Patents

Literature

83results about How to "Good film adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

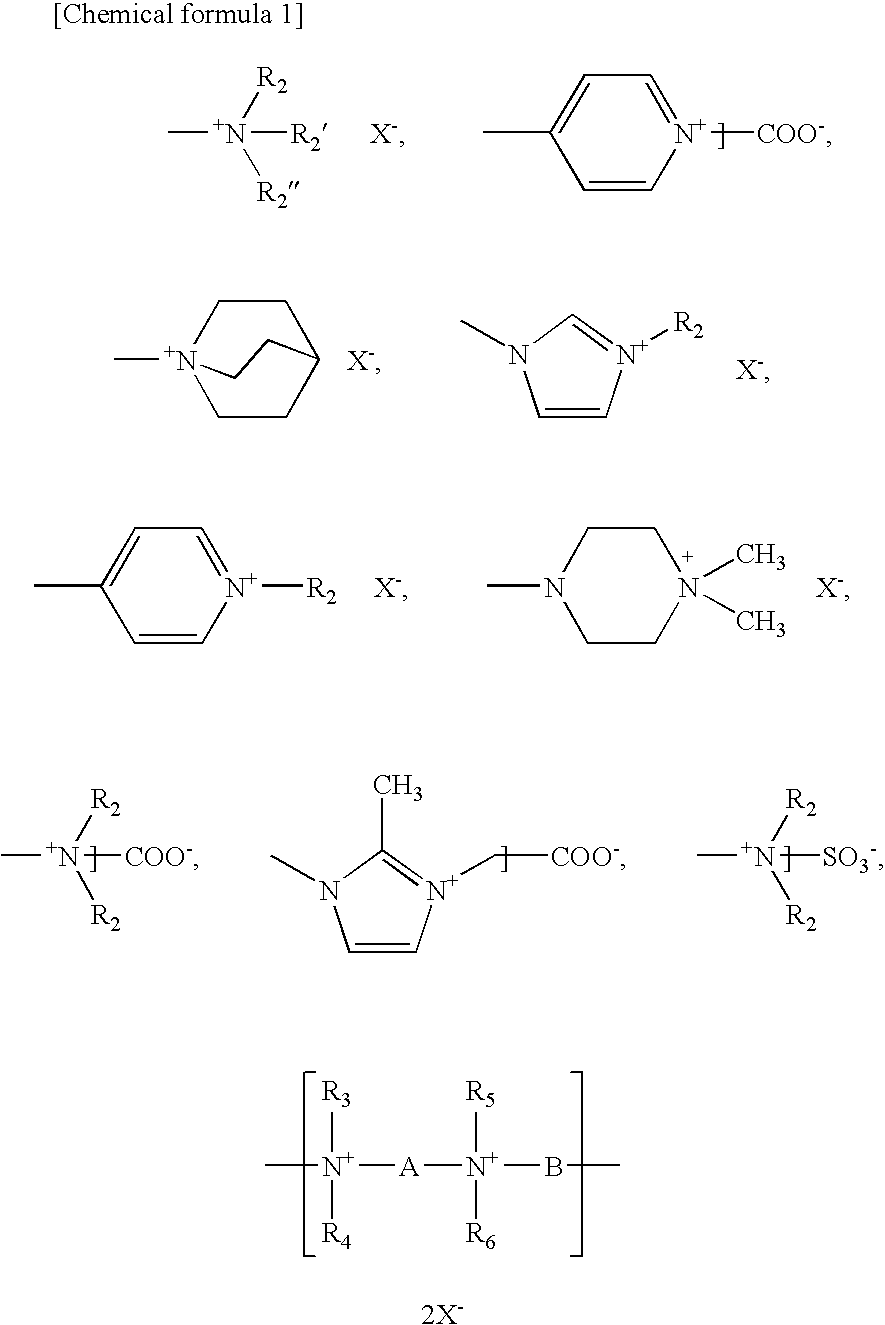

Aqueous resin dispersion, method for producing same, coating material, and multilayer body

ActiveUS20090226728A1Easy dischargeMaintain good propertiesFilm/foil adhesivesSynthetic resin layered productsPolyolefinPolymer science

To provide an aqueous dispersion of a resin wherein dispersed particles are stable with fine particle sizes and whereby bleeding out is suppressed, which is thus useful as e.g. a surface treating agent for a polyolefin substrate, an adhesive or a coating material.A resin dispersion having dispersed in water a polymer (C) having a hydrophilic polymer (B) bonded to a polyolefin (A) in a ratio of (A):(B)=100:5 to 100:500 (weight ratio); a method for producing the resin dispersion; and a coating material and a laminate, employing it.

Owner:MITSUBISHI CHEM CORP

Anticorrosive waterproof nano industrial coating and its preparing method

InactiveCN1709994ASignificant heavy-duty anti-corrosion performanceSignificant coating acid resistanceCoatingsUltravioletSolvent

The invention discloses a kind of new industry dope. It comprises of two kinds of materials of following weight shares: Component A 95 - 105 and Component B 2 - 8 shares; thereinto, Component A is made from such materials as membrane forming object, pigment, filling agent, auxiliary agent, compound nanometer dispersing agent and solvent; Component B is made from nanometer Sb2O3 and mixed organic solvent carriers. The dope of the invention has following advantages: at room temperature, it has prominent heavy anticorrosion performance, and has excellent performances of acid resistance, alkali resistance, salt mist resistance, oil resistance, chemical reagent resistance, waiting resistance and ultraviolet resistance; it also has excellent fire protection and waterproof performance; the clinging strength of smearing membrane is good, membrane forming speed is fast, and performance is stable.

Owner:王继征

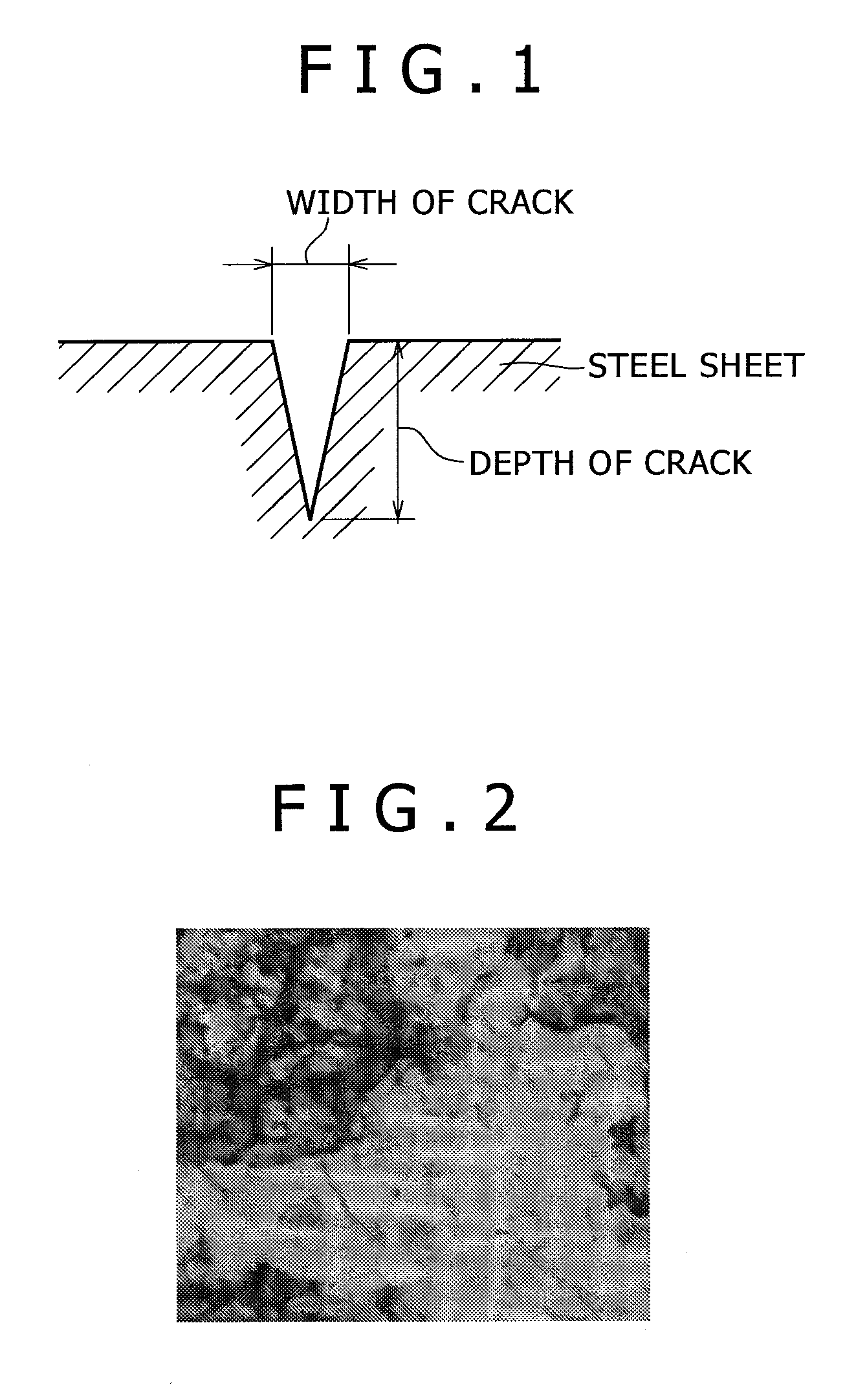

High-strength cold-rolled steel sheet excellent in coating adhesion, workability and hydrogen embrittlement resistance, and steel component for automobile

InactiveUS20090053096A1Good film adhesionImprove machinabilityFurnace typesHeat treatment furnacesChemical compositionComposite oxide

A cold rolled steel sheet satisfying on the basis of percent by mass the chemical composition of 0.06-0.6% C, 0.1-2% Si, 0.01-3% Al, 1-4% Si+Al, 1-6% Mn, Si / Mn≦0.40, in which there exists 10 or more pieces / 100 μm2 of Mn—Si composite oxide having Mn—Si atom ratio (Mn / Si) of 0.5 or over and major axis of from 0.01 μm to 5 μm and also having a covering ratio of 10% or below at which the surface of the steel sheet is covered with oxide containing Si as the main component.

Owner:KOBE STEEL LTD

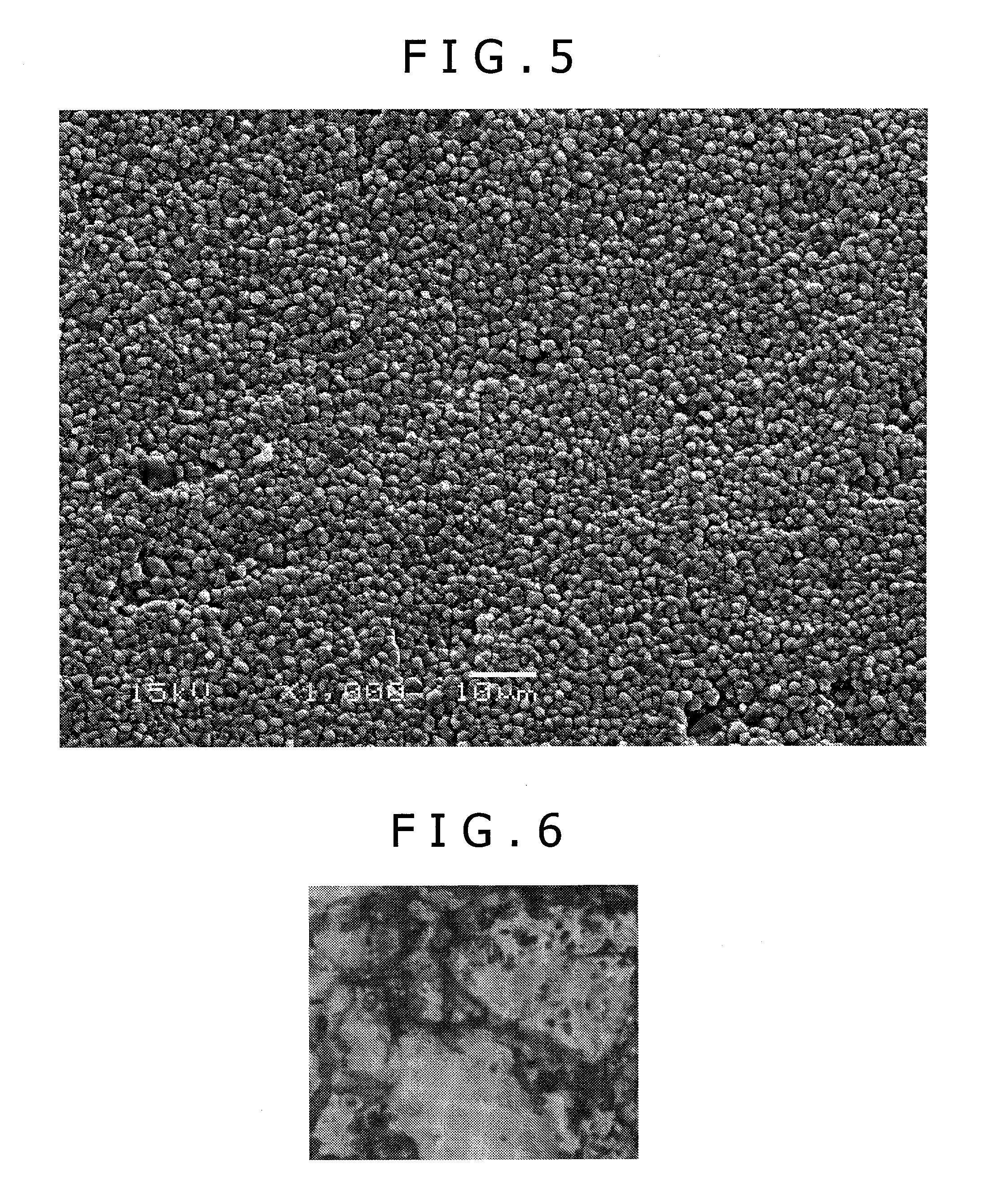

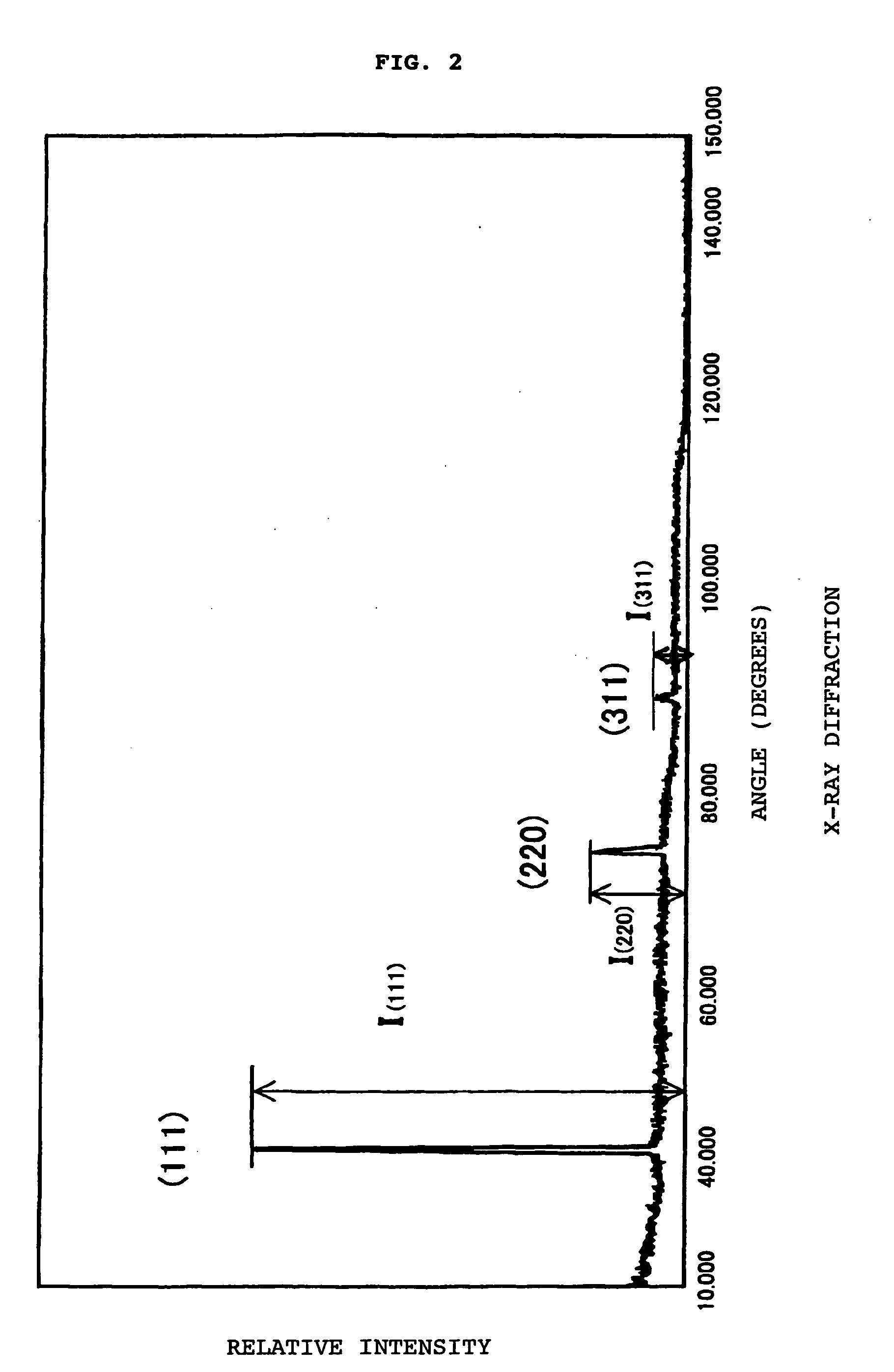

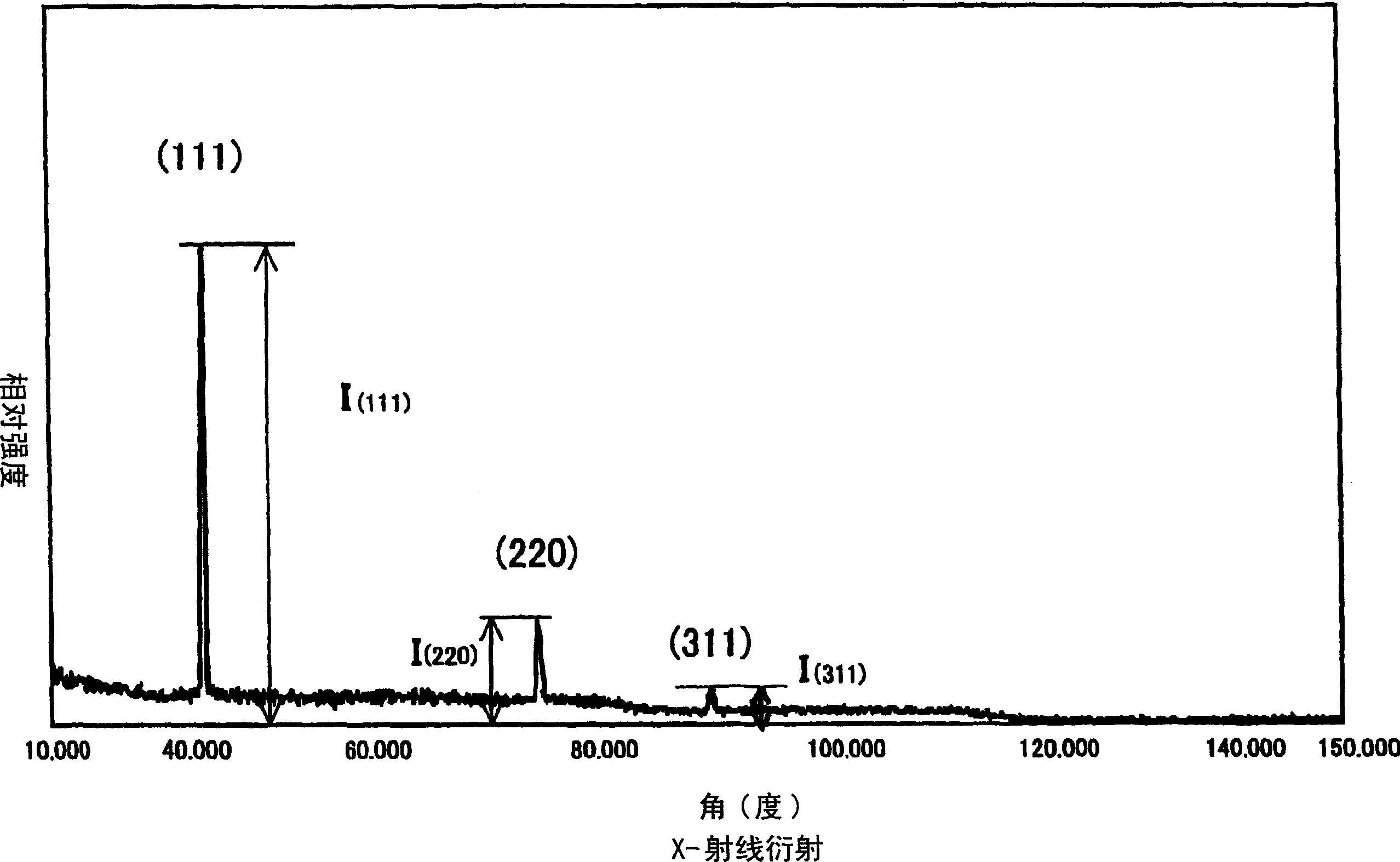

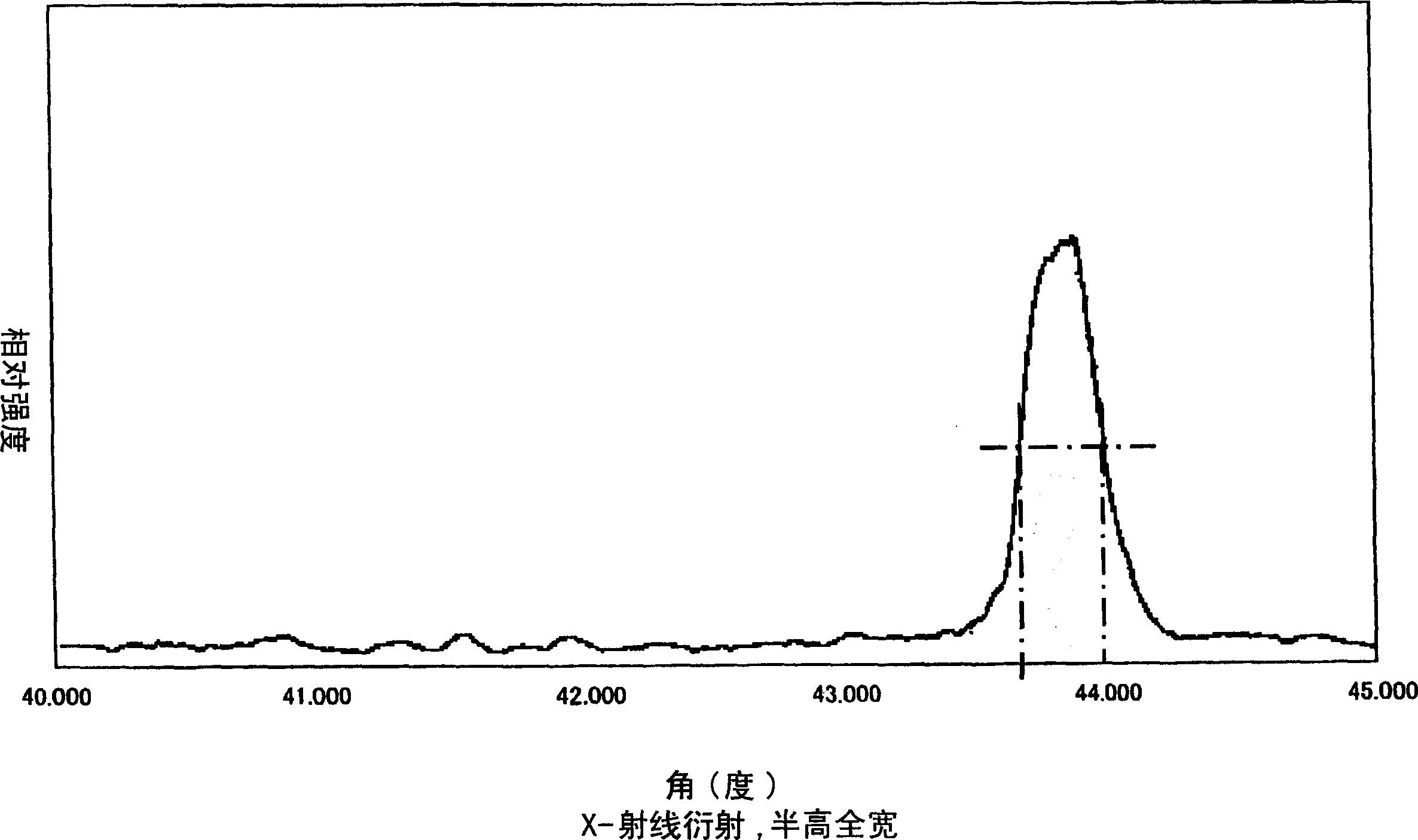

Diamond-coated electrode and method for producing same

InactiveUS20060144702A1Low resistanceGood film adhesionPhysical/chemical process catalystsUltra-high pressure processesDiamond electrodesCoated electrodes

A diamond electrode having a sufficiently low resistance is disclosed which is realized by increasing the amount of boron added thereto. A method for producing a high-performance, high-durability electrode is also disclosed by which adhesiveness between a diamond coating and a substrate and separation resistance during electrolysis are sufficiently increased. An electrode composed of a substrate and a diamond layer coating the substrate is characterized in that the electrode is composed of a base coated with diamond and the diamond contains boron in such an amount that the boron concentration is not less than 10,000 ppm but not more than 100,000 ppm. The base is preferably made of an insulating material.

Owner:SUMITOMO ELECTRIC IND LTD

Diamond-coated electrode and method for producing same

InactiveCN1735716AGood electrolyte peel strengthLower resistanceElectrodesElectrical resistance and conductanceDiamond electrodes

A diamond electrode having a sufficiently low resistance is disclosed which is realized by increasing the amount of boron added thereto. A method for producing a high-performance, high-durability electrode is also disclosed by which adhesiveness between a diamond coating and a substrate and separation resistance during electrolysis are sufficiently increased. An electrode composed of a substrate and a diamond layer coating the substrate is characterized in that the electrode is composed of a base coated with diamond and the diamond contains boron in such an amount that the boron concentration is not less than 10,000 ppm but not more than 100,000 ppm. The base is preferably made of an insulating material.

Owner:SUMITOMO ELECTRIC IND LTD

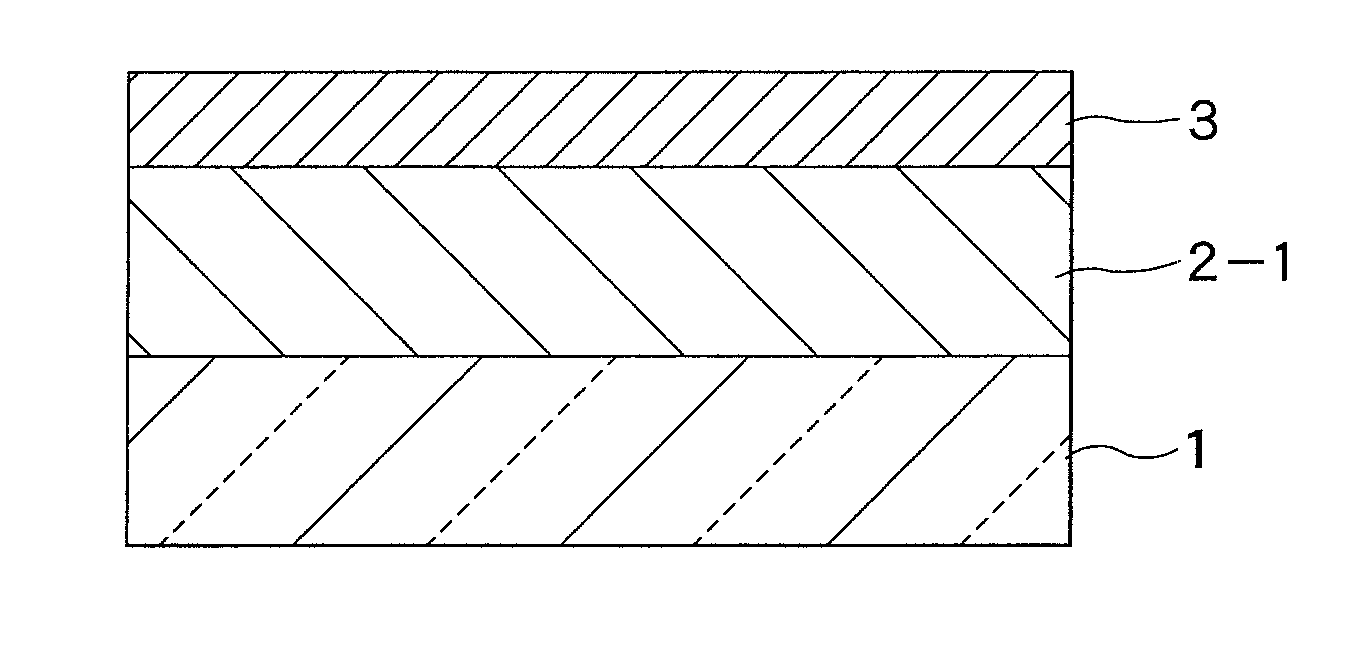

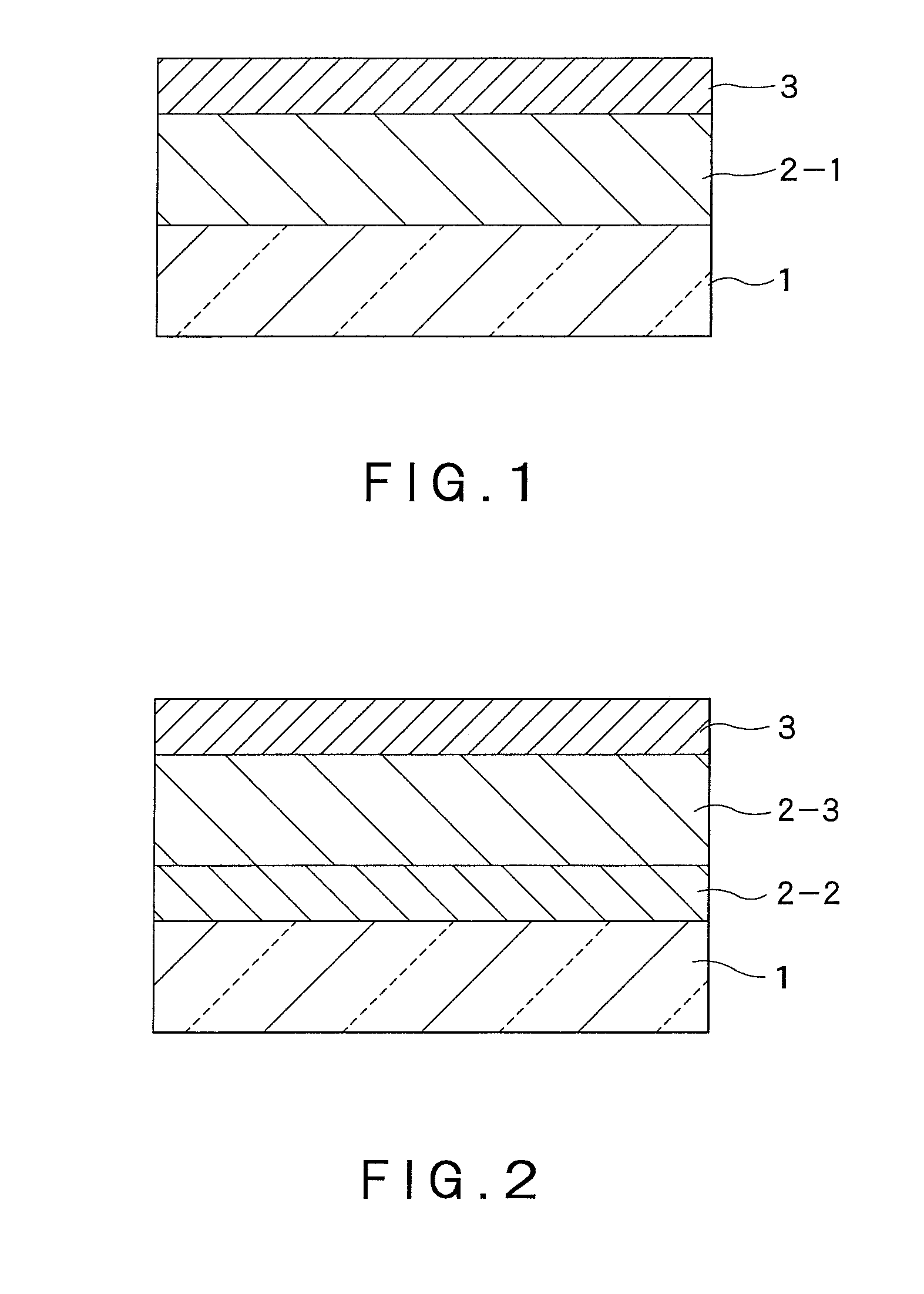

Antistatic Antireflection Film Free From Occurrence Of Interference Fringes

InactiveUS20080192351A1Prevent interference fringeInhibit deteriorationLayered productsElectrically-conductive paintsAntistatic agentRefractive index

There is provided an antireflection film that can prevent the occurrence of interference fringes and, at the same time, has antistatic properties and excellent coating film adhesion. The first antireflection film comprises a transparent base material film 1 and, provided on the transparent base material film in the following order, an antistatic hardcoat layer 2-1 comprising an antistatic agent selected from polymeric antistatic agents, crosslinking group-containing low-molecular antistatic agents, and electrically conductive antistatic agents and having hard properties, and a low-refractive index layer 3 having a lower refractive index than an underlying layer in direct contact with the low-refractive index layer. The occurrence of interference fringes can be prevented by bringing the absolute value of the difference in refractive index between the transparent base material film 1 and the antistatic hardcoat layer 2-1 to not more than 0.03.

Owner:DAI NIPPON PRINTING CO LTD

Aqueous coating agent and gas barrier film

ActiveUS20160040035A1Excellent gas barrier performanceImprove cohesive strengthPolyureas/polyurethane adhesivesSynthetic resin layered productsPolyamine CompoundSolid component

An aqueous coating agent of the invention comprising (A) an aqueous polyurethane resin containing a polyurethane resin having an acid group and a polyamine compound, (B) a water-soluble polymer, and (C) an inorganic layered mineral as main constituents, wherein solid formulation ratios of the aqueous polyurethane resin (A), the water-soluble polymer (B) and the inorganic layered mineral (C) occupied in a total solid content of the aqueous coating agent are within approximate ranges indicated below.Aqueous polyurethane resin (A): 5 to 60 mass %Water-soluble resin (B): 25 to 80 mass %Inorganic layered compound (C): 8 to 20 mass %

Owner:TOPPAN PRINTING CO LTD

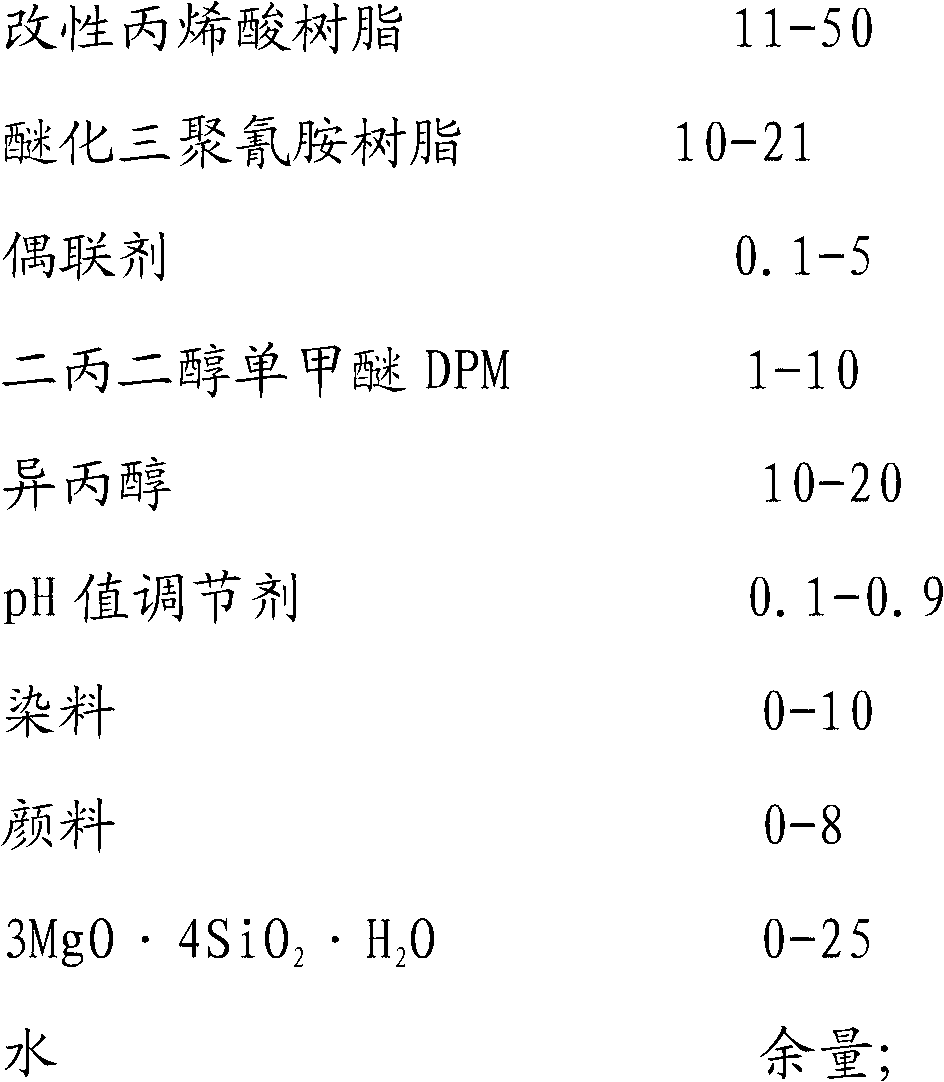

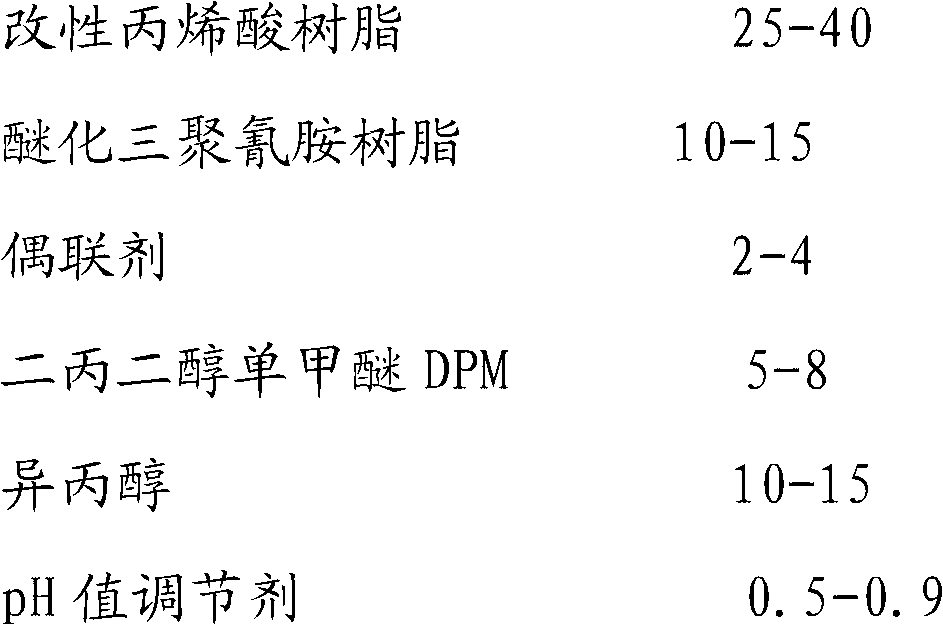

Water-soluble paint, preparation method and spraying technique thereof

The invention discloses a water-soluble paint, and a preparation method and spraying technique thereof. Modified acrylic resin is added into the formula of the water-soluble paint, so that the baking film-forming temperature of the paint is dropped from common 180 DEG C to 110-160 DEG C; a coupling agent is added, so that the film-forming attachment of the water-soluble paint can be greatly improved, and the hardness of the paint film achieves or exceeds National Standard 5B; and the product coated with the paint can keep the favorable paint film attachment effect for a long time. The spraying technique-wet-on-wet technique effectively overcomes the defects of low production efficiency and high energy consumption due to repeated spraying and repeated baking in the existing technique, greatly enhances the production efficiency of the spraying construction, and greatly saves the energy consumption.

Owner:ZHUHAI CBB CHEM

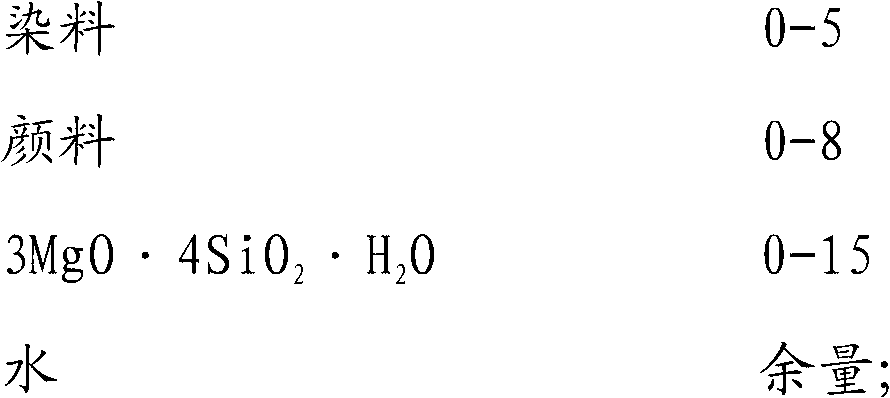

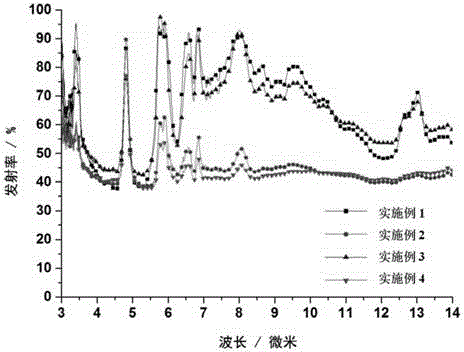

Multicolor infrared low-emissivity environmental protection coating

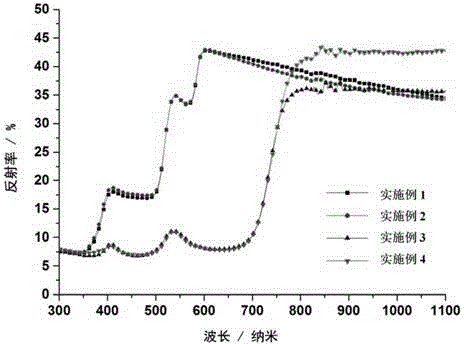

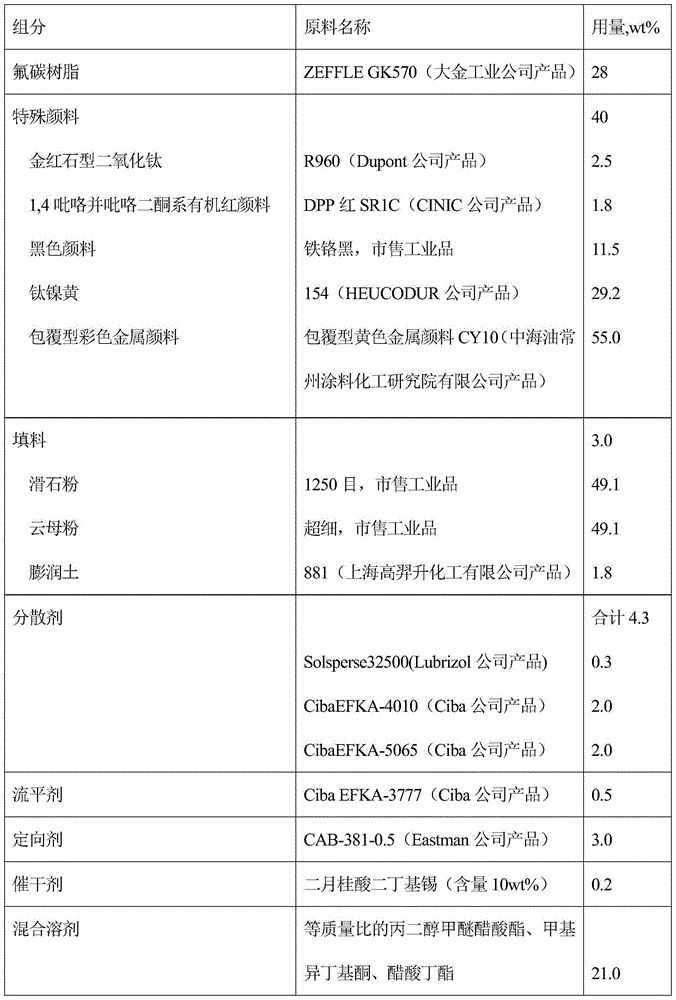

ActiveCN104403440AHigh infrared reflectivityGood infrared transmittancePolyurea/polyurethane coatingsCamouflage paintsTitaniumFluorocarbon

The invention relates to a multicolor infrared low-emissivity environmental protection coating. The coating comprises a component A and a component B, and when in use, the component A and the component B are uniformly mixed according to the mass ratio of 1:10. The component A is aliphatic polyisocyanate; the component B comprises the following components in percent by mass: 20 to 30 percent of fluorocarbon resin, 35 to 50 percent of special pigment, 0 to 5 percent of filler, 1 to 5 percent of a dispersant, 0.1 to 1 percent of a flatting agent; 3 to 8 percent of a directing agent, 0.01 to 0.3 percent of a drier, and 15 to 25 percent of a mixed solvent, wherein the special pigment comprises the following pigments: 0 to 10 percent of titanium dioxide rutile, 0 to 5 percent of 1, 4 diketopyrrolopyrrole series organic red pigment, 0 to 25 percent of chromium oxide green, 0 to 8 percent of titanium-nickel yellow pigment, 0 to 5 percent of black pigment, and 50 to 95 percent of coated color metallic pigment. The average emissivity of the thermal infrared band of the coating is 0.40 to 0.65, and the heavy metal content meets the requirement.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Hydraulic transfer method

InactiveUS6902642B2Good transferabilitySuperior in designed appearanceLamination ancillary operationsDecorative surface effectsPrinting inkMetallic substrate

Using a hydraulic transfer film wherein a transfer layer is composed of a decorative layer made of a printing ink coating film or a paint coating film, the transfer layer is hydraulically transferred onto a target body for transfer made of a metal substrate having a cured coating film layer in which a xylene absorption amount is within a range from 3.5 to 100 g / m2. Alternatively, using a hydraulic transfer film wherein a transfer layer has a protective layer made of a radiation-curable resin or a thermosetting resin, the transfer layer is hydraulically transferred onto a target body for transfer made of a metal substrate having a cured coating film layer in which a xylene absorption amount is within a range from 10 to 100 g / m2. Because of good hydraulic transferability and good coating film adhesion between the metal substrate and the transfer layer, it is made possible to produce a metal substrate, which can be stored for a long period and is superior in designed appearance and also has a transfer layer with an arbitrary shape bonded firmly thereto.

Owner:DAINIPPON INK & CHEM INC

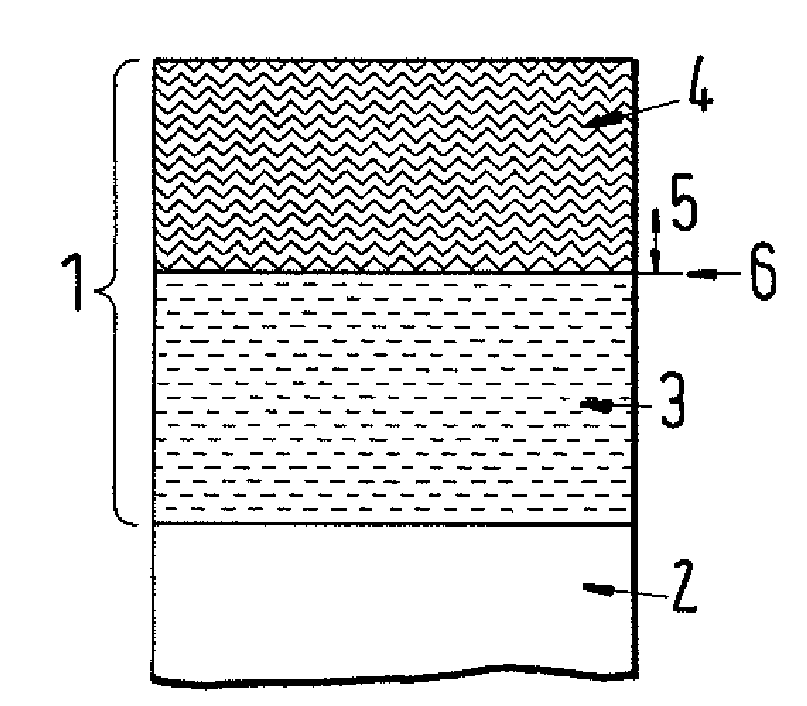

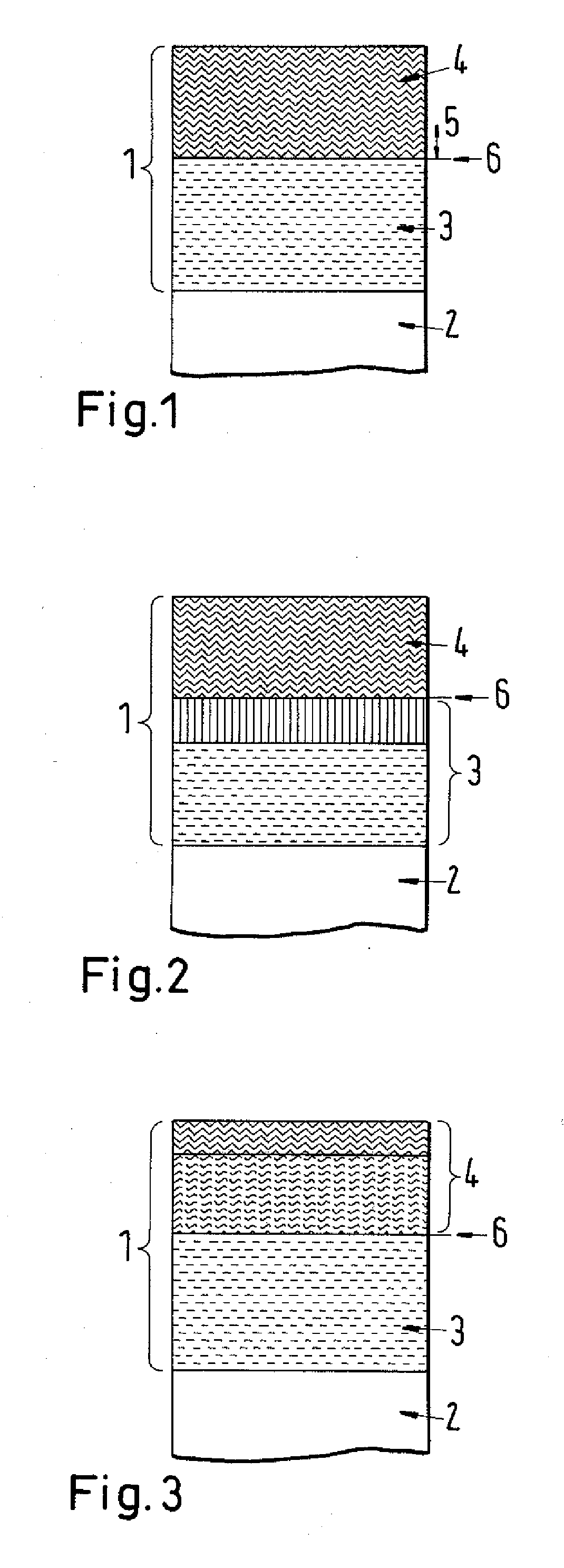

Multilayer Film-Coated Member And Method For Producing It

ActiveUS20100028636A1Solve the lack of resistanceGood film adhesionPigmenting treatmentVacuum evaporation coatingTarget surfaceTemperature control

The invention provides a multilayer film-coated member which has both sufficient heat resistance and sufficient abrasion resistance and has excellent coating film adhesion strength so that it can sufficiently exhibit the capability of the coating film even in cutting environments that may be more and more severe, and provides a method for producing it. The multilayer film-coated member is fabricated by coating the surface of a substrate with at least two hard coating films having different compositions, wherein the first composition hard film of the outermost layer of the hard coating films represented by SiaBbNcCdOe with a+b+c+d+e=1, 0.1≦a≦0.5, 0.01≦b≦0.2, 0.05≦c≦0.6, 0.1≦d≦0.7 and 0<e≦0.2, the second composition hard coating film of the lower layer below the first composition hard coating film is a hard film having at least two selected from Al, Ti, Cr, Ni, Ce, Mg, Nb, W, Si, V, Zr and Mo and N and at least one selected from B, C, and S and the oxygen content of the film within a range of at least 25 nm from the interface of the first composition hard coating film that is in contact with the underlying layer toward the surface of the first composition hard coating film is limited to a range of less than 3.5 atm. %. The method for producing the multilayer film-coated member comprises forming the first composition hard coating film under temperature control to keep the substrate temperature not higher than 400° C., and comprises forming it, after the coating target surface is cleaned through preliminary discharging, at a sputtering output power of less than 2500 W up to a thickness of at least 5 nm from the interface to the underlying layer.

Owner:SULZER METAPLAS

Method for displaying three-dimensional pattern through vacuum coating

ActiveCN103243301AGood film adhesionStrong metal textureVacuum evaporation coatingSputtering coatingTitanium dioxidePolyethylene terephthalate

The invention relates to a method for displaying a three-dimensional pattern through vacuum coating. The method comprises the following steps of: machining a PET (polyethylene terephthalate) film into preset shape and size; carrying out optical vacuum evaporation on the surface of the PET film for preparing a continuous metal-texture thin film, and then coating a first titanium dioxide film layer, a second silicon dioxide film layer and a third titanium dioxide film layer in sequence; placing the coated PET film below a printer screen board, carrying out screen printing on a discontinuous metal-texture silver thin film, and then putting the printed PET film into a baking oven for baking; putting the PET film after screen printing into a stripping solution for soaking and stripping; and allowing one side of the PET film after coating and screen printing to be stuck with a glass panel, and carrying out defoaming treatment after the completion of film laminating. The products prepared by the method are strong in metal texture, good in weatherability, stable in preparation process and suitable for mass production, and effectively solves the defects of the prior art.

Owner:DONGGUAN HUAQING OPTICAL TECH

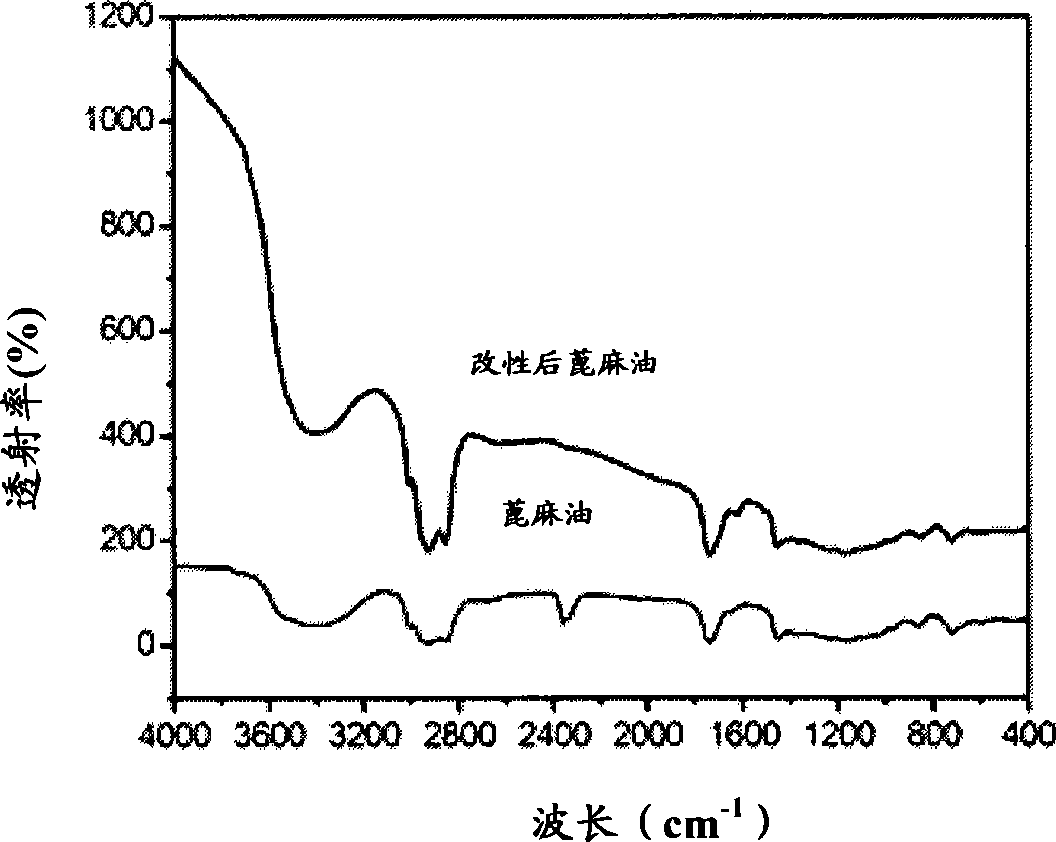

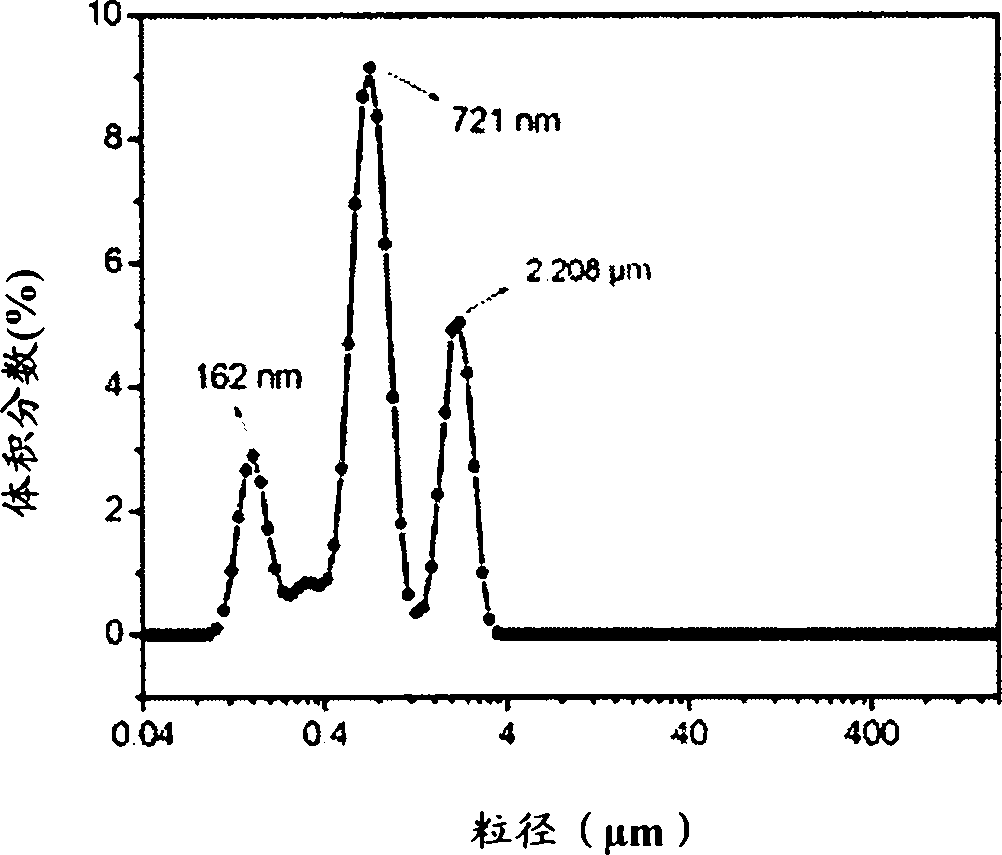

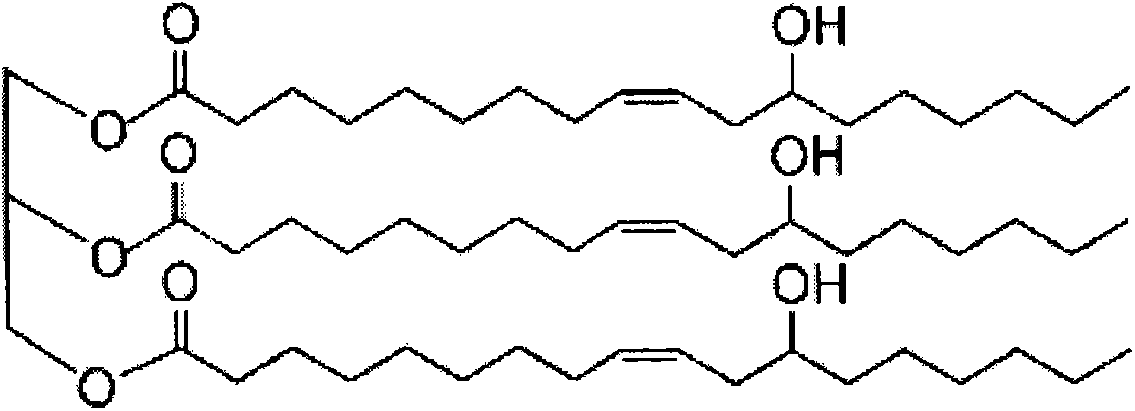

Environment-friendly vegetable oil-based polyurethane binder resin, corrugated board ink and preparation method of environment-friendly vegetable oil-based polyurethane binder resin

The invention relates to the field of corrugated board printing inks and particularly relates to environment-friendly vegetable oil-based polyurethane binder resin, a corrugated board ink and a preparation method of the environment-friendly vegetable oil-based polyurethane binder resin. The polyurethane binder resin is obtained by acting a vegetable oil-based polyurethane prepolymer, a hydrophilic chain extender, a micromolecule chain extender, a neutralizer and water, wherein the vegetable oil-based polyurethane prepolymer is obtained by reacting polyacrylate-modified vegetable oil, low polymer polyatomic alcohol and diisocyanate; and the vegetable oil-based polyurethane water-based ink is obtained by mixing pigments, a defoaming agent, water-based paraffin and water into the vegetable oil-based polyurethane binder resin. The water-based ink has good printability and has good biodegradability by using the vegetable oil to substitute most of organic polymers as synthetic raw materials of the binder resin; and the grain size of the ink is controlled within a micro-nano range, so that the ink is dried on the surface of the corrugated board very well to achieve film-forming and bonding effects.

Owner:江苏兴文包装有限公司

Multilayer film-coated member and method for producing it

ActiveUS8309235B2Solve the lack of resistanceGood film adhesionPigmenting treatmentOther chemical processesOxygen contentCoating

A multilayer film-coated member is fabricated by coating the surface of a substrate with at least two hard coating films having different compositions, wherein the first composition hard film of the outermost layer is represented by SiaBbNcCdOe with a+b+c+d+e=1, 0.1≦a≦0.5, 0.01≦b≦0.2, 0.05≦c≦0.6, 0.1≦d ≦0.7 and 0<e≦0.2, the second composition hard coating film having at least two selected from Al. Ti, Cr, Ni, Ce. Mg, Nb, W, Si, V, Zr and Mo and N and at least one selected from B, C, O and S and the oxygen content of the film at least 25 nm from the interface of the first composition hard coating film that is in contact with the underlying layer toward the surface of the first composition hard coating film is limited to a range of less than 3.5 atm. %.

Owner:SULZER METAPLAS

Polyester Resin For Coating Metal Plate, Resin-Coated Metal Plate Being Coated With the Same, and Metal Can and Lid

ActiveUS20090011162A1Maintain good propertiesIncrease resistanceSynthetic resin layered productsDomestic containersCarboxylic acidPolyester resin

A polyester resin for metal plate coating which contains a dimer acid in an amount of 2 to 10 mol %, as a dicarboxylic acid component and has a weight average molecular weight (Mw) ranging from 70,000 to 160,000. Thus, there can be provided a polyester resin for metal plate coating that has not only excellent film forming capability and corrosion resistance but also excellent impact resistance. Further, there can be provided a resin-coated metal plate excelling in properties, such as corrosion resistance, impact resistance (dent resistance), workability and flavor, and provided, fabricated from the resin-coated metal plate, a metal can and can lid.

Owner:TOYO SEIKAN KAISHA LTD

Coating solution for forming insulating film with excellent corrosion resistance property and film close adhesion property and film intensity without chrome and a method for making the insulation film on non-oriented electrical steel sheet by using it

ActiveUS20090324837A1Good film adhesionHigh film strengthPretreated surfacesMetallic material coating processesChromium freeEpoxy

There is provided a chromium-free coating composition for forming an insulation film, the composition having excellent corrosion resistance and excellent film adhesion and film strength after stress relief annealing (SRA), including, based on a 100 g phosphate solution having a solid content of 60% by weight, in which monoaluminum phosphate and monozinc phosphate are mixed at a 1:1 ratio: 0.5˜5 g of a solid in which cobalt hydroxide and strontium hydroxide are mixed at a 1:1 ratio: 100˜300 g of an emulsified polyester resin or an emulsified epoxy resin having a solid content of 20% by weight; 3˜10 g of aluminum silicate having a solid content of 20% by weight; and 0.1˜6 g of a titanium chelate.

Owner:POHANG IRON & STEEL CO LTD

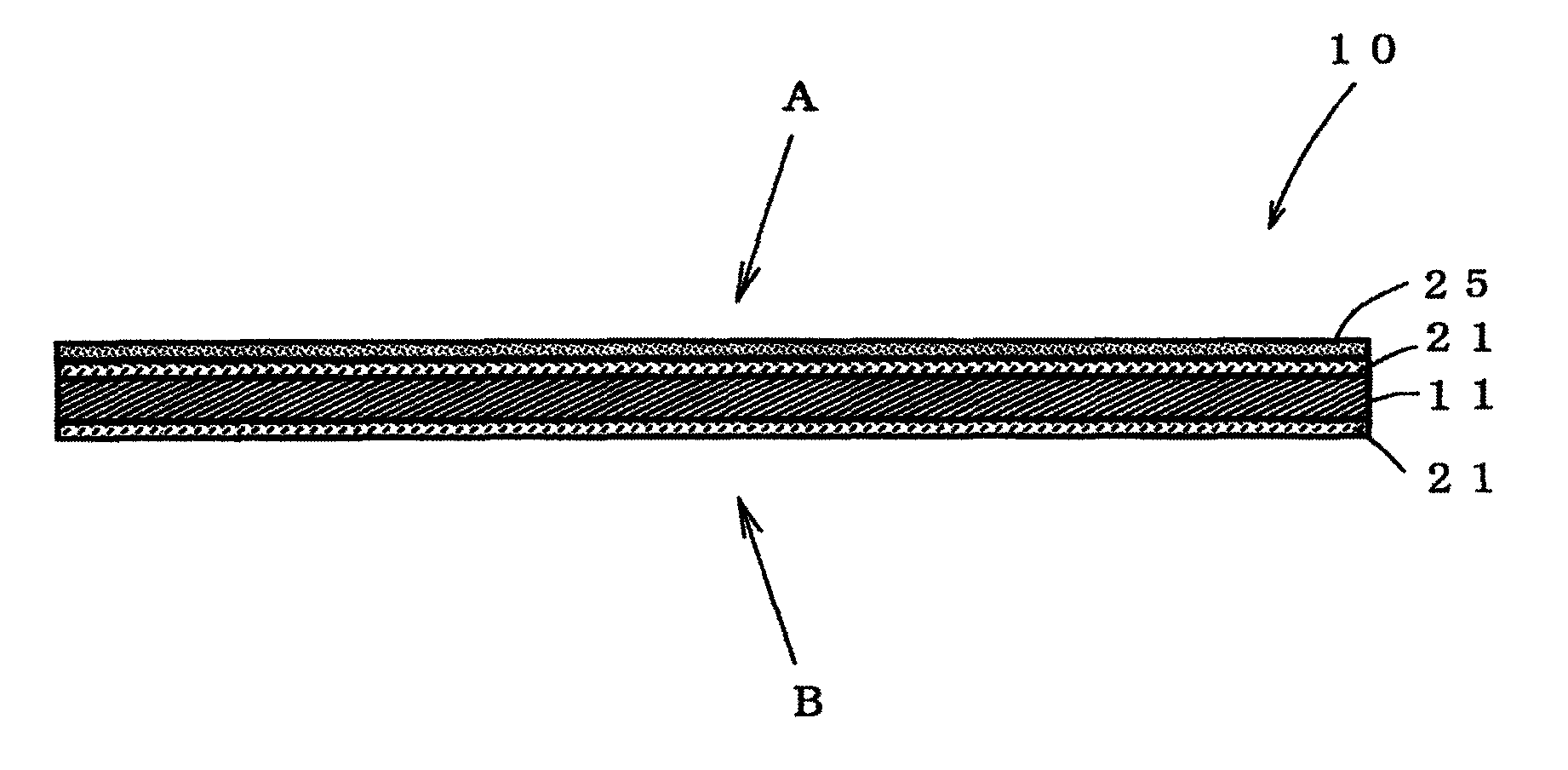

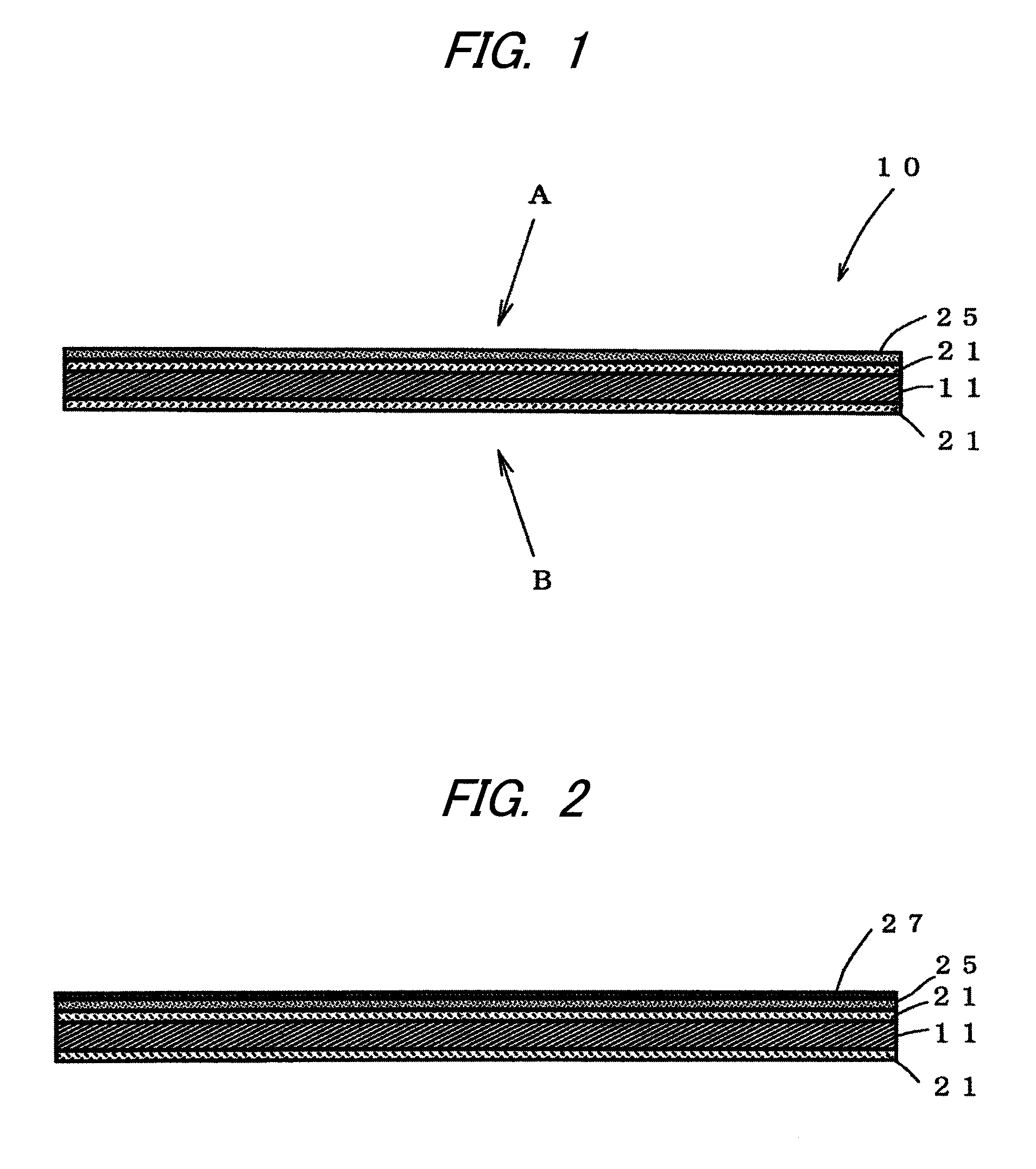

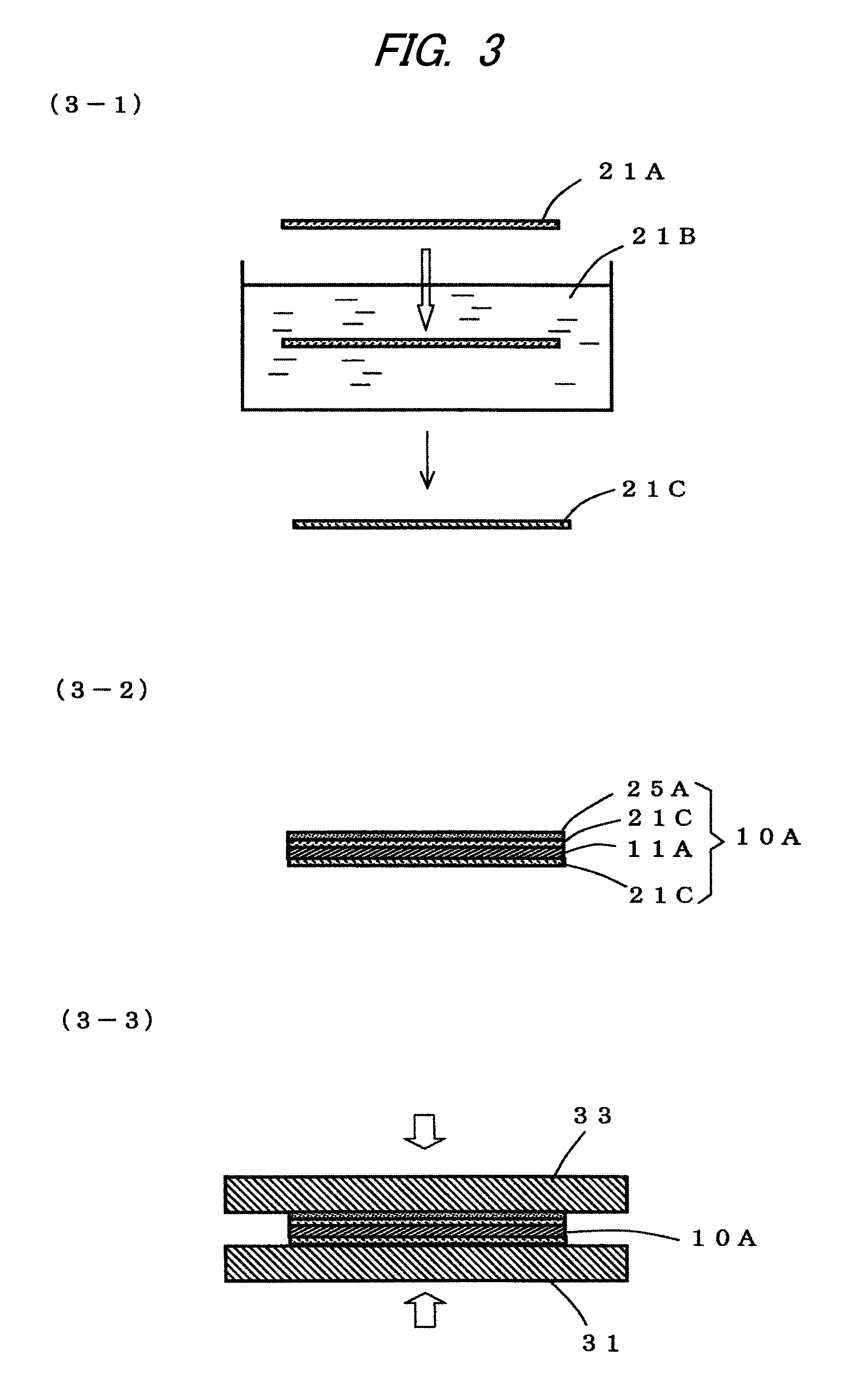

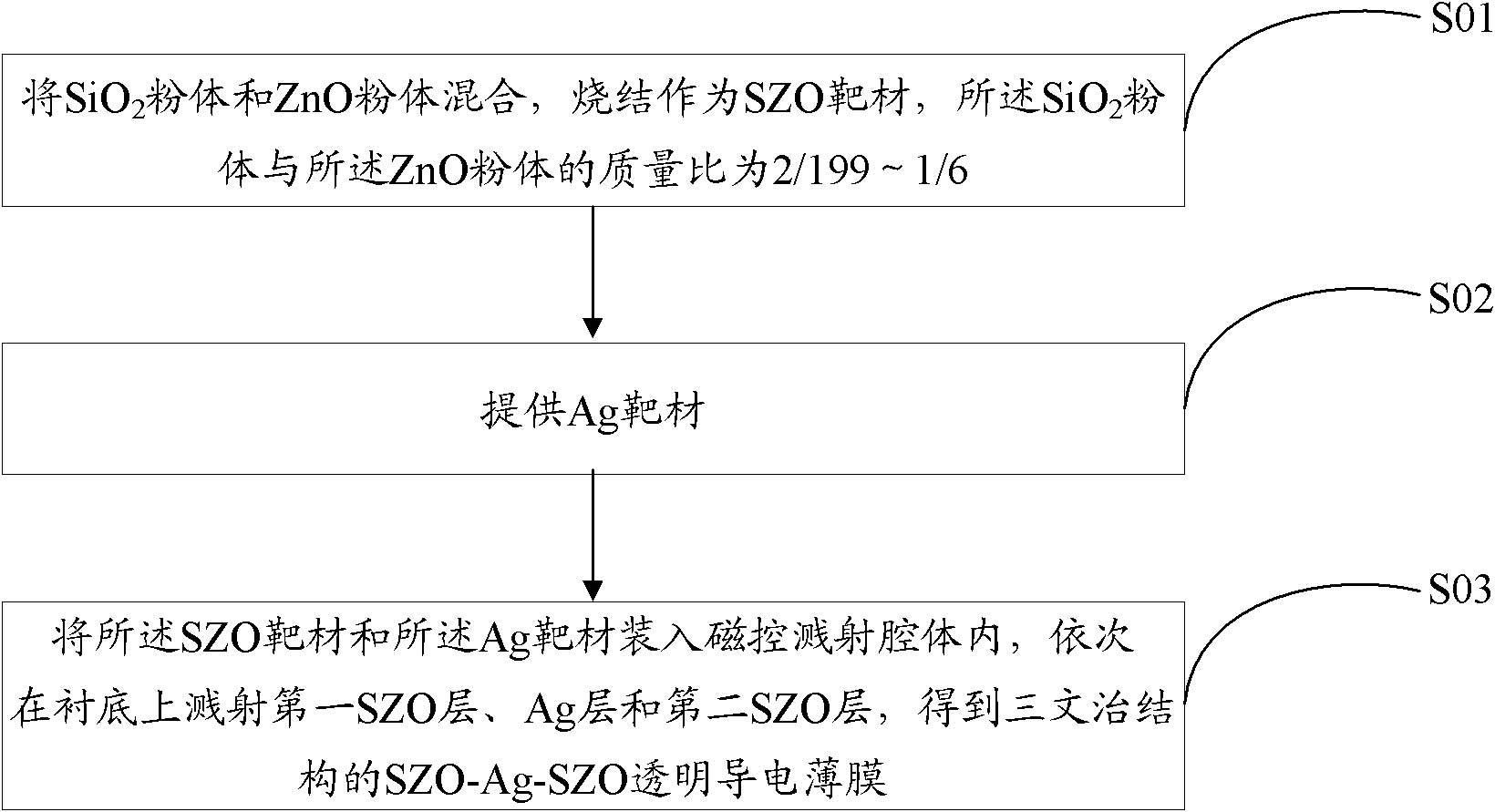

Fiber-reinforced molded product and method for manufacturing the same

ActiveUS9132607B2Reduce surface roughnessGood lookingLaminationLamination apparatusFiberSurface roughness

A fiber-reinforced molded product 10 includes a core material 11, a fiber reinforcing material 21 laminated on at least one surface of the core material 11, and a surface material 25 laminated on the fiber reinforcing material 21. The core material 11, the fiber reinforcing material 21, and the surface material 25 are integrated. The fiber reinforcing material 21 includes a fiber fabric 21A and a thermosetting resin 11B and 21B impregnated into the fiber fabric 21 and cured. The surface material 25 includes a porous sheet 25A having open cells, the number of the cells being 8 to 80 cells / 25 mm, and the thermosetting resin 11B and 21B moved out of the fiber fabric 21 into the porous sheet 25A and cured, and the surface material 25A has a surface roughness Rz of 30 μm or less.

Owner:INOAC CORP

Aqueous acrylic resin emulsion, preparation method, and coating composition thereof

The present invention relates to an aqueous acrylic resin emulsion, a preparation method, and an application of the aqueous acrylic resin emulsion in a coating material. Polymerization raw materials of the aqueous acrylic resin emulsion comprise the following components: methyl methacrylate, butyl acrylate, hydroxyl acrylic, methyl acrylamide, azobisisobutylnitrile, amino-2-methyl-1-propanol, mercaptoethanol, propylene glycol monobutyl ether, ethylene glycol monobutyl ether and deionized water. The aqueous acrylic resin emulsion is prepared by adding the azobisisobutylnitrile in batch. An aqueous plating coating material adopting the aqueous acrylic resin emulsion as the base resin is further prepared.

Owner:浙江明泉新材料科技有限公司

Environment-friendly water-based fingernail paint

InactiveCN102552071ALow film forming temperatureGood film adhesionCosmetic preparationsToilet preparationsChemistryEmulsion

The invention discloses an environment friendly water-based fingernail paint, which comprises the following components by weight percentage: 10-20% of deionized water, 50-70% of water-based acrylic emulsion, 6-8% of ethanol, 1-2% of thickener, 2-4% of texanol film forming adjuvant, 0.005-0.015% of defoamer, 0.2-0.3% of dimethylethanolamine, 0.02-0.04% of leveling agent, 2-4% of non-resin water-based transparent color paste, 4-7% of pearl-luster pigment and 4-6% of propylene glycol. The main raw material of the fingernail paint adopts the nanometer thermoplastic water-based acrylic resin, so that the adhesive force of paint film is good, and the main raw material of the formula belongs to the water-based system, so that the fingernail paint is dried rapidly after being painted on a fingernail, the cleaning and makeup removal operation are simple, no toxic organic solvents exist in the formula, no harm is caused to the fingernail during painting, and further, no pungent odors and gases are generated.

Owner:WENZHOU BANGXUAN TECH

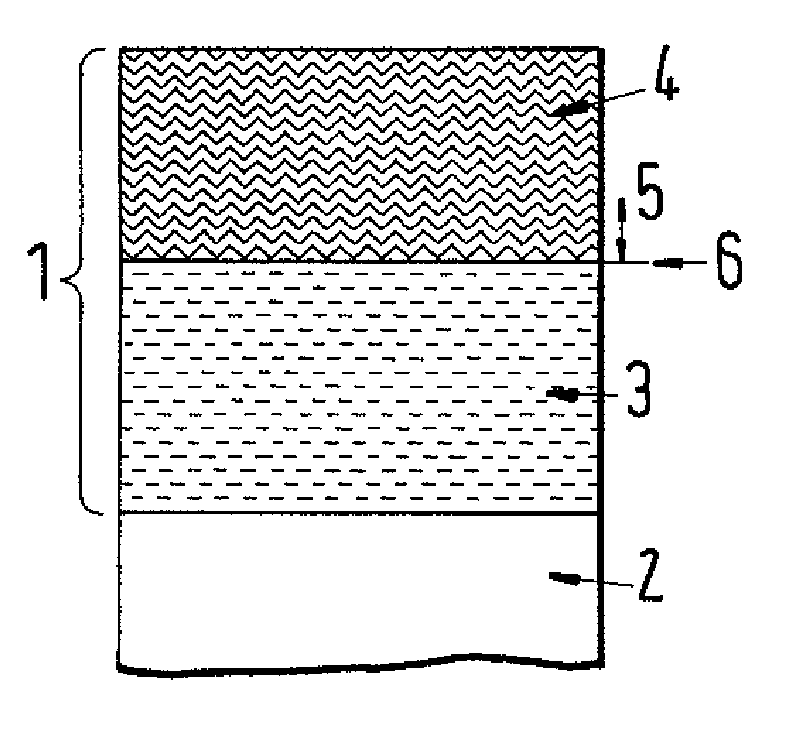

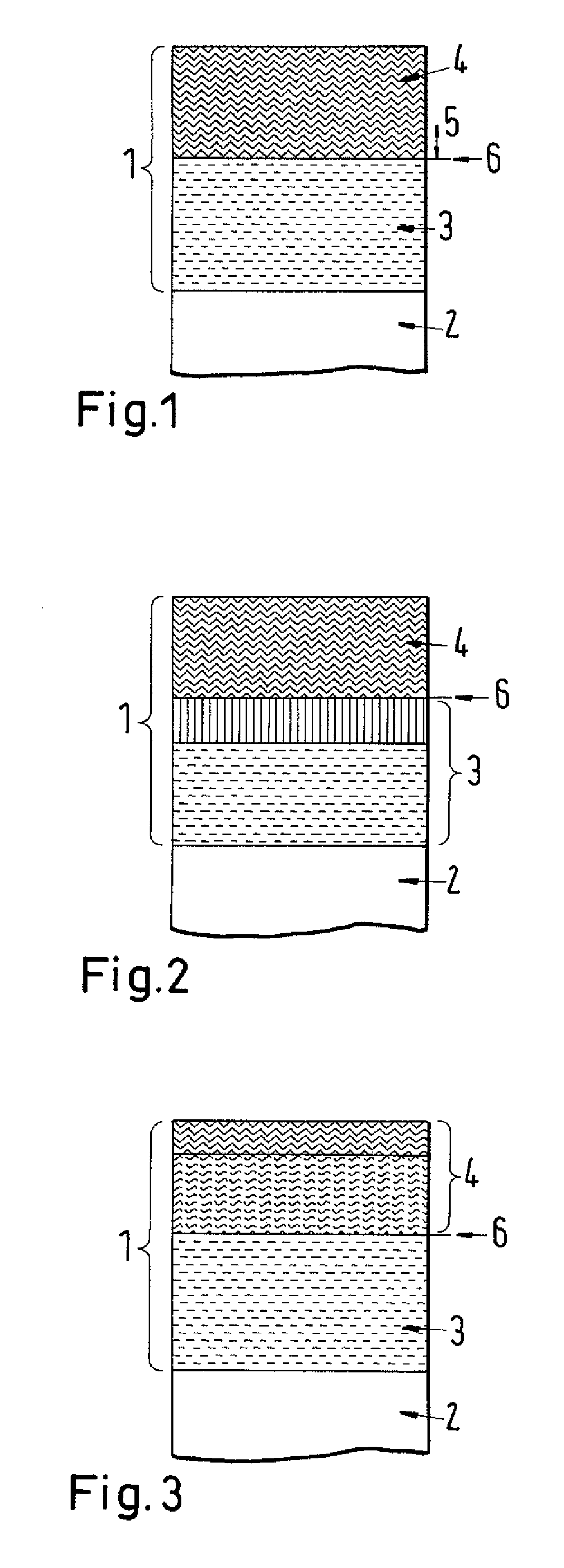

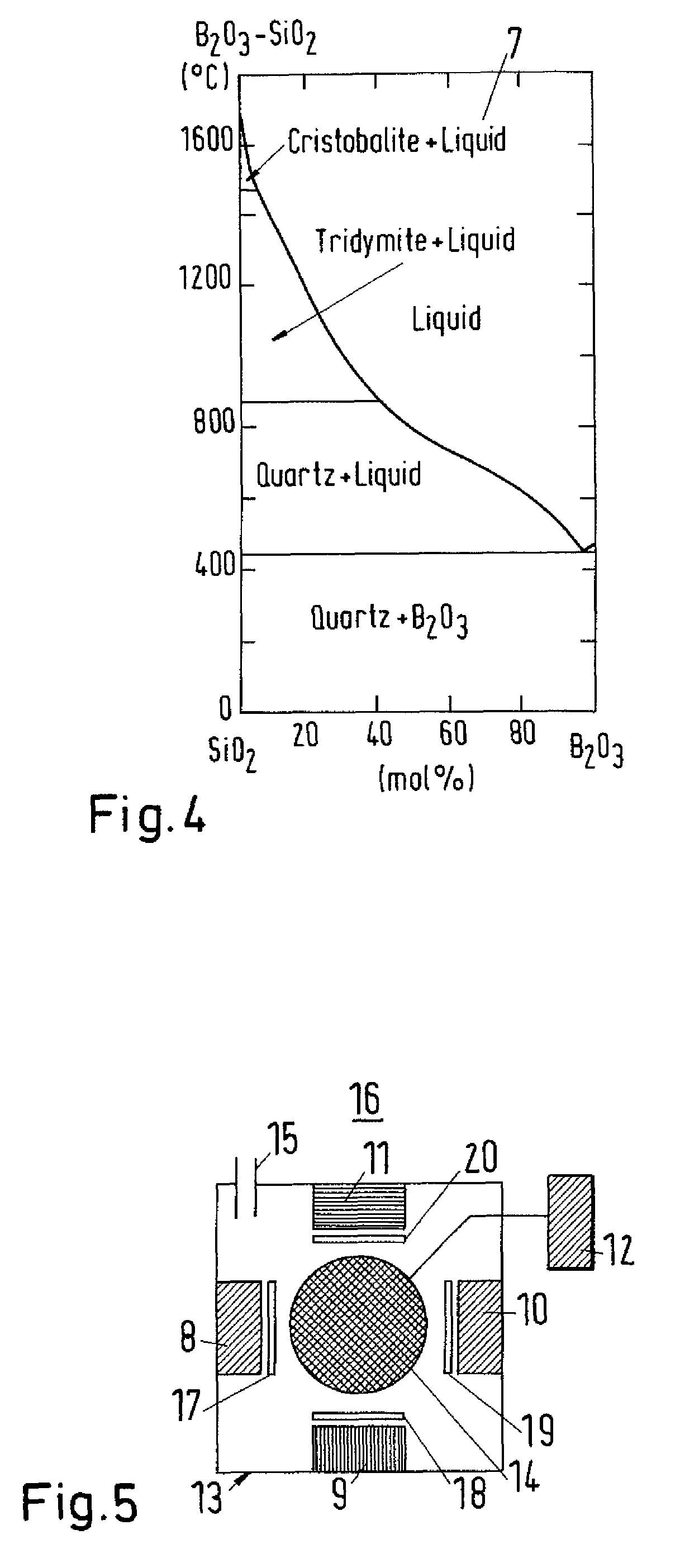

Combination antiabrasion layer

InactiveUS6368717B1Improve protectionHigh affinityLiquid surface applicatorsLayered productsPolymer scienceThin membrane

A combination wear protection film for components made of substrates susceptible to wear is described. The film has a wear-resistant surface film that contains one or more of the elements carbon, nitrogen, or boron, the proportion of this element-or, if more than one of these elements is present, the sum of the proportions of the elements present-is at least 30% by atomic weight, preferably at least 40% by atomic weight; and a support film, located between a substrate and the surface film and made of a plasma polymer, that exhibits a quasi-continuous transition in modulus of elasticity and optionally in hardness from a value of a base film to a value of the surface film. A method for producing a wear protection film of this kind, and objects equipped with the wear protection film is also described.

Owner:ROBERT BOSCH GMBH +1

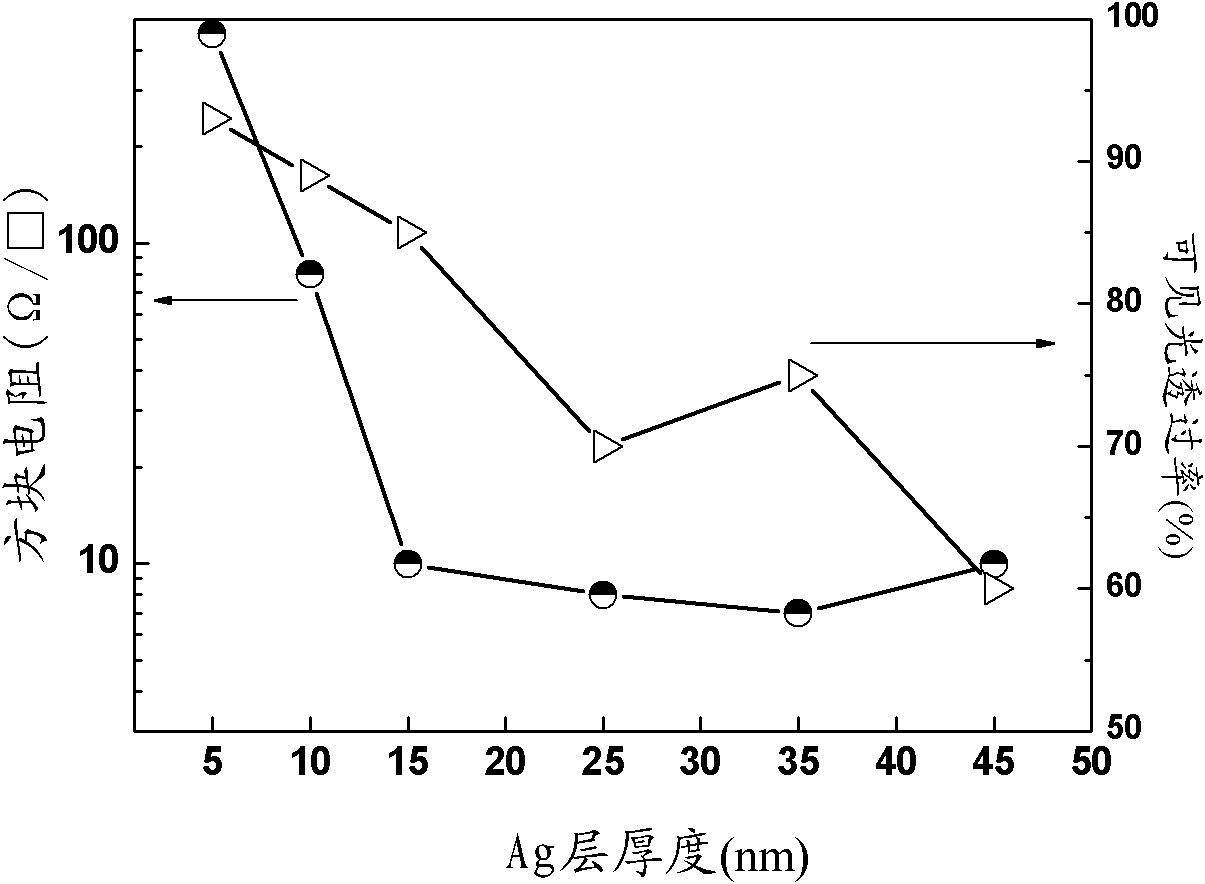

Preparation method of multilayer transparent conductive thin film as well as prepared thin film and application thereof

InactiveCN102134699AIncrease deposition rateConductiveVacuum evaporation coatingSputtering coatingSemiconductor materialsElectrically conductive

The invention relates to the field of preparing semiconductor materials and provides a preparation method of a multilayer transparent conductive thin film as well as a prepared thin film and an application thereof. The method comprises the following steps: mixing SiO2 powder with ZnO powder and sintering to serve as an SZO target, wherein the mass ratio of the SiO2 powder to the ZnO powder is 2 / 199-1 / 6; providing an Ag target; and putting the SZO target and the Ag target into a magnetic-control sputtering cavity, orderly sputtering a first SZO layer, an Ag layer and a second SZO layer on a substrate so as to obtain an SZO-Ag-SZO transparent conductive thin film which is of a sandwich structure. The invention also provides the multilayer transparent conductive thin film obtained by using the method and the application of the film in semiconductor photoelectric devices.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

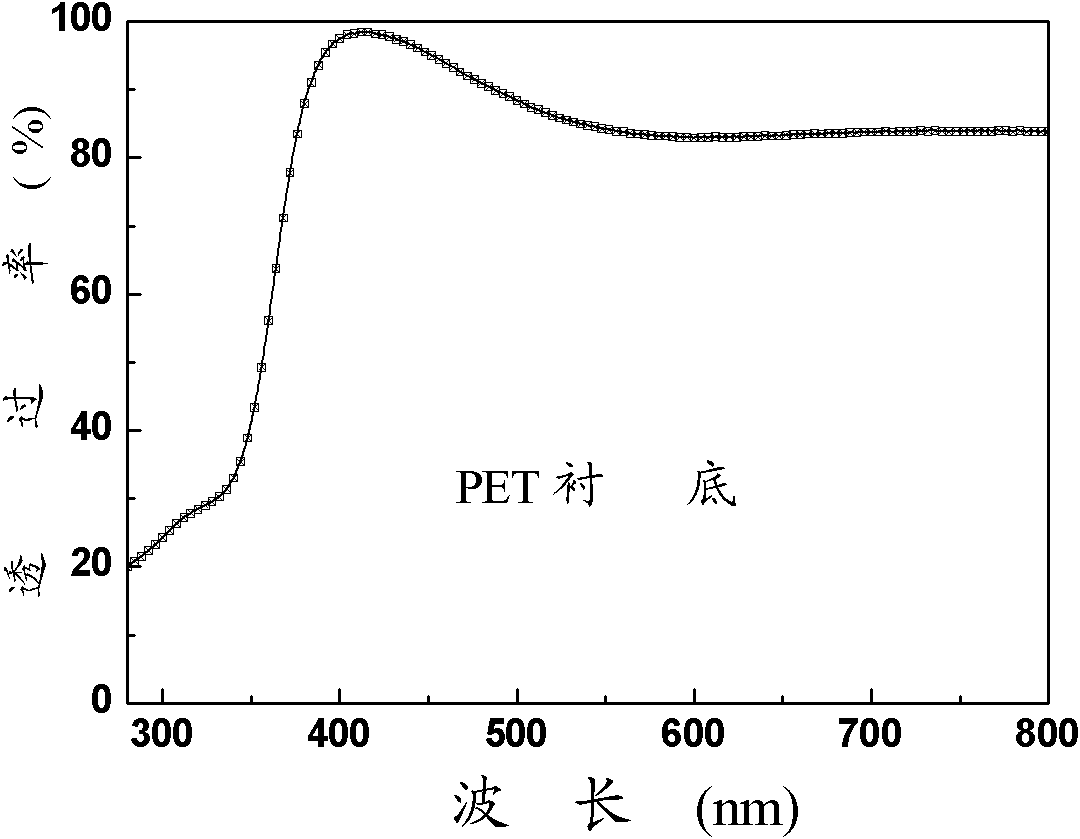

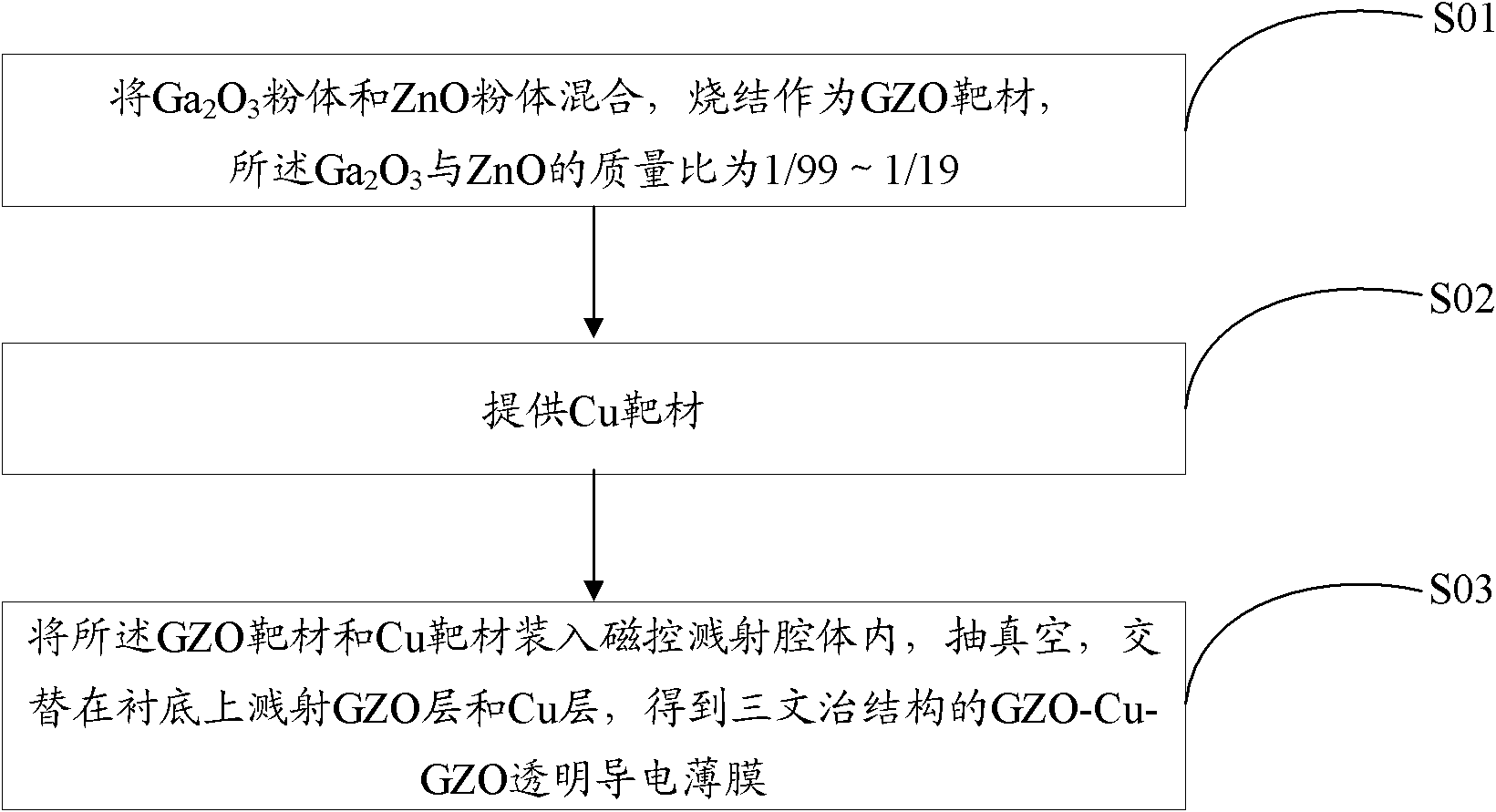

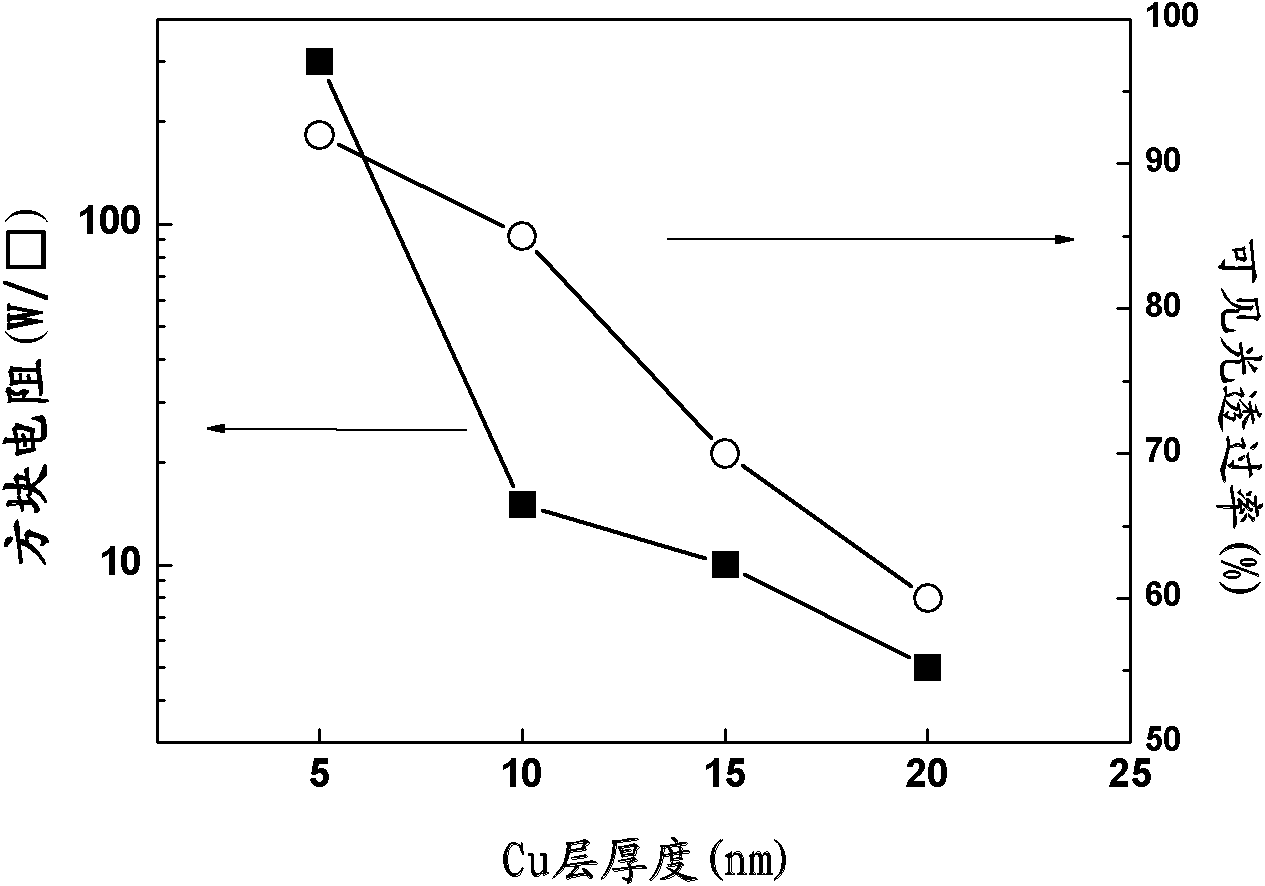

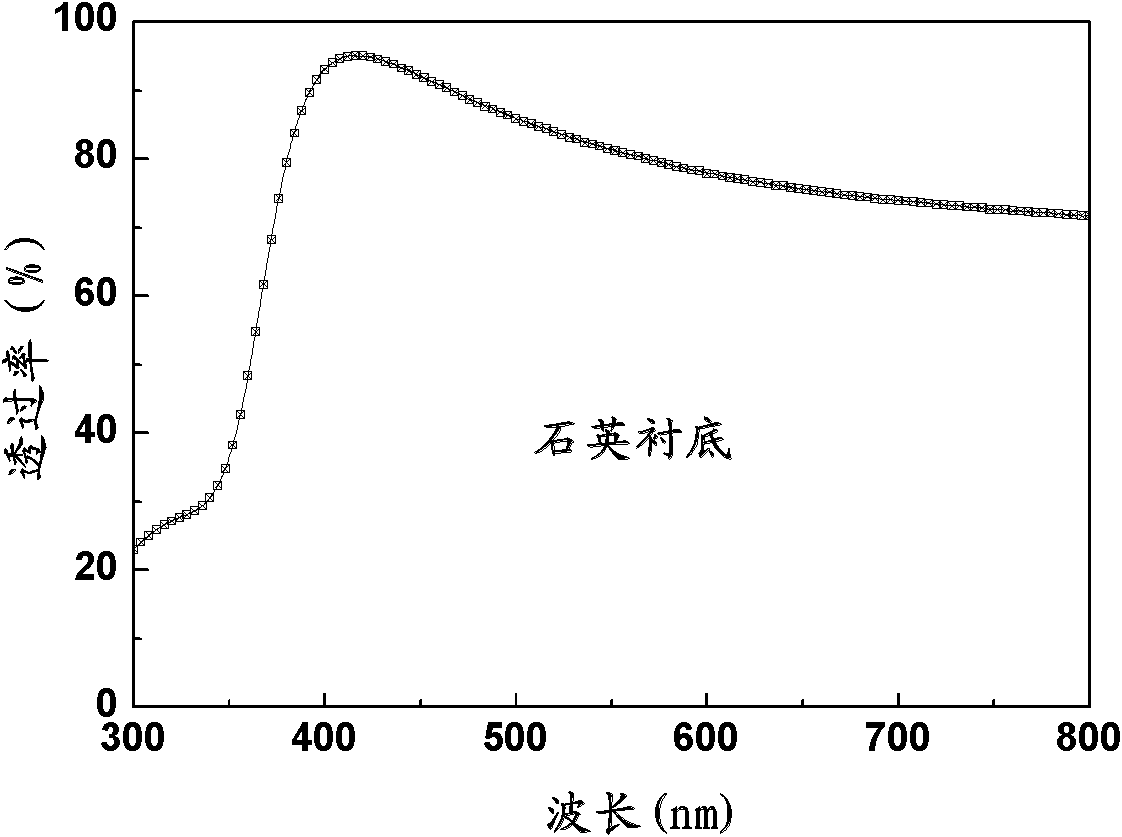

Preparation method of multilayer transparent conductive film, film prepared thereby, and application thereof

InactiveCN102134704AIncrease deposition rateLower substrate temperatureVacuum evaporation coatingSputtering coatingSemiconductor materialsSemiconductor

The invention relates to the preparation field of semiconductor material, and provides a preparation method of a multilayer transparent conductive film, the film prepared thereby, and the application thereof. The preparation method comprises the steps of: mixing Ga2O3 powder and ZnO powder, sintering the mixture and taking the product as GZO target material, wherein the mass ratio between the Ga2O3 powder and ZnO powder is 1 / 99-1 / 19; providing Cu target material; putting the GZO target material and the Cu target material into a magnetron sputtering cavity; vacuumizing and alternately sputtering a GZO layer and a Cu layer on a substrate; and finally obtaining the GZO-Cu-GZO transparent conductive film with a sandwich structure. The invention also provides the multilayer transparent conductive film prepared by the method, and the application of the film in a semiconductor photoelectric device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Hydrophobic anti-fouling acrylic latex paint

InactiveCN102816491AGood film adhesionStrong covering powerAntifouling/underwater paintsPaints with biocidesWeather resistanceEmulsion

The invention relates to a hydrophobic anti-fouling acrylic latex paint which contains the following components in parts by mass: 35-45 parts of water, 0.05-0.1 part of dispersant, 0.01-0.05 part of defoaming agent, 0.04-0.1 part of preservative, 0.02-0.08 part of mold preventive, 2-4 parts of kaolin, 3-8 parts of titanium white powder, 5-6 parts of coarse whiting powder, 5-8 parts of quartz powder, 45-65 parts of acrylic emulsion, 0.15-0.3 part of thickener, 5-10 parts of anti-fouling agent and 2-6 parts of hydrophobing agent. The hydrophobic anti-fouling acrylic latex paint provided by the invention is high in quality, low in cost and affordable, has good stain resistance, scrub resistance and weather resistance, and can be coated on side walls and the like in offices, classrooms and houses. Besides, ink, befouled water and the like sprayed on the wall can be cleaned very easily.

Owner:WUJIANG WUHUA HARDWARE PROD

Aqueous resin dispersion, method for its production, coating material and laminate

ActiveUS8158727B2Easy dischargeMaintain good propertiesEmulsion paintsThin material handlingPolymer sciencePolyolefin

Owner:MITSUBISHI CHEM CORP

External wall fireproof reflective heat-insulation inorganic coating material and preparation method thereof

InactiveCN111019416AImprove heat resistanceImproved reflective insulation performanceFireproof paintsAntifouling/underwater paintsSilicic acidPhosphate

The invention relates to an external wall fireproof reflective heat-insulation inorganic coating material, which comprises a base material, a filler, an auxiliary agent and water, wherein the base material comprises, by weight, 15-20 parts of lithium silicate, 15-20 parts of nano long hydrocarbonyl silane modified silica sol, 4-6 parts of nano hydroxyl magnesium silicate and 2-5 parts of an aluminum dihydrogen phosphate aqueous solution, and the filler is prepared from the following components in parts by weight: 20 to 25 parts of IR-1000 near-infrared reflective titanium dioxide, 10 to 15 parts of wollastonite powder, 10 to 15 parts of talcum powder and 1 to 5 parts of nano titanium dioxide. The invention also discloses a preparation method of the external wall fireproof reflective heat-insulation inorganic coating material. The coating material has the advantages of being free of VOC, not prone to combustion, good in high temperature resistance, capable of achieving reflective heat-insulation, not prone to corrosion and resistant to mould.

Owner:NIPPONPAINT SICHUAN CO LTD

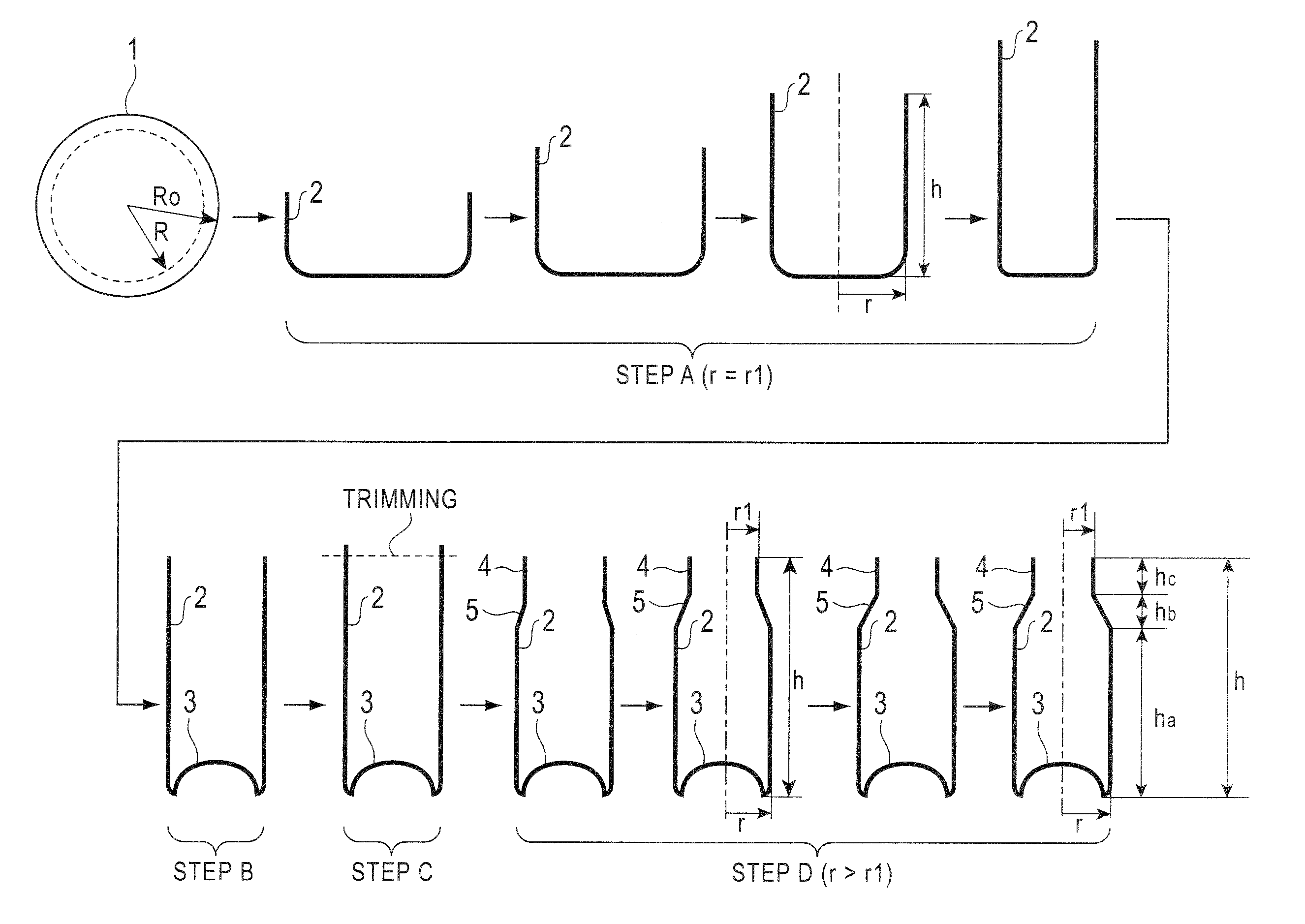

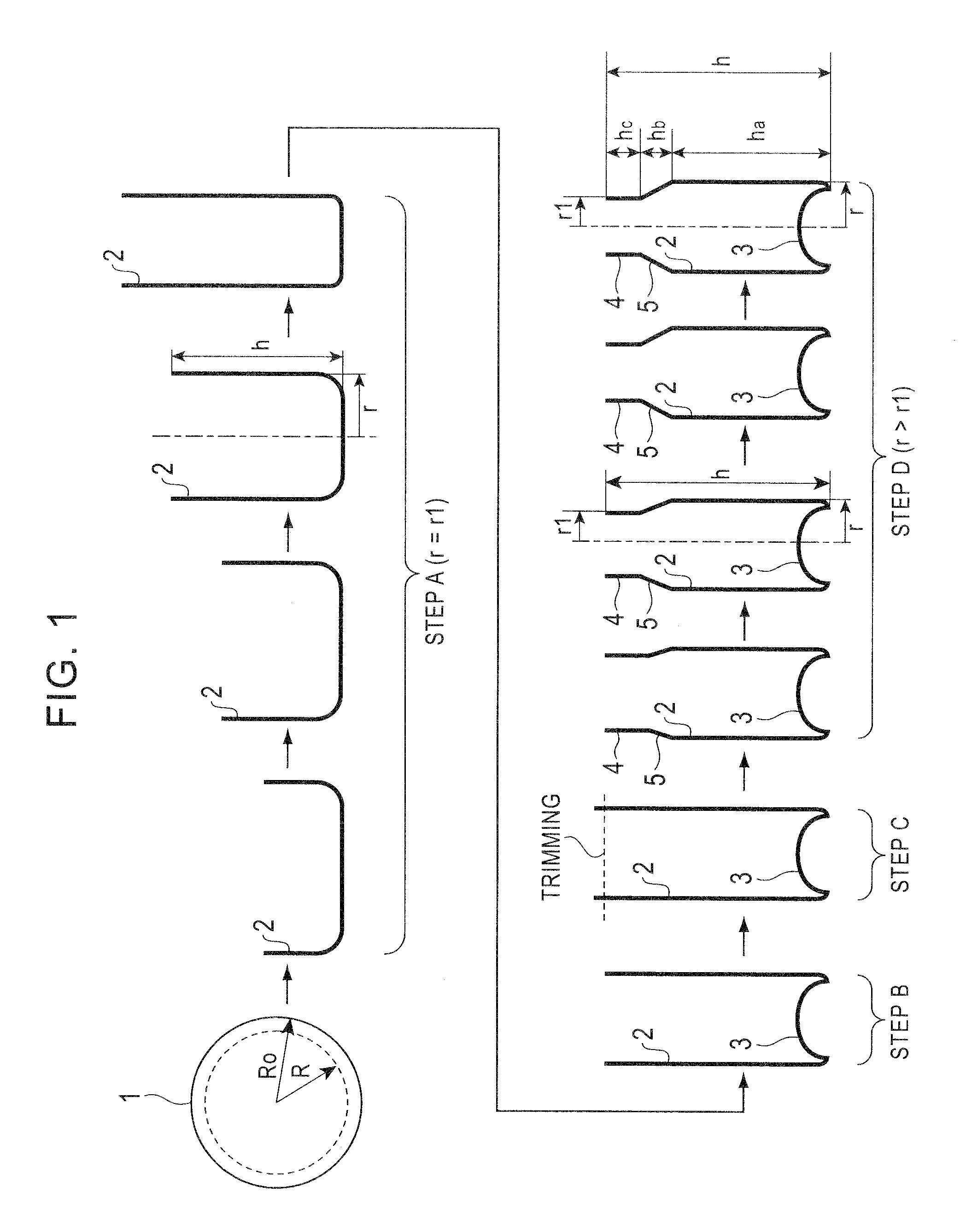

Laminate steel sheet for two-piece can, method for production of two-piece can, and two-piece laminate can

InactiveUS20100000632A1Reduce surface frictionReduce processing stressSynthetic resin layered productsCans/barrels/drumsSheet steelSurface roughness

A laminated steel sheet for a two-piece can body with a high strain level satisfying the following formulae, the polyester resin layer composing the laminated steel sheet having a center line surface roughness (Ra) of 0.2 μm to 1.8 μm:r1≦r, 0.1≦r1 / R≦0.25, and 1.5≦h / (R−r)≦4wherein h is the height of the two-piece can body, r is the maximum radius, r1 is the minimum radius, and R is the radius of the circular laminated steel sheet before forming having the same weight as the can body.

Owner:JFE STEEL CORP

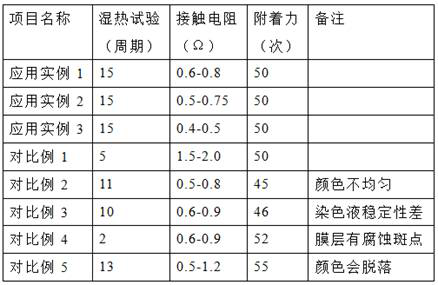

Electrochemical conductive oxidizing technology method of aluminum and aluminum alloy

The invention relates to an electrochemical conductive oxidizing technology method of aluminum and aluminum alloy, and belongs to the technical field of nonferrous metal material surface electrochemistry. The method comprises the steps of organic solvent degreasing treatment, chemical degreasing treatment, alkaline etching treatment, glaring treatment, electrolysis treatment, neutralizing treatment, dyeing treatment and sealing treatment. Through the method, a layer of conductive oxidizing film which can be in diversified colors is formed on the surface of an aluminum alloy workpiece, and has good corrosion resistance, electrical conductivity, color consistency and paint film adhesion; by means of the oxidizing film, the requirements of 15 cycles of a damp heat test can be met; the contact resistance of any positions of the film is smaller than 0.9 omega; and the conductive converting film (conductive oxidizing film) does not fall off after being stuck to paper self-adhesive tape 100 times, and the conductive converting film (conductive oxidizing film) does not fall off after being erased by a sand-free eraser manually at common pressure 50 times so that the aluminum and aluminum alloy can be applied to a wide variety of fields of aerospace, ships, architecture, electrical engineering, chemistry, transportation, automobiles and the like.

Owner:云南昆船机械制造有限公司

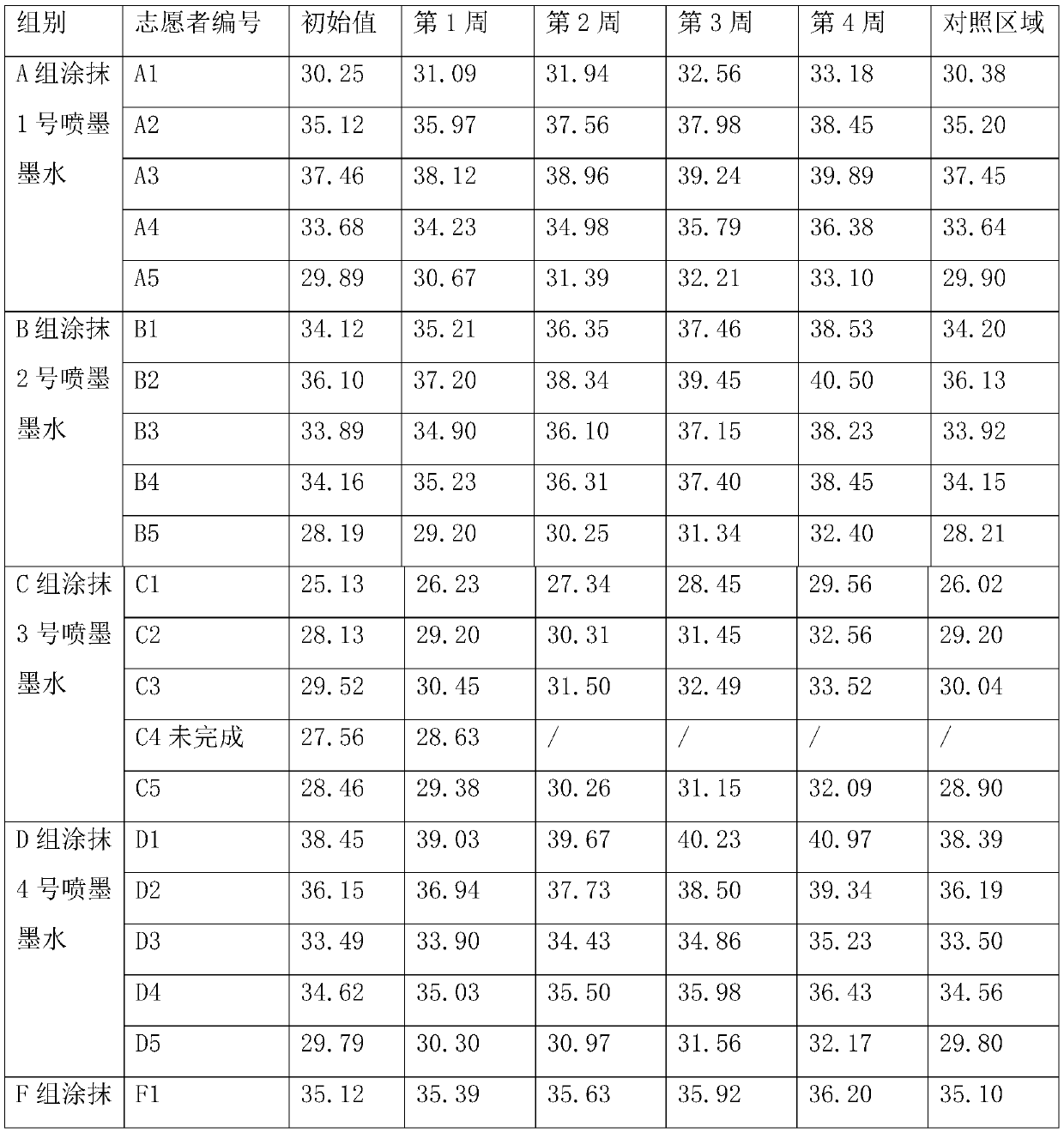

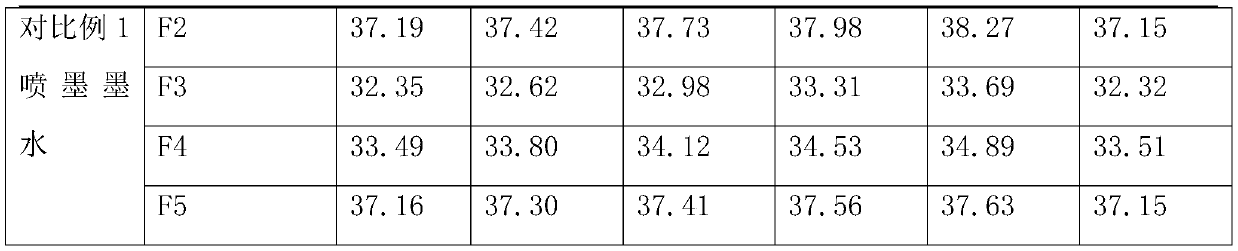

Customized whitening inkjet ink and preparing method and application thereof

PendingCN110464663AEasy to cleanUniform dropletCosmetic preparationsToilet preparationsSolventSolution state

The invention discloses a customized whitening inkjet ink which comprises a solvent and whitening and skin brightening functional substances. The customized whitening inkjet ink has the suspensibilityof 50-100%, preferentially 70-100%. The whitening and skin brightening functional substances have the particle size smaller than or equal to 5 micron, preferentially 1 micron. The whitening and skinbrightening functional substances include one or more at an arbitrary ratio of compound type whitening and skin brightening functional substances, extract type whitening and skin brightening functional substances, peptide and enzyme type whitening and skin brightening functional substances, pearl powder, titanium dioxide and silica. The customized whitening inkjet ink is uniform in droplet, smooth, fine and stable, and the ink is in a solution state or evenly-dispersed state, is high in adhesion to a film fabric and is applied to skin care, repairing and beautifying or medical patches.

Owner:李和伟

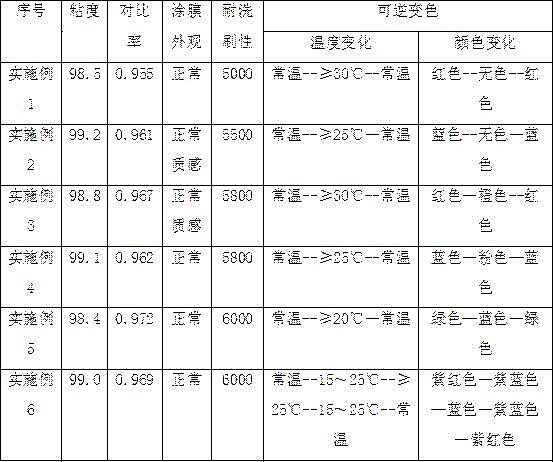

Temperature-sensitive colour-changeable artistic coating and preparation method thereof

InactiveCN106047017AExtended service lifeLong-lasting coating appearanceCoatingsDefoaming AgentsTitanium dioxide

The invention discloses temperature-sensitive colour-changeable artistic coating and a preparation method thereof. The temperature-sensitive colour-changeable artistic coating is prepared from the following raw materials in percentage by weight: 20-30% of water, 0.1-1% of a thickening agent, 0.1-0.5% of auxiliary, 0.1-1% of a dispersing agent, 0.1-0.5% of a wetting agent, 0.1-0.5% of a defoaming agent, 5-20% of titanium dioxide, 5-10% of kaolin, 0.1-0.5% of bactericide, 0.1-0.5% of a mould inhibitor, 0.5-1.0% of dihydric alcohol, 0.5-1.5% of a coalescing agent, 30-40% of silicon-containing acrylic polymer and 0.5-10% of microcapsule temperature-sensitive colour powder. The prepared temperature-sensitive colour-changeable artistic coating has good reversible colour changing function, excellent paint film properties in adhesion, handfeel, doodling resistance, concave-convex three-dimensional texture effect and the like and can provide more personalized colour space and creative artistic function for people in the aspect of decoration and renovation of buildings.

Owner:四川嘉宝莉涂料有限公司

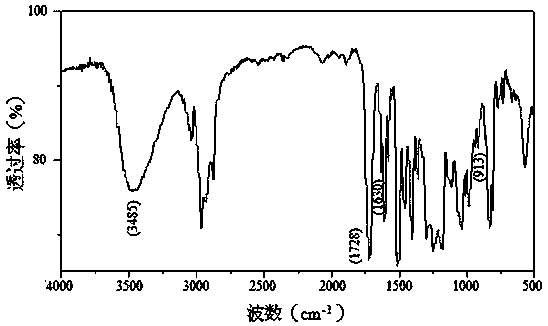

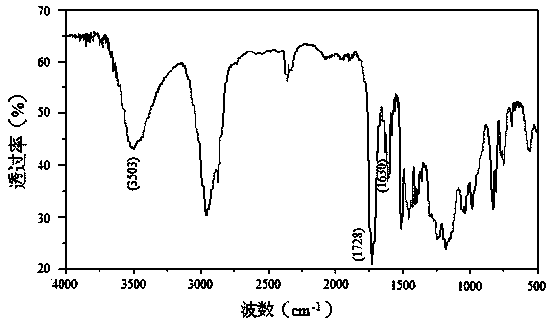

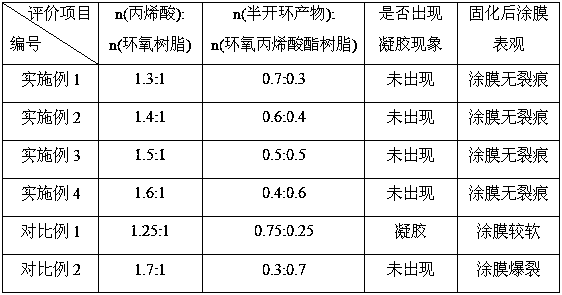

Polyacrylic resin with side-chain modification of hybrid epoxy acrylate and synthesis method

The invention discloses polyacrylic resin with side-chain modification of hybrid epoxy acrylate and a synthesis method. The polyacrylic resin is mainly prepared from the following raw materials: carboxylated polyacrylate, hybrid epoxy acrylate, an alkaline catalyst and a polymerization inhibitor. The method comprises the following steps of: mixing the carboxylated polyacrylate and the hybrid epoxyacrylate, adding the alkaline catalyst and the polymerization inhibitor in the heating process, carrying out insulated reaction till the acid value is 3-5 mgKOH / g, cooling and obtaining the polyacrylic resin. The polyacrylic resin disclosed by the invention has the advantages of low viscosity, fast photocuring speed, good adhesion of a cured coating film, high hardness and good flexibility and the like, can be used for the fields of flexible sealing ends and the like in production of paper, floors and liquid-crystal displays; the method is short in reaction time and low in cost and is suitable for industrial production.

Owner:湖南恒旺新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com