Patents

Literature

138 results about "Continuous transition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Those are known as first-order phase transitions. A continuous phase transition, or second-order transition, forms defects—such as domain walls, cosmic strings, and textures—where some of the matter is stuck between regions in distinct states.

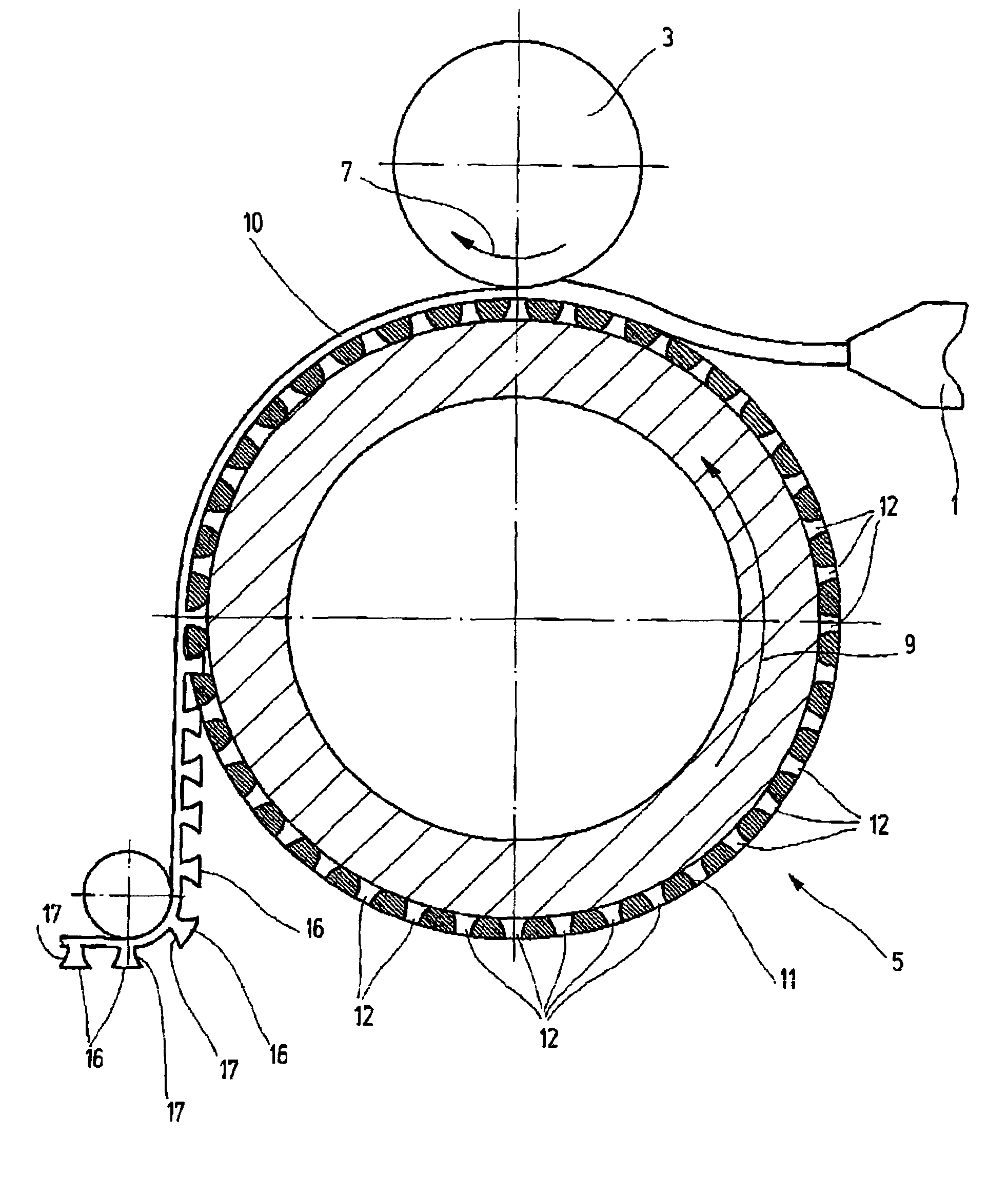

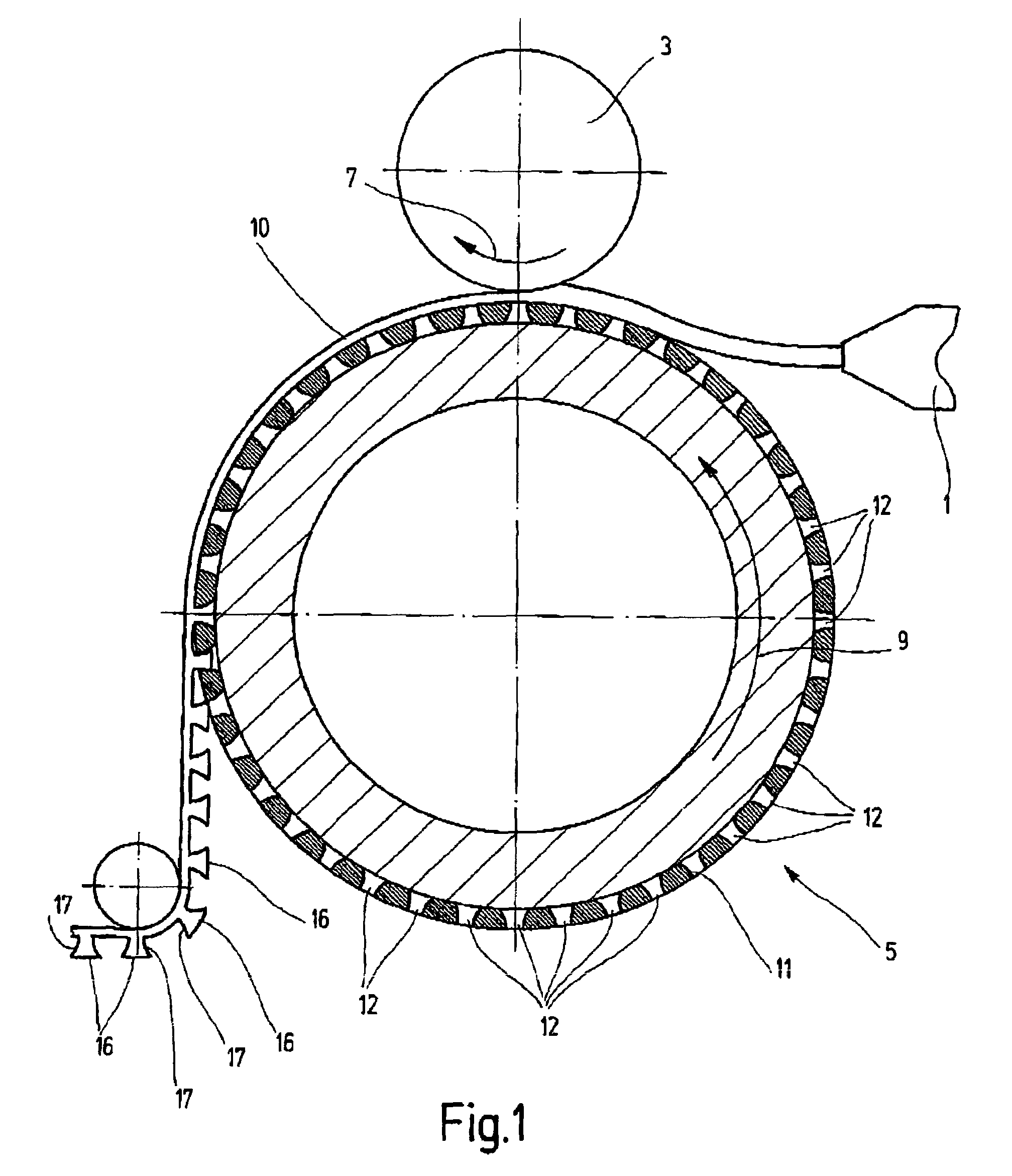

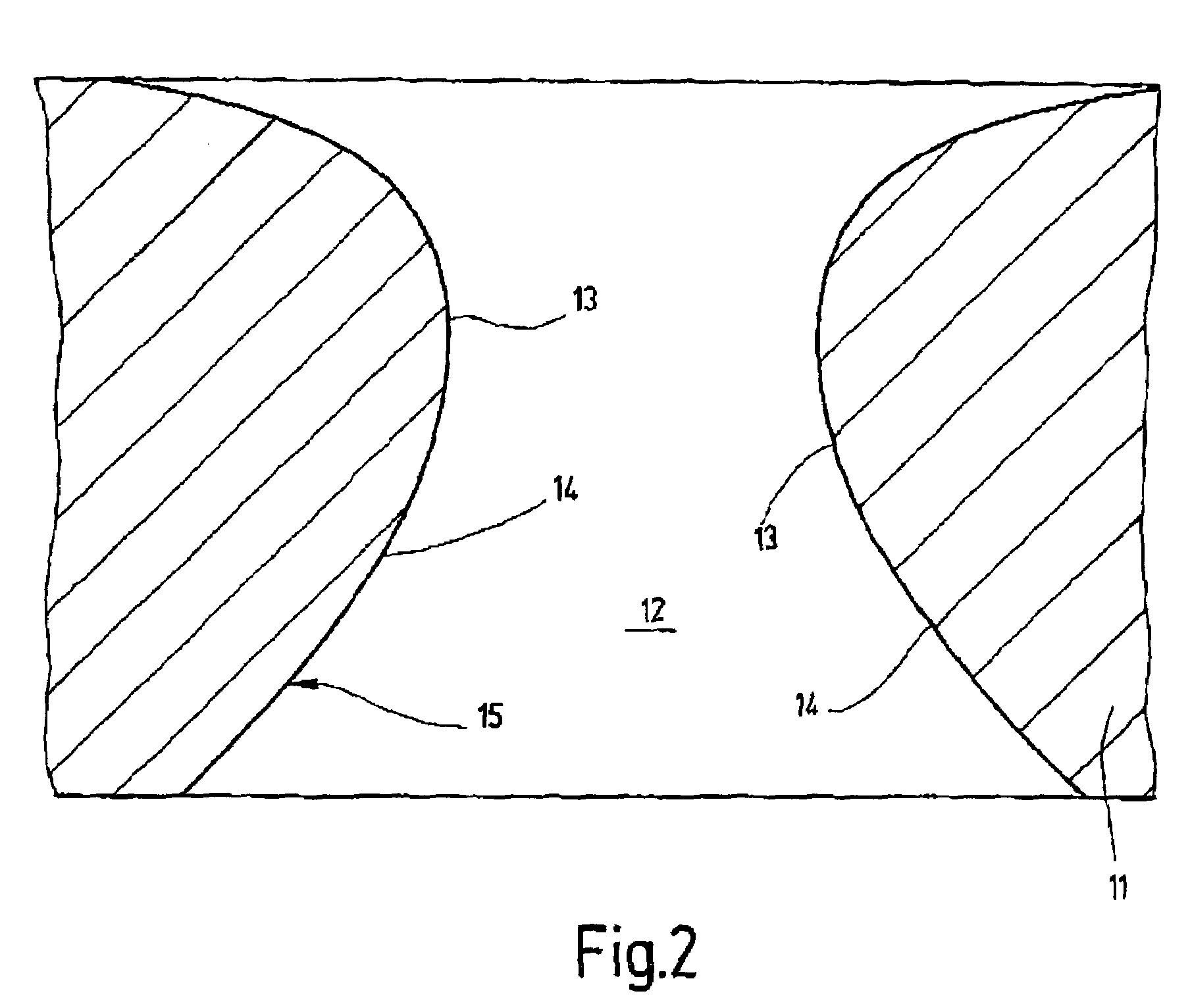

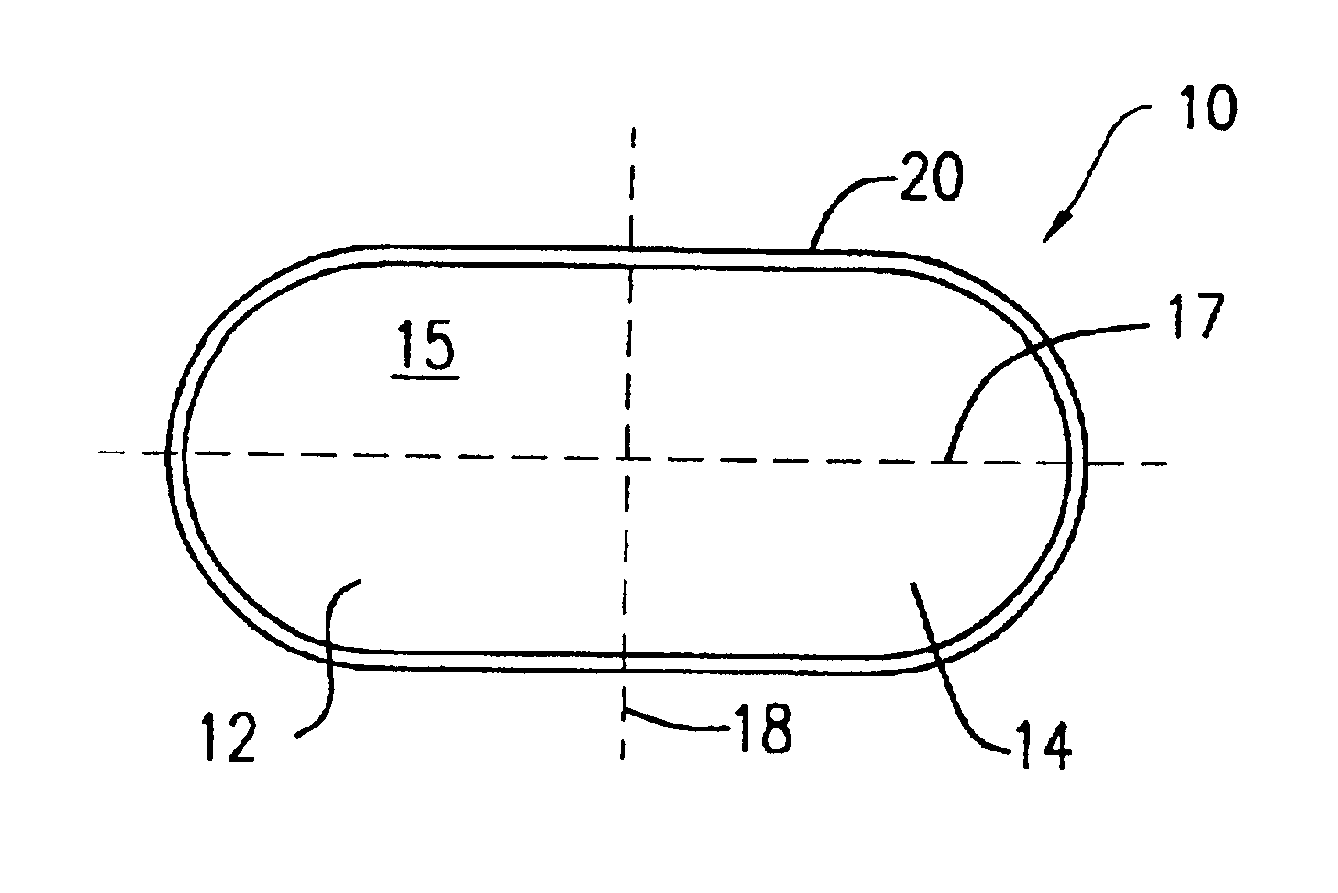

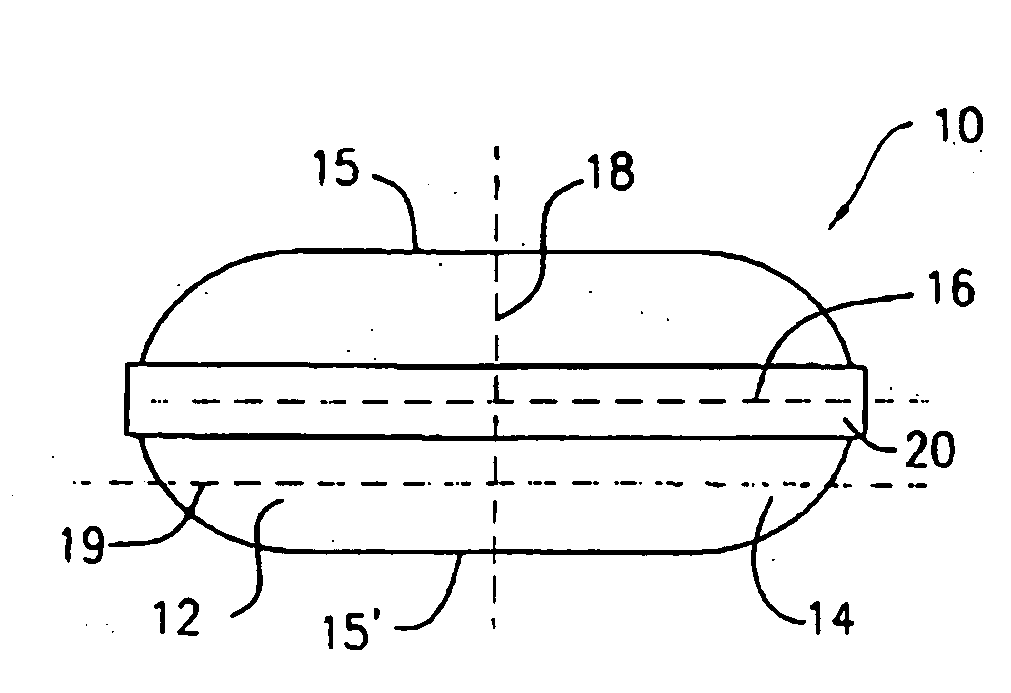

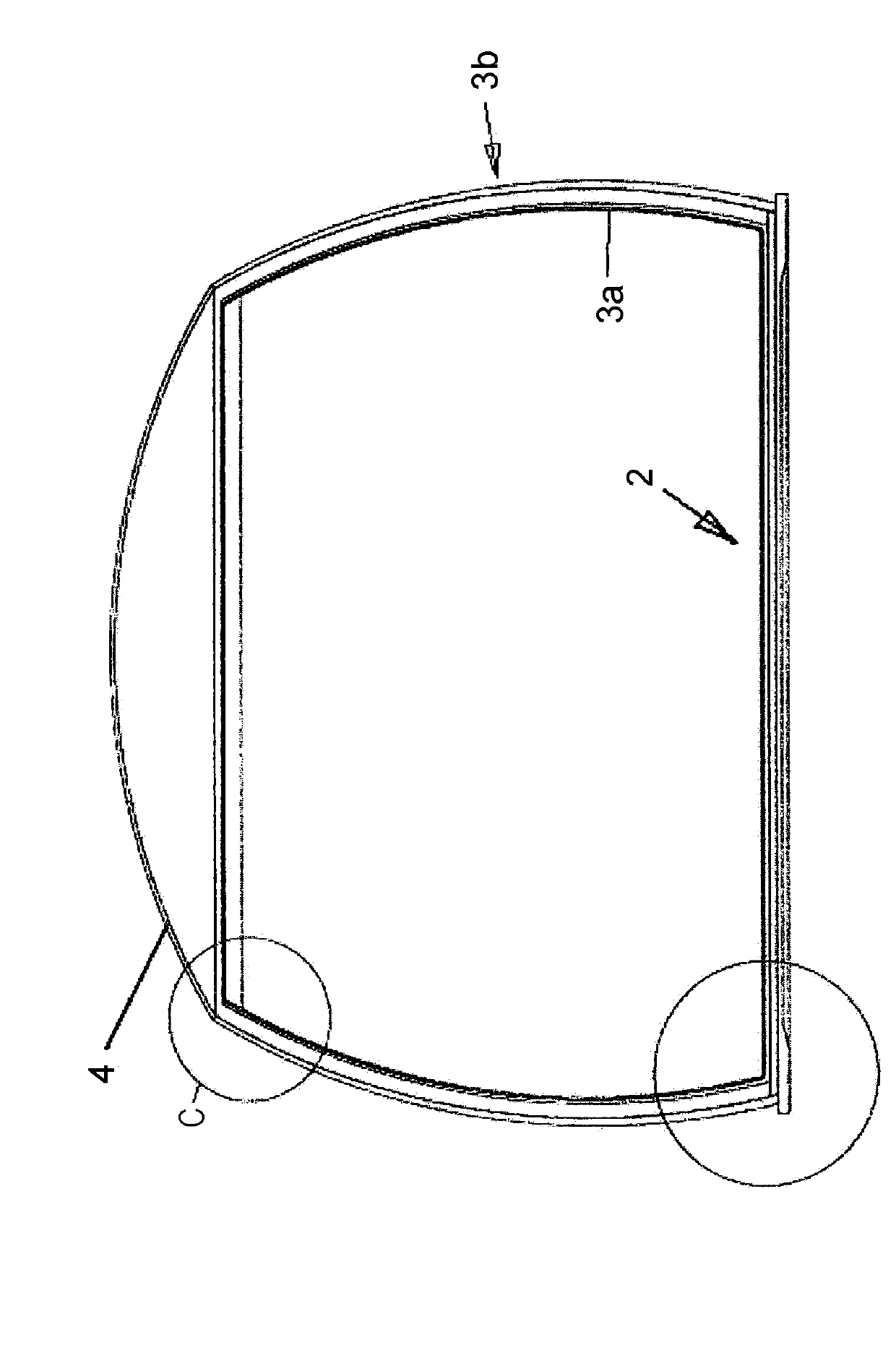

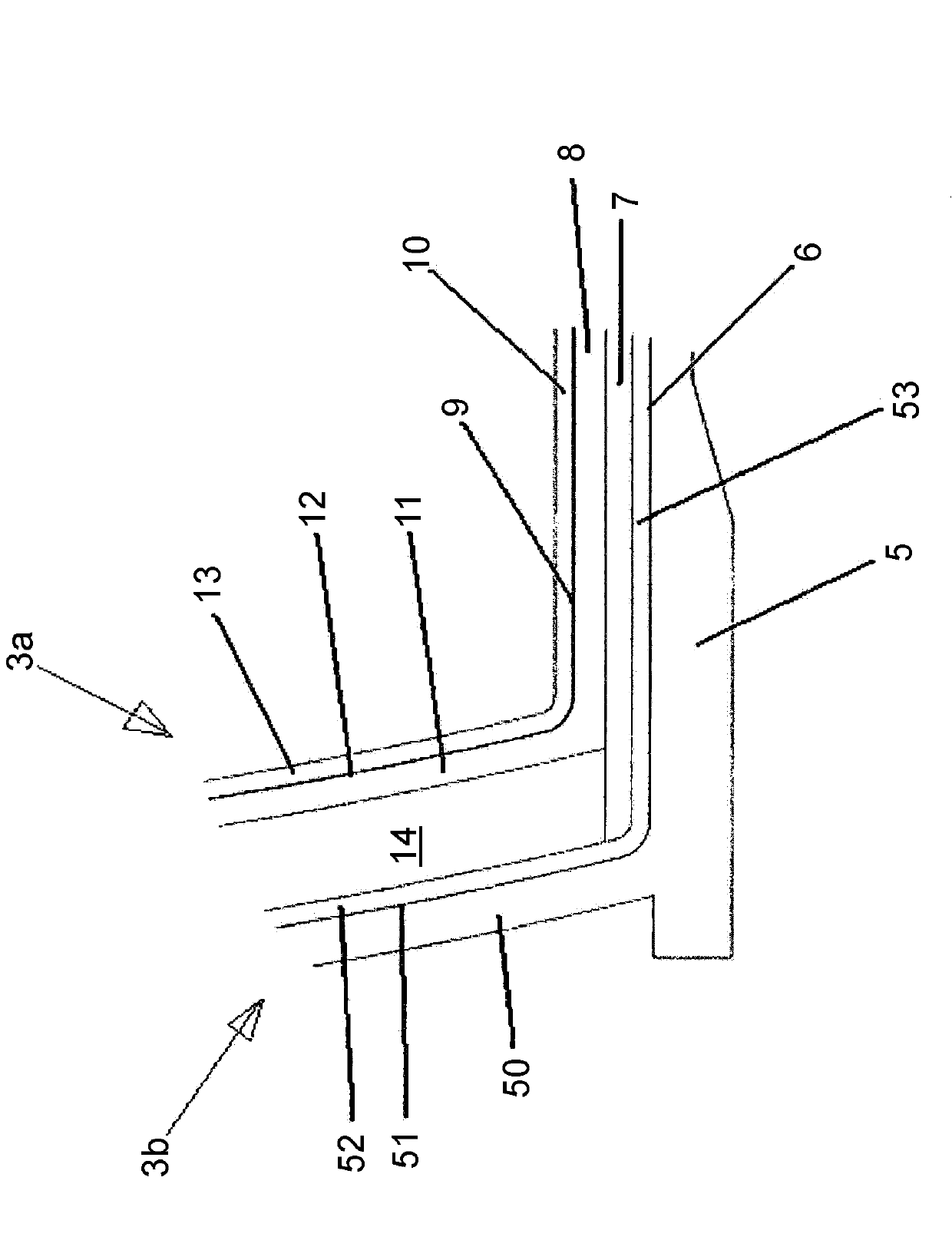

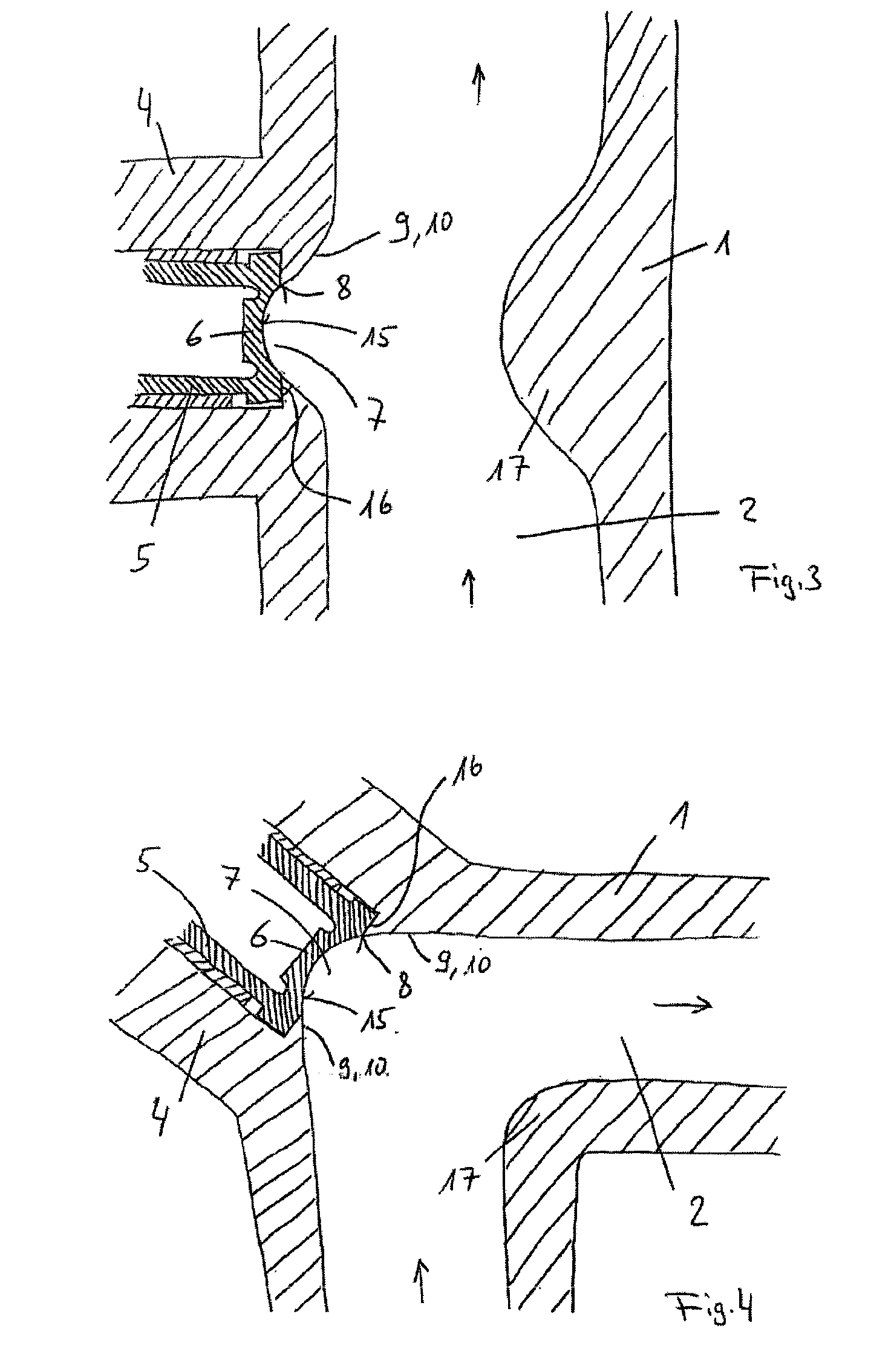

Method for producing an adhesive closing element

InactiveUS7198743B2Easy to demouldFavorable closing behaviorDischarging arrangementArtificial filament physical treatmentEngineeringHooking

A process for produces an adhesive closing element including a plurality of hook elements connected to a backing (10) forming a single piece with the hook elements and being disposed symmetrically thereon. The hook elements are provided in the form of a stem component (17) having a head piece (16). A deformable material is introduced into a forming zone in between a production master (3) and a forming tool (5). The opposite-lying defining walls, at least when seen in a longitudinal section of the respective forming cavity (12), are provided with a continuous convex trajectory. A continuous transition between the cross-sectional forms of the stem component (17) and the head piece (16) is provided for a hooking of the backing (10) resulting in seamless removal.

Owner:GOTTLIEB BINDER

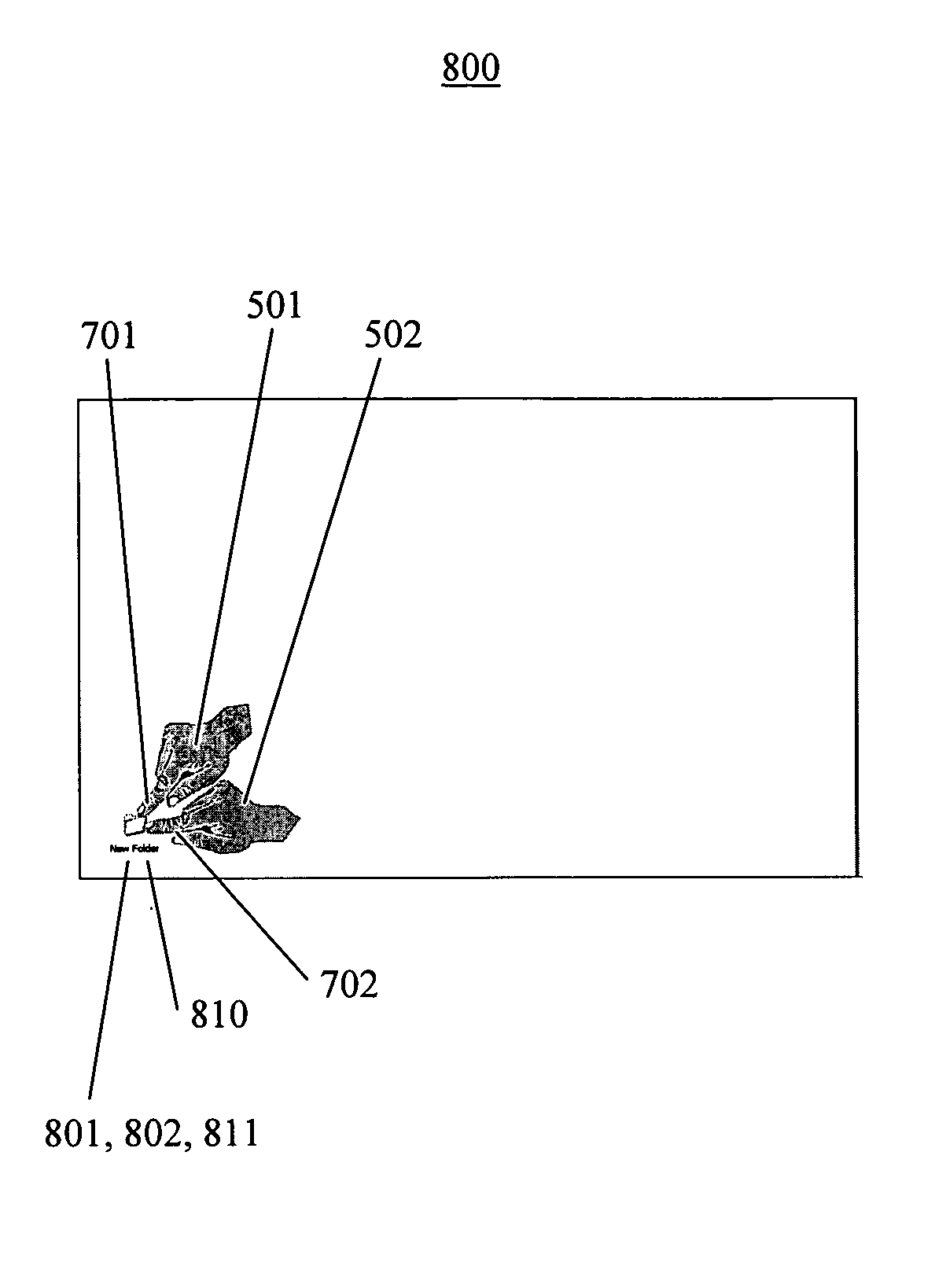

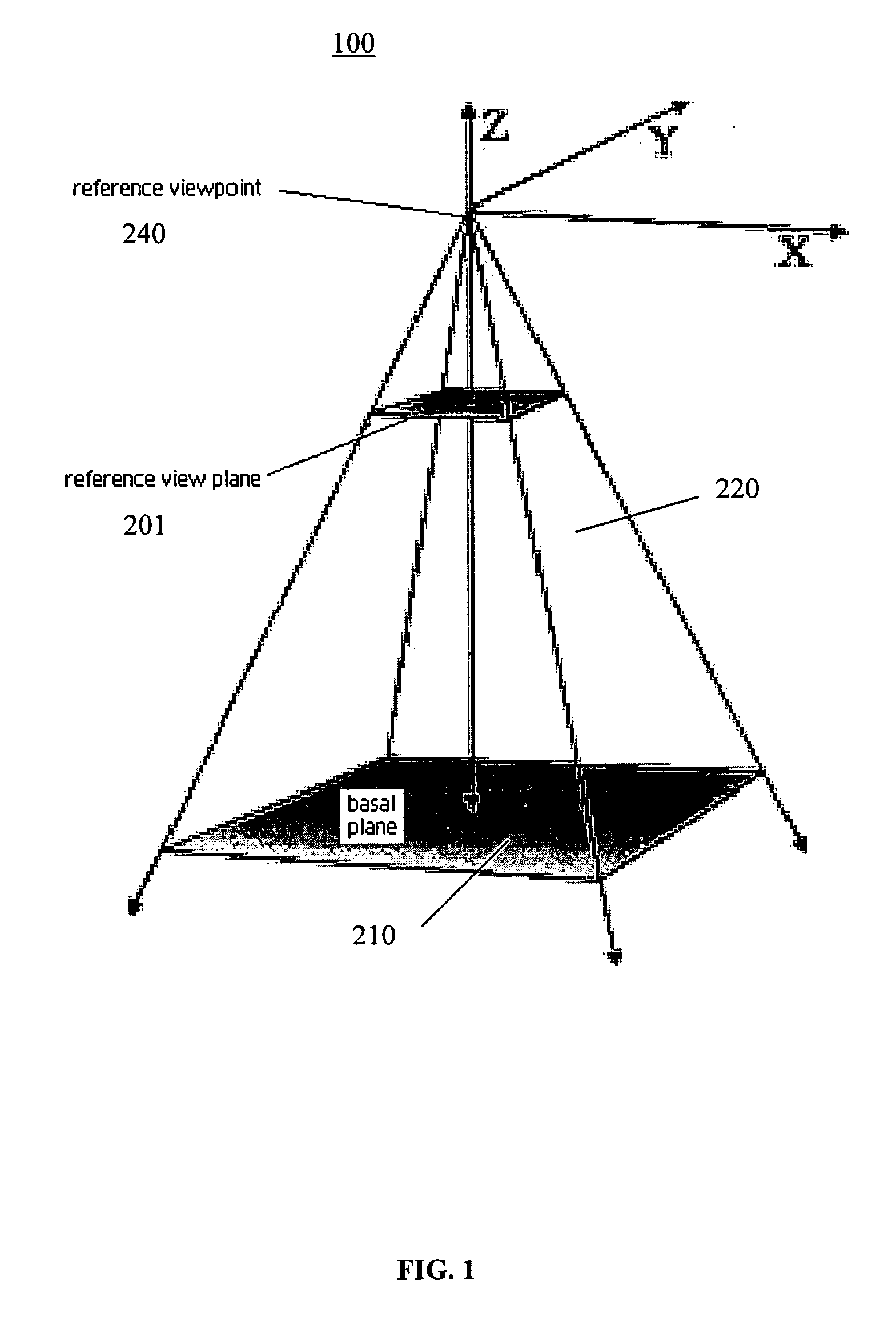

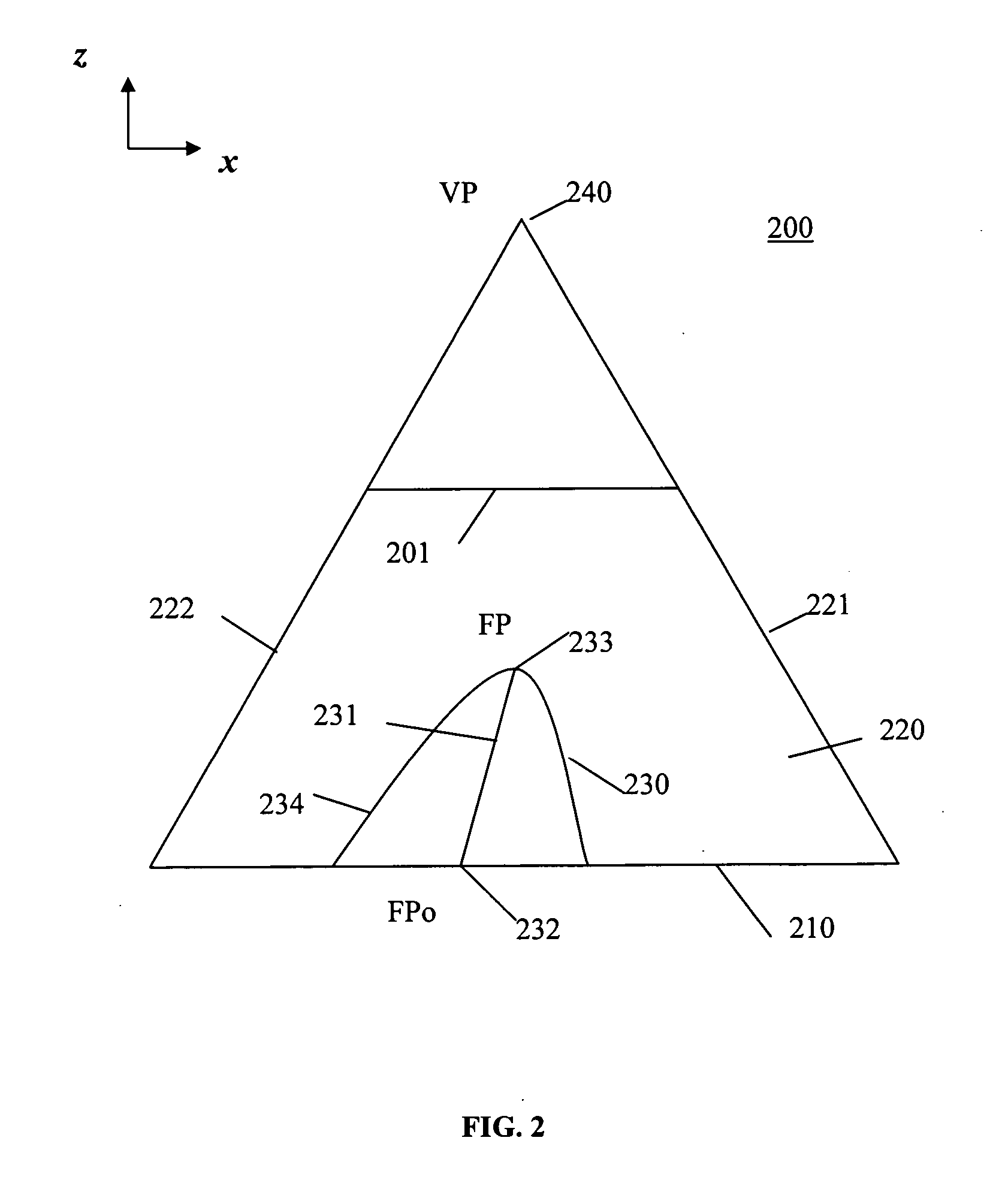

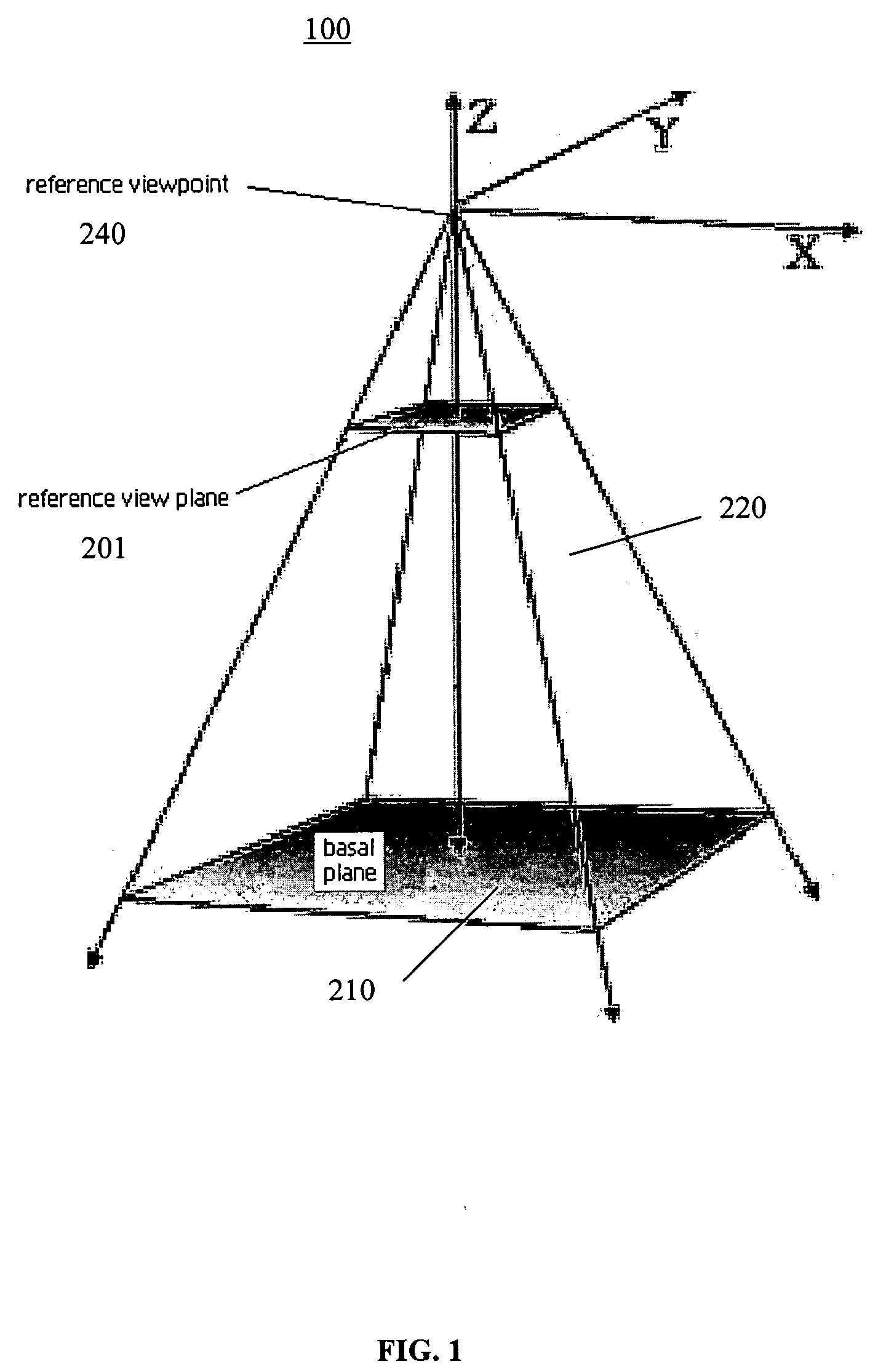

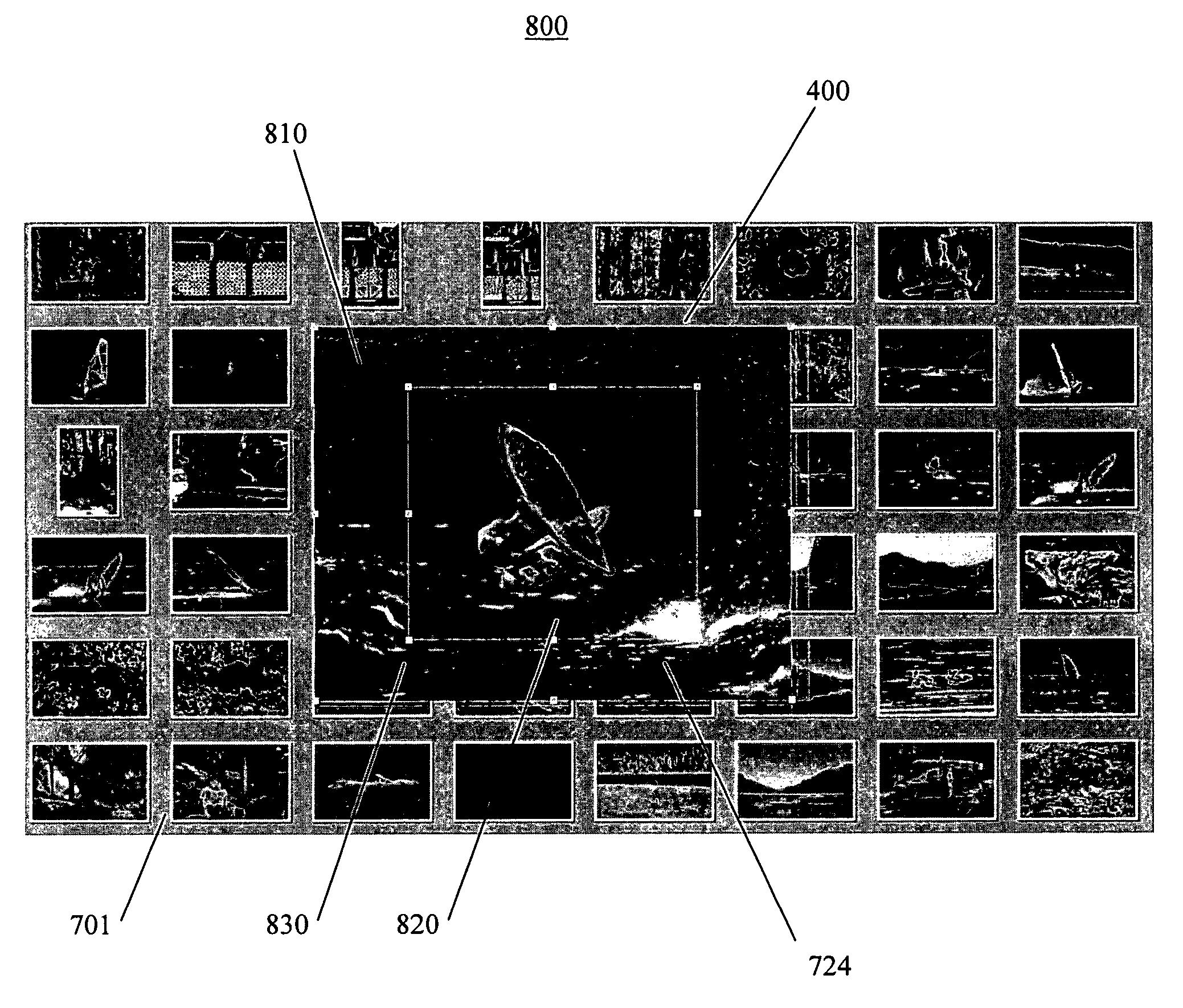

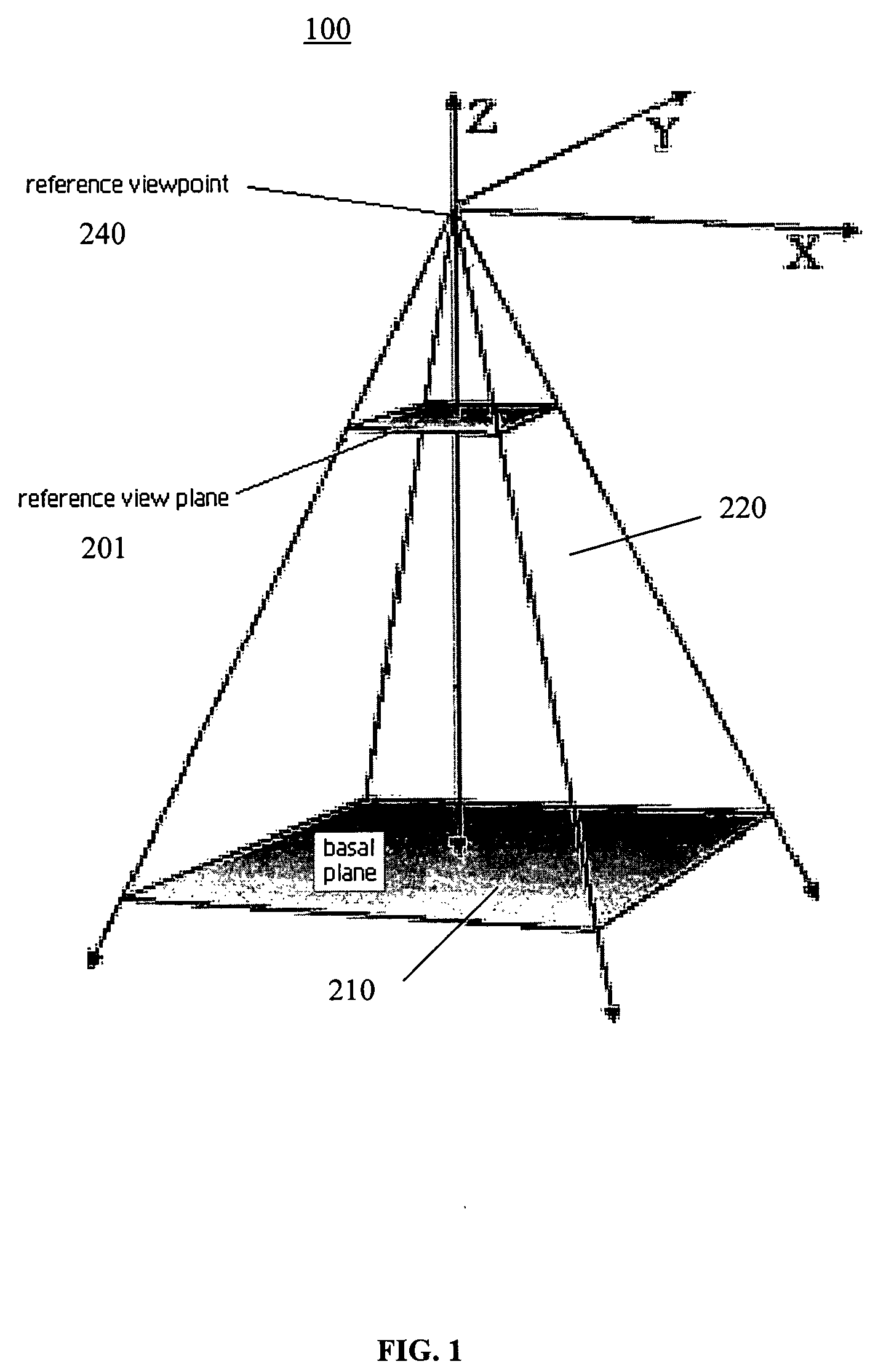

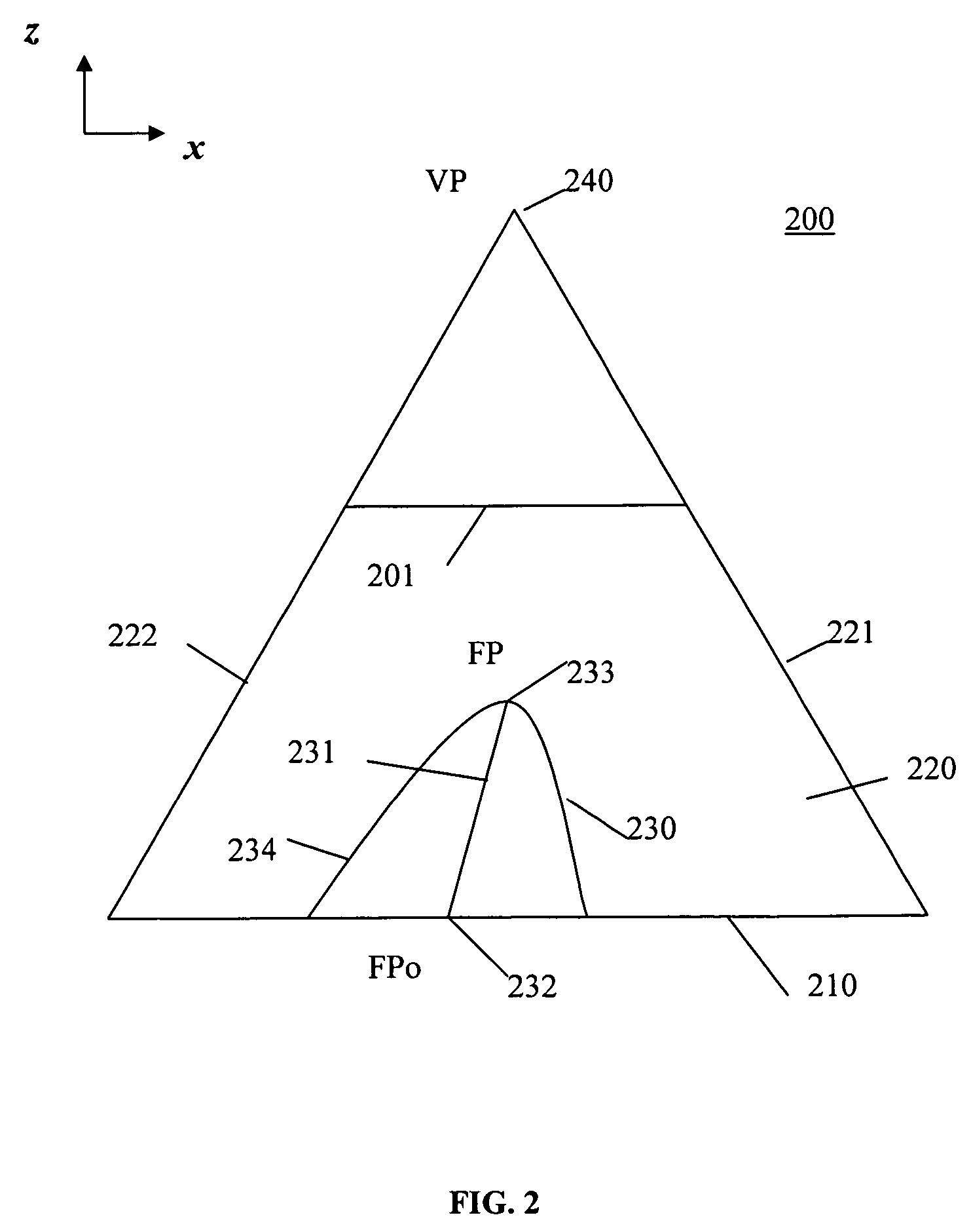

Interacting with detail-in-context presentations

InactiveUS20060082901A1Easy accessGeometric image transformationInput/output processes for data processingShoulder regionMagnification

A method for generating a presentation of a region-of-interest in an original image for display on a display surface, the method comprising: establishing a lens for the region-of-interest, the lens having a focal region with a magnification for the region-of-interest at least partially surrounded by a shoulder region across which the magnification varies to provide a continuous transition from the focal region to regions outside the lens; receiving a first signal for selecting the shoulder region; while receiving the first signal, receiving a second signal for selecting the focal region and for adjusting a position of the focal region relative to the shoulder region to define a degree and a direction of a folding of the focal region over the shoulder region for the lens; and, applying the lens to the original image to produce the presentation.

Owner:NOREGIN ASSETAB N V L L C +1

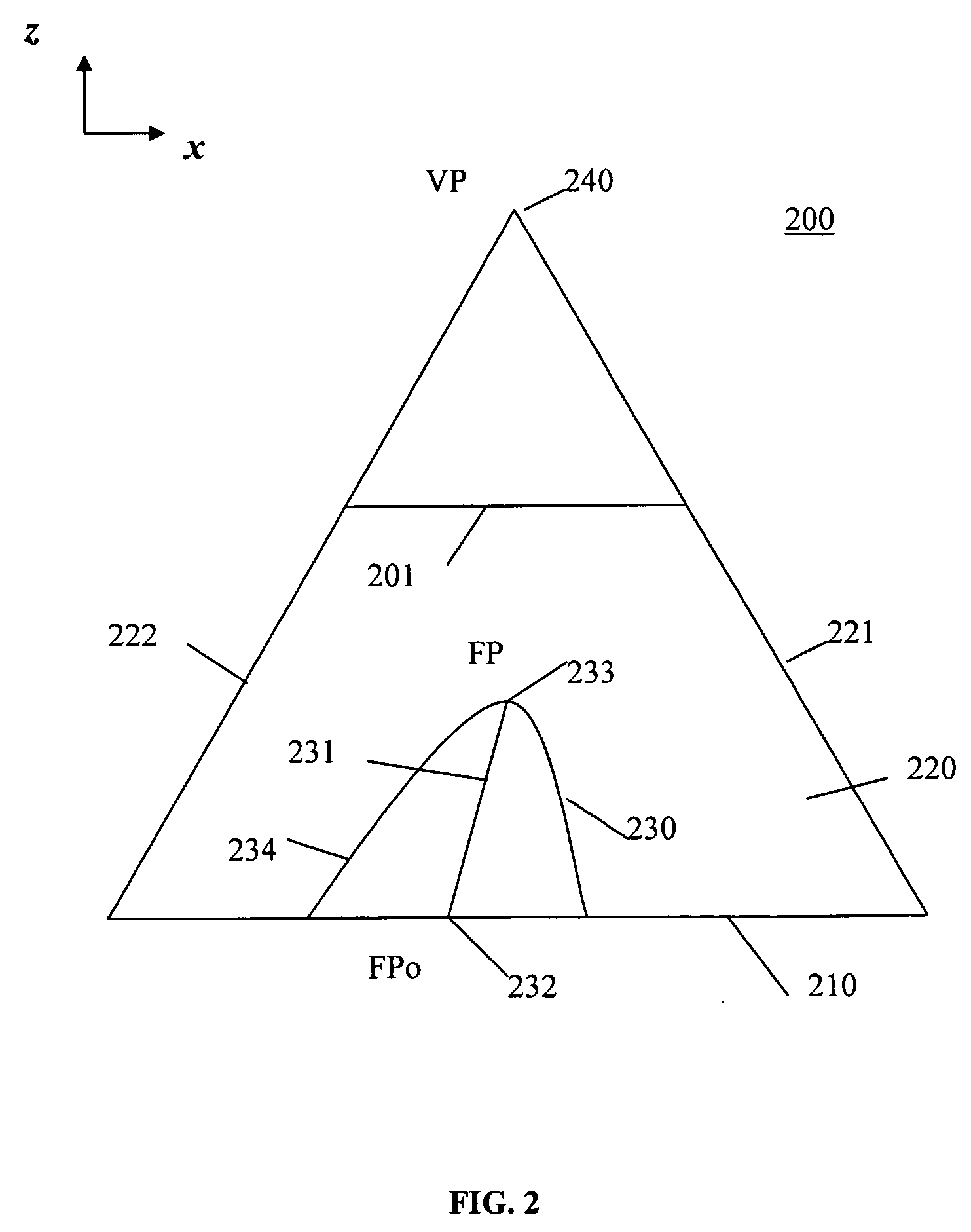

Compound lenses for multi-source data presentation

InactiveUS20060098028A1Geometric image transformationRoad vehicles traffic controlCamera lensShoulder region

A method in a computer system for generating a presentation of a region-of-interest in an original image for display on a display screen, the original image having one or more images relating to the region-of-interest, the method comprising: establishing a lens for the region-of-interest, the lens having a focal region with a magnification for the region-of-interest at least partially surrounded by a shoulder region across which the magnification varies to provide a continuous transition from the focal region to regions outside the lens; subdividing the focal region into one or more facets, each facet for displaying a respective image relating to the region-of-interest; and, applying the lens to the original image to produce the presentation.

Owner:CALLAHAN CELLULAR L L C

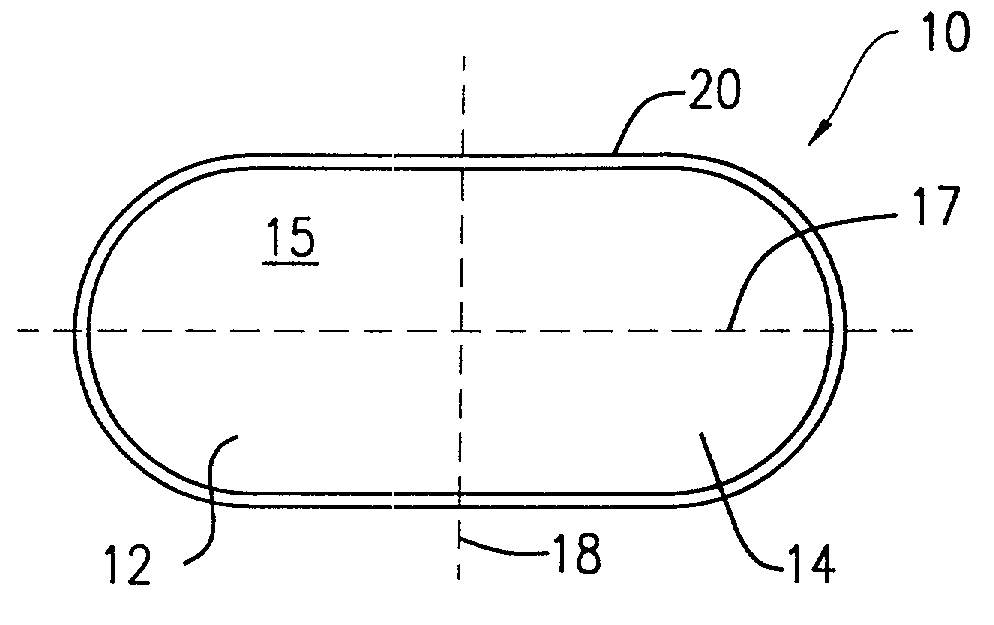

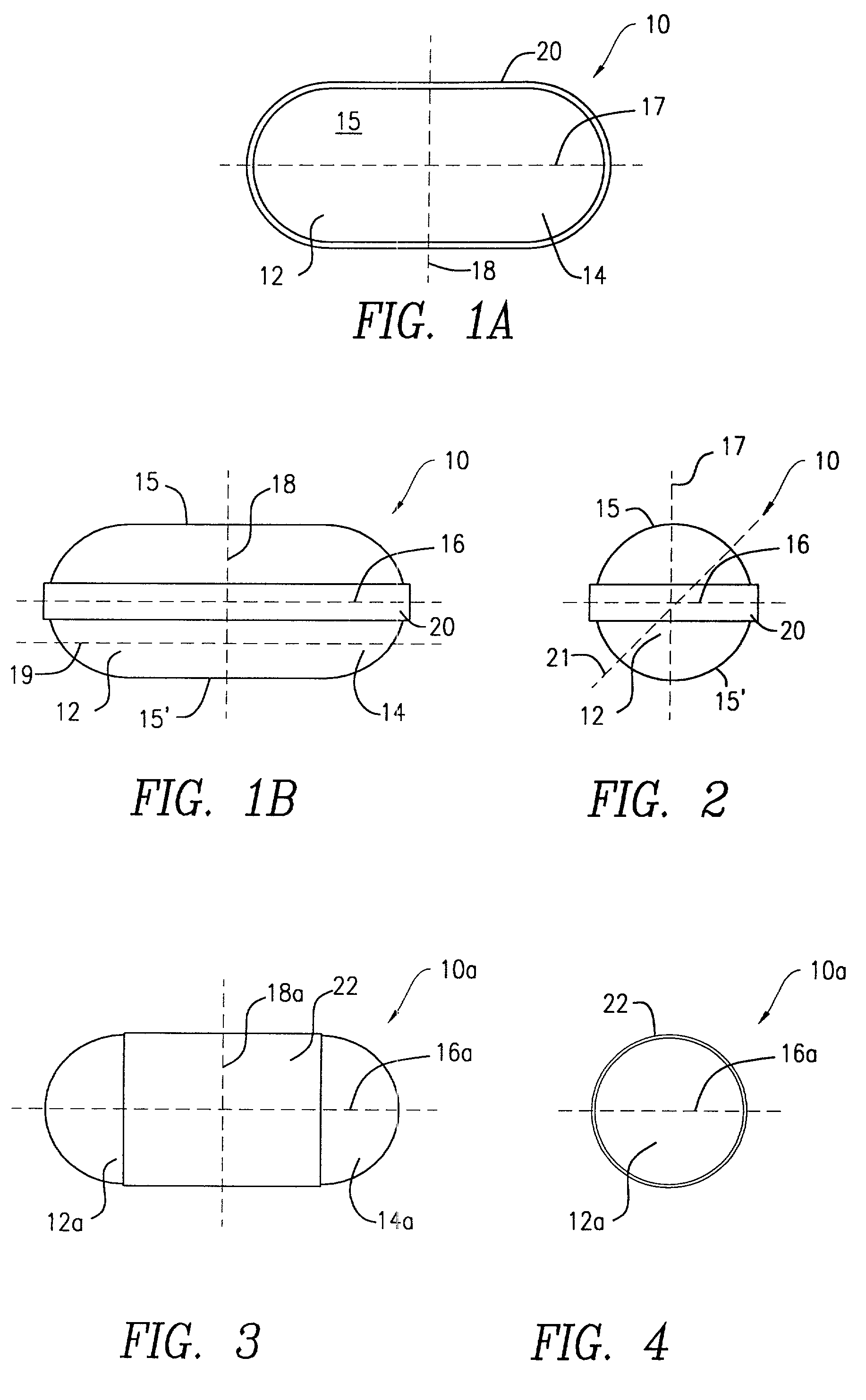

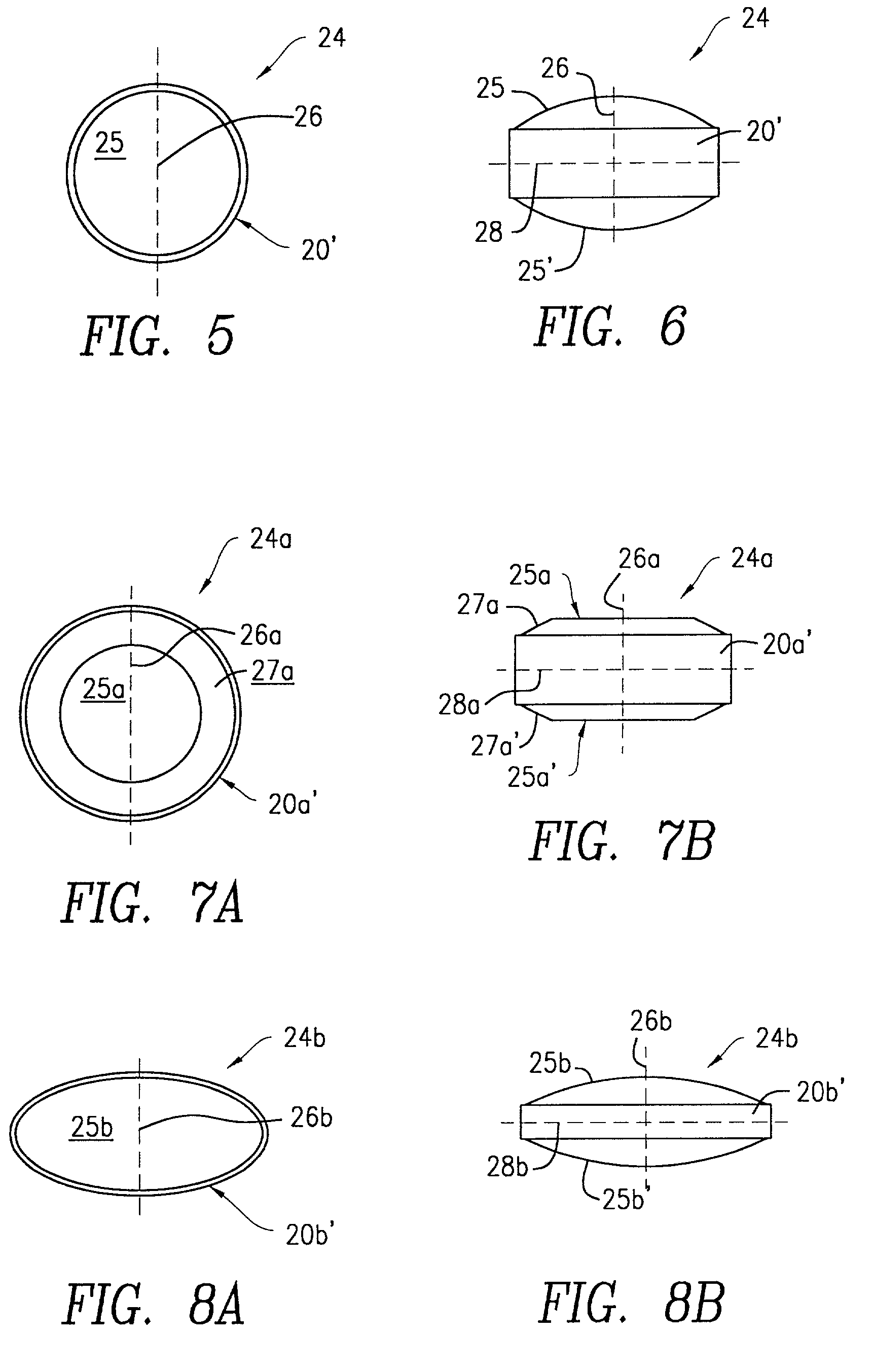

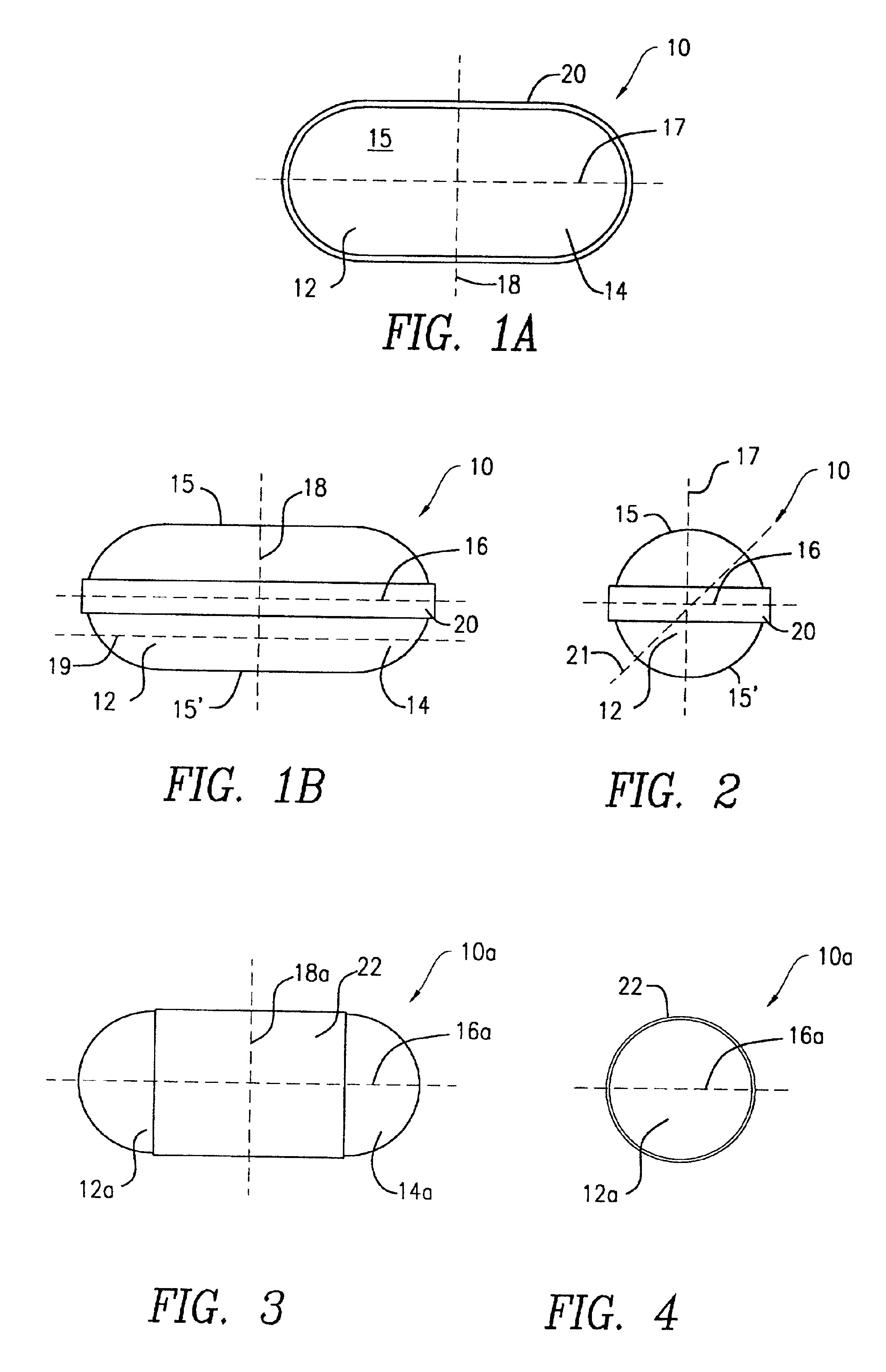

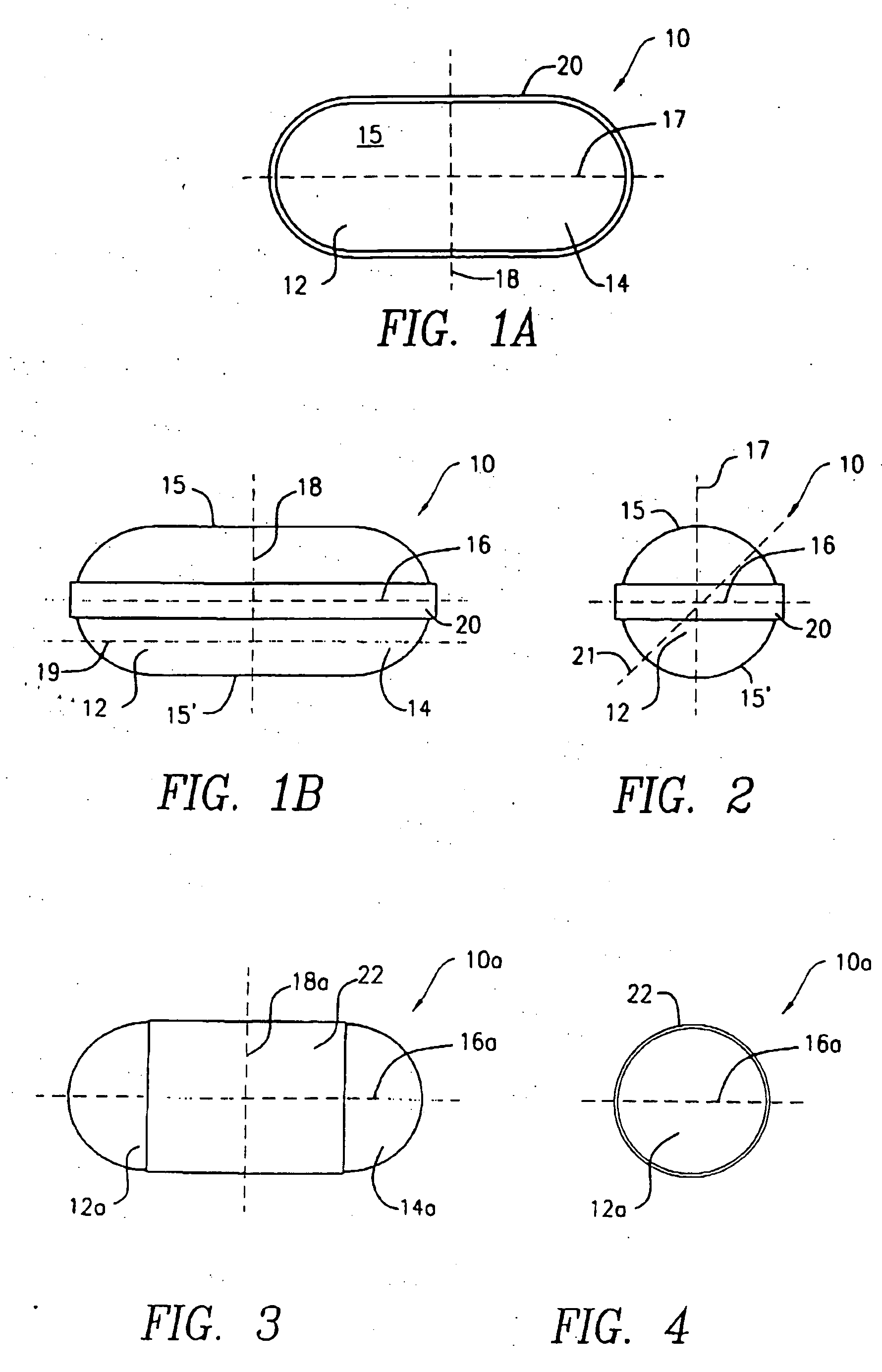

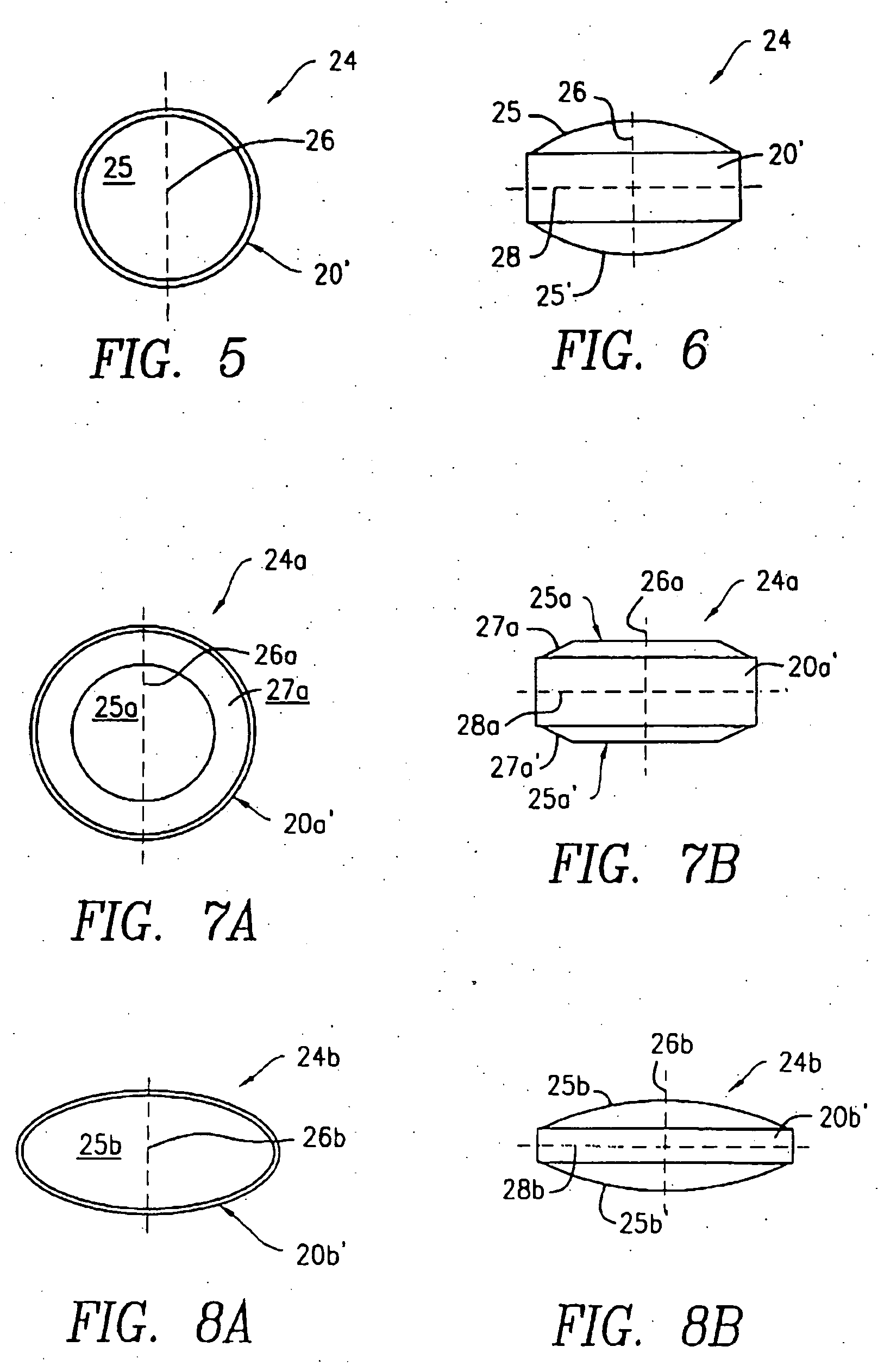

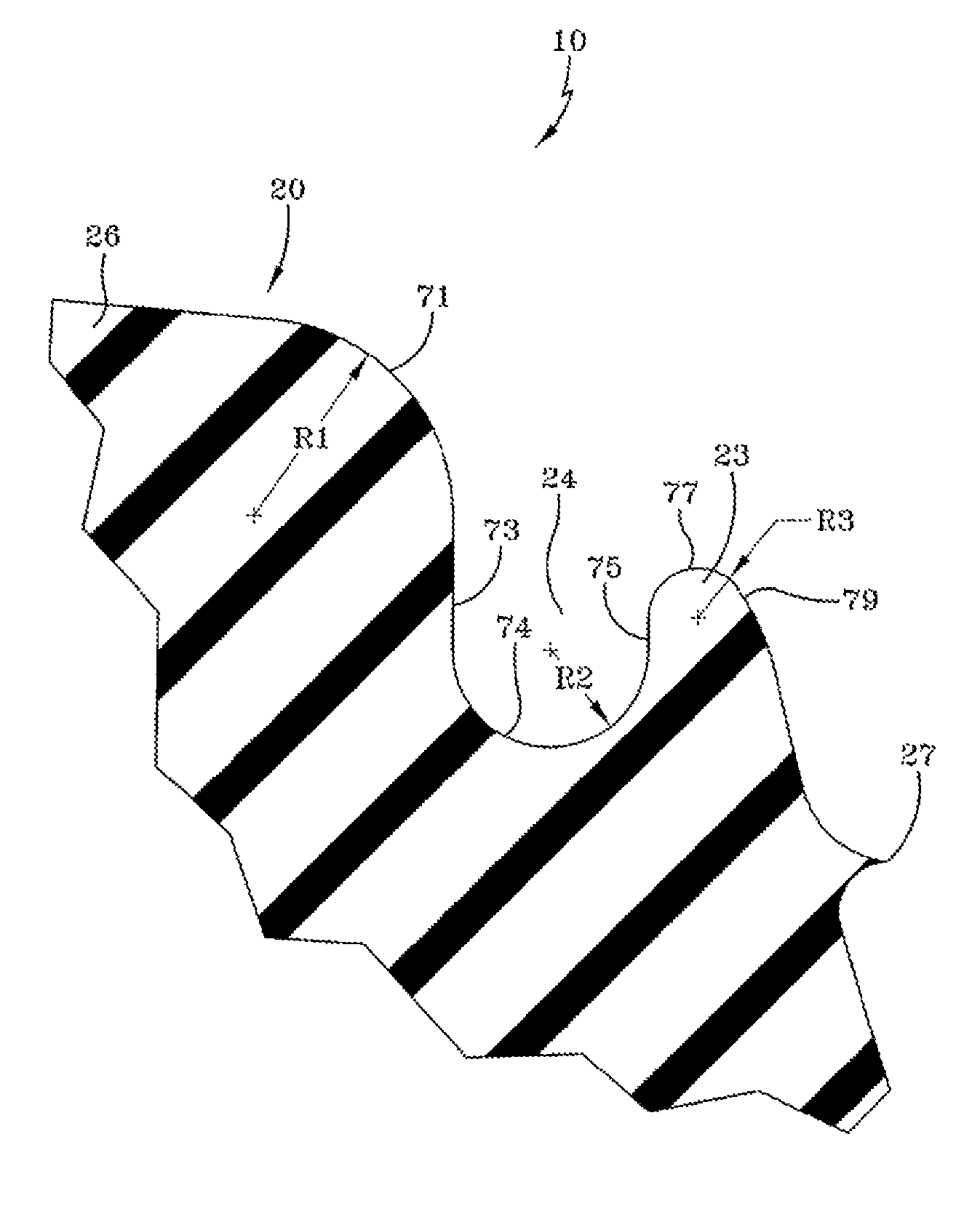

Enrobed core

An enrobed a core, such as a tablet core, that has a coating made of one or more patterned films each having portions that are visually distinct (e.g., differently colored) from one another and having a transition line segment between these visually distinct portions. At least a portion of an outer surface of the core is covered with the film or films, such that the transition line segments form a substantially continuous transition line on the coating and a film seam is formed which is different from the transition line. Where the patterned films are bi-colored, the resulting enrobed core can be bi-colored, or the resulting enrobed core can have a coating with at least four visually distinct portions alternately arranged thereon, thereby forming a “checkerboard” pattern on the coating. In either case, the film seam of the coating is different from the transition line of the coating.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

Compound lenses for multi-source data presentation

InactiveUS7995078B2Geometric image transformationRoad vehicles traffic controlCamera lensShoulder region

A method in a computer system for generating a presentation of a region-of-interest in an original image for display on a display screen, the original image having one or more images relating to the region-of-interest, the method comprising: establishing a lens for the region-of-interest, the lens having a focal region with a magnification for the region-of-interest at least partially surrounded by a shoulder region across which the magnification varies to provide a continuous transition from the focal region to regions outside the lens; subdividing the focal region into one or more facets, each facet for displaying a respective image relating to the region-of-interest; and, applying the lens to the original image to produce the presentation.

Owner:CALLAHAN CELLULAR L L C

Process for enrobing a core

A process for enrobing a core, such as a tablet core, uses a coating that is made of a patterned film having portions that are visually distinct (e.g, differently colored) from one another and having a transition line segment between these visually distinct portions. At least a portion of an outer surface of the core is covered with the film, such that the transition line segment forms a substantially continuous transition line on the coating and such that a film seam is formed which is different from the transition line. Alternatively, the coating is formed from two such patterned films, in which case the outer surface of the core is covered with the two films such that the two transition line segments cooperate to form a substantially continuous transition line on the coating and a film seam is formed which is different from the transition line. Prior to covering the outer surface of the core, the two films may be oriented such that the resulting enrobed core has a bi-colored coating with two visually distinct portions each lying on opposite sides of the transition line of the coating. The two films may also be oriented such that the resulting enrobed core has four alternately arranged colored portions, two of which are of a first color and the other two of which are of a second color, thereby resulting in a “checkerboard” effect.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

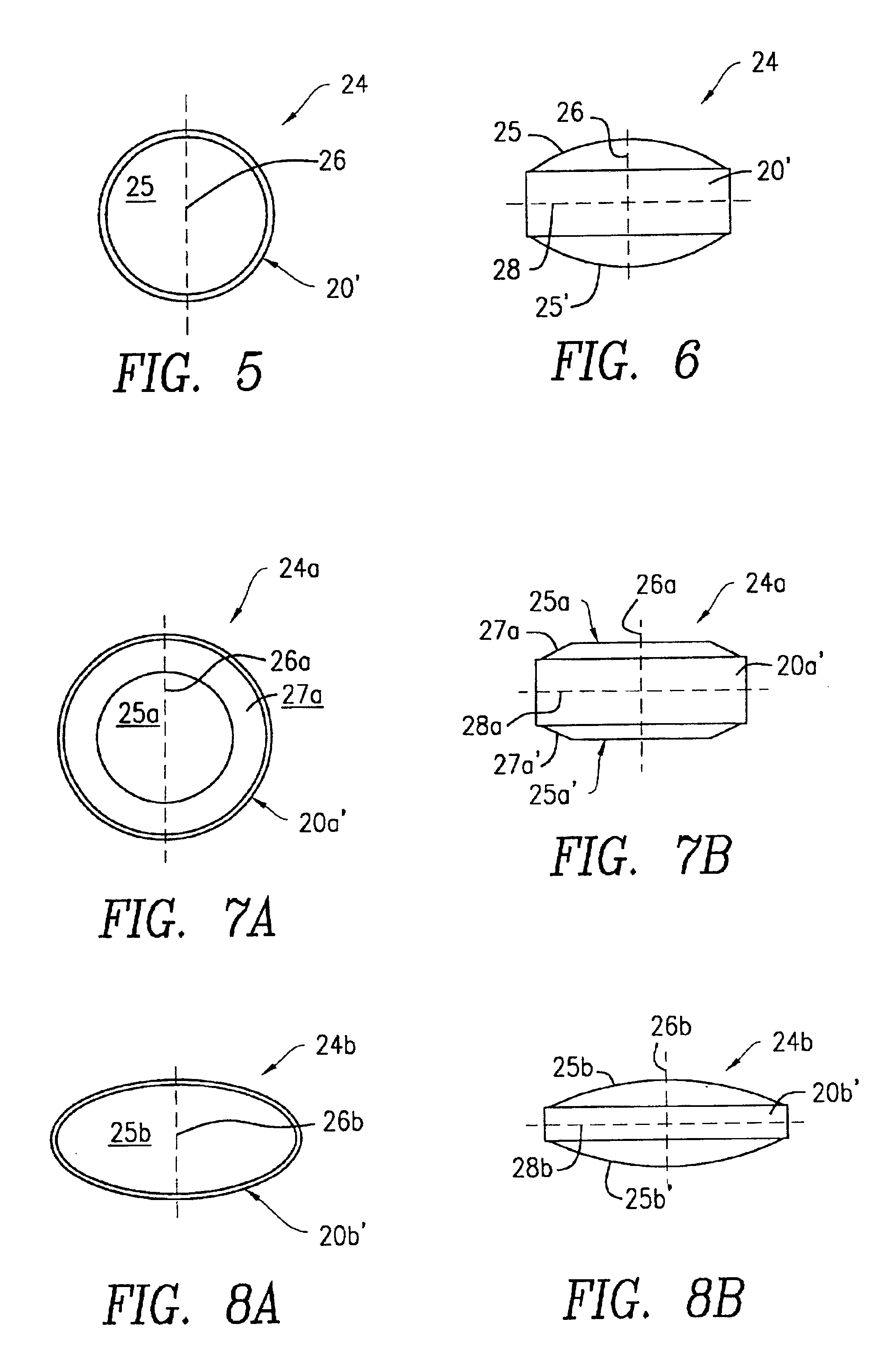

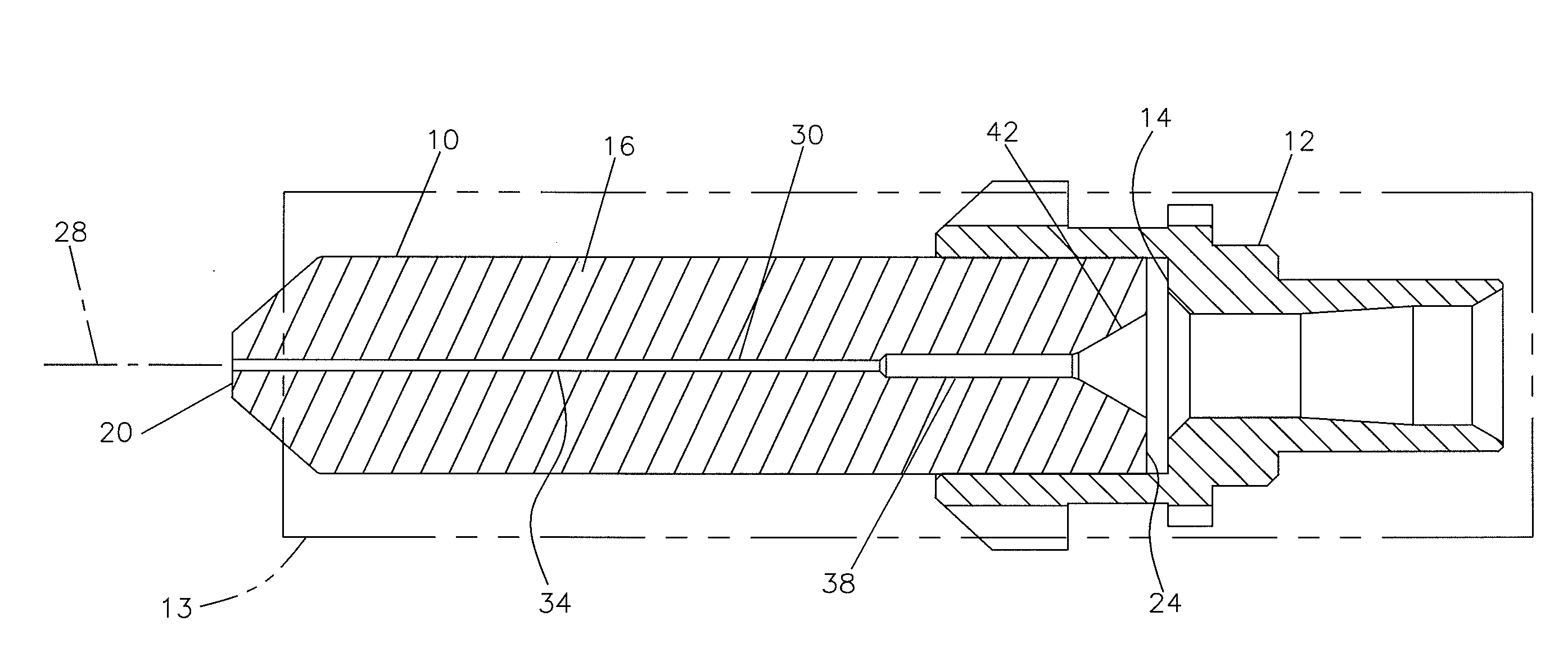

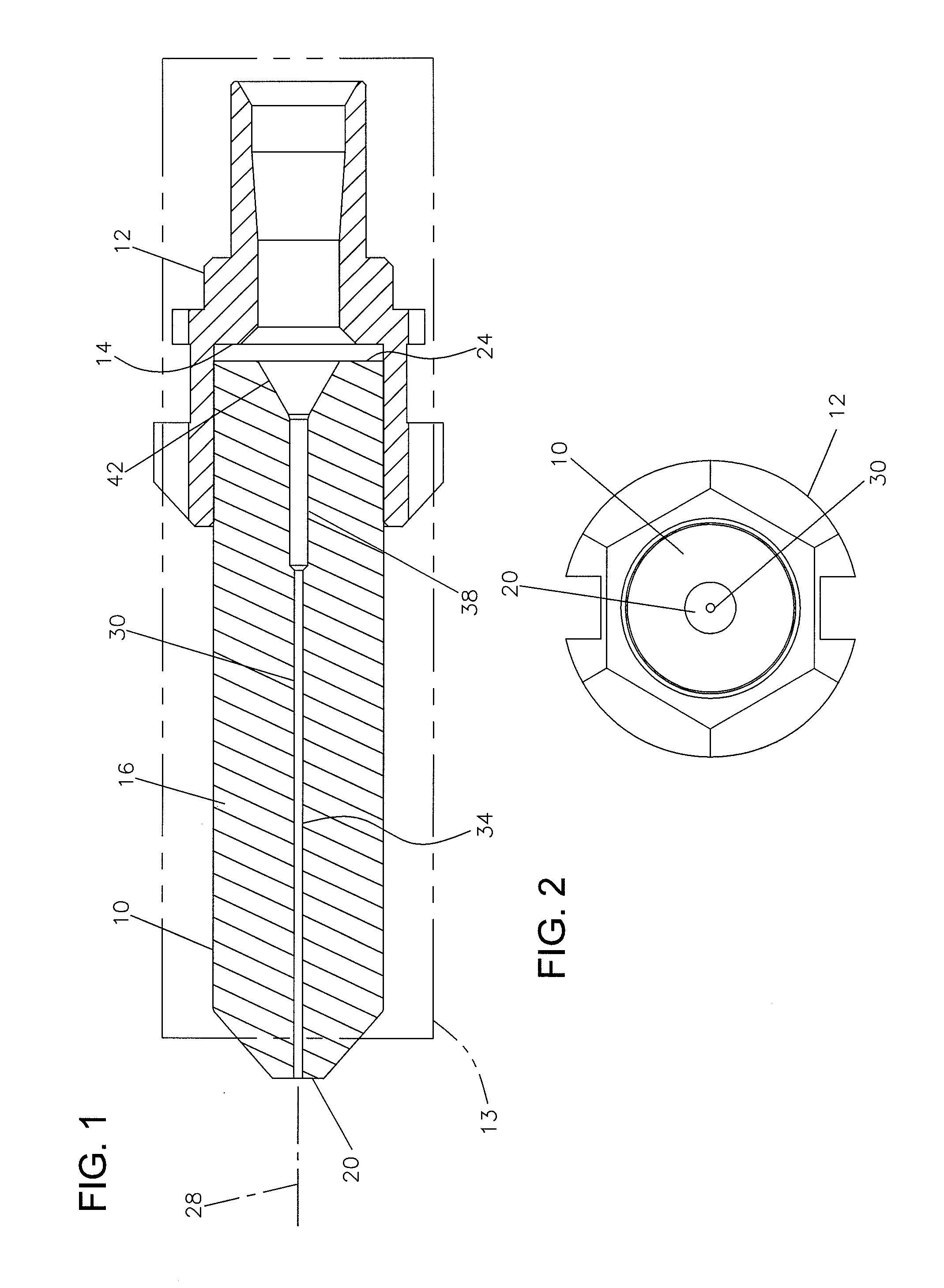

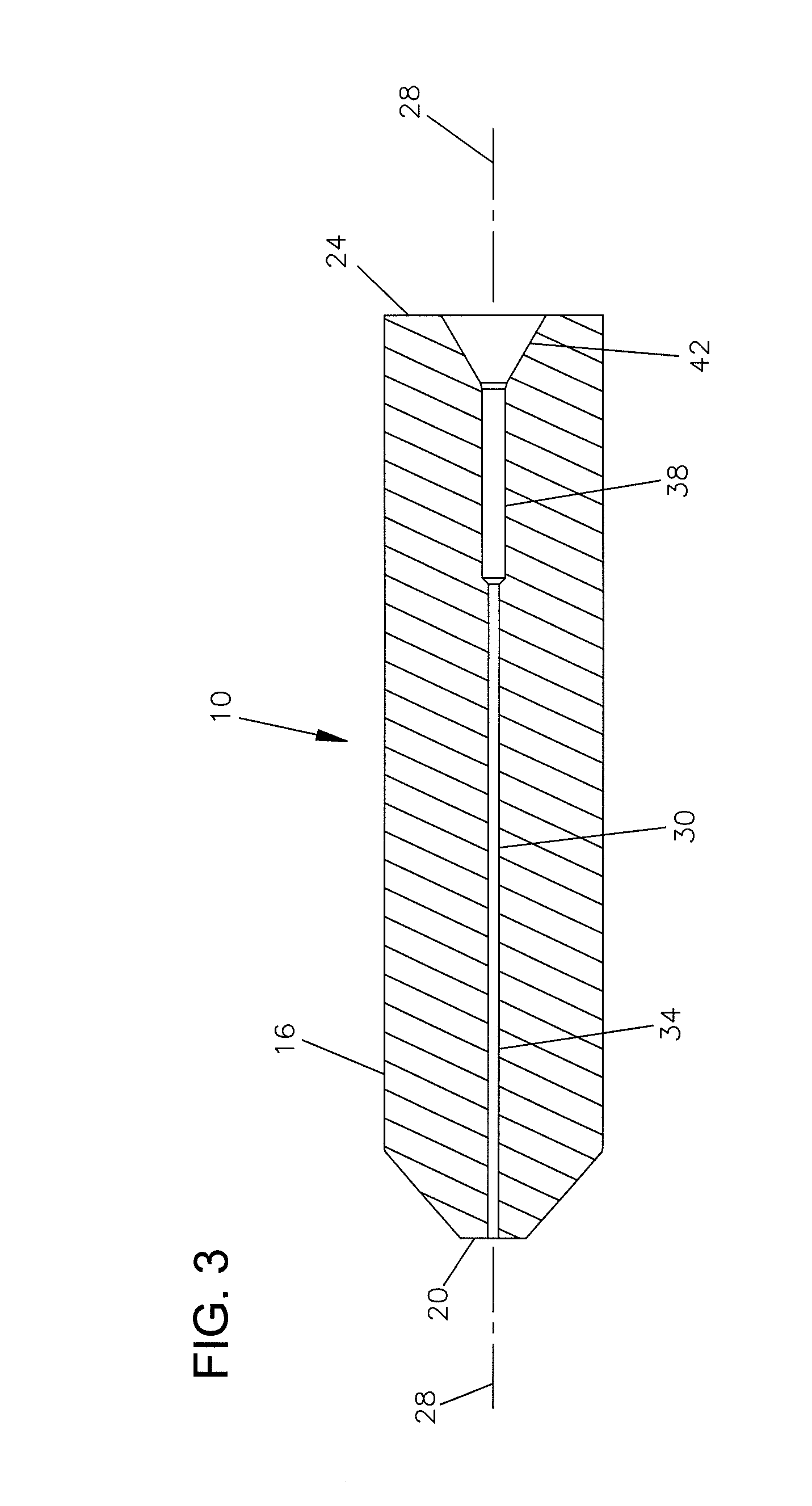

Dual inner diameter ferrule device with smooth internal contours and method

A fiber optic ferrule includes a body extending from a first end to a second opposite end, with the body including an axial passage extending between the first and the second ends. The axial passage includes a first diameter portion having a diameter of at least 125 microns, a second diameter portion having a diameter of at least 250 microns and less than a diameter of a buffer, and a smooth and continuous transition between the first and the second diameter portions. The second diameter portion is positioned between the first diameter portion and the second end. The axial passage further defines a tapered shape at the second end extending inward from the second end toward the second diameter portion. In certain embodiments, another smooth and continuous transition can be provided between the taper shape and the second diameter portion. In certain embodiments, the axial passage is smooth and continuous between the first and the second ends of the body. A hub holds the ferrule. A method of assembling a terminated fiber optic cable is also provided.

Owner:COMMSCOPE TECH LLC

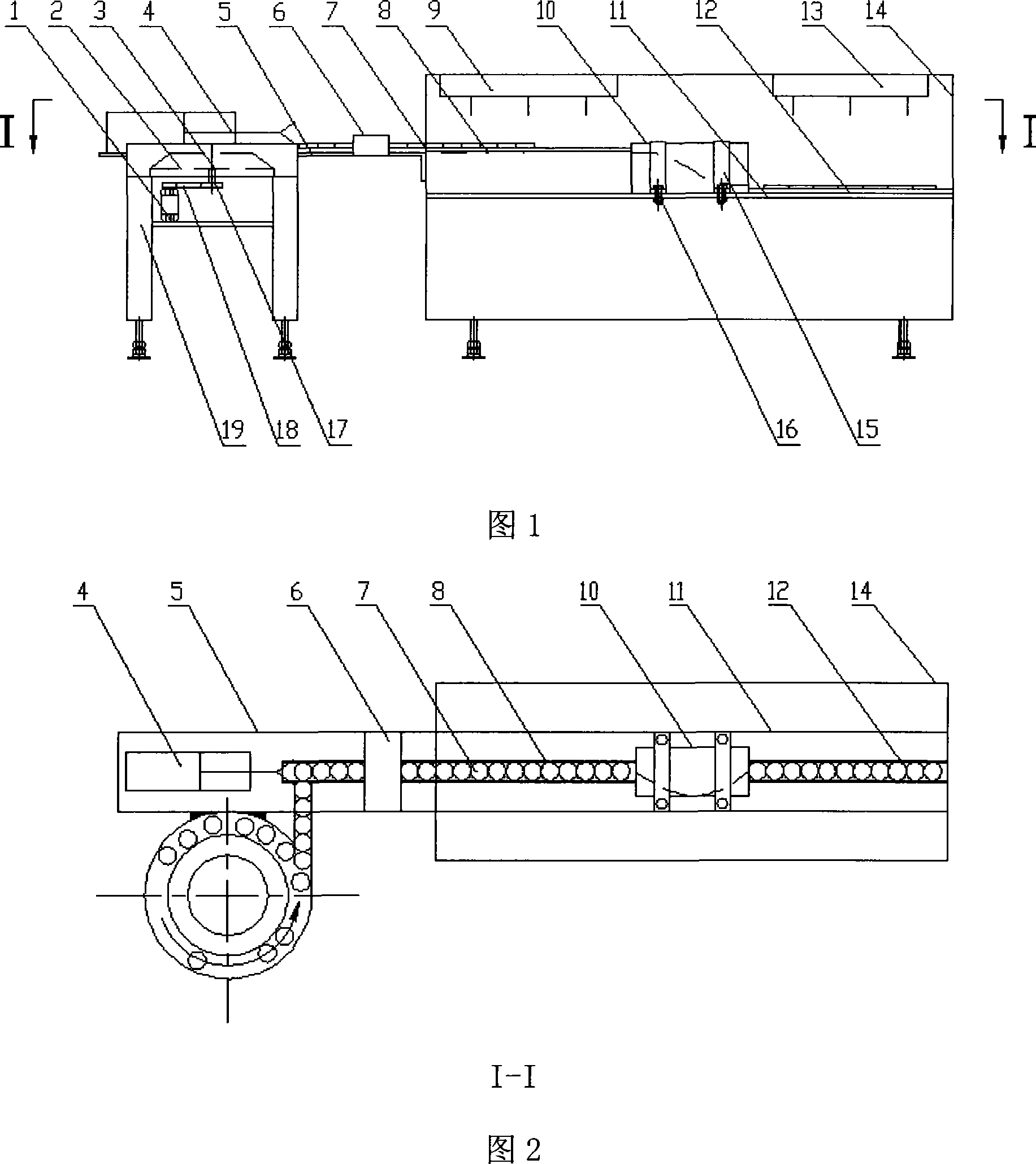

Small-sized bearing continuous roll-over spraying cleaning device

InactiveCN101168157AOvercoming the inefficiency of flippingOvercome efficiencyCleaning using liquidsConveyor partsElectric machineryEngineering

The invention relates to a cleaning device with continuous overturning and spraying of small size bearing, in particular to a novel cleaning method and a novel cleaning device for conducting continuous transition, turn-over and double faces spray-cleaning to remove various polluting materials left by a plurality of working procedures for small size precise bearing. A cleaning device with continuous overturning and spraying of small size bearing is composed of a feeding apparatus and a spray-cleaning device. The feeding apparatus is composed of an electric motor, a feeding rotation disk, a rotating shaft, an air cylinder, a supporting plate of air cylinder, a demagnetizer, a left track, a belt pulley, a belt and a feeding support. The double faces spray-cleaning apparatus is composed of the left track, a left spraying header, a turn-over device, a track supporting beam, a right track, a right spraying header, a spraying fluid return tank, screws and snap rings. The continuous turn-over device is composed of a cylinder and a cylindrical sleeve. Continuous spray-cleaning has the advantages of reliability, simple structure, convenient operation, low cost, high efficiency, man energy economy, which reduces cleaning cost and increases the usage performance and market competitive strength of medium and small sized finish products of precise bearing.

Owner:DALIAN UNIV OF TECH

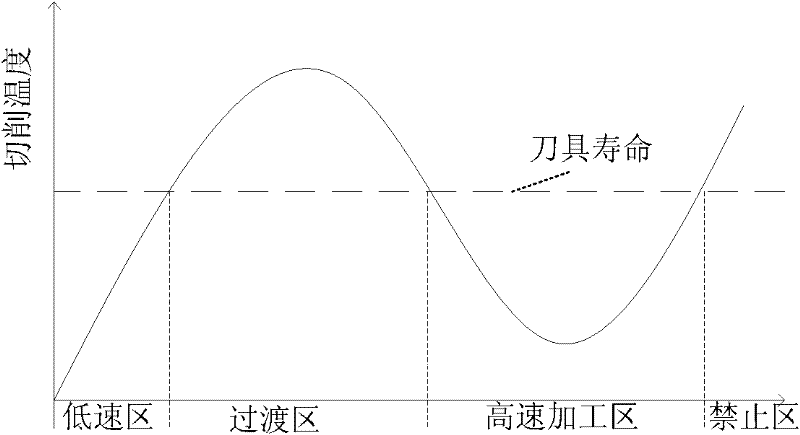

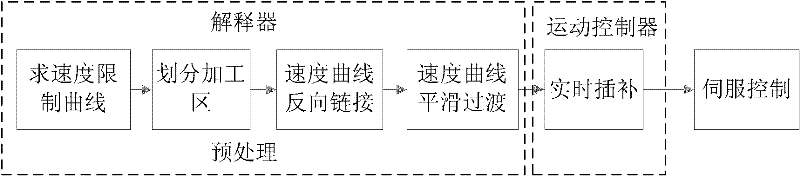

High-speed processing-oriented surface quality preferred spline real-time interpolation method

ActiveCN102540978AAchieve continuous transitionSmooth processing speed curveProgramme controlComputer controlMotion controllerComputer science

The invention relates to a high-speed processing-oriented surface quality preferred spline real-time interpolation method, which comprises the following steps of: preprocessing a processing path in an interpreter of a numerical control system to obtain a processing speed curve; inputting the obtained processing speed curve into a motion controller of the numerical control system to perform real-time interpolation; and transmitting coordinate information obtained by the real-time interpolation to a servo device to drive a motor to run. According to a surface quality preferred spline real-time interpolation algorithm provided by the invention, continuous transition of uniaxial acceleration is realized through limitation of uniaxial acceleration and smooth transition of speed curve, so that a smooth processing speed curve is obtained, and automatic adjustment of a speed planning algorithm of different processing intervals is realized.

Owner:SHENYANG GOLDING NC & INTELLIGENCE TECH CO LTD

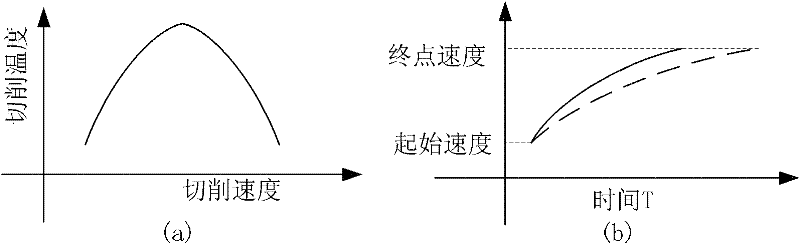

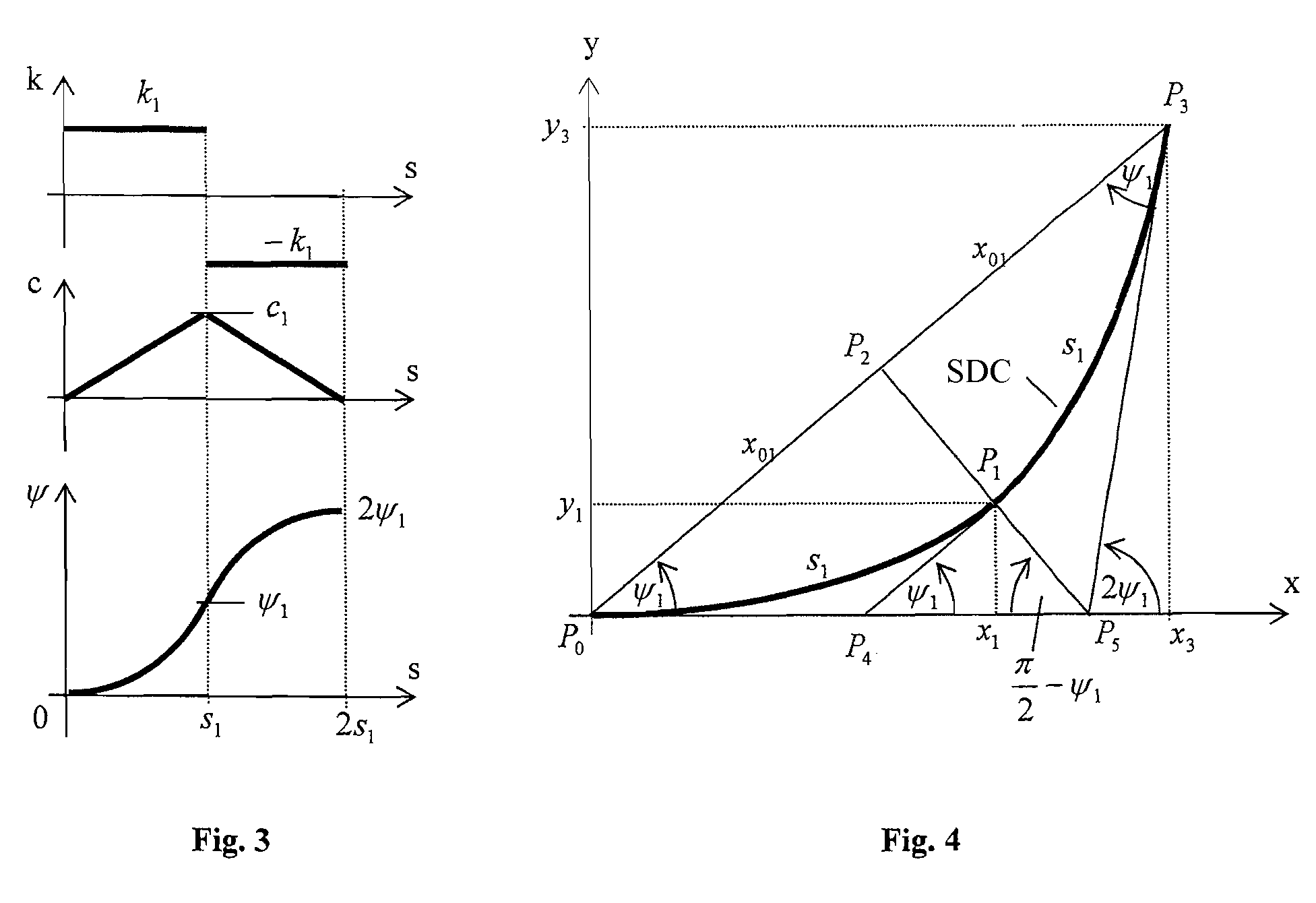

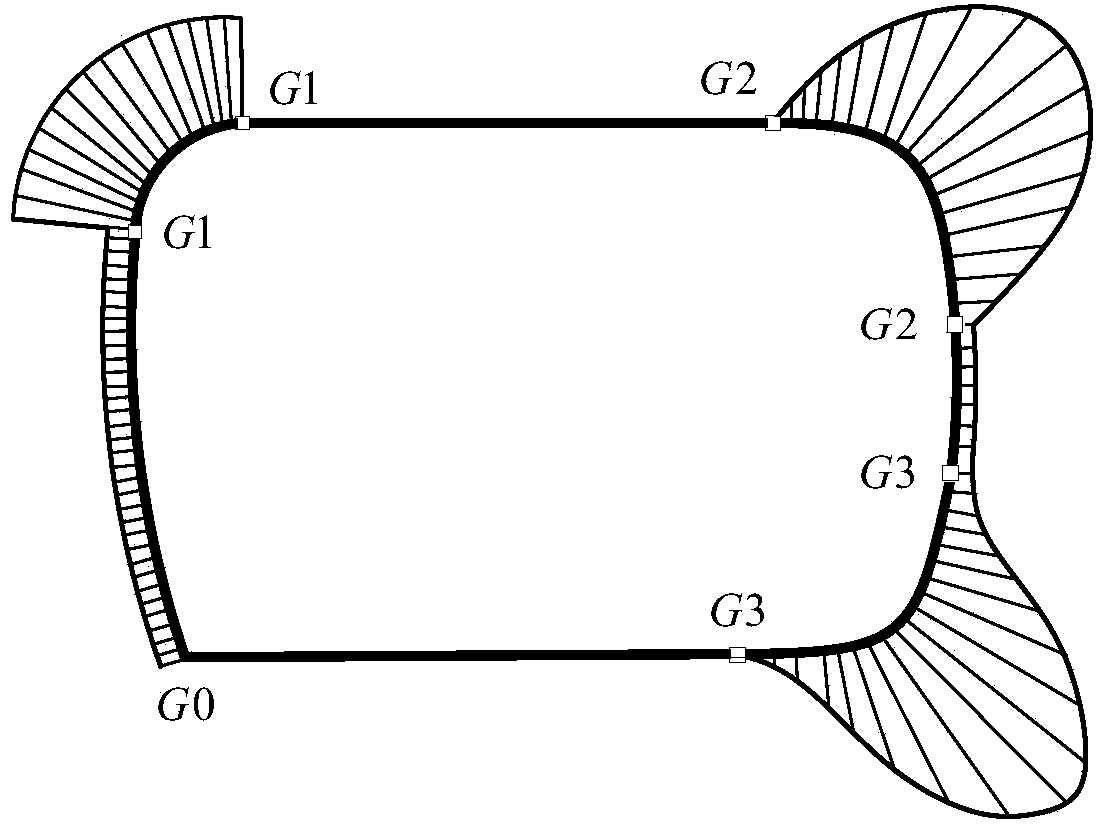

Path planning

The present invention relates to a method of determining the path of a vehicle along a two-dimensional plane intended to control the movement of the vehicle by means of a driver-assisting system, where the path interconnects an initial state and a terminal state and each of the states Zi=[xi, yi, ψi, ci] along the path is characterized by four state coordinates with xi and yi being the Cartesian coordinates of a point Pi, ψi being the direction angle of the tangent line, and ci being the curvature of the path at point Pi, and where the path is made up of a number of elementary paths meeting at junction points JPi such that the four state coordinates of state Zi are characterized by a continuous transition at the junction points JPi.

Owner:HELLA KG HUECK & CO

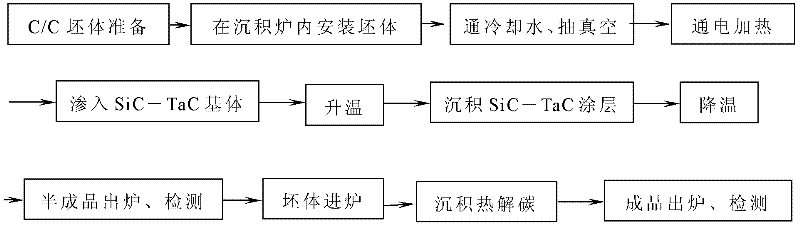

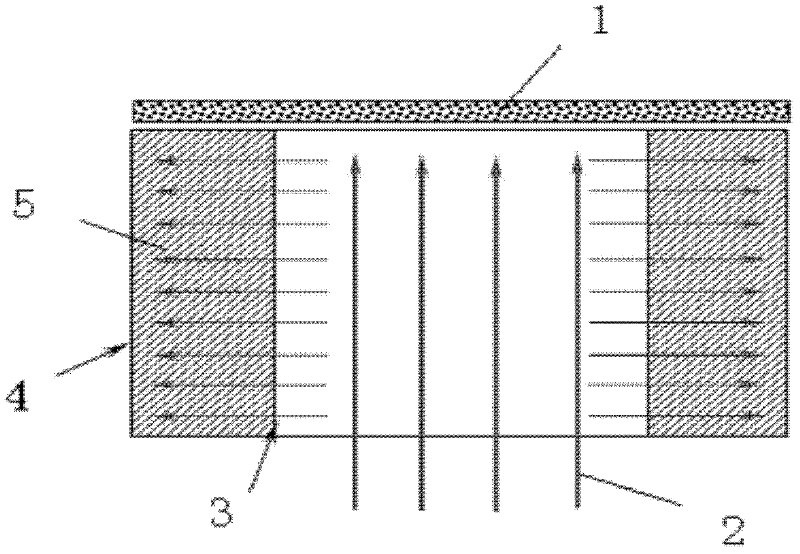

A kind of sic-tac coating/matrix synergistically modified c/c composite material and preparation method thereof

ActiveCN102295474AMitigate Thermal MismatchHigh coefficient of thermal expansionSurface layerHigh density

The invention discloses a SiC-TaC coating / matrix collaborative modified C / C composite material and its preparation method. The composite material provided by the invention comprises two parts. The portion below the surface of the C / C composite material is the matrix modified portion with the thickness being 0.1-10mm. In addition, carbide in the C / C composite material emerges in gradient distribution. The portion which is deposited on the surface of a carbon material is a coating portion with the thickness being 10-300 microns. The preparation method of the composite material comprises the following steps of: cutting a C / C green body at the density of 0.80g / cm<3>-1.60g / cm<3> into an annular shape or a plate shape, followed by ultrasonic cleaning and drying, placing into a multifunctional CVD furnace, depositing carbide on the surface layer and surface of the C / C green body by controlling deposition parameters, further densifying the green body by the use of pyrolytic carbon so as to obtain the high-density coating / matrix collaborative modified C / C composite material. The main advantages of the invention are as follows: by the penetration of carbide through the surface layer of the C / C composite material, the thermal expansion coefficient of the matrix is raised, the interfacial bonding state is improved, a continuous transition of carbide is formed between the coating and the matrix, and the metallurgical bonding is accomplished between the coating and the matrix.

Owner:CENT SOUTH UNIV

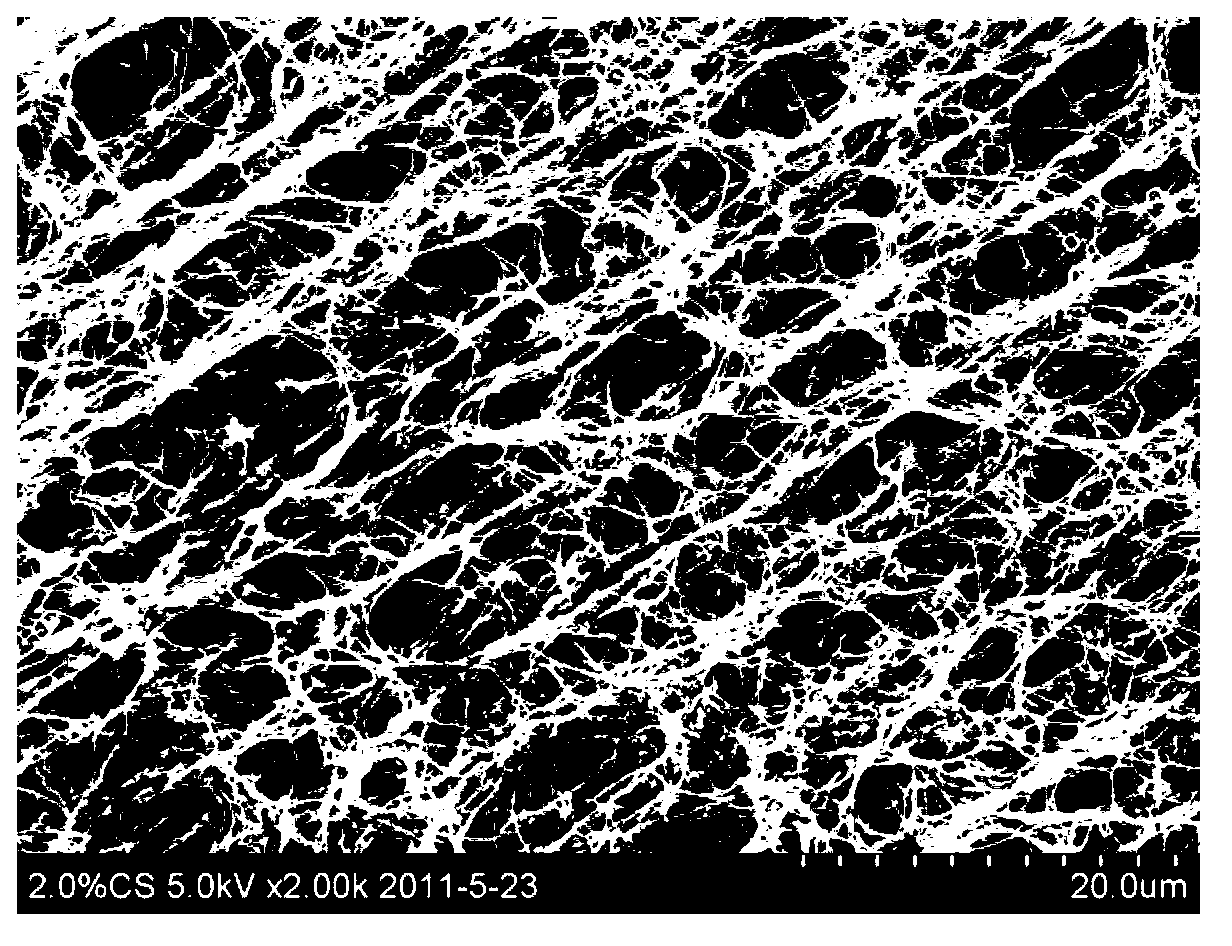

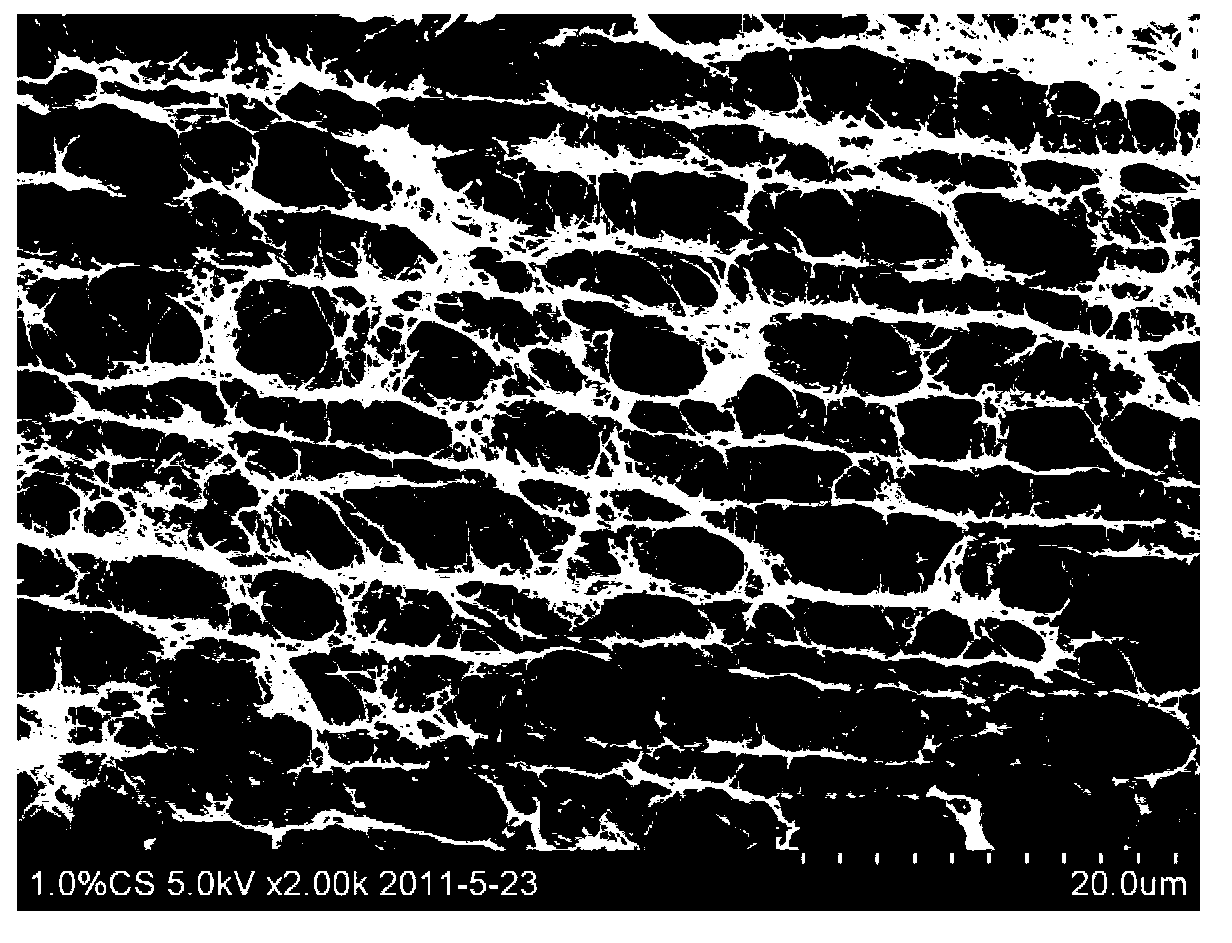

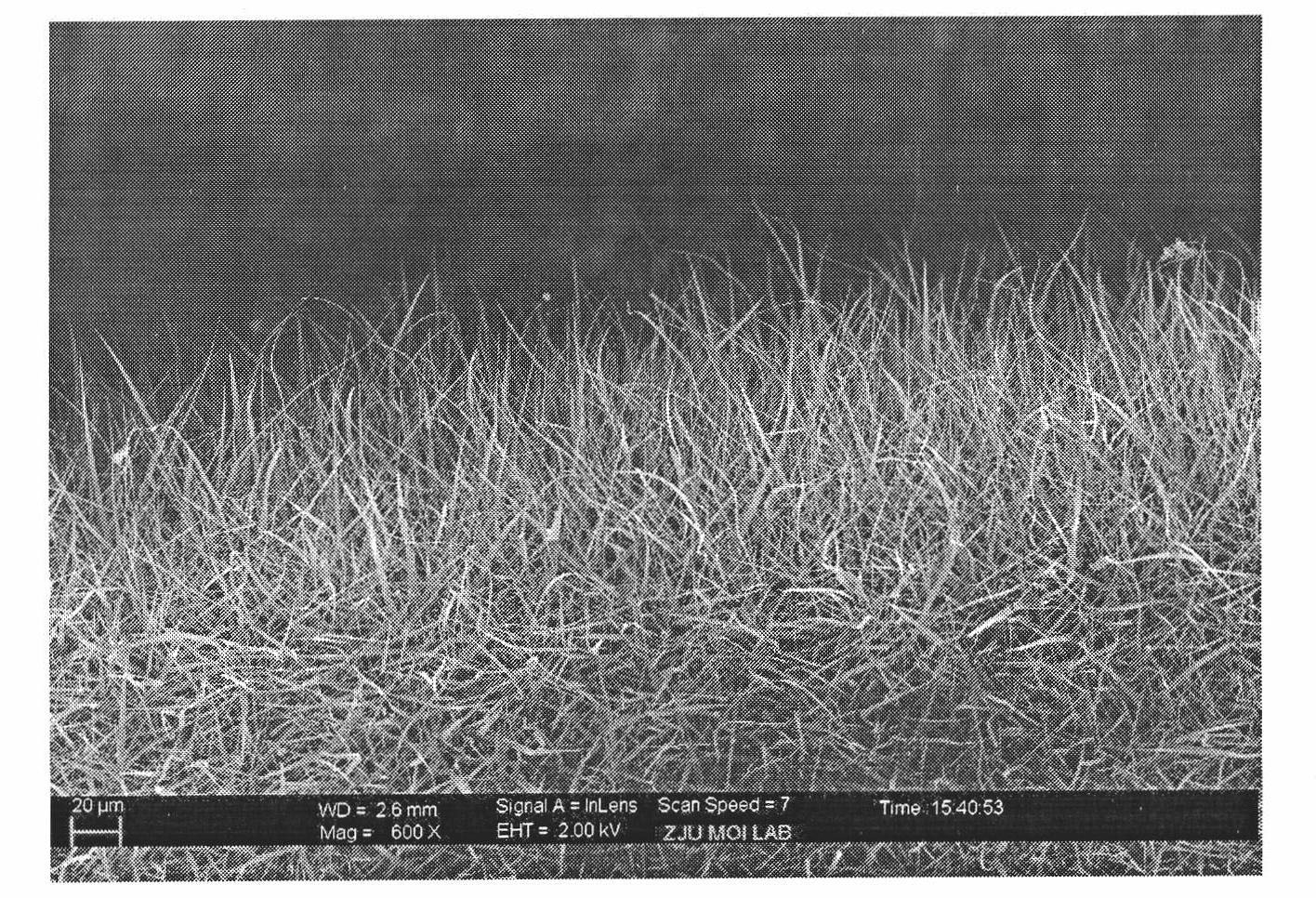

Bacterial cellulose membrane with gradient structure and preparation method thereof

ActiveCN103233050AThe preparation process is easy to controlWide variety of sourcesMicroorganism based processesFermentationWound dressingFermentation

The invention discloses a bacterial cellulose membrane in a gradient structure and a preparation method of the bacterial cellulose membrane. The bacterial cellulose membrane is prepared by the steps of adding crop starch in a fermentation culture solution, heating for gelatinizing the mixture, adding a thickening agent into the gelatinized mixture, and carrying out static culture; and the bacterial cellulose membrane has a gradient structure with continuous transition from a compact upper surface downwards to a loose lower surface. The in-site fast controllable preparation of the gradient structure of the bacterial cellulose membrane can be realized by adjusting the proportion of the crop starch to the thickening agent. The preparation method of the bacterial cellulose membrane disclosed by the invention has the advantages that the resources of raw materials are wide, biosynthesis process is mild and pollution-free, and the product is environment-friendly, safe, low in production cost, controllable in process and designable and has a bright large-scale production prospect. The bacterial cellulose membrane with the gradient structure is suitable for the fields of cosmetics and biomedical materials including a facial mask, a cooling paste, a wound dressing, an artificial skin and the like.

Owner:DONGHUA UNIV

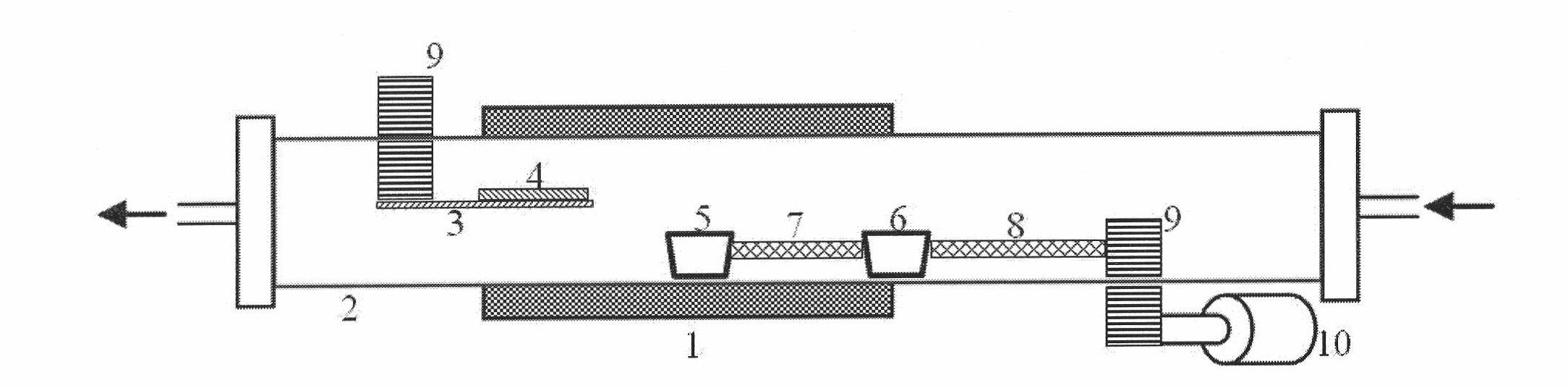

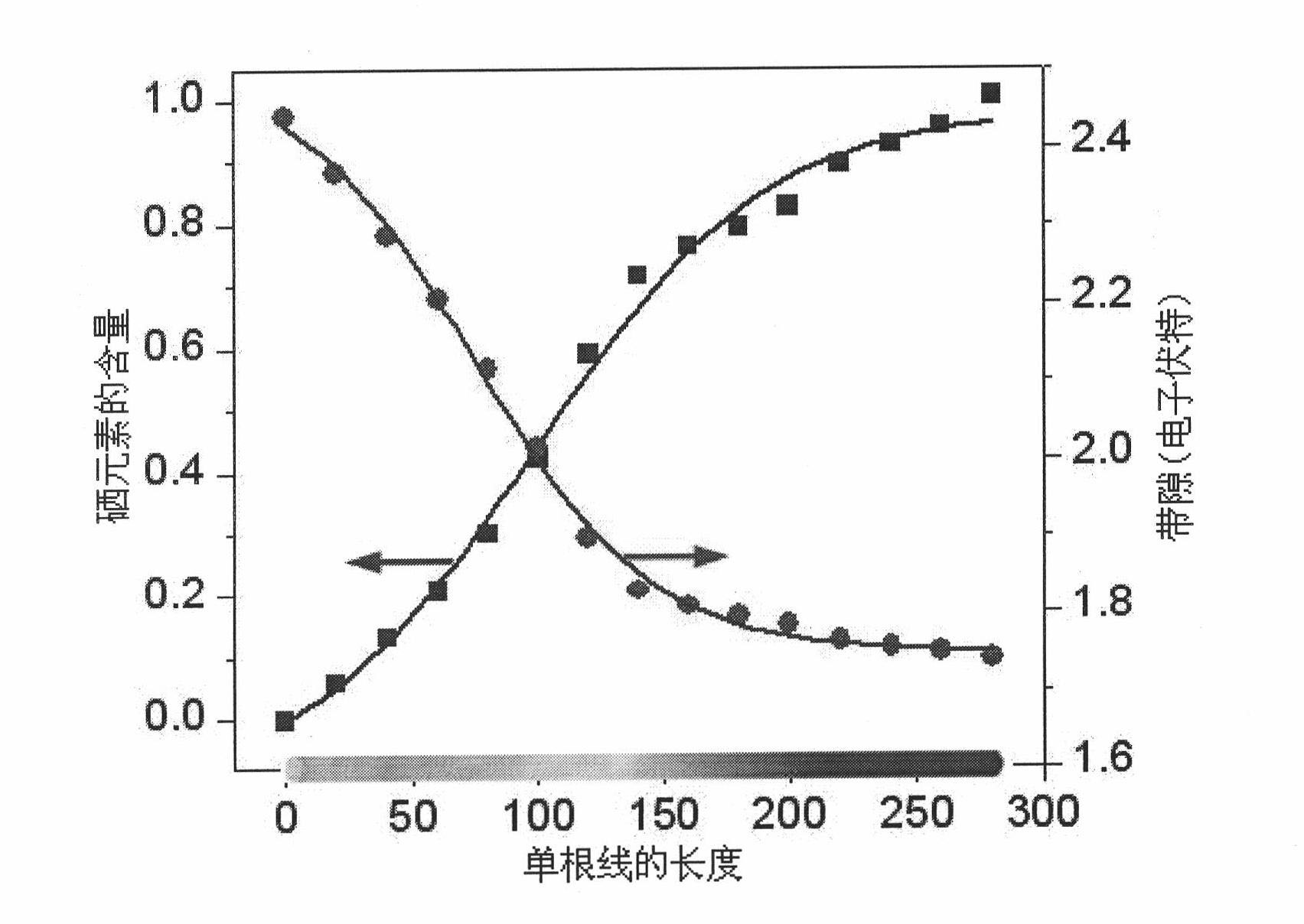

Method and device for preparing cadmium selenide sulfide nano material with monotonous and continuous variable band gap

InactiveCN101941681AEasy to prepareLow costNanostructure manufactureBinary selenium/tellurium compoundsConcentration ratioCadmium sulfide

The invention discloses a method and a device for preparing a cadmium selenide sulfide nano material with monotonous and continuous variable band gap. According to the preparation method, based on a vapor deposition method, the positions of a cadmium sulfide quartz boat and a cadmium selenide quartz boat in a tubular high-temperature furnace are adjusted through a magnet to continuously adjust the vapor concentration ratio of cadmium sulfide to cadmium selenide during growing the nano material so as to realize monotonous continuous transition of the band gap on the same nano band or nano wire. The preparation method is simple and low in cost; the ratio of sulfur element to selenium element on the prepared single nano material can be continuously transited to 0: 1 from 1: 0; and the nano material has potential application value in the fields of tunable lasers, wideband lasers, white light LEDs, wide spectrum detectors and the like.

Owner:ZHEJIANG UNIV

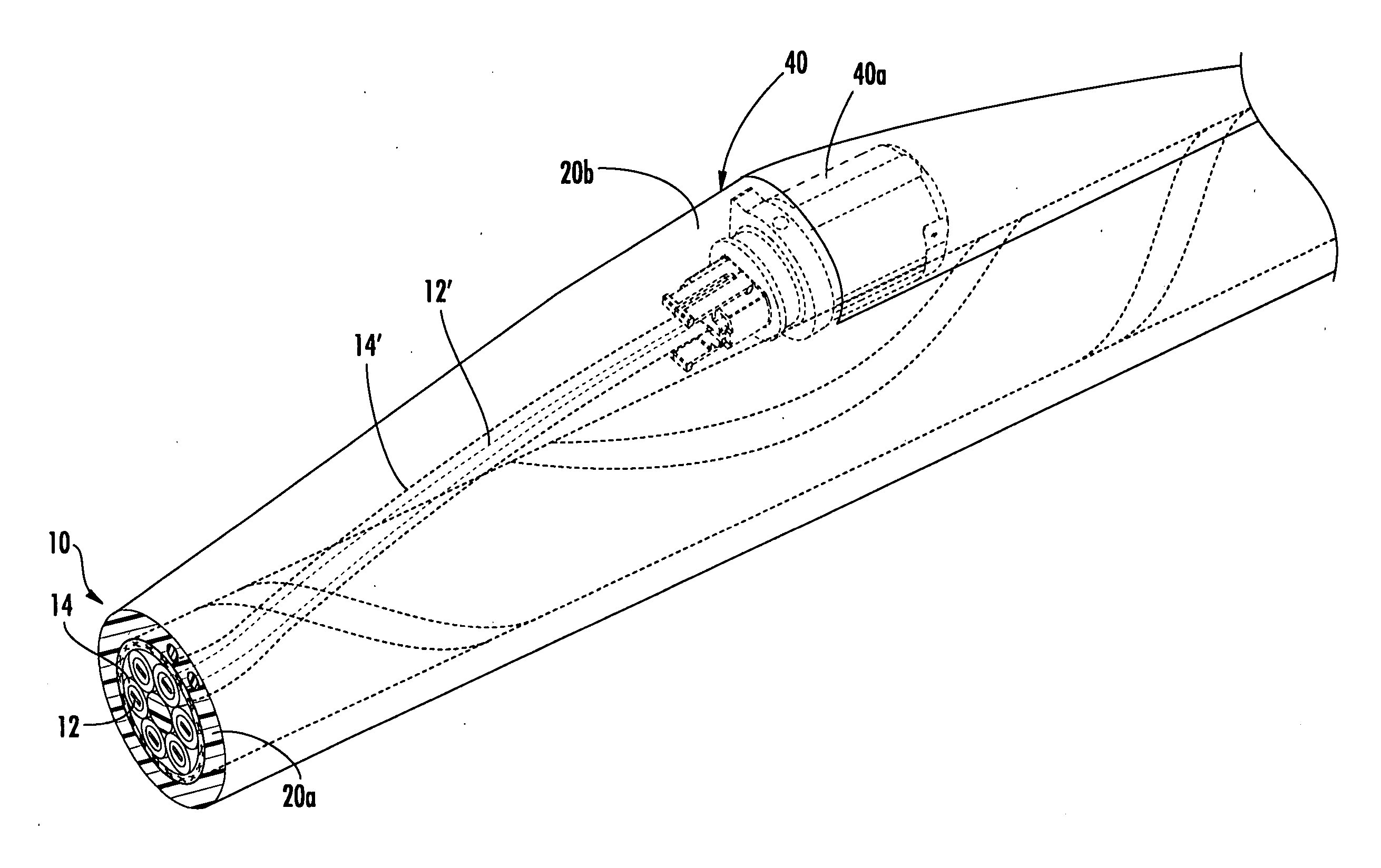

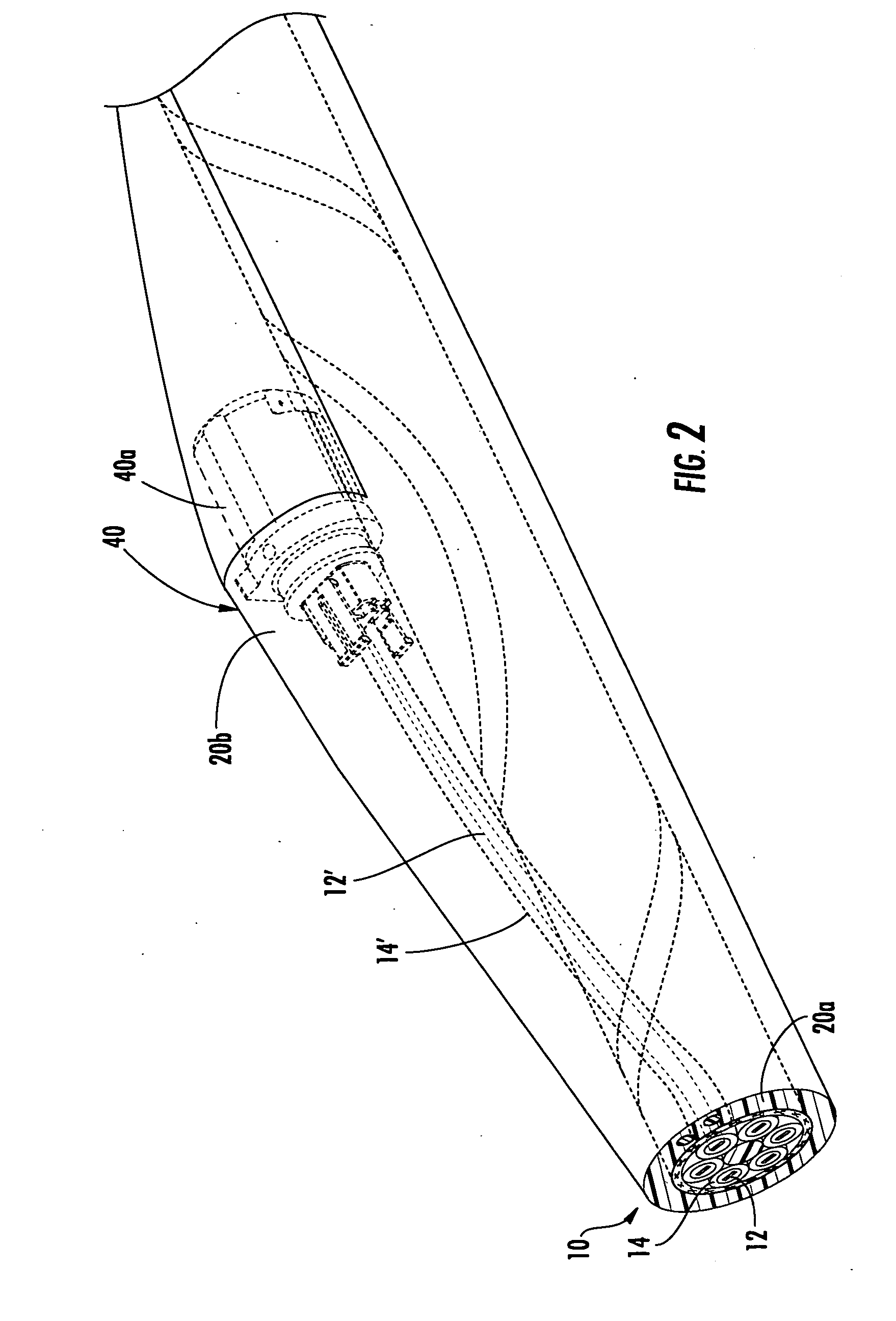

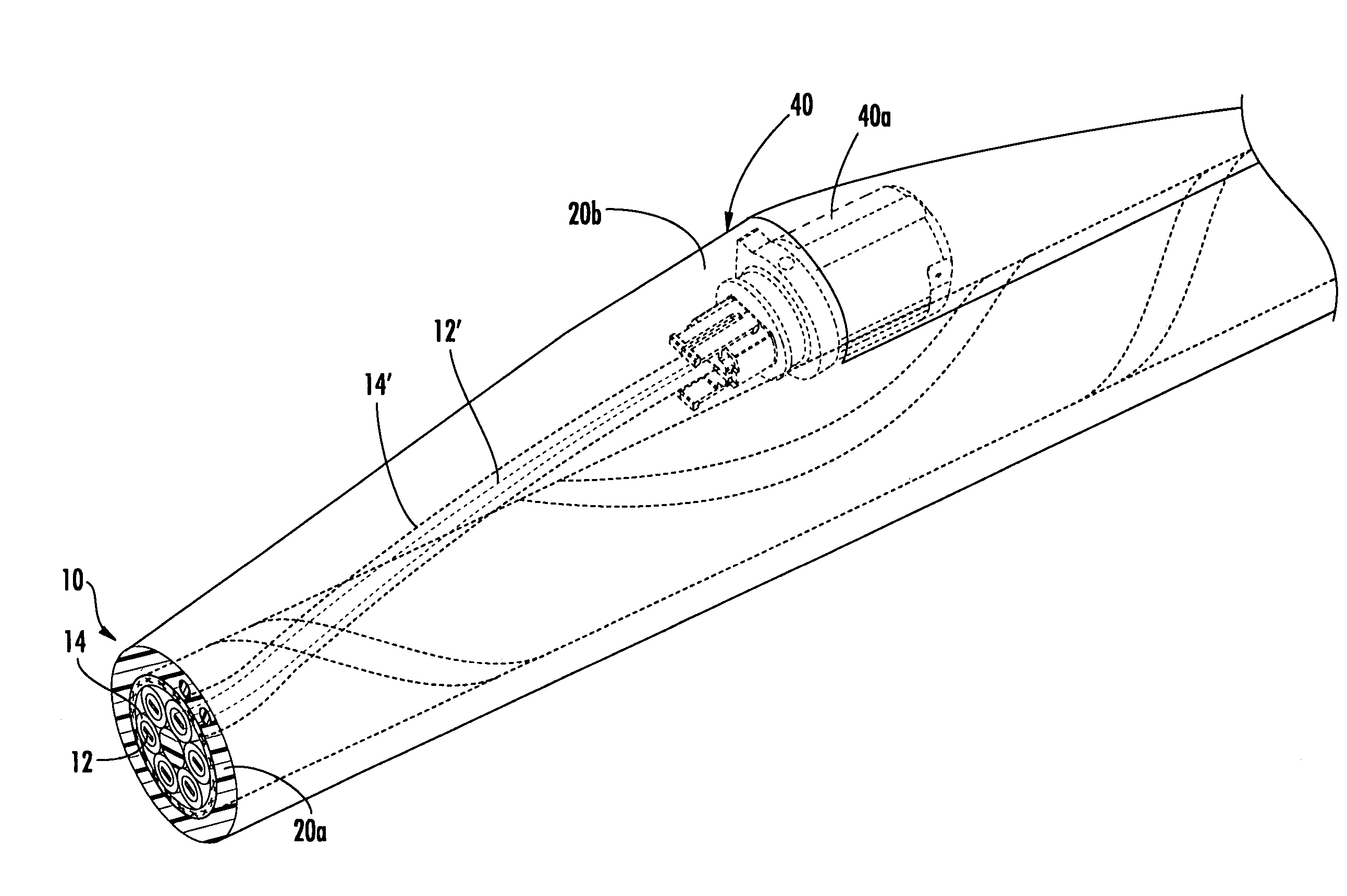

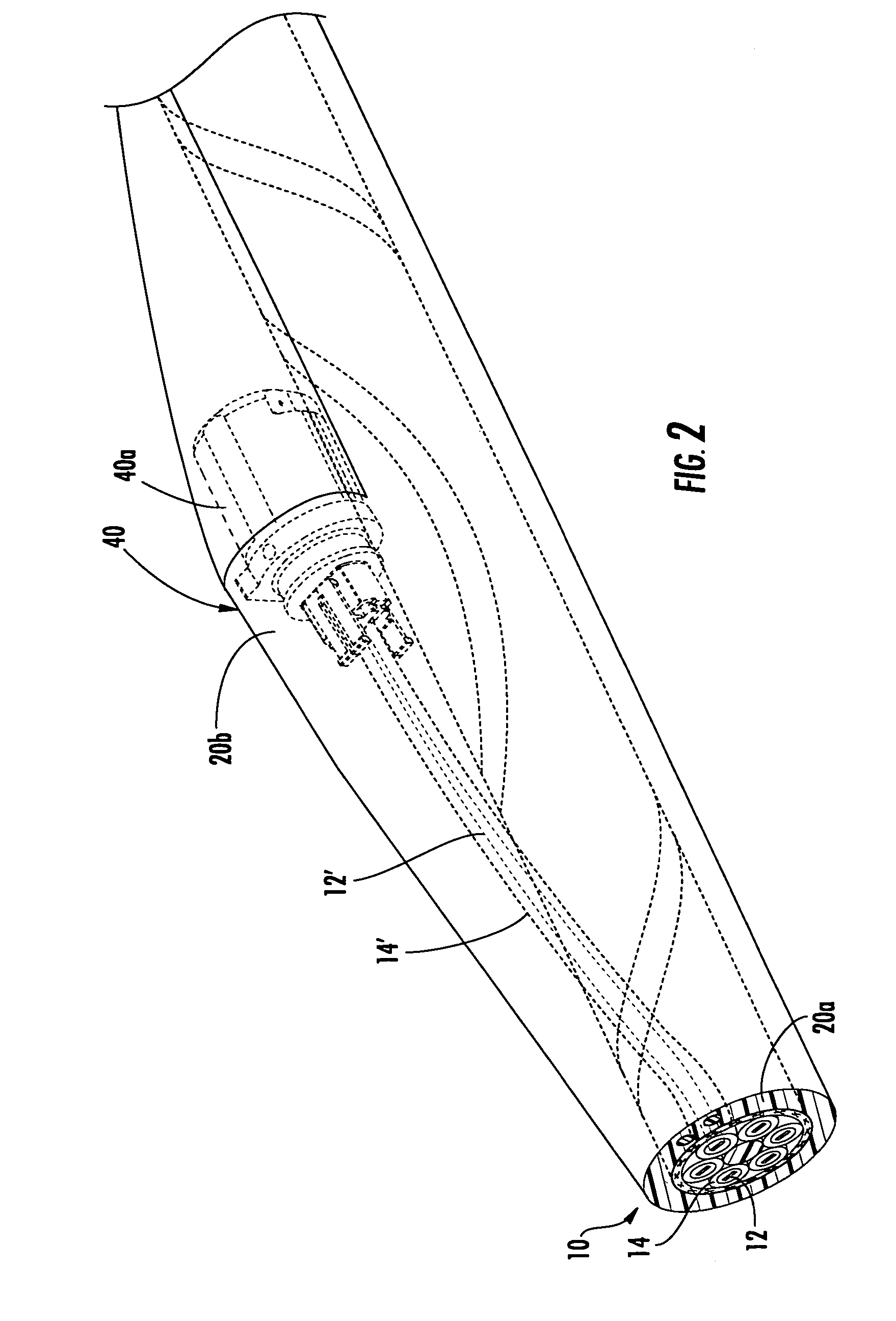

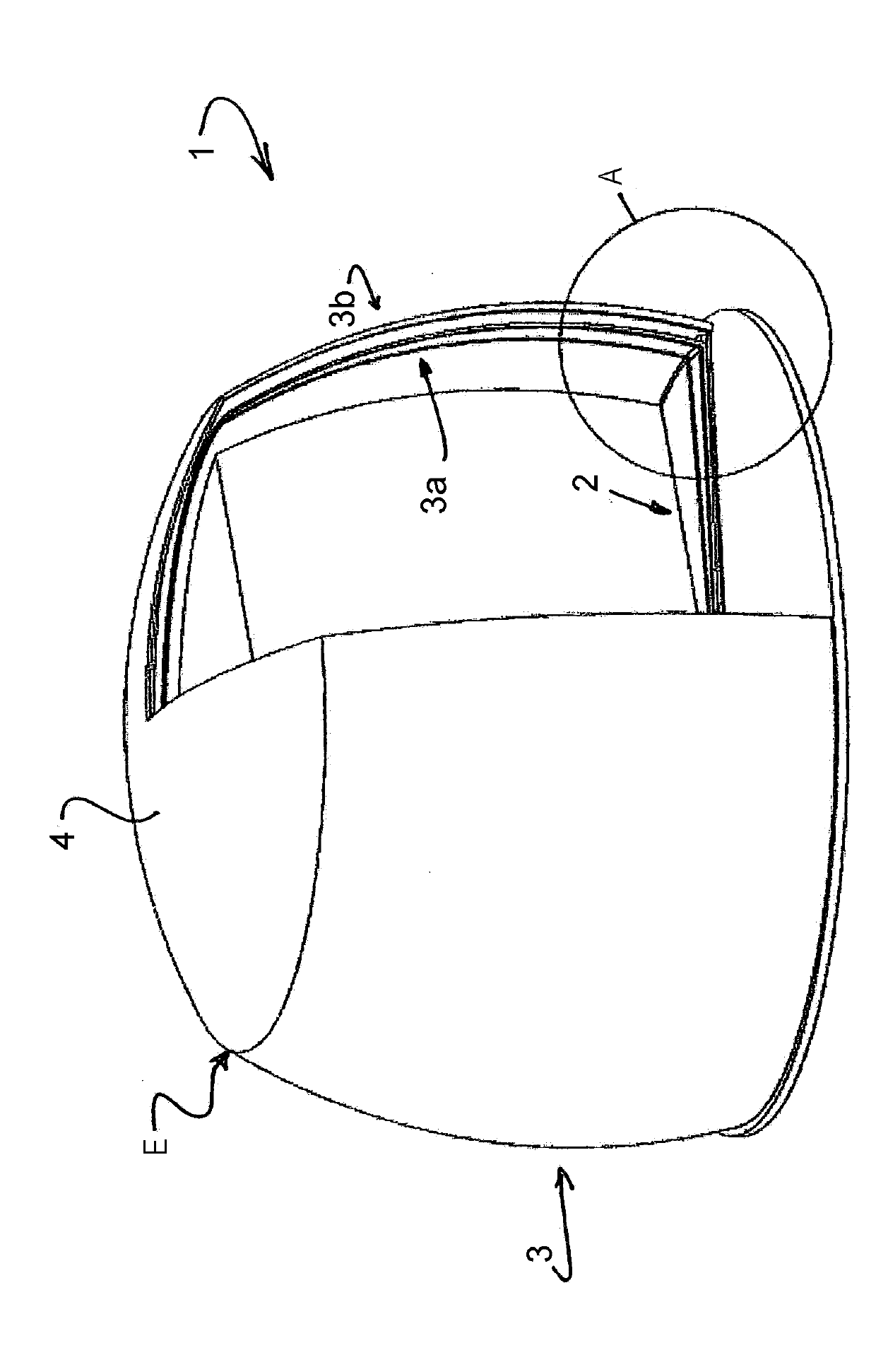

Fiber optic cables having at least one tether optical fiber

InactiveUS20070140640A1Easy networkingEasy and fast accessFibre mechanical structuresBundled fibre light guideFiberEngineering

A distribution fiber optic cable including a plurality of optical fibers, a main cable body with some of the plurality of optical fibers being disposed within the main cable body, at least one tether optical fiber, and a cable jacket. The at least one tether optical fiber is one of the plurality of optical fibers that transitions during manufacturing from a first location within the main cable body to a tether access location for a portion of the distribution cable. The cable jacket includes a main cable body jacket and a tether access jacket portion that are connected together by a continuous transition that is applied during cable manufacturing. Thus, the craftsman may conveniently access the at least one tether optical fiber for distribution into the optical network.

Owner:CORNING OPTICAL COMM LLC

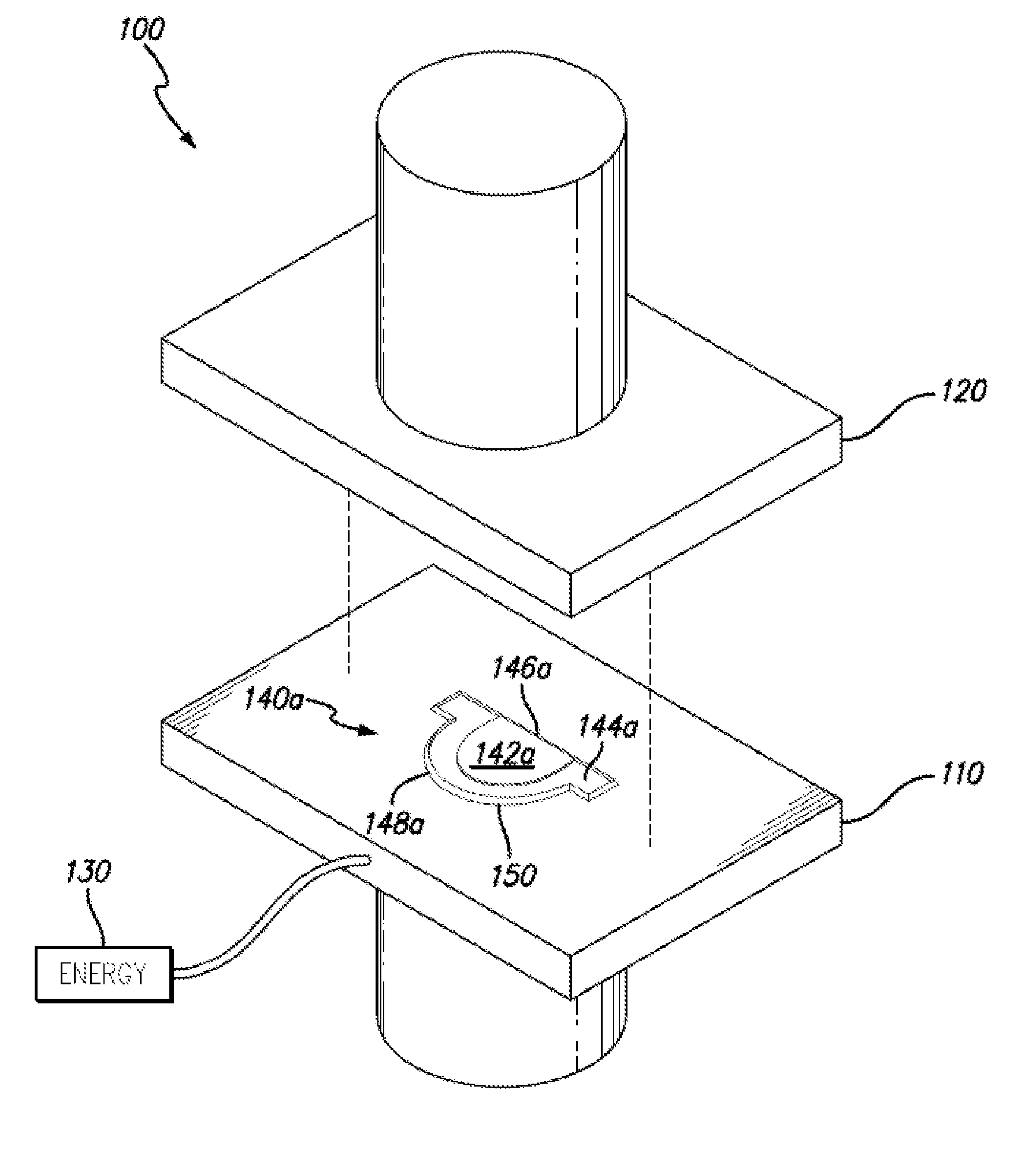

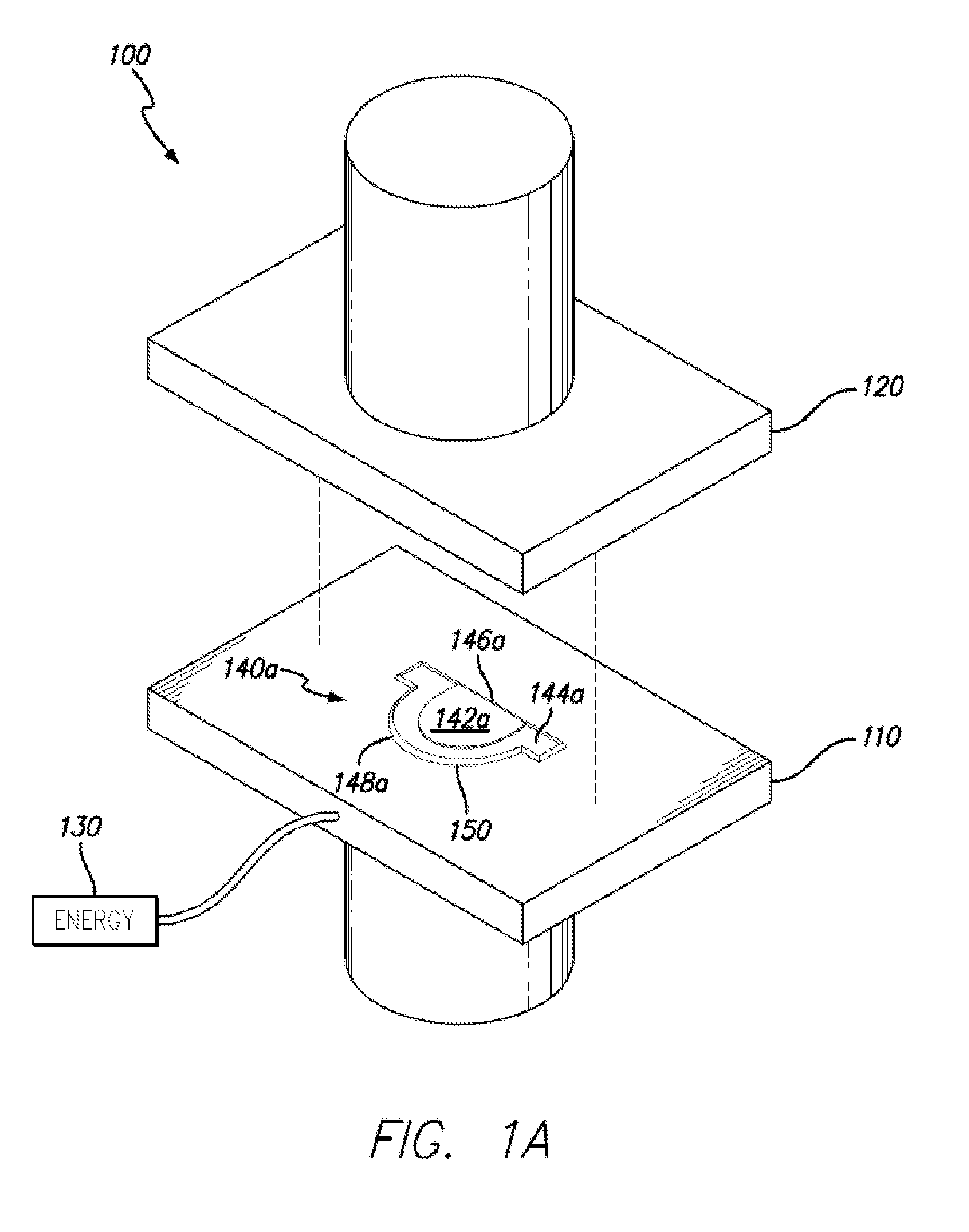

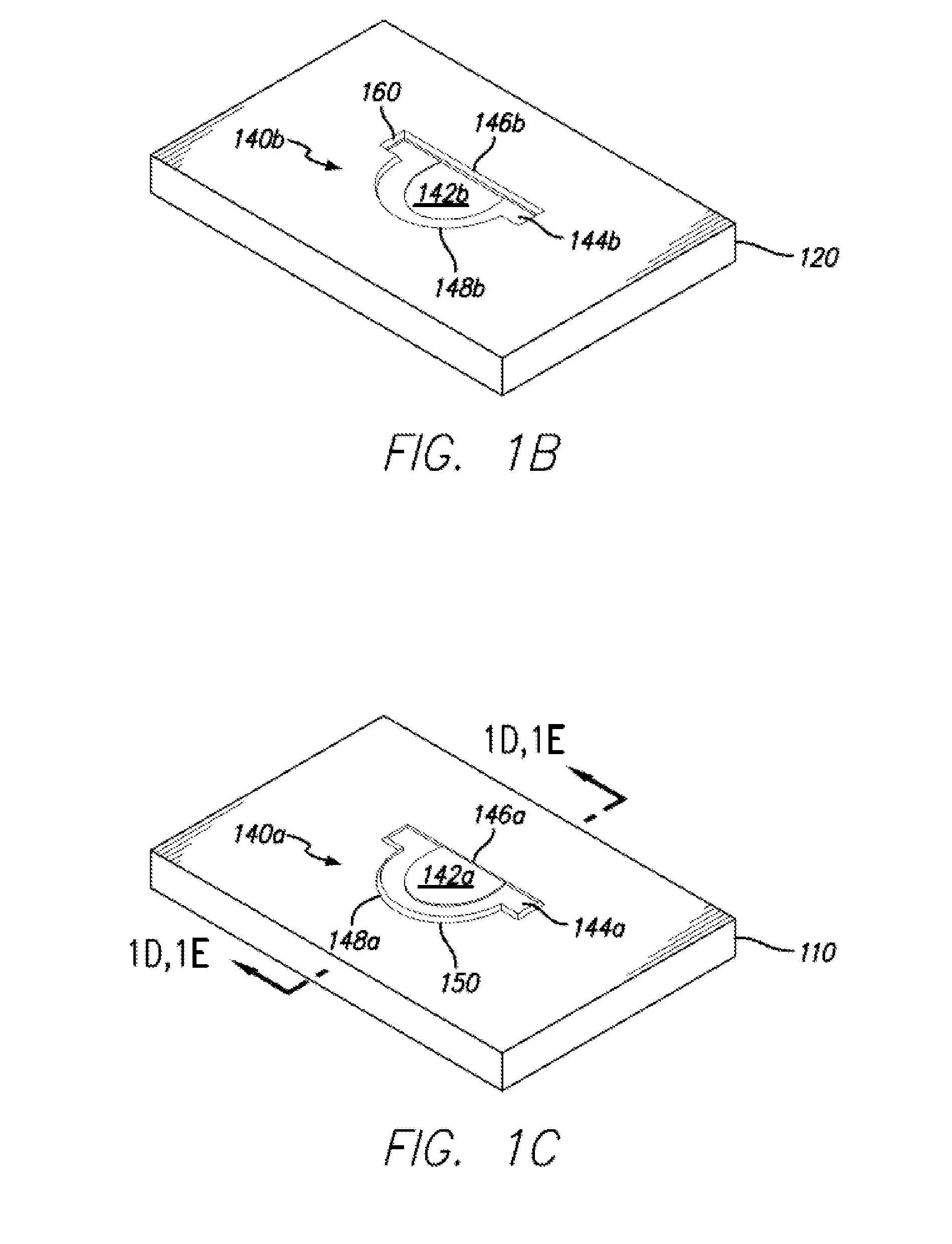

Method and apparatus for preparing a contoured biological tissue

ActiveUS20150091219A1Control thicknessHeart valvesAuxillary shaping apparatusBiological tissueEnergy source

An assembly and methods for providing a contoured biological tissue are described. The assembly comprises a first plate and a second plate. The first plate is configured to receive a biological tissue. The second plate is configured to apply a compressive force on the biological tissue that is disposed on the first plate. One or both of the first and second plates comprise a defined shape and a contoured area within the defined shape. The contoured area comprises at least first and second elevations and a continuous transition between the first and second transitions. One or more energy sources is associated with one or both of the first and second plates. The one or more energy sources delivers energy while the second plate applies the compressive force on the biological tissue disposed on the first plate.

Owner:EDWARDS LIFESCIENCES CORP

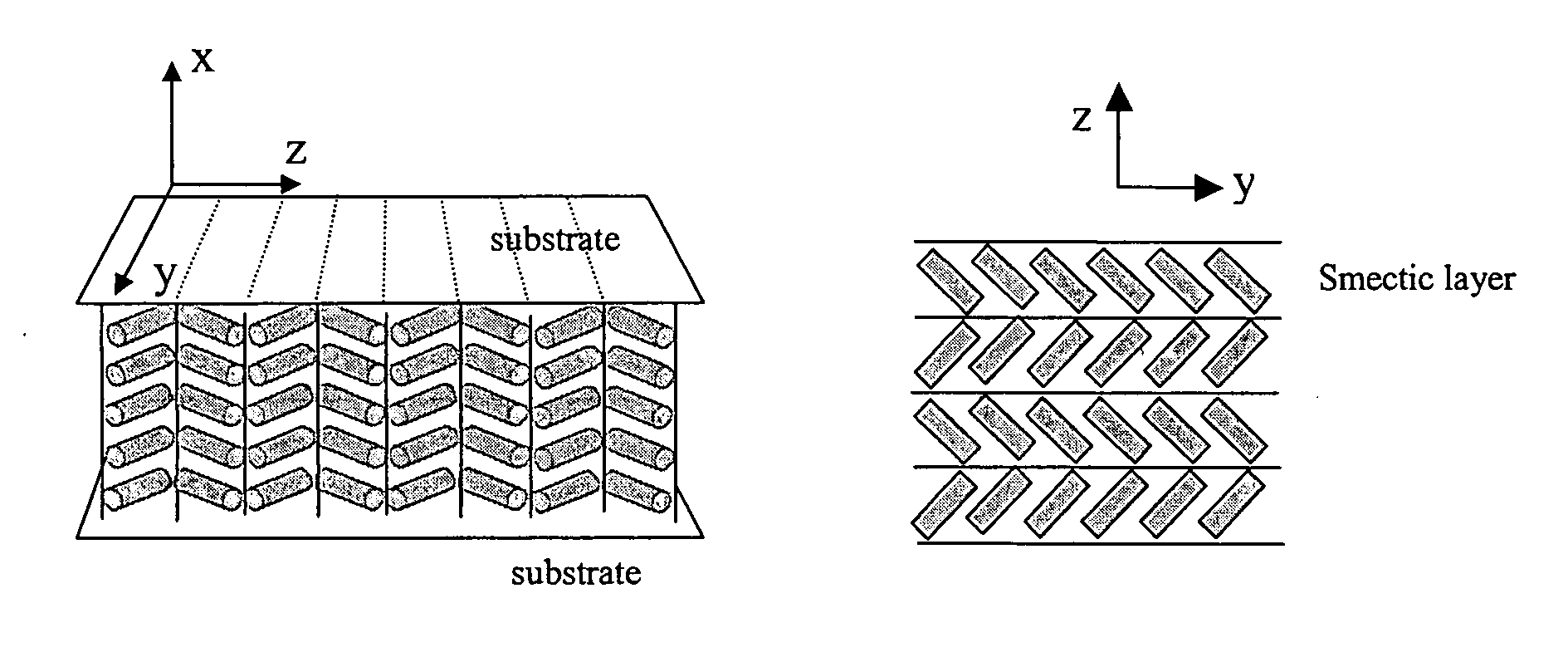

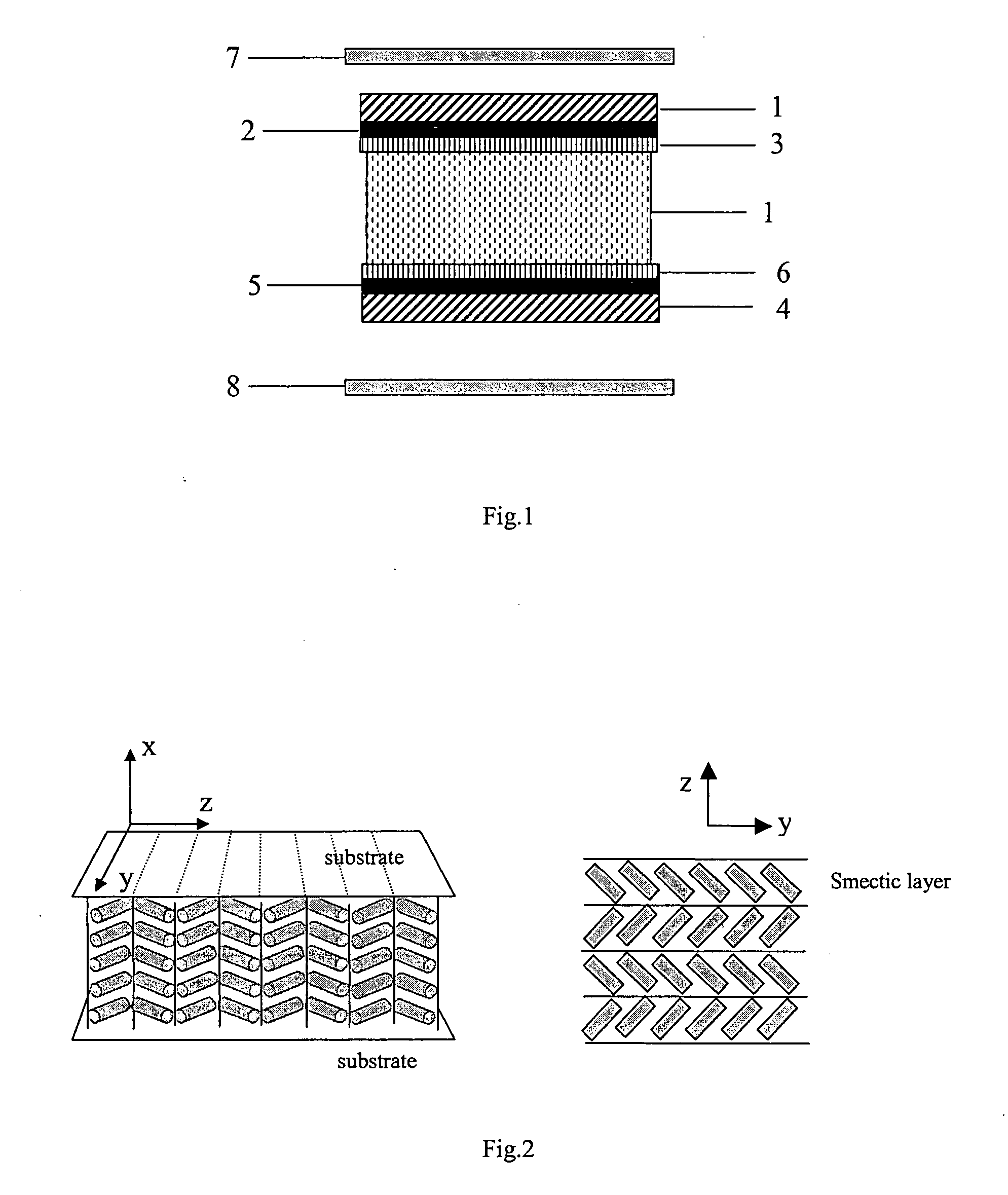

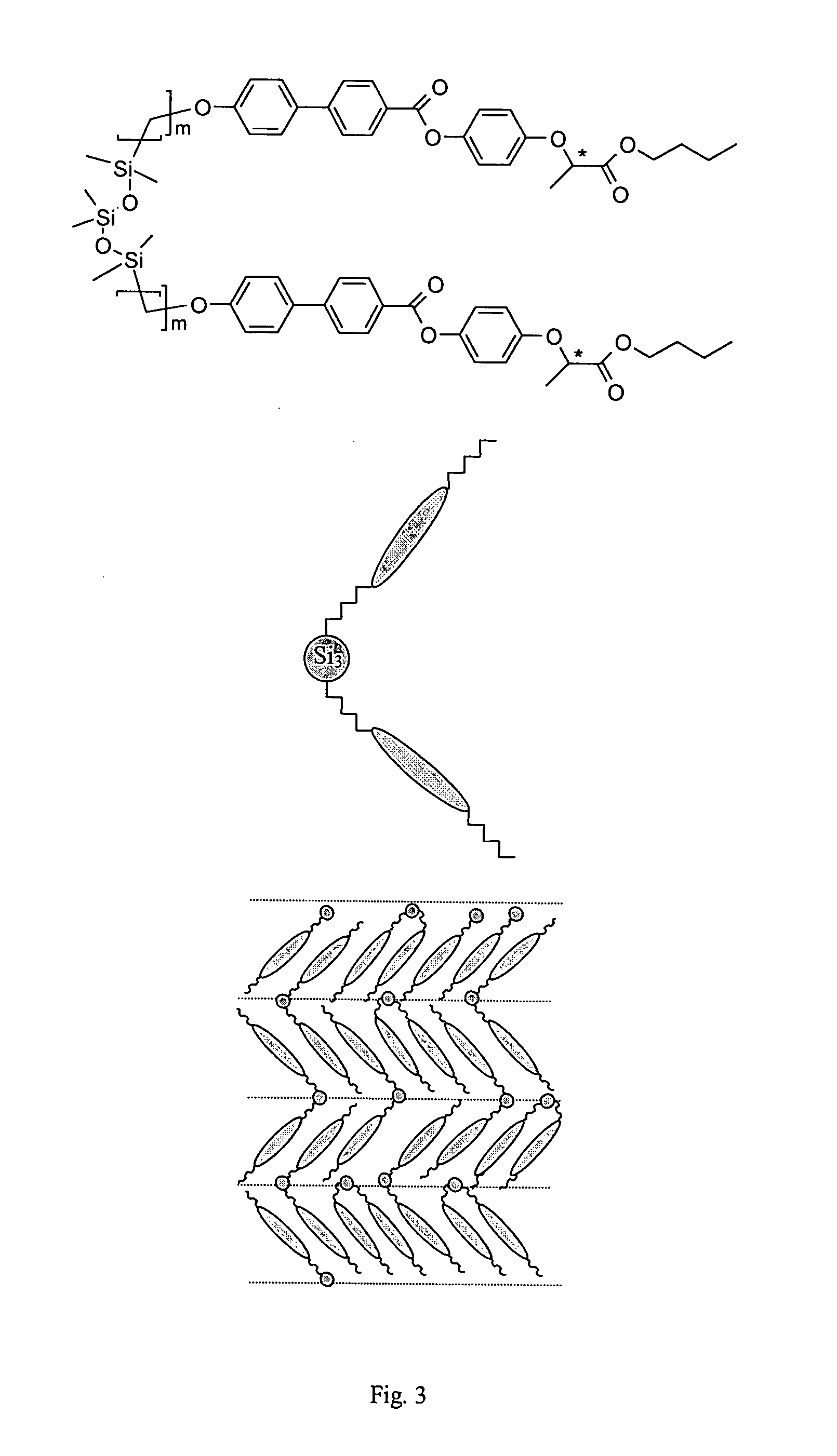

Liquid crystal device for generation and fast switching of high contrast images

InactiveUS20080049175A1Quick switchIncrease contrastLiquid crystal compositionsNon-linear opticsPolarizerElectric field

An electro-optic device including a liquid crystal material is disclosed, comprising antiferroelectric liquid crystals with large molecular tilt θ of about 45° degrees, disposed between two flat glass or polymer substrates. The liquid crystal molecules are preferably oriented parallel to the substrates (so-called HAF texture). The device is e.g. placed between two crossed polarizers so that in field-off conditions the impinging light is not passing through the device due to the isotropic optical properties of the antiferreoelectric liquid crystal aligned in HAF texture. An applied electric field induces a continuous transition of the optically isotropic antiferreoelectric (AF) state to ferroelectric (F) one which is birefringent enabling the transmission of light. The field-induced continuous switching between the optically isotropic antiferreoelectric state and the birefringent ferroelectric state enables the generation and fast switching of high contrast as well as generation of grey scale levels.

Owner:LACHEZAR KOMITOV

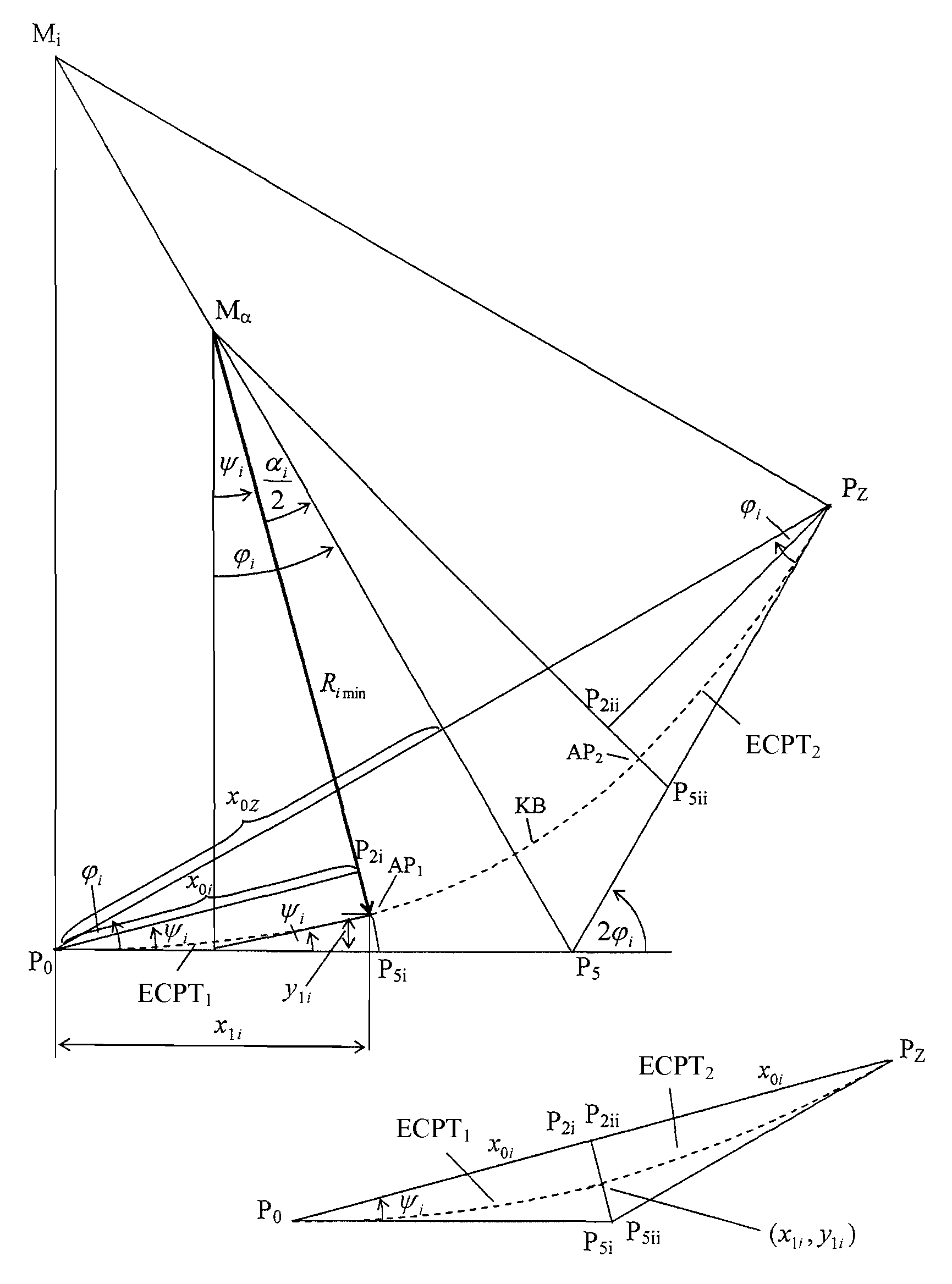

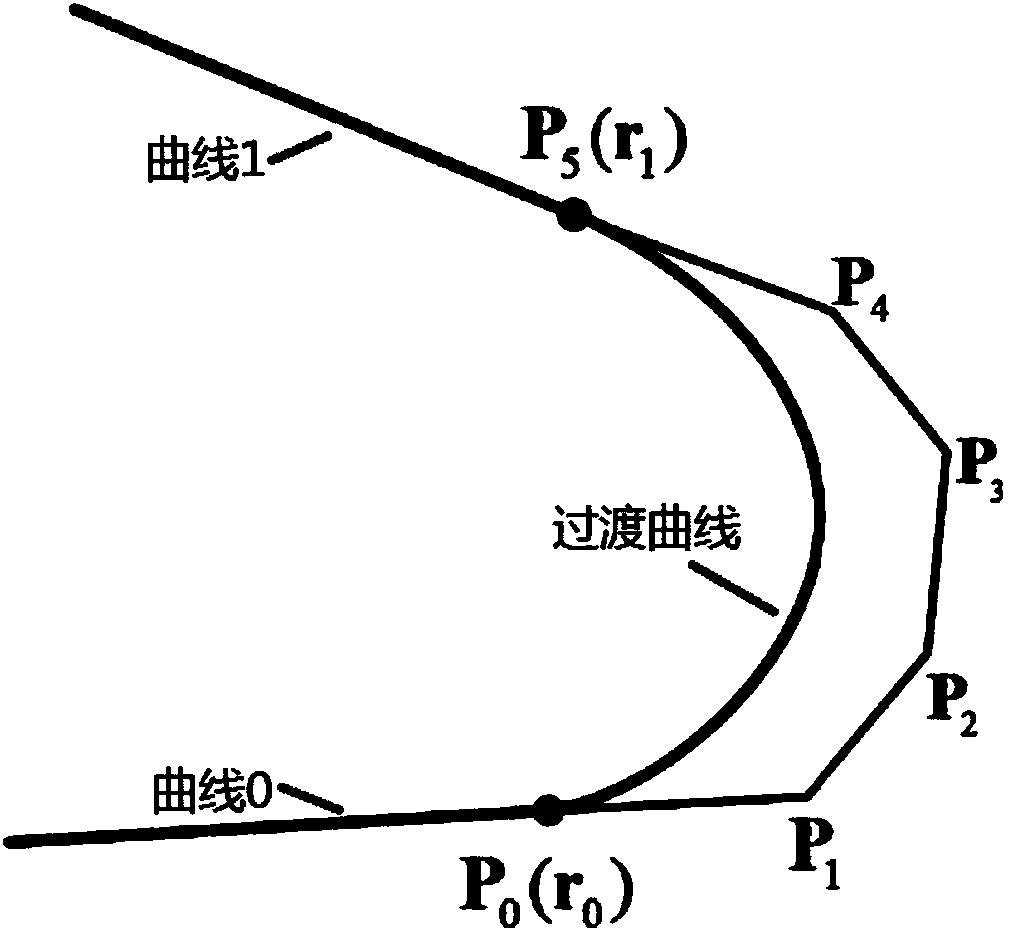

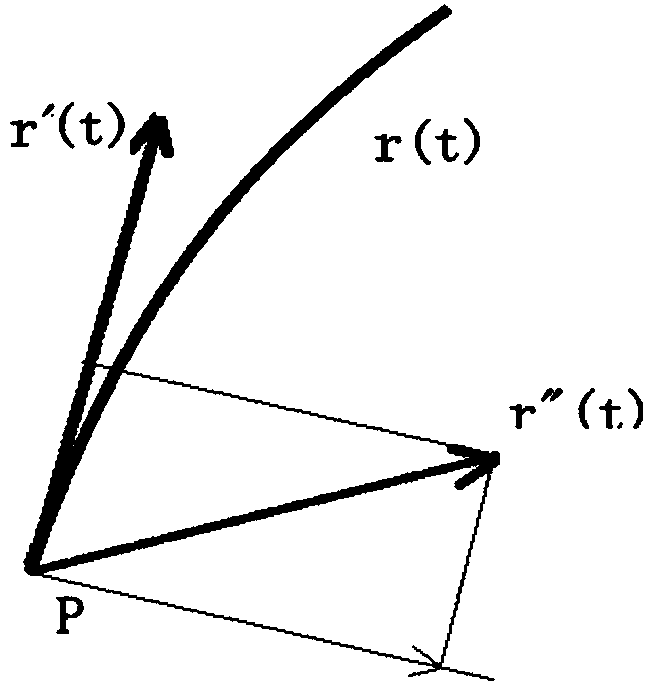

Continuous transition curve constitution method based on quintic Bezier curve

InactiveCN103646150AEasy and intuitive controlsConvenient Interaction DesignSpecial data processing applicationsInteractive designInteraction design

The invention discloses a G3 continuous transition curve constitution method based on a quintic Bezier curve. The method comprises the following steps: step 1, working out the first-order steering vector and the second-order steering vector at the end point of a primitive curve; step 2, enabling the primitive curve and a transition curve to satisfy a G2 continuity condition at the connection point; step 3, on the basis of the step 2, enabling the primitive curve and the transition curve to satisfy G3 continuity at the connection point; step 4, inversely calculating the reference mark of a quintic Bezier transition curve; step 5, normally calculating the quintic Bezier transition curve according to the control peak in the step 4. According to the invention, a Bezier curve is adopt to construct the transition curve, so that the advantages of controlling the shape of the curve easily and visually and providing convenience for interactive design can be achieved; besides, the few the parameters are, the few the orders are, so that the calculation frequency is low, and the memory space occupied in a computer is relatively small; the invention can be applied to construction of transition curves in CAD modeling.

Owner:BEIHANG UNIV

Fiber optic cables having at least one tether optical fiber

InactiveUS7555181B2Easy networkingEasy and fast accessFibre mechanical structuresBundled fibre light guideFiberEngineering

Owner:CORNING OPTICAL COMM LLC

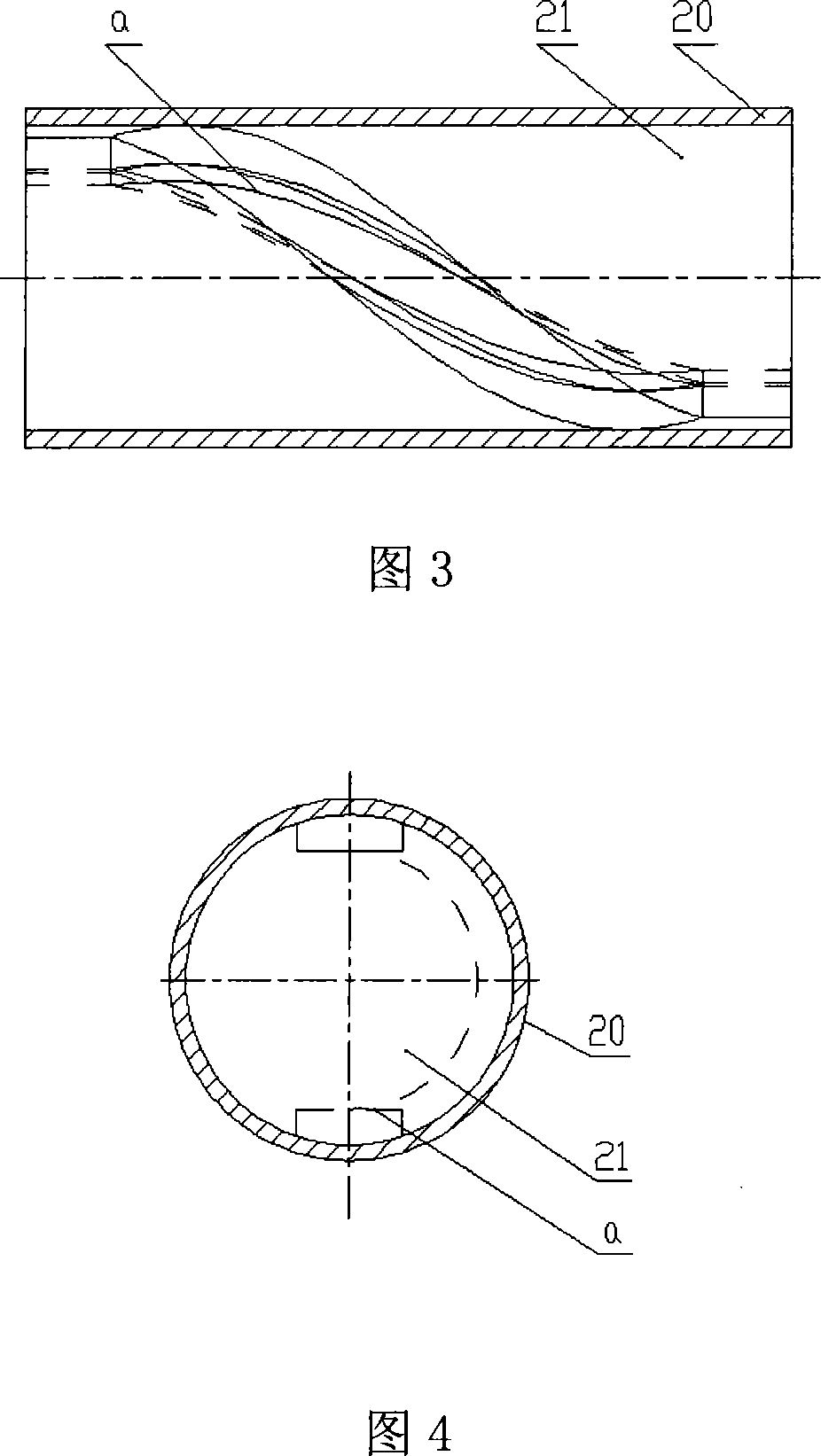

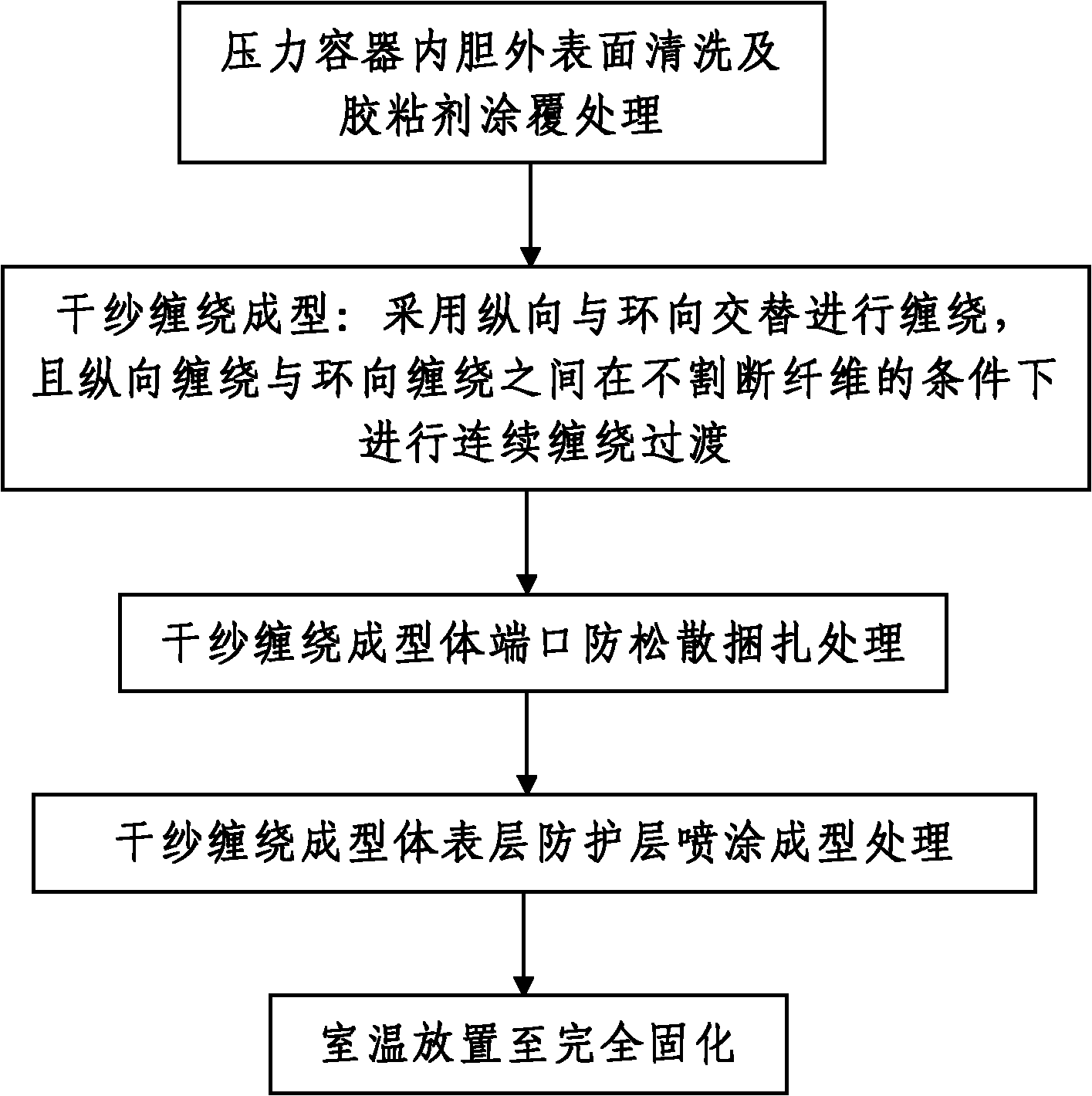

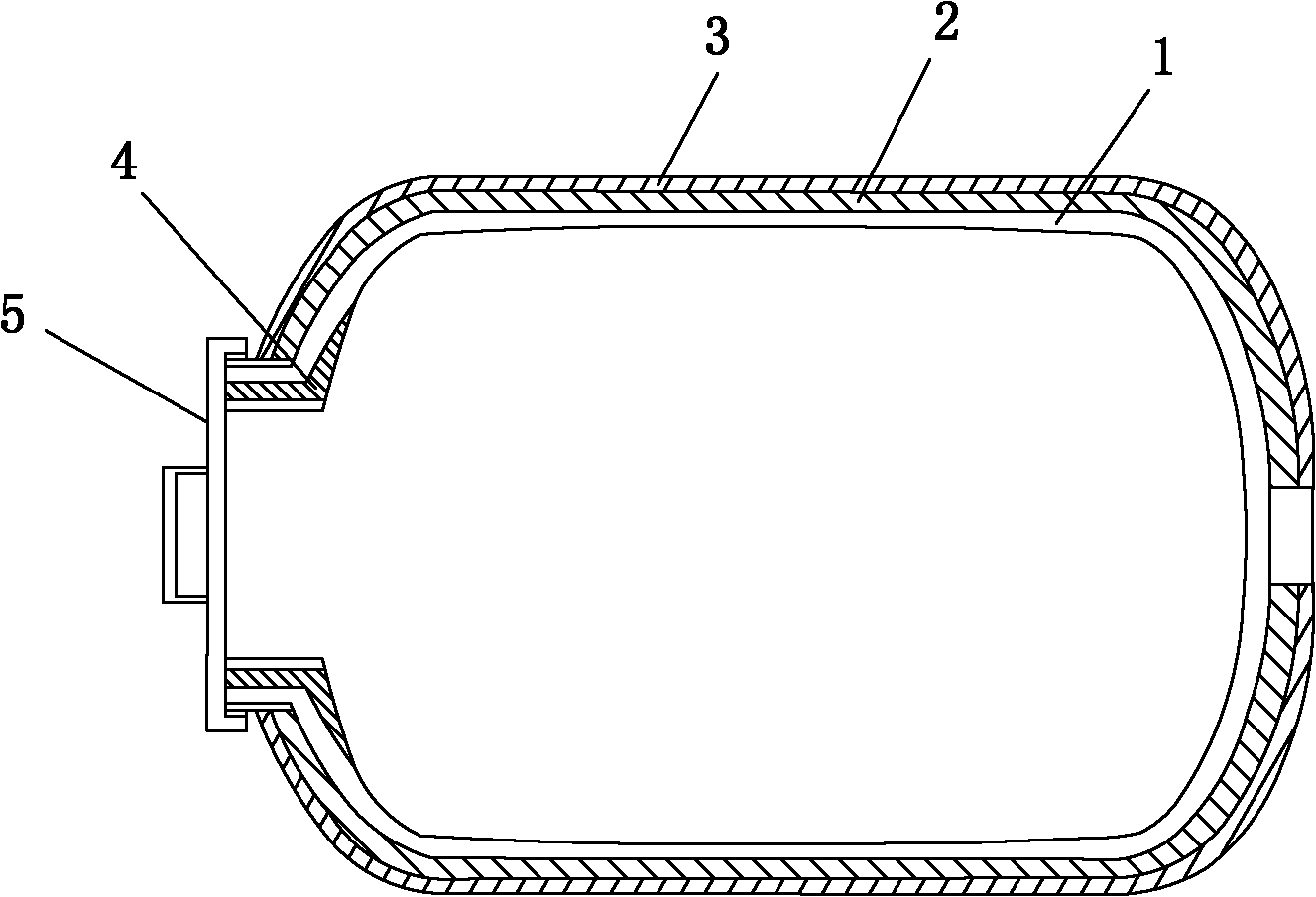

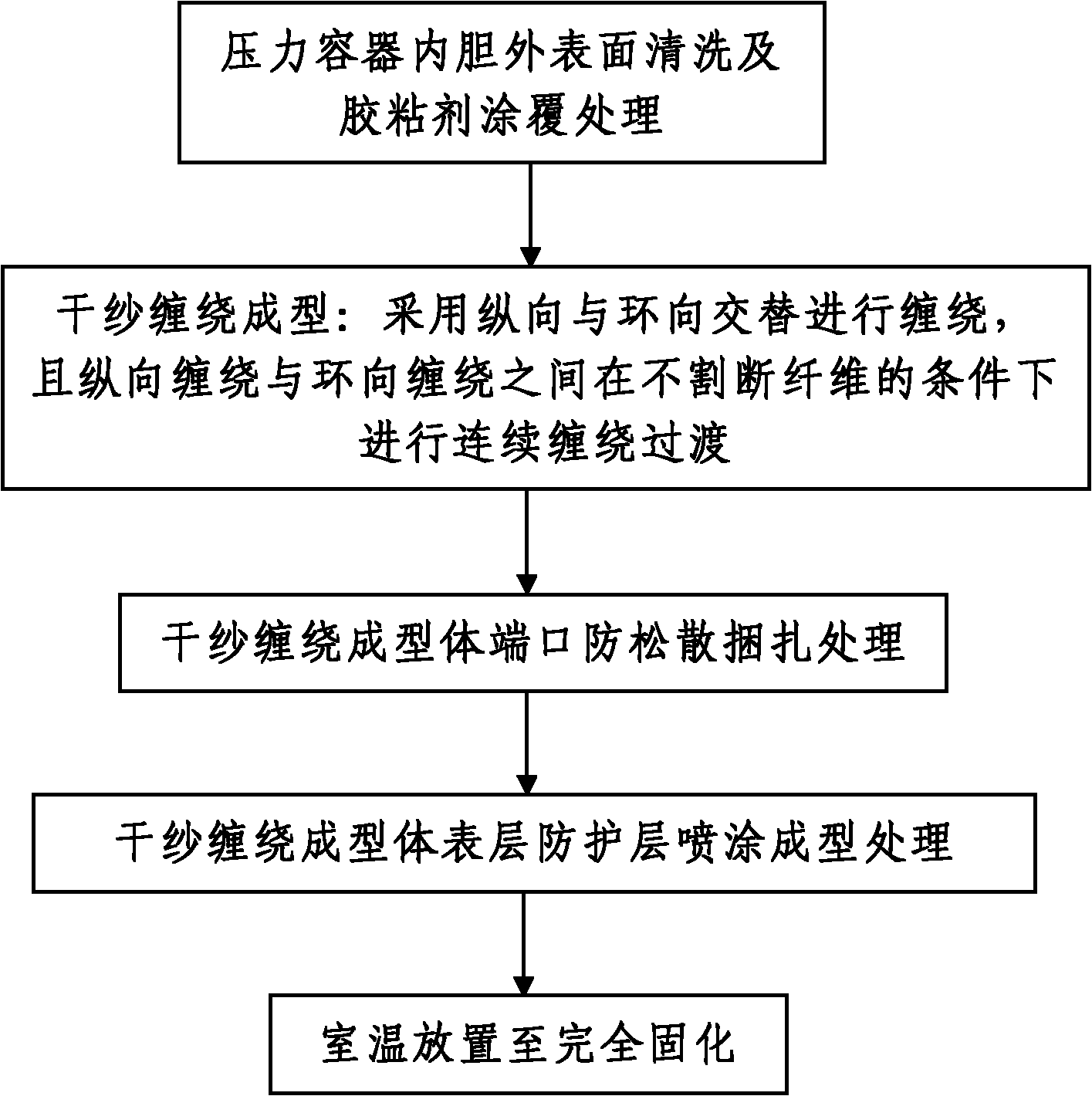

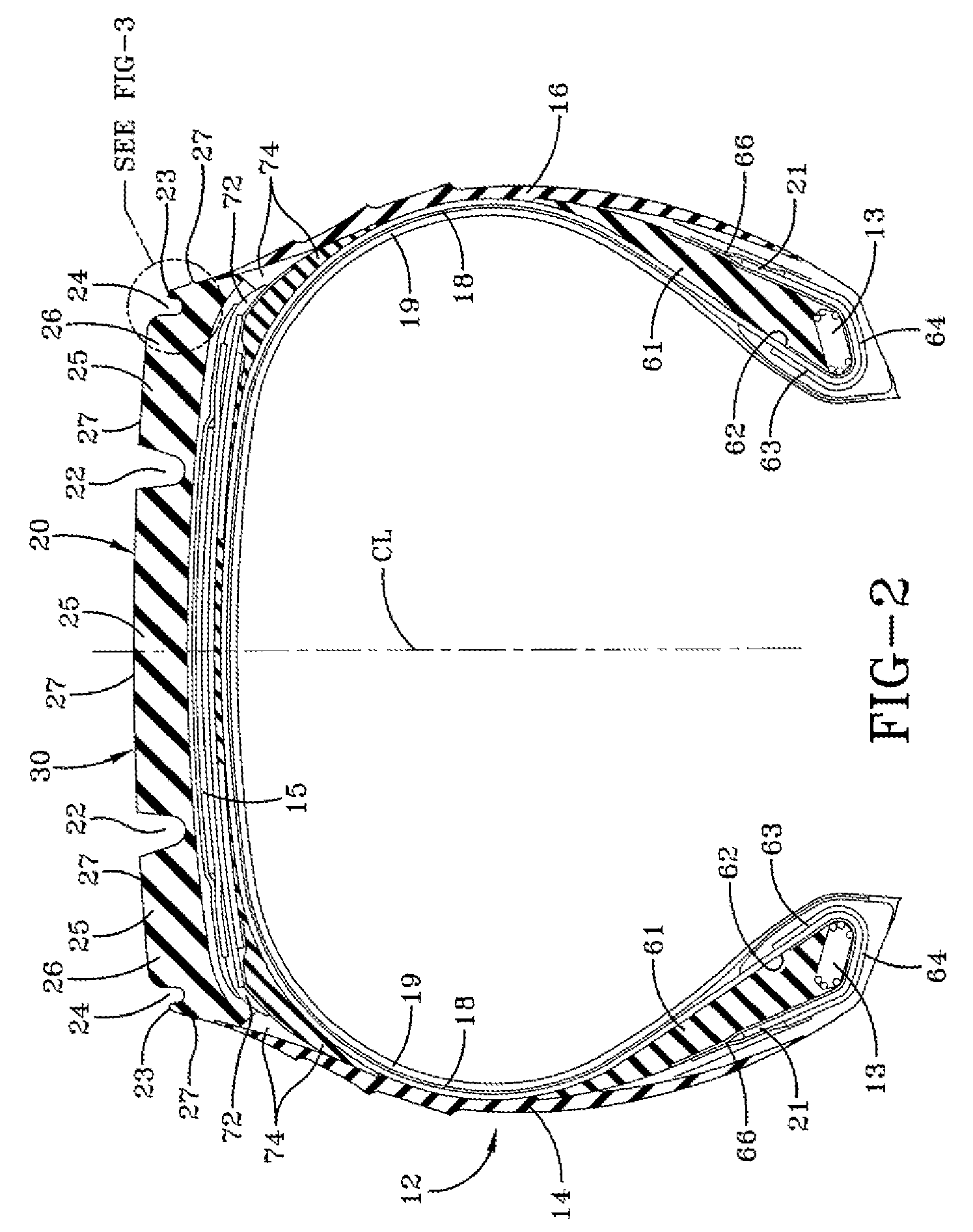

Dry yarn winding forming method for pressure container

The invention discloses a dry yarn winding forming method for a pressure container. The method comprises the following steps: 1. carrying out outer surface treatment on an inner container of the pressure container, namely coating an adhesive uniformly on the outer surface of the inner container of the cleaned pressure container; 2. carrying out dry yarn winding forming, namely winding on the outer surface of the inner container of the pressure container in a winding mode of alternative longitudinal winding and hoop winding, and carrying out continuous transition between the longitudinal winding and hoop winding under the condition that fibers are not cut off; 3. carrying out loose-proof strapping treatment on the port of a dry yarn winding forming body; 4. carrying out spraying forming treatment on a protective layer at the surface layer of the dry yarn winding forming body; and 5. placing and solidifying at room temperature. The dry yarn winding forming method for the pressure container provided by the invention has the advantages of reasonable design, simplicity and convenience in operation, convenience in control and good winding forming effect; and because an impregnation process and a solidifying process link are omitted, a plurality of practical problems, such as complex forming technology, longer production cycle, higher cost, no large scale of industrial production andthe like, of the existing winding forming process can be solved effectively.

Owner:XIAN AEROSPACE COMPOSITE MATERIALS INST

Enrobed core

An enrobed a core, such as a tablet core, that has a coating made of one or more patterned films each having portions that are visually distinct (e.g., differently colored) from one another and having a transition line segment between these visually distinct portions. At least a portion of an outer surface of the core is covered with the film or films, such that the transition line segments form a substantially continuous transition line on the coating and a film seam is formed which is different from the transition line. Where the patterned films are bi-colored, the resulting enrobed core can be bi-colored, or the resulting enrobed core can have a coating with at least four visually distinct portions alternately arranged thereon, thereby forming a “checkerboard” pattern on the coating. In either case, the film seam of the coating is different from the transition line of the coating.

Owner:BUNICK FR J

Cryogenic liquid storage tank

InactiveCN102369386AReduce thicknessQuality improvementVessel manufacturingVessel geometry/arrangement/sizeInsulation layerReinforced concrete

Owner:IGLO CONTRACTORS

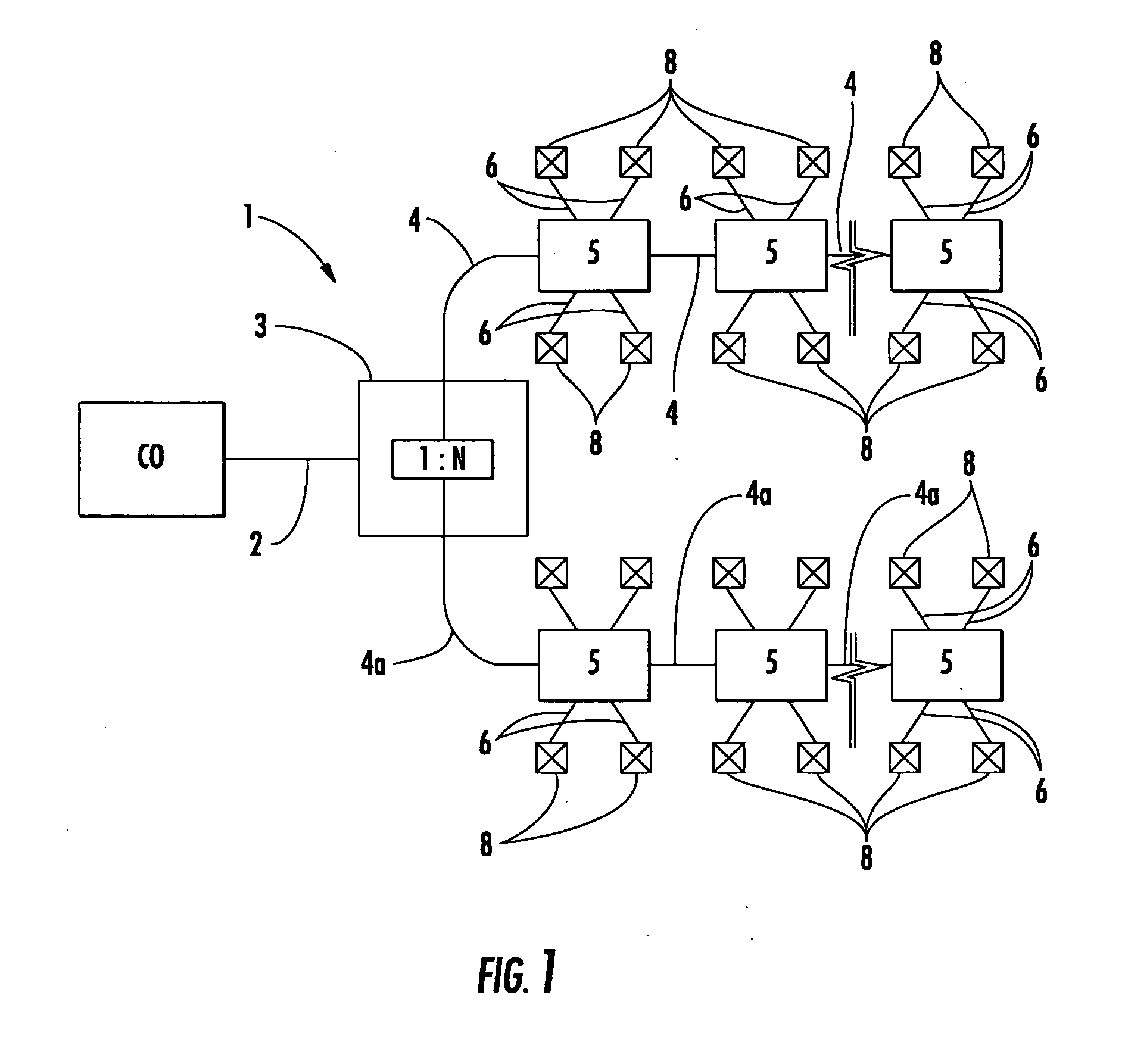

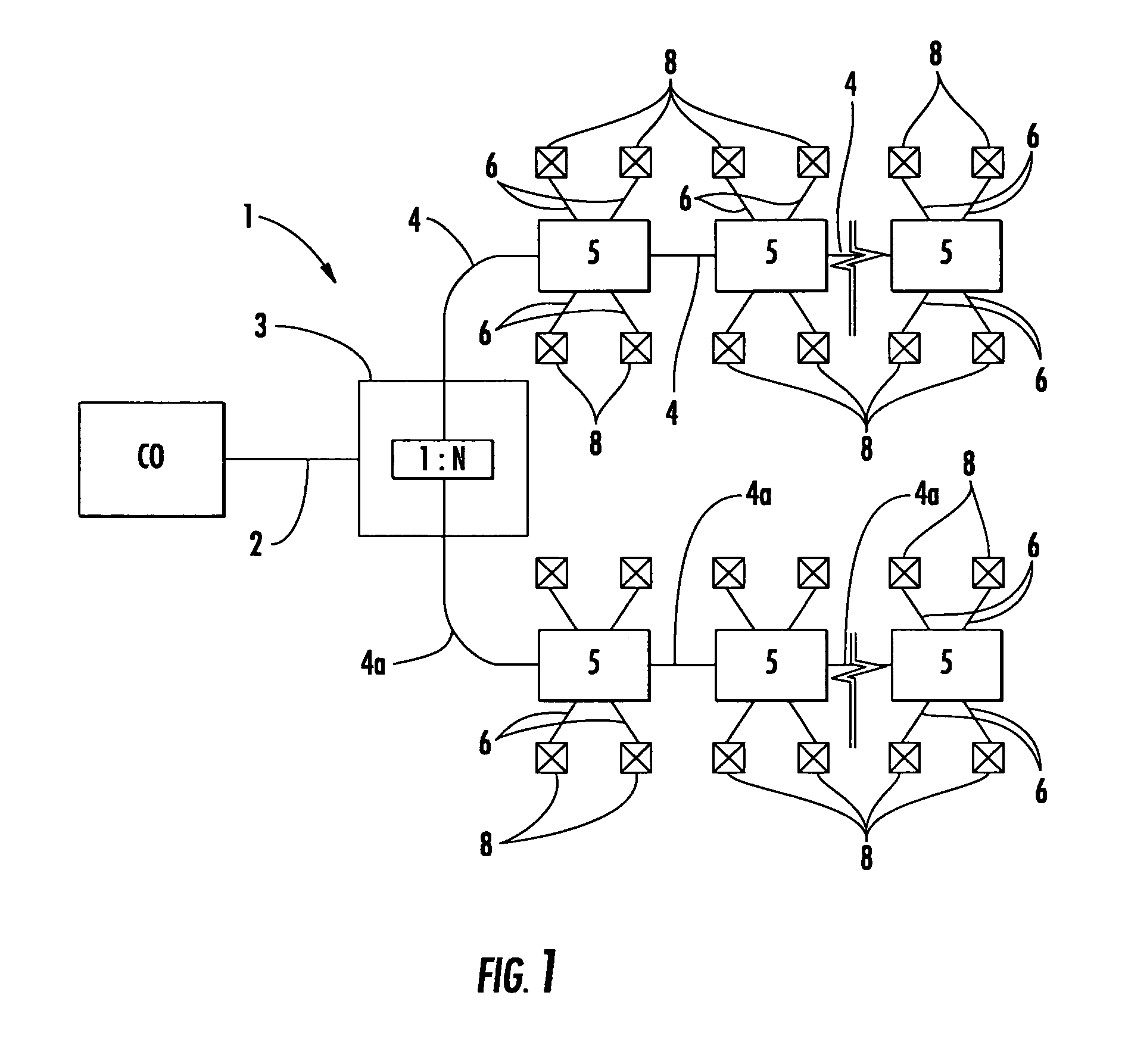

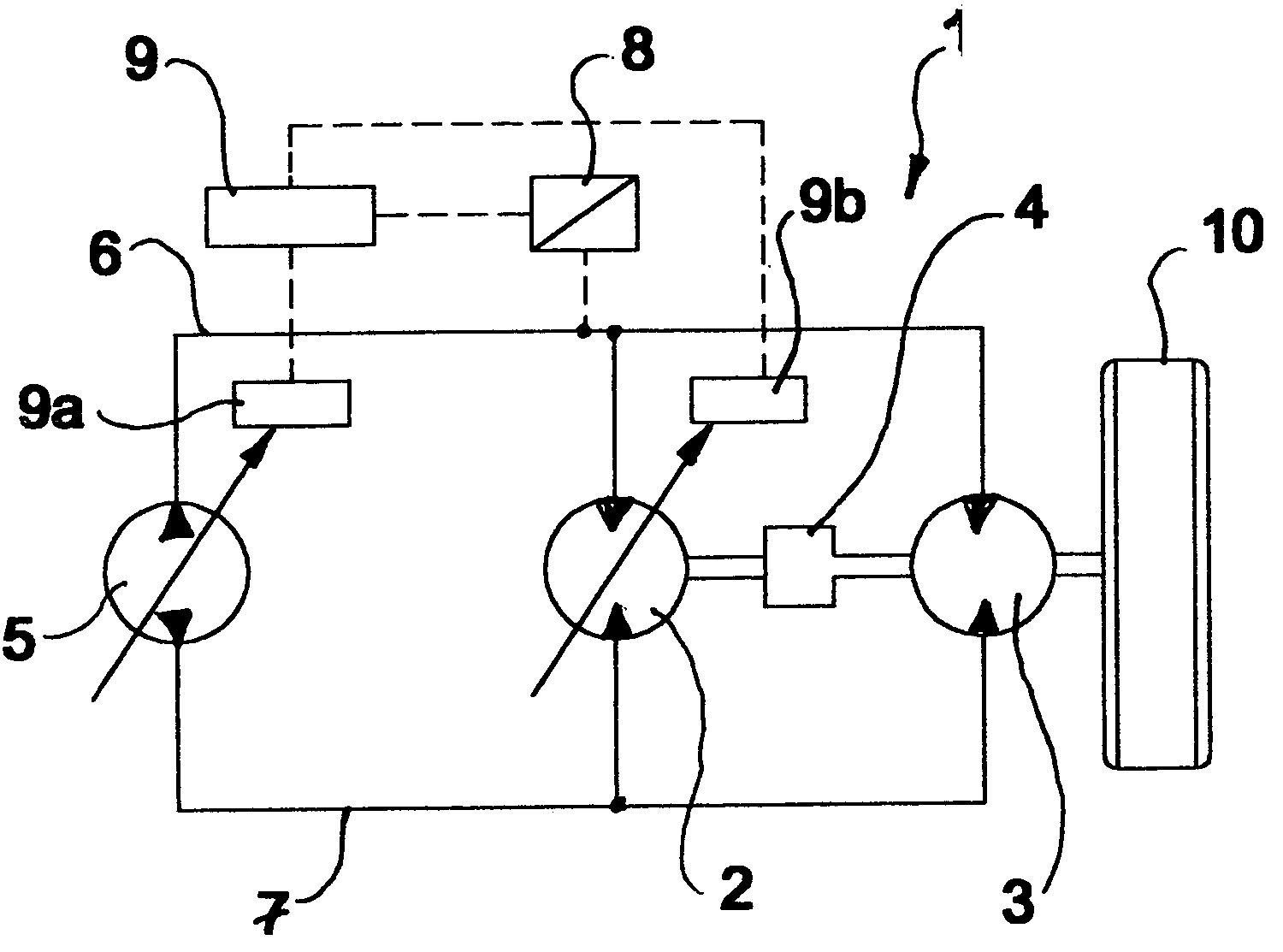

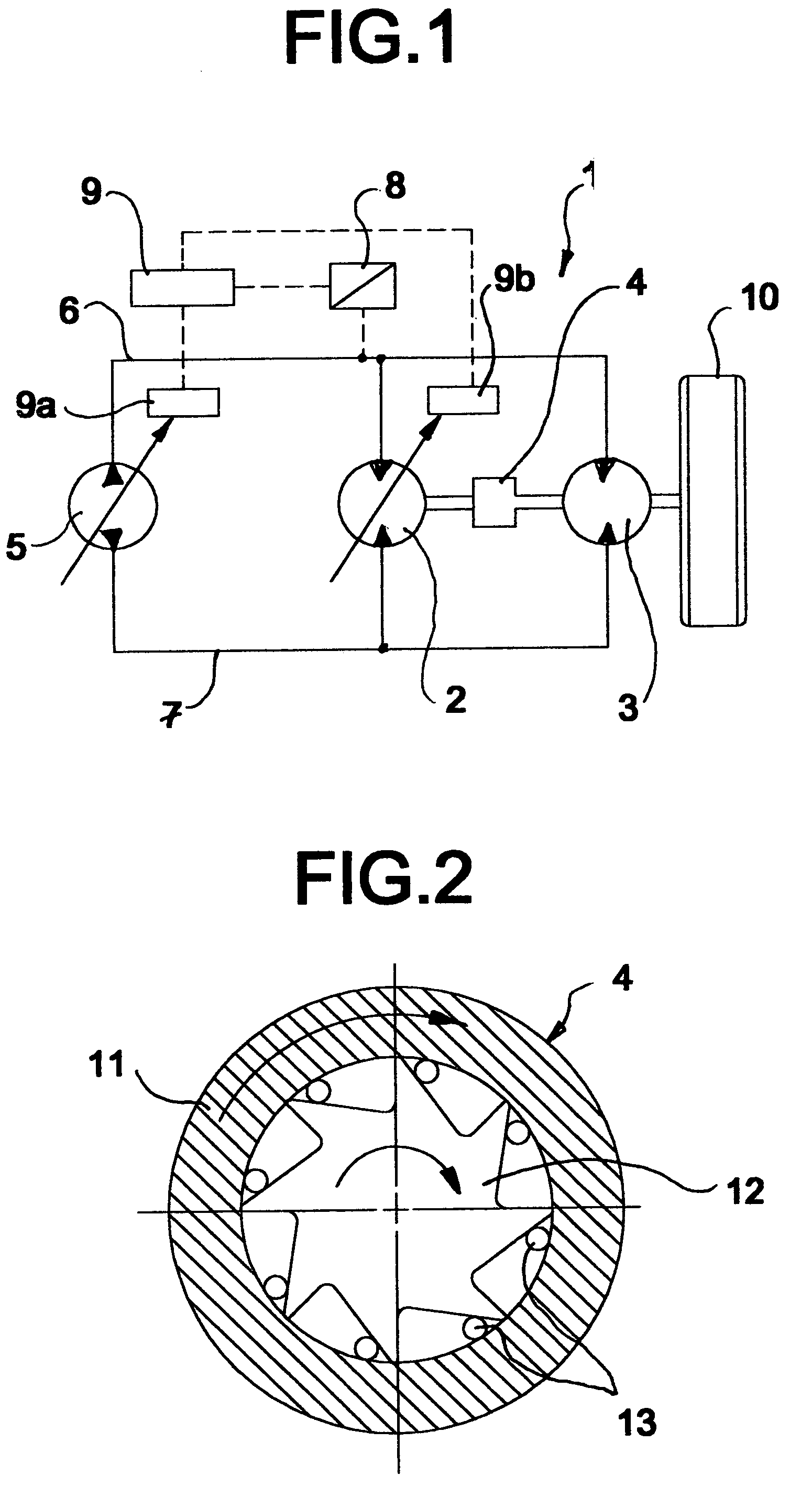

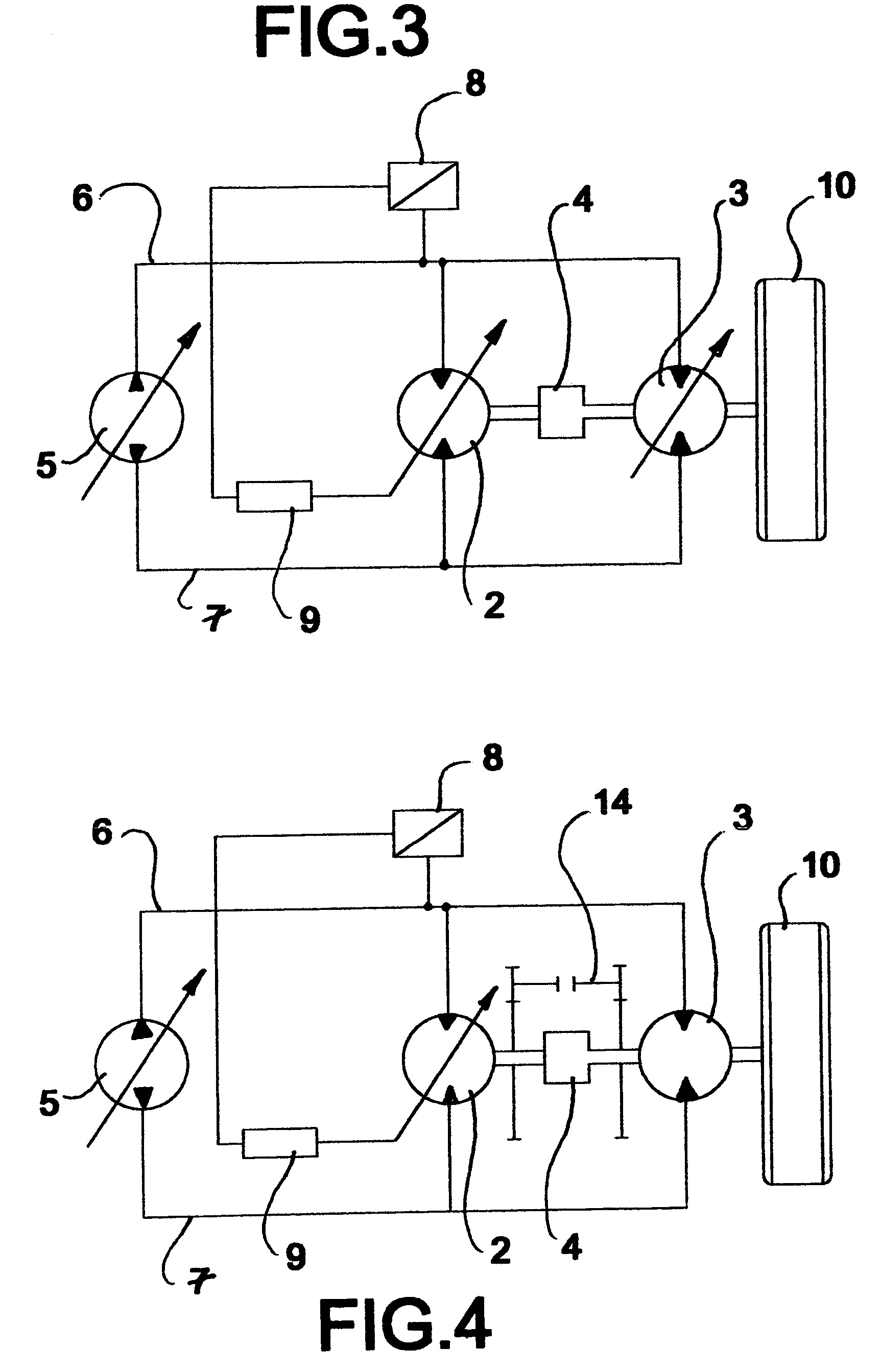

Hydrostatic multi-motor drive

With a hydrostatic multi-motor drive unit with a least two hydraulic motors acting upon a common load, a solution should be created, with which a further operating range is covered by the use of several motors and at the same time a simple as possible and problem free coupling of the motors is assured. Furthermore, a method for controlling the drive unit is indicated, which permits continuous transitions between the different operating ranges. This is achieved in that the motors (2, 3) are connected with each other through at least one freewheel device (4), in which the motor (2) arranged after the freewheel device has a variable displacement volume.

Owner:CNH BAUMASCHEN

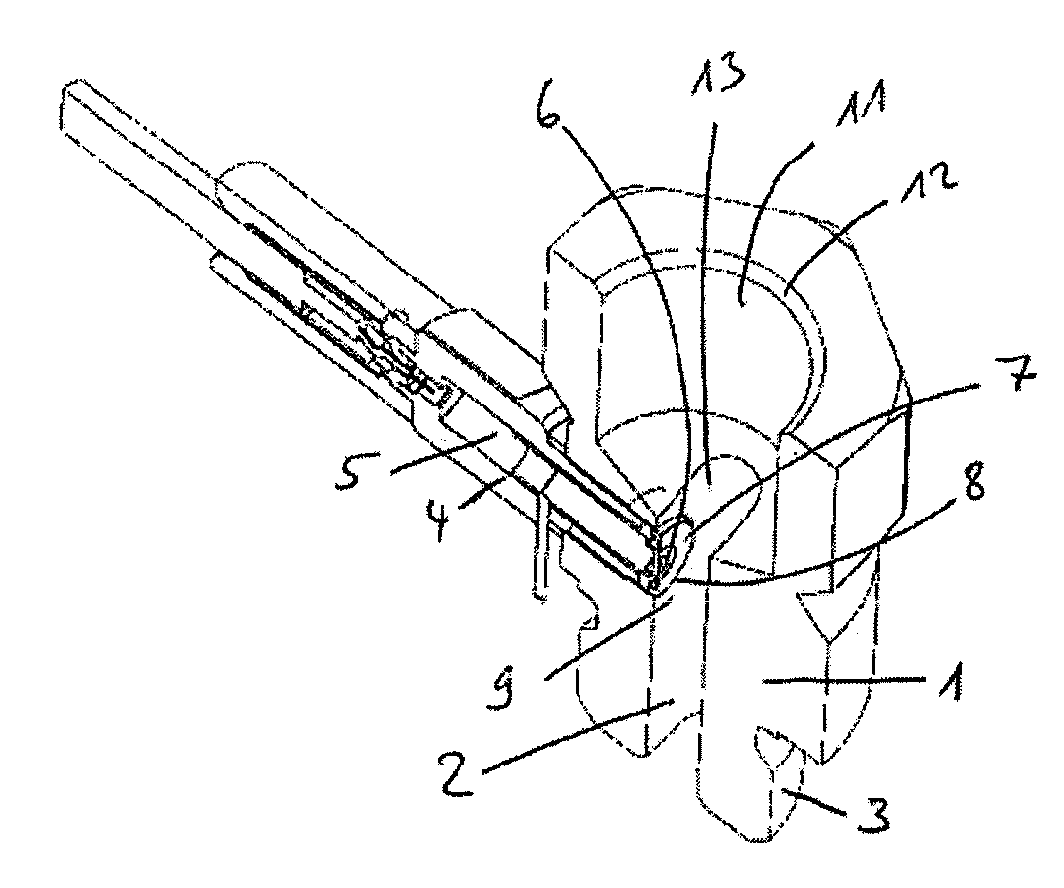

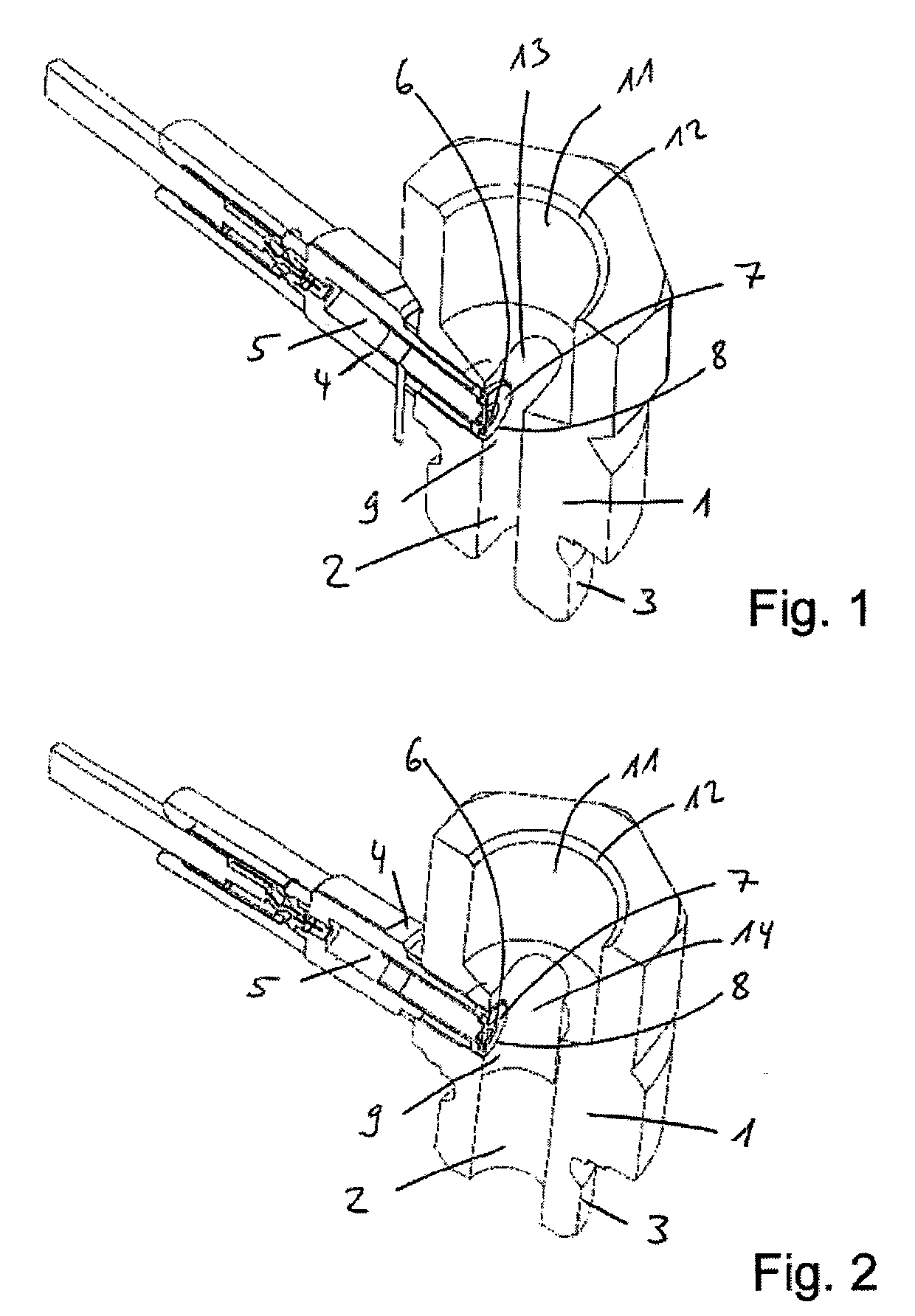

Adapter for pressure sensors

The invention relates to an adapter for pressure sensors for monitoring long-term cylinder pressures in internal combustion engines, said adapter comprising a housing 1 with a gas duct 2, a connection 3 to a cylinder cover of an internal combustion engine, a rear opening 11 of the gas duct 2 from the housing 1 with an apparatus 12 for closing this rear opening 11 in a gastight manner, and a connection 4 for inserting a pressure sensor 5 with a sensor membrane 6. The idea underlying the invention is that the transition line 8 of the opening 7 in the gas duct 2, which is reached by the sensor membrane 6 in the inserted state in order to be exposed to the gas pressure in the gas duct 2, is on a plane. The transition line 8 forms the transition from the contour of the gas duct 2 to the connection to the sensor 5. This enables a continuous transition from the sensor membrane 6 to the contour of the gas duct 2.

Owner:KISTLER HLDG AG

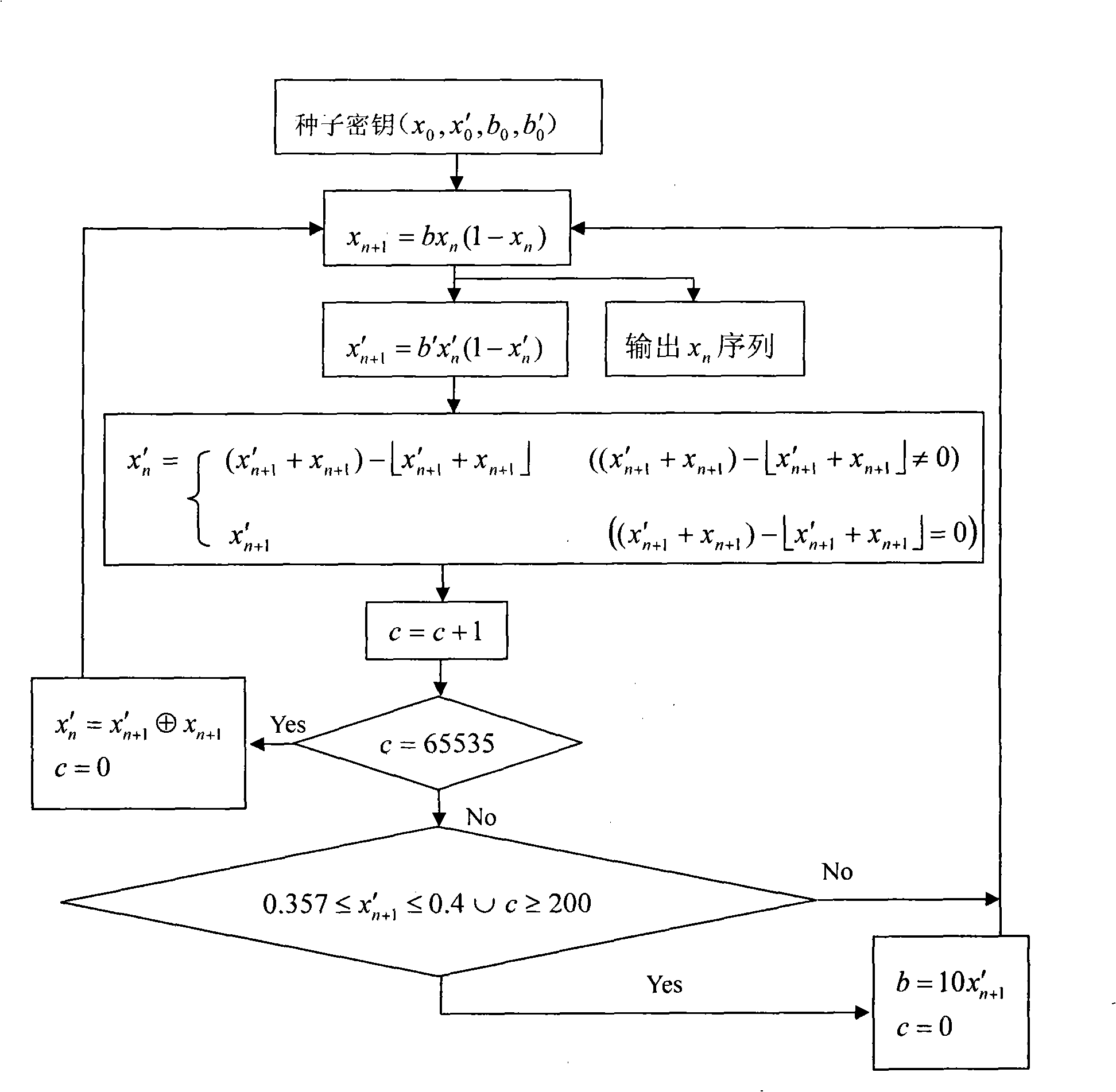

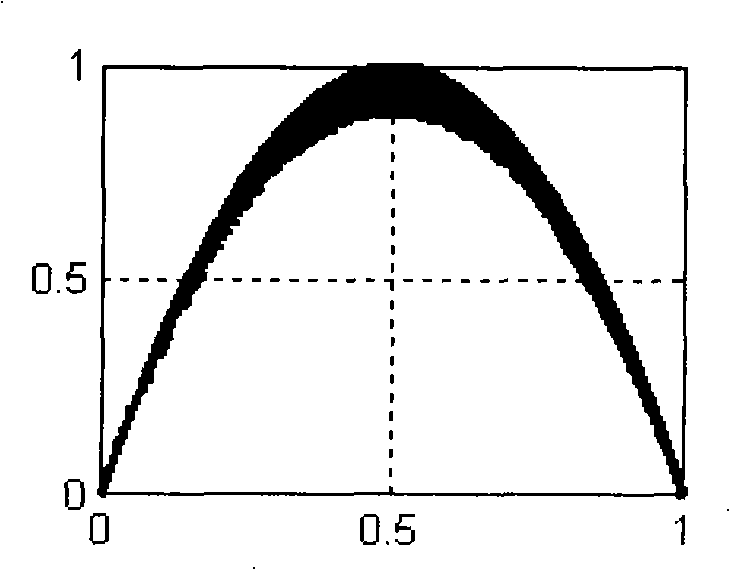

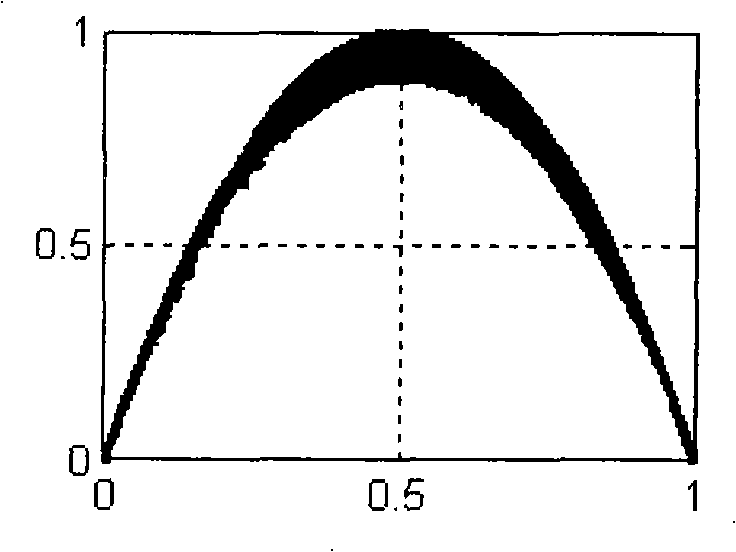

Method for generating chaos sequence

InactiveCN101330378ASolve the degradation problemDoes not affect output dynamicsSecuring communicationComplex mathematical operationsPasswordChaotic systems

The invention relates to a sequence generating method, in particular to a chaotic sequence generating method. A double Logistic mapping coupled structure is adopted, wherein one mapping is used as an excitation parameter generator, and the other mapping is used a chaotic sequence generator. Excitation parameters generated through the excitation parameter generator are utilized to update control parameters of the chaotic sequence generator, thereby enabling the track of the chaotic sequence generator for outputting sequences to conduct continuous transition on a chaotic mapping ensemble, so as to reach the purposes of prolonging the output track of the chaotic sequence and strengthening the uniform distribution of the output sequence, prevent a chaotic system from entering a short period track and resulting in the influence on the safety of chaotic password, and promote the real application of chaotic password.

Owner:CHANGSHU NANJING NORMAL UNIV DEV RES INST

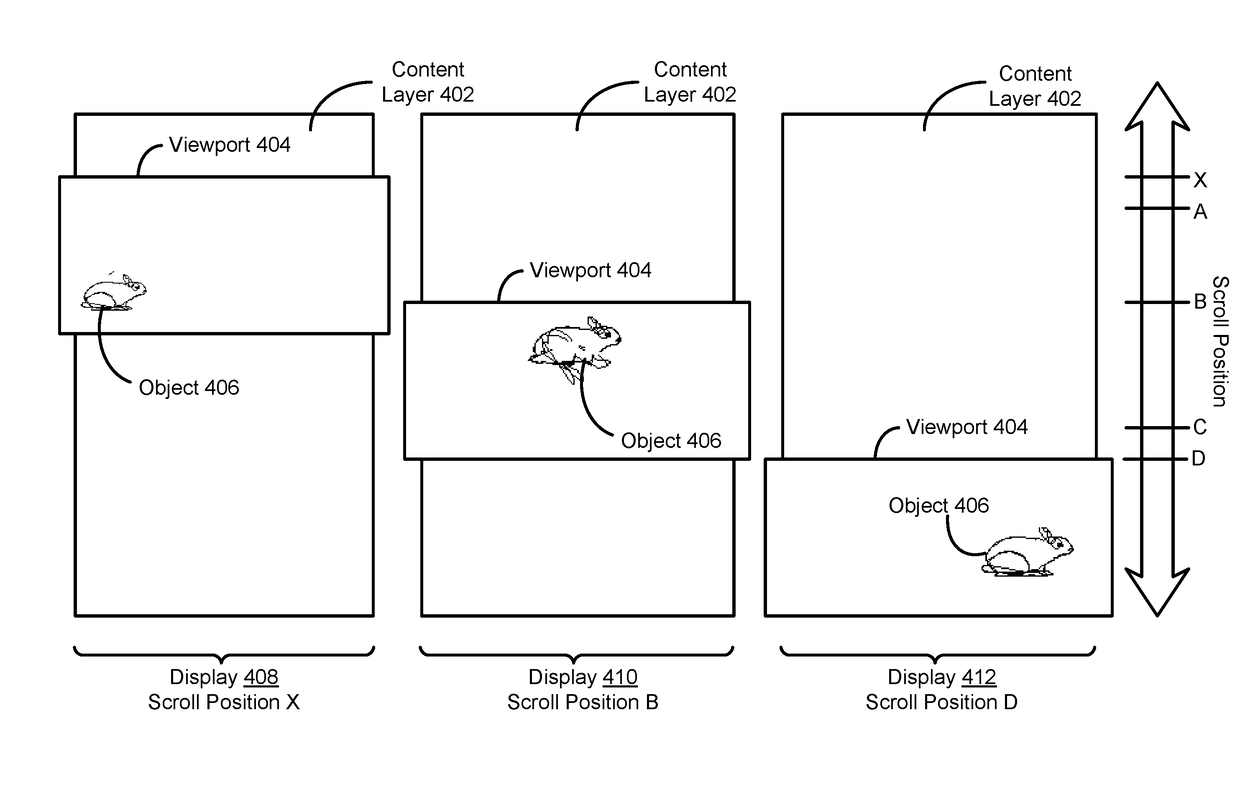

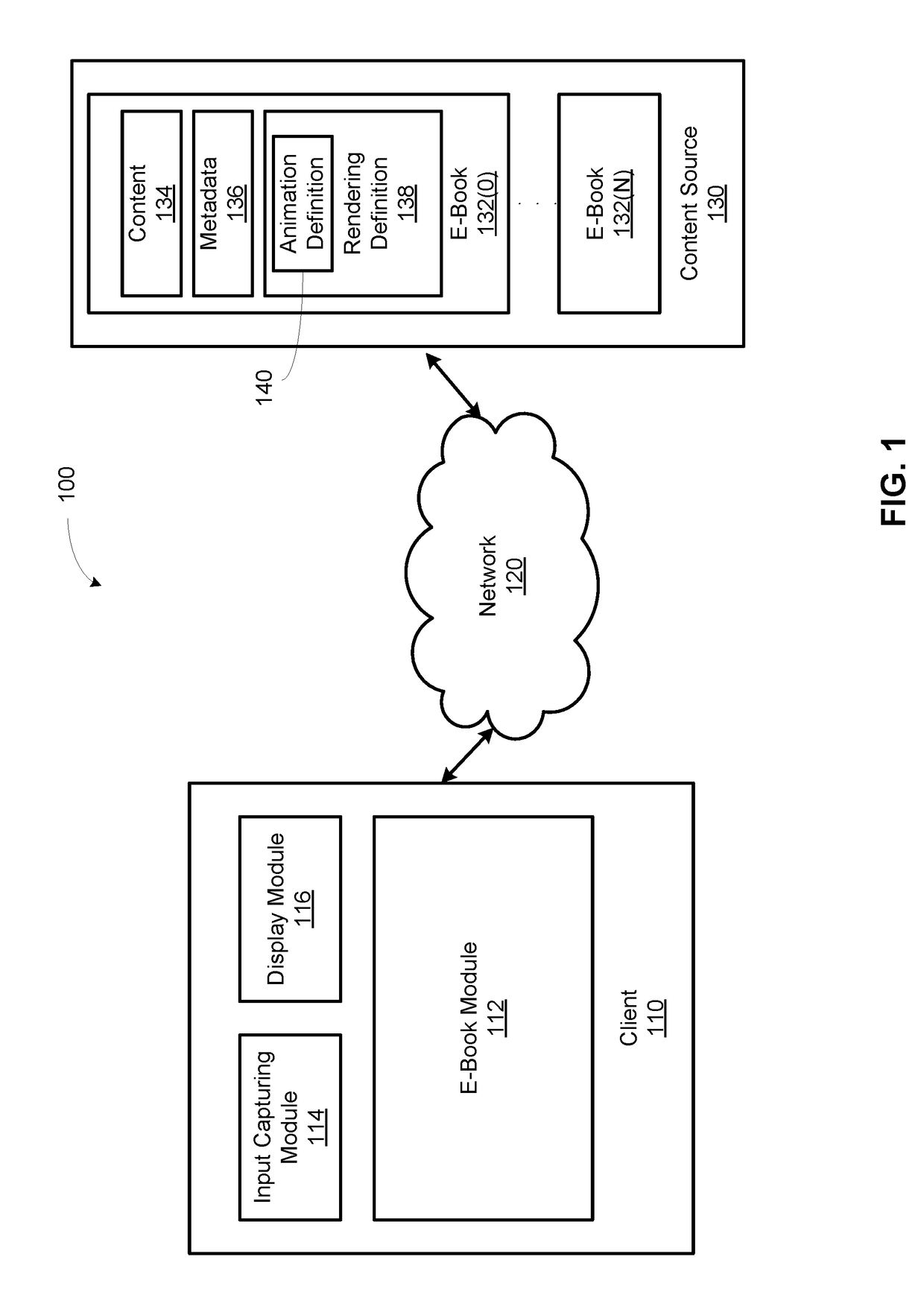

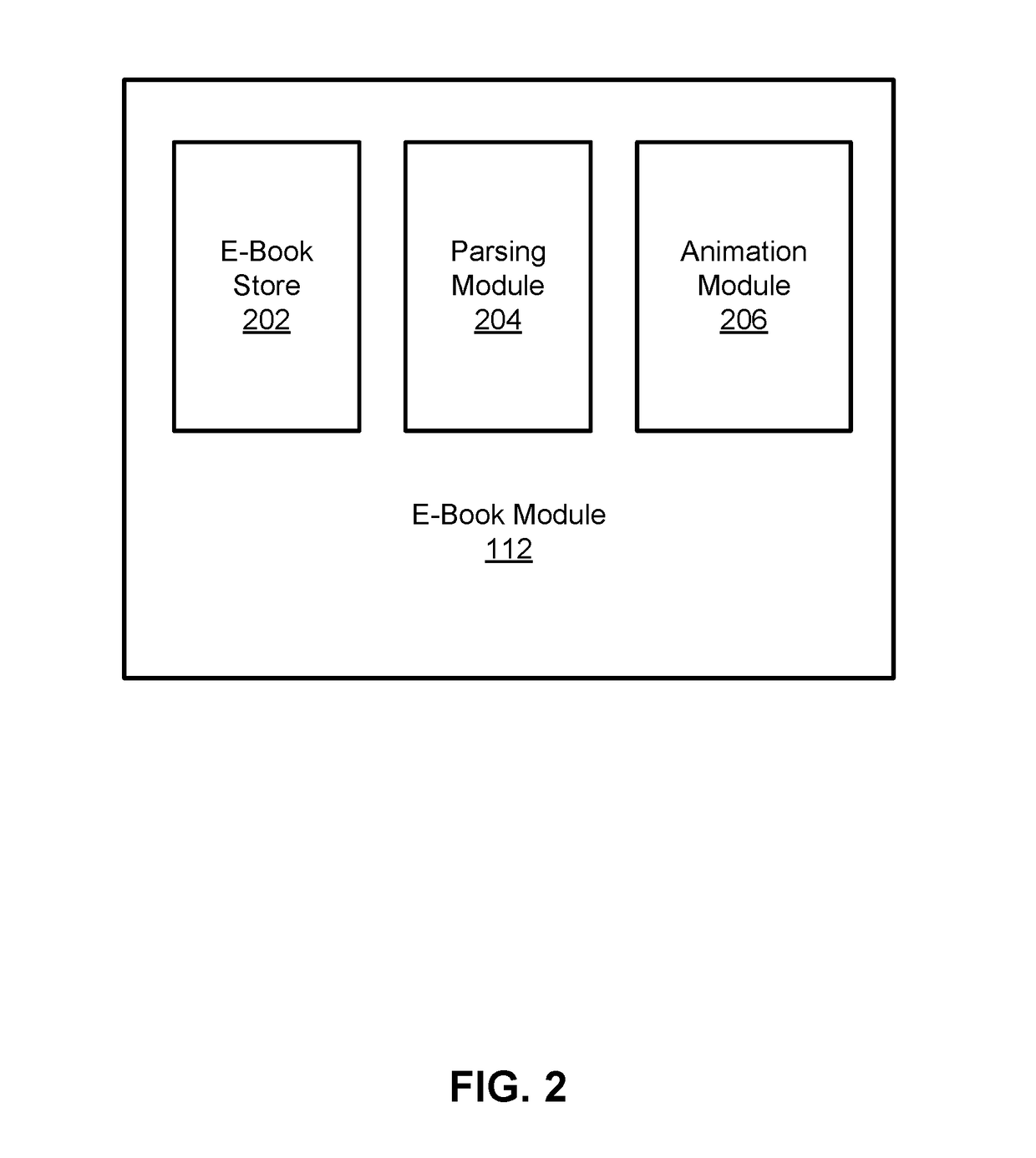

Transition controlled e-book animations

An e-book includes a rendering definition that specifies how content of the e-book is to be displayed to a user and how the user may interact with the displayed content. The rendering definition defines, for each portion of the e-book, the visual layout of content associated with the portion when the portion is displayed. The rendering definition also defines transition controlled animations for objects displayed in association with the content. The transition controlled animation of an object is an interpolation of the object over time and space that is manipulated by a continuous transition input. The transition input causes a transition from one portion of the e-book to another portion of the e-book. The transition controlled animation of the object is performed during transition from one portion of the e-book to the other portion.

Owner:GOOGLE LLC

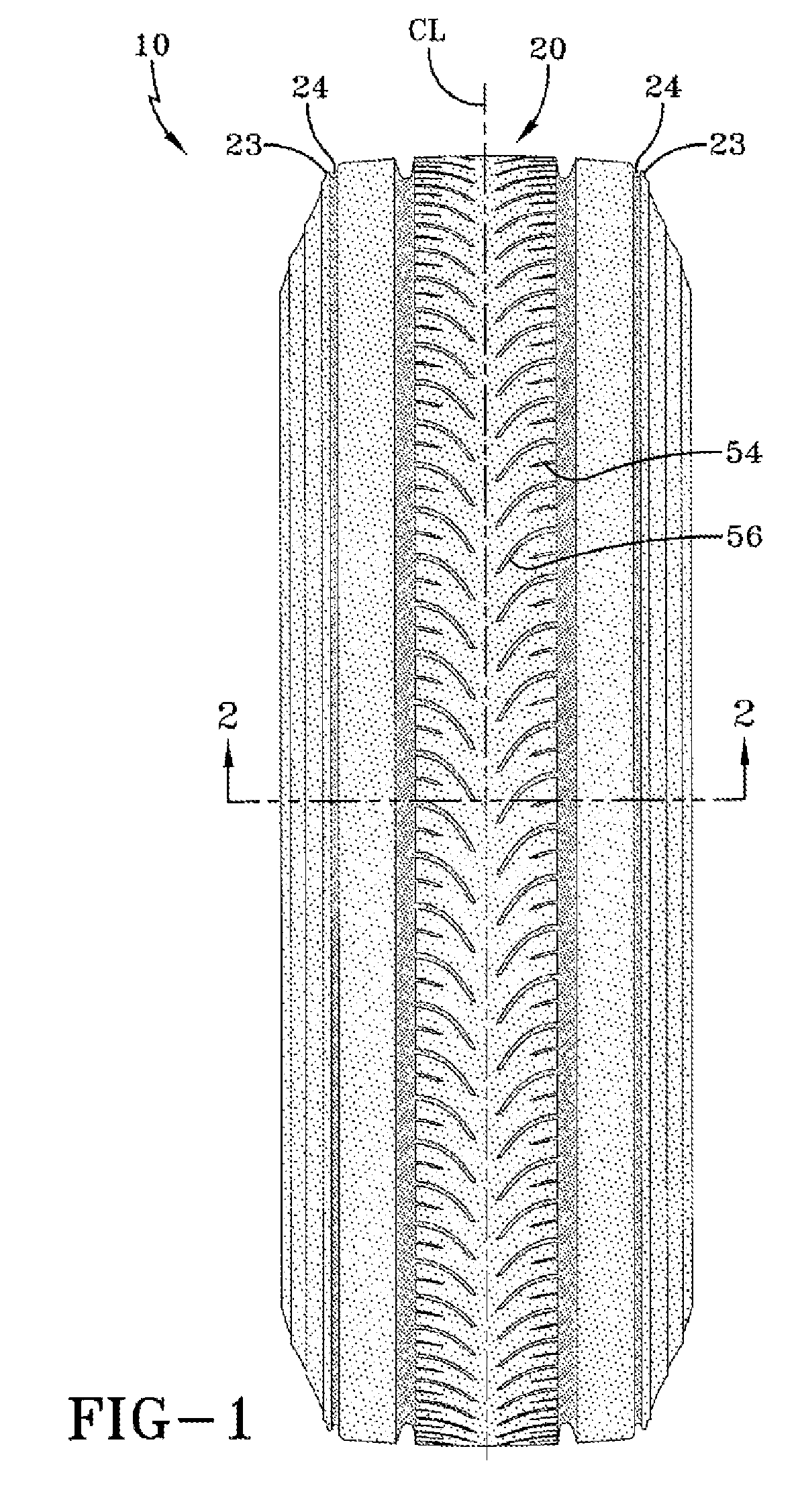

Decoupling groove for pneumatic tire tread

Owner:THE GOODYEAR TIRE & RUBBER CO

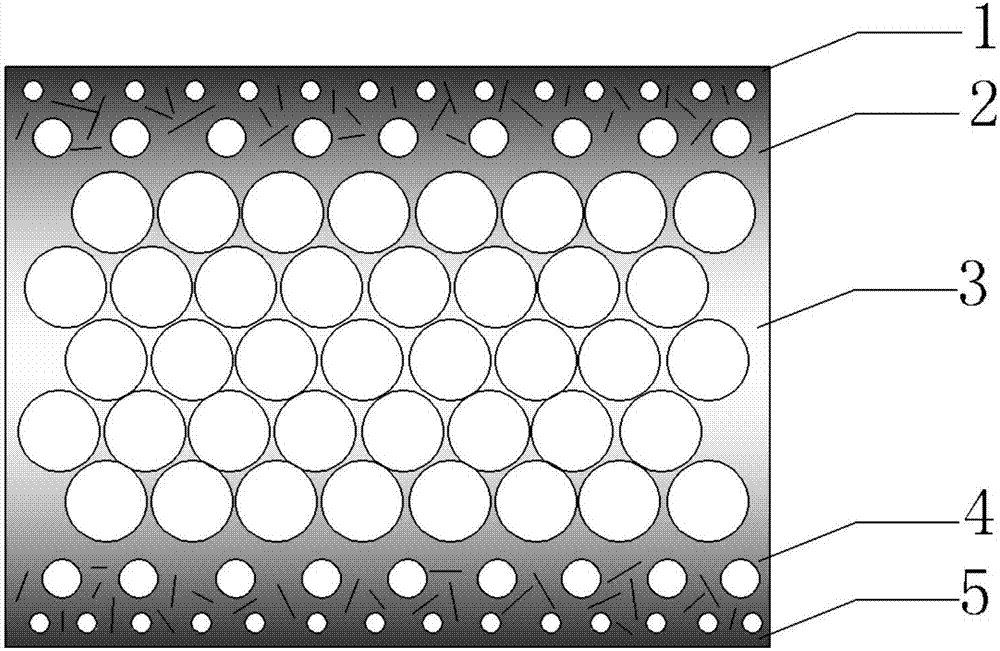

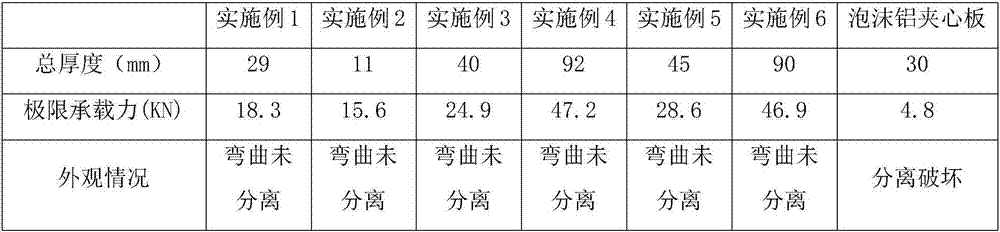

Nano foamed aluminum composite sandwich panel with gradient interface and preparation method thereof

The invention provides a nano foamed aluminum composite sandwich panel with a gradient interface and a preparation method thereof. The nano foamed aluminum composite sandwich panel with the gradient interface comprises upper and lower metal surface layers, upper and lower middle layers and a core layer. The core layer is a foamed aluminum sandwich layer with the gradient interface. The upper and lower middle layers are nano material and foamed aluminum composite layers. The upper and lower metal surface layers are made of one of aluminum, aluminum alloy, steel, titanium and titanium alloy. No clear interface exists between the upper and lower metal surface layers and the upper and lower middle layers as well as between the upper and lower middle layers and the foamed core layer, and a gradient interface area exists. Compositions and structures in the interface area achieve continuous transition, and mechanical strength of the nano material and foamed aluminum composite reinforced sandwich panel is high. The foamed aluminum sandwich panel prepared through the method is high in mechanical strength, long in service life, not prone to layering, capable of solving the surface layer stripping problem happening when the foamed aluminum sandwich panel is stressed and prolonging the service life of the foamed aluminum sandwich panel, simple in preparation method and high in size controllability.

Owner:DONGGUAN JIAQIAN NEW MATERIAL TECH CO LTD

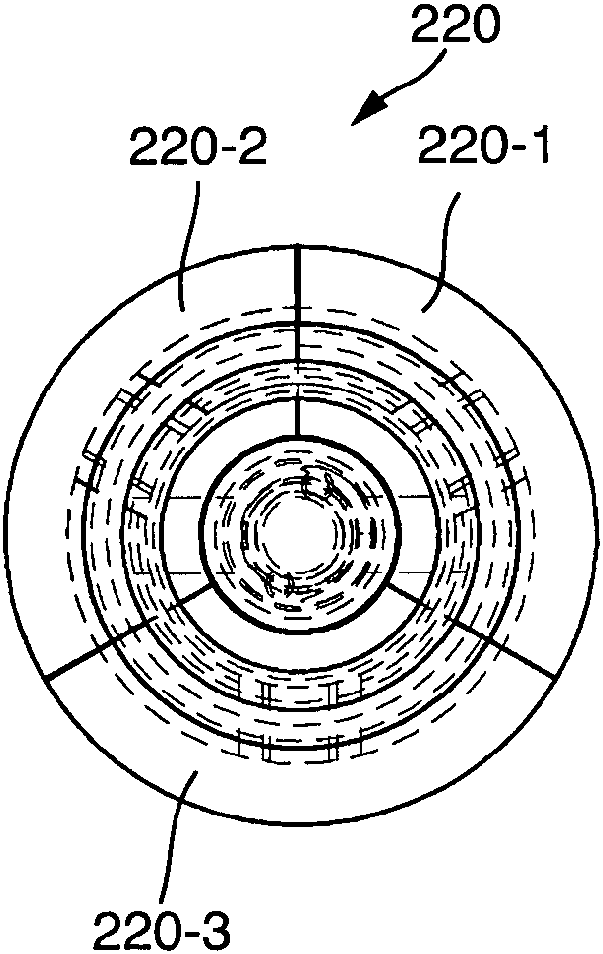

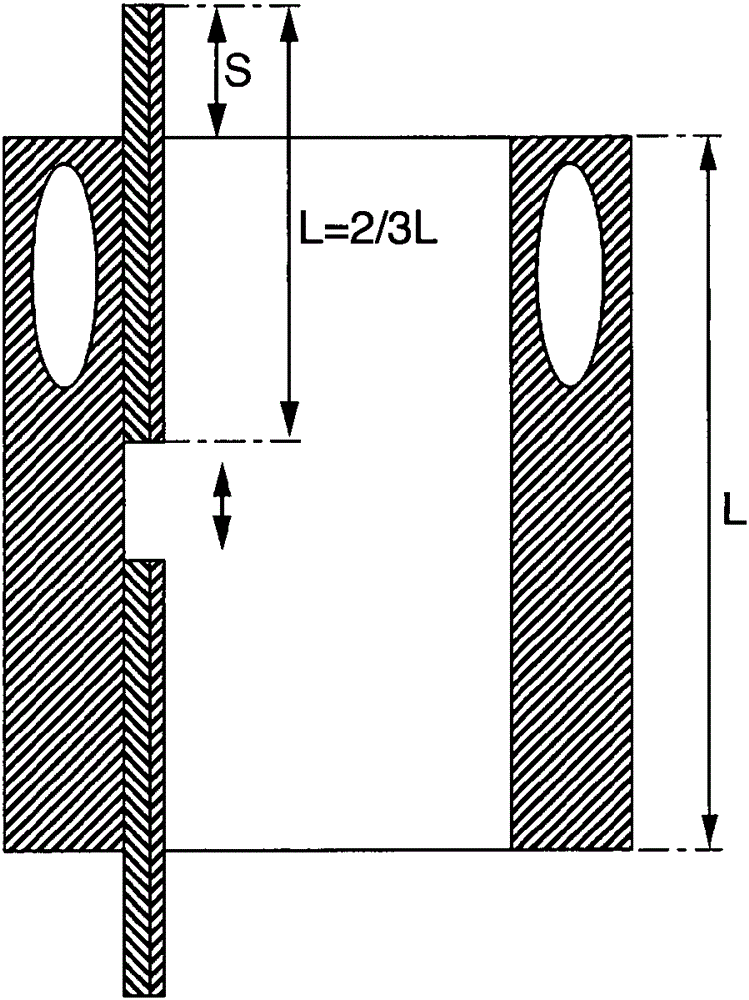

Honing method and honing tool

ActiveCN105246649AAvoid leaningAvoid uneven wearHoning toolsHoning machinesReciprocating motionEngineering

In a honing method for machining the internal surface of a bore in a workpiece with the aid of at least one honing operation, during a honing operation an expandable honing tool is moved up and down within the bore in order to produce a reciprocating movement in the axial direction of the bore and at the same time is rotated in order to produce a rotary movement superimposed on the reciprocating movement. In the process, a bottle-shaped bore is produced, said bore having a first bore section with a first diameter after a bore inlet, a second bore section with a second diameter greater than the first diameter away from the bore inlet, and a transition section having a continuous transition from the first diameter to the second between the first and the second bore section. In this case, during at least one honing operation use is made of an annular tool (200) which has at least one annular cutting unit (220) with a plurality of radially adjustable cutting-material bodies that are distributed around the circumference of a tool body and are formed as honing segments that are wide in the circumferential direction and narrow in the axial direction, wherein an axial length, measured in the axial direction, of the honing segments is less than the width measured in the circumferential direction and the axial length of the cutting region equipped with cutting-material bodies is less than the effective outside diameter of the honing tool. The method is particularly suitable for honing cylinder running surfaces in the production of cylinder blocks or cylinder liners for reciprocating piston machines.

Owner:ELGAN DIAMANTWERKZEUGE

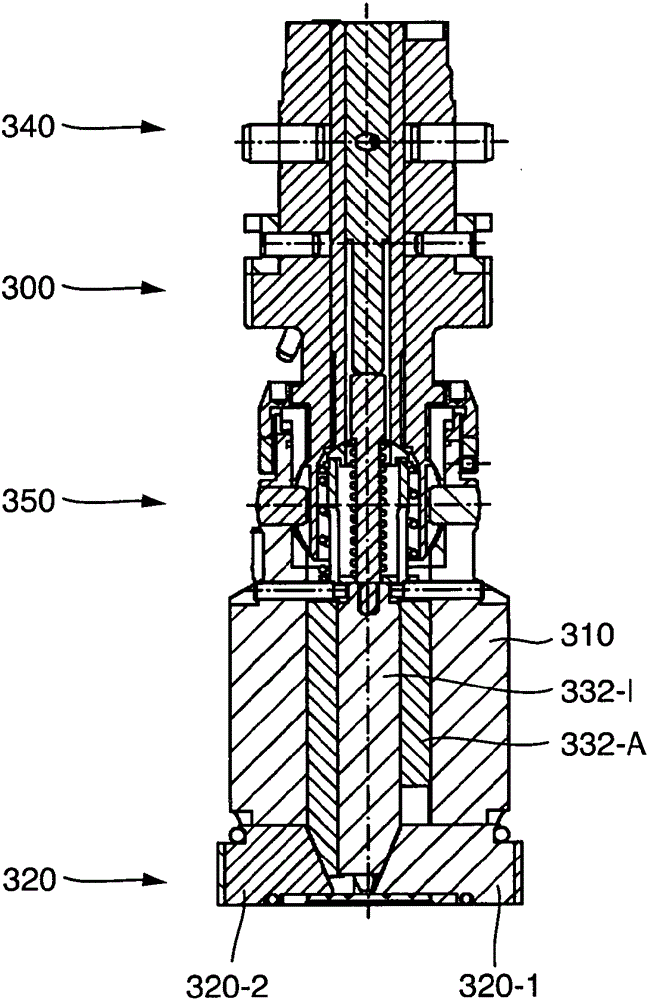

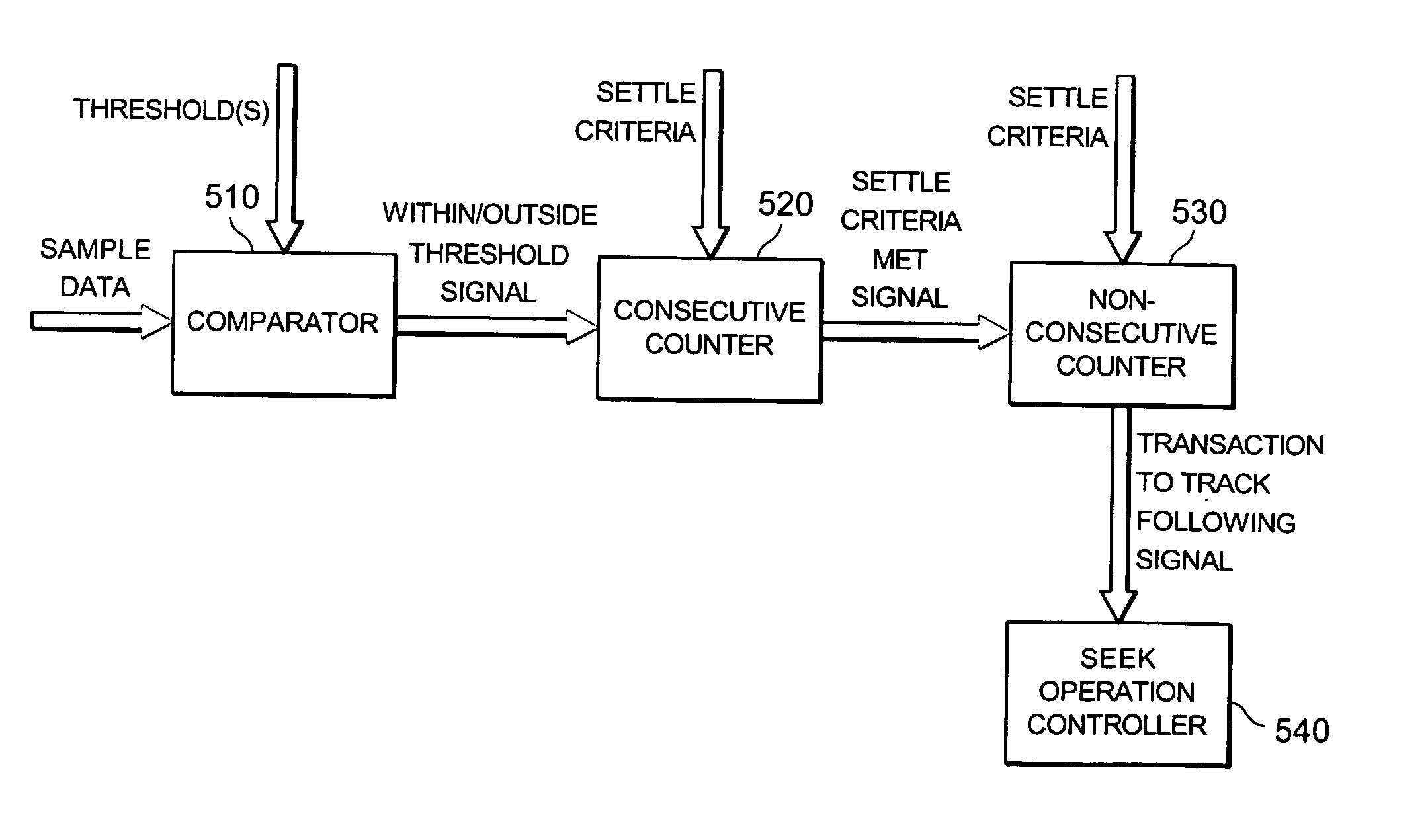

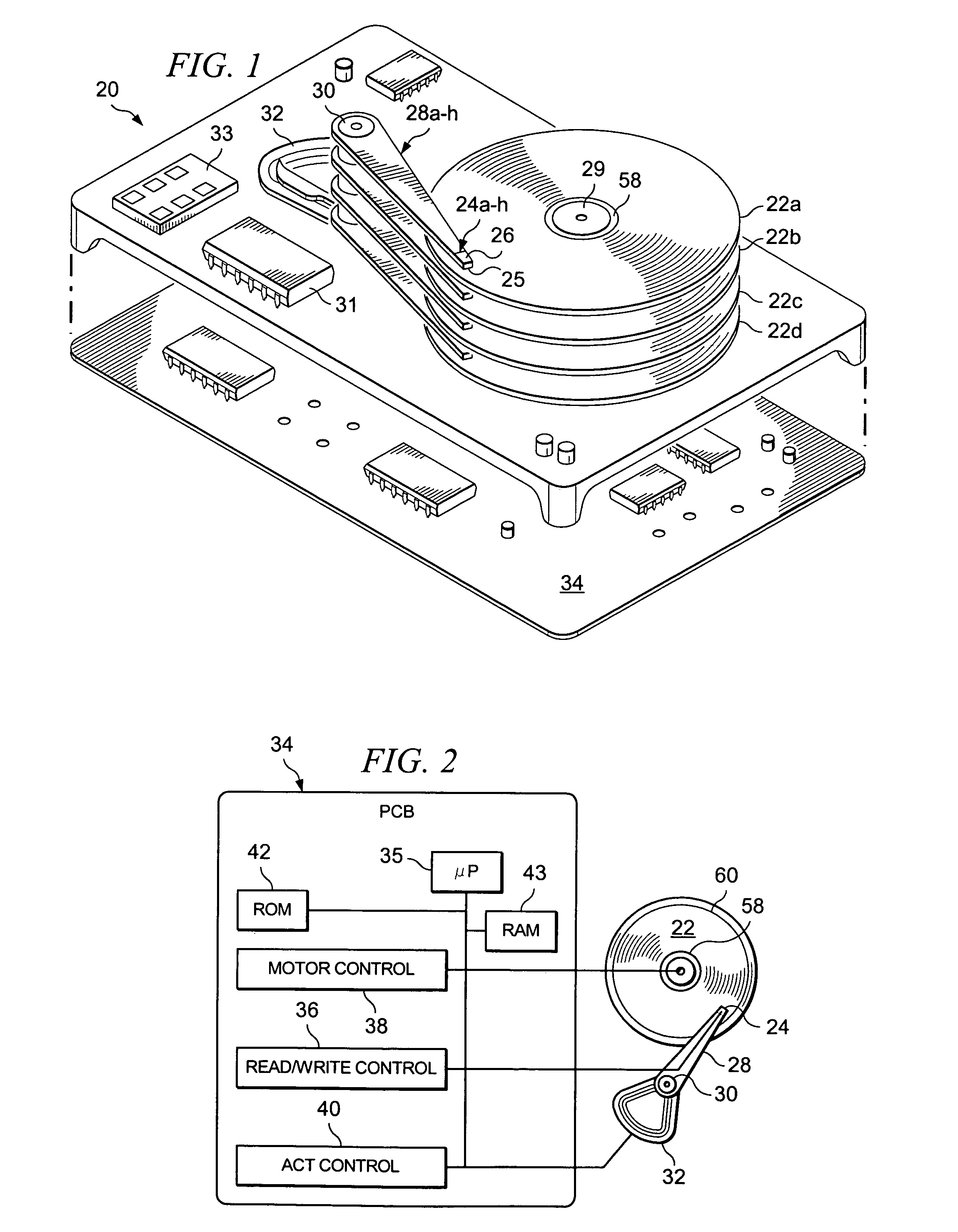

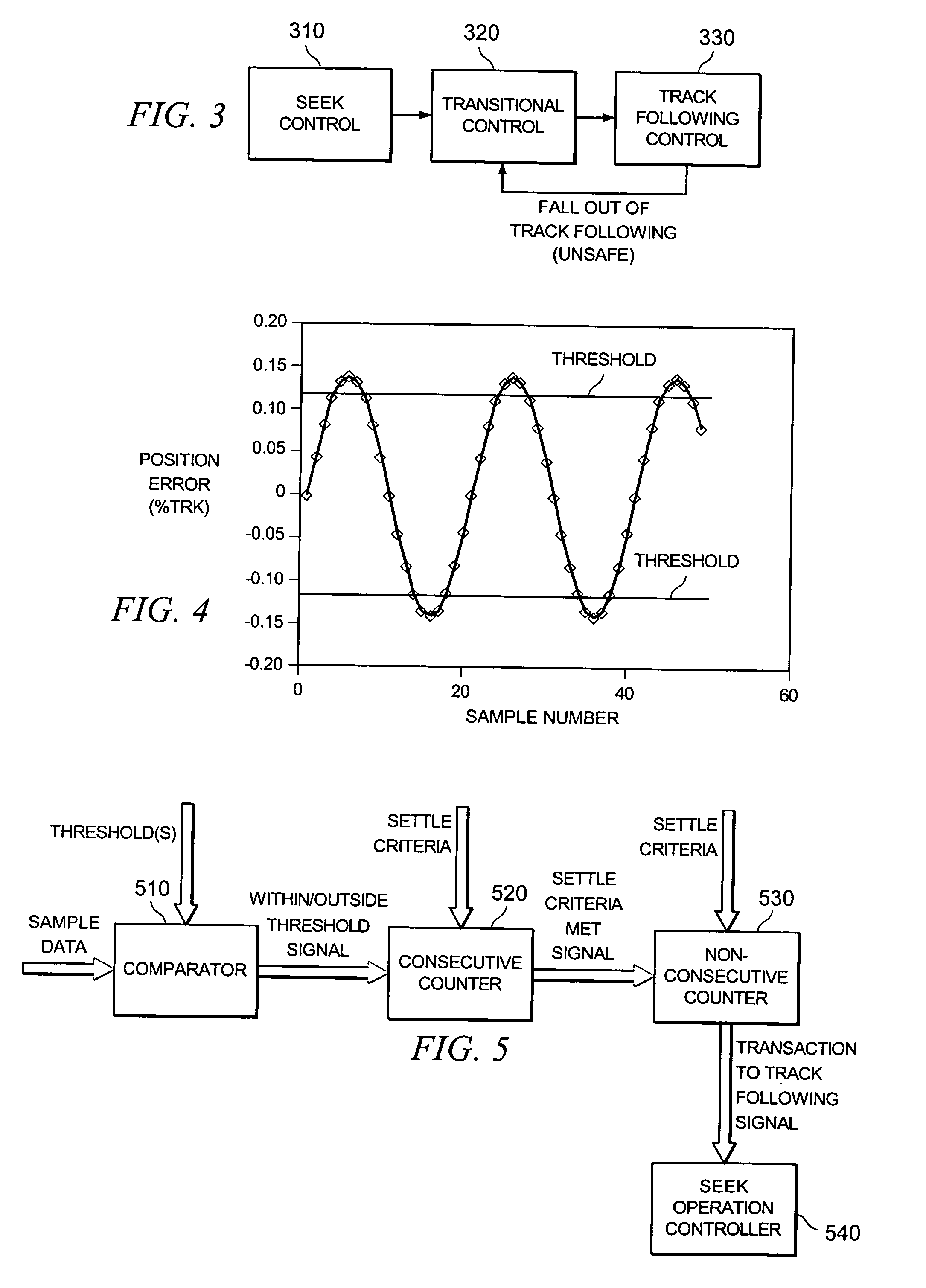

Non-consecutive transitional mechanism for seek operations when transitioning from a seek control to a track following control

InactiveUS20050046984A1Extended stabilization timeRecord information storageCarrier monitoringCONSECUTIVE SAMPLEReal-time computing

A method and apparatus for improving the settle time and thus, the transition from seek control to track following control in a disc drive system are provided. With the apparatus and method, two counters are provided—a consecutive counter and a non-consecutive counter. The consecutive counter counts consecutive samples that meet threshold requirements. The non-consecutive counter counts non-consecutive groups of consecutive samples that meet threshold requirements. When the consecutive counter reaches a first predetermined value, the non-consecutive counter is incremented and the consecutive counter is reset to zero. When the non-consecutive counter reaches a second predetermined value, a track following control mechanism is initiated to thereby transition from a seek control operation to a transitional control operation and finally a track following control operation.

Owner:SEAGATE TECH LLC

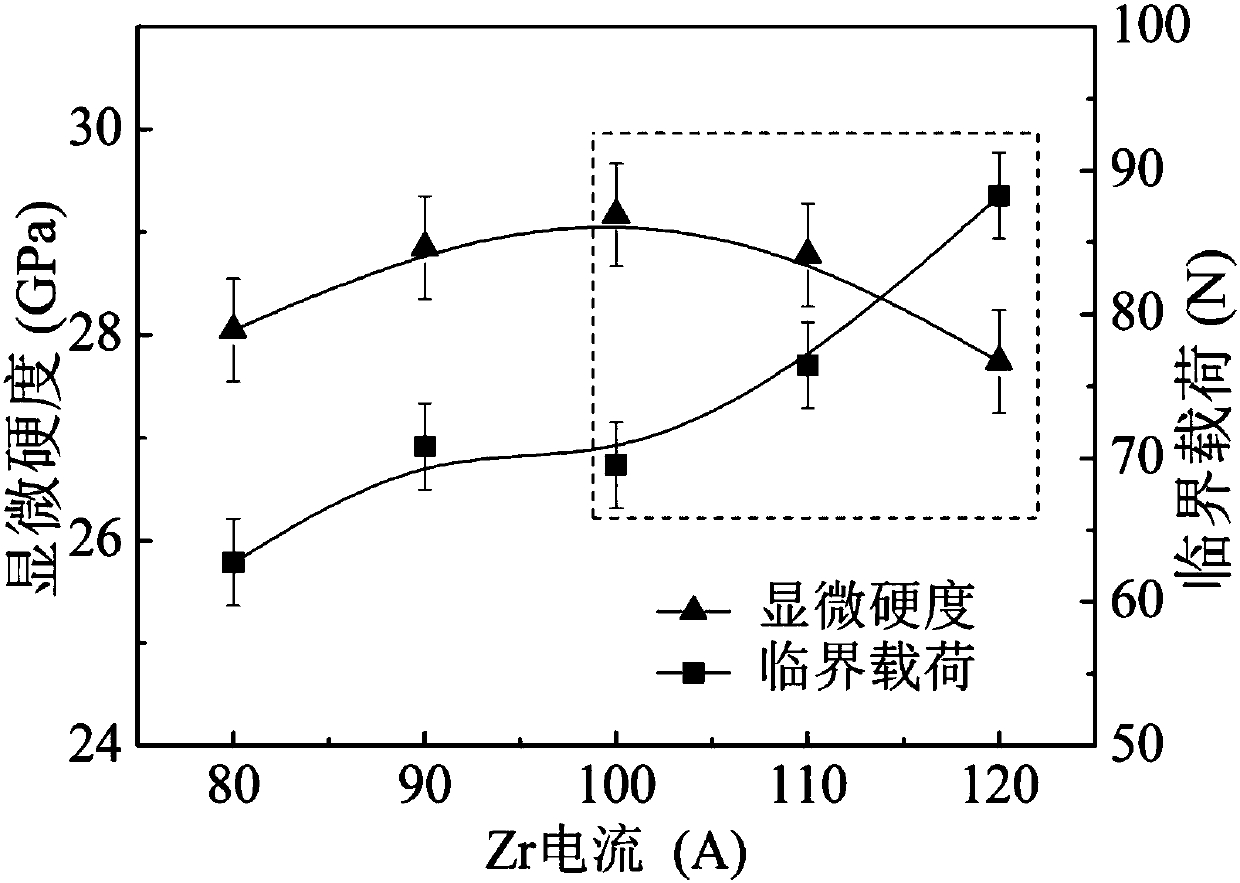

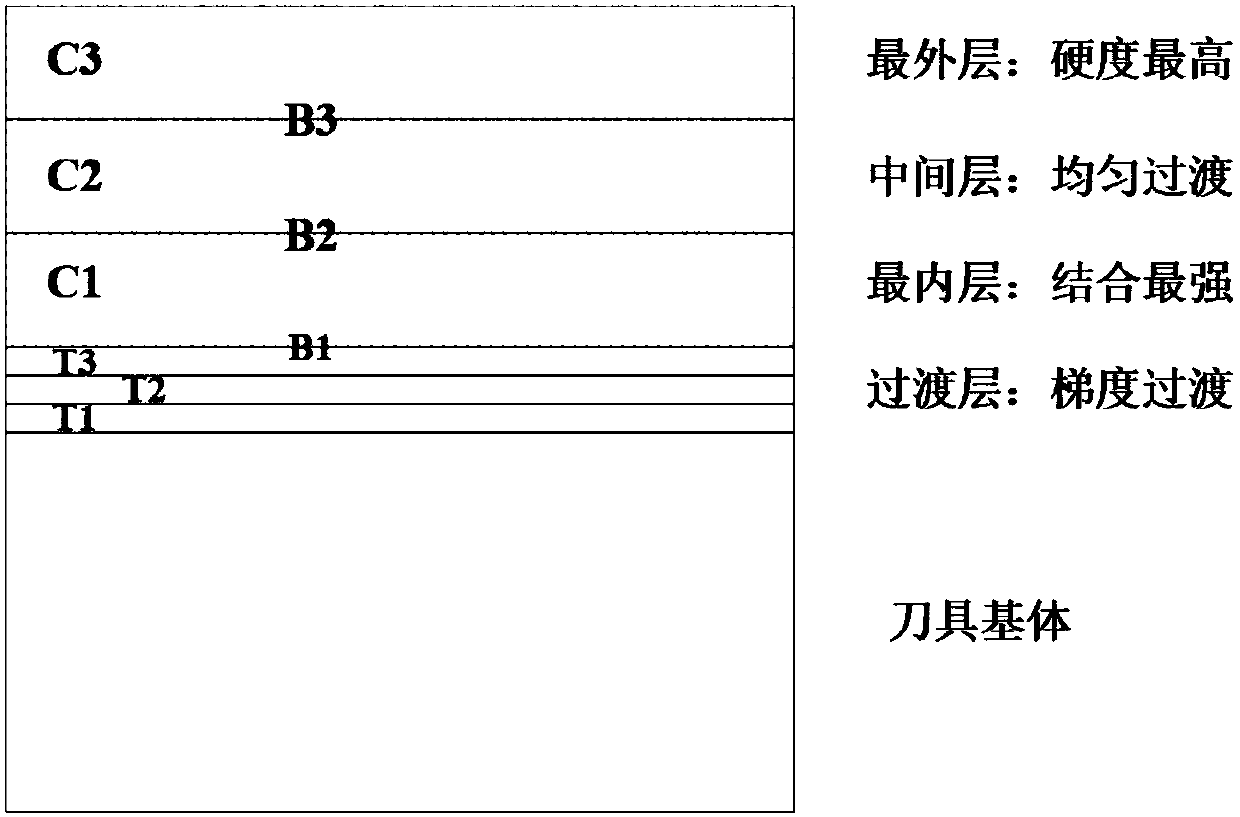

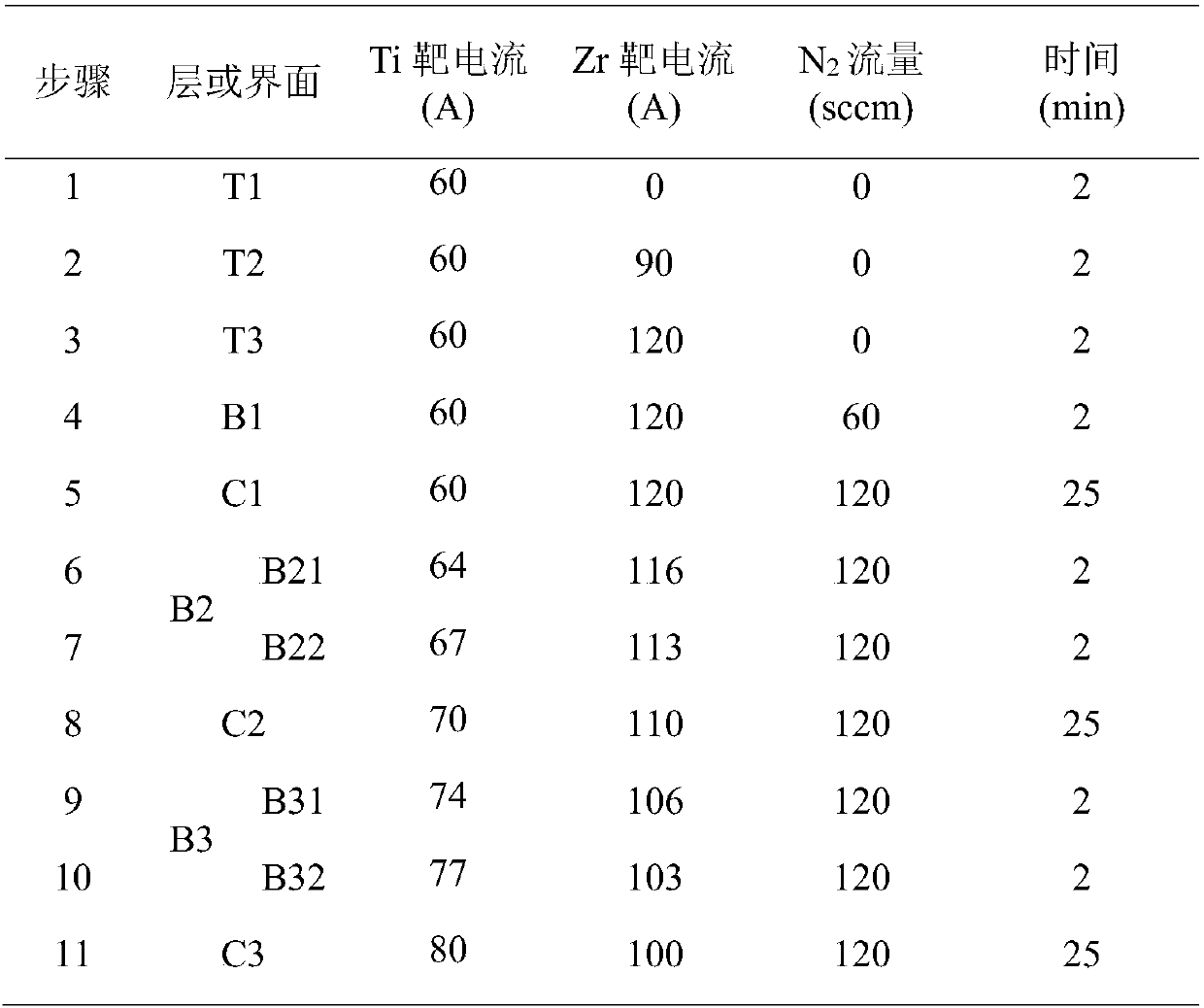

Preparation method of multi-dimensional gradient coating layer on surface of cutter

InactiveCN107675133AHigh hardnessHigh bonding strengthVacuum evaporation coatingSputtering coatingStress concentrationTreatment field

The invention relates to a preparation method of a multi-dimensional gradient coating layer on a surface of a cutter, and belongs to the technical field of metal cutting and cutter coating. The multi-dimensional gradient coating layer adopts the same coating material system; and components and performances of each deposition layer are controlled through controlling process parameters of the deposition process, so that the components and the mechanical performances of each deposition layer can realize continuous transition from inner layer to outer layer, the mutation of interface element components, physical performances and mechanical performances is prevented, the stress concentration caused by mismatch on interfaces is effectively relieved, and the coating reliability in the use processis improved. The outermost layer of the multi-dimensional gradient coating layer prepared by the method is high in hardness, so that the surface wear resistance can be effectively improved; the interfaces of internal deposition layers are high in bonding strength to effectively improve the coating capacity of resisting such destructions and failures as stripping / layered stripping; and the methodcan be widely applied to the coating treatment field of cutting tools and wear resisting surfaces.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com