Patents

Literature

8018results about "Fluid handled" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

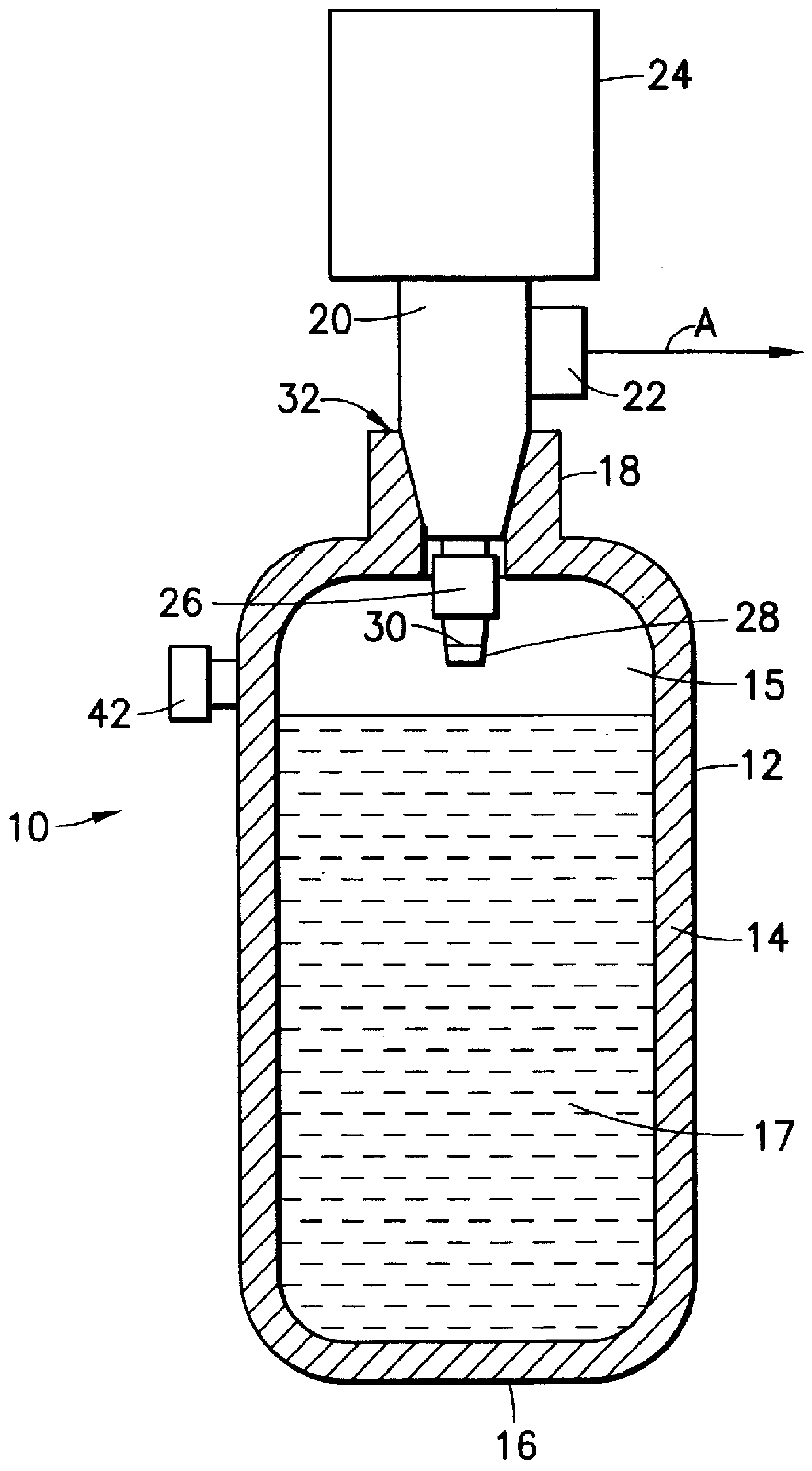

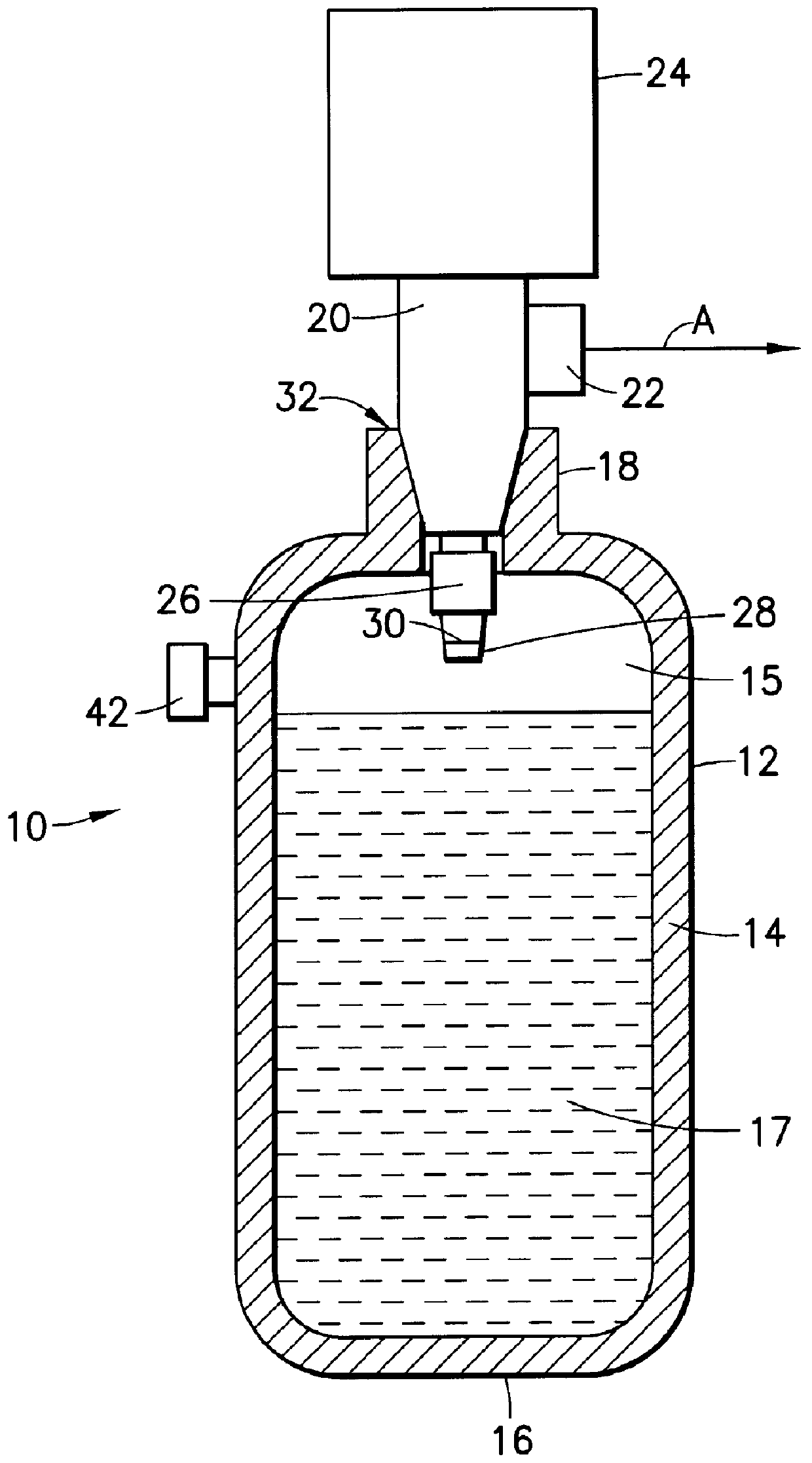

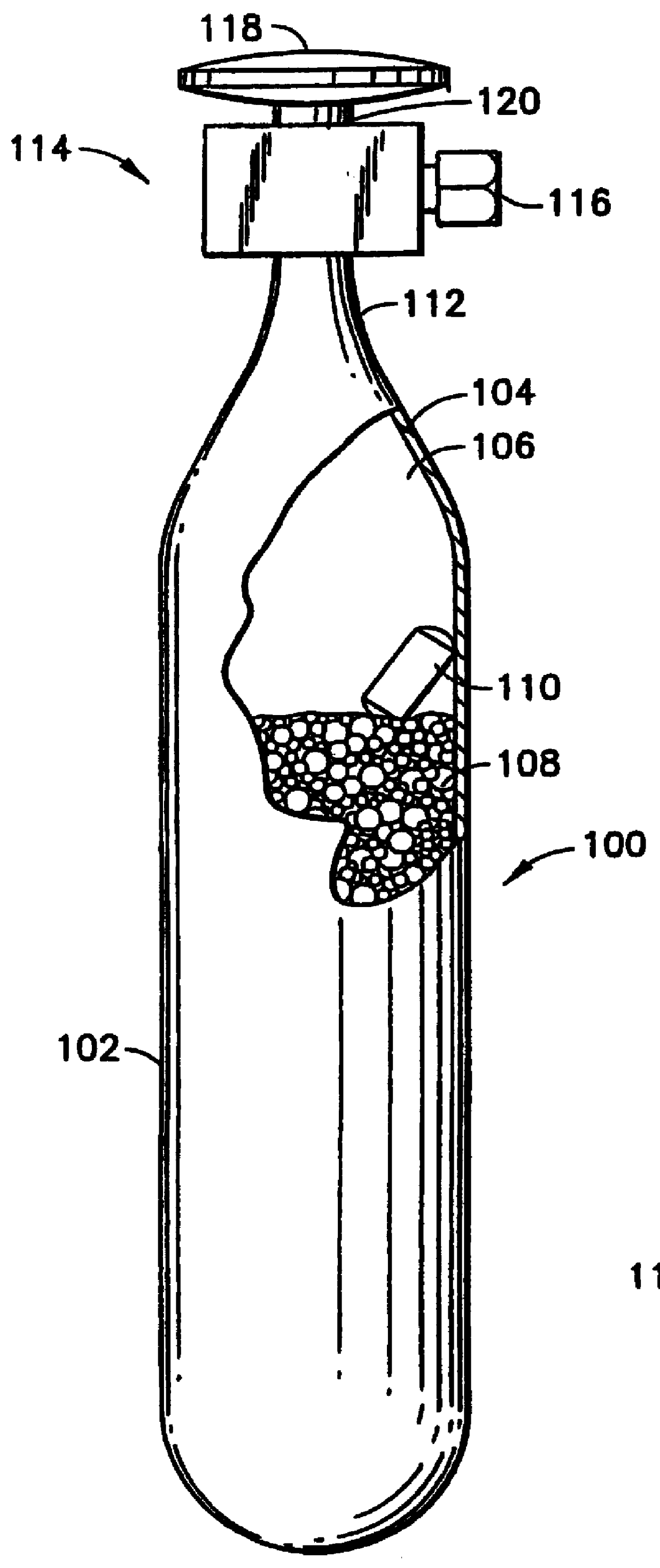

Fluid storage and dispensing system

InactiveUS6089027ACostPerformanceContainer filling methodsVacuum evaporation coatingSingle stageSorbent

A fluid storage and dispensing system comprising a vessel for holding a fluid at a desired pressure. The vessel has a pressure regulator, e.g., a single-stage or multi-stage regulator, associated with a port of the vessel, and set at a predetermined pressure. A dispensing assembly, e.g., including a flow control means such as a valve, is arranged in gas / vapor flow communication with the regulator, whereby the opening of the valve effects dispensing of gas / vapor from the vessel. The fluid in the vessel may be constituted by a liquid that is confined in the vessel at a pressure in excess of its liquefaction pressure at prevailing temperature conditions, e.g., ambient (room) temperature. In another aspect, the vessel contains a solid-phase sorbent material having sorbable gas adsorbed thereon, at a pressure in excess of 50 psig. The vessel may have a >1 inch NGT threaded neck opening, to accommodate the installation of an interior regulator.

Owner:ENTEGRIS INC

Fluid storage and dispensing system

InactiveUS6101816AMinimize the possibilityUse minimizedContainer filling methodsVacuum evaporation coatingLiquid stateProduct gas

A fluid storage and dispensing system comprising a vessel for holding a fluid at a desired pressure. The vessel has a pressure regulator associated with a port of the vessel, and set at a predetermined pressure. A dispensing assembly, e.g, including a flow control means such as a valve, is arranged in gas / vapor flow communication with the regulator, whereby the opening of the valve effects dispensing of gas / vapor from the vessel. The fluid in the vessel may be constituted by a liquid which is confined in the vessel at a pressure in excess of its liquefaction pressure at prevailing temperature conditions, e.g., ambient (room) temperature. A phase separator such as a gas / vapor-permeable liquid-impermeable membrane, may be associated with the regulator, as a barrier to flow of liquid into the regulator, when the contained fluid in the vessel is in a liquid state.

Owner:ENTEGRIS INC

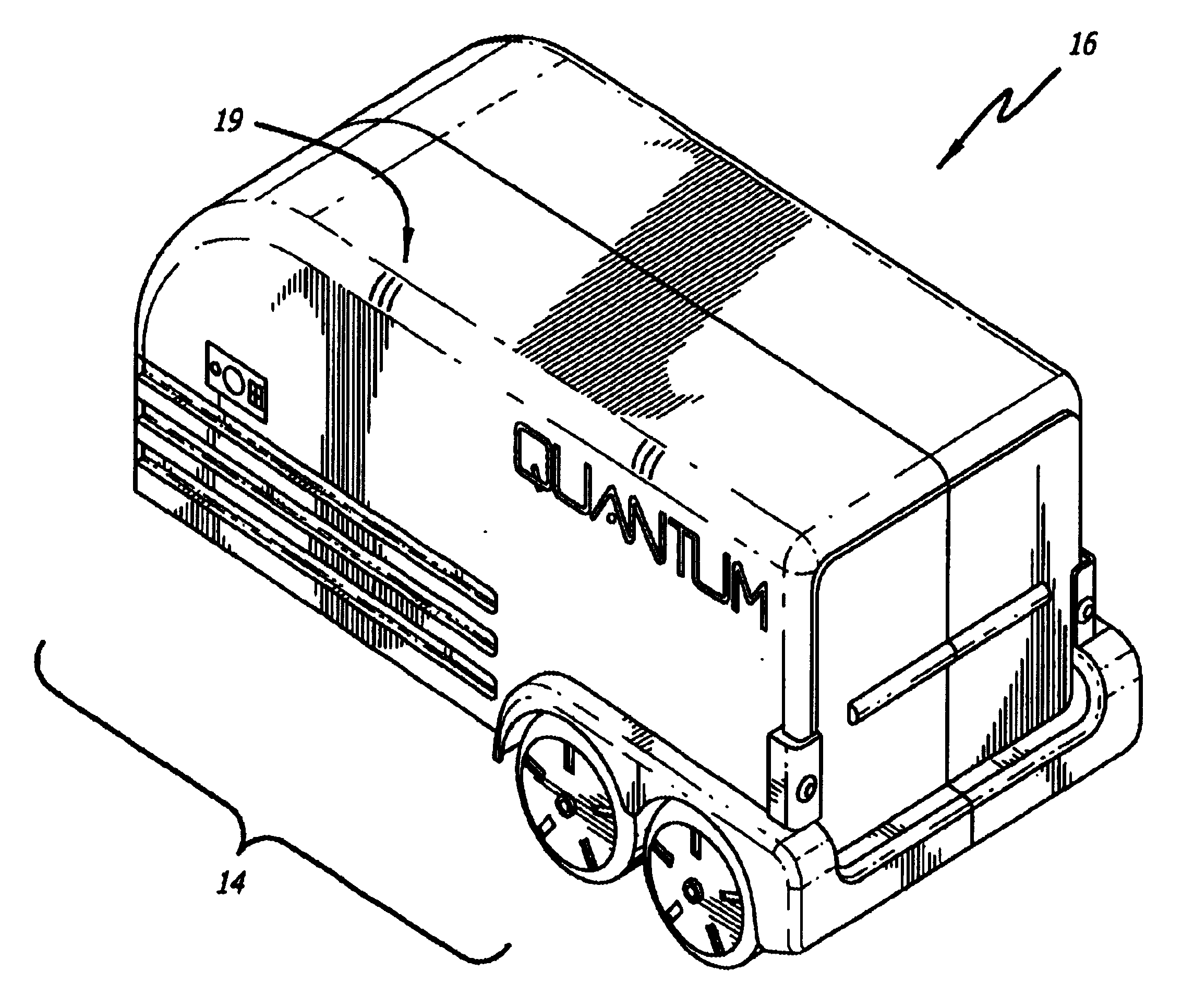

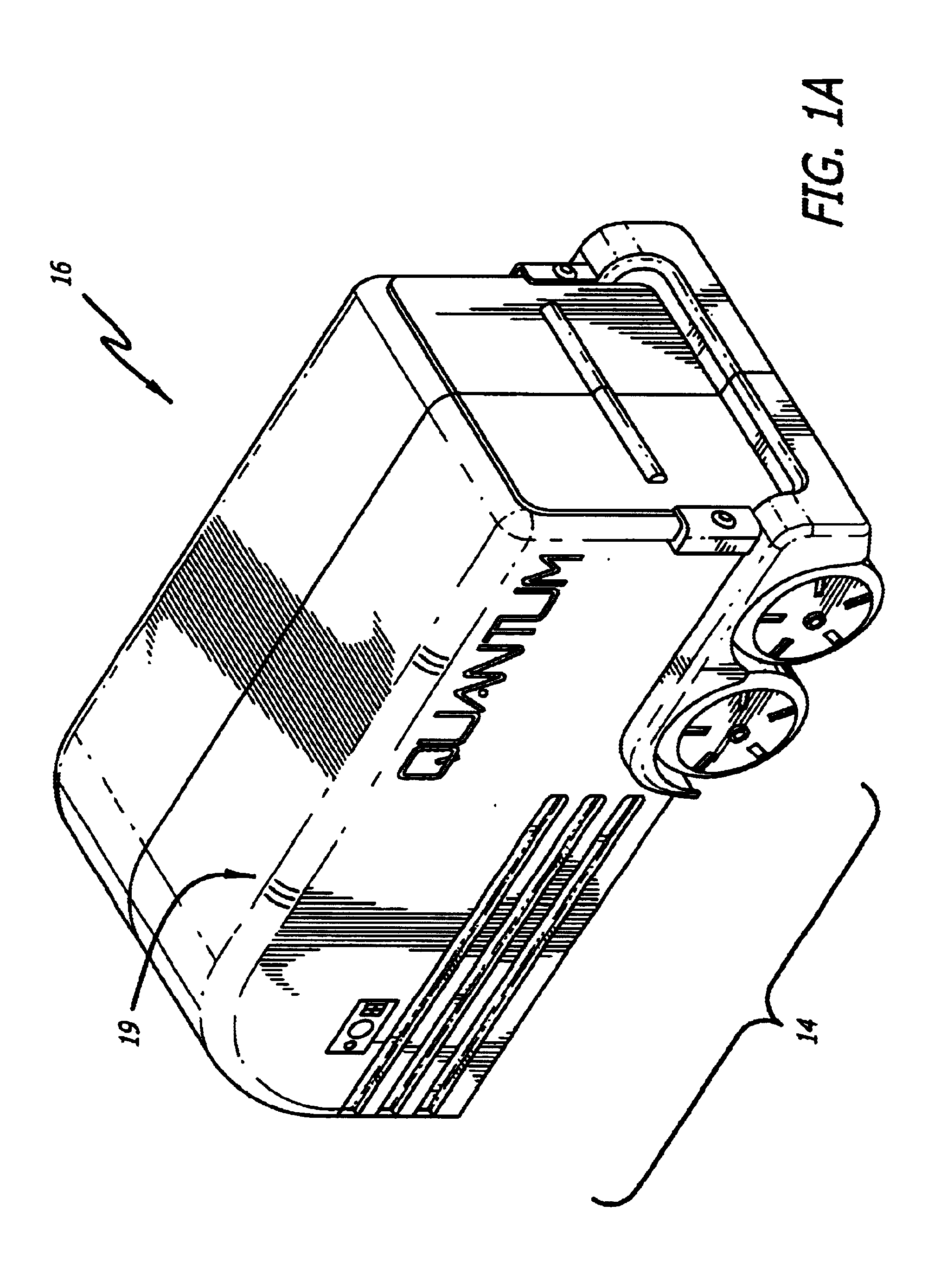

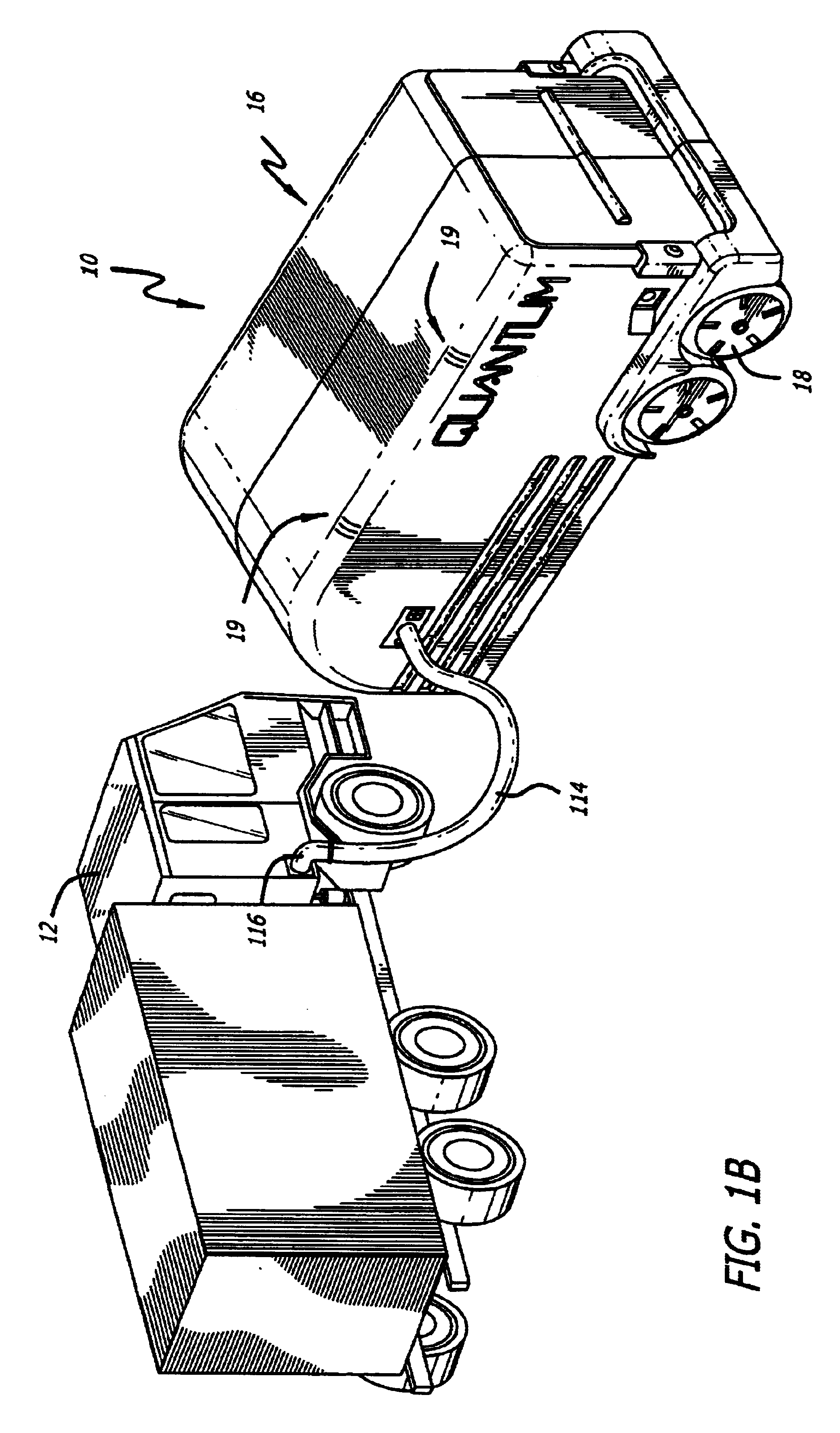

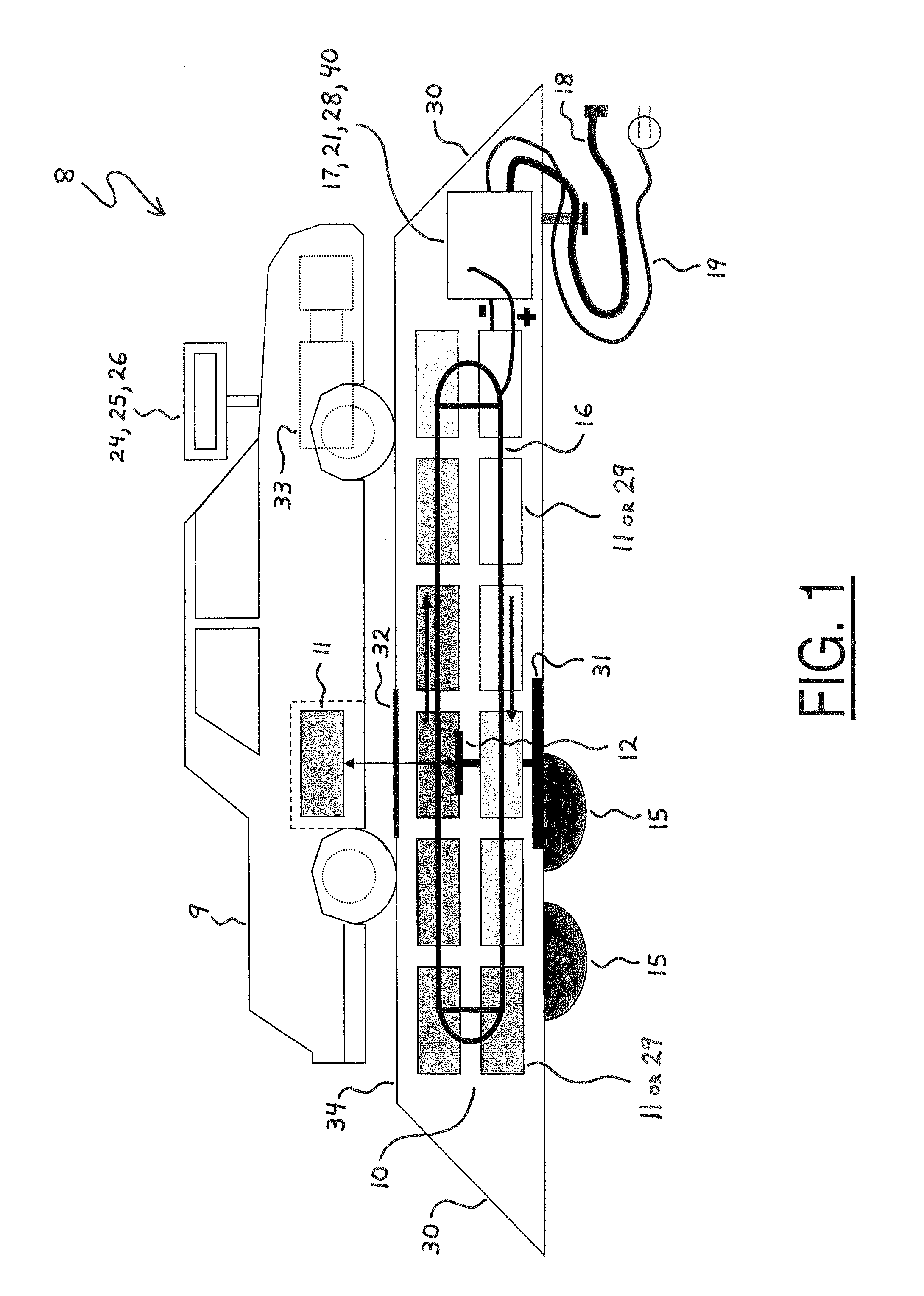

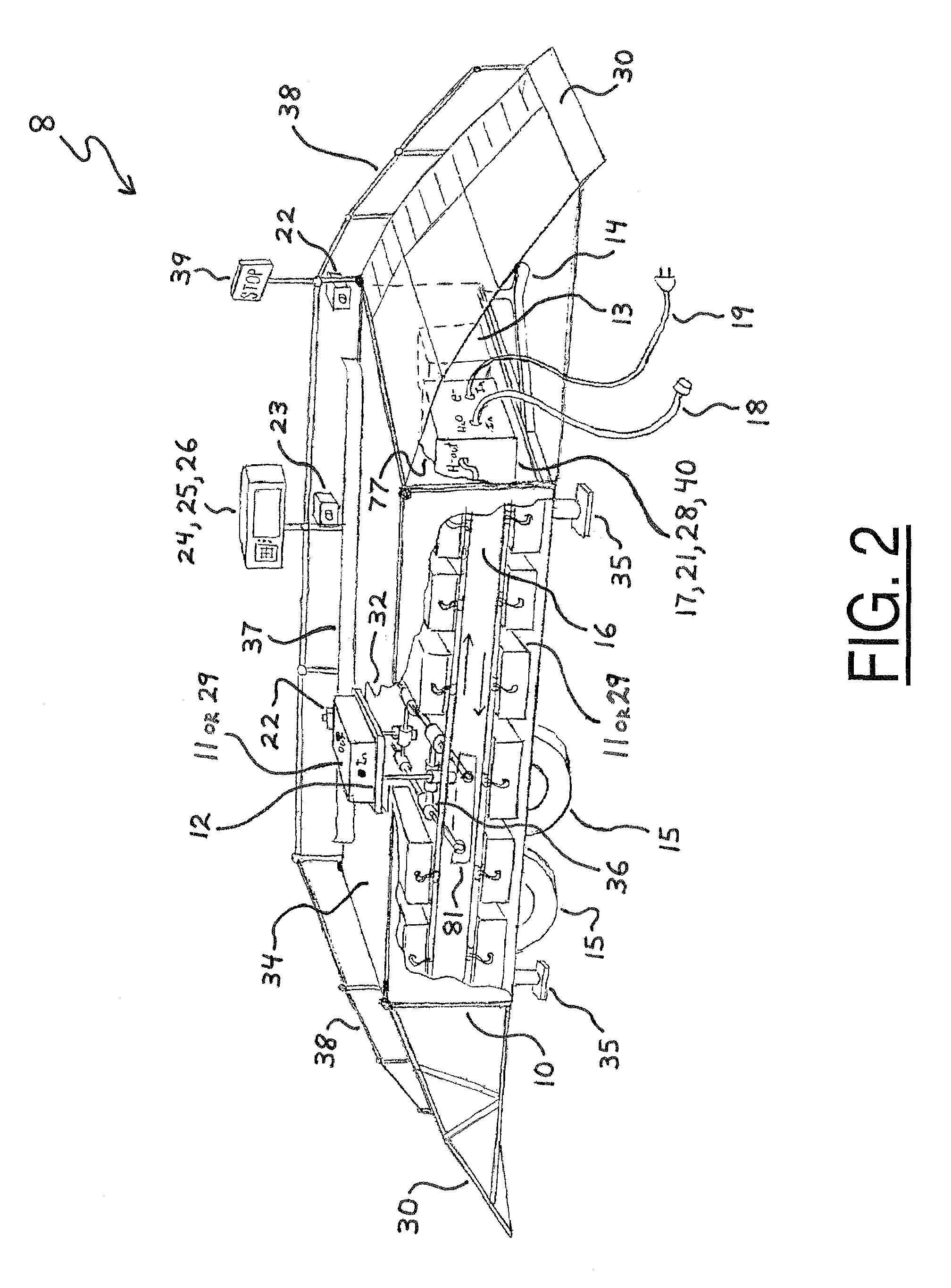

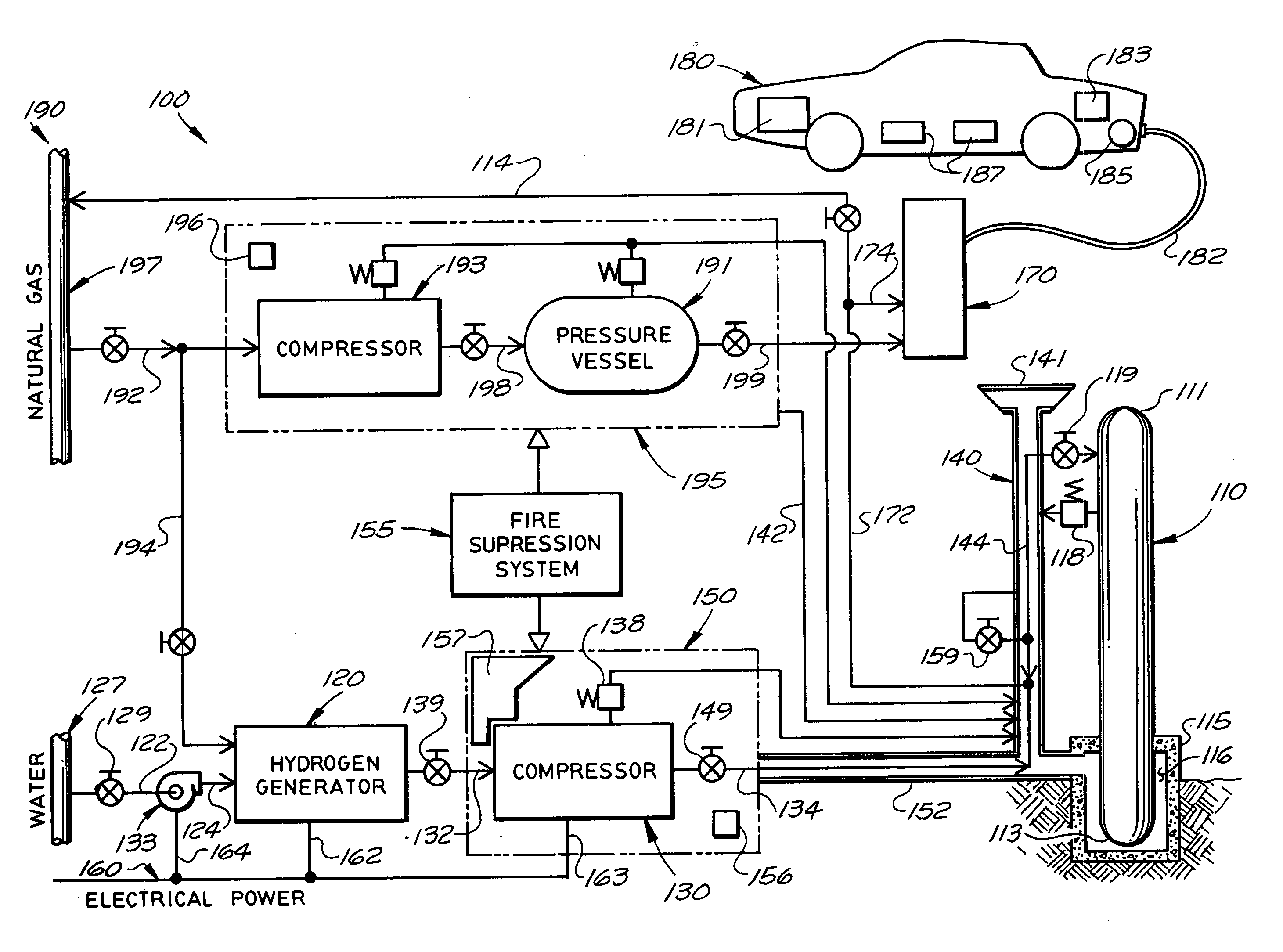

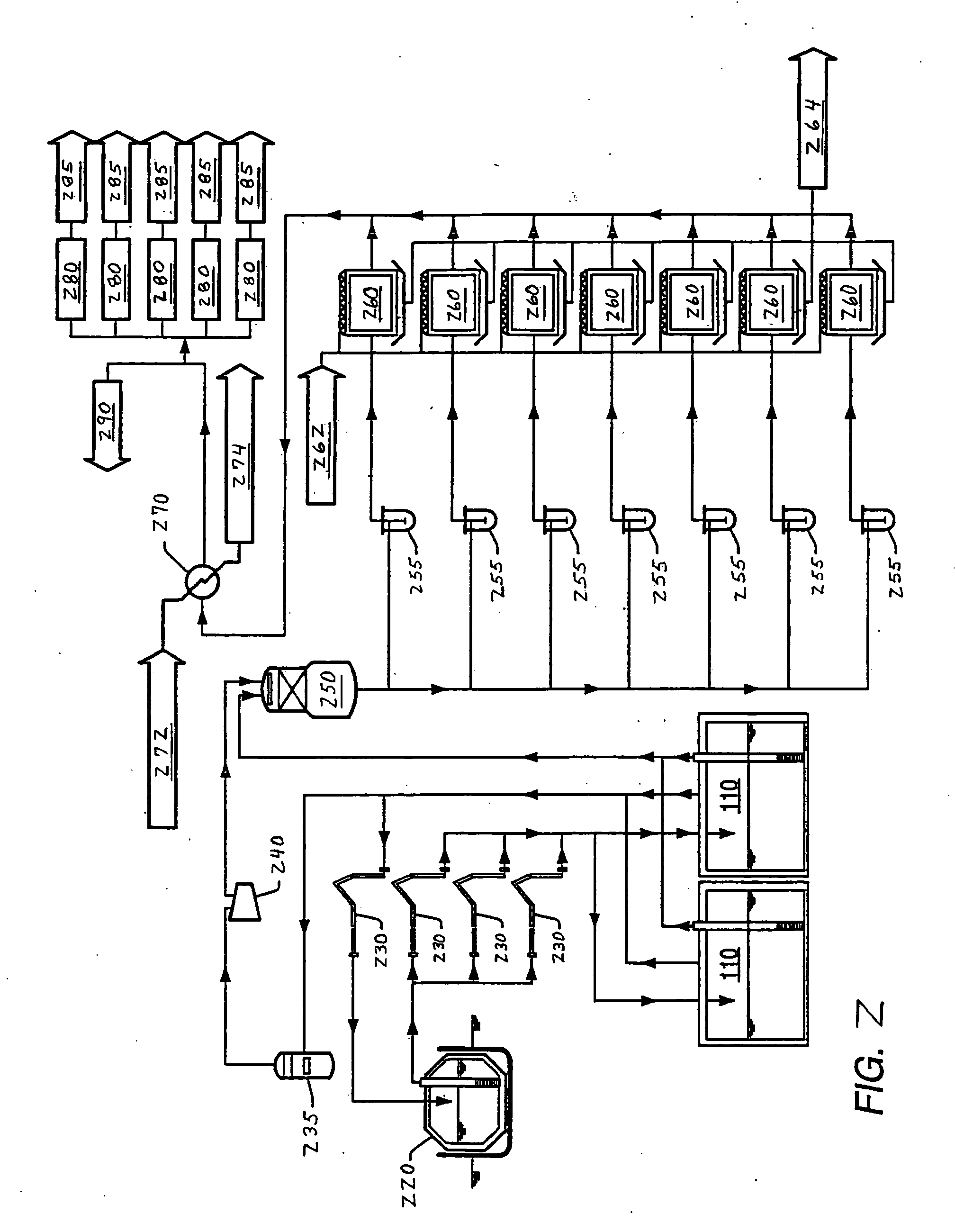

Transportable hydrogen refueling station

InactiveUS6755225B1Easy to monitorReduce riskTank vehiclesGas handling applicationsHigh pressureGaseous hydrogen

A portable hydrogen refueling stations which can dispense gaseous hydrogen from one or more internal high pressure tanks. The refueling station can be refilled with a lower pressure hydrogen gas feed and then compressed for storage within the refueling station.

Owner:QUANTUM FUEL SYST TECH WORLDWIDE INC

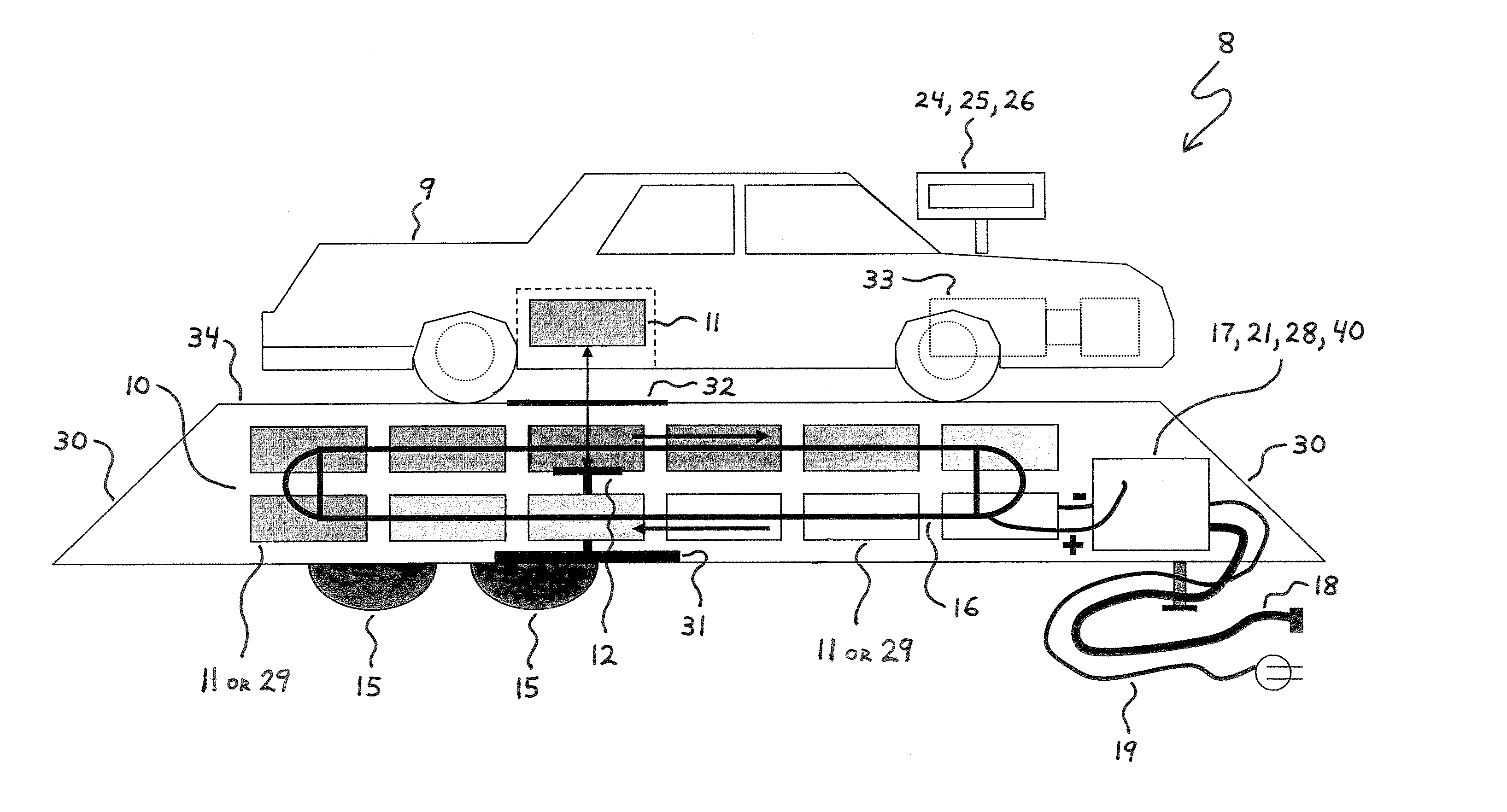

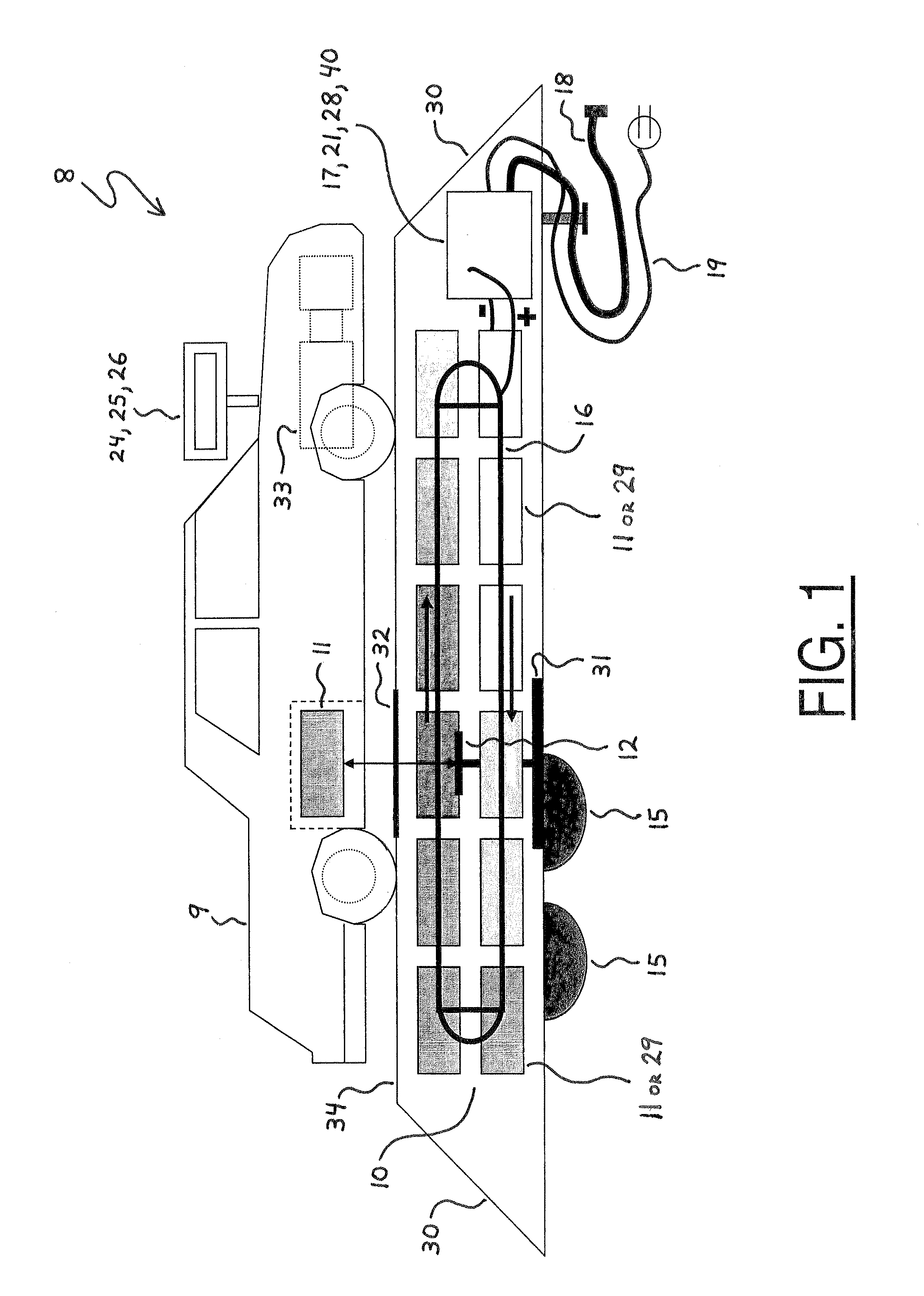

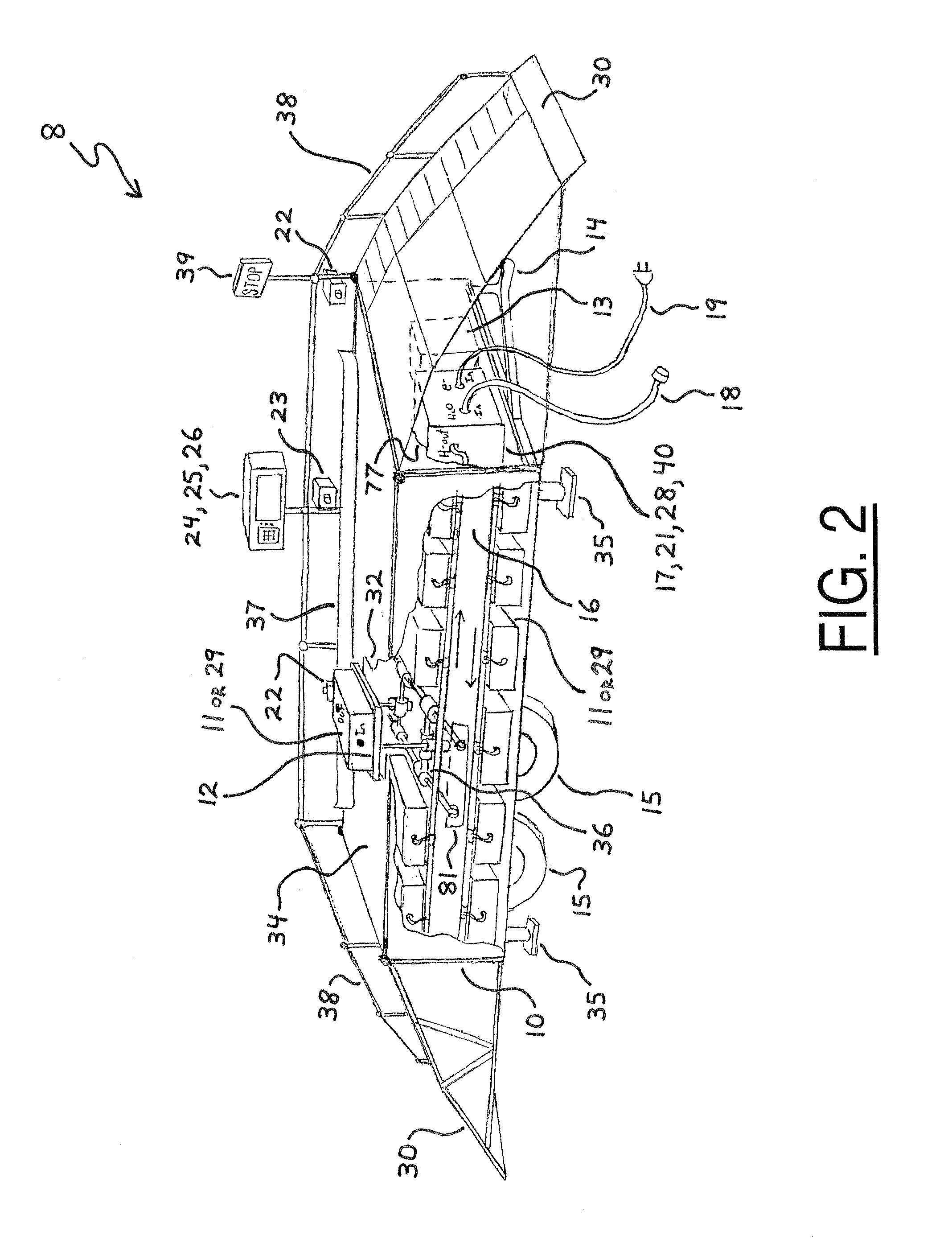

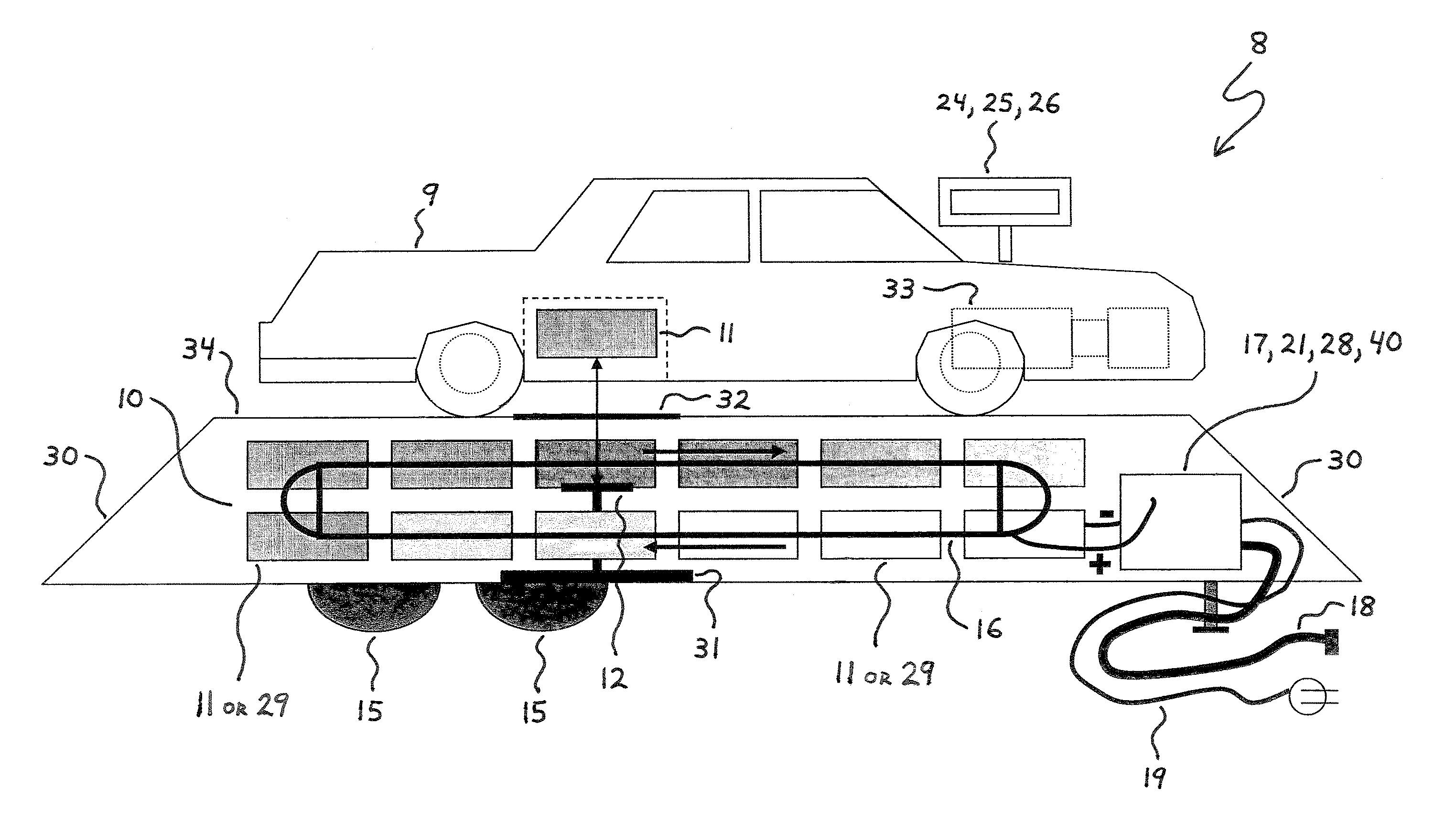

System for replenishing energy sources onboard different types of automotive vehicles

A service station facility for replenishing various motivational energy sources onboard different types of automotive vehicles is disclosed herein. In one embodiment, the service station facility includes a rack, replaceable fuel tanks, a service module, and an electronic computer control system. The replaceable fuel tanks are stocked on the rack and substantially filled with various fluids, such as hydrogen, which are utile as motivational energy sources within fuel-operated automotive vehicles. The service module is mounted on the rack, and the electronic computer control system is connected in electrical communication with the service module. In this configuration, the service module is controllably operable to receive a depleted replaceable fuel tank from a fuel-operated automotive vehicle and also selectively deliver one of the filled replaceable fuel tanks onboard the automotive vehicle. In another embodiment, the service station facility may also stock replaceable batteries for selective delivery onboard battery-operated automotive vehicles.

Owner:CAPIZZO PETER DAVID

System for replenishing energy sources onboard different types of automotive vehicles

Owner:CAPIZZO PETER DAVID

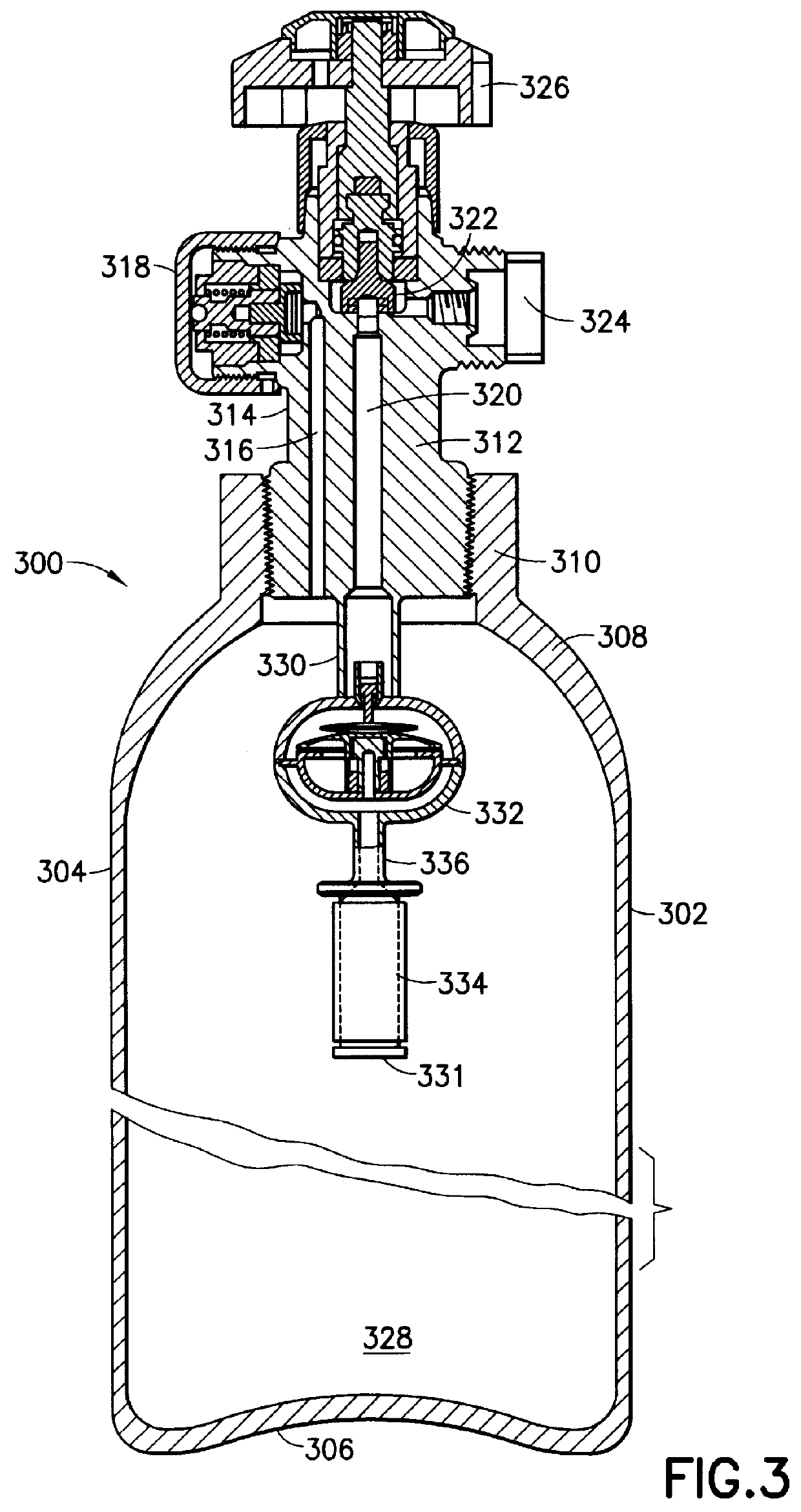

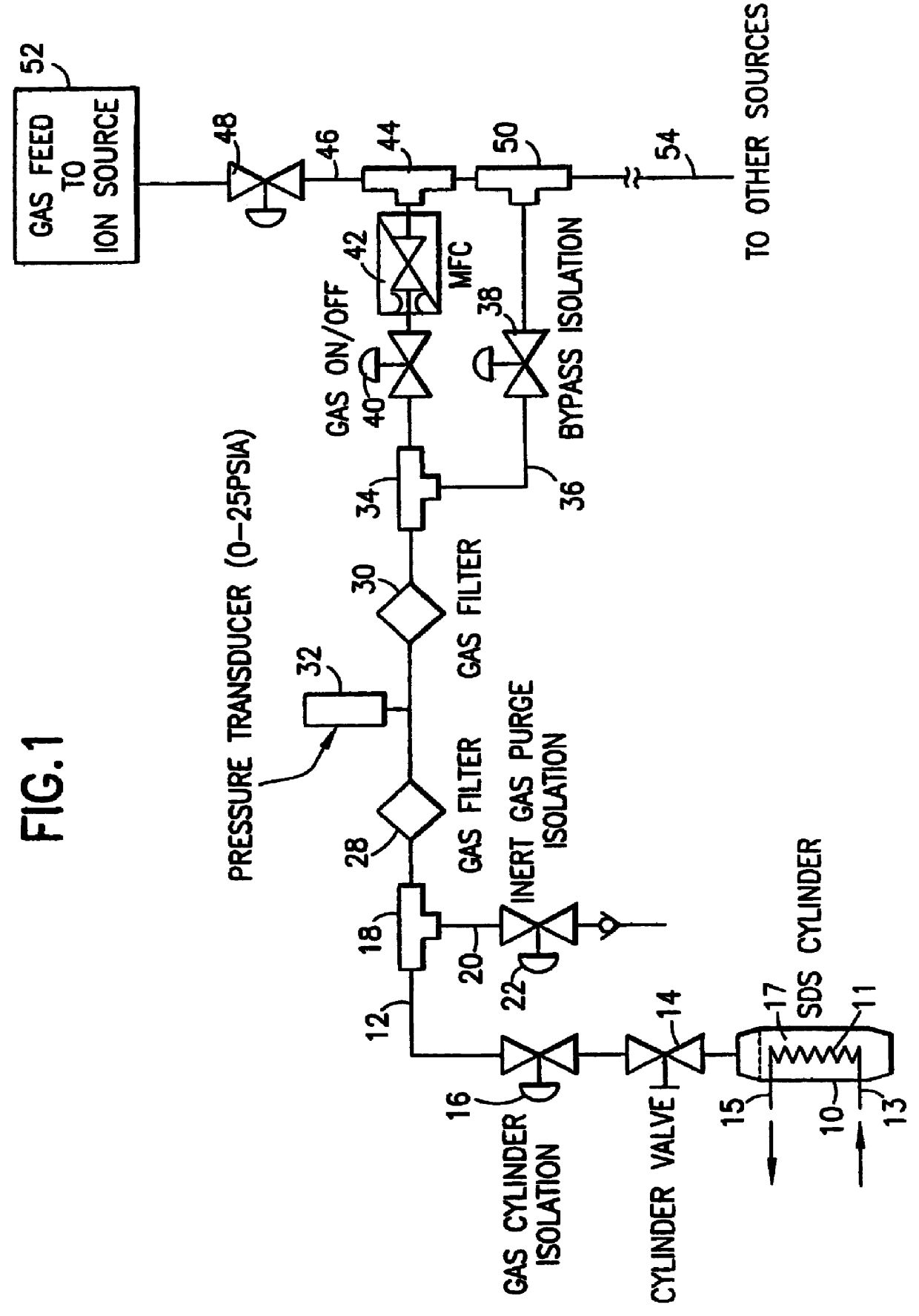

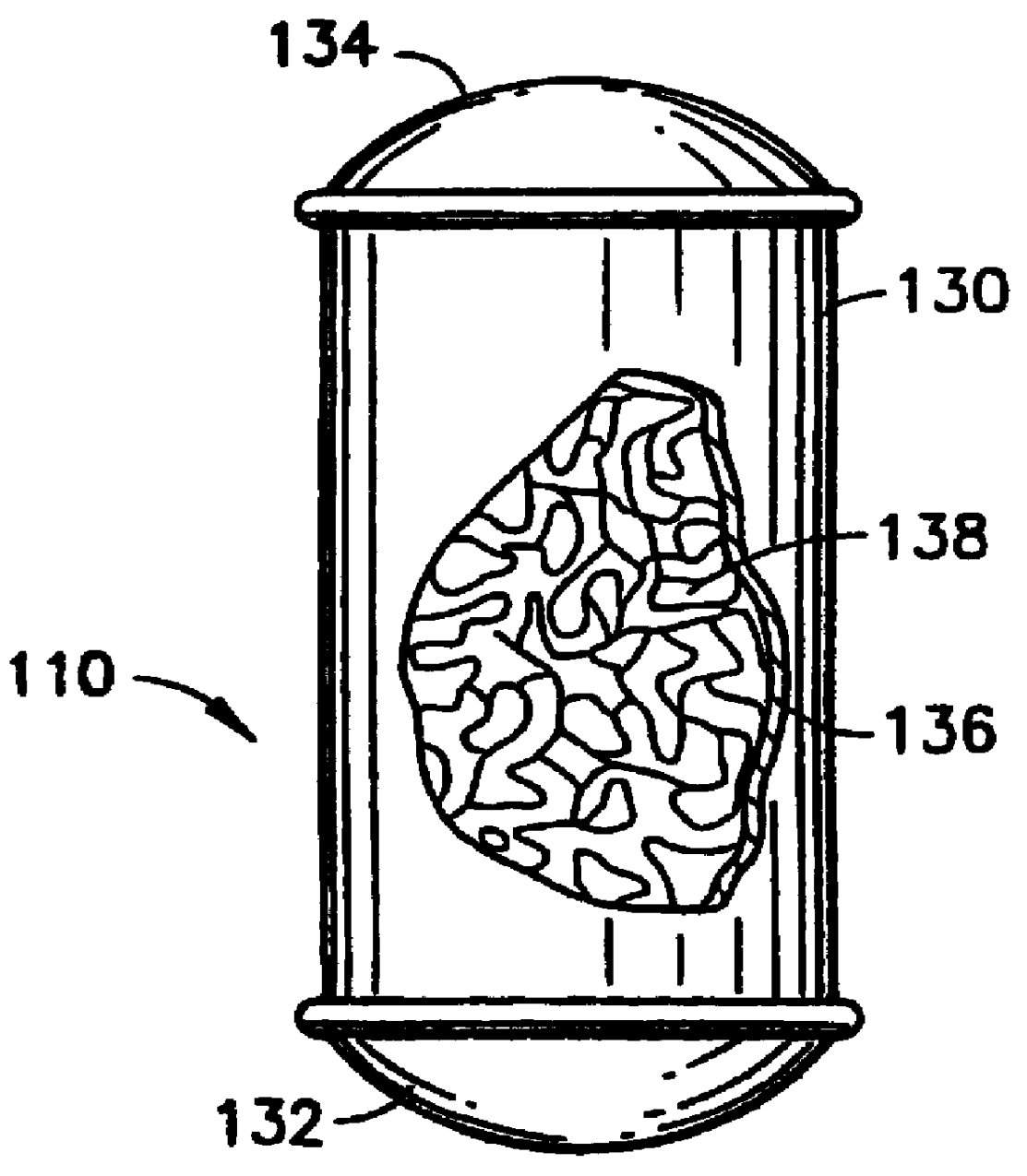

Sorbent-based gas storage and delivery system for dispensing of high-purity gas, and apparatus and process for manufacturing semiconductor devices, products and precursor structures utilizing same

A sorbent-based gas storage and dispensing system, including a storage and dispensing vessel containing a solid-phase physical sorbent medium having a sorbate gas physically adsorbed thereon. A chemisorbent material is provided in the vessel to chemisorb the impurities for gas phase removal thereof in the storage and dispensing vessel. Desorbed sorbate gas is discharged from the storage and dispensing vessel by a dispensing assembly coupled to the vessel. The chemisorbent may be provided in a capsule including an impurity-permeable, but sorbate gas-impermeable membrane, and installed in the vessel at the time of sorbent material loading. Semiconductor manufacturing processes and products manufactured by such processes are described.

Owner:ENTEGRIS INC

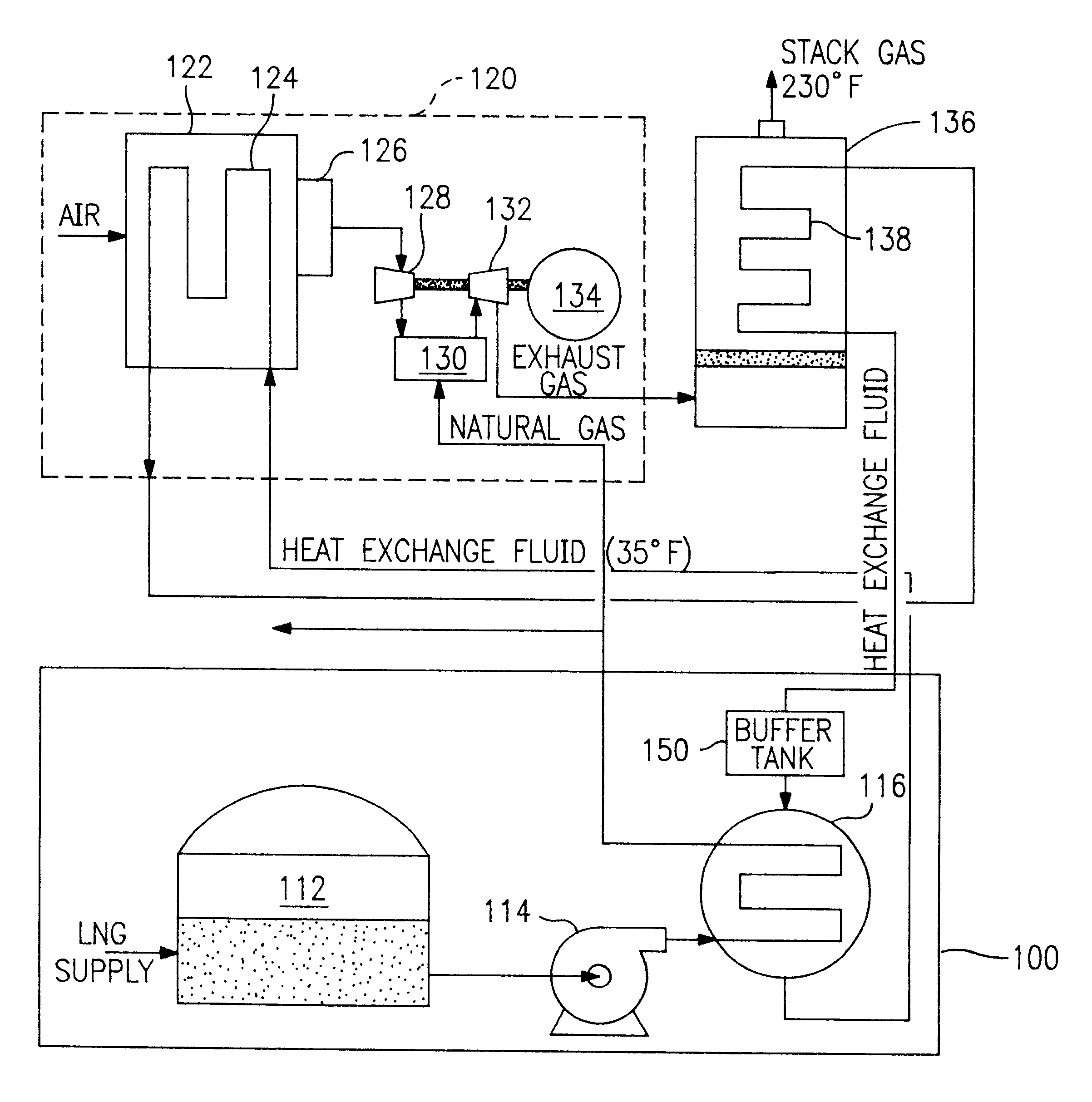

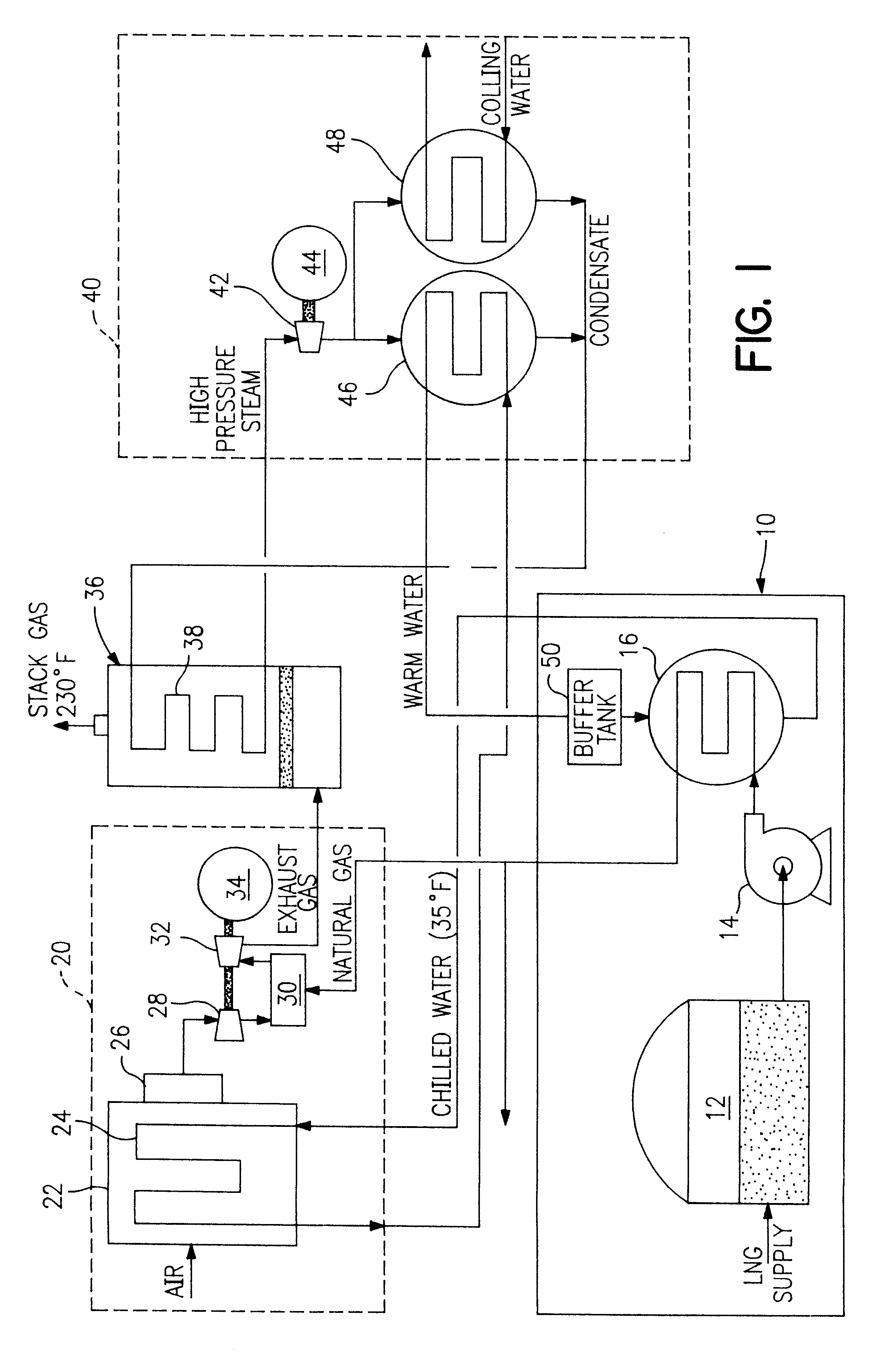

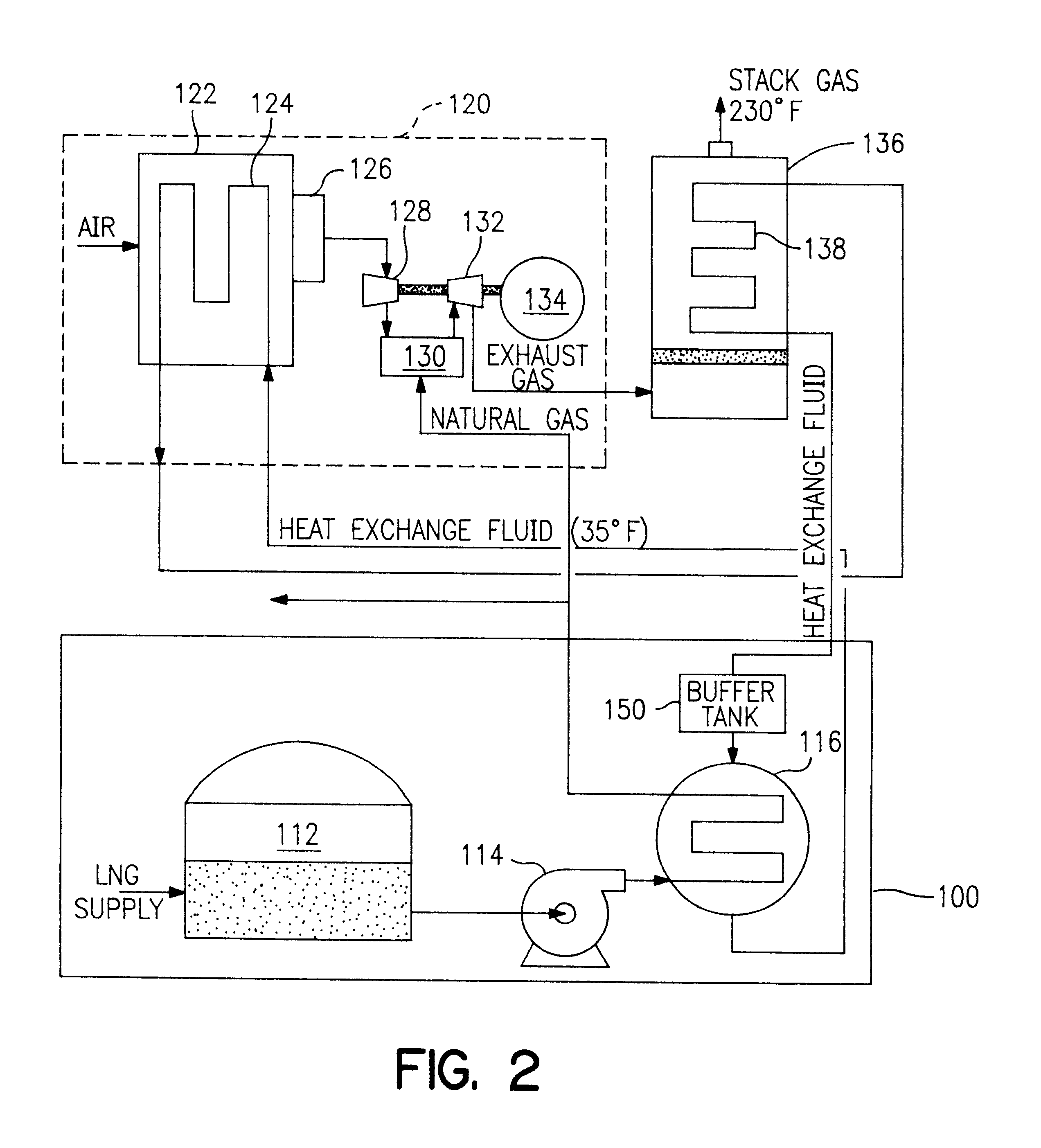

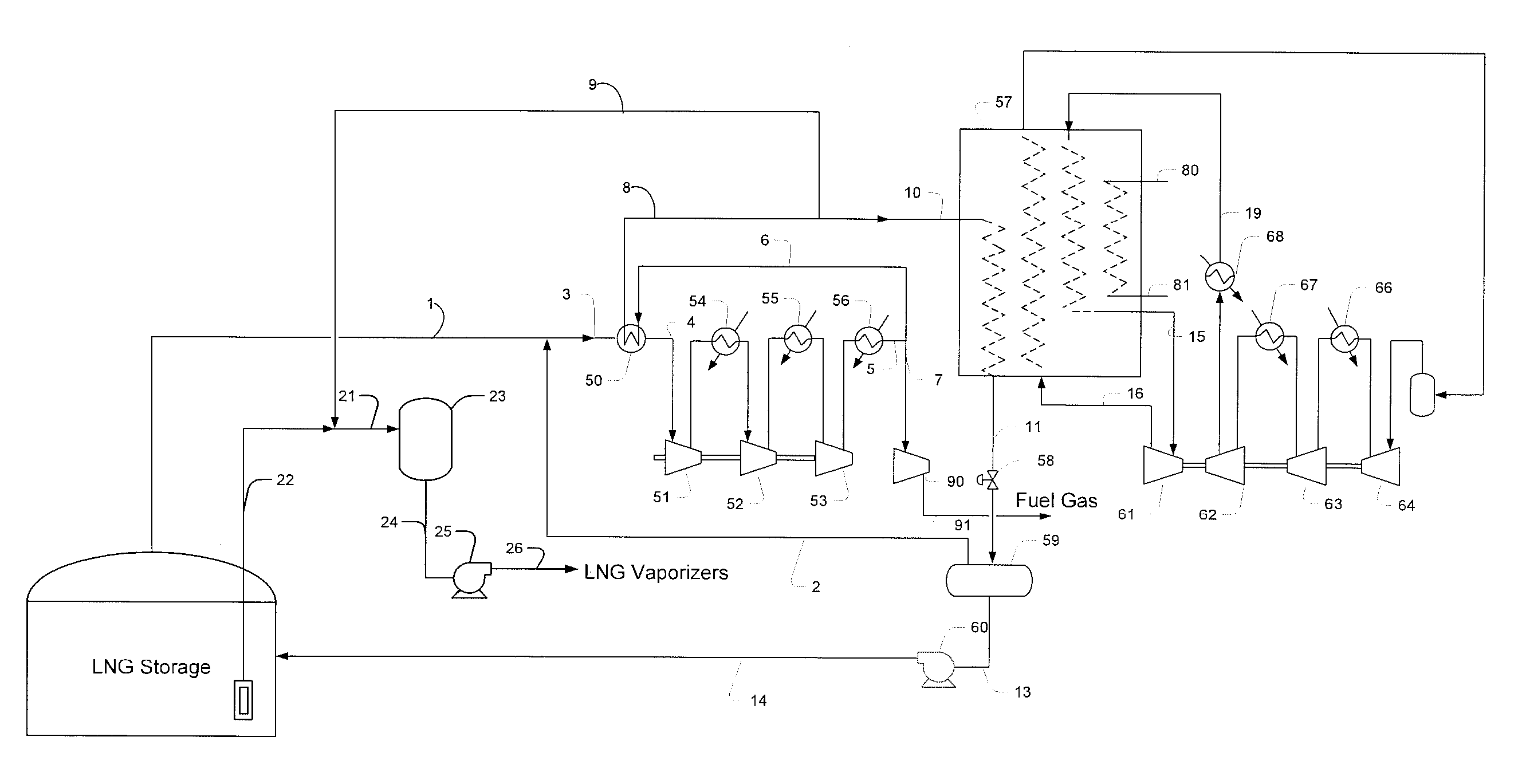

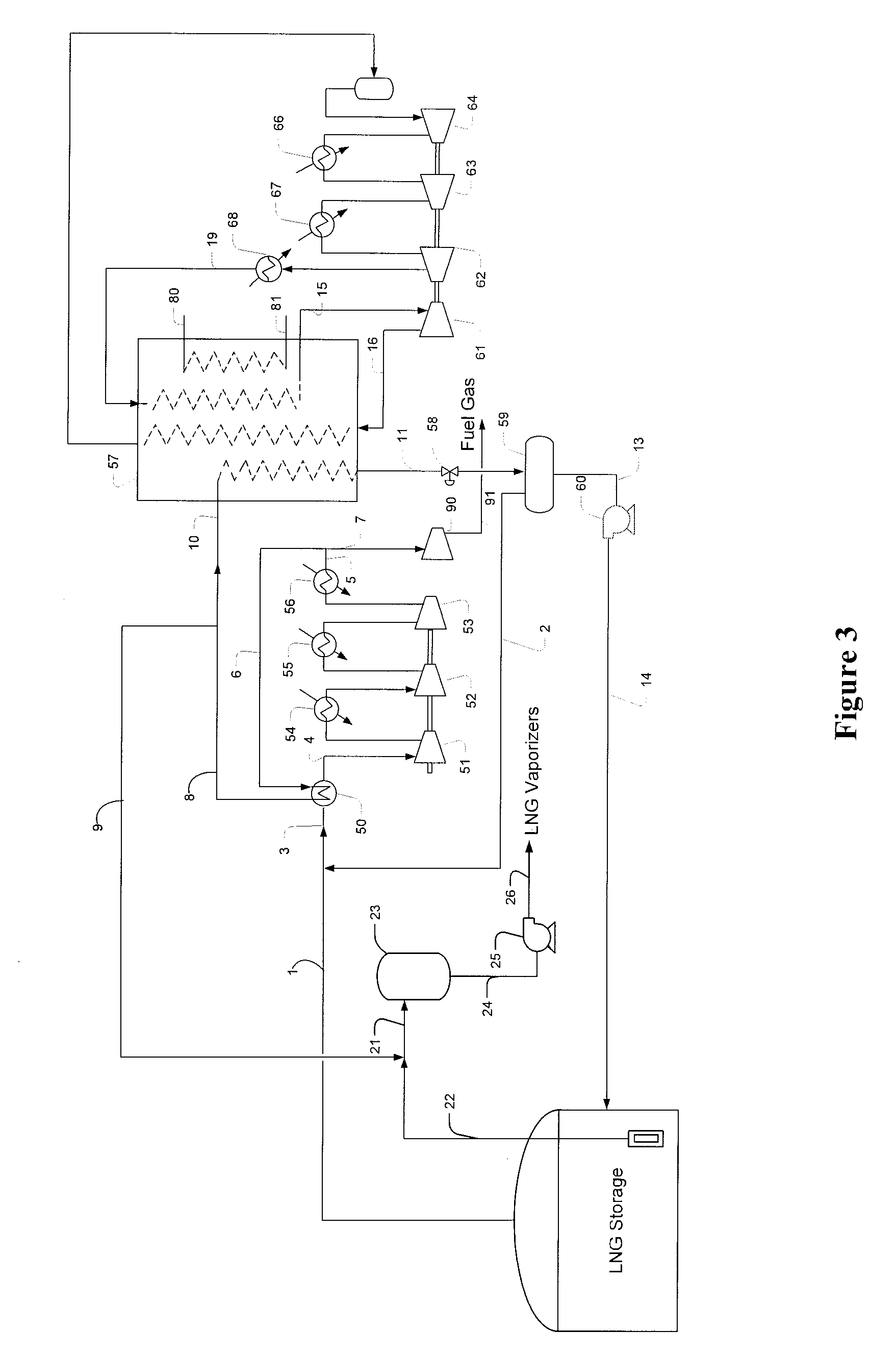

Liquified natural gas (LNG) fueled combined cycle power plant and a (LNG) fueled gas turbine plant

InactiveUS6374591B1Improve efficiencyParts are smallGas handling applicationsGas turbine plantsCombustion chamberPower station

A process and system which improves the capacity and efficiency of a power plant. A LNG supply system fuels the plant. Gasified LNG in a combustor mixes with the air from an air compressor to provide the hot combustion gas for a gas turbine. The expanding LNG is used to chill a heat exchange fluid, e.g. water, which heat exchange fluid cools and densifies the intake air for the air compressor. Subsequently, the heat exchange fluid is used in another heat exchange step and is then re-chilled and recycled to cool and densify the intake air.

Owner:SUEZ LNG NA

Method of passivating a gas vessel or component of a gas transfer system using a silicon overlay coating

A method of passivating the interior surface of a gas storage vessel to protect the surface against corrosion. The interior surface of the vessel is first dehydrated and then evacuated. A silicon hydride gas is introduced into the vessel. The vessel and silicon hydride gas contained therein are heated and pressurized to decompose the gase. A layer of silicon is deposited on the interior surface of the vessel. The duration of the silicon depositing step is controlled to prevent the formation of silicon dust in the vessel. The vessel is then purged with an inert gas to remove the silicon hydride gas. The vessel is cycled through the silicon depositing step until the entire interior surface of the vessel is covered with a layer of silicon. The vessel is then evacuated and cooled to room temperature.

Owner:SILCOTEK CORP

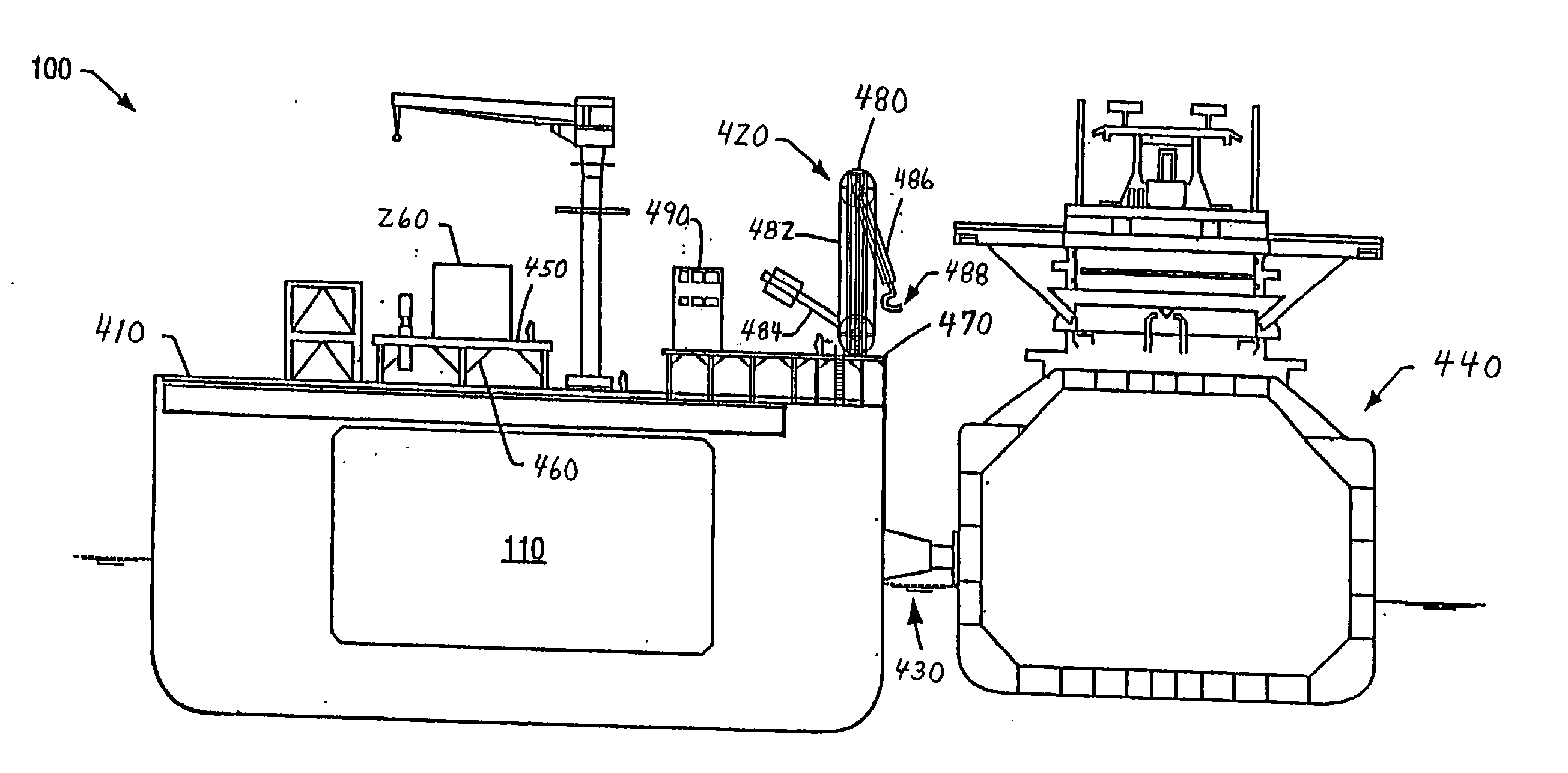

System and process for transporting LNG by non-self-propelled marine LNG carrier

Marine LNG carrier and method of operating the marine LNG carrier. The LNG carrier carries LNG in at least one tank. Gas composed of evaporated LNG within the at least one tank is removed. The gas is fed to at least one gas consuming prime mover of the LNG carrier. Power is provided with the at least one gas consuming prime mover. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:ARGENT MARINE MANAGEMENT

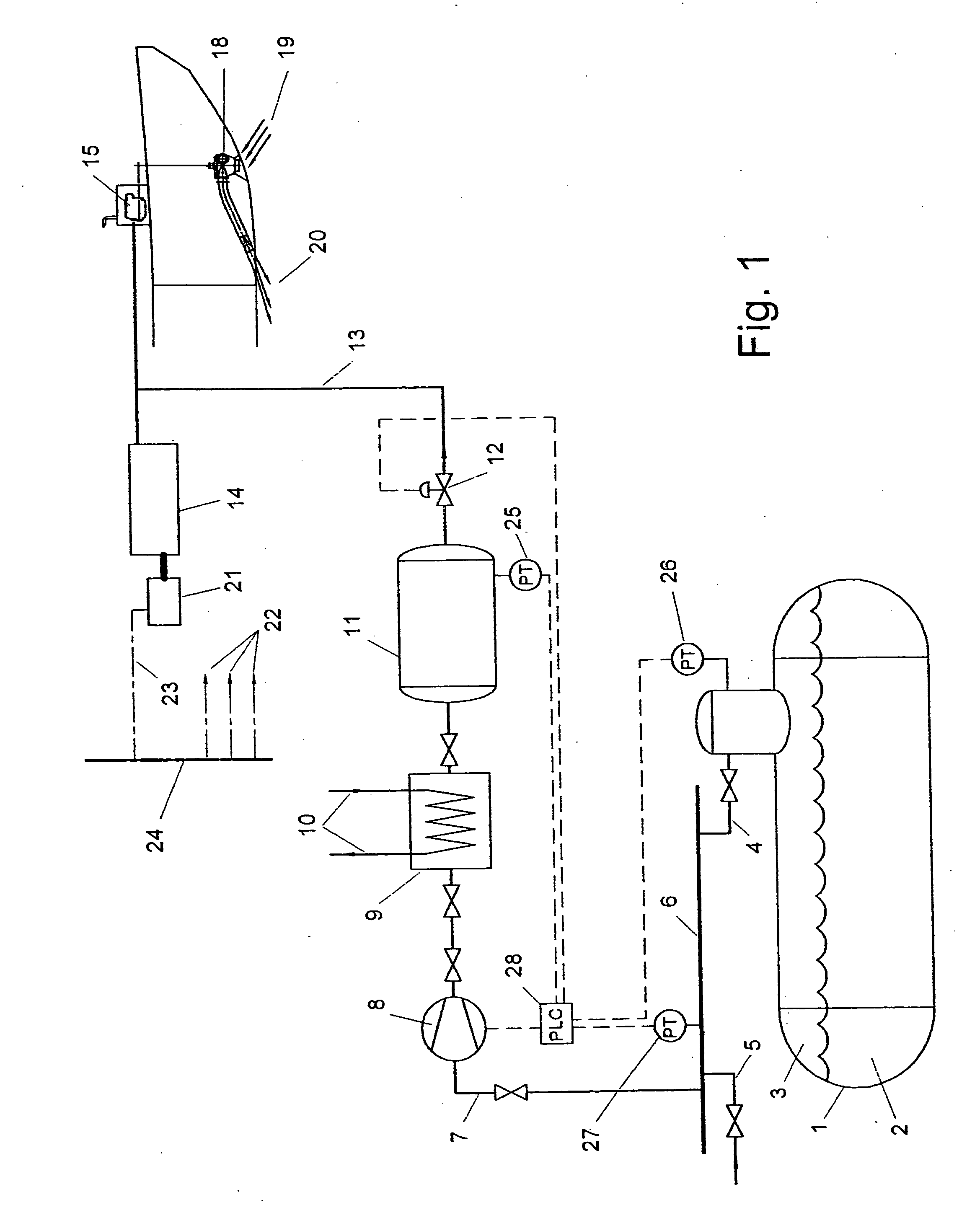

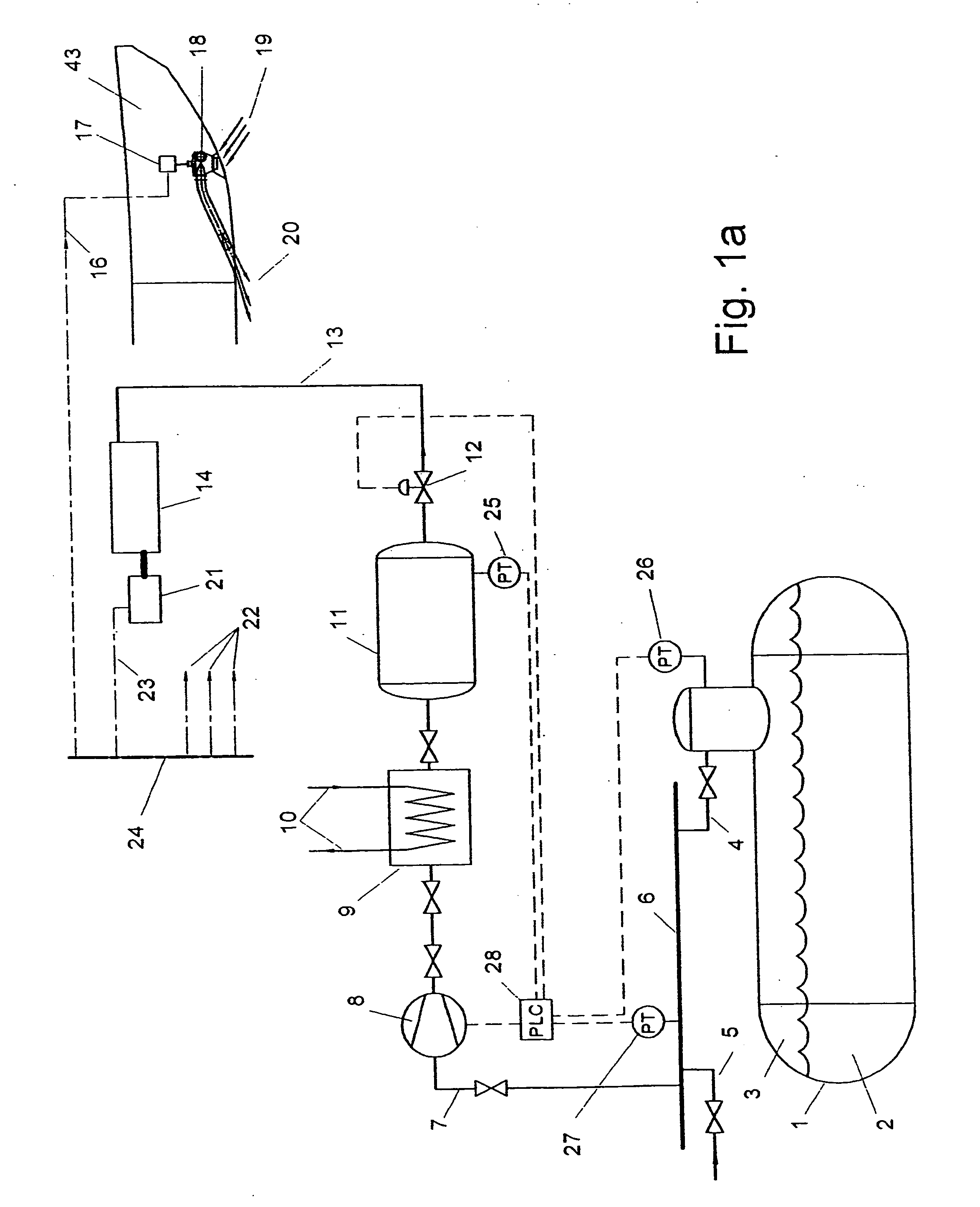

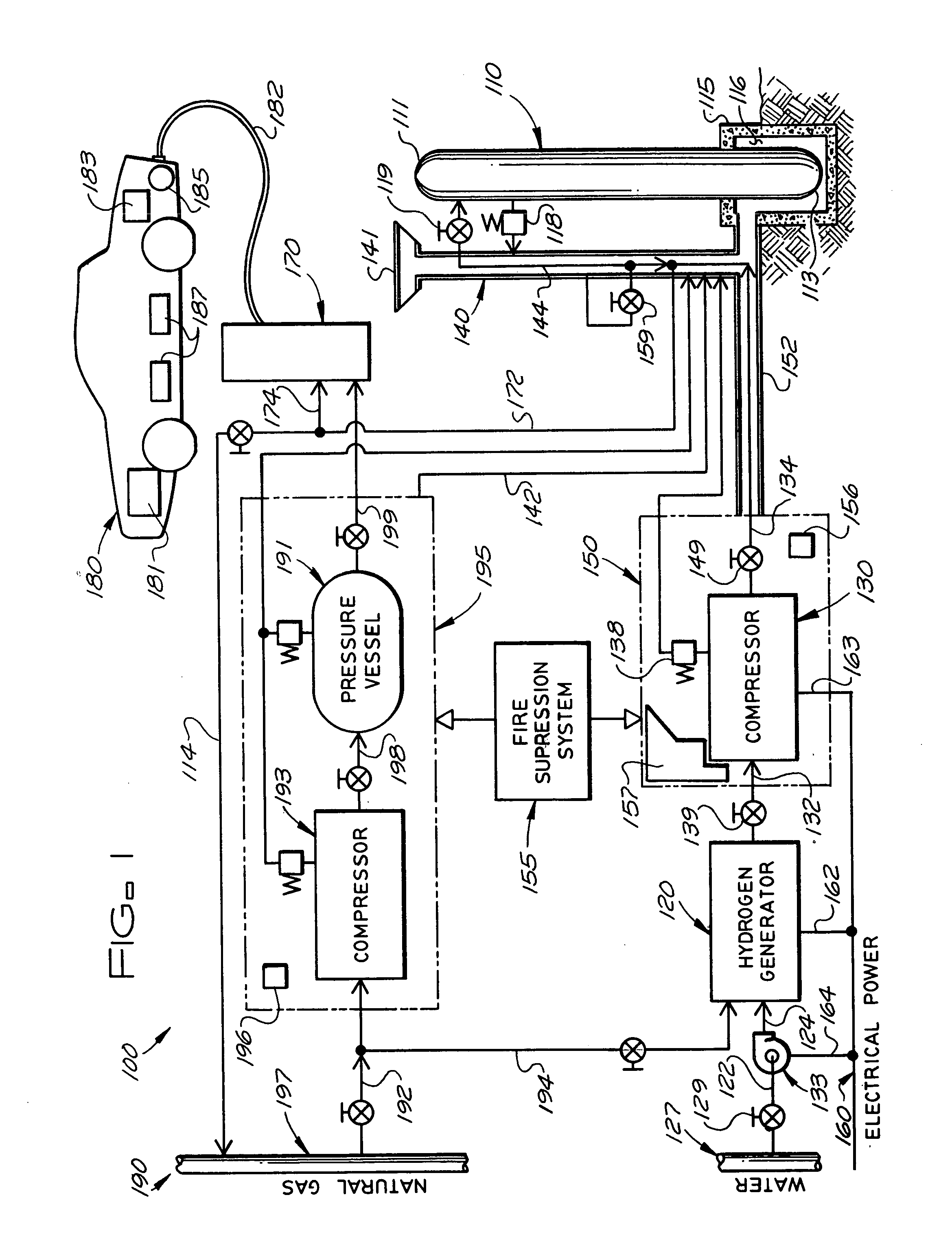

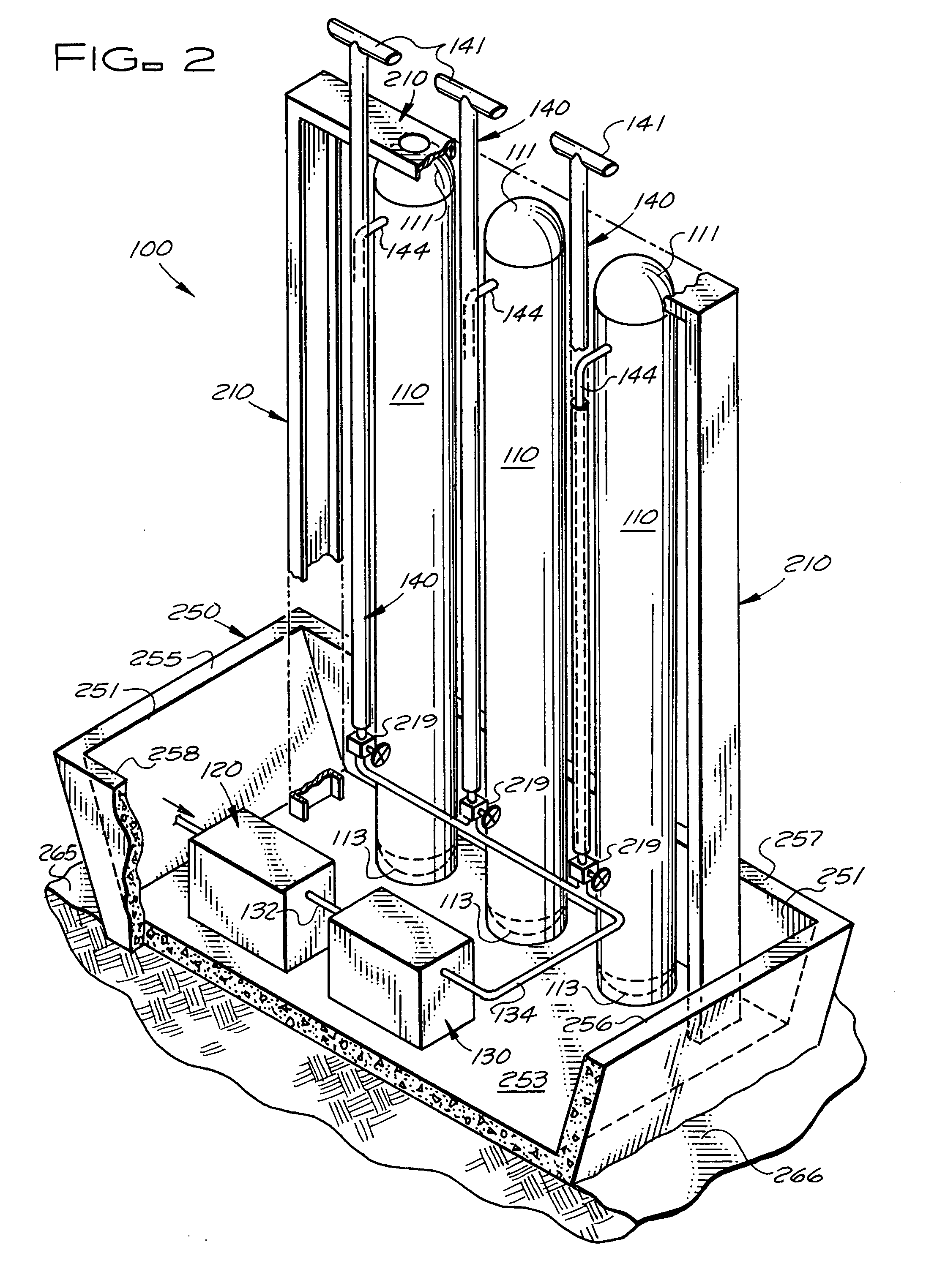

Hydrogen handling or dispensing system

InactiveUS20050000802A1Avoid burnsCheap manufacturingLiquid fillingGas handling applicationsHydrogenHuman life

Systems for handling and / or dispensing hydrogen or a mixture of fuels containing hydrogen gas including refueling stations for hydrogen-powered vehicles. Pure hydrogen or various mixtures ratios of hydrogen and CNG may be dispensed. Hydrogen handling equipment may include a hydrogen generator, a pressurizing apparatus or compressor, pressure vessels, piping, valves, vent pipes, and / or a dispenser. Substantially vertical orientation of pressure vessels may reduce the amount of land required and facilitate installation in urban environments. Pressurization may take place before hydrogen generation to reduce the power required for pressurization. Safety features include enclosures and surrounding walls that lean away from the equipment. Any leaking hydrogen, fires, or explosions may be contained and / or directed upward, protecting human life and property. Systems may be shop assembled and certified.

Owner:ARIZONA PUBLIC SERVICE

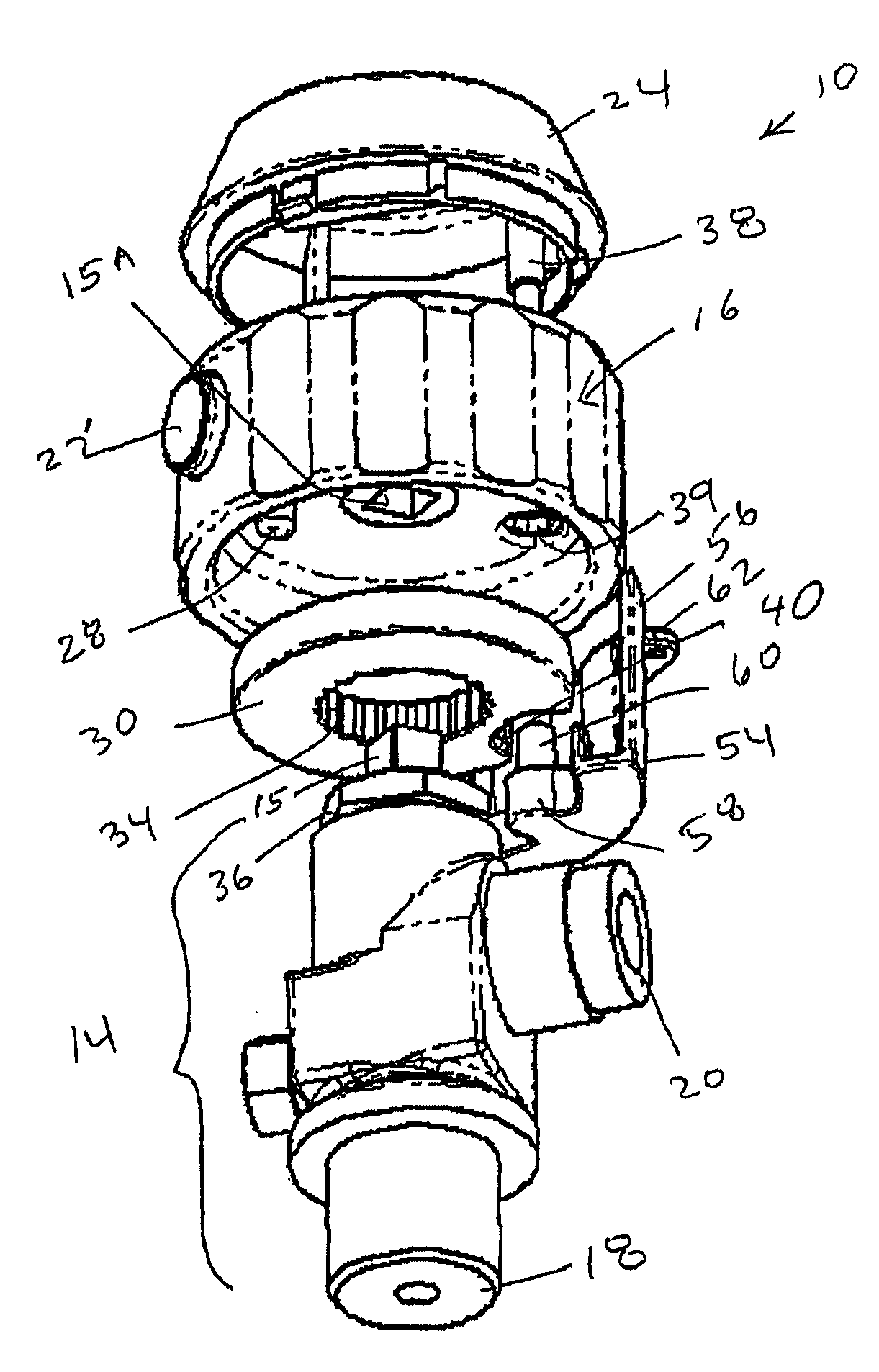

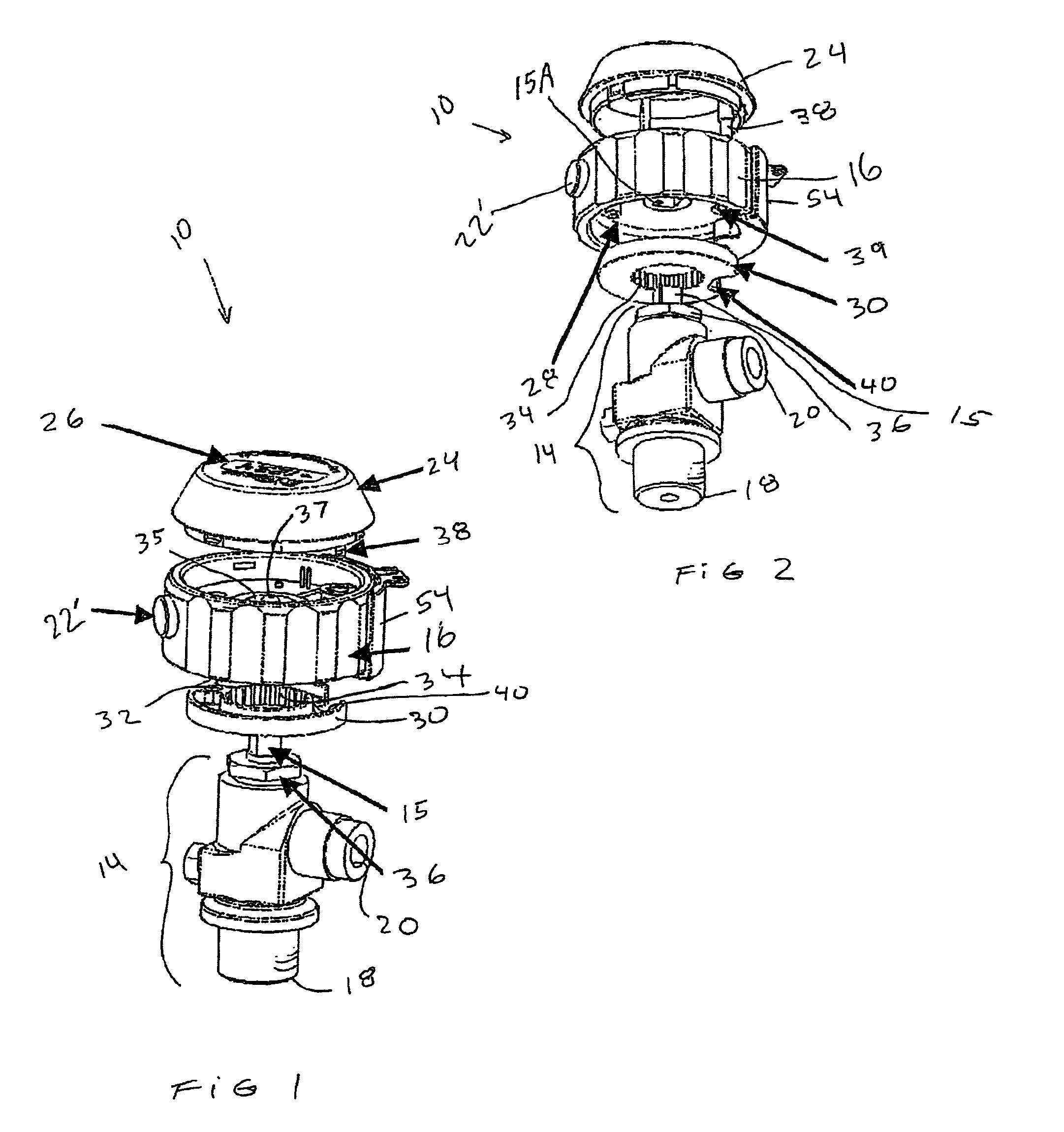

Valve with smart handle

A valve with a smart handle including a memory module to log relevant data. A sensor on the handle determines when the valve is open, and this triggers the start of timers and recording of the “open” event in a log in the memory module. When the valve is closed, the sensor triggers stopping of the timers and recording of the “closed” event in the log. The timer information is used to calculate the duration of the time “open” event, and this, together with the actual date and time of the opening and closing of the valve are recorded in the log. Other relevant information, such as cylinder fill date, cylinder I.D. number, batch number, and patient name or account number may also be logged in the memory module. The log of the events and the corresponding dates and times may be used to prepare invoices for billing gas treatments, for inventory control, and for other record-keeping and control functions.

Owner:VENTEK +1

Metal-organic frameworks with exceptionally high capacity for storage of carbon dioxide at room-temperature

InactiveUS20070068389A1Promote absorptionSufficiently flexibleInternal combustion piston enginesExhaust apparatusCo2 storageRoom temperature

A carbon dioxide storage system includes a container and a conduit attached to the container for introducing or removing a carbon dioxide-containing composition from the container. A carbon dioxide storage material is positioned within the container. The carbon dioxide-storage material includes a metal-organic framework, which has a sufficient surface area to store at least 10 carbon dioxide molecules per formula unit of the metal-organic framework at a temperature of about 25° C.

Owner:RGT UNIV OF MICHIGAN

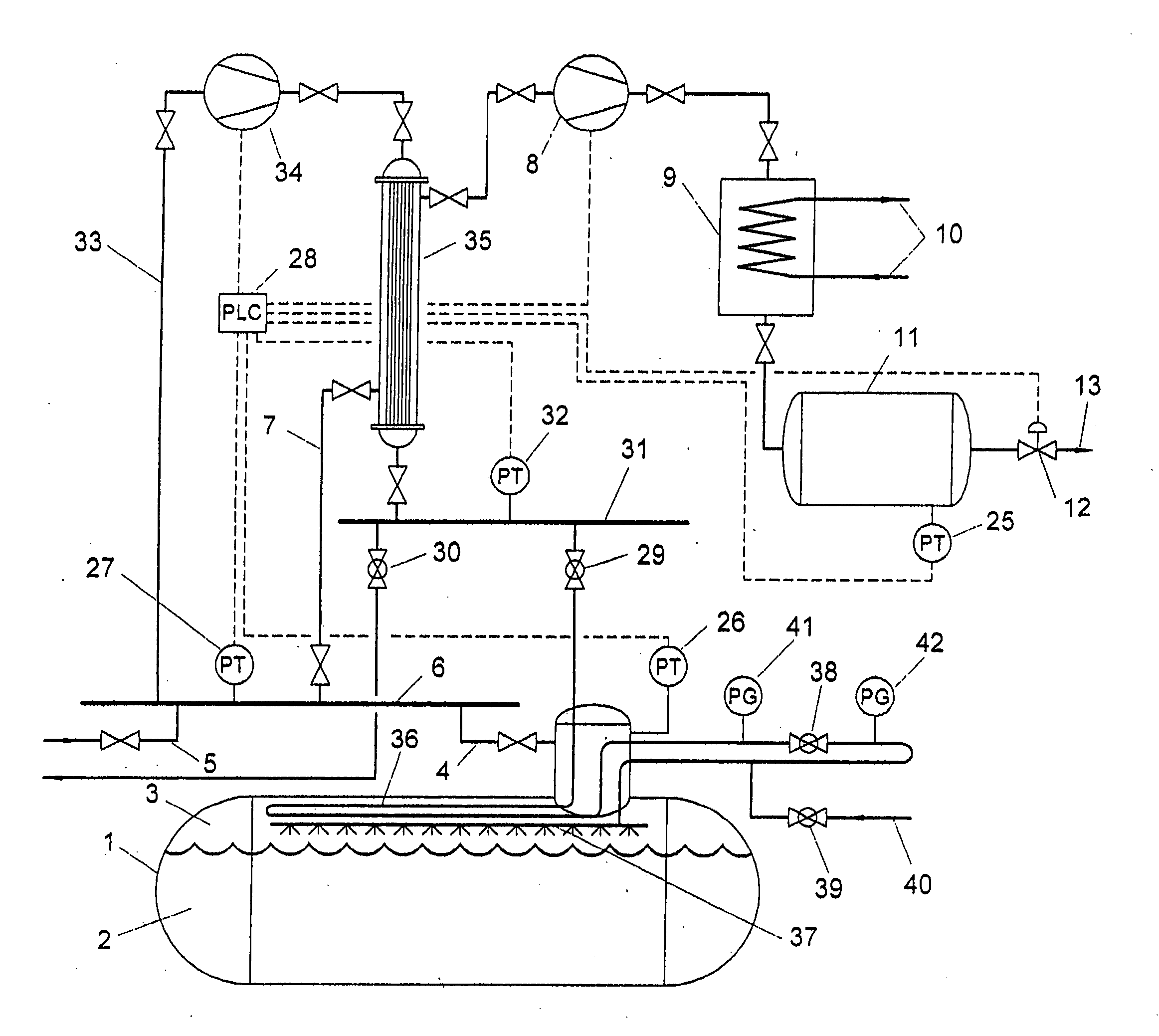

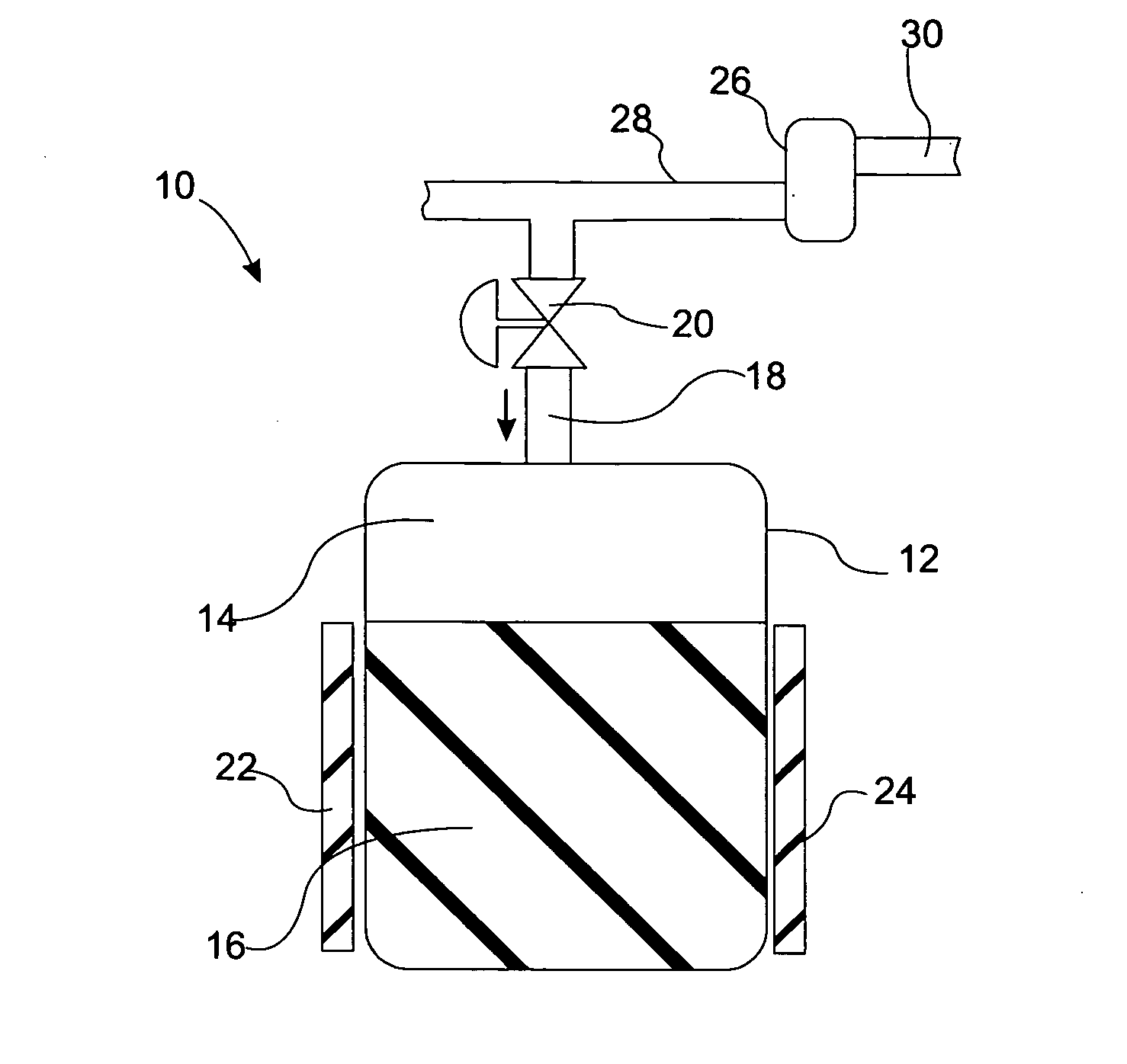

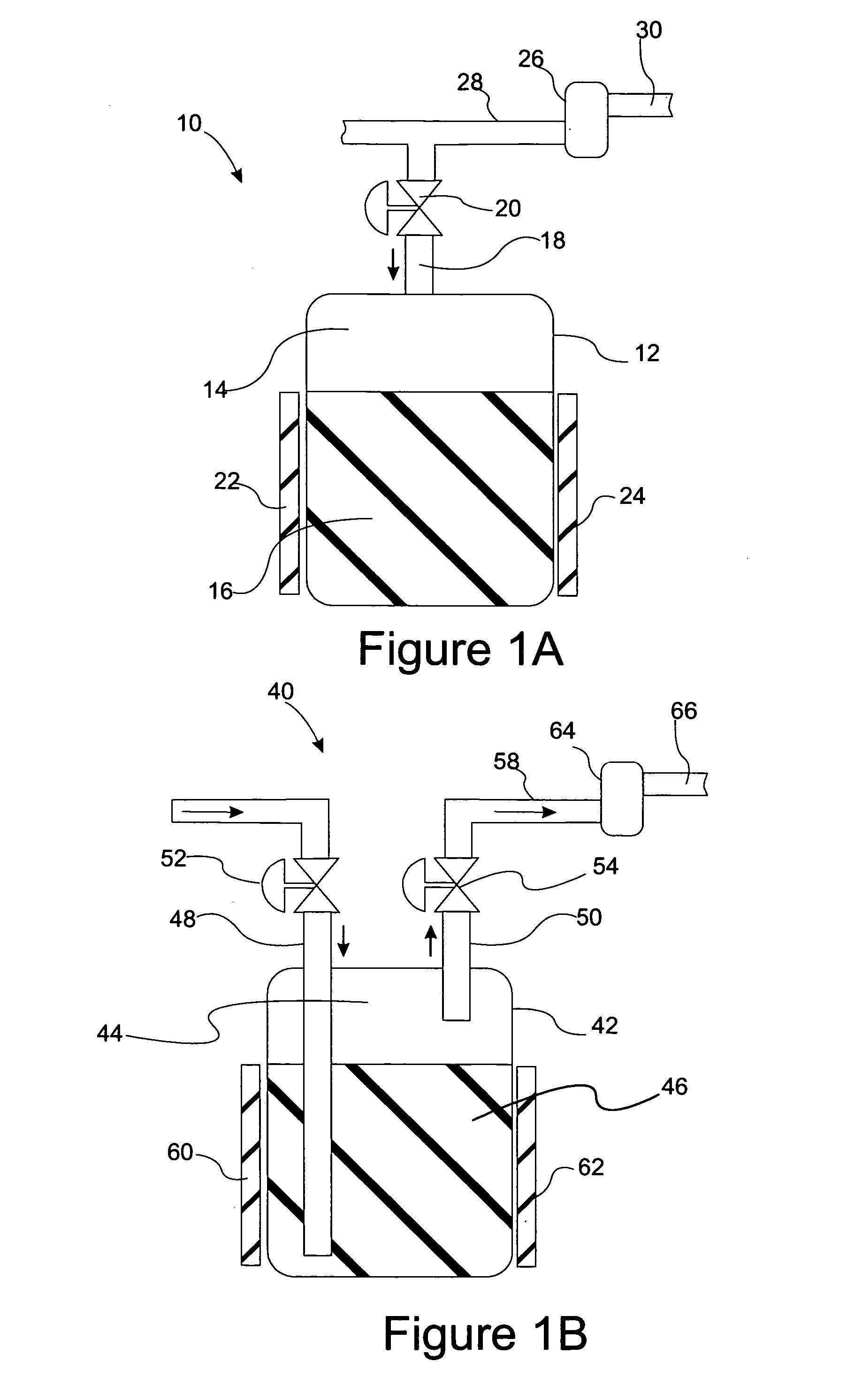

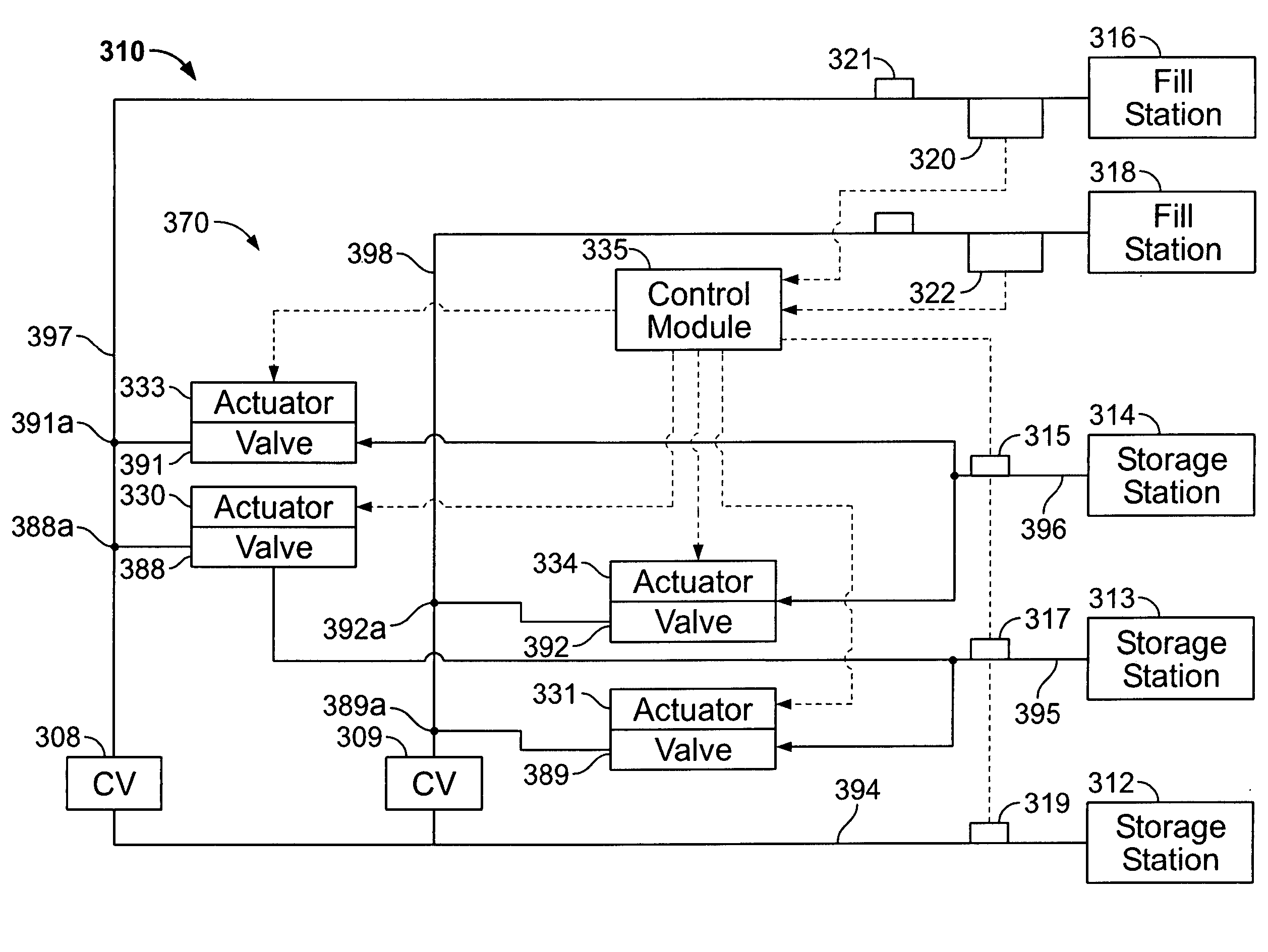

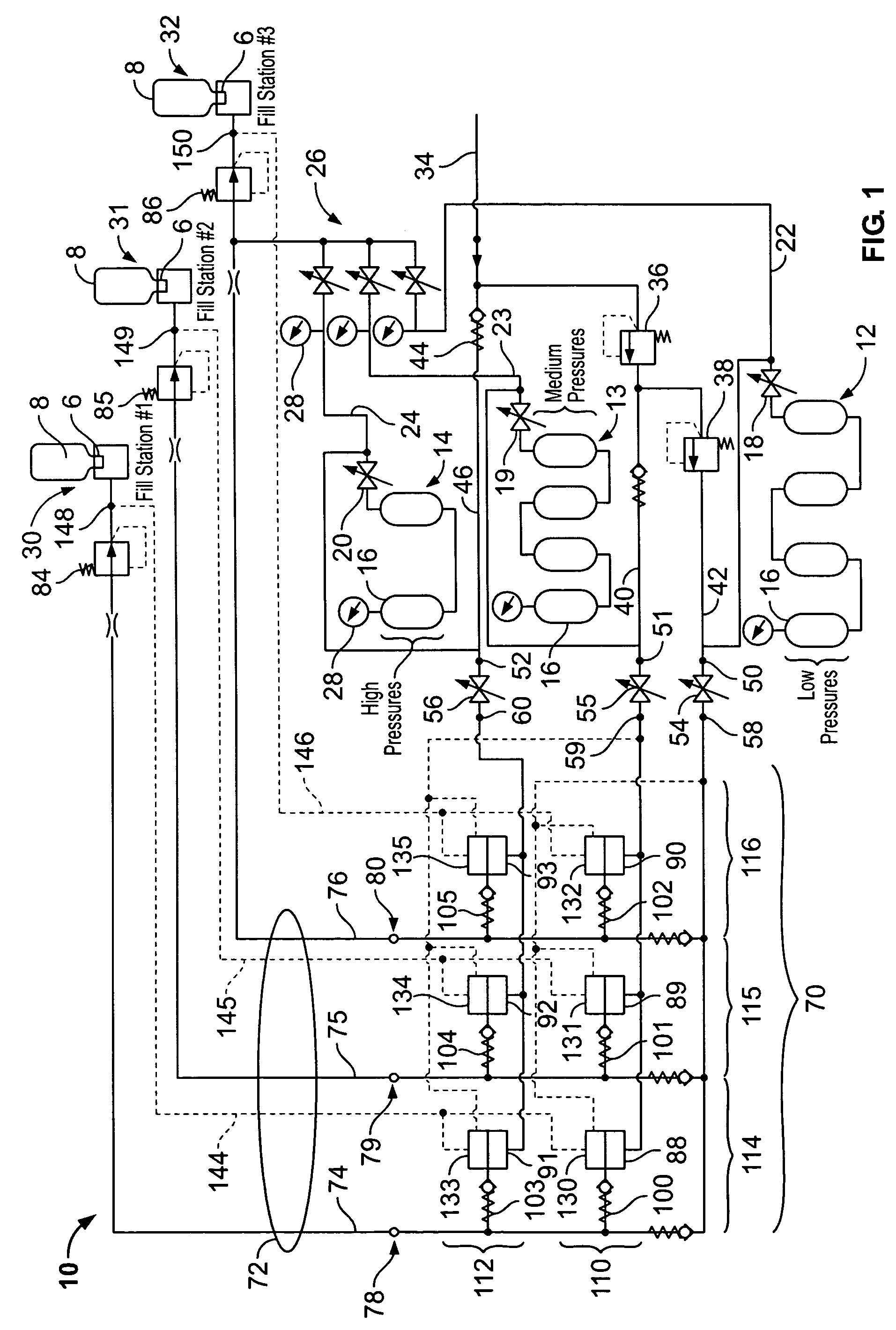

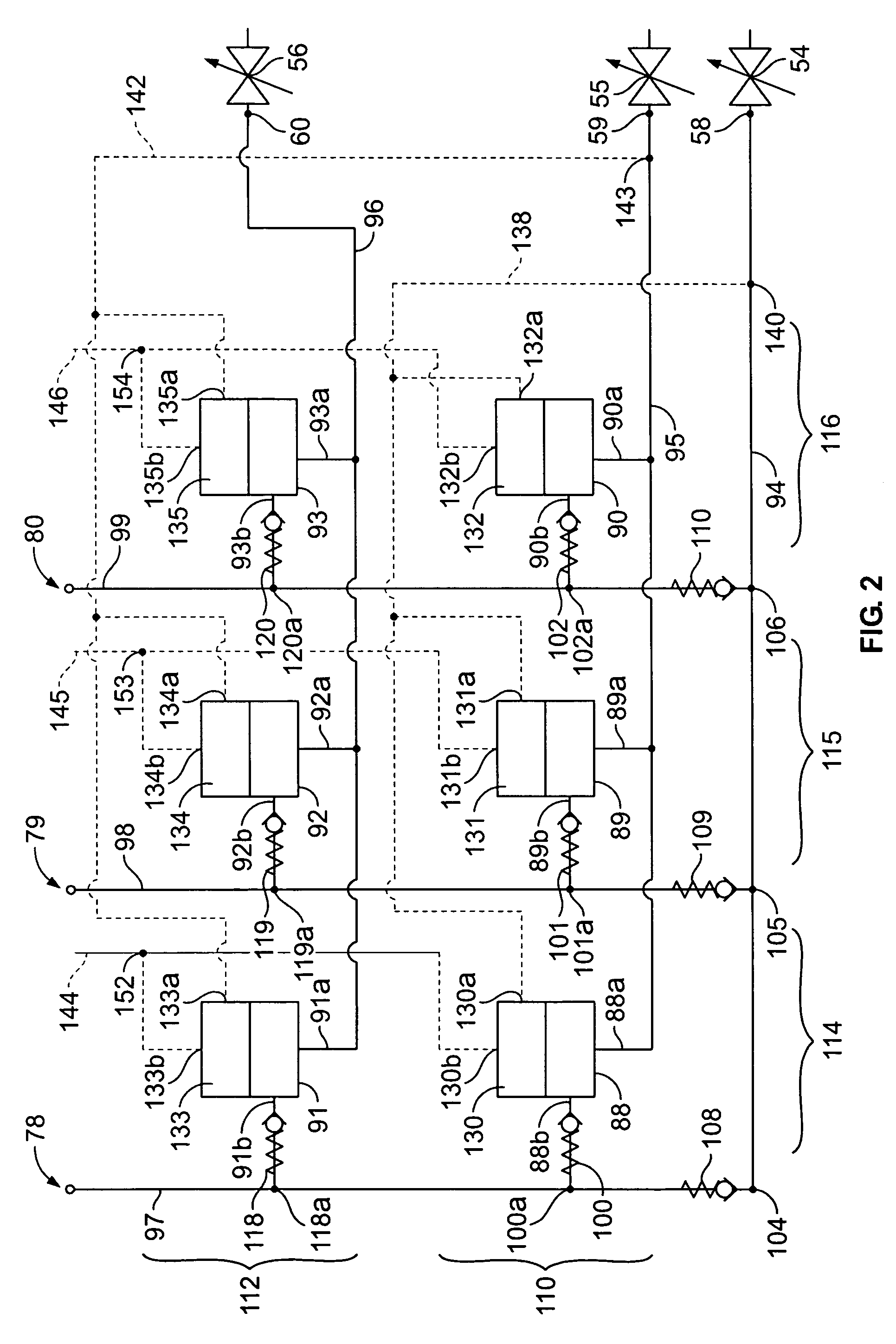

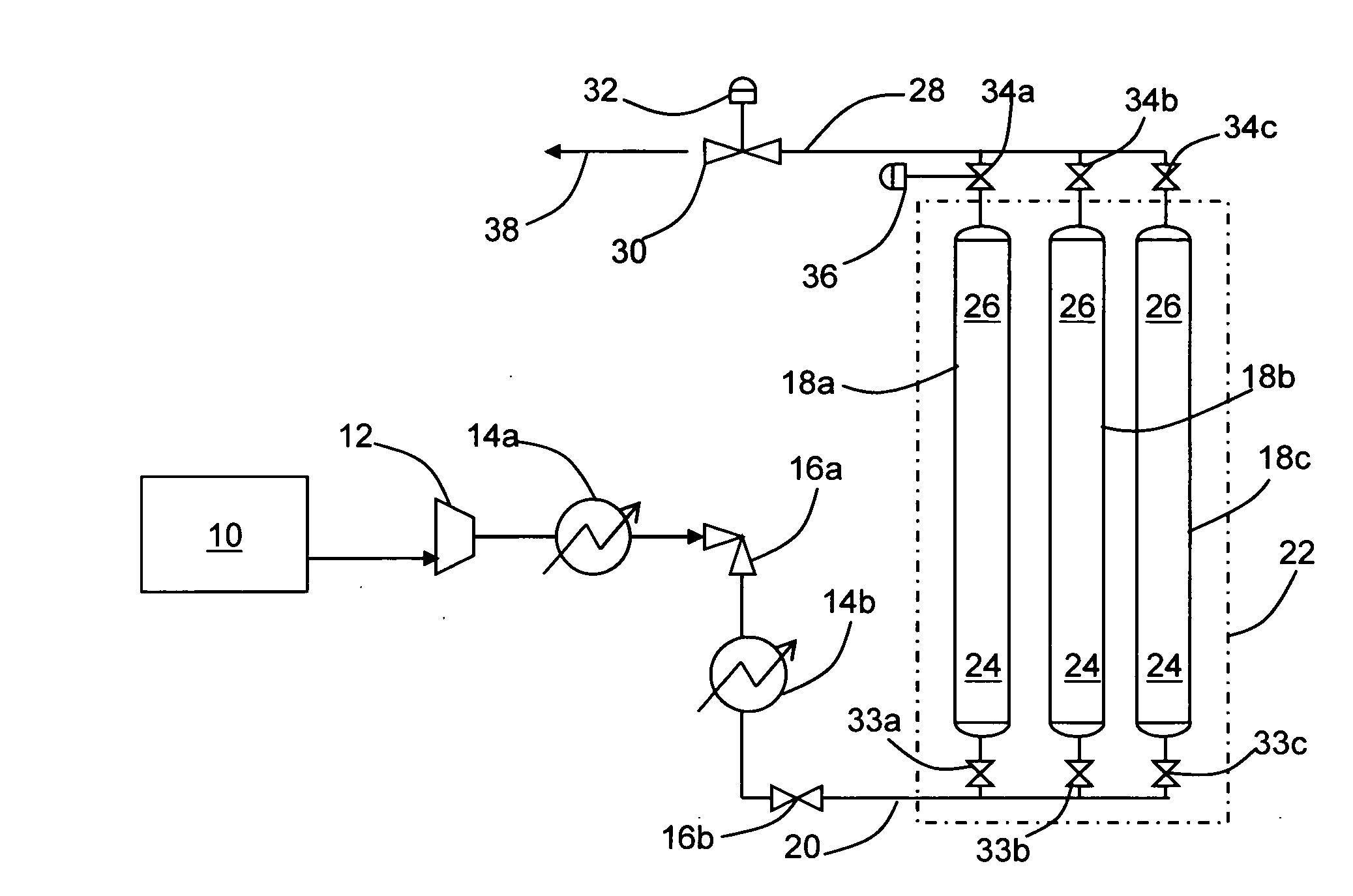

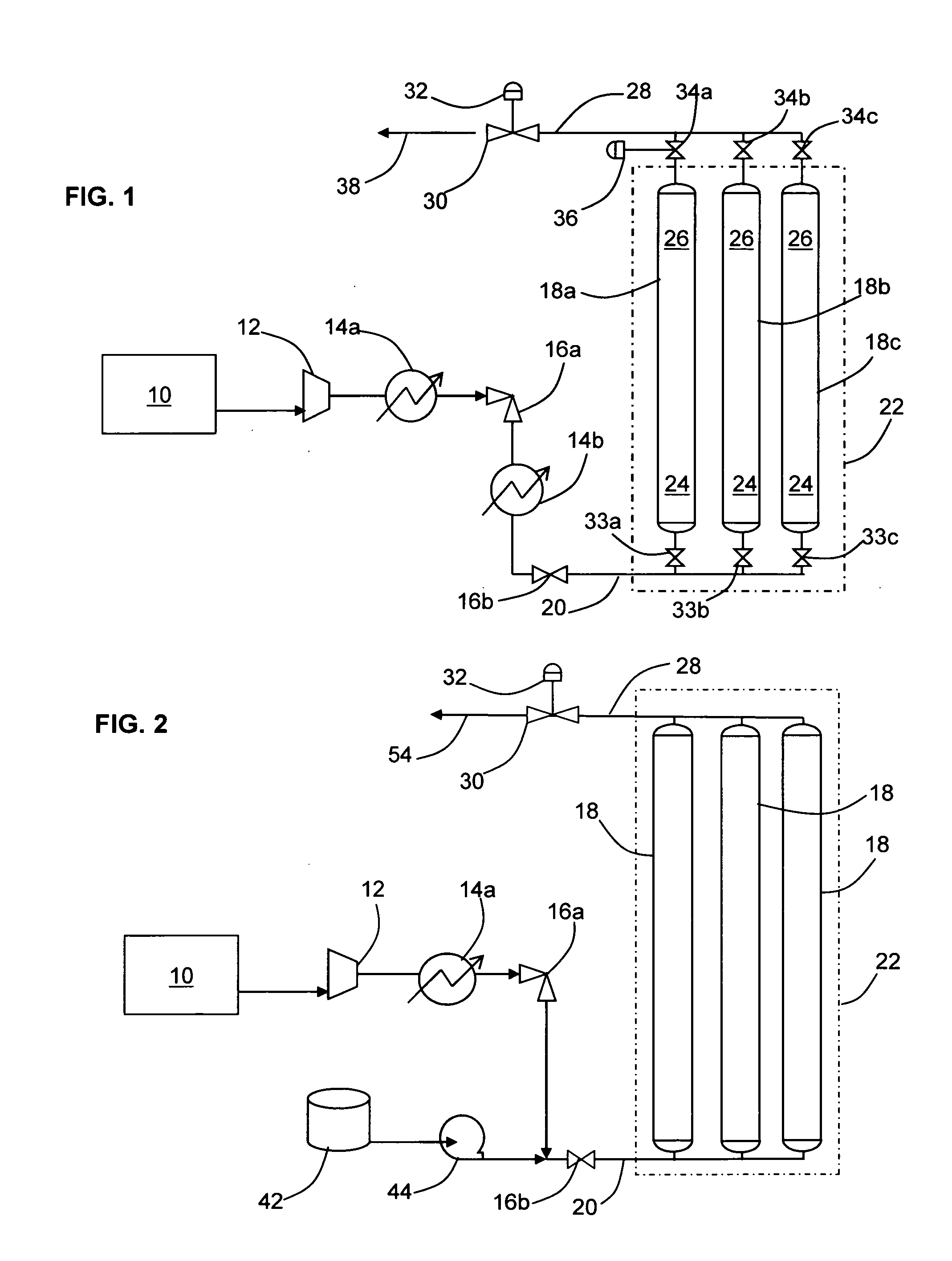

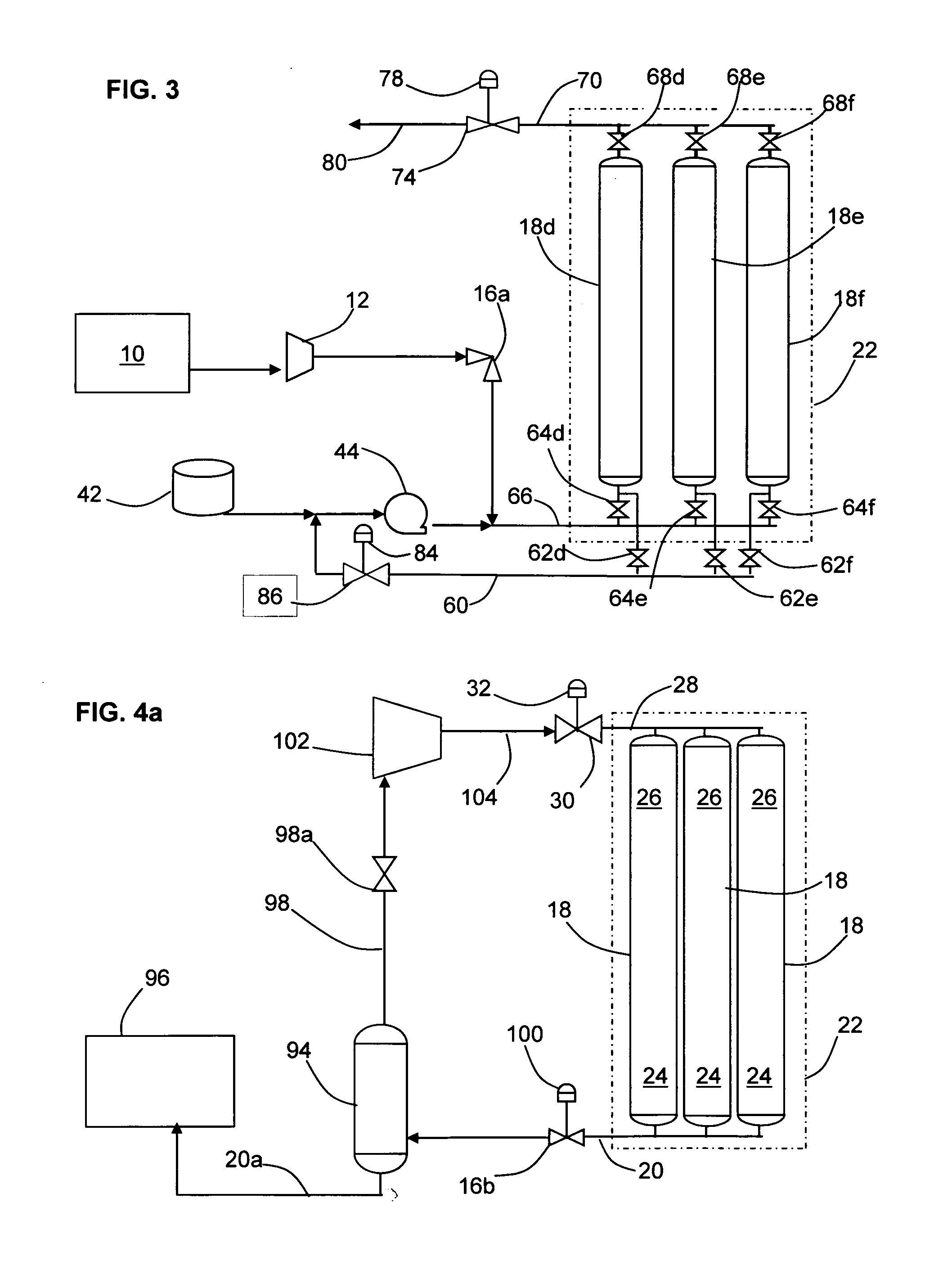

Method and system for independently filling multiple canisters from cascaded storage stations

A canister filling system is provided for independently filling multiple canisters from a common set of storage stations prioritized in a cascaded manner. The system includes first and second fill stations configured to receive and independently fill canisters with pressurized gas. First and second storage stations store gas at corresponding first and second charge pressures, respectively. A supply-chain joins each of the first and second fill stations to both of the first and second storage stations. First and second valve assemblies are provided in the supply-chain to monitor, independent of one another, the canister pressures at the corresponding first and second fill stations. The canister pressures represent the pressure within corresponding canisters. The first and second valve assemblies automatically open and close to permit and prevent discharge of gas from the first and second storage stations, independent of one another, to automatically switch between the first and second storage stations based on the canister pressures. In one embodiment, the valve assembly includes a combination of sequence valves and check valves. Alternatively, the valve assembly may be controlled by electronic sensors and electronic solenoids. The electronic sensors detect the canister pressures and the charge pressures at the storage stations. The electronic solenoids open and close the valves based on the sensed canister pressures.

Owner:SCOTT TECH INC

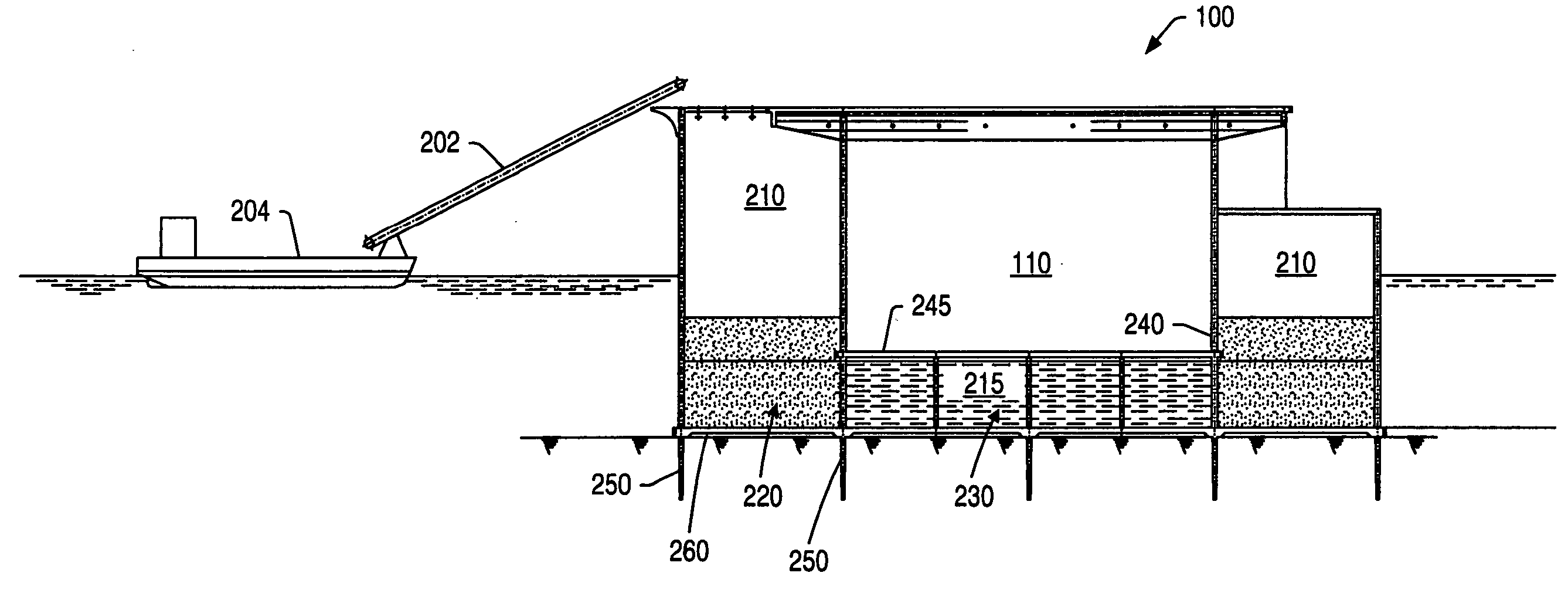

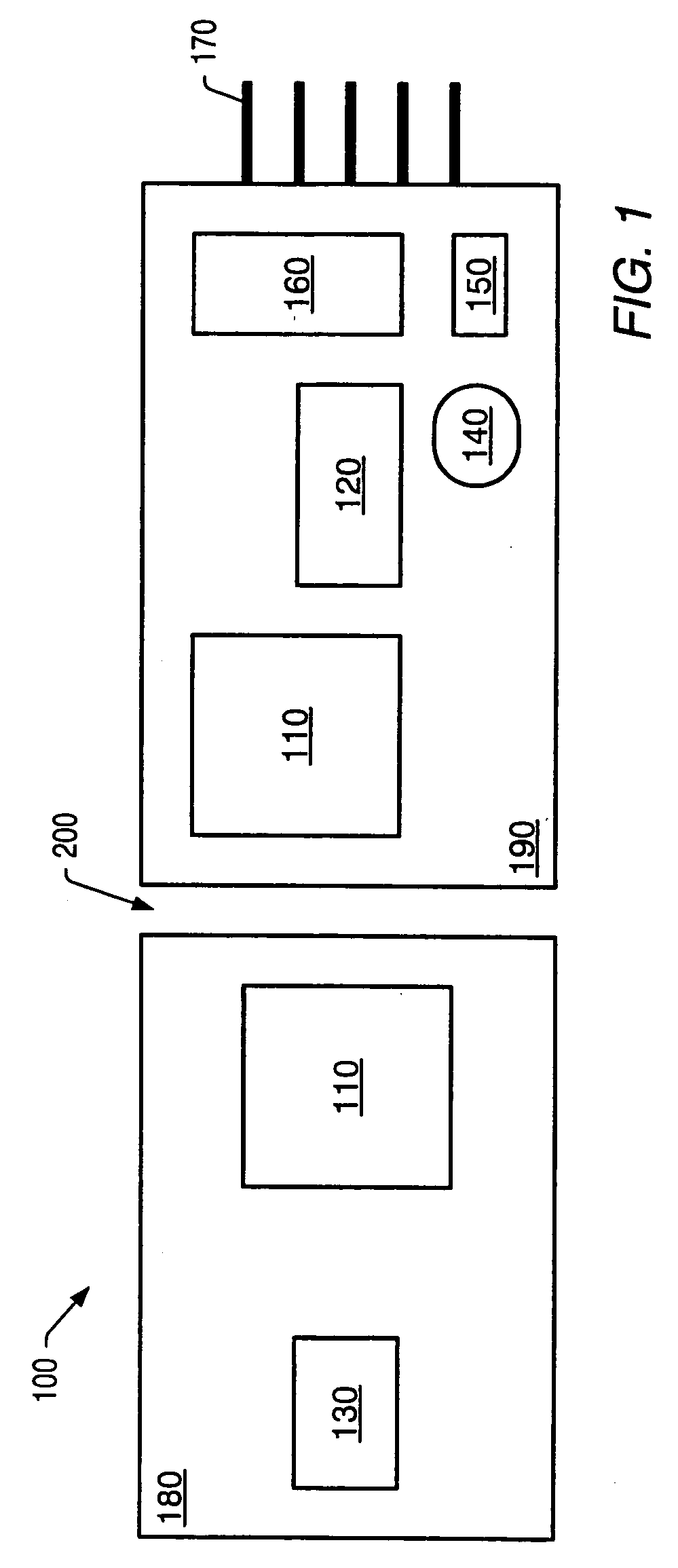

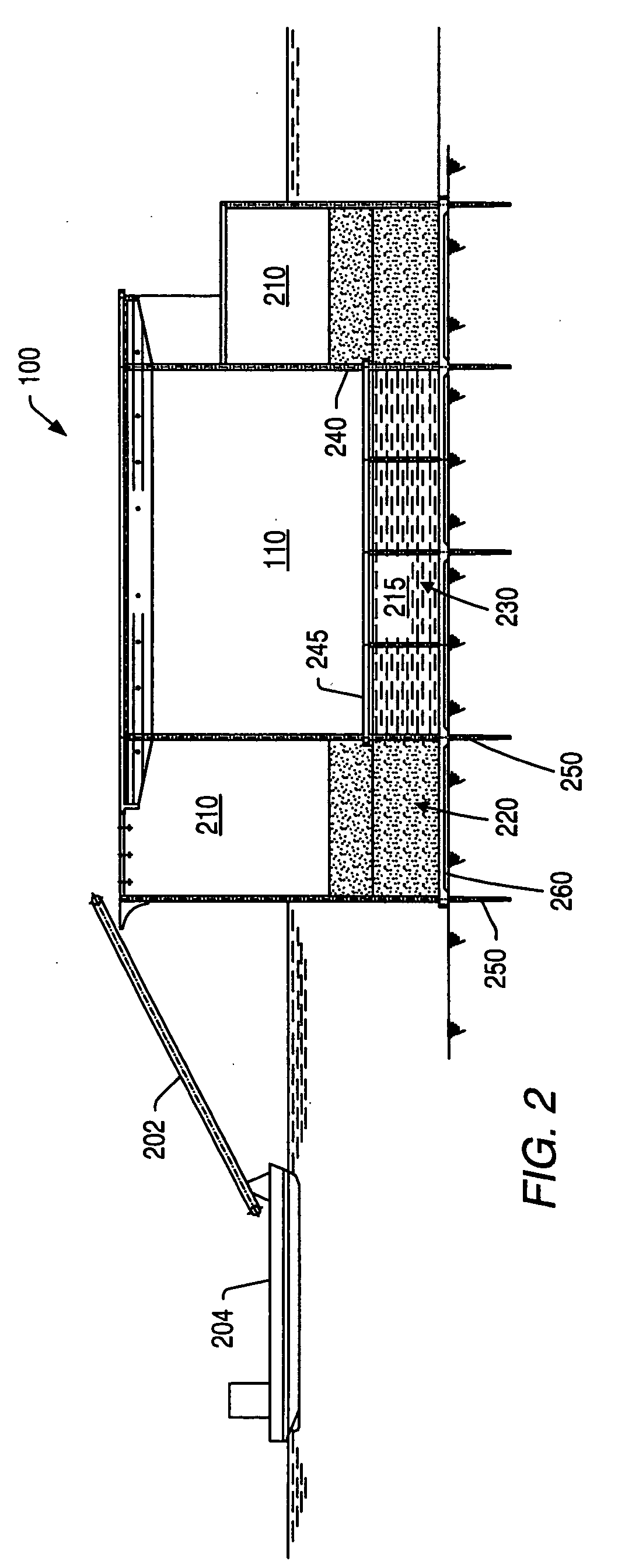

Liquefied natural gas floating storage regasification unit

InactiveUS20060156744A1Reduce the amount requiredProvide protectionGas handling applicationsGas handling/storage effectsMooring systemMarine engineering

An offshore liquefied natural gas floating storage regasification unit that may receive, store, and process liquefied natural gas from carriers. A floating storage regasification unit may include transfer equipment to offload liquefied natural gas from a carrier, a first mooring system to provide for mooring of a floating storage regasification unit at a location in a body of water, a second mooring system to provide for mooring a carrier to the floating storage regasification unit, and combinations thereof. A portion of the floating storage regasification unit may be composed of a double-hull containment structure.

Owner:SHELL OIL CO

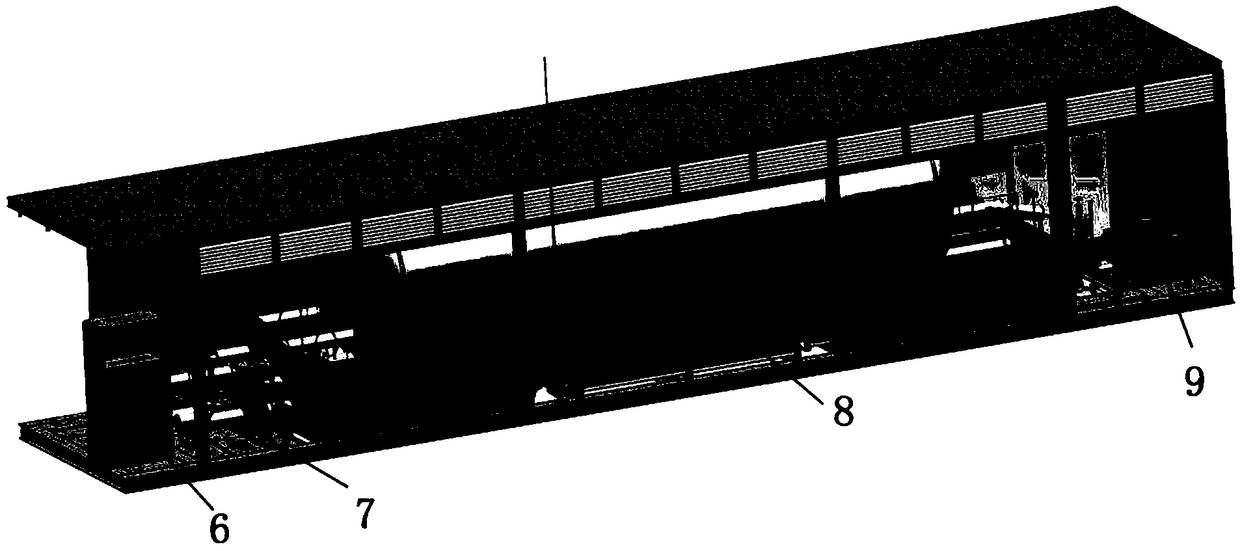

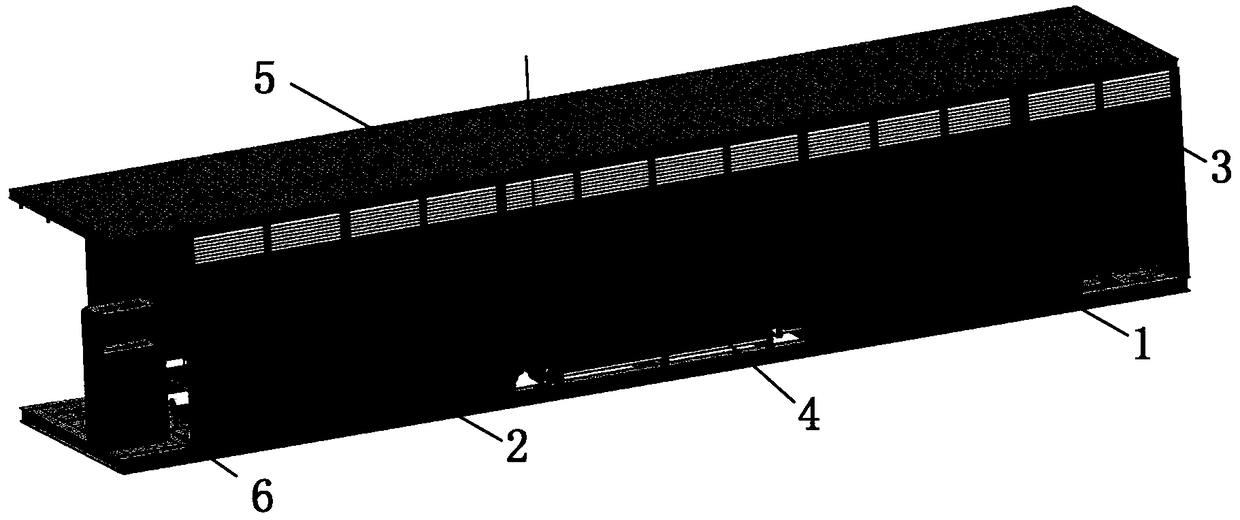

LNG/L-CNG skid-mounted gas station

PendingCN109027662AFunction increaseShort construction periodVessel mounting detailsVessel geometry/arrangement/sizeEngineeringIndustry standard

The invention discloses a LNG / L-CNG skid-mounted gas station. The LNG / L-CNG skid-mounted gas station comprises a first sled base, a second sled base, a LNG pump sled, a low-temperature storage tank, aL-CNG pump sled and a gas filling machine; the L-CNG pump sled is arranged on the first sled base; the low-temperature storage tank, the L-CNG pump sled and the gas filling machine are integrated onthe second sled base in sequence; an unloading table is additionally arranged at the end, near the gas filling machine, of the second sled base; the end, near the low-temperature storage tank, of thesecond sled base is movably connected with the first sled base; the low-temperature storage tank discharges liquid by the head and tail ends; fences are arranged on two sides of the first sled base and the second sled base; the first sled base is connected with the end, near the low-temperature storage tank, of the second sled base; top cover plates are arranged at the tops of the fences; and thehorizontal plane of the top cover plates is higher than the horizontal plane of the top of the low-temperature storage tank. The LNG / L-CNG skid-mounted gas station has the following beneficial effects: through high integration degree, the country and industry standards are met, and the functions of an integrated gas station are expanded; and through the mode of discharging the liquid by the head and tail ends of the low-temperature storage tank, the generation of BOG is greatly reduced, and the liquid outlet speed is accelerated.

Owner:JEREH OIL & GAS ENG

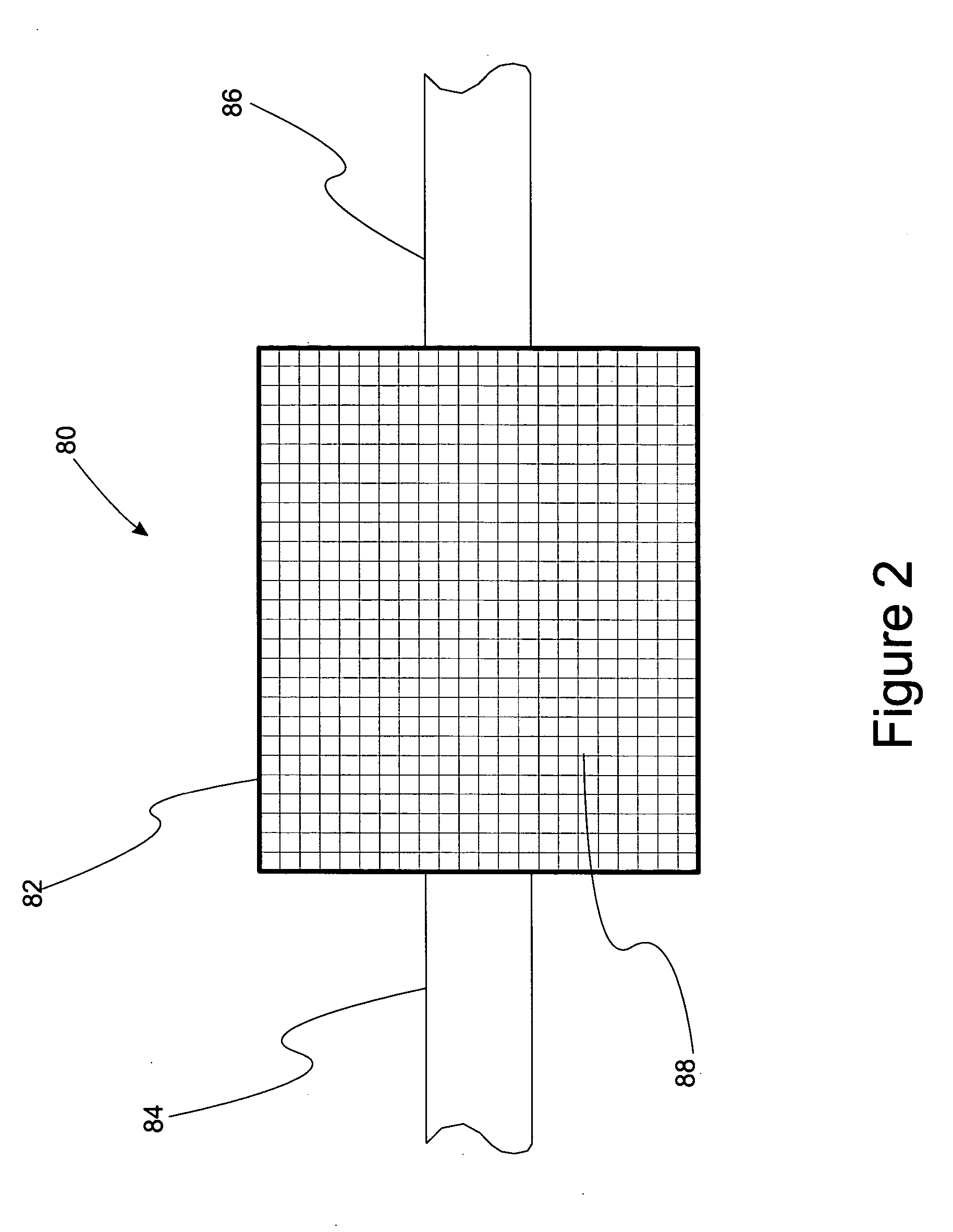

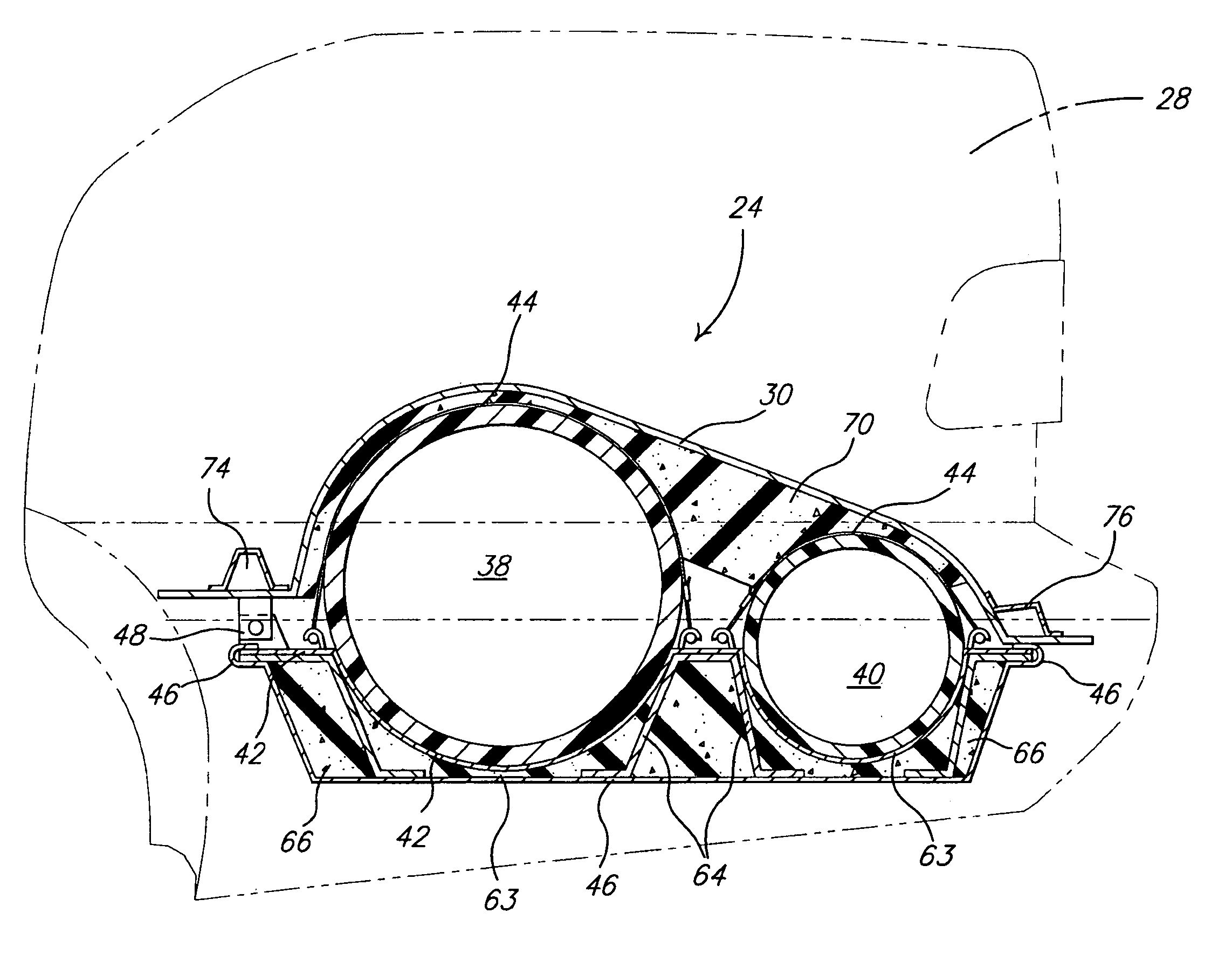

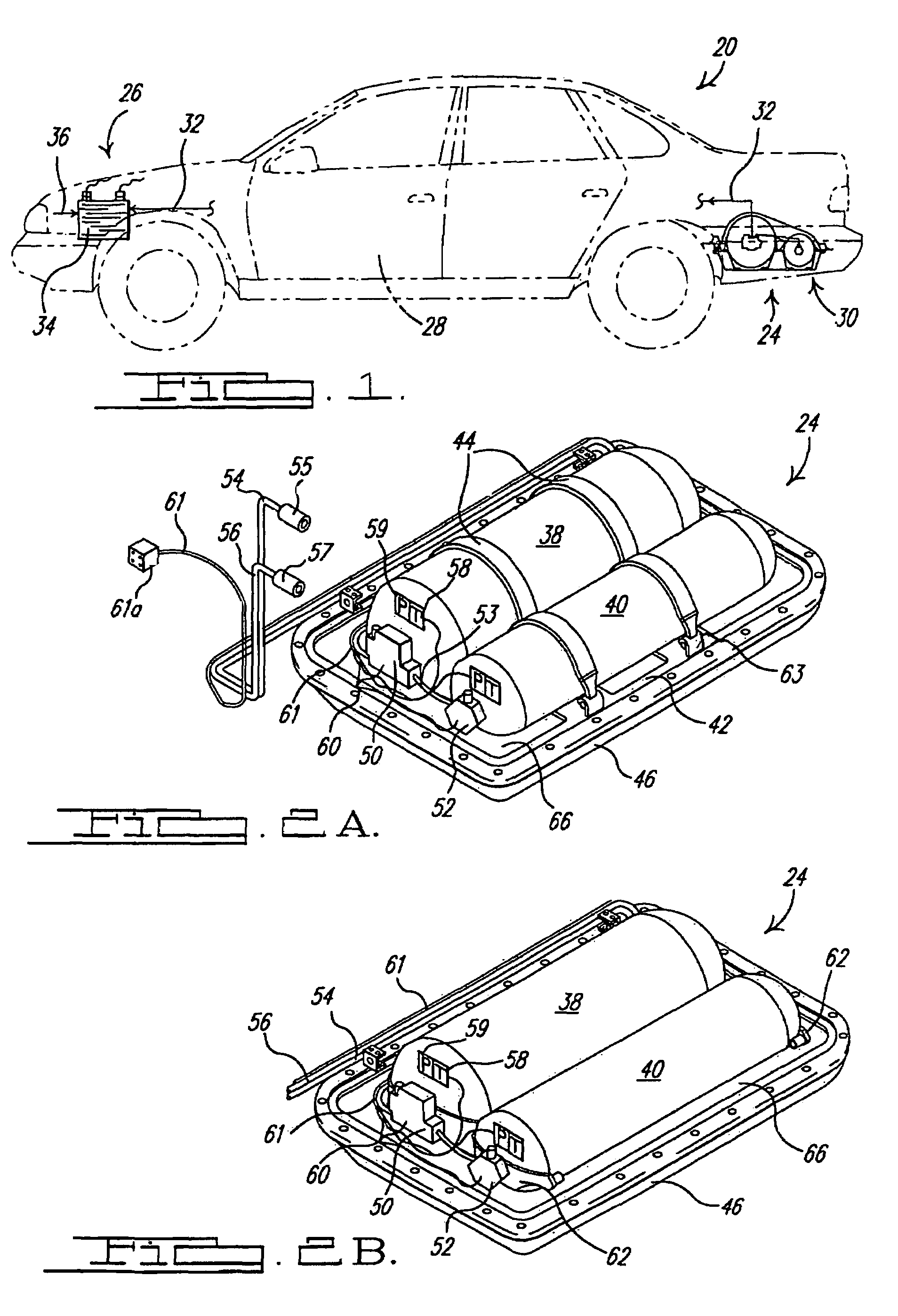

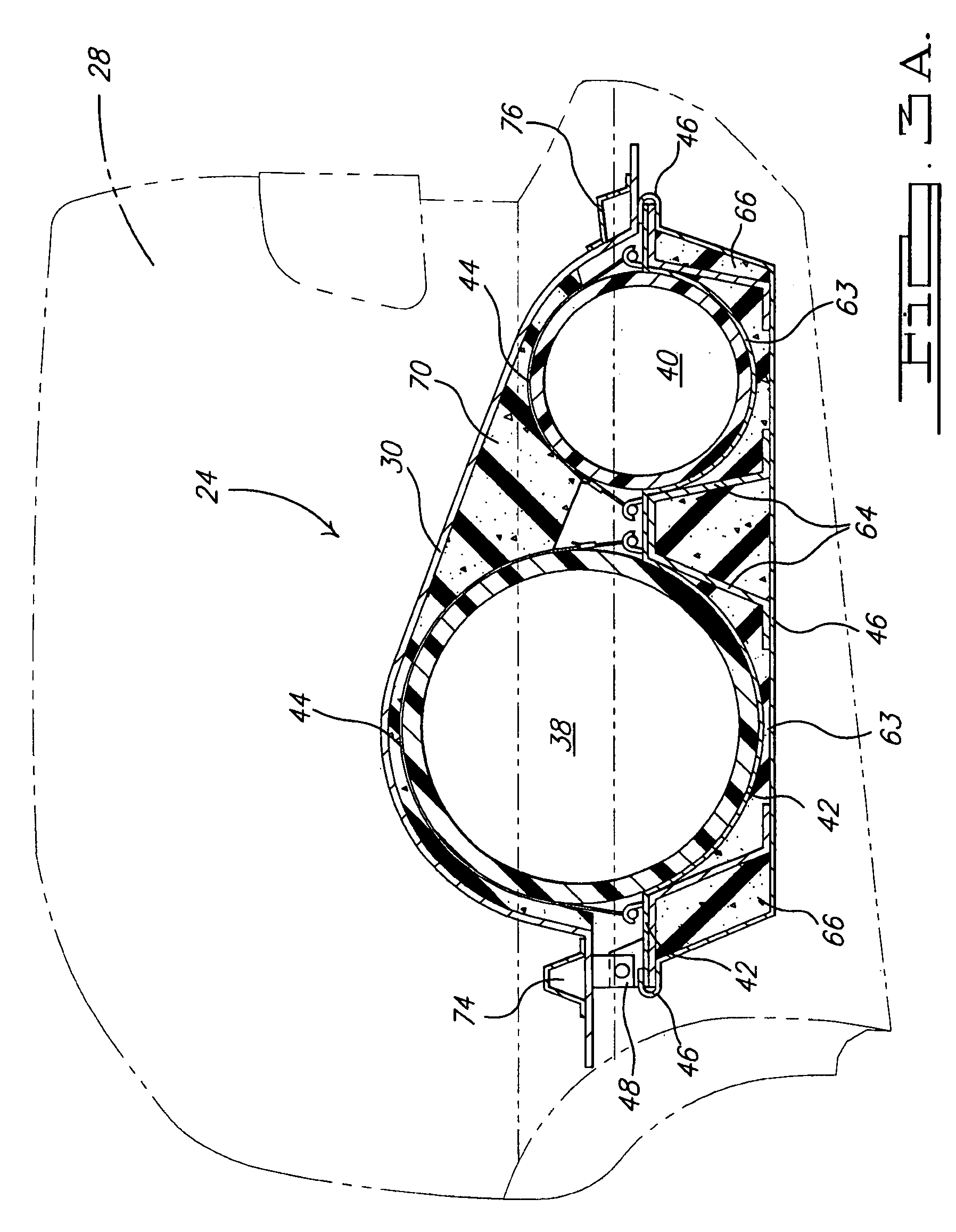

Modular fuel storage system for a vehicle

A gaseous fuel storage system for a vehicle is disclosed. The fuel storage system can be installed as a modular unit in the vehicle. The fuel storage system is pivotable relative to the vehicle to allow easy accessibility to the storage tanks without requiring the storage tanks to be unmounted from the vehicle. The fuel storage system also provides protection for the storage tanks through the use of shielding and energy absorbing material.

Owner:GM GLOBAL TECH OPERATIONS LLC

Apparatus and method for flowing compressed fluids into and out of containment

ActiveUS20080209916A1Adjustable temperatureGas handling applicationsGas handling/storage effectsChemical compositionCompressed fluid

Methods for loading a compressed fluid, such as natural gas, into and discharging the compressed fluid out of containment are provided. The compressed fluid is injected into a bottom portion of a container system for storage and / or transport until a target pressure is reached after which gas is withdrawn from an upper portion of the container system at a rate to maintain the target pressure while the compressed fluid is injected in the bottom portion. The compressed fluid is cooled through an expansion valve and by refrigerated chillers or by injecting a cold liquid of the same chemical composition as the compressed fluid, such as liquid natural gas, into the compressed fluid prior to injection into the container system. Withdrawal or discharge from the container system to a receiving facility begins with blow down from the bottom portion of the container system without a displacement fluid and continues until pressure falls below an acceptable differential pressure. The discharge stream is passed through a separator and a light gas from the separator is pressurized and injected into an upper portion of the container system to drive the compressed fluid out the bottom. The light gas is pressurized using either a compressor or a heated tank system, where two vessels operate in parallel, trapping and heating the light gas and then discharging to the container system from one while filling the other and alternating the operation between the two.

Owner:WHITE CHARLES N +1

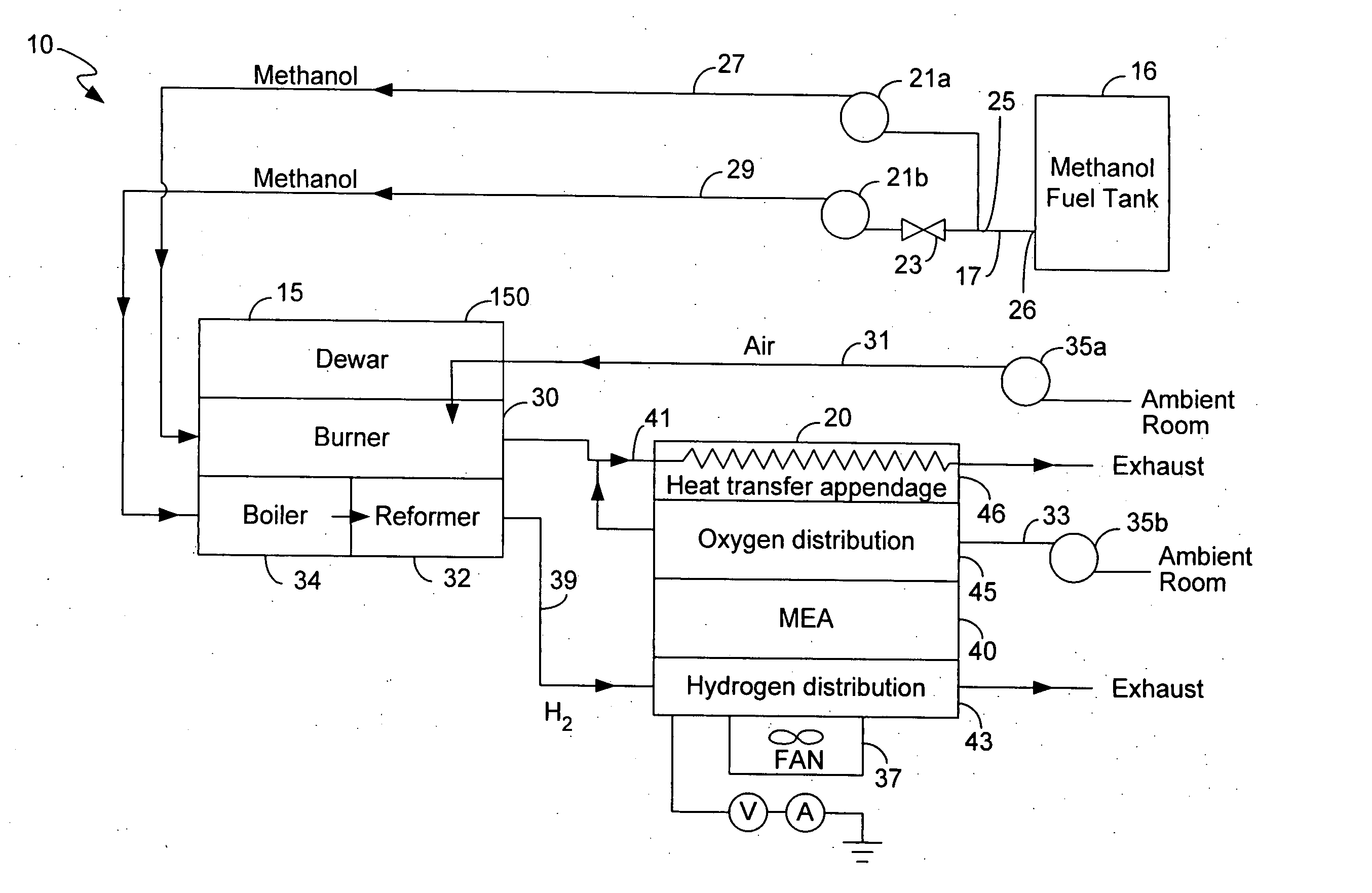

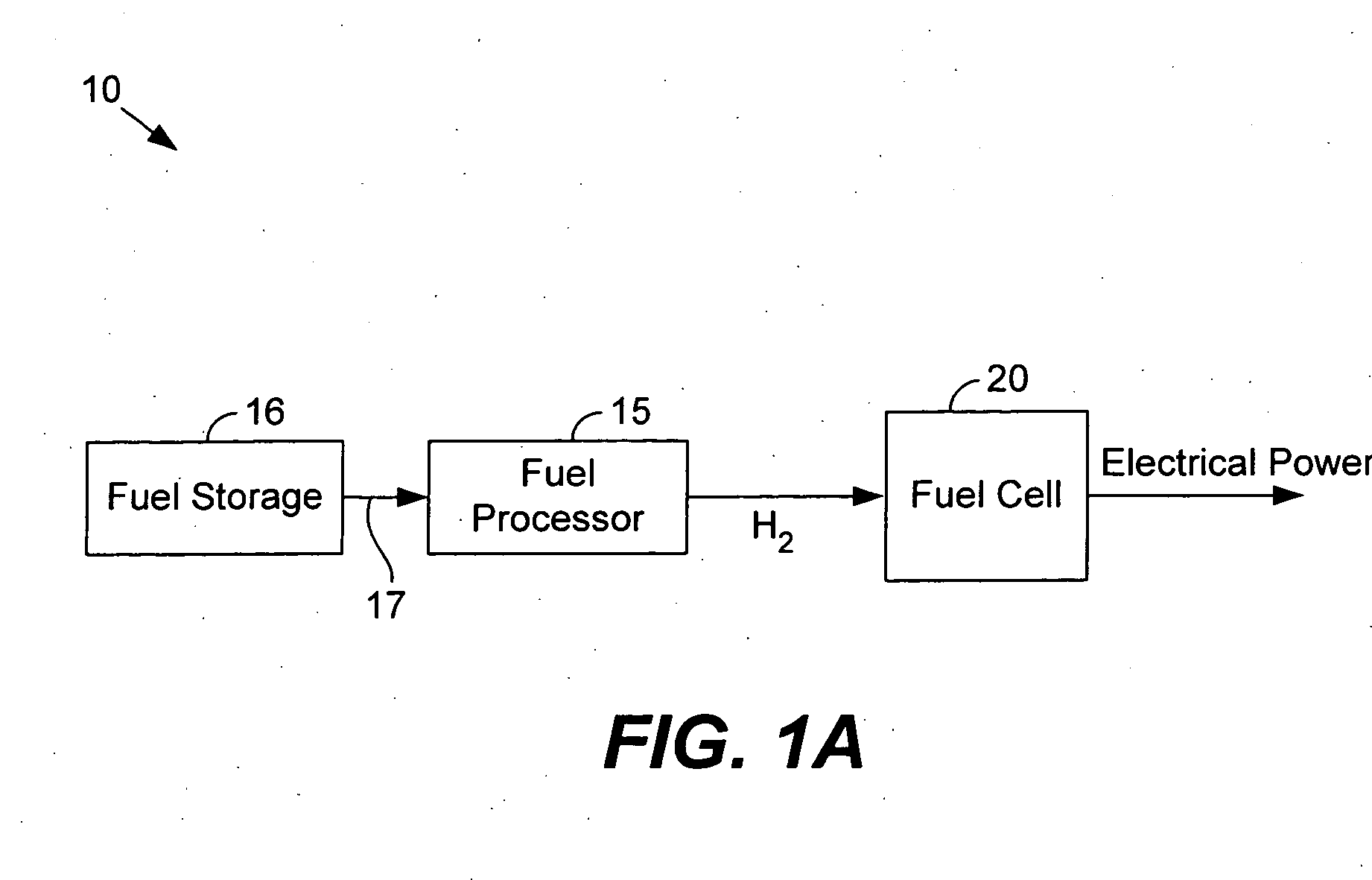

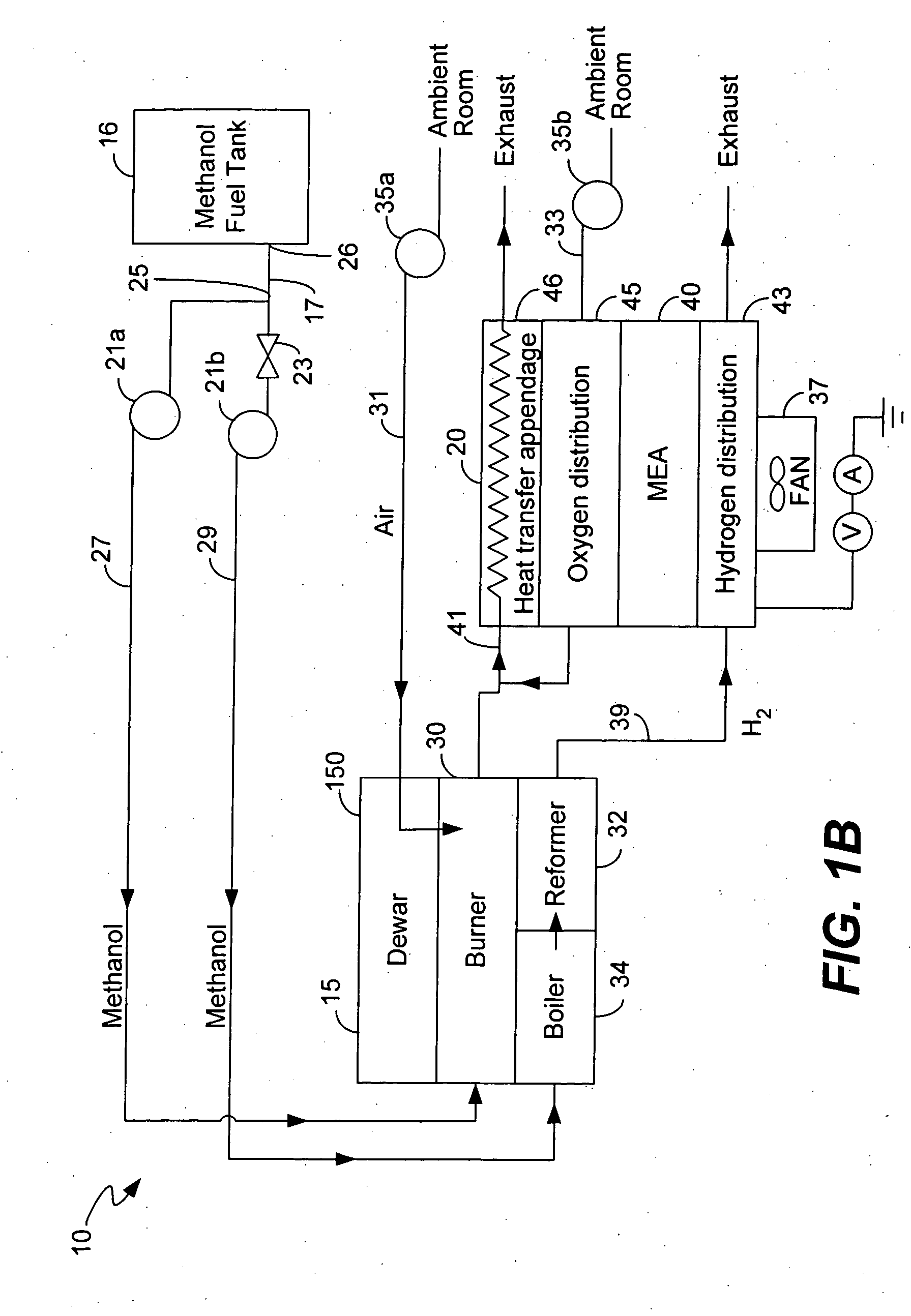

Portable fuel cartridge for fuel cells

InactiveUS20050008908A1Promote hydrogen productionPromote productionFuel cell heat exchangeReactant parameters controlHydrogen fuelElectron

Described herein is a portable storage device that stores a hydrogen fuel source. The storage device includes a bladder that contains the hydrogen fuel source and conforms to the volume of the hydrogen fuel source. A housing provides mechanical protection for the bladder. The storage device also includes a connector that interfaces with a mating connector to permit transfer of the fuel source between the bladder and a device that includes the mating connector. The device may be a portable electronics device such as a laptop computer. Refillable hydrogen fuel source storage devices and systems are also described. The refillable system comprises a hydrogen fuel source refiner that includes the mating connector and provides the hydrogen fuel source to the storage device. Hot swappable fuel storage systems described herein allow a portable hydrogen fuel source storage device to be removed from a fuel processor or electronics device it provides the hydrogen fuel source to, without shutting down the receiving device or without compromising hydrogen fuel source provision to the receiving device for a limited time.

Owner:ULTRACELL LLC

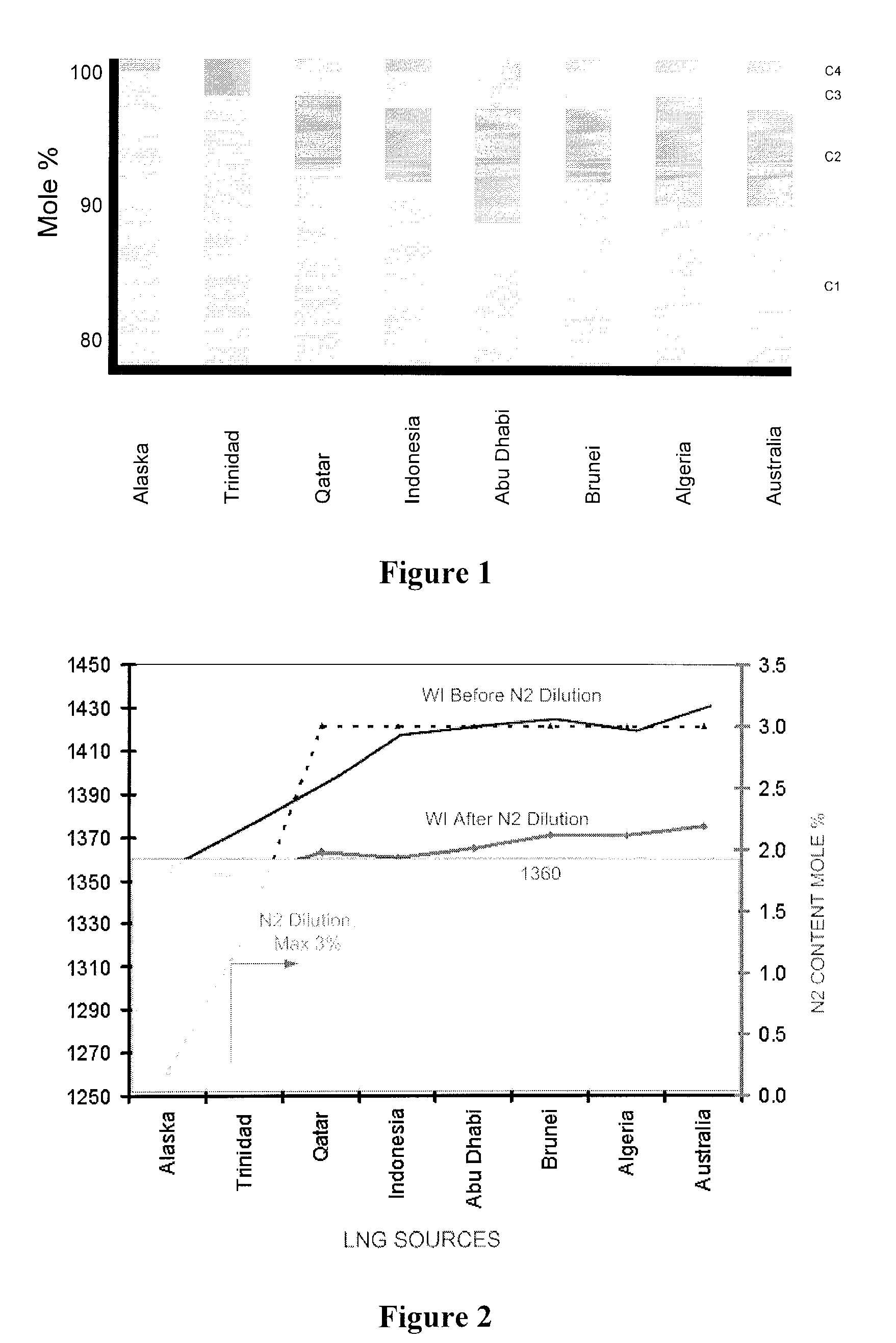

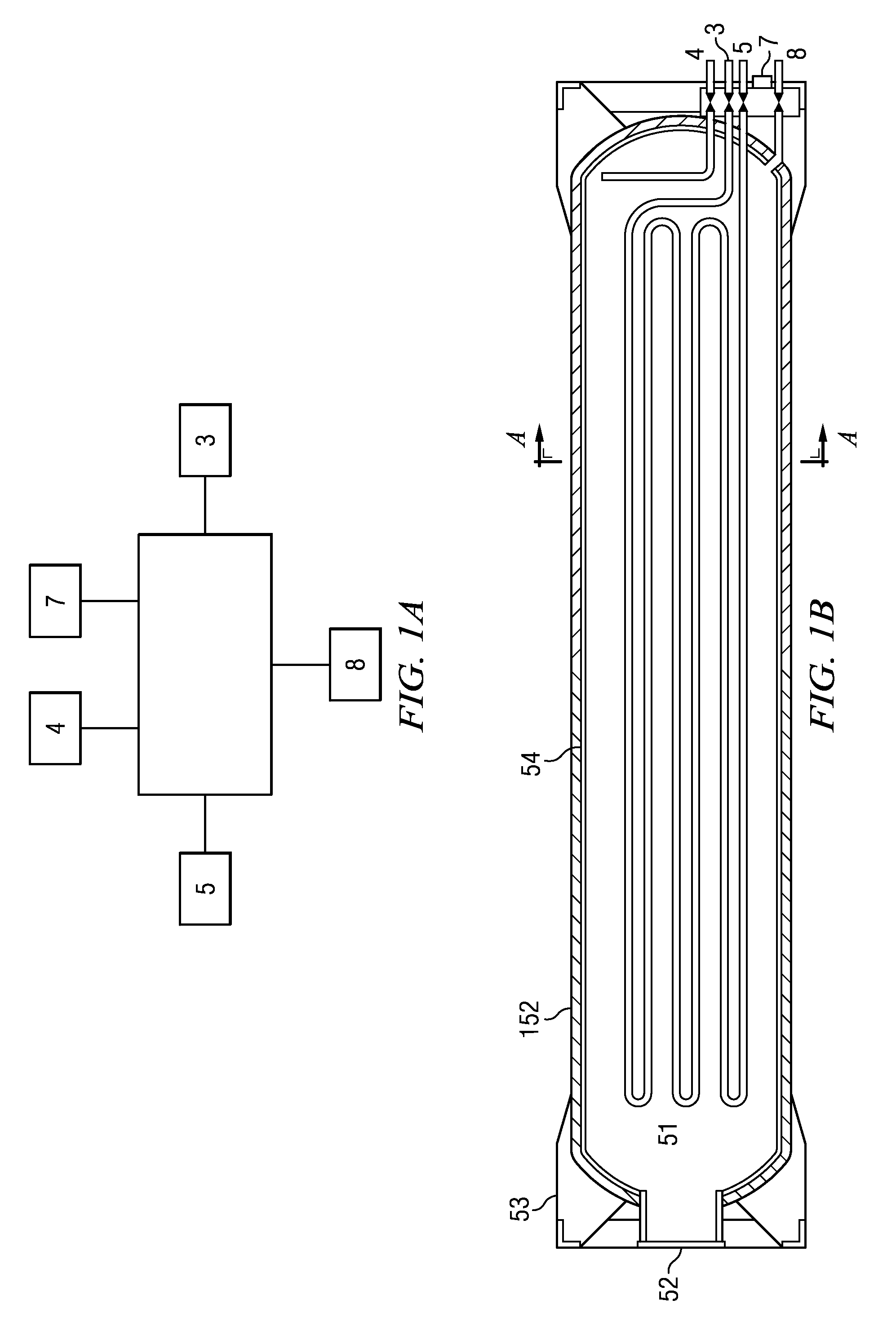

Methods and Configurations of Boil-off Gas Handling in LNG Regasification Terminals

InactiveUS20110056238A1Stable storage tank pressure controlStable controlSolidificationLiquefactionProcess engineeringWobbe index

A LNG storage and regasification plant includes a reliquefaction unit in which boil-off vapors from the storage tanks are re liquefied and recycled back to the LNG storage tanks for tank pressure and Wobbe index control. Preferably, LNG cold is used for reliquefaction and operational flexibility is achieved by feeding a portion of the pressurized boil-off gas to a fuel gas header and / or to be recondensed by the sendout LNG.

Owner:FLUOR TECH CORP

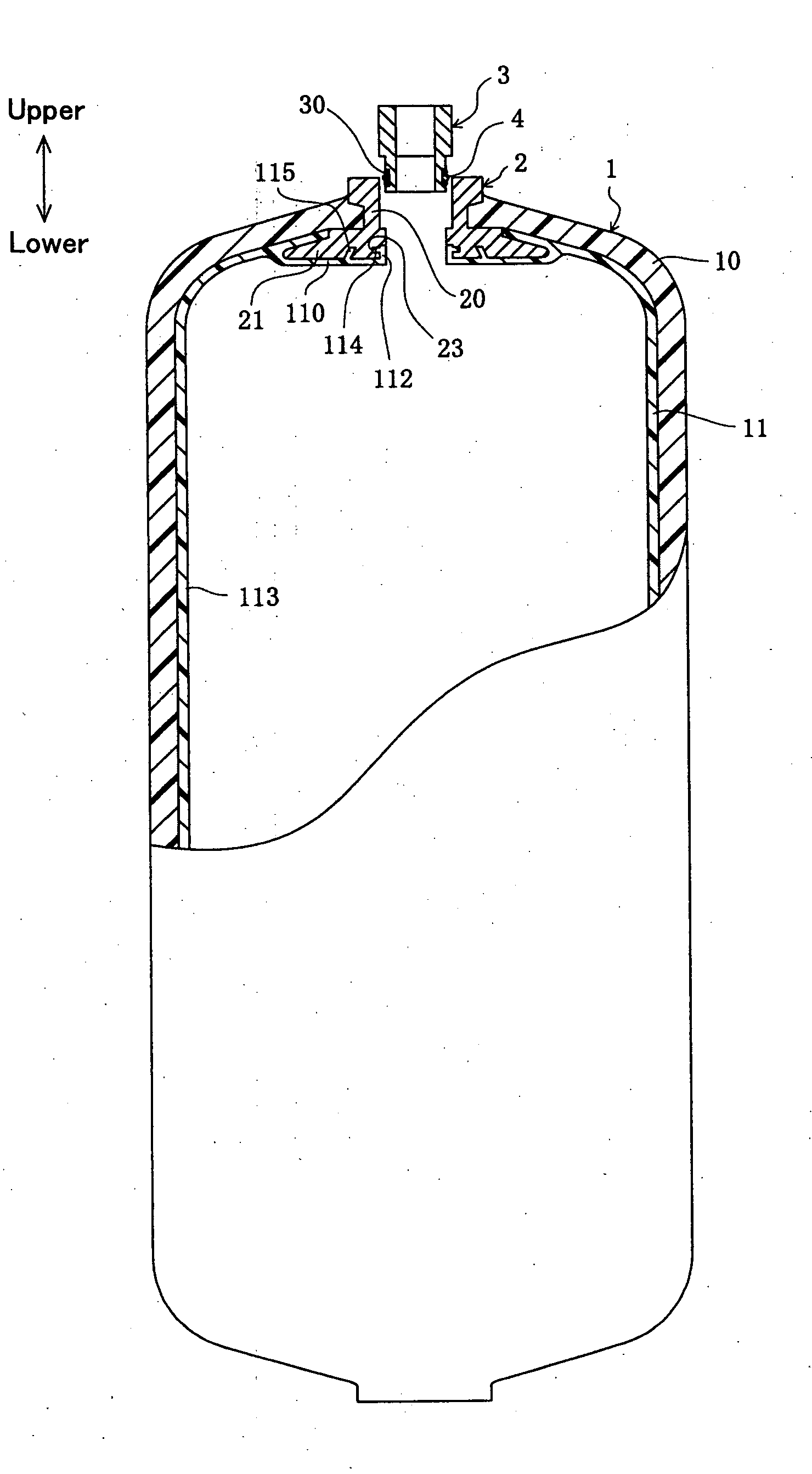

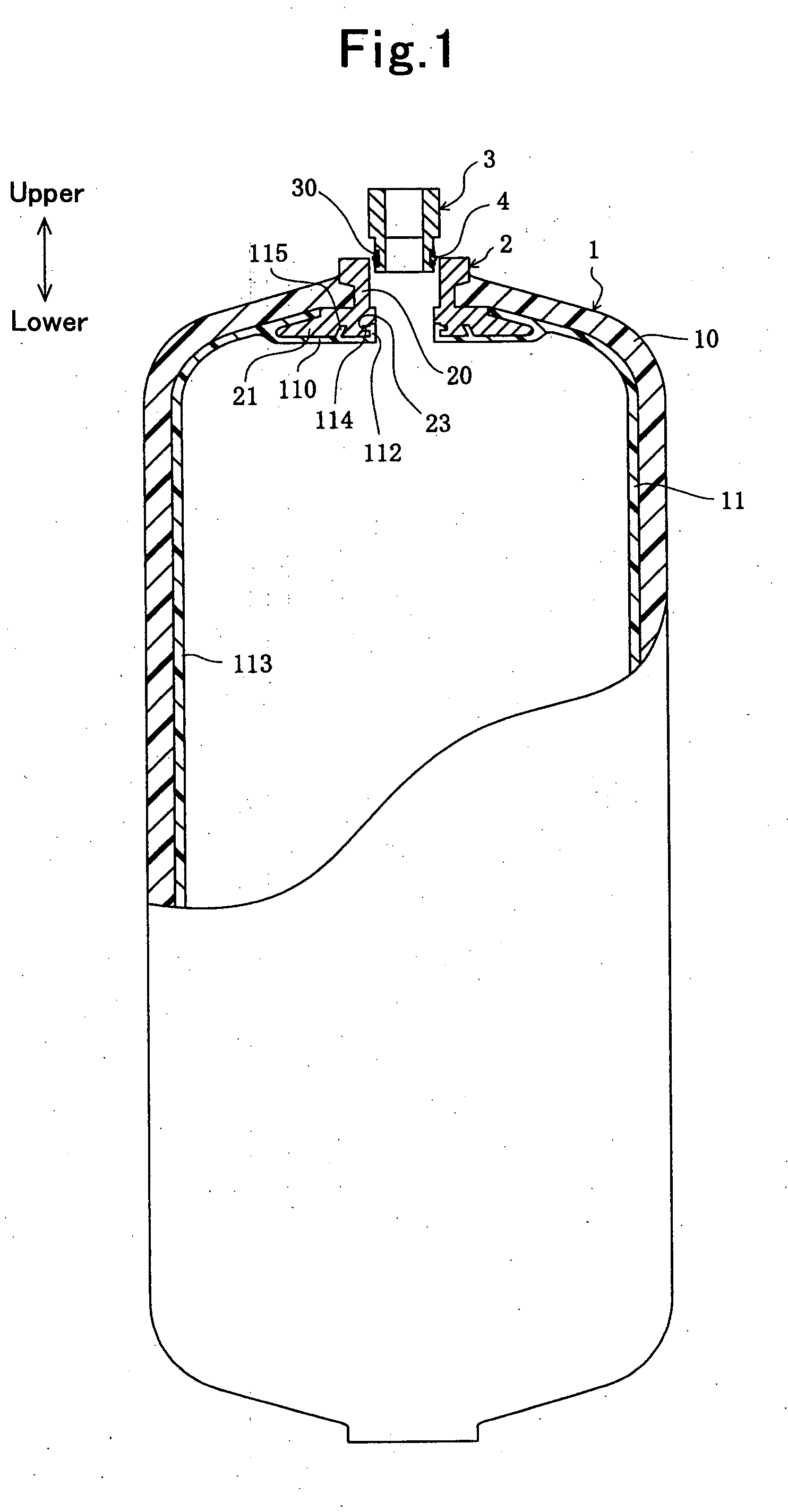

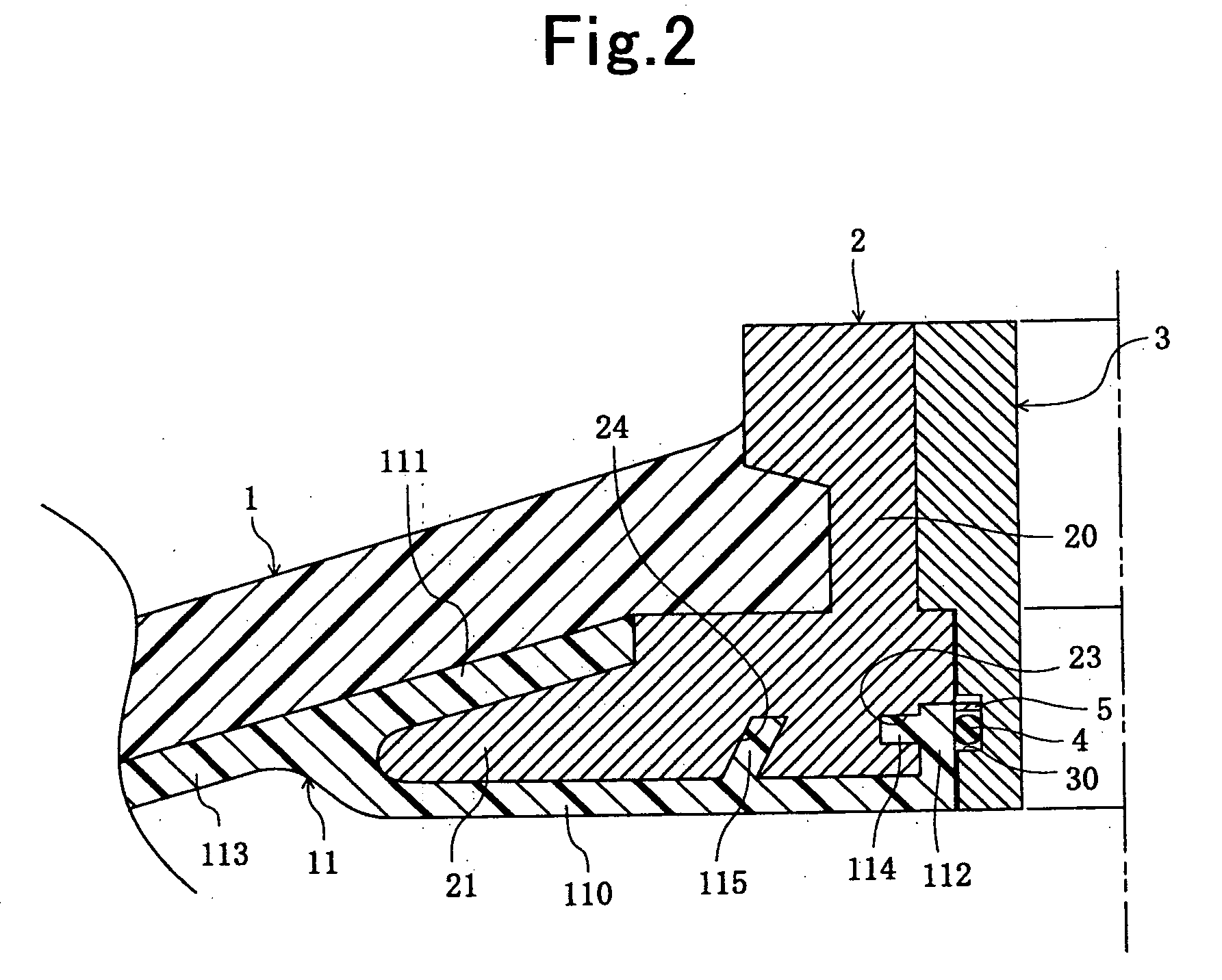

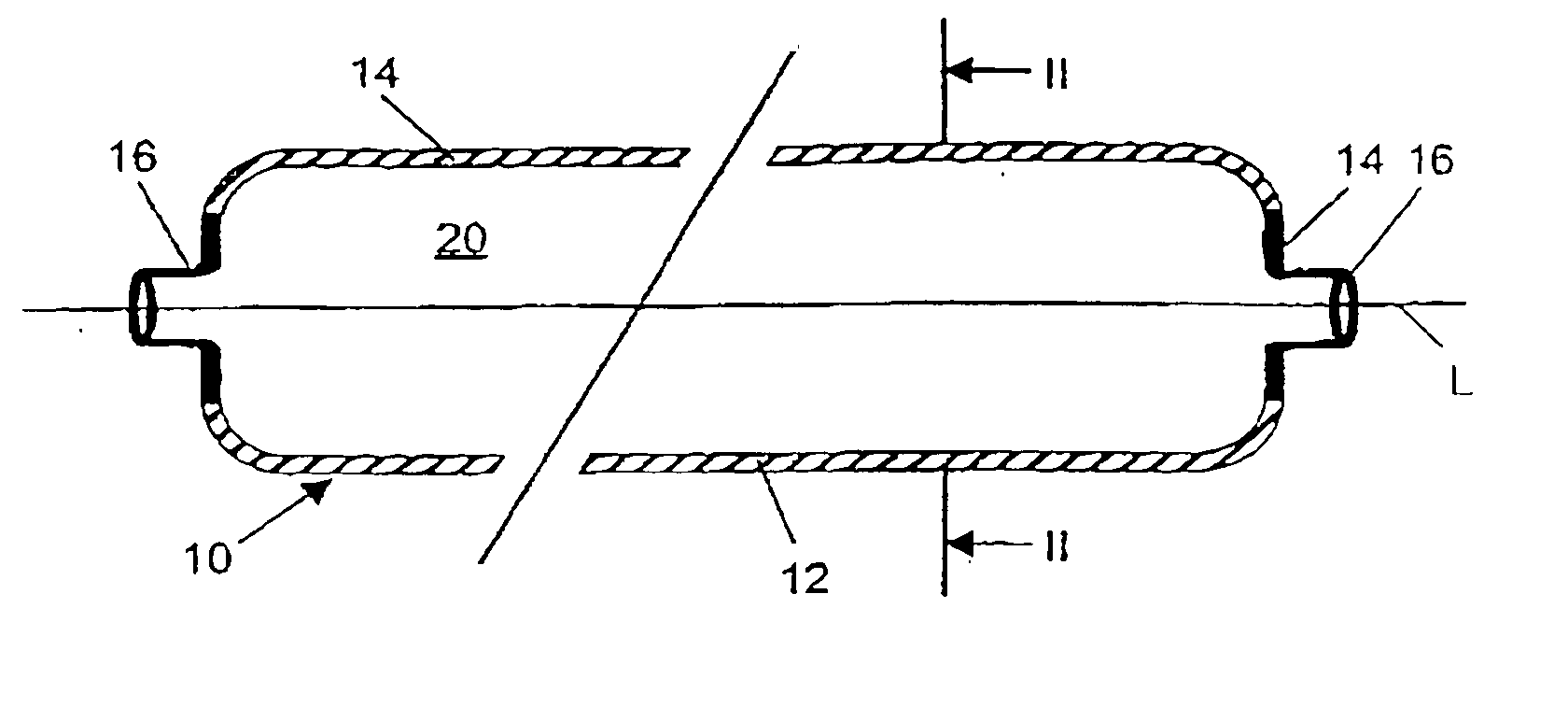

Pressure vessel

A pressure vessel capable of securely sealing a mouth ring with a liner portion, and being manufactured at low costs. A boss seal part 112 is provided in a liner portion 11 of the pressure vessel, and an inner peripheral surface of a boss part 20 of a mouth ring 2 is covered with the boss seal part 112. A boss-side collar part 114 is provided in the boss seal part 112 so as to project outwardly, and a sealing member 4 composed of a resilient body is disposed in a space between an inner peripheral surface of the boss seal part 112 and an outer peripheral surface of the valve 3.

Owner:TOYODA GOSEI CO LTD +1

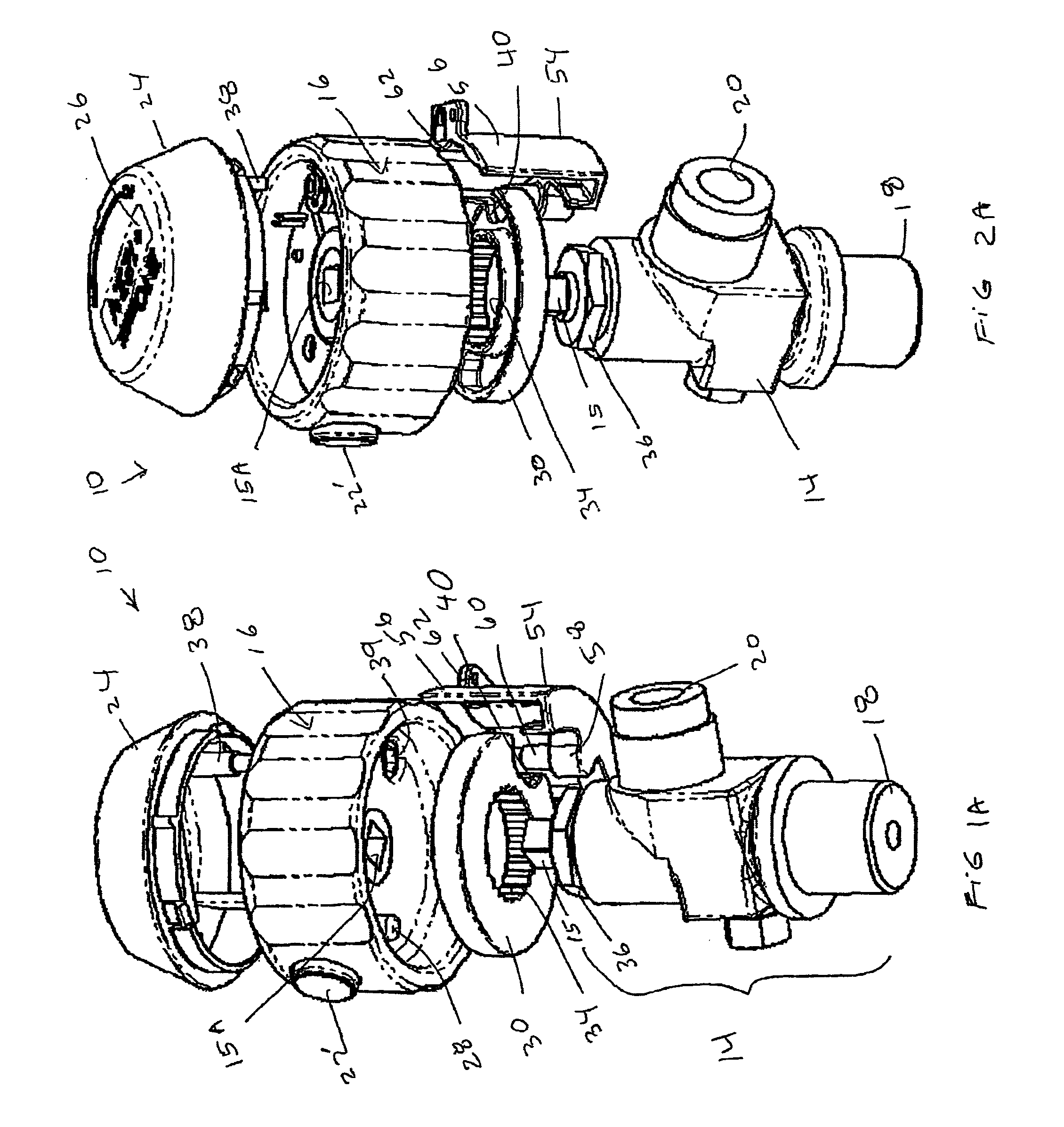

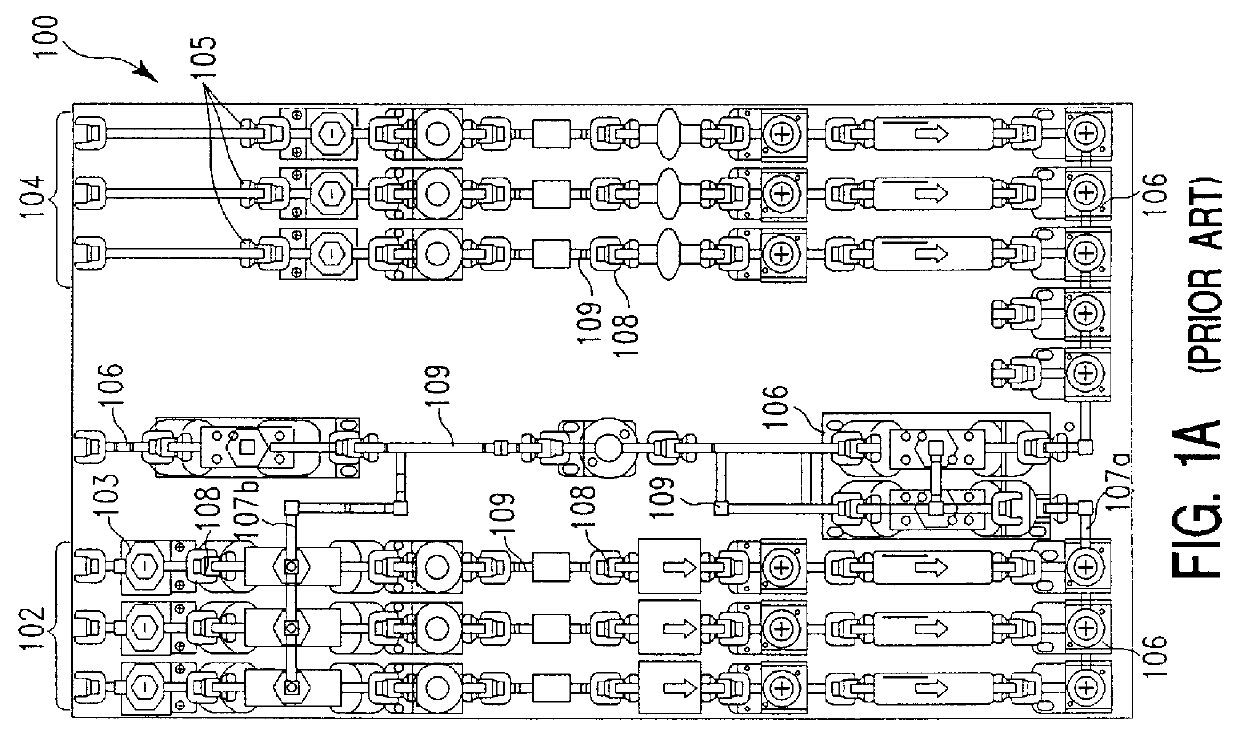

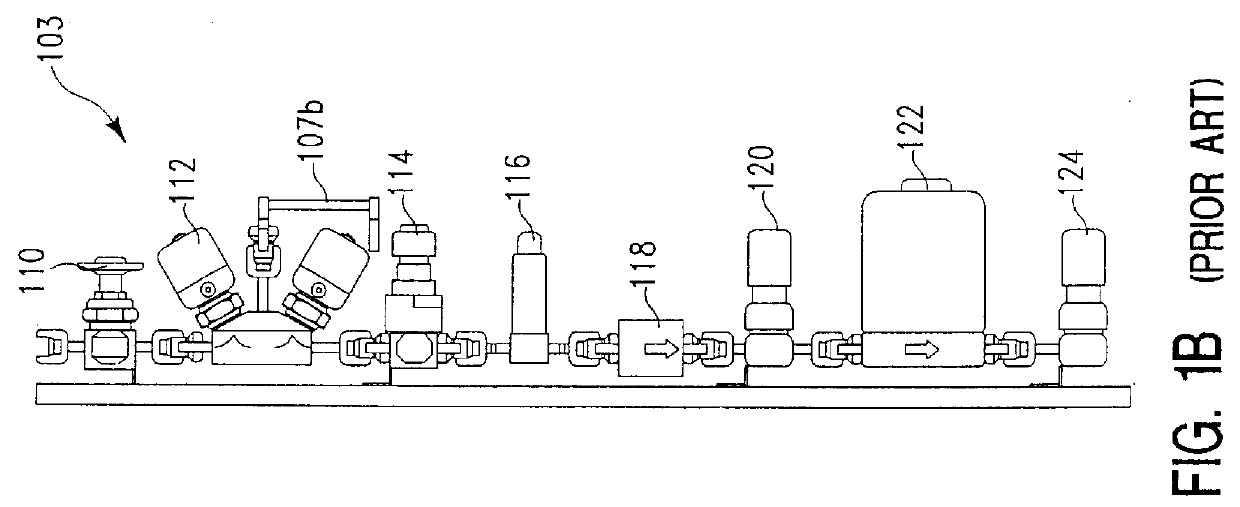

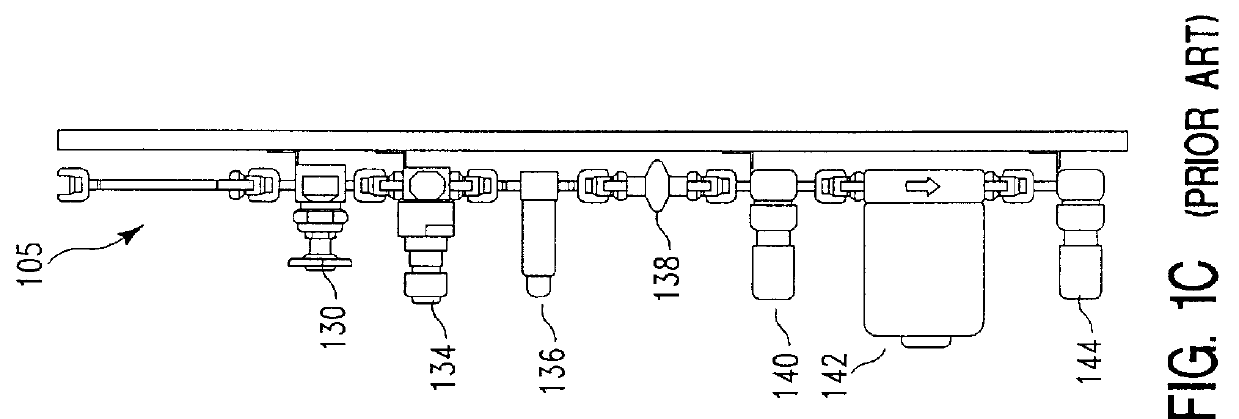

Modular fluid flow system with integrated pump-purge

This disclosure describes a modular, monolithic pump-purge system which can be integrated into a modular, monolithic fluid handling system without creating a closed tolerance loop. In particular, the pump-purge system comprises a plurality of valves mounted on a modular and monolithic manifold which can be attached to the modular, monolithic fluid handling system. At least a portion, and preferably all of the fluid transfer conduits necessary for either applying a vacuum (or other evacuation means) to a fluid handling system conduit which is to be evacuated (pumped), or for transfer of flushing fluid within a conduit (purging) are present within monolithic manifolds of the fluid handling system. The modular, monolithic manifold of the pump-purge system contains openings and fluid flow conduits which correspond with openings and fluid flow conduits of the modular, monolithic fluid handling system, to enable evacuation or flushing of a selected fluid flow conduit within the fluid handling system. To avoid the formation of a closed tolerance loop, it is necessary that the pump-purge manifold or a portion of the modular, monolithic fluid handling system manifold to which it is attached be sufficiently free-floating to permit making of all necessary connections without creating stress which can lead to an increased rate of corrosion or failure of the connection. In a preferred embodiment gas handling system, the gas handling flow lines which make up the system are comprised of individual sticks of gas handling elements, each of which is attached to the manifold of the pump-purge system so that it is free-floating.

Owner:APPLIED MATERIALS INC

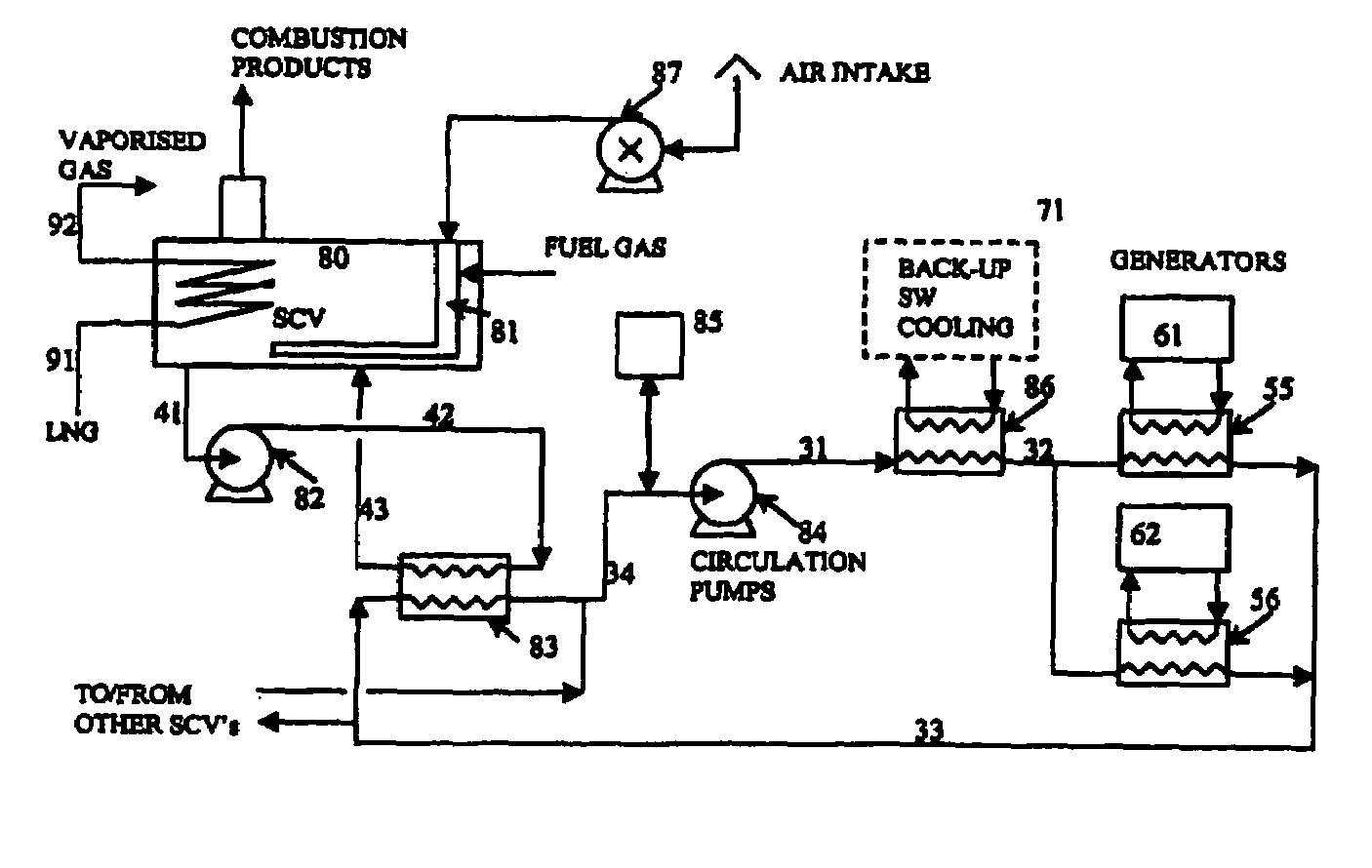

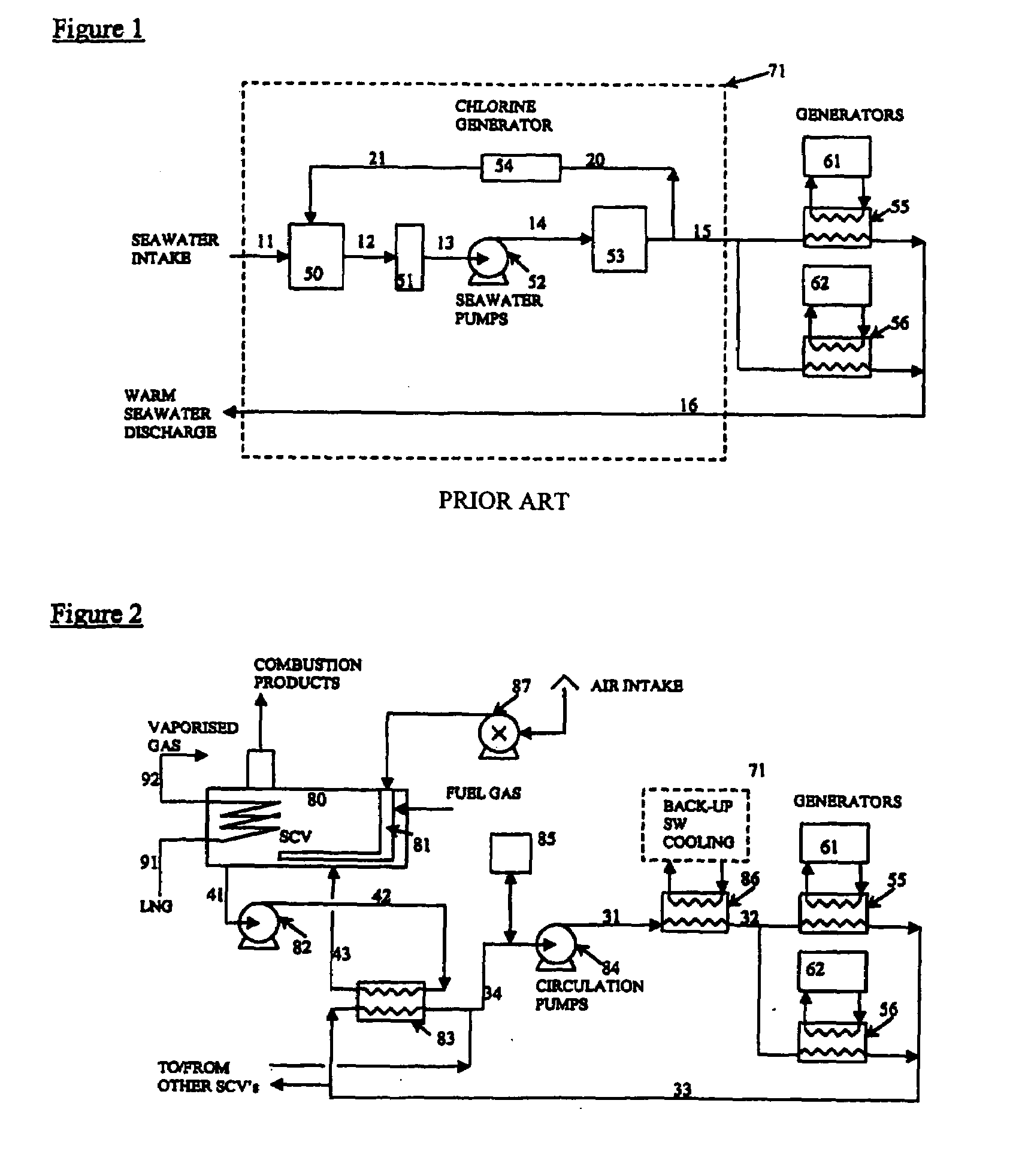

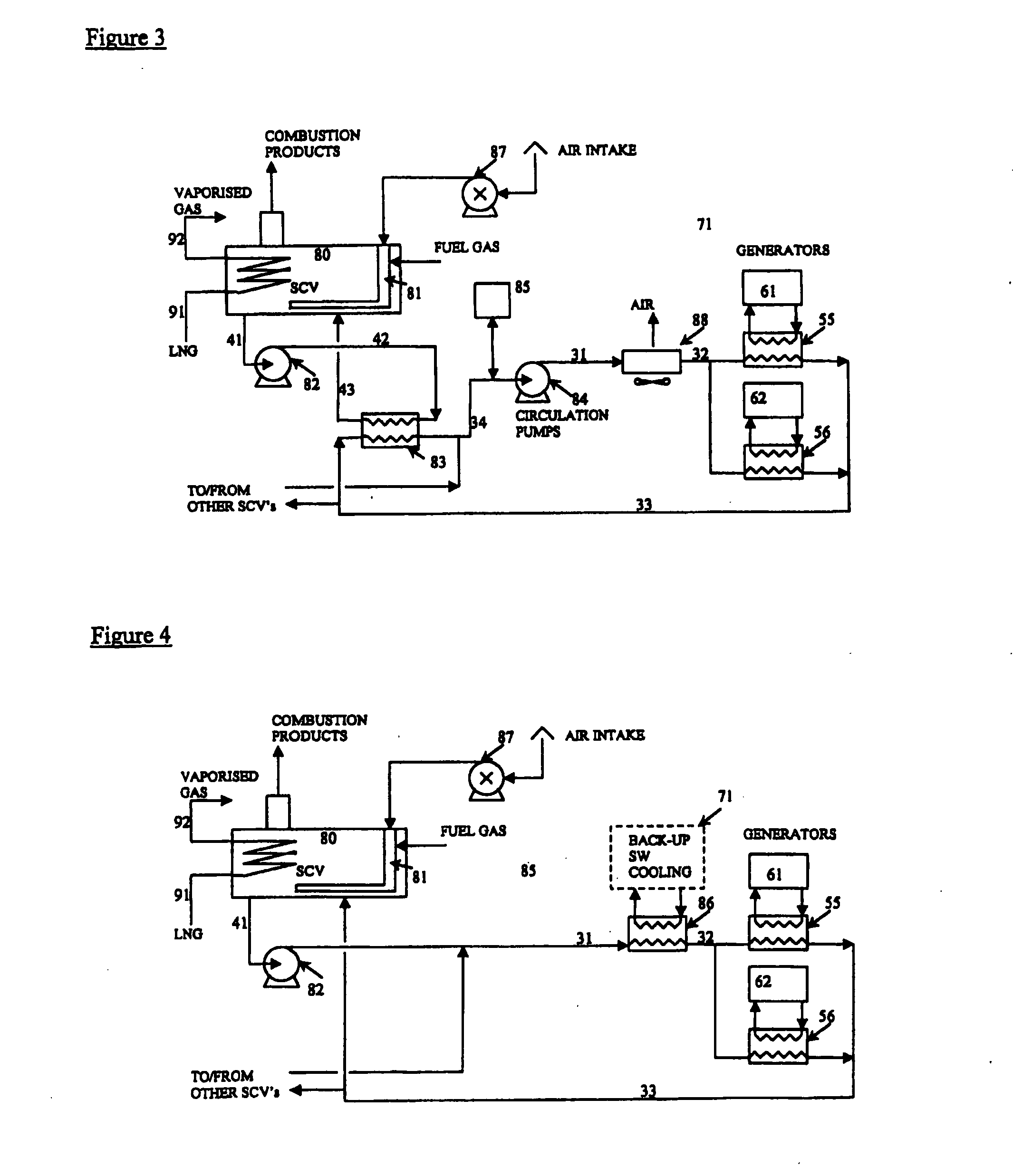

Heat recovery system

InactiveUS20080047280A1Easy to replenishReduce and even eliminateGas handling/storage effectsFluid transferredClosed loopEngineering

A heat recovery system comprising: an LNG warmer; at least one item of equipment requiring cooling and thereby generating waste heat; a heat exchanger arranged to provide heat exchange between the LNG warmer and the waste heat, whereby said waste heat can be used to provide warming for the LNG; wherein said heat exchanger is a closed loop heat exchange means, whereby the heat exchange fluids in said heat exchanger are substantially retained within the heat exchanger during operation of the system. This enables the system to be operated offshore without needing to use the surrounding seawater to provide cooling for the waste heat from the equipment.

Owner:BHP BILLITON INNOVATION PTY LTD

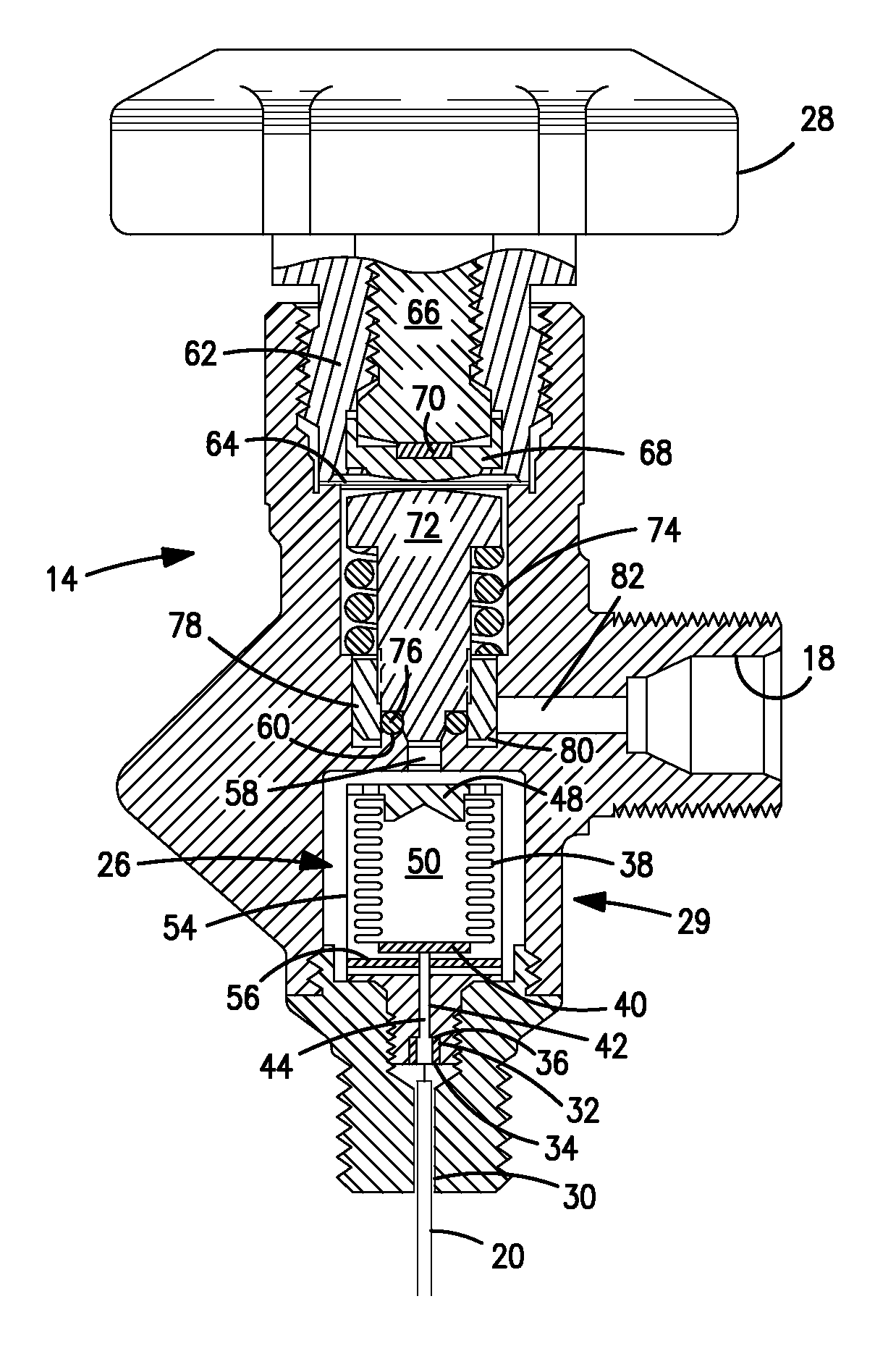

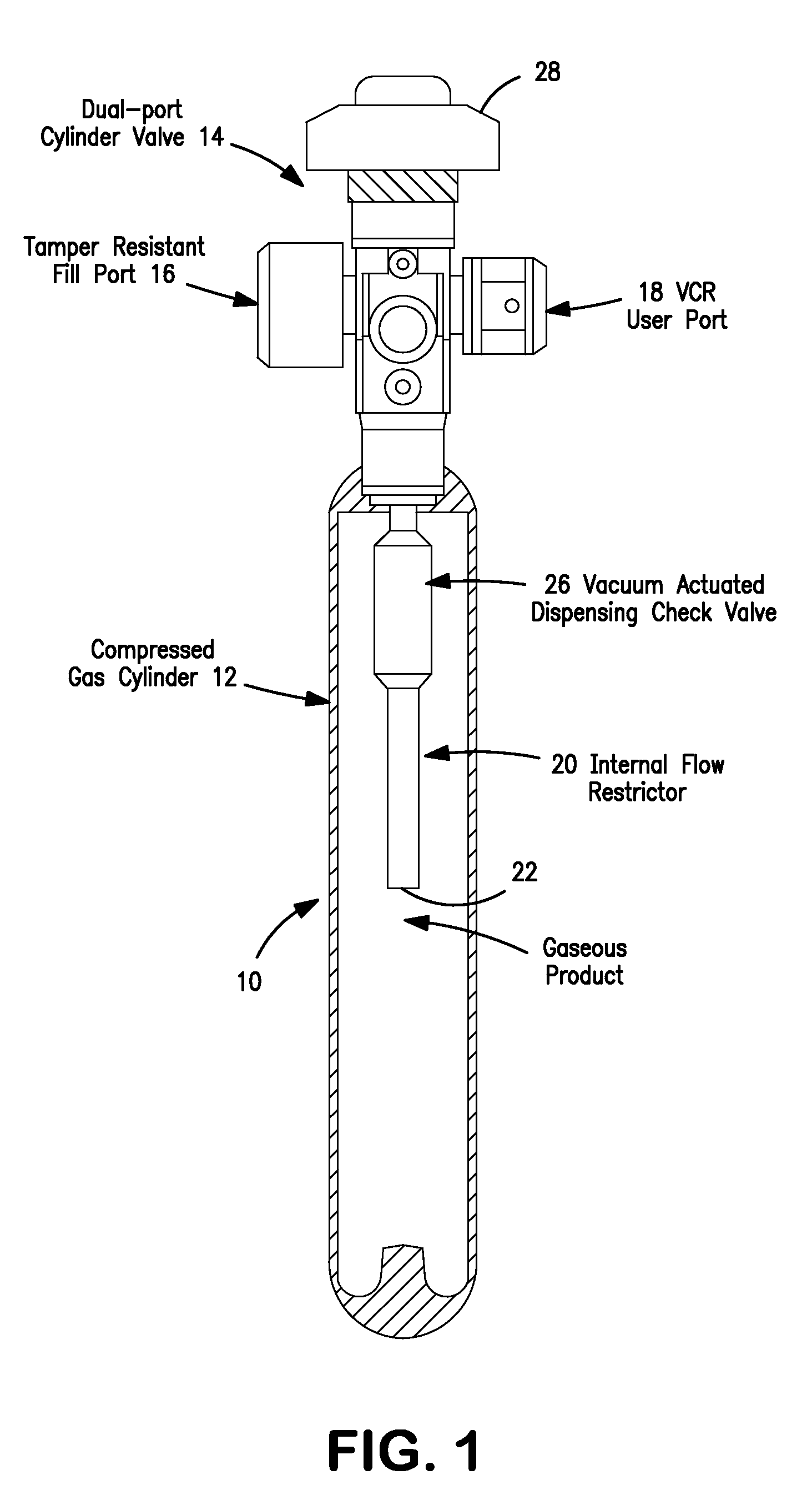

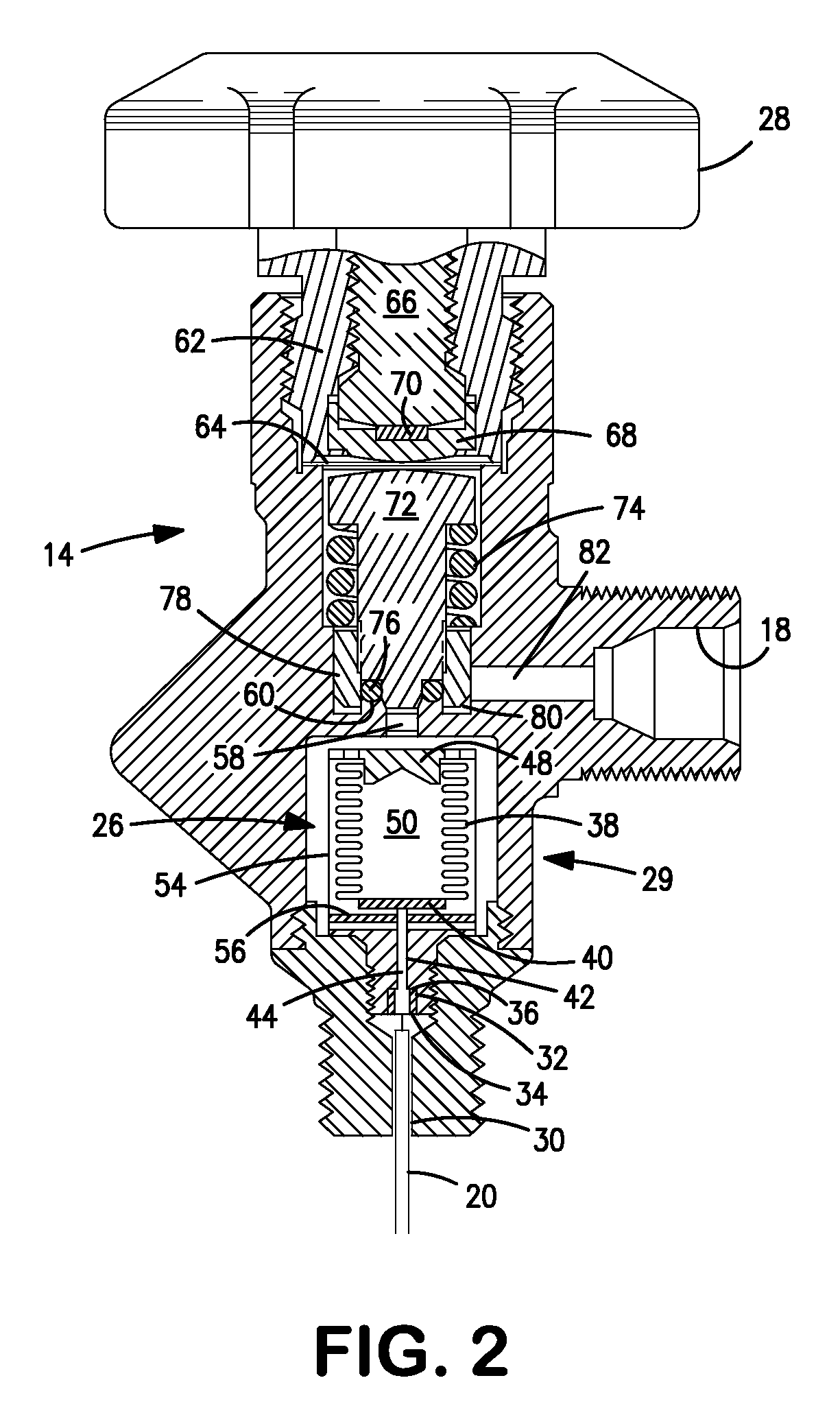

Vacuum actuated valve for high capacity storage and delivery systems

The invention relates to a re-configured valve design to accommodate a high volume of product in the delivery system and the dispensation of product upon the application of a predetermined vacuum condition on the downstream side of the valve.

Owner:PRAXAIR TECH INC

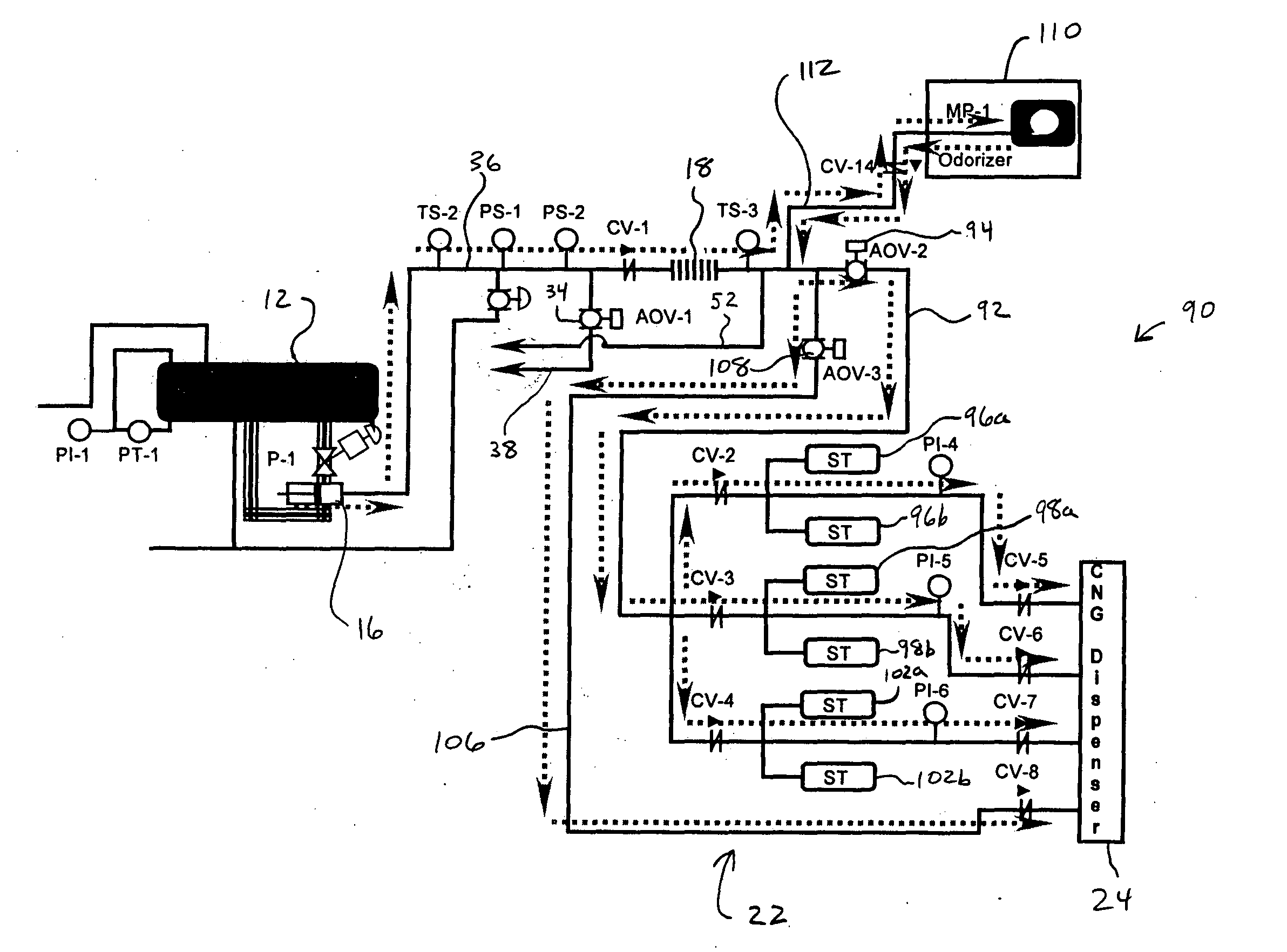

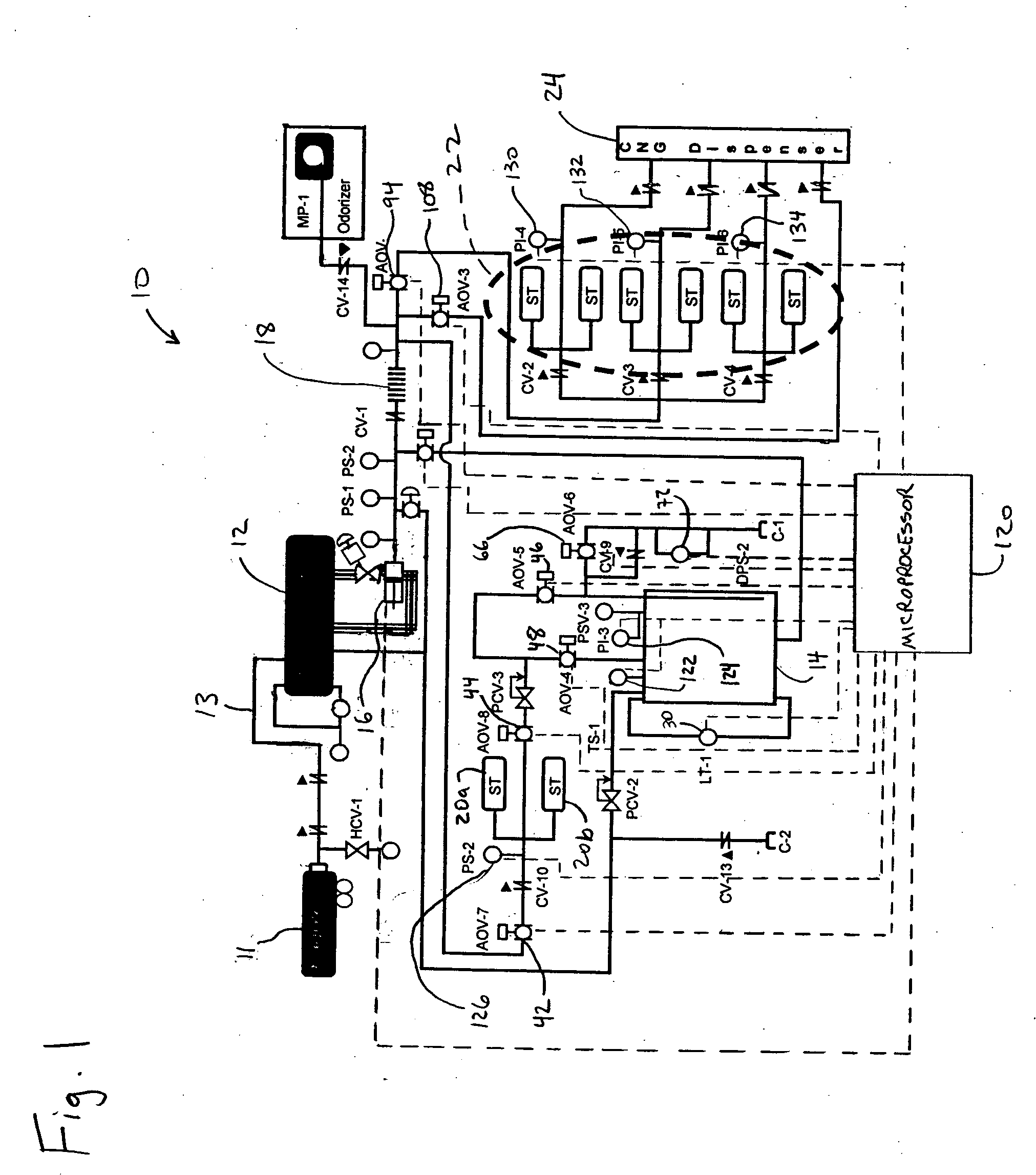

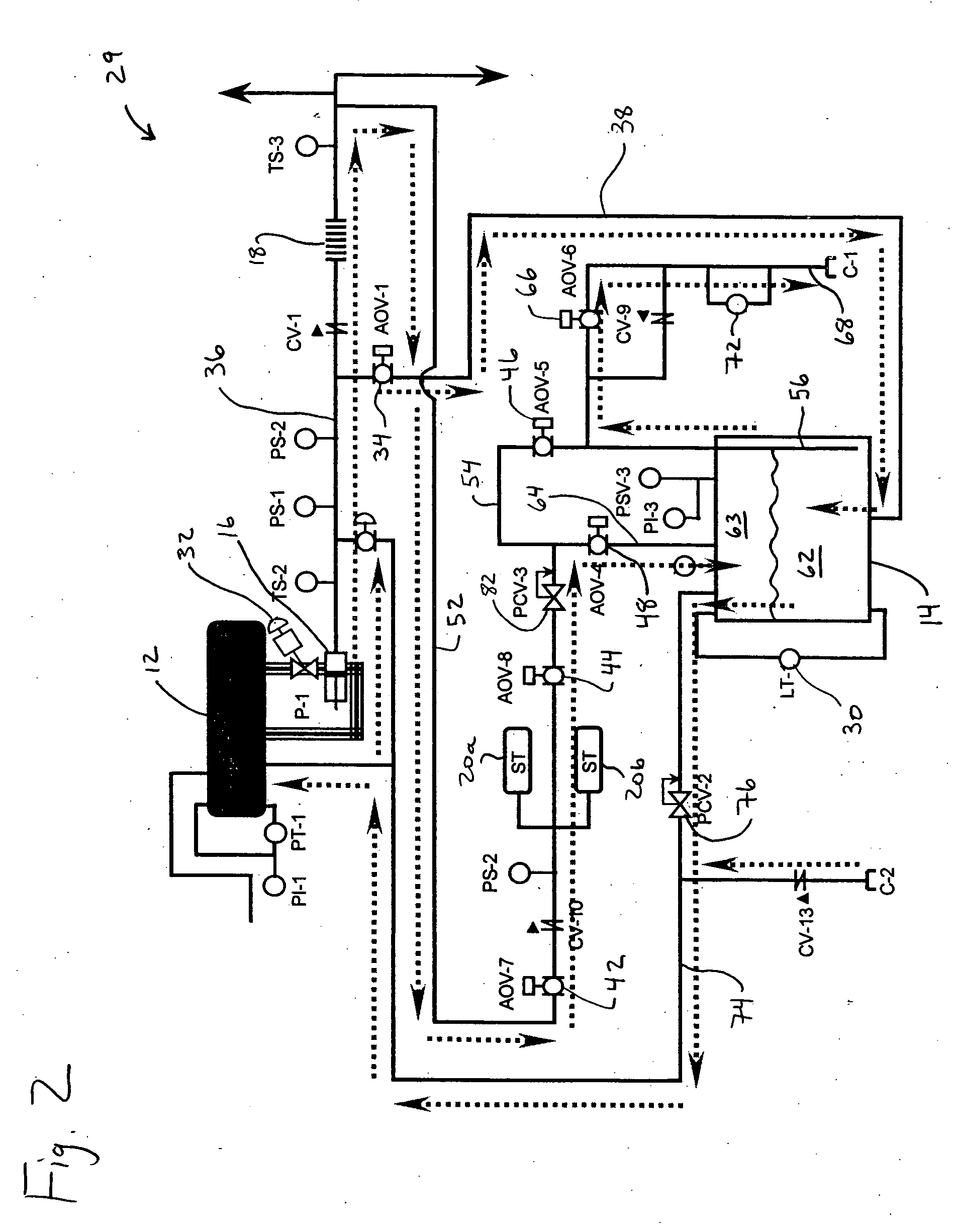

Liquid and compressed natural gas dispensing system

InactiveUS20050016185A1Distribute quicklyEliminate timeGas handling applicationsGas handling/storage effectsCompressed natural gasProcess engineering

A system dispenses both liquid natural gas (LNG) and compressed natural gas (CNG). A bulk tank contains a supply of LNG which is pumped to a smaller storage tank. After the storage tank is refilled, LNG from the bulk tank is pumped to a vaporizer so that CNG is produced. The CNG may be routed to the LNG in the storage tank to condition it. It is also used to recharge a pressurizing cylinder that is placed in communication with the head space of the storage tank when it is desired to rapidly dispense LNG to a vehicle. A bank of cascaded storage cylinders alternatively may receive CNG from the vaporizer for later dispensing through the system CNG dispenser. The CNG from the vaporizer may also be dispensed directly via the system CNG dispenser.

Owner:CHART INC

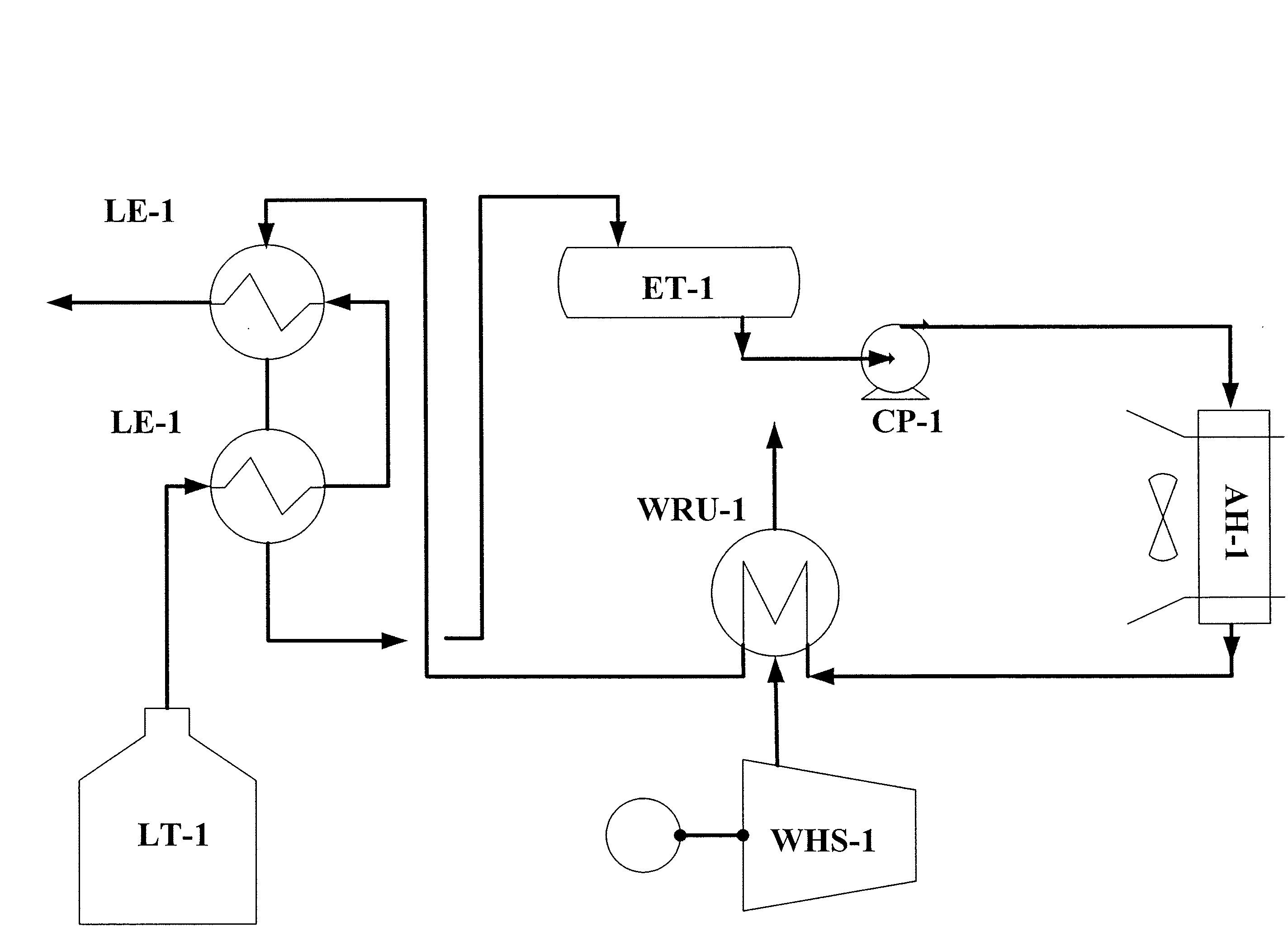

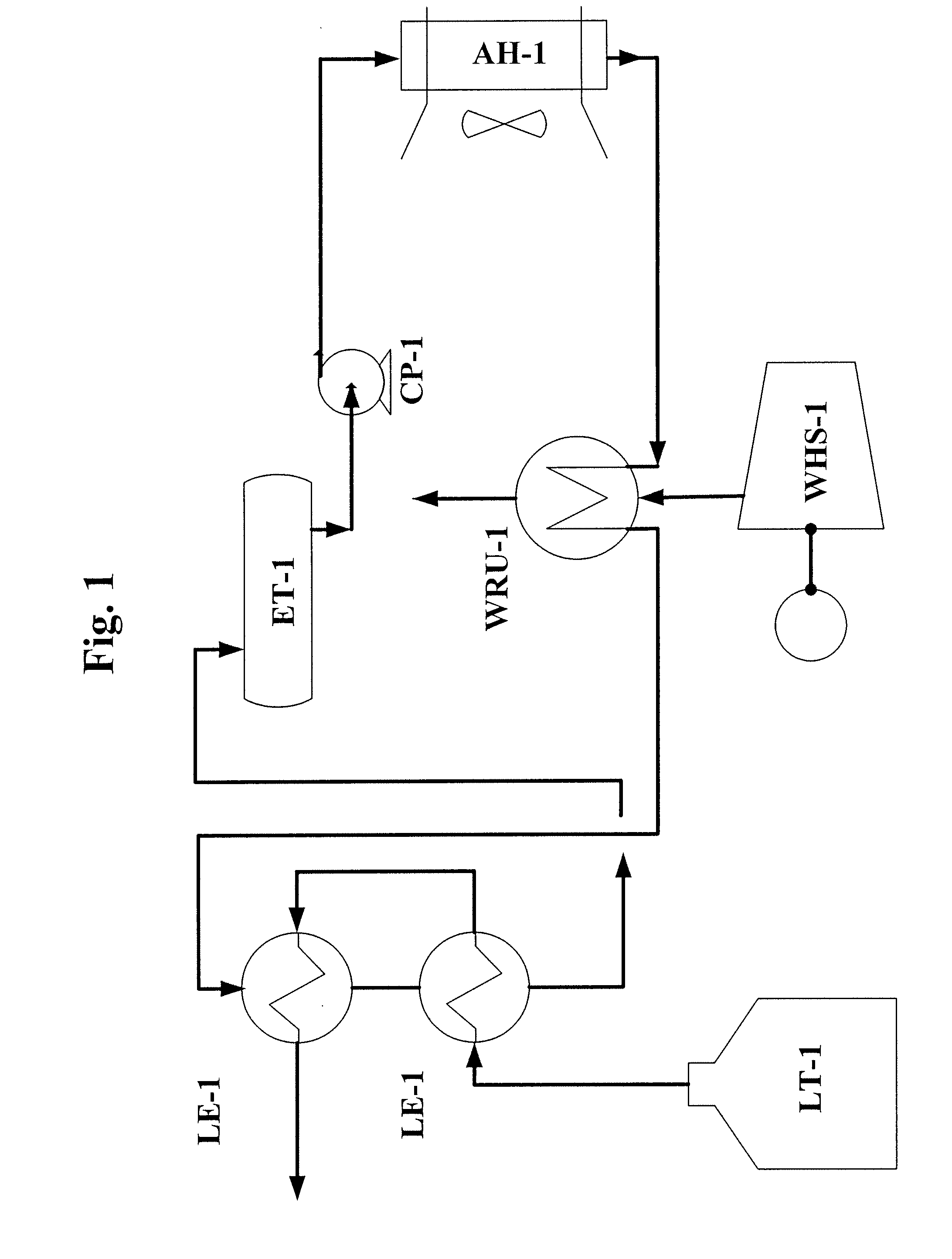

Ecological Liquefied Natural Gas (LNG) Vaporizer System

InactiveUS20080178611A1Gas handling applicationsGas handling/storage effectsProcess engineeringAmbient air

An approach is provided for vaporizing liquefied natural gas (LNG). A system utilizing closed circulation of a heat transfer medium heated by ambient air and waste heat from a waste heat source vaporizes the LNG.

Owner:AMEC FOSTER WHEELER USA CORP

Liquefied natural gas structure

InactiveUS20050115248A1Easy transferProvide protectionGas handling/storage effectsSolid materialMarine engineeringTower

An offshore liquefied natural gas structure may receive, store, and process liquefied natural gas from carriers. A structure may be a gravity base structure. A structure may include a system of ballast storage areas, transfer equipment to offload liquefied natural gas from a carrier, docking equipment to allow direct mooring with carriers, platforms to elevate equipment, water intake systems to provide water to the structure, wave deflectors, and / or projections extending from a bottom of the structure. A portion of the structure may be composed of lightweight concrete. Pipelines may be coupled to the structure to export processed natural gas onshore. Living quarters, flare towers, and export line metering equipment may be included on the structure.

Owner:SHELL OIL CO

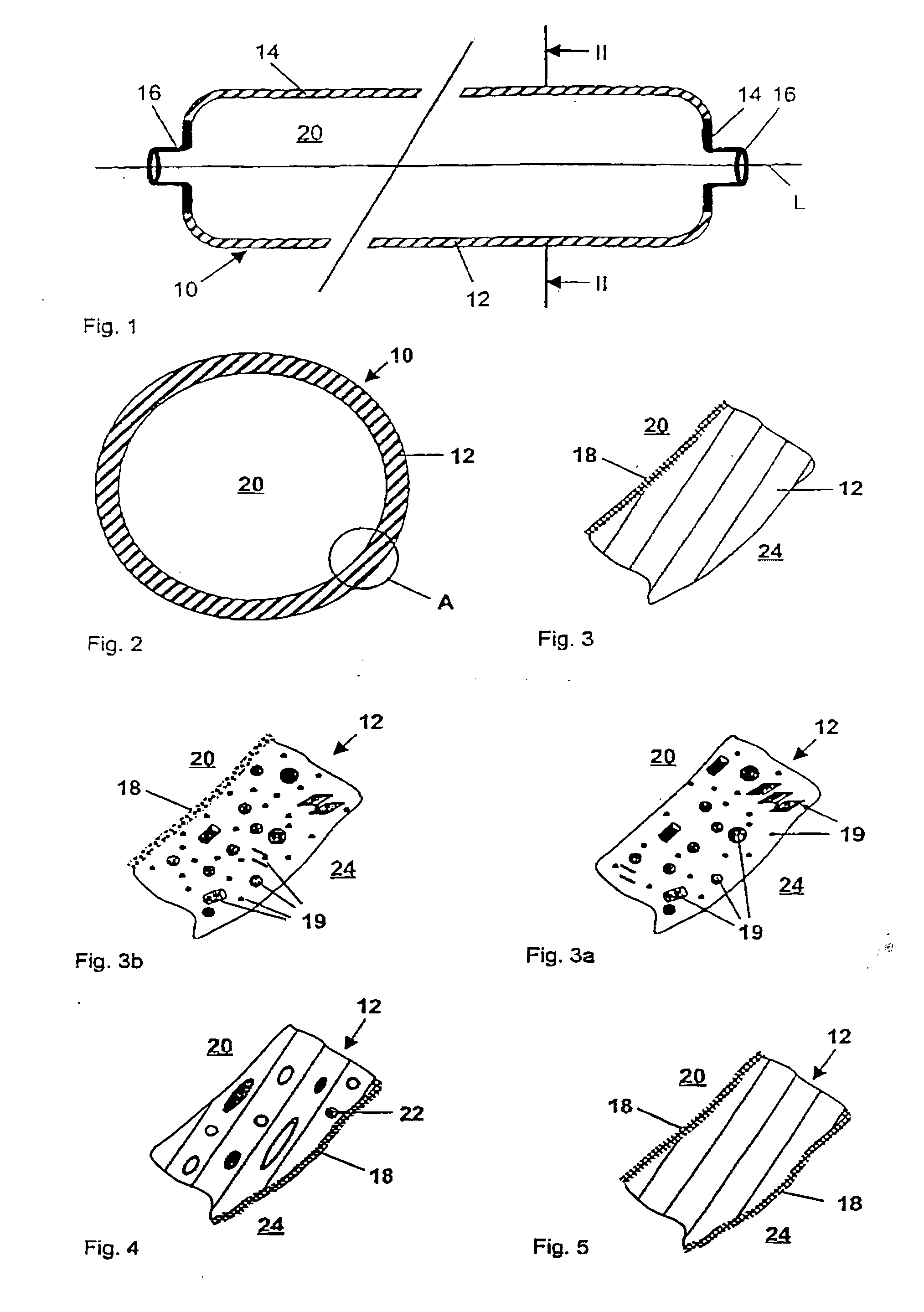

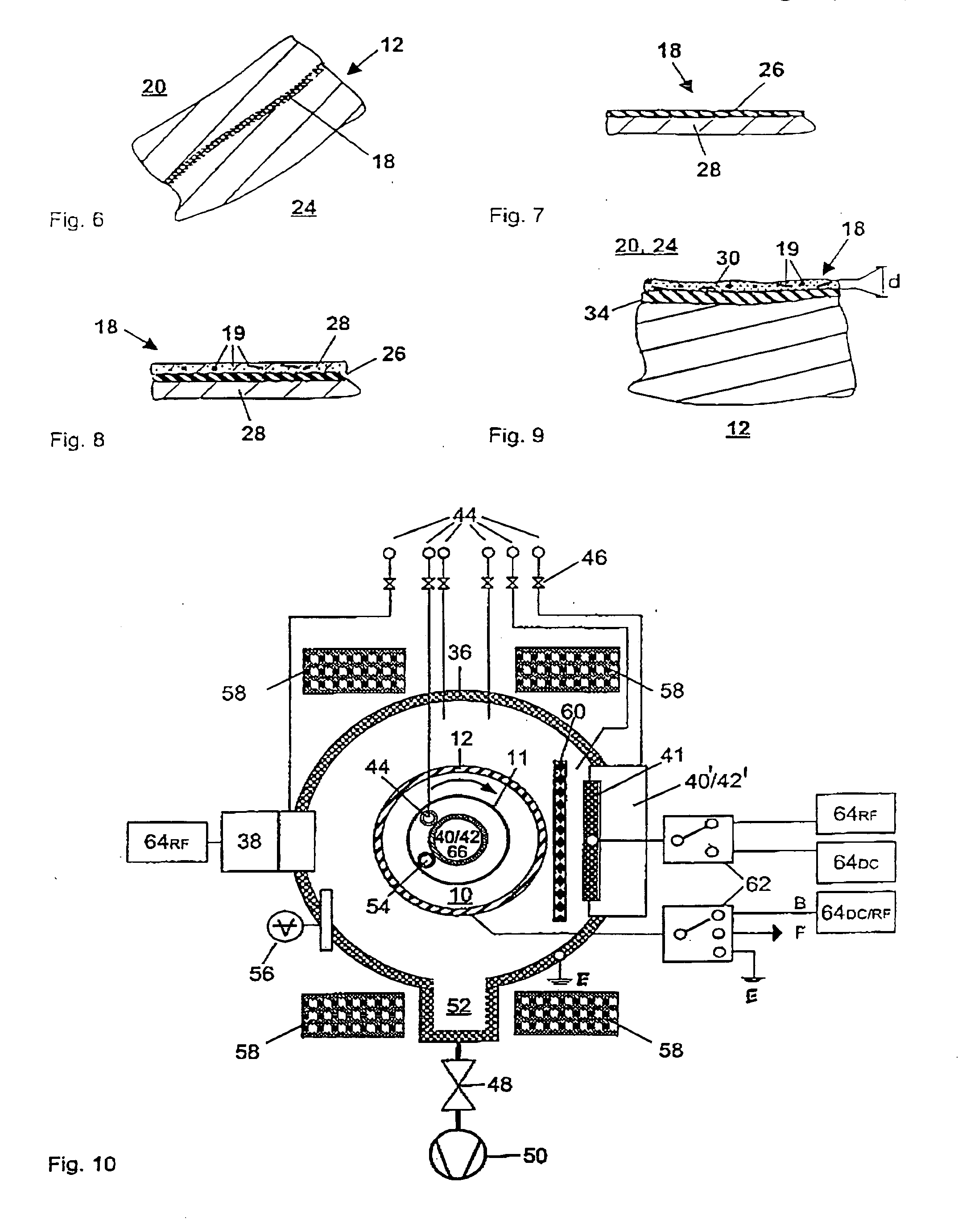

Gastight container

InactiveUS20040149759A1Reduce quality problemsNegligible in recyclingAircraft componentsVessel mounting detailsHydrogenComposite film

The invention relates to a gastight, pressure-resistant storage and / or transport container (10) for low-molecular, reactive filling media, especially for hydrogen, oxygen, air, methane and / or methanol. Said container has a high filling pressure and is embodied in an essentially rotationally symmetric manner, having at least one connector cap (15) with a sealing device (16). The wall (12) of the container is essentially comprised of a thermoplastic synthetic material having at least one diffusion barrier (18, 19) system and / or a diffusion barrier and anti-corrosion system (18, 19). In order to offer protection for hydrogen and oxygen containers, the diffusion barrier system can be embodied in the form of at least one compact layer and / or can contain finely dispersed, distributed reactive nanoparticles (18) in the wall (12) of the container, in at least one composite film (28) and / or in at least one diffusion barrier layer (18).

Owner:MOSER EVA MARIA +1

Clathrate hydrate modular storage, applications and utilization processes

Methods, apparatuses and systems directed to clathrate hydrate modular storage, applications and utilization processes. In one implementation, the present invention provides a method of creating scalable, easily deployable storage of natural gas and thermal energy by assembling an array of interconnecting, modular gas clathrate hydrate storage units.

Owner:SOLID GAS TECH

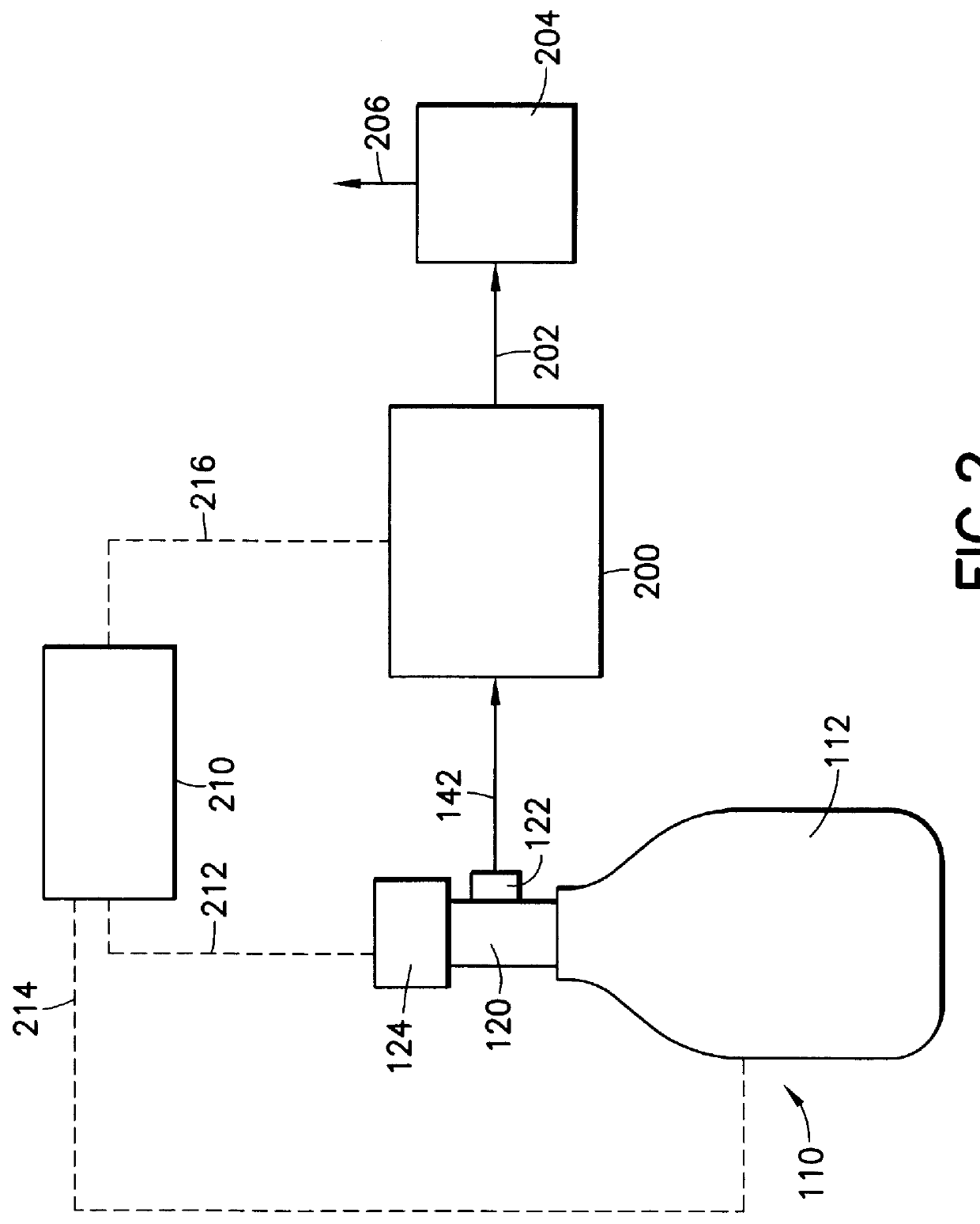

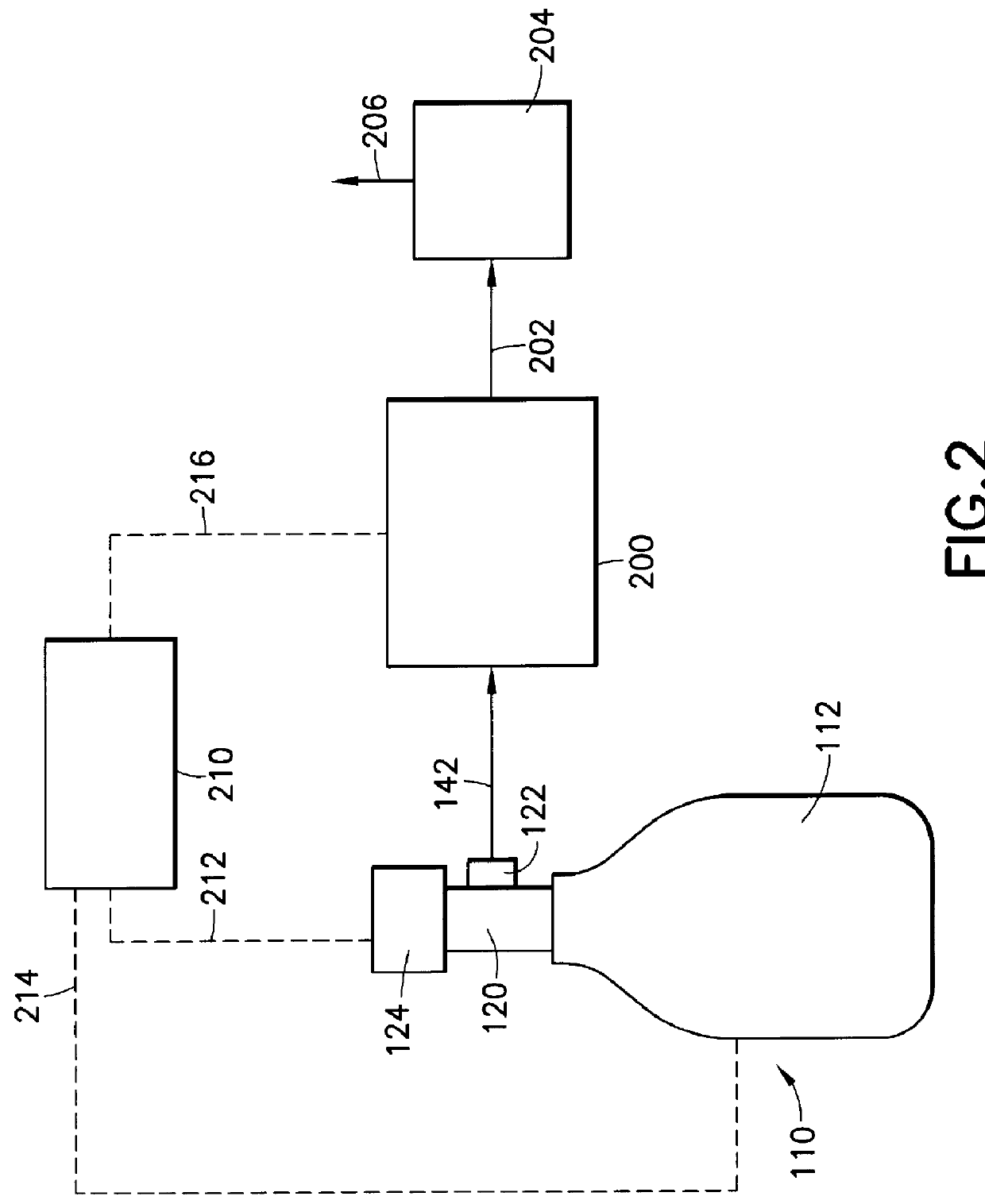

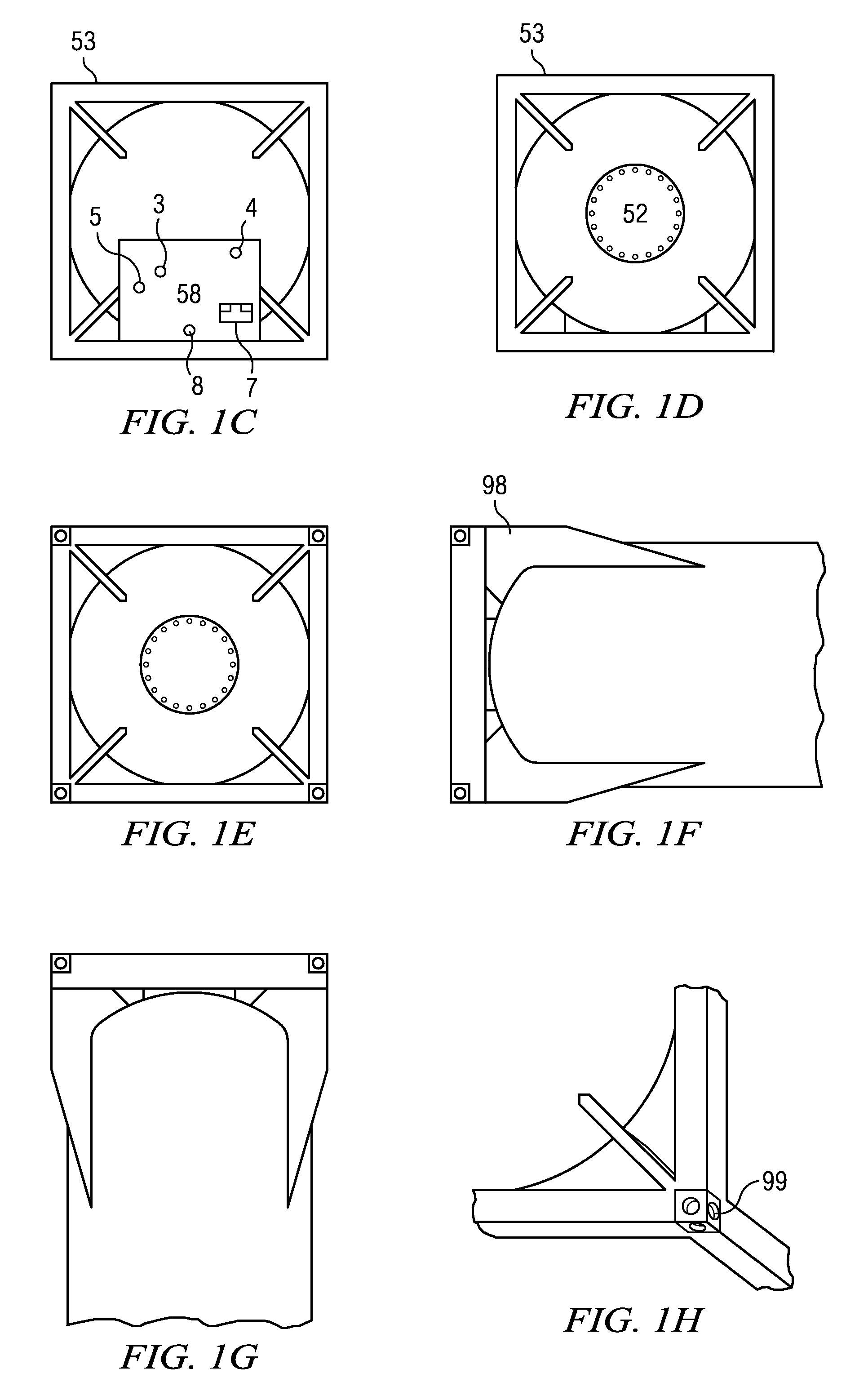

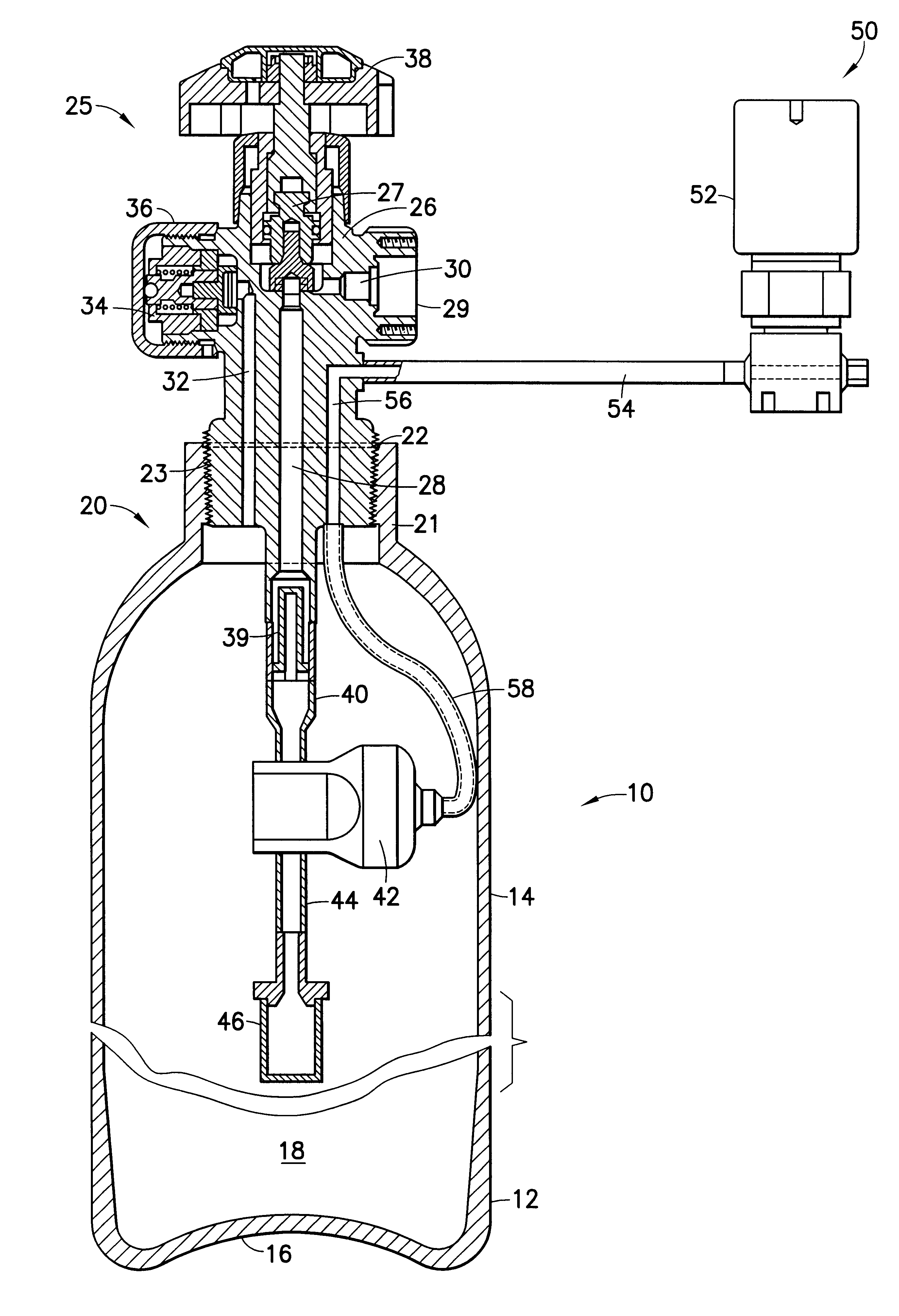

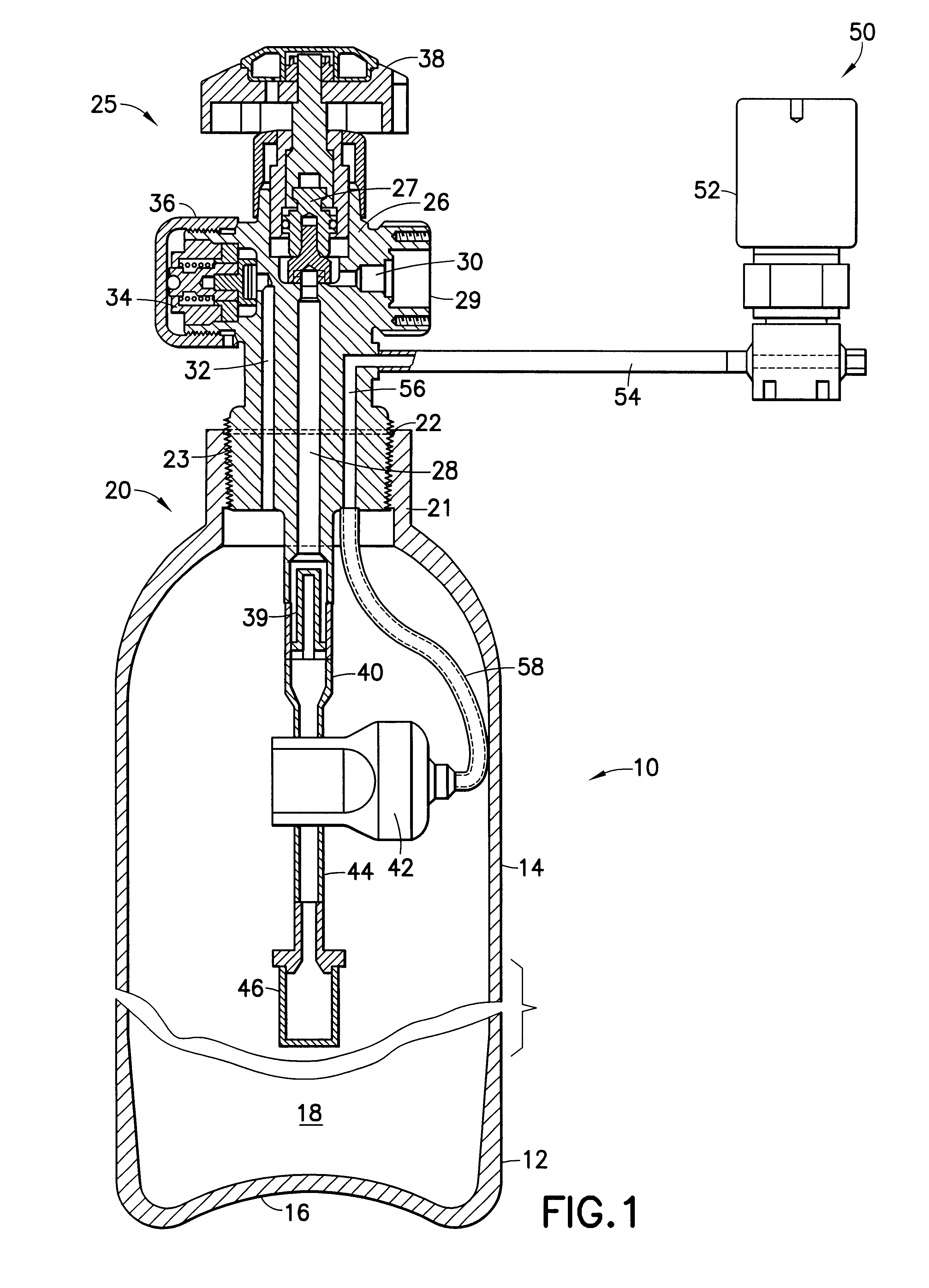

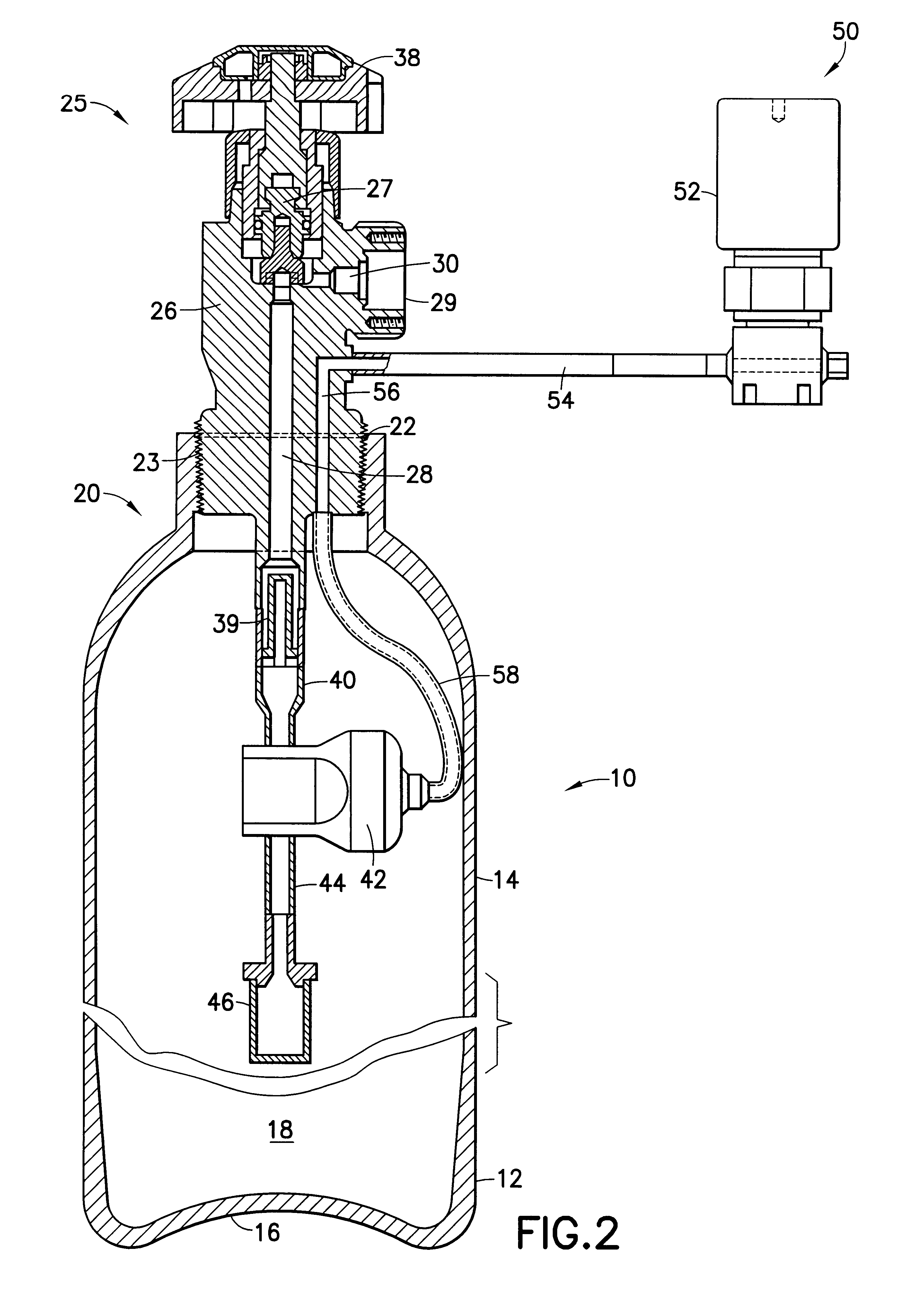

Fluid storage and dispensing system featuring interiorly disposed and exteriorly adjustable regulator for high flow dispensing of gas

InactiveUS6257000B1CostPerformanceContainer filling methodsSemiconductor devicesEngineeringAtmospheric pressure

A fluid storage and dispensing system including a vessel for holding a fluid, an adjustable set point pressure regulator in the interior volume of the vessel, a dispensing assembly in fluid flow communication with the regulator for dispensing fluid at a pressure determined by the set point of the regulator, and an adjusting assembly exterior to the vessel for in situ adjustment of the set point of the internally disposed regulator. By such arrangement, fluid storage and dispensing operations can have respectively differing regulator set point pressures, as for example a sub-atmospheric pressure set point for storage and a super-atmospheric pressure set point for dispensing.

Owner:ENTEGRIS INC

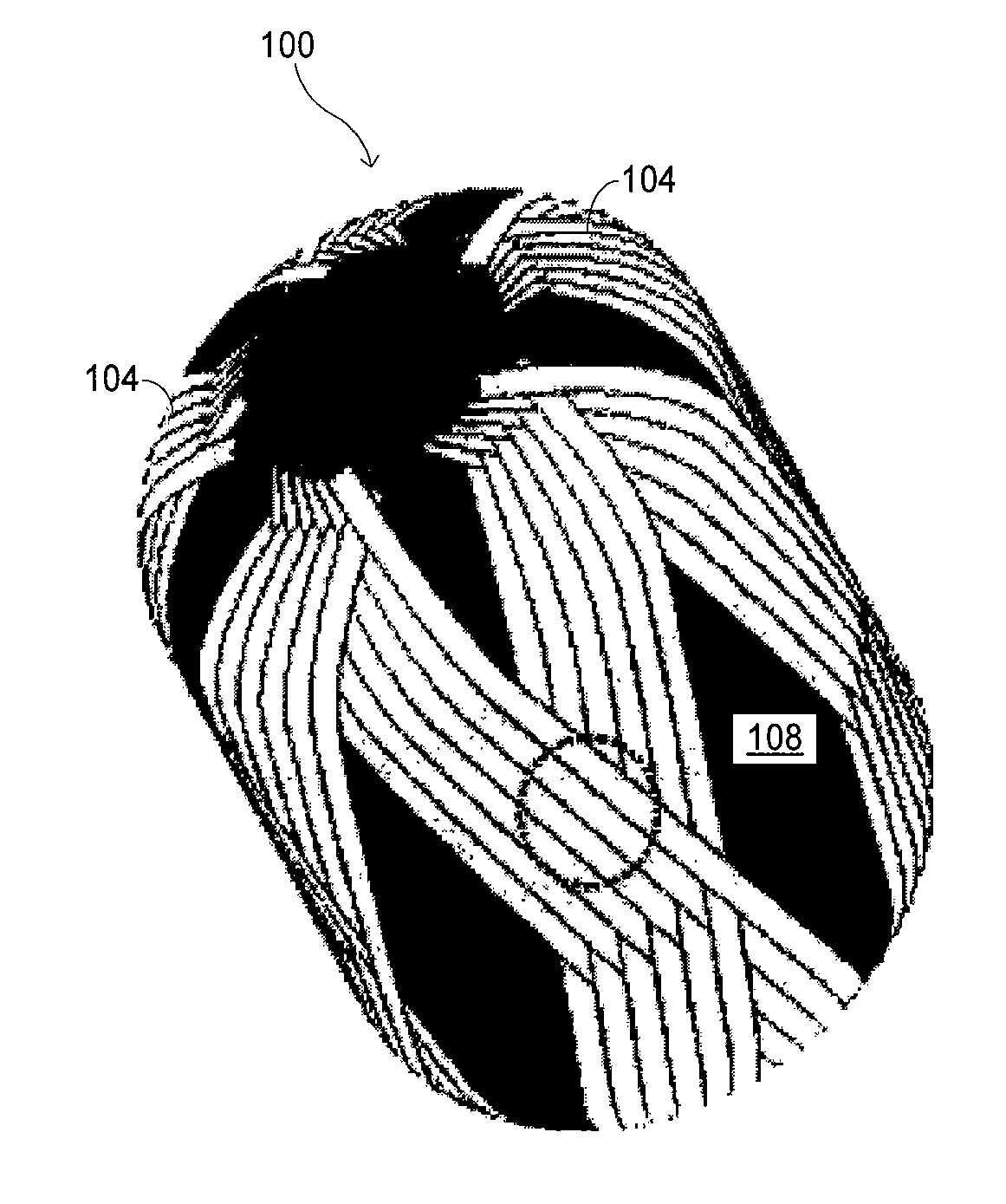

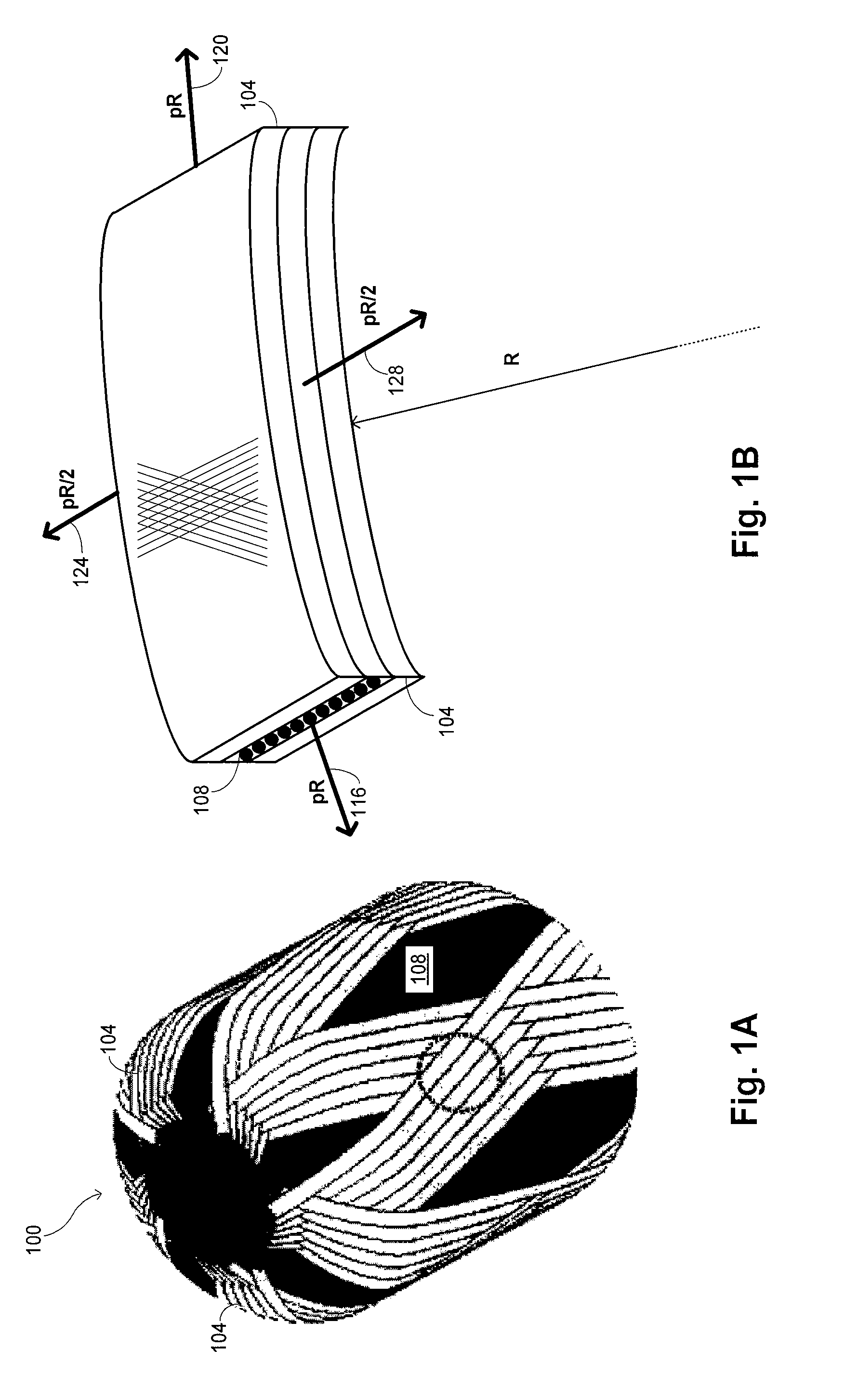

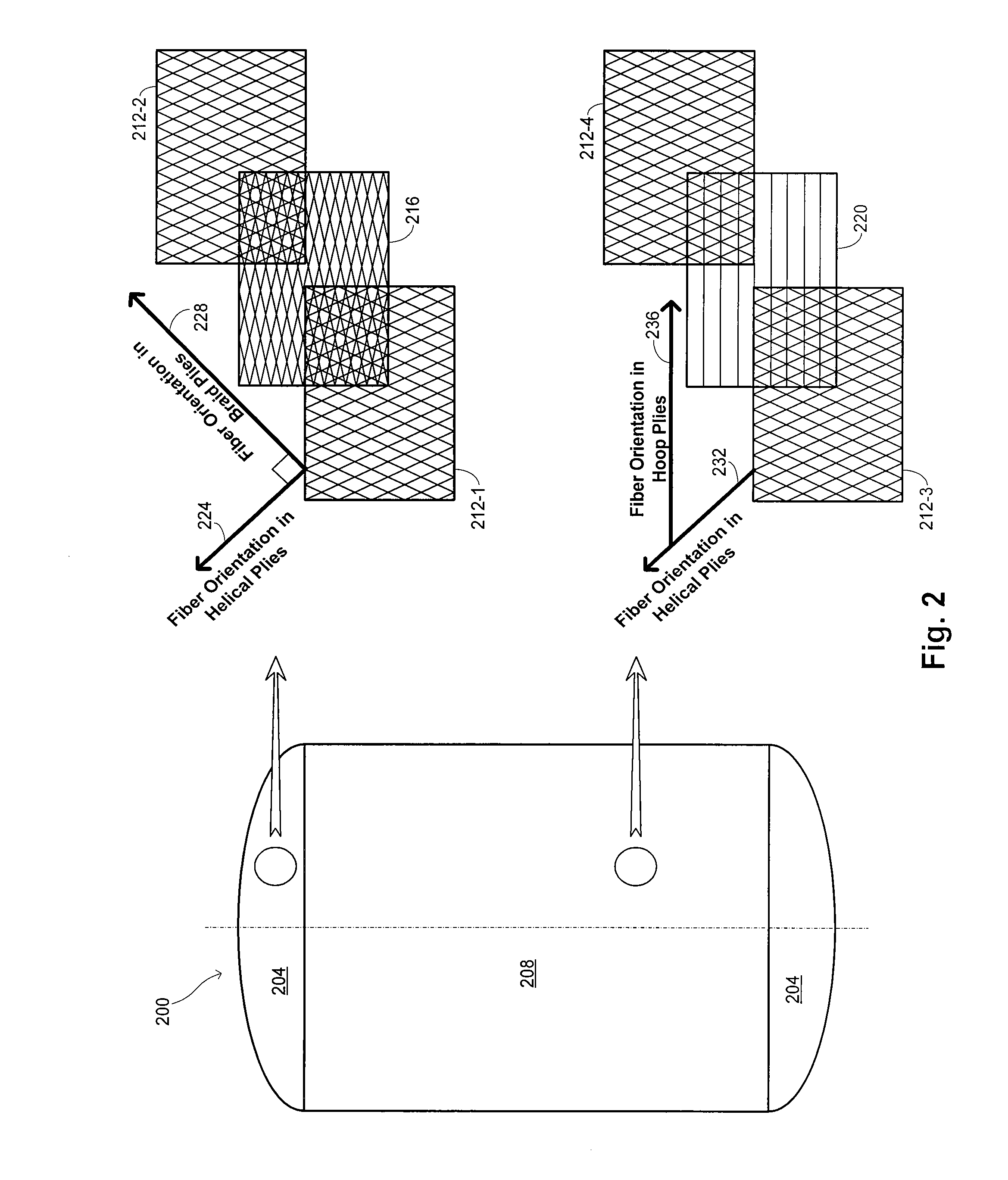

Damage and leakage barrier in all-composite pressure vessels and storage tanks

ActiveUS20090314785A1Superior barrier against leakageStrengthAdhesive processesGas handling applicationsFiberAxis of symmetry

A linerless tank structure has a body that defines an enclosed interior volume. The body has a cylindrical section having an axis of symmetry and a dome section coupled with the cylindrical section. The construction of the pressure vessel includes multiple fiber plies. At least one of the fiber plies is a helical ply having fibers traversing the dome helically about the axis of symmetry. At least a second of the fiber plies is a braided or woven ply.

Owner:COMPOSITE TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com