Patents

Literature

1017 results about "Lithium fluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium fluoride is an inorganic compound with the chemical formula LiF. It is a colorless solid, that transitions to white with decreasing crystal size. Although odorless, lithium fluoride has a bitter-saline taste. Its structure is analogous to that of sodium chloride, but it is much less soluble in water. It is mainly used as a component of molten salts. Formation of LiF from the elements releases one of the highest energy per mass of reactants, second only to that of BeO.

Lithium titanate composite electrode material with surface coating layer

InactiveCN101764209AChange physical propertiesChange chemical propertiesCell electrodesMagnesium phosphateMagnesium orthophosphate

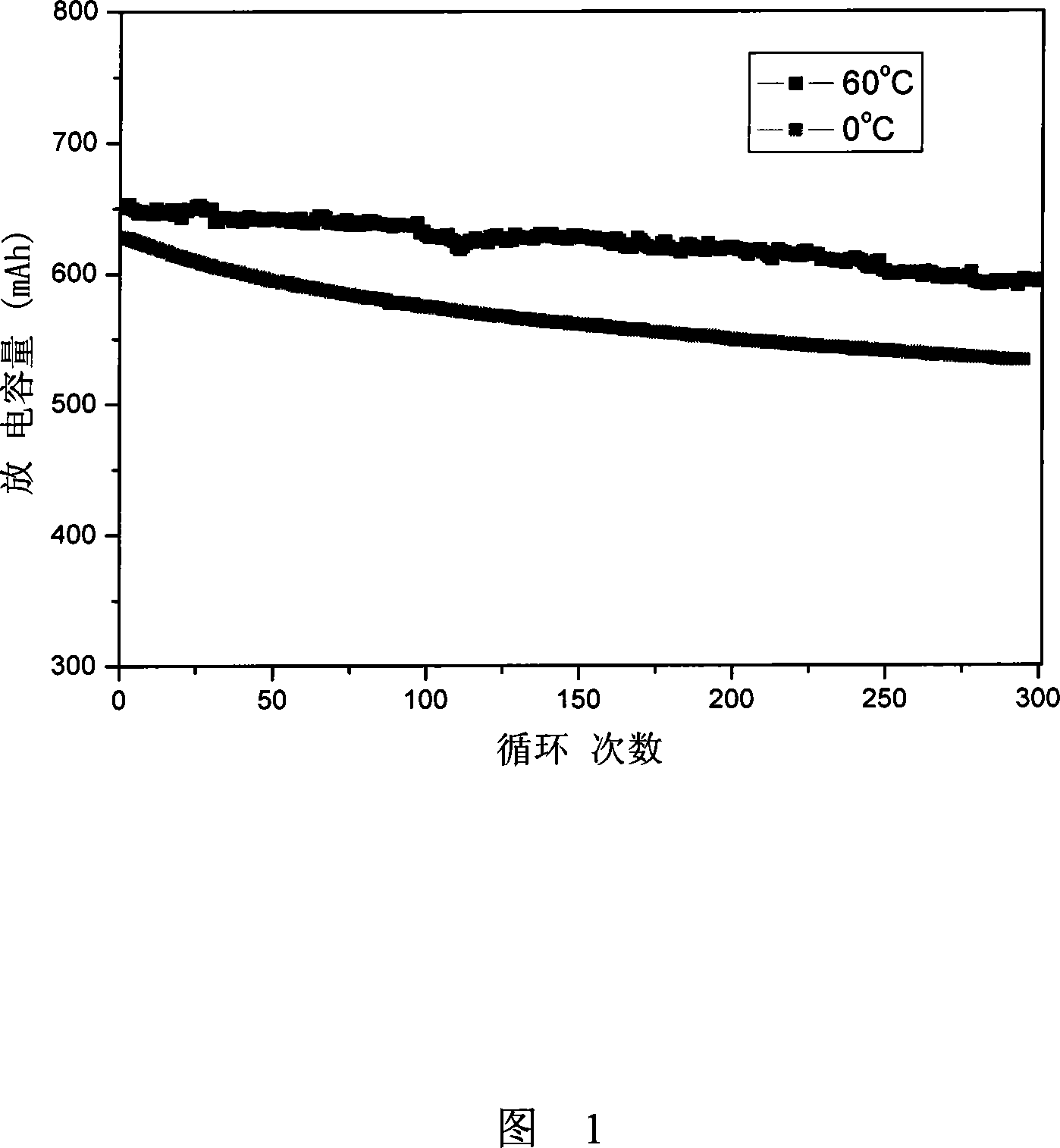

The invention relates to a battery electrode material, in particular to a lithium titanate composite electrode material with surface coating layer; in the lithium titanate composite electrode material with surface coating layer, the electrode material is composed of lithium titanate particles and a coating layer coated with the surface of the lithium titanate particles; the particle size of the lithium titanate particles is 100nm-95mum, the average thickness of the surface coating layer is 0.2nm-5m, and the particle diameter of the composite electrode material is 0.1-100mum; the material of the surface coating layer is one or mixture of more than one kind of insulation oxide, insulation composite oxide, aluminium phosphate, magnesium phosphate, lithium fluoride, lithium phosphate or LiMPO4, wherein M is magnesium, ferrum, cobalt, nickel, chromium, titanium or vanadium; in the invention, by carrying out surface coating treatment to the surfaces of the existing lithium titanate particles, a layer of protective film is formed on the surface, so as to change the physical and chemical characteristics of the surface of the lithium titanate active material, the surface can not be reacted with electrolyte even if under overpotential condition, so as to avoid ballooning and ensure the capacity and the circularity of the battery not to be reduced.

Owner:SUZHOU PHYLION BATTERY

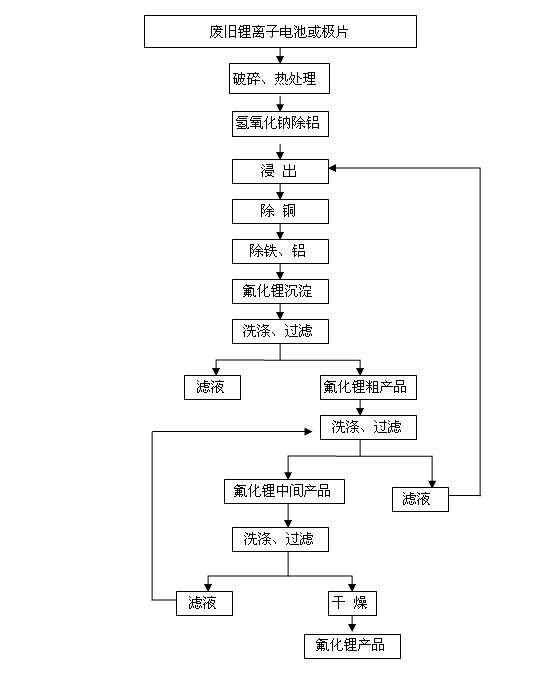

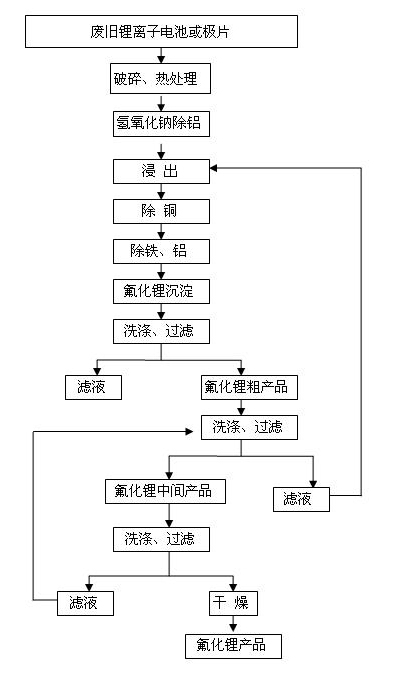

Method for recovering lithium from waste lithium ion battery and waste pole piece

ActiveCN101942569AHigh recovery rateEffectively realize comprehensive recyclingProcess efficiency improvementPhysical chemistryLithium-ion battery

The invention discloses a method for recovering lithium from a waste lithium ion battery and a waste pole piece. The method comprises the following steps of: (1) crushing the waste lithium ion battery or the waste pole piece by using a crusher, placing the crushed material in a high-temperature furnace and removing an adhesive from the crushed material by thermal processing to obtain powder; (2) removing aluminum from the powder by dissolving the aluminum in sodium hydroxide solution and filtering the solution to obtain low-aluminum filter mud; (3) leaching the low-aluminum filter mud with acid and a reducing agent to obtain lixivium; (4) removing impurities such as iron, copper, aluminum and the like from the lixivium by a chemical method; (5) precipitating lithium in the lixivium with fluorine salt to obtain a lithium fluoride rough product; (6) washing the lithium fluoride rough product, filtering and drying to obtain a lithium fluoride product; and (7) returning filtrate obtained after the lithium fluoride rough product is washed to the step (3) for processing. By the method of the invention, the lithium fluoride product has purity of over 98.0 percent and the primary recoveryrate of lithium is between 75 and 92 percent; and the method of the invention has the advantages of simple process, low cost, easy industrial production and high economic benefit.

Owner:HUNAN BRUNP RECYCLING TECH

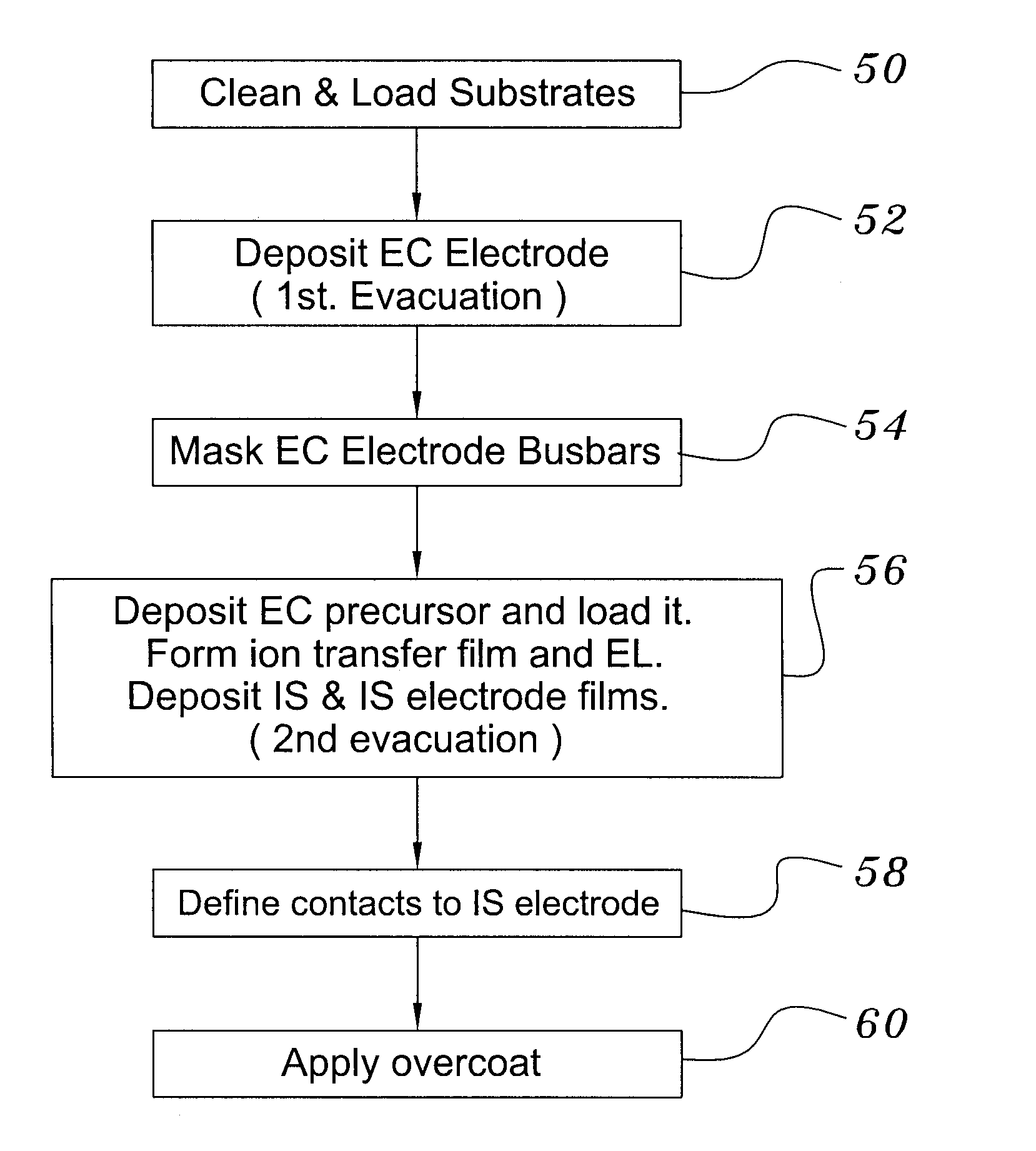

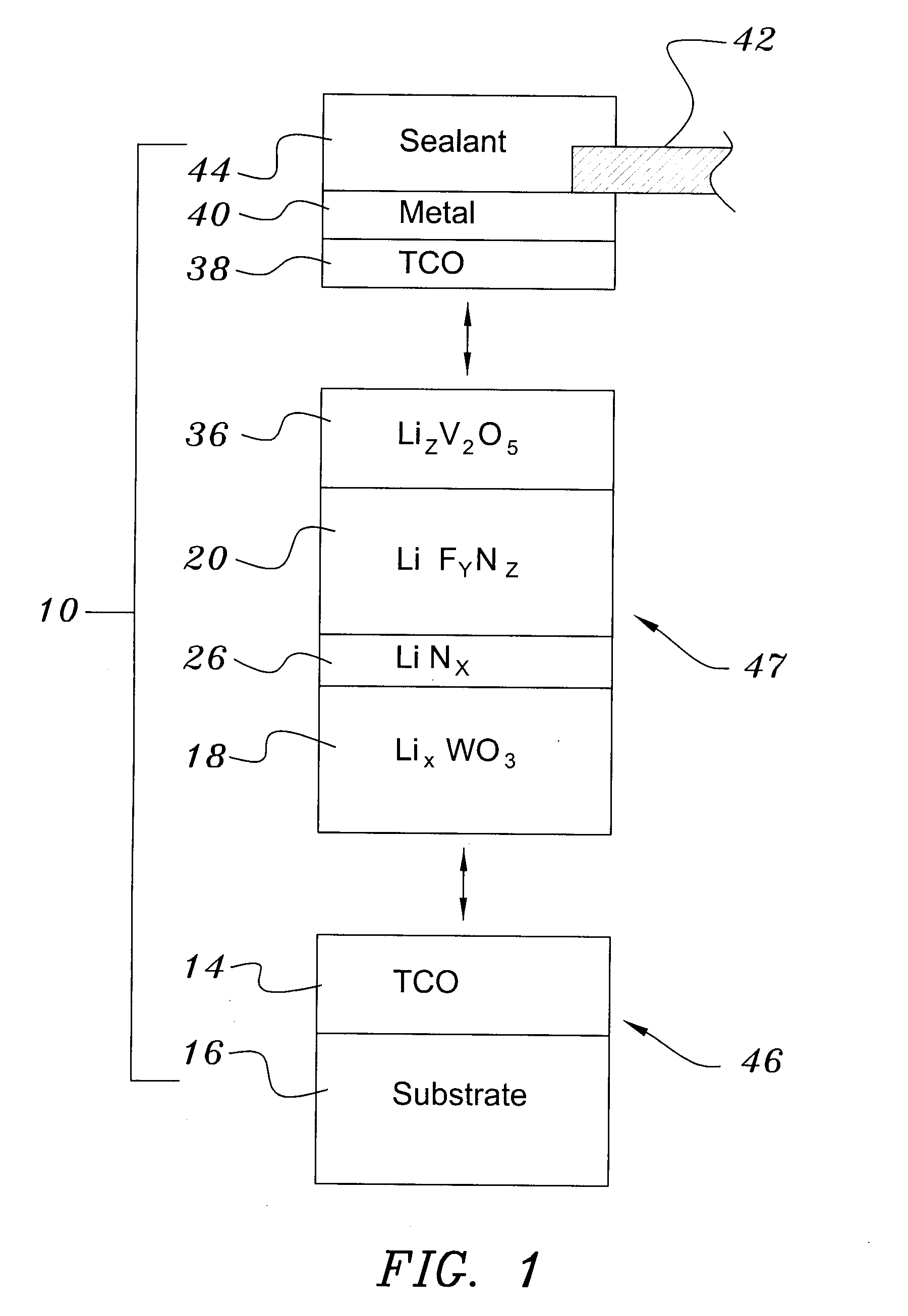

Electrochromic Device with Self-forming Ion transfer Layer and Lithium Fluoro-Nitride Electrolyte

ActiveUS20070292606A1Solve many processesReduce usageCoatingsSpecial surfacesEvaporationElectrochromism

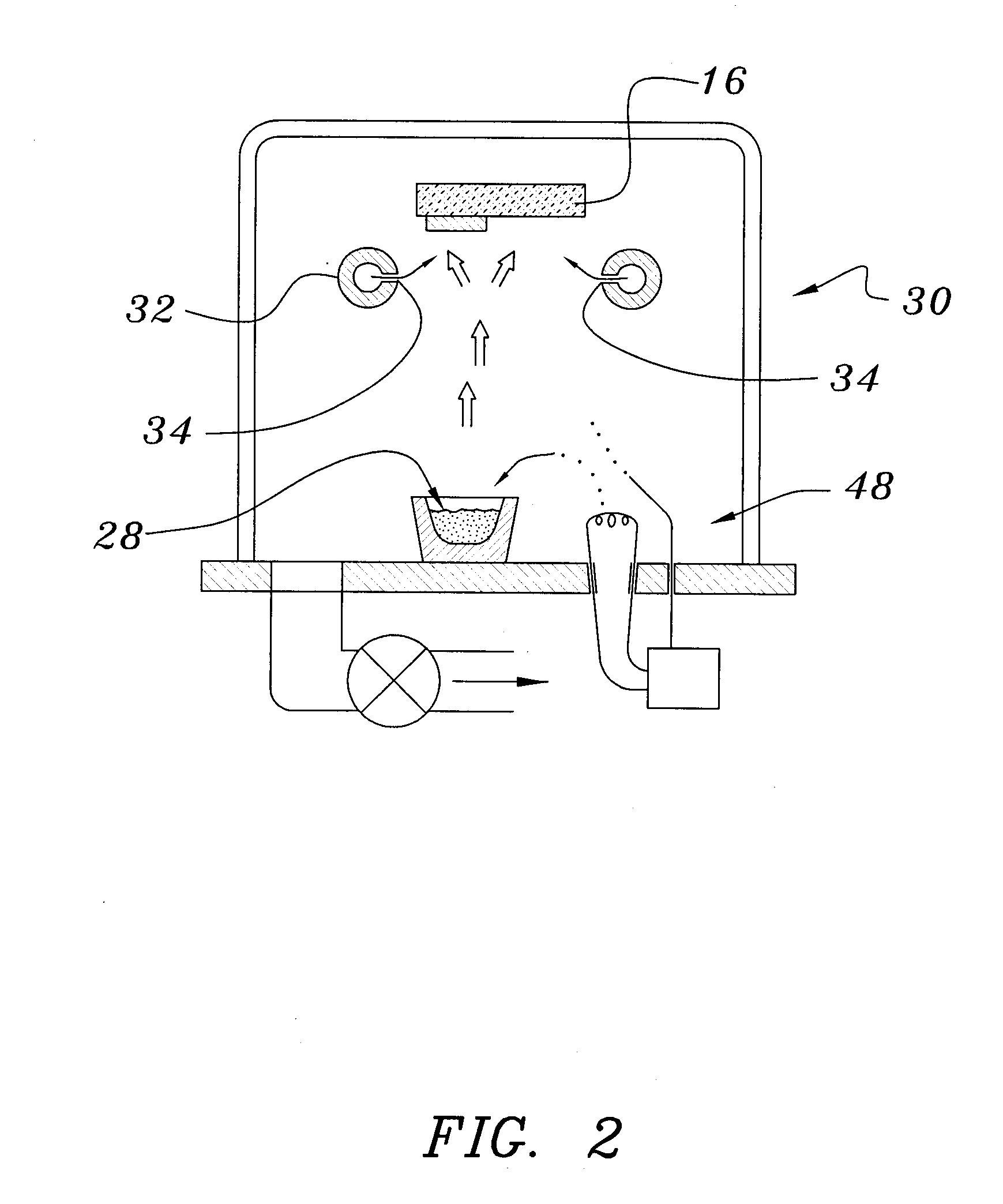

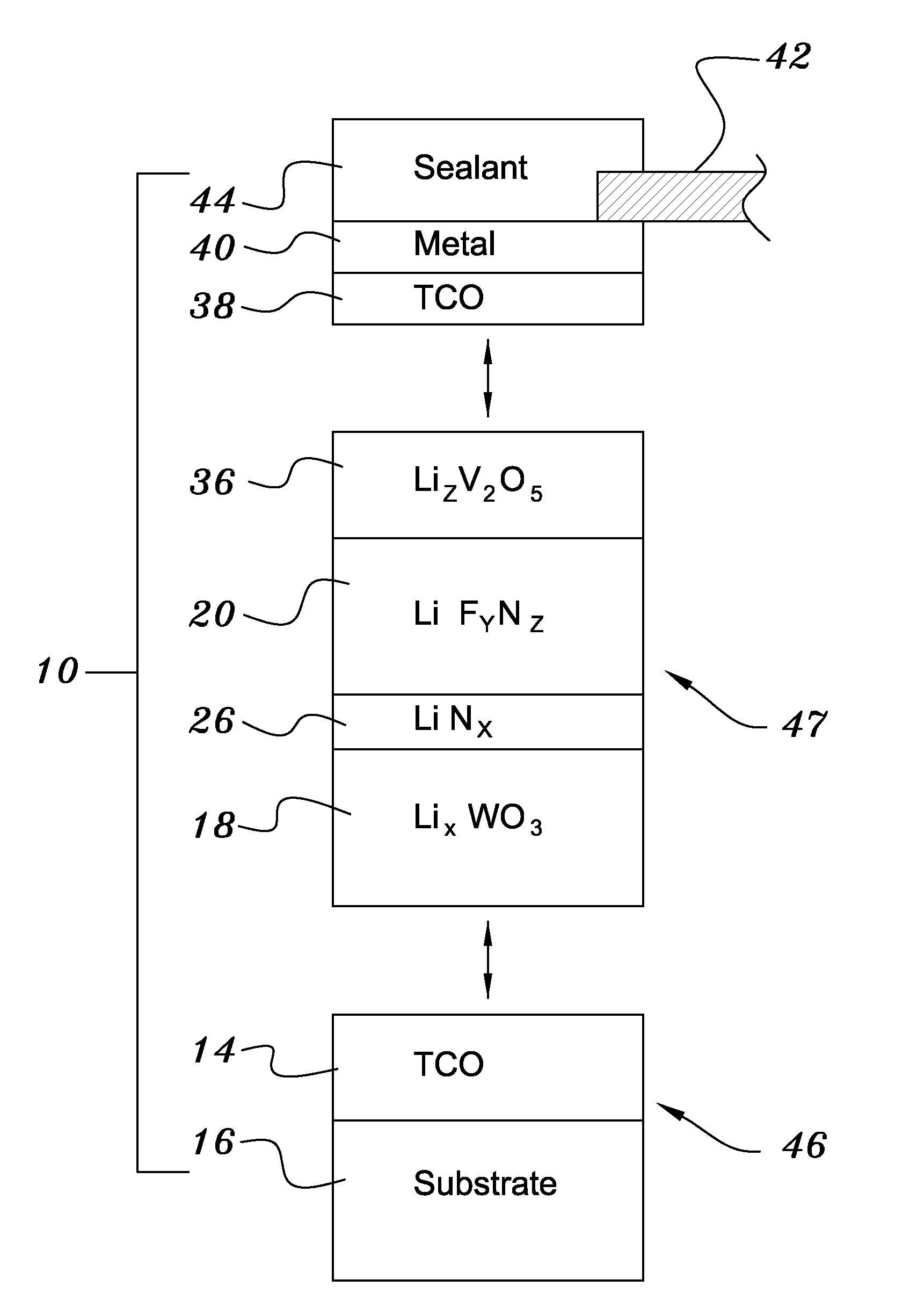

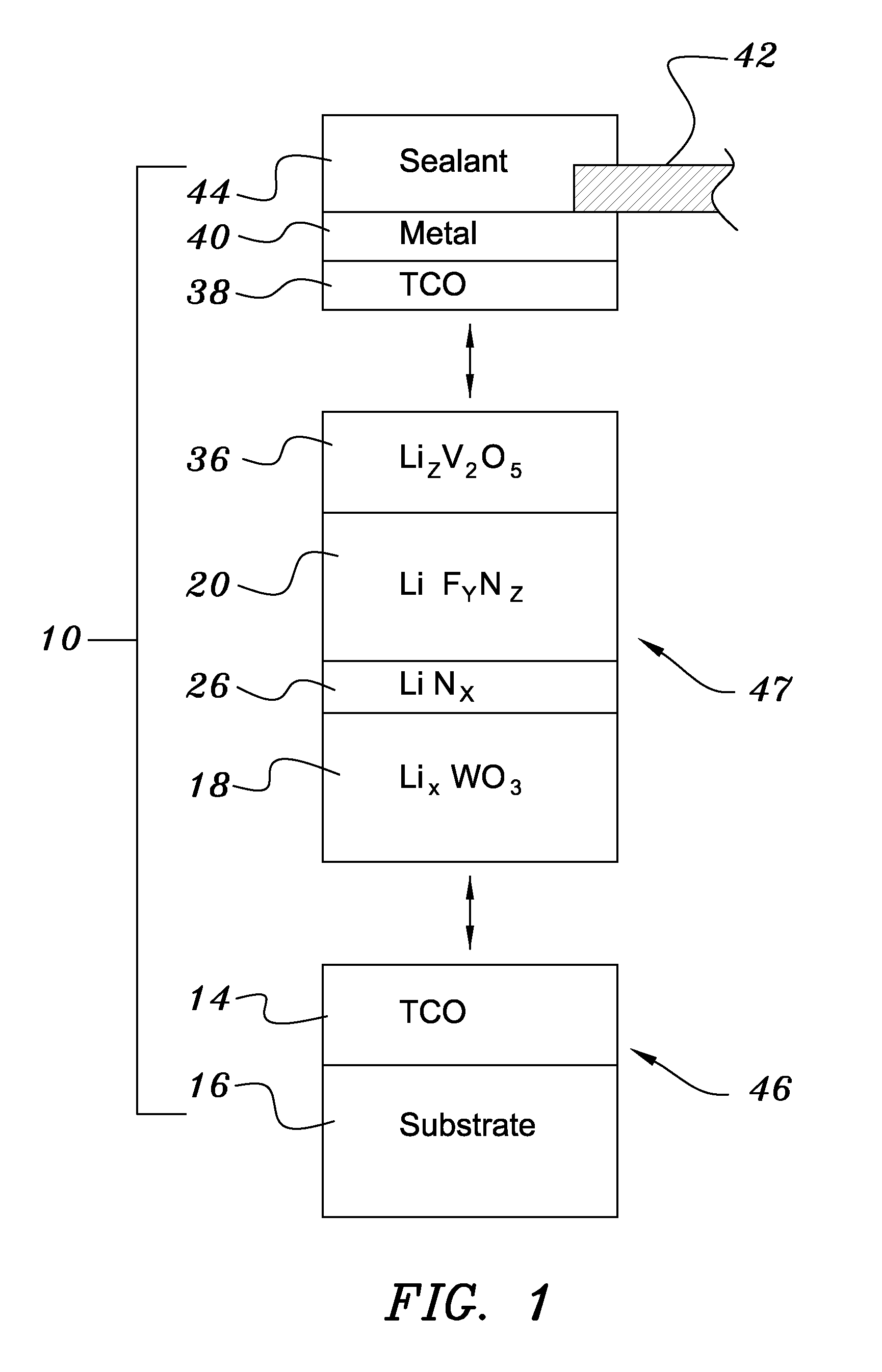

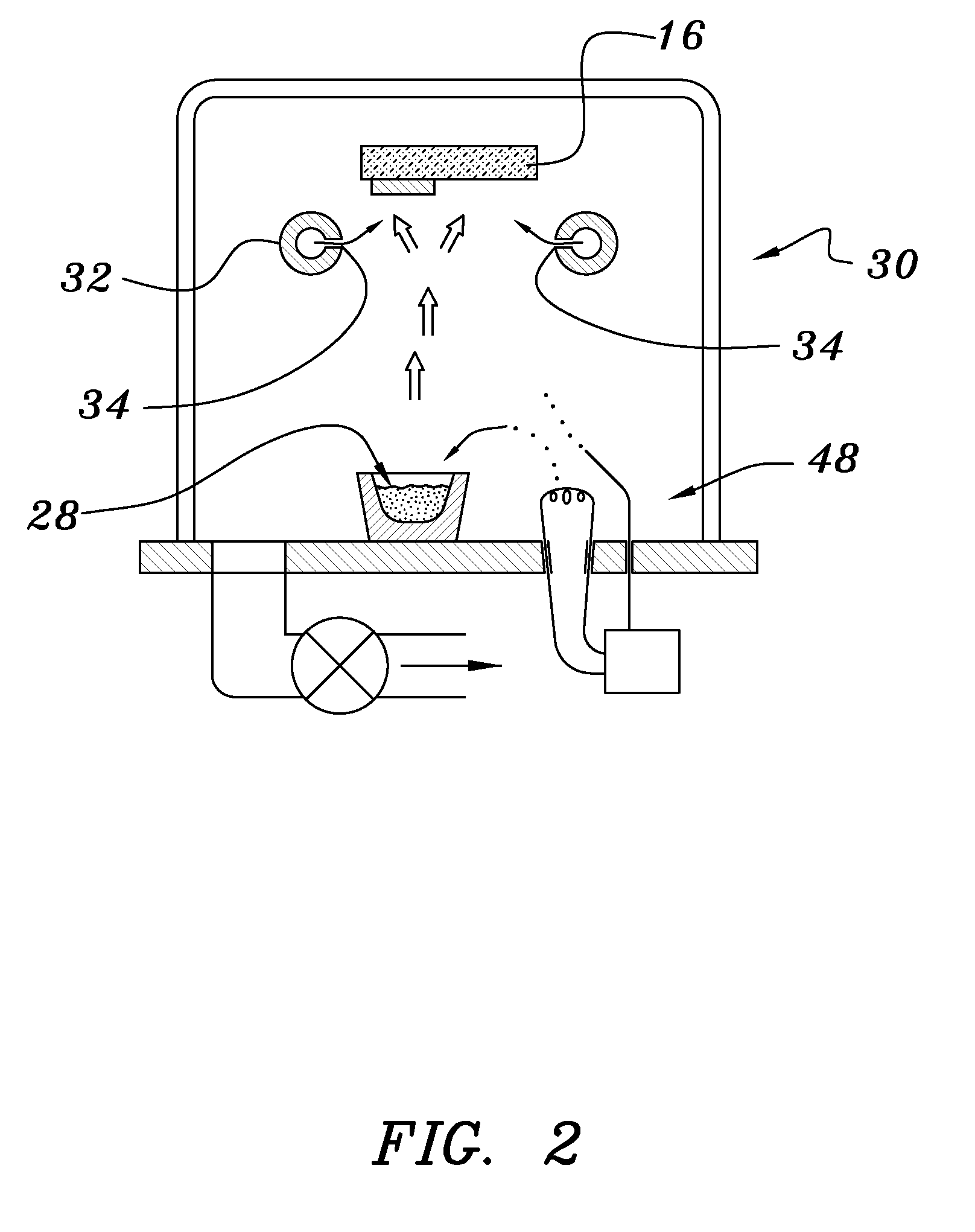

A method of preparing an electrochromic device involves forming multiple layers of selected materials on a substrate in a vacuum processing chamber. A first of these layers is an electrode layer deposited directly on the substrate and used for making contact to a subsequently deposited precursor film, preferably tungsten oxide, from which an electrochromic layer is formed by lithium loading in the presence of ionized nitrogen. This not only forms the electrochromic layer by diffusion of the lithium into the tungsten oxide, but also forms a thin lithium nitride ion transfer layer on the then exposed surface. Subsequently, a lithium fluoro-nitride electrolyte layer is formed on the ion transfer layer by evaporation from a lithium fluoride source in the presence of ionized nitrogen. An ion storage layer, which may be a vanadium oxide and a transparent second electrode layer are subsequently vacuum deposited.

Owner:ECLIPSE ENERGY SYST

Electrochromic device with self-forming ion transfer layer and lithium-fluoro-nitride electrolyte

ActiveUS7265891B1Solve many processesReduce usageElectrolytic capacitorsNon-linear opticsEvaporationElectrochromism

An electrochromic device is prepared by forming multiple layers of selected materials on a substrate in a vacuum processing chamber. A first of these layers is an electrode layer deposited directly on the substrate and used for making contact to a subsequently deposited precursor film, preferably tungsten oxide, from which an electrochromic layer is formed by lithium loading in the presence of ionized nitrogen. This not only forms the electrochromic layer by diffusion of the lithium into the tungsten oxide, but also forms a thin lithium nitride ion transfer layer on the then exposed surface. Subsequently, a lithium fluoro-nitride electrolyte layer is formed on the ion transfer layer by evaporation from a lithium fluoride source in the presence of ionized nitrogen. An ion storage layer, which may be a vanadium oxide and a transparent second electrode layer are subsequently vacuum deposited.

Owner:ECLIPSE ENERGY SYST

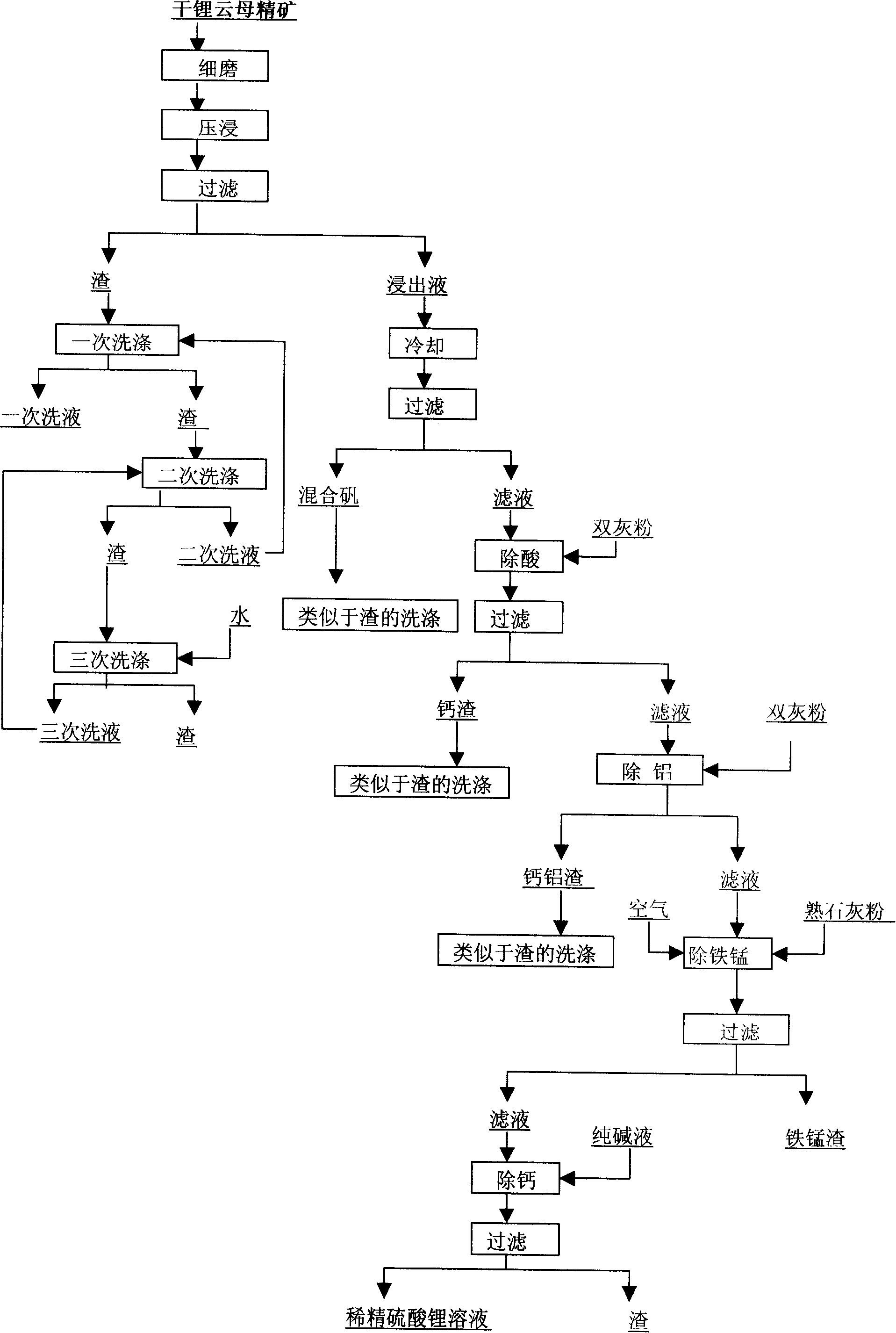

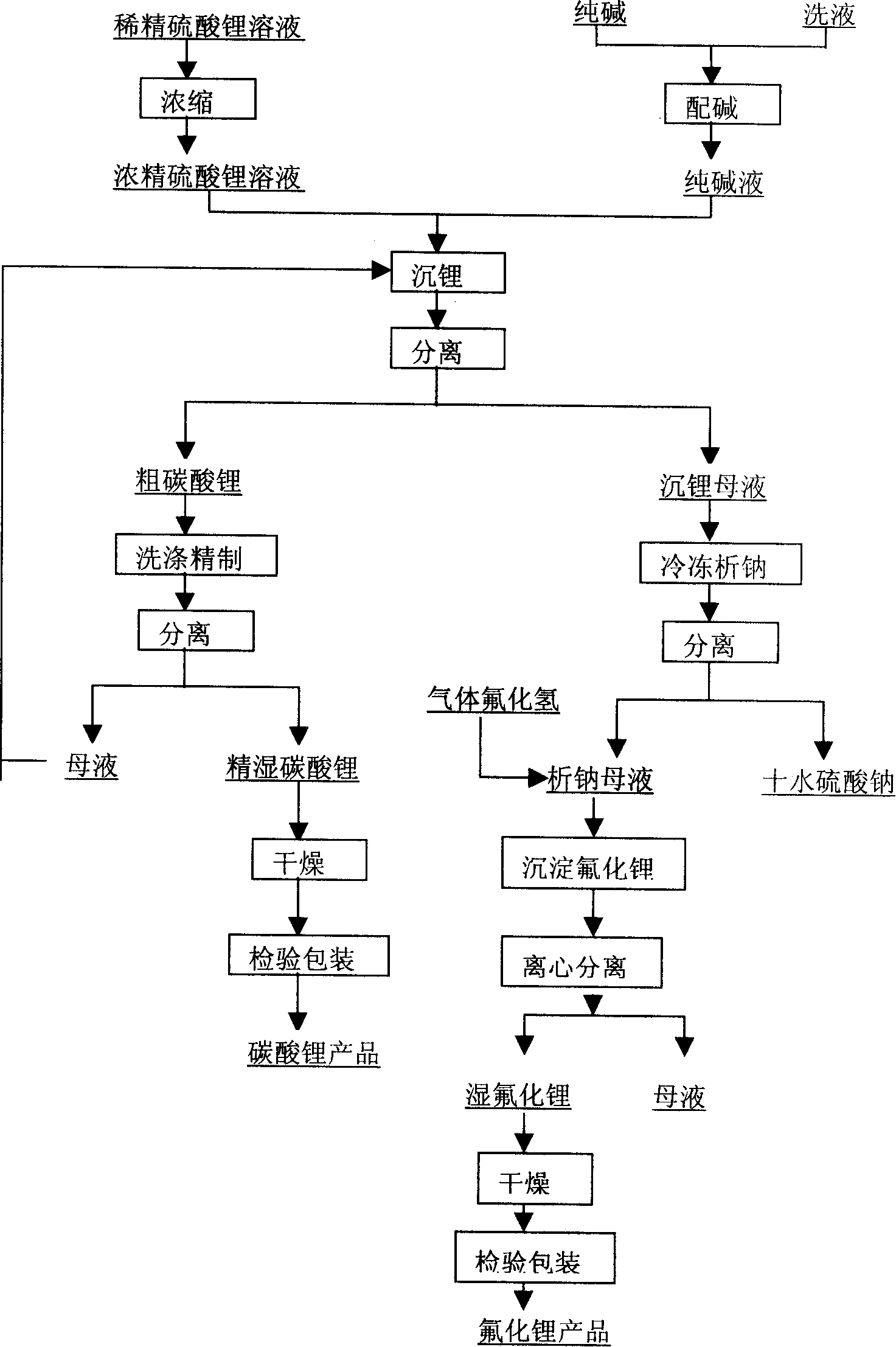

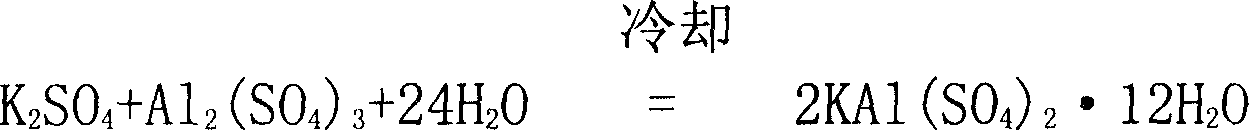

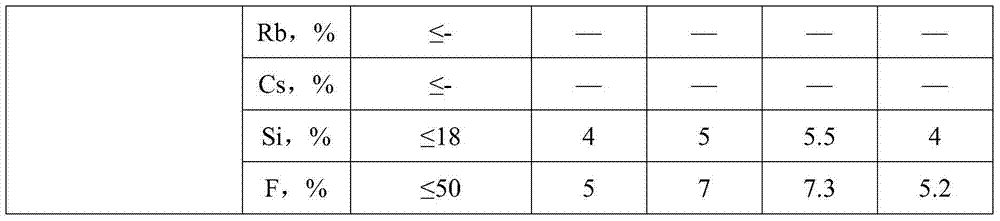

Method for producing refined lithium sulfate solution used in lepidolite lithium-extracting technique by sulfuric acid process

Provided is a process for producing refined lithium sulfate solution of lepidolite lithium extracting technology with sulfuric acid process, which takes lepidolite clean ore as raw material and sequentially includes the following steps, including leaching, alum cooling and decanting, acid removing, aluminum removing, decontaminating and deliming, thereby achieving refined lithium sulfate solution. The alum cooling and decanting process of the invention can precipitate kalium, rubidium and caesium in alum form, thereby the separation of lithium and kalium, rubidium and caesium is easily achieved, and the achieved alum dregs of kalium, rubidium and caesium are blend alum with high purity, which creates perfect condition for comprehensive utilization and simultaneously reduces the burdens of the separation of lithium and aluminum. The aluminum removing process can easily achieve the separation of lithium and aluminum. The process of the invention has the advantages that the energy consumption is relatively low, and the lithium yield is relatively high, most of the residues can be used and the process is favorable for comprehensive utilization. The invention further provides a process for producing lithium carbonate and lithium fluoride with the achieved refined lithium sulfate solution.

Owner:GANFENG LITHIUM CO LTD

Magnesium alloy non cyanogen plating copper chemical plating nickle and its plating process

InactiveCN1598059AImprove bindingUniform coating thicknessSuperimposed coating processCopper platingChemical plating

The invention discloses a method of plating Nickel with magnalium alloy without cyanogen and the plating technique. The direction for the plating solution is: 20 to 80g.dm-3 of copper charred phosphate; one or several of the 60 to 320g.dm-3 of sodium charred phosphate or Potassium charred phosphate or 60 to 250g.dm-3 of sodium citric acid, 5 to 20g.dm-3 of Potassium sodium tartaric acid, 60 to 250g.dm-3 of HEDP and 60 to 250g.dm-3 of amine ethylene; one or several of the 5 to 20g.dm-3 of hydrogen amine di-fluorin or 5 to20 g.dm-3 sodium fluoride or 5 to 20g.dm-3 of Potassium fluoride or 5 to 20g.dm-3 of lithium fluoride. The plating solution chooses the nickel sulfate or alkali type nickel carbonate or nickel acetic acid as the main salt and adds the reducing agent, combination agent and stabilization agent. The plating technique adopts the acid plating copper-plating three nickel-plating chromium. The invention has little pollution to the environment, high binding power and erosion-proof property.

Owner:GCI SCI & TECH +1

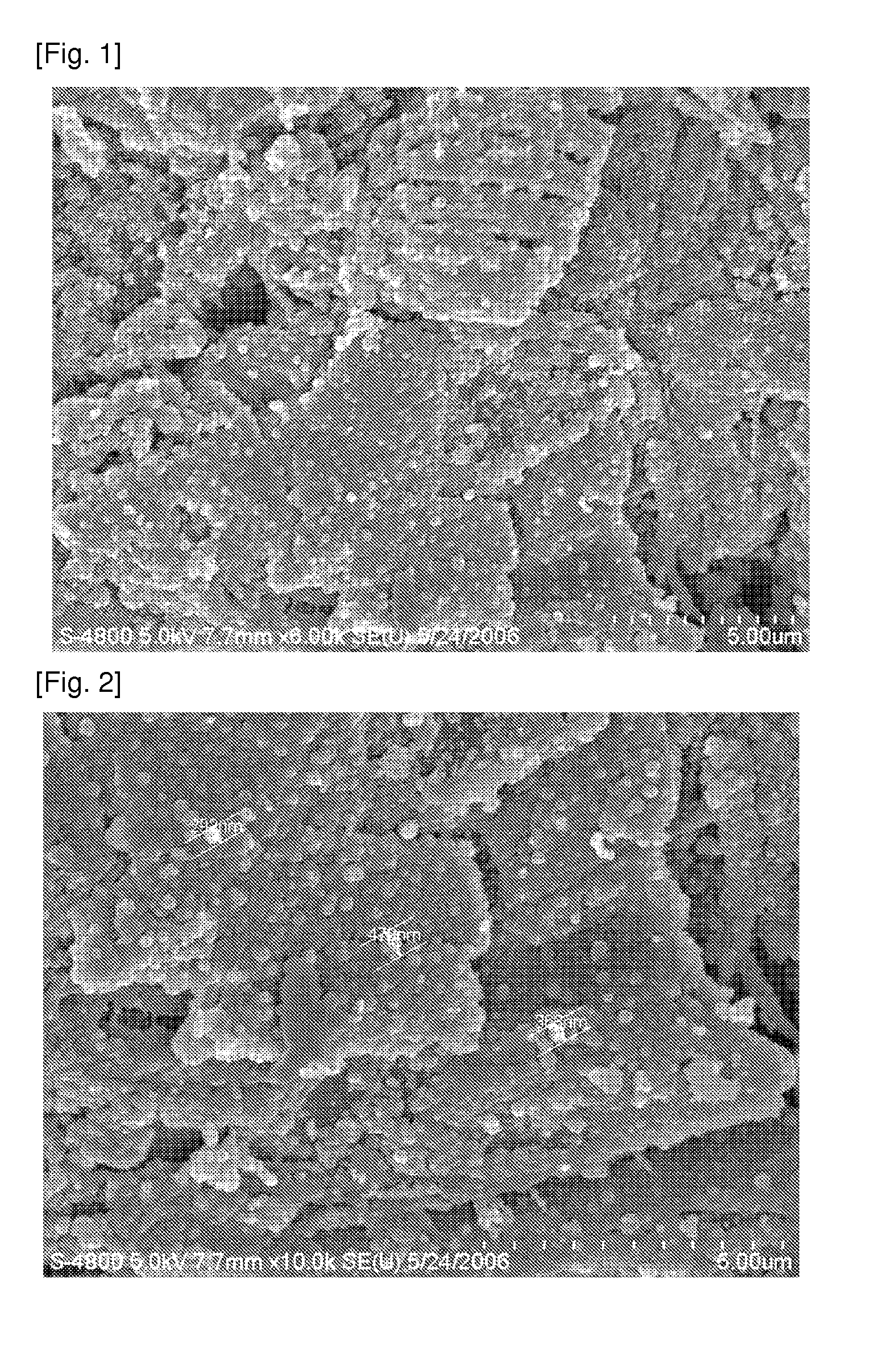

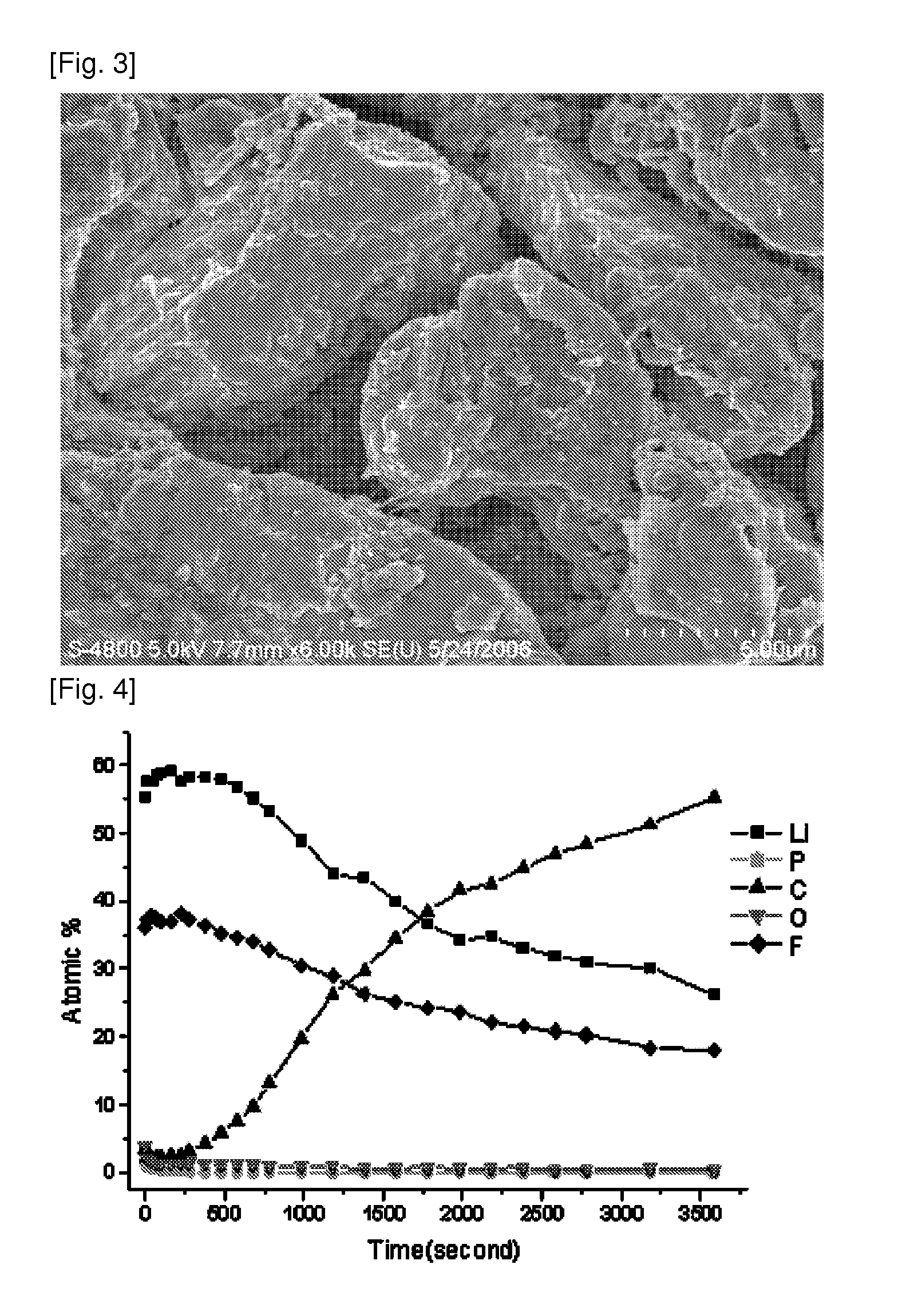

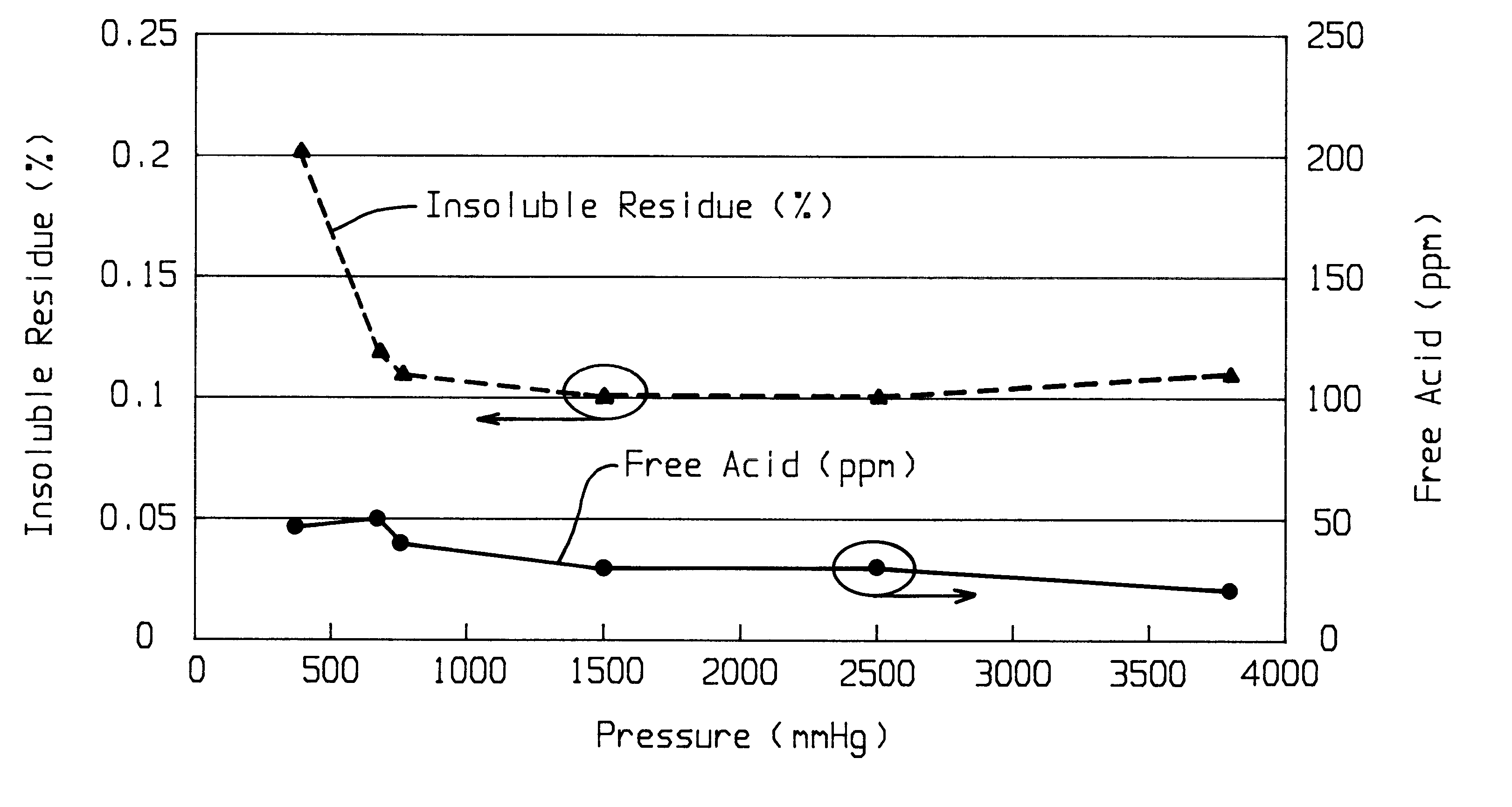

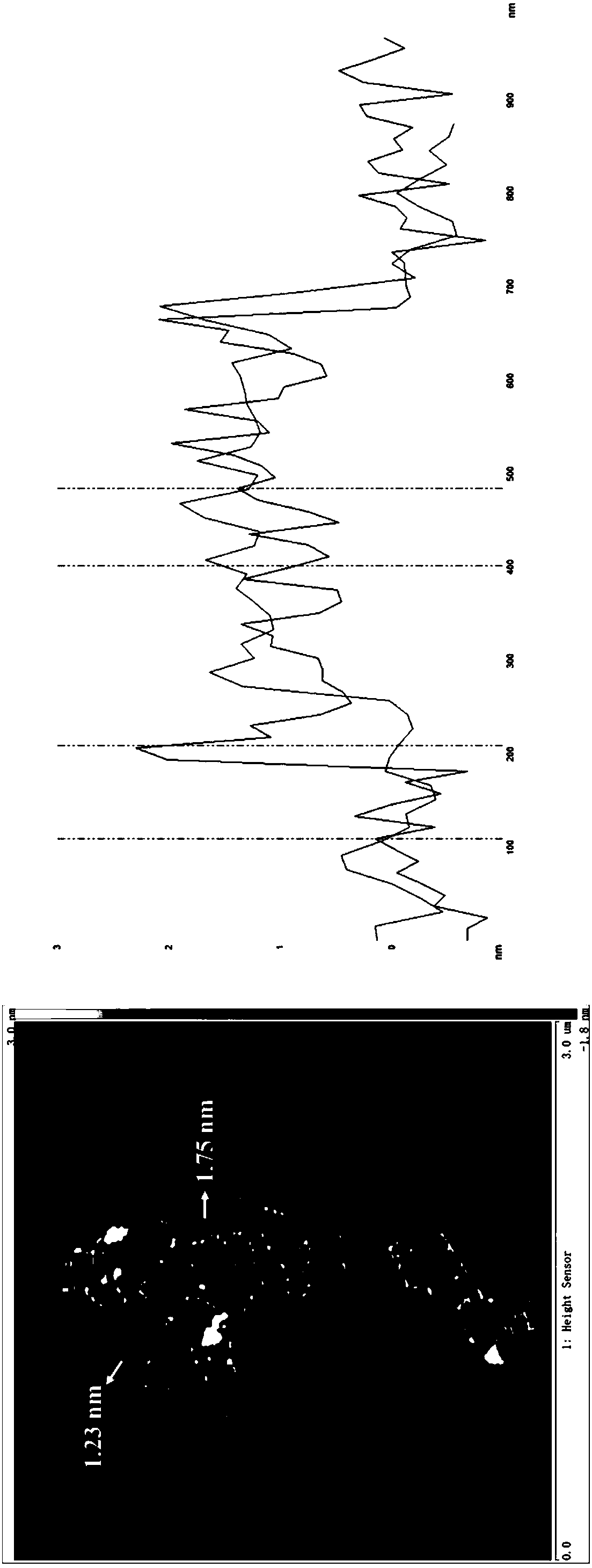

Anode coated with lithium fluoride compounds, method for preparing the same, and lithium secondary battery having the same

ActiveUS20110177388A1Prevent degradationElectrochemical processing of electrodesActive material electrodesBattery chargePhysical chemistry

An anode for a lithium ion secondary battery includes an anode, and a LiF-based coating layer formed with LiF-based particles on a surface of the anode. The LiF-based coating layer has a thickness of 0.05 to 1 μm. The anode allows the LiF-based coating layer created by side reaction of LiPF6 during a battery charging / discharging process to be relatively uniformly formed on the anode surface, thereby elongating the life cycle of a lithium ion secondary battery.

Owner:LG ENERGY SOLUTION LTD

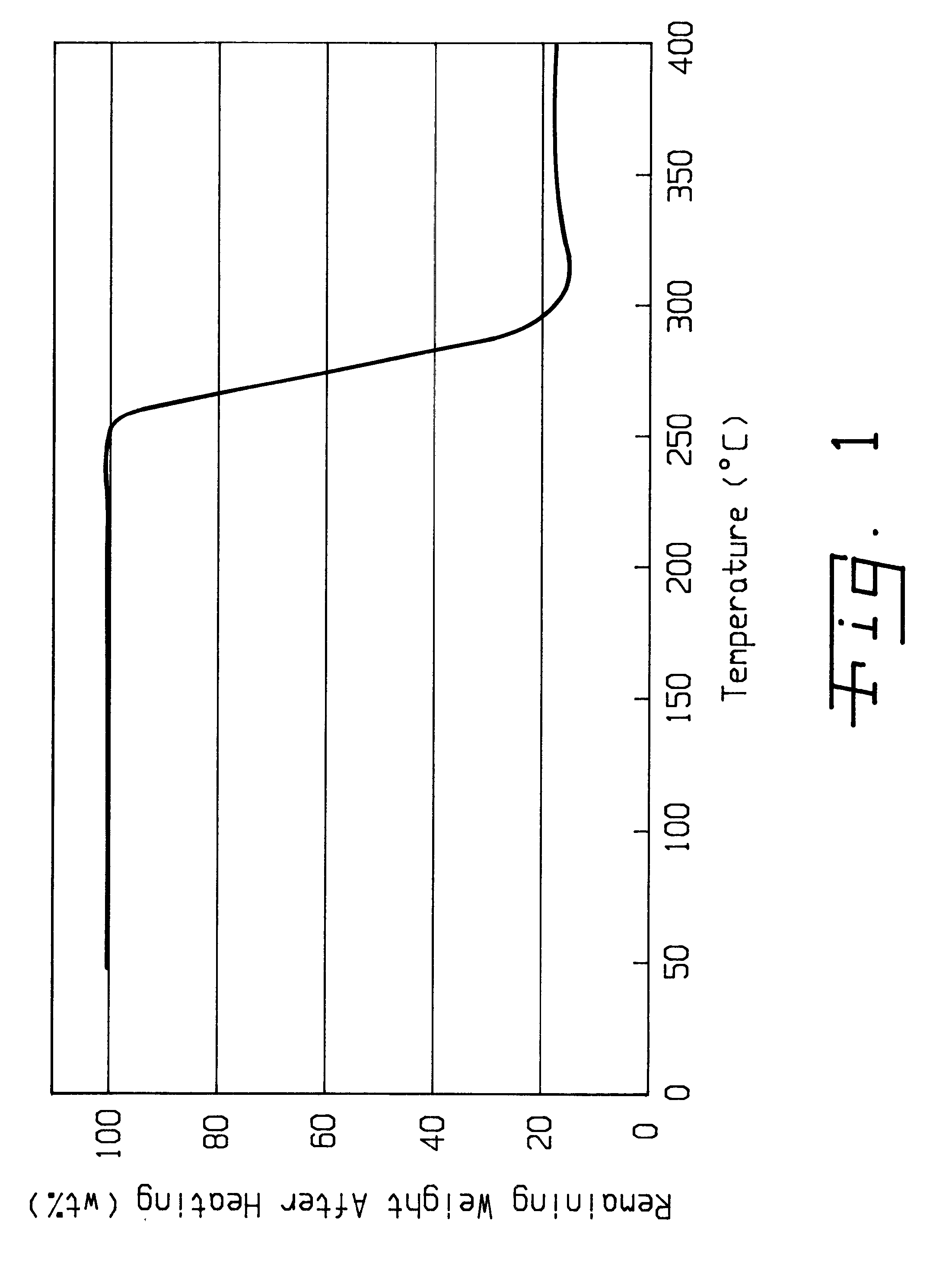

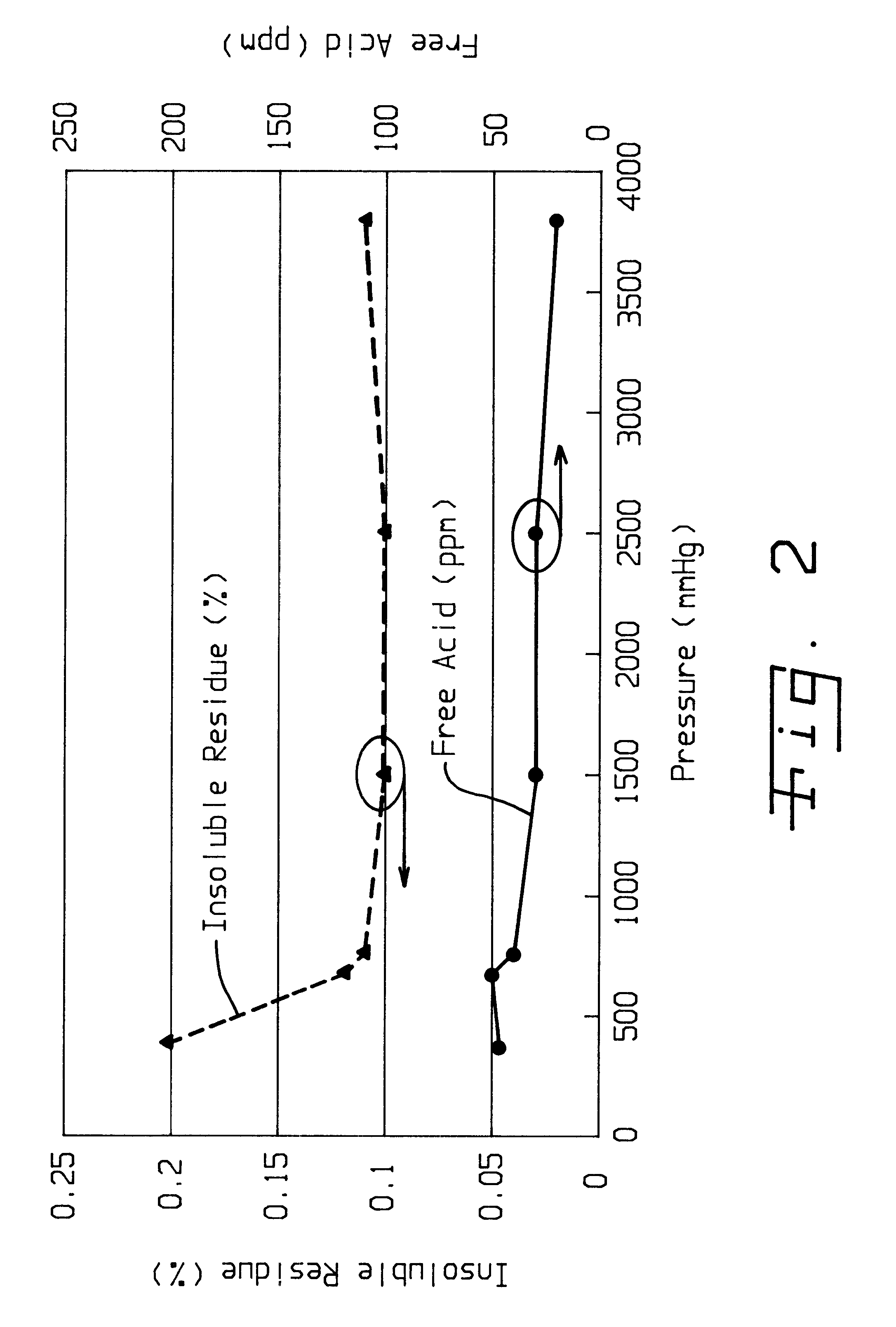

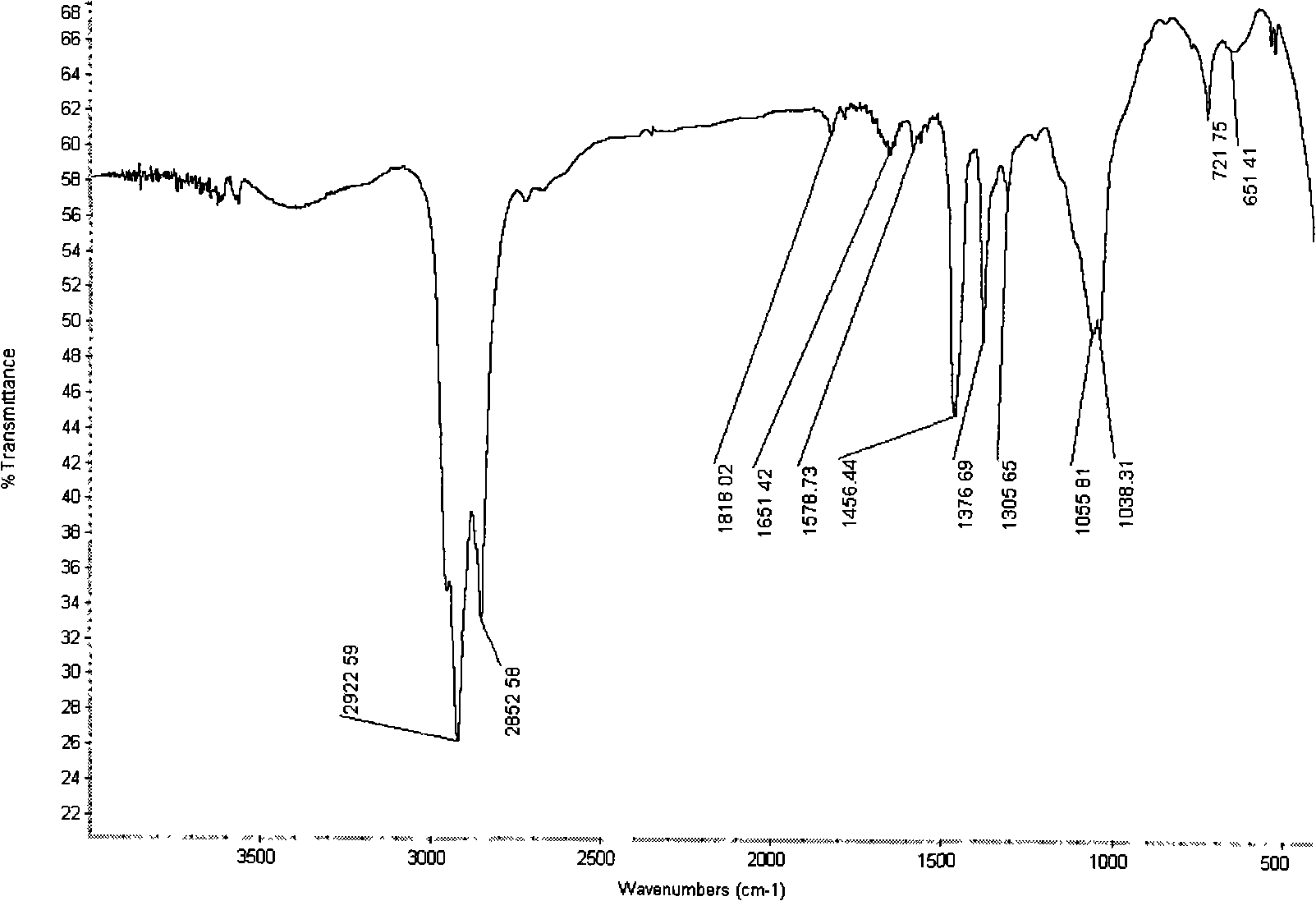

Method of purifying lithium hexafluorosphate

InactiveUS6514474B1Phosphorus halides/oxyhalidesNon-aqueous electrolyte accumulatorsHydrogen fluoridePhosphor

A method of purifying lithium hexafluorosphate that allows to purify lithium hexafluorophosphate, useful as lithium secondary cell electrolyte, organic synthesis medium or the like, to an extremely high purity is provided. Lithium hexafluorophosphate containing harmful impurities such as oxyfluoride, lithium fluoride is purified by adding phosphoric chloride. The purification is performed in the presence of phosphoric chloride and hydrogen fluoride of the quantity equal or superior to the equivalent amount for reacting them, and then by converting lithium fluoride to lithium hexafluorophosphate with generated phosphor pentafluoride.

Owner:STELLA CHEMIFA CORP

Preparation method of lithium hexafluorophosphate

ActiveCN102009972ARich sourcesReduce manufacturing costPhosphorus compoundsPhosphoric acidNitrogen gas

The invention relates to a preparation method of lithium hexafluorophosphate. The preparation method comprises the following steps of: (1) distilling to obtain hydrogen fluoride liquid of which the purity is over 99.99 weight percent; (2) reacting the high-purity hydrogen fluoride liquid with phosphorus pentachloride to obtain mixed gas of the phosphorus pentafluoride and hydrogen chloride; (3) introducing the mixed gas of the phosphorus pentachloride and the hydrogen chloride into hydrogen fluoride and lithium fluoride, reacting at a certain temperature and under certain pressure to obtain solution of lithium hexafluorophosphate, exhausting hydrogen chloride gas at regular time, and absorbing by using water to prepare byproduct hydrochloric acid; and (4) crystallizing and separating, namely filtering the solution of lithium hexafluorophosphate, delivering filtrate into a crystallizing slot, separating the lithium hexafluorophosphate out at the temperature of between -70 and 80 DEG C, filtering, and performing primary drying and secondary drying to obtain a lithium hexafluorophosphate product, wherein the residual hydrogen fluoride gas is displaced by nitrogen. The preparation method has readily available raw materials and is easy to operate, the purity of the obtained lithium hexafluorophosphate product is over 99.9 percent, the moisture is lower than 10ppm, and the production requirements of lithium ion electrolytic cells are met.

Owner:MORITA NEW ENERGY MATERIALS ZHANGJIAGANG CO LTD

Thermal spray compositions for abradable seals

Owner:SULZER METCO CANADA INC

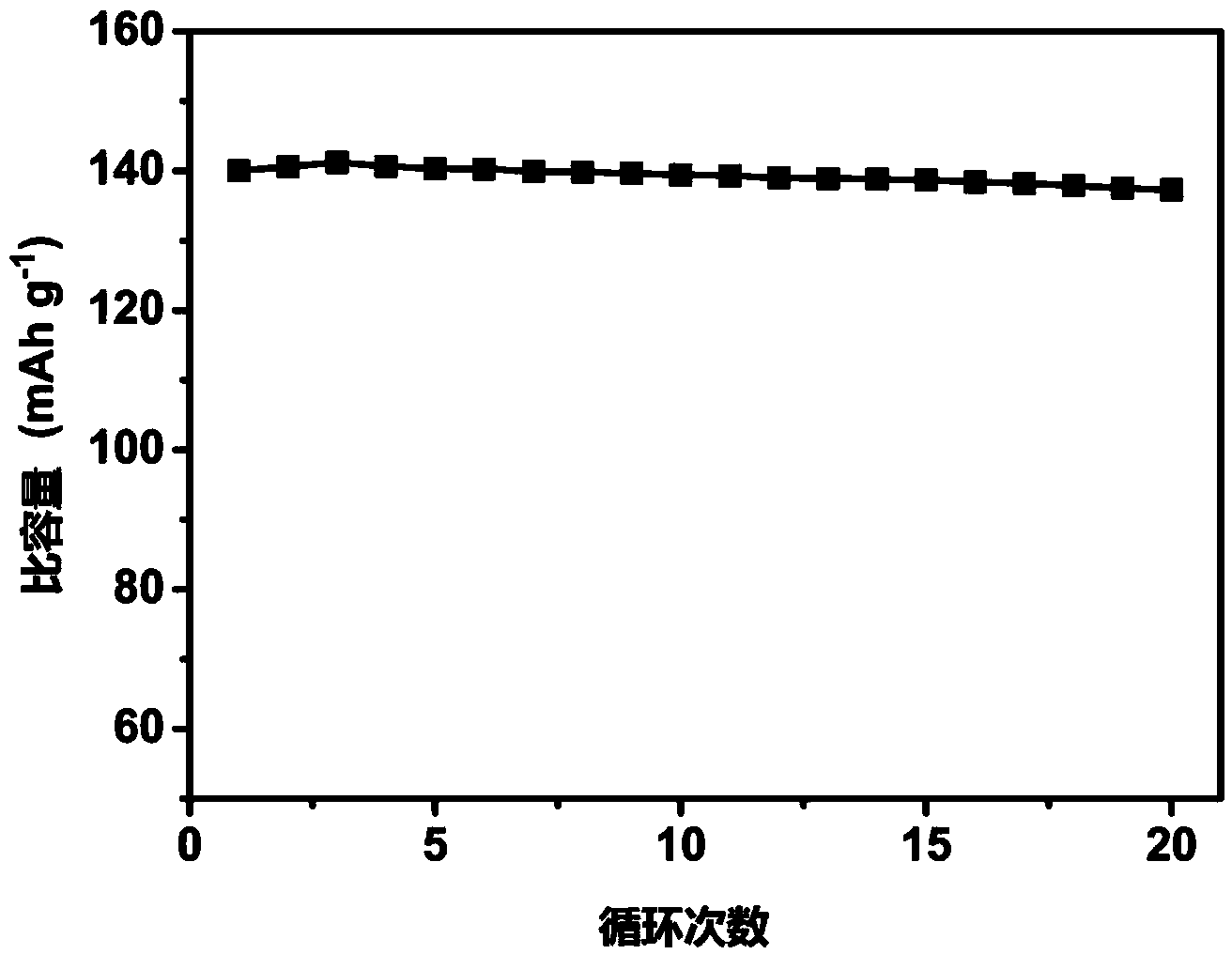

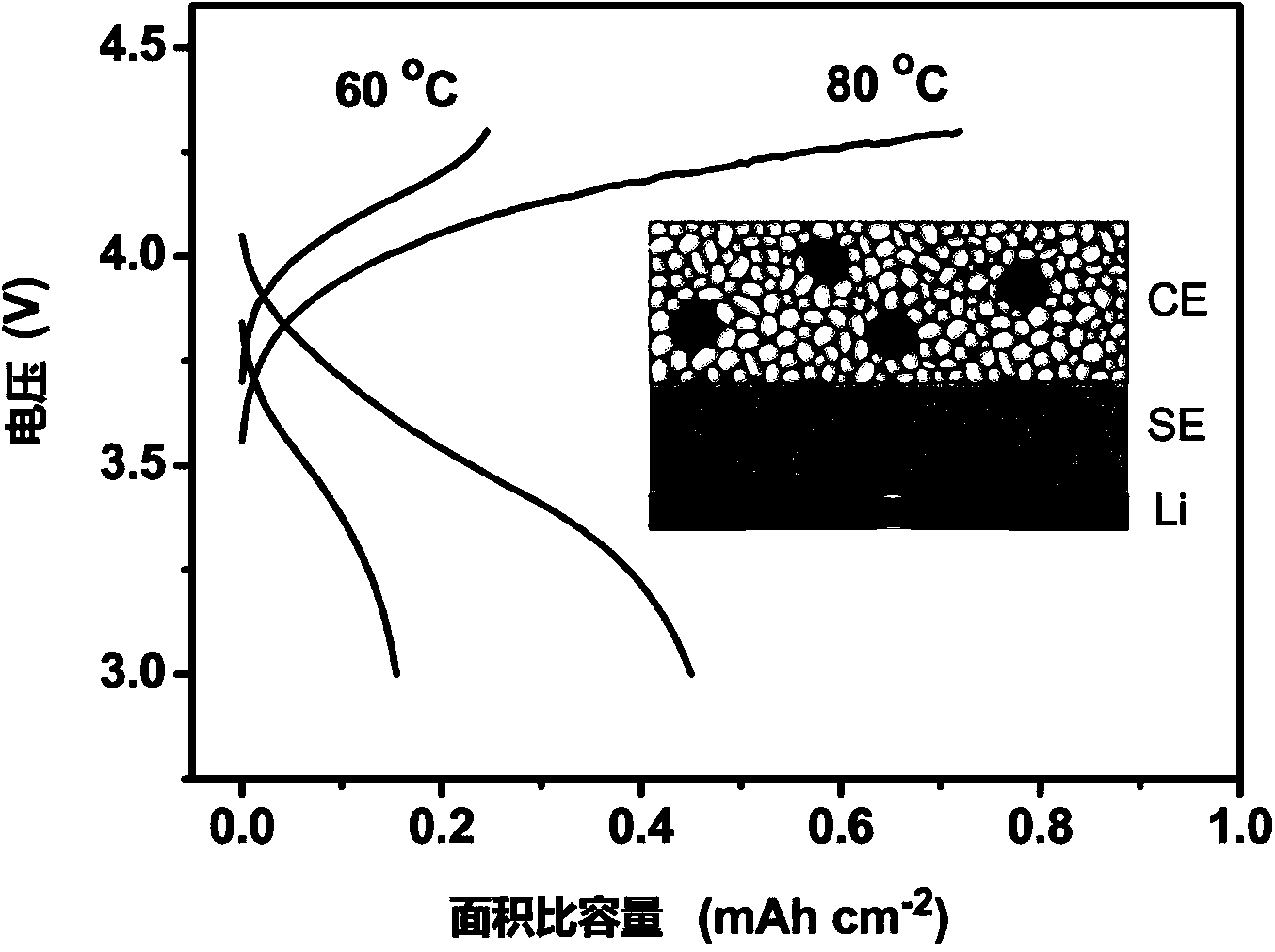

Composite positive electrode of lithium ion battery as well as preparation method and application to all-solid-state battery thereof

ActiveCN103956458AShorten migration distanceIncrease energy densityCell electrodesSecondary cellsSolid state electrolyteTin dioxide

The invention discloses a composite positive electrode of a lithium ion battery as well as a preparation method and application to an all-solid-state battery thereof. The composite positive electrode of the lithium ion battery comprises a positive active material, inorganic solid electrolyte and a conductive oxide additive, wherein the positive active material is any one of lithium cobaltate, lithium manganate, lithium iron phosphate and nickel-cobalt-manganese ternary material; the inorganic solid electrolyte is at least one of lithium borate, lithium metaborate and lithium fluoride; the conductive oxide additive is any one of indium tin oxide, indium oxide, tin dioxide, zinc oxide, nickel oxide and ferroferric oxide. The method comprises the steps of (1) mixing the positive active material, the inorganic solid electrolyte and the conductive oxide additive, carrying out ball milling, drying, and carrying out tabletting to obtain a ceramic piece; and (2) sintering the ceramic piece to obtain the composite positive electrode. The composite positive electrode is good in mass ratio capacity, area ratio capacity and cycle performance, can be used for preparing the all-solid-state lithium ion battery, and can be used at high temperature.

Owner:TSINGHUA UNIV

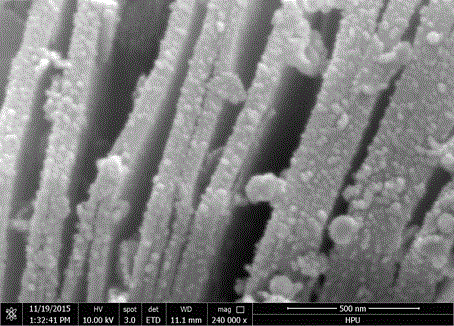

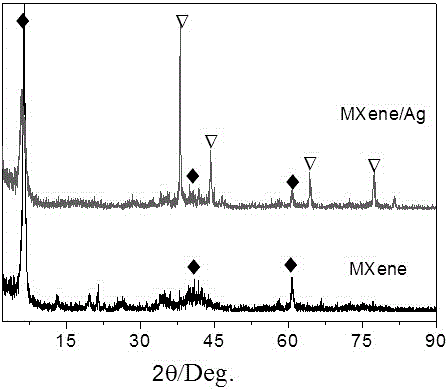

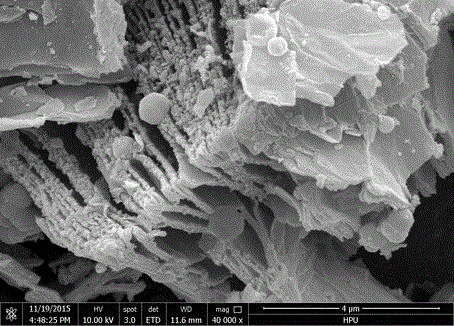

Two-dimension carbide loaded metal simple substance nano-powder, and preparation method and application thereof

InactiveCN105854913AAvoid uneven loadThe load is easy to controlPhysical/chemical process catalystsWater/sewage treatment by irradiationReducing agentLithium fluoride

The invention relates to two-dimension carbide loaded metal simple substance nano-powder, and a preparation method and an application thereof. The preparation method comprises the following steps: (1) soaking MAX phase ceramic powder in a hydrochloric acid solution in which lithium fluoride is dissolved, stirring, centrifugally separating, washing with deionized water and ethyl alcohol, drying and then acquiring solid powder, namely, two-dimension carbide; (2) dissolving the two-dimension carbide in a metal saline solution and preparing into a mixing solution; (3) adding a reducing agent aqueous solution into the mixing solution while stirring, reacting for 0.5-2h at room temperature, and washing and drying the solid precipitate acquired by centrifuging the turbid liquid after ending the reaction, thereby acquiring the two-dimension carbide loaded metal simple substance nano-powder. According to the invention, the uniform loading of metal simple substance nano-particles on the surface of the two-dimension carbide and between the layers is realized; according to the method, various metal simple substance nano-particles are loaded onto the two-dimension carbide; the prepared two-dimension carbide loaded metal simple substance nano-powder as a photocatalyst has excellent application prospect in the field of treating organic pollutants in sewage.

Owner:HENAN POLYTECHNIC UNIV

Lithium metal battery lithium negative electrode surface modification method, and lithium metal battery

ActiveCN108448058ASimple processEasy to operateElectrode manufacturing processesCell seperators/membranes/diaphragms/spacersHigh energyShielding gas

The invention discloses a lithium metal battery lithium negative electrode surface modification method, and a lithium metal battery. The modification method comprises the following steps: a lithium metal negative electrode is impregnated in or coated with a fluorine-containing ionic liquid in a dry protection gas atmosphere, is fluorinated, and is taken out to make a protection layer rich in lithium fluoride formed on the surface of the metal lithium negative electrode in order to obtain a lithium fluoride coated metal lithium negative electrode. The lithium fluoride protection layer obtainedby surface fluorination is very uniform and dense, and can reduce the consumption of lithium metal and an electrolyte and inhibit the formation of lithium dendrites in order to make the metal lithiumnegative electrode have a high specific discharge capacity, a long cycle life and a good safety, so the stability and the high efficiency of the lithium metal battery in a long cycle process are achieved, use requirements of a high-energy and high-power power battery are met, the industrialization process of the lithium metal battery is facilitated, and lithium metal battery has a wide applicationprospect.

Owner:SOUTH CHINA UNIV OF TECH

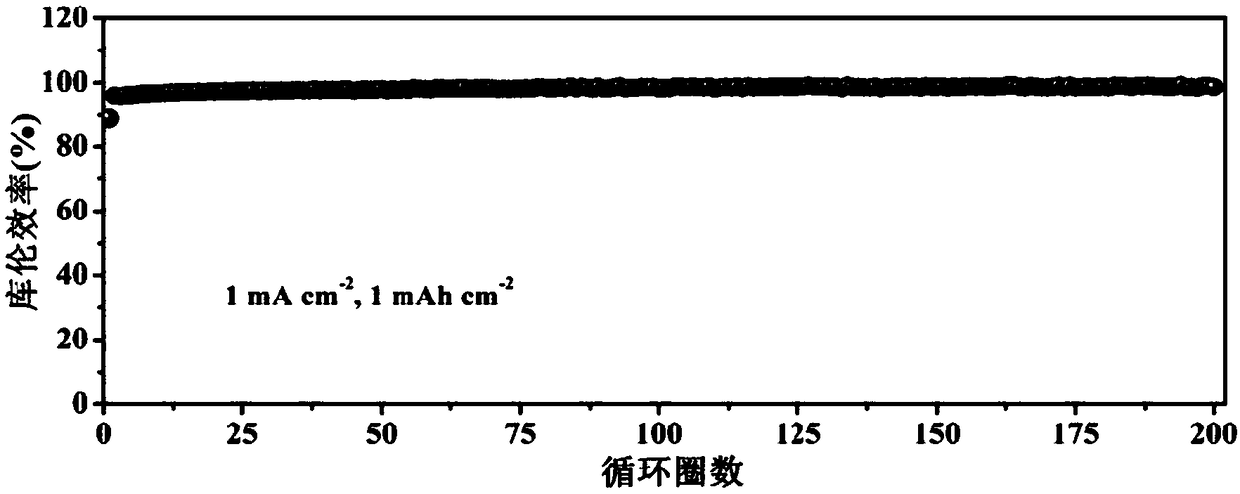

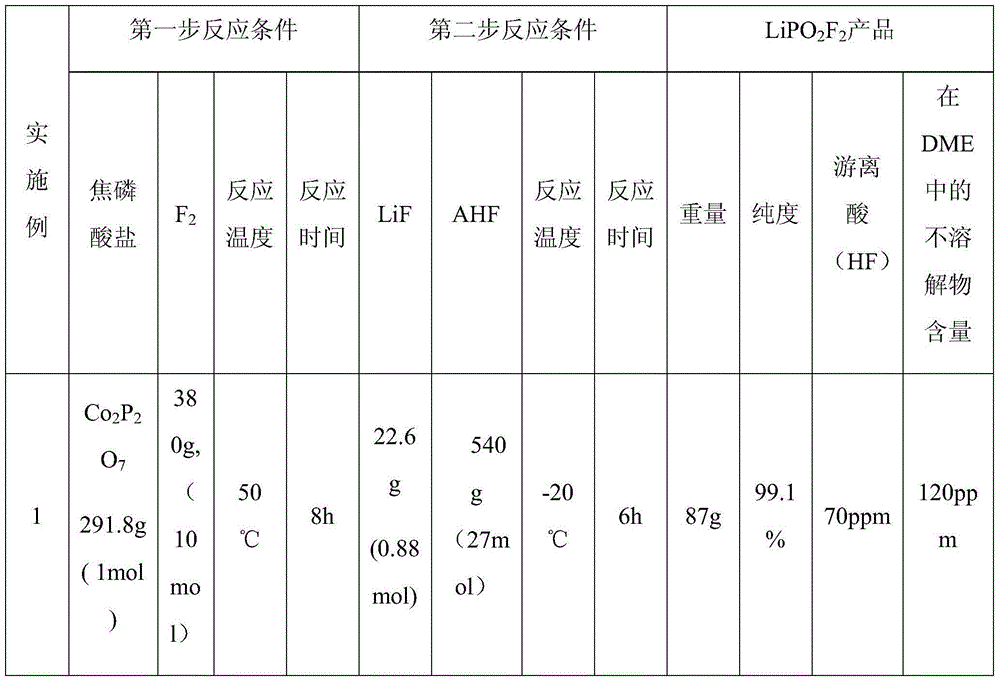

Preparation method of difluoro-lithium phosphate and lithium ion battery non-aqueous electrolyte

ActiveCN104445133AHigh purityEasy to purifySecondary cellsPhosphorus compoundsHydrogen fluoridePyrophosphate

The invention provides a preparation method of difluoro-lithium phosphate. The preparation method comprises the following steps: reacting pyrophosphate with fluorine to generate a mixed gas; introducing the obtained mixed gas into an anhydrous hydrogen fluoride solution of lithium fluoride for reaction, and crystallizing, filtering and drying after the reaction to obtain a difluoro-lithium phosphate product. The invention also provides a lithium ion battery non-aqueous electrolyte containing the difluoro-lithium phosphate prepared by the method. The preparation method provided by the invention has the advantages of simple process, low cost and high product purity.

Owner:ZHEJIANG KAISN FLUOROCHEM

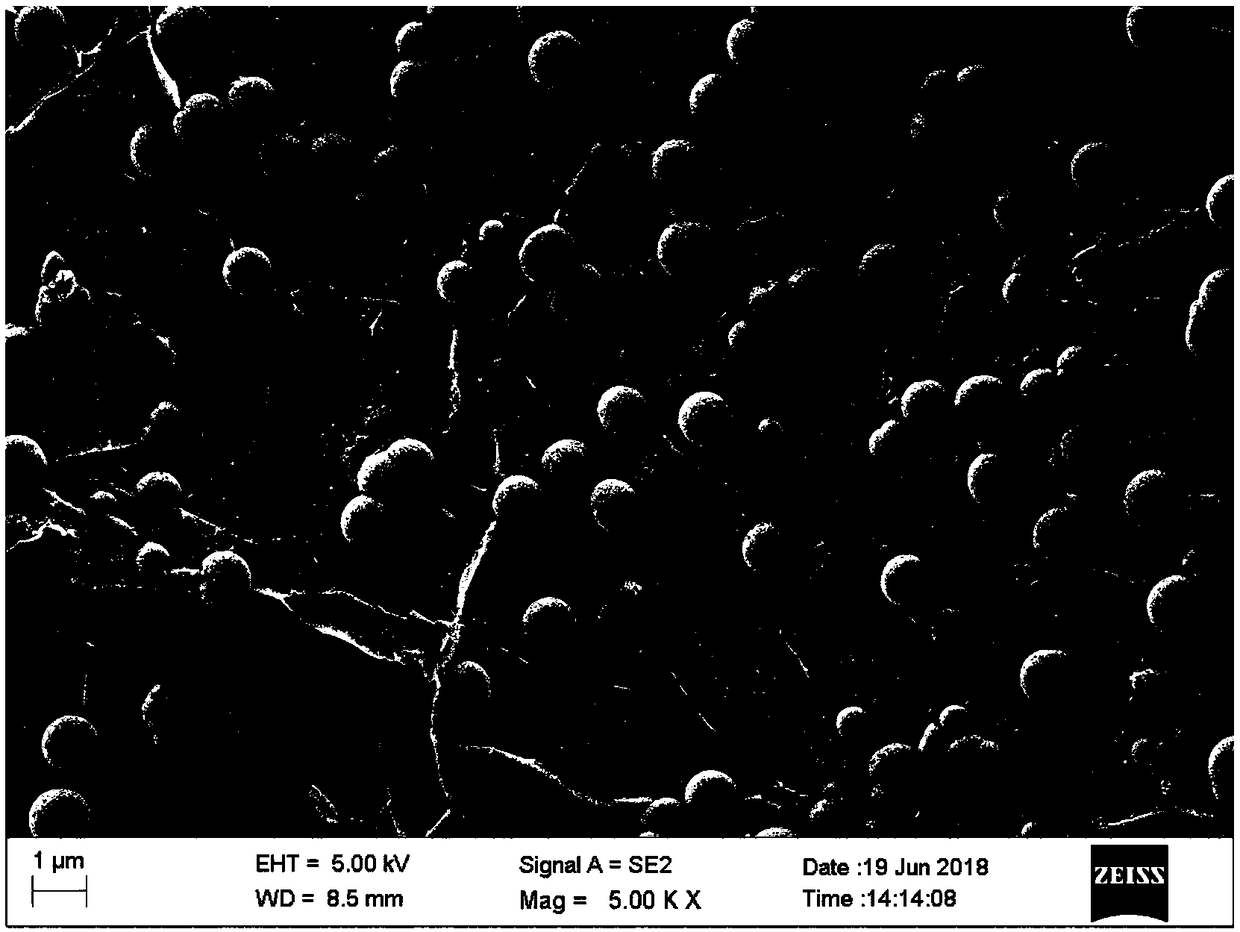

Flexible MXene self-supporting membrane/metal composite material and preparation method and application thereof

ActiveCN108987674ASimple processSave materialMaterial nanotechnologyElectrode manufacturing processesFiltrationMetal particle

The invention provides a preparation method for forming an electrode sheet on a flexible MXene self-supporting membrane through electroplating micro-nanometer metal particles. The invention belongs tothe preparation field of battery negative electrode materials. The technical scheme adopted by the invention is as follows: (1) etching stripping MAX with lithium fluoride and hydrochloric acid, centrifuging, washing, shaking and recentrifuging to obtain MXene suspension. (2) Flexible MXene self-supporting membrane was obtained by vacuum filtration. (3) Plating a layer of micro / nanometer metal particles on MXene film in electroplating bath at constant current or voltage. The flexible MXene self-supporting membrane prepared by the invention has good mechanical properties, It can not only simplify the process, save the cost and meet the needs of industrialization, but also can be used as negative electrode material to obtain batteries with high specific capacity, good cycling stability andbetter conductivity.

Owner:SHANDONG UNIV

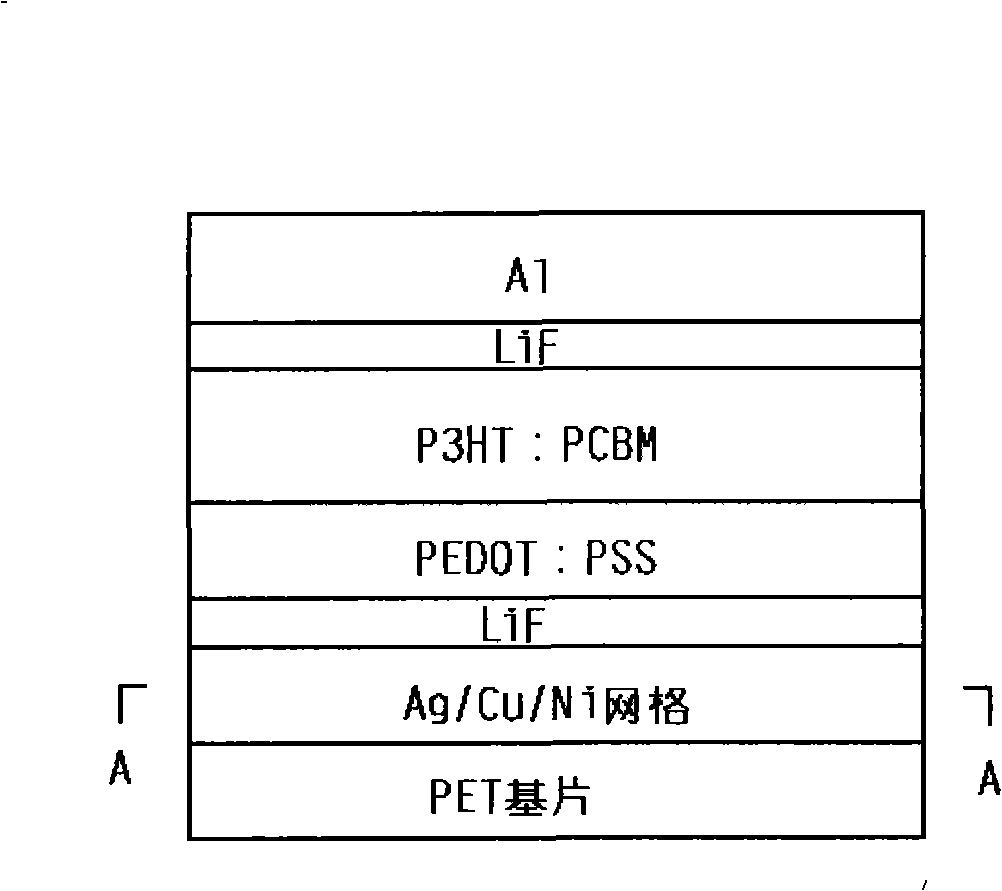

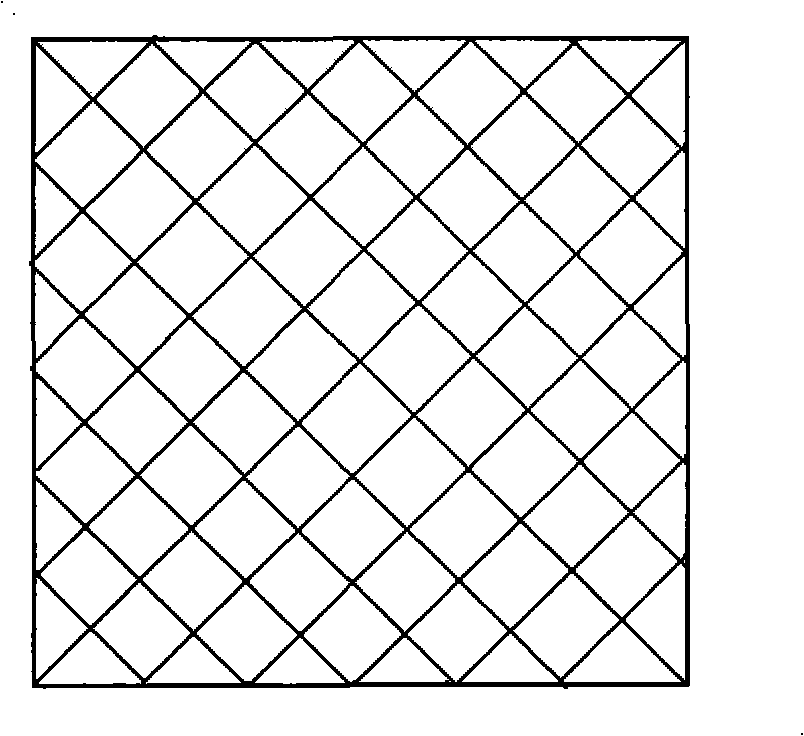

Flexible polymer solar battery of anode layer of metal grid and preparation method

InactiveCN101540371AImprove balanceImprove performanceVacuum evaporation coatingSolid-state devicesHole transport layerSolar battery

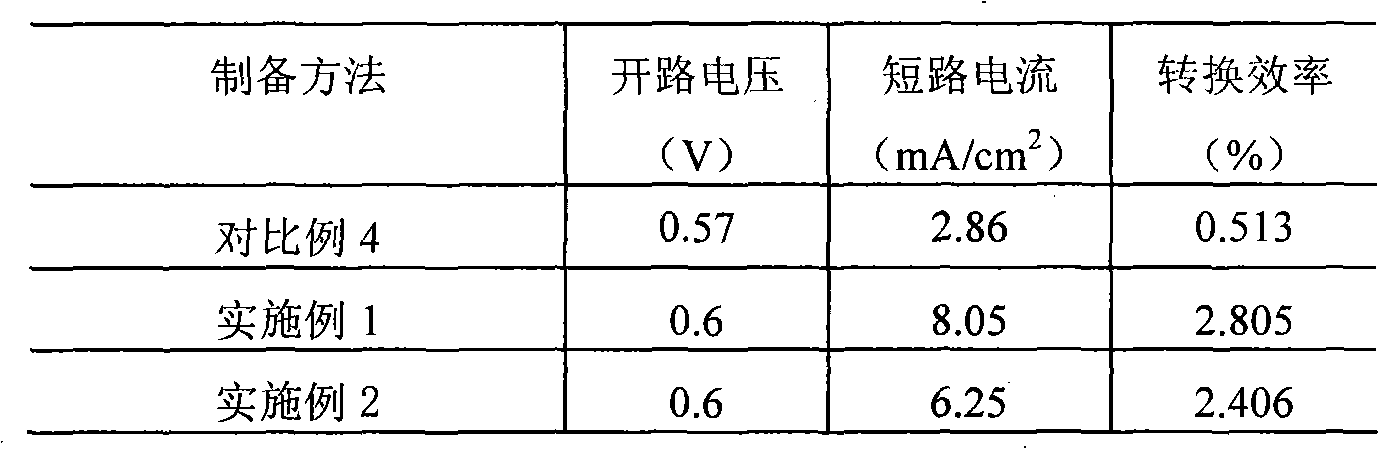

The invention relates to a flexible polymer solar battery of an anode layer of a metal grid, which comprises a flexible substrate, an anode layer, a hole transport layer, an active layer, an electron transfer layer and an Al electrode cathode and is characterized in that the anode layer is made from one or more of composition metal wire grid materials of Ag, Cu, and Ni. In the solar battery, a silver, copper and nickel (Ag: Cu: Ni) metal grid / LiF combined electrode is used as the anode; compared with the battery prepared by a common flexible substrate ITO electrode, the flexible solar battery prepared by taking P3HT / PCB as the active layer can show up better performance; after a layer of lithium fluoride (LiF) layer with the thickness of 2nm is added between the Ag: Cu: Ni metal grid and the polythiophene derivative doped polystyrolsulfon acid (PEDOT: PSS) layer, the film formation of PEDOT: PSS on the surface of the anode is improved, the balance between the hole and the electron transport is enhanced, and compared with the battery with the common flexible substrate ITO electrodes, the energy conversion efficiency is obviously improved.

Owner:HEBEI UNIVERSITY

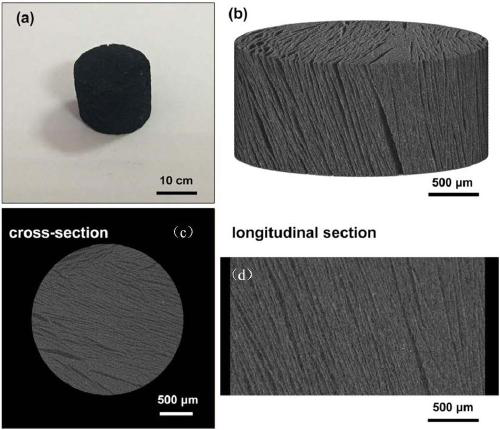

Preparation method of MXene/cellulose composite aerogel

InactiveCN109679146AHigh strengthImprove conductivityMagnetic/electric field screeningPorosityFreeze-drying

The invention relates to the field of aerogel and electromagnetic absorbing materials, in particular to a preparation method of MXene / cellulose composite aerogel. The preparation method includes the steps that firstly, MAX phase ceramic powder is added into a mixed water solution of lithium fluoride, hydrochloric acid and hydrofluoric acid in a certain proportion for etching to obtain MXene nano-powder; a cellulose sol method is adopted, cellulose powder is added into a mixed water solution of sodium hydroxide and urea in a certain proportion, and a transparent cellulose mixed solution is prepared by cooling the mixture to -12 DEG C; the temperature is maintained, the MXene nano-powder is added into the cellulose mixed solution, and then the appropriate amount of epichlorohydrin is added to the mixture and the mixture is stirred thoroughly for chemical crosslinking; the temperature is raised, and the obtained homogeneous mixture is subjected to a gel reaction; and a gel product is frozen directionally and then freeze-dried to obtain the MXene / cellulose composite aerogel. The composite aerogel has the characteristics of low density, high porosity, good absorbing performance, wide absorbing frequency band and the like, and is convenient to use and suitable for large-scale application in the aerospace field.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing difluorine oxalic acid boracic acid lithium

InactiveCN101139352AImprove solubilityImprove high temperature cycle performanceGroup 3/13 element organic compoundsLithium compoundLithium-ion battery

The present invention discloses a preparation method of the difluoride lithium oxalate borate. The method is characterized in that the compounds containing the fluorin, boron, lithium and oxalate react at a certain temperature and under a certain pressure to produce the crude material of the difluoride lithium oxalate borate; then the organic solvent is used for extracting and purifying; finally, the recrystallization and vacuum drying are done to get the battery-level lithium fluoride oxalate borate. The advantage is that the preparation method of the difluoride lithium oxalate borate can improve the high-temperature and low-temperature performance, the cycle performance, power characteristics and other comprehensive performances of the lithium-ion battery.

Owner:ZHANGJIAGANG GUOTAI HUARONG NEW CHEM MATERIALS CO LTD

Methods for preparing phosphorus pentafluoride gas and preparing lithium hexafluorophosphate using the gas

ActiveCN101353161AEasily hydrolyzedStrong moisture absorptionPhosphorus halides/oxyhalidesLithiumPhysical chemistry

A preparation method of phosphorus pentafluoride gas comprises a step of causing phosphorus pentachloride to react with anhydrous hydrogen fluoride, wherein, the reaction occurs in the presence of a solvent. A preparation method of lithium hexaflourophosphate comprises a contact reaction between solid lithium fluoride and phosphorus pentafluoride gas, wherein the phosphorus pentafluoride gas is prepared by the method of the invention. Compared with the preparation method of the lithium hexaflourophosphate with the phosphorus pentafluoride gas as the raw material in the prior art, the phosphorus pentafluoride gas prepared by the preparation method of the invention has higher purity and lower cost. The yield of the lithium hexaflourophosphate prepared by the method of the invention is higher than 93%, and the purity thereof is up to 99.95%.

Owner:BYD CO LTD

Plating solution of magnesium alloy nickle sulfate main salt and technology of chemical plating thereof

InactiveCN1598053ALow priceReduce manufacturing costLiquid/solution decomposition chemical coatingChemical platingThiourea

The invention discloses a plating solution of magnalium alloy Nickel sulfate and its chemical plating technique. The plating solution is made up of: (1) 5 to 40g.dm-3 of Nickel sulfate, (2) 10 to 50g.dm-3 of reducing agent of hypo-phosphite sodium; (3) one or several of the 2.5 to 30g.dm-3of the citric acid or tri-sodium citric acid, 2.5 to 30g.dm-3of the lactic acid, 2.5 to 30g.dm-3of the acetic acid, 2.5 to 30g.dm-3of the malic acid, 2.5 to 30g.dm-3 of the third acid and 2.5 to 30g.dm-3of the buta-acid; (4) one or several of the 5 to 30g.dm-3of Potassium fluoride, 5 to 30g.dm-3of sodium fluoride, 5 to 30g.dm-3of lithium fluoride and 5 to 30g.dm-3of NH4HF2; (5) 0.1 to 3g.dm-3of sulphur carbamide. The plating steps include: washing with ultrasonic->washing with alkali->washing with acid->activation->dipping it in the zinc solution->getting rid of the activation solution->secondary dipping it in the zinc solution->chemical plating->passivation and sealing the holes. The invention is featured by little pollution to the environment, low cost, uniform film and simpel technique.

Owner:HUNAN UNIV

Preparation method of lithium fluoride

InactiveCN102030344AHigh yieldYield over 97%, high purityLithium halidesHydrofluoric acidLithium hydroxide

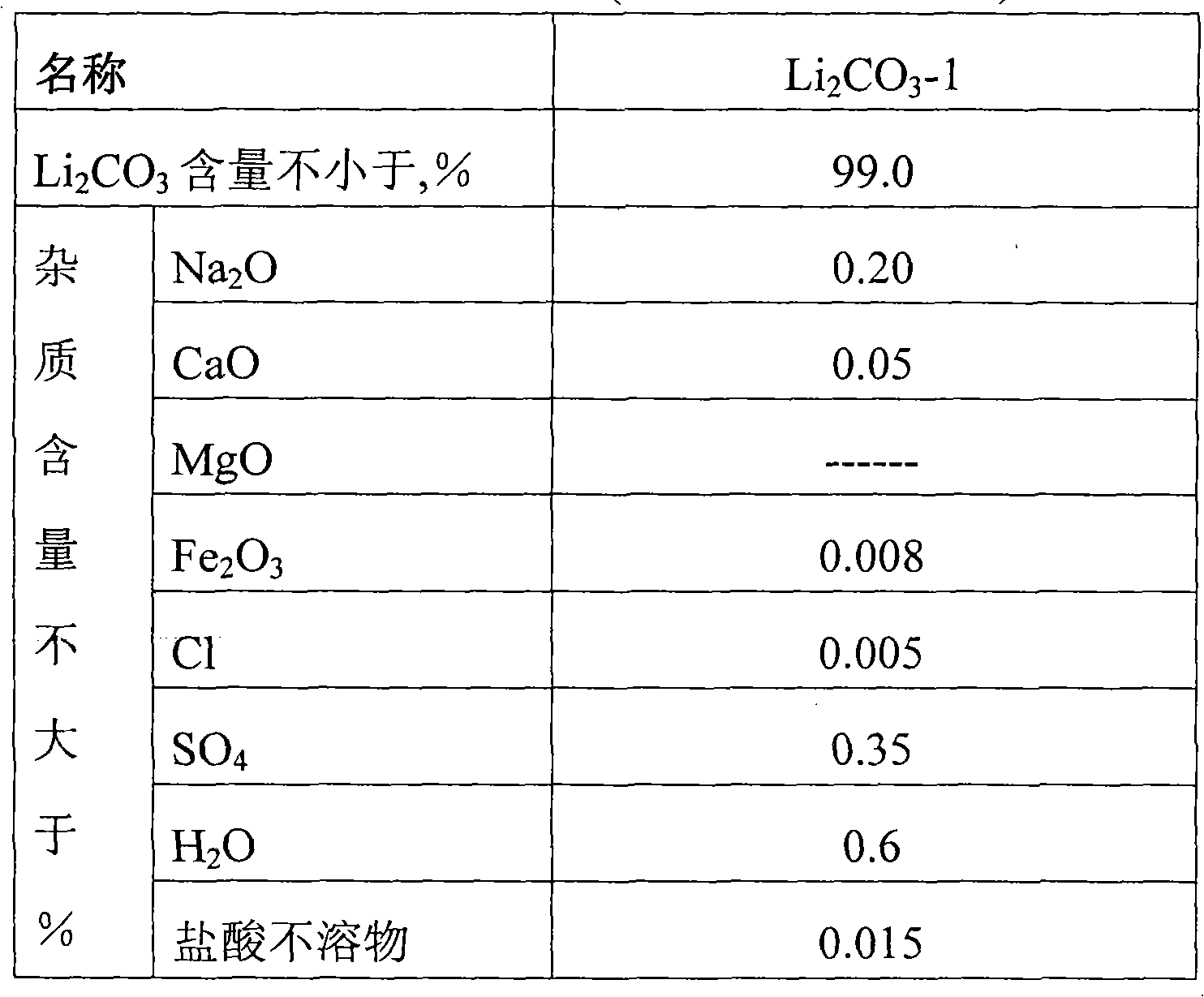

The invention provides a preparation method of lithium fluoride, which comprises the following steps: (1) introducing carbon dioxide into water, then adding the raw material lithium carbonate to obtain a lithium bicarbonate solution, then adding a precipitant, introducing carbon dioxide until the pH of the solution is 8-9, filtering, and collecting the lithium bicarbonate solution; and (2) adding hydrofluoric acid to the filtrate obtained in the step (1), carrying out fluoridation, then adding a lithium hydroxide solution, regulating the pH of the system to be 7-7.5, then filtering, collecting the filter cake, and drying to obtain the product lithium fluoride. In the invention, the industrial grade lithium carbonate is used, the total yield of the technical process achieves more than 97%, the purity is as high as 99.9% or above, and the impurity content in the product is as low as 80PPm or below.

Owner:SHANGHAI CHINA LITHIUM INDAL

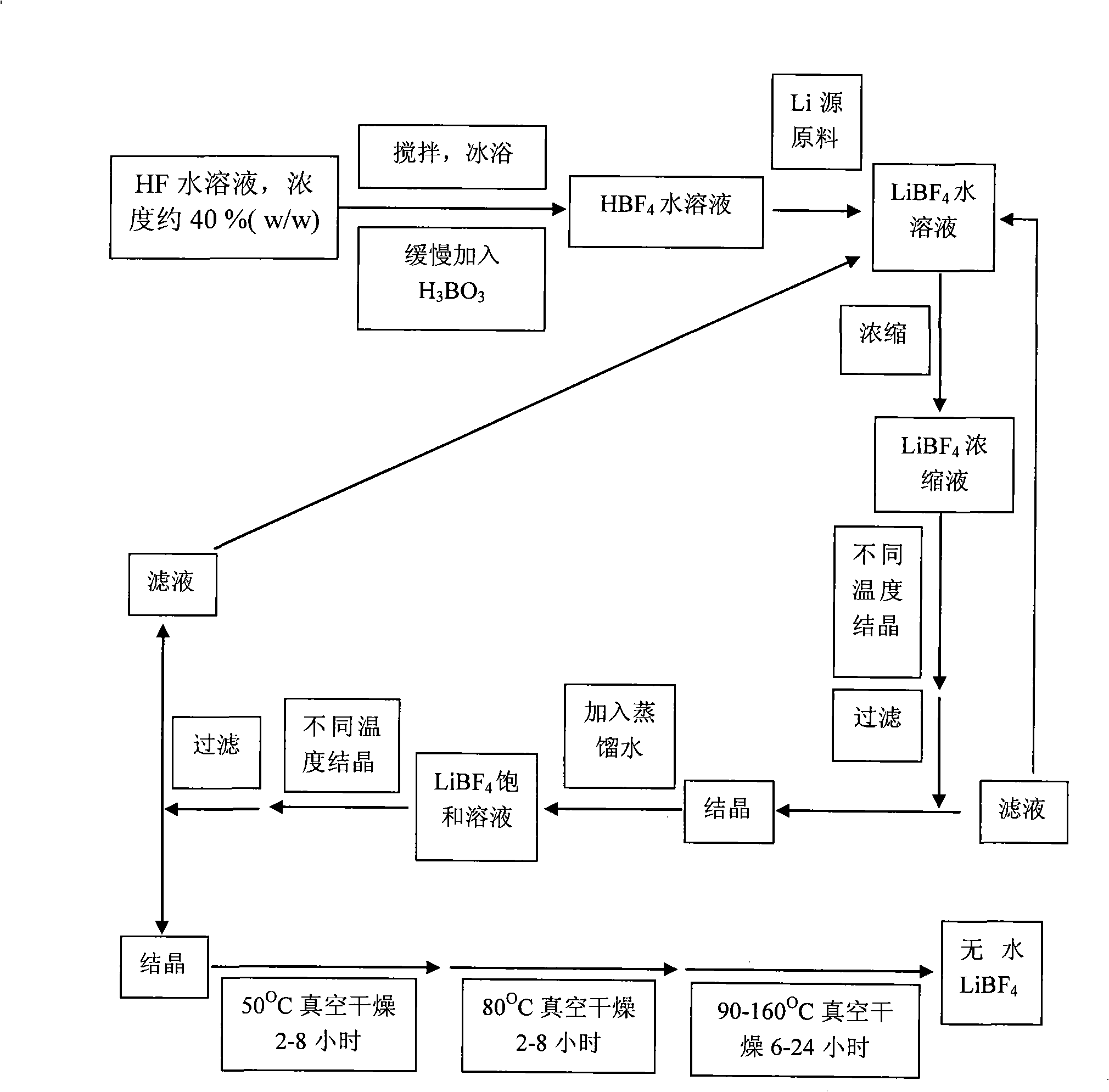

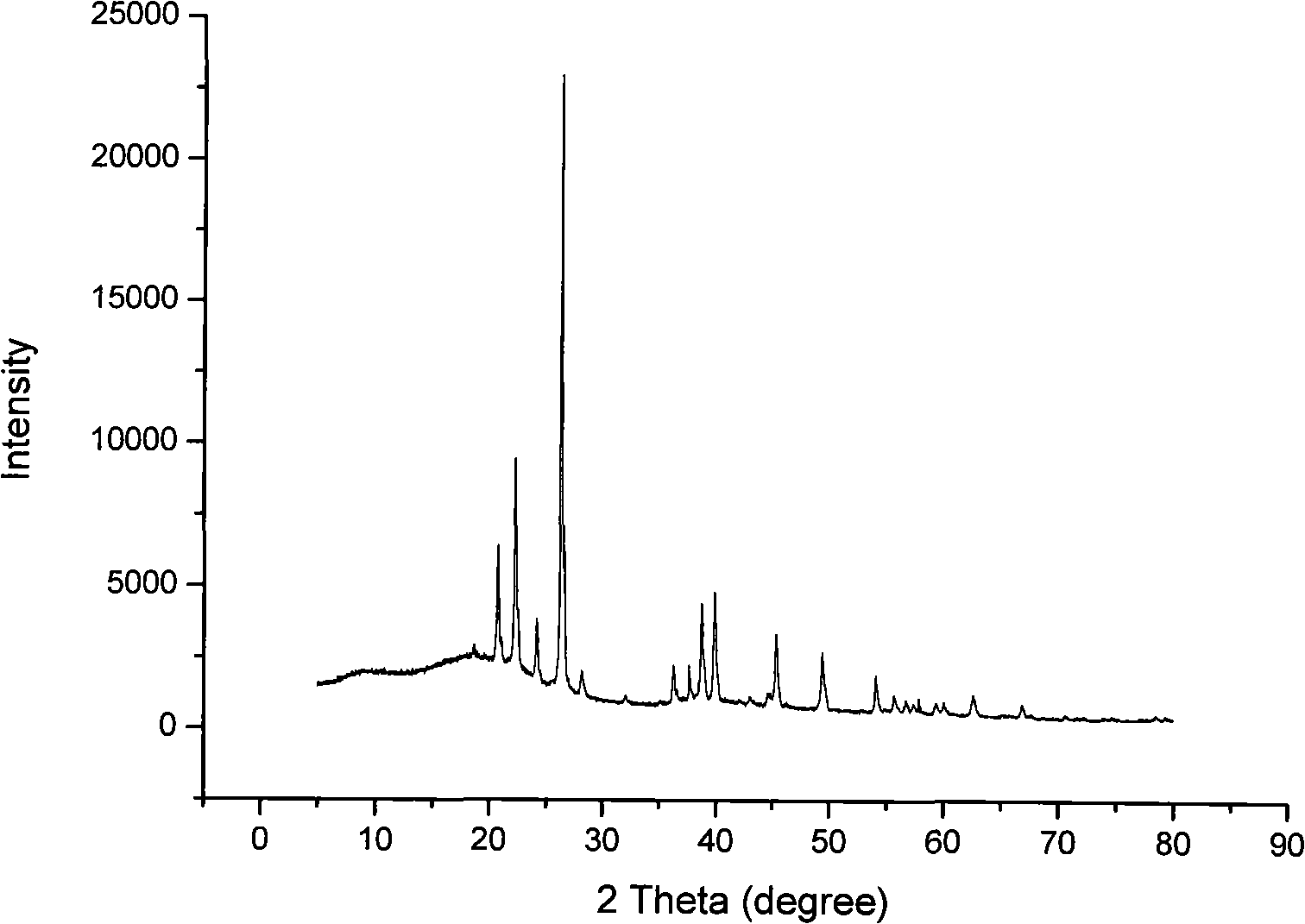

Method of preparing waterless lithium terafluoroborate

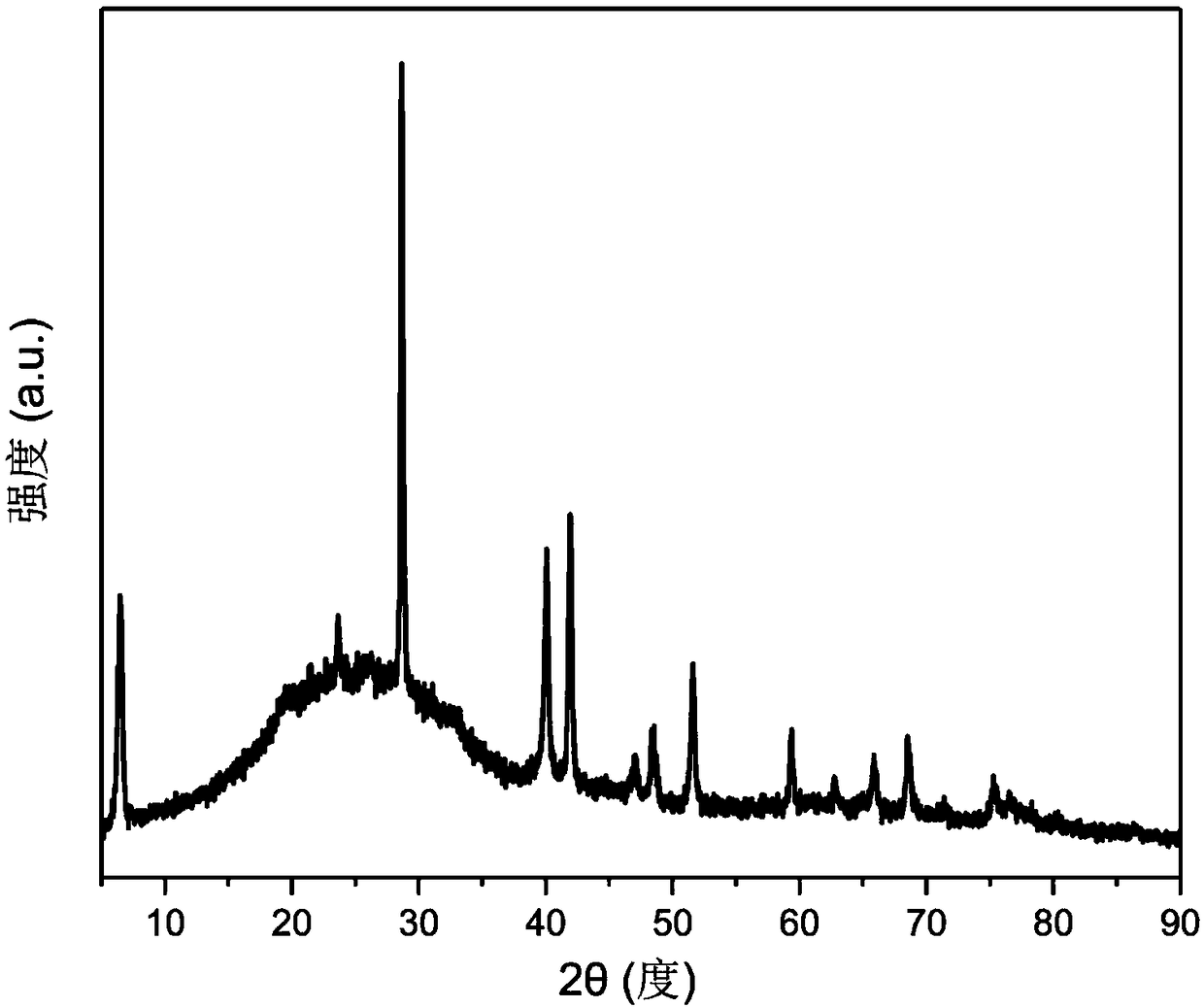

InactiveCN101318664AThe product quality is quiteEfficient removalTretrafluoboric acidLithium hydroxideX-ray

The invention relates to a method for preparing an anhydrous lithium tetrafluoroborate which comprises the following steps: a lithium source including lithium hydroxide, lithium carbonate, and the like, reacts with fluorine hydride and boric acid to obtain lithium tetrafluoroborate solution, then the lithium tetrafluoroborate solution is condensed, crystallized and recrystallized, ground, and vacuum dried to obtain the anhydrous lithium tetrafluoroborate. The method of the invention adopts a staged temperature rise control, the process of the preparation is simple, raw materials are cheap and the preparation cost is low, no organic solvent is used during the synthetic process, no poison is produced, therefore, the method accords with the concept of green environmental protection, the anhydrous lithium tetrafluoroborate prepared by the method is determined by a X-ray diffraction map, the diffraction peak is clear and sharp and completely matches the standard card, which shows that the product prepared by the method of the invention is anhydrous LiBF4 with complete crystal form, the quality of the product is equal to the quality of the anhydrous lithium tetrafluoroborate prepared by the reaction of lithium fluoride and boron trifluoride.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

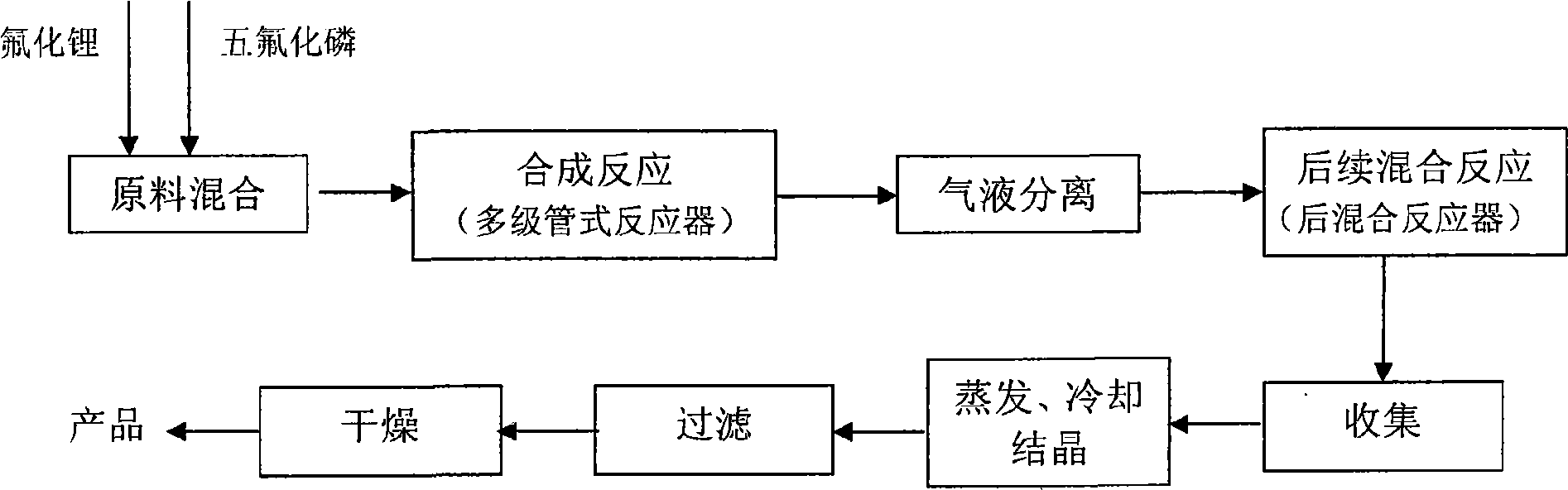

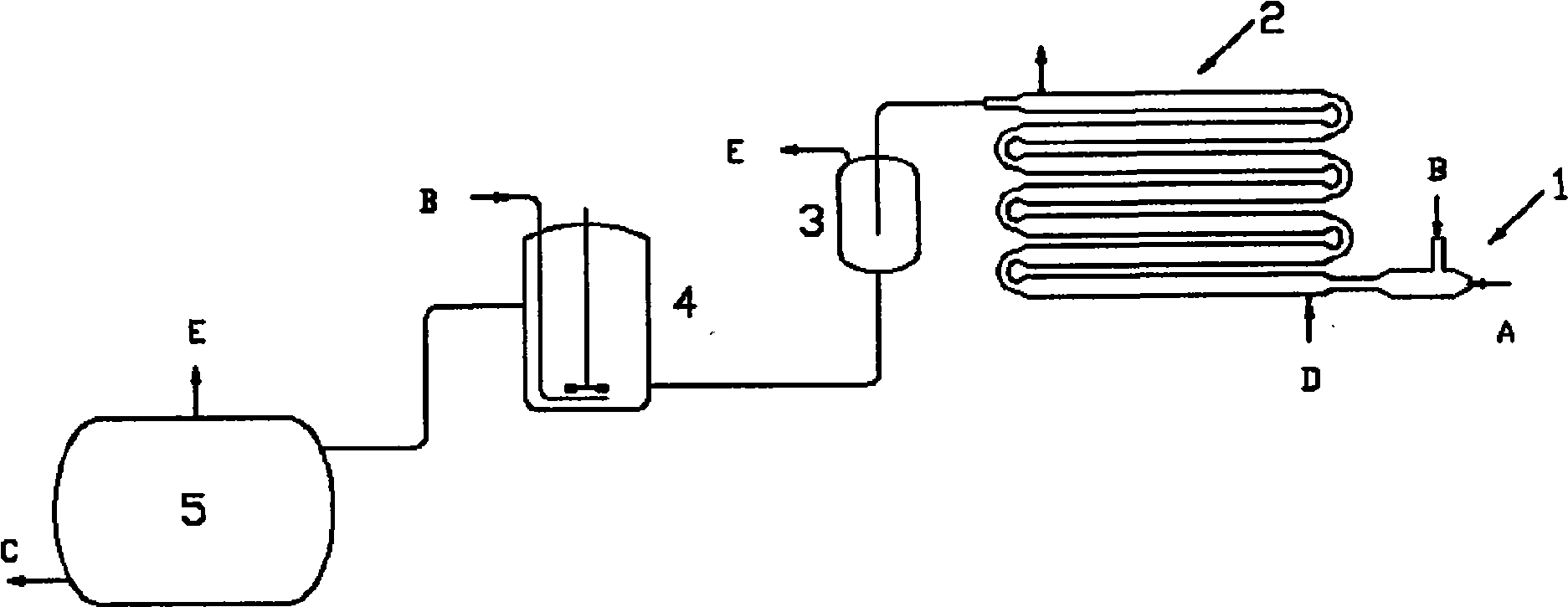

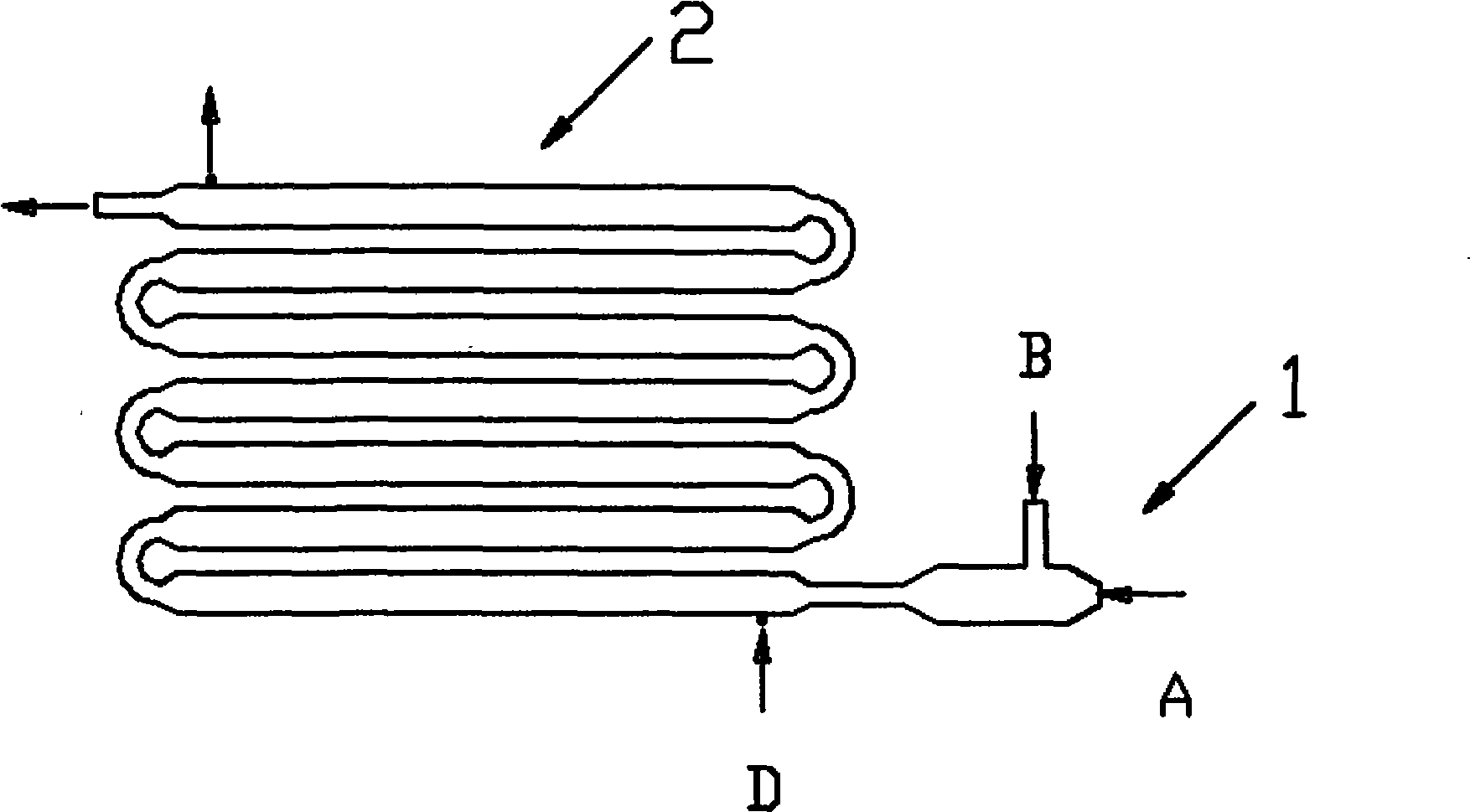

Process and device for continuous preparation of lithium hexafluorophosphate

ActiveCN101544361AAchieve conversionAchieve serializationSecondary cellsPhosphorus compoundsLiquid productFiltration

The invention discloses a process for the continuous preparation of lithium hexafluorophosphate and a device thereof. The process comprises the following steps that: a fluorine hydride solution A of lithium fluoride and phosphorus pentafluoride or a mixed gas of the phosphorus pentafluoride and other gases are subjected to raw material mixing; the raw material mixture undergoes a multistage synthetic reaction; the product of the multistage synthetic reaction enters a gas-liquid separator to remove unreacted gases; the liquid product of the multistage reaction undergoes a consequent hybrid reaction and the product of the consequent hybrid reaction is reacted with the additionally introduced phosphorus pentafluoride gas B to remove a micro amount of possibly unreacted lithium fluoride in the solution; the product of the reaction is then subjected to evaporation, cooling, crystallization, filtration and drying to form lithium hexafluorophosphate crystal with a purity of 99.9 percent; and a parent solution obtained after separation and crystallization is added with the lithium fluoride to form the raw material solution A for cycle use. The invention adopts a multistage tubular reactor which has excellent mass and heat transfer performance and can realize full gas-liquid contact, continuous material feeding and discharging and the like and consequently realize the continuous operation of a production process.

Owner:산산어드밴스드머테리얼스(취저우)컴퍼니리미티드

Preparation method of surface organic modified titanium carbide nanosheet

PendingCN108557822ALess corrosiveImprove operational safetyTitanium carbideNanotechnologyHeat stabilityHigh surface

The invention relates to a preparation method of a surface organic modified titanium carbide nanosheet, belonging to the technical field of preparation of nano materials. The preparation method comprises the following steps: etching an aluminum atom layer in titanium aluminum carbide by virtue of a mixed solution of lithium fluoride and hydrochloric acid so as to prepare titanium carbide precipitates, re-dispersing the titanium carbide precipitates into water, carrying out ultrasonic treatment and centrifugation so as to remove precipitates, and extracting supernatant liquid, so as to obtain titanium carbide nanosheet suspension liquid; and finally adding a surfactant water solution to react, so as to obtain the surface organic modified titanium carbide nanosheet. Compared with a method for etching titanium aluminum carbide by virtue of hydrofluoric acid, the method for preparing titanium carbide by etching the aluminum atom layer in titanium aluminum carbide by virtue of the mixed solution of lithium fluoride and hydrochloric acid has the advantages that the corrosivity is reduced, and the operation safety is improved; and the surface organic modified titanium carbide nanosheet prepared by virtue of the preparation method has relatively high surface activity and heat stability, has good compatibility with high-molecular materials and can be uniformly dispersed into the high-molecular materials, so that the mechanical properties, flame retardance and thermal properties of the high-molecular materials are improved.

Owner:HEFEI UNIV

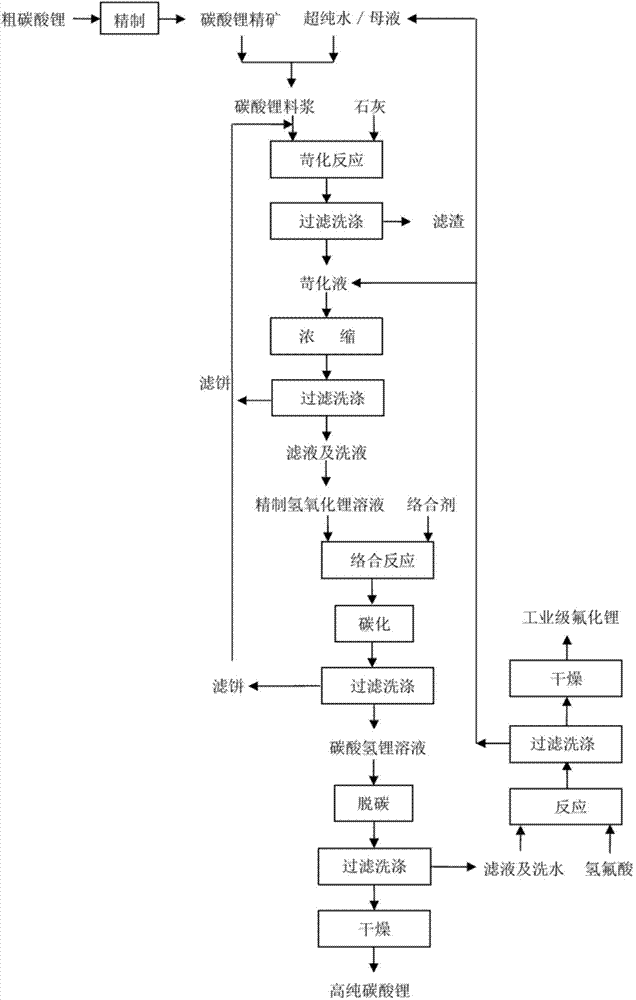

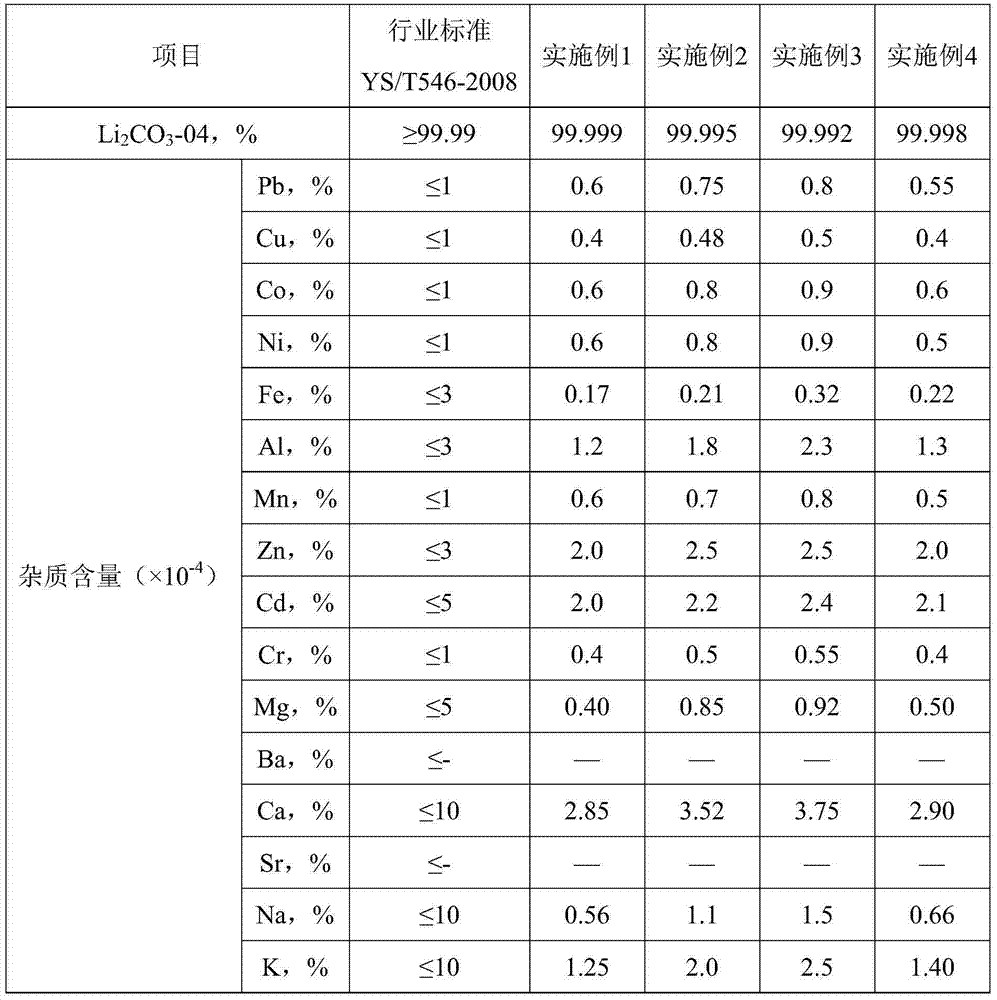

Method for preparing high-purity lithium carbonate with co-production of lithium fluoride by employing crude lithium carbonate

ActiveCN104326495ASolve the single preparation raw materialSolve the costProductsReagentsLithium hydroxideCarbonization

The invention discloses a method for preparing high-purity lithium carbonate with co-production of lithium fluoride by employing crude lithium carbonate. The method includes following steps: (1) preparing the crude lithium carbonate into lithium carbonate concentrate; (2) preparing the lithium carbonate concentrate into a slurry material with addition of lime and performing filtration to obtain a crude lithium hydroxide solution; (3) concentrating and filtering the crude lithium hydroxide solution, adding a complexing agent to remove impurity metal ions to obtain a refined lithium hydroxide solution; (4) feeding CO2 into the refined lithium hydroxide solution for carbonization and performing filtration to obtain a lithium bicarbonate solution; and (5) heating the lithium bicarbonate solution, performing a filtering and washing process, drying a filter cake to obtain the high-purity lithium carbonate, mixing the filtrate and a washing liquid with addition of hydrofluoric acid, performing a filtering and washing process, and then drying the filter cake to obtain the lithium fluoride. By means of the method, impurity ions in the high-purity lithium carbonate is in the trace-amount grade. The quality of the high-purity lithium carbonate is better in an industrial requirement in YS / T546-2008. Problems of poor quality, low lithium yield and high production cost in preparation of the high-purity lithium carbonate from salt lake lithium are solved.

Owner:河南省氟基新材料科技有限公司

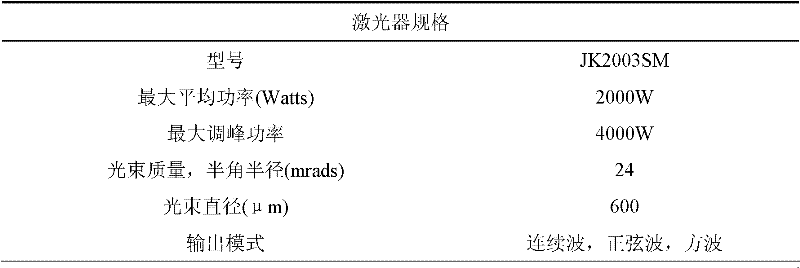

Active agent for laser welding and method for laser welding by utilizing same

InactiveCN102179645AStrong penetrating powerIncrease profitWelding/cutting media/materialsSoldering mediaAluminium chlorideLithium chloride

The invention discloses an active agent and a method for carrying out surface treatment on materials to be welded of aluminium and aluminium alloys so as to improve the energy utilization rate of the aluminium and the aluminium alloys, deepen the fusion depth of welding seams and further obtain higher welding quality. The active agent for laser welding consists of a chloride and a fluoride, wherein the mass ratio of the chloride to the fluoride is (1-2): (1-4); the chloride is at least one of lithium chloride, sodium chloride, potassium chloride, zinc chloride, magnesium chloride, aluminium chloride, calcium chloride or tin chloride; and the fluoride is at least one of lithium fluoride, sodium fluoride, magnesium fluoride or calcium fluoride. When the surface treatment is carried out, firstly the fluoride and the chloride are mixed fully and uniformly, water is added to form a supersaturated solution, then the supersaturated solution is coated on the surface of a welded test piece as a coating agent, then drying is carried out, and finally laser welding is carried out under the condition of gas protection.

Owner:TIANJIN UNIV

Brazing flux without corrosion for aluminum and aluminum alloy brazing

InactiveCN101439449ASimple preparation processLow costWelding/cutting media/materialsSoldering mediaPotassium fluorideTin Fluorides

The invention relates to a corrosion-free soldering flux used for braze welding aluminium and aluminium alloy. Counted by weight percentage, the soldering flux used for braze welding the aluminium and aluminium alloy comprises the following components: 32.0-34.0 percent of cesium fluoride, 44.0-46.5 percent of aluminium fluoride, 20.5-23.5 percent of potassium fluoride, 0.5-2.5 percent of one, two or three materials selected from tin fluoride, zinc fluoride and lithium fluoride. The corrosion-free soldering flux of the invention has low melting point and better soldering performance.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

Method for preparing potassium hexafluoro phosphate

The invention relates to Li ion battery technique, a lithium hexafluoro- phosphate preparing method, characterized in comprising the process steps of: using easy sublimation property of phosphorus pentachloride, heating and sublimating it to remove nonvolatile components, refining industrial anhydrous hydrogen fluoride to remove water and heavy metal impurities; reacting them with each other to prepare mixed gas of phosphorus pentachloride and hydrogen chloride; leading the mixed gas into anhydrous hydrogen fluoride of lithium fluoride, reacting, crystallizing and separating and drying to obtain pure lithium hexafluoro-phosphate.

Owner:TIANJIN CHEM RES & DESIGN INST

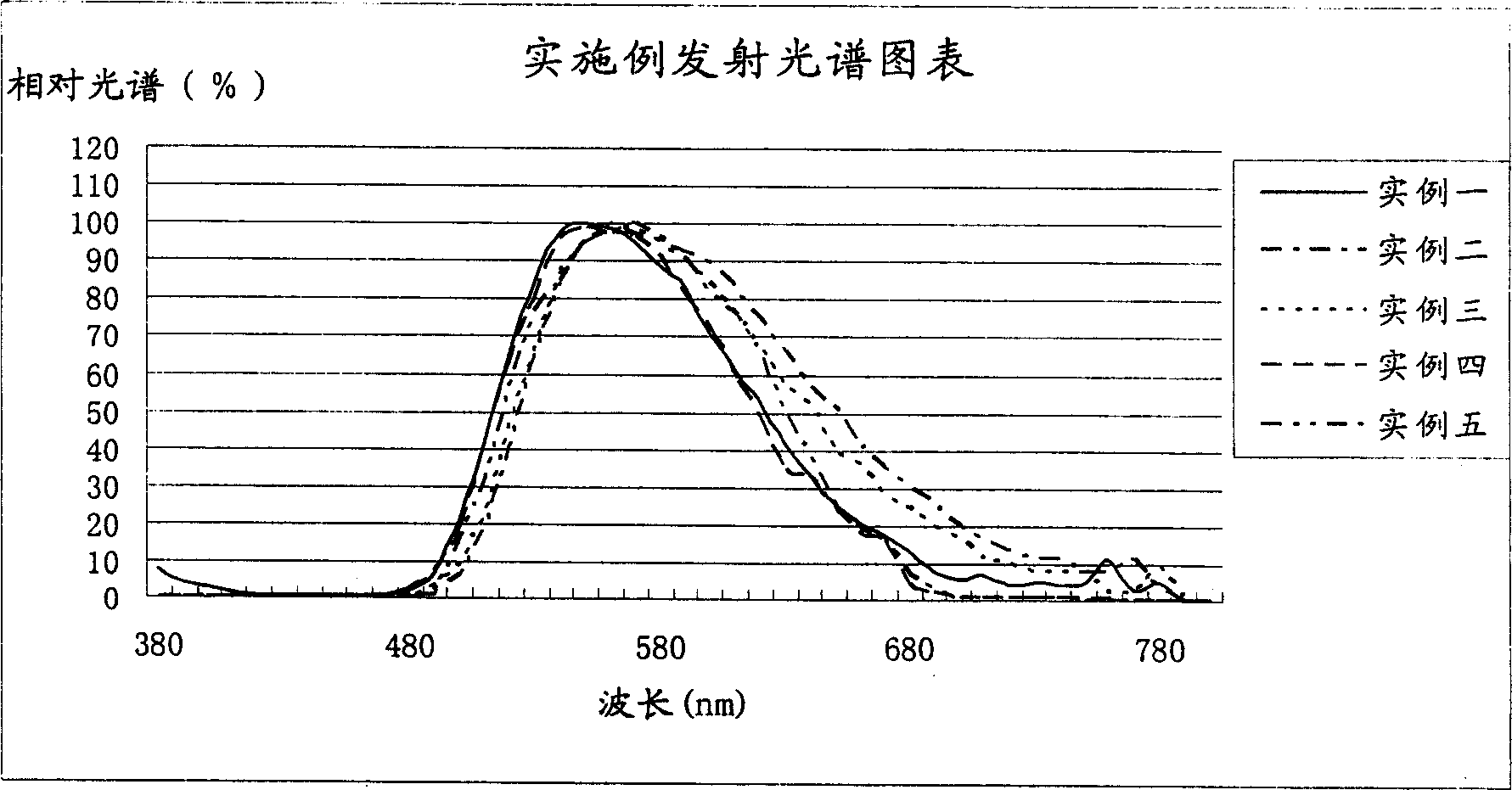

Synthesis of YAG luminescent material for white LED

InactiveCN1818016AImprove luminous brightnessLow attenuation characteristicsGas discharge lamp usageLuminescent compositionsLithium chlorideRare earth

Synthesis of yttrium aluminum garnet luminescent material for white light LED is carried out by proportioning by chemical component formula (Y1-x-yMyCex) 3Al5O12, weighing raw material, mixing with flux additive, putting into corundum crucible, firing in oxidation atmosphere furnace, crushing, mesh screening, acid washing by dilute nitric acid solution to indifference, extraction filtering, drying powders, firing the powder at reduction atmosphere, and screen grading to obtain the final product. It uses two kinds or above of boric acid, barium fluoride, strontium fluoride, lithium chloride or lithium fluoride as composite flux and mixes with other rare earth or metal oxide. It has excellent single crystal particular growth, powder fluidity, better brightness and low decrement.

Owner:常熟市江南荧光材料有限公司

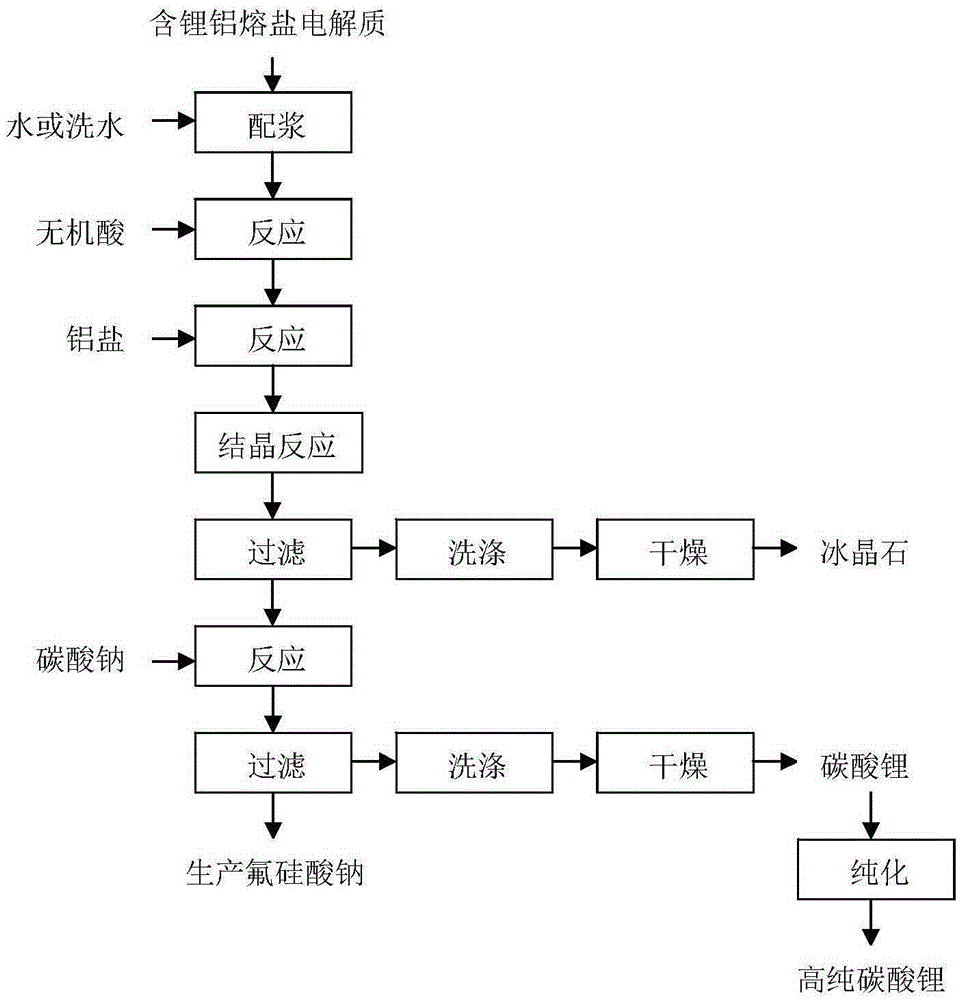

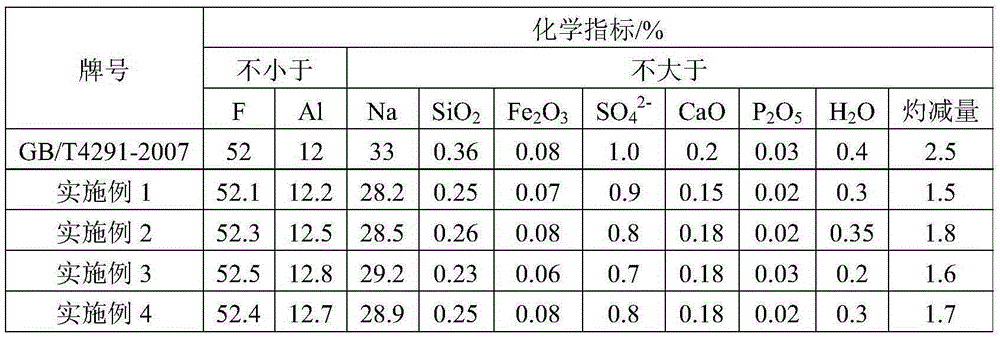

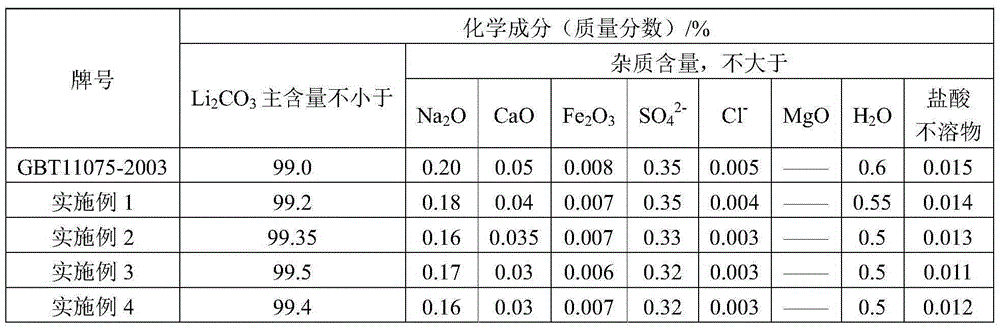

Lithium-aluminum-contained electrolyte comprehensive recycling method

ActiveCN105349786AImprove qualityRunning balance and stabilityProcess efficiency improvementLithiumSlurry

Owner:DO FLUORIDE CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com