Patents

Literature

1470results about How to "Great operating flexibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process and system for preparing low-carbon olefin from methanol or dimethylether

InactiveCN1356299AReduce wearReduce aggregationHydrocarbon from oxygen organic compoundsChemical recyclingAlkaneGas solid

A process for preparing low-carbon olefin from methanol or dimethyl ether includes loading its raw material and silicon aluminium phosphate (SAPO34) molecular sieve as catalyst into gas-solid parallel down-flowing fluidized bed reactor, super-short contact, reaction, fast gas-solid separation to separating resultant from catalyst to prevent secondary reaction, and regerating catalyst for cyclic use. Its advantages include high output rate (93%), high conversion rate of raw material, and less by-product.

Owner:TSINGHUA UNIV

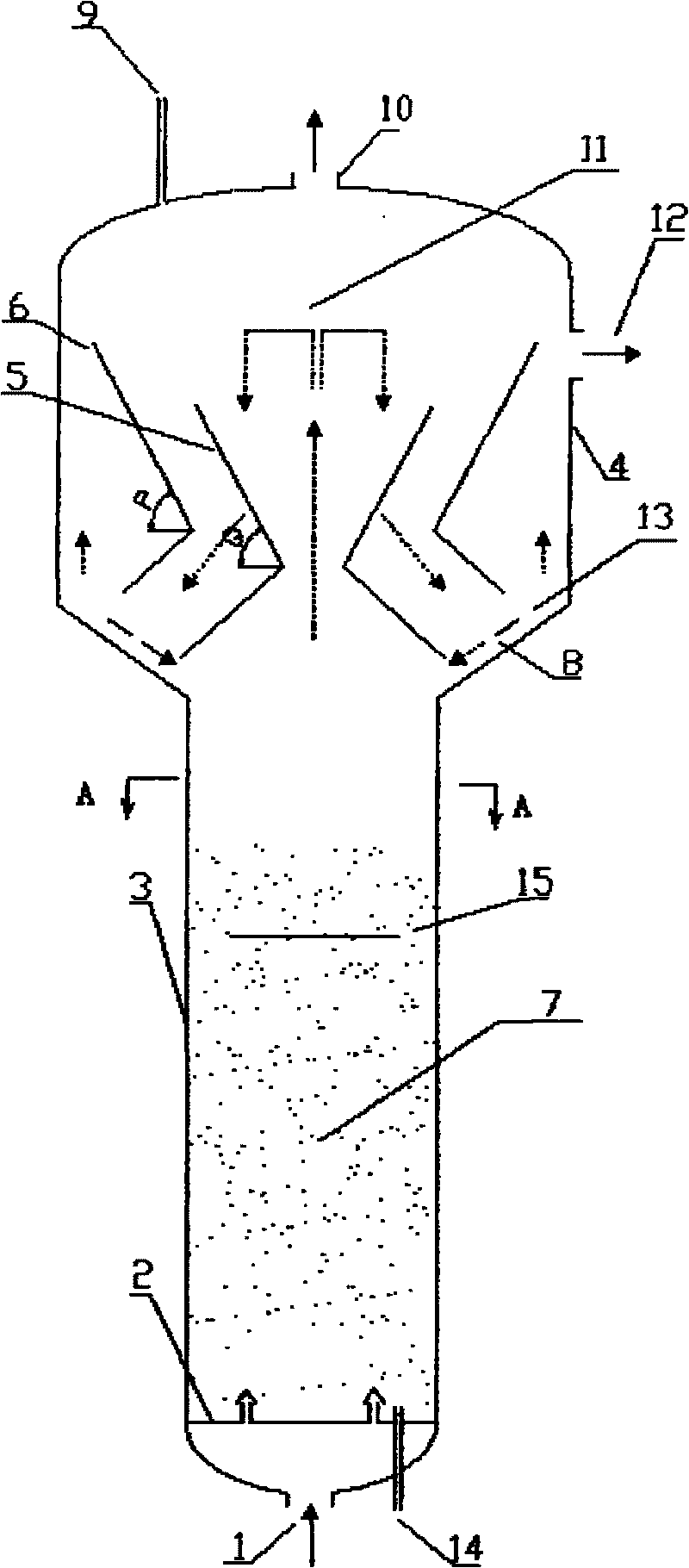

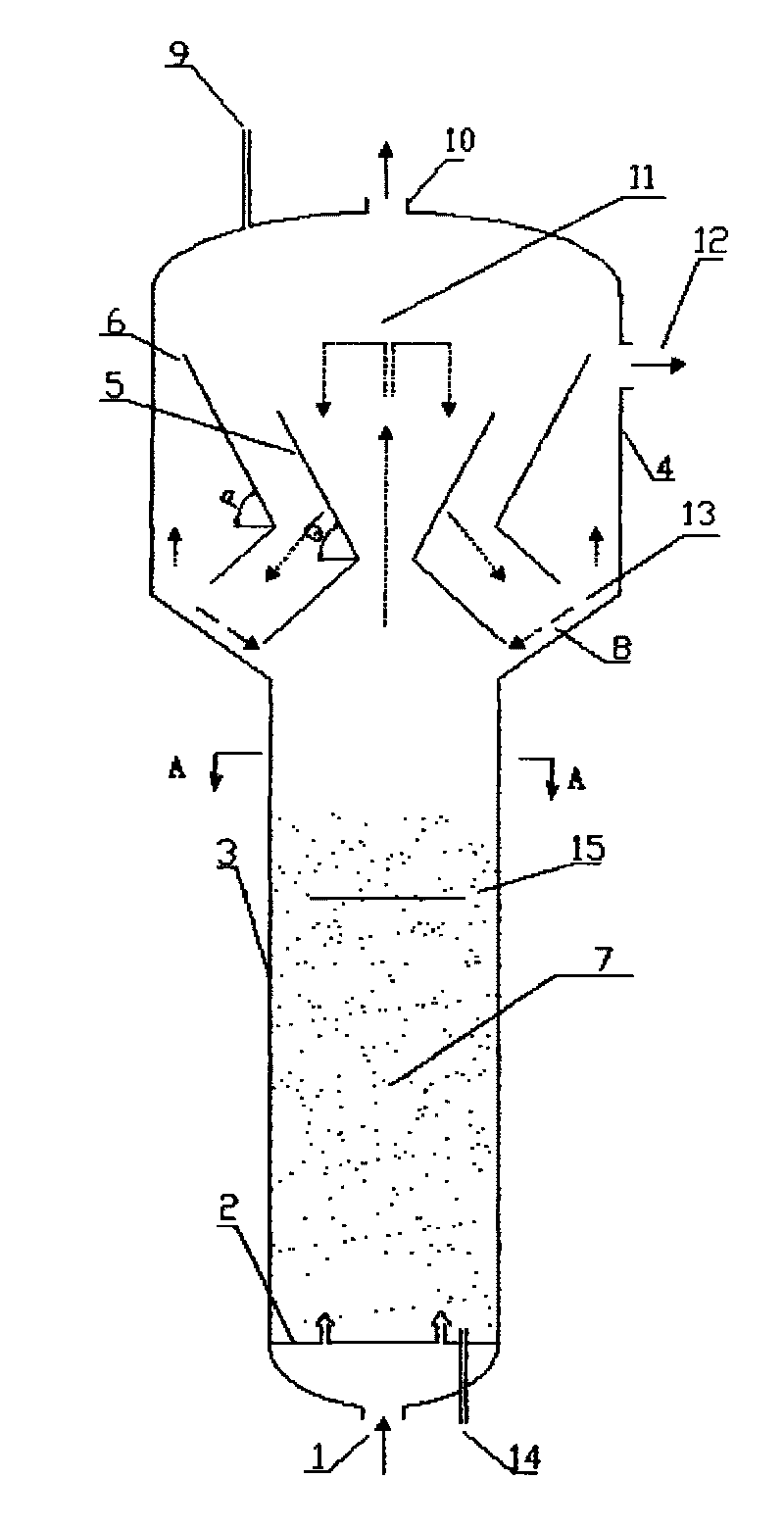

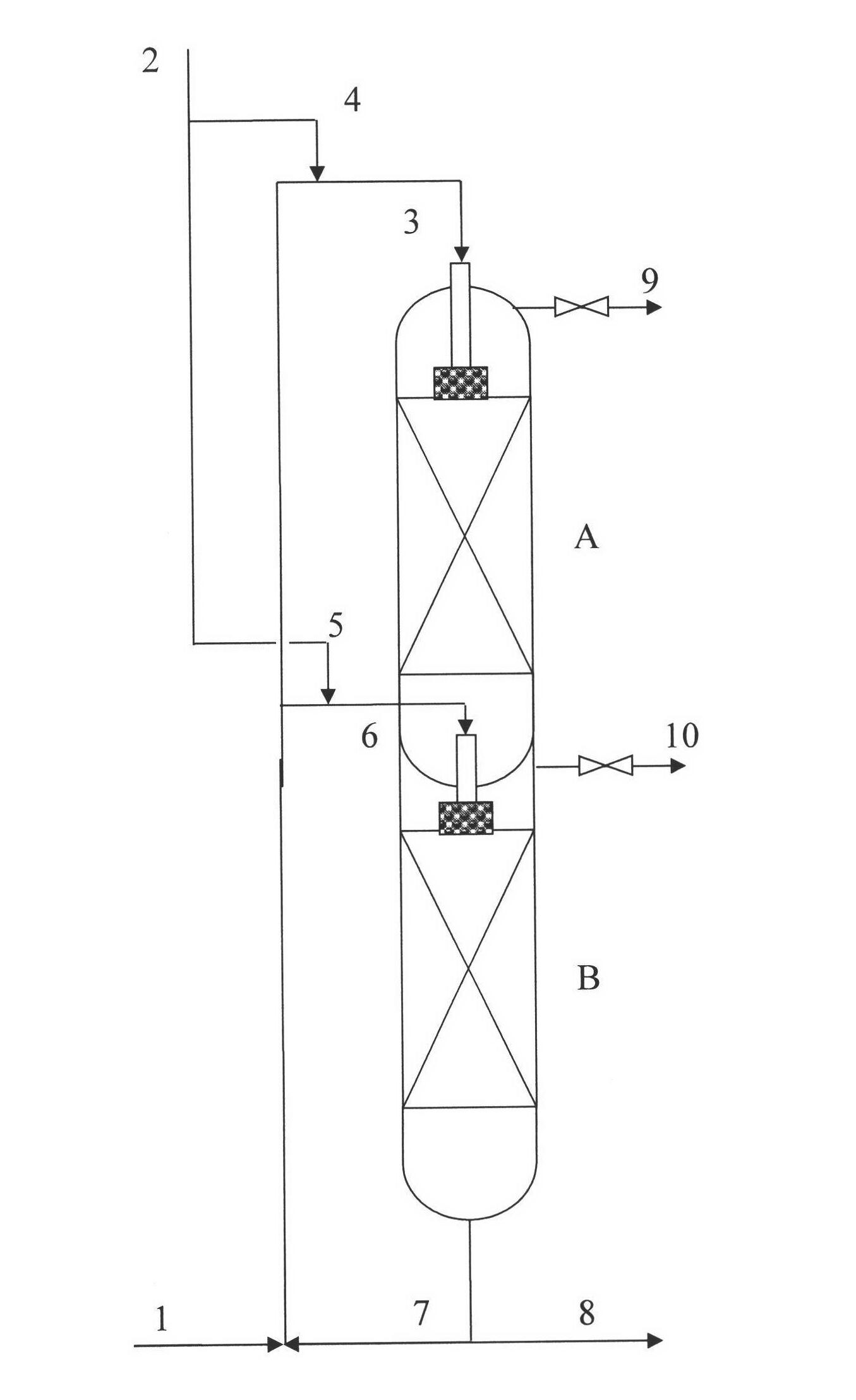

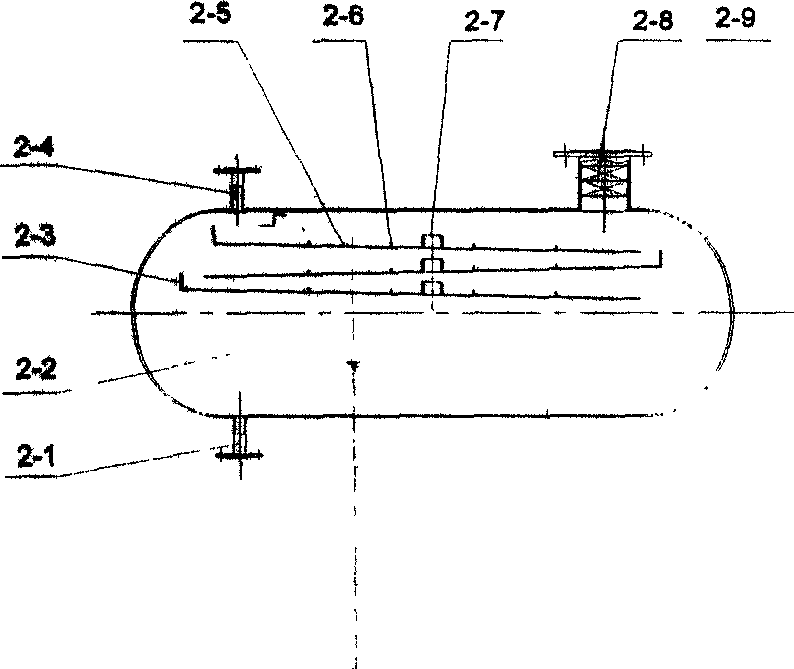

Novel bubbling bed reactor

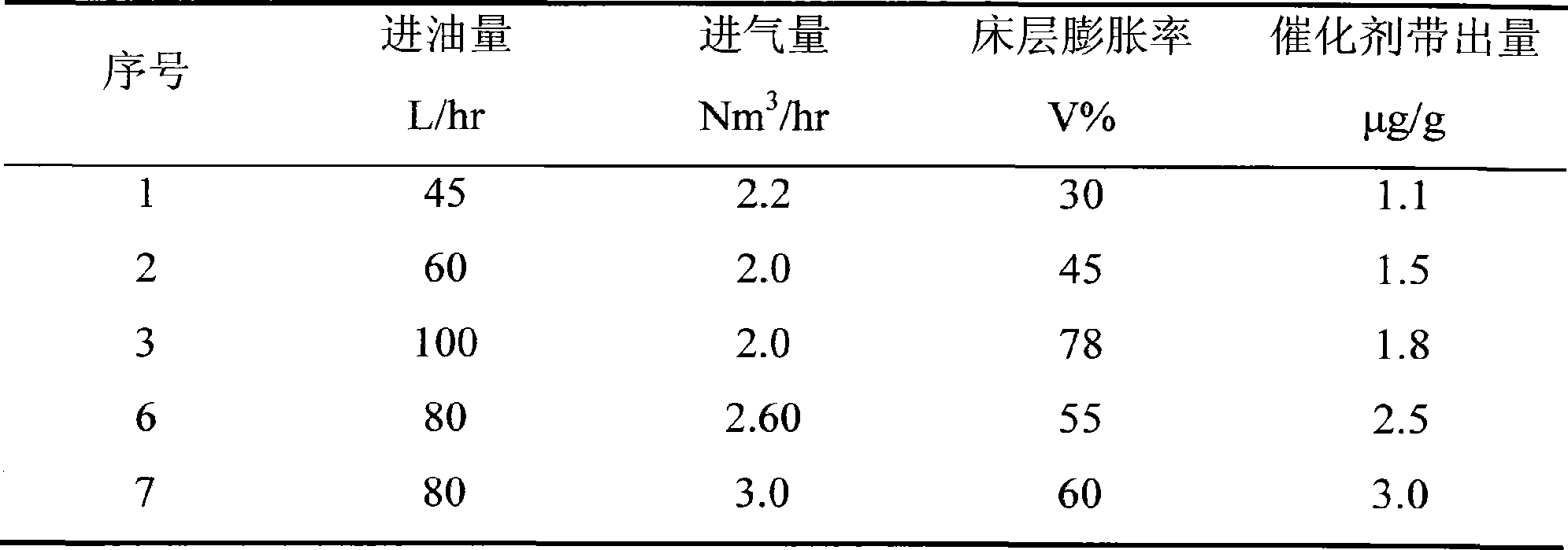

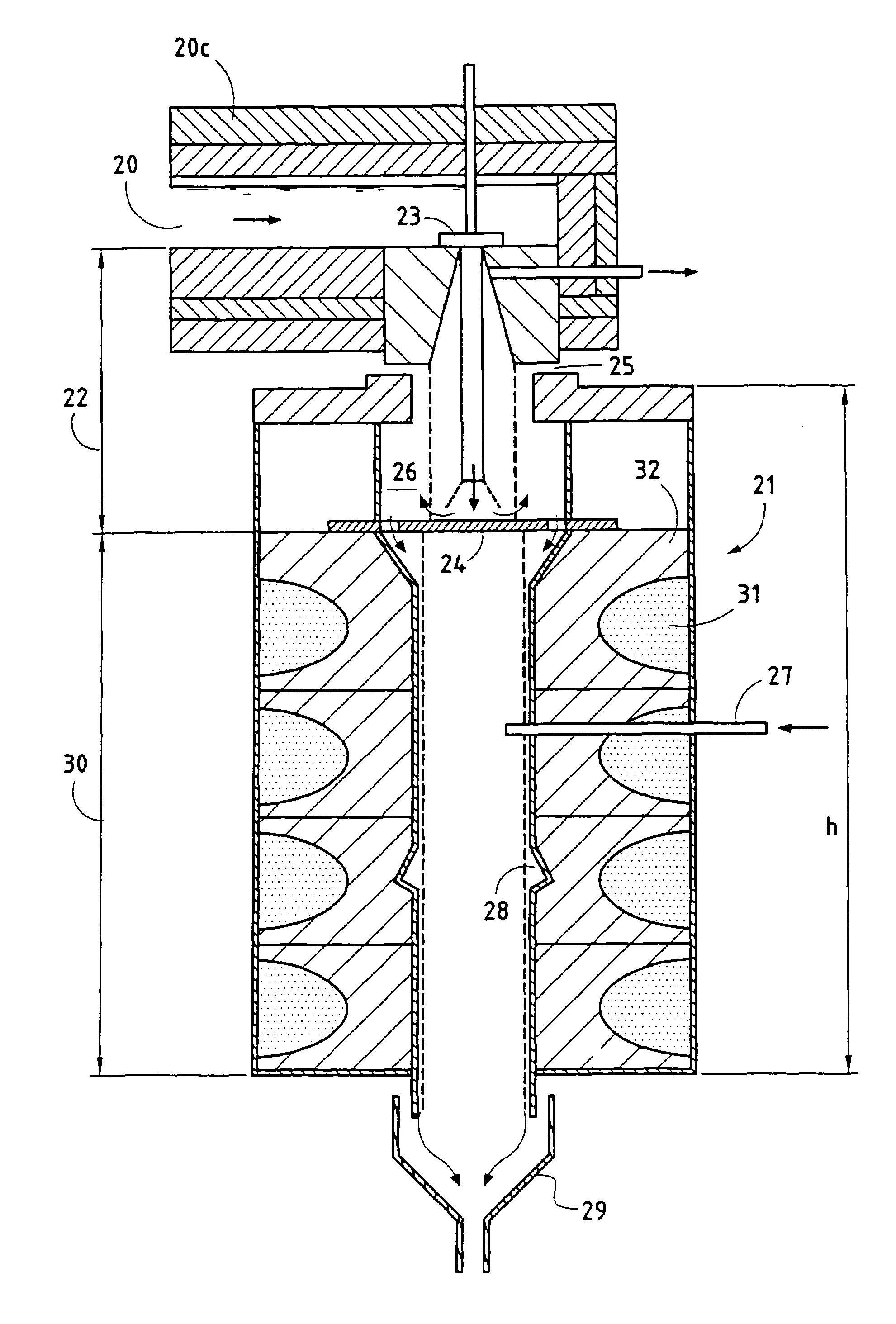

ActiveCN101376092AGreat operating flexibilityEfficient separationHydrocarbon oils refiningChemical/physical processesConvex structureChemical reaction

The invention discloses a new fluidized bed hydrogenation reactor. The fluidized bed hydrogenation reactor of the invention comprises a cylinder-shaped reactor shell perpendicular to the ground, a three-phase separator arranged at the upper part in the reactor shell and a guiding structure arranged at the middle upper part of the reactor. The guiding structure is an annular convex structure arranged on the inner wall of the reactor and has the lengthwise section of a trapezoid or an arc along the axle of the reactor. The combination of the guiding structure and the three-phase separator increases the operating flexibility of the three-phase separator, and ensures the high-efficiency separation on the three-phase separator, thereby greatly reducing the carrying amount of catalyst. The fluidized bed hydrogenation reactor of the invention can be applied to the chemical reactions between different liquids or gases and solid grains under the condition of contacting, and is characterized by large catalyst inventory, high reactor utility ratio, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

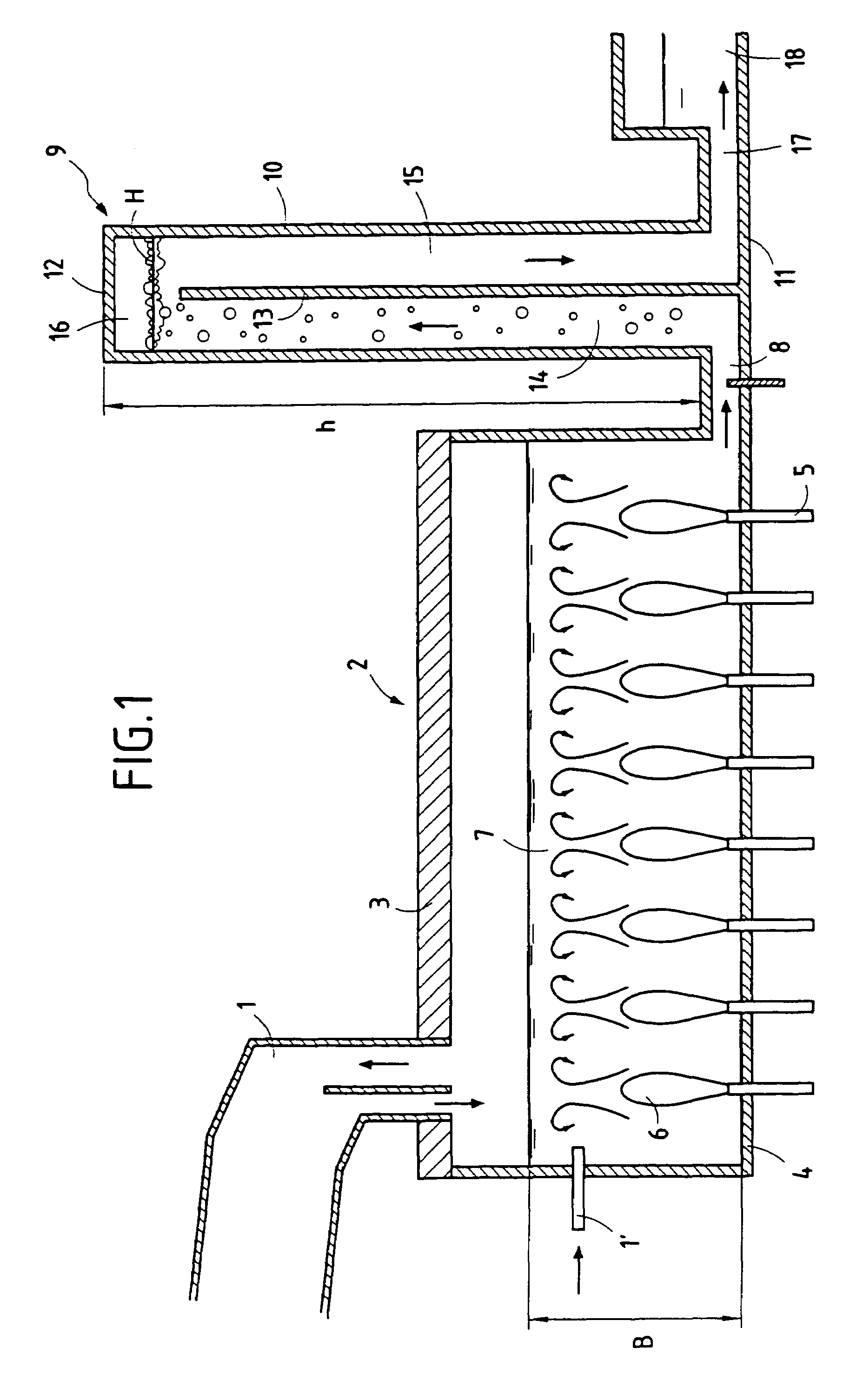

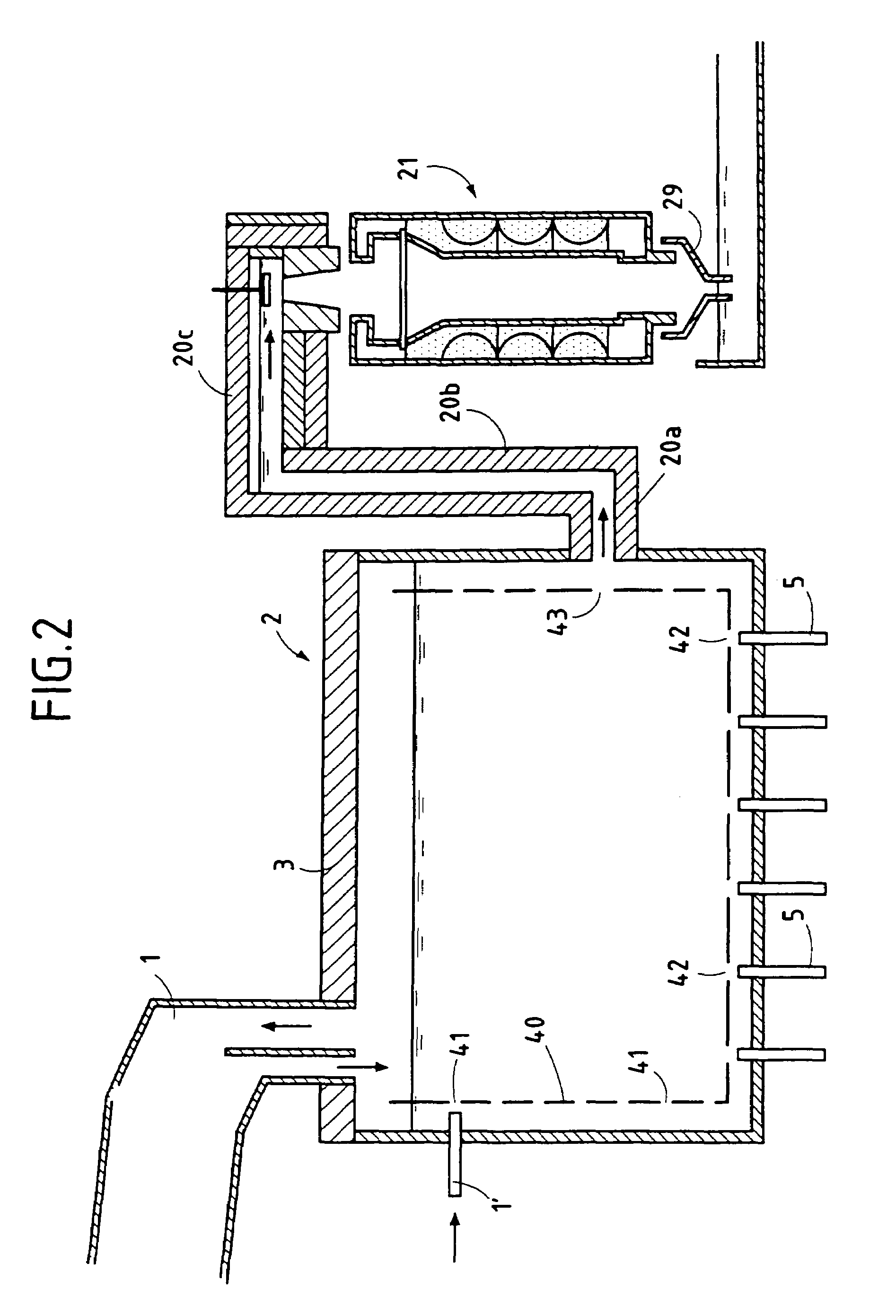

Method and device for melting and refining materials capable of being vitrified

InactiveUS7624595B2Speed up the processGreat operating flexibilityCharging furnaceGlass furnace apparatusVitrificationThermal energy

A process for melting and refining vitrifiable materials, such that all or part of the thermal energy necessary for melting the said vitrifiable materials is supplied by the combustion of fossil fuel(s) with at least one oxidizer gas, the fuel(s) / gas or the gaseous products resulting from the combustion being injected below the level of the mass of vitrifiable materials (7). The refining of the vitrifiable materials after melting comprises at least one step of subjecting them to subatmospheric pressure while centrifuging.

Owner:SAINT-GOBAIN GLASS FRANCE

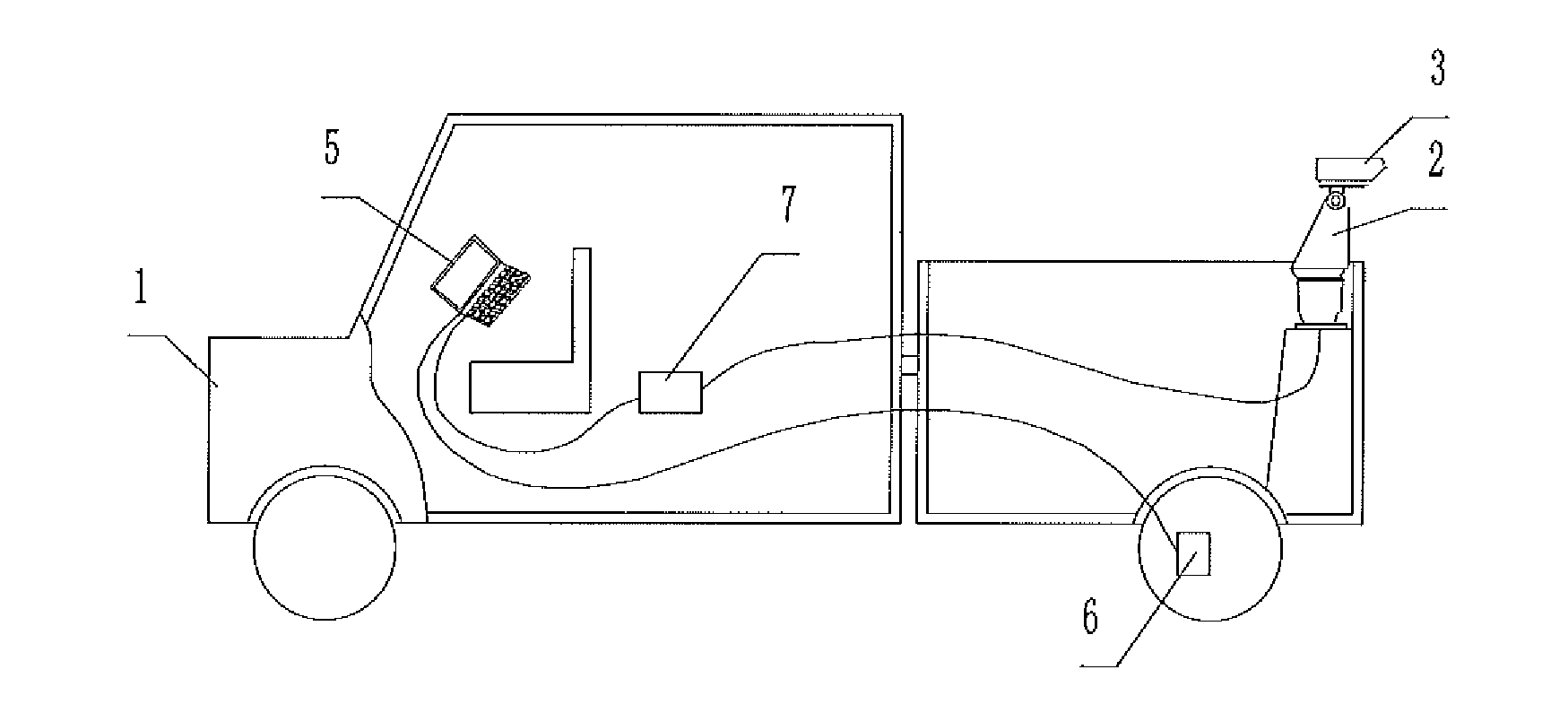

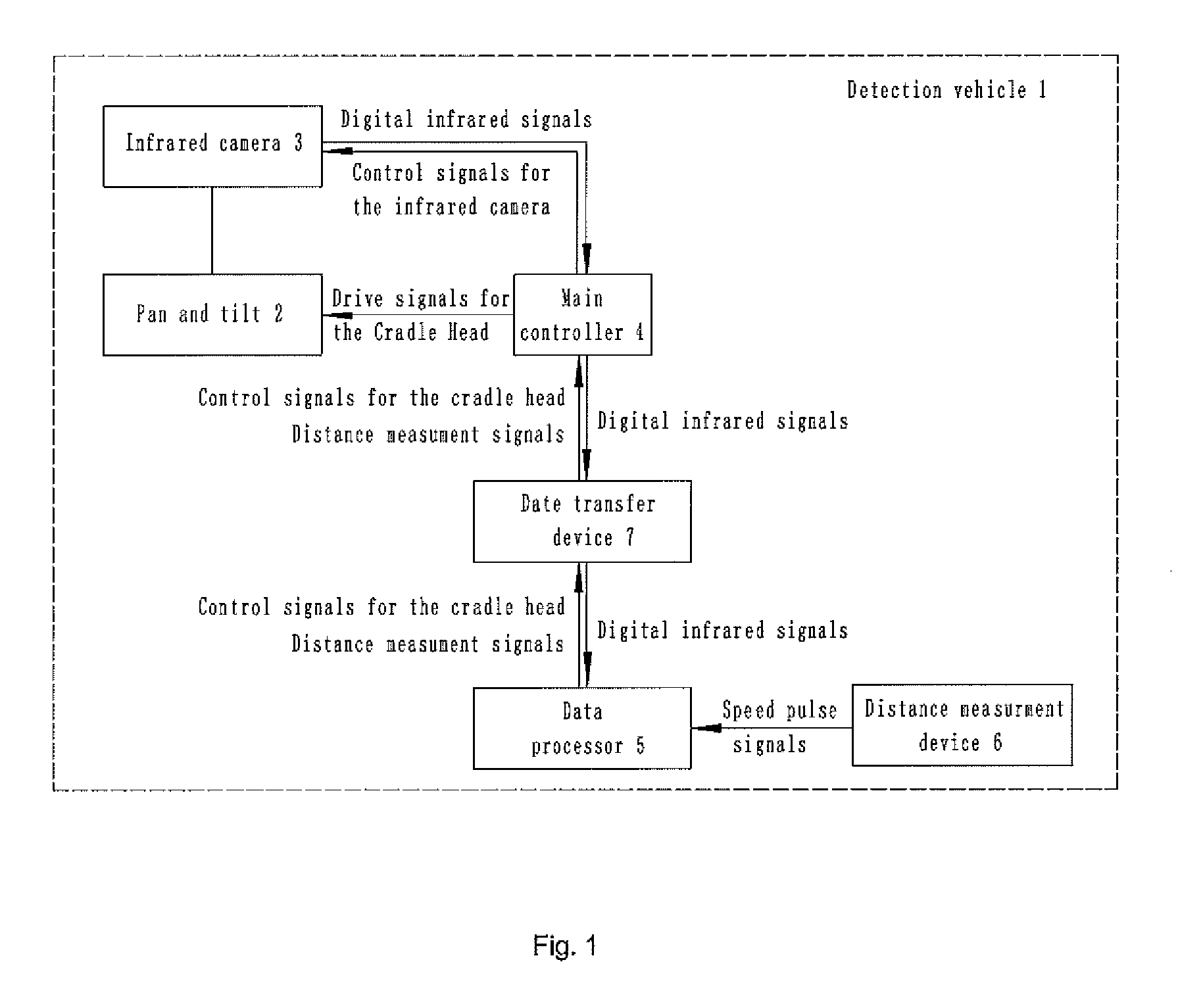

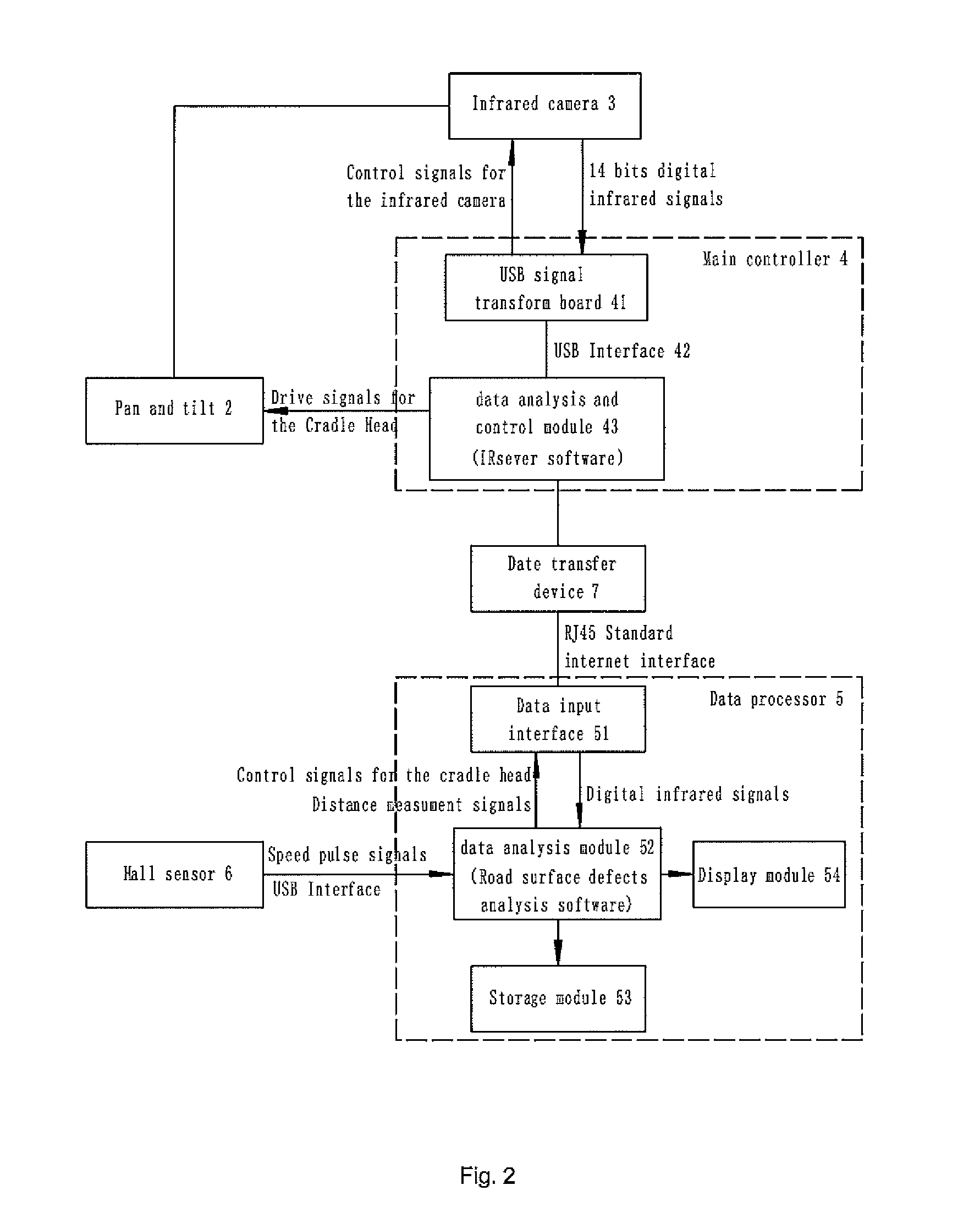

System and method for road surface defects detection

InactiveUS20120218411A1Improves existing maintenance techniqueAccurate timingTelevision system detailsColor television detailsEngineeringRoad surface

A system and method for road surface defects detection based on infrared imaging technology, while the system comprising: a detection vehicle traveling on a detected road surface; a pan and tilt provided on the detection vehicle and rotate horizontally and vertically with respect to the detection vehicle; an infrared camera detachably set on the pan and tilt, which is used to capture infrared thermal images of the detected road surface, and to output inferred thermal image digital signals about the inferred thermal images including temperature values of the detected road surface; a main controller provided on the detection vehicle and connected to the pan and tilt and the infrared camera respectively, which is used to control capture actions of the infrared camera, to control angles of the horizontal and vertical rotations of the pan and tilt, and to transform the infrared thermal image digital signals output from the infrared camera into digital signals to be used in standard network transmission; and a data processor, used to receive the digital infrared signals to be analyzed and processed to determine the type and location of defects on the detected road surface. The system of the present application has excellent operation flexibility and is able to visually display details of the defects.

Owner:GUANGZHOU SAT INFRARED TECH

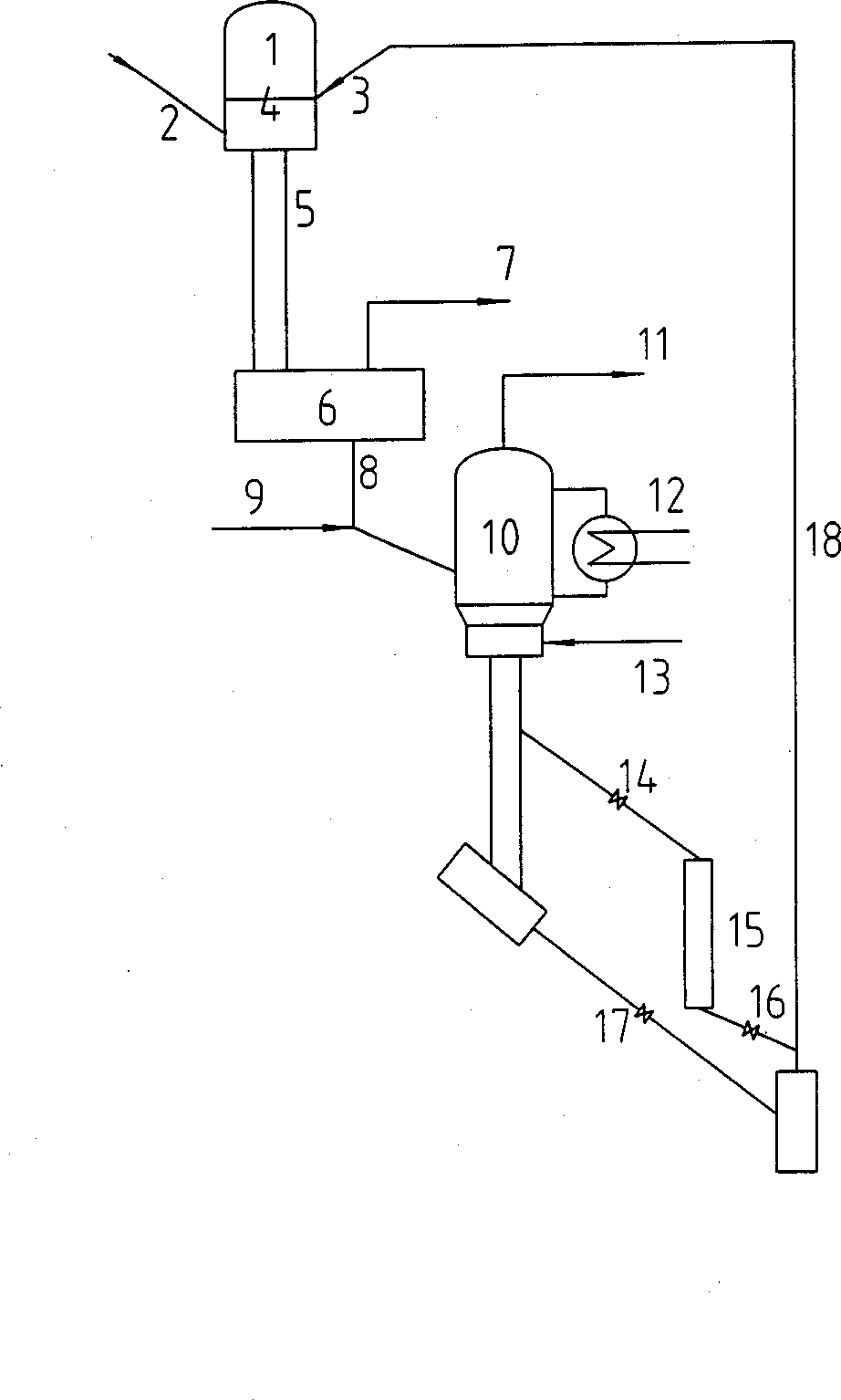

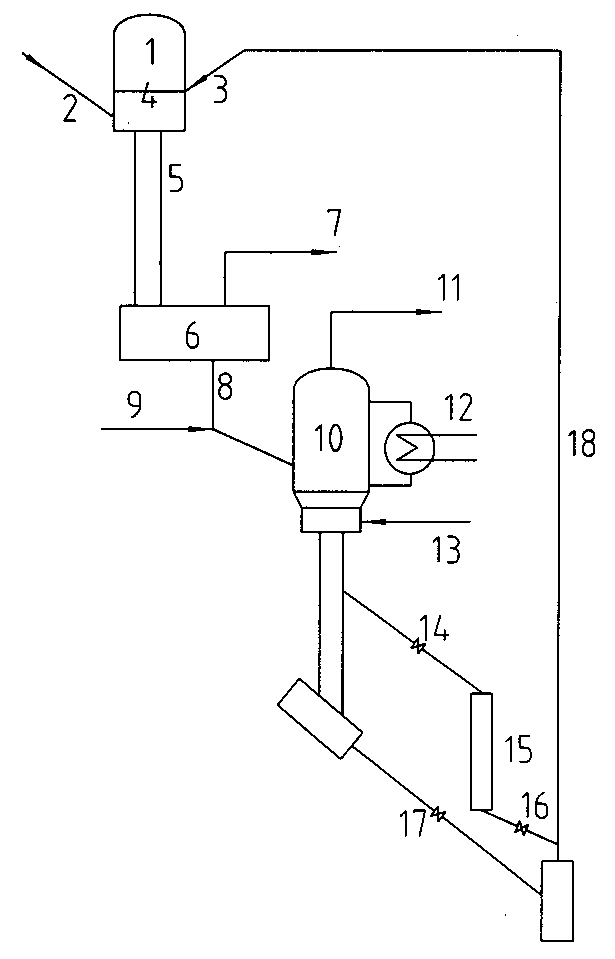

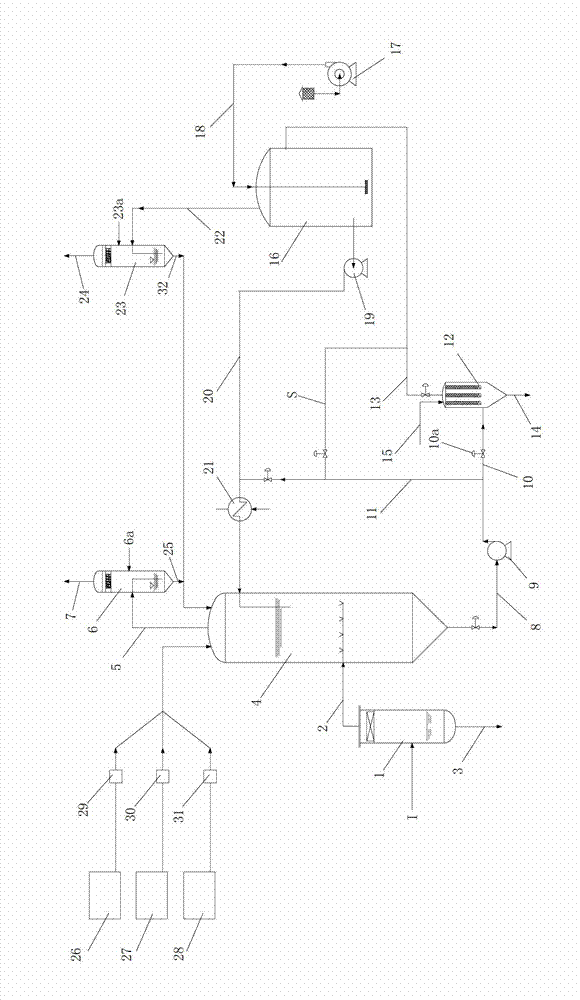

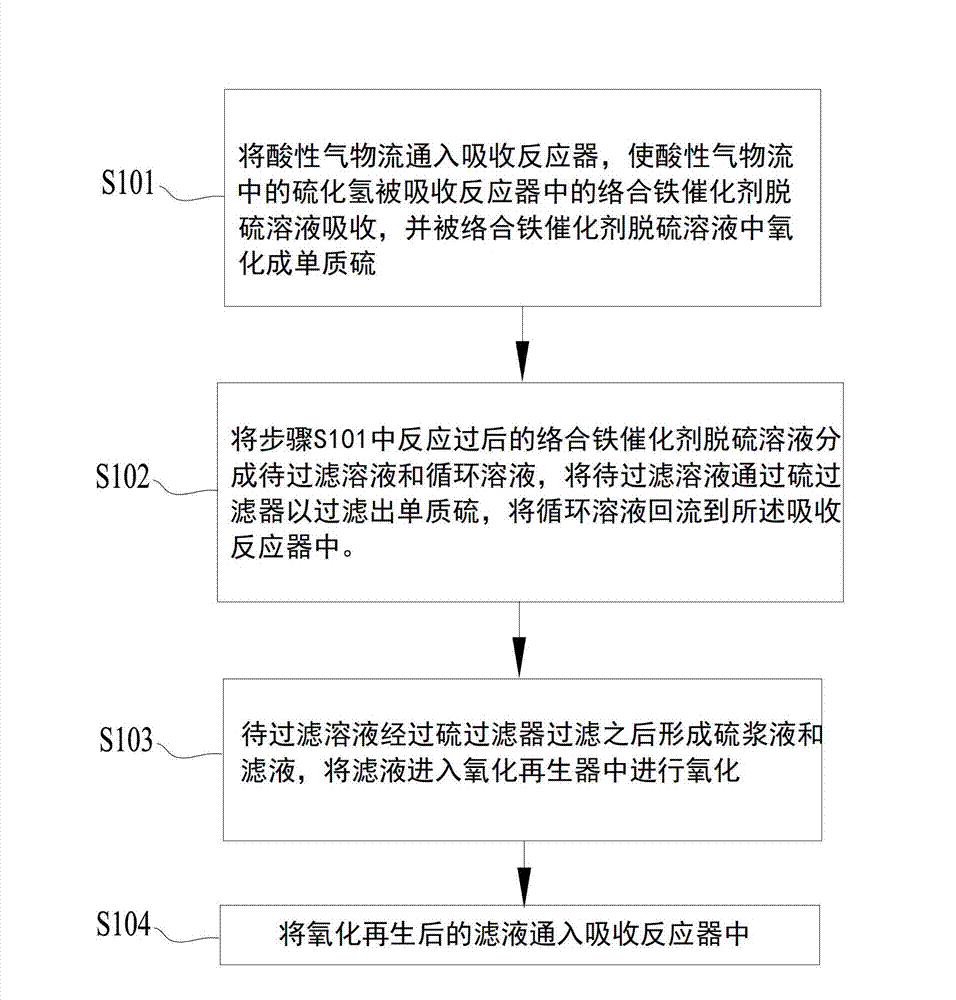

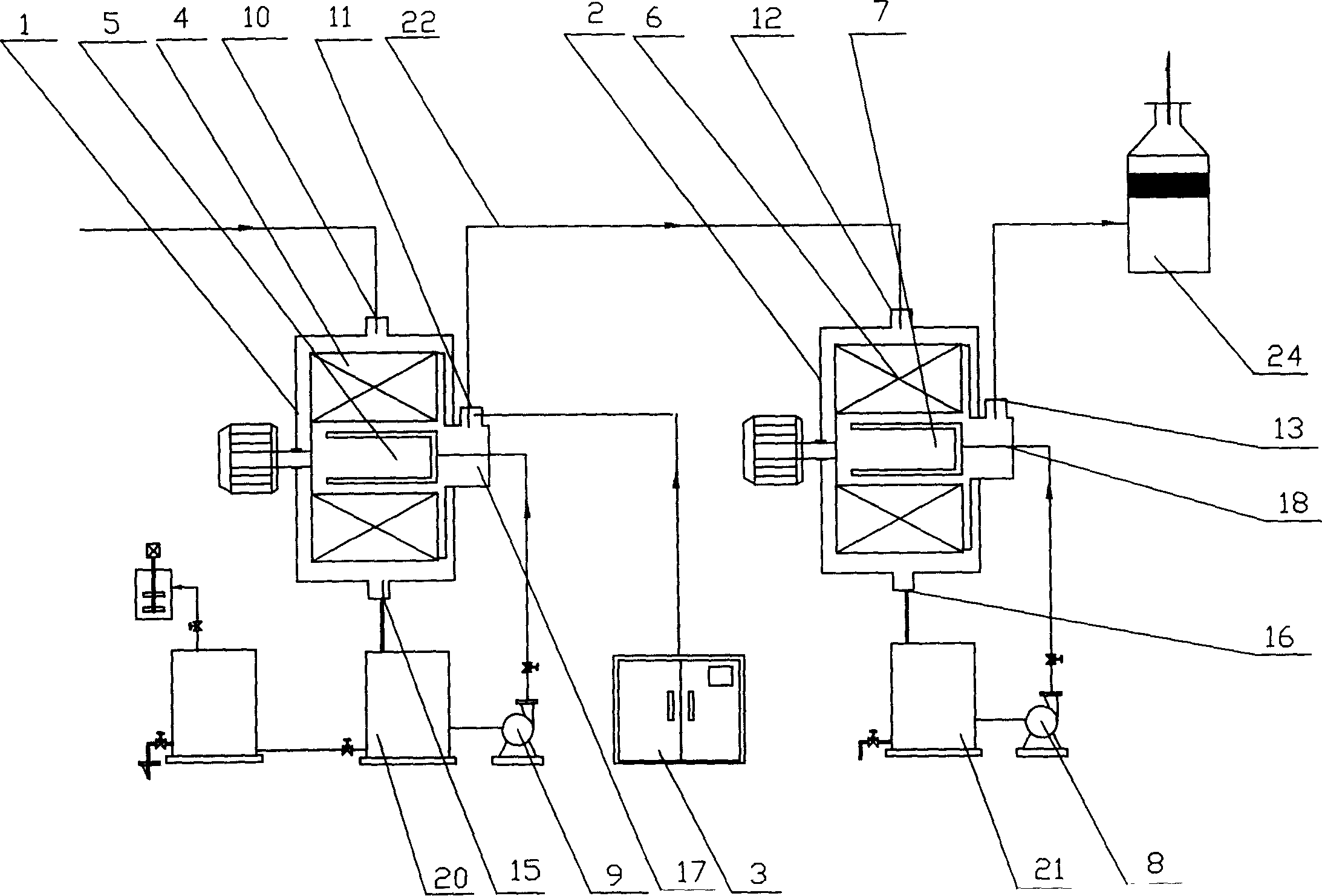

Treatment system and treatment method for removing hydrogen sulfide from acid gas

ActiveCN102895870ALow internal sulfur concentrationReduce the concentration of sulfurDispersed particle separationSulfur preparation/purificationPtru catalystPhysical chemistry

The invention relates to a treatment system and a treatment method for removing hydrogen sulfide from acid gas. The treatment system comprises an absorption reaction unit, a sulphur filtering unit, a solution regeneration unit, a temperature control unit and a medicament deliver unit, wherein the absorption reaction unit has a ferrum-catalyst desulfuration solution, is used for absorbing hydrogen sulfide contained in the acid gas introduced in the ferrum-catalyst desulfuration solution, and oxidizing the hydrogen sulfide into sulphur; the sulphur filtering unit is used for filtering the sulphur; and the solution regeneration unit is used for oxidizing and regenerating the filtered ferrum-catalyst desulfuration solution. The sulphur filtering unit is positioned between the absorption reaction unit and the solution regeneration unit. According to the system and the method, the sulphur is filtered from the solution before the step of oxidation and regeneration, so that the sulphur can not be deposited at the bottom end of an oxidization regenerator, the concentration of the sulphur in the system is low, so that the system can operate stably for a long time, and has good operational flexibility under various work conditions; the structure of equipment can be simplified; the investment is saved; and the construction period is also saved.

Owner:美景(北京)环保科技有限公司

Purification technology and equipment of waste gas containing high concentration nitrogen oxide

ActiveCN1830526AEnhanced mass transferImprove responseDispersed particle separationHigh concentrationNitrogen dioxide

A process for cleaning the waste gas containing high-concentration NOx includes such steps as gathering the fume, coming in rotary filler bed, diffusing into rotary filler, spraying the absorptive liquid to filler, countercurrent absorption, mixing the treated gas with oxidant to oxidize NO to NO2, coming in rotary filler bed, absorbing by absorptive liquid, defrosting, and exhausting. Said absorptive liquid can be cyclically used. Its apparatus is also disclosed.

Owner:ZHONGBEI UNIV

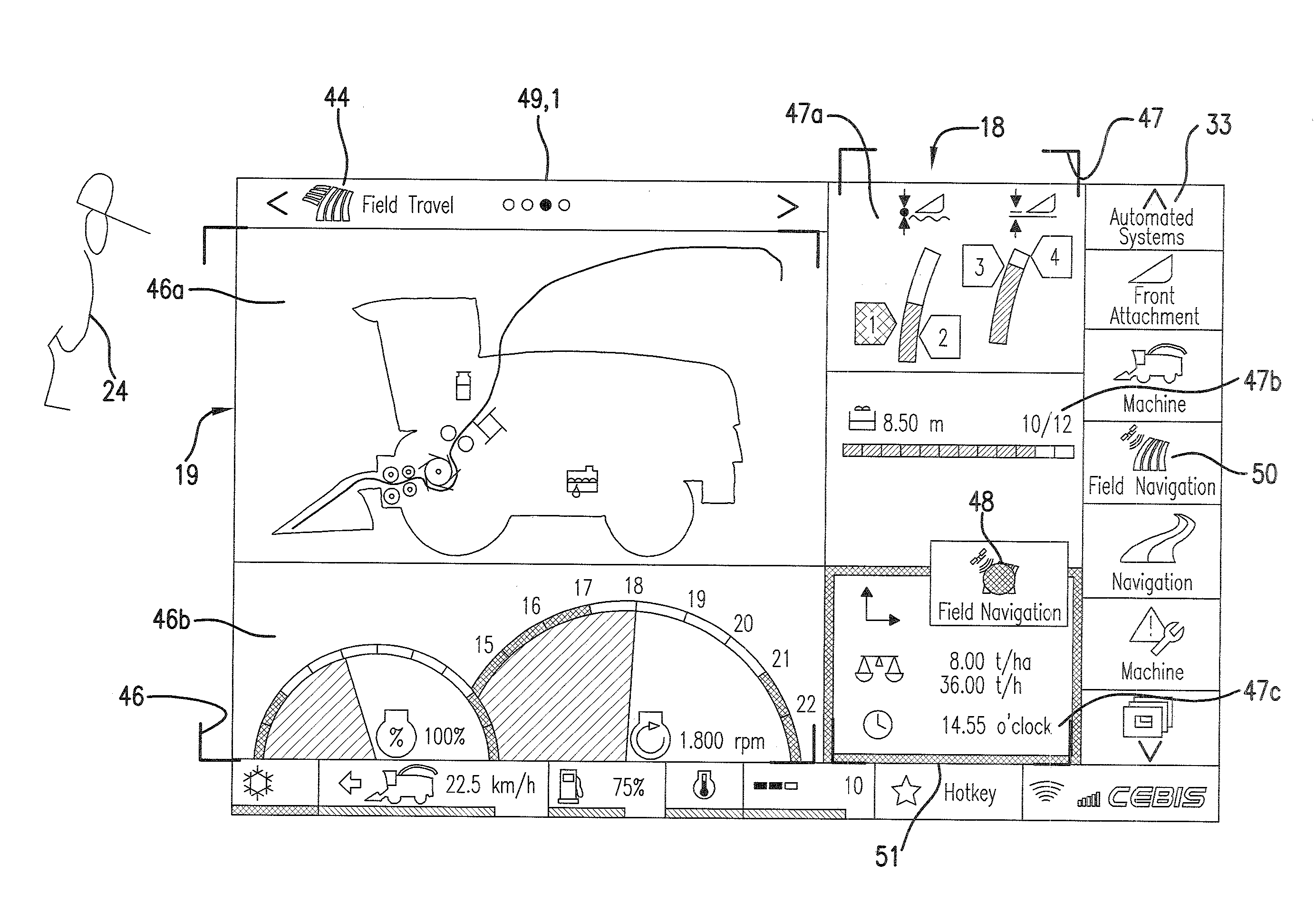

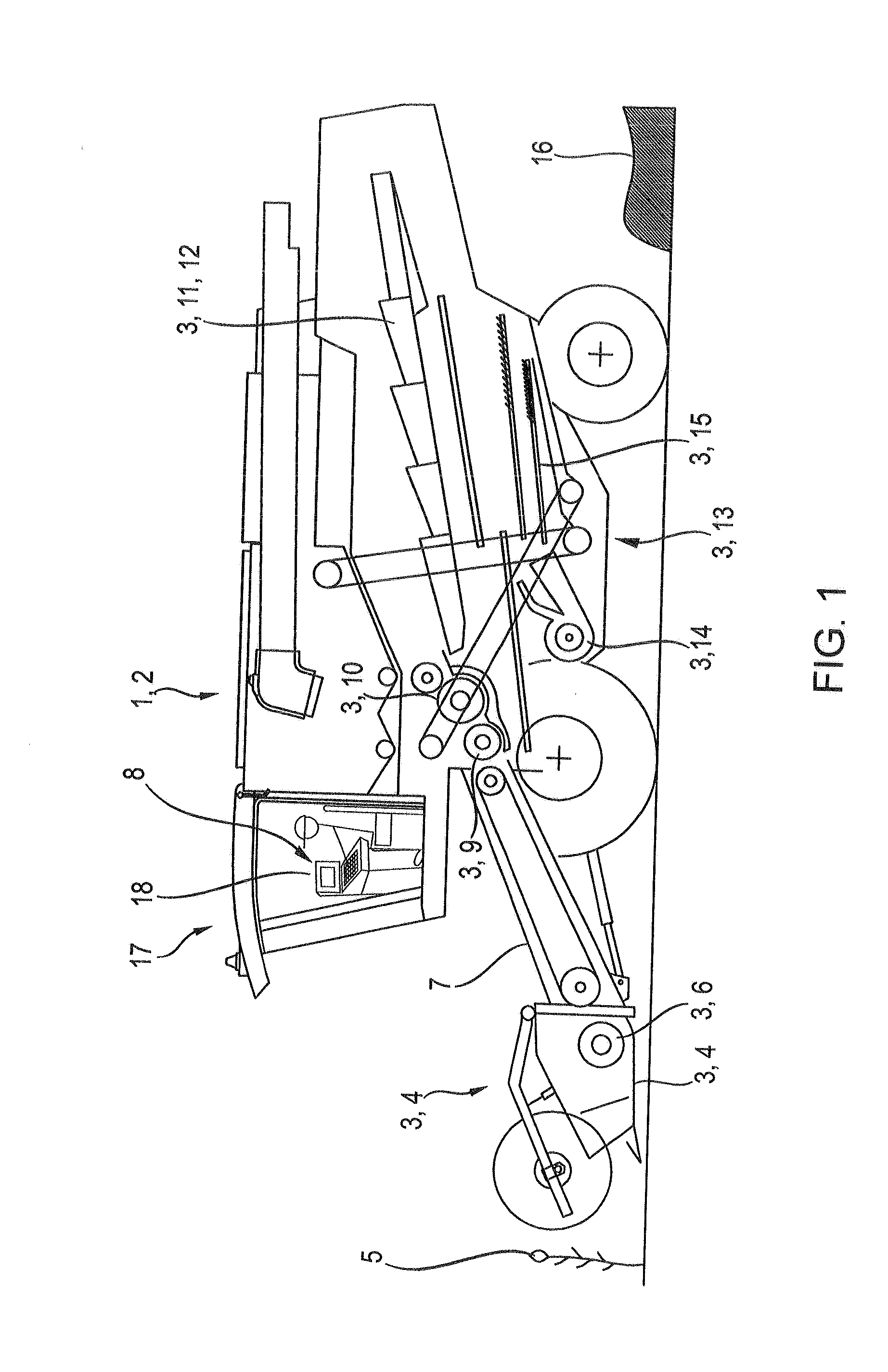

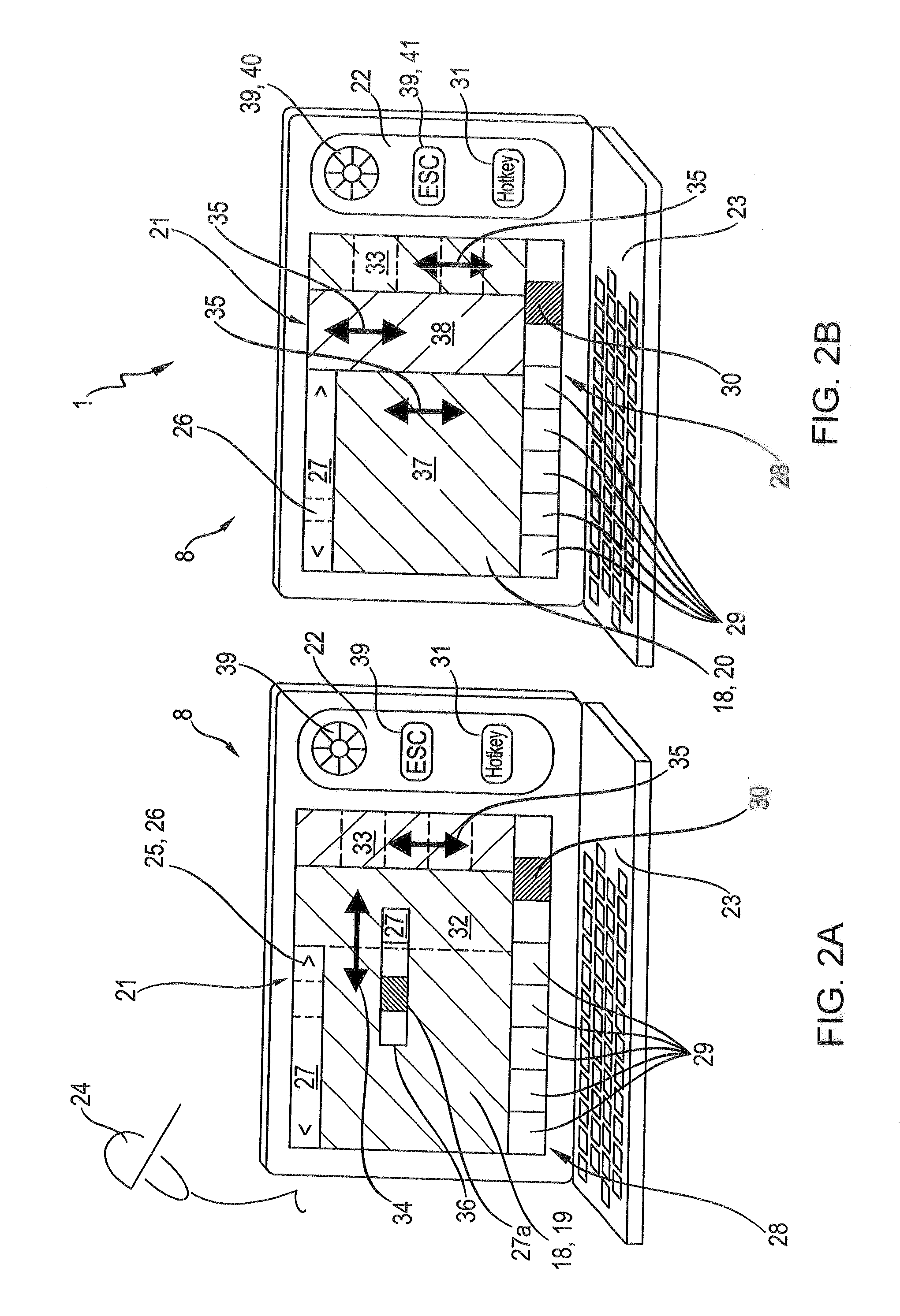

Electronic control and display unit

InactiveUS20140053092A1Quick navigationIncrease scrolling speedMowersInput/output processes for data processingMarine navigationDisplay device

An electronic control and display unit includes a display and at least one control unit. The display has a set of visualization regions and can be operated in navigation levels. The display is subdivided into visualization regions within a navigation level and at least a portion of the visualization regions are movable relative to others of the visualization regions.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

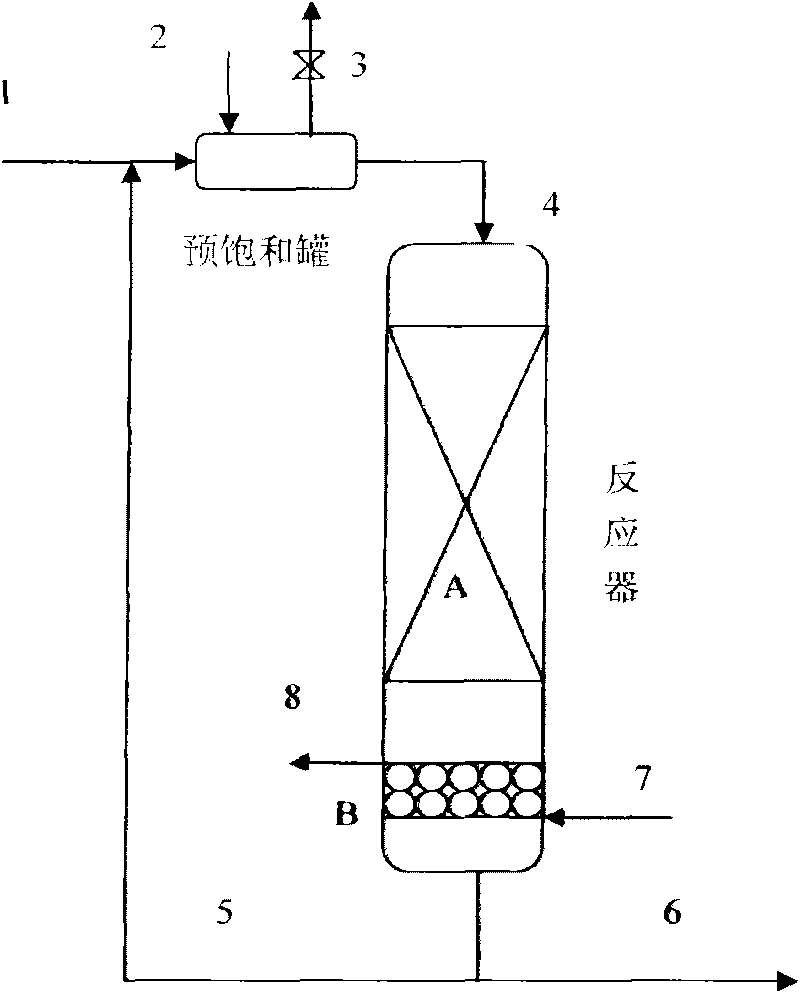

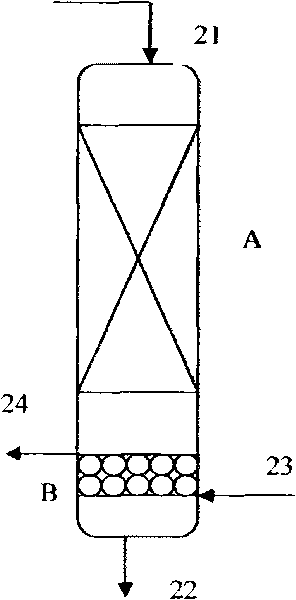

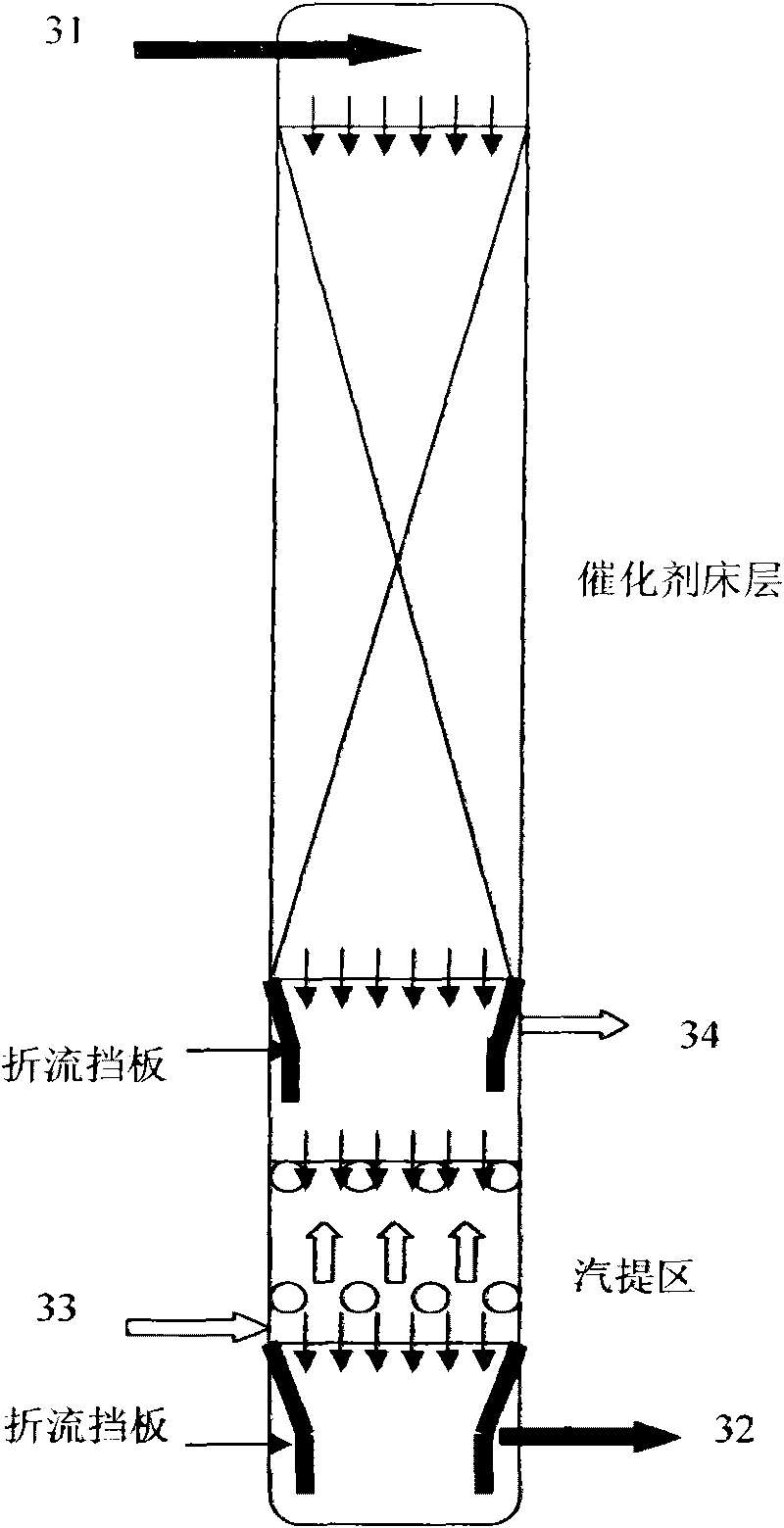

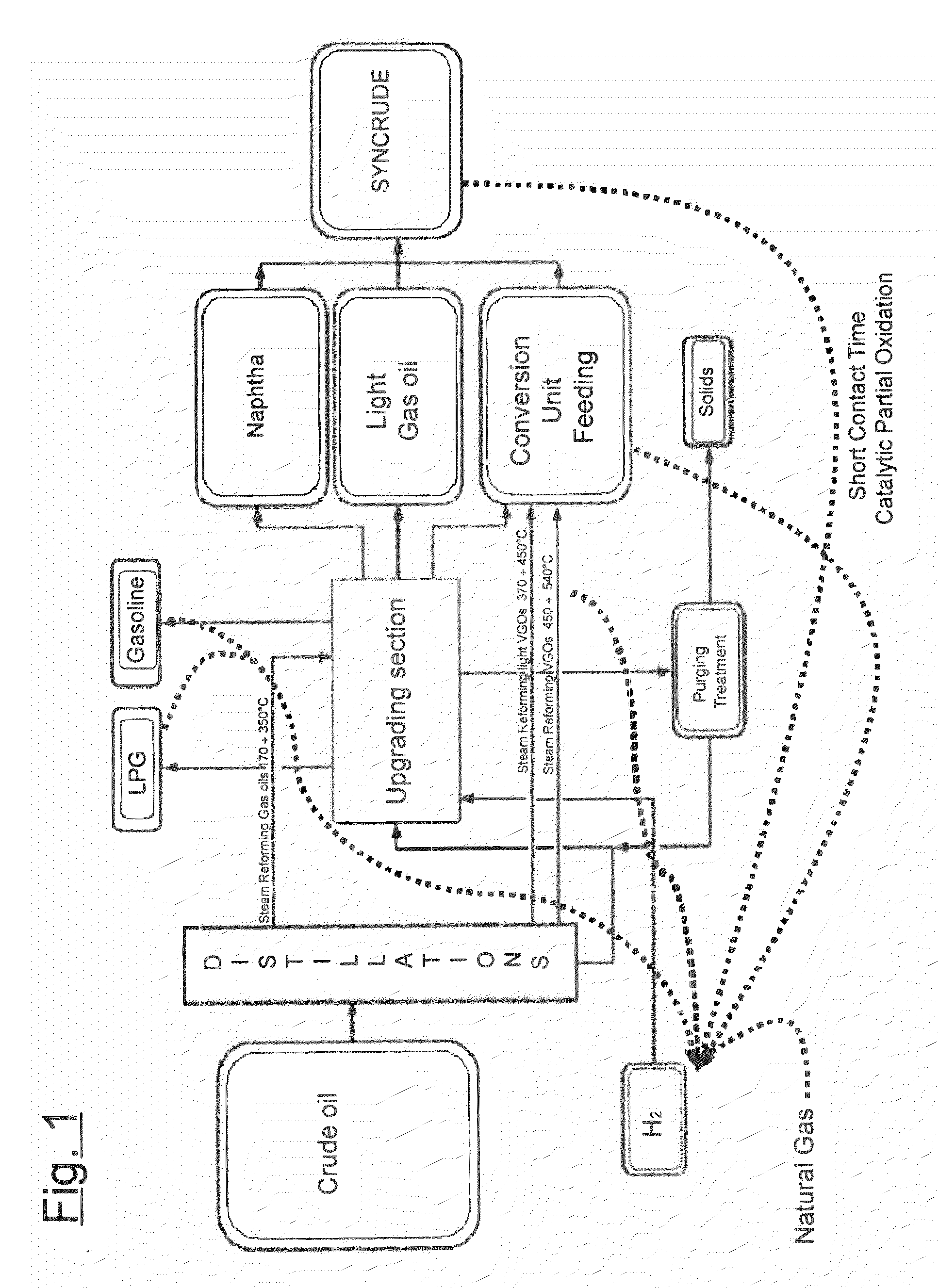

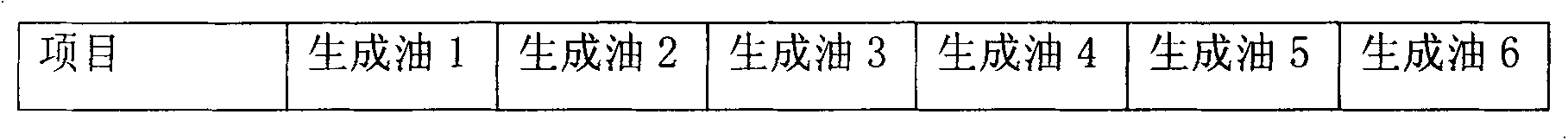

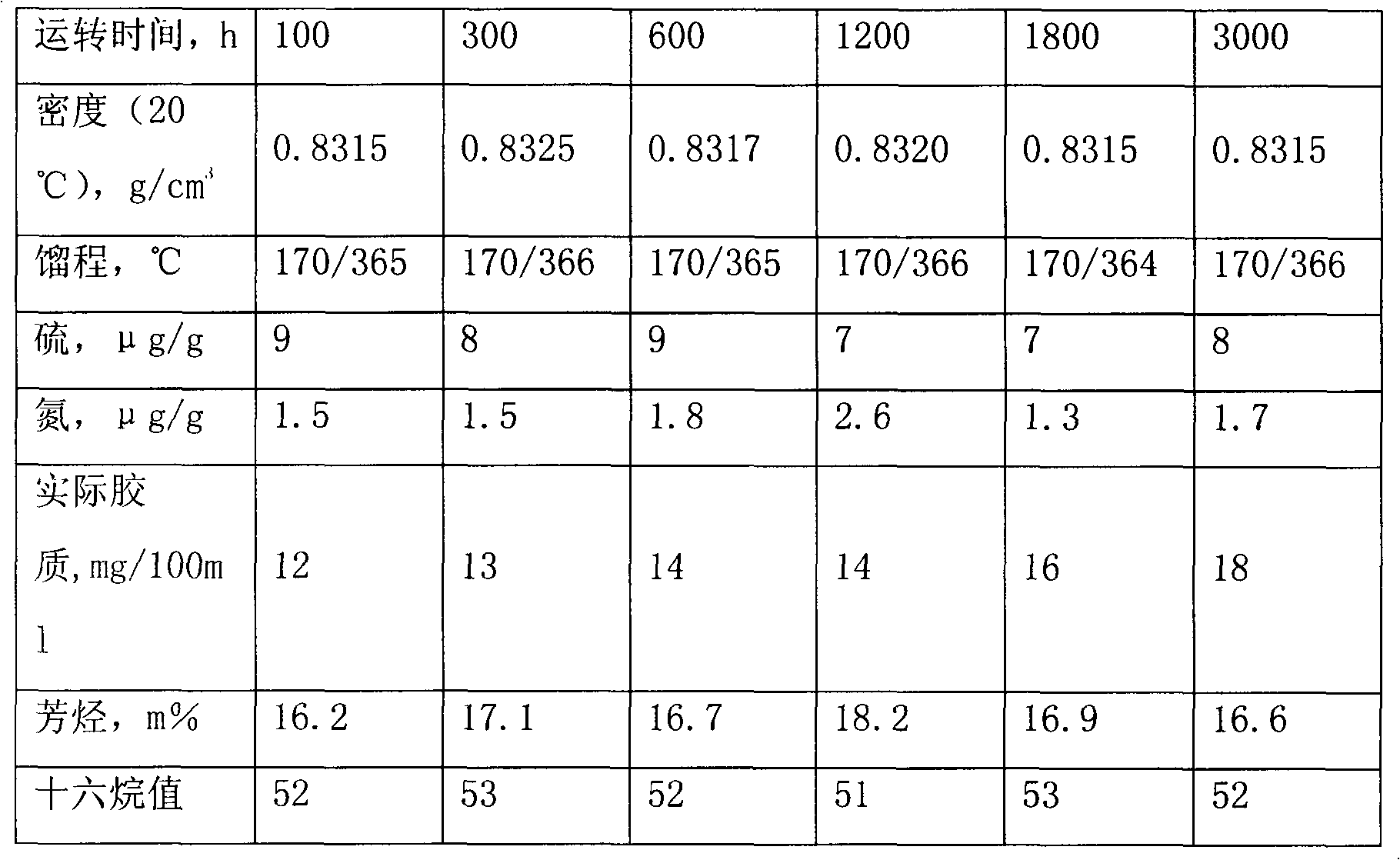

Method for producing clean fuels through low-cost hydrogenation

InactiveCN101724443ALow costGreat operating flexibilityRefining to eliminate hetero atomsSide productKerosene

The invention discloses a distillate oil two-phase hydroprocessing method, which comprises the following steps of: performing hydrogen saturation on raw materials, hydrogen and circulating hydroprocessing products in a pre-saturation high-pressure tank to form a two liquid-phase mixture of the raw materials, the hydroprocessing products and the hydrogen; separating the hydrogen from the liquid-phase mixture; and putting the mixture with saturated dissolved hydrogen in a single-stage or multi-stage inner cross-flow reactor under the condition of a hydrogenation process. The inner cross-flow reactor adopted by the invention has the functions of catalyzing the hydrogenation reaction and steam stripping the reaction side products such as H2S, NH3 and the like from a reaction system, so the hydrogenation reaction efficiency is greatly enhanced. At the same time, the method does not need a hydrogen circulating link and a circulating hydrogen compressor so as to greatly reduce the equipment investment and the operation cost. The method not only can be applied to hydrogen desulfurization, denitrification and dearomatization for the distillate oil such as gasoline, kerosene, diesel oil and the like, but also can be applied to the technical process for producing high-quality clean fuels by mild hydrocracking the distillate oil such as a VGO raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

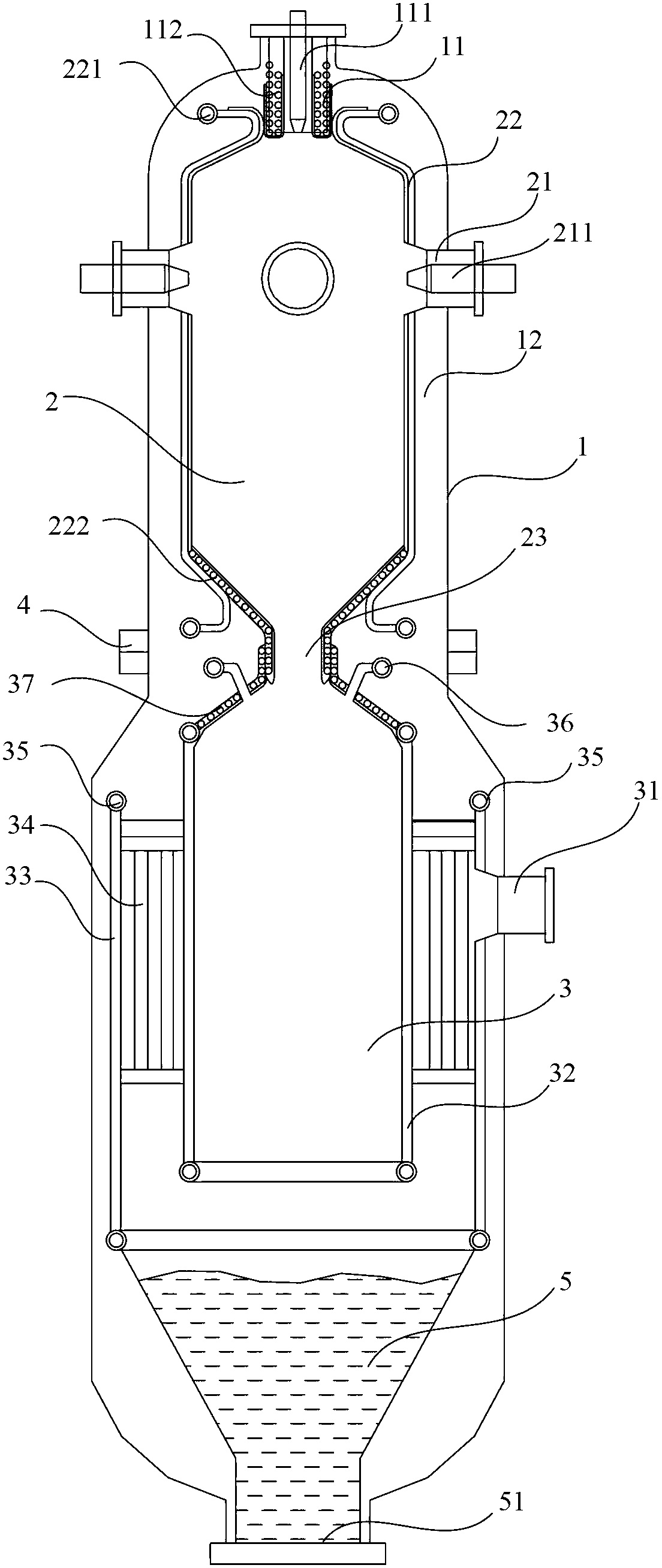

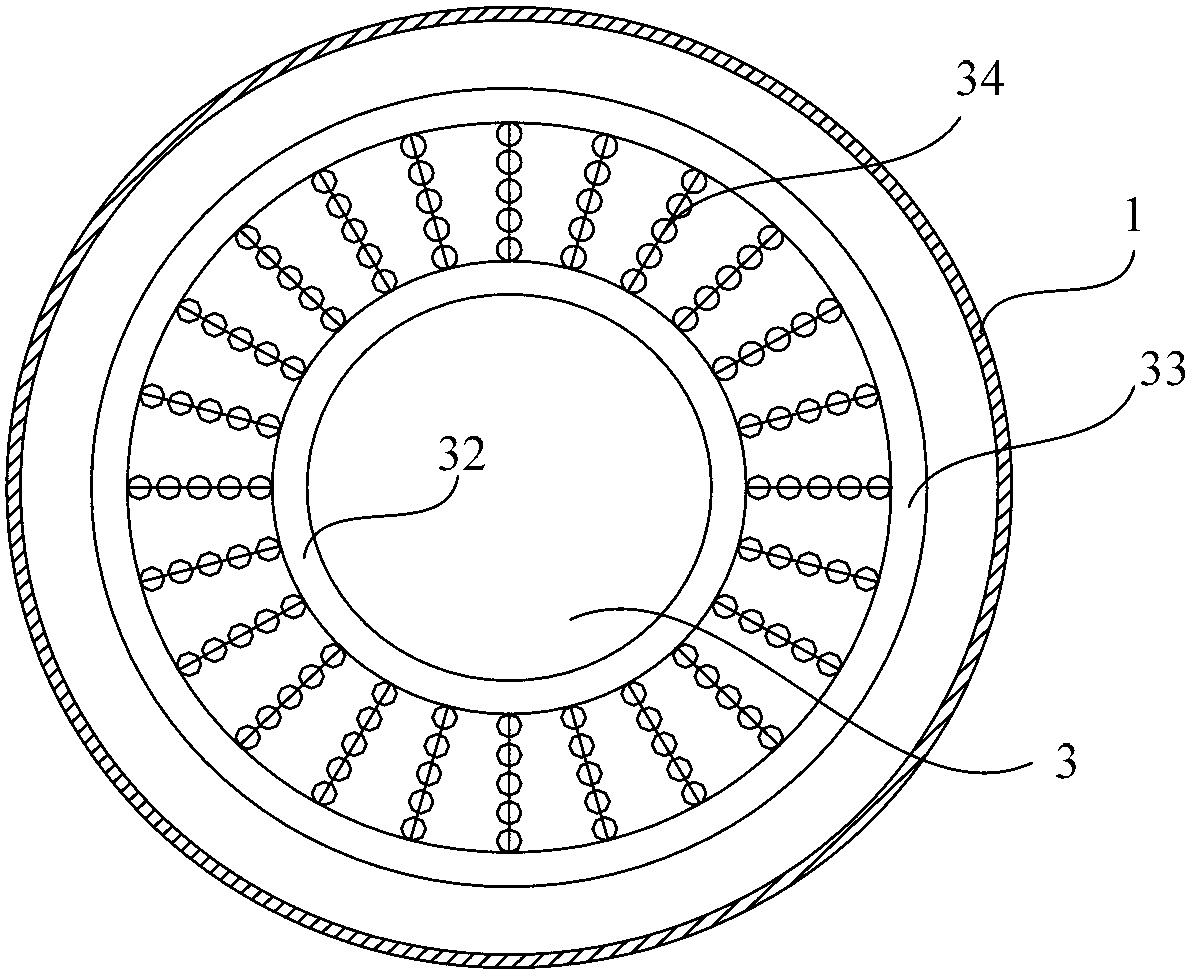

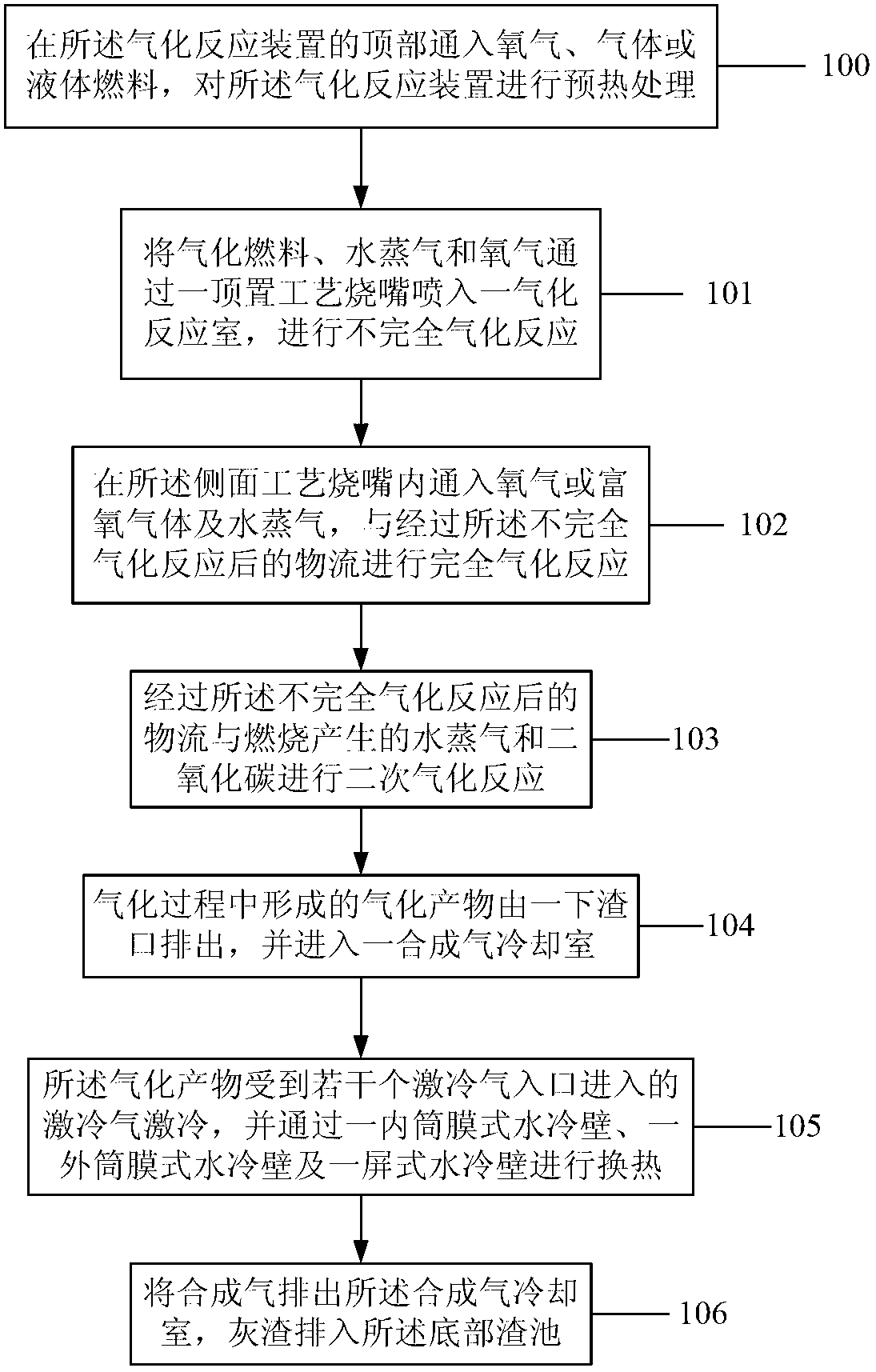

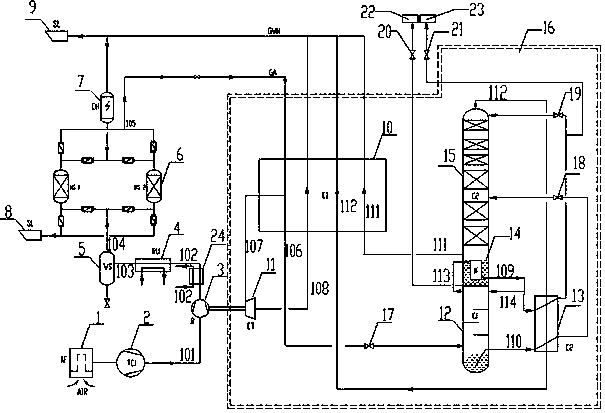

Staged-pressurization gasification reaction device for dry pulverized coal and gasification method thereof

InactiveCN102703129AEffective cooling and solidificationReduce size areaGranular/pulverulent flues gasificationSyngasSlag

The invention discloses a staged-pressurization gasification reaction device for dry pulverized coal. A first burner chamber internally provided with a top-arranged process burner is arranged at the top part of the gasification reaction device; a layer of second burner chamber internally provided with a side-surface process burner is arranged on the side surface at the upper part of the gasification reaction device and along the peripheral direction; a slag hole is also arranged in the bottom of the gasification reaction device; multiple chilling gas inlets are arranged at the upper end part of a synthesis gas cooling chamber; and further, the synthesis gas cooling chamber is also provided with an inner cylinder membrane wall, an outer cylinder membrane wall and a screen wall. The invention further discloses a gasification method, which includes steps as follows: S1, gasified fuel, water vapor and oxygen are sprayed into the gasification reaction chamber for incomplete gasification reaction; S2, oxygen or oxygen rich gas and water vapor are injected into the side surface process burner so as to carry out complete gasification reaction and secondary gasification reaction; S3, gasified products enter the synthesis gas cooling chamber from the slag hole; and S4, synthesis gas is discharged from the synthesis gas cooling chamber, and ash residues are discharged into a bottom slag basin. According to the invention, the service life of the furnace liner is prolonged, and the practical operation flexibility is enhanced.

Owner:SHANGHAI BOILER WORKS

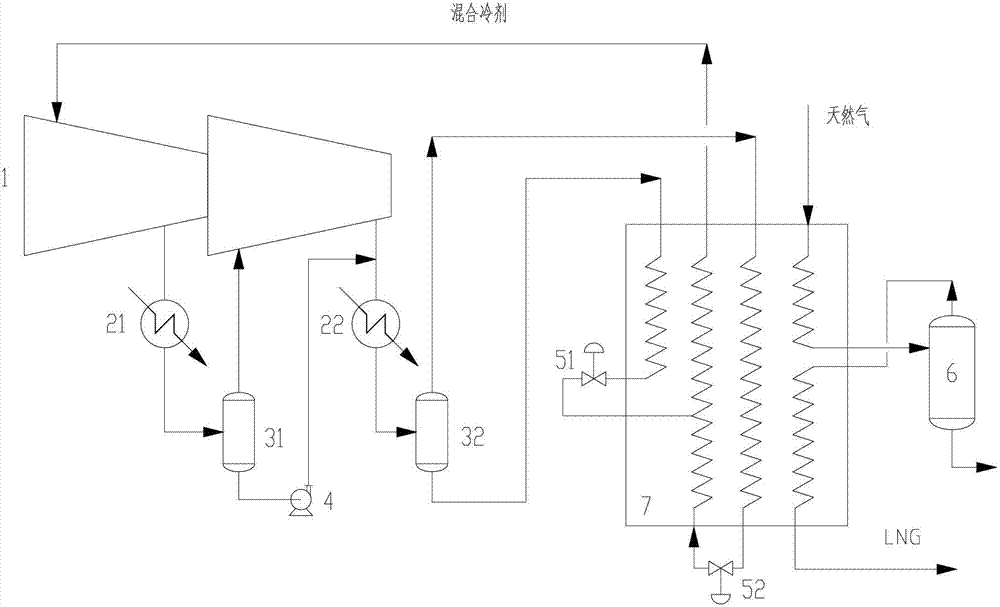

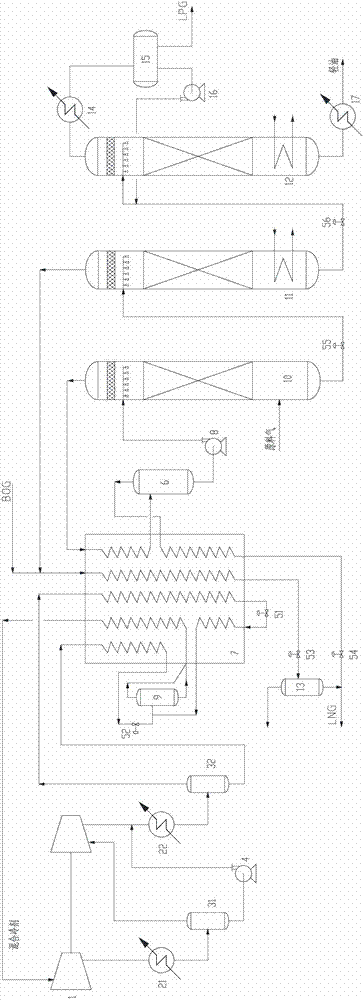

Method and device for carrying out liquefaction and heavy hydrocarbon treatment on natural gas

ActiveCN103031169AEconomical and reliableReasonable designSolidificationLiquefactionGas phaseLarge range

The invention relates to a process for carrying out liquefaction and heavy hydrocarbon treatment on natural gas, which comprises a low temperature liquefaction process and a heavy hydrocarbon treatment process. The low temperature liquefaction process comprises the following step that mixed refrigerant provides refrigerating capacity for the natural gas which is subjected to partial heavy hydrocarbon removal in the heavy hydrocarbon treatment process so as to implement cooling, complete heavy hydrocarbon removal and liquefaction on the natural gas in a cold box to obtain LNG (Liquefied Natural Gas); the heavy hydrocarbon treatment process comprises the following steps that the natural gas rich in heavy hydrocarbon is subjected to partial heavy hydrocarbon in a heavy hydrocarbon washing tower and the removed heavy hydrocarbon sequentially enters a deethanizing column and a rectifying column to be subjected to removal of light components and be separated into LPG (Liquefied Petroleum Gas) and light oil. According to the process disclosed by the invention, by-products, i.e. the LPG and the light oil, are also produced when the LNG is produced, the process route is advanced and the process is economical and reliable; the process can be suitable for the condition that raw material gas comprises aromatic hydrocarbon such as benzene and the like, the aromatic hydrocarbon such as the benzene and the like are removed along with the heavy hydrocarbon component and the cold box is prevented from being frozen and blocked; the process has large operation elasticity and can be suitable for natural gas heavy hydrocarbon content in a large range; the mixed refrigerant is adopted to circulate the flow and provide refrigerating capacity and gas-phase and liquid-phase refrigerants respectively enter the cold box to carry out heat exchange, so that heat exchange curves of cold and hot fluids are further matched; and the adopted refrigerating flow can effectively avoid liquid accumulation at the bottom of the cold box.

Owner:XINDI ENERGY ENG TECH

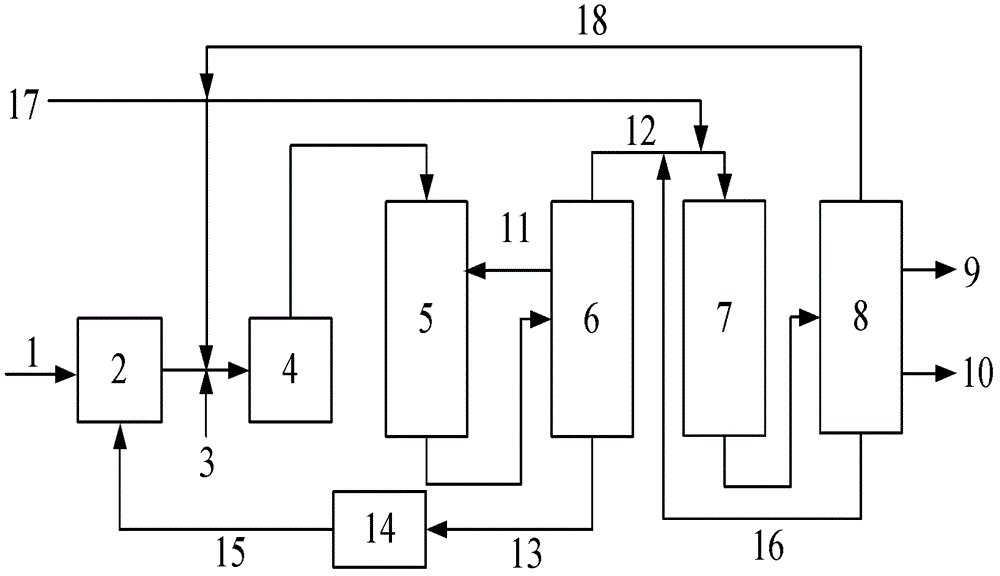

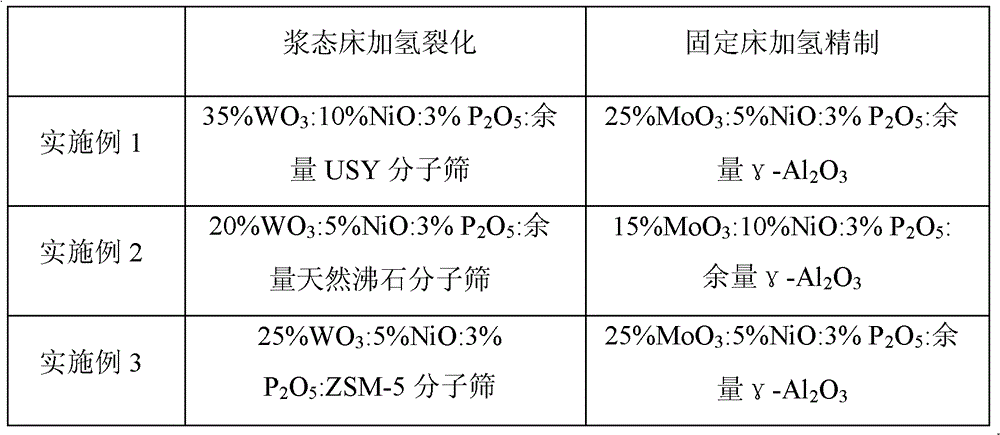

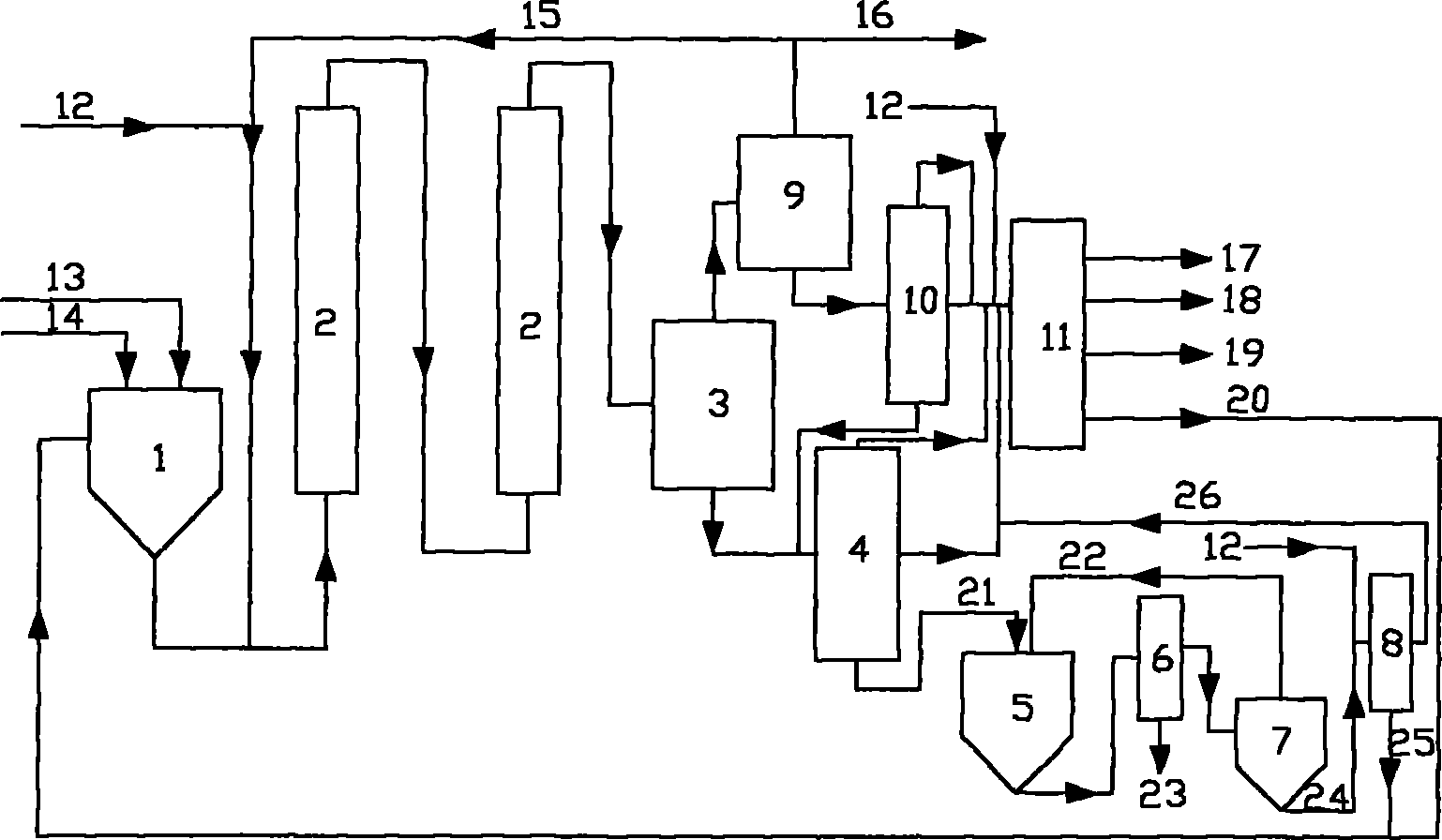

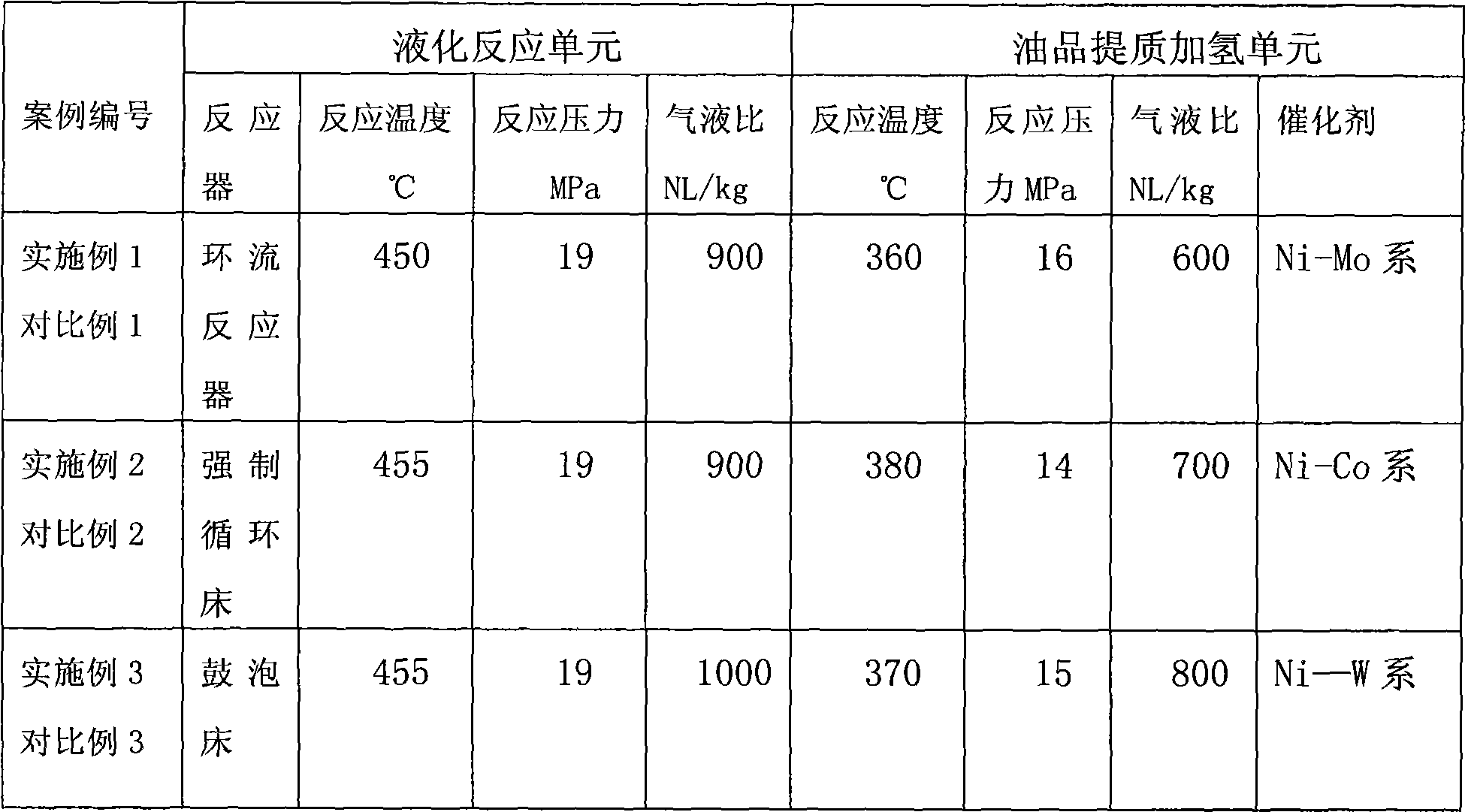

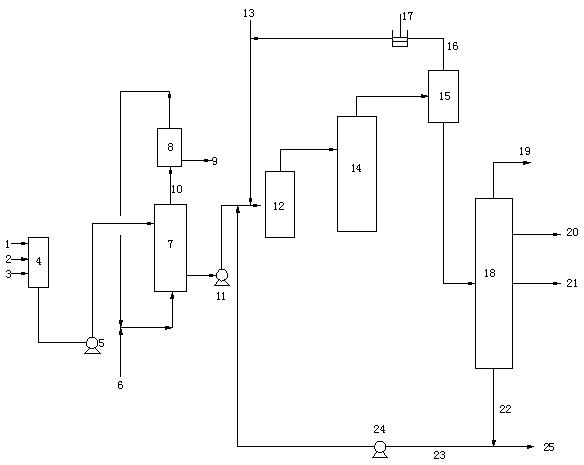

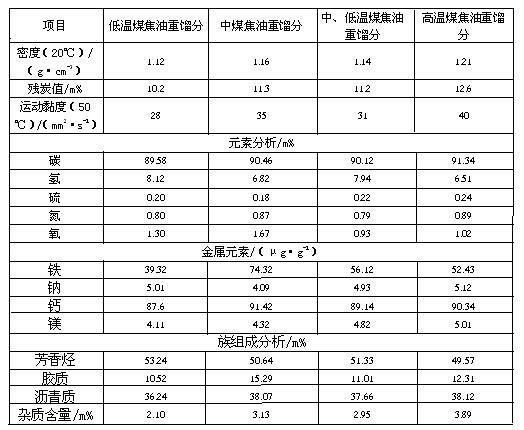

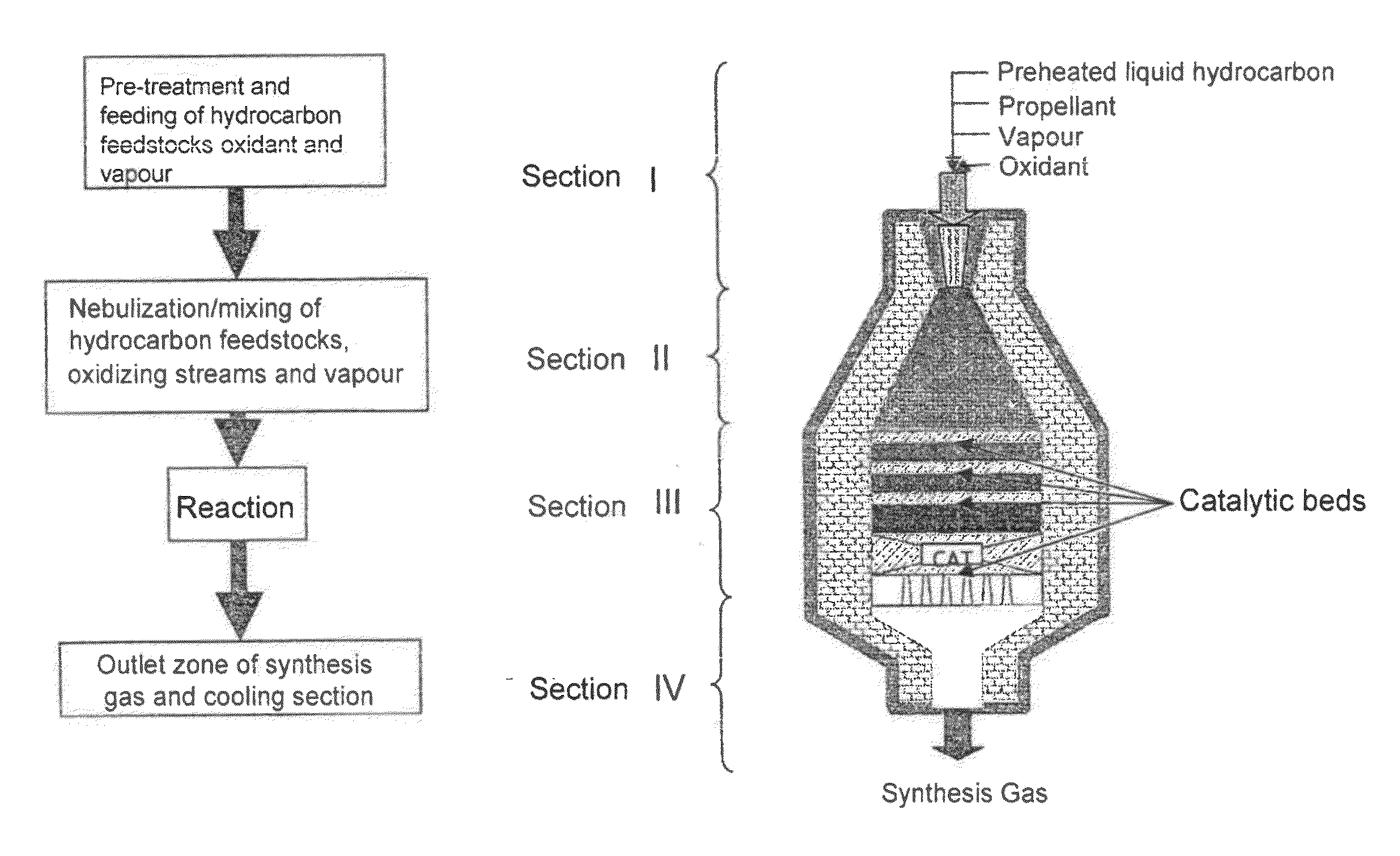

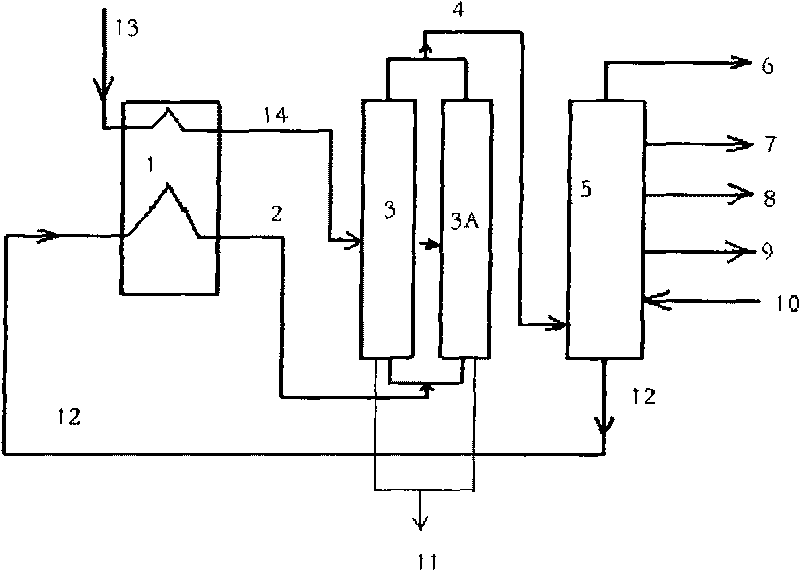

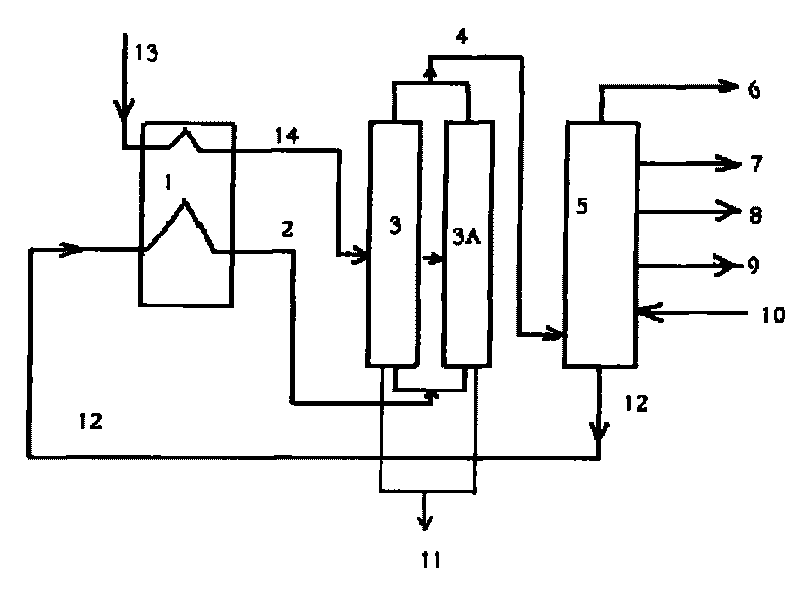

Coal tar full-fraction hydrogenation method for coupling slurry bed and static bed

The invention relates to a coal tar full-fraction hydrogenation method for coupling a slurry bed and a static bed. The coal tar full-fraction hydrogenation method mainly comprises a coal tar material pretreatment unit, a slurry bed hydrocracking unit, a primary hydrogenation product fractionation unit, a static bed hydrorefining unit, and a product distilling unit, wherein the coal tar full-fraction oil is subjected to pretreatment such as dewatering and dedusting, and enters a slurry bed reactor to carry out hydrocracking reaction after being mixed and pre-heated together with a hydrocracking catalyst; the reacted primary hydrogenation product enters the static bed hydrorefining unit through a light component obtained by fractionation; the middle fraction and the catalyst return to a slurry bed hydrogenation reactor in a circulating manner; a light component returns to a tar pretreatment unit to hydrogenate in circulation after removing a part of catalyst and coke generated in a cracking manner, and the light component is rectified to obtain naphtha and diesel oil product after common hydrorefining. The method is coal tar full-fraction hydrogenation; the utilization rate of the coal tar is improved to the maximal extent; and the coking of the heavy component of the coal tar and inactivation of the catalyst are effectively delayed by the process for coupling the slurry bed and the static bed, and the production cycle is also prolonged.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Heat-pipe low-temperature multi-effect sea water desalinating system and process flow

ActiveCN102557168AIncrease profitAchieve fadeGeneral water supply conservationSeawater treatmentEngineeringVacuum pump

The invention discloses a heat-pipe low-temperature multi-effect sea water desalinating system which comprises a plurality of groups of heat-pipe multi-effect evaporators, a steam injector TVC (Thermal Vapor Compressor), a cooler, an air water release device, a steam-water separator, a water ring vacuum pump, a sea water pump, a fresh water pump, a turbine intermediate pressure cylinder and a turbine low pressure cylinder. The invention also discloses a process flow of the heat-pipe low-temperature multi-effect sea water desalinating system, comprising the steps of: extracting steam through the turbine intermediate pressure cylinder, ejecting circulation steam in the cooler and exhaust steam of the turbine low pressure cylinder through the steam injector TVC to ensure that the circulation steam and the exhaust steam of the turbine low pressure cylinder are changed into higher-quality steam to enter the heat-pipe evaporators, condensing and releasing heat of the steam at a heat absorption end through a heat pipe, transferring the heat to heating and atomized sea water at the other end; heating next-stage sea water through taking the heated and vaporized sea water as the heat source of the next multi-effect evaporator while cooling the heated and vaporized sea water to generate fresh water; heating the sea water which cools the last-stage steam entering the cooler and exhausting the generated non-condensable gas through the air water release device; pumping the non-condensable gas of the multi-effect evaporators through the water ring vacuum pump to ensure that the system runs in a negative-pressure state; and discharging concentrated water out of the system through a pipeline and pumping the fresh water to a fresh water tank through a permeated water pump.

Owner:国能朗新明环保科技有限公司

Treatment process of high-ammonia and low-sulfur gas

InactiveCN102381686ASolve processing problemsRaise the burning ammonia temperatureSulfur preparation/purificationThermodynamicsProcess engineering

The invention relates to the technical field of sulfur recovery and in particular relate to a treatment process of high-ammonia and low-sulfur gas, and the method is used for solving the technical problem of unsmooth Claus reaction resulting from low enthalpy value of the high-ammonia and low-sulfur gas. The treatment process comprises the following steps: (1) introducing fuel gas, acid gas, oxygen and air into the front part of a combustion furnace for combustion so as to generate high-temperature process gas; and (2) introducing acid gas containing no ammonia from the middle part of the combustion furnace so as to react with the high-temperature process gas generated in the step (1). By adopting the treatment process, the treatment amount of the whole device can be changed flexibly so that the device can stably run within a great load range, thus being of great social significance for reduction of environmental pollution.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD

Method for directly liquefying coals with function of maximizing utilization of liquefied residues

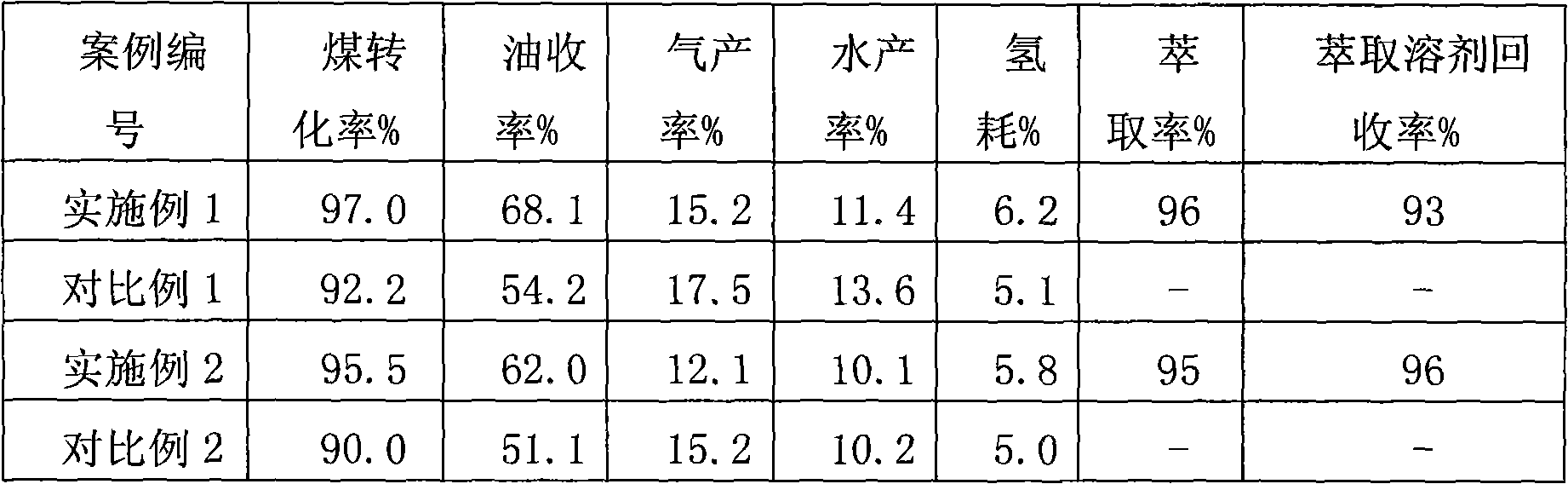

ActiveCN102010741AGreat operating flexibilityHigh air hold-upLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesEconomic benefitsOil separation

The invention relates to a method for directly liquefying coals with a function of maximizing utilization of liquefied residues. The method comprises the following technical steps: preparing coal paste; carrying out hydrotreating and liquefaction on the coal paste; carrying out oil separation treatment on the obtained oil product; carrying out upgrading and hydrotreating on the obtained product; carrying out hot extraction on the residues and then carrying out solid-liquid separation on the residues; and recovering the solvent; and carrying out hydrotreating treatment on the mixture of heavy oils and asphalt materials so as to obtain the final product, then taking the heavy oils as recycled solvent to prepare the coal paste, and the like. The method provided by the invention has the advantages that because of organically combining the liquefaction process and the residue extraction, the utilization of liquefied residues is maximized, the conversion rate of coal is improved, the yieldsof light and middle oils subjected to coal liquefaction are improved by 10 to 60 percent, and the quality of oil is improved, thereby greatly enhancing the economic benefits of direct coal liquefaction plants and improving environment protection; and the method provided by the invention has important economic and social significances, and can widely be applied to the field of coal direct liquefaction.

Owner:CHINA COAL RES INST

Liquid oxygen and liquid nitrogen preparation device and method

InactiveCN104061757AIncrease subcoolingReduce gasification lossSolidificationLiquefactionAir filterEngineering

The invention relates to a liquid oxygen and liquid nitrogen preparation device and method. The device comprises a self-cleaning air filter, an air compressor, a cold air unit, a separator, a molecular sieve adsorber, a main heat exchanger, a lower tower, an upper tower, a subcooler and an expander. The raw material of the device is air. The air passes through the self-cleaning air filter, the air compressor, the supercharging end of the expander, the cold air unit and the molecular sieve adsorber in sequence and then enters a cold box; after passing through the main heat exchanger, a part of the air is pumped out of the lower middle portion of the main heat exchanger and enters the expanding end of the turbo expander for adiabatic expansion; expanded air is reheated by the main heat exchanger and then sent out of the cold box; the remaining air is cooled to a liquefaction point, goes out of the main heat exchanger and enters the lower tower for rectification. A liquid oxygen product is pumped out of the bottom of the lower tower and then conveyed to a liquid oxygen storage tank; a liquid nitrogen product is pumped out of the main cold liquid nitrogen side and then conveyed to a liquid nitrogen storage tank. According to the liquid oxygen and liquid nitrogen preparation device and method, operation is simple in the technological process, the extraction rate is high, energy consumption is low, and meanwhile equipment investment cost is low.

Owner:KAIFENG AIR SEPARATION GROUP

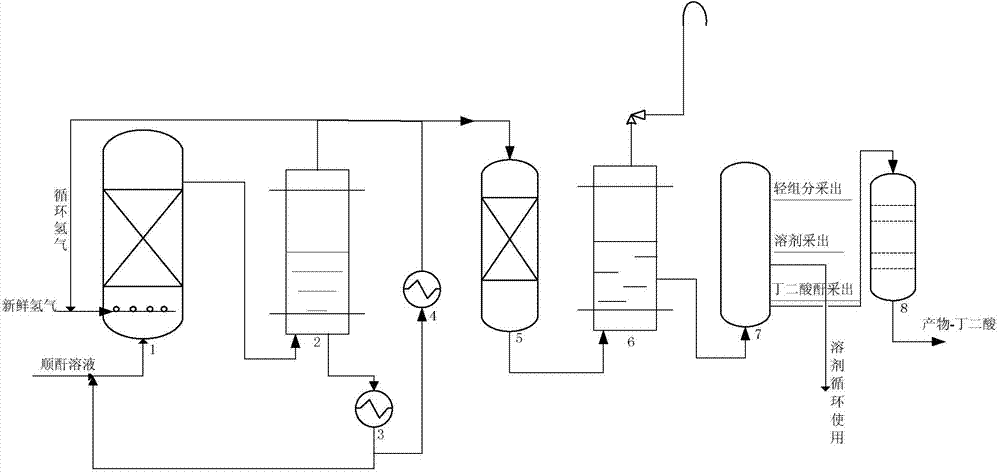

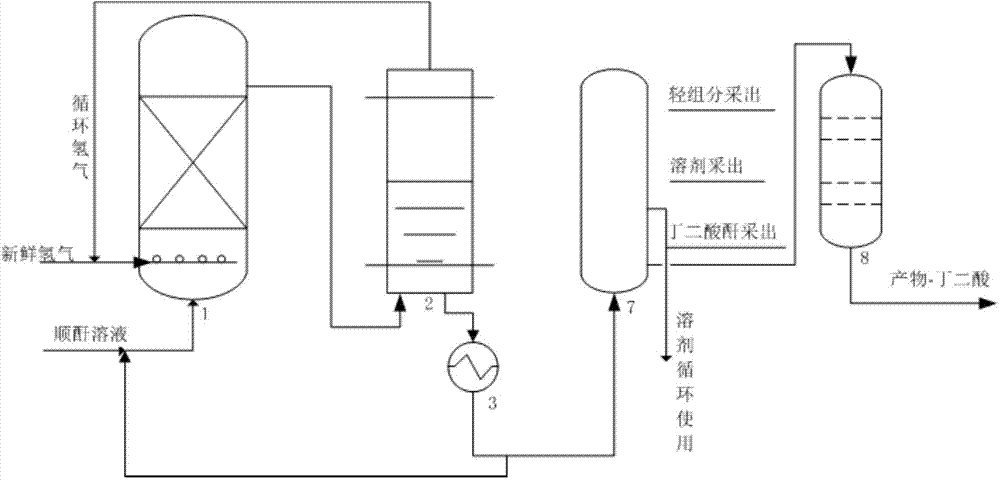

Technological process for continuously producing succinic anhydride and co-producing succinic acid through maleic anhydride hydrogenation

ActiveCN103570650AControl the average operating temperatureUniform reaction temperaturePreparation from carboxylic acid anhydridesFixed bedReaction temperature

The invention discloses a technological process for continuously producing succinic anhydride and co-producing succinic acid through maleic anhydride catalytic hydrogenation. The whole process comprises three steps, namely, reaction, rectification and hydrolysis, wherein two stages of hydrogenation reactors are used for reaction, a primary hydrogenation reactor is a fixed bed reactor with hydrogen entering from the lower part and reaction liquid exiting from the upper part, and a secondary hydrogenation reactor is a trickle bed reactor with hydrogen and reaction liquid entering from the upper part and exiting from the lower part. The technological process adopts an external circulating heat radiation manner, and reaction heat is uniformly removed, so that the average operation temperature of the whole reactor is effectively controlled, and the reaction temperature in the whole main reactor is balanced. Furthermore, the primary hydrogenation reactor adopts the manner that both the maleic anhydride solution and hydrogen flow upward simultaneously, so that the reaction temperature of the whole reactor is controlled to be balanced, local hot spot temperature is effectively controlled and lowered, and the reactants are prevented from polymerizing and depositing carbon or coking.

Owner:SHANXI UNIV

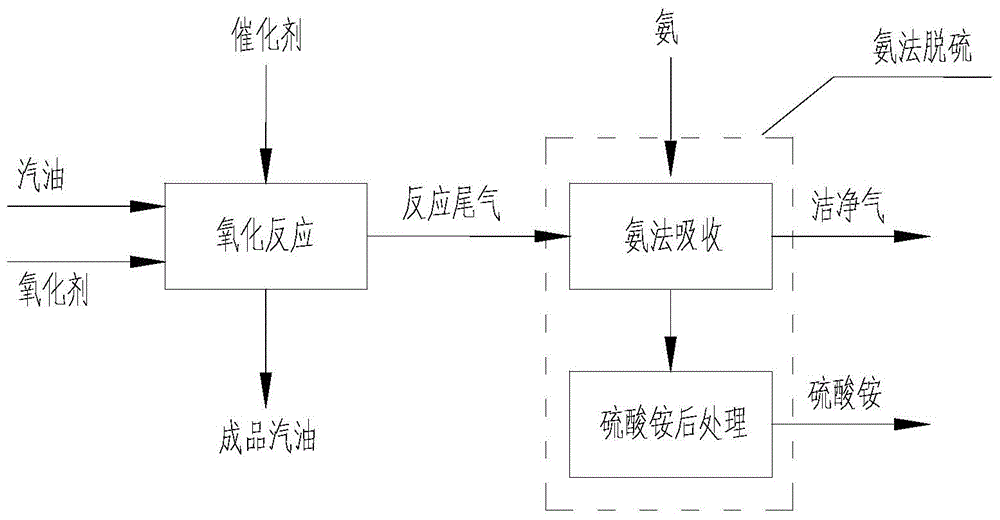

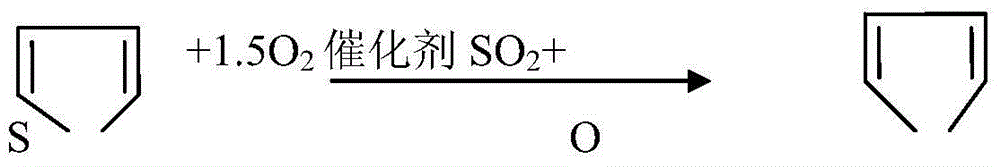

Gasoline-oxidation ammonia-process desulfurization method

InactiveCN104946296ARealize recycling of resourcesImprove desulfurization efficiencyRefining with oxygen compoundsDispersed particle separationGasolineComponents of crude oil

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

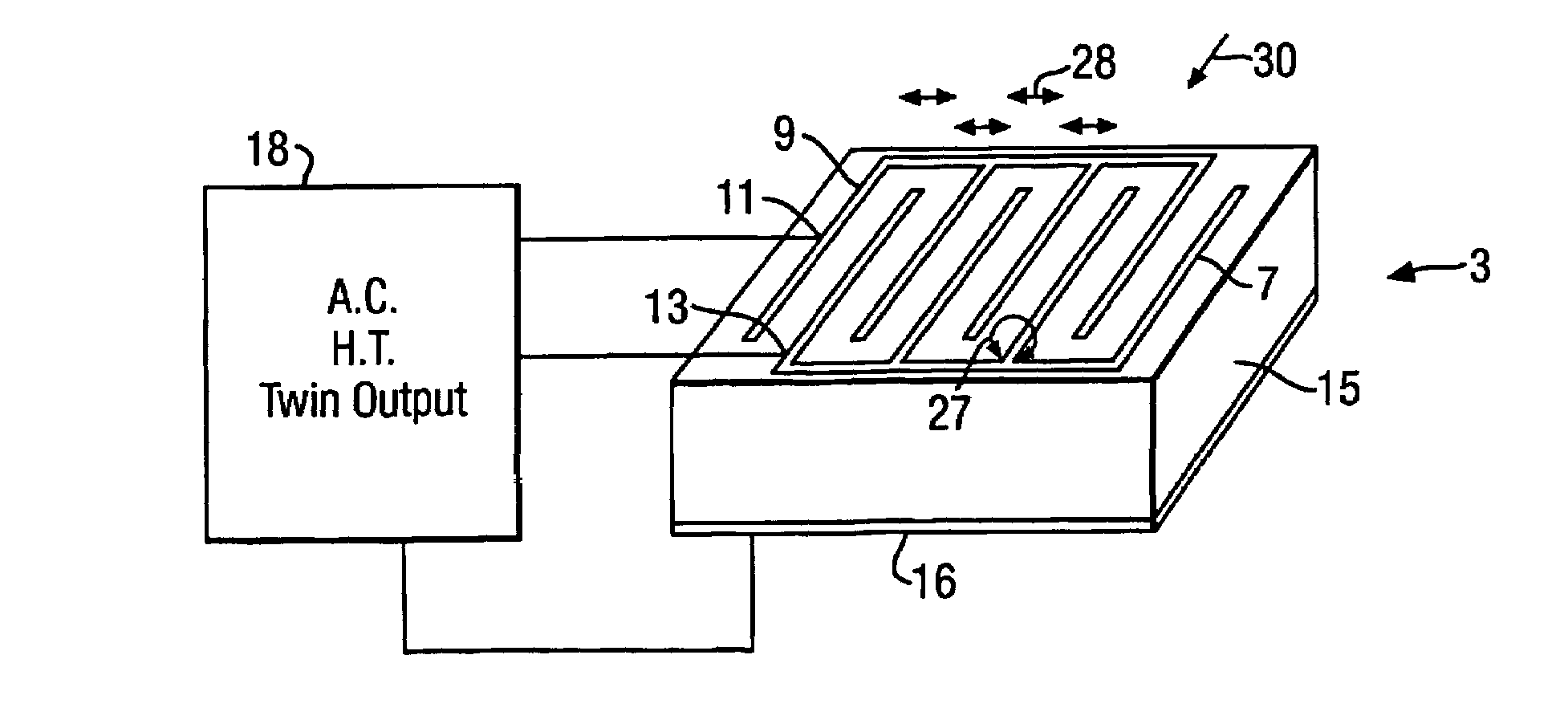

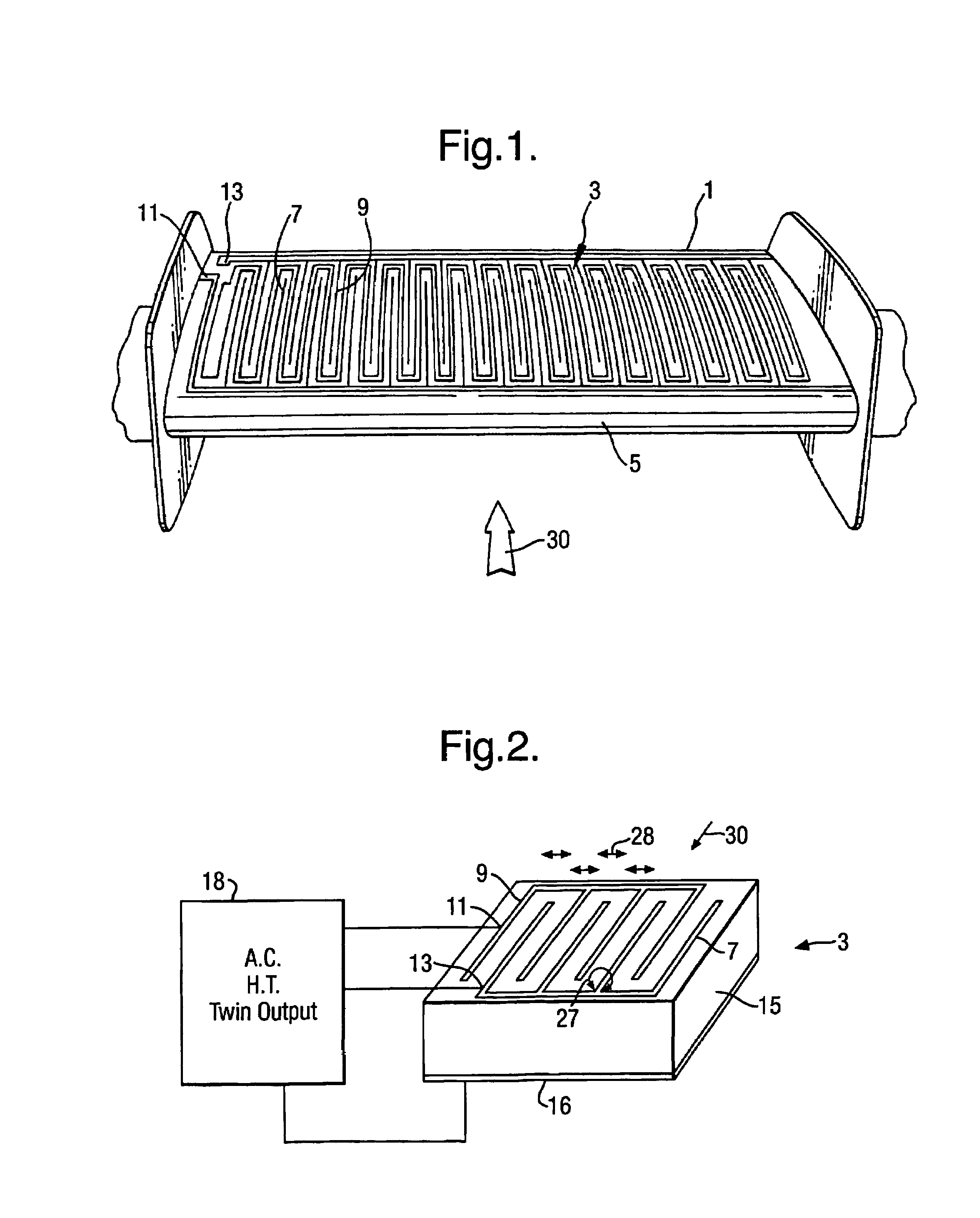

Turbulent flow drag reduction

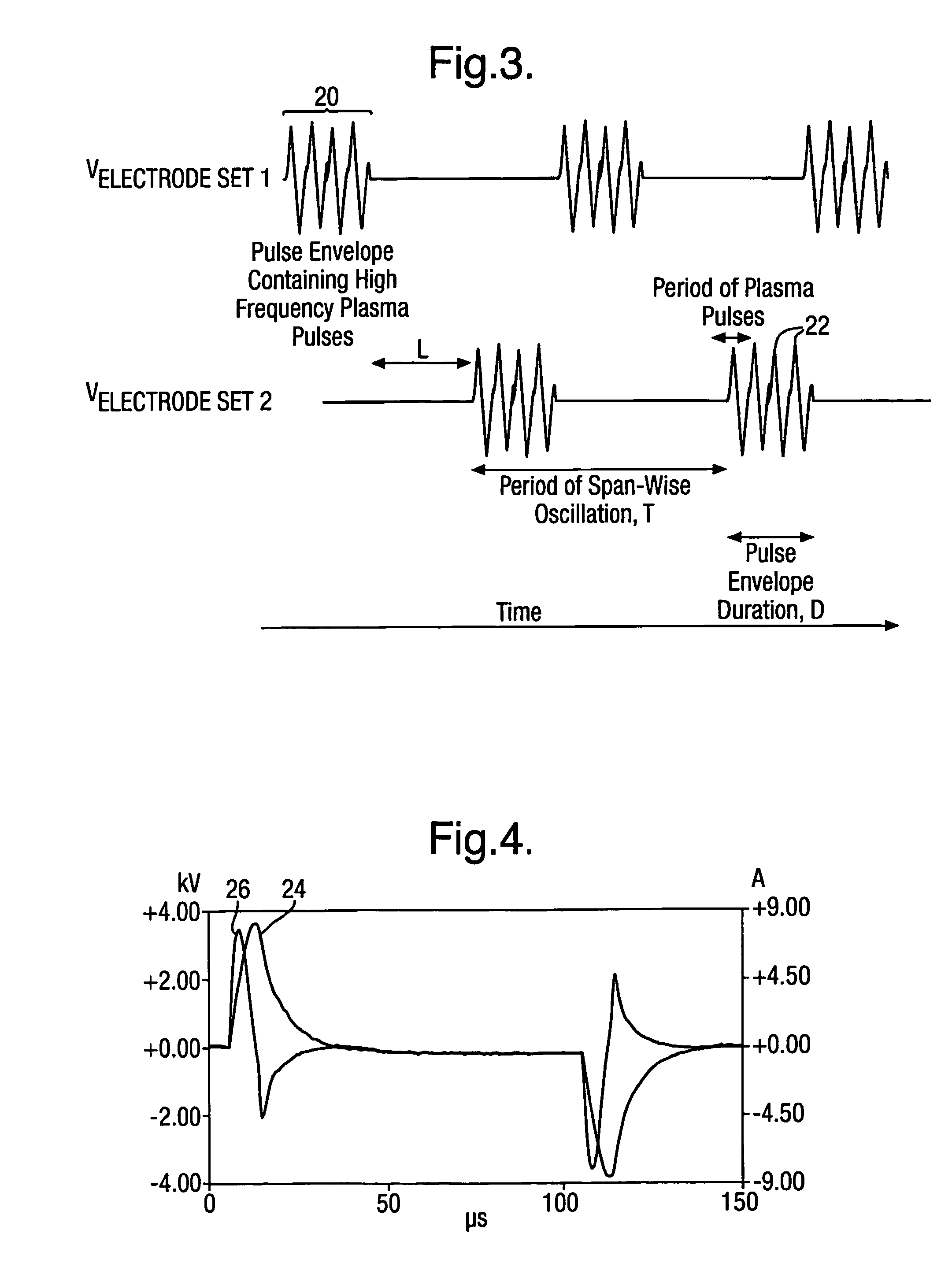

InactiveUS7017863B2Reduce resistanceObject's drag can be reducedBoundary layer controlsWingsPlasma generatorEngineering

The present invention relates to apparatus for influencing fluid flow over a surface, and more particularly, but not exclusively, to turbulent boundary layer flow drag reduction for an aircraft. The present invention provides such apparatus including a plasma generator comprising first and second spaced-apart independently controllable electrodes operable to cause a change in direction of the flow of the fluid over the surface.

Owner:AIRBUS OPERATIONS LTD

Coal tar heavy fraction suspension-bed hydrocracking method and system thereof

InactiveCN101962571AHigh yieldSimple structureTreatment with hydrotreatment processesHydrogenGasoline

The invention belongs to the technical field of coal chemical industry, and provides a coal tar heavy fraction suspension-bed hydrocracking method. The method comprises the following steps: mixing raw materials of coal tar heavy fractions with a catalyst and a vulcanizing agent to form a uniform mixed material; vulcanizing the catalyst in the mixed material under the action of hydrogen; preheating the vulcanized mixed material, and then allowing the preheated material to enter a suspension-bed reactor for hydrocracking reaction; and fractionating the product from the suspension-bed reactor to finally obtain gaseous hydrocarbon, gasoline fractions, diesel fractions and tail oil. In the invention, by directly adopting the hydrocracking method with a coal tar heavy fraction suspension bed and a system thereof, the coal tar heavy fractions can keep light weight, and the yield of the fuel oil product hydrogenated by coal tar can be effectively increased; and the suspension-bed hydrogenation reactor has simple structure without a bed layer, thus causing no phenomena such as blockage, increased pressure drop, overtemperature and the like occurred on the reaction bed layer, and the reactor further has the characteristics of great operation flexibility, long operation cycle, being safe and stable, easy control and the like.

Owner:DALIAN UNIV OF TECH

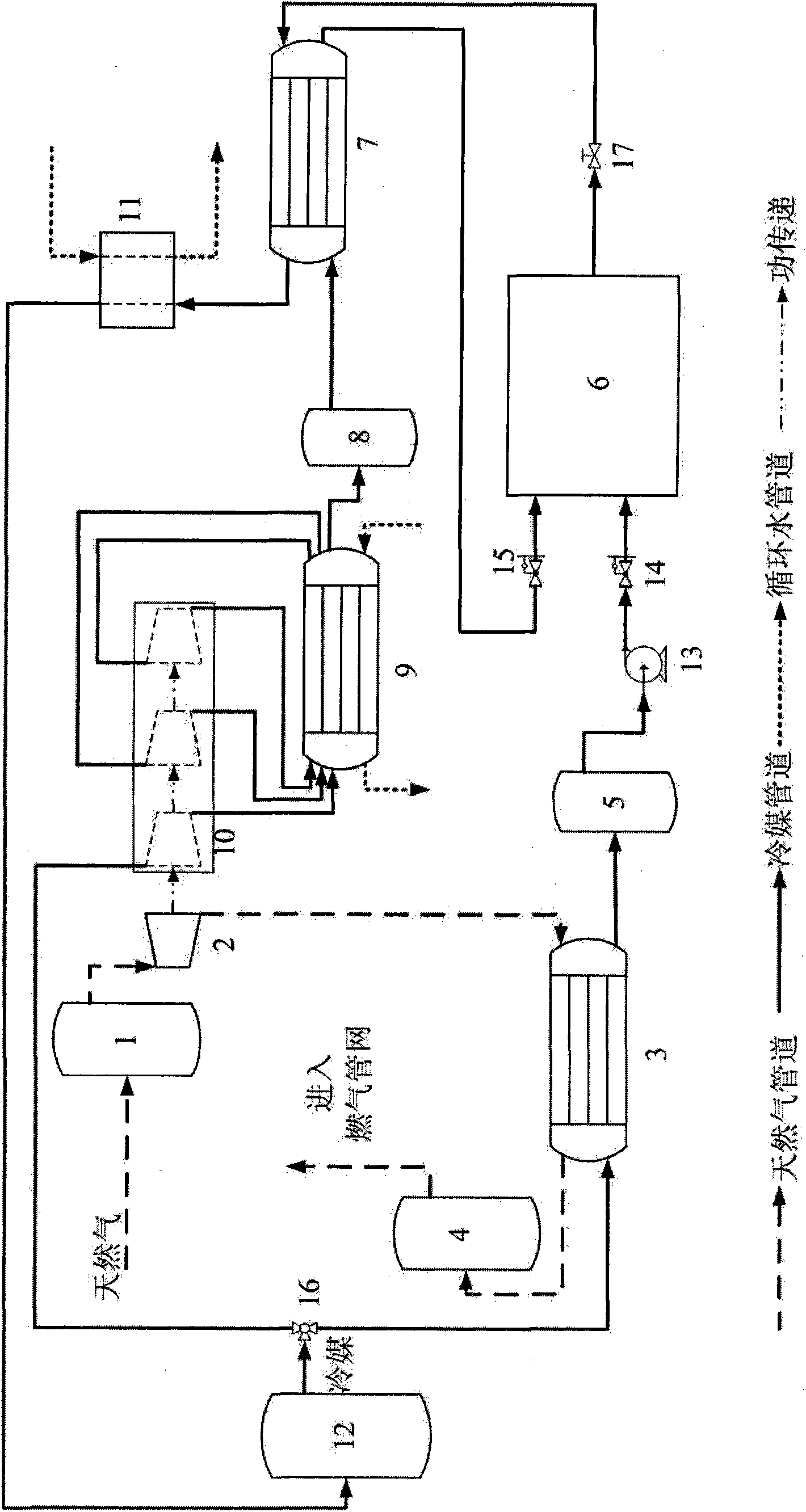

Method and device for efficient utilization of pressure energy of natural gas pipeline network

InactiveCN101852529AGreat operating flexibilityReduce power consumptionRefrigeration devicesAir conditioning systemsRefrigerantEngineering

The invention discloses a method and a device for efficient utilization of pressure energy of a natural gas pipeline network. The method of the invention comprises natural gas pressure energy refrigeration and cold energy utilization. The method comprises the following steps of: exchanging heat between a normal-temperature liquid refrigerant from a third refrigerant storage tank and a low-temperature gaseous refrigerant from a refrigeration storage, reducing the temperature to between 17 and 22 DEG C, reducing the pressure to 0.1MPa through a pressure regulating valve, and delivering the liquid refrigerant into the refrigeration storage at the temperature of 32 DEG C below zero; meanwhile, reducing the pressure of a refrigerant of a second refrigerant storage tank to 0.1MPa through the pressure regulating valve, and delivering the refrigerant into the refrigeration storage at the temperature of 32 DEG C below zero; raising the temperature of the low-temperature gaseous refrigerant after exchanging the heat with the normal-temperature liquid refrigerant to 0 DEG C, then exchanging heat between the low-temperature gaseous refrigerant and circulating water to reduce the temperature of the circulating water and raise the temperature of the low-temperature gaseous refrigerant to between 10 and 15 DEG C, and returning the low-temperature gaseous refrigerant to a first refrigerant storage tank for recycle and later use. The method and the device can remarkably improve the utilization rate of the pressure energy of the pipeline network, and have great economic benefit and broad development space.

Owner:SOUTH CHINA UNIV OF TECH

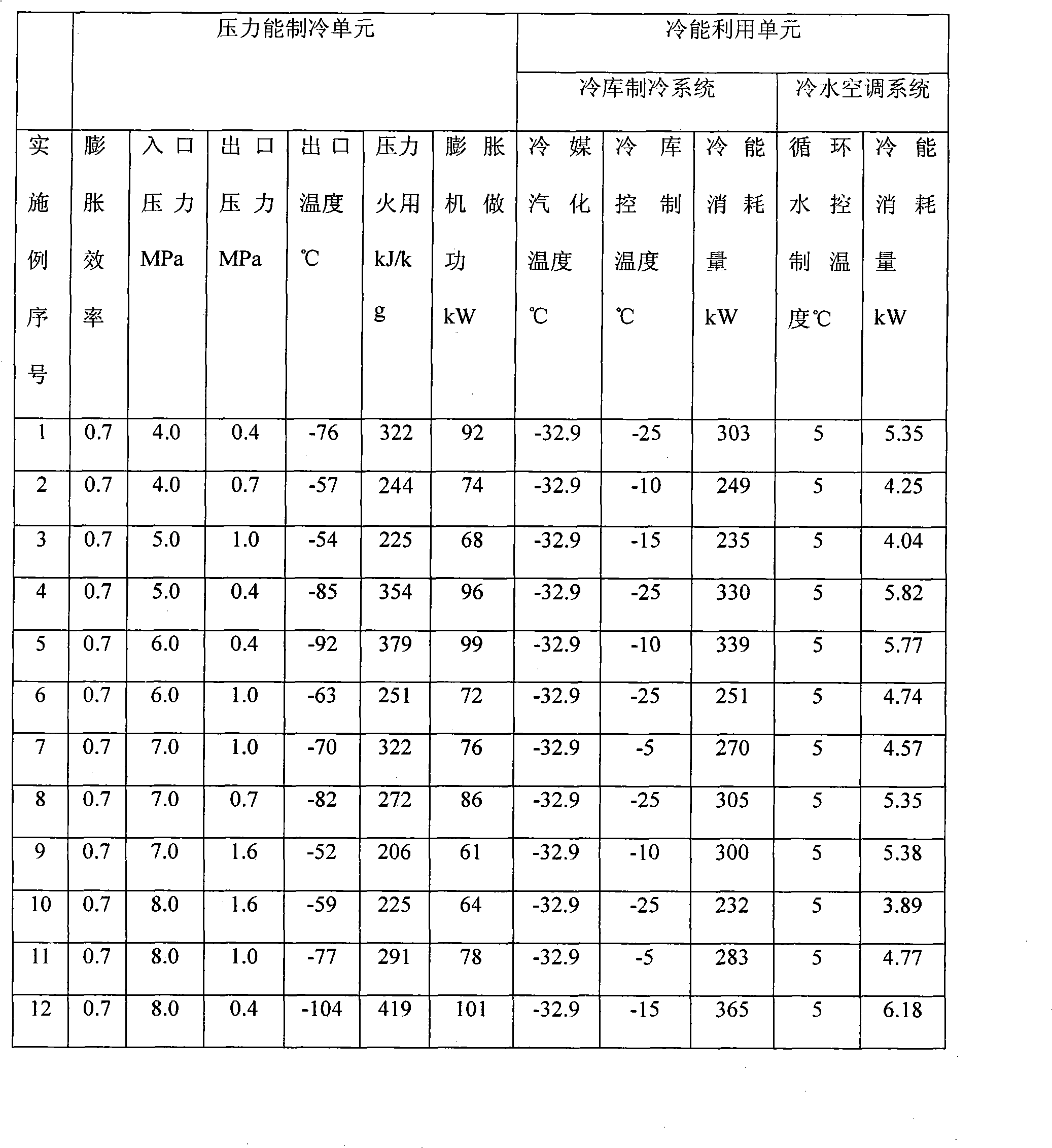

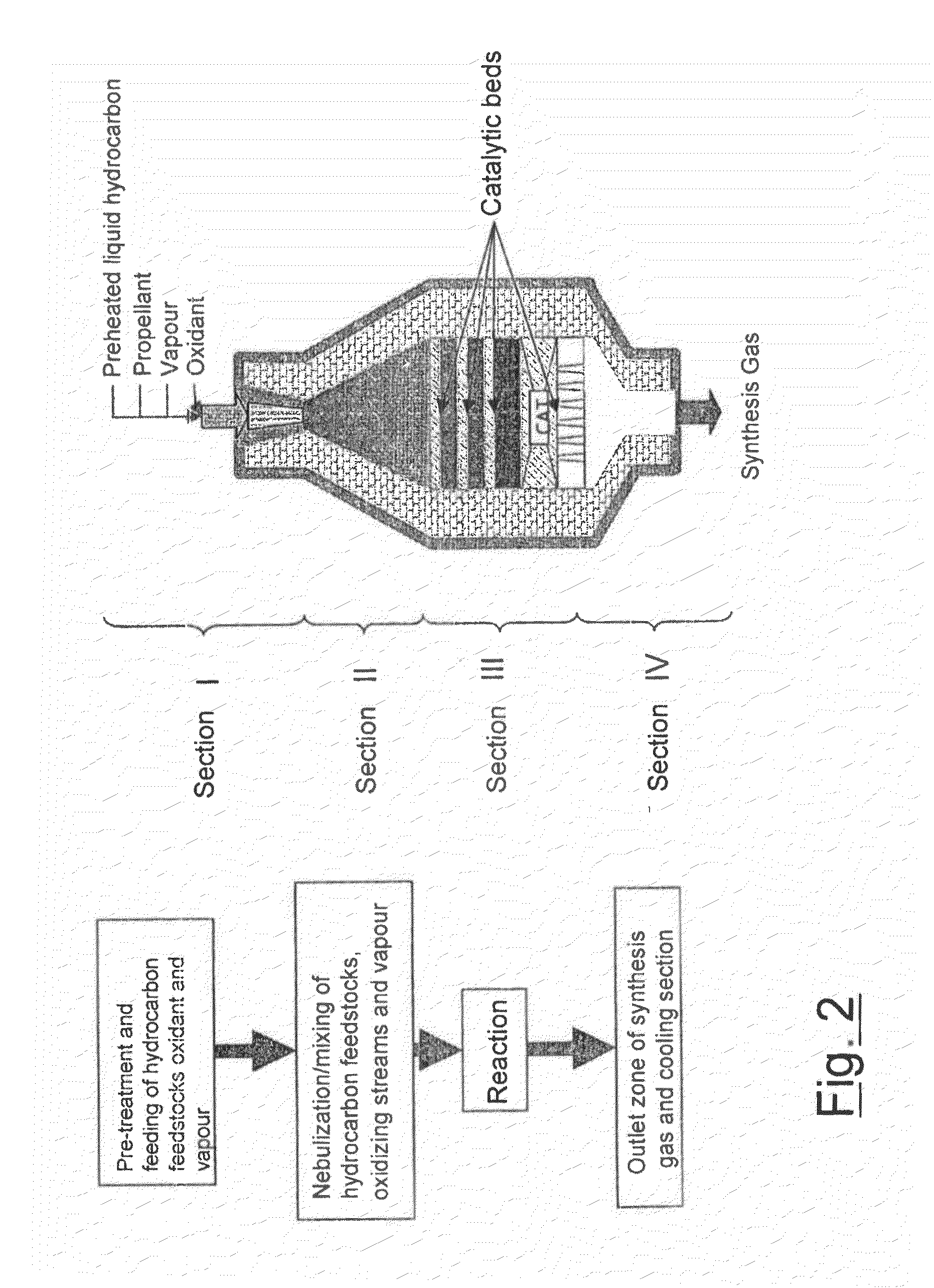

Process for the production of synthesis gas and hydrogen starting from liquid or gaseous hydrocarbons

An apparatus, containing: (I) an inlet section into which a liquid and optionally a gaseous reagent stream is fed, the inlet section containing a device, which nebulizes and / or vaporizes the liquid stream, the device optionally utilizing vapor and / or a gaseous hydrocarbon stream as propellant; (II) a mixing section containing a chamber having a cylindrical or truncated-conical geometry, which mixes the reagent stream exiting the inlet section (I), to form a reaction mixture; (III) a reaction section including i) a first structured catalytic bed a ii) a structured catalytic bed heating device, in which the reaction mixture exiting the mixing section (II) flows through each layer of the first structured catalytic bed with a contact time varying from 0.01 to 10 ms, to produce a mixture of reaction products; and IV) a cooling section of the mixture of reaction products leaving the reaction section (III).

Owner:ENI SPA

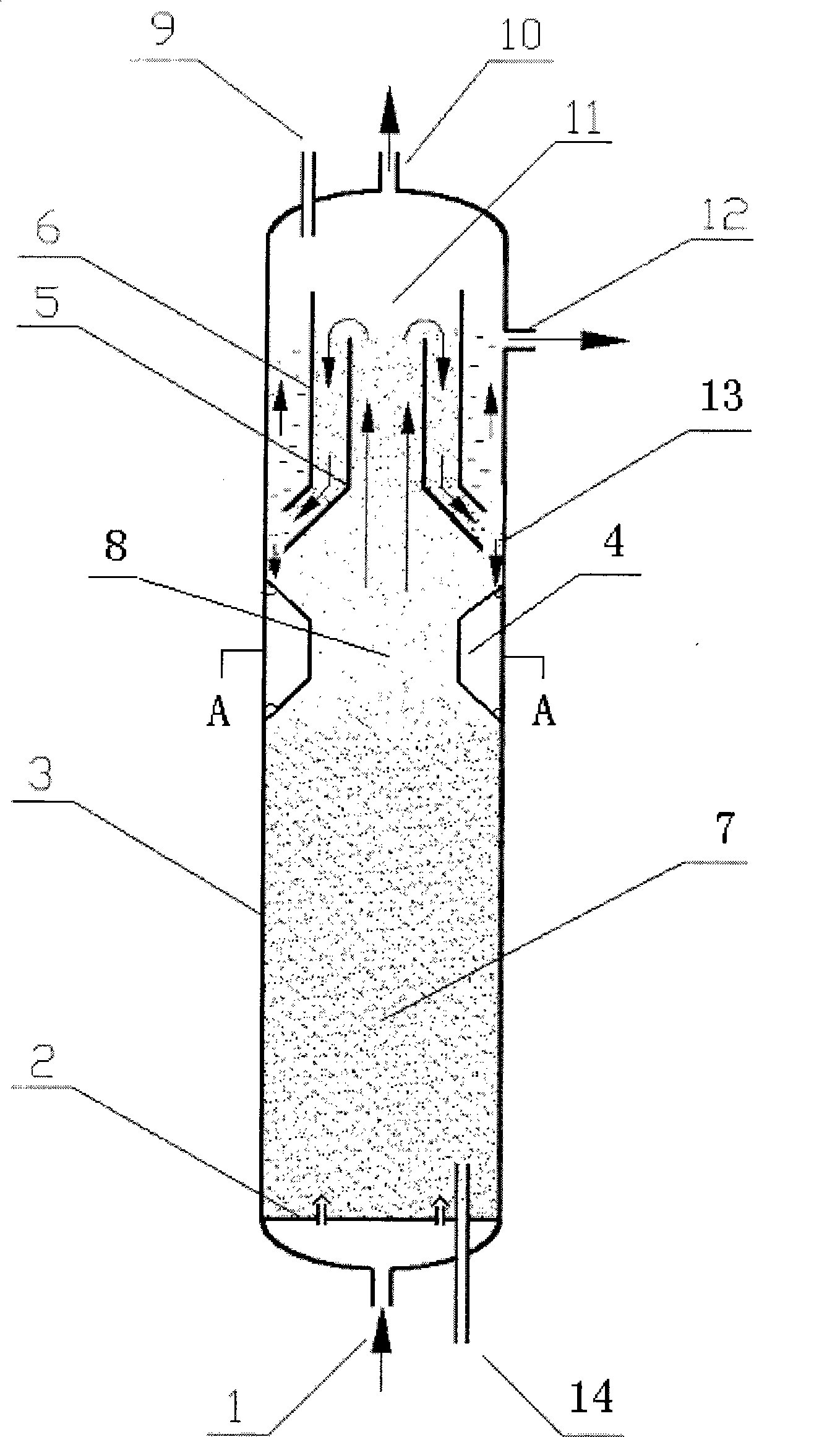

Fluidized bed reactor

ActiveCN101721960AGreat operating flexibilityEfficient separationChemical/physical processesChemical reactionFluidized bed

The invention discloses a fluidized bed reactor which comprises a reactor shell and a three-phase separator, the three-phase separator is arranged at the upper part inside the reactor shell and is of a sleeve structure comprising an inner sleeve and an outer sleeve, the upper ends and lower ends of the inner sleeve and the outer sleeve are both of opening structures, the inner sleeve and the outer sleeve are respectively composed of an upper section and a lower section, the upper sections of the inner sleeve and the outer sleeve are in reverse frustum structures, and the lower sections of the inner sleeve and the outer sleeve are in frustum structures. By designing a novel three-phase separating structure, the invention can further improve separating effect, reduce catalyst carrying-out amount, and enhance the operation elasticity of the three-phase separator. The reactor is mainly applicable to chemical reactions between liquid and gas substances of different types and solid particles under contact condition, and has the advantages of large catalyst inventory, high reactor use ratio, simple structure, easy operation and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing clean diesel by full liquid phase hydrogenation

ActiveCN102358847ALow costGreat operating flexibilityTreatment with hydrotreatment processesSolid phasesPoor quality

The invention relates to a method for producing clean diesel by full liquid phase hydrogenation. The method comprises the following steps that: raw materials, hydrogen and a circulating liquid hydrogenated product are subjected to hydrogen saturation in a pipeline to form a liquid-phase raw material / hydrogenated product / hydrogen mixture; under a hydrogenation process condition, the liquid-phase mixture with saturated dissolved hydrogen sectionally enters a multi-stage conventional hydrogenation reactor. According to the present invention, with the hydrogenation reactor, the hydrogenation reaction is catalyzing, the reaction by products such as H2S and NH3 are discharged out of the reaction system; the materials contacting the solid-phase catalyst are the liquid-phase reaction materials so as to improve the hydrogenation reaction efficiency; the method does not require the hydrogen circulating so as to substantially reduce the equipment investment and the operation cost; the method provided by the present invention can be used in hydrogenation, desulfurization, denitrogenation and dearomatization refinement for poor-quality diesel fuel fractions, and can be applicable for the technical process for producing high-quality clean diesel by using the fraction oil such as VGO raw material mild hydrocracking.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Oil gas absorptive reclaiming method and apparatus

InactiveCN1806894AHigh recovery rateGreat operating flexibilityDispersed particle separationDesorptionTower

The invention relates the method and unit of oil gas absorption and recovery. The course of oil gas recovery comprises three parts: absorbing tower absorbing and separating, desorption tank desorbing and thickening and recovery tower absorbing and recovering. The unit comprises air-tight loading crane tube, accumulating equipment, absorption tower, dissolvent pump, desorption horizontal tank, vacuum pump, recovery tower, rich petrol pump, and lean petrol pump. In desorption horizontal tank there are 2-4 baffles, and the grade of slope of baffles is 0.01-0.02. On the baffles there are some low-weir plates, on the top of the baffles there are guide boards, and in the middle of the baffles there are permeability cells. At the exit of desorption horizontal tank there is demisting filler, and the bottom of it there is exit of absorbing agent. That the oil gas is absorbed and recovered at normal temperature and normal pressure is intermittent operation to save the cost of equipment investment and operation. The invention possesses high recovery ratio, and big operating flexibility. The treatment medium is the oil gas discharged at the course of convention oil accumulating.

Owner:CHINA PETROLEUM & CHEM CORP +1

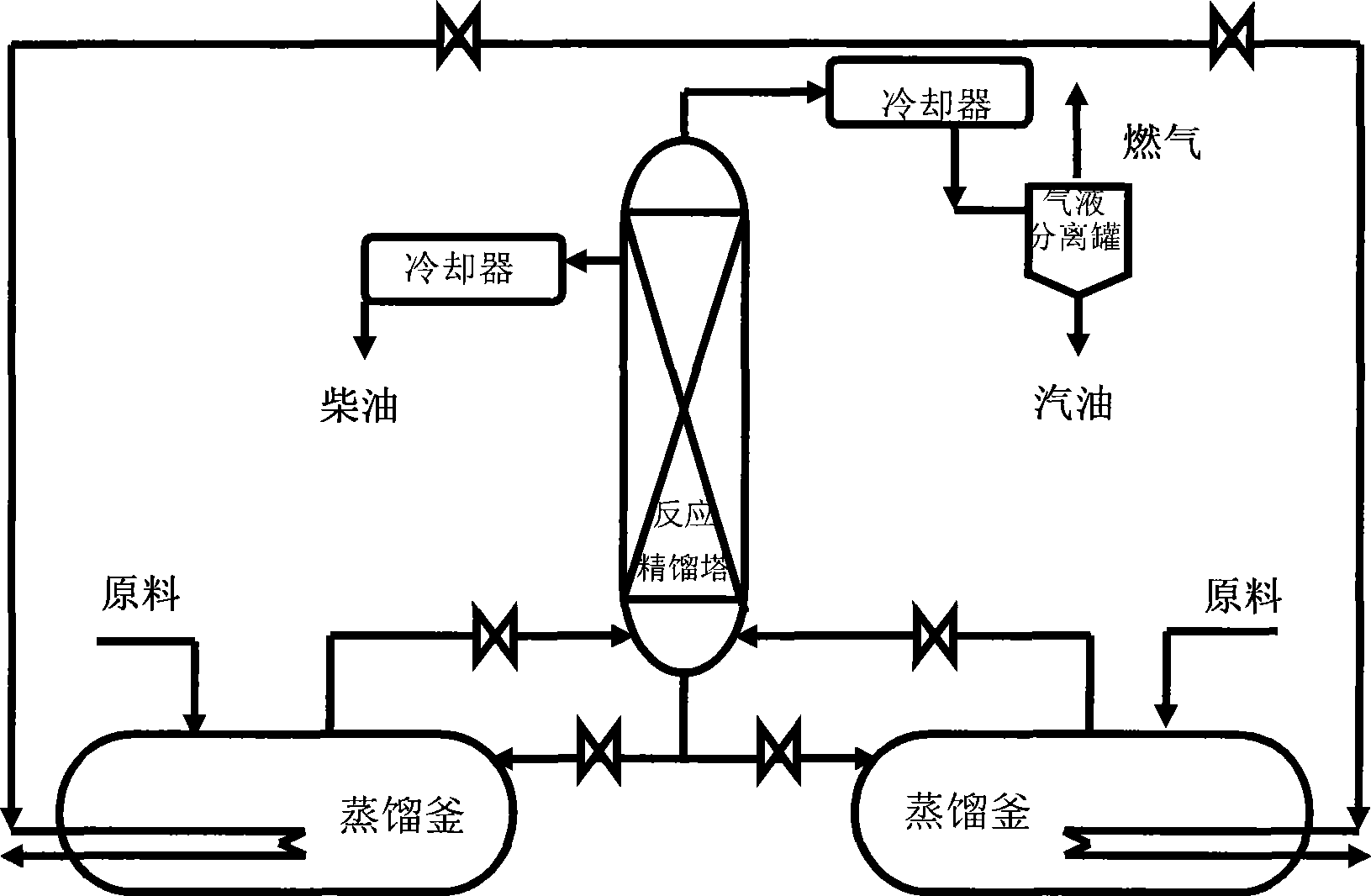

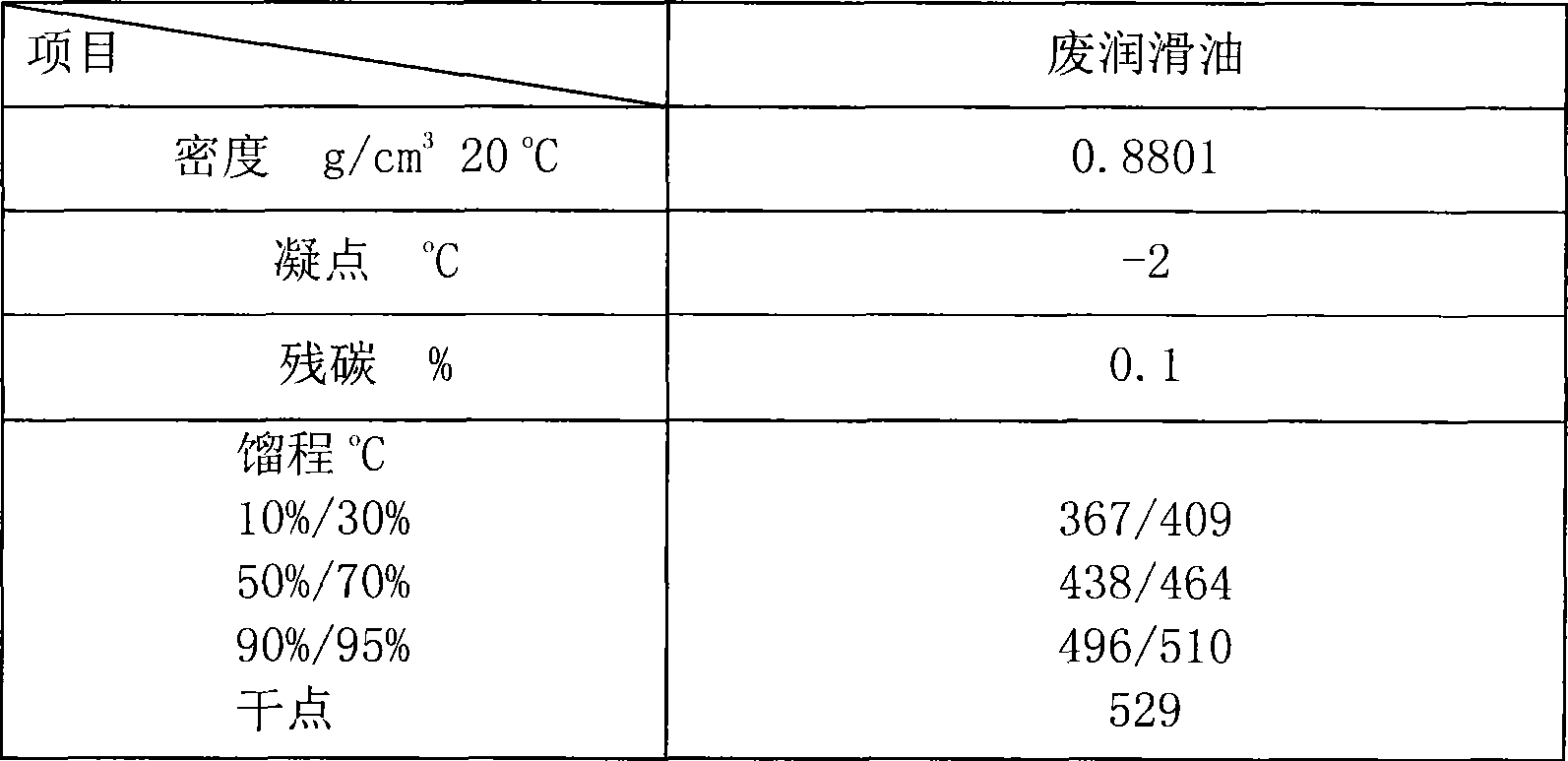

Method for producing petrol and diesel oil by recycling waste lubricant oil

ActiveCN101475870ASimple processLow costHydrocarbon distillationLubricant compositionDistilled oilGas phase

The invention relates to a method for producing gasoline and diesel fuel through resource utilization of waste lubricant oil, which belongs to the technical field of environmental protection and energy resources. The method comprises: integrally performing the vapor phase catalytic cracking process on molecular sieve / alumina catalyst of the waste lubricant oil and the fractionation and separation process of reaction products in a reaction fractionator; injecting crude waste oil into a distillation kettle, and adopting waste residue and fuel gas generated during conversion of the waste lubricant oil for heating, wherein the temperature of the distillation kettle is controlled to be between 250 and 500 DEG C; making distilled oil gas enter the reaction fractionator which is filled with the molecular sieve / alumina catalyst for reaction and rectification when the distillation kettle is heated to 250 DEG C, wherein the ratio of the catalyst to oil is controlled to be between 1 and 20; and cutting the oil into the gasoline and the diesel fuel according to the distilled temperature, wherein fuel gas generated by reaction and residual cinder can be used for heating the distillation kettle, and generated fuel gas can be used for heating the distillation kettle. The method has the advantages of wide range of raw materials, normal-pressure reaction and separation, simple technological flow, high conversion and selectivity of products, long service life of the catalyst, comprehensive utilization of the fuel gas and the cinder, no secondary pollution, large operating flexibility of a production apparatus, and small investment.

Owner:DALIAN UNIV OF TECH

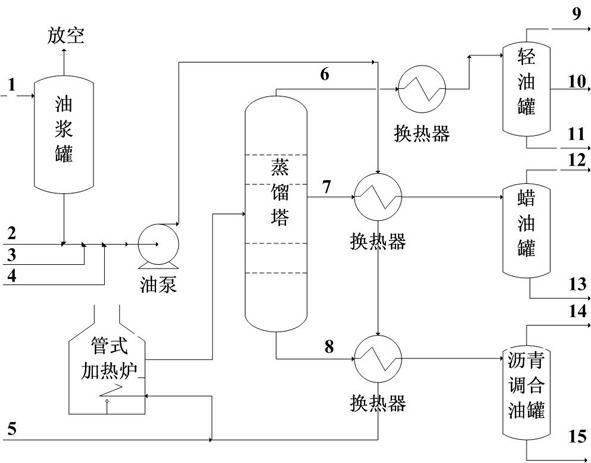

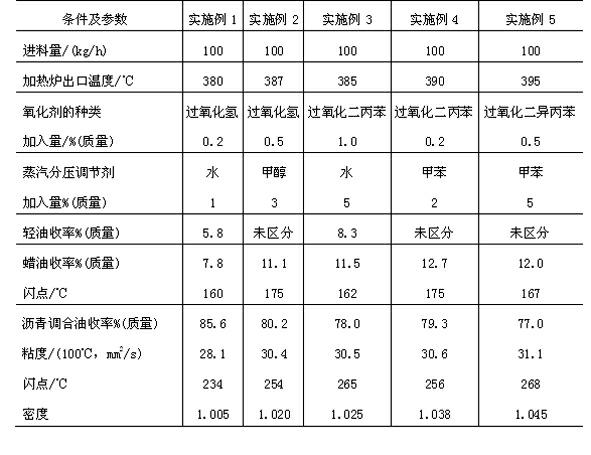

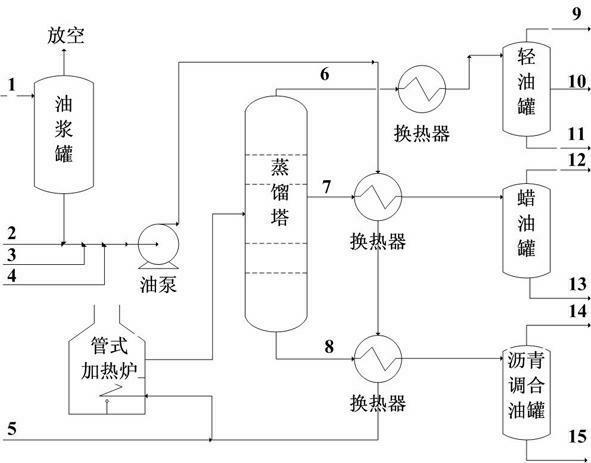

Method for producing asphalt blending oil by normal pressure distillation of catalytic slurry oil

InactiveCN102559250ALess investment in equipmentSimplify operating proceduresTreatment with plural serial refining stagesWaxBoiling point

Owner:甘黎明 +2

Production method of needle coke raw material

ActiveCN101724420AExpand sourceThe method flow is simpleCoking carbonaceous materialsDecompositionCoke rate

The invention discloses a method of needle coke raw material by using delay coking technique to treat FCC slurry oil and conventional coking raw material. The method comprises: introducing FCC slurry oil with low temperature into a delay coking tower from the upper part inside the tower, leading the introduced FCC slurry oil to be contacted with high temperature oil gas generated by the conventional coking raw material which is introduced into the tower from the bottom and treated by high temperature decomposition, and reacting under the condition of delay coking; and separating the generated oil gas in a coking fractionating tower, and obtaining the needle coke raw material. In the method, as the FCC slurry oil enters into the coking tower at the lower temperature, the decomposition temperature of the conventional coking raw material is lowered, the high temperature decomposition time of the raw material is shortened, the occurrence of secondary reaction is reduced, green coke rate is reduced, the stable operation cycle of a signal tower is prolonged, and light components which have high reaction activity and are not beneficial to producing the needle coke, heavy components with high polymerization activity, and a great deal of impurities such as catalyst powder, heavy metal and the like can be removed. The obtained needle coke has high yield and good properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

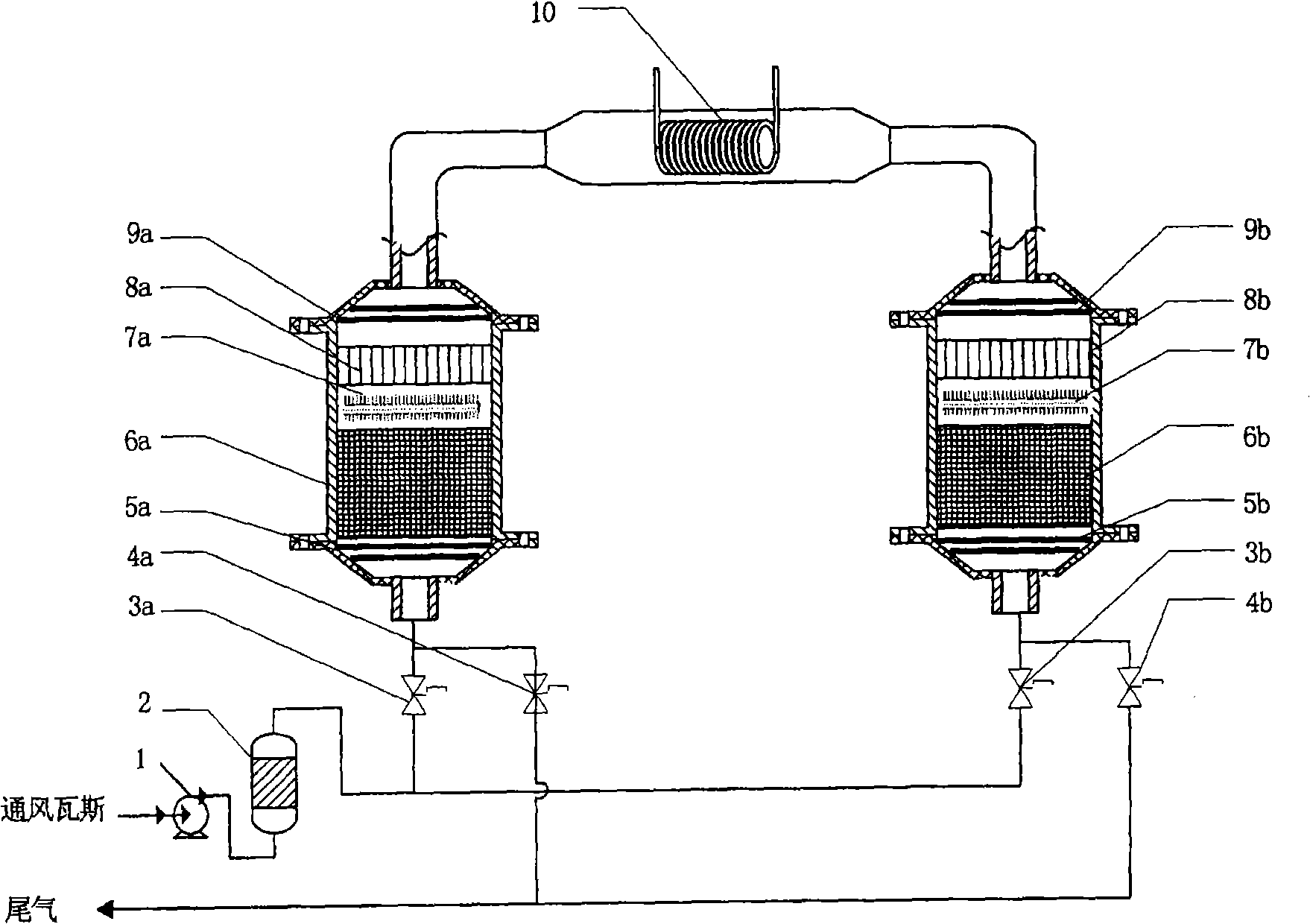

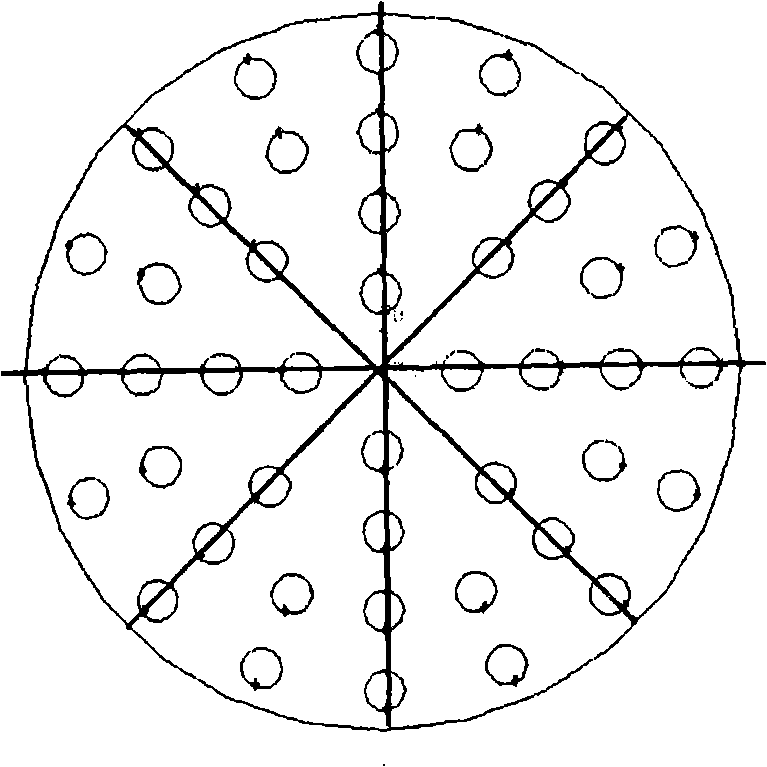

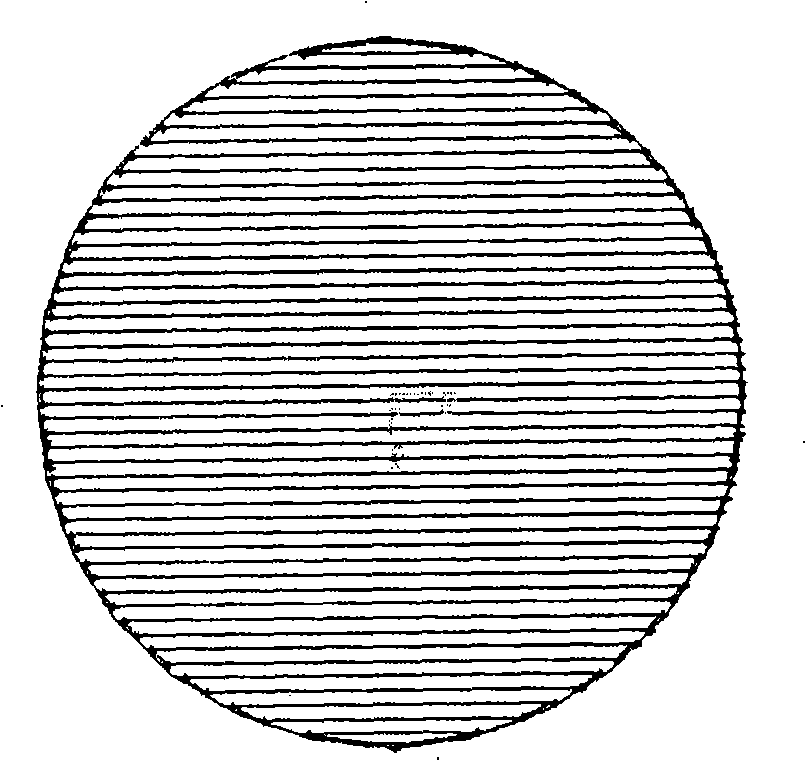

Apparatus for comprehensively utilizing coal mine to ventilate mash gas

InactiveCN101275744AImprove anti-blocking performanceHigh strengthIncinerator apparatusHoneycombProcess engineering

A device for the coal ventilation gas comprehensive utilization, a reactor outlet end with the same structure is connected into a U-shape reactor through a heat taking device; the entrance of the reactor is filled with a honeycomb heat retaining mass; the outlet end is a catalyst bed layer; an electric heater is arranged between the heat retaining mass outlet end and the catalyst bed layer; the entrance of the raw gas is provided with a valve set for controlling the conversion of the current direction in the reactor; the raw gas enters the reactor, and generates the catalytic combustion on the catalyst bed layer; a saddle type bed temperature distribution is realized in the reactor by processing the periodic switch through the current direction of the reaction gas, the burning end gas is fetched out by the heat taking device. The invention has higher heat reclaim efficiency; when the concentration of the methane in the ventilation gas and the flow of the ventilation gas change, the high efficiency selfheating operation can be realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

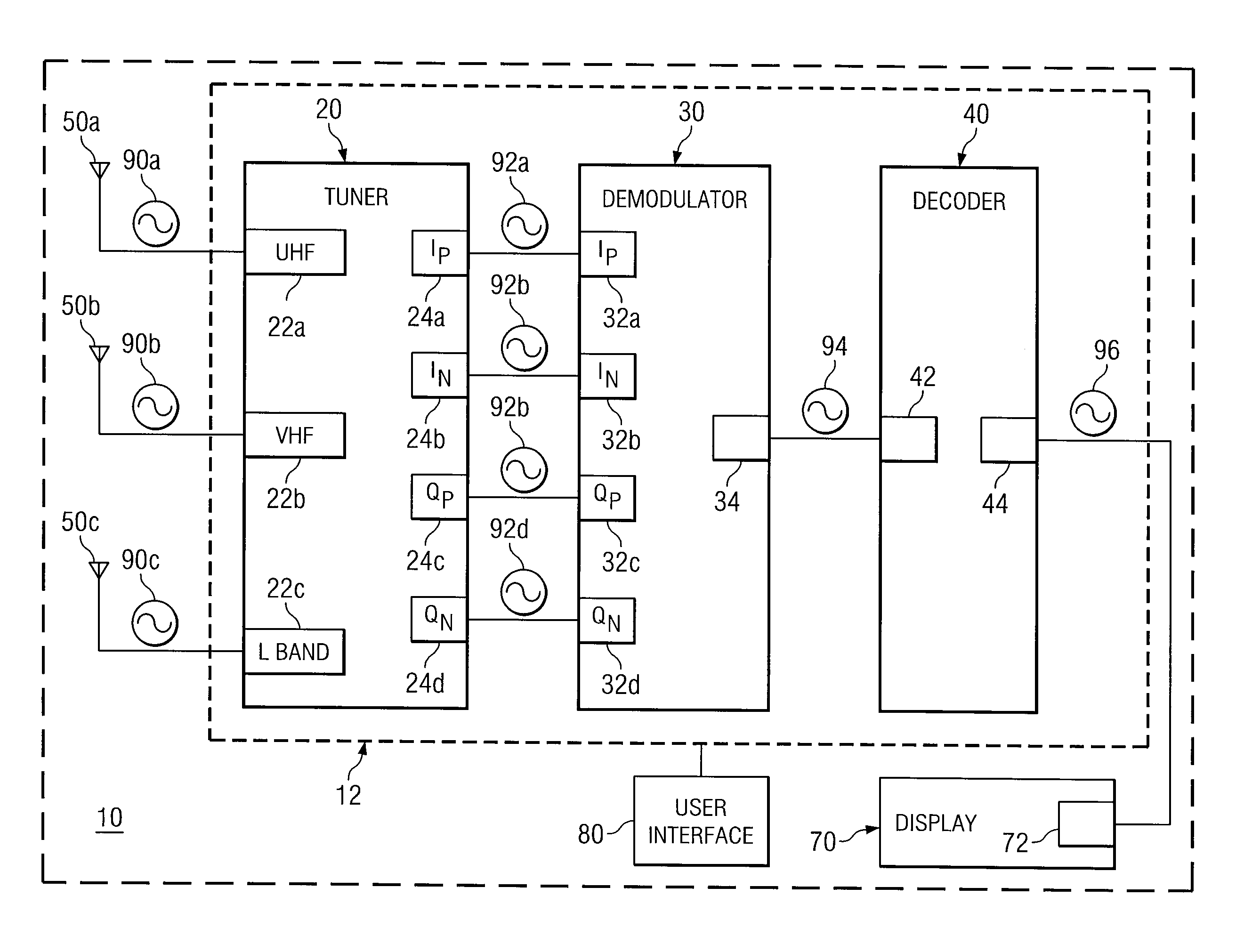

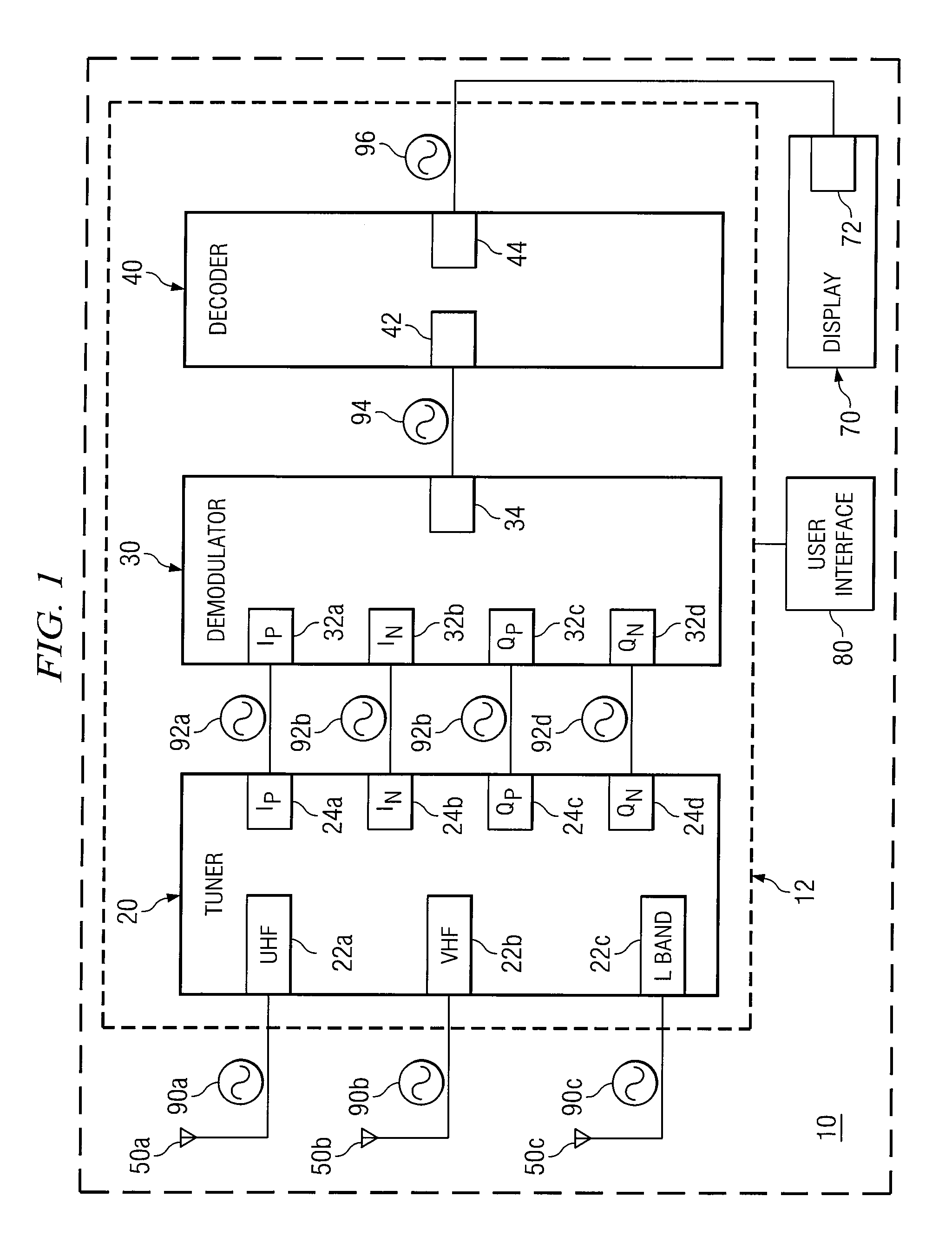

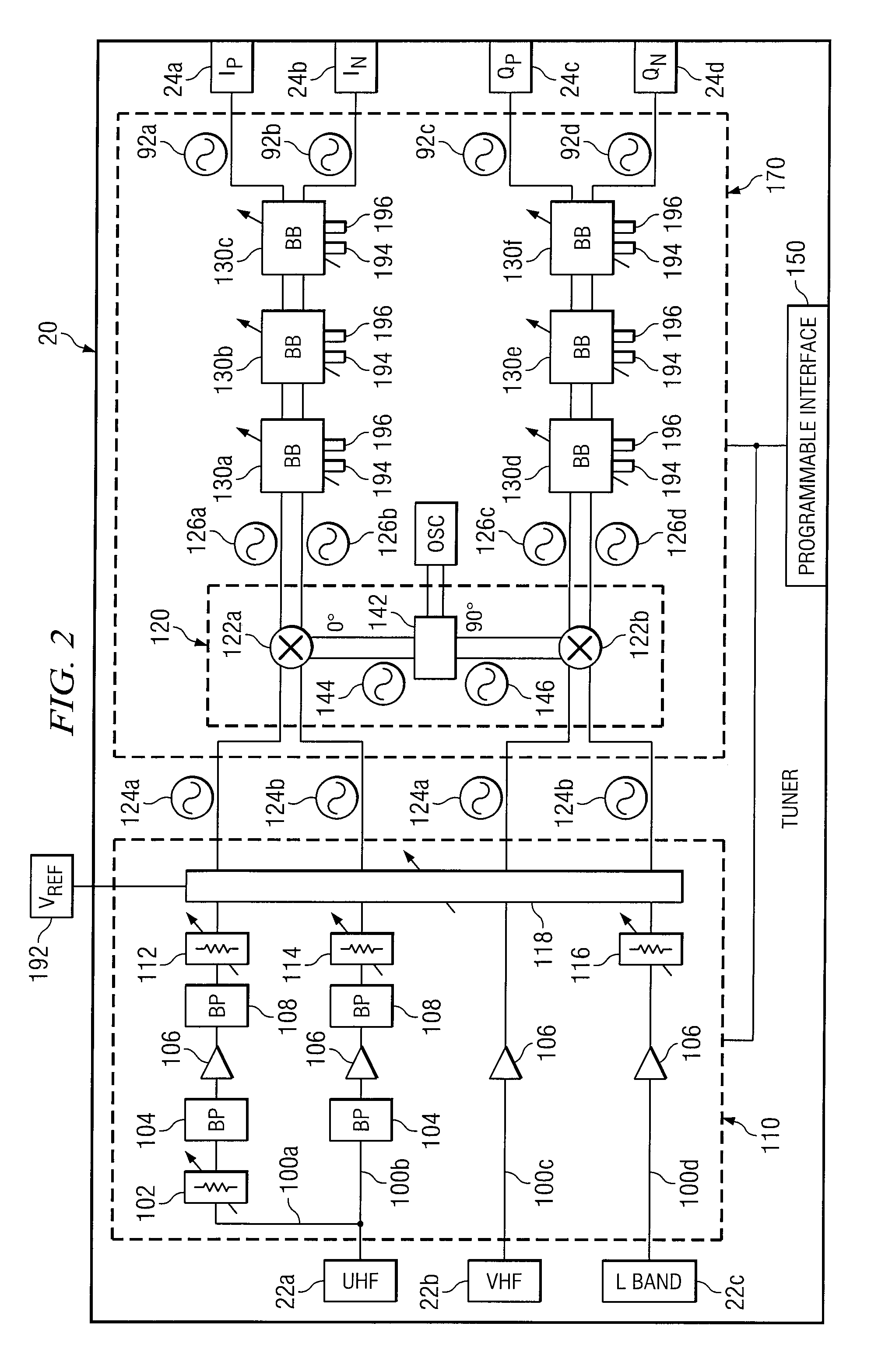

Multi-band broadcast tuner

InactiveUS20060276149A1Disadvantages and reduced eliminatedSignal reduced eliminatedRadio transmissionRelay systems monitoringMulti bandFrequency spectrum

A system for receiving radio-frequency signals includes a first input path, a second input path, a selector, and a mixer. The first input path is capable of transmitting to the mixer a first input signal propagating in a first portion of the radio-frequency spectrum, while the second input path is capable of transmitting to the mixer a second input signal propagating in a second portion of the radio-frequency spectrum. The selector is capable of selectively coupling one of the first input path and the second input path to the mixer. Additionally, the mixer is capable of receiving an input signal and downconverting at least a portion of the input signal that is propagating within a selected frequency range. The mixer is also capable of outputting the downconverted portion of the input signal.

Owner:ZORAN CORPORATION

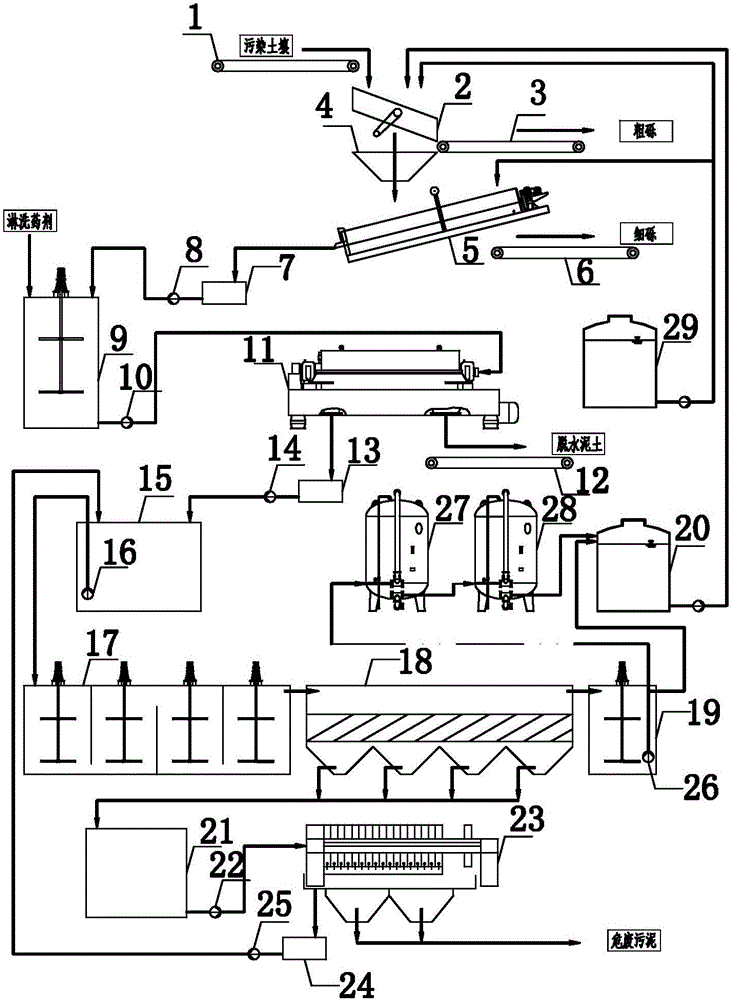

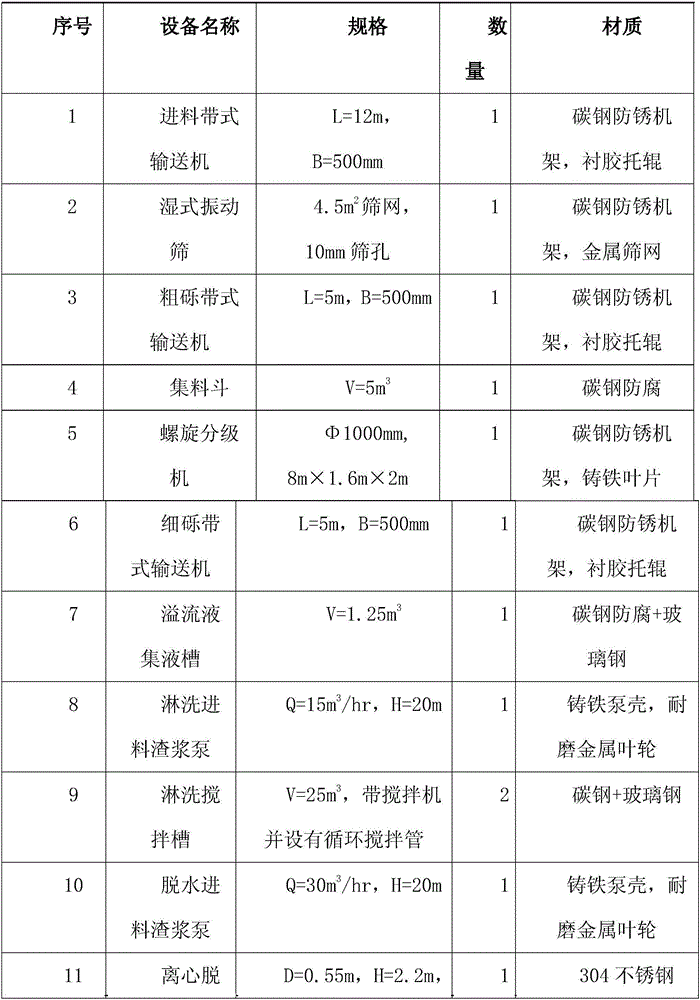

Soil ectopic leaching restoring complete equipment

ActiveCN105772497AEasy to useReduce total rinse volumeSludge treatment by de-watering/drying/thickeningWater contaminantsSoil textureUltimate tensile strength

The invention provides soil ectopic leaching restoring complete equipment, belongs to the technical field of site contamination repairing, and solves the problems that existing leaching equipment is generally poor in soil texture applicability, single in repairable pollutant, numerous and jumbled in leaching equipment system, high in operation intensity, large in water consumption and drainage quantity and the like. The equipment comprises a wet-type screening mechanism, a spiral classifying mechanism, a leaching restoring mechanism, a waste water treatment mechanism and a waste water recycling mechanism which are arranged successively, and polluted soil is separated from the spiral classifying mechanism and the leaching restoring mechanism via the wet-type screening mechanism to obtain coarse gravels, fine gravels and clean soil so as to implement a soil ectopic leaching restoring process. The soil ectopic leaching restoring complete equipment is suitable for restoring of heavy metal and / or organic polluted soil and ectopic leaching restoring of soil with different grain diameters, and has the advantages of wide application range, good decrement effect, stable repairing effect, simplicity and convenience in operation and running, small water consumption, high waste water recycling rate and the like.

Owner:SHANGHAI GREENMENT ENVIRONMENTAL TECH CO L

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com