Patents

Literature

353results about "Extrusion mandrels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tubular articles with varying wall thickness and method of manufacturing same

Owner:AAM INT S A R L

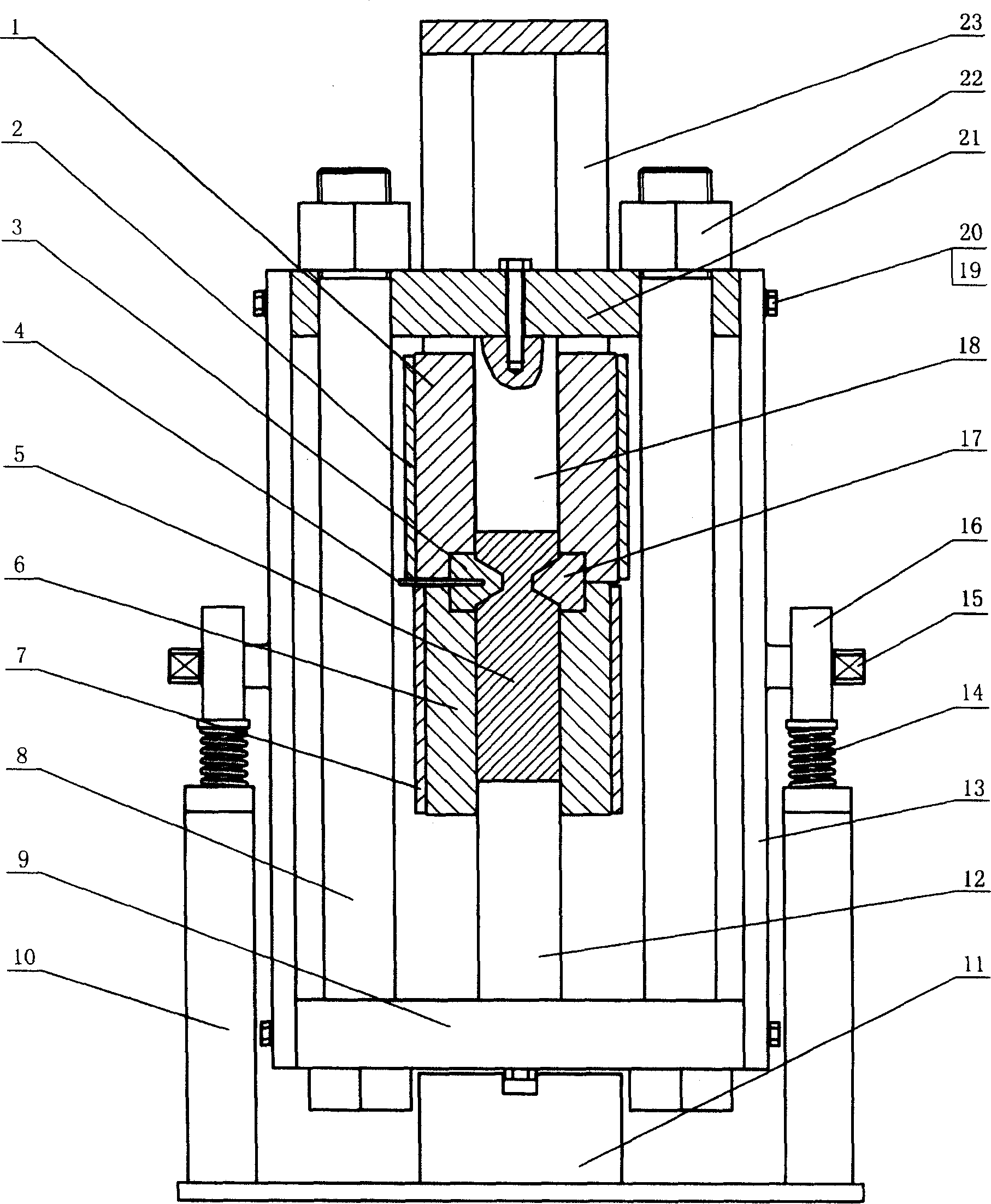

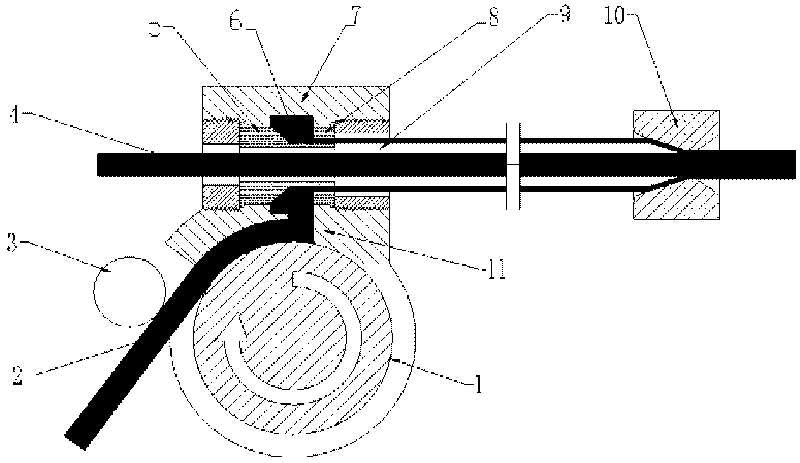

Device and method for preparing fine-grained material by directly extruding continuous variable cross section

InactiveCN101767120AUniform refinementImprove mechanical propertiesExtrusion diesExtrusion mandrelsMaterials preparationIngot

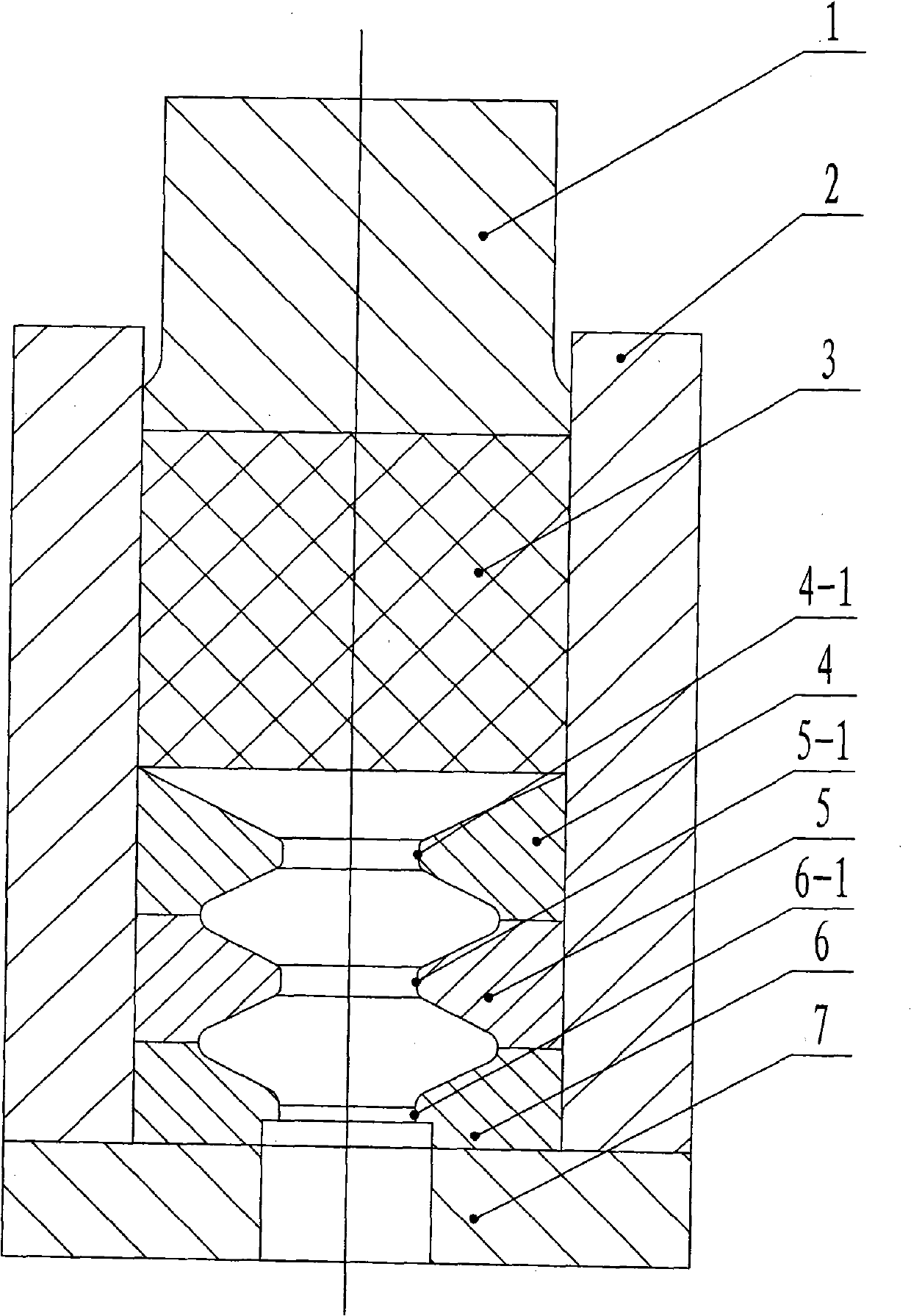

The invention relates to a device and a method for preparing fine-grained material by directly extruding a continuous variable cross section, which relate to a device and a method for preparing fine-grained material. The invention solves the problems of the traditional fine-grained material preparation methods that the procedures are complicated, the process requirements are high, the texture orientation is significant, the defects of folds and material interface superposition are easy to occur in processing and preparation and the preparation methods are difficult to be implemented in production. A primary transition die cavity, a secondary transition die cavity and a core die cavity of the preparation device of the invention are combined to form an axial corrugated extrusion cavity of the continuous variable cross section; the preparation method of the invention comprises the following steps: the preparation device is assembled; an ingot is arranged in a female die, a punch head is put it, a punch head is put in, the die orifice on a core die extrusion end is closed, the punch head descends, the ingot is extruded form a primary transition die orifice and a secondary transition die orifice, the punch head continues to descend, and the ingot is upset and deforms; and the closure is removed, the punch head continues to descend, and the ingot is extruded and formed. The invention requires simple equipment and few production procedures, and is easy to be implemented and popularized in production.

Owner:HARBIN UNIV OF SCI & TECH

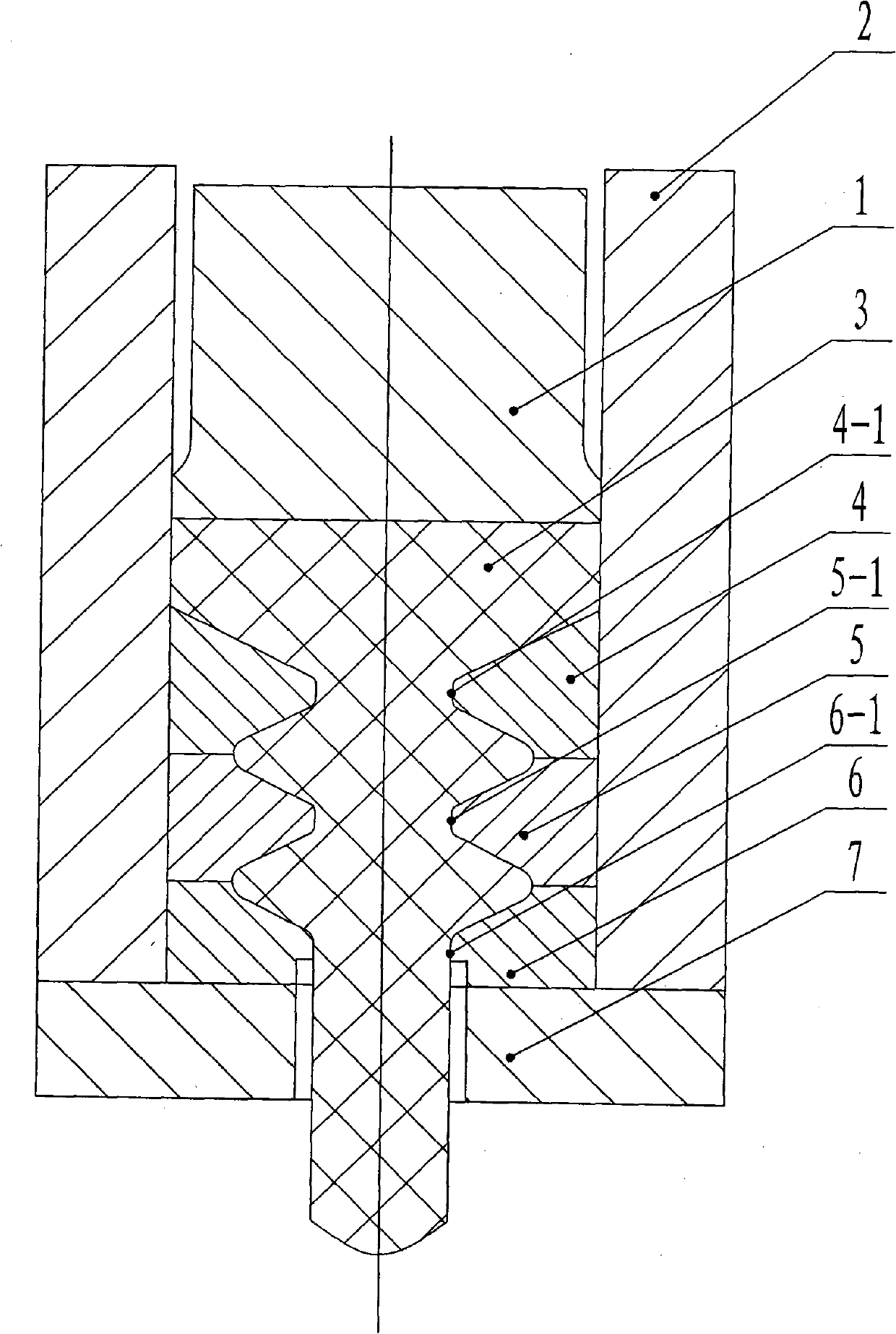

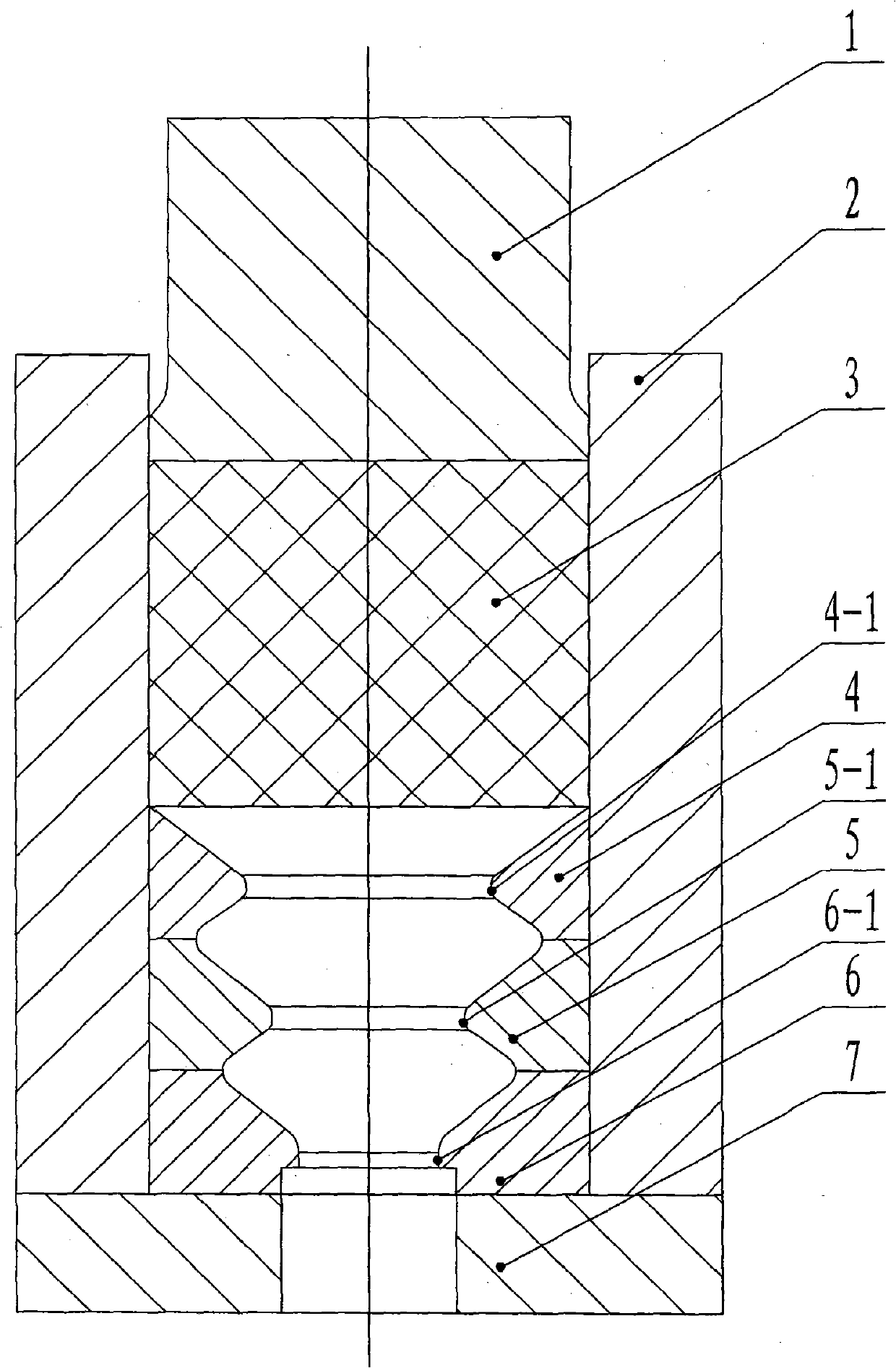

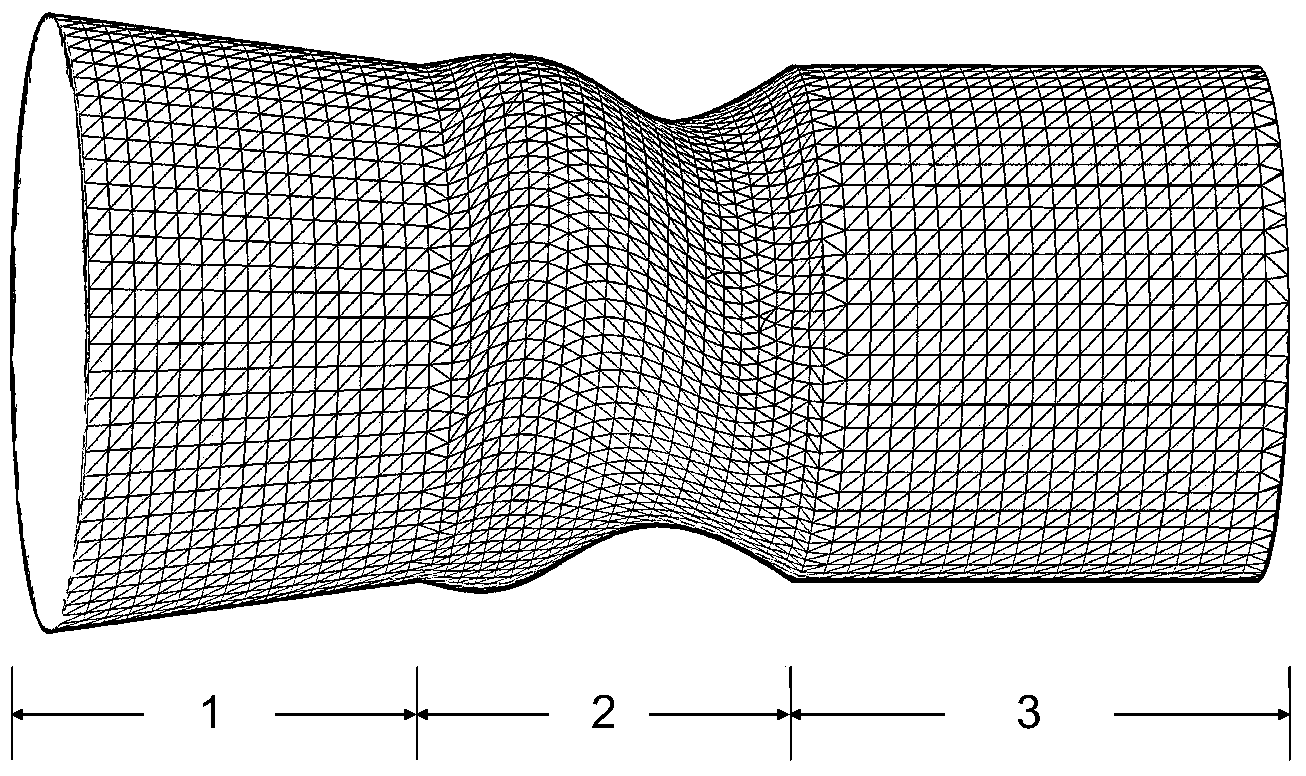

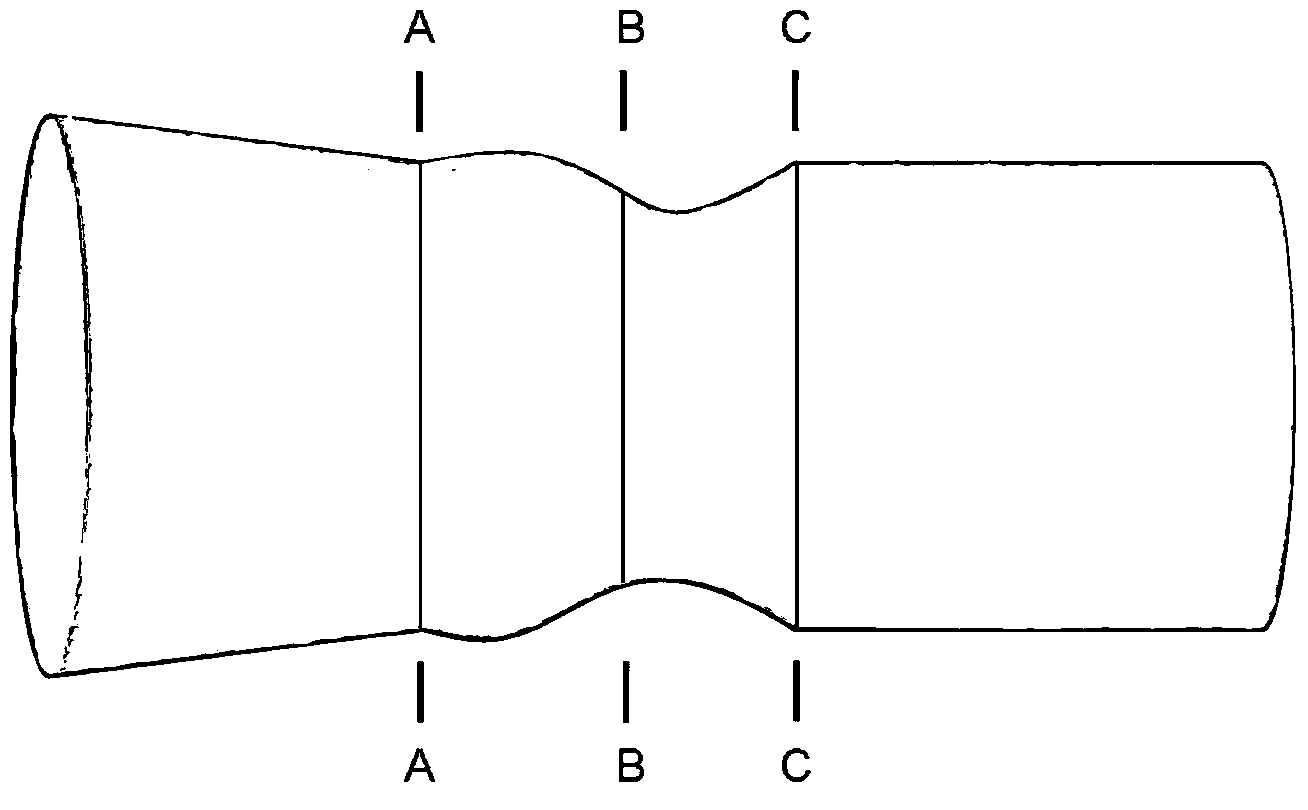

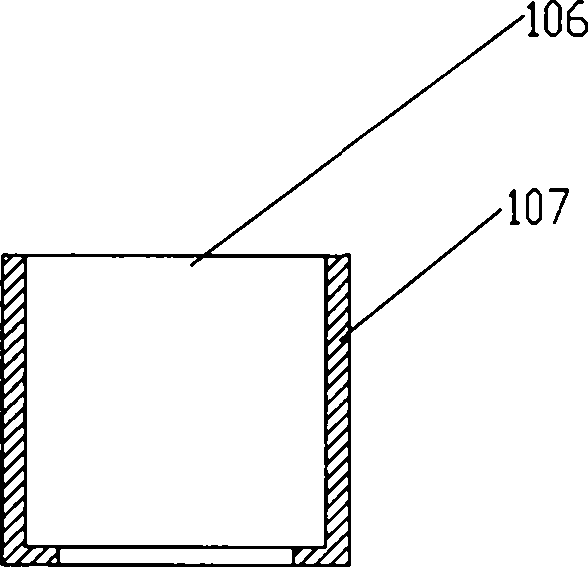

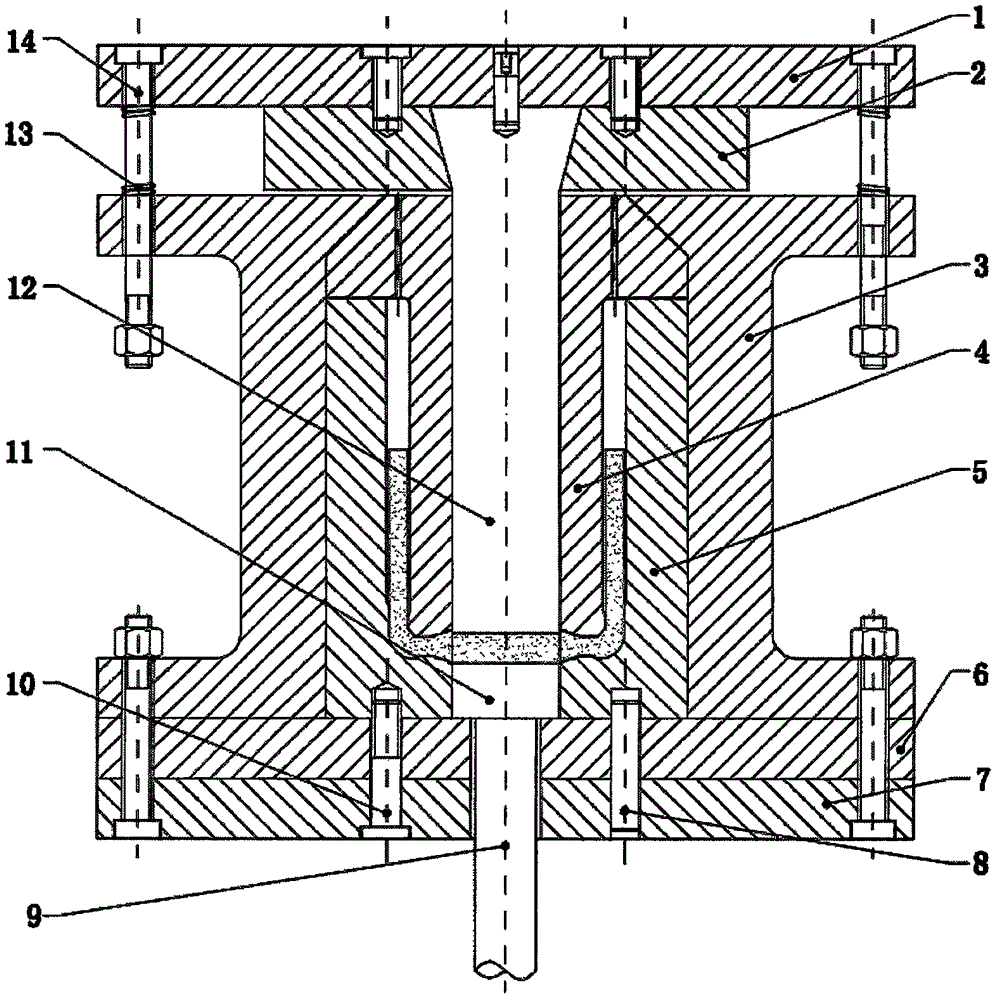

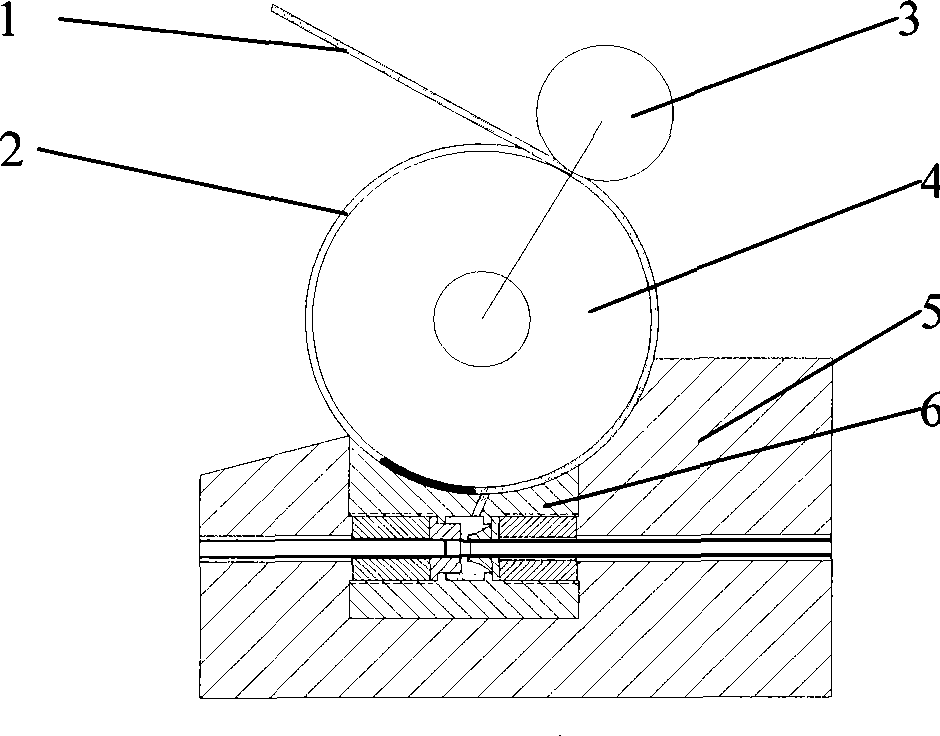

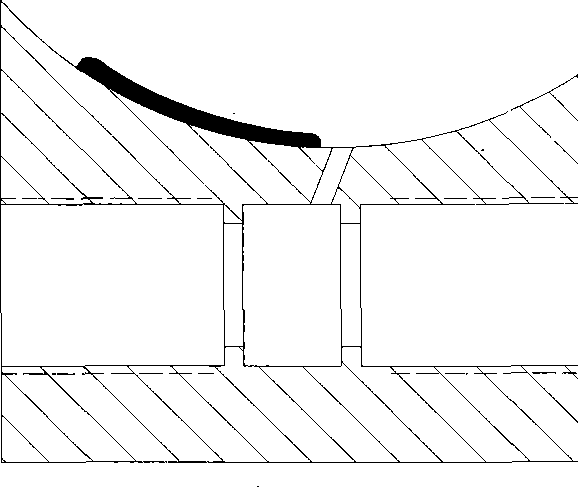

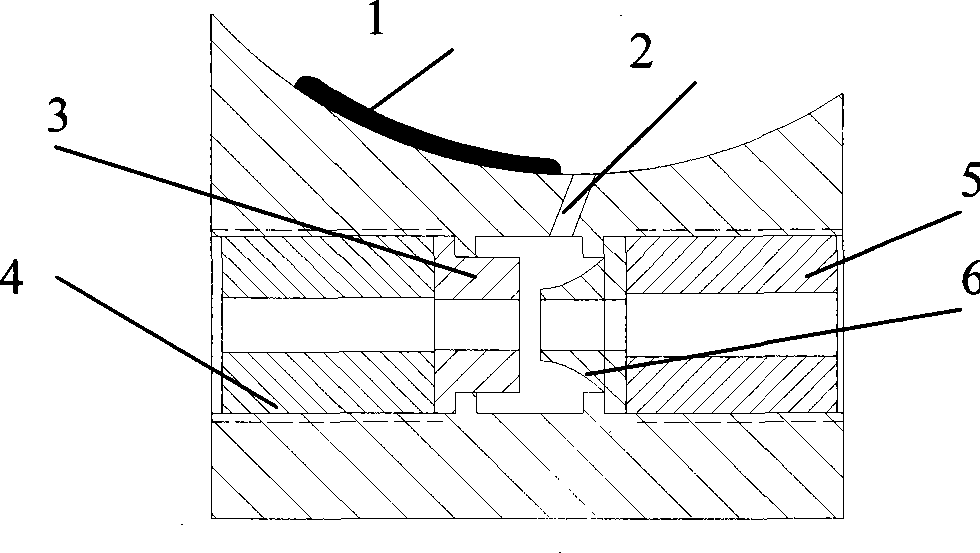

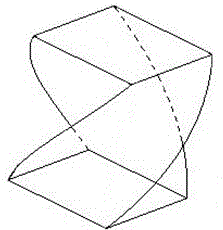

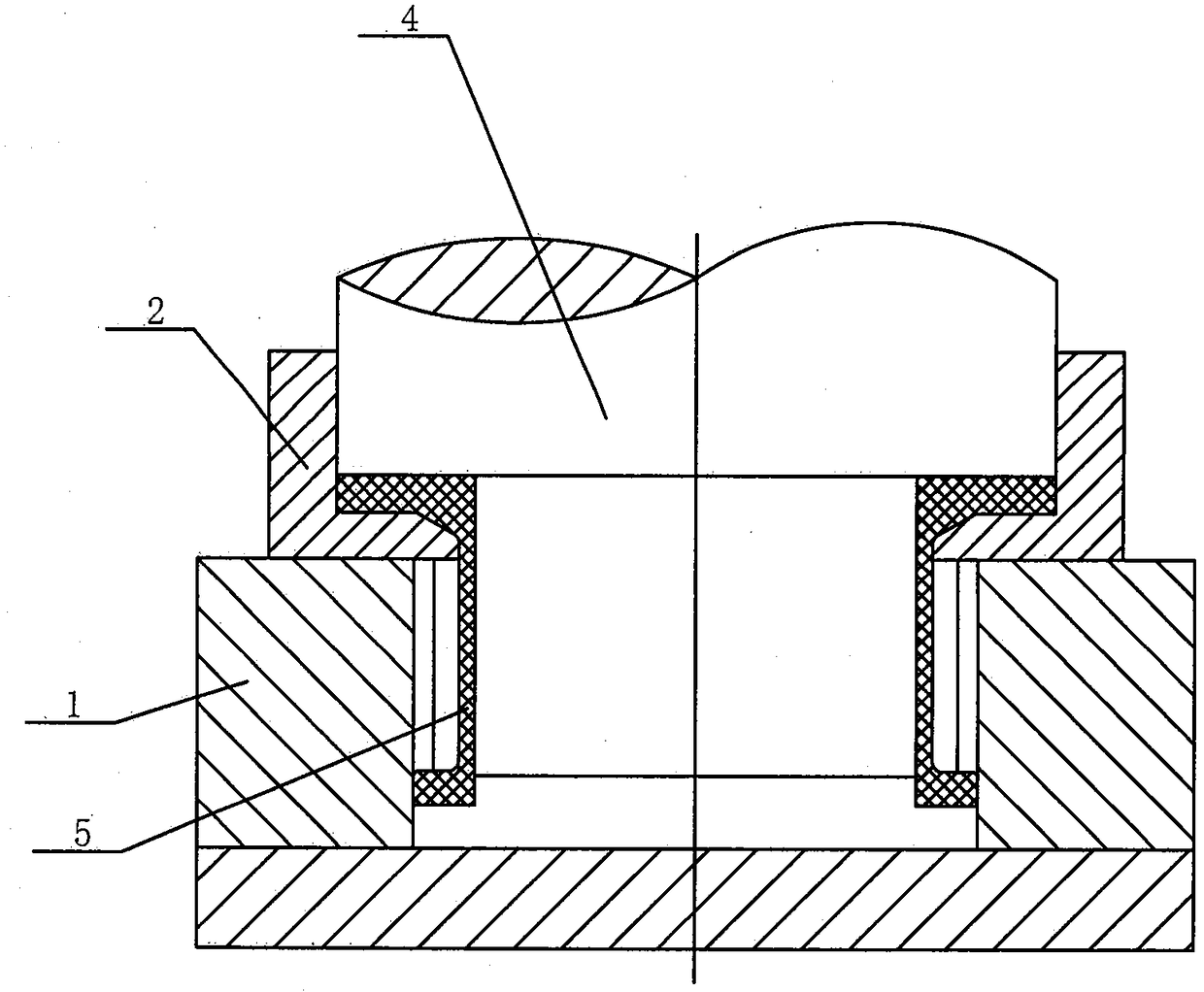

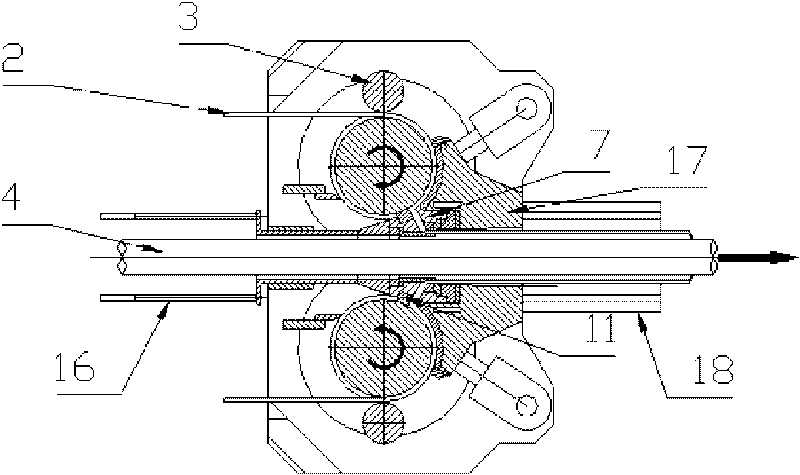

Equal-passage variable-cross-section extruding mold and extrusion forming method for pipes

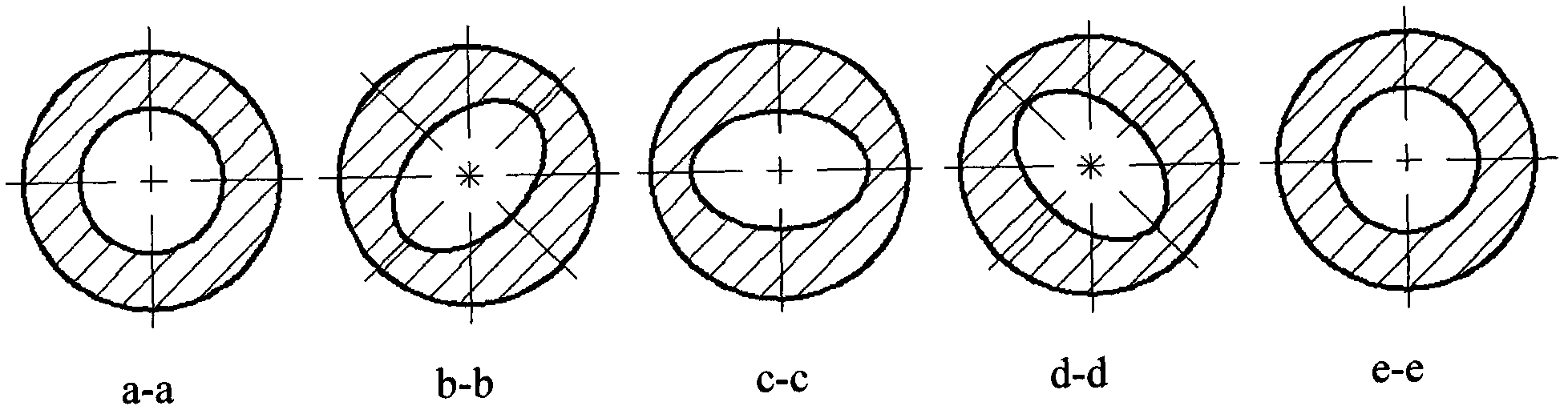

InactiveCN102430609AImproved strain distributionIncrease stressExtrusion diesExtrusion mandrelsStress distributionShear stress

The invention relates to an equal-passage variable-cross-section extruding mold and an extrusion forming method for pipes. The equal-passage variable-cross-section extruding forming is adopted, so the extruding forming of the pipes is formed through the twisting shearing deformation and the upsetting deformation on the cross section, and the combination of various deformation modes in one extruding process is realized. The pipe walls are in a strong three-direction press stress state through being limited by die cavities and polyurethane foam filling agents, in the deformation stage of circle-ellipse-circle and ellipse twisting change, materials enter twisting shearing deformation zones of the metal transition regions, the material internal tissues generate rotation and shearing stress under the effect of the shearing stress, the orientation of the material tissue structure is caused, i.e. a new tissue structure is formed, and the material tissue structure under the same deformation degree is improved. The mold and the method have the advantages that deformation degree higher than that of the traditional forming process can be obtained, the strain distribution and the stress distribution inside the pipes are improved, residue casting tissues of the pipes can be favorably crushed, the forms and the distribution of inclusions are changed, and the internal tissue defects of the pipes are eliminated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

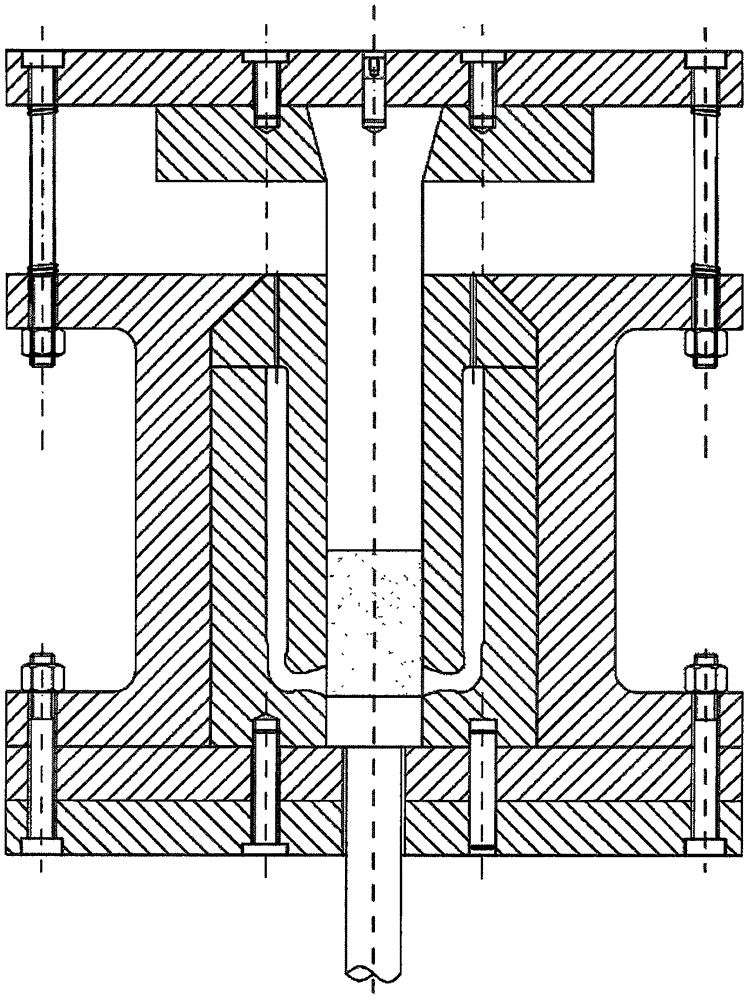

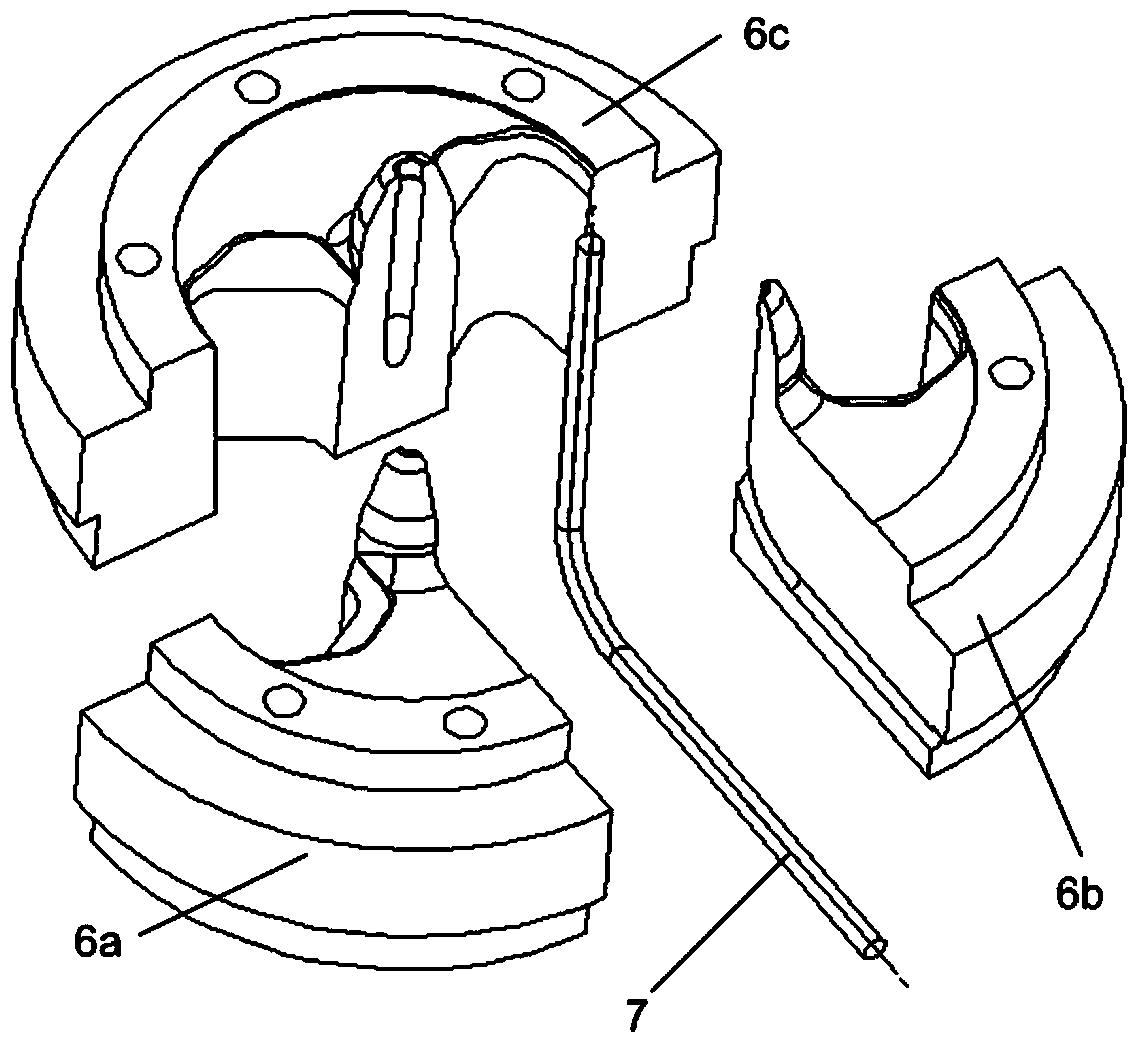

Circular channel and corner based extruding and moulding mold and circular channel and corner based extruding and moulding method of magnesium alloy cup-shaped component

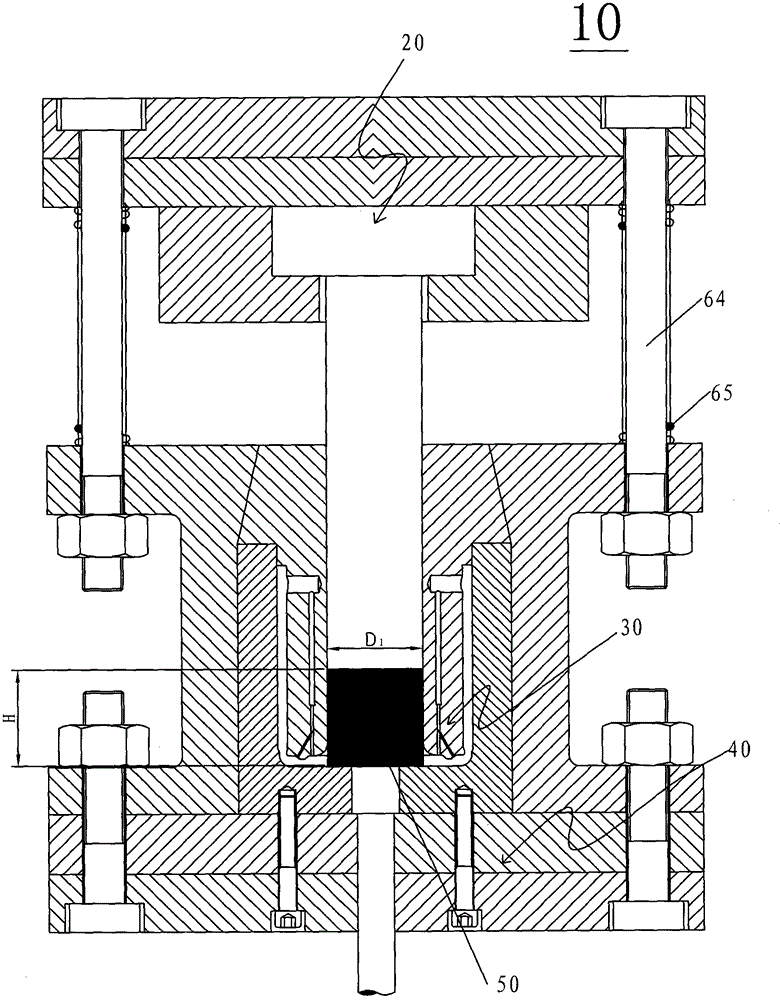

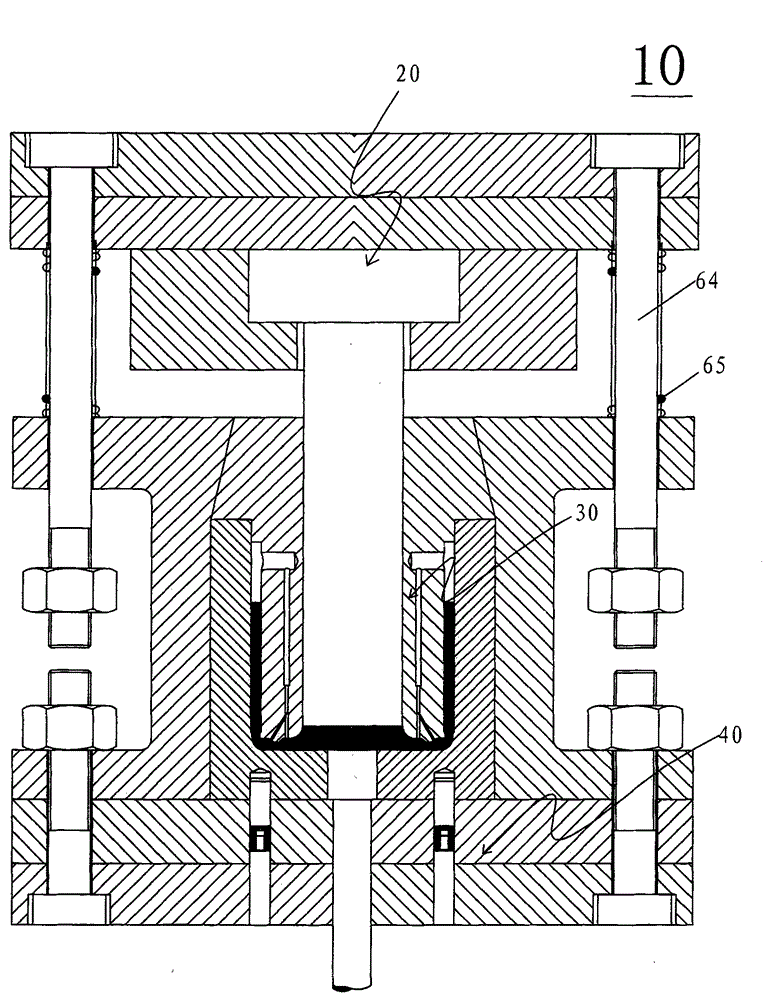

ActiveCN104588428AGood formabilityReduce performance anisotropyExtrusion diesExtrusion mandrelsChinese charactersMetal

The invention discloses a circular channel and corner based extruding and moulding mold and a circular channel and corner based extruding and moulding method of a magnesium alloy cup-shaped component. The mold mainly adopting a combined die, and the combined die comprises a U-shaped lower die and a T-shaped upper die; the middle part of the T-shaped upper die is provided with a long l-shaped cavity; the T-shaped upper die is arranged on the U-shaped lower die; and the cross section of the cavity of a formed rotor is shaped like a Chinese character 'shan'. A blank is put in the l-shaped cavity in the middle of the T-shaped upper die, the upper end of the blank is extruded by a male die, the metal on the lower end of the blank is deformed by upsetting to flow radially, and while being further deformed by upsetting, the metal is backwards extruded and deformed to flow axially along the wall of a female die, so that the cylindrical wall of the cup-shaped component is formed. By adopting the circular channel and corner based extruding and moulding mold, the magnesium alloy can be greatly improved in forming capacity and significantly refined and compacted in structure, the performance anisotropy of the magnesium alloy cup-shaped component can be reduced, and the manufacturing process of the high-performance magnesium alloy cup-shaped component can be shortened.

Owner:ZHONGBEI UNIV

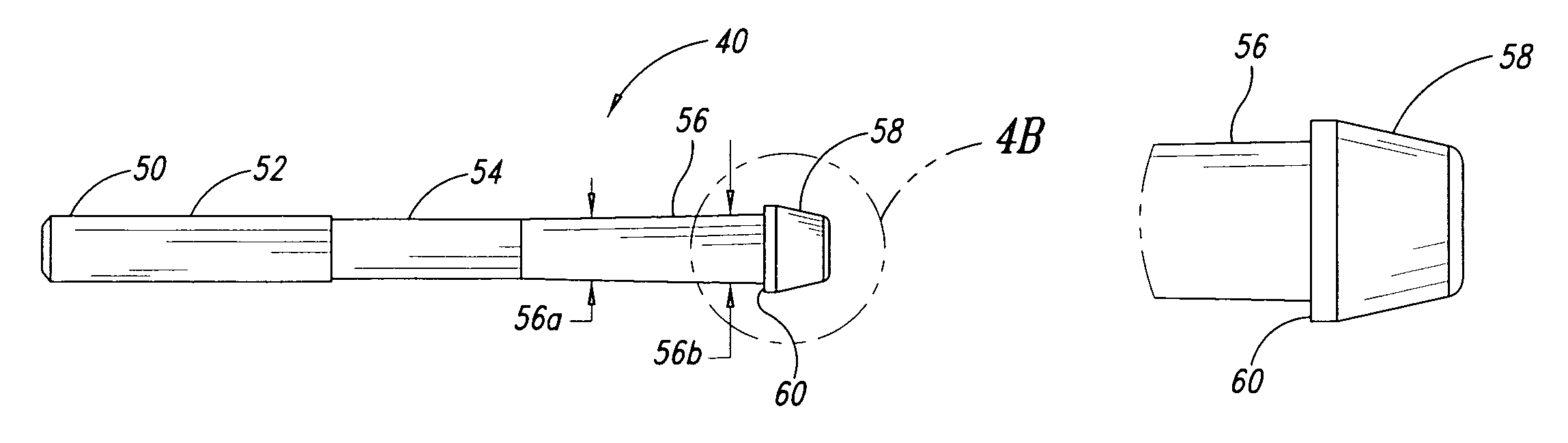

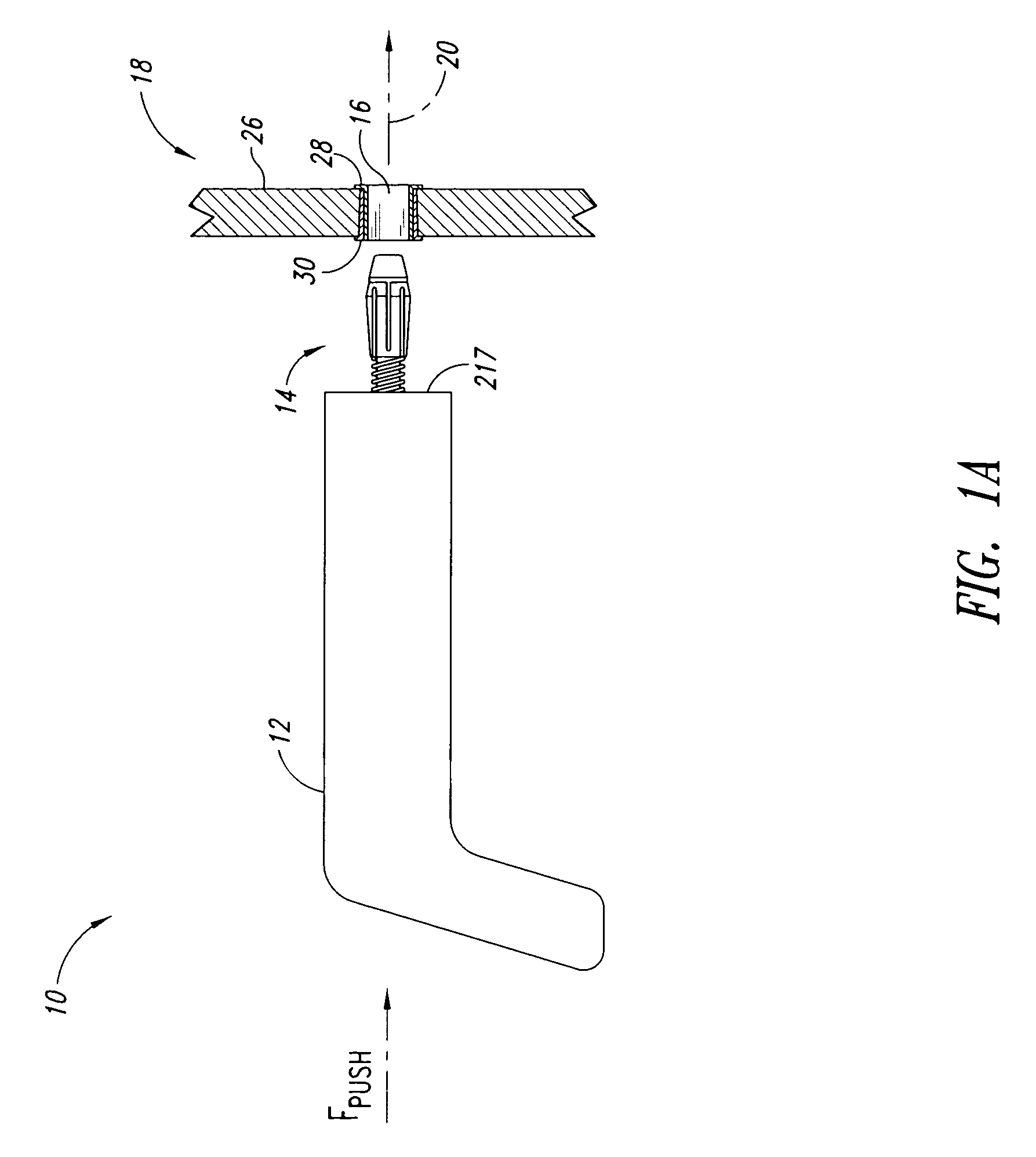

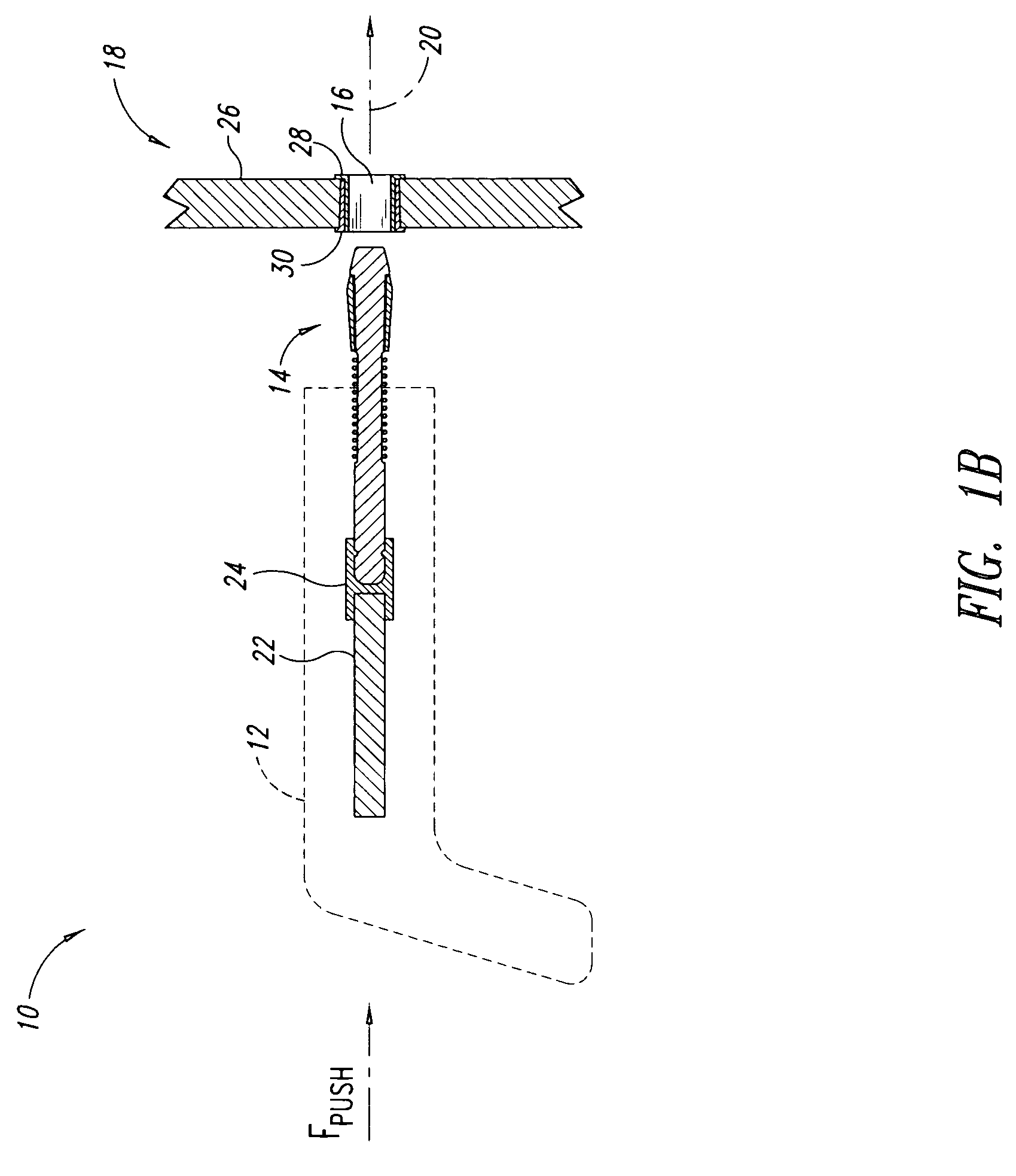

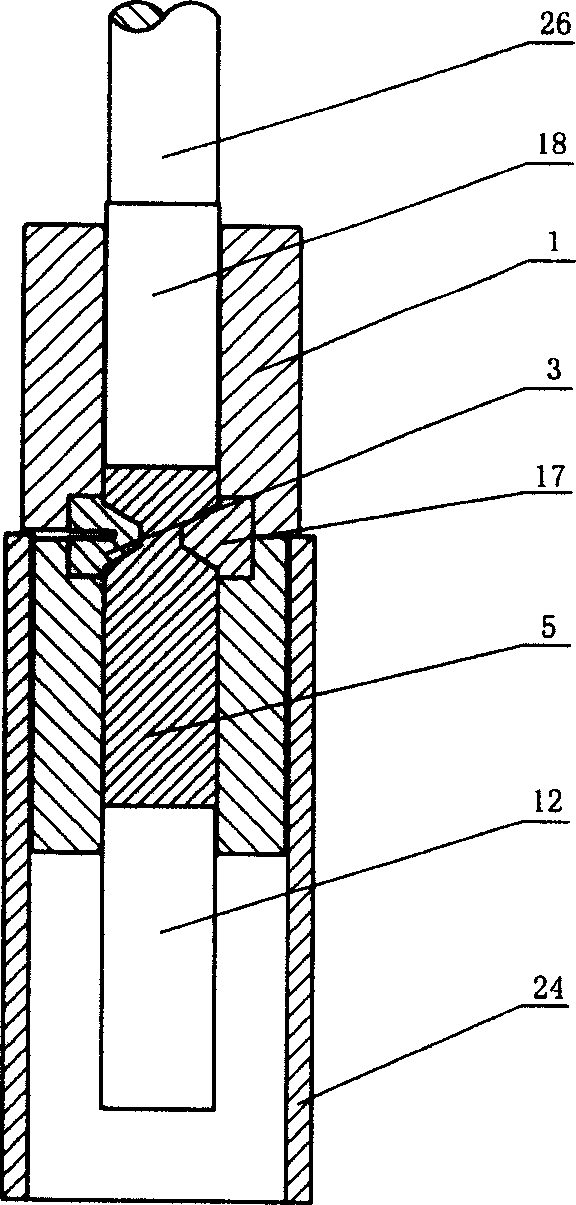

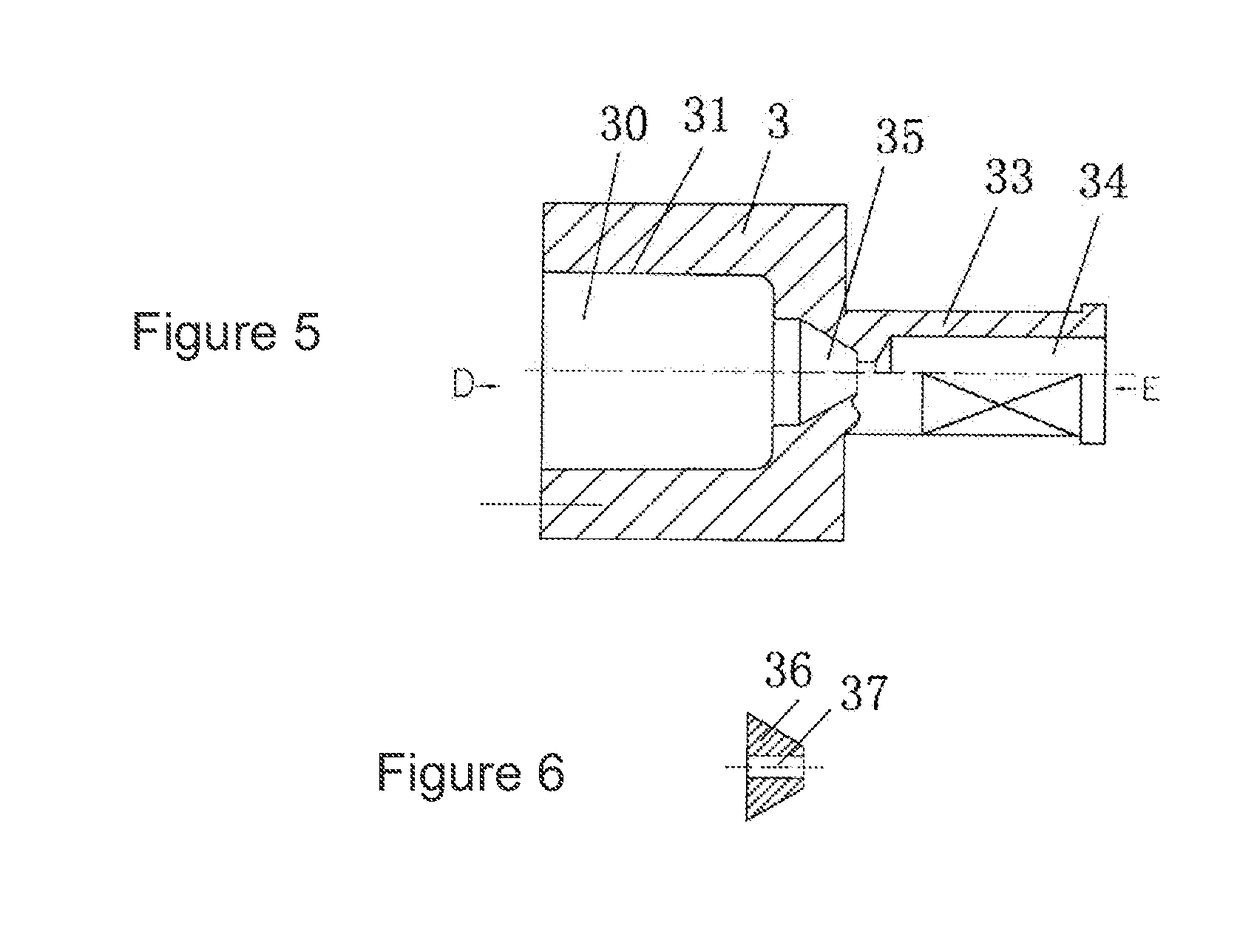

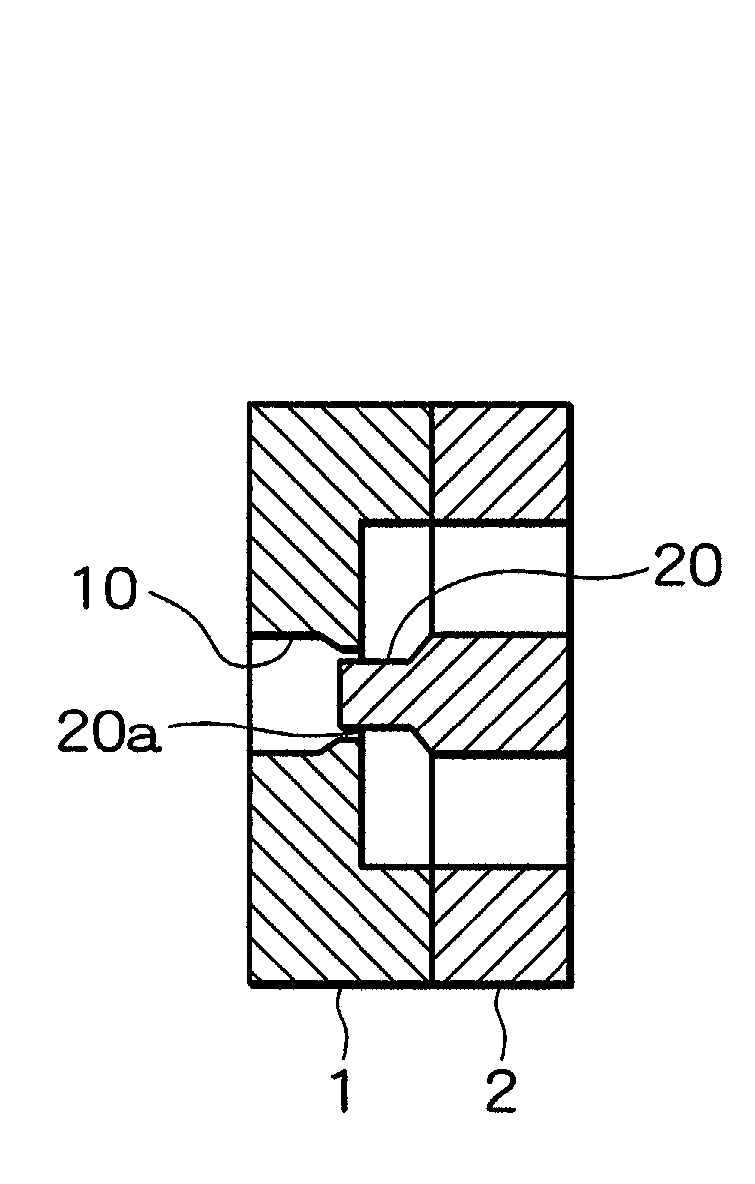

Mandrel assembly and method of using the same

ActiveUS7509829B2Restrict movementExtrusion mandrelsForging/hammering/pressing machinesEngineeringMechanical engineering

A mandrel assembly has a mandrel, a biasing member, and a outer member. The biasing member biasly maintains the outer member in a first position, which corresponds to a contoured portion of the mandrel, when the outer member is either on the access or the blind side of a workpiece. The biasing member is compressible to allow the outer member to move into a second position as the outer member is moved through an opening in the workpiece. In the first position, the outer member includes a maximum outer circumference that is larger than the opening of the structural workpiece. In the second position, the outer member includes a maximum outer circumference that fits within the opening of the structural workpiece.

Owner:FATIGUE TECH

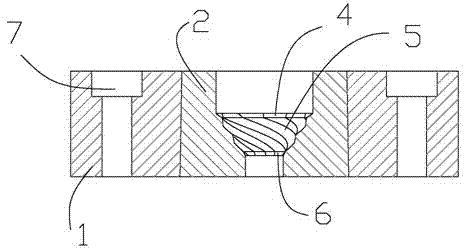

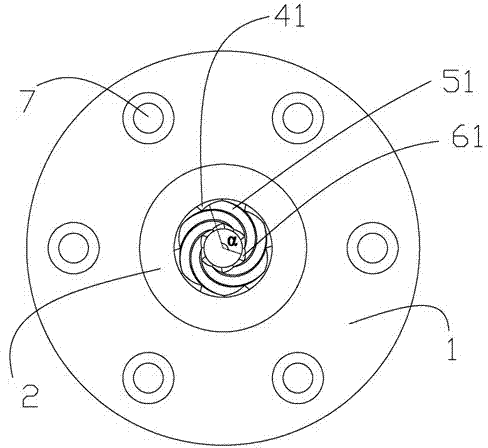

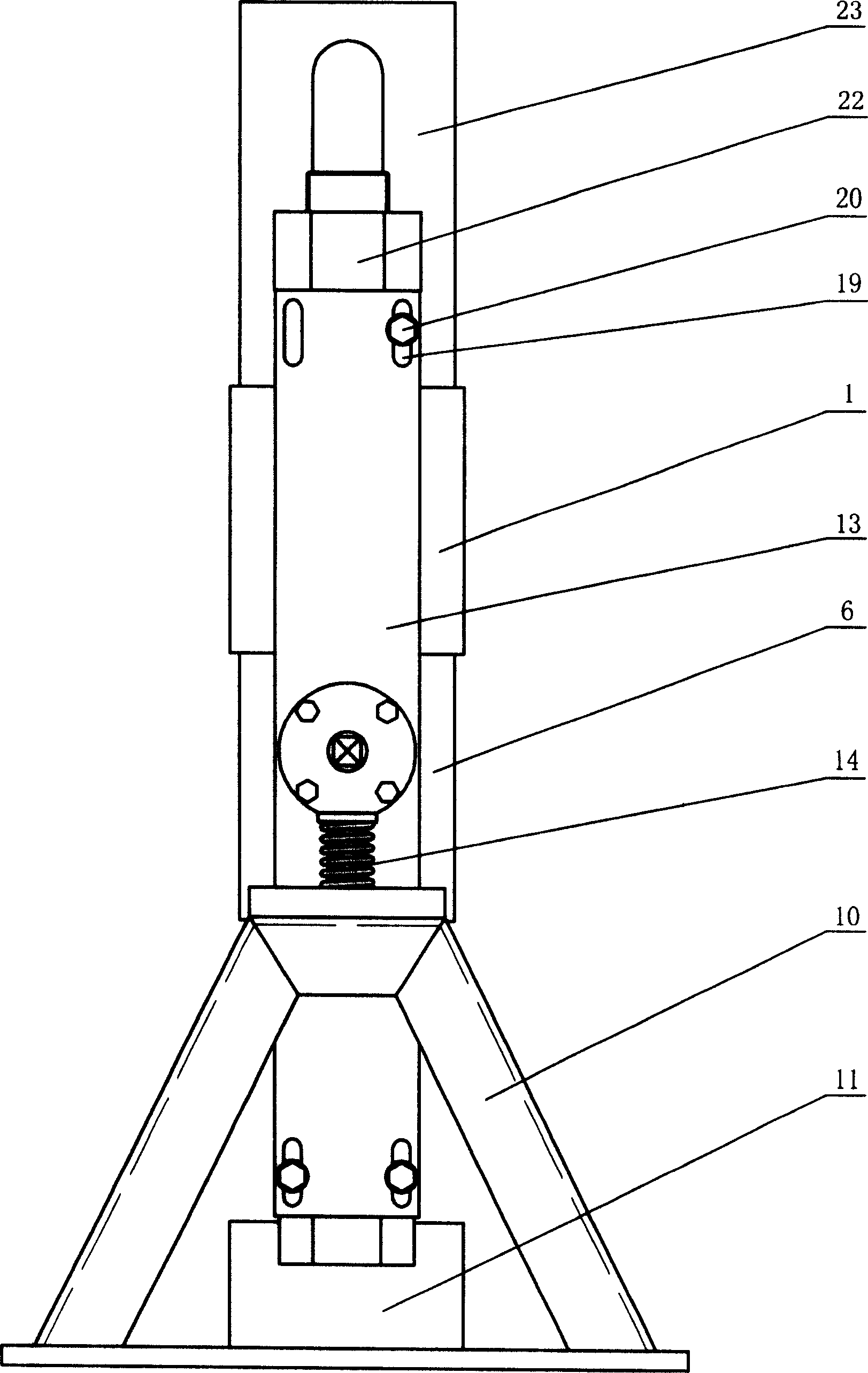

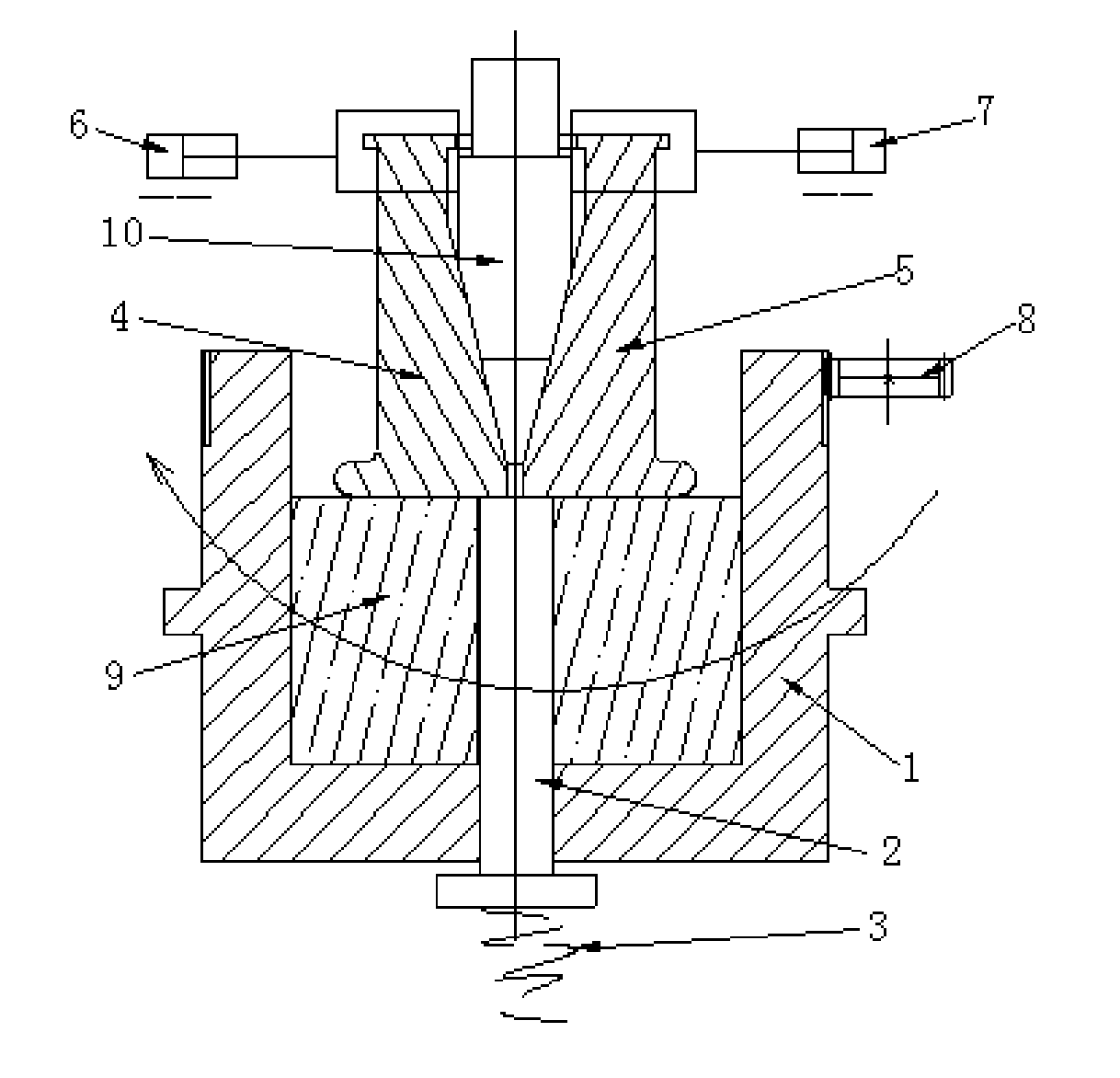

Vortex extrusion type large-plastic deformation device

ActiveCN103785702AIncrease work intensityRealize the twistExtrusion diesExtrusion mandrelsInterference fitExtrusion

The invention discloses a vortex extrusion type large-plastic deformation device which comprises a device main body, wherein the device main body comprises an outer-layer reinforcing ring and an inner-layer concave die in interference fit with the outer-layer reinforcing ring, the inner-layer concave die is provided with a twisting extrusion chamber which is necked from the upper port to the lower port, a twisting extrusion deformation region is formed in the twisting extrusion chamber and comprises a deformation band composed of a plurality of stripe projections or a plurality of stripe grooves, the upper end portions of the stripe projections or the stripe grooves are capable of extending to the upper port of the twisting extrusion chamber, and the lower end portions of the stripe projections or the stripe grooves are capable of extending to the lower port of the twisting extrusion chamber. The vortex extrusion type large-plastic deformation device integrates twisting and extrusion techniques, so that the device is capable of realizing twisting of a material without rotating the die with an extra device and capable of achieving the same effect only through structural design; besides, the device is capable of preventing sliding between the material and the die while twisting; moreover, the device is simple and convenient in design.

Owner:HEFEI UNIV OF TECH

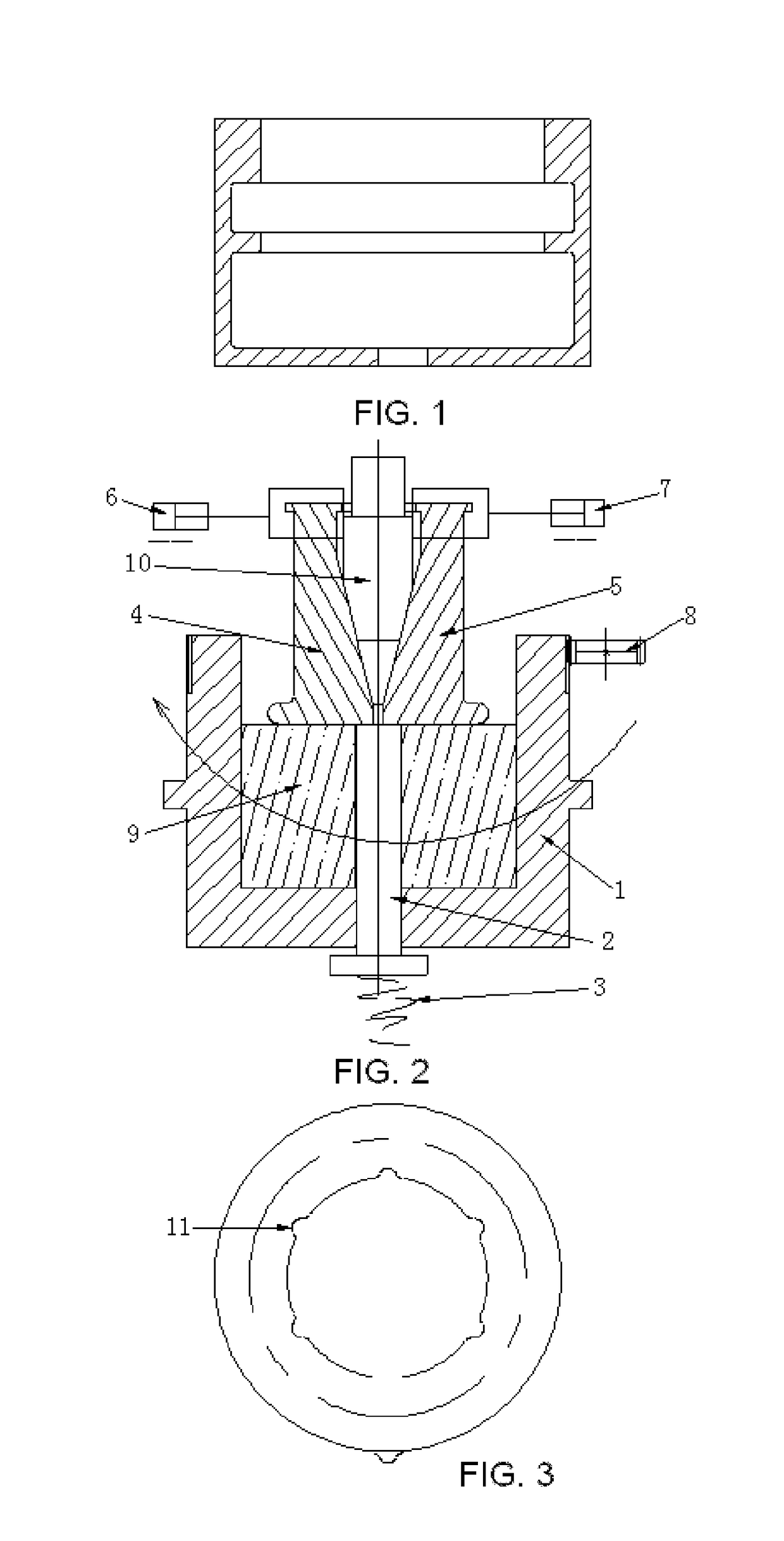

Equal-channel extrusion mold for forming powder superalloy blank

InactiveCN103447341ASimple structureImprove general performanceExtrusion diesExtrusion mandrelsShear stressAlloy

The invention discloses an equal-channel extrusion mold for forming a powder superalloy blank, which is specifically used for improving the organizational characteristics of a powder superalloy blank. After a forging blank enters the mold, the round section of the forging blank is twisted to be elliptical and then to be round again, the deformation is combination of twisting and shearing deformation and extruding deformation, and thus the combination of multiple deformation modes in one-pass extruding process is realized. At the transitional section of deformation and twisting, due to the twisting deformation of the elliptical twisting surface, the blank rotates and is subjected to shearing strain under the action of shearing stress so as to realize shearing and crushing of crystal grains and further achieve the effect of refining the grains; simultaneously, since the blank is limited by a mold cavity, the intracrystalline deformation of the blank in the state of pressure stress is difficult, and thus the development of various original microscopic defects in a deformed body can be inhibited; since the refining effect of the grains in the extruding process is obvious, original grain boundaries are eliminated thoroughly, and the comprehensive mechanical property of the powder superalloy blank is obviously improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

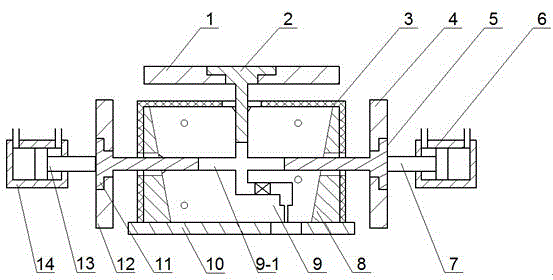

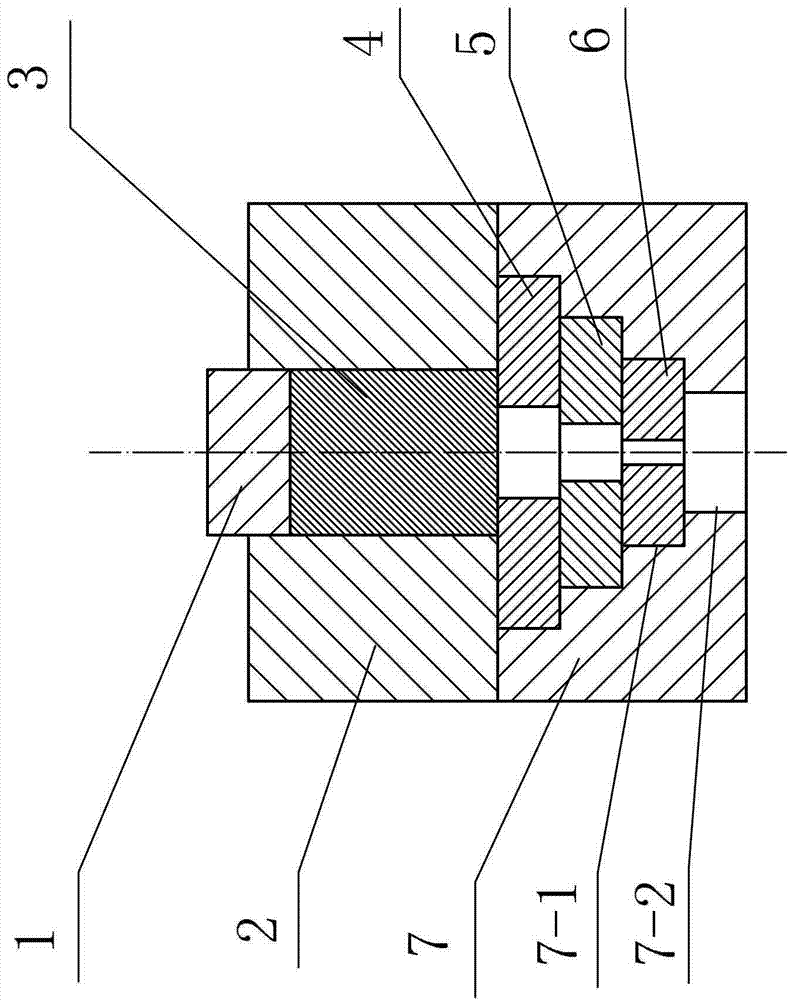

Extrusion forming mold for cylinder with rib-equipped inner and outer special-shaped surfaces

InactiveCN103567248ASolve difficult to shapeSolve the demoulding problemExtrusion diesExtrusion mandrelsPre stressMaterials science

The invention discloses an extrusion forming mold for a cylinder with rib-equipped inner and outer special-shaped surfaces. The extrusion forming mold comprises an upper mold plate, a core shaft, a separated concave mold, a prestressed ring, a separated convex mold mechanism, a lower mold plate, an ejection mechanism and a mold release mechanism, wherein the upper end of the core shaft is fixedly arranged below the upper mold plate, and the lower end of the core shaft is provided with a cone-shaped head; the prestressed ring is arranged above a lower backing plate, and a straight-wall cavity is formed in the middle of the prestressed ring; an ejection rod mechanism comprises an ejection rod and an ejection block, the ejection rod is movably arranged in an ejection rod through hole of the lower mold plate, and the ejection block is arranged at the bottom of the straight-wall cavity; the separated concave mold is integrally and movably arranged in the straight-wall cavity and is longitudinally divided into more than two petals, a concave mold cavity is formed in the middle of the separated concave mold, and a inverted-cone-shaped mold-separating cavity is formed in the outer periphery of the top of the separated concave mold; the separated convex mold mechanism is integrally arranged in the concave mold cavity and comprises a separated convex mold and a convex mold fixing plate, an inverted cone-shaped cavity is formed in the middle of the separated convex mold, a cone-shaped head is formed at the outer periphery of the top of the separated convex mold, the separated convex mold is divided into more than two petals, and each convex mold can slide on the convex mold fixing plate along the radial direction; the mold release mechanism comprises a stroke extending block and a stroke returning ring, a cone-shaped ring cavity is formed in the middle of the stroke returning ring, and the stroke extending block is a wedge-shaped block.

Owner:ZHONGBEI UNIV

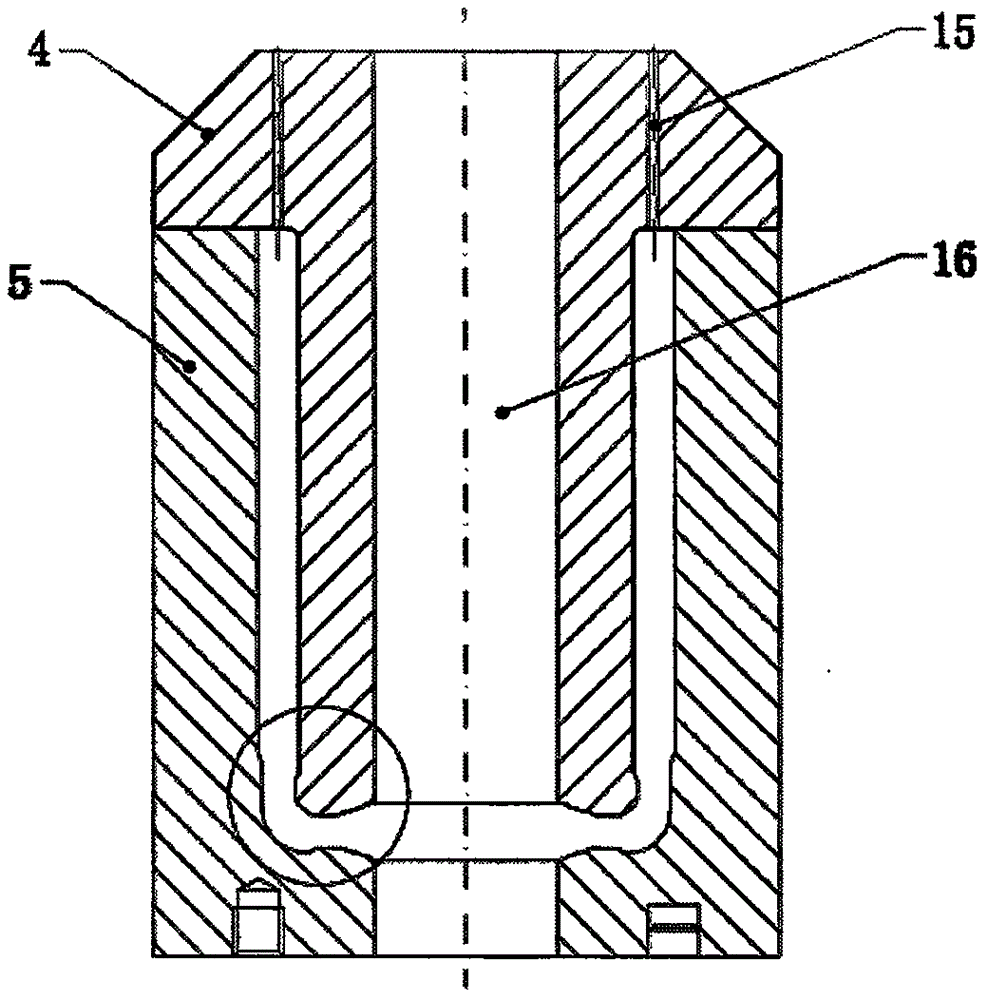

Differential extrusion forming die of high-performance magnesium alloy cup-shaped part

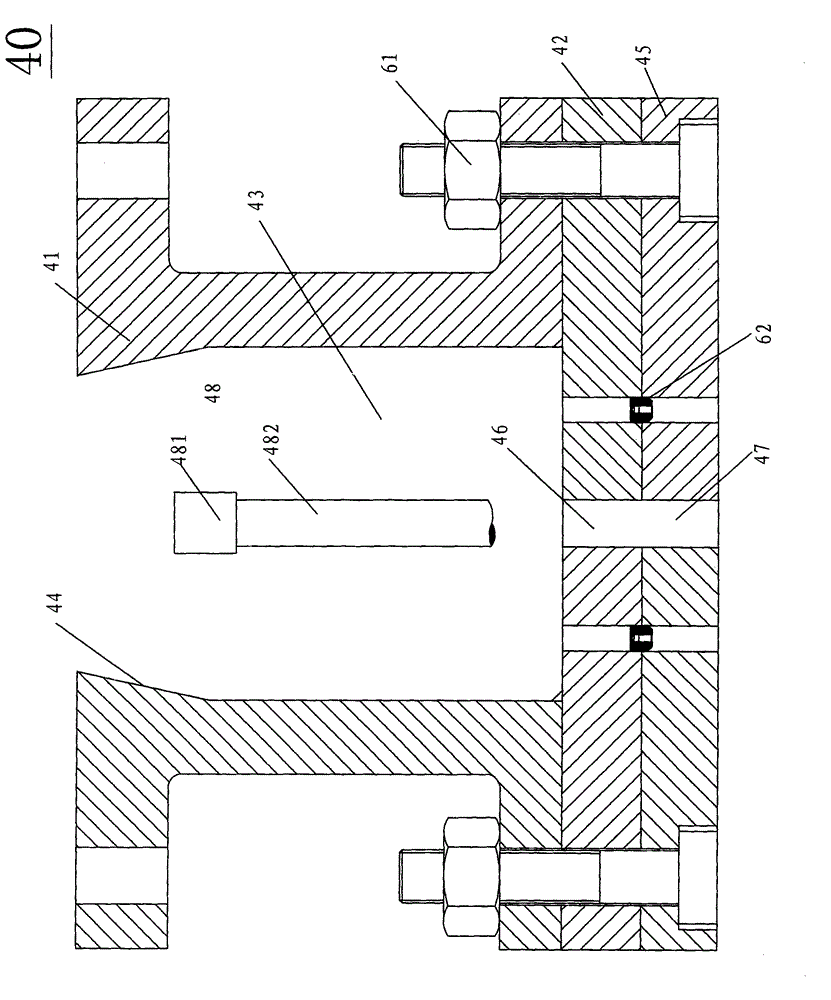

ActiveCN106825098AIncrease the number of deformationsIncrease the amount of plastic deformationExtrusion diesExtrusion mandrelsChinese charactersMachining process

The invention discloses a differential extrusion forming die of a high-performance magnesium alloy cup-shaped part and relates to the technical field of metal plastic machining processes and forming. A combined type female die comprising a T-shaped upper female die body and a U-shaped lower female die body is adopted. A cylindrical cavity is formed inside the T-shaped upper concave die body mounted on the U-shaped lower concave die body, and the cross section of a formed revolution body cavity is shaped like the Chinese character 'shan'. Staggered ladder type differential extrusion steps are arranged at the bottom of the extrusion cavity shaped like the Chinese character 'shan'. The magnesium alloy cup-shaped part is extruded through the extrusion cavity shaped like the Chinese character 'shan' and the staggered ladder type differential extrusion steps at the bottom of the cavity, so that the forming capacity of a magnesium alloy material is improved greatly, a high compact structure and large plastic deformation are obtained, the grain refining effect is significant, the effect of removing grain dual modality distribution of the cylinder wall of the cup-shaped part is obvious, and the manufacturing process of the high-performance magnesium alloy cup-shaped part is accelerated.

Owner:ZHONGBEI UNIV

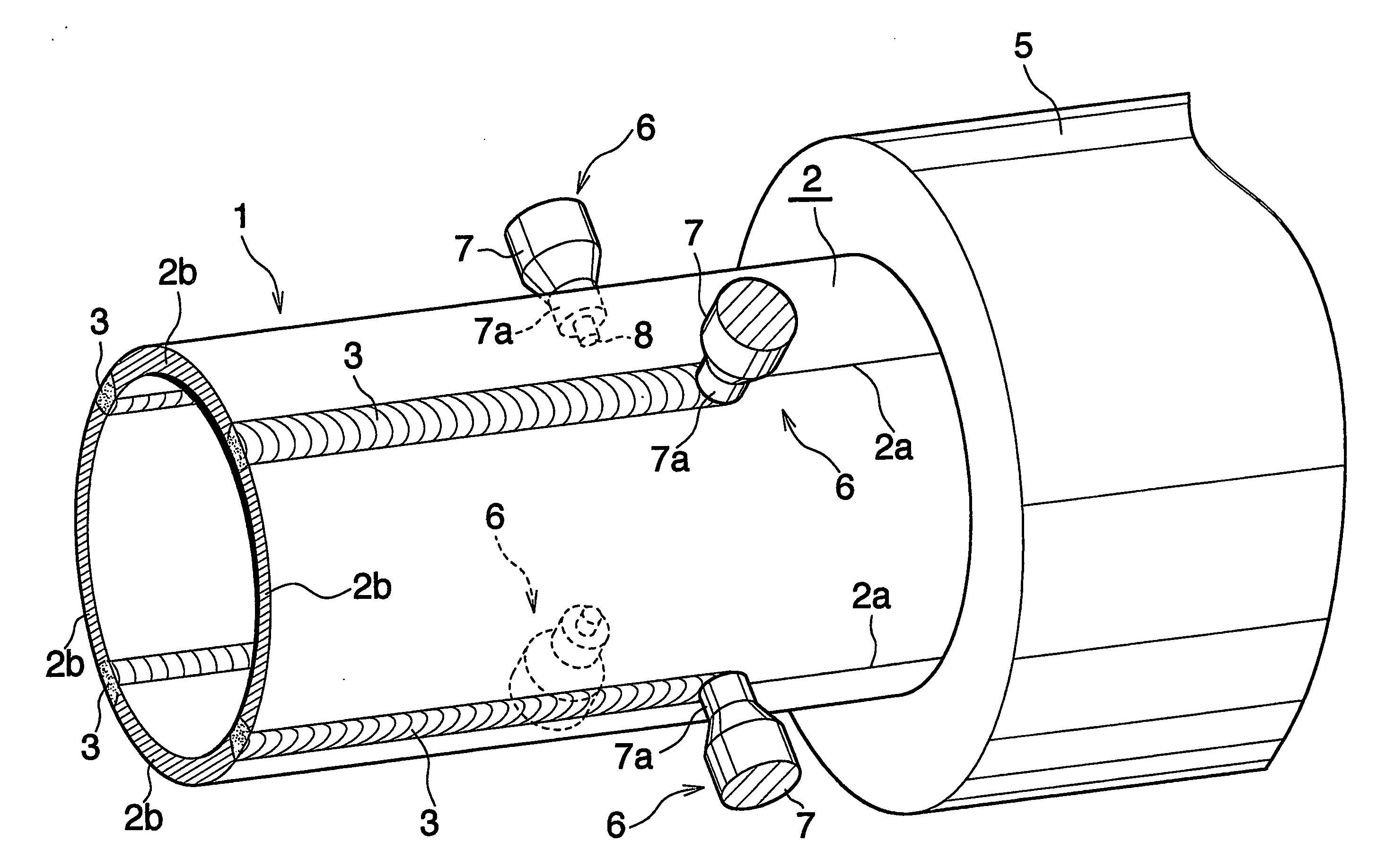

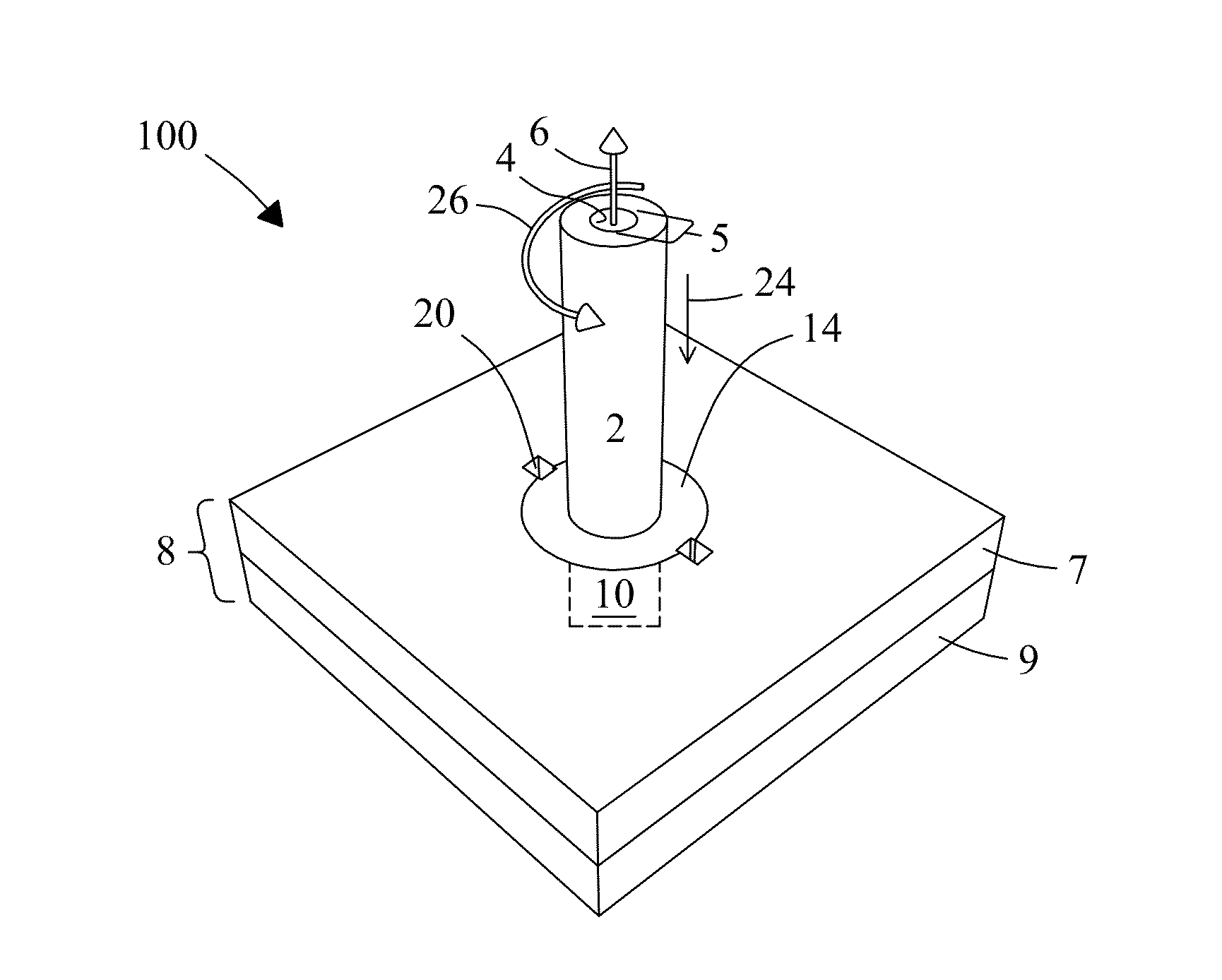

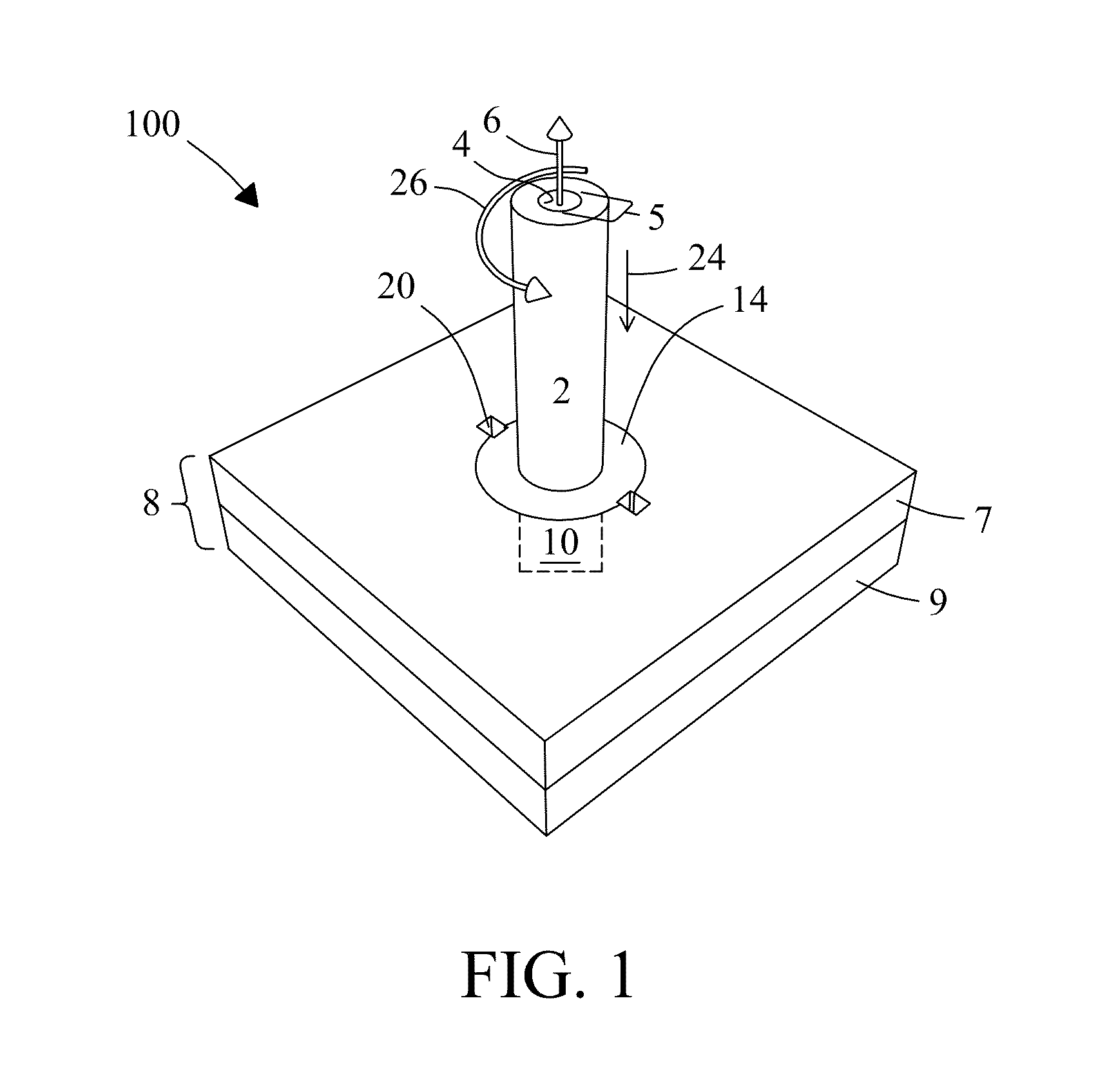

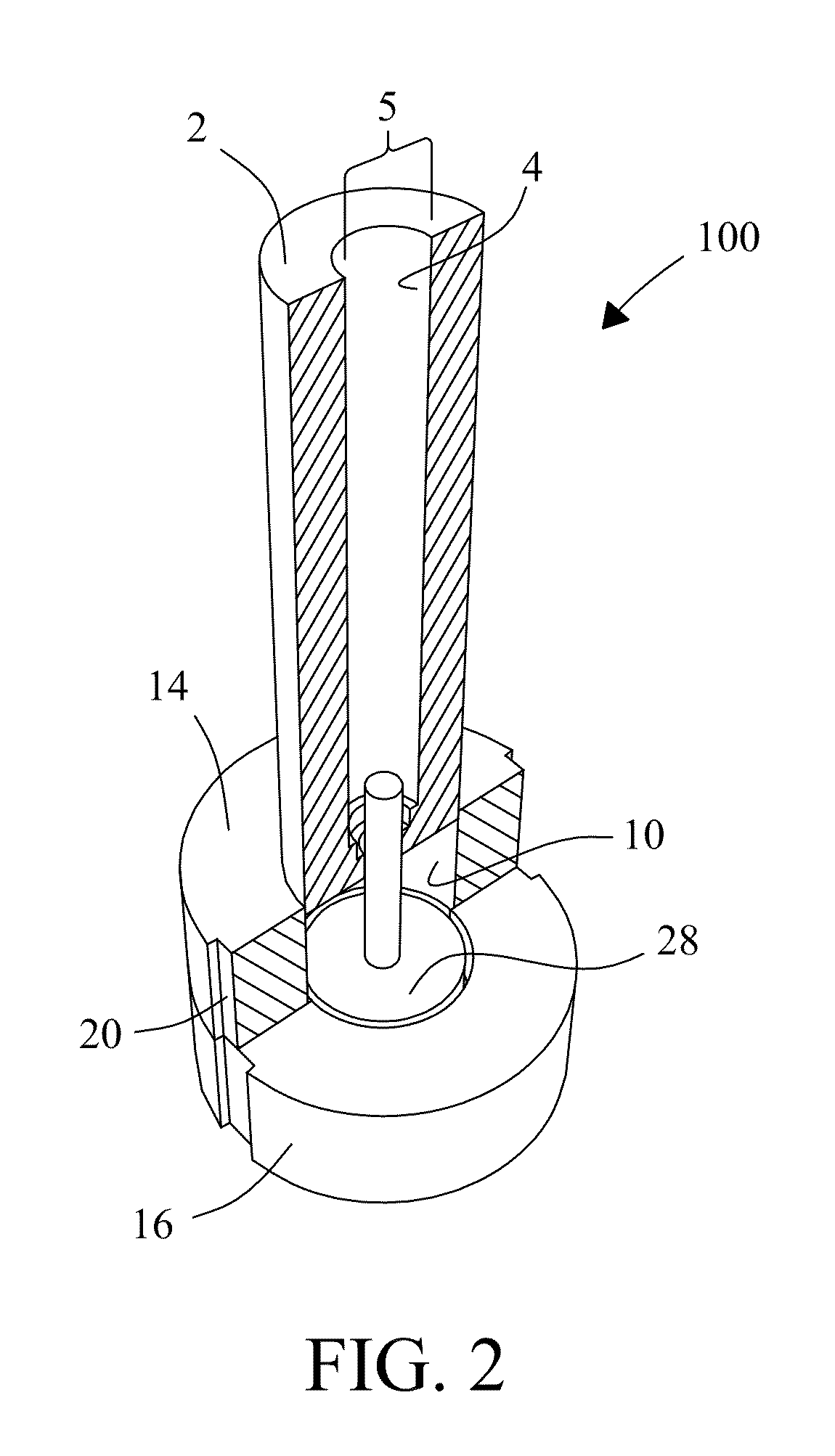

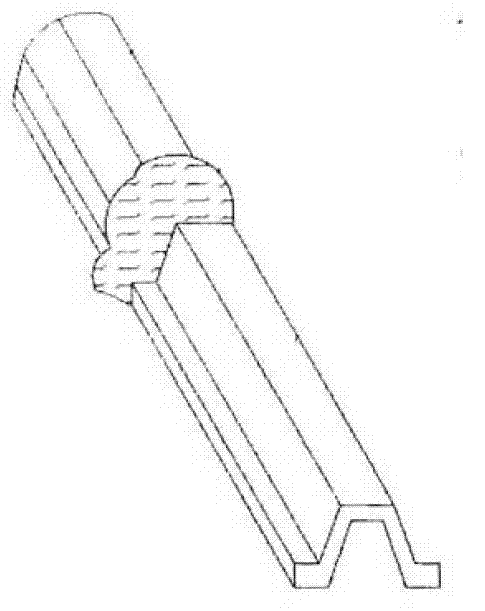

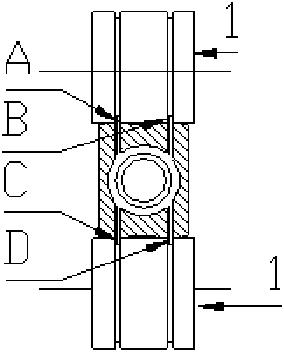

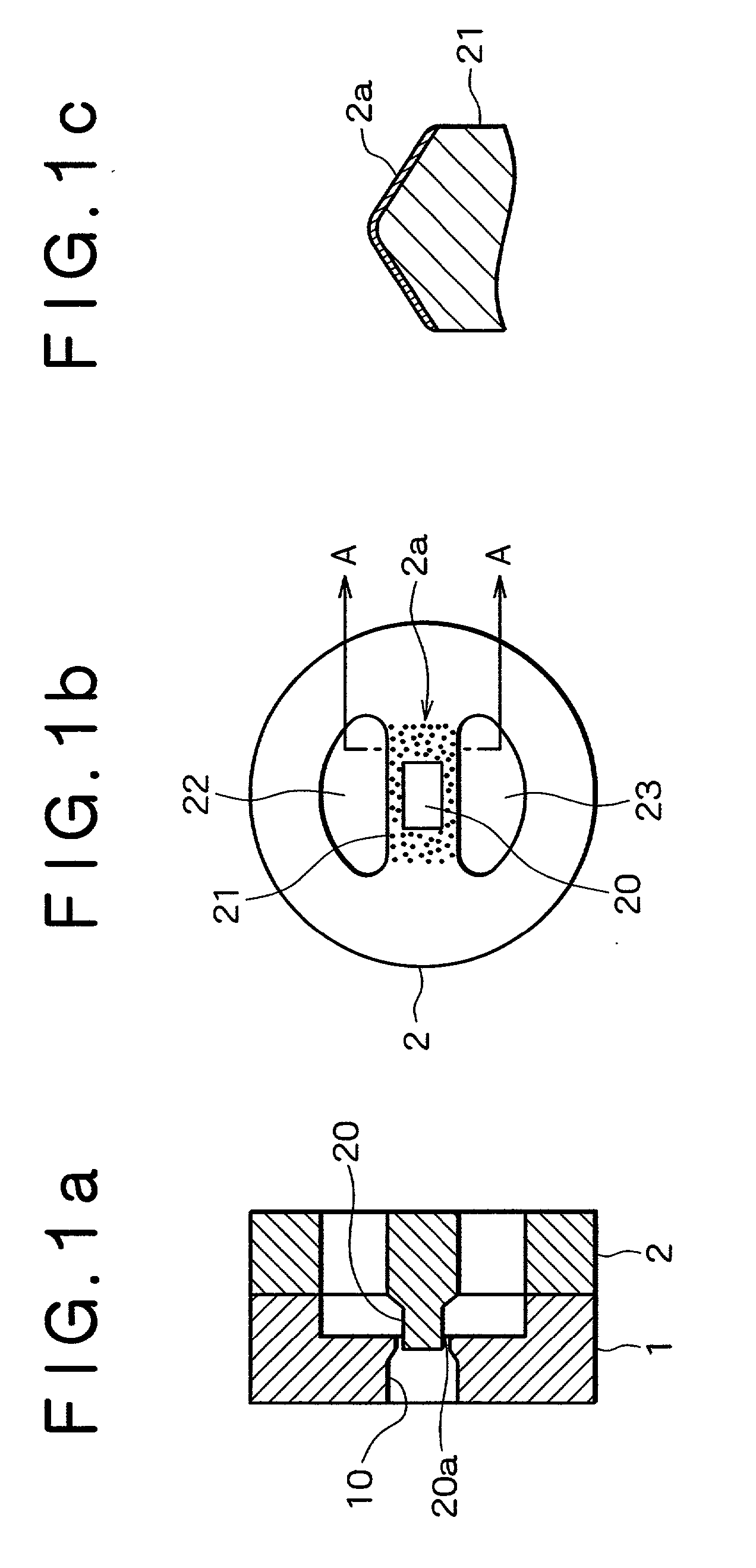

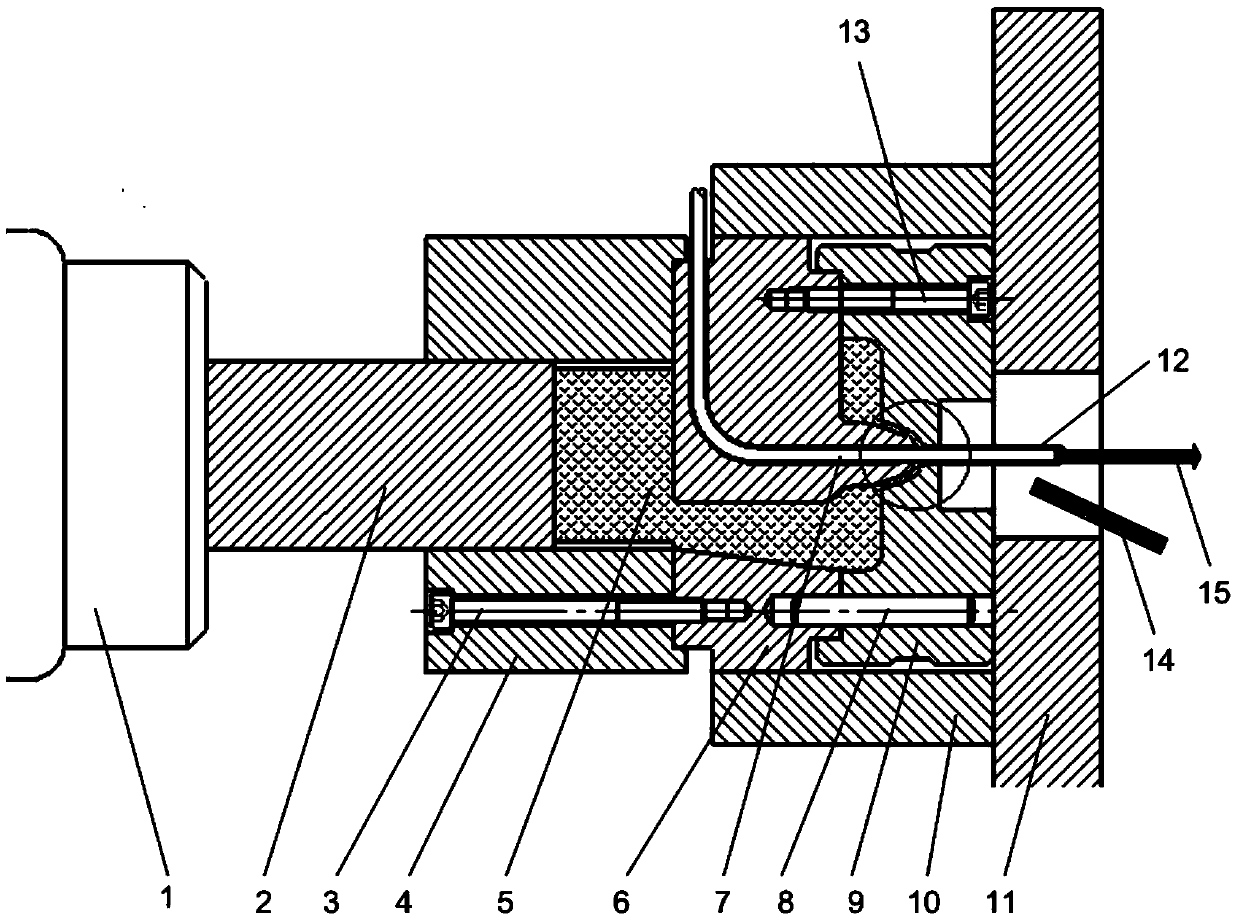

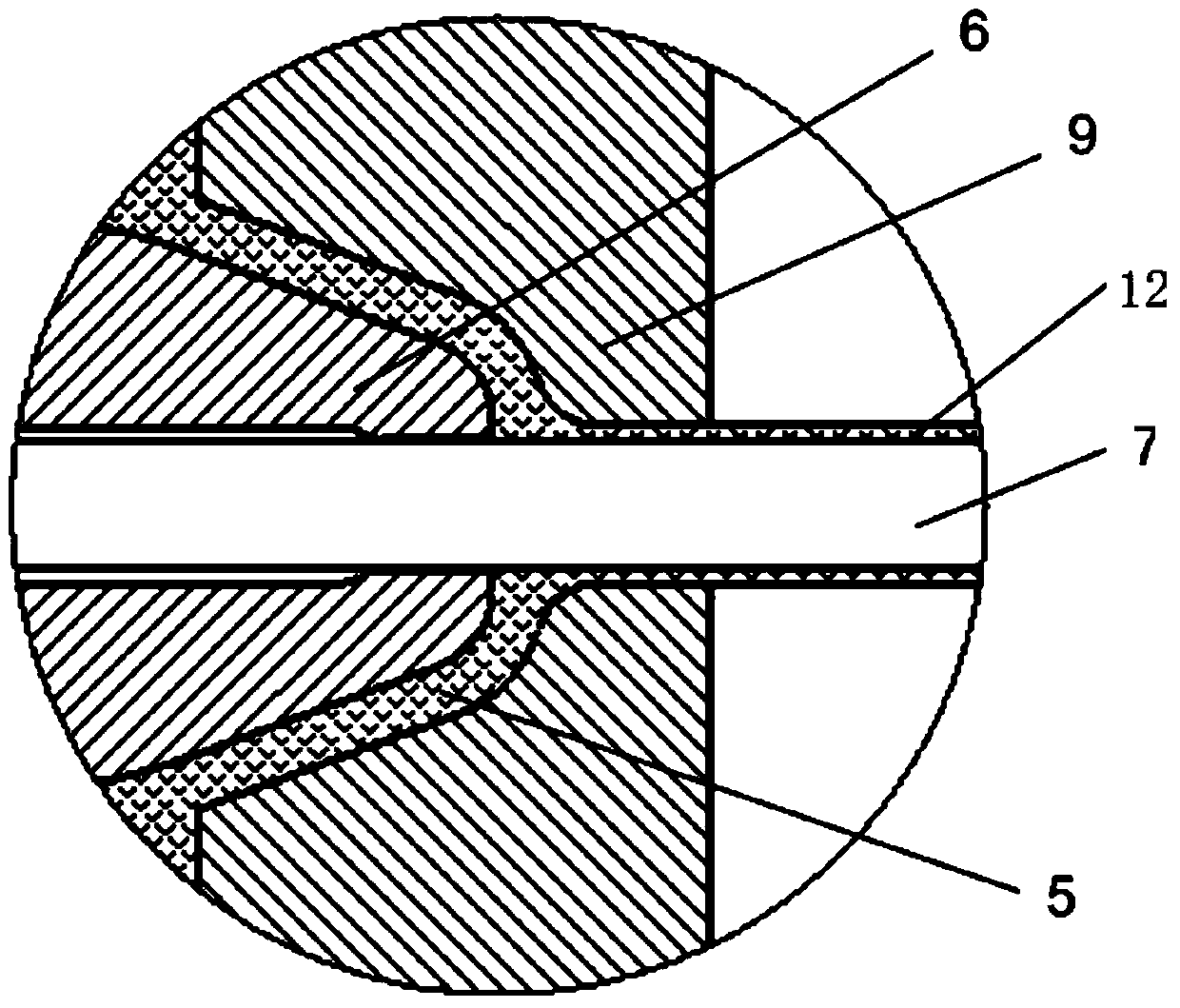

Tubular metal body, method of producing same, liner for pressure vessel and method of producing same

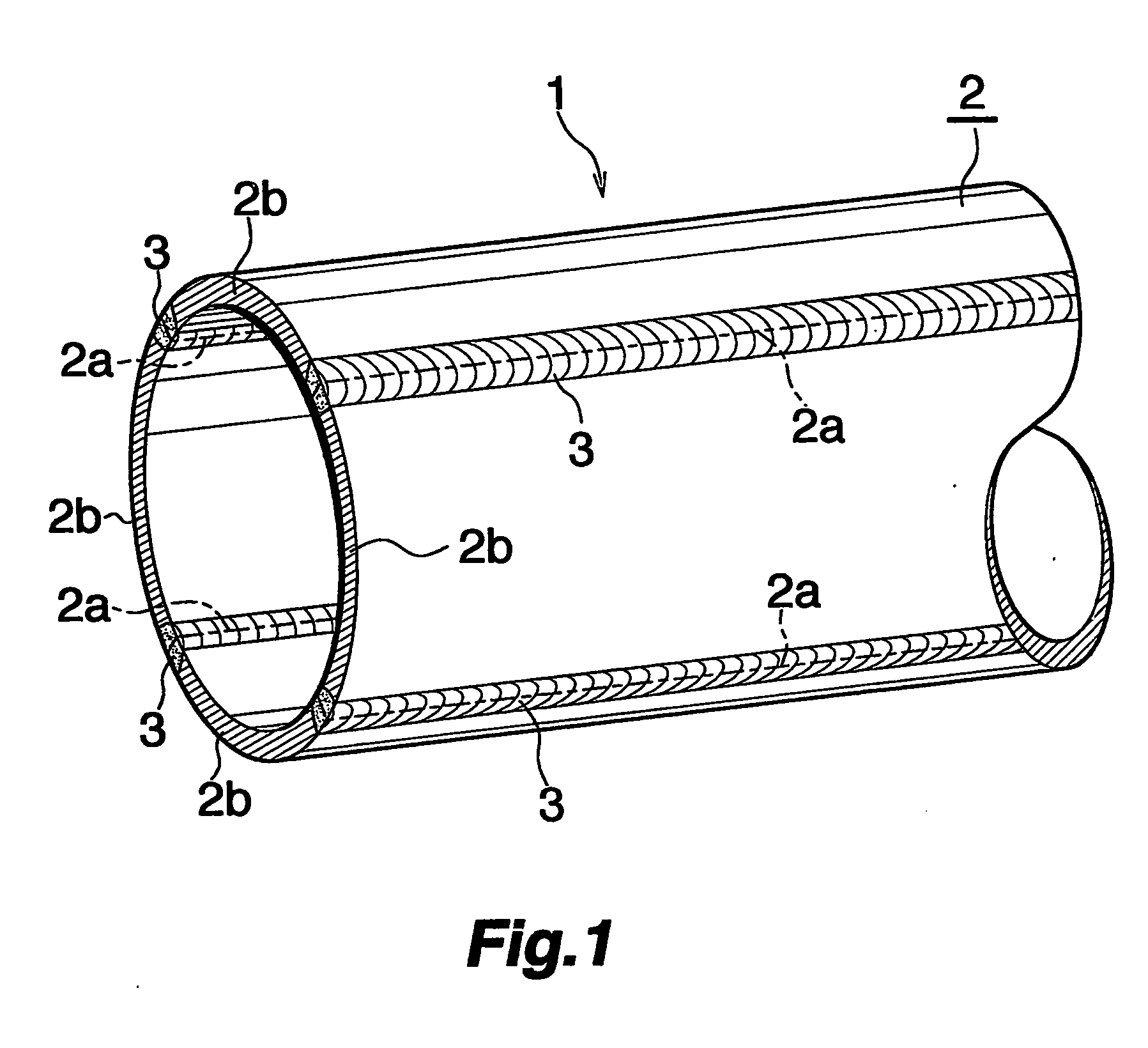

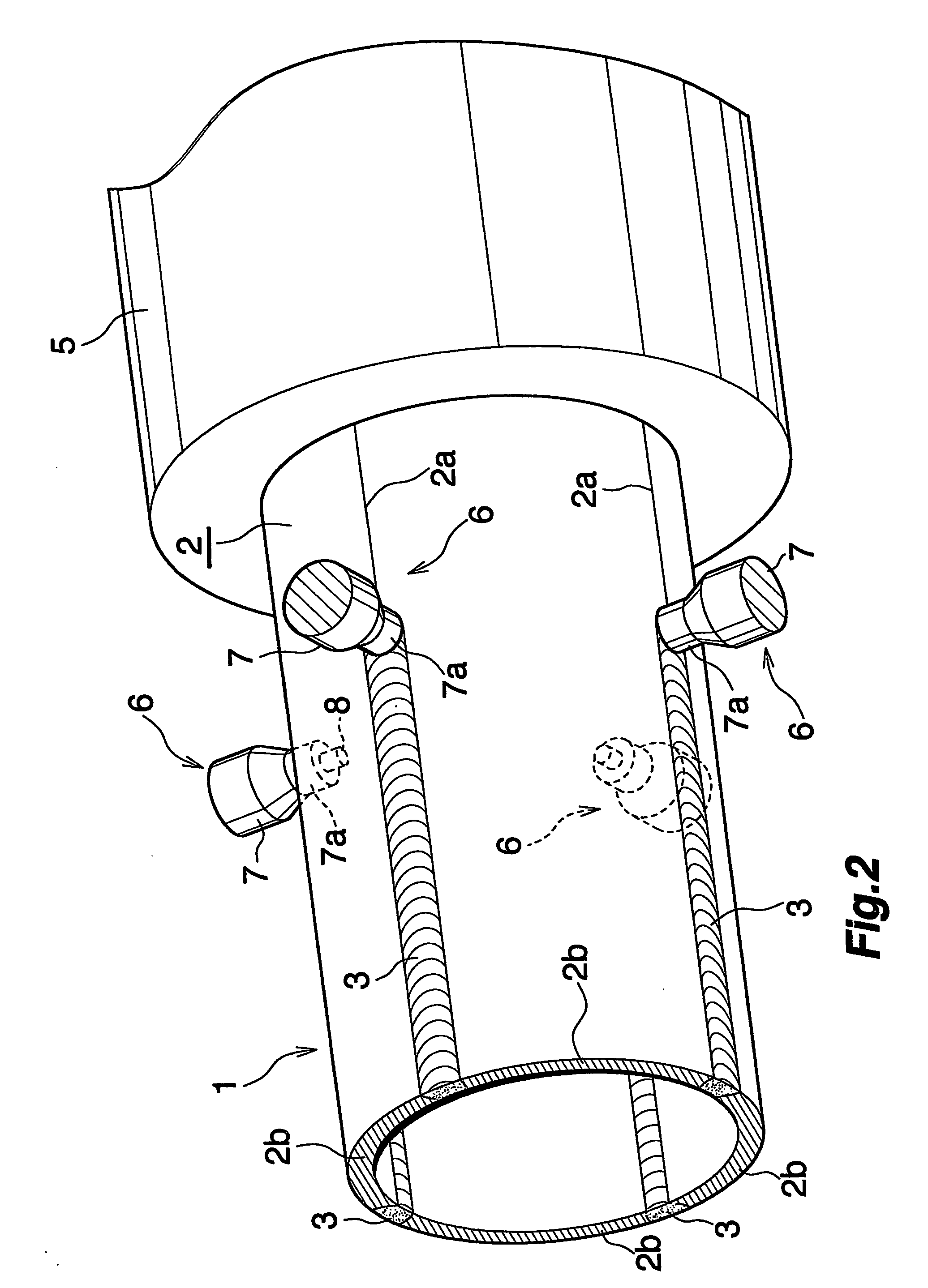

InactiveUS20060260376A1Easy to produceHigh elongationFuel cell auxillariesGas handling applicationsHigh pressureLarge size

A tubular metal body 1 comprises a tube 2 extruded through a porthole die and composed of a plurality of components 2b joined to one another with a plurality of joint portions 2a extending over the entire length of the tube. The base material metal of the extruded tube 2 in each of the joint portions 2a is subjected to a modifying treatment to produce finely divided crystal grains. The modifying treatment for the extruded tube 2 is conducted preferably by frictionally agitating each joint portion using a probe 8 of a friction agitation joining tool 6. The tubular metal body 1 is available with an increased length in a larger size and has high pressure resistance.

Owner:SHOWA DENKO KK +1

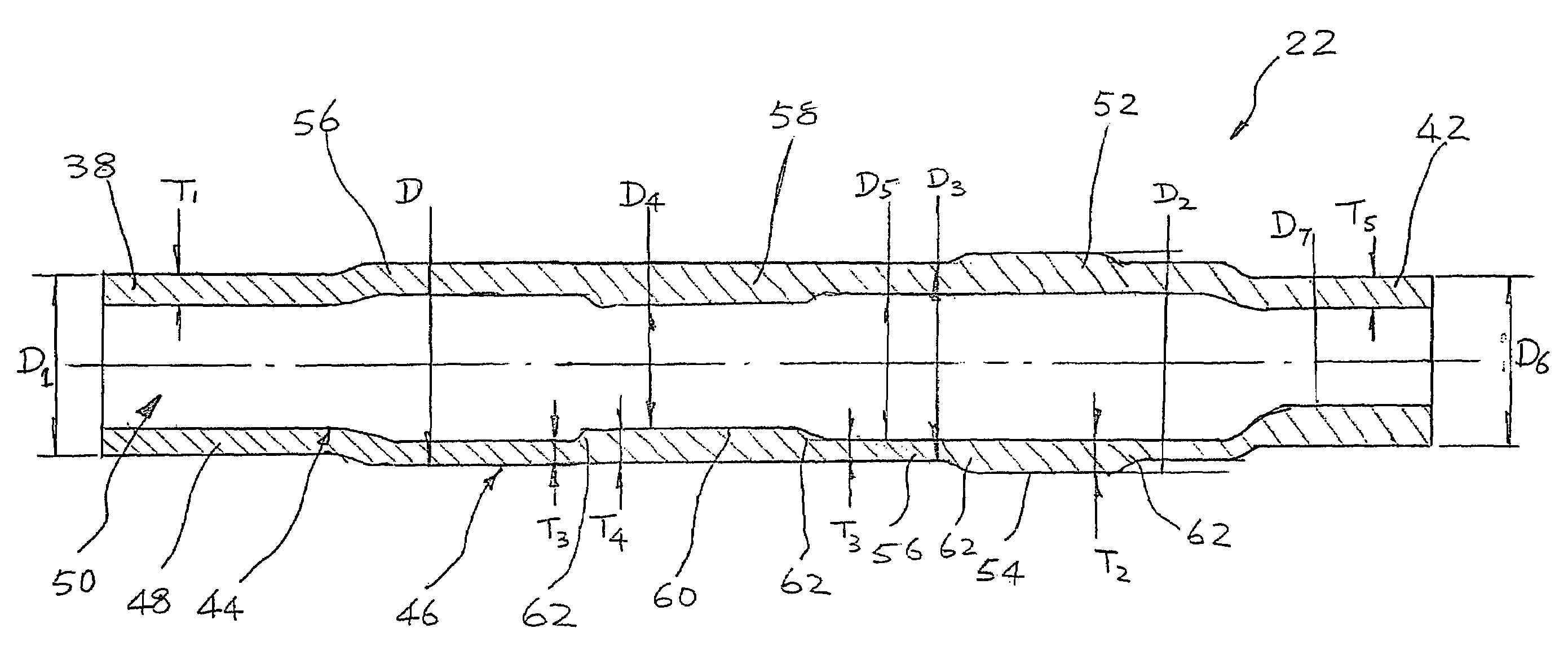

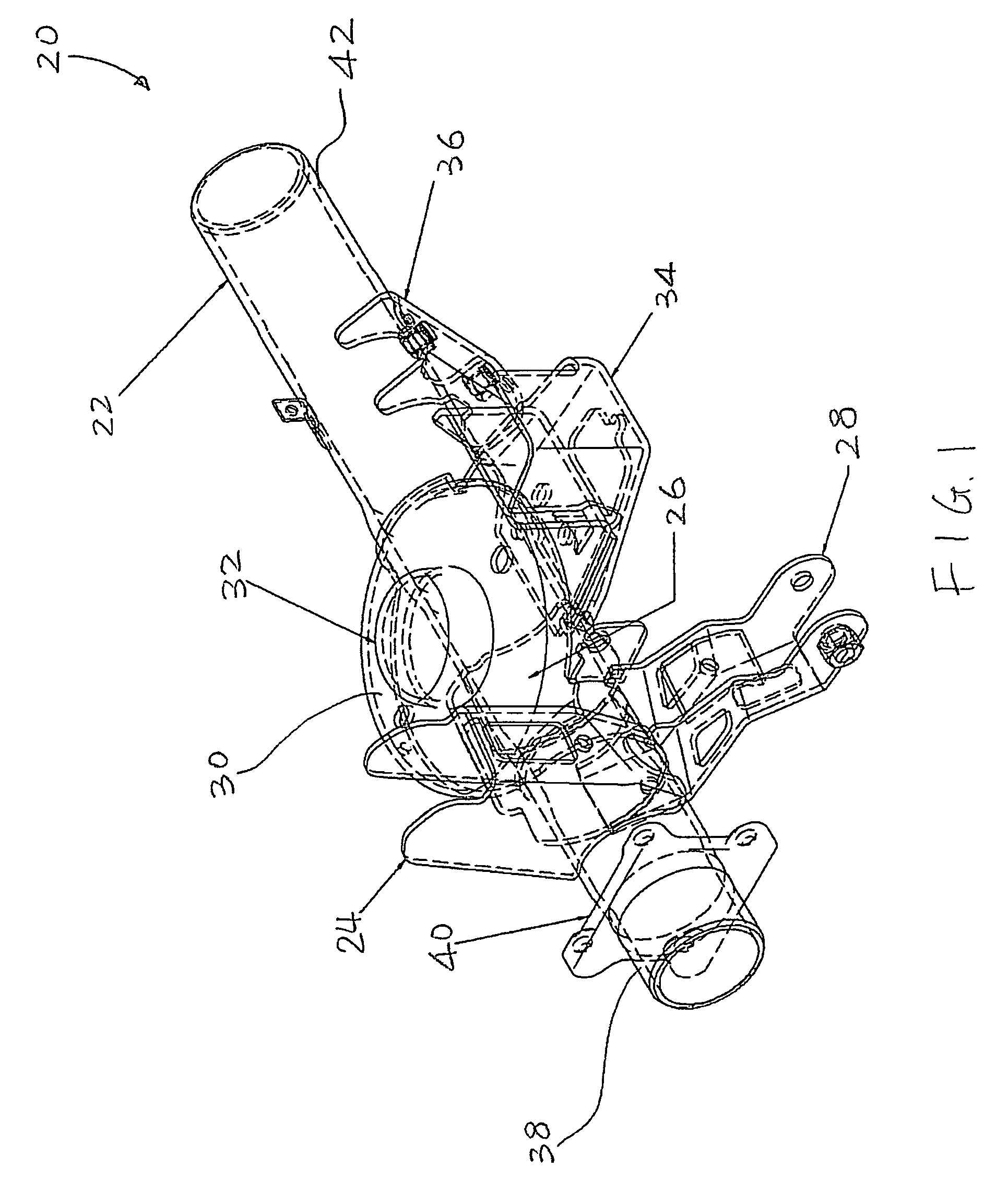

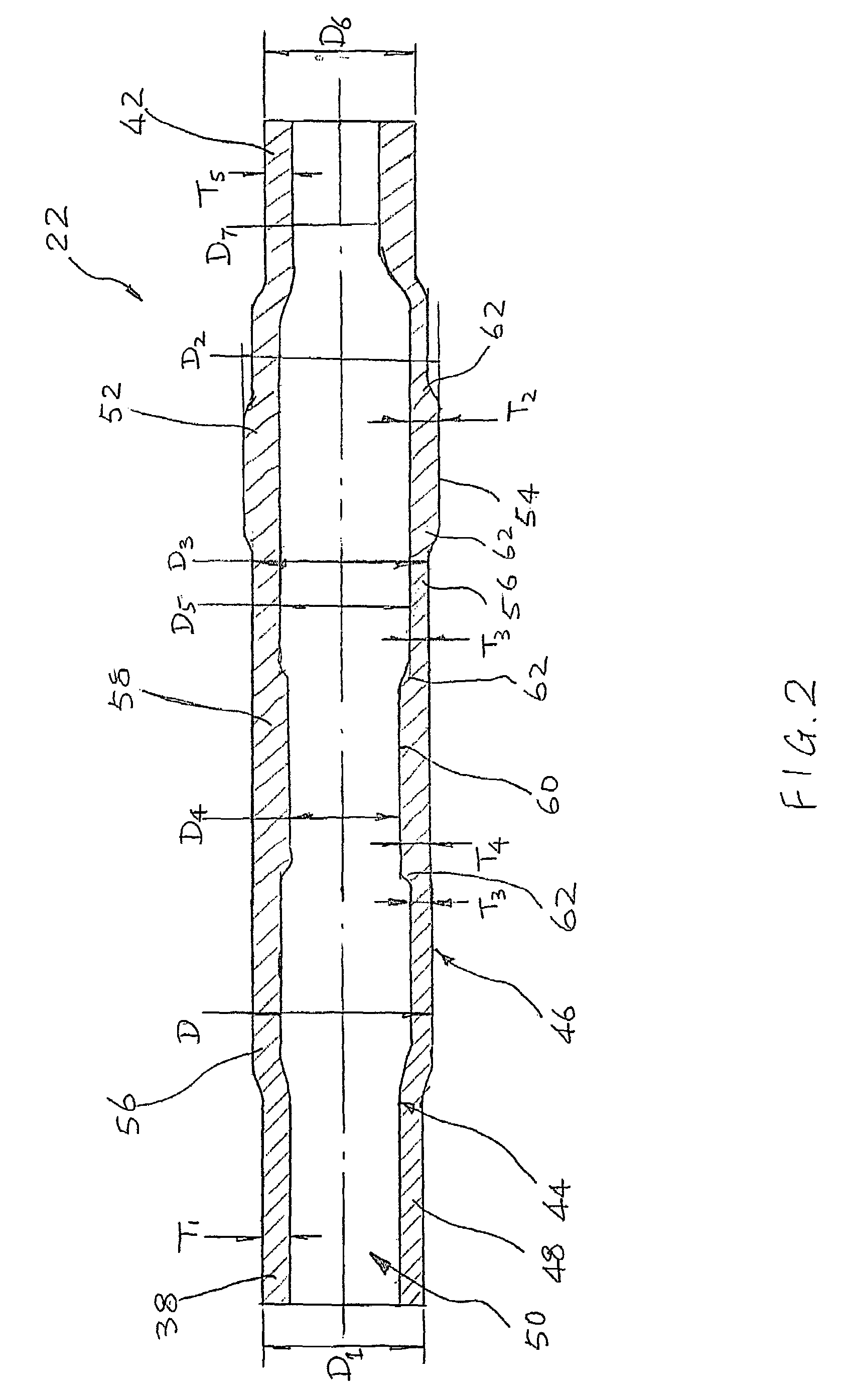

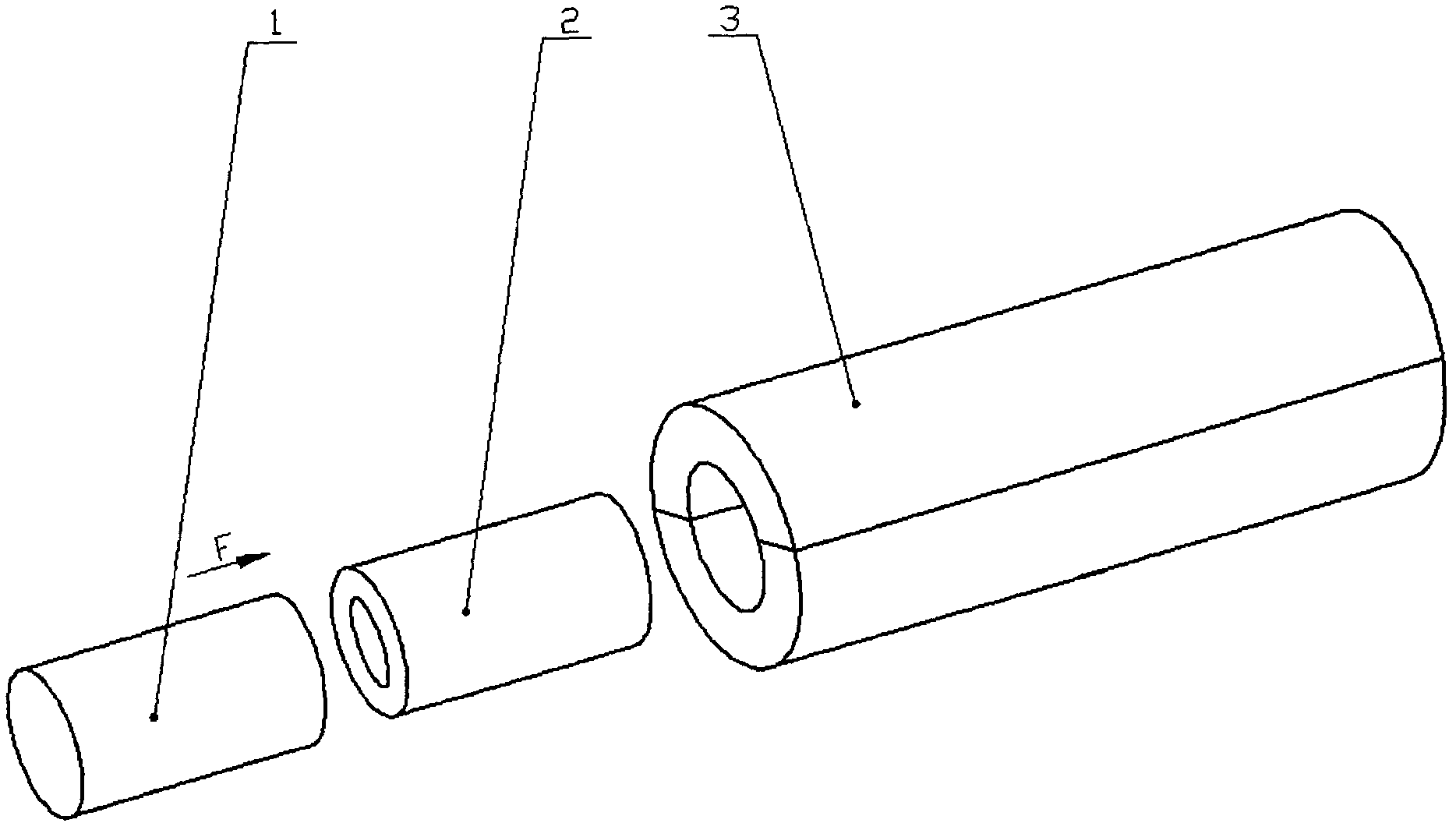

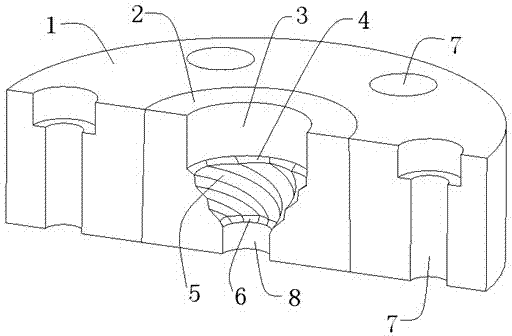

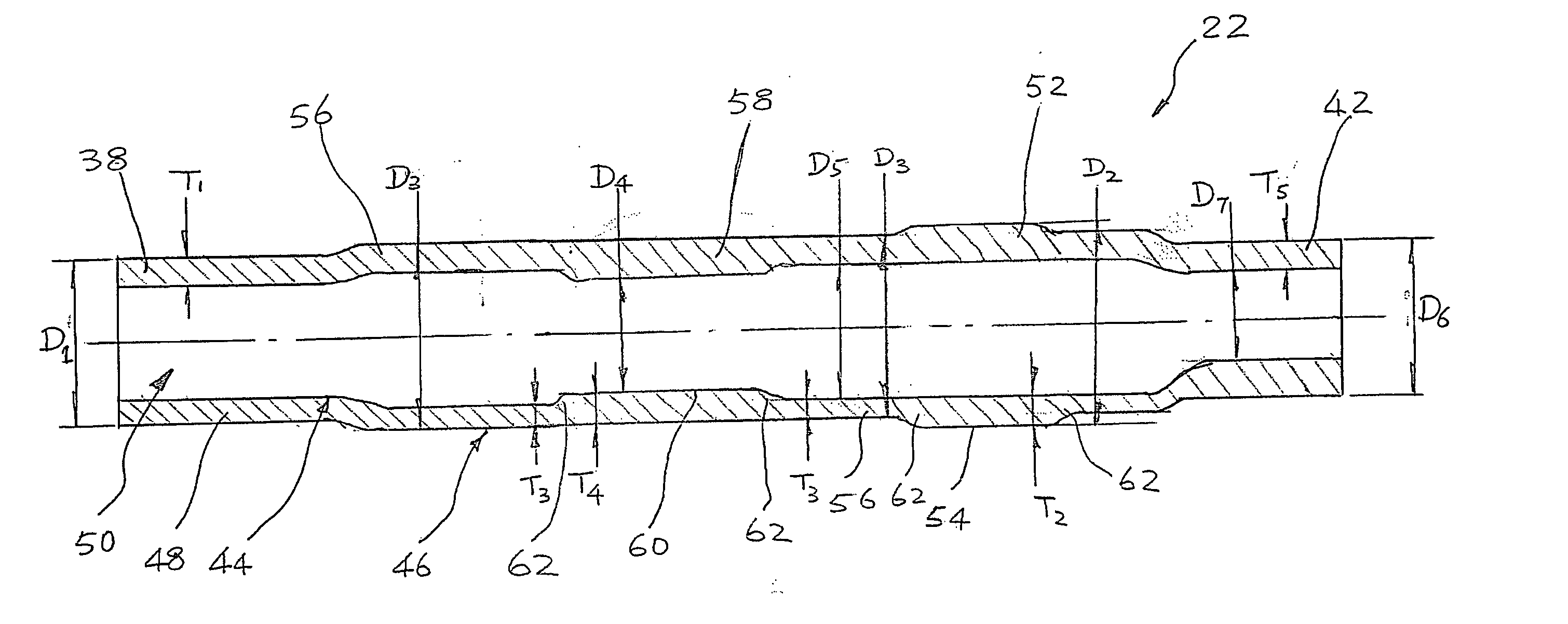

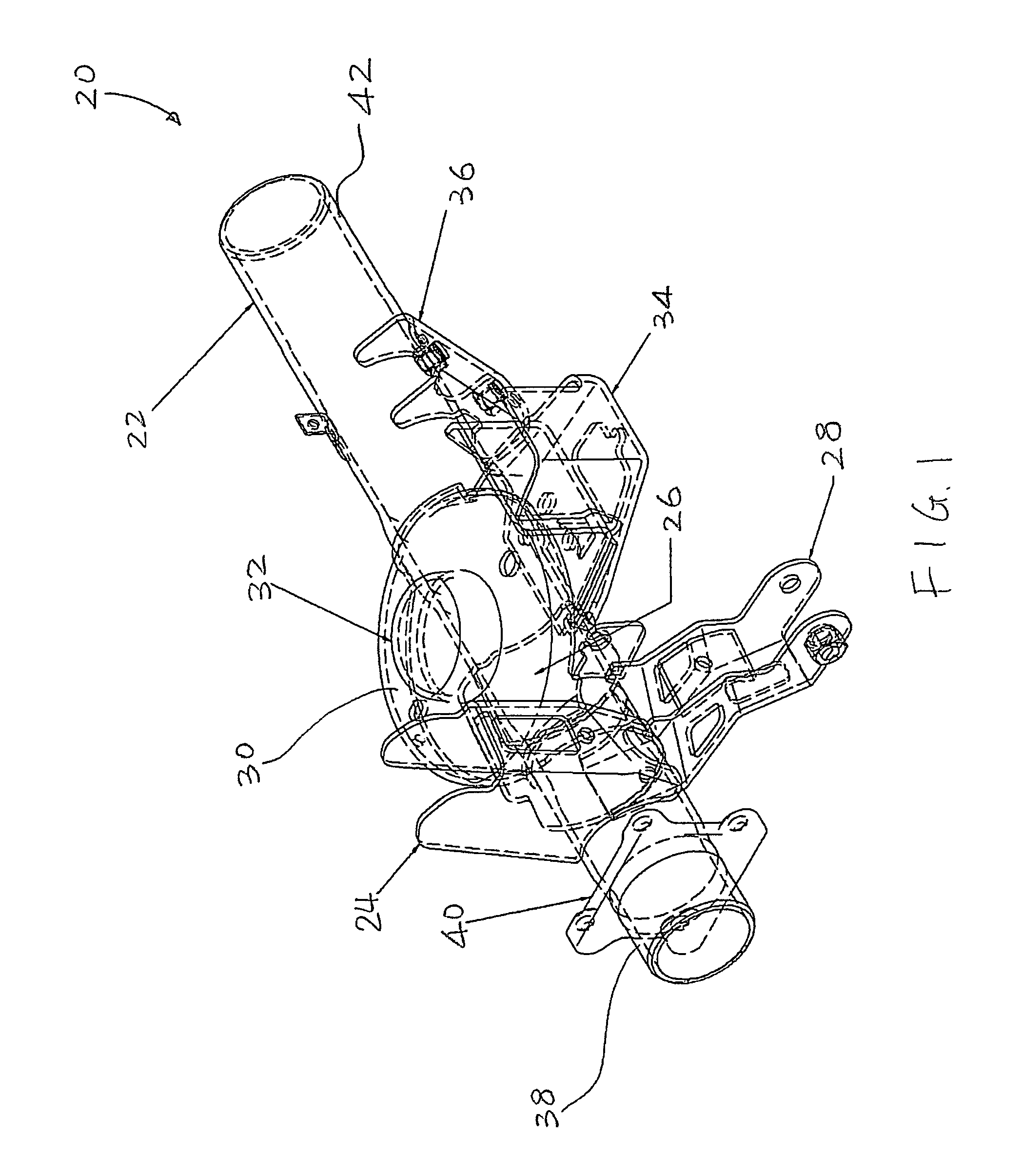

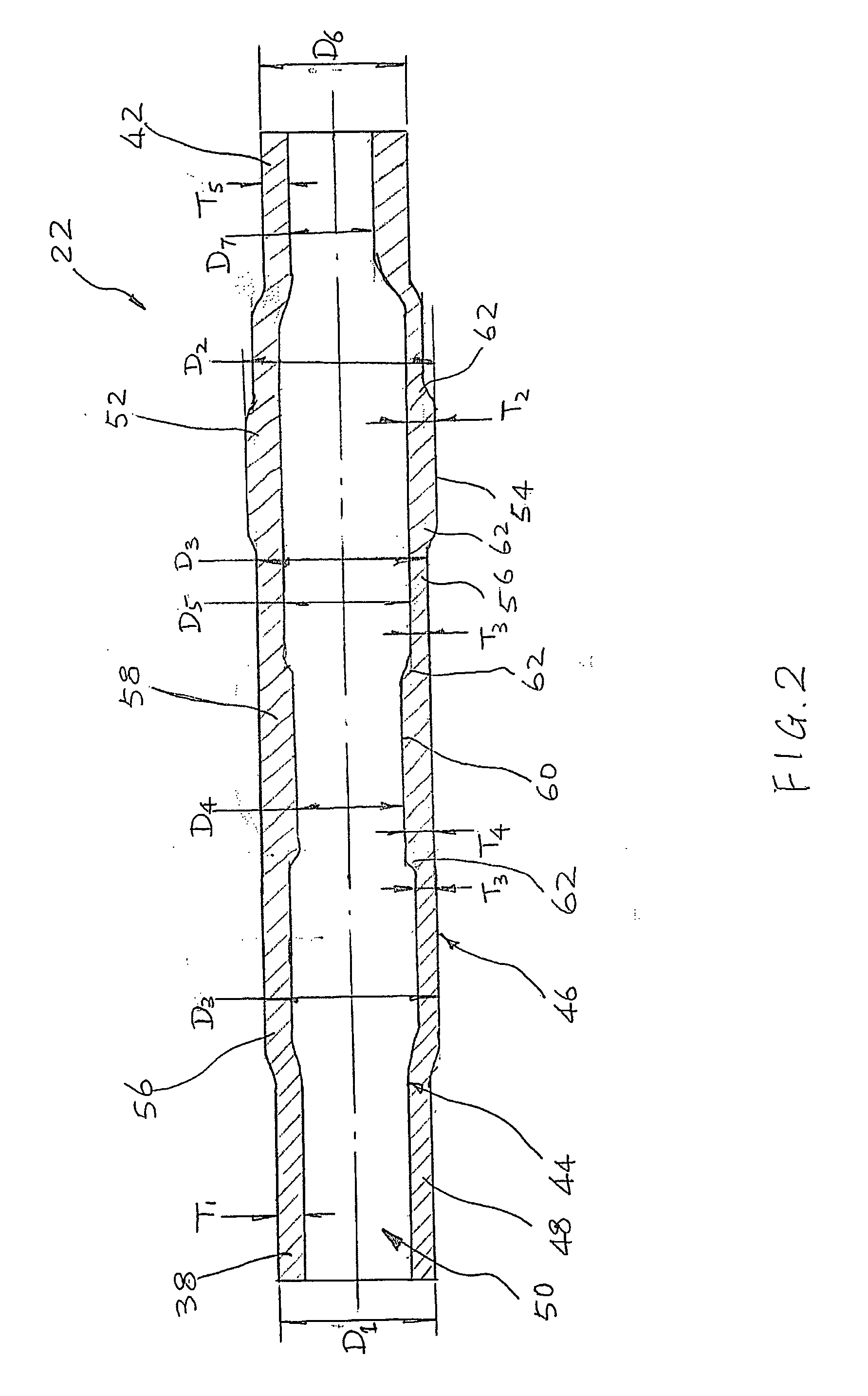

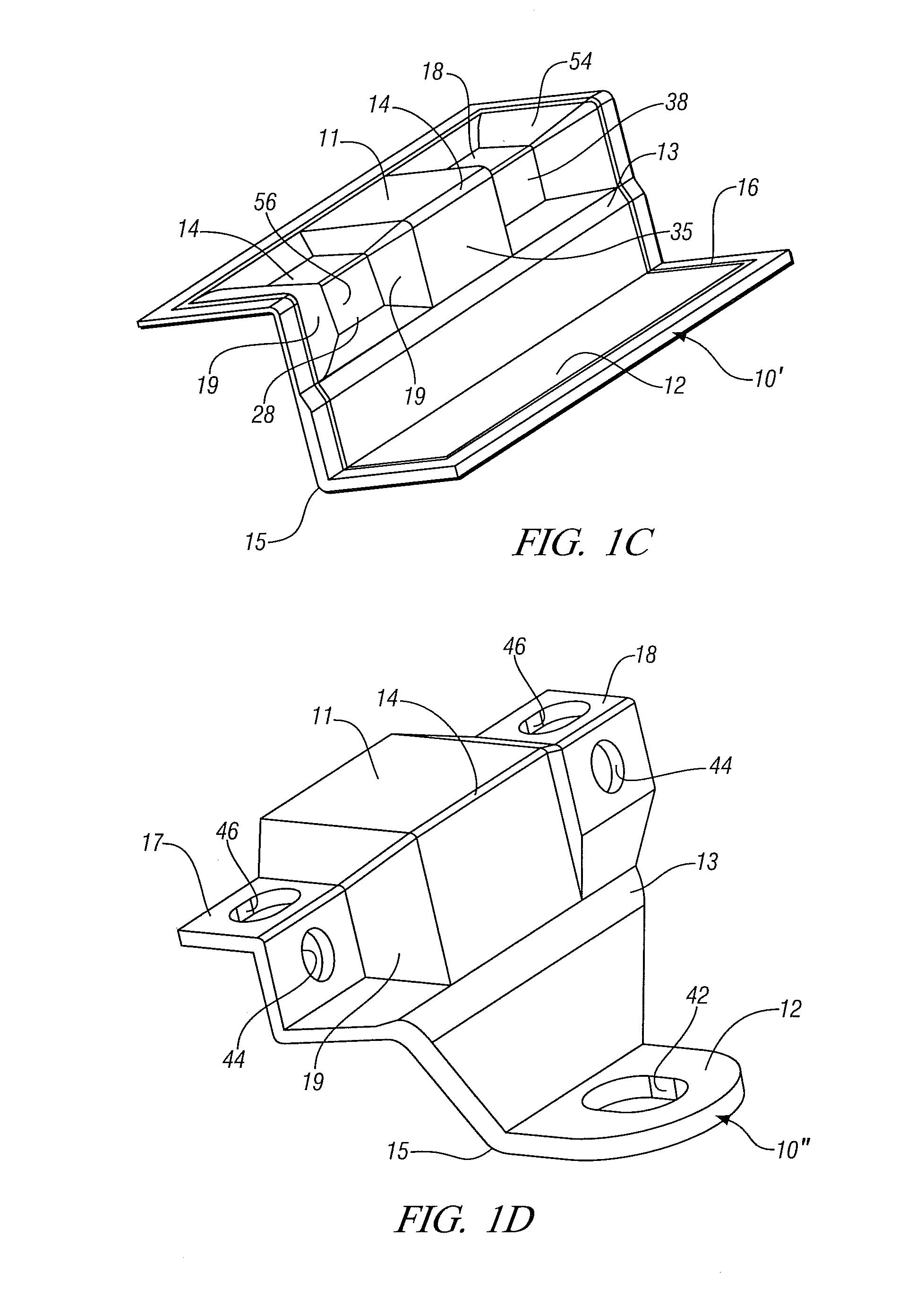

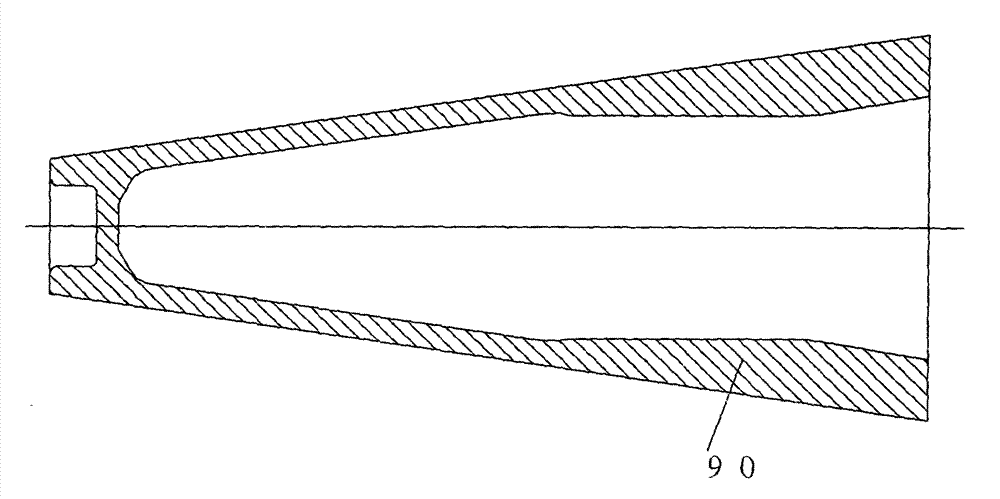

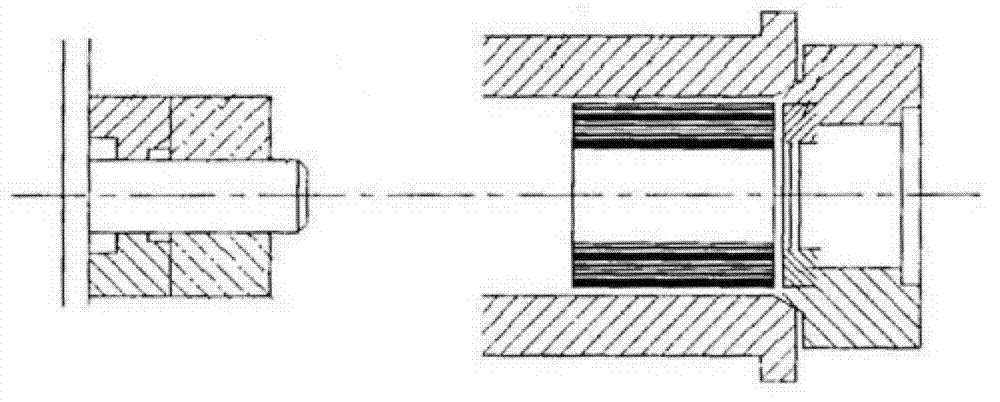

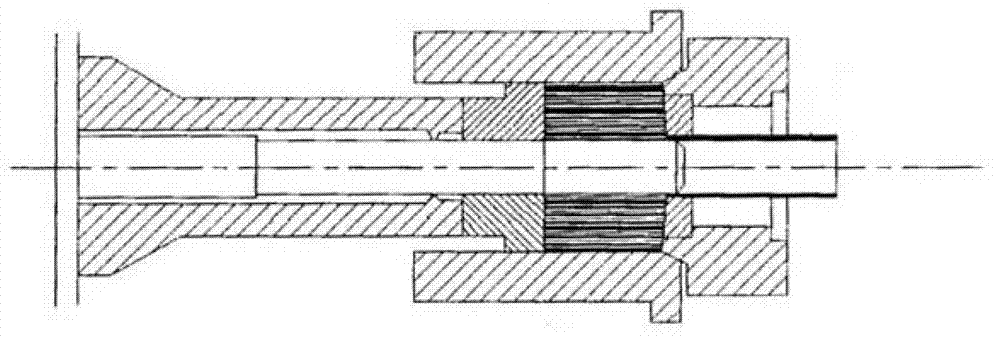

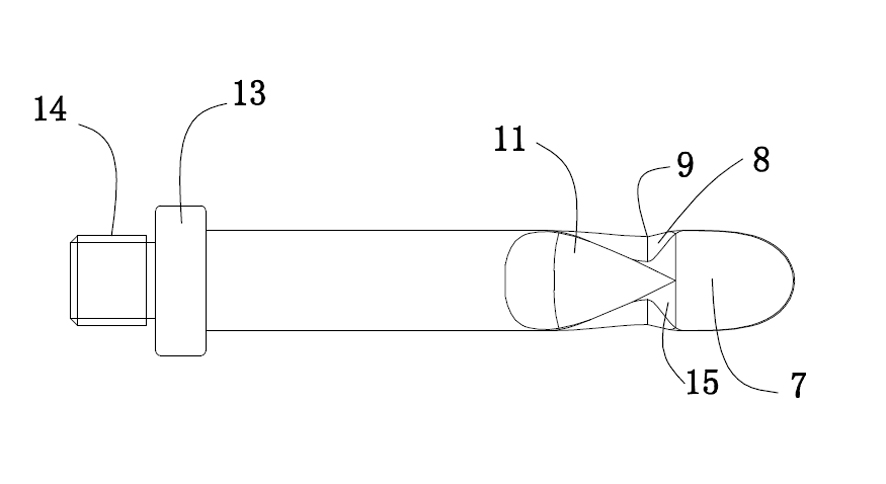

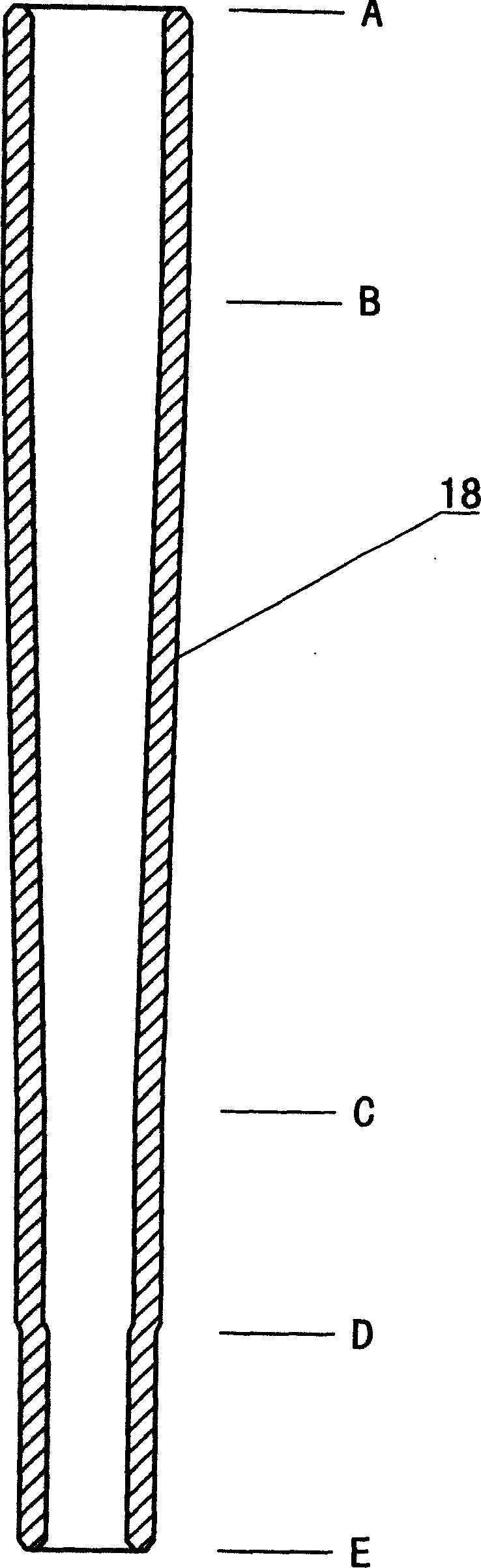

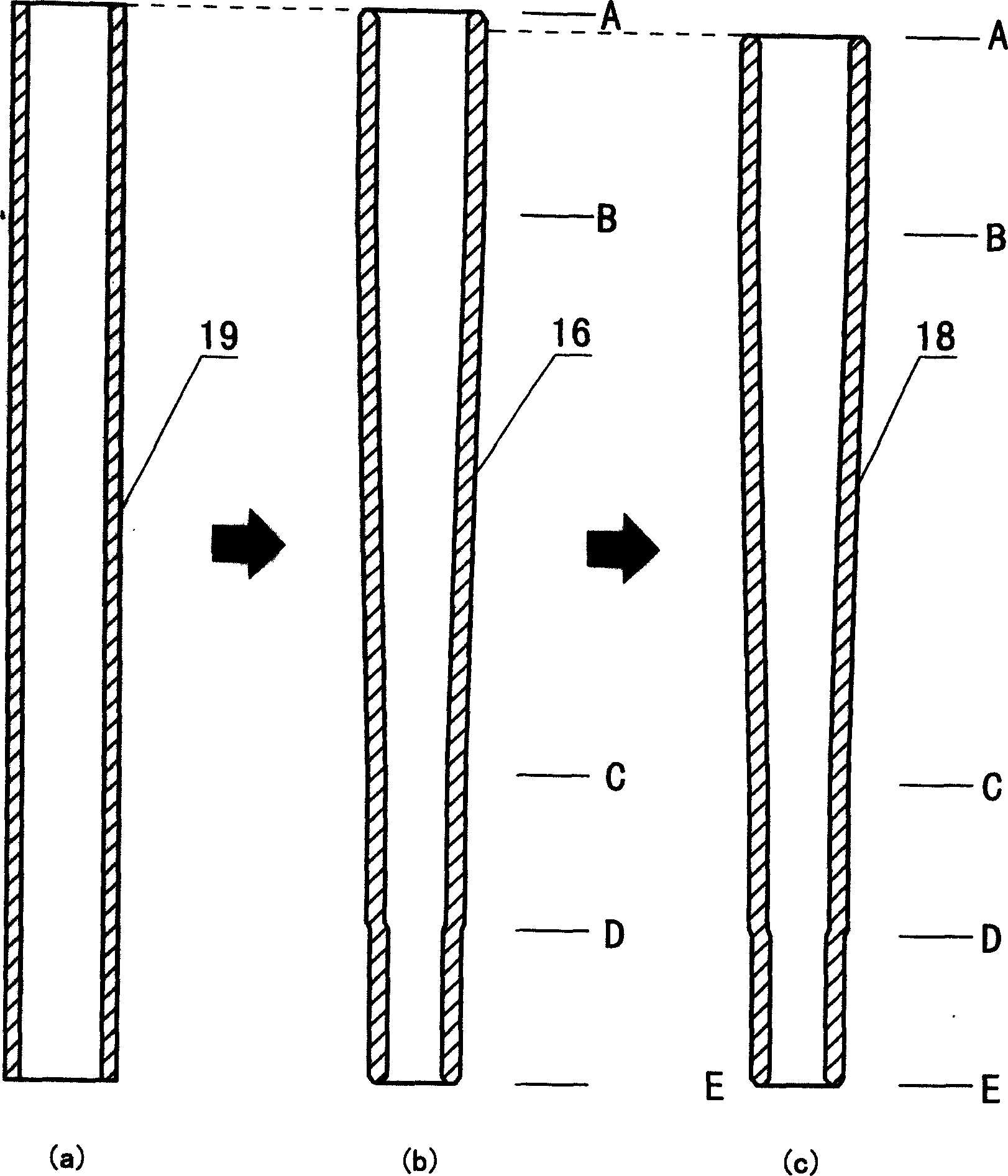

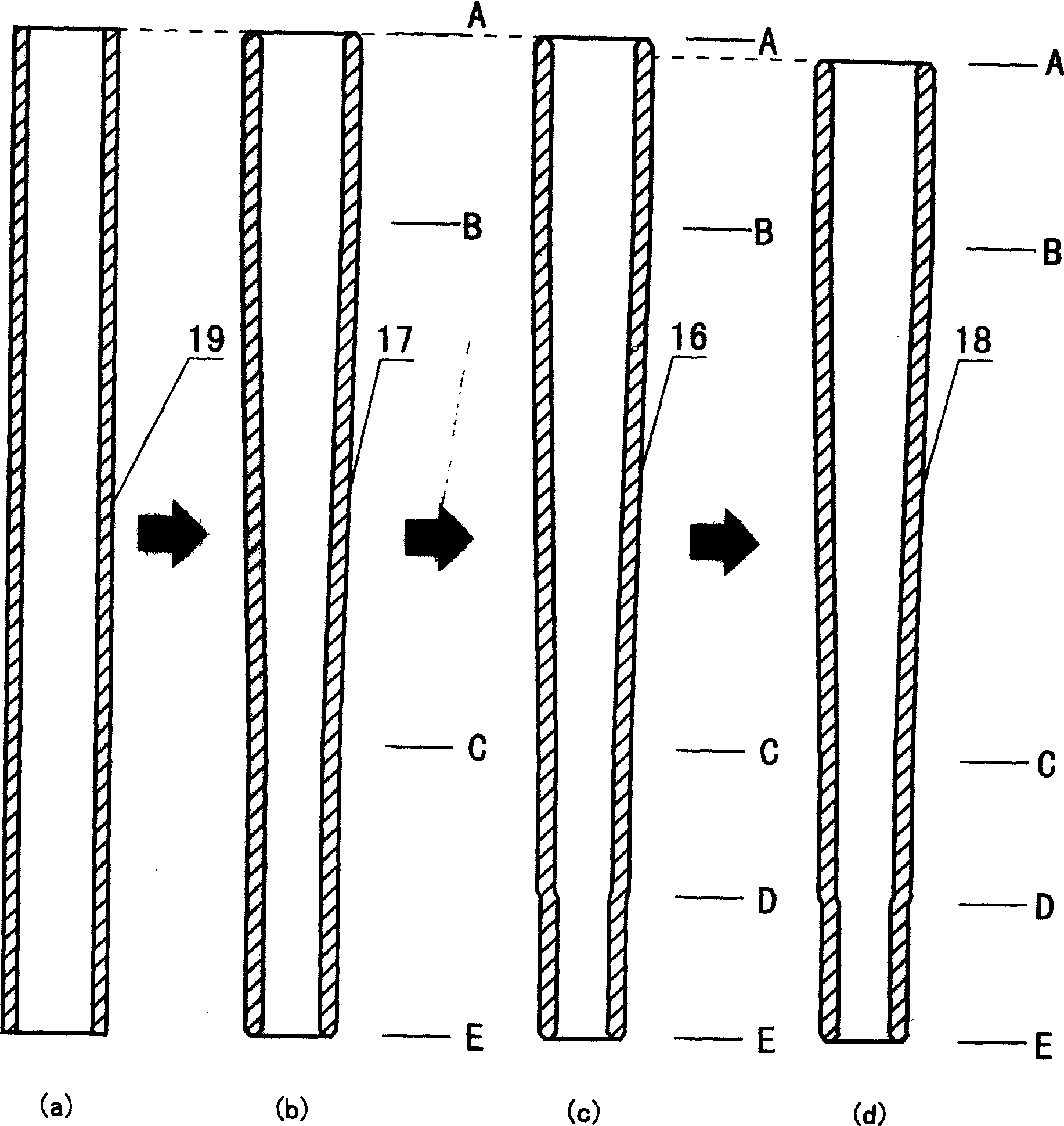

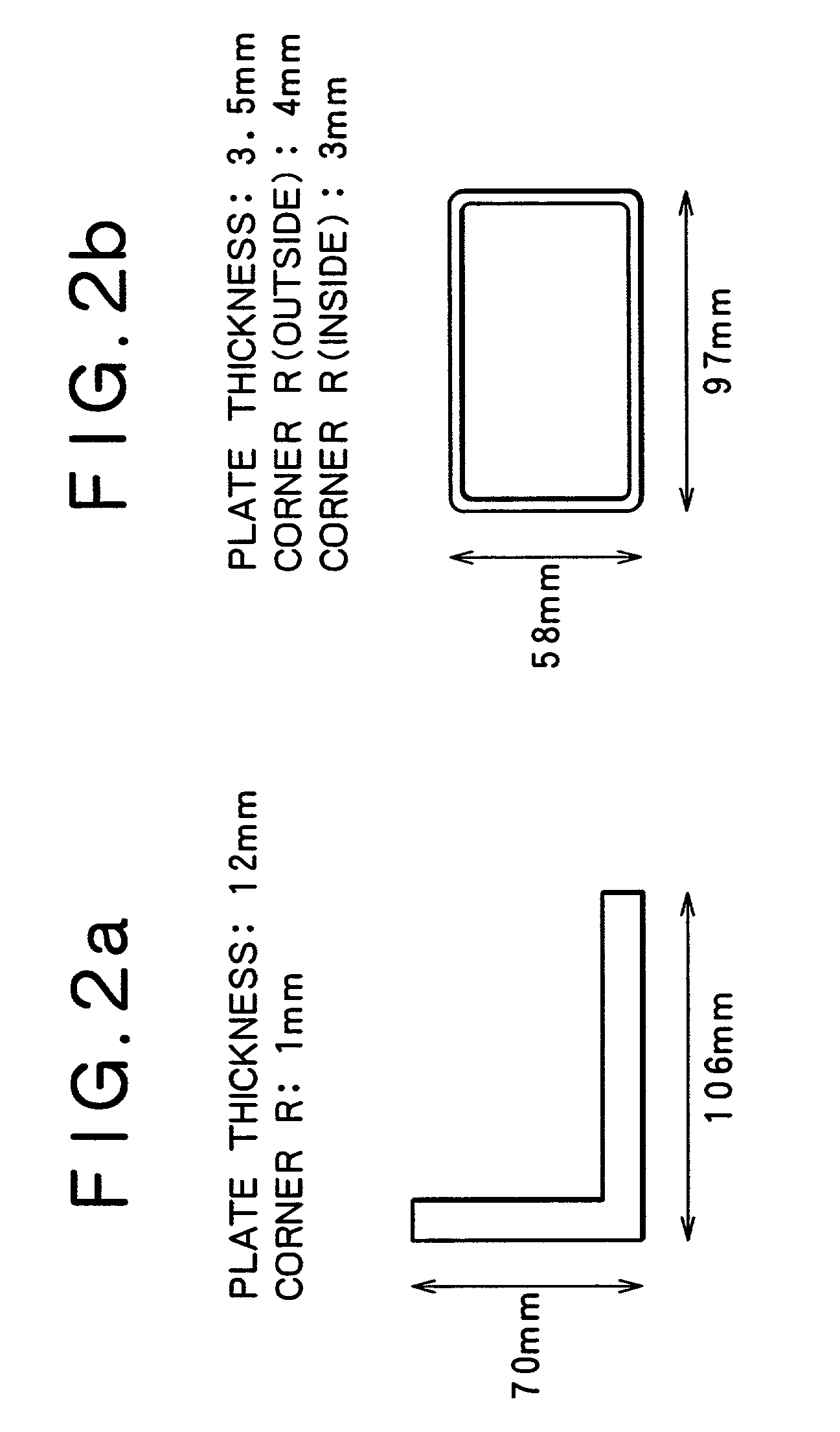

Tubular articles with varying wall thickness and method of manufacturing same

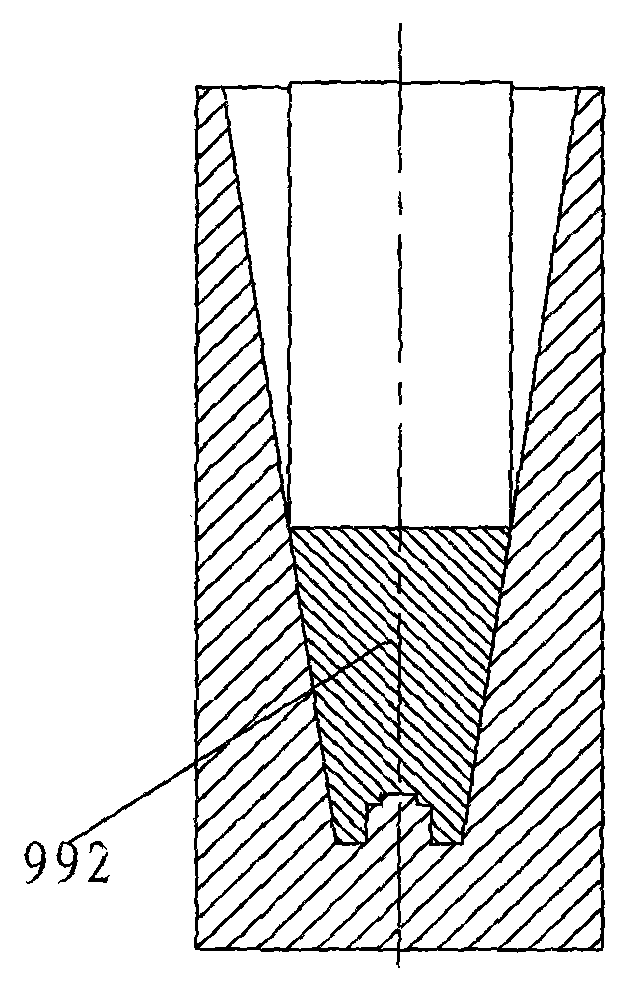

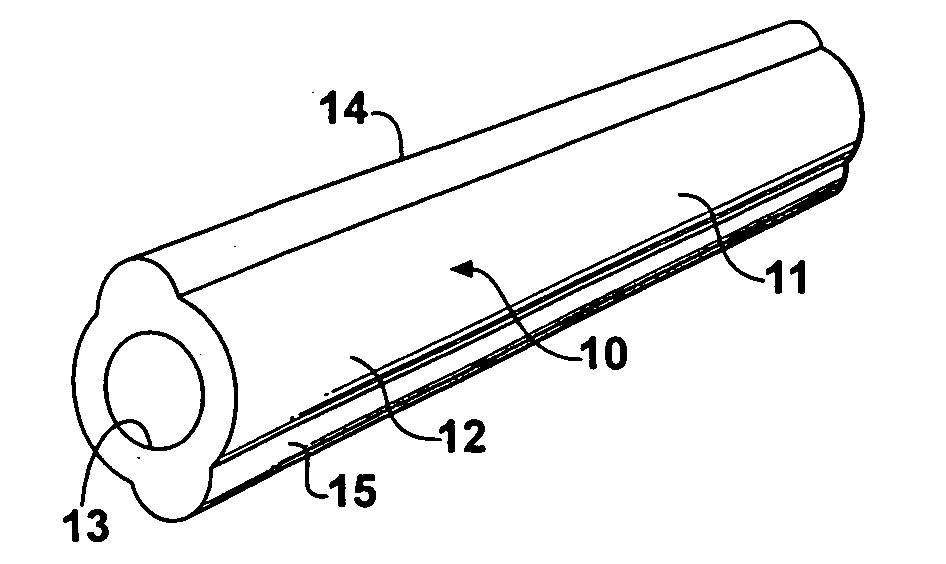

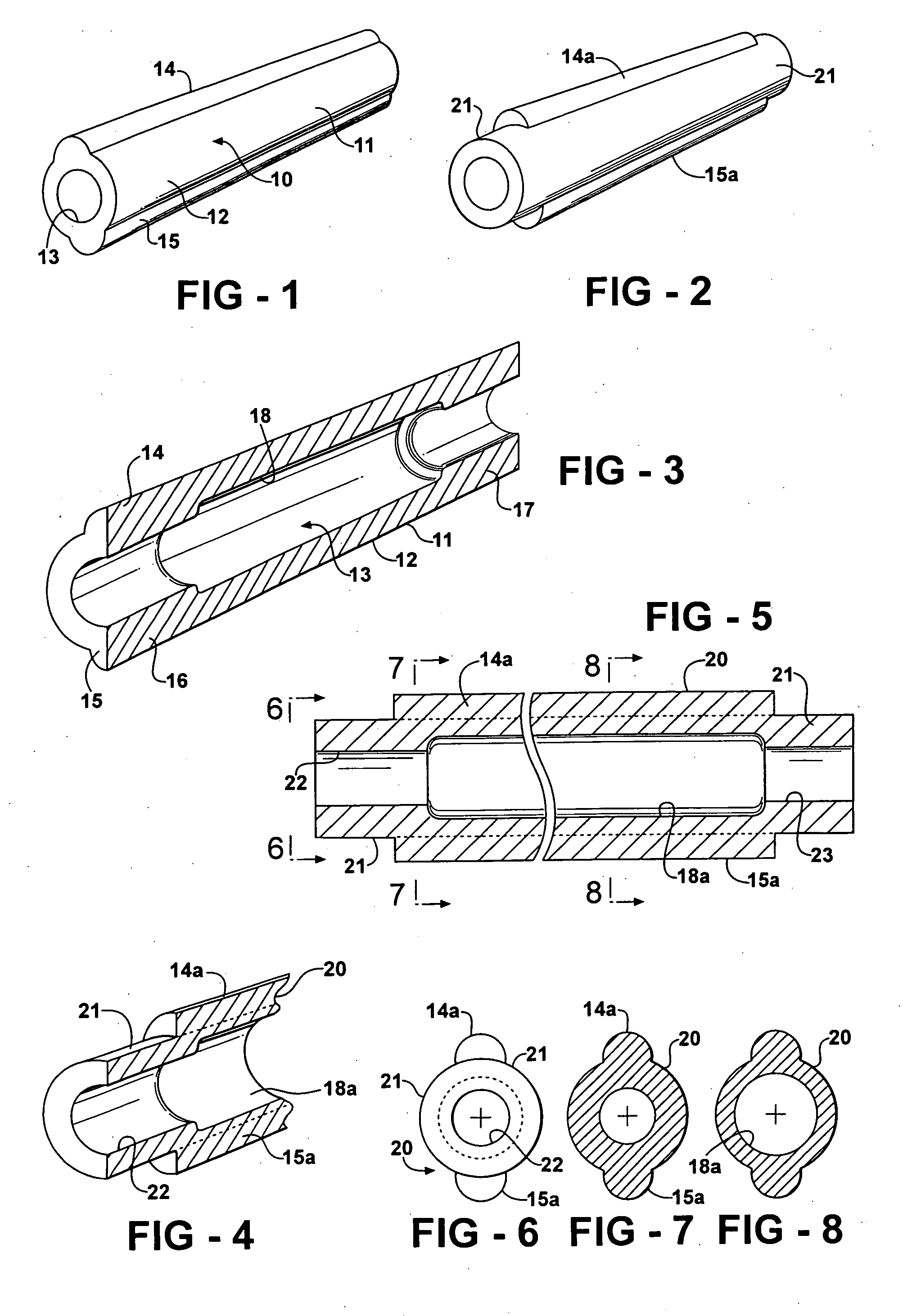

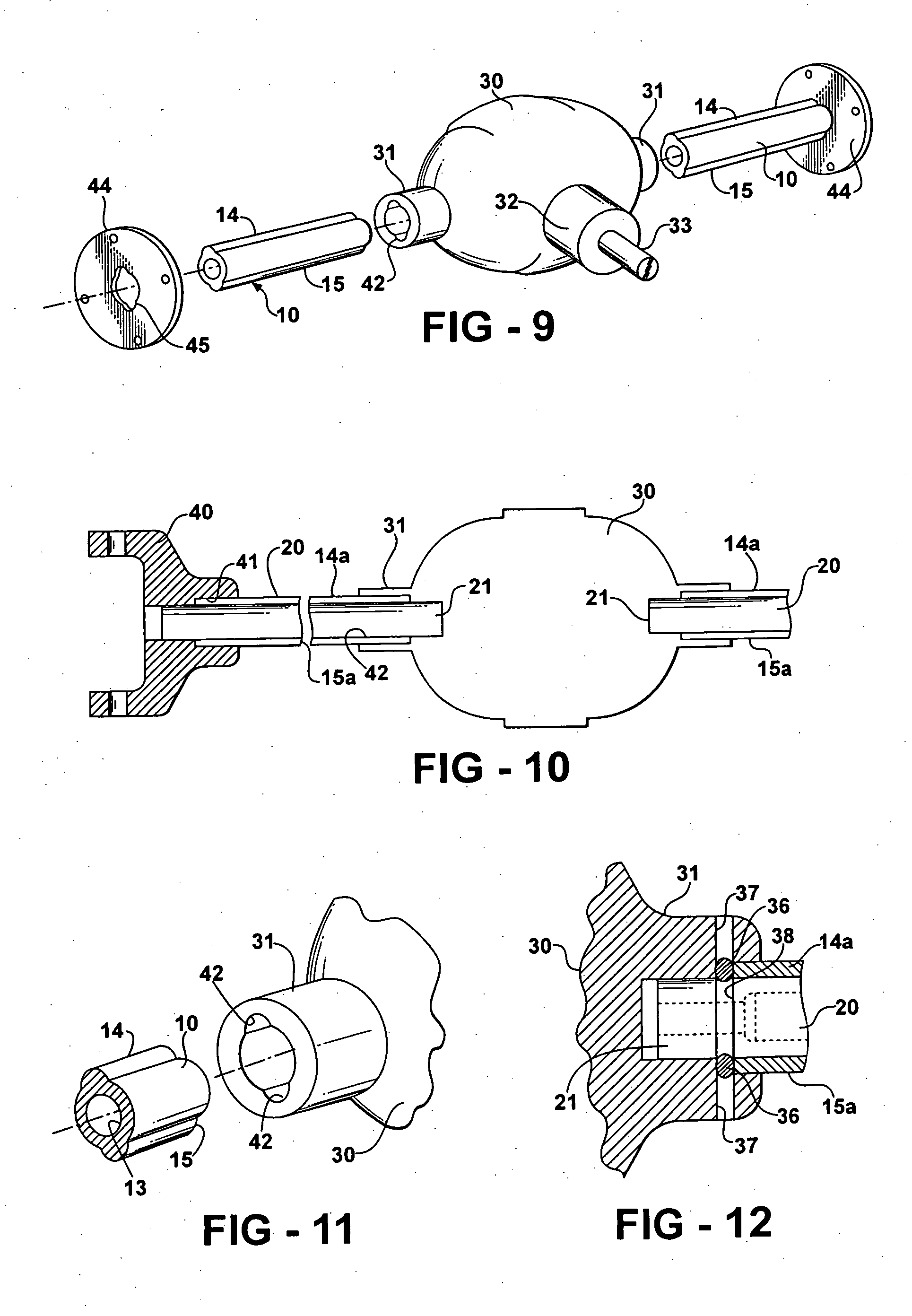

A method for manufacturing a one-piece axle tube housing with localized sections of increased wall thickness includes providing a tube blank, inserting a mandrel having a reduced diameter profile, passing the tube through an extrusion die to conform the tube to the shape of the mandrel; and extraction of the mandrel from the tube to cause outward deformation of the tube at specific locations. A further reducing step may be used to form the final desired profile, including reduced inner and outer diameters along sections of the axle tube housing.

Owner:AAM INT S A R L

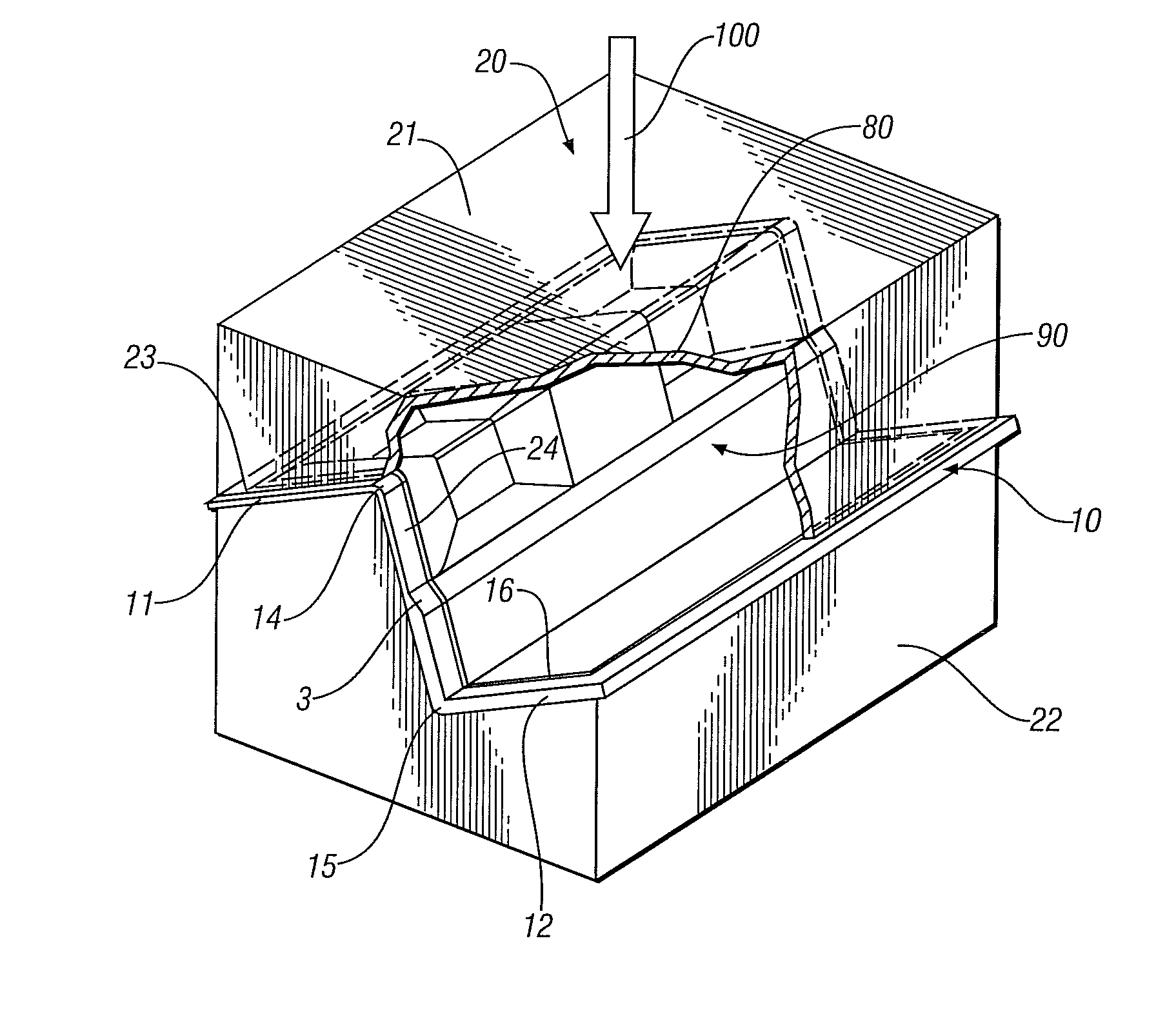

System and process for formation of extrusion structures

InactiveUS20140283574A1Improve performanceImprove propertiesExtrusion containersExtrusion mandrelsEngineeringMechanical engineering

An extrusion apparatus and process are disclosed that produce high-performance extrusion structures. The extrusion apparatus includes a shear tool that applies a rotational shear force and an axial extrusion force to the face of a billet material that plasticizes the billet material. Plasticized material is extruded through an extrusion die along the length of the inner bore of the shear tool which yields hollow and solid extrusion structures. The process refines the microstructures of the extrusion structures and extrusion materials.

Owner:BATTELLE MEMORIAL INST

Copper aluminum composite pipes shaping method

InactiveCN101380648AAchieve metallurgical compoundingRealize the craftExtrusion mandrelsAir conditioningAluminum composites

The invention discloses a shaping method for a Cu-Al compound tube. In the method, a floating plug technology is combined with a continuous squeezing technology; on a single-wheel double-slot continuous squeezing wrapping machine, the floating plug is utilized for realizing to continuously wrap aluminum or an aluminum alloy with a certain thickness on the copper tube. For one aspect, the floating plug plays the roles of supporting the copper tube and ensuring the intensity of a core for successful shaping; for the other aspect, the floating plug can freely float during the process of wrapping and shaping for achieving the demands on the size of an inner hole and the high precision of an inner surface, thus obtaining the Cu-Al compound tube which is metallurgically combined and achieving the combination between the continuous squeezing and the floating plug technology. The outer diameter of the Cu-Al compound tube is decided by the size of the inner hole of a cavity block. The method can realize the metallurgical compounding for the double metals of aluminum and copper, has a simple technique, saves energies, can realize continuous production, can effectively reduce the costs for the heat exchangers used for a refrigeratory and an air conditioning and has excellent application prospect.

Owner:KUNMING UNIV OF SCI & TECH

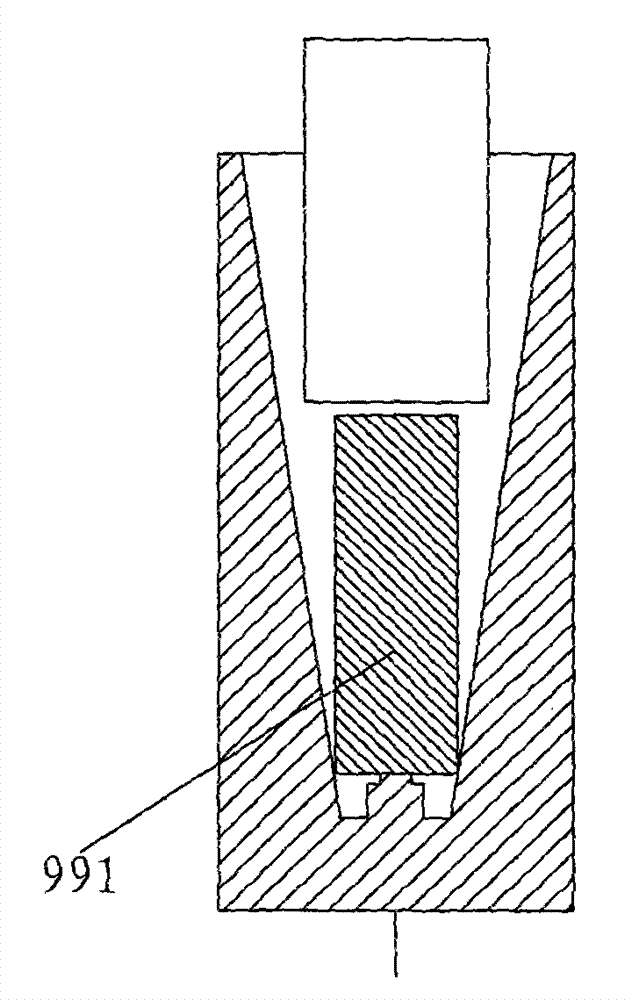

Reciprocating extrusion grain refining equipment and extrusion refining method therewith

InactiveCN1751817ASave energyReduce manufacturing costExtrusion diesExtrusion mandrelsEngineeringPlastic property

A reciprocating squeezer for fining crystal grains is composed of squeezing cylinder, die set consisting of male die and female die, upper and lower transverse connecting beams of dies, two screw bolts at both sides of die set and passing through said transverse beams, two transverse beams for turning the die set over, axles and its frame, and springs. Its squeezing method includes such steps as closing die set, squeezing and upsetting, turning the die set over by 180 deg, and squeezing and upsetting again.

Owner:XIAN UNIV OF TECH

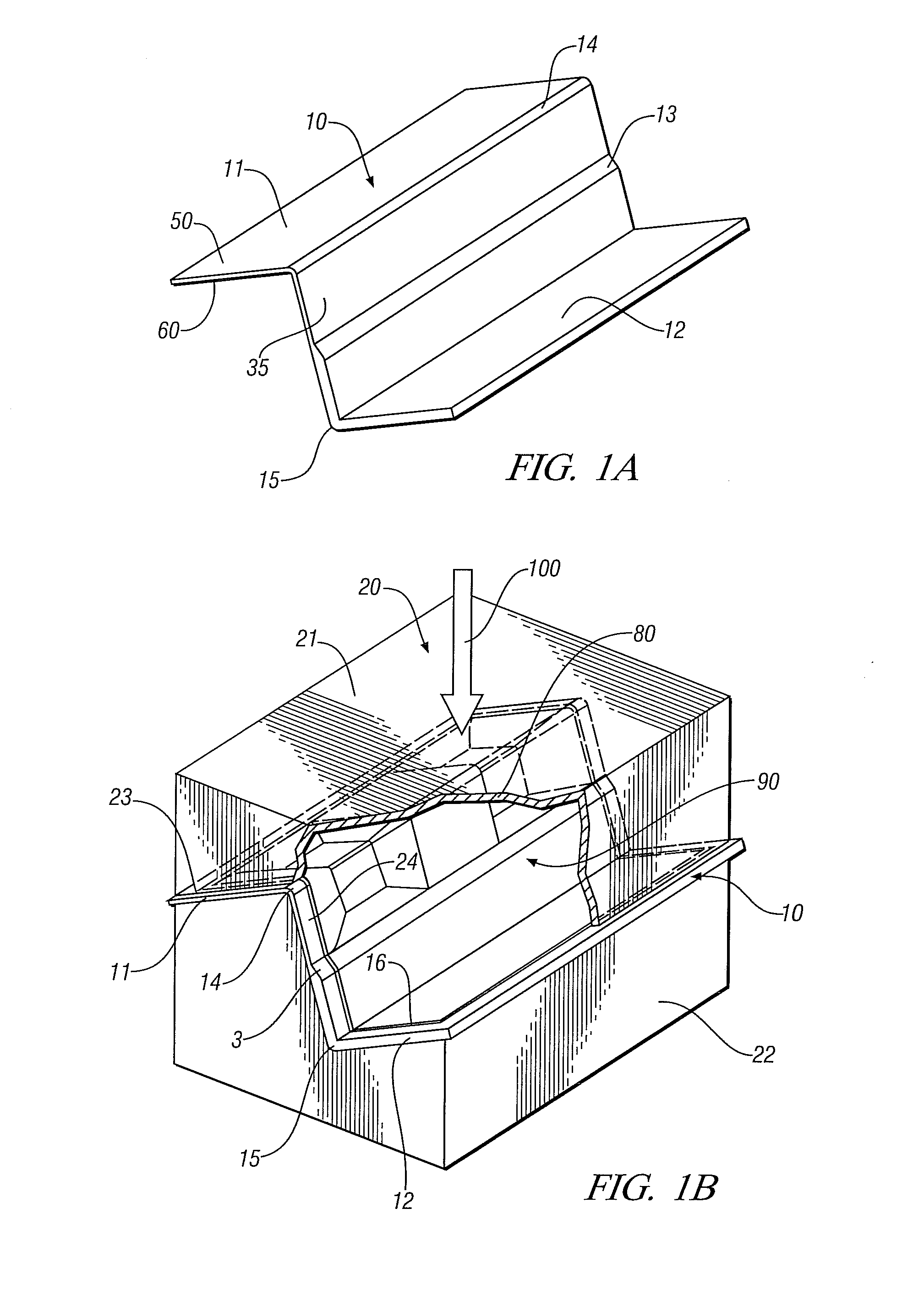

Forming of complex shapes in aluminum and magnesium alloy workpieces

A billet of an aluminum alloy or magnesium alloy is formed by a combination of forming operations into a desired article of complex, but open shape. In a first step a billet is heated and extruded to form an extruded workpiece profile having at least first and second sections of different thicknesses. The extruded workpiece may be shaped so that the respective sections are at an angle to each other. The extruded workpiece is then further formed against a forming surface so that the shape of least one of the sections is further formed toward the shape of the article. The methods are suitable for efficient manufacture of many like complex shapes such as brackets and reinforcement members, and even container pans for computers and other electronic devices.

Owner:GM GLOBAL TECH OPERATIONS LLC

Large-sized multi-nozzle pipe hot extrusion forming process formulation and mold design method

InactiveCN103537509AIncrease productivityShorten the manufacturing cycleExtrusion diesExtrusion containersStructure propertyEngineering

The invention discloses a large-sized multi-nozzle pipe hot extrusion forming process formulation and mold design method. Taking a double-nozzle pipe for example, the method comprises the following steps: determining the size of each part of an unmachined double-nozzle pipe after hot extrusion forming; determining the size of an initial pipe blank; determining the position of the center of a prefabricated hole and the size of the aperture; determining amount of compression in the axial direction of the pipe blank with the prefabricated hole, of which oxide skin is removed, required for finishing hot extrusion forming of a second nozzle; determining amount of compression in the axial direction of the pipe blank required for continuing to finish hot extrusion forming of a first nozzle; determining the dimensional parameter of a key part of the hot extrusion mold; selecting the structural form of the hot extrusion mold; determining the extrusion capacity parameter and selecting forming equipment; determining a technological flow of the double-nozzle pipe hot extrusion forming process. According to the method, a pipe inner hole and a nozzle inner hole can be directly formed, the structural strength at the nozzle is improved, the metal mechanic property and the structure property are improved, the manufacturing period is shortened, and the material utilization rate is improved.

Owner:UNIV OF SCI & TECH BEIJING

Multi-directional composite multi-channel screw extrusion die for metal blank

ActiveCN104438415AUniform deformationImprove tissue performance uniformityExtrusion diesExtrusion mandrelsStructure propertyEngineering

The invention relates to a multi-directional composite multi-channel screw extrusion die for a metal blank. The extrusion die is formed by embedding two semicircular grooves with semi-symmetric tapers in a die sleeve with a taper, wherein a heating ring is mounted outside the die sleeve; a combined die and the die sleeve are connected to an upper die plate at the lower part; metal blank extrusion passages are formed in the horizontal and vertical directions inside the combined die, and an upper punch, a left punch and a right punch which are T-shaped are precisely arranged on a crossed passage in a matched mode; a spiral groove is formed in the lower passage of the extrusion passage; a section of extrusion die holes with reduced cross sectional areas are formed in the outlet passage of the combined die. The die can solve the problem that the blank size is short after repeated extrusion, so that the plastic deformation capacity, surface quality and structure property of the blank are improved, and a block ultra-fine grain material with excellent performance can be prepared at a lower temperature; the die is simple in structure, convenient to assemble and disassemble and easy to put and fetch materials, so that the material forming efficiency is effectively improved, the blank deformation is continuous, coordinated and stable, and the structure and performance after deformation are better.

Owner:XUZHOU UNIV OF TECH

Extrusion moulding combined mould of large long-cone horn cylinder member

InactiveCN103567249ASave material costSave processing costExtrusion diesExtrusion mandrelsMaterials scienceExtrusion moulding

The invention discloses an extrusion moulding combined mould of a large long-cone horn cylinder member. The extrusion moulding combined mould comprises an upper general mould plate, a lower general mould plate, a male mould, a female mould and a discharging mechanism, wherein the male mould is detachably fixed on the upper mould plate and comprises an upsetting male mould punch, a pre-forming male mould punch and a final-forming male mould punch; the female mould carries out transverse splitting and comprises a first section of female mould and a second section of female mould, the first section of female mould forms a general female mould, and is movably fixed on the lower mould plate, and the second section of female mould is detachably fixed between the first section of female mould and the lower mould plate; the upper mould plate is fixed with the upsetting male mould punch, the first section of female mould and the lower mould plate are fixedly combined to form an upsetting mould, the pre-forming male mould punch is used for replacing the upsetting male mould punch to be fixed on the upper mould plate, a discharging plate is fixed above the first section of female mould to form a pre-forming mould, the final-forming male mould punch is used for replacing the pre-forming male mould punch to be fixed on the upper mould plate, and the second section of female mould is cushioned between the first section of female mould and the lower mould plate to form a final-forming mould.

Owner:ZHONGBEI UNIV

Light weight, stiffened, twist resistant, extruded vehicle axle

ActiveUS20070137277A1Resist bending and flexingIncrease beam intensityExtrusion diesExtrusion mandrelsTorsional loadTroffer

Owner:AAM INT S A R L

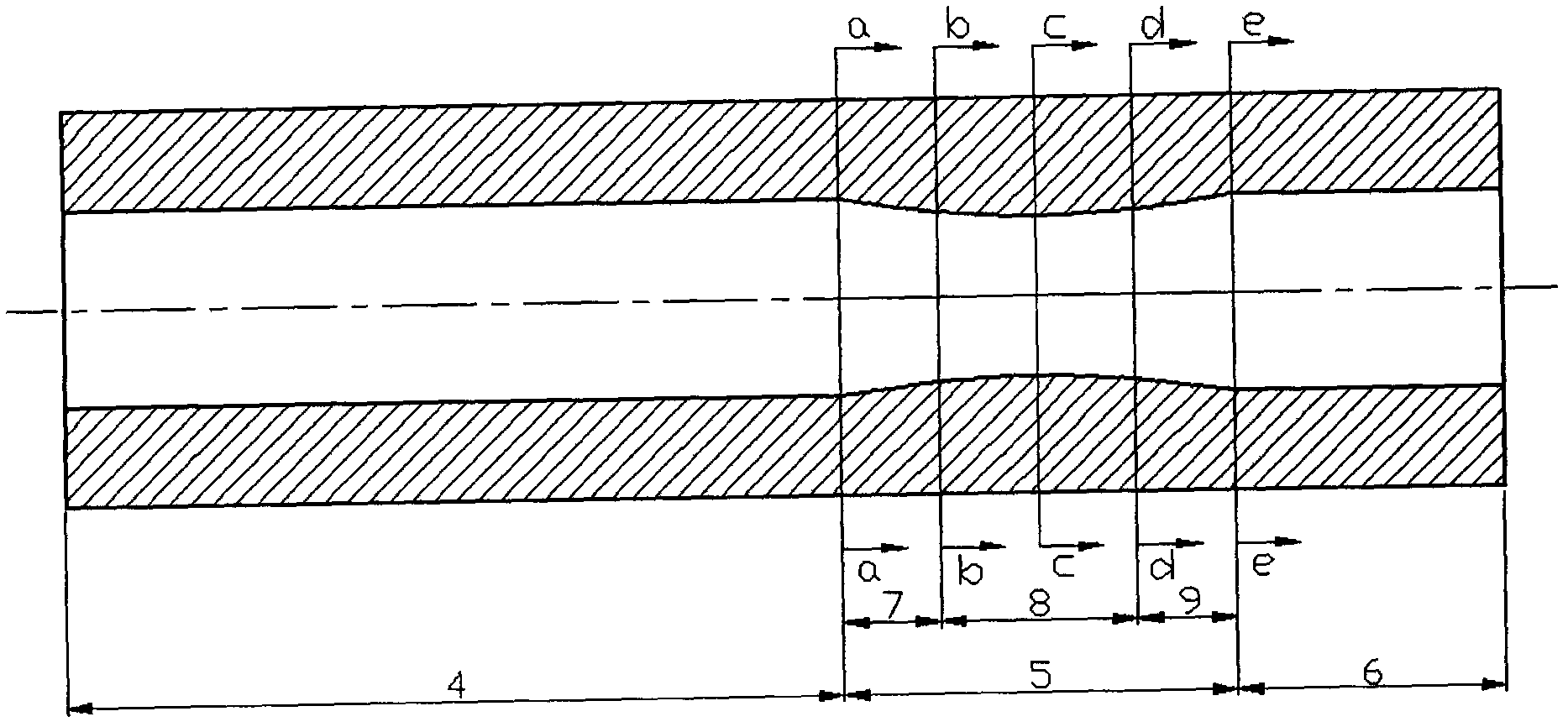

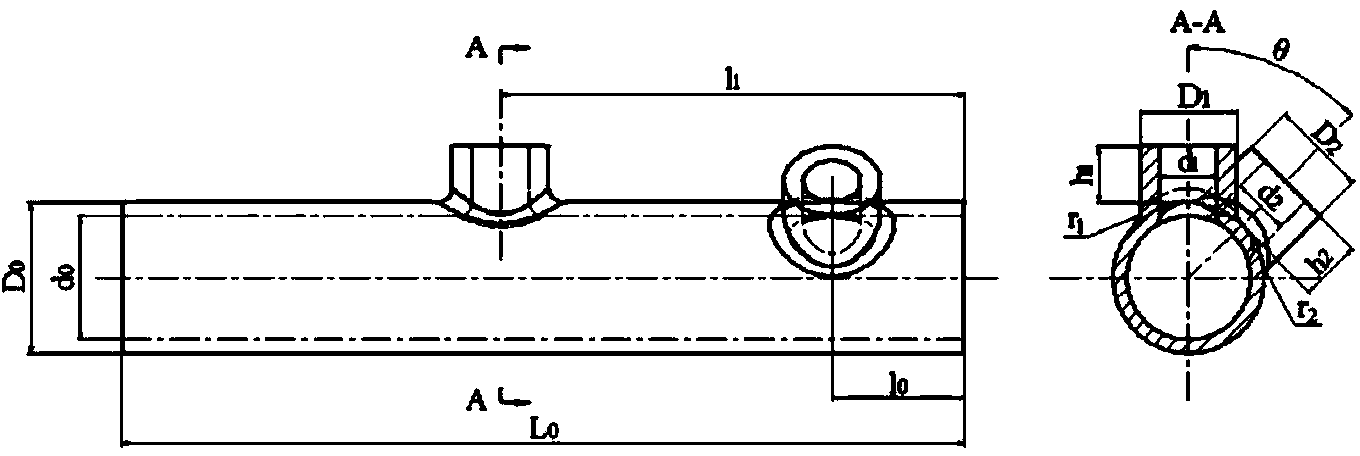

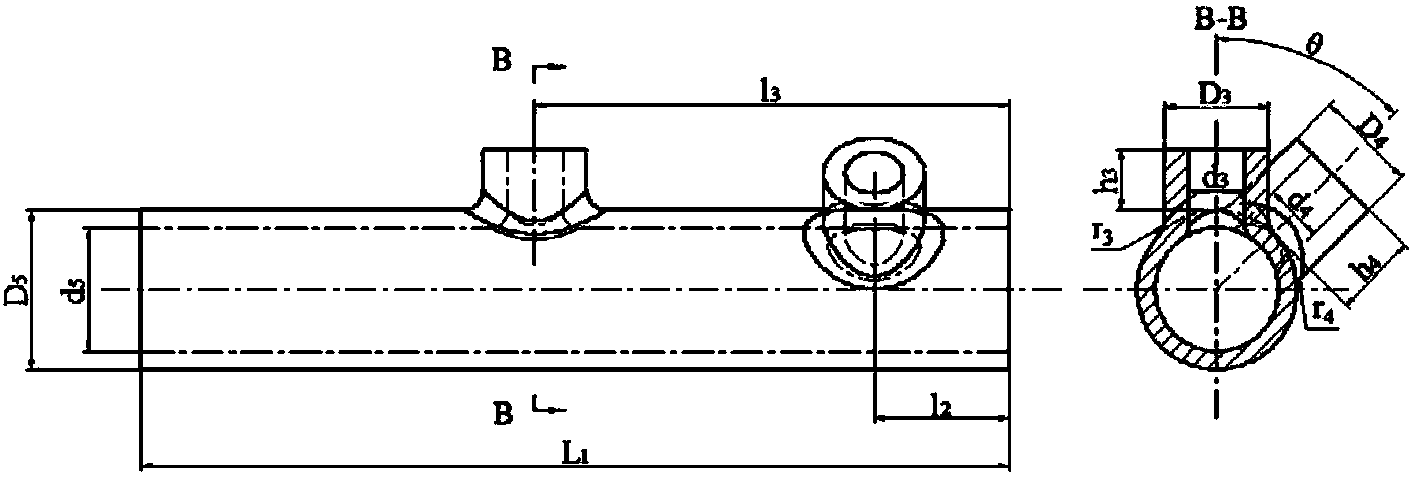

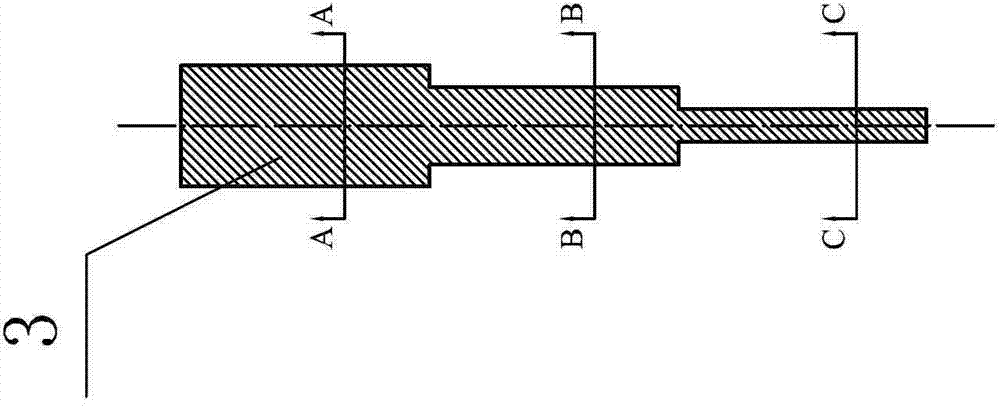

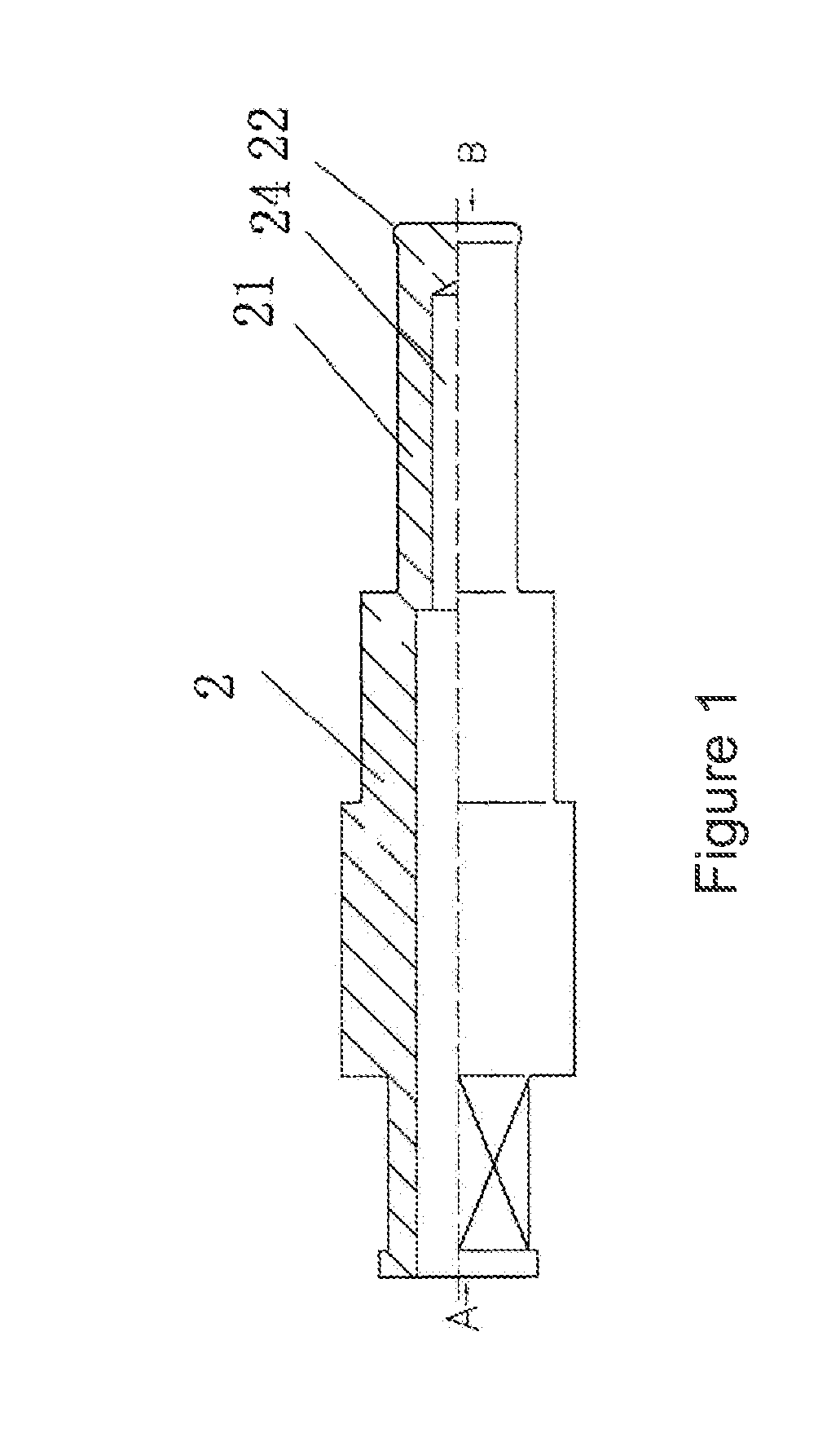

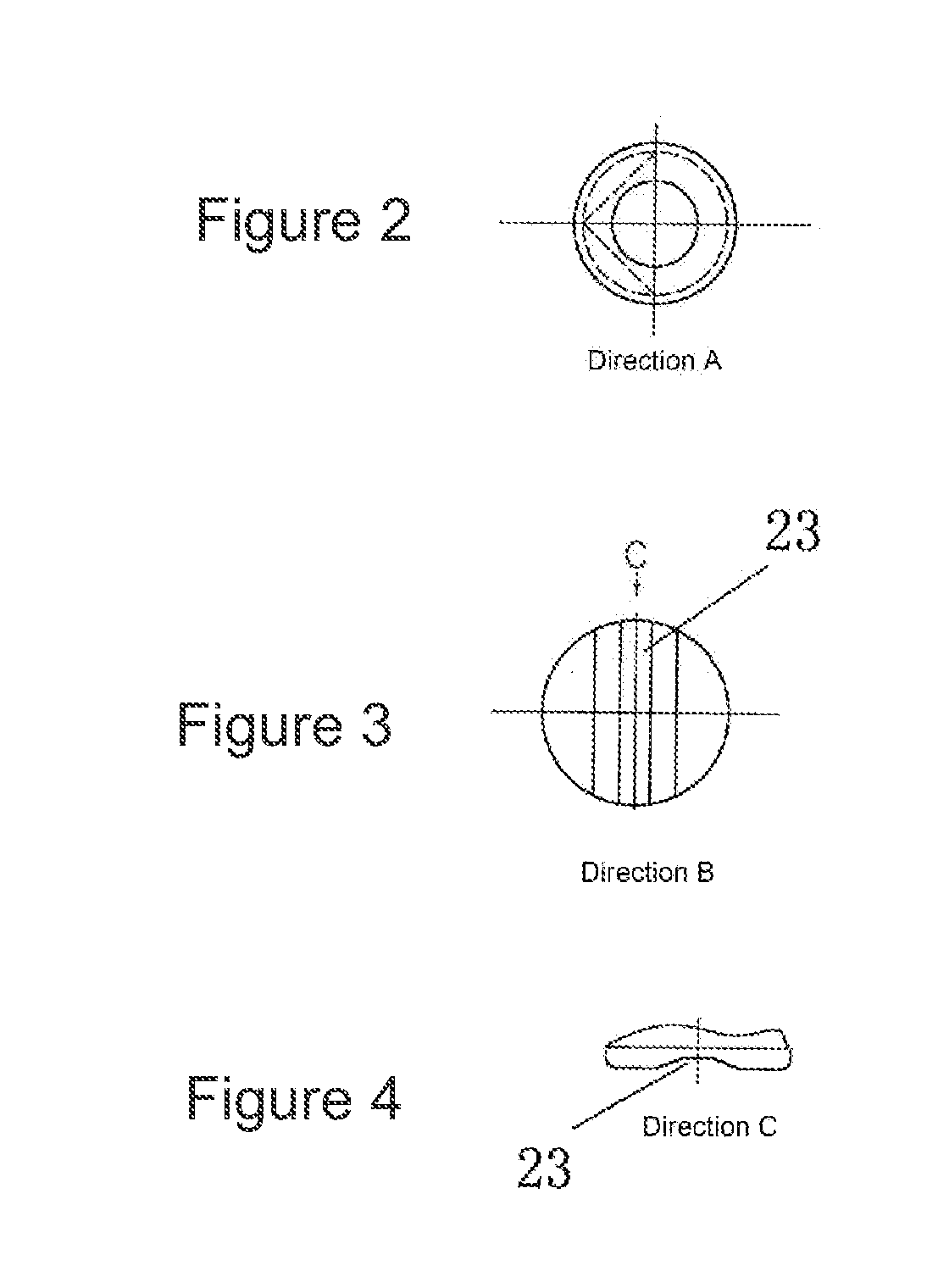

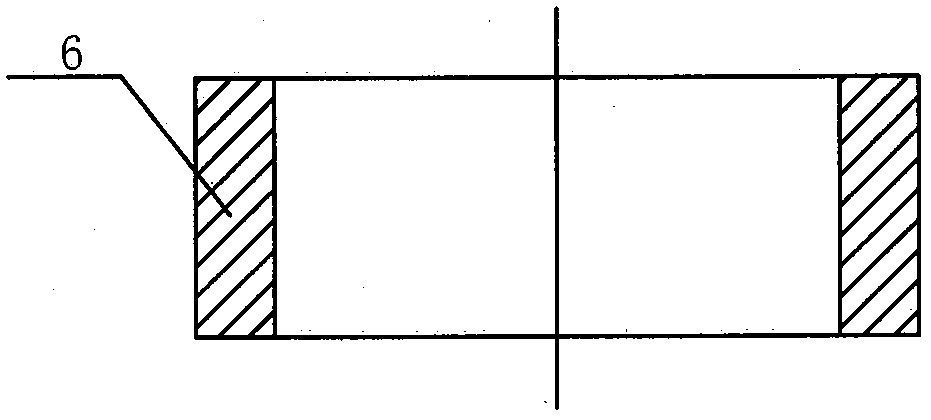

Producing method of aluminum alloy seamless stage variable section pipe and preparation device

InactiveCN102921754AImprove stabilityHigh dimensional accuracyExtrusion mandrelsMetallurgyMaximum diameter

The invention discloses a producing method of an aluminum alloy seamless stage variable section pipe and a preparation device. A mould adopts a multi-stage step extruding needle. The extruding steps are as follows: taking the first stage with the maximum diameter of the multi-stage step extruding needle to the middle of a working belt of an extruding die, forming a wall-thinned pipe body through the first stage with the maximum diameter of the multi-stage step extruding needle; when the length of the wall-thinned pipe reaches the design requirement, enabling the multi-stage step extruding needle to return to the second stage, taking a second stage to the middle of the working belt of the extruding die, forming a wall-thickened pipe body by the second stage of the multi-stage step extruding needle; and until the step number fits for the requirement, cutting off the shaped aluminum alloy pipe by a cutting machine. The invention can produce the aluminum alloy seamless stage variable section pipe; and the aluminum alloy seamless stage variable section pipe is high in dimensional precision, firm, and high in producing efficiency; therefore, the production cost is reduced; and the aluminum alloy seamless stage variable section pipe realizes the structural optimal design, so that the material is saved and the self-weight of the member is lightened.

Owner:GUANGDONG WEIYE ALUMINUM FACTORY GRP

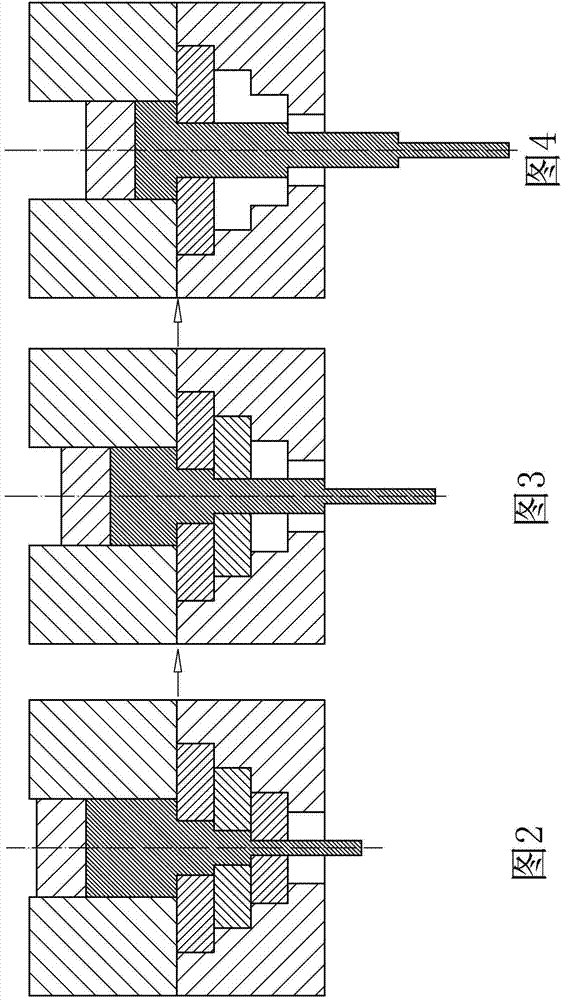

Modularized extrusion molding apparatus and method for section bar with order-variable cross sections

ActiveCN103480682ASolve technical problemsReduce the number of processesExtrusion diesExtrusion mandrelsProcess engineeringMechanical engineering

The invention provides a modularized extrusion molding apparatus and a modularized extrusion molding method for a section bar with order-variable cross sections, belonging to the field of extrusion processing technology. The invention overcomes the problems of numerous procedures, high process requirements, a substantial texture tendency and difficult implementation of conventional preparation methods for bars with different cross sections and defects like easy generation of folds and superposition of material interfaces, etc. during processing and preparation. The cavity of a first-order module, the cavity of a second-order module and the cavity of a third-order module of the apparatus are combined and form an axial step-like extrusion die cavity with a continuous order-variable surface. The method comprises the following steps: assembling the apparatus; and placing a blank material in an extrusion cylinder, putting in a punch, allowing the punch to descend so as to extrude the blank material from the die orifice of the first-order module, the die orifice of the second-order module and the die orifice of the third-order module, stopping descending of the punch, removing the third-order module, allowing the punch to go a distance downwardly, then stopping descending of the punch, removing the second-order module and allowing the punch to descend again so as to realize extrusion molding of the blank material. The invention has the following beneficial effects: the apparatus is simple, the number of production procedures is small, and the method can be easily implemented, popularized and applied in production.

Owner:福建祥鑫股份有限公司

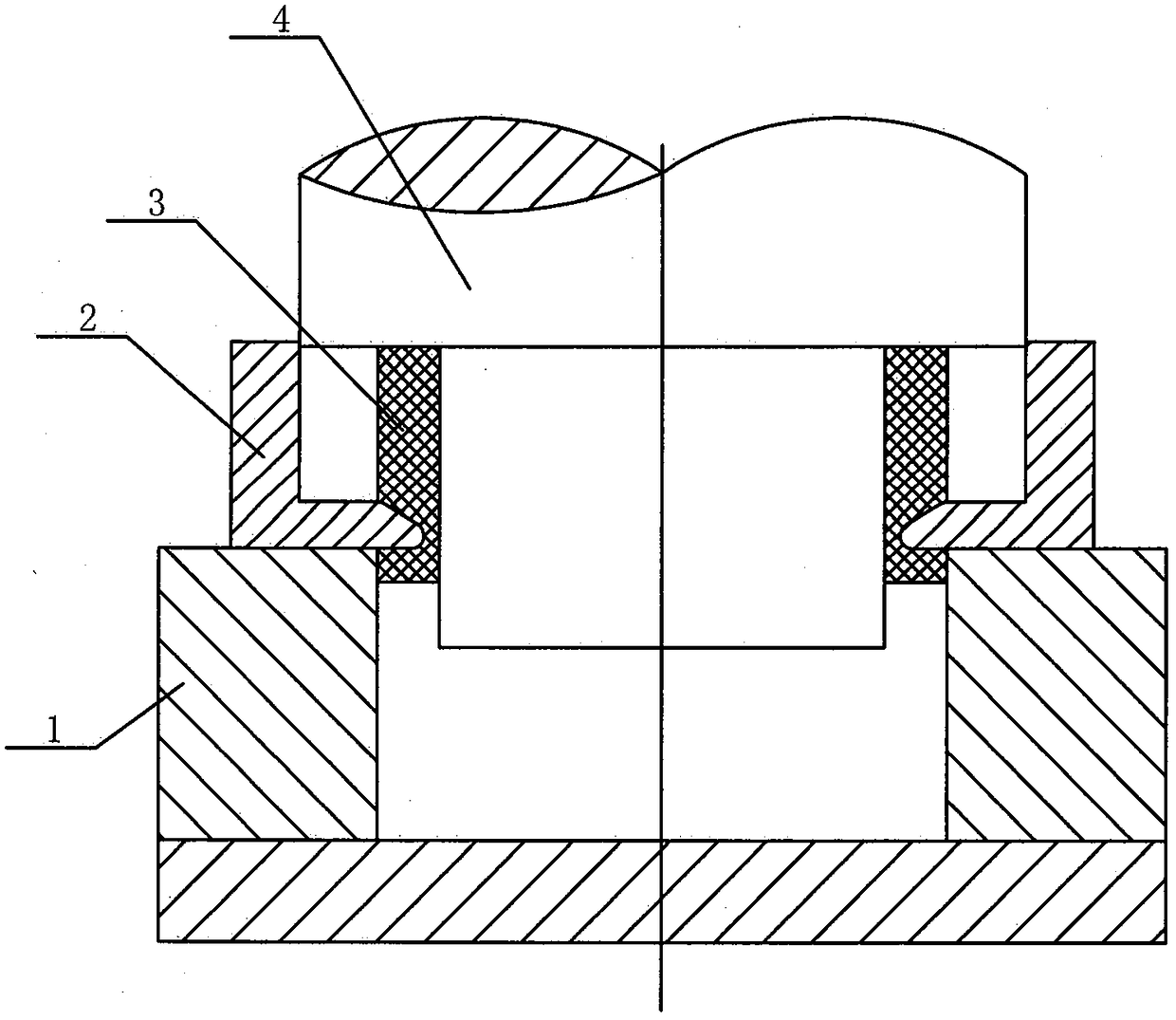

Rotary Extrusion Producing Method for Producing Inner Ring Rib with Large Aspect Ratio Formed of Hollow Billet

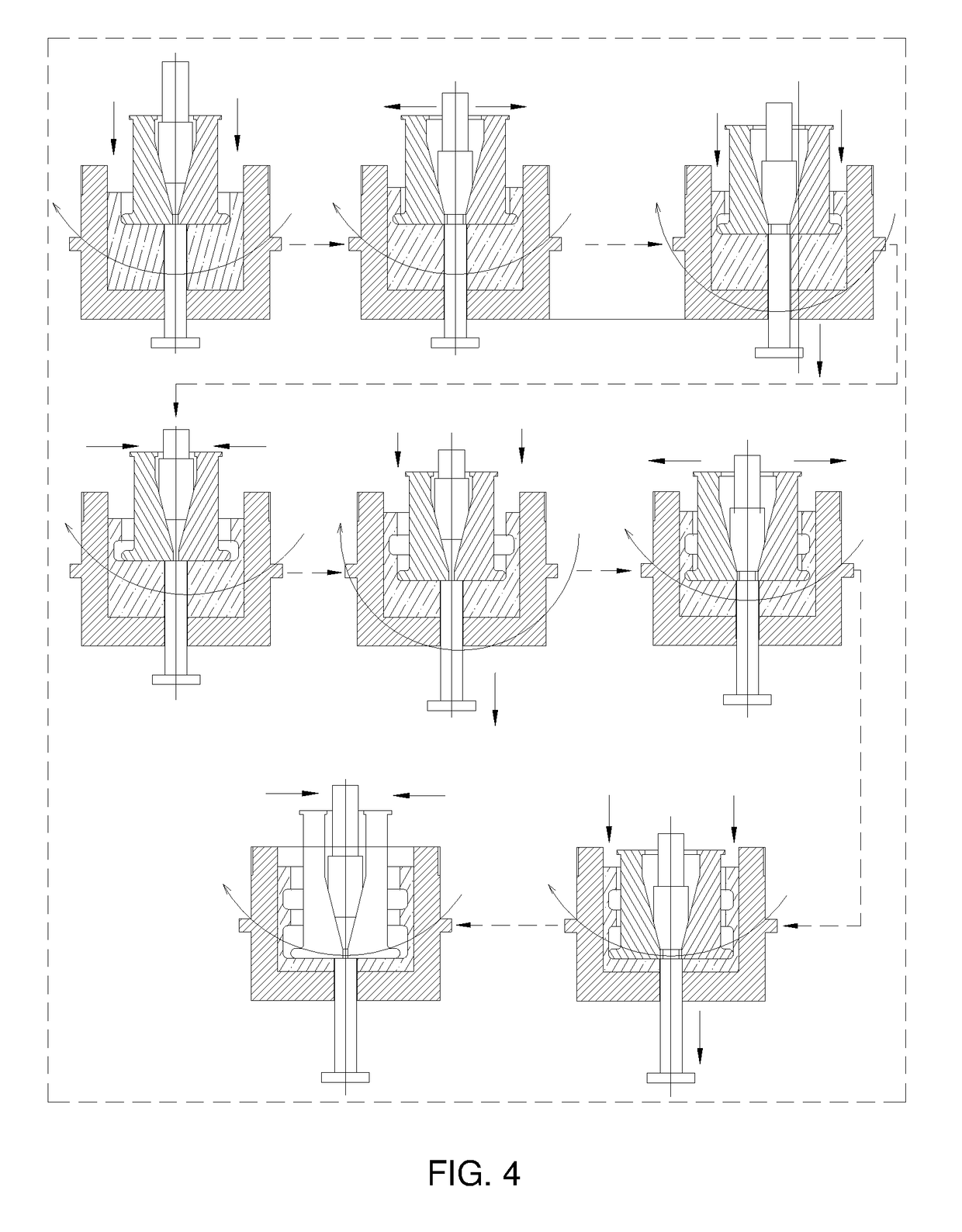

ActiveUS20180056351A1Easy to useEasy to operateExtrusion diesExtrusion mandrelsHydraulic cylinderEngineering

The present invention discloses a rotary extrusion producing method for producing an inner ring rib with a large aspect ratio formed of a hollow billet, which includes: combining, at an initial stage of rotary extrusion, two convex dies together and driving, by a slider on a press machine, left and right half convex dies to extrude a blank downward to form an initial profile of a transverse rib; dragging respectively, by left and right horizontal hydraulic cylinders, the left and right half convex dies to move in a radial direction, to form an initial cylindrical wall, so as to achieve a purpose of forming the transverse rib, once the blank is extruded downward by a certain depth, where a head of a mandrel is set to be at a certain conical degree, and a certain number of processed pits are distributed on an inner cavity of a concave die.

Owner:ZHONGBEI UNIV

Method of forming a cup shaped aluminum magnesium alloy article by rotary extrusion

ActiveUS20180369888A1Axial loading force is reducedReduce loadExtrusion diesExtrusion mandrelsMaterials scienceMagnesium alloy

Provided is a method of forming a cup-shaped aluminum-magnesium-alloy article by rotary extrusion, including the following steps. (1) Blanking. (2) Performing rotary extrusion: placing a cylindrical billet into a concave die cavity, wherein a peripheral wall of the cavity of the concave die is provided with at least two symmetrical axial grooves; inserting a convex die into the concave die cavity, wherein an end of a working region of the convex die is provided with a groove of a trapezoidal cross section; subjecting the convex die to forward extrusion and heating, and simultaneously rotating and heating the concave die, wherein an integral torque is formed during the extrusion process of the convex die by using the cylindrical billet inside the groove having a trapezoidal cross section, and wherein a synchronized rotation with the concave die is achieved by using a metallic billet that flows into the axial groove. (3) Demolding.

Owner:ZHONGBEI UNIV

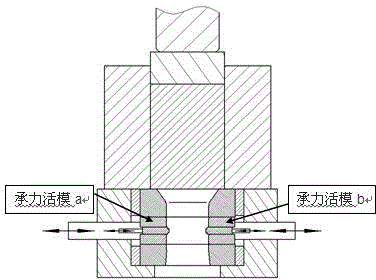

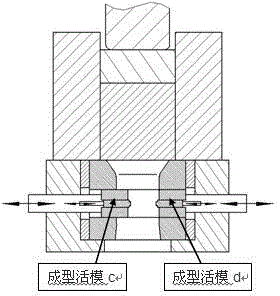

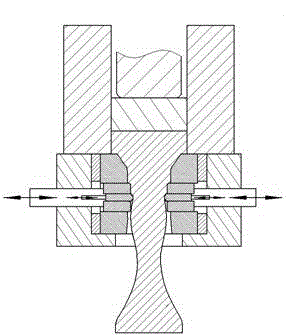

Extruding method for two-dimension function-variation continuous variable-cross-section profile

ActiveCN104607487ASolve the problem that the shape is simple and the length is limited by the size of the moldPromote rapid developmentExtrusion diesExtrusion mandrelsDiameter ratioMechanical engineering

The invention provides an extruding method for a two-dimension function-variation continuous variable-cross-section profile, and aims at solving the forming problem of a continuous variable-cross-section member showing function variation along the length direction. By coordinating the rapid response cooperation motion among a bearing segmented die, a molding segmented die and an extrusion rod, controllable continuous variable-cross-section precise molding for a member which possesses a relatively large length-diameter ratio and has the cross section shape relatively substantially changing along the profile length direction is realized.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Axial-radial flow dividing extrusion forming method for thin-walled wide-flange vertical bar tubular member

ActiveCN109078994AReduce production processShort preparation processExtrusion diesExtrusion mandrelsVertical barEngineering

The invention discloses an axial-radial flow dividing extrusion forming method for a thin-walled wide-flange vertical bar tubular member. The axial-radial flow dividing extrusion forming method comprises the following steps that 1. blank blanking is carried out; 2, homogenizing heat treatment is carried out to prepare a circular column preforming member; 3, an axial-radial flow dividing extrusionforming die for the thin-walled wide-flange vertical bar tubular member is used for conducting partial radial extrusion on the preforming member, a bottom flange and partial longitudinal ribs are formed, and a first semi-finished product is manufactured; 4, axial-radial flow dividing extrusion is carried out, a thin wall, the wide flange and outer longitudinal ribs thereof are formed at the same time through one-time die loading, and a second semi-finished product is manufactured; and 5, heat treatment and outer surface machining are carried out, and the final tubular member is manufactured. The thin wall, the wide flange and the outer longitudinal ribs thereof can be formed at the same time through one-time die loading by means of the axial-radial flow dividing extrusion forming method, the manufacturing process is shortened, the labor intensity is reduced, and the axial-radial flow dividing extrusion forming method has the advantages that the manufacturing process is short, the precision is high, and the low cost is good.

Owner:ZHONGBEI UNIV

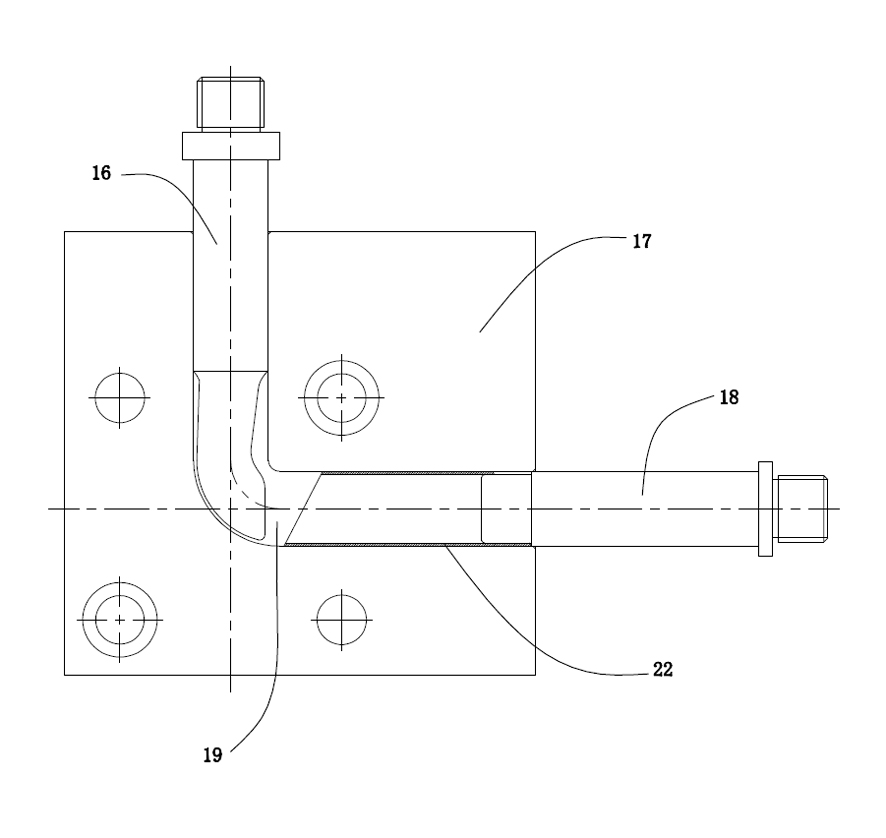

Metal elbow cold extrusion molding device

InactiveCN101954389ALess bending timeEasy to operateExtrusion diesExtrusion mandrelsPipe fittingMaterials science

The invention relates to a metal elbow cold extrusion molding device for processing metal pipe fittings. The invention solves the defects of serious loss of filters, long process time and high bending cost of pipe fittings in the traditional pipe bending technology which needs filling. The metal elbow cold extrusion molding device comprises an extrusion mold core which can be inserted into a mold cavity and a core pushing stick for pushing the pipe fittings to be processed. The extrusion mold core comprises a basic shaft and a working end. The basic shaft is adapted to the inner diameter of the mold cavity, at least one gap equal with the wall thickness of the pipe fitting is arranged between the working end and the inner wall of the mold cavity, the projection of the working end along with the axial direction of the basic shaft is of a round shape, and the round shape is consistent with the inner diameter of the pipe fitting to be processed. The axial projection of the working end is of the round shape, then the pipe fitting can be repaired when the working end exits, the end part of the pipe fitting is of the round shape, the pipe fitting is formed by extruded and bended one-step molding and does not need cooling, the bending time is short, the operation is simple, the efficiency is high, the shape of the end part of the final pipe fitting is more in line with requirements, and the precision is higher.

Owner:ZHE JIANG TIAN XING PIPE

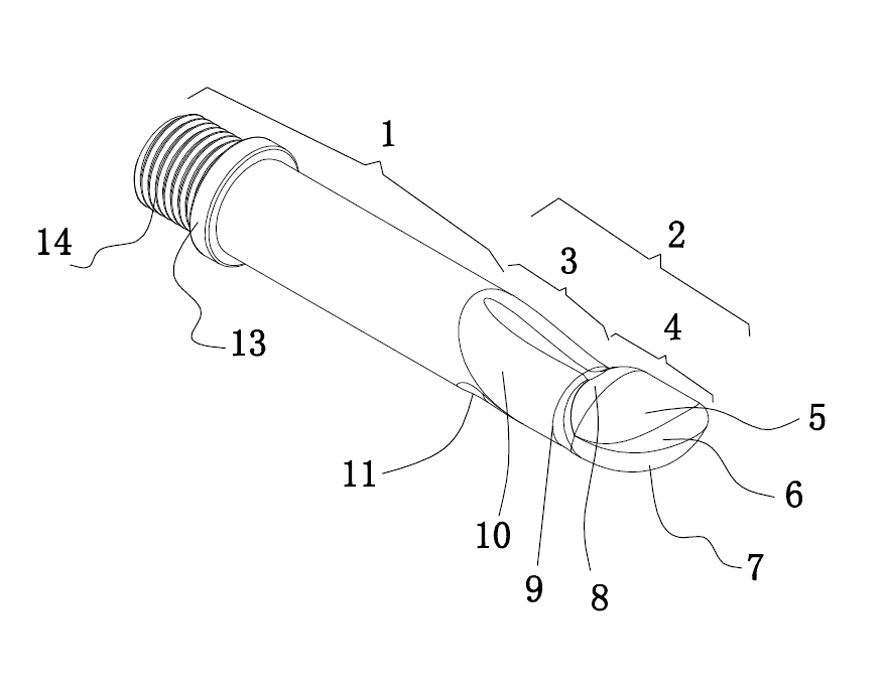

Method and equipment for producing directional vertical taper pipe in motorcycle through cold extrusion

ActiveCN1600468ASimple methodReduce processExtrusion diesExtrusion mandrelsHydraulic pumpEngineering

A cold extrusion technology for machining the vertical conic stearing tube of motorcycle includes reducing hoop, hole enlargnig and plumply shaping to obtain the target product with conic internal hole, cylindrical upper segment, and stepped cylindrical lower segment. The extrusion apparatus for reducing hoop and enlarging hole is composed of lower and upper demoulding buffer cylinders and shaping cylinder. The extrusion apparatus for plumply shaping consists of demoulding cylinder and extruding cylinder.

Owner:艾德义

Four-channel tapered die forming vertical continuous extrusion cladding method and equipment

ActiveCN101716614ASmall locking forceThe direction of feeding and discharging is reasonableExtrusion diesExtrusion mandrelsEngineeringMechanical engineering

The invention relates to the field of continuous extrusion cladding. The invention relates to a multichannel tapered die forming continuous extrusion cladding method which is realized in a way that: when four or six blanks are fed simultaneously, the blanks are driven in by extrusion rollers and evenly sent to a die cavity on the same circumference, and then are cladded on the core wire surface after passing through the tapered die cavity. The invention adopts the four-channel tapered die forming method, thereby ensuring the flowing uniformity of interior materials in the tool set and realizing the production of large-diameter tubing and large-diameter cladding. The invention uses the tapered die structure to form, so that the materials can be cladded on the core wire surface tightly and firmly without adding a drawing process. The production of tubing and sheath wires adopts the same equipment and the same tool set, and therefore, the equipment can be used for multiple purposes.

Owner:大连康丰科技有限公司

Aluminum or aluminum alloy extrudeing die

There is disclosed an aluminum or aluminum alloy extruding die, which comprises Co-group alloy, Ni-group alloy, Cr-group alloy or like high temperature wear-resistant alloy coating applied by thermal spraying on a required die surface portion having been formed in the shape of a rough surface having surface roughness Rz of 5 mum or more. Preferably, after application of the alloy coating, the die is held at a temperature in the range from 500 to 800° C. for a predetermined period of time or the alloy coating surface is so roughened as to have surface roughness Rz of 10 mum or less.

Owner:FURUKAWA SKY ALUMINUM CORP

Device and process for realizing amorphous metal continuous wire cladding by virtue of extrusion

ActiveCN104190736AEasy to processEasy to removeExtrusion diesExtrusion mandrelsWear resistanceAmorphous metal

The invention discloses a device and a process for realizing amorphous metal continuous wire cladding by virtue of extrusion. The device comprises a wire traction device, an extrusion convex die, an extrusion cylinder, an extrusion concave die and a setting cover, wherein the size of the extrusion cylinder is matched with that of the extrusion convex die; the extrusion cylinder is fixedly connected with the extrusion concave die; the extrusion concave die is fixedly connected with the setting cover; the extrusion cylinder, the extrusion concave die and the setting cover define an extrusion convex die channel, a blank chamber, a shunt chamber, a welding chamber and a forming chamber; a cooling gas spray pipe is arranged at an outlet of the forming chamber; a wire inlet is formed in the wall of the extrusion concave die; a section of wire channel is formed in each of the die body and the die core; a blank shunt chamber is formed in the periphery of the die core and is communicated with the blank chamber; and blanks and wires are mixed and coated in the welding chamber. According to the device and process disclosed by the invention, the surfaces of the wires are coated with amorphous metals, and the surface quality of the wires is improved, so that the wires have excellent corrosion resistance and wear resistance, the application range of the wires is widened, and the service lives of the wires are prolonged.

Owner:滕州市产品质量监督检验所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com