Micro-carbon high-strength deep-punching steel with niobium and chromium, and preparation method thereof

A high-strength, deep-drawing technology, applied in the field of micro-carbon high-strength deep-drawing steel and its preparation, can solve the problems of unfavorable matrix texture optimization, strength to be improved, and reduced matrix texture strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

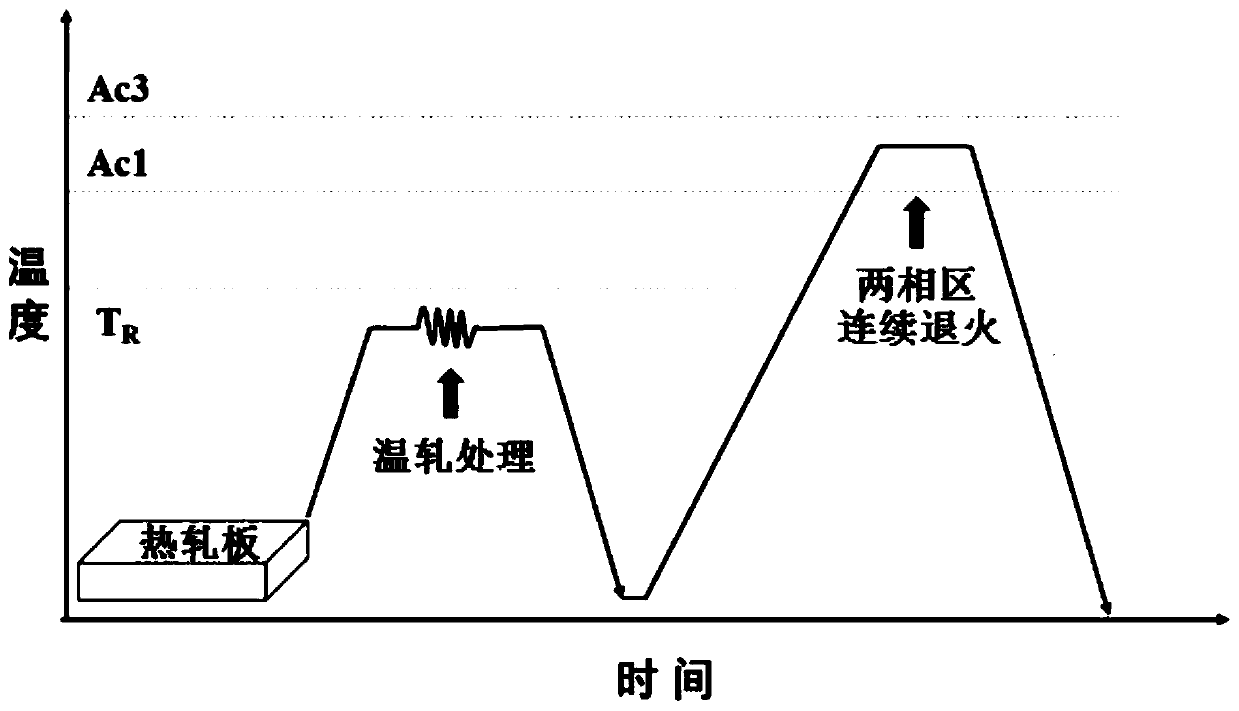

[0039] The present invention also provides a method for preparing niobium-chromium-containing micro-carbon high-strength deep-drawing steel described in the above technical solution, comprising the following steps:

[0040] Hot-rolling the raw steel billet to obtain a hot-rolled plate;

[0041] Carrying out warm-rolling treatment to the hot-rolled plate to obtain a warm-rolled plate;

[0042] Continuous annealing in the two-phase region is carried out on the warm-rolled plate to obtain a micro-carbon high-strength deep-drawing steel containing niobium and chromium.

[0043] In the present invention, the elemental composition of the raw steel slab is consistent with the composition of the niobium-chromium-containing micro-carbon high-strength deep-drawing steel described in the above technical solution, and will not be repeated here.

[0044] The invention hot-rolls the raw steel slab to obtain a hot-rolled plate. In the present invention, the hot rolling includes sequential ...

Embodiment 1

[0054] The raw material alloy was vacuum smelted in a 50KG vacuum electromagnetic induction furnace, and after the cast billet was forged into a 35mm thick slab, the micro-carbon high-strength deep-drawing steel containing niobium and chromium was prepared. The composition of the raw material alloy is shown in Table 1.

[0055] The preparation process of micro-carbon high-strength deep-drawing steel containing niobium and chromium is as follows: the slab (ie raw steel billet) is kept at 1200 °C for 2 hours, and then hot-rolled on a two-roll hot rolling mill. The rolling temperature is 1150 °C, hot Rolling 6 times to 3.8mm, the deformation amount is 60%, the final rolling temperature is 880°C, and then water-cooled to 700°C to simulate coiling to obtain a hot-rolled sheet;

[0056] The hot-rolled sheet is subjected to warm rolling treatment, and the hot-rolled sheet is rolled to 1.5mm at a heating rate of 78°C / s to a heating temperature of 450°C to obtain a warm-rolled sheet;

...

Embodiment 2

[0063] The composition of the raw material alloy is shown in Table 1, and other processes are the same as in Example 1 to obtain a micro-carbon high-strength deep-drawing steel containing niobium and chromium.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com