Epoxy acrylate modified high anticorrosion heat insulation paint containing porous ceramic addictive and production method thereof

An acrylic resin, modified technology, applied in the field of coating chemistry, can solve the problems of high unit cost, environmental hazards, aging resistance, poor heat resistance and heat insulation performance, and achieve excellent mechanical properties, simple production process, and bending resistance good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] According to the actual needs of customers, the desired product effect can be obtained by adjusting the inventive formula. The following will further illustrate the present invention through specific embodiments, but it does not mean limiting the protection scope of the present invention.

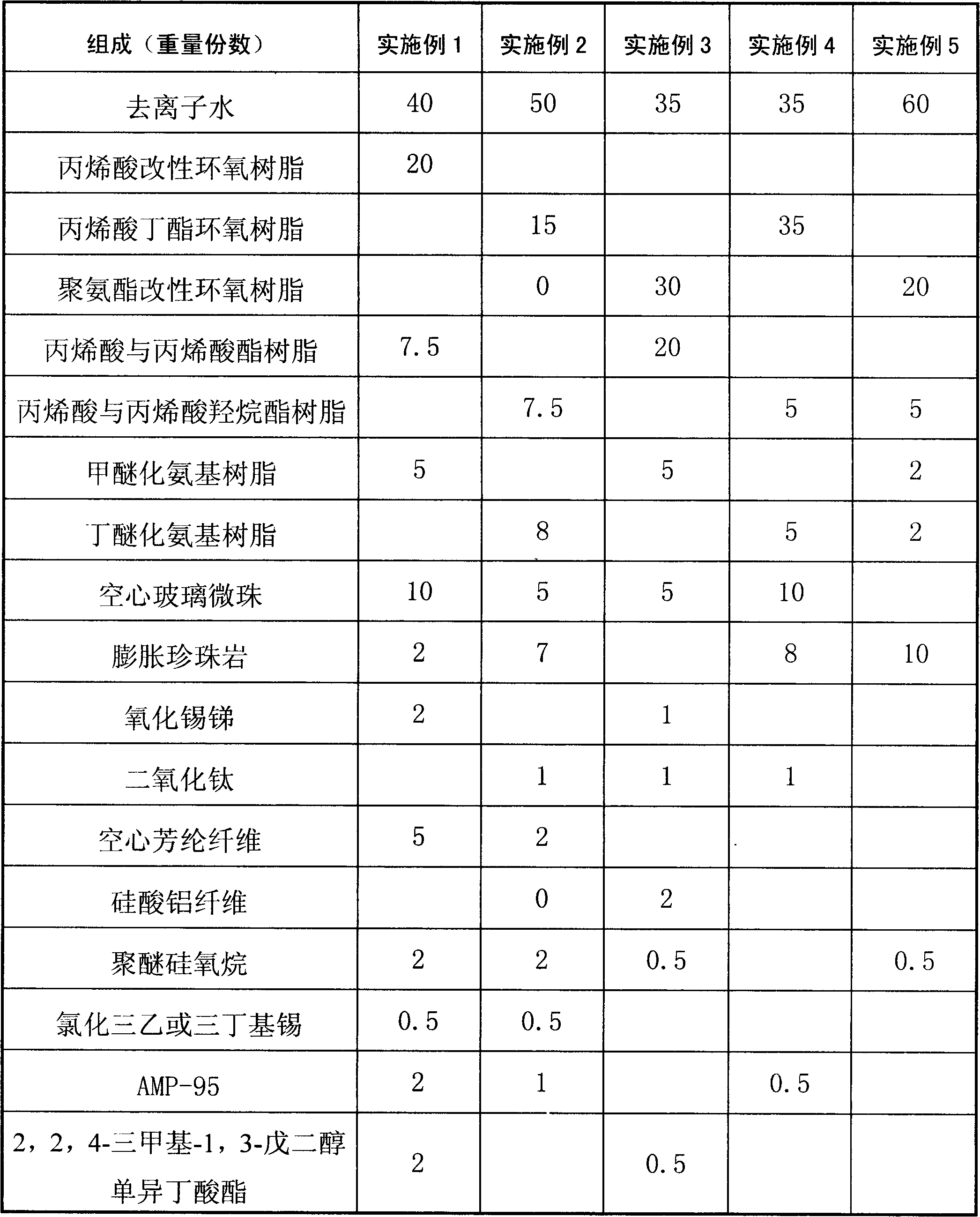

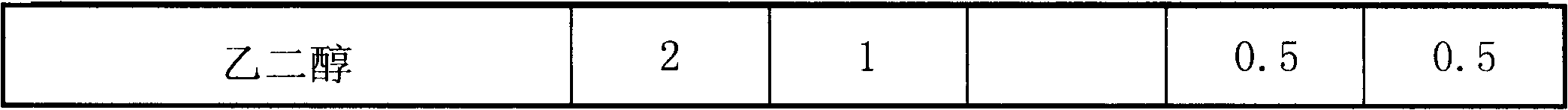

[0035] Accurately weigh each component according to the formula, add deionized water, modified epoxy resin, modified acrylic resin, and amino resin into the reaction kettle in turn, start the agitator, and mix evenly; adjust the pH value of the system to between 7-9 Then add additives, heat insulation materials, reinforcing materials in turn, stir at high speed for 1-3 hours, and mix evenly to obtain the inventive product. Composition formula is as shown in table 1:

[0036] Table 1 Coating composition formula

[0037]

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com