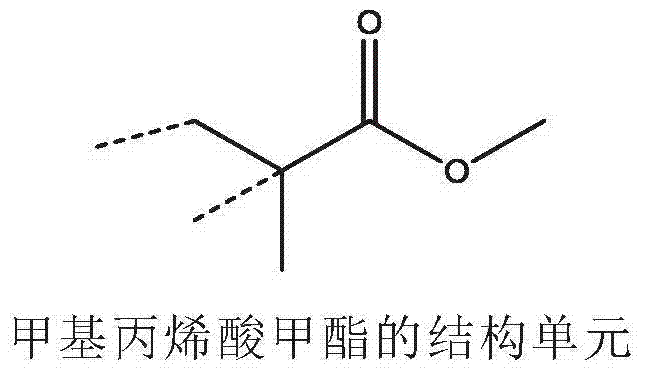

Stable aqueous dispension of particle polymers containing structural units of 2-(methacryloyloxy) ethyl phosphonic acid and composites thereof

一种甲基丙烯酰氧基、水性分散液的技术,应用在所述胶乳粒子的复合物领域,能够解决限制效用等问题,达到高产率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

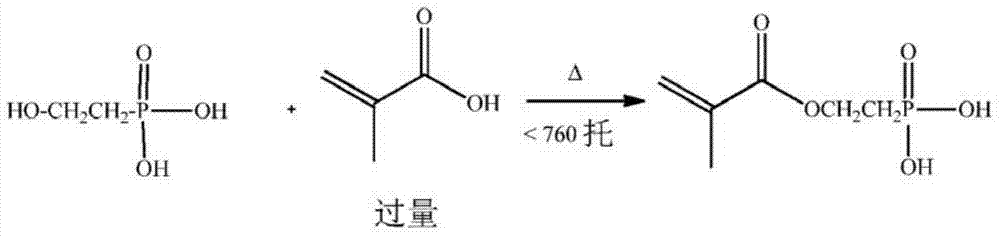

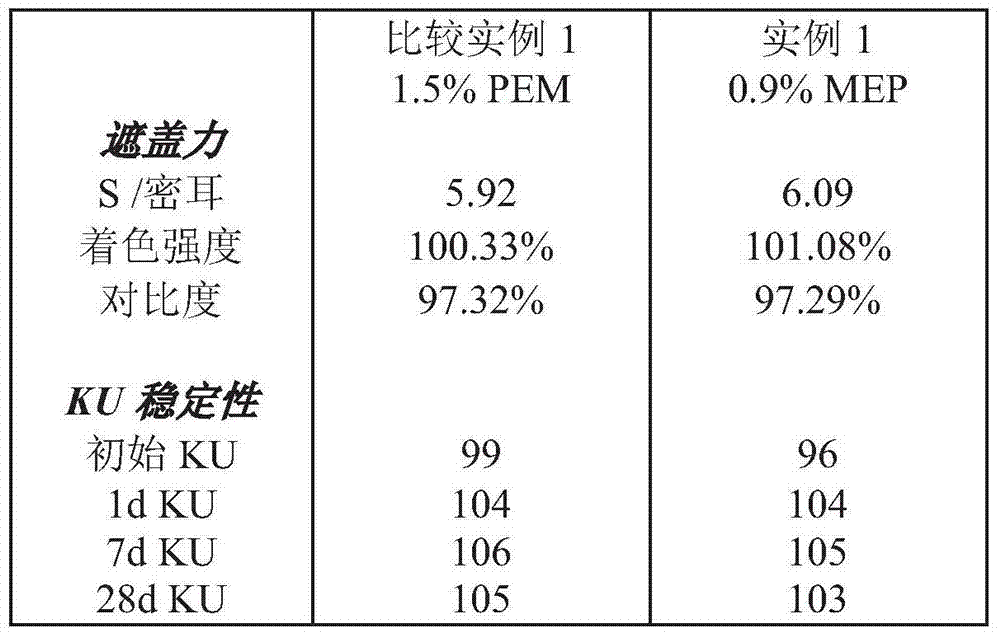

[0028] Example 1 - Preparation of MEP-containing latex particles

[0029] The first monomer emulsion was prepared by mixing deionized water (200 g), Disponil FES 993 anionic surfactant (28.25 g, 30% active), butyl acrylate (285.6 g), methyl methacrylate (202.32 g), 2 -(methacryloyloxy)ethylphosphonic acid (16.11 g, 95% active) and sodium 4-vinylbenzenesulfonate (7.53 g, 90% active). The second monomer emulsion was prepared by mixing deionized water (420 g), Disponil FES 993 anionic surfactant (28.75 g, 30% active), butyl acrylate (666.4 g), methyl methacrylate (511.65 g), 4 - Prepared with sodium vinylbenzenesulfonate (3.78 g, 90% active) and ureidomethacrylate (17 g, 50% active).

[0030] To a 5 L 4 neck round bottom flask equipped with paddle stirrer, thermometer, nitrogen inlet and reflux condenser was added deionized water (900 g) and Disponil FES 993 anionic surfactant (17 g, 30% active). in N 2 The contents of the flask were heated to 84° C. at 100° C. and stirring wa...

example 2

[0046] Example 2 - Preparation of MEP-containing latex particles with acorn morphology

[0047] A. Preform Preparation

[0048] The first monomer emulsion was prepared by mixing deionized water (200 g), Disponil FES 993 anionic surfactant (21.3 g, 30% active), butyl acrylate (371.2 g), methyl methacrylate (213.15 g), methanol Allyl acrylate (9.6 g), 2-(methacryloxy)ethylphosphonic acid (35.0 g, 95% active) and methacrylic acid (12.8 g).

[0049] equipped with paddle stirrer, thermometer, N 2 A 5 liter four necked round bottom flask with inlet and reflux condenser was charged with deionized water (600 g) and Disponil FES 32 anionic surfactant (64 g, 30% active). in N 2 The contents of the flask were heated to 85°C under atmosphere and stirring was started. A portion of the first monomer emulsion (70 g) was then added, followed by the rapid addition of aqueous sodium persulfate (2.56 g in 30 g deionized water) and another rinse of deionized water (5 g). After stirring for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com