Oil gas absorptive reclaiming method and apparatus

A technology of oil gas and absorption tower, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of less oil and gas recovery technology in the absorption method, the inability to regenerate light diesel oil, and large volatilization loss, so as to prevent environmental pollution. And fire and explosion hazards, saving equipment investment and operating costs, the effect of large operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

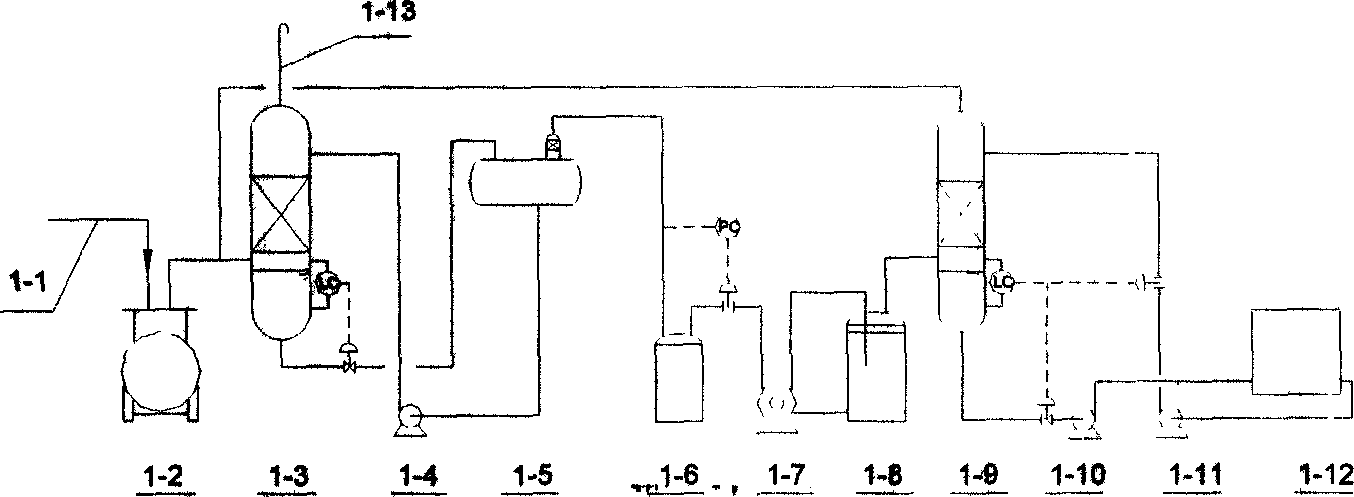

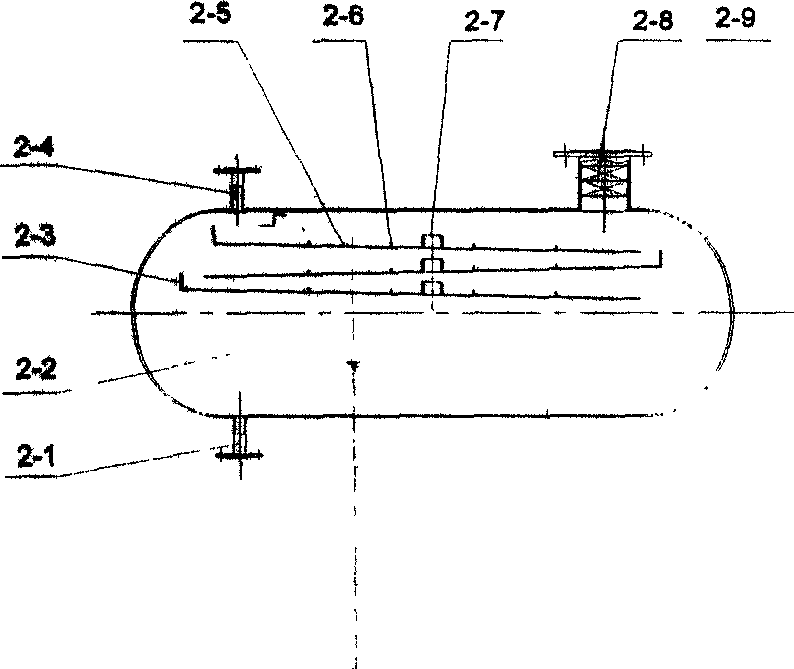

[0033] Such as figure 1 As shown, the embodiment of the present invention includes: airtight loading crane pipe 1-1, oil product storage and transportation equipment (such as railway oil tank car, automobile oil tank car) 1-2, absorption tower 1-3, solvent pump 1-4 , desorption horizontal tank 1-5, buffer tank 1-6, vacuum pump 1-7, gas-liquid separation tank 1-8, recovery tower 1-9, rich gasoline pump 1-10, lean gasoline pump 1-11, oil tank 1 -12. The desorption horizontal tank 1-5 is a key equipment among the present invention, and its embodiment structure is as follows figure 2 shown. Its inside is provided with and is 2~4 layers of partitions, such as partitions 2-5. The separators all have a certain slope, and the directions are different, and the slope is 0.01-0.02. Several road toothed baffle plates 2-6 are welded on the dividing plate. The toothed baffle plate 2-6 upper edge is processed into a sawtooth shape, and the lower edge is firmly welded on the dividing pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com