Aluminum alloy bar for automobile hub and automobile hub

A technology of aluminum alloy wheels and automobile wheels, which is applied in the field of aluminum alloy materials, can solve the problems of affecting the appearance of the wheels, difficult to remove impurities, and scrapping of the wheels, so as to avoid the precipitation of excessive element residues, prolong the service life and improve the cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

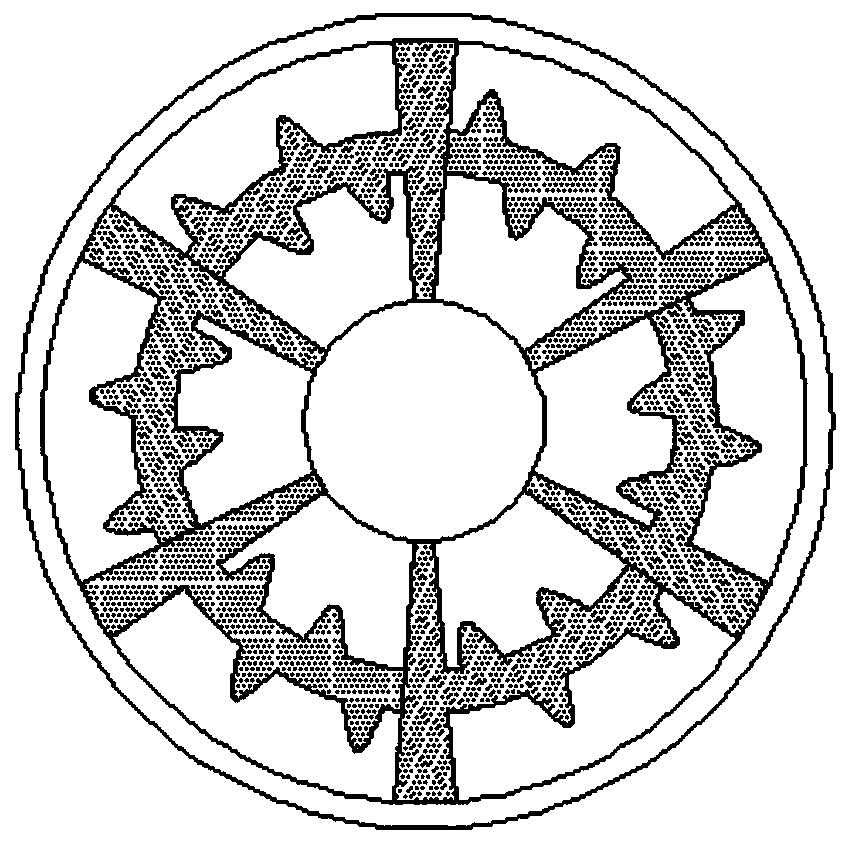

Image

Examples

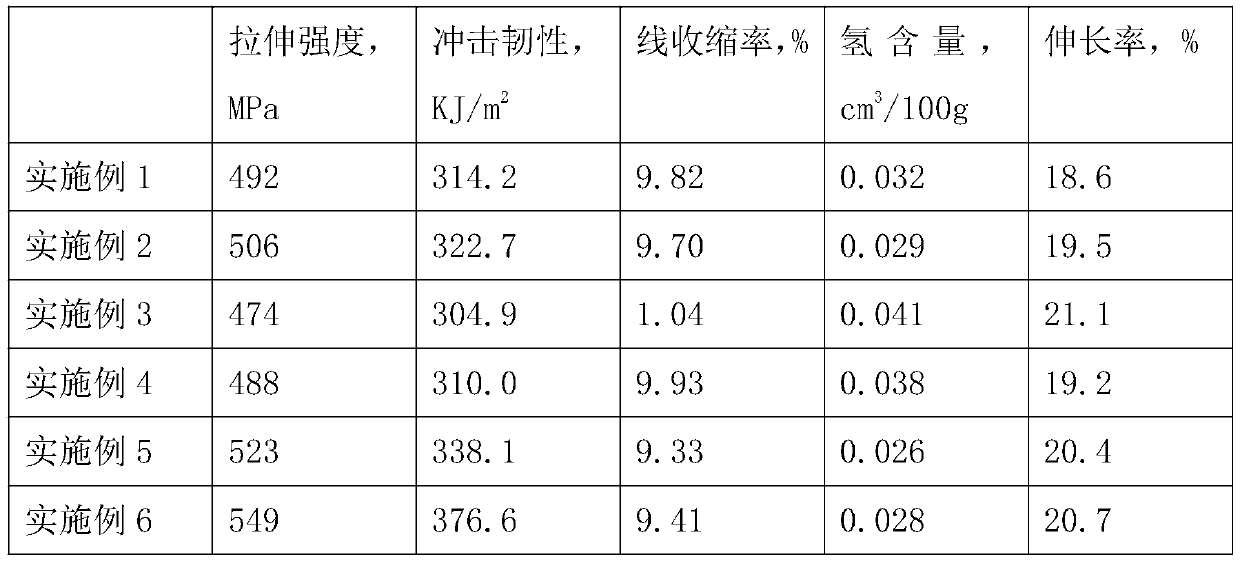

Embodiment 1

[0034] An aluminum alloy bar material for an automobile wheel hub, comprising the following elemental components in mass percentage: Cu 2.7%, Mg 0.5%, Mn 0.5%, Si 0.6%, RE 0.1%, M X (N,B) Y 0.6%, FeX (N,B) Y For metal nitride, metal boride, M includes V, Ti, Hf.

[0035] in,

[0036] RE is a mixture of Sc, Ce, and Pr, and the mass ratio of the three is Sc 60wt%, Ce 30wt%, and Pr 10wt%;

[0037] m X (N,B) Y Medium metal nitride M X N Y The content ratio is 40wt%, the metal boride M X B Y The proportion of the content is 60wt%, and the proportion of the metal element V is more than 50wt%, and the proportion of Ti is more than 35wt%.

[0038]Aluminum alloy bar material for automobile wheel hub, the preparation method is as follows:

[0039] 1) Take the material in proportion, place the raw material in an inert atmosphere for heat treatment for 1-2h, and then put the raw material into smelting in the order of Al, 1 / 2Mg, Mn, Si, Cu, Fe, 1 / 3RE (760-790°C ), after melting...

Embodiment 2

[0047] An aluminum alloy bar material for an automobile wheel hub, comprising the following element components in mass percentage: Cu 2.7%, Mg 0.7%, Mn 0.3%, Si 0.35%, RE 0.15%, M X (N,B) Y 0.8%, FeX (N,B) Y For metal nitride, metal boride, M includes V, Ti, Hf.

[0048] in,

[0049] RE is a mixture of Sc, Ce, and Pr, and the mass ratio of the three is Sc 65wt%, Ce 20wt%, and Pr 15wt%;

[0050] m X (N,B) Y Medium metal nitride M X N Y The content ratio is 45wt%, the metal boride M X B Y The proportion of content is 55wt%, and the proportion of metal element V is more than 50wt%, and the proportion of Ti is more than 35wt%.

[0051] The aluminum alloy bar stock for automobile wheel hub, preparation method is the same as embodiment 1, and its specific parameters are adjusted as follows:

[0052] Step 1) inert atmosphere is N 2 , Ar two mixed gas, the volume ratio of the two in the mixed gas is 1:1

[0053] The gas in step 2) is N 2 、C 2 Cl 6 One or more mixed gas...

Embodiment 3

[0056] An aluminum alloy bar material for an automobile wheel hub, comprising the following element components in mass percentage: Cu 3.0%, Mg 0.4%, Mn 0.5%, Si 0.4%, RE 0.15%, M X (N,B) Y 0.5%, FeX (N,B) Y For metal nitride, metal boride, M includes V, Ti, Hf.

[0057] in,

[0058] RE is a mixture of Sc, Ce, and Pr, and the mass ratio of the three is Sc 55wt%, Ce 30wt%, and Pr 15wt%;

[0059] m X (N,B) Y Medium metal nitride M X N Y The content ratio is 45wt%, the metal boride M X B Y The proportion of content is 55wt%, and the proportion of metal element V is more than 50wt%, and the proportion of Ti is more than 35wt%.

[0060] The aluminum alloy bar stock for automobile wheel hub, preparation method is the same as embodiment 1, and its specific parameters are adjusted as follows:

[0061] The inert atmosphere in step 1) is Ar.

[0062] The gas in step 2) is N 2 , Cl 2 Mixed gas, calculated on the basis of 100L molten metal, the gas input rate is 3.5L / h; the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com