Multi-directional composite multi-channel screw extrusion die for metal blank

A technology of screw extrusion and metal billet, which is applied in the direction of metal extrusion die, metal extrusion mandrel, etc., can solve the problems of low working efficiency of the mold, limited plastic deformation ability, short billet size, etc., and achieve good plasticity and deformability Good, solve the effect of short size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

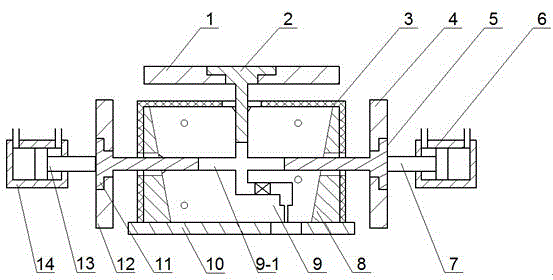

[0020] exist figure 1 Among them, the multi-directional composite multi-channel screw extrusion die for metal blanks includes: upper platen 1, upper punch 2, heating ring 3, right platen 4, right punch 5, right hydraulic cylinder 6, right piston rod 7, die sleeve 8. Combined die 9, extrusion channel 9-1, lower template 10, left punch 11, left template 12, left piston rod 13, left hydraulic cylinder 14; The tapered semicircular die is fixedly connected by positioning pins and bolts to form a combined die 9, and embedded in a die sleeve 8 with the same taper, and a heating ring 3 is installed outside the die sleeve 8; the combined die 9 and the die sleeve 8 is fixedly connected to the lower template 10 at its lower part, and the lower template 10 is fixed on the workbench of the three-way extrusion hydraulic press; in the horizontal and vertical directions inside the combined die 9, a cross-shaped metal billet extrusion channel 9- 1. The vertical upper channel of the extrusion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com