Pueraria powder and preparation method thereof

A technology of pueraria powder and ultra-fine pulverization, which is used in food preparation, ultra-high pressure food processing, food drying, etc., can solve the problem of waste of effective components of pueraria, maintain nutritional value, ensure hygiene and safety, and improve extraction rate and utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

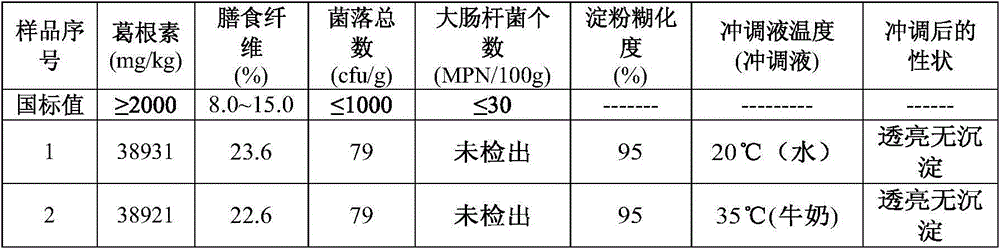

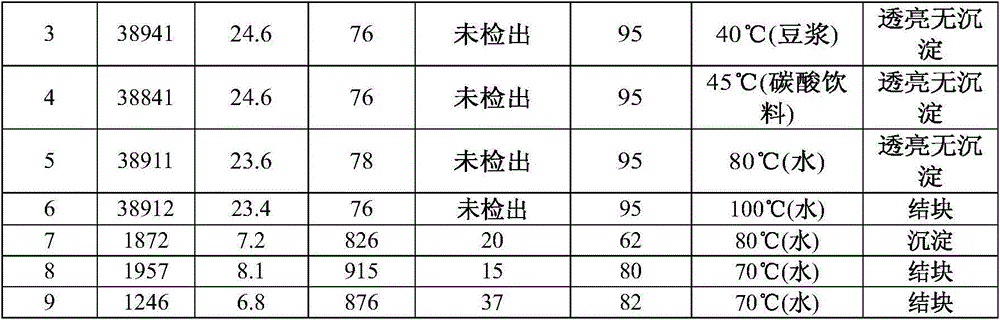

Examples

Embodiment 1

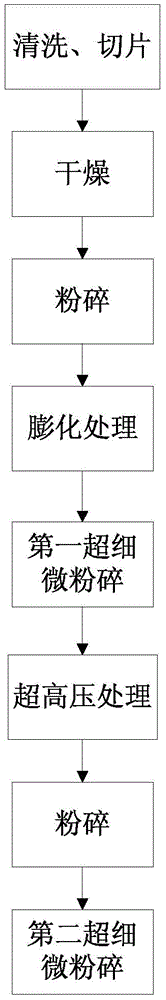

[0039] see figure 1 , slice after cleaning the sediment on the kudzu root, keep the thickness uniform in the process of slicing, the dehydration drying temperature is 80 ℃, the drying time is 90 minutes, and the raw materials are crushed and passed through an 80-mesh sieve.

[0040] The undersize was extruded and puffed by using a screw extruder at a temperature of 95°C, with a feed water content of 2% and a screw speed of 150r / min to obtain puffed materials.

[0041] The crushing time of the puffed material is 30 minutes, the crushing temperature is -20°C; the moisture content of the feed is less than 2%; the particle size of the sample is larger than 20 mesh, and the first ultra-fine crushing is carried out to 800-1000 mesh, and the material is packed in polyethylene plastic bags. After evacuating the double-layer packaging, carry out ultra-high pressure treatment, the ultra-high pressure treatment pressure is 300MPa, the pressure holding time is 30 minutes, the transmission...

Embodiment 2

[0043] see figure 1 , slice after cleaning the silt on the kudzu root, keep the thickness uniform in the process of slicing, the temperature of dehydration and drying is 75 ℃, the drying time is 90 minutes, and the raw materials are crushed and passed through an 80-mesh sieve.

[0044] The undersize was extruded and puffed by using a screw extruder at a temperature of 80°C, with a feed water content of 3% and a screw speed of 200r / min to obtain puffed materials.

[0045] The crushing time of the puffed material is 30 minutes, the crushing temperature is -20°C; the moisture content of the feed is less than 2%; the particle size of the sample is larger than 20 mesh, and the first ultra-fine crushing is carried out to 800-1000 mesh, and the material is packed in polyethylene plastic bags. After evacuating the double-layer packaging, carry out ultra-high pressure treatment, the ultra-high pressure treatment pressure is 600MPa, the pressure holding time is 15 minutes, the transmiss...

Embodiment 3

[0047] see figure 1 , after cleaning the sediment on the kudzu root, slice it, and keep the thickness uniform during the slice process. The gradient drying conditions are: drying at 30°C for 30 minutes; drying at 60°C for 20 minutes; drying at 80°C for 2 hours. Raw materials are crushed and passed through a 80-mesh sieve.

[0048] The undersize was subjected to extrusion and puffing treatment by using a screw extruder at a temperature of 90° C., a feed water content of 4%, and a screw speed of 170 r / min to obtain puffed materials.

[0049] The crushing time of the puffed material is 30 minutes, the crushing temperature is -20°C; the moisture content of the feed is less than 2%; the particle size of the sample is larger than 20 mesh, and the first ultra-fine crushing is carried out to 800-1000 mesh, and the material is packed in polyethylene plastic bags. After vacuuming the double-layer packaging, carry out ultra-high pressure treatment, the ultra-high pressure treatment pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| crush indicators | aaaaa | aaaaa |

| gelatinization degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com