Method for recovering rare earth elements from neodymium-iron-boron wastes

A rare earth element and neodymium iron boron technology is applied in the production process of high-efficiency recovery of neodymium iron boron waste, the regeneration and use of rare earth resources, and can solve the problems of rare earth metal impurities, low performance, and rare earth elements not being recycled. , to reduce the production cost, improve the use value, and improve the recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

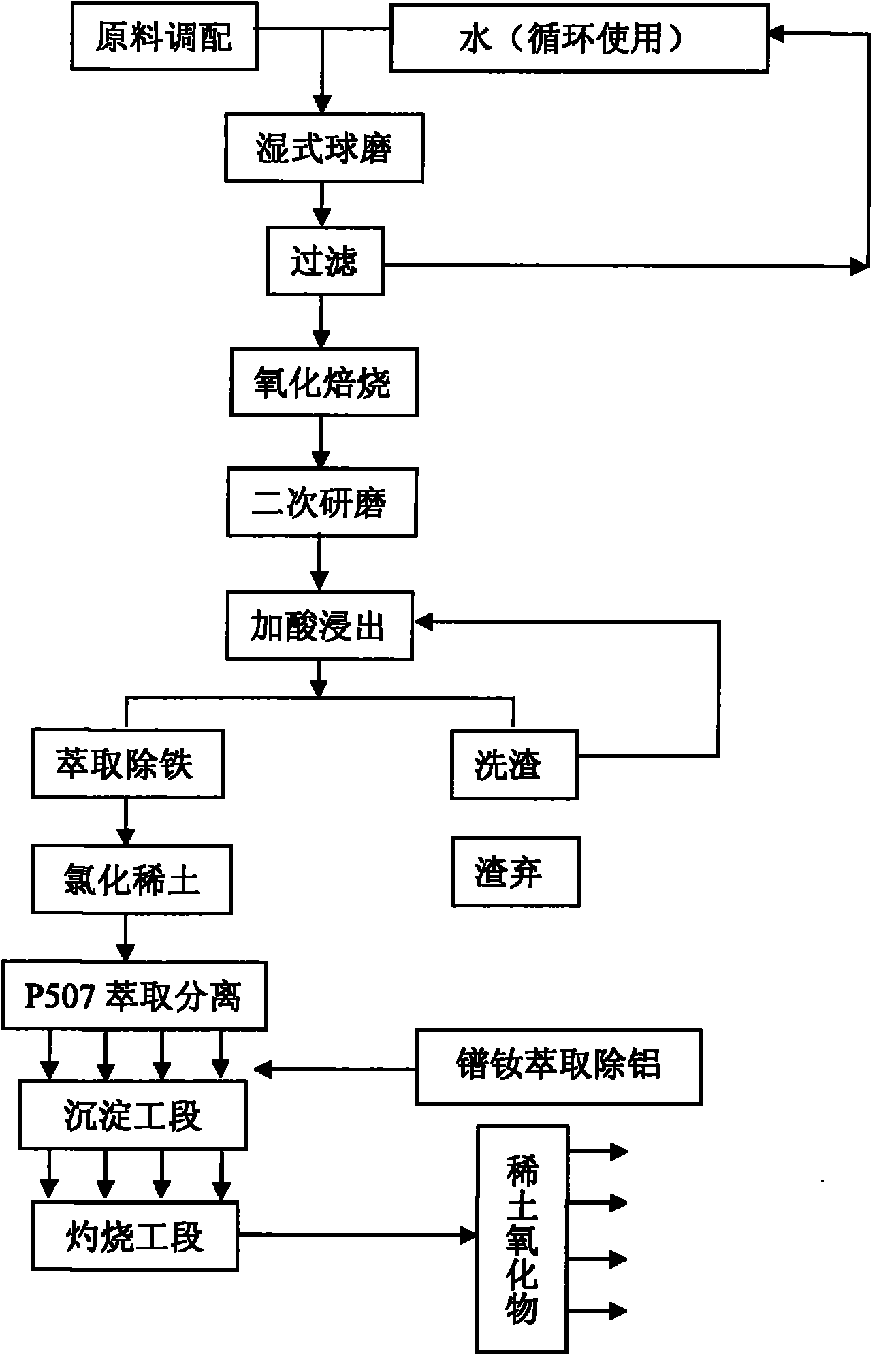

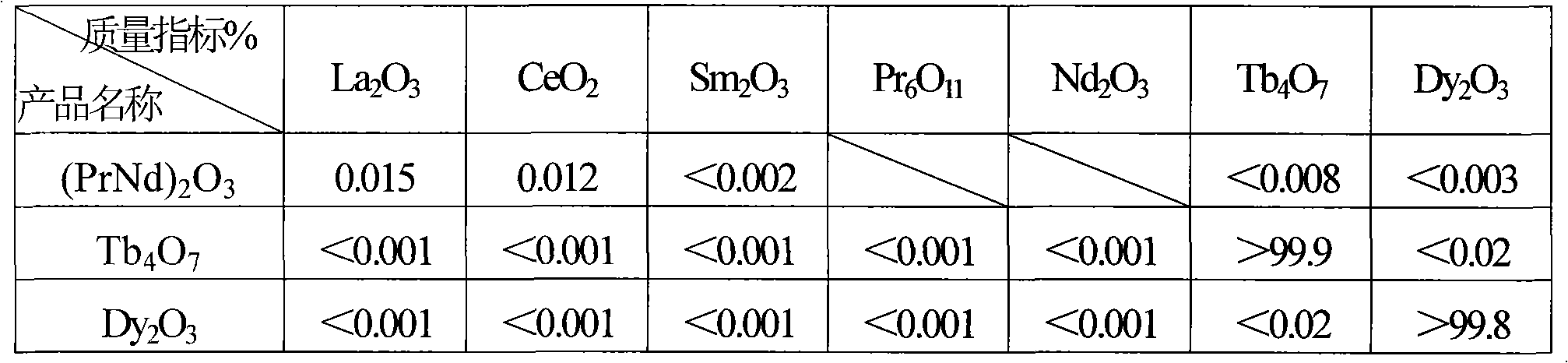

[0061] Prepare 2000kg of NdFeB waste, mix it with deionized water and grind it to 140 mesh, and the particle size is detected to be more than 95% of the particles larger than 120 mesh. The ground mud is subjected to vacuum filtration to make the water content less than 30%, and oxidized at 800°C-950°C for 2 hours to make the oxidation rate reach more than 98%. The oxidation product is thrown into the reaction tank after secondary grinding, and 5mM of 3mol / L hydrochloric acid is added 3 , Stir and heat to make the temperature of the slurry in the reaction tank reach 90°C, keep it warm for 3 hours, and separate the solid and liquid with a chamber filter press. Transfer the clear liquid to the clarification equipment for use, and then add 1.0m of solid slag 3 water and 0.1m 3 Hydrochloric acid is stirred to wash the slag twice, and the water for the third time is returned to the leaching process for recycling. Finally, after the solid-liquid separation of the chamber filter pre...

Embodiment 2

[0073] 1000kg of NdFeB waste was wet ball milled into 200-mesh mud, oxidized at 800°C for 90 minutes to make the oxidation rate over 95%, put it into the reaction tank after secondary grinding, and added 2.5mol hydrochloric acid 2m 3 , Stir and heat to make the temperature of the slurry in the reaction tank reach 90°C, keep it warm for 3 hours, and separate the solid and liquid with a chamber filter press. Transfer the clear liquid to the clarification equipment for use, and then add 0.5m of solid slag 3 water, 0.1m 3 Stir and wash the slag with hydrochloric acid, and then separate the solid and liquid through a chamber filter press, the clear liquid is merged into the clarification equipment, and the slag is discarded. Then the feed liquid of the clarification equipment is transferred into the preparation container for extracting and removing iron, and the clean rare earth feed liquid is obtained by extracting and removing iron, and the rare earth elements are separated thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com