Preparation method of MXene/cellulose composite aerogel

A composite airgel and cellulose technology, applied in the direction of electrical components, magnetic field/electric field shielding, etc., can solve the problems that MXene cannot be prepared into airgel materials, low microwave absorption performance, low conductivity, etc., and achieve excellent reflection loss , high absorption, enhanced conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

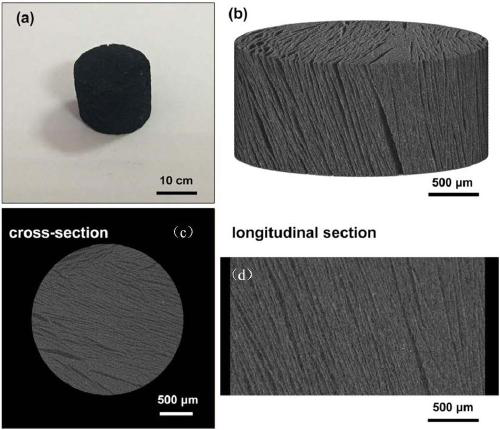

[0030] In this embodiment, the preparation method of MXene / cellulose composite aerogel is as follows:

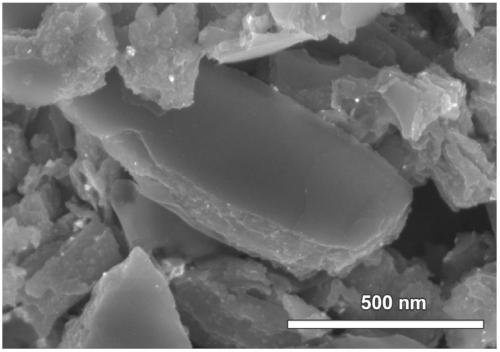

[0031] 1. Named Ti by chemical etching 3 AlC 2 MAX Phase Ceramic Powder Preparation of Ti 3 C 2 . In a typical chemical etching process, the molar ratio of LiF, HCl, HF and water is n(LiF):n(HCl):n(HF):water = 2:3:1:100, in 500 ml poly Gently stir in the acrylic bottle. Then, the Ti 3 AlC 2 Powder (200 nm particle size, 20 g) was gradually added to the mixture and the reaction was kept at 40°C for 10 hours. The resulting product was washed with deionized water and centrifuged 5 times. Finally, the obtained Ti was dried with a vacuum freeze dryer 3 C 2 powder.

[0032]2. The sol-gel preparation of cellulose is carried out by alkali metal sodium hydroxide / urea solution, and the mass ratio of cellulose powder (particle size is 5 microns), NaOH, urea and water is wt% (cellulose): wt% ( NaOH): wt% (urea): wt% (water) = 5:7:12:100, mixed together to form a uniform solu...

Embodiment 2

[0042] In this embodiment, the preparation method of MXene / cellulose composite aerogel is as follows:

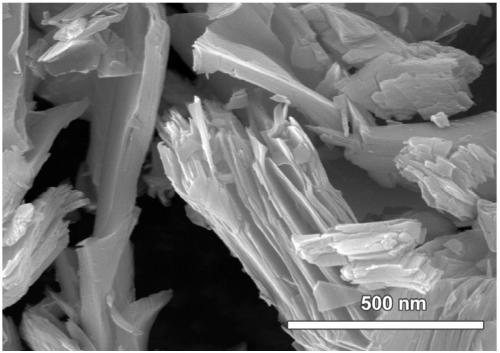

[0043] 1. Named Nb by chemical etching 2 Preparation of Nb from AlC MAX Phase Ceramic Powder 2 C, its size is 30 to 300 nanometers in thickness and 100 to 500 nanometers in length. In a typical chemical etching process, the molar ratio of LiF, HCl, HF and water is n(LiF):n(HCl):n(HF):water = 3:4:1:100, in 500 ml poly Gently stir in the acrylic bottle. Then, the Nb 2 AlC powder (particle size 180 nm, 30 g) was gradually added to the mixture and the reaction was kept at 30°C for 20 hours. The resulting product was washed with deionized water and centrifuged 5 times. Finally, the obtained Nb was dried with a vacuum freeze dryer 2 C powder.

[0044] 2. The sol-gel preparation of cellulose is carried out by alkali metal sodium hydroxide / urea solution, and the mass ratio of cellulose powder (particle size is 100 microns), NaOH, urea and water is wt% (cellulose): wt% ( NaOH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com