Patents

Literature

205 results about "Phosphorus acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

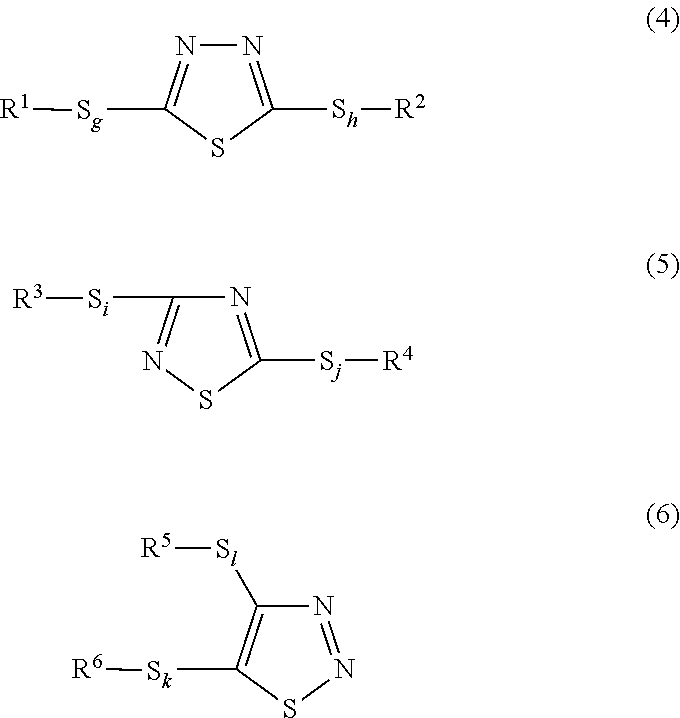

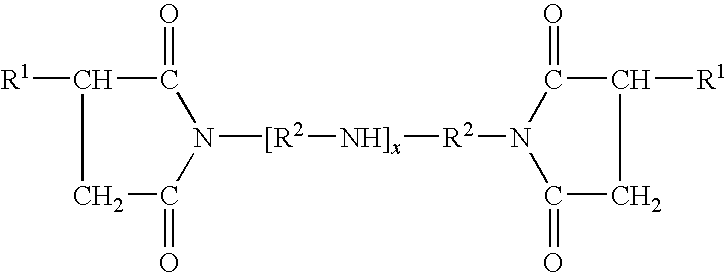

Multifunctional Dispersants

The present invention provides a composition comprising the product prepared by hearing together: (a) a dispersant; and (b) a 1,3-dicarboxylic acid or 1,4-dicarboxylic acid of an aromatic compound, or a reactive equivalent thereof; and at least one of: (c) 2,5-dimercapto-1,3,4-thiadiazole or a hydrocarbyl-substituted 2,5-dimercapto-1,3,4-thiadiazole, or an oligomer thereof; (d) a borating agent; and (e) a phosphorus acid compound, or a reactive equivalent thereof, said heating being sufficient to provide a reaction product of (a), (b), and (c), (d), or (e), which is soluble in an oil of lubricating viscosity. The invention further provides a use for the composition.

Owner:THE LUBRIZOL CORP

Technique for cleanly recovering byproduct methyl chloride of glyphosate acid

InactiveCN1446782ARealize cleaner productionEasy to operateGroup 5/15 element organic compoundsHalogenated hydrocarbon separation/purificationPhosphorus acidChloride

A process for recovering chloromethane from the tail gas exhausted in the procedure of preparing glyphosate by phosphorus acid-phytanic acid method is disclosed. As said tail gas contains chloromethane (20-90%) and impurities (methanol, methylal, H2O and hydrogen chloride), it uses solvent to absorb impurities, or condenses the impurities, or convents the impurities to chloromethane, so obtaininghigh-purity chloromethane.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Preparation method for wear resistant fire-retardant coating

ActiveCN101570650AImprove working environmentImprove work efficiencyFireproof paintsO-Phosphoric AcidSodium phosphates

The invention provides a preparation method for wear resistant fire-retardant coating with simple construction process, good wear resistance and relatively low cost. The raw material of the wear resistant fire-retardant coating selects plate-shaped tabular alumina, brown alumina and high-quality bauxite chamotte as aggregate, selects plate-shaped tabular alumina powder, flint clay powder, alpha-Al2O3 micropowder and ceramic powder as fine powder, selects 42.5 mass percent industrial phosphoric acid solution, solid aluminium dihydrogen phosphate and clay powder as bonding agents, selects fused magnesite as a curing agent and selects sodium borate and sodium hexametahposphate as sintering aids. The wear resistant fire-retardant coating can be directly smeared on the surfaces of a wear resistant fire-retardant material liner and a water cooling wall pipe, fills up technical blank of resisting the wear on metal by using a non metal coating at a high temperature of 900 DEG C, provides a new repairing method for a non metal wear resistant fire-retardant material liner, has simple construction process, can obviously improve working environment of workers, reduce the labor intensity and improve the working efficiency of maintaining a circulating fluid bed boiler heated surface metal pipe wall and the wear resistant fire-retardant material liner.

Owner:TONGDA REFRACTORY TECH CO LTD

Coating compositions having improved stability

ActiveUS20060047062A1Improve shelf lifeReduce gassing and gellationConductive materialNon-conductive material with dispersed conductive materialChemistryEmulsion

This invention relates to waterborne coating compositions having improved compatability with metal pigments, i.e., improved shelf life and reduced gassing and gellation. The compositions comprise at least one aqueous dispersion of (1) at least one emulsion copolymer polymerized from (a) at least one ethylenically unsaturated anionic monomer and (b) at least one other olefinically unsaturated monomer, said copolymer being made using at least one phosphate surfactant having at least one phosphorus acid group or salt thereof, said copolymer being crosslinked, and (2) at least one non-water soluble metal pigment. The compositions are useful in paints and other coatings.

Owner:LUBRIZOL ADVANCED MATERIALS INC

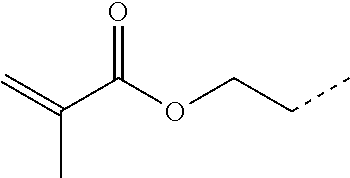

Bimodal adsorbing latex

ActiveUS20150011695A1Increase heightImprove hiding efficiencyEmulsion paintsPolymer sciencePhosphoric acid

The present invention relates to a composition comprising a stable aqueous dispersion of large acrylic based polymer particles and small acrylic based polymer particles wherein the large polymer particles comprise structural units of a phosphorus acid monomer or a salt thereof; and wherein the small polymer particles comprise a substantial absence of structural units of any phosphorus acid monomer and salts thereof. The bimodal dispersion of the present invention provides a way of making a high solids adsorbing latex with high hiding efficiency.

Owner:ROHM & HAAS CO +1

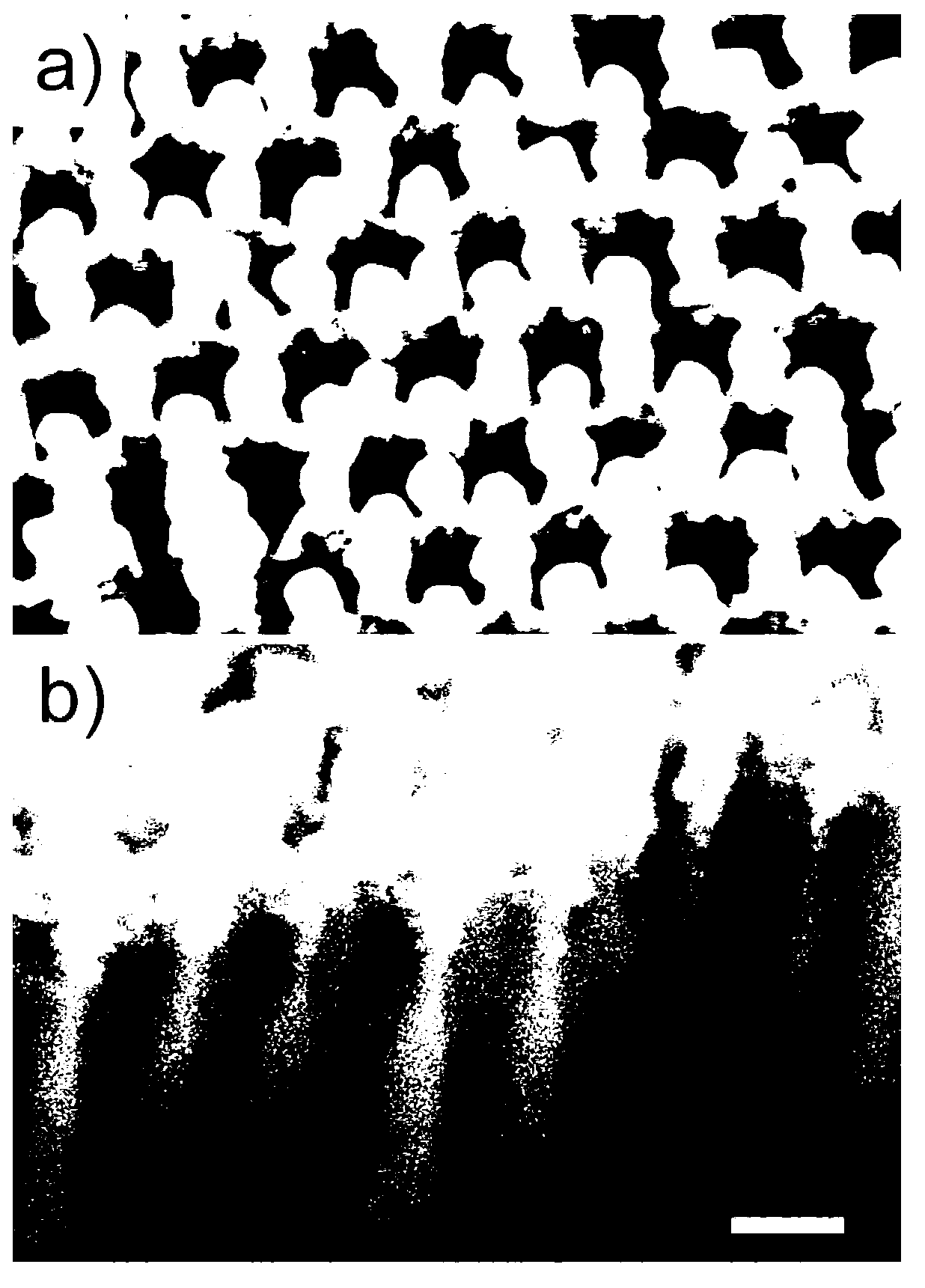

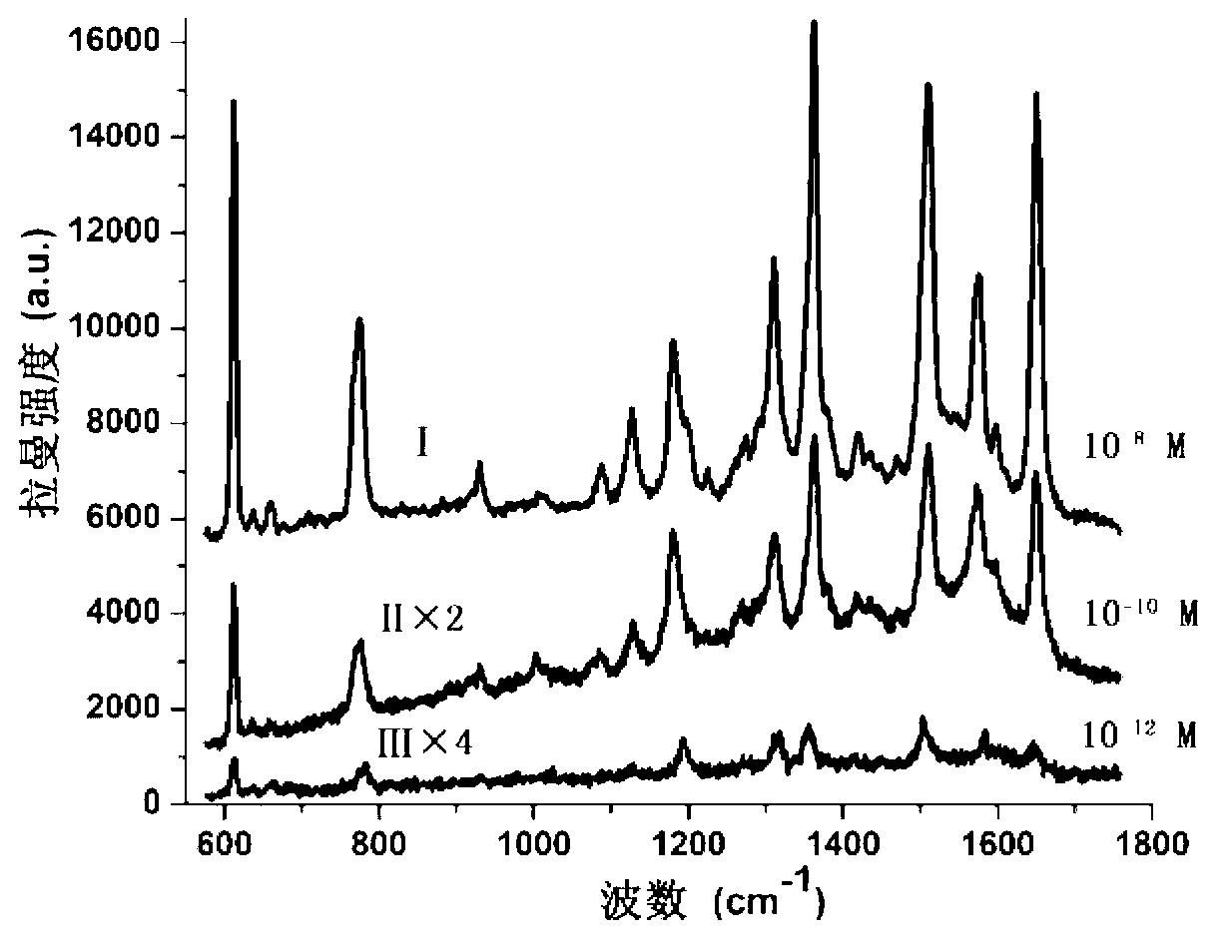

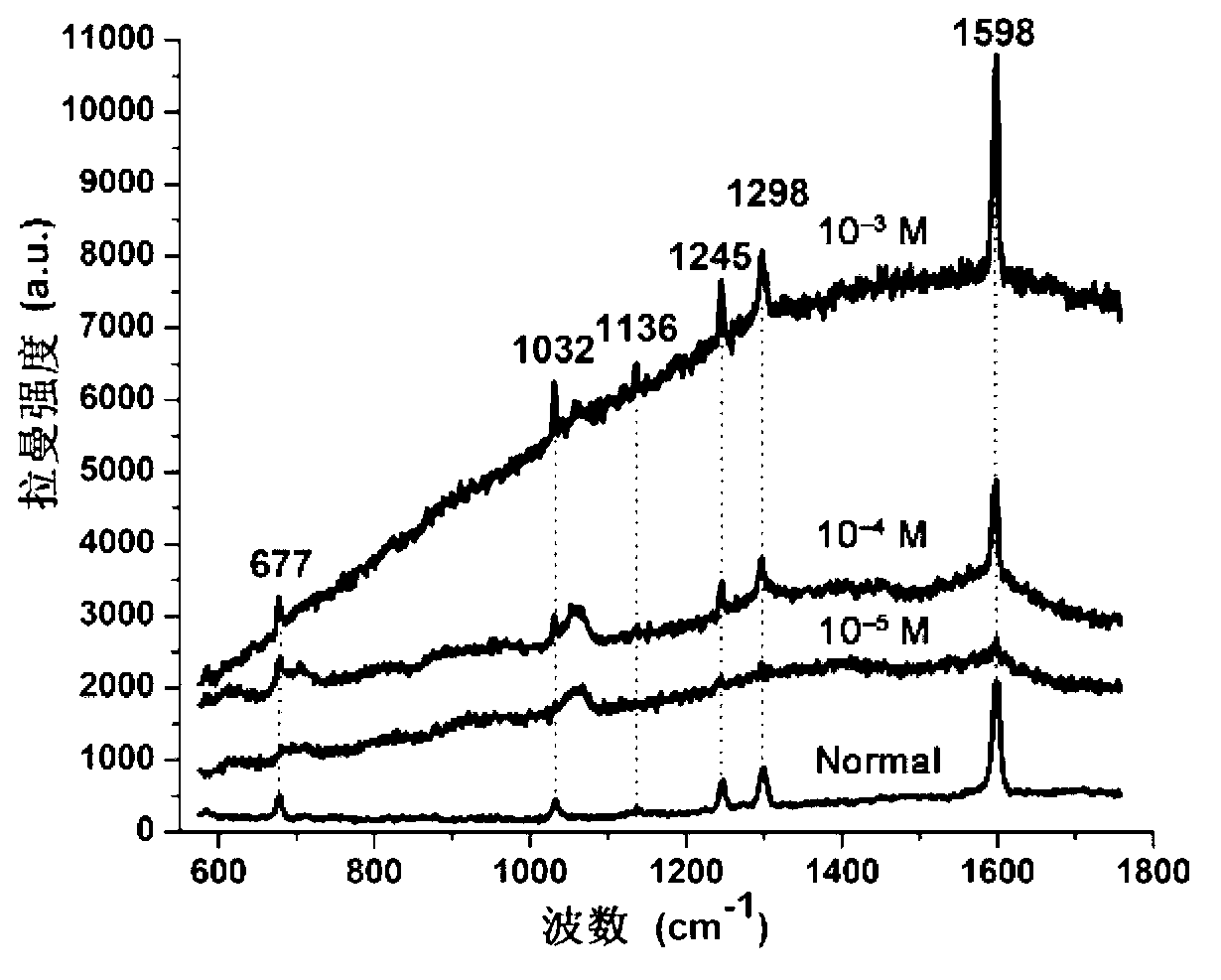

Silver nanometer column array erected on orifice of porous alumina template and preparation method and application thereof

InactiveCN103060878AMaintain propertiesHigh SERS activityVacuum evaporation coatingSurface reaction electrolytic coatingOXALIC ACID DIHYDRATEPhosphorus acid

The invention discloses a silver nanometer column array erected on the orifice of a porous alumina template and a preparation method and application thereof. The silver nanometer column array is characterized in that silver nanometer columns with the heights of 30-200 nanometers and the diameters of 30-60 nanometers are sequentially hexagonally arrayed on the periphery of the orifice of the porous anodic alumina template with taper holes; and silver nanometer particles with the particle size of 5-40 nanometers are attached to the walls of the taper holes. The preparation method comprises the following steps of: firstly placing an aluminum sheet into an oxalic acid solution, and carrying out anodization at direct-current voltage for at least 2 hours; then placing into a phosphorus-chromium acid mixed solution, and soaking for at least 3 hours to obtain an intermediate product; then firstly placing the intermediate product into the oxalic acid solution, carrying out the anodization at the direct-current voltage for at least 20 seconds, then placing the intermediate product into a phosphorus acid solution, and soaking for at least 1 minute; repeating the process for at least 10 times to obtain the alumina template with the holes in the shape of the taper holes; and then placing the alumina template into an ion sputter for silver sputtering so as to prepare a target product. The silver nanometer column array disclosed by the invention can be used as an active base of surface-enhanced Raman scattering; and the content of rhodamine or tetrachlorobiphenyl which is attached to the silver nanometer column array is measured by using a laser Raman spectrometer.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

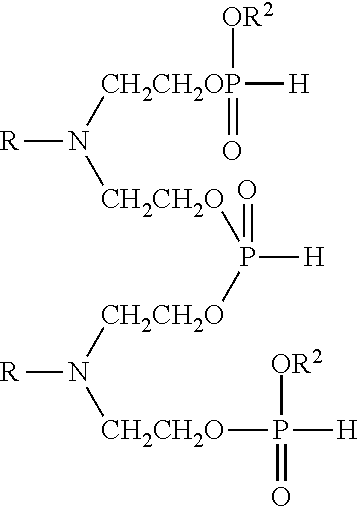

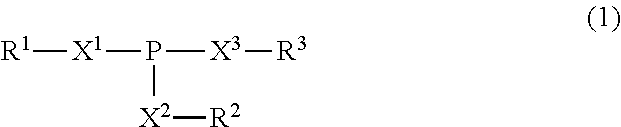

Polymeric Phosphorus Esters for Lubricant Applications

A lubricant composition of an oil of lubricating viscosity and a polymeric phosphorus ester comprising the condensation product of a monomeric phosphorus acid or an ester thereof with a diol having two hydroxy groups separated by a chain of 4 to about 100 atoms exhibits good volatility, corrosion, wear, and / or seal performance in lubrication of a transmission.

Owner:THE LUBRIZOL CORP

Polyamide resin composition

A polyamide resin composition comprising a polyamide (X) having a diamine constituent unit which is mainly composed of a m-xylylenediamine unit and a dicarboxylic acid constituent unit which is mainly composed of an adipic acid unit; and specific amounts of a phosphorus acid antioxidant and alkaline component. The polyamide (X) is characterized by a specific range of terminal-group concentration balance and a specific amino-group reaction rate. This composition can simultaneously achieve inhabitation of yellow discoloration and reduction of number of gels or fish eyes.

Owner:MITSUBISHI GAS CHEM CO INC

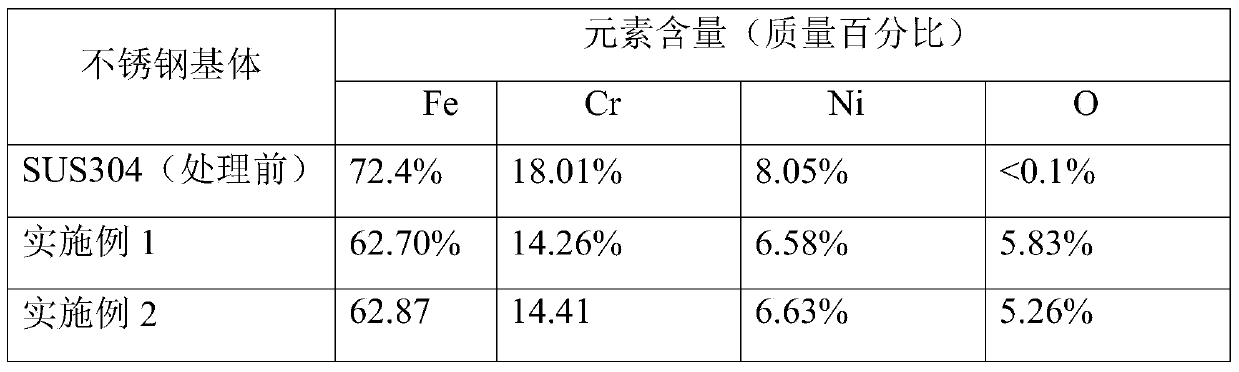

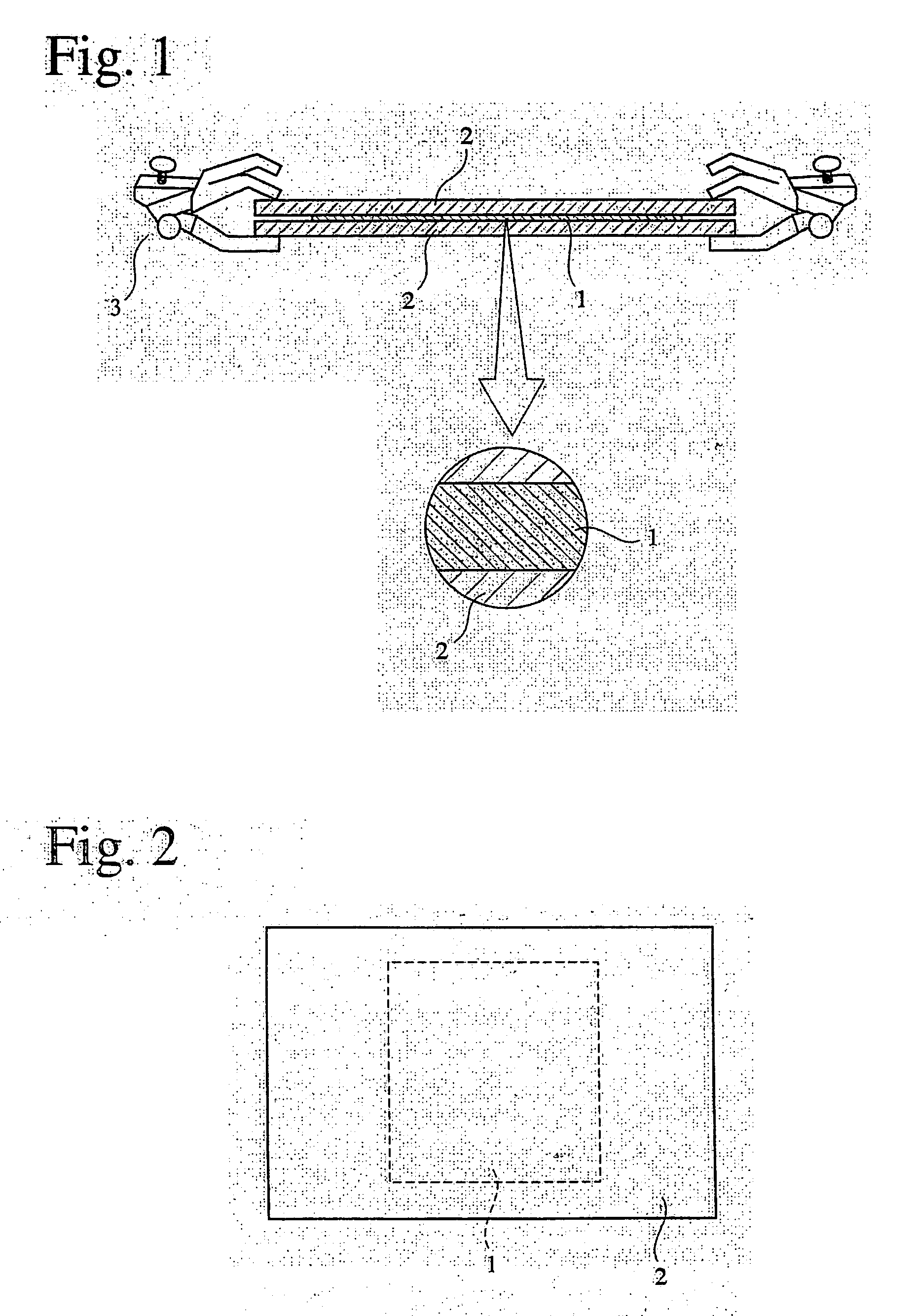

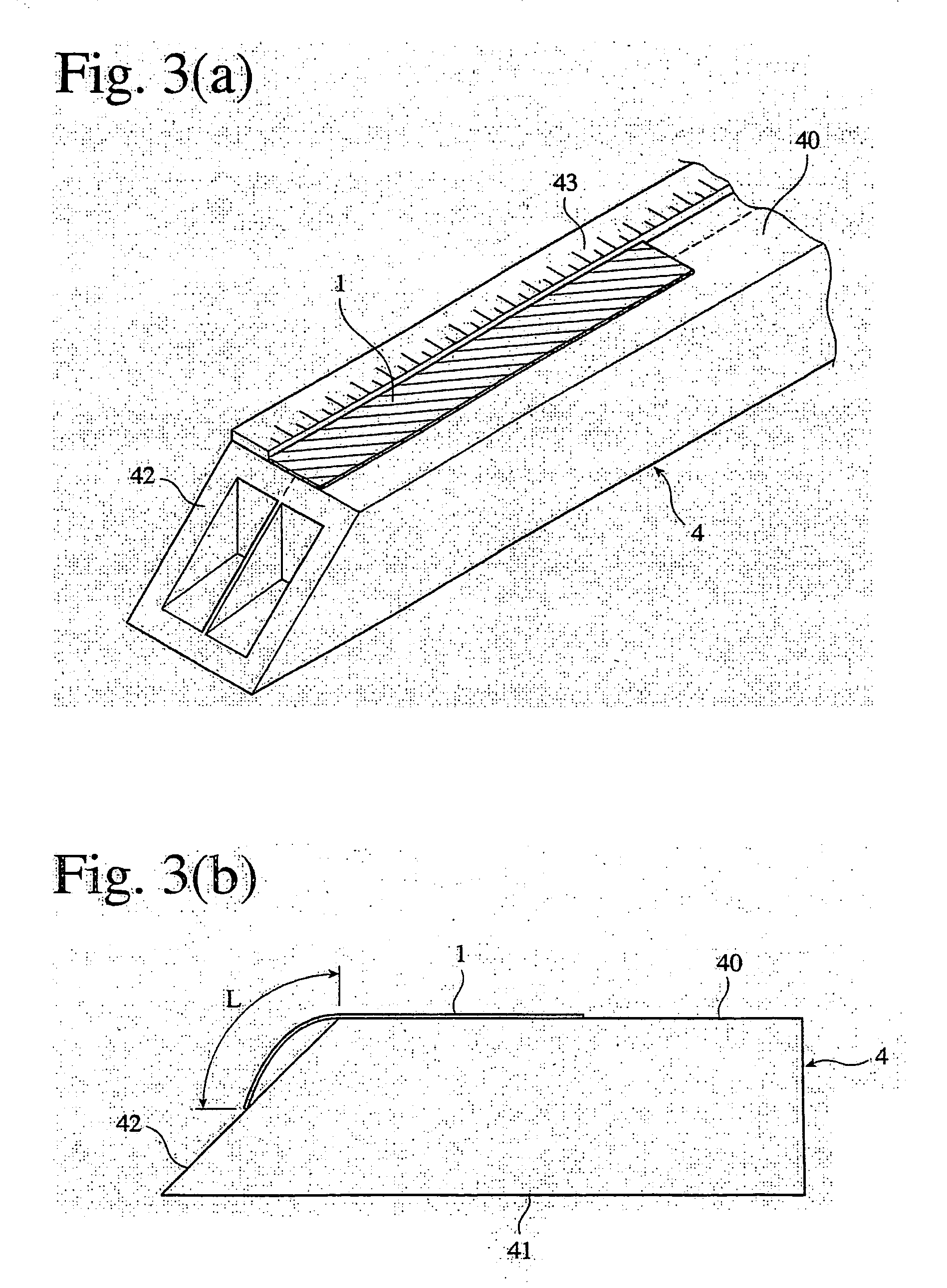

Surface treatment method for metal substrate, the metal substrate, and metal-resin composite and production method of same

ActiveCN105500600AImprove the decorative effectImprove bindingCoatingsPhosphorus acidPhosphoric acid

The invention discloses a surface treatment method for a metal substrate, the metal substrate prepared therethrough, and a metal-resin composite and a production method of the same. The surface treatment method includes the steps of (1) pre-treating the metal substrate with a mixed acid solution composed of two or more of sulfuric acid, citric acid and phosphorus acid to form irregular corroded holes in the surface of the metal substrate; and (2) performing electrochemical corrosion to the metal substrate in an alkaline solution or chemically soaking the metal substrate in an acidic solution. The metal substrate subjected to the surface treatment is placed into a die to perform injection moulding through a thermoplastic resin composition to obtain the integrated metal-resin composite. The invention also provides the production method of the integrated metal-resin composite which is excellent in binding force. The production method is easy to carry out and low in cost.

Owner:BYD CO LTD

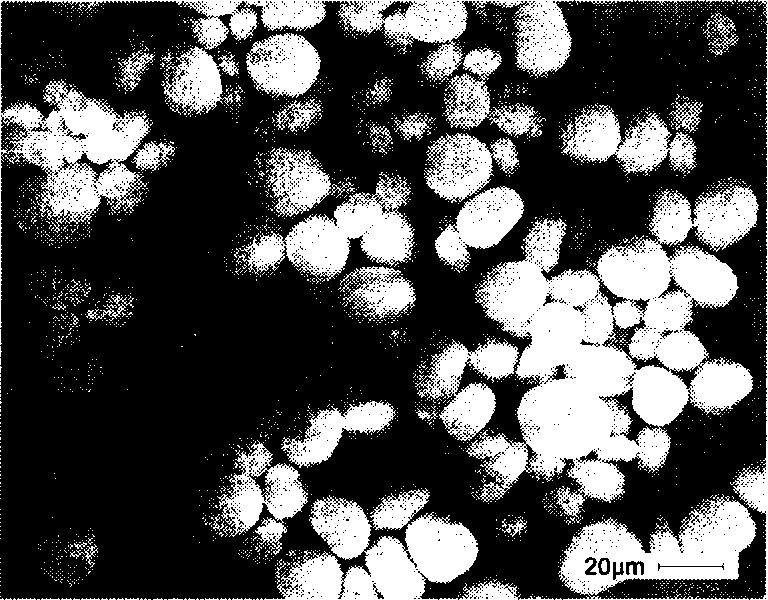

Spherical porous high-density LiFePO4 powder and process for preparing same

The invention refers to a method which prepare high-density global c, using ferrous salt, phosphorus acid, ammonia and lithium hydrate, lithium phosphate as initial material, firstly, adding ferrous salt solution and phosphor fountain in reactor by metering pump, adjusting pH value in reactor by queous alkali, occurring deposition react, the precipitate overflowing along with mother liquid, washing, filtrating and drying the effluent deposit would receive global hydrated ferrous phosphate; confecting ferrous phosphate and lithium phosphate suspend, getting mole ratoo of Li+:Fe2+:PO43- is 1:1:1, then adding carbon fountain, getting lithium phosphate and ferrous phosphate mix prodromal body after intimate mixing, solid-liquid separation; Calcining prodromal body for 5-30h in 500-800Deg C inertia and deoxidized atmosphere, cooling to room temperature with furnace, then getting global ferric lithium phosphate powder. The grain-size range of this powder is 0.5-30 mum, particle mean size is 8-13 mum, tap density is as high as 1.5- 2.0g / cm3, first discharge capacity is bigger than 120mAh / g, discharge voltage flat roof is 3.4V, hasing fine application foreground.

Owner:JIANGSU UNIV

Coating compositions having improved stability

ActiveUS7459496B2Improve compatibilityExtended shelf lifeConductive materialNon-conductive material with dispersed conductive materialPolymer scienceActive agent

This invention relates to waterbone coating compositions having improved compatability with metal pigments, i.e., improved shelf life and reduced gassing and gellation. The composition comprise at least one aqueous dispersion of (1) at least one emulsion copolymer polymerized from (a) at least one ethylenically unsaturated anionic monomer and (b) at least one other olefinically unsaturated monomer, said copolymer being made using at least one phosphate surfactant having at least one phosphorus acid group or salt thereof, said copolymer being crosslinked, and (2) at least one non-water soluble metal pigment. The compositions are useful in paints and other coatings.

Owner:LUBRIZOL ADVANCED MATERIALS INC

Coating compositions for containers

A coating composition comprising a polyether polyol having a hydroxyl functionality of 3 to 8 and the reaction product of:(i) a phosphorus acid, and(ii) a polyepoxide and / or a polyester.The compositions are useful for coating containers of all sorts, such as food and beverage containers. The compositions can be formulated to be substantially free of bisphenol A (BPA), bisphenol A diglycidyl ether (BADGE) and other derivatives of BPA.

Owner:PPG IND OHIO INC

A method for corroding sapphire graphic substrate by wet-process

ActiveCN1700449ALow densityImprove crystal qualityLaser detailsFinal product manufactureHydrofluoric acidPhosphorus acid

This invention relates to humid erosion sapphire pattern underlay method, which comprises the following steps: adopting general C surface sapphire silicon dioxide mask layer coated; using technique of etching technique to the silicon dioxide mask pattern along [1100] or [1120] direction; using sulfur acid or mixture liquid of sulfur and phosphorus acids as erosion liquid underlay; finally using the rare hydrofluoric acid liquid to erode the mask layer to get the sapphire round underlay.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

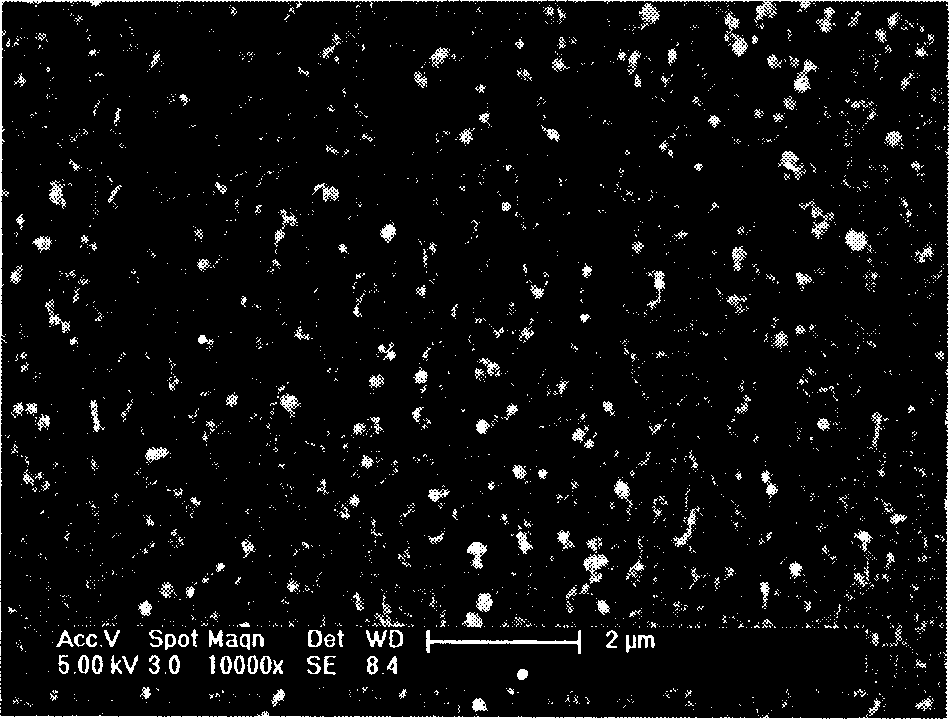

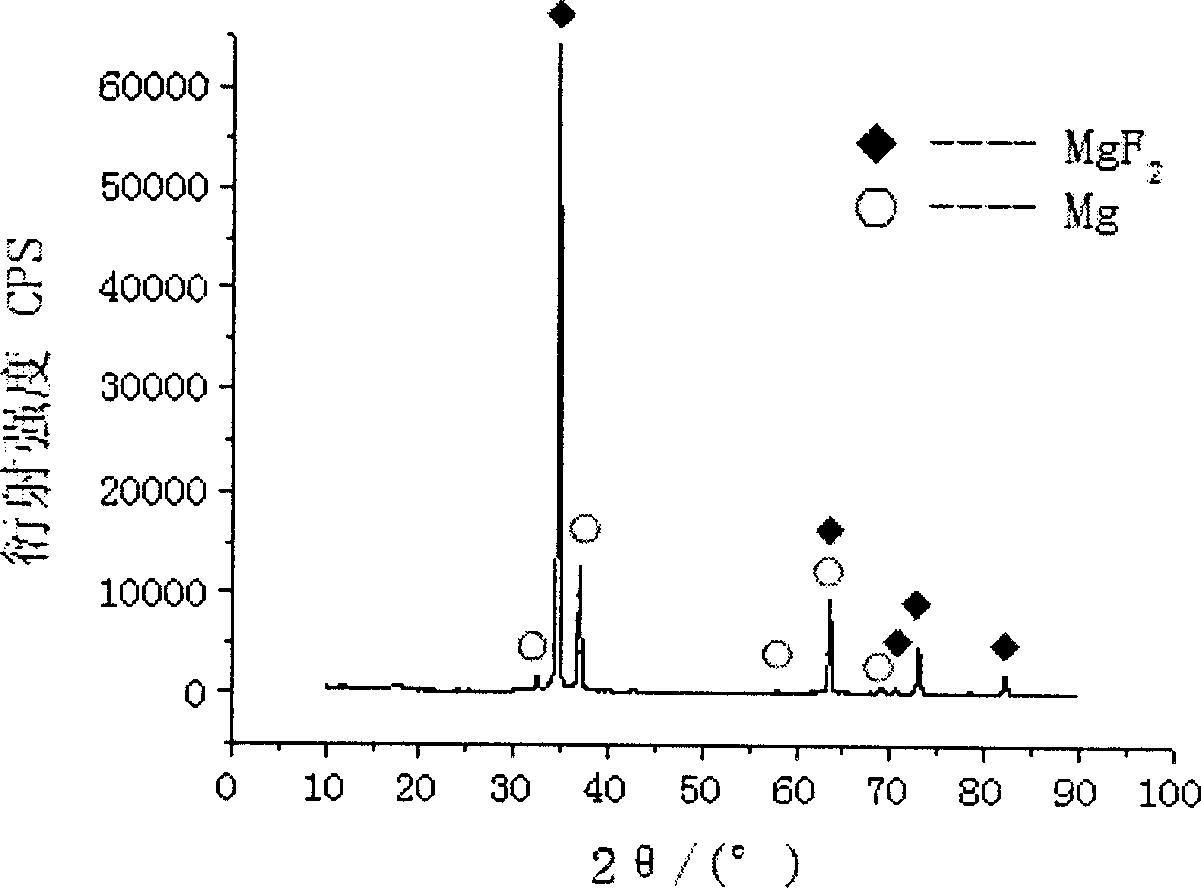

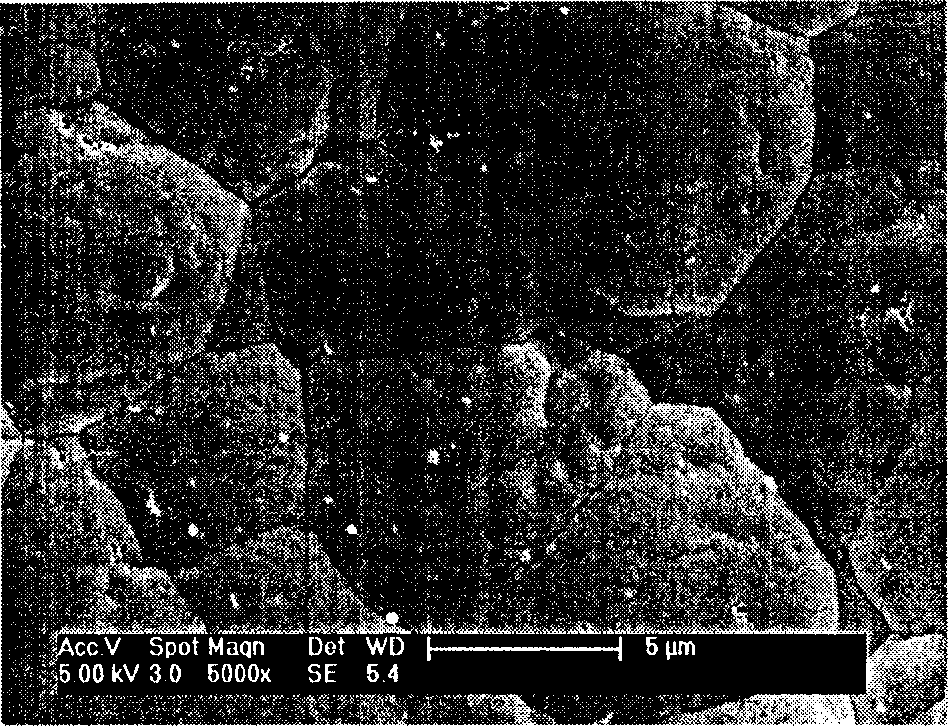

Method for treating surface of magnesium or alloy thereof

This invention provides a method of surface treatment for magnesium or its alloy, which comprises the following steps: first, degreasing the surface of works, then immersing magnesium or its alloy into the treatment fluid and stirring the solution, the immersed temperature is indoor temperature, the immersed time is 0.5-10min. Said treatment fluid comprises 0.5%-10% oxalic acid, 0.5%-15% phosphorus acid, 1%-10% ammonium acid fluoride, 1%-3% inhibitor, 0.0005%-0.001% humectant by mass percent,and deionized water which is residual. Said inhibitor is one or more than of thiourea, hexamethylenetetramine and citric acid, and its proportioning is optional. Said humectant is sodium dodecyl sulfonate, OP-10 or carbowax. The invention has the merits such as high processing speed, simple process, less depletion and environmental protection.

Owner:SOUTHEAST UNIV

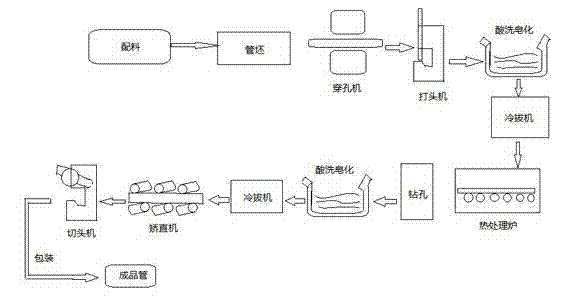

Manufacturing method of vehicle seamless steel tubes

The invention relates to a manufacturing method of vehicle seamless steel tubes. Surface quality of finished products can be improved through twice phosphorus acid saponification processing and secondary cold drawing processing; during manufacturing, external and internal quality of the products can be guaranteed through twice test, performance index of the steel tubes with the tensile strength larger than or equal to 500Mpa and extension larger then or equal to 10% and internal and external surface roughness smaller than or equal to 0.4 micrometers can be achieved by directly using saw cutting without heat treatment and mechanical machining, requirements of the steel tubes of vehicle parts on strength, toughness and surface quality are met, and meanwhile, technical requirement of processing-free steel tube parent materials of the vehicle parts can be met.

Owner:泰州双马节能科技有限公司

Method for manufacturing low-pressure chemical synthesis foil for aluminum electrolysis capacitor and middle treatment groove

InactiveCN101235529ANo loss of capacitanceHigh passivation treatment efficiencyElectrolytic capacitorsPhosphatisationChemical synthesisElectricity

The invention relates to a method for forming foil by low voltage of an aluminum electrolytic capacitor and a treatment groove for forming foil, wherein the method comprises the following steps: placing the formed foil which is treated by forming treatment under the highest forming voltage into a medium treatment groove and a groove solution, and proceeding the medium treatment, then proceeding subsequent forming treatment, an electrode plate which is corresponded with the formed foil is arranged in the treatment groove, the groove solution comprises phosphorus acid and / or ammonium phosphate component, the medium treatment comprises the following steps: placing the anode of direct current power supply on the formed foil, placing the cathode of the direct current power supply on an electrode plate, imposing electricity to the forming foil, the voltage value of the imposing electrical treatment is lower than that of the highest formed. The forming method of the invention and the treatment groove has the advantages that the efficiency of deactivation treatment is high, the coverage of the deactivation treatment is more comprehensive and thoroughly, which can simultaneously obtain higher electrostatic capacity, good water resistance and hydratability.

Owner:乳源县立东电子科技有限公司

CMP Fluid and Method for Polishing Palladium

ActiveUS20120100718A1Improve polishing rateStable polishing rateOther chemical processesSemiconductor/solid-state device manufacturingOrganic solventPhosphorus acid

The CMP polishing liquid for polishing palladium of this invention comprises an organic solvent, 1,2,4-triazole, a phosphorus acid compound, an oxidizing agent and an abrasive. The substrate polishing method is a method for polishing a substrate with a polishing cloth while supplying a CMP polishing liquid between the substrate and the polishing cloth, wherein the substrate is a substrate with a palladium layer on the side facing the polishing cloth, and the CMP polishing liquid is a CMP polishing liquid comprising an organic solvent, 1,2,4-triazole, a phosphorus acid compound, an oxidizing agent and an abrasive.

Owner:RESONAC CORP

Composite phosphate inorganic adhesive for 3D sand mold printing and preparation method thereof

ActiveCN105127361AGood collapsibilityExcellent resistance to moisture absorptionAdditive manufacturing apparatusFoundry mouldsO-Phosphoric AcidPhosphate

The invention belongs to the field of auxiliary casting materials and relates to a composite phosphate inorganic adhesive for 3D sand mold printing and a preparation method thereof. The composite phosphate inorganic adhesive for 3D sand mold printing comprises the following components in percentage by mass: 4.5-9.5% of aluminum hydroxide, 1-4% of magnesium carbonate, 2.5-6.5% of boric acid, 30-70% of 85% industrial phosphoric acid, 0.5-1.5% of carbamide, 1-3% of xylitol, 1-3% of D-sorbitol, 0.5-1.5% of citric acid, 1.5-6.5% of aluminum triphosphate, 1.5-6.5% of aluminum dihydrogen tripolyphosphate and 7-37% of deionized water. According to the technical scheme, the composite phosphate inorganic adhesive for 3D sand mold printing has the beneficial effects that the prepared composite phosphate inorganic adhesive is low in viscosity and high in adhesion strength; after the composite phosphate inorganic adhesive is roasted at the high temperature over 600 DEG C, the composite phosphate inorganic adhesive is low in residual strength; the adhesive is excellent in collapsibility and excellent in moisture absorption resistance.

Owner:NINGXIA KOCEL MOLD

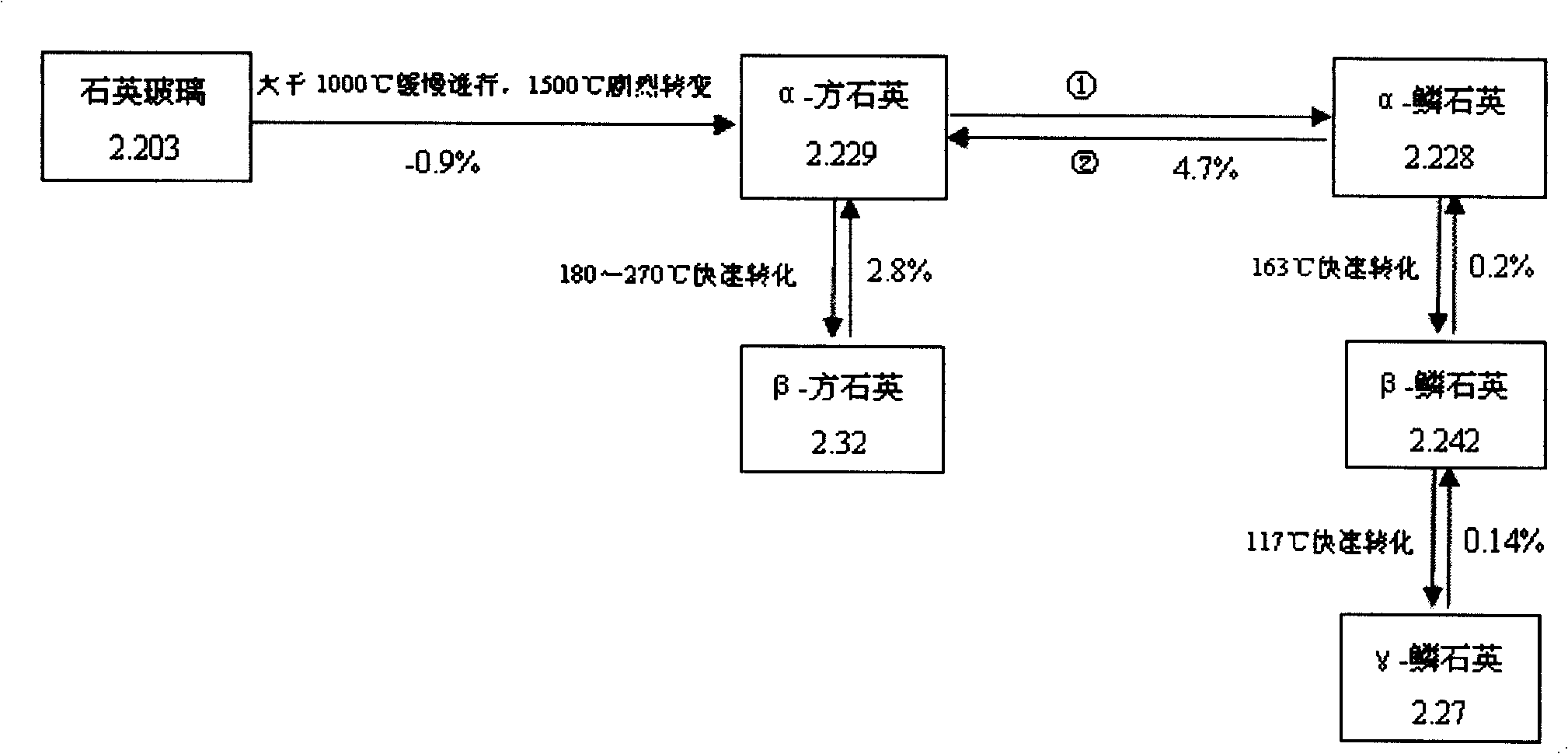

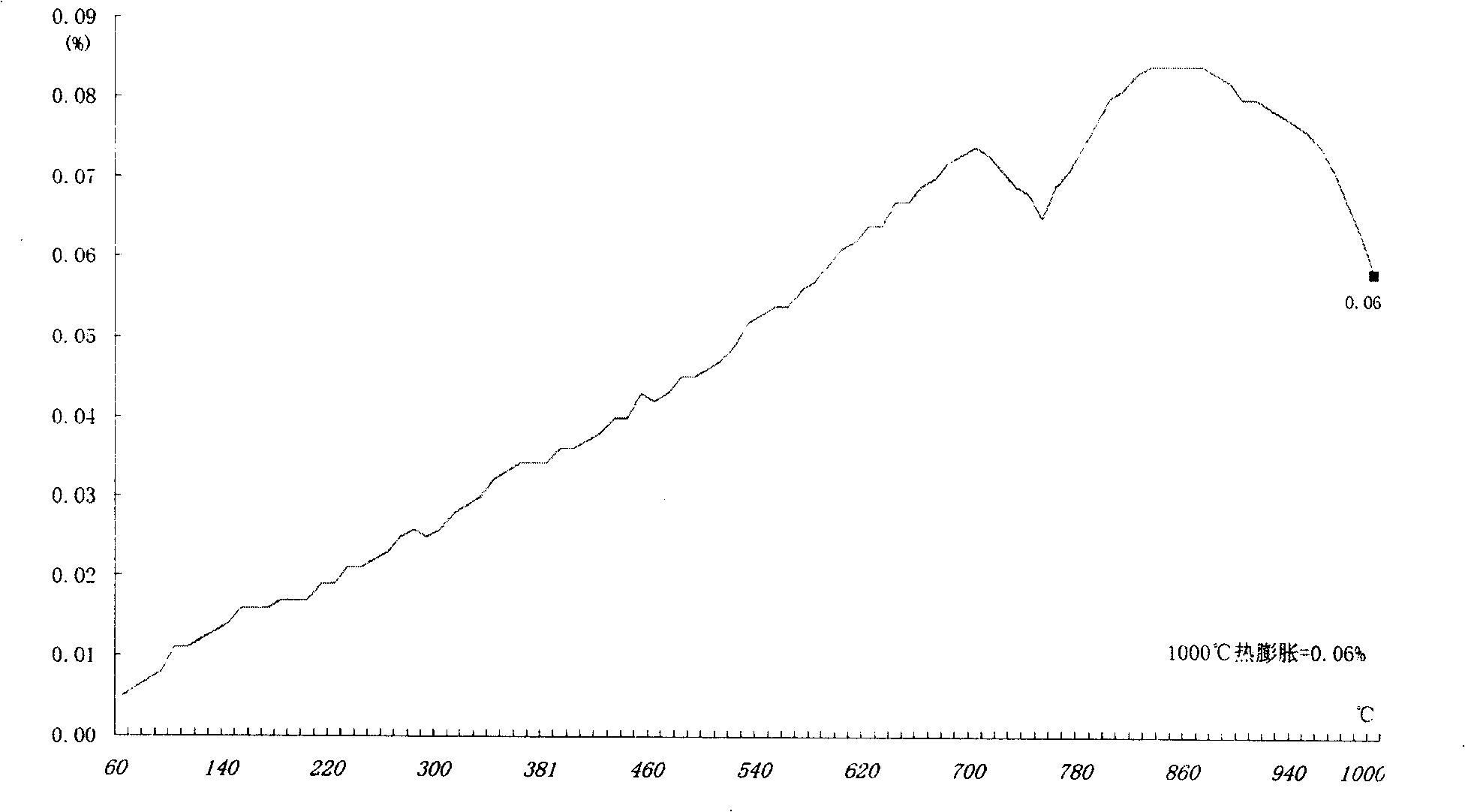

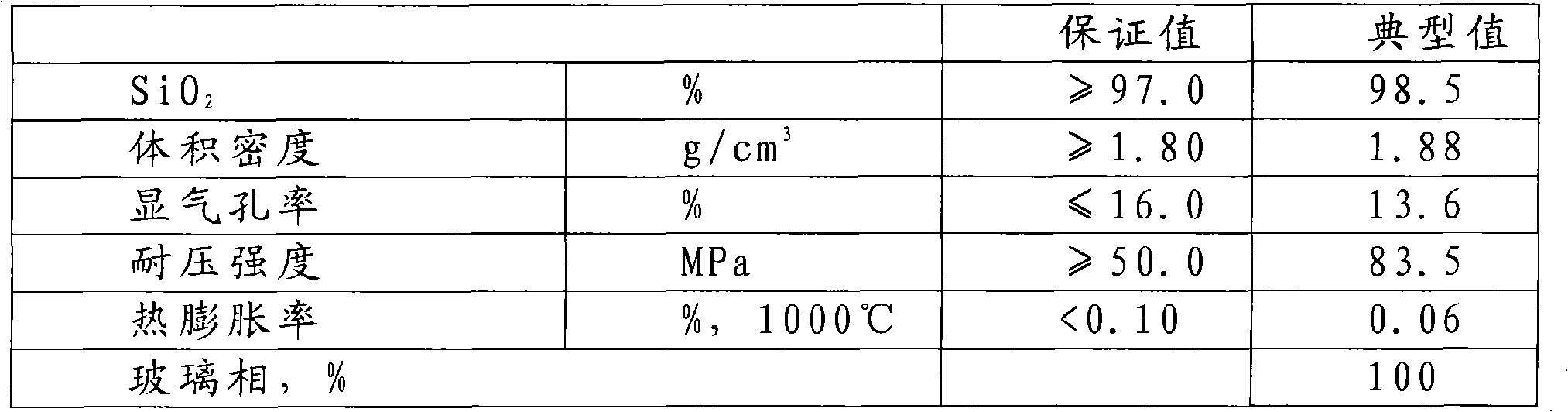

Fused quartz block for glass kiln hot repair and manufacturing method thereof

InactiveCN101323531ALow thermal expansionImproved thermal shock stabilityGlass furnace apparatusGlass productionPhosphoric acidPlasticizer

The invention provides a fused silica brick used for hot patching of glass furnaces and a production method thereof, which can solve the problem existing in the prior art that rapid hot patching can not be carried out. The fused silica brick of the invention has low coefficient of thermal expansion and high thermal shock resistance, thus being able to meet the rapid hot patching requirement of the key parts of kiln crown, port, breast wall, regenerator, and the like of the glass furnaces after being damaged. The technical proposal is that: the fused silica brick used for hot patching of the glass furnaces contains ingredients as follows: fused silica: 5 portions to 15 portions with 2mm to 5mm of grain size, 10 portions to 30 portions with 1mm to 2mm of grain size; 15 portions to 35 portions with 0.1mm to 1mm of grain size and 25 portions to 45 portions with 0mm to 0.044mm of grain size; 1 portion to 2 portions of agglutinant, 1 portion to 2 portions of plasticizer and 1 portion to 6 portions of anchoring agent, wherein, the aggluinant is SiO2 micropower with SiO2 content higher than 96.8 percent, the plasticizer is silicasol and the anchoring agent is phosphoric acid for industrial use with concentration of 80 percent to 90 percent.

Owner:山东耐材集团中齐耐火有限公司

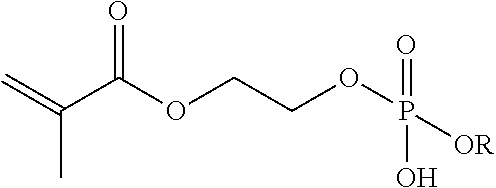

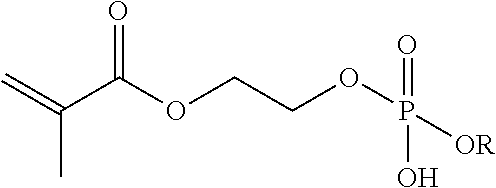

Latex functionalized with phosphorus acid and photoinitiator groups

The present invention is a composition comprising a stable aqueous dispersion of polymer particles comprising structural units of a phosphorus acid monomer or a salt thereof and structural units of a photoinitiator monomer. Gloss retention of paints containing the latex described herein is markedly improved over paints that do not have photoinitiator chemically bound to the latex particles.

Owner:ROHM & HAAS CO

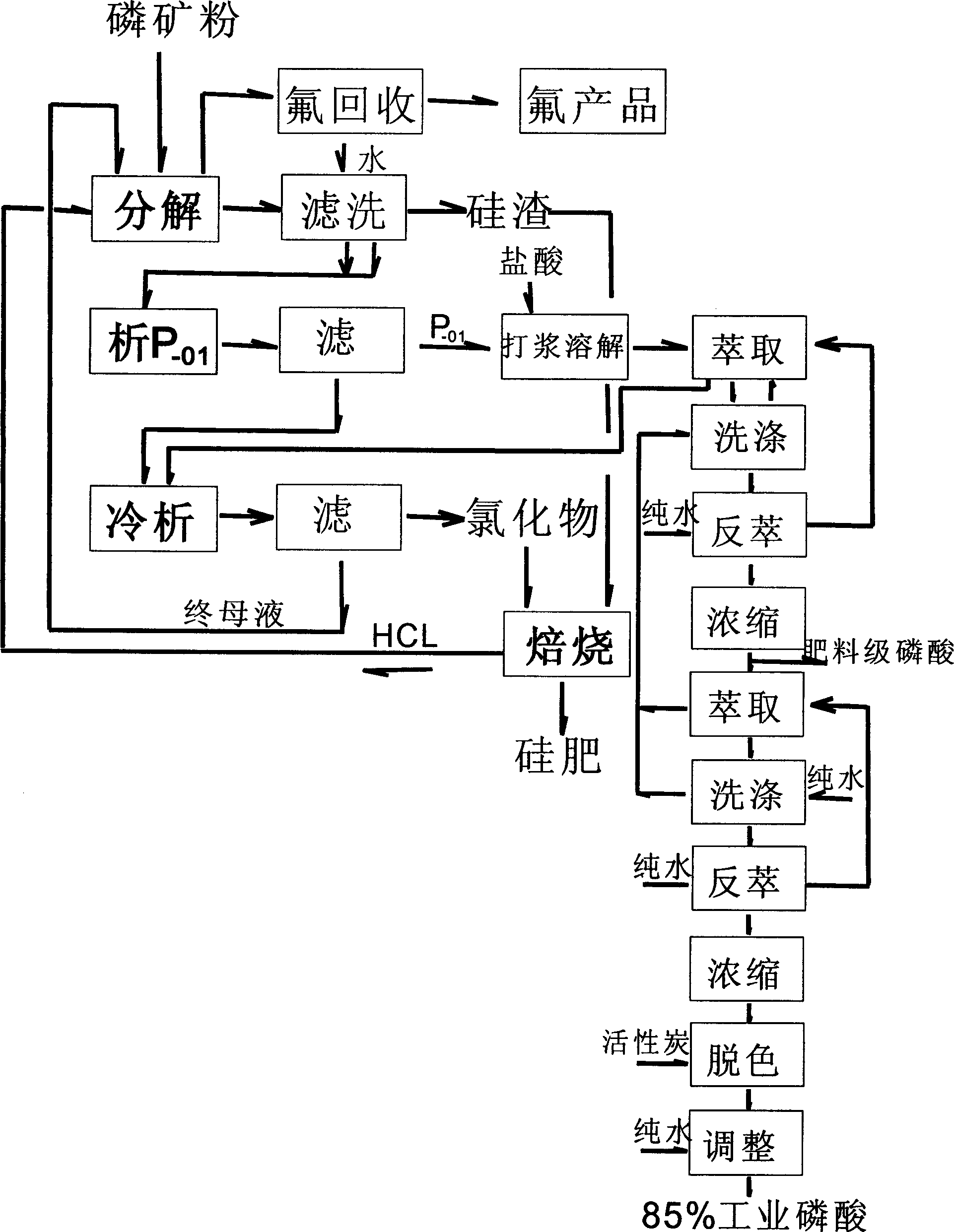

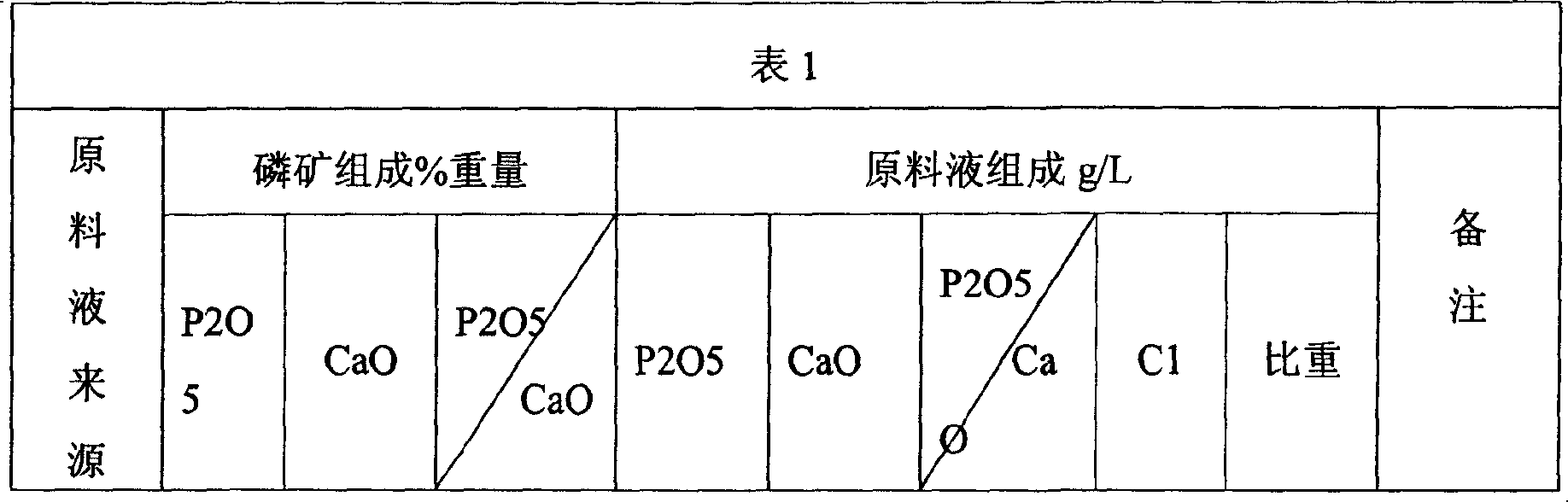

Process for mfg. industrial phosphoric acid by low-grade phosphorus deposit in hydrogen chloride decomposition

A process for preparing industrial phosphoric acid by use of hydrochloric acid to decompose the low-and medium-grade phosphorus ore includes such steps as using hydrochloric acid to decompose phosphorus ore to obtain calcium chlorophosphate, using hydrochloric acid to prepare slurry, dissolving the calcium chlorophosphate in it, extracting by tri-butyl phosphate, concentrating, extracting by tri-butyl phosphate and isopropyl ether, concentrating, and de-coloring to obtain 85% industrial phosphoric acid. Its advantage is no environmental pollution.

Owner:湖北中磷科技有限公司

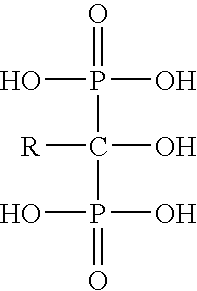

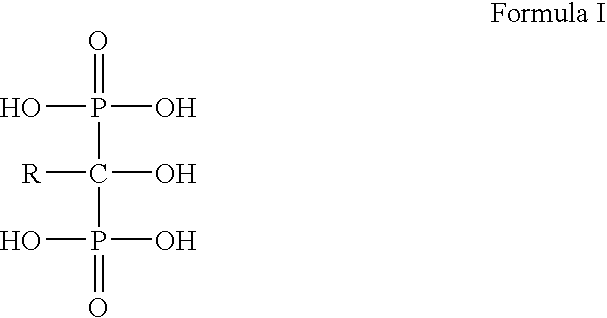

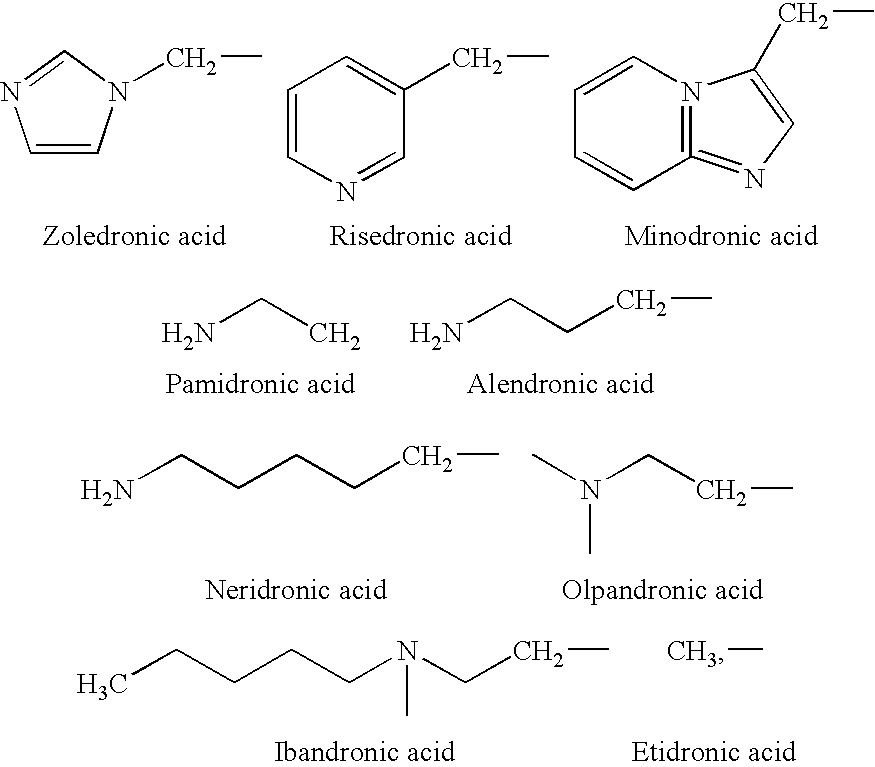

Process for the preparation of biphosphonic acids

An improved process for bisphosphonylation of acids, substituted acids to obtain compounds with the formulausing phosphorus trihalide, phosphorus acid, in presence of phenolic compounds as diluent / solvent.

Owner:AUROBINDO PHARMA LTD

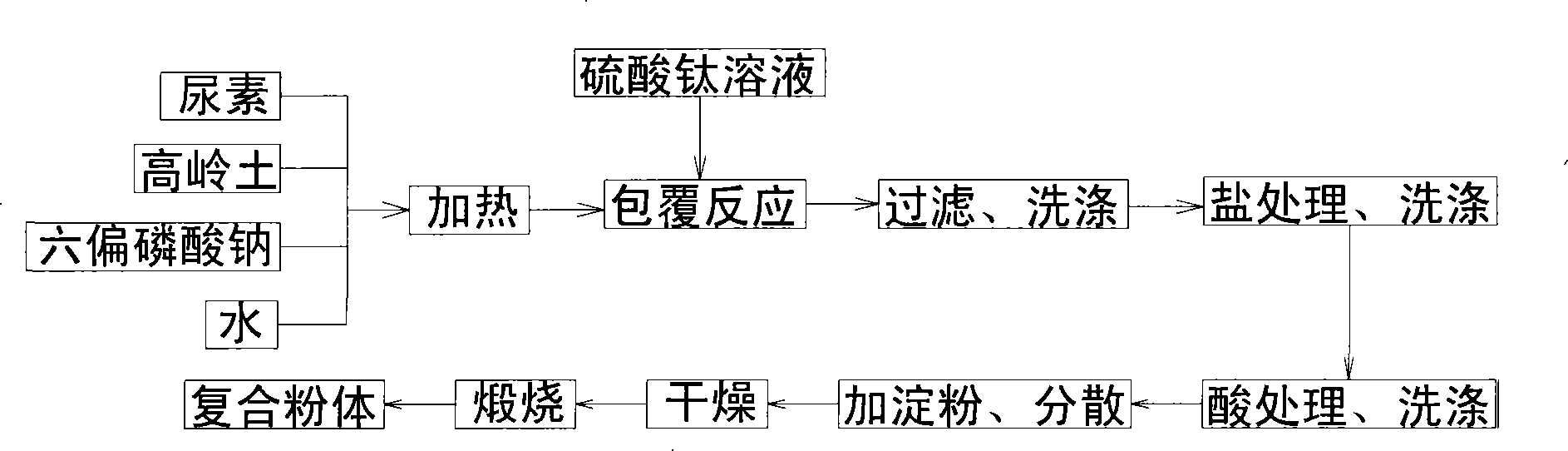

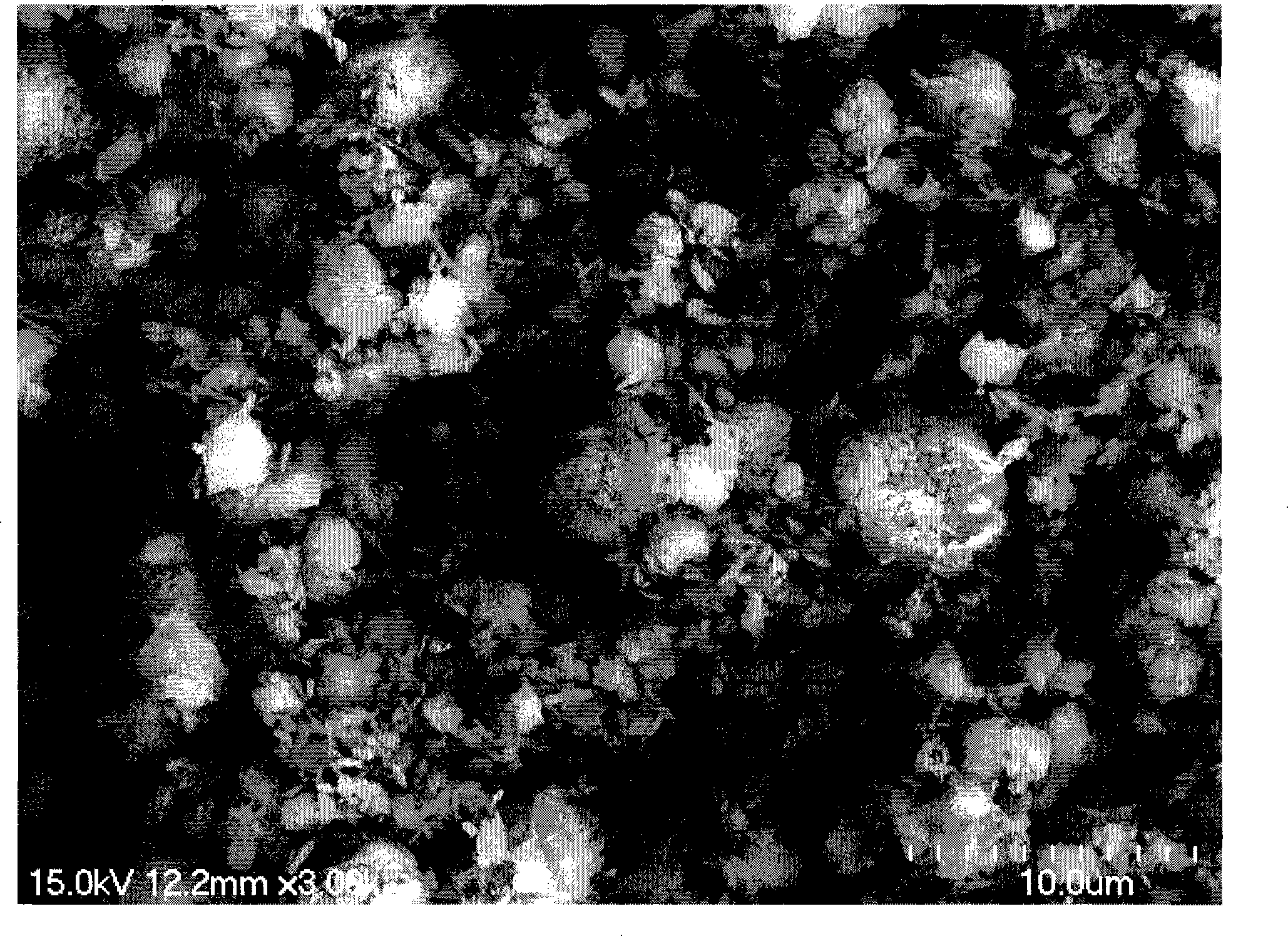

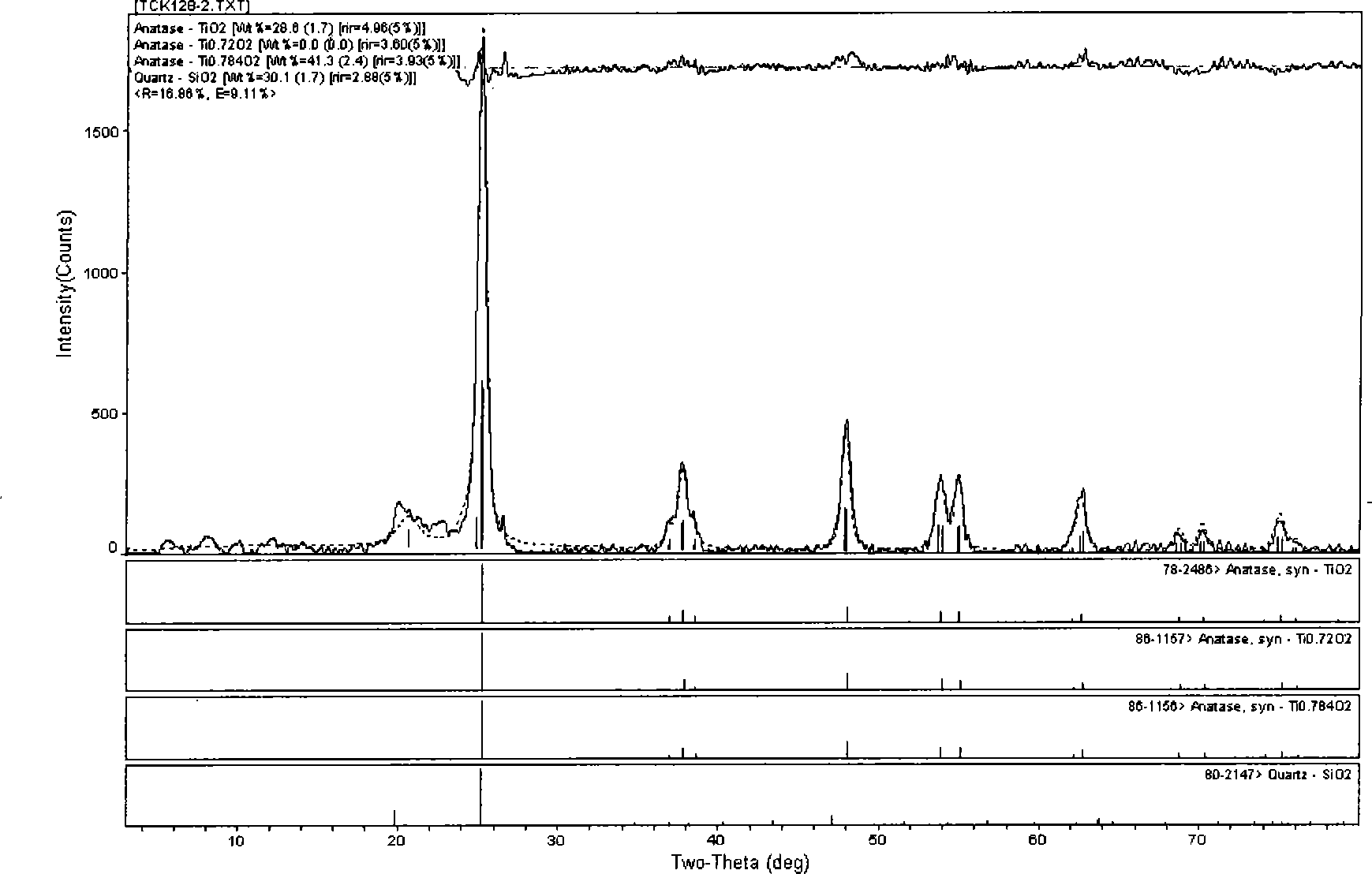

Titania coating kaolinite compound powder and method for preparing same

InactiveCN101250337AUniform whitenessSmall particle size distribution rangeInorganic pigment treatmentSODIUM METAPHOSPHATESodium phosphates

Titanium oxide coating kaolin composite powder belongs to a process for producing composite white pigment powder through the inorganic treatment method. The raw material formulation is formed by following components with percentage by weight: 12%-18% titanium sulfate, 6%-9% kaolin, 10%-19% carbamide, 0.15%-0.30% sodium hexametaphosphate, 0.5%-1.2% starch, 0.04%-0.08% water-soluble carbonate, 0.01%-0.05% phosphorus acid and rest amount of water. The preparation process comprises the steps of coating reacting, water scouring, salt treatment, acid treatment, dispersion, drying and calcination. The titanium oxide coating kaolin composite powder which is prepared through adopting the homogenous precipitation method has the advantages of even whiteness and small particle size distribution range, and each index all approximates to the index of titanium white powder.

Owner:中国高岭土有限公司

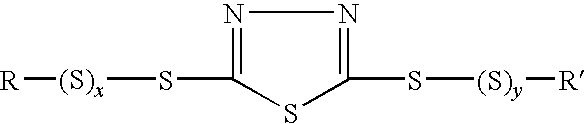

Zinc-Free Farm Tractor Fluid

A lubricating composition comprising an oil of lubricating viscosity; an amine salt of a phosphorus acid ester; a thiadiazole copper corrosion inhibitor; an overbased metal detergent; a boron compound; and at least one friction modifier provides good lubrication of a mechanical device such as a farm tractor, even though such composition is substantially free from zinc dialkyldithiophosphate.

Owner:THE LUBRIZOL CORP

Method for separating and purifying natto kinase by ion exchange

InactiveCN1594560ASimple separation processShorten the production cyclePeptide preparation methodsEnzymesFiltrationFreeze-drying

The invention discloses a method for separating and purifying Natto kinase mainly using ion exchange chromatography. The steps are composed of crude enzyme liquid preparation, gel chromatography and ion exchange chromatography, activating bacillus subtilis through slant medium, medium culture and fermenting in ferment medium, natto kinase being secreted to fermented solution by bacillus subtilis, centrifuging to collecting upper clear solution, then proceeding (NH#-[4])#-[2]SO#-[4] graded precipitation, redissolving using phosphorus acid buffer, adding redissolved solution to gel chromatography column to proceeding gel filtration, collecting elution peak containg natto kinase, adding fraction of having natto kinase activity from gel filtration to inon exchange chromatography column, proceeding adsorbing, collecting elution peak containg natto kinase, freeze drying to get purified natto kinase. The invention has merits of condition, low cost, simple process , easy operation ,high purity and short production period, etc.

Owner:ZHEJIANG UNIV

Lubricating oil composition for transmissions

ActiveUS20150376544A1Excellent characteristicsMaintain good propertiesLiquid carbonaceous fuelsLubricant compositionHeat resistancePhosphorus acid

A lubricating oil composition for transmissions having improved fuel saving properties, excellent metal fatigue prevention properties, and heat resistance containing: a lubricating base oil containing (A) a mineral base oil having a 100° C. kinematic viscosity of 1.5 mm2 / s or higher and 3.5 mm2 / s or lower, a pour point of −25° C. or lower, a viscosity index of 105 or greater, a % Cp of 85 or greater, a % CN of 2 or greater and 20 or less and a % CA of 3 or less and (B) a monoester-based base oil having a 100° C. kinematic viscosity of 2 to 10 mm2 / s; (C) a phosphorus acid ester; and (D) a boronated ashless dispersant, the ratio of the mass percent of boron to the mass percent of phosphorus in the composition (B / P) being from 0.07 to 0.42, and the composition having a 100° C. kinematic viscosity of 2.5 to 4.0 mm2 / s is described.

Owner:JX NIPPON OIL & ENERGY CORP +1

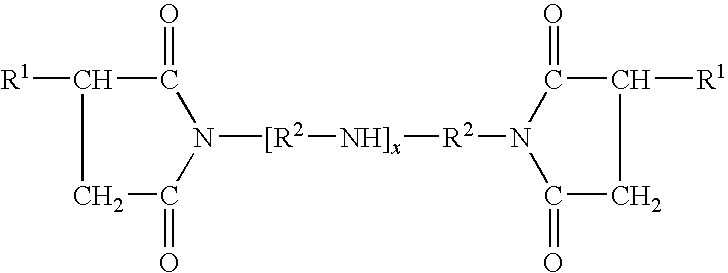

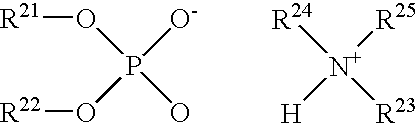

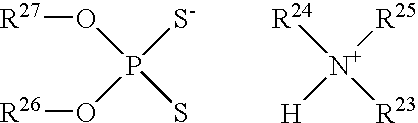

Multifunctional dispersants

The present invention provides a composition comprising the product prepared by hearing together: (a) a dispersant; and (b) a 1,3-dicarboxylic acid or 1,4-dicarboxylic acid of an aromatic compound, or a reactive equivalent thereof; and at least one of: (c) 2,5-dimercapto-1,3,4-thiadiazole or a hydrocarbyl-substituted 2,5-dimercapto-1,3,4-thiadiazole, or an oligomer thereof; (d) a borating agent; and (e) a phosphorus acid compound, or a reactive equivalent thereof, said heating being sufficient to provide a reaction product of (a), (b), and (c), (d), or (e), which is soluble in an oil of lubricating viscosity. The invention further provides a use for the composition.

Owner:THE LUBRIZOL CORP

Polyamide resin composition

A polyamide resin composition comprising a polyamide (X) having a diamine constituent unit which is mainly composed of a m-xylylenediamine unit and a dicarboxylic acid constituent unit which is mainly composed of an adipic acid unit; and specific amounts of a phosphorus acid antioxidant and alkaline component. The polyamide (X) is characterized by a specific range of terminal-group concentration balance and a specific amino-group reaction rate. This composition can simultaneously achieve inhabitation of yellow discoloration and reduction of number of gels or fish eyes.

Owner:MITSUBISHI GAS CHEM CO INC

Phosphorus-acid-group-containing (meth) acrylamide, its polymer and use thereof, and their production methods

InactiveUS20070173549A1Improve conductivityHigh densityElectrolysis componentsIon-exchanger regenerationPolymer scienceMeth-

A phosphorus-acid-group-containing (meth)acrylamide polymer having high electrolytic group density and excellent conductivity is obtained by introducing a phosphorus acid group into a (meth)acrylamide monomer which may be N-substituted, and polymerizing the resultant monomer. This polymer is usable for conductive resins, proton-conductive polymer electrolyte membranes and coating agents.

Owner:UNI CHEM

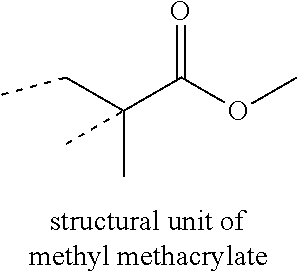

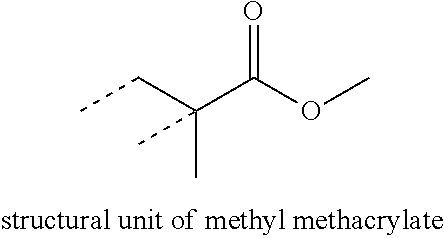

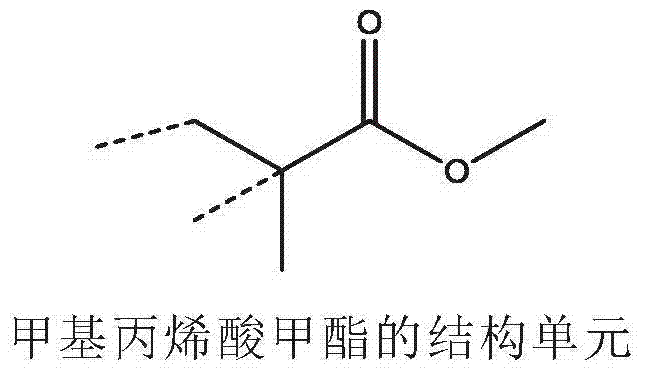

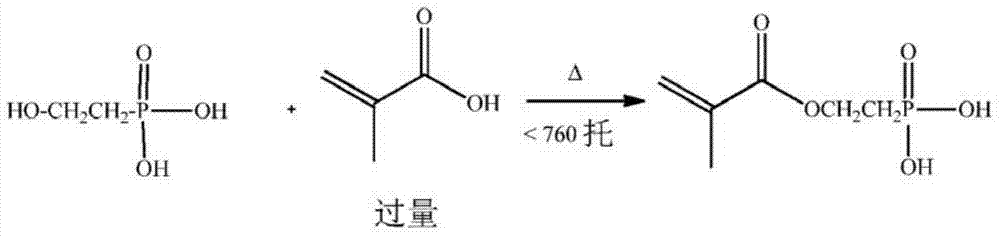

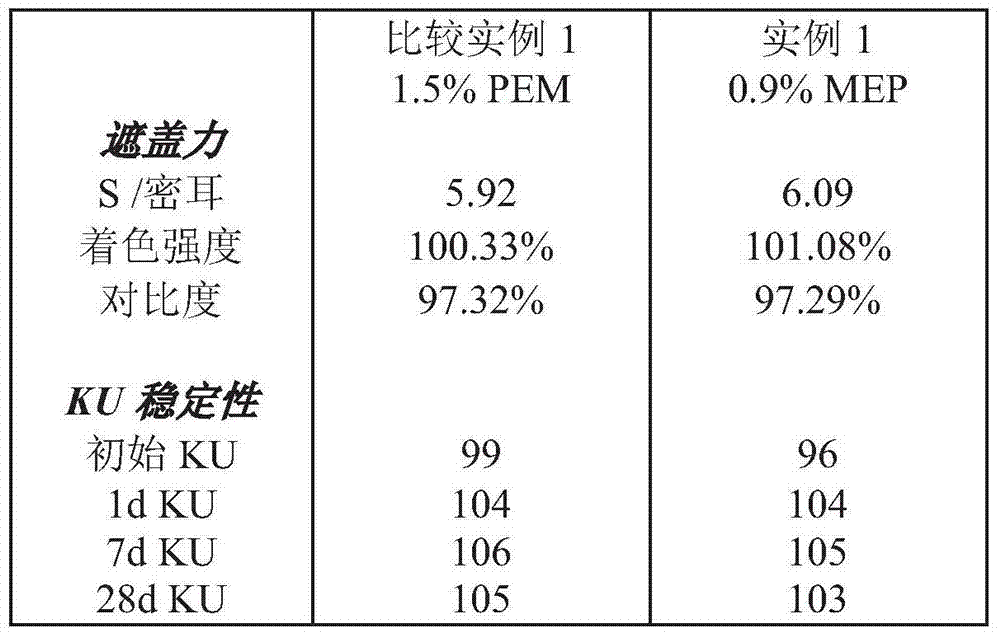

Stable aqueous dispension of particle polymers containing structural units of 2-(methacryloyloxy) ethyl phosphonic acid and composites thereof

The present invention is a composition comprising a stable aqueous dispersion of polymer particles comprising structural units of a nonionic monoethylenically unsaturated monomer; 2 (methacryloyloxy)ethyl phosphonic acid (MEP) or a salt thereof; and a sulfur acid monomer or carboxylic acid monomer or a combination thereof or a salt thereof, as well as a composite comprising the polymer particles adsorbed to the surface of a pigment particle such as TiO2. The composition and composite are prepared using the phosphorus acid monomer MEP, which can be prepared in high purity with low residual non-polymerizable phosphorus acid, thereby reducing the load of neutralizing agent required to achieve the targeted pH as compared with phophoethyl methacrylate (PEM).

Owner:ROHM & HAAS CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com