Patents

Literature

7197results about "Base-materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

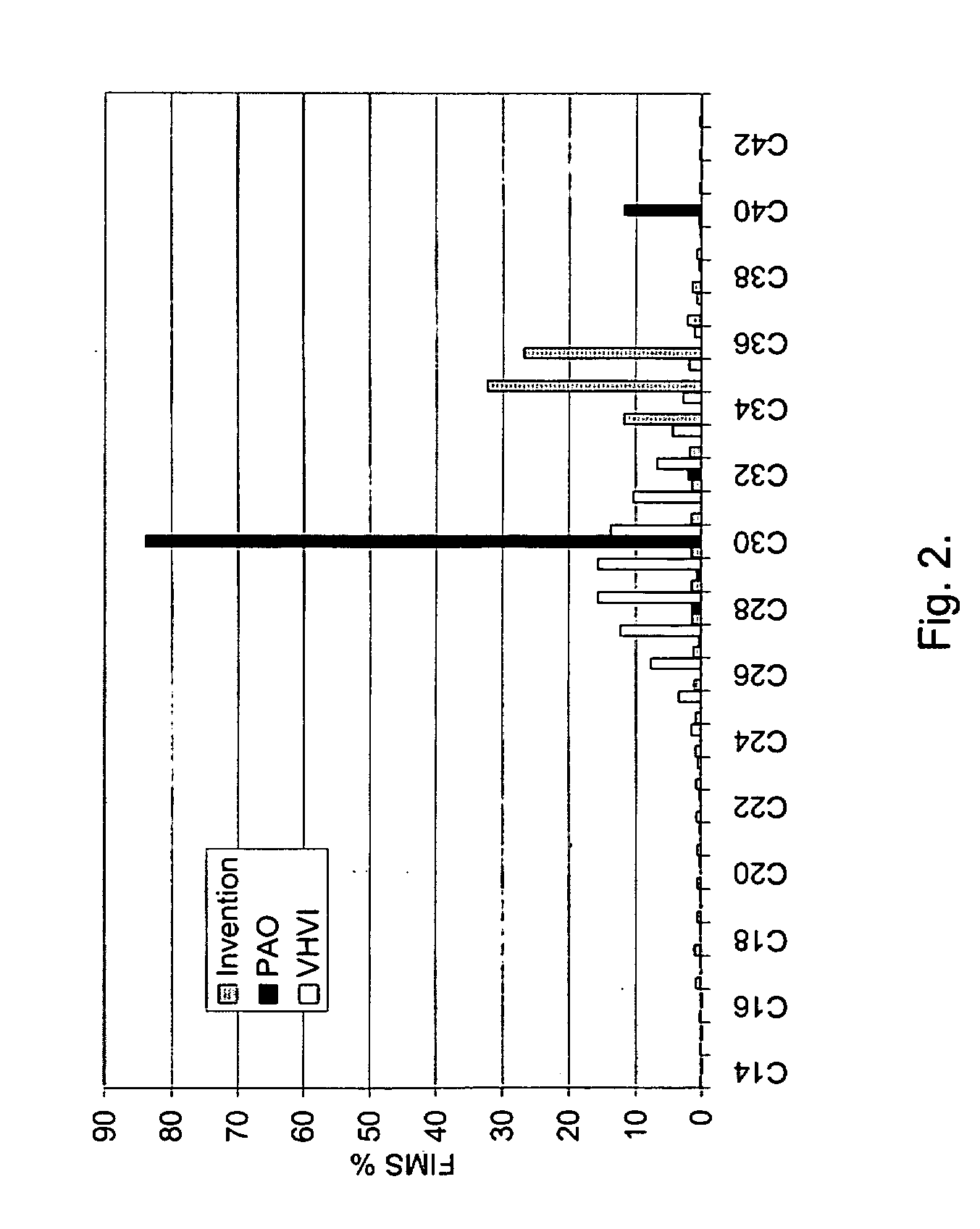

Premium synthetic lubricant base stock having at least 95% non-cyclic isoparaffins

InactiveUS6080301ARefining to change hydrocarbon structural skeletonHydrocarbon purification/separationParaffin waxAlkane

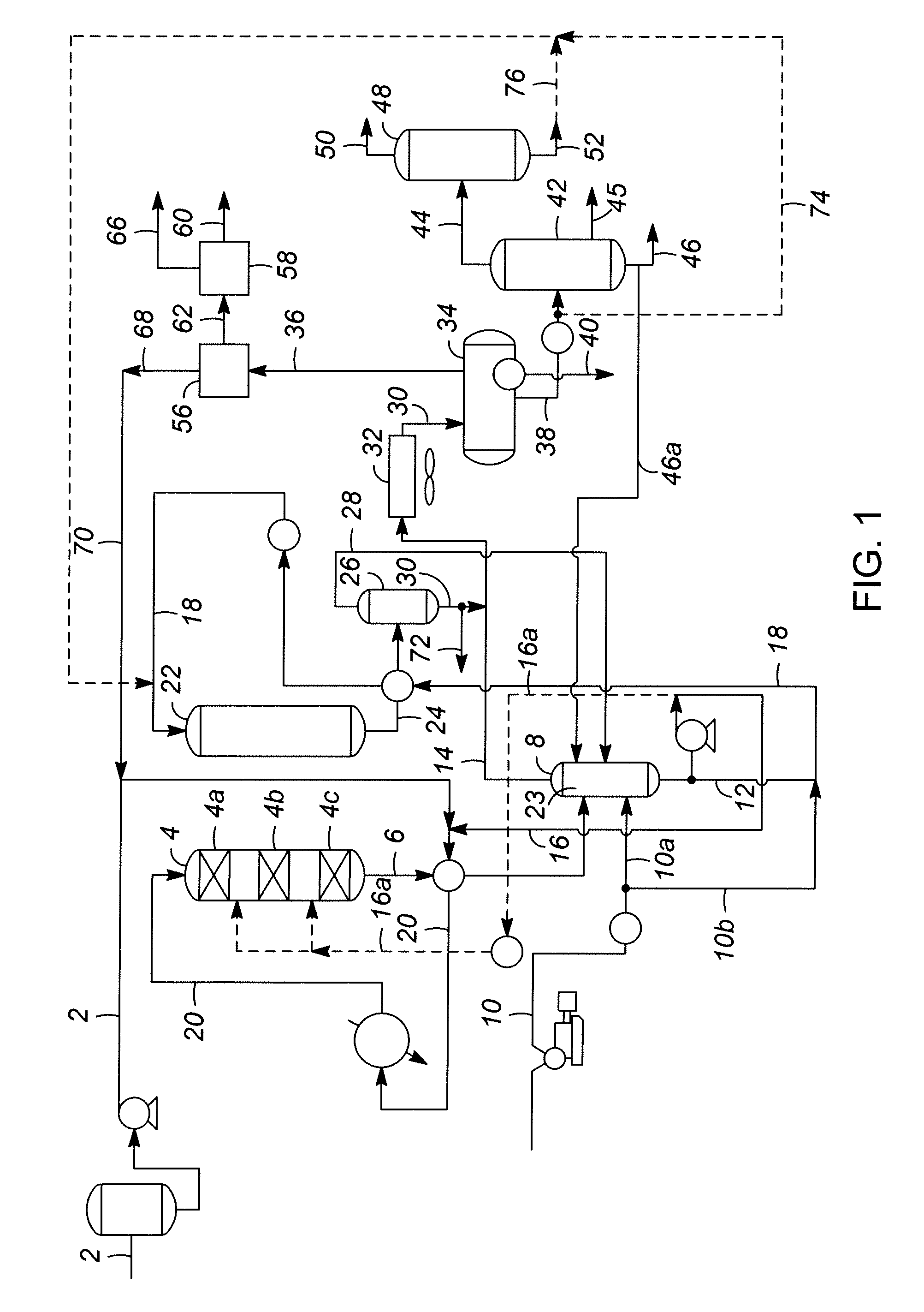

A premium synthetic lubricating oil base stock having a high VI and low pour point is made by hydroisomerizing a Fischer-Tropsch synthesized waxy, paraffinic feed wax and then dewaxing the hydroisomerate to form a 650-750 DEG F.+ dewaxate. The waxy feed has an initial boiling point in the range of about 650-750 DEG F., from which it continuously boils up to at least 1050 DEG F. and has a T90-T10 temperature difference of at least 350 DEG F. The feed is preferably hydroisomerized without any pretreatment, other than optional fractionation. The 650-750 DEG F.+ dewaxate is fractionated into two or more base stocks of different viscosity.

Owner:EXXON RES & ENG CO

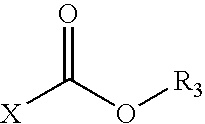

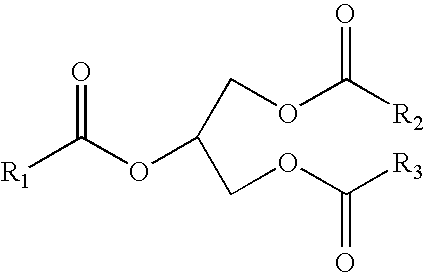

Lubricant and fuel compositions containing hydroxy carboxylic acid and hydroxy polycarboxylic acid esters

InactiveUS20050198894A1Reduce the amount requiredWithout diminishing anti-wear performanceOrganic chemistryLiquid carbonaceous fuelsCarboxylic acidMedicinal chemistry

Disclosed herein is a composition comprising: (A) a lubricant or a hydrocarbon fuel; (B) at least one hydroxy carboxylic acid ester or hydroxy polycarboxylic acid ester having the generic formula defined herein; and (C) at least one phosphorus-containing additive.

Owner:CHEMTURA CORP

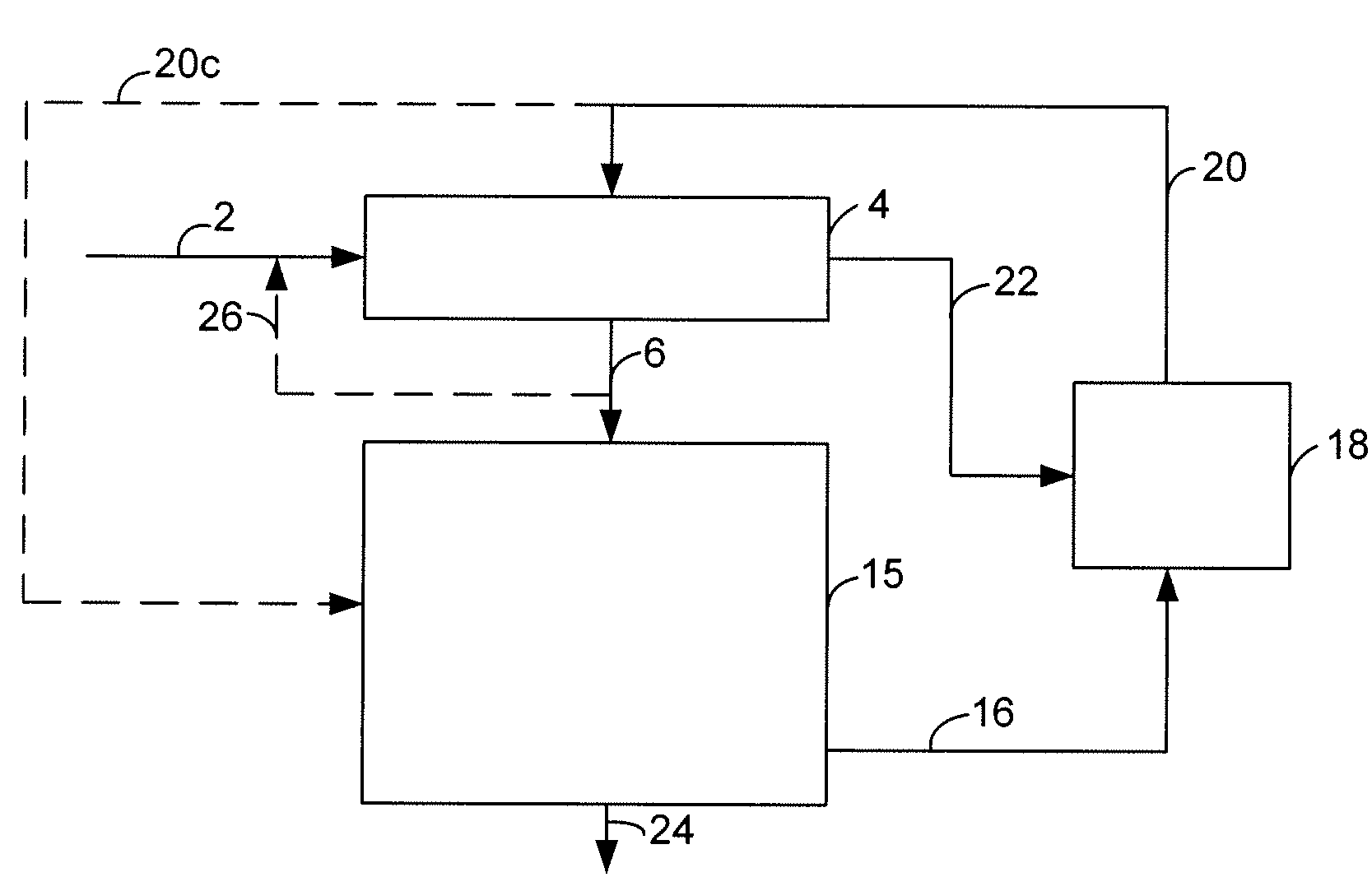

Production of synthetic lubricant and lubricant base stock without dewaxing

InactiveUS6103099AThermal non-catalytic crackingRefining to change hydrocarbon structural skeletonAutomatic transmissionBoiling point

A lubricating base stock useful for forming lubricants such as a multigrade automotive oils, automatic transmission oils, greases and the like is prepared by hydroisomerizing a waxy hydrocarbon feed fraction having an initial boiling point in the 650-750 DEG F. range and an end point of at least 1050 DEG F., synthesized by a slurry Fischer-Tropsch hydrocarbon synthesis process. The hydroisomerization forms a hydroisomerate containing the desired base stock which is recovered, without dewaxing the hydroisomerate. The hydroisomerization is conducted at conditions effective to convert at least 67 wt. % of the 650-750 DEG F.+ waxy feed hydrocarbons to lower boiling hydrocarbons. When combined with a standard lubricant additive package, these base stocks have been formed into multigrade automotive crankcase oils, transmission oils and hydraulic oils meeting the specifications for these oils.

Owner:EXXON RES & ENG CO

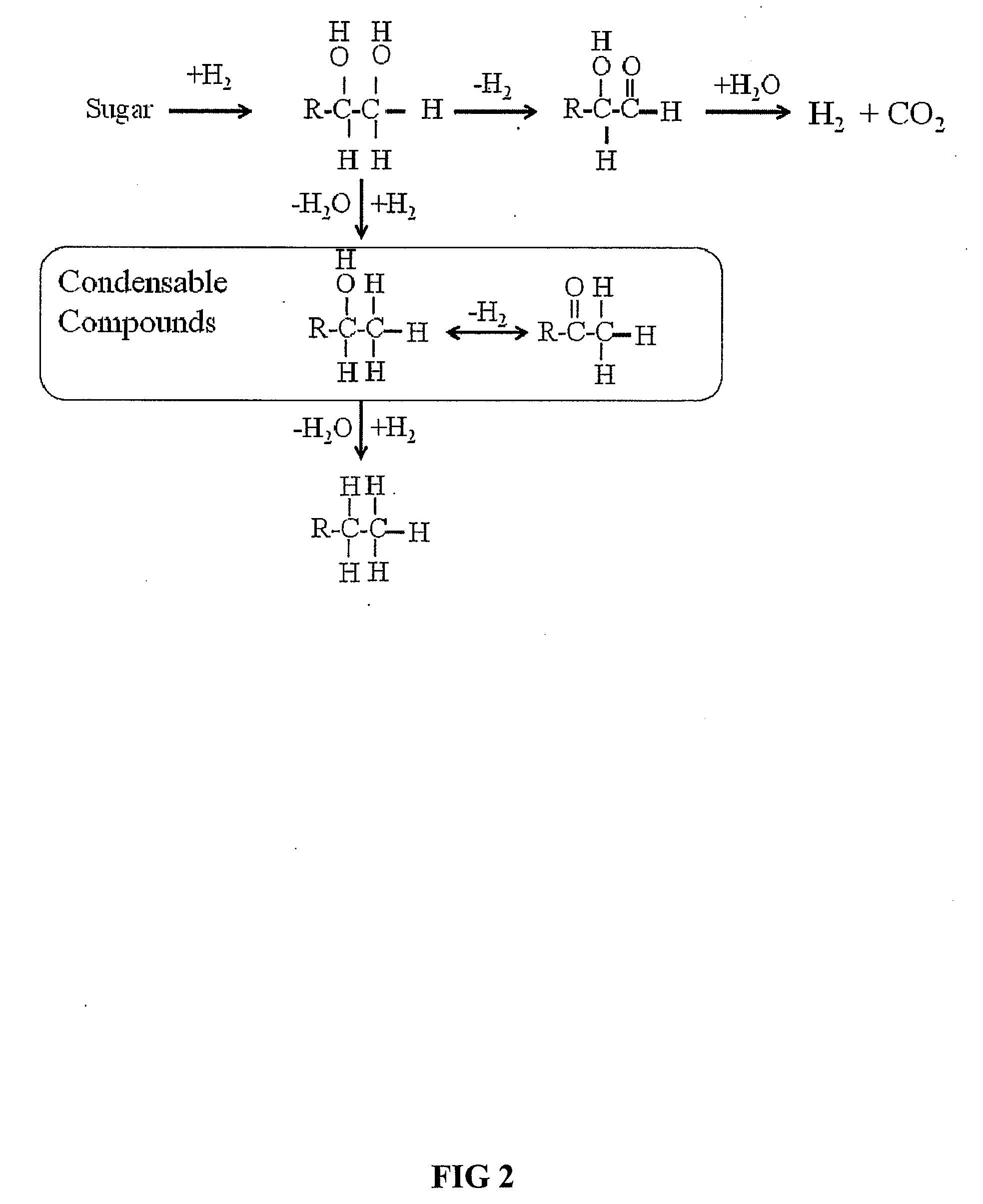

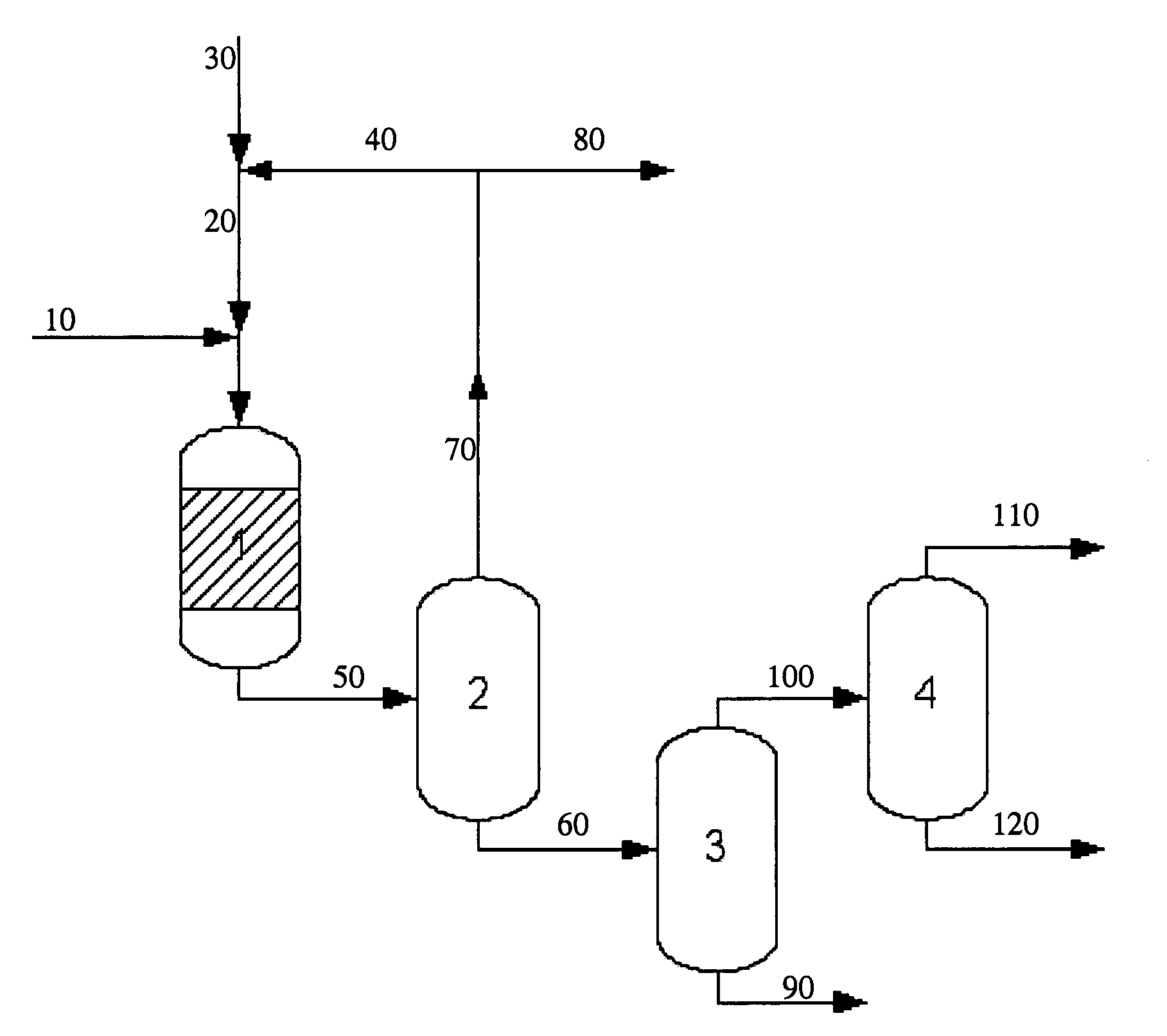

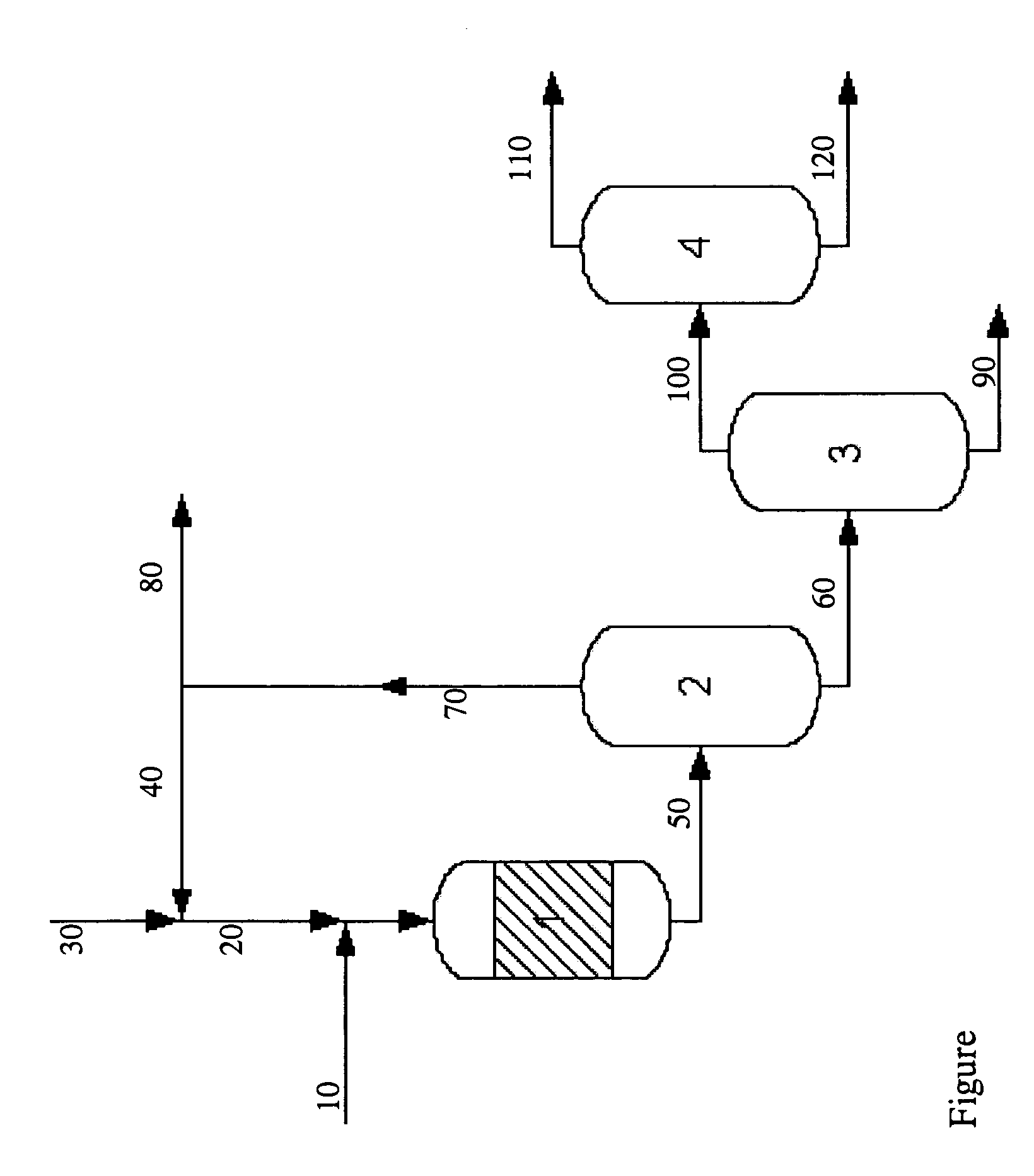

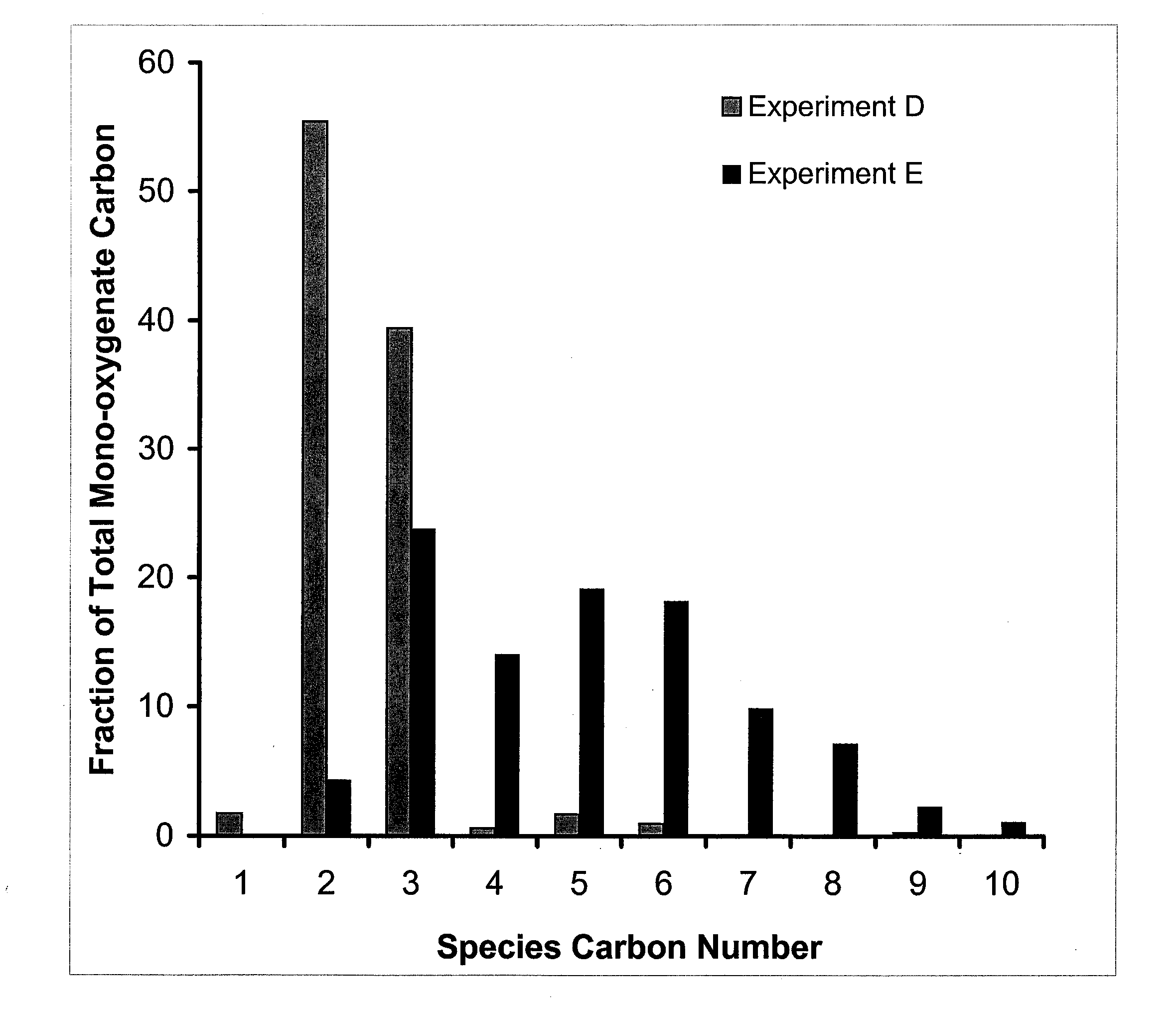

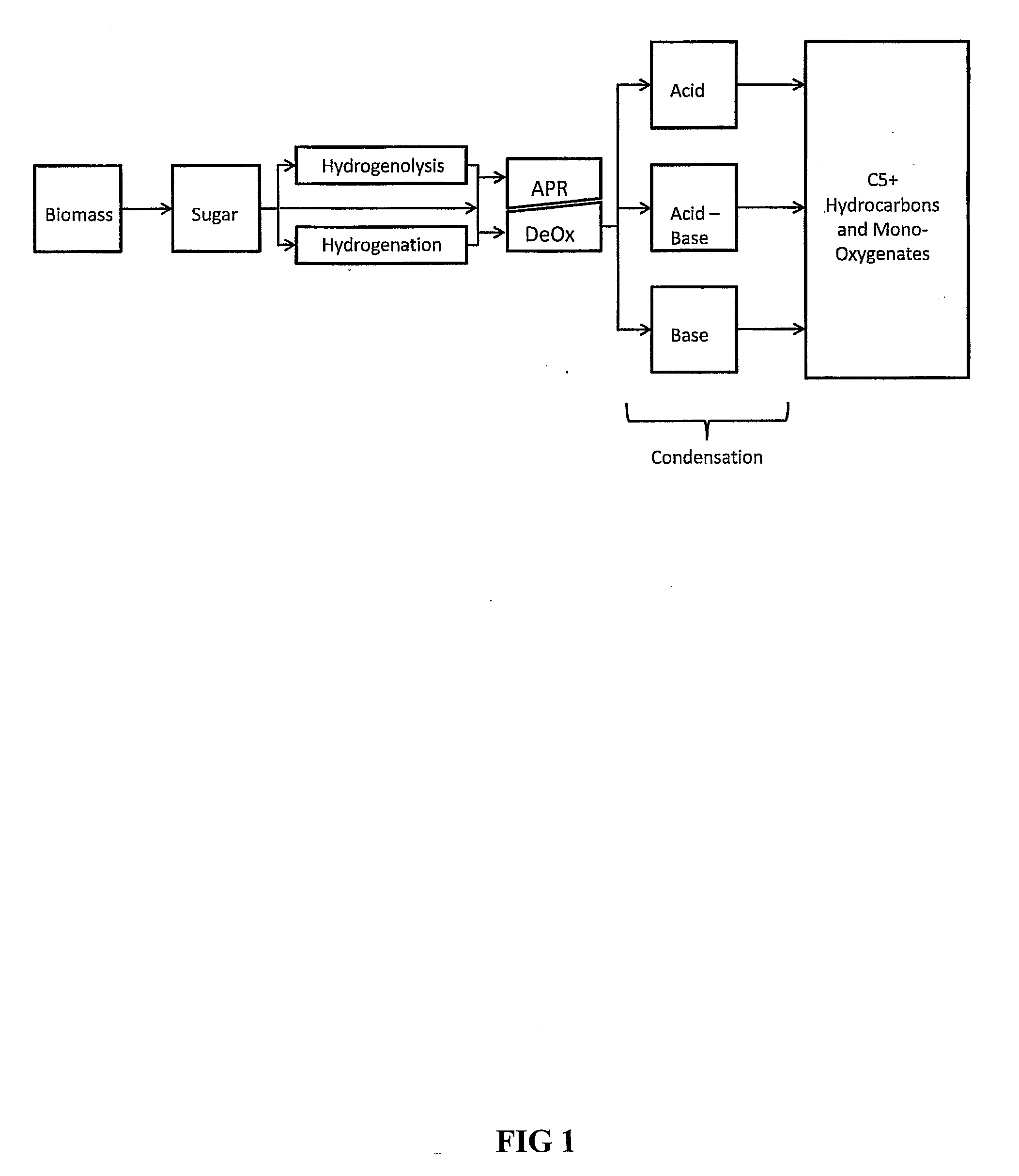

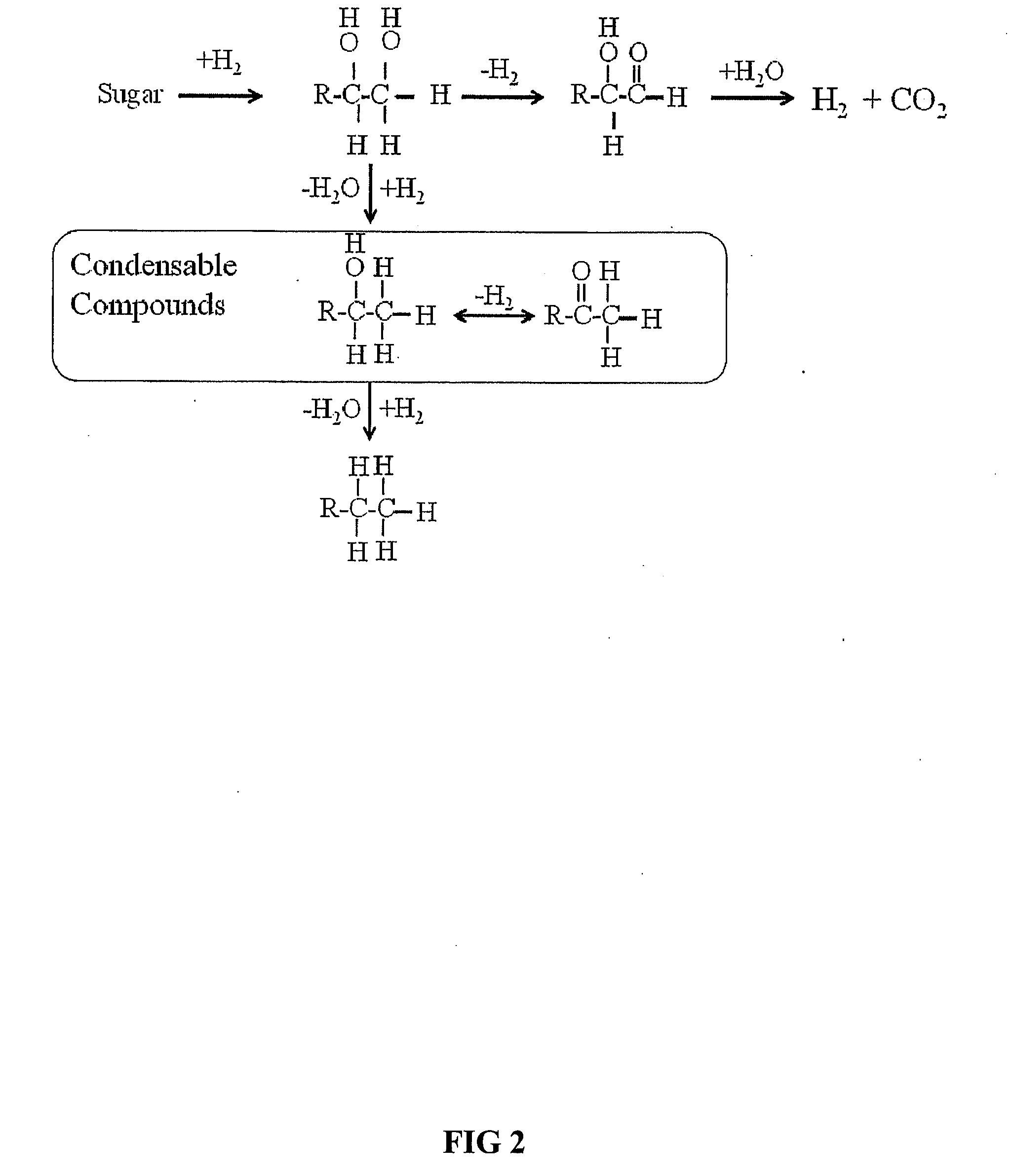

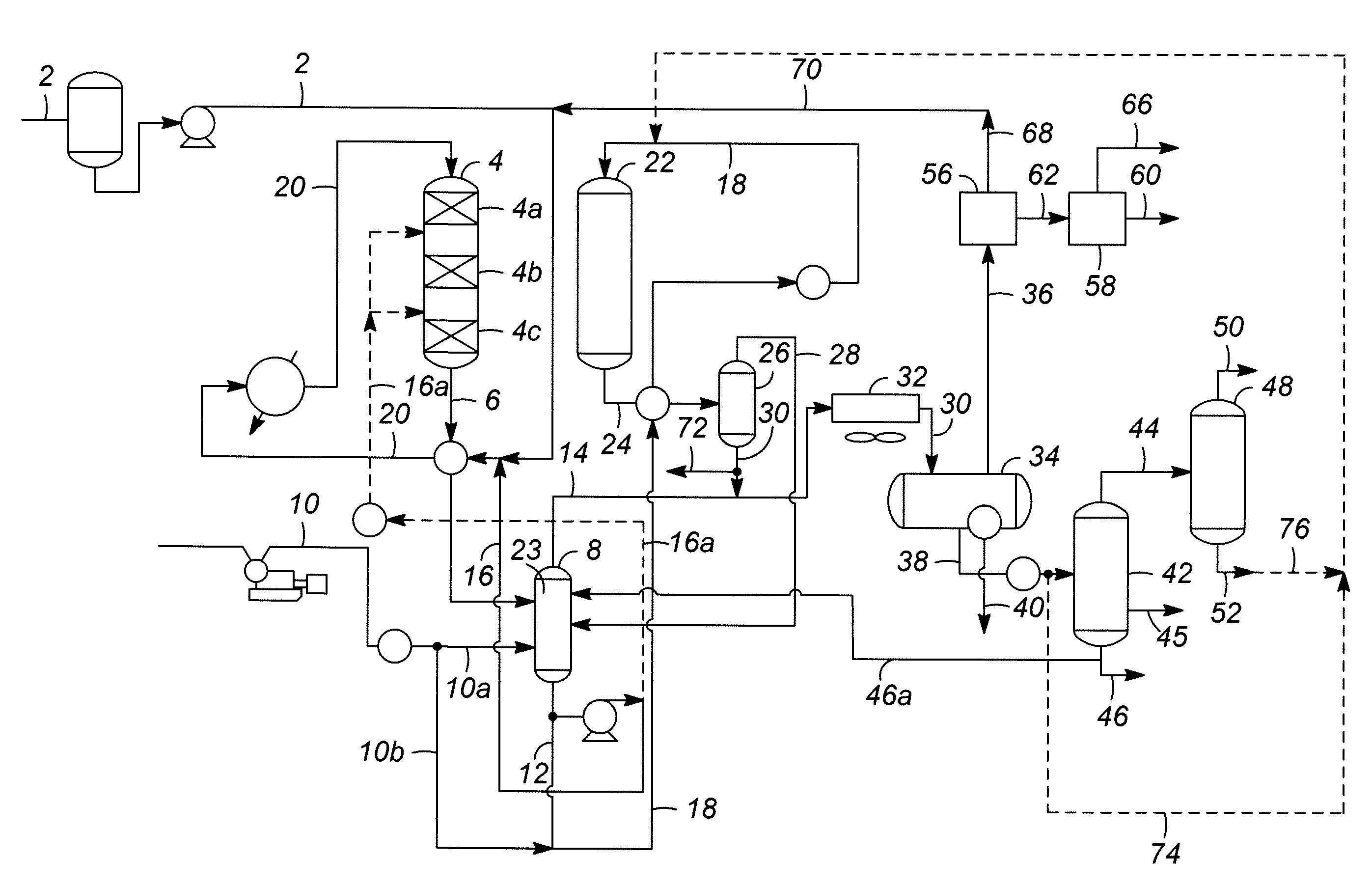

Synthesis of liquid fuels and chemicals from oxygenated hydrocarbons

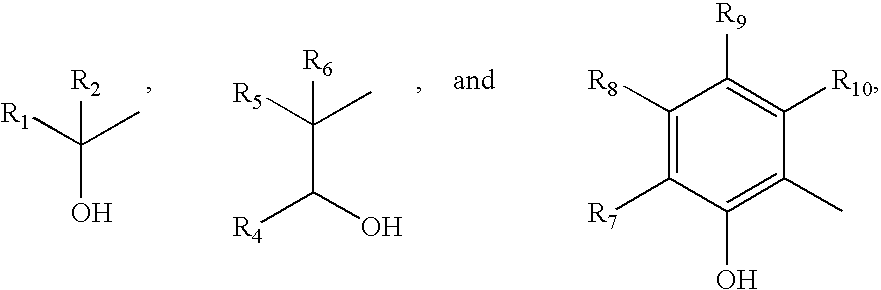

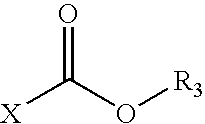

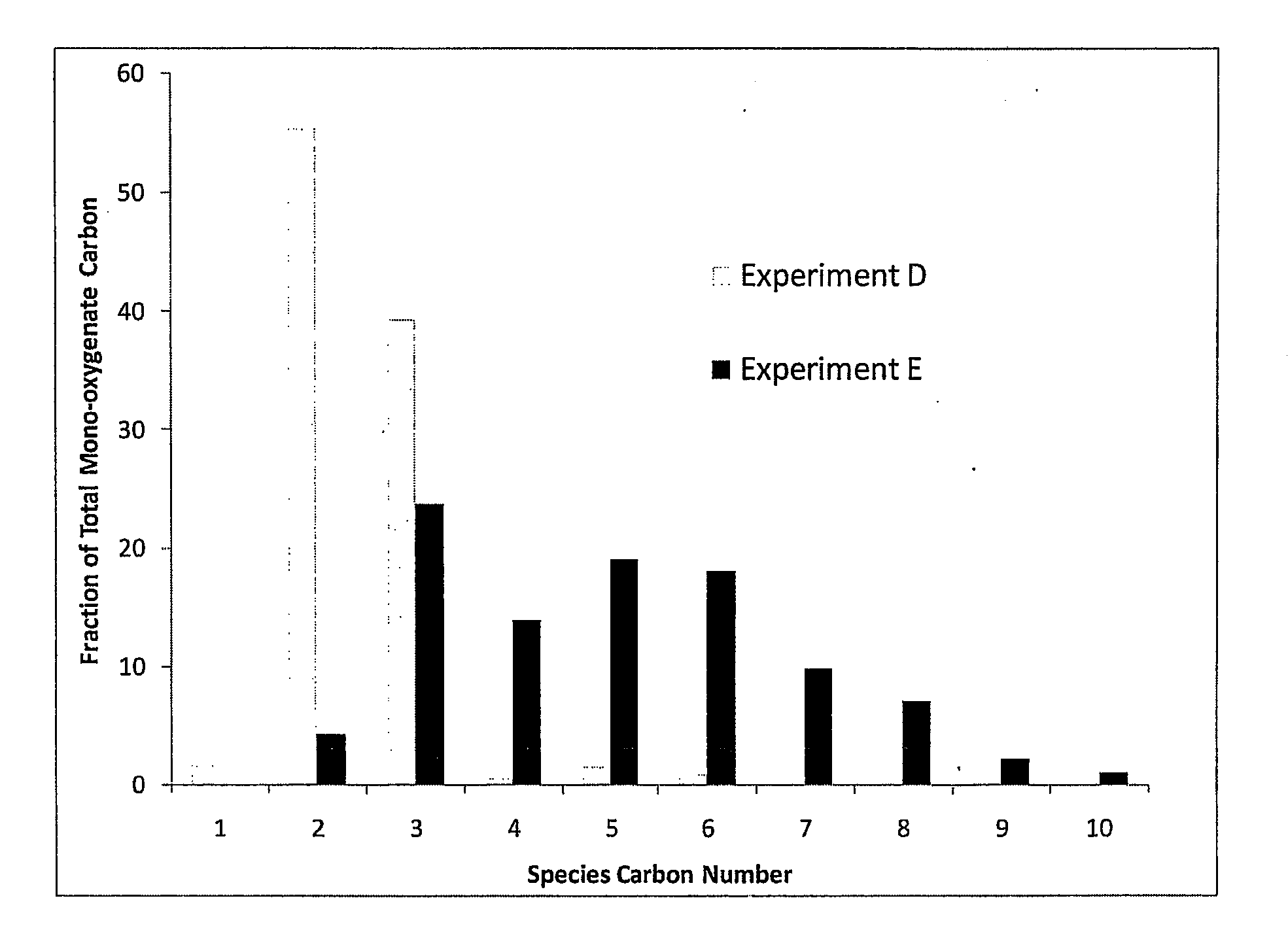

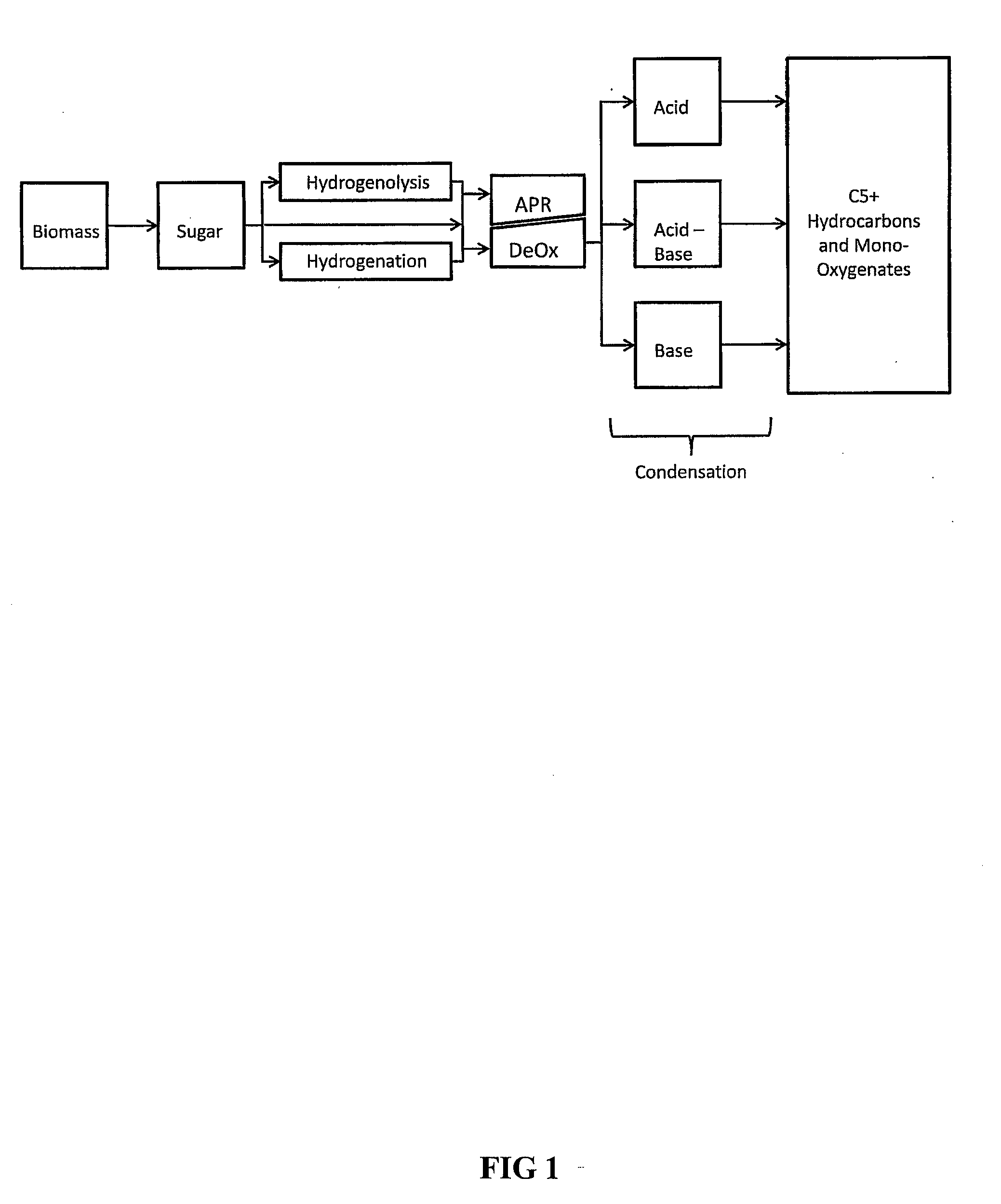

ActiveUS20080300435A1Oxygen-containing compound preparationLiquid hydrocarbon mixture productionFuranLiquid fuel

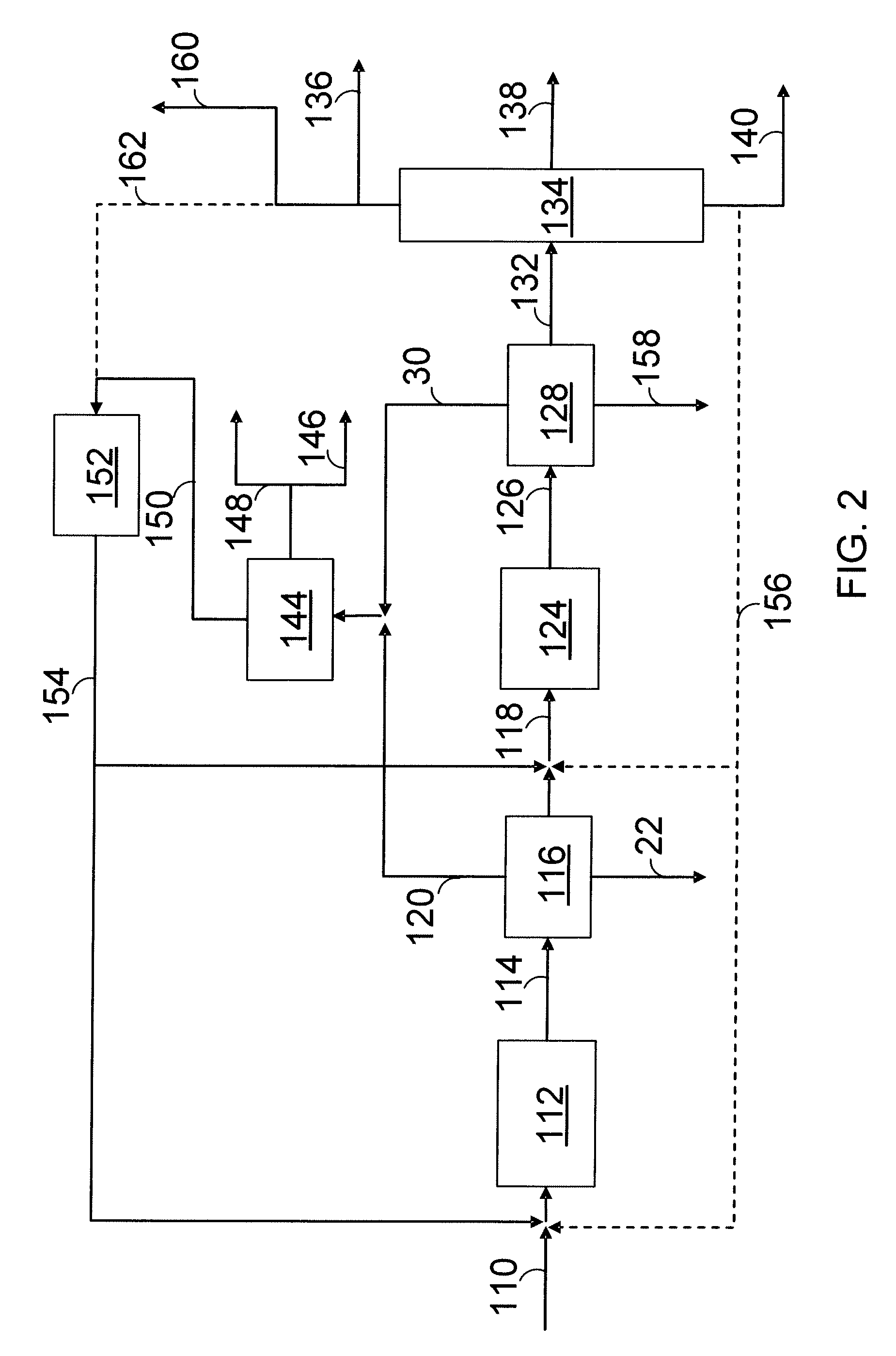

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to hydrocarbons, ketones and alcohols useful as liquid fuels, such as gasoline, jet fuel or diesel fuel, and industrial chemicals. The process involves the conversion of mono-oxygenated hydrocarbons, such as alcohols, ketones, aldehydes, furans, carboxylic acids, diols, triols, and / or other polyols, to C4+ hydrocarbons, alcohols and / or ketones, by condensation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

Production of diesel fuel from vegetable and animal oils

A process for producing a fuel composition from vegetable and / or animal oil comprises hydrodeoxygenating and hydroisomerizing the oil in a single step. The fuel composition has acceptable lubricity and comprises a mixture of C14 to C18 paraffins having a ratio of iso to normal paraffins of 2 to 8 and less than 5 ppm sulfur.

Owner:BEN GURION UNIVERSITY OF THE NEGEV

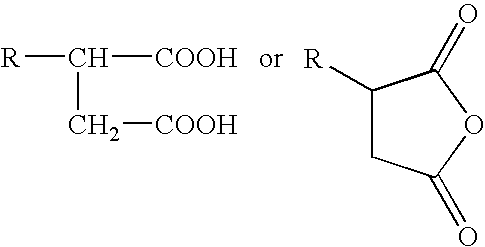

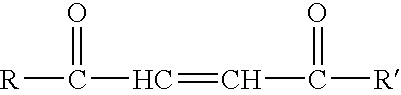

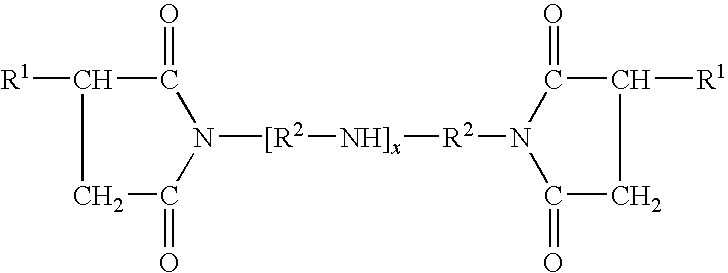

Low-chlorine, polyolefin-substituted, with amine reacted, alpha-beta unsaturated carboxylic compounds

A composition of matter comprising an amine acylated with a hydrocarbyl group substituted carboxylic acylating agent containing an average of from 1.3 to 1.6 groups derived from α,β-unsaturated carboxylic compounds per Mn of the hydrocarbyl group, wherein the hydrocarbyl group has Mn determined by GPC ranging from 1500 to 3000, the amine comprises polyamine bottoms and said acylated amine has total base number (TBN) ranging from 17 to 35. A method for preparing the composition, lubricating oils containing the composition and, in another embodiment, lubricating oil compositions of this invention further comprising a metal overbased sulfonate detergent.

Owner:THE LUBRIZOL CORP

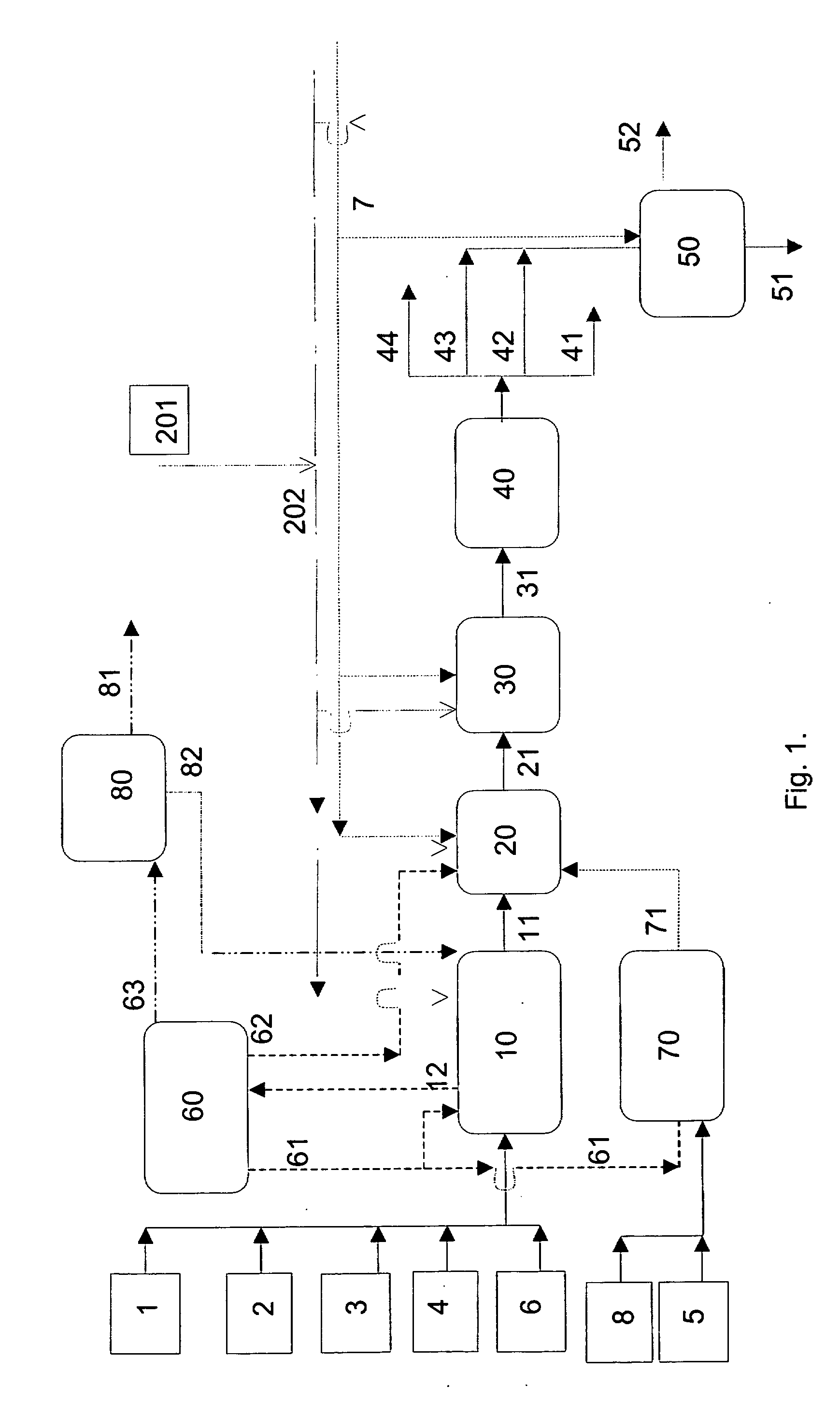

Process for producing a saturated hydrocarbon component

ActiveUS20070131579A1Reduce carbon dioxide emissionsIncrease carbon dioxide loadProductsReagentsCarboxylic acidBase oil

The invention relates to a process for producing high-quality saturated base oil or a base oil component based on hydrocarbons. The process of the invention comprises two main steps, the oligomerization and deoxygenation. A biological starting material containing unsaturated carboxylic acids and / or esters of carboxylic acids is preferably used as the feedstock.

Owner:NESTE OIL OY

Tetrafluoropropene compositions and uses thereof

InactiveUS20100122545A1Lower global warming potentialCompressorHeat pumpsAir conditioningHeat transfer fluid

The present invention relates to compositions for use in refrigeration, air-conditioning, and heat pump systems wherein the composition comprises a tetrafluoropropene and at least one other component. The compositions of the present invention are useful in processes for producing cooling or heat, as heat transfer fluids, foam blowing agents, aerosol propellants, and fire suppression and fire extinguishing agents.

Owner:EI DU PONT DE NEMOURS & CO

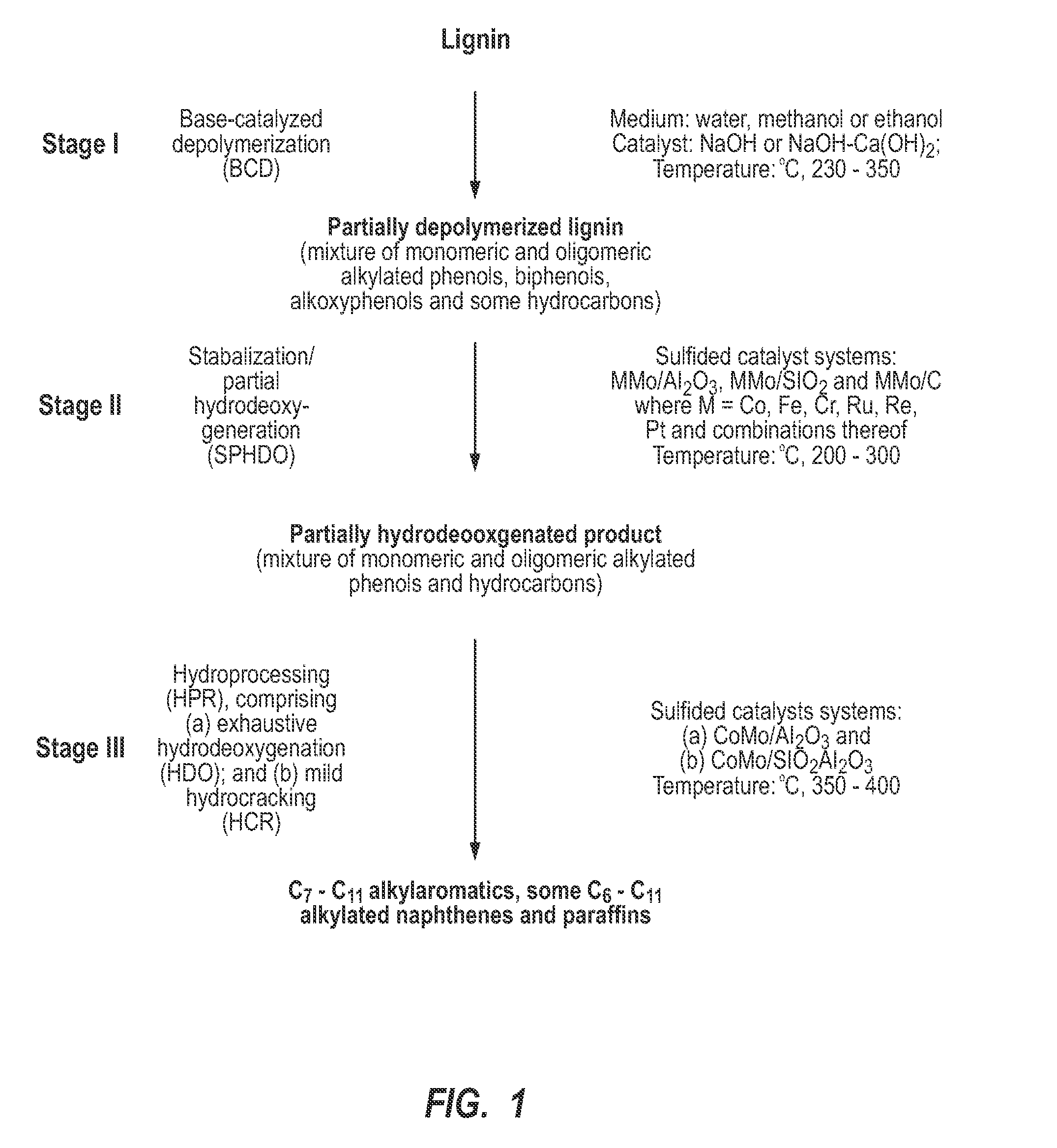

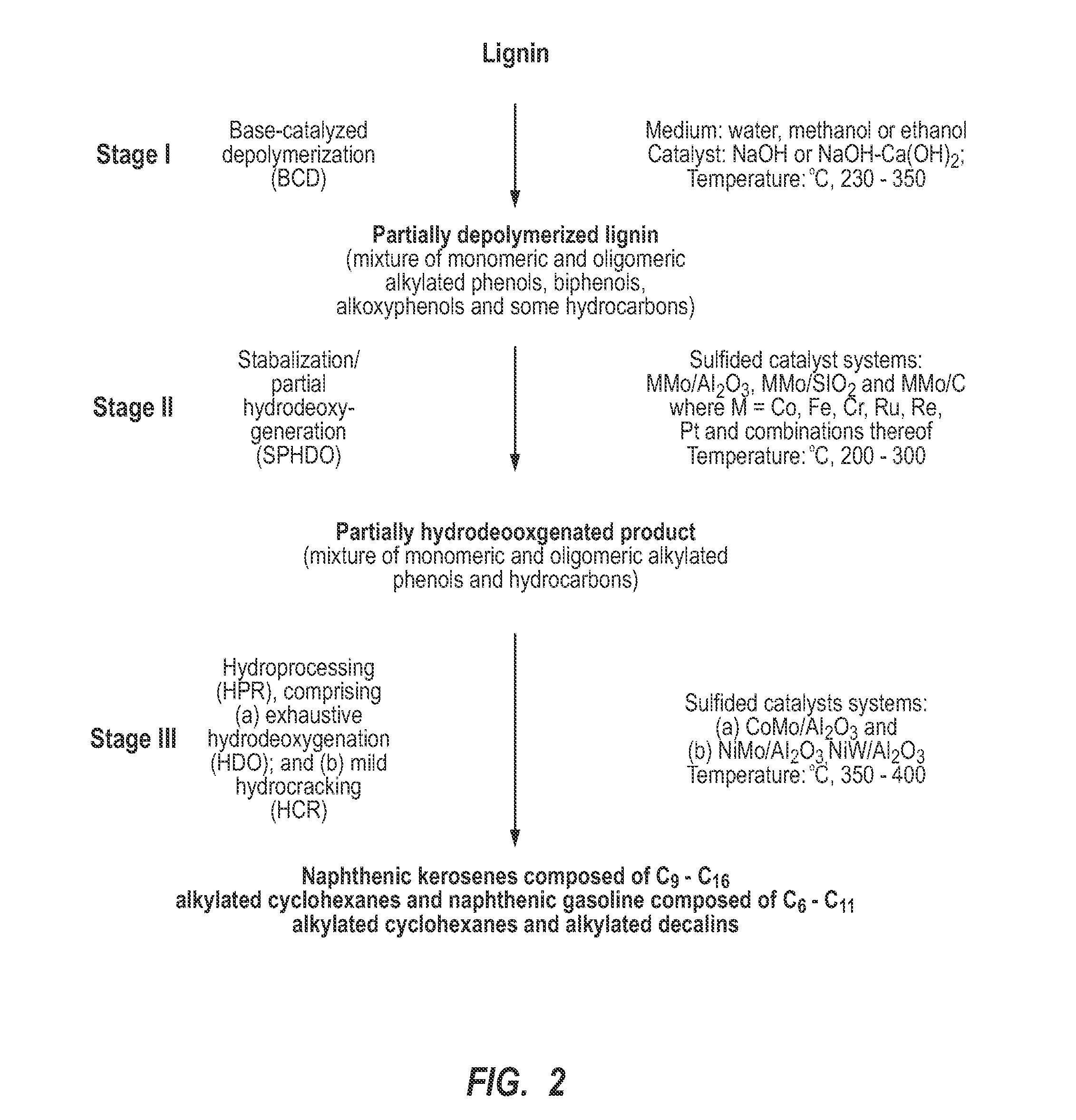

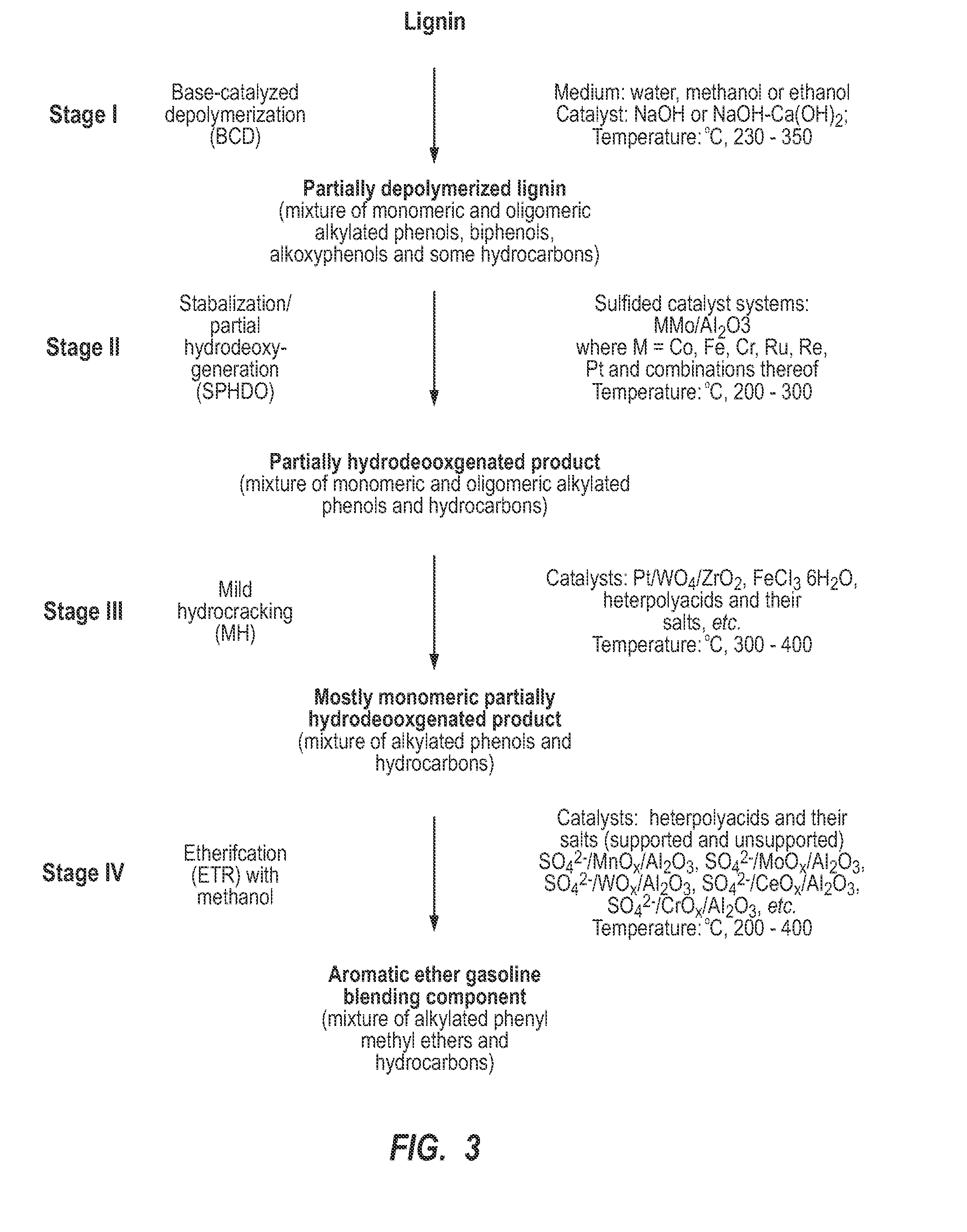

Processes for catalytic conversion of lignin to liquid bio-fuels and novel bio-fuels

InactiveUS20080050792A1Increase productionAcceptable processing conditionBiofuelsSolid fuelsLiquid productLignin degradation

Processes for conversion of lignin to liquid products such as bio-fuels and fuel additives are disclosed and described. A process for conversion of a lignin material to bio-fuels can include subjecting the lignin material to a base catalyzed depolymerization reaction to produce a partially depolymerized lignin. The partially depolymerized lignin can then be subjected to a stabilization / partial hydrodeoxygenation reaction to form a partially hydrodeoxygenated product. Following partial hydrodeoxygenation, the partially hydrodeoxygenated product can be reacted in a hydroprocessing step to form a bio-fuel. Each of these reaction steps can be performed in single or multiple steps, depending on the design of the process. The production of an intermediate partially hydrodeoxygenation product and subsequent reaction thereof can significantly reduce or eliminate reactor plugging and catalyst coking. A variety of useful bio-fuels such as fuels, fuel additives, and the like, including gasoline and jet or rocket fuels are describe which can be readily produced from renewable lignin materials in an improved conversion process.

Owner:UNIV OF UTAH RES FOUND

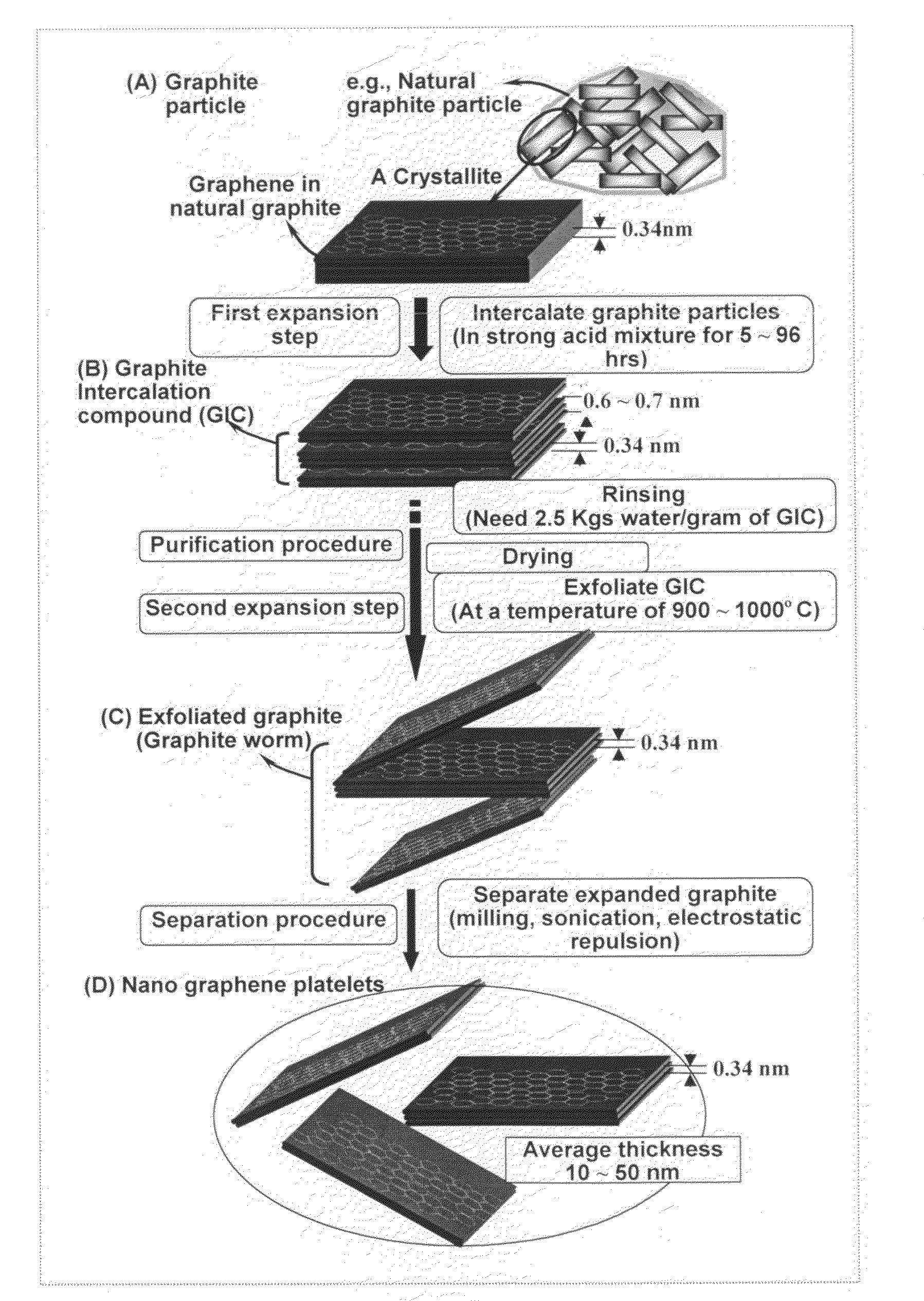

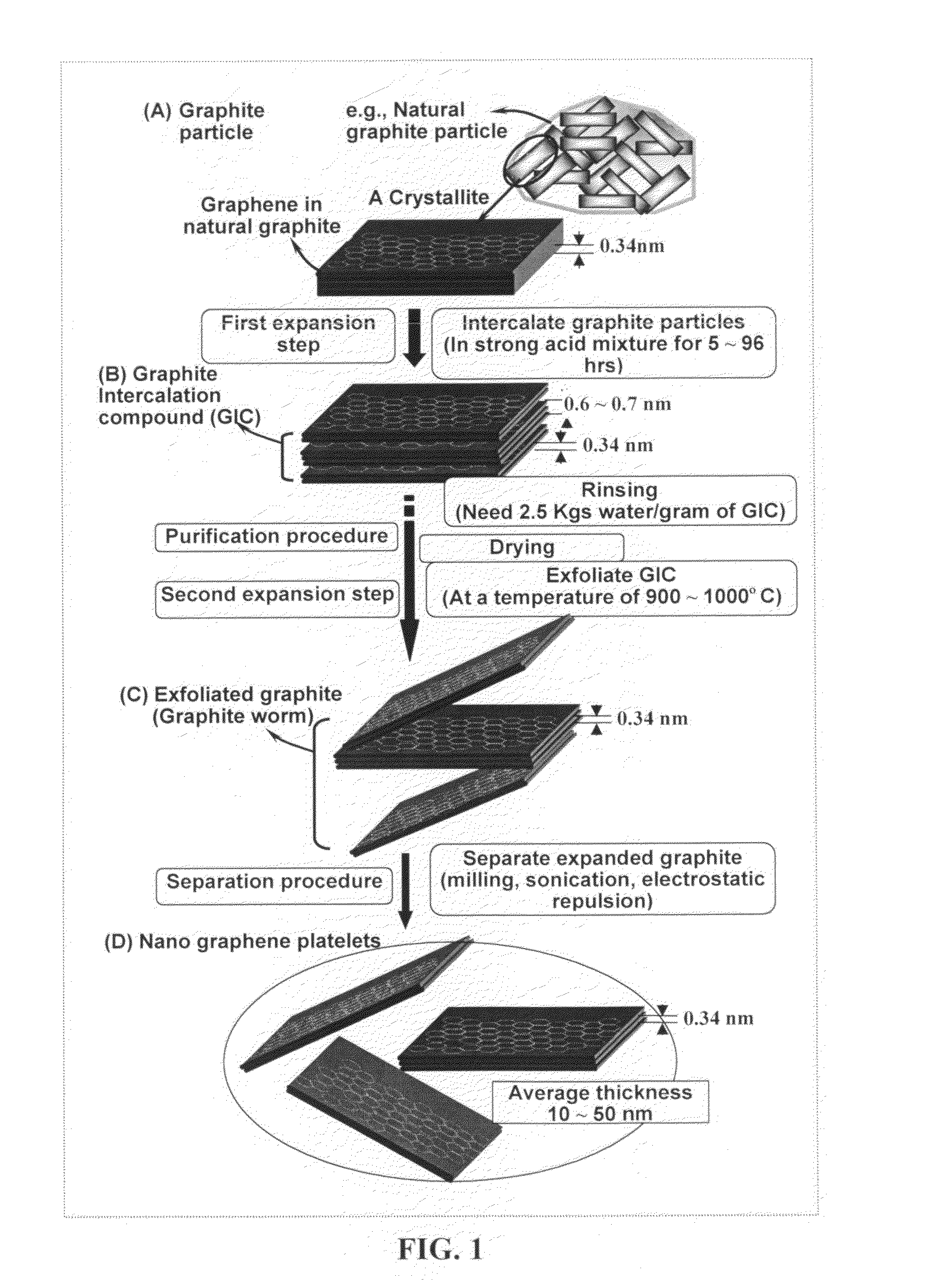

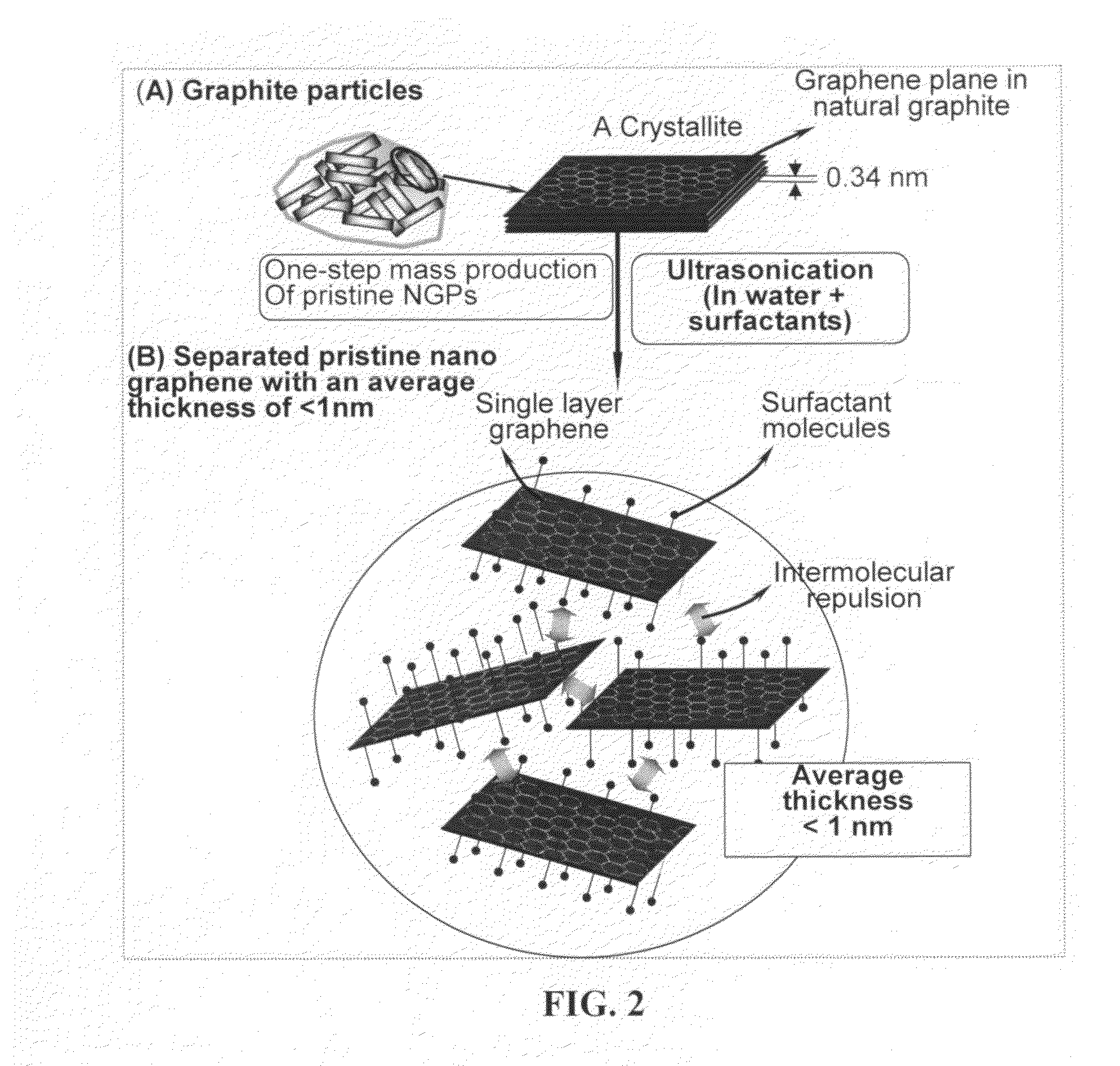

Nano graphene-modified lubricant

ActiveUS20110046027A1Modulate viscosityImprove the lubrication effectAdditivesBase-materialsCarbon nanotubeSingle layer graphene

A lubricant composition having improved lubricant properties, comprising:(a) a lubricating fluid; and (b) nano graphene platelets (NGPs) dispersed in the fluid, wherein nano graphene platelets have a proportion of 0.001% to 60% by weight based on the total weight of the fluid and the graphene platelets combined. Preferably, the composition comprises at least a single-layer graphene sheet. Preferably, the lubricating fluid contains a petroleum oil or synthetic oil and a dispersant or surfactant. With the addition of a thickener or a desired amount of NGPs, the lubricant becomes a grease composition. Compared with graphite nano particle- or carbon nanotube-modified lubricants, NGP-modified lubricants have much better thermal conductivity, friction-reducing capability, anti-wear performance, and viscosity stability.

Owner:GLOBAL GRAPHENE GRP INC

Micro-emulsion type metal cutting liquor composition

InactiveCN101240217AEasy to handleImprove the lubrication effectAdditivesBase-materialsMaterials scienceCutting fluid

Disclosed is a microemulsifying metal-cutting-fluid composition, comprising base oil or oily agent, mixed alcohol-amine, boric acid, anionic surfactant, nonionic surfactant, antirust agent, copper alloy corrosion inhibitor, preservative, deionized water and the like. The invention has the advantages of excellent lubricity, cooling ability, cleaning ability and a long lifetime of metal cutting fluid, being suited to various metal processing technologies such as cutting, reaming, boring, grinding. Also, the wastewater is easy to treat.

Owner:益田润石(北京)化工有限公司

Synthesis of liqiud fuels and chemicals from oxygenated hydrocarbons

ActiveUS20080300434A1Oxygen-containing compound preparationHydrocarbon purification/separationFuranCarboxylic acid

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to hydrocarbons, ketones and alcohols useful as liquid fuels, such as gasoline, jet fuel or diesel fuel, and industrial chemicals. The process involves the conversion of mono-oxygenated hydrocarbons, such as alcohols, ketones, aldehydes, furans, carboxylic acids, diols, triols, and / or other polyols, to C4+ hydrocarbons, alcohols and / or ketones, by condensation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

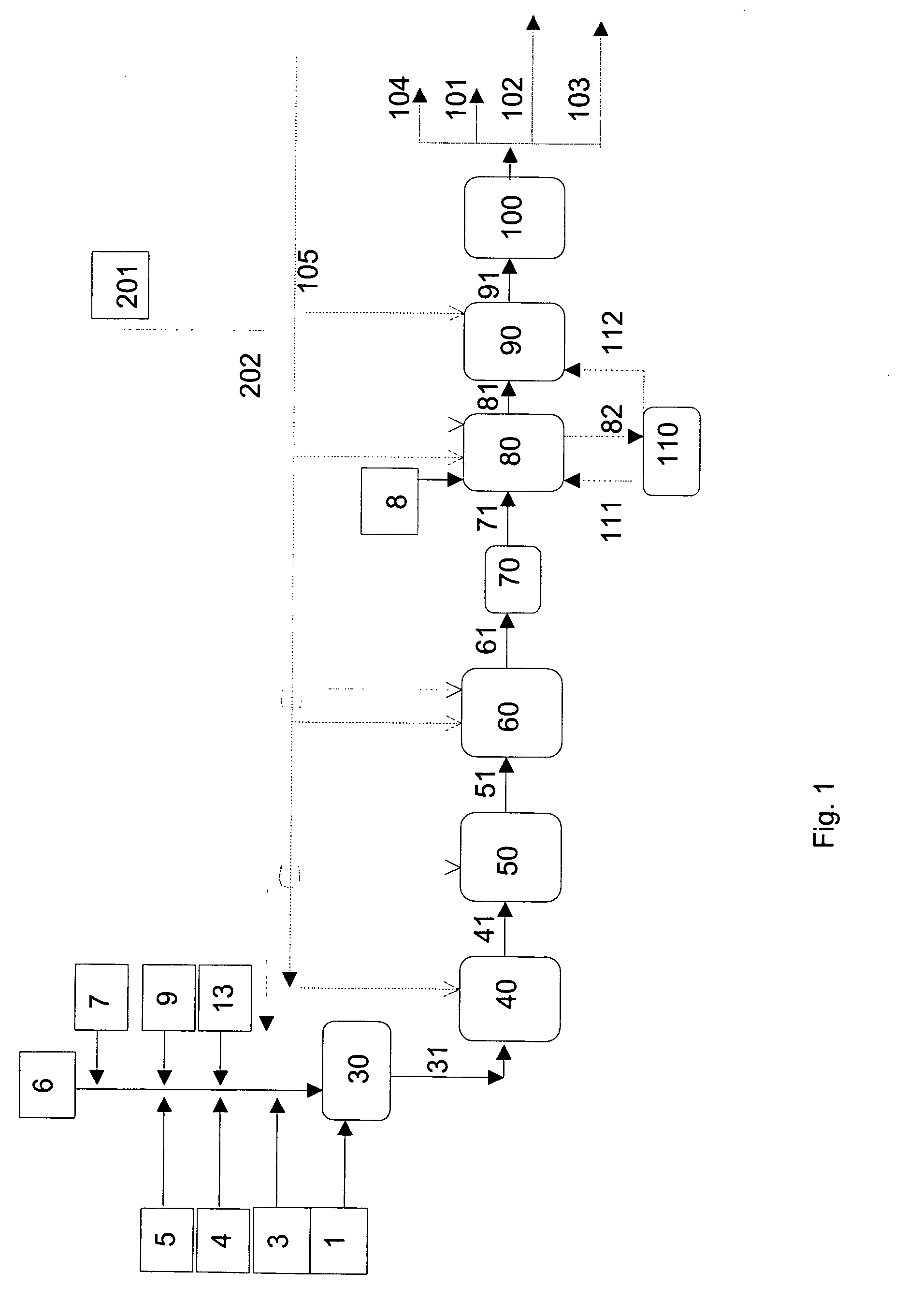

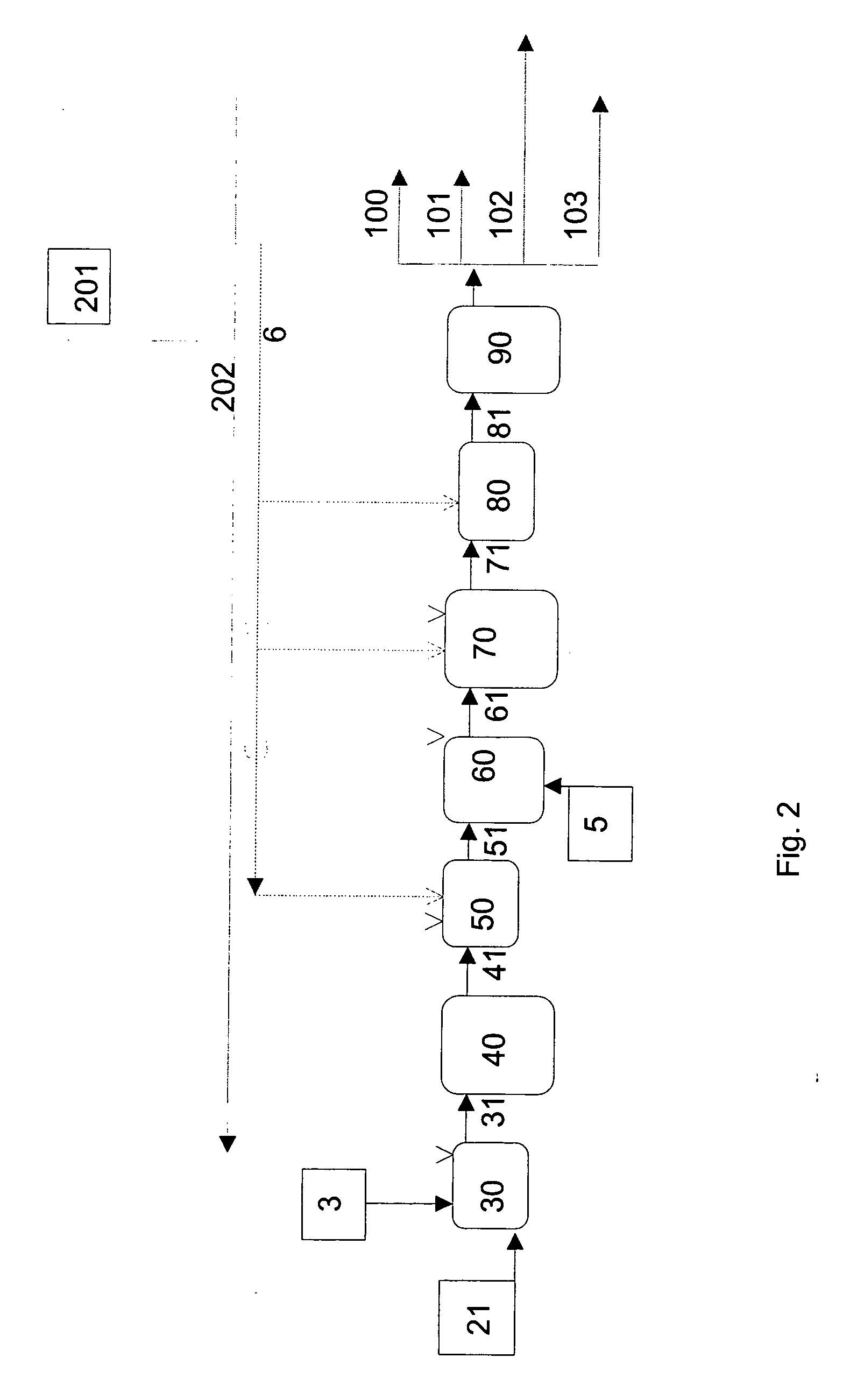

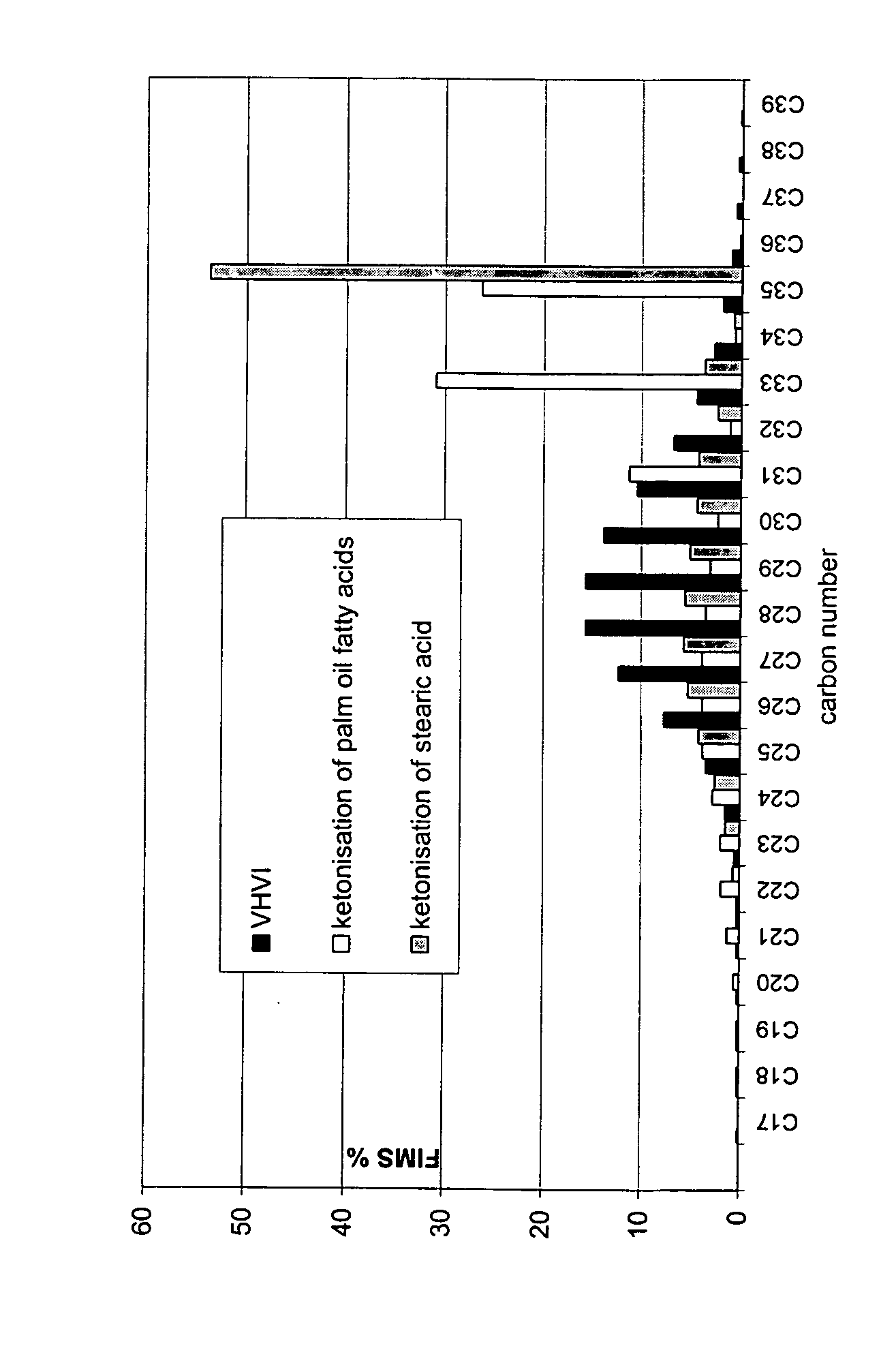

Process for producing a hydrocarbon component

ActiveUS20070161832A1Reduce carbon dioxide emissionsImprove low temperature performanceFatty oils/acids recovery from wasteFatty acid hydrogenationIsomerizationHydrodeoxygenation

The invention relates to a process for producing a new type of high-quality hydrocarbon base oil of biological origin. The process of the invention comprises ketonisation, hydrodeoxygenation, and isomerization steps. Fatty acids and / or fatty acid esters based on a biological raw material are preferably used as the feedstock.

Owner:NESTE OIL OY

Low molecular weight ethylene/alpha-olefin interpolymer as base lubricant oils

A lubricant composition comprises an ethylene / α-olefin interpolymer having a number average molecular weight of less than 10,000 g / mol as a base oil and at least one oil additive. The ethylene / α-olefin interpolymer has at least one molecular fraction which elutes between 40° C. and 130° C. when fractionated using TREF, characterized in that the fraction has a molar comonomer content of at least 5 percent higher than that of a comparable random ethylene interpolymer fraction eluting between the same temperatures, wherein said comparable random ethylene interpolymer has the same comonomer(s) and has a melt index, density, and molar comonomer content (based on the whole polymer) within 10 percent of that of the ethylene / α-olefin interpolymer.

Owner:DOW GLOBAL TECH LLC

Production of Blended Fuel from Renewable Feedstocks

A process for producing a blended fuel from a paraffin rich component and a cyclic rich component, where each of the components are generated from a renewable feedstock, is presented. The paraffin rich component is generated from a first renewable feedstock comprising at least one component selected from the group consisting of glycerides, free fatty acids, biomass, lignocellulose, free sugars, and combinations thereof. The cyclic rich component is generated from a second renewable feedstock comprising at least one component selected from the group consisting of glycerides, free fatty acids, free fatty alkyl esters, biomass, lignocellulose, free sugars, and combinations thereof. The blended fuel may a gasoline boiling point range blended fuel, a diesel boiling point range blended fuel, an aviation boiling point range blended fuel, any combination thereof, or any mixture thereof.

Owner:UOP LLC

Finished lubricating comprising lubricating base oil with high monocycloparaffins and low multicycloparaffins

ActiveUS20050133407A1Improve Oxidation StabilityReduce wearRefining to change hydrocarbon structural skeletonLiquid hydrocarbon mixture productionMolecular sieveWax

A process for manufacturing a finished lubricant by: a) performing Fischer-Tropsch synthesis on syngas to provide a product stream; b) isolating from said product stream a substantially paraffinic wax feed having less than about 30 ppm total nitrogen and sulfur, and less than about 1 wt % oxygen; c) dewaxing said feed by hydroisomerization dewaxing using a shape selective intermediate pore size molecular sieve comprising a noble metal hydrogenation component, wherein the hydroisomerization temperature is between about 600° F. (315° C.) and about 750° F. (399° C.), to produce an isomerized oil; and d) hydrofinishing said isomerized oil, whereby a lubricating base oil is produced having specific desired properties; and e) blending the lubricating base oil with at least one lubricant additive.

Owner:CHEVROU USA INC

Lubricating oil formulations

Lubricating oil compositions having excellent thermal and oxidative stability, wear control, copper corrosion control and compatibility with seal materials comprising a mineral oil having a) a Viscosity Index of greater than 110 and an aniline point of greater than 110 DEG C. and / or b) a linear+single ring paraffin content of greater than 68 wt %, and at least one polymer selected from olefin (co) polymer(s), polyalkyl (meth) acrylate(s) and mixtures thereof. The lubricating oil compositions are particularly useful as manual transmission and axle lubricants.

Owner:AFTON CHEM INTANGIBLES

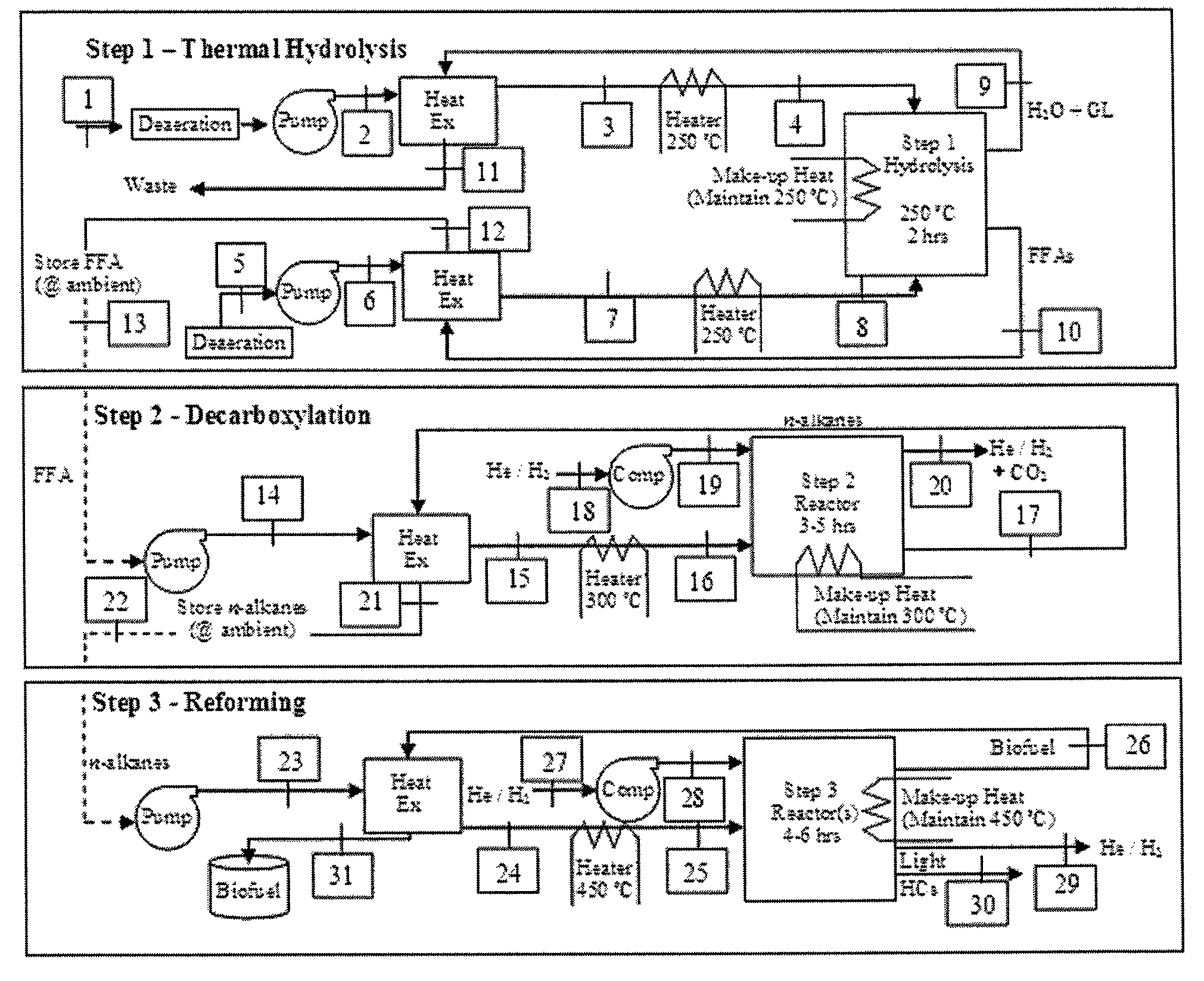

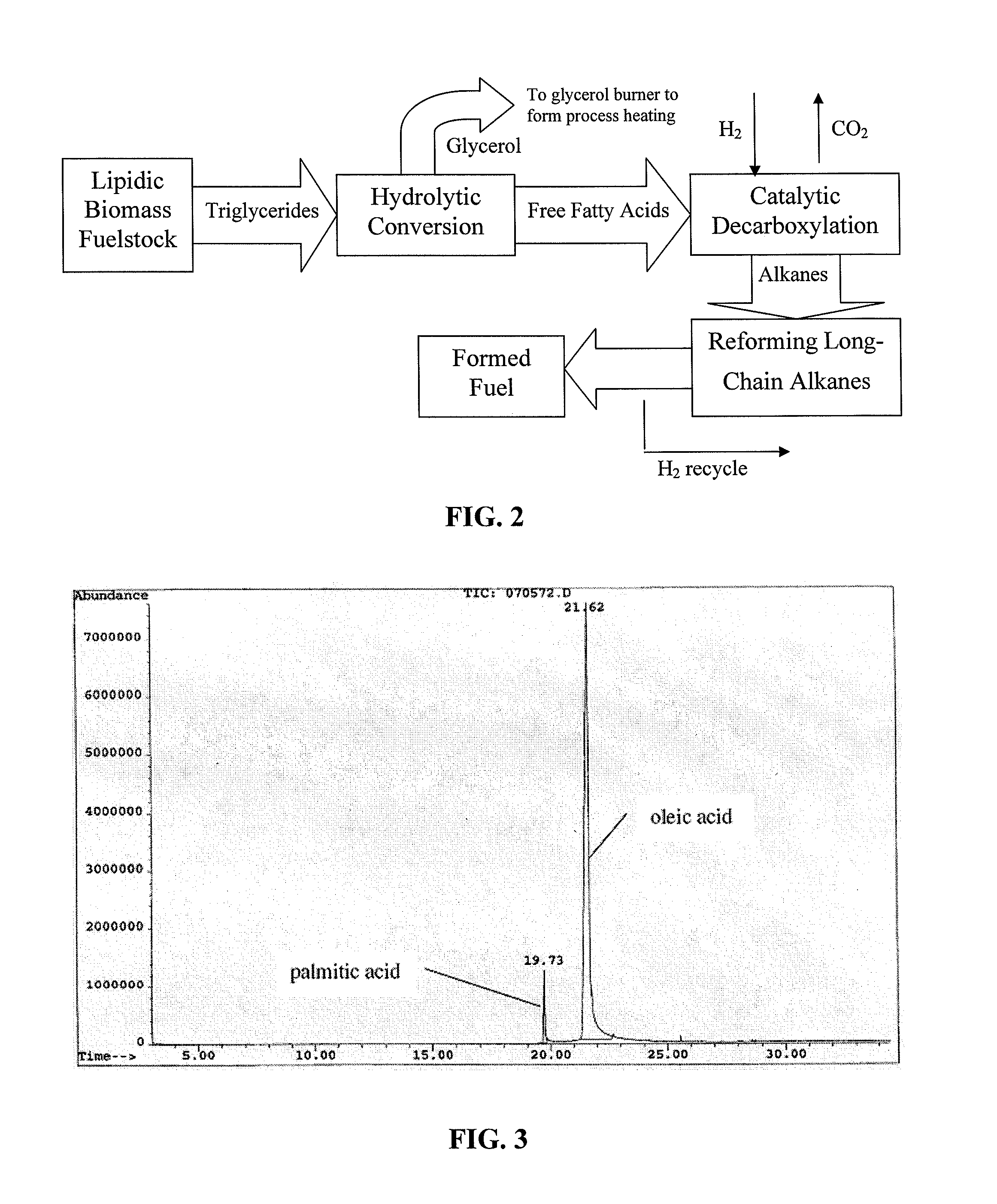

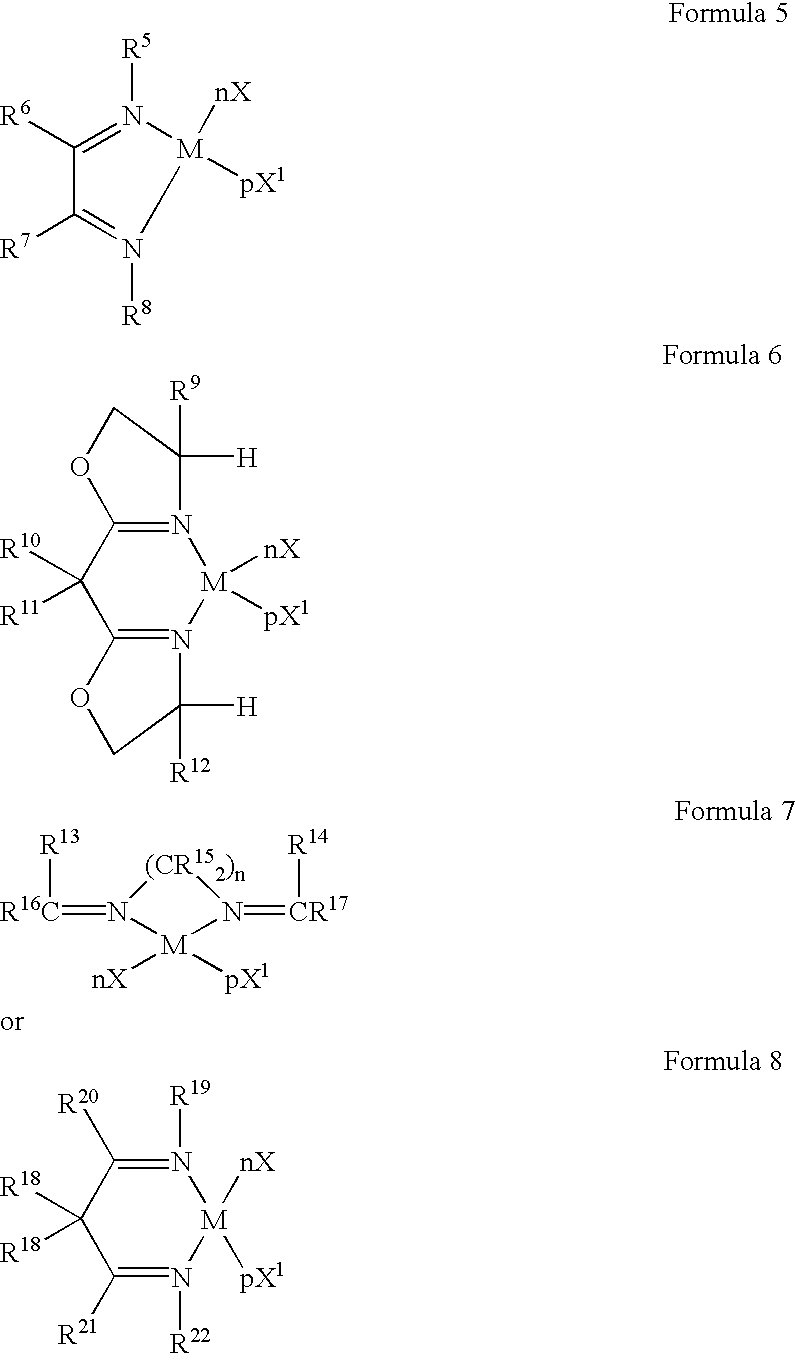

Process for conversion of biomass to fuel

ActiveUS7816570B2Meet growth needsEasy to processFatty acid esterificationRefining to change hydrocarbon structural skeletonAlkaneChain length

Owner:NORTH CAROLINA STATE UNIV

Oligomer oils and their manufacture

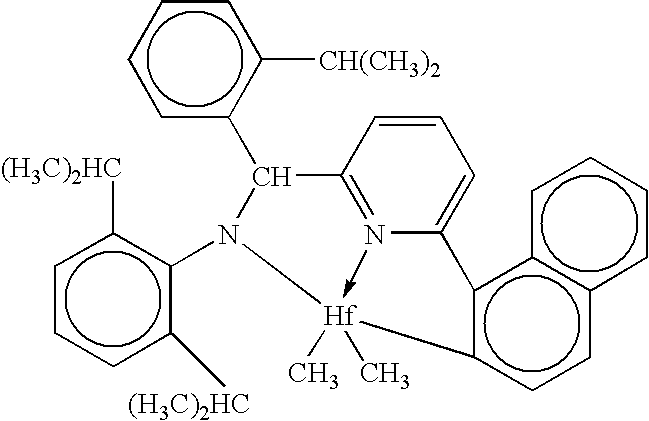

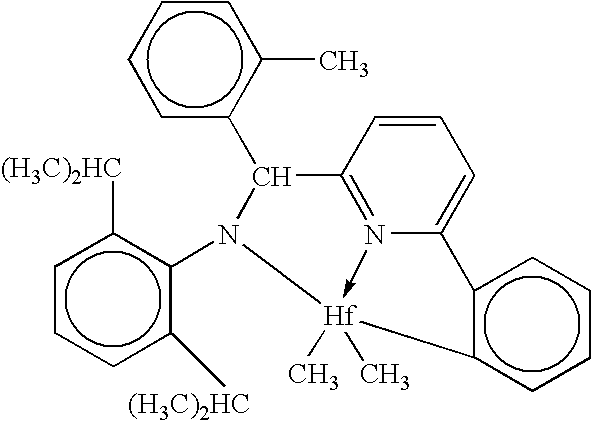

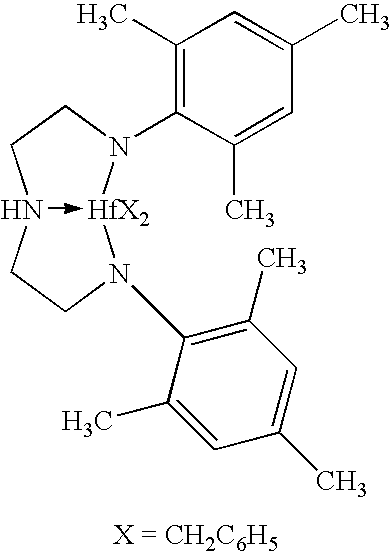

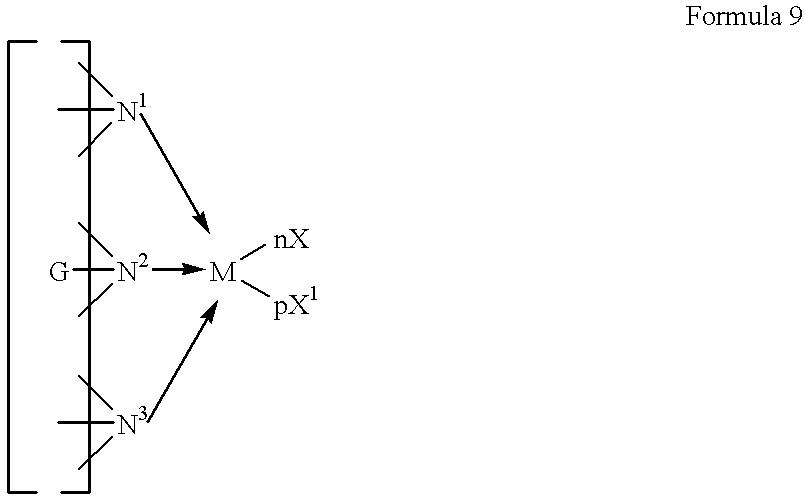

InactiveUS6548724B2Speed up the processImprove distributionOrganic-compounds/hydrides/coordination-complexes catalystsLiquid hydrocarbon mixtures productionOligomerAlkene

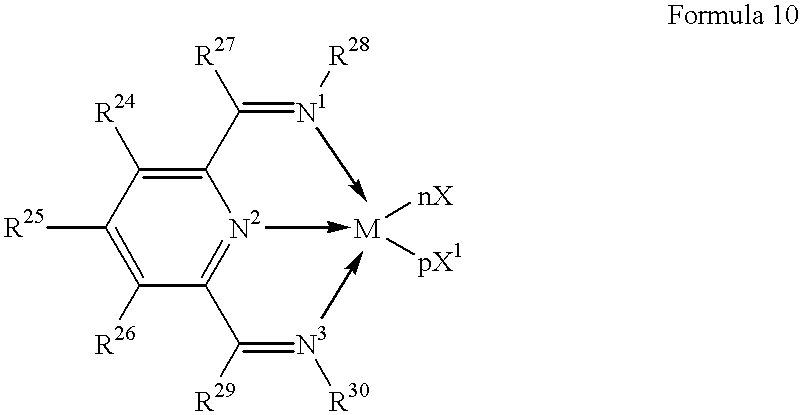

A multistep process for the selective production of an oligomer oil having predetermined properties in which the first step involves the polymerization of a feedstock containing one or more C3 to C20 1-olefins in the presence of a catalyst comprising a bulky ligand transition metal catalyst and in which a subsequent step involves the olgiomerization of at least a preselected fraction of the product of the first step.

Owner:INEOS USA LLC

Multifunctional Dispersants

The present invention provides a composition comprising the product prepared by hearing together: (a) a dispersant; and (b) a 1,3-dicarboxylic acid or 1,4-dicarboxylic acid of an aromatic compound, or a reactive equivalent thereof; and at least one of: (c) 2,5-dimercapto-1,3,4-thiadiazole or a hydrocarbyl-substituted 2,5-dimercapto-1,3,4-thiadiazole, or an oligomer thereof; (d) a borating agent; and (e) a phosphorus acid compound, or a reactive equivalent thereof, said heating being sufficient to provide a reaction product of (a), (b), and (c), (d), or (e), which is soluble in an oil of lubricating viscosity. The invention further provides a use for the composition.

Owner:THE LUBRIZOL CORP

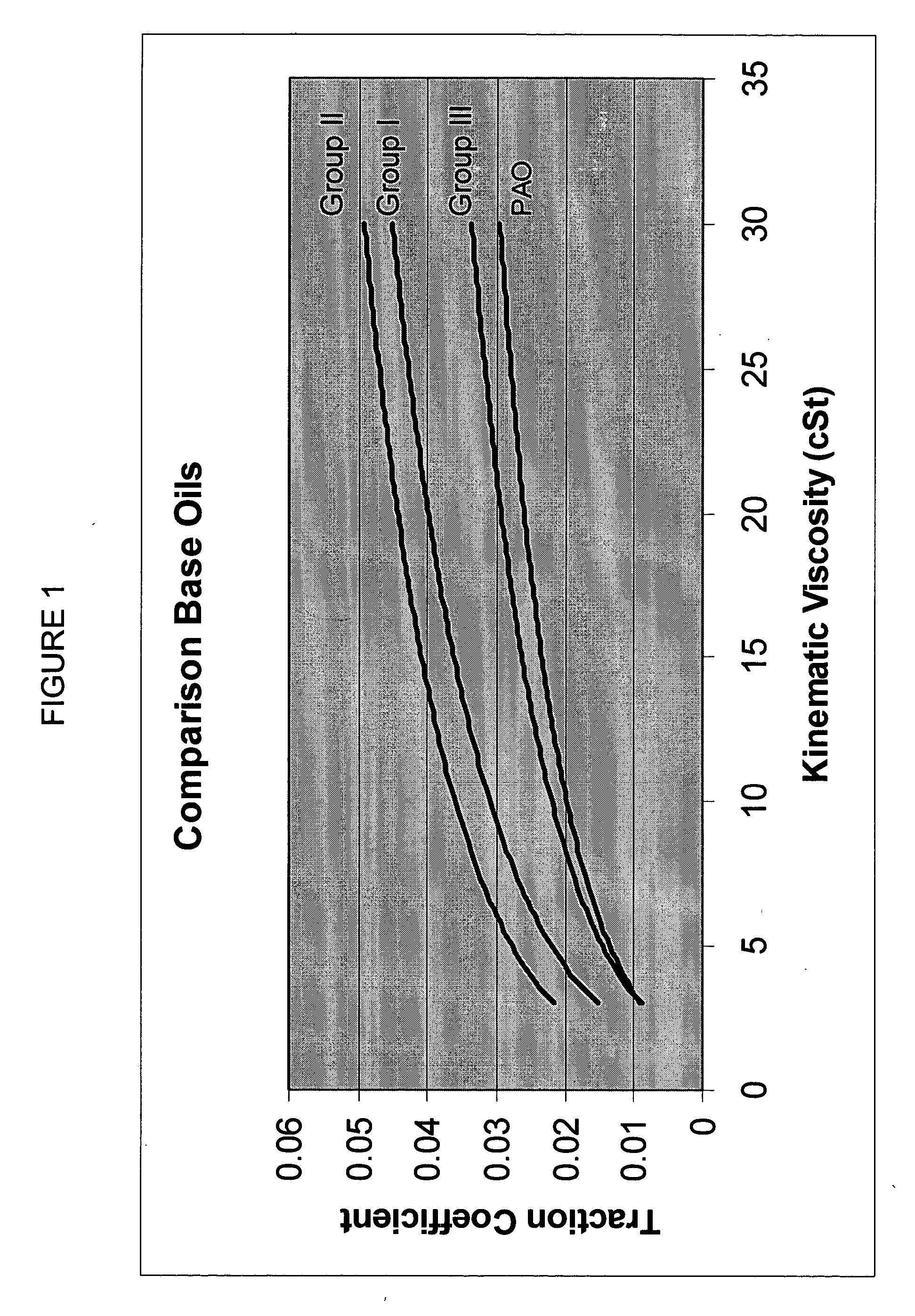

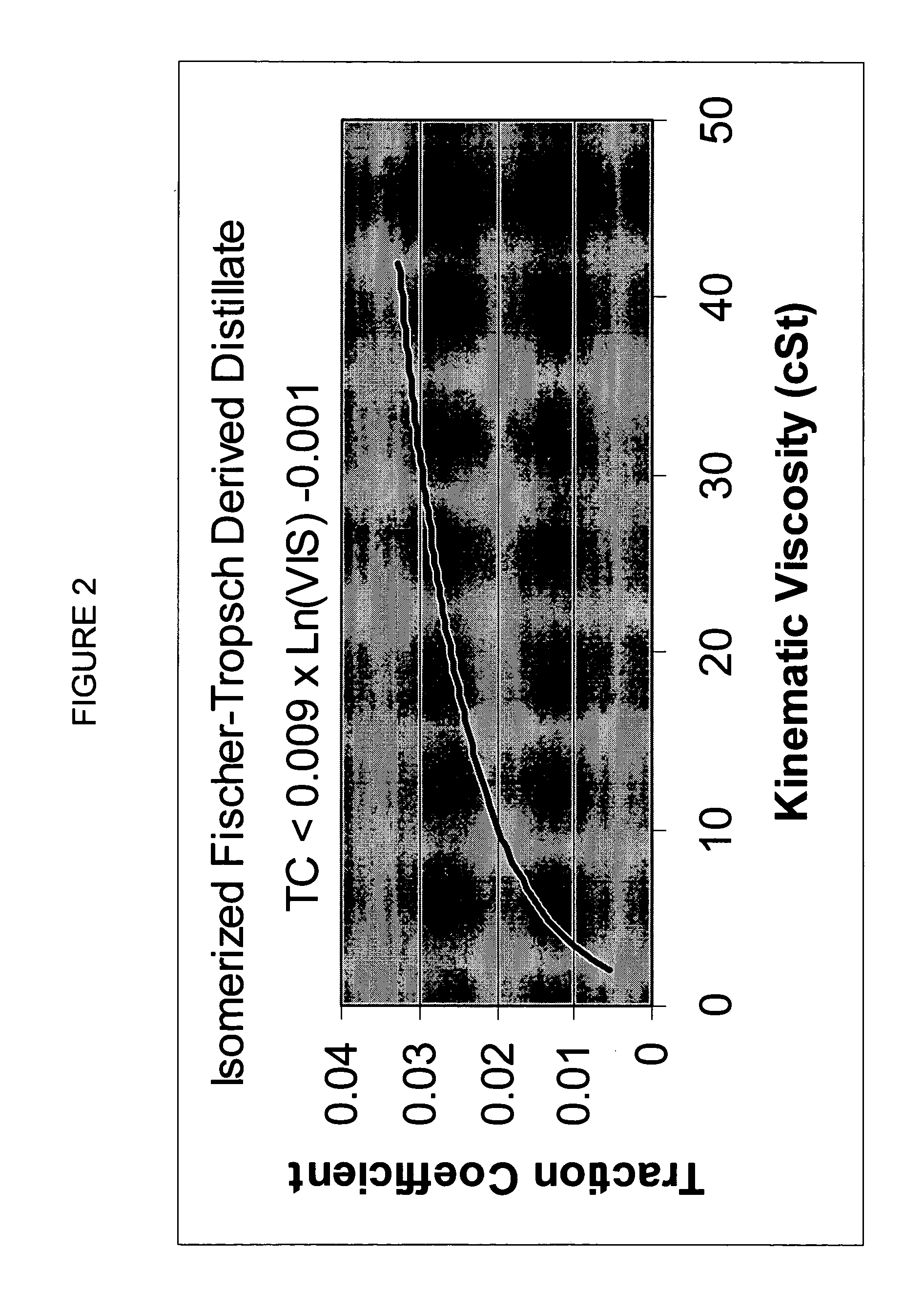

Method of operating a wormgear drive at high energy efficiency

InactiveUS20050241990A1Reducing traction coefficientToothed gearingsGear lubrication/coolingHigh energyBase oil

This invention is directed to a method of operating a wormgear drive at high energy efficiency comprising filling an oil reservoir with a wormgear lubricant comprising an isomerized Fischer-Tropsch derived distillate fraction having a low traction coefficient and operating the wormgear drive with the filled oil reservoir at an equilibrium temperature between 20 and 225 degrees C. This invention is also directed to a process for reducing the traction coefficient of a higher-traction coefficient lubricating base oil by blending it with an isomerized Fischer-Tropsch derived distillate fraction. This invention is also directed to a wormgear lubricant comprising an isomerized Fischer-Tropsch distillate fraction and between 2 and 50 weight percent thickener.

Owner:CHEVROU USA INC

Oligomer oils and their manufacture

InactiveUS6548723B2Speed up the processImprove distributionOrganic-compounds/hydrides/coordination-complexes catalystsLiquid hydrocarbon mixtures productionPolymer scienceOligomer

Owner:INEOS USA LLC

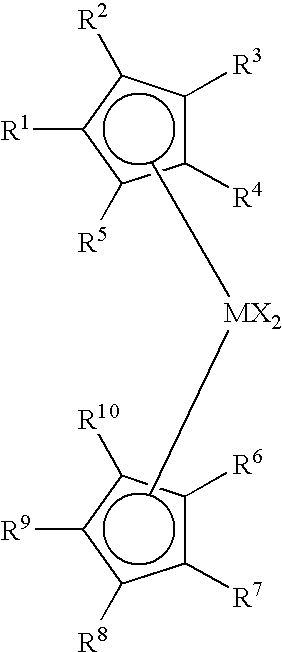

Process to produce low viscosity poly-alpha-olefins

ActiveUS20070043248A1Hydrocarbon by hydrogenationHydrocarbons from unsaturated hydrocarbon additionPolyolefinAlpha-olefin

This invention relates to a process to produce a polyalpha-olefin comprising: 1) contacting one or more alpha-olefin monomers having 3 to 24 carbon atoms with an unbridged substituted bis cyclopentadienyl transition metal compound having: 1) at least one non-isoolefin substitution on both cyclopentadientyl rings, or 2) at least two substitutions on at least one cyclopentadienyl ring, a non-coordinating anion activator, and optionally an alkyl-aluminum compound, where the molar ratio of transition metal compound to activator is 10:1 to 0.1:1, and if the alkyl aluminum compound is present then the molar ratio of alkyl aluminum compound to transition metal compound is 1:4 to 4000:1, under polymerization conditions wherein: i) hydrogen is present at a partial pressure of 0.1 to 50 psi, based upon the total pressure of the reactor or the concentration of the hydrogen is from 1 to 10,000 ppm or less by weight; ii) wherein the alpha-olefin monomer(s) having 3 to 24 carbon atoms are present at 10 volume % or more based upon the total volume of the catalyst / activator / alkylaluminum compound solutions, monomers, and any diluents or solvents present in the reaction; iii) the residence time of the reaction is at least 5 minutes; iv) the productivity of the process is at least 43,000 grams of total product per gram of transition metal compound; v) the process is continuous or semi-continuous, and vi) the temperature in the reaction zone does not rise by more than 10° C. during the reaction; and vii) ethylene is not present at more than 30 volume % of the monomers entering the reaction zone; and 2) obtaining a polyalpha-olefin (PAO), optionally hydrogenating the PAO, wherein the PAO comprises at least 50 mole % of a C3 to C24 alpha-olefin monomer, and wherein the PAO has a kinematic viscosity at 100° C. of 20 cSt or less.

Owner:EXXONMOBIL CHEM PAT INC

Premium synthetic lubricants

InactiveUS6475960B1Refining to change hydrocarbon structural skeletonHydrocarbon purification/separationAntioxidantBoiling point

Premium synthetic lubricants comprise a synthetic isoparaffinic hydrocarbon base stock and an effective amount of at least one, and typically a plurality of lubricant additives such as a detergent, dispersant, antioxidant, antiwear additive, pout point depresant, VI improver and the like. The base stock is derived from a waxy, paraffinic, Fischer-Tropsch synthesized hydrocarbon feed fraction having an initial boiling point in the range of about 650-750° F. and continuously boiling up to at least 1050° F., by a process which comprises hydroisomerizing the feed and dewaxing the isomerate. The waxy feed has a T90-T10 temperature difference of at least 350° F. and is preferably hydroisomerized without any pretreatment, other than optional fractionation. The lubricant may also contain hydrocarbonaceous and synthetic base stock material. Lubricants, such as fully formulated multigrade automotive crankcase and transmission oils formed by adding a suitable additive package to the isoparaffinic base stock have exhibited performance superior to similar fully formulated oils based on both PAO and conventional, petroleum derived base stocks.

Owner:EXXON RES & ENG CO

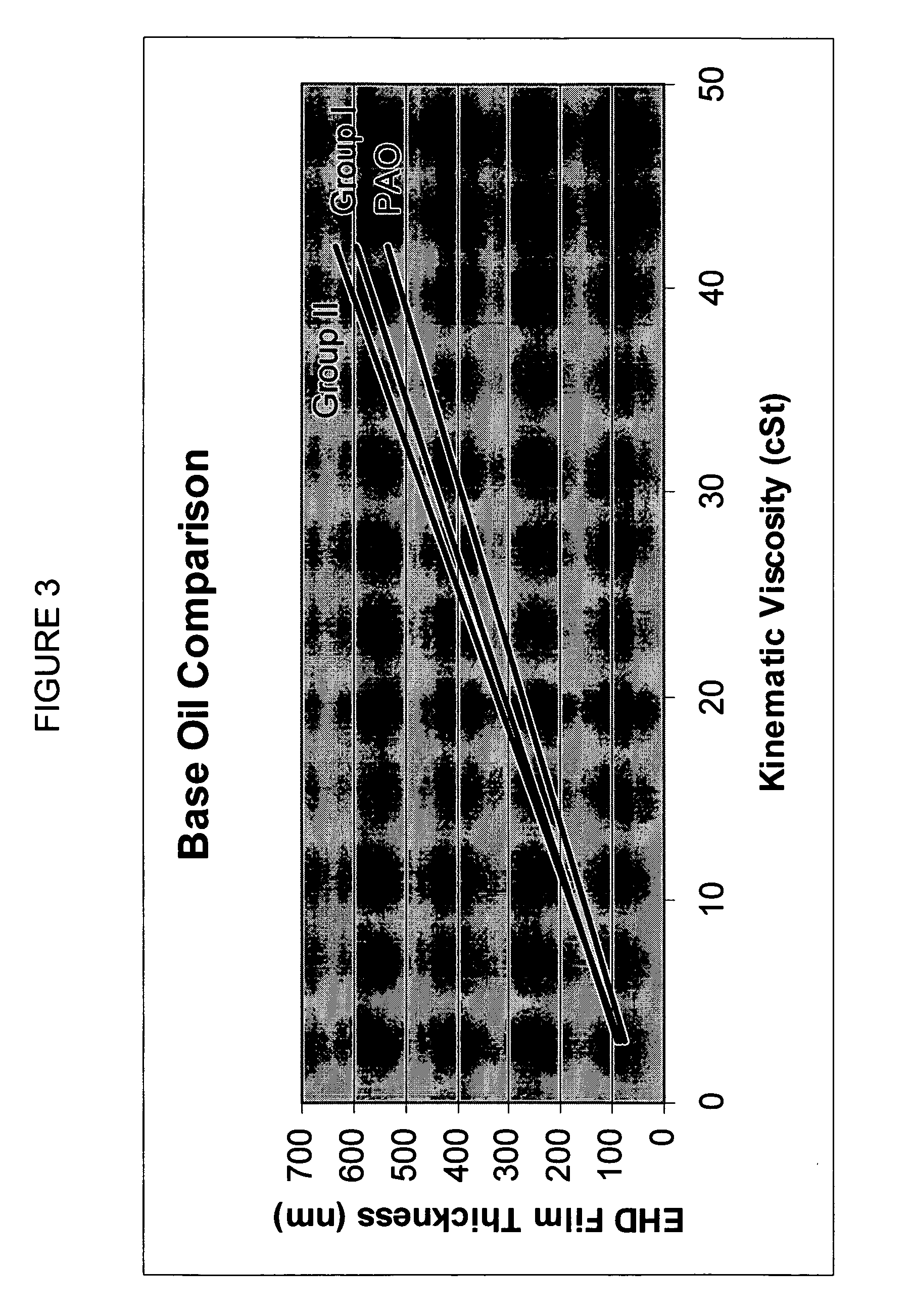

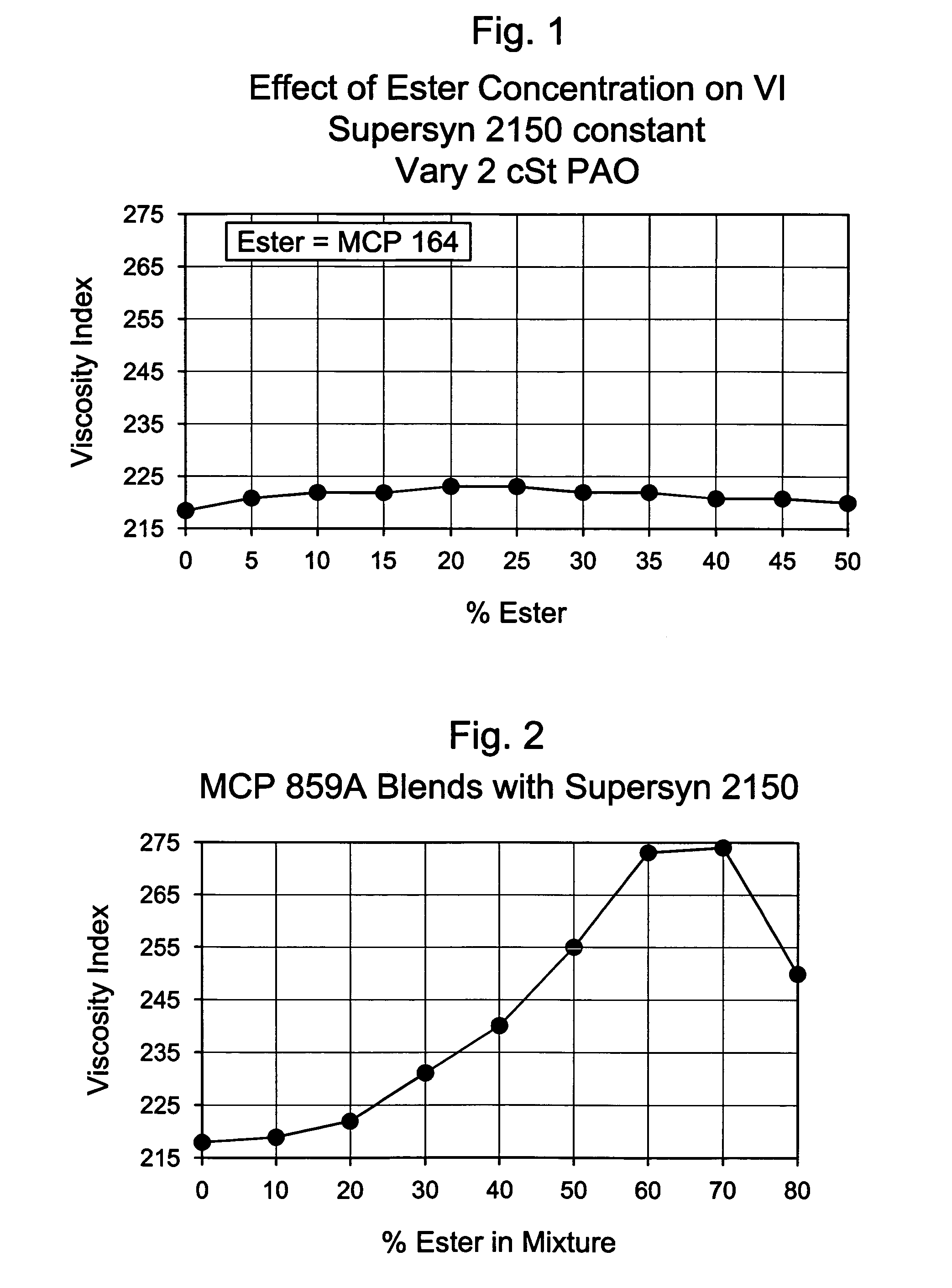

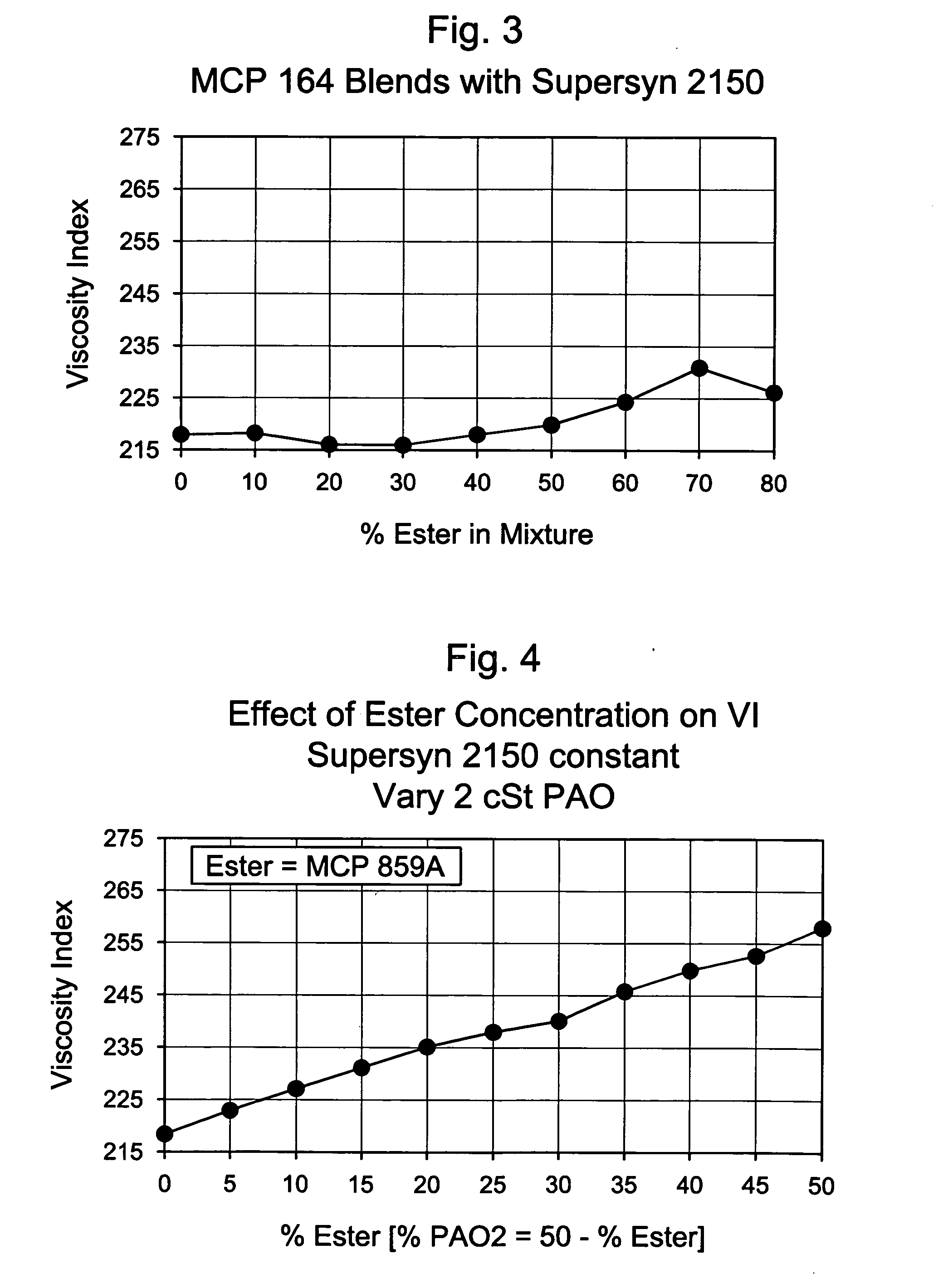

Lubricating fluids with enhanced energy efficiency and durability

The present invention comprises novel lubricating compositions, automotive gear lubricating compositions, and fluids useful in the preparation of finished automotive gear lubricants and finished gear oils, and methods of preparation thereof. One embodiment of the present invention comprises a lubricating composition comprising a blend of a PAO having a viscosity of greater than or equal to about 40 cSt. at 100° C. and less than or equal to about 1,000 cSt. at 100° C. and an ester having a viscosity of less than or equal to about 2.0 cSt. at 100° C., wherein said blend of said PAO and said ester has a viscosity index greater than or equal to the viscosity index of the PAO.

Owner:EXXONMOBIL CHEM PAT INC

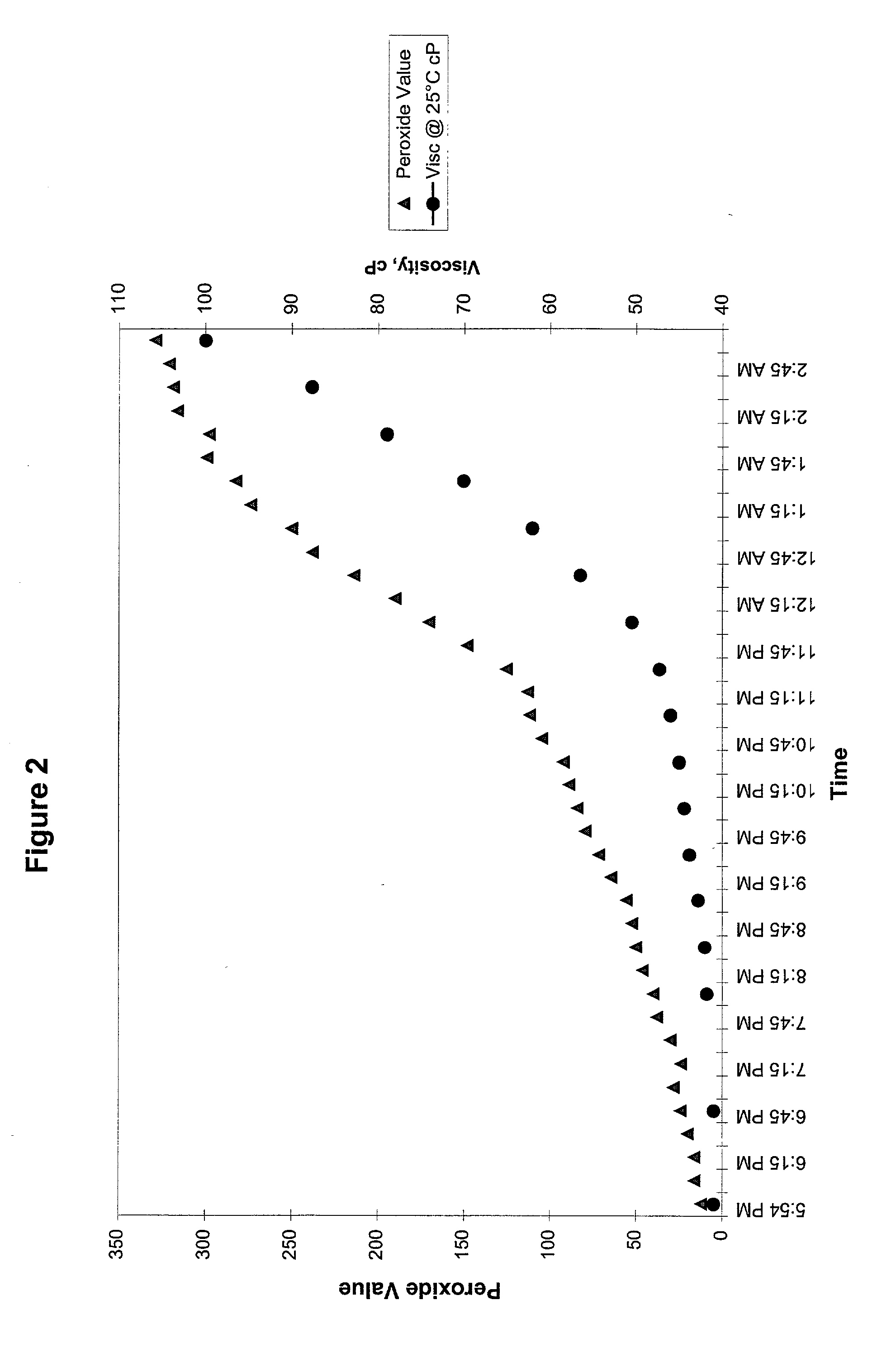

Reactive oil compositions and uses thereof

InactiveUS20020103091A1Low viscosityImprove abilitiesEsterified saccharide compoundsSugar derivativesPolyolOxygen

A process for modifying an unsaturated polyol fatty acid ester stock, such as an unsaturated triacylglycerol oil, to enhance its reactivity provided. The method includes reacting the unsaturated polyol fatty acid ester stock with an oxygenating agent, such as an oxygen-containing gas. Tempering oils containing reactive polyol fatty acid esters and methods for their production and use are also provided.

Owner:CARGILL INC

Oil of Brassica napus

InactiveUS6169190AOrganic compound preparationFatty substance preservation using additivesBrassicaAntioxidant

Oil produced from the seed of Brassica napus plant has an oleic acid content of 71.4-77.4% and a linoleic acid content of no more than 3%. The oil is useful in food and industrial applications. The oil has substantially improved oxidative stability relative to normal rapeseed oil, when both are identically treated with antioxidant.

Owner:LANUZA JUAN ENRIQUE ROMERO +1

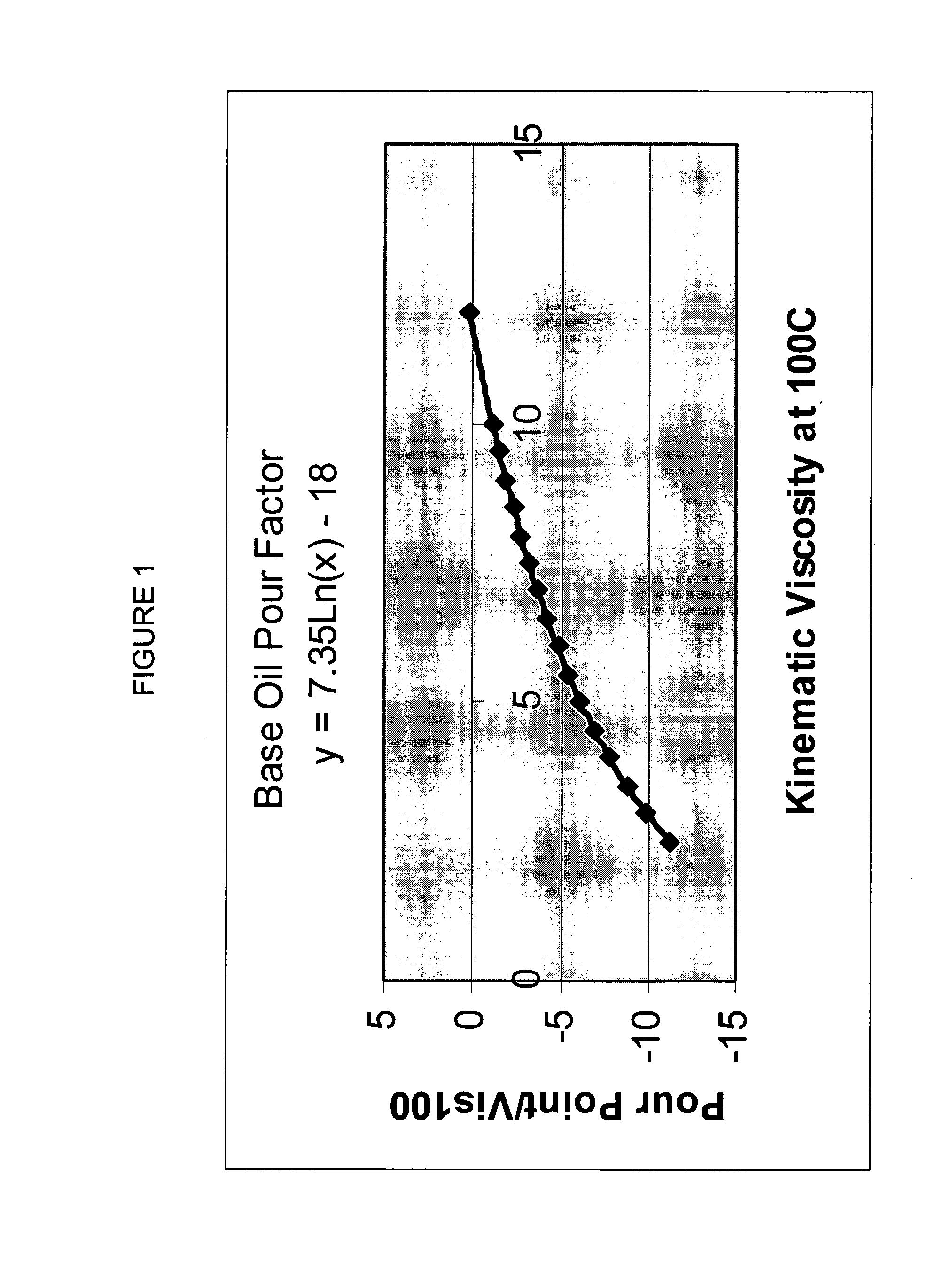

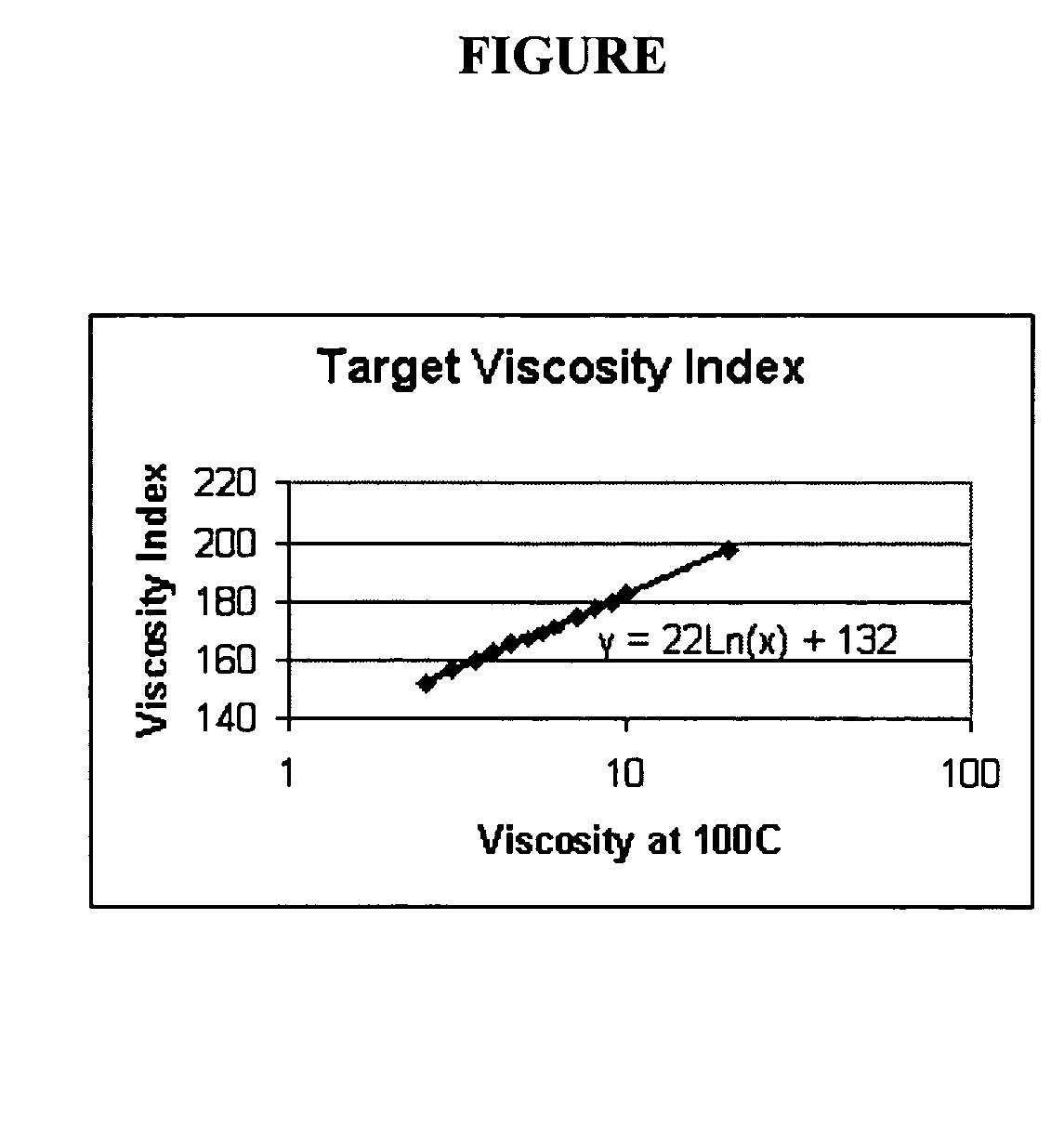

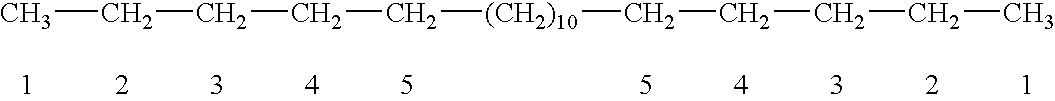

Lubricant base oils with optimized branching

The present invention relates to lubricant base oils comprising paraffinic hydrocarbon components having optimized branching. These lubricant base oils comprising paraffinic hydrocarbon components with optimized branching have low amounts of branching overall with the branching concentrated toward the center of the lubricant base oil molecules. The present invention also relates to processes of producing these lubricant base oils from waxy feeds and commercial finished lubricants comprising these lubricant base oils.

Owner:CHEVROU USA INC

Production of Aviation Fuel from Biorenewable Feedstocks

ActiveUS20090158637A1Refining to change hydrocarbon structural skeletonHydrocarbon purification/separationAlkaneVegetable oil

A process has been developed for producing aviation fuel from renewable feedstocks such as plant oils and animal fats and oils. The process involves treating a renewable feedstock by hydrogenating and deoxygenating to provide n-paraffins having from about 8 to about 24 carbon atoms. At least some of the n-paraffins are isomerized to improve cold flow properties. At least a portion of the paraffins are selectively cracked to provide paraffins meeting specifications for different aviation fuels such as JP-8.

Owner:UOP LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com