Medium-entropy MAX phase material, medium-entropy two-dimensional material and preparation method of medium-entropy MAX phase material

A two-dimensional material, two-dimensional sheet technology, applied in chemical instruments and methods, inorganic chemistry, nanotechnology, etc., can solve the problems of difficulty in preparing a single phase, easy decomposition or separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

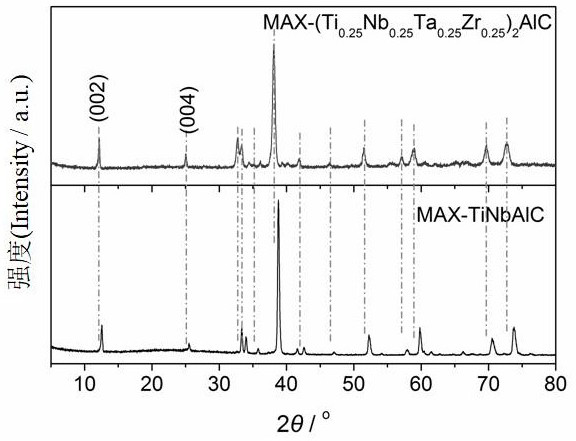

[0041] The present embodiment provides a kind of medium entropy MAX phase material, and its general chemical formula is M n+1 AX n , the M element is selected from three or four transition metal elements and lanthanide elements, wherein, the M element contains at least two transition metal elements or lanthanide elements capable of forming a solid solution; A is selected from VIIB, VIII, IB, IIB , at least one of IIIA, IVA, VA and VIA group elements; X is at least one of carbon, nitrogen, boron or oxygen elements, n 1, 2, 3, 4, 5 or 6, corresponding to "211" configuration, "312" configuration, "413" configuration, "514" configuration, "615" configuration and "716" configuration MAX phase.

[0042] Among them, M transition metal elements are selected from IIIB, IVB, VB, VIB, VIIB, VIII, IB, IIB group elements, usually, M elements include but not limited to: scandium, yttrium, titanium, zirconium, hafnium, vanadium, niobium , tantalum, chromium, molybdenum, tungsten, and thre...

Embodiment 2

[0050] This embodiment provides a method for preparing a medium-entropy MAX phase material, comprising steps:

[0051] Dosing step: according to the stoichiometric ratio of each element in the general chemical formula of the MAX phase material, determine the demand for weighing the raw material containing the element;

[0052] Sintering step: sintering the weighed raw materials at a predetermined temperature under a protective atmosphere or a vacuum environment to obtain a medium-entropy MAX phase material; wherein, the M element in the MAX phase material is three or four transition metal elements and lanthanide elements , wherein, the M element contains at least two transition metal elements or lanthanide elements capable of forming a solid solution; the A element is at least one selected from VIIB, VIII, IB, IIB, IIIA, IVA, VA and VIA group elements; X element is at least one of carbon, nitrogen, boron or oxygen, n is 1, 2, 3, 4, 5 or 6.

[0053] Under the high temperature...

Embodiment 3

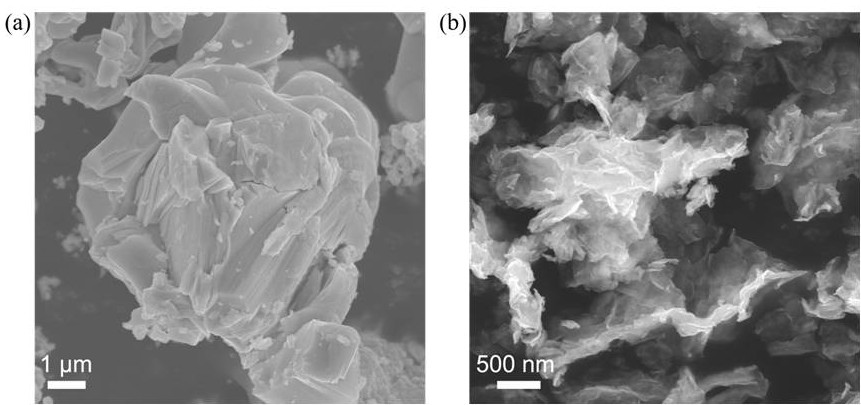

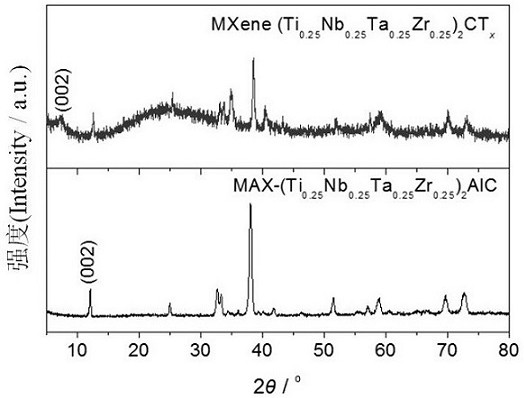

[0059] This embodiment provides a method for preparing a medium-entropy two-dimensional material, including:

[0060] The step of preparing the MAX phase: using the preparation method of the medium entropy MAX phase material in Example 2 to prepare the medium entropy MAX phase material, which will not be repeated here;

[0061] Etching step: reacting the medium-entropy MAX phase material with an etchant, so that the etchant selectively etches the A component in the MAX to obtain a medium-entropy two-dimensional material.

[0062] Optionally, the etchant is a hydrofluoric acid solution, the mass concentration of hydrofluoric acid can be between 1% and 50%, the reaction temperature is between 0 and 100°C, and the reaction time is between 5min and 100h; The etchant is an acid solution + fluoride salt system, wherein the acid solution can be one or more of hydrochloric acid, sulfuric acid, nitric acid and phosphoric acid, and the fluoride salt used can be lithium fluoride, sodium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com