Patents

Literature

2394 results about "Ethyl acrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethyl acrylate is an organic compound with the formula CH₂CHCO₂CH₂CH₃. It is the ethyl ester of acrylic acid. It is a colourless liquid with a characteristic acrid odor. It is mainly produced for paints, textiles, and non-woven fibers. It is also a reagent in the synthesis of various pharmaceutical intermediates.

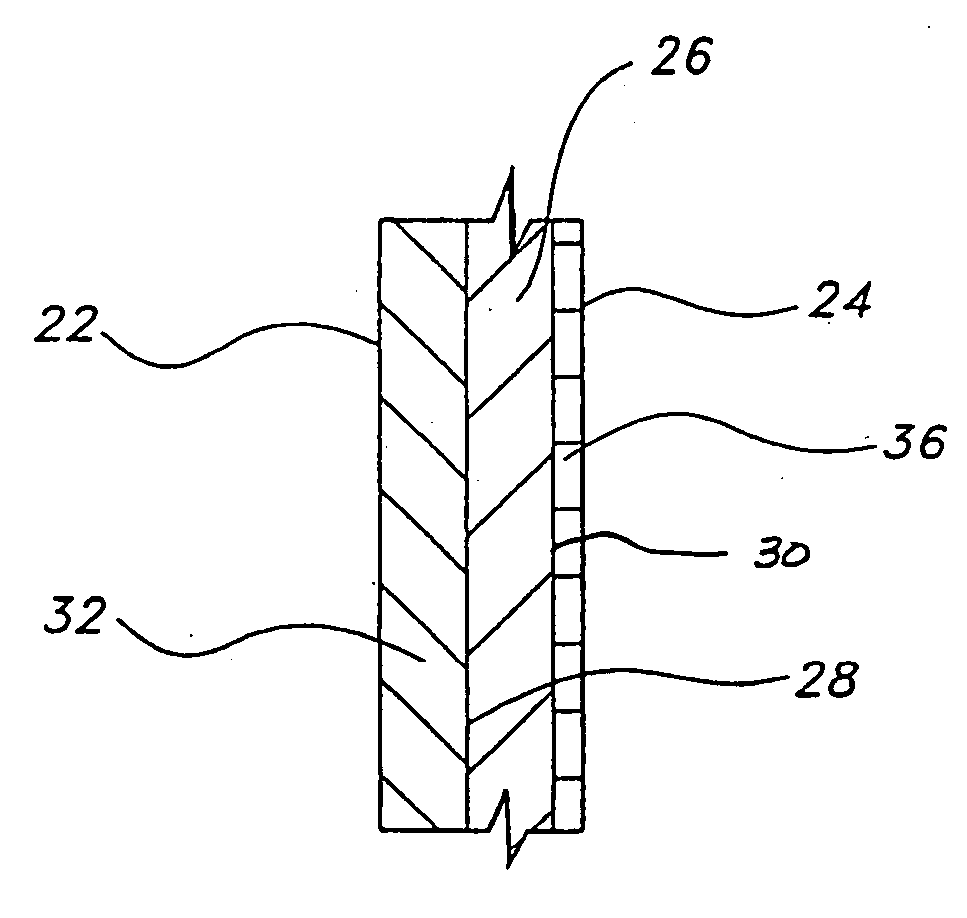

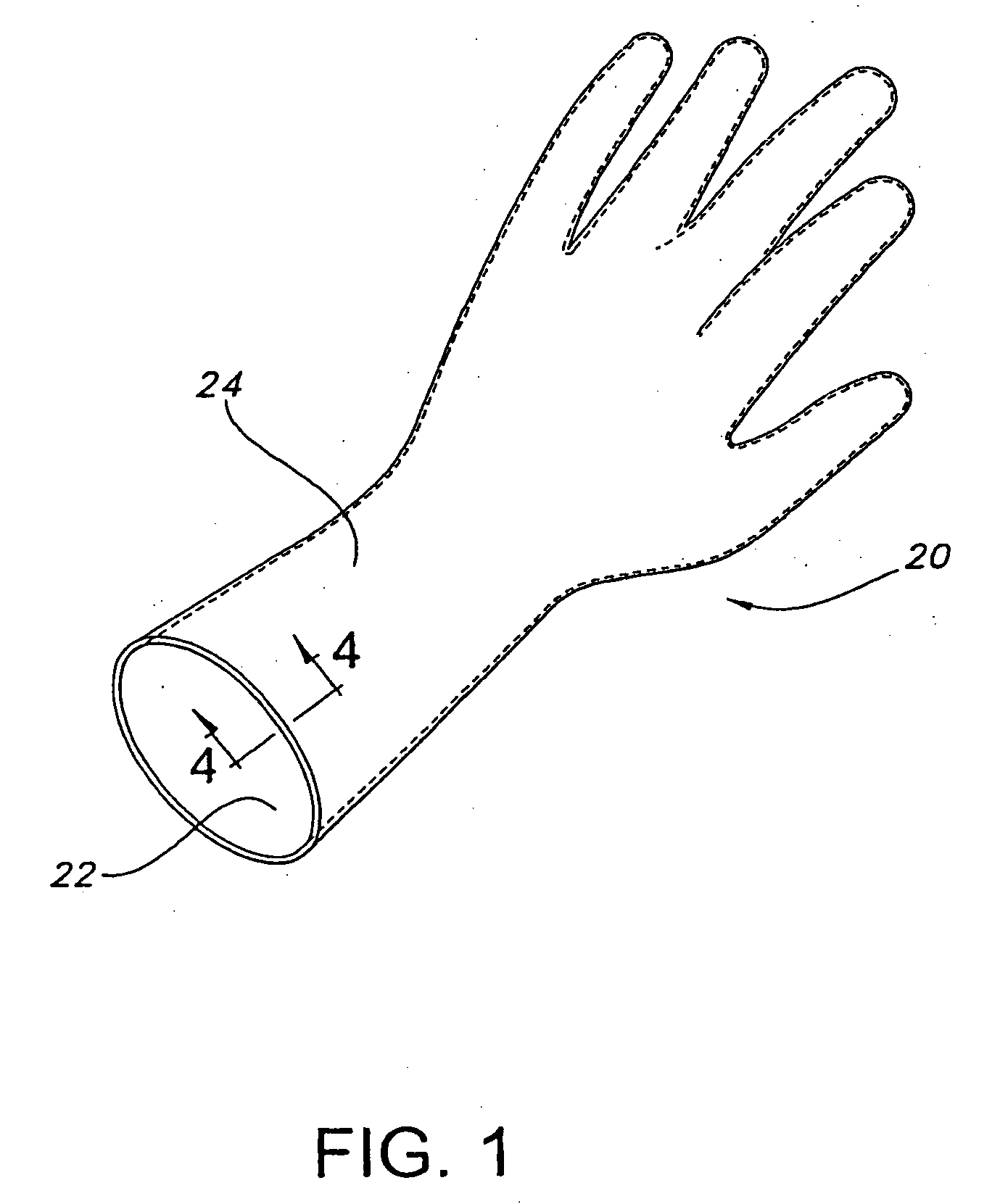

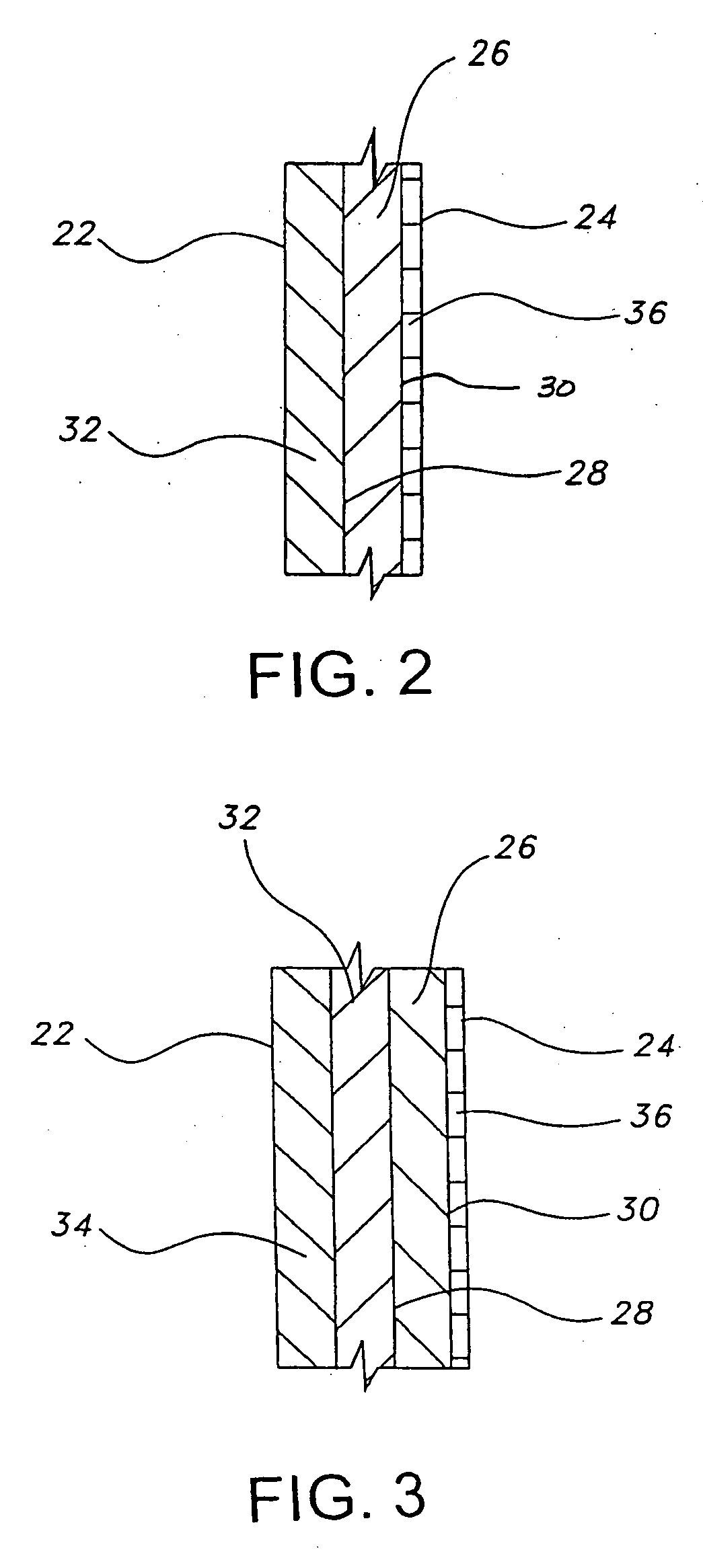

Gloves with hydrogel coating for damp hand donning and method of making same

InactiveUS20060141186A1Garment special featuresDiagnostics(Hydroxyethyl)methacrylateOrganic chemistry

Disclosed herein is an elastomeric article having a hydrogel donning coating. The hydrogel donning coating is made of a copolymer of hydroxy ethyl acrylate (HEA), hydroxy ethyl methacrylate (HEMA), and acrylic acid. The hydrogel donning coating is applied to the elastomeric article using an aqueous hydrogel dipping solution containing the hydrogel donning coating copolymer. The aqueous hydrogel dipping solution demonstrates thixotropic characteristics which allows for better manufacturing process control.

Owner:KIMBERLY-CLARK WORLDWIDE INC

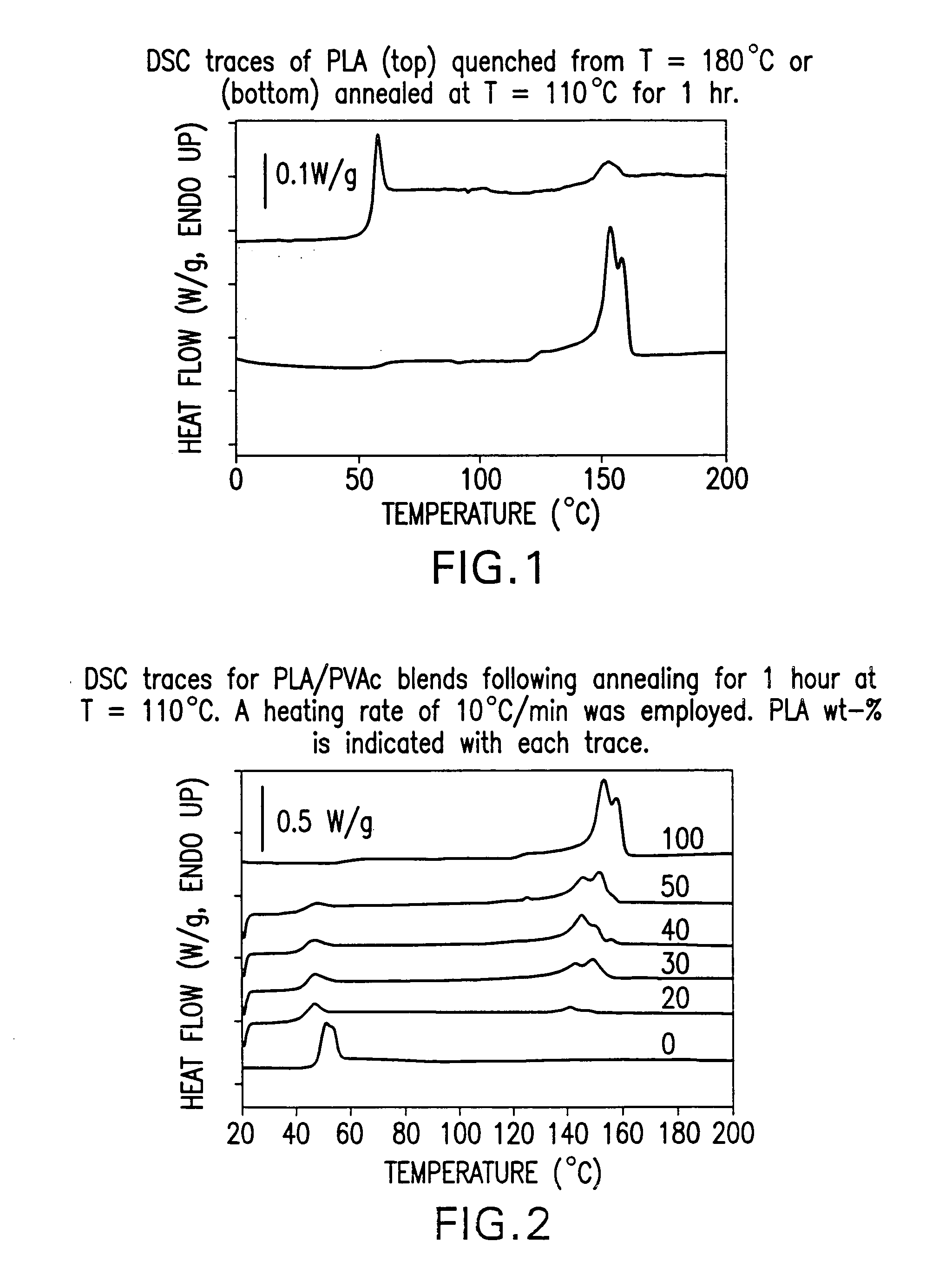

Blends of amorphous and semicrystalline polymers having shape memory properties

InactiveUS20040122174A1High modulusImprovement in critical temperatureDental impression compositionsPoly(methyl methacrylate)Ethyl acrylate

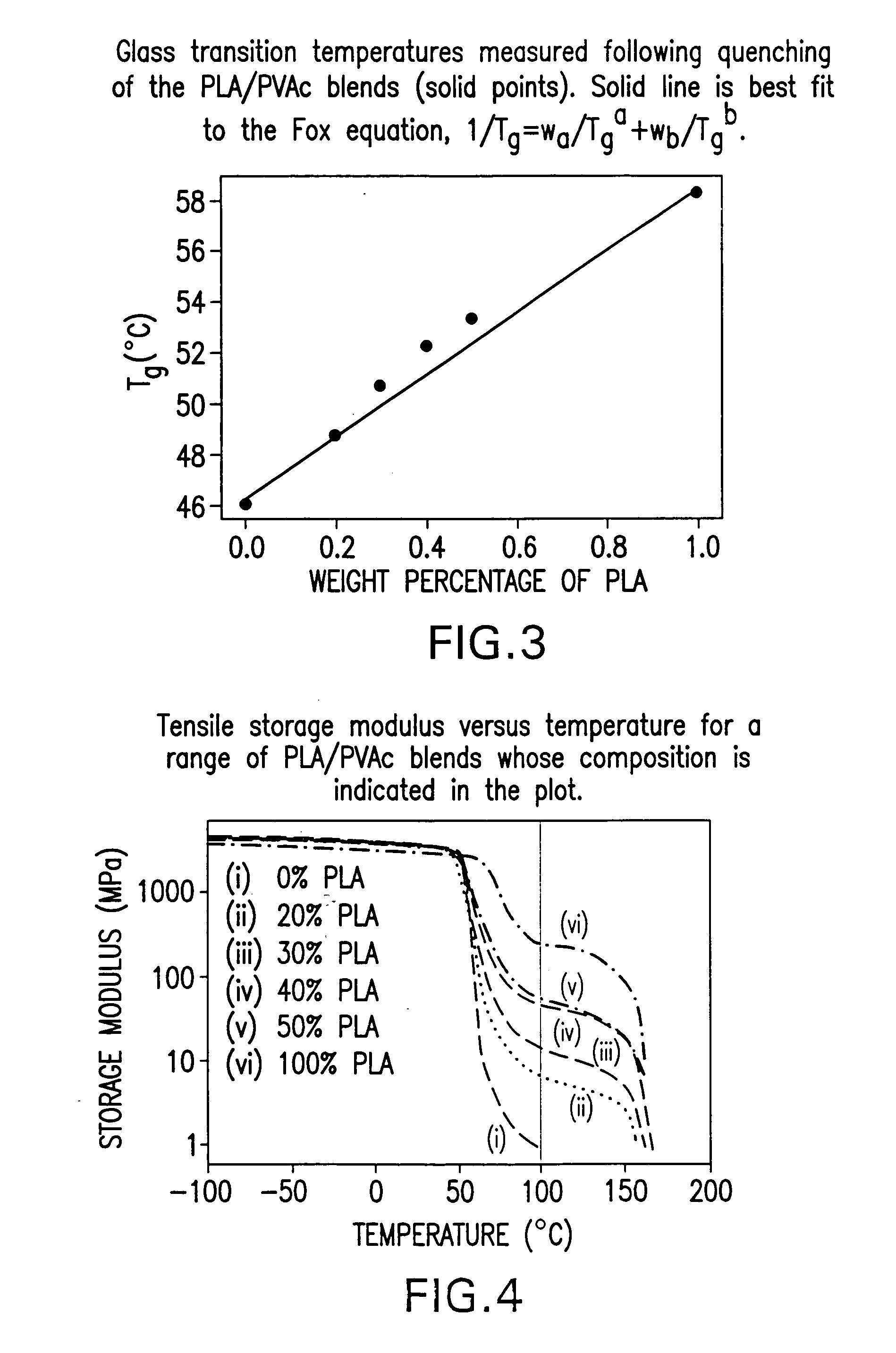

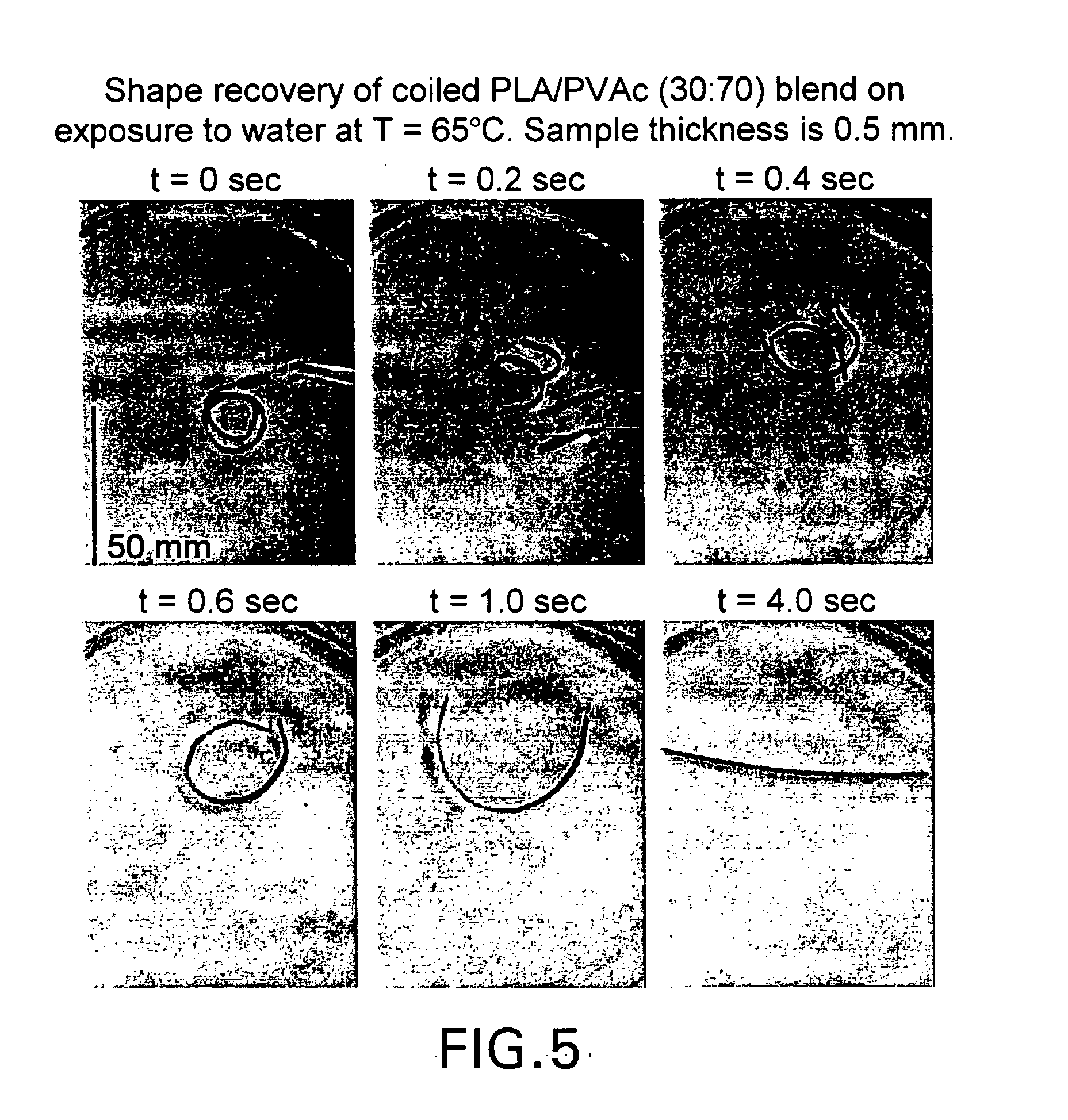

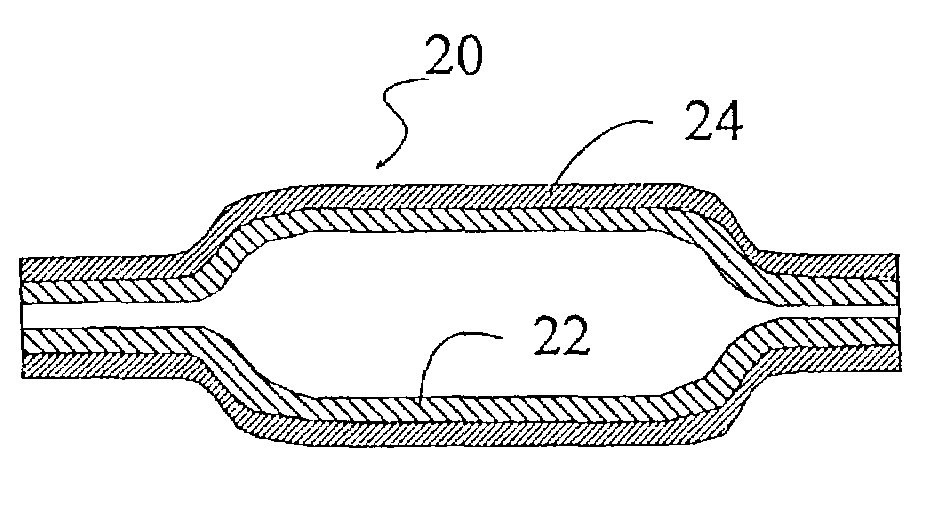

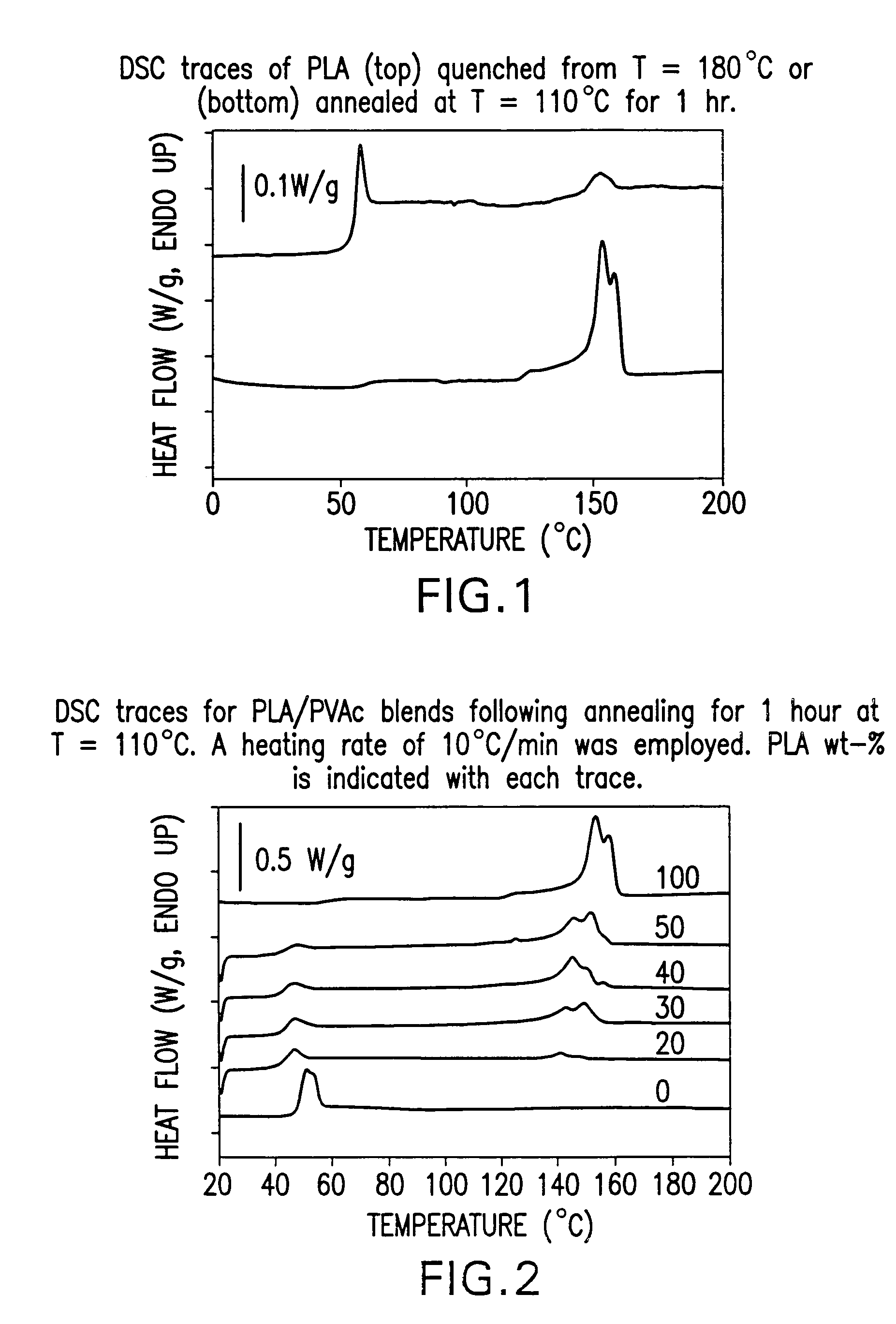

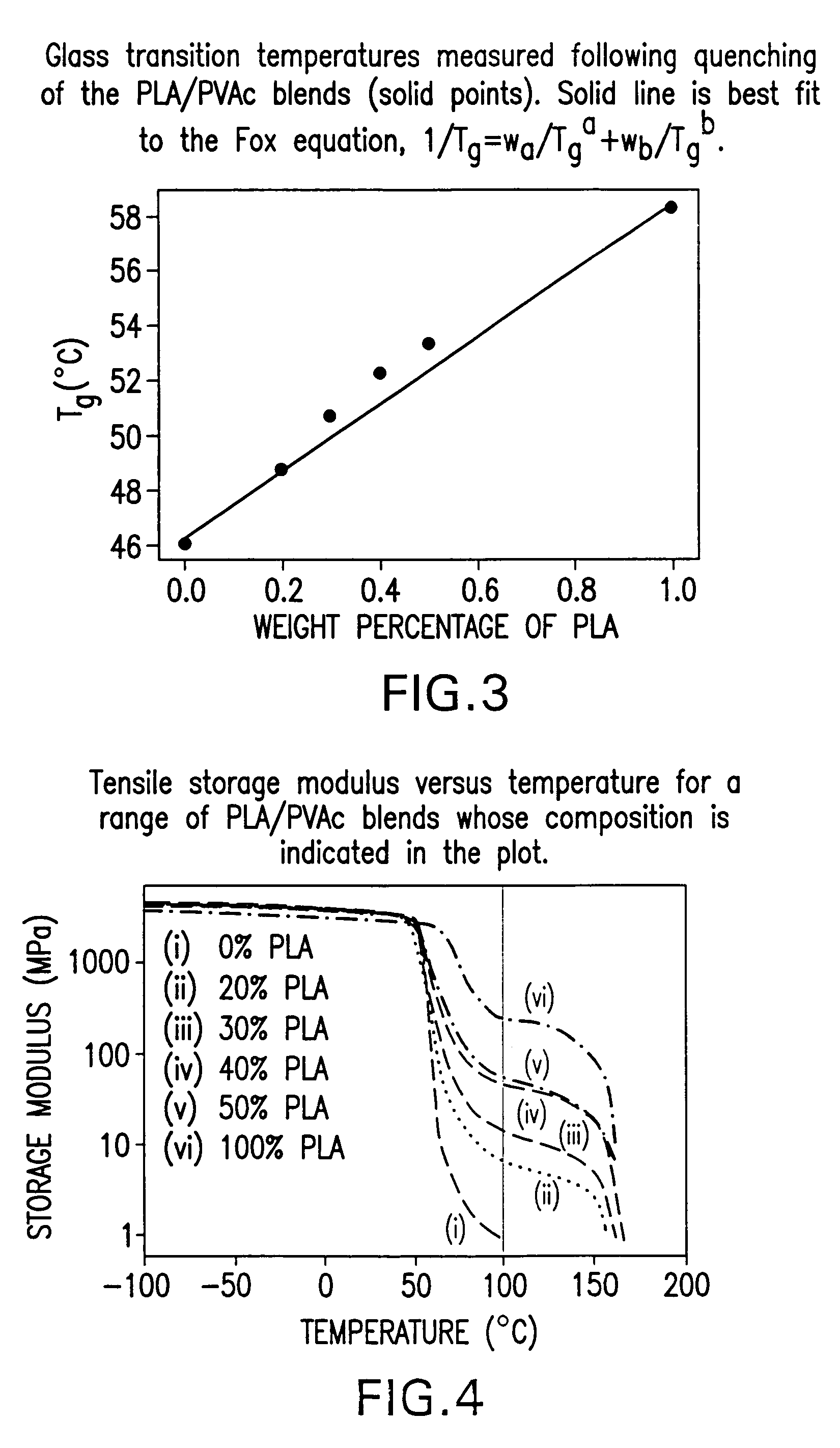

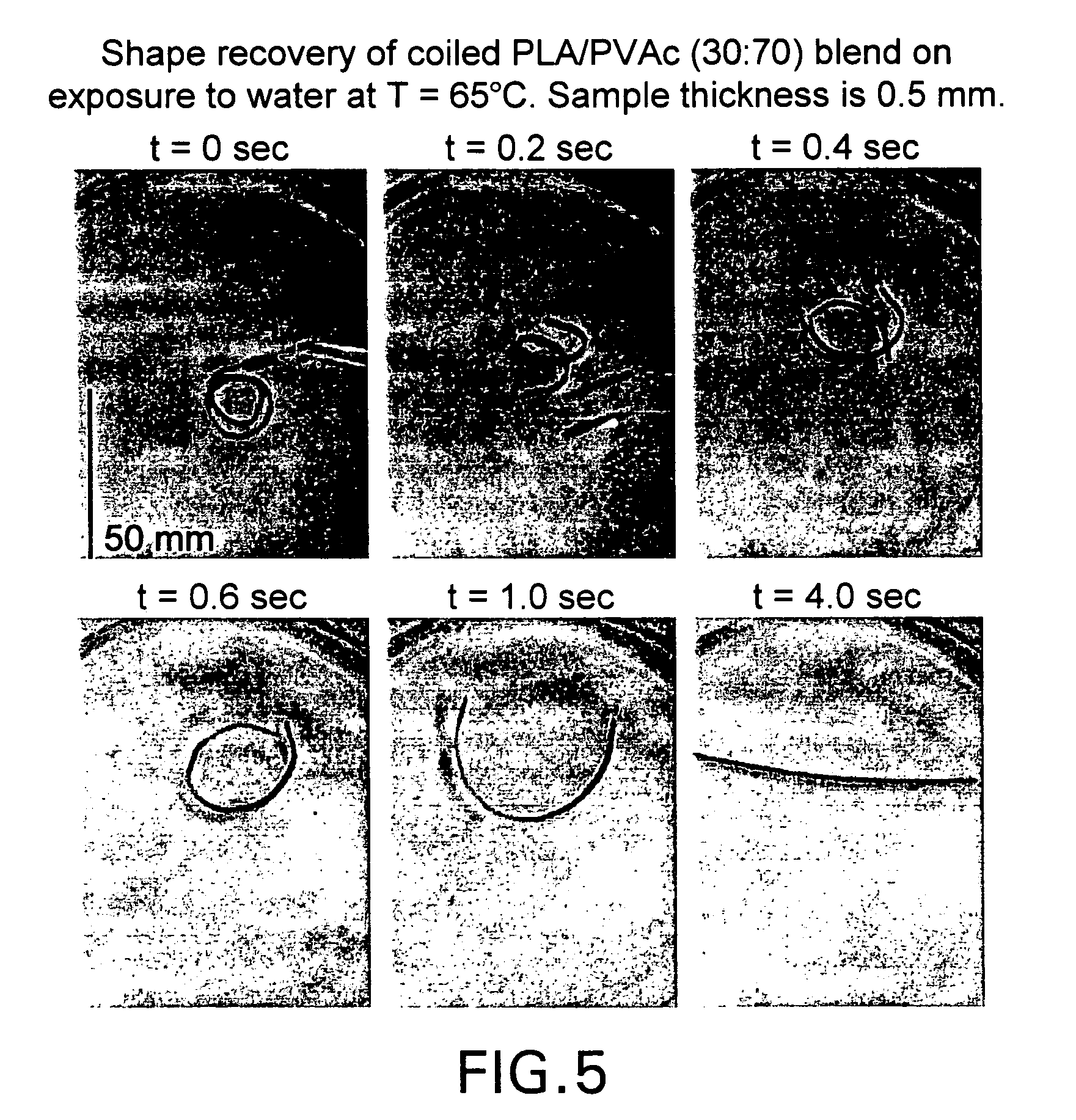

Blends of amorphous and semicrystalline polymers having shape memory properties were prepared by blending a crystalline polymer such as poly(vinylidene fluoride), polylactide, poly(hydroxxybutyrate), poly(ethylene glycol) polyethylene, polyethylene-co-vinyl acetate, poly(vinyl chloride), poly(vinylidene chloride) and copolymers of poly(vinylidene chloride) and poly(vinyle chloride) and an amorphous polymer such as poly(vinyl acetate), poly methyl acrylate, poly ethyl acrylate, atactic poly methyl methacrylate, isotactic poly methyl methacrylate, syndiotactic poly methyl methacrylate and other poly alkyl methacrylates. The method for preparing the polymeric materials and applications thereof, for example, as smart medical devices, are also disclosed.

Owner:UNIV OF CONNECTICUT

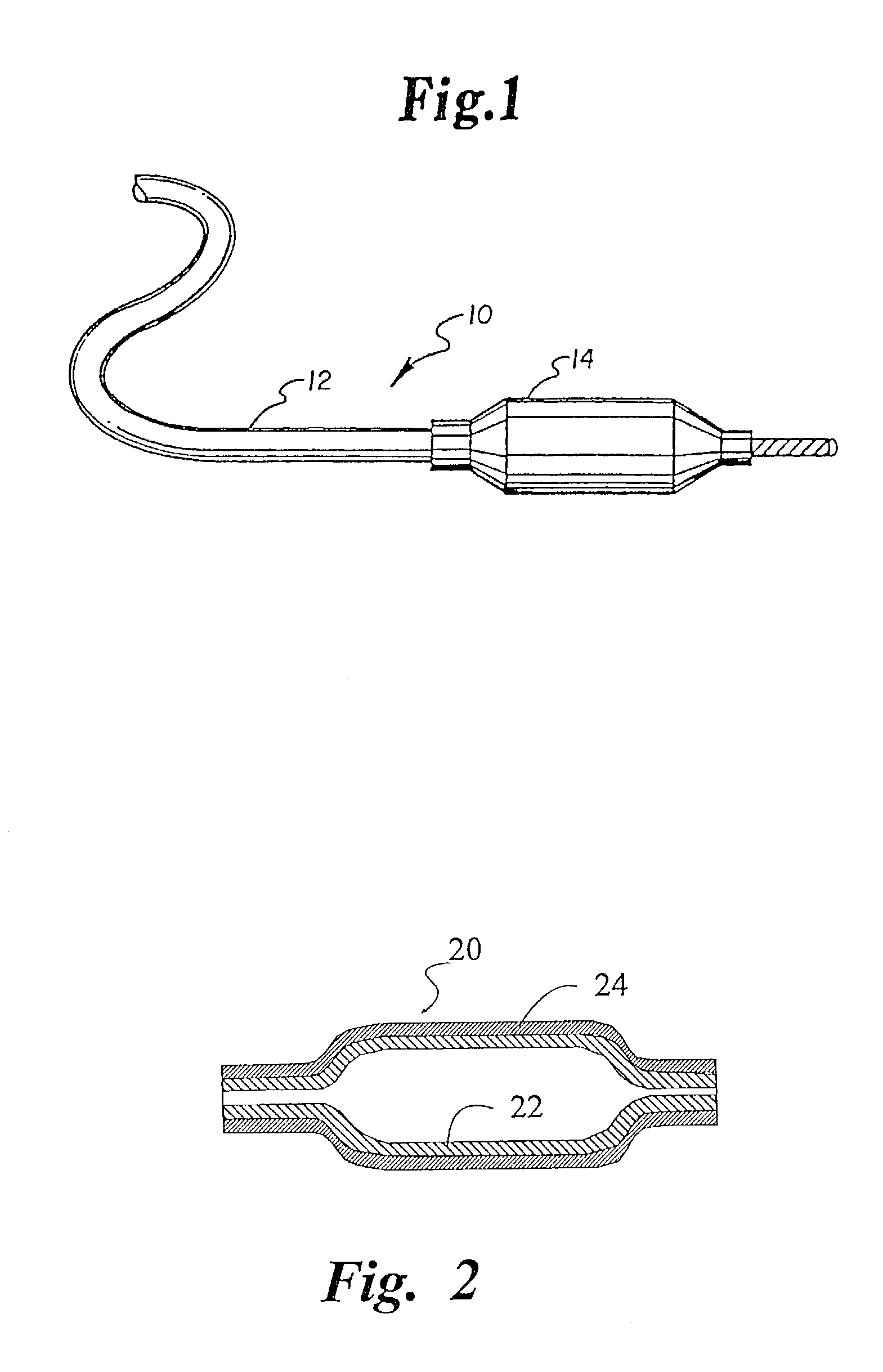

Balloons made from liquid crystal polymer blends

Balloons for use on medical devices such as catheter balloons are formed from polymer blend products which include a liquid crystal polymer (LCP), a crystallizable thermoplastic polymer, especially thermoplastic polyesters such as PET, and a compatabilizer. The compatabilizer may be an ethylene-maleic anhydride copolymer, an ethylene-methyl acrylate copolymer, an ethylene-methyl acrylate copolymer, an ethylene-methyl acrylate-maleic anhydride terpolymer, an ethylene-methyl-methacrylic acid terpolymer, an acrylic rubber, an ethylene-ethyl acrylate-glycidyl methacrylate terpolymer or a mixture of two or more such polymers.

Owner:BOSTON SCI SCIMED INC

Non-crosslinking halogen-free flame-retardant cable insulating material or sheath material and preparation method thereof

ActiveCN103012941ACause damageReduce manufacturing costPlastic/resin/waxes insulatorsInsulated cablesElastomerHalogen

The invention discloses a non-crosslinking halogen-free flame-retardant cable insulating material or sheath material, comprising the following components in part by weight: 100 parts of ethylene and ethylene copolymer and / or ethylene propylene diene monomer, 0-20parts of compatilizer, 20-250 parts of halogen-free flame retardant, 0-5 parts of antioxidant, 0-5 parts of lubricating agent, 0-40 parts of polymeric elastomer, 0-3 parts of coupling agent, and 0-20parts of color master batch, wherein the ethylene and ethylene copolymer are selected from one or more of the following materials: ethylene-vinyl acetate copolymer, ethylene-methyl acrylate copolymer, ethylene-ethyl acrylate copolymer and the like. According to the halogen-free flame-retardant cable insulating material or sheath material, the insulating layer or the sheath layer prepared by the uncrosslinked halogen-free flame-retardant cable insulating material or sheath material can be adaptive to the environment at -40 to 80 DEG C, and the material can not generate poisonous gases such as halogen hydride in case of fire, so that harm to lives and property loss can not be caused by the poisonous gases such as halogen hydride; and besides, the production cost of the material is low.

Owner:SHENZHEN WOER NEW ENERGY ELECTRICAL TECH CO LTD

High temperature self-crosslinking halogen-free flame retardant cable insulation material or sheath material and method for preparing high temperature self-crosslinking halogen-free flame retardant cable insulation material or sheath material

ActiveCN103012940AReduce manufacturing costPlastic/resin/waxes insulatorsInsulated cablesElastomerPolymer science

The invention discloses a high temperature self-crosslinking halogen-free flame retardant cable insulation material or sheath material. The cable insulation material or sheath material comprises the following components in parts by weight: 100 parts of ethylene and copolymer thereof and / or ethylene propylene diene monomer, 0-20 parts of compatilizer, 20-250 parts of halogen-free flame retardant, 0-5 parts of antioxidant, 0-5 parts of lubricating agent, 0.01-5 parts of peroxide crosslinking agent, 0-40 parts of polymer elastomer, 0-3 parts of coupling agent and 0-20 parts of color masterbatch; and the ethylene and the copolymer thereof are selected from one or a plurality of the following materials of ethylene-vinyl acetate copolymer, ethylene-methyl acrylate copolymer, ethylene-ethyl acrylate and the like. The high temperature peroxide crosslinking agent crosslinks under the temperature condition of above 150 DEG C only, during a cable material mixing extrusion and insulating layer or sheath layer formation process, chemical crosslinking or micro-crosslinking cannot be caused, but the high temperature peroxide crosslinking agent generates a crosslinking function when the temperature is higher than 150 DEG C in the case of fire, so that the production cost is lowered.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

Halogen-free flame-retardant thermal-shrinkage sleeve materials and sleeve prepared thereby

ActiveCN1629216AWon't happenRaw materials are readily availableTubular articlesLow-density polyethyleneLinear low-density polyethylene

The invention provides a bittern-free flame-proof thermal contraction sleeve which comprises (by weight ratio), (1) 100 parts of one or more selected from ethane-vinyl acetate copolymer (EVA), ethene-ethyl acrylate copolymer (EEA), low density polyethylene (LDPE), linear low density polyethylene (LLDPE), (2) 5-50 parts of one or more selected from ethylene-propylene terpolymerisate rubber (EPDM), ethylene propylene rubber (EPM), dimethyl silicone rubber (MQ), methylvinyl silicone rubber (VMQ), methylsilicone rubber with phenyl and vinyl Group (PVMQ), thermoplastic elastomer styrene - butadiene - styrene blocked copolymer (SBS), styrene-isoprene blocked copolymer (SIS), (3) 50-100 parts of bittern-free flame retardant, and (4) 0.5-6 parts of coupling agent.

Owner:深圳市沃尔热缩有限公司

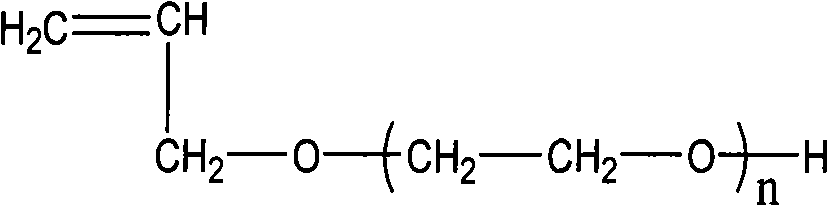

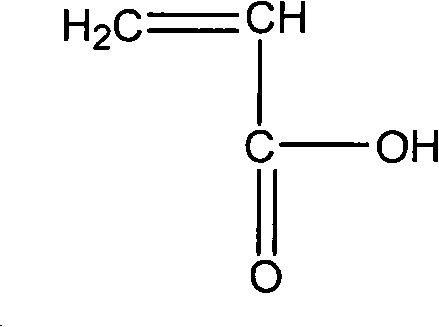

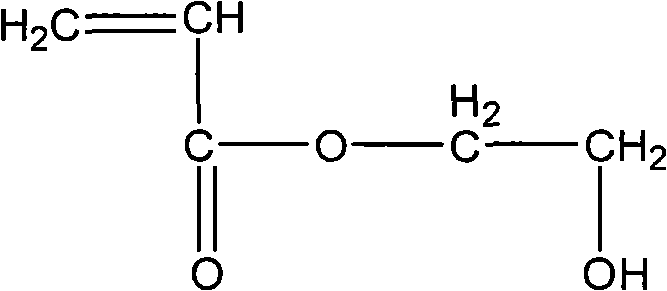

Ethers polycarboxylic acid water reducing agent and preparation

The invention discloses an ether polycarboxylic water reducing agent which is obtained through water solution copolymerization of three types of monomers of 10-70 percent of allyl polyxyethylated alcohol ether, 20-70 percent of acrylic acid and 10-30 percent of hydroxy-ethyl acrylate. Due to the introduction of hydroxy-ethyl acrylate, the ether polycarboxylic water reducing agent reduces the self-polymerization proportion of the acrylic acid, improves the copolymerization proportion, and greatly reduces the cost of the raw materials; in addition, the molecular weight of the polymer is controllable, the water reduction rate is high, the loss of slump constant with the time is low, and the prepared concrete has high fluidity, good workability, and enough early strength in the beginning of hardening. Besides, the preparation technique of the ether polycarboxylic water reducing agent is a one-step method, the operation is simple, the reaction conditions are easy to control, the production period is short, and the ether polycarboxylic water reducing agent is green and environment-friendly, has low cost and is applicable to industrial production on large scale.

Owner:杭州传化建筑新材料有限公司

Propellantless pump sprays and pump foams containing an anionic copolymer of methacrylic acid and ethyl acrylate

InactiveUS6482394B1Improve flexural strengthImprove distributionCosmetic preparationsHair cosmeticsAnionic polymersEthyl acrylate

Hair treatment compositions in the form of pump sprays and pump foams that are free from propellant gases comprise at least one cationic and at least one anionic polymer having methacrylic and ethyl units.

Owner:BASF AG

Dosage form and method for producing the same

ActiveUS20050152977A1Quick releaseDelay releasePowder deliveryNervous disorderAdditive ingredientCoated drugs

The invention relates to a process for producing a coated drug form or a drug form in the form of an active ingredient matrix, by processing a copolymer, an active pharmaceutical ingredient, a core if present and / or pharmaceutically customary excipients in a conventional manner by melting, injection molding, extrusion, wet granulation, casting, dipping, spreading, spraying or compression to form a coated drug form and / or to form an active ingredient matrix, characterized in that a copolymer is used which is composed of 20 to 33% by weight methacrylic acid, 5 to 30% by weight methyl acrylate, 20 to 40% by weight ethyl acrylate and more than 10 to 30% by weight butyl methacrylate and, if desired, 0 to 10% by weight further vinylically copolymerizable monomers, with the proviso that the glass transition temperature of the copolymer in accordance with ISO 11357-2, section 3.3.3, is 55 to 70° C. The invention further relates to the drug form produced in accordance with the invention, to the copolymer, and to the use thereof.

Owner:EVONIK OPERATIONS GMBH

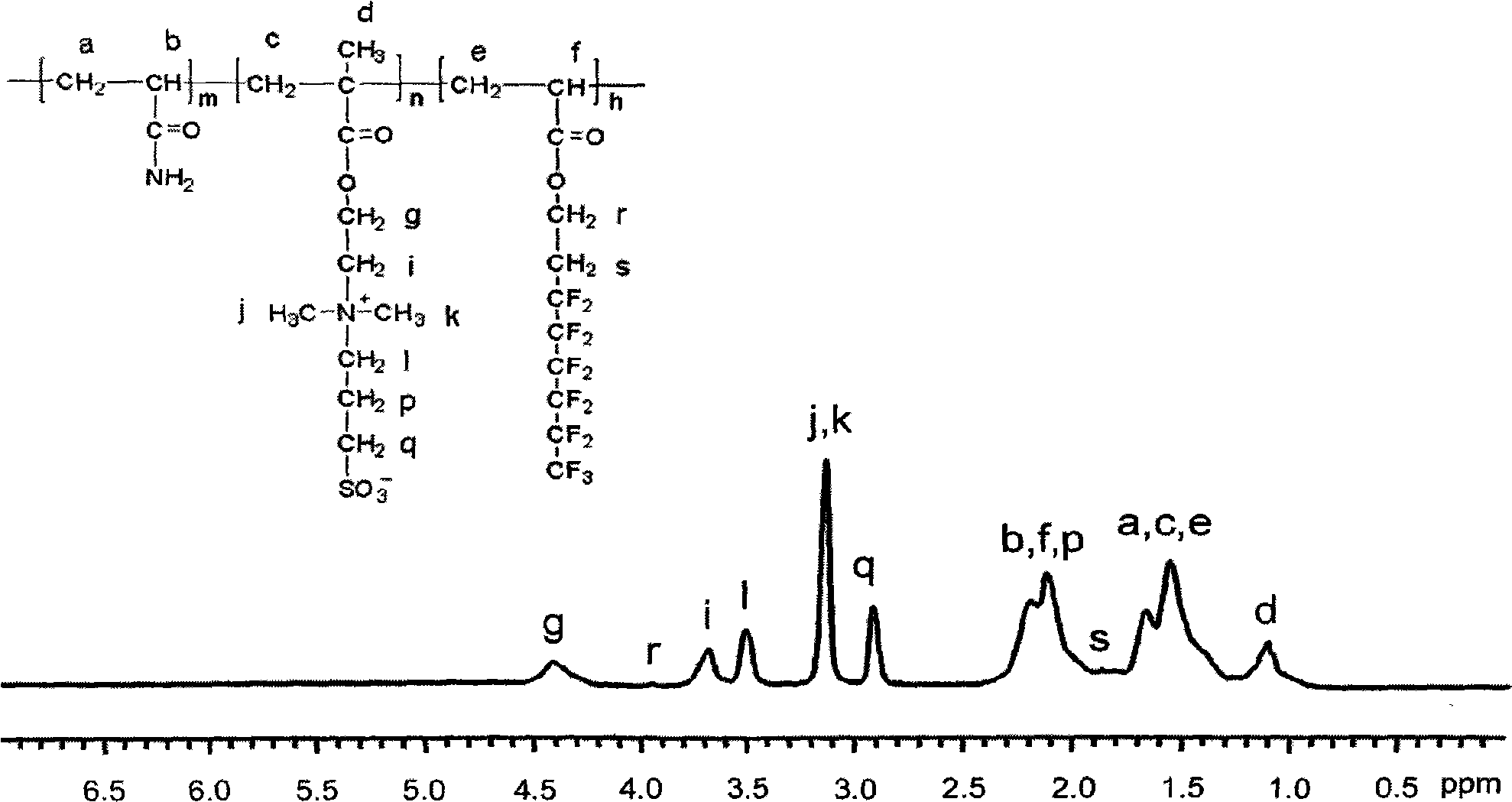

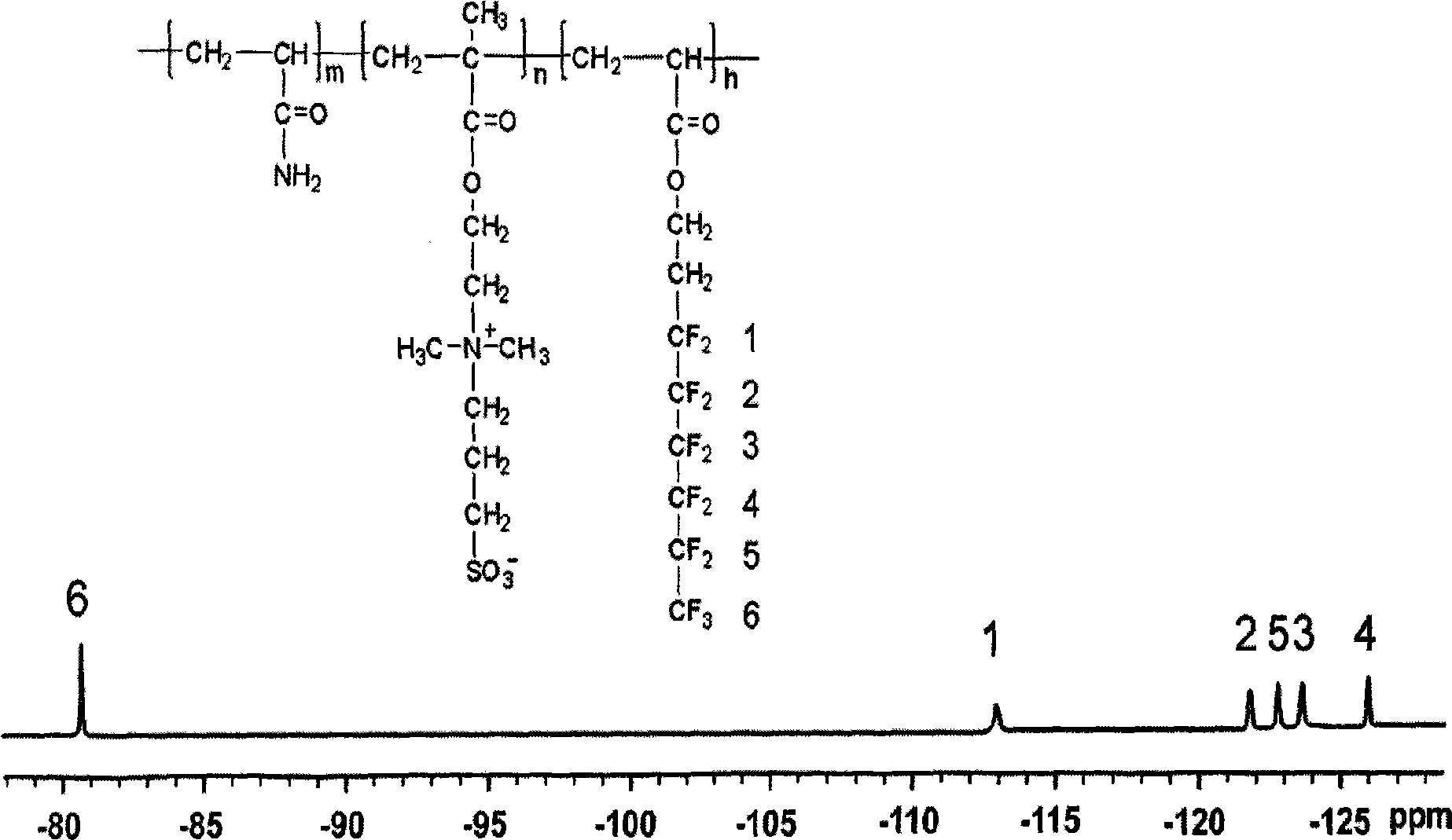

Method for preparing fluorine-containing modified amphoteric water-soluble polymer

The invention relates to a method for preparing a fluorine-containing modified amphoteric water-soluble polymer, in particular to a method for preparing the fluorine-containing modified amphoteric water-soluble polymer by a cosolvent method and belongs to the technical field of water-soluble macromolecular synthesis. Methacryloyl ethyl-N and N-dimethyl propanesulfonic acid (DMAPS) as amphoteric monomers and perfluoro hexyl ethyl acrylate (PFHEA) and acrylamide (AM) as hydrophobic monomers are copolymerized in a single solvent; azobisisobutyronitrile (AIBN) is used as a catalyst; and the fluorine-containing modified amphoteric water-soluble polymer is obtained. The polymer has good water solubility and remarkable interface activity, thickening, shearing resistance, temperature resistance and salt resistance. Through a mixed solution of anhydrous acetone and anhydrous ether, the polymer is precipitated, dried and pulverized to obtain a powdery product; and the powdery product has wide application prospect in the development of an oil field, dope, printing, household chemical, medicament and other fields.

Owner:SHANDONG UNIV

Coated Particles Containing Pharmaceutically Active Agents

ActiveUS20090324716A1Pretreated surfacesPharmaceutical non-active ingredientsPolymer scienceActive agent

The present invention features a tablet including particles containing a pharmaceutically active agent, wherein the particles are coated with (a) a first film layer containing a modified release polymer; and (b) a second film layer containing (i) a first polymer, wherein the first polymer is a polymer of ethyl acrylate and methyl methacrylate and (ii) a second polymer, wherein the second polymer is a polymer of methyl acrylate, methyl methacrylate and methacrylic acid.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

Blends of amorphous and semicrystalline polymers having shape memory properties

InactiveUS7208550B2High modulusDental impression compositionsPoly(methyl methacrylate)Glycol synthesis

Blends of amorphous and semicrystalline polymers having shape memory properties were prepared by blending a crystalline polymer such as poly(vinylidene fluoride), polylactide, poly(hydroxxybutyrate), poly(ethylene glycol) polyethylene, polyethylene-co-vinyl acetate, poly(vinyl chloride), poly(vinylidene chloride) and copolymers of poly(vinylidene chloride) and poly(vinyle chloride) and an amorphous polymer such as poly(vinyl acetate), poly methyl acrylate, poly ethyl acrylate, atactic poly methyl methacrylate, isotactic poly methyl methacrylate, syndiotactic poly methyl methacrylate and other poly alkyl methacrylates. The method for preparing the polymeric materials and applications thereof, for example, as smart medical devices, are also disclosed.

Owner:UNIV OF CONNECTICUT

Electrode and preparation method therefor

ActiveCN107437622AImprove the high conductivity at room temperatureHigh strengthCell electrodesSecondary cellsLow-density polyethyleneEpoxy

The invention provides an electrode and a preparation method therefor. The electrode comprises a current collector and an active material layer arranged on the current collector; the electrode also comprises a coating layer arranged between the current collector and the active material layer; the coating layer comprises a polymer substrate and a conductive agent; the polymer substrate is selected from one or more of low-density polyethylene, high-density polyethylene, epoxy resin, polyvinylidene fluoride, an ethylene-ethyl acrylate copolymer, an ethylene-vinyl acetate copolymer, polybutylene, cellulose acetate and polyamide; and the conductive agent is selected from one or more of acanthosphere-shaped Ni powder, acanthosphere-shaped Cu powder, acanthosphere Al powder and acanthosphere-shaped tungsten carbide. The electrode has the advantages of low normal-temperature resistor and high PTC strength, so that improvement of safety performance of a lithium ion battery can be facilitated.

Owner:CONTEMPORARY AMPEREX TECH CO

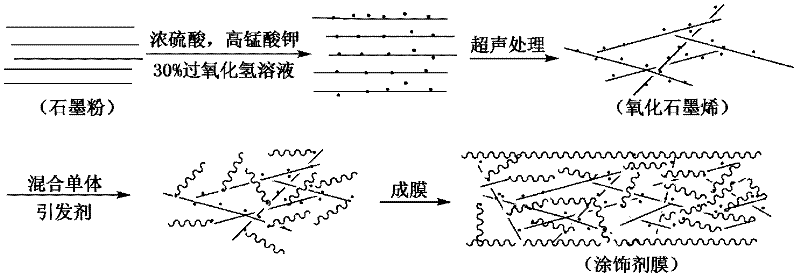

Preparation method of acrylic resin/graphene oxide nanometer composite leather finishing agent

The invention relates to a preparation method for an acrylic resin / graphene oxide nanometer composite leather finishing agent. In the preparation method, a nanometer graphene oxide suspension liquid is formed through peeling and dispersing; and then the acrylic resin / graphene oxide nanometer composite acrylic resin finishing agent is prepared through in-situ polymerization. The preparation methodcomprises the following specific steps: carrying out oxidization and ultrasonic stripping on natural graphite powder to prepare graphene oxide; adding graphene oxide to a mixed monomer of methyl acrylate, ethyl acrylate, butyl acrylate, acrylic acid and hydroxyethyl acrylate under the action of ultrasonic waves; and carrying out in-situ free radical copolymerization reaction under the action of an initiator ammonium persulfate to obtain the acrylic resin / graphene oxide nanometer composite leather finishing agent. The preparation method has the characteristics that the acrylic resin / graphene oxide nanometer composite leather finishing agent with excellent film-forming hand feel, strength and anti-static performances and no heat bonding and cold brittleness defects is prepared by using the specific laminated structure and performance of graphene oxide.

Owner:JIANGSU BESCON PHARMA

Cable semiconductive shield compositions

InactiveUS20020032258A1Special tyresPower cables with screens/conductive layersAliphatic unsaturated hydrocarbonGram

A composition comprising: (a) one or more copolymers selected from the group consisting of (I) a copolymer of ethylene and vinyl acetate containing about 10 to about 50 percent by weight vinyl acetate and having a melt mass flow rate of about 1 to about 100 grams per 10 minutes; (II) a copolymer of ethylene and ethyl acrylate containing about 10 to about 50 percent by weight ethyl acrylate and having a melt mass flow rate of about 1 to about 100 grams per 10 minutes; and (III) a copolymer of ethylene and butyl acrylate containing about 10 to about 50 percent by weight butyl acrylate and having a melt mass flow rate of about 1 to about 100 grams per 10 minutes, and based upon 100 parts by weight of component (a): (b) about 55 to about 200 parts by weight of a linear copolymer of ethylene and an alpha-olefin having 3 to 12 carbon atoms, the copolymer having a melt mass flow rate of about 0.1 to about 30 grams per 10 minutes and a density of 0.870 to 0.944 gram per cubic centimeter; (c) about 5 to about 50 parts by weight of polypropylene having a melt mass flow rate of about 0.5 to about 30 grams per 10 minutes and a density of 0.900 to 0.920 gram per cubic centimeter; (d) about 2 to about 50 parts by weight of an organopolysiloxane having the following formula: R1xR2ySiO(4-a-b) / 2 wherein R1 is an aliphatic unsaturated hydrocarbon group; R2 is an unsubstituted or substituted monovalent hydrocarbon group excluding aliphatic unsaturated hydrocarbon groups; x is equal to or greater than 0 but less than 1; y is greater than 0.5 but less than 3; x+y is greater than 1 but less than 3; a is greater than 0 but equal to or less than 1; and b is equal to or greater than 0.5 but equal to or less than 3; (e) about 10 to about 350 parts by weight of carbon black; and (f) optionally, up to about 2 parts by weight of an organic peroxide.

Owner:NIPPON YUNIKAA

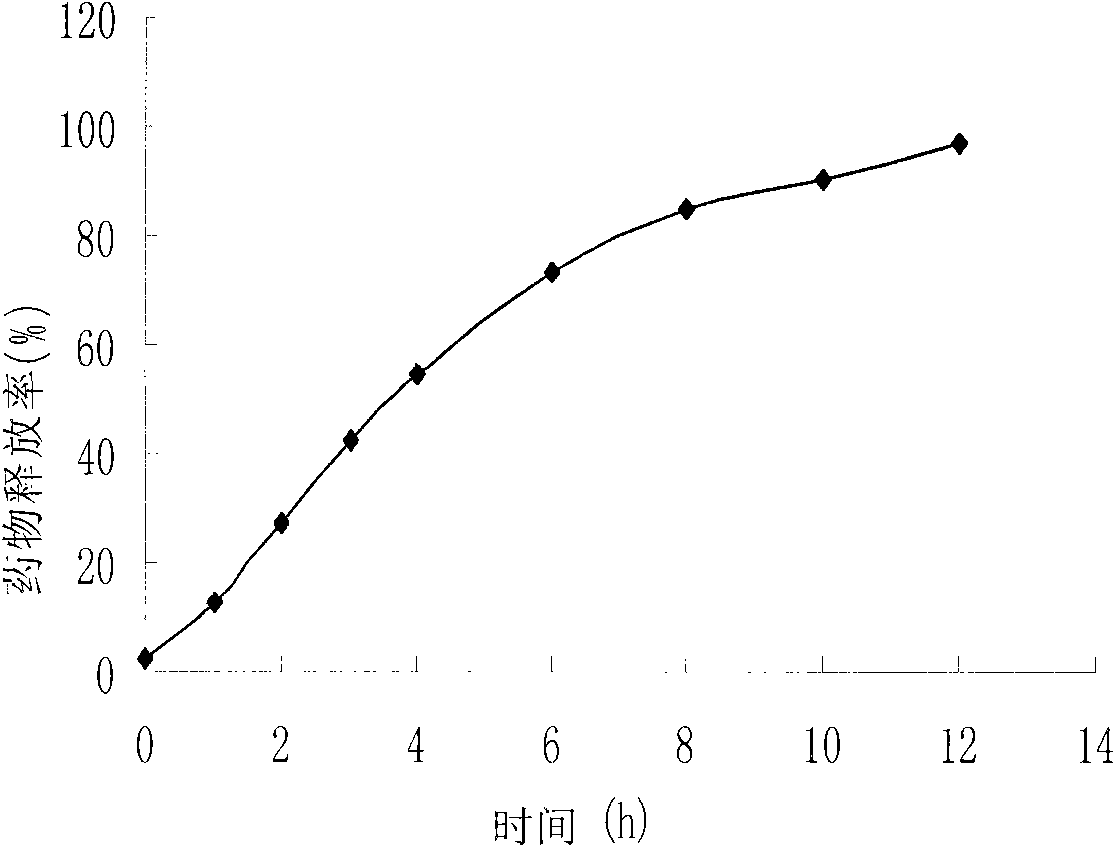

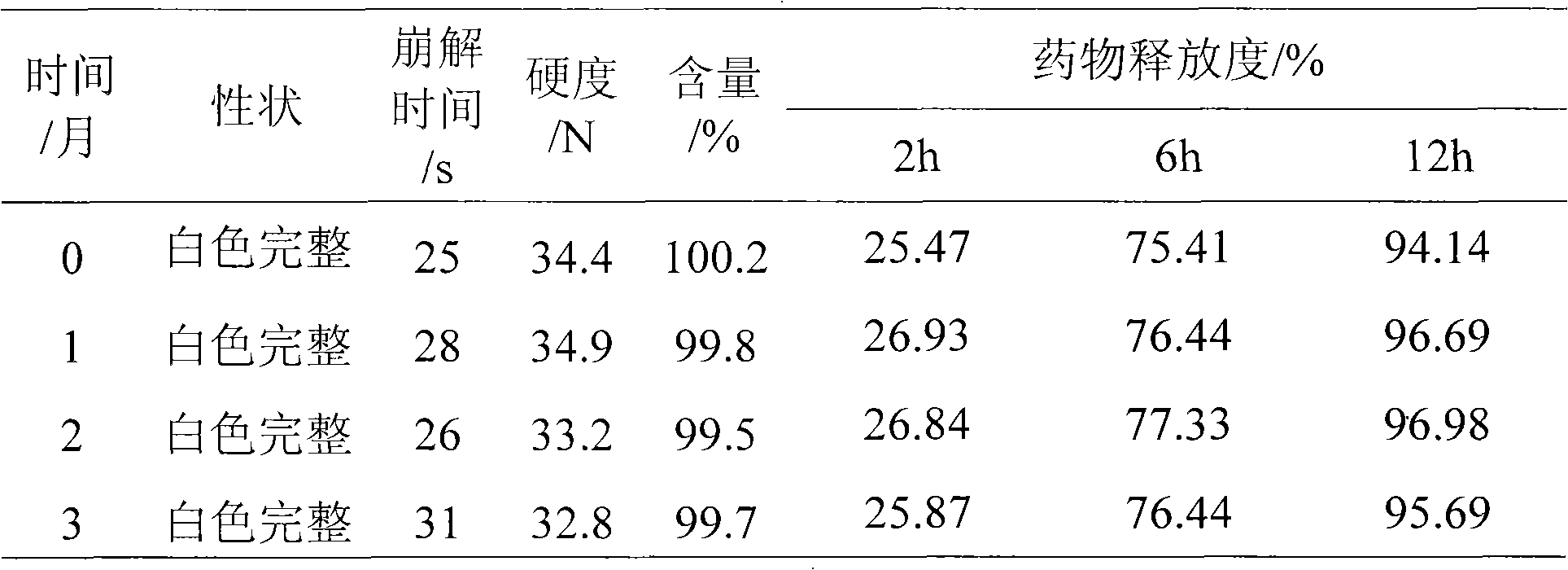

Water-insoluble medicine sustained-release pellet, sustained-release orally disintegrating tablet thereof and preparation method thereof

InactiveCN101862297ASmall particle sizeHigh strengthOrganic active ingredientsAntipyreticSustained release pelletsSide effect

The invention discloses a water-insoluble medicine sustained-release pellet, a sustained-release orally disintegrating tablet thereof and a preparation method thereof. The water-insoluble medicine sustained-release pellet comprises a hollow pellet core, a medicine layer, an insulation layer and a sustained-release layer, wherein the sustained-release layer comprises the following ingredients: 54 to 88 percent of sustained-release materials, 2 to 30 percent of antitackiness agents and 1 to 30 percent of pore-foaming agents, wherein the percentage is the mass percentage in the sustained-release layer, wherein the sustained-release materials are one kind or several kinds of materials selected from ethyl acrylate and methyl methacrylate copolymers, polyvinyl acetate and ethyl cellulose. Through regulating the coating combinations and filling auxiliary materials to be pressed into orally disintegrating tablets, the medicine can be slowly released for more than 8 to 13 hours, so the stable blood medicine concentration can be maintained, the side effect is reduced, the medicine taking times can be reduced, and the medicine taking is convenient. The invention conforms to zero-grade release, has the advantages of high final accumulated medicine release amount, high efficacy, strong selectivity, good mouth feeling, simple production steps and high efficiency, and can be applied to large-scale production.

Owner:SHANGHAI INST OF PHARMA IND +1

Encapsulant compositions, methods of manufacture and uses thereof

ActiveUS20100295091A1Increased durabilityIncreased moisture protectionSpecial tyresLaminationMeth-Sealant

An encapsulant composition containing about 15 to about 50 wt % of an ethylene / ethyl acrylate / maleic anhydride copolymer containing about 20 to about 40 wt % of an ethylene / glycidyl (meth)acrylate copolymer; about 2 to about 30 wt % of an ethylene / butyl acrylate / maleic anhydride copolymer; about 5 to about 50 wt % of polyethylene, about 0.05 to about 5 wt % of an adhesion promoter; and optionally about 0.01 to about 2 wt % of at least one additive. The composition is useful for encapsulating thin film devices. The disclosure also relates to a method of encapsulating thin film devices with the composition and to devices produced by the method.

Owner:SK GEO CENTRIC CO LTD

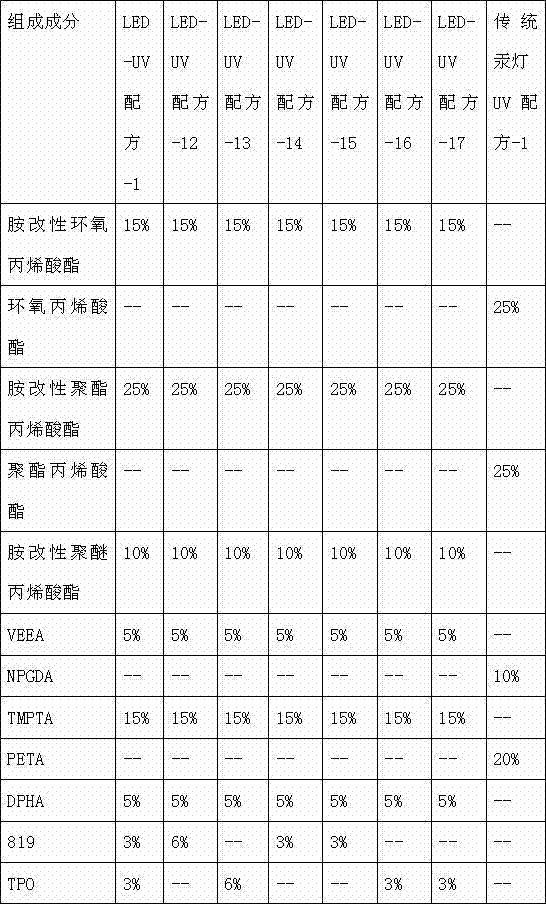

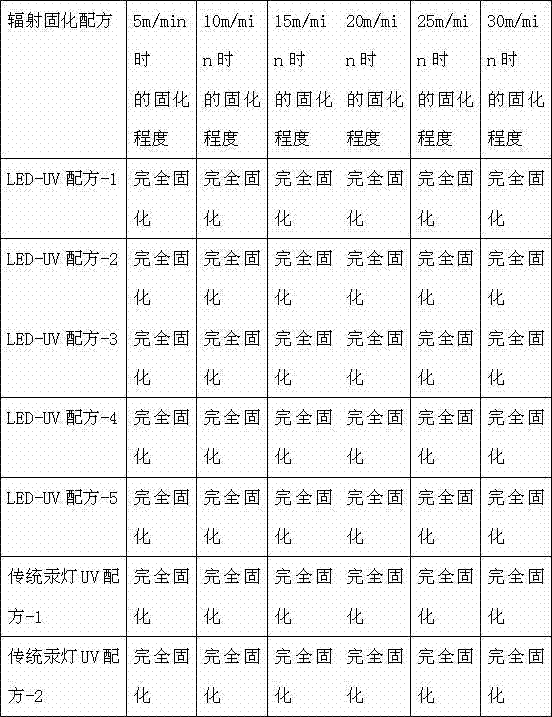

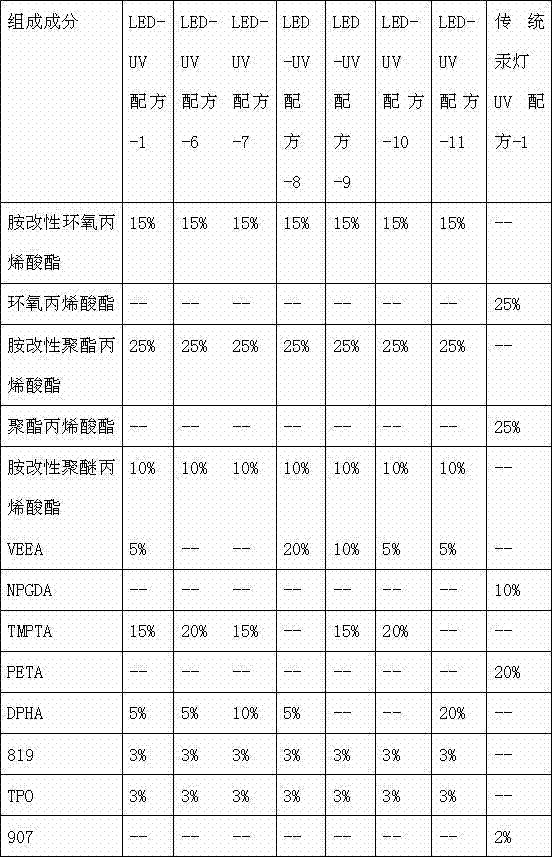

LED-UV surface light source light-curing silk-screen printing ink composition and preparation method thereof

The present invention relates to the field of ink and a preparation process thereof, and particularly to a LED-UV surface light source light-curing silk-screen printing ink composition and a preparation method thereof. The composition is characterized by comprising 25-55% by weight of an LED-UV resin and 10-25% by weight of an LED-UV monomer, wherein the LED-UV resin is a mixture comprising one or a plurality of materials selected from an amine-modified epoxy acrylate resin, an amine-modified polyester acrylate resin, and an amine-modified polyether acrylate resin, and the LED-UV monomer is a mixture comprising one or a plurality of materials selected from a 2-(vinylethoxy)ethyl diacrylate monomer, a trimethylolpropane triacrylate monomer, and a dipentaerythritol hexaacrylate monomer. The LED-UV surface light source light-curing silk-screen printing ink composition of the present invention has advantages of rapid curing speed, good film coating property, high glossiness, environment protection, energy saving, and the like.manufacturing process

Owner:东营华科新材料科技有限公司

Ink composition for ink jet recording

InactiveUS20100285221A1Excellent in color developabilityGood fixabilityDuplicating/marking methodsInksMeth-Acid value

An ink composition for ink jet recording, contains at least a dispersoid in which a pigment can be dispersed in water, and a polymer microparticle, in which an average particle diameter of the dispersoid is 20 to 300 nm, the polymer microparticle contains at least 70% by weight or more of an alkyl(meth)acrylate containing ethyl acrylate and / or a cyclic alkyl(meth)acrylate, a(meth)acrylic acid, and an ethylene based unsaturated monomer having a saturated or an unsaturated ring as a monomer component, a glass transition temperature and an acid value thereof are 0° C. or below and 50 mgKOH / g or less, respectively.

Owner:SEIKO EPSON CORP

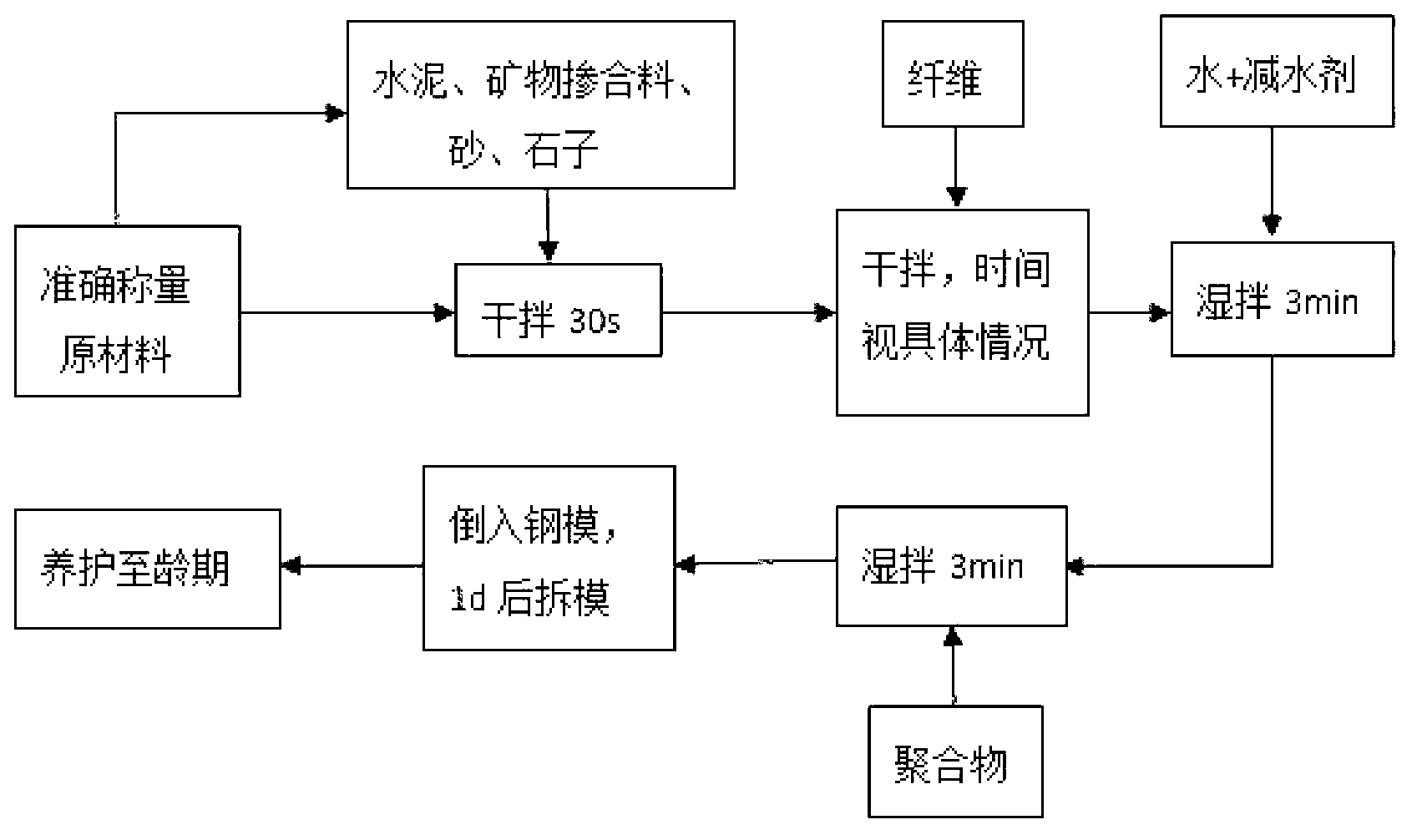

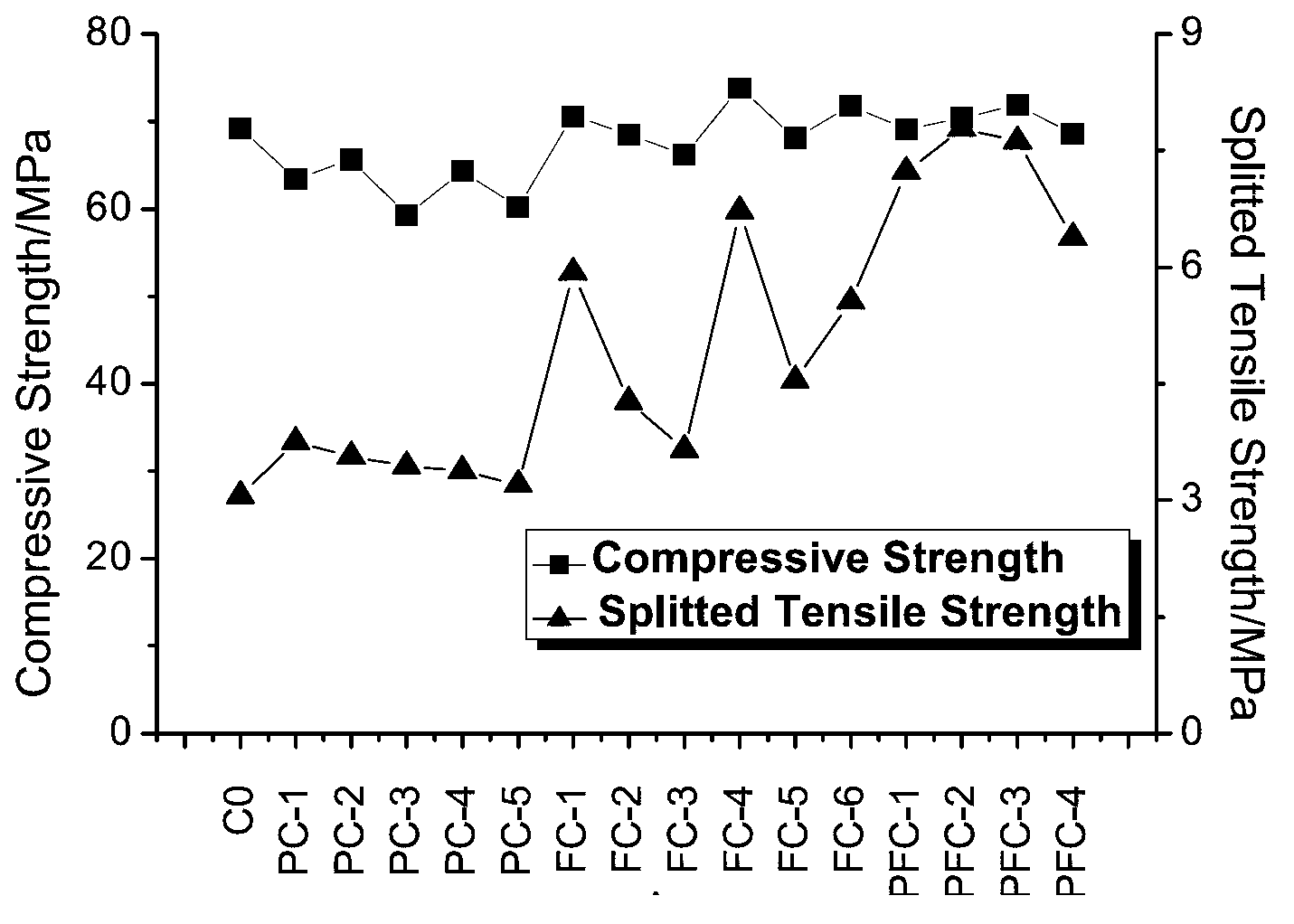

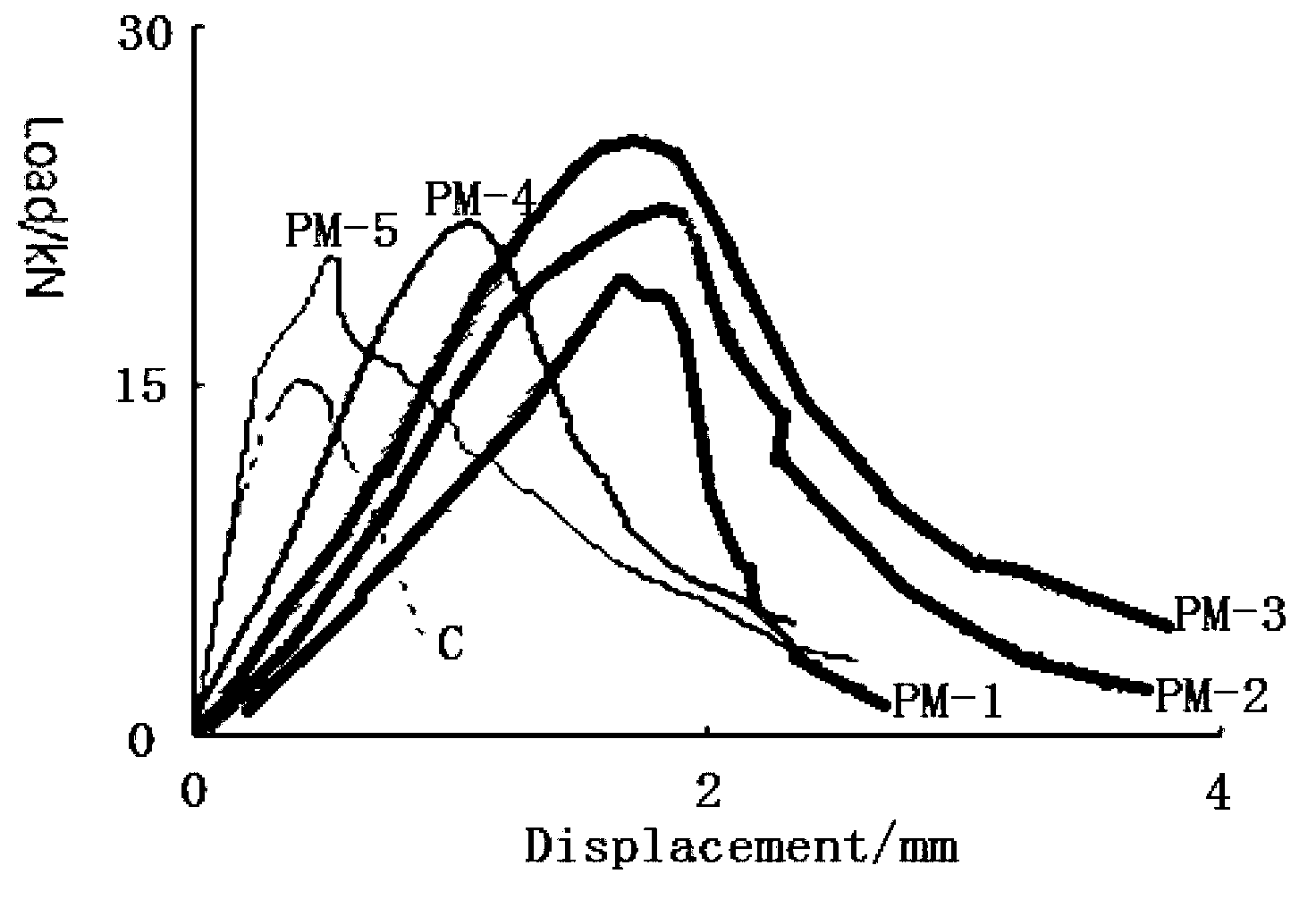

Fibre-polymer compound toughened concrete and preparation method for same

The invention discloses a fibre-polymer compound toughened concrete and a preparation method for the same. The basic raw materials of the concrete are coarse aggregate, fine aggregate, portland cement, fly ash and a polycarboxylic water reducer; moreover, fibres and a polymer are added, the fibres are any one of end-hook type steel fibres, superfine type steel fibres, modified polyester fibres, polyvinyl alcohol fibres, basalt fibres and cellulose fibres, and are doped in a ratio that the volume doped amount in per 1 m<3> concrete is 0.08%; and the polymer is any one of ethylene-vinyl acetate copolymer, ethyl acrylate, styrene-acrylate copolymer, vinyl acetate-acrylate copolymer and organosilicone acrylate, and the doped amount of each polymer is 10% based on the mass of the portland cement and the fly ash. The preparation method comprises the following steps of: pouring stone, sand, a gelling material, fibres, and water dissolved with a water reducer, and then stirring according to a blending mode of pouring dry materials at first and then pouring wet materials; and pouring the polymer, and stirring and forming.

Owner:SOUTHEAST UNIV

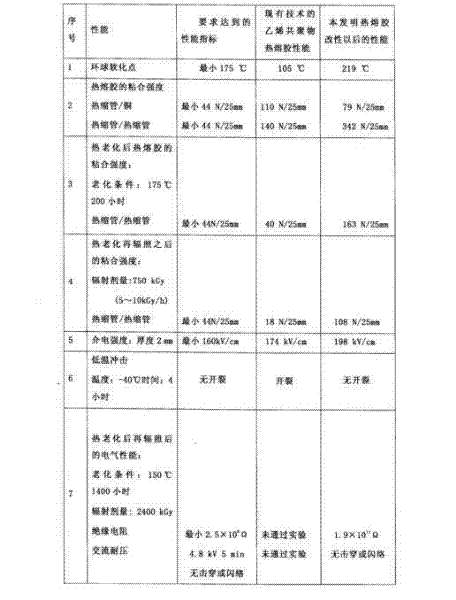

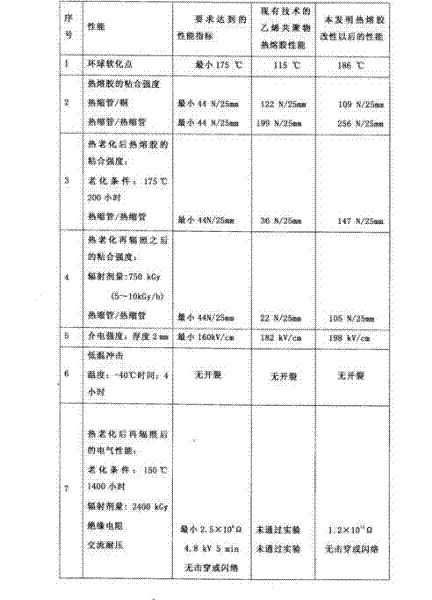

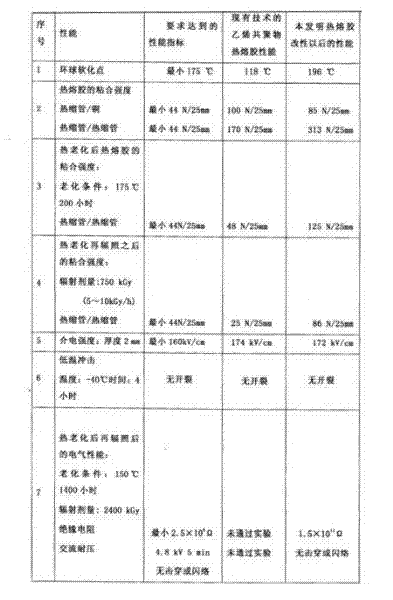

Hot melt adhesive for cable accessories in nuclear island of nuclear power plant and preparation method thereof

ActiveCN102250563AImprove performanceReduce liquidityNon-macromolecular adhesive additivesElastomerPolyolefin

The invention relates to a hot melt adhesive for cable accessories in a nuclear island of a nuclear power plant, and the hot melt adhesive is composed of the following components in parts by weight: 100 parts of ethylene copolymer hot melt adhesive, 30-100 parts of polyolefin elastomer and 5-10 parts of composite antioxidant, wherein the ethylene copolymer hot melt adhesive comprises one or more of ethylene-vinyl acetate copolymer hot melt adhesive, ethylene-ethyl acrylate copolymer hot melt adhesive, and ethylene-methyl acrylate copolymer hot melt adhesive; the polyolefin elastomer is a molecular-chain-saturated ethylene and C3-C20 alpha-olefin copolymer; and the composite antioxidant is one or more of a hindered phenolic antioxidant, a sulfur-containing antioxidant and an ester antioxidant. The hot melt adhesive provided by the invention can be applied to the cable accessories in the nuclear island of the nuclear power plant, and can also be used in aviation, shipping, nuclear submarine and other fields with higher performance requirements on the hot melt adhesive.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +1

Textile water-based pigment printing binding agent and preparation method

ActiveCN102605648AMeet printing requirementsHigh fastnessEster polymer adhesivesDyeing processTextile printerPolymer science

The invention relates to a textile water-based pigment printing binding agent and a preparation method. The textile water-based pigment printing binding agent is prepared in a way that acrylonitrile, ethyl acrylate, butyl acrylate, crylic acid, hydroxyethyl methacrylate, acrylamide, sodium dodecyl sulfate, alcohol dodecyl polyoxyethylene (10) ether, deionized water, ammonium persulfate and sodiumhydrogen sulfite are subjected to emulsion polymerization and then are mixed with pyrolysis closed polyurethane crosslinking agent according to proportion. The product is cured in low temperature condition, has remarkable advantages in the aspects of dry rubbing fastness, wet rubbing fastness, soaping fastness and the like, is simple and easily-controllable in production operation, and is energy-saving and environment-friendly.

Owner:LIAONING FIXED STAR FINE CHEM

Cable semiconductive shield compositions

A composition comprising:(a) one or more copolymers selected from the group consisting of (I) a copolymer of ethylene and vinyl acetate containing about 10 to about 50 percent by weight of units of vinyl acetate; (II) a copolymer of ethylene and ethyl acrylate containing about 10 to about 50 percent by weight of units of ethyl acrylate; and (III) a copolymer of ethylene and butyl acrylate containing about 10 to about 50 percent by weight of units of butyl acrylate;(b) about 55 to about 200 parts by weight, based upon 100 parts by weight of component (a), of a linear copolymer of ethylene and an alpha-olefin having 3 to 12 carbon atoms, and a density of 0.870 to 0.944 grama per cubic centimeter;(c) about 1 to about 50 parts by weight, based upon 100 parts by weight of component (a), of an organopolysiloxane;(d) about 10 to about 350 parts by weight, based upon 100 parts by weight of component (a), of carbon black; and(e) from 0 to about 2 parts by weight of an organic peroxide, the composition effective for being cross-linked, without a catalyst, with water to provide a cross linked composition.

Owner:NIPPON YUNIKAA

Method for preparing fluorine-containing acrylate emulsion

The invention discloses a method for preparing fluorine-containing acrylate emulsion. The fluorine-containing acrylate emulsion is prepared from perfluoroalkyl ethyl acrylate and acrylic monomers which are used as main materials, persulfate which is used as the initiator, and a compound emulsifier by adopting the semi-continuous titration polymerization process. The titration mode is adopted in the whole reaction process, the heat is preserved after finishing titrating, the reaction process is convenient to control, and the finally prepared fluorine-containing acrylate emulsion has excellent performance and high performance-price ratio, is environmental friendly and safe and can be cured at normal temperature to form a film. The detection on the emulsion paint prepared from the fluorine-containing acrylate emulsion shows that the emulsion paint can resist scrubbing of 10,000 times without changing, can resist both acid and base for 120 hours without blistering and powder falling in addition to slight loss of gloss and color and can resist ageing for 5,000 hours without blistering, stripping and cracking. The content of solid (the mass percent of non-volatile matters) in the fluorine-containing acrylate emulsion is more than 45%, and the water repellent angle of the coating of the fluorine-containing acrylate emulsion is more than 100 degrees.

Owner:JINZHOU DPF TH CHEM CO LTD

Waterborne aluminium foil adhesive and preparation method thereof

InactiveCN102153971AGood adhesionHigh peel strengthMonocarboxylic acid ester polymer adhesivesEster polymer adhesivesFunctional monomerPolymer science

The invention discloses a waterborne aluminium foil adhesive and a preparation method thereof and belongs to the field of adhesives. The aluminium foil adhesive is a composite adhesive with solid content of 40 to 50 percent, which is prepared by using monomers, an emulsifier, protective colloid, an initiator, a buffer, a pH (potential of hydrogen) regulator, a plasticizer, a waterborne assistant and deionized water as the raw materials through pre-emulsification, seed reaction, polymerization reaction and compounding. The monomers in the raw materials comprise hard monomers, soft monomers andfunctional monomers, wherein the hard monomers adopt vinylacetate and methyl acrylate; the soft monomers adopt ethyl acrylate and butyl acrylate; and the functional monomers adopt any one of acrylic acid or methacrylic acid and N-hydroxymethyl acrylamide. The waterborne aluminium foil adhesive has the advantages of low cost, high stripping strength and good leveling property and is simple and convenient to operate.

Owner:BEIJING COMENS NEW MATERIALS

Non-whitening emulsion pressure sensitive adhesives

InactiveCN1284106ALow hazeAdhesiveNon-macromolecular adhesive additivesEster polymer adhesivesMethacrylateEmulsion

Water resistant, low haze acrylic emulsion pressure sensitive adhesive compositions for use in decorative, light management or optical articles are disclosed. These emulsion pressure sensitive adhesives comprise (a) 50-90% by weight n-butyl acrylate, and (b) 10-50% by weight 2-hydroxy ethyl acrylate, or 2-hydroxy ethyl methacrylate, hydroxy propyl acrylate monomer, or mixtures thereof. These emulsion pressure sensitive adhesives can be used in wet lamination processes, and exhibit less than 2% increase in haze, less than 2% increase in opacity and greater than 95% transmittance after the wet lamination process.

Owner:3M CO

Macromolecule material cold keeping agent making method

InactiveCN1570016ALow costUse low concentrationHeat-exchange elementsPolymer science(Hydroxyethyl)methacrylate

The invention discloses a macromolecule material cold keeping agent making method which consists of, preparing aqueous solution of polymers having strong hydrophilic radicals in the molecular structure, charging propenoic acid, hydroxyethyl methacrylate and maleic anhydride monomer, mixing homogeneously, charging bis-ethyl acrylate cross linking agent, agitating homogeneously, charging potassium peroxodisulfate initiating agent, mixing homogeneously, obtaining macromolecular material, dissolving into water of different mass.

Owner:TSINGHUA UNIV +2

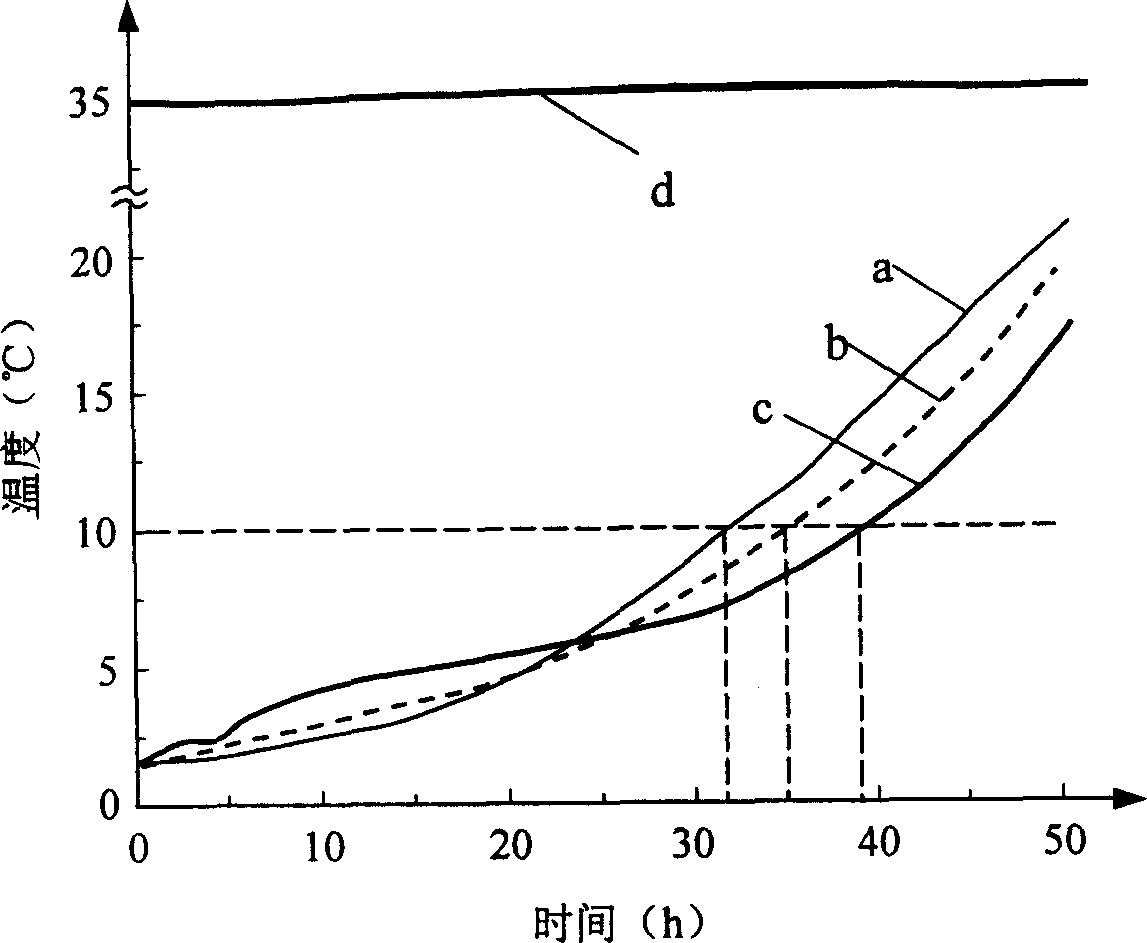

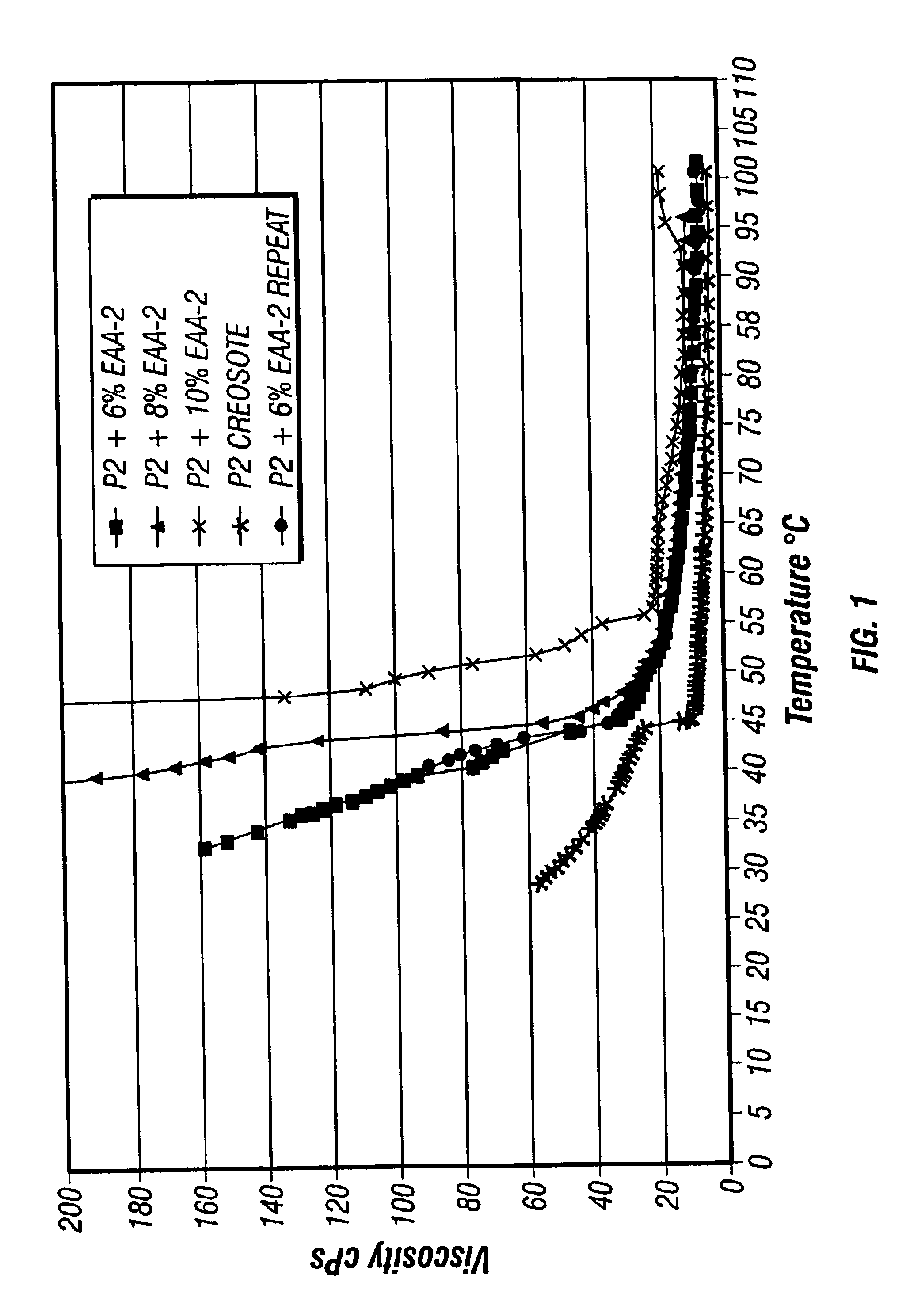

Wood treatment composition and method of use

A wood treatment composition for the preservation of wood comprises a mixture of creosote and a polymer which is miscible with the creosote at about 200° F. and does not substantially phase-separate when the wood treatment composition is under ambient conditions. The polymer may include, but is not limited to, ethylene vinyl acetate copolymers, ethylene methyl acrylate copolymers, ethylene ethyl acrylate copolymers, ethylene butyl acrylate copolymers, ethylene acrylic acid copolymers, ethylene methacrylic acid copolymers, ethylene methyl methacrylic acid copolymers, ethylene styrene interpolymers, styrene acrylic acid copolymers, styrene methacrylic acid copolymers, styrene methyl acrylate copolymers, styrene butadiene styrene block copolymers, styrene ethylene butylene styrene block copolymers, or a blend thereof. Preferably, the creosote is present in an amount of at least 50 percent by weight of the composition. Such compositions can be used to treat wood surfaces to prolong the service life of the wood.

Owner:DOW GLOBAL TECH LLC

The preparation method of epa ethyl ester and dha ethyl ester

ActiveCN102285880AHigh yieldSimple and fast operationOrganic compound preparationCarboxylic acid esters preparationFraction CollectorAutomatic control

The invention discloses a method for preparing ethyl eicosapentaenate (EPA) and ethyl docosahexaenoate (DHA) and relates omega-3 long-chain polyunsaturated fatty acids. The method comprises: preparing prepared solution to be separated by using a fish oil coarse raw material, which contains ethyl EPA and ethyl DHA, and using an organic solvent as a solvent; transferring the prepared solution to be separated into a material storage tube of a semi-prepared / prepared high-efficiency liquid chromatography-mass spectrum combined apparatus system, starting the semi-prepared / prepared high-efficiency liquid chromatography-mass spectrum combined apparatus system of which a mobile phase is aqueous solution of methanol or ethanol, balancing a chromatographic column, sampling automatically, separating and purifying ethyl EPA and ethyl DHA, and trigging a distillate collector by a mass spectrum online detection signal to collect pure ethyl EPA liquid and ethyl DHA liquid separately and automatically; and subjecting the pure ethyl EPA and ethyl DHA to reduced pressure concentration, extraction and reduced-pressure concentration respectively and thus obtaining ethyl EPA and ethyl DHA, of which the purities are both over 99 percent. The method is characterized by simple and convenient operation and high yield and is suitable for automatic control and synchronous separation.

Owner:THIRD INST OF OCEANOGRAPHY STATE OCEANIC ADMINISTATION

Friction-reducing and abrasive composite materials with reactive nanometer inorganic particles/epoxy and production thereof

A reactive nanometer inorganic particle / epoxy resin abrasive composite material and its production are disclosed. The composite material consists of epoxy resin 90-99wt%, nanometer inorganic particle 1-10wt% and graft monomer 0.1-5%. The graft monomer is mixture of any kind or several kinds of methyl acrylic acid ethylene oxide ester, acrylic amide, phenylethylene, ethyl acrylate, methyl ethyl acrylate or butyl acrylate. The process is carried out by surface graft modifying nanometer grains, inducing reactive polymer, epoxy resin curing reacting and forming chemical connection between nanometer grains and resin matrix. It has better anti-friction and wear-resistant performances and is simple. It can be used for epoxy resin coating and various miniature devices.

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com