Method for batch preparation of monodisperse submicrometer silica powder

A technology of silicon dioxide powder and silicon dioxide, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of increasing energy consumption, loss of volatile solvents, and time-consuming, so as to reduce the space occupied area and the preparation process. , The effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

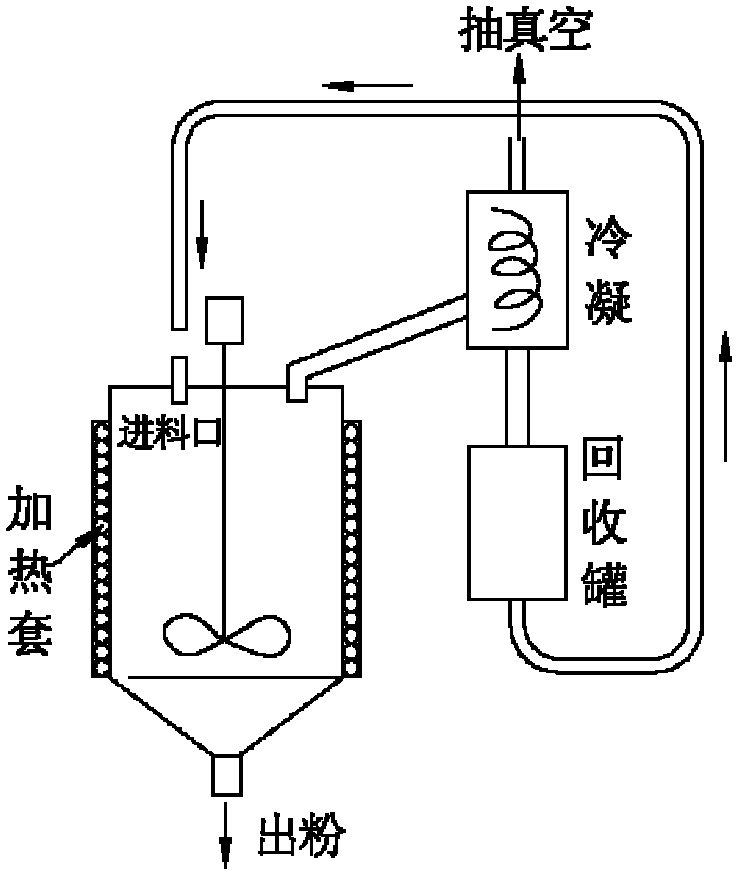

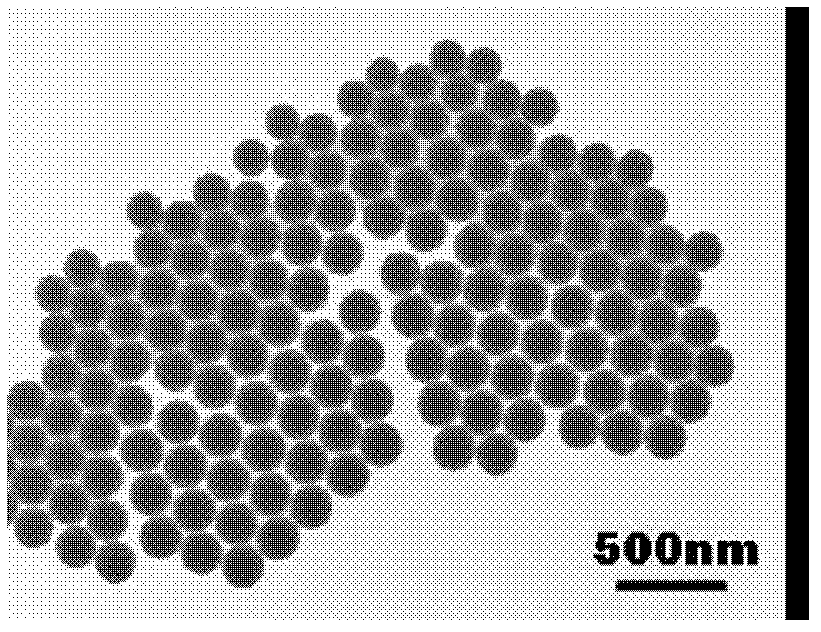

[0029] Preparation of 150nm monodisperse silica powder by seed method: (1) Add 21 liters of ethanol, 520 milliliters of water, and 1840 milliliters of ammonia water to a 50-liter reactor, heat to 40-60 degrees, and add 1100 milliliters of ethyl orthosilicate under stirring , after 8 hours of reaction, add 11 liters of tetraethyl orthosilicate and 1800 milliliters of water in batches, and continue to react for 8 hours to obtain a dispersion of silicon dioxide, add 4 milliliters of SCA-903, and stir for 4 hours; (2) close Feed hole, open the air extraction port, evaporate and condense the mixed solvent into the recovery tank at 40-60 degrees, measure the pH value of the solution for the next feeding, after the air extraction is completed, discharge from the bottom of the reaction kettle Obtain silica powder.

Embodiment 2

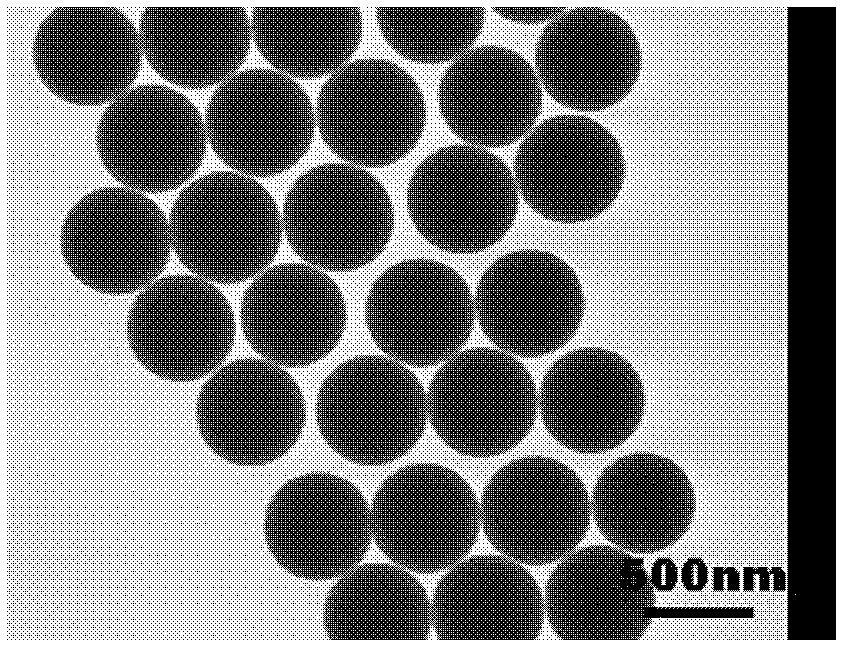

[0031] Preparation of 450nm monodisperse silica powder by seed method: (1) Add 21 liters of ethanol, 1360 milliliters of water, and 1840 milliliters of ammonia water to a 50-liter reactor, heat to 40-60 degrees, and add 1100 milliliters of ethyl orthosilicate under stirring After 8 hours of reaction, add 9 liters of tetraethyl orthosilicate and 1400 milliliters of water in batches, and continue to react for 8 hours to obtain a dispersion of silicon dioxide, add 4 milliliters of SCA-903, and stir for 4 hours; (2) close Feed hole, open the air extraction port, evaporate and condense the mixed solvent into the recovery tank at 40-60 degrees, measure the pH value of the solution for the next feeding, after the air extraction is completed, discharge from the bottom of the reaction kettle Obtain silica powder.

Embodiment 3

[0033] Preparation of high-concentration dispersion of 150nm monodisperse silica (1) Add 21 liters of ethanol, 520 milliliters of water, and 1,840 milliliters of ammonia water into a 50-liter reactor, heat to 40-60 degrees, and add 1,100 milliliters of ethyl orthosilicate under stirring After 8 hours of reaction, add 11 liters of ethyl orthosilicate and 1800 milliliters of water in batches, and continue the reaction for 8 hours to obtain a dispersion of silicon dioxide with a concentration of about 10%; add 4 milliliters of SCA-903 and stir for 4 hours ; (2) Close the feeding hole, open the air extraction port, evaporate and condense the mixed solvent into the recovery tank at 40-60 degrees, and control the dispersion of silica in the reactor by controlling the extraction time and the weight of the recovery liquid. According to the concentration of the liquid, it is possible to prepare a silica dispersion liquid of any concentration with a solid content of 10% to 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com