Patents

Literature

1956 results about "Salt resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Salt sensitivity is a measure of how your blood pressure responds to salt intake. People are either salt-sensitive or salt-resistant. Those who are sensitive to salt are more likely to have high blood pressure than those who are resistant to salt.

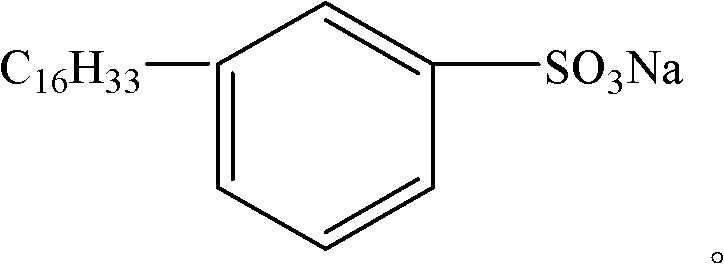

Oil-displacing agent for enhancing crude oil recovery efficiency in tertiary recovery

InactiveCN101665685AOvercome elasticityOvercome structureDrilling compositionSalt resistanceActive agent

The invention relates to an oil-displacing agent for enhancing crude oil recovery efficiency in tertiary recovery and a preparation method thereof, belonging to the technical field of intensified oilproduction in oil fields. The surface active agent used in the invention comprises following components in percentage by weight: 0.01-0.3 percent of water soluble high molecular polymer, 0-20 percentof non-ionic surface active agent, 5-65 percent of anion active agent, 0-5 percent of ampholytic active agent, 0.01-1.5 percent of additive and the balance of water. The oil-displacing agent and the polymer are based on a novel intensified oil displacing system which has complementary structure and good compatibility and is obtained by various associations and the interaction among molecules. Thesystem has the performances of high temperature resistance, salt resistance, higher viscosity, ultralow interfacial tension, and the like, is in accordance with the environmental requirement and can obviously enhance the oil recovery efficiency of oil fields after being used for oil-displacing.

Owner:TIANJIN NORMAL UNIVERSITY

Micro-ecological preparation and application thereof

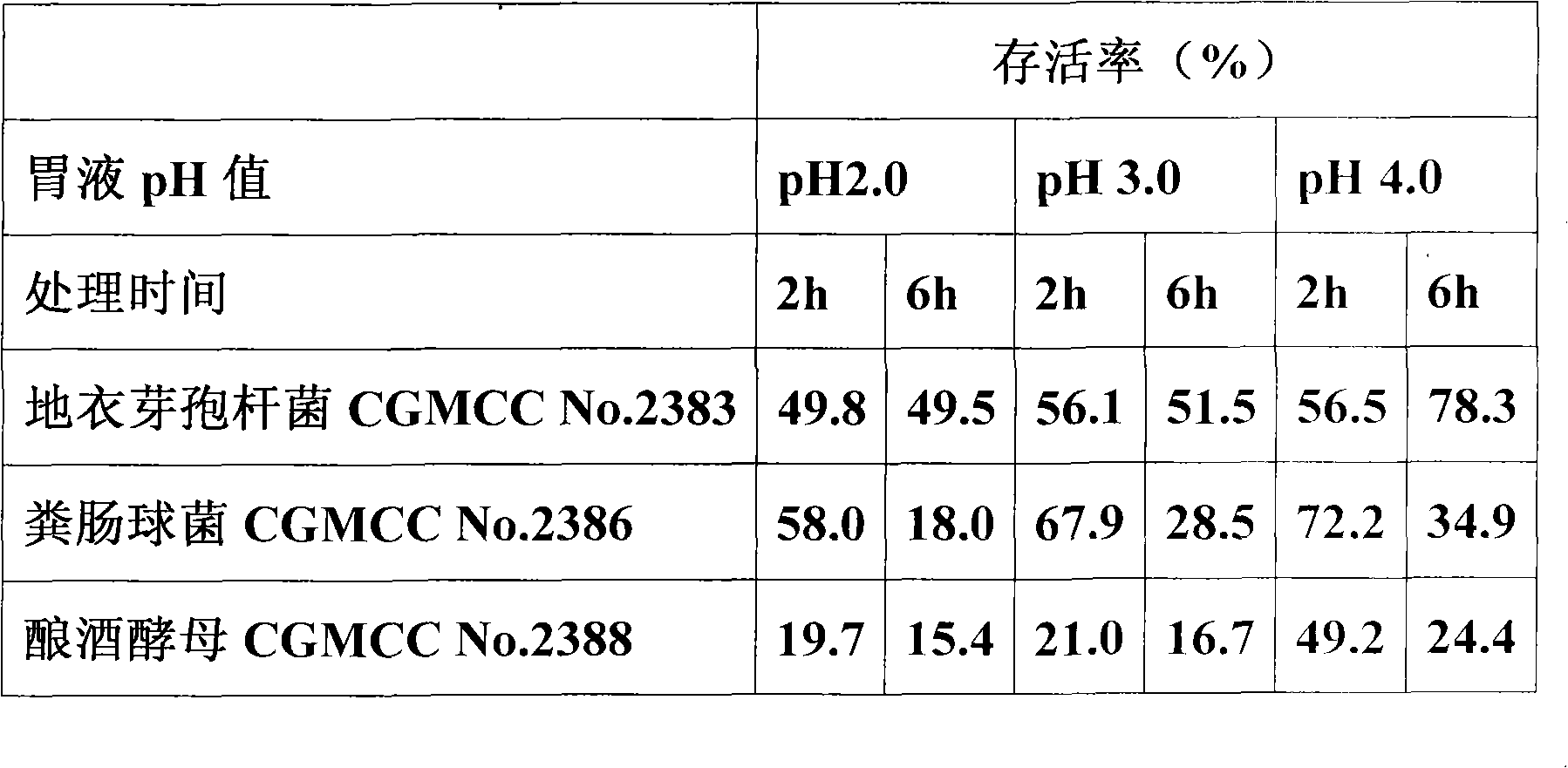

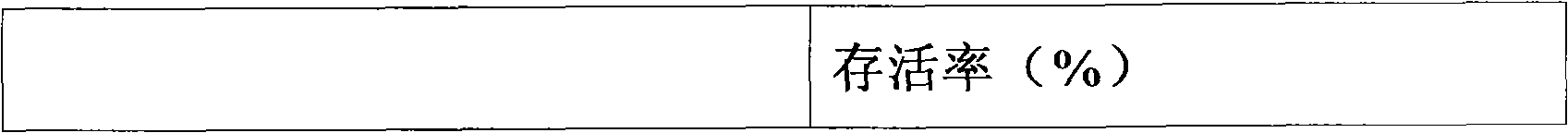

The invention relates to a micro-ecological preparation and the application thereof, in particular to a micro-ecological preparation containing a variety of probiotics and the application thereof. The micro-ecological preparation contains any three or four of the components including CGMCC No. 2383 bacillus licheniformis powder, bacillus subtilis powder, CGMCC No. 2386 enterococcus faecalis powder, lactobacillus acidophilus powder, and CGMCC No. 2388 saccharomyces cerevisiae. The micro-ecological preparation has content of live bacteria, has the adversity resistance such as gastric acid resistance, bile salt resistance, high-temperature resistance, common antibiotic resistance, and the like and the probiotic functions of producing acid and enzyme and resisting pathogenic bacteria. The variety and the proportion of the probiotics and carrier can be determined according to different kinds of animals and different animal growth phase. The micro-ecological preparation can improve the feed utilization efficiency, increase the yield of meat, eggs and milk, promote the growth of the animal, improve the immunity and the disease resistance of the animal, replace the antibiotic and improve the quality of the animal product.

Owner:BEIJING DABEINONG TECH GRP CO LTD +1

Acrylic amide modified graft copolymer, preparation method and application thereof

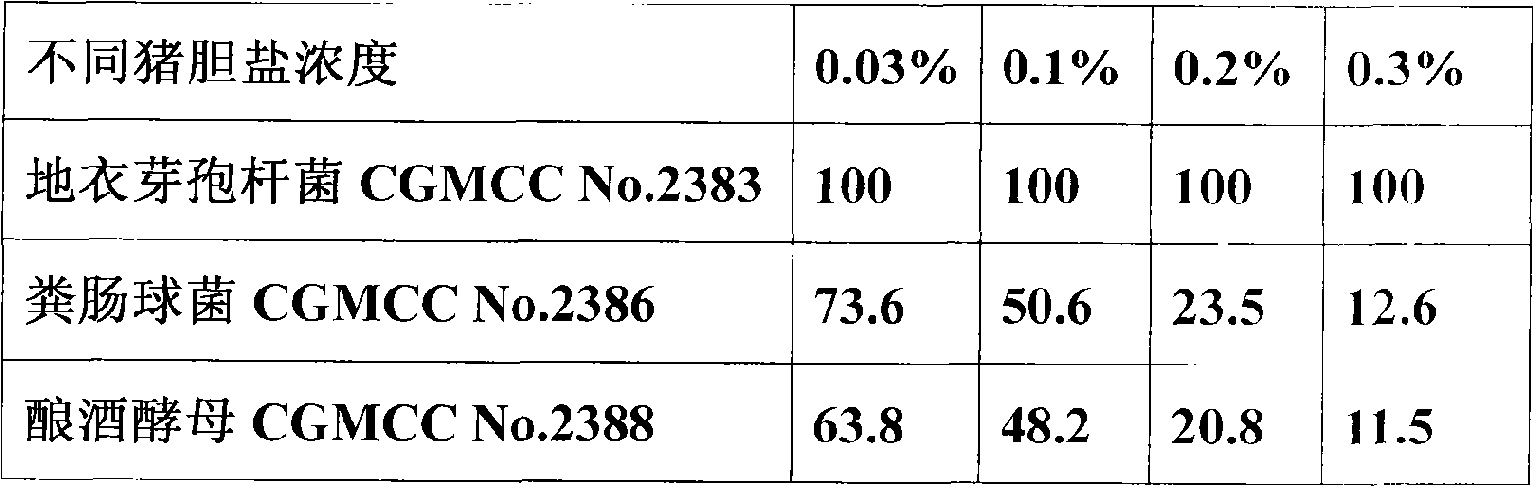

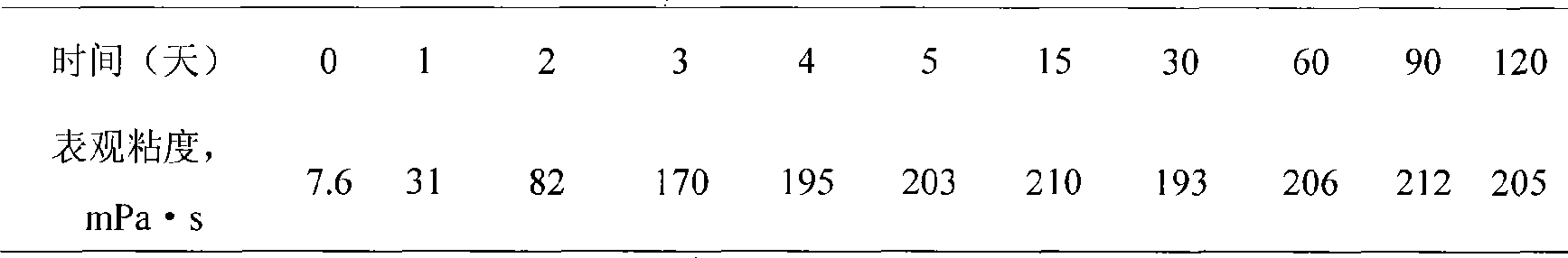

The invention discloses an acrylamide modified graft copolymer and a preparation method and usage thereof. The invention is characterized in that 20 parts of acrylamide, 1-20 anionic monomer and / or cationic monomer, 0.1-15 macromonomer, 0.05-10 ionic lyophobic monomer and 50-1000 deionized water are added into a three-necked reaction bottle, the pH value is adjusted to be 3-9, N2 is introduced for 30min, then 0.002-0.5 part of initiator persulfate is added at 30-75 DEG C, the reaction lasts 8-36h, then copolymer PAB is obtained, and finally water is used for dilution to obtain strong PAB solution. During polymerization, no surfactant is used, and the macromonomer with a long chain and the ionic lyophobic monomer with intermolecular association function are introduced into the copolymer PAB, so the capabilities of cooperative tackification and salt-resistance between the rigid conformation of a molecular chain and the intermolecular association can be played optimally, the PAB exhibits unique solution property and has higher colloidal viscosity in high saline solution than in fresh water, and the PAB obtains the capabilities of tackification, salt resistance, low surface tension and strong molecular association and can be used for the oil-displacing acrylamide modified graft copolymer. The copolymer is prepared into water solution with mass concentration of 0.2-3.0g / L and surfactant concentration of 0.01-2 mmol / L, then the water solution is added into a mixing vessel by a stirring device, and then a polymer oil-displacing agent with tackification, salt resistance and cutting resistance is obtained. The PAB has the functions of both a tackifier and a macromolecule surfactant. The copolymer PAB is prepared into water solution which has mass concentration of 0.05-7%, so the macromolecule surfactant with excellent surface activeness can be obtained and then applicable to an emulsifier, an emulsion splitter, a solubilizer and a wetting agent.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Acrylic amide modified polymer micro-crosslinking gel and preparation thereof

InactiveCN101475691AImprove solubilityGood viscosity increasing effectDrilling compositionPolymer scienceSulfite salt

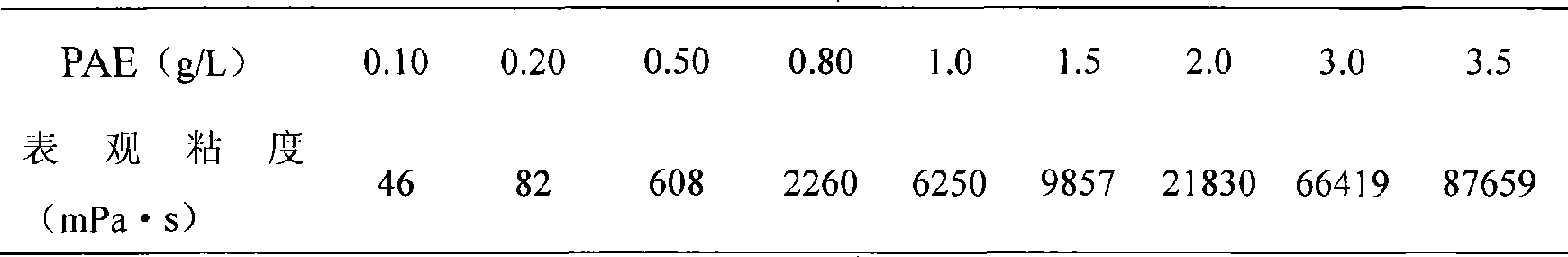

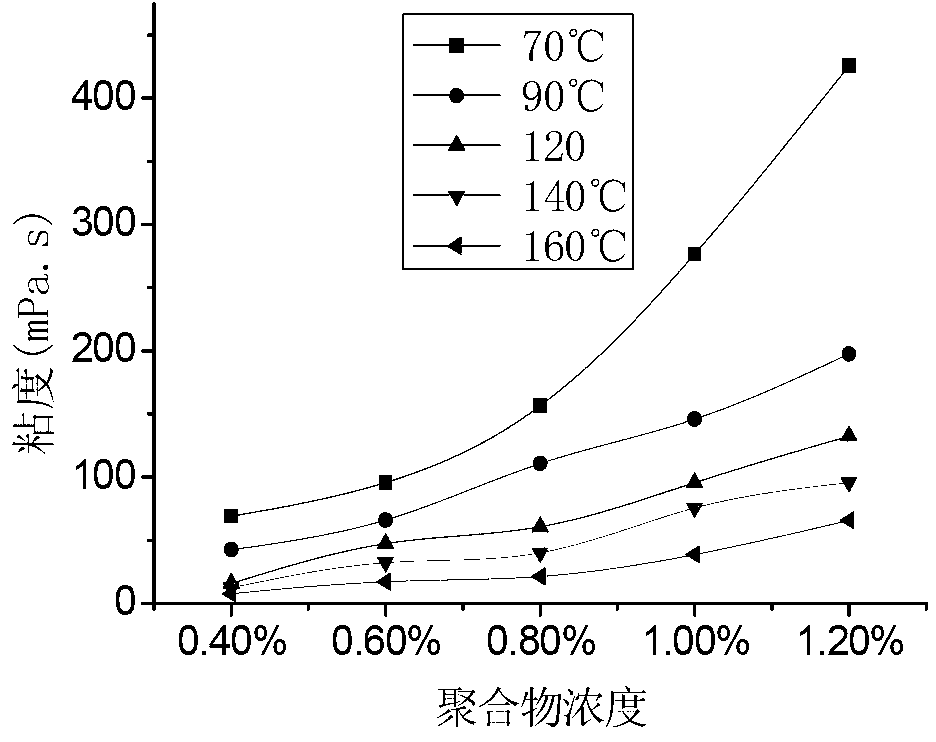

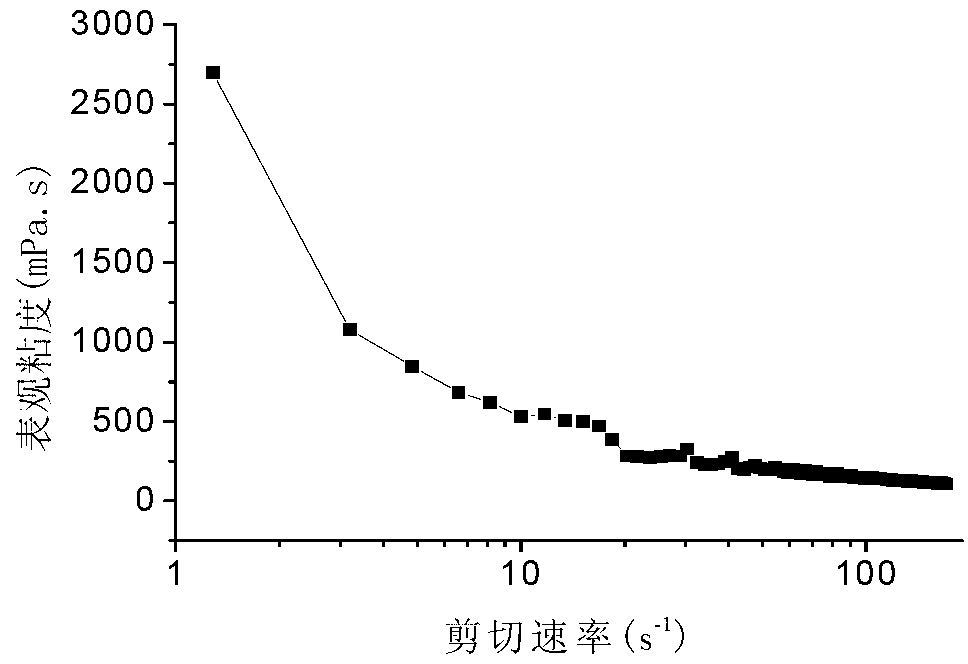

The invention discloses acrylamide modified polymer micro-crosslinking gel and a preparation method thereof. The preparation method is characterized in that the method comprises the following steps that: acrylamide modified polymer PAE containing functional macro monomer is prepared into an aqueous solution with the concentration between 0.1 and 4g / L, the concentration of crosslinking agent between 0.01 and 1.0g / L, the concentration of surface active agent between 0.01 and 8mmol / L and the concentration of heat stabilizer sodium sulfite between 0.005 and 1.0g / L; the aqueous solution is added in a mixing container with a stirring device and is stirred evenly at room temperature; the pH value of the solution is adjusted between 4 and 11 to prepare a polymer solution system of the acrylamide modified polymer micro-crosslinking gel used for tertiary oil recovery and displacement, oil displacement modification, profile modification or water plugging; and the polymer solution system undergoes micro crosslinking during flowing inside an oil layer to form the gel. The acrylamide modified polymer micro-crosslinking gel has ideal elasticity, difficult dehydration, stable performance and excellent performances on tackifying, temperature resistance, salt resistance, shearing resistance and ageing resistance.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

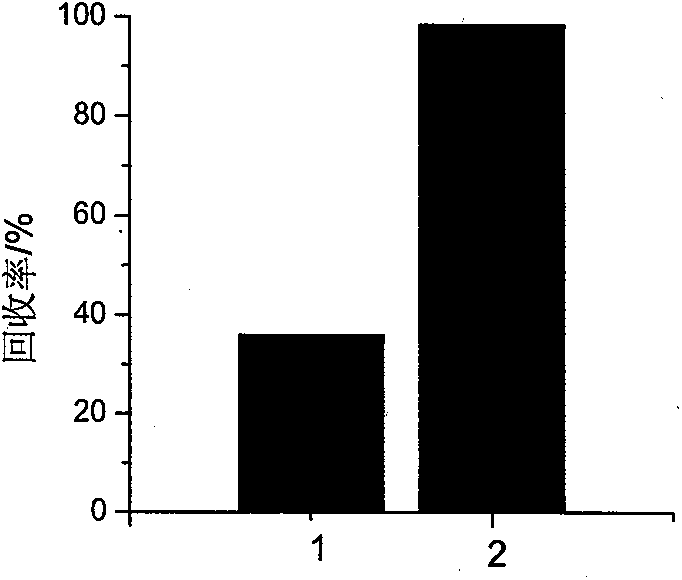

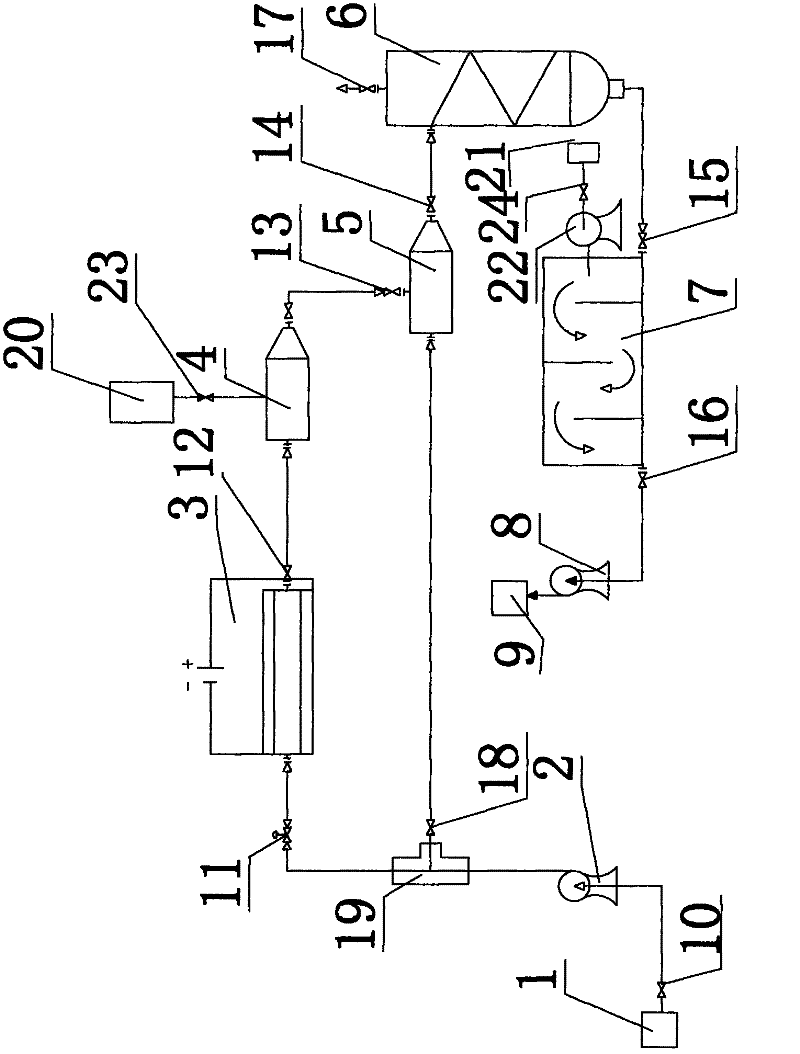

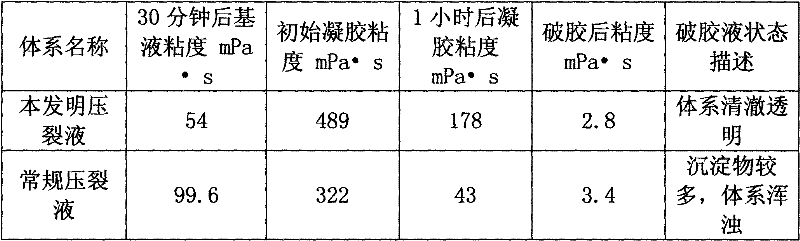

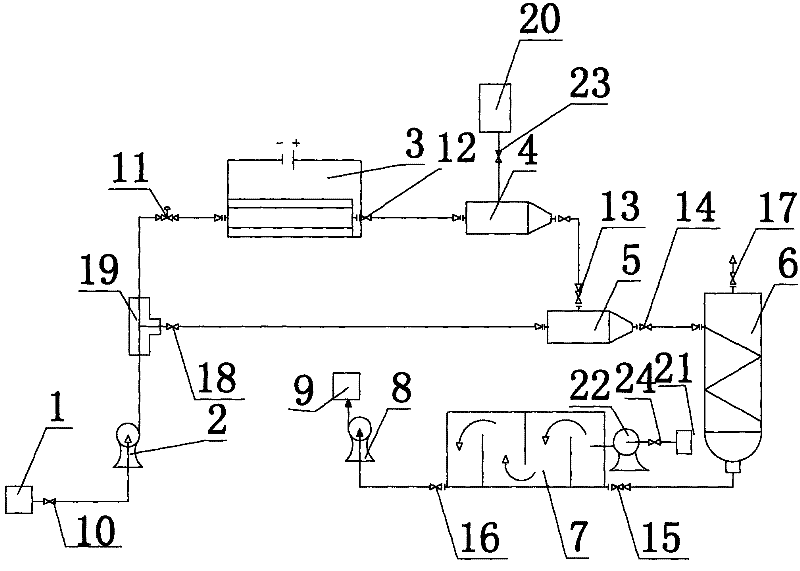

Association-type non-crosslinking fracturing fluid and preparation method thereof

Owner:SOUTHWEST PETROLEUM UNIV

High adhesion-promotion salt resistant water-soluble copolymer, preparation method and application thereof

InactiveCN101293944AImprove salt resistanceGood viscosity increasing effectDrilling compositionPolymer scienceBottle

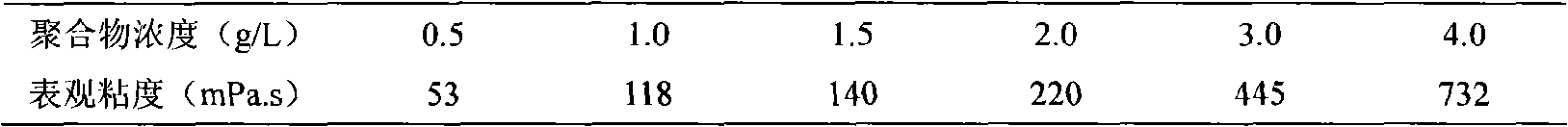

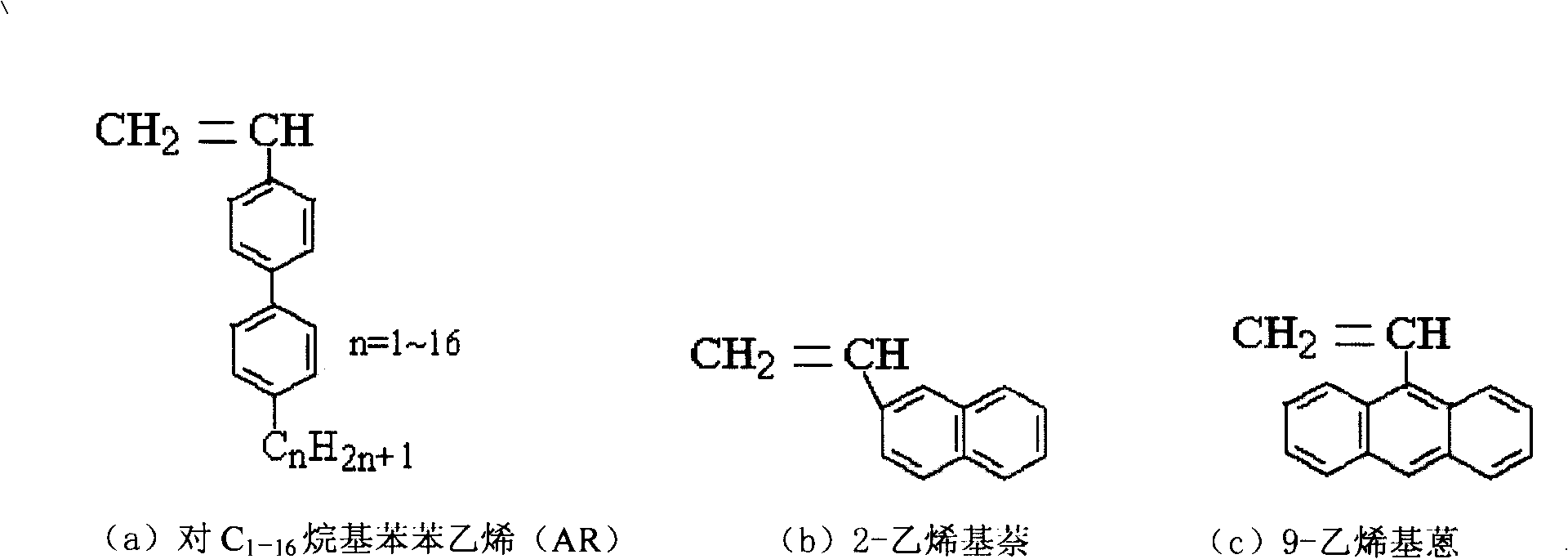

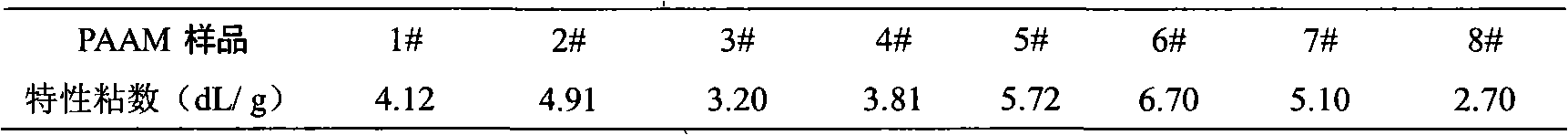

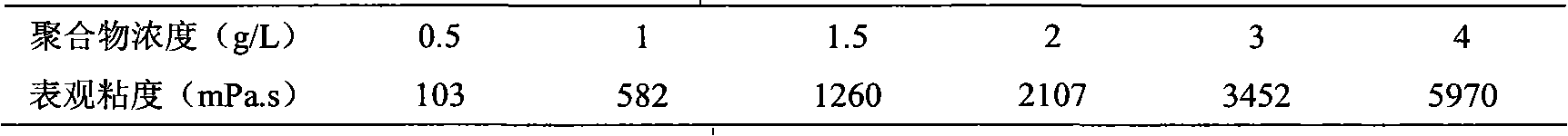

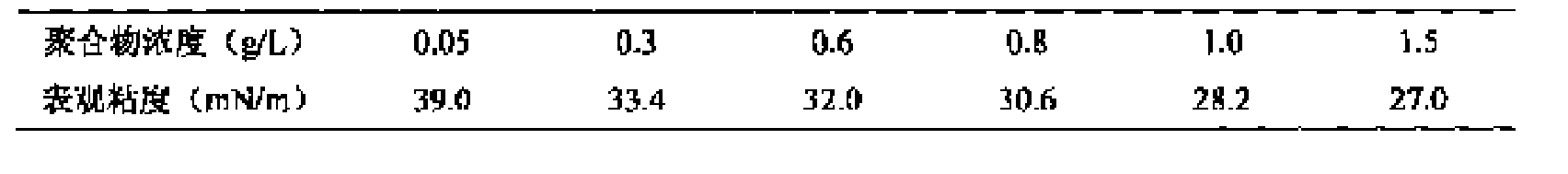

The invention discloses a water soluble copolymer with high viscosity and salt resistance, and a preparation method and an application thereof. The preparation method comprises the steps of: adding acrylamide 20 weight parts, an anionic monomer or / and a cationic monomer 0.1-15 weight parts,, a vinyl polycyclic aromatic hydrocarbon 0.05-4 weight parts,, a surfactant 0.5-90 weight parts,, and deionized water 70-900 weight parts, into a three-neck reaction bottle, adjusting the solution pH to 2.5-9, introducing N2 for 30min, adding an initiator persulfate 0.001-0.2 weight parts, at 20-70DEG C, and reacting for 6-36 hours to obtain a low-molecular weight water soluble copolymer with molecular association ability, high viscosity and salt resistance, which can be used in intermediate-permeability oil reservoir and low-permeability oil reservoir development. An associated water soluble polymer oil displacement agent is obtained by preparing the copolymer into an aqueous solution with copolymer concentration of 0.3-3 g / L and surfactant concentration of 0.01-4 mmol / L, adding into a mixer with a stirring device, and stirring uniformly at room temperature; and the obtained oil displacement agent has high viscosity, salt resistance, temperature resistance and shear resistance, and can be used in intermediate-permeability oil reservoir and the low-permeability oil reservoir development.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

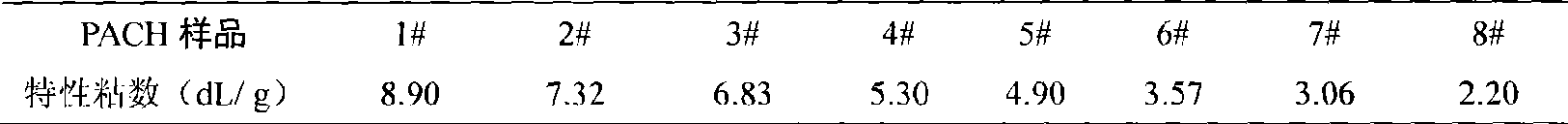

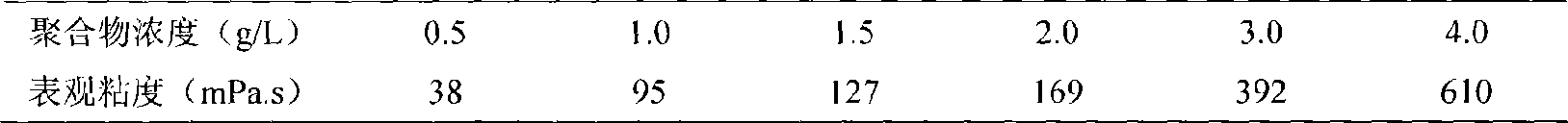

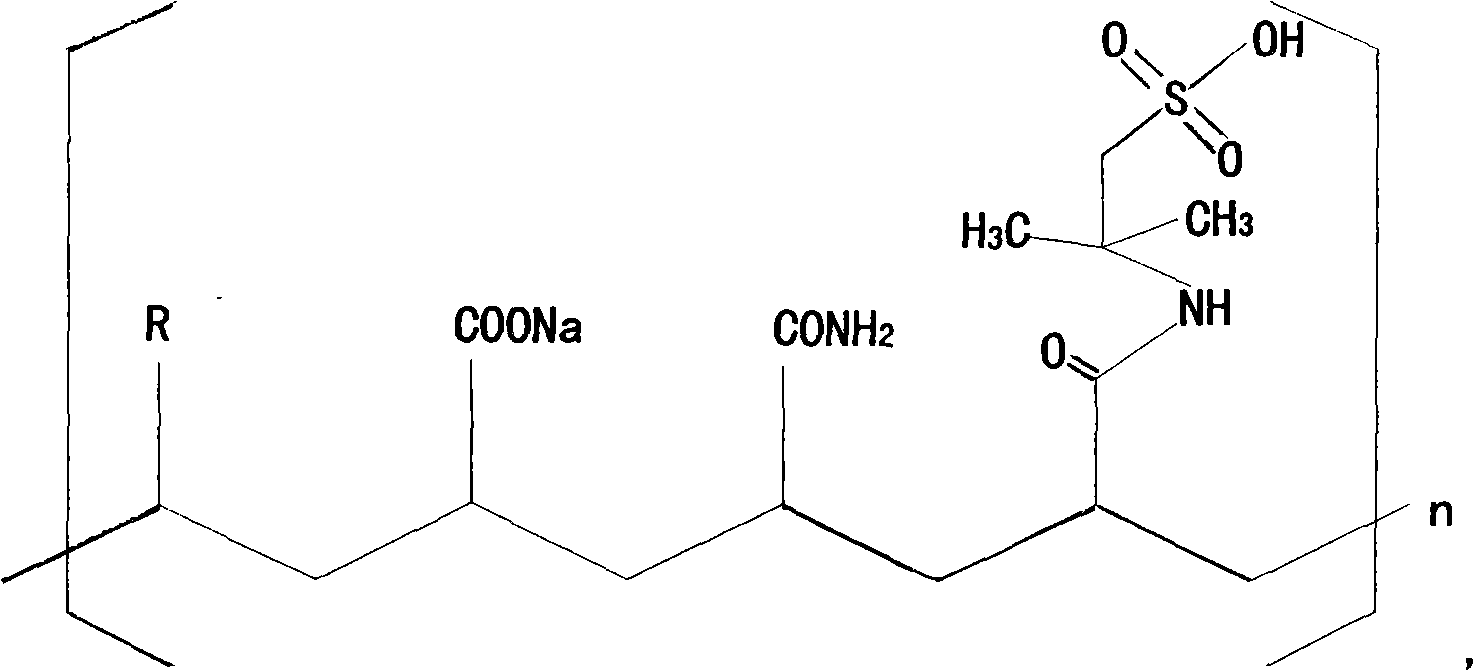

Non-linear associating water-soluble quadripolymer, and preparation and use thereof

InactiveCN101463116AImprove rigidityHigh temperature resistanceTransportation and packagingMixingIonChemistry

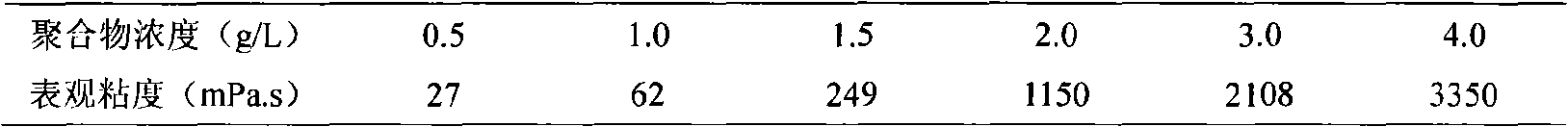

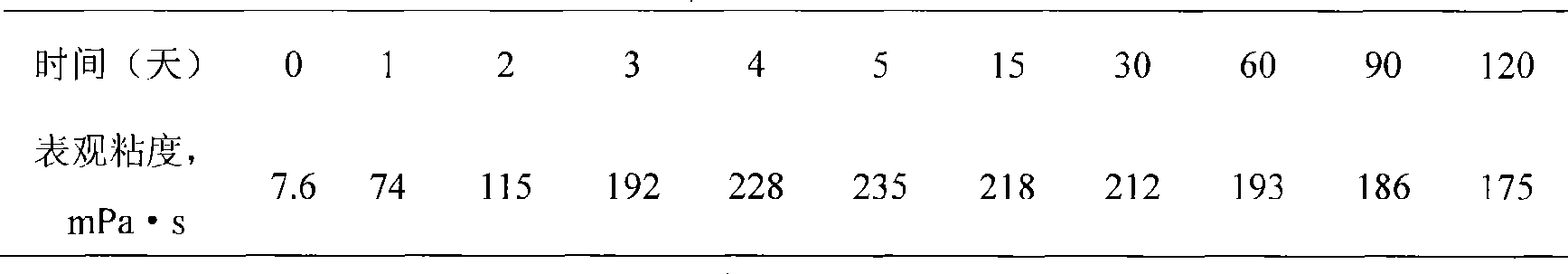

The invention discloses a non-linear associated water soluble quadripolymer as well as a preparation method and use thereof, comprising: adding 20 parts of acrylamide, 1-20 parts of nionic monomer or / and cationic monomer, 0.1-15 parts of macromonomer, 0.05-10 parts of hydrophobic monomer, 0.1-50 parts of surfactant and 60-1000 parts of deionized water to a three-necked reaction flask, adjusting the pH to be 3-9, adding 0.002-1 part of initiator (persulphate) at 30-75 DEG C after introducing N2 for 30min, reacting for 8-36h to obtain the quadripolymer PACH, diluting with water, and obtaining concentrated PACH solution. The macromonomer with a long chain and the hydrophobic monomer with a molecular association function are simultaneously introduced in a copolymer PACH, which can obtain the best synergistic viscosifying between rigid conformation of a molecular chain and molecular association and salt resistance. The non-linear associated water soluble quadripolymer is obtained. The copolymer is prepared into aqueous solution with the mass concentration of 0.2-3g / l and the surfactant concentration of 0.01-2mmol / l, added to a mixing vessel with a stirring device and evenly stirred at the room temperature to obtain a viscosified, salt-resistant and shear-resistant polymer oil displacement agent. The PACH has dual functions of a viscosifier and a high molecular surfactant; minute amount of a low molecular surfactant is added to the PACH solution, thus improving the apparent viscosity of the solution, reducing the surface tension of solution and the water-oil interfacial tension, and being beneficial to improving the crude oil recovery ratio. A copolymer PABE is prepared into the aqueous solution with the mass concentration of 0.05-7% to obtain high molecular surfactant with excellent surface activity, and the high molecular surfactant is used as an emulsifier, a demulsifier, a solubilizer and a wetting agent.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

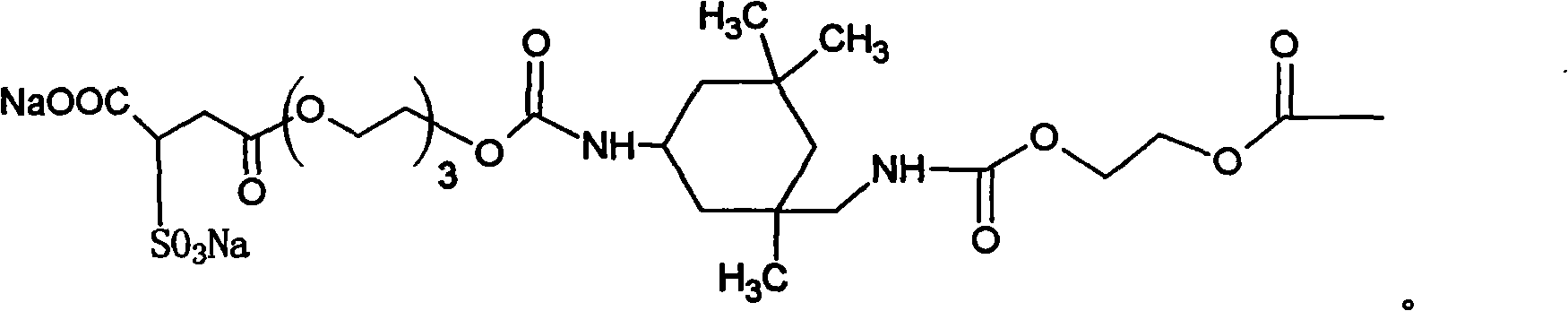

Comb-type structure activity polymer and its preparation technique and application

InactiveCN101260171AGood water solubilityHigh molecular weightDrilling compositionFunctional monomerHigh surface

The invention discloses a comb-type structural reactive polymer with the molecular weight ranging between 1x10<5> and 5x10<6>, wherein the main chain of the reactive polymer is obtained through the copolymerization of acrylamide monomer and functional monomers such as 2-acrylamido-2-methylpropanesulfonic acid and acrylic acid sodium salt, etc., which endues polymer aqueous solution with higher apparent viscosity and better temperature resistance and salt resistance; and the branched chain of the reactive polymer consists of unsaturated macromonomer molecule, which endues the polymer aqueous solution with higher surface activity. The invention also discloses a preparation method for the polymer, comprising the following steps: firstly, through process operation including esterification, prepolymerization and sulfonation, polyurethanes active macromonomer with a novel structure is prepared; then, under the action of oxidation reduction initiator, the copolymerization reaction of the active macromonomer and other functional micromolecule monomers is initiated quickly at low temperature. The comb-type structural reactive polymer can be used as oil displacement agent and has the advantages of high molecular weight and low surface tension, etc.

Owner:SHANDONG UNIV

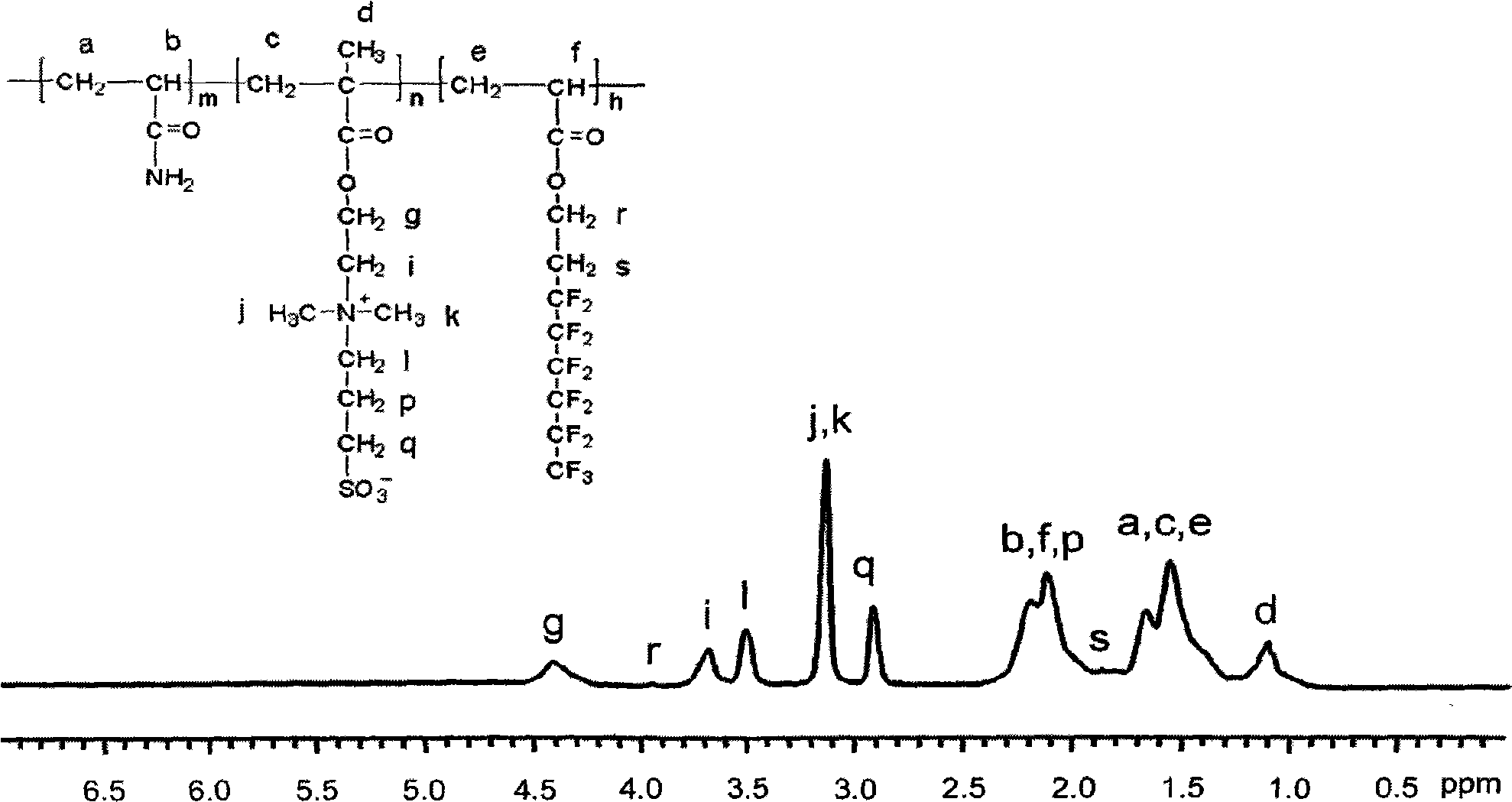

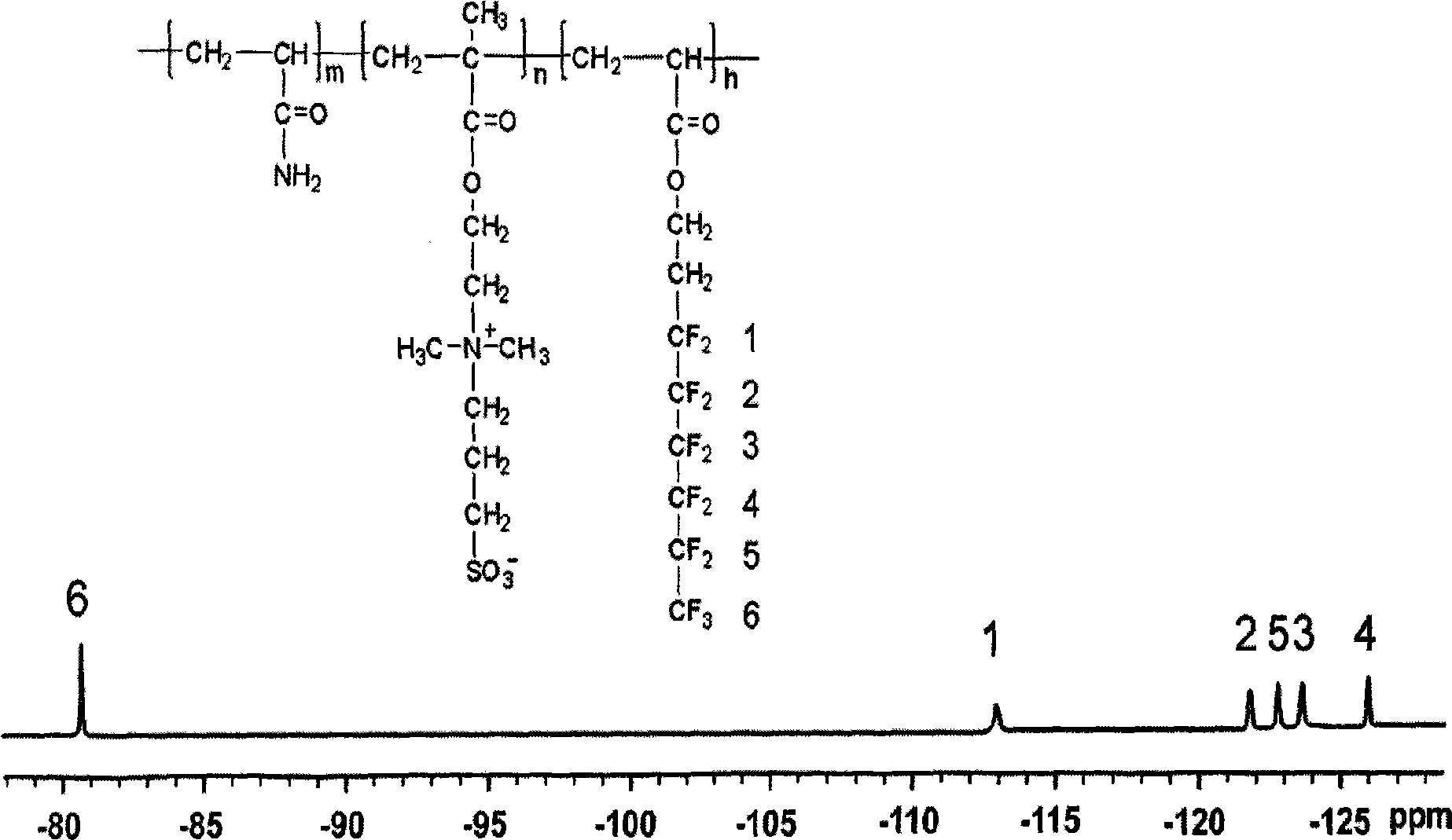

Method for preparing fluorine-containing modified amphoteric water-soluble polymer

The invention relates to a method for preparing a fluorine-containing modified amphoteric water-soluble polymer, in particular to a method for preparing the fluorine-containing modified amphoteric water-soluble polymer by a cosolvent method and belongs to the technical field of water-soluble macromolecular synthesis. Methacryloyl ethyl-N and N-dimethyl propanesulfonic acid (DMAPS) as amphoteric monomers and perfluoro hexyl ethyl acrylate (PFHEA) and acrylamide (AM) as hydrophobic monomers are copolymerized in a single solvent; azobisisobutyronitrile (AIBN) is used as a catalyst; and the fluorine-containing modified amphoteric water-soluble polymer is obtained. The polymer has good water solubility and remarkable interface activity, thickening, shearing resistance, temperature resistance and salt resistance. Through a mixed solution of anhydrous acetone and anhydrous ether, the polymer is precipitated, dried and pulverized to obtain a powdery product; and the powdery product has wide application prospect in the development of an oil field, dope, printing, household chemical, medicament and other fields.

Owner:SHANDONG UNIV

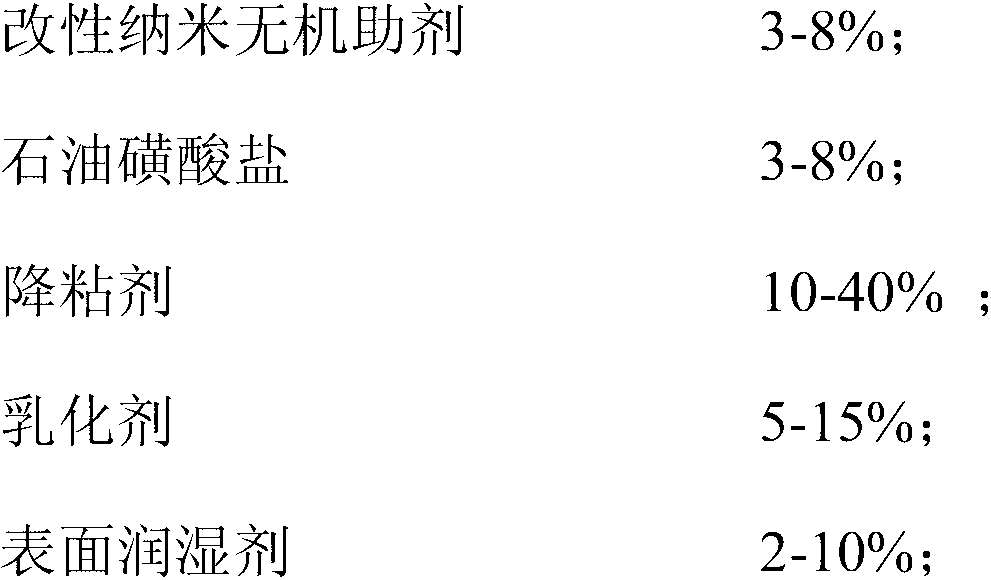

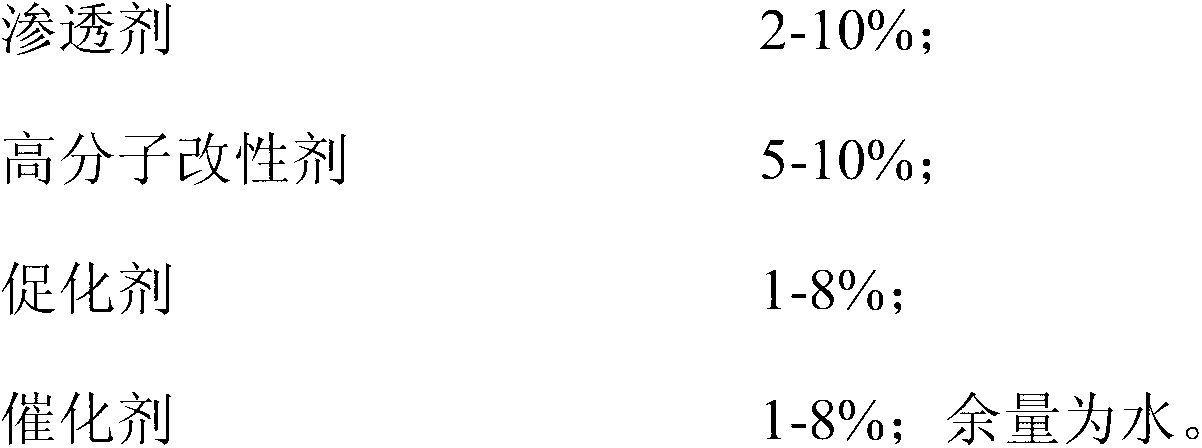

Nano composite high-temperature-resistant extraction aid for thickened oil and super-thickened oil recovery and preparation method thereof

ActiveCN103320110AGood viscosity reductionReduce dosageDrilling compositionSalt resistanceTemperature resistance

The invention discloses a nano composite high-temperature-resistant extraction aid for thickened oil and super-thickened oil recovery. The nano composite high-temperature-resistant extraction aid is prepared from 3-8 weight percent of modified nano-silica, 3-8 weight percent of petroleum sulfonate, 10-40 weight percent of a viscosity reducer, 5-15 weight percent of an emulsifier, 2-10 weight percent of a surface wetting agent, 2-10 weight percent of a penetrating agent, 5-10 weight percent of a high polymer modifier, 1-8 weight percent of a catalyst and the balance of water. The preparation method comprises the following steps: polymerizing the petroleum sulfonate, viscosity reducer, a promoting agent and the catalyst at the temperature of 60-150 DEG C for 2-6 hours according to a ratio, adding the modified nano inorganic aid, and uniformly mixing; and finally, adding the emulsifier, surface wetting agent, penetrating agent, high polymer modifier and water according to the ratio, and mixing for 1-2 hours. The nano composite high-temperature-resistant extraction aid for thickened oil and super-thickened oil recovery has high high-temperature resistance and excellent emulsification and salt resistance, the production efficiency can be greatly improved, and the recovery rate is reduced.

Owner:GUNGHO CHARGE TIANJIN REFINED PETROLEUM TECH DEV

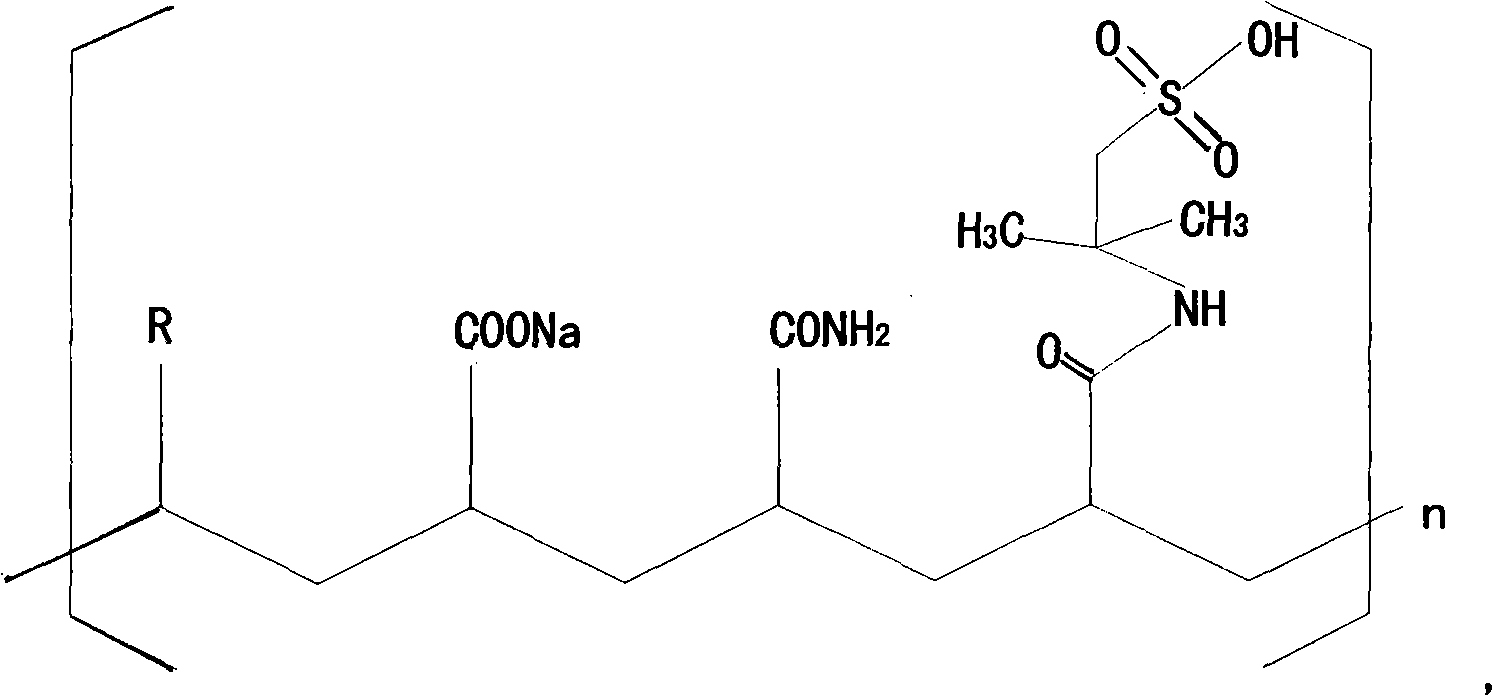

Temperature and salt resistant copolymer for oil field and preparation method thereof

ActiveCN102372818AAvoid hydrolysisImprove stabilityDrilling compositionSalt resistanceFracturing fluid

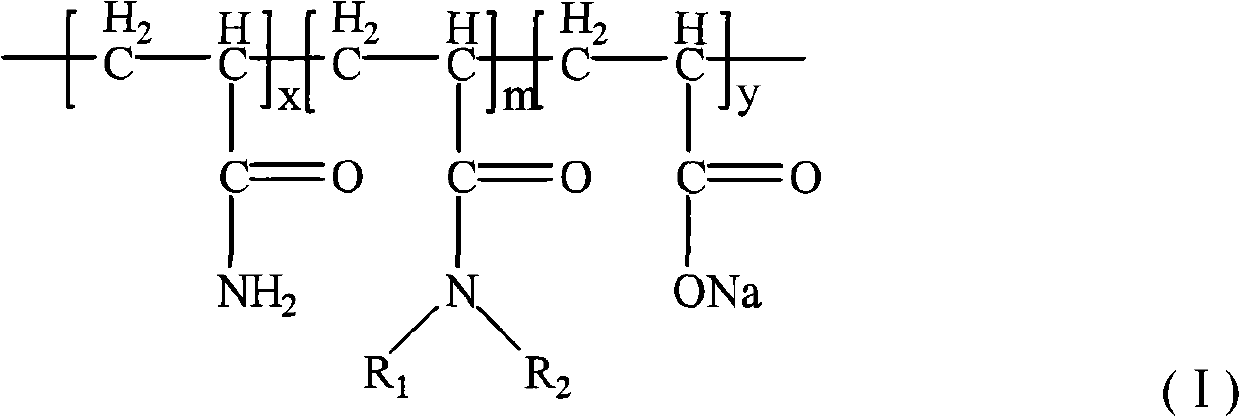

The invention relates to a temperature and salt resistant copolymer KWKY-PAD for oil field and a preparation method thereof, and mainly solves the problem that polyacrylamide is easy to hydrolyze at high temperature and high salinity in the prior art. The temperature and salt resistant copolymer KWKY-PAD as shown in formula (I) is obtained by the copolymerization of acrylamide and a N-alkyl substituted acrylamide derivative. The technical scheme provided by the invention greatly solves the problem. By the adoption of the preparation method, the hydrolytic stability of the copolymer is raised,and the copolymer has good viscosifying ability and hydrolytic stability at high temperature and high salinity as well as good temperature and salt resistance. The copolymer provided by the inventioncan be used in an oil displacement agent for oil extraction in oil field, and also can be used in oil field application fields of a thickening agent of fracturing fluids, a water plugging profile modification agent, a drilling fluid processing agent and the like. In addition, the preparation method requires less monomer, is simple and is suitable for industrialization.

Owner:CHINA PETROLEUM & CHEM CORP +1

Salt- and temperature-resistant emulsification viscosity reducer for heavy oil

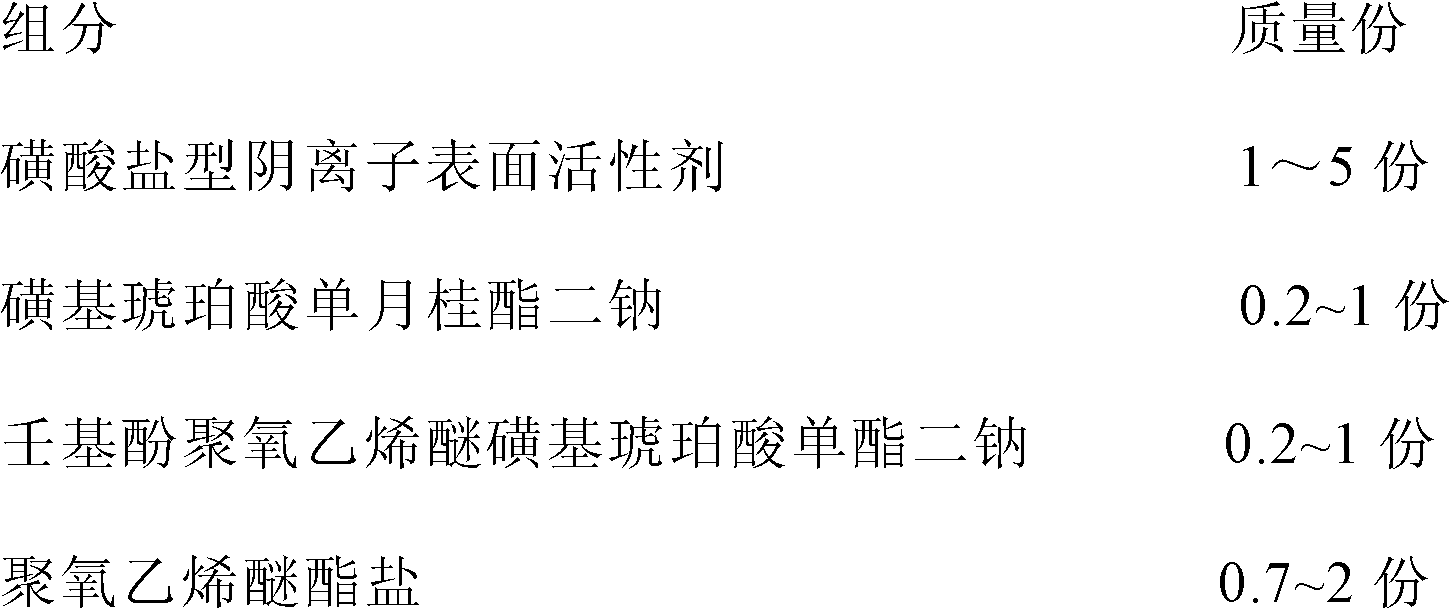

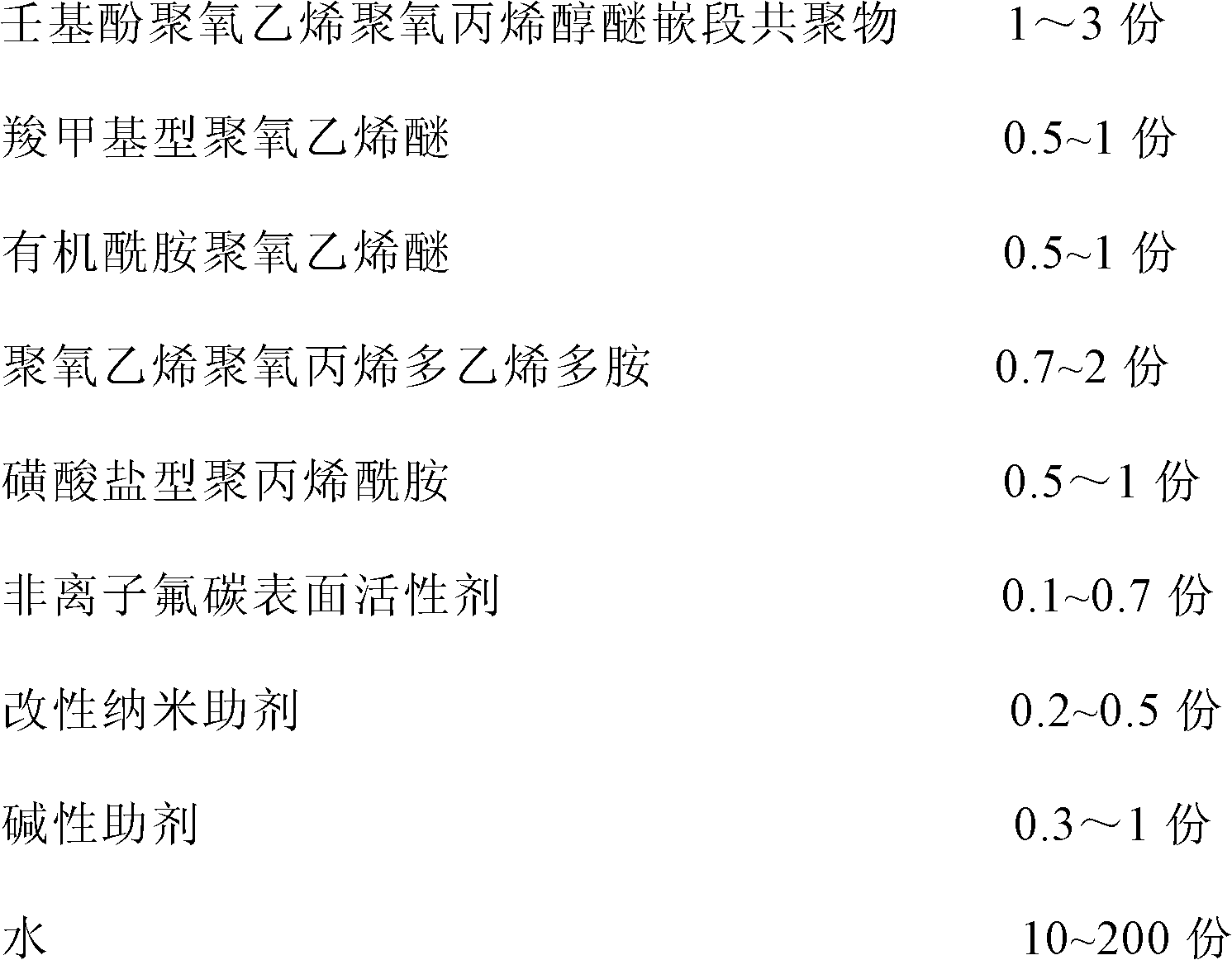

The invention relates to a salt- and temperature-resistant emulsification viscosity reducer for thick oil. The emulsification viscosity reducer is applied in oil fields for emulsification viscosity reduction of heavy oil and super heavy oil and is characterized by comprising the following components by mass: 1 to 5 parts of sulfonate anionic surfactant, 0.2 to 1 part of disodium monolauryl sulfosuccinate, 0.2 to 1 part of polyoxyethylene nonylphenyl ether disodium monoester sulfosuccinate, 0.7 to 2 parts of polyoxyethylene ether ester salt, 1 to 3 parts of polyoxyethylene nonylphenyl-polyoxypropylene alcohol ether block copolymer, 0.5 to 1 part of carboxymethyl polyoxyethylene ether, 0.5 to 1 part of organic amide polyoxyethylene ether, 0.7 to 2 parts of polyoxyethylene polyoxypropylene polyethylene polyamine, 0.5 to 1 part of sulfonate polyacrylamide, 0.1 to 0.7 part of nonionic fluorocarbon surfactant, 0.2 to 0.5 part of a modification nanometer auxiliary agent, 0.3 to 1 part of an alkalescence auxiliary agent and 10 to 200 parts of water. The beneficial effects of the emulsification viscosity reducer are as follows: salt resistance is up to 24*10<4> mg / L, resistance to a temperature as high as 150 DEG C is realized, and emulsification viscosity reduction of super heavy oil with a viscosity of 500 Pa.s at a temperature of 50 DEG C is realized.

Owner:PETROCHINA CO LTD

Method for preparing salt-resistant stain-resistant bentonite with adsorption function

ActiveCN104030308AIncrease the areaHigh ion exchange capacitySilicon compoundsContaminated waterStain

The invention provides a method for preparing salt-resistant stain-resistant bentonite with adsorption function. The method comprises the following steps: performing sodium treatment, namely milling natural calcium bentonite to pass through a sieve with the granularity of 50-150 meshes, adding the bentonite into an aqueous solution of a sodium treatment agent, stirring, performing sodium treatment and reacting at the temperature of 50-90 DEG C for 1-4 hours, and drying to obtain sodium-based bentonite; and modifying, namely milling the sodium-based bentonite to pass through a sieve with the granularity of 150-250 meshes, drying and mixing with a modifier at normal temperature, and obtaining the product. The bentonite prepared by the method is high in expansibility, has high salt resistance, high stain resistance and good adsorption performance, can be used for underground seepage prevention of high salinity complex water bodies and also can be used for treating heavy metal ions and organic pollutants in contaminated water.

Owner:HOHAI UNIV

Surface treatment method of aluminum alloy and treatment liquid

InactiveCN101709459AImprove anti-corrosion performanceUniform thicknessLiquid/solution decomposition chemical coatingSalt resistanceChemical plating

The invention relates to a surface treatment method of aluminum alloy, which comprises the following steps of: pre-treating: removing oil stains on the aluminum alloy surface by adopting an alkali degreasing solution; alkali washing: purifying the aluminum alloy surface at 50-60 DEG C by adopting alkali wash to remove a natural oxide film on the aluminum alloy surface; acid pickling: treating the aluminum alloy surface at room temperature for 1-5 minutes by adopting a pickling solution to further remove residual spots left on the aluminum alloy surface after alkali washing; and chemically plating Ni-P: forming a Ni-P plating layer on the aluminum alloy surface by adopting a pre-prepared chemical plating Ni solution with pH value of 5-6.5 at 85-90 DEG C for 90-240 minutes. By adopting a chemical plating Ni-P layer process to form a uniform favorable plating layer with good acid resistance, alkali resistance and salt resistance outside an aluminum alloy shell, the invention avoids the phenomena of uneven thickness of a protective layer and spraying missing on a complex structure part, and remarkably improves the anticorrosion performance of the aluminum alloy.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Epoxy ester modified aqueous alkyd resin and preparation method thereof

The invention discloses an epoxy ester modified aqueous alkyd resin and a preparation method thereof. The method comprises the following steps of: preparing alkyd resin, synthesizing epoxy ester, and synthesizing the epoxy ester modified aqueous alkyd resin: stirring and mixing epoxy ester and basic alkyd resin in mass ratio of 0.2:1-0.5:1, 1-3 parts of organic tin catalyst and 5-15 parts of dimethyl benzene, and performing reflux reaction at the temperature of 180 DEG C for 1-2 hours until the acid value is measured to be less than 7mgKOH / g; and water-dissolving the modified alkyd resin. A product provided by the invention keeps superior performances of paint dryness, glossiness, durability, flexibility, hardness, higher solubility and the like of the alkyd resin, has superior cohesive property, salt fog resistance and good self-drying property of the epoxy resin, and can keep that a coating has superior solvent resistance and chemical resistance.

Owner:SOUTH CHINA UNIV OF TECH

Hydrophobically associating polymer and mixed surfactant binary compound oil displacement system

InactiveCN102504794ATemperature resistanceImprove salt toleranceDrilling compositionSalt resistancePolymer science

The invention relates to a hydrophobically associating polymer and mixed surfactant binary compound oil displacement system for use in tertiary oil extraction. The system mainly comprises the following components in percentage by weight: 0.1 to 0.3 percent of hydrophobically associating polymer, 0.1 to 0.6 percent of surfactant and 99.2 to 99.8 percent of water. The hydrophobically associating polymer in the system has high temperature resistance, high salt resistance and viscosity increasing capacity and can largely reduce dosage of polymer; and with high solubilizing capacity, the polymer can increase the dissolution of the surfactant in sewage, thereby increasing the use concentration of the surfactant. The oil displacement system which is dissolved by sewage from extraction can save lots of fresh water; with high viscosity increasing capacity, the system can effectively control flow rate, increase swept volume, increase oil water interface tension to 10<-3>mN / m and increase the oil extraction rate; and because of high stability and injection property, the system can be injected in large dose. According to an indoor oil displacement experiment, the binary compound oil displacement system can improve the extraction rate by over 20 percent compared with that of water displacement. The system without alkali avoids serious damage to the oil layer and corrosion and damage to oilpipes and has a great application prospect.

Owner:SOUTHWEST PETROLEUM UNIV

Composite surfactant and preparation method thereof

InactiveCN103965851AOrganic compound preparationSulfonic acids salts preparationSalt resistanceAlcohol

The invention relates to a composite surfactant and a preparation method thereof, and mainly solves the problems of bad interface activity, bad temperature and salt resistance, and oil-water interface tension force rise caused by concentration reduction in a stratum migration process of surfactants used as a main component of oil displacement agent systems in the prior art. The composite surfactant is an alkyl alcohol or alkyl phenol polyoxyethylene polyoxypropylene ether carboxylate or sulfonate and zwitterionic surfactant composite surfactant, can well solve the problems, and can be used in tertiary oil recovery production of oilfields.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polyacrylamide inorganic nano composite drilling fluid aid and preparation method thereof

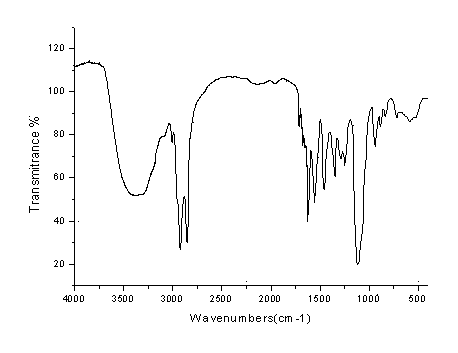

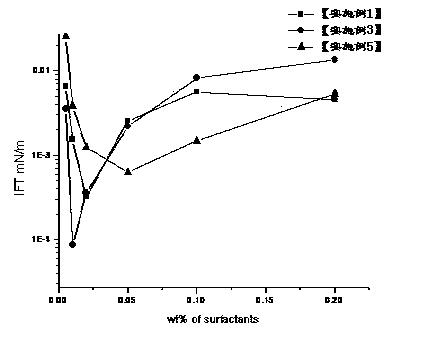

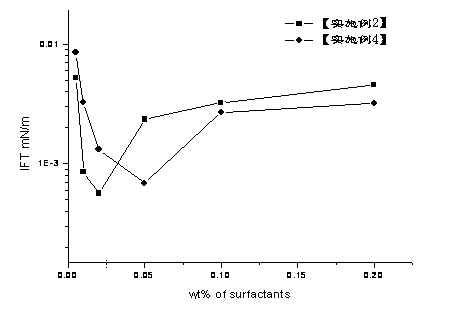

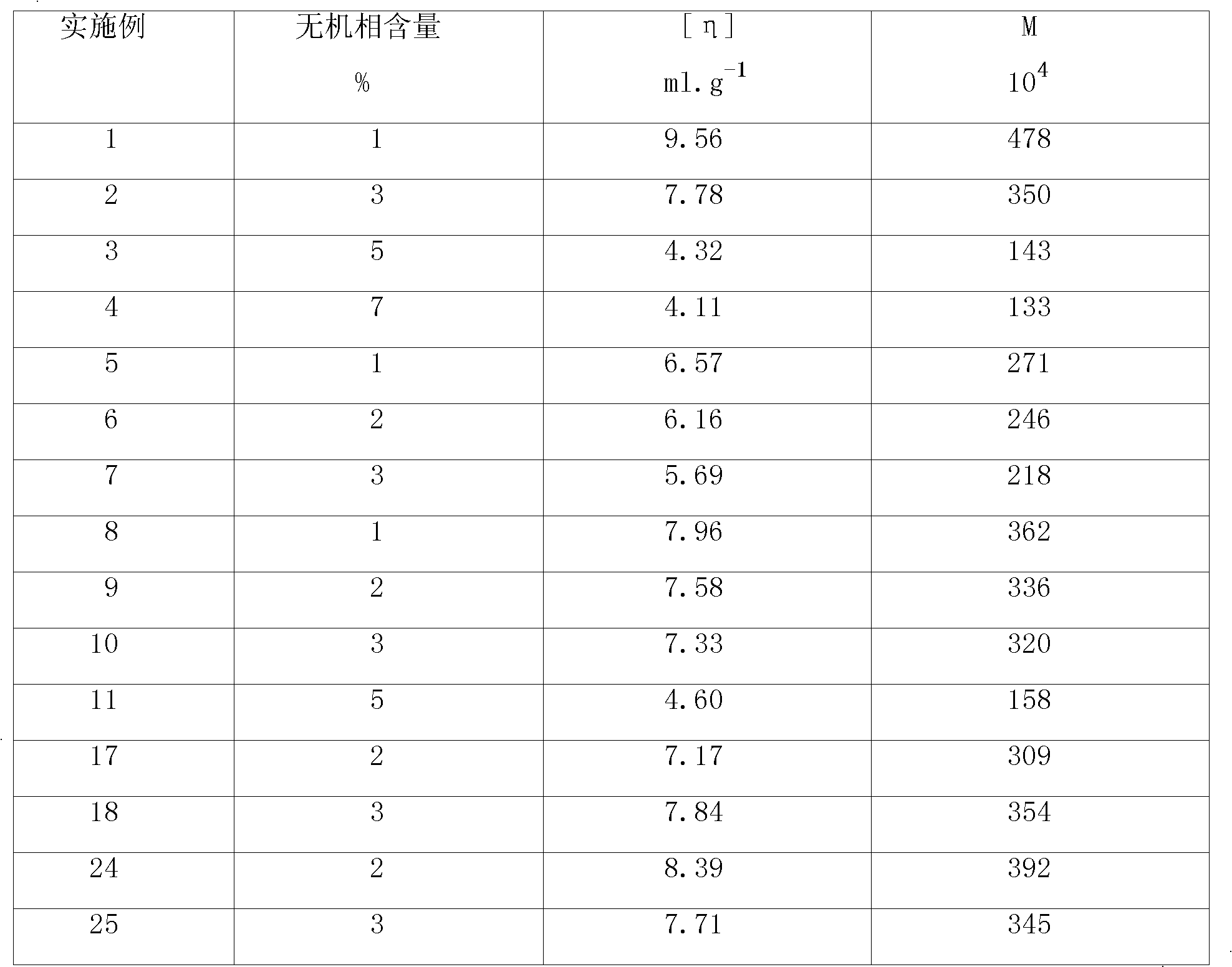

The invention discloses a polyacrylamide inorganic nano composite material prepared by adopting a polymerization composite method of polyacrylamide and nano inorganic phase and a drilling fluid aid. The inorganic material is nano dispersed suspension formed by co-precipitation hydrothermal reaction and surface treatment reaction of laminated silicate, nitrate or the both. The suspension is mixed with acrylamide aqueous solution, cosolvent and complexing agent; and the mixture is polymerized under the initiation of persulfate and sulfite to form the polyacrylamide nano composite material with proper molecular weight, good water solubility and good tackifying effect, wherein the dimension of the inorganic phase is 30 to 70 nanometers. The drilling fluid prepared from the composite material has remarkable viscosity increment, good rheological property and filtration control, temperature and salt resistance and protection property on a reservoir layer, and improves the yield and recovery rate.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Carbon dioxide foam system added with hydrophilic nanoparticles for oil displacement and preparation method for carbon dioxide foam system

ActiveCN105038756ADiffusion rate is fastObvious disproportionationDrilling compositionSalt resistanceInorganic salts

The invention relates to a carbon dioxide foam system added with hydrophilic nanoparticles for oil displacement and a preparation method for the carbon dioxide foam system. The carbon dioxide foam system is prepared from the following components in parts by mass: 0.1-0.3 part of a nonionic surfactant, 1-2 parts of hydrophilic nanoparticles, 0.01-0.2 part of inorganic salt, 0.2-0.8 part of carbon dioxide and 100 parts of water. The preparation method comprises: after preparing a foaming agent in proportion, uniformly dispersing the foaming agent by using an ultrasonic wave dispersing instrument; and introducing carbon dioxide into a stirring cup and stirring the mixture by virtue of a Waring Blender method to obtain the carbon dioxide foam system. Compared to carbon dioxide foam generated by a common surfactant, the carbon dioxide foam added with hydrophilic nanoparticles is better in temperature resistance and salt resistance, and compared to a foaming agent added with hydrophobic nanoparticles, the carbon dioxide foam system is low in cost and good in dispersing stability and is more liable to be popularized and applied in a field site.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Strong-inhibition and strong-blockage aluminum-based anti-collapse water-based drilling fluid

The invention discloses a novel aluminum-based anti-collapse agent and provides a strong-inhibition and strong-blockage aluminum-based anti-collapse water-based drilling fluid system by combining the performance requirement of drilling fluid based on the novel aluminum-based anti-collapse agent. The strong-inhibition and strong-blockage aluminum-based anti-collapse water-based drilling fluid contains the following substances in parts by weight: 100 parts of fresh water, 4 parts of sodium bentonite, 0.1-1 part of a coating inhibitor, 0.3-5 parts of a strong amine inhibitor, 0.5-5 parts of a filtrate reducer, 0.3-1 part of a thickening agent, 1-5 parts of a lubricating agent and 0.5-5 parts of an efficient aluminum-based blocking agent. The key technique of the invention is to provide use of the aluminum-based anti-collapse agent as a mud rock blocking anti-collapse agent in drilling fluid. After an aluminum-based blockage anti-collapse agent acts with a rock core with same thickness, the time required for transferring differential pressure of 1MPa is substantially shortened in comparison with the time (about 1.5 hours) required for transferring differential pressure in a blank rock core, so that the aluminum-based blockage anti-collapse agent has excellent blockage performance. Compared with the prior art, the strong-inhibition and strong-blockage aluminum-based anti-collapse water-based drilling fluid has the following advantages that (1) an amine inhibitor has prominent inhibition performance, and the hydration dispersion inhibition capacity of shale of the drilling fluid system is strong; (2) the anti-collapse agent has prominent inhibition performance and strong blockage anti-collapse capacity, and the hydration expansion inhibition capacity of shale of the drilling fluid system is strong; (3) the water-based drilling fluid system has relatively good rheological property and strong temperature resistance, salt resistance and calcium and inferior soil pollution resistance; and (4) the system contains less treating agents and is simple to prepare and convenient to maintain.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Seawater-based fracturing fluid and preparation method thereof

ActiveCN102417814AEnables continuous mixingTemperature resistanceDrilling compositionSalt resistancePolymer science

The invention belongs to the technical field of development of oil fields, and particularly relates to a seawater-based fracturing fluid which is suitable for preparing sweater and can be used for realizing continuous blending and a preparation method thereof. The seawater-based fracturing fluid is prepared from the following raw materials in part by weight: 0.5-1.5 parts of thickening agent, 0.3-1.0 parts of crosslinking agent, 0.2-0.6 parts of surfactant, 0.01-0.2 parts of pH value regulating agent, 0.01-0.2 parts of viscosity breaker, 46.5-64 parts of seawater and 35-50 parts of desalted seawater. The seawater-based fracturing fluid has the advantages of suitability for preparing seawater, capability of realizing continuous blending, high temperature resistance, high salt resistance, high shear resistance and quick dissolvability.

Owner:张春雨

Synthetic method of salt tolerant quadripolymer superabsorbent resin

The invention relates to a synthetic method of a salt tolerant quadripolymer superabsorbent resin, comprising the following steps of: adding cyclohexane and a dispersant Span-80 into a 3-mouth flask, stirring and heating up to the temperature of 60-68 DEG C, dropwisely adding a hydrophilic cross-linking agent, an initiator and a comonomer by a constant-voltage titration tunnel, staying at constant temperature for 1 hour after the addition, heating up to the temperature of 70-75 DEG C and reacting for 2-3 hours, cooling to room temperature, pouring the obtained product into a beaker with enough methanol, fully depositing, followed by pumping filtration by a vacuum pump, repeatedly washing by the use of methanol, and drying in a vacuum chamber at the temperature of 80-90 DEG C to obtain a white powder, namely the salt tolerant quadripolymer superabsorbent resin. The invention has the following beneficial effects: the technology is simple; the requirement on equipment is low; the resin prepared by the synthetic method has strong water absorption, fast water absorption rate, excellent water retention, high strength in the superabsorbent state, good light and thermal stability as well as salt tolerance which is remarkably improved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Nano silicon dioxide/polymer oil-displacing agent and synthesizing method thereof

InactiveCN103160268AStrong shear resistanceEnhanced overall recoveryDrilling compositionSalt resistanceFunctional monomer

The invention discloses a nano silicon dioxide / polymer oil-displacing agent and a synthesizing method thereof. The oil-displacing agent is a terpolymer consisting of the following raw materials in percentage by mass: 60.5 to 69.9 percent of acrylamide, 30 to 35 percent of crylic acid, and 0.1 to 4.5 percent of nano silicon dioxide functional monomer. The synthesizing method comprises the following steps of: adding the nano silicon dioxide functional monomer, the acrylamide and the crylic acid into a three-neck flask; regulating the pH value to 7.0-7.5 with sodium hydroxide solution to prepare solution with the monomer total mass concentration of between 10 and 20 percent, and introducing nitrogen for 40 minutes; introducing an initiator, and reacting for 4 to 8 hours at 30 to 55 DEG C; and cleaning with absolute ethanol, baking and crushing to obtain terpolymer. The oil-displacing agent is strong in anti-shearing performance, and excellent in temperature and salt resistance.

Owner:SOUTHWEST PETROLEUM UNIV

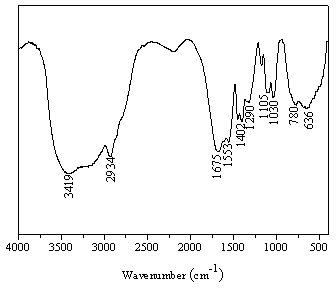

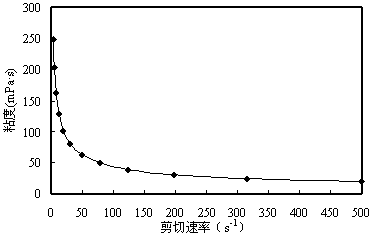

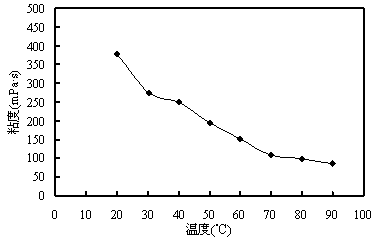

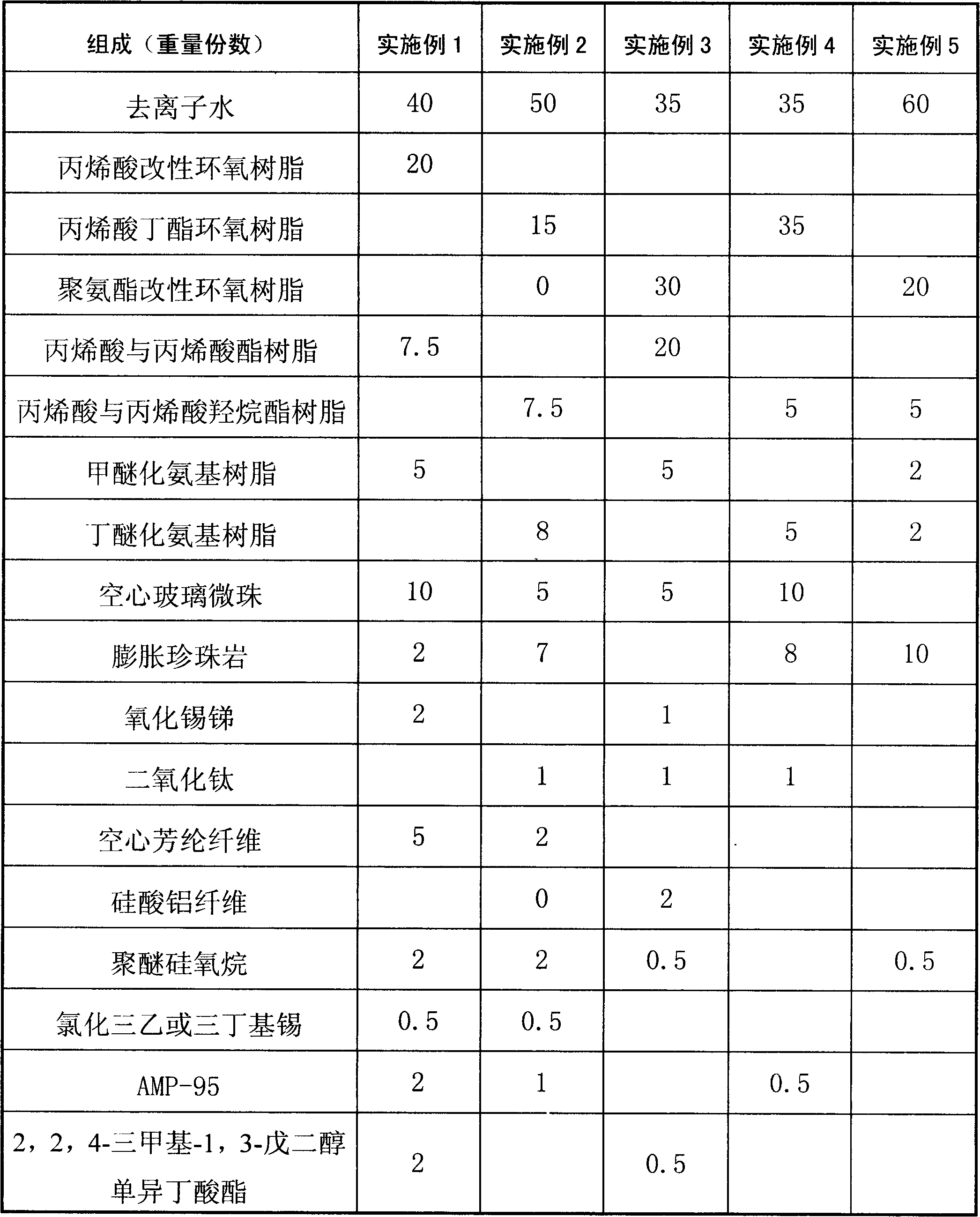

Epoxy acrylate modified high anticorrosion heat insulation paint containing porous ceramic addictive and production method thereof

InactiveCN103450773AStrong adhesionHigh hardnessAnti-corrosive paintsEpoxy resin coatingsEpoxyAcrylic resin

The invention relates to a kind of heat insulation paint with a high anticorrosion performance and a preparation method thereof. The anticorrosion heat insulation paint is composed of following components in percentage by weight: 35 to 60% of deionized water, 20 to 40% of modified epoxy resin, 5 to 30% of modified acrylic resin, 1 to 8% of amino resin, 10 to 25% of heat insulation materials, 0 to 8% of strengthening materials, and 1 to 10% of auxiliary agent. The preparation method comprises following steps: orderly adding deionized water, modified epoxy resin, modified acrylic resin, and amino resin into a reactor, starting the stirrer, evenly mixing the materials, adjusting the pH value of the system to a range of 7 to 9, then orderly adding the auxiliary agent, the heat insulation materials, and the strengthening materials, stirring for 1 to 3 hours in a high speed, and evenly mixing so as to obtain the anticorrosion heat insulation paint. The preparation method has the advantages of simple technology, high production efficiency, and low energy consumption. The prepared paint does not contain any organic solvent, so no solvent will volatilize during the coating solidification process, so no pollution is generated to the environment. The paint has the advantages of excellent mechanical properties of bonding strength, hardness, scratch resistance, wear resistance, and water resistance, and good properties of anticorrosion, salt smog resistance, forming ability, heat resistance, and deflection resistance.

Owner:BOYIFEI EQUIP INST FOR NEW MATERIALS

Polymer microspheres for high temperature hypersalinity reservoir deep profile control and preparation method thereof

InactiveCN101619119AExpand the affected volumeEnhanced overall recoveryDrilling compositionPolymer scienceMicrosphere

The invention provides polymer microspheres for high temperature hypersalinity reservoir deep profile control and a preparation method thereof. In the method, based on the method that photopolymerization is used to prepare the polymer microspheres, heat and salt resistance polymer materials such as sodium 3-acryloylamino-3-methyl butyrate, 2-acryloylamino-2-methylpropane sulfonic acid, acrylamide monomer and the like and water-soluble anionic monomer are adopted and dispersant and cross-linking agent are added as so to form oil-water mixed emulsion in the mixed medium of surfactant and solvent; then initiator is decomposed by ultraviolet through photopolymerization under controllable temperature so as to initiate emulsion polymerization and 50-500nm of microspheres are formed. The invention utilizes the ability of microspheres that microspheres can be dispersed in arbitrary concentration and injected in the water and can gradually swell after entering in depth of the formation to plug the pore throat so as to effectively plug the high permeable strip of the formation, expand the water swept volume, significantly increase crude oil recovery of water flooding reservoir and is applicable to high temperature hypersalinity reservoir deep profile control.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +4

Preparation method for non-ionic reactive water-borne epoxy resin emulsion

InactiveCN104558524AImprove water-based effectGood dispersionEpoxy resin coatingsFreeze thawingEpoxy

The invention provides a preparation method for non-ionic reactive water-borne epoxy resin emulsion. A preparation process for the non-ionic reactive water-borne epoxy resin emulsion comprises the following steps: simultaneously adding a certain amount of non-ionic hydrophilic segment polyethylene glycol and boron trifluoride diethyl etherate serving as a catalyst into epoxy resin, performing stable reaction for 3-8 hours to obtain non-ionic reactive epoxy resin, then strongly stirring at the temperature of 50 DEG C, and uniformly and dropwise adding distilled water to form water-dispersed epoxy resin emulsion by a phase inversion technology. The preparation method has the benefits that the particle size of the dispersion phase of the prepared non-ionic reactive water-borne epoxy resin emulsion is dozens to hundreds of nanometer; both under high-speed centrifugation and long-time storage, the non-ionic reactive water-borne epoxy resin emulsion is high in stability; furthermore, the emulsion is higher in dilutability, salt resistance, alkali resistance, high temperature resistance, and freeze-thaw stability. The raw materials used in the method are simple, efficient, environment-friendly, safe and non-toxic and can be widely applied to the fields of coatings, composite materials and the like.

Owner:BEIJING UNIV OF CHEM TECH

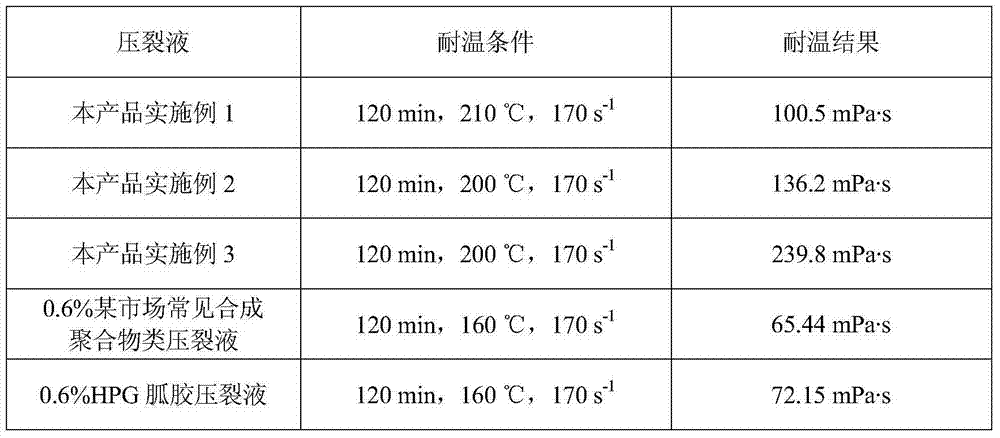

High-temperature-resistant gelled fracturing fluid, and preparation method and application thereof

ActiveCN103484094AEasy to crosslinkReduce harmFluid removalDrilling compositionSalt resistancePolymer science

The invention relates to a high-temperature-resistant gelled fracturing fluid, and a preparation method and application thereof. The fracturing fluid is mainly prepared from the following components in percentage by mass: 0.4-0.8% of anionic polymer, 0.05-0.20% of crosslinking agent, 0.02-0.16% of pH regulator, 0.01-0.10% of delayed crosslinker, 0.1-0.8% of cleanup additive, 0.01-0.09% of viscosity breaker and the balance of water. The anionic polymer is a terpolymer and is copolymerized from the following components in percentage by weight: 60-70% of acrylamide monomer, 15-25% of anionic monomer, 5-15% of cationic monome, totaling 100%. The fracturing fluid can resist the high temperature of 210 DEG C above, has the advantages of crosslinkability, capability of carrying sand, shear resistance, salt resistance, no residue and the like, and is used for fracturing yield increase of hypotonic high-temperature ultra-deep wells.

Owner:PETROCHINA CO LTD +2

High temperature-resistance salt-resistance oil well cement filtrate reducer

The invention discloses a high temperature-resistance salt-resistance oil well cement filtrate reducer. The raw materials used in the production of the reducer comprise AMPS(2-acrylamido-2-methyl propane sulfonic acid), acrylic acid, acrylamide, sodium hydroxide, potassium persulfate and water in a mass part ratio of 32-36:2.5-3:12-15:4-6:0.3-0.5:120. The high temperature-resistance oil well cement filtrate reducer prepared according to the formula is applicable to all-grade cement in accordance with API standards; the additive amount of the reducer in a slurry system at a high temperature of 210 DEG C is 5 to 8 percent of the total volume of slurry; and the water loss rate in well cementation can be effectively controlled within 50ml.

Owner:山东胜油固井工程技术有限公司

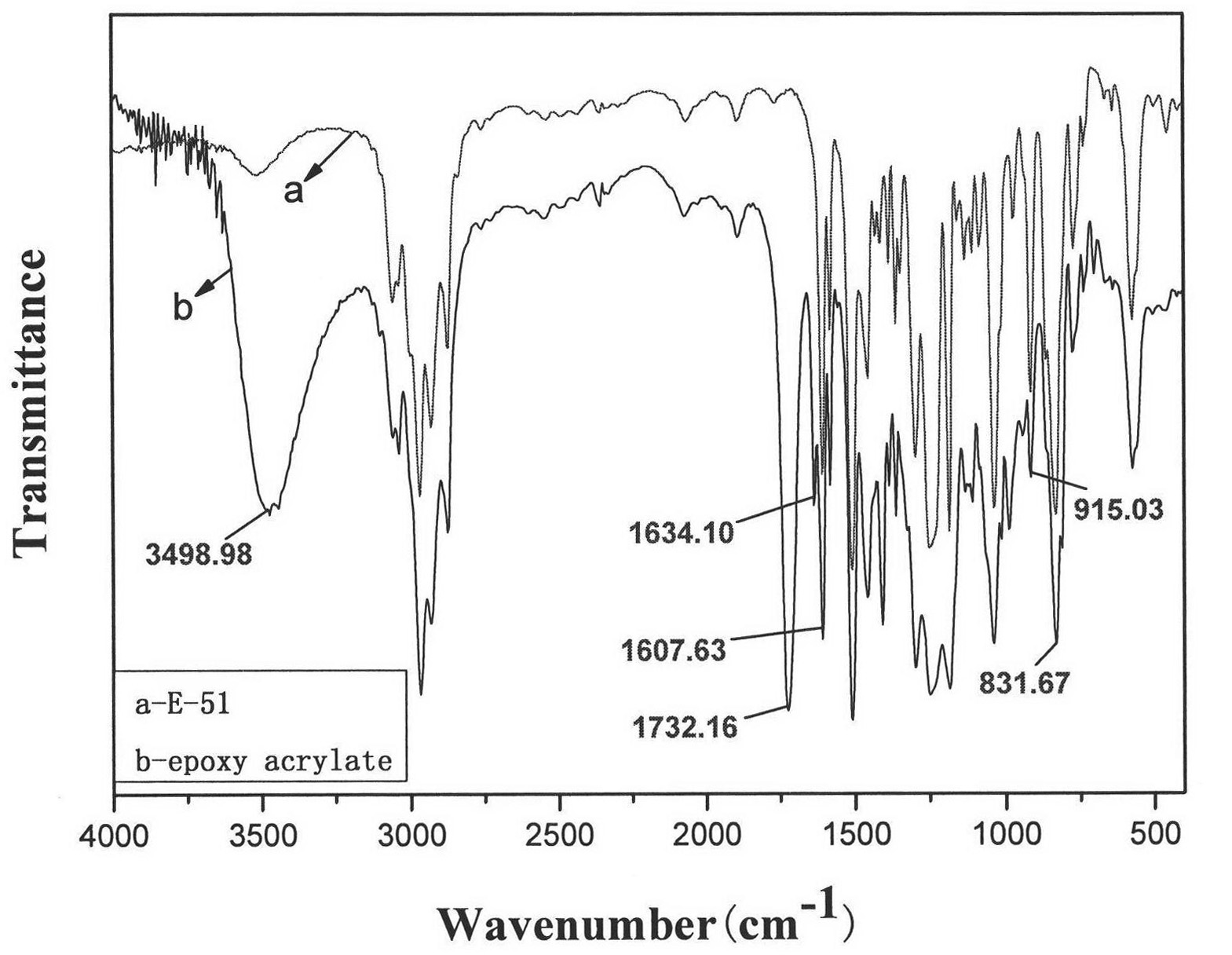

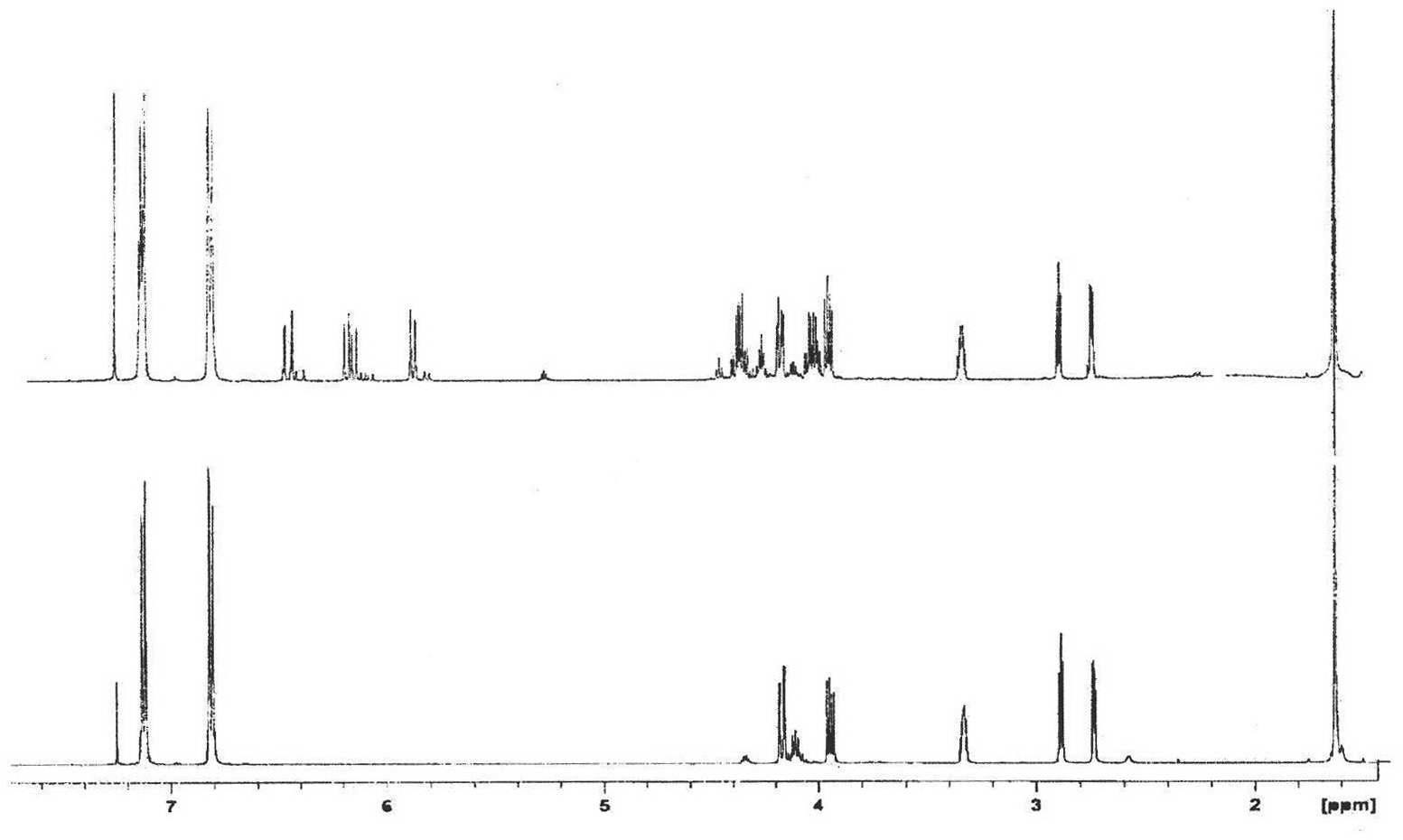

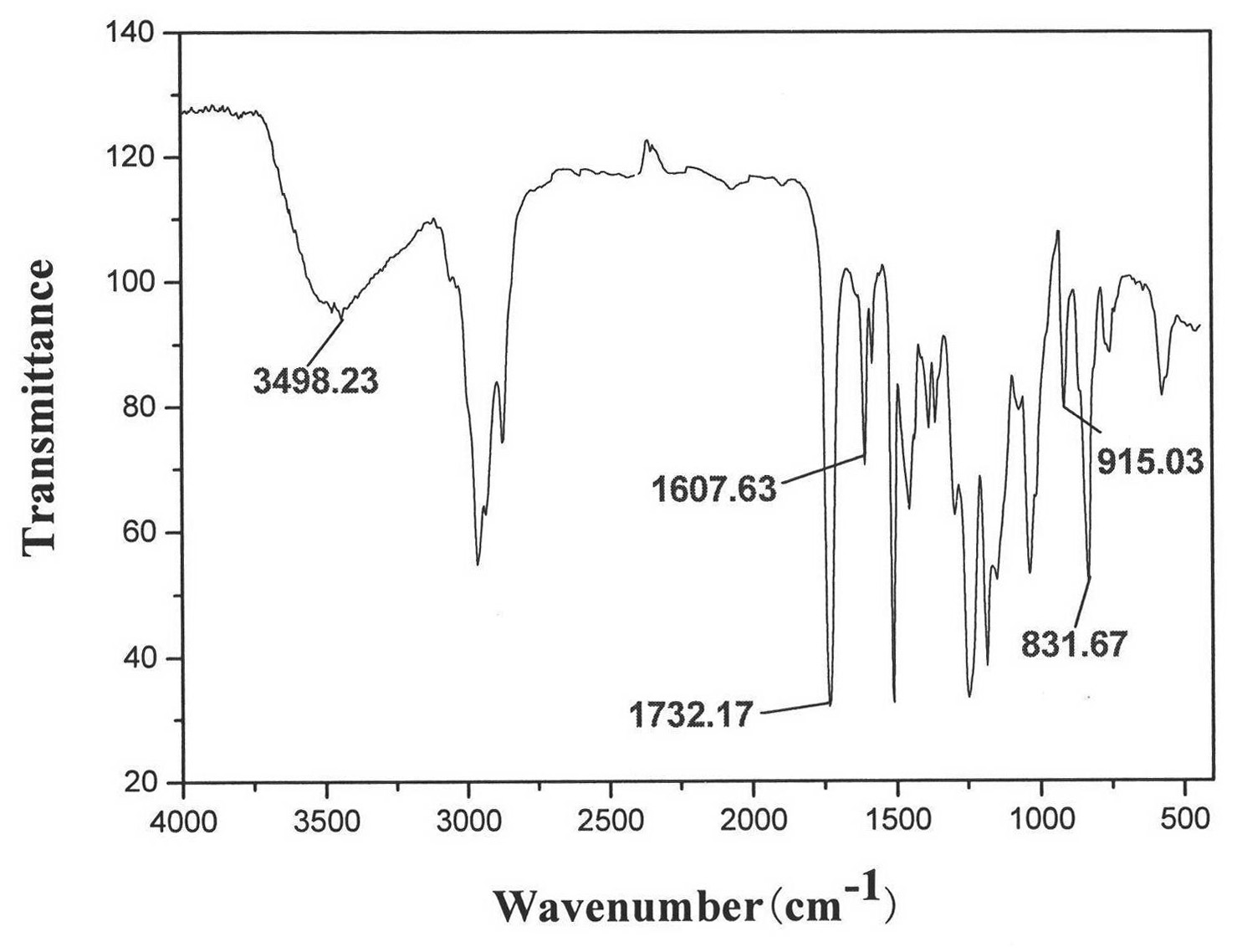

Waterborne epoxy acrylate-grafted composite emulsion and preparation method thereof

The invention relates to the field of manufacture of epoxy acrylate composite resin materials, in particular to a waterborne epoxy acrylate-grafted composite emulsion and a preparation method thereof. The process mainly comprises the following steps of: firstly, by taking a polymerizing monomer as a dispersing medium, enabling epoxide resin and acrylic acid to react under the action of tetrabutylammonium bromide to generate an epoxy acrylate monomer; and secondly, pre-emulsifying the epoxy acrylate monomer and other monomers and then enabling the epoxy acrylate monomer and other monomers to generate a copolymerization reaction to prepare the waterborne epoxy acrylate-grafted composite emulsion by adopting a semi-continuous seeded emulsion polymerization method. According to the process, the copolymerization monomer is used as a solvent dispersing medium for the esterification reaction of the epoxide resin and the acrylic acid in the first step and is also a monomer of the copolymerization reaction in the second step; an organic solvent in the reaction of the first step is prevented from being removed by adopting reduced pressure distillation, so that the influence of residual solvent on the performance of the product is avoided; the waterborne epoxy acrylate-grafted composite emulsion has high grafting rate and can be used for improving the compatibility of the epoxide resin and acrylic acid resin and enhancing the performances of the water resistance, the adhesive force, the salt resistance and the like of a coating and can be widely applied to the fields of metal coatings, building coating materials and the like.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

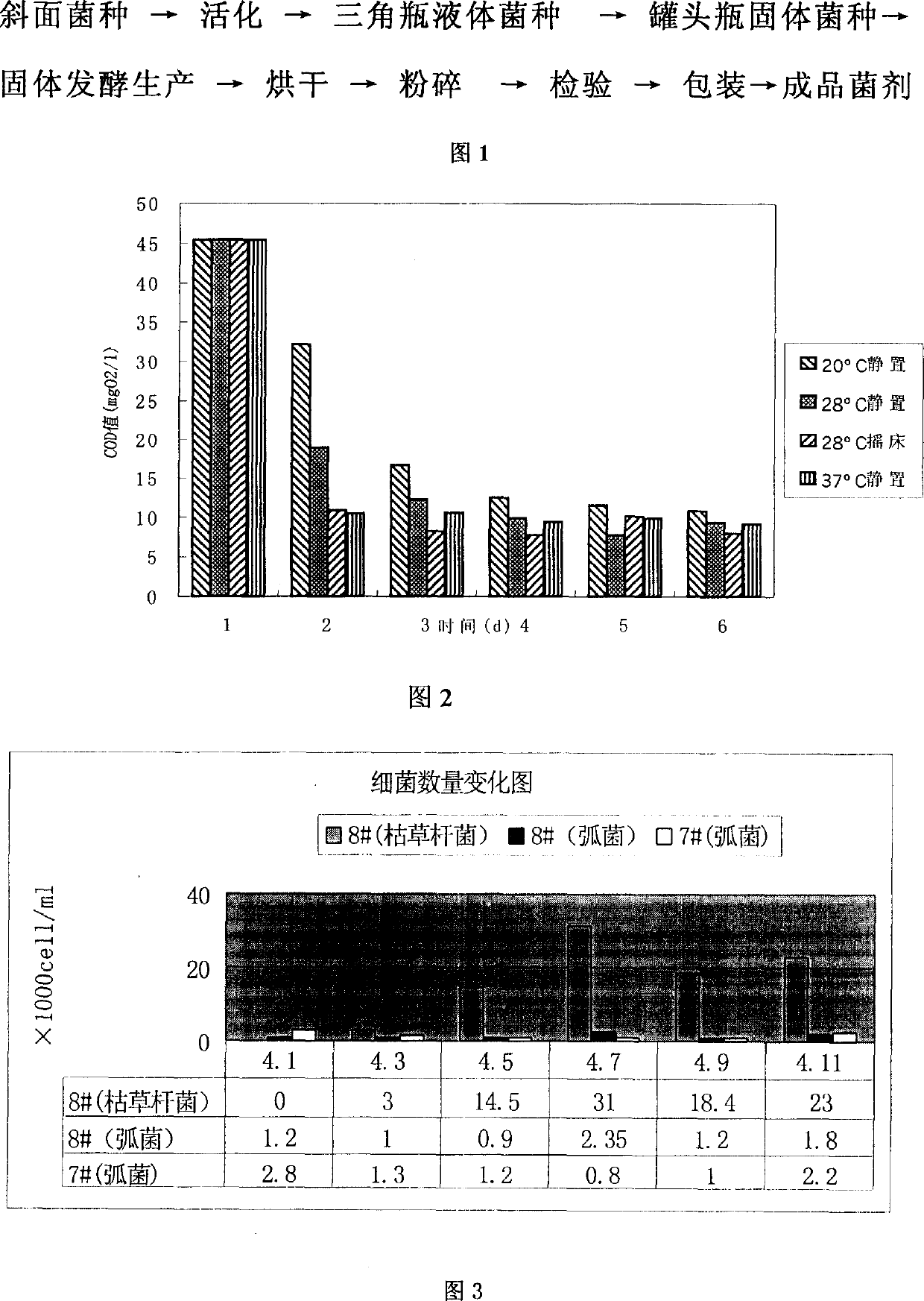

Water-purifying bacillus subtilis, bacterial agent and solid fermenting process and use

InactiveCN1508243AQuality improvementReduce production inputBacteriaBiological water/sewage treatmentSalt resistanceWater quality

The invention relates to a water-quality purifying Bacillus substilis, CCTCC, M202045, and Bacillus substilis preparation. It uses Bacillus substilis to cultivate and ferment in proper C-N ratio in the solid culture medium, and then dries to produce the preparation. The efficiency of the Bacillus substilis to eliminate water body COD is high. The Bacillus substilis can quickly degrade organics, and has a certain denitrifying and residue degrading ability, and stronger sulfide degrading ability. The test result shows that: COD eliminated can reach 76% in 24 hours, and the Bacillus substilis has excellent characters of salt resistance, osmotic pressure resistance, and maintaining the pH value of the breeding water body.

Owner:HUAZHONG AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com