Technique for producing double-layer copper brazing steel tube for air-conditioner

A technology for brazing steel pipes and production processes, which is applied in the field of manufacturing engineering to achieve good deep drawing performance and uniform deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

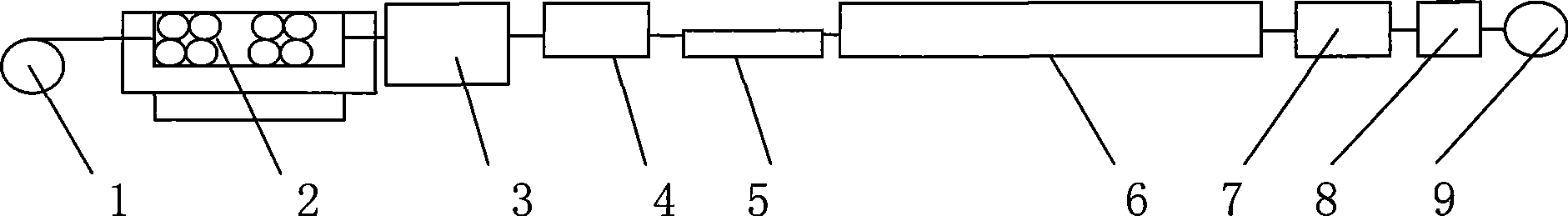

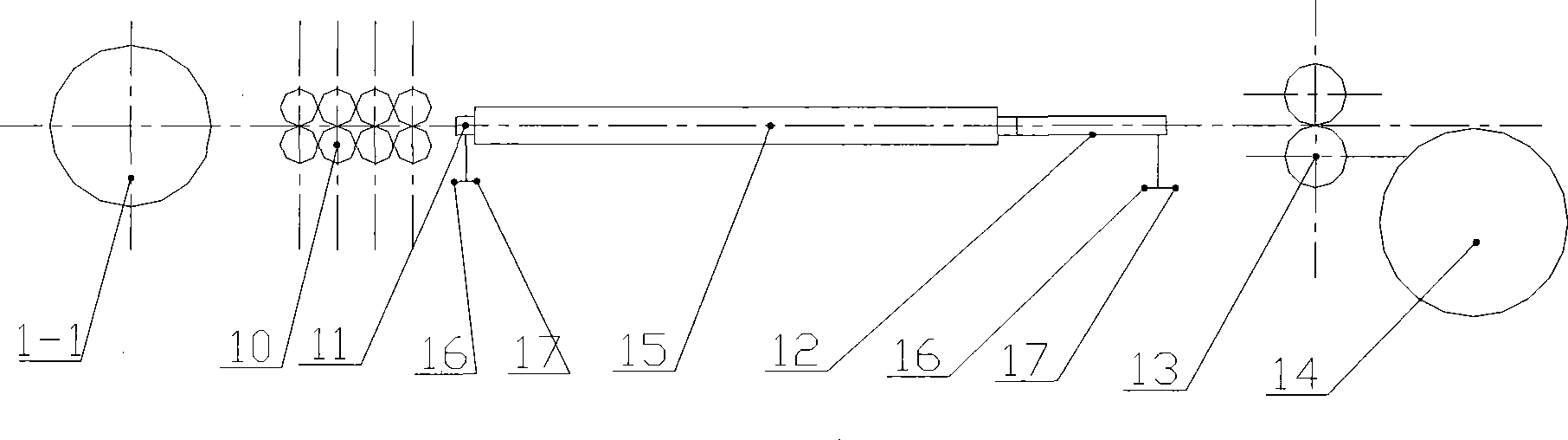

[0032] see figure 1 , Pipe making: the copper-plated steel strip of the double-layer welded pipe produced by the present invention selects ultra-low carbon interstitial-free steel [W(C)3 Decompose the protective gas pipeline valve, fill the brazing furnace 3, the closed pipeline 4, and the stainless steel pipe 5 with NH 3 Decompose the protective gas; start the production line, adjust the temperature of the brazing furnace 3 to 1084°C + 30°C for brazing with copper as the brazing material, and send the brazed double-layer brazed steel pipe into the internal passage NH 3 In the airtight cooling pipe 4 that decomposes the protective gas, the outside of the pipe 4 is cooled with circulating water, so that the double-layer brazed steel pipe can be quickly cooled below the melting point of copper to prevent copper lumps; it is continuously sent into the stainless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com