Patents

Literature

493results about How to "Raise the recrystallization temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel plate with low welding crack sensitivity and production method thereof

InactiveCN101096738AHigh strengthMeet the requirements of different site construction process conditionsRoll mill control devicesHeat treatment process controlChemical compositionSheet steel

The invention discloses a low-welding crack sensitivity steel board and manufacturing method, which comprises the following parts: not more than 0.07% C, 0.15-0.40% Si, 1.00-1.60% Mn, not more than 0.015% P, not more than 0.010% S, not more than 0.30% Cu, not more than 0.50% Ni, not more than 0.30% Cr, not more than 0.30% Mo, not more than 0.08% V, not more than 0.08% Nb, 0.010-0.020% Ti, not more than 0.003% B, Fe and inevitable impurity. The invention is characterized by the following: (1)displaying lower welding crack sensitivity component with Pcm not more than 0.20%; (2)mating the strength and flexibility reasonably with fitful yielding ratio; (3)making the price and property of the steel board superior to the congeneric import product; (4)making the maximum breadth of steel board to 4000mm; (5)simplifying the technique to ensure higher flatness without quenching water.

Owner:WUYANG IRON & STEEL

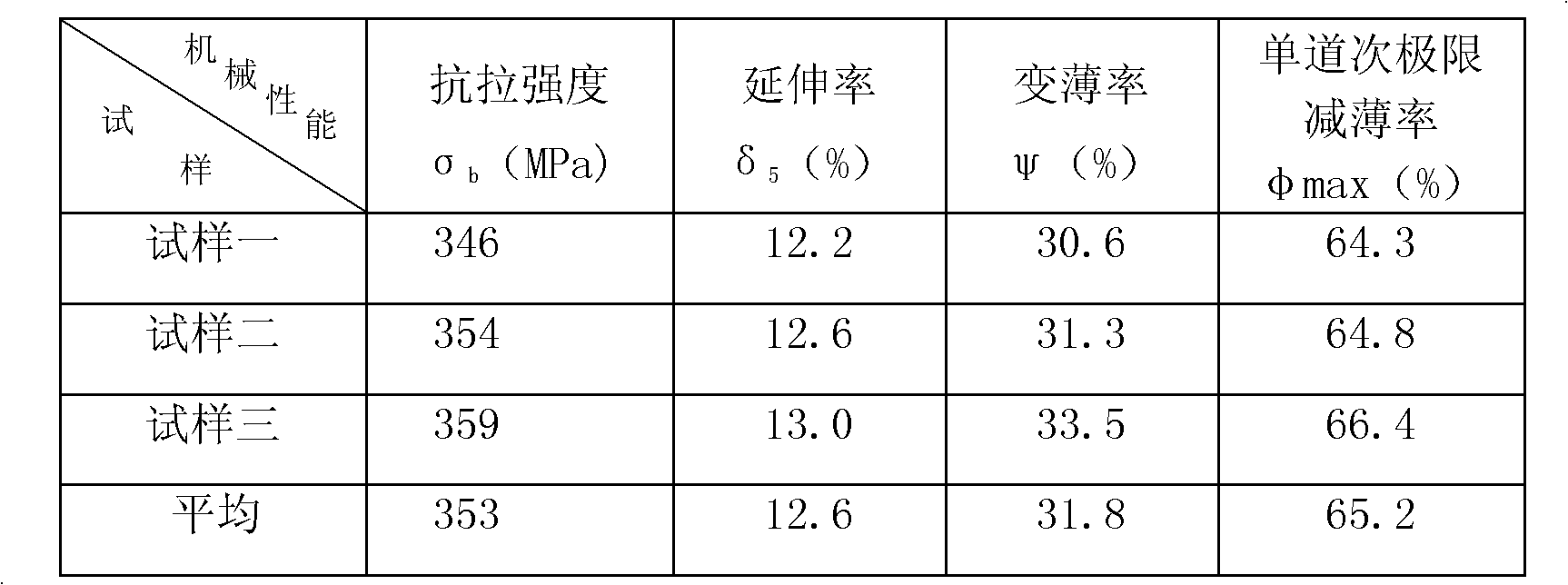

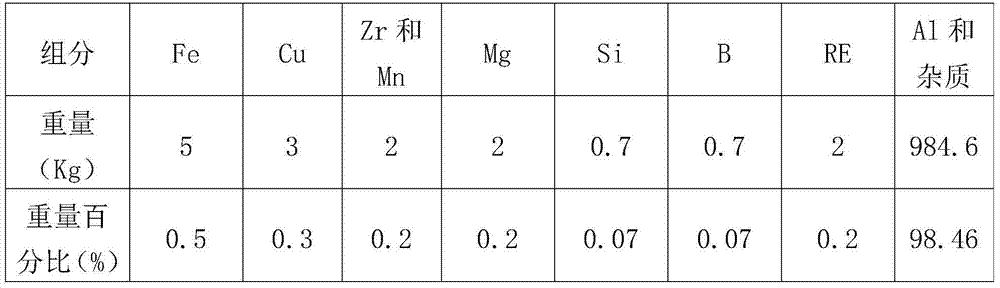

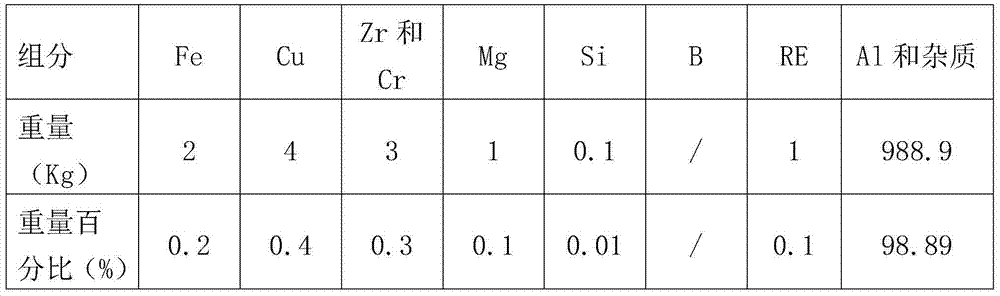

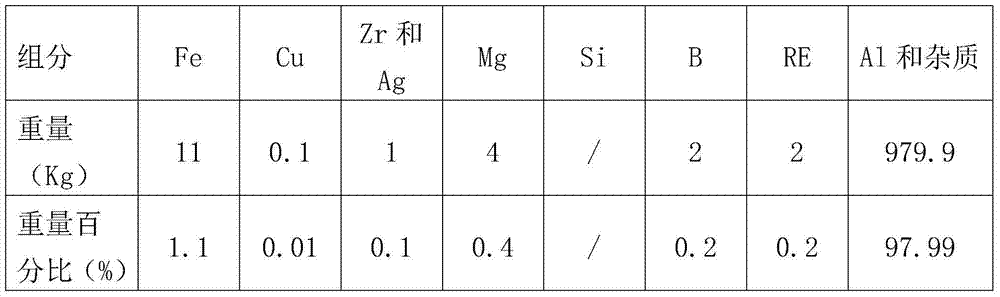

Manufacturing method of high-strength automobile aluminum-alloy rim material

The invention relates to a manufacturing method of a high-strength automobile aluminum-alloy rim material, which relates to a manufacturing method of automobile fitting materials. The manufacturing method comprises the following steps of: preparing materials; smelting; adding a refiner; adjusting components; refining; casting; quenching; carrying out aging treatment; and packaging to prepare the high-strength automobile aluminum-alloy rim material which comprises 0.4-0.8 percent of Si, 0.8-1.2 percent of Mg, 0.16-0.22 percent of Ti, 0.2-0.3 percent of Zn, 0.6-0.8 percent of Fe, 0.15-0.4 percent of Cu, 0.08-0.32 percent of Cr, 0.1-0.2 percent of Mn, 0.02-0.06 percent of RE rare earth, 0.02-0.06 percent of Zr, 0.02-0.06 percent of Sr and the balance of Al. The invention has reasonable process parameter and simple manufacturing method, and the manufactured aluminum-alloy rim material has the advantages of high strength, good mechanical performance and the like and is suitable for being popularized and used in small, medium and large automobiles.

Owner:卢森锴

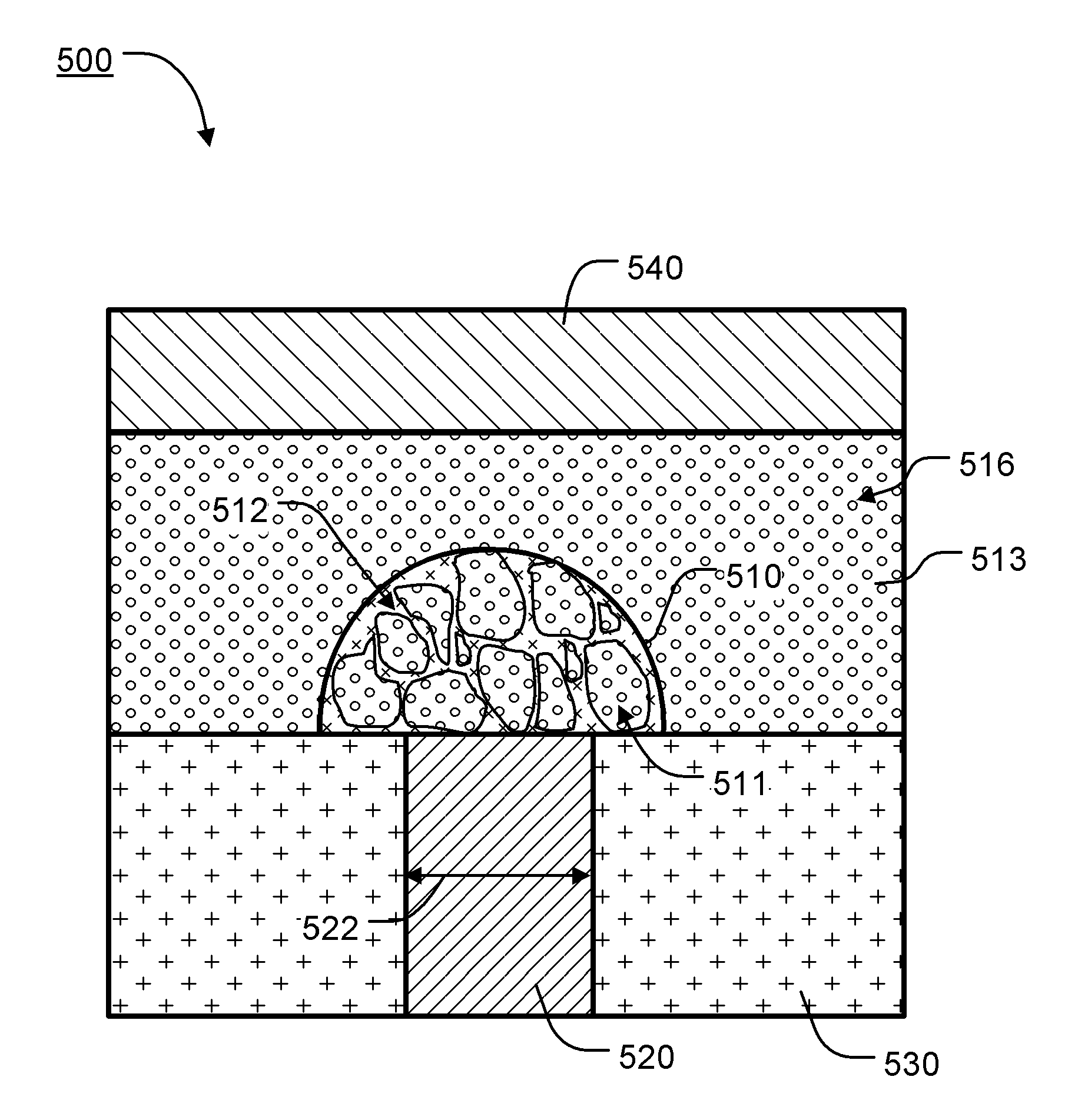

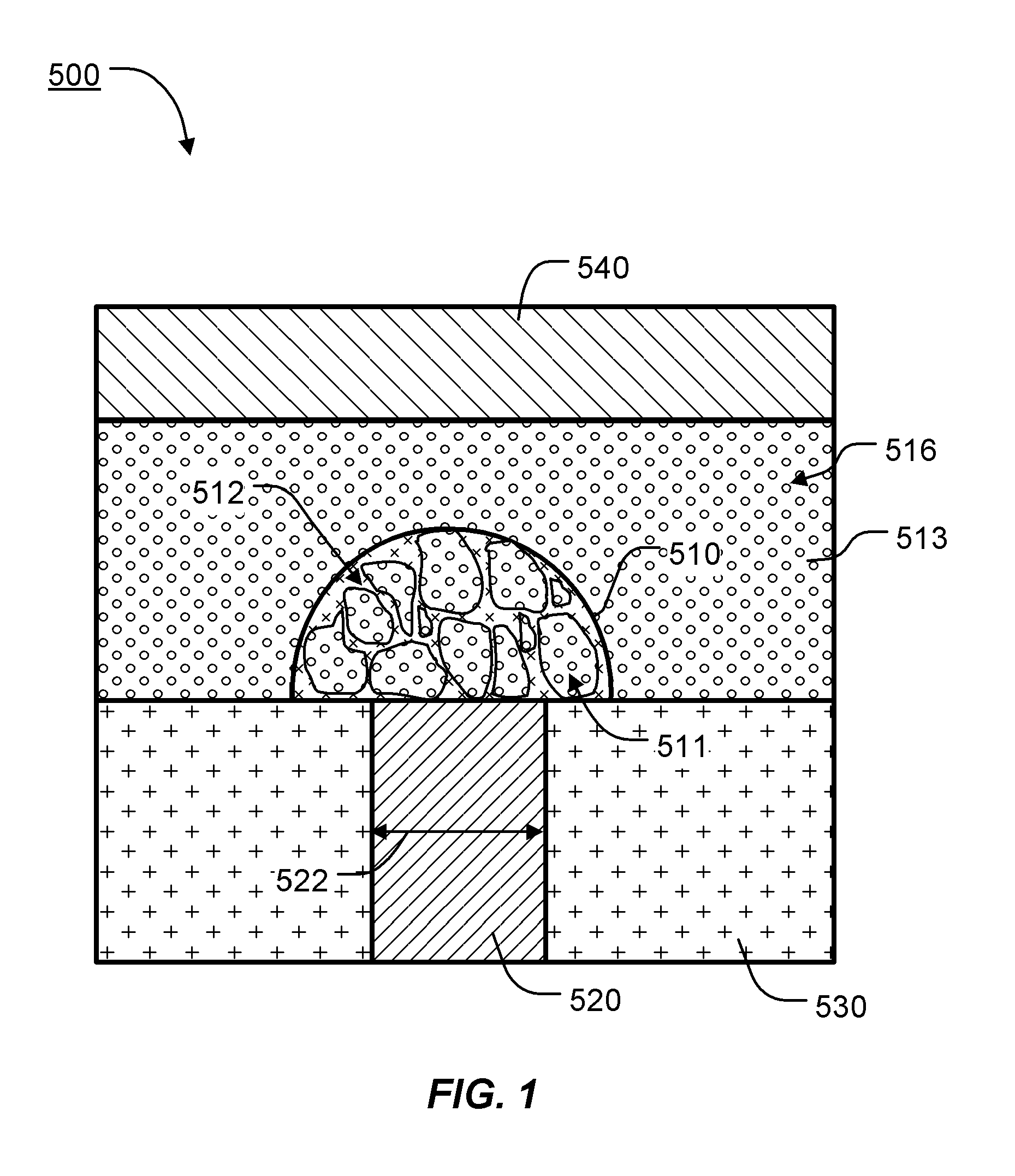

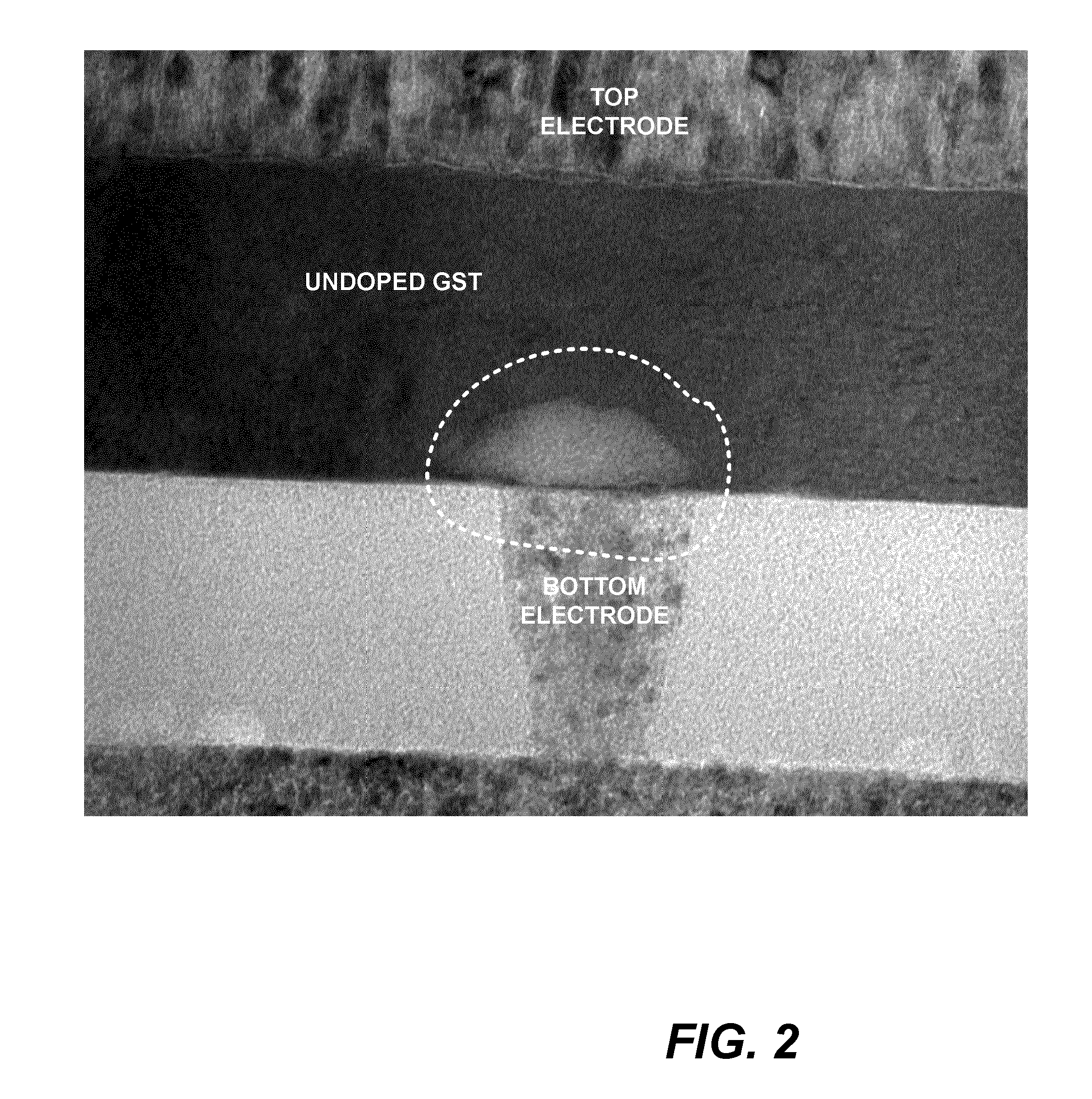

Phase change structure with composite doping for phase change memory

InactiveUS20110049456A1Improve staminaRaise the recrystallization temperatureSemiconductor/solid-state device manufacturingBulk negative resistance effect devicesDopantPhase-change memory

A memory device is described using a composite doped phase change material between a first electrode and a second electrode. A memory element of phase change material, such as a chalcogenide, is between the first and second electrodes and has an active region. The phase change material has a first dopant, such as silicon oxide, characterized by tending to segregate from the phase change material on grain boundaries in the active region, and has a second dopant, such as silicon, characterized by causing an increase in recrystallization temperature of, and / or suppressing void formation in, the phase change material in the active region.

Owner:MACRONIX INT CO LTD +1

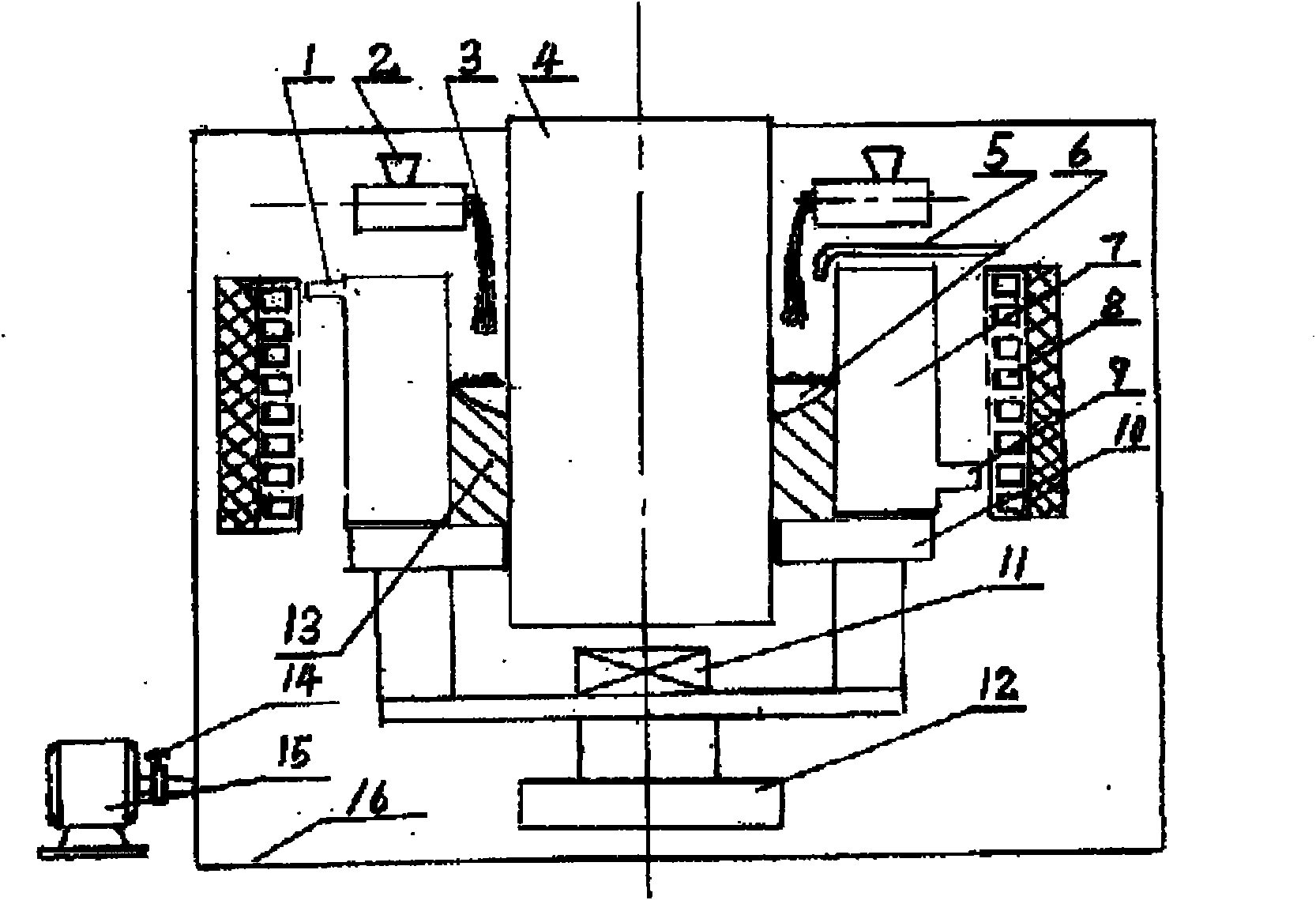

Process and equipment for preparing nanoparticle-reinforced metal matrix composite material

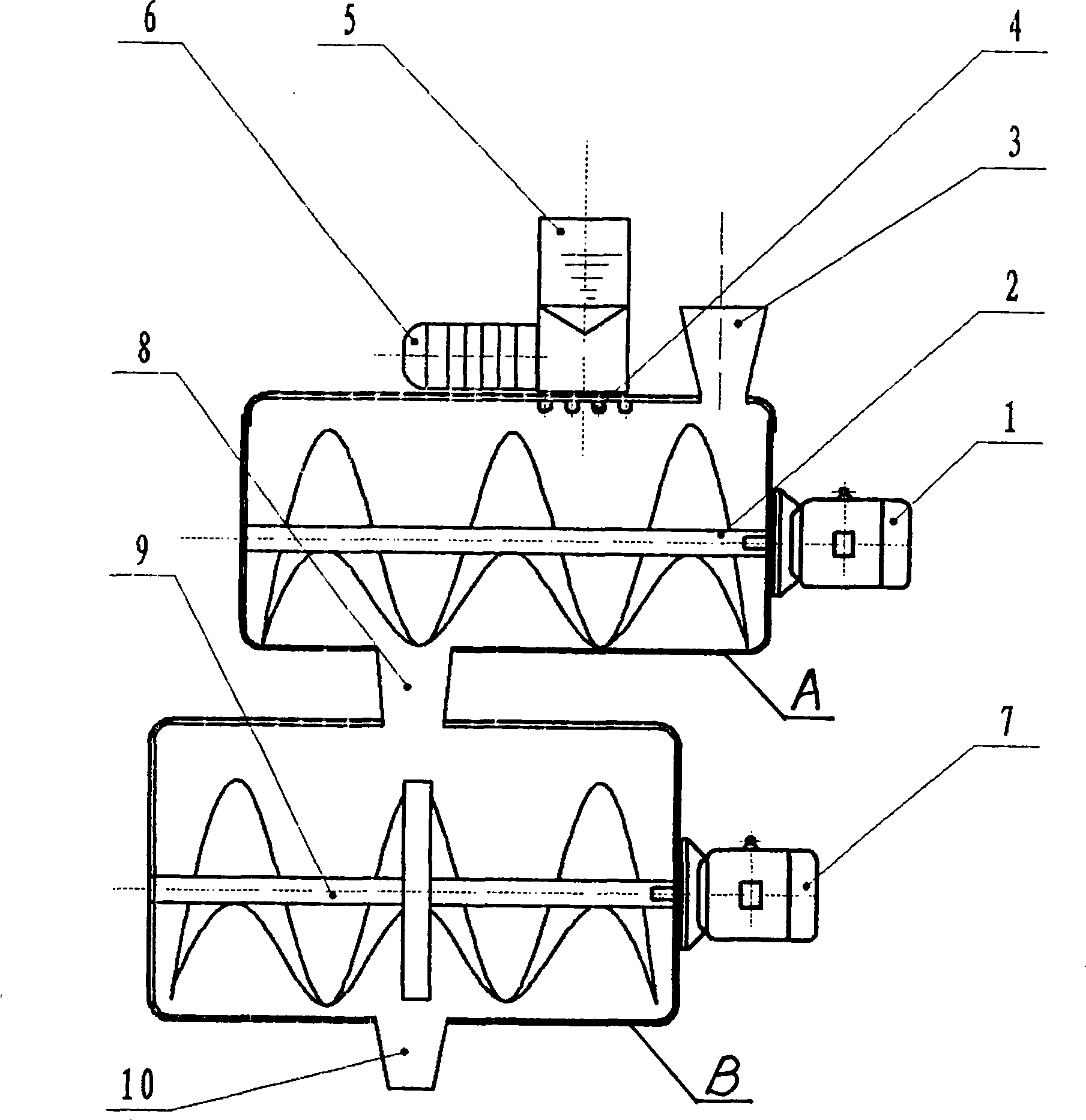

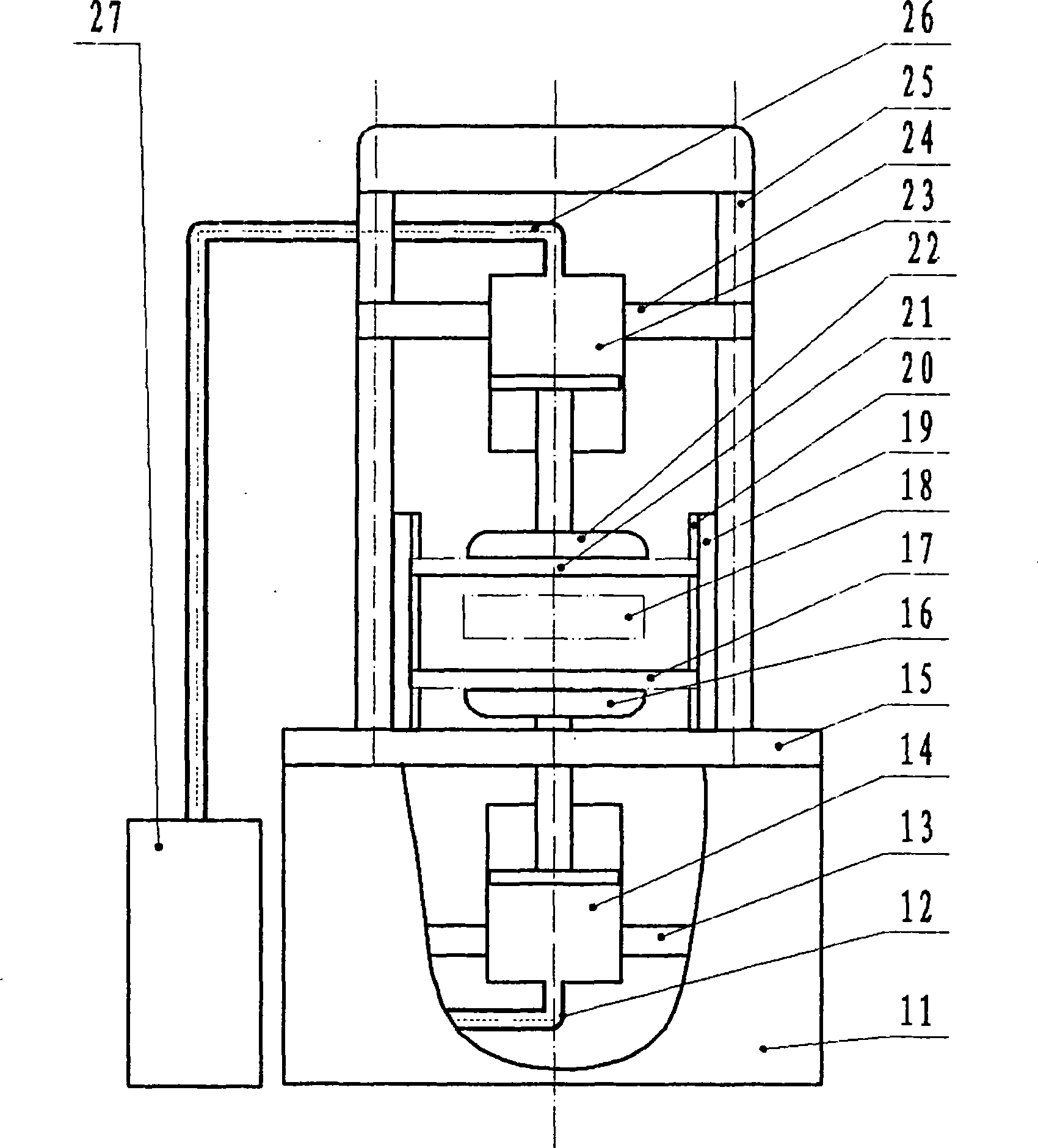

The invention discloses a process and equipment for preparing a nanoparticle-reinforced metal matrix composite material. The process comprises the following steps of: mixing reinforcing nanoparticles with matrix metals and a grain growth inhibitor in a stirring ball mill together, and then loading the mixture into a steel pipe; casting the mixture together with the matrix metals in a water cooling crystallizer or casting and forming the mixture together with a molten metal in a casting mould; and performing quick solidification and crystallization after electromagnetic stirring and ultrasonic vibration to ensure that the two phase materials achieve complete metallurgical bonding, wherein because of the electromagnetic stirring and the ultrasonic vibration, the two phase materials are mixed more uniformly, and all properties of the composite material can be further improved. by using the process and the equipment, a production process is simple, the cost is low, the efficiency is high, the product performance is high, the process is easy to control, the external dimensions of products are not limited by the process, and large-sized nanoparticle-reinforced metal matrix composite materials can be manufactured.

Owner:丁家伟

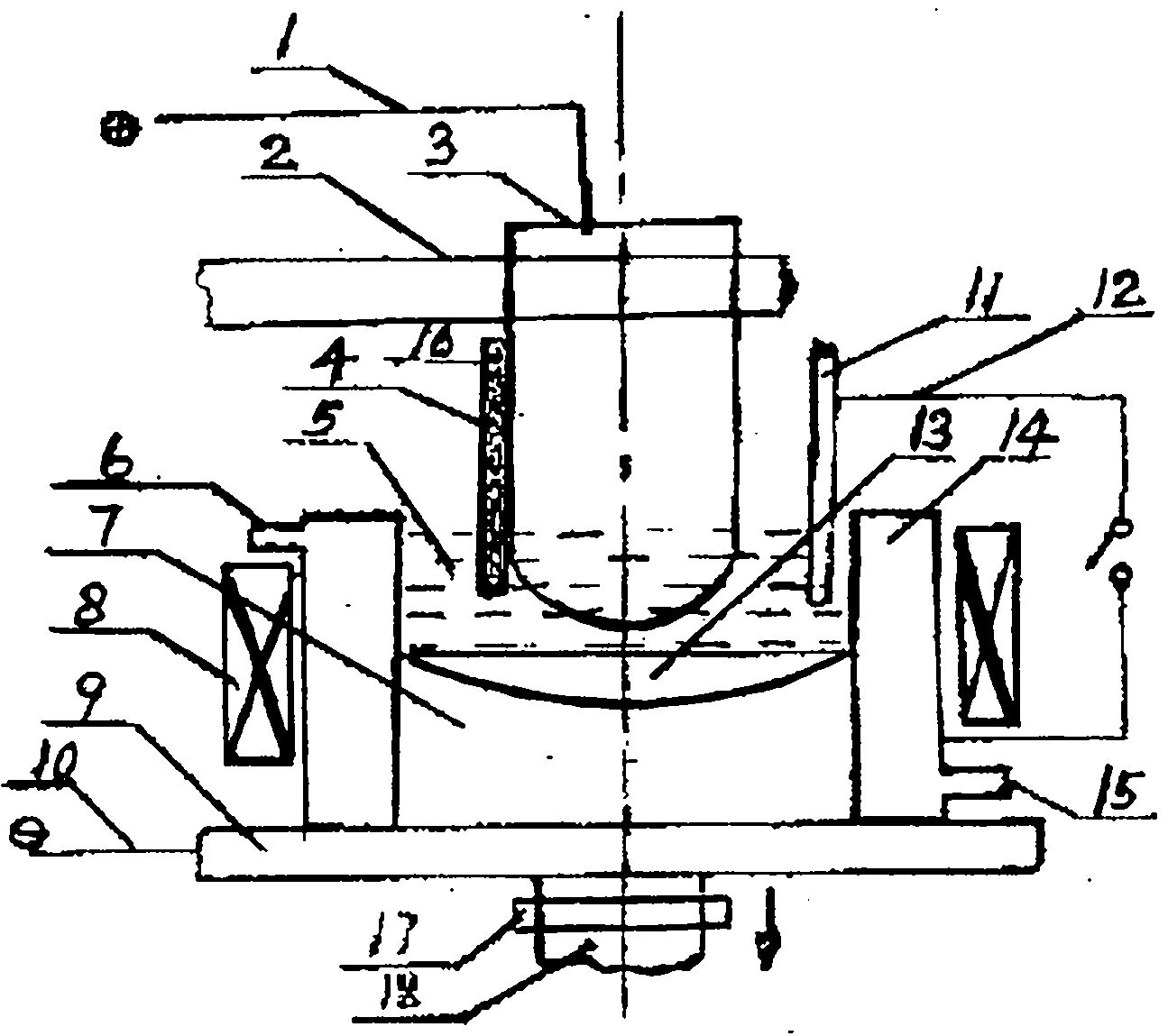

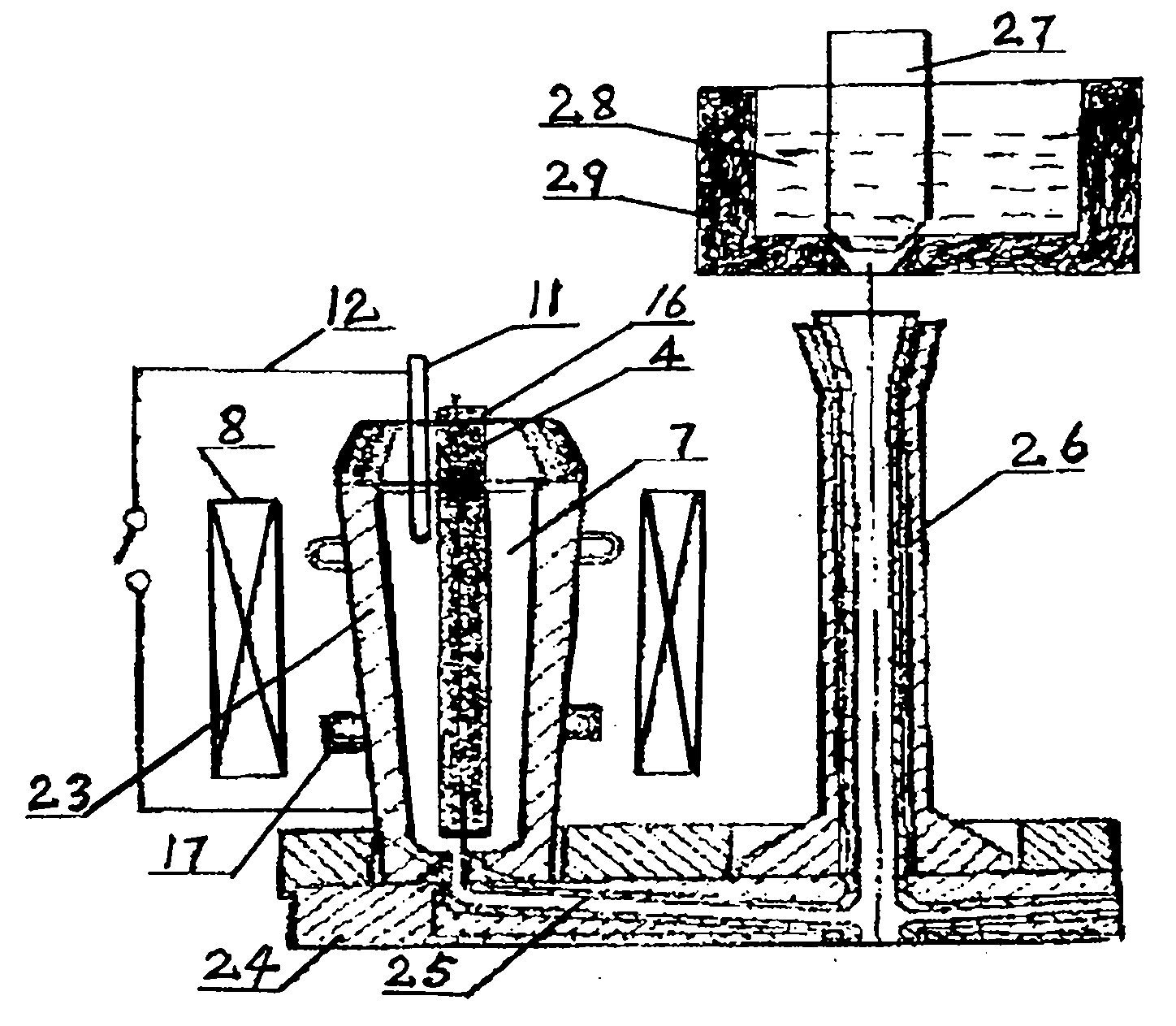

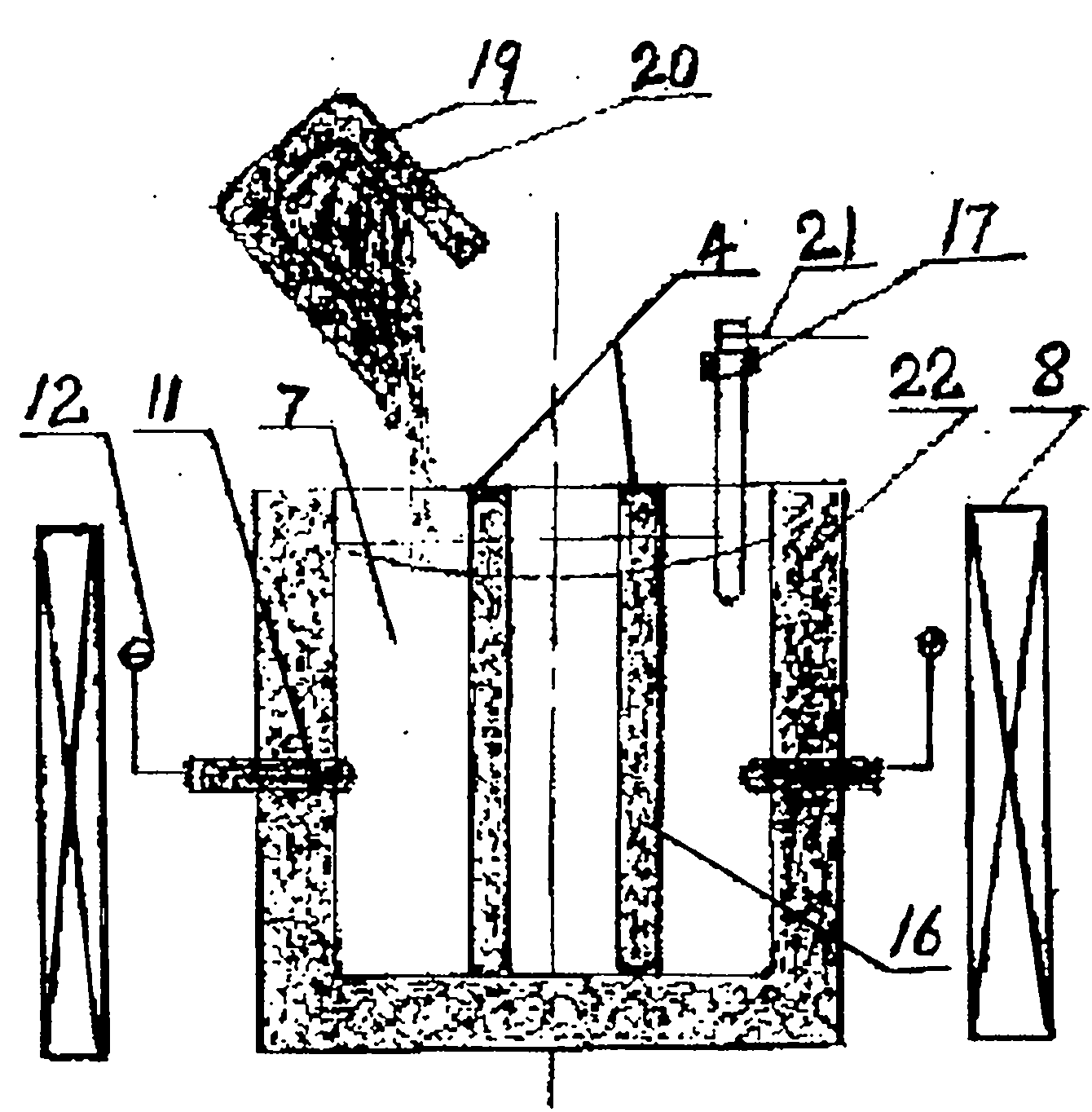

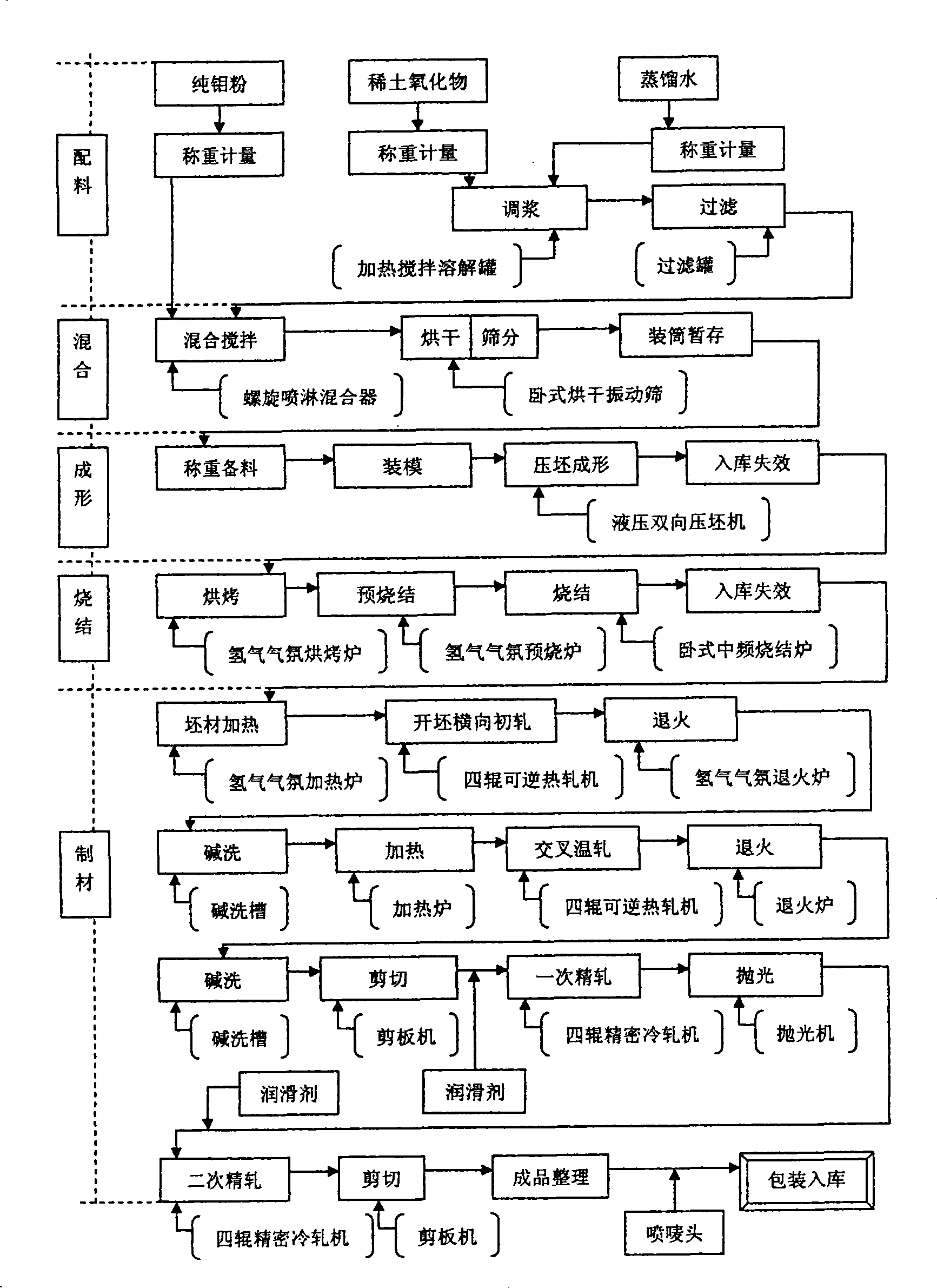

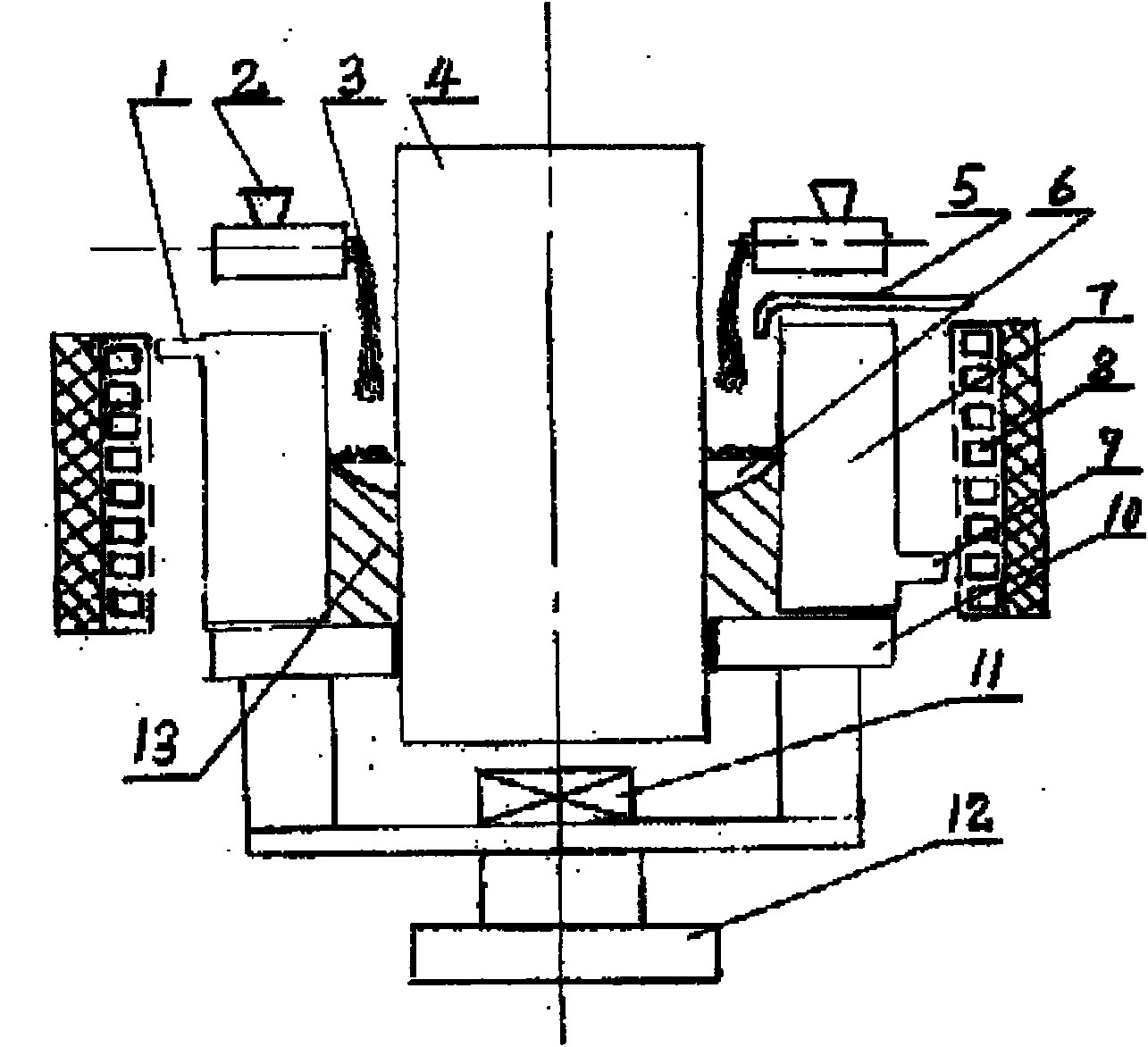

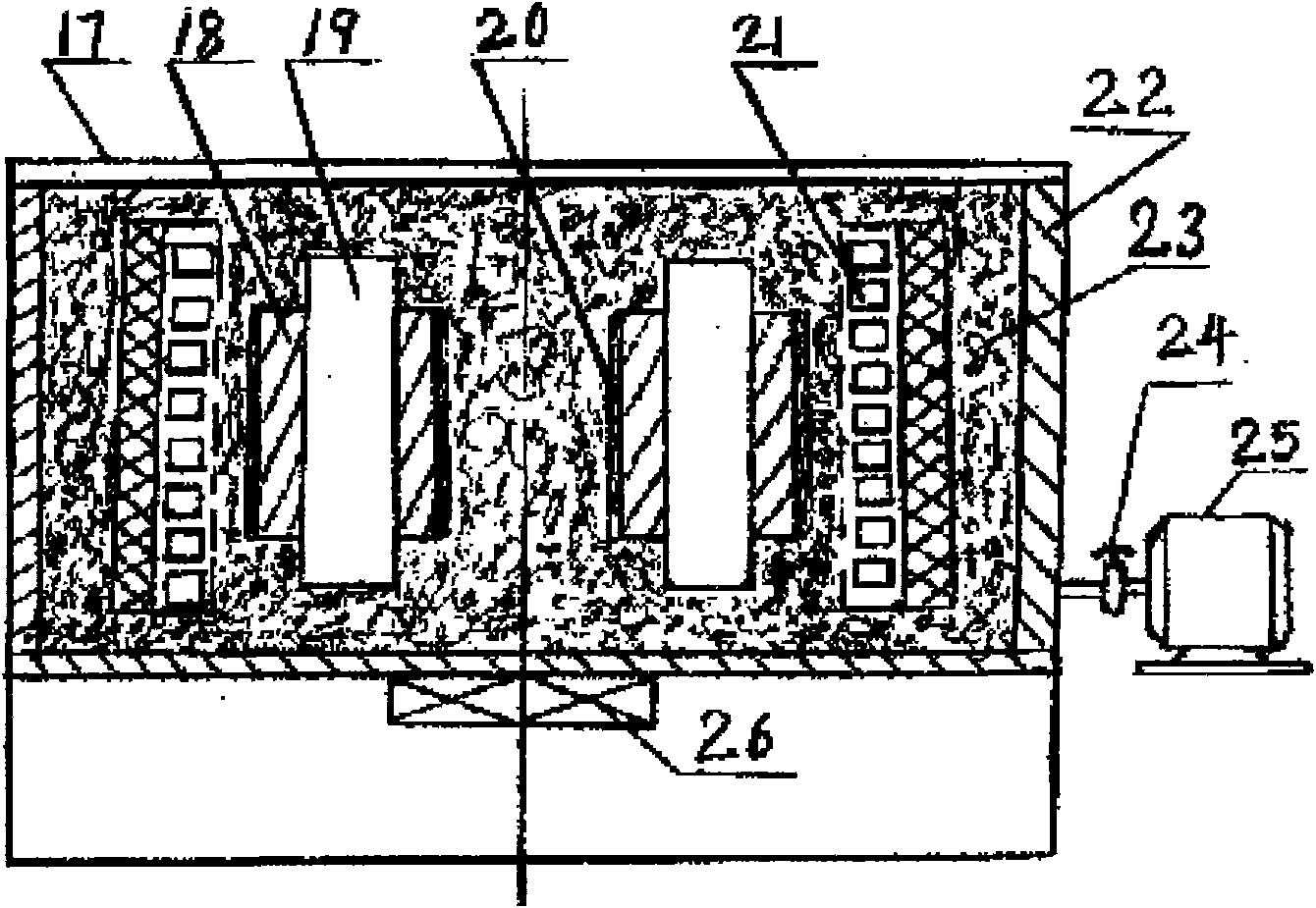

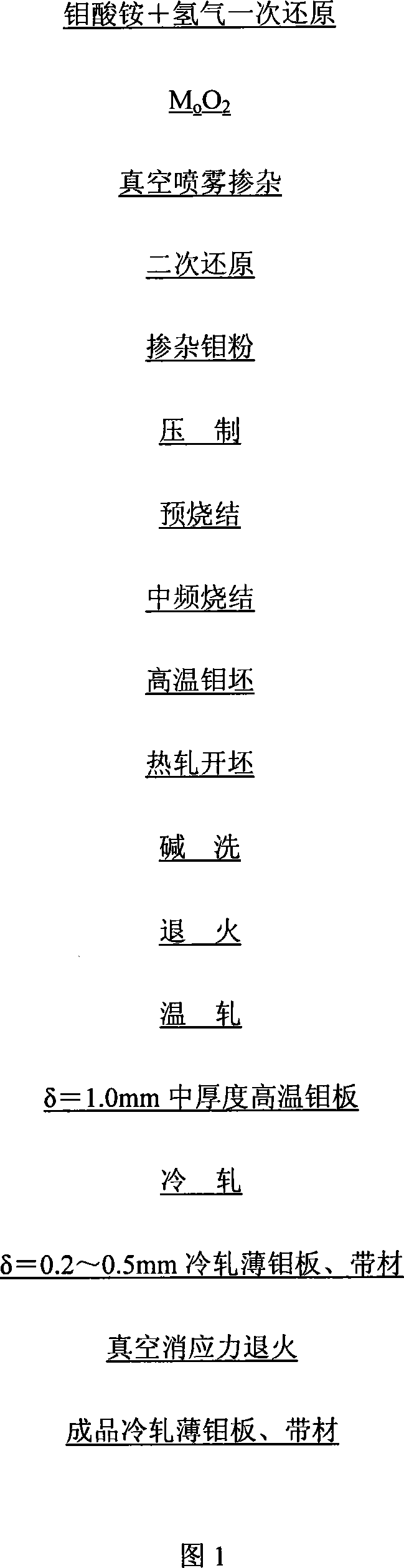

Manufacturing technology of molybdenum-based rare-earth alloy slab and equipment thereof

ActiveCN101423911AFull atomic diffusionFull liquidityRoll mill control devicesMetal rolling arrangementsExtensibilityManufacturing technology

The invention relates to a process for manufacturing the molybdenum based rare earth alloy plate and equipment for manufacturing the same, wherein pure molybdenum powder is simultaneously added with four rare earth oxides of ZrO2, Y2O3, La2O3 and Nd2O3 according to certain ratio, by utilizing the chrematistics of long and large crystal grain and strong sag resistance and anti-creep property of rare earth alloy elements and the dispersion strengthening function, the re-crystallization temperature of the metal molybdenum is increased, the mechanical performances of the molybdenum based material such as tensile property, yielding behavior and extensibility are improved, and the application range of the molybdenum based material is widened; and the manufacturing process comprises production procedures of material preparation treatment, mixing treatment, forming treatment, sintering treatment, material making treatment and the like and the setting of various technical parameters of special technical equipment and process. With the preparation process, the molybdenum based rare earth alloy plate which has the advantages of good electric conductivity and heat conductivity, excellent high-temperature resistance and corrosion resistance and better mechanical performances such as tensile property, yielding behavior and extensibility, and fills in domestic blank and can replace the imported material can be manufactured.

Owner:四平市北威钼业有限公司

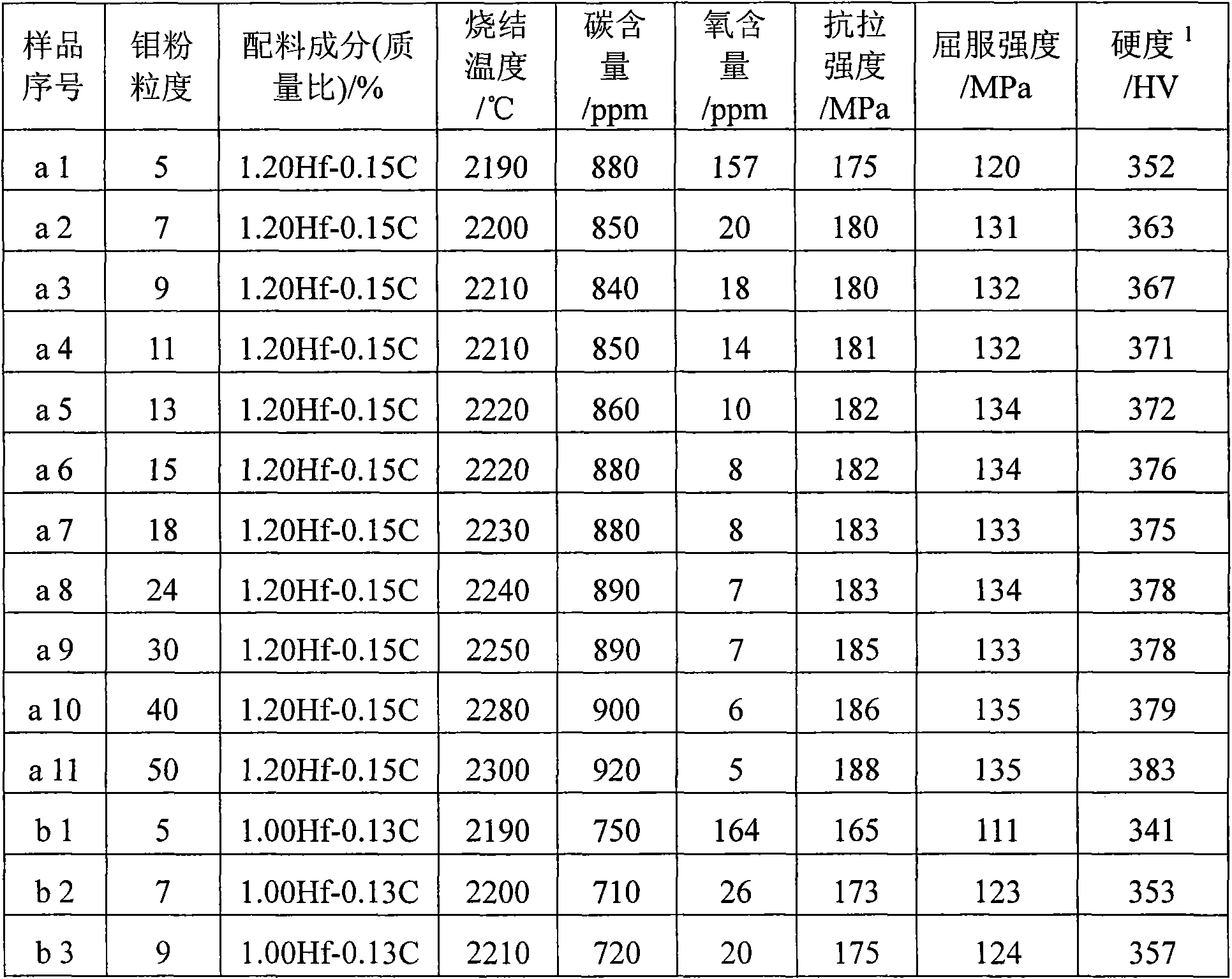

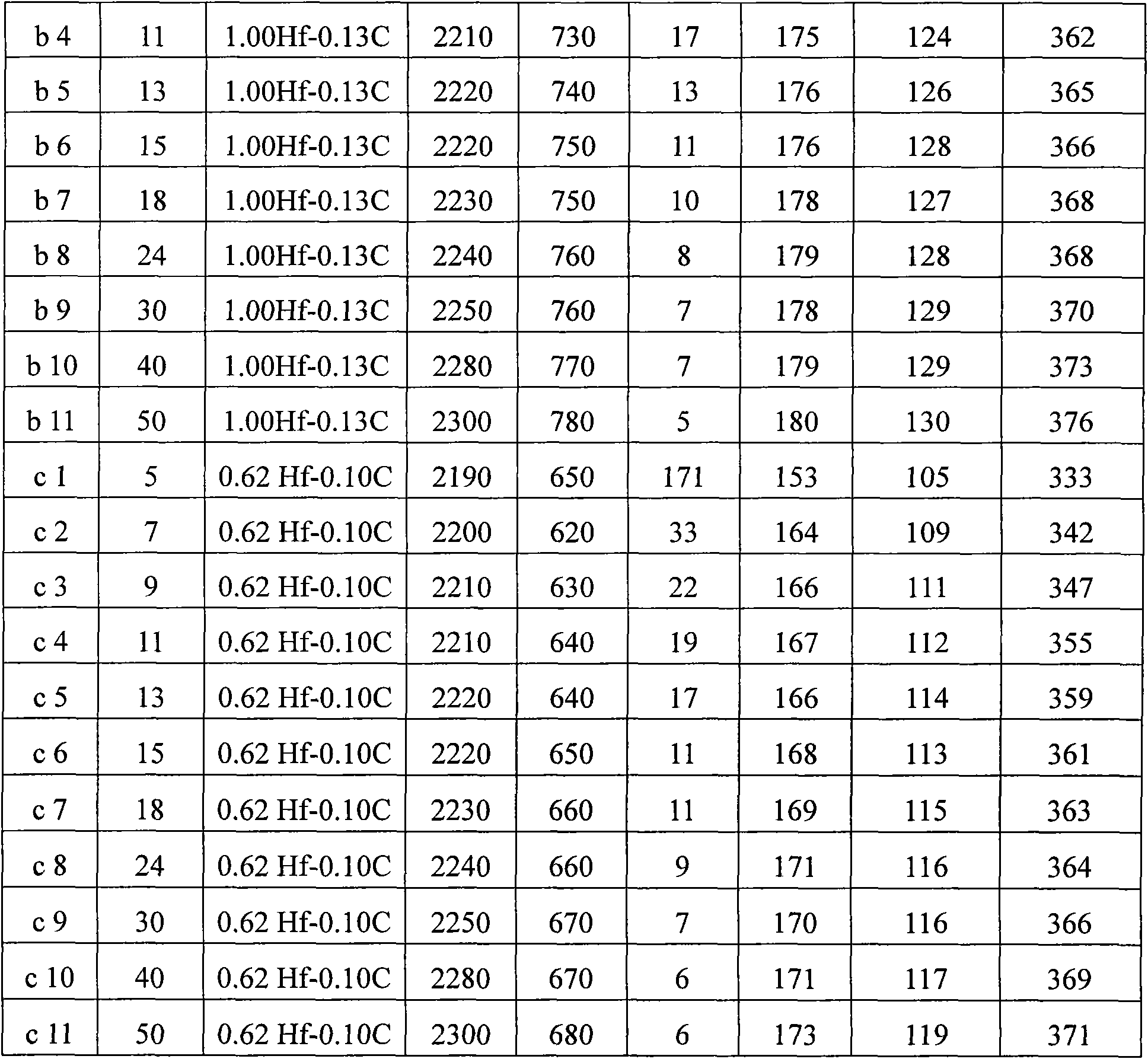

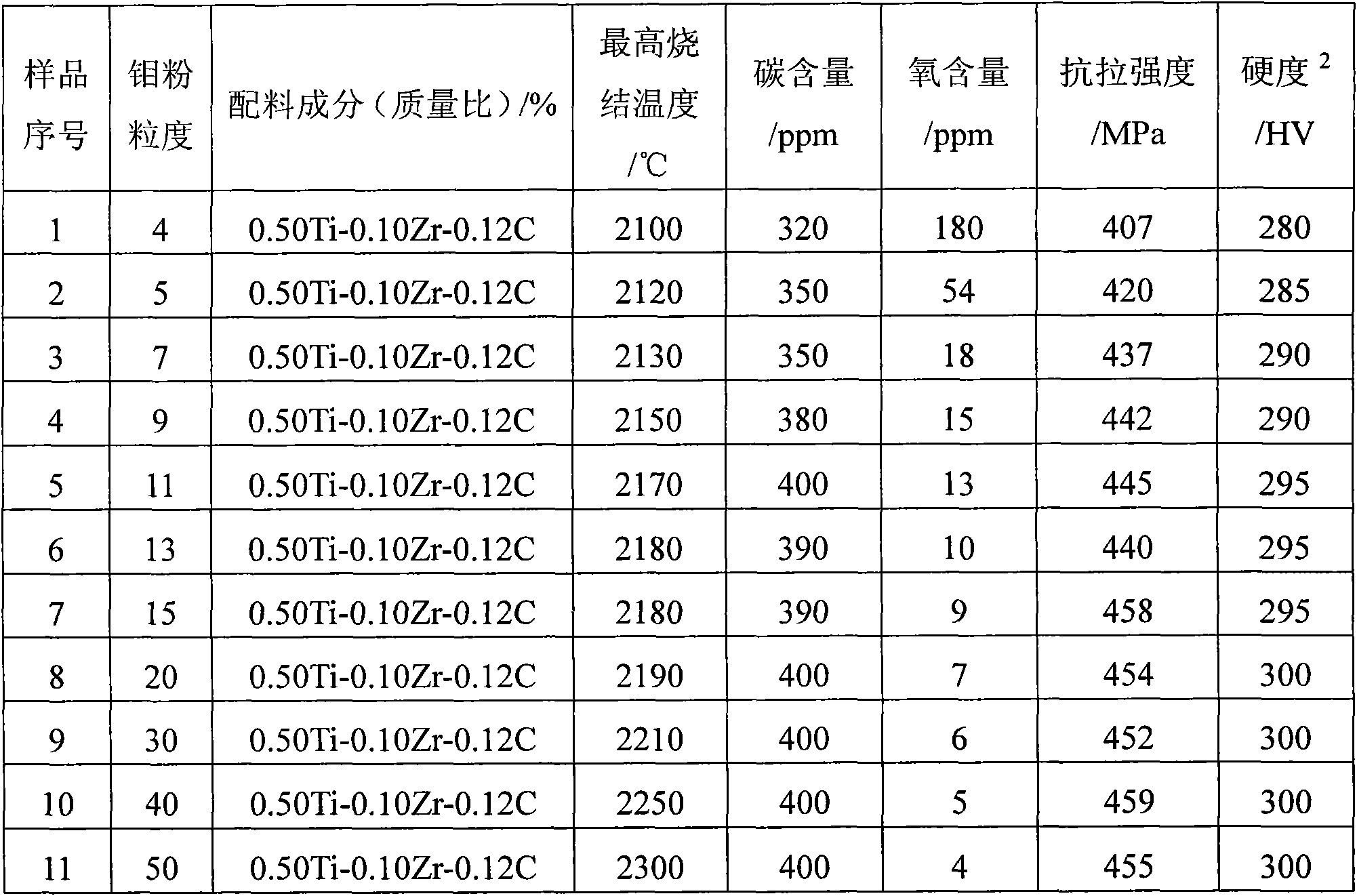

Preparation method of low-oxygen molybdenum alloy and application thereof

InactiveCN102041402AReduce oxygen contentOxygen content less impurityX-ray tube electrodesForging/hammering/pressing machinesMass ratioAlloy

The invention provides a preparation method of a low-oxygen molybdenum alloy. The method comprises the following steps: 1) selecting raw materials: uniformly mixing industrial molybdenum powder with Fisher particle size of 3-100 mum, powder containing strengthening elements with Fisher particle size of 3-10 mum, and carbon simple substance powder with Fisher particle size of 0.1-3 mum at certain mass ratio; 2) forming the raw materials: performing static pressing or mould pressing treatment on the mixed raw materials under pressure of 100-300 MPa to obtain formed blank; and 3) sintering the raw materials: sintering the formed blank in vacuum, hydrogen or inert gas environment at the high temperature of between 1,800 and 2,300 DEG C for 5-15 h to obtain the low-oxygen molybdenum alloy. Through the invention, the problem of high oxygen content of the molybdenum alloy prepared by powder metallurgy is solved. The low-oxygen molybdenum alloy prepared by the method can be used for preparing an X-ray tube rotating anode target, a composite target-based target, a high-temperature crucible, a hot-forging die and a high-temperature ceramic gasket.

Owner:XIAN GEMEI METAL MATERIAL

Low-density ultrahigh-strength steel and preparation method thereof

ActiveCN106244927ALow costIn line with the development concept of energy saving and emission reductionChemical compositionCarbide

The invention relates to low-density ultrahigh-strength steel and a preparation method thereof, and belongs to the field of metal materials. The steel comprises the following chemical components in percentage by mass: 0.6 to 1.6 percent of C, 5 to 10 percent of Al, 15 to 30 percent of Mn, 0.01 to 0.2 percent of Nb, 0.1 to 3 percent of Mo, less than or equal to 5 percent of Cr, less than or equal to 0.5 percent of Ti, less than or equal to 2 percent of Si, less than or equal to 0.6 percent of B, and the balance of Fe and unavoidable impurity elements. According to the low-density ultrahigh-strength steel and the preparation method thereof, a NbMoC phase which is finely dispersed precipitates by compounding and adding the Nb and the Mo; precipitation is strengthened by cooperating with a kappa-carbide; the tensile strength reaches over 1,350 MPa, the elongation reaches over 10 percent and the density is 6.8 to 7.0 g / cm<3>; the low-density ultrahigh-strength steel is low in cost, is suitable for light weight of traffic transportation tools, such as vehicles and airplanes, and meets the development concept of energy conservation and emission reduction.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

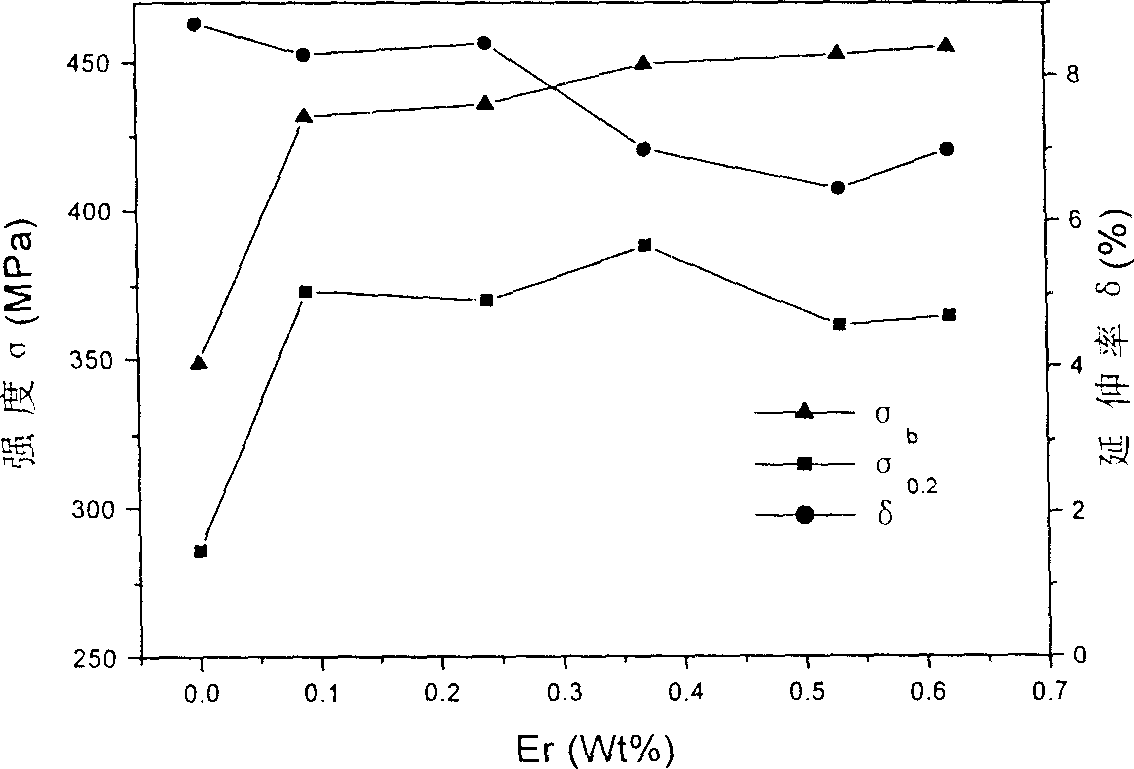

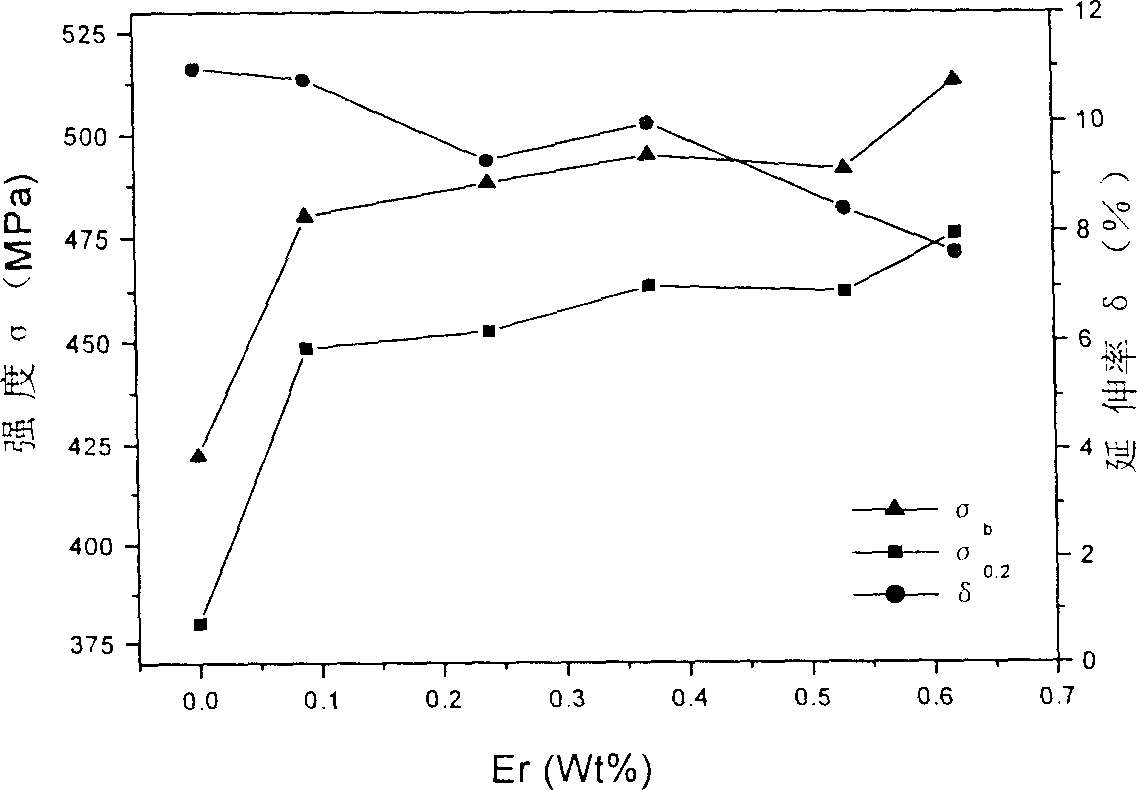

Al-Zn-Mg-Er rare earth aluminium alloy

The present invention relates to metal alloy technology. The key of the present invention is the addition of RE element Er in the experiment determined amount 0.1-0.7 wt% into the alloy. During the preparation process of the Al-Zn-Mg-Er alloy, Al-Er intermediate alloy through vacuum smelting is added into Al-Zn-Mg alloy. The addition of Er can fine obviously the alloy grains, raise alloy strength greatly and suppress re-crystallization. In addition, Er is relatively cheap and its addition has no significant increase in production cost. On the basis of Al-Zn-Mg alloy as one of the typical industrial Al alloy, one series of Er containing Al-RE alloy may be developed and used in astronautics, aeronautics, traffic and other fields.

Owner:BEIJING UNIV OF TECH

Laser sinter powder with metal soaps, process for its production, and moldings produced from this laser sinter powder

InactiveUS20080300353A1Increase resistanceLarge tensile strainAdditive manufacturing apparatusFibre treatmentTensile strainSurface finish

A sinter powder containing a polyamide and metal soaps, in particular particles of a salt of an alkanemonocarboxylic acid. A process for laser sintering, and to moldings produced from the sinter powder. The moldings formed using the powder have advantages in appearance and in surface finish when recyclability in the selective laser sintering (SLS) process is taken into account. Moldings produced from recycled sinter powder have improved mechanical properties, in particular in the modulus of elasticity and tensile strain at break.

Owner:DEGUSSA AG

Thin-wall 6-series aluminum profile for rail transit vehicle body and preparation method thereof

The invention belongs to the technical field of aluminum alloy manufacturing, and relates to a thin-wall 6- series aluminum profile for a rail transit vehicle body and a preparation method thereof. The aluminum alloy comprises the following components in percentage by weight, 0.5-0.65% of Si, less than or equal to 0.25% of Fe, less than or equal to 0.10% of Cu, 0.03-0.15% of Mn, 0.45-0.55% of Mg,less than or equal to 0.05% of Cr, less than or equal to 0.05% of Zn, less than or equal to 0.10% of Ti, less than or equal to 0.05% of a single impurity, less than or equal to 15% of total impuritiesand the balance Al. The temperature of the homogenization treatment is 550-580 DEG C, the content of elements such as Mn and Cr is reduced, the recrystallization temperature in the alloy extrusion process is reduced, the nucleation density and the proportion of recrystallization of the aluminum profile in the wall thickness direction during extrusion of the aluminum profile are increased, the characteristic that recrystallization is easy to occur when the thin-wall sectional materials are extruded is fully utilized, a product with the uniform and consistent surface layer core grain structureis obtained in the extrusion process, and the method for improving the recrystallization temperature of the alloy by increasing the content of Mn and Cr elements is subverted.

Owner:中铝特种铝材(重庆)有限公司

Semi-solid die-casting aluminum alloy material and die-casting molding method using same

A semi-solid die-casting aluminum alloy material comprises 6%-9% of Si, 0-0.3% of Cu, 0.25%-0.55% of Mn, 0.2%-0.5% of Mg, 0.6%-1.2% of Fe, 0-0.15% of Ni, 0-0.15% of Zn, 0-0.15% of Pb, 0-0.05% of Sn, 0-0.2% of Ti, 0-0.15% of impurities, and the balance Al. The content of Si is controlled to be 6%-9% and the content of Fe is controlled to be 0.6%-1.2%, so that the good die-casting molding performance, corrosion resistance and demoulding effect are ensured; meanwhile, 0.25%-0.55% of Mn is added to form a MnAl6 compound, so that the harmful effect of iron is effectively weakened; also, Mn can hinder the recrystallization process of aluminum alloy, the recrystallization temperature is increased, and favorable conditions are provided for the semi-solid pulping process of alloy slurry; in addition, 0.2%-0.5% of Mg is contained properly so as to improve the tensile strength.

Owner:FUJIAN KINRUI HIGH TECH CO LTD

High-intensity aluminum alloy powder material for manufacturing additional material and preparation method thereof

InactiveCN107502795ARaise the recrystallization temperatureIncrease temperatureAdditive manufacturing apparatusMetallurgyHigh intensity

The invention discloses a high-intensity aluminum alloy powder material for manufacturing an additional material. The high-intensity aluminum alloy powder material for manufacturing the additional material comprises the following components in percentage by mass: 3-7% of Mg, 0.50-0.90% of Sc, 0.02-0.20% of Zr, 0.01-0.1% of Cr, 0.1-0.4% of Fe, 0.05-0.2% of Cu, 0.05-0.2% of Mn, 0.01-0.15% of Ti, 0.1-0.25% of Si, 0.1-0.25% of Zn, and the balance Al, wherein the sum of the abovementioned components in percentage by mass is 100%. The invention also discloses a preparation method of the high-intensity aluminum alloy powder material for manufacturing the additional material. With the adoption of the high-intensity aluminum alloy powder material for manufacturing the additional material, the problem that existing aluminum alloy powder cannot completely meet the requirement on intensity of parts.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

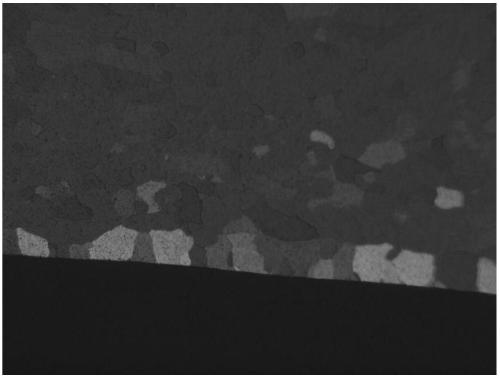

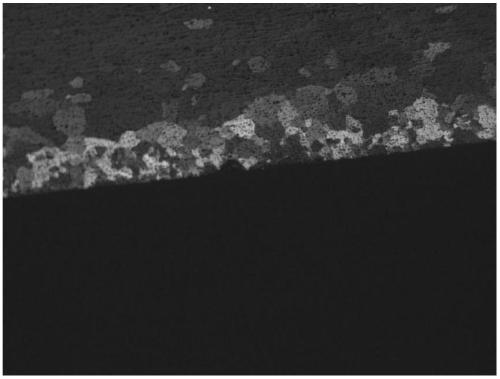

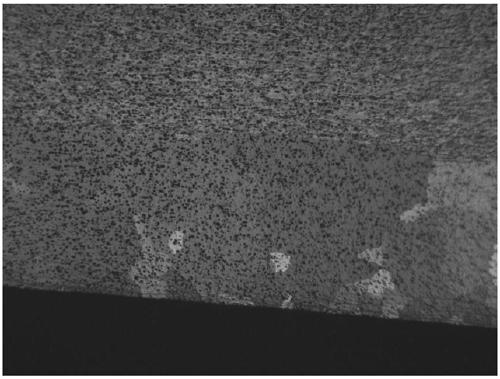

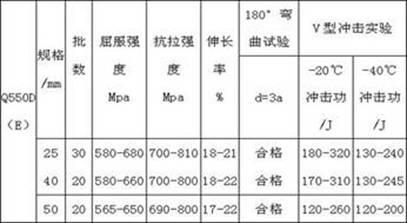

Q550 D high-quality structural iron medium and heavy plate and production method thereof

ActiveCN102433498ARaise the recrystallization temperatureImprove toughnessRoll force/gap control deviceTemperature control deviceEnergy consumptionSteel plates

The invention discloses a Q550 D high-quality structural iron medium and heavy plate, produced by smelting and rolling C, Si, Mn, Nb, V, Ti, Mo, B, Als and Fe. According to the invention, by properly adjusting the content and proportion of C, Mn, Nb, V, Ti, and Mo in the Q550D(E), strictly controlling the content of P and S, and cooperating the production technology disclosed herein, the characteristics of low carbon equivalent, high strength, high toughness, good weldability and the like of the structural iron medium and heavy plate can be guaranteed, the production technology can be simplified, the production flow can be shortened, and the production energy consumption can be reduced. The Q550 D high-quality structural iron medium and heavy plate is suitable for large-scale production operation.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

A kind of preparation method of nano rare earth oxide doped molybdenum alloy electrode material

The invention relates to a preparation method of a molybdenum alloy electrode material doped with nano rare oxides. According to the preparation method, molybdenum powder is used as a raw material, the molybdenum powder and nano rare oxide powder are uniformly mixed by adopting a solid-solid doping method, wherein the nano rare oxides are lanthana oxide, cerium oxide or mixed rare earth oxide; and then the molybdenum alloy electrode material doped with different kinds and contents of nano rare earth oxides is prepared through adopting the processes of sieving, pressing and forming, sintering,forging and vacuum annealing heat treatment under certain temperature. The preparation method disclosed by the invention and the heat treatment process are simple and feasible; and the molybdenum alloy electrode material doped with the nano rare earth oxides, which is prepared by using the method disclosed by the invention, has the characteristics of uniform tissues, high compactness, high strength, high recrystallization temperature, high elongation rate, favorable deep processing performance, and the like.

Owner:XIAN FULAI ELECTRICAL ALLOY

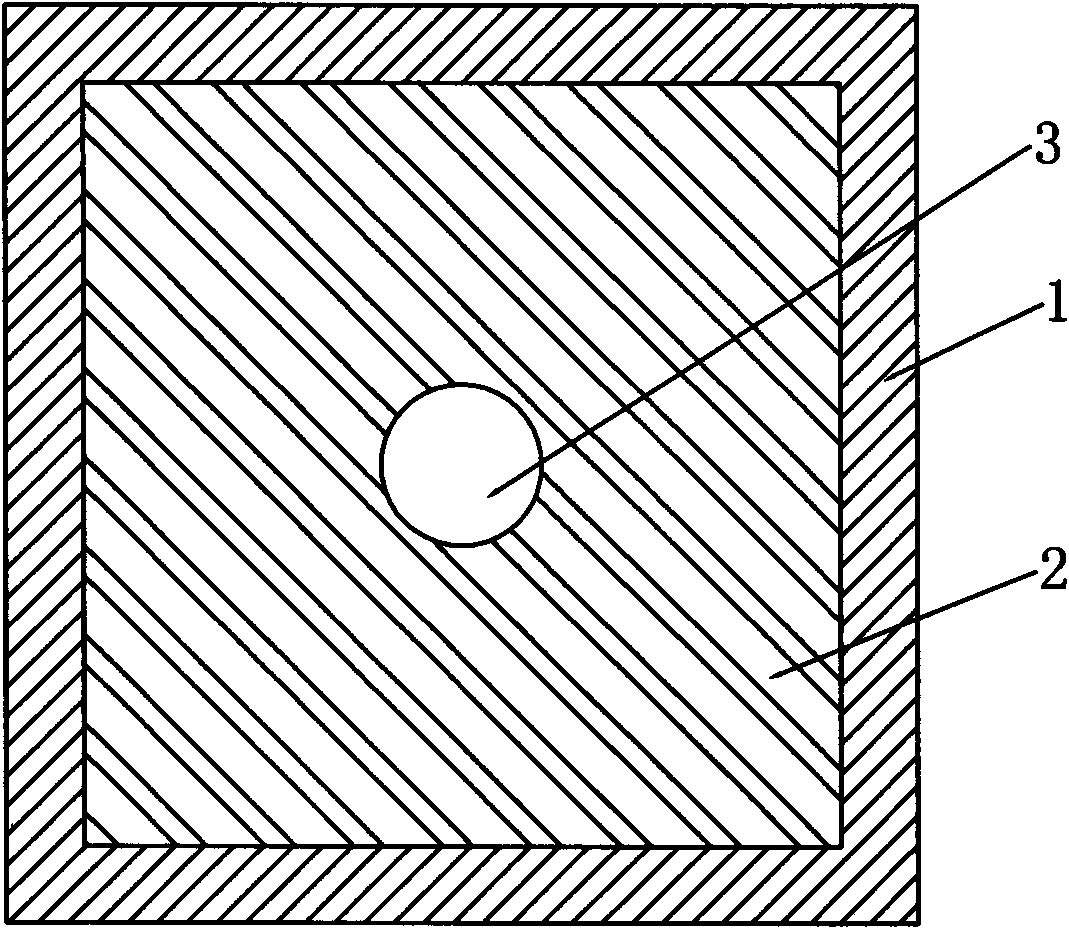

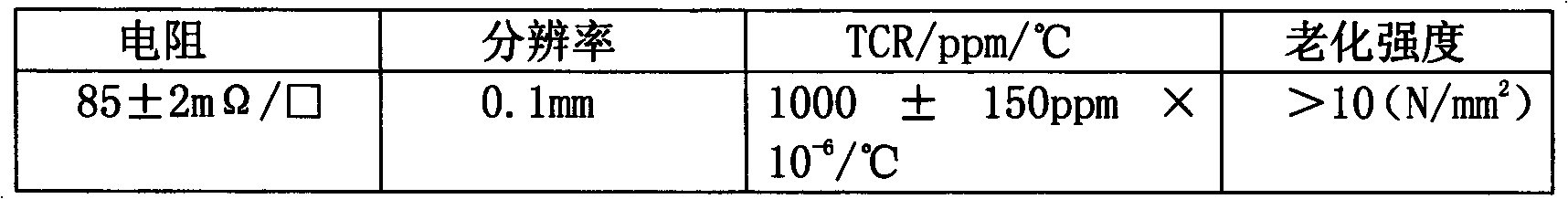

High-temperature aluminum alloy base rare earth thick film circuit electric heating element and preparation technology thereof

ActiveCN102158993ALow costImprove thermal efficiencyNon-conductive material with dispersed conductive materialHeating element materialsRare earthFar infrared

The invention discloses an aluminum alloy base plate-based rare earth thick film circuit controllable electric heating element and a preparation technology thereof. The electric heating element comprises a substrate and a series electronic sizing agent, wherein the series electronic sizing agent is prepared on the substrate, the series electronic sizing agent comprises a packaging sizing agent and a rare earth electrode sizing agent, and a rare earth medium sizing agent and the series electronic sizing agent respectively consist of a function phase, an inorganic bonding phase and an organic dissolvent carrier. The series electronic sizing agent is prepared on an aluminum alloy base plate in the manner of a thick film circuit. The series electronic sizing agent further comprises a series rare earth electric resistance sizing agent. The invention further discloses the prescription of the aluminum alloy base plate, the packaging sizing agent, the series rare earth electric resistance sizing agent, the rare earth electrode sizing agent and the rare earth medium sizing agent. The invention has the advantages of being high-speed in heat transfer and heat dissipation, even and controllable in heating temperature field, good in compatibility, firm in combination, large in power density, high in heat resistance and impact resistance, and the electric heating element has high-temperature far infrared function, are green, environment-friendly, energy-saving, low-carbon, safe and reliable.

Owner:GUANGDONGSHENG YUCHEN ELECTRONICS & TECH CO LTD

Zinc alloy for manufacturing die

Owner:ZHUZHOU SMELTER GRP

Micro-nano-alloy bimetal composite material preparation technique and device thereof

The invention relates to a micro-nano-alloy bimetal composite material preparation technique and a device thereof; one of wear-resistant and corrosion-resistant ferrous metal material, non-ferrous metal material and various self-fluxing alloy is prepared into power; then, the powder is added with less than or equal to 0.8% of one or combination in CeO2, Y2O3 and La2O3, 0.3-1.5% of MgO, 0.3-1.8% of CaF2, 0.0-1.5% of B, 0.1-0.8% of Nb, 0.1-1.0% of Ti, 0.1-2.0% of grain refining and recrystallization inhibitor according to the mass percent; or the powder is added with 1-40% of carbide, nitride, micro-nano or nano particles of boride; and the mixture is put into a high-energy stirring ball grinding mill for grinding and ball milling, so that the micro-nano or nano alloy powder can be prepared. A variable frequency induction heating device is adopted for cladding and melting vacuum or inert gas, so that a workpiece can be melted and coated with a micro-nano or nano scale alloy cladding layer which has the grain size of 0.1-35mm and is wear-resistant and corrosion-resistant, and the bimetal composite material can be prepared. The invention overcomes the defects in various coating techniques in China at present, can complete the preparation of the workpiece with the cladding layer having high thickness for once, does not need repeated coating and sintering, has high material utilization rate, low machining allowance and preparation cost, simple preparation technique and high production efficiency.

Owner:泰州海天机械配件有限公司

Method for preparing Mo-Si-Al-K cold-rolling thin molybdenum plate band

The invention relates to a Mo-Si-Al-K cold rolling thin molybdenum strip and a preparation method thereof. The invention is characterized in that the preparation process is: sintering the Mo-Si-Al-K into high temperature molybdenum billet; pre-annealing before the rolling at the temperature of 1300-1400 DEG C; implementing the hot rolling cogging processing on the high temperature molybdenum billet with the first pass deformation of 20 to 30 percent; implementing the intermediate annealing, the alkali washing and the warm rolling at the temperature of 900-1100 DEG C when the rolling deformation reaches to 70 to 75 percent to obtain a middle thick molybdenum strip; cold cooling the middle thick molybdenum strip into the specification of a finally finished product; implementing the vacuum stress relief annealing on the finished product at the temperature of 800-850 DEG C. And then the high temperature cold rolling thin molybdenum strip required by the invention is obtained. The product obtained through the invention is provided with strong high temperature strength and high recrystallization temperature. The cold rolling thin molybdenum strip product has the good properties of surface quality, high size precision, strong high temperature strength, good plasticity, long service life, etc. and can be widely used to produce molybdenum crucibles, boats, anodes of transmitting tubes with large power (U type), gate molybdenum tubes, heating unit, heat shields and other structural parts.

Owner:JINDUICHENG MOLYBDENUM CO LTD

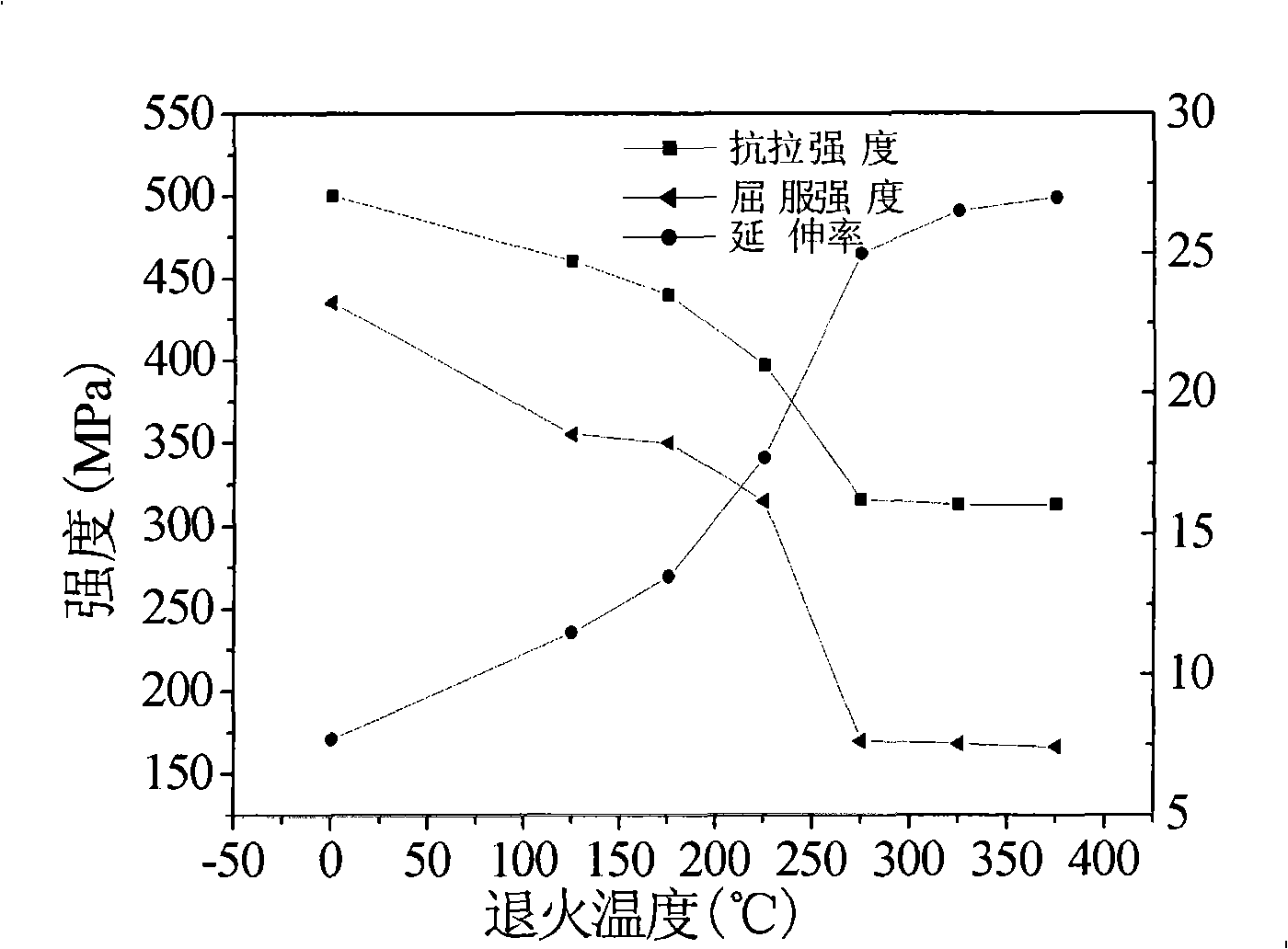

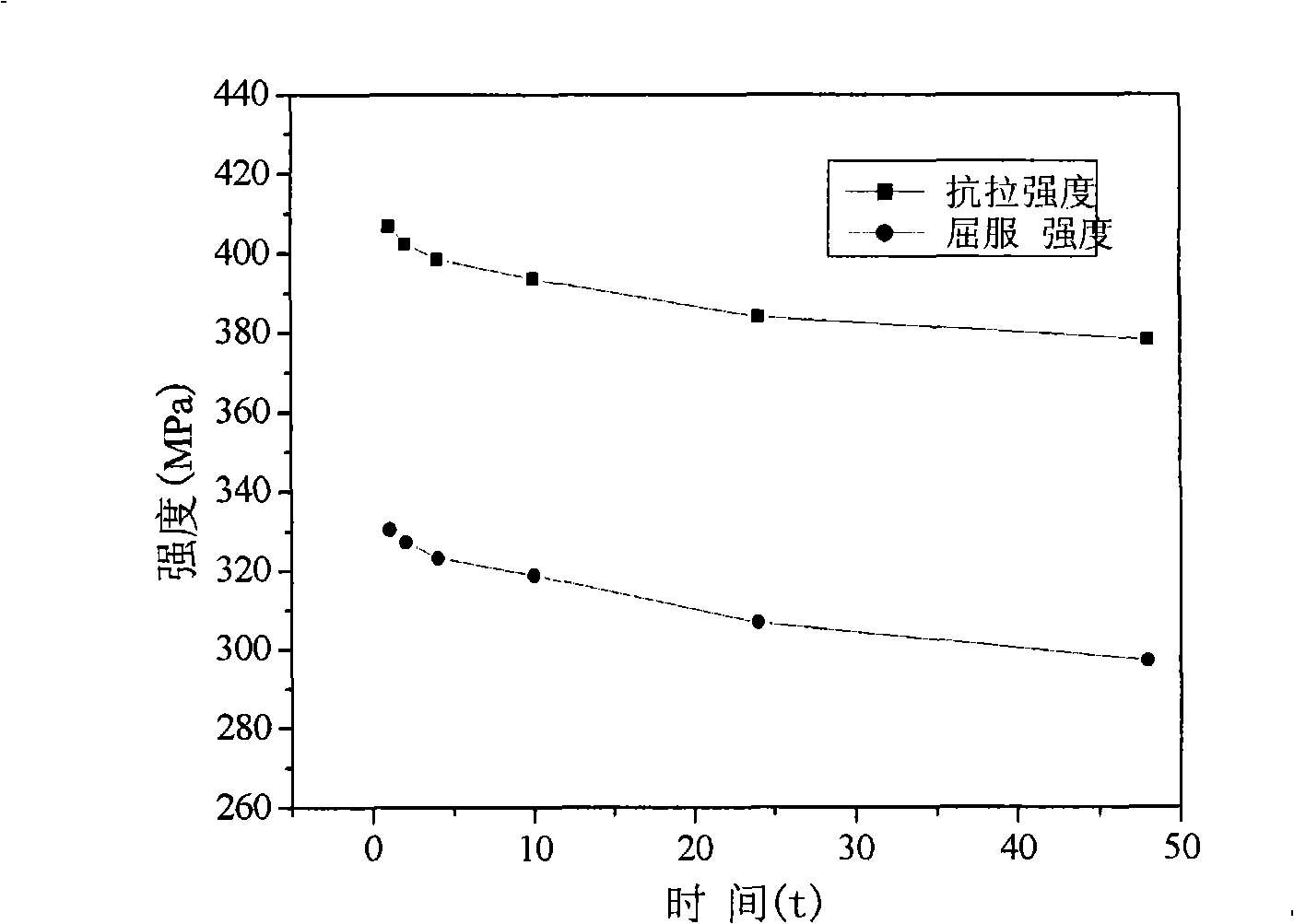

Thermal treatment process for erbium-containing aluminum-magnesium-manganese wrought aluminium alloy

The thermal treatment process for an aluminum-magnesium-manganese wrought aluminum alloy containing erbium belongs to the filed of metal alloys. The existing aluminum alloy thermal treatment process has the problems of strength reducing, corrosion resisting performance reducing after long term use, etc. The invention aims at providing the thermal treatment process for an aluminum-magnesium-manganese cold-rolled sheet containing erbium, which is realized by homogenizing annealing, hot rolling, cold rolling, stabilizing annealing and other process steps, wherein the stabilizing annealing process comprises the steps that, a cold-rolled sheet is annealed at the temperature of 100-400 DEG C and insulated for 1-48h; the annealing temperature and the insulating time are preferably 125-250 DEG C and 1-8h respectively. The thermal treatment process of the invention ensures the alloy to acquire excellent corrosion resisting performance under the condition that the high plasticity of the aluminum-magnesium-manganese cold-rolled sheet containing erbium is kept at a higher level; the treated alloy can be used for a long time with basically constant performance, and the service range of the alloy is wide.

Owner:BEIJING UNIV OF TECH

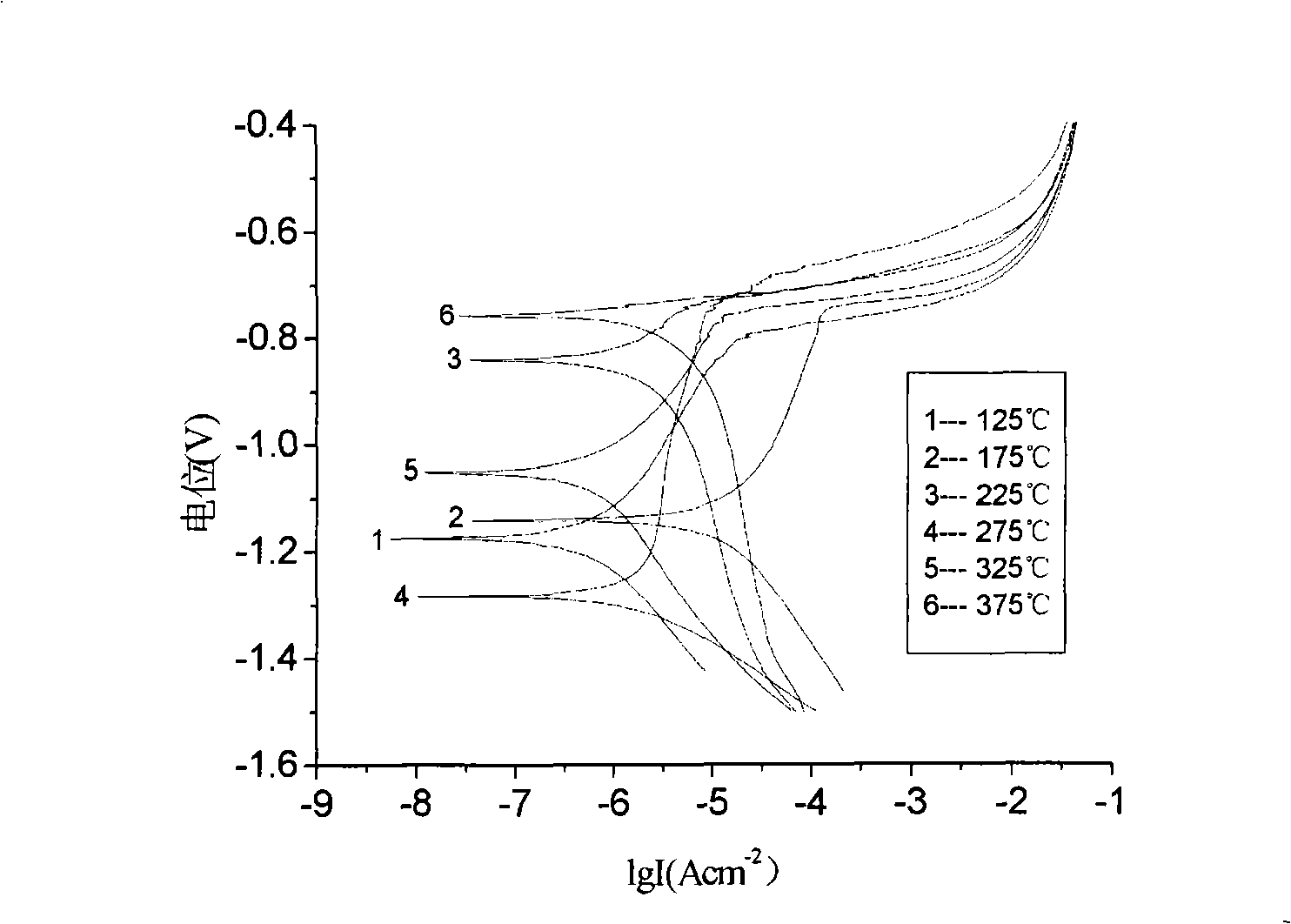

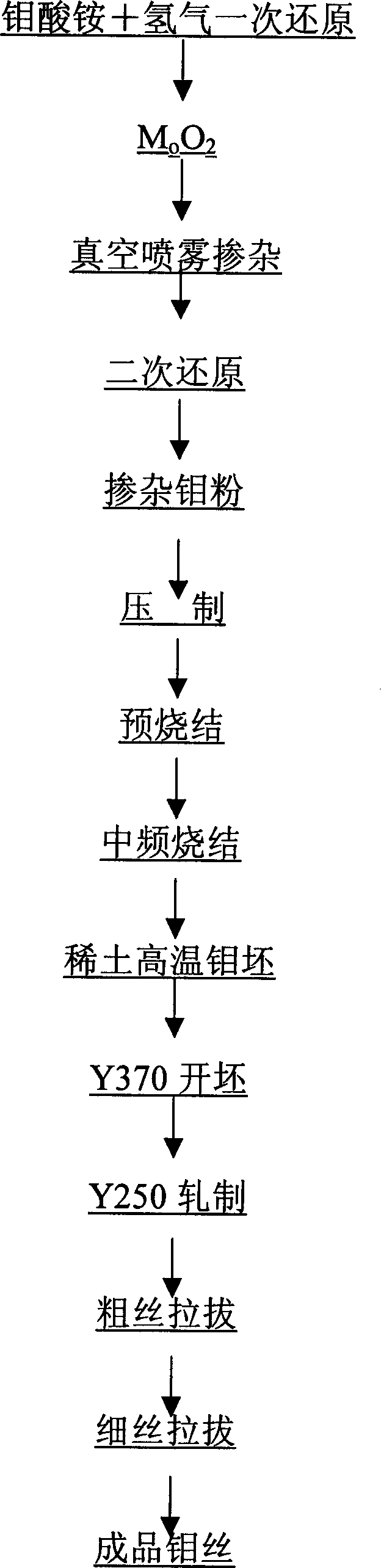

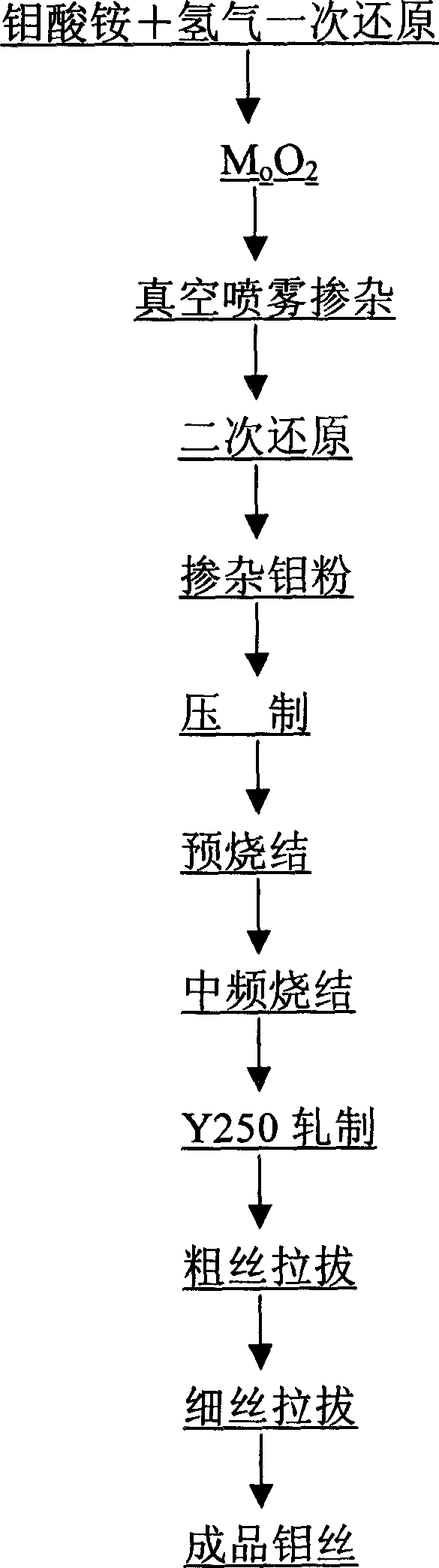

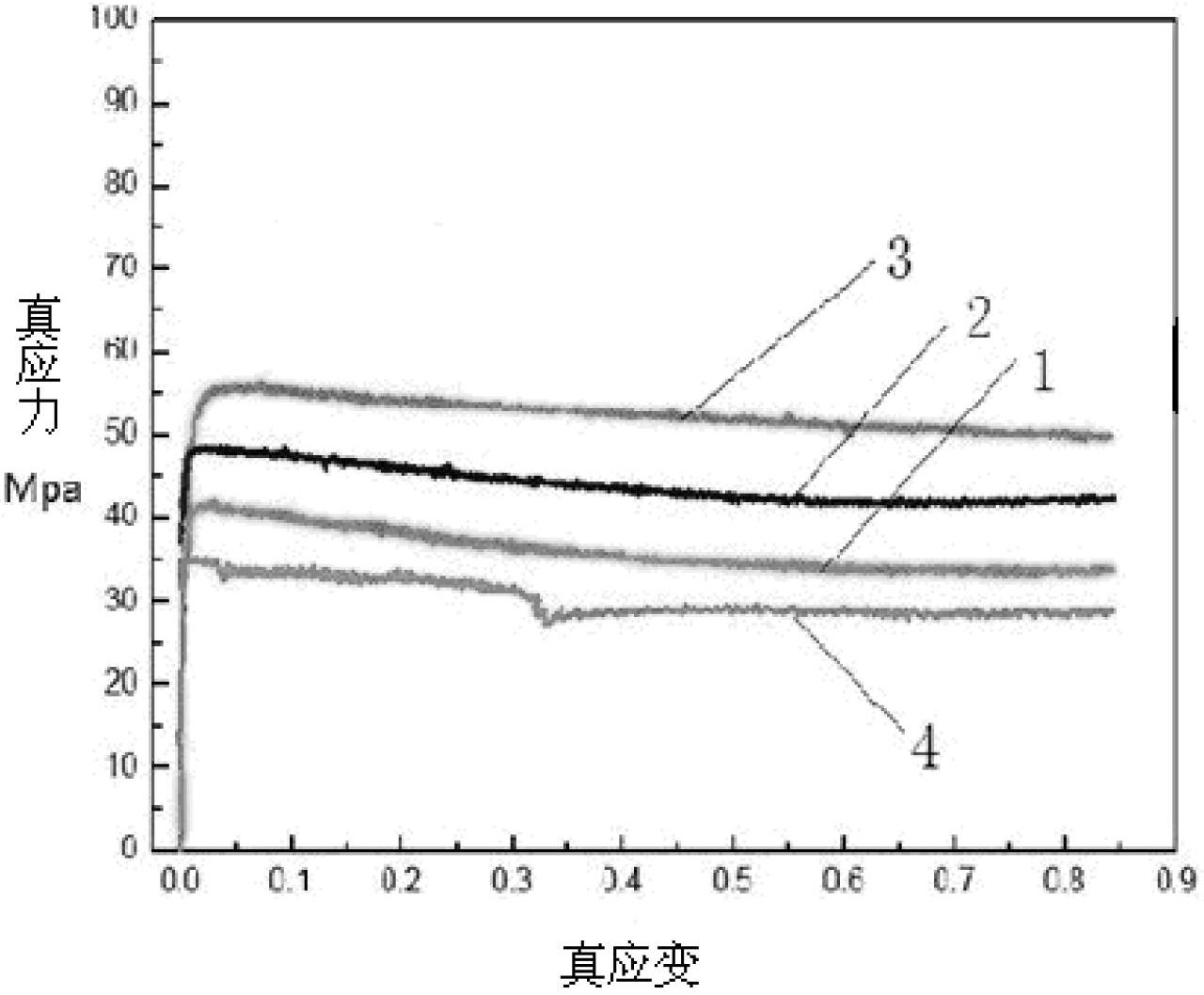

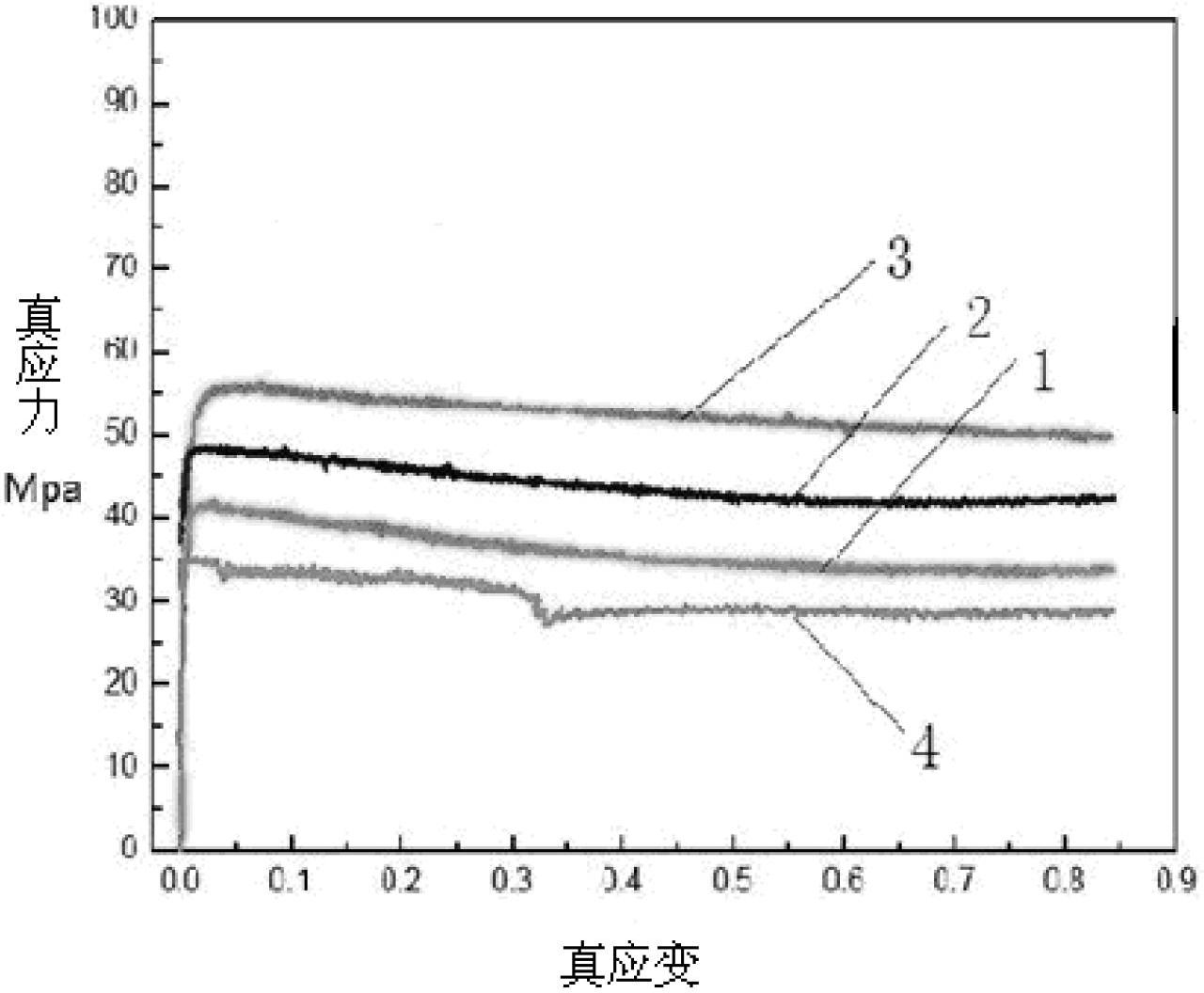

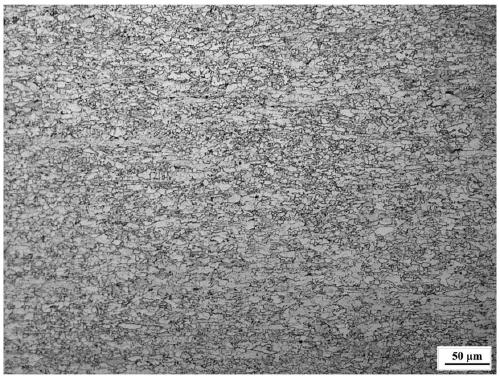

Rare earth molybdenum alloy wire and preparation method thereof

InactiveCN1876875ARaise the recrystallization temperatureHigh strengthTemperature control deviceHeat treatment process controlRare earthAlloy

The invention relates to a rare-earth molybdenum alloy wire and its process for preparing. The invention is characterized in that the said alloy wire contains two rare-earth oxides including lanthanum oxide and Y oxide(mass %) which is 0.4 %-1.0% of the alloy amount and the proportion by weight of lanthanum oxide and Y oxide is 4:1. The process for preparing is different from the traditional powder metallurgy productive technology, which includes performing double-cone vacuum drying and liquid-solid doping at molybdenum dioxide stage, then performing secondary reduction to prepare binary rare-earth doping molybdenum powder, finally preparing rare-earth doping molybdenum wire with Mo-La-Y of 0.5-0.8mm diameter by impression, agglomeration and pressure processing procedure. Compared with the pure molybdenum, the product is of good high-temperature behavior and high recrystallization temperature which increases by 300-500 DEG C than the pure molybdenum, and is of high intensity and abrasive resistance, low ductility and long durability, which has wide application in the mechanical process industry.

Owner:JINDUICHENG MOLYBDENUM CO LTD

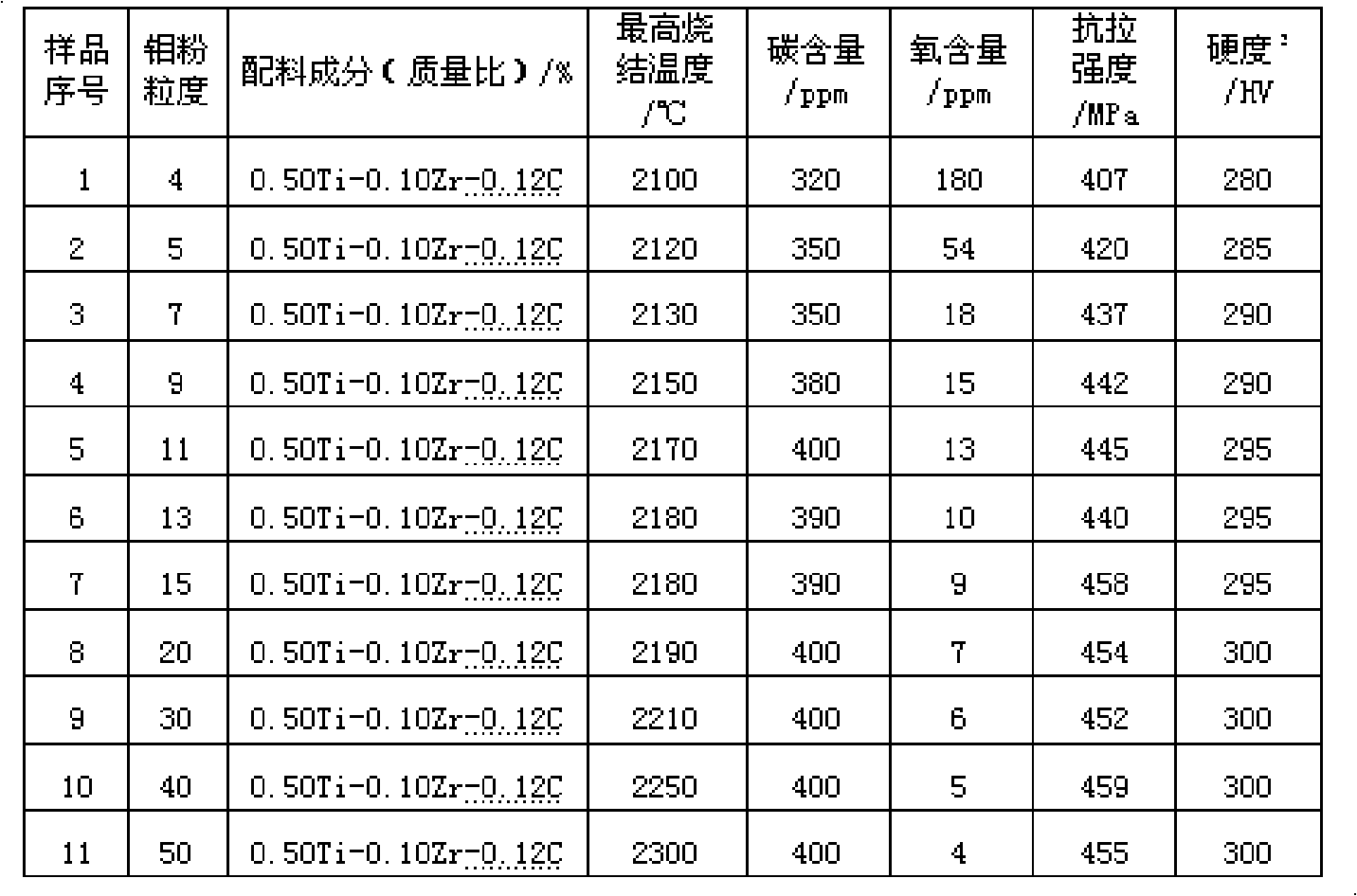

Method for preparing low-oxygen titanium-zirconium-molybdenum (TZM) alloy and application

ActiveCN102041404AReduce oxygen contentOxygen content less impurityX-ray tube electrodesForging/hammering/pressing machinesTitanium zirconiumAlloy

The invention provides a method for preparing a low-oxygen titanium-zirconium-molybdenum (TZM) alloy, which comprises the following steps of: 1) selecting raw materials, namely, uniformly mixing industrial molybdenum powder with the Fisher particle size of 4 to 50 mu m, powder containing titanium and zirconium and with the Fisher particle size of 3 to 10 mu m, and simple substance carbon powder with the Fisher particle size of 0.1 to 3 mu m according to a certain mass ratio; 2) shaping the raw materials, namely, treating the mixed raw materials under the pressure of 100 to 300 Mpa to obtain a shaped blank; and 3) sintering the raw materials, namely, sintering the shaped blank in the environment of vacuum, hydrogen or inert gas at the temperature of 1,800 to 2,300 DEG C for 5 to 15h to obtain the low-oxygen TZM alloy. The method solves the problem of high oxygen content of the TZM alloy prepared by a powder metallurgy method. The low-oxygen TZM alloy prepared by the method can be used for the preparation of a rotating anode of an X-ray tube, a composite target substrate, a high-temperature crucible, a hot-forging die and a high-temperature ceramic pad.

Owner:XIAN GEMEI METAL MATERIAL

Mo-La-Ce rare earth molybdenum alloy wire and preparation method thereof

InactiveCN1876874ARaise the recrystallization temperatureHigh strengthTemperature control deviceHeat treatment process controlCerium nitrateHigh rate

The invention relates to a Mo-La-Ce rare-earth molybdenum alloy wire and its process for preparing. The invention is characterized in that the said molybdenum alloy wire contains 0.4 %-1.0% lanthanum oxide and cerium oxide(mass %) and the proportion by weight of lanthanum oxide and cerium oxide is 4:1. The process for preparing is different from the traditional powder metallurgy productive technology, which includes performing vacuum drying and liquid-solid doping for molybdenum dioxide, lanthanum nitrate and cerium nitrate solution, then performing secondary reduction to prepare binary rare-earth doping molybdenum powder, finally preparing rare-earth doping molybdenum wire with Mo-La-Ce of 0.5-0.8mm diameter by impression, agglomeration and pressure processing procedure. The raw materials of this invention is cheap and facile, and the prepared molybdenum wire is of high tensile strength, strong abrasive resistance and simple process and is inflexible, and has high rate of finished products, good compatibility and long durability.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Preparation method for graphene rare earth aluminum alloy high-conductive material

ActiveCN107099708AReduce the degree of reunionLow densityConductive materialMetal/alloy conductorsRare earthConductive materials

The invention discloses a preparation method for a graphene rare earth aluminum alloy high-conductive material. The method comprises the following steps: adding aluminum scrap, silicon calcium alloy, copper aluminum alloy, zinc aluminum alloy, magnesium ingot, rare earth aluminum alloy and graphene into a smelting furnace for smelting; performing ladle analysis, thereby acquiring an aluminum alloy solution; casting and rolling the aluminum alloy solution, thereby acquiring aluminum alloy; performing homogenization treatment on the aluminum alloy; performing ageing treatment, thereby acquiring the graphene rare earth aluminum alloy high-conductive material. According to the preparation method for the graphene rare earth aluminum alloy high-conductive material, provided by the invention, the technical parameters are reasonably set, the graphene structure is optimized and the overall performance of the aluminum alloy is effectively improved, so that the acquired graphene rare earth aluminum alloy high-conductive material has excellent electric conductivity, heat resistance, arc altitude resistance and mechanical properties.

Owner:ANHUI NANYANG NEW MATERIAL TECH CO LTD

High-sag-resistance brazing composite aluminum alloy foil for heat exchanger

InactiveCN102676884AReduce corrosion potentialImproved Brazing Welding AbilityLaminationLamination apparatusManganeseImpurity

The invention discloses high-sag-resistance brazing composite aluminum alloy foil for a heat exchanger, which consists of a core and a clad. The thickness of the clad accounts for 8-15% of the total thickness of the composite aluminum alloy foil. The core comprises the following components by weight: 1.4-1.6% of manganese, 0.4-0.6% of silicon, 0.50-0.90% of iron, 1.00-1.60% of zinc, 0.10-0.50% of vanadium, 0.05-0.30% of zirconium, 0.05-0.30% of titanium, and the balance of aluminum and inevitable impurities, wherein the contents of copper and magnesium in the impurities are both smaller than 0.05%. The alloy provided by the invention can be rolled into controlled atmosphere brazing (CAB) composite aluminum alloy foils for heat exchangers. The composite aluminum alloy foil disclosed by the invention has reasonable component ratio, easy manufacturing, good corrosion resistance, and high sag resistance after brazing, and is suitable for large-scale industrial production.

Owner:长沙众兴新材料科技有限公司

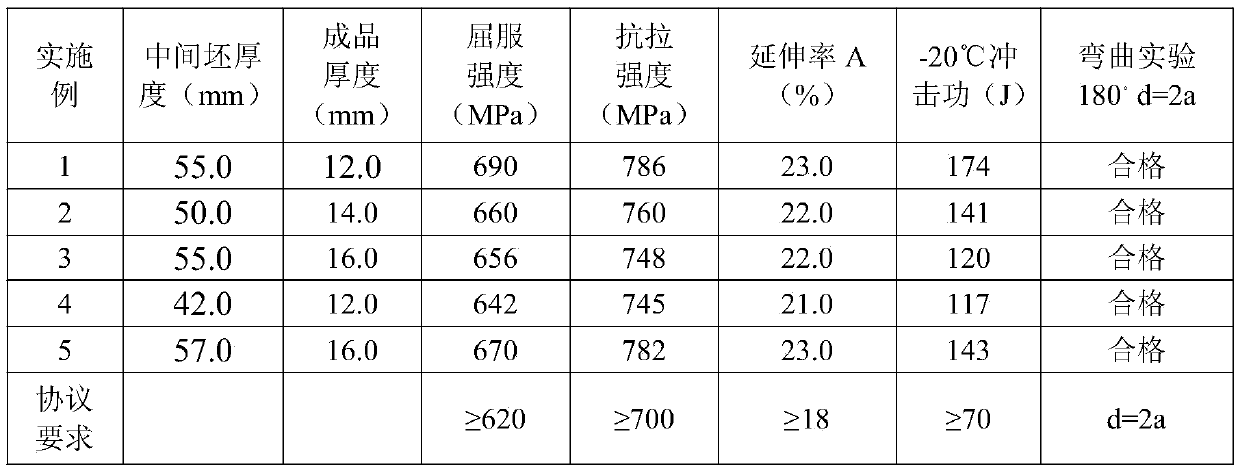

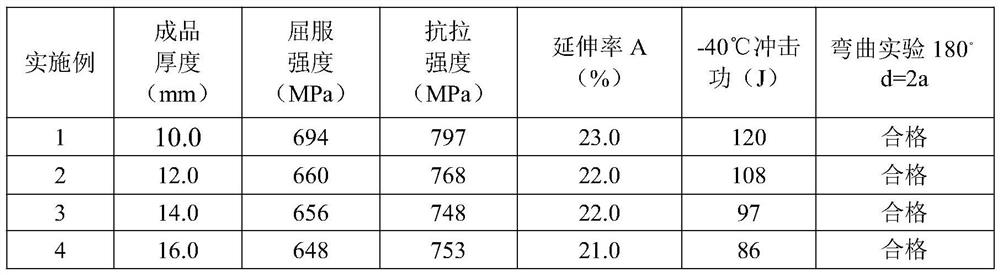

12.0-16.0 mm thick high-toughness 700MPa grade automobile beam steel and production method thereof

InactiveCN111549288AHigh strengthImprove low temperature impact toughnessUltimate tensile strengthToughness

The invention discloses 12.0-16.0 mm thick high-toughness 700MPa grade automobile beam steel and a production method thereof. The beam steel comprises the following chemical components of, in percentage by weight, 0.06 %-0.0 9 % of C, 0.10 %-0.30 % of Si, 1.60 %-1.90 % of Mn, smaller than or equal to 0.020 % of P, smaller than or equal to 0.005 % of S, 0.020 %-0.050 % of Alt, 0.04 %-0.06 % of Nb,0.06 %-0.10 % of Ti, smaller than or equal to 0.0050 % of N, and the balance Fe and inevitable impurities. The invention also discloses the production method of the beam steel. According to the beam steel and the method, the metallographic structure of the automobile beam steel is ferrite and pearlite, wherein the content of the pearlite is smaller than 10 %, and the grain size is larger than or equal to 12 level; and a rolling technology is optimized to produce the automobile beam steel which is thick and good in strength and toughness matching, so that the specification range of the automobile beam steel with the strength level is widened.

Owner:BAOTOU IRON & STEEL GRP

Rare-earth heat-resistant aluminum alloy guide wire material and preparation method thereof

InactiveCN110343912AHigh strengthImprove heat resistanceConductive materialMetal/alloy conductorsHeat resistanceRare earth

The invention provides a rare-earth heat-resistant aluminum alloy guide wire material and a preparation method thereof. The aluminum alloy guide wire material consists of the following elements in percentage by weight: 5.00%-15.00% of Ce, 0.15%-0.70% of Zr, 0.01%-0.50% of Y, 0.01%-5.00% of Fe, 0.10%-5.00% of Mg, 0.05%-8.00% of Si, 0.001%-5.00% of Cu, 0.001%-0.40% of Co, 0.001%-0.85% of B, 0.001%-0.2% of Ti, 0.001%-0.15% of V, 0.001%-0.12% of Cr, 0.001%-0.12% of Mn, 0.001%-0.15% of Ni and the balance of aluminum. The high-strength high-conductivity heat-resistant aluminum alloy has high conductivity and high heat resistance.

Owner:SHANGHAI JIAO TONG UNIV

Al-Fe-Cu-Mg aluminum alloy for cables for coal mines, aluminum alloy cable and preparation method of alloy cable

PendingCN104294093AImprove performanceImprove mechanical strength, tensile propertiesMetal/alloy conductorsCable/conductor manufactureCoalOmega

The invention discloses an Al-Fe-Cu-Mg aluminum alloy for cables for coal mines, which comprises 0.2-1.1% of Fe, 0.01-0.4% of Cu, 0.01-0.4% of Mg, 0-0.1% of Si, 0-0.2% of B, and the balance of Al and impurities, wherein the electrical resistivity of the aluminum alloy is not greater than 0.028264 Omega.mm<2> / m, the elongation at break is not less than 10%, and the number of times of 90-degree fatigue bending is greater than or equal to 30. An aluminum alloy cable is prepared by the steps of melting, casting and rolling the aluminum alloy material so as to obtain an aluminum alloy rod, carrying out drawing, bunch-stranding and softening on the aluminum alloy rod so as to obtain an aluminum alloy cable core, and carrying out extruded insulation, cabling, extruded sheathing or armoring on the cable core; and the prepared aluminum alloy cable has the characteristics of high strength, high electric conductivity, good bending performance and the like, and can satisfy the requirements on the properties of cables in the field of coal mines.

Owner:ANHUI JOY SENSE CABLE

Low-crack-sensitivity and low-yield-ratio ultra-thick steel plate and preparation method therefor

An ultra-heavy steel plate with low cracking sensitivity and low yield ratio, the mass percentages of chemical components of the steel plate are C 0.05-0.09; Si 0.2-0.4; Mn 1.3-1.6; Al 0.02-0.04; Nb 0.03-0.08; V 0.03-0.08; Cr 0.1-0.5; Ni 0.1-0.5; Mo 0.1-0.3; Cu 0.2-0.5; Ti 0.01-0.02; P≤0.015; S≤0.003; N≤0.007, the balance being Fe and inevitable impurities; the carbon equivalent is ≤0.43, the cold cracking sensitivity coefficient Pcm is ≤0.20. A low cracking sensitivity and low yield ratio steel plate with a thickness of 40-70 mm is manufactured by the process steps of KR molten iron pretreatment-converter smelting-LF refining-RH vacuum degassing-continuous casting-lid-covering slow cooling for the continuous casting slabs-casting slabs heating-controlled rolling-controlled cooling-hot straightening-air cooling and so on.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Aluminum alloy rod with heat resistance and production method of aluminum alloy rod

The invention discloses an aluminum alloy rod with heat resistance. The aluminum alloy rod comprises not larger than 0.10% of Si, 0.10%-0.20% of Fe, not larger than 0.05% of Mg, not larger than 0.0045% of V+Ti +Cr + Mn, 0.02%-0.10% of Zr, smaller than 0.03% of Cu, smaller than 0.003% of B, smaller than 0.02% of the other single impurity, smaller than 0.1% of all the impurities and the balance aluminum. According to a production method of the aluminum alloy rod with the heat resistance, a covering agent is spread, oxidative slagging is reduced, an electromagnetic stirrer is opened, a cold material is molten quickly, the temperature is kept uniform, the compositions are uniform, slag skimming is conducted, a melt is kept clean, high-purity N2 and a refined powder spraying agent are adopted for powder spraying and refining, on-line filtering and dedusting are conducted, degassing is conducted, and the heat-resistant alloy rod meeting the production requirement is obtained. The obtained product is stable and uniform in component, compact in internal structure, smooth and clean in surface and superior in physical performance. The method is an optimum production method for producing the aluminum alloy rod with the heat resistance and is specially used for production of high-end heat-resistant alloy materials.

Owner:HENAN ZHONGFU ALUMINUM ALLOY

Rare earth treated thick 700 MPa-grade automobile beam steel strip and manufacturing method thereof

InactiveCN111809110AHigh strengthImprove low temperature impact toughnessRare-earth elementSteel belt

The invention discloses a rare earth treated thick 700 MPa-grade automobile beam steel strip. The rare earth treated thick 700 MPa-grade automobile beam steel strip comprises the following chemical components in percentage by weight: 0.06-0.09% of C, 0.10-0.30% of Si, 1.60-1.90% of Mn, no more than 0.020% of P, no more than 0.005% of S, 0.020-0.050% of Alt, 0.04-0.06% of Nb, 0.07-0.10% of Ti, no more than 0.0040% of N, 0.00100-0.0030% of Ce, and the balance of Fe and inevitable impurities. The invention further discloses a manufacturing method of the rare earth treated thick 700 MPa-grade automobile beam steel strip. The alloy component design adopts Nb-Ti microalloy, contains no noble element Mo, and aims to fully exert such characteristics as modification of rare earth inclusions, grainrefining and improvement of low-temperature impact toughness through adding rare earth elements; and through matching with optimized heating and rolling processes, automobile beam steel with thick specification and excellent toughness matching is produced, and the specification range and the use temperature range of the strength-grade automobile beam steel are widened.

Owner:BAOTOU IRON & STEEL GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com