MXene/lithium sulfide/carbon composite cathode material and preparation method thereof

A technology of positive electrode materials and composite materials, applied in the field of MXene/lithium sulfide/carbon composite positive electrode materials and its preparation, can solve the problems of low discharge capacity and small specific capacity, and achieve good rate performance, high specific capacity and good cycle performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preparation method of MXene / lithium sulfide / carbon composite cathode material, comprising the following steps:

[0043] (1) Weigh 5gTi 3 AlC 2 , add 10% HF solution, react at 30°C for 10h, filter and dry to obtain Ti 3 C 2 .

[0044] (2) Weigh 6.4g of lithium sulfate and dissolve it in water, add 12.8g of carbon black, mix evenly under stirring conditions, and then dry to obtain a carbon black / lithium sulfate composite material.

[0045] (3) Put the carbon black / lithium sulfate composite material in step (2) in a tube furnace, and heat it to 800° C. for 2 hours under the protection of high-purity argon to obtain lithium sulfide / carbon material.

[0046] (4) Ti in step (1) 3 C 2 Mix with the lithium sulfide / carbon material in step (3) at a mass ratio of 1:1, and ball mill for 1 hour to obtain Ti 3 C 2 / lithium sulfide / carbon composite cathode material.

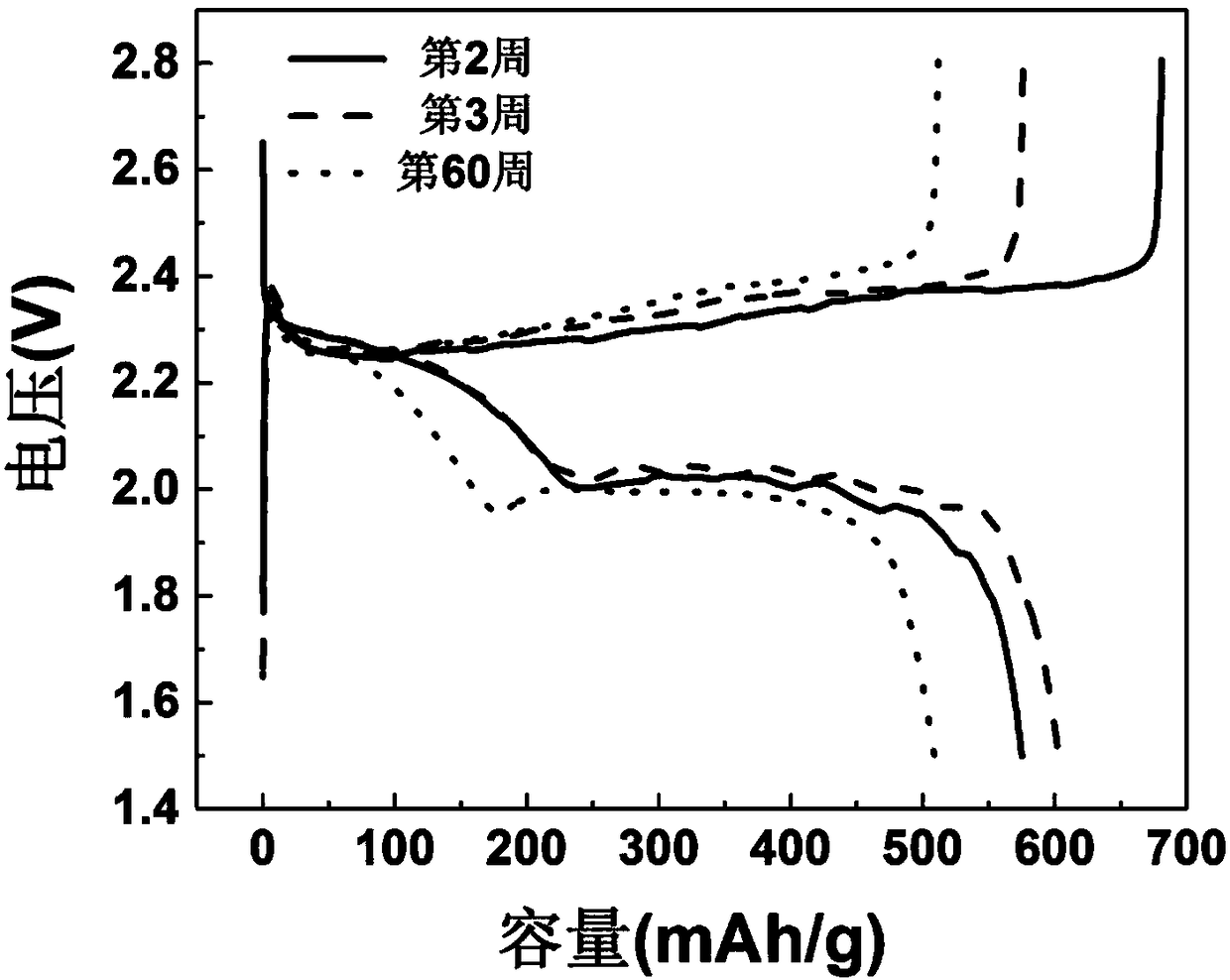

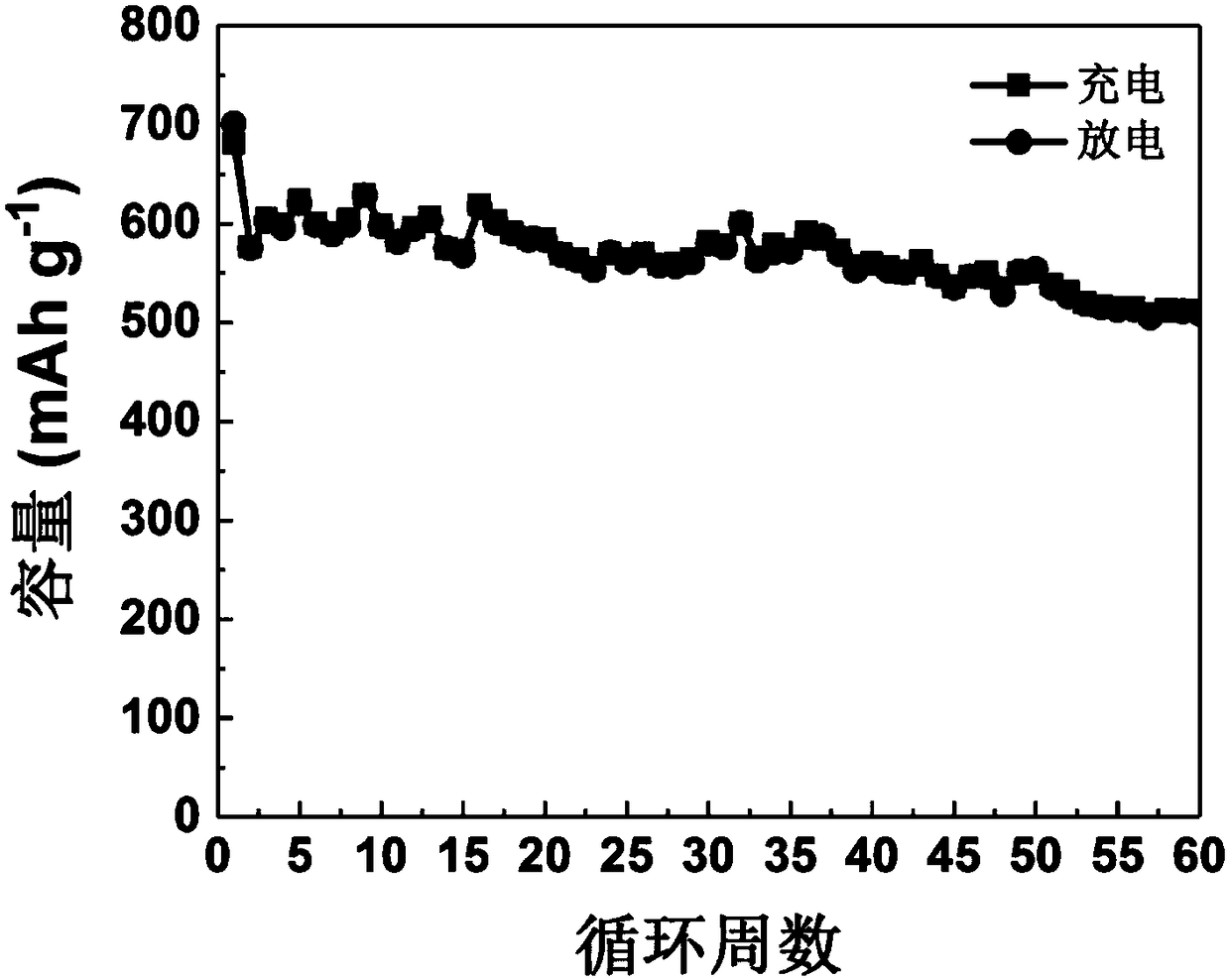

[0047] To the Ti obtained in this embodiment 3 C 2 / lithium sulfide / carbon composite cathode material for...

Embodiment 2

[0052] A preparation method of MXene / lithium sulfide / carbon composite cathode material, comprising the following steps:

[0053] (1) Weigh 5gTi 2 AlC, add 1% HF solution, react at 90°C for 0.5h, filter and dry to obtain Ti 2 c.

[0054] (2) Weigh 6.4g of lithium sulfate and dissolve it in water, add 64g of graphite and mix uniformly under stirring conditions, then dry to obtain graphite / lithium sulfate composite material.

[0055] (3) Put the graphite / lithium sulfate composite material in step (2) in a tube furnace, and heat it to 300° C. for 3 hours under the protection of high-purity nitrogen to obtain lithium sulfide / carbon material.

[0056] (4) Ti in step (1) 2 C is mixed with the lithium sulfide / carbon material in step (3) at a mass ratio of 1:3, and ball milled for 0.5h to obtain Ti 2 C / lithium sulfide / carbon composite cathode material.

Embodiment 3

[0058] A preparation method of MXene / lithium sulfide / carbon composite cathode material, comprising the following steps:

[0059] (1) Weigh 5gTi 3 AlC 2 , add 50% HF solution, react at 0°C for 48h, filter and dry to obtain Ti 3 C 2 .

[0060] (2) Weigh 6.4g of lithium sulfate and dissolve it in water, add 32g of graphene and mix evenly under stirring conditions, then dry to obtain graphene / lithium sulfate composite material.

[0061] (3) Put the graphene / lithium sulfate composite material in step (2) in a tube furnace, and heat it to 1500° C. for 1 hour under the protection of high-purity nitrogen to obtain lithium sulfide / carbon material.

[0062] (4) Ti in step (1) 3 C 2 Mix with the lithium sulfide / carbon material in step (3) at a mass ratio of 1:10, and ball mill for 2 hours to obtain Ti 3 C 2 / lithium sulfide / carbon composite cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com