Process for extracting litchi polyphenol from litchi

A technology of litchi polyphenols and litchi, applied in the field of preparation of litchi extract, to achieve the effect of improving production technology, high content and shortening production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

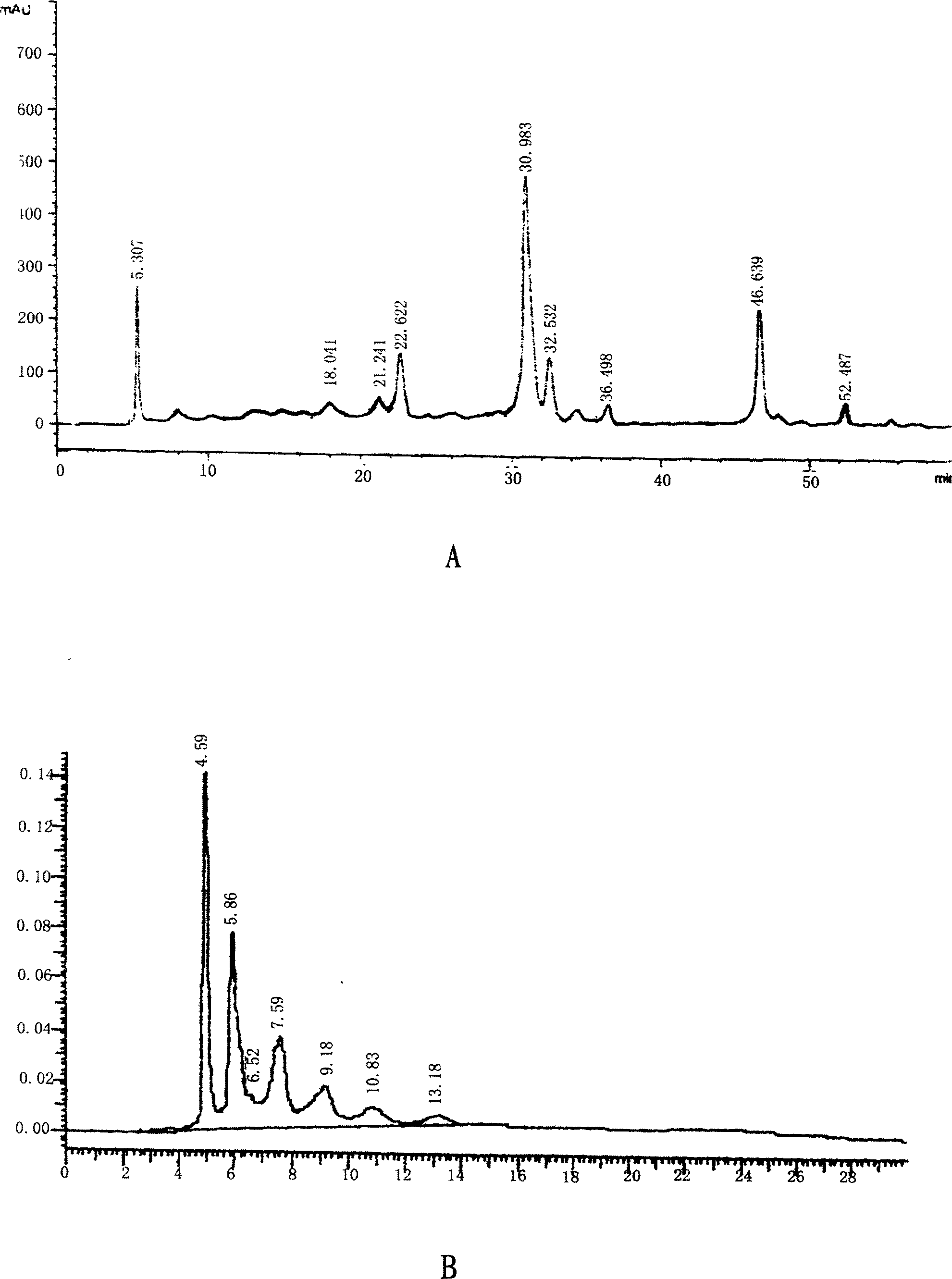

Image

Examples

Embodiment 1

[0095] 1) Pre-treatment: crushing litchi cores after sorting and removing impurities;

[0096] 2) Extraction: Mix the raw materials and deionized water in a ratio of 1:3 and put them into the extraction tank, heat to boil and keep the temperature for 2 hours, collect the first extraction material liquid, and add 3 times the amount of deionized water for the second extraction water, heat to boil and keep warm for 2 hours, and collect the second extraction material liquid.

[0097] 3) Concentration under reduced pressure: the extract is introduced into a concentrator for concentration under reduced pressure, the temperature is controlled below 60° C., and the degree of vacuum is controlled above 0.06 MPa.

[0098] 4) Centrifugation: the concentrated extract is centrifuged by a centrifuge.

[0099] 5) The concentrated and centrifuged extract directly enters the macroporous resin column;

[0100] 6) Wash the column with water until the effluent is clear;

[0101] 7) Wash the co...

Embodiment 2

[0106] 1) Pretreatment: crush the lychee skin.

[0107] 2) Extraction: Put qualified raw materials into a clean extraction tank, add 5 times the amount of 65% (v / v) ethanol, and reflux for the first 3 hours of extraction, count from the boiling of the solvent, control the temperature at 80°C, and keep warm until the time is up. Squeeze out the liquid medicine, then add 3 times the amount of 65% (v / v) ethanol for reflux extraction for 2 hours for the second time, and combine the filtrates;

[0108] 3) Recover ethanol: pump the extracted medicinal solution into a concentration tank for concentration under reduced pressure and recover ethanol, the temperature is controlled below 60°C, and the vacuum degree is controlled above 0.06Mpa. After recovering until there is no alcohol smell, the medicine is hydraulically injected into the liquid storage tank;

[0109] 4) Add water, let it stand, and cool it down: the ratio of the medicinal solution to the raw material for recovering eth...

Embodiment 3

[0117] 1) Pre-treatment: mixing and pulverizing litchi skin and litchi core after picking and removing impurities;

[0118] 2) Extraction: Mix qualified raw materials with ethanol with a weight concentration of 70% in a ratio of 1:10, and perform ultrasonic extraction. The extraction conditions are working frequency 60kHz, time 90min, and extraction 2 times;

[0119] 3) Recovery of propanol: pump the extracted medicinal solution into a concentration tank for concentration under reduced pressure and recovery of propanol. The temperature is controlled below 60°C and the vacuum degree is controlled above 0.06Mpa. After recovering until there is no alcohol smell, the medicine is hydraulically injected into the liquid storage tank;

[0120] 4) Add water, let it stand, and cool it down: the ratio of the medicinal solution to the raw material for recovering propanol should be controlled at about 1:3, if it is not enough, add water, let it stand still, and cool it down;

[0121] 5) C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com