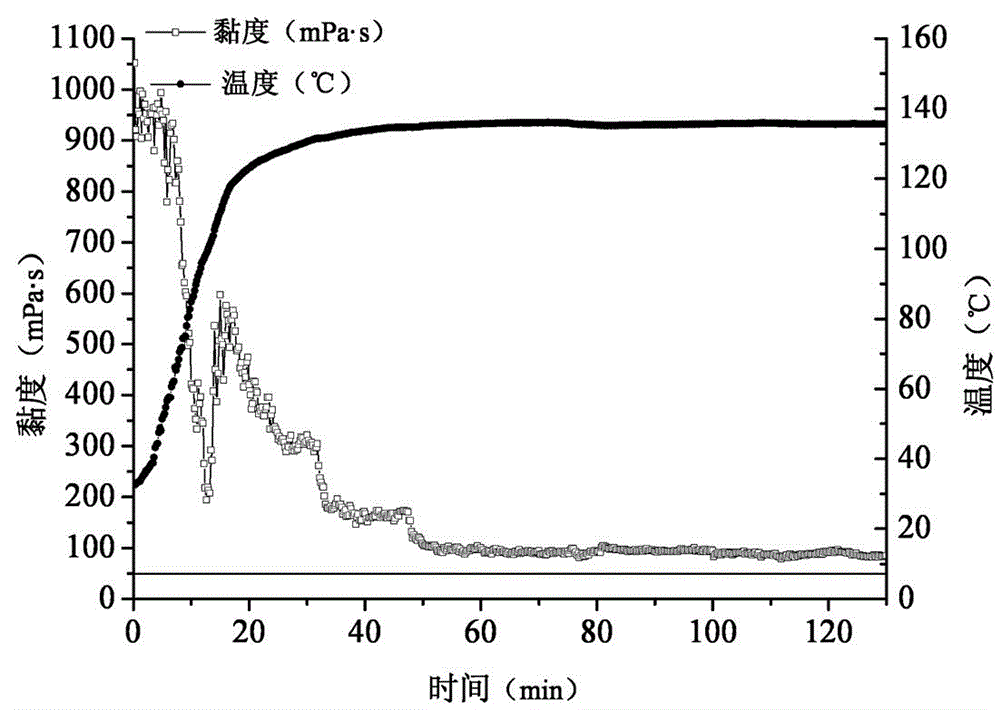

Organic boron-zirconium cross-linking agent and preparation method thereof

InactiveCN104447831AGood effectSave energyGroup 4/14 element organic compoundsDrilling compositionPolyolAlcohol

The invention provides an organic boron-zirconium cross-linking agent and a preparation method thereof, and belongs to the technical field of oilfield fracturing fluids. The invention provides a preparation method of an organic boron-zirconium cross-linking agent, and the preparation method is used for solving the problems of expensive selected raw materials, strict preparation conditions, cumbersome preparation procedures and the like of the existing organic boron-zirconium cross-linking agent during preparation. The preparation method comprises the following steps: adding inorganic zirconium salt and isopropanol in water, uniformly stirring, then introducing ammonia gas and carrying out a reflux reaction at 55-60 DEG C for 0.5-1 hour; then adding polyhydric alcohols, alpha-hydroxyl sodium carboxylate and alkanolamine, continuing to react for 2-4 hours, then adding the boron solution prepared from an inorganic boron compound and methanol, and continuing to react for 2-4 hours, thereby obtaining the organic boron-zirconium cross-linking agent. The preparation method provided by the invention is moderate and easily controllable in preparation conditions, and simple in preparation process and easy to operate; the organic boron-zirconium cross-linking agent prepared by the method is applied to a high-temperature-resistant fracturing fluid system, and the formed gel has good temperature resistance and shear resistance at a high temperature above 135 DEG C.

Owner:SOUTHWEST PETROLEUM UNIV

Environment-friendly, high-efficient and composite liquid cement grinding aid and preparation method thereof

The invention relates to an environment-friendly, high-efficient and composite liquid cement grinding aid and a preparation method thereof. The grinding aid is prepared from following materials: 1-20 parts of triethanolamine, 1-20 parts of triisopropanolamine, 10-20 parts of glycerol, 10-20 parts of molasses, 2-8 parts of propylene glycol, 3-6 parts of sodium tripolyphosphate, 3-8 parts of sodiumhexametaphosphate and 30-50 parts of water. The grinding aid of the invention has low toxicity, does not volatilize and has stable source, sufficient supply, simple processing and preparation and lowcost; the indexes meet standard requirement of JC / T667-2004 Cement Grinding Aid; after the cement is doped, the distribution and shape of the separated particles can be improved and no bad influence for cement quality exists; the yield and quality of the cement are good. The performance is stable, the price is low and the performance cost ratio is high. The adaptability is wide, the doping quantity is low, the grinding effect is improved, the free calcium oxide in the cement is reduced, and the early strength and long-term strength of the cement are improved.

Owner:SHENYANG JIANZHU UNIVERSITY

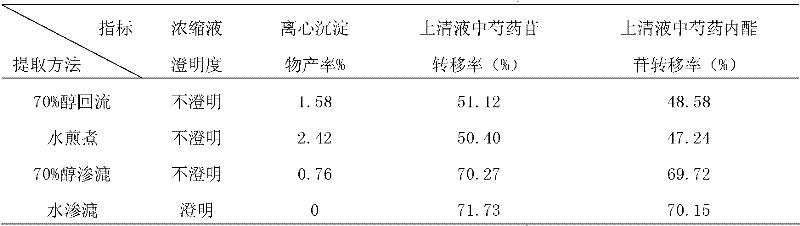

The preparation method of total paeoniflorin

ActiveCN102258588ALow costHigh extraction rateNervous disorderAntipyreticPropanolGlycoside formation

The invention provides a preparation method of peony general glycoside, which comprises the following steps: soaking radix paeoniae alba or red paeonia in 2-10 times (weight) of hydrophilic solvent, wherein the hydrophilic solvent is water or a water solution containing less than 30% of methanol, ethanol, propanol and isopropanol; after soaking, percolating at low temperature of 5-40 DEG C; and concentrating the percolate, filtering to obtain the extracting solution, and passing the extracting solution through macroporous resin. The transfer rate of penoniflorin and peony Albiflorin is 85-90%, and the purity of the peony general glycoside extract is high.

Owner:北京采瑞医药科技研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com