Patents

Literature

142results about How to "Reduce microbial content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Freely-blended instant substitutional tea and making method thereof

InactiveCN106234712AReduce product volumeEasy to carryTea substituesUltrafiltrationHealth maintenance

The invention relates to freely-blended instant substitutional tea and a making method thereof. The substitutional tea is composed of one or more natural plant essences. A making method of the natural plant essences includes the following steps that S1, effective portions of natural plants are smashed to be 60-200 mesh, and water is added for soaking; S2, material liquid obtained in S1 is subjected to homogeneous wall-breaking extraction at the temperature of 30-55 DEG C, filtering for impurity removal is carried out, and filtrate is obtained for use; S3, the filtrate obtained in S2 is subjected to filtering separation sequentially through a micro-filtration membrane, an ultrafiltration membrane and a nanofiltration membrane, and effective ingredient enriched products are obtained; S4, the enriched products obtained in S3 are subjected to vacuum drying and smashed to be 50-100 mesh, and the natural plant essences are obtained. Each single plant of traditional substitutional tea is extracted into an instant powder product, the size of the products is effectively reduced, the products are conveniently carried by a customer, and the customer can freely blend the products according to the taste and health maintenance requirement of the customer.

Owner:GUANGDONG AUTHENTEA BIOTECH INC

Instant spice powder preparation method

InactiveCN108030053APreserve the active flavor componentsWith standardized productionFood scienceWater solubleEmbedding Agent

The invention relates to a seasoning preparation method, and especially relates to an instant spice powder preparation method. The method comprises the following steps: raw material preparation, dispersion, pre-emulsification, embedding, blending, and packaging; an oil dispersant, an emulsifier, an embedding agent, a carrier are added, resin essential oil of whole spice can be fully dispersed, andis processed to water-soluble oil powder. The preparation method has the advantages of simple technology and low cost, realizes instant dissolution of the spice in water, and cannot influence original taste of the spice.

Owner:洛阳味之泉调味技术有限公司

Preparation method of liquid acidic pectinase

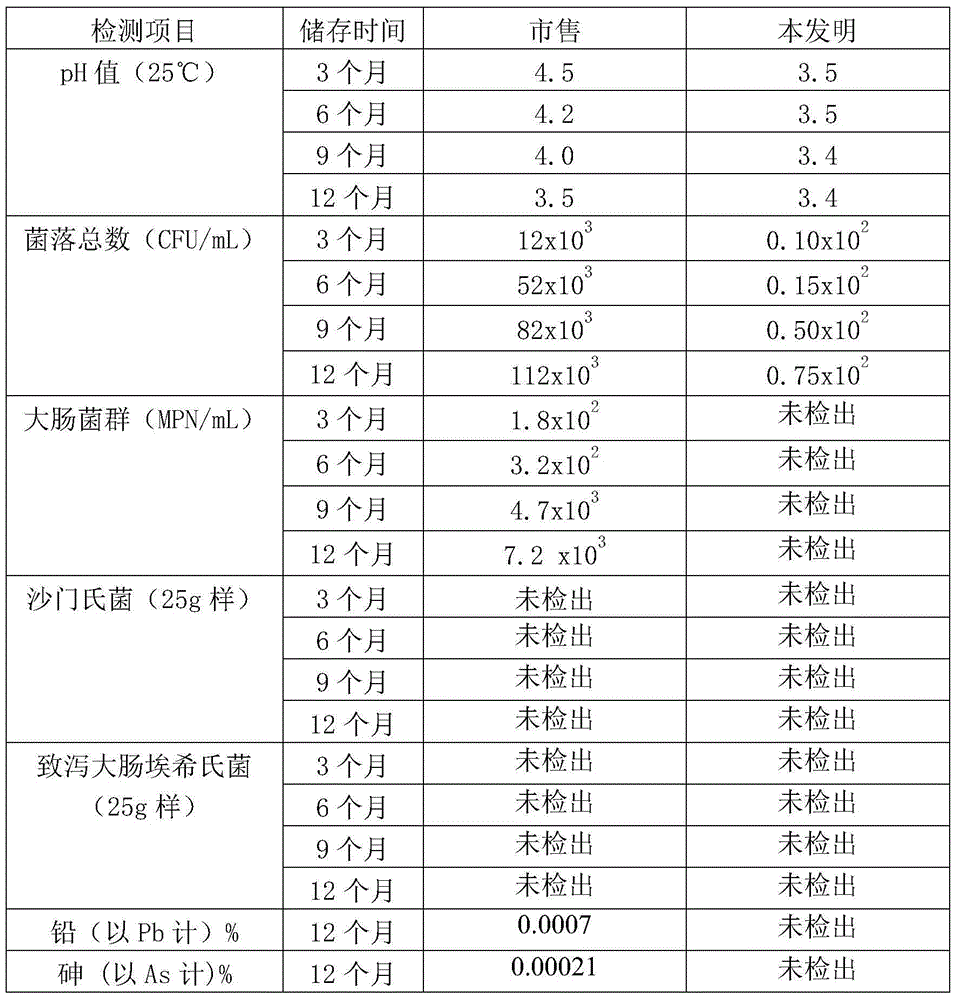

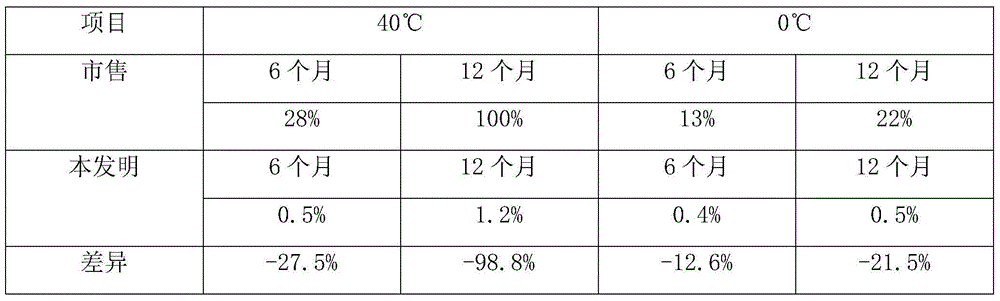

InactiveCN104531653AExtended shelf lifeGood antibacterial propertiesGlycosylasesLyasesPectinaseHigh pressure

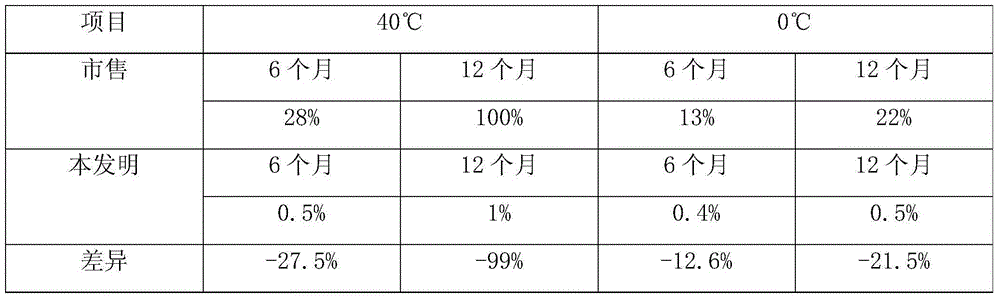

The invention discloses a preparation method of a liquid acidic pectinase, belonging to the technical field of enzyme preparations. The preparation method of the liquid acidic pectinase comprises the steps of treating a fermented crude enzyme solution and a blended concentrated solution at normal temperature by using a high-voltage pulsed electric field, and adding a pectin decomposer, a Chinese herb extract, modified dietary fibers and other natural plant raw materials in a blending process, wherein chemical preservatives do not need to be added, and low-temperature treatment is not needed; and then, degerming, filtering, and carrying out sterile filling to obtain the liquid acidic pectinase with stability and long shelf life. Experiments prove that the total bacterial count is 68-102CFU / mL if the liquid acidic pectinase prepared by using the preparation method is stored at room temperature for 12 months; and the enzyme activity loss ratios are respectively 1-1.4% and 0.5-1.1% if the liquid acidic pectinase is stored at 40 DEG C and 0 DEG C for 12 months. The preparation method is simple in process, convenient to operate, energy-saving and environment-friendly.

Owner:湖南新鸿鹰生物工程有限公司

Method used for preparing fresh rice noodles via rice dry milling method

InactiveCN103637061ASatisfy granularity requirementsReduce water consumptionFood mechanical treatmentFood shapingSlurryAnti ageing

The invention discloses a method used for preparing fresh rice noodles via rice dry milling method, and belongs to the field of rice deep processing. According to the method, fresh rice noodles are obtained via steps such as raw material cleaning, rice cleaning, texture adjusting, milling, slurry mixing, paste steaming, noodle extruding, water washing and cooling, sterilizing, anti-aging processing, and packaging. The method is capable of realizing water conservation and emission reduction in fresh rice noodle production processes, reducing product background microbial content, increasing product yield, reducing production cost, and obtaining products with excellent and stable quality. The method possesses significant importance for development of fresh rice noodle processing technology of our country and for scaled production of fresh rice noodle industry; and industrialization prospect of the method in future is promising.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Methods for treating skin conditions

InactiveUS20040131710A1Reduce microbial contentNot induce significant malodorCosmetic preparationsBiocideSynthetic retinoidSkin.status

This invention relates to methods and compositions for treating and ameliorating skin conditions including acne, rosacea and wrinkling caused by photodamage or intrinsic aging. More particularly, this invention relates to compositions containing certain natural extracts and natural or synthetic retinoids.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

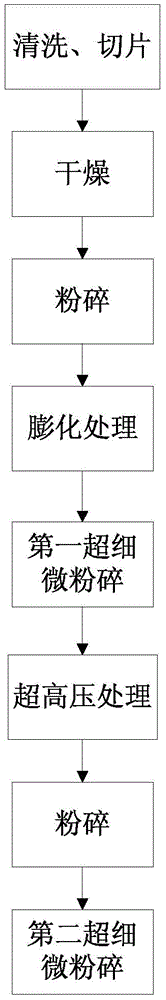

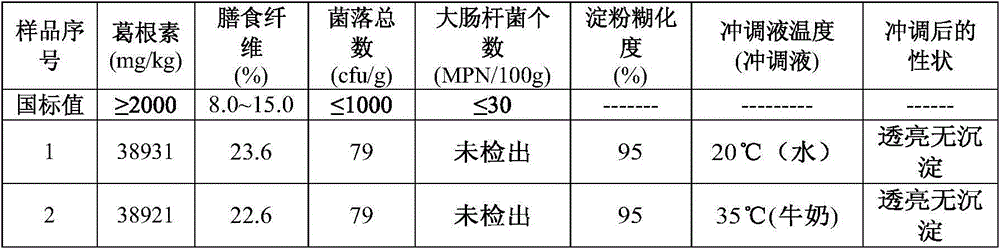

Pueraria powder and preparation method thereof

InactiveCN104026512AHigh extraction rateIncrease profitUltra high pressure food processesFood dryingUltra high pressureDietary fiber

The invention provides pueraria powder and a preparation method thereof. Puffing treatment, first super fine crushing and ultra-high pressure treatment are performed on pueraria raw materials to obtain the pueraria powder, wherein the ultra-high pressure treatment condition includes that pressure is 300-600 MPa, pressure holding time is 15-30 minutes, and a pressure transferring medium is water at room temperature. The content of puerarin in the obtained pueraria powder can reach 38941mg / kg, the content of dietary fibers is 24.6%, and the pueraria powder is not caked at the brewing temperature of 20-100 DEG C.

Owner:WUGANG HEXIN AGRI PROD

Superhigh-pressure fresh keeping method for fresh rosa roxburghii

InactiveCN105360277AReduce inactivationReduce impact qualityFruit and vegetables preservationReverse osmosisRosa roxburghii fruit

The invention discloses a superhigh-pressure fresh keeping method for fresh rosa roxburghii. The superhigh-pressure fresh keeping method comprises the following steps of cleaning the rosa roxburghii: cleaning the rosa roxburghii with ultrasound high-pressure water cleaning equipment for 15-25 minutes; removing stabs of the rosa roxburghii: removing the external stabs of the rosa roxburghii fruits with a rotary mill; weighing the rosa roxburghii and loading the rosa roxburghii in bags: based on the unit of 3-8 kilograms of the rosa roxburghii in each bag, loading the rosa roxburghii in HDPE bags; injecting water for vacuum sealing: injecting reverse osmosis water to the HDPE bags loaded with the rosa roxburghii, and performing vacuum sealing to form rosa roxburghii water bags; using a superhigh-pressure processing technique, putting the rosa roxburghii water bags in a processing container of a high-pressure processing machine, and applying stationary liquid pressure of 100-800MPa, wherein the processing time is 5-10 minutes; and taking out the processed rosa roxburghii water bags, and preserving the rosa roxburghii water bags under normal atmospheric temperature. According to the superhigh-pressure fresh keeping method disclosed by the invention, the original flavor and the nutrient value can be maintained, the refrigeration and circulation shelf life can be prolonged, and the superhigh-pressure fresh keeping method has the same food safety grade as a conventional thermization method, and maintains the characteristics of flavor and the like.

Owner:贵州华南理工生物工程有限公司

Method for treating coking biochemical effluent by microwave-oxidation-coagulation technology

ActiveCN101767912AReduce usageImprove processing efficiencyWater/sewage treatment by magnetic/electric fieldsMultistage water/sewage treatmentSludge cakeMicrowave oven

The invention provides a method for treating coking biochemical effluent by microwave-oxidation-coagulation technology, which comprises the following steps of: A, adding a mixed reagent consisting of H2O2 and Fe2+ into the coking biochemical effluent until the mass concentration of hydrogen peroxide in water is between 0.01 and 1 percent, and controlling the pH to between 2.0 to 6.0; B, delivering the mixed liquid into an industrial microwave oven for processing for 5 to 60s; C, regulating the pH value of the mixed liquid to between 6.0 and 6.5 or 7.5 and 8.5, and carrying out oxidation treatment for 1 to 4 hours under an aeration condition that the aeration rate is 10 to 40m<3> / h; D, adding a coagulant into the liquid until the mass concentration of the coagulant in the liquid is betweenone millionth and one hundred thousandth; E, precipitating and separating; F, filtrating the liquid to obtain process effluent for recycling; and G, collecting sludge, separating the liquid from the sludge; and returning the liquid to the step D, and filter-pressing the sludge to obtain sludge cakes. The method realizes recycling, does not discharge sewage, and effectively solves the problem thatpresent coking sewage is difficult to treat and to recycle.

Owner:云南天朗环境科技有限公司

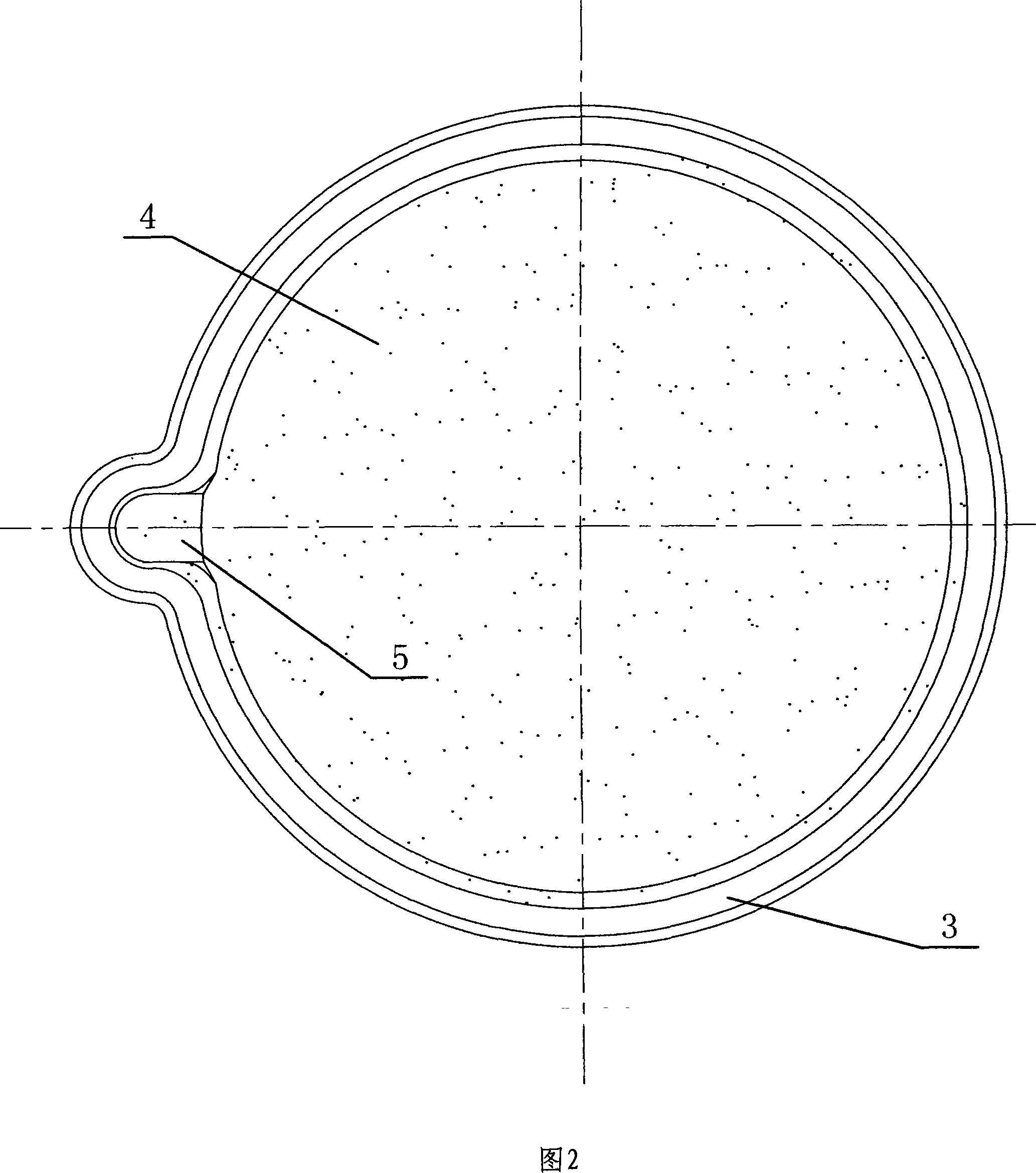

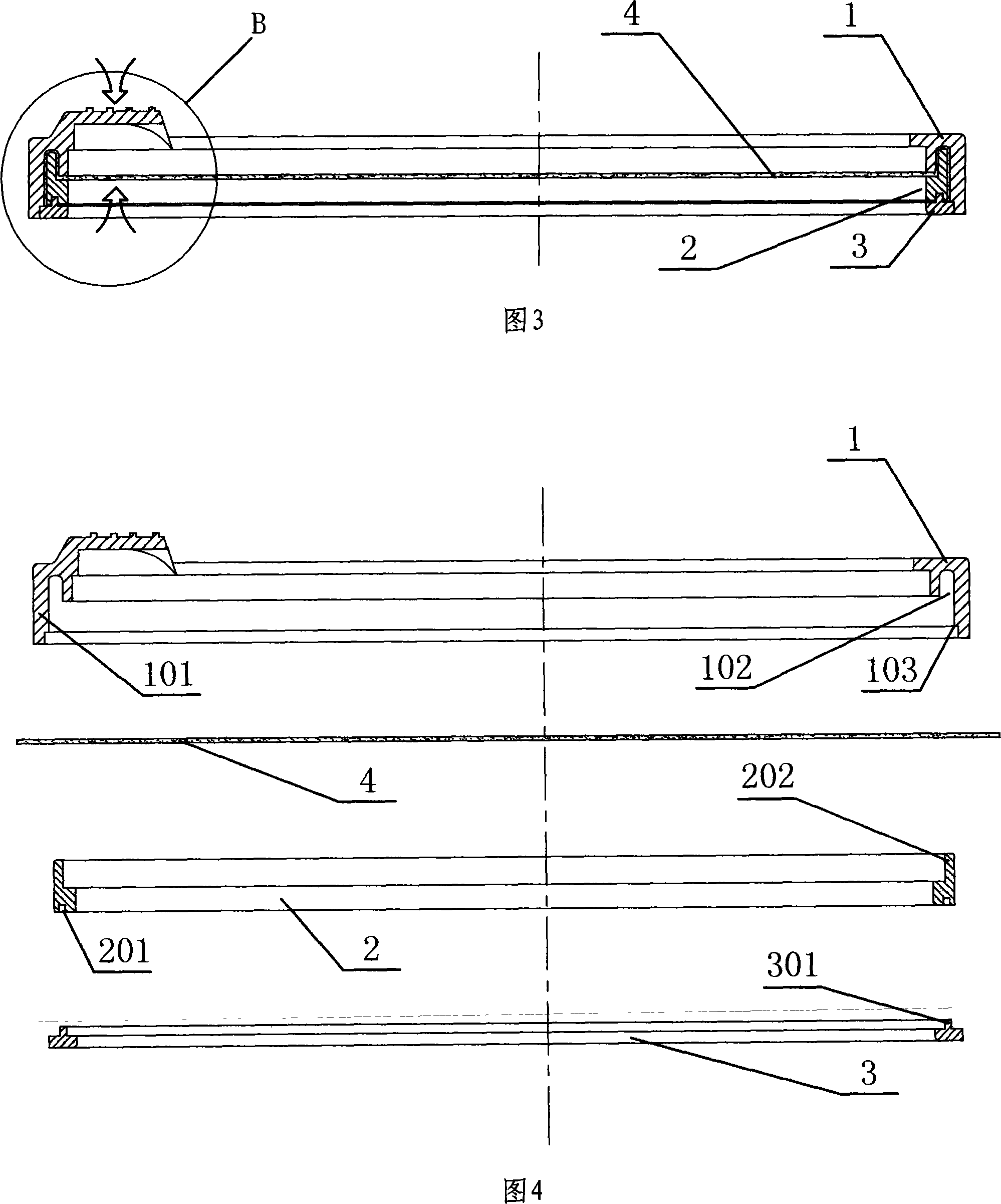

Vacuum 000 storage method and fresh-keeping cover thereby

InactiveCN101234681AEffective headroomSo as not to damageClosuresPackaging under vacuum/special atmosphereSocial benefitsPolyurethane membrane

The invention discloses a vacuum storage method and a refreshing cover thereof. The method includes the following steps: a polyurethane membrane fixed at a frame is covered on a container opening, pinched inward and then released; as the membrane recovers the plane state, the inside of the container generates relative vacuum to reach the effect of enclosed vacuum refreshing. At the same time, the invention also discloses the refreshing cover, consisting of a cover surface and a circular frame, wherein, the cover surface is the polyurethane membrane fixedly arranged on the frame which is provided with a handle for opening the cover protruding out from an outer circumference. The invention provides a device adopting a high-elasticity plastic membrane with a fixed frame and a locking mechanism and a vacuum refreshing method, which greatly prolong the time of corruption and degeneration of food; at the same time, compared with the conventional method and device, the invention is more convenient and effective and has the advantages of stable and reliable work, low manufacture cost, and high economic and social benefits. The invention is applied to the objects and the packaging methods requiring vacuum storage such as medical instruments, drugs, etc.

Owner:SHANGHAI MUYE TRADING

Rapid fermentation process for preparing fermented soybeans by pure strains

ActiveCN101984853AControllable formationShorten fermentation timeFood preparationVegetable oilSoybean product

The invention provides a rapid fermentation process for preparing fermented soybeans by pure strains, which comprises the following steps: cooking and curing the soaked soybeans with a water level higher than the soaked beans; inoculating the pure mucor strains after intermediate culture; fermenting at constant temperature and humidity for 48-72 hours to obtain mucor blank; adding salt and slicedginger; compacting, sealing and fermenting in the case of voidage being less than 5%; dehydrating with circulating hot air; frying with vegetable oil at the temperature of 170-190 DEG C for 30-50 seconds; mixing with blending materials timely; hot-filling at 85-90 DEG C; pressing tightly so that the oil level is 1-1.5cm higher than the surface of the beans; and carrying out vacuum sealing to finally obtain the instant fermented soybeans after being cooled. The process provided by the invention has the advantages of scientific process design, short process cycle, good color stability, continuous industrial production, controllable process, stable quality and no addition of preservative and anti-staling agent and color fixative, and can obtain the fermented soybeans which are significantly different from the products of other types, thus providing a feasible method for safely and conveniently producing fermented soybean products.

Owner:HUNAN AGRICULTURAL UNIV

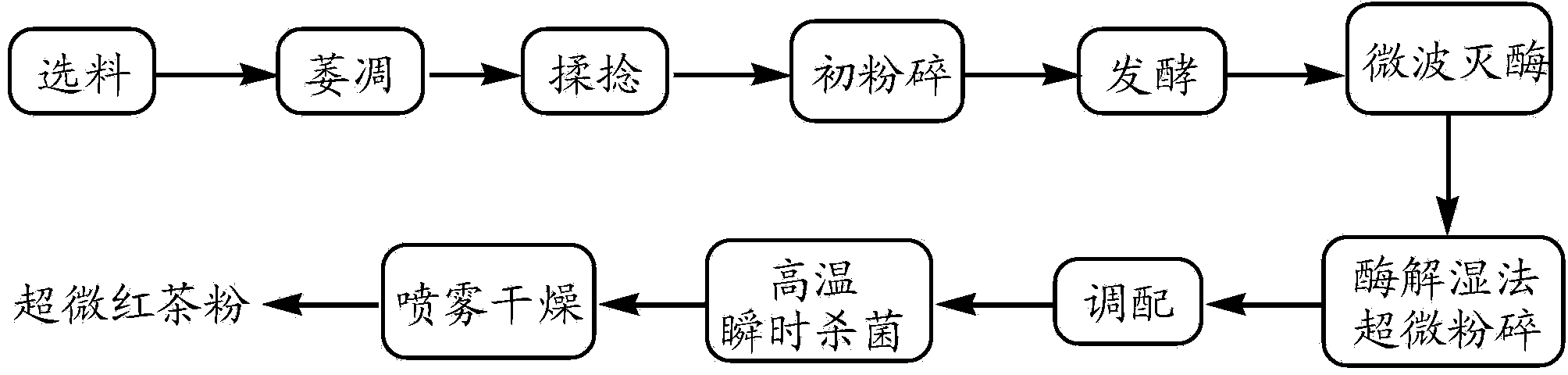

Method for preparing ultrafine black tea powder by wet-process grinding

ActiveCN104322724ALarge specific surface areaGood colorPre-extraction tea treatmentTea extractionMicrowaveAdditive ingredient

The invention provides a method for preparing ultrafine black tea powder by wet-process grinding. The method comprises the following steps: withering, rolling and primarily grinding fresh tea leaves and then fermenting; carrying out microwave enzyme deactivation to keep primarily-formed tea powder color and luster, and aroma of the tea leaves; mixing the cooled primarily-grinded leaves with a cellulase-pectase solution to prepare a tea water mixed liquid; grinding the tea water mixed liquid for 2-3 times at intervals by using a pipeline type high-shearing grinding machine; carrying out beta-CD burying on the crushed tea pulp; and then carrying out high-temperature instant sterilization, and spraying and drying to obtain the ultrafine black tea powder. The method for preparing the ultrafine black tea powder has low energy consumption and small noises; and the prepared ultrafine black tea powder has less loss of nutrition ingredients, fine powder, good color and luster, good wettability and excellent mouth feel.

Owner:SHENBAO INDAL CORP SHENZHEN

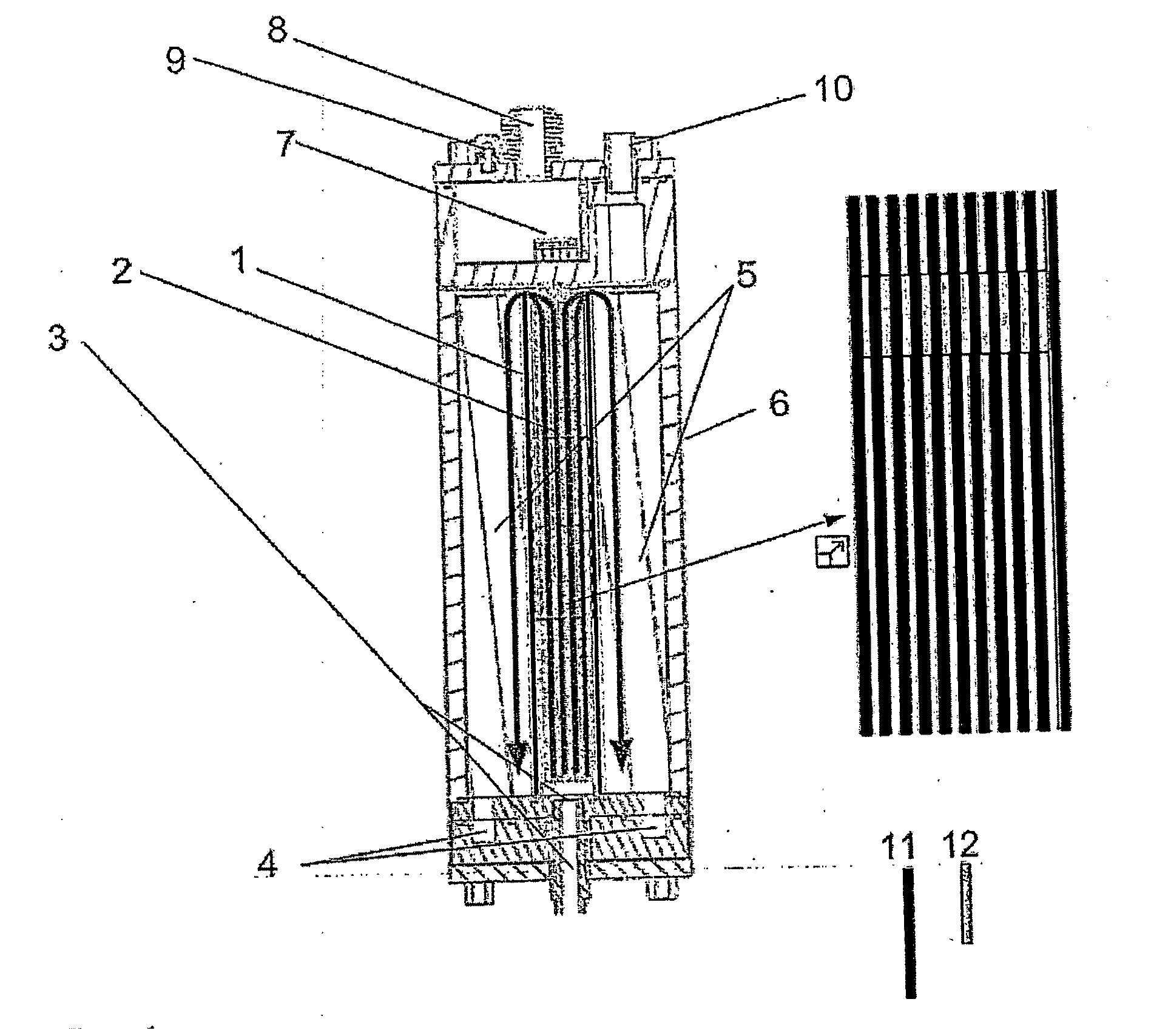

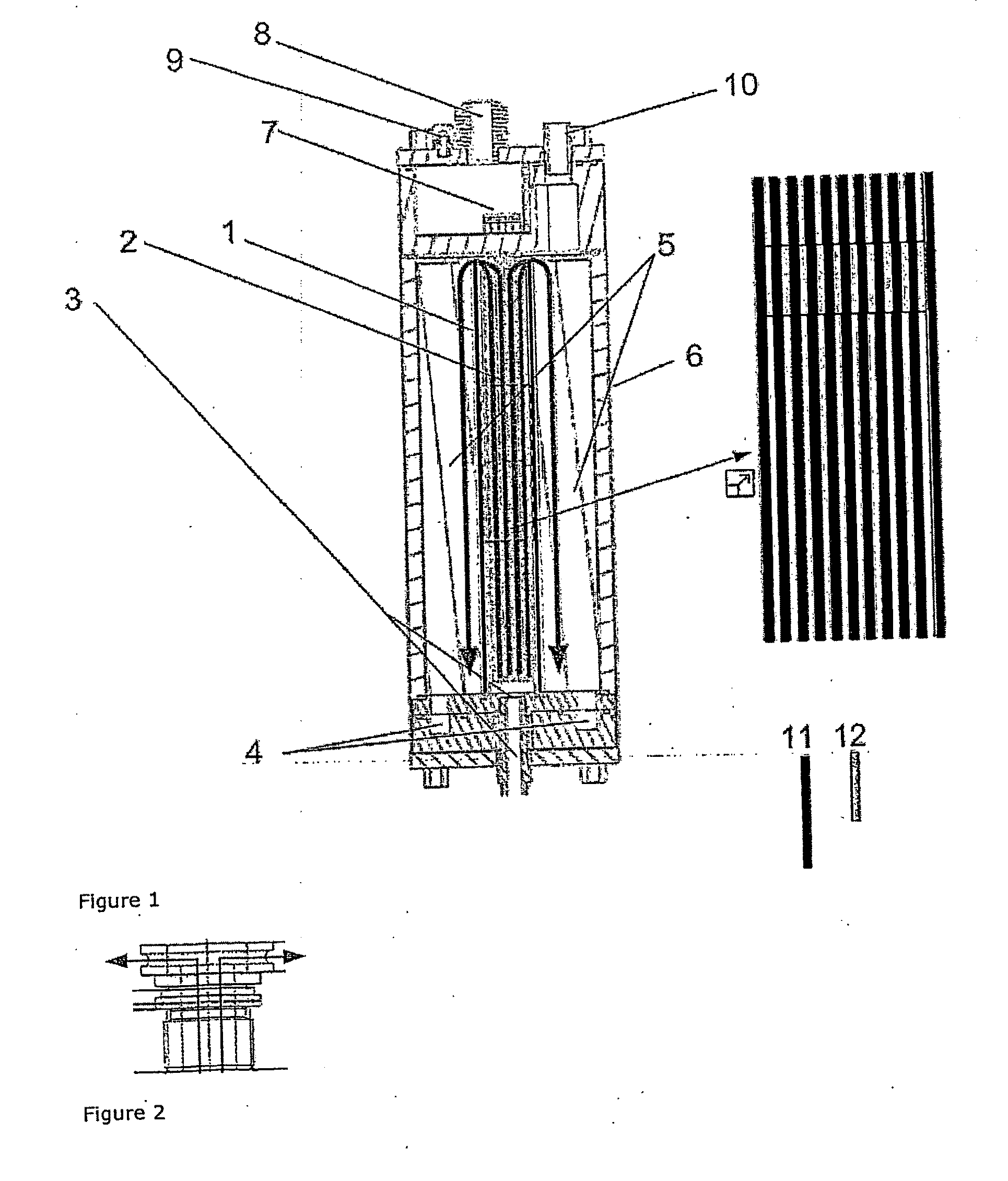

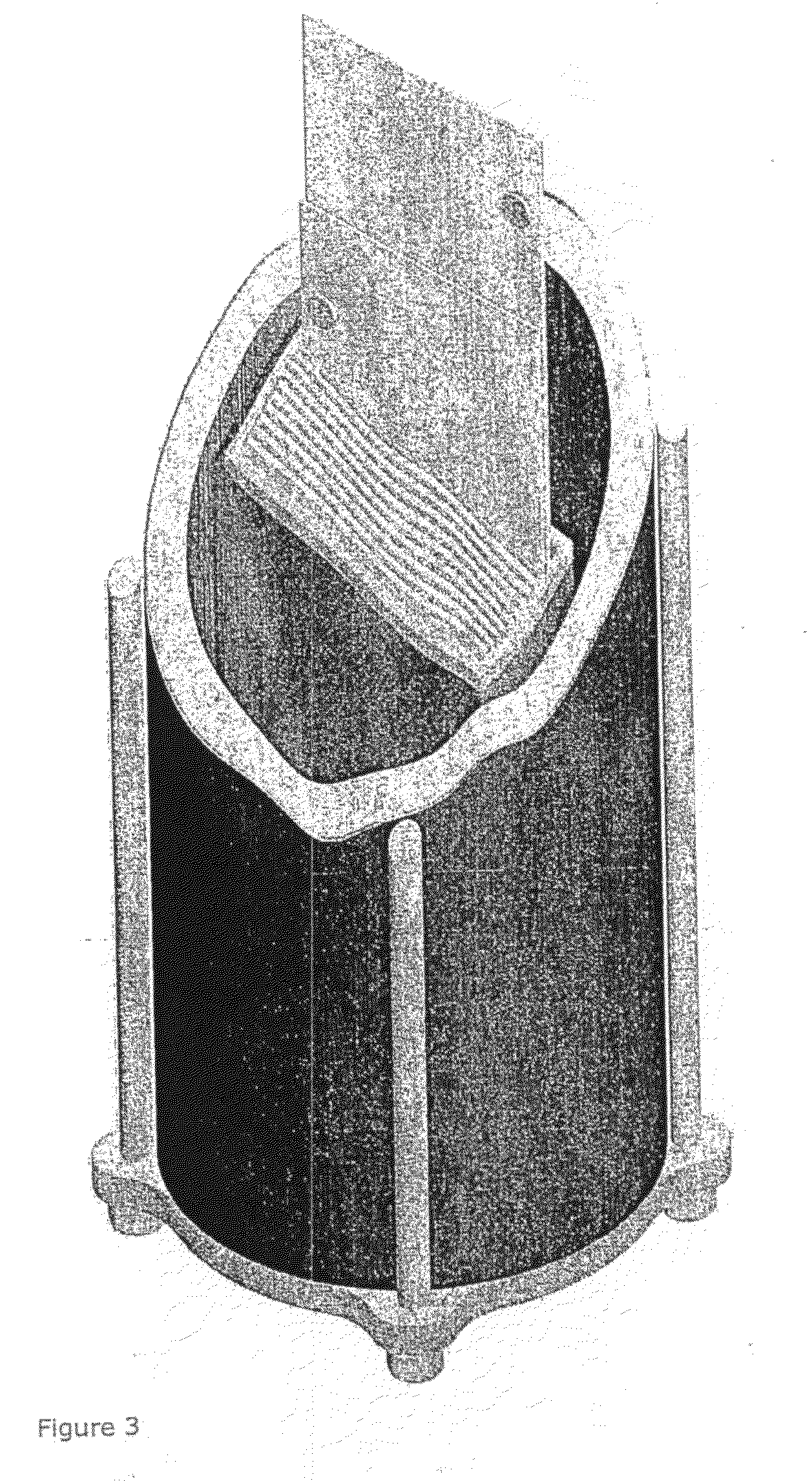

Device and process for removing microbial impurities in water based liquids as well as the use of the device

InactiveUS20110198300A1Effective disinfectionImprove efficiencyCellsWater treatment parameter controlWater basedWastewater

The present invention relates to the technical filed of electrochemical elimination or reduction of microbial impurities of liquids. The liquids treated may inter alia include wastewater, industrial process water and water intended for human consumption. The device comprises a disinfection chamber connected through a liquid inlet located in the bottom of a base area by a manifold; an inner chamber housing an electrode stack comprising at least two perforated electrode plates made of conductive material symmetrically placed at a distance of 1-5 mm connected in parallel via connector mounted at the chamber; said electrode plates being separated from each other and the chamber wall at a fixed distance by spacers, and arranged such that in perpendicular plane view 60-100% of the area of passage is covered by the electrodes; an outer chamber; an outer shell; a liquid outlet; connectors for wiring connecting the connector and one or more external power supply units, each of the above elements being designed such that said liquid has a forward velocity of 2-50 cm / s and an initial perpendicular velocity component above 10 cm / s and wherein further the current density is above 5 mA / cm2.

Owner:ADEPT WATER TECH

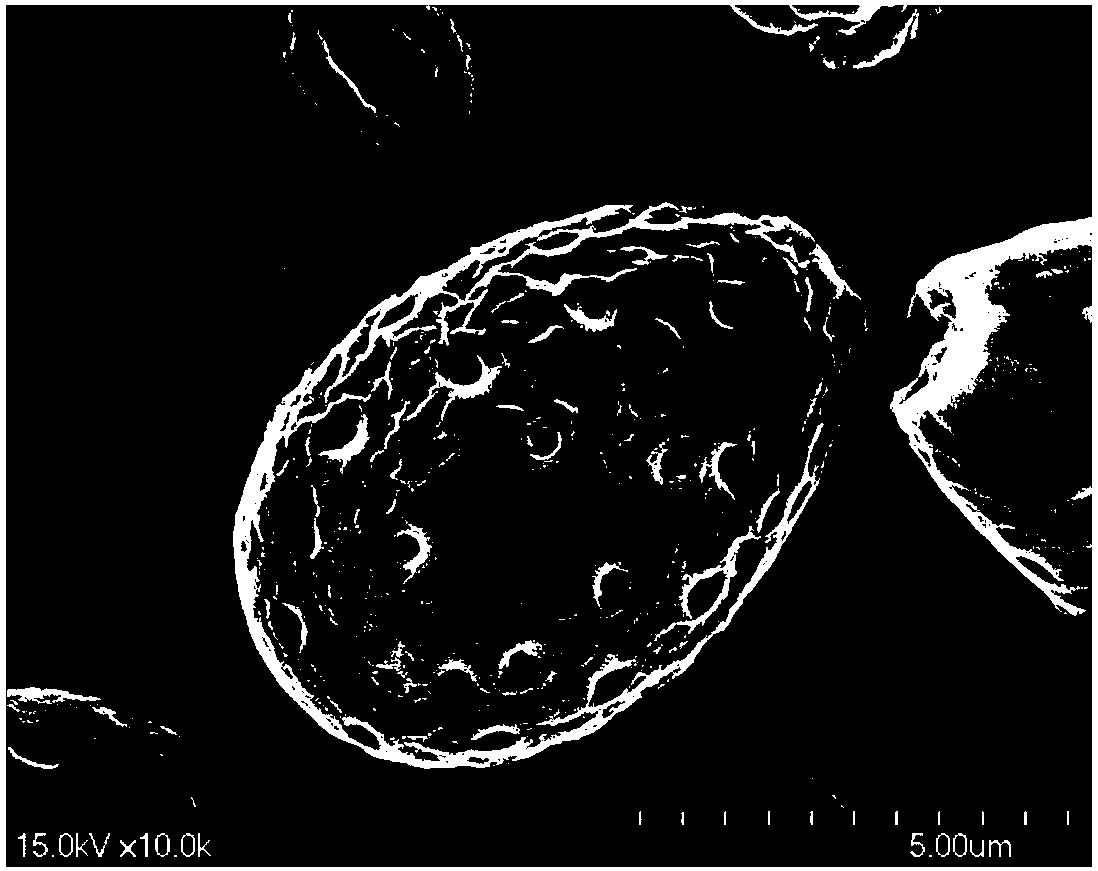

Bitter-taste ganoderma lucidum spore powder and preparation method thereof

ActiveCN107661360AEasy to enrichLess impuritiesOrganic active ingredientsFood ingredientsGanoderma lucidumChemistry

The invention provides a preparation method of bitter-taste ganoderma lucidum spore powder, relating to the field of medicines or health products. The preparation method comprises the steps of removing impurities from ganoderma lucidum spores, and carrying out ice-bath and heating extraction, microfiltration membrane filtration, drying sterilization and wall breakage, so as to obtain the ganodermalucidum spore powder. According to the preparation method, by combining repeated impurity removal, shrunken shell filtration and wall breakage after extraction, the content of bitter-taste substancesin the ganoderma lucidum spore powder are effectively increased; ganoderma lucidum total triterpene in the ganoderma lucidum spores is taken as a representative of the bitter-taste substances, and the content of the ganoderma lucidum total triterpene can reach 5%-8%; and meanwhile, the bitter-taste substances in the ganoderma lucidum spore powder can be increased, and the content of ganoderan canreach 6%-10%.

Owner:ZHEJIANG SHOUXIANGU PHARMA CO LTD +1

Preserving agent for salted yolk and processing method of salted yolk

The invention discloses a preserving agent for salted yolk and a processing method of the salted yolk. The preserving agent of the salted yolk consists of the following raw materials in parts by weight of 55-65 parts of salt, 80-85 parts of sodium alginate, 130-135 parts of sodium dihydrogen phosphate, 10-15 parts of Baijiu, and 1-2 parts of potassium sorbate. The processing method of the salted yolk is characterized by comprising the following steps of enabling the yolk to be immersed in the preserving agent, and performing preserving at 20-30 DEG for 48-72h; and placing the preserved yolk inthe place of 30-40 DEG C for 1-1.5h, taking out the baked yolk, uniformly applying the edible oil onto the taken yolk, placing the applied yolk in the pace of 45-55 DEG C for baking for 0.25-0.5h, and performing sterilizing, so that the salted yolk is obtained. According to the preserving agent disclosed by the invention, the probability that the surface of the salted yolk is cracked can be effectively reduced, the condition that salted yolk is stuck to form blocks can be avoided, and the yolk is beautiful and bright in color.

Owner:HUBEI SHENDAN HEALTHY FOOD

Freeze dried abelmoschus esculentus slice preparation method

InactiveCN104996934AReduce pesticide residuesReduce microbial contentFood ingredient as antioxidantSugar food ingredientsBiotechnologyAlkaline water

The present invention discloses a freeze dried abelmoschus esculentus slice preparation method, belonging to the technical field of food processing. The abelmoschus esculentus is used as raw materials; and then, the abelmoschus esculentus is selected, trimmed, and rinsed, is soaked in alkaline water and blanched in an alkaline hot water, is cooled and sliced, is mixed and stirred with sugar syrup, is frozen in stages, and is freeze-dried under vacuum, thereby obtaining the abelmoschus esculentus slices. The preparation method solves the long-standing technical problems of deformation, dull color and poor taste of conventional abelmoschus esculentus dehydrated products. With the application of low temperature freezing, drying and dehydrating processes, the obtained product can be directly consumed. At the same time, in order to preserve the natural green color of the abelmoschus esculentus, the abelmoschus esculentus is soaked, washed, blanched and de-enzymed with the alkaline solution; the natural reductive sugar syrup is added; and the slow freezing technology is applied. Thus, the obtained product maintains the natural color and luster, shape and smell to a largest degree. Moreover, the freeze dried abelmoschus esculentus slice preparation method is suitable for a large-scale industrial production.

Owner:FUJIAN MINZHONG ORGANIC FOOD

Production process for microorganism control of soy sauce powder

ActiveCN111317121AAdd flavorGreat tasteFood thermal treatmentAcidic food ingredientsBiotechnologyMicroorganism

The invention discloses a production process for microorganism control of soy sauce powder. The production process is characterized in that a proper embedding material and different addition proportions are selected, and meanwhile, sterilization and aroma enhancement are carried out in combination with different acidification pH; the embedding material and the rest auxiliary materials required bya formula are stirred, mixed and heated for reaction in a reaction kettle according to the formula, and cooling is performed after the reaction; the cooled auxiliary materials and the acidized and sterilized soy sauce are dissolved and stirred uniformly, and a feed liquid is filtered and sterilized; the feed liquid is subjected to spray drying, and the inlet / outlet temperature of a spray-drying tower and the retention time of powder in the spray-drying tower are controlled; and the powder is collected and packaged and stored later. The production process reduces the microorganism content of the finished product and the original flavor of the soy sauce powder to the maximum extent, and provides soy sauce powder with lower microorganism content and more pleasant flavor for the application field of the soy sauce powder.

Owner:上海爱普食品工业有限公司

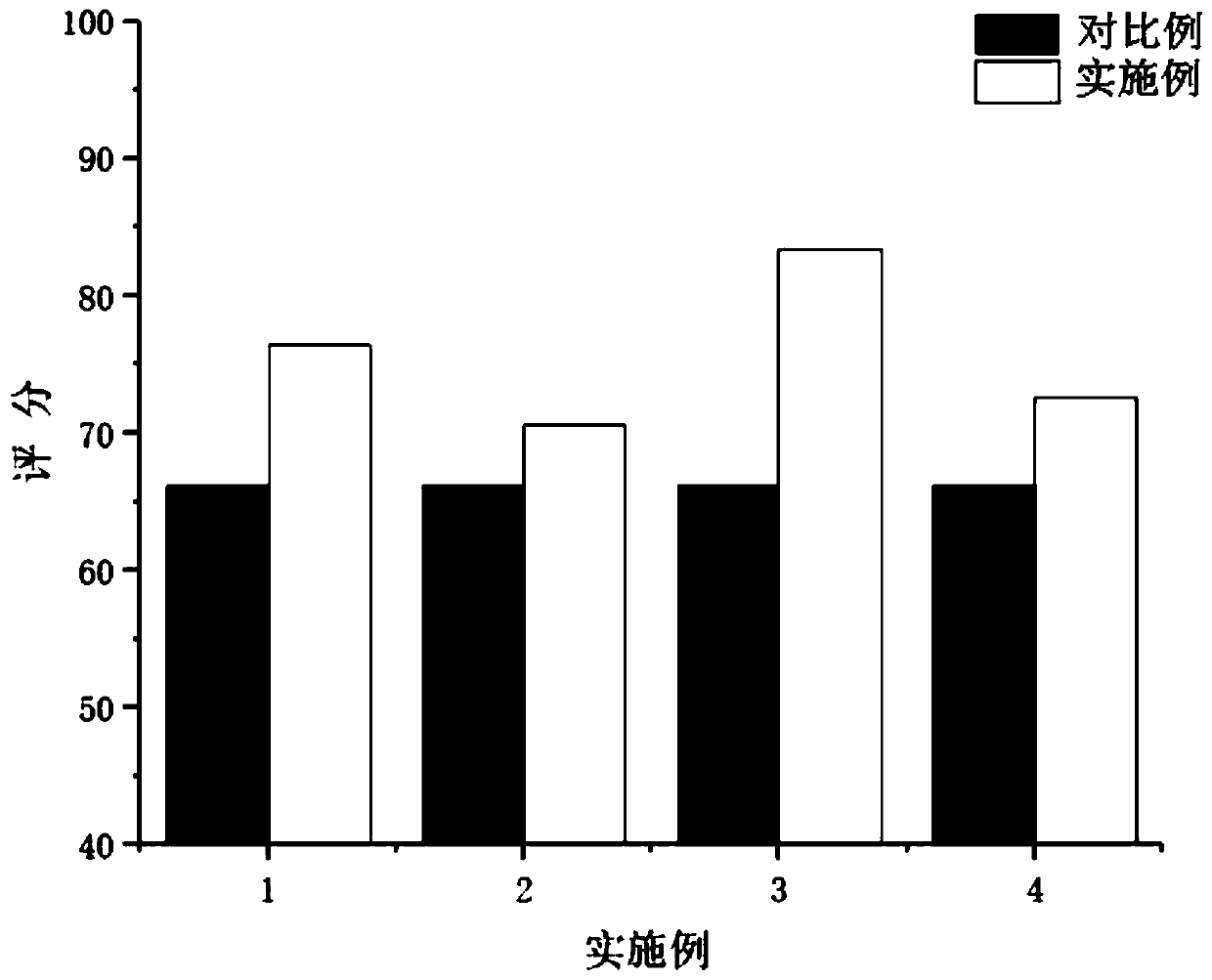

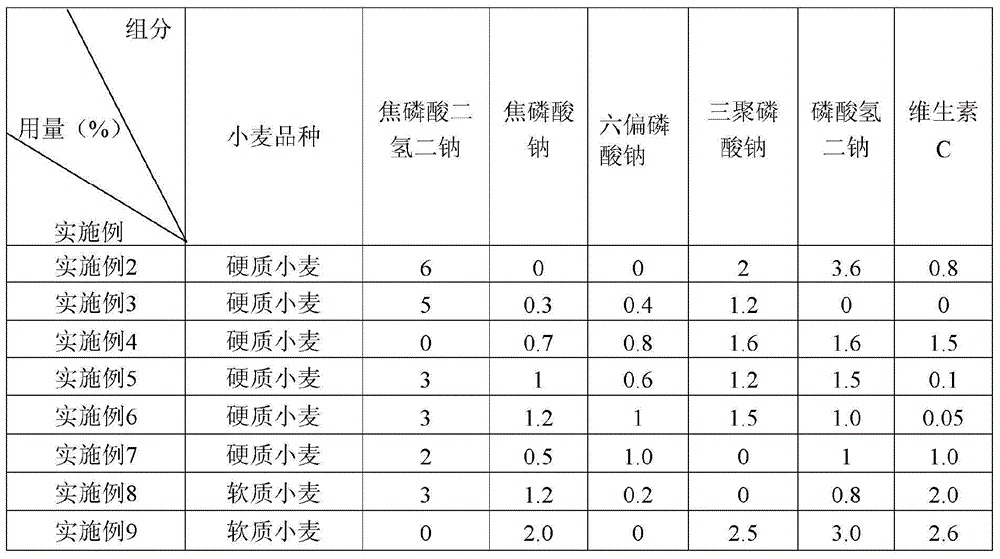

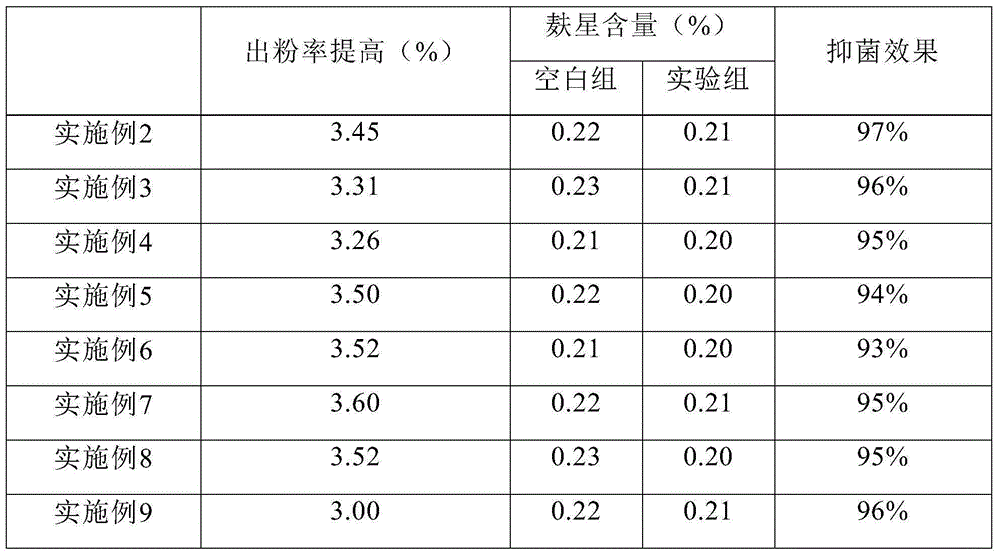

Wheat quality improving modifier and application thereof

The invention relates to a wheat quality improving modifier and application thereof. The wheat quality improving modifier is prepared from, by weight, 1.0%-12% of phosphate, 0.05%-5% of VC and the balance water, wherein VC is ascorbic acid and analogues or derivatives thereof or ascorbic acid and analogues thereof or salts of the analogues. The quality improving modifier is also in the form of solid powder. The invention further comprises application of the wheat quality improving modifier in wheat wetting, wheat flour milling, increasing of the flour extraction rate in the wheat flour milling process, reduction of bran scraps generated in the wheat flour milling process and / or inhibition of microorganism growth and reproduction in the wheat flour milling process. According to the wheat quality improving modifier and application thereof, the wheat processing performance can be well improved, then the processing precision of wheat flour is improved, the quality of the wheat flour is improved, the flour extraction rate is increased, and then flour milling power consumption and cost are reduced; meanwhile, the microorganism content of the wheat can be effectively decreased, and the flour safety is improved.

Owner:益海(石家庄)粮油工业有限公司

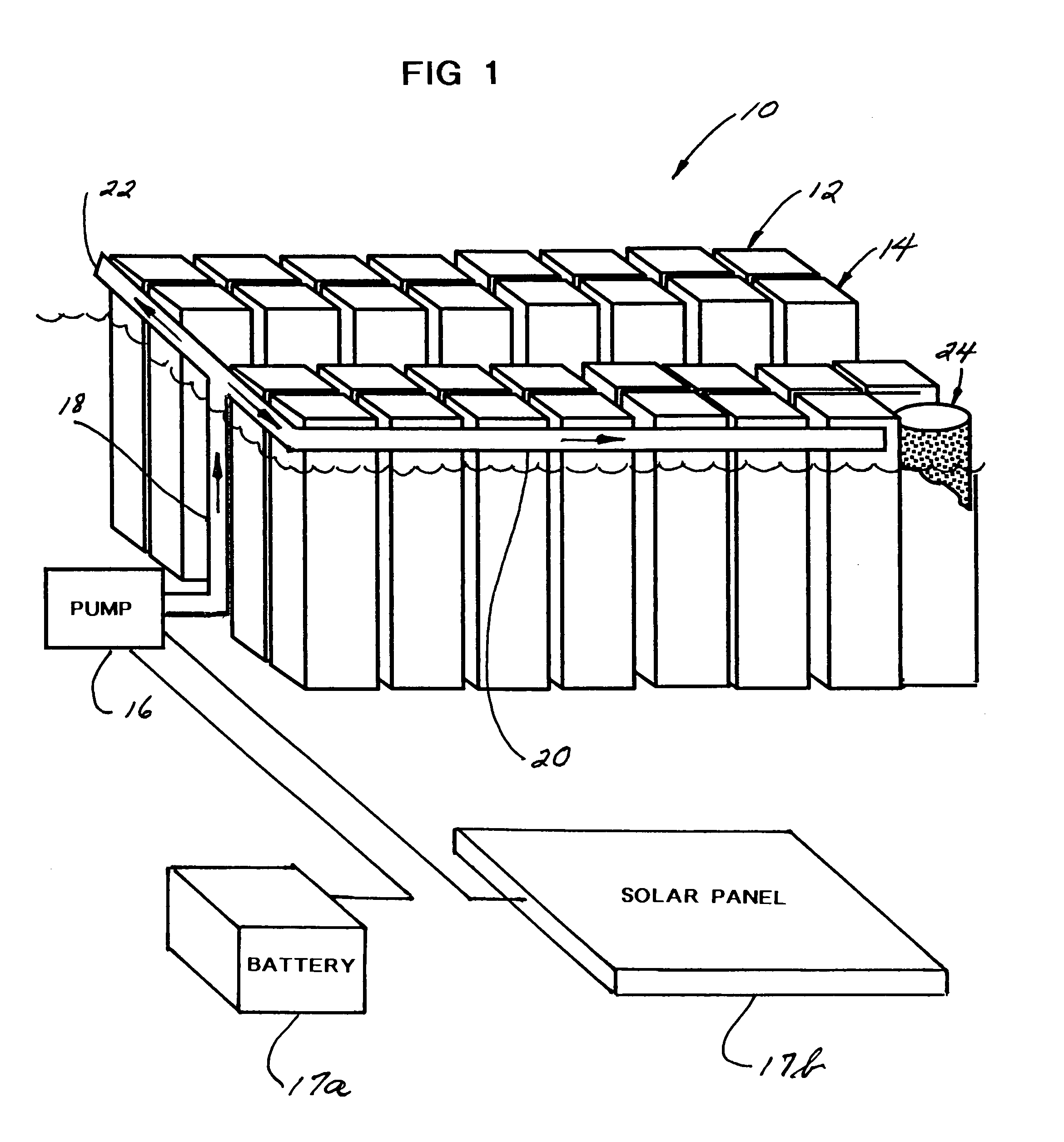

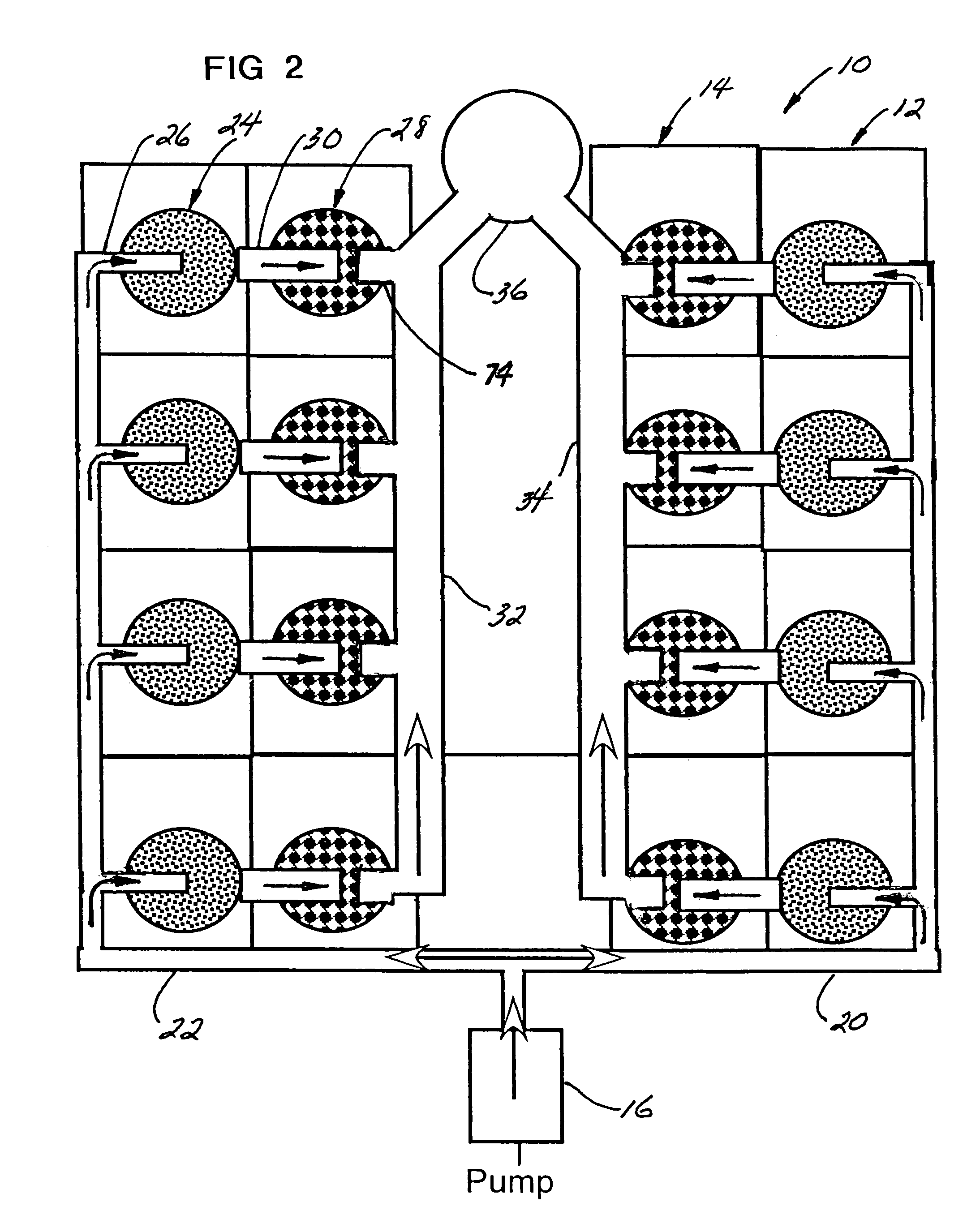

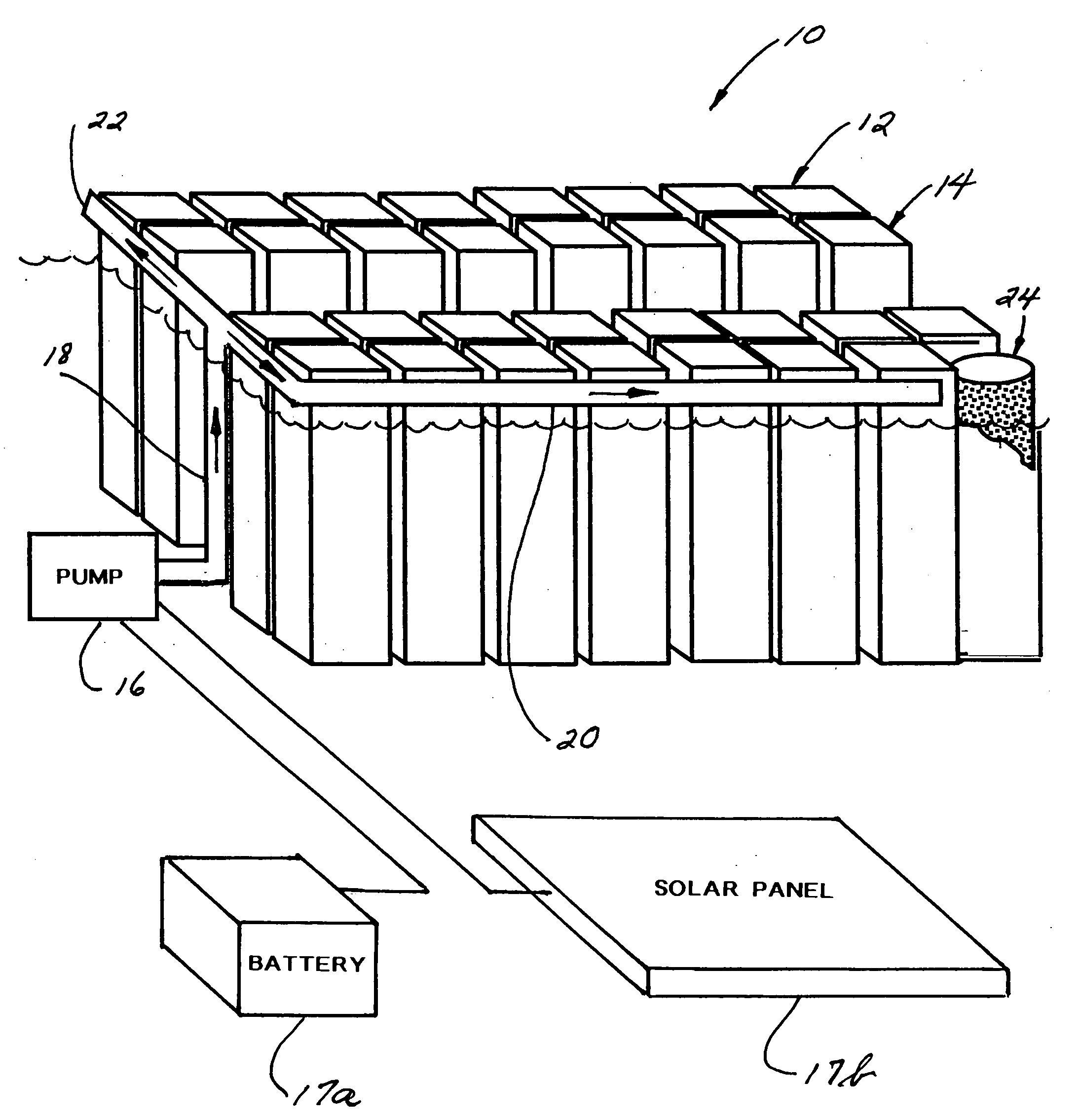

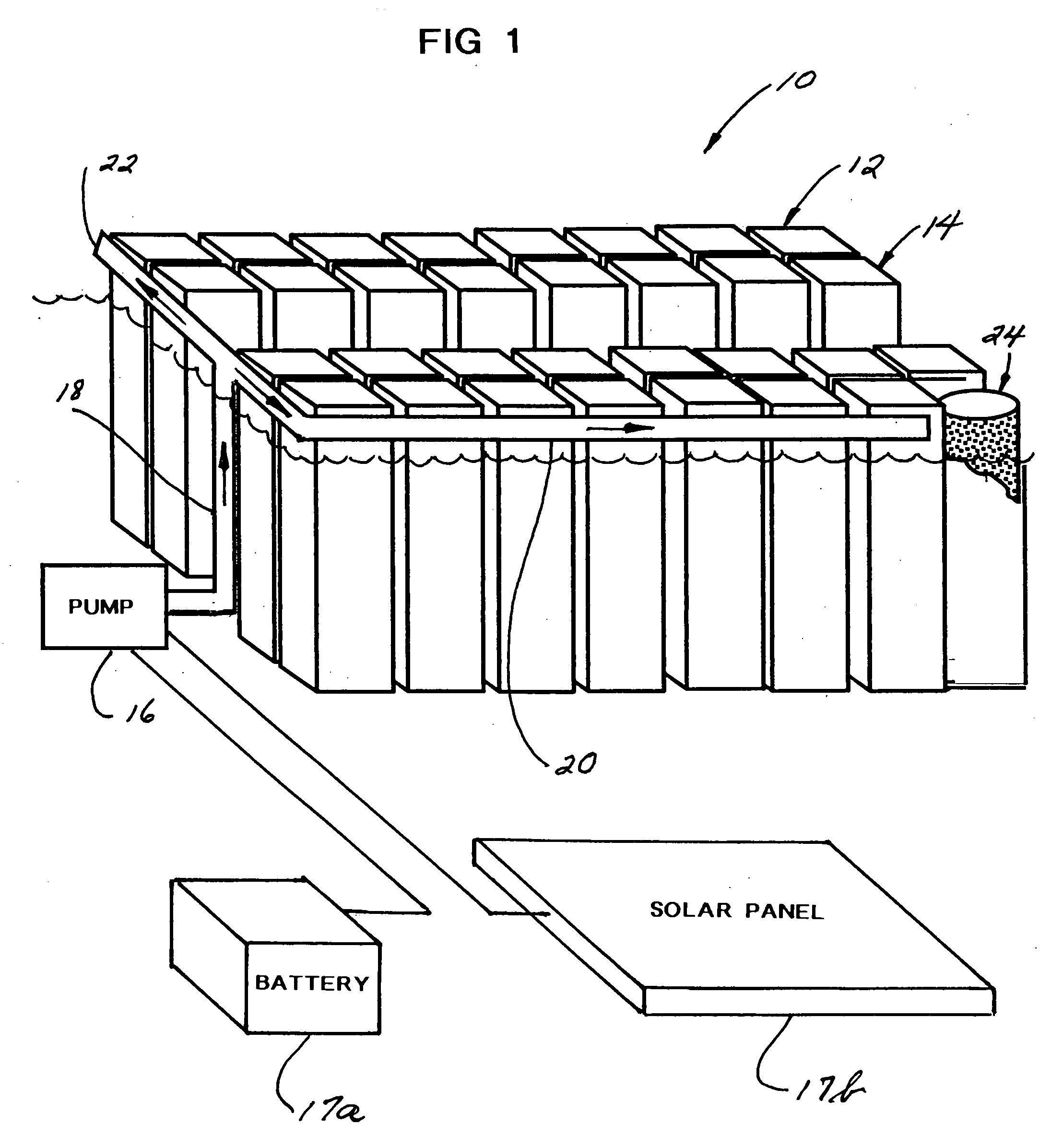

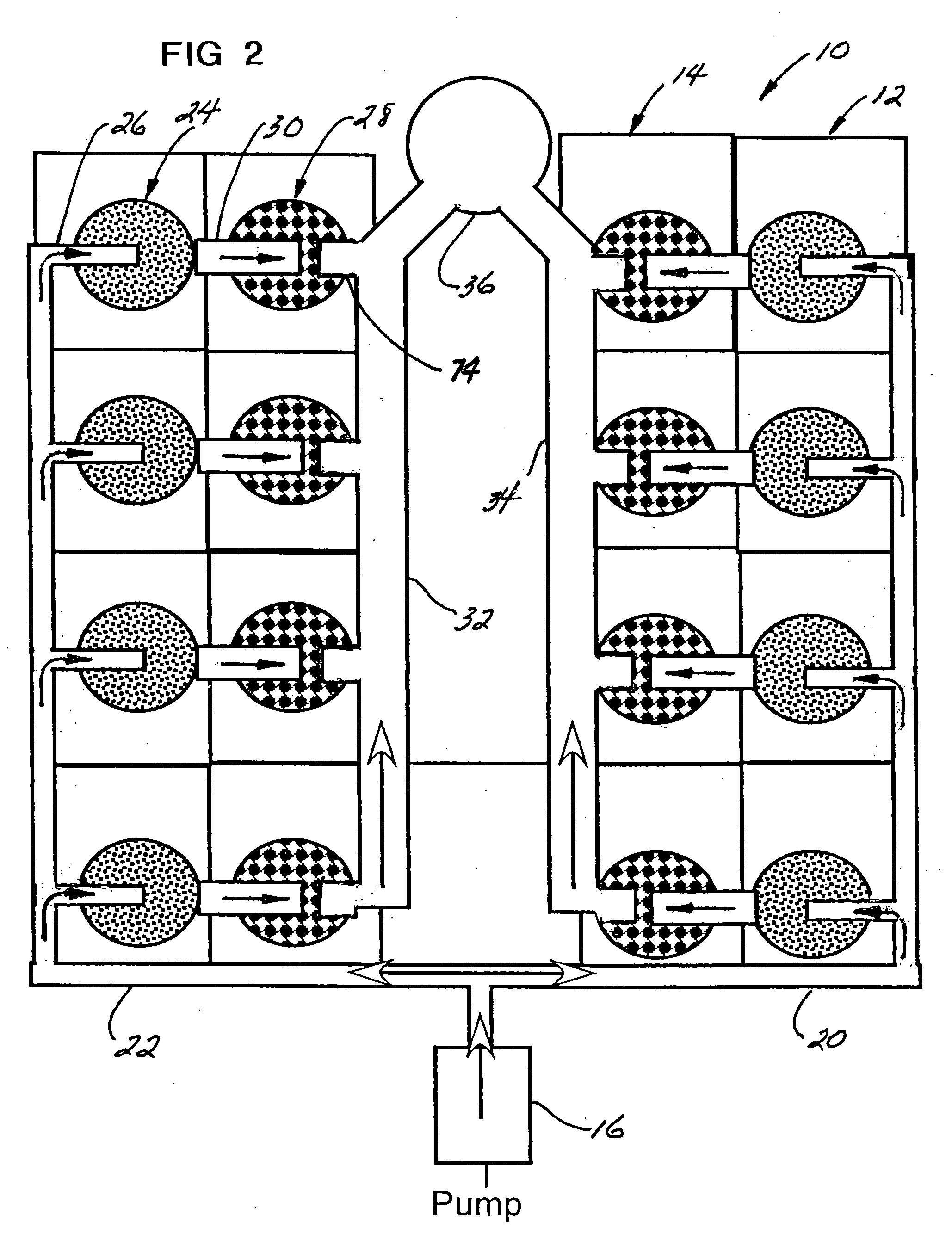

Dual cell nitrogen removal apparatus

InactiveUS7666302B2Reduce nitrateReduce microbial contentGeneral water supply conservationBiological treatment apparatusNitrogen removalNitrate

A water treatment apparatus including a series of pairs of water filtration cells of an upwelling type. Each cell of each pair has a longitudinally extending water conduit in fluid communication between an upper and a lower end of each cell. The first cell of each pair is a fluidized bed type containing a biologically active media, the water entering a bottom of this cell upwelling through the biologically active media to discharge from a discharge port at or near the top of the first cell. The second cell of each pair has the upper end of its water conduit in fluid communication with the discharge port of the paired first cell and contains media which removes nitrates from the water entering and upwelling through the nitrate removing media for discharge from the second cell.

Owner:JENKINS DAVID W

Lithium alginate production process

The invention provides a lithium alginate production process.The lithium alginate production process includes steps: (1) performing alkali digestion of brown algae to prepare alginic acid; (2) adding the alginic acid and a certain quantity of a composite lithium salt into a neutralization reactor to react for 50-70min until the alginic acid and the composite lithium salts are completely neutralized to form lithium alginate, wherein neutralization reaction includes solid-phase neutralization reaction and liquid-phase neutralization reaction with ethyl alcohol serving as a medium; consumption of the composite lithium salt is 7-15% of that of the alginic acid; the composite lithium salt is composed of lithium carbonate and lithium acetate, and a ratio of the lithium carbonate to the lithium acetate is 80-90:10-20; (3) performing centrifuging, plunger extruding granulation, drying and grinding to obtain lithium alginate in required meshes.The lithium alginate prepared according to the process is 100-2000mPa.s in viscosity, 40-320 in mesh number, 6.0-8.0 in pH value, smaller than or equal to 15.0% in moisture content and 14-28% in ash content.In addition, the lithium alginate production process can be implemented under the condition of existing sodium alginate solid-phase and liquid-phase neutralization production technology.

Owner:青岛海之林生物科技开发有限公司

Preparation method of liquid acidic pectinase with strong stability

InactiveCN104450660AIncrease contentImprove adsorption capacityEnzyme stabilisationPectinaseFiltration

The invention discloses a preparation method of liquid acidic pectinase with strong stability, and belongs to the technical field of preparation of enzyme preparations. The preparation method of the liquid acidic pectinase with strong stability does not need addition of a chemical preservative and low-temperature treatment, and the liquid acidic pectinase with strong stability, which is stable and has a relatively long quality guarantee period, can be obtained by fermenting a crude enzyme solution and blending a concentrated solution by adopting a high-voltage pulse electric field at normal temperature, adding natural plant raw materials including a pectin decomposed product, a Chinese medicinal herb extract, modified dietary fibers and the like during blending, and then performing aseptic filtration and sterile filling. Experiments prove that the liquid acidic pectinase with strong stability, prepared by the method disclosed by the invention, has the total number of bacterial colonies of 75-110CFU / mL after being stored for 12 months at room temperature; and the enzyme activity loss rates of the liquid acidic pectinase which is stored for 12 months at 40 DEG C and 0 DEG C are 1.2-1.4% and 0.5-1.1% respectively.

Owner:邵素英

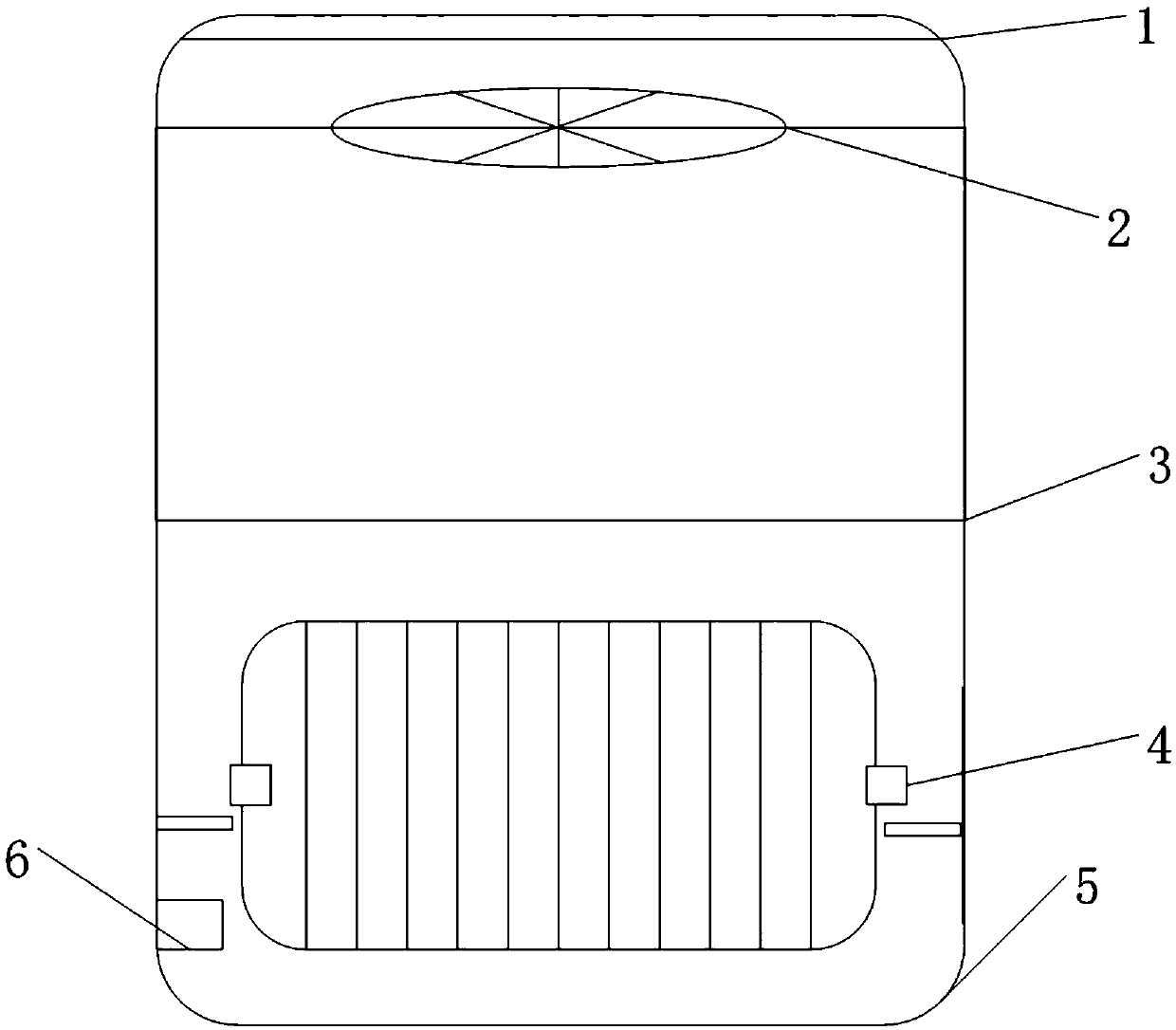

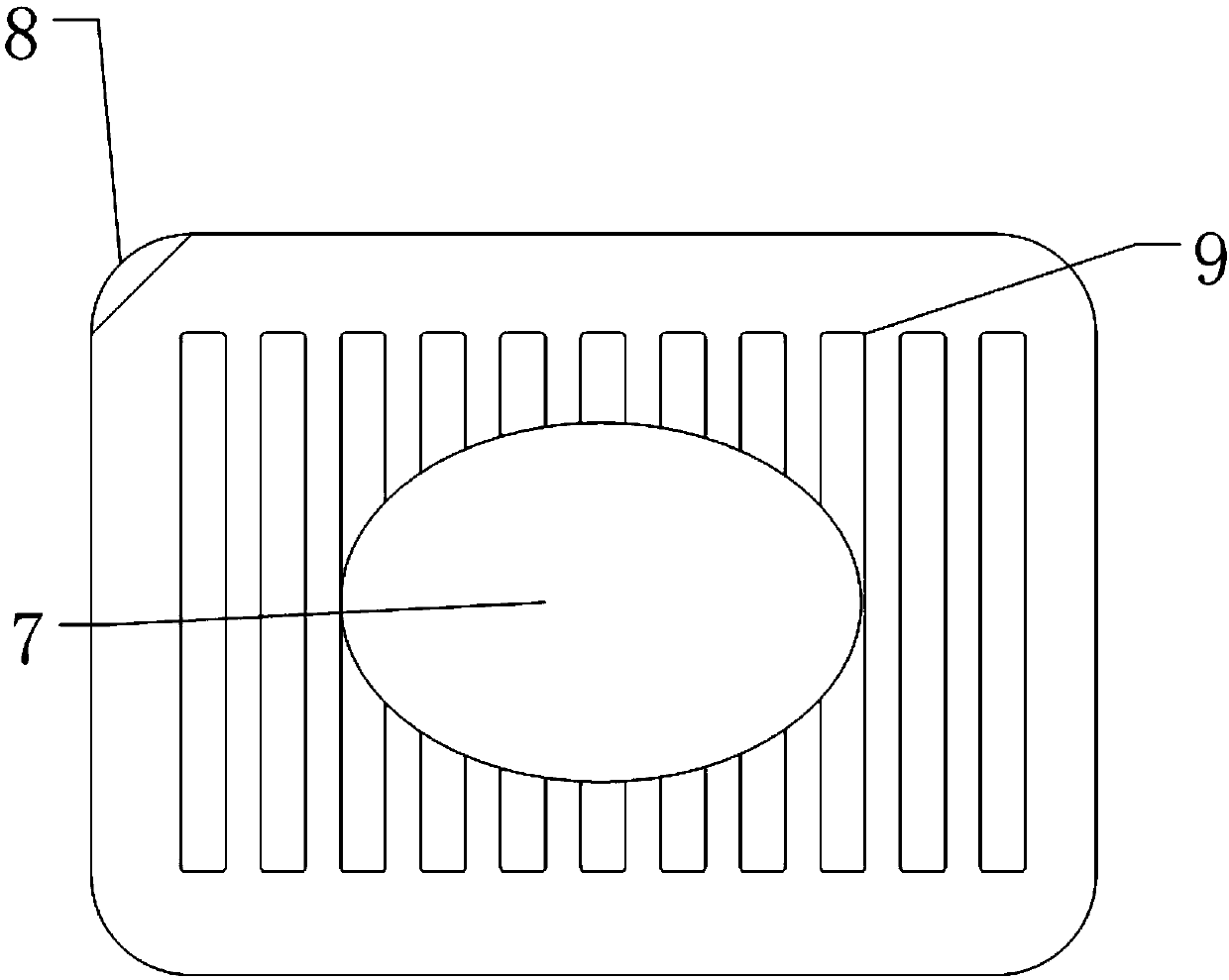

Air sterilization device and sterilization method

InactiveCN109621680AIncrease humidityReduce microbial contentCombination devicesDeodrantsCentrifugal fanWater tanks

The invention discloses an air sterilization device and sterilization method. The air sterilization device comprises a machine housing, a centrifugal fan, a filter rolling shaft and a water tank, wherein the centrifugal fan, the filter rolling shaft and the water tank are all arranged in the machine housing, the water tank is located at the bottom of the machine housing, the filter rolling shaft is installed above the water tank, the centrifugal fan is installed at the upper portion of the machine housing, the top face of the machine housing is provided with an air inlet, a filter screen is arranged between the air inlet and the centrifugal fan, the side face of the upper portion of the machine housing is provided with an air outlet and a water inlet, the lower portion of the machine housing is provided with a transparent water level observing window, and the bottom is provided with a water outlet; an air sterilization agent is contained in the water tank, and the filter rolling shaftis provided with a plurality of grooves. The air sterilization device achieves air sterilization, plays an air purifying effect, can also eliminate peculiar smell in air, increases indoor humidity, reduces influenza occurrence rate, is quick and convenient to operate, good in sterilization effect, simple in use and convenient to popularize and use.

Owner:ZHEJIANG UNIV

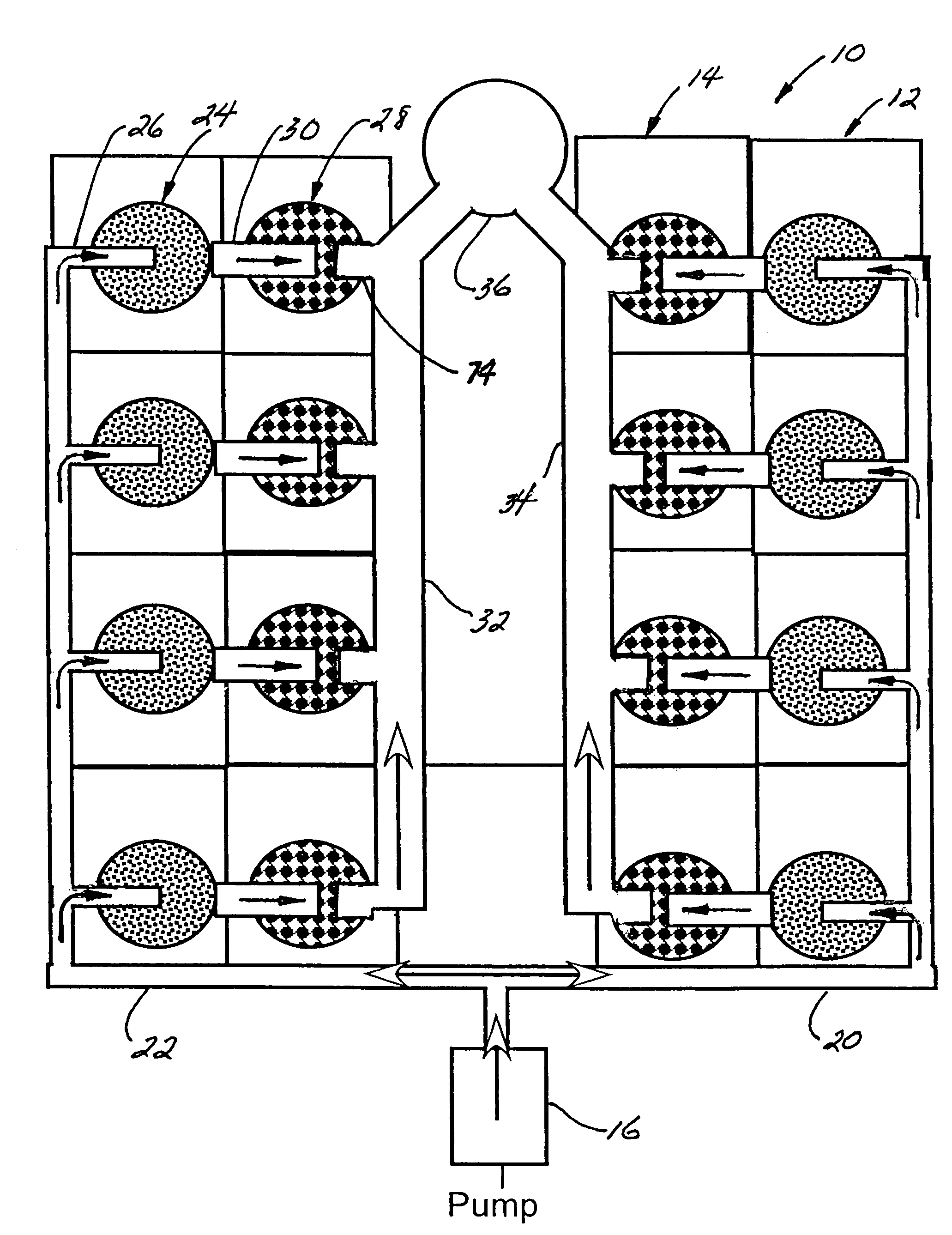

Dual cell nitrogen removal apparatus

InactiveUS20100000921A1Reduce nitrateReduce microbial contentTreatment using aerobic processesGeneral water supply conservationNitrogen removalNitrate

A water treatment apparatus including a series of pairs of water filtration cells of an upwelling type. Each cell of each pair has a longitudinally extending water conduit in fluid communication between an upper and a lower end of each cell. The first cell of each pair is a fluidized bed type containing a biologically active media, the water entering a bottom of this cell upwelling through the biologically active media to discharge from a discharge port at or near the top of the first cell. The second cell of each pair has the upper end of its water conduit in fluid communication with the discharge port of the paired first cell and contains media which removes nitrates from the water entering and upwelling through the nitrate removing media for discharge from the second cell.

Owner:JENKINS DAVID W

Production technology of magnesium alginate

The invention provides production technology of magnesium alginate. The production technology comprises the following steps: (1) preparing alginic acid from brown algae via alkali digestion; (2) adding alginic acid and a certain amount of composite magnesium salt into a reactor, and reacting for 50-75 min till alginic acid and composite magnesium salt are neutralized and are completely converted to magnesium alginate, wherein the neutralization reaction comprises a solid-phase neutralization reaction and a liquid-phase neutralization reaction taking alcohol as a medium; (3) using the composite magnesium salt with the amount being 7-15% of that of alginic acid; (4) taking magnesium chloride and basic magnesium salt, the ratio of which is 10-20:80-90, to prepare the composite magnesium salt, wherein (5) the basic magnesium salt comprises one or more of magnesium bicarbonate, magnesium hydroxide, magnesium carbonate, magnesium oxide, magnesium acetate, and magnesium silicate; and (6) performing centrifugation, plunger extruding granulation, drying, and pulverizing to prepare magnesium alginate with a required mesh size. Magnesium alginate prepared in the invention has the viscosity in a range of 100-2000 mPa.s, the mesh size in a range of 40-320 mesh, the pH value in a range of 6.0-8.0, a water content no more than 15.0%, and an ash content in a range of 14-28%. The production technology can be realized in a condition of conventional solid-phase, and liquid-phase neutralization production technology of algin.

Owner:青岛海之林生物科技开发有限公司

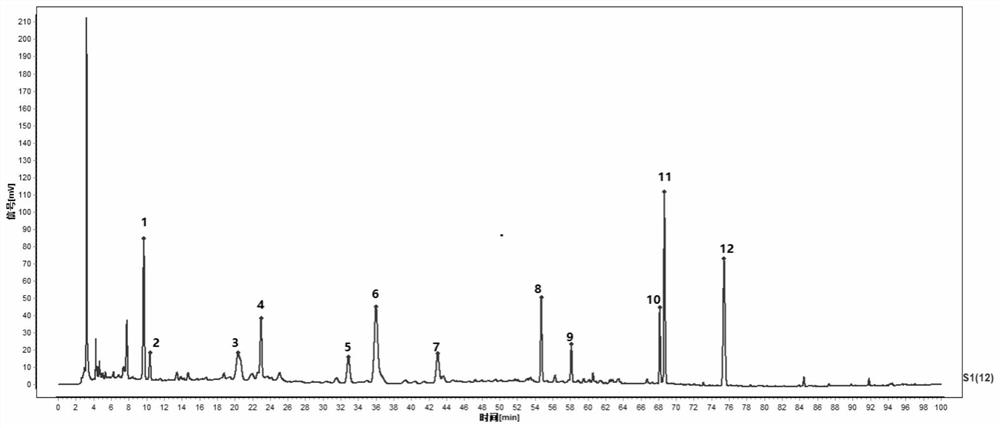

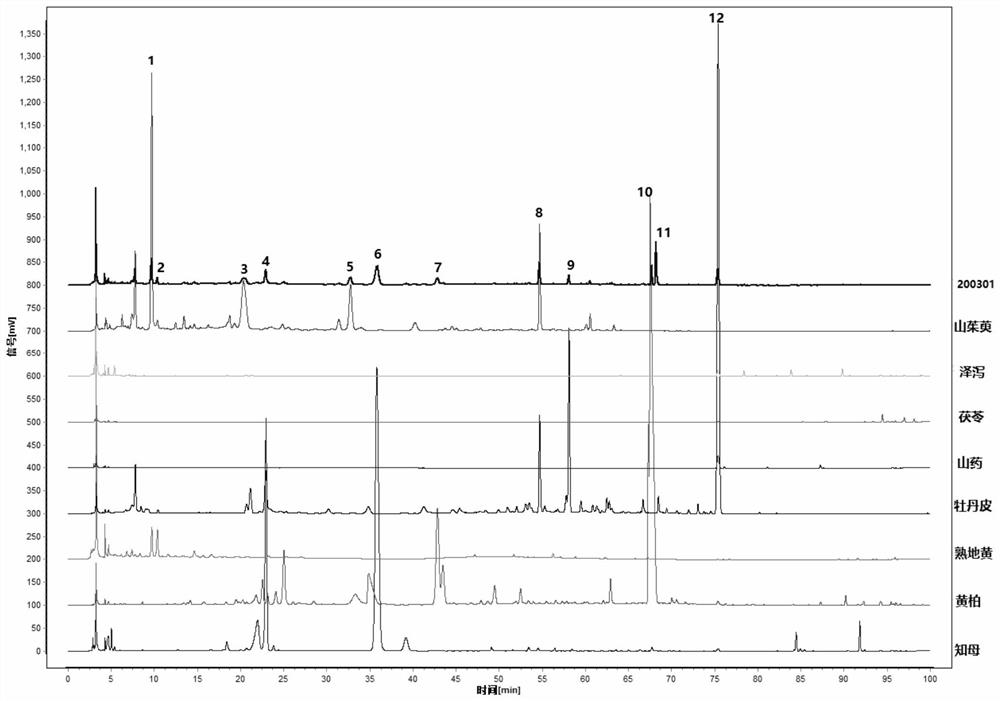

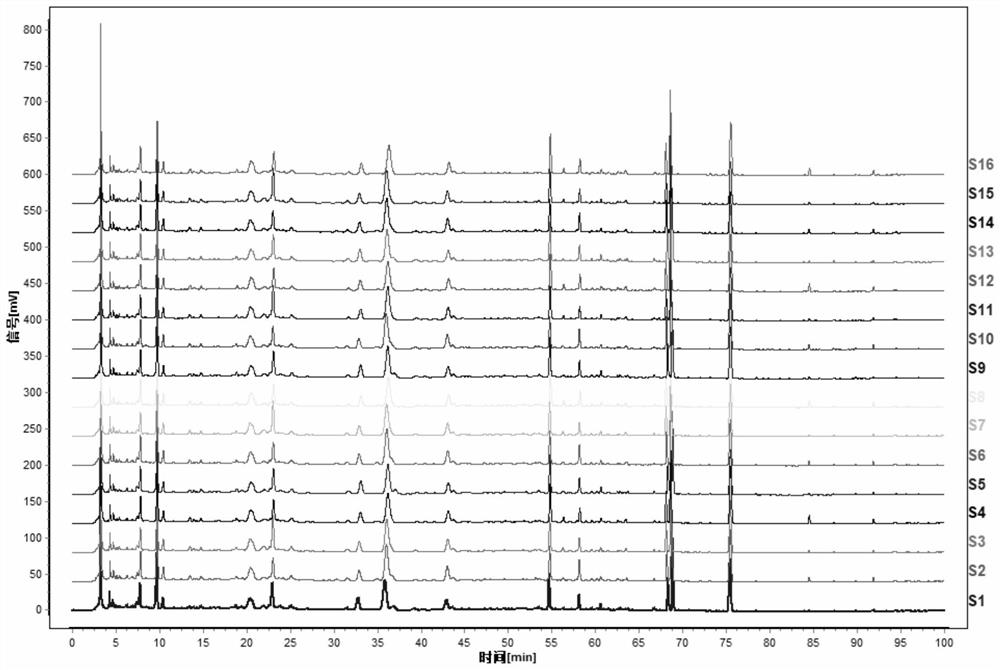

Detection method and application of fingerprint spectrum of Zhibai Dihuang pill

The invention provides a detection method of a fingerprint spectrum of a Zhibai Dihuang pill. The invention further provides an application of the fingerprint spectrum detection method of the Zhibai Dihuang pill in quality detection of components in the Zhibai Dihuang pill and a quality detection method of the Zhibai Dihuang pill. The invention further provides a method for determining the contentof the five components in the Zhibai Dihuang pill. The invention further provides a screening method of the fingerprint spectrums of the multiple medicinal materials in the Zhibai Dihuang pill. According to the detection method and application of the fingerprint spectrum of the Zhibai Dihuang pill, the high performance liquid fingerprint spectrum of the Zhibai Dihuang pill is established, five chemical components in the Zhibai Dihuang pill can be quantitatively analyzed, affiliation confirmation is carried out on chromatographic peaks of single medicinal materials in the Zhibai Dihuang pill,effective monitoring can be carried out from a raw material source, the quality of raw medicinal materials is strictly controlled, and the amount of effective components in the Zhibai Dihuang pill isensured to be relatively stable, so that the safety and effectiveness of clinical medication are ensured.

Owner:HEHUANG PHARMA SHANGHAI

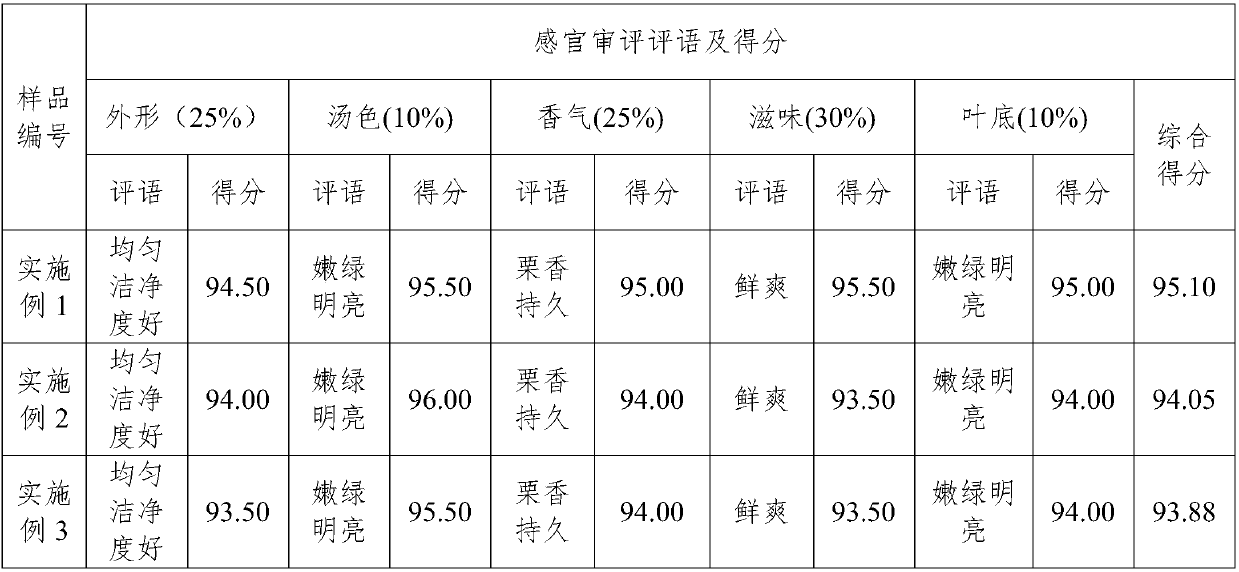

Processing method for producing high-end green tea from Shiqian moss tea variety

The invention discloses a processing method for producing high-end green tea from a Shiqian moss tea variety. The processing method comprises the following steps: withering, fixation, fresh leaf tedding, tea strip tidying and trimming, step-by-step drying, screening, air classification, blending, microwave drying aroma enhancement and finished product packaging. By controlling the temperature andtime in the process steps and the parameters of moisture and the like in processed tea leaves, most organic matters in the tea leaves are preserved, so that the quality of the tea leaves is remarkablyimproved.

Owner:石阡裕和原生态农牧发展有限公司

Breathing mask with filtering and purifying functions

InactiveCN105413078AHigh activityReduce microbial contentBreathing filtersBreathing masksExhalationDuring expiration

The invention discloses a breathing mask with filtering and purifying functions. The breathing mask comprises a face guard and a canister. The face guard comprises a guard body, eye windows, an interphone, a breathing valve and a fastener. The breathing mask is characterized by further comprising a double-layer exhalation valve or a multi-layer exhalation valve, and the double-layer exhalation valve or the multi-layer exhalation valve is composed of two or more exhalation valve blocks which are connected and combined in series; grids are arranged between the exhalation valve blocks as well as between the exhalation valve blocks and the guard body; an air inlet is formed in the bottom of the guard body; the air inlet is connected with the canister through an air guiding pipe; the canister comprises a first adsorption assembly, a catalyze assembly and a second adsorption assembly which are stacked in the front-back direction. By means of catalysts, benzene, methylbenzene, xylene, ethylbenzene, styrene, formaldehyde, acetaldehyde and acrolein in the air in a building are removed till the concentration is below 0.01 milligram / m<3>, and meanwhile the content of microorganisms in recycled air is remarkably reduced.

Owner:WUXI QINGYANG MACHINERY MFG

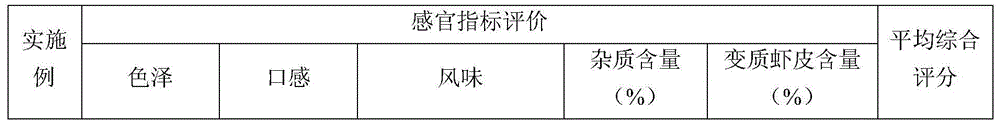

Production method of instant dried small shrimps

The invention belongs to the technical field of food processing, and particularly relates to a production method of instant dried small shrimps, wherein the production method comprises the following steps: step one, cleaning small shrimps; step two, soaking and removing impurities; step three, carrying out centrifugal dehydration; step four, seasoning the small shrimps; step five, cooking; six step, drying; and step seven, packaging. According to the production method of the instant dried small shrimps, the obtained instant dried small shrimps have the advantages of high quality, good taste, excellent color and luster, and easy chewing; volatile salt-based nitrogen is effectively removed, and the removal rate is 80% or more; with adopting of a new microwave spouting drying technology, energy is saved by 70% or more than that of general hot wind drying; the product has extremely low microbial content, the total number of bacteria is 5000 cfu / g or less, and no pathogenic bacteria are detected. The preparation method is simple, and is more energy saving and is more prone to realization of productization production compared with conventional drying.

Owner:ZHEJIANG PHARMA COLLEGE +1

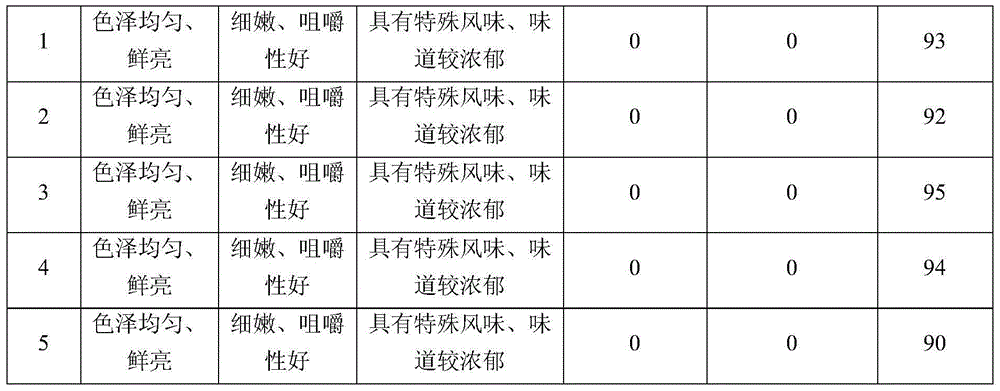

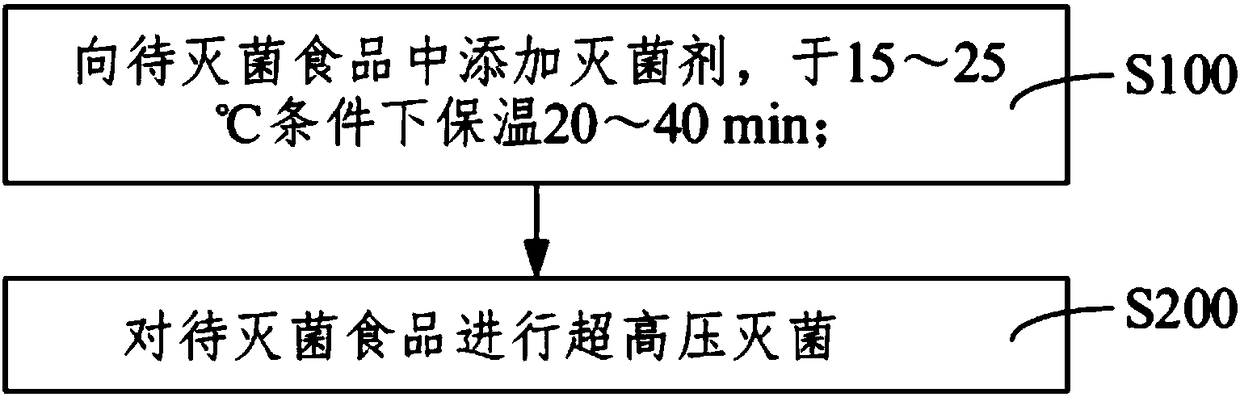

Sterilization method of germination bacteriostatic agent

InactiveCN108077711AReduce microbial contentExtended shelf lifeFood preservationFood ingredient for microbe protectionMicroorganismMicrobiology

The invention discloses a sterilization method. The sterilization method comprises the following steps of adding a germination bacteriostatic agent to foods to be sterilized, and performing heat insulation at 15-25 DEG C for 20-40min; and performing superhigh pressure sterilization on the foods to be sterilized, wherein the germination bacteriostatic agent comprises a germinant and a bacteriostatic agent. Before the superhigh pressure sterilization, an appropriate quantity of the germination bacteriostatic agent is added, so that microorganism spores in the foods to be sterilized can be germinated; and the microorganism spores are induced to be germinated, and then superhigh pressure sterilization is performed, so that the sterilization efficiency in the step of superhigh pressure sterilization is improved. The advantage that the superhigh pressure sterilization is small in influence on the color, the flavor and the mouth feel of the foods to be sterilized can be maintained, the content of microorganisms in the sterilized foods can also be greatly reduced, and particularly the content of the microorganism spores can be reduced, so that the sterilized foods can be applied to foods having severe requirements for content of the microorganisms, such as yoghourt, and industrial production and application are convenient.

Owner:北京爱果坊科技有限公司

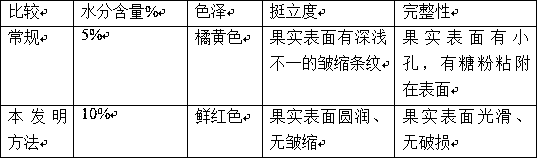

Processing method and application of slightly lyophilized Chinese wolfberries

ActiveCN108041153AReduce microbial contentReduce pesticide residuesFruit and vegetables preservationFreeze-dryingNatural state

The invention discloses a processing method of slightly lyophilized Chinese wolfberries. The method comprises the following steps of soaking, cleaning, freeze-drying protection and freeze-drying. Themethod mainly relates to the following steps in detail: adding a freeze-drying protective agent containing 1-10% w / w of trehalose and 0.5-1% w / w of calcium chloride to washed Chinese wolfberries; uniformly spraying the protective agent on the surface of the Chinese wolfberries by adopting atomization spray heads; putting the Chinese wolfberries into a freeze-drying machine, and starting vacuumizing under the condition of no heating and no freezing; keeping a negative pressure for 10 to 30 minutes as the pressure drops to 60 Pa; and maintaining a vacuum degree for 2-5h. according to the lyophilized fresh Chinese wolfberry fruits produced by adopting a vacuum freeze-drying technology, the method maintains the original natural state of fresh Chinese wolfberry fruits, and the color, the appearance shape and the appearance and mouth feel after rehydration of the lyophilized Chinese wolfberry fruits are basically the same as that of the picked fresh Chinese wolfberry fruits. The method maintains the integrity and stiffness of dried Chinese wolfberry cells, and reduces the production cost of products, and the products are easier to preserve in marketing sale process.

Owner:早康枸杞股份有限公司

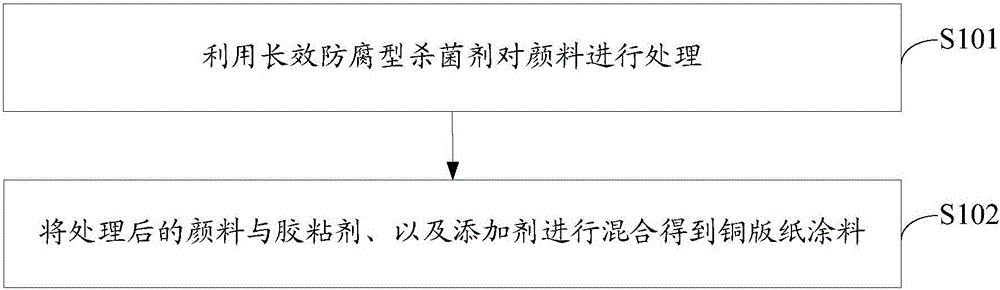

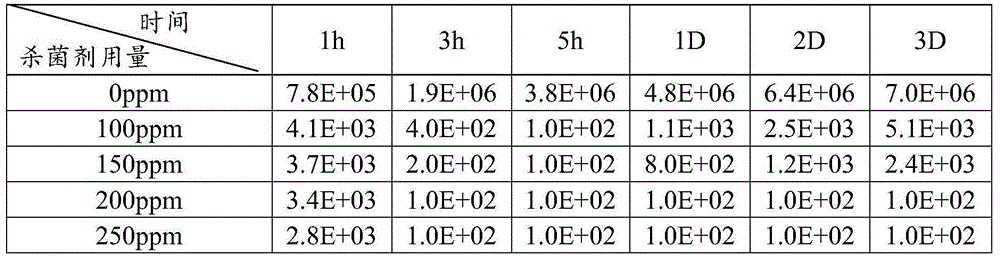

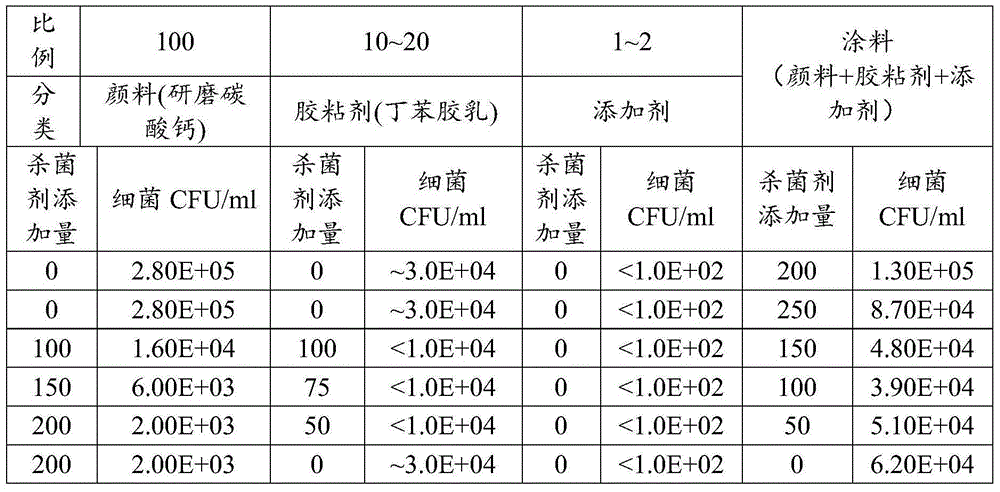

Preparation method for coated paper coating material and coated paper

ActiveCN106400591AReduce microbial contentMicrobial content controlDefoamers additionCoatings with pigmentsFungicideCopper

The invention discloses a preparation method for a coated paper coating material and coated paper. The preparation method for the coated paper coating material comprises the steps of carrying out treatment on pigments by using a long-acting anticorrosive fungicide, and mixing the treated pigments with a tackifier and additives, thereby obtaining the coated paper coating material. The pigment content accounts for 80% to 90% or more the total weight of the coating material formula, the pigments are treated through the fungicide so as to lower the microbe content of the pigments, and thus the problem of deterioration caused by too high microbe content of raw materials can be effectively avoided; and the microbe content of the final coating material can be effectively controlled on the basis of reducing the use level of the fungicide for treating the coating material.

Owner:GOLD EAST PAPER JIANGSU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com