Chemically modified high-efficiency heat-resistant ASA graft copolymer and preparation method thereof

A graft copolymer and chemical modification technology, which is applied in the field of chemical synthesis and modification of new materials, can solve the problems of low modification efficiency of ASA copolymer, product impact, and large appearance impact, and achieve high impact performance and improved heat resistance. Sexual, method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

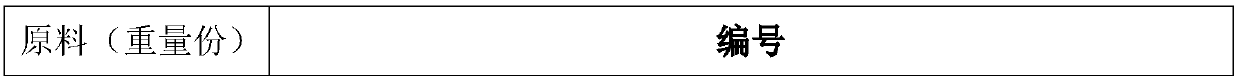

Embodiment 1

[0038] This embodiment discloses the preparation of the ASA graft copolymer of the present invention, specifically:

[0039] Step 1. Preparation of silicone pre-emulsion: Add 30 g of trimethyltriphenylcyclotrisiloxane, 0.3 g of dialkoxysiloxane, methacryloxypropyl trimethoxysilane to the reactor 0.5g, 2g of sodium dodecylsulfonate, 150g of deionized water, stirred at room temperature for 40min, then placed in an emulsifier and emulsified at a speed of 6000r / min for 5min to obtain a silicone pre-emulsion;

[0040] Add 50g of deionized water into a reactor with a stirrer and stir, and raise the temperature to 60°C, continuously drop the pre-prepared silicone pre-emulsion, drop it at a uniform speed until complete, then raise the temperature to 90°C, and react for 4h to obtain Silicone emulsion;

[0041] Step 2. Preparation of PBA base latex: add 10 g of the silicone emulsion obtained in step 1 to the reactor equipped with a stirrer, and then add 100 g of deionized water, 0.3 g ...

Embodiment 2

[0046]Step 1. Preparation of silicone pre-emulsion: Add 30 g of trimethyltriphenylcyclotrisiloxane, 0.3 g of dialkoxysiloxane, methacryloxypropyl trimethoxysilane to the reactor 0.5g, 2g of sodium dodecylsulfonate, 150g of deionized water, stirred at room temperature for 40min, then placed in an emulsifier and emulsified at a speed of 6000r / min for 5min to obtain a silicone pre-emulsion;

[0047] Add 50g of deionized water into a reactor with a stirrer and stir, and raise the temperature to 60°C, continuously drop the pre-prepared silicone pre-emulsion, drop it at a uniform speed until complete, then raise the temperature to 90°C, and react for 4h to obtain Silicone emulsion;

[0048] Step 2. Preparation of PBA base latex: add 20 g of the silicone emulsion obtained in step 1 to the reactor equipped with a stirrer, then add 100 g of deionized water, 0.3 g of sodium dodecylsulfonate, and 1 g of potassium persulfate , stirred, and the temperature was raised to 60°C, and the pre-...

Embodiment 3

[0053] Step 1. Preparation of silicone pre-emulsion: Add 30 g of trimethyltriphenylcyclotrisiloxane, 0.3 g of dialkoxysiloxane, methacryloxypropyl trimethoxysilane to the reactor 0.5g, 2g of sodium dodecylsulfonate, 150g of deionized water, stirred at room temperature for 40min, then placed in an emulsifier and emulsified at a speed of 6000r / min for 5min to obtain a silicone pre-emulsion;

[0054] Add 50g of deionized water into a reactor with a stirrer and stir, and raise the temperature to 60°C, continuously drop the pre-prepared silicone pre-emulsion, drop it at a uniform speed until complete, then raise the temperature to 90°C, and react for 4h to obtain Silicone emulsion;

[0055] Step 2. Prepare PBA base latex: add 30 g of the silicone emulsion obtained in step 1 to the reactor equipped with a stirrer, then add 100 g of deionized water, 0.3 g of sodium dodecylsulfonate, and 1 g of potassium persulfate , stirred, and the temperature was raised to 60°C, and the pre-prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com