Wheat quality improving modifier and application thereof

An improver, conditioning technology, applied in application, grain processing, grain milling, etc., can solve the problems of increasing the difficulty of separating bran and endosperm, reducing the activity of lipoxygenase, and increasing the cost of wheat processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0112] (1) The physical and chemical indicators of the raw material wheat were determined by the national standard method, including bulk density (the National Standard of the People's Republic of China GB5498-85 Grain and Oil Seed Inspection Bulk Density Determination Method), moisture content (GB / T24898-2010 Grain and Oil Inspection Wheat Moisture Content Determination) and incomplete grains (GB / T 5494-2008 Impurities and imperfect grains inspection of grain and oilseeds). This embodiment adopts durum wheat with a bulk density of 776g / L, a moisture content of 11.6%, and imperfect grains of 8.5%.

[0113] (2) wheat conditioning

[0114] ① The target moisture content of wheat is set at 16%. According to the calculation according to the following formula, it is determined that the amount of water added per 1 kg of wheat is 51.2 g during this moistening;

[0115] Amount of water added = [(target moisture - original moisture) / 86]*wheat quality,

[0116] Among them: water additi...

Embodiment 2~9

[0127] The physical and chemical property indicators and experimental parameters of wheat used in each blank group and experimental group in Examples 2 to 9 are shown in Table 1 below. Except for using tap water instead of the corresponding wheat conditioning solution, the blank group and experimental group under the same embodiment were all The same starting materials, methods and specific parameters were used.

[0128] Table 1

[0129]

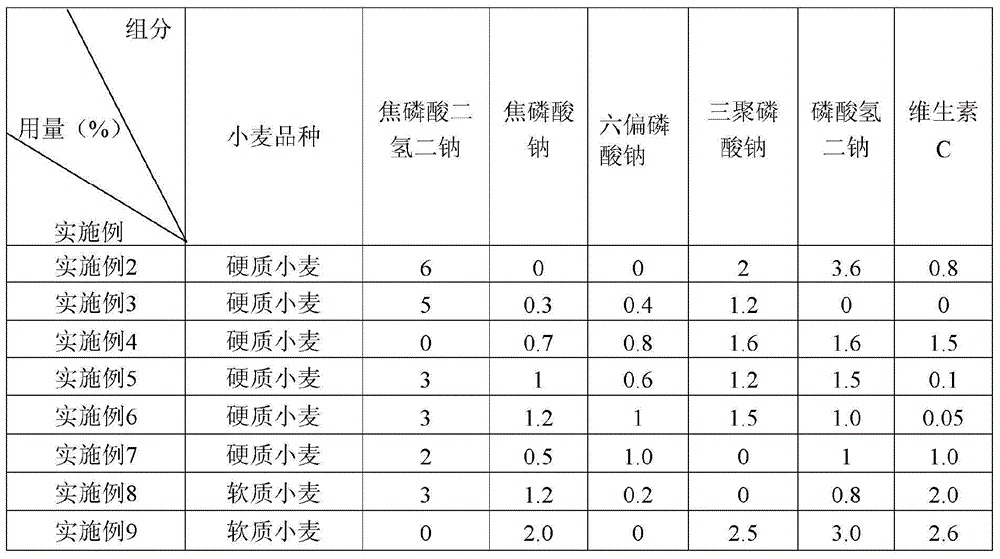

[0130] Prepare different tempering solutions as shown in Table 2, and other conditions are the same as in Example 1.

[0131] Table 2

[0132]

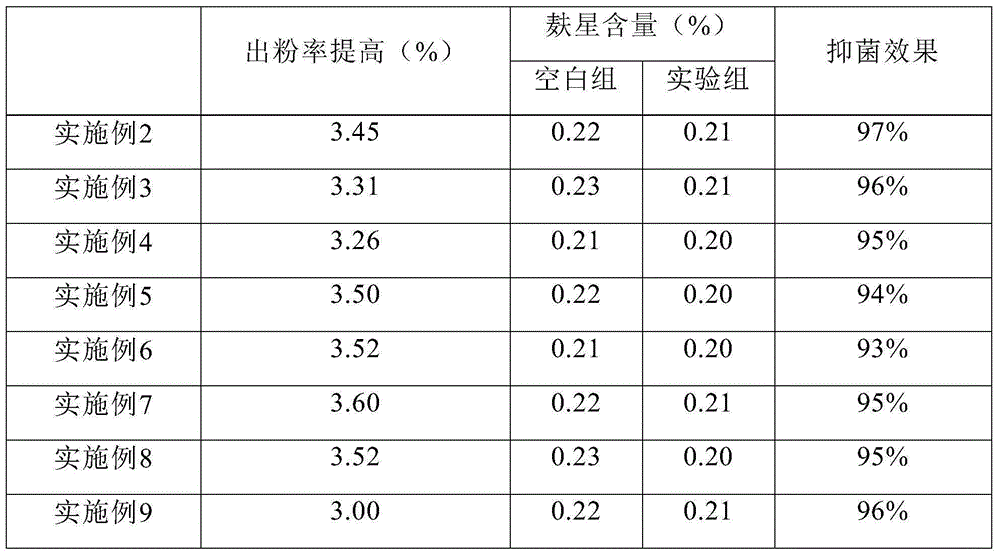

[0133] Each embodiment is carried out flour extraction rate, bran star and bacteriostasis detection, and the result is as shown in table 3 below:

[0134] table 3

[0135]

[0136] Wherein, the improvement of the powder extraction rate and the antibacterial effect are the results compared with the corresponding blank group in each embodiment.

[0137] Comparing the powder obtained in Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com