Rare earth molybdenum alloy wire and preparation method thereof

A technology of molybdenum alloy and wire, which is applied in the field of rare earth molybdenum alloy wire and its preparation, can solve the problems of low strength, short service life and poor wear resistance of pure molybdenum wire, and achieve good product consistency, long service life, The effect of strong wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

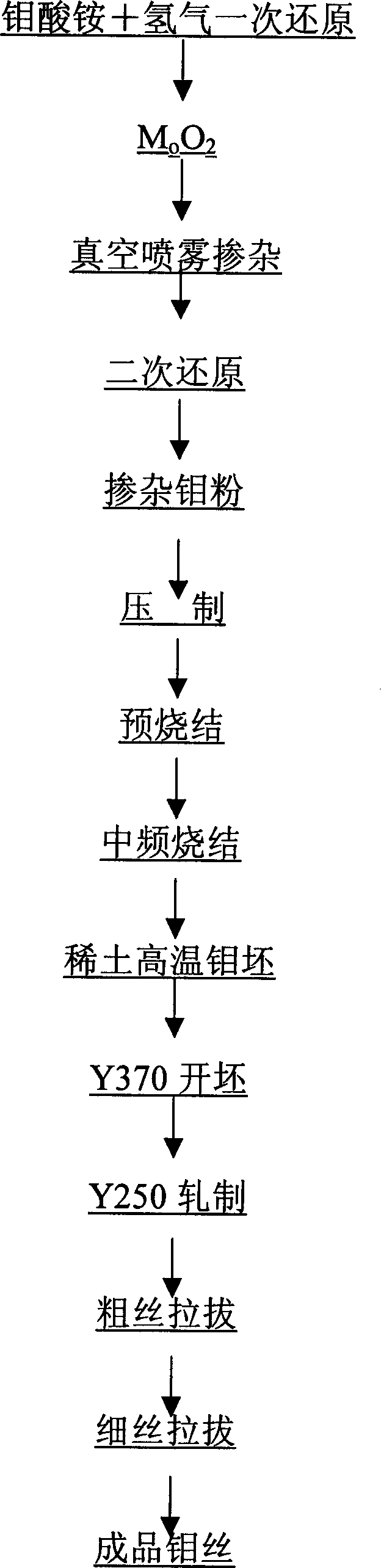

Image

Examples

Embodiment 1

[0020] Ammonium dimolybdate was used as a raw material to add hydrogen to carry out a reduction to obtain molybdenum dioxide; two rare earth oxides were weighed according to weight percentage and dissolved with concentrated nitric acid for later use; molybdenum dioxide and La(NO 3 ) 3 , Y(NO 3 ) 3 The solution is doped in a double-cone vacuum drying doping pot, where the pressure of the air compressor pump is 0.2MPa, the drying temperature of the doping pot is 70°C, and the vacuum degree inside the doping pot needs to be controlled above 0.06MPa; Molybdenum dioxide is subjected to secondary hydrogen reduction in a four-tube high-temperature muffle furnace, and the hydrogen flow rate is 2.2M 3 / H, the loading capacity of the boat is 1.0kg / boat, and the speed of pushing the boat is 4 boats / 60min; the Mo-La-Y doped molybdenum powder is subjected to cold isostatic pressing to obtain 48mmMo-La-Y rare earth doped molybdenum Rods, the pressing pressure of cold isostatic pressing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com