Patents

Literature

56 results about "Strain hardening exponent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

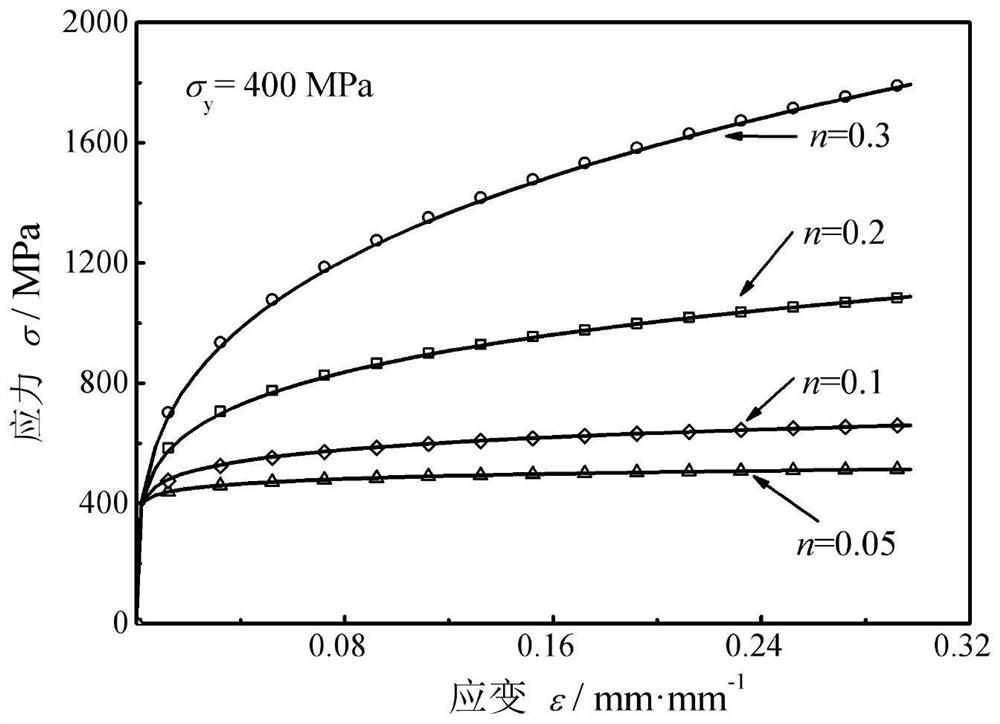

The strain hardening exponent (also called strain hardening index), noted as n, is a material's constant which is used in calculations for stress–strain behavior in work hardening. σ = K ε ⁿ, where σ represents the applied stress on the material, ε is the strain, and K is the strength coefficient.

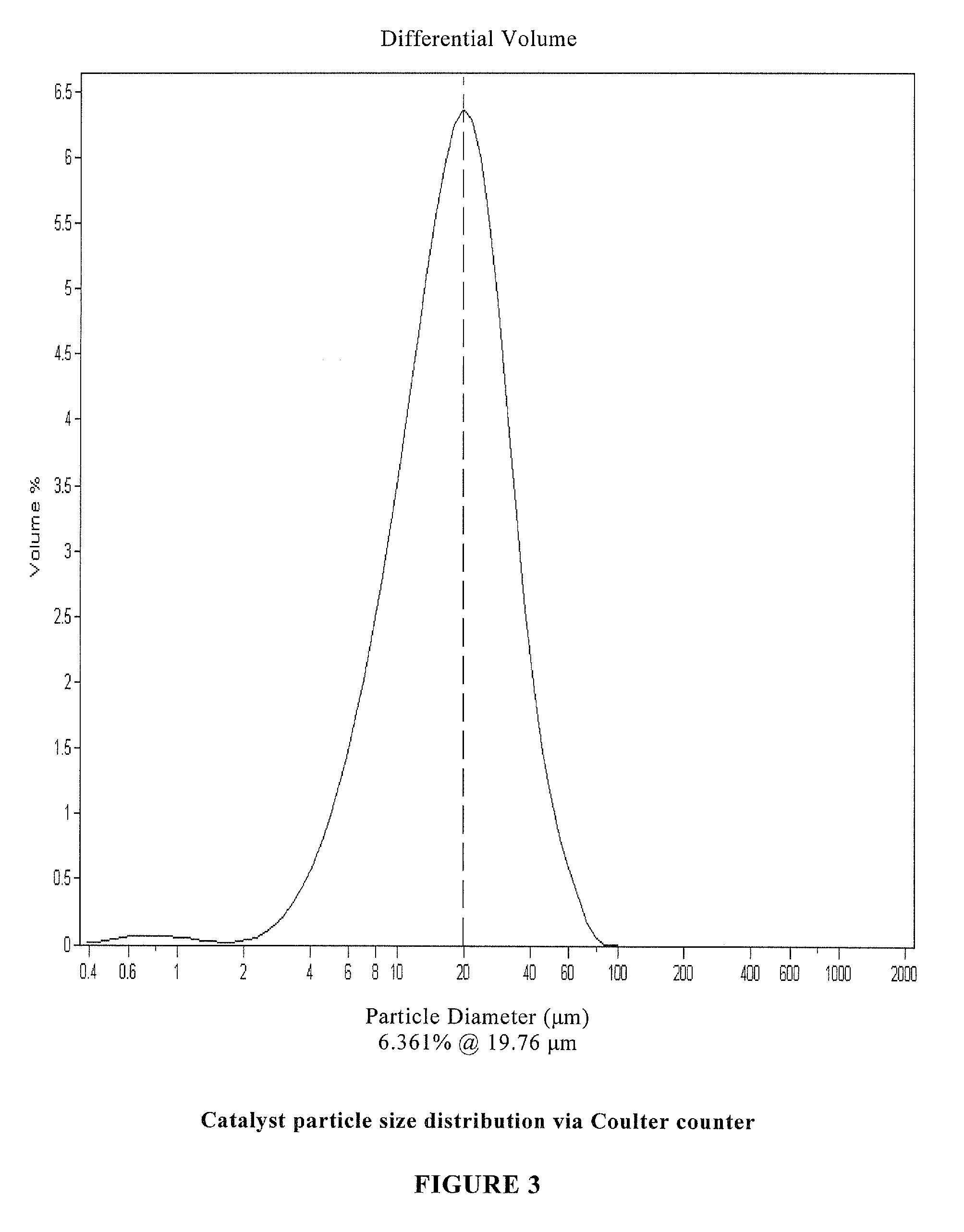

Heterogeneous In-Reactor Polymer Blends

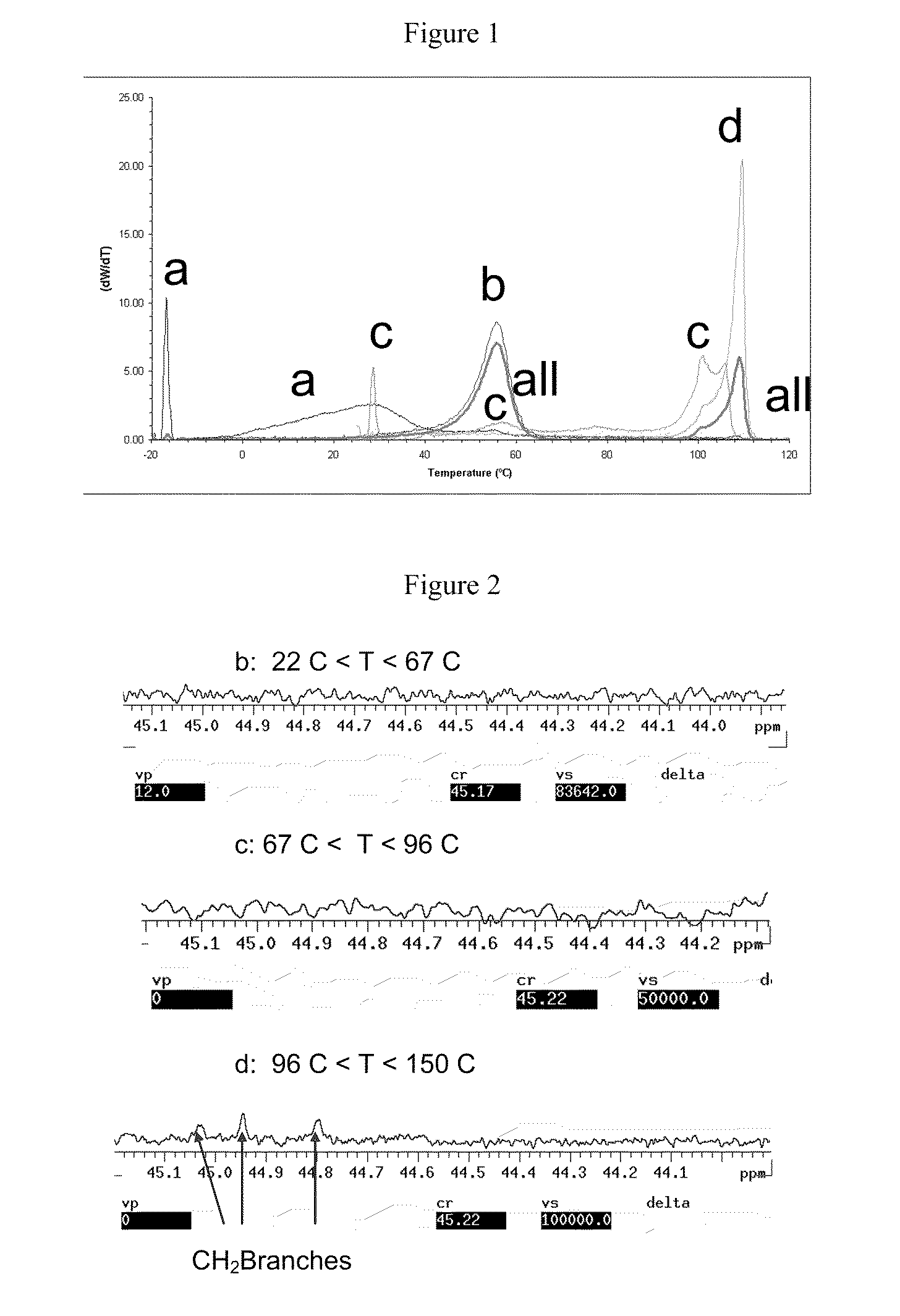

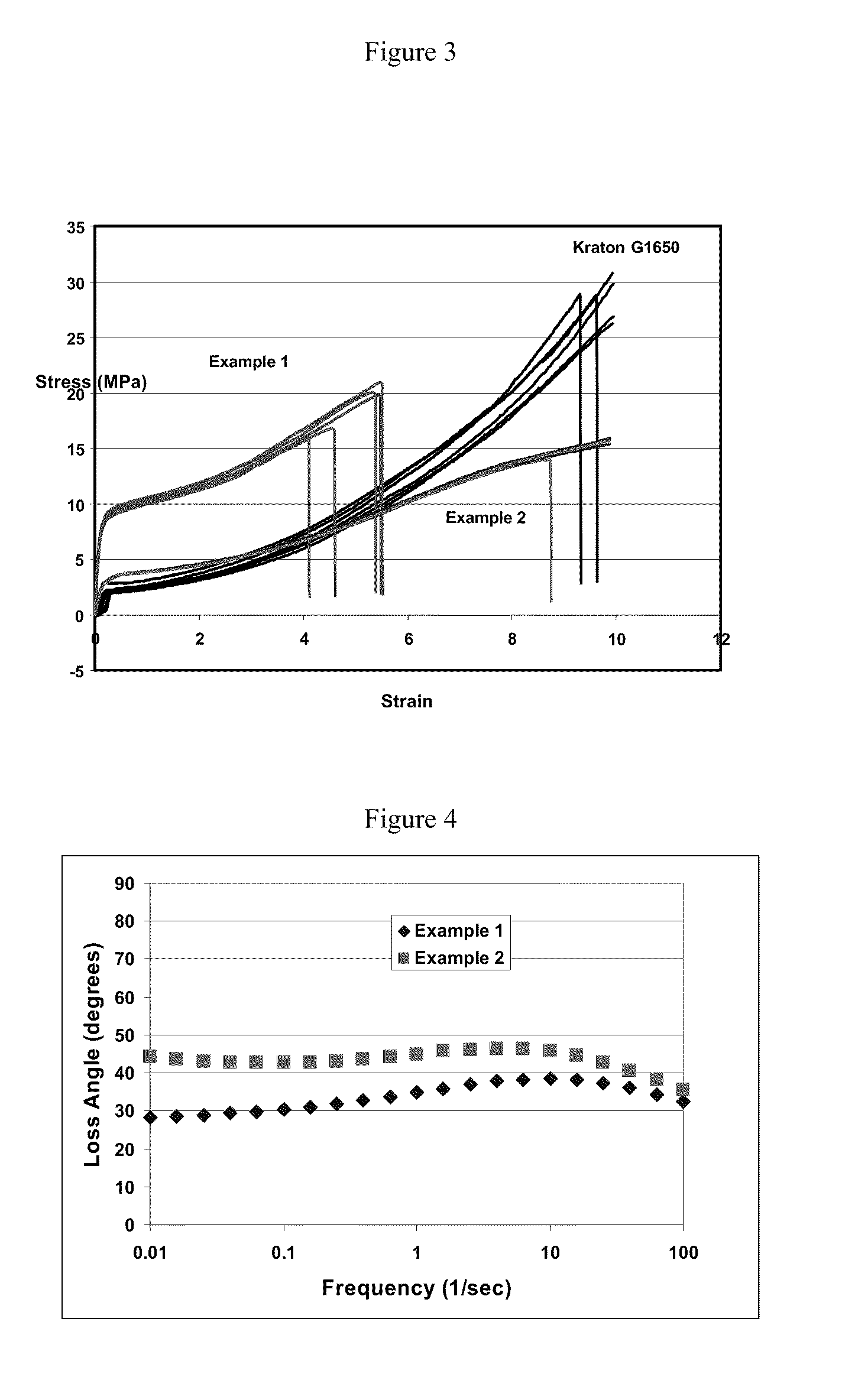

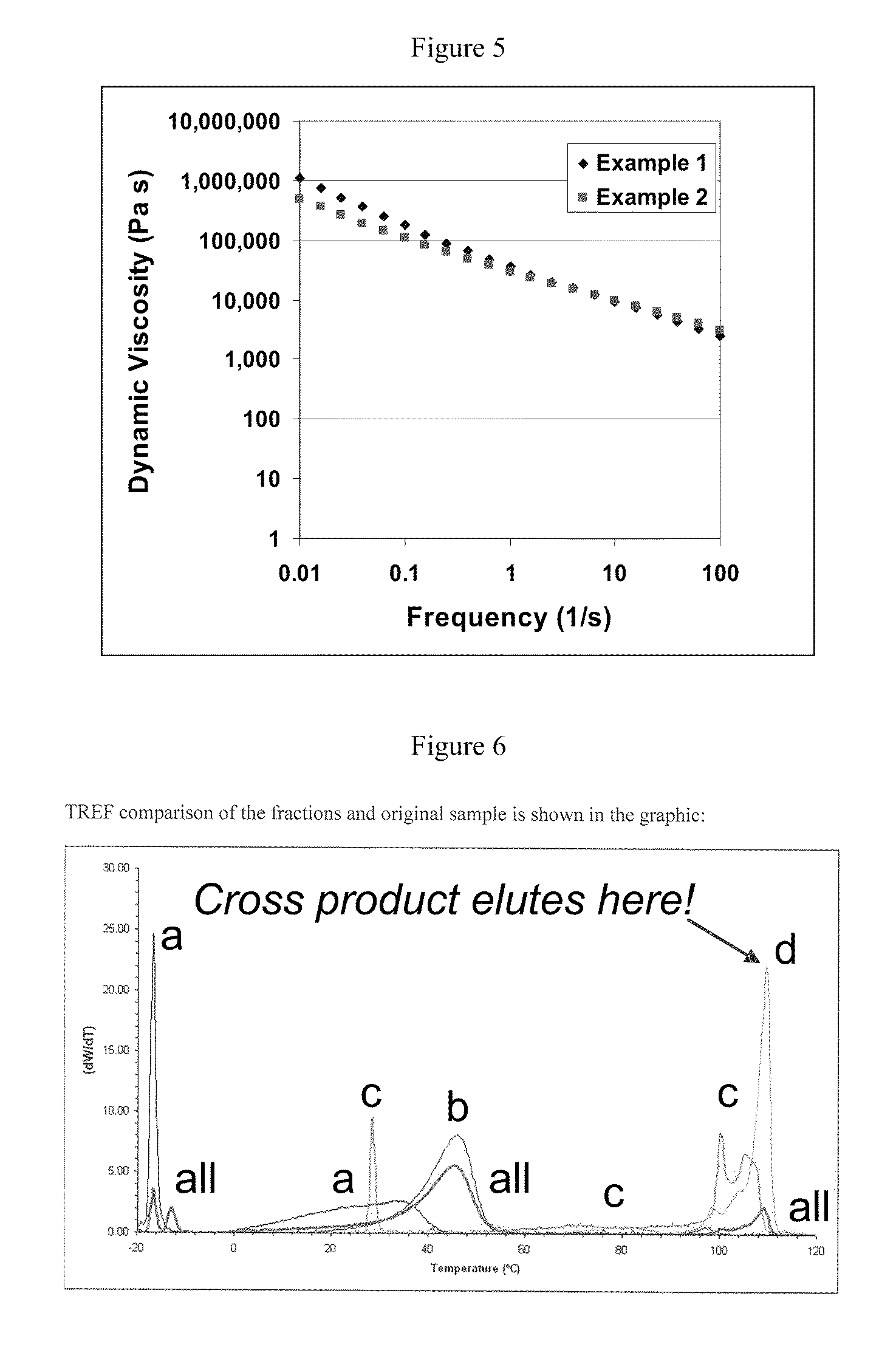

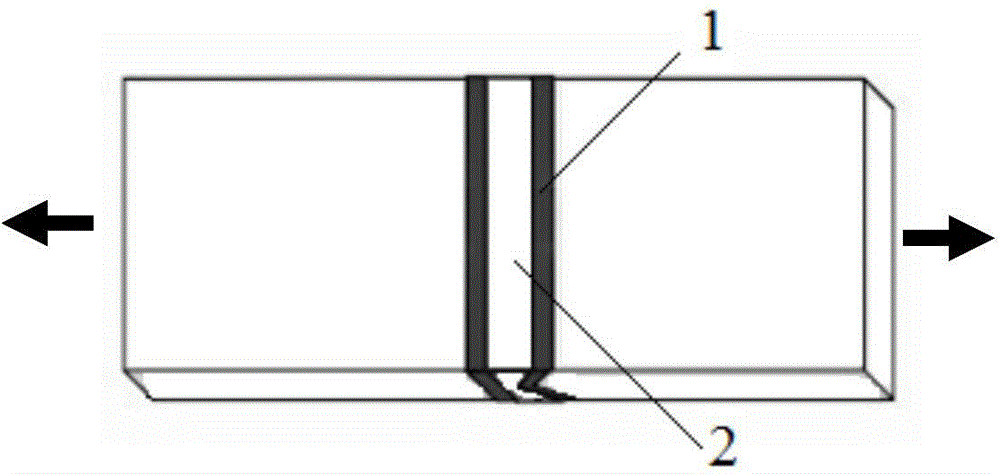

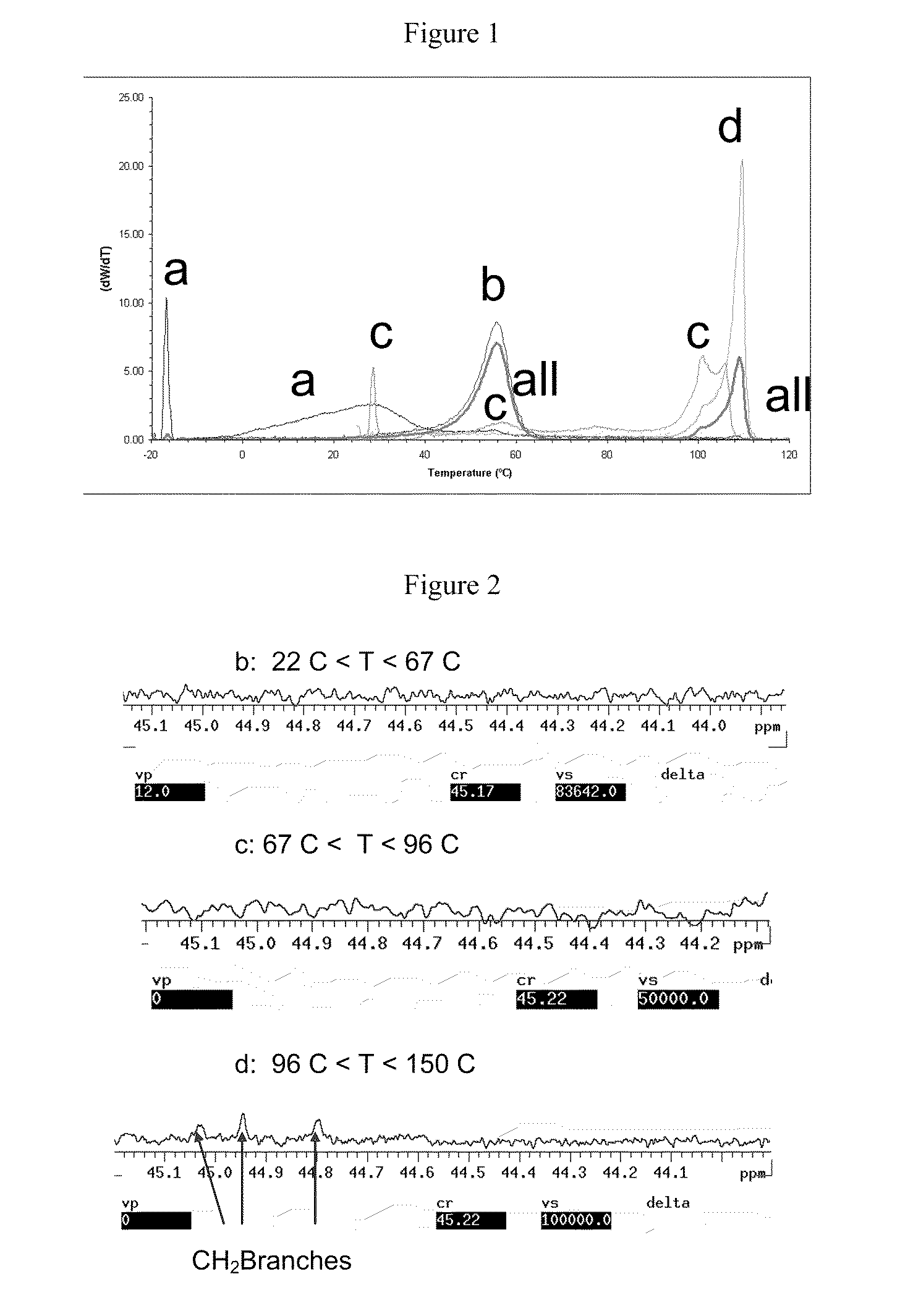

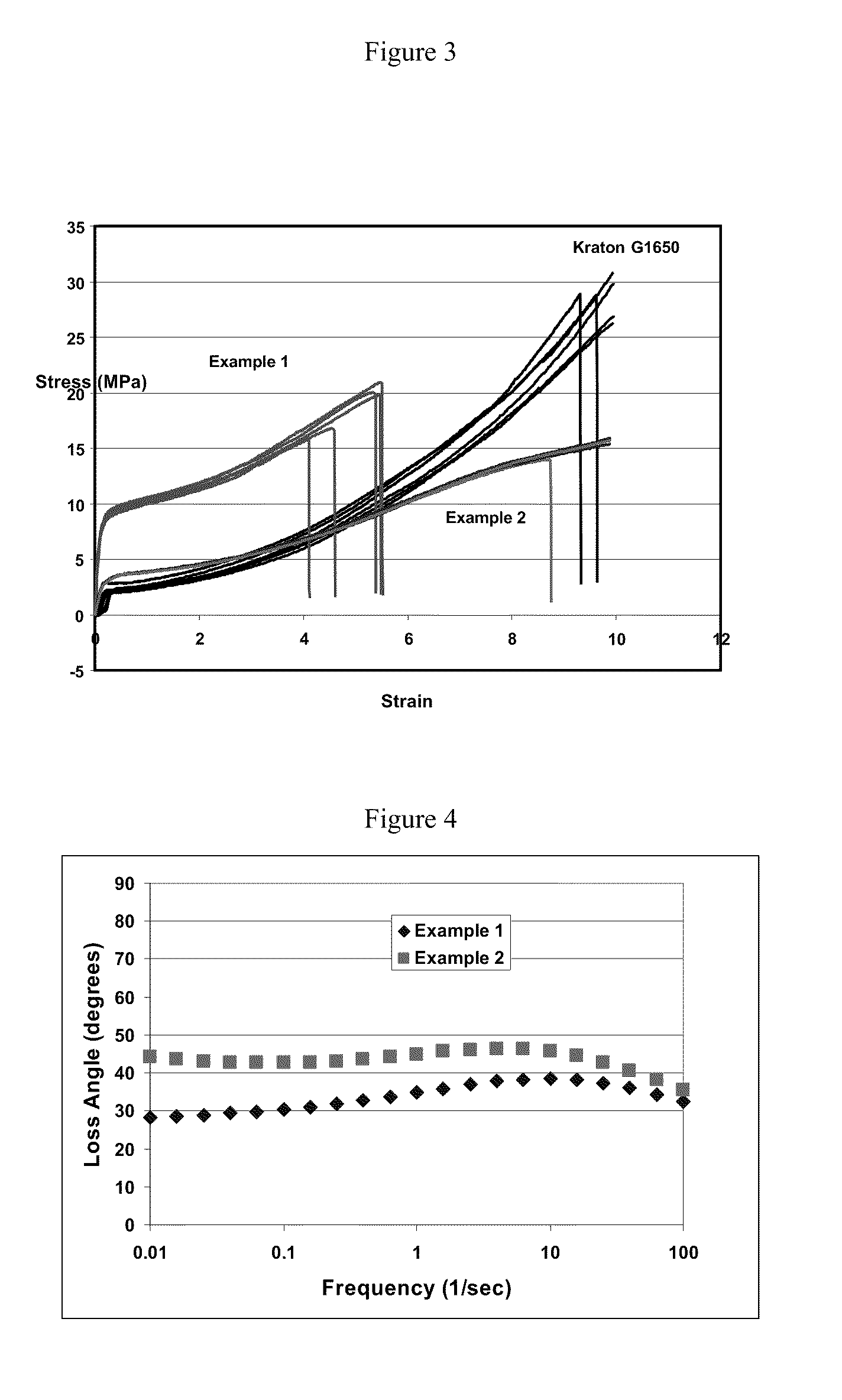

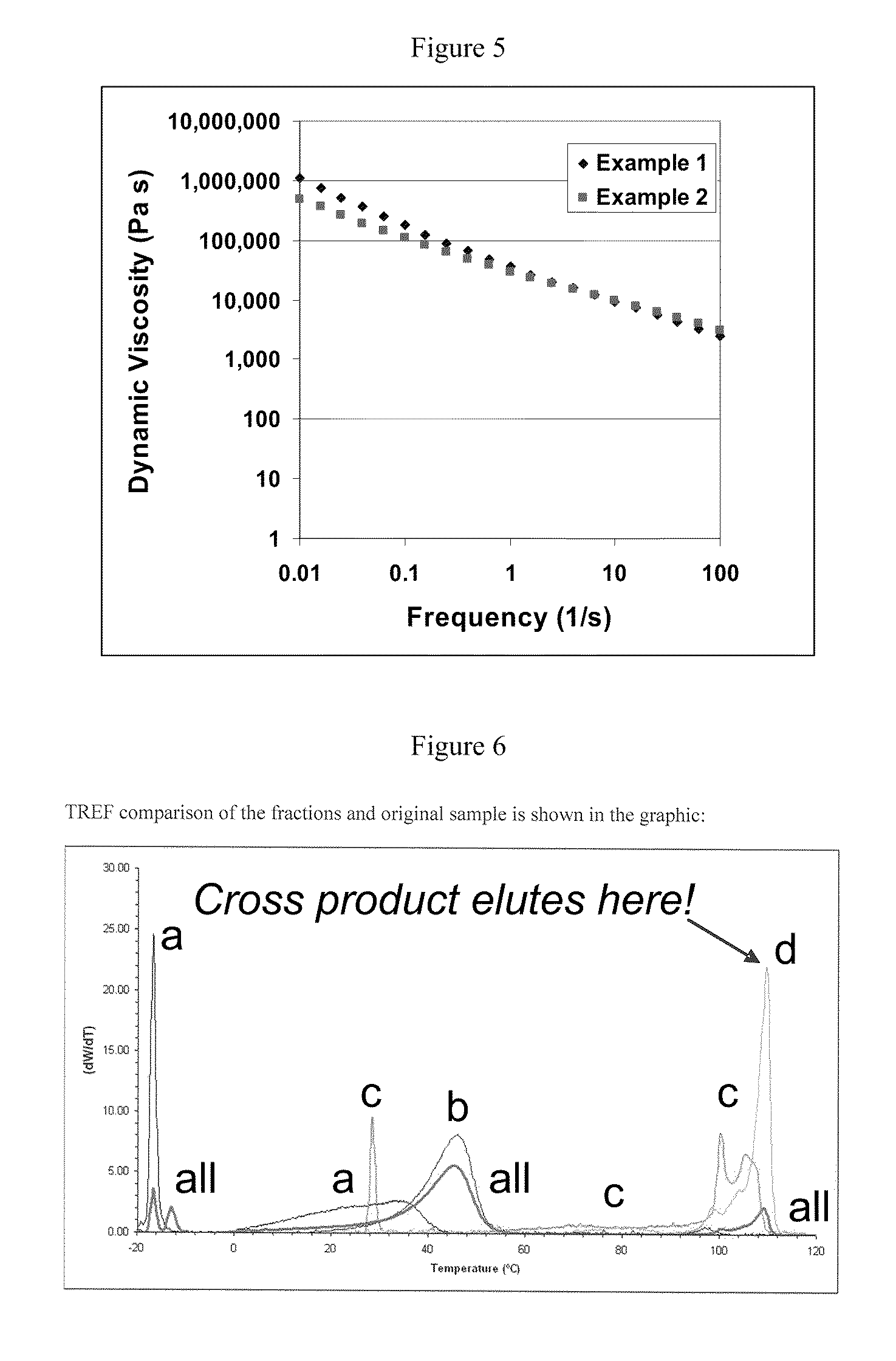

An in-reactor polymer blend comprises (a) a propylene-containing first polymer; and (b) an ethylene-containing second polymer such that the polymer blend comprises between about 50 wt % and about 80 wt % units derived from ethylene and between about 50 wt % and about 20 wt % units derived from propylene. The blend is substantially free of dienes and the content of ethylene in the second polymer in the form of ethylene-ethylene-ethylene triads is at least 40%. The second polymer contains at least 0.1 branch having 8 or more carbon atoms per 10,000 carbons. In addition, the blend has a strain hardening index of at least 1.8, a shear thinning slope in the plot of log(dynamic viscosity) versus log(frequency) of less than −0.2 and exhibits at least two peaks when subjected to Differential Scanning Calorimetry (first melt) corresponding to a first melting point of at least 150° C. and a second melting point of at least 40° C. such that the difference between the first and second melting temperatures is at least 20° C.

Owner:EXXONMOBIL CHEM PAT INC

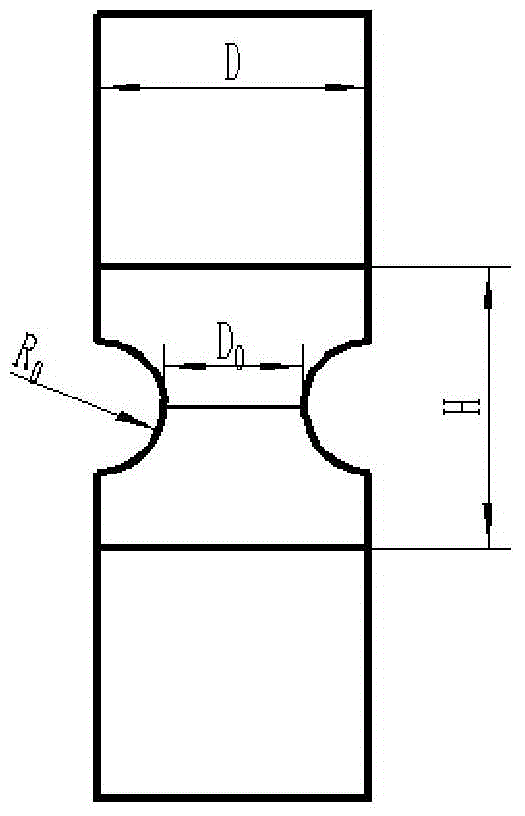

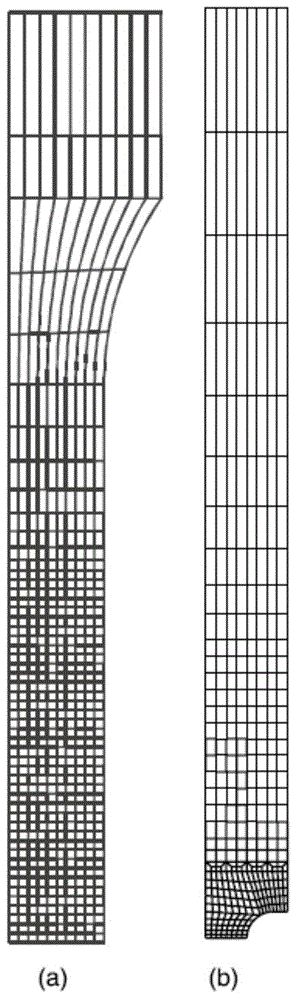

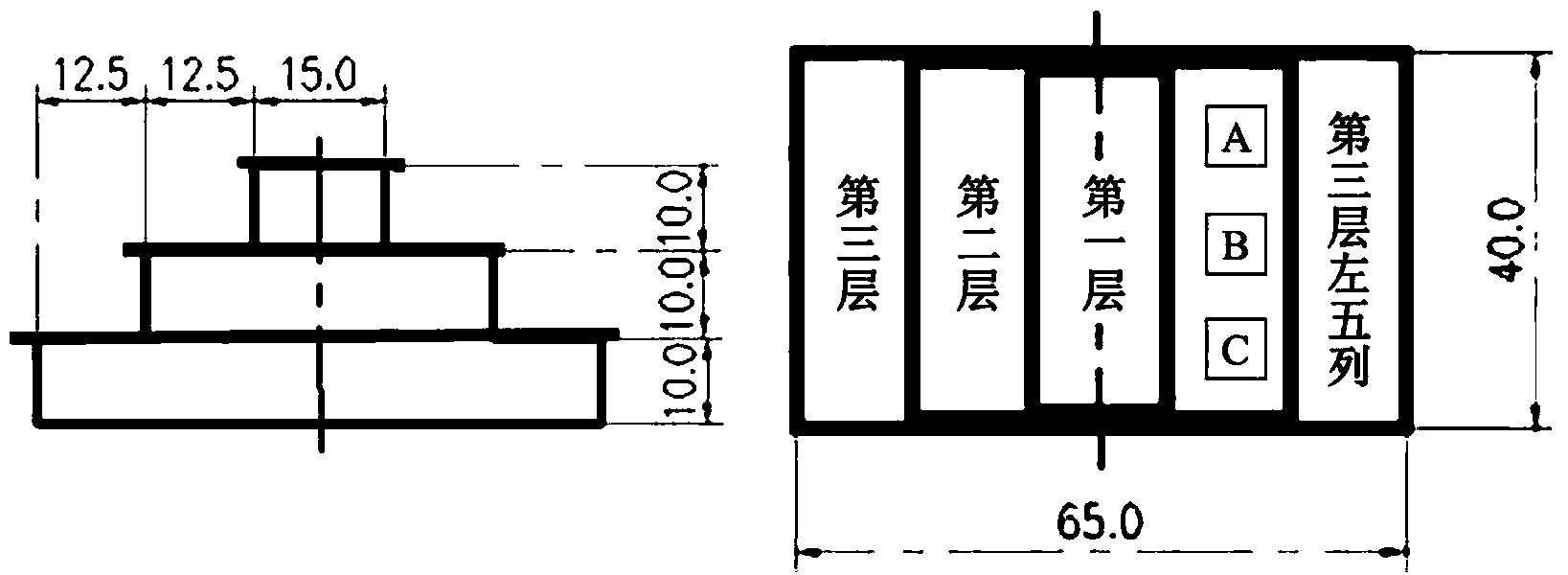

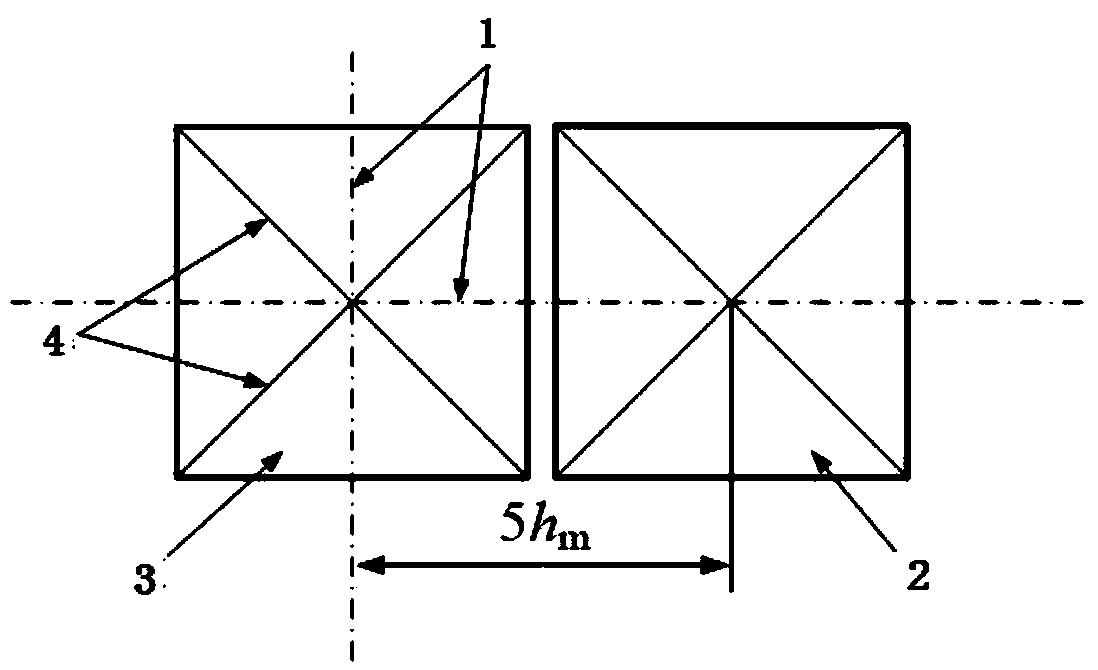

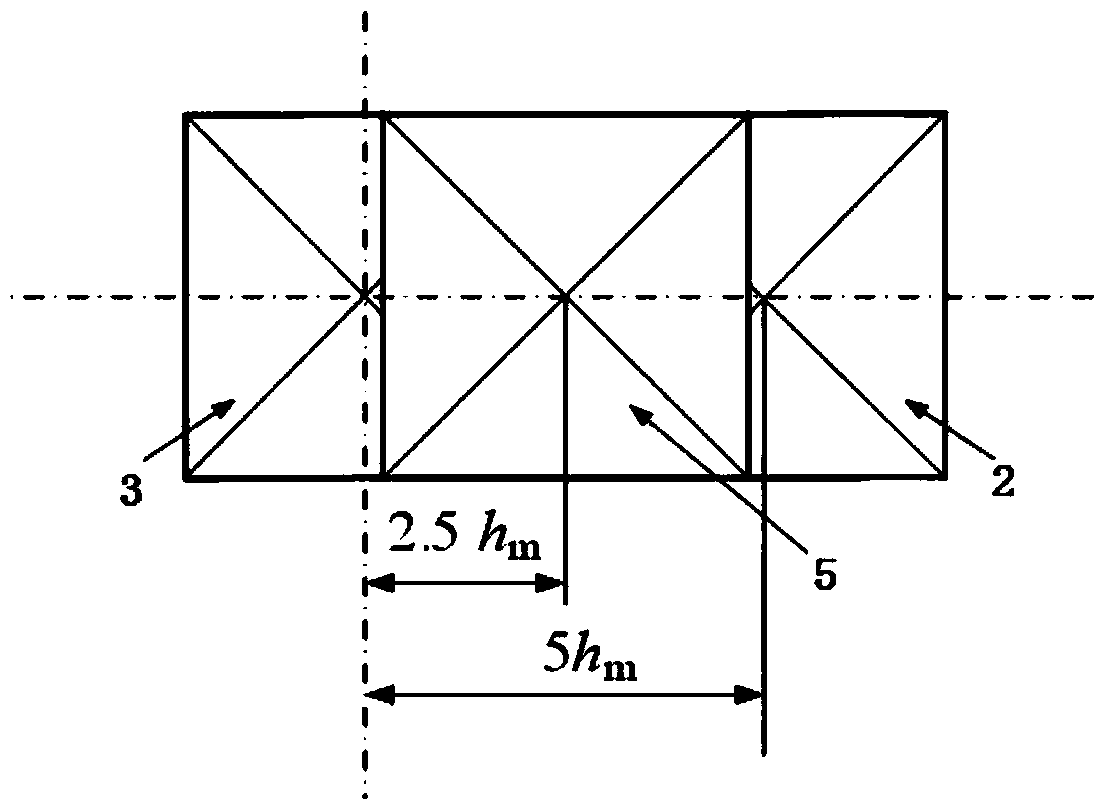

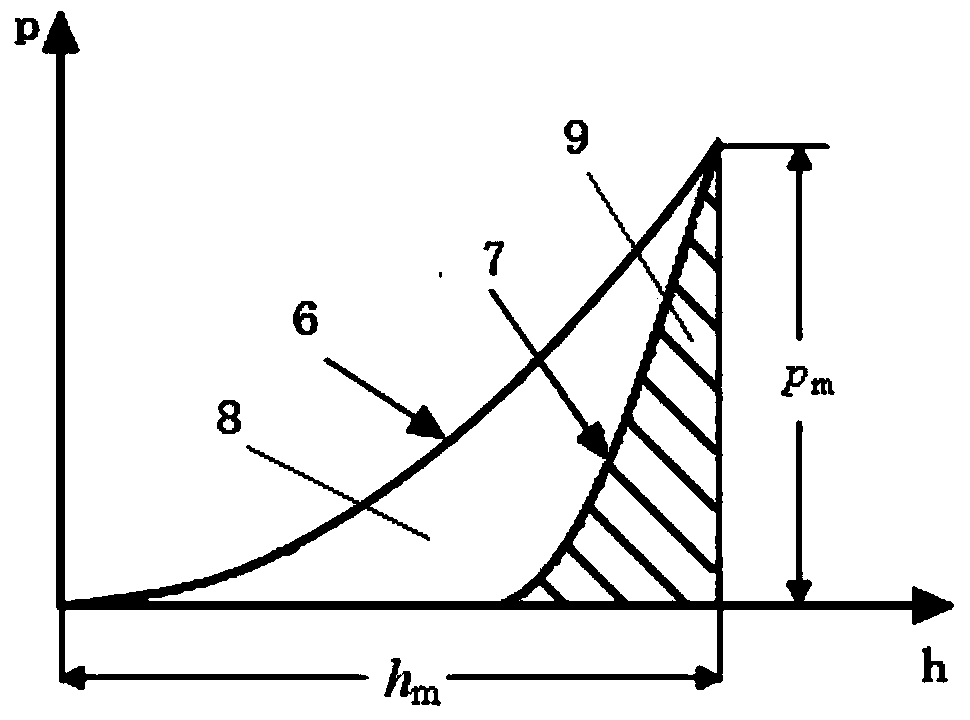

Measuring method for real stress-strain curve of metal welding structure

ActiveCN104596845AAccurate measurementOvercoming the difficulty of distinguishing different regions of material propertiesMaterial strength using tensile/compressive forcesGeometric factorStress–strain curve

A measuring method for a real stress-strain curve of a metal welding structure comprises the steps: firstly, measuring a real stress-strain curve of a notch tensile test, wherein a real fracture strain at a maximum load is a strain hardening index of a metal of a to-be-measured position; calculating real stress-strain curves of notch tensile samples by finite element calculating software, to obtain the real stress-strain curves of the notch tensile samples with different notch sizes, fitting and establishing the relationship between the notch size and a geometric factor, and establishing a geometric factor expression containing the notch size and the real fracture strain at the maximum load and other influence factors; according to a load separation theory and the obtained relational expression and expression, the real stress-strain curve of the metal of the to-be-measured region of the metal welding structure is obtained. Through the small-size notch tensile test and a series of established relationships, the locality of the to-be-measured material region is accurately transmitted to a whole single-region material.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for measuring residual stress on surface of metal sample based on micro indentation

InactiveCN103969108AAccurate measurementThe operation process is simple and convenientMaterial strength using tensile/compressive forcesInvestigating material hardnessResidual strainMeasurement cost

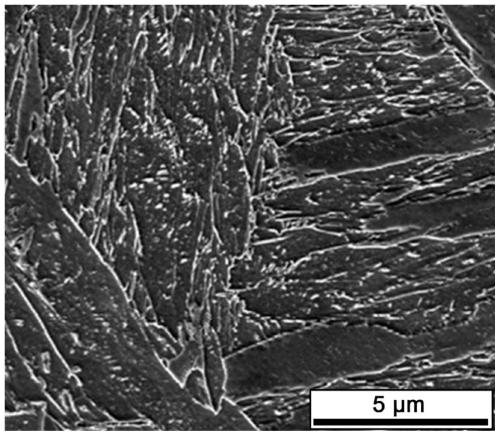

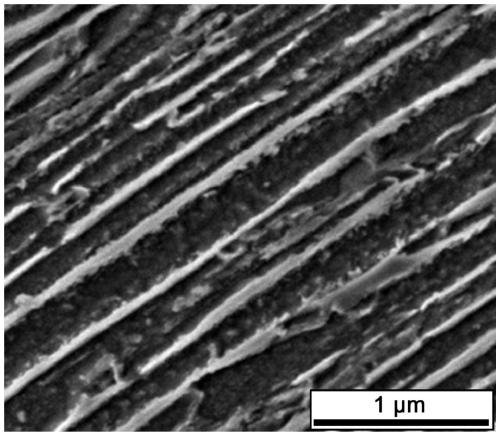

The invention discloses a method for measuring residual stress on surface of a metal sample based on micro indentation. The method comprises the following steps: performing a micro indentation test on the surface of the sample by utilizing a Vickers microhardness tester, recording the indentation morphology by adopting a scanning electron microscope, and obtaining the nominal projection area and actual projection area of the indentation on the surface of the sample through calculation for diagonal length and side length of the micro indentation; obtaining a strength coefficient and strain hardening index of the material through a standard tensile test; and obtaining a theoretical formula for measuring the residual stress through an indentation method and containing the ratio of the actual projection area to the nominal projection area of the micro indentation, the strength coefficient and strain hardening index based on the hypothesis for the two-dimension isometric residual stress field on the surface of the sample, and further obtaining the residual strain and residual stress on the surface of the sample. The measurement method belongs to basically nondestructive or micro-damage measurement and has the advantages of low measurement cost, simplicity and convenience in operation and high measurement efficiency. If being combined with a portable high-power optical microscope with a distance measurement function, the method can be popularized and applied in the field of engineering.

Owner:UNIV OF SCI & TECH BEIJING

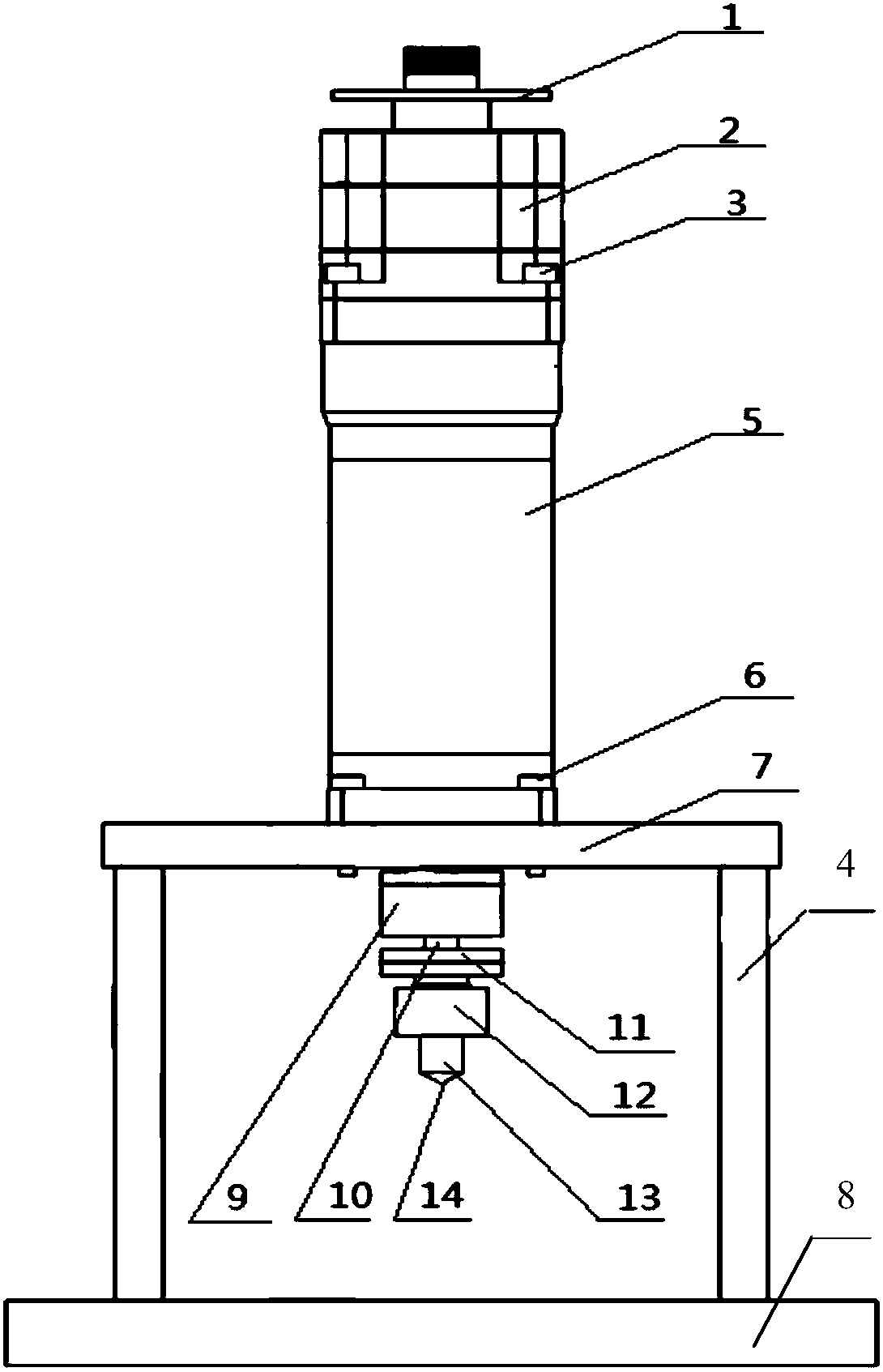

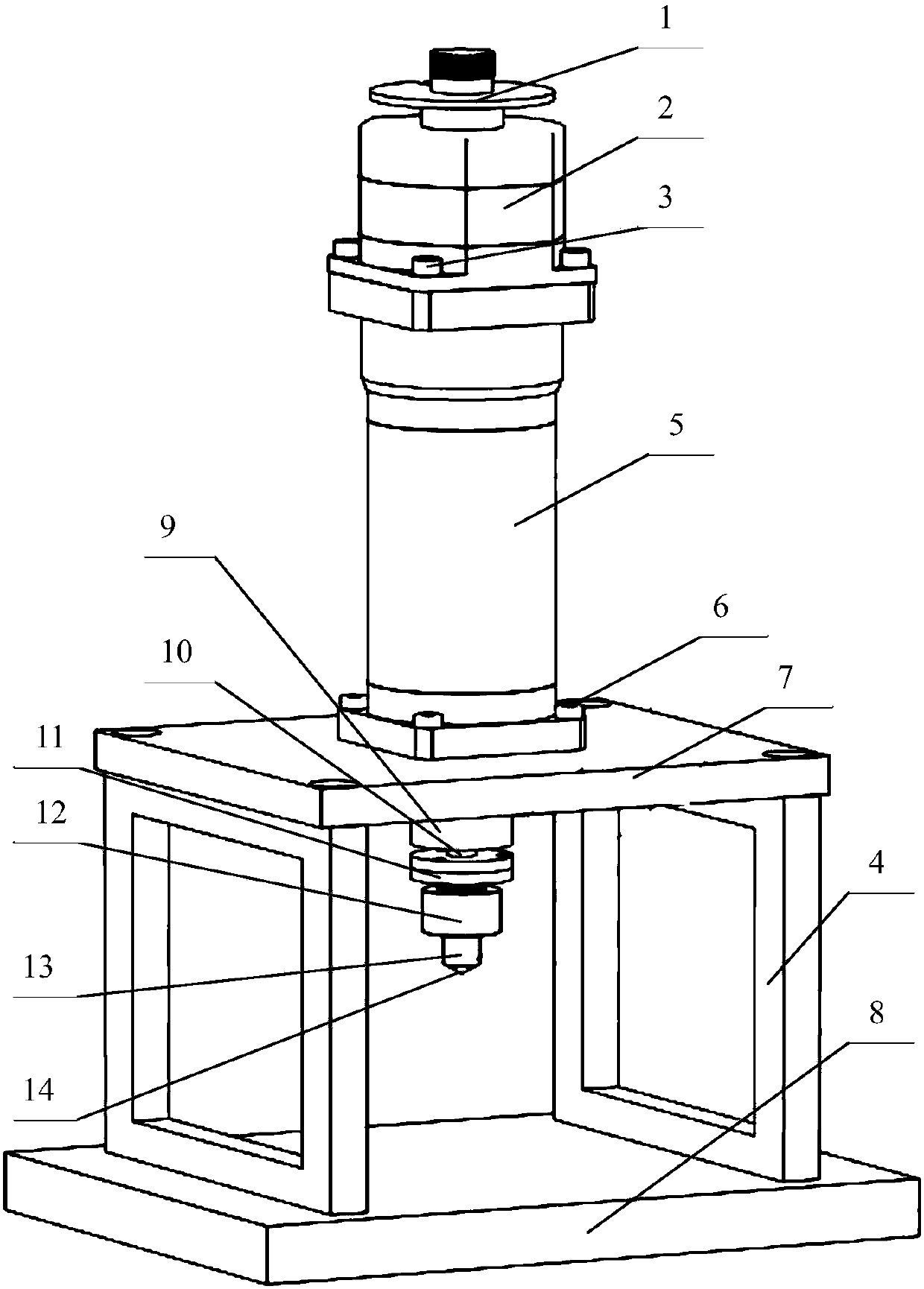

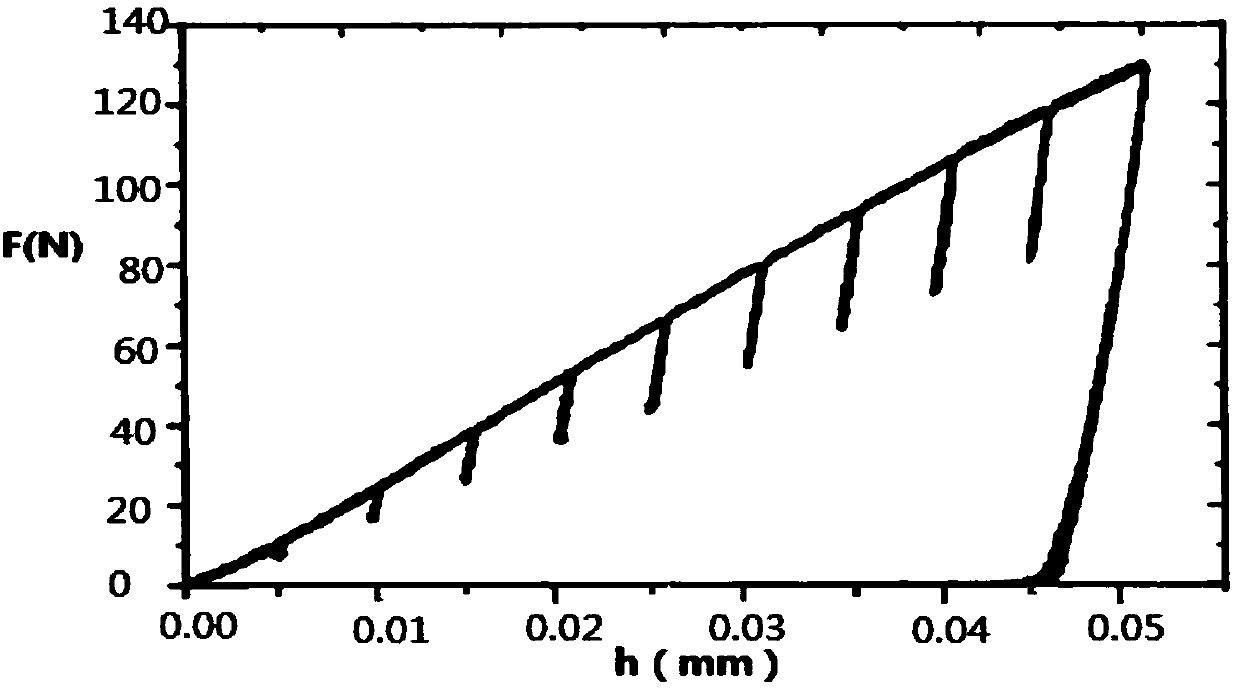

Device and method of measuring yield strength and strain hardening exponent of metal material by indentation method

PendingCN107860671AAchieve losslessAchieving minimal loss measurementsInvestigating material hardnessPropellerMetallic materials

The invention discloses a device of measuring yield strength and a strain hardening exponent of a metal material by an indentation method. The device comprises a servo motor, a pressure propeller anda transverse plate that are sequentially connected from the top down, wherein the pressure propeller is internally provided with a pressure rod; the pressure rod is driven by the servo motor and penetrates through the transverse plate and a pressure sensor; a pressure rod bottom plate is arranged at the lower end of the pressure rod; the lower part of the pressure rod bottom plate is sequentiallyconnected with a pressure head base, a pressure head connecting rod and a pressure head; four corners of the transverse plate are connected with a magnetic pressure platform via side plates; the servomotor and the pressure sensor are connected with a computer; and the yield strength and the strain hardening exponent are calculated by a load-displacement curve. According to the device, the computer controls the motor to allow output displacement of the motor to be capable of accurately tracking and reproducing input displacement; nondestructive and micro-destructive measurement of a measured object to be detected are achieved; and mechanical properties of the metal material are characterized by the micro-load continuous indentation method by taking a load and depth in an indentation process as response values.

Owner:NANJING UNIV OF TECH +1

Process for producing double-layer wrapped welding tube used for connecting indoor/outdoor units of air conditioner

InactiveCN101045276AHigh plastic strain ratioPlastic strain is higher than rFurnace typesHeat treatment process controlCopper platingShielding gas

A technology for manufacturing a rolled and welded dual-layer tube used for the connection between indoor and outdoor units of air conditioner includes such steps as decoiling the copper plated steel band made of low-carbon non-gap atomic steel, spreading on rolling machine, rolling it by 720 deg. to become a dual-layer tube, soldering in NH3 gas, annealing in NH3 gas, cooling, spraying passivated water, and coiling.

Owner:芜湖源大管业有限公司

Heterogeneous in-reactor polymer blends

Owner:EXXONMOBIL CHEM PAT INC

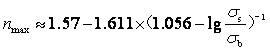

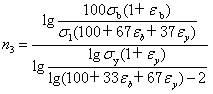

Method for determining maximum strain hardening exponent according to strength of steel-iron material

InactiveCN102628775AThe maximum strain hardening exponent obtainedLow costMaterial strength using tensile/compressive forcesUltimate tensile strengthStrain stiffening

The invention discloses a method for determining the maximum strain hardening exponent according to the strength of a steel-iron material. The method comprises the following steps of: I, deducing a formula among the yield strength, tensile strength and maximum strain hardening exponent of the steel-iron material; II, determining the yield strength and tensile strength of the steel-iron material to be detected; and III, calculating the maximum strain hardening exponent of the steel-iron material according to the formula deduced in the step I. The method has the characteristic of quick, convenient and accurate acquisition of the maximum strain hardening exponent according to the strength of the steel-iron material.

Owner:XI'AN PETROLEUM UNIVERSITY

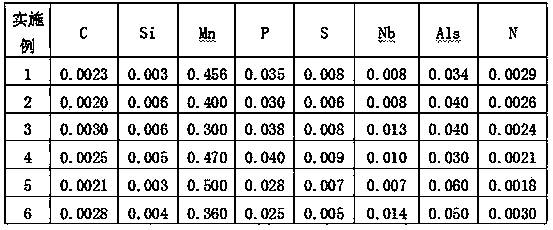

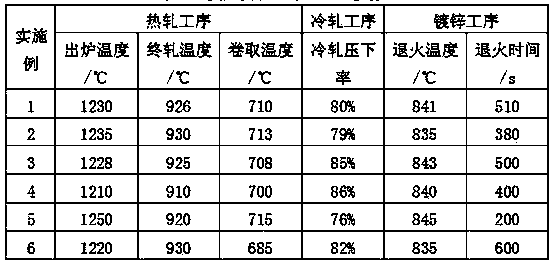

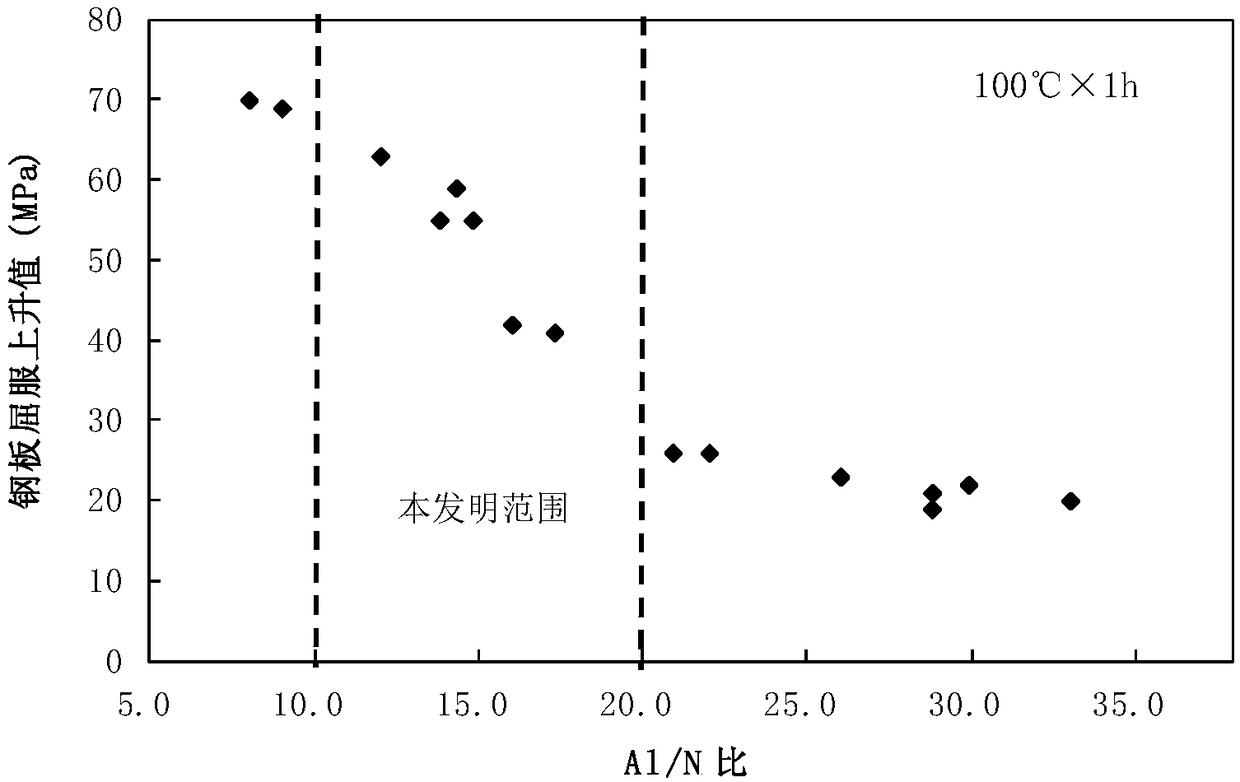

Galvanized bake hardening steel and production method thereof

InactiveCN104213020AImprove stamping effectImprove the baking effectHot-dipping/immersion processesChemical compositionEconomic benefits

The invention discloses galvanized bake hardening steel and a production method thereof. The production method comprises procedures of hot rolling, cold rolling and galvanizing; a substrate comprises the following chemical components in percentage by weight: 0.002-0.003% of C, Si not higher than 0.006%, 0.3-0.5% of Mn, 0.025-0.040% of P, S not higher than 0.009%, 0.007-0.014% of Nb, 0.030-0.060% of Als, N not higher than 0.0030%, and the balance of Fe. The chemical components are designed, and the technological parameters of the hot rolling, cold rolling and galvanizing procedures are adjusted and optimized, so that the Nb-contained bake hardening steel for deep drawing with excellent comprehensive performance can be successfully produced without adding other alloy elements; the substrate produced by the method is easily galvanized; and the galvanized bake hardening steel with excellent surface quality can be produced. A galvanized plate produced by the method has such characteristics as proper yield strength, high n value (strain hardening index) and r value (plastic strain ratio) and good bake hardenability; and meanwhile, the alloy content is reasonably matched, the production cost is reduced, and the considerable economic benefit is brought to enterprises.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Polypropylene foam

ActiveUS20090176902A1Improved foam surface propertyHigh surface flatnessPolymer sciencePolypropylene

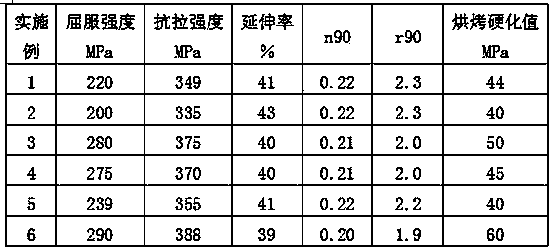

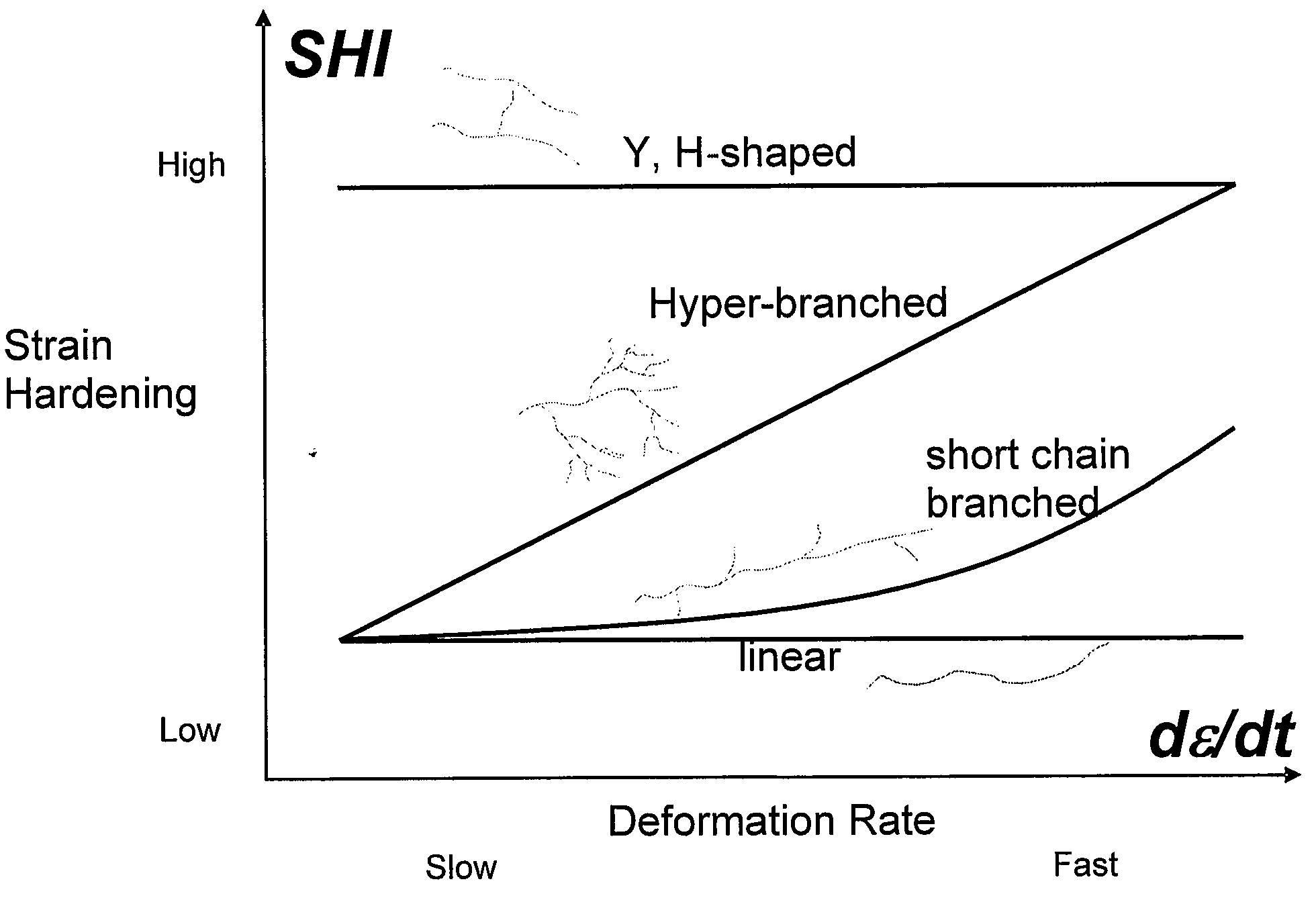

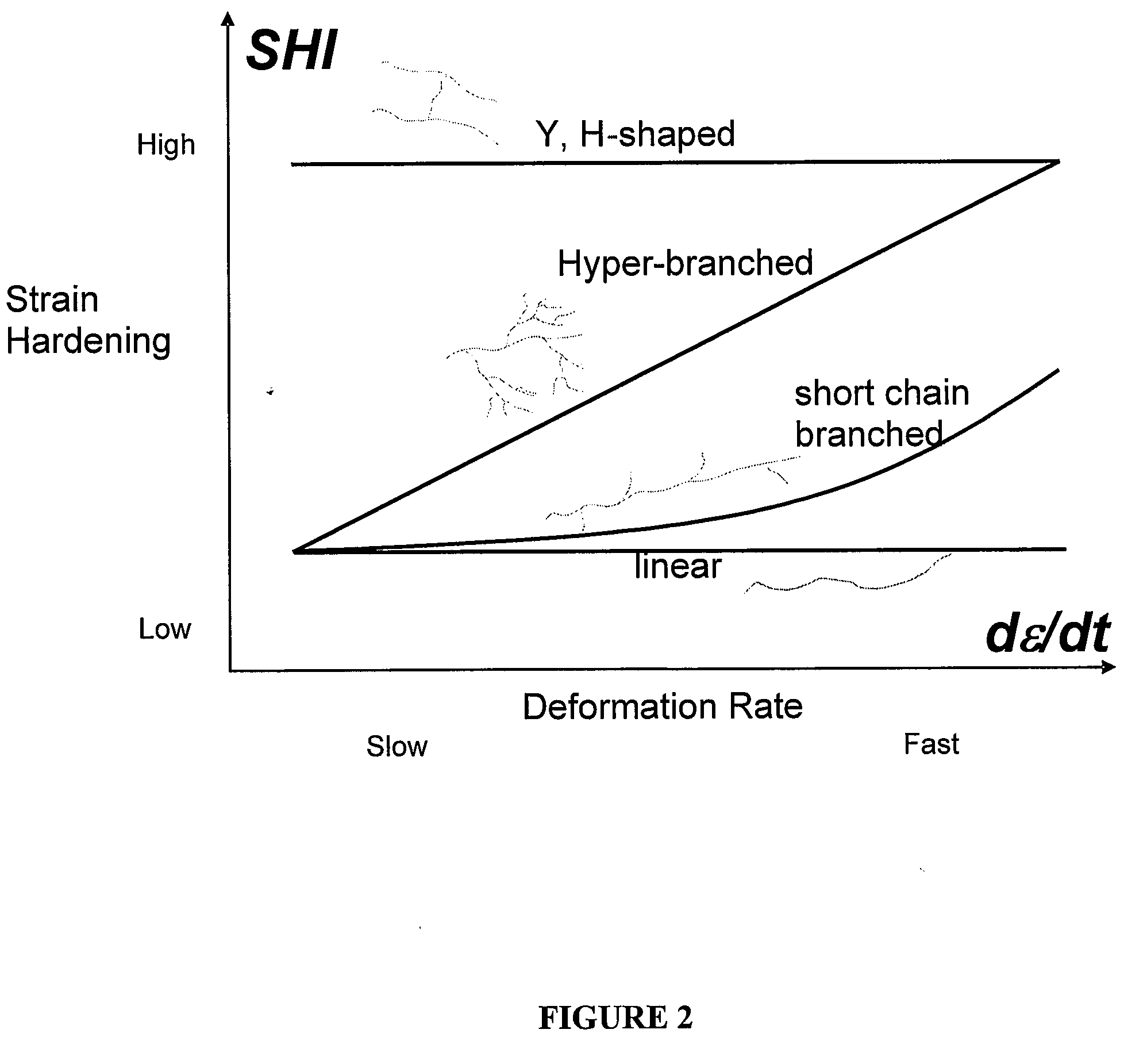

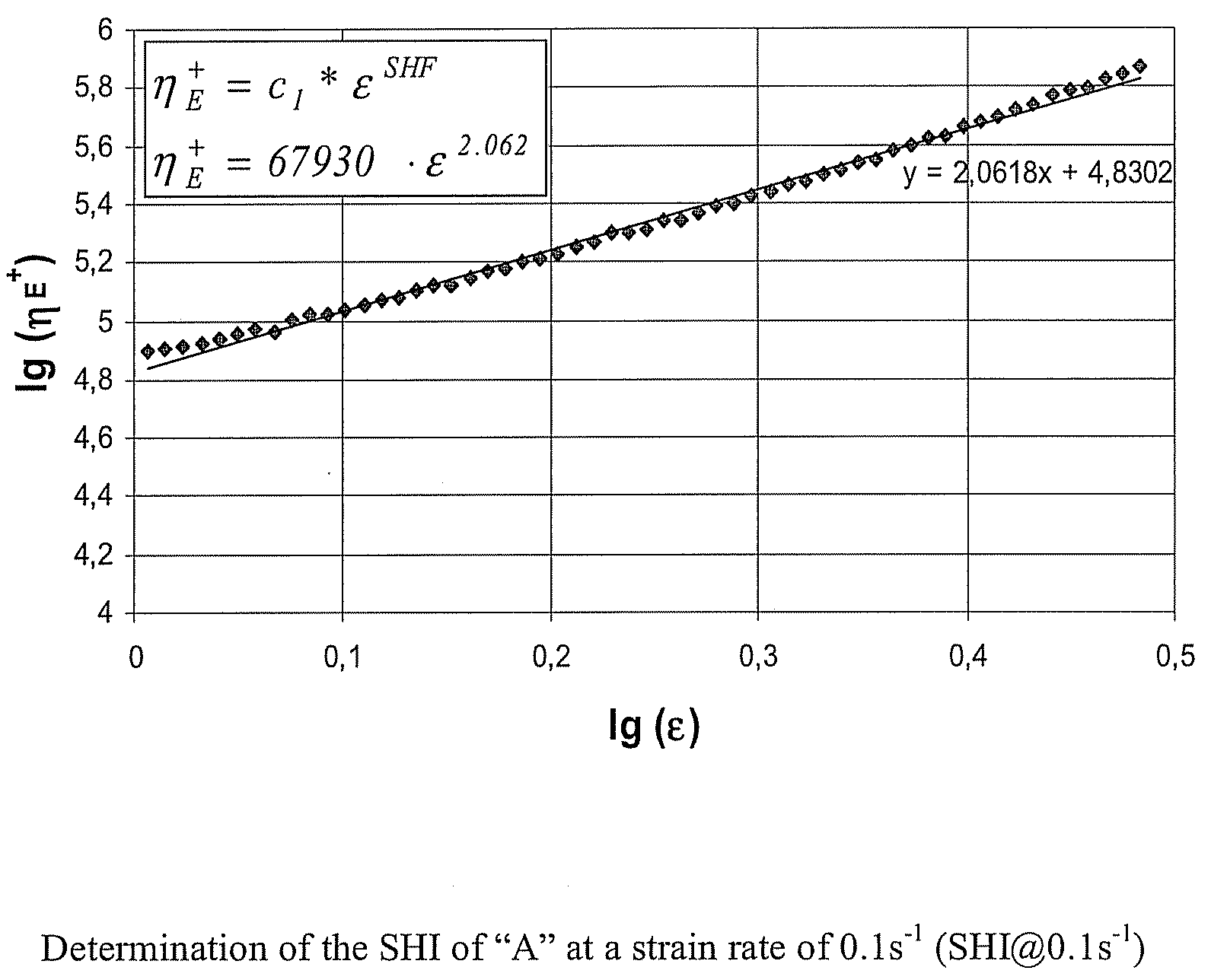

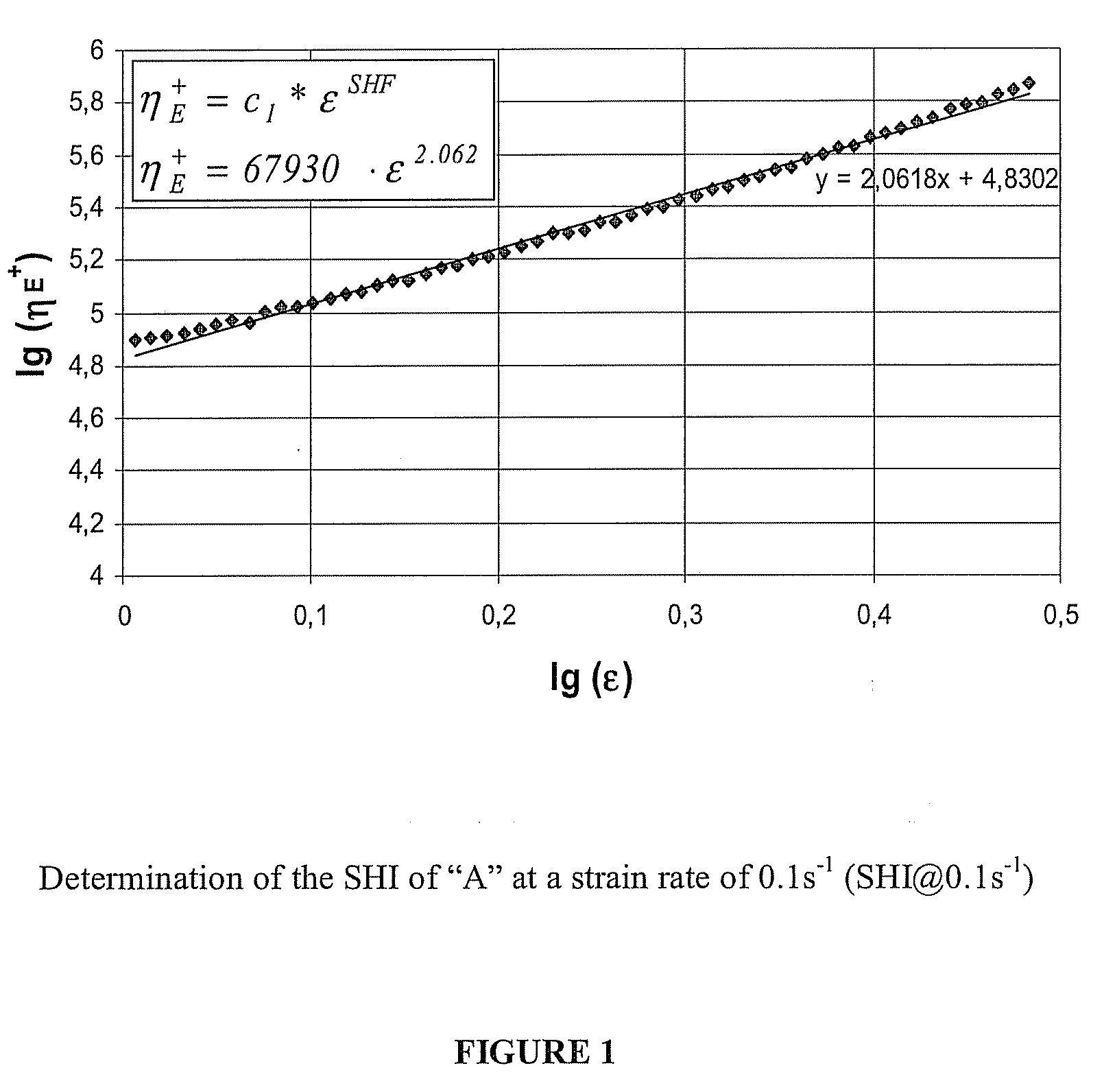

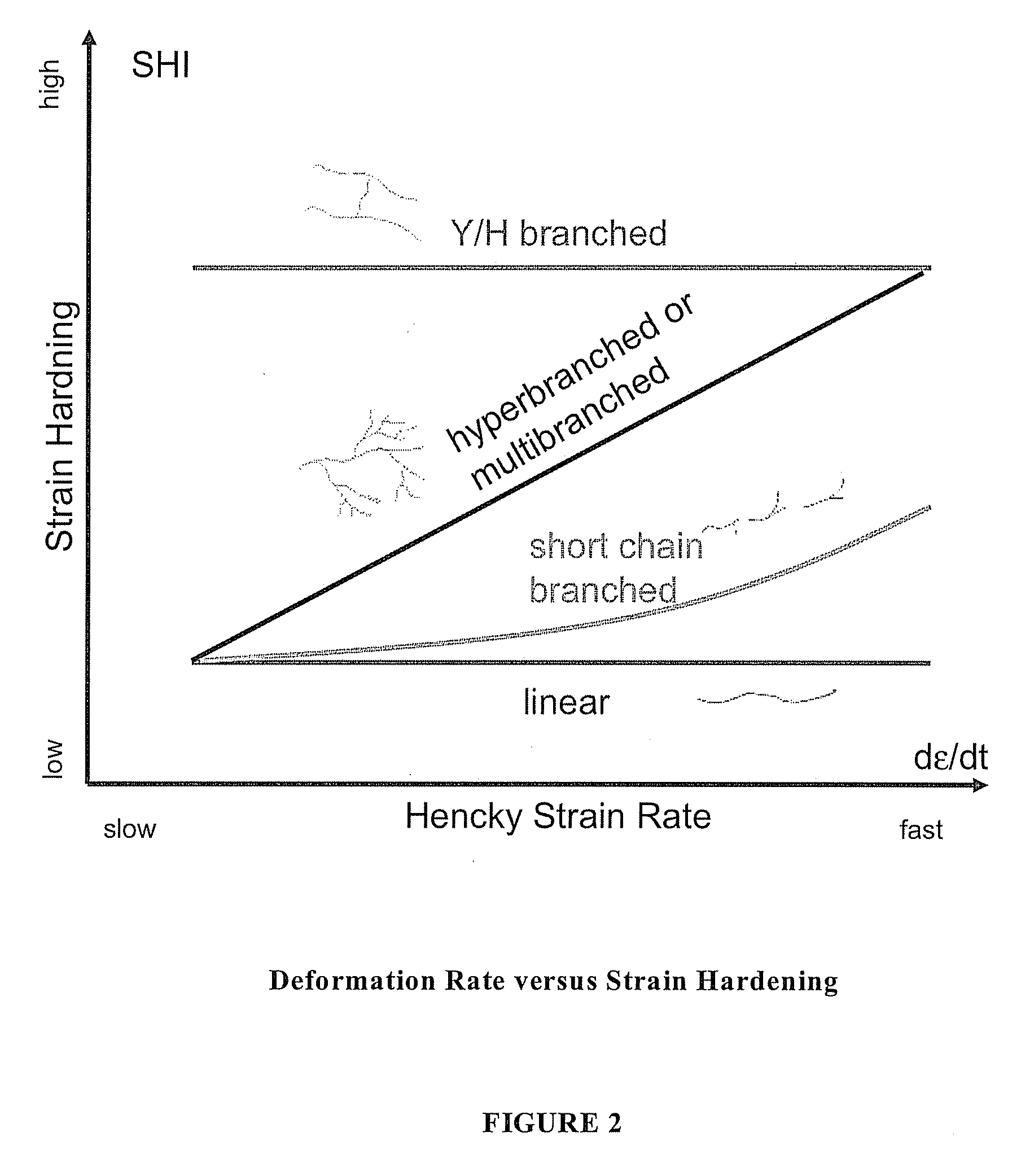

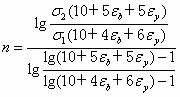

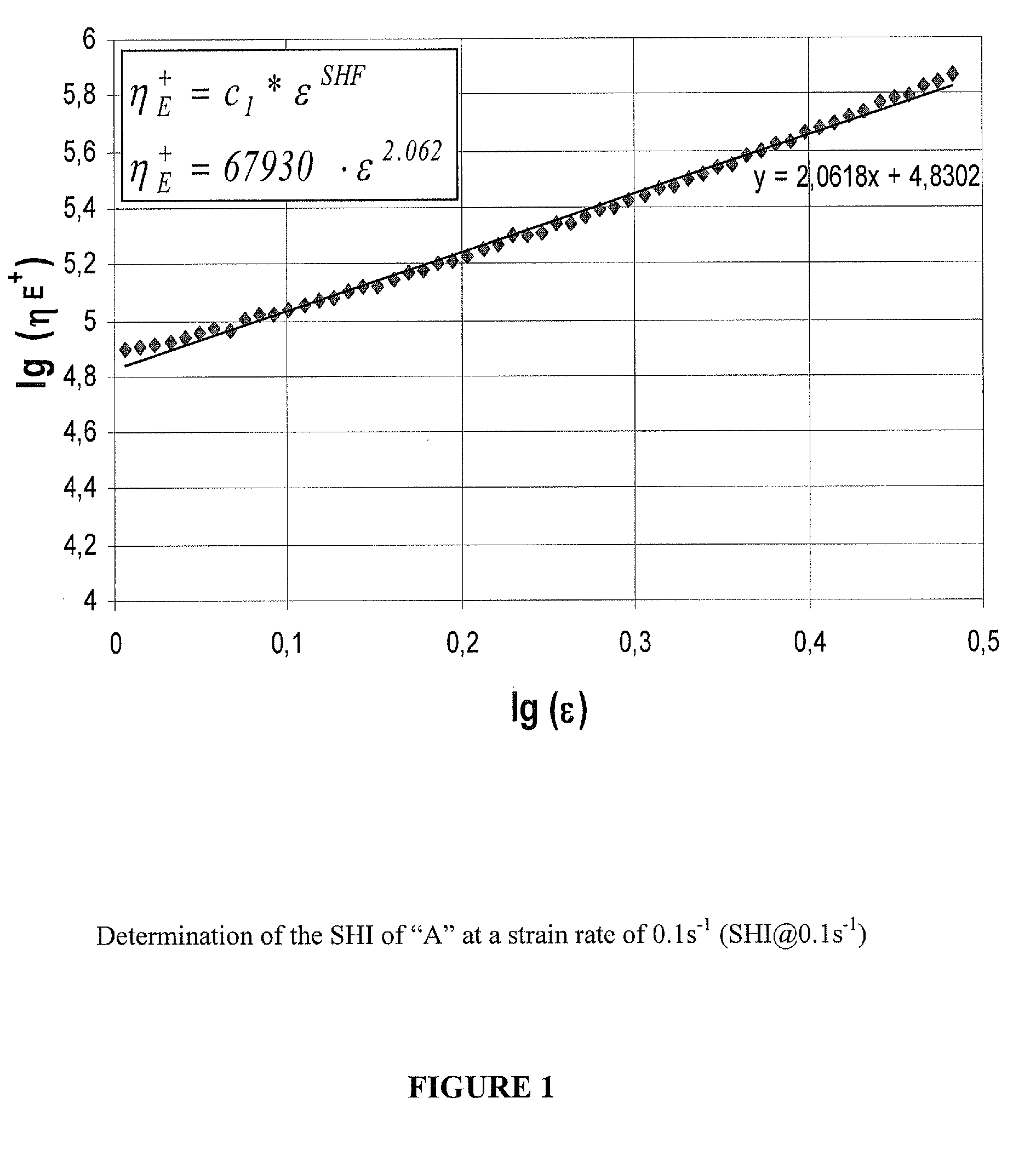

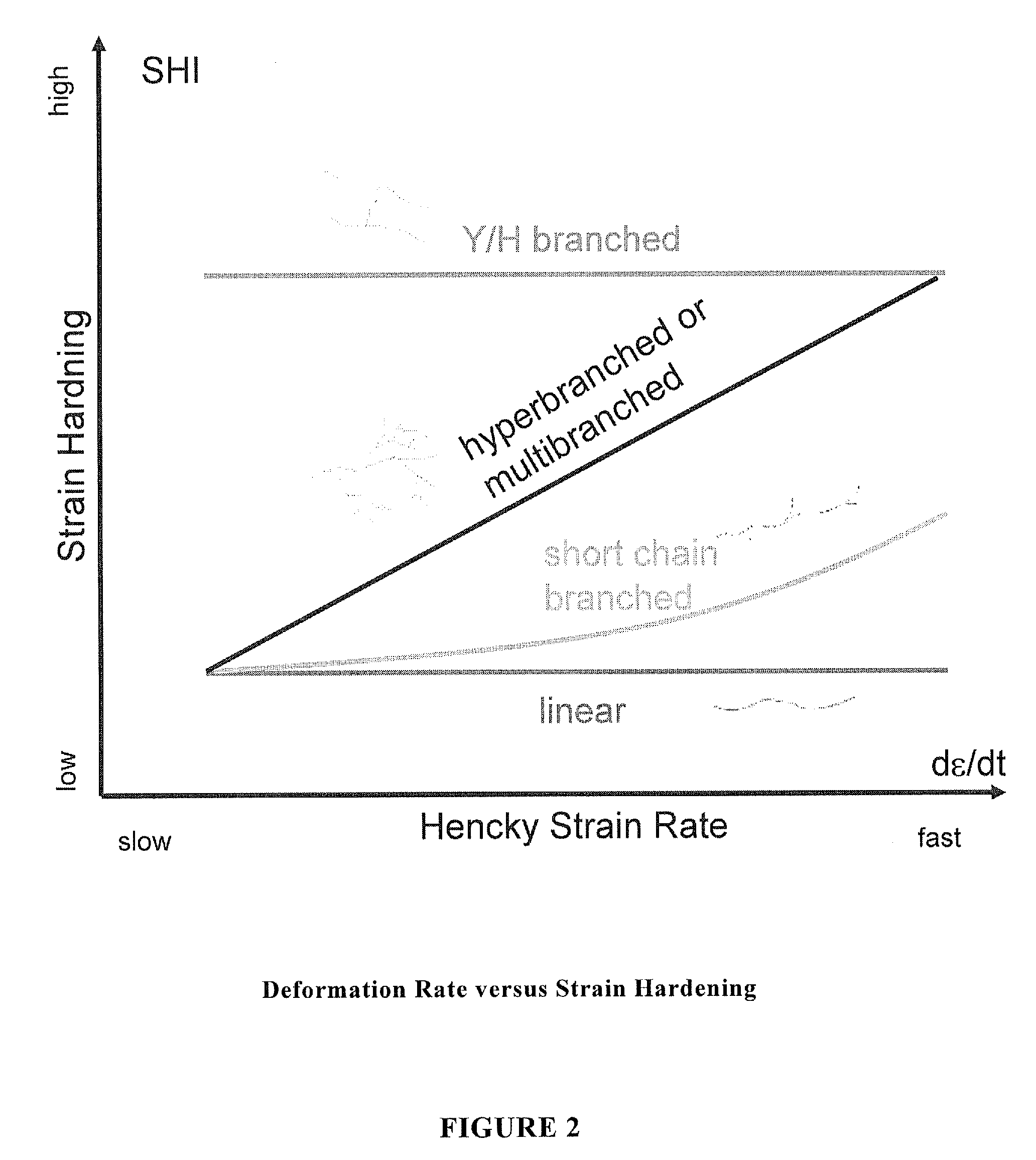

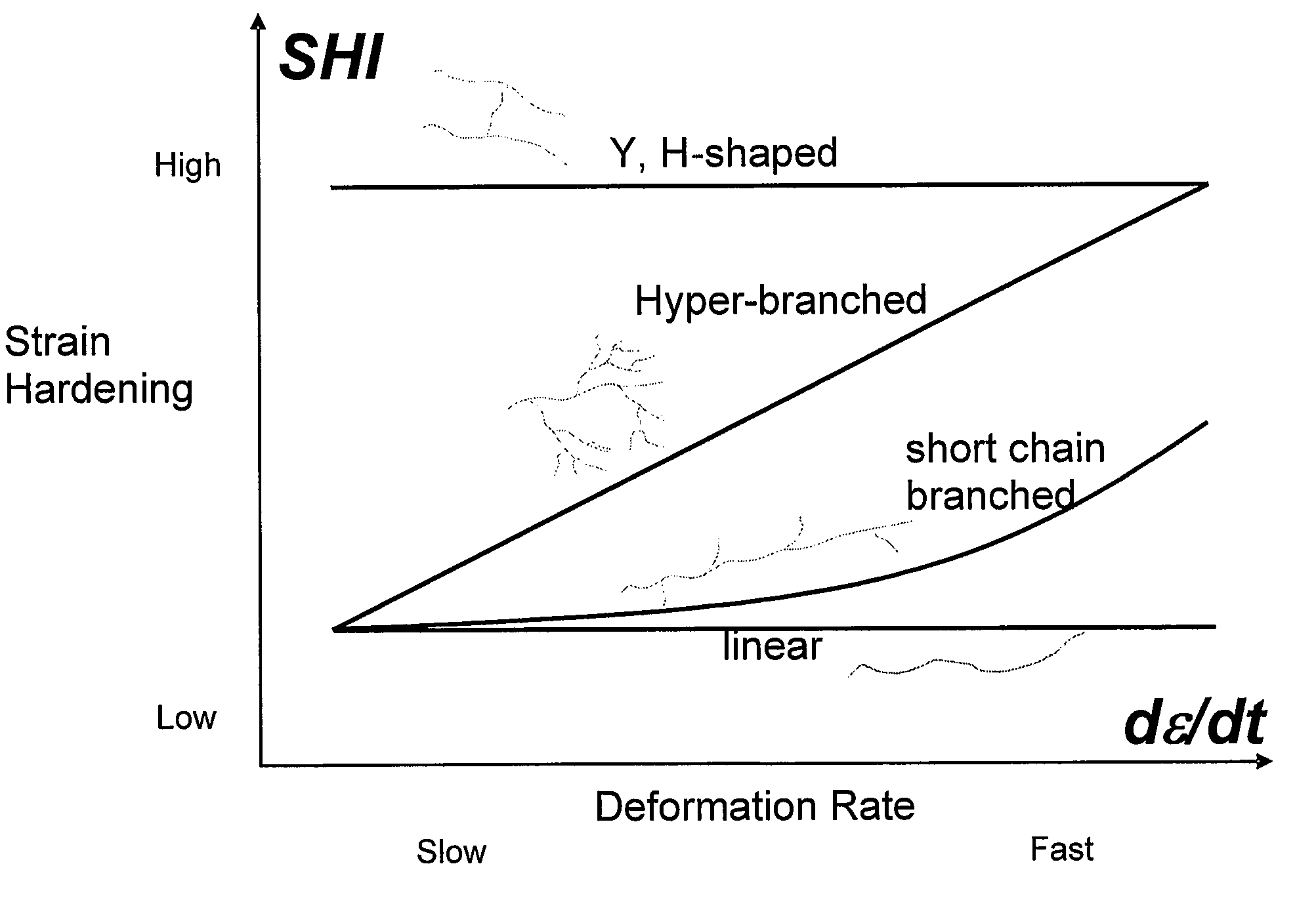

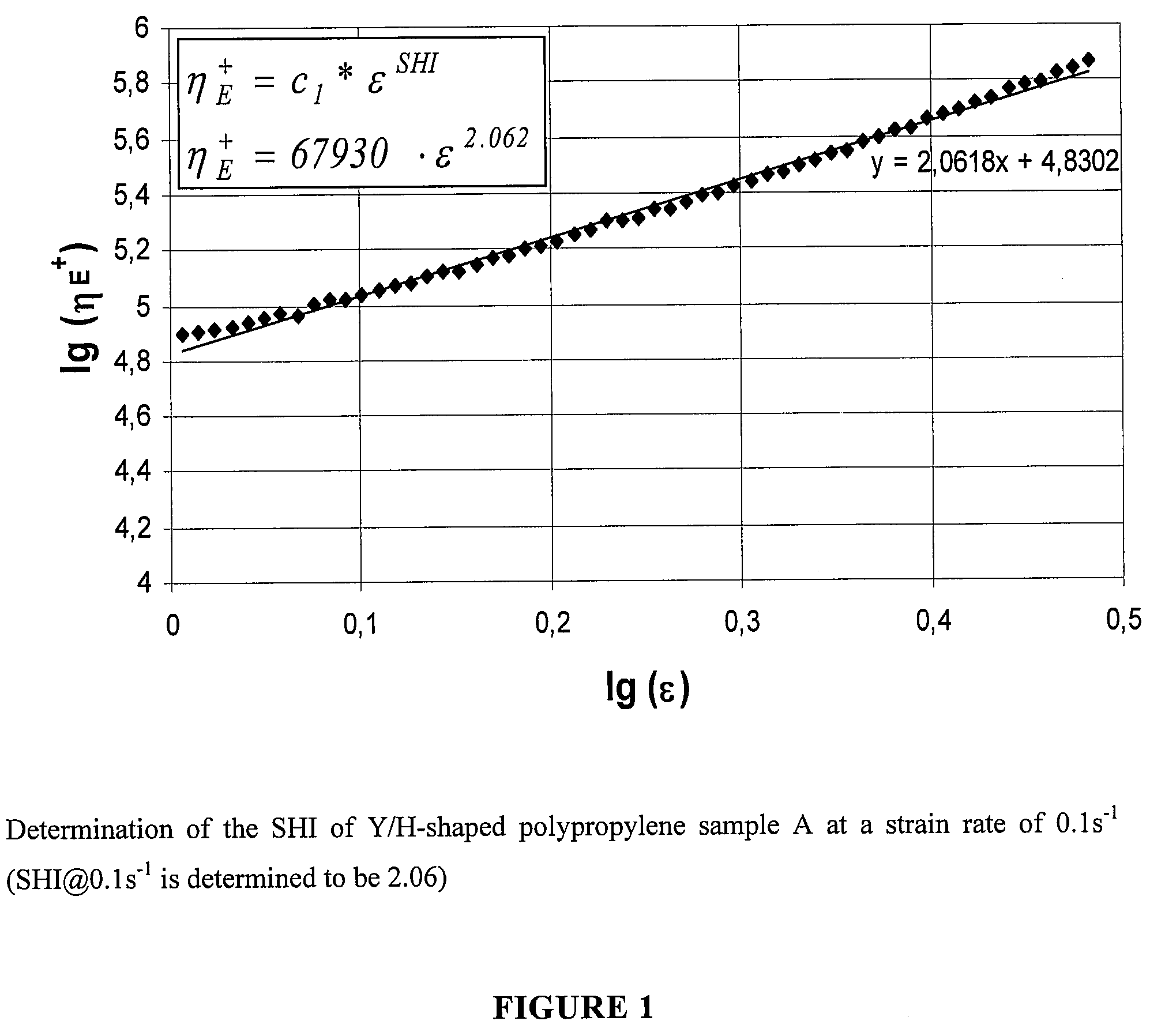

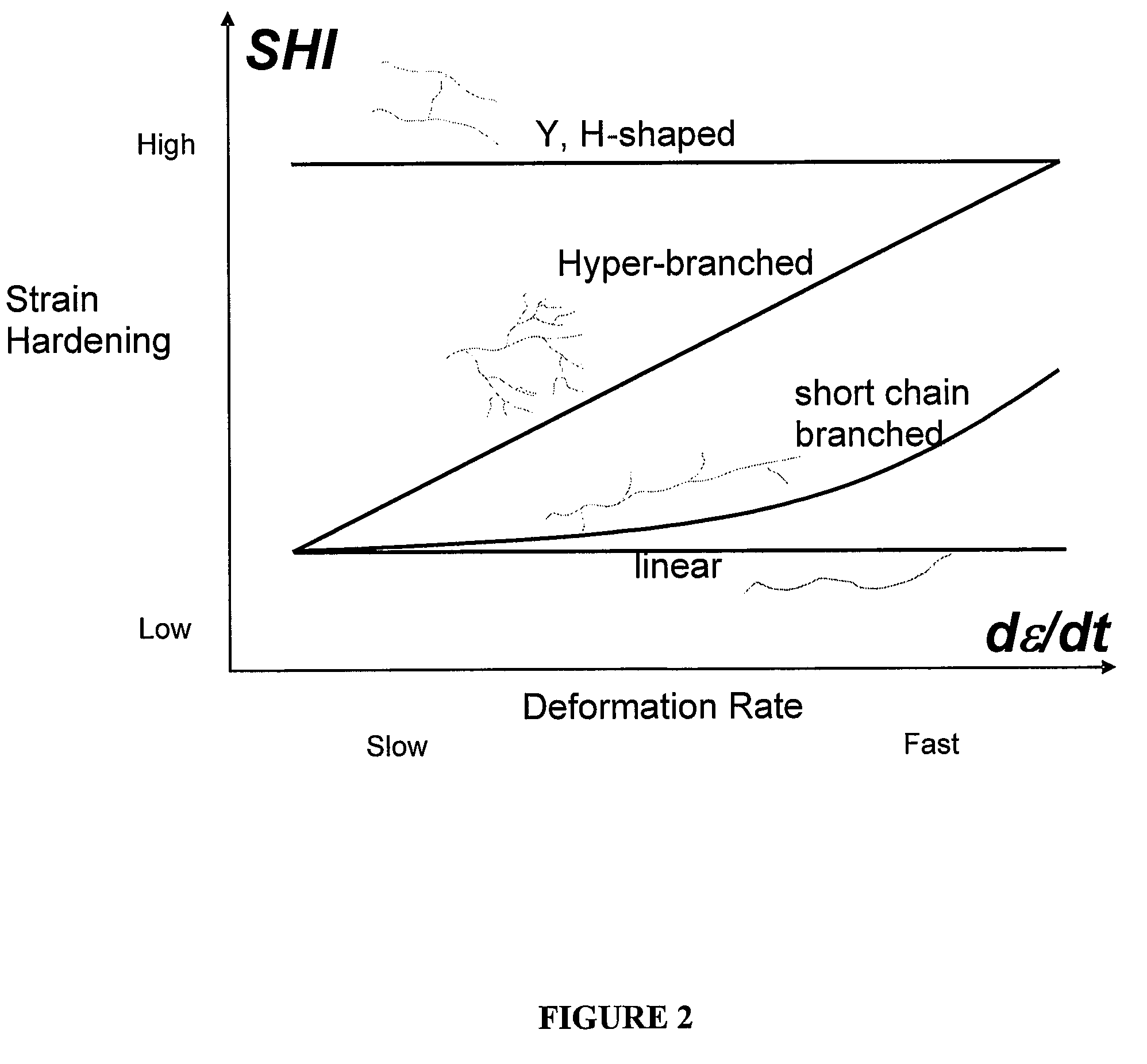

The present technology relates to a foam comprising a polypropylene material. The polypropylene material is produced in the presence of a metallocene catalyst, and the foam and / or the polypropylene has a branching index g′ of less than 1.00 and a strain hardening index (SHI@1 s−1) of at least 0.30 measured by a deformation rate dε / dt of 1.00 s−1 at a temperature of 180° C., where the strain hardening index (SHI) is defined as the slope of the logarithm to the basis 10 of the tensile stress growth function (log(ηE+)) as a function of the logarithm to the basis 10 of the Hencky strain (log(ε)) in the range of Hencky strains between 1 and 3.

Owner:BOREALIS TECH OY

Short-chain branched polypropylene

InactiveUS20090131611A1Improve balanceSpecific degreeBulk chemical productionPolypropylenePhotochemistry

A short-chain-branched polypropylene having xylene solubles of at least 0.5 percent by weight is provided. In certain embodiments the polypropylene has a strain hardening index of at least 0.15 as measured by a deformation rate of 1.00 s−1 at a temperature of 180° C. In certain embodiments, the strain hardening index is defined as the slope of the logarithm to the basis 10 of the tensile stress growth function as function of the logarithm to the basis 10 of the Hencky strain for the range of the Hencky strains between 1 and 3. The polypropylene may have xylene solubles in the range of 0.5 to 1.5 percent by weight. In certain embodiments, the polypropylene has a strain hardening index in the range of 0.15 to 0.30. In certain embodiments, the polypropylene has a melting point of at least 148° C.

Owner:BOREALIS TECH OY

Instrumentation indentation test method for elastic-plastic parameters of material based on single Vickers pressure head

InactiveCN103411833AAchieving a strain hardening exponentRealize high-precision testingMaterial strength using tensile/compressive forcesMetallic materialsElastic plastic

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Method for improving elongation rate and strain hardening index n value of cold-rolled deep-drawing steel

PendingCN110438312AImprove deformation abilityImprove forming stabilityProduction lineStrain stiffening

The invention discloses a method for improving elongation rate and strain hardening index n value of cold-rolled deep-drawing steel. The method comprises the steps of carrying out cold rolling by adopting a cold rolling reduction rate of 58%-77%, then carrying out cover annealing, and flattening to obtain the cold-rolled deep-drawing steel. The elongation rate of the cold-rolled deep-drawing steelis more than 40%, and the strain hardening index n value is 0.22-0.25. According to the method for improving the elongation rate and the strain hardening index n value of the cold-rolled deep-drawingsteel, through optimizing the production process method, the obtained cold-rolled deep-drawing steel has higher elongation rate and strain hardening index n value, the expansion and ductility performance of a steel plate material is improved, and the probability of fracture of the steel material in the expansion process is reduced; the production qualified rate is improved; and the method for improving the elongation rate and the strain hardening index n value of the cold-rolled deep-drawing steel is improved on the basis of an original steel production line, process parameter control is optimized, and industrial production improvement is facilitated.

Owner:BAOTOU IRON & STEEL GRP

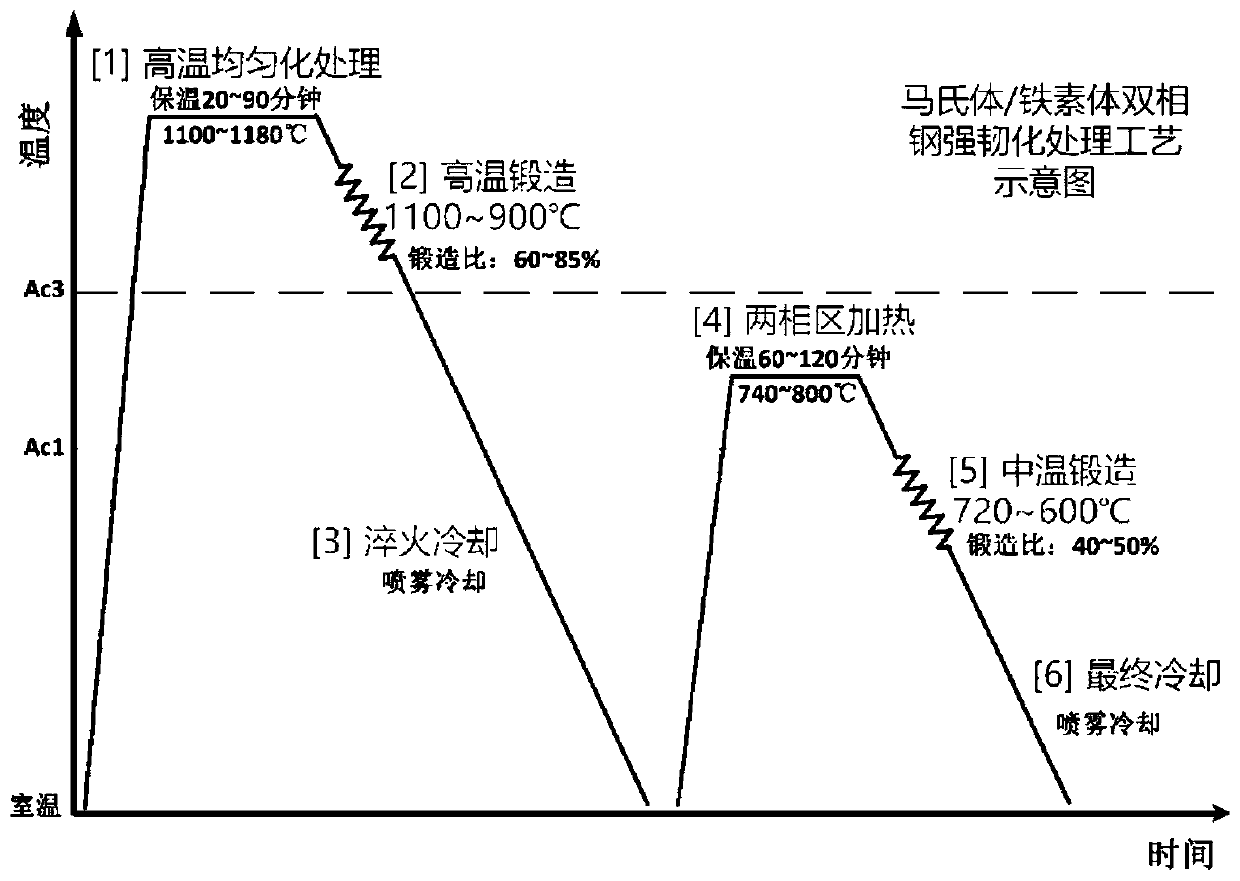

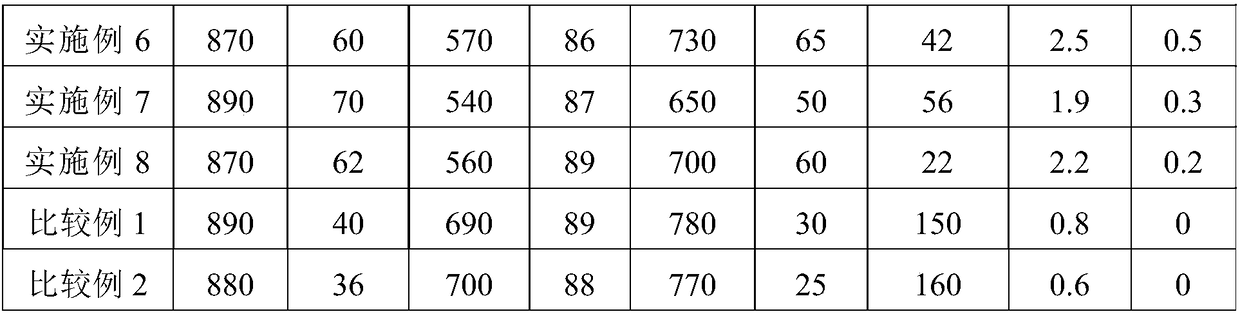

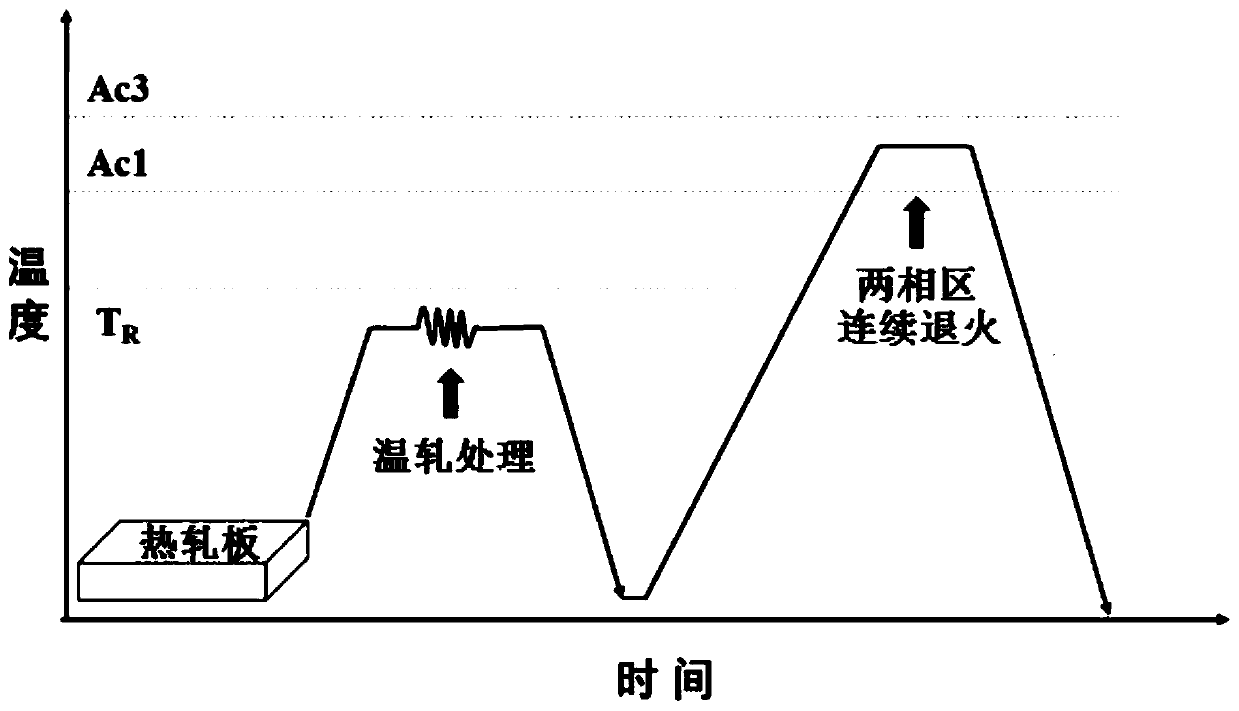

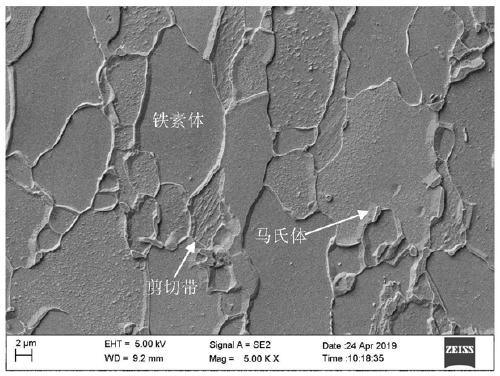

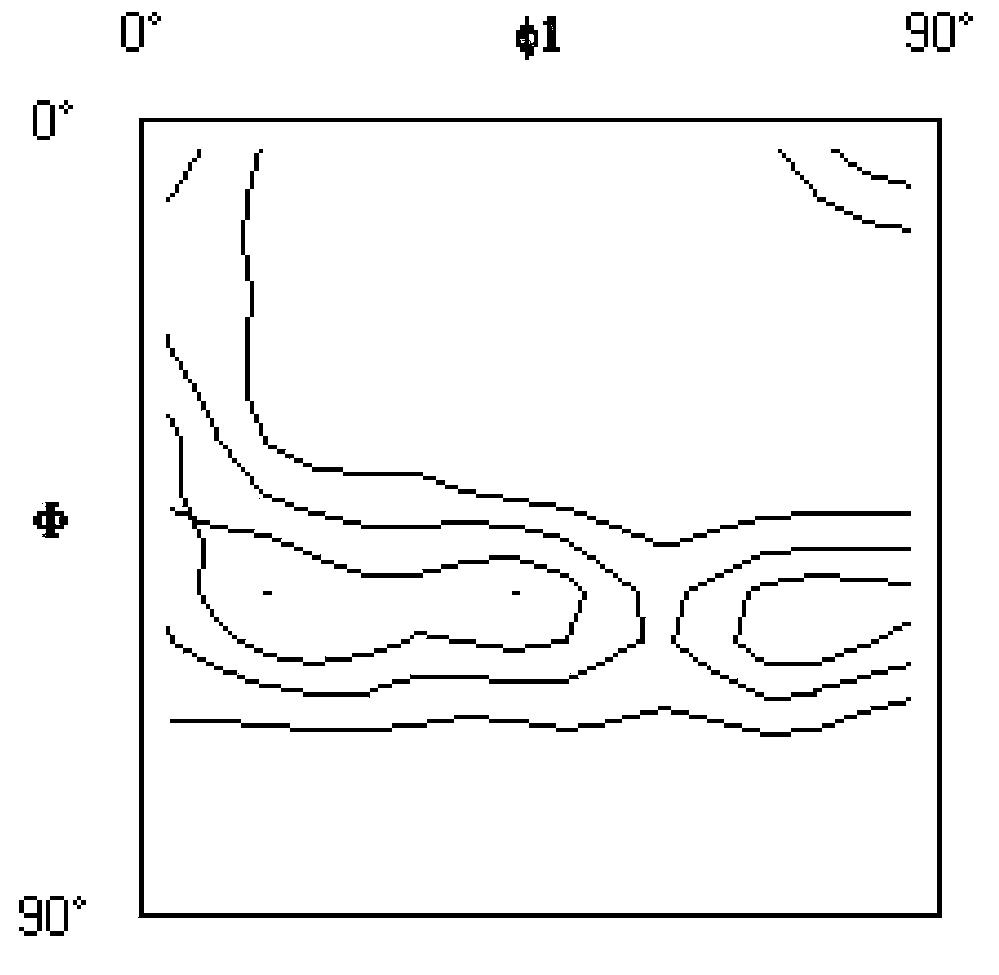

Strengthening-toughening treatment process for high-strength martensite/ferrite dual-phase steel, and dual-phase steel

InactiveCN110396583AAvoid adverse effects of plasticityTo achieve the effect of grain refinementHigh intensityQuenching

The invention discloses a strengthening-toughening treatment process for high-strength martensite / ferrite dual-phase steel, and the dual-phase steel. The dual-phase steel with fine crystalline grainsand a dual-phase structure of lamellar ferrite and lamellar lath martensite is finally obtained through a two-time forging process comprising high-temperature forging and medium-temperature forging, and a two-phase region quenching process, and by adopting a process of lamellar refining for replacing a traditional process of granular refining; the adverse effects on the plasticity due to the reduction of n value (strain hardening exponent) which is caused by the traditional granular refining are avoided, the lamellar refining for crystalline grains is realized, the effect of crystalline grainrefining is achieved, and strengthening-toughening treatment is completed; and the martensitic structure content in the dual-phase steel which is obtained through the treatment process is not lower than 40%, and compared with a sample treated by a common process, the tensile strength sigma b can be increased by more than 60%, and the plasticity can be increased by more than 70%, so that the strength and toughness of the martensite / ferrite dual-phase steel are remarkably improved.

Owner:XIJING UNIV

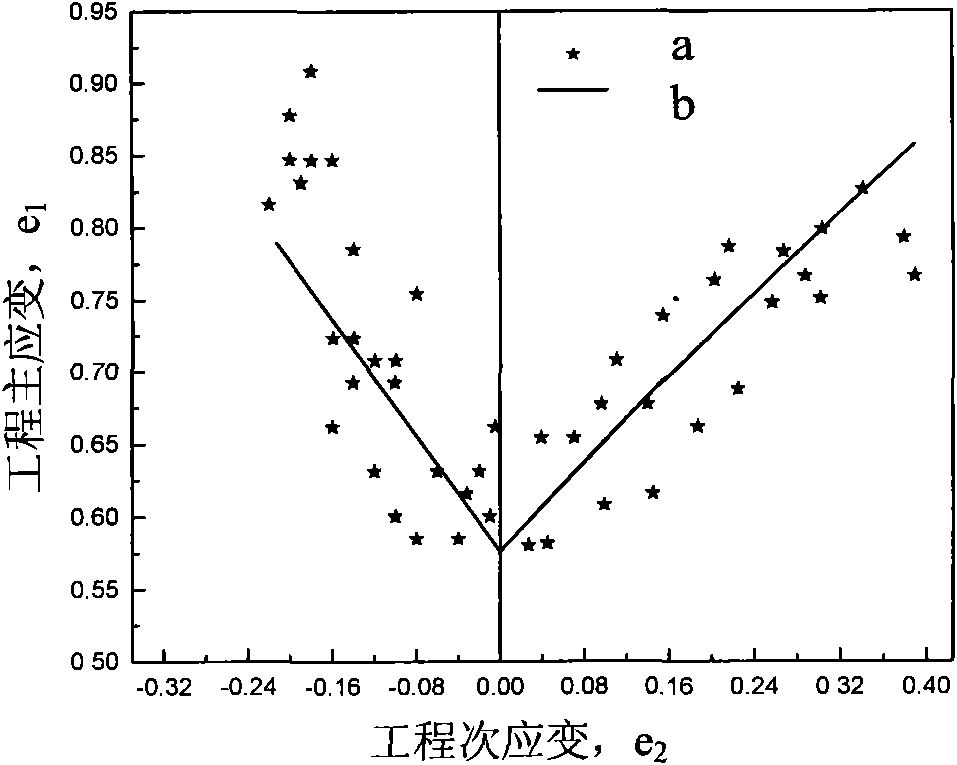

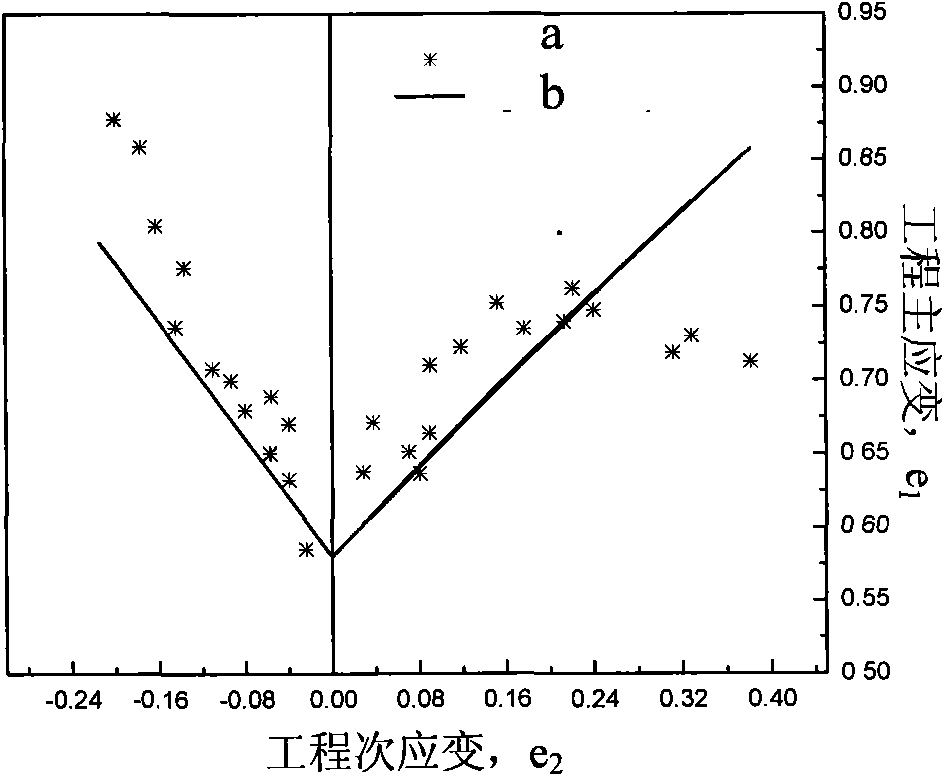

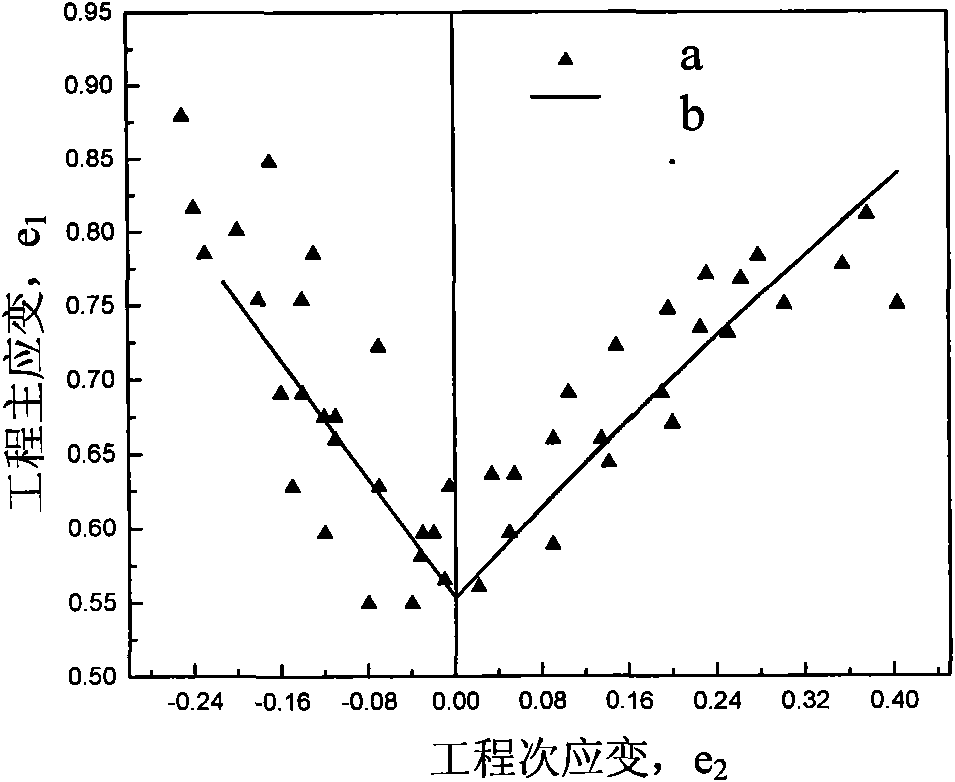

Experimental method for building forming limit diagram of transformation induced plasticity steel plate

InactiveCN101599094AEfficient evaluation of formabilityReduce testing workloadSpecial data processing applicationsForming limit diagramPunching

The invention discloses an experimental method for building forming limit diagram of transformation induced plasticity steel plates, relating to the building method of forming limit diagrams. The method of the invention comprises the following steps: (1) the thickness and the strain hardening index of the transformation induced plasticity steel plate are determined; (2) the limit strain value of the transformation induced plasticity steel plate under the condition of plane strain state is calculated; (3) a strain coordinate system is built, data is synthesized on the coordinate system so as to build the forming limit diagram of the transformation induced plasticity steel plate. The invention is an effective tool for solving the transformation induced plasticity steel plate material punching problem, can successfully predict transformation induced plasticity steel plate material invalidation, effectively estimates the forming performance and reduces the existing measuring workload for building a shaping limit diagram.

Owner:NORTHEASTERN UNIV

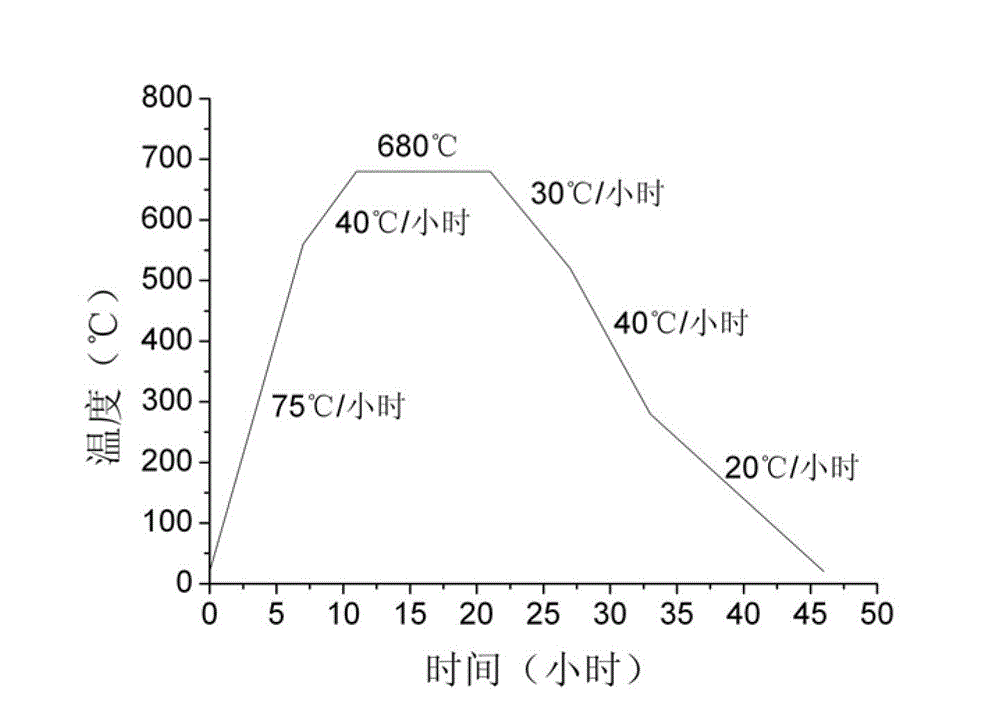

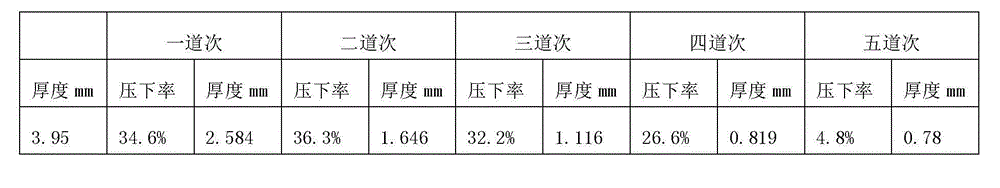

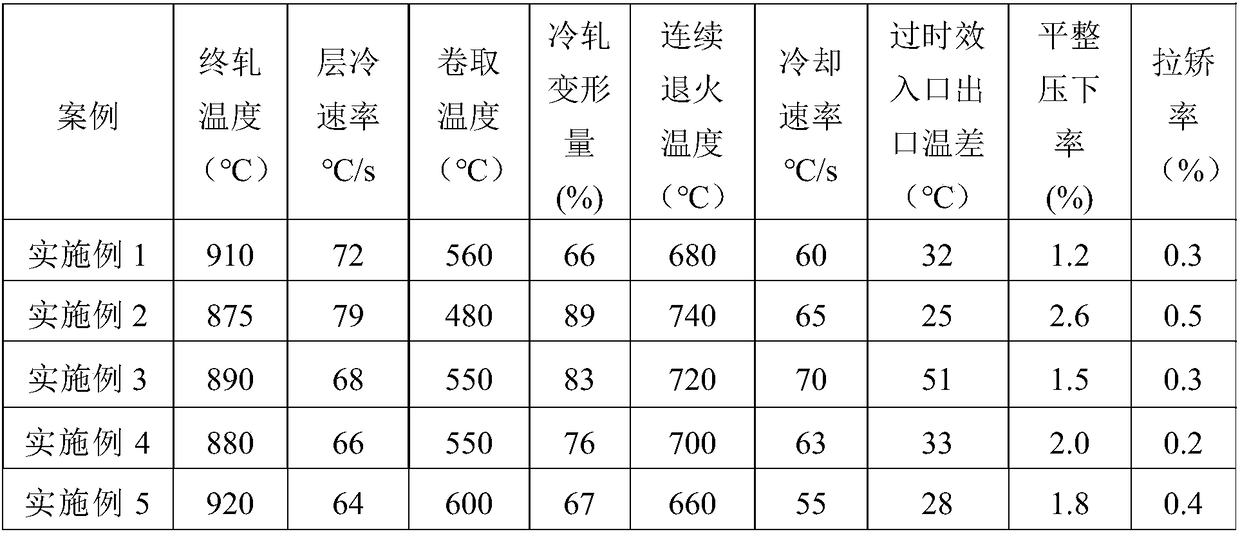

Ultra-deep-draw Ti-IF steel cold rolling and annealing process

The invention relates to an ultra-deep-draw Ti-IF steel cold rolling and annealing process. A steel plate blank comprises the following chemical components in percentage by weight: less than or equal to 0.005% of C, less than or equal to 0.2% of Mn, less than or equal to 0.01% of P, less than or equal to 0.008% of S, more than or equal to 0.015% of Alt, 0.04-0.064% of Ti, less than or equal to 0.006% of N and balance of Fe and microimpurities which can not be detected; five-pass cold rolling is adopted in a cold rolling process, and the total rolling reduction of the five-pass cold rolling is 75-85%; inlet rolling speed and outlet rolling speed are respectively 260KN and 29KN; and an anneal process comprises two-stage warming, wherein heating rates are respectively 70-85 DEG C / h and 30-45 DEG C / h, annealing temperature is 680-720 DEG C, holding time is 8-15 hours, then three-stage cooling is adopted, cooling rates are respectively 25-35 DEG C / h, 35-45 DEG C / h, 15-25 DEG C / h, and finally cooling to room temperature is carried out. The ultra-deep-draw Ti-IF steel cold rolling and annealing process provided by the invention has the advantages that the tensile strength after the process is carried out is up to 290-320MPa, the yield strength is 100-160MPa, the strain hardening index is more than or equal to 0.25, and the planar aeolotropy degree is less than or equal to 0.60.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Copper alloy sheet, connector comprising copper alloy sheet, and method for producing copper alloy sheet

ActiveCN106460099AExcellent bending workabilityHigh strengthCoupling contact membersDeflection coefficientArea ratio

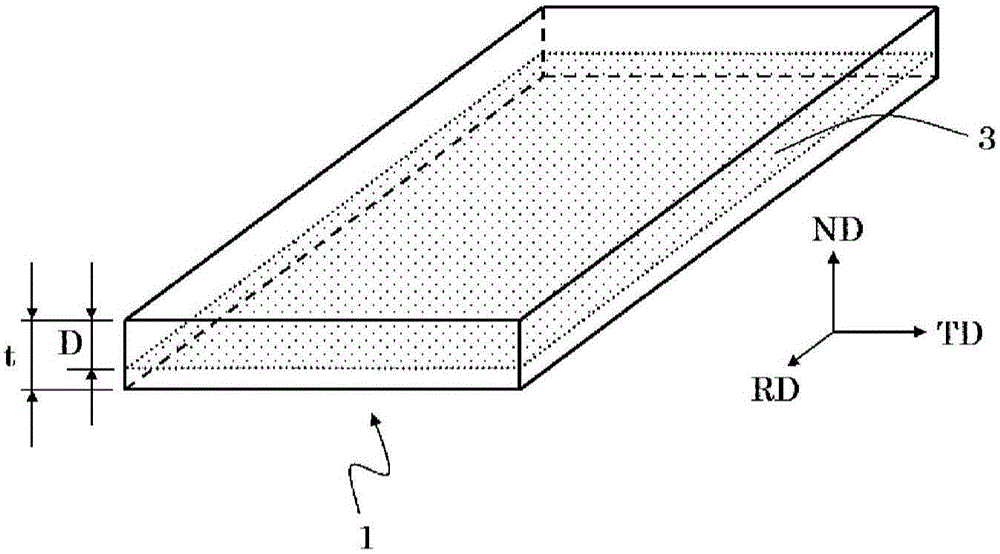

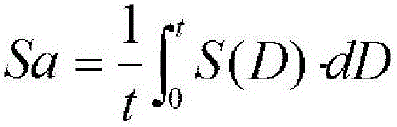

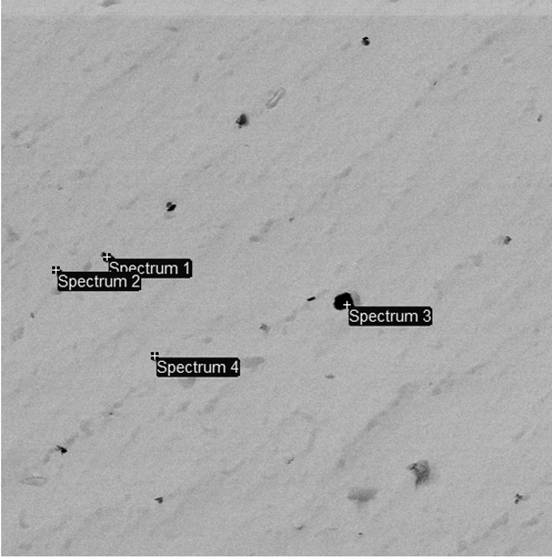

Provided is a copper alloy sheet having a composition containing 1.0 to 6.0 mass% Ni, and 0.2 to 2.0 mass% Si, further containing a total of 0 to 3.000 mass% of at least one type of element selected from the group comprising B, Mg, P, Cr, Mn, Fe, Co, Zn, Zr, Ag and Sn, with the remainder comprising copper and unavoidable impurities, wherein: the strain hardening exponent, nRD, in the rolling direction, RD, is 0.010 to 0.150; and the ratio, nRD / nTD, between nRD and the strain hardening component, nTD, in the transverse direction, TD, is 0.500 to 1.500. On the surface parallel to the rolled surface of the copper alloy sheet at a depth D, the average value, Sa, of the area ratio, S(D), of crystal grains in which the angle of deviation from cube orientation {001}<100> is within 15 degrees, is 5.0 to 30.0%. Thus, the copper alloy sheet has: excellent bendability; excellent strength; a low deflection coefficient as a spring property after bending work; and little specificity for each of the properties of bendability, strength and deflection coefficient in the rolling direction and transverse direction.

Owner:FURUKAWA ELECTRIC CO LTD

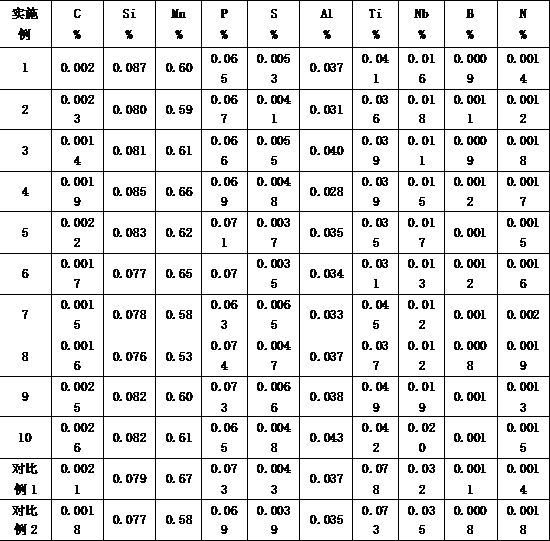

Strip steel with excellent performance at low temperature secondary processing and with tensile strength being 390 MPa and production method

The invention discloses strip steel with excellent performance at low temperature secondary processing and with tensile strength being 390 MPa. The steel comprises the following components of, by wt%,0.0008%-0.0028% of C, 0.07%-0.1% of Si, 0.5%-0.7% of Mn, 0.060%-0.075% of P, less than or equal to 0.008% of S, 0.02-0.05% of Al, 0.02%-0.06% of Ti, 0.006%-0.022% of Nb, 0.0005%-0.0015% of B, and less than or equal to 0.002% of N. The production steps comprise smelting and casting into a blank, cast blank heating, rough rolling, finish rolling, coiling, cold rolling after acid pickling, continuous annealing treatment, slow cooling, rapid cooling, aging treatment and flattening. According to the steel, under the premise of guaranteeing mechanical property, a plastic strain ratio is 1.6-1.8r<90>, a strain hardening index is 18-0.19n<90>, a brittle transition temperature of the secondary processing is stabilized at minus 60-minus 70 DEG C, the quantities of the elements Ti and the Nb are reduced, the cost is reduced by no less than 5%, the surface of a steel plate is free of carbonization edges and bonding defects, and the steel is used for an outer cover of an automobile in a more severe cold area.

Owner:武汉钢铁有限公司

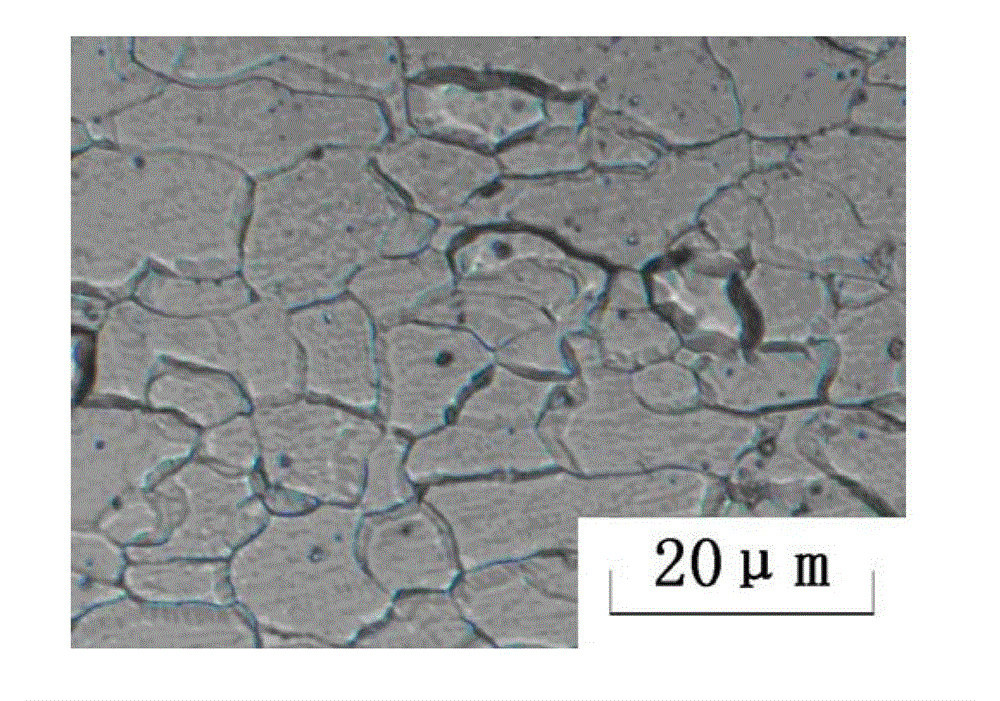

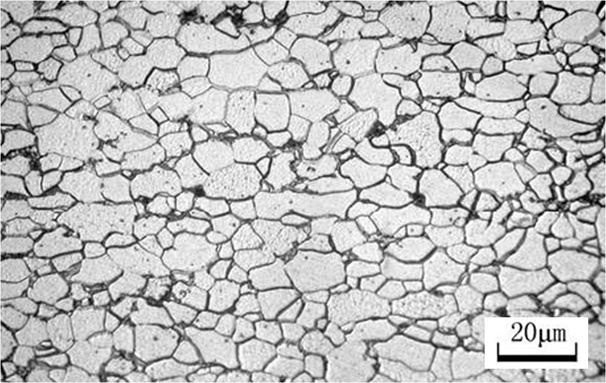

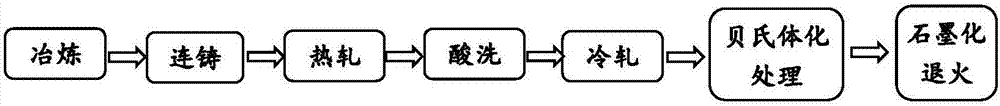

Preparation method of graphitized cold-rolled high-carbon steel plate for stamping forming

The invention discloses a preparation method of a graphitized cold-rolled high-carbon steel plate for stamping forming, and belongs to the technical field of metallurgy. The preparation method is characterized in that besides conventional methods like smelting, continuous casting, hot rolling, acid pickling and cold rolling, technological processes like bainite treatment and graphitizing annealing are adopted, wherein the bainite treatment is adopted for providing a good preparation structure for the graphitizing annealing; isothermal transformation is carried out in a manner that isothermal treatment with the temperature being 30-50 DEG C above Ac3 is carried out and then rapid cooling to a lower bainite transition temperature range is carried out; and the graphitizing annealing mainly adopts the isothermal treatment with the temperature being 620 DEG C to Ac1. The steel plate prepared by the preparation method mainly consists of graphite and ferrite grains structurally, graphite particles are distributed uniformly, the mean diameter of the graphite particles is approximately 5 micrometers, and the mean diameter of the ferrite grains is approximately 20 micrometers. Due to such structural characteristics, the high-carbon steel plate has the same plasticity and softness as low-carbon steel, and thus has the good stamping forming property, a yield ratio of the high-carbon steel plate is less than or equal to 0.60, the strain hardening exponent is greater than or equal to 0.2, and the planar anisotropy is less than or equal to 0.20.

Owner:UNIV OF SCI & TECH BEIJING

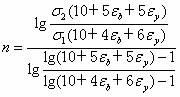

Method for quickly determining metal material strain hardening index

InactiveCN102507326AEasy accessConvenient and accurate access toMaterial strength using tensile/compressive forcesMetallic materialsStrain stiffening

The invention relates to a method for quickly determining a metal material strain hardening index. The method comprises the following steps of: first, according to the tension test data, drawing a tension curve sigma-epsilon; second, determining a starting point for generating strain hardening effect; third, determining an end point for generating strain hardening effect; fourth, determining two key points: namely (epsilon1, sigma1) and (epsilon2, sigma2) on the tension curve; and fifth, according to a formula, calculating the strain hardening index. The method provided by the invention has the characteristics of easy operation, high efficiency and no influence of human factors.

Owner:XI'AN PETROLEUM UNIVERSITY

Biaxially oriented polypropylene film

The present technology relates to a biaxially oriented polypropylene film. The biaxially oriented polypropylene film comprises a polypropylene material having xylene solubles of at least 0.5 percent by weight. The polypropylene also has a strain hardening index of at least 0.15 measured at a deformation rate dε / dt of 1.00 s−1 at a temperature of 180° C. In certain embodiments, the strain hardening index is defined as the slope of a logarithm to the basis 10 of a tensile stress growth function as a function of a logarithm to the basis 10 of a Hencky strain for the range of Hencky strains between 1 and 3.

Owner:BOREALIS TECH OY

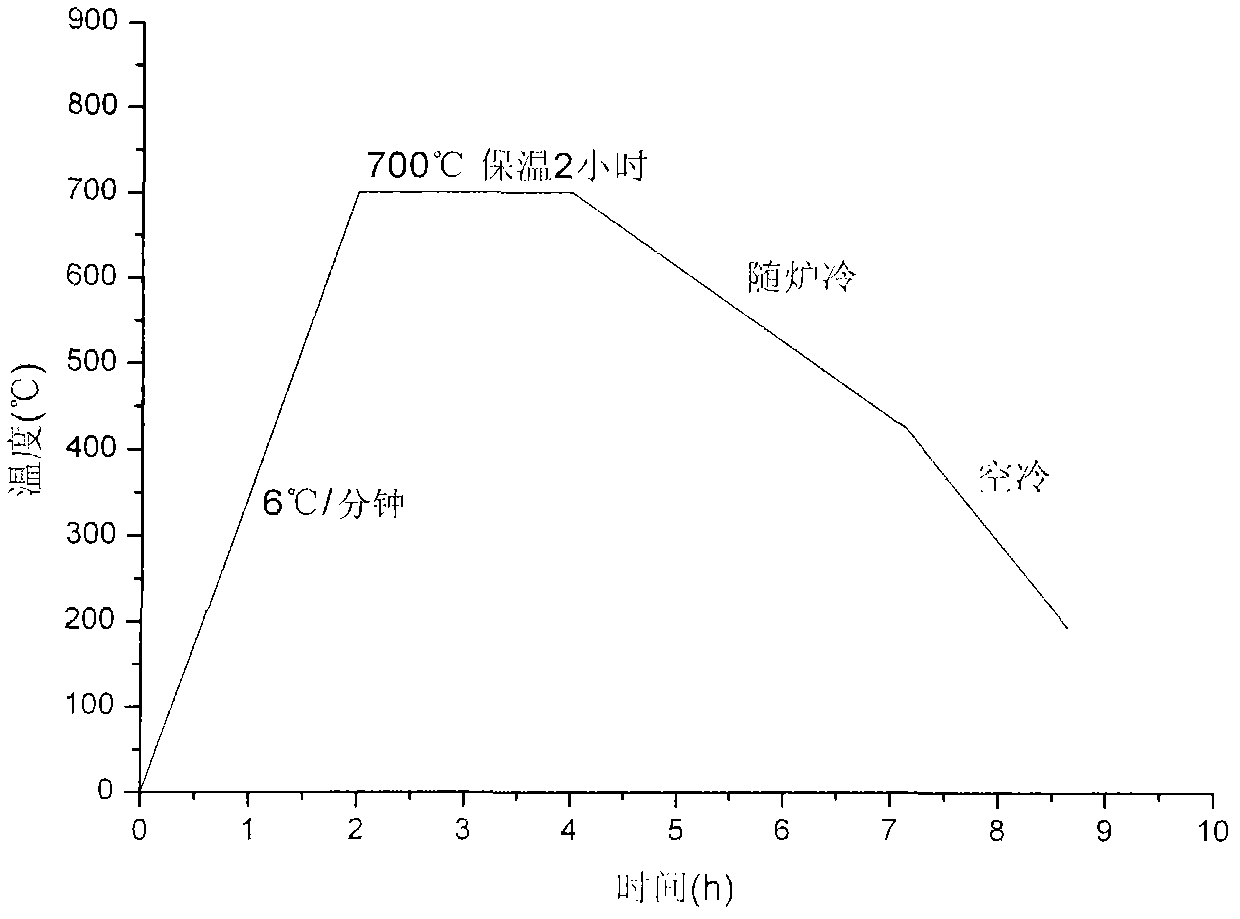

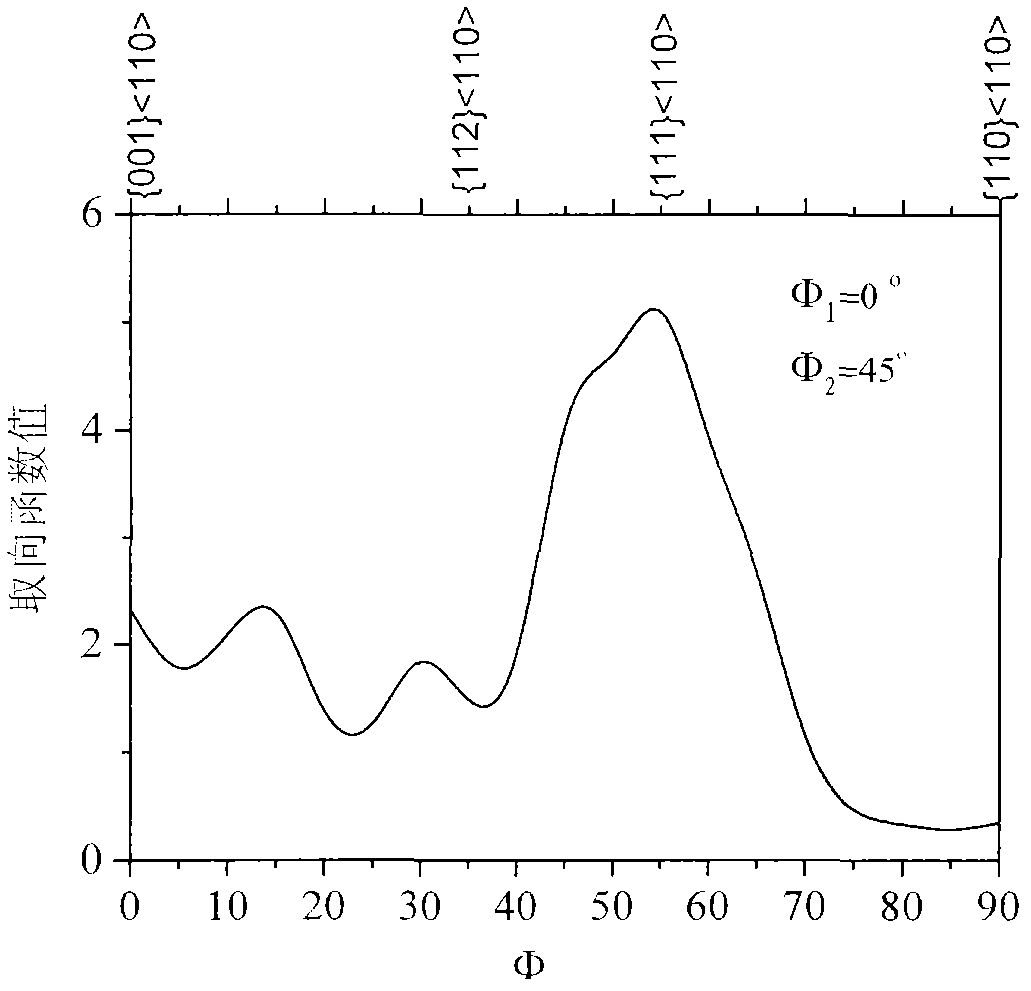

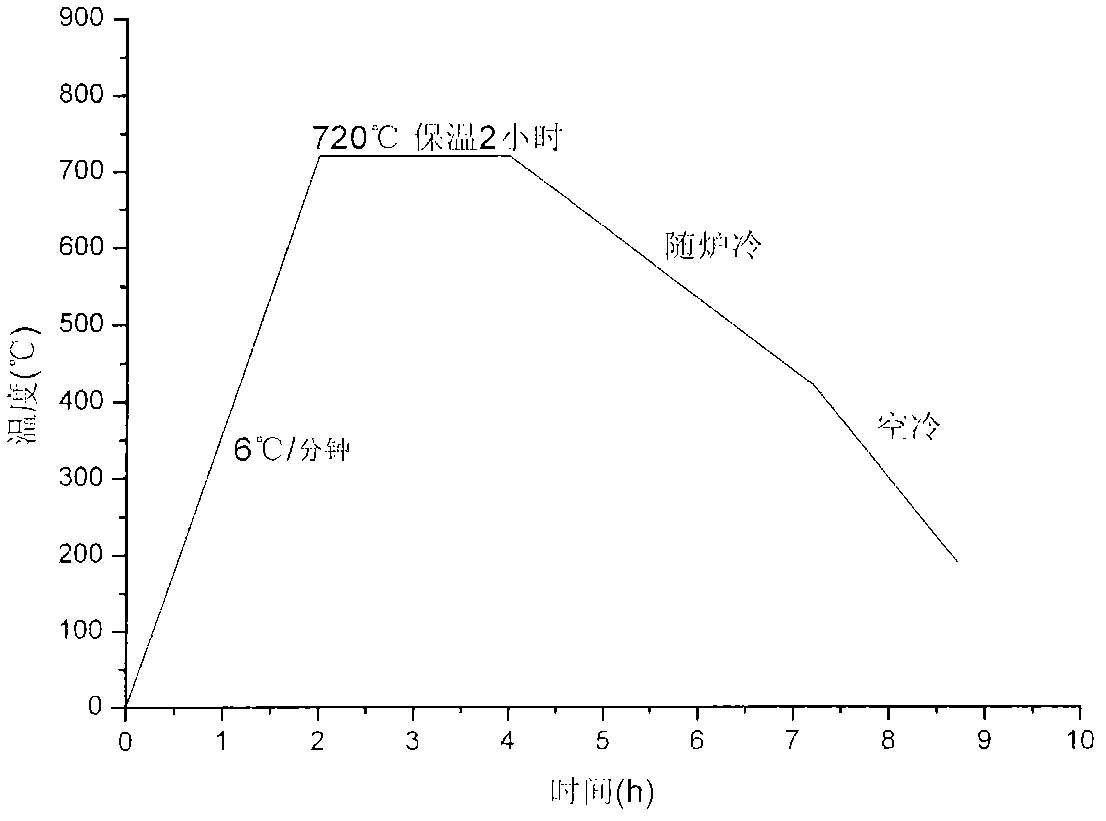

IF steel containing niobium and titanium for advanced automobile and annealing process

InactiveCN102517498AIncrease productivityImprove performanceFurnace typesHeat treatment furnacesTest sampleNiobium

The invention relates to IF steel containing niobium and titanium for an advanced automobile and an annealing process, which belong to the technical field of metallurgy. The IF steel containing the niobium and the titanium for the advanced automobile and the annealing process are characterized in that continuous heating is adopted in the annealing procedure, the heating rate is 4 to 8 DEG C / minute, the annealing temperature is 700 to 750 DEG C, the heat-preservation time is 1 to 10 hours, and the material is cooled to 400 to 450 DEG C along with a furnace and is taken out of the furnace for air cooling. By the mode, IF steel with excellent deep drawability can be obtained; a test sample of the IF steel after being processed by the process has excellent deep drawability; in a longitudinal direction, the tensile strength reaches 290 to 330MPa, the yield strength is 125 to 155MPa, and the elongation rate is 40 to 55 percent; in a transverse direction, the tensile strength reaches 310 to 340MPa, the yield strength is 120 to 190MPa, and the elongation rate is 40 to 55 percent; and the plane anisotropy delta r of the strain hardening index is not greater than 0.25.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Polypropylene foam

The present technology relates to a foam comprising a polypropylene material. The polypropylene material is produced in the presence of a metallocene catalyst, and the foam and / or the polypropylene has a branching index g′ of less than 1.00 and a strain hardening index (SHI@1 s−1) of at least 0.30 measured by a deformation rate dε / dt of 1.00 s−1 at a temperature of 180° C., where the strain hardening index (SHI) is defined as the slope of the logarithm to the basis 10 of the tensile stress growth function (log(ηE+)) as a function of the logarithm to the basis 10 of the Hencky strain (log(ε)) in the range of Hencky strains between 1 and 3.

Owner:BOREALIS TECH OY

Double-layer winding-soldering pipe production technology for connection of indoor/outdoor unit of air conditioner

InactiveCN101255933AHigh plastic strain ratioPlastic strain is higher than rRigid pipesCopper platingMolding machine

The present invention provides a production process of double wall brazed tube for connecting air-condition indoor and outdoor machine, putting a horizontally striping double-sided copperplating steel belt made from low-carbon gapless atomic steel on a uncoiling disk; coil rolling the copperplating steel belt at 720 degrees on forming machine to form double wall brazed tube canister; entering brazing furnace, and injecting decomposed protection gas NH3 in the furnace to solder; entering the double wall brazed tube after soldering to sealing cooling tube filled with decomposed protection gas NH3 to cool, and cooling slowly and cooling again; spraying and drying directly by passivation water; collecting to disk shape by winder and the disk shaped double wall brazed tube is obtained. The disk shaped double wall brazed tube is processed by off-line controllable atmosphere bright annealing and fixed length. The double wall brazed tube obtained by present invention has plastic strain ratio r >2.0, strain hardening index n >0.25, elongation delta >45%, yield strength delta s <150 Mp; when installing as air-condition connecting pipe, can realize manual molding in installing scene of air-condition connecting pipe, can't appear staved and cockled phenomenon of the tube wall, and reduces partial energy consume at the same time.

Owner:芜湖源大管业有限公司

Method for precisely determining hardening index of material

InactiveCN102607949AMaterial strength using tensile/compressive forcesMetallic materialsGreek letter epsilon

The invention relates to a method for precisely determining a hardening index of a material. The method comprises the following steps of: 1, drawing a tensile curve Sigma-Epsilon according to tensile test data; 2, determining a starting point for generating a strain hardening action and determining a terminal point for generating the strain hardening action; 3, determining two key points (Epsilon 1, Sigma 1), (Epsilon 2, Sigma 2) on the tensile curve; and 4, dividing a strain hardening interval into three sections by using the key points, respectively determining and comparing strain hardening indexes of the three sections, dividing one section with the maximum strain hardening index into three sections, respectively determining the strain hardening indexes of the three sections, and comparing the maximum strain hardening index of the three current sections with the maximum strain hardening index of the last circulation, if the error is in a specified range, determining the maximum strain hardening index of the three current sections as the strain hardening index of the material, and if the error is beyond the specified range, circulating till the error meets the provision. The method disclosed by the invention has the characteristics of high precision, controllable precision according to the demands and freedom of influences of personal factors.

Owner:XI'AN PETROLEUM UNIVERSITY

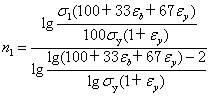

Steel plate with axial bearing capacity and excellent formability used for cans and manufacturing method thereof

Disclosed is a steel plate with axial bearing capacity and excellent formability used for cans and a manufacturing method thereof. The steel plate comprises the following components, by weight: 0.020%-0.080% of C, no more than 0.030% of Si, 0.20%-1.00% of Mn, no more than 0.020% of P, 0.0020%-0.0080% of N, and Al, with the balance being Fe and unavoidable impurities, wherein 10<=Al / N<=20. High yield strength and a rising value of the yield strength after baking can be obtained by controlling hot rolling, cold rolling, continuous annealing temperature and other processes. The invention aims atthe material with processing requirements of axial bearing capacity after can making baking, and the steel plate with axial bearing capacity and excellent formability is obtained according to component and process design. The yield strength of the steel plate is greater than 300 MPa, the strain hardening index (n value) is greater than 0.15, the rising value of the yield strength after baking of the steel plate is no less than 30 MPa, and the axial bearing capacity obtained after the can making baking is no less than 218 kg. The problem that the axial bearing capacity of the steel plate is insufficient after the can making baking is solved.

Owner:BAOSHAN IRON & STEEL CO LTD

Micro-carbon high-strength deep-punching steel with niobium and chromium, and preparation method thereof

ActiveCN110484697AReduce hot brittlenessImprove deep drawing performanceFurnace typesHeat treatment furnacesPunchingNiobium

The invention belongs to the technical field of alloy, and particularly relates to micro-carbon high-strength deep-punching steel with niobium and chromium, and a preparation method thereof. The micro-carbon high-strength deep-punching steel with niobium and chromium comprises the following ingredients, by mass, 0.01% to 0.03% of C, 0.1% to 0.5% of Si, 1.5% to 2.0% of Mn, 0.01% to 0.06% of P, equal to or smaller than 0.015% of S, 0.1% to 0.5% of Cr, 0.01% to 0.05% of Nb, smaller than 0.01% of N, the balance Fe and unavoidable impurities, wherein the molar ratio of Nb to C ranges from 0.05 to 1to 0.3 to 1, and the molar ratio of Cr to C ranges from 1 to 1 to 3 to 1. According to the micro-carbon high-strength deep-punching steel with niobium and chromium, the tensile strength is 510 MPa, the elongation is 29.1%, the strain hardening index is 0.22, the plastic strain ratio is 1.5, and the good strength and the good deep punching performance are achieved as well.

Owner:JIANGXI UNIV OF SCI & TECH

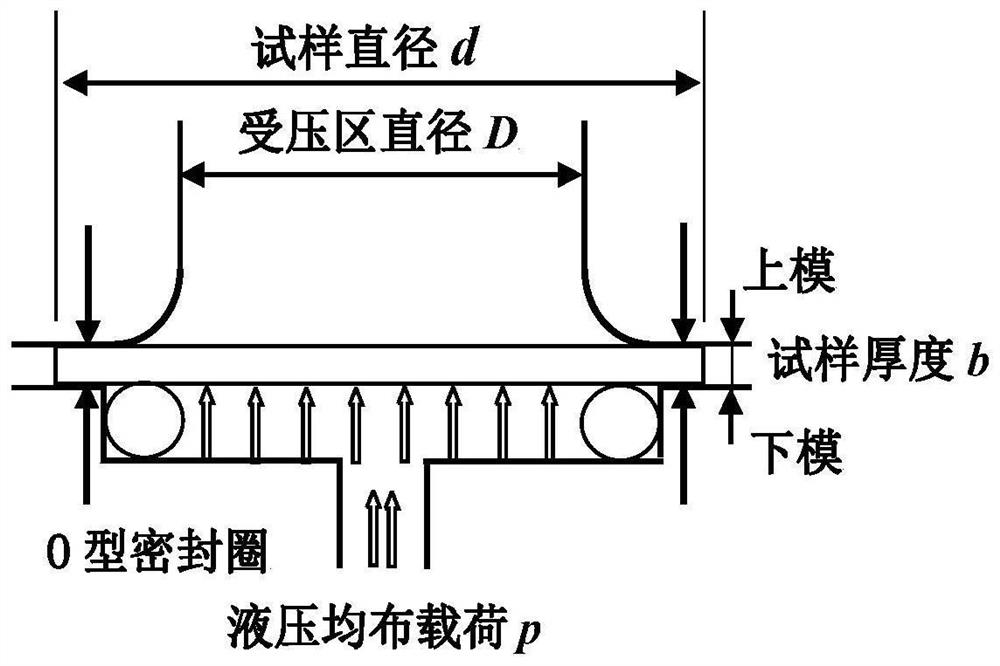

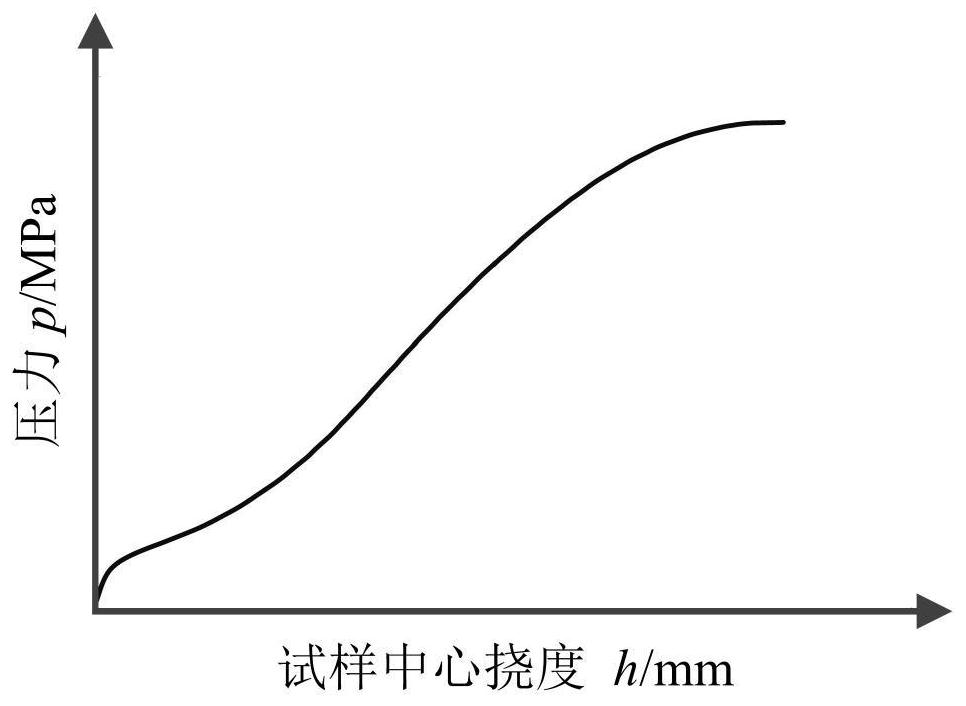

Method for determining uniaxial stress-strain relationship of material based on high-temperature hydraulic bulging sample test

ActiveCN112284921ASimple test methodHigh precisionMaterial strength using tensile/compressive forcesTest sampleEngineering

The invention discloses a method for determining uniaxial stress-strain relationship of a material based on a high-temperature hydraulic bulging sample test, and the method comprises the following steps: preparing a test sample, carrying out a hydraulic bulging test on the test sample to obtain a pressure center deflection test curve of the test sample, and obtaining an external force work centerdeflection curve of the sample based on the pressure center deflection test curve, obtaining the yield strength and the strain hardening index of the material by utilizing the external force work center deflection curve, and further determining the uniaxial stress-strain relationship of the material. According to the method for determining the uniaxial stress-strain relationship of the material, the uniaxial stress-strain relationship of the material is obtained through a hydraulic bulging micro-sample test technology, and material parameters of the uniaxial stress-strain relationship curve ofthe material can be obtained only by simply analyzing and calculating a pressure center deflection test curve obtained through the test; the obtained result is high in precision, a large number of tests are not needed, the test method and the test principle are relatively simple, and engineering application is very convenient.

Owner:SUZHOU NUCLEAR POWER RES INST +3

Method for improving stamping forming performance of graphitized steel plate

The invention discloses a method for improving stamping forming performance of a graphitized steel plate and belongs to the technical field of steel and iron material processing. The method is characterized in that warm deformation of ferrite dynamic recrystallization is conducted on the graphitized steel plate obtained after graphitization treatment through a warm deformation technology; and thestamping forming performance of the graphitized steel plate is improved by controlling refining and homogenization of ferrite dynamic crystalline grains. The method comprises the specific steps that the graphitized steel plate obtained after graphitization treatment is heated to 550-710 DEG C; after temperature equalization is achieved, flat roll rolling with the rolling reduction being 8-15% is conducted; and after rolling, the graphitized steel plate is air-cooled to the room temperature. According to the graphitized steel plate treated through the method, the ferrite crystalline grains arerefined and homogenized; the stamping forming performance is good; the yield ratio is less than or equal to 0.56; the strain hardening index is greater than or equal to 0.25; and the plane anisotropism is less than or equal to 0.15.

Owner:UNIV OF SCI & TECH BEIJING

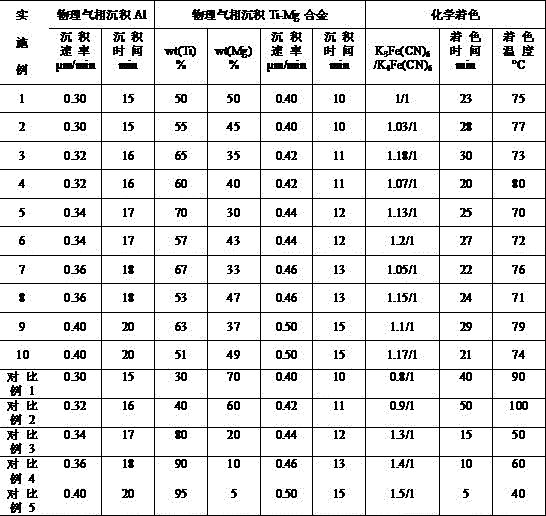

Production method of light-metal composite plating steel strip for top-grade doors and windows

ActiveCN105925936AGuaranteed mechanical propertiesSolve forming difficultiesVacuum evaporation coatingSputtering coatingRoom temperatureHardness

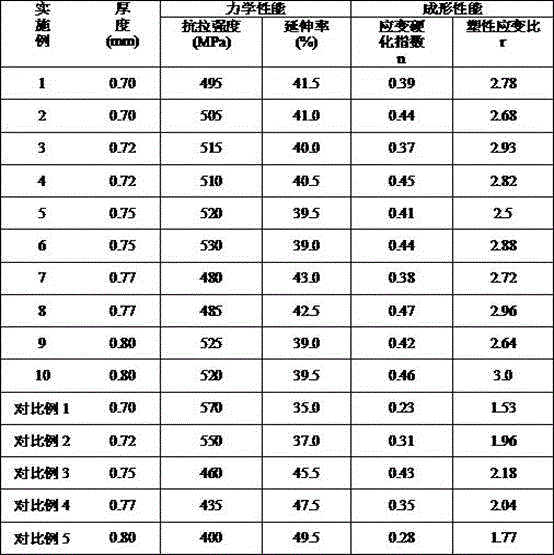

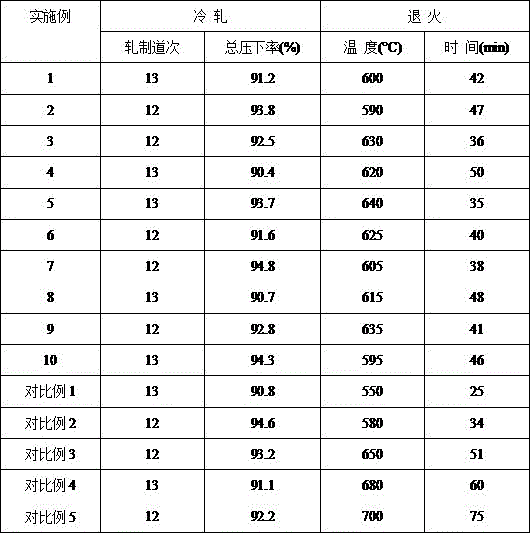

The invention relates to a production method of a light-metal composite plating steel strip for top-grade doors and windows. The production method comprises a cold-rolling procedure and a strip manufacturing procedure, wherein the cold-rolling procedure comprises the following steps of using an ordinary Q215 hot rolled and acid pickled coil as a raw material, performing cold rolling, performing regular degreasing, and performing annealing. The strip manufacturing procedure comprises the following steps of performing uncoiling, performing stripping and removing burrs; and performing physical vapor deposition on metal Al, performing physical vapor deposition on Ti-Mg, performing chemical tinting, performing natural cooling to the room temperature after water scrubbing and stoving are completed, and performing coiling. According to the steel strip produced by the production method disclosed by the invention, the Rel is 480-530MPa; the elongation percentage is 39-43%; the strain hardening exponent n is 0.37-0.47; the plastic strain ratio r is 2.5-3.0; the surface hardness of the plating on the surface of the product is 58-62 HRC; the color of the surface of the plating is bright blue or bright green. After being repeatedly wiped for 10000 times, the changing rate of the hardness valve is less than or equal to 0.1%. According to a comparing test between the light-metal composite plating steel strip disclosed by the invention and a hot-dipped zinc ordinary plate based on routine, when the hot-dipped zinc ordinary plate is exposed for 5400 d under atmospheric environment, the light loss rate is less than or equal to 0.2%, the corrosion area is less than or equal to 0.5%, the surface performance is good and the corrosion resistance performance is good.

Owner:武汉钢铁有限公司

Browman constitutive optimization model of aluminum alloy stress-strain relation and application of Browman constitutive optimization model

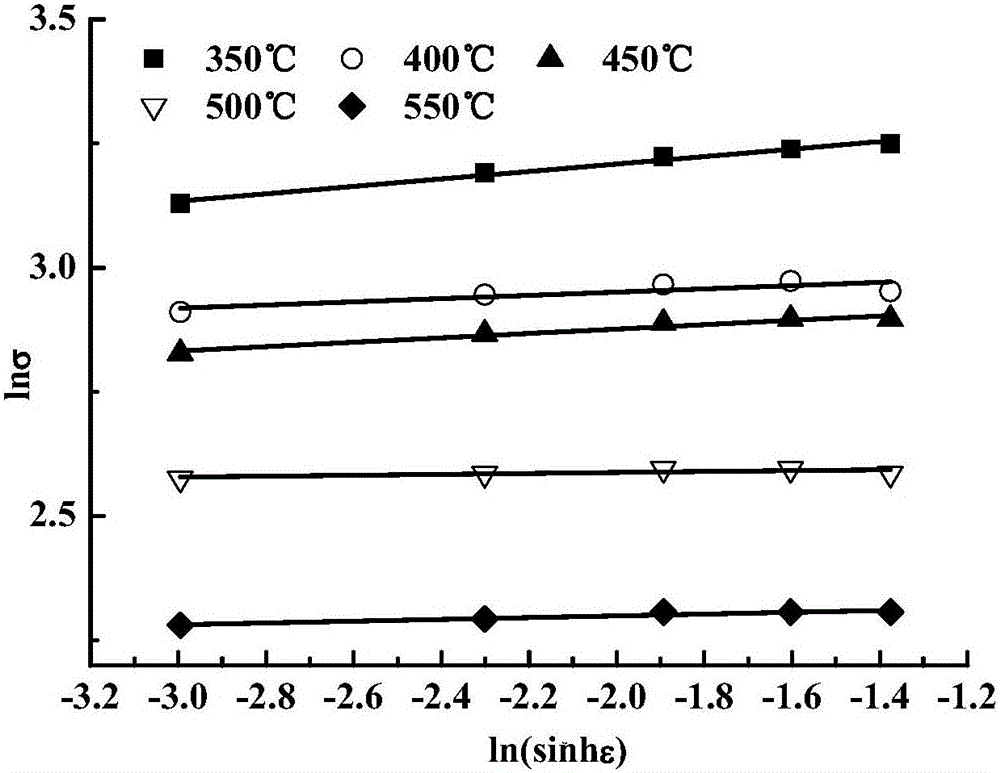

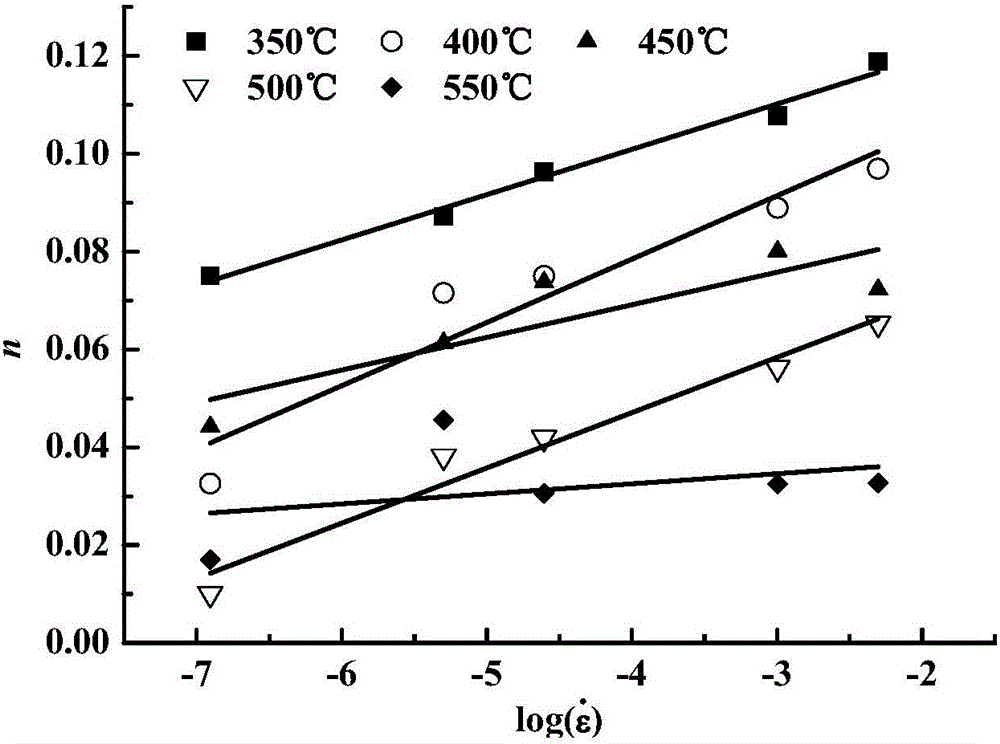

ActiveCN105910886AReveal the law of stress changing with strainImprove forecast accuracyStrength propertiesLeast squaresStrain rate

The invention relates to a Browman constitutive optimization model of an aluminum ally stress-strain relation and application of the Browman constitutive optimization model. Combined with aluminum alloy stress-strain experimental data, a strength coefficient, a strain hardening index and a strain rate sensitivity index are calculated according to a least square method, a stress-strain relational expression based on the Browman constitutive optimization model is determined, and aluminum alloy performance is predicated. Compared with the prior art, the Browman constitutive optimization model has the advantages of high prediction accuracy and capability of accurately revealing the rule that the stress of aluminum alloy changes along with strain.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com