Patents

Literature

1084results about How to "Uniform deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

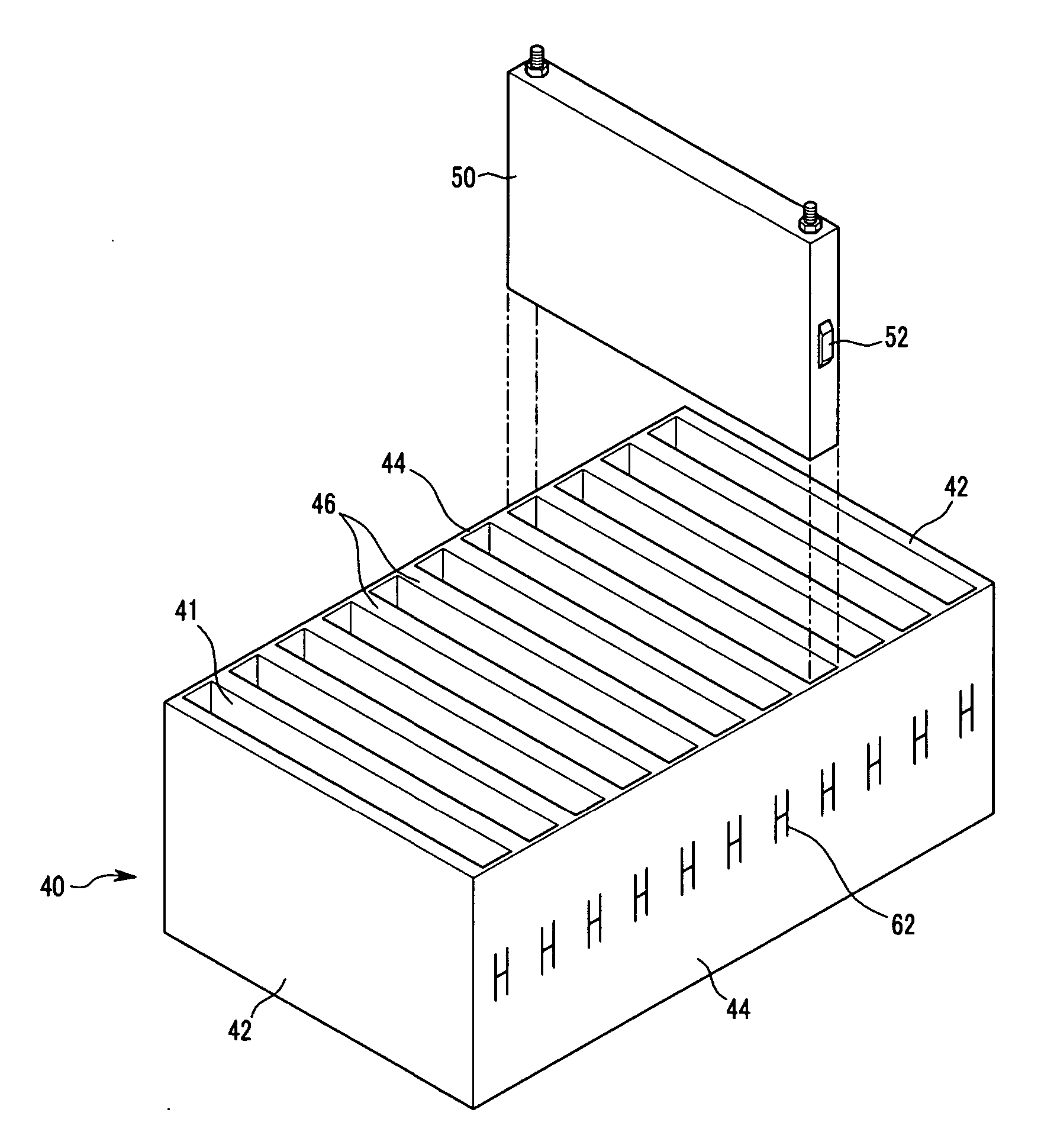

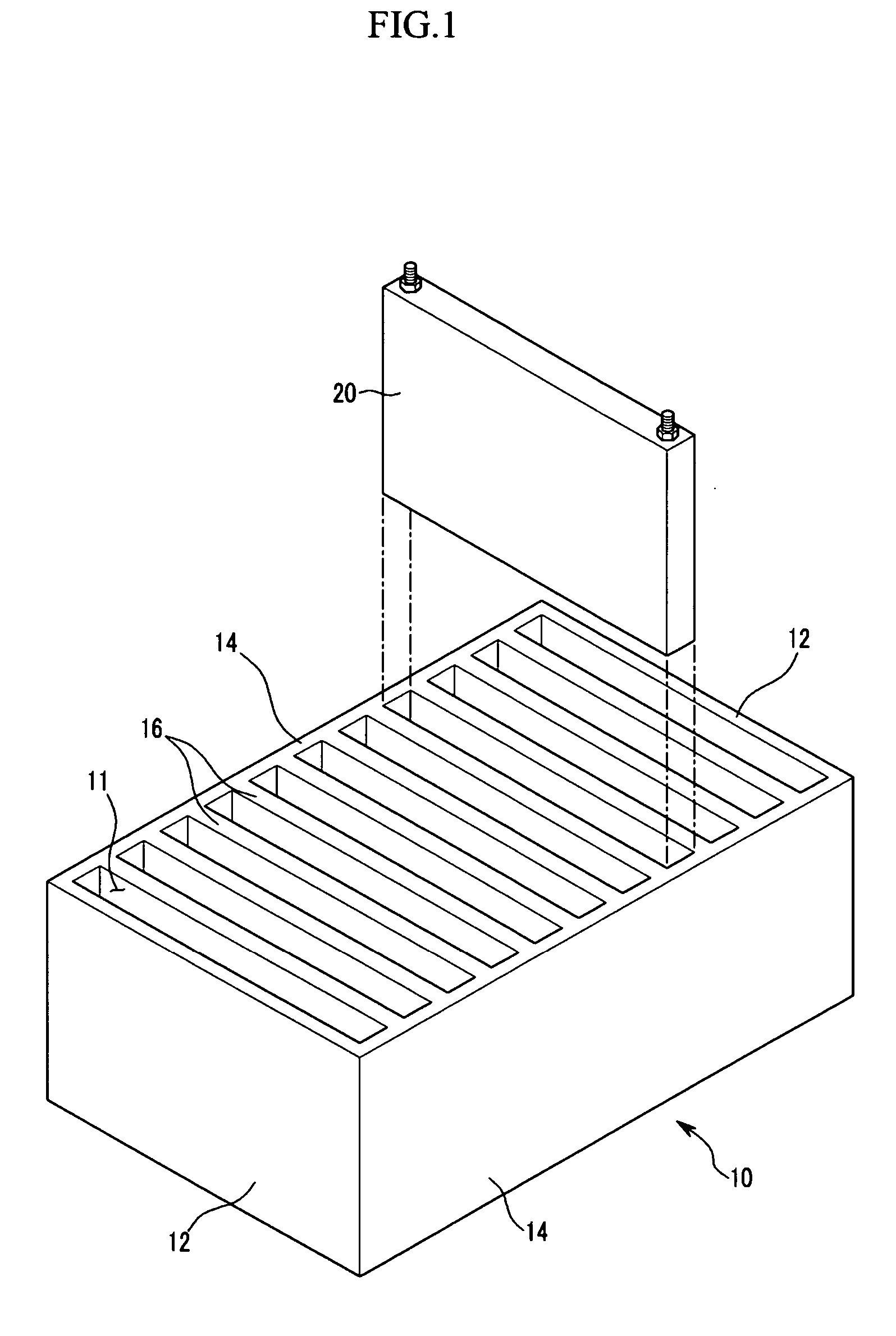

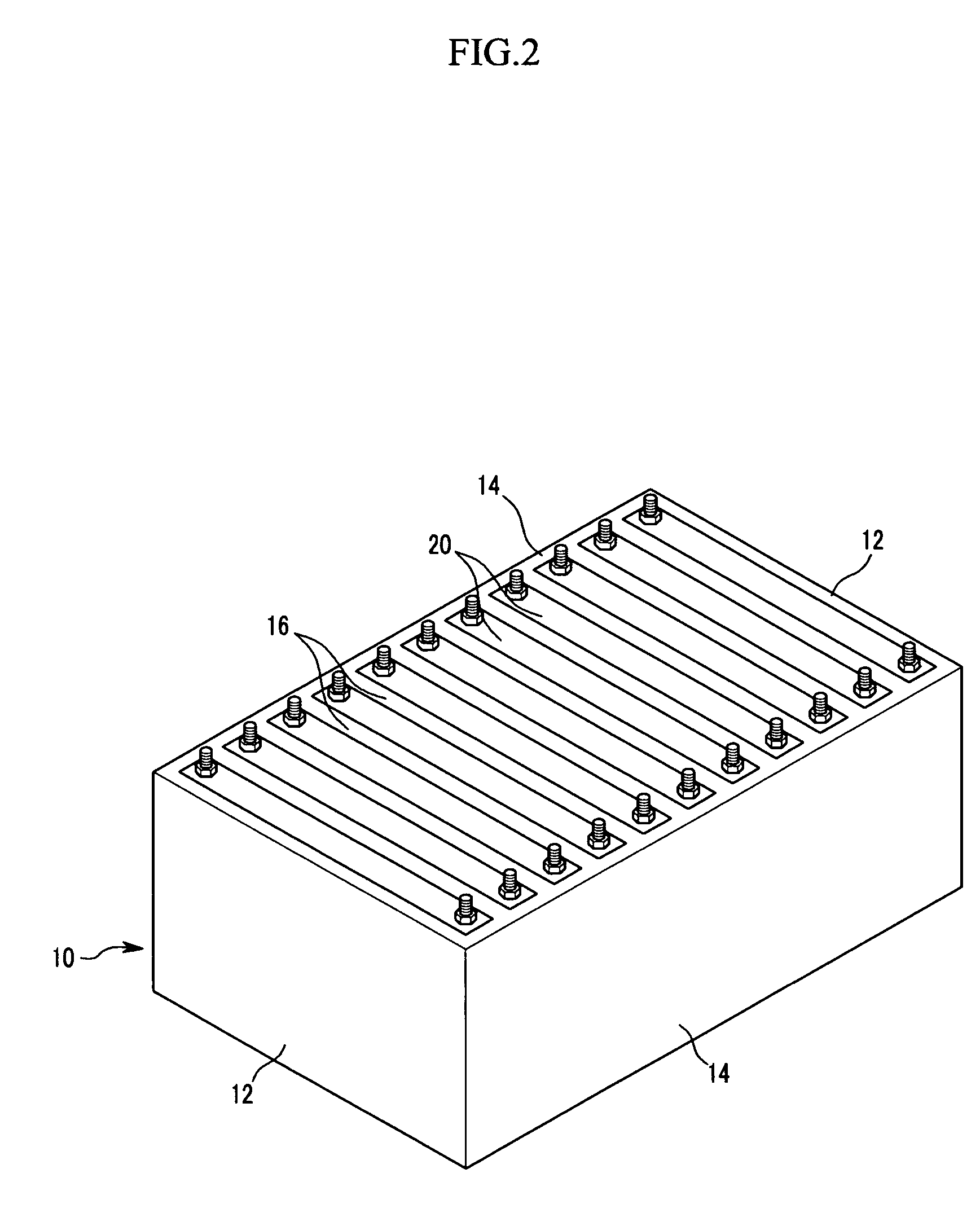

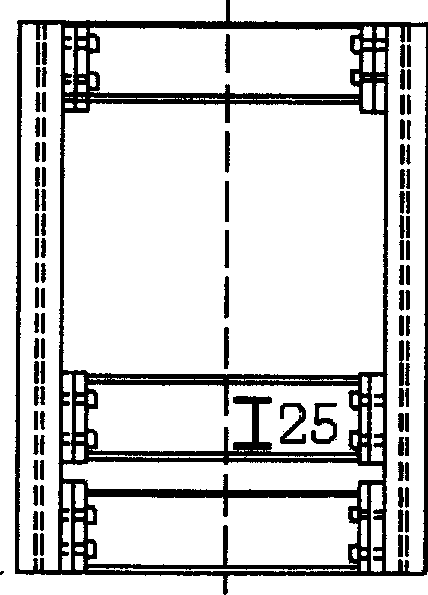

Battery module

InactiveUS20060093899A1Uniform deformationIncrease engagementLarge-sized flat cells/batteriesCell component detailsElectrical and Electronics engineering

Owner:SAMSUNG SDI CO LTD

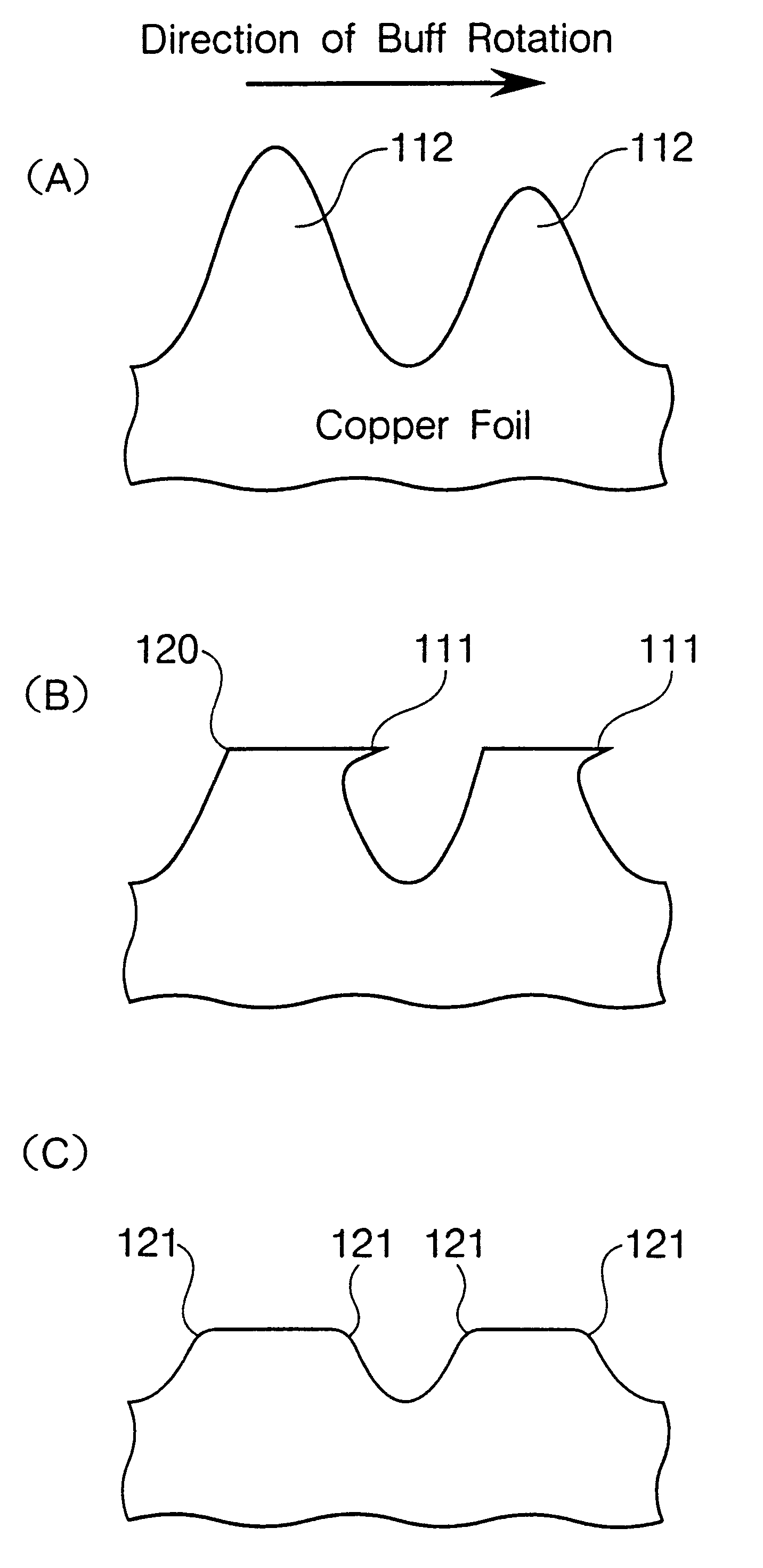

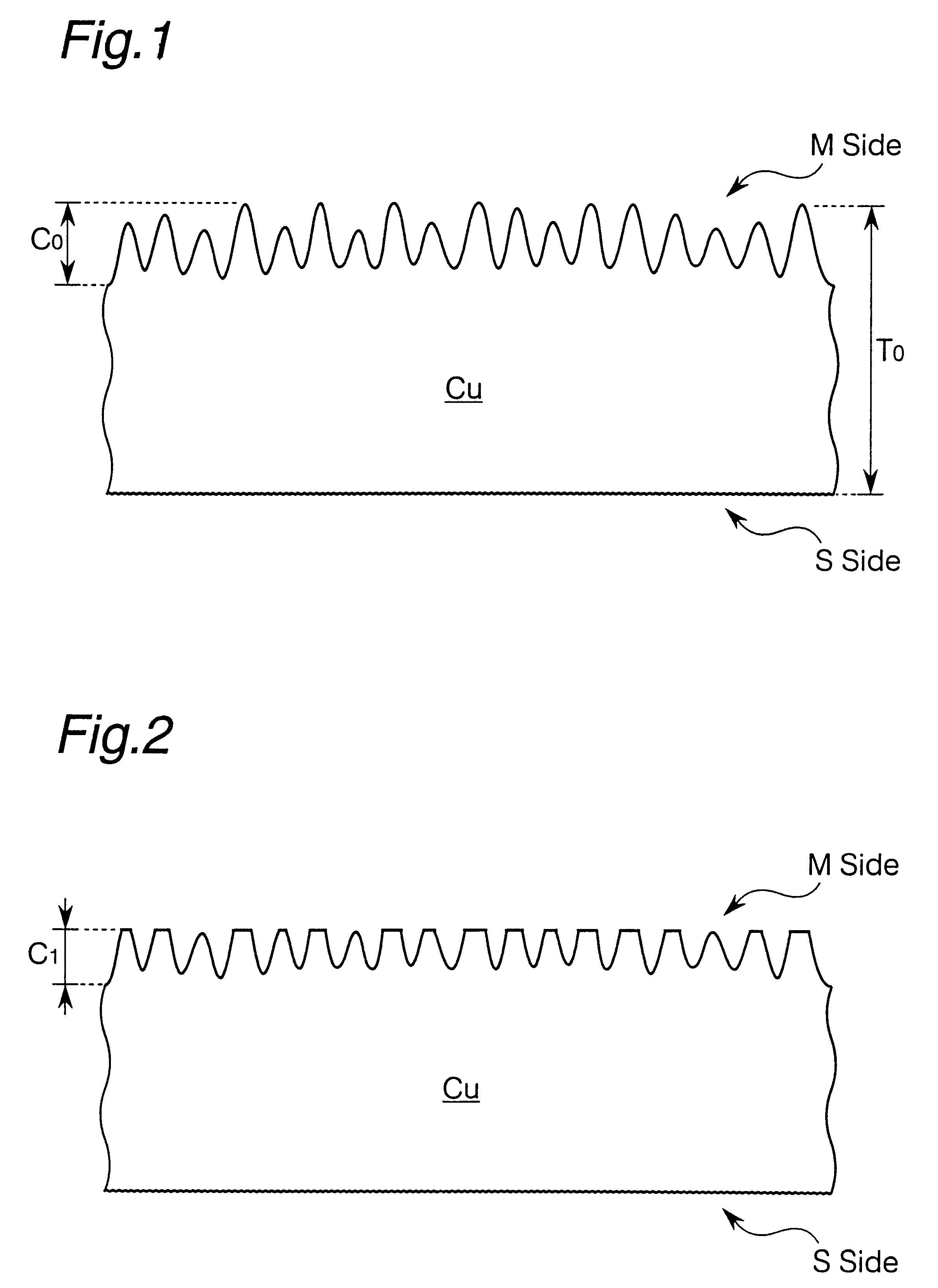

Electrodeposited copper foil with its surface prepared, process for producing the same and use thereof

InactiveUS6475638B1Eliminate deformationHigh peel strengthInsulating substrate metal adhesion improvementLapping machinesSurface roughnessCopper foil

A process for producing an electrodeposited copper foil with its surface prepared, comprising the steps of: subjecting an electrodeposited copper foil having a shiny side and a matte side whose average surface roughness (Rz) is in the range of 2.5 to 10 mum to at least one mechanical polishing so that the average surface roughness (Rz) of the matte side becomes in the range of 1.5 to 3.0 mum; and subjecting the matte side having undergone the mechanical polishing to a selective chemical polishing so that the average surface roughness (Rz) of the matte side becomes in the range of 0.8 to 2.5 mum. The invention further provides an electrodeposited copper foil with its surface prepared, produced by the above process, and still further provides PWBs and a multilayer laminate of PWBs, produced with the use of the above electrodeposited copper foil with its surface prepared. The mechanical polishing followed by chemical polishing of the matte side enables obtaining an electrodeposited copper foil with its surface prepared, the matte side of which exhibits excellent properties, and hence enables obtaining PWBs and a multilayer PWBs which have excellent properties.

Owner:MITSUI MINING & SMELTING CO LTD

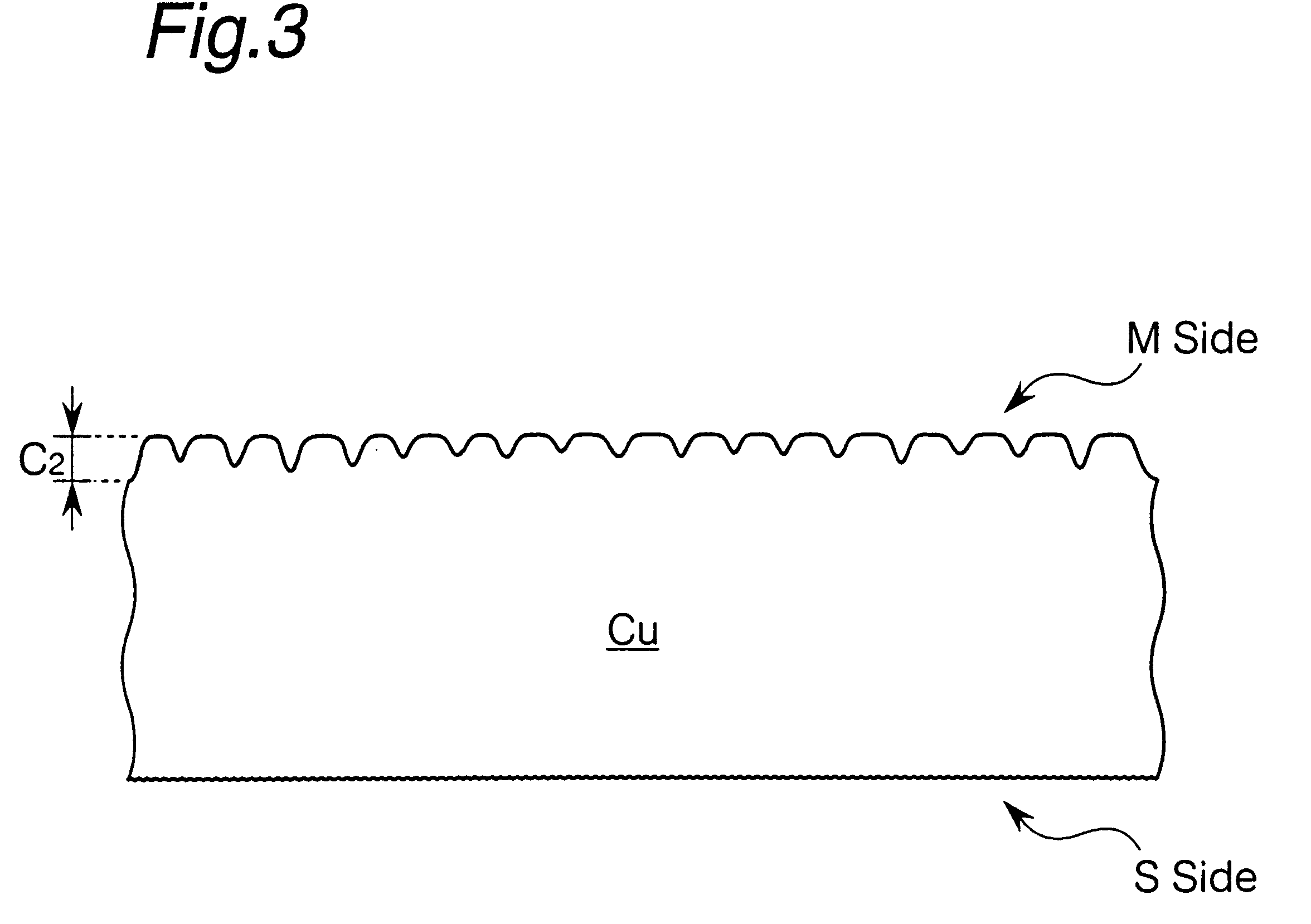

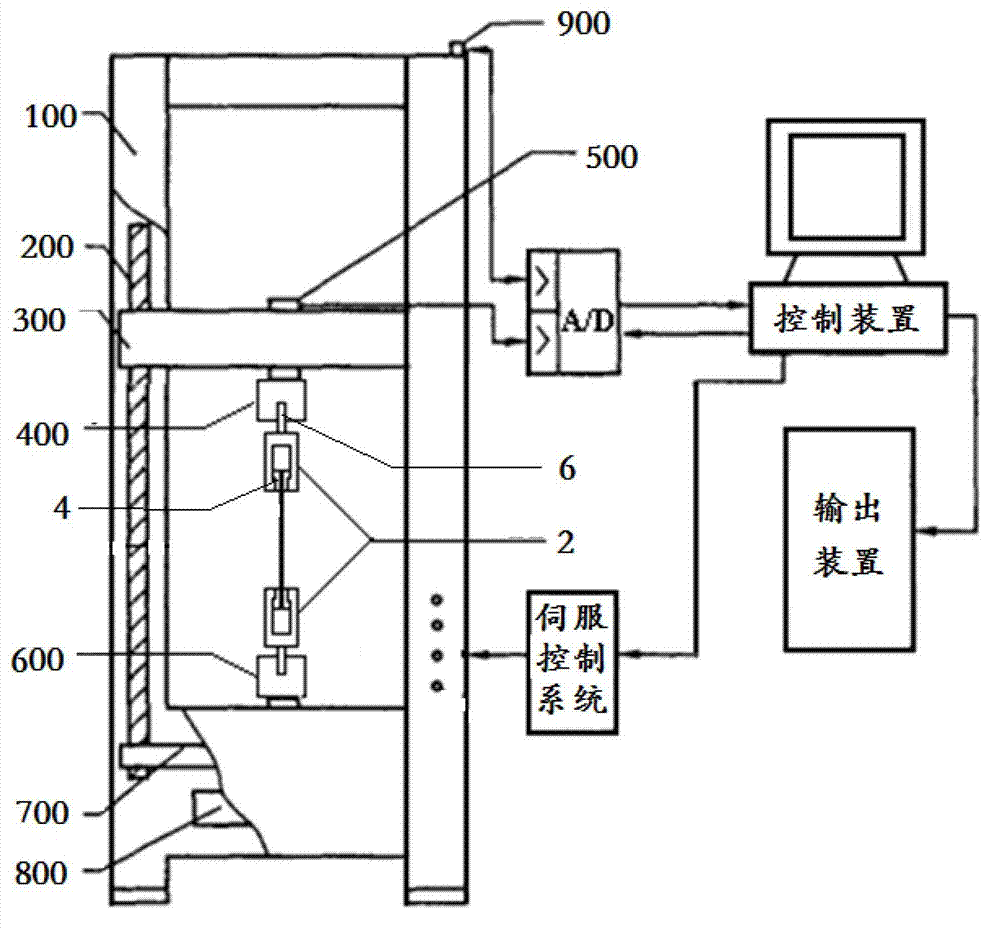

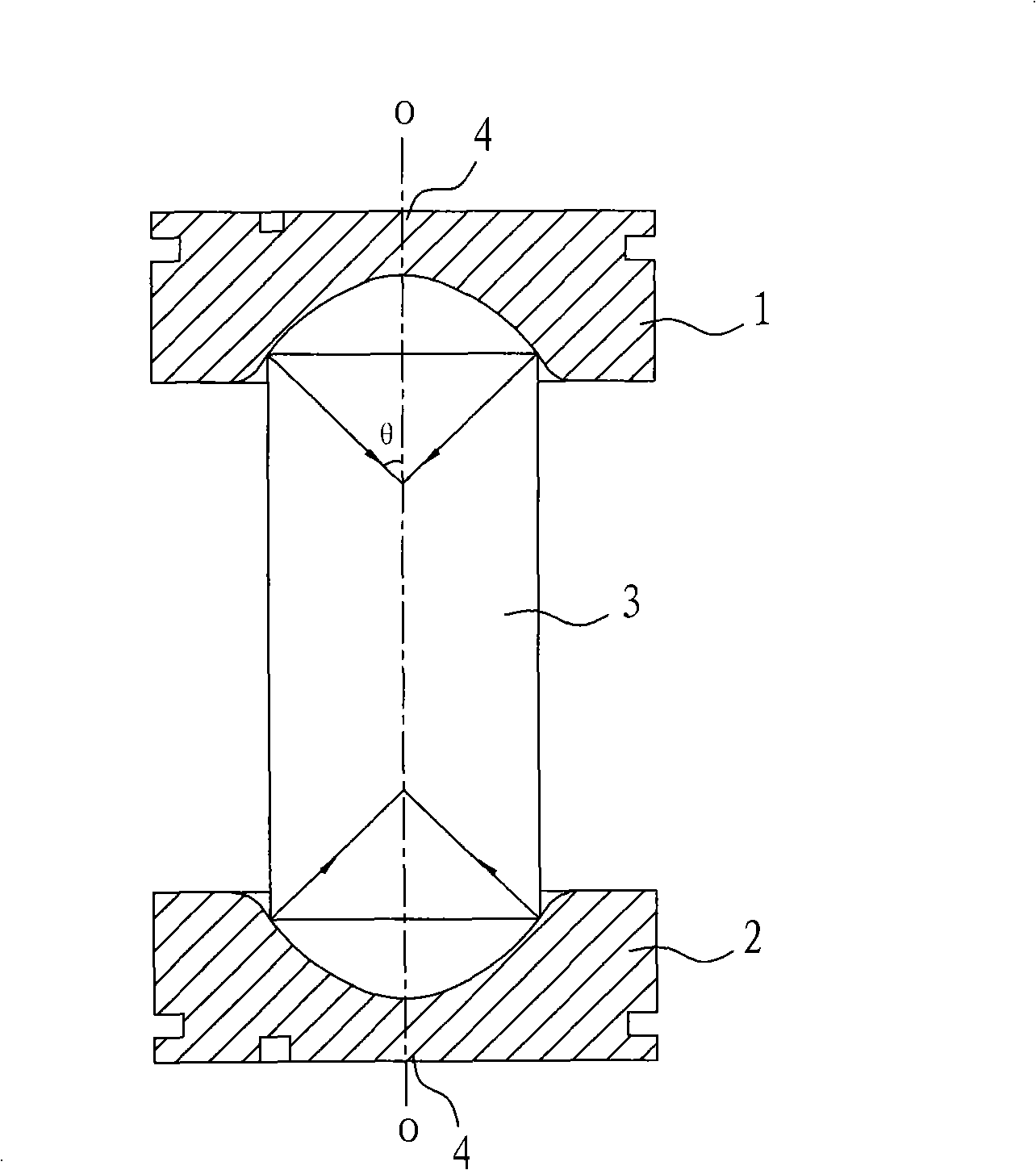

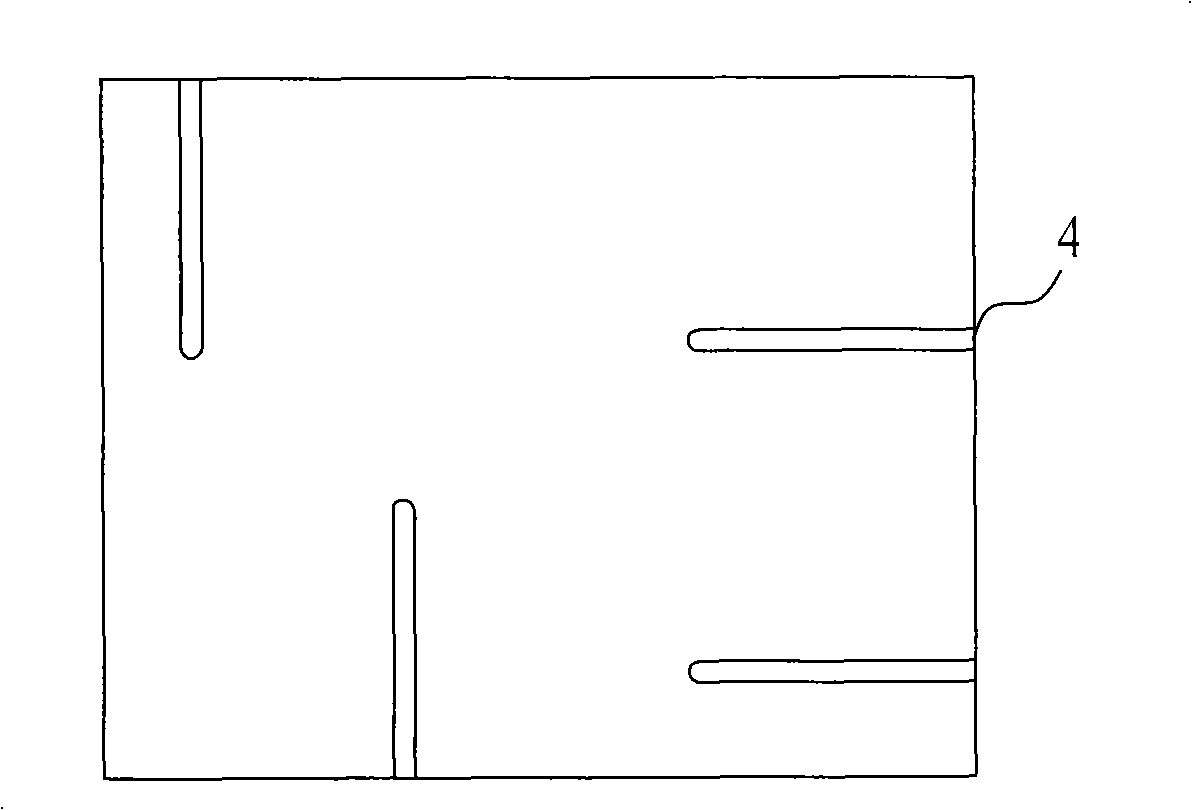

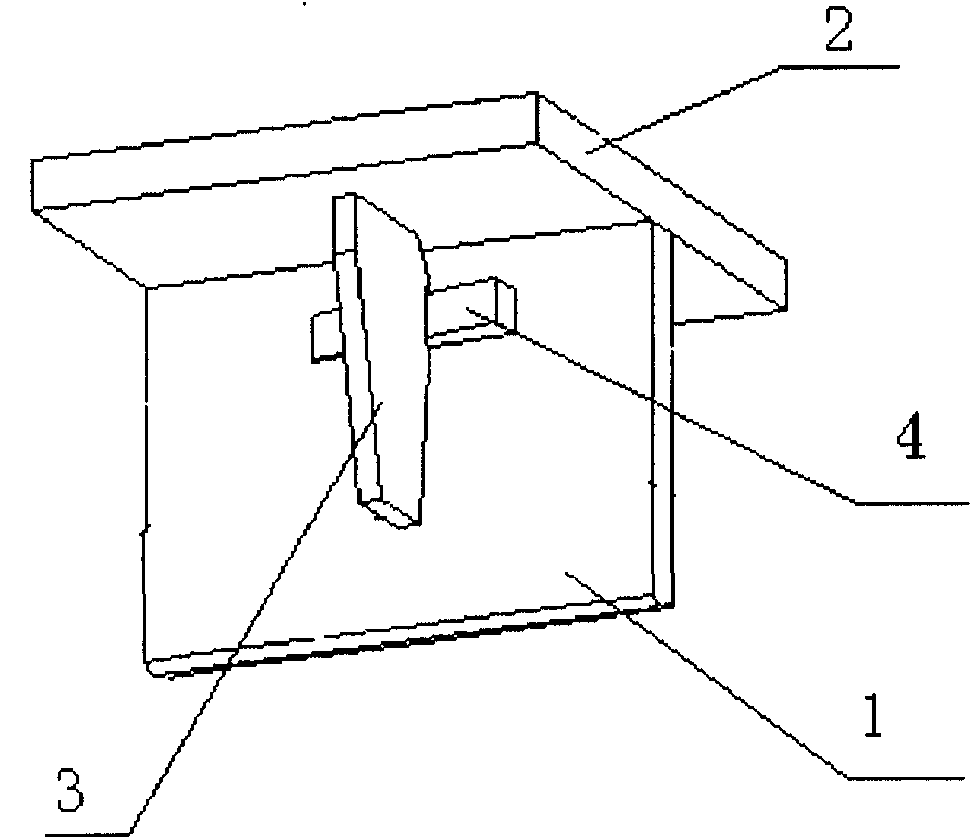

Clamp, device with clamp for testing mechanical property of hyper-elastic material and method

InactiveCN102768149AUniform deformationQuick disassemblyMaterial strength using tensile/compressive forcesData acquisitionHyper elastic

The invention relates to a device and a method for testing mechanical property of a hyper-elastic material. The device mainly comprises a reinforcing piece (4) at the end of a test piece and a test piece clamp, wherein the reinforcing piece (4) has a trapezoidal cross section; a clamping port of the clamp is an inclined surface; the reinforcing piece (4) is adhered to the end of the test piece and is arranged in the clamp, the inclined surface of the clamp tightly clamps the inclined surface of the reinforcing piece (4), and the clamp is self-locked in the tensioning process and is prevented from locally deforming. The device is applied to multiple stress-strain tests of the hyper-elastic material such as uniaxial tension, equally biaxial tension and planar tension (pure shear). Stress data is acquired by a data acquisition system of an electronic universal testing machine, and the strain data is acquired by a charge coupled device (CCD) image acquisition device. Due to the technical scheme, the clamping force is high when the tension is high in the process of tensioning the test piece, so that the test piece is uniformly stressed, more accurate testing data can be obtained, and the mechanical property parameters of the hyper-elastic material obtained accordingly are more reliable.

Owner:TSINGHUA UNIV

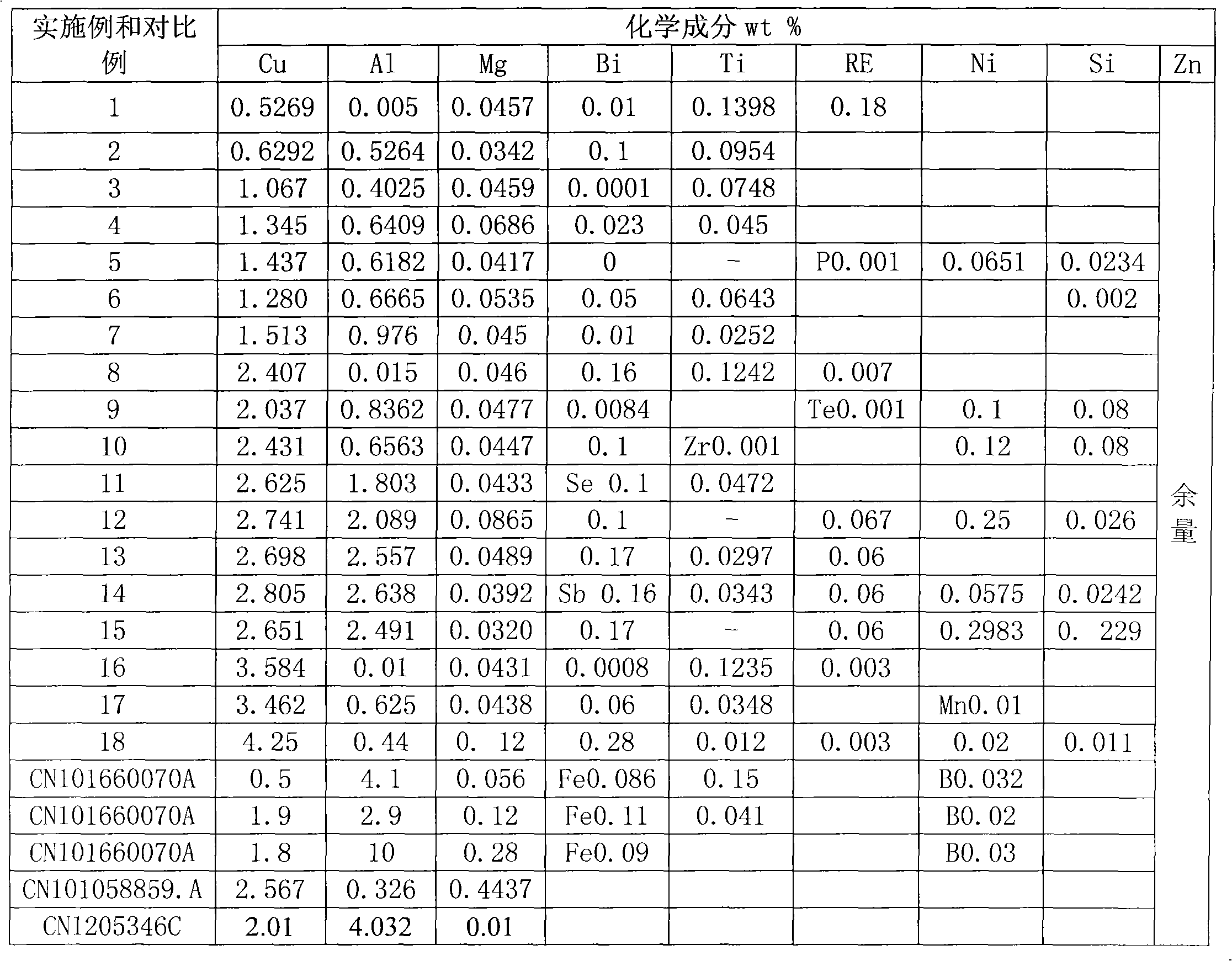

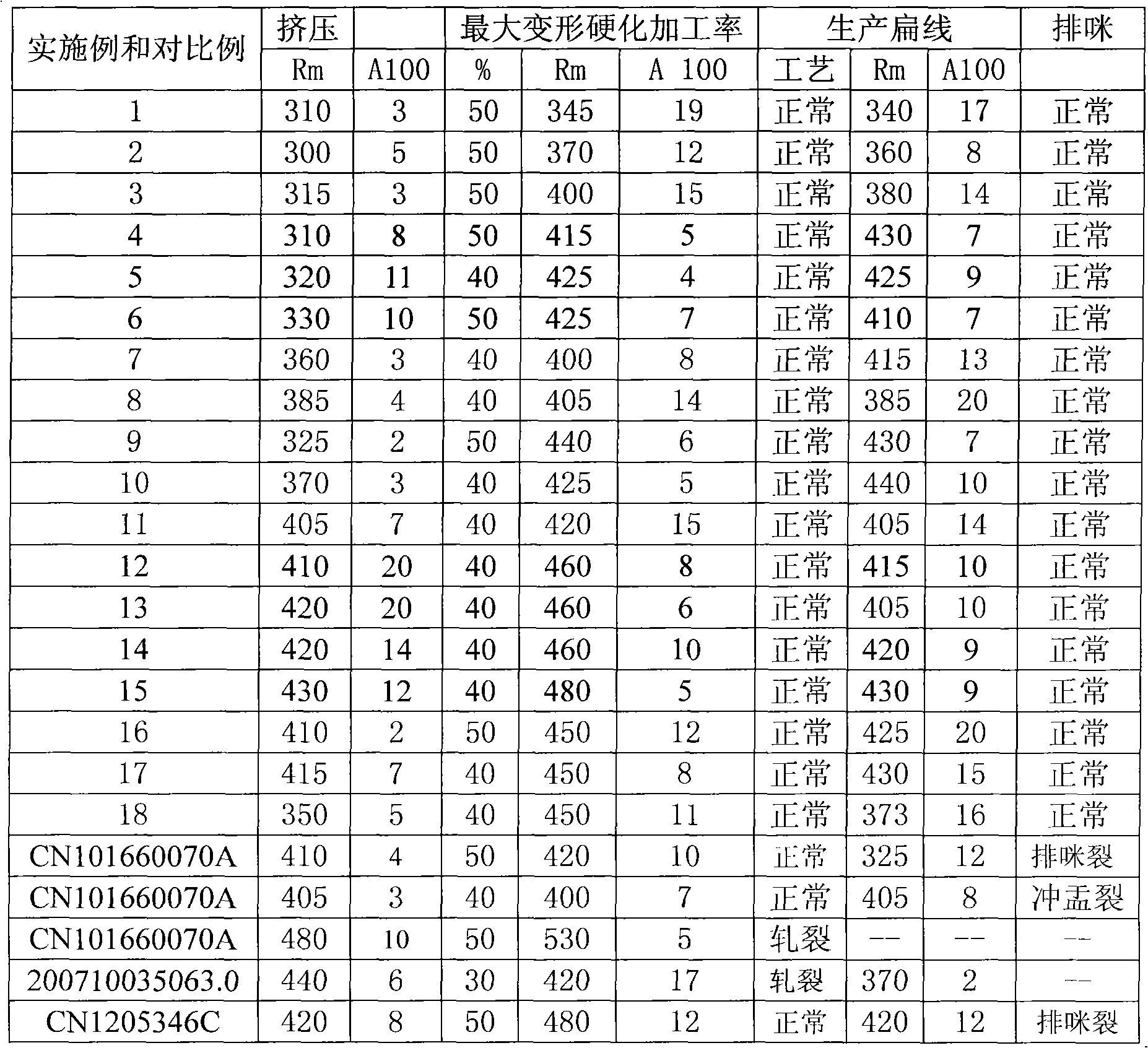

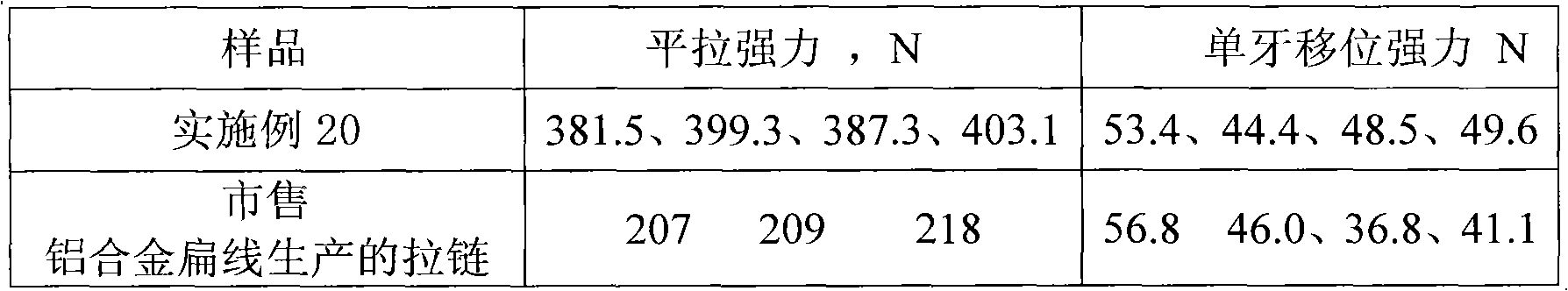

Zinc alloy for zipper tooth belt and preparation method of zipper tooth belt

ActiveCN102011029AOvercoming difficult deformationMeet the mechanical performance requirementsSlide fastenersZinc alloysImpurity

The invention discloses a zinc-alloy zipper tooth belt produced by a row microphone method, in particular to zinc alloy for a zipper tooth belt and a preparation method of the zipper tooth belt. The alloy comprises the following components by weight percent: 0.5-5% of Cu, 10-4.5% of Al, 0.01-0.2% of Mg and the balance of X, Y, Zn and unavoidable impurities, wherein the sum of the percentages of the components is 100%; the X is selected from at least one of 0.0001-0.5% of Bi, 0.01-0.19% of Ti, 0.001-0.3% of RE, 0.001-1% of Ni and 0.001-1% of Si; and Y is selected from at least one of Mn, Co, Nb, Zr, Cr, Ca, P, Sb, Te and Se. By adopting the deformed zinc alloy and the alloy producing method disclosed in the invention, the production of the zipper line can be met, and the zipper tooth belt can be produced smoothly by the row microphone method; and the produced zipper can be processed into different colors.

Owner:NINGBO POWERWAY ALLOY MATERIAL

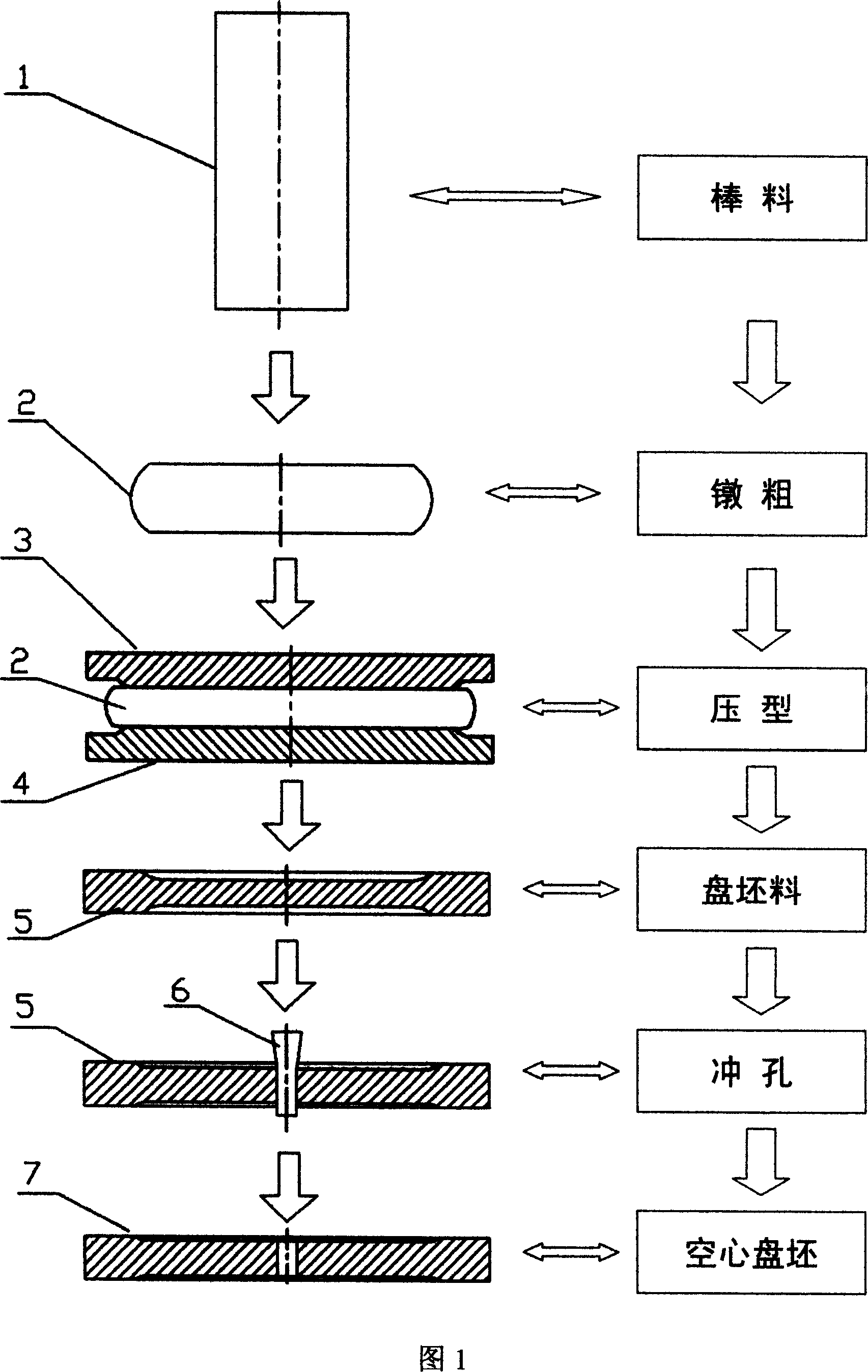

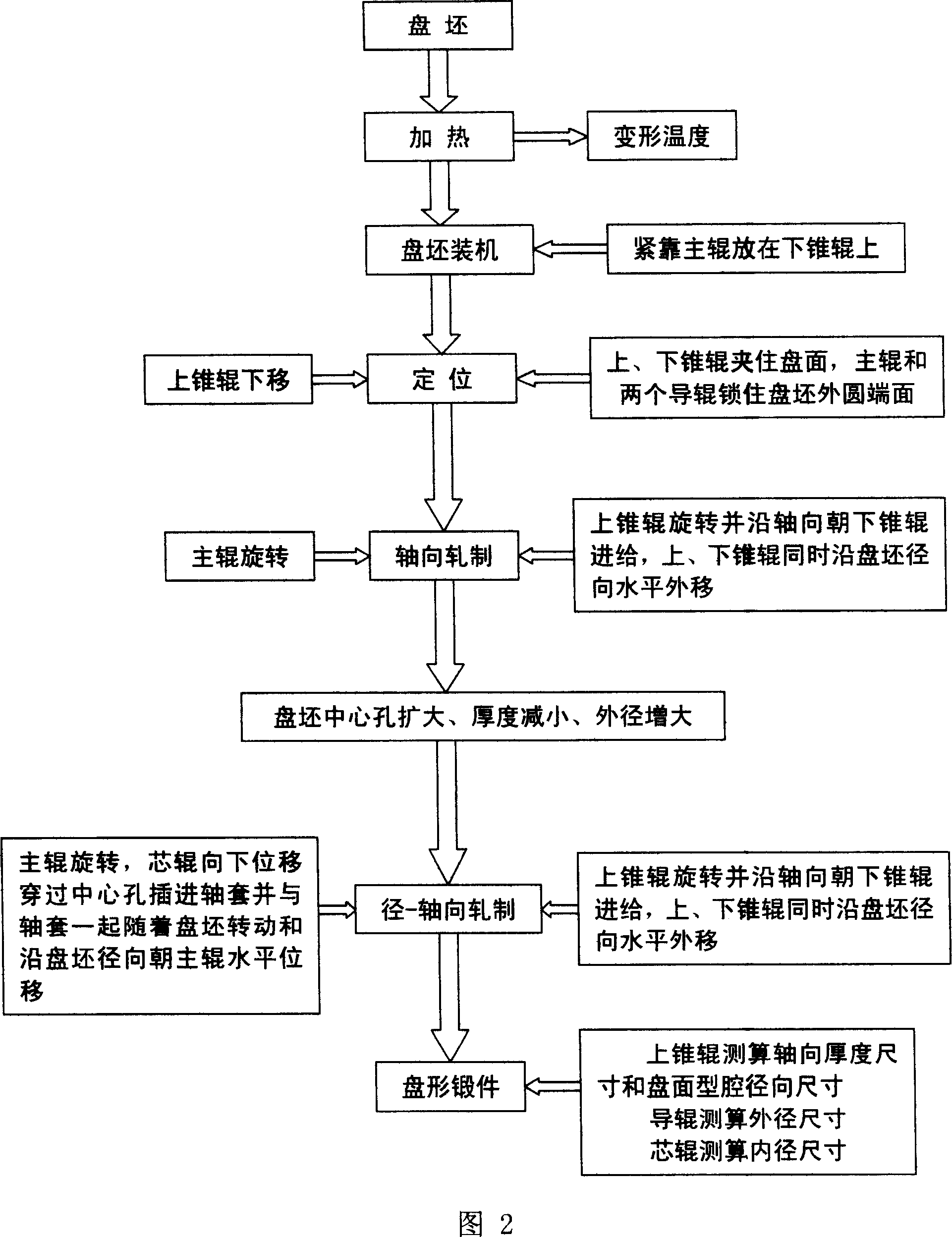

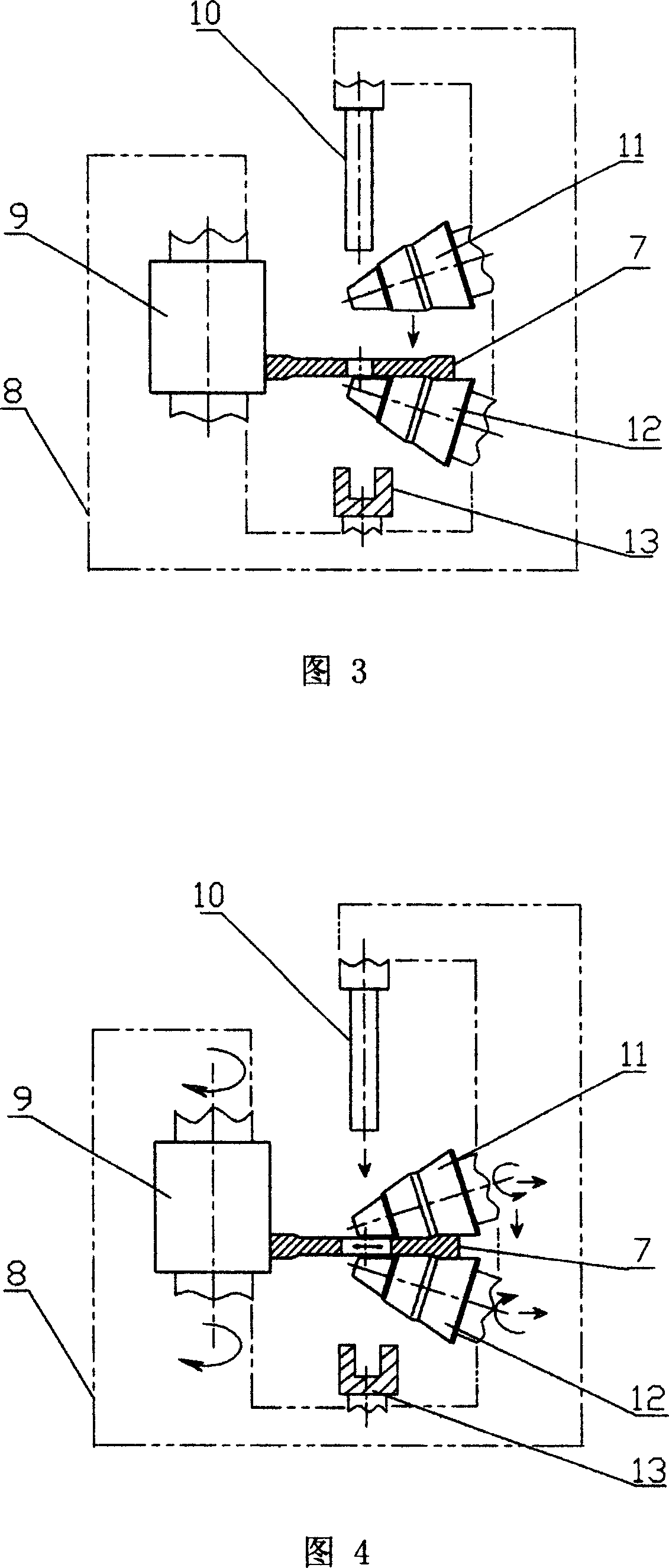

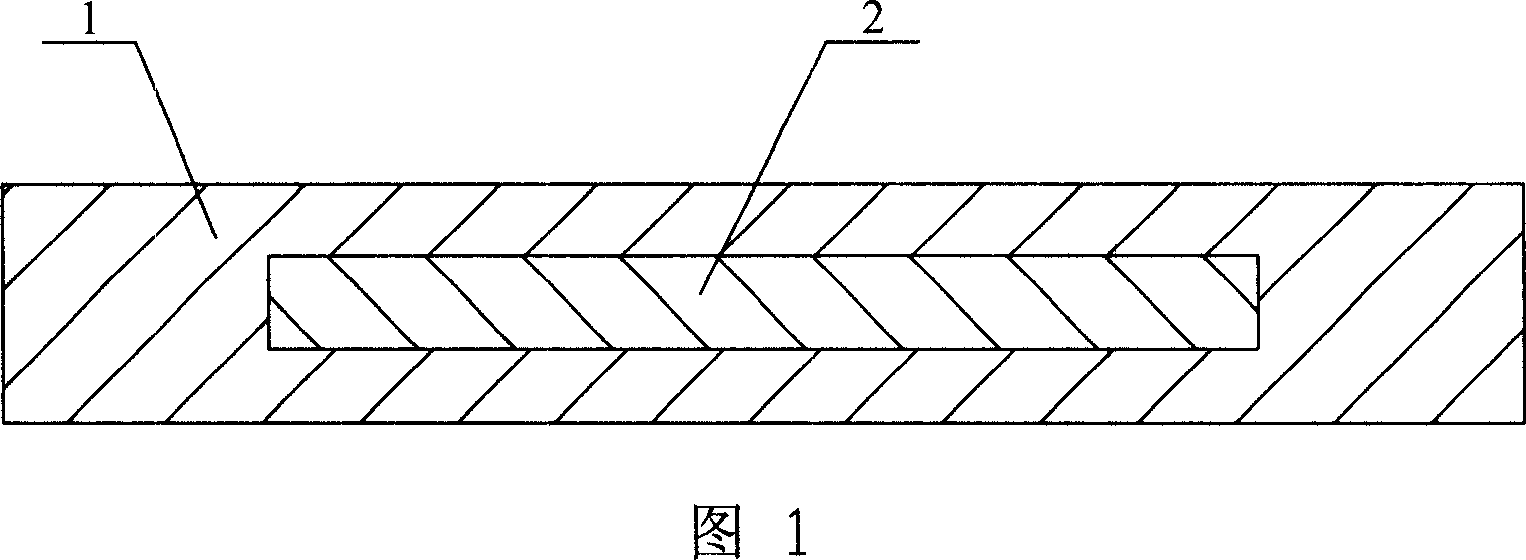

Rolling forming process for large hollow disc forging

ActiveCN101020282ARadial wall thickness reductionReduce axial thicknessRoll force/gap control deviceMeasuring devicesMaterials scienceMetal

The technological process of rolling and forming large hollow disc forging includes the steps of: deforming metal rod material, heating, upsetting to form cake blank, profiling to obtain disc blank, punching hole to obtain hollow disc blank, heating, locating, axial rolling, radial and axial rolling, and measuring size to obtain hollow disc forging. The rolling process has axial rolling force of (2-5)x10<5> kg, radial rolling force of (5-20)x10<4> kg, and broadening speed of 5-15 mm / s. The rolled disc forging has outer diameter of 800-3000 mm, inner diameter of 300-2000 mm and thickness of 30-250 mm. By means of altering the conic size and sizes of the conic roll, disc forgings of different sizes may be rolled. The present invention can form disc forging continuously and form large forging in small apparatus.

Owner:GUIZHOU ANDA AVIATION FORGING

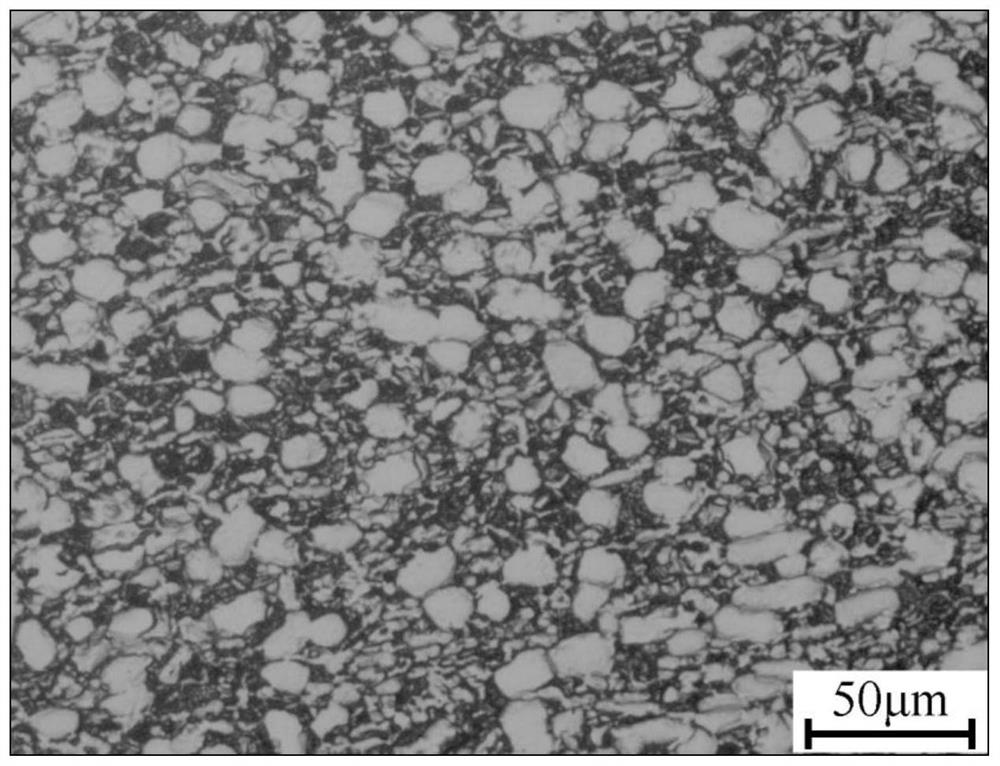

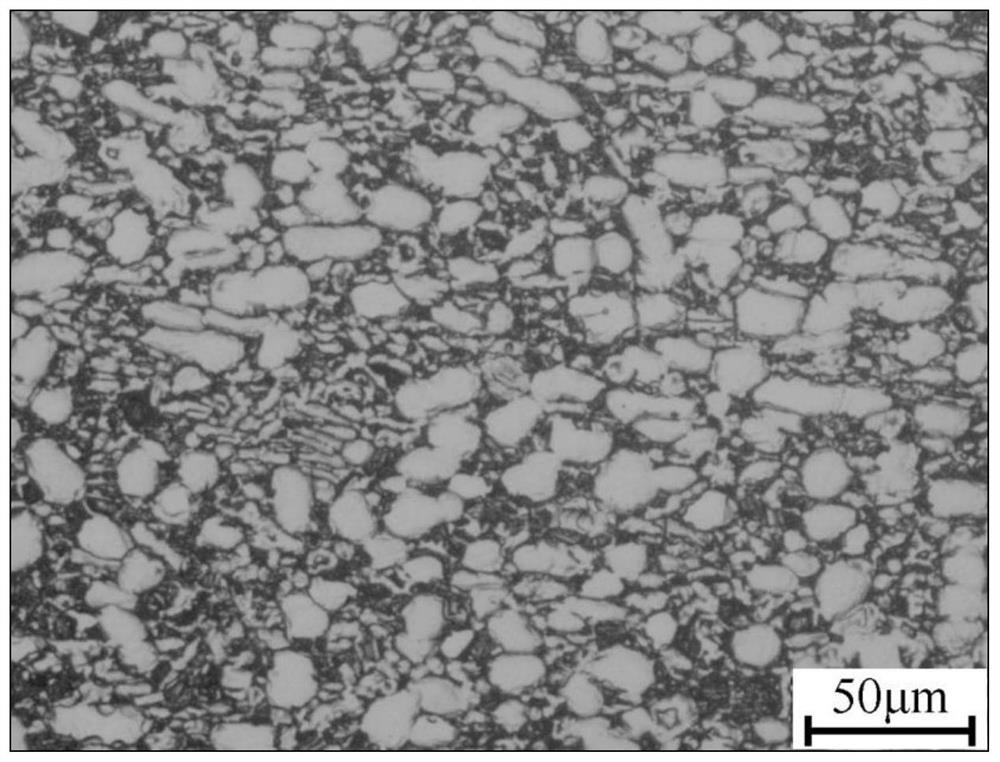

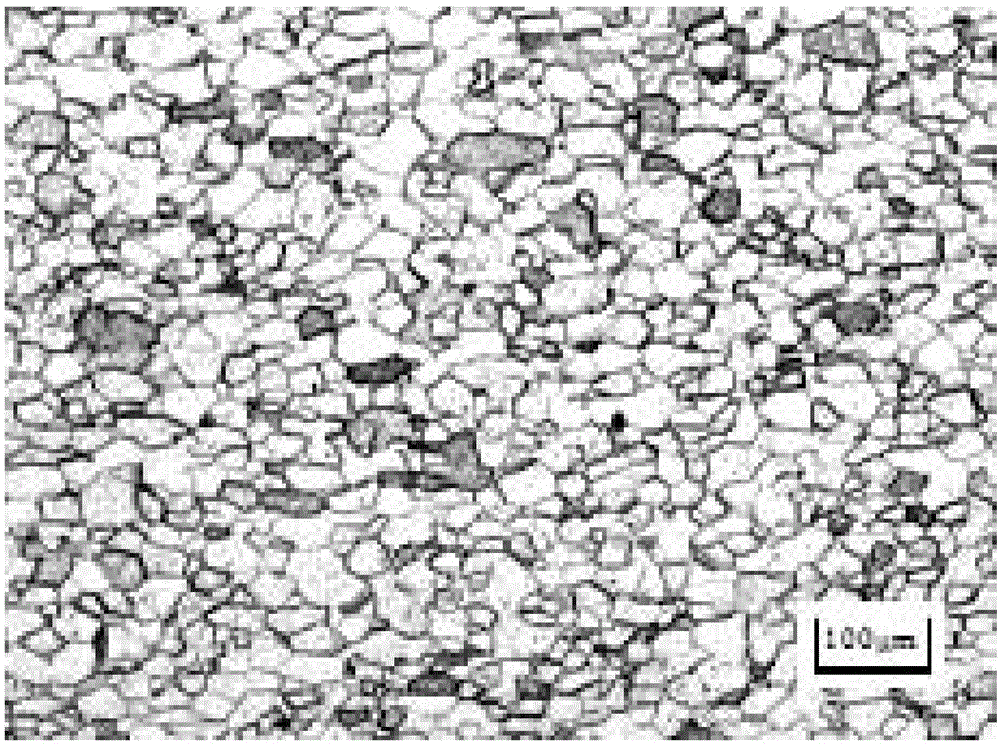

Method for preparing TiAl alloy plate by argon atomization in powder metallurgy

ActiveCN102513537AThe overall thickness is thinImprove mechanical propertiesMetal rolling arrangementsMechanical propertyImpurity

The invention relates to a method for preparing a TiAl alloy plate by argon atomization in powder metallurgy. The method comprises the following steps of: reducing the content of inclusions in TiAl alloy powders by purity smelting in a cold-wall crucible and high-purity argon atomization; performing hot isostatic pressure compaction on the high-purity prealloy powder which is atomized by pure argon under such conditions that the temperature is 1100 to 1300 DEG C, the pressure is 140 to 200 MPa and the compaction time is 2 to 4 hours; removing coatings of the alloy blank after hot isostatic pressure compaction and then performing surface treatment and coating; heating alloy and rolling at a high temperature; and removing coatings to obtain a powder TiAl alloy plate. The plate has the advantages of uniform deformation, good surface quality, fine and uniform texture, low oxide and impurity contents, small thickness, good overall mechanical property and high quality and reliability. The method solves the key problems in development and application of TiAl alloy powder-metallurgy plates, and provides a technical support for innovation and progress of civil industry and aerospace industry.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Copper alloy plate for electric and electronic parts having bending workability

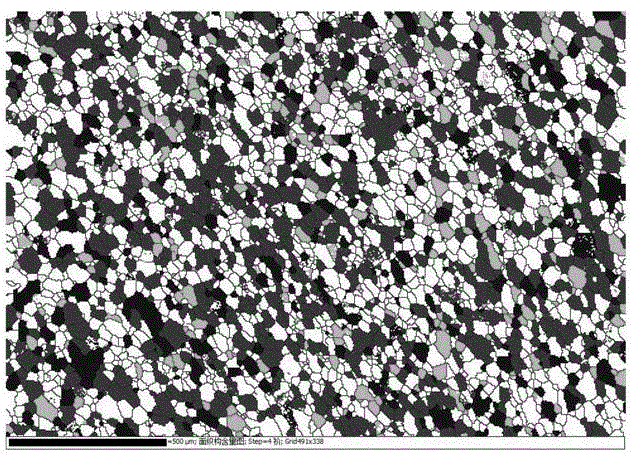

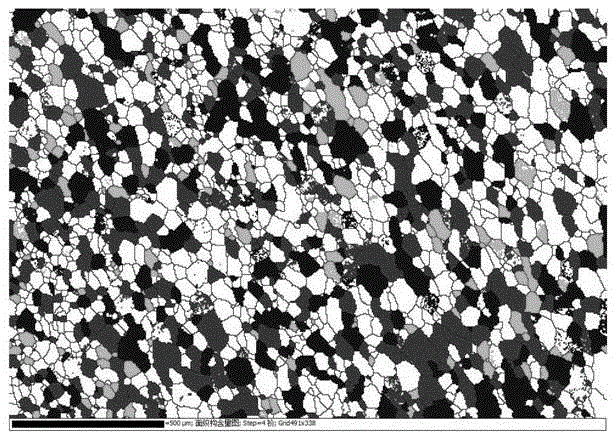

ActiveUS20090010797A1Improvement and stabilization of bendabilityUniform deformationSemiconductor/solid-state device detailsPrinted circuit aspectsMicrostructureHigh intensity

A Cu—Fe—P copper alloy sheet which has the high strength and the high electrical conductivity compatible with excellent bendability is provided. The Cu—Fe—P copper alloy sheet contains 0.01% to 3.0% of Fe and 0.01% to 0.3% of P on a percent by mass basis wherein the orientation density of the Brass orientation is 20 or less and the sum of the orientation densities of the Brass orientation, the S orientation, and the Copper orientation is 10 or more and 50 or less in the microstructure of the copper alloy sheet.

Owner:KOBE STEEL LTD

Method for preparation of Yt-containing TiAl intermetallic compound plate material

InactiveCN101011705AImprove rolling deformation abilityUniform deformationTemperature control deviceFurnace typesYttriumHeating furnace

The invention discloses a making method of TiAl metal compound board with yttrium, which comprises the following steps: 1. fusing TiAl metal block with 0.01-0.6at.% yttrium; 2. making jacket through stainless steel or titanium alloy; 3. placing block in the jacket after heating; 4. placing TiAl metal compound block in the heating furnace to 950-1320 deg.c; rolling; cooling to indoor temperature; 5. removing jacket; obtaining the product.

Owner:HARBIN INST OF TECH

Technique for producing double-layer copper brazing steel tube for air-conditioner

InactiveCN101480671AAchieve uniform deformationGood deep drawing performanceFurnace typesHeat treatment process controlSteel tubeDecomposition

The invention relates to double-layer brazing steel-pipe production technology used for an air conditioner. A slitting double-side copperizing steel band made of low-carbon interstitial free (IF) steel is horizontally placed on a decoiling disc and is coiled and rolled on a forming machine in an angle of 720 DEG to form a double-layer curly brazing pipe barrel, the double-layer curly brazing pipe barrel is sent to a brazing furnace, decomposition protective gas NH3 is led to the brazing durance to braze, and a brazed double-layer curly brazing pipe is led to a closed cooling pipe internally filled with the decomposition protective gas NH3 to be cooled and then slowly cooled and further cooled; then the double-layer curly brazing pipe is directly sprayed by passivating liquid and then dried; finally, the double-layer curly brazing pipe is coiled by the reeling machine into a coil, conventional continuous acid copperization is carried out on the surface of the double-layer curly brazing pipe after annealing, and the inner wall of the double-layer curly brazing pipe is repeatedly washed by chloroform or carbon tetrachloride to obtain a double-layer copper-brazed steel pipe which meets the operating requirements. Furthermore, the double-layer copper-brazed steel pipe obtained from the production technology has the plastic strain ratio r of being more than 2.0, the strain hardening exponent n being more than 0.25, the specific elongation delta being more than 45 percent, and the yield strength deltas being less than 150MPa. Besides, the corrosion resisting time of a neutral salt spray (NSS) testing is more than 500h, and a corrosion resisting protective layer can not be damaged under the temperature between 700 DEG C and 900 DEG C.

Owner:芜湖源大管业有限公司

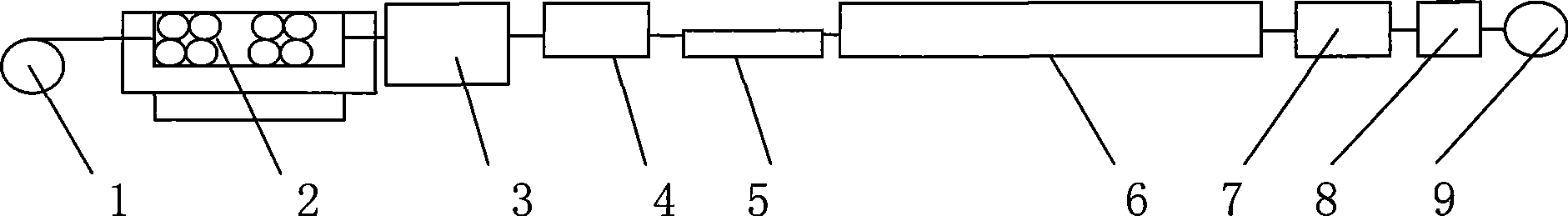

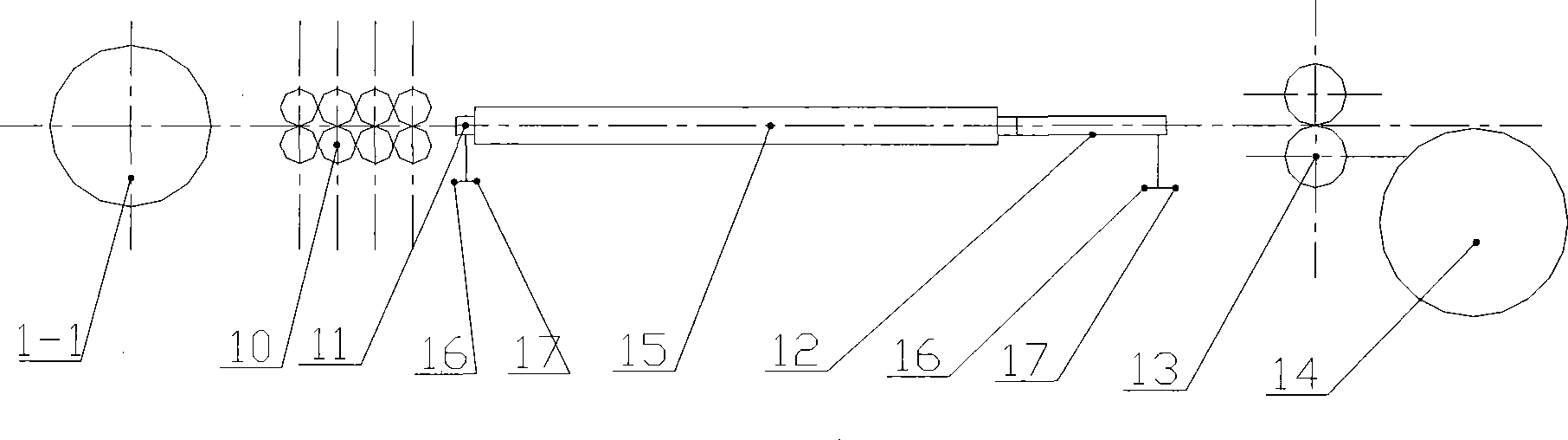

Method for rolling titanium and titanium alloy bar wire bar with three-roller type Y continuous rolling mill

InactiveCN101152653AImprove surface qualityFew beginningsTemperature control deviceMetal rolling stand detailsLow noiseWire rod

The invention provides a method for rolling of titanium and titanium alloy bar and wire rod with three-roller Y continuous rolling mill. The technical proposal of the invention is as follows that the three-roller Y continuous rolling mill group is used for 6 to 18 pass continuous rolling of heated titanium and titanium alloy bar billet of phi50mm to form bar billet of 30 to 8mm (or hexagonal and triangular structure of 24 to 8mm) or rolling wire billet of phi20 to 8mm. by adopting the method, bar billet of phi50mm can be rolled into bar billet of phi30 to 8mm (or triangular and hexagonal structure) or rolling wire billet of phi20 to 8mm after heated for one time. Compared with the prior methods of multiple fire time casting, swaging, two-roller transverse-arrangement non-continuous rolling and two-roller longitudinal-arrangement continuous rolling, all of which are used for production of titanium and titanium alloy bar or rolling wire billet, the invention not only has the advantages of high efficiency, energy saving, low noise, small occupying and high precision of the size as well as good organization perforation of titanium and titanium alloy bar and wire rod, but also can produce triangular or hexagonal section and other allotype section.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

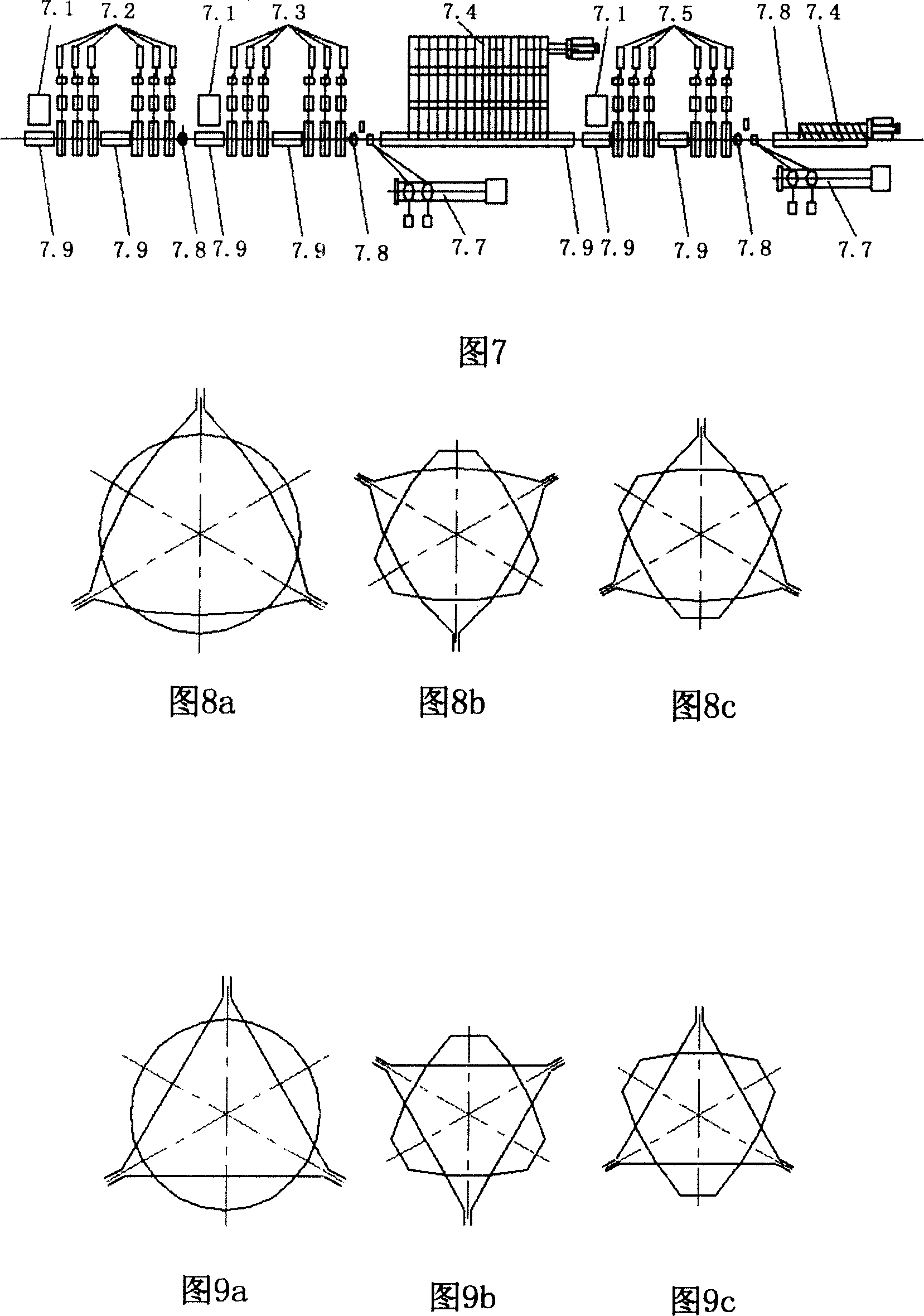

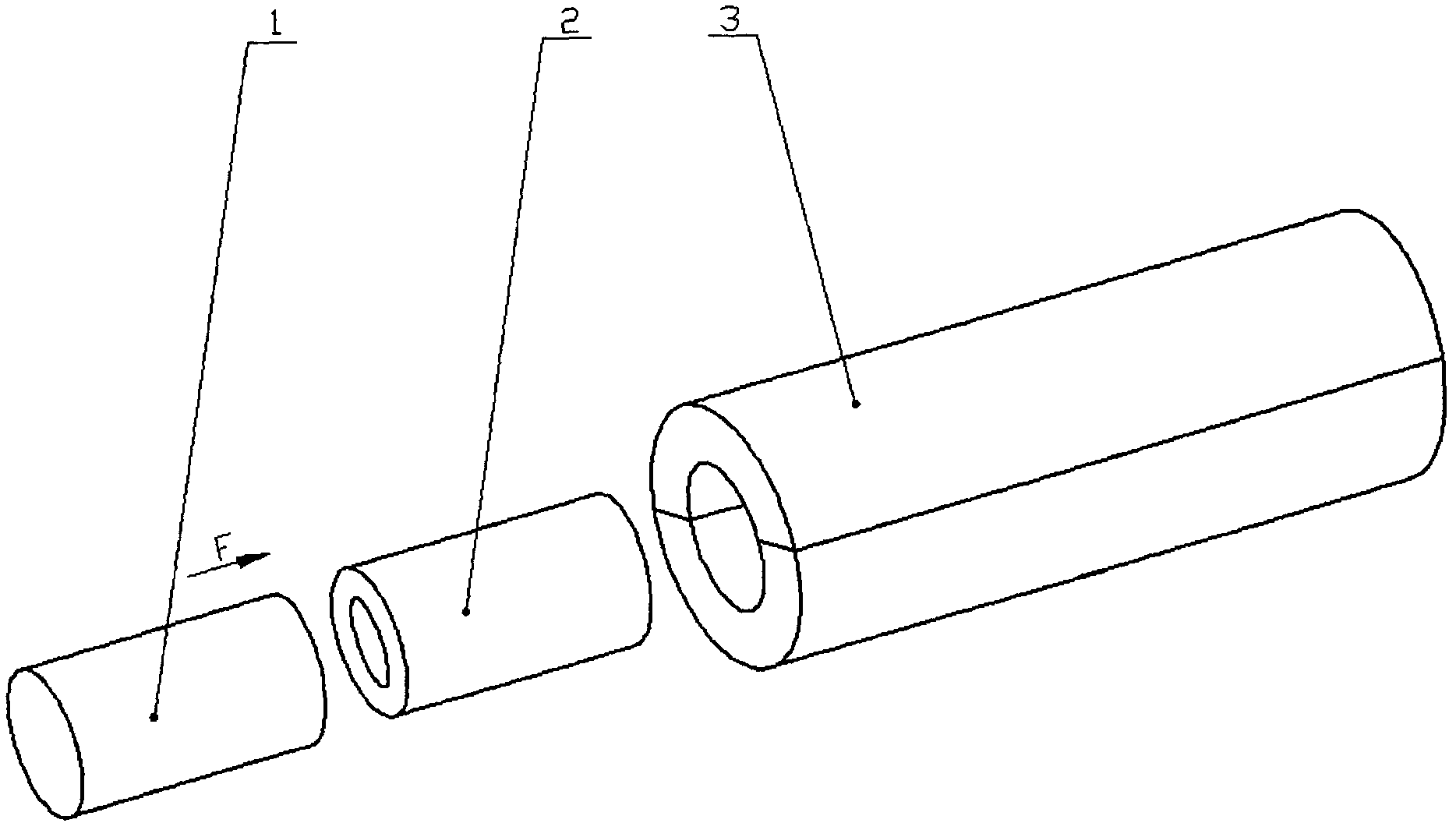

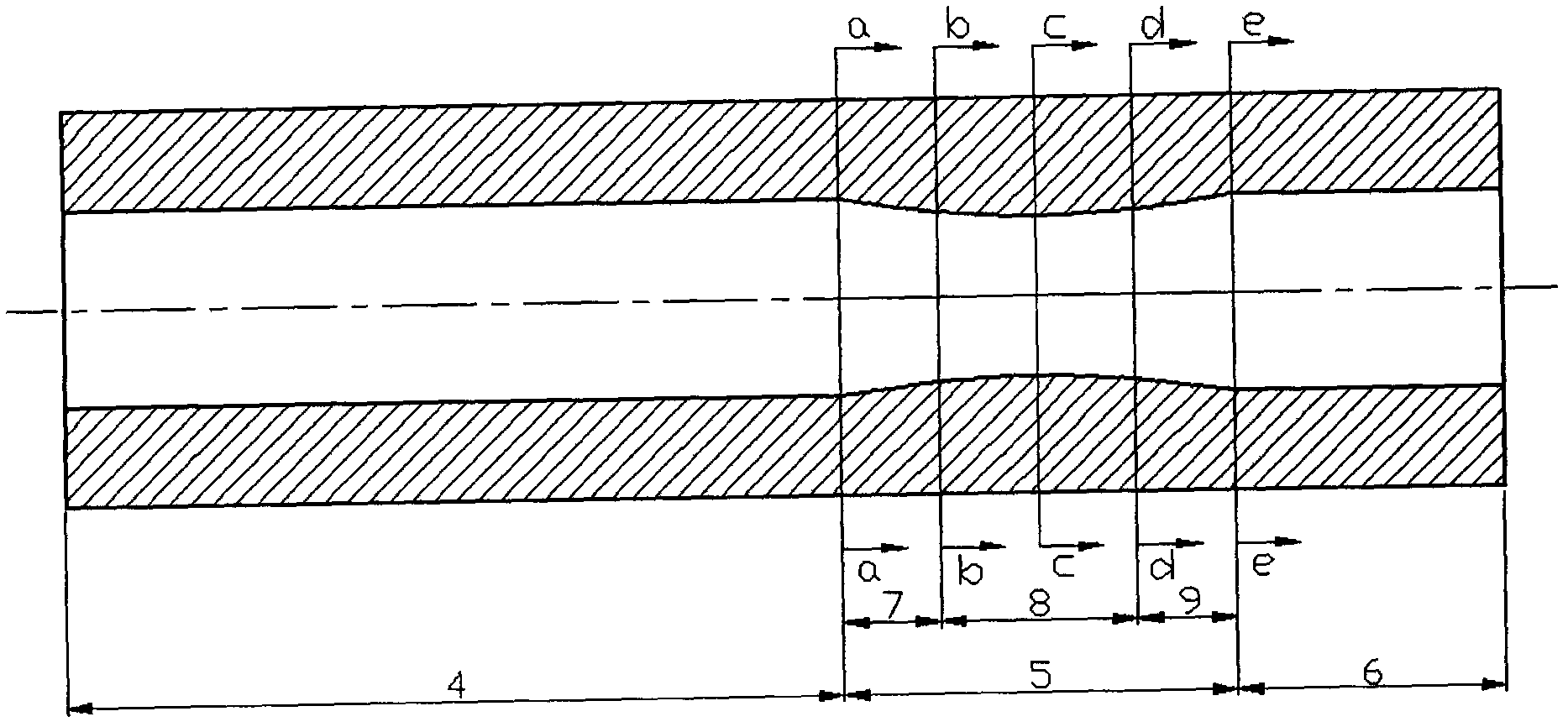

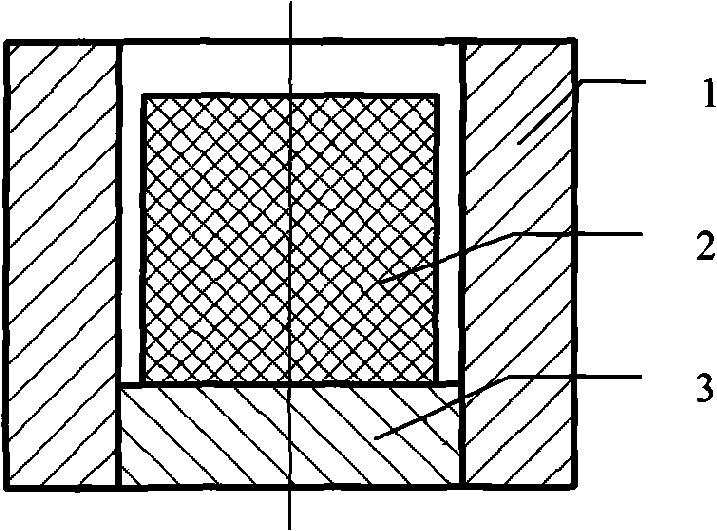

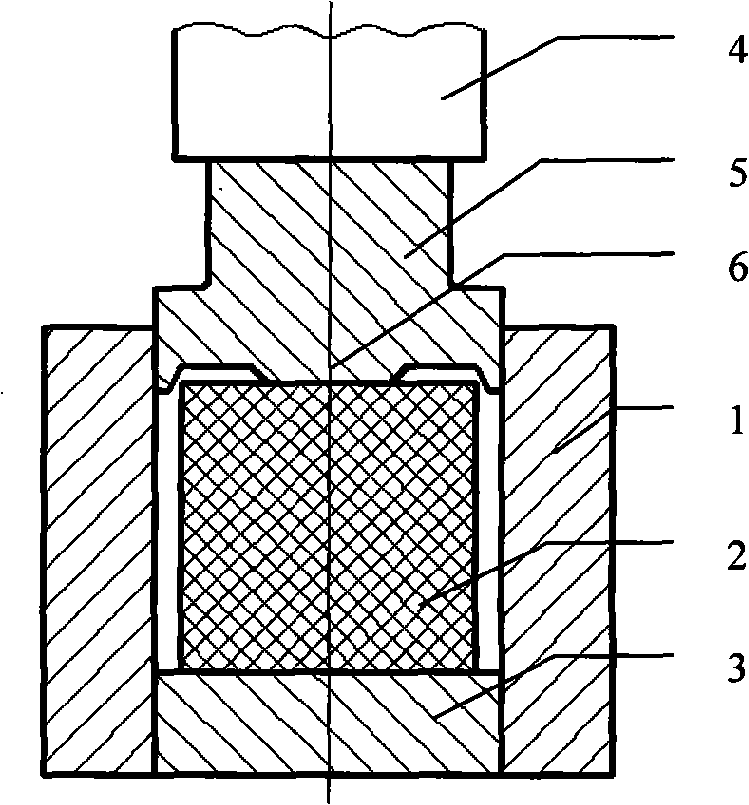

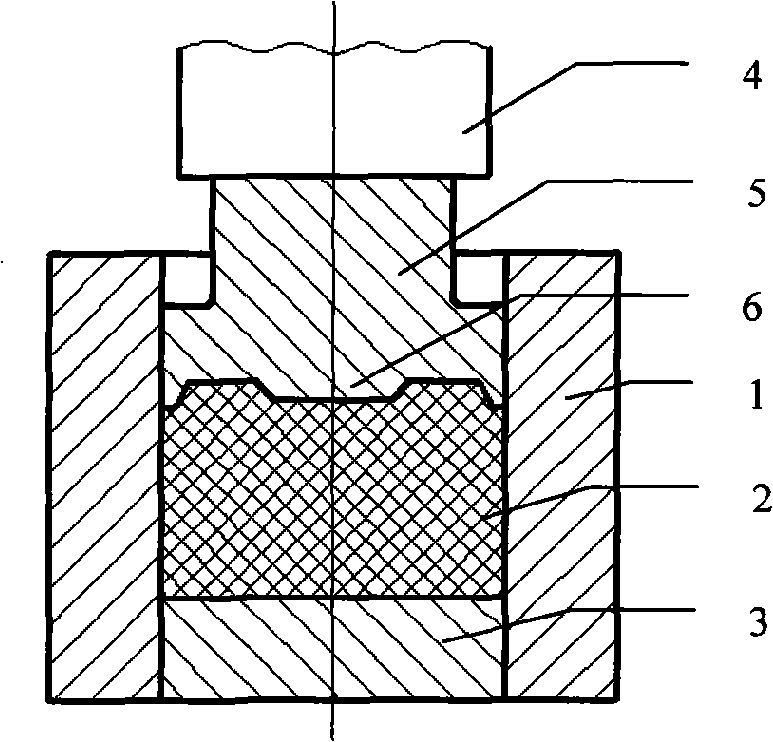

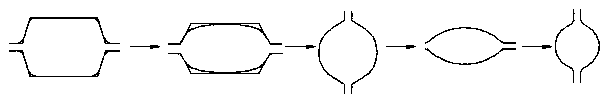

Equal-passage variable-cross-section extruding mold and extrusion forming method for pipes

InactiveCN102430609AImproved strain distributionIncrease stressExtrusion diesExtrusion mandrelsStress distributionShear stress

The invention relates to an equal-passage variable-cross-section extruding mold and an extrusion forming method for pipes. The equal-passage variable-cross-section extruding forming is adopted, so the extruding forming of the pipes is formed through the twisting shearing deformation and the upsetting deformation on the cross section, and the combination of various deformation modes in one extruding process is realized. The pipe walls are in a strong three-direction press stress state through being limited by die cavities and polyurethane foam filling agents, in the deformation stage of circle-ellipse-circle and ellipse twisting change, materials enter twisting shearing deformation zones of the metal transition regions, the material internal tissues generate rotation and shearing stress under the effect of the shearing stress, the orientation of the material tissue structure is caused, i.e. a new tissue structure is formed, and the material tissue structure under the same deformation degree is improved. The mold and the method have the advantages that deformation degree higher than that of the traditional forming process can be obtained, the strain distribution and the stress distribution inside the pipes are improved, residue casting tissues of the pipes can be favorably crushed, the forms and the distribution of inclusions are changed, and the internal tissue defects of the pipes are eliminated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

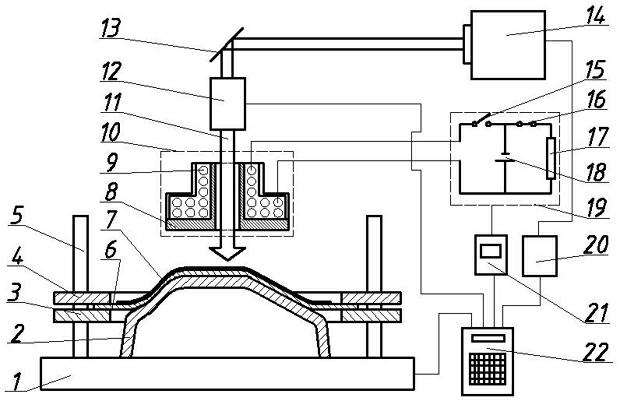

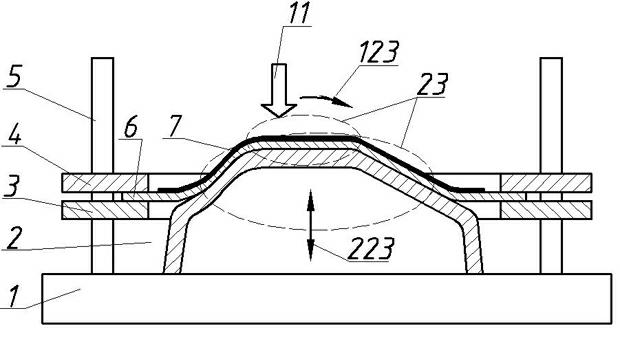

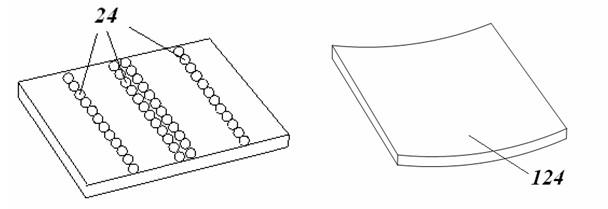

Method and device for laser pulse and electromagnetic pulse composite forming of metal sheet

InactiveCN102125951AMeet the forming requirementsLocality of changeManufacturing technologyEnergy absorption

The invention discloses a method and device for laser pulse and electromagnetic pulse composite forming of a metal sheet and relates to the technical field of processing and manufacturing fastening holes. The head part of an energy absorption rod (10) is a conical surface; a high-power pulse laser outputs an annular laser pulse (8) by means of a light spot regulator (15); the annular laser pulse (8) accommodates the tip part of the conical surface on the head part of the energy absorption rod (10) in a hollow part of a laser beam, and meanwhile, the annular laser pulse (8) is acted on the conical surface on the head part of the energy absorption rod (10) to induce plasma (17) to explode and generate impact waves acted on the internal walls of the fastening holes, so that the fastening holes are strengthened. The method and the device are suitable for strengthening the fastening holes with small diameter; the hollow part of the annular laser pulse (8) keeps away from the tip part of the conical surface of the energy absorption rod (10), so that the energy absorption rod (10) is difficult to damage, which is beneficial to continuously working and achieving a good strengthening effect.

Owner:JIANGSU UNIV

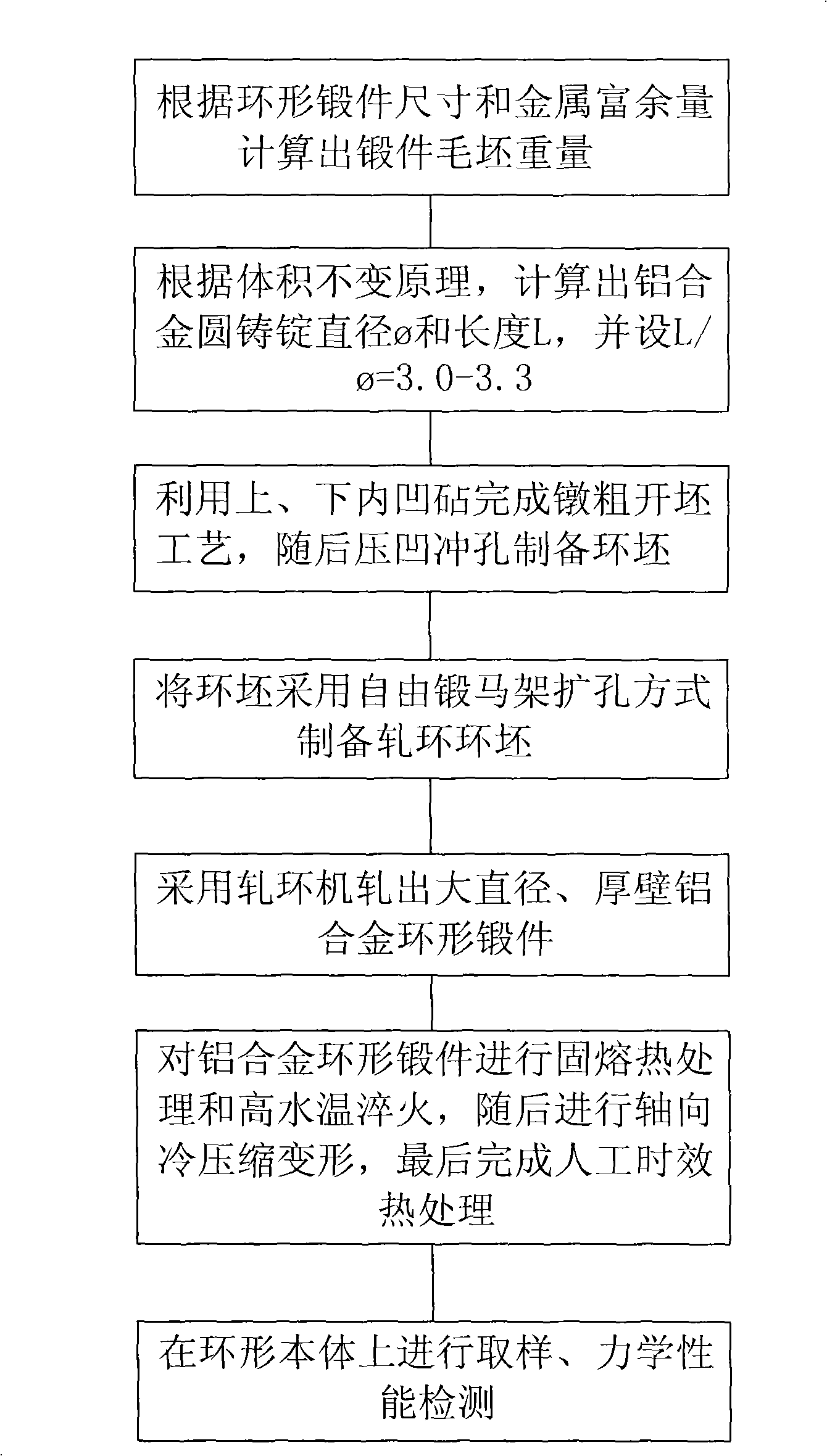

Method for manufacturing aluminium alloy rings with high performance and low residual stress

ActiveCN101537466AImprove performanceFully deformedRoll mill control devicesMetal rolling arrangementsThick wallQuenching

The invention discloses a method for manufacturing aluminium alloy rings with high performance and low residual stress, comprising the following technical steps: 1) calculating blank weight of forgings according to size and metal residual content of ring forgings; 2) calculating the diameter Phi and length L of aluminium alloy round ingots according to the volume constancy principle; 3) finishing the upsetting and cogging processes by using upper and lower recessed anvils, and preparing ring blank by shallow recessing and punching; 4) preparing rolling ring blank by using flat-die forging trestle broaching on the ring blank; 5) rolling out aluminium ring forgings with big diameter and thick wall by using a ring rolling mill; 6) carrying out solution heat treatment and high water temperature quenching, then carrying out axial cold compression and deformation, and finally finishing artificial aging heat treatment; and 7) carrying out crack detection on the ring by using ultrasonic according to the standard requirement, and carrying out sampling and mechanic performance detection on the main body of the ring complying with the standard requirement. The method has the advantages of high metal utilization rate, complete and uniform deformation from the surface to the core of the ring, high performance, low residual stress and the like.

Owner:SOUTHWEST ALUMINUM GRP

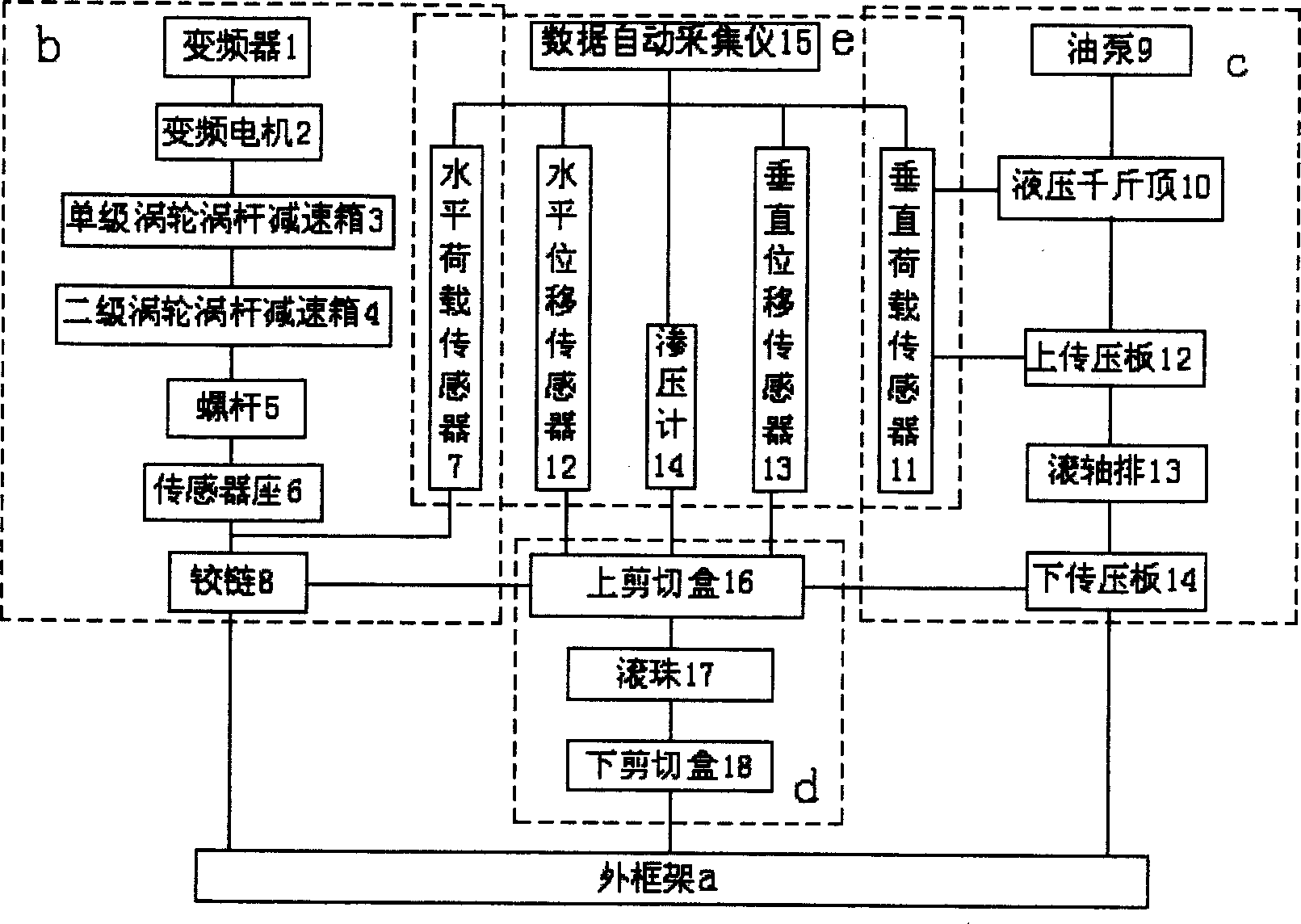

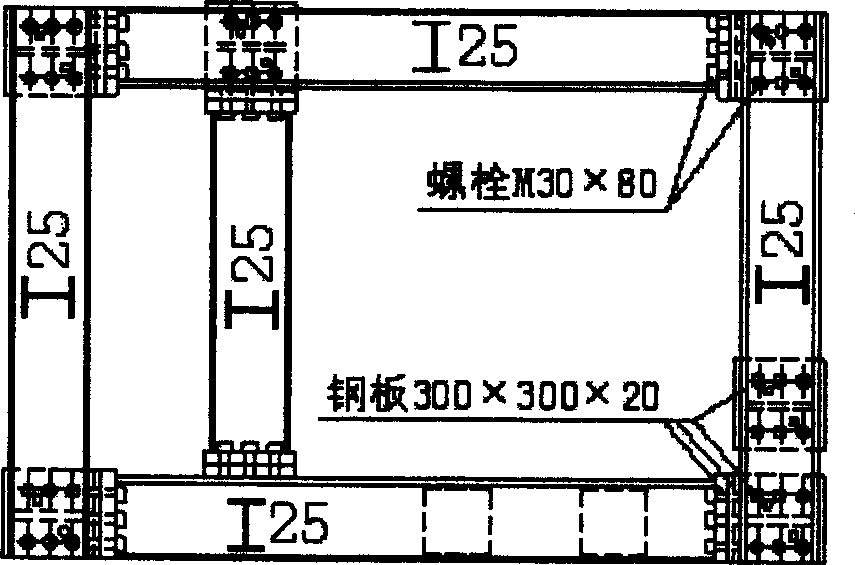

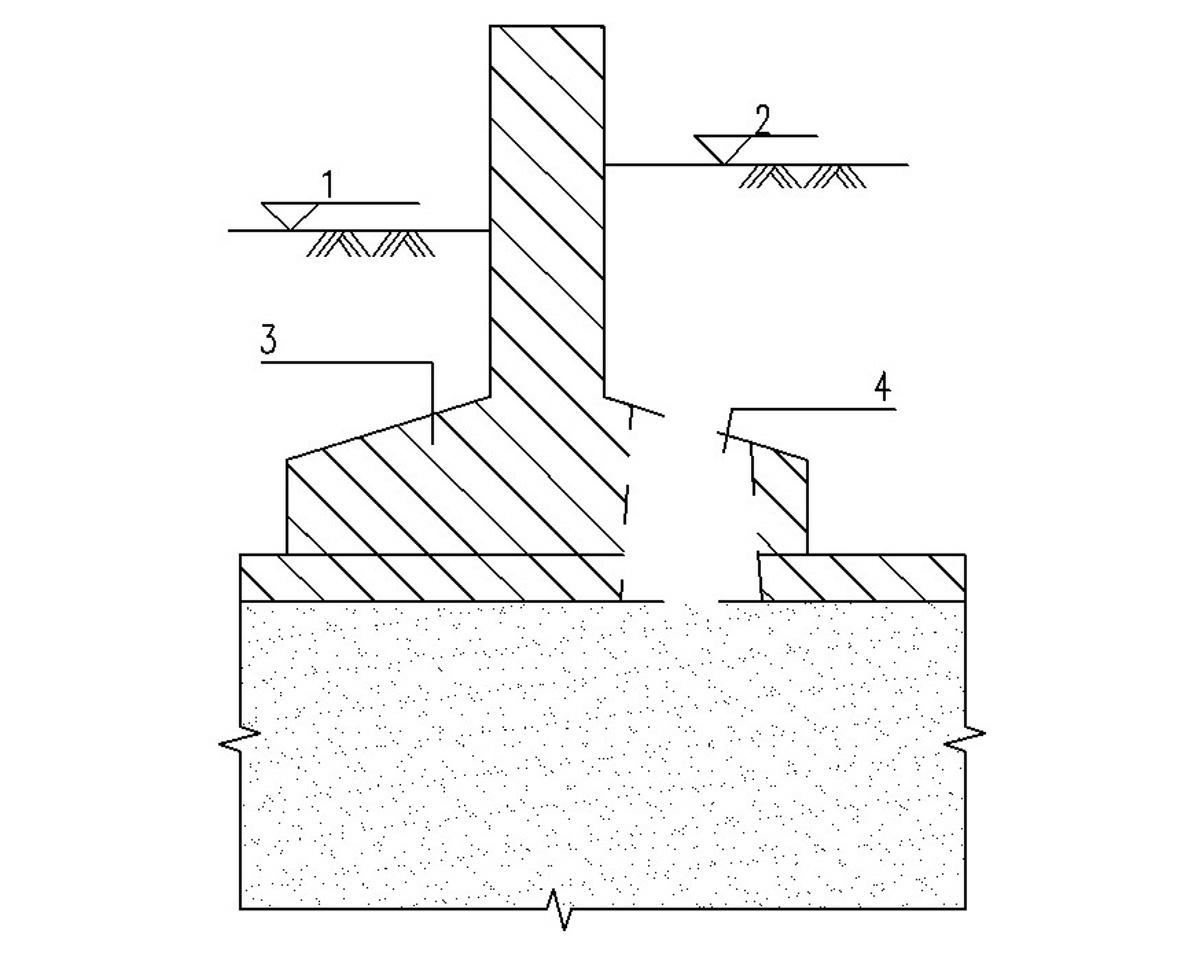

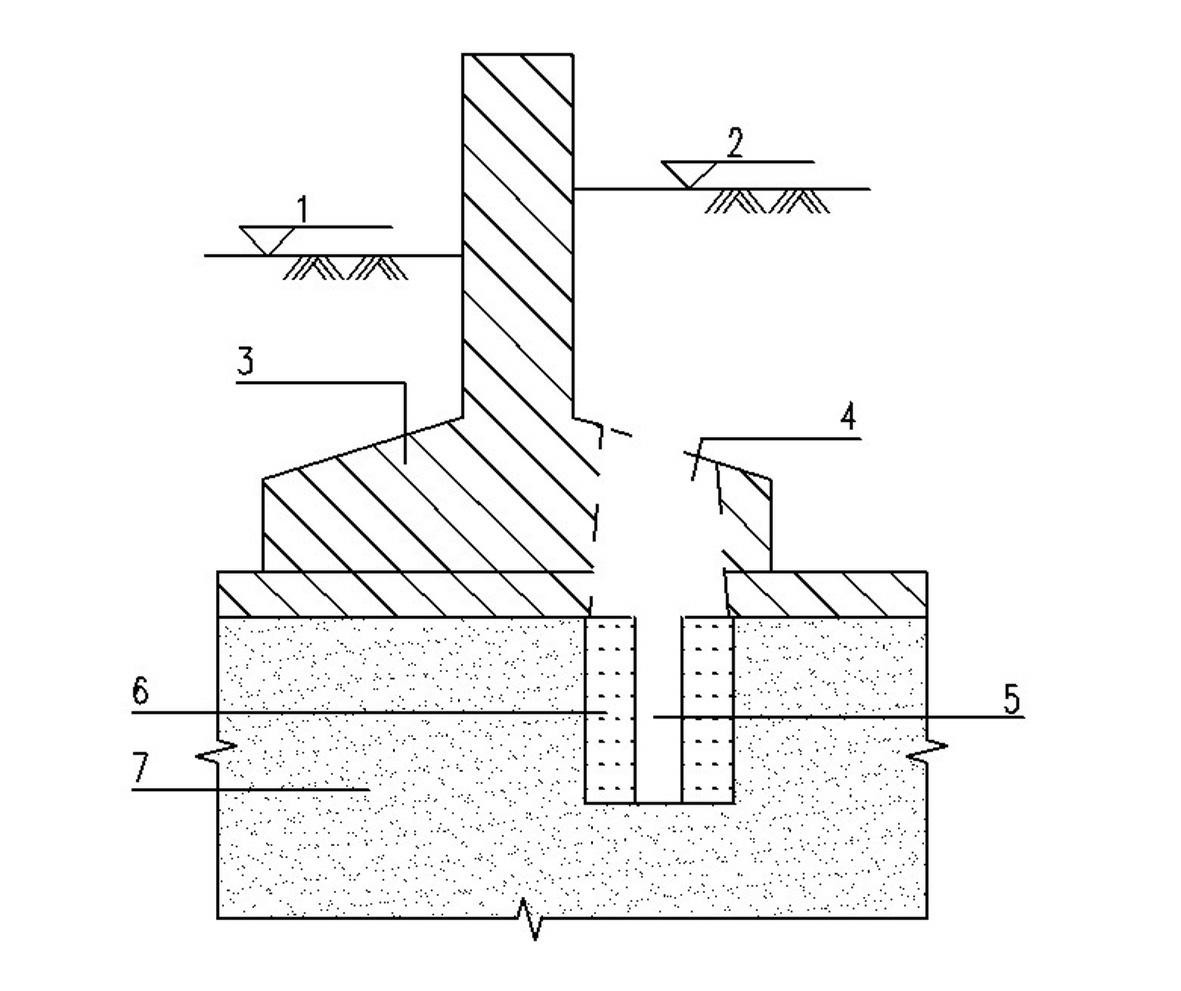

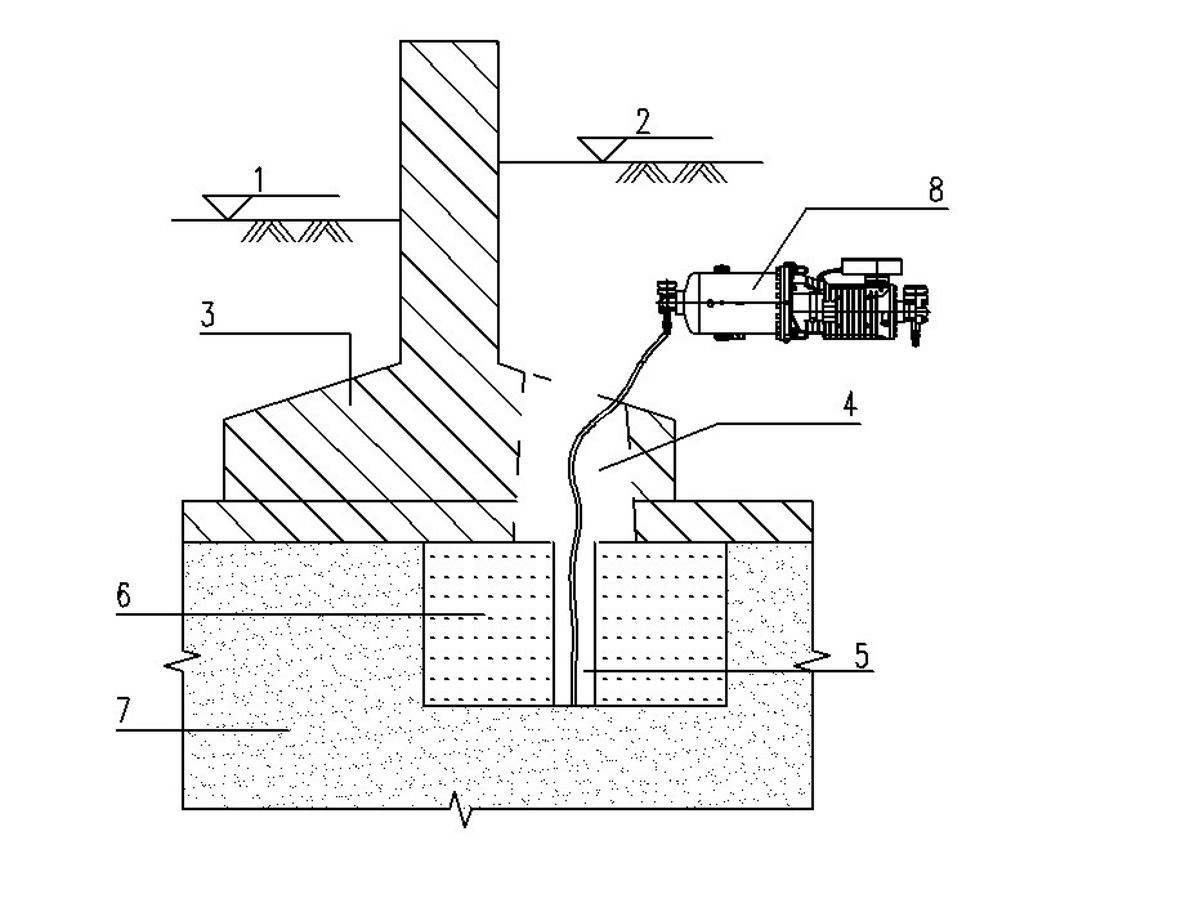

Rock-soil mechanics direct shear experimental system

InactiveCN1641336AKeep constantUniform deformationMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesSoil mechanicsElectric machinery

The invention discloses a straight cut testing system for rock and earth mechanics, relating to a cutting system. The invention is composed of outer frame, horizontal loading system, vertical loading system, cut box, and measuring system; the horizontal loading system, the vertical loading system, the cut box and the cut box are fixed on the outer frame, respectively; the horizontal loading system, the vertical loading system and the measuring system are connected with the cut box, respectively. The invention has high measuring accuracy and good stability; all the data are automatically collected, thus reducing artificial reading error; it adopts variable frequency electric motor so as to reduce the manufacturing cost on the premise of assuring a stable cutting speed; all the parts are removable, convenient to transport and install. It can be used in determining peak values and remaining shearing strength of fine earth, coarse earth and soft rock and provide strength parameter for engineering design and rock and earth stability.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

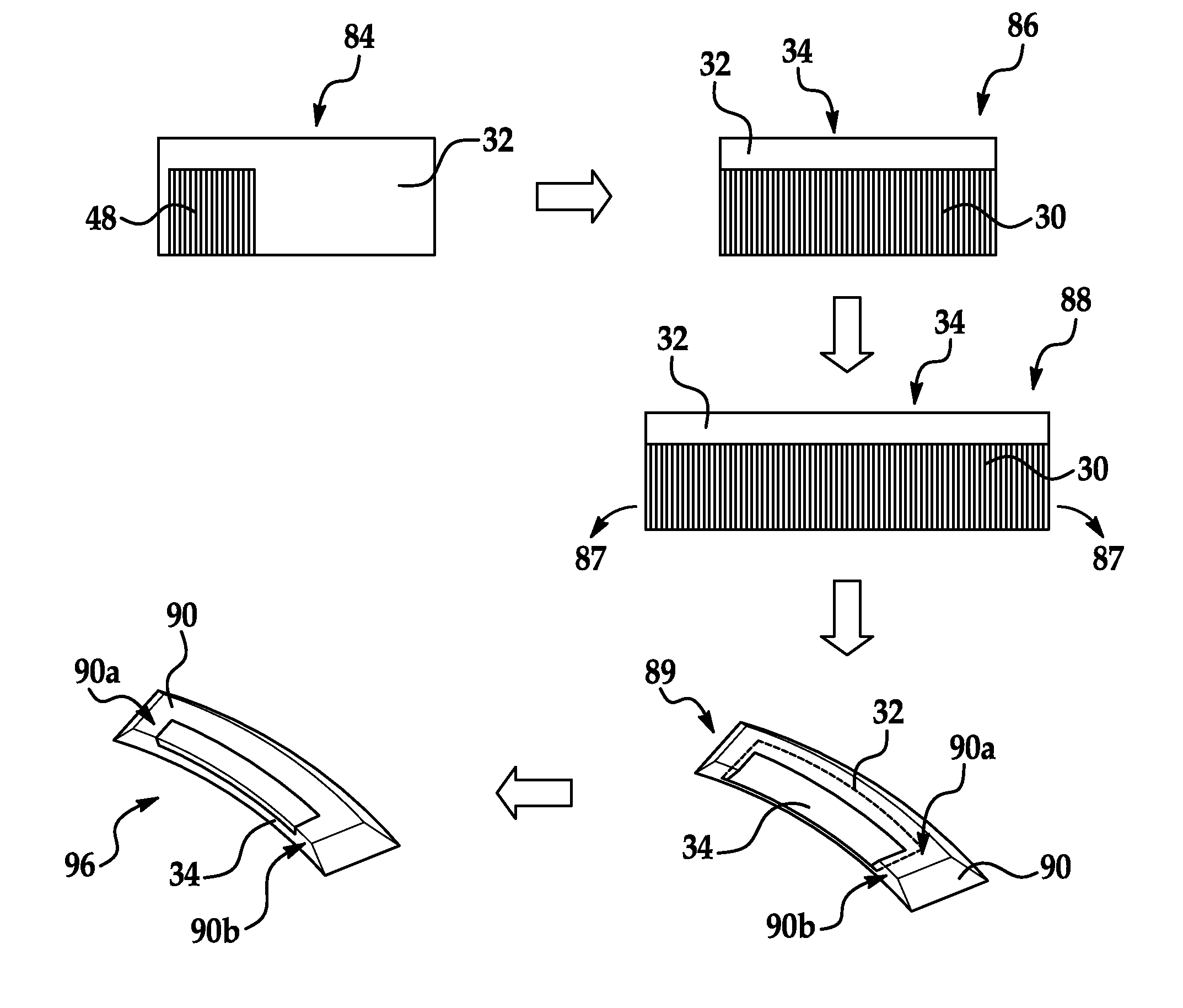

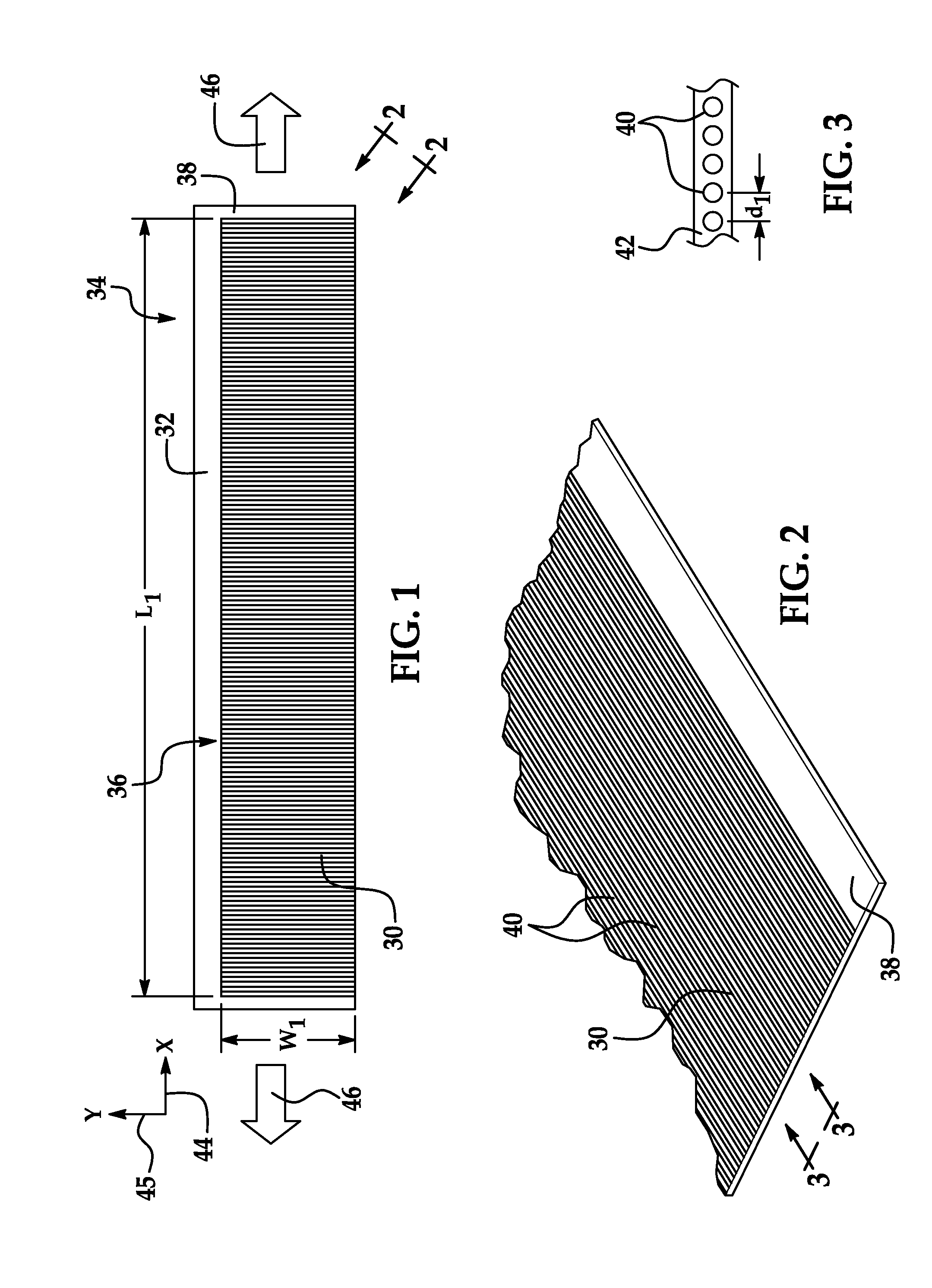

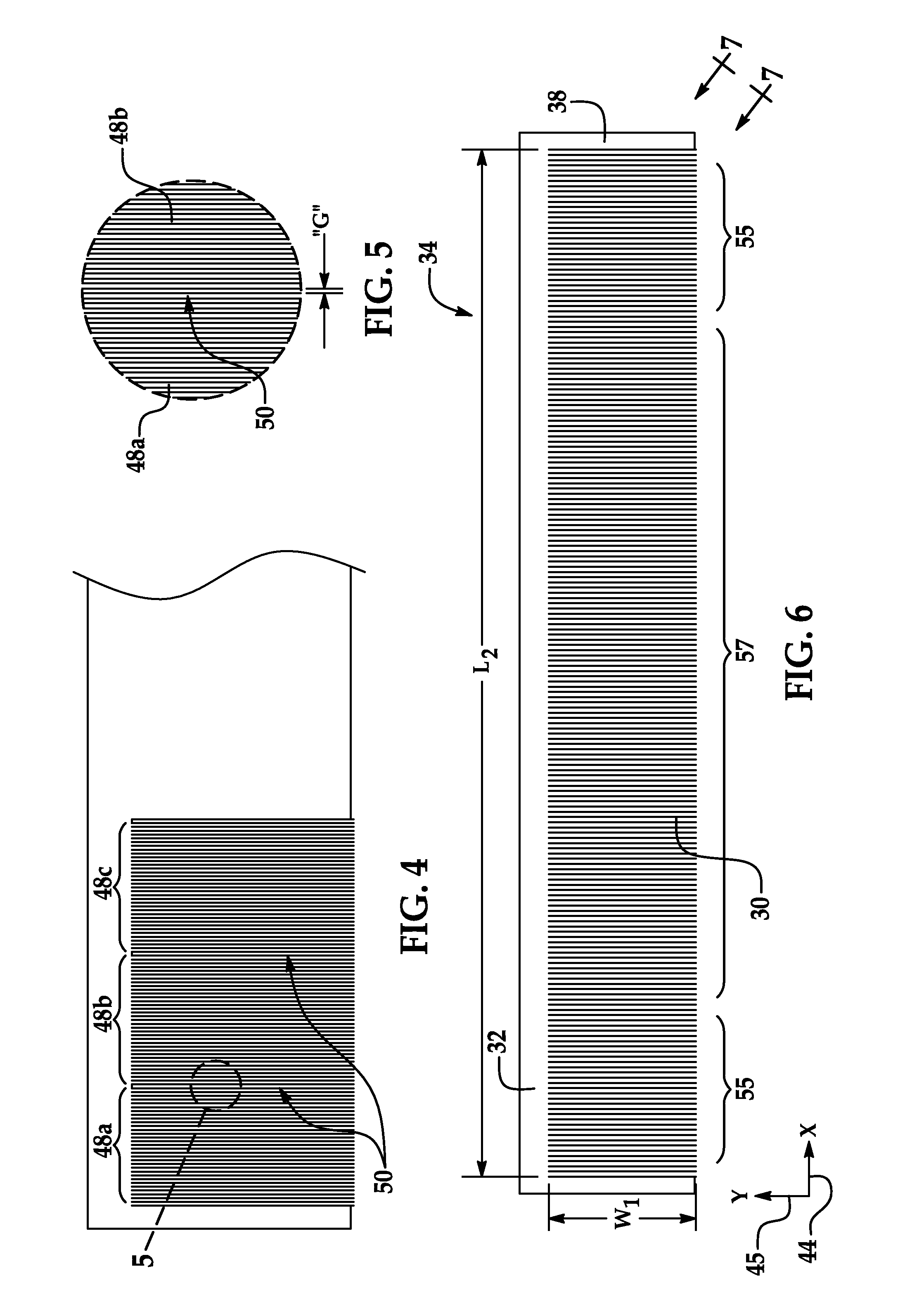

Method of Fabricating a Curved Composite Structure Using Composite Prepreg Tape

ActiveUS20140065354A1Avoid the needPrecise positioningLamination ancillary operationsLaminationEngineeringFlange

A method is provided of fabricating a composite stiffener having a curved web and at least one curved flange. A substantially straight length of unidirectional prepreg tape is placed on a carrier. The at least one curved flange is formed by using the carrier to steer a first portion of the tape onto a first curved tool surface. The curved web is formed by using the carrier to form a second portion of the tape onto a second curved tool surface.

Owner:THE BOEING CO

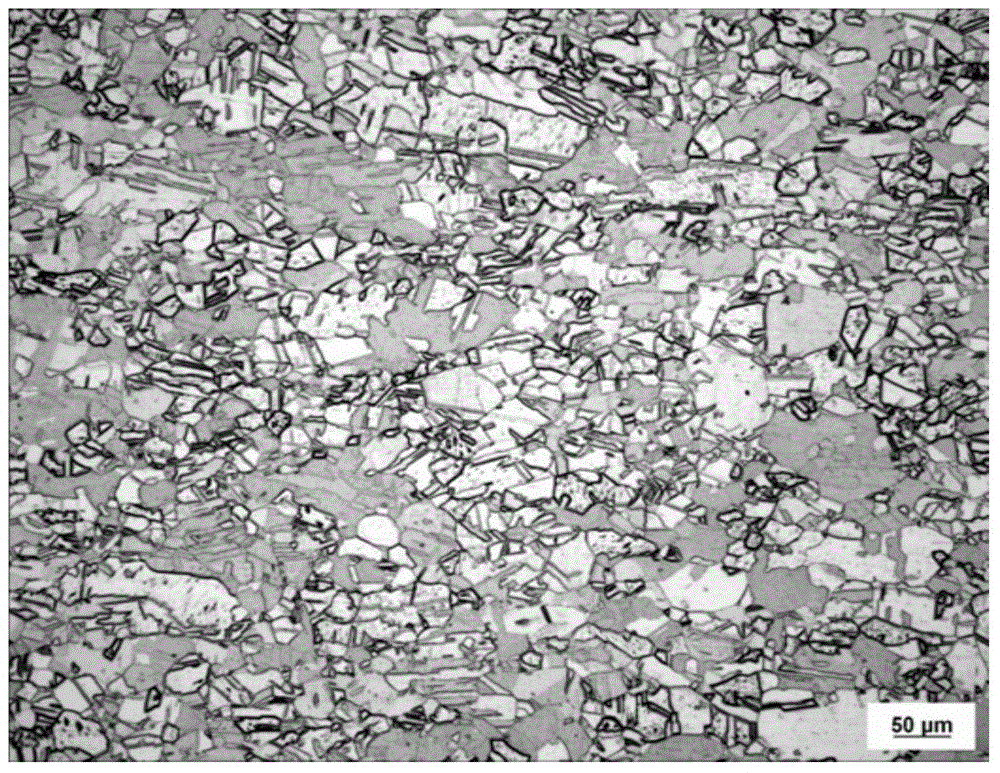

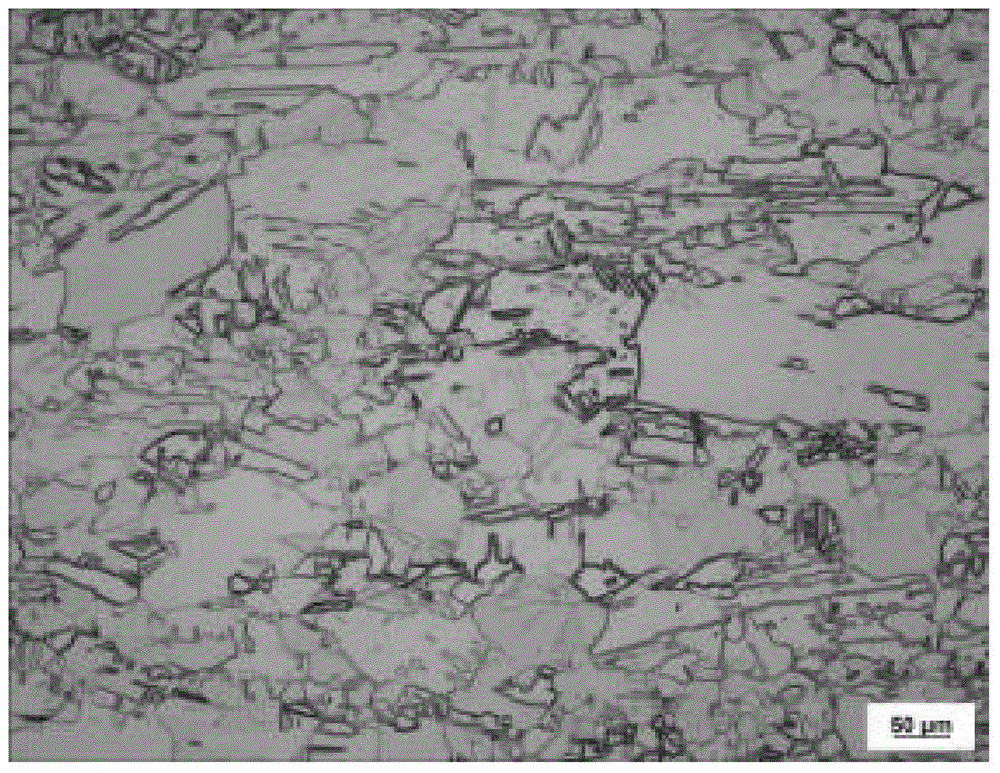

Cast ingot cogging forging technology for improving structure uniformity of forging stocks of titanium alloy

The invention discloses a cast ingot cogging forging technology for improving the structure uniformity of large-thickness forging stocks of titanium alloy. Cogging forging is carried out on the titanium alloy two heating times under the condition of the heating temperature of 1150 DEG C and 1100 DEG C; the titanium alloy is forged at a heating time under the condition of the heating temperature being 20-45 DEG C below the temperature of a beta phase transformation point; the titanium alloy is forged at a heating time under the condition of the heating temperature being 30-80 DEG C above the temperature of the beta phase transformation point; the titanium alloy is forged 2-5 heating times under the condition of the heating temperature being 20-45 DEG C below the temperature of the beta phase transformation point, and then the large-size titanium alloy forging stocks with the even structure are obtained. The cast ingot cogging forging technology is suitable for large cast ingot cogging and forging stock forging of titanium alloy of an alpha type or an alpha-beta type or an approximate-beta type, and requirements for manufacturing of large-size titanium alloy casting pieces or parts which are needed for manufacturing planes and have high requirements for structure temperature uniformity can be met.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

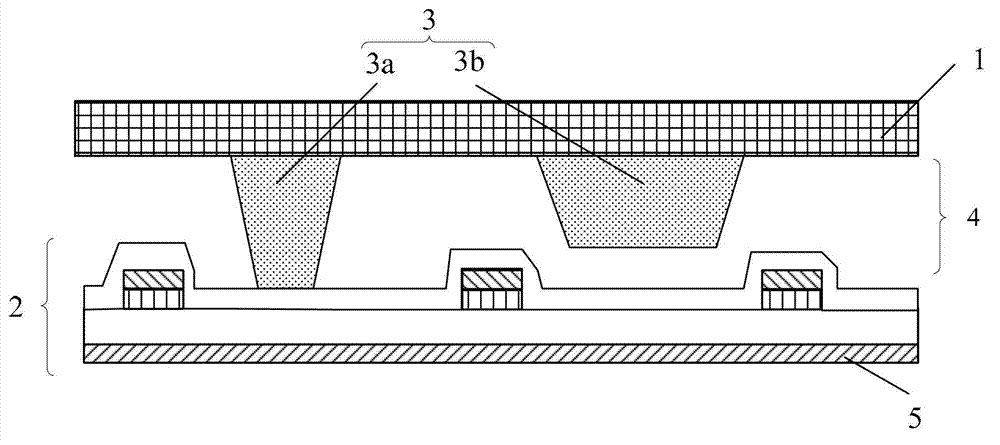

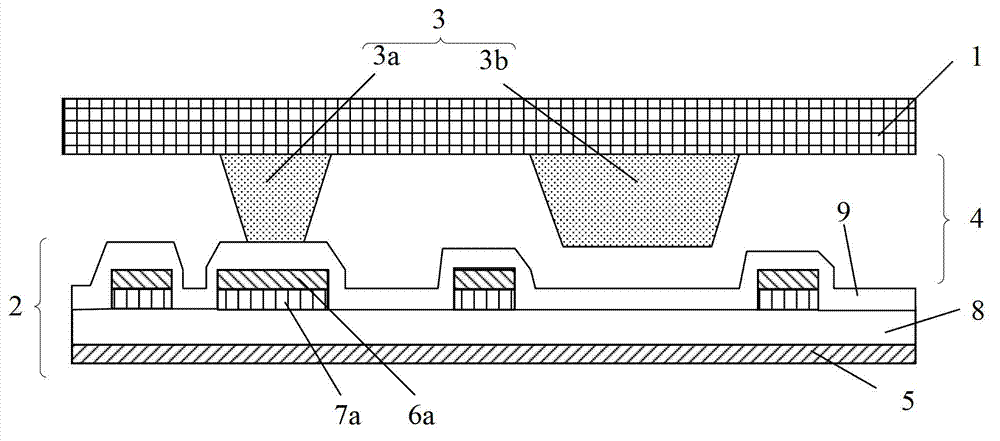

Liquid crystal display panel and manufacturing method thereof

ActiveCN102955297AGuaranteed compression performanceIncrease marginNon-linear opticsLiquid-crystal displayLiquid crystal

The embodiment of the invention provides a liquid crystal display panel and a manufacturing method thereof, relating to the display field. The problem of low-temperature bubbles of the display panel can be effectively solved; and the anti-pressure capability of the display panel can be ensured, so that the quality of a display picture can be ensured. The liquid crystal display panel comprises an upper substrate, a lower substrate, a liquid crystal layer and a spacer, wherein the liquid crystal layer and the spacer are arranged between the upper substrate and the lower substrate; and the liquid crystal display panel is characterized in that the spacer is arranged in an area corresponding to a grid line in the liquid crystal display panel. The liquid crystal display panel provided by the embodiment of the invention is applied to manufacturing of liquid crystal displays.

Owner:BOE TECH GRP CO LTD +1

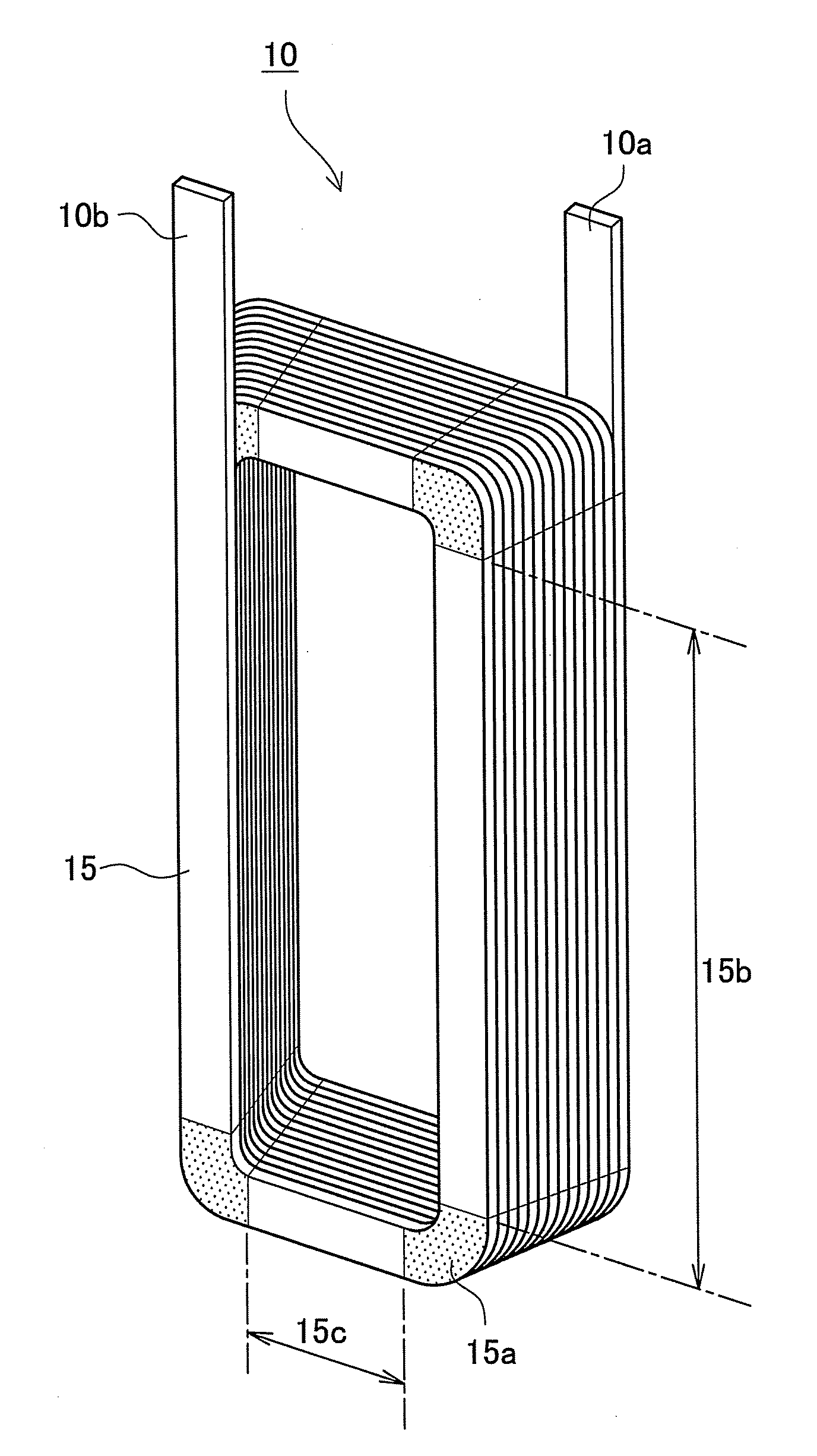

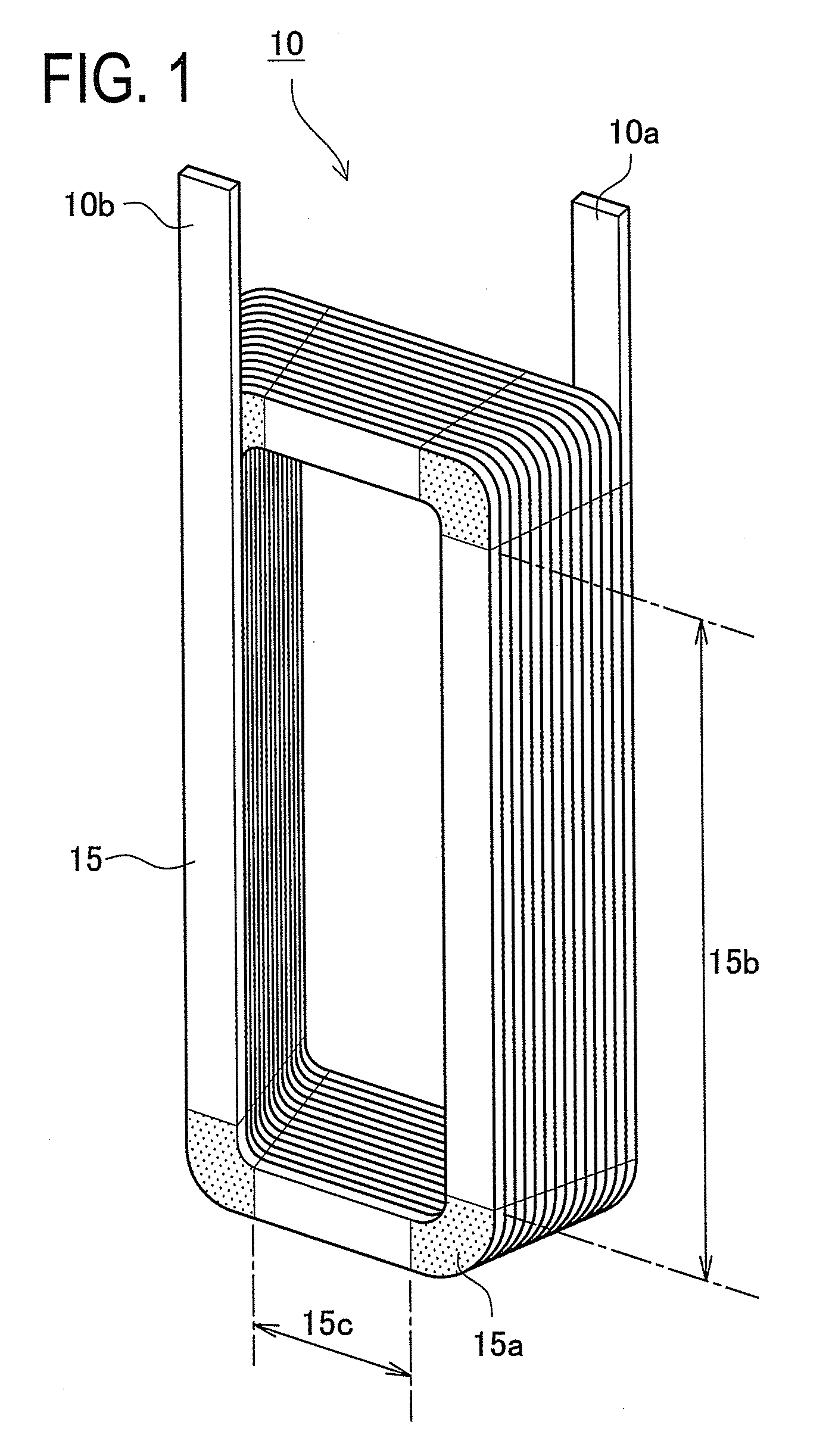

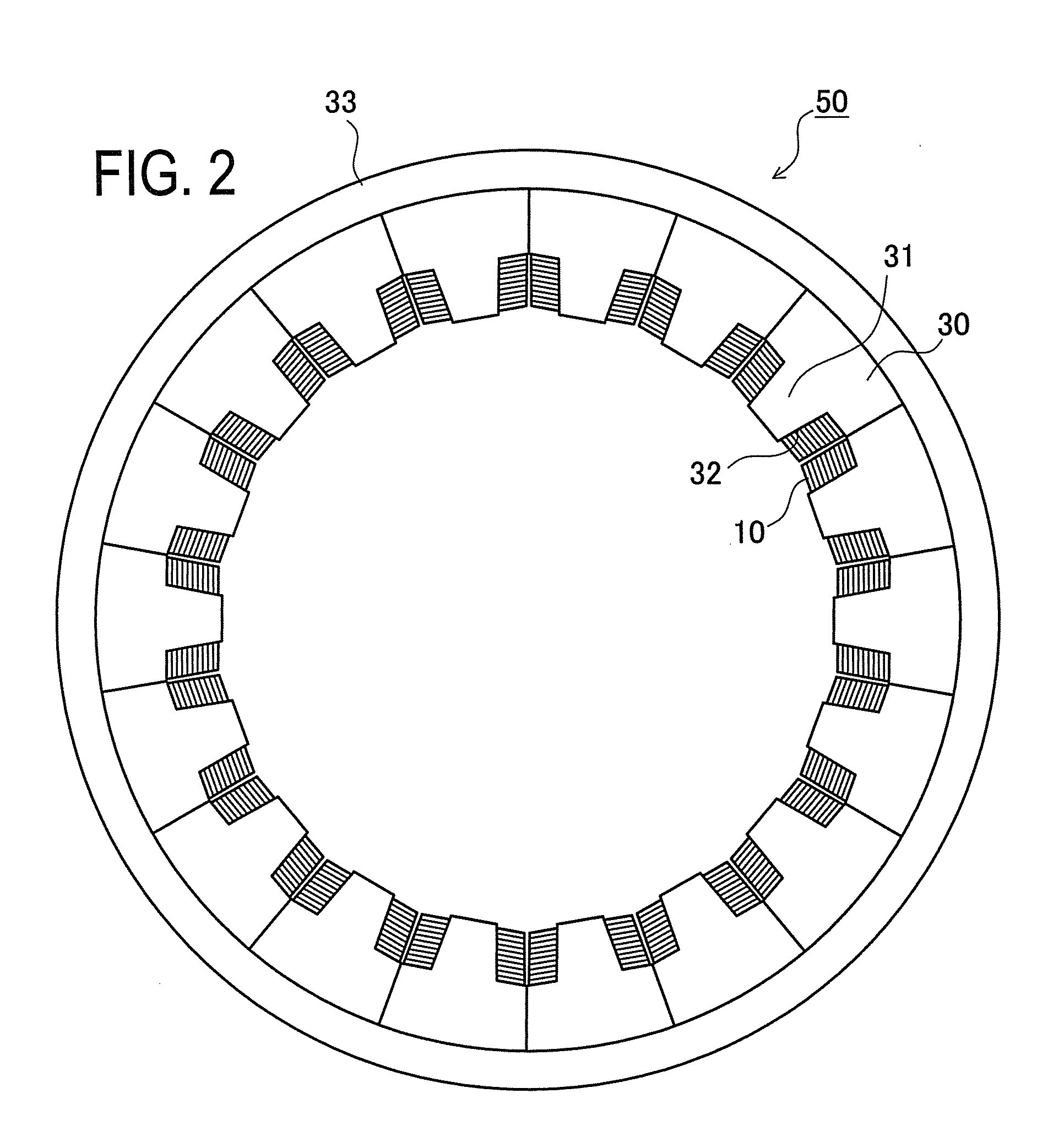

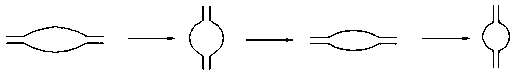

Coil production method, coil of motor, and stator of motor

InactiveUS20100026133A1Reduce thicknessHigh space factorSynchronous machinesAsynchronous induction motorsStatorElectrical conductor

A coil production method capable of improving the space factor of a rectangular conductor with respect to the slot of a stator core, a coil of a motor, and a stator of a motor. The coil production method in which one surface of a rectangular conductor is brought into contact with a shaft with guide, and edgewise bending is performed along the curved surface of the shaft, wherein a deforming mechanism for reducing the plate thickness of a plate thickness changed portion corresponding to each of four corners of a coil over the entire width of the rectangular conductor is provided, the deformation mechanism is used to deform the plate thickness changing portion, and the plate thickness changing portion of the rectangular conductor is edgewise-bent to form a coil.

Owner:TOYOTA JIDOSHA KK

Deviation rectifying method for building

ActiveCN102660969ASmall disturbance rangeSolve the difficulty of correctionFoundation engineeringPore water pressureBuilding construction

The invention relates to the technical field of building construction, in particular to a deviation rectifying method for a building. The method includes the steps: a, drilling pile pressing holes in the indoor environment of the building and positioning the drilling pile pressing holes on a foundation of the building; b, selecting at least two pile pressing holes with less settlement according to uneven settlement conditions of the building; c, drawing out soil in the selected pile pressing holes, inflating formed soil drawing-out holes, forming negative excess pore water pressure in soil bodies on the peripheries of the soil drawing-out holes and then draining water in the soil drawing-out holes; and d, pressing anchor rod piles into the pile pressing holes and sealing the piles. The deviation rectifying method has the advantages that after practice examination, the soil is drawn out of the pile pressing holes to rectify deviation, the building uniformly deforms during back inclination, the deviation rectifying effect is fine, and deviation rectifying design requirements are met.

Owner:SHANGHAI GEOTECHN INVESTIGATIONS & DESIGN INST

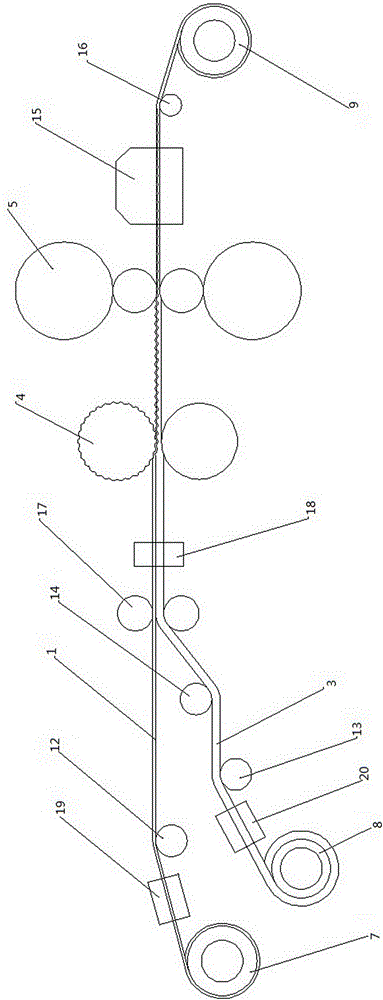

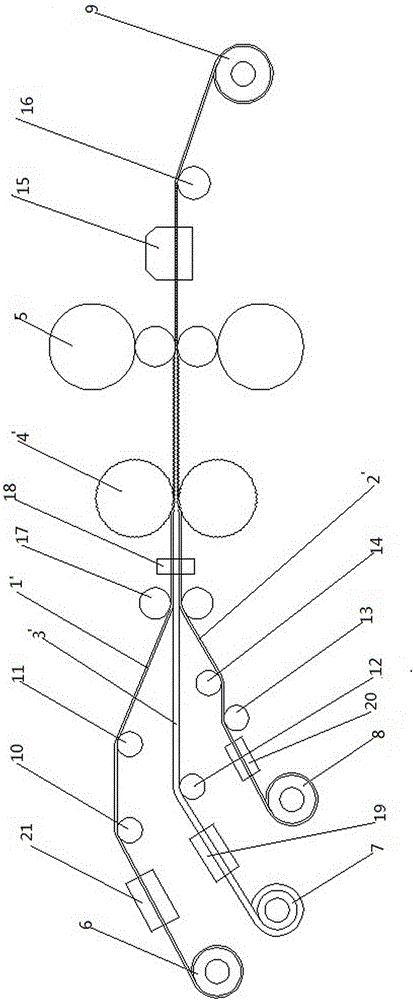

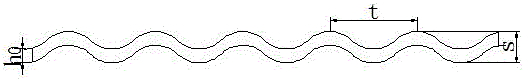

Device and method for producing metal composite sheet strips through corrugated-flat continuous rolling

ActiveCN105057386AHigh bonding strengthUniform deformationMetal rolling arrangementsCrazingContinuous annealing

The invention discloses a device and method for producing metal composite sheet strips through corrugated-flat continuous rolling. The method is characterized in that a base material steel coil and a composite material steel coil are uncoiled through uncoilers, cleaned through a cleaning device to remove oxide layers and then rolled into a composite sheet strip through a corrugated-flat cold continuous rolling unit, and the composite sheet strip is annealed through a continuous annealing device and then coiled to obtain a composite sheet coil. The corrugated-flat cold continuous rolling unit is composed of a double-roller corrugated rolling mill and a four-roller flat rolling unit. When double-layer sheet strips need to be produced, a roller system of the double-roller corrugated rolling mill comprises a corrugated roller and a flat roller, and the corrugated roller always makes contact with a large-deformation-resistance metal layer; when three-layer sheets need to be produced, the roller system of the double-roller corrugated rolling mill comprises two corrugated rollers, and the two corrugated rollers make contact with a large-deformation-resistance composite layer. In corrugation section dimensions, the corrugation depth is s, and the corrugation width is t; the thickness of the large-deformation-resistance metal layer is h0, i.e., s / h0=(0.1-10), and t=(10-20)s. By using the corrugated-flat cold continuous rolling unit, the problem that composite sheet strips buckle, crack and have large residual stress due to the difference of deformation resistances of dissimilar metals is solved, and the composite ratio is high.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

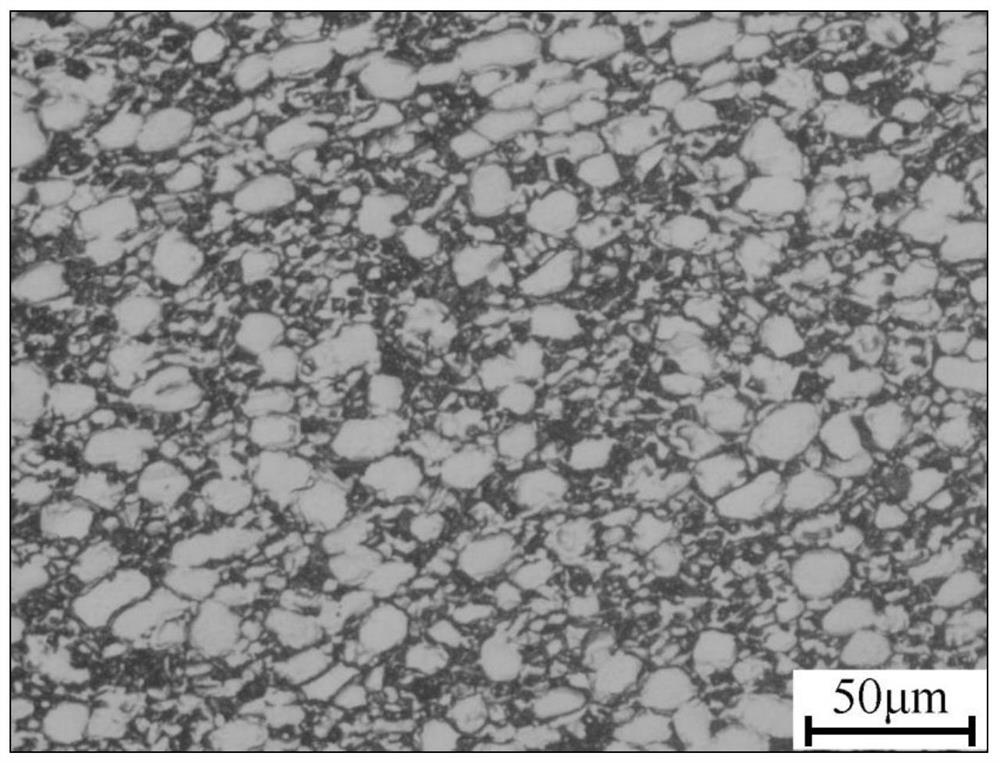

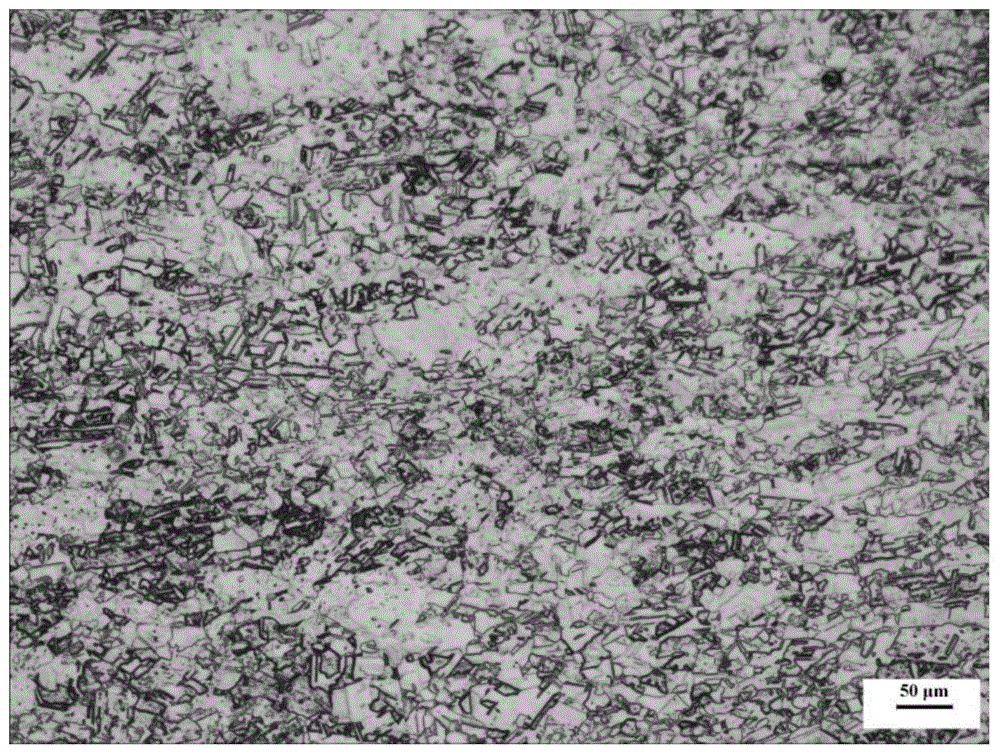

Processing method of fine-grain superplastic TA15 titanium alloy medium-thickness plate

The invention discloses a processing method of a fine-grain superplastic TA15 titanium alloy medium-thickness plate. The processing method comprises the following steps that 1, vacuum consumable arc melting is carried out to obtain a TA15 titanium alloy cast ingot; 2, after heat preservation, a primary forging stock is obtained through upsetting, drawing, cogging and forging; 3, after heat preservation, a second-stage forging stock is obtained through beta-phase region upsetting and drawing forging; 4, upsetting and drawing forging in an alpha + beta two-phase region is carried out to obtain afourth-stage forging stock; 5, a forge piece is obtained through upsetting, drawing and finish forging; 6, after heat preservation, a first-fire rolled plate blank is obtained through first-fire rolling; 7, after heat preservation, a second-fire rolled plate blank is obtained through second-fire rolling; and 8, the TA15 titanium alloy medium-thickness plate is obtained through annealing treatment. According to the processing method of the fine-grain superplastic TA15 titanium alloy medium-thickness plate, the corresponding deformation temperature is selected and combined with multi-heating-number large-deformation upsetting and drawing forging, so that the TA15 titanium alloy cast ingot with a coarse structure is crushed under the large deformation, driving force is provided for recrystallization, the grain refinement and homogenization degree is improved, and the fine-grain superplasticity TA15 titanium alloy medium-thickness plate is obtained.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

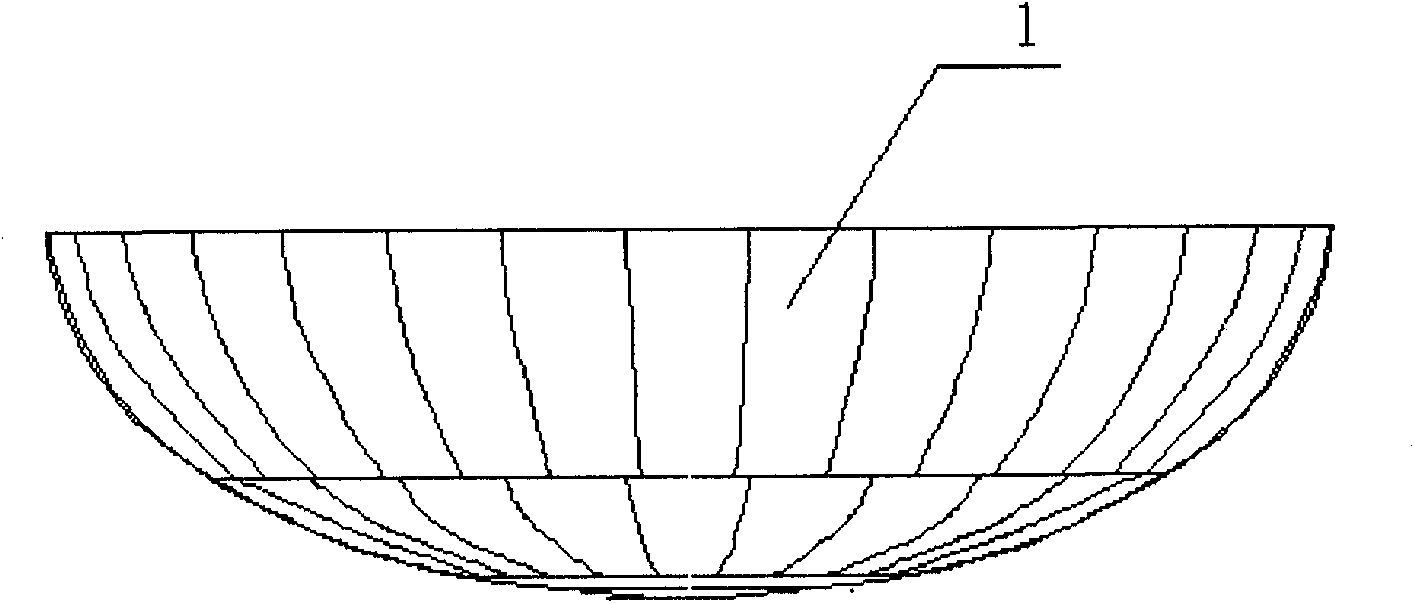

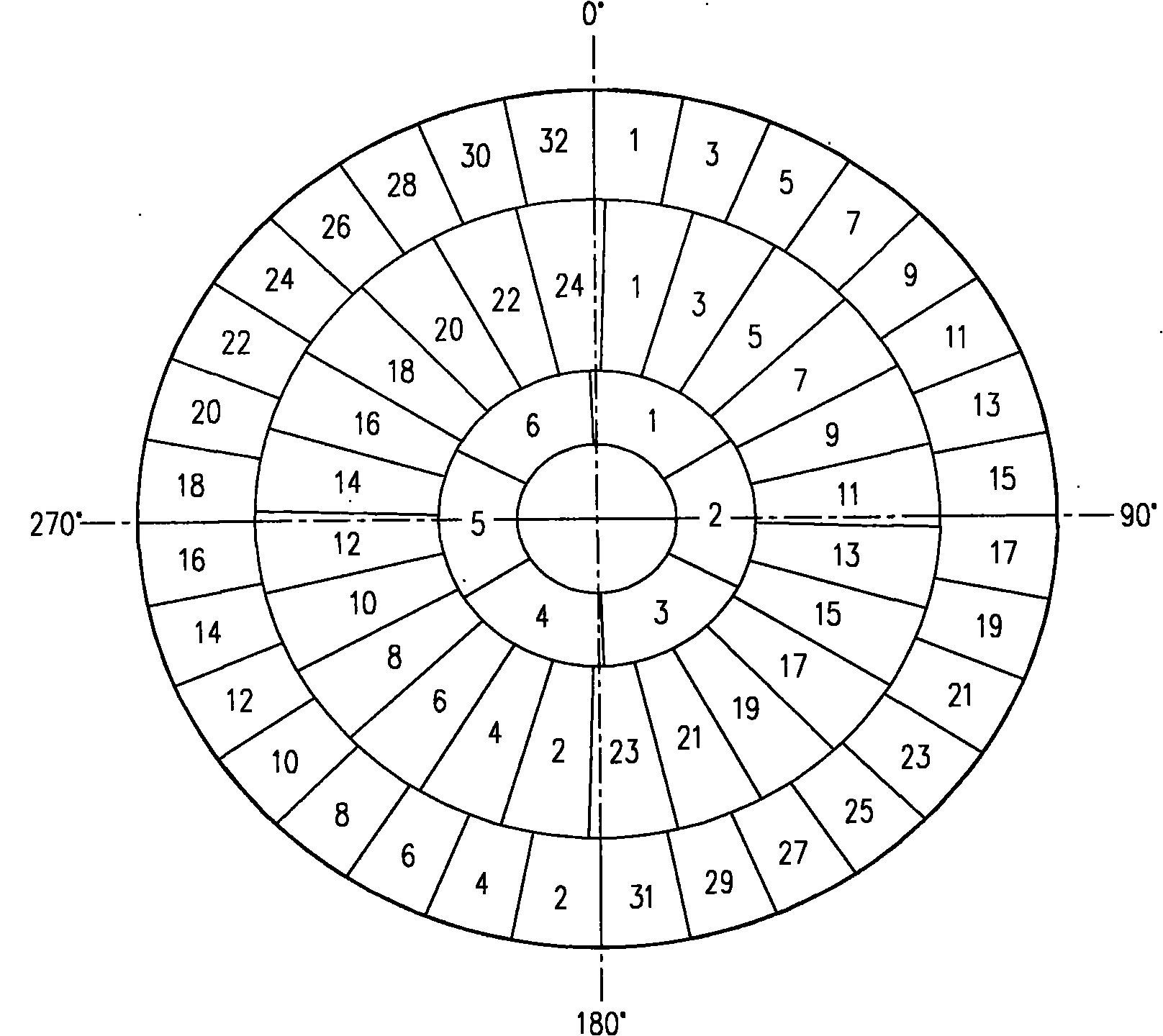

Method for manufacturing superlarge spherical seal head

ActiveCN101829856ARealize formingUniform deformationNuclear energy generationContainmentSheet steelEngineering

The invention provides a method for manufacturing a superlarge spherical seal head, which comprises the steps of: providing a first group of steel plates to form a first ring part of a spherical seal head, wherein the closed end of the spherical seal head is formed by the first ring part; providing at least one group of steel plates to form at least one middle ring part of the spherical seal head; and providing the last group of steel plates to form an outmost ring part of the spherical seal head, wherein the open end of the spherical seal head is formed by the outmost ring part. Corresponding steel plates of adjacent groups and adjacent steel plates of each group of steel plates are finally interconnected through welding. A sectional forming method is applied to the spherical seal head, the seal head is formed step by step through deformation of each area, and larger deformation is dispersed and localized, therefore, the deformation of each area can be even to effectively avoid defects, such as crinkles and the like.

Owner:CHINA NUCLEAR IND 23 CONSTR

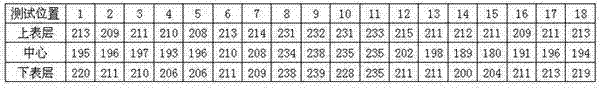

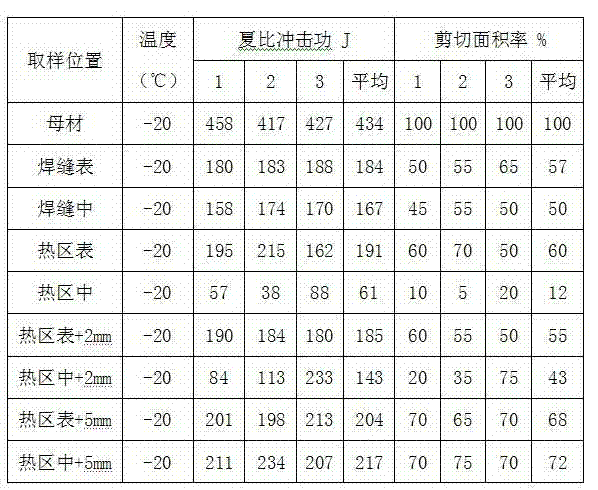

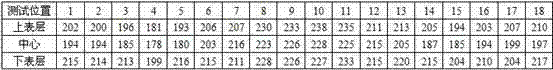

Manufacturing method of X65 pipeline steel longitudinal submerged arc welded pipe for undersea use

ActiveCN102310119AUniform deformationUniform performanceArc welding apparatusUltrasound testMagnetic particle inspection

The invention discloses a manufacturing method of an X65 pipeline steel longitudinal submerged arc welded pipe for undersea use. The manufacturing process of the steel pipe comprises: edge milling, edge prebending, JCO moulding, prewelding, inside welding, outside welding, first ultrasonic inspection, first x-ray inspection, mechanical expanding, hydrostatic test, chamfering, groove machining, second ultrasonic inspection, second x-ray inspection, pipe end magnetic particle inspection and appearance quality inspection. The method of the invention makes each part of the X65 steel grade ongitudinal submerged arc welded pipe with a diameter of phi 762mm and wall thickness of 28.6-30.2mm has uniform deformation and performances in the process of JCO moulding; the method in the invention solves the problem that local heating of the steel pipe during welding results in severely reduced strength and toughness as well as elongation; the method provided in the invention also provides a solution to the problems of increased strength and reduced toughness and uniform elongation caused by work hardening during steel pipe mechanical expanding.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Manufacturing method for X90 pipeline steel longitudinal submerged arc welding pipe

The invention discloses a manufacturing method for X90 pipeline steel longitudinal submerged arc welding pipe, the mass percent of the X90 pipeline steel consisting of: C 0.04-0.08%, Mn1.60-2.0%, Si 0.15-0.45%, S<=0.006%, P<=0.010%, Ni 0.20-0.50%, Mo 0.10-0.30%, Ti 0.010-0.020%, Al 0.015-0.050%, Nb 0.05-0.10%, V<= 0.05%, N <= 0.01%, Cu 0.10-0.30%, Cr <= 0.35%, B <= 0.004%, the rest is Fe, wherein Ceq <= 0.50, Pcm<= 0.25; the inside welding and outside welding adopt 4-wire submerged arc automatic welding. The welding pipe of the invention has advantages of tenacious welding joints and uniform performance.

Owner:CNPC BOHAI EQUIP MFG +2

Hot impact extrusion process and device for large annular barrel type forged piece

ActiveCN101537438ASolve process problemsImprove uniformityExtrusion containersRams/plungersImpact extrusionLubricant

The invention relates to a hot impact extrusion process and a device for a large annular barrel type forged piece, which belongs to the technical field of hot forming of a large hollow forged piece. The process comprises the following steps: firstly, an extrusion cushion is placed on a press platform; secondly, the blanks to be heated are put on the extrusion cushion; thirdly, an extrusion cylinder is sleeved on the extrusion cushion; fourthly, a profiling punch is applied with force so that a mold cavity is filled with the blanks; fifthly, the lubricant is added; sixthly, a solid punch is applied with force so that the blanks are extruded to the set position of the process; seventhly, a hollow punch is sleeved on the solid punch and applied with pressure, so that the blanks are extruded to the set positioned of the process; eighthly, the extrusion cushion is taken out and a bottom flushing drain cap is replaced; and ninthly, the core material at the bottom is flushed out through the hollow punch. The devices required for finishing the process comprise an extrusion cylinder, an extrusion cushion, a profiling punch, a solid punch, a hollow punch, a solid extension rod, a hollow extension rod and a bottom flushing drain cap. The invention solves the difficult problems existing in the large annular barrel forged piece of long process flow of free forging, more forging times and large reverse extrusion molding for die forging and improves the utilization ratio of the material and the molding quality of the forged piece.

Owner:NANJING DEV ADVANCED MFG

Processing method of fine-grain superplastic TA15 titanium alloy sheet

ActiveCN103978032ASmall horizontal and vertical performance gapUniform deformationMetal rolling stand detailsMetal rolling arrangementsBatch productionControllability

The invention provides a processing method of a fine-grain superplastic TA15 titanium alloy sheet. The processing method includes steps of firstly, heating a TA15 titanium alloy sheet blank; secondly, performing first rolling to obtain first semi-finished sheet blanks; thirdly, heating the first semi-finished sheet blanks; fourthly, performing second rolling to obtain second semi-finished sheet blanks; fifthly, manufacturing several second semi-finished sheet blanks into a ply rolling pack; sixthly, heating the ply rolling pack; seventhly, performing third rolling and annealing, performing alkaline washing, acid pickling, sanding and shearing after unpacking, and obtaining a fine-grain superplastic TA15 titanium alloy sheet. The fine-grain superplastic TA15 titanium alloy sheet processed by the processing method is uniform in texture, fine in grains and excellent in superplasticity and consistence of performance, and has excellent process controllability and stability in batch production.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Mould for continuous extrusion production of high-width-thickness-ratio profiles

InactiveCN102407244AExtended service lifeReduce extrusion pressureExtrusion diesThermodynamicsEngineering

The invention relates to a mould for the continuous extrusion production of profiles, which can be used for producing large-sized (high-width-thickness-ratio) profiles by using a small-capacity continuous extruder, and belongs to the technical field of metal continuous extrusion. In the invention, an inlet of an opening of the mould is provided with a diversion trench which is completely same as an outlet of an expansion module cavity in shape and size; a 'dumbbell-shaped' diversion trench is arranged behind the diversion trench; a choking surface with a choked angle of 8-15 DEG and a promoted angle of 50-90 DEG is arranged behind the 'dumbbell-shaped' diversion trench through design, and the height of the choking surface is 5-15 mm. A mould design method in the invention is used for the continuous extrusion production of profile products in general specifications, can reduce extrusion forces, increase the productivity, lower the mould loss, and improve the service life of the mould.

Owner:KUNMING UNIV OF SCI & TECH +1

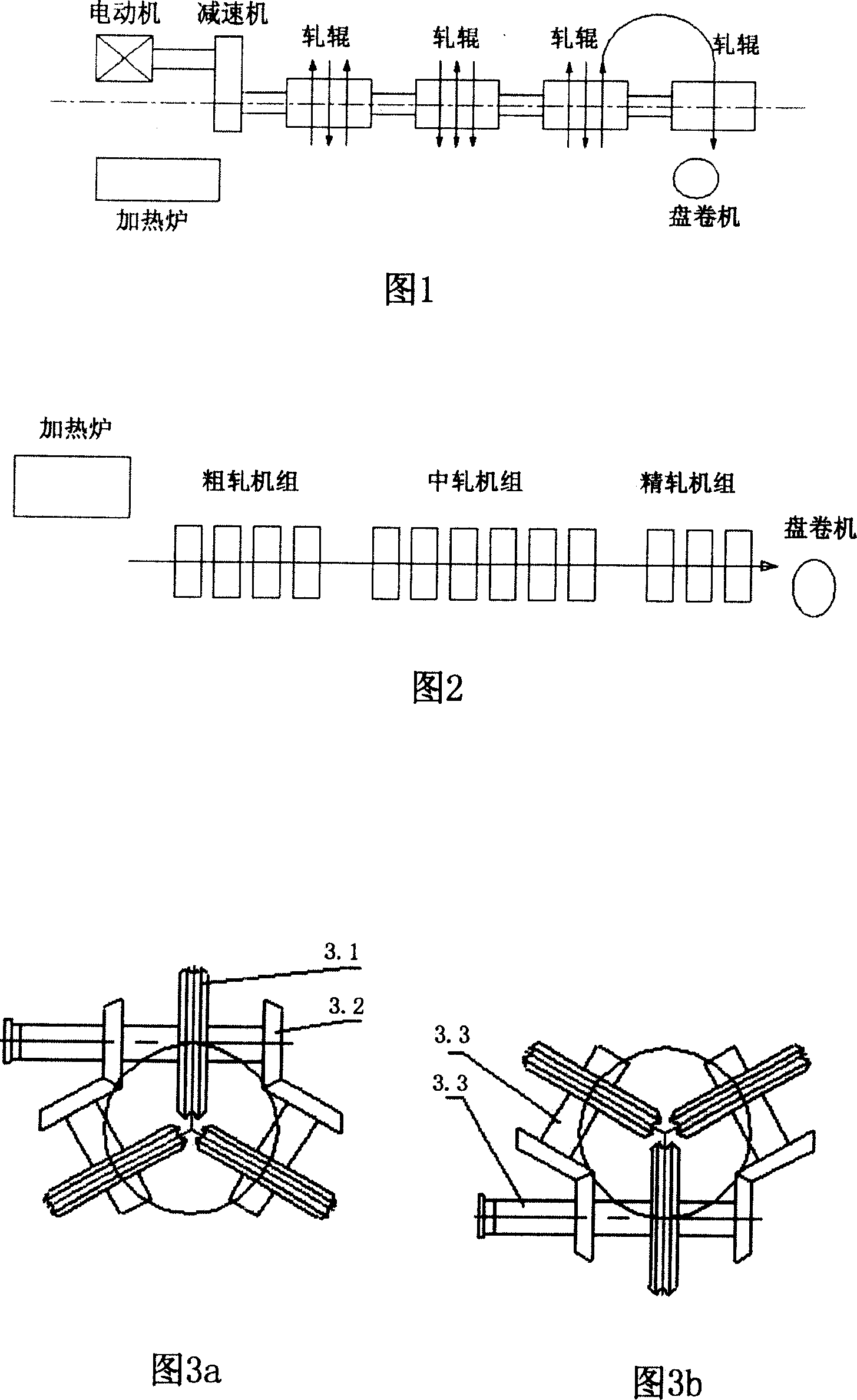

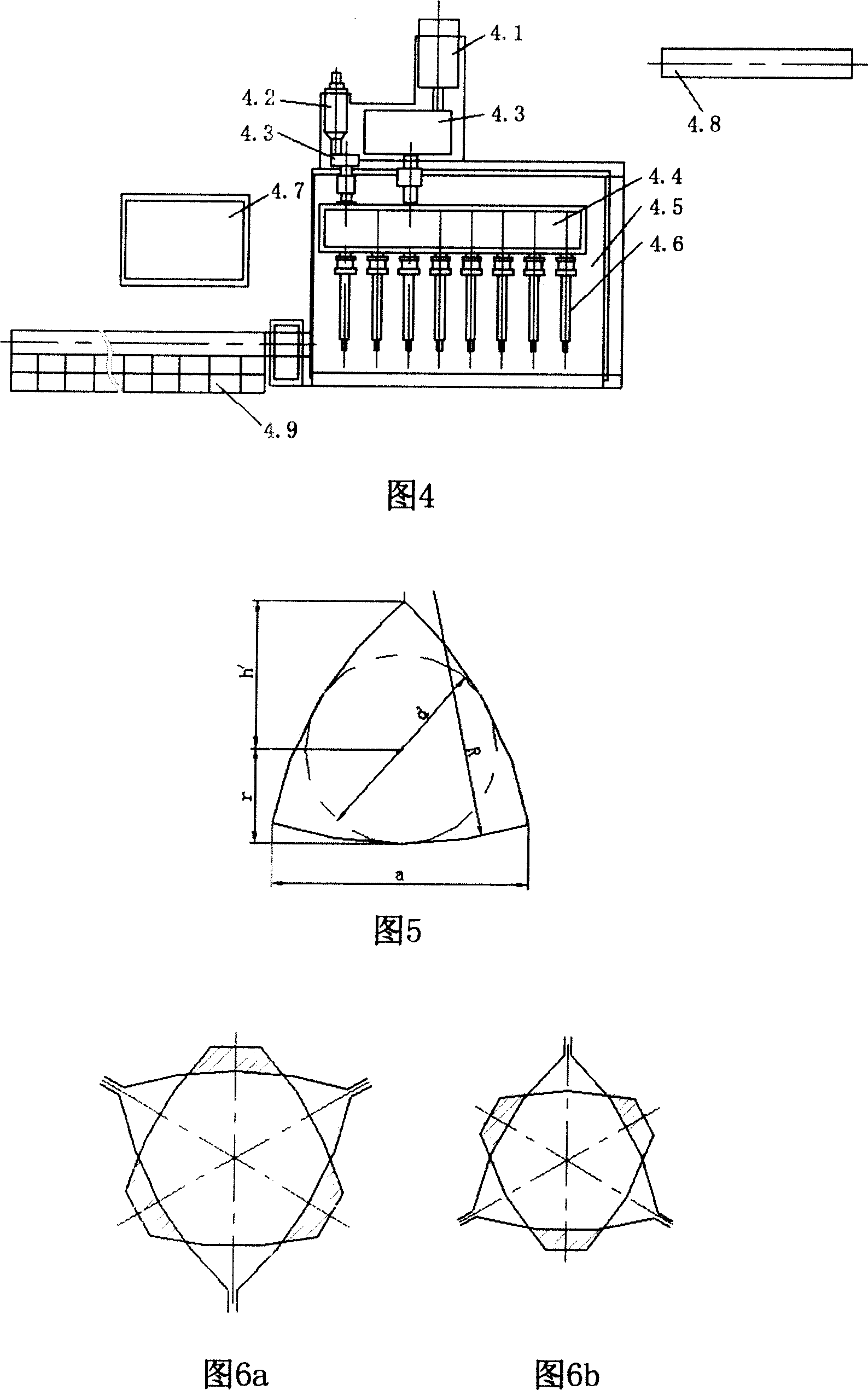

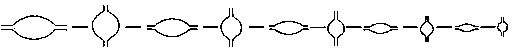

Rolling technology for stainless steel wire rod

ActiveCN104259199AVarious sizesUniform deformationMetal rolling arrangementsWork in processStainless steel wire

The invention discloses a rolling technology for a stainless steel wire rod. The technology comprises the following technological steps of blank preparation, heating treatment and groove rolling. The stainless steel wire rod is rolled from rough to fine through rough rolling, intermediate rolling and secondary intermediate rolling; rough rolling comprises five rolling steps; according to the first rolling step, corner machining is carried out on a square billet; according to the second rolling step, the blank with the machined corner is machined to be in an oval shape; according to the third rolling step, the oval blank is machined to be in a round shape; according to the fourth rolling step, the round blank is machined to be in an oval shape; according to the fifth rolling step, the oval blank is machined to be in a round shape. Intermediate rolling comprises nine rolling steps; secondary intermediate rolling comprises five rolling steps. According to rough rolling, intermediate rolling and secondary intermediate rolling, the oval blank and the round blank are converted, and finally a semi-finished product with the round section is formed. When pre-finish rolling, finish rolling, spinning, controlled cooling, packaging and groove rolling are carried out, the square billet with the machined corner after the first rolling step is directly transited to be in the oval-round hole type, the deformation degree is even, defects are small, the size of the blank capable of being rolled is diversified, and the range of a rolled-out part is expanded.

Owner:WUXI XINGCHENG HUAXIN STEEL

Tantalum target and manufacturing method thereof

ActiveCN104451567AFully brokenUniform deformationVacuum evaporation coatingSputtering coatingIngotThermal treatment

The invention provides a tantalum target and a manufacturing method thereof; the manufacturing method comprises the steps: firstly, performing a first forging to a tantalum ingot and obtaining a primary forged blank; performing a second forging and a first thermal treatment to the primary forged blank obtained in the previous step and obtaining a secondary forged blank; performing a third forging and a second thermal treatment to the secondary forged blank obtained in the previous step and obtaining a tertiary forged blank; performing a fourth forging and a third thermal treatment to the tertiary forged blank obtained in the previous step and obtaining a quartus forged blank; and finally, rolling and performing a fourth thermal treatment to the quartus forged blank obtained in the previous step and obtaining the tantalum target; the first forging is a rotary forging; the temperature of the first forging is 800-1400 degrees centigrade. The prepared tantalum target is uniform in texture distribution, small in grain size and capable of satisfying usage requirements in high-level semiconductor film-coating industries.

Owner:NINGXIA ORIENT TANTALUM IND

Preparation method of high-purity copper target

ActiveCN104694888AImprove processing efficiencyReduce plastic deformation resistanceVacuum evaporation coatingSputtering coatingSputteringCopper

The invention discloses a preparation method of a high-purity copper sputtering target, belonging to the technical field of sputtering targets. The method mainly comprises the following steps: carrying out upsetting and stretching plastic deformation on a high-purity copper target blank; cooling the target blank after multiple rounds of upsetting and stretching deformation; carrying out rolling deformation on the cooled high-purity copper target blank to prepare a high-purity copper target blank; and then carrying out thermal treatment on the target blank to obtain the high-purity copper target with fine and uniform tissues. The preparation method has the advantages that the high-purity copper target is prepared by adopting the method combining plastic deformation with thermal treatment; grains of the target prepared by the method are fine and are uniform in distribution, thus completely meeting the requirements of sputtering; meanwhile, the consistency and repeatability of the processing technology are ensured by adopting plastic processing equipment with controllability; the method is simple in process, flexible in equipment operation and high in production efficiency and is suitable for large-scale industrial production.

Owner:GRIKIN ADVANCED MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com