Method for preparing fluorine-containing modified amphoteric water-soluble polymer

A water-soluble polymer, amphoteric technology, applied in the field of water-soluble polymer synthesis, can solve the problems of harsh reaction conditions of surfactants, expensive fluorosurfactants, difficult to purify surfactants, etc., and achieves high yields , safe to use and easy to store

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

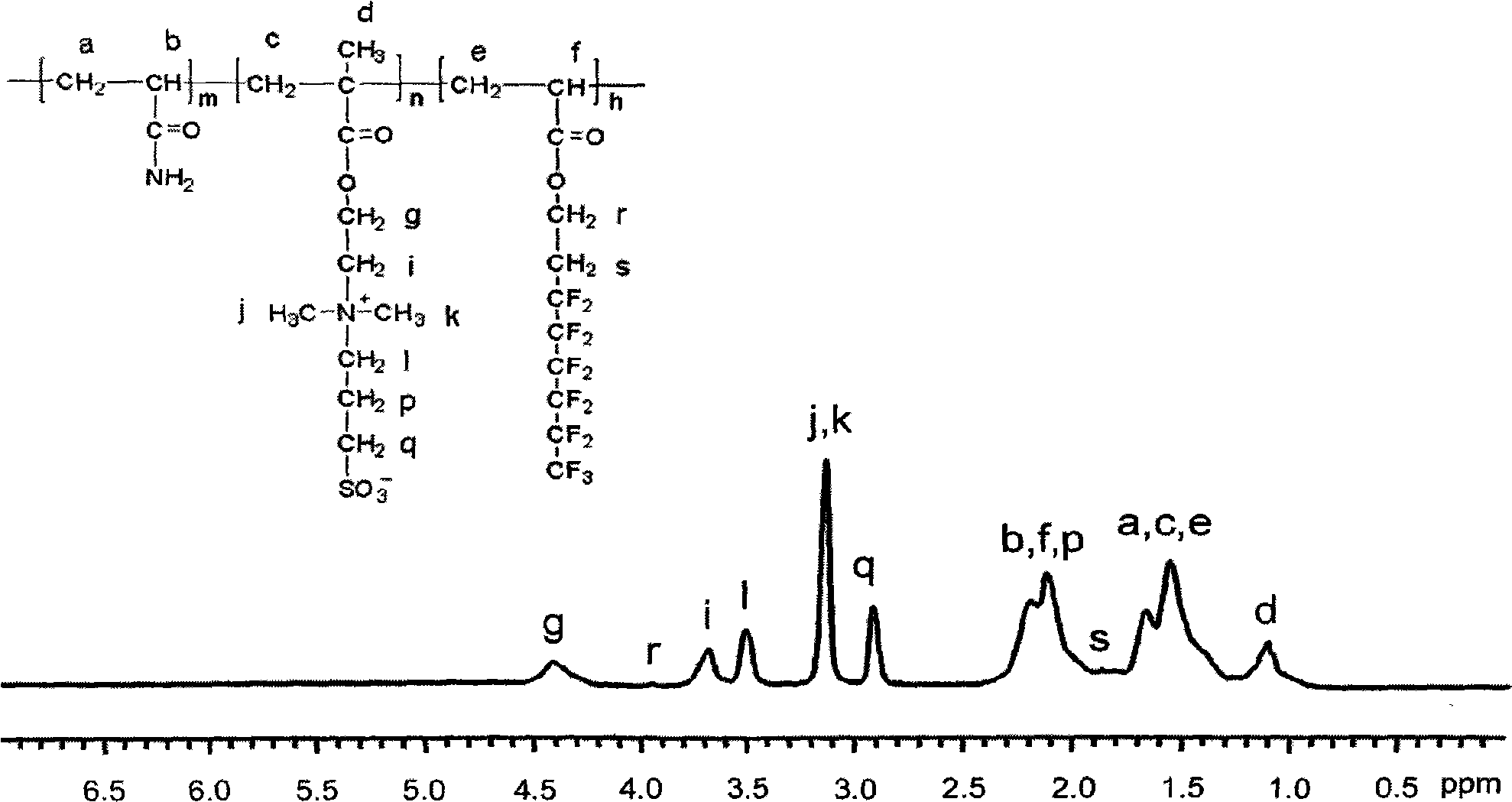

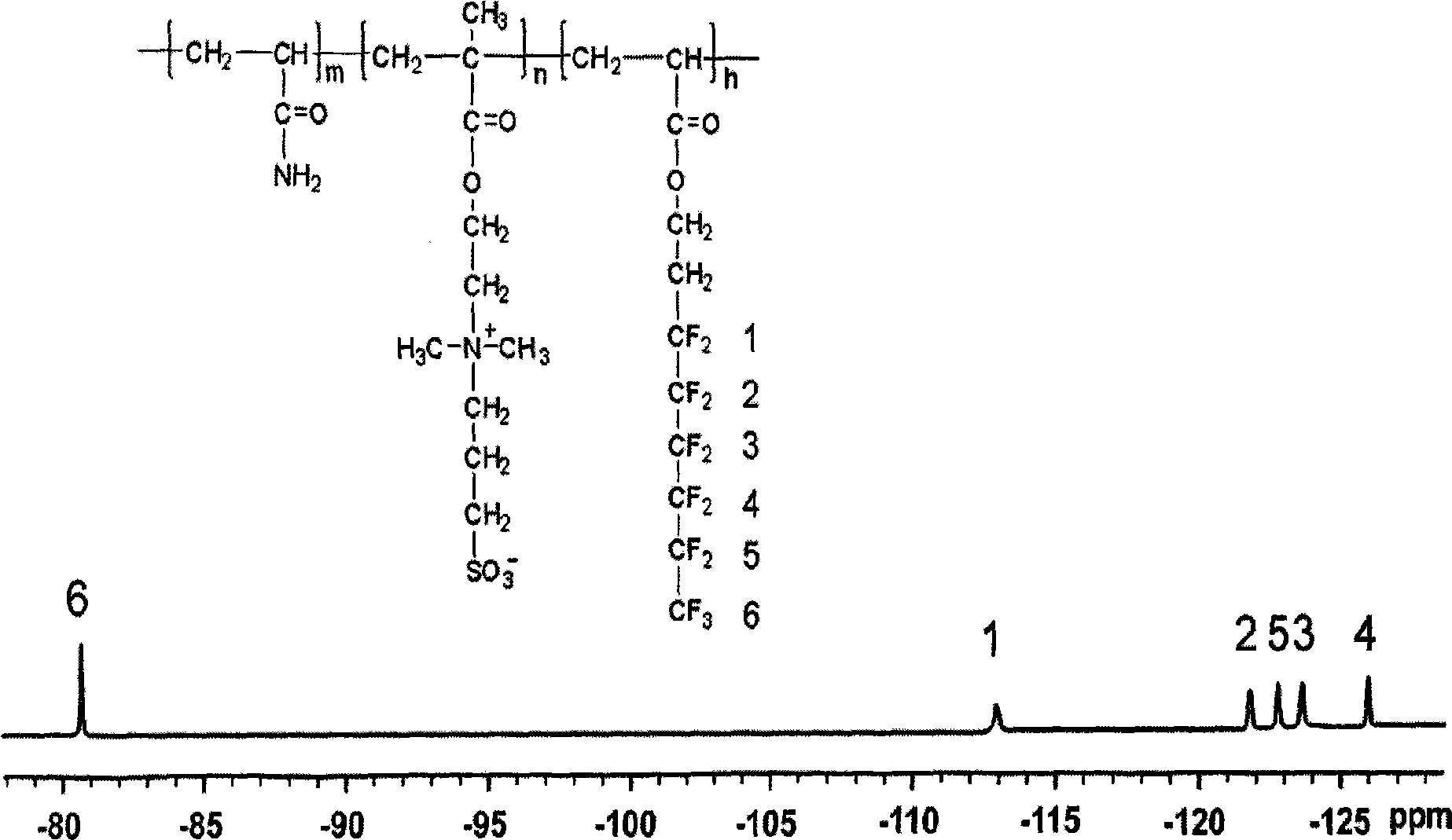

[0042] Weigh 2.2g methacryloyloxyethyl-N, N-dimethylpropanesulfonate (DMAPS) and 0.3g perfluorohexyl ethyl acrylate (PFHEA) into tube and thermometer, and measure 100mL dimethyl sulfoxide into the four-necked bottle, seal it tightly, and stir it with magnetic force to dissolve it completely. Weigh 7.5g of acrylamide (AM) into the above mixture, stir to dissolve it. Weigh and add 0.08 g of azobisisobutyronitrile (AIBN) into the above mixture, stir to dissolve, put the four-neck flask in a constant temperature water bath at 25°C, and stir for 30 minutes to pass nitrogen and remove oxygen. Then add a condenser tube with anhydrous calcium chloride drying tube on the top of the round bottom flask, raise the temperature of the water bath to 60°C and react for 12 hours to obtain a uniform viscous transparent mixture. The solid was precipitated with a mixed solution of anhydrous acetone and anhydrous ether (v / v=5:5), and dried to obtain 9.08 g of a solid product of a fluorine-contain...

Embodiment 2

[0044] As described in Example 1, the difference is that the monomer feed ratio was changed to AM 8.6g, DMAPS 1.1g, and PFHEA 0.3g to obtain 8.7g of fluorine-containing modified amphoteric water-soluble polymer powder.

Embodiment 3

[0046] As described in Example 1, the difference is that the monomer feed ratio was changed to AM 8.0g, DMAPS 1.7g, and PFHEA 0.3g to obtain 9.7g of fluorine-containing modified amphoteric water-soluble polymer powder product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com