Patents

Literature

298 results about "MAX phases" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

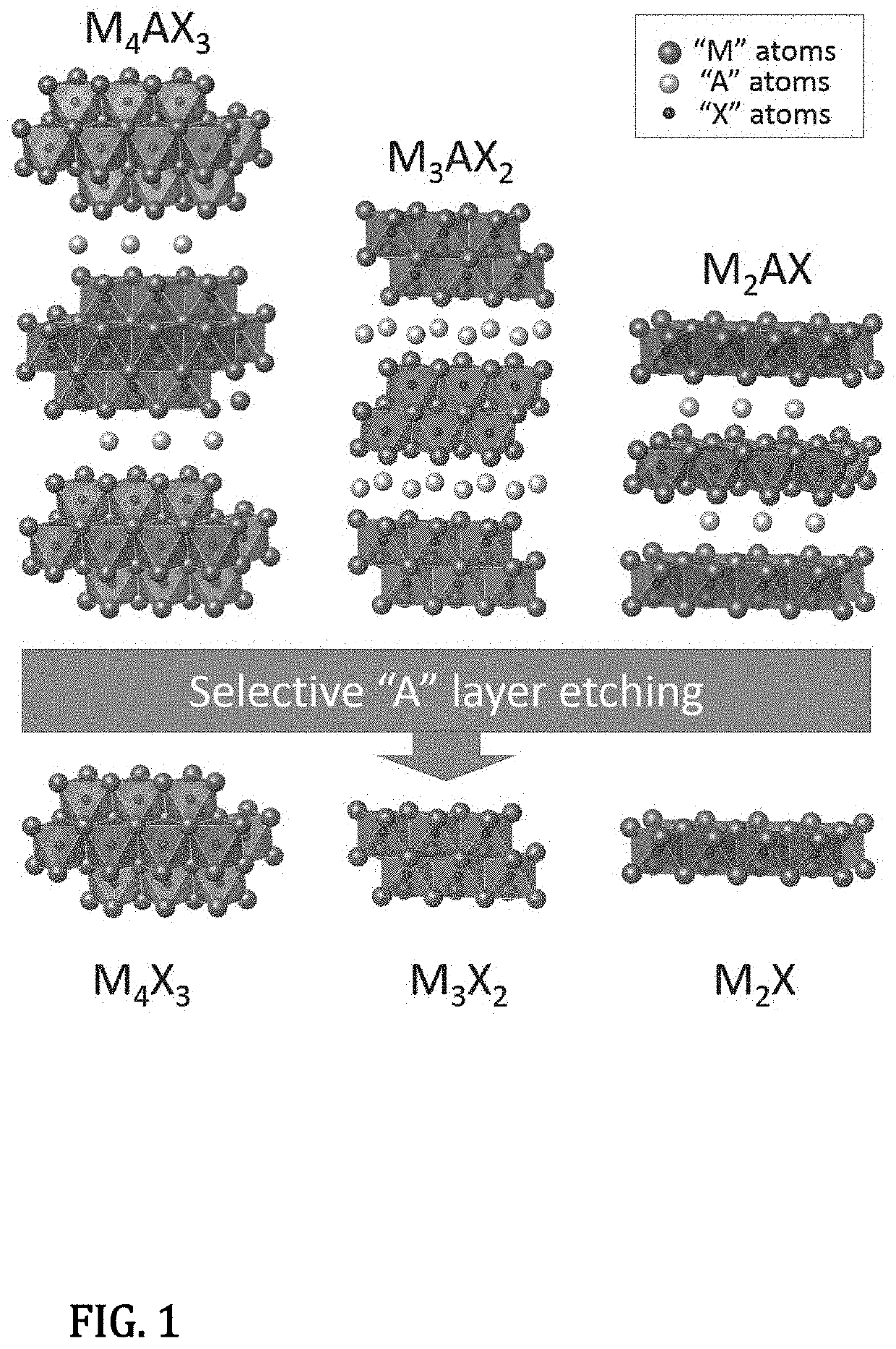

The MAX phases are layered, hexagonal carbides and nitrides which have the general formula: Mₙ₊₁AXₙ, (MAX) where n = 1 to 3, and M is an early transition metal, A is an A-group (mostly IIIA and IVA, or groups 13 and 14) element and X is either carbon and/or nitrogen. The layered structure consists of edge-sharing, distorted XM₆ octahedra interleaved by single planar layers of the A-group element.

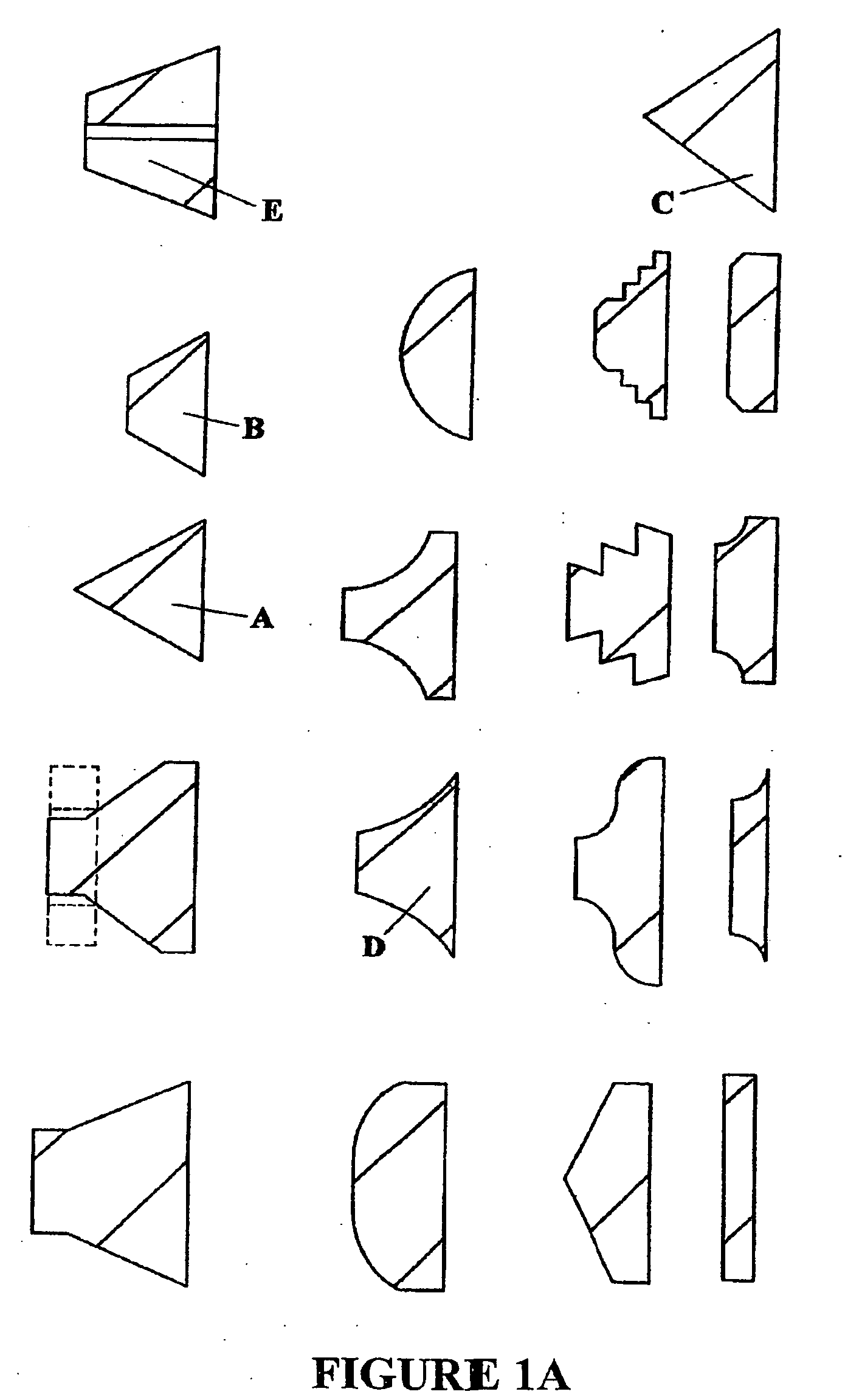

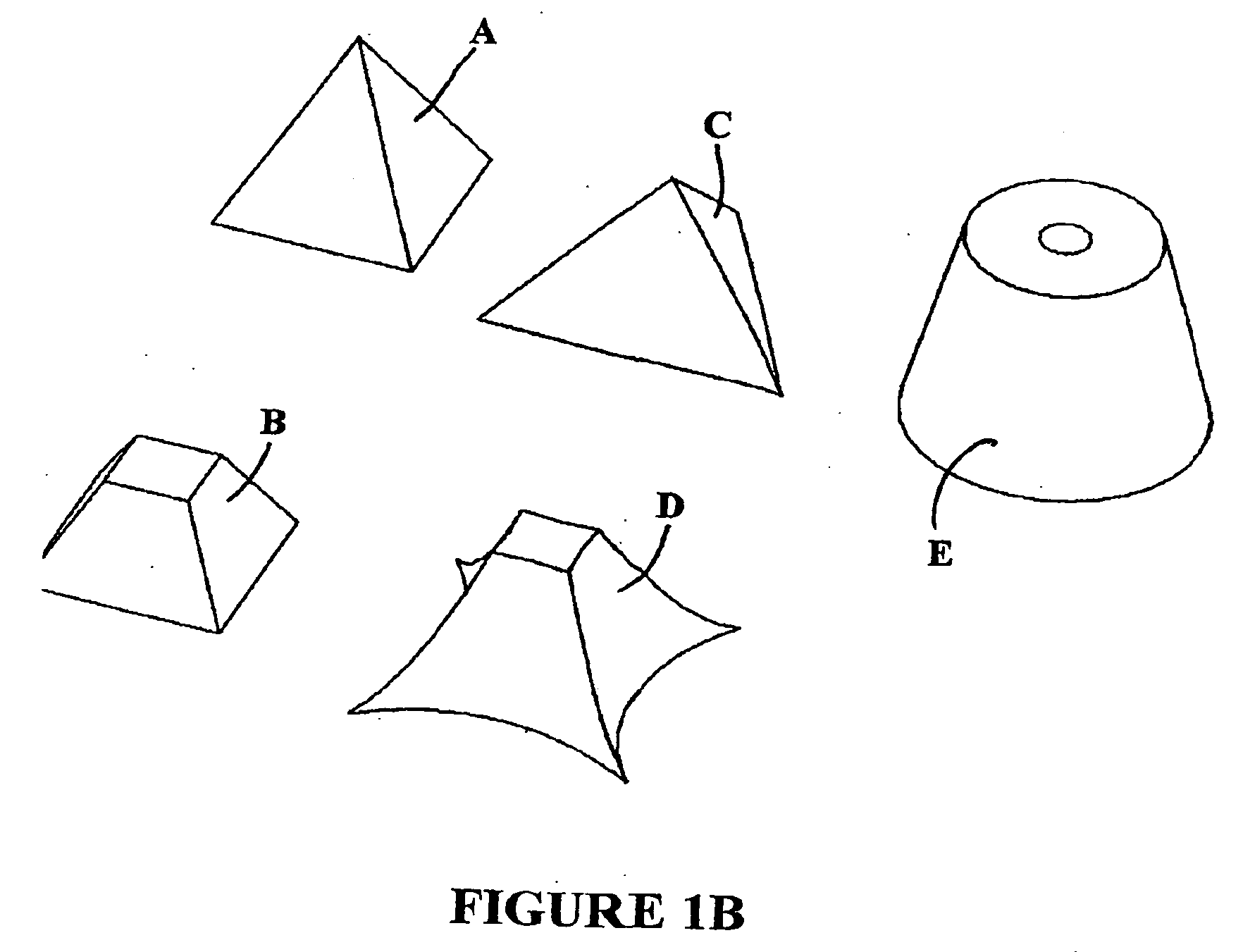

Carrier body and method

InactiveUS20050132957A1Inhibition formationAvoids build-up formationLiquid surface applicatorsChemical vapor deposition coatingNitrogenEngineering

The present invention relates to a method and a carrier body for coating cutting tools for chip removal. The carrier body is adapted to be used during coating of cutting tool inserts in a CVD and / or a MTCVD method. The carrier body is at least partially comprised of a material selected from the MAX phase family, i.e. Mn+1AXn (n=1,2,3) wherein M is one or more metals selected from the groups IIIB, IVB, VB, VIB and VIII of the periodic table of elements and / or their mixture, A is one or more metals selected from the groups IIIA, IVA, VA and VIA of the periodic table of elements and / or their mixture, and wherein X is carbon and / or nitrogen.

Owner:SECO TOOLS AB +1

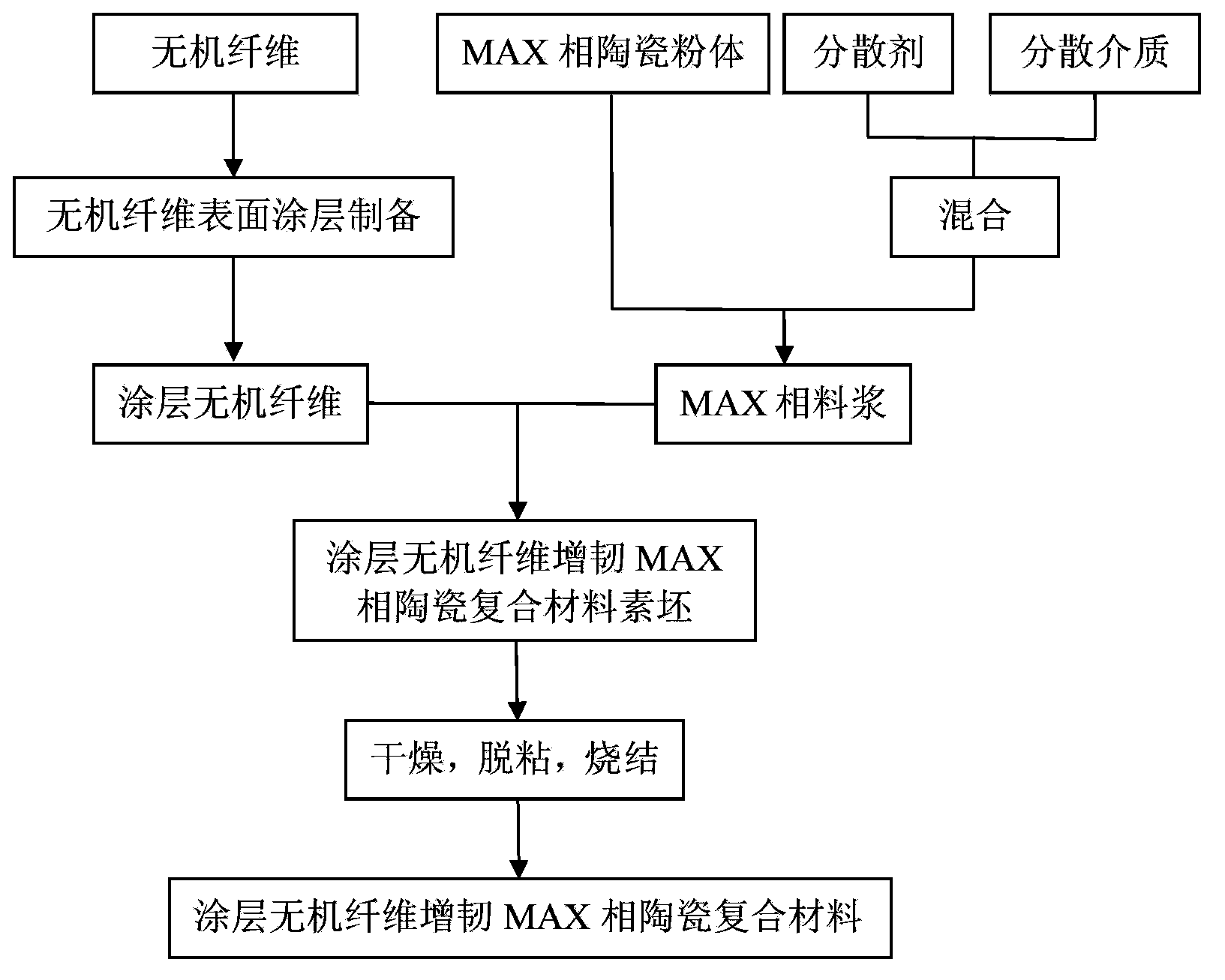

Coating inorganic fiber toughened MAX phase ceramic composite material, preparation method and uses thereof

ActiveCN103910532AAppropriate bonding interface strengthFree control of interface strengthNuclear energy generationContainmentAviationFiber

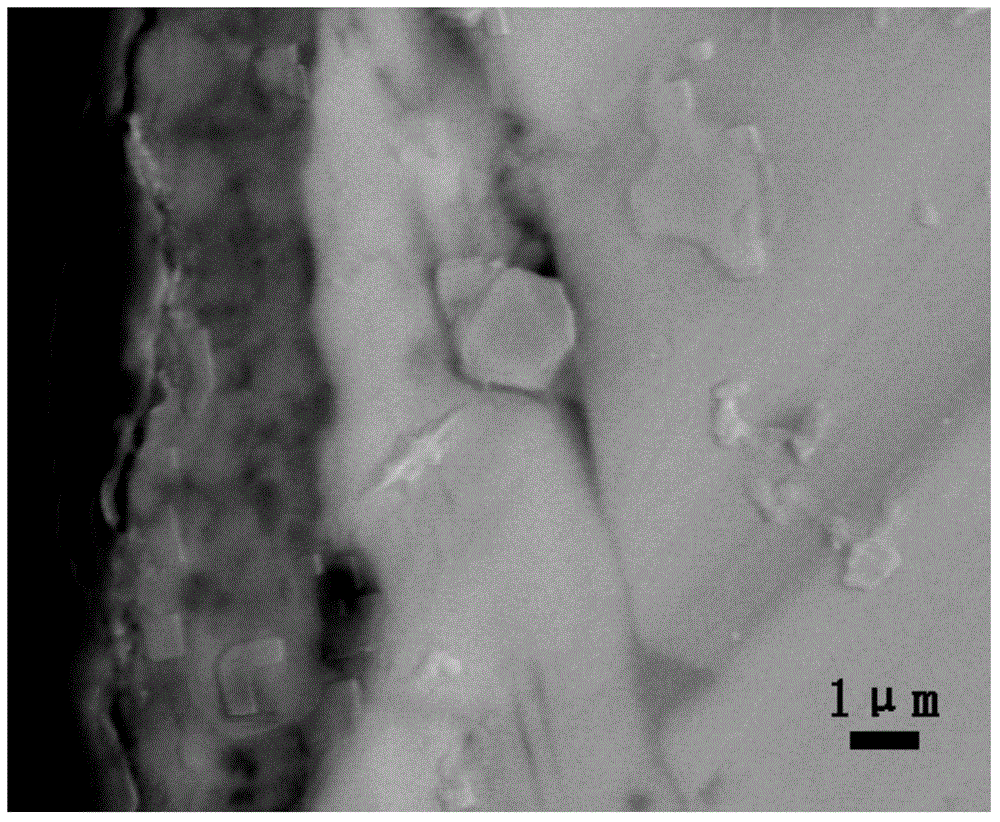

The present invention provides a coating inorganic fiber toughened MAX phase ceramic composite material and a preparation method thereof. The composite material adopts a MAX phase ceramic material as a matrix and adopts coating inorganic fibers as a toughening phase, wherein the coating inorganic fiber content is 0.5-90% (by volume), and the coating inorganic fibers are completely dispersed in the matrix and are inorganic fibers with the surface coated with the coating. Compared with the composite material in the prior art, the composite material of the present invention has the following characteristics that: the interface reaction between the inorganic fibers and the MAX phase ceramic can be effectively inhibited, the thermal expansion coefficient and elasticity modulus matching degree between the inorganic fibers and the MAX phase ceramic can be effective regulated, the effective improvement of the fracture toughness and the high temperature resistance of the MAX phase ceramic composite material can be achieved, the problems of high brittleness and insufficient use reliability of the MAX phase ceramic can be fundamentally solved, and the coating inorganic fiber toughened MAX phase ceramic composite material has potential application prospects in the high technology fields of civil use, aviation, aerospace, nuclear industry and the like, and is especially for the fission and fusion reactor nuclear power plant inner wall structure material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

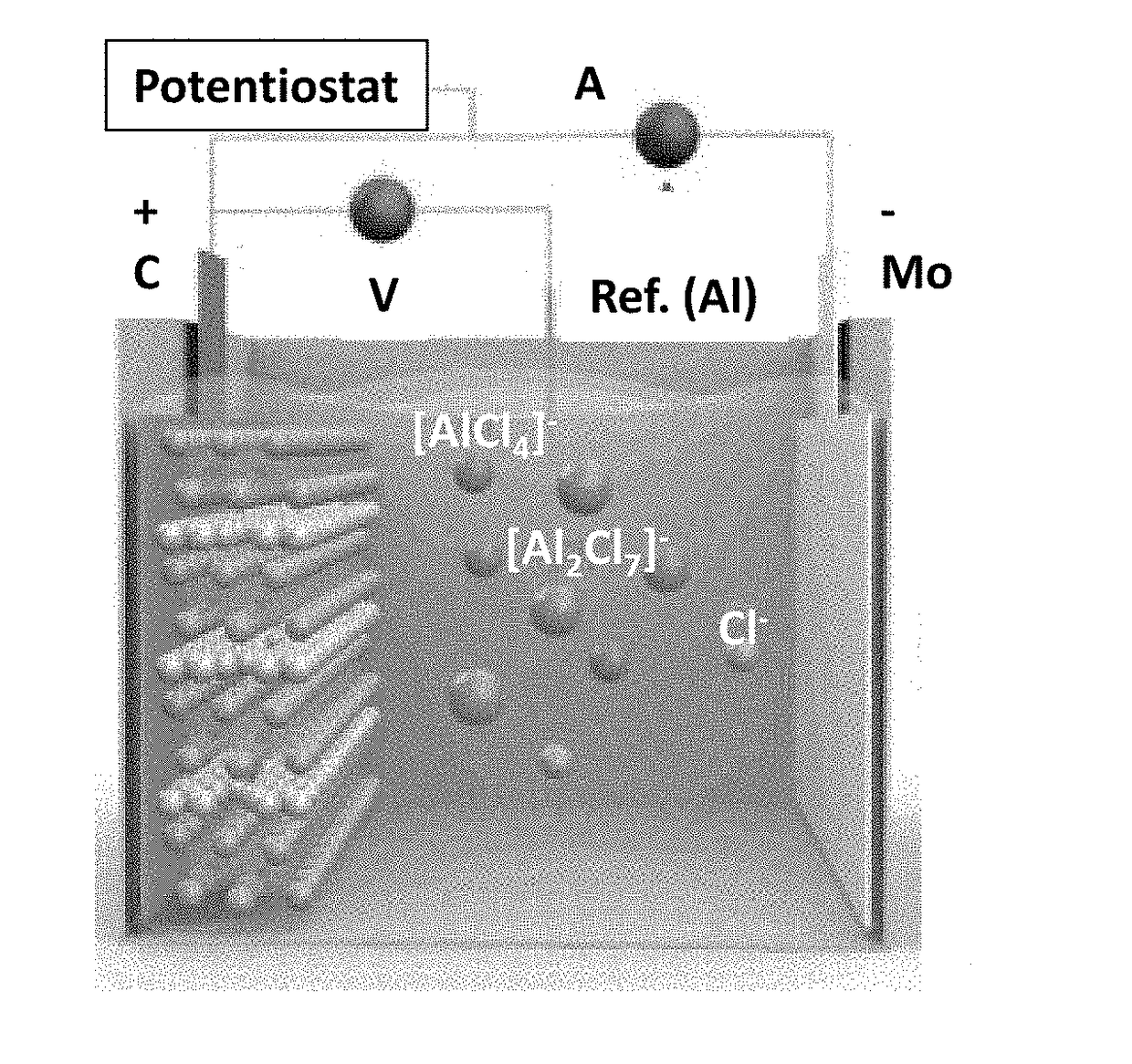

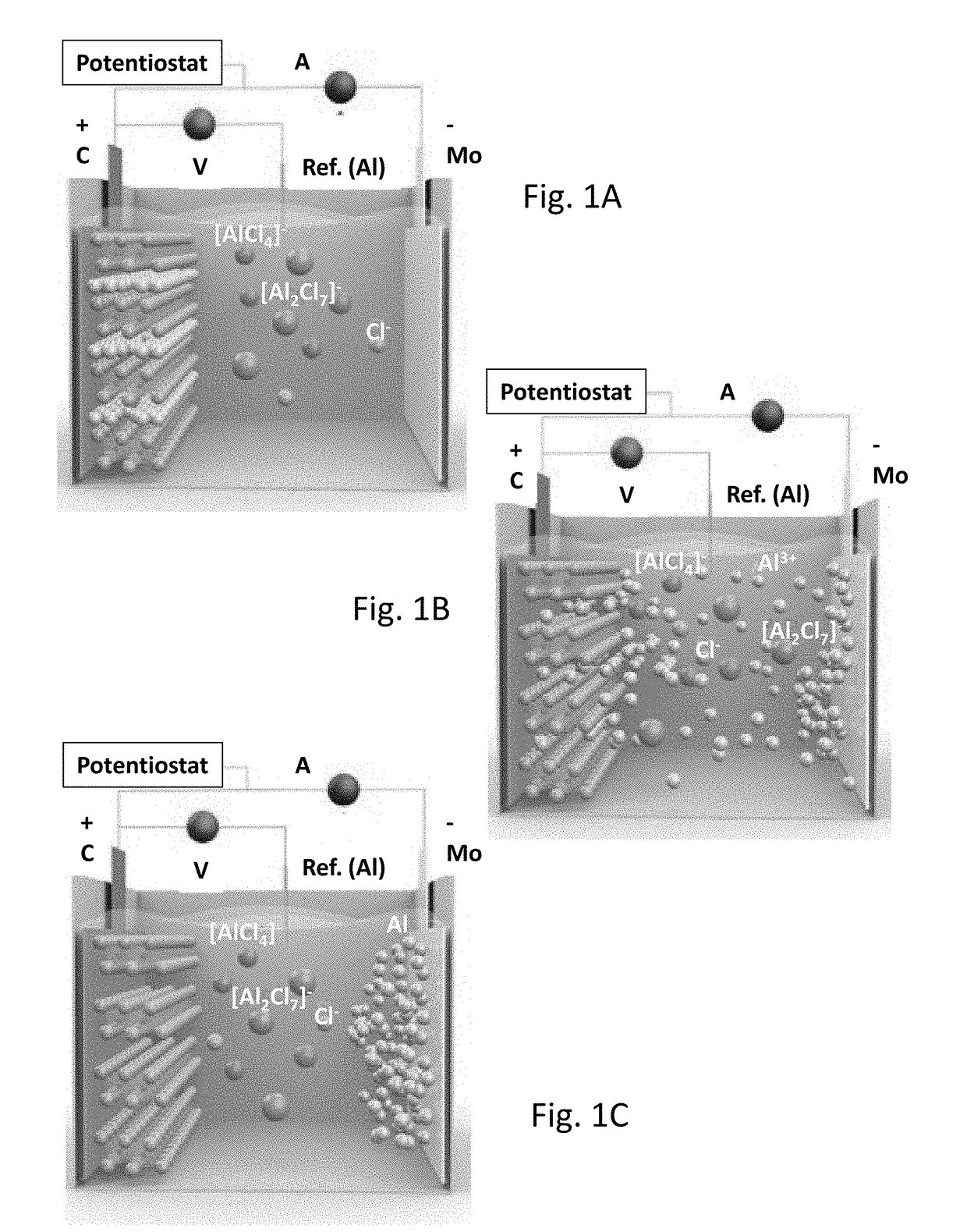

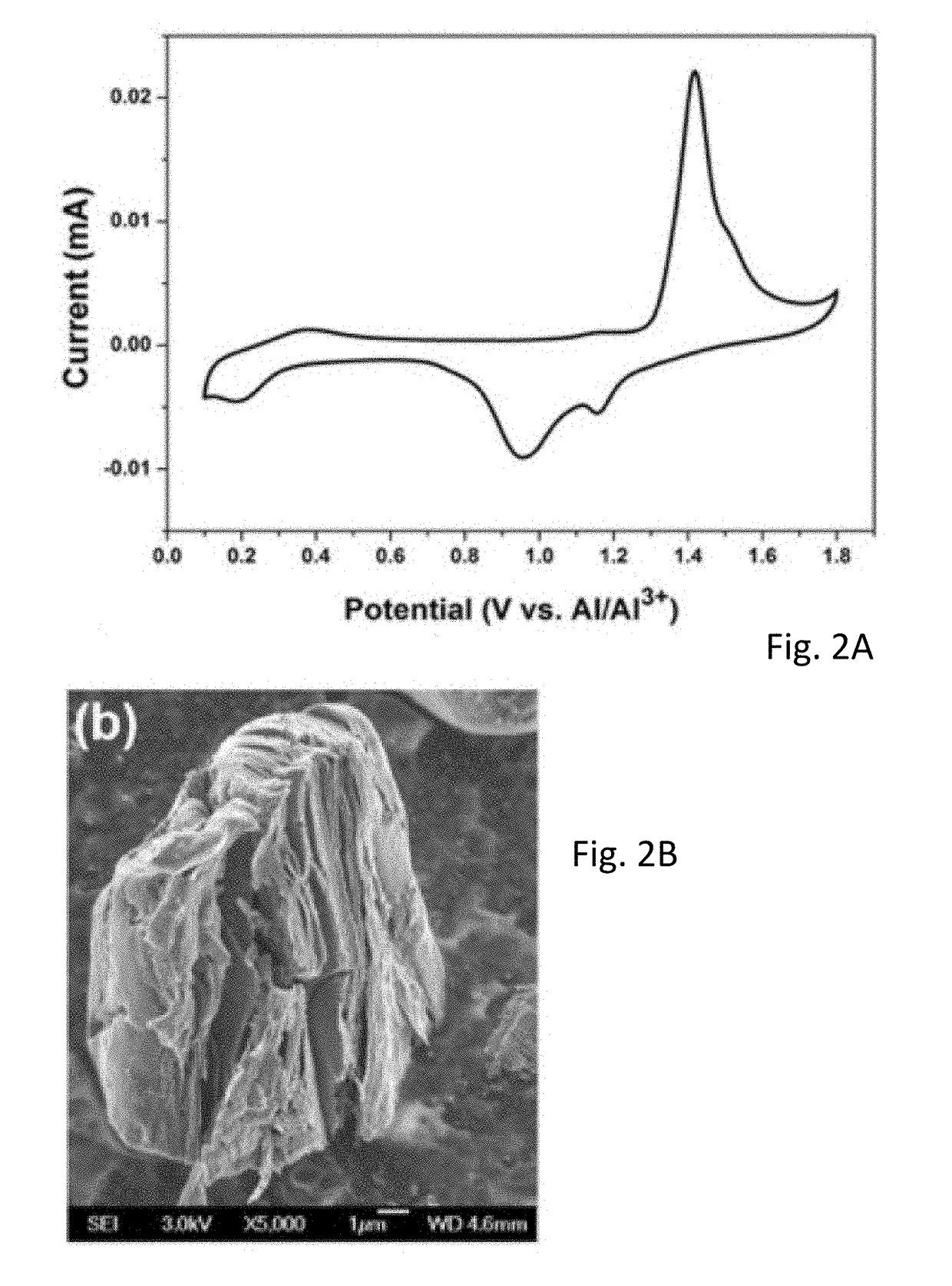

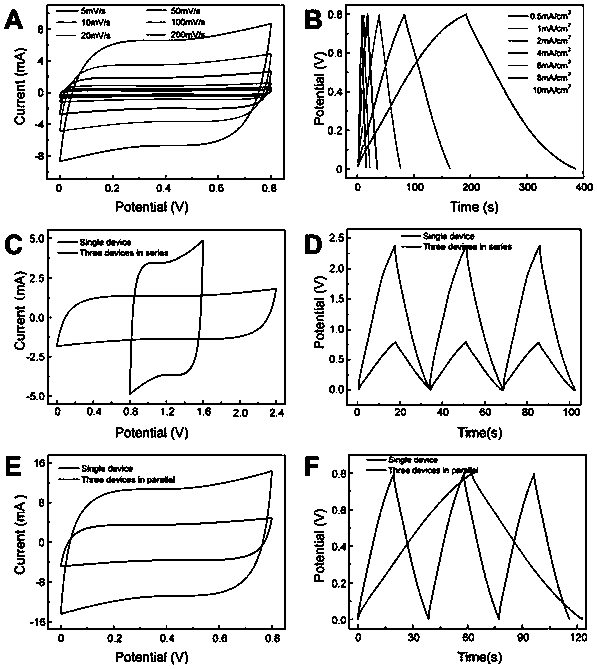

Electrochemical systems comprising mxenes and max phase compositions and methods of using the same

Disclosed herein are electrochemical cells comprising electrodes prepared from layered materials comprising a substantially two-dimensional ordered array of cells having an empirical formula of Mn+1Xn, where M comprises a transition metal selected from the group consisting of a Group IIIB metal, a Group IVB metal, a Group VB metal, a Group VIB metal, and any combination thereof, X is CxNy wherein x+y=n, and n is equal to 1, 2, or 3. Also disclosed herein are batteries comprising the electrochemical cells and methods for electrochemically preparing MXene compositions with the use of the electrochemical cells.

Owner:AUBURN UNIV

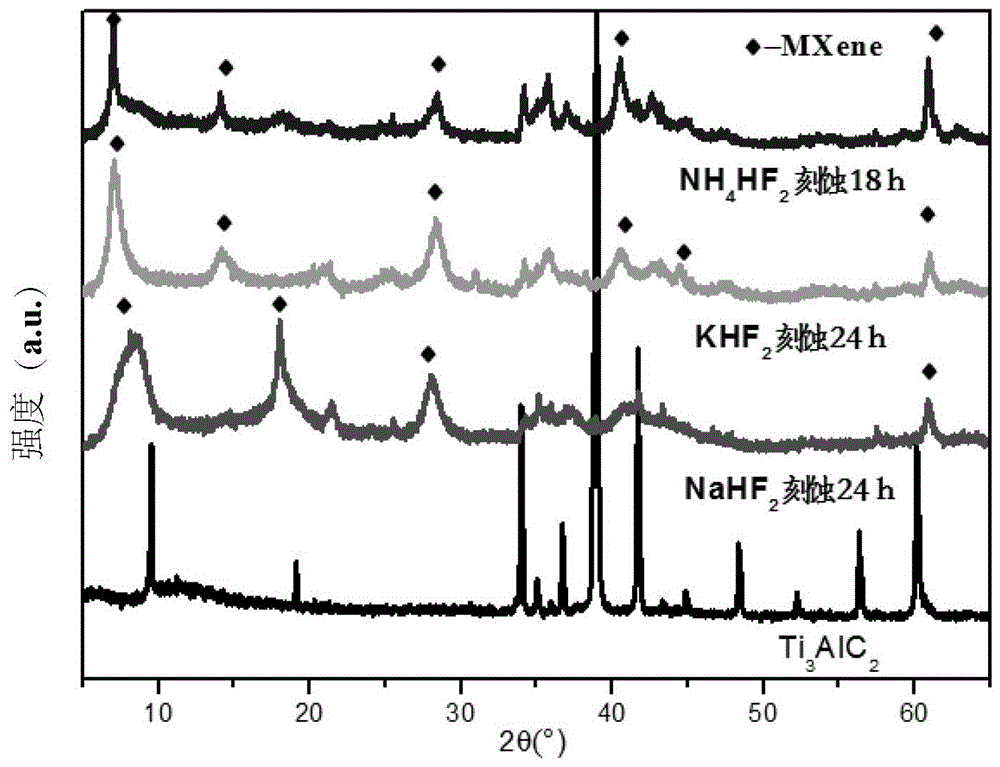

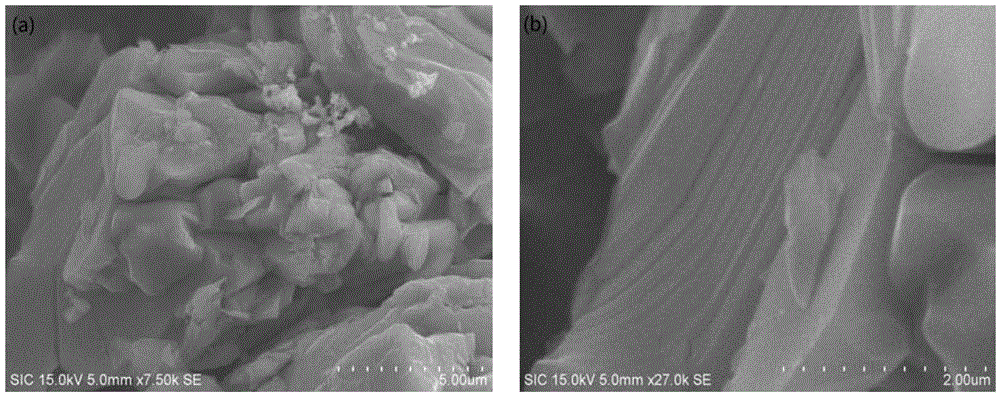

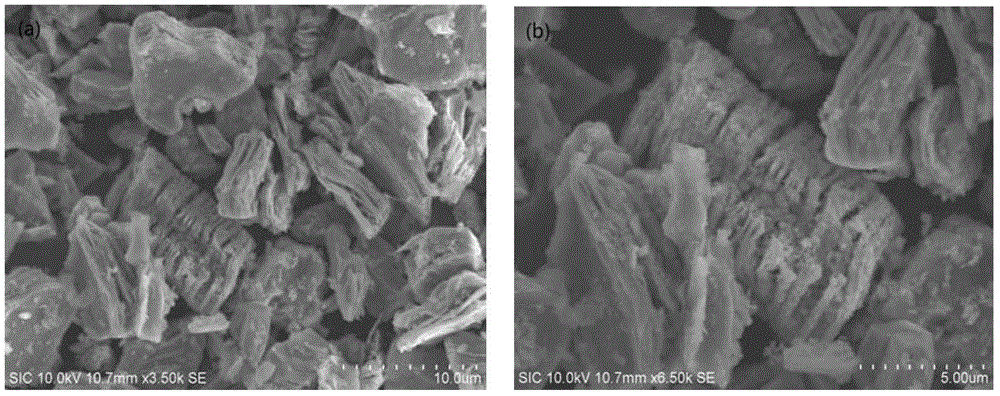

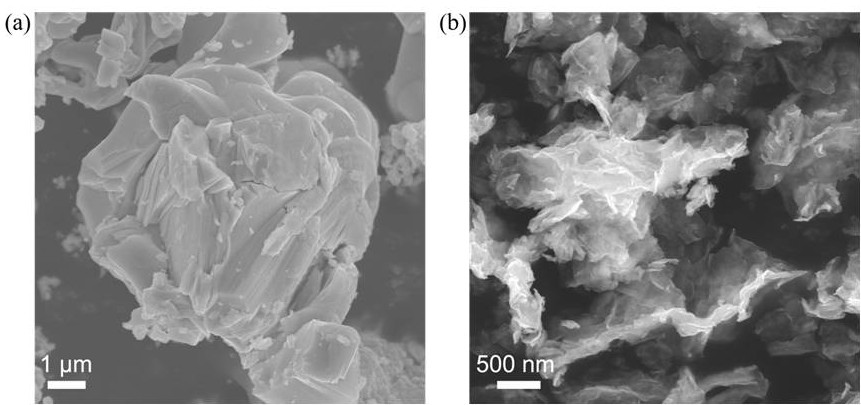

Preparing method for two-dimensional crystal MXene nanometer material

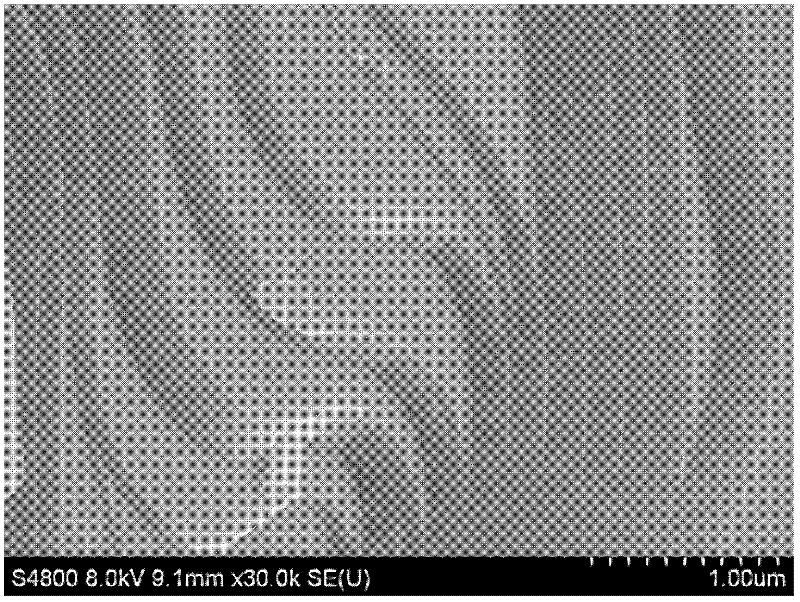

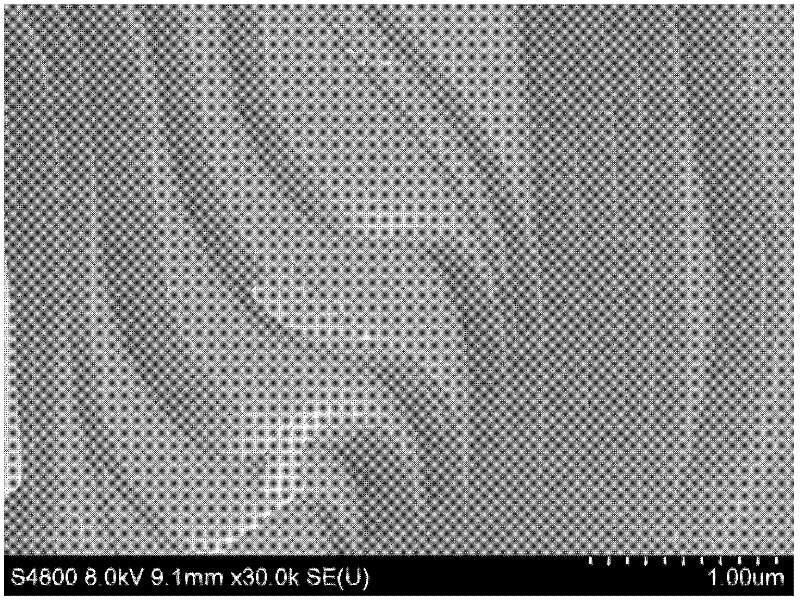

InactiveCN106220180AObvious two-dimensional layered structureSimple methodSupercapacitorTwo dimensional crystal

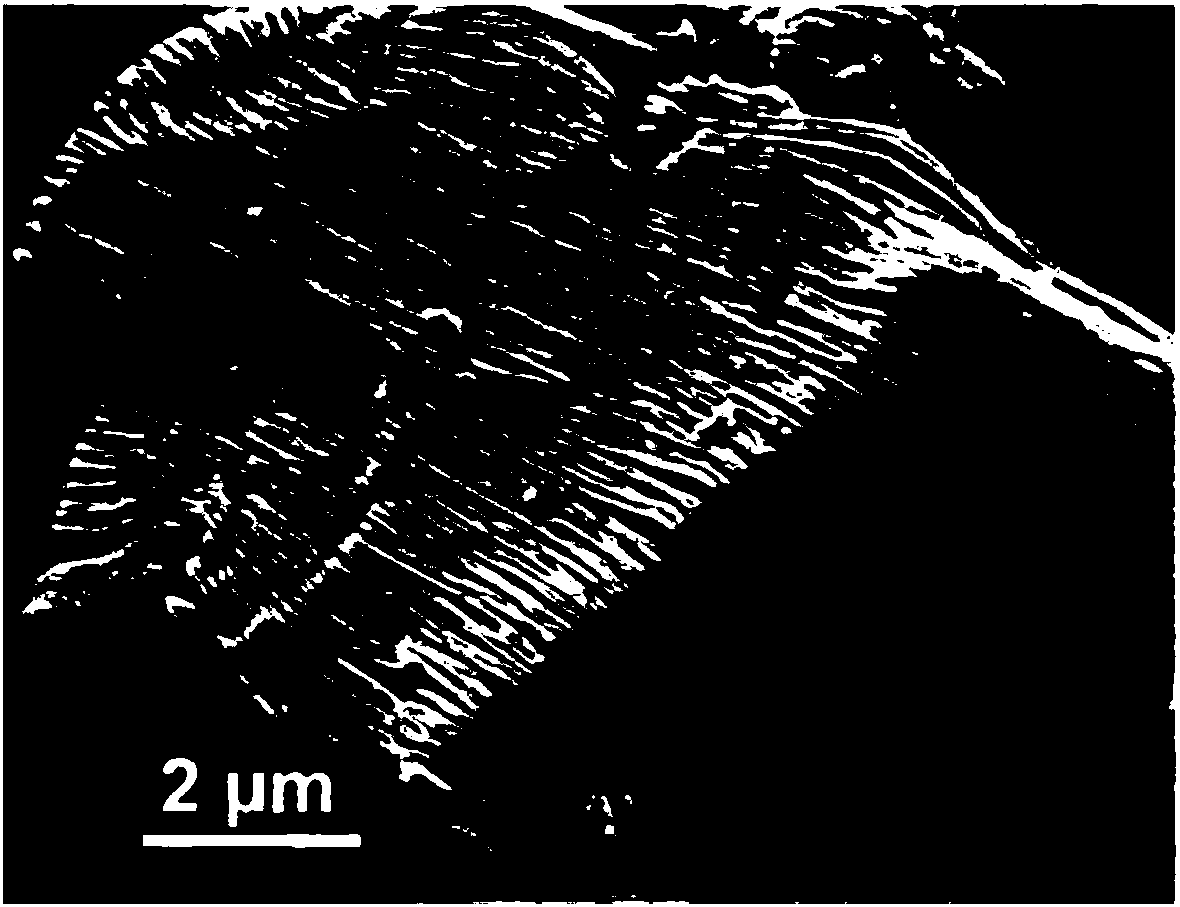

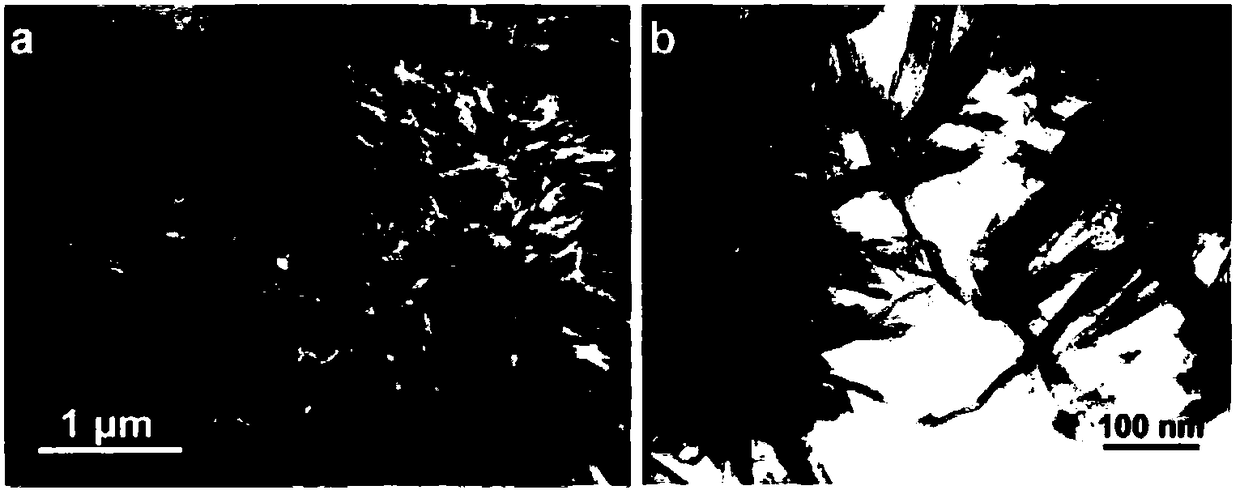

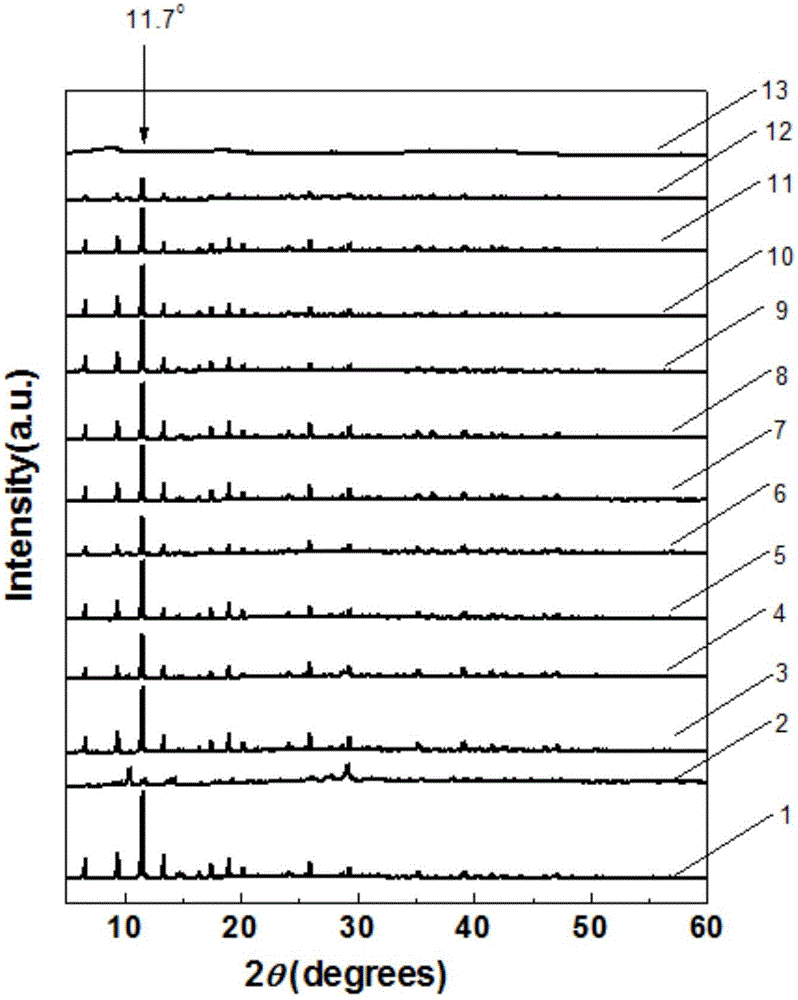

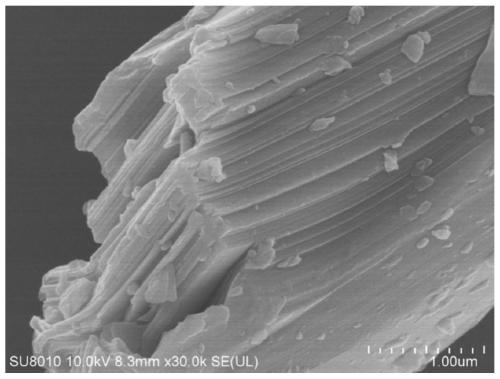

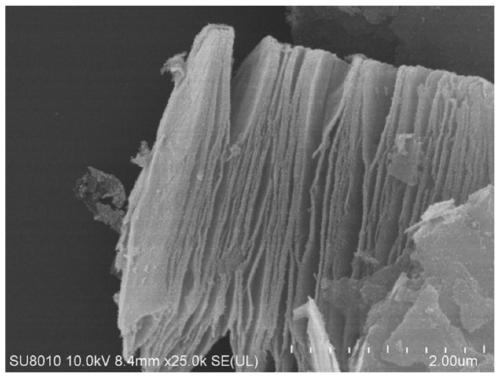

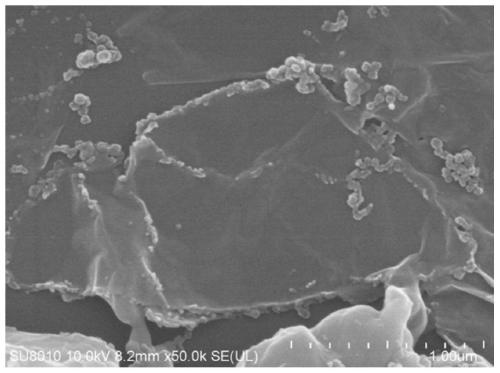

The invention relates to a preparing method for a two-dimensional crystal MXene nanometer material. The preparing method comprises the steps that a high-purity ternary lamellar MAX-phase ceramic block material is ground and then screened, and MAX-phase ceramic powder is obtained; the MAX-phase ceramic powder and HF acid salt crystals are weighed in the mass ratio of 2:(5-15) and then added into deionized water, an etching reaction is carried out at 30-85 DEG C, washing and drying are carried out, and the two-dimensional crystal MXene nanometer material is obtained. The MXene nanometer material prepared through the method has an obvious graphene-like two-dimensional lamellar structure and is expected to be applied to the fields such as supercapacitors, lithium ion batteries and adsorption; the MAX phase is subjected to etching treatment with acid salt, the method is simple and easy to implement, safe and reliable, and large-scale industrialized popularization is easy.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Fiber-toughened ceramic-based composite material with ternary-layer-shaped MAX phase interface layer and preparation method of composite material

InactiveCN106083117AImprove antioxidant capacityImprove radiation resistanceHeat conductingMaterials science

The invention provides a fiber-toughened ceramic-based composite material with a ternary-layer-shaped MAX phase interface layer. A ternary-layer-shaped MAX phase material is introduced to serve as an interface layer, and therefore the anti-irradiation property, the heat-conducting property and the anti-oxidation property of the ceramic-based composite material can be effectively improved; in addition, through multiple fracture energy absorbing mechanisms of the MAX phase material, fracture energy can be effectively absorbed, extension of cracks in the ceramic-based composite material is hindered, and therefore the toughness and the damage tolerance of the ceramic-based composite material are improved. Accordingly, the application fields of the composite material are effectively widened, and the composite material has good application prospects in the fields of aerospace thermal structure materials, nuclear energy structural materials and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

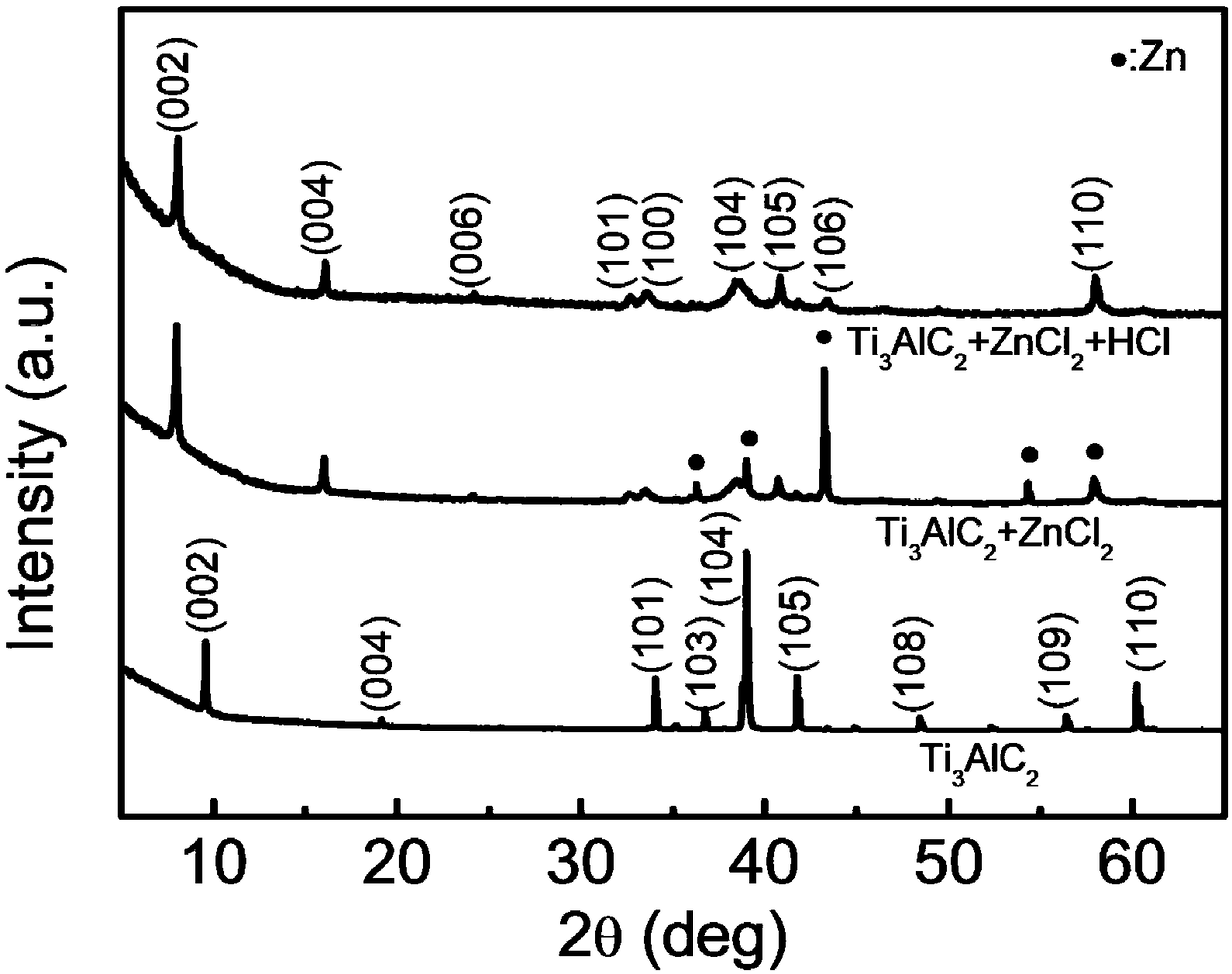

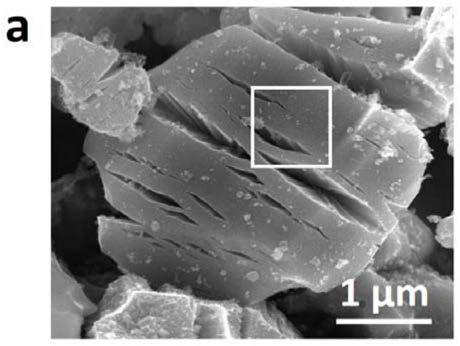

Two-dimension carbide loaded metal simple substance nano-powder, and preparation method and application thereof

InactiveCN105854913AAvoid uneven loadThe load is easy to controlPhysical/chemical process catalystsWater/sewage treatment by irradiationReducing agentLithium fluoride

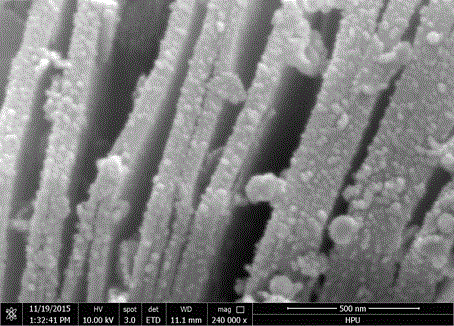

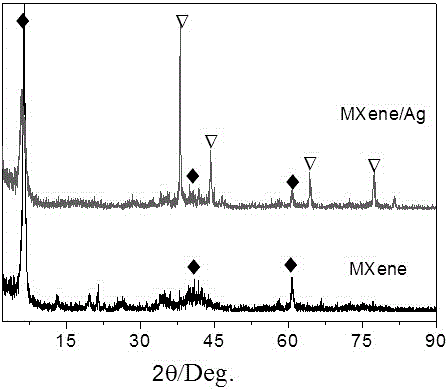

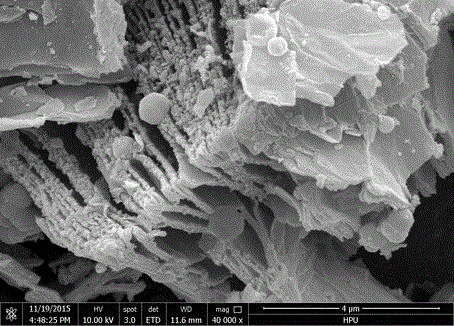

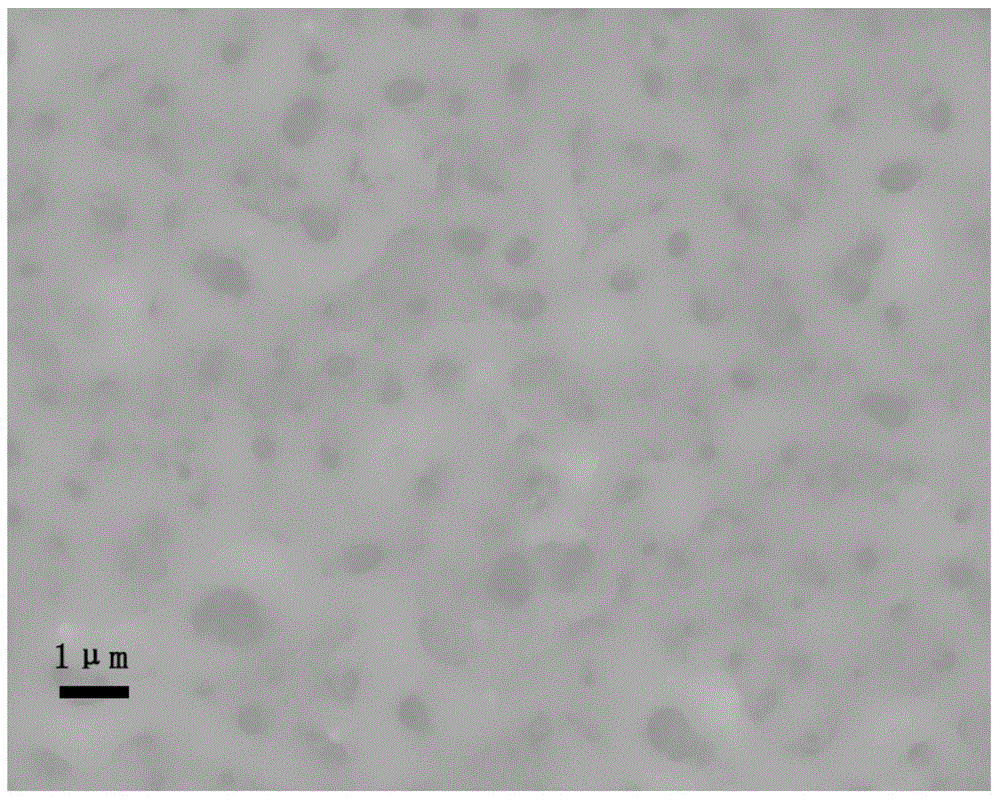

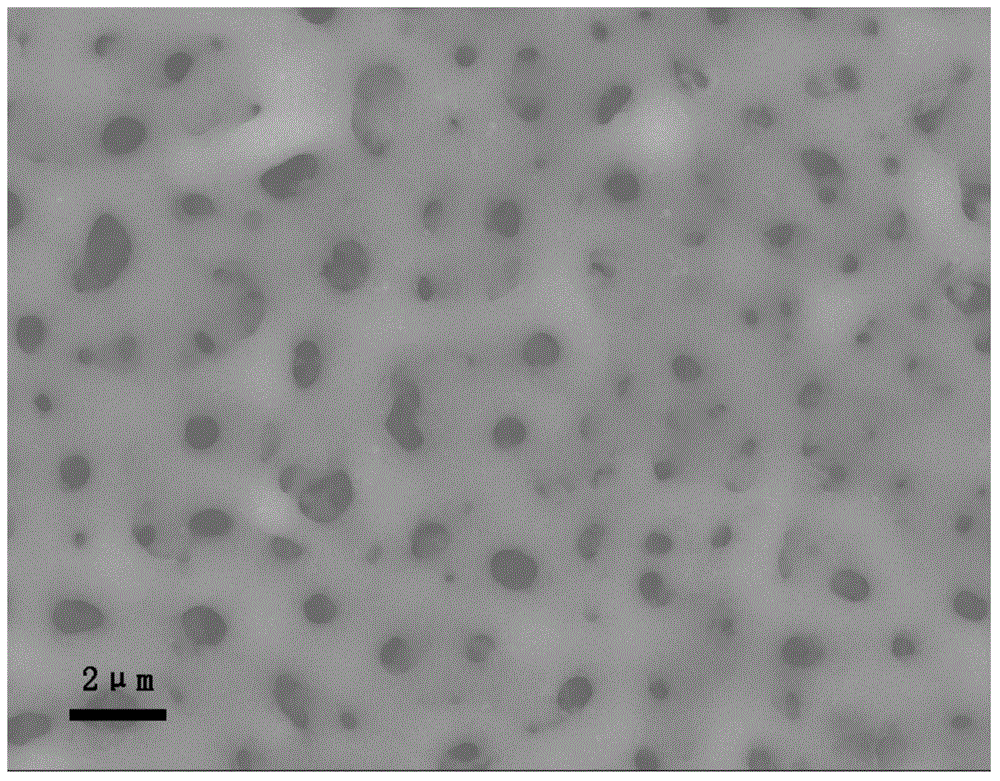

The invention relates to two-dimension carbide loaded metal simple substance nano-powder, and a preparation method and an application thereof. The preparation method comprises the following steps: (1) soaking MAX phase ceramic powder in a hydrochloric acid solution in which lithium fluoride is dissolved, stirring, centrifugally separating, washing with deionized water and ethyl alcohol, drying and then acquiring solid powder, namely, two-dimension carbide; (2) dissolving the two-dimension carbide in a metal saline solution and preparing into a mixing solution; (3) adding a reducing agent aqueous solution into the mixing solution while stirring, reacting for 0.5-2h at room temperature, and washing and drying the solid precipitate acquired by centrifuging the turbid liquid after ending the reaction, thereby acquiring the two-dimension carbide loaded metal simple substance nano-powder. According to the invention, the uniform loading of metal simple substance nano-particles on the surface of the two-dimension carbide and between the layers is realized; according to the method, various metal simple substance nano-particles are loaded onto the two-dimension carbide; the prepared two-dimension carbide loaded metal simple substance nano-powder as a photocatalyst has excellent application prospect in the field of treating organic pollutants in sewage.

Owner:HENAN POLYTECHNIC UNIV

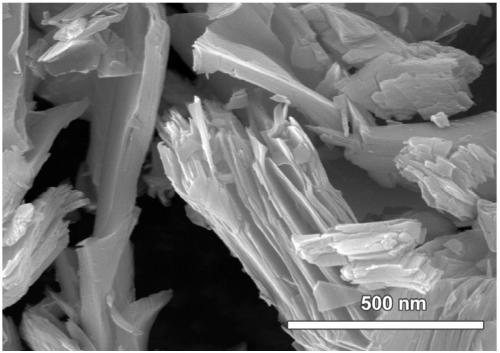

Method for preparing high-purity MAX-phase ceramic powder

InactiveCN102633505AHigh activityUniform distribution of temperature fieldChemical measurementBall mill

The invention discloses a method for preparing high-purity MAX-phase ceramic powder. The method includes approximately weighing raw materials according to stoichiometric ratios of various elements in a chemical formula of a MAX-phase ceramic material at first; then uniformly mixing the raw materials by the aid of a ball mill, placing mixture of the raw materials in a mold and prepressing the mixture to obtain a prepressed intermediate body; and finally placing the prepressed intermediate body into a special microwave oven, controlling the temperature rise rate by means of adjusting the microwave power in inertial atmosphere, increasing the temperature to a sintering temperature, keeping heat for a certain period, realizing furnace cooling to the room temperature, and grinding the mixture to obtain the MAX-phase ceramic powder with high purity, an excellent shape and a unique layered structure. The method for preparing the MAX-phase ceramic powder is speedy, efficient, energy-saving and environment-friendly and is low in cost and easy to realize large-scale production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation method of MXene/cellulose composite aerogel

InactiveCN109679146AHigh strengthImprove conductivityMagnetic/electric field screeningPorosityFreeze-drying

The invention relates to the field of aerogel and electromagnetic absorbing materials, in particular to a preparation method of MXene / cellulose composite aerogel. The preparation method includes the steps that firstly, MAX phase ceramic powder is added into a mixed water solution of lithium fluoride, hydrochloric acid and hydrofluoric acid in a certain proportion for etching to obtain MXene nano-powder; a cellulose sol method is adopted, cellulose powder is added into a mixed water solution of sodium hydroxide and urea in a certain proportion, and a transparent cellulose mixed solution is prepared by cooling the mixture to -12 DEG C; the temperature is maintained, the MXene nano-powder is added into the cellulose mixed solution, and then the appropriate amount of epichlorohydrin is added to the mixture and the mixture is stirred thoroughly for chemical crosslinking; the temperature is raised, and the obtained homogeneous mixture is subjected to a gel reaction; and a gel product is frozen directionally and then freeze-dried to obtain the MXene / cellulose composite aerogel. The composite aerogel has the characteristics of low density, high porosity, good absorbing performance, wide absorbing frequency band and the like, and is convenient to use and suitable for large-scale application in the aerospace field.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

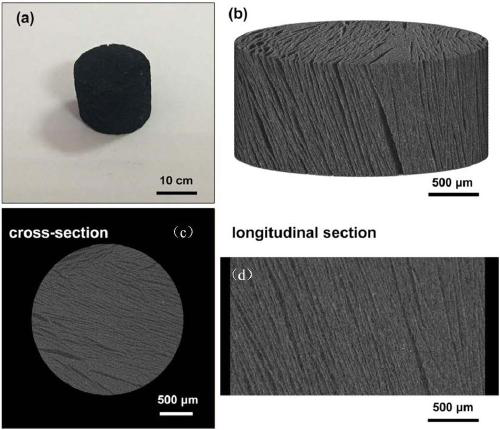

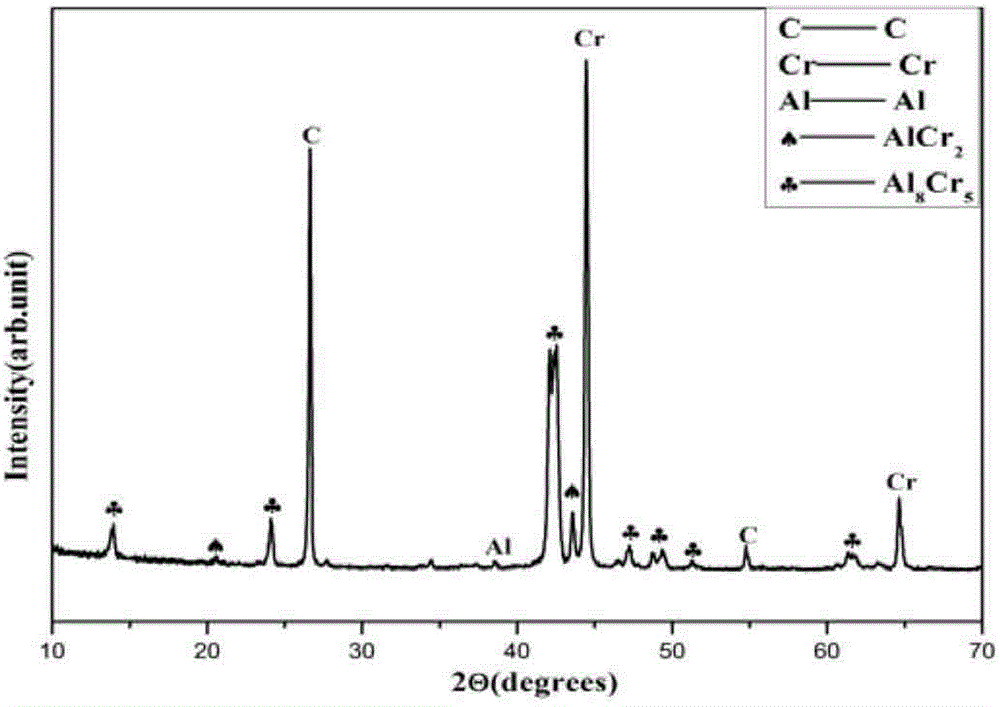

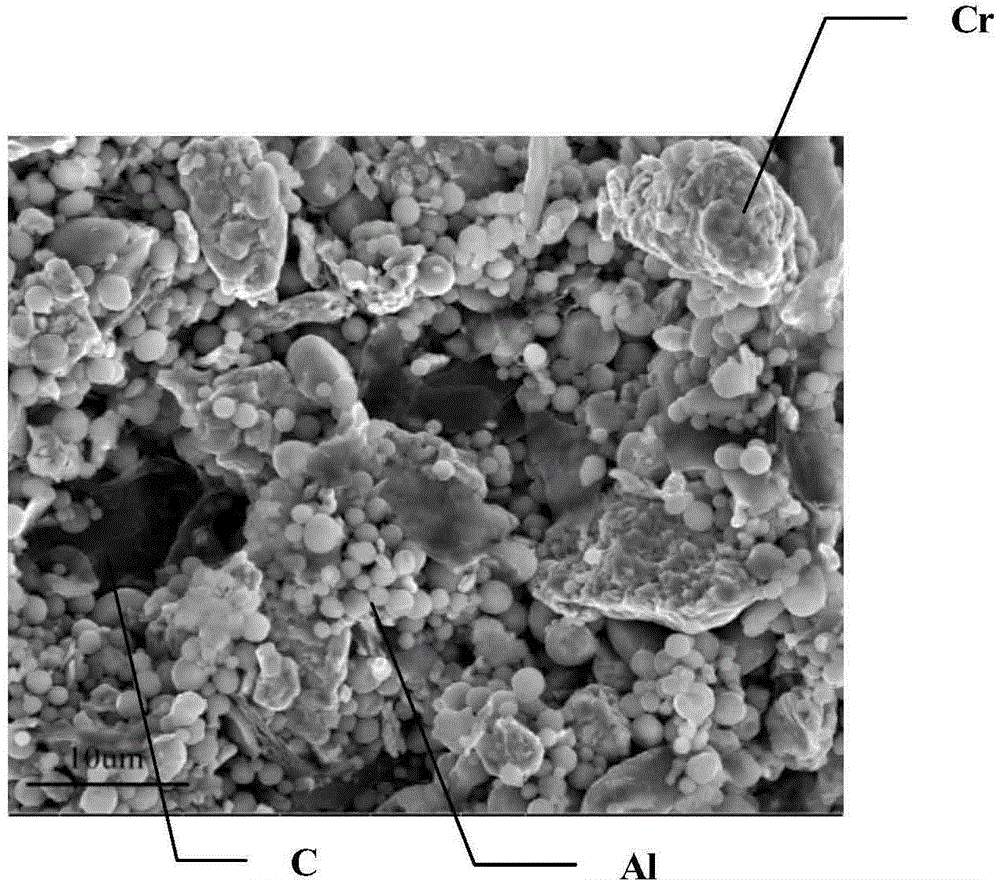

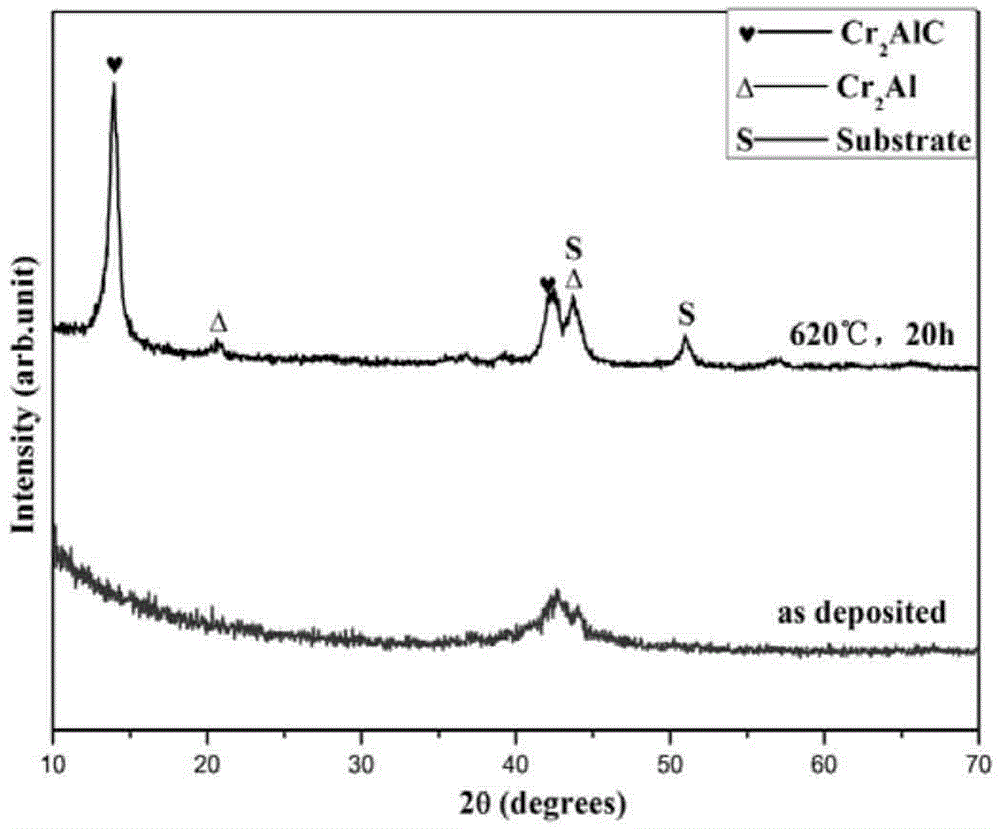

Method for efficiently preparing ternary laminar MAX phase ceramic coating layer at low temperature

InactiveCN104894516AReduce manufacturing costSimple processVacuum evaporation coatingSputtering coatingGas phaseCeramic coating

The invention relates to a preparation technology of a ternary laminar MAX phase ceramic coating layer, and in particular, provides a method for efficiently preparing a ceramic coating layer with a ternary laminar MAX phase as a main phase at low temperature by a physical vapor deposition technology. M, A and X element powders with a certain mol ratio or electrically conducted binary and ternary compound powders are uniformly mixed and pressed to produce a cathode target at a certain temperature; the physical vapor deposition (multi-arc ion plating or magnetron sputtering) is adopted under optimized process conditions; and then, the crystallization heat treatment is adopted, thereby realizing the preparation of the ceramic coating layer with the MAX phase as the main phase by a two-step method. The method has the characteristics of deposition at room temperature, easy adjustment of target components, simple process, high deposition efficiency and low cost, has obvious advantages in the aspect of preparing the MAX phase coating layer, can solve the problems of high cost and complicated process in traditional preparation of the MAX phase coating layer, and promotes the large-scale industrial production of the MAX phase coating layer.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

N-doped MXene material and preparation method and application thereof

InactiveCN108831760AHigh pseudocapacitanceImprove conductivityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceActive site

The invention relates to N-doped MXene material and preparation method and application thereof. The N-doped MXene material is obtained by performing intercalation and stripping to obtain single-layeror few-layer of MXene after an MAX-phase ceramic material is etched to remove an A atomic layer and then placing the material in a mixed gas of ammonia gas and argon for calcination. The N-doped MXenematerial provided by the invention has a single-layer sheet-shaped structure, the electrolyte ion transmission rate is improved, an N element is uniformly coated on a surface of the MXene layer, thefaradic pseudo-capacitance and the conductivity of the MXene are improved, the anisotropy of the MXene is reduced, and the MXene arrangement is more compact and in order; moreover, the N element is coated on the surface of the MXene sheet layer, more electrochemical active sites are exposed, great convenience is provided for electrolyte ion transmission and exchange, and the N-doped MXene materialhas more excellent electrochemical performance and superhigh specific capacitance.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Method for making electromagnetic shielding fabric based on two-dimensional layered MXene nanosheets and product

InactiveCN109868646AImprove flexibilityImprove shielding effectMagnetic/electric field screeningVegetal fibresHydrofluoric acidPhysical chemistry

The invention provides a method for making an electromagnetic shielding fabric based on two-dimensional layered MXene nanosheets and the product. The method is characterized by including the followingsteps that 1, the fabric is pretreated, oil stains and impurities on the surface of the fabric are removed, and cleaning and drying are performed; 2, a certain amount of MAX phase Ti3AlC2 is weighedand soaked in a hydrofluoric acid solution with the concentration of 10-50%, a stirring reaction lasts for 18-24 hours, and then MXene powder is obtained after cleaning and drying; 3, the MXene powderis dissolved in a certain amount of water, and an MXene solution is obtained; 4, one side of the pretreated fabric is spray-coated with the MXene solution layer by layer and dried, the other side ofthe fabric is spray-coated with the MXene solution layer by layer and dried, and the MXene modified fabric is obtained. The process is simple and reasonable, operation is easy, the prepared electromagnetic shielding fabric is excellent in electromagnetic shielding effect, and the comfort level of the fabric is not affected.

Owner:QINGDAO UNIV

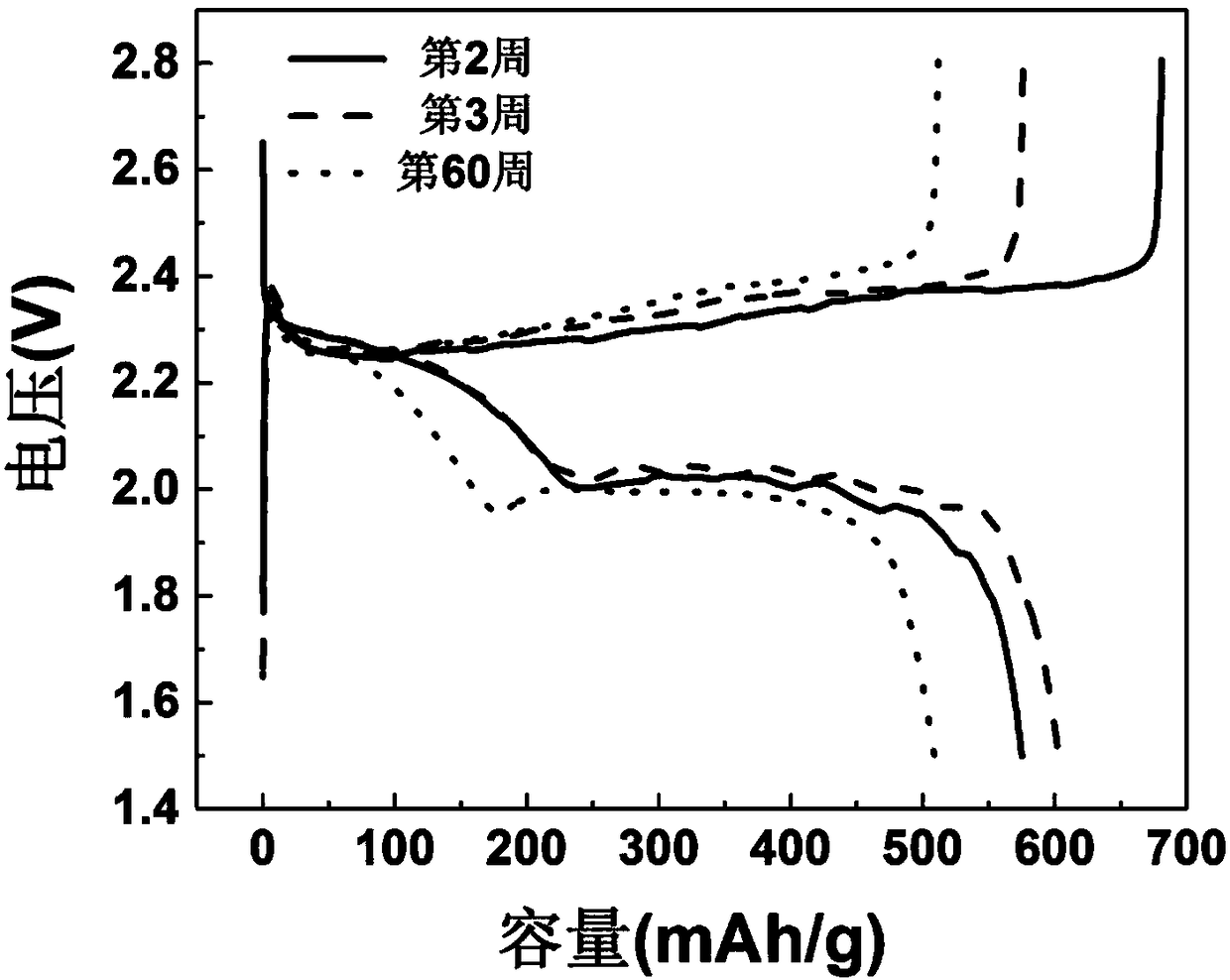

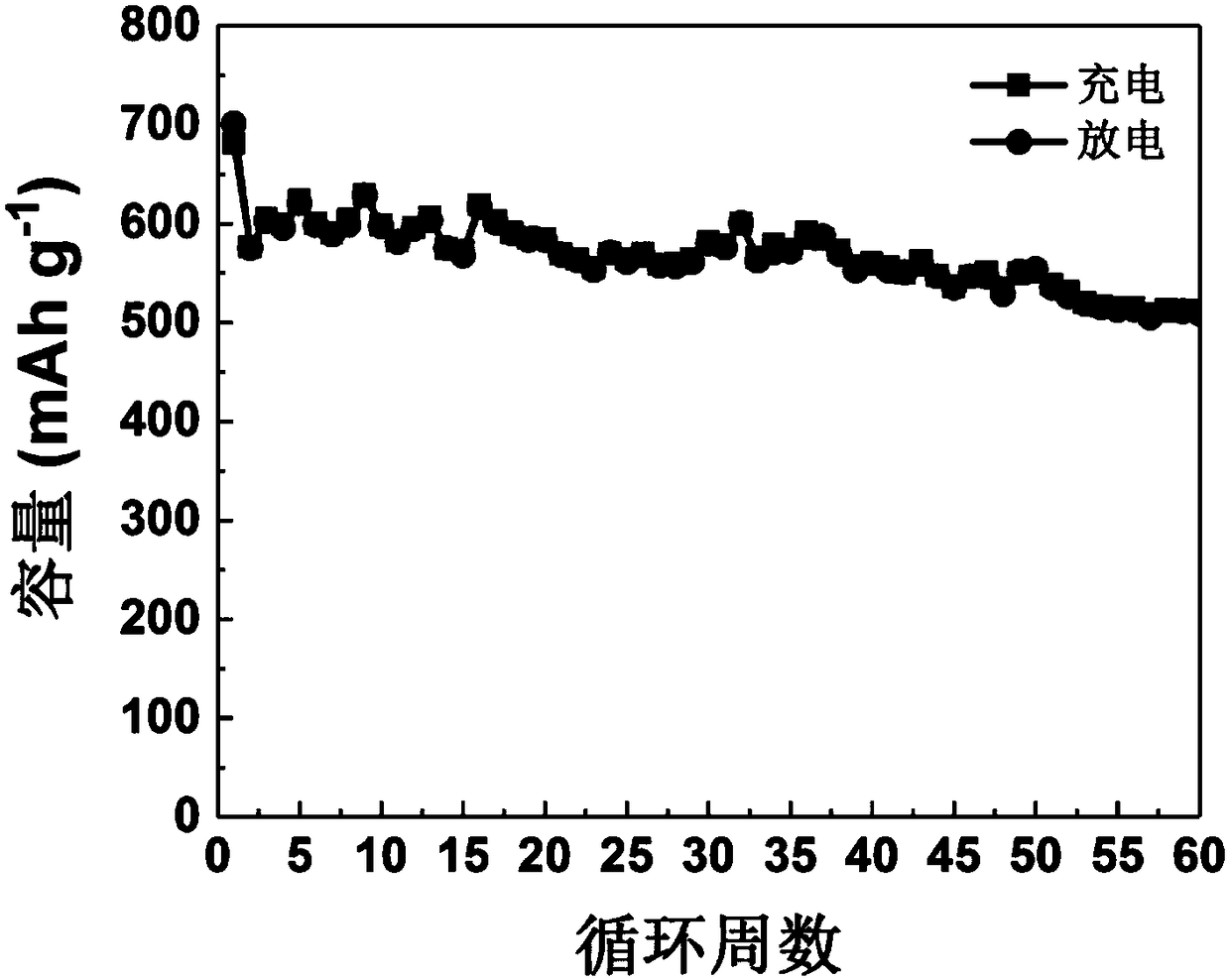

MXene/lithium sulfide/carbon composite cathode material and preparation method thereof

ActiveCN108258222AImprove conductivityHigh specific capacityCell electrodesSecondary cellsCarbon compositesLithium sulphate

The invention relates to an MXene / lithium sulfide / carbon composite cathode material and a preparation method of the MXene / lithium sulfide / carbon composite cathode material. The method comprises the following steps: (1) etching an MAX phase powder with an acid, filtering, washing and drying to obtain an MXene nanometer material with a porous structure; (2) preparing a solution from lithium sulfate,proportionally mixing with a carbon material or a carbon precursor, preparing a carbon / lithium sulfate or carbon precursor / lithium sulfate composite material; (3) heating the carbon / lithium sulfate or carbon precursor / lithium sulfate composite material in the step (2) under the protective atmosphere, reducing the above composite material into a lithium sulfide / carbon material by means of thermalreduction; (4) mixing the MXene nanometer material with the porous structure obtained in the step (1) with the lithium sulfide / carbon in the step (3), and ball-milling to obtain the MXene / lithium sulfide / carbon composite cathode material. Compared with the prior art, the prepared MXene / lithium sulfide / carbon composite cathode material has the advantages of high electrical conductivity, high specific capacity, good cycle performance, good rate capability, simple preparation process and the like.

Owner:SHANDONG UNIV

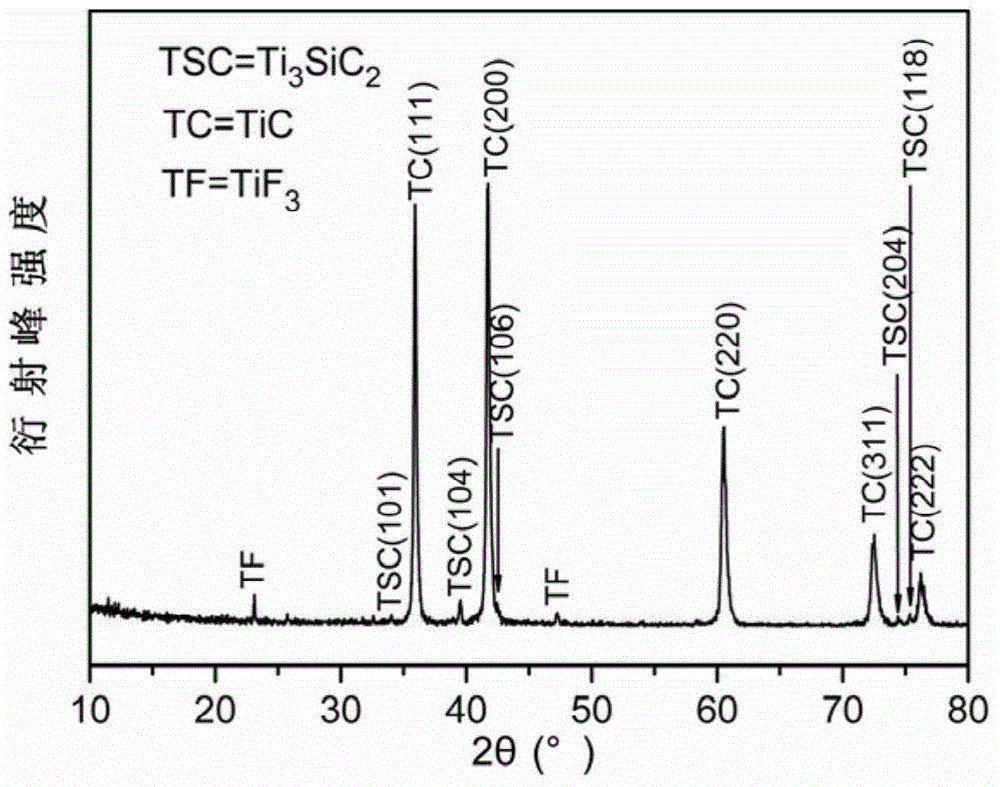

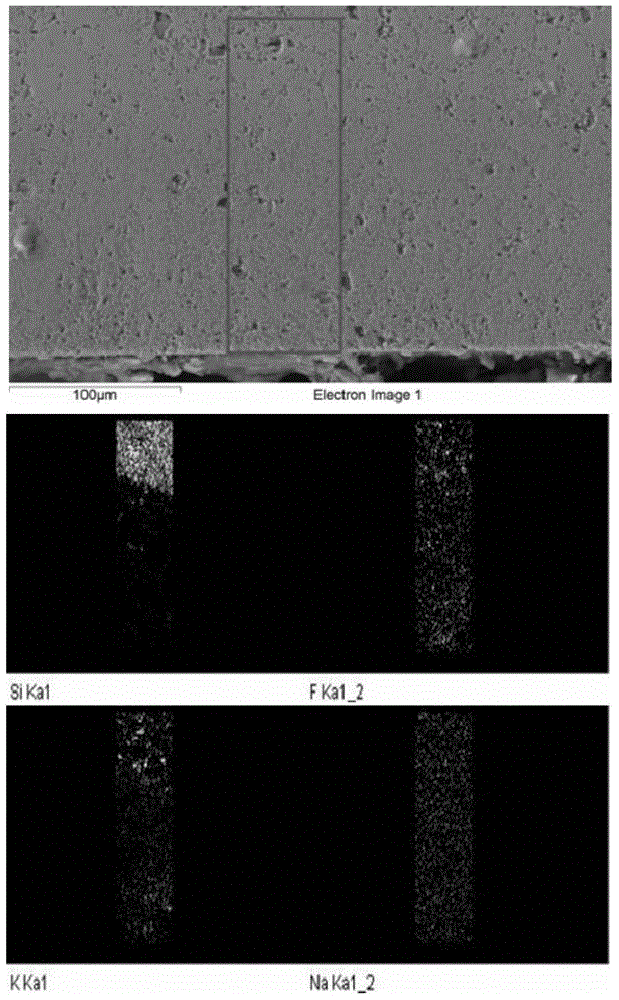

Production method of nuclear fuel clad element

ActiveCN104628395AImprove mechanical propertiesImprove thermal conductivityOptical rangefindersNuclear energy generationComposite ceramicSlurry

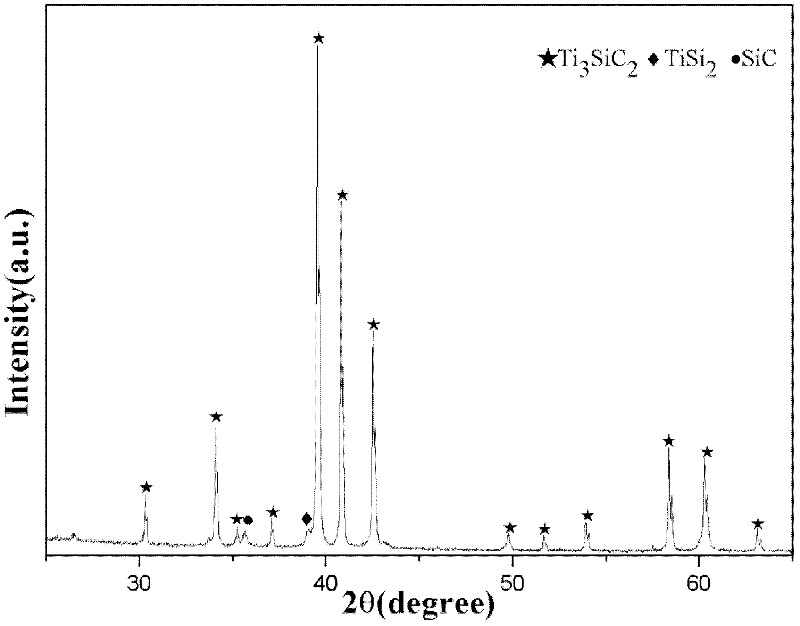

The invention provides a production method of a nuclear fuel clad element. The method comprises the following steps: selecting an MAX phase ceramic material, silicon carbide, an MAX phase-based composite ceramic material or a silicon carbide-based composite ceramic material, processing the above ceramic material to prepare a slurry, carrying out vacuum defoaming, making a ceramic film with the thickness of 10[mu]m-10mm on a base band through a curtain coating or draw-off process, winding to make a clad element blank, drying, carrying out rubber discharging, sintering, and carrying out surface treatment to obtain the nuclear fuel clad element. The production method has the advantages of simplicity, easy implementation, low cost, overcoming of the disadvantage of difficult processing of ceramic materials, high production efficiency, short cycle and easy industrialization. When the ceramic material is a Ti3SiC2-baed ceramic material, the ceramic material can resist molten fluorine salt corrosion, and can be used as a fluorine salt fuel clad element material in a nuclear reactor, so practical demands of a thorium-based fourth generation fission reactor nuclear energy system on the structure material are met.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

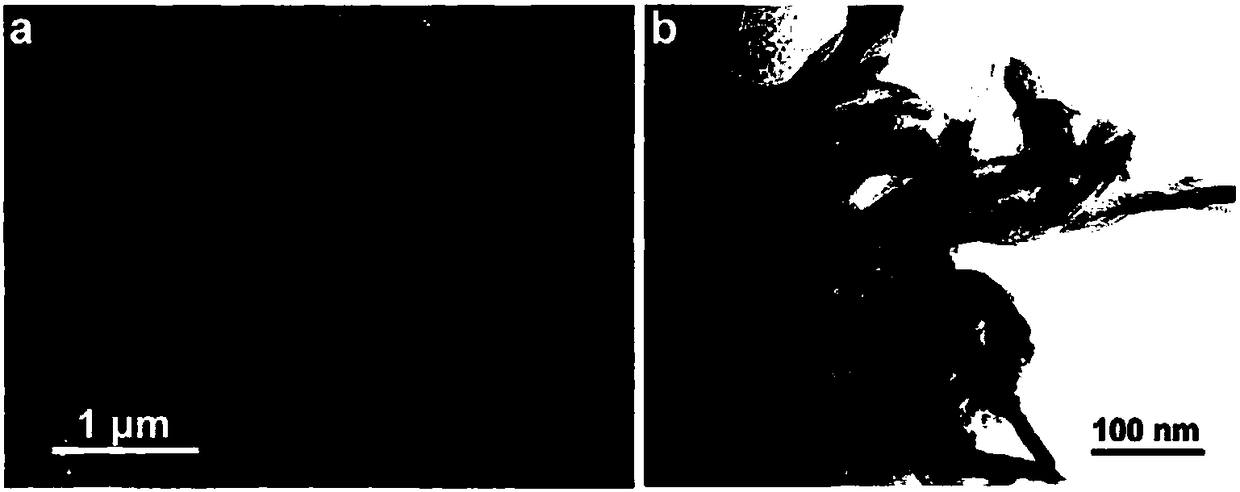

Two-dimensional metal carbonitride derived nano-material and preparation method therefor

ActiveCN108658122AStrong structural adjustabilityWide choice of chemical compositionAlkali titanatesNanowireMicrosphere

The invention discloses a two-dimensional metal carbonitride derived nano-material and a preparation method therefor. The derived nano-material has a chemical composition represented as AMO, wherein Ais alkali metal, M is a transition metal element in an MXene precursor, and O is an oxygen element; and the derived nano-material has a sea-urchin-shaped microsphere structure, a porous network structure or a nano-wire microsphere structure, and ultrathin nano-ribbons or ultrafine nano-wires serve as basic structural units of the derived nano-material. The preparation method for the derived nano-material comprises the steps of treating a dense layered ternary metal carbide (MAX phase) material with an etching agent so as to prepare accordion-shaped two-dimensional MXene, and then, carrying out oxidating and alkalizing treatment on the accordion-shaped MXene material, thereby obtaining derived materials of different nanostructures. According to the method disclosed by the invention, through adopting the special layered MXene as a precursor, derived materials with a variety of unique nanostructures can be prepared in a regulated and controlled manner; and the method is easy and feasible, can be used for preparing nanostructures, which are not easily achieved by other methods, and has an important application prospect in the fields of electrochemical energy storage, catalysis, adsorption and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

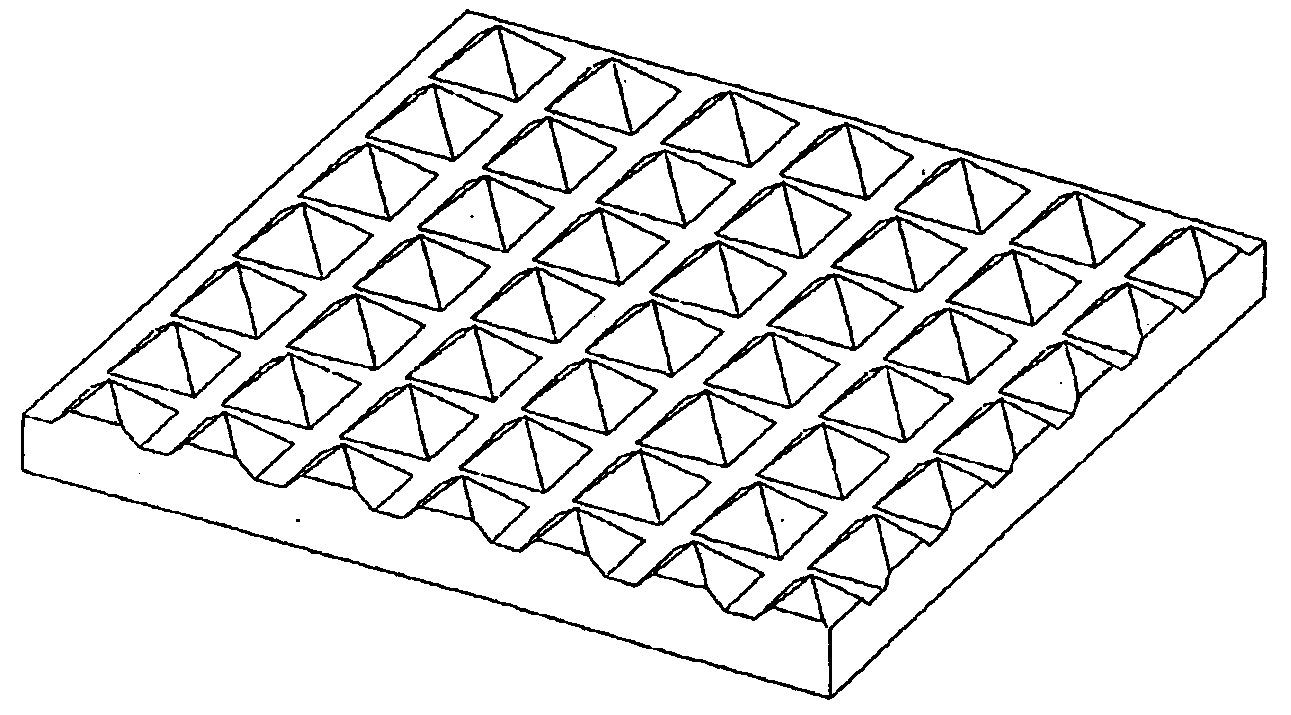

Porous conductive MAX phase ceramics and preparation method and use thereof

InactiveCN101747075APrecise control of porosityPorosity adjustablePhysical/chemical process catalystsCeramicwarePorous ceramicsAtmosphere

The invention relates to a porous conductive ceramics, in particular to a porous conductive MAX phase (Ti3SiC2, Ti3AlC2 or Ti2AlC) ceramics with a through hole structure, and a preparation method and a use thereof. The porosity of the porous ceramics is adjustable within the range of 20-65%, the ceramics comprises a through hole structure, and the openporosity is more than 85%. The preparation method comprises the steps of taking MAX phase ceramic powder as a raw material, molding, carrying out pressureless sintering in an atmosphere furnace, keeping the sintering temperature at 1200-1400 DEG C, and leading the sintering time to be 0.5-3 hours. The MAX phase conductive ceramics with the through hole structure prepared by the pressureless sintering method can be used as a catalyst carrier material for automobile exhaust purification. The invention can solve the problems of liquid phase, a large number of closed pores in the generated hole and the like during the sintering process by optimizing the molding pressure, the sintering temperature and the time precise control of the porosity.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Sulfur-oxygen doped MXene-carbon nanotube composite material and application thereof in lithium-sulfur battery

ActiveCN109449405AImprove stabilityEasy transferMaterial nanotechnologyCell electrodesLithium–sulfur batteryCarbon nanotube

The invention relates to a high-specific capacity lithium-sulfur battery positive electrode material and preparation method thereof. The lithium-sulfur battery positive electrode material is a sulfur-oxygen doped MXene-carbon nanotube composite material. The composite material is prepared according to the steps of taking MAX-phase ceramic powder as a raw material, preparing an MXene-carbon nanotube composite material by a vapor deposition method, obtaining an oxygen-doped MXene-carbon nanotube by hydrogen peroxide immersion, and performing sulfur doping by a ball-milling and hot melting method. When the sulfur-oxygen doped MXene-carbon nanotube composite material is used as a positive electrode material applied to the lithium-sulfur battery, the sulfur-oxygen doped MXene-carbon nanotube composite material has the characteristics of extremely high conductivity and large surface area, a discharging intermediate product lithium polysulfide can be effectively absorbed, and a shuttle effectis reduced.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

Preparation method of hybrid material, hybrid material and application of hybrid material

ActiveCN106513056AHigh hydrothermal stabilitySimple methodOther chemical processesHybrid capacitor electrodesHydrofluoric acidMetal-organic framework

The invention discloses a preparation method of a hybrid material, the hybrid material and application of the hybrid material. The preparation method comprises the following steps: selectively eroding a MAX phase with hydrofluoric acid to synthesize MXene, and then adding the MXene into a precursor solution for synthesizing an MOF (Metal-Organic Framework) to synthesize the hybrid material. According to the invention, hybridization preparation of the two-dimensional metal carbonitride MXene and MOF hybrid material is performed just by adding the MXene during the synthesizing process of the MOF, the method is simple, and the hydrothermal stability of the MOF can be remarkably improved.

Owner:NANJING UNIV OF TECH

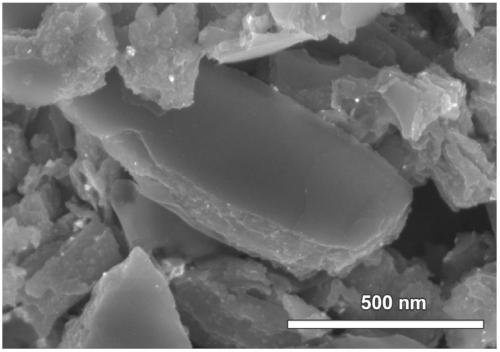

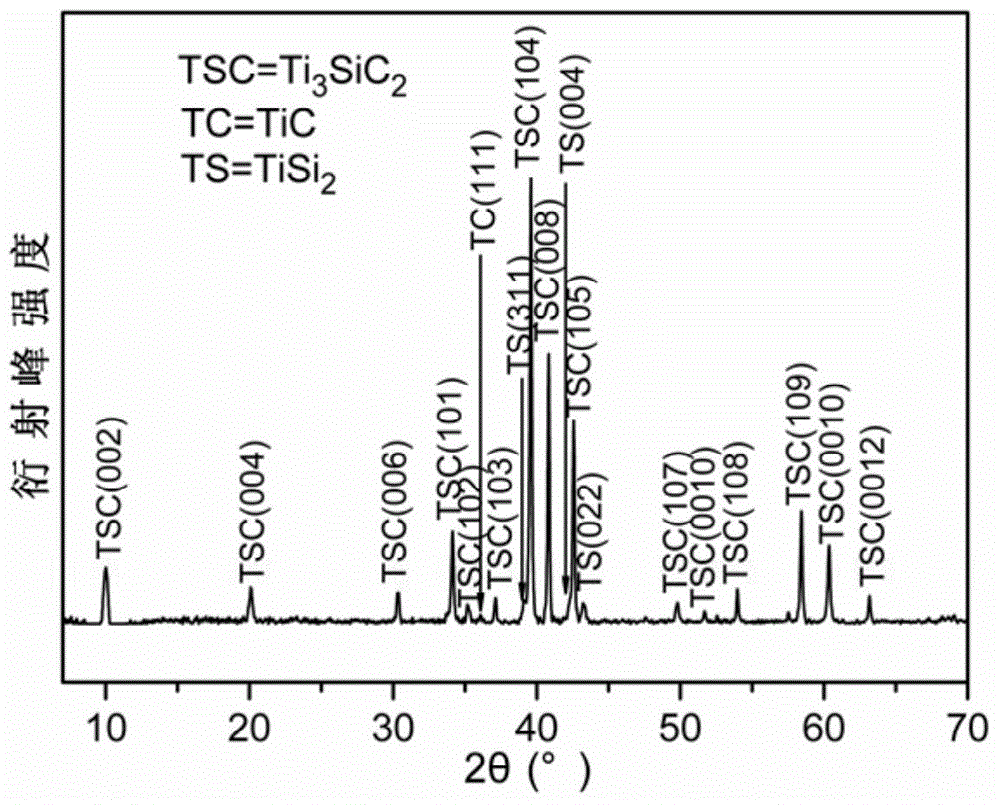

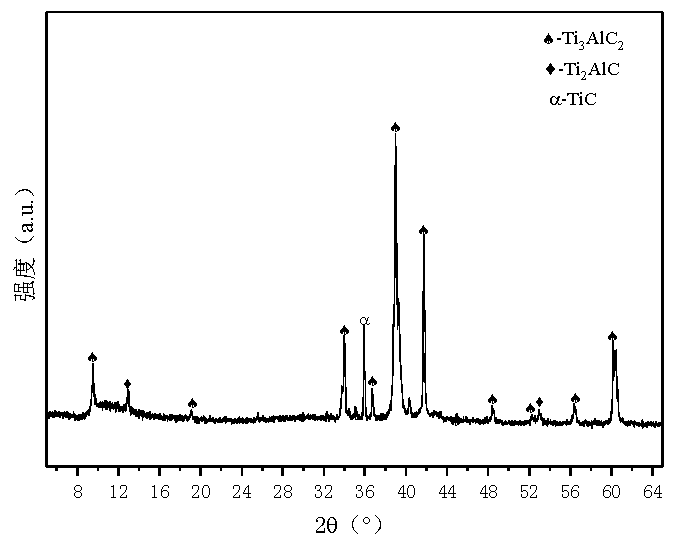

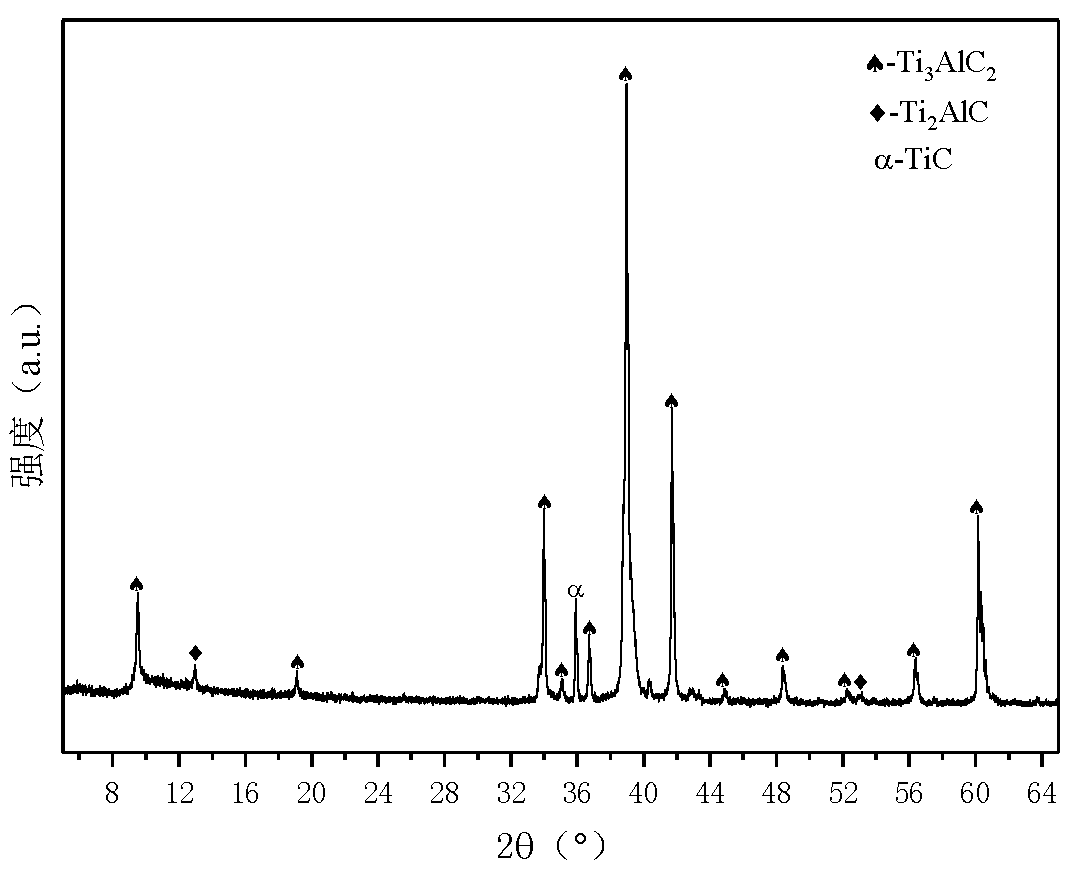

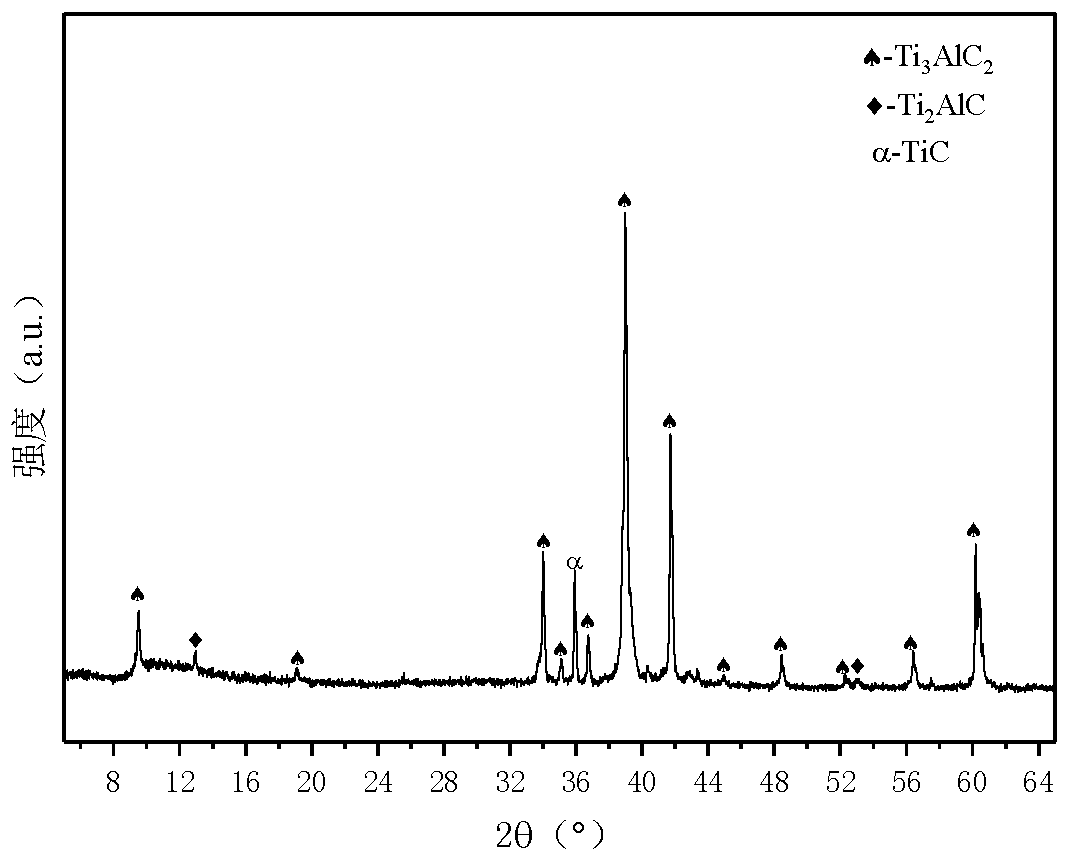

Method for preparing MAX phase ceramic Ti3AlC2 powder by molten salt method low temperature sintering

The invention relates to a method for preparing MAX phase ceramic Ti3AlC2 powder by molten salt method low temperature sintering. The method is as follows: TiH2 powder, Al powder and TiC powder as rawmaterial powder are mixed with a molten salt to obtain a mixed raw material, the molten salt is KCl and / or NaCl, and the resulting mixed raw material is placed in a protective atmosphere, sintered at1000-1250 DEG C for a certain period of time, pulverized and washed to obtain the MAX phase ceramic Ti3AlC2 powder.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

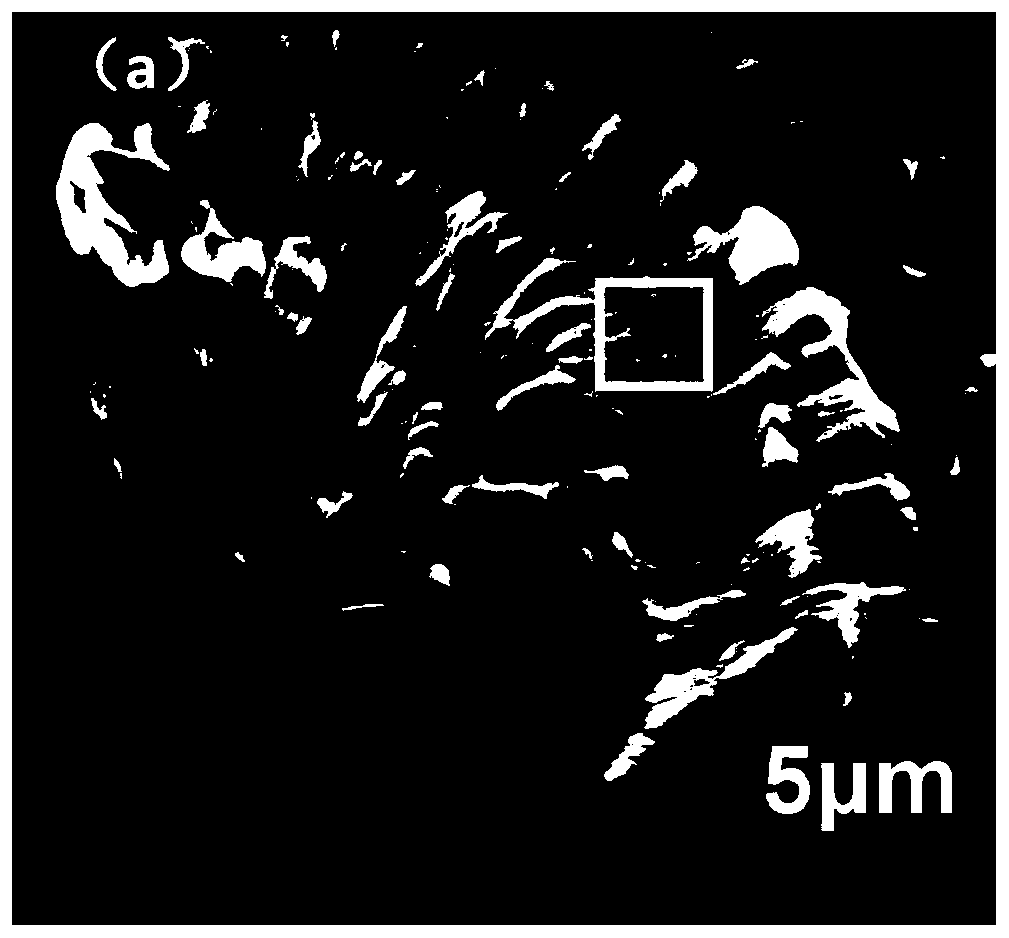

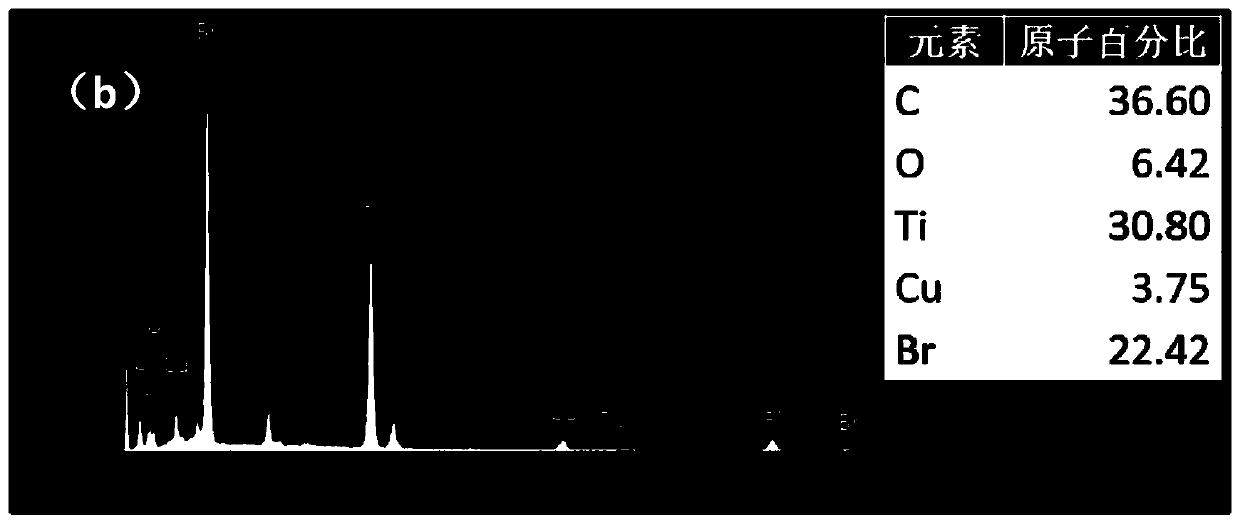

MXene material and preparation method and application thereof

InactiveCN110540236AExcellent chemical stabilityExcellent thermal stabilityTantalum compoundsTitanium compoundsHalogenIodide

The invention discloses an MXene material and a preparation method and application thereof. A molecular formula of the MXene material is shown as M<n+1>X<n>Br<2> or M<n+1>X<n>I<2>, where M is Sc, Ti,V, Cr, Zr, Nb, Mo, Hf, Ta and the like, X is C and / or N element, and n is 1, 2, 3 or 4. The preparation method comprises the following steps: mixing a precursor MAX phase material, a transition metalbromide and / or a transition metal iodide, and carrying out a high temperature reaction to obtain the MXene material with Br or I as a surface group. The MXene material with Br or I as the surface group can be used independently as a large-capacity, high-stability halogen battery electrode, the -Br and -I groups can carry out a reversible redox reaction between MXene layers, a stable reaction source is provided for battery charging and discharging, and the feature is not possessed by other element groups such as -F, -Cl, and -O.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Wear resistant coating with enhanced toughness

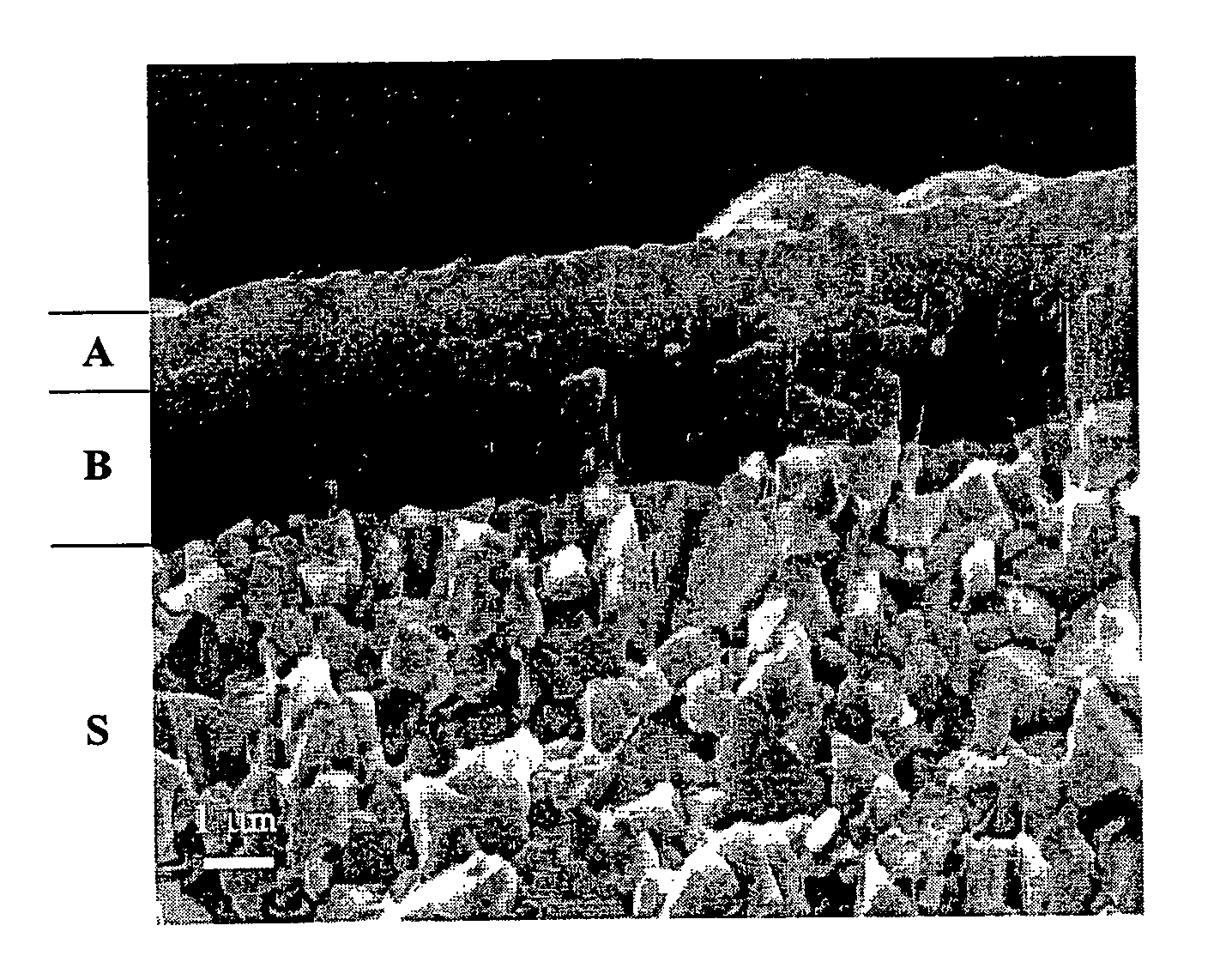

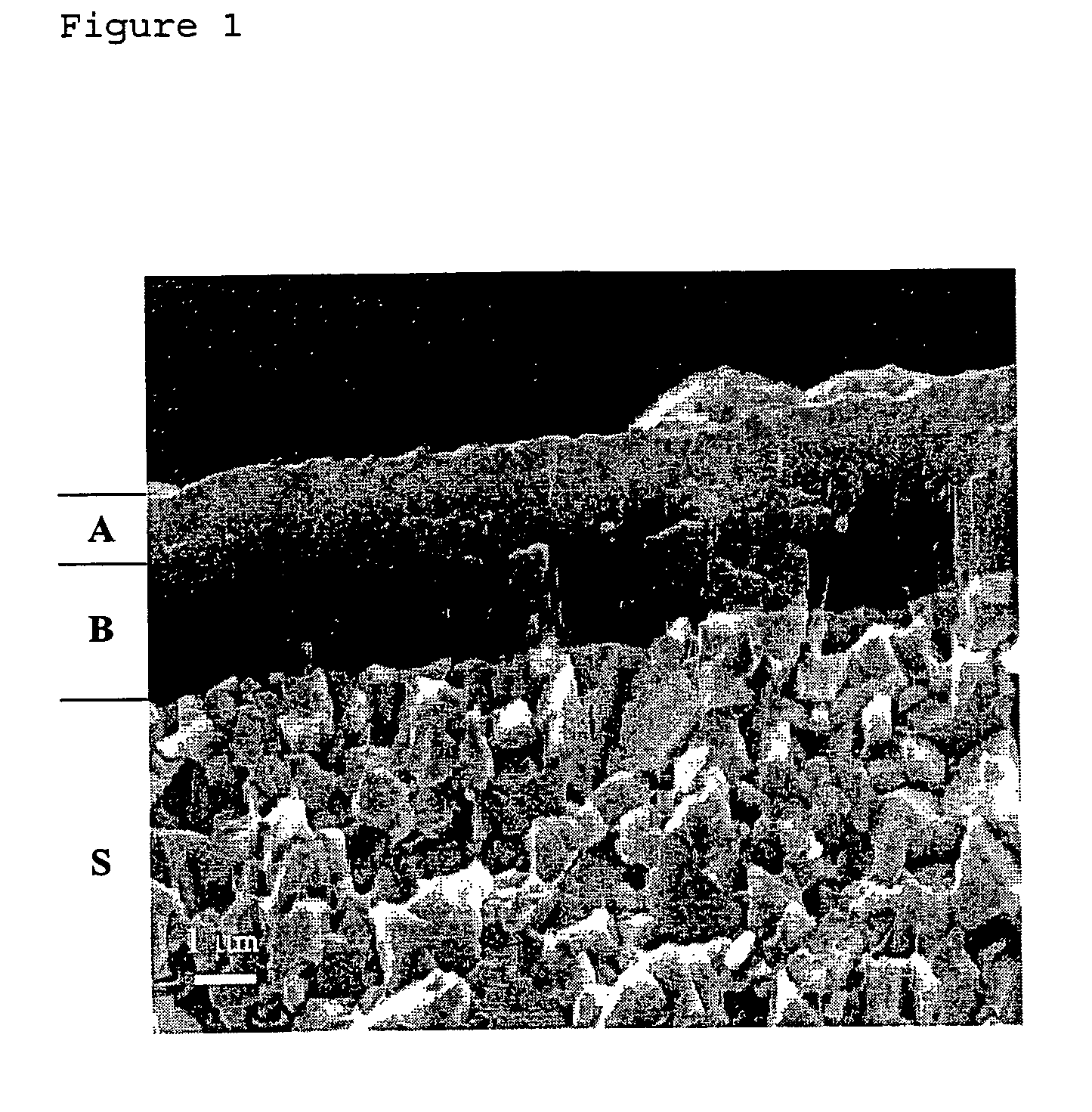

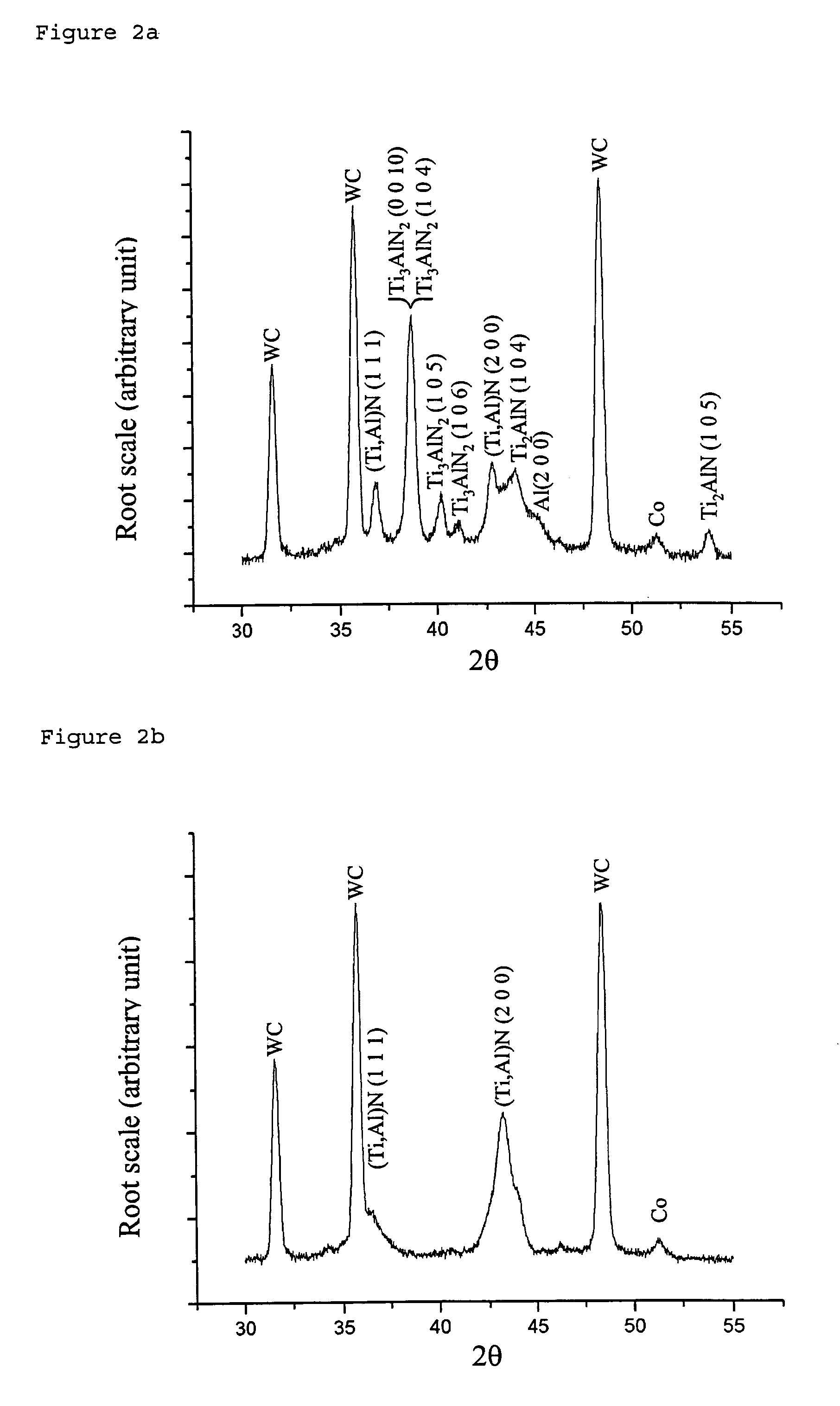

InactiveUS7067203B2Improve toughnessPigmenting treatmentOther chemical processesWear resistantToughness

The present invention relates to a cutting tool insert comprising a substrate and a coating. The coating composed of one or more layers of refractory compounds of which at least one layer comprises a so called MAX-phase defined as Mn+1AXn where n is 1, 2 or 3, M is one of the elements Ti, Zr, Hf, V, Nb, Ta, Cr or Mo, A is Al, Si or S, X is C, N and / or B.

Owner:SANDVIK INTELLECTUAL PROPERTY AB +1

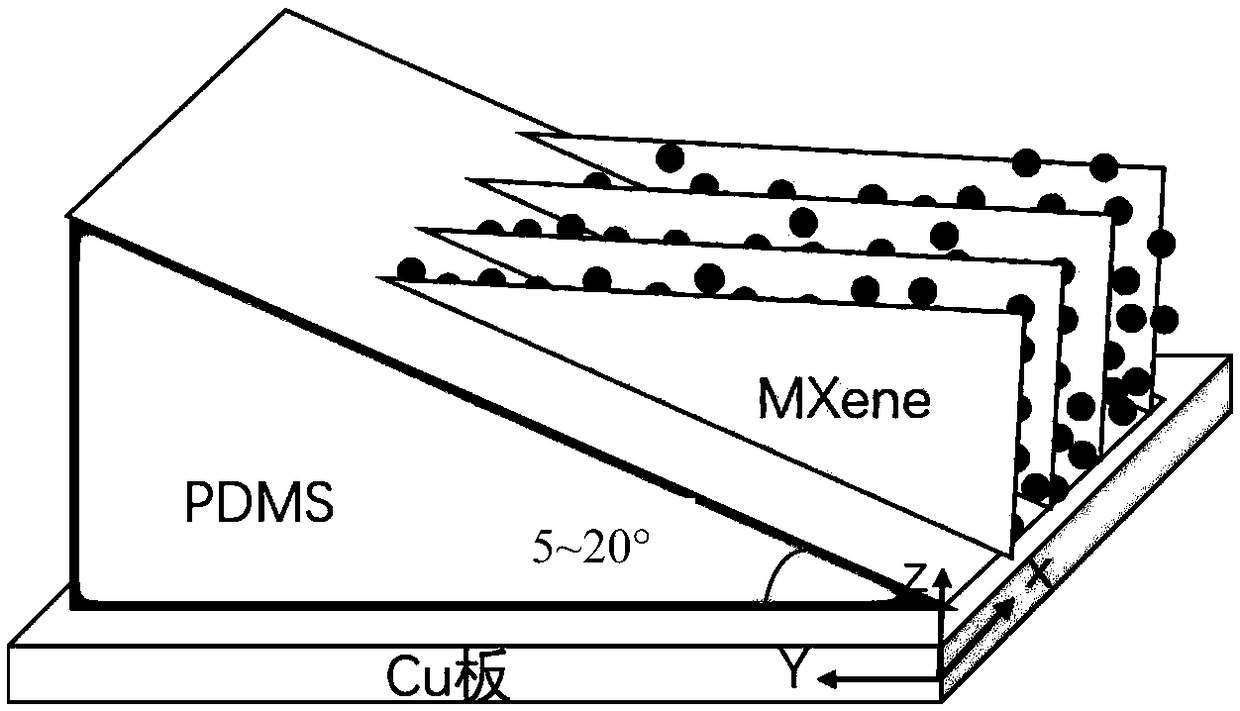

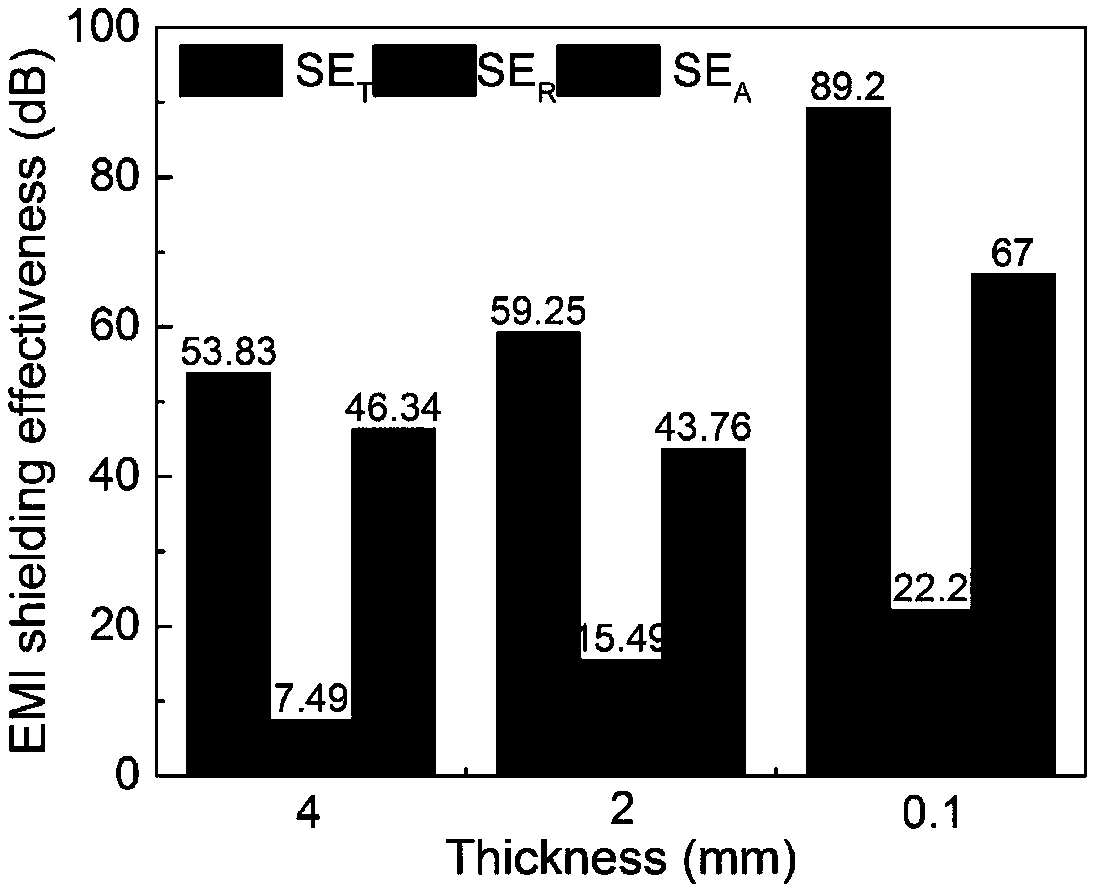

Three-dimensional layered MXene electromagnetic shielding foam and preparation method thereof

InactiveCN108811478AHigh mechanical strengthHigh electromagnetic shieldingMagnetic/electric field screeningEtchingElectromagnetic shielding

The invention relates to three-dimensional layered MXene electromagnetic shielding foam and a preparation method thereof and aims at solving the problems that an existing porous electromagnetic shielding material is low in absorbing and shielding effectiveness, poor in mechanical property and complicated in preparation process. According to the technical scheme, few-layer MXene dispersion liquid is prepared through wet chemical etching of an MAX phase; the dispersion liquid is directionally frozen through a bidirectional freezing process; and MXene aerogel is prepared through vacuum drying. The prepared MXene aerogel is of a layered structure, is long in range and ordered and has a good compression cycle characteristic, and the strength retention can reach over 60%. The total electromagnetic shielding effectiveness can reach 60-100dB; and the absorbing and shielding effectiveness can be adjusted through compressing the foam, so that the absorption-dominated electromagnetic shielding characteristic is achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

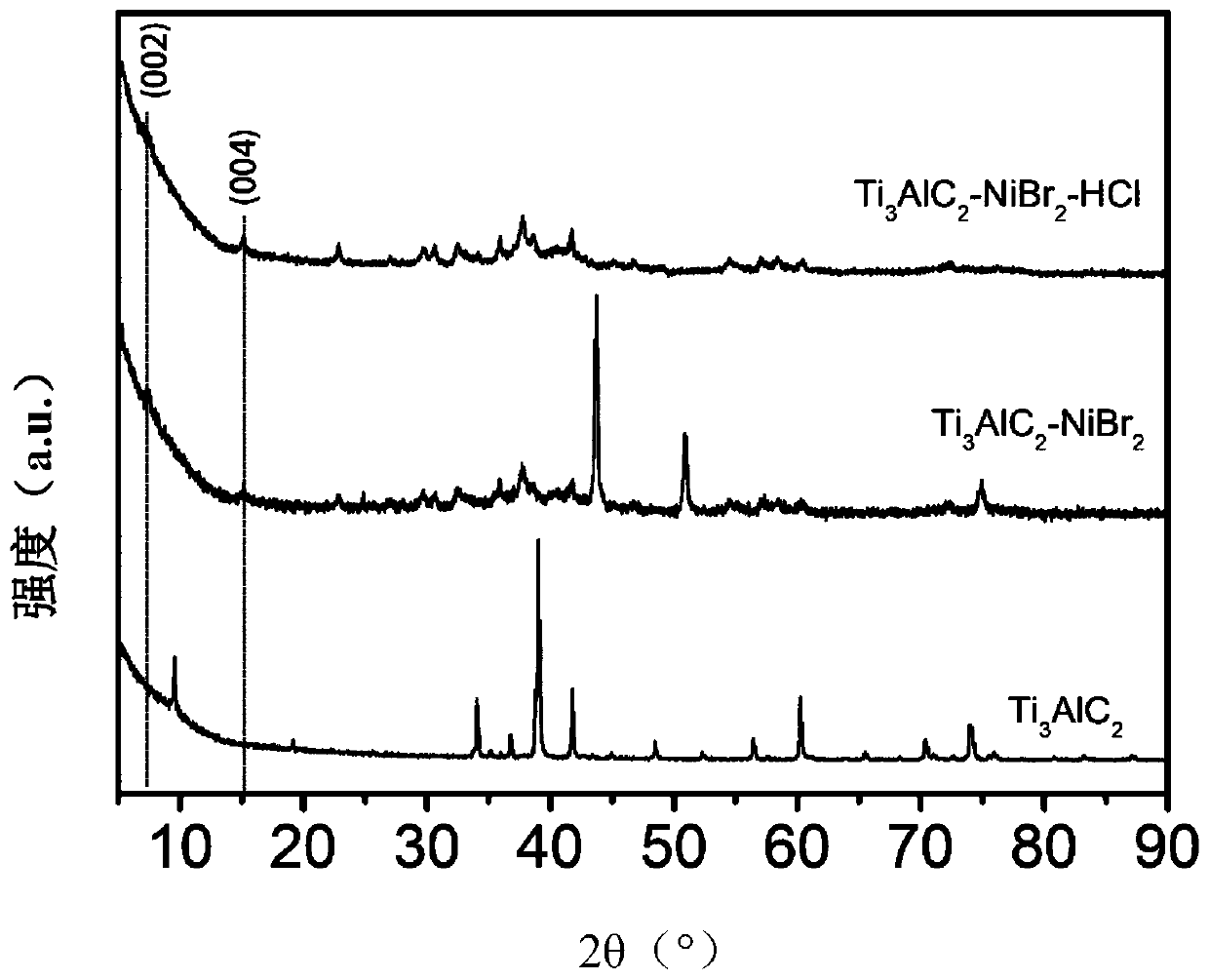

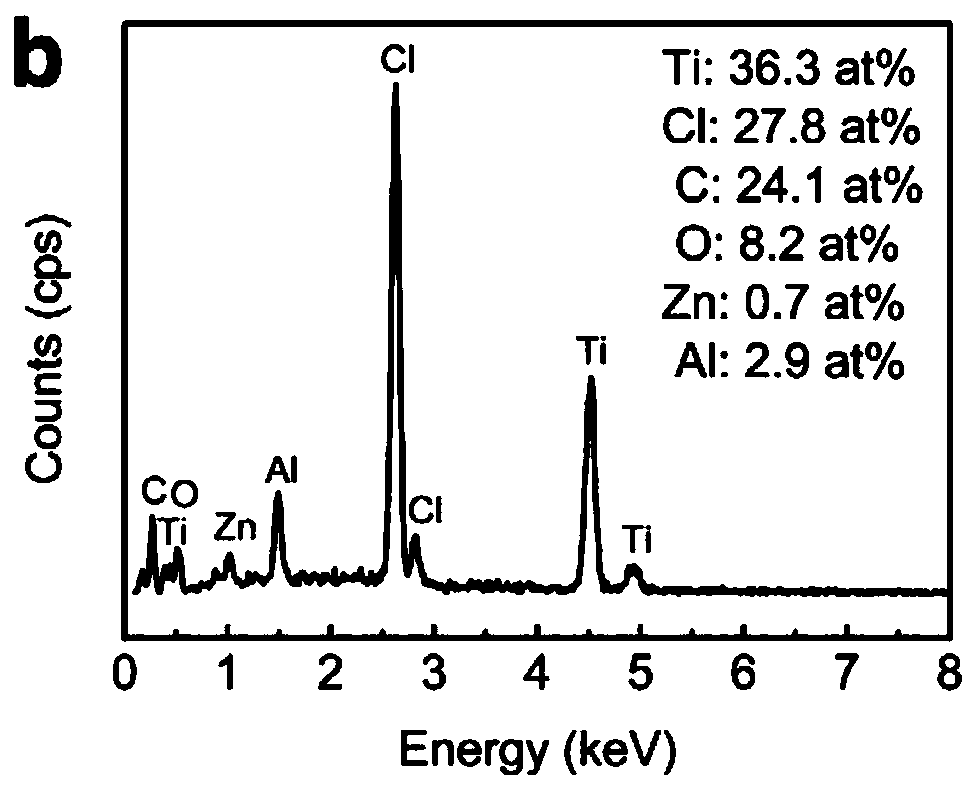

MXene material taking Cl as surface group as well as preparation method and application of MXene material

ActiveCN109437177ARich adjustable spaceSimple manufacturing methodCarbon compoundsCapacitancePtru catalyst

The invention discloses an MXene material taking Cl as a surface group as well as a preparation method and application of the MXene material. The molecular formula of the MXene material taking the Clas the surface group is expressed as Mn<+1>XnCl2, wherein M is any one or a combination of more than two of elements such as Sc, Ti, V, Cr, Zr, Nb, Mo, Hf and Ta, X is any one or a combination of twoof C and N, and n is 1, 2, 3 or 4. The preparation method comprises the following steps: mixing a precursor MAX phase material with transition metal chloride, carrying out high-temperature reaction at400 to 800 DEG C and then carrying out post treatment to obtain the MXene material taking the Cl as the surface group. The preparation method disclosed by the invention is simple, feasible, and environmentally friendly; the obtained MXene material taking the Cl as the surface group is better applied to the fields of electrode materials, supercapacitor materials, electromagnetic absorbing and shielding materials, catalysts and the like for electrochemical energy storage.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

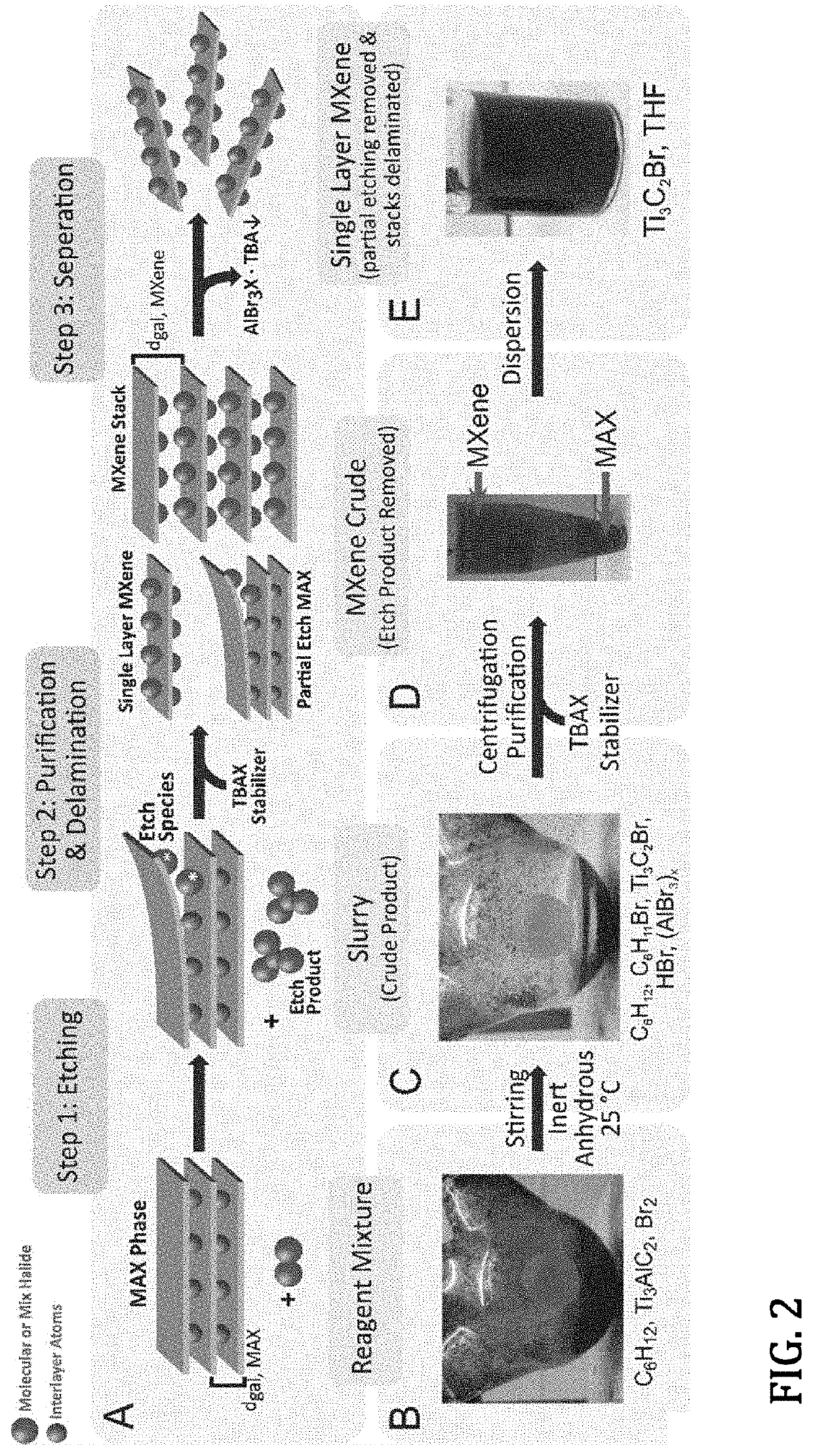

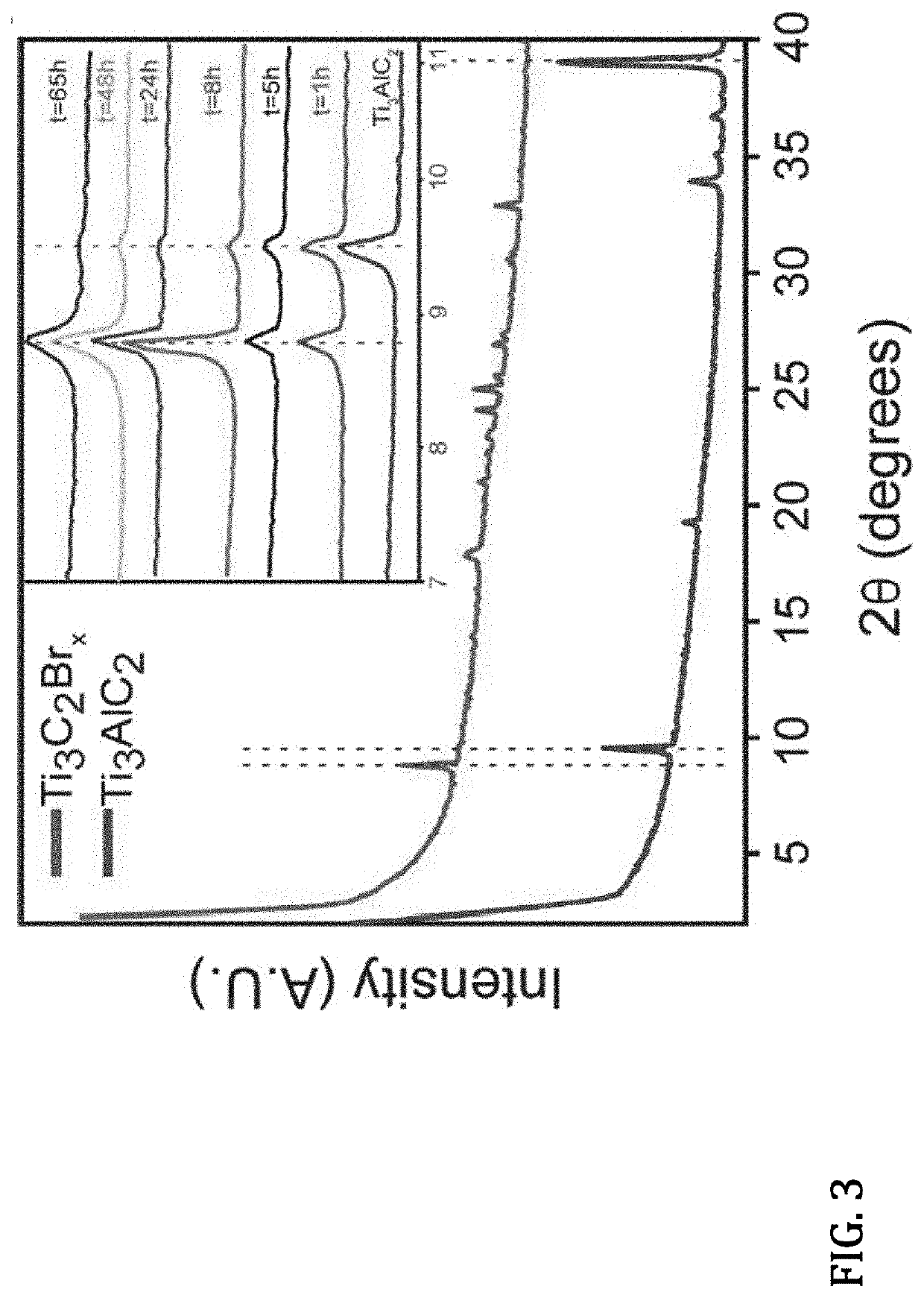

Preparation of Layered MXene via Elemental Halogen Etching of MAX Phase

PendingUS20210139379A1Good dispersionImprove conductivityNitrogen compoundsCarbon compoundsEtchingIndium

A method of making a layered MXene material comprises a) introducing dried MAX phase powder into a vessel under anhydrous, inert conditions, the MAX phase powder comprising a general formula of Mn+1AXn (n=1, 2, 3, or 4), wherein M is a transition metal or p-block metalloid selected from the group consisting of Ti, Zr, Hf, V, Nb, Ta, Cr, Mo, W, Re, Cu, Ni, Ag, Zn, Cd, In, Sn, and Pb; interlayer A is a Group III, IV, or V metalloid selected from the group consisting of Al, Si, Ga, Ge, In, Sn, Pb, As, Bi, Sb, and X is one of C (carbon) and N (nitrogen); b) introducing a halogen and solvent to the dried MAX phase to create a halogen solution having a predetermined concentration; c) allowing a reaction to proceed for about 24 hours between 30-90° C. to create a reaction slurry comprising a MXene material.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

Preparation method for in-situ generated Ti3SiC2-phase toughening silicon carbide ceramic matrix composite material

The invention belongs to the technical field of the ceramic matrix composite material preparation, and particularly relates to a preparation method for an in-situ generated Ti3SiC2-phase toughening silicon carbide ceramic matrix composite material. The method comprises the following steps: enabling TiC powder, connection resin and an organic solvent to be prepared as slurry, and preparing prepregwith fibers, to obtain a fiber / C-TiC porous body through hot-pressing and carbonizing, covering the surface of the porous body by using Si powder, and generating Ti3SiC2 in situ in a process of generating a silicon carbide matrix by using a high-temperature melting silicon permeation technology. The method is capable of not only eliminating the residual silicon content in the matrix, but also weakening the adverse effect of silicon to mechanical properties of the composite material; in addition, because of an own stratified structure of a MAX-phase material, while the ceramic matrix compositematerial bears load, a crack is expanded to the layer interface and is hindered so that deflection or passivation is produced, the stress concentration of the point of the crack is weakened, and the toughening to the ceramic matrix composite material is finally realized.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

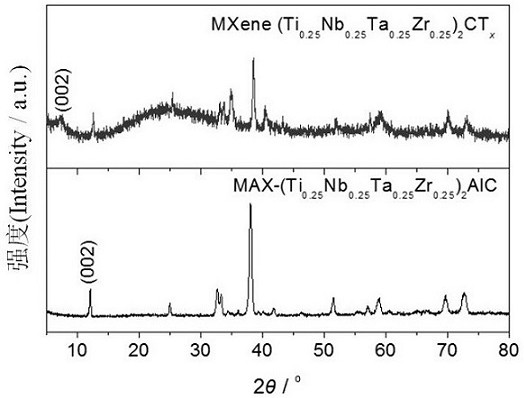

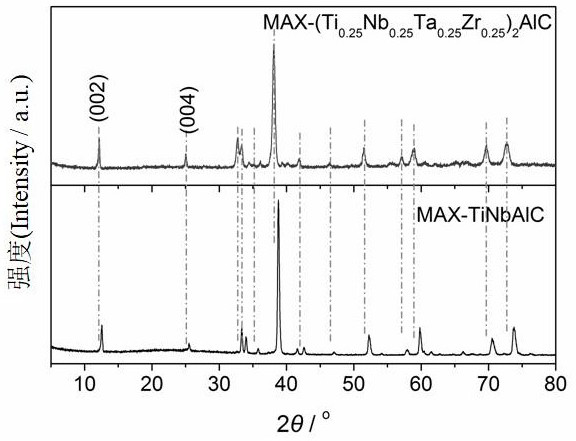

Medium-entropy MAX phase material, medium-entropy two-dimensional material and preparation method of medium-entropy MAX phase material

InactiveCN112811906ADeepen theoretical researchIncrease varietyCarbon compoundsNanotechnologyElectronic structurePhysical chemistry

The invention discloses a medium-entropy MAX phase material, a medium-entropy two-dimensional material and a preparation method thereof, wherein the chemical general formula of the medium-entropy MAX phase material is Mn + 1AXn, and the medium-entropy MAX phase material is characterized in that an M element is selected from three or four transition metal elements and lanthanide elements; the M element contains at least two transition metal elements or lanthanide elements capable of forming a solid solution; the A element is selected from at least one of VIIB, VIII, IB, IIB, IIIA, IVA, VA and VIA family elements; the X is at least one of carbon, nitrogen, boron or oxygen, and n is 1, 2, 3, 4, 5 or 6. A medium-entropy two-dimensional material can be obtained after the component A in the medium-entropy MAX phase material is etched. In the invention, the medium-entropy MAX phase material and the medium-entropy two-dimensional material which can stably exist in a single phase are prepared by introducing the multi-component transition metal capable of achieving solid solution, inducing the structure to generate lattice distortion and optimizing the electronic structure.

Owner:BEIHANG UNIV

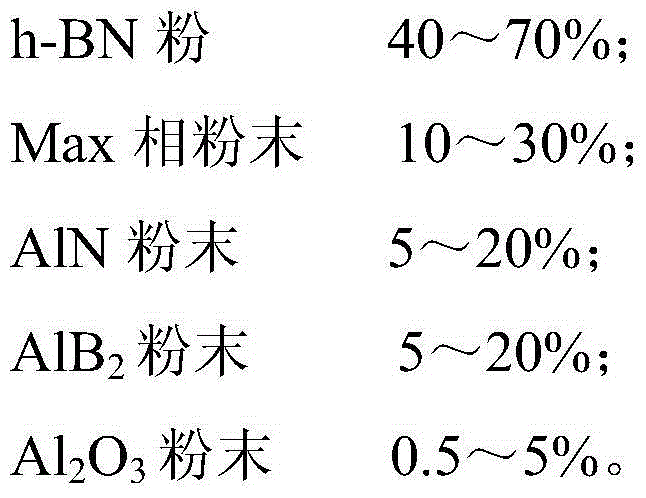

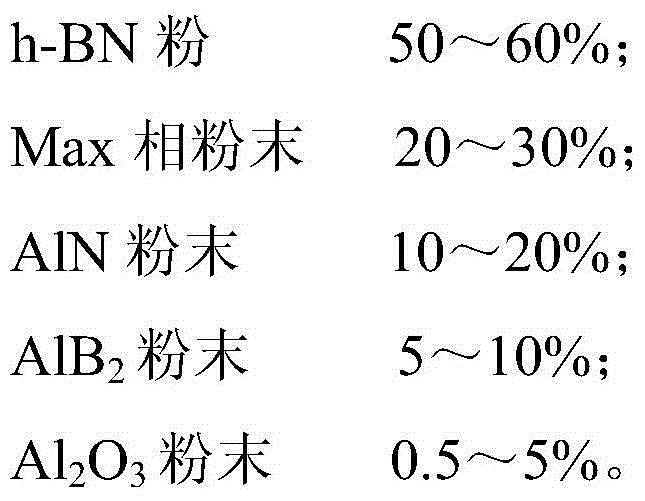

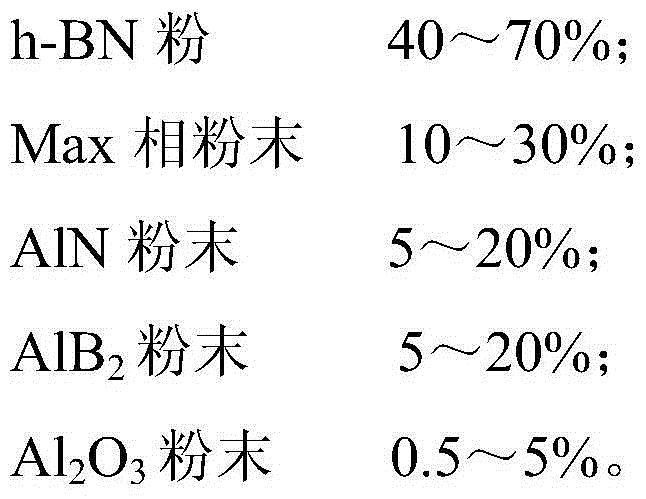

Max phase-boron nitride composite ceramic side seal plate for thin-strip casting and manufacturing method of Max phase-boron nitride composite ceramic side seal plate

The invention discloses a Max phase-boron nitride composite ceramic side seal plate for thin-strip casting and a manufacturing method of the Max phase-boron nitride composite ceramic side seal plate. The side seal plate comprises the following components in percentage by mass: 40-70% of h-BN powder, 10-30% of Max phase powder, 5-20% of AlN powder, 5-20% of AlB2 powder and 0.5-5% of Al2O3 powder. The manufacturing method comprises the following steps: 1) preparing Max phase powder; 2) preparing mixed slurry: namely mixing the h-BN powder, the Max phase powder, the AlN powder, the AlB2 powder and the Al2O3 powder in percentage by mass and then adding a mixed solvent to mix and fully and uniformly mixing the mixture to obtain mixed slurry; 3) preparing mixed powder; and 4) sintering the mixed powder. According to the method disclosed by the invention, the ceramic side seal plate for double roll thin-strip casting is manufactured by using a ceramic formula. The prepared side seal plate has the characteristics of being high in compactness and high in rupture strength. The compactness is 93-98%, the rupture strength at the room temperature reaches 300-500MPa, the strength of the side seal plate in the using process is fully guaranteed, and the side seal plate is not hardened.

Owner:武汉钢铁有限公司

FeCo/MXene compound, and preparation method and application thereof

ActiveCN109701572ASimple and safe operationSave materialPhysical/chemical process catalystsElectrodesCatalytic effectNitrogen gas

The invention discloses a FeCo / MXene compound, and a preparation method and application thereof. The method comprises the following steps: taking a MAX phase of a ternary stratified material as a rawmaterial, and repeatedly carrying out washing and centrifuging by an etching method to obtain multi-layer MXene in the lower-layer liquid and obtain few-layer MXene in the upper layer liquid; and mixing water solutions of ferric salt, cobalt salt and urea with a dispersion liquid of the few-layer MXene, carrying out heating under protection of nitrogen, carrying out stirring for reacting, and centrifuging and washing the obtained reactant to obtain the FeCo / MXene compound. The method for preparing the MXene has the advantages that operation is simple and safe, a glassy-carbon electrode supporting the FeCo / MXene compound is used as a working electrode to research a process of electrocatalysis of anode water oxidation, the initial potential is low, and the catalytic effect is good.

Owner:LIAONING UNIVERSITY

MAX phase ceramic and composite material surface modification processing method thereof

The invention relates to the field of material surface modification processing, in particular to MAX phase ceramic and a composite material surface modification processing method thereof. A micro-arc oxidation method is adopted for generating oxide film layers on the MAX phase ceramic and a composite material surface of the MAX phase ceramic in situ, and mainly, the MAX phase ceramic with M being valve metal elements (Ti, Mg, Al, Zr, Nb, Ta and the like) and solid solutions or second-phase modified composite materials with the MAX phase ceramic being bases are processed. A micro-arc oxidation processing technology is adopted so that the composite oxide film layers which are well combined with base bodies compactly can be prepared on the surfaces of ceramic materials. The method is low in cost, simple in technology, environmentally friendly, and capable of being applied on a large scale and remarkably improving the surface hardness, the corrosion resistance, the abrasion resistance, high-temperature thermal stability and other performance of the MAX phase ceramic materials with good performance of ceramic and metal and the composite materials of the MAX phase ceramic materials.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

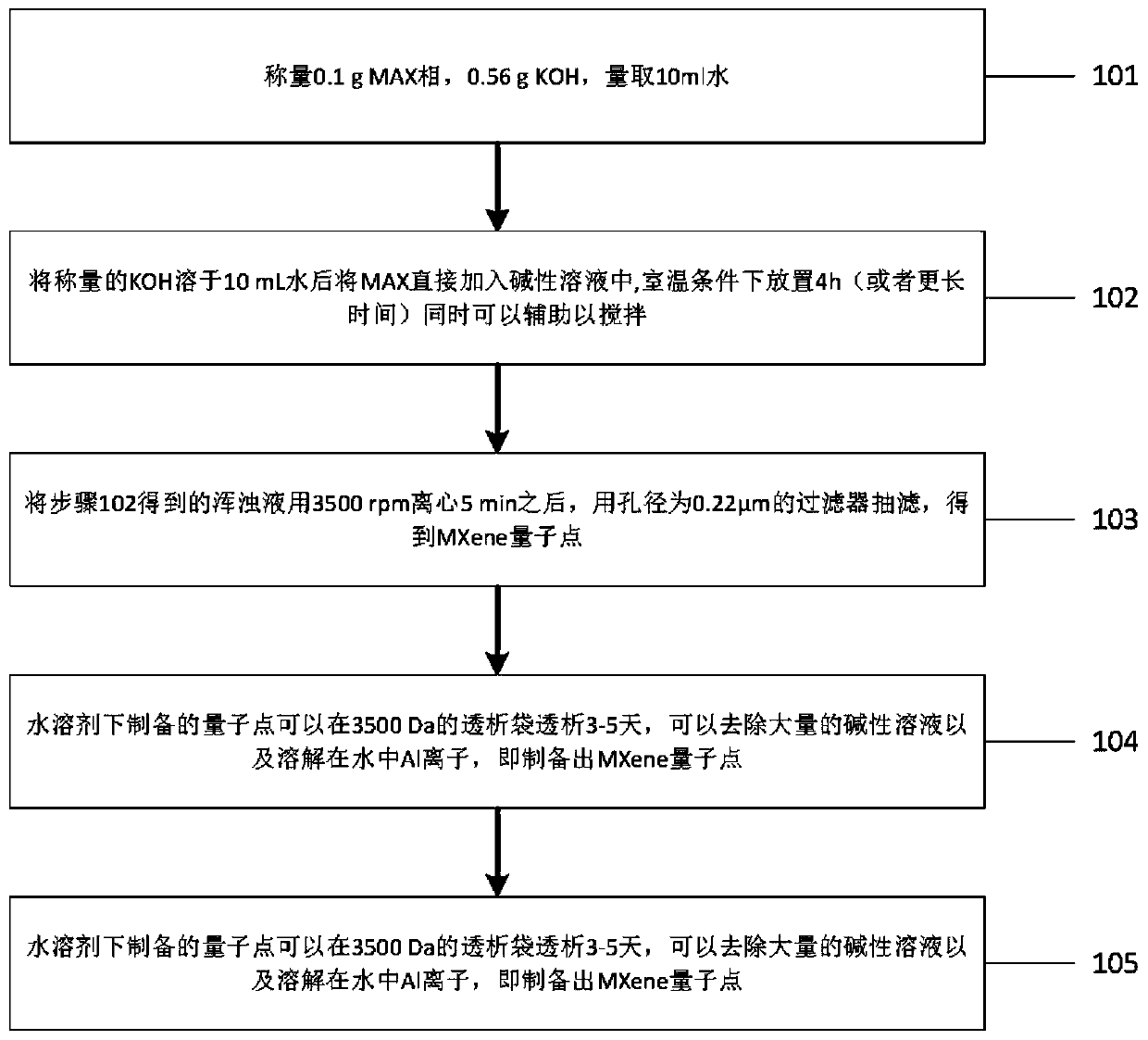

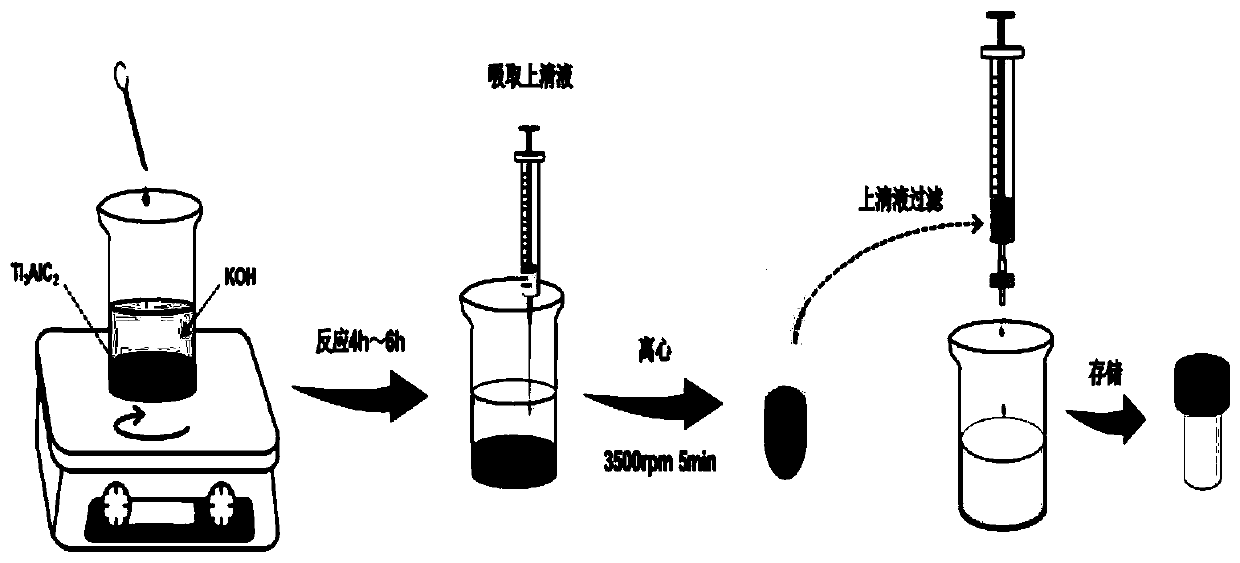

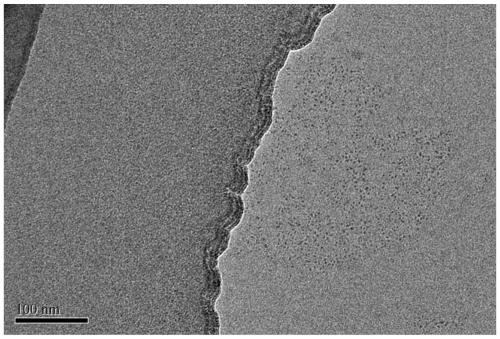

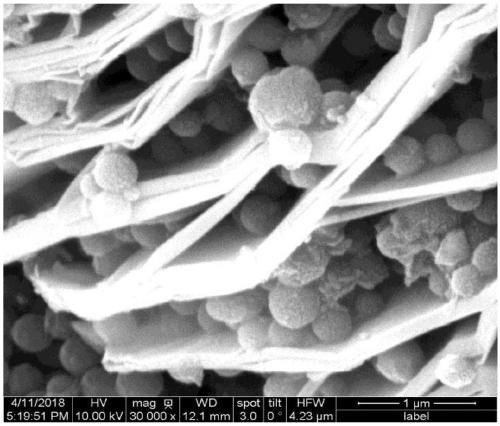

Method for preparing MXene quantum dot by etching with alkali liquor

ActiveCN110371979ASave raw materialsLow costNitrogen compoundsTitanium carbideOrganic solventSemiconductor materials

The invention relates to a method for preparing a MXene quantum dot by etching with an alkali liquor, belonging to the field of semiconductor materials. The method comprises the following steps: weighing a MAX phase, an alkaline compound and water for subsequent usage; dissolving the alkaline compound into the water so as to form an alkaline solution; adding the MAX phase into the alkaline solution, and placing an obtained solution under the condition of a room temperature so as to form a turbid solution; centrifuging the turbid solution obtained in the step 3, and carrying out vacuum filtering through a filter so as to obtain a MXene quantum dot containing alkaline solution; dialyzing the MXene quantum dot containing alkaline solution so as to remove alkaline ions and metal ions in the solution; and mixing an organic solvent with the MAX phase under stirring so as to prepare the MXene quantum dot. The method provided by the invention has the advantages of simple preparation process, environmental friendliness, low cost, less time consumption and applicability to large-scale production; meanwhile, the MXene quantum dot is proved to have universality to a MAX material.

Owner:UNIV OF SCI & TECH BEIJING

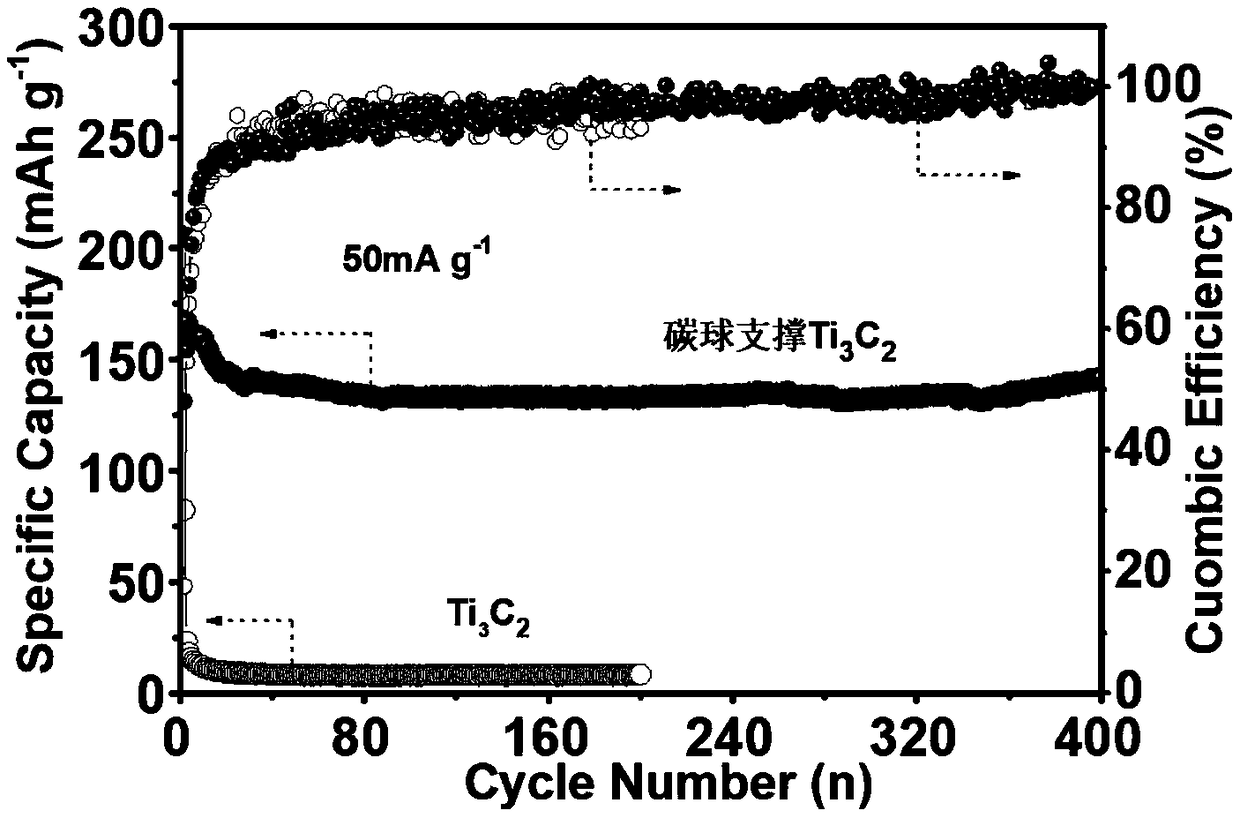

Preparation and application methods of nanometer carbon sphere-supported MXene composite material

InactiveCN109449402AImprove cycle stabilityIncrease spacingCell electrodesSecondary cellsSurface-active agentsMagnesium battery

The invention discloses preparation and application methods of a nanometer carbon sphere-supported MXene composite material. The preparation method comprises the steps of etching MAX-phase ceramic powder to obtain two-dimensional carbide MXene by a mixed solution of sodium fluoride and hydrochloric acid; synthesizing a nanometer carbon sphere by a hydrothermal method; and preparing a mixed solution from the MXene, a cationic surface active agent and the nanometer carbon sphere by electrostatic interaction, and performing stirring, centrifuging and drying under a room temperature, thereby obtaining the nanometer carbon sphere-supported MXene composite material powder. The preparation method is simple and safe and is low in cost. The nanometer carbon sphere-supported MXene composite materialis used as a magnesium battery positive electrode material, the interlayer distance of the MXene can be expanded, more surface active sites are exposed, ion transmission passages are increased, meanwhile, the problem of stack and agglomeration of an MXene piece layer during the circulation process is also solved, the magnesium storage capacity of the MXene is further substantially improved, the nanometer carbon sphere-supported MXene composite material has favorable cycle stability and is an excellent magnesium battery positive electrode material.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com