Patents

Literature

857 results about "Hydrogen flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst for preparing propylene by propane dehydrogenation and its prepn.

InactiveCN101015802AHigh selectivityImprove reaction stabilityCatalyst carriersHydrocarbonsAdhesiveDehydrogenation

The invention relates to a catalyst for dehydrogenating propane to prepare propone, which uses thermal-resistant oxide as carrier, uses palladium-group metal as main catalyst, uses IV A group metal and rare-earth metal as agents, uses halogen as modifier, and uses inorganic oxide with high temperature resistance as adhesive. The inventive catalyst under high temperature and low pressure has higher propane transfer rate, propone selectivity and reaction stability. And the preparation comprises that at 60-100Deg. C, immerging thermal-resistant oxide with rare-earth metal water solution for 2-10h, at 60-180Deg. C baking for 2-10h, at 400-600Deg. C baking for 3-10h, immerging said carrier and the water solution which contains palladium metal and IVA metal at 60-100Deg. C for 2-10h, and baking for 2-10h at 60-180Deg. C, adding adhesive, protruding agent and acid gel solvent, protruding and shaping, baking for 2-10h at 60-180Deg. C, activating for 3-10h at 400-600Deg. C, and reducing for 2-10h in hydrogen flow at 400-600Deg. C.

Owner:SOUTHEAST UNIV

Method for improving catalyst reacting activity in the propylene producing through propane dehydrogenation

InactiveCN101138734AHigh reactivityHigh mechanical strengthMolecular sieve catalystsHydrocarbonsRare earthDehydrogenation

A method to promote the activity of a catalyst for dehydrogenation of propane to propylene is as follows: (1) an inorganic oxide bonding agent, a promoter and an acid solvent are added into a heat-resistant oxide; then after the oxide bonding agent, the promoter, the acid solvent and the oxide are kneaded evenly, the oxide is molded by rolling or band-extruding; (2) the catalyst carrier prepared is dried for 2 to 10 hours under the temperature of 60 centigrade degrees, and calcined under the temperature of 400 to 800 degrees; (3) the calcined carrier is immersed in a rare earth metal water solution under the temperature of 60 to 100 centigrade degrees for 2 to 10 hours; (4) the catalyst carrier modified by the rare earth is immersed in a water solution comprising platinum metal elementsand the fourteenth metal elements under the temperature of 400 to 600 centigrade degrees for 2 to 10 hours, and then the carrier is filtered, washed with distilled water, dried under the temperature of 60 to 180 centigrade degrees for 2 to 10 hours, and calcined under the temperature of 400 to 600 centigrade degrees for 2 to 10 hours; (5) the catalyst prepared is activated in the air under the temperature of 400 to 600 centigrade degrees for 3 to 10 hours, and reduced in a hydrogen flow under the temperature of 400 to 600 centigrade degrees for 2 to 10 hours; the reduced catalyst is used for catalytic reaction for dehydrogenation of propane to propylene.

Owner:SOUTHEAST UNIV

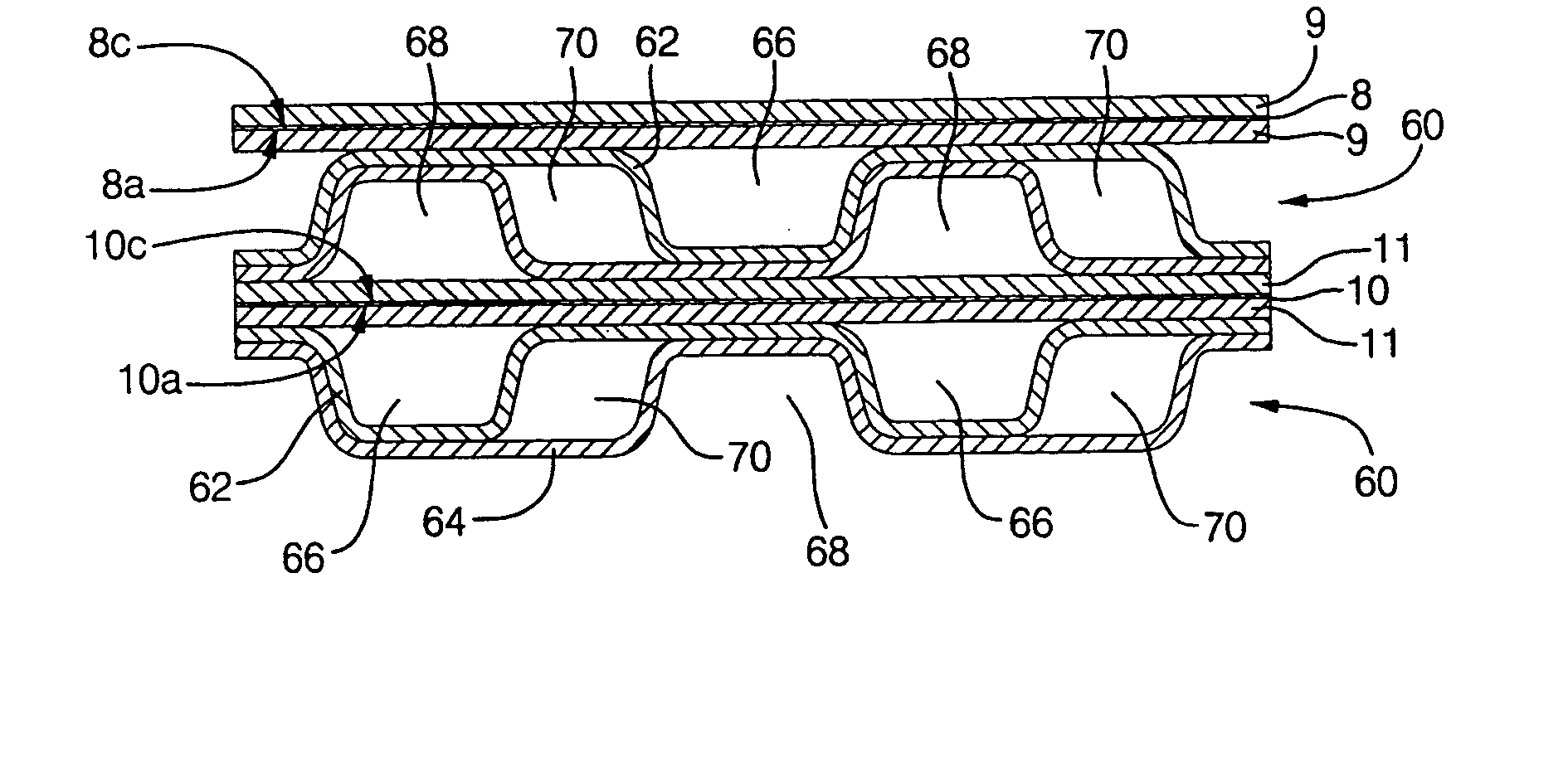

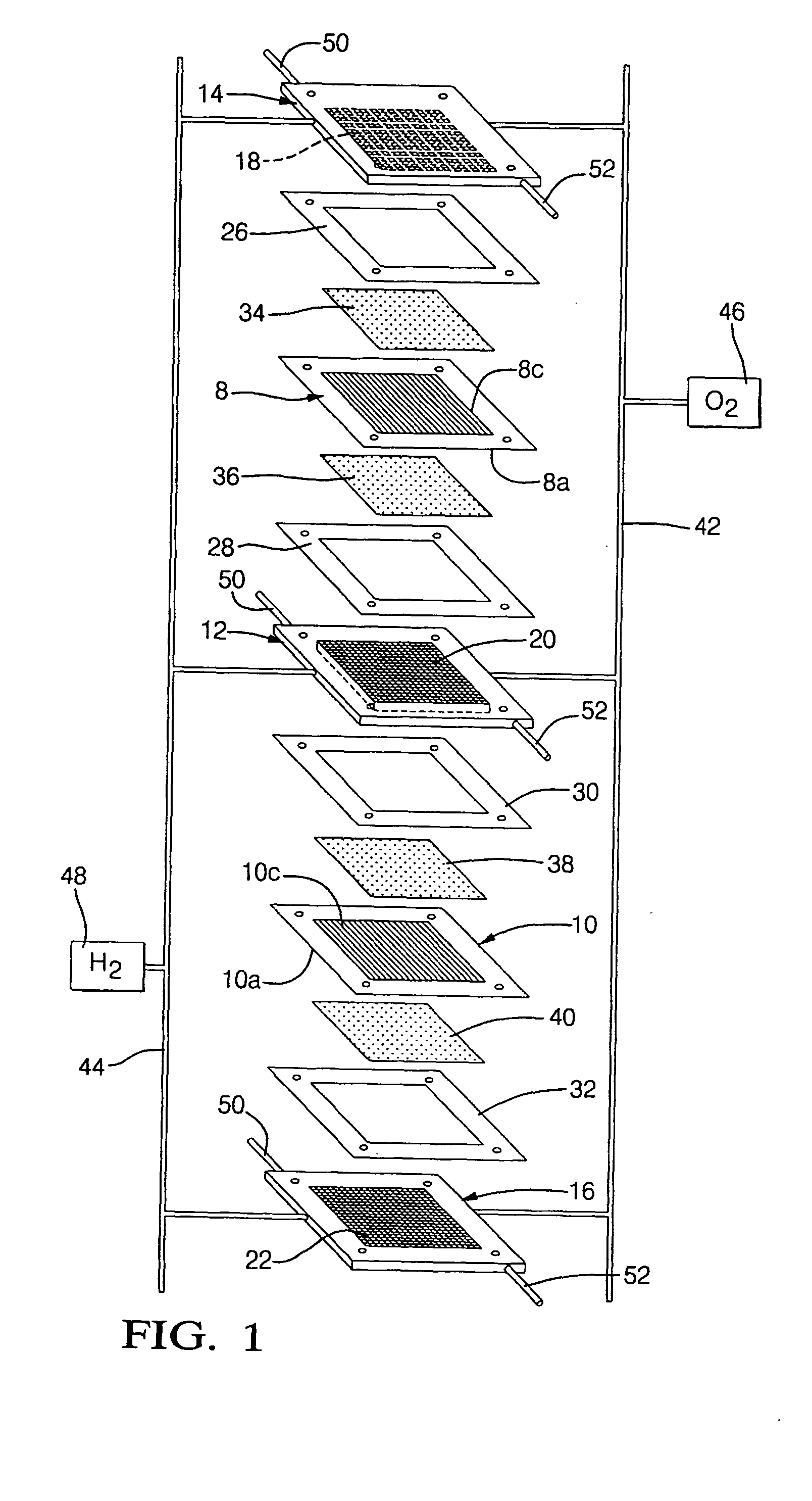

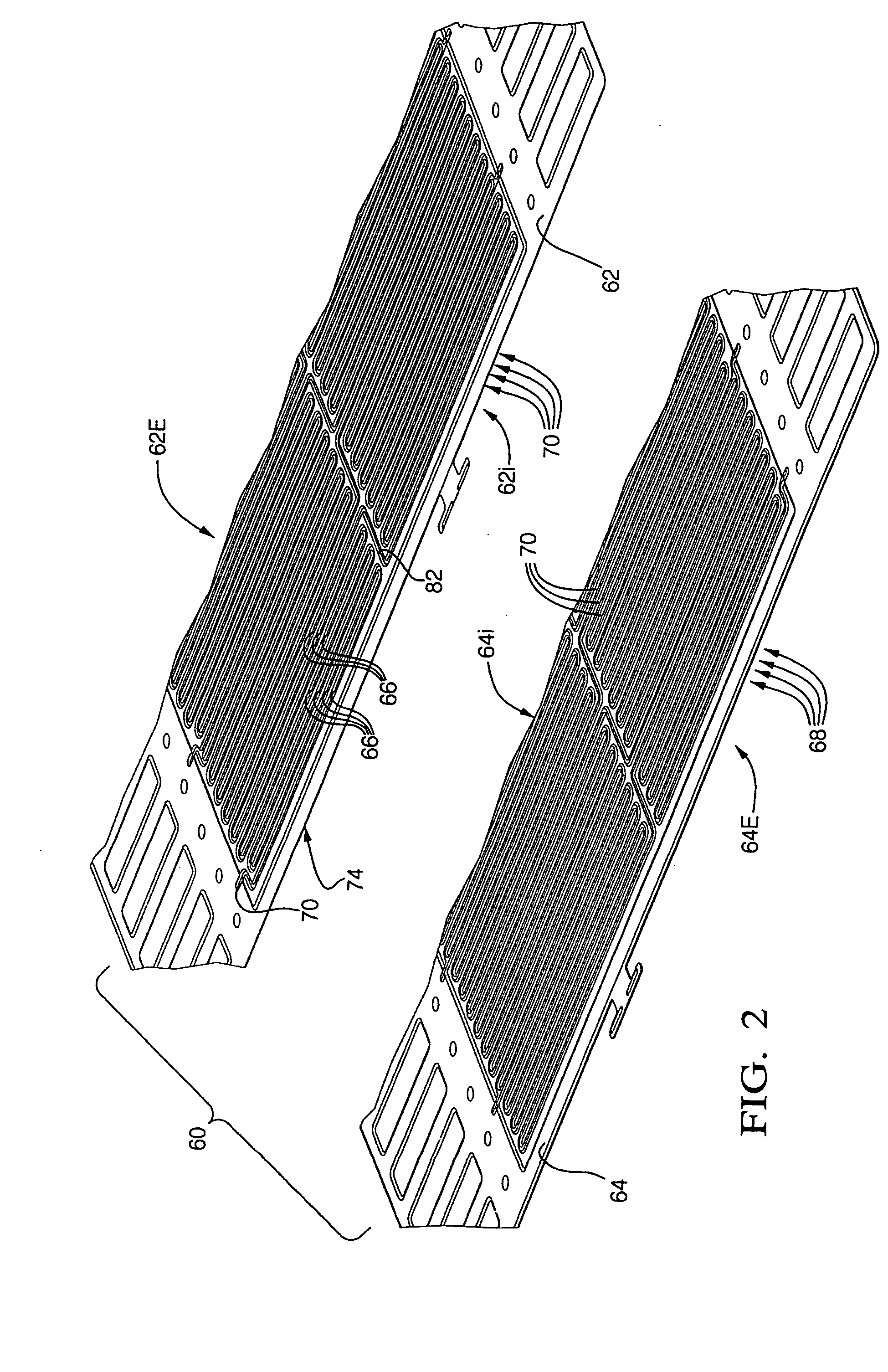

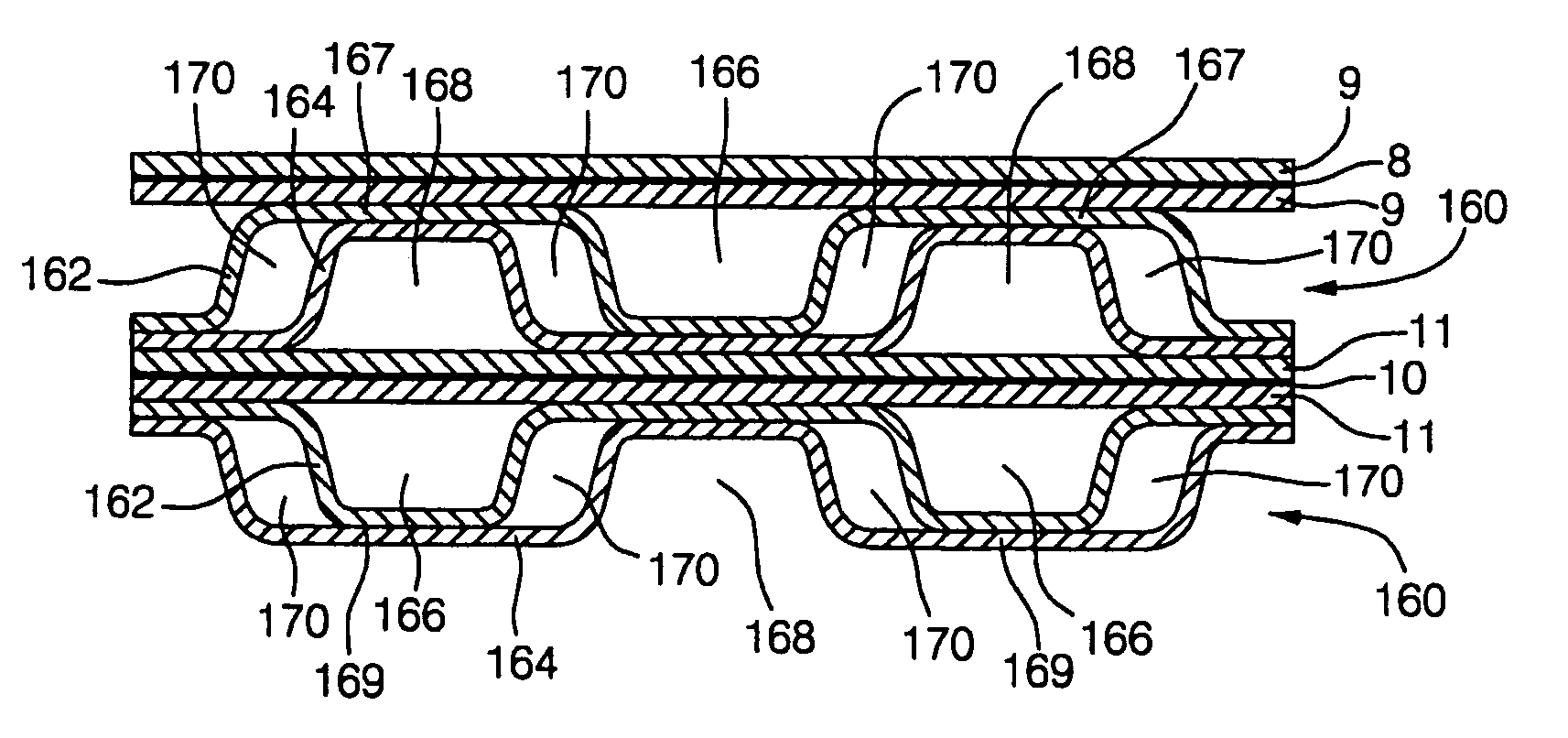

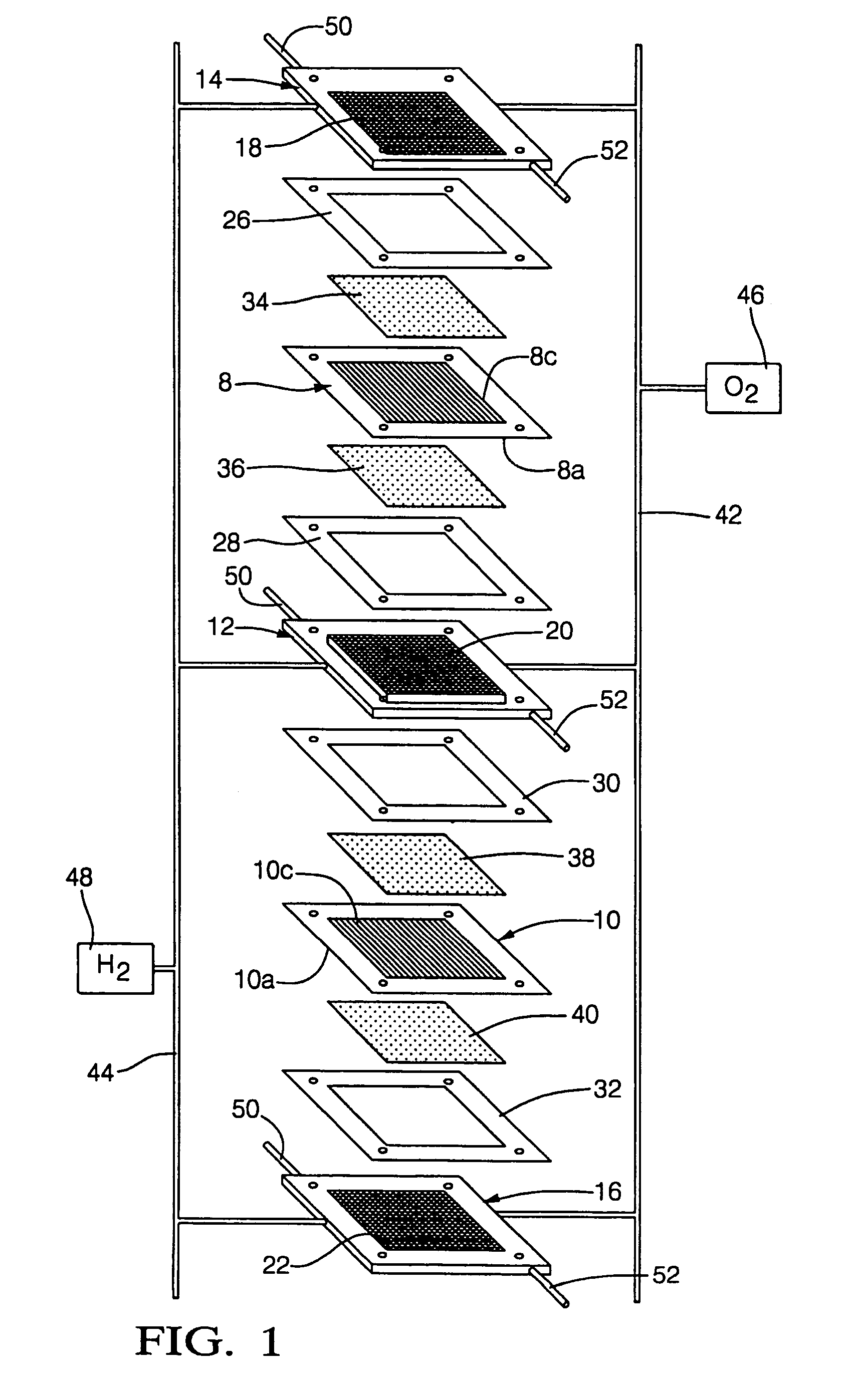

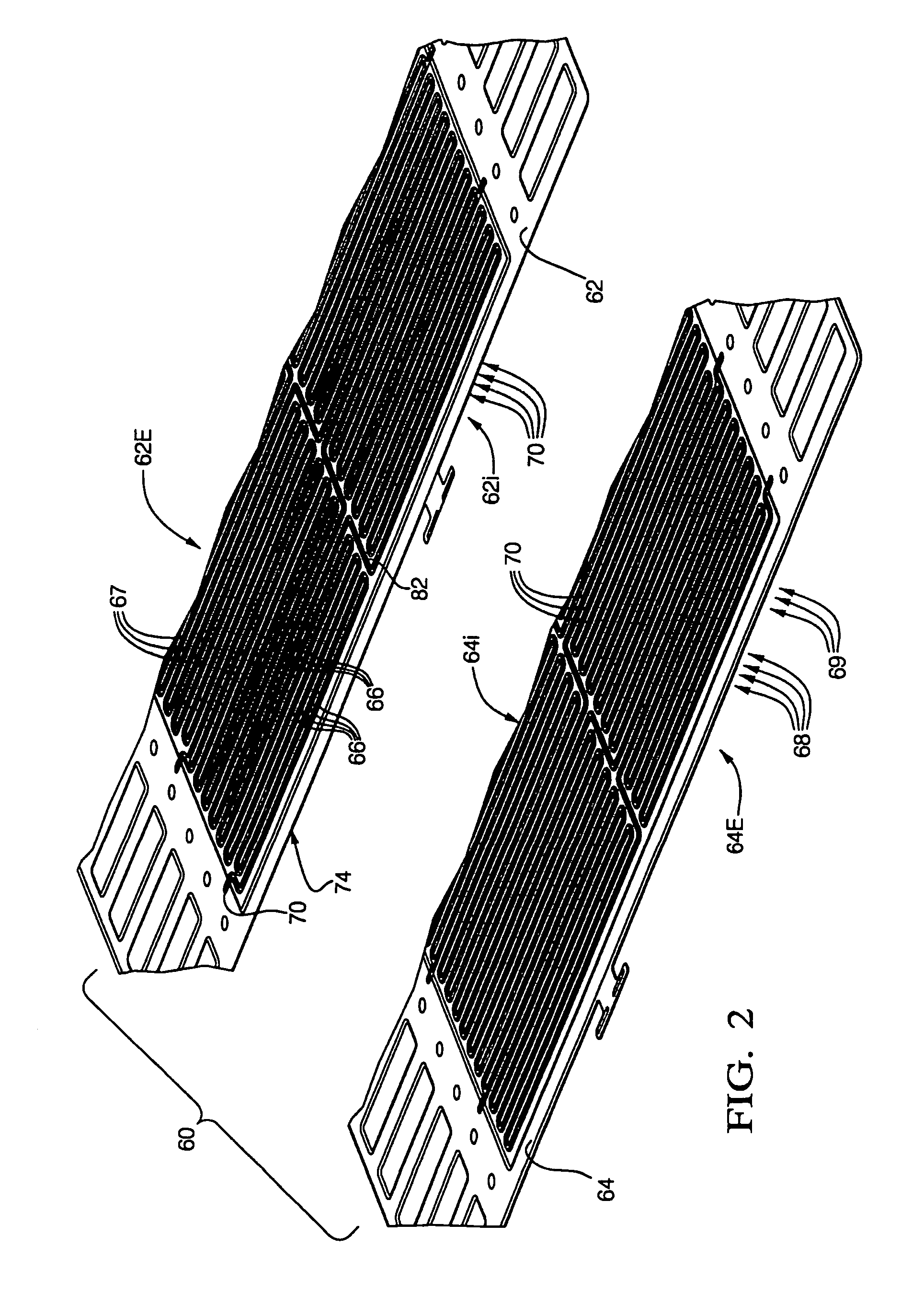

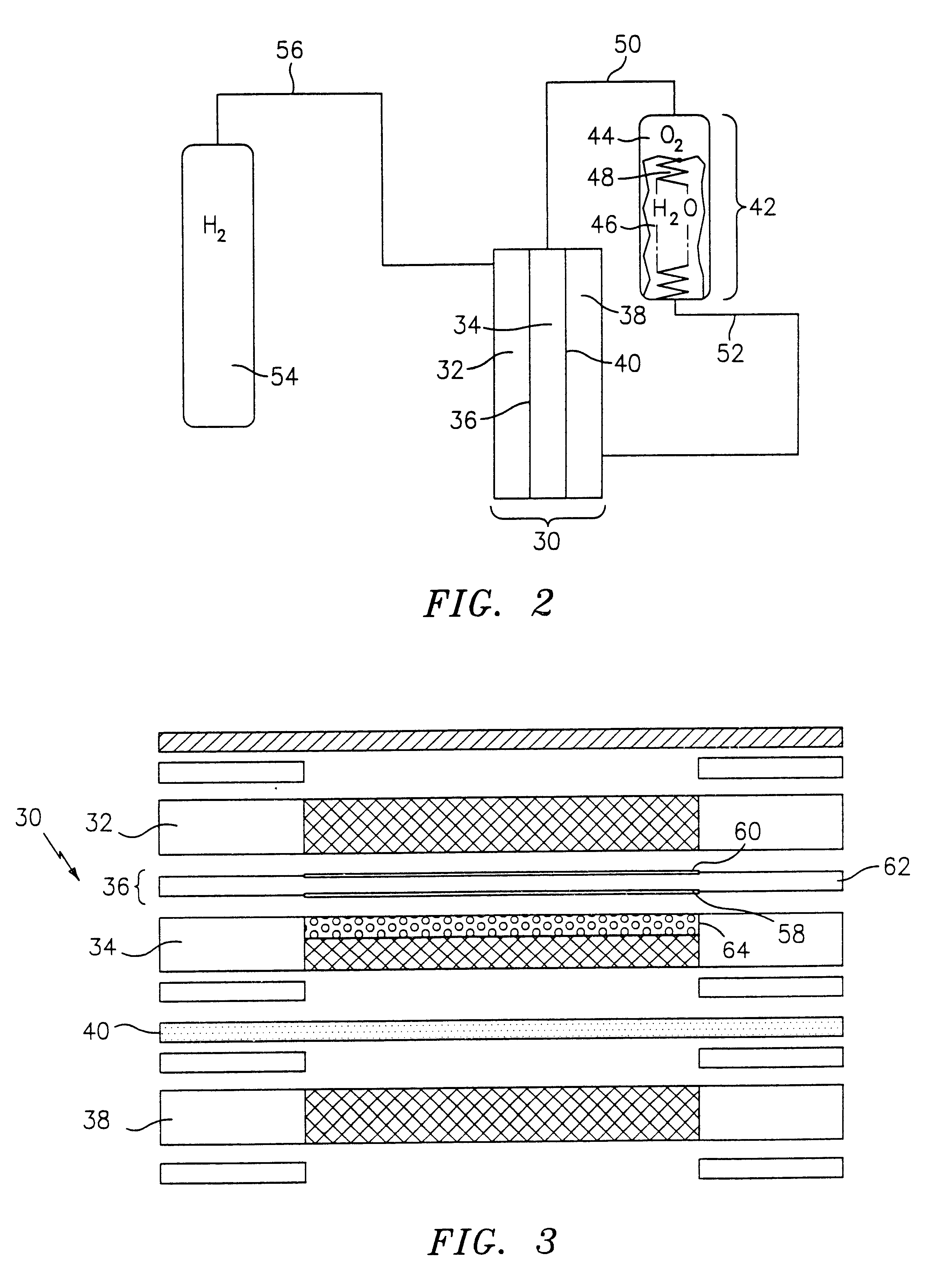

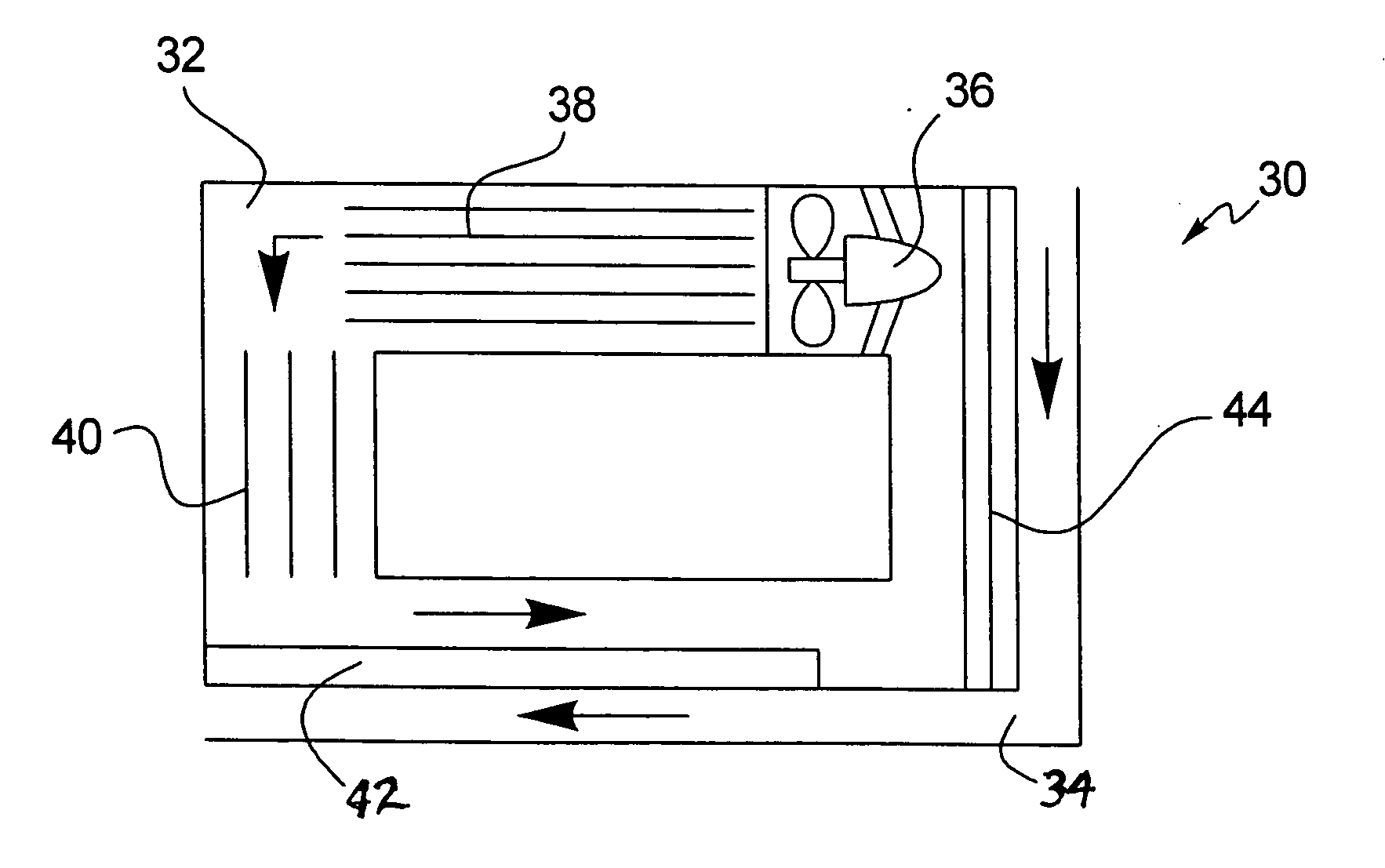

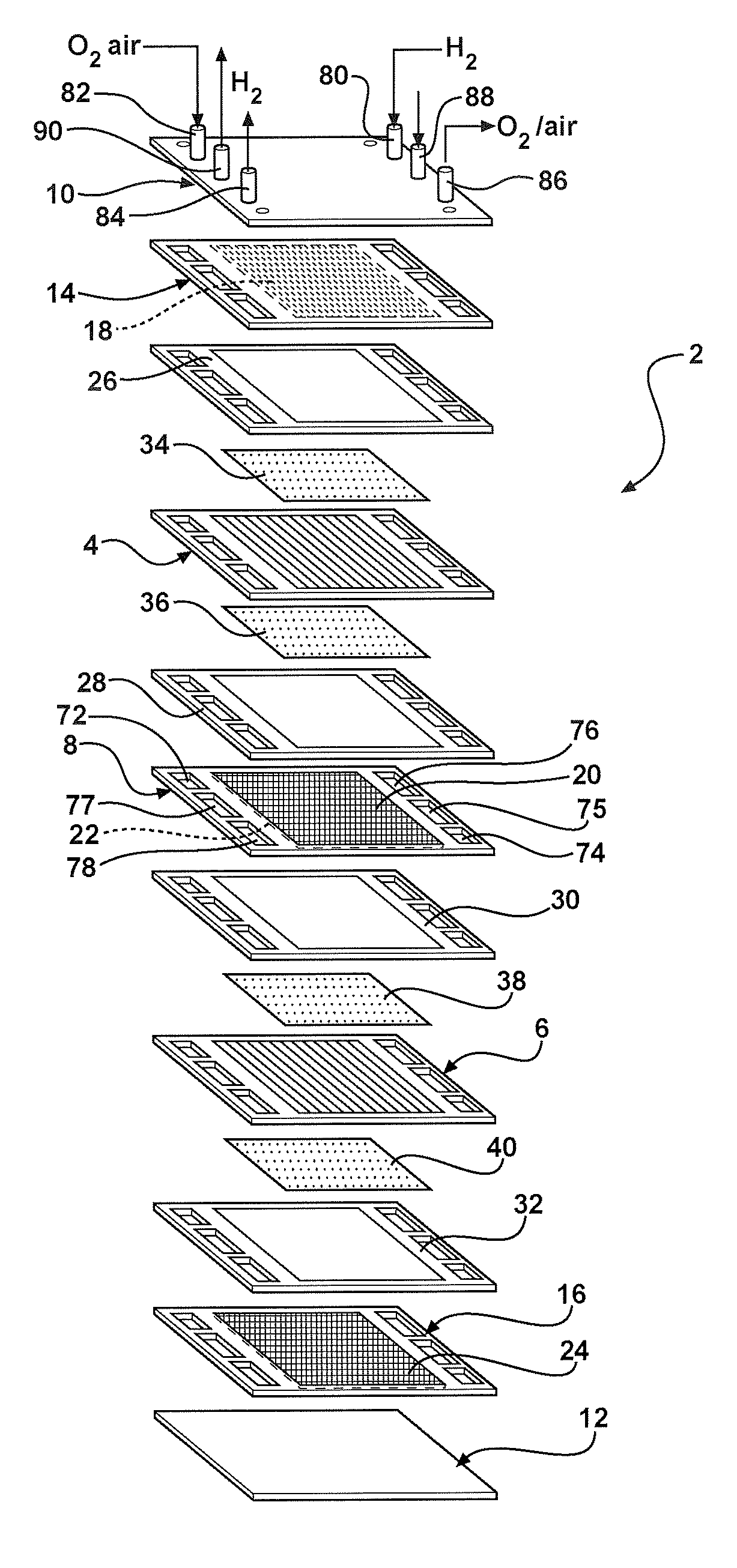

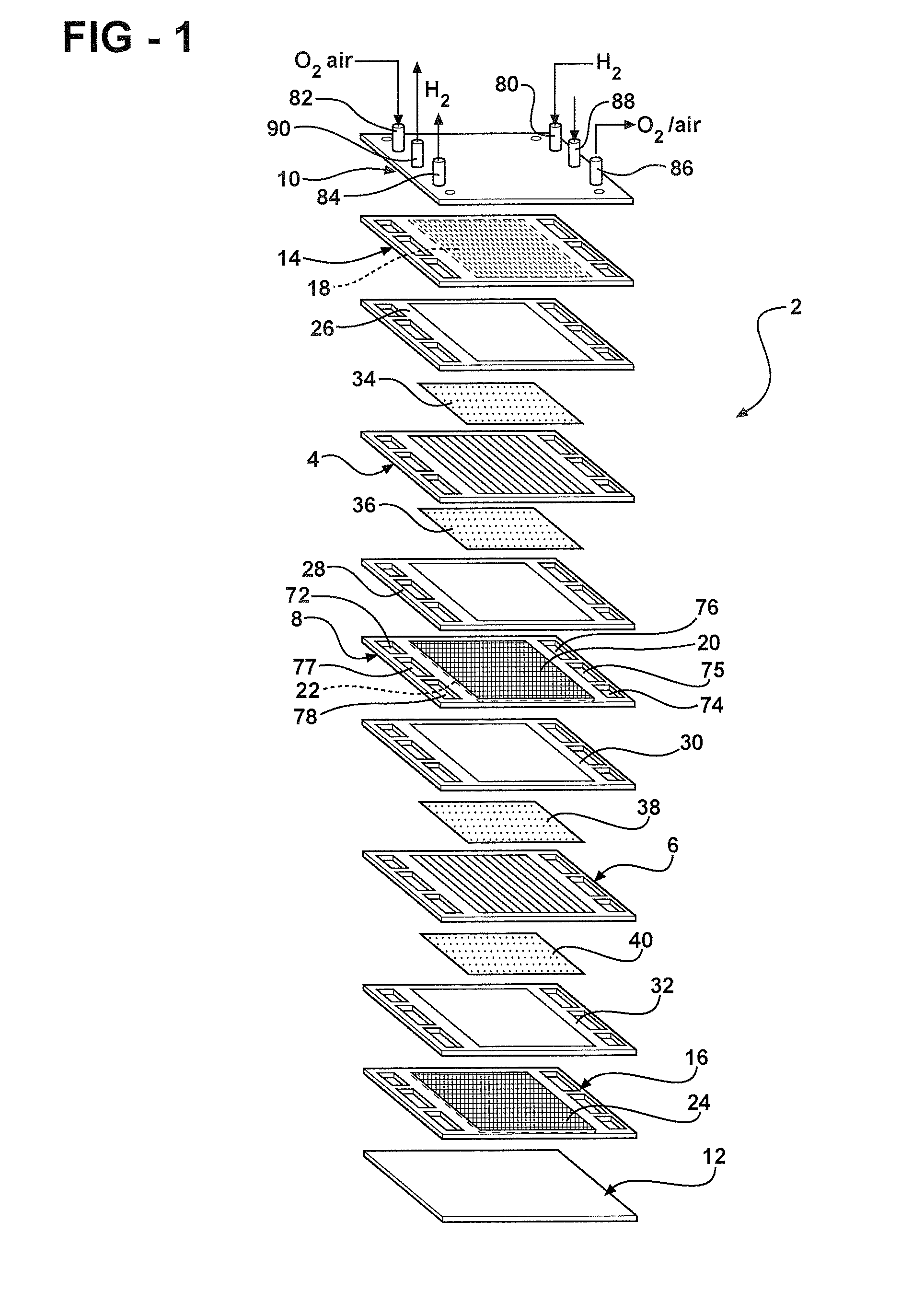

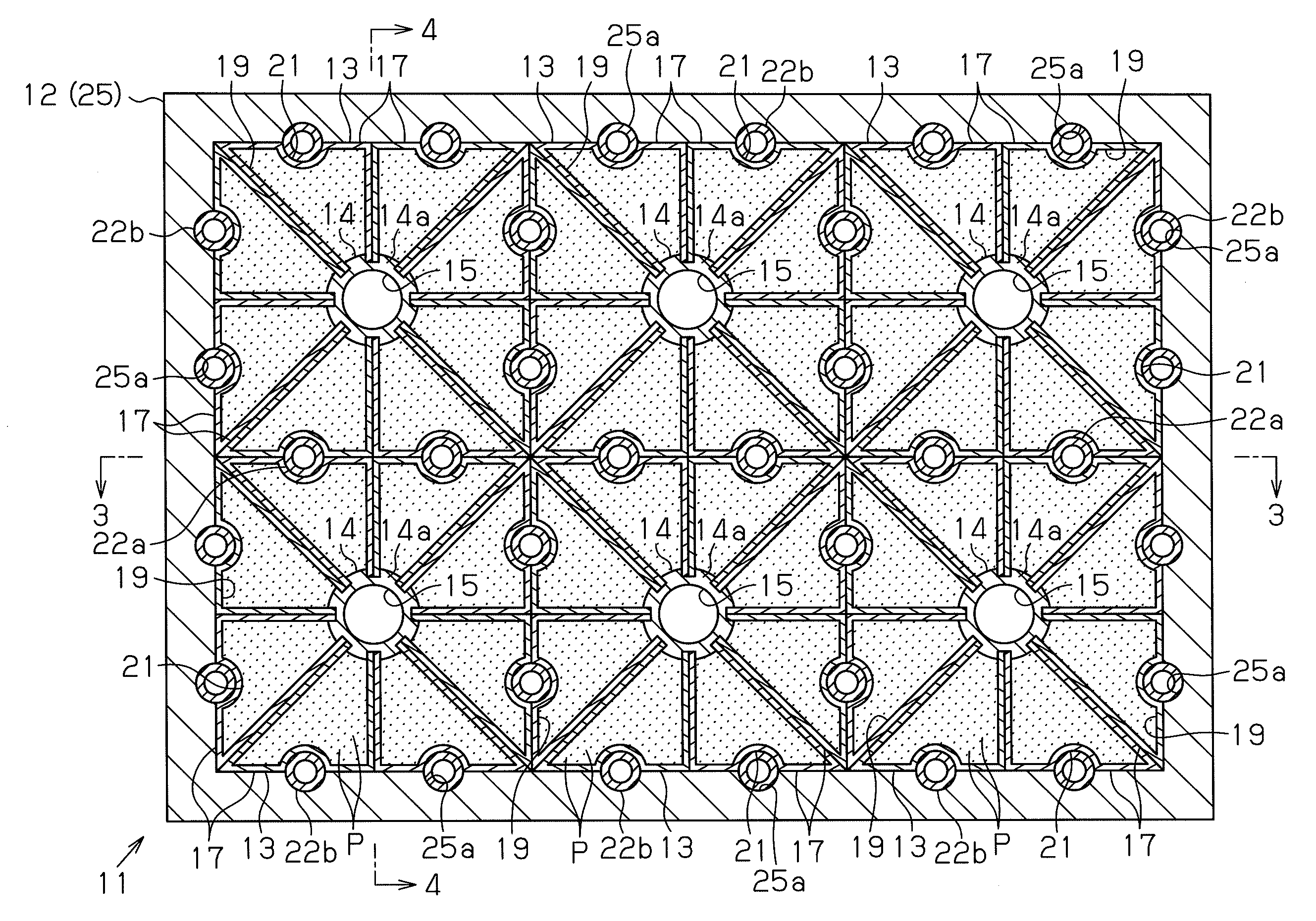

Nested bipolar plate for fuel cell and method

Between adjacent MEA's is a bipolar plate assembly having a first sub-plate with a flow channel which is open to the anode side of the one of the MEA's. A second sub-plate has a flow channel which is open to the cathode side of the adjacent MEA. The sub-plates are nested together to form a coolant flow channel between the sub-plates. The coolant flow path has a height dimension wherein the distance between the adjacent MEA's is substantially unaffected by the height dimension of the coolant flow path. A method of manufacturing a bi-polar plate assembly includes forming a closed coolant flow channel between the sub-plates by nesting the sub-plates together. A method of operating a fuel cell includes passing the coolant through a flow path having a height dimension which is substantially aligned with the height dimension of the hydrogen flow path, the oxygen flow path, or both.

Owner:GM GLOBAL TECH OPERATIONS LLC

Nested bipolar plate for fuel cell and method

Between adjacent MEA's is a bipolar plate assembly having a first sub-plate with a flow channel which is open to the anode side of the one of the MEA's. A second sub-plate has a flow channel which is open to the cathode side of the adjacent MEA. The sub-plates are nested together to form a coolant flow channel between the sub-plates. The coolant flow path has a height dimension wherein the distance between the adjacent MEA's is substantially unaffected by the height dimension of the coolant flow path. A method of manufacturing a bi-polar plate assembly includes forming a closed coolant flow channel between the sub-plates by nesting the sub-plates together. A method of operating a fuel cell includes passing the coolant through a flow path having a height dimension which is substantially aligned with the height dimension of the hydrogen flow path, the oxygen flow path, or both.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method for starting operation of catalyst for hydrocracking in oxidation state

InactiveCN101003749AStrong resistance to sulfur poisoningImprove hydrogenation performanceHydrotreatment operations starting-upOxidation stateNitrogen gas

This invention relates to a start-up method for oxidation-state hydrocracking catalyst used in oil refinery process. The method comprises: loading the oxidation-state hydrocracking catalyst into a reactor, introducing nitrogen to replace air in the reactor and pipelines, pressurizing to meet the pressure requirement of hydrocracking, switching to hydrogen after nitrogen flow is stable, raising the temperature of the catalyst bed to meet the temperature requirement of catalyst reduction after hydrogen flow is stable, keeping the temperature, adjusting the temperature of the catalyst bed to meet the temperature requirement of hydrocracking, adjusting hydrogen flux to meet the flux requirement of hydrocracking, and introducing hydrocarbon reactants. The method does not need pre-sulfurization of the catalyst with additional sulfurization agent, thus can avoid the problems caused by pre-sulfurization, and partially reduced catalyst has higher hydrocracking activity.

Owner:XIAMEN UNIV

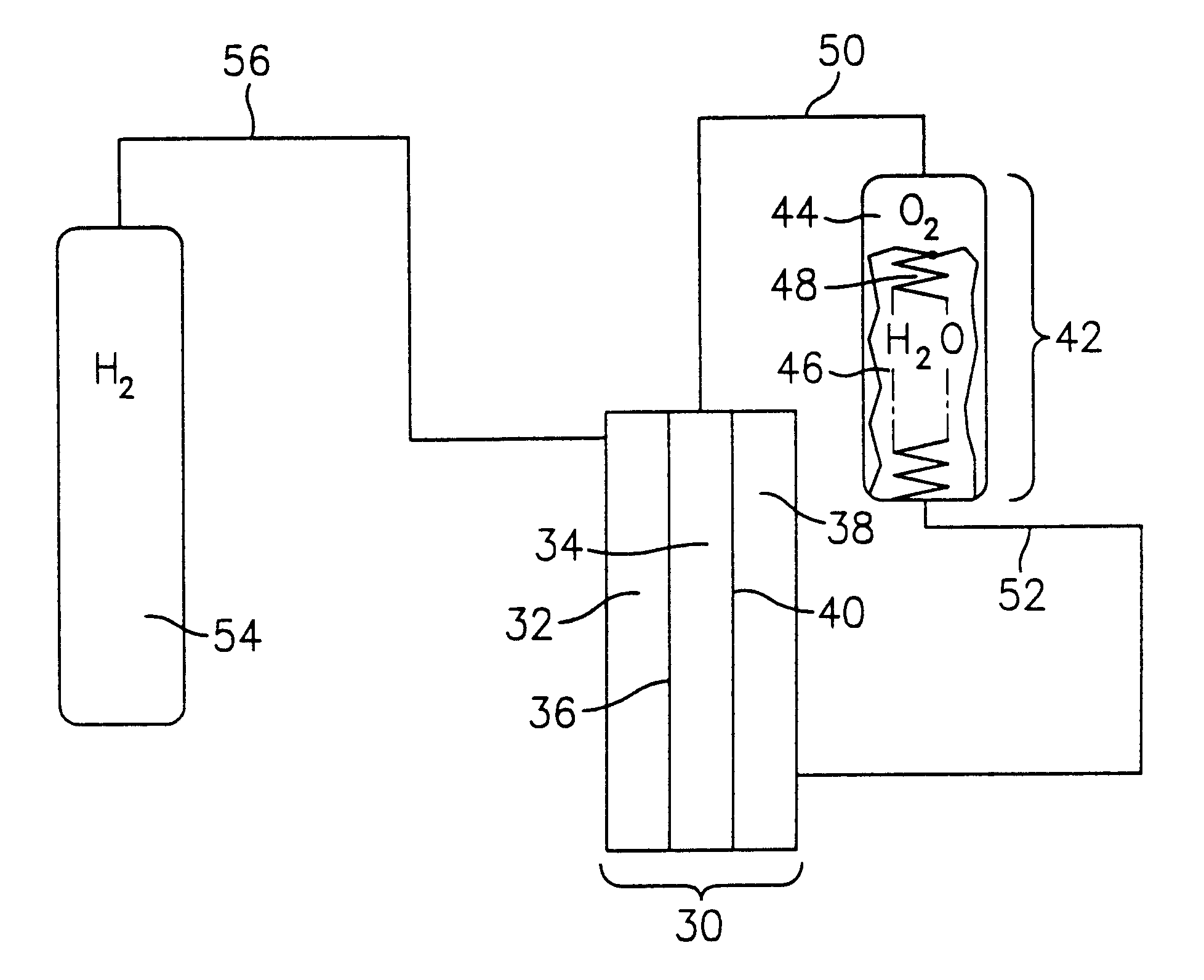

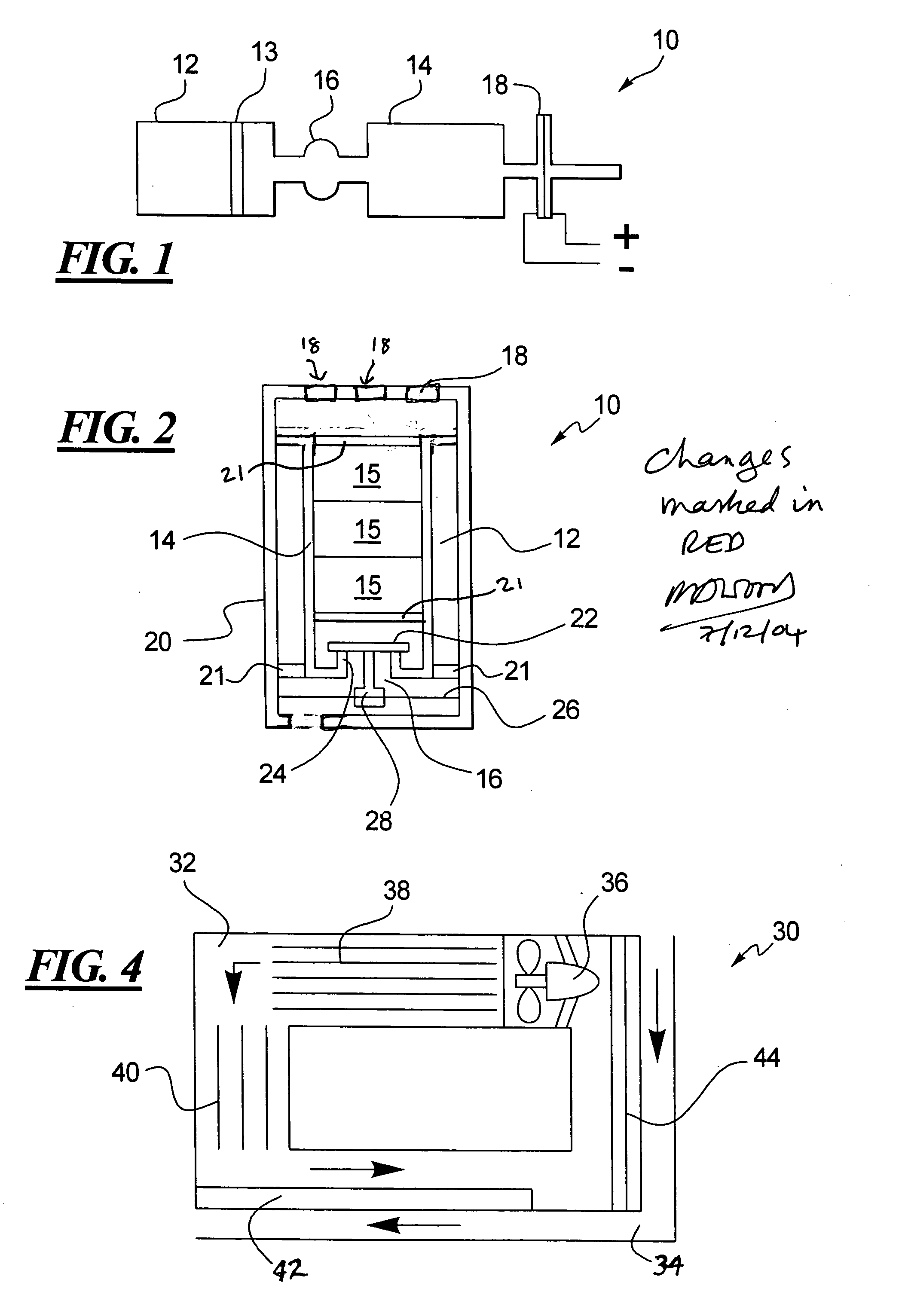

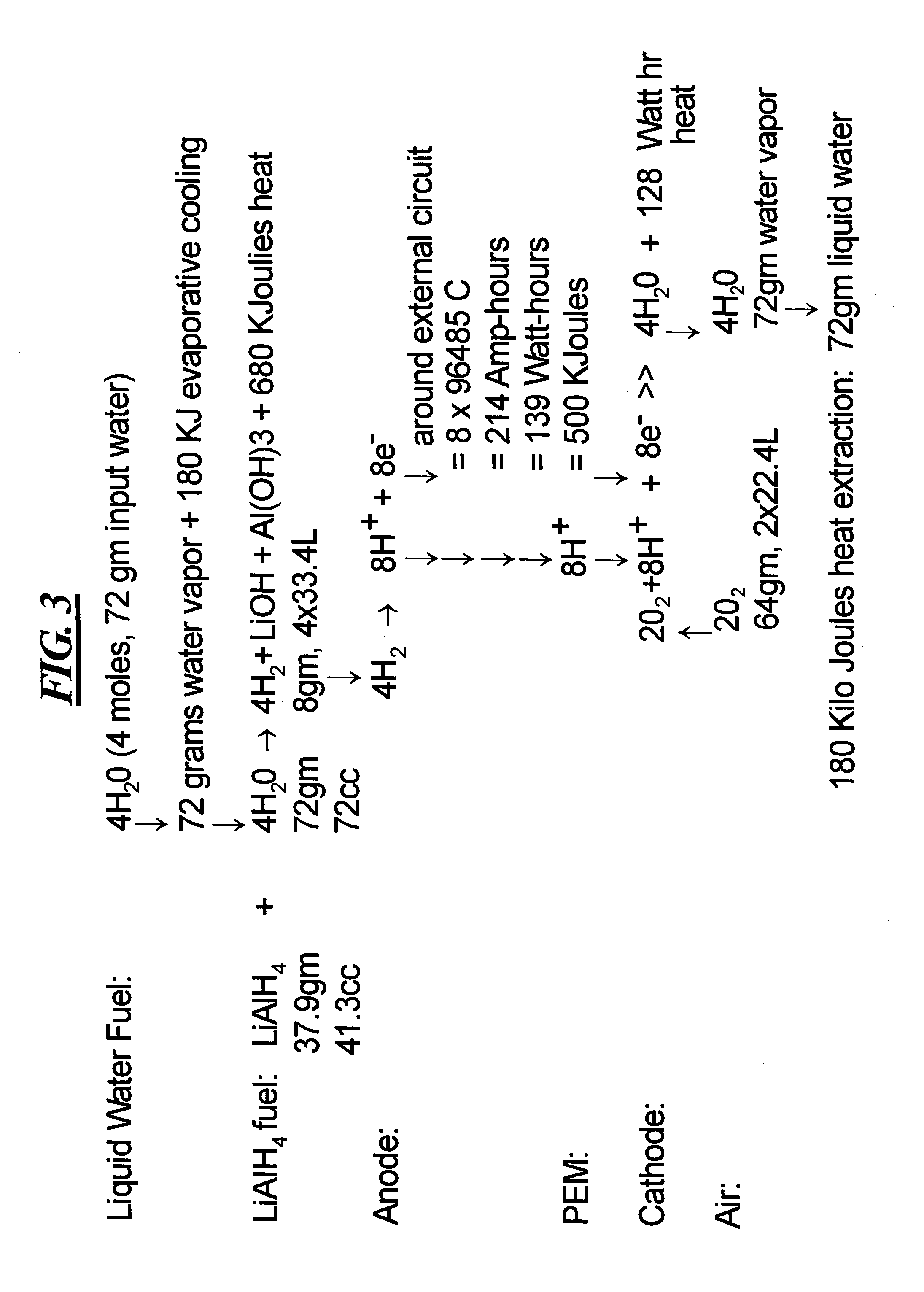

Low gravity electrochemical cell

An electrochemical cell system includes a hydrogen electrode; an oxygen electrode; a membrane disposed between the hydrogen electrode and the oxygen electrode; and a compartmentalized storage tank. The compartmentalized storage tank has a first fluid storage section and a second fluid storage section separated by a movable divider. The compartmentalized storage tank is in fluid communication with the electrochemical cell. Further, an electrochemical cell includes a hydrogen electrode; an oxygen electrode; an electrolyte membrane disposed between and in intimate contact with the hydrogen electrode and said oxygen electrode; an oxygen flow field disposed adjacent to and in intimate contact with the oxygen electrode; a hydrogen flow field disposed adjacent to and in intimate contact with the hydrogen electrode; a water flow field disposed in fluid communication with the oxygen flow field; and a media divider disposed between the oxygen flow field and the water flow field.

Owner:PROTON ENERGY SYST

Electrical power generator

A power generator has a hydrogen flow path through which moisture is induced to flow to a hydrogen-containing fuel that reacts with the moisture to produce hydrogen. The moisture passes to the hydrogen flow path through a water exchange membrane from a water vapor flow path. A fuel cell between the hydrogen flow path and the water vapor flow path reacts with the hydrogen in the hydrogen flow path to produce electricity, and to also principally produce the moisture in the water vapor flow path.

Owner:HONEYWELL INT INC

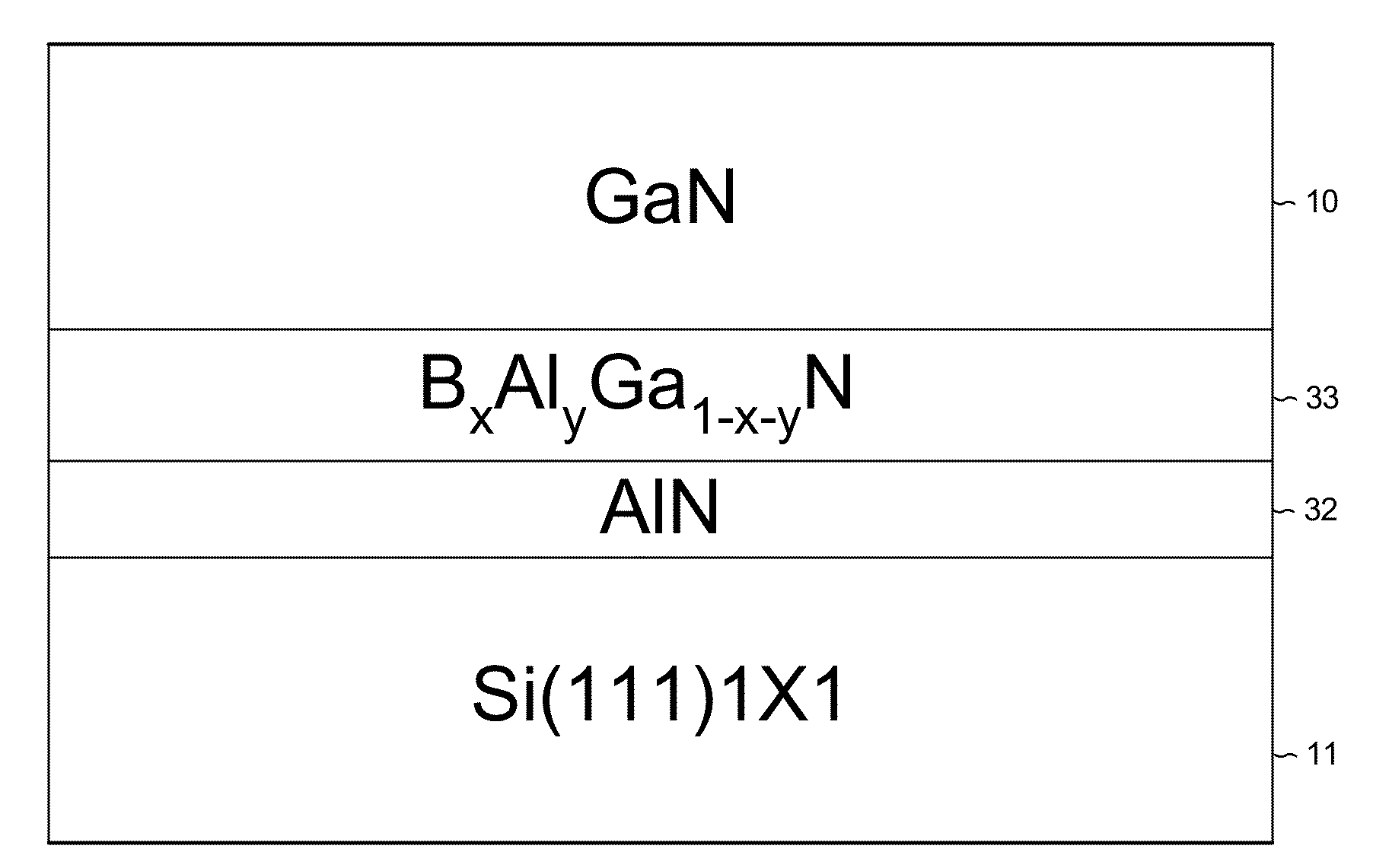

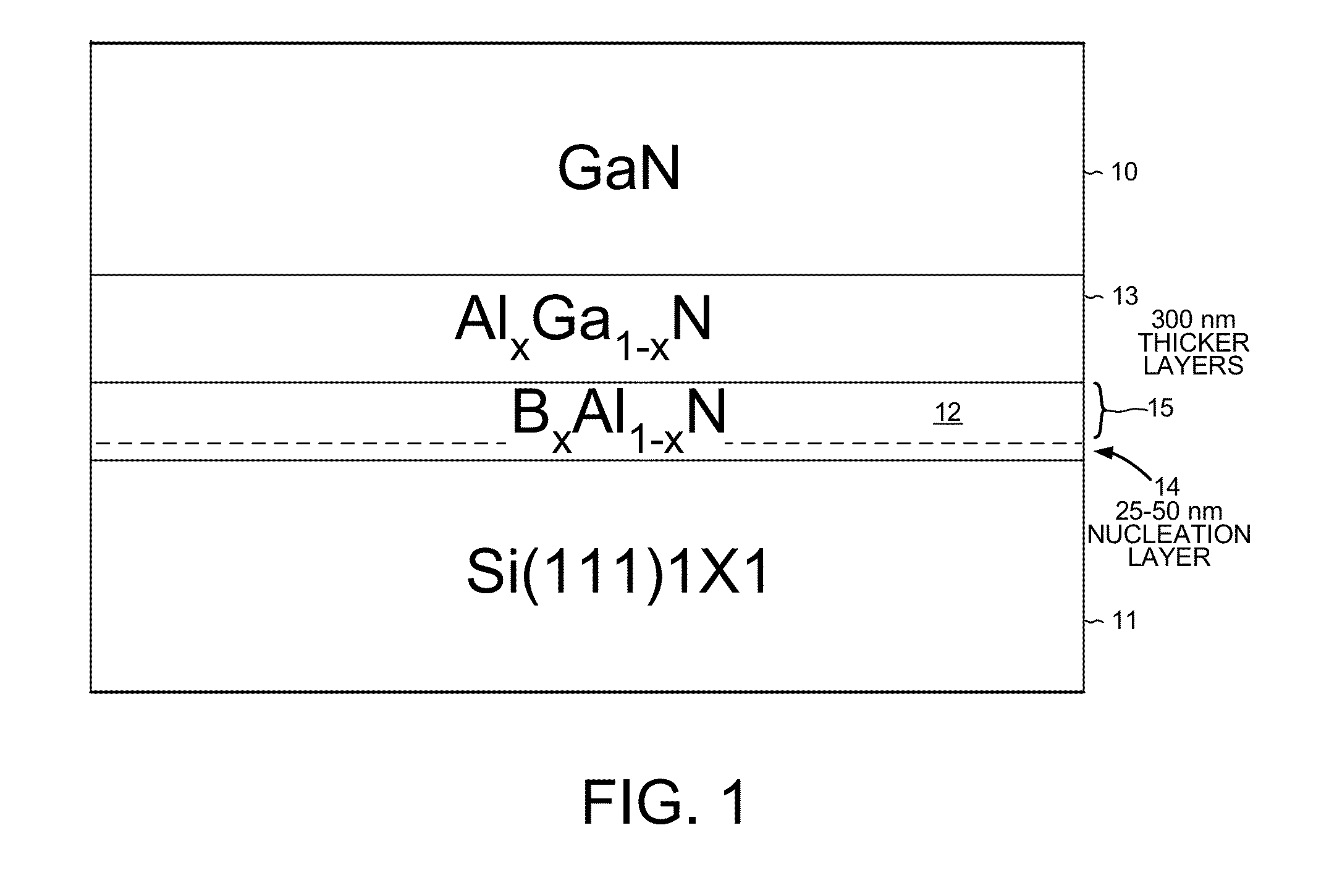

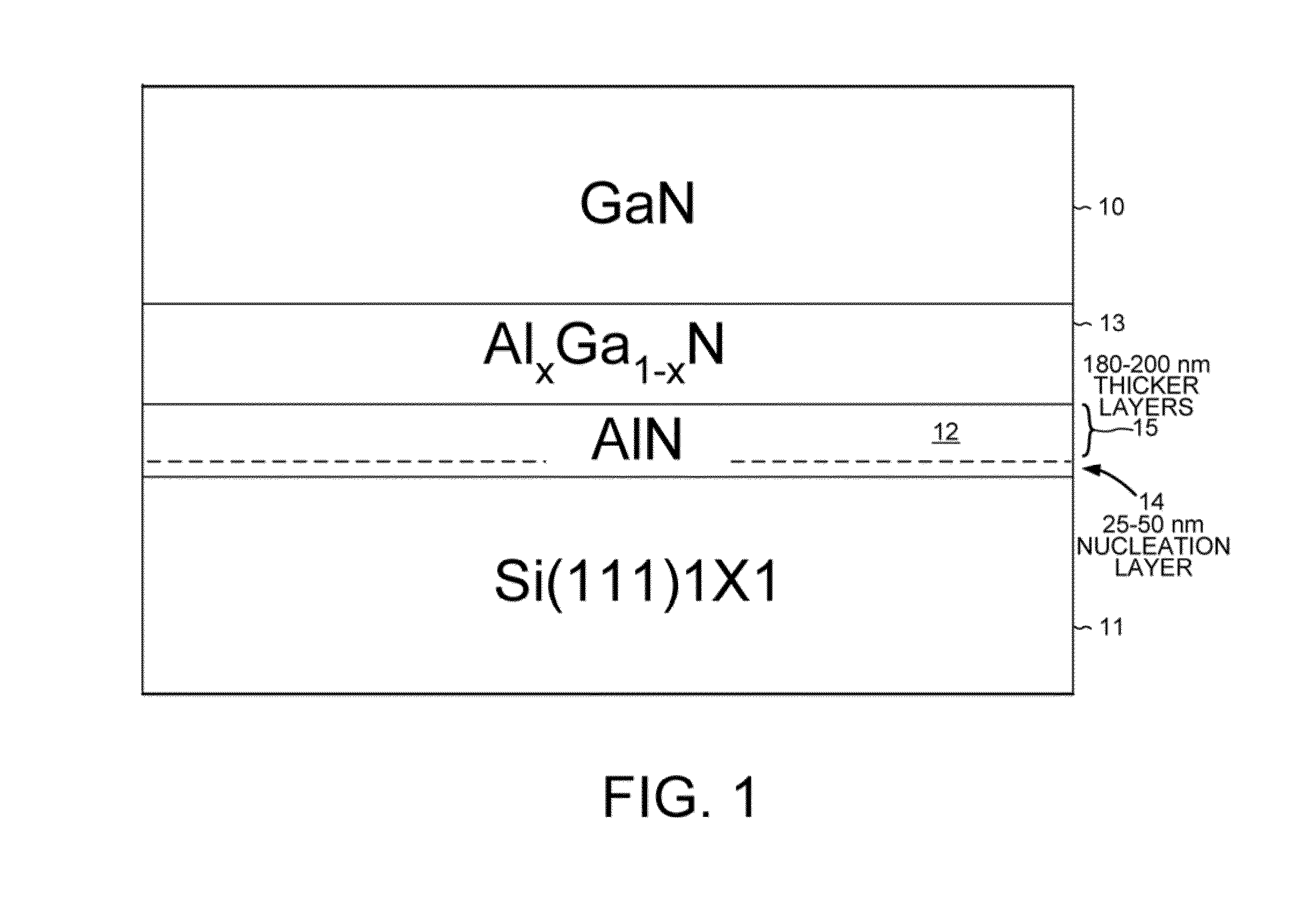

Boron-Containing Buffer Layer for Growing Gallium Nitride on Silicon

InactiveUS20130026482A1Small sizeMore stressSemiconductor/solid-state device manufacturingSemiconductor devicesNitrogenBoron containing

A silicon wafer used in manufacturing GaN for LEDs includes a silicon substrate, a buffer layer of boron aluminum nitride (BxAl1-xN) and an upper layer of GaN, for which 0.35≦x≦0.45. The BAlN forms a wurtzite-type crystal with a cell unit length about two-thirds of a silicon cell unit length on a Si(111) surface. The C-plane of the BAlN crystal has approximately one atom of boron for each two atoms of aluminum. Across the entire wafer substantially only nitrogen atoms of BAlN form bonds to the Si(111) surface, and substantially no aluminum or boron atoms of the BAlN are present in a bottom-most plane of atoms of the BAlN. A method of making the BAlN buffer layer includes preflowing a first amount of ammonia equaling less than 0.01% by volume of hydrogen flowing through a chamber before flowing trimethylaluminum and triethylboron and then a subsequent amount of ammonia through the chamber.

Owner:KK TOSHIBA

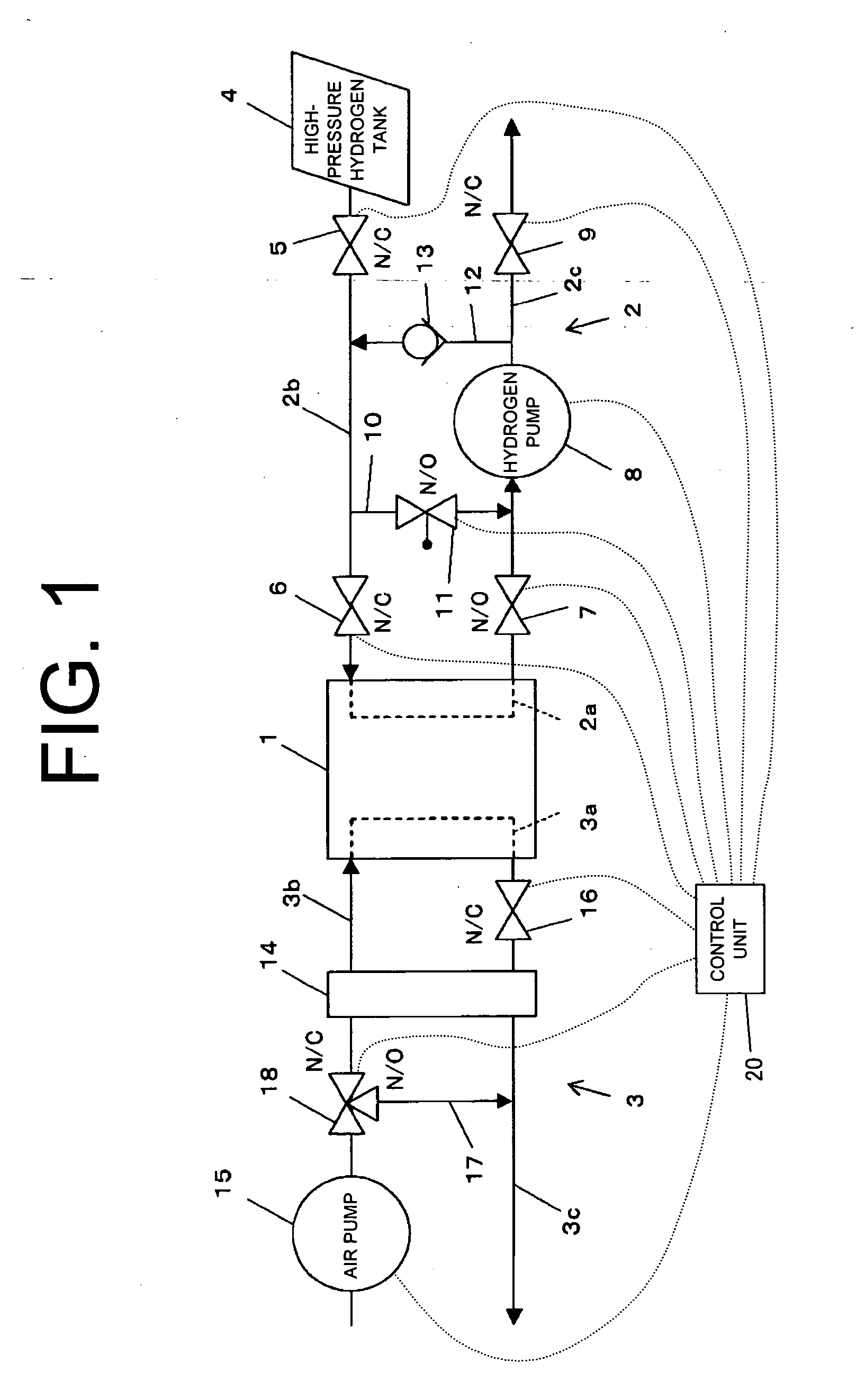

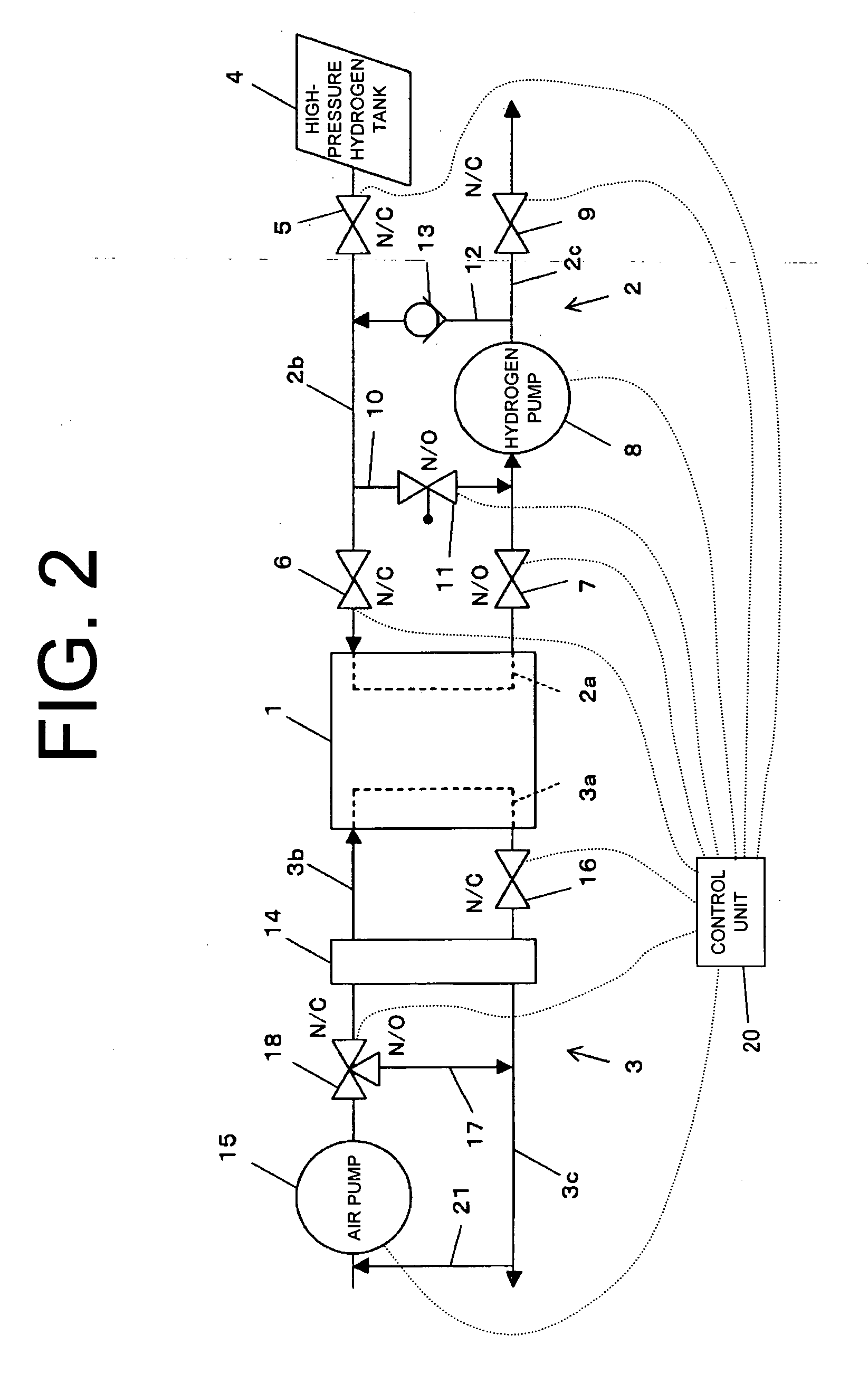

Fuel cell system

InactiveUS20050112424A1Efficient heatingSimple structureFuel cells groupingRegenerative fuel cellsFuel cellsGas passing

A fuel cell system includes a fuel cell stack, a hydrogen flowing passage, an air flowing passage and a control valve. At least one of the gas flowing passages includes a bypass, a selecting means, a gas flowing means and a control unit. The bypass allows a gas to flow therethrough so as to detour the fuel cell stack and the control valve. The selecting means selects one of a passage which passes through the fuel cell stack and the bypass. The gas flowing means flows the gas to the bypass. In the control unit, the through passage is selected by the selecting means when the system is operated, The bypass is selected by the selecting means when the operation of the system is stopped. The gas is flowed to the bypass by operating the gas flowing means when the control valve is frozen thereby heating the control valve.

Owner:TOYOTA IND CORP

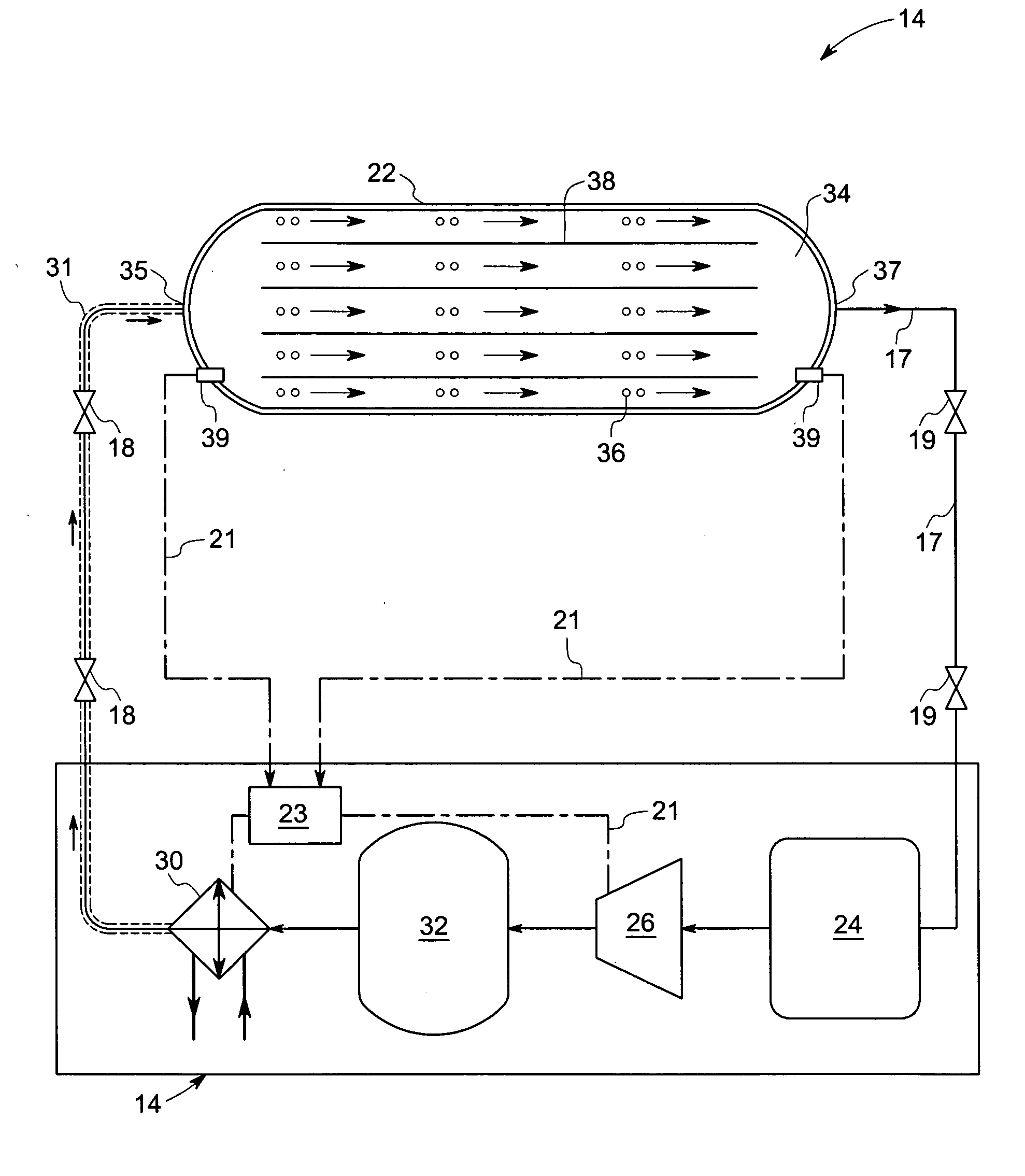

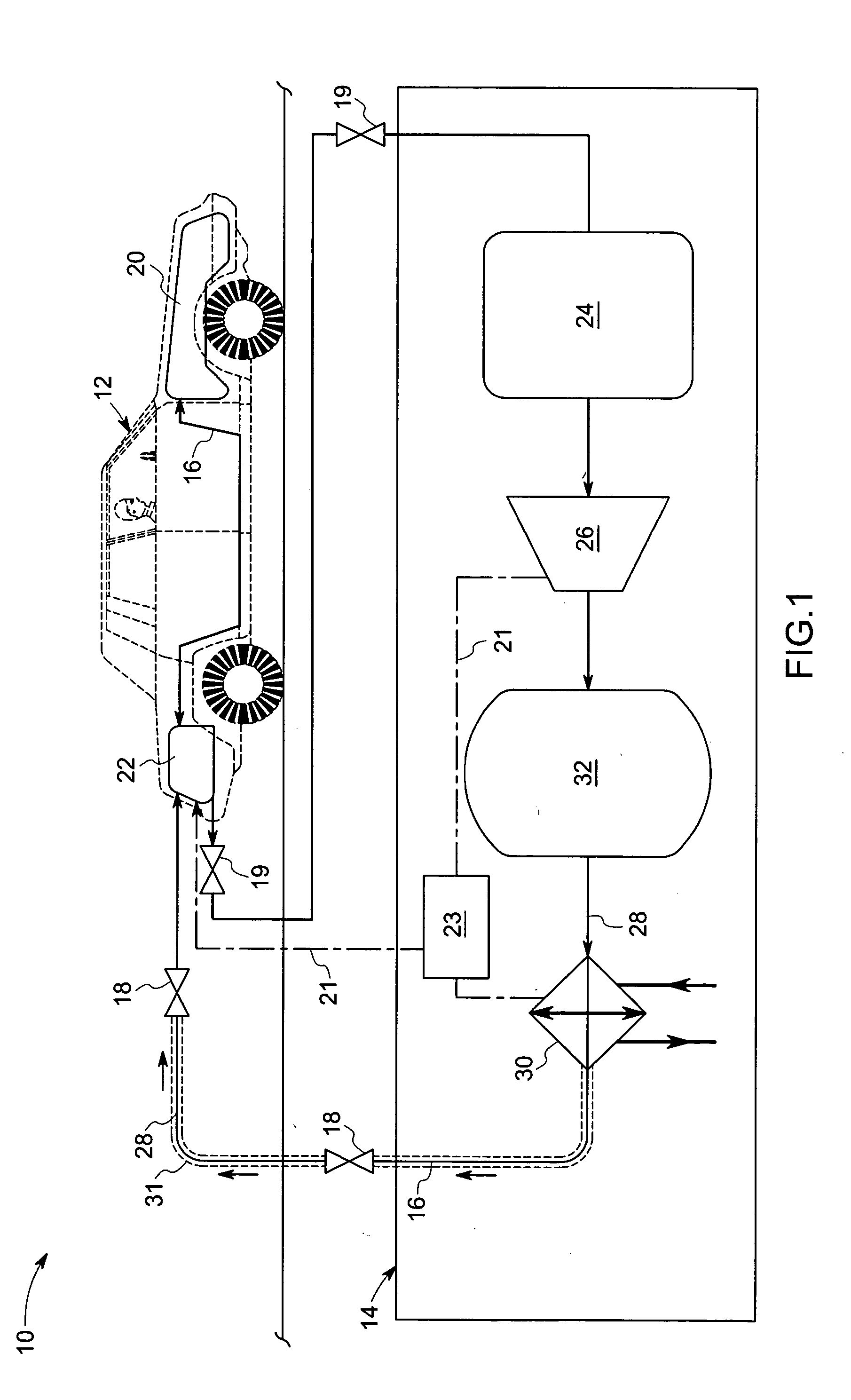

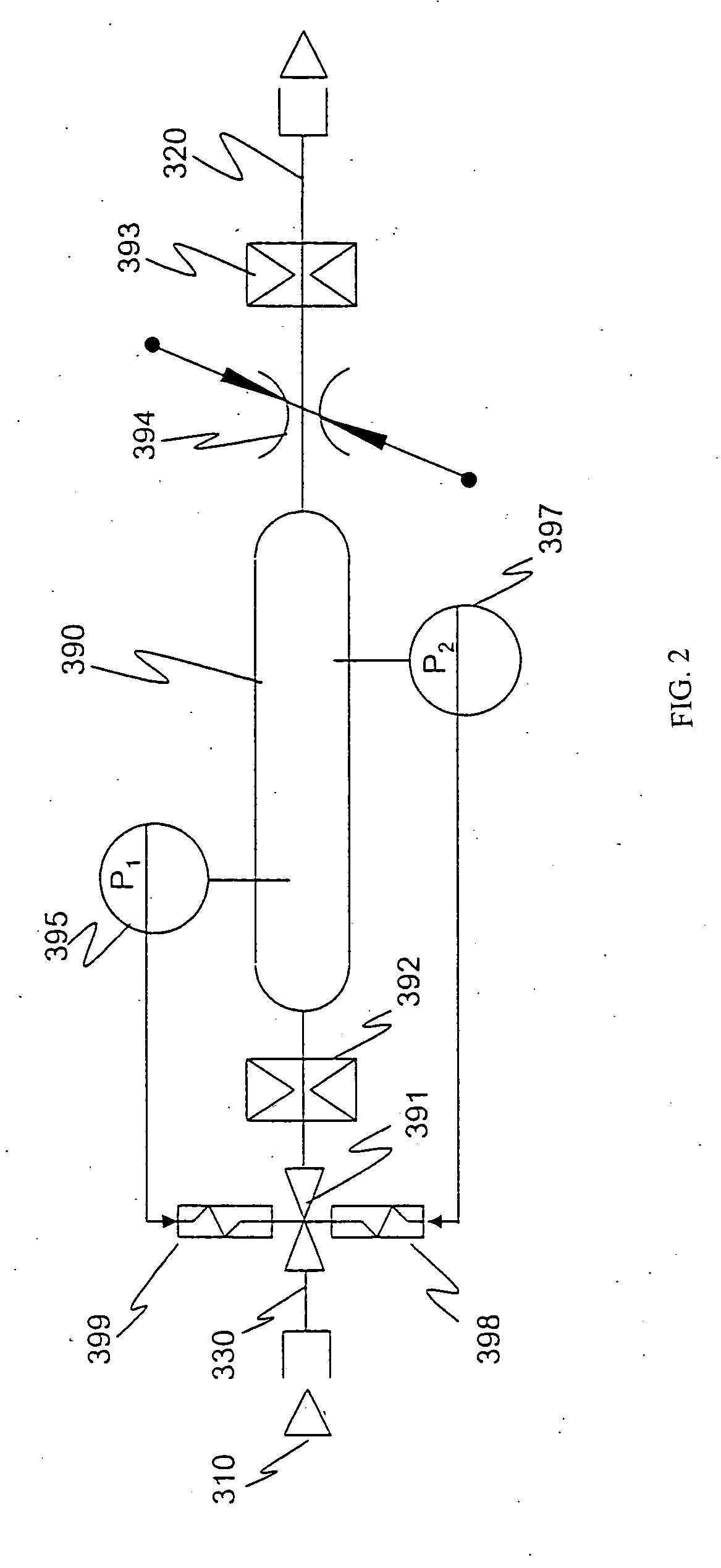

System and method for storing and discharging hydrogen

A hydrogen fuel system comprises an open gas circuit that includes a source of hydrogen. The hydrogen fuel system also includes a compressor that forces a flow of hydrogen from the source of hydrogen through the open gas circuit, and a hydrogen storage vessel comprising an inlet and an outlet. The hydrogen fuel system may also include a hydrogen storage bed being disposed within the hydrogen storage vessel between the inlet and the outlet, the hydrogen storage vessel being adapted to form a portion of the open gas circuit so that the hydrogen storage bed is cooled by convection while hydrogen flows through the open gas circuit.

Owner:GENERAL ELECTRIC CO

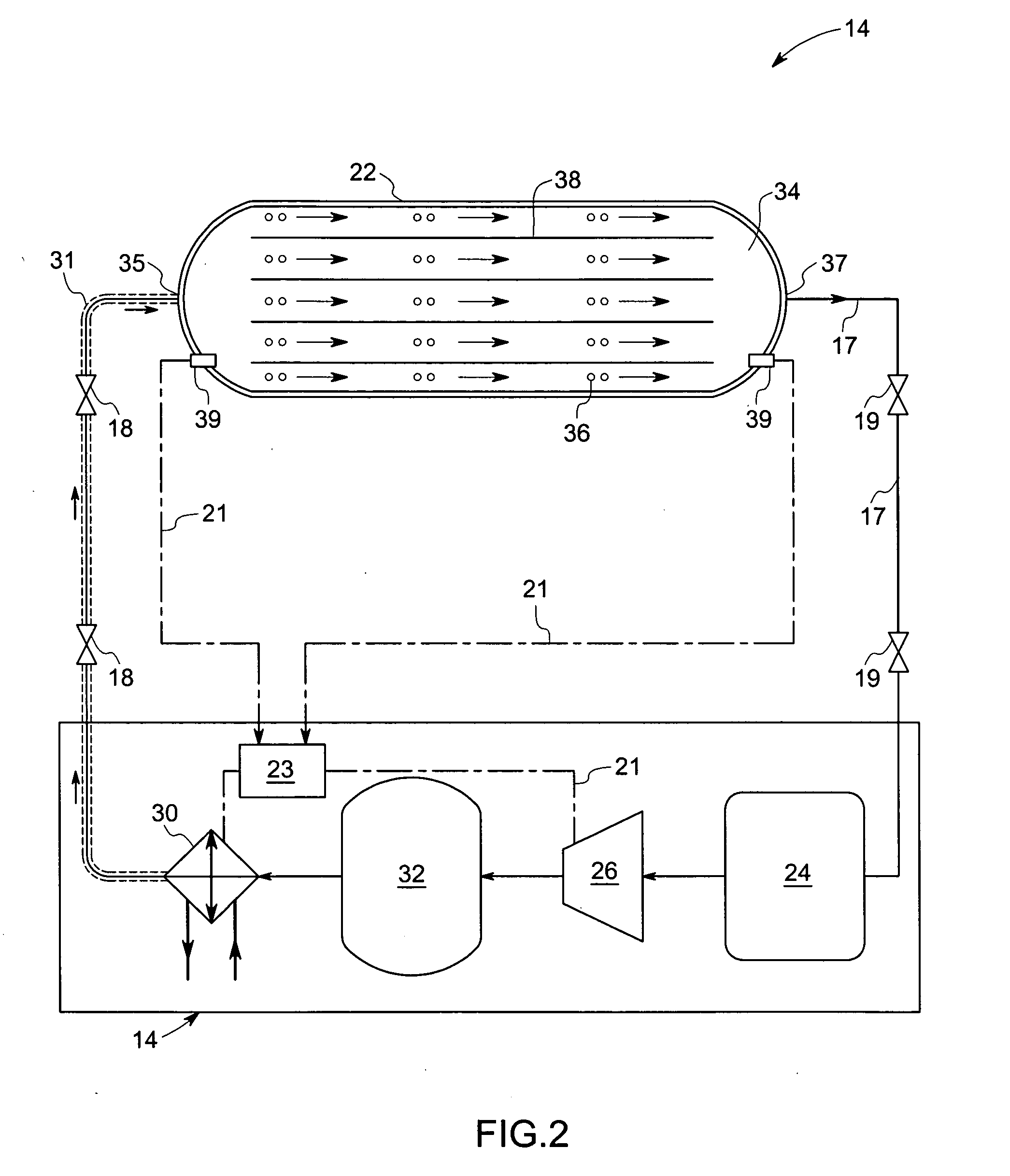

Method and Apparatus for Achieving Higher Cooling Rates of a Gas During Bypass Cooling in a Batch Annealing Furnace of Cold Rolling Mills

ActiveUS20120024516A1Improve cooling effectWork treatment devicesIndirect heat exchangersNanofluidAqueous medium

A method and apparatus to increase the cooling rate of gas used in a batch annealing furnace of cold rolling mills under bypass cooling. The invention makes use of the higher heat transfer capacities of nanocoolants developed by a high-shear mixing of nanoparticles and stabilizers in a basic aqueous medium for cooling heated hydrogen flowing through a heat exchanger during bypass cooling of the batch annealing furnace. The nanofluid is prepared in a nanofluid preparation unit.

Owner:TATA STEEL

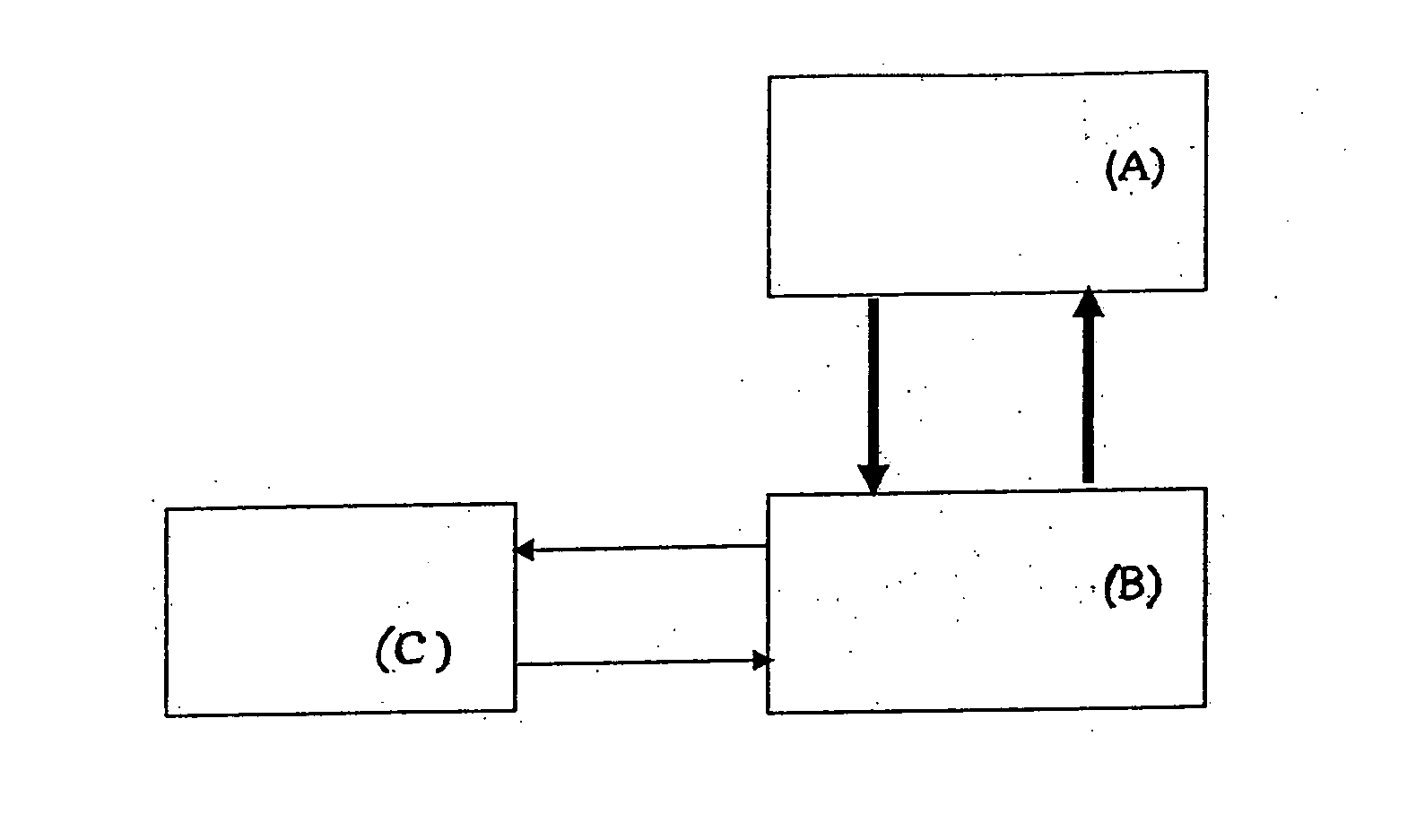

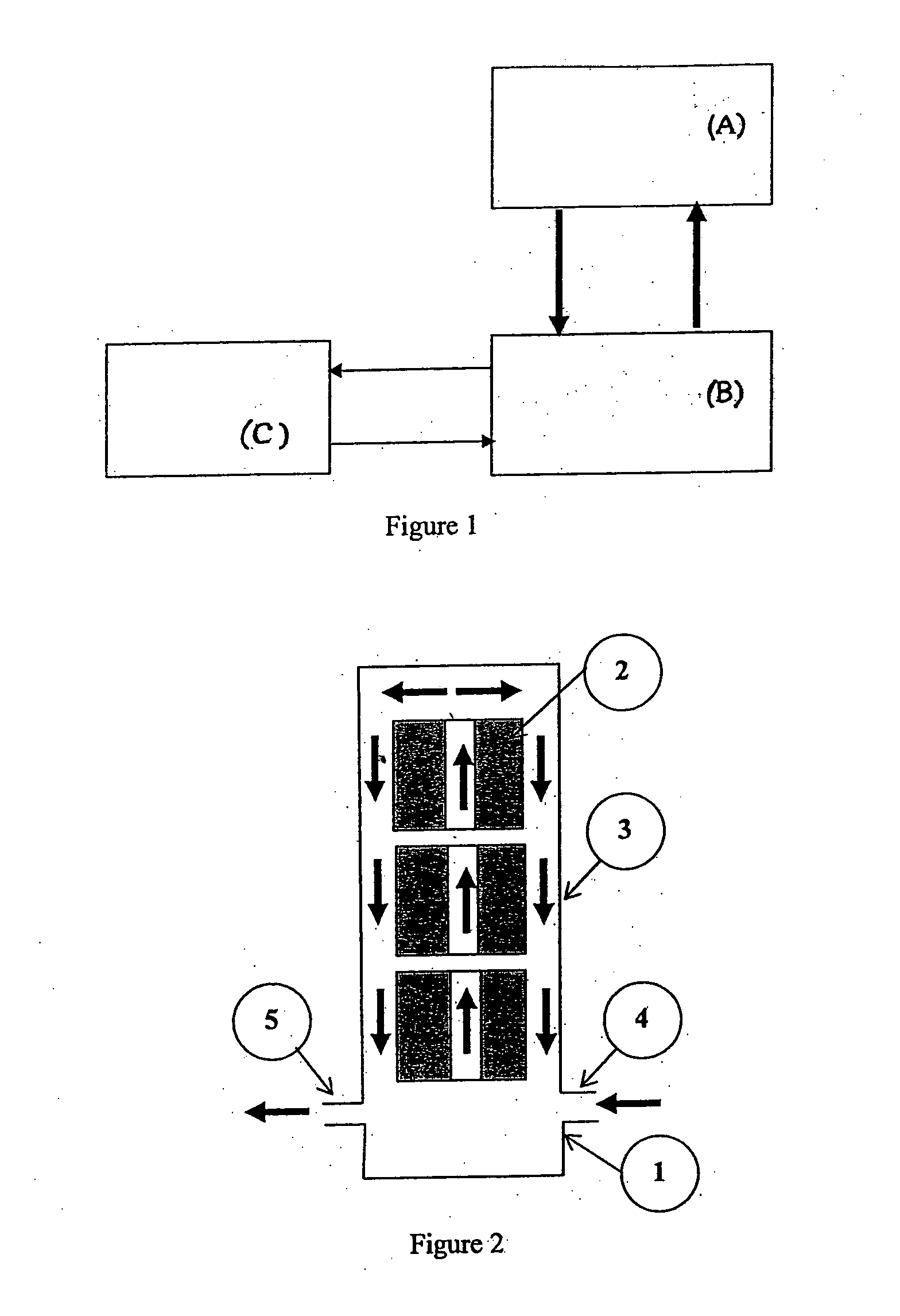

Air conditioner cooling and heating device utilizing hydrogen-storage alloy technology and control method thereof

InactiveCN1548856AUniform cooling and heating effectEnergy efficient heating/coolingClimate change adaptationCooling effectEngineering

The warming and cooling air conditioner adopting hydrogen storing alloy technology includes several reactors filled with hydrogen storing alloy; hydrogen pipeline connecting the reactors; pump unit connected in the pipeline; and hydrogen flow converting valve in the pipeline between the pump unit and the reactors. The warming and cooling air conditioning method adopting hydrogen storing alloy technology includes the repeated control steps of: starting the pump unit while the warming and cooling air conditioner operates; judging the reaction converting point constantly; and controlling the hydrogen flow converting valve to alter the hydrogen flow direction after reaching some reaction converting point. The present invention has homogeneous warming and cooling effect and can utilize the pump unit performance at most.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

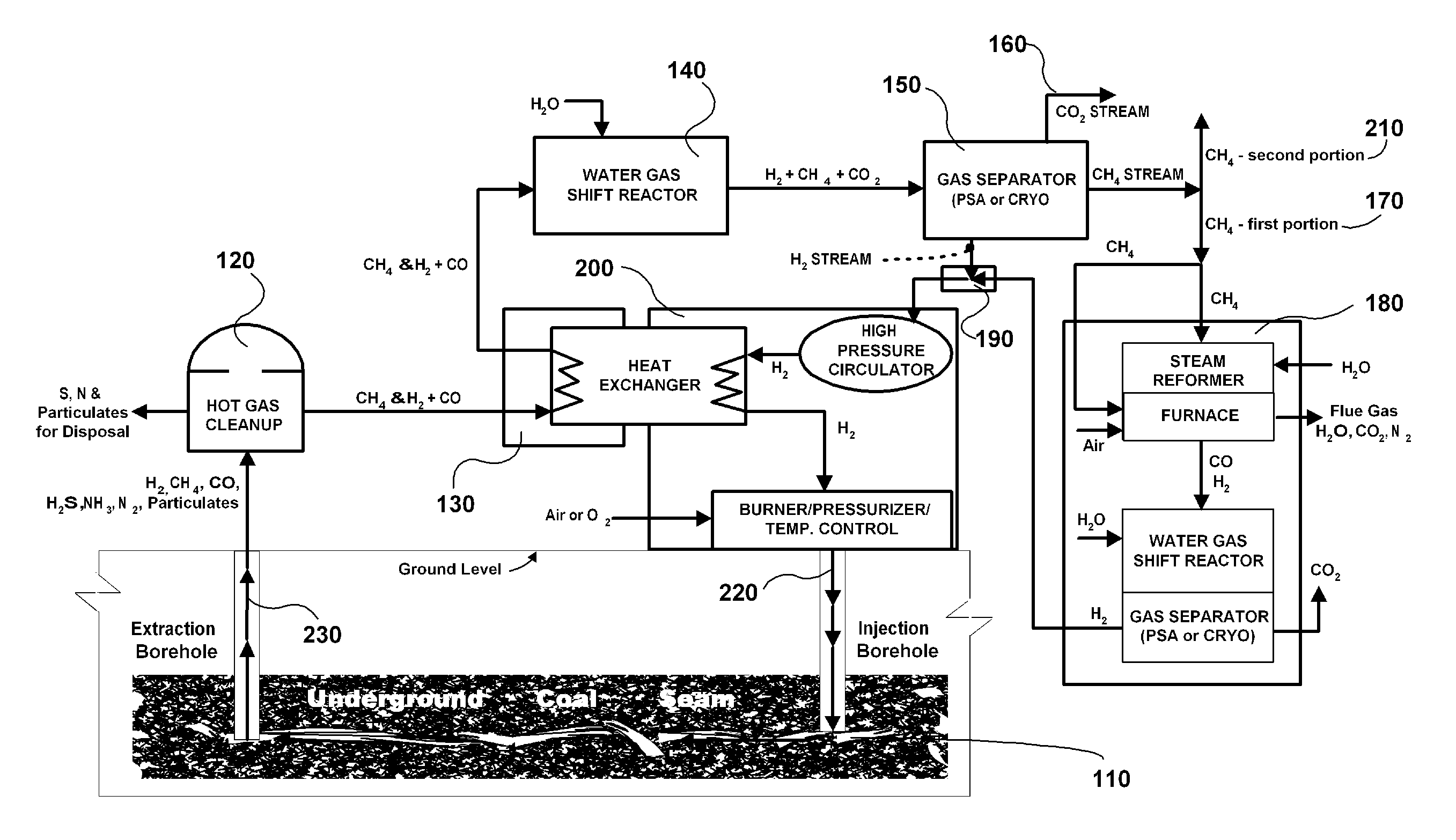

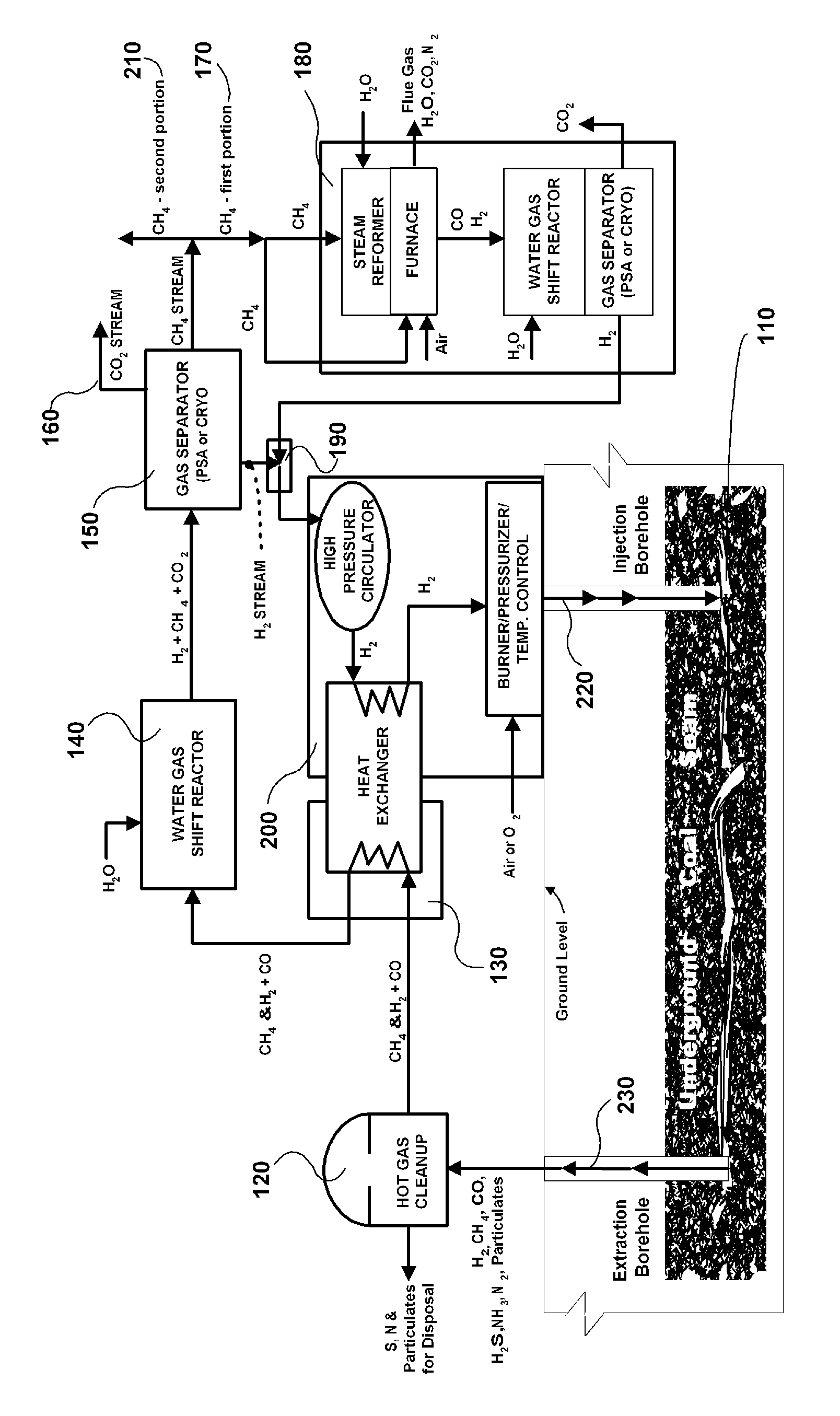

Pumped carbon mining methane production process

The invention is a continuous process for producing methane from an underground coal bed or an above ground carbon-containing resource using hydrogen as a recycling working fluid. For an underground coal seam, the process includes injecting (220) hydrogen into the coal seam to form a reaction effluent of methane, hydrogen and carbon monoxide; extracting the reaction effluent (230) for processing above ground; cleaning the reaction effluent (120); cooling the cleaned reaction effluent (130) and processing it through a water gas shift reactor (140); separating (150) hydrogen, methane, and carbon dioxide into separate streams; producing the carbon dioxide stream (160) as a product gas; processing a first portion (170) of the methane stream in a steam reformer, water gas shift reactor and gas separator (180) to produce segregated flows of hydrogen and carbon dioxide, combining the segregated hydrogen flow with the separated hydrogen stream (190); heating and repressurizing (200) the combined hydrogen stream to the temperature and pressure of the hydrogen in the first step; producing a second portion (210) of said methane stream as a product gas; and injecting (220) the combined hydrogen stream into the underground coal bed to continue the process.

Owner:HCE

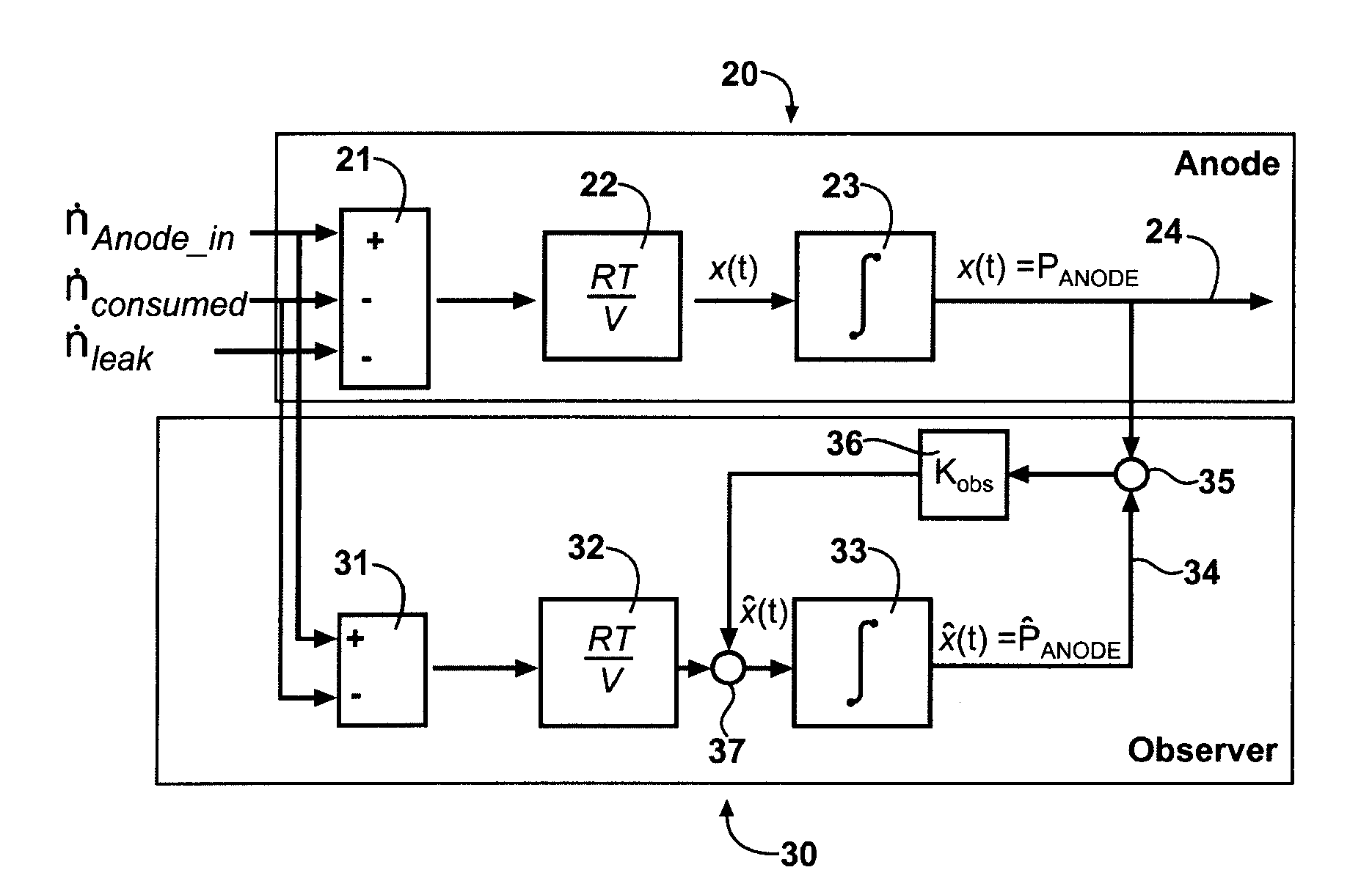

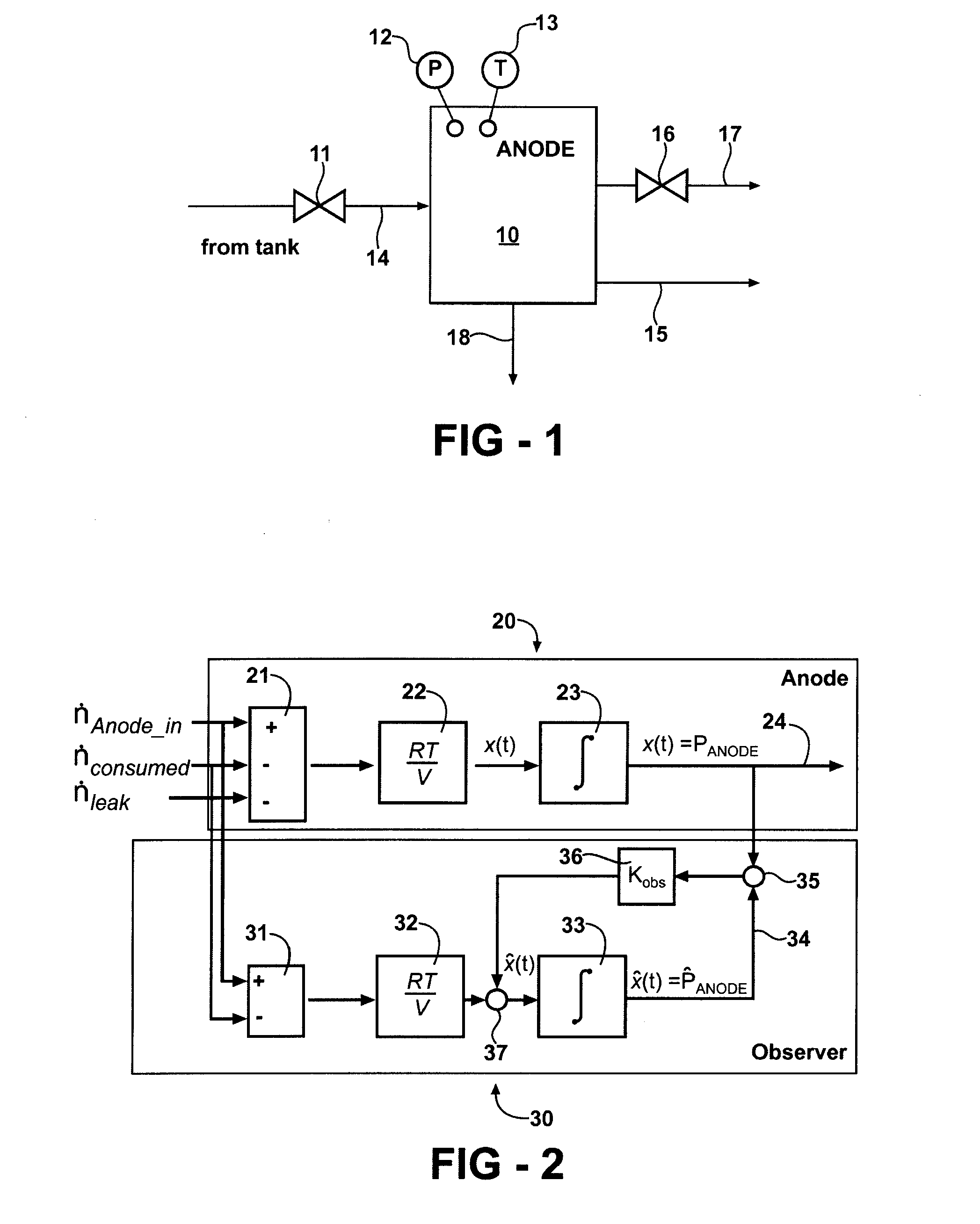

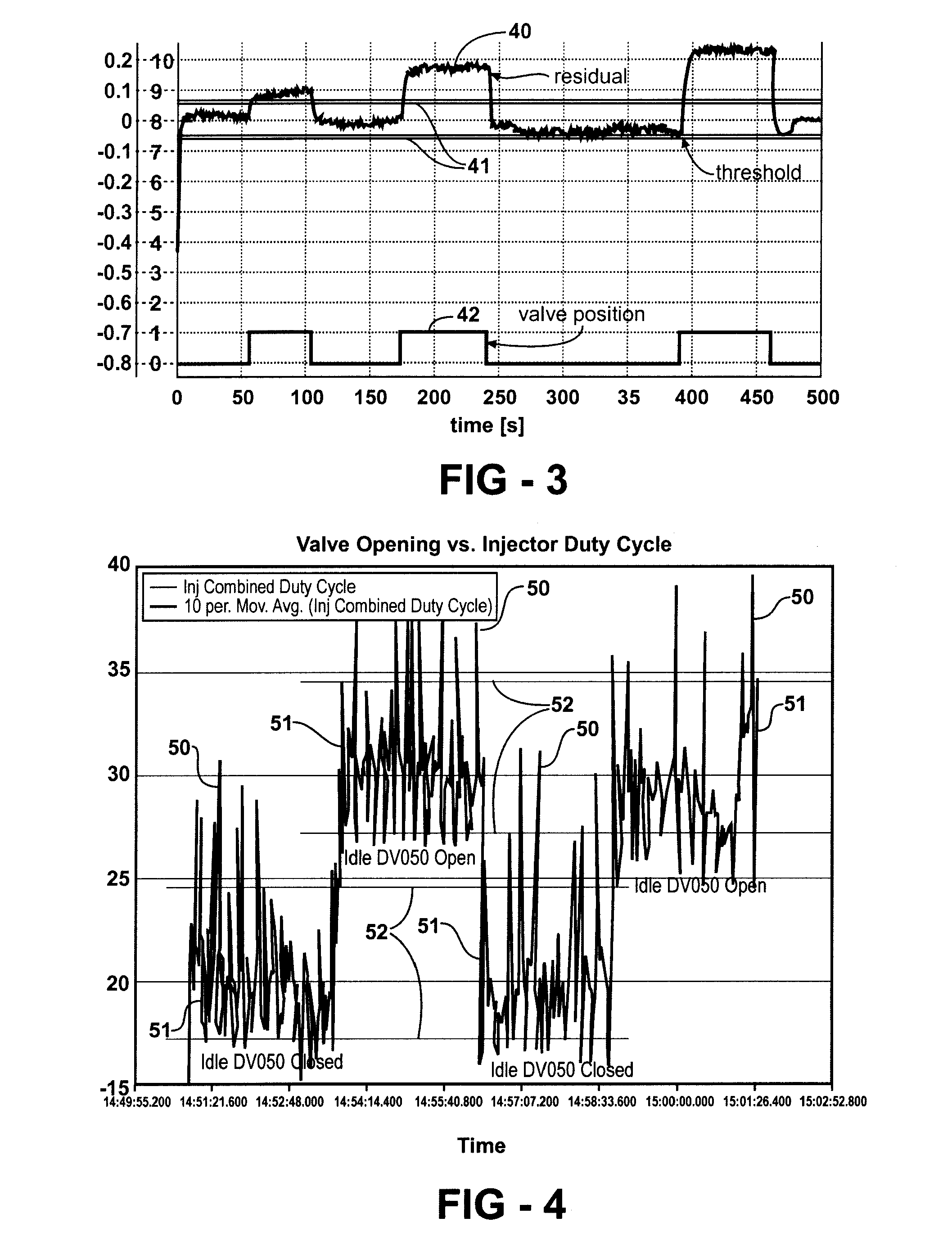

Leak detection in a fuel cell system

InactiveUS20080141760A1Measurement of fluid loss/gain rateFuel cell heat exchangeEngineeringLeak detection

A diagnostic method of detecting component failures in a fuel cell anode subsystem involves estimating fuel flow through injectors and comparing the estimated flow with a model based upon the system parameters. An observer based model is used to determine a residual value, the difference between the hydrogen input and the hydrogen consumed, and the residual is compared with a threshold range. In alternative embodiments, the stack current and the state of the valves are used to calculate the required hydrogen flow through the injectors and the duty cycle of an injector is compared to a tolerance range.

Owner:GM GLOBAL TECH OPERATIONS LLC

System and method for storing and discharging hydrogen

A hydrogen fuel system comprises an open gas circuit that includes a source of hydrogen. The hydrogen fuel system also includes a compressor that forces a flow of hydrogen from the source of hydrogen through the open gas circuit, and a hydrogen storage vessel comprising an inlet and an outlet. The hydrogen fuel system may also include a hydrogen storage bed being disposed within the hydrogen storage vessel between the inlet and the outlet, the hydrogen storage vessel being adapted to form a portion of the open gas circuit so that the hydrogen storage bed is cooled by convection while hydrogen flows through the open gas circuit.

Owner:GENERAL ELECTRIC CO

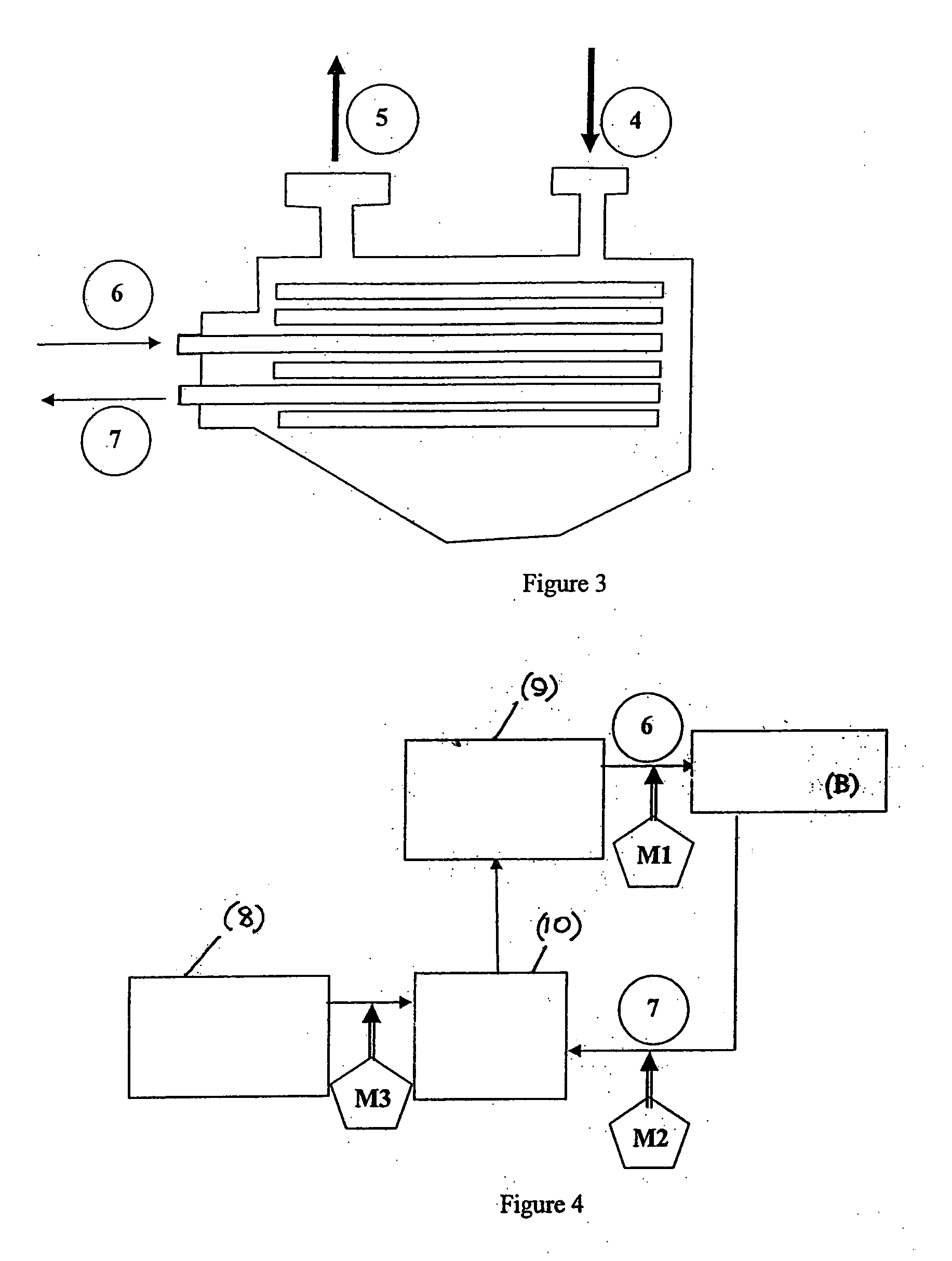

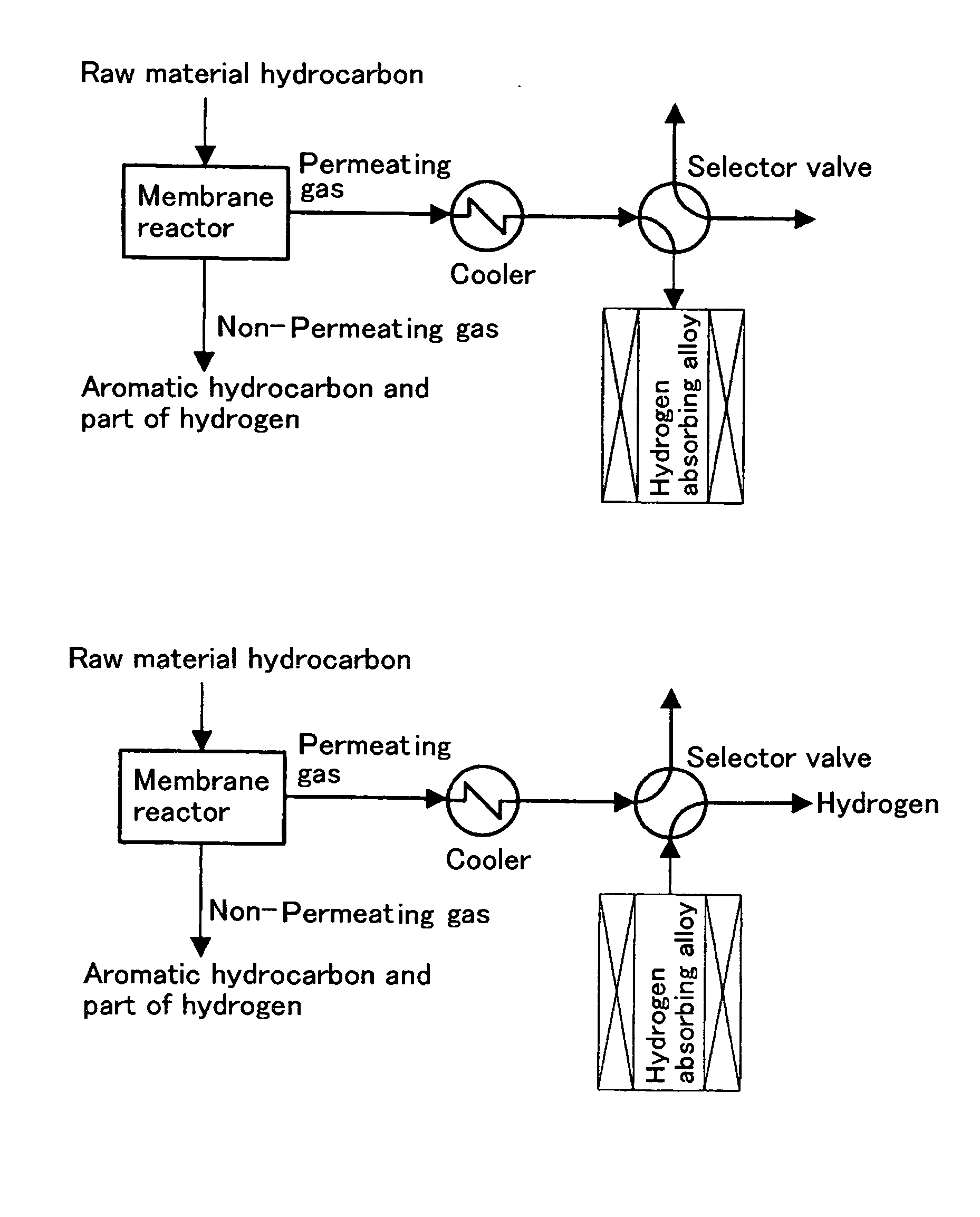

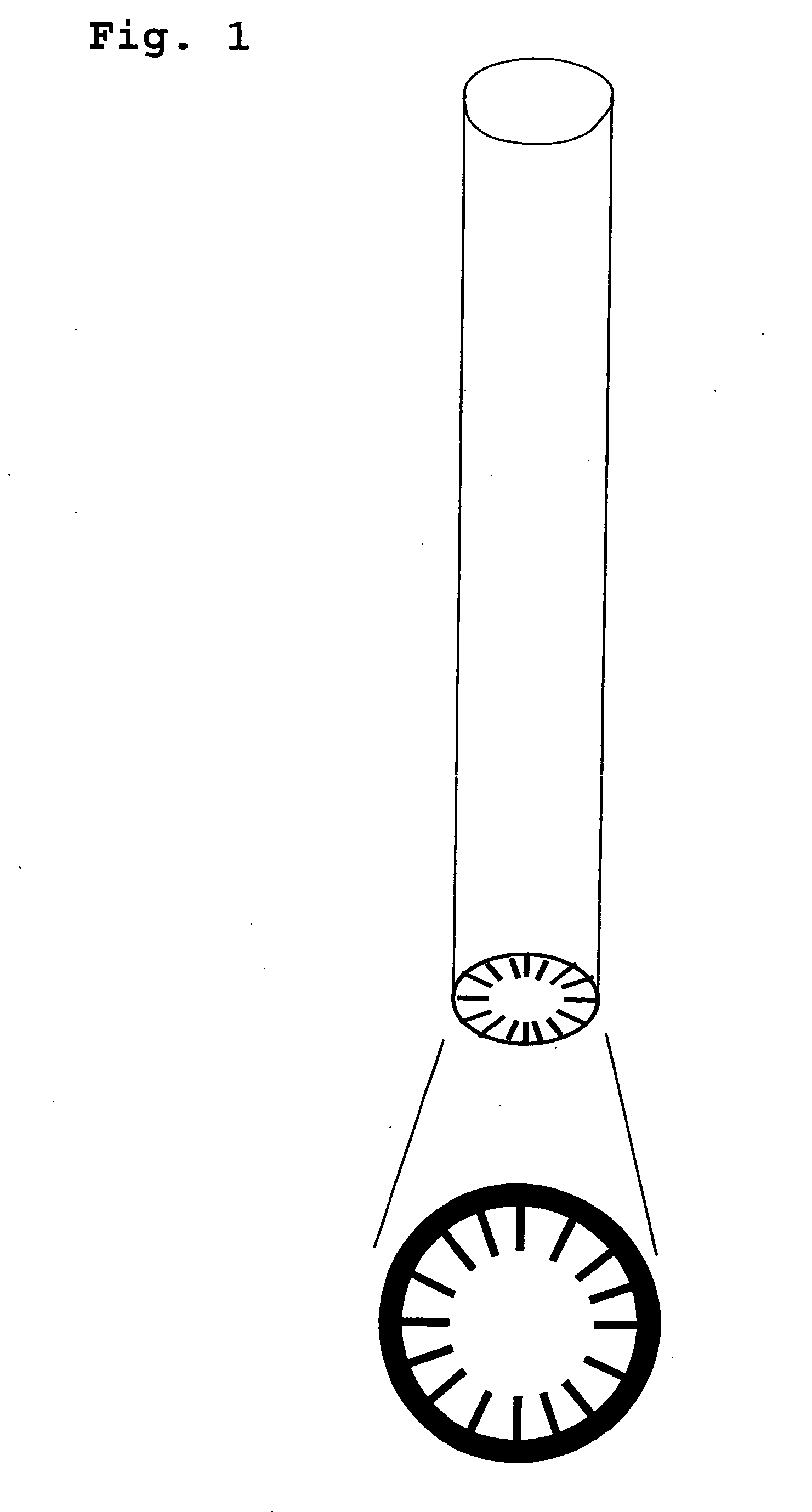

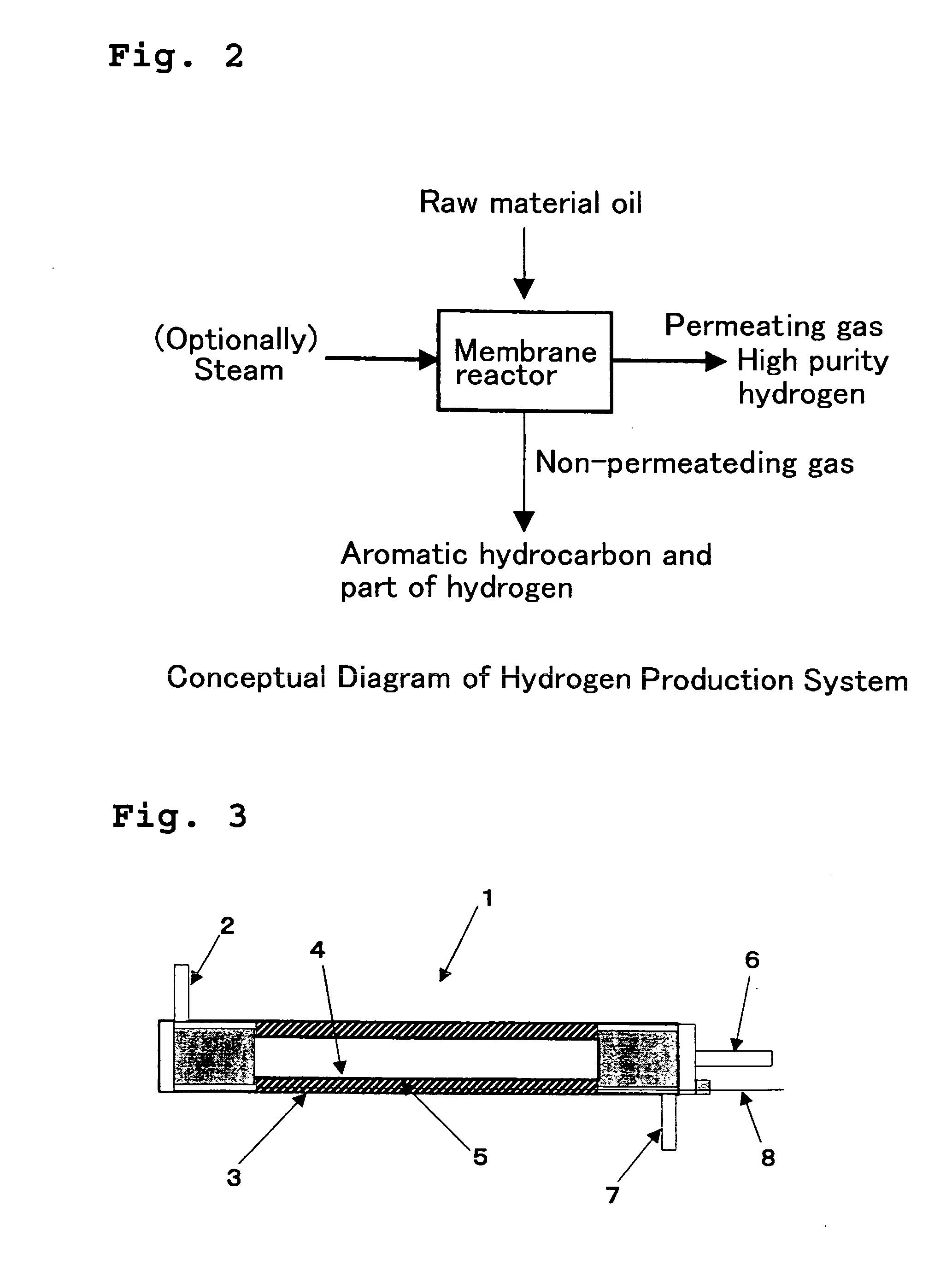

Method for Producing Hydrogen and System Therefor

InactiveUS20080234527A1Efficient productionReduce pressureOrganic chemistry methodsHydrogen/synthetic gas productionDouble tubeDehydrogenation

The present invention provides a hydrogen production method capable of producing hydrogen with good efficiency while solving problems such as separation, lower-temperature reaction and heat supply in production of hydrogen by dehydrogenation reaction of raw material oil. Within a reaction tube of a double-tube structure comprising an inner tube composed of a hydrogen separating membrane, a metallic outer tube having a plurality of internal fins, and a metal oxide layer and further a catalyst supported on the fins, hydrocarbon having cyclohexane ring is dehydrogenated to produce hydrogen and aromatic hydrocarbon, and selective membrane separating operation of hydrogen is performed within the reaction system while conducting the dehydrogenation to remove mainly the hydrogen on a permeating side and obtain mainly the aromatic hydrocarbon on a non-permeating side. The other method comprises absorbing at least part of the resulting hydrogen flow to a hydrogen absorbing (storing) alloy to make the pressure on the hydrogen permeating side of the hydrogen separating membrane lower than that on the non-permeating side.

Owner:NIPPON OIL CORP

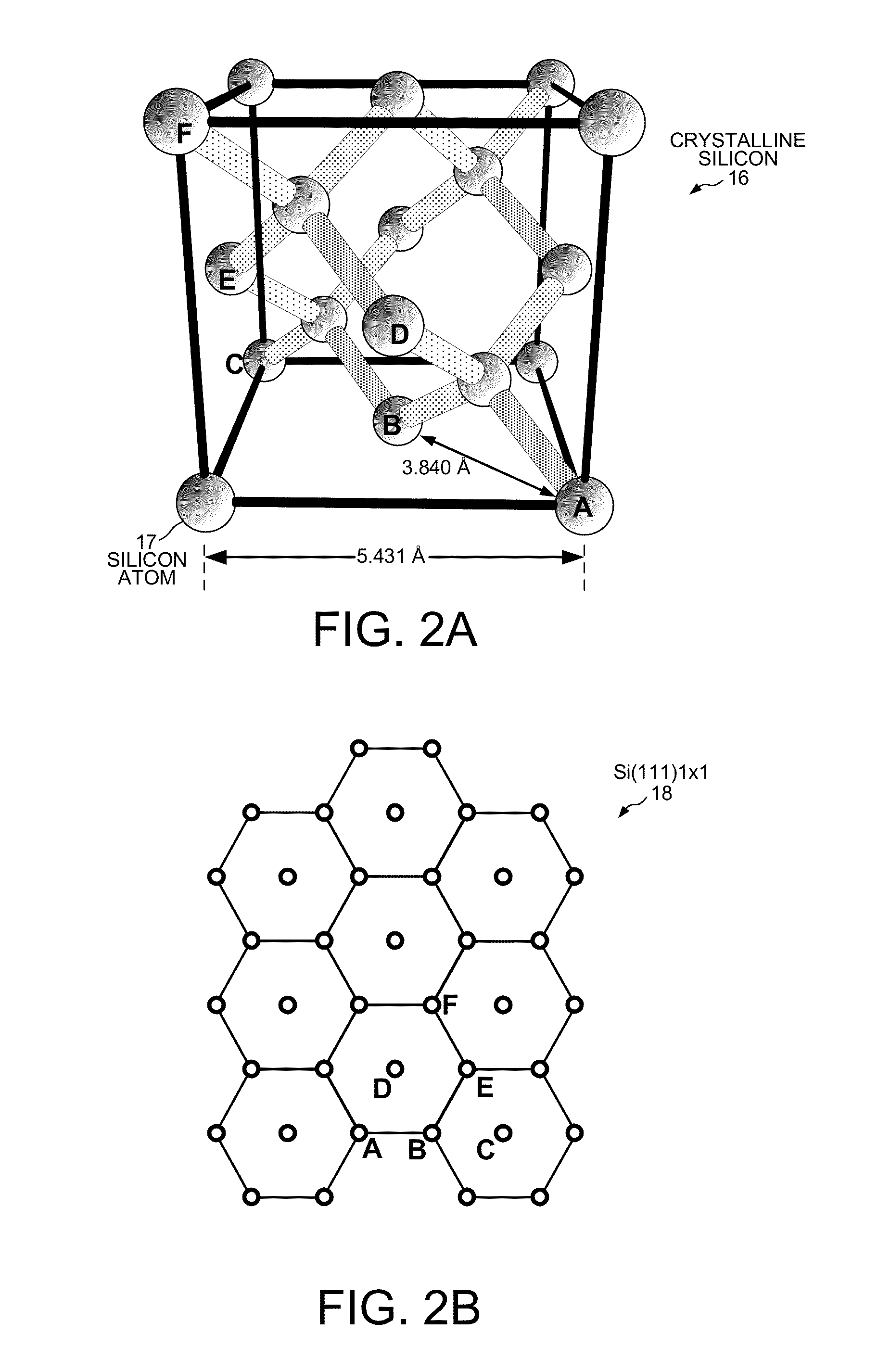

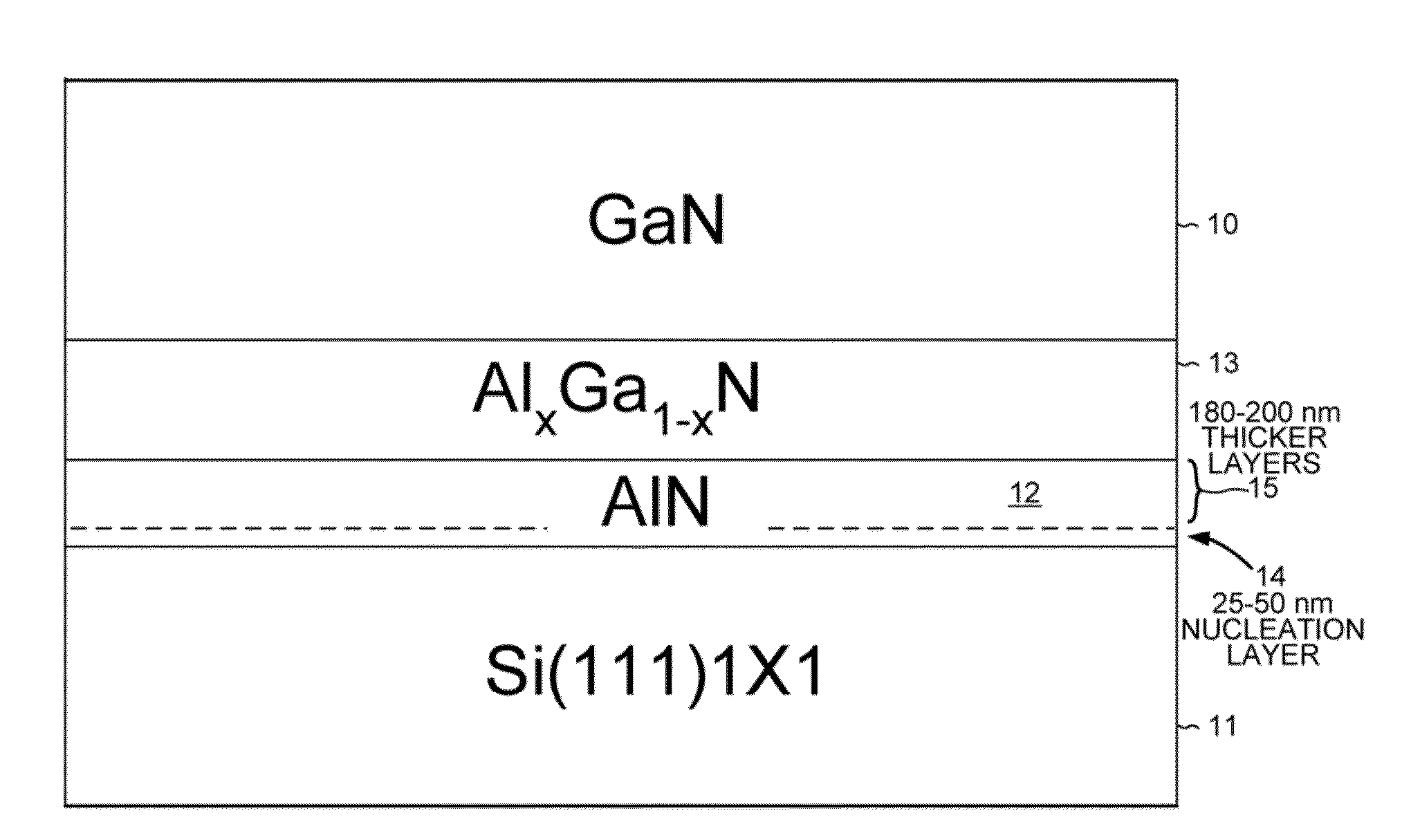

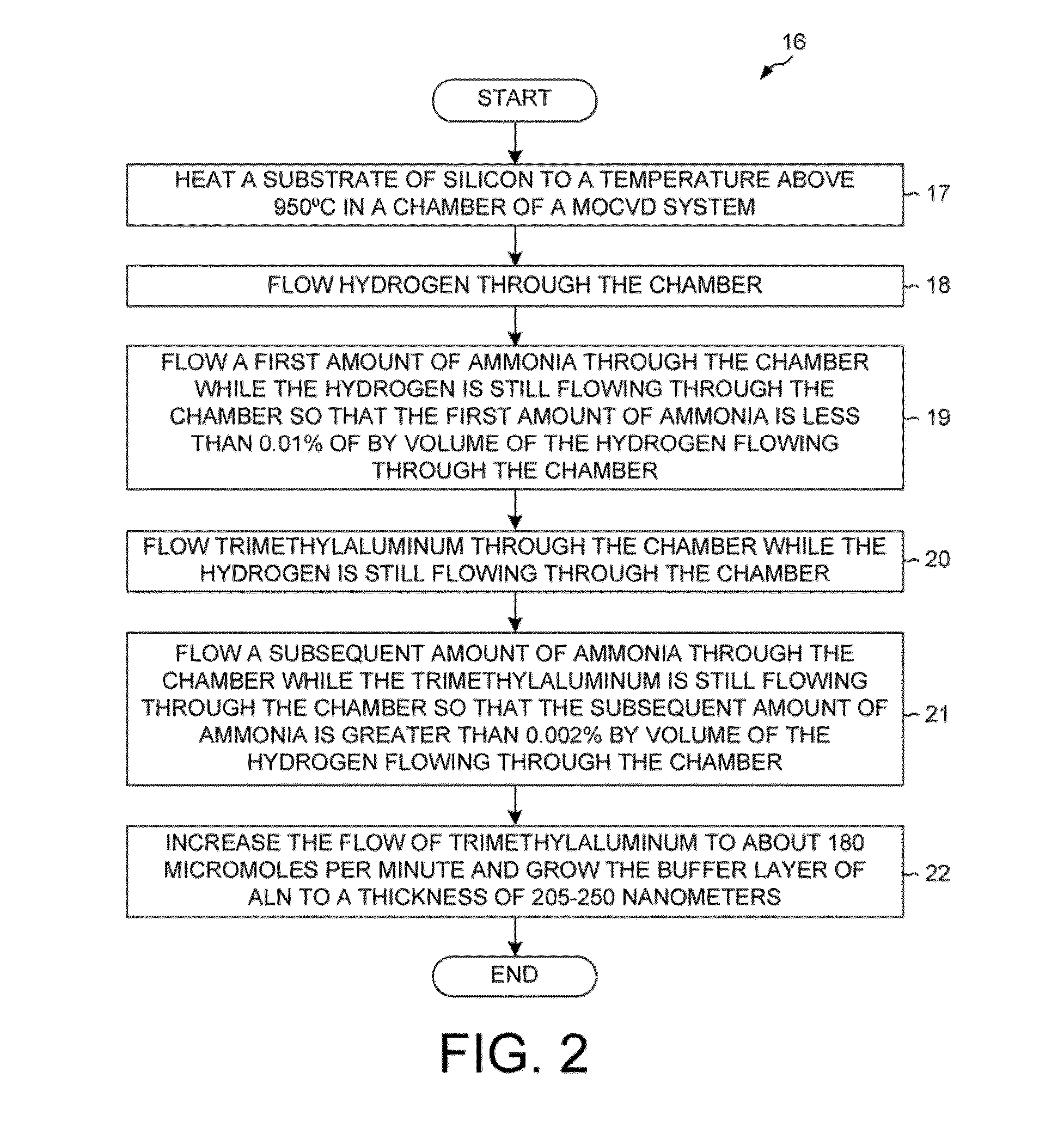

Nucleation of Aluminum Nitride on a Silicon Substrate Using an Ammonia Preflow

InactiveUS20130026480A1Polycrystalline material growthSemiconductor/solid-state device manufacturingNitrogenNucleation

A silicon wafer used in manufacturing crystalline GaN for light emitting diodes (LEDs) includes a silicon substrate, a buffer layer of aluminum nitride (AlN) and an upper layer of GaN. The silicon wafer has a diameter of at least 200 millimeters and an Si(111)1×1 surface. The AlN buffer layer overlies the Si(111) surface. The GaN upper layer is disposed above the buffer layer. Across the entire wafer substantially no aluminum atoms of the AlN are present in a bottom most plane of atoms of the AlN, and across the entire wafer substantially only nitrogen atoms of the AlN are present in the bottom most plane of atoms of the AlN. A method of making the AlN buffer layer includes preflowing a first amount of ammonia equaling less than 0.01% by volume of hydrogen flowing through a chamber before flowing trimethylaluminum and then a subsequent amount of ammonia through the chamber.

Owner:KK TOSHIBA

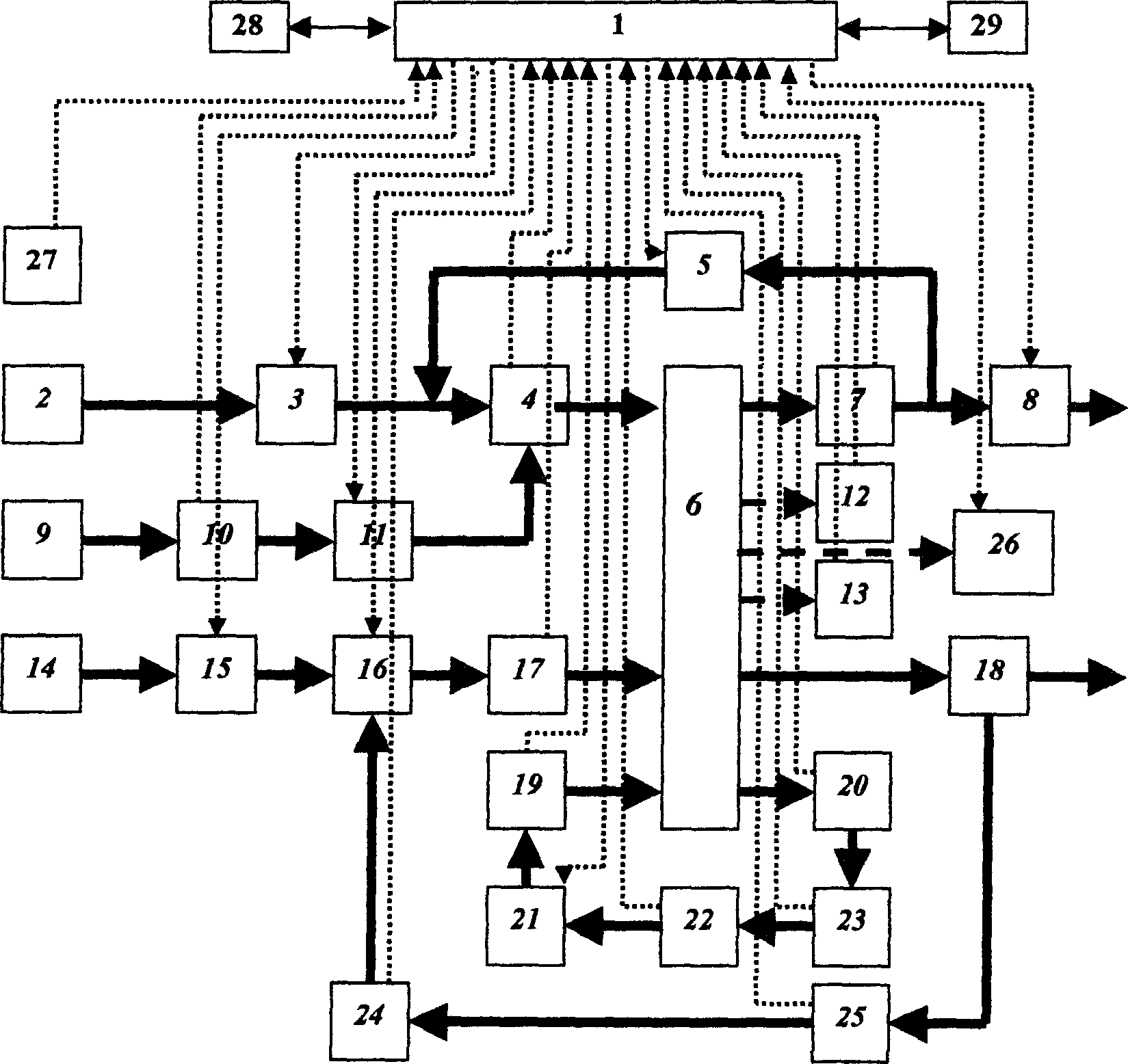

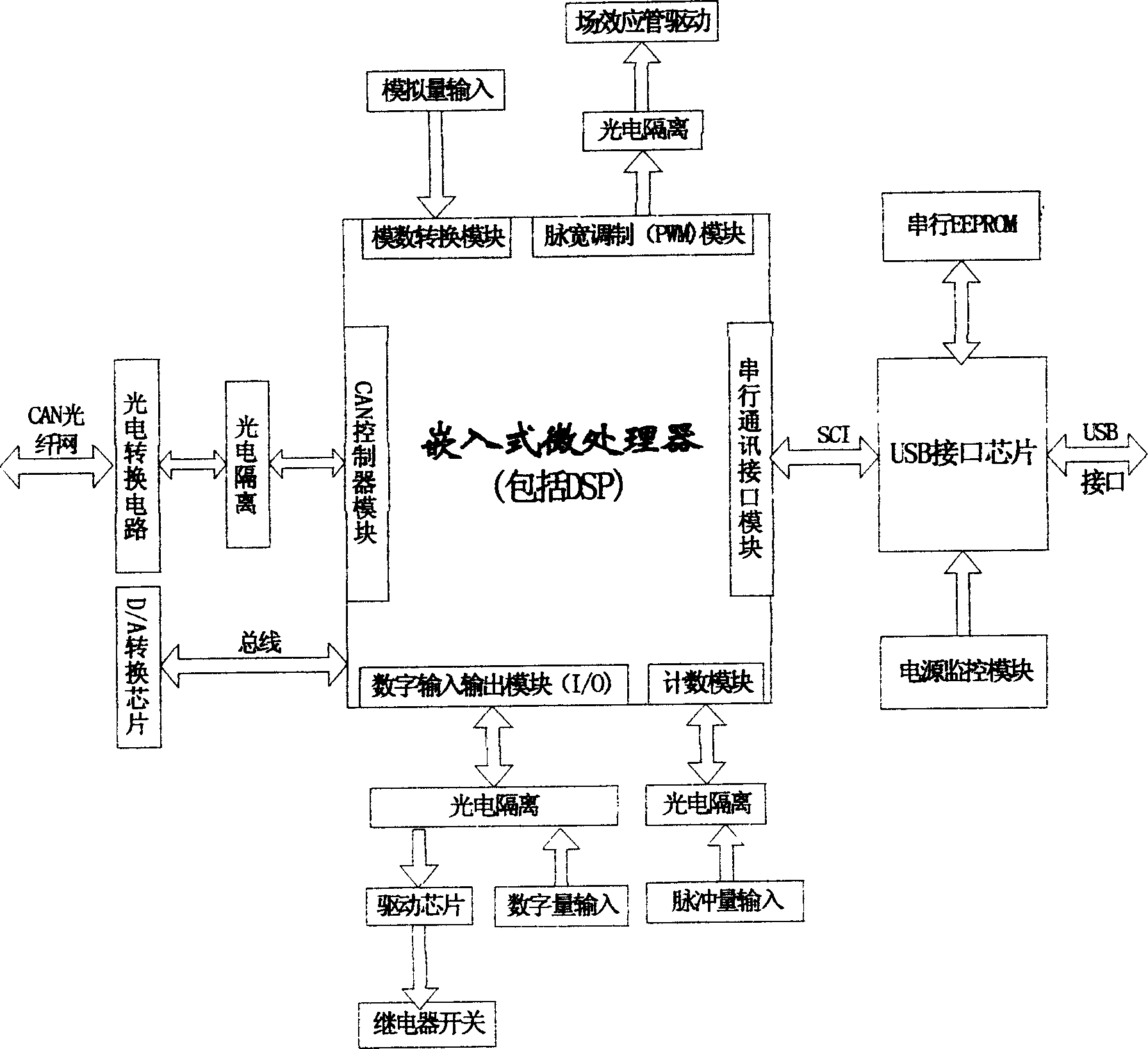

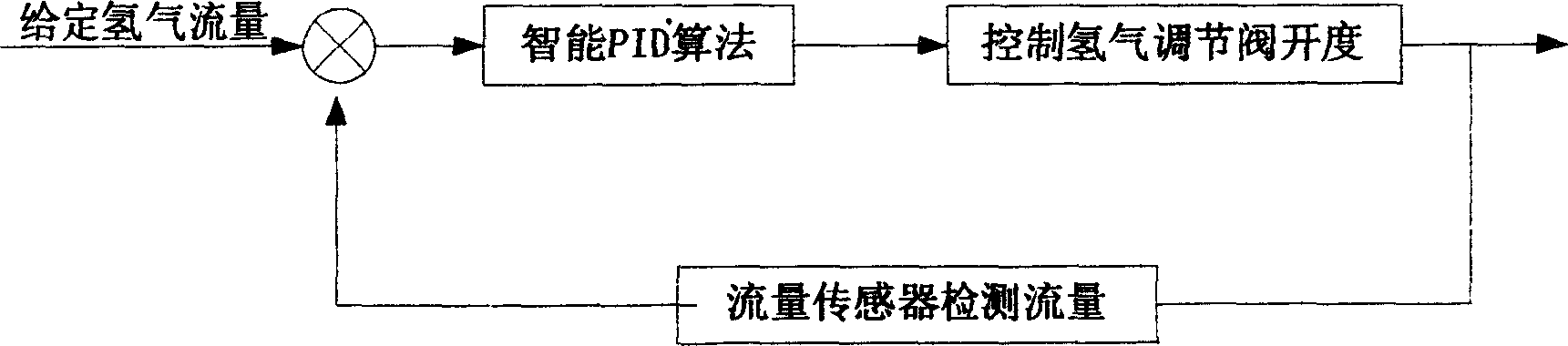

Vehicular fuel battery engine control method and apparatus

InactiveCN1632978AEnsure safe workReasonable layoutFuel cell auxillariesControl systemMotor controller

This invention relates to a car fuel battery motor control method and device, which comprises the following: fuel battery motor controller, air supply system, hydrogen supply system, cooling water recycling system, communication monitor system, fault test alarming and single battery test system. Wherein the controller controls the hydrogen supply system and adjusts the hydrogen flow and pressure according to the orders from CAN bus and current working status and adjusts air supply system and air flow and pressure and timely exchanges the data to judge the current working status is normal.

Owner:WUHAN UNIV OF TECH

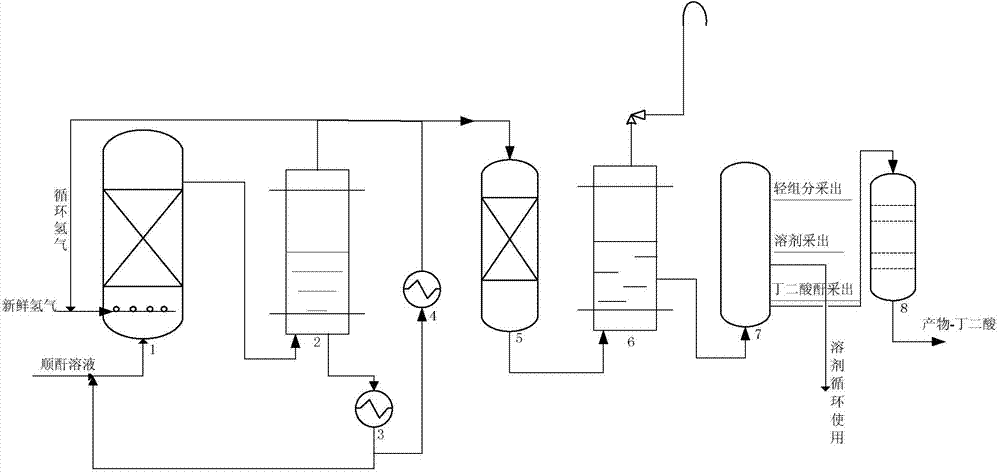

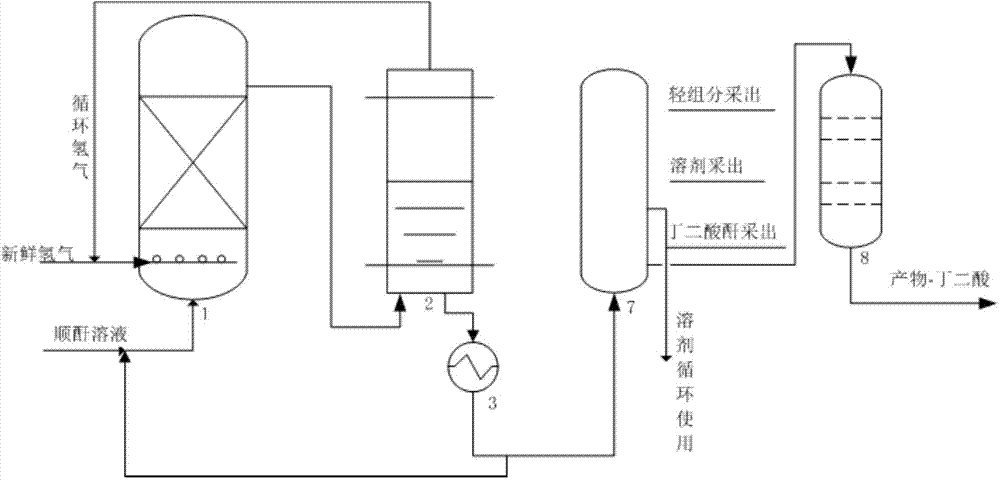

Technological process for continuously producing succinic anhydride and co-producing succinic acid through maleic anhydride hydrogenation

ActiveCN103570650AControl the average operating temperatureUniform reaction temperaturePreparation from carboxylic acid anhydridesFixed bedReaction temperature

The invention discloses a technological process for continuously producing succinic anhydride and co-producing succinic acid through maleic anhydride catalytic hydrogenation. The whole process comprises three steps, namely, reaction, rectification and hydrolysis, wherein two stages of hydrogenation reactors are used for reaction, a primary hydrogenation reactor is a fixed bed reactor with hydrogen entering from the lower part and reaction liquid exiting from the upper part, and a secondary hydrogenation reactor is a trickle bed reactor with hydrogen and reaction liquid entering from the upper part and exiting from the lower part. The technological process adopts an external circulating heat radiation manner, and reaction heat is uniformly removed, so that the average operation temperature of the whole reactor is effectively controlled, and the reaction temperature in the whole main reactor is balanced. Furthermore, the primary hydrogenation reactor adopts the manner that both the maleic anhydride solution and hydrogen flow upward simultaneously, so that the reaction temperature of the whole reactor is controlled to be balanced, local hot spot temperature is effectively controlled and lowered, and the reactants are prevented from polymerizing and depositing carbon or coking.

Owner:SHANXI UNIV

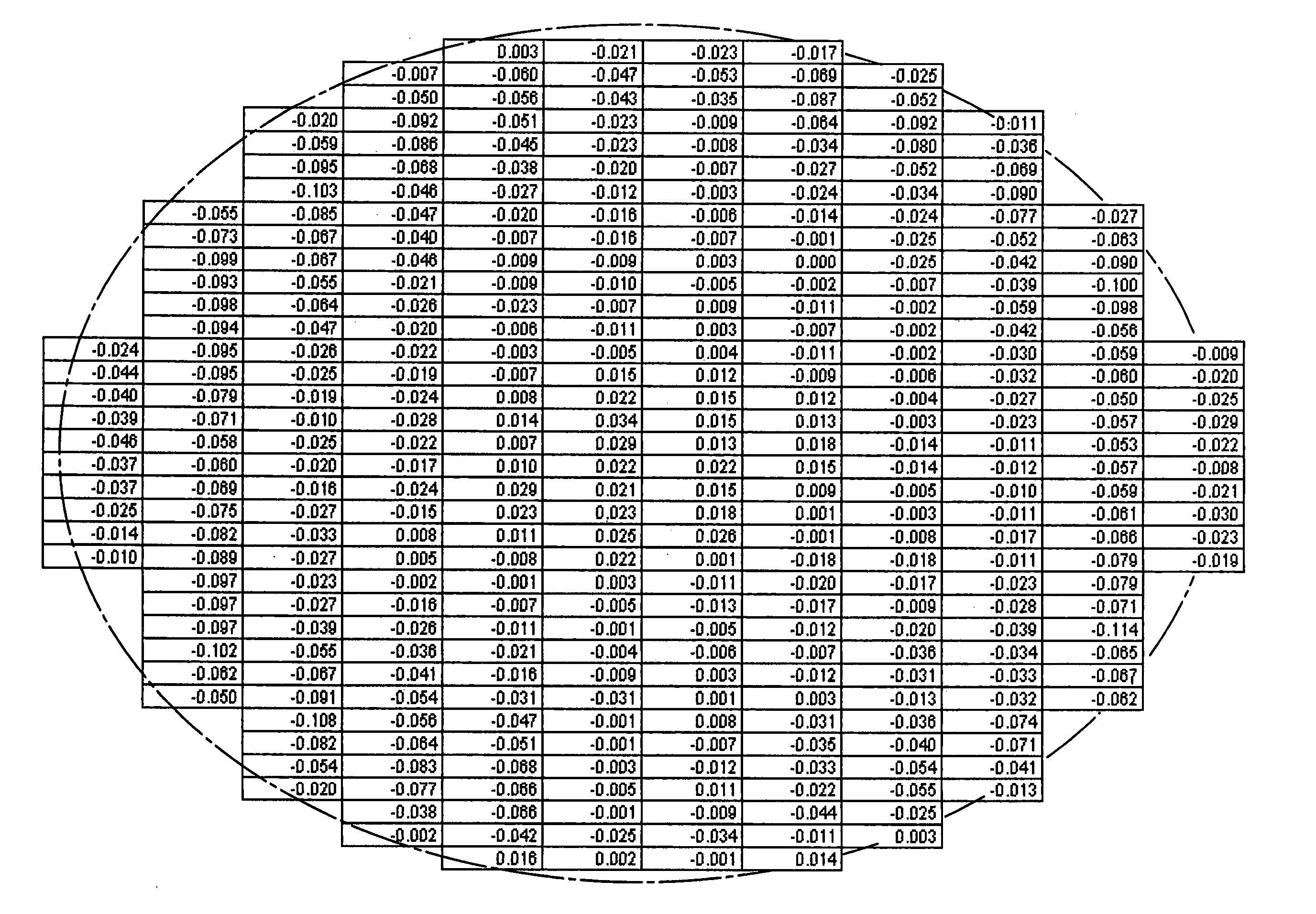

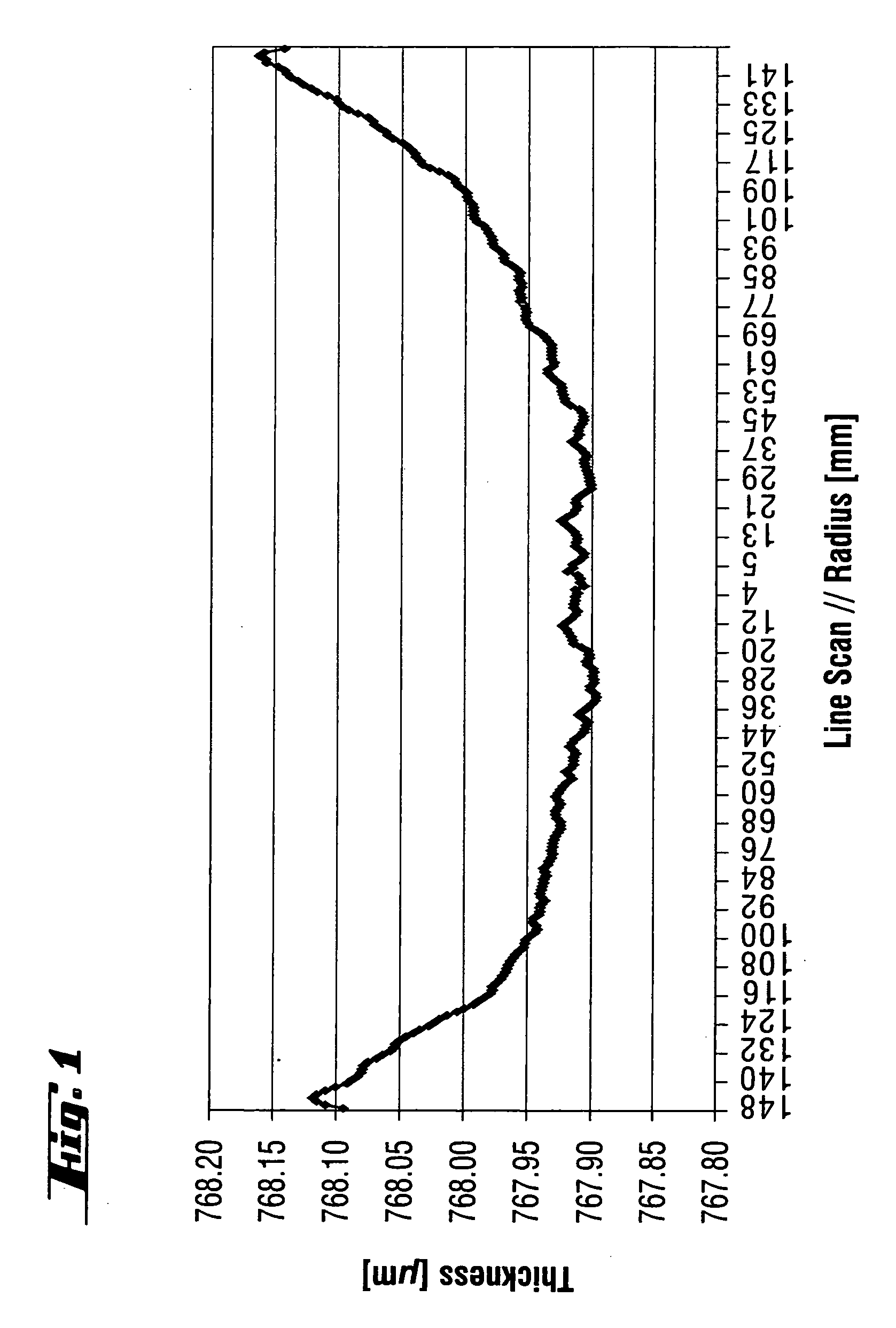

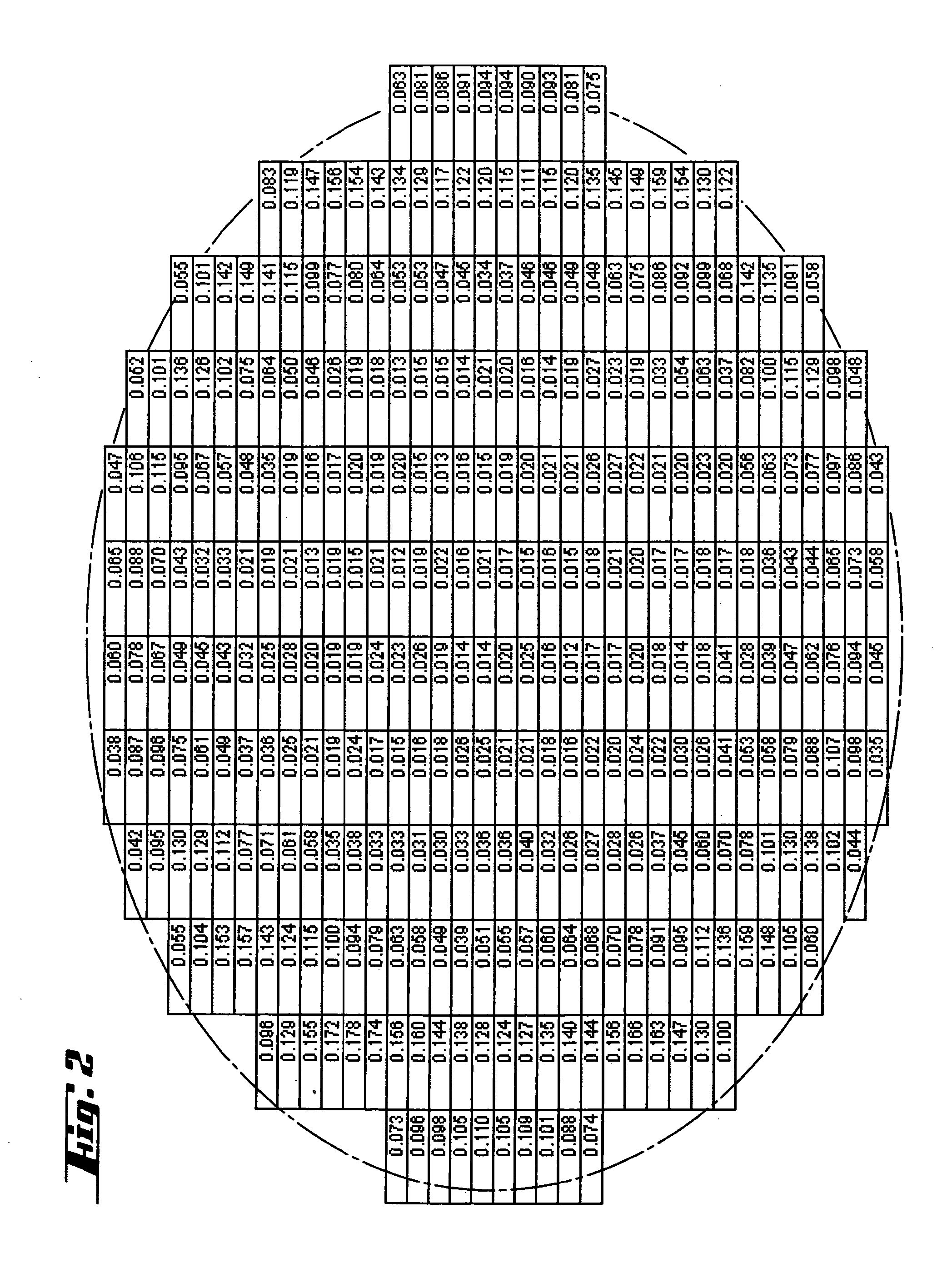

Epitaxially coated silicon wafer and method for producing epitaxially coated silicon wafers

ActiveUS20070066036A1Improve flatnessReduce trafficPolycrystalline material growthSemiconductor/solid-state device manufacturingSusceptorWafering

A multiplicity of silicon wafers polished at least on their front sides are provided and successively coated individually in an epitaxy reactor by a procedure whereby one of the wafers is placed on a susceptor in the epitaxy reactor, is pretreated under a hydrogen atmosphere at a first hydrogen flow rate, and with addition of an etching medium to the hydrogen atmosphere at a reduced hydrogen flow rate in a second step, is subsequently coated epitaxially on its polished front side, and removed from the reactor. An etching treatment of the susceptor follows a specific number of epitaxial coatings. Silicon wafers produced thereby have a global flatness value GBIR of 0.07-0.3 μm relative to an edge exclusion of 2 mm.

Owner:SILTRONIC AG

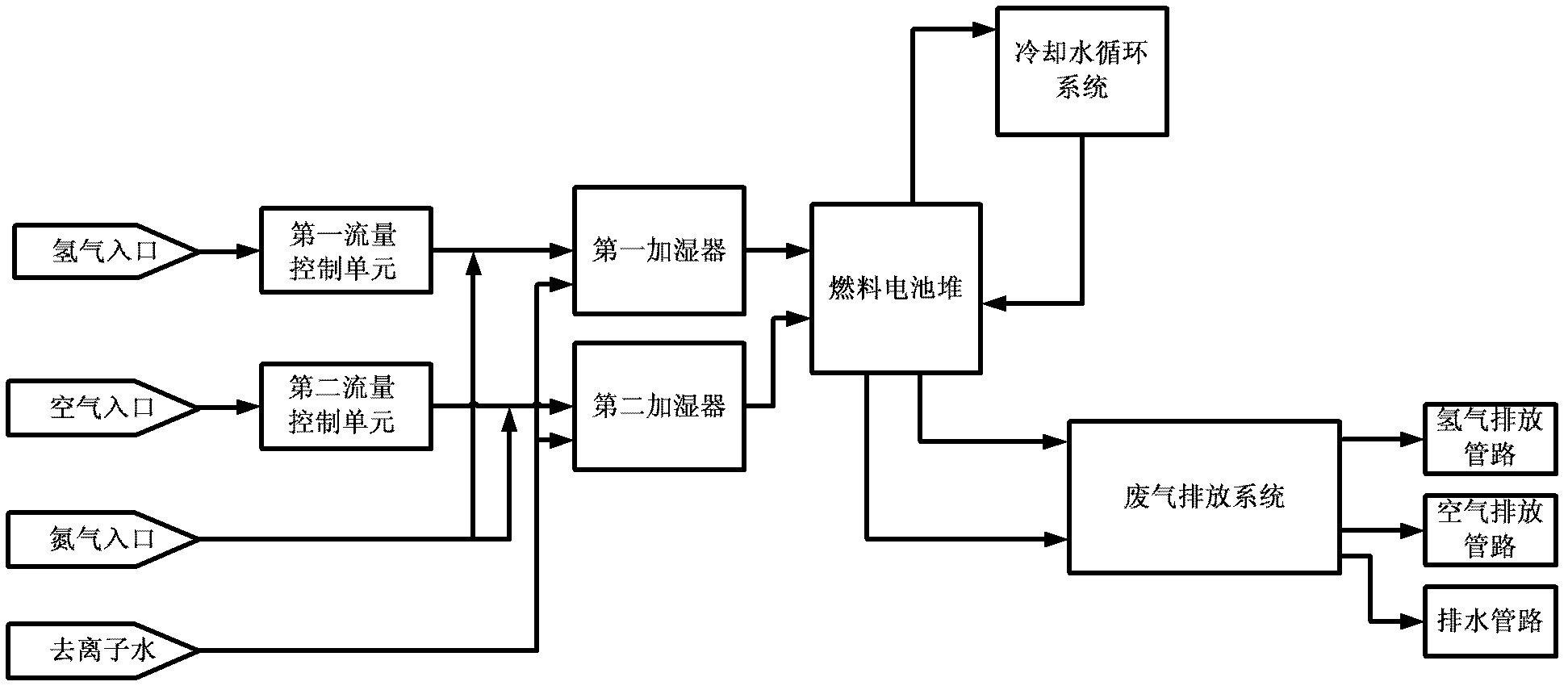

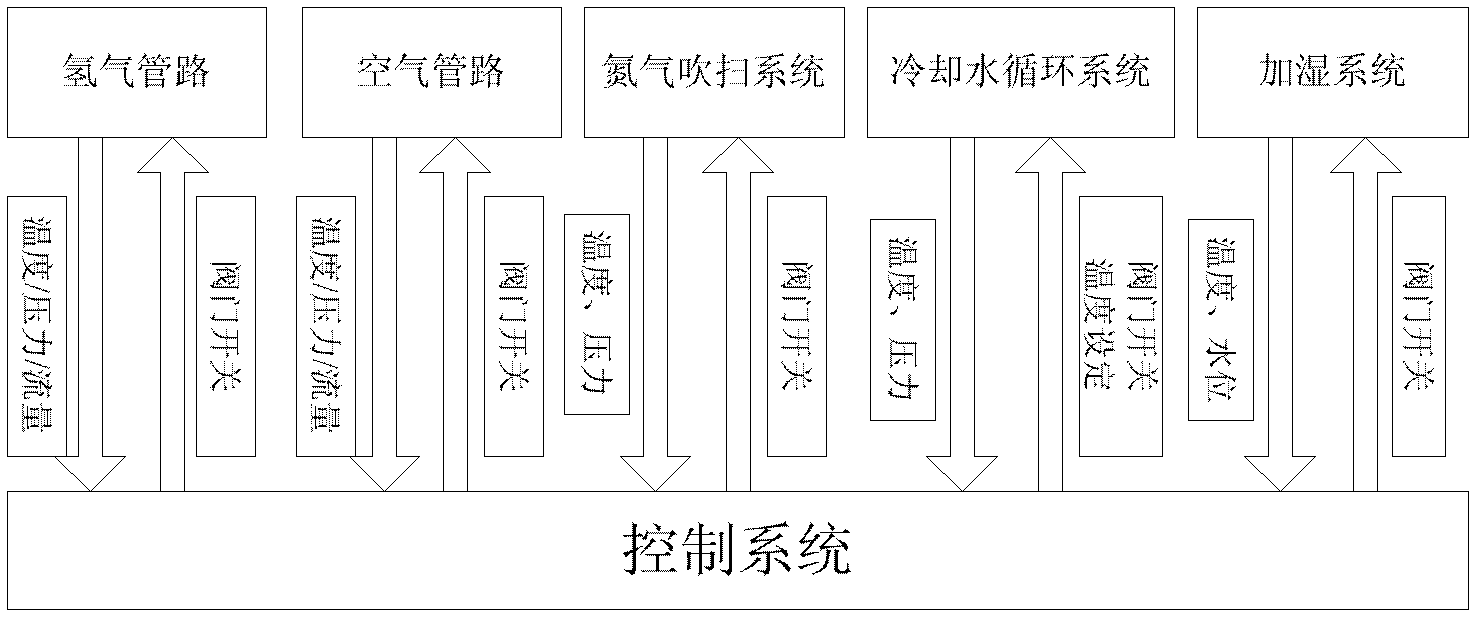

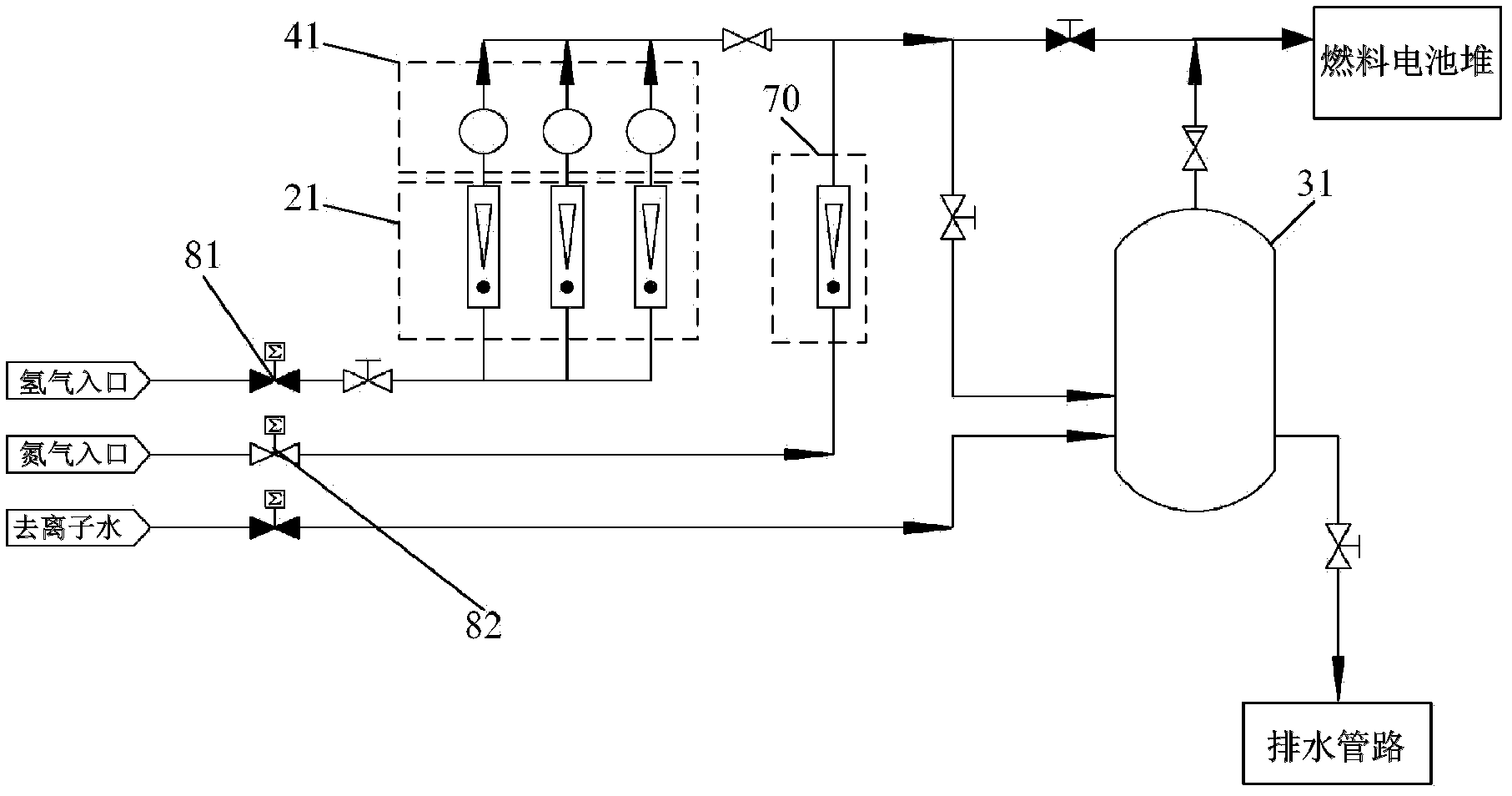

Device for testing fuel cell stacks

The invention provides a device for testing fuel cell stacks, which comprises a working gas supply system connected with a fuel cell, and a control system. The working gas supply system comprises a hydrogen pipe and an air pipe; wherein a first flow control unit for detecting and controlling the flow of hydrogen is arranged on the hydrogen pipe; a second flow control unit for detecting and controlling the flow of air is arranged on the air pipe; and the control system is electrically connected with the first flow control unit and the second flow control unit respectively, and is used for collecting detecting signals sent by the first flow control unit and the second flow control unit so as to record the hydrogen flow in the hydrogen pipe and the air glow in the air pipe. the device has the advantages of effectively solves the problem that the correlation data of hydrogen and air flow and fuel cell performance parameters under the loading condition of fuel cell stacks cannot be detected in the prior art.

Owner:DONGFANG ELECTRIC (CHENGDU) HYDROGEN FUEL CELL TECH CO LTD

Hydrogen supply pressure regulator

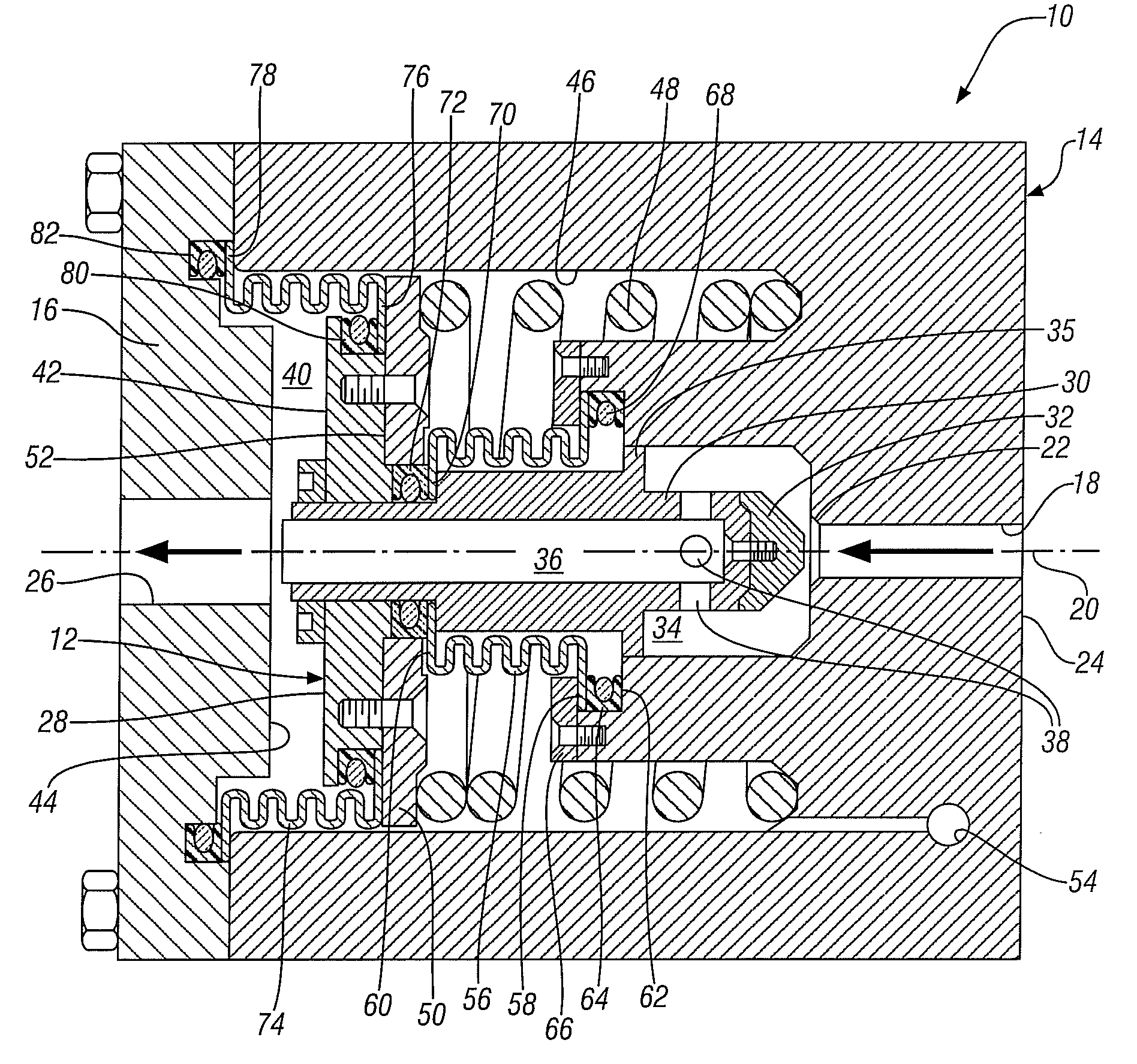

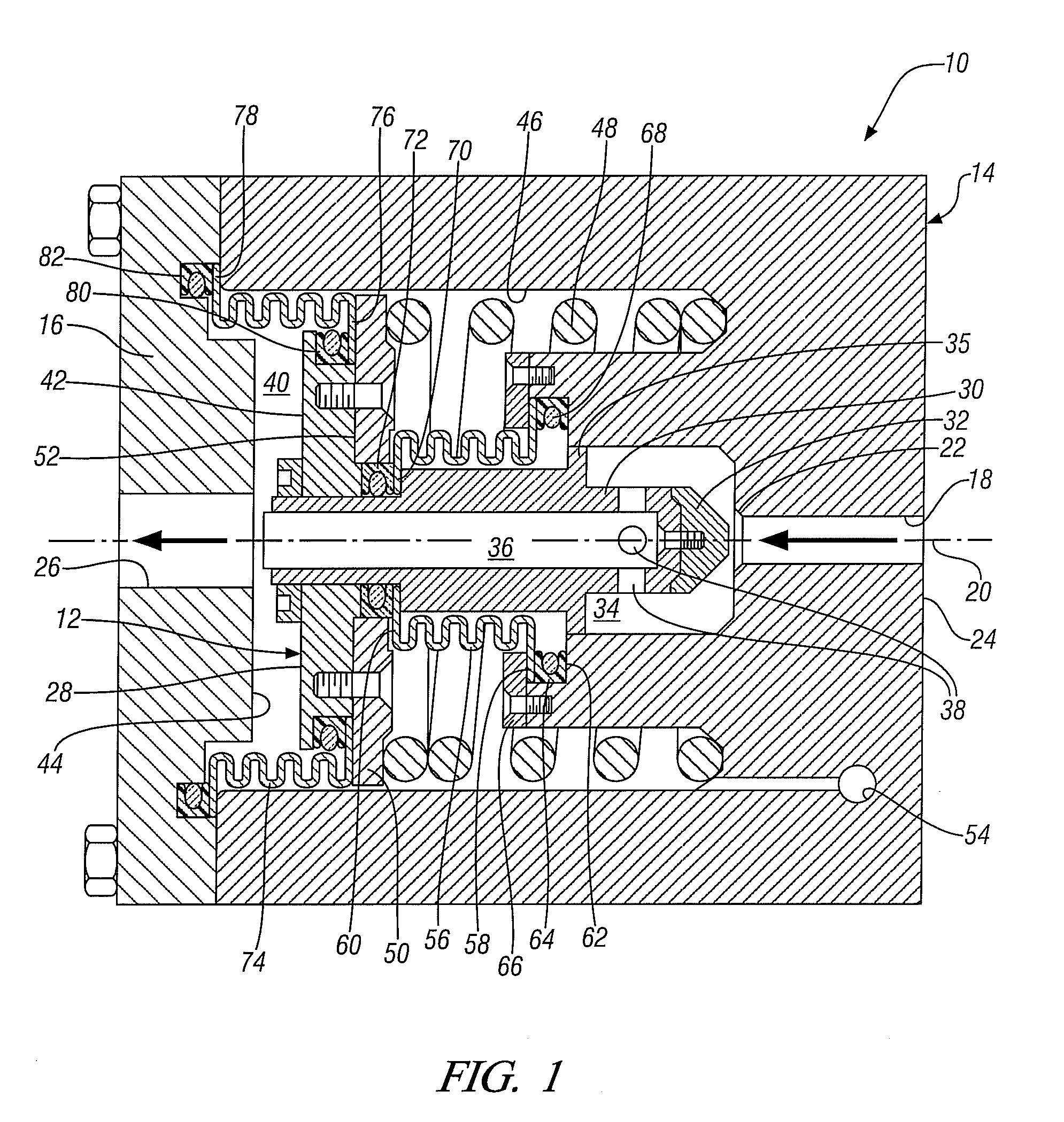

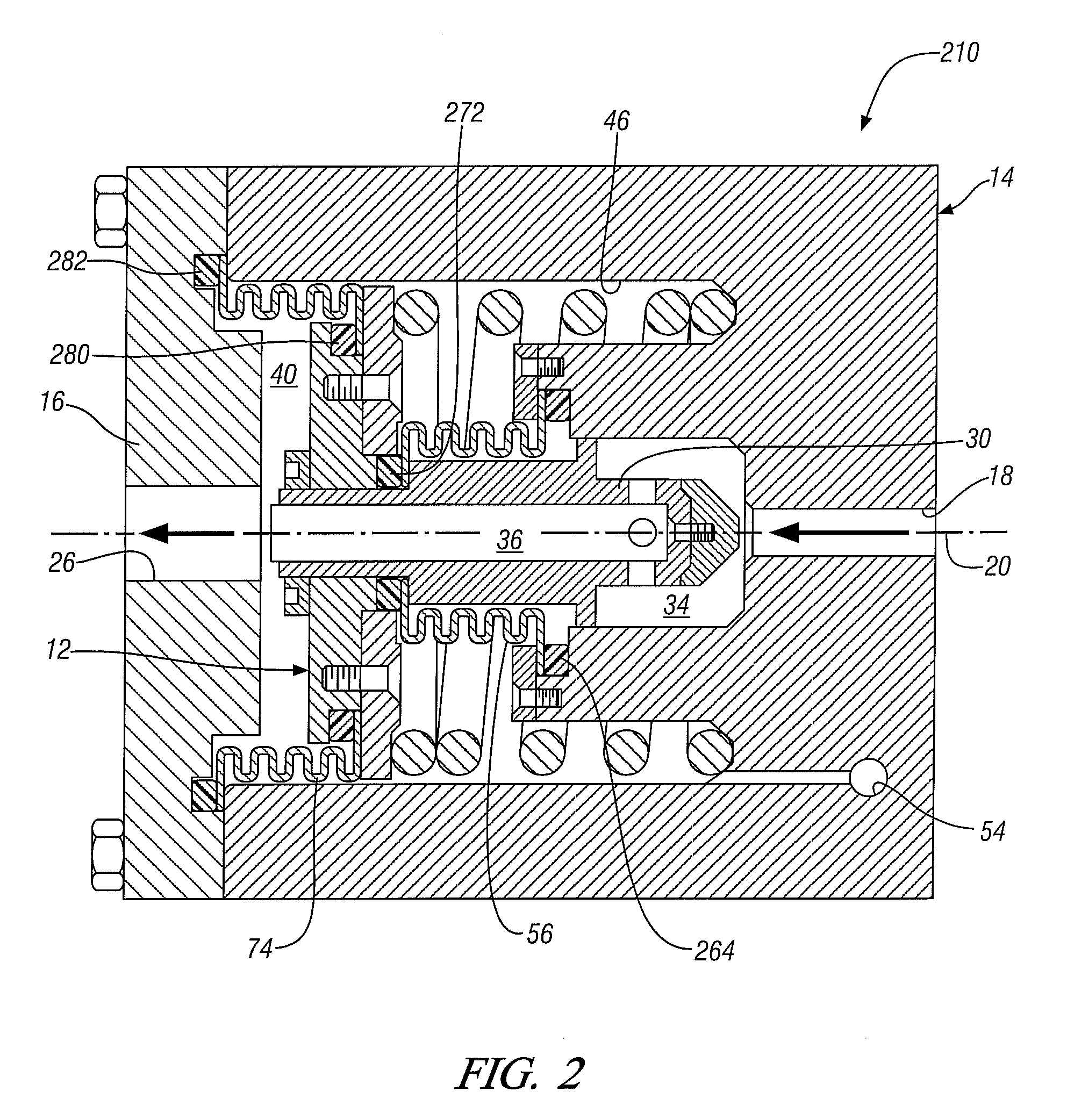

InactiveUS20090242043A1Prevent leakageReduce frictionOperating means/releasing devices for valvesReactant parameters controlHydrogen pressureHigh pressure hydrogen

Hydrogen gas flow from high pressure storage to a lower pressure hydrogen-using device is managed using one or more axial flow pressure regulators comprising a cup-shaped housing with an inlet for high pressure hydrogen gas at one end of the flow axis and a closure with a low pressure hydrogen outlet at the other end of the flow axis. A piston head with a piston stem are aligned on the flow axis and a hydrogen flow passage is formed up the stem and through the piston head to the hydrogen flow outlet. One or more combinations of a corrugated tubular bellows (or like expansive sealing vessel) with static seals attaching one bellows end to the piston stem or head and the other bellows end to the housing or closure are used to accommodate axial movement of the piston while isolating and containing hydrogen gas flow from a high pressure chamber at a flow entrance to the piston stem to a low hydrogen pressure chamber at the piston head and closure outlet.

Owner:GM GLOBAL TECH OPERATIONS LLC

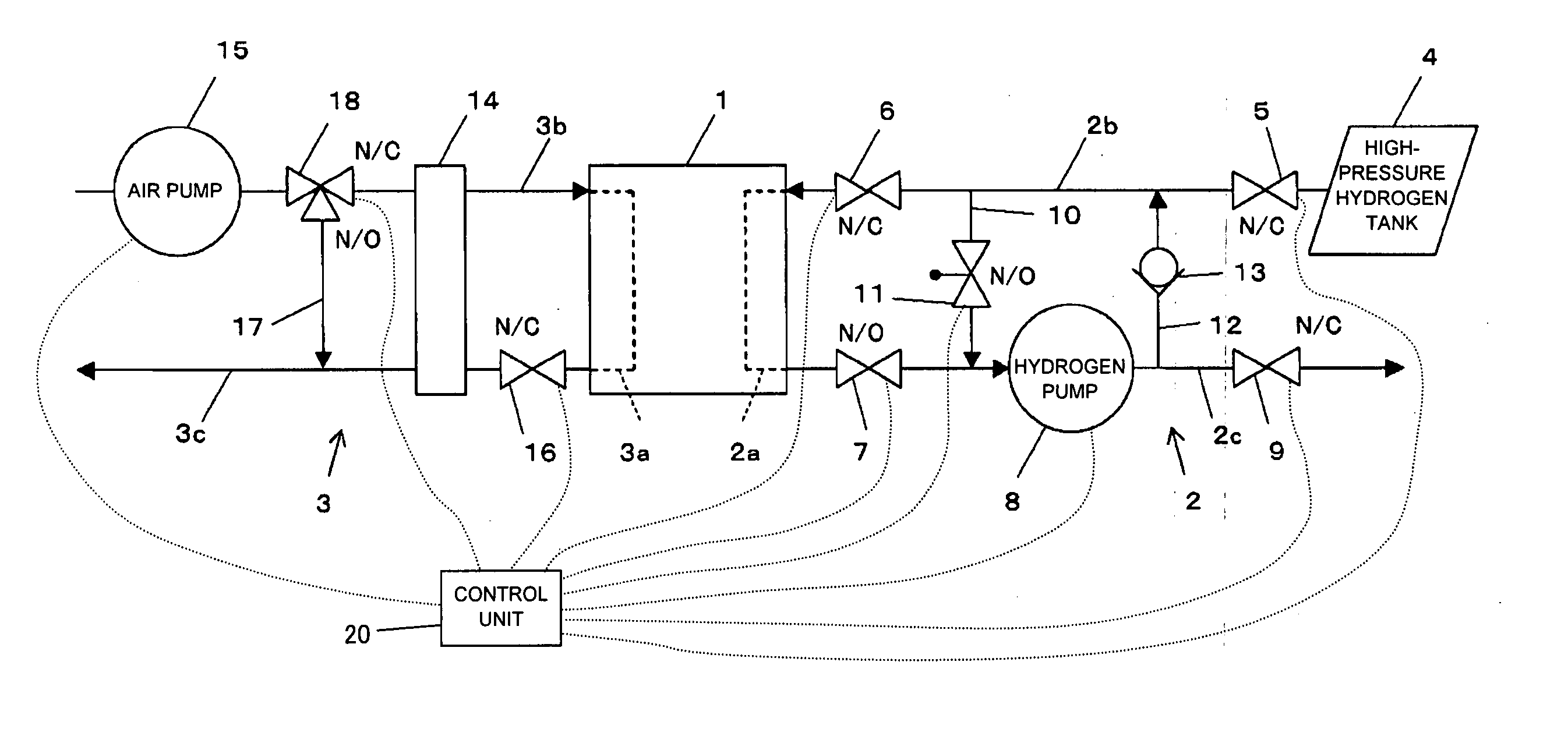

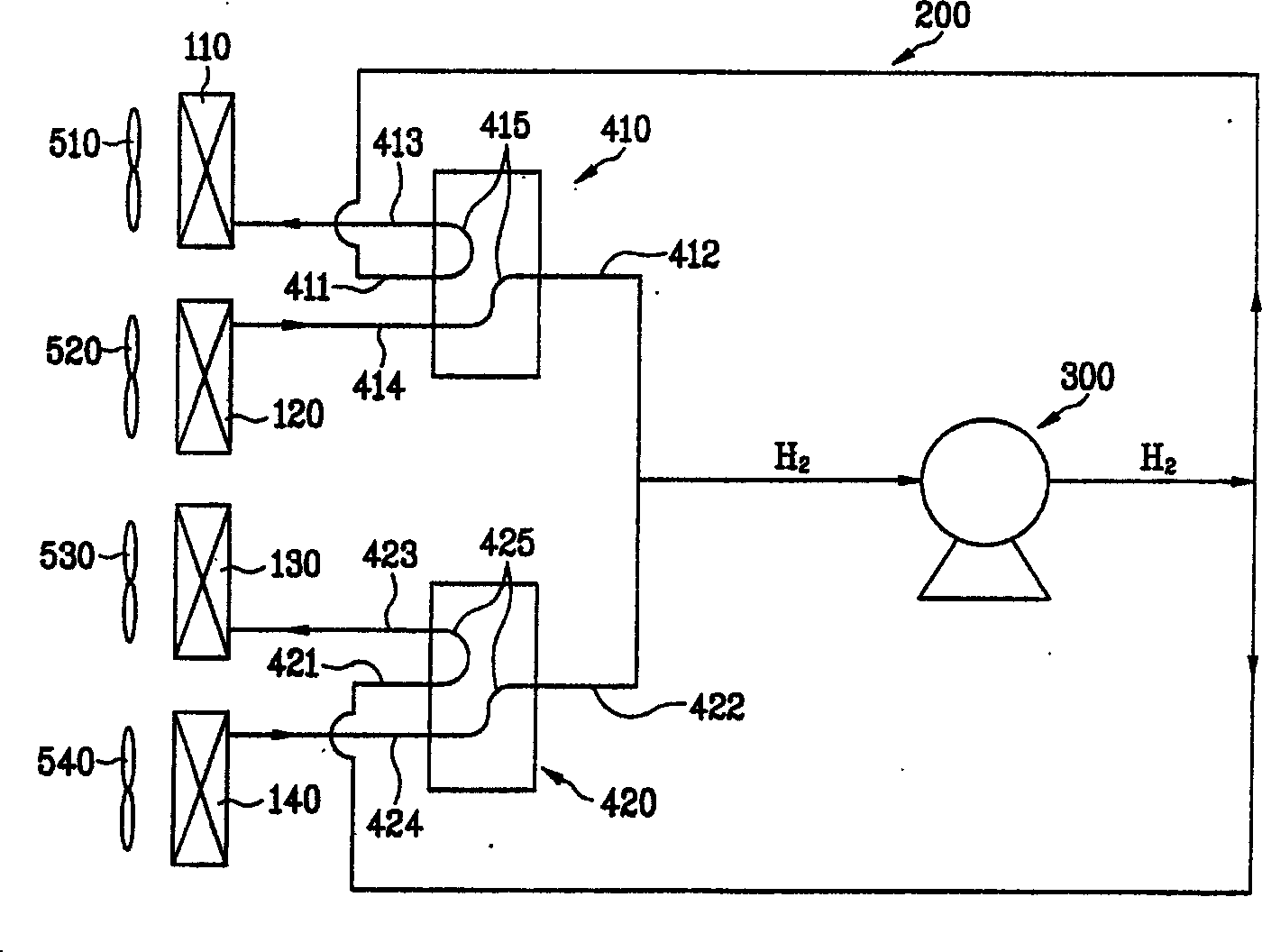

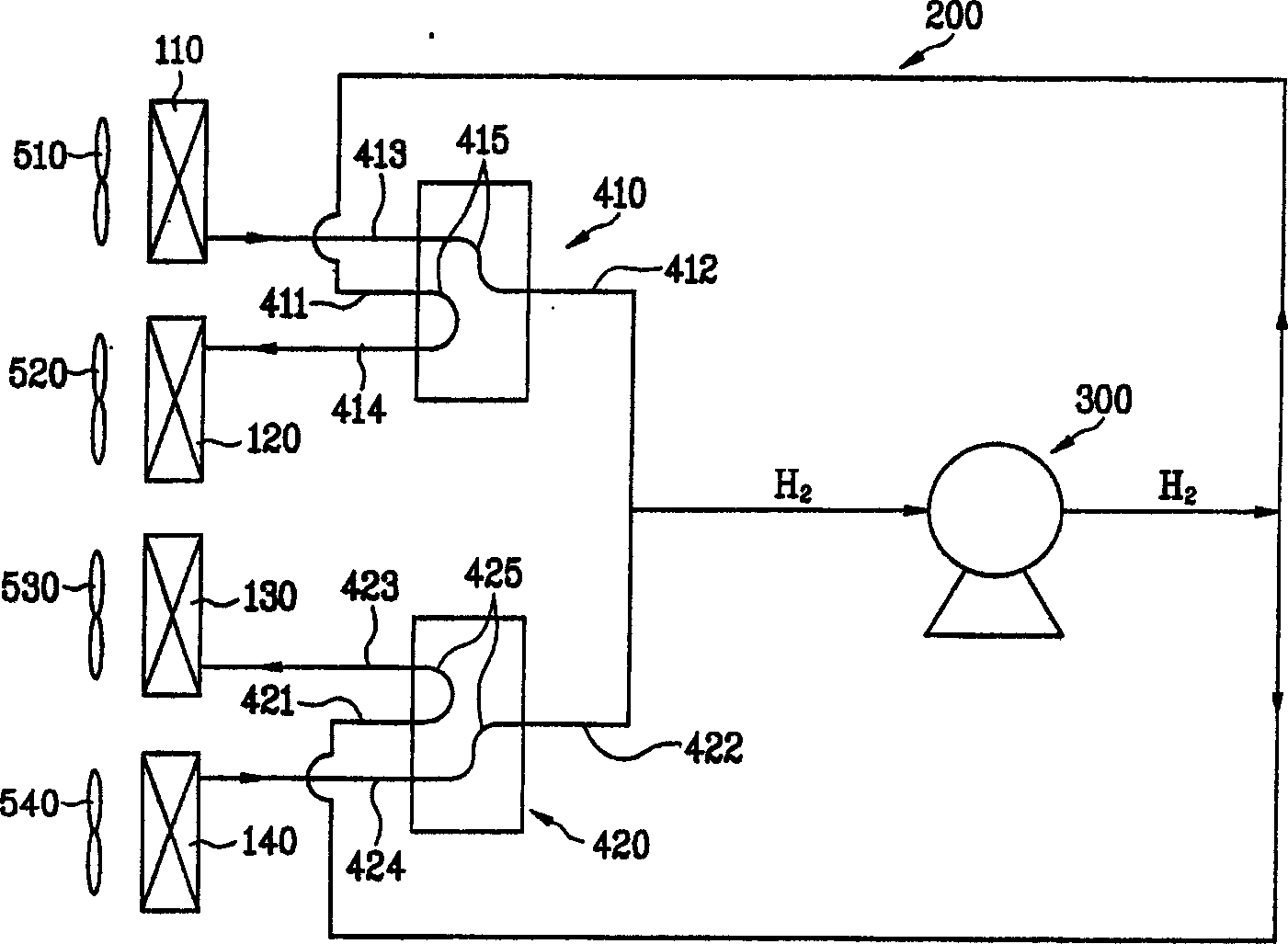

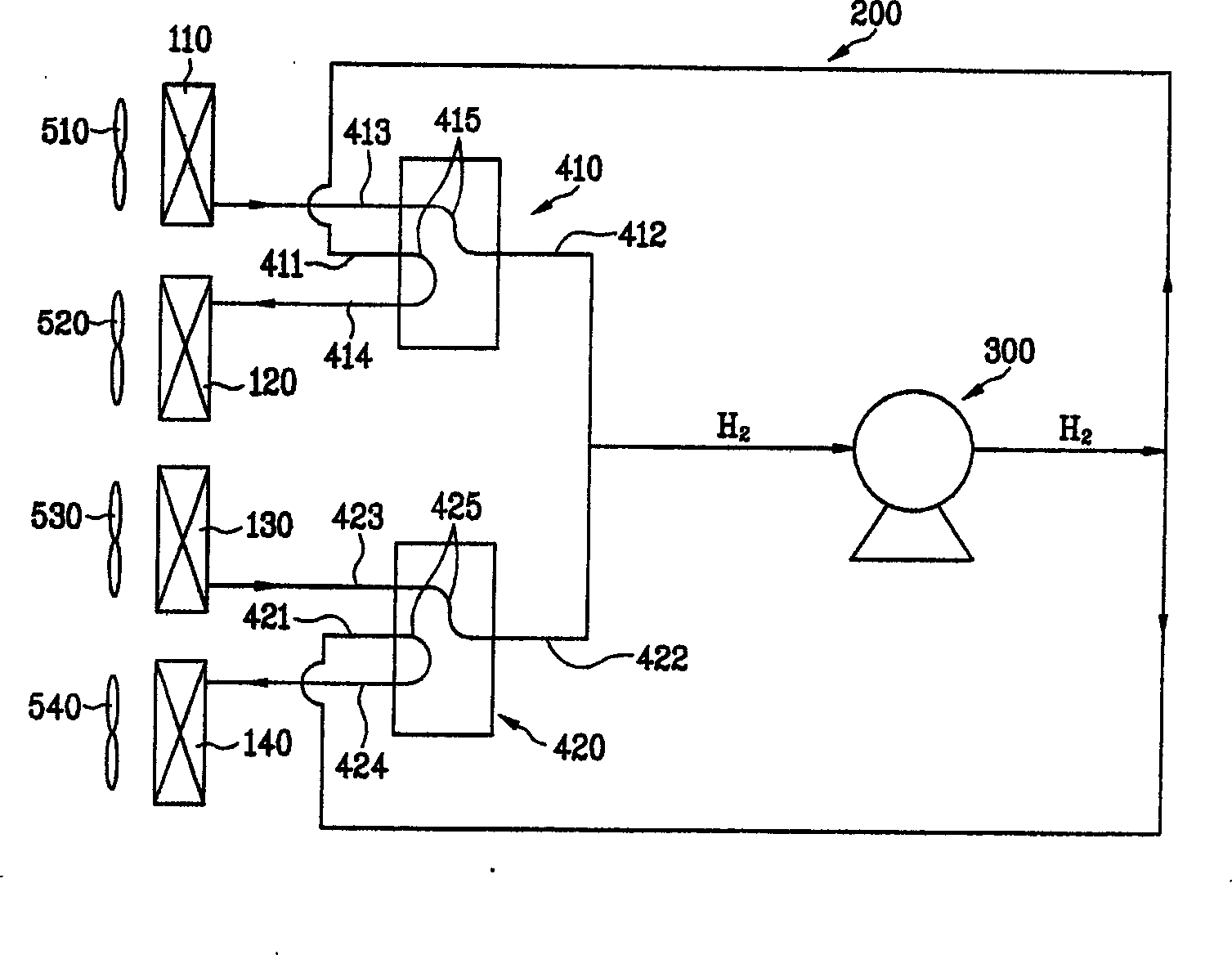

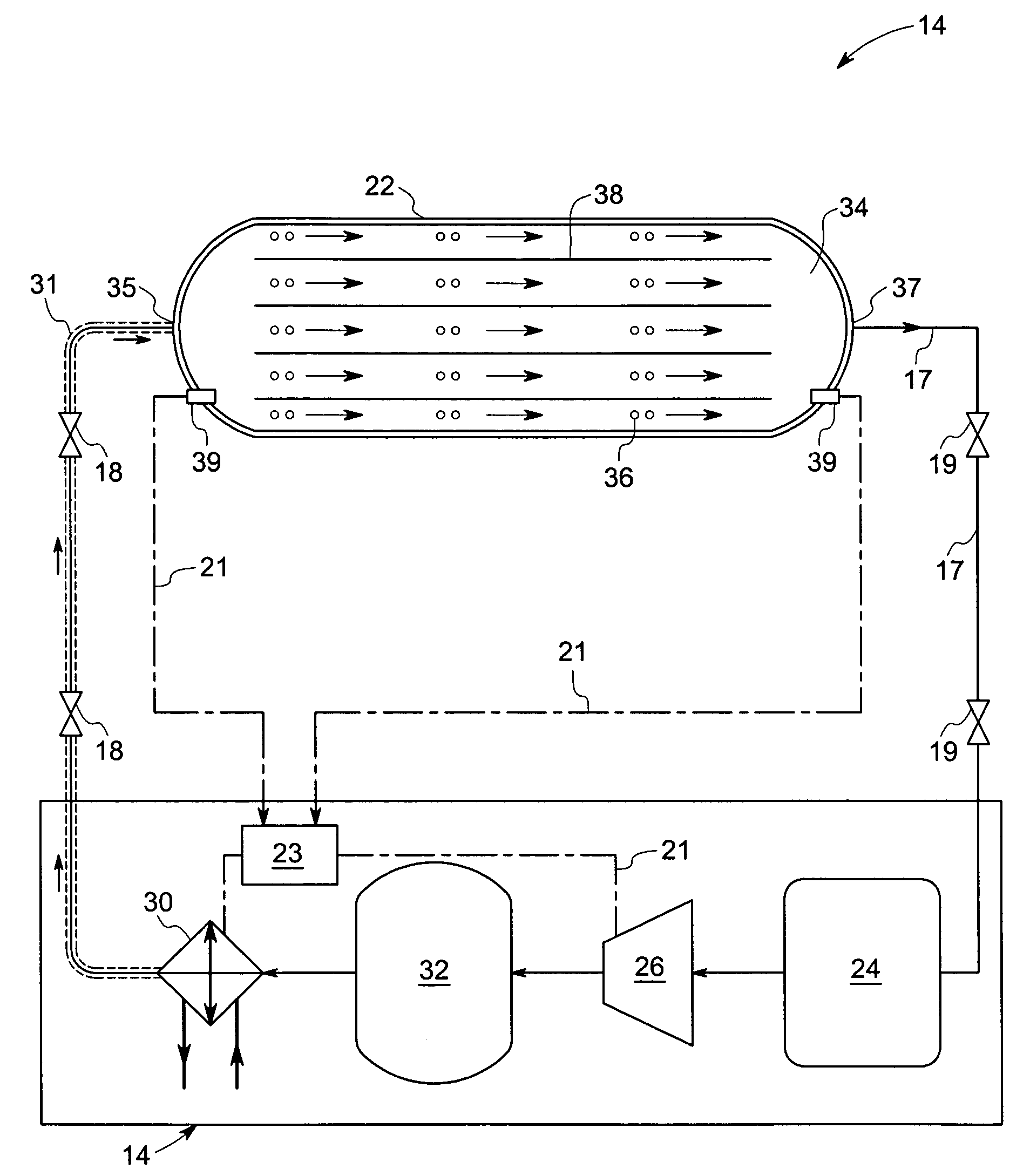

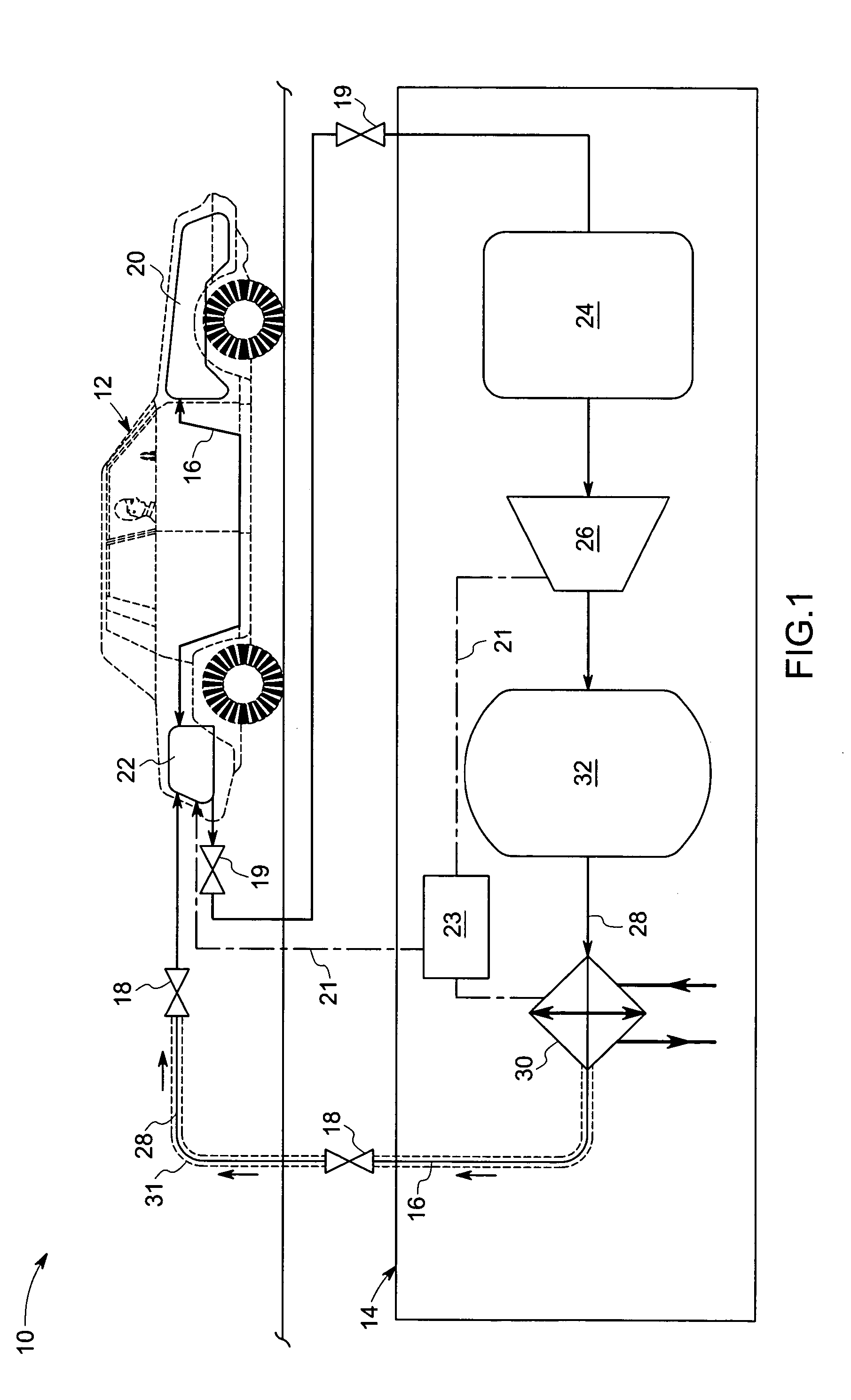

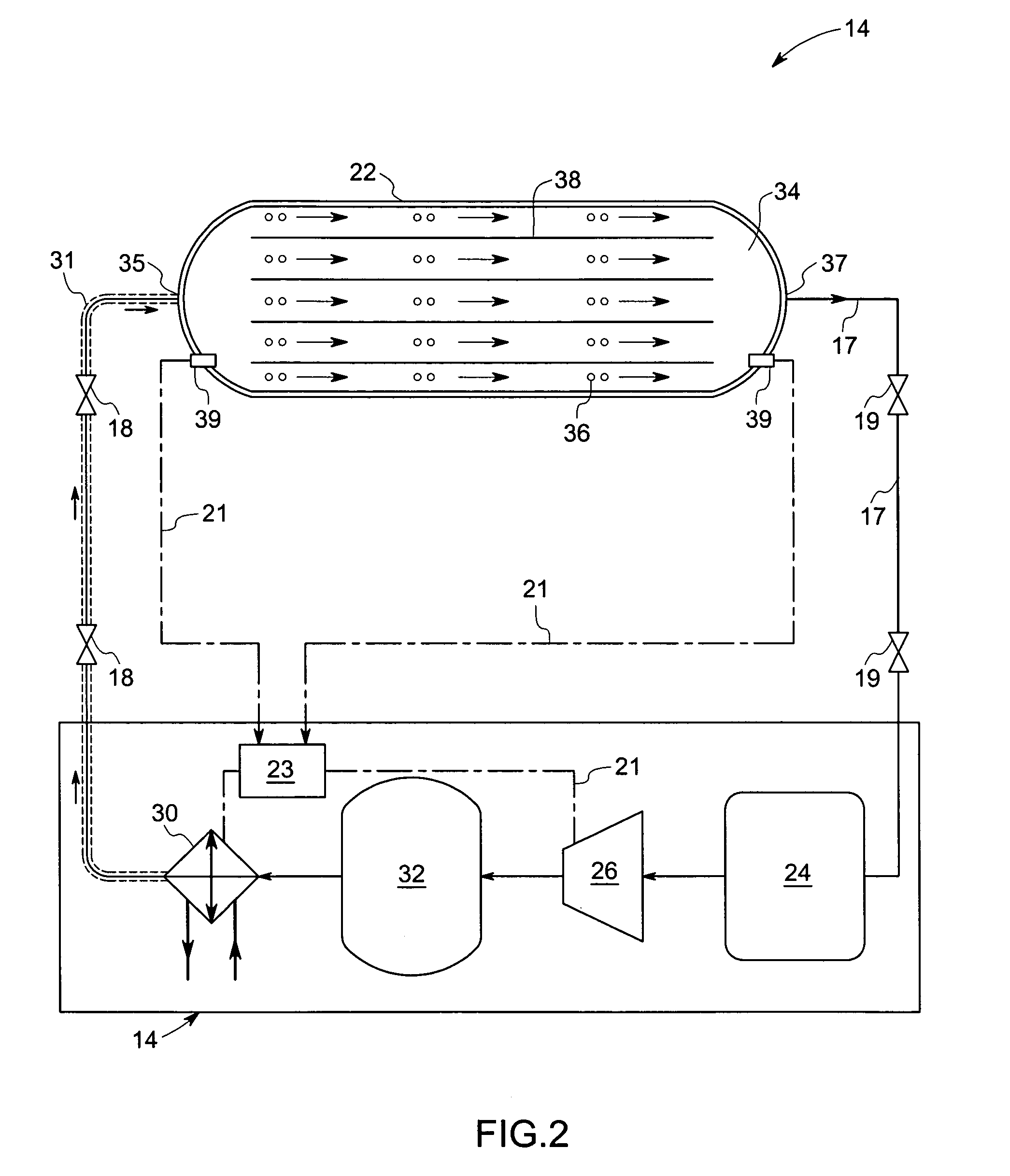

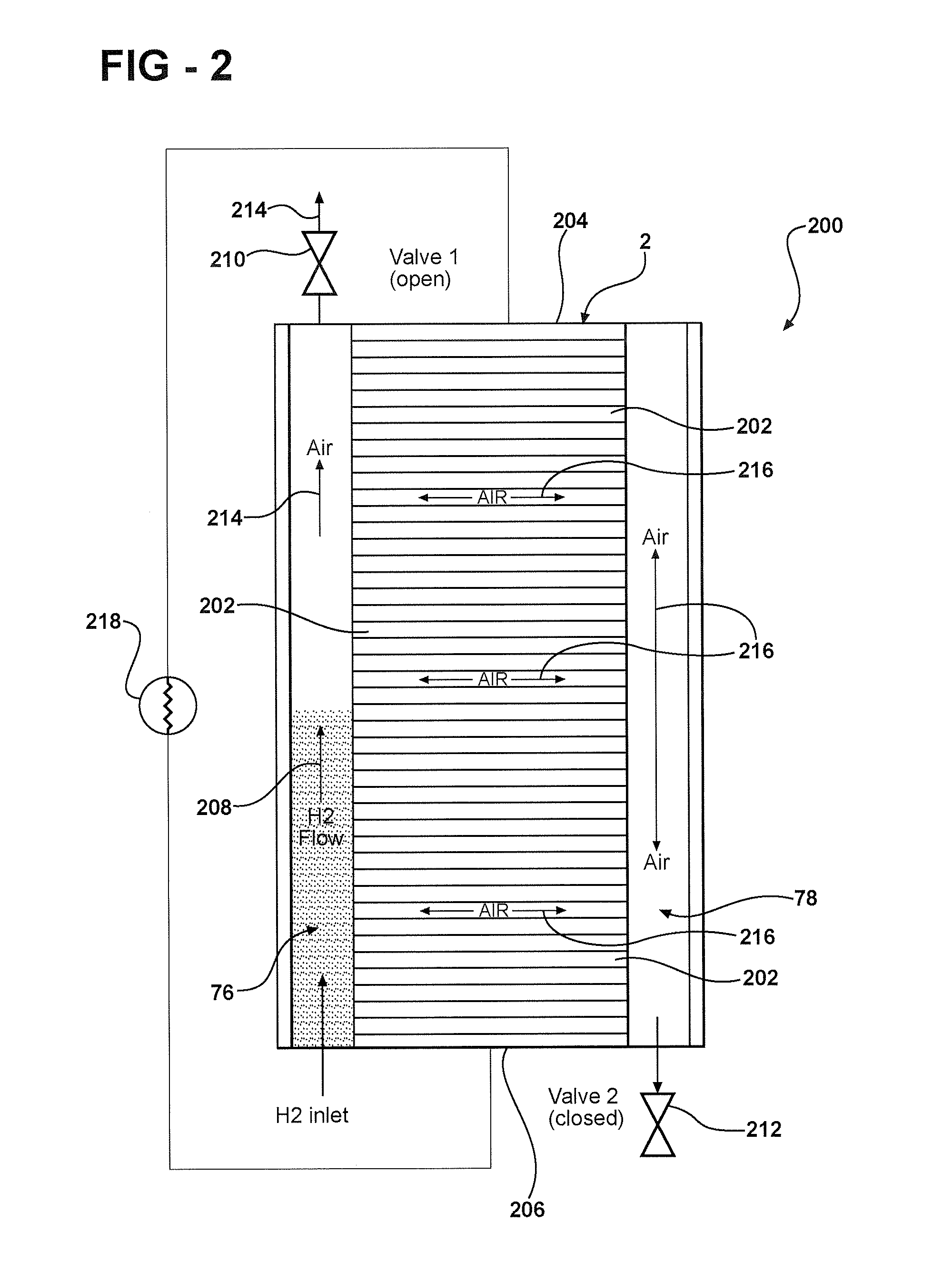

Method for fuel cell start-up with uniform hydrogen flow

ActiveUS20080311437A1Minimizes hydrogen exhaust emissionOptimize allocationFuel cells groupingFuel cell auxillariesFuel cellsHydrogen flow

A fuel cell system is provided having a fuel cell stack including a plurality of fuel cells. The fuel cell system includes an anode supply manifold in fluid communication with the plurality of fuel cells, the anode supply manifold adapted to deliver a anode supply stream to the plurality of fuel cells; an anode exhaust manifold in fluid communication with the anodes of the plurality of fuel cells, the anode exhaust manifold adapted to receive an anode exhaust stream from the plurality of fuel cells; a first valve in fluid communication with the anode supply manifold; and a second valve in fluid communication with the anode exhaust manifold. A method of starting the fuel cell system is also provided. The fuel cell system and method militates against a non-uniform distribution of the anode supply stream to the anodes of the plurality of fuel cells.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method for producing high-melting-point wax through fischer-tropsch synthesis product

ActiveCN104673383AMeet different market needsGreat operating flexibilityTreatment with hydrotreatment processesWaxDistillation

The invention relates to a method for producing high-melting-point wax through a fischer-tropsch synthesis product. A raw material flow enters a first distillation unit first and is distilled under certain temperature and pressure to be separated into a wax oil fraction flow and a heavy fraction flow; the heavy fraction flow enters a second distillation unit and is distilled under certain temperature and pressure to be separated into medium wax flow and a high-melting-point wax flow; the high-melting-point wax flow and a hydrogen flow enters a hydrogeneration refinement unit, and the high-melting-point wax after hydrogeneration is separated into a first material flow and a hydrogenerated high-melting-point wax flow; the hydrogenated high-melting-point wax flow enters a third distillation unit and is distilled under certain temperature and pressure to be separated into a first high-melting-point wax flow and a second high-melting-point wax flow. With the adoption of the method, various high-melting-point wax products are produced, and the problem that the color number of a product is excessively small due to heat coking in the separation process of materials is solved.

Owner:YANKUANG ENERGY R&D CO LTD

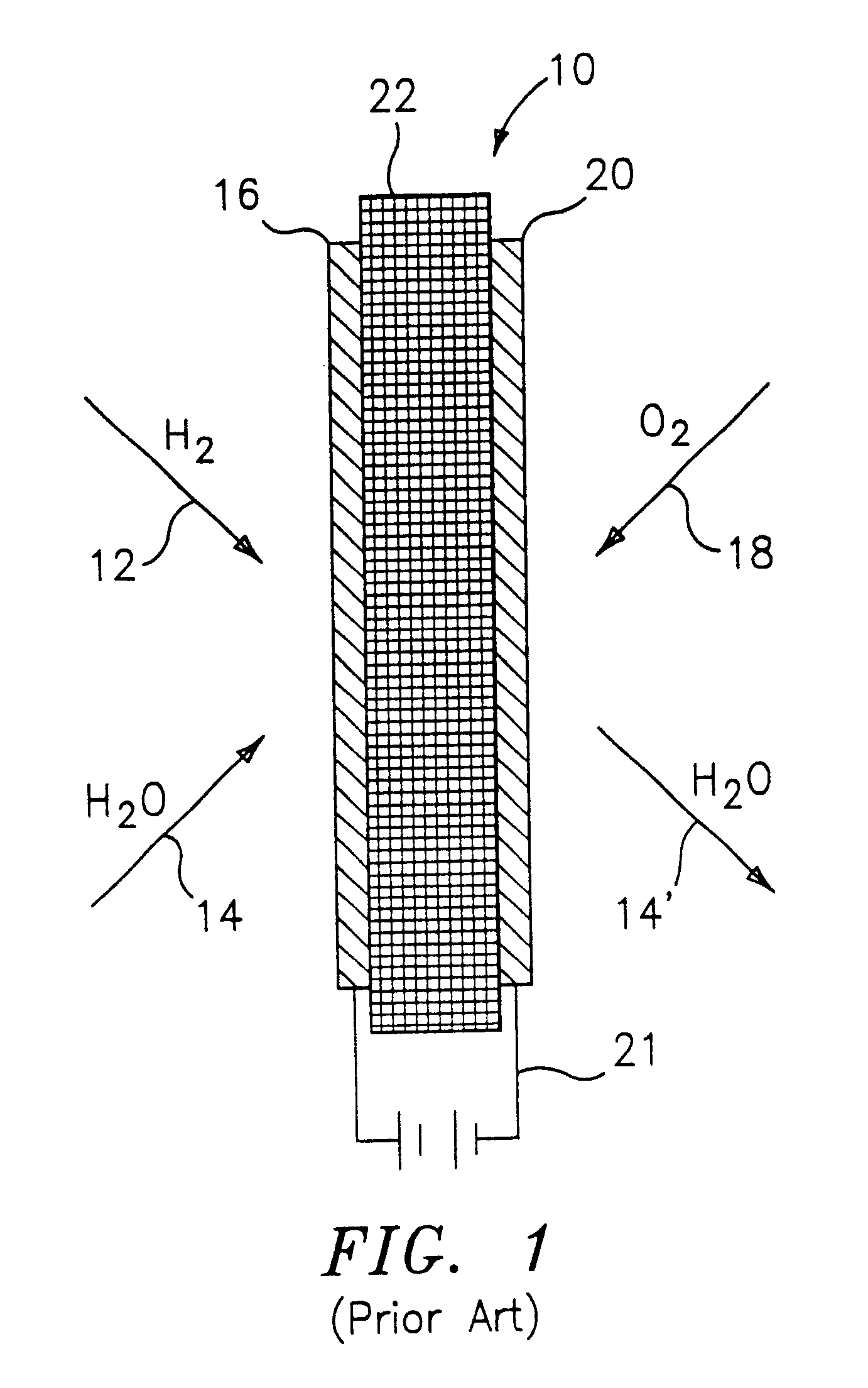

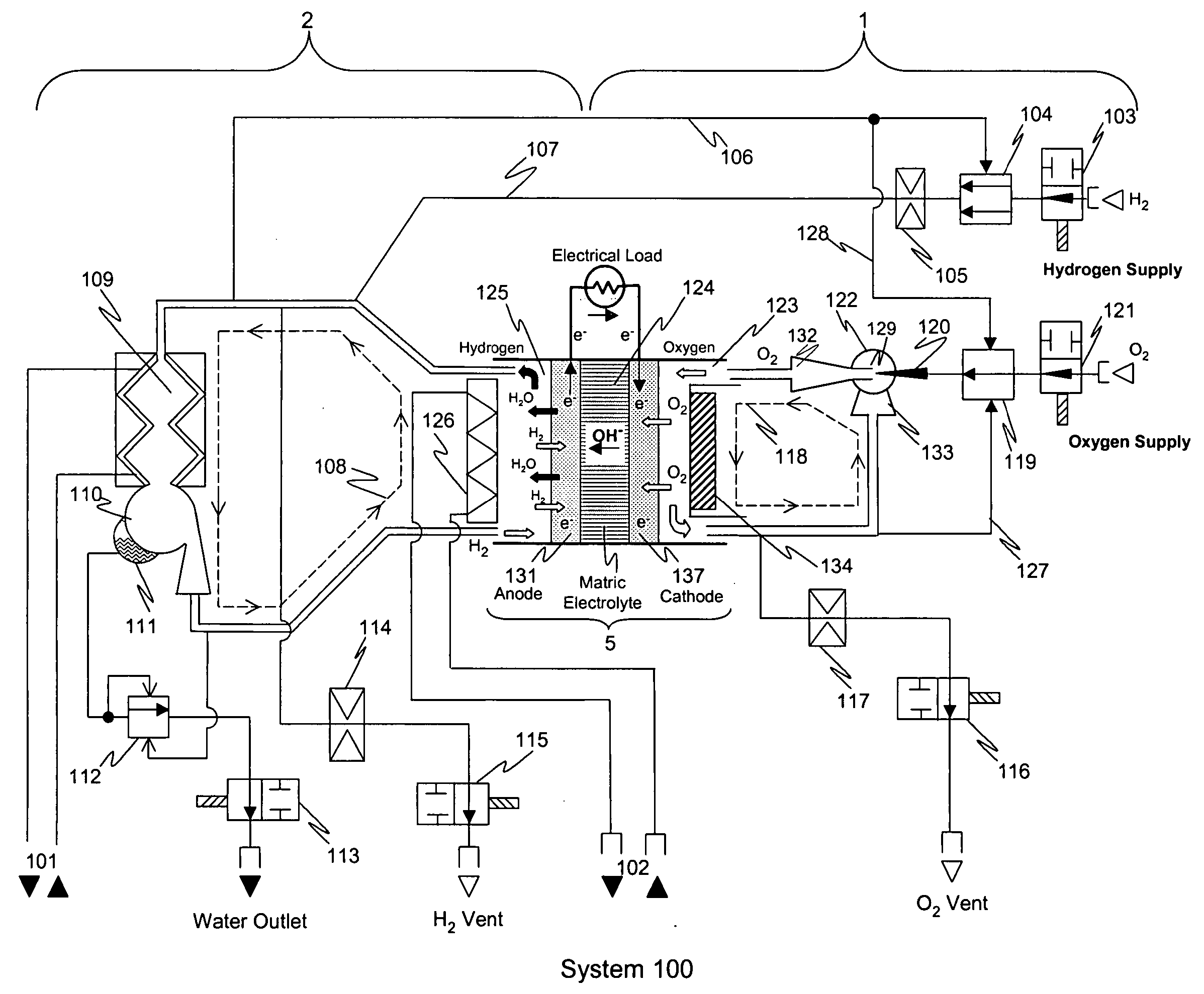

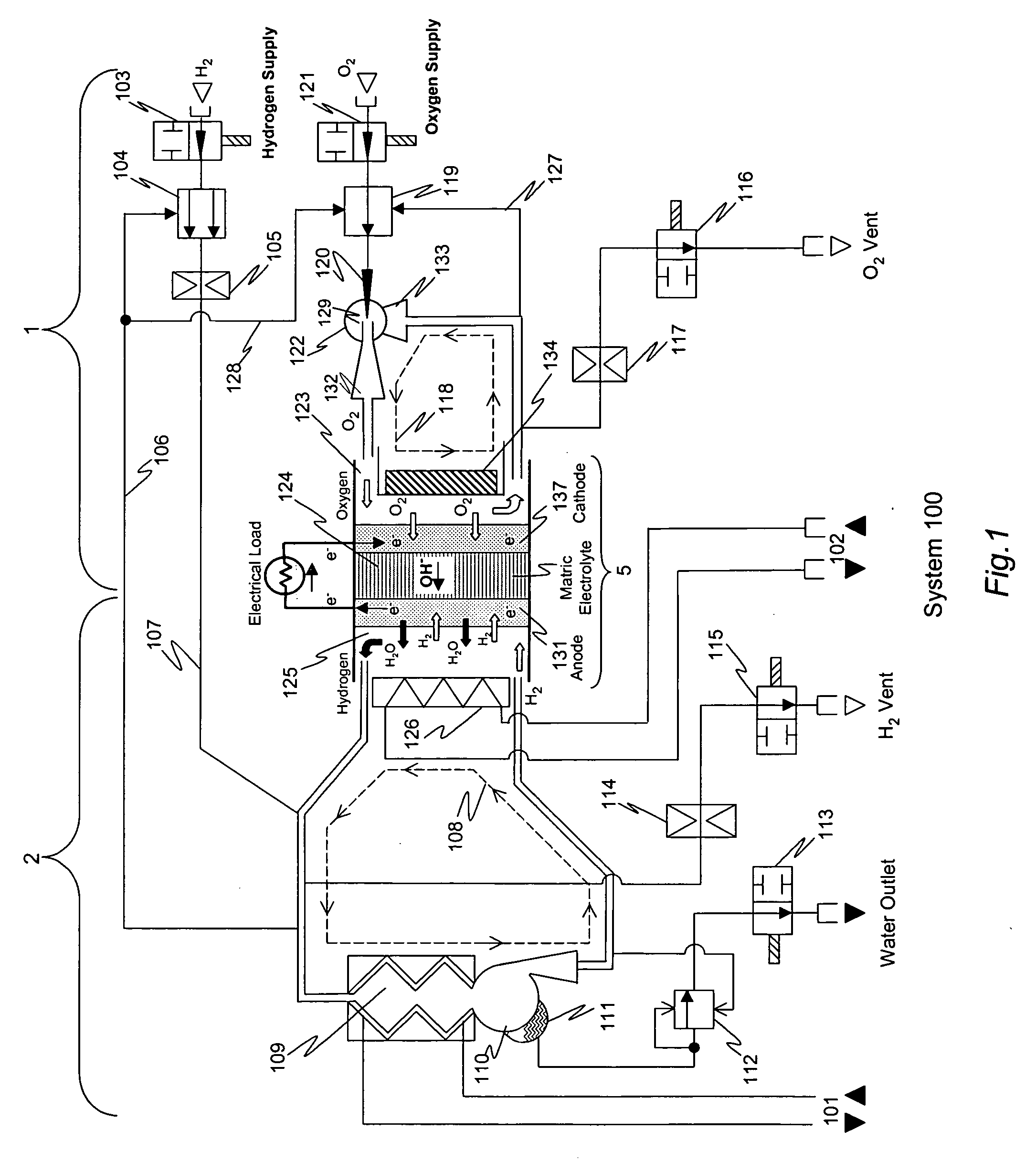

Alkaline electrolyte fuel cells with improved hydrogen-oxygen supply system

InactiveUS20050112454A1Electrolyte holding meansFuel cell auxillariesElectrochemical responseFuel cells

A recirculating hydrogen-oxygen alkaline fuel-cell (AFC) includes an alkaline matrix electrolyte interposed between a porous anode and porous cathode, and an oxygen flow network in fluid connection with the porous cathode. The oxygen flow network has an input portion for supplying oxygen and an output portion for removing oxygen and reaction products after electrochemical reaction. A hydrogen flow network is in fluid connection with the porous anode. The hydrogen network has an input portion for supplying hydrogen and an output portion for removing hydrogen and reaction products after electrochemical reaction. At least one of the oxygen flow network and the hydrogen flow network includes a feedback conduit to form a recirculation loop. The recirculation loop feeds back a portion of the hydrogen or oxygen flow after electrochemical reaction to the input portion.

Owner:ENER1

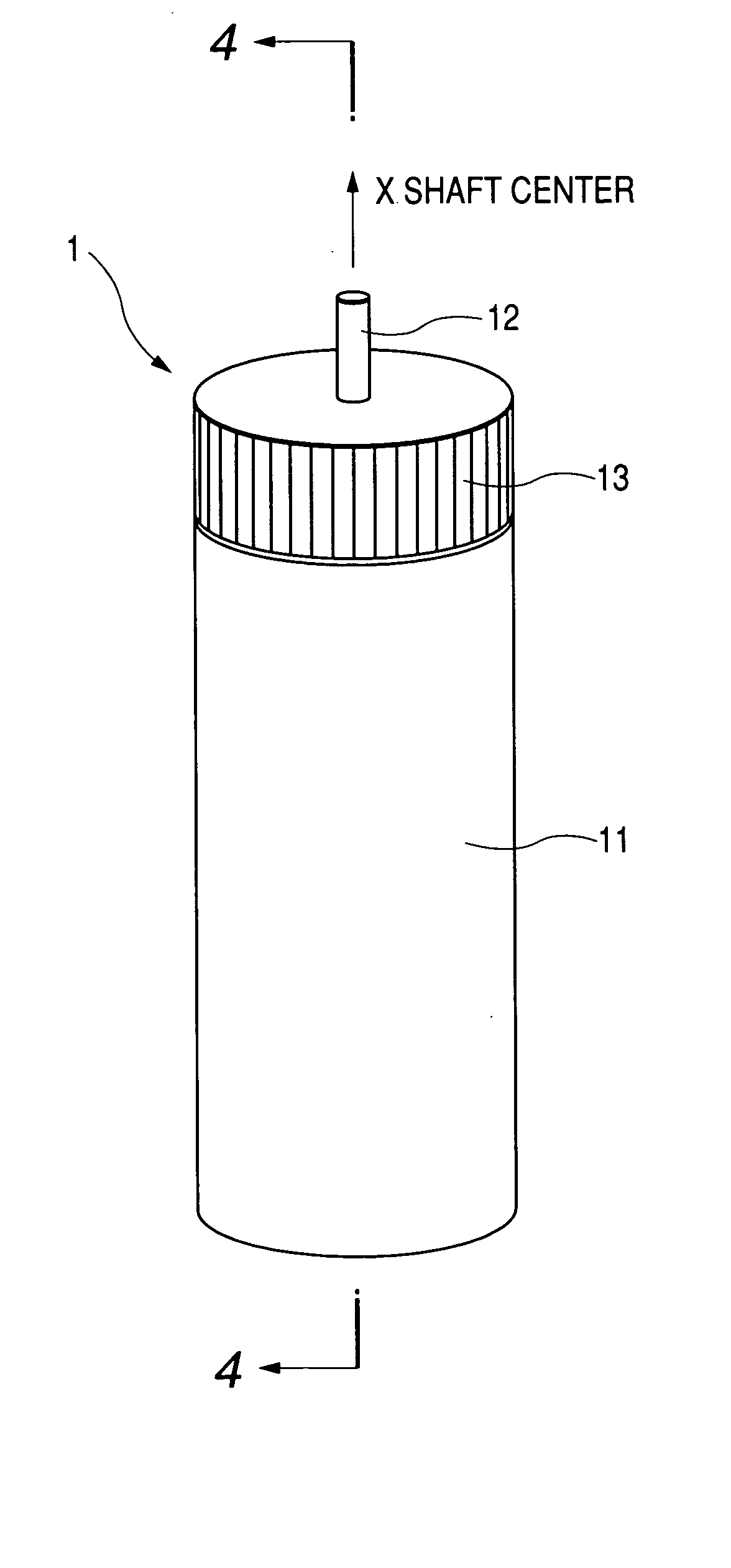

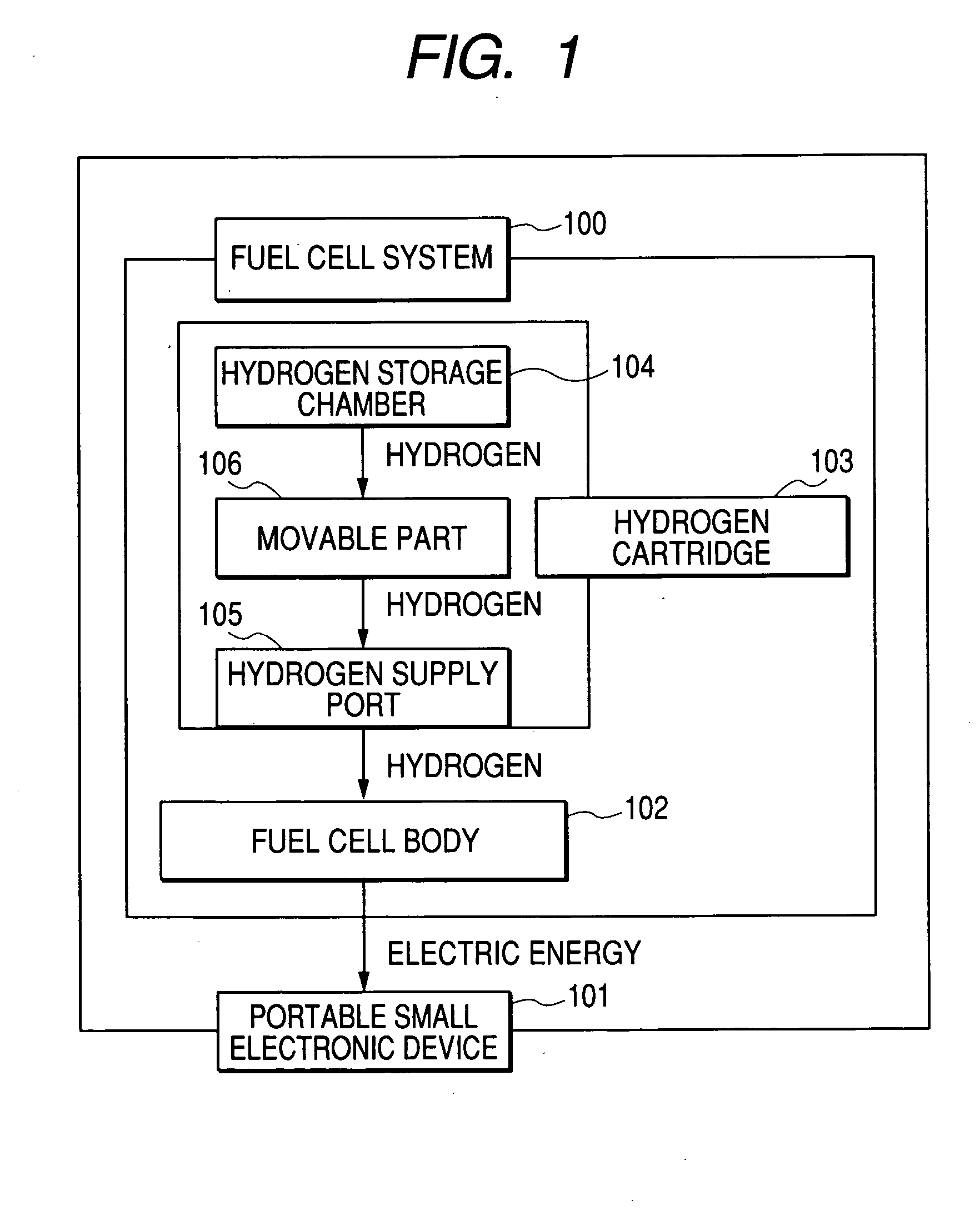

Hydrogen cartridge, fuel cell system and method of attaching hydrogen cartridge

InactiveUS20050106441A1Prevent leakageSafe handlingReactant parameters controlLiquid materialProcess engineeringHydrogen supply

There are provided a hydrogen cartridge for a fuel cell for supplying hydrogen to a fuel cell body comprising a hydrogen storage chamber for storing hydrogen, a movable part which is movably connected to the hydrogen storage chamber and has a hydrogen flow path for allowing hydrogen to flow therethrough, and a hydrogen supply port which is formed integrally with the movable part and communicates with the hydrogen flow path, wherein the cartridge takes an open state in which the hydrogen storage chamber, the hydrogen flow path and the hydrogen supply port are connected to each other, or a closed state in which the hydrogen storage chamber, the hydrogen flow path and the hydrogen supply port are not connected to each other, by movement of the movable part or the hydrogen storage chamber, and a fuel cell system having the hydrogen cartridge incorporated therein, whereby it is possible to prevent leakage of hydrogen due to unstable connection between the hydrogen cartridge and a fuel cell body and to assure safety in handling.

Owner:CANON KK

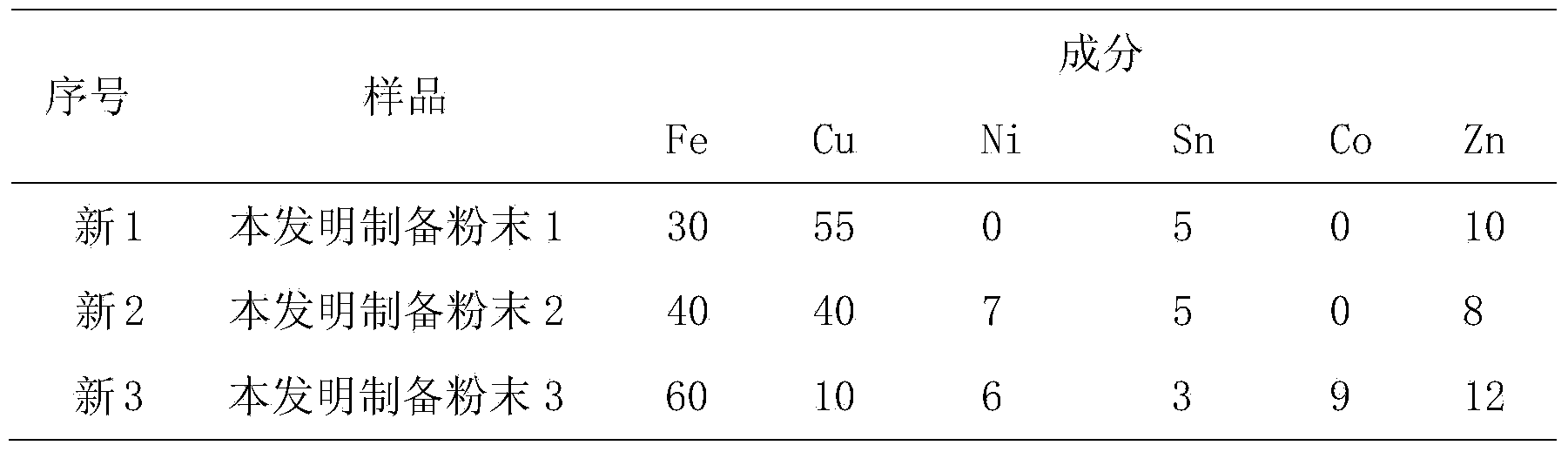

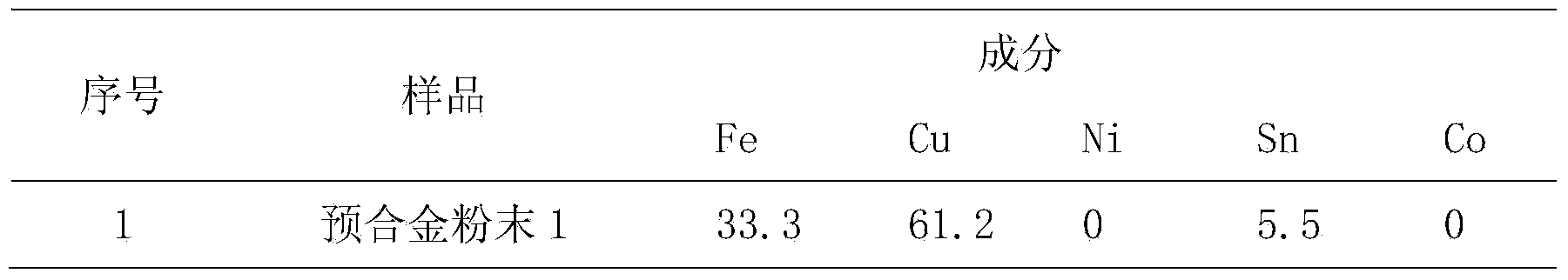

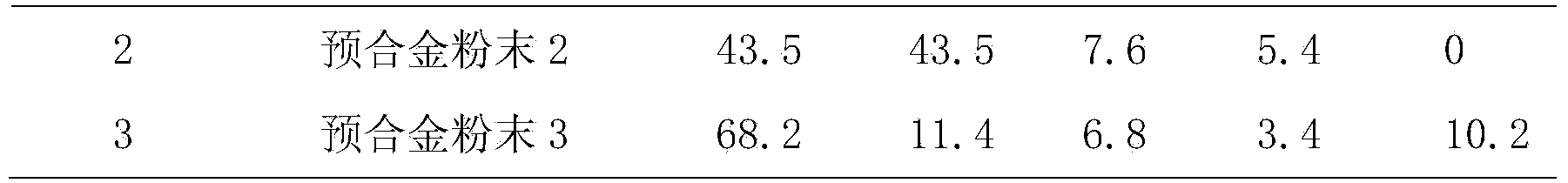

Method for preparing iron-based prealloy powder

The invention discloses a method for preparing iron-based prealloy powder. The method includes the steps that (1) iron-based bulk metal is prepared, the content of Fe is 30wt%-90wt%, the content of Cu is 10wt%-70wt%, and the melting point is no more than 1,800 DEG C; (2) smelting water atomization powder process treatment is conducted on the metal, so that the iron-based prealloy powder is obtained; (3) the treated powder is dried; (4) after drying of the atomization powder is completed, low-melting metal simple substance powder is added, the melting point is no more than 500 DEG C, and the content is no more than 15wt%; (5) the low-melting metal powder and the dried powder are evenly mixed; (6) reduction treatment is carried out on the mixed powder through a reduction furnace, hydrogen flow is controlled to be 20m<3> / h-30m<3> / h, and reduction time is no less than 2h; (7) large particles are sieved and removed to obtain the iron-based prealloy powder. The method is easy to implement and simple and convenient to operate, by the aid of a high-temperature diffusion and evaporation cohesion principle in the reduction process, the content of produced Zn is 2-15% that of the iron-based prealloy powder, and the iron-based prealloy powder has the advantages of being low in oxygen content, simple in preparation mode and good in cold pressing formability.

Owner:HUBEI EXIN DIAMOND TECH

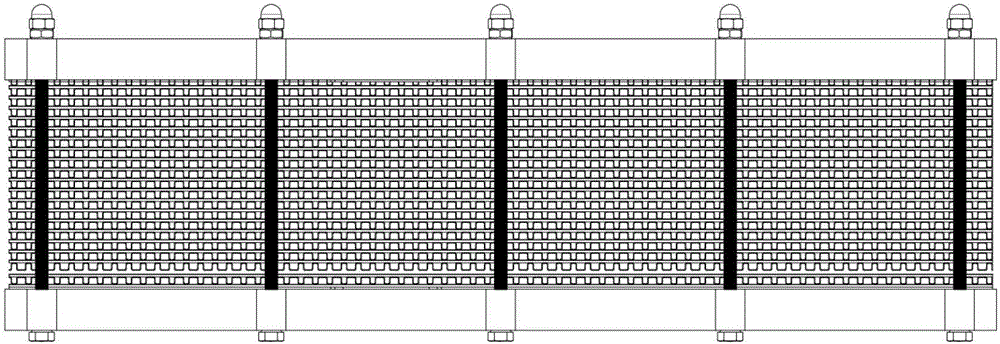

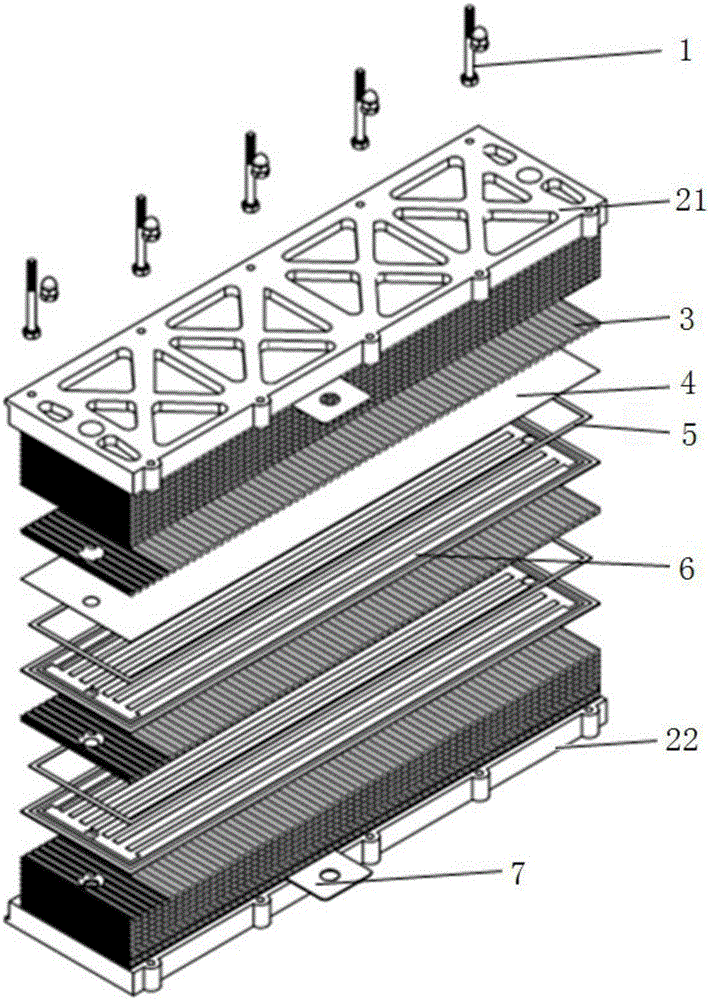

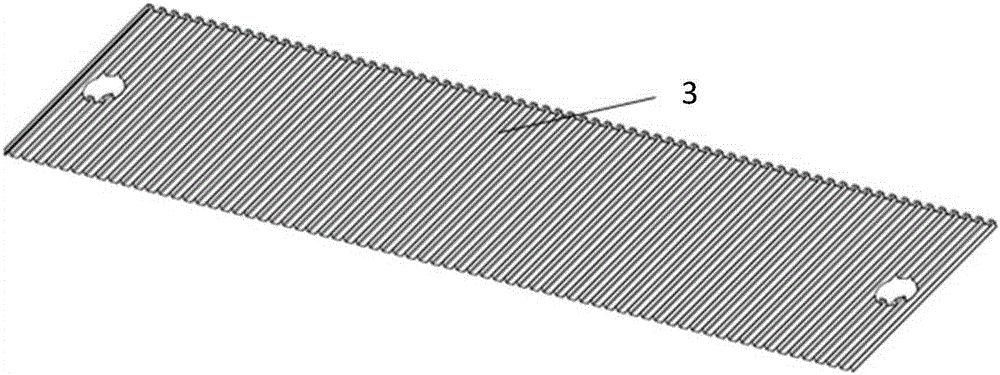

Integrated metal-graphite composite bipolar plate fuel cell light electric stack and manufacturing method thereof

ActiveCN106848362AHigh strengthHigh mechanical strengthFuel cells groupingFinal product manufactureFuel cellsNegative temperature

The invention relates to an integrated metal-graphite composite bipolar plate fuel cell light electric stack. An integrated metal-graphite composite bipolar plate is used for the integrated metal-graphite composite bipolar plate fuel cell light electric stack, the integrated metal-graphite composite bipolar plate comprises a metal corrugated plate and a graphite plate, the metal corrugated plate is a negative pole plate, a raised ridge inner chamber is an oxygen flow field, and meanwhile a raised ridge takes a heat-radiating rib into consideration; the graphite plate is a positive pole plate, the surface of one side of the graphite plate body is provided with a hydrogen flow field, the edge of the surface of one side of the graphite plate body is provided with a sealing groove, and the other side of the graphite plate body is provided with a graphite plate corrugated structure; and the graphite plate is embedded into the metal corrugated plate by the graphite plate corrugated structure, and the graphite plate and the metal corrugated plate are connected as a whole. The performance and the stability of the electric stack are remarkably improved. Because a negative temperature coefficient thermistor material is added in the graphite plate material, the cold starting time can be remarkably reduced, and the electric stack can be used normally at a higher temperature above 60 DEG C.

Owner:TSINGHUA UNIV

Hydrogen gas storing device

InactiveUS20100236767A1High strengthAvoid damageReversible hydrogen uptakeFixed capacity gas holdersHydrogen flowElectrical and Electronics engineering

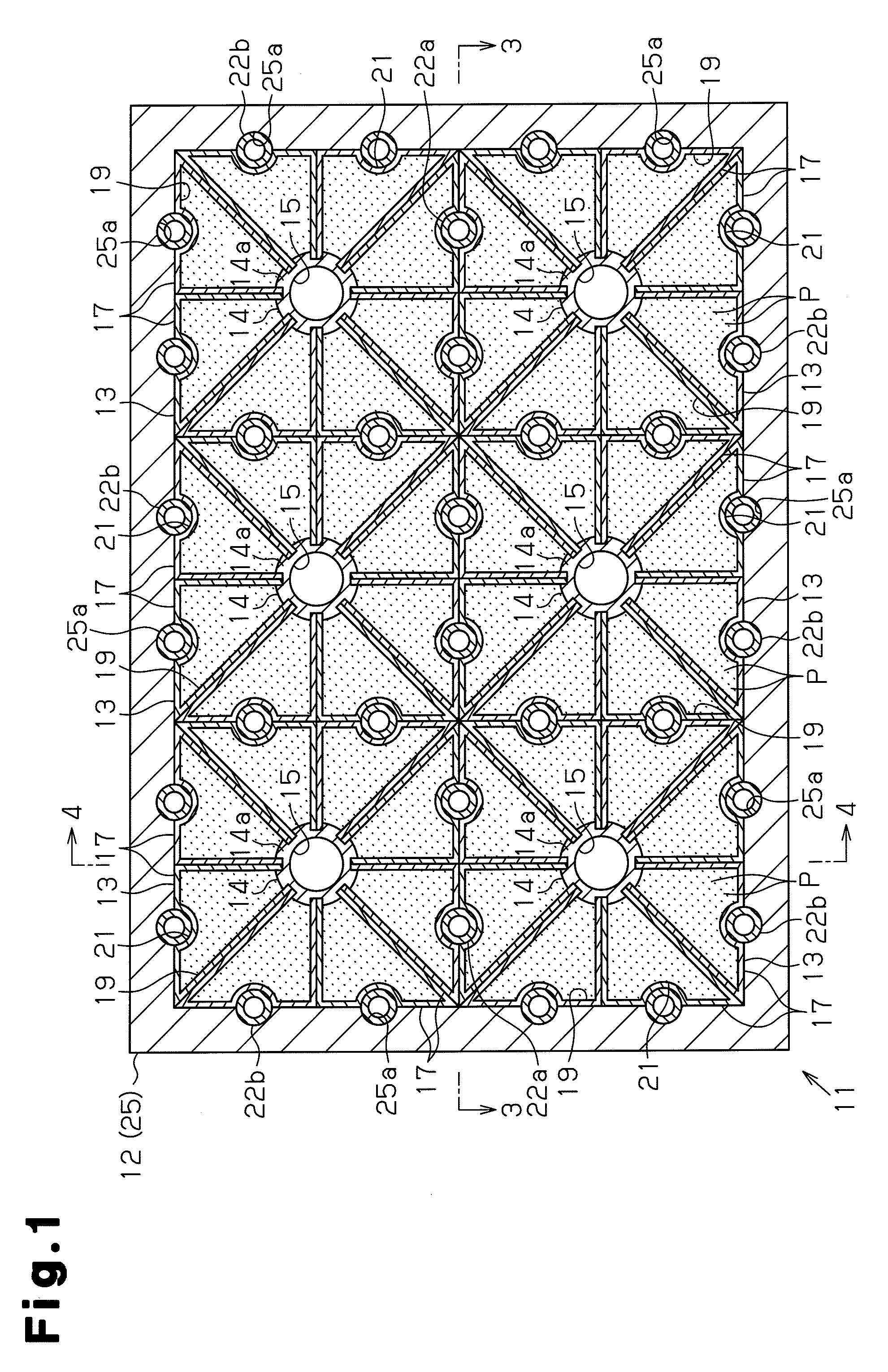

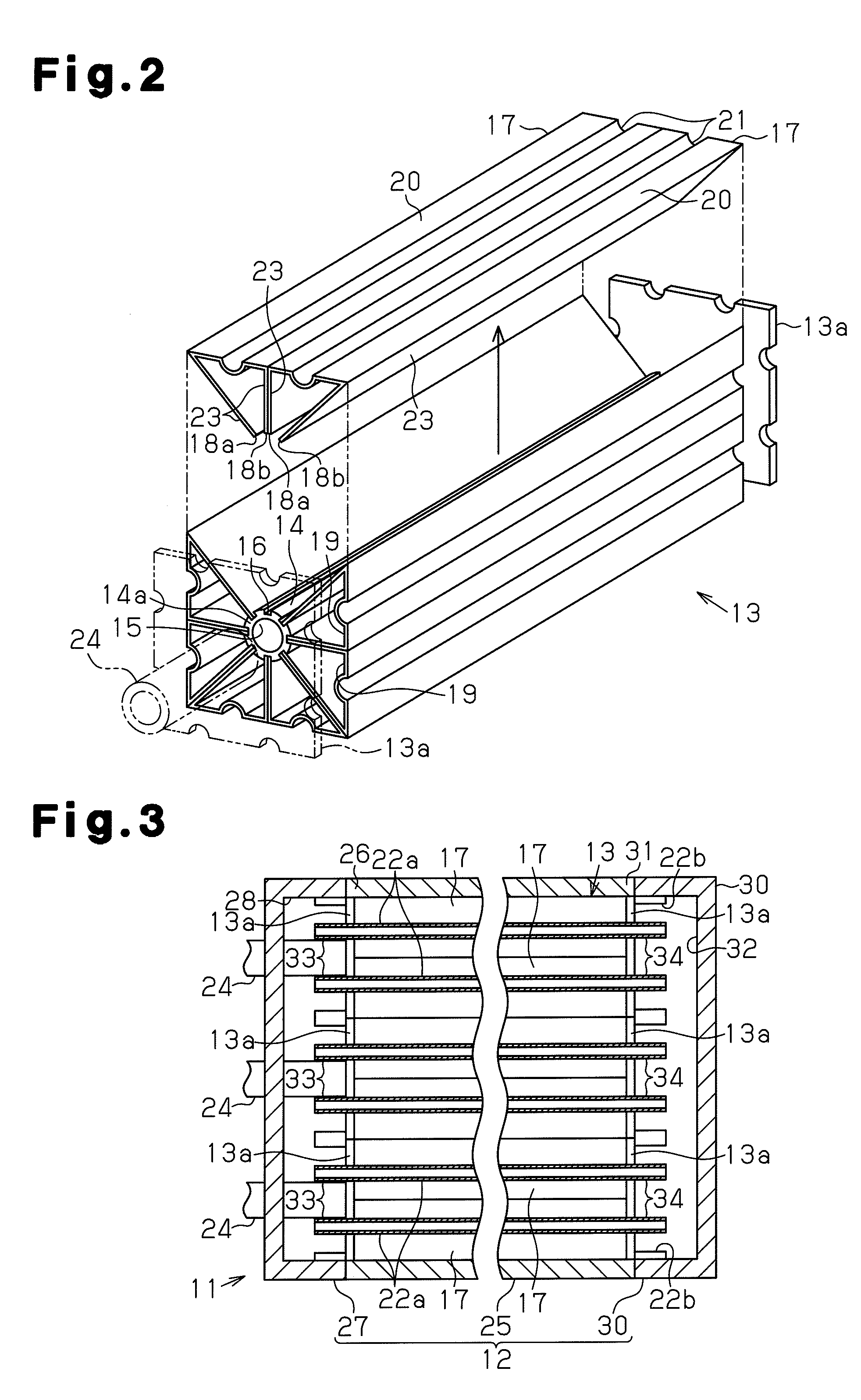

A plurality of MH tank modules (13) each include a cylindrical porous member (14). The porous member (14) is formed as a hydrogen flow path (15) through which hydrogen can flow and has straight grooves formed on the outer circumferential surface. A plurality of fins (17) are attached to the porous member (14). A first edge and a second edge of each fin (17) are fitted in different grooves. The fins (17) define a plurality of accommodation chambers (19) for accommodating MH powder P. The MH tank modules (13) are accommodated in the housing while being arranged adjacent to each other to form a predetermined shape. Heat medium pipes (22a, 22b) are arranged in the housing (12) so as to contact the fins (17) and correspond to the accommodation chambers (19). Heat medium flows through the heat medium pipes (22a, 2b). Therefore, it is possible to provide a hydrogen gas storing device that easily increases the number of places to be installed in and facilitates the installment.

Owner:TOYOTA IND CORP +1

Preparation method of aluminum alloy wear-resistant coating

InactiveCN103103469AImprove bindingHigh bonding strengthMolten spray coatingWear resistantSand blasting

The invention relates to a preparation method of an aluminum alloy wear-resistant coating. The preparation method comprises the following steps of: carrying out sand blasting roughening treatment on the surface of an aluminum alloy matrix; spraying a metal alloy coating on the surface of the aluminum alloy matrix by using a plasma spraying system; subsequently spraying ceramic powder on the metal alloy coating by using the plasma spraying system so as to obtain the aluminum alloy wear-resistant coating, wherein the parameters of the plasma spraying process are as follows: the spraying distance is 80-100mm, the powder feeding rate is 60-65g / min, the argon flow is 30-40L / min, the hydrogen flow is 7-9L / min, the current is 55A and the voltage is 60-65V. The metal alloy coating is a Ni-Al alloy coating. The granularity of the Ni-Al alloy powder is 50-100mu m. The preparation method has the beneficial effects that the aluminum alloy wear-resistant coating with good binding strength is prepared by using a plasma spraying process, and due to the introduction of a Ni-Al transit layer, the aluminum alloy can be well bonded with the coating.

Owner:龙口市丛林铝材有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com