Method for recovering lithium from waste lithium ion battery and waste pole piece

A lithium-ion battery and lithium recovery technology, applied in the field of lithium recovery, can solve the problems of low industrialization value, insignificant economic benefits, and large site demand, achieving considerable economic value, low cost, and pollution-free effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

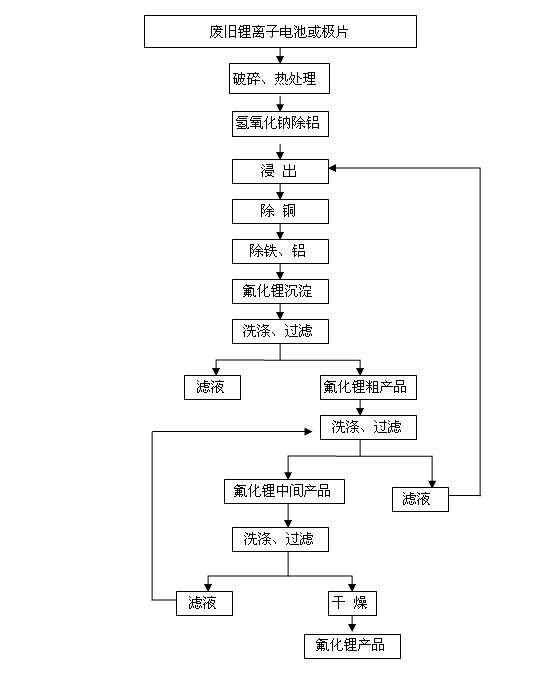

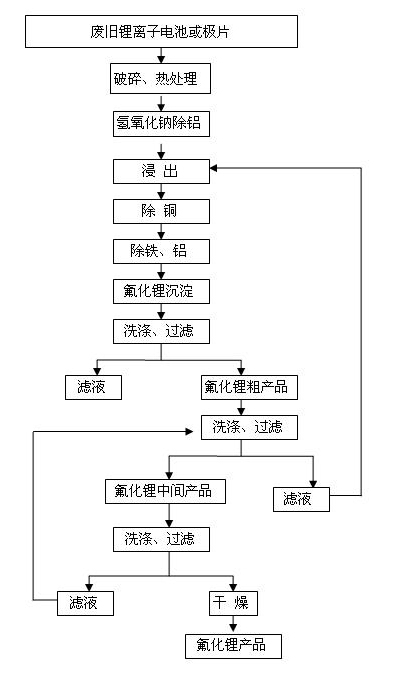

Image

Examples

Embodiment 1

[0024] Take 2kg of waste lithium cobaltate positive electrode pieces, crush them with a vertical high-speed rotary crusher, sieve them with an 80-mesh standard sieve, and keep the under-sieved materials in a high-temperature electric furnace at 600°C for 4 hours, and the weight of the burned materials is 1.82kg. Add 7L of sodium hydroxide solution with a mass content of 5.0% to the reactor, then slowly add 1.5kg of burnt matter, keep the temperature at about 65°C, continue stirring for 1h, filter, and wash the filter residue to obtain low-aluminum cobaltate lithium filter sludge. Put the low aluminum cobaltate lithium filter sludge in the reactor, add 8L of 2.7mol / L sulfuric acid, slowly add 1.2L of 30% hydrogen peroxide, keep the temperature at about 85°C, keep stirring, react for 1.5h, filter, and measure the leachate The ingredients are as shown in Table 1:

[0025] Table 1. Leaching solution composition

[0026]

Embodiment 2

[0037] Use a vertical high-speed rotary crusher to crush the waste lithium-ion battery whose positive electrode is nickel-cobalt-lithium manganese oxide. After crushing, use an 80-mesh standard sieve to sieve. Keep 2kg of the sieve in a high-temperature electric furnace at 600°C for 4 hours. It weighs 1.78kg. Add 4.0% 7L sodium hydroxide solution to the reactor, then slowly add 1.5kg of burnt matter, keep the temperature at about 65°C, keep stirring for 1h, filter, and wash the filter residue to obtain low aluminum nickel cobalt lithium manganate and copper lithium carbon pink. Put low aluminum nickel cobalt lithium manganate and copper-containing lithium carbon powder in the reactor, add 8L of 2.8mol / L sulfuric acid, slowly add 1.3L of 30% hydrogen peroxide, keep the temperature at about 85°C, keep stirring, and react for 1.5h. filter. The ingredients in the leachate are measured as shown in Table 5:

[0038] Table 5. Leaching solution composition

[0039]

[0040] A...

Embodiment 3

[0050] Take 2 kg of waste lithium manganese oxide positive electrode, crush it with a vertical high-speed rotary crusher, and then sieve it with an 80-mesh standard sieve. Keep the under-sieved material in a high-temperature electric furnace at 600°C for 4 hours, and the weight of the burned material is 1.81 kg. Add 4.2% 8L sodium hydroxide solution to the 12L reactor, then slowly add 1.5kg of burnt matter, keep the temperature at about 65°C, keep stirring for 1h, filter, and wash the filter residue to obtain low aluminum manganate filter sludge. Put the low alumina lithium manganese oxide filter sludge in the reactor, add 7L of 3.1mol / L sulfuric acid, slowly add 1.4L of 30% hydrogen peroxide, keep the temperature at about 85°C, keep stirring, react for 1.5h, and filter. Components in the leachate are measured as shown in Table 9:

[0051] Table 9. Leaching solution composition

[0052]

[0053] At 85°C, slowly add sodium hydroxide solution to the leaching soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com