Cryogenic liquid storage tank

一种低温液体、存储罐的技术,应用在气体/液体分配与储存、固定容量储气罐、气体处理/储存目的等方向,能够解决构造计划易被中断等问题,达到减少蒸发的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

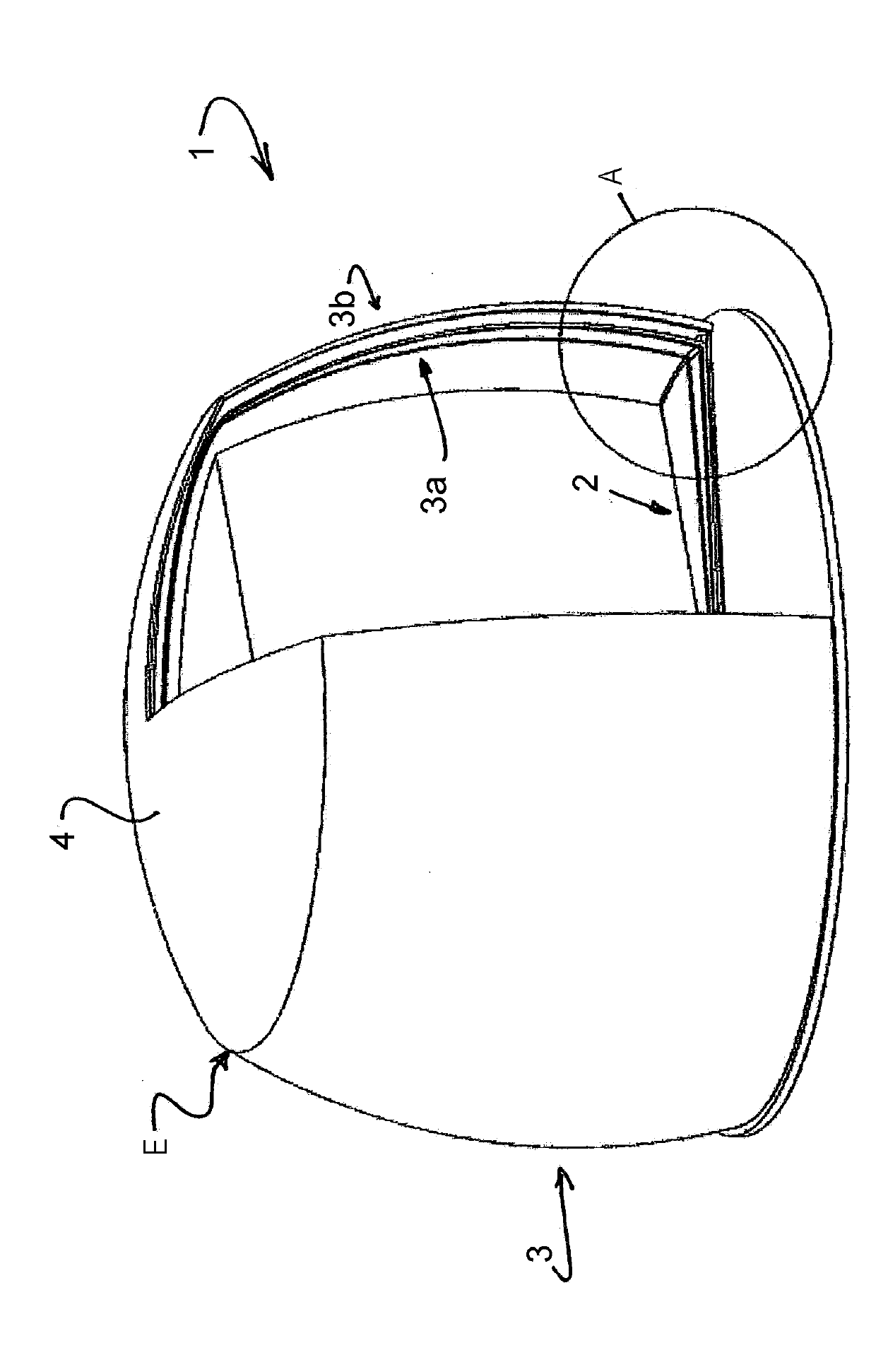

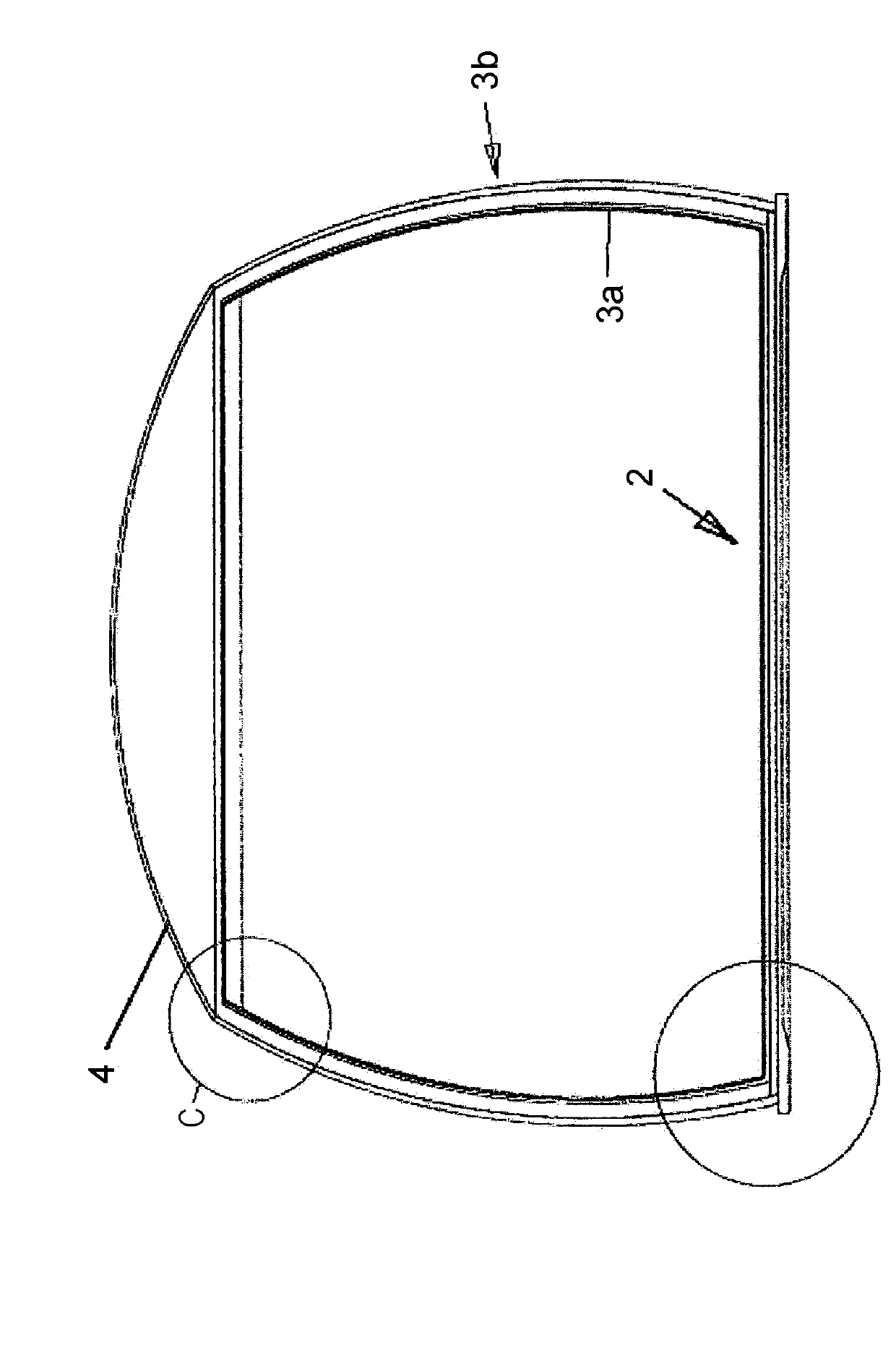

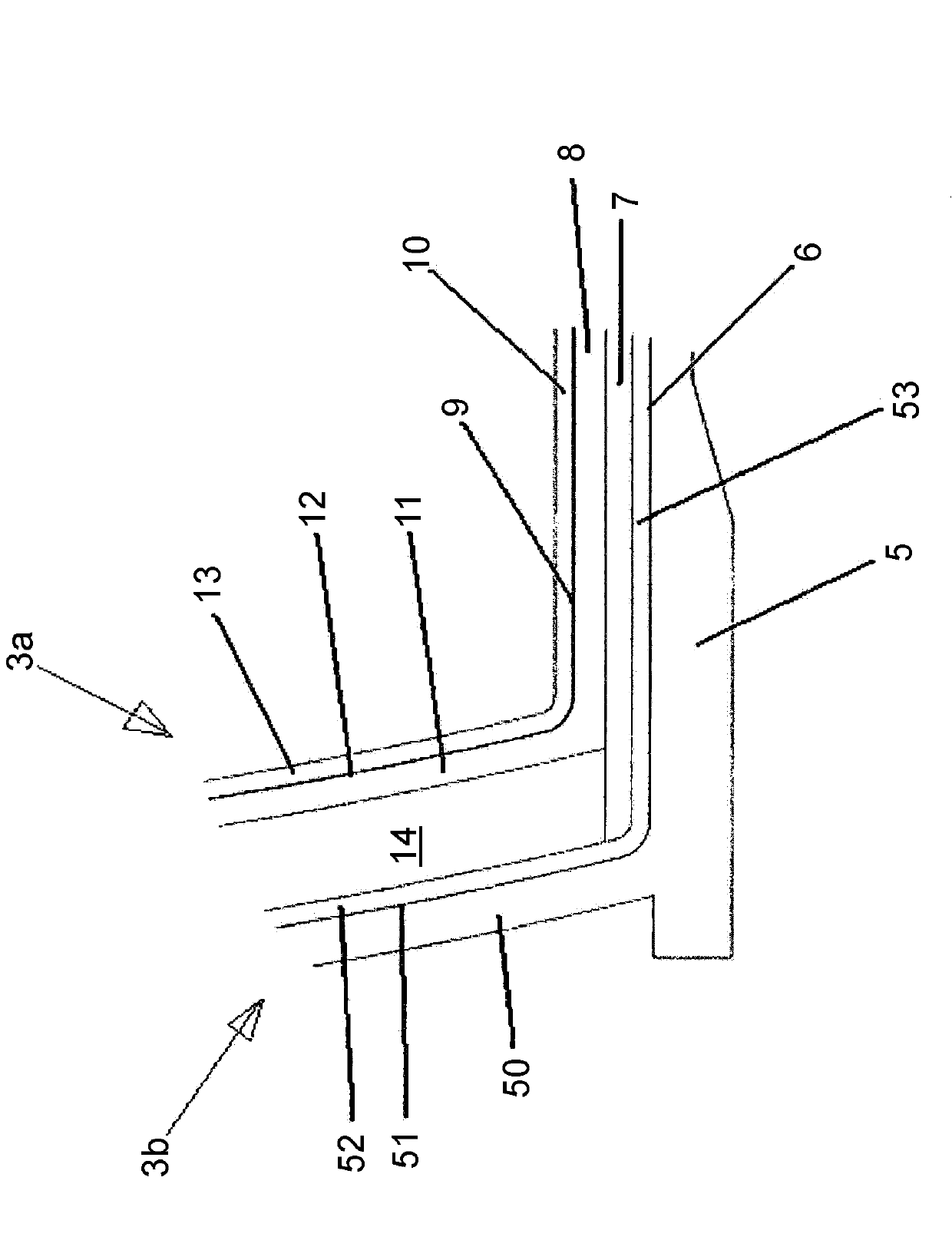

[0066] Referring now to the accompanying drawings, Figure 1 to Figure 3 An embodiment of a storage tank 1 according to the invention is illustrated. The storage tank 1 comprises an inner tank part and an outer tank part, referred to herein as inner vanes 3a and outer vanes 3b. The tank wall 3 is formed on the circular base 2 . A dome 4 closes the top of the tank 1 .

[0067] as from figure 1 and figure 2 It can be clearly seen that the side wall 3 of the tank is substantially circular in plan shape, but differs from conventional tanks in this embodiment of the invention in that the side wall is not straight but curved in vertical section , to present the raised face to the exterior of the can. At the lower edges of the side walls, the side walls slope outwardly from the base. The side walls 3 are curved inwardly from the base to its upper edge, giving the can's outwardly convex shape.

[0068] In the embodiment shown, the foundation 2 comprises a solid footing, such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com