Patents

Literature

967 results about "Coating adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly metal surface treating agent and using method thereof

InactiveCN101701336ALarge specific surface areaStrong corrosion resistanceMetallic material coating processesStrong acidsFluoride

The invention discloses an environment-friendly metal surface treating agent and a using method thereof. The treating agent comprises fluoride, zircon salt, silane, silicon dioxide, accelerating agent, dispersing agent and stabilizing agent. A conversion coating having the advantages of being compact and even, strong in corrosion resistance and excellent in adhesive force of the coating is respectively formed on the metal surface of steel and zinc; a treatment method of the metal surface treating agent is simple and is operated at the normal temperature; the original phosphating treatment equipment can be used without any change; and strong acid and strong base are not used as the treating agent; therefore, the environment-friendly metal surface treating agent is safe in production without emission, and is the best substitute product of the phosphating treatment technique and an energy-saving type environment-friendly product.

Owner:芜湖市瑞杰环保材料科技有限公司

Metal surface treatment agent

InactiveCN102787310AReduce corrosion rateReduce surface tensionMetallic material coating processesNitrogenous heterocyclic compoundIonic liquid

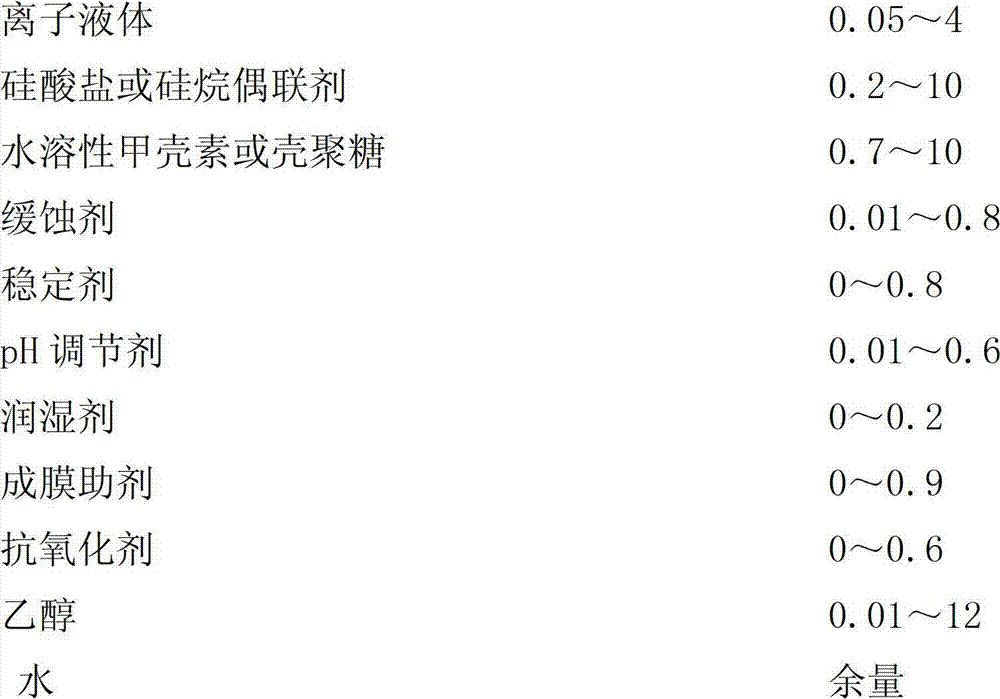

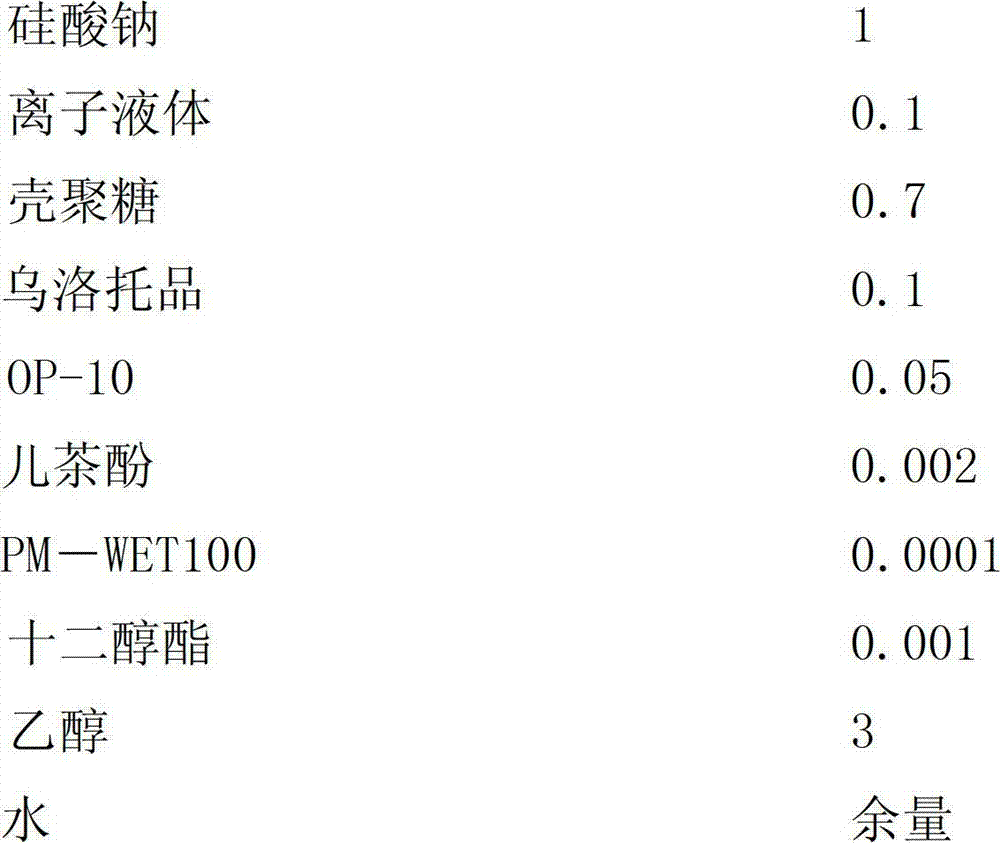

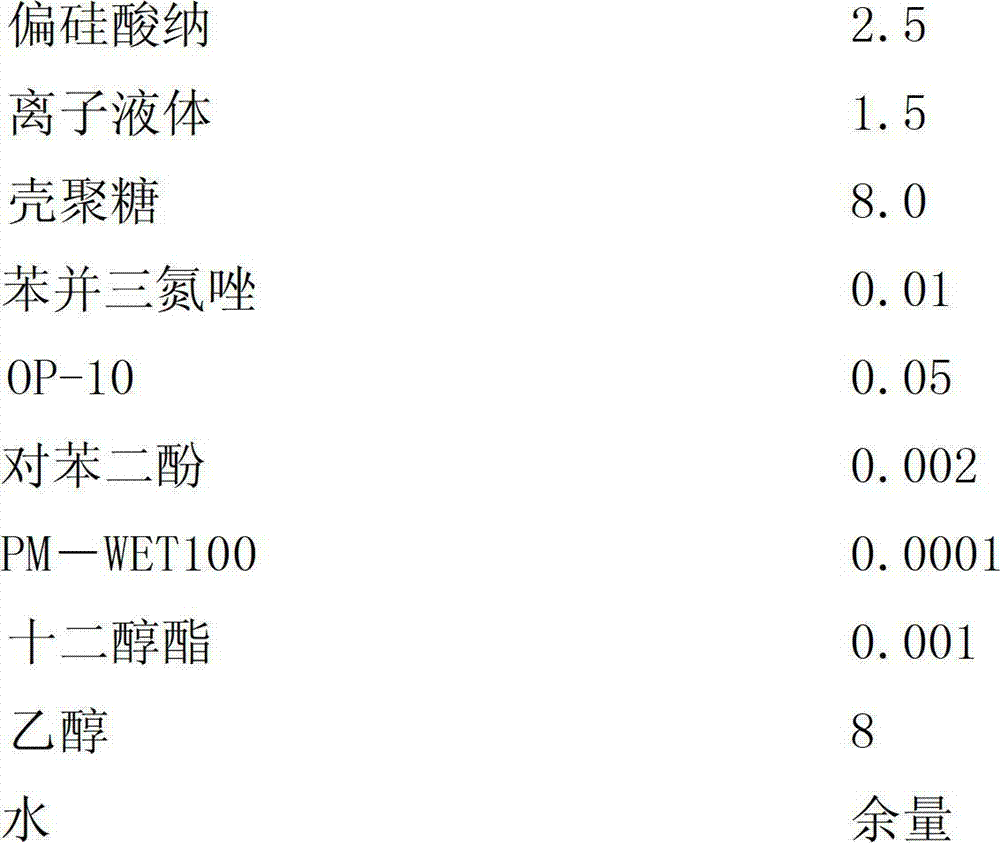

The invention provides a metal surface treatment agent composed of aqueous solution or aqueous emulsion containing ionic liquid. The metal surface treatment agent comprises the ionic liquid, silicate or silane coupling agent, water-soluble chitin or chitosan, corrosion inhibitor, stabilizer, pH modifier, wetter, coalescing agent, antioxidant, ethanol and water, the ionic liquid is room-temperature ionic liquid consisting of nitrogenous heterocyclic compound cations and inorganic or organic anions, one or more of nanoscale titanium dioxide, zirconium oxide or zirconium fluoride is uniformly mixed into the silicate or silane coupling agent by the weight equivalently accounting for 3%-25% of that of the silicate or silane coupling agent. A chemical conversion coating is formed on a metal surface by the metal surface treatment agent, can inhibit corrosion of the metal surface, and has a fine coating performance. The metal surface treatment agent is used for treating cold-rolled plates, galvanized plates and aluminum plates, and the metal surface treated by the metal surface treatment agent has the coating adhesion force equivalent to that of a metal surface treated by a phosphorus-containing metal surface treatment agent.

Owner:DALIAN POLYTECHNIC UNIVERSITY

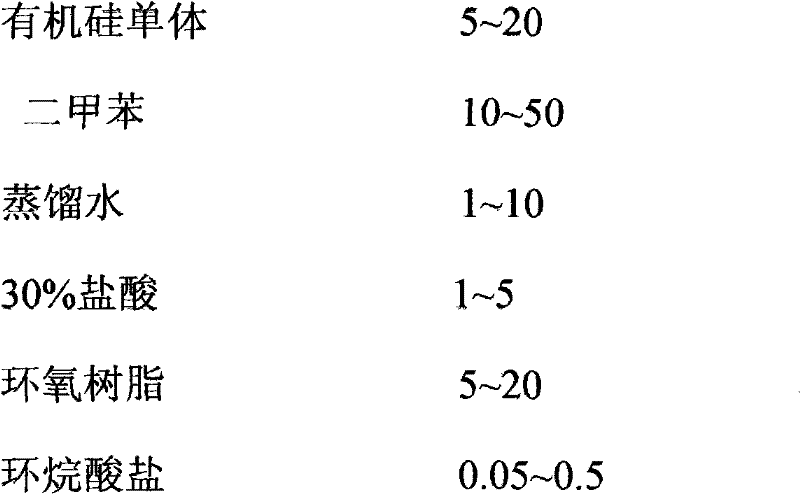

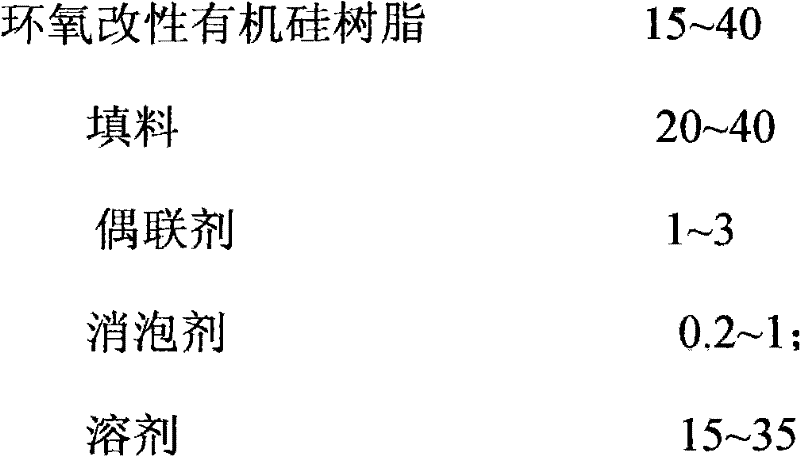

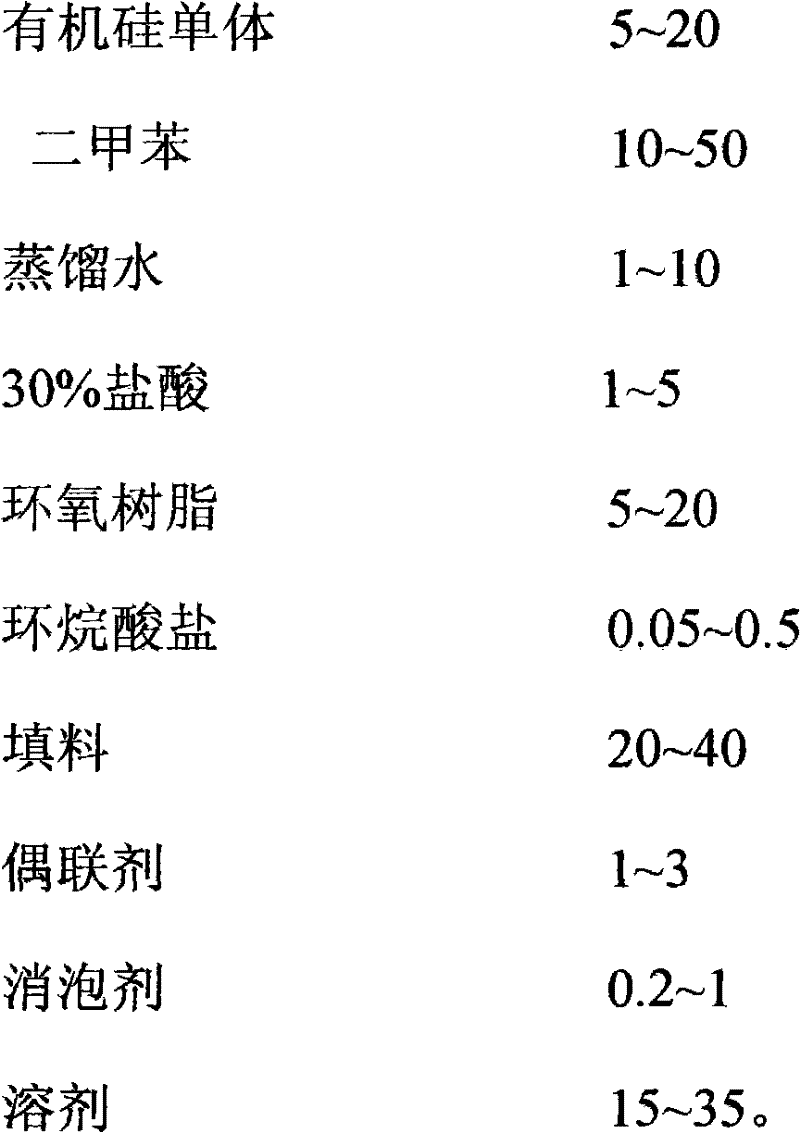

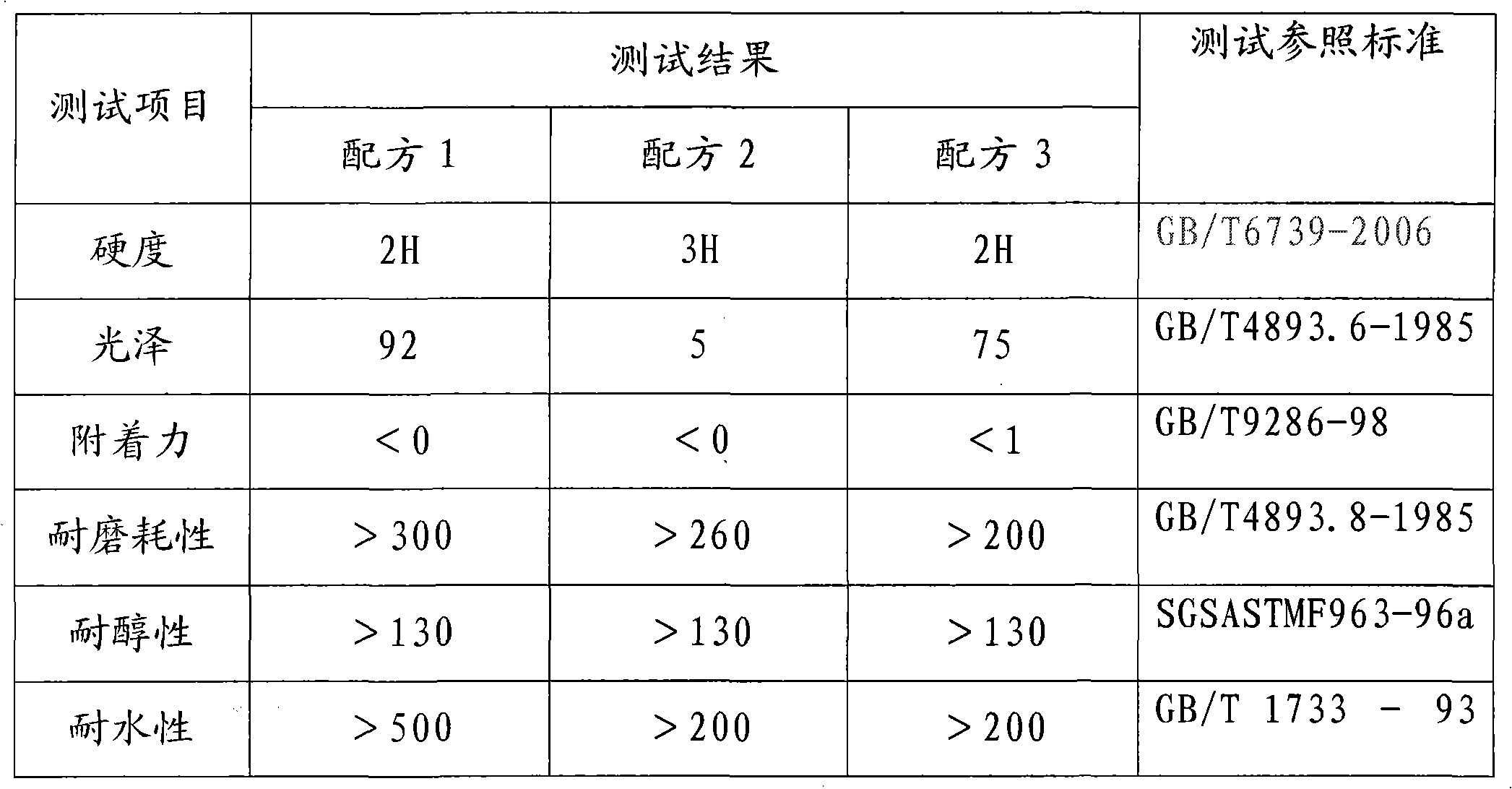

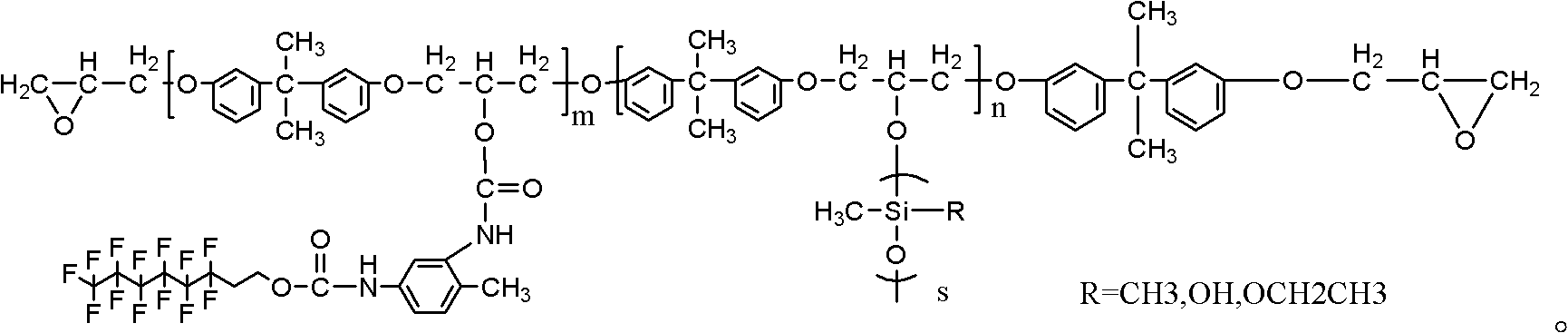

Preparation method of epoxy-modified insulated thermal-conductive high-temperature resistant organosilicon coating and its products

The invention provides a preparation method of an epoxy-modified insulated thermal-conductive high-temperature resistant organosilicon coating, comprising the following steps: preparing raw materials; synthesizing an organosilicon pre-polymer; synthesizing an epoxy-modified organosilicon resin; and preparing the epoxy-modified insulated thermal-conductive high-temperature resistant organosilicon coating. The invention also provided the epoxy-modified insulated thermal-conductive high-temperature resistant organosilicon coating prepared by the method. The coating is composed by the epoxy modified organosilicon resin, fillers, a coupling agent and solvents. The coating prepared by the method in the invention takes account of insulation, thermal-conductivity, and high-temperature resistance at the same time, has coating adhesion of first level, hardness of 5H, a breakdown voltage of 1800V / 0.5mA, 2 seconds, a heat transfer coefficient of larger than 100W / (m<2>.K), and no obviously changed coating at a temperature of 250 DEG C for 24 hours, therefore the coating can be widely used in various industrial equipment and household appliances.

Owner:DONGGUAN HONGDA POLYUREFHANE RESIN +2

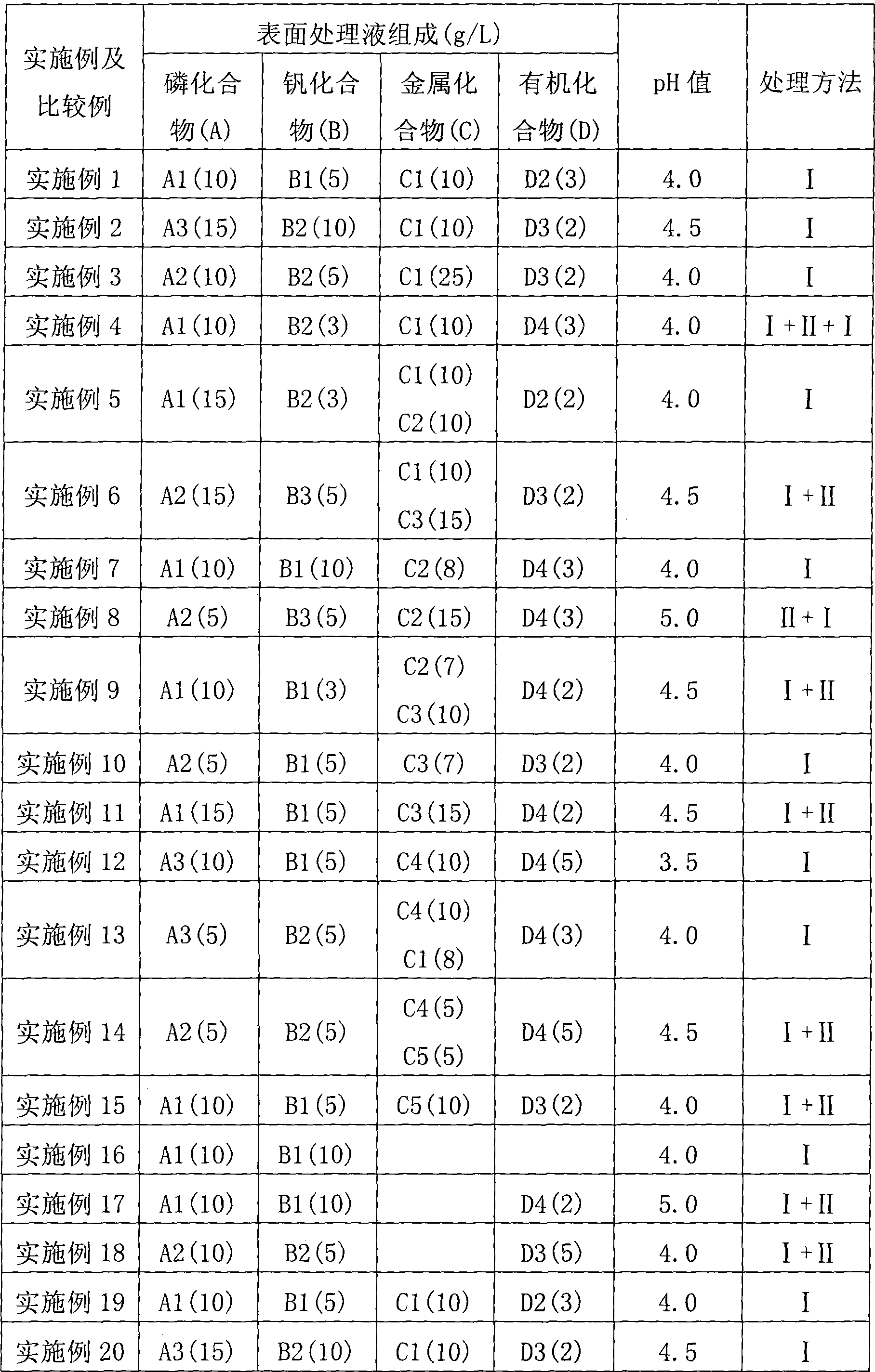

Surface treatment liquid, surface treatment method and tin-plated steel sheet by surface treatment

ActiveCN101545107AExcellent resistance to sulfur spotsExcellent paint wettingMetallic material coating processesPhosphateManganese

The invention provides a surface treatment liquid used for tin-plated steel sheets, which contains 1 to 50 g / L of phosphorus compound, 1 to 20 g / L of vanadium compound, 1 to 30 g / L of compound selected from one or more of molybdenum, zirconium, titanium, manganese and tungsten metal compounds, and 1 to 10 g / L of one or more compounds with at least one functional group of hydroxyl, carbonyl, carboxyl and phosphate. The invention also provides a surface treatment method using the surface treatment liquid, and a tin-plated steel sheet treated by the surface treatment liquid. By using the surface treatment liquid and the surface treatment method of the invention, chromium which is unfavorable for the environment is not contained in the process of producing the tin-plated steel sheets, and the cost is low. The tin-plated steel sheet has favorable sulfide spot resistance, paint wetting performance, coating adhesion and processing performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Aqueous dispersions containing ionomer resins and rust-preventive ionomeric coatings made therefrom

The present invention is directed to an aqueous dispersion composition which comprises an ethylene-unsaturated carboxylic acid ionomer resin (A) neutralized with a mixture of ions including at least one divalent metal ion and at least one ammonium ion, (B) a non-water soluble vapor phase corrosion inhibitor, and (C) water. The dispersion exhibits good shelf-life and excellent rust-prevention properties. Durable corrosion resistant ionomeric coatings can be easily formed therefrom, which when applied to metal surfaces and baked, can form a rust-preventive coating layer showing excellent coating adhesion both to the metal surface and to an over coat paint. Such coatings are particularly useful when applied to a vehicle body or part thereof.

Owner:PERFORMANCE MATERIALS NA INC

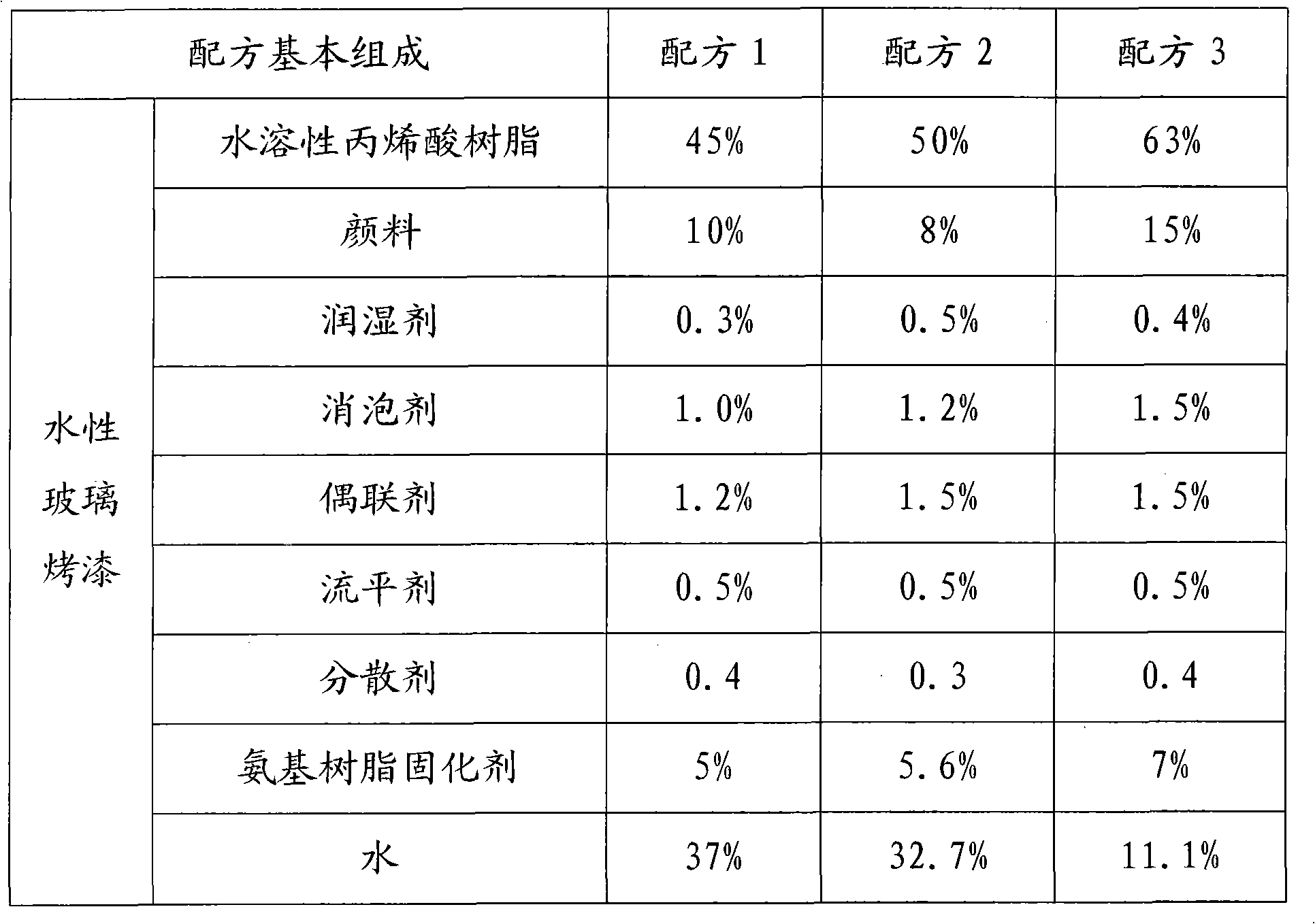

Water-based baking paint for glass substrate and preparation and use methods thereof

InactiveCN101845255ASimplify the construction processMeet the use requirementsCoatingsPolymer scienceAcrylic resin

The invention discloses a water-based baking paint for a glass substrate and a preparation method and the application thereof; the formula of the water-based glass baking paint comprises the following components in parts by weight: 45 to 63 percent of water-soluble acrylic resin, 5 to 7 percent of methylated amino resin, 5 to 15 percent of water-based paste, 1.2 to 1.5 percent of coupling agent, 2 to 5 percent of additive and 25 to 30 percent of deionized water. When the baking paint is prepared, first the water-soluble acrylic resin, defoamer, wetting agent, leveling agent, dispersant and some water are sequentially added into a stirring tank to be stirred, is added with the water-based slurry and the like to be stirred and dispersed at high speed; and finally the methylated amino resin, the coupling agent and the rest water are sequentially added in to be stirred into a uniform coating system. The invention also provides a use method of the glass baking paint. When being applied to ground glass, hard glass and other substrates, the coating has the advantages of simple preparation process, convenient construction, strong coating adhesion, high hardness, water resistance, good heat resistance and the like.

Owner:FUJIAN HANSEN PAINT

High-voltage power transmission line ice-covering-proof paint and preparation method thereof

InactiveCN102146249AImprove thermal conductivityImprove hydrophobicityEpoxy resin coatingsTransformerLow temperature curing

The invention discloses high-voltage power transmission line ice-covering-proof paint and a preparation method thereof. The preparation method comprises the following steps: using toluene diisocynate, tridecafluoro-octanol, butyl acetate, organosilicon modified epoxy resin, epoxy resin curing agent, organic solvent, nanographite and carbon nanotubes as raw materials to react and ensure that long-carbon-chain fluoro-alcohol is grafted in the molecular chain of epoxy resin, and adding nanographite and carbon nanotubes in the modified epoxy resin to prepare the paint with good hydrophobicity and thermal conductivity. The paint is mainly used in the coating of the high-voltage power transmission line and the coatings of equipment such as the insulator and the transformer case; and the paint has high coating adhesion, is ice-covering-proof and environmental friendly, has the advantages of corrosion resistance, ultraviolet resistance and aging resistance, and no pollution. Compared with the traditional acrylic paint, the paint has the advantages of simple preparation technology and excellent room temperature curing performance and low temperature curing performance, and is convenient to construct and operate.

Owner:甘肃省电力公司检修公司 +1

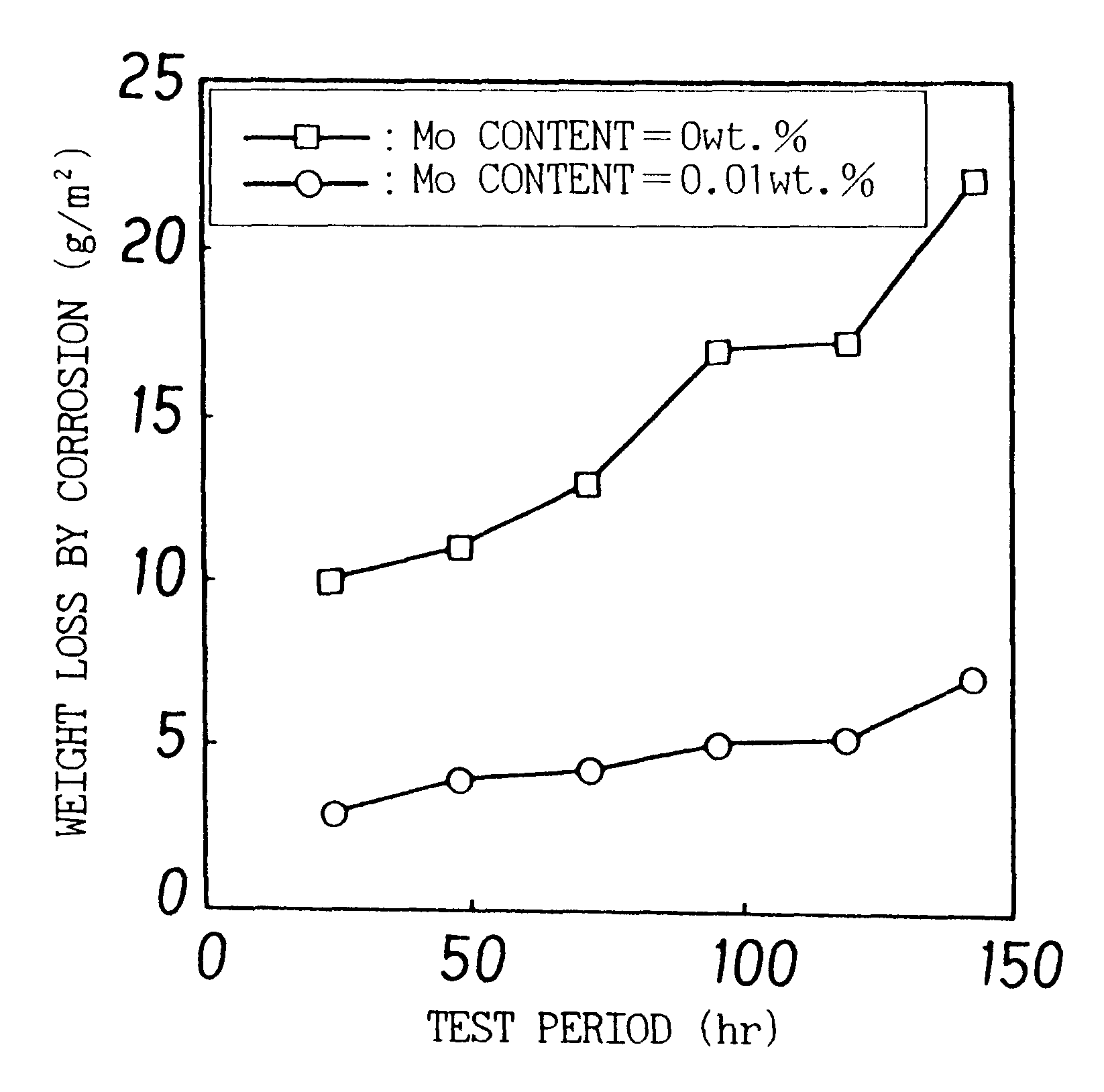

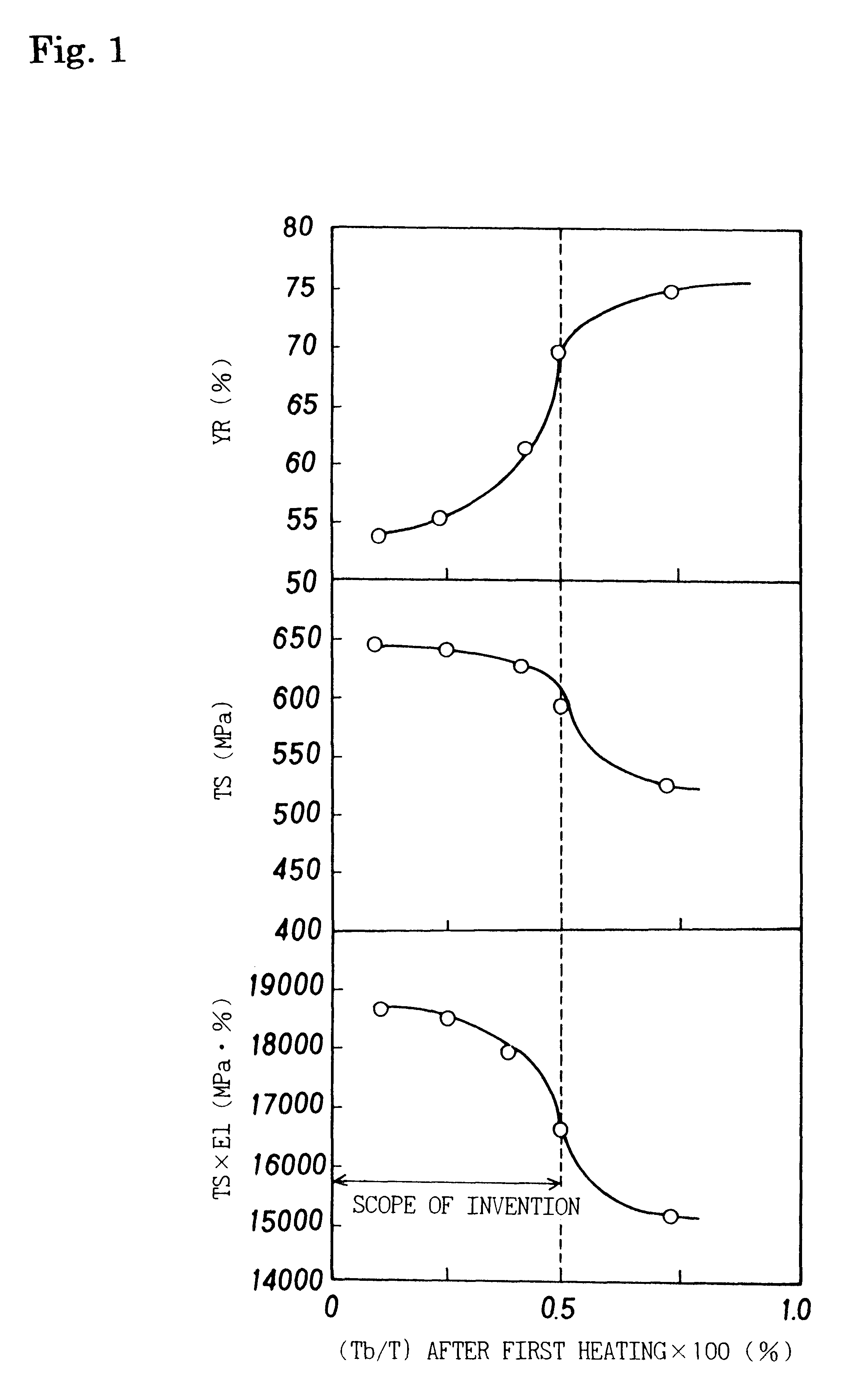

High strength thin steel sheet, high strength alloyed hot-dip zinc-coated steel sheet, and method for producing them

InactiveUS6410163B1Improve the plating effectImproving threadabilityHot-dipping/immersion processesLiquid surface applicatorsSheet steelHigh intensity

The present invention provides a high strength thin excellent workability and galvanizability, having a composition comprising from 0.01 to 0.20 wt. % C, up to 1.0 wt. % Si, from 1.0 to 3.0 wt. % Mn, up to 0.10 wt. % P, up to 0.05 wt. % S, up to 0.10 wt. % Al, up to 0.010 wt. % N, up to 1.0 wt. % Cr, from 0.001 to 1.00 wt. % Mo, and the balance Fe and incidental impurities, wherein a band structure comprising a secondary phase has a thickness satisfying the relation Tb / T<=0.005 (where, Tb: average thickness of the band structure in the thickness direction of steel sheet; T: steel sheet thickness), and a manufacturing method thereof, and a manufacturing method of a high strength hot-dip galvanized steel sheet or a high strength galvannealed steel sheet applying hot-dip galvanizing or further galvannealing, and giving an excellent workability, a high tensile strength, and excellent galvanizability, coating adhesion and corrosion resistance.

Owner:KAWASAKI STEEL CORP

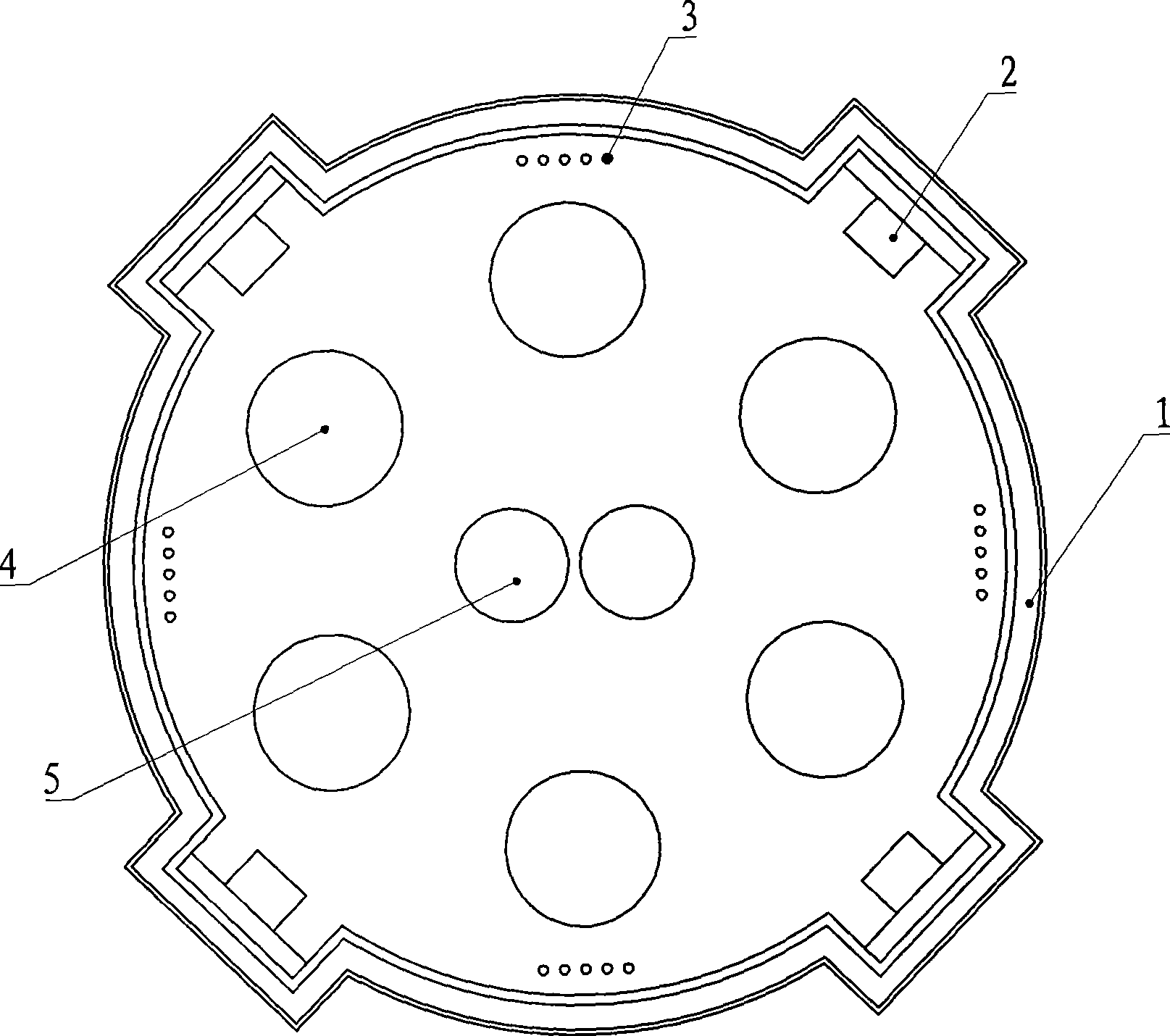

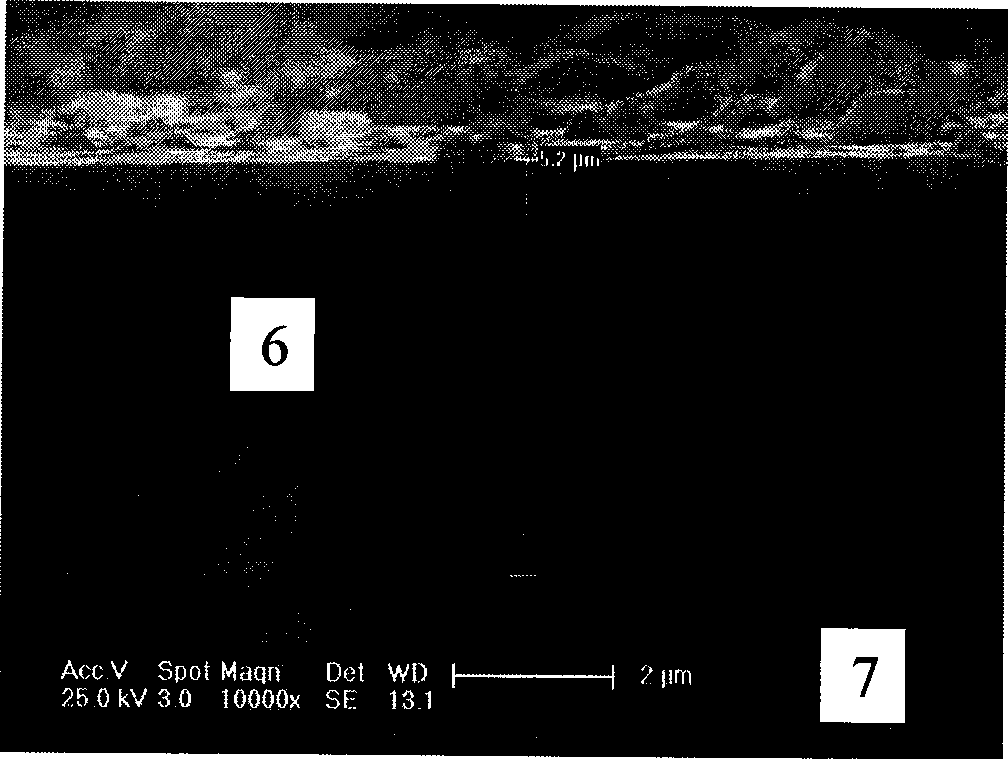

PVD nano composite ceramic coating screw and method for manufacturing same

InactiveCN101518935ASolve pollutionIncreased microhardnessLayered productsVacuum evaporation coatingCarbon filmDiamond-like carbon

The invention provides a PVD nano composite ceramic coating screw. A screw substrate (7) is coated with a coating (6) consisting of a bonding layer, a primary wear-resistance layer and a lubricating layer sequentially. The method for manufacturing the screw comprises the following steps: firstly, depositing a 50 to 100 nanometer thick transitional metal bonding layer at an air pressure of 0.1 Pa; secondly, depositing a 2 to 5 micrometer thick composite ceramic layer as the primary wear-resistance layer at a temperature of between 350 and 400 DEG C, a voltage of between -50 and -200 volts and an air pressure of 0.2 to 1Pa; and finally, depositing a 1 to 3 micrometer transitional metal doped diamond carbon film layer as the lubricating layer at a temperature of between 100 and 150 DEG C, a voltage of between -50 and -150 volts and an air pressure of 0.1 to 0.5Pa. Compared with the prior art, the screw has the advantages of having lubricating performance, along with high hardness (more than 40GPa Hv hardness) and excellent wear resistance (friction coefficient about 0.1). The method is free from pollution and the coating has strong adhesive force.

Owner:舟山市汉邦机械科技有限公司

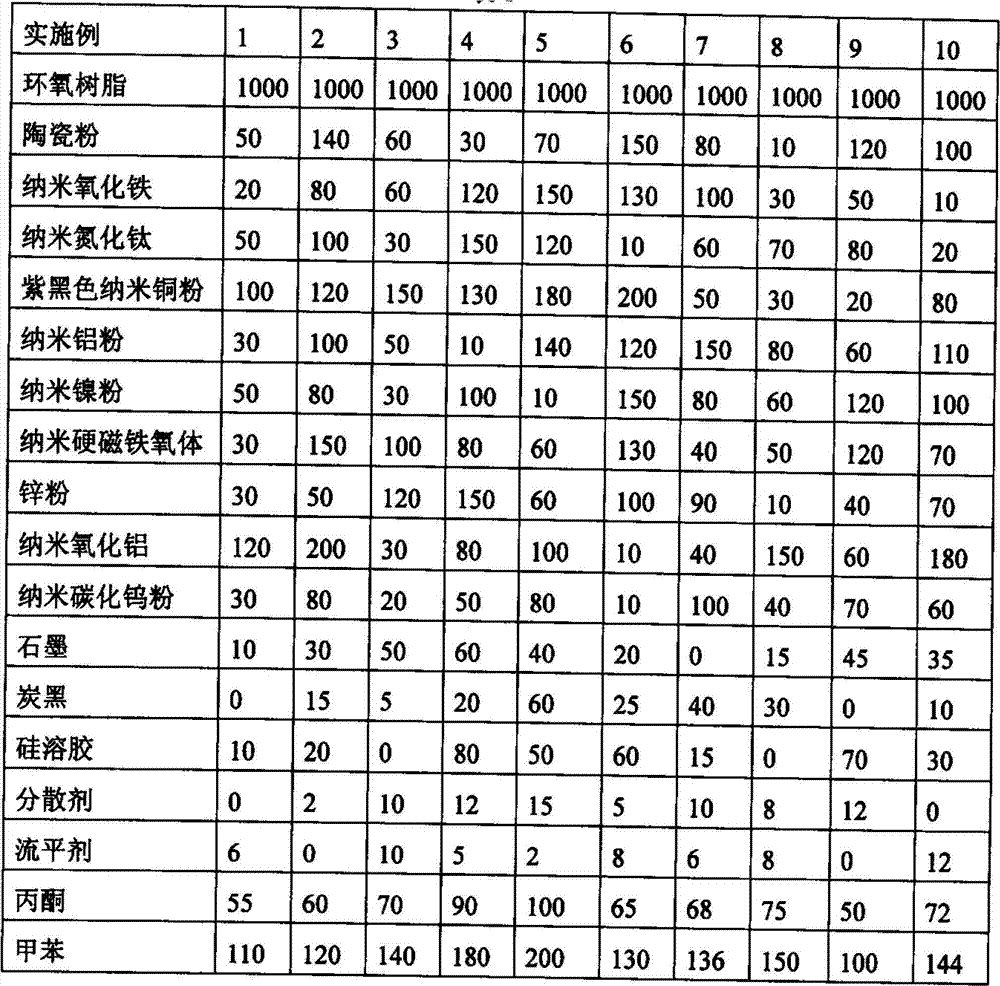

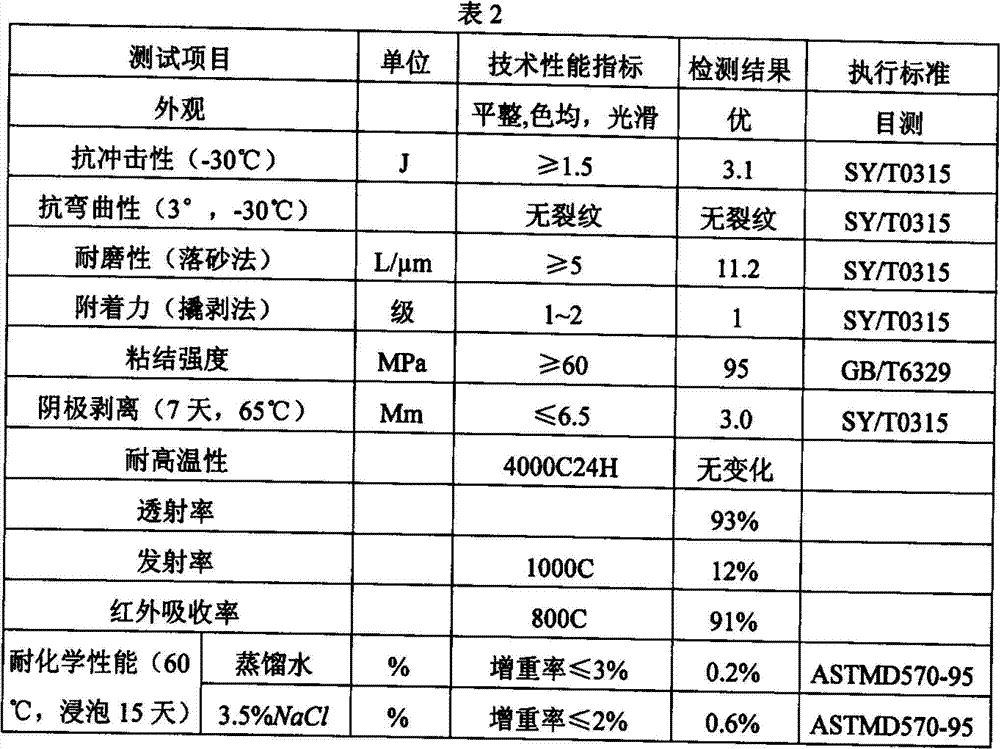

Solar heat absorbing paint and manufacturing method thereof

InactiveCN103589275APromote absorptionImprove corrosion resistanceRadiation-absorbing paintsEpoxy resin coatingsEpoxyHigh absorption

A solar heat absorbing paint is prepared by mixing a nano magnetic powder, a variety of nano metal powders, a ceramic powder, epoxy resin and a variety of additives. The paint provided by the invention is prepared by evenly mixing and stirring the components in the formula at room temperature. The production process is simple, convenient, economical and environment-friendly. The paint provided by the invention can be used individually; and a coating of the paint has high absorption rate, high thermal conductivity, low radiation, high temperature resistance, high stability, strong adhesion, compactness and stability. The paint is ideal for solar energy absorption, can be widely used as the heat absorbing coating for solar collector, and absolutely can substitute the existing expensive solar energy absorption coating.

Owner:上海陆亿新能源有限公司

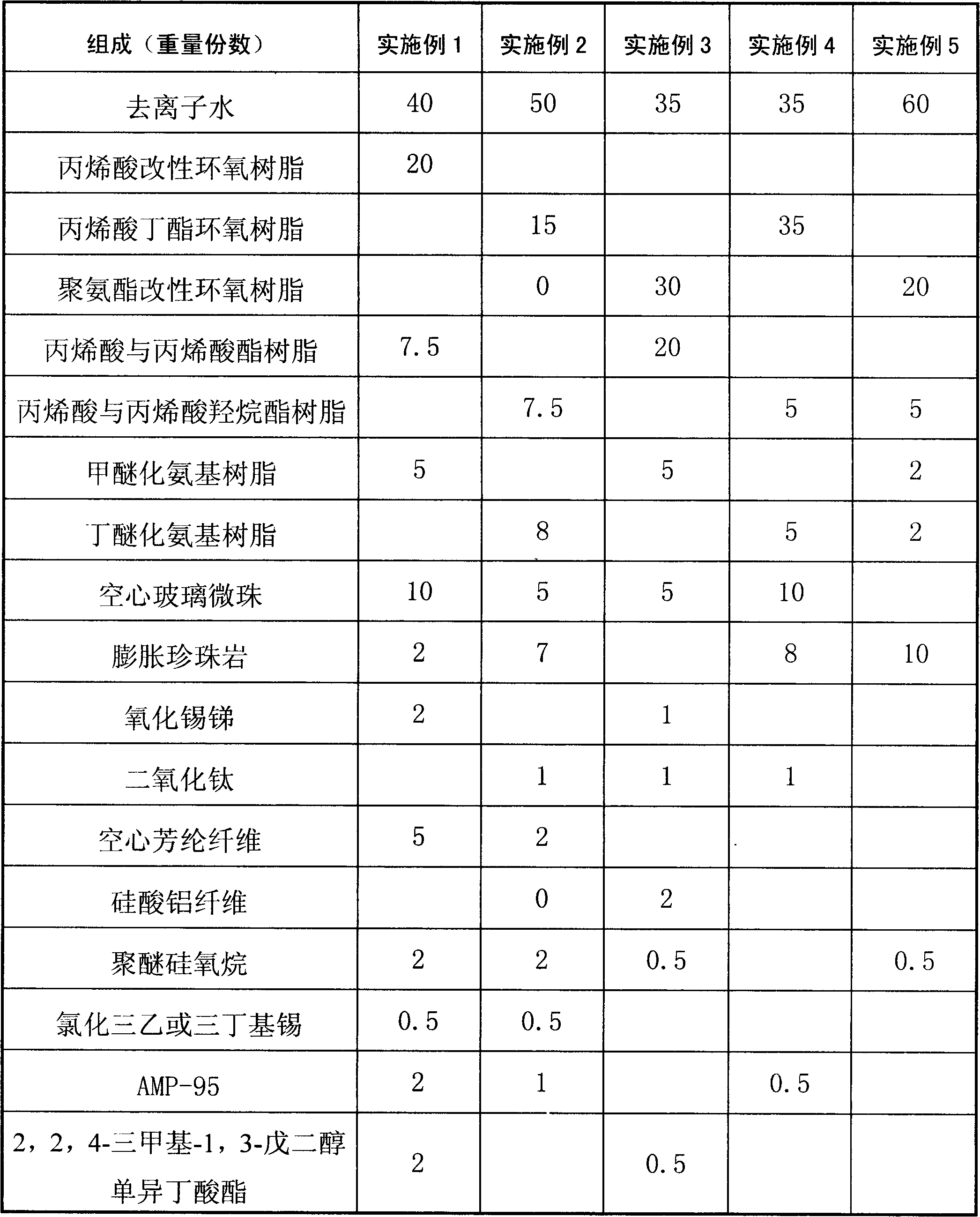

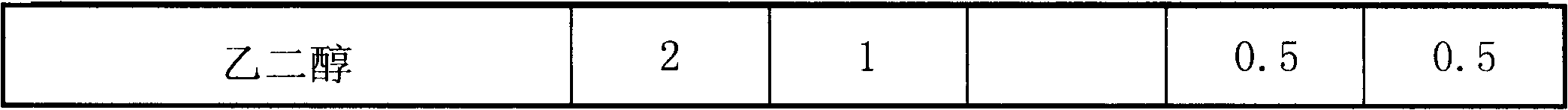

Epoxy acrylate modified high anticorrosion heat insulation paint containing porous ceramic addictive and production method thereof

InactiveCN103450773AStrong adhesionHigh hardnessAnti-corrosive paintsEpoxy resin coatingsEpoxyAcrylic resin

The invention relates to a kind of heat insulation paint with a high anticorrosion performance and a preparation method thereof. The anticorrosion heat insulation paint is composed of following components in percentage by weight: 35 to 60% of deionized water, 20 to 40% of modified epoxy resin, 5 to 30% of modified acrylic resin, 1 to 8% of amino resin, 10 to 25% of heat insulation materials, 0 to 8% of strengthening materials, and 1 to 10% of auxiliary agent. The preparation method comprises following steps: orderly adding deionized water, modified epoxy resin, modified acrylic resin, and amino resin into a reactor, starting the stirrer, evenly mixing the materials, adjusting the pH value of the system to a range of 7 to 9, then orderly adding the auxiliary agent, the heat insulation materials, and the strengthening materials, stirring for 1 to 3 hours in a high speed, and evenly mixing so as to obtain the anticorrosion heat insulation paint. The preparation method has the advantages of simple technology, high production efficiency, and low energy consumption. The prepared paint does not contain any organic solvent, so no solvent will volatilize during the coating solidification process, so no pollution is generated to the environment. The paint has the advantages of excellent mechanical properties of bonding strength, hardness, scratch resistance, wear resistance, and water resistance, and good properties of anticorrosion, salt smog resistance, forming ability, heat resistance, and deflection resistance.

Owner:BOYIFEI EQUIP INST FOR NEW MATERIALS

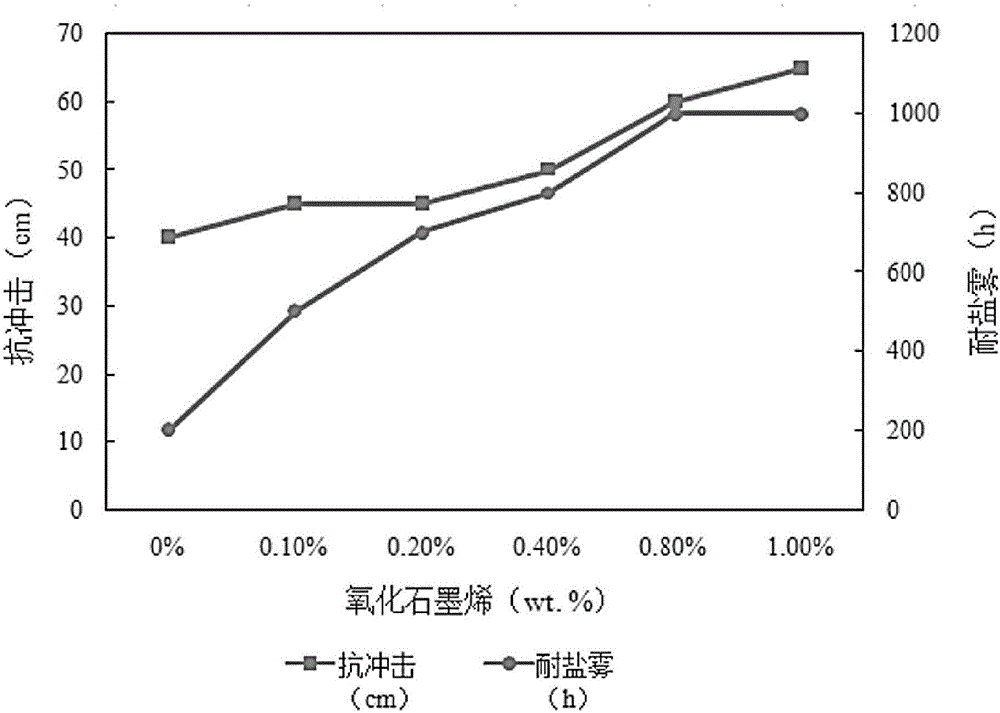

Graphene oxide modified water-based epoxy anticorrosive paint

InactiveCN106497338AAccelerated corrosionImprove impact resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyWater based

Disclosed is a graphene oxide modified water-based epoxy anticorrosive paint. The graphene oxide modified water-based epoxy anticorrosive paint is composed of paint modifying single-layer graphene oxide, water-based epoxy resin, rust-resisting pigment, filling, assistant water-based epoxy resin compound formula and water-based epoxy resin curing agent, wherein the single-layer graphene oxide is of a flake-shaped structure, which is 0.8-1.2 nm thick, and the inside of the layer is a hexagonal structure formed by carbon atom sp2 hybrid orbits. The graphene oxide modified water-based epoxy anticorrosive paint can significantly improve the shock-resisting performance and the anticorrosive performance, maintain optimal coating adhesion and reach up to a hardness level of 4H, thereby meeting the requirements on coating mechanical properties.

Owner:上海碳源汇谷新材料科技有限公司

Method for preparing magnesium-based ceramic coating by micro-arc oxidation-electrophoretic deposition

InactiveCN103194782ABiologically activeImprove corrosion resistanceAnodisationElectrophoretic coatingsPlasma electrolytic oxidationMicro arc oxidation

The invention discloses a method for preparing a magnesium-based ceramic coating by micro-arc oxidation-electrophoretic deposition. The method comprises the following steps of: immersing preheated magnesium alloy taken as an anode in an electrolyte, taking a micro-arc oxidation stainless steel electrolytic cell as a cathode, adopting a direct-current pulsed micro-arc oxidation device, carrying out micro-arc oxidation for 10-25 minutes under the conditions that the electric current is 10-20A / dm<2>, the duty ratio is 37.5-50%, and the temperature of the electrolyte is 20-30 DEG C, taking out the anode, naturally drying, thus obtaining magnesium alloy subjected to micro-arc oxidation; immersing the magnesium alloy subjected to micro-arc oxidation and taken as the anode in electrophoretic deposition liquid, taking the stainless steel electrolytic cell as the cathode, adopting a pulsed power supply, carrying out electrophoretic deposition treatment for 10-30 minutes under the conditions that the voltage is 250-350V, and the duty ratio is 37.5-50%, naturally cooling, thus obtaining the magnesium-based ceramic coating. The adhesive force of the biological nanometer coating is obviously enhanced, the toughness and the corrosion resistance of the coating are improved, and the coating has certain biological activity.

Owner:ZHEJIANG UNIV OF TECH

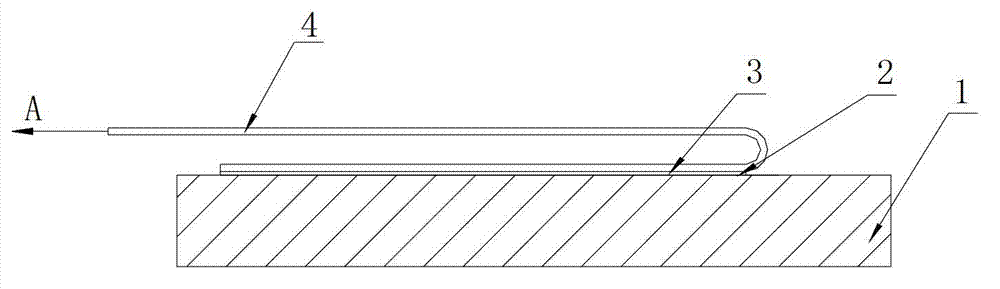

Method for measuring adhesive force of lithium ion battery pole piece coating

ActiveCN102788746AEasy to measureGood repeatabilityUsing mechanical meansMaterial analysisElectrical batteryPole piece

The invention discloses a method for measuring the adhesive force of a lithium ion battery pole piece coating, comprising the following steps: taking a test base plate, bonding a layer of a transparent adhesive tape on the surface of the test base plate, bonding a layer of a double faced adhesive tape on the adhesive-free surface of the transparent adhesive tape, bonding the other adhesive surface of the double faced adhesive tape onto the coating of a pole piece to be tested by pressing, and reserving an unbonded part at one end in the length direction of the pole piece; clamping the reserved unbonded part by a stretch chuck of a stretch testing machine, bending the pole piece in the length direction of the pole piece and stretching, after peeling the coating of the pole piece to be tested, reading the adhesive force value of the pole piece coating. According to the invention, without changing the technological conditions and process flow of the battery manufacturing technique, the adhesive force value of the pole piece coating can be conveniently measured with small error and good repeatability, and the invention provides the design and manufacturing process of batteries with a reliable basis.

Owner:中创新航科技(江苏)有限公司

High-strength cold-rolled steel sheet excellent in coating adhesion, workability and hydrogen embrittlement resistance, and steel component for automobile

InactiveUS20090053096A1Good film adhesionImprove machinabilityFurnace typesHeat treatment furnacesChemical compositionComposite oxide

A cold rolled steel sheet satisfying on the basis of percent by mass the chemical composition of 0.06-0.6% C, 0.1-2% Si, 0.01-3% Al, 1-4% Si+Al, 1-6% Mn, Si / Mn≦0.40, in which there exists 10 or more pieces / 100 μm2 of Mn—Si composite oxide having Mn—Si atom ratio (Mn / Si) of 0.5 or over and major axis of from 0.01 μm to 5 μm and also having a covering ratio of 10% or below at which the surface of the steel sheet is covered with oxide containing Si as the main component.

Owner:KOBE STEEL LTD

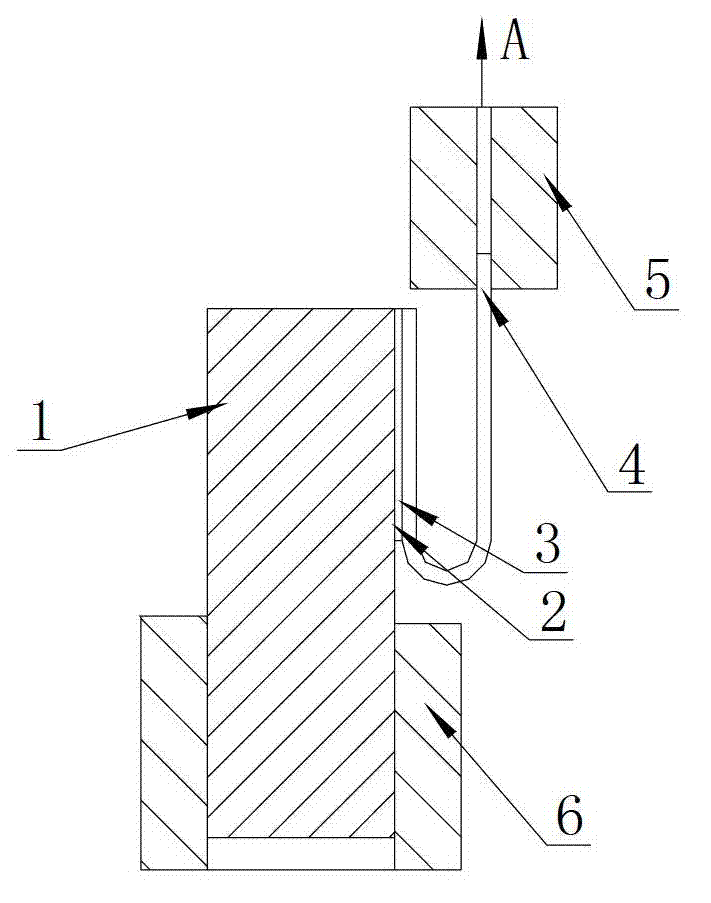

Hot press-formed article and a method for its manufacture

ActiveUS20060121305A1Improve corrosion resistanceNot readily peel offAnodisationHot-dipping/immersion processesSolderabilitySolid solution

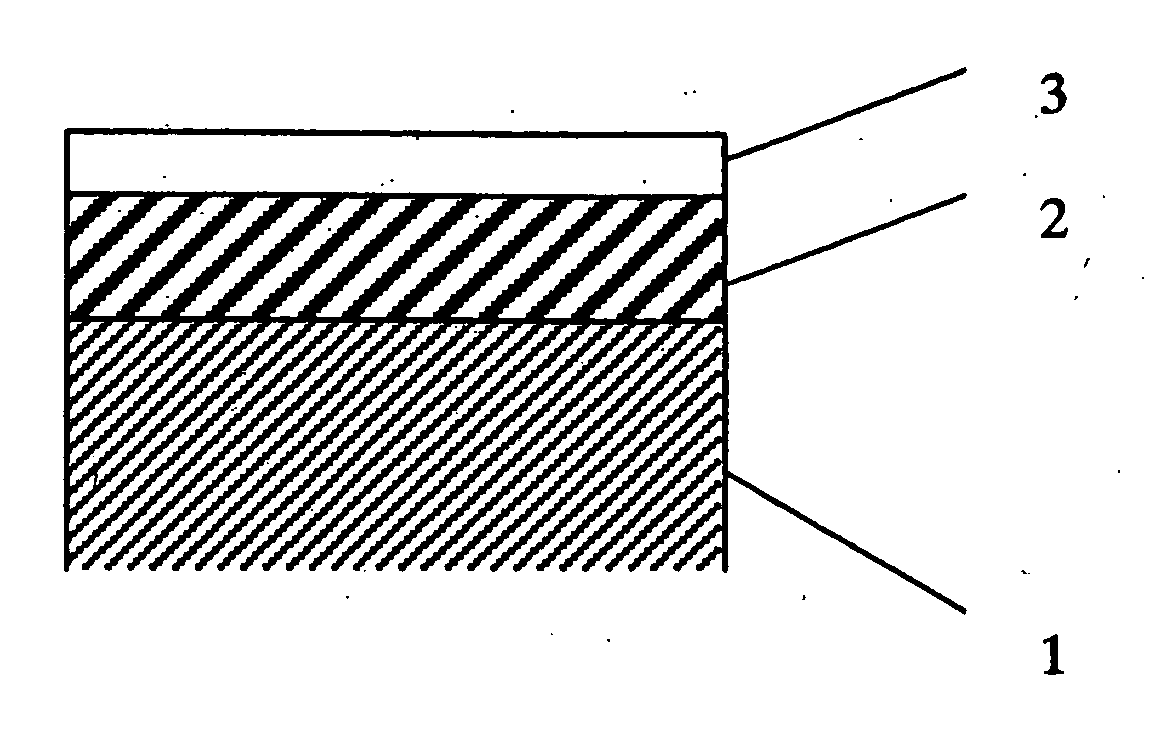

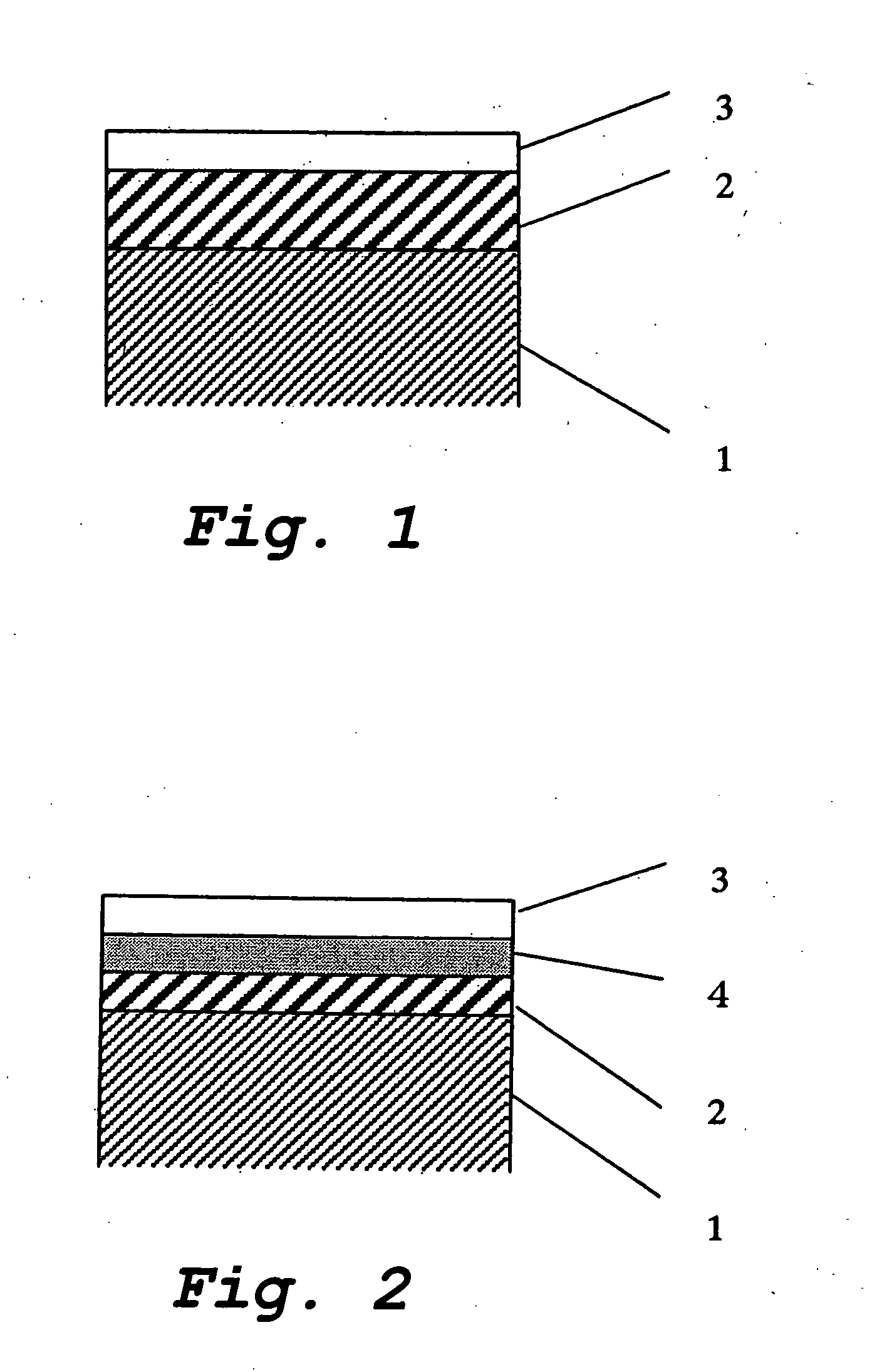

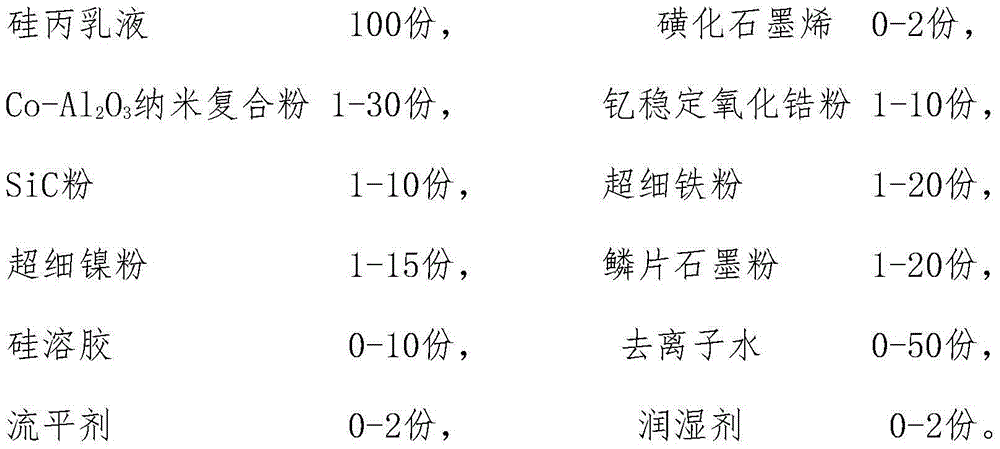

A hot press-formed article having improved corrosion resistance and coating adhesion when coated is obtained by hot press forming of a zinc-based plated steel material. It has a zinc-based plating layer comprising an iron-zinc solid solution phase and atop it a zinc oxide layer. The average thickness of the zinc oxide layer which is the outermost layer is at most 2 μm. A hot press-formed article having a good appearance and excellent corrosion resistance, coating adhesion, post-coating corrosion resistance, and weldability has a layer (2) consisting essentially of an iron-zinc solid solution phase atop a base material steel sheet (1). It also has a zinc oxide layer (3) with an average thickness of at most 5 μm as an uppermost layer, but it does not have a substantial amount of an iron-zinc intermetallic compound phase. The total amount of Al contained in the iron-zinc solid solution layer (2) and the zinc oxide layer (3) is at most 0.5 g / m2, and / or the total amount of Al oxides contained in these layers is at most 5 mg / m2.

Owner:NIPPON STEEL CORP +2

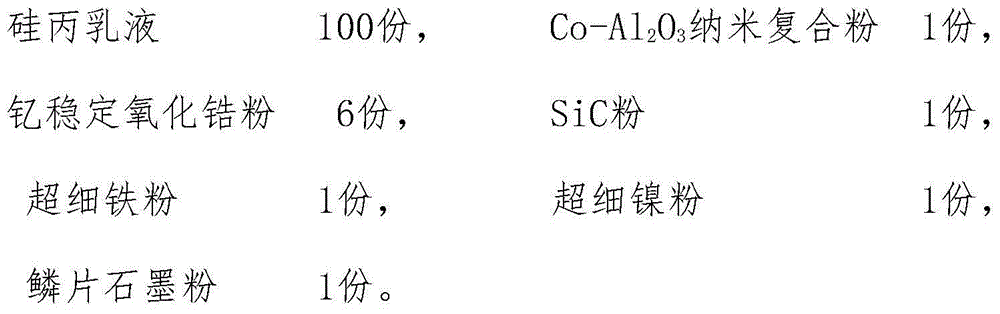

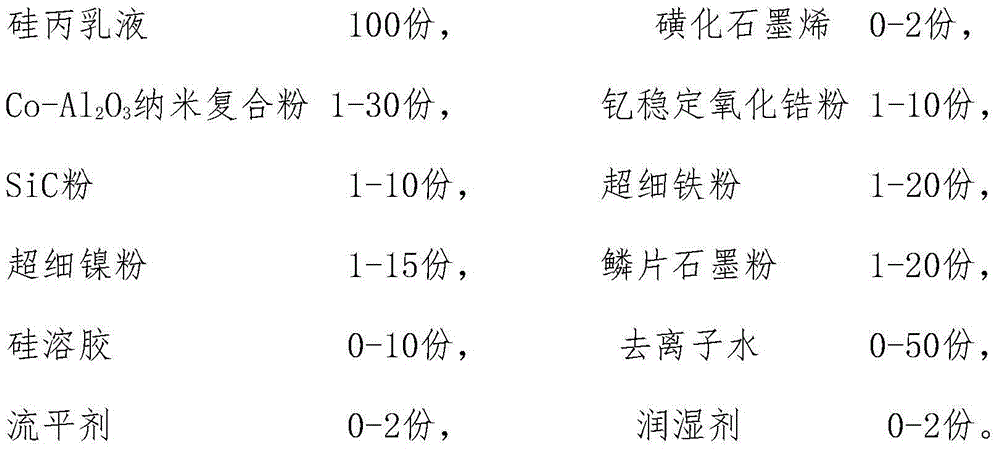

Aqueous solar energy heat-absorbing coating

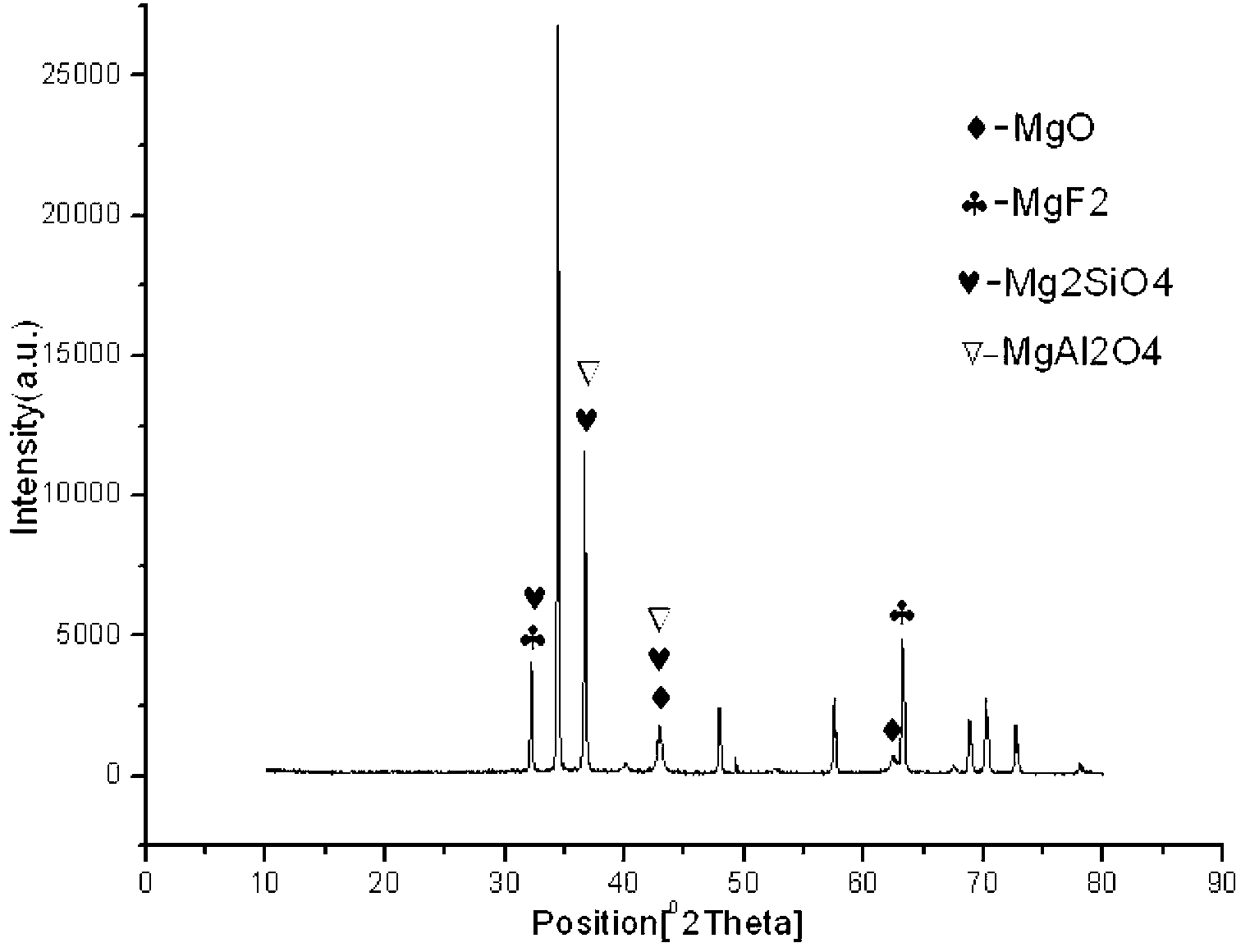

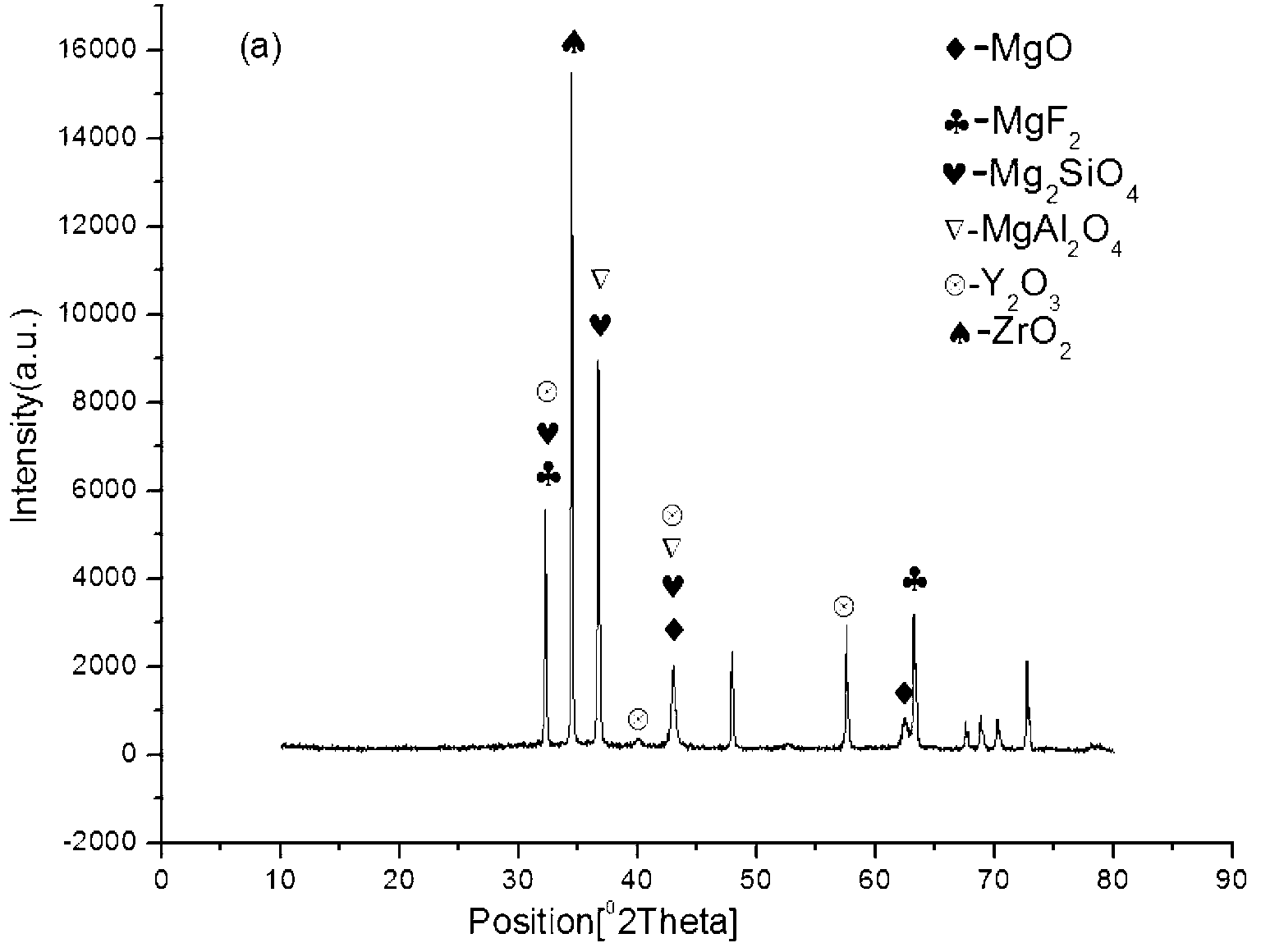

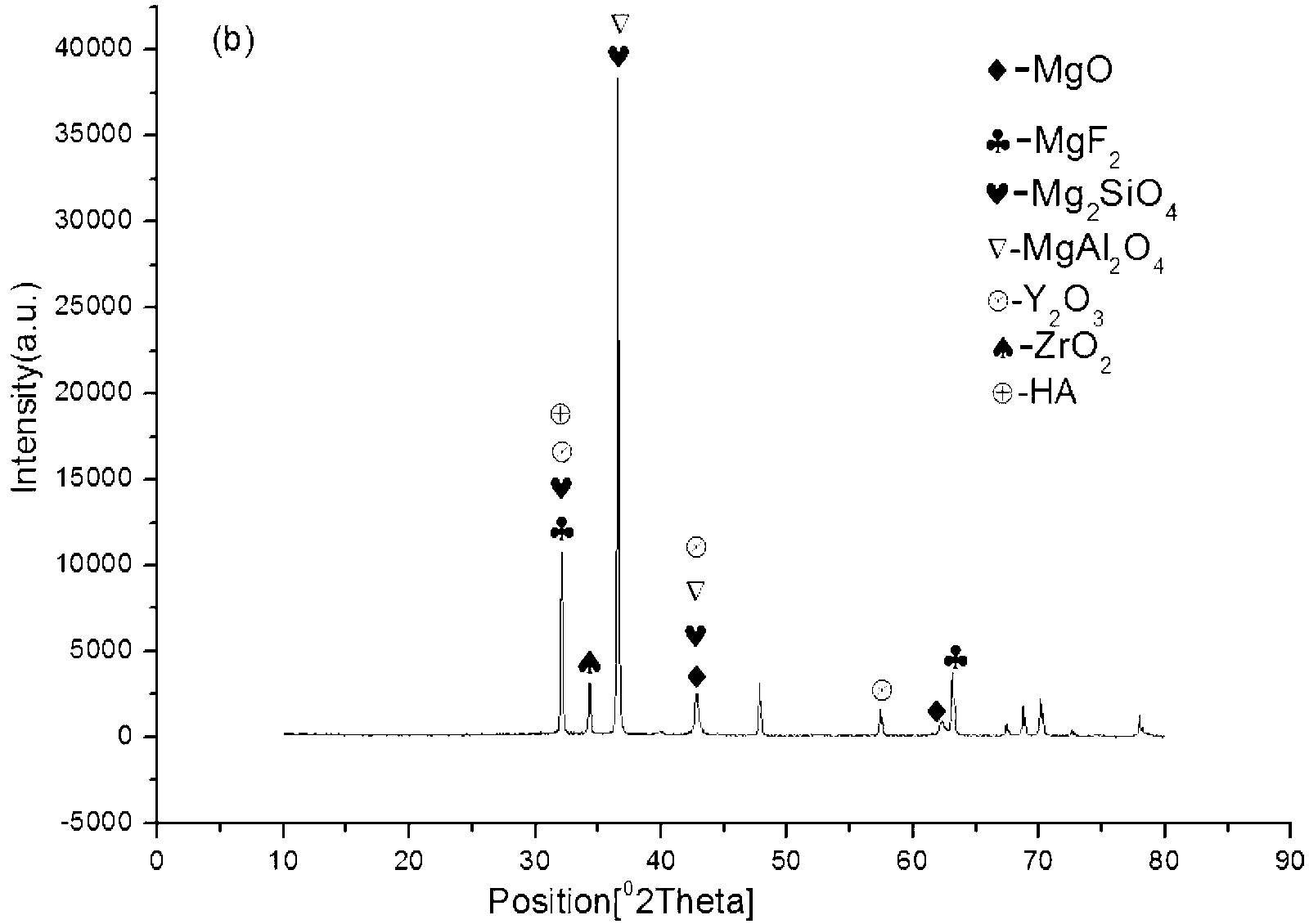

ActiveCN104387880AImprove absorption rateImprove thermal conductivityRadiation-absorbing paintsRoom temperatureYttria-stabilized zirconia

The invention discloses an aqueous solar energy heat-absorbing coating. The uniformly mixed aqueous solar energy heat-absorbing coating is prepared by carrying out defibrination on an organosilicone-modifed acrylic emulsion (silicone-acrylic emulsion), sulfonated graphene, Co-Al2O3 nano-composite powder, yttria-stabilized zirconia powder, SiC powder, superfine iron powder, superfine nickel powder, flake graphite powder, silica sol, deionized water, a flatting agent and a wetting agent in a sand grinding machine at the room temperature in a certain proportion. The aqueous solar energy heat-absorbing coating has the properties that the absorptivity is 0.90-0.94, the emissivity is 0.18-0.20, the coating adhesive force is 4B-5B level, the pencil hardness is H, and the stability and the environmental protection property are high; the aqueous solar energy heat-absorbing coating is simple in preparation process, low in cost, suitable for industrial production and especially applicable to solar energy heat-absorbing coatings of a solar heat absorber.

Owner:ZHONGSHAN TAILAI PAINT CHEM

Concrete structure heavy-duty nano composite coating and protection method

The invention relates to a heavy anti-corrosion nano composite coating and a protection method for a concrete structure. The protection method belongs to a method for protecting the reinforced concrete structure. The heavy anti-corrosion nano composite coating for the concrete structure has a three-layer structure and comprises nano modified epoxy sealing coatings, a nano modified epoxy micaceous iron oxide intermediate paint and a nano modified fluorine-containing polyurethane finish or a fluorine-containing polysiloxane finish from inside to outside in turn. By adoption of the nano composite coating protection technology to perform anti-corrosion coating on the concrete structure, the anti-corrosion service life can reach more than 20 years, and the adhesion of the coating can be doubled compared with a common anti-corrosion coating; the coating has better impact resistance, sediment incrustation resistance, weathering resistance and flexibility; and the construction method is simple, and easy to popularize and apply, and has low cost.

Owner:JIANGSU CUMT DAZHENG SURFACE ENG TECH

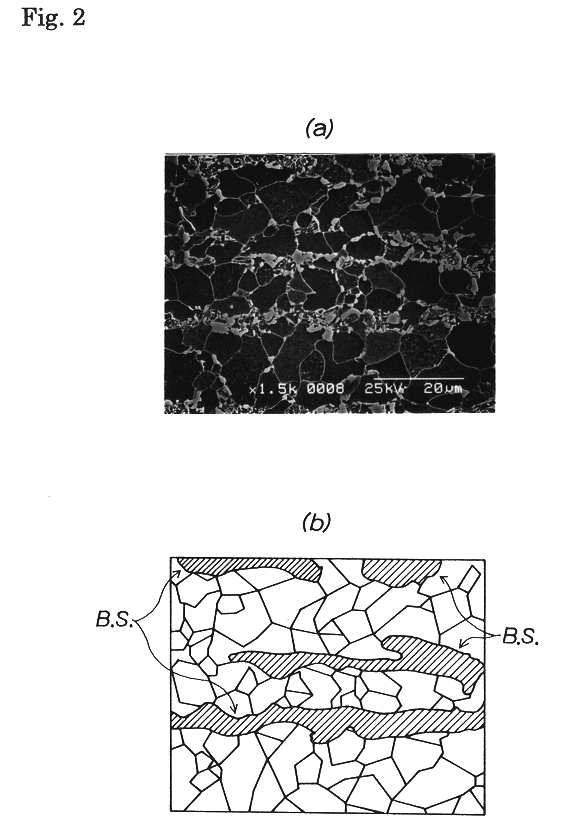

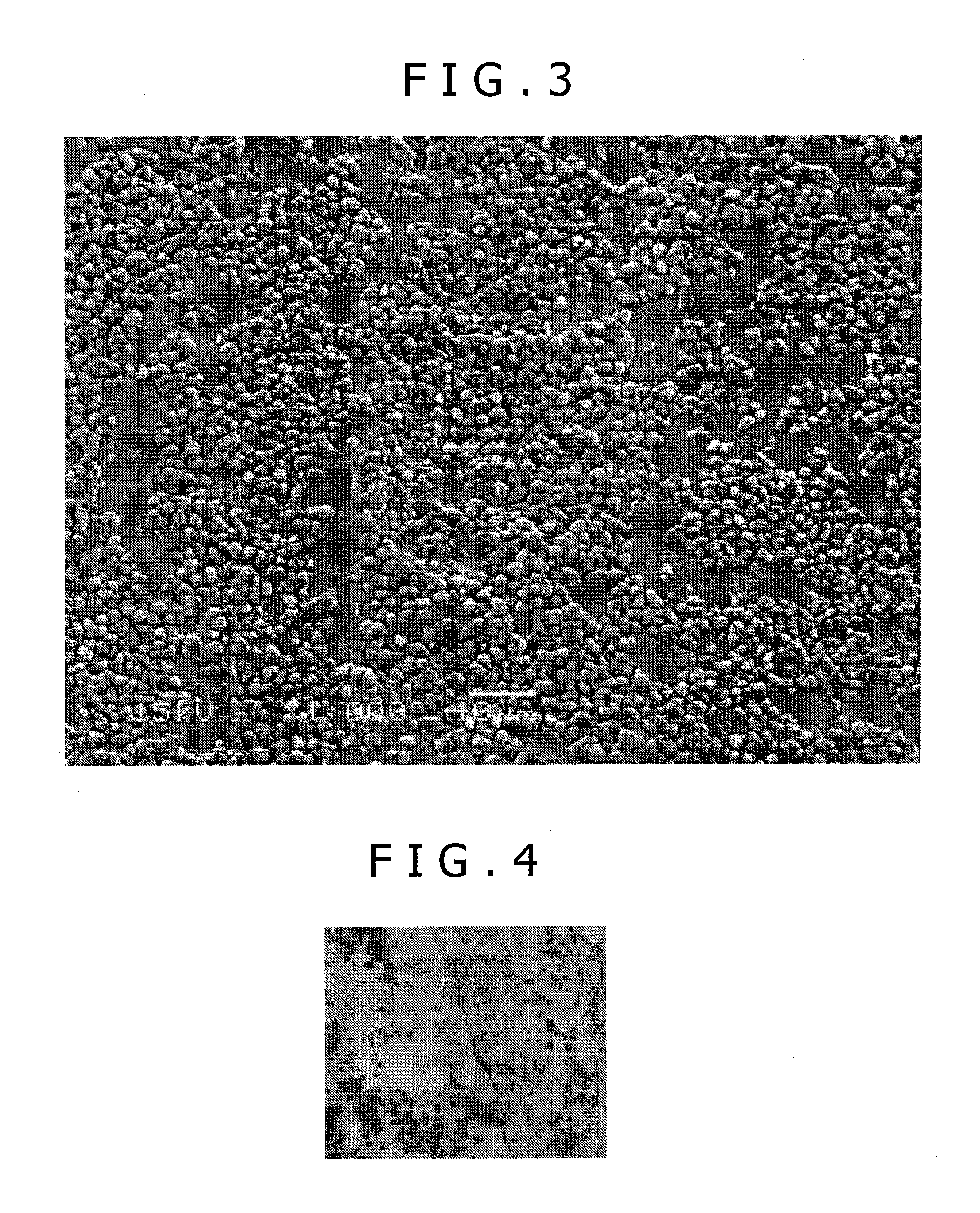

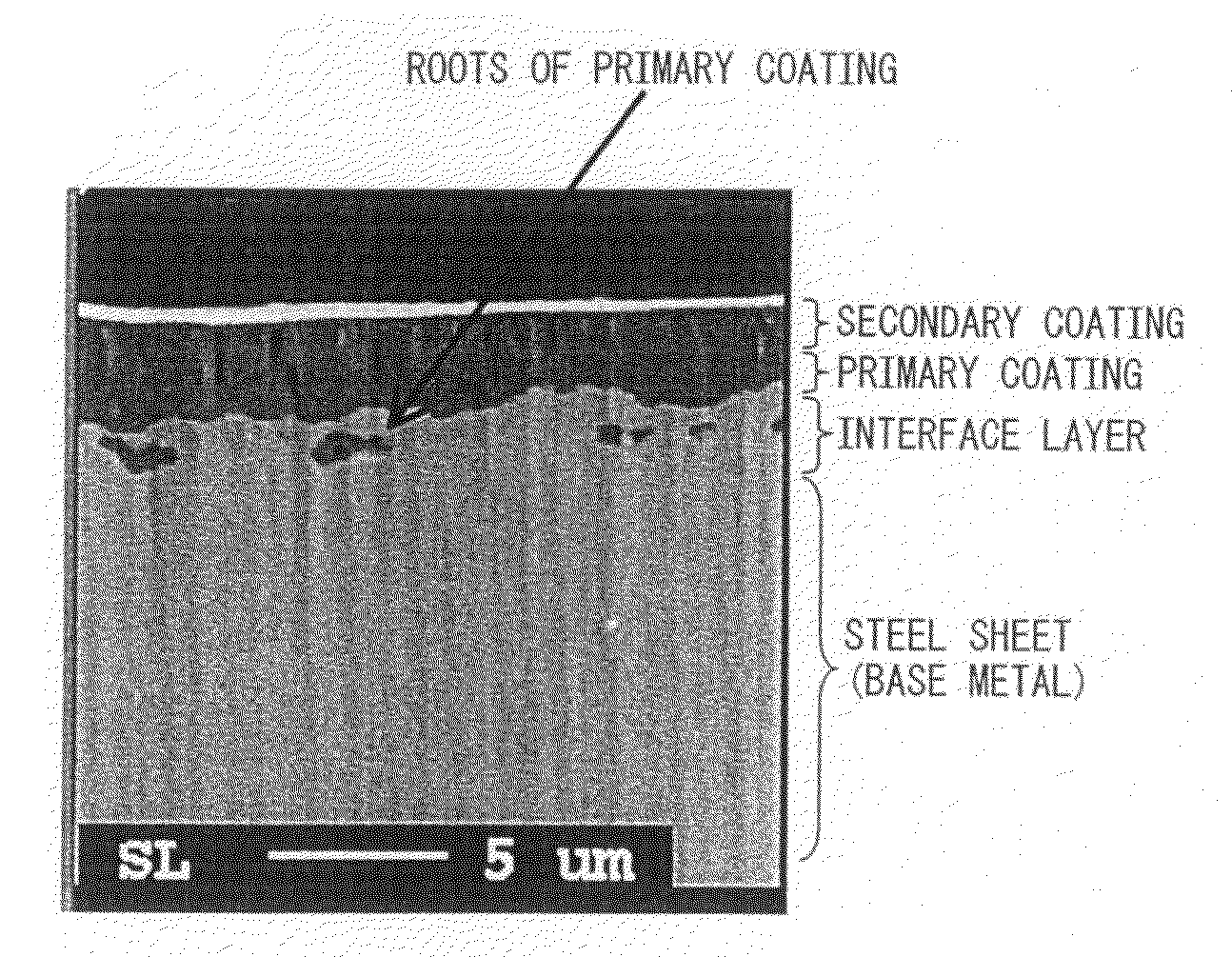

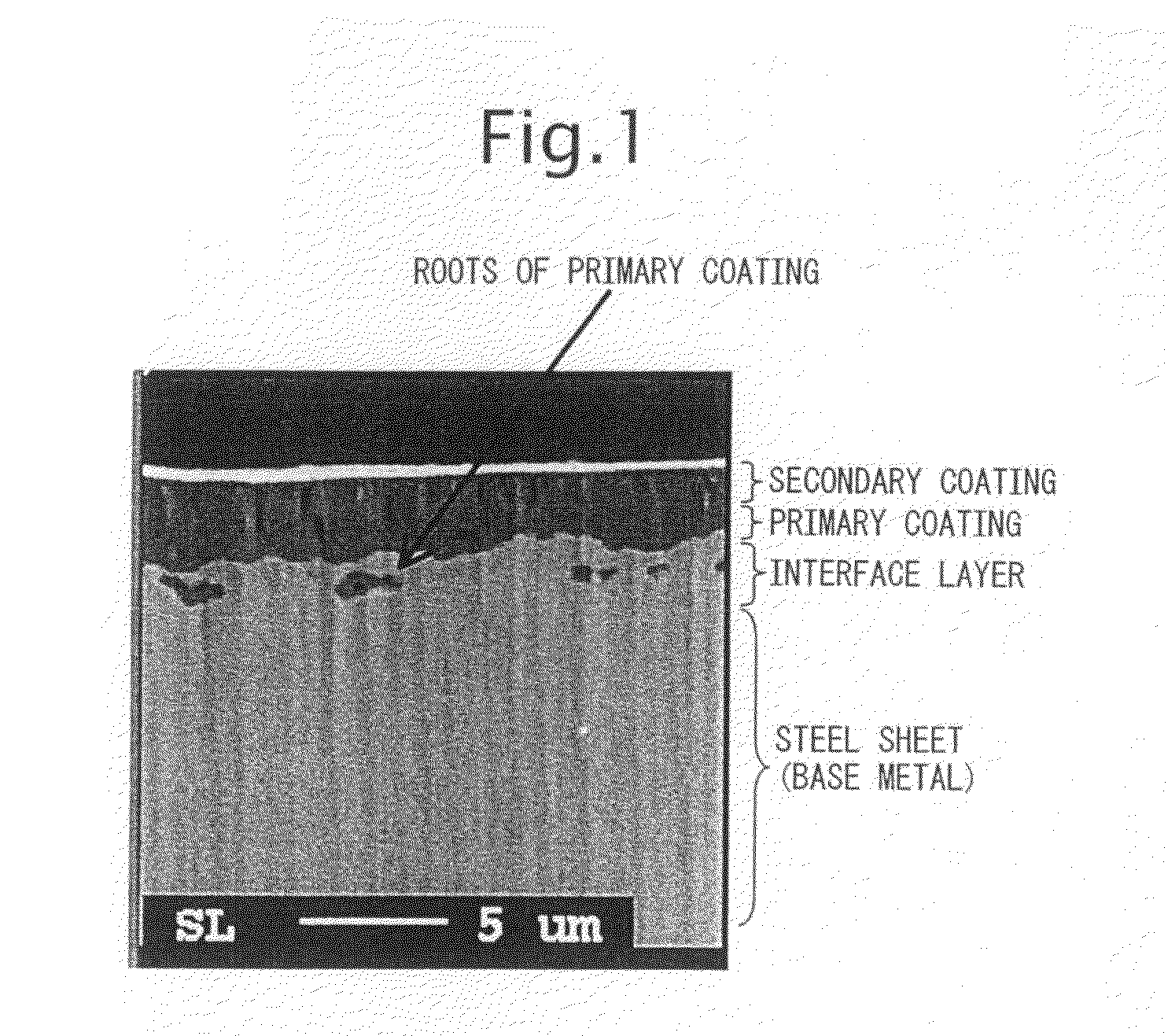

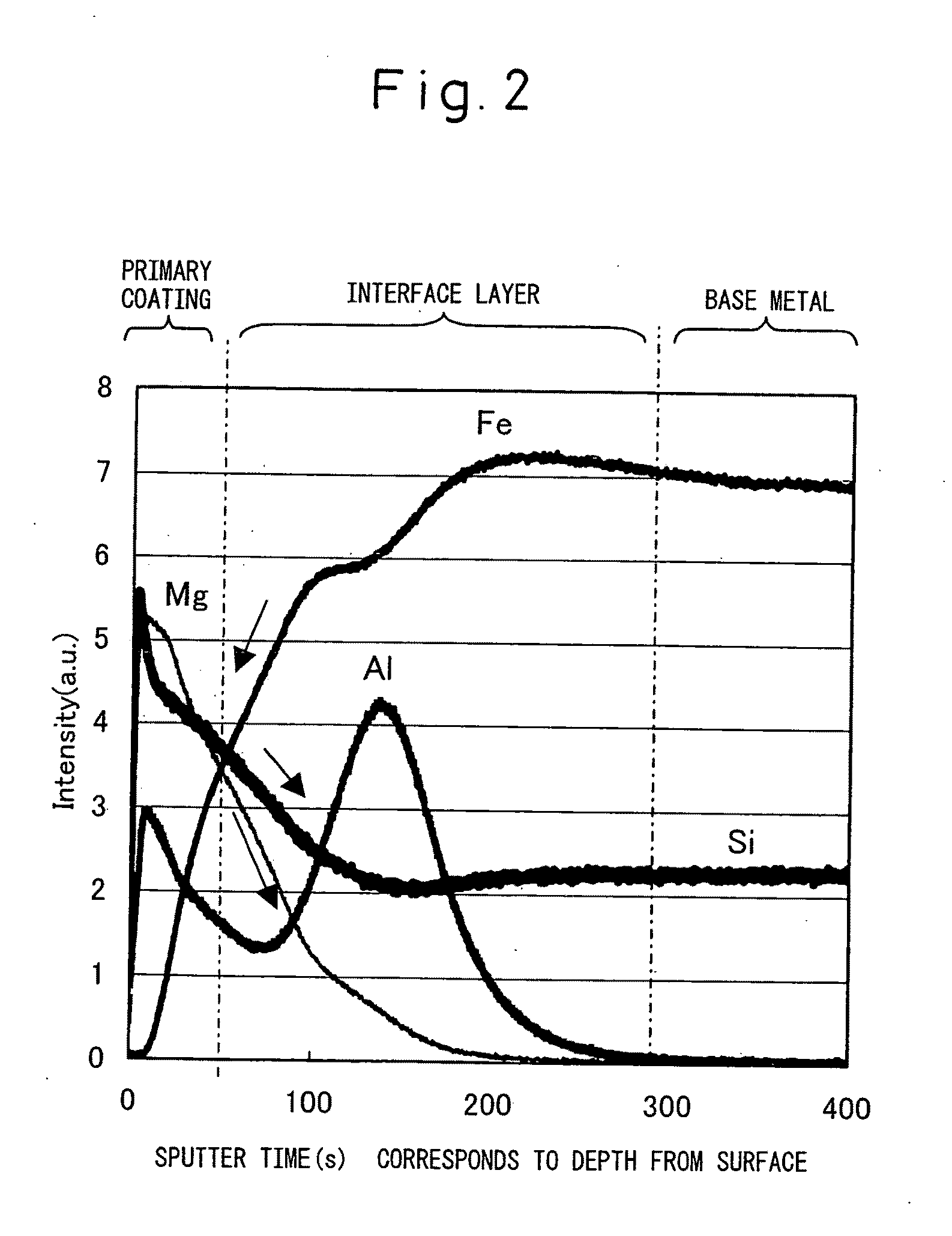

Grain-oriented electrical steel sheet excellent in coating adhesion and method of producing the same

ActiveUS20100055481A1Improve coating adhesionLow coating exfoliation area rateInorganic material magnetismSolid state diffusion coatingElectrical steelTransformer

Grain-oriented electrical steel sheet excellent in coating adhesion is provided. The steel sheet contains Si: 2 to 7% mass % and has a primary coating composed mainly of forsterite on its surface. A compound (A) containing one or more elements selected from among Ca, Sr and Ba, at least one rare earth metal, and sulfur is incorporated in the primary coating so as to reside in the interface layer between the primary coating and the steel sheet. As a result, occurrence of primary coating exfoliation at regions that are strongly worked during manufacture of a wound core transformer or the like is prevented.

Owner:NIPPON STEEL CORP

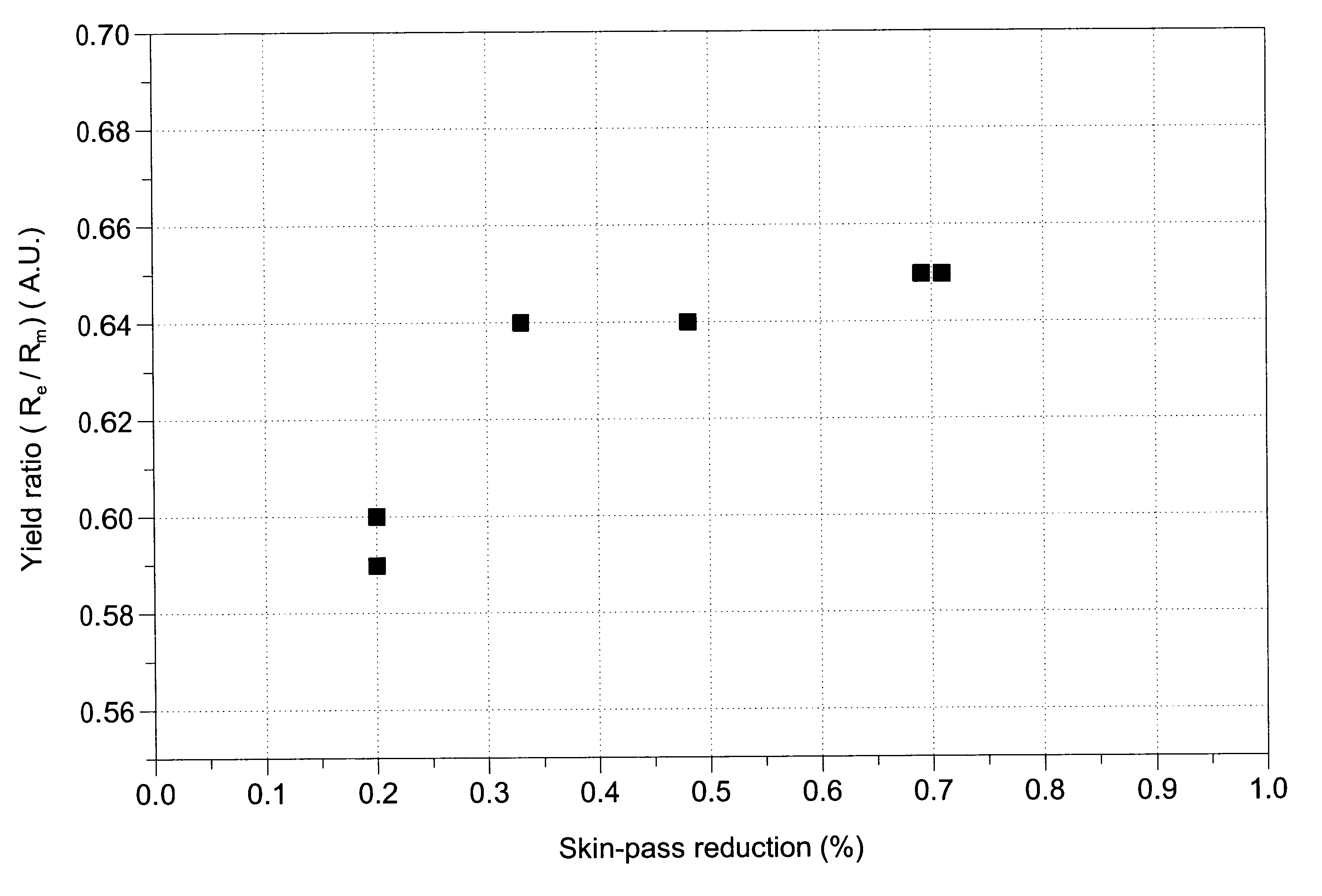

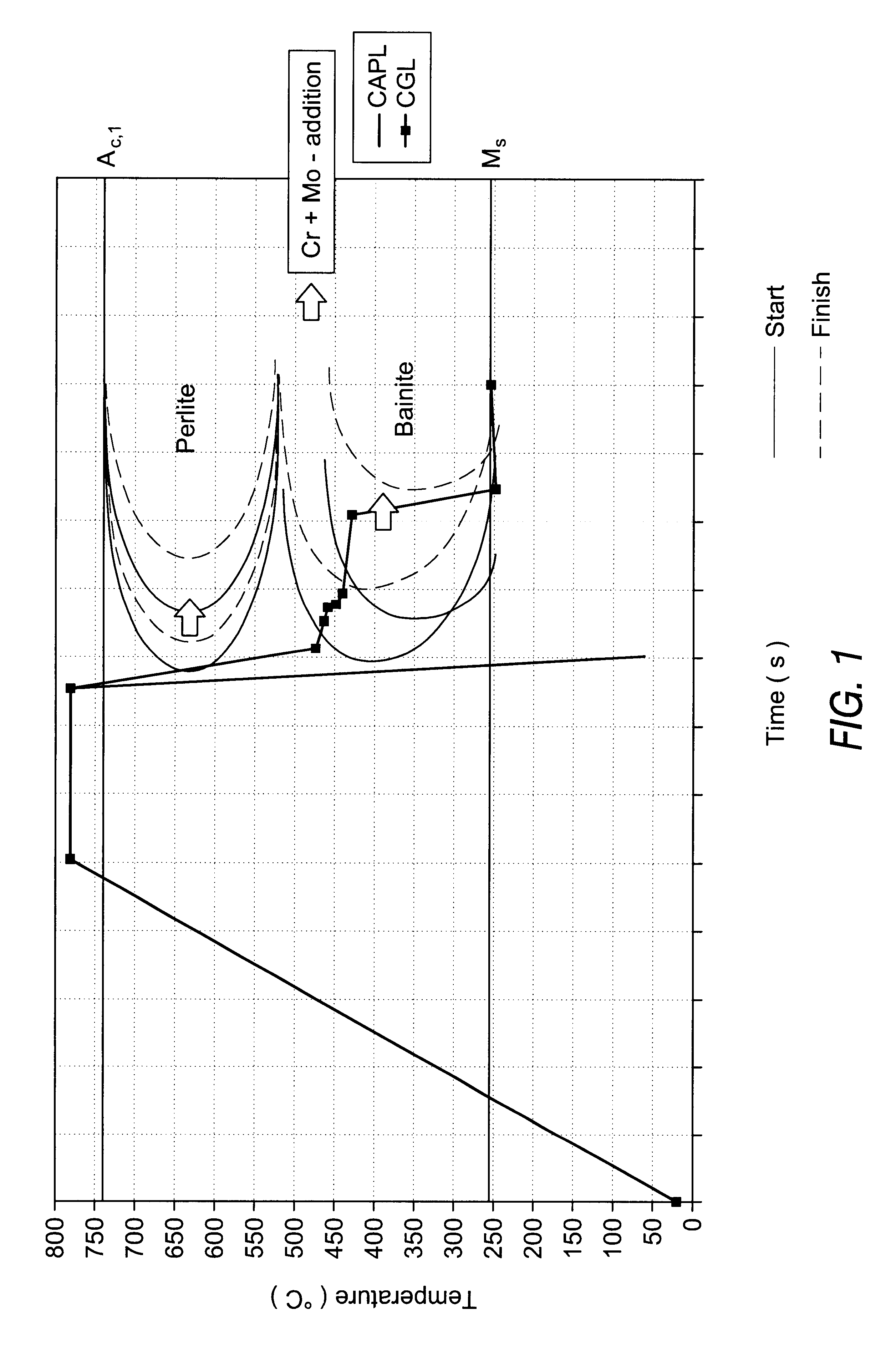

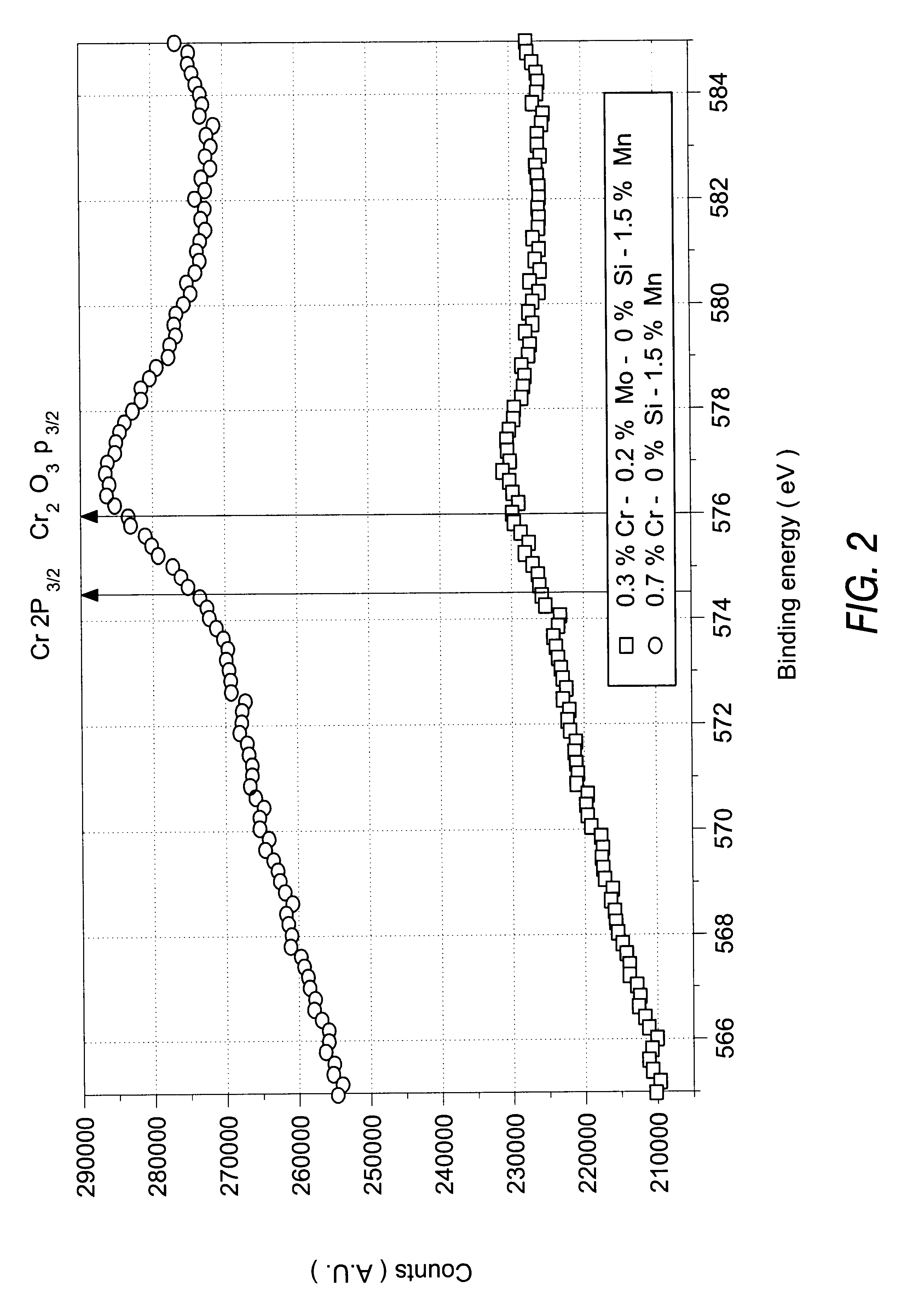

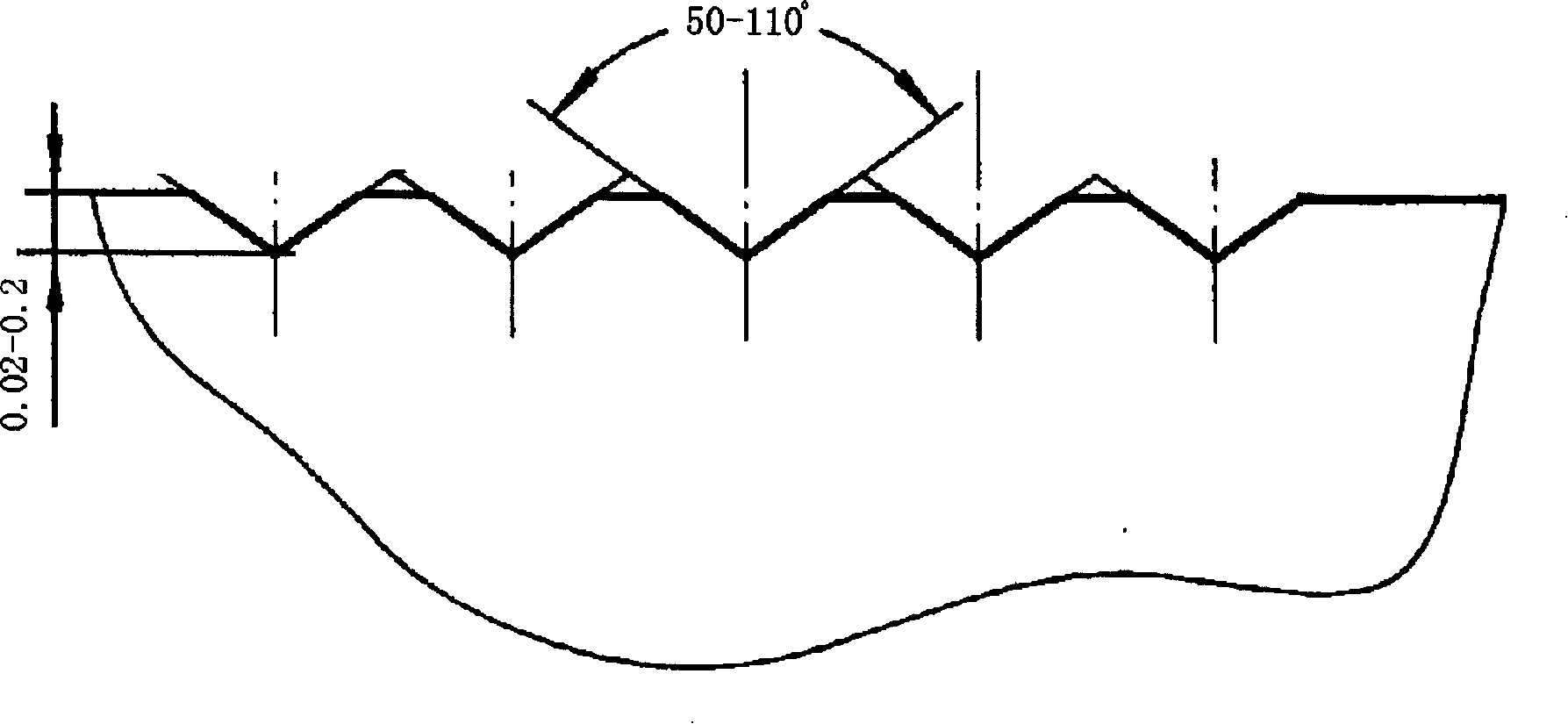

Method of production of cold-rolled metal coated steel products, and the products obtained, having a low yield ratio

InactiveUS6641931B2High strengthGood molding effectHot-dipping/immersion processesFurnace typesManganeseYield ratio

The present invention aims to produce a cold rolled metal coated multi-phase steel, characterized by a tensile strength of at least 500 MPa, a yield ratio (Re / Rm) lower than 0.65 in skinned conditions, lower than 0.60 in unskinned conditions, and with good metal coating adhesion behavior. In the case of the aluminized steel according to the invention, the steel also has superior resistance to temperature corrosion up to 900° C. and excellent mechanical properties at this high temperature. The hot metal coated steel product having a steel composition with a manganese content lower than 1.5%, chrome content between 0.2 and 0.5%, molybdenum content between 0.1 and 0.25%, and a relation between the chrome and molybdenum content as follows Cr+2 Mo higher than or equal to 0.7%, undergoes a thermal treatment in the hot dip metal coating line defined by a soaking temperature between Ac1 and Ac3, a primary cooling speed higher than 25° C. / sec and a secondary cooling speed higher than 4° C. / sec.

Owner:SIDMAR

Anti-sticking and wear resistant polyurea coating and its preparation method

ActiveCN102492357ASolve the adhesionSolve corrosivePolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention relates to an anti-sticking and wear resistant polyurea coating and its preparation method. The coating is prepared by blending of component A and component B. Specifically, the component A is synthesized by the following raw materials by weight: 90-120 parts of isocyanate, 40-60 parts of polyether polyol and 20-30 parts of fluorocarbon diol; and the component B is prepared by the following raw materials by weight: 500-800 parts of polyether amine, 400-600 parts of organosilicon diamine, 300-400 parts of high activity polyether polyol, 400-500 parts of an amino chain extender, 80-100 parts of an amino cross-linking agent, 100-150 parts of a high boiling point diluent, 5-10 parts of a composite catalyst, 400-600 parts of composite nano-metal oxide surface active materials, 600-800 parts of a filling material, and 40-60 parts of a pigment. The invention also includes a preparation method of the anti-sticking and wear resistant polyurea coating. A coating layer obtained by spraying of the anti-sticking and wear resistant polyurea coating in the invention has strong adhesion, and has good adhesion resistance, wear resistance, corrosion resistance, as well as impact resistance. Therefore, the anti-sticking and wear resistant polyurea coating of the invention is especially suitable for spraying on the lining surface of a heavy transport dump truck.

Owner:湘江涂料科技有限公司

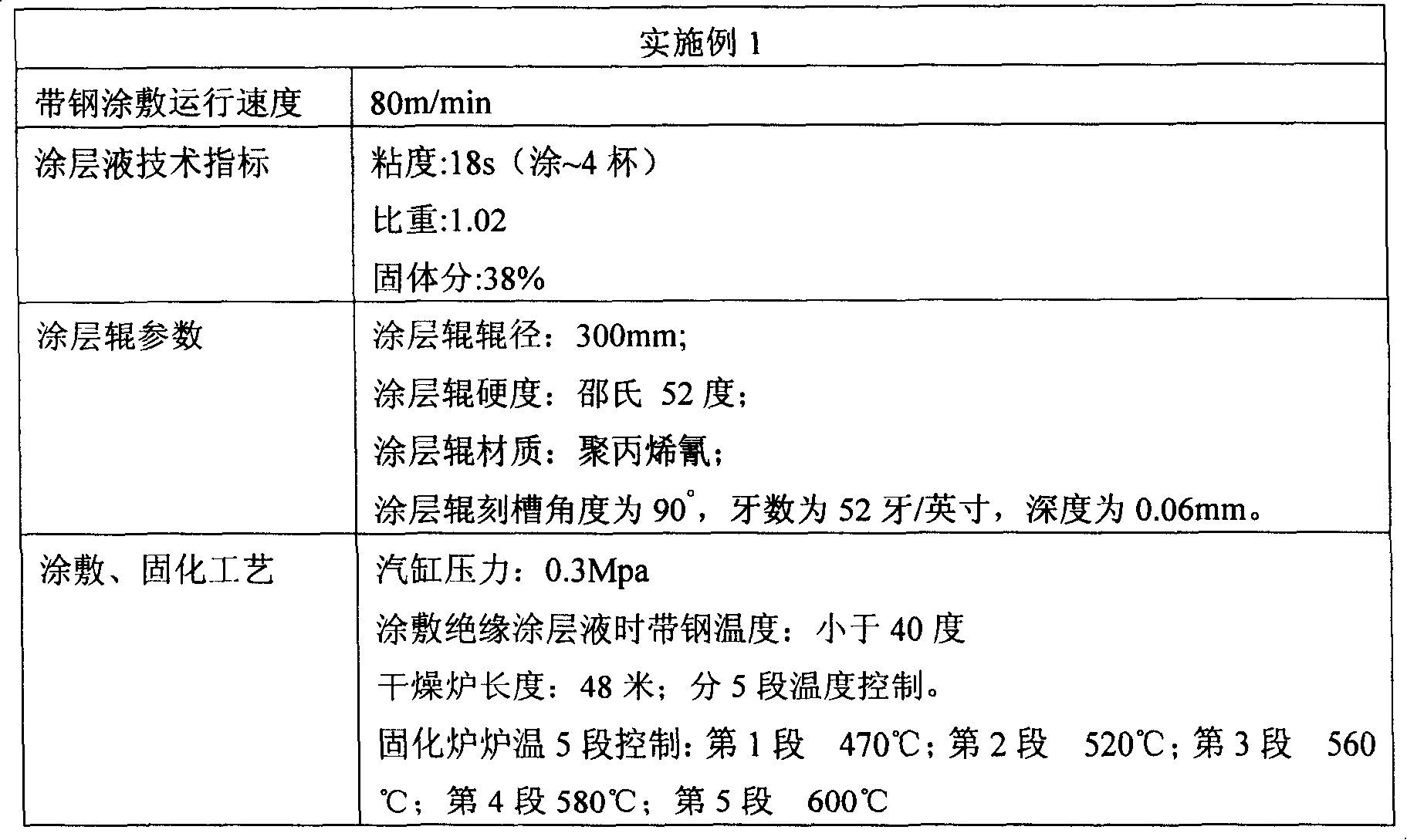

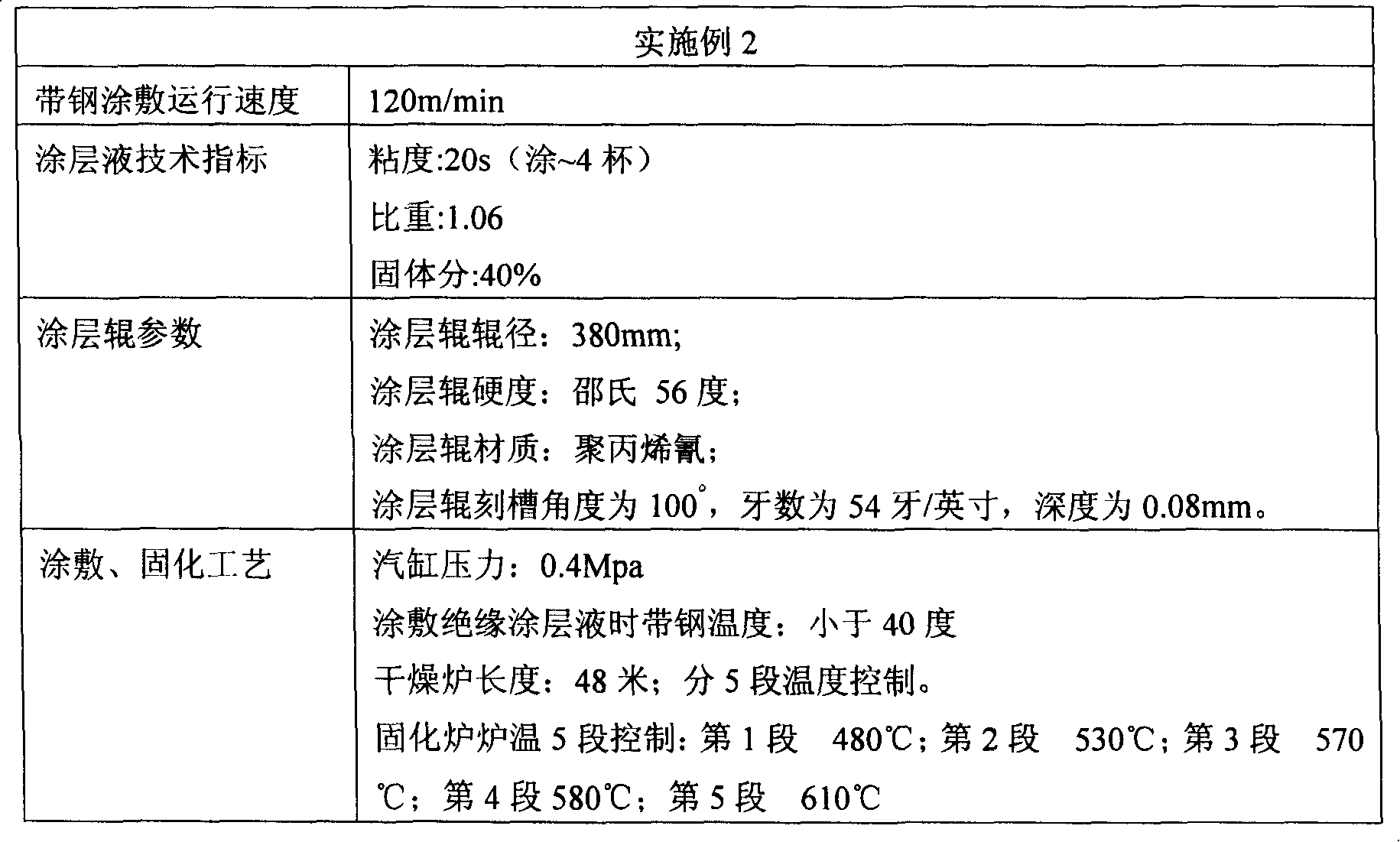

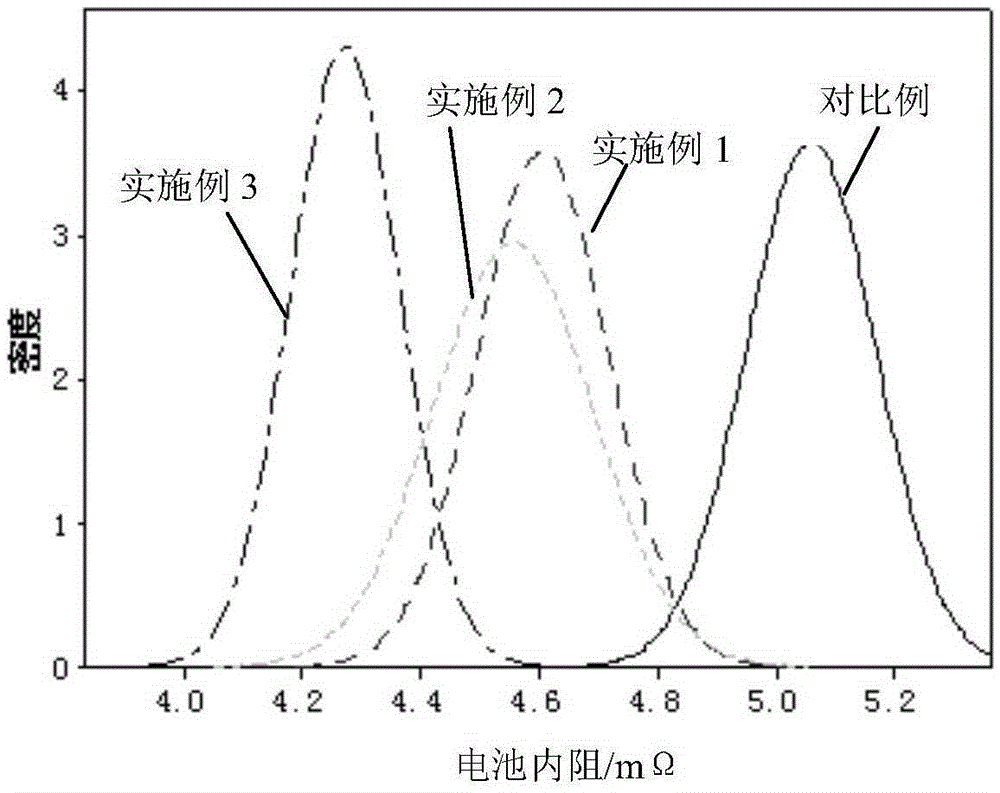

Coating method of cold-rolled silicon steel chromium-free insulating coatings, coating rubber roll and coating liquid

InactiveCN101209440ASmooth and even colorUniform colorPretreated surfacesCoatingsChromium freeStrip steel

The invention discloses a coating method of chrome-free insulation coatings of cold rolling silicon steels, a coating rubber roller and coating solution, which is characterized in that technique parameters of the coating rubber roller, operation speed of a unit, composition of the insulation coating solution, specific gravity of the coating solution, temperature of a curing furnace, coating, drying, curing, etc. are selected to carry out optimization for coating band steels. The invention has the advantages and effects lie in that water is employed to disperse the insulation coating solution of chrome-free one-component silicon steels; two rubber rollers with carving grooves are used; in a certain speed and pressure, through curing in a certain temperature, a cold rolled silicon steel plate coating is produced and has the thickness of 1-3 mm, smooth and uniform surface, adhesive force of coating (O grade), insulation property (more than 600 Omega / mm<2>), good rust-proof capability, refrigerant resistance and good punching shear property and has uniform color, luster, no packing, good appearance and environmental production process and products, thus fully meeting the requirements of ROHS Instructions of European Union and national environmental protection policy of the insulation coating of the cold rolling silicon steels.

Owner:ANGANG STEEL CO LTD

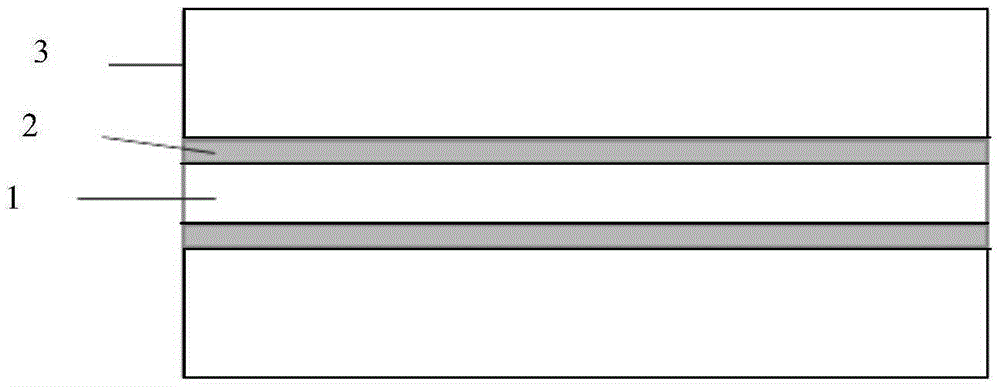

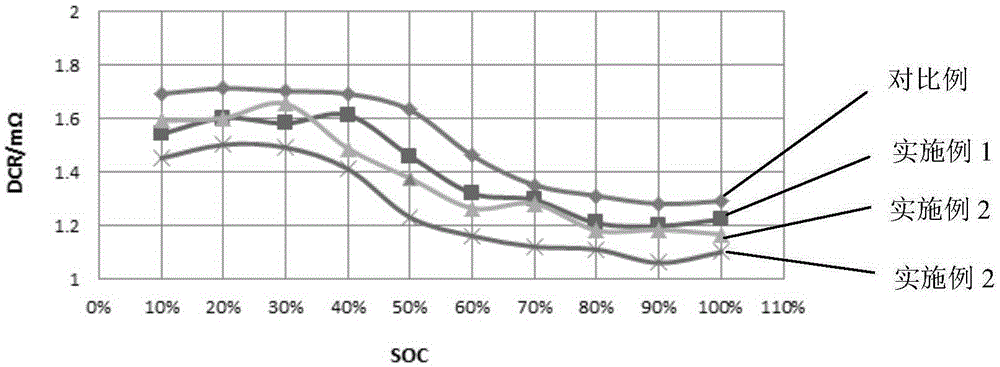

Lithium ion battery waterborne positive electrode composite collector, positive plate, manufacturing methods for lithium ion battery waterborne positive electrode composite collector and positive plate, and lithium ion battery

ActiveCN105261760ALower internal resistanceImprove high rate discharge performanceFinal product manufactureElectrode carriers/collectorsHigh rateAluminium-ion battery

The invention relates to a lithium ion battery waterborne positive electrode composite collector, a positive plate, manufacturing methods for the lithium ion battery waterborne positive electrode composite collector and the positive plate, and the lithium ion battery, and belongs to the technical field of lithium ion batteries. The lithium ion battery waterborne positive electrode composite collector is prepared by the following steps of adding a binder into a solvent to uniformly mix to obtain a binder solution, wherein the mass ratio of the binder to the solvent is 1:10-30; adding a conductive agent to the binder solution, uniformly mixing, grinding and emulsifying to obtain a conducive slurry, wherein the mass ratio of the conductive agent to the binder is 1-99:1; and coating the surface of the positive electrode collector with the prepared conductive slurry, and drying to obtain the lithium ion battery waterborne positive electrode composite collector. The problem of low flexibility of the waterborne positive plate is greatly solved by the lithium ion battery waterborne positive electrode composite collector; and meanwhile, the adhesive force of the coating layer is improved, the internal resistance of the battery is reduced, and the high-rate discharge performance and the cycle performance of the battery are improved.

Owner:CALB CO LTD

Water-based fluorocarbon top coat for wind-powered blades and method for preparing water-based fluorocarbon top coat

ActiveCN102675998AImprove adhesionGood flexibilityAntifouling/underwater paintsPaints with biocidesWater basedLow speed

The invention discloses a water-based fluorocarbon top coat for wind-powered blades and a method for preparing the water-based fluorocarbon top coat and relates to the field of protective paint. According to the water-based fluorocarbon topcoat for wind powered blades, through compounding an hydroxyl acrylic emulsion and a water-based fluorocarbon emulsion and crosslinking hydroxyl acyclic acid with isocyanate so as to form a netted film, thus the coating adhesion, flexibility, chemical medium resistance, wear resistance of a coating are increased; due to the addition of the water-based fluorocarbon emulsion, the weather fastness of the coating is improved, and the gloss retention, color retention and chalking resistance of the coating are excellent; under the condition of stirring a water-dispersed isocyanate curing agent at a lower speed, an ideal emulsion is formed easily through mixing, thereby ensuring the performance of paint; and because of the introduction of a light stabilizer, the lightfastness, color retention and chalking resistance of the coating are improved.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

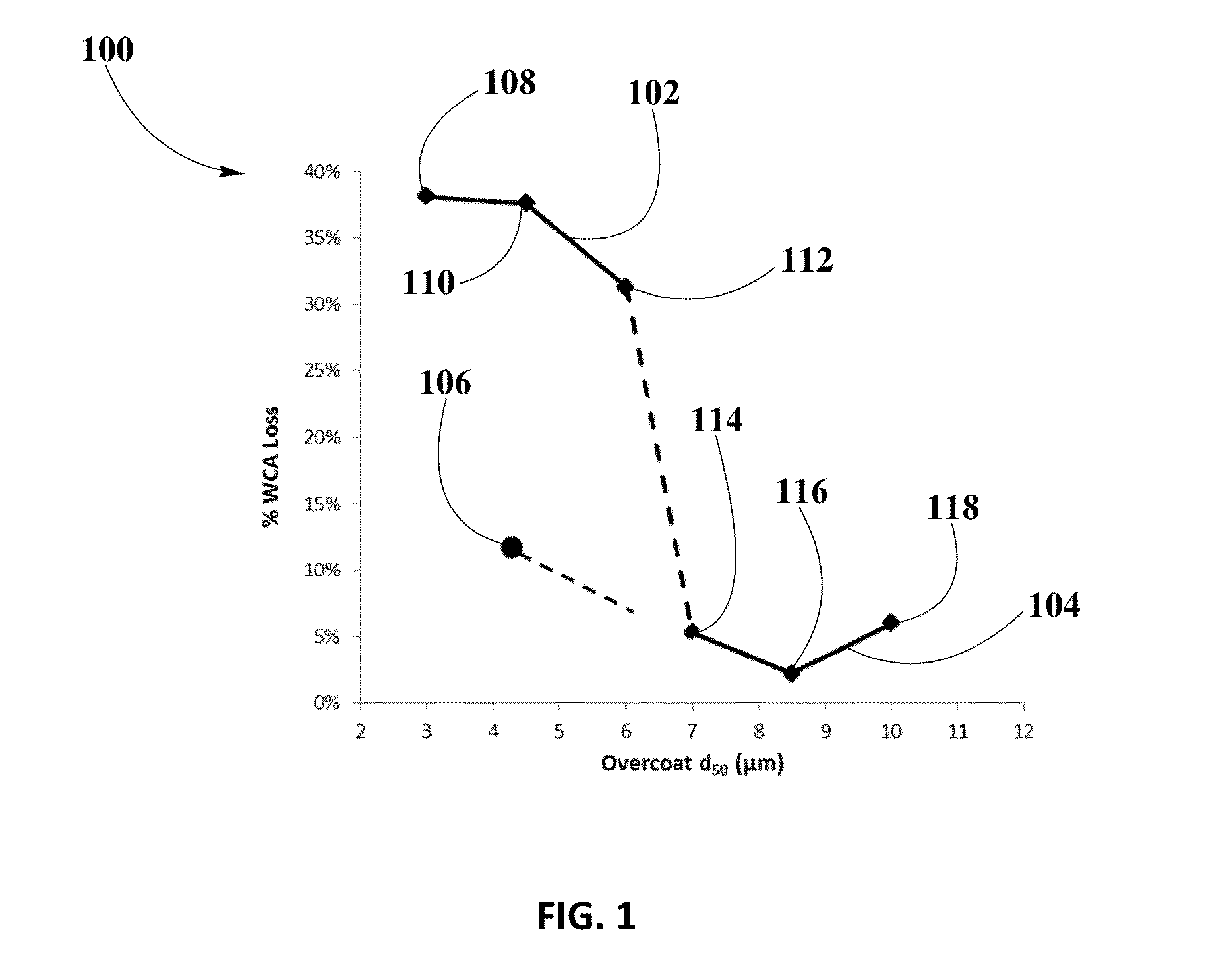

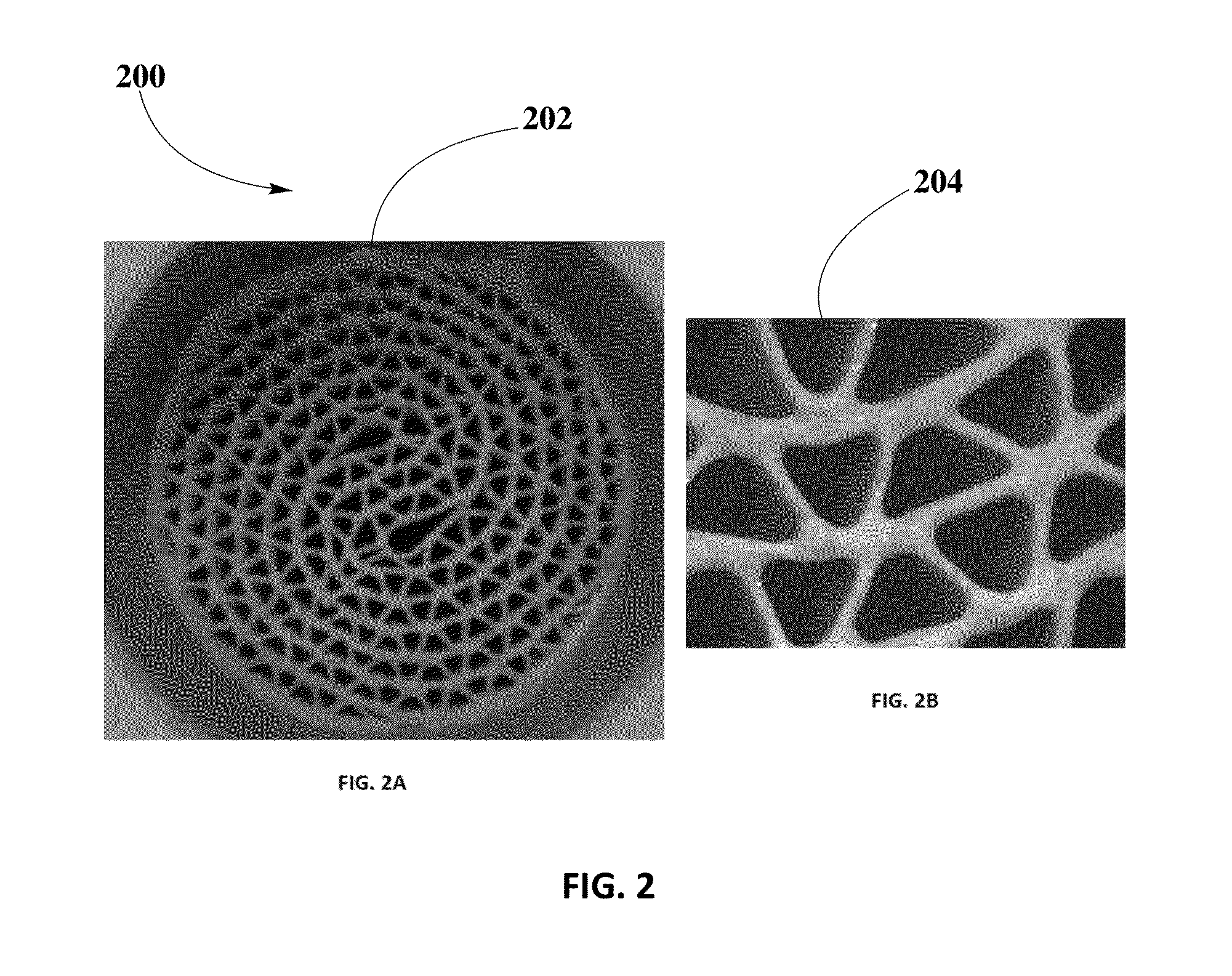

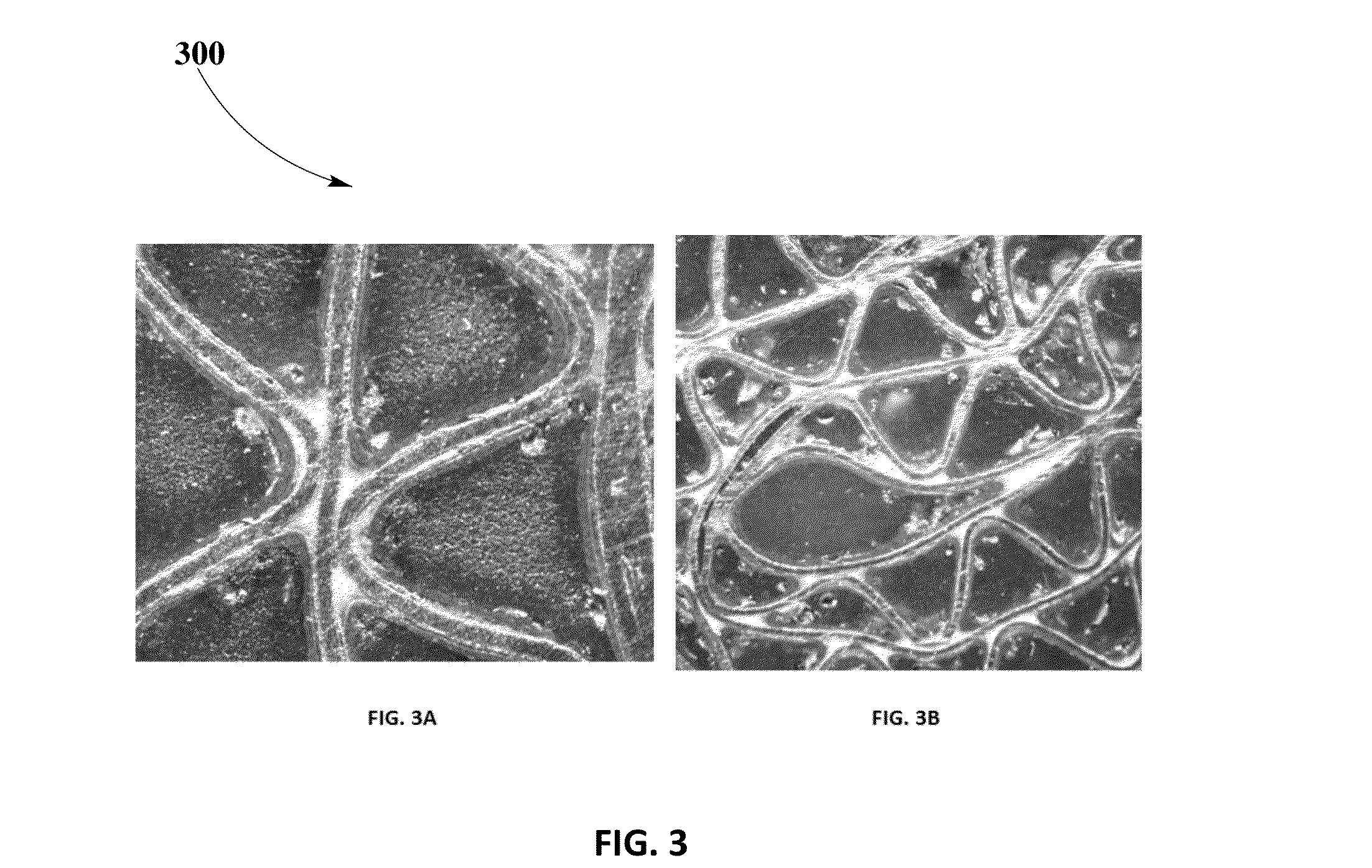

Minimizing Washcoat Adhesion Loss of Zero-PGM Catalyst Coated on Metallic Substrate

InactiveUS20150018204A1Reduction of WCA lossHigh activityDispersed particle separationCatalyst activation/preparationSlurrySolid content

Solutions to the problem of washcoat and / or overcoat adhesion loss of ZPGM catalyst on metallic substrates are disclosed. Present disclosure provides an enhanced process for improving WCA to metallic substrates of ZPGM catalyst systems. Reduction of WCA loss and improved catalyst activity may be enabled by the selection of processing parameters determined from variation of rheological properties by the solid content of the overcoat slurry and variation of the overcoat slurry particle size distribution to produce desirable homogeneity, specific loading, and adherence of the coating on metallic substrates. Processing parameters may be applied to a plurality of metallic substrates of different geometries and cell densities.

Owner:CLEAN DIESEL TECHNOLOGIES

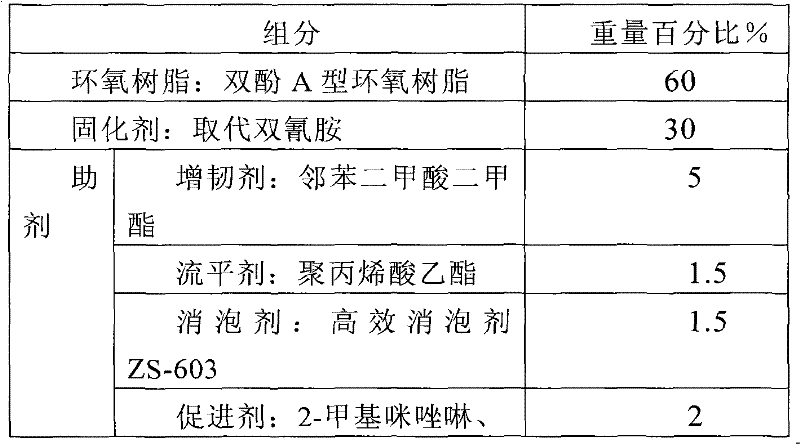

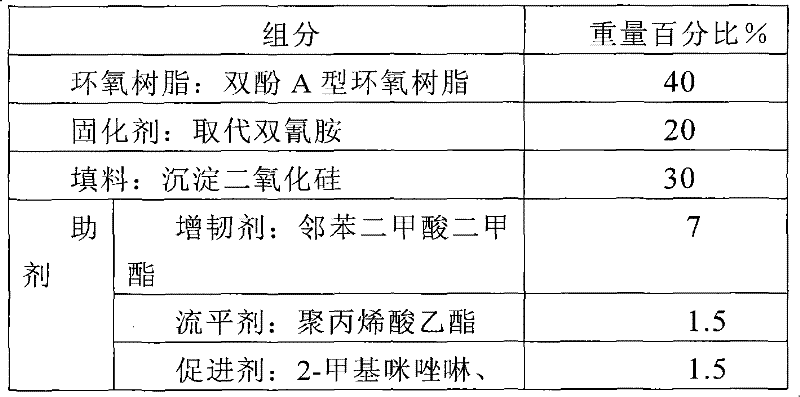

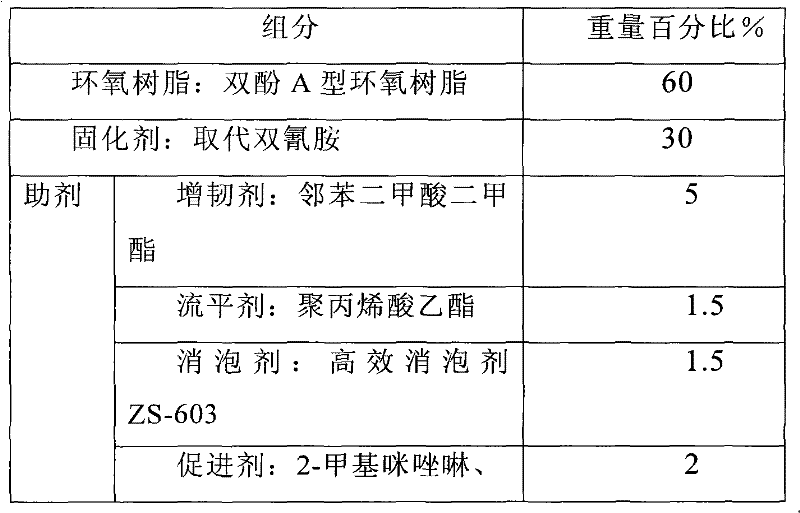

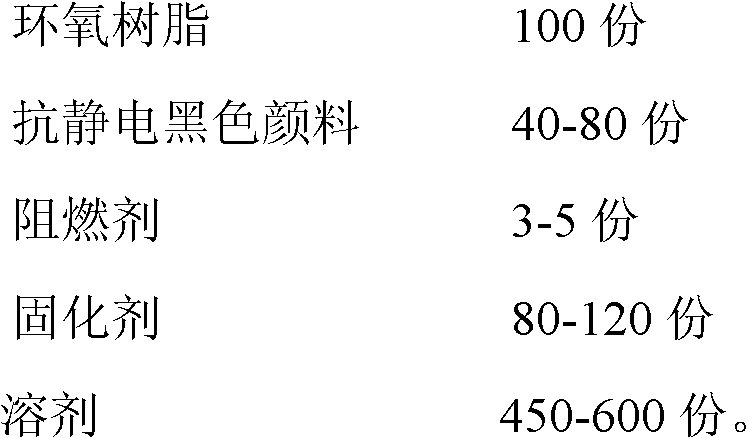

A kind of epoxy powder insulation anticorrosion coating

InactiveCN102294869AStrong adhesionImprove insulation performanceSynthetic resin layered productsAnti-corrosive paintsEpoxyMelt extrusion

The invention belongs to thermosetting epoxy powder insulation anticorrosion paint. It consists of a primer and a top coat, which together form an electrically insulating and anti-corrosion coating. The primer is composed of epoxy resin, curing agent and auxiliary agent; the surface coating is composed of epoxy resin, curing agent, filler and other auxiliary agents; both the primer and the surface coating are made by melt extrusion mixing method Powdered product. The primer coating does not contain or contains less filler, so the adhesion of the formed primer coating is not affected; the surface coating bears the main functions of electrical insulation and anti-corrosion, so the coating of the present invention has strong adhesion, excellent electrical insulation performance, and has Anti-corrosion, anti-rust, anti-mildew, heat-resistant, wear-resistant and other functions, and has the characteristics of low cost.

Owner:NINGBO KEXIN CORROSION CONTROL ENG

Alloy antiseptic composite coating for coal mine underground gas pipe

ActiveCN102181191AImprove corrosion resistanceImprove flame retardant performanceCorrosion preventionAnti-corrosive paintsElectrical resistance and conductanceCombustion

The invention discloses an alloy antiseptic composite coating for a coal mine underground gas pipe. The coating is formed by compounding an aluminum, zinc and chromium coating which is formed by sintering a coating sprayed onto a pipe wall at the temperature of between 300 and 350 DEG C, and a flame retardant antistatic antiseptic coating II which is formed by sintering a coating which is sprayedonto the coating II at the temperature of between 160 and 180 DEG C. The hardness of the alloy antiseptic composite coating is more than or equal to 2H; the impact intensity is more than or equal to 50kg.cm; the coating adhesion is more than or equal to a level 3; neutral salt spray resistance is more than 500h; the indexes of the flam resistance are that: the arithmetic mean value of the flame combustion time of six test pieces is less than or equal to 3s, the arithmetic mean value of the flame combustion time of one test piece is less than or equal to 8s; and the arithmetic mean value of the spark combustion time of six test pieces is 0s and the unit value of the spark combustion time of one test piece is 0s; and the index of conductivity performance is that: surface resistance is less than or equal to 1*10<6>Omega.

Owner:ANHUI HAICHENG RAILWAY EQUIP TECH

Cr/CrAlN gradient coating technology of supercritical water-cooled reactor fuel can surface

InactiveCN102787300ARelieve heat stressEnhanced interface bindingVacuum evaporation coatingSputtering coatingOxidation resistantAustenite

The invention belongs to the surface modification technology of a nuclear reactor structure material, and concretely relates to a Cr / CrAlN gradient coating technology of a supercritical water-cooled reactor fuel can surface. The technology comprises the steps of treating before plating, bias backwashing, arc ion reinforced reaction magnetron sputtering, sequential deposition of a Cr transition coating and a CrAlN gradient coating on the surface of an austenitic stainless steel matrix, and coating thermal treatment. The Cr / CrAlN gradient coating technology enables the oxidation resistant temperature of the Cr / CrAlN gradient coating to reach above 700DEG C, the hardness of the Cr / CrAlN gradient coating to reach above 2200Hv, the adhesion of the Cr / CrAlN gradient coating to reach above 35N, and the high temperature oxidation resistance, the combination force, the thermal shock resistance and the mechanical performances of the supercritical water-cooled reactor fuel can surface to be good, so the coordination and the unification of the structure and the functions of the surface coating are realized, thereby the use performances and the service life of the supercritical water-cooled reactor fuel are effectively improved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

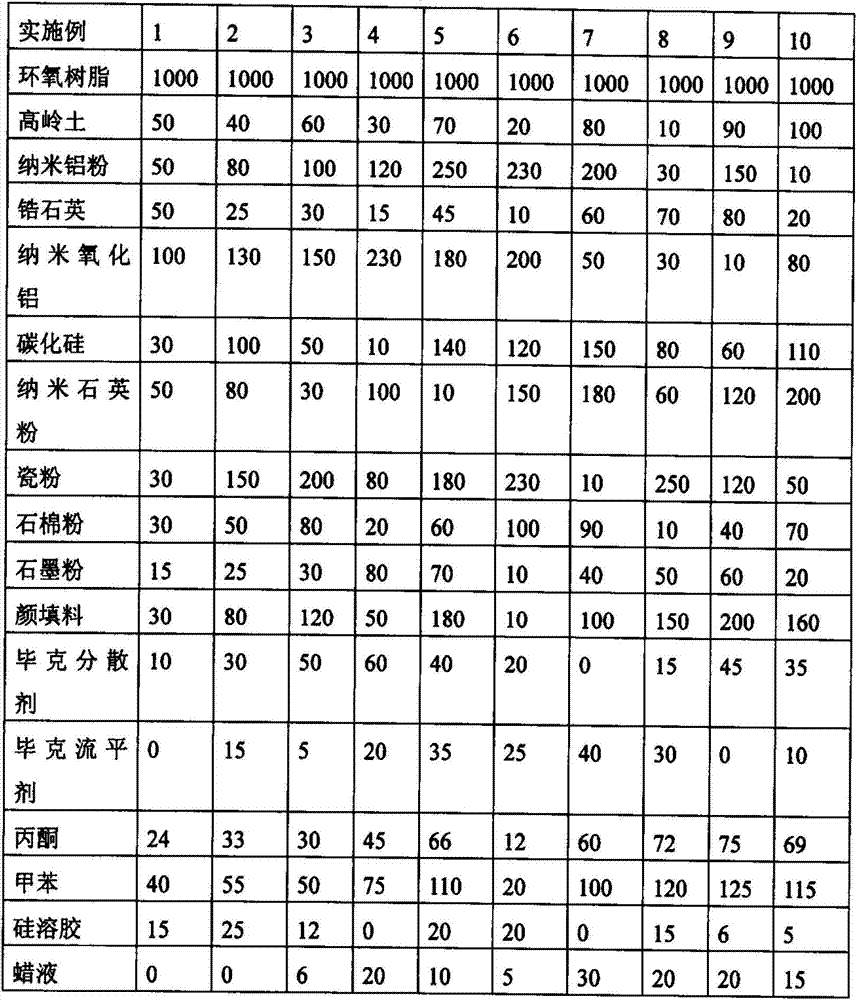

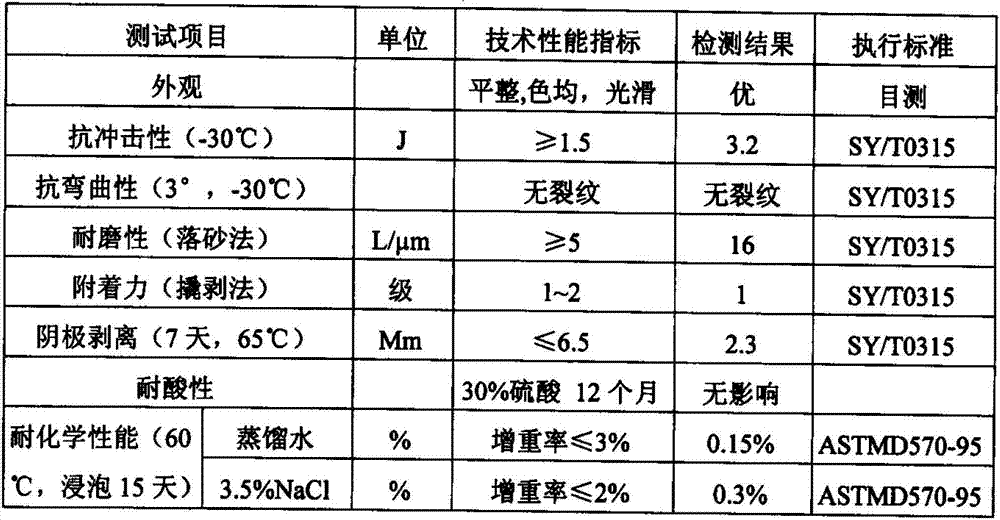

Manufacturing method of metal ceramic anticorrosive paint

ActiveCN103589273AImprove wear resistanceImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyNano al2o3

A metal ceramic anticorrosive paint mainly includes kaolin, nanometer aluminium powder, nano alumina, silicon carbide, nano quartz powder, ceramic powder, asbestos powder, graphite powder, a pigment, a filler, epoxy resin, an additive and a mixed organic solvent. The solid powders are subjected to nano ultrafine treatment to reach a granularity of 20-200 nm. The paint provided by the invention is a single-component paint, which is simple in manufacturing process, economical and environment-friendly. The coating of the paint does not require a primer and can be used alone without adding special finish. The coating has excellent wear resistance, corrosion resistance, impact resistance, stability, strong adhesion, compactness and stability, and can effectively prevent erosion by acid, alkali, salt and seawater. In addition, the paint can be widely applied to oil pipeline, oil storage tank, chemical equipment, ships, bridges, offshore platforms and other steel structure buildings.

Owner:SHANGHAI JIANYE TECH ENG

Polyurethane dull white paint for woodenware

The present invention is one kind of dull white finishing polyurethane paint for wood ware. The present invention features that the dull white finishing paint is compounded with three components, including the component A comprising modified alkyd resin, titanium white powder, nitro cotton, etc.; the component B comprising n-butyrate and HDI-90; and component C comprising n-butyrate and toluene. The dull white finishing paint has excellent yellowing resistance, powerful adhesion, high hardness, high wear resistance, good leveling property, and high environment protecting property.

Owner:GUANGDONG BADESE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com