Zinc-Free Farm Tractor Fluid

a technology of zinc-free farm tractor and fluid, which is applied in the direction of additives, lubricant compositions, petroleum industry, etc., can solve the problems of contaminated fluid, zdp hydrolysis, and consequent loss of corrosion protection for yellow metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example b-1

[0028]Phosphorus pentoxide (about 64 grams) is added at about 58° C. over a period of about 45 minutes to about 514 grams of hydroxypropyl O,O-di(4-methyl-2-pentyl)phosphorodithioate (prepared by reacting di(4-methyl-2-pentyl)-phosphorodithioic acid with about 1.3 moles of propylene oxide at about 25° C.). The mixture is heated at about 75° C. for about 2.5 hours, mixed with a diatomaceous earth and filtered at about 70° C. The filtrate contains about 11.8% by weight phosphorus, about 15.2% by weight sulfur, and an acid number of 87 (bromophenol blue).

example b-2

[0029]A mixture of about 667 grams of phosphorus pentoxide and the reaction product of about 3514 grams of diisopropyl phosphorodithioic acid with about 986 grams of propylene oxide at about 50° C. is heated at about 85° C. for about 3 hours and filtered. The filtrate contains about 15.3% by weight phosphorus, about 19.6% by weight sulfur, and an acid number of 126 (bromophenol blue).

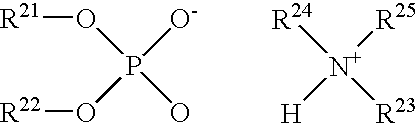

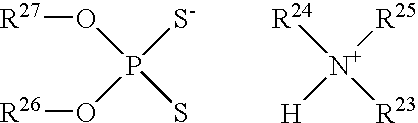

[0030]Acidic phosphoric acid esters may be reacted with ammonia or an amine, including polyamines, to form an ammonium salt. The salts may be formed separately and then the salt of the phosphorus acid ester may be added to the lubricating composition. Alternately, the salts may also be formed in situ when the acidic phosphorus acid ester is blended with other components to form a fully formulated lubricating composition.

[0031]The amines which may be suitable for use as the amine salt include primary amines, secondary amines, tertiary amines, and mixtures thereof. The amines include those with at least o...

examples

[0087]Lubricant compositions are prepared from the components listed in the following Tables:

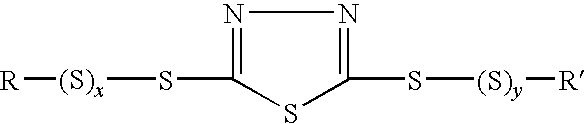

TABLE 1Example 1: ComponentAmount, %Borated succinimide dispersant, including 33% oil,0.51.9% B (boron source)Dispersant / corrosion inhibitor comprising DMTD reacted1.0with an ester dispersant, containing about 10% DMTD,49% oilC12-14 alkyl amine salt of mono and diesters of0.4phosphoric acid (extreme pressure agent)Glycerol monooleate (commercial grade) (friction0.5modifier)Oleamide (friction modifier)0.35Tall oil acid, product with diethanolamine and boric0.2acid (antiwear agent, boron source)Dibutyl hydrogen phosphite (anti-wear agent)0.25Di-t-butyl phenol (antioxidant)0.2Calcium alklbenzenesulfonate detergent, including0.842% oil, 400 TBN (detergent)Oil of lubricating viscositybalance

TABLE 2ComponentEx 2Ex 3Ex 4Ex 5Ex 6Ex 7Ex 8Borated succininimide0.250.250.250.250.250.250.25dispersant as in Ex. 1Oleylamine friction modifier0.110.110.110.110.110.110.15Alkyl amine salt of phosphoric0.50.50....

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com