Method for producing high-melting-point wax through fischer-tropsch synthesis product

A technology of Fischer-Tropsch synthesis and high melting point, which is applied in the treatment of hydrocarbon oil, petroleum industry, hydrogenation process, etc., can solve the problem of low color number of the product, and achieve the effect of simple process flow, easy operation and large operation flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

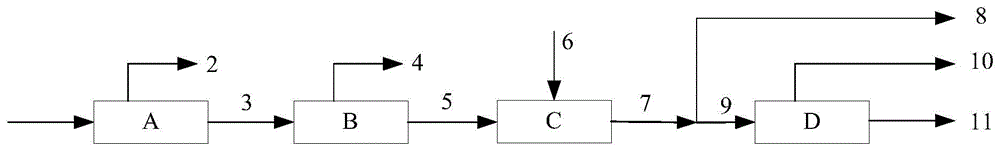

[0036] A kind of method of producing high melting point wax by Fischer-Tropsch synthesis product, technological process is as figure 1As shown, the raw material stream 1 is a Fischer-Tropsch synthetic wax stream, and its properties are shown in Table 1. First, it enters the first distillation unit A. Under the conditions of 150 ° C and 2.5 Pa, the stream is divided into a wax oil fraction stream 2 and a heavy fraction stream 3. The distillate stream 3 enters the second distillation unit B. Under the conditions of 240°C and 2.2Pa, the stream is divided into a medium wax stream 4 and a high melting point wax stream 5; Co / Mo-Al 2 o 3 Catalyst, under the conditions of 300°C and 5MPa, high melting point wax 7 was obtained. The high melting point wax 7 is divided into two streams of the first stream 8 and the hydrogenated high melting point wax stream 9, the first stream 8 is used as No. 100-104 wax; the hydrogenated high melting point wax stream 9 enters the third distillation un...

Embodiment 2

[0040] A kind of method of producing high melting point wax by Fischer-Tropsch synthesis product, technological process is as figure 1 As shown, the raw material stream 1 is a Fischer-Tropsch synthetic wax stream, which first enters the first distillation unit A, and under the conditions of 180 ° C and 40 Pa, the stream is divided into a wax oil fraction stream 2 and a heavy fraction stream 3, and the heavy fraction stream 3 enters the second distillation unit A. Distillation unit B, under the conditions of 240 ° C and 10 Pa, divides the stream into medium wax stream 4 and high melting point wax stream 5; high melting point wax stream 5 enters hydrofining unit C, and the Co / Mo-Al 2 o 3 Catalyst, under the conditions of 320°C and 6MPa, high melting point wax 7 was obtained. The high melting point wax 7 is divided into two streams, the first stream 8 and the hydrogenated high melting point wax stream 9, the first stream 8 is used as No. 100-104 wax; the hydrogenated high meltin...

Embodiment 3

[0044] A kind of method of producing high melting point wax by Fischer-Tropsch synthesis product, technological process is as figure 1 As shown, the raw material stream 1 is a Fischer-Tropsch synthetic wax stream, which first enters the first distillation unit A, and under the conditions of 130 ° C and 2.5 Pa, the stream is divided into a wax oil fraction stream 2 and a heavy fraction stream 3, and the heavy fraction stream 3 enters the first distillation unit A. The second distillation unit B, under the conditions of 230 ° C and 1.5 Pa, divides the stream into medium wax stream 4 and high melting point wax stream 5; 2 o 3 Catalyst, under the conditions of 290°C and 5MPa, high melting point wax 7 was obtained. The high melting point wax 7 is divided into two streams, the first stream 8 and the hydrogenated high melting point wax stream 9, the first stream 8 is used as No. 100-104 wax; the hydrogenated high melting point wax stream 9 enters the third distillation unit D, at 28...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com