Patents

Literature

70 results about "Wobbe index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

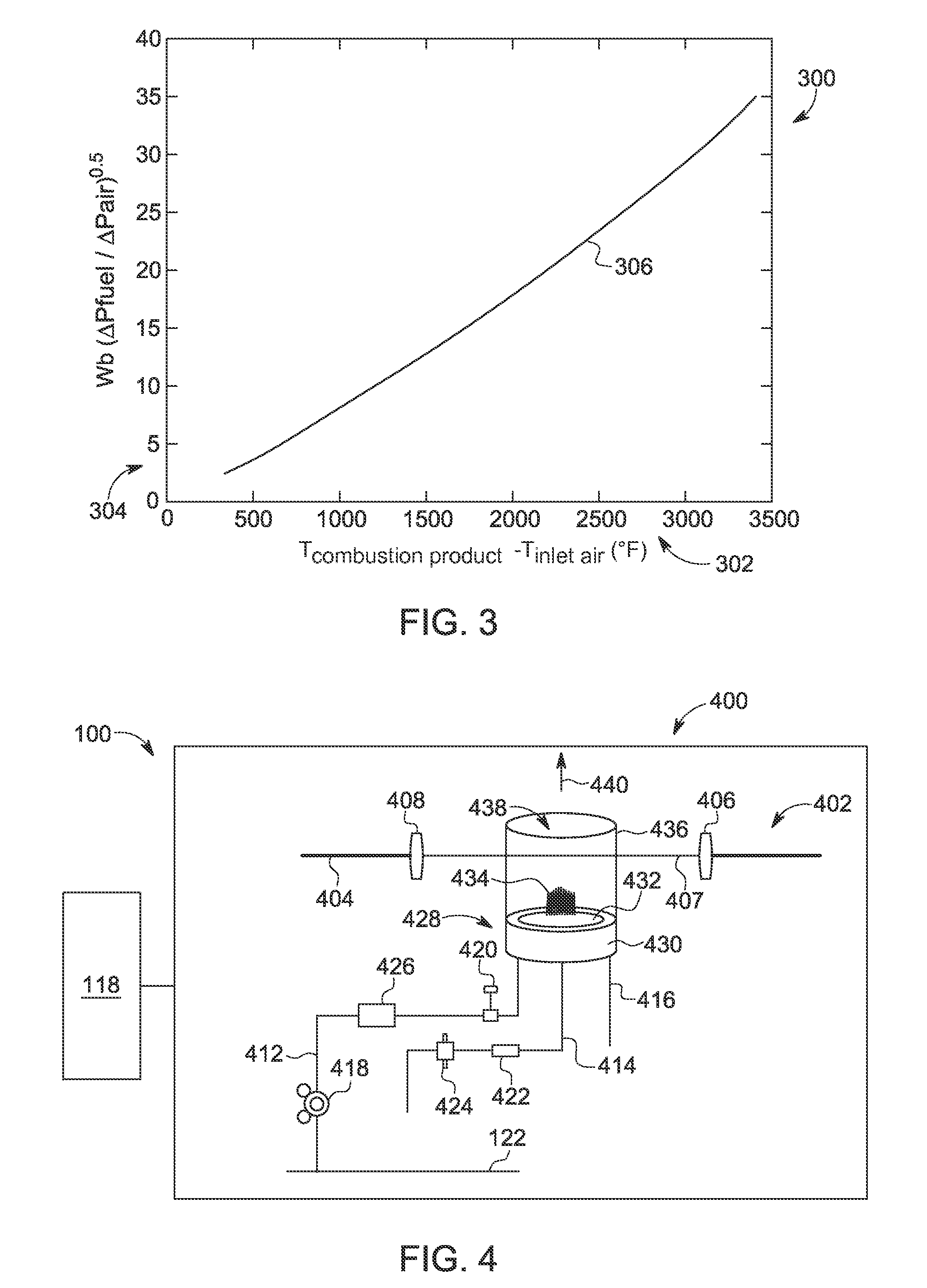

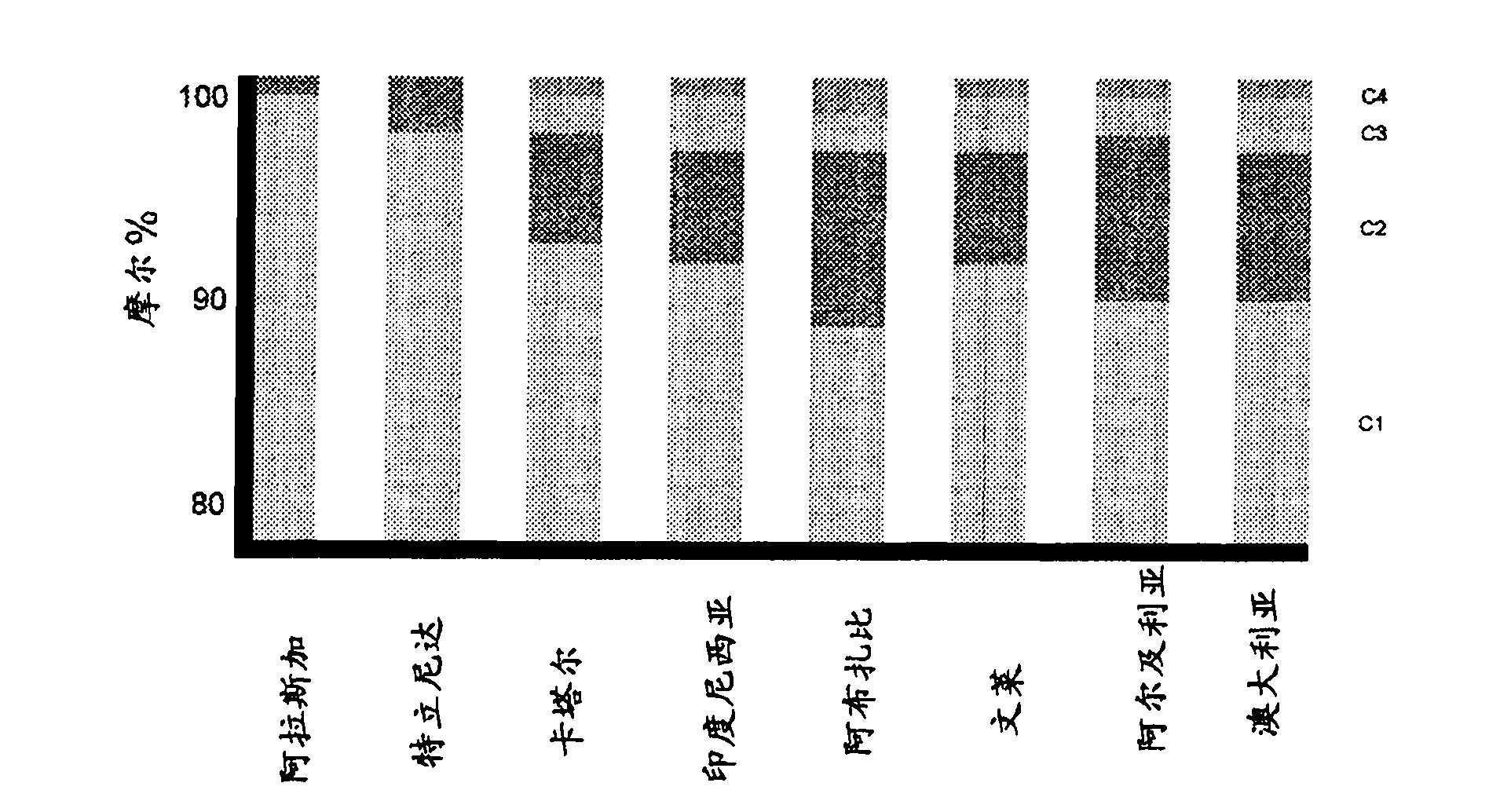

The Wobbe Index (WI) or Wobbe number is an indicator of the interchangeability of fuel gases such as natural gas, liquefied petroleum gas (LPG), and town gas and is frequently defined in the specifications of gas supply and transport utilities. If VC is the higher heating value, or higher calorific value, and GS is the specific gravity, the Wobbe Index, IW, is defined as: IW=VC/√(GS). The Wobbe Index is used to compare the combustion energy output of different composition fuel gases in an appliance (fire, cooker etc.).

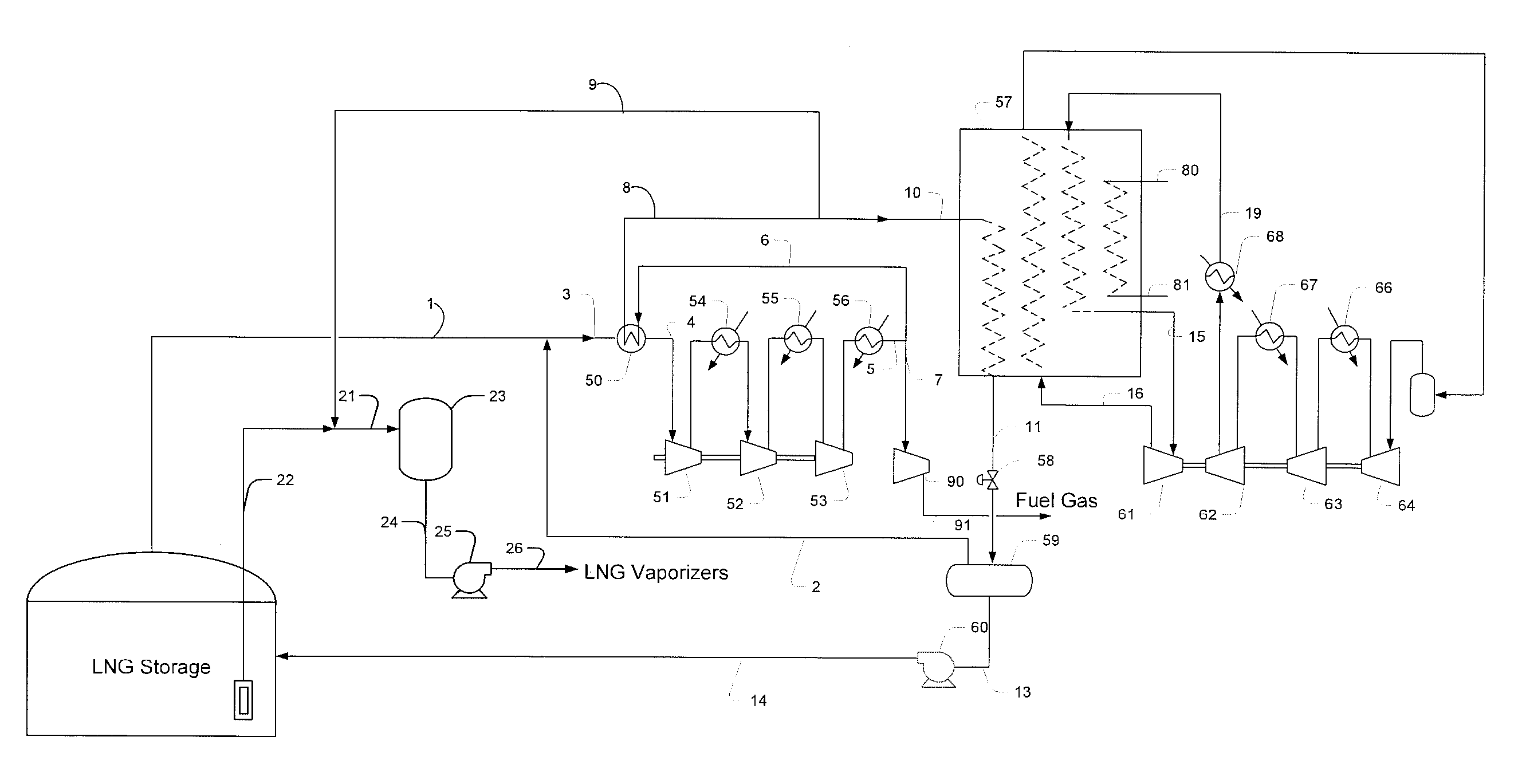

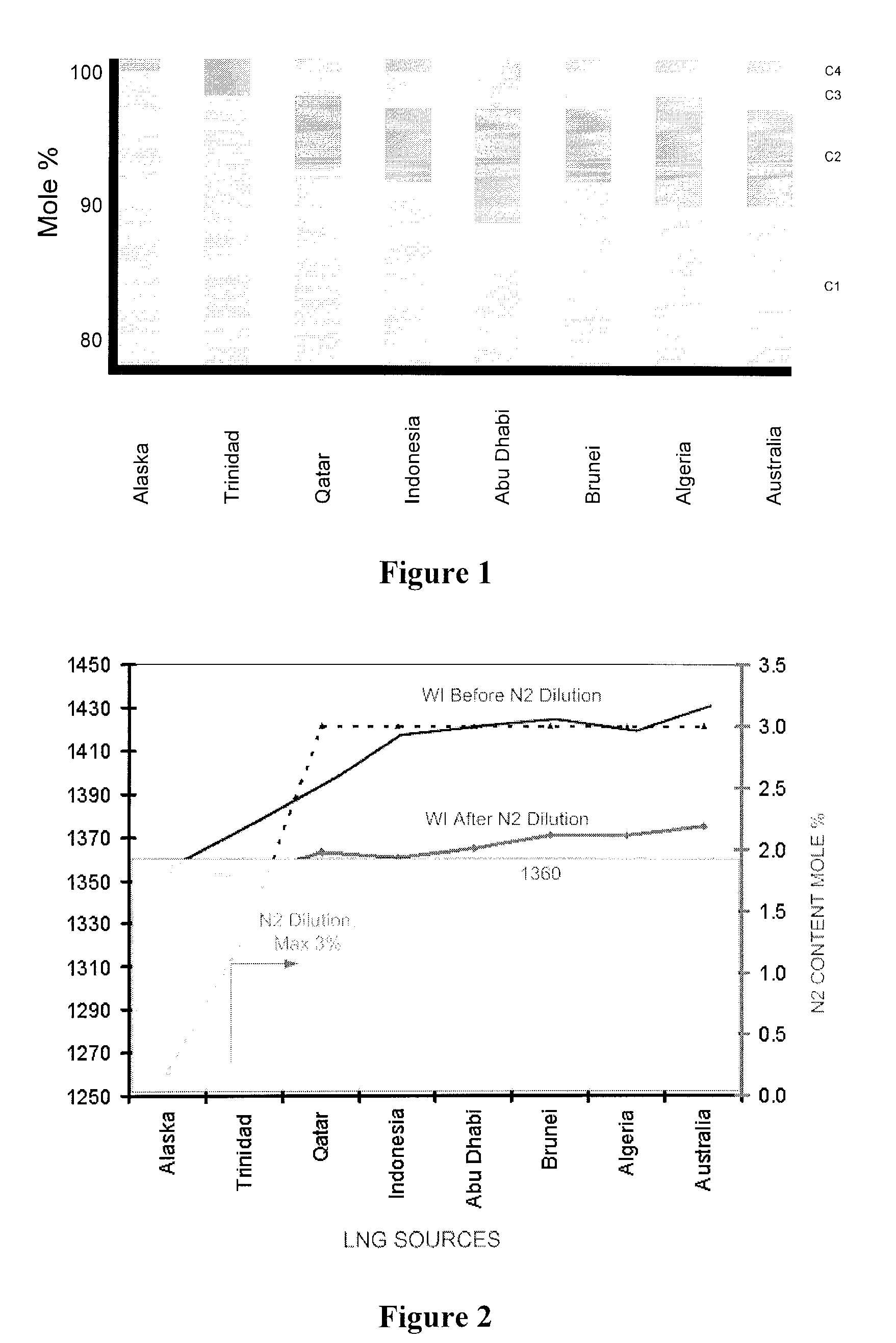

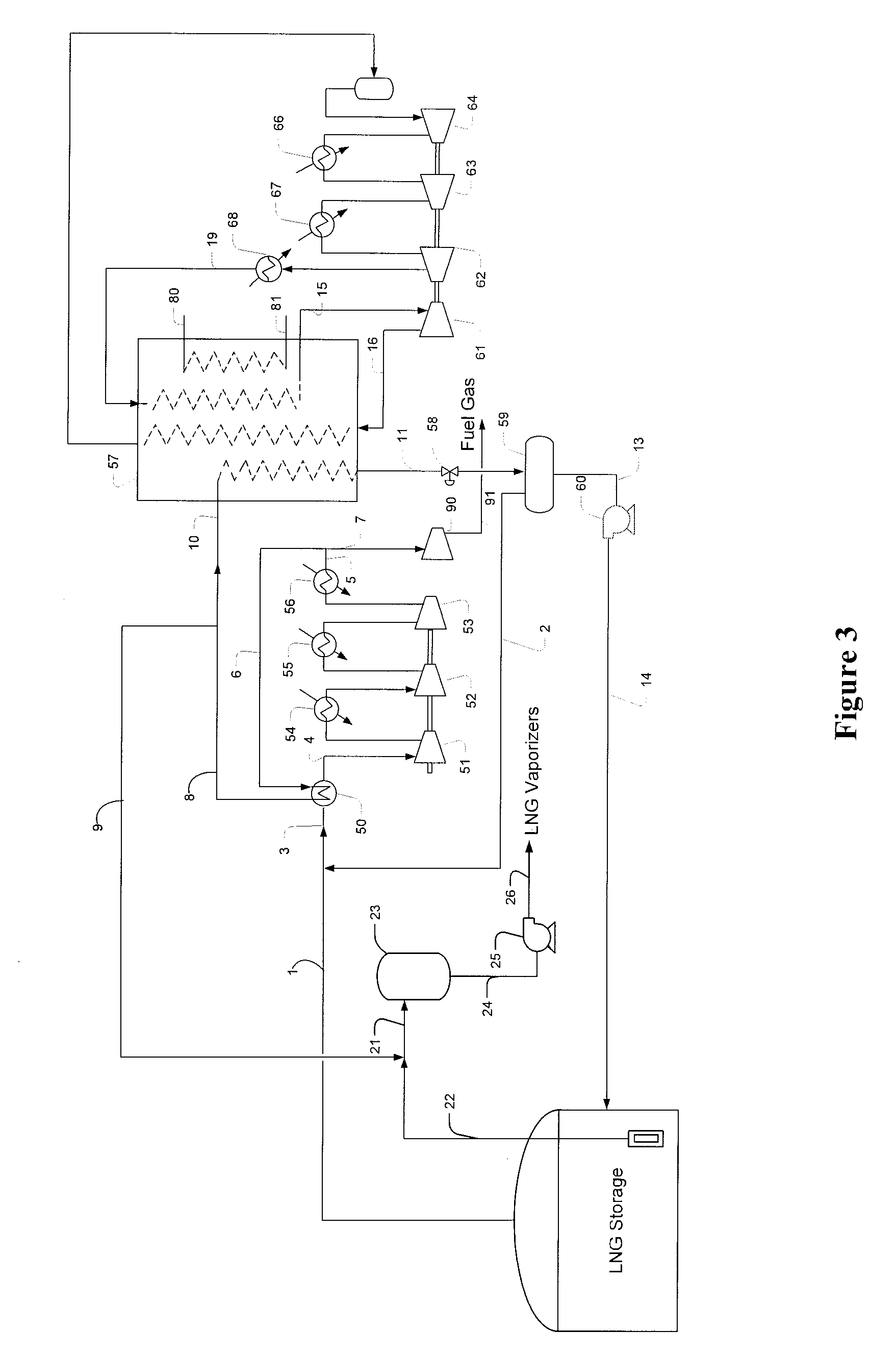

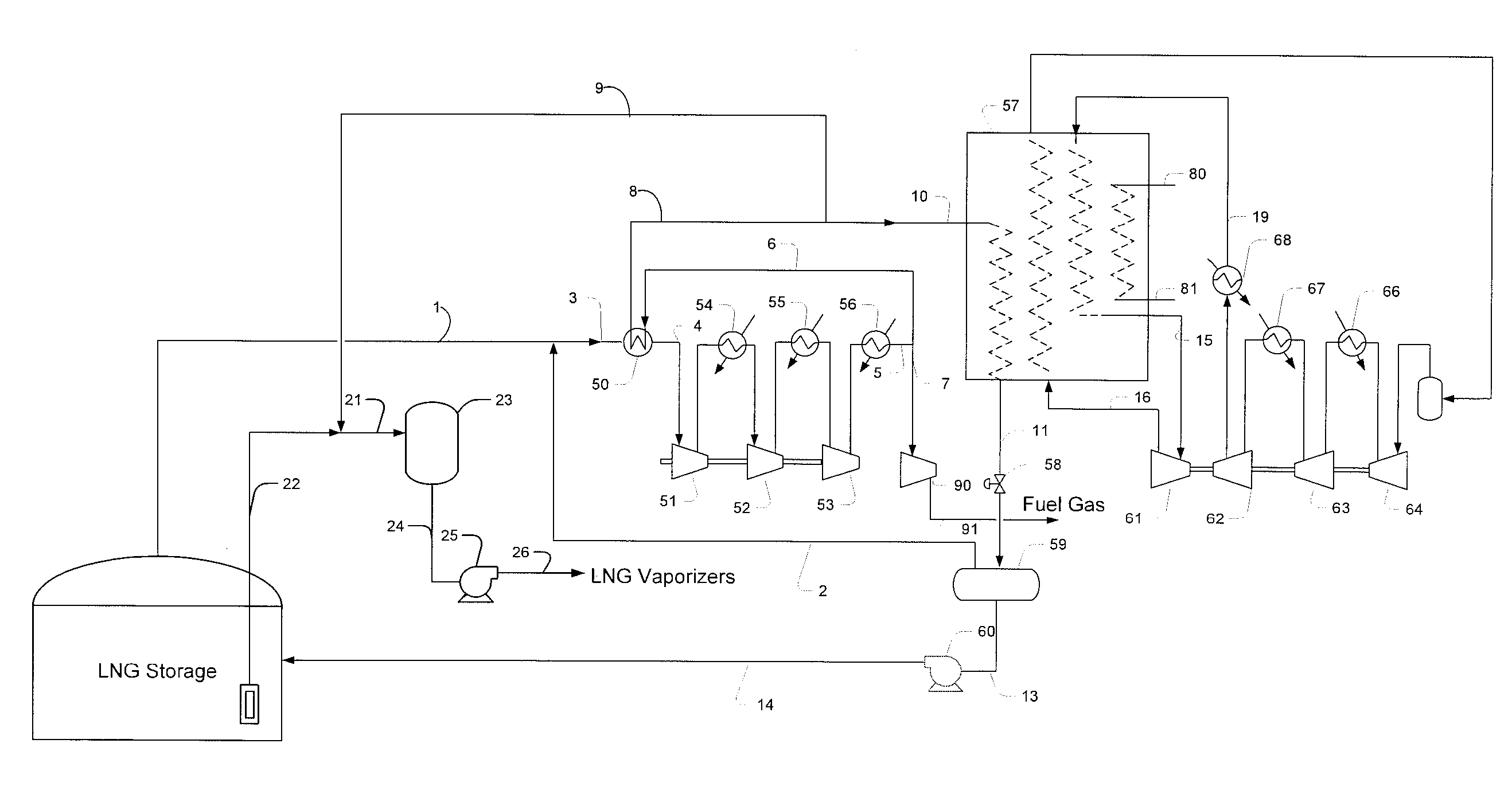

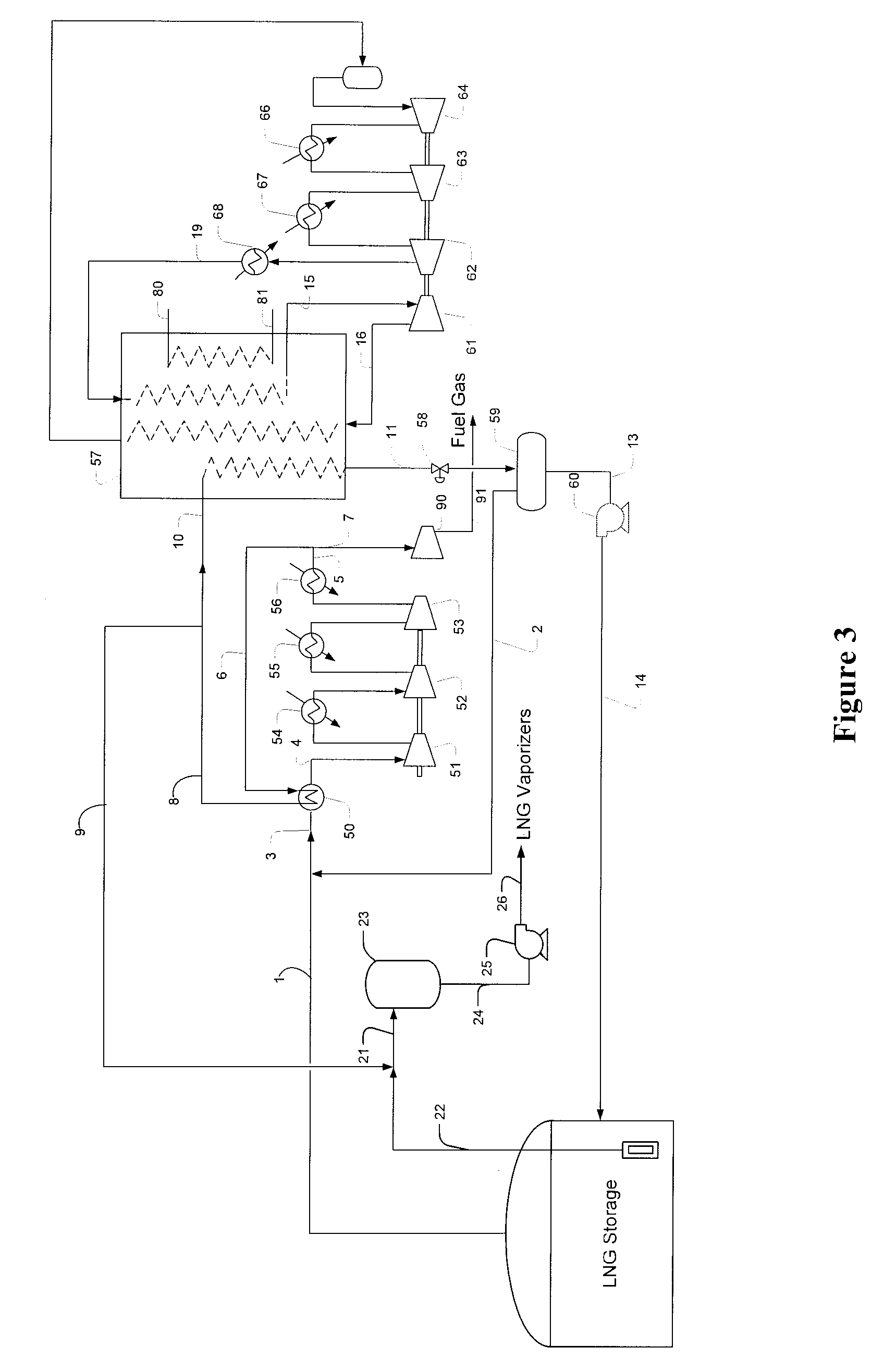

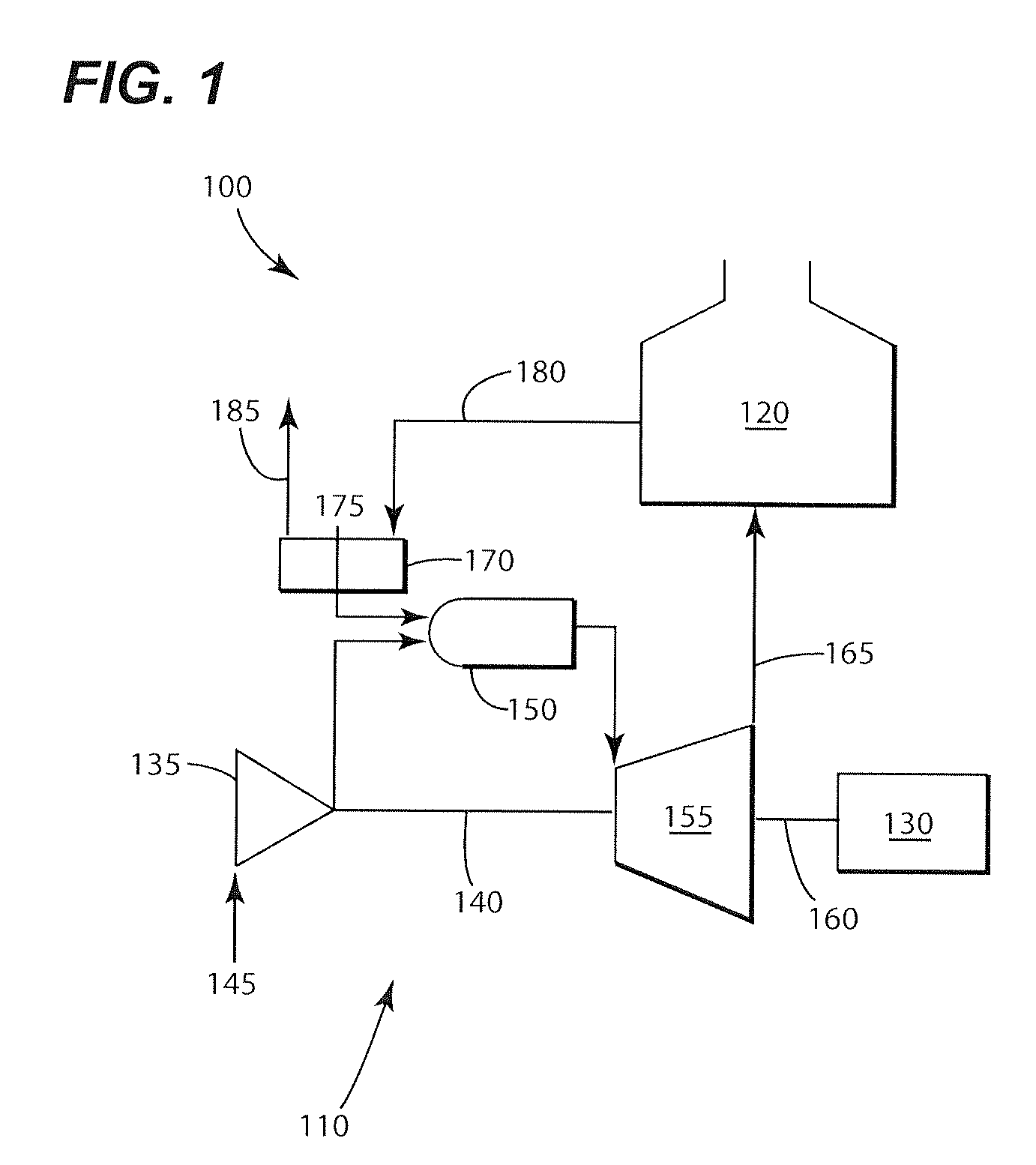

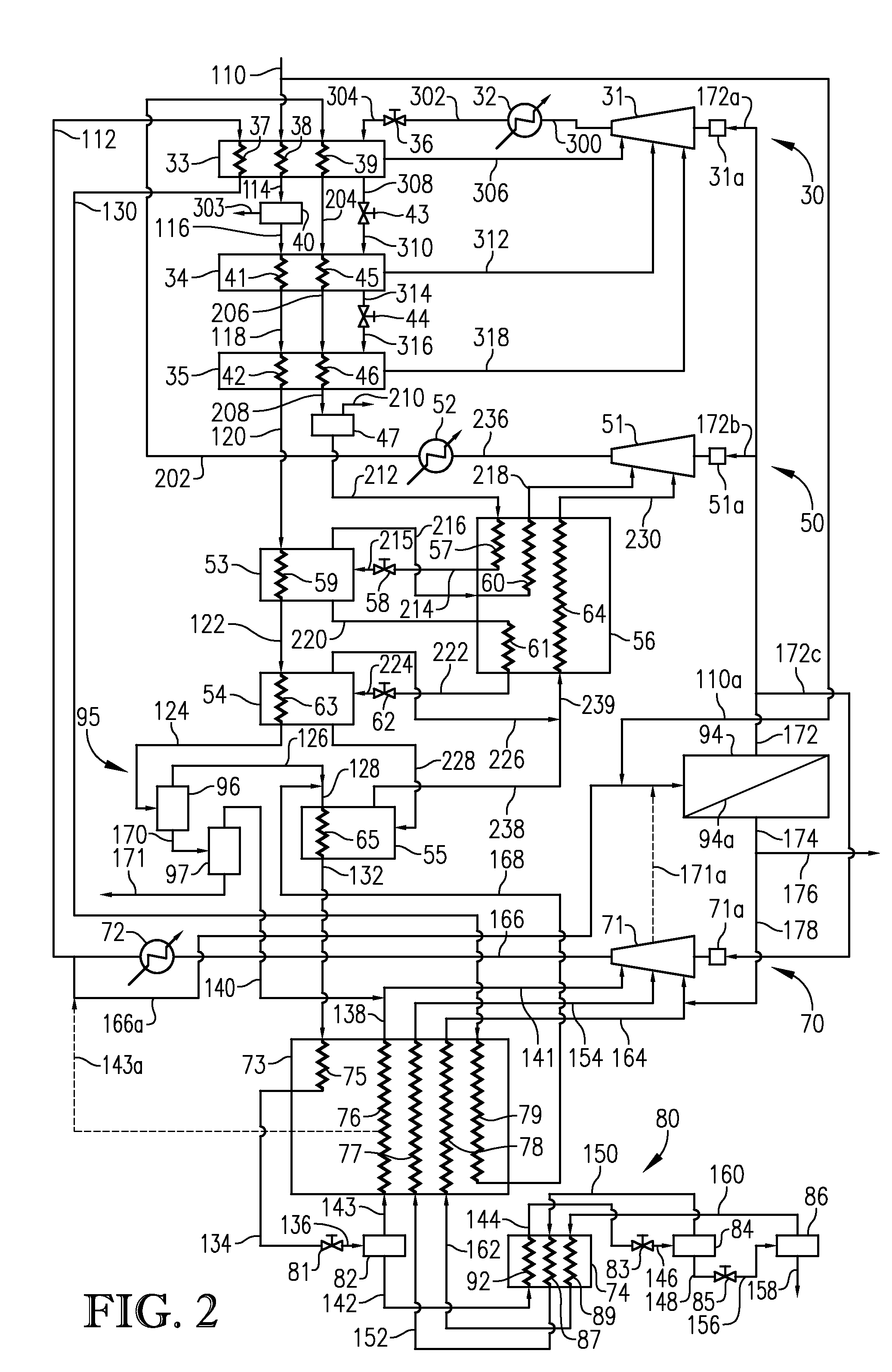

Methods and Configurations of Boil-off Gas Handling in LNG Regasification Terminals

InactiveUS20110056238A1Stable storage tank pressure controlStable controlSolidificationLiquefactionProcess engineeringWobbe index

A LNG storage and regasification plant includes a reliquefaction unit in which boil-off vapors from the storage tanks are re liquefied and recycled back to the LNG storage tanks for tank pressure and Wobbe index control. Preferably, LNG cold is used for reliquefaction and operational flexibility is achieved by feeding a portion of the pressurized boil-off gas to a fuel gas header and / or to be recondensed by the sendout LNG.

Owner:FLUOR TECH CORP

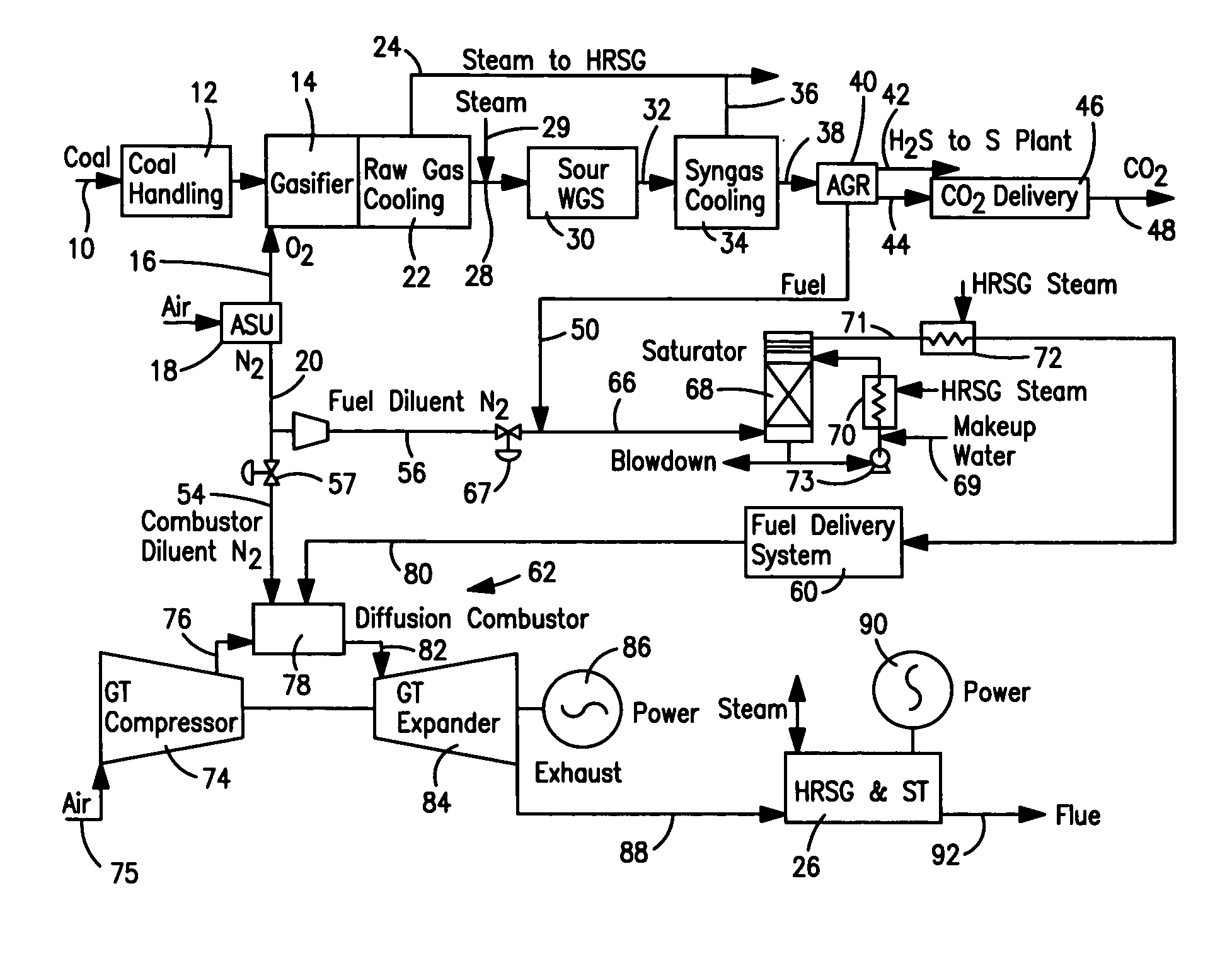

Method of maintaining a fuel Wobbe index in an IGCC installation

InactiveUS7690204B2Low indexFuel supply regulationGaseous fuel feeder/distributionWater-gas shift reactionNitrogen

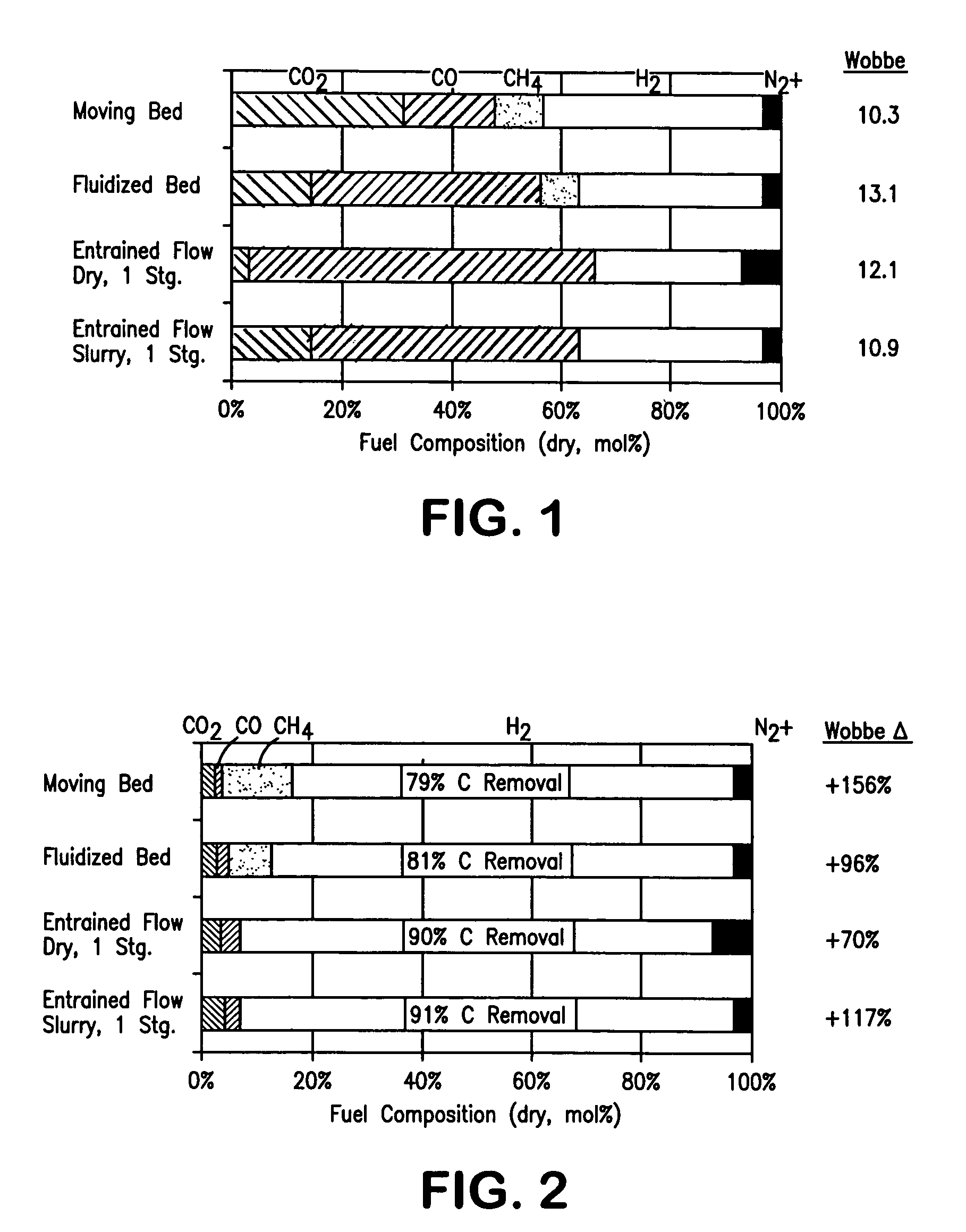

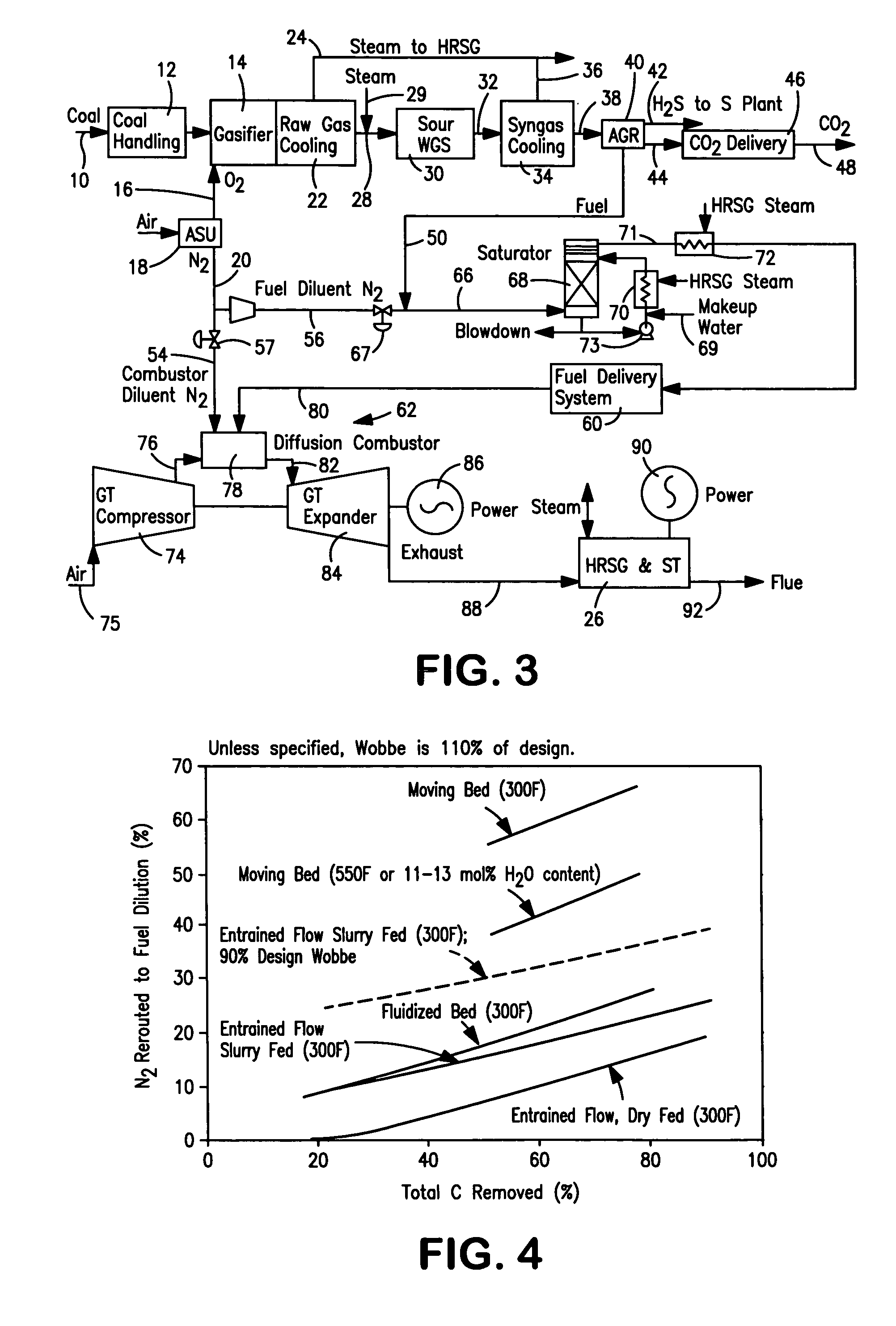

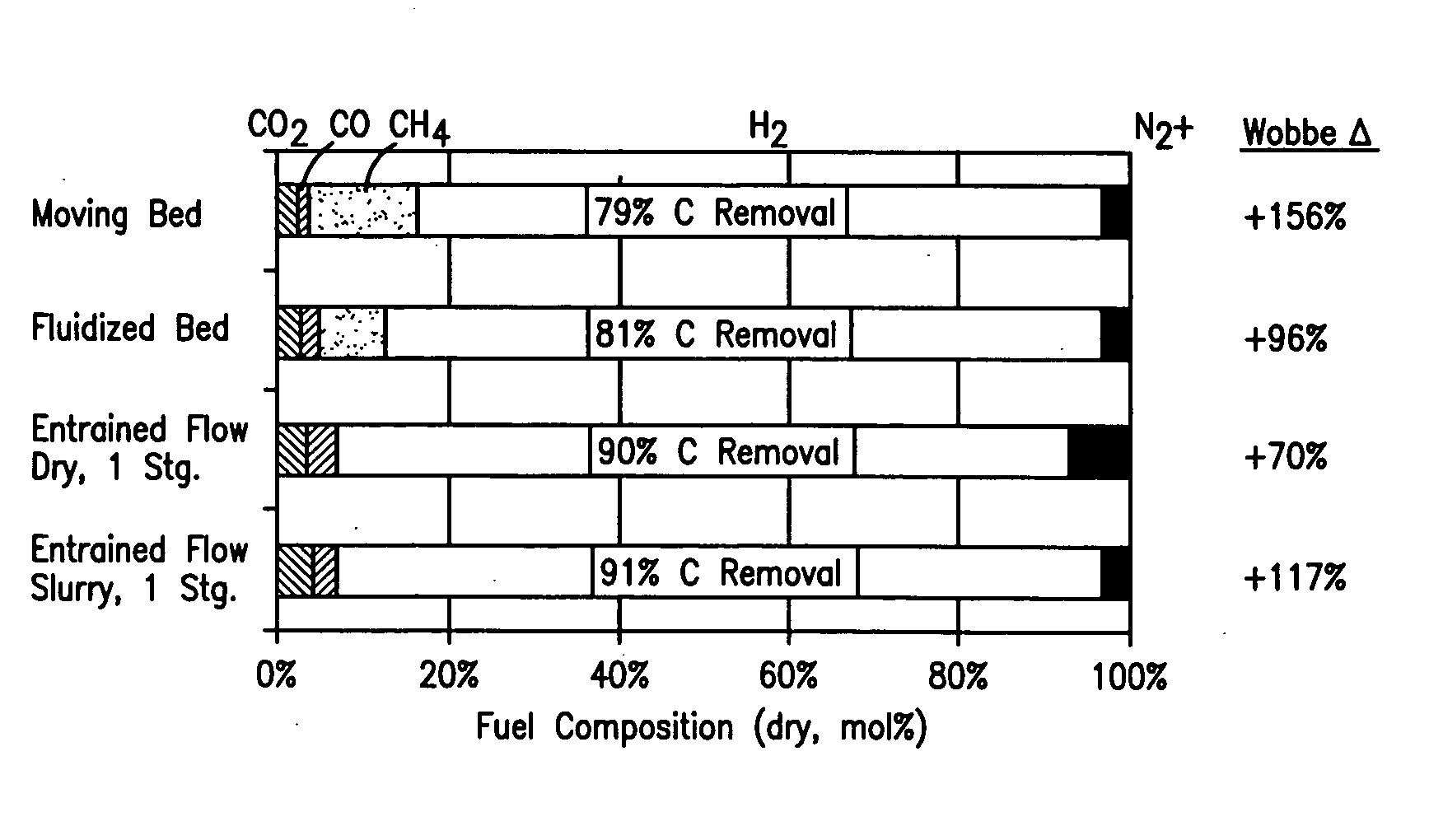

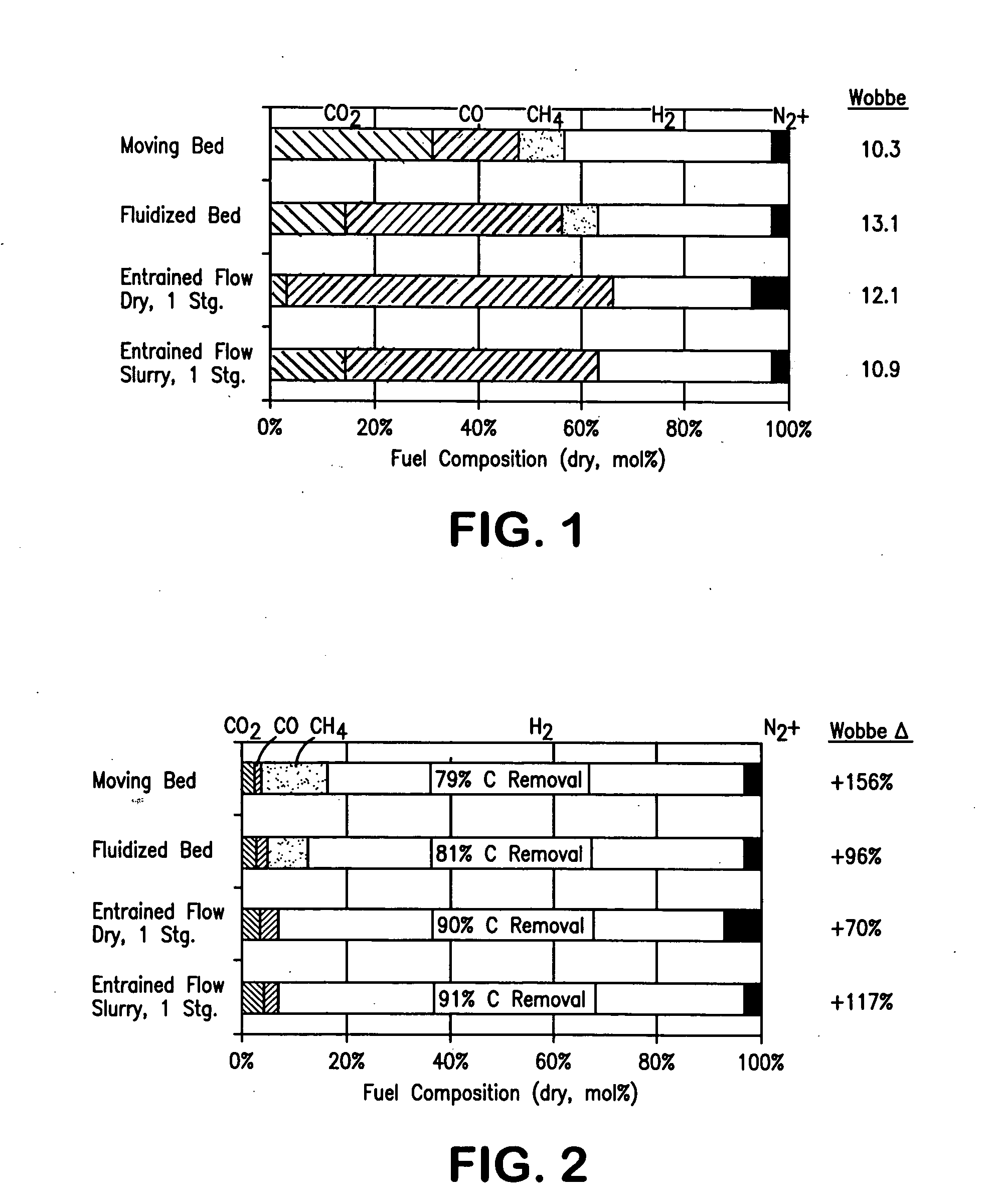

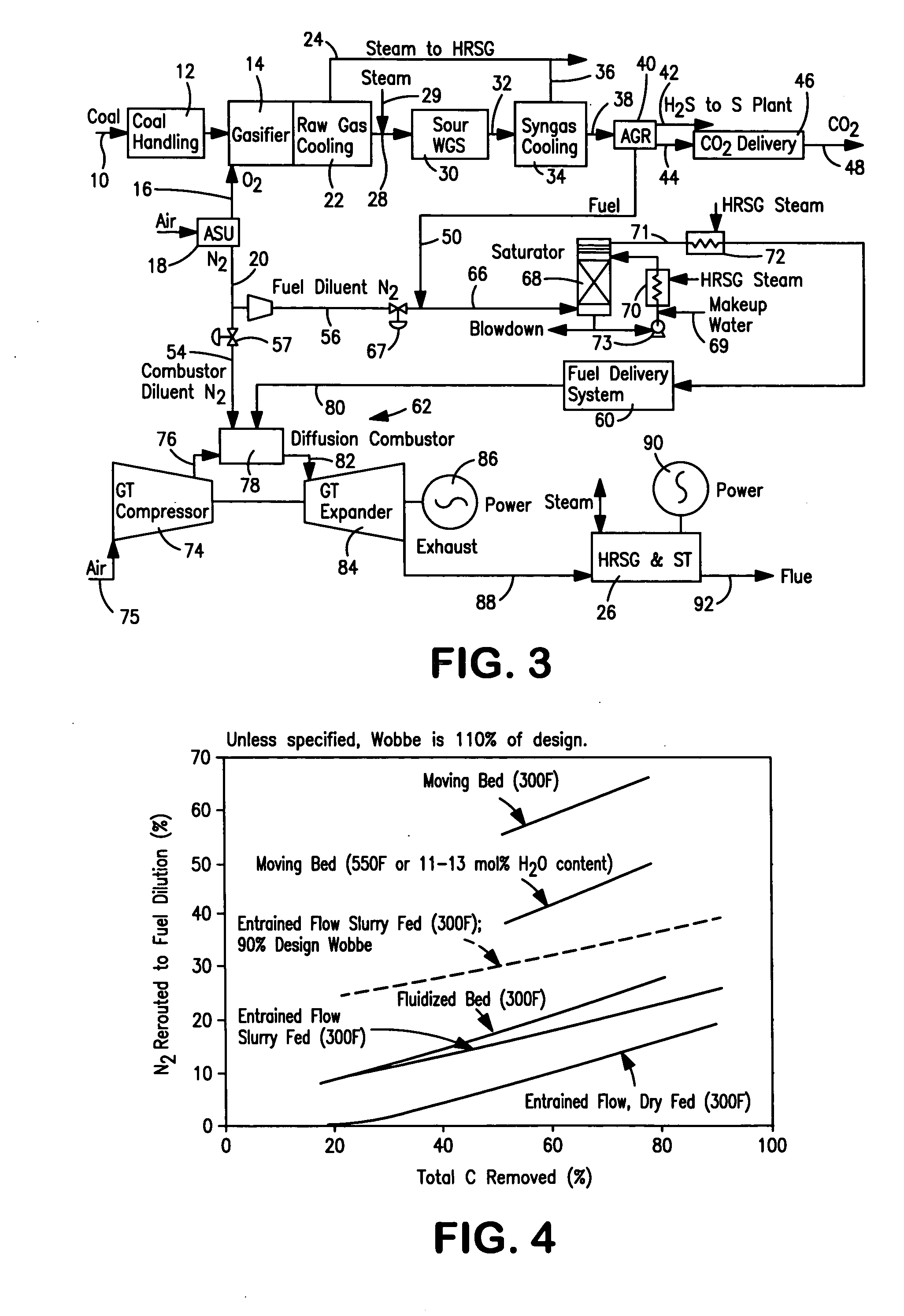

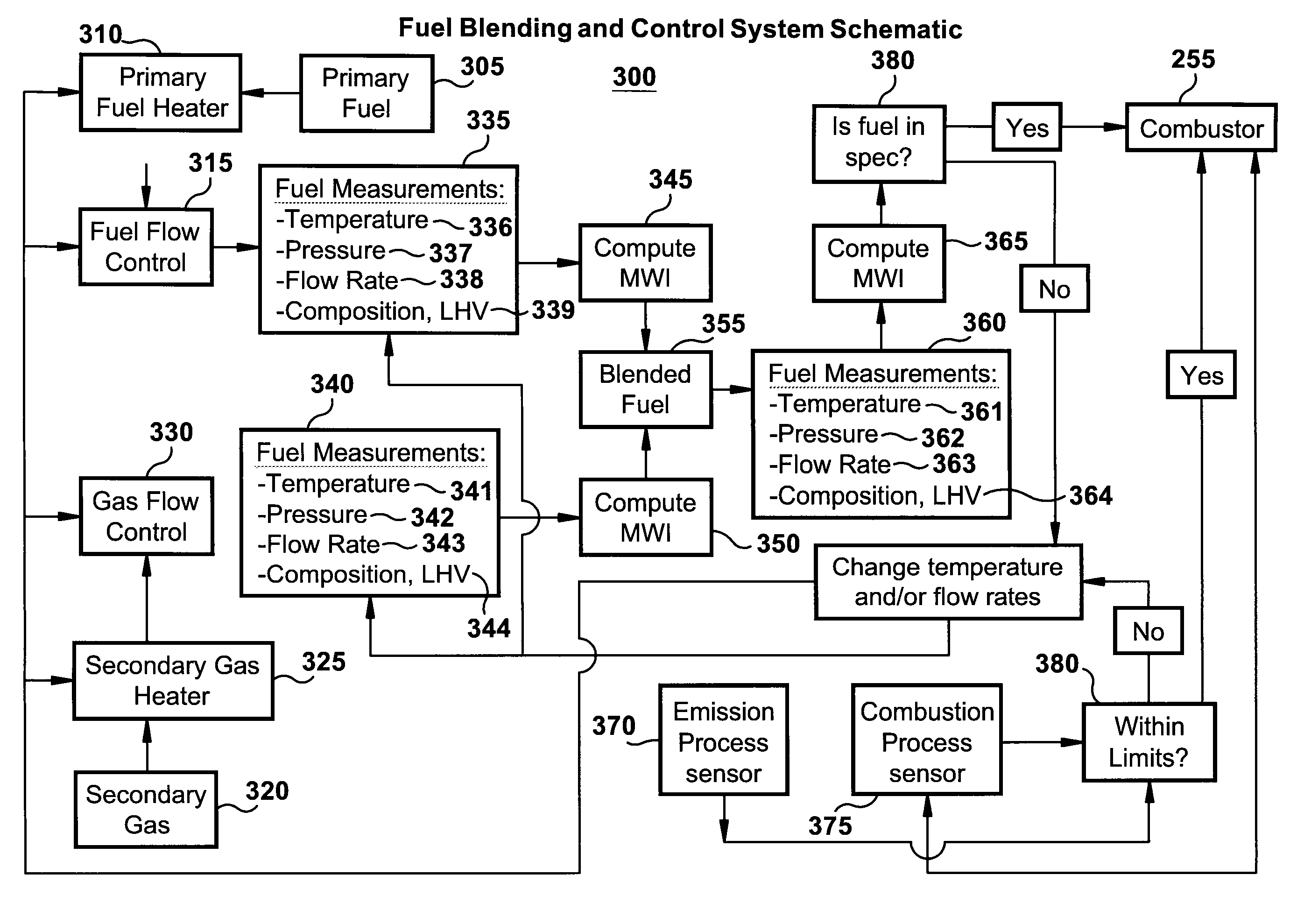

A method of reducing a modified Wobbe index of a fuel stream fed to diffusion combustors of a gas turbine that is used in connection with an IGCC installation in which a nitrogen stream is fed into the head ends of the combustor of NOx control and the modified Wobbe index of the fuel stream has been increased in an amount that is greater than at least about 10 percent of a design Wobbe index for the fuel to be fed to the gas turbine. The reason for the increase is the conversion of the carbon monoxide within the fuel stream to hydrogen and carbon dioxide by a water gas shift reaction and subsequent removal of the carbon dioxide. The nitrogen stream is maintained at the same level both with and without conversion and subsequent removal of carbon atoms. The nitrogen stream is divided to subsidiary streams that are respectively fed into the head end of the combustors and that are mixed with a fuel to lower the modified Wobbe index to acceptable levels for the gas turbine.

Owner:PRAXAIR TECH INC

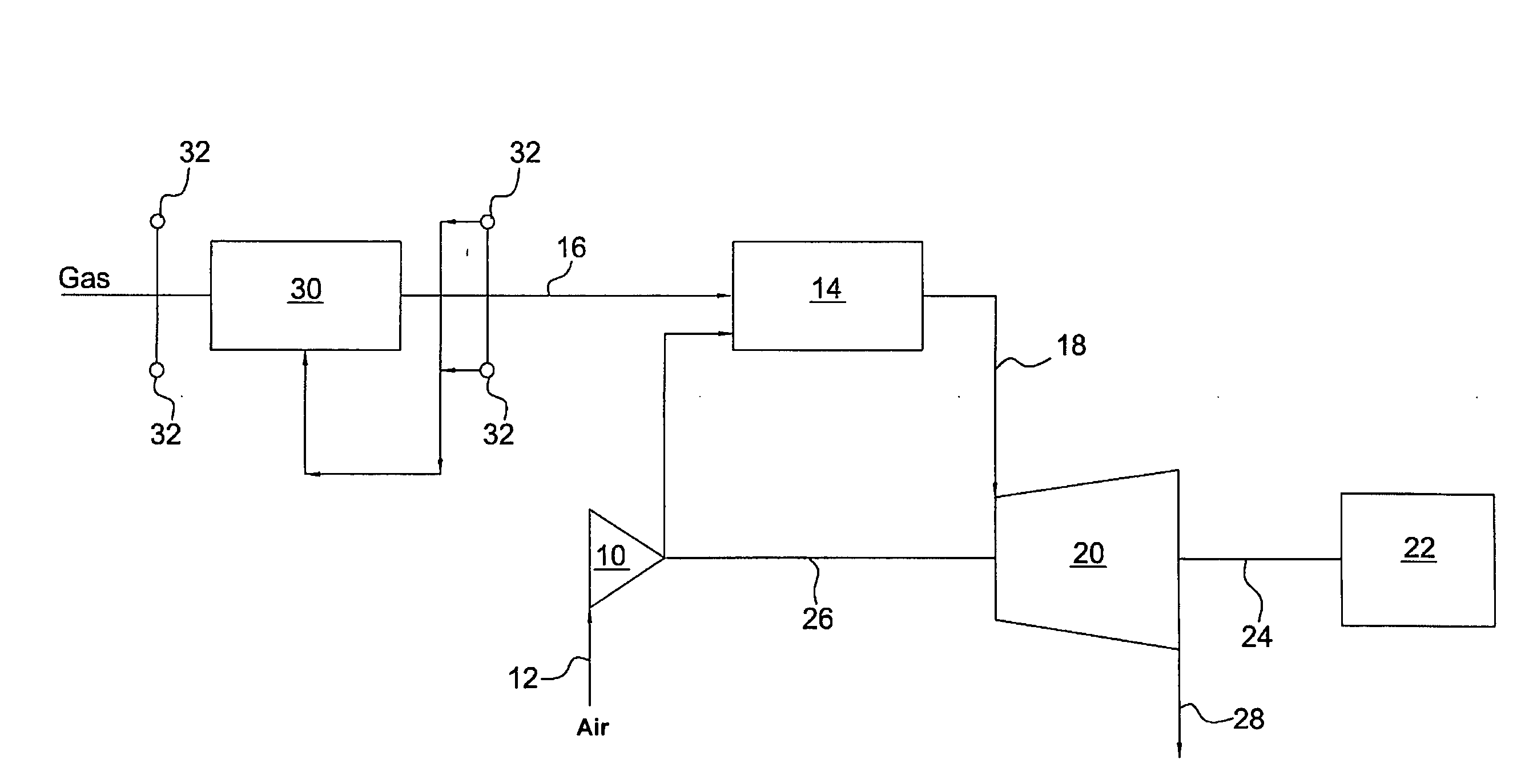

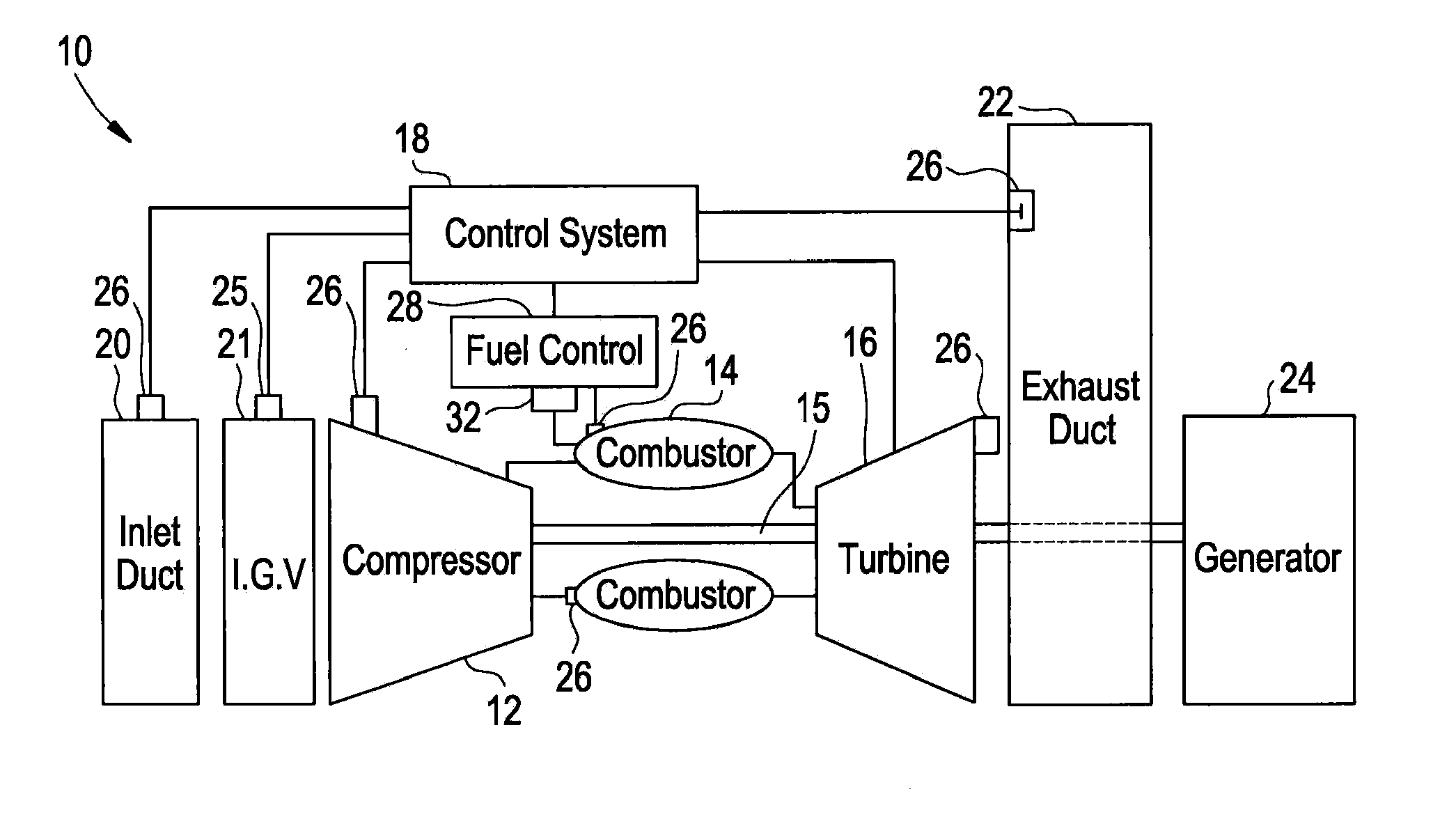

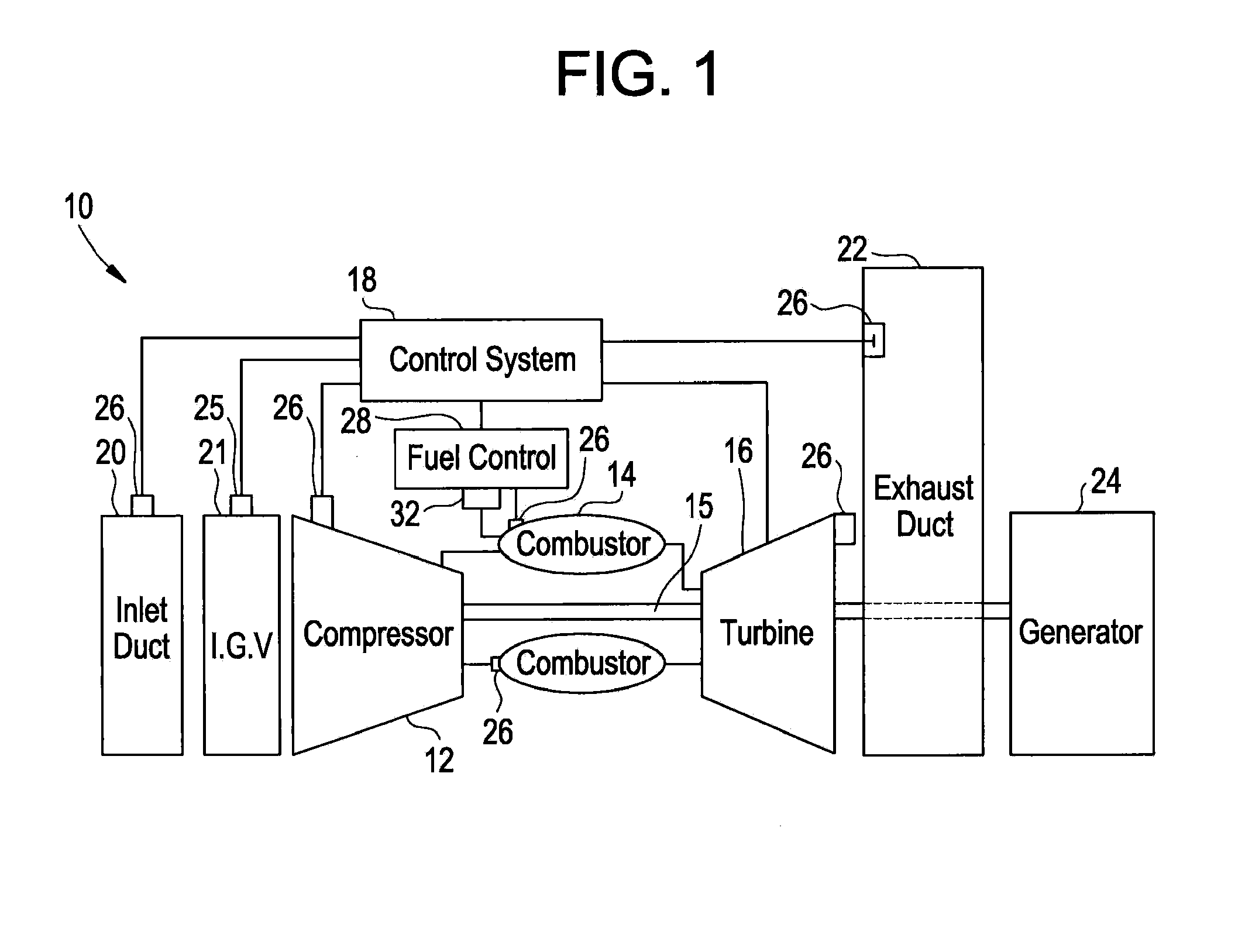

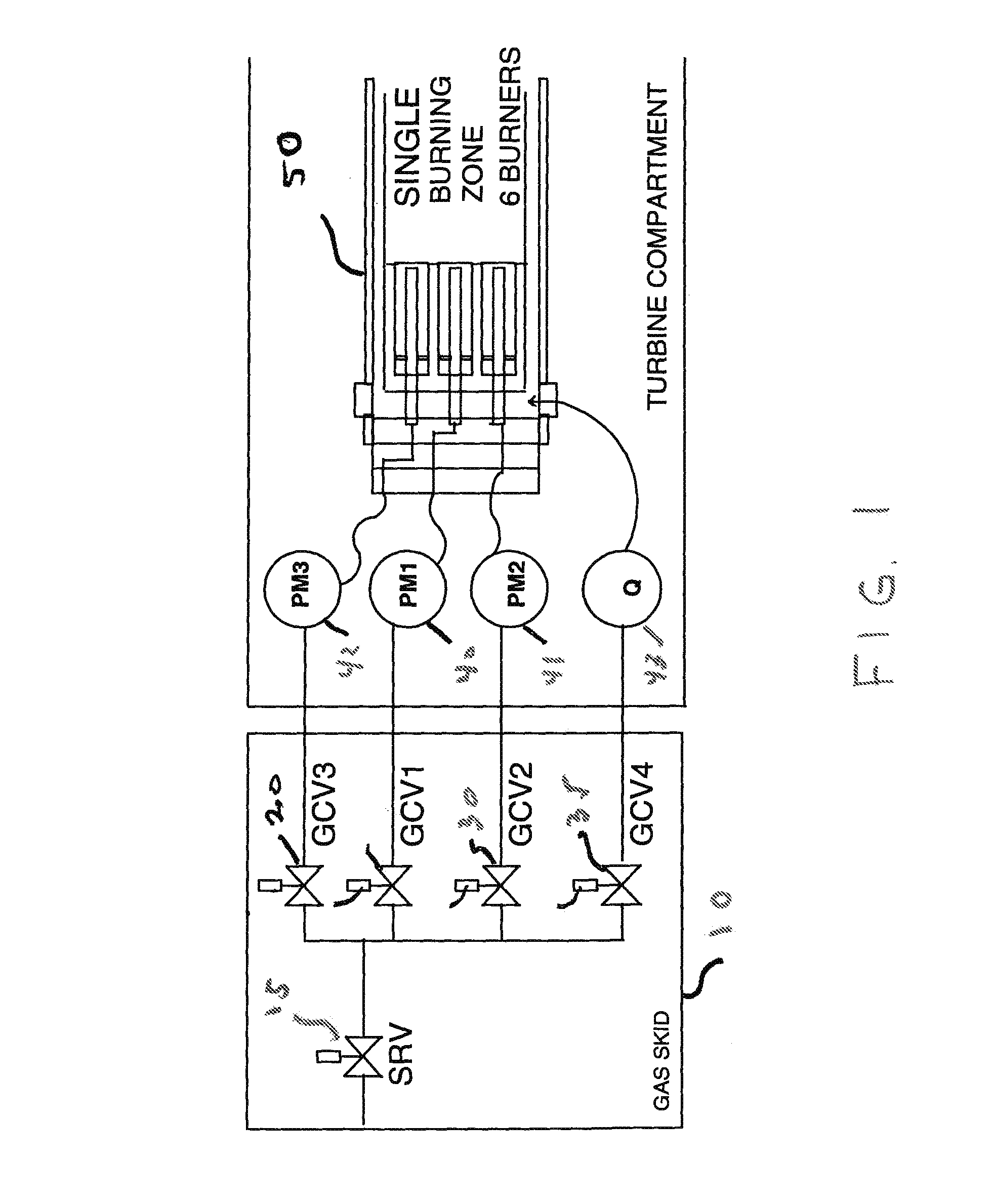

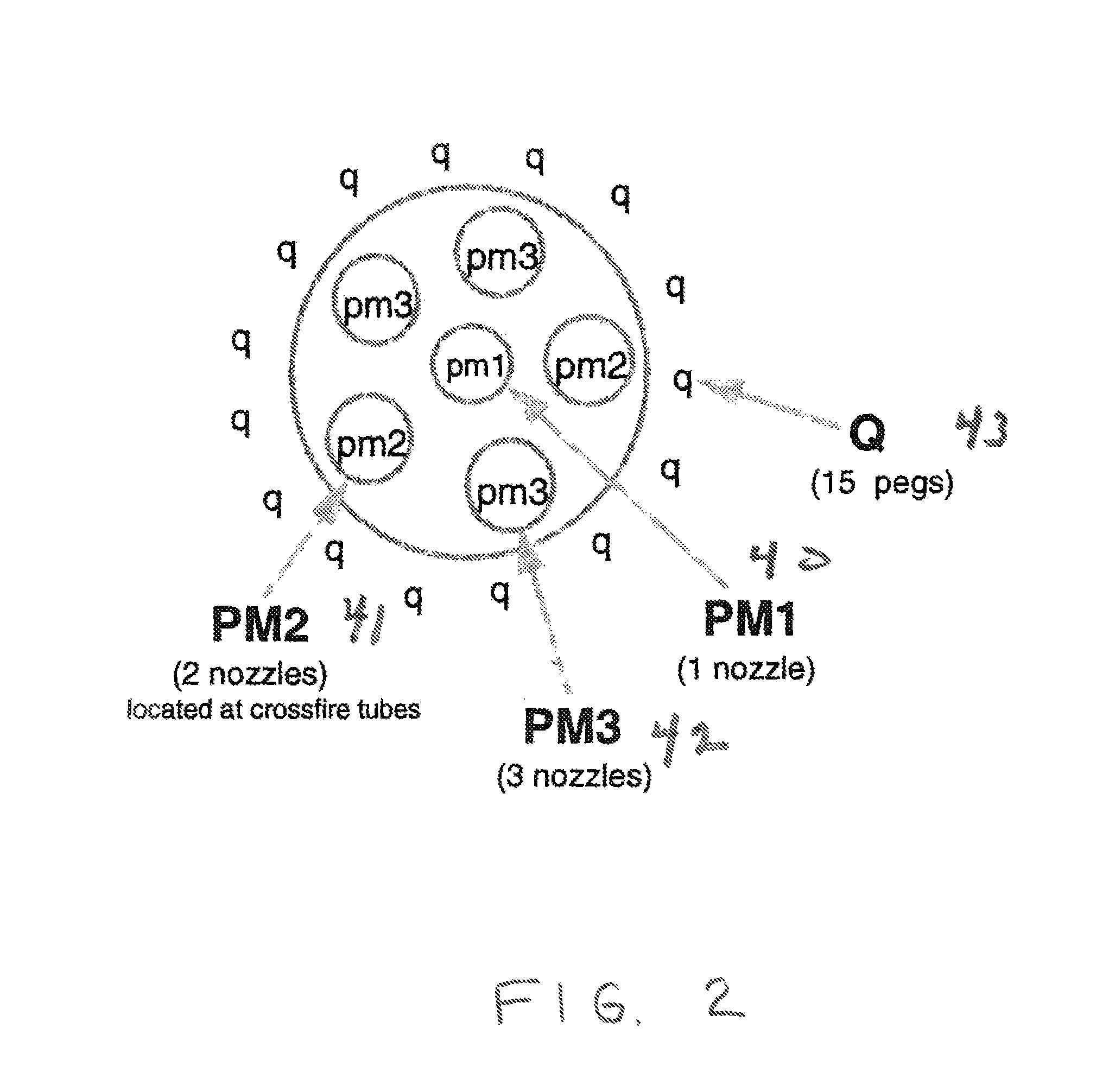

System and method for automatic fuel blending and control for combustion gas turbine

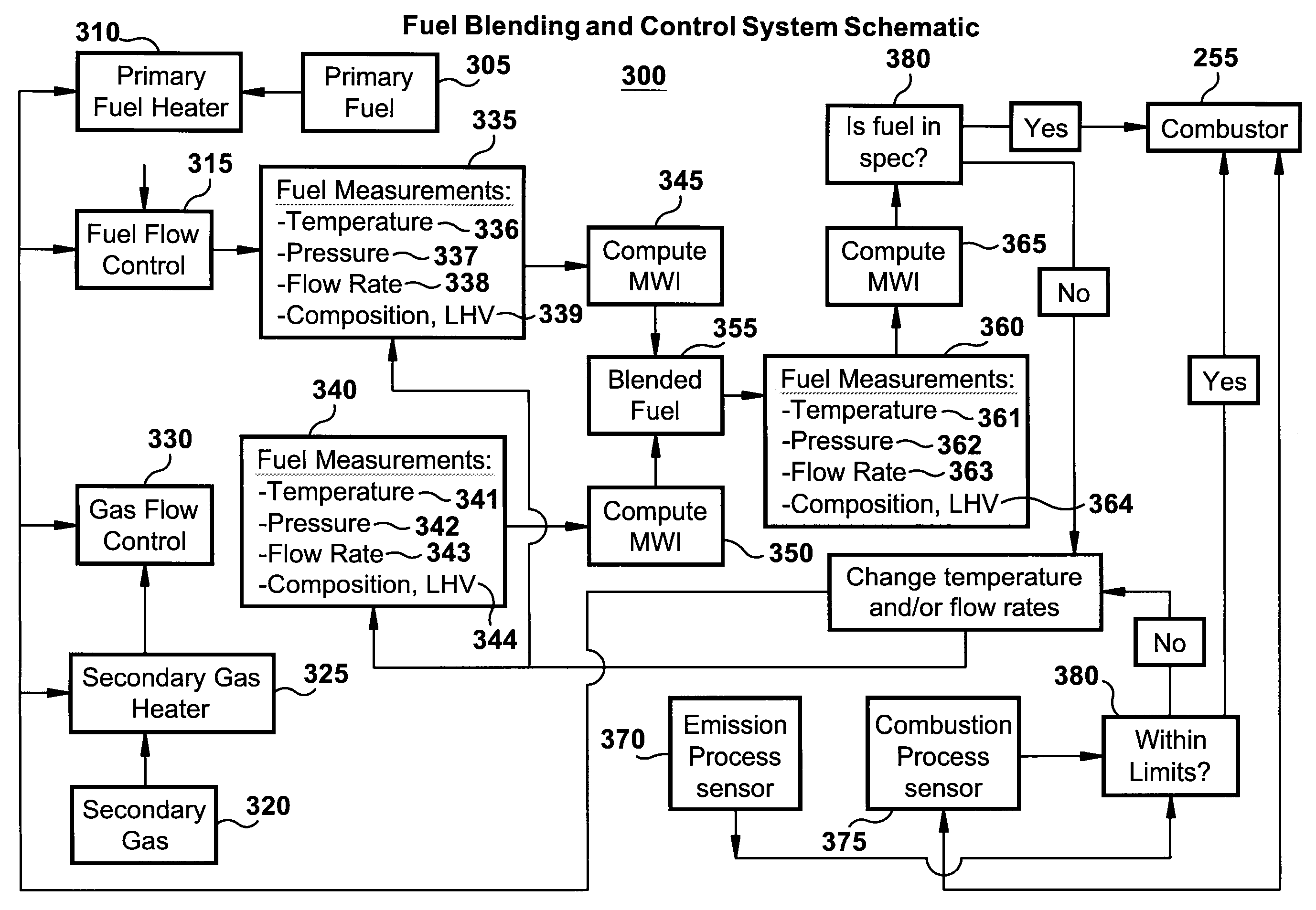

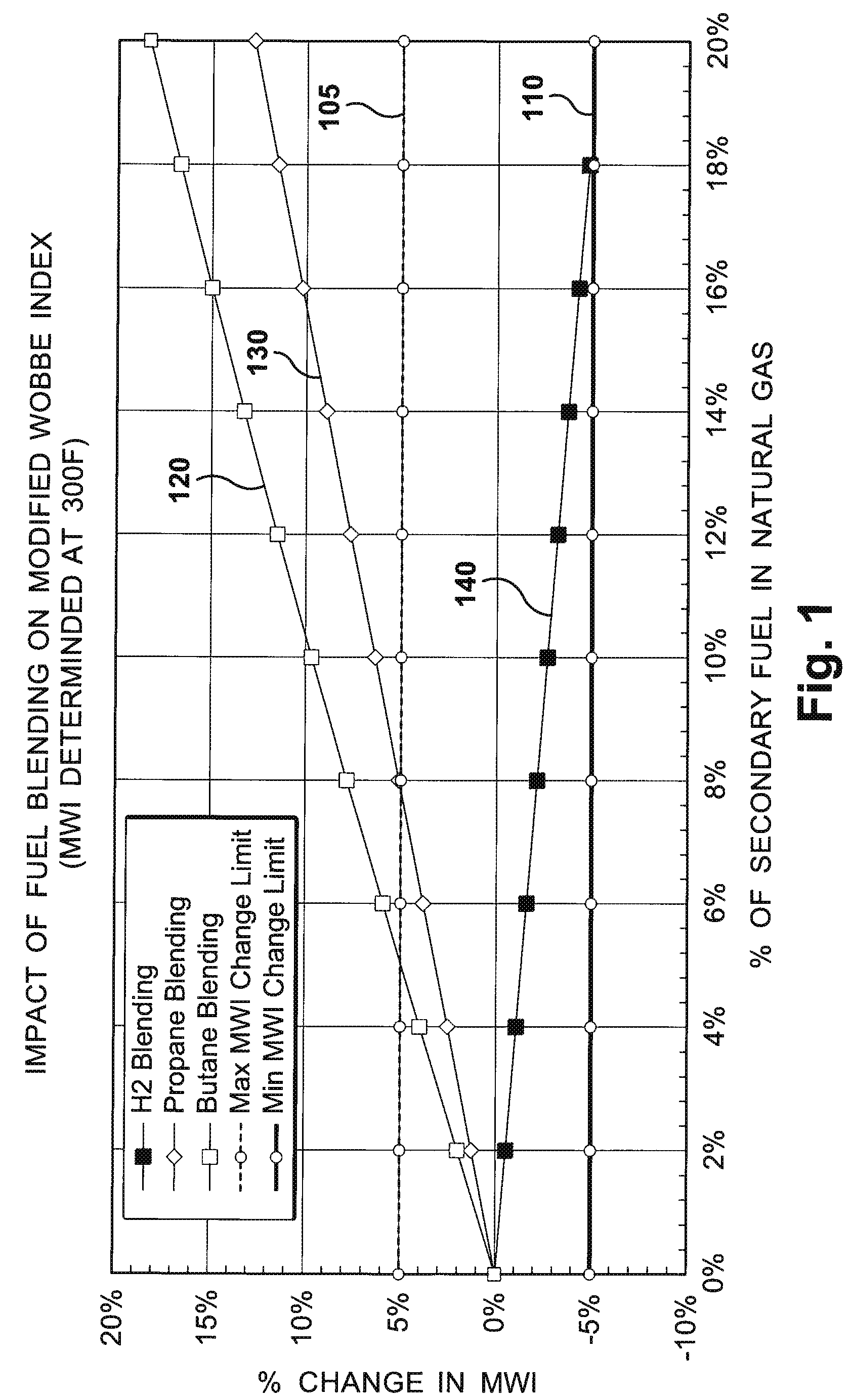

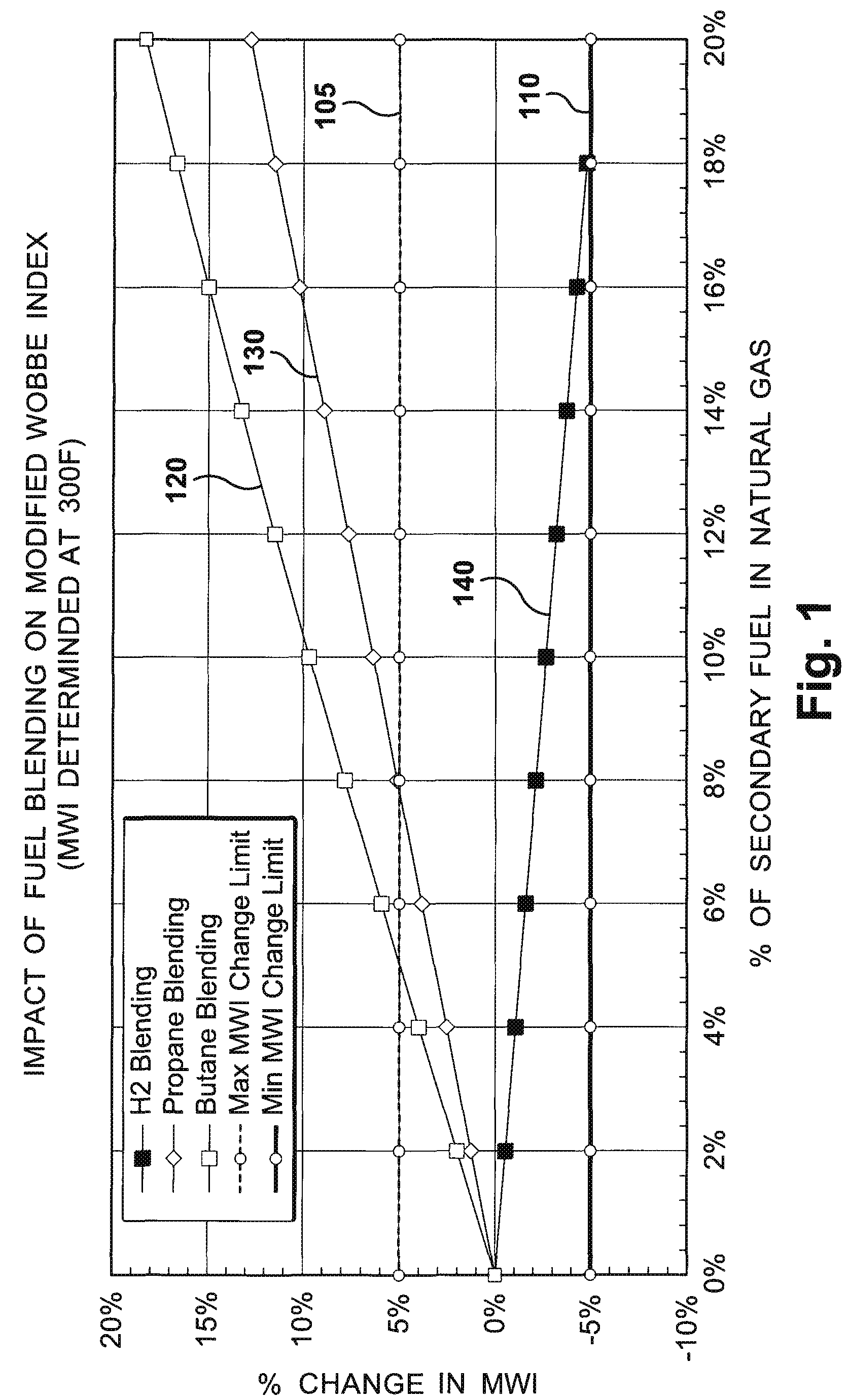

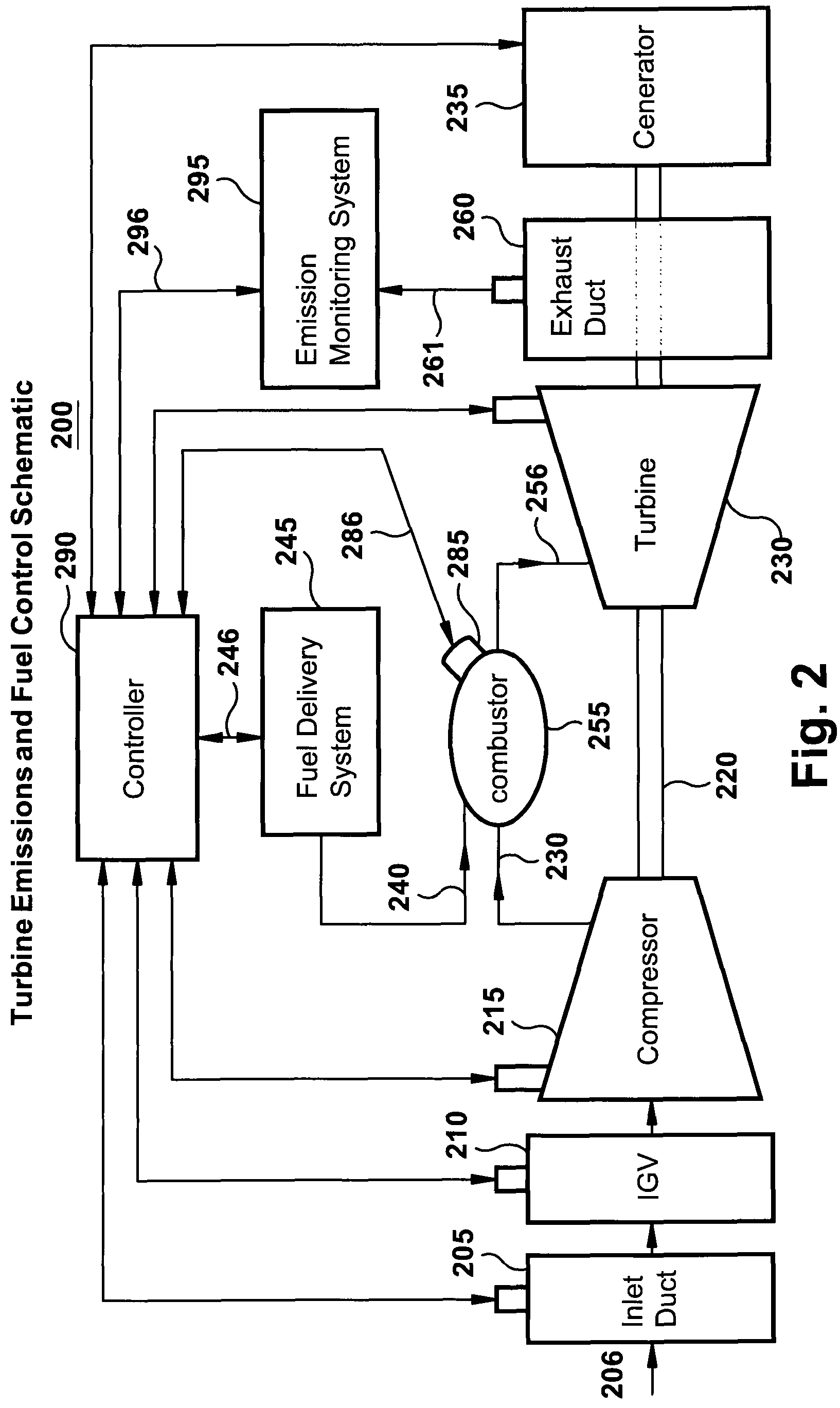

A flexible and automatic system and method for blending an inexpensive secondary gas with a primary gas fuel for operation of a Dry Low NOx gas turbine. The secondary gas may be a gas fuel such as hydrogen, ethane, butane, propane and liquefied natural gas or an inert gas. Combustion dynamics are avoided by controlling the blended fuel within a permissible range for a Modified Wobbe Index. Combustion dynamics and gas turbine exhaust emissions may also be monitored to maintain safe combustion with the blended fuel. A gas turbine control system may adjust the blend and temperature of the primary gas fuel and the secondary gas to promote desired combustion.

Owner:GENERAL ELECTRIC CO

Methods of adjusting the Wobbe Index of a fuel and compositions thereof

Novel methods of providing fuels to a gas-to-liquids facility are disclosed. A gas-to-liquids facility typically operates in a remote location and therefore must supply its own energy needs. These facilities are often sustained by fuels having different heating values, and for smooth operation while transitioning from one fuel to another, (such as during startup, shut down, and emergencies) the Wobble Indices of the two fuels cannot greatly vary from one another. According to embodiments of the present invention, the Wobble Index of either or both of the fuels is adjusted such that their ratio is less than or equal to about 3. The fuel having the higher Wobble Index may be natural gas, and materials such as nitrogen, carbon dioxide and flue gas may be added to lower its Wobble Index. The fuel having the lower Wobble Index may be the tail gas of a Fischer-Tropsch synthesis, and materials such as methane, ethane, LPG, or natural gas may be added to raise its Wobble Index. Alternatively, carbon dioxide may be removed from the tail gas to raise its Wobble Index.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

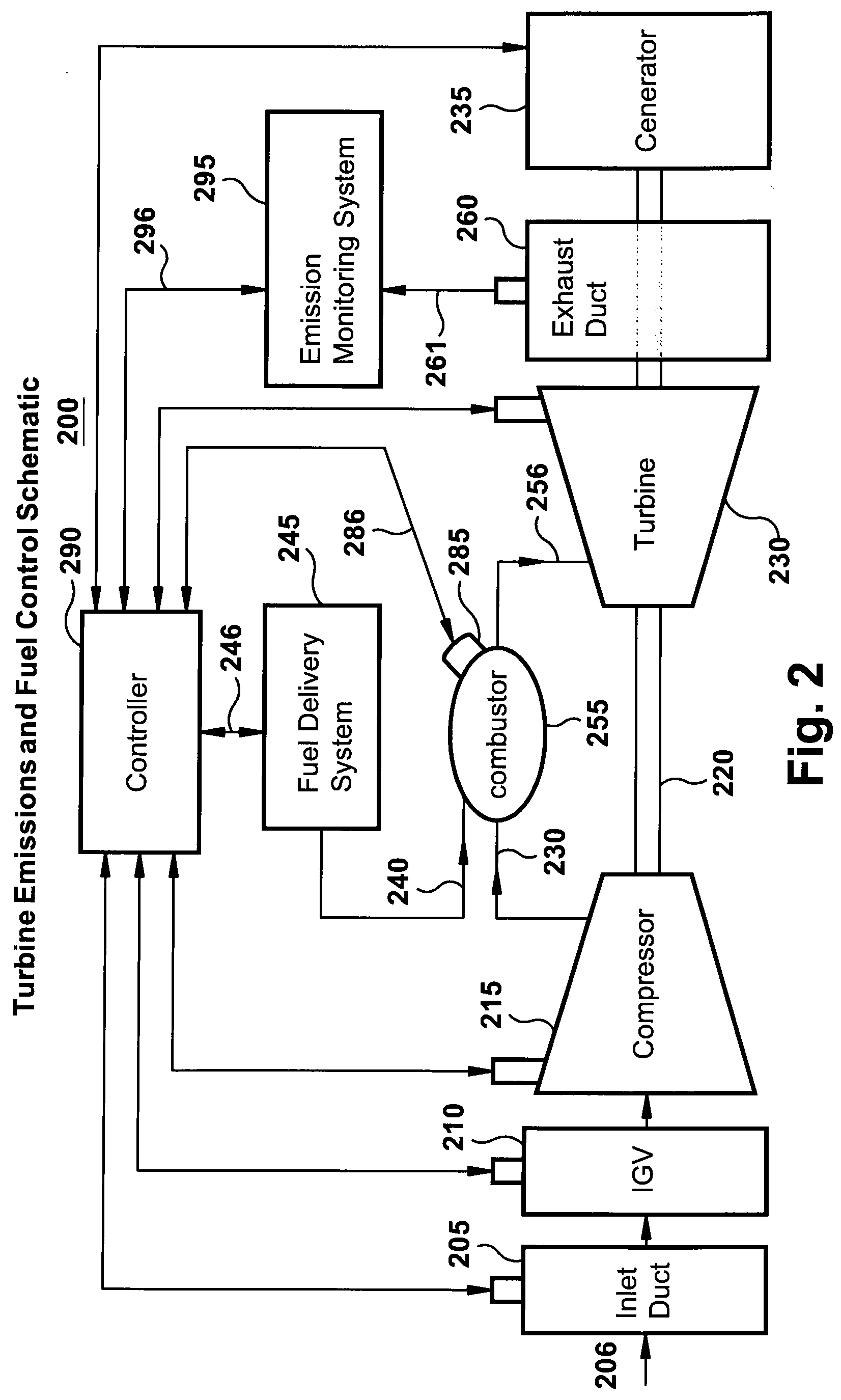

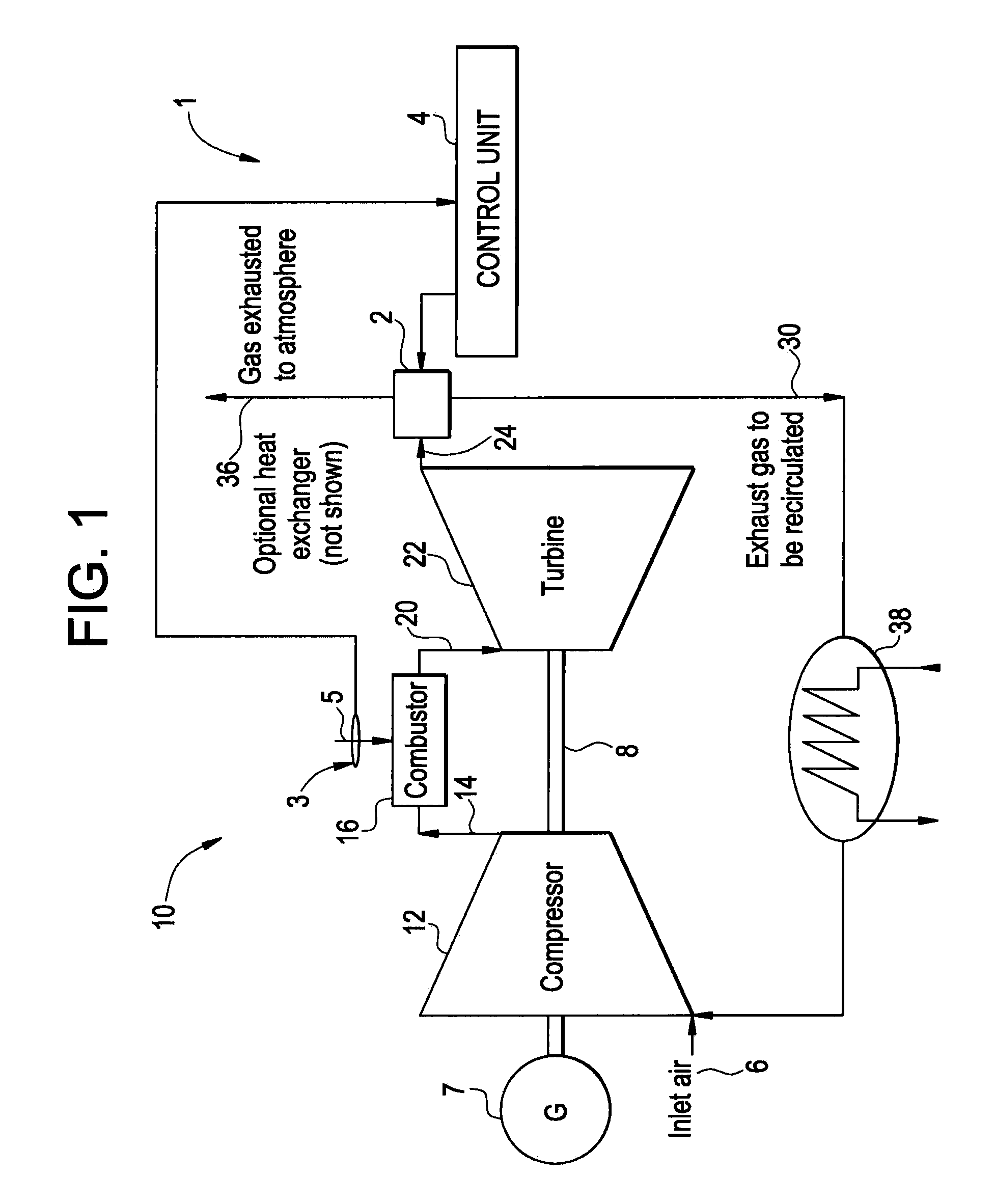

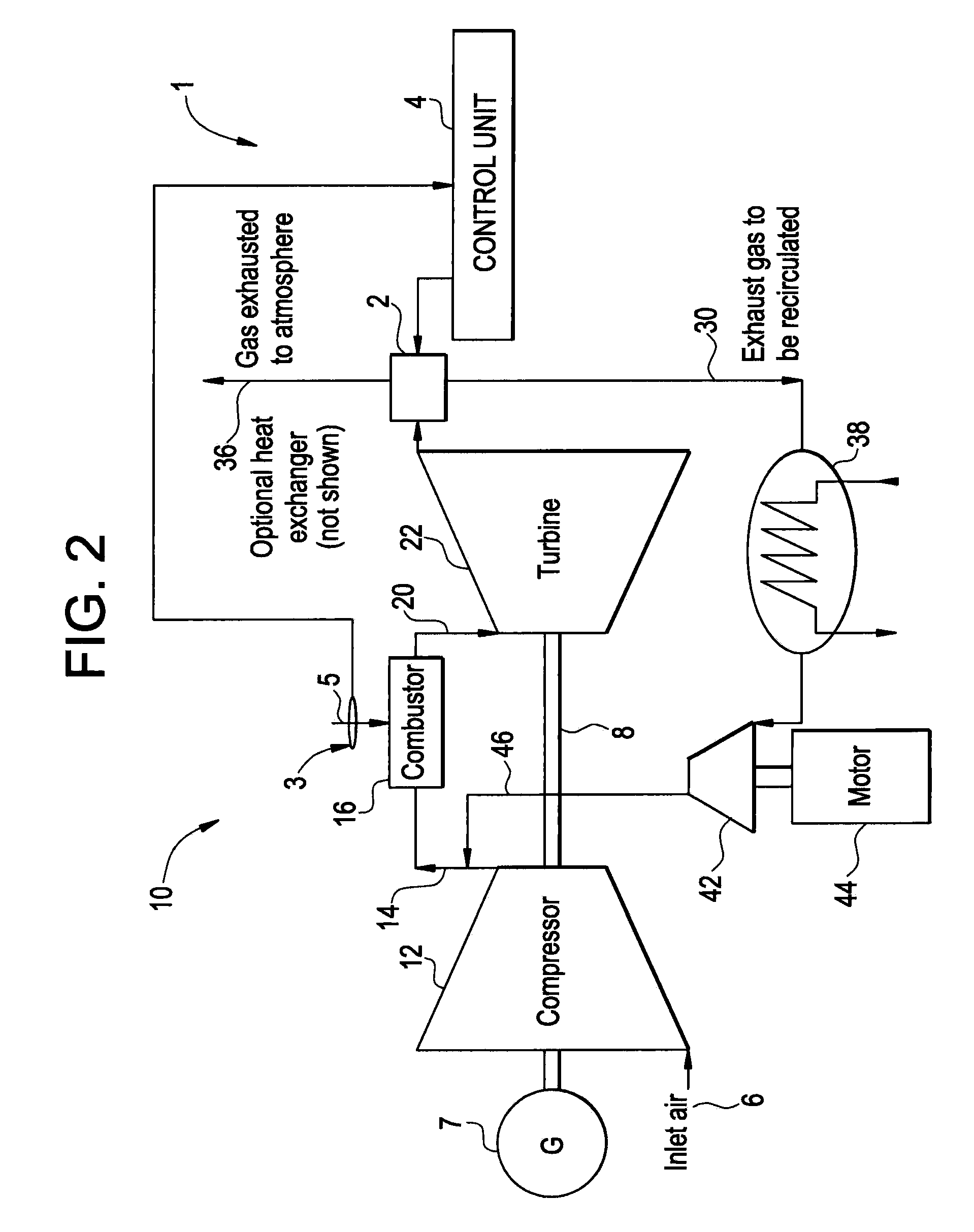

Exhaust gas recirculation system, turbomachine system having the exhaust gas recirculation system and exhaust gas recirculation control method

An exhaust gas recirculation system that includes an exhaust gas recirculation regulator operatively connectable to a turbomachine system, and regulating a predetermined amount of exhaust gas to be recirculated. The exhaust gas recirculation system further includes a measuring unit that measures fuel composition of incoming fuel, and a control unit connected to the EGR regulator and the measuring unit, and determining a Wobbe Index and / or reactivity of the incoming fuel based on the measured fuel composition and determining the predetermined amount of exhaust gas to be recirculated based on the determined Wobbe Index and / or reactivity.

Owner:GENERAL ELECTRIC CO

Method of maintaining a fuel Wobbe index in an IGCC installation

InactiveUS20070082306A1Low indexFuel supply regulationGaseous fuel feeder/distributionWater-gas shift reactionProcess engineering

A method of reducing a modified Wobbe index of a fuel stream fed to diffusion combustors of a gas turbine that is used in connection with an IGCC installation in which a nitrogen stream is fed into the head ends of the combustor of NOx control and the modified Wobbe index of the fuel stream has been increased in an amount that is greater than at least about 10 percent of a design Wobbe index for the fuel to be fed to the gas turbine. The reason for the increase is the conversion of the carbon monoxide within the fuel stream to hydrogen and carbon dioxide by a water gas shift reaction and subsequent removal of the carbon dioxide. The nitrogen stream is maintained at the same level both with and without conversion and subsequent removal of carbon atoms. The nitrogen stream is divided to subsidiary streams that are respectively fed into the head end of the combustors and that are mixed with a fuel to lower the modified Wobbe index to acceptable levels for the gas turbine.

Owner:PRAXAIR TECH INC

System and method for automatic fuel blending and control for combustion gas turbine

A flexible and automatic system and method for blending an inexpensive secondary gas with a primary gas fuel for operation of a Dry Low NOx gas turbine. The secondary gas may be a gas fuel such as hydrogen, ethane, butane, propane and liquefied natural gas or an inert gas. Combustion dynamics are avoided by controlling the blended fuel within a permissible range for a Modified Wobbe Index. Combustion dynamics and gas turbine exhaust emissions may also be monitored to maintain safe combustion with the blended fuel. A gas turbine control system may adjust the blend and temperature of the primary gas fuel and the secondary gas to promote desired combustion.

Owner:GENERAL ELECTRIC CO

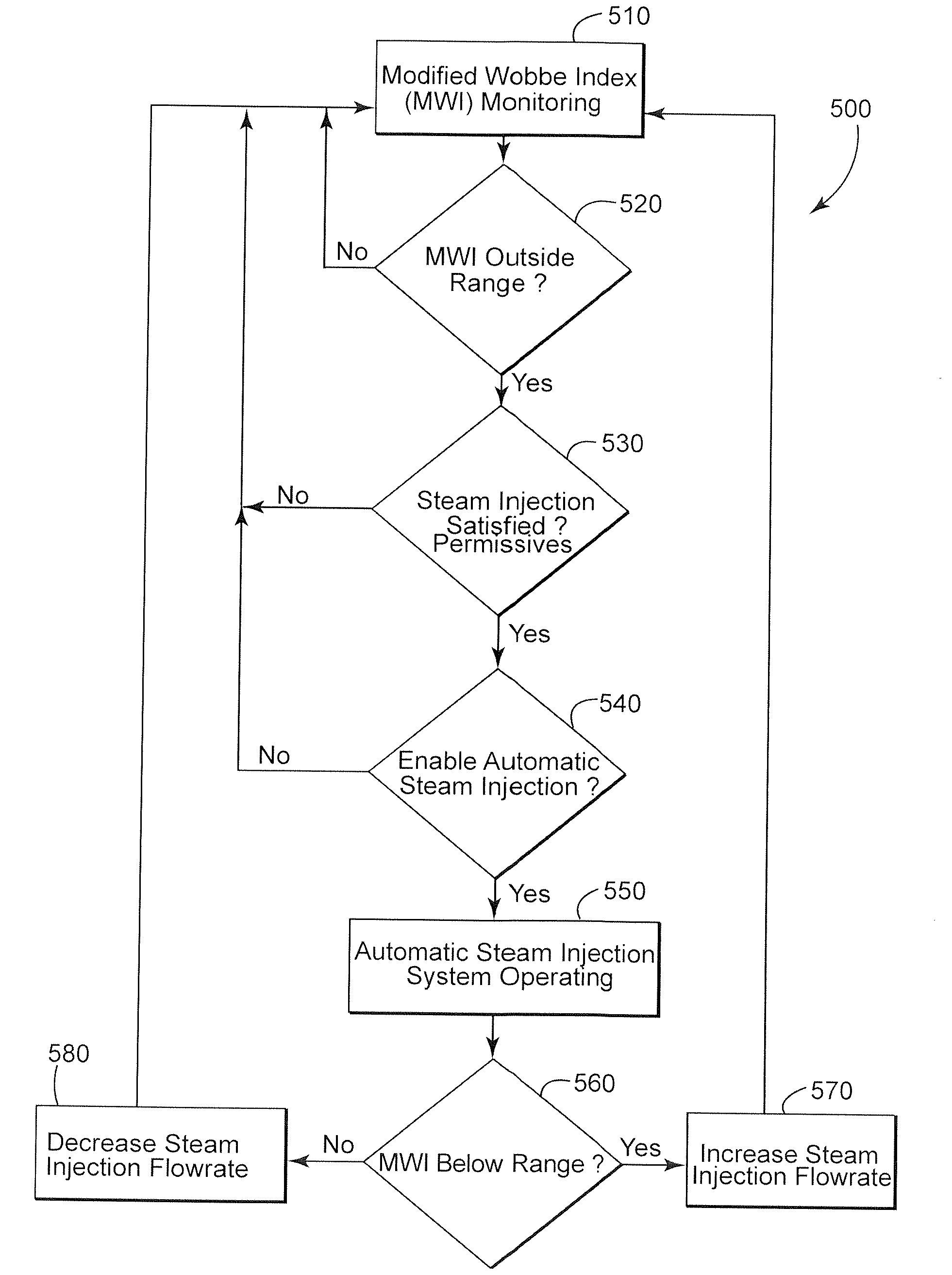

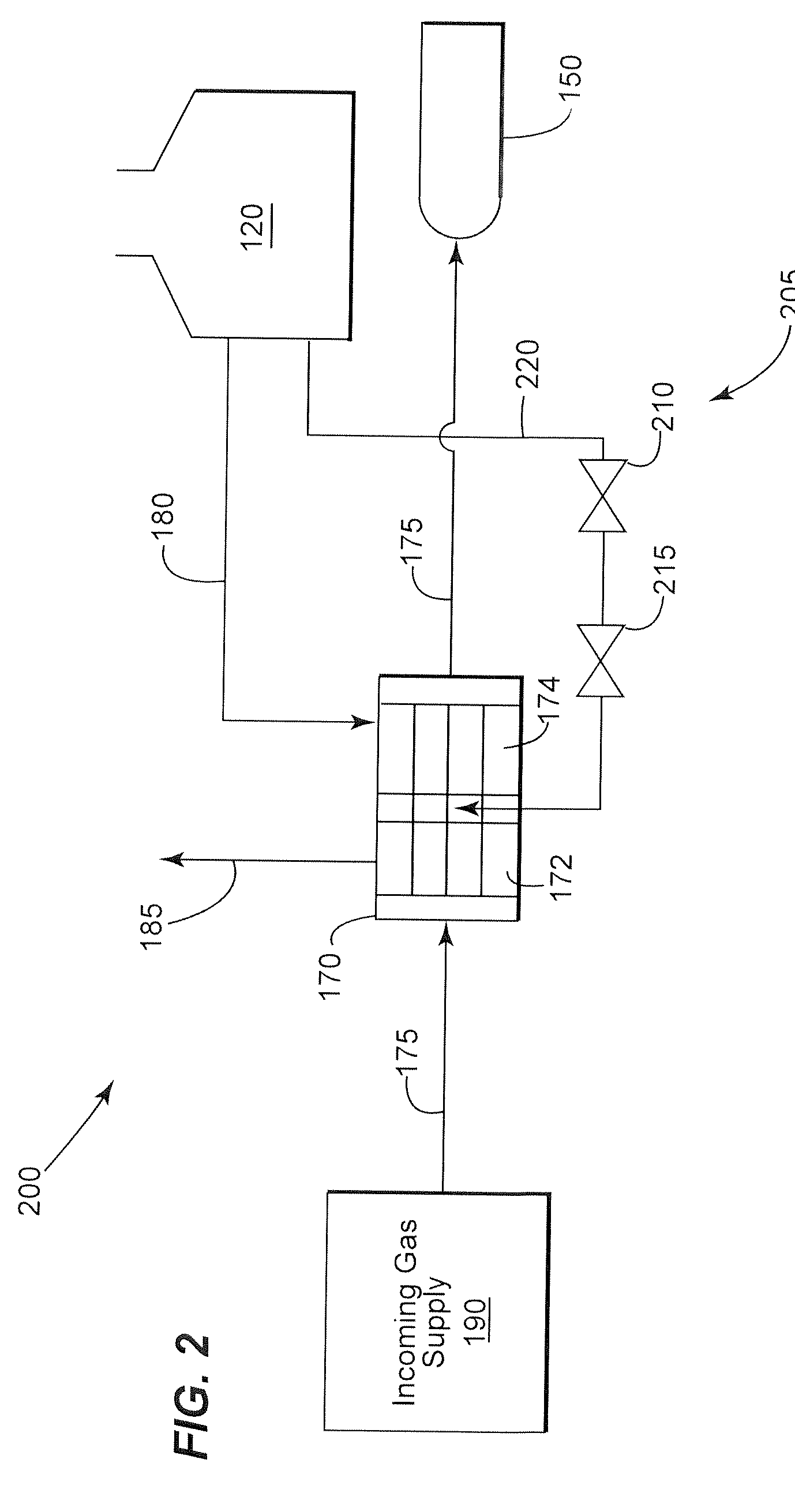

Method and system for modulating the modified wobbe index of a fuel

A method and system for modulating the Modified Wobbe Index (MWI) of a fuel is provided. A variety of industrial components, which may require a gas fuel, such as but not limiting of, a heavy-duty gas turbine; an aero-derivative gas turbine; or a boiler may utilize the method and system. The method and system may provide an industrial component comprising at least one steam injection system, wherein the at least one steam injection system injects steam into at least one fuel supply line upstream of a combustion system to modulate the MWI of at least one fuel. The method and system may also determine whether the MWI of the at least one fuel is outside of a predetermined range; and utilize the at least one steam injection system to automatically inject the steam at a flowrate for adjusting the MWI of the at least one fuel.

Owner:GENERAL ELECTRIC CO

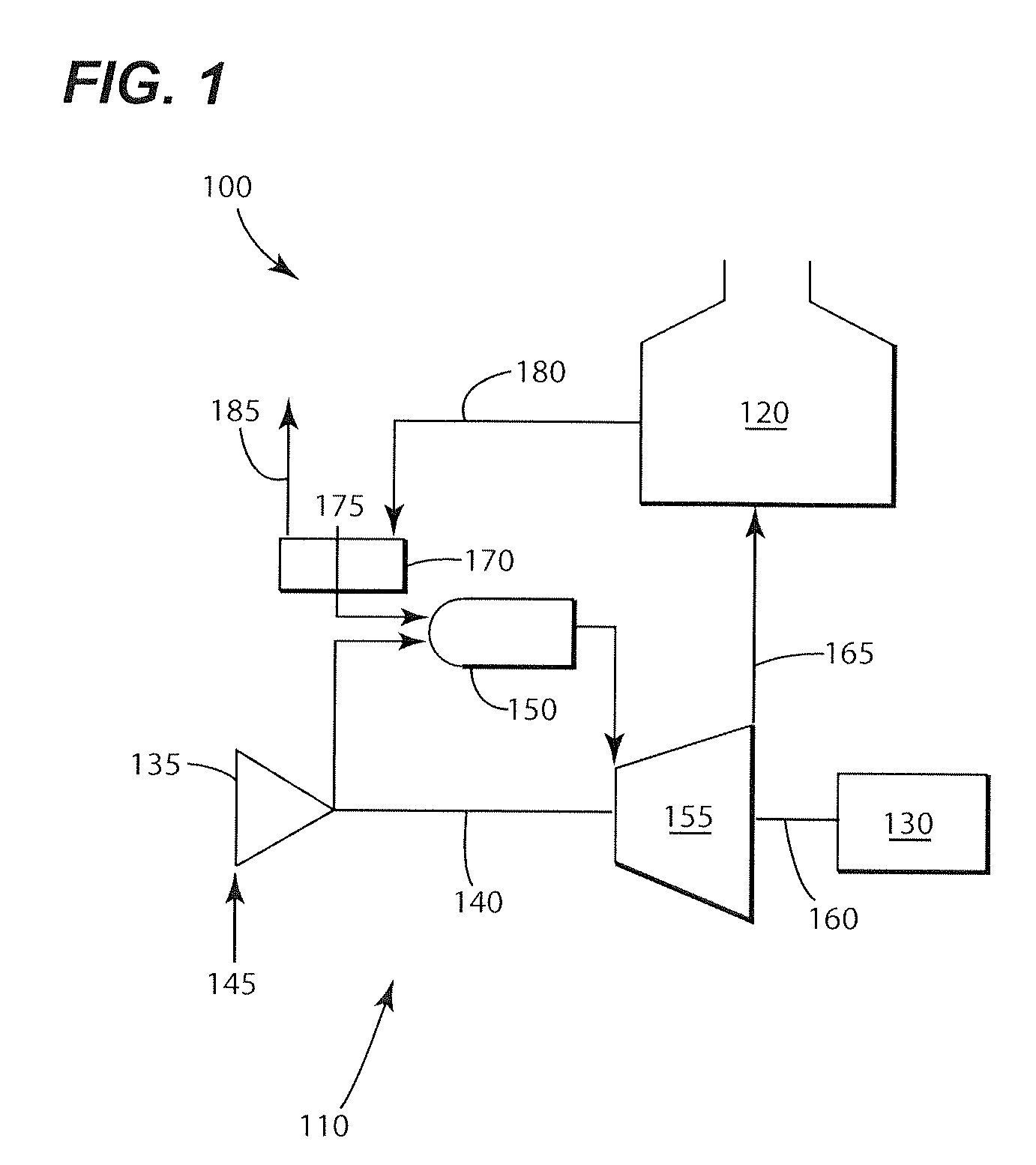

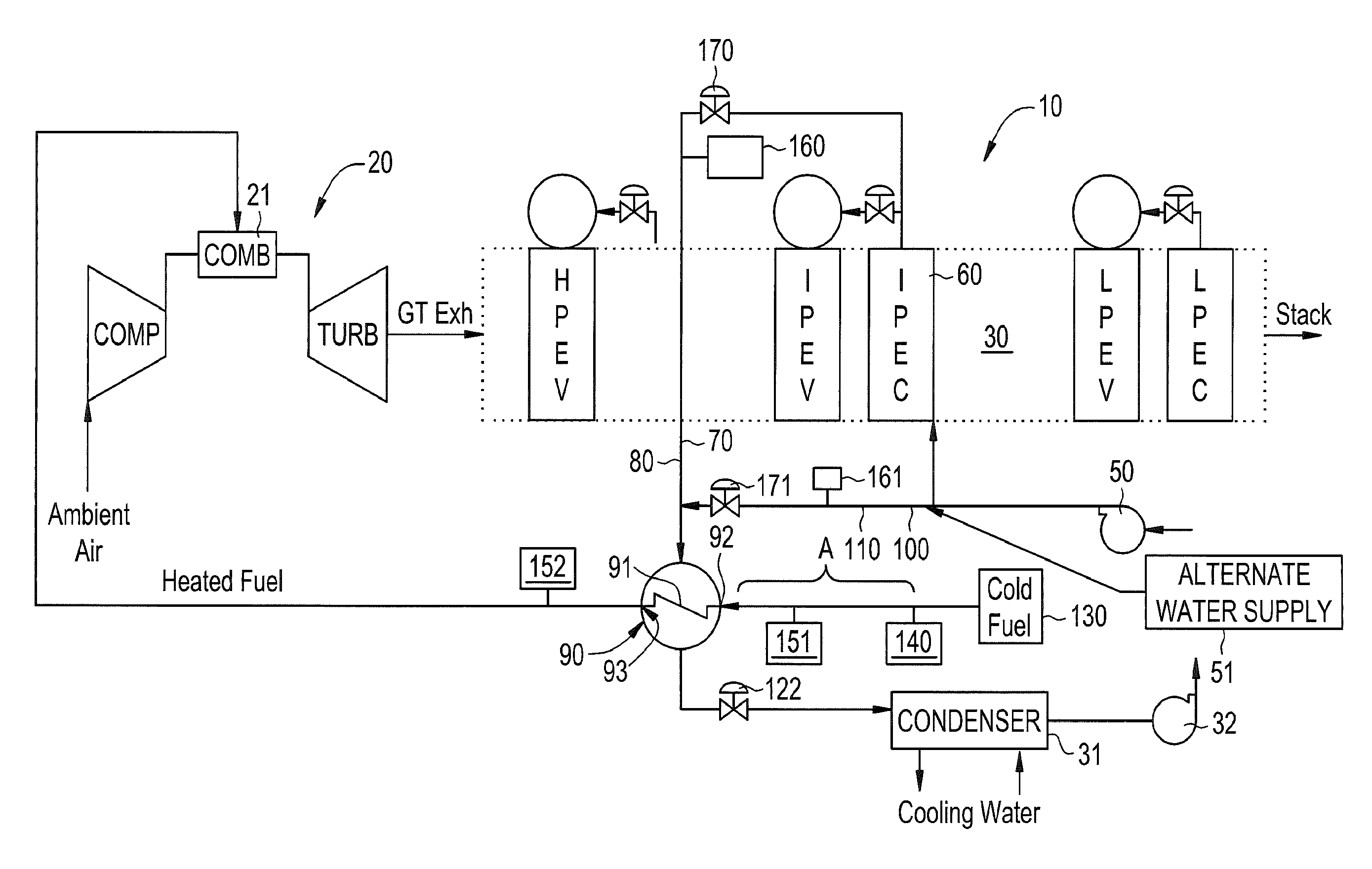

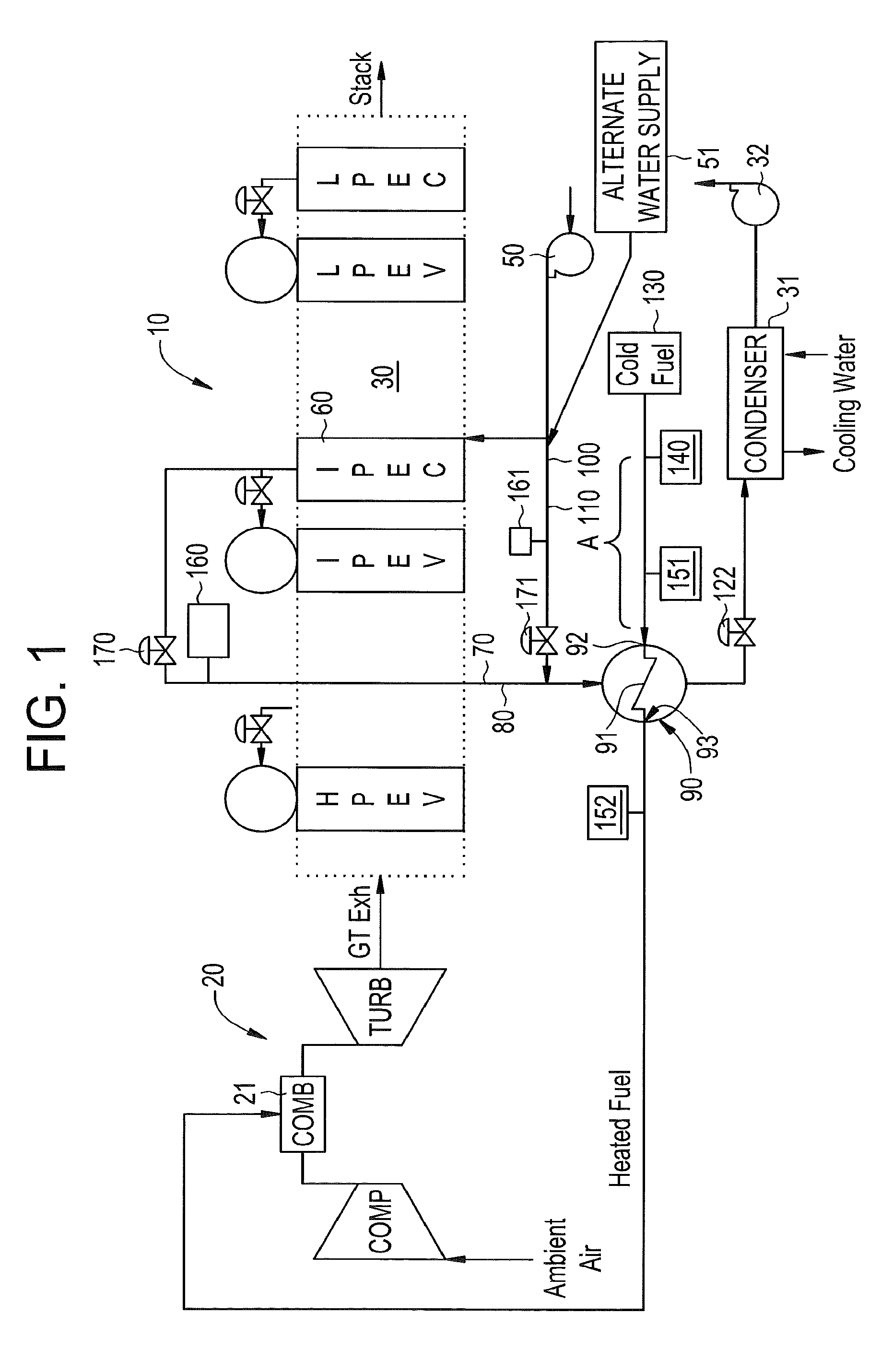

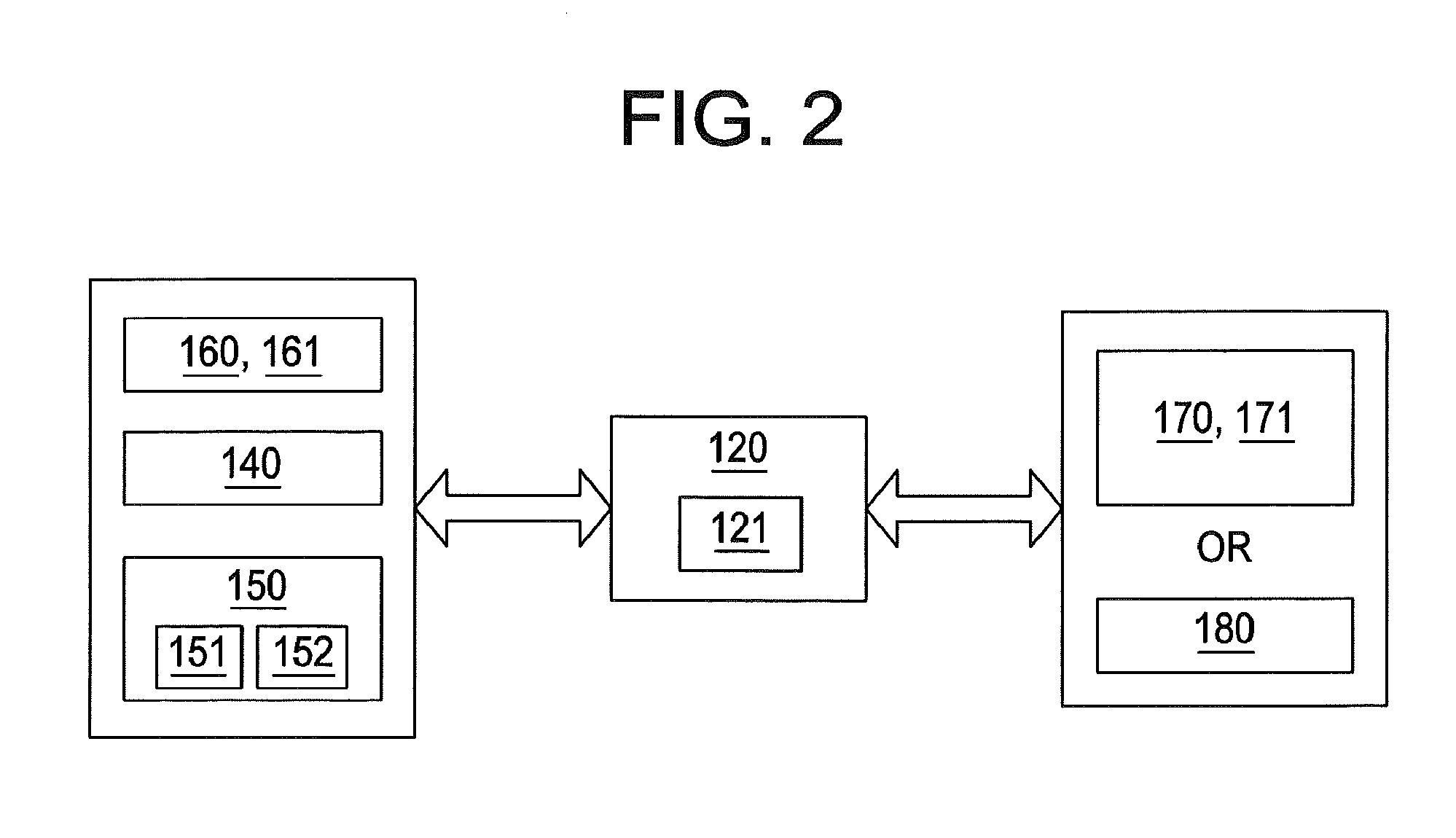

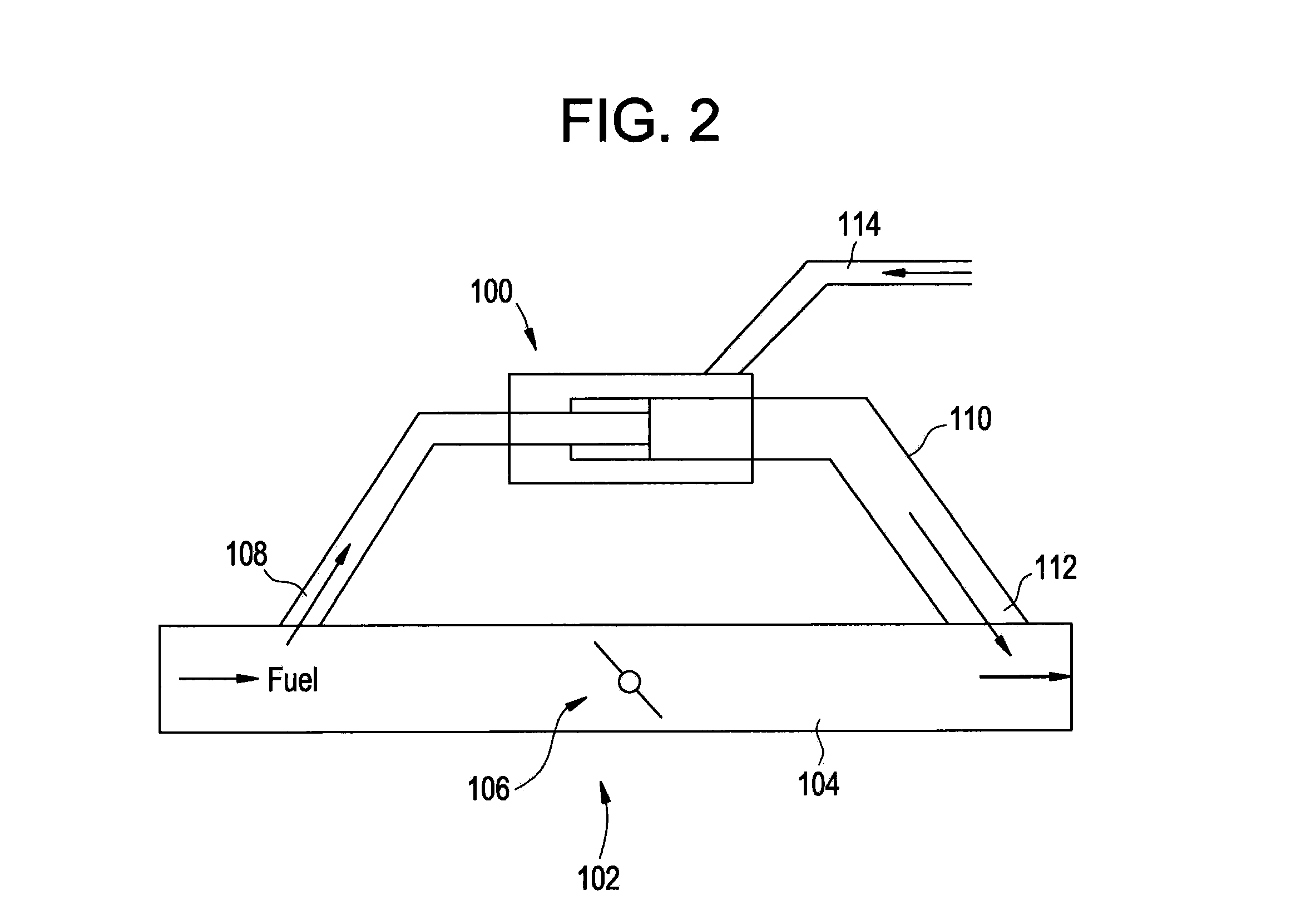

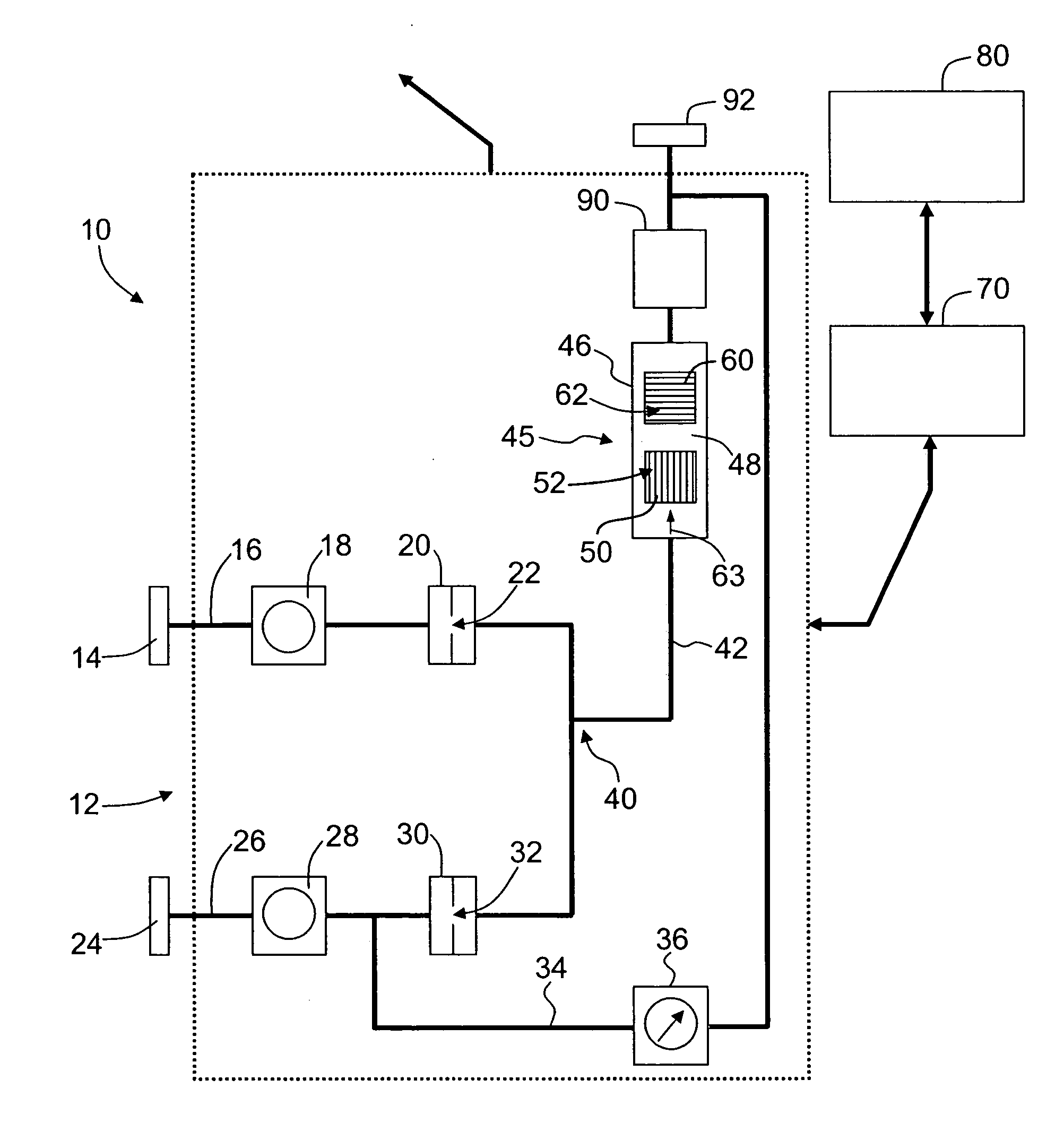

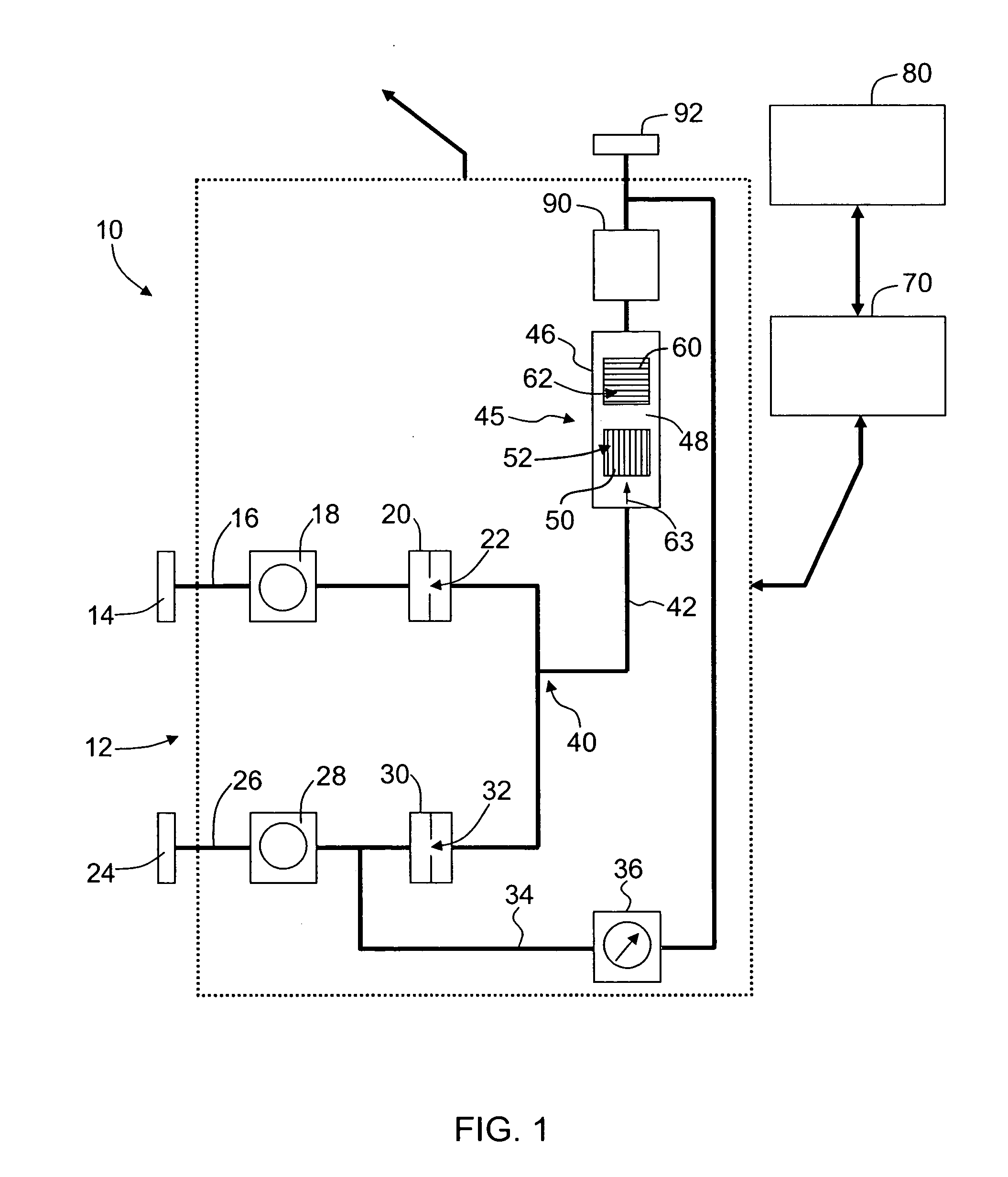

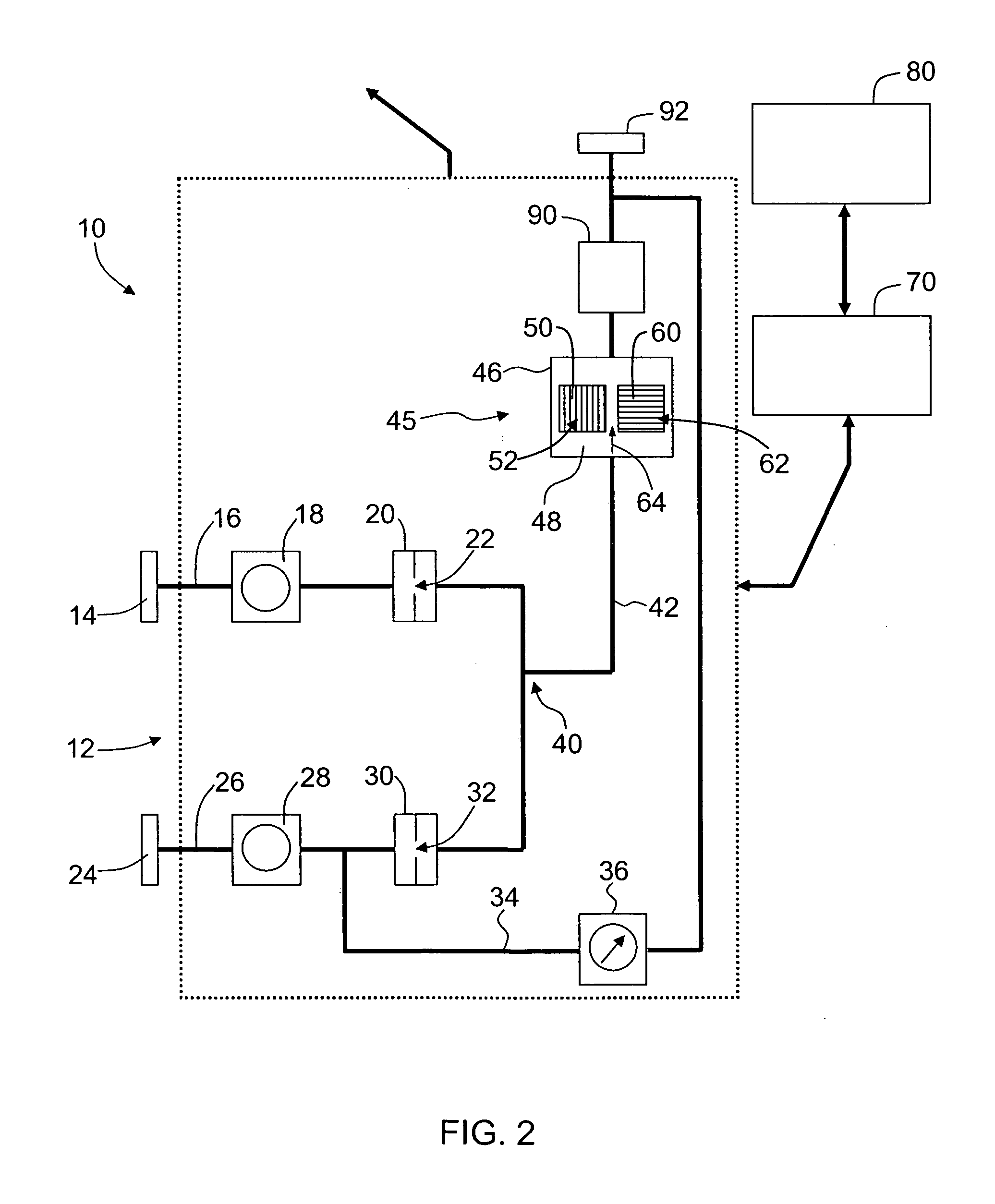

Fuel heater system including hot and warm water sources

A system is provided and includes first and second water supplies at first and second relatively high and low temperatures, respectively, a heat exchanger, coupled to the water supplies, through which fuel and relative amounts of the water supplies at the first and second temperatures flow for fuel heating and a controller, operably interposed between the water supplies and the heat exchanger, to select and / or modulate the relative amounts of the water supplies permitted to flow through the heat exchanger to heat the fuel to a temperature based on a heating requirement to meet a modified wobbe index (MWI) rating.

Owner:GENERAL ELECTRIC CO

Method and apparatus for combusting syngas within a combustor

A method for operating a combustor is provided. The method includes supplying a predetermined amount of a first gaseous fuel to the combustor, wherein the first gaseous fuel has a first Modified Wobbe Index (MWI) and a first fuel reactivity, and supplying a predetermined amount of a second gaseous fuel to the combustor, wherein the second gaseous fuel has a second MWI that is lower than the first MWI and a second fuel reactivity that is higher than the first fuel reactivity. The method also includes mixing the first and second gaseous fuels together to form a blended gaseous fuel, and injecting the blended gaseous fuel into the combustor.

Owner:GENERAL ELECTRIC CO

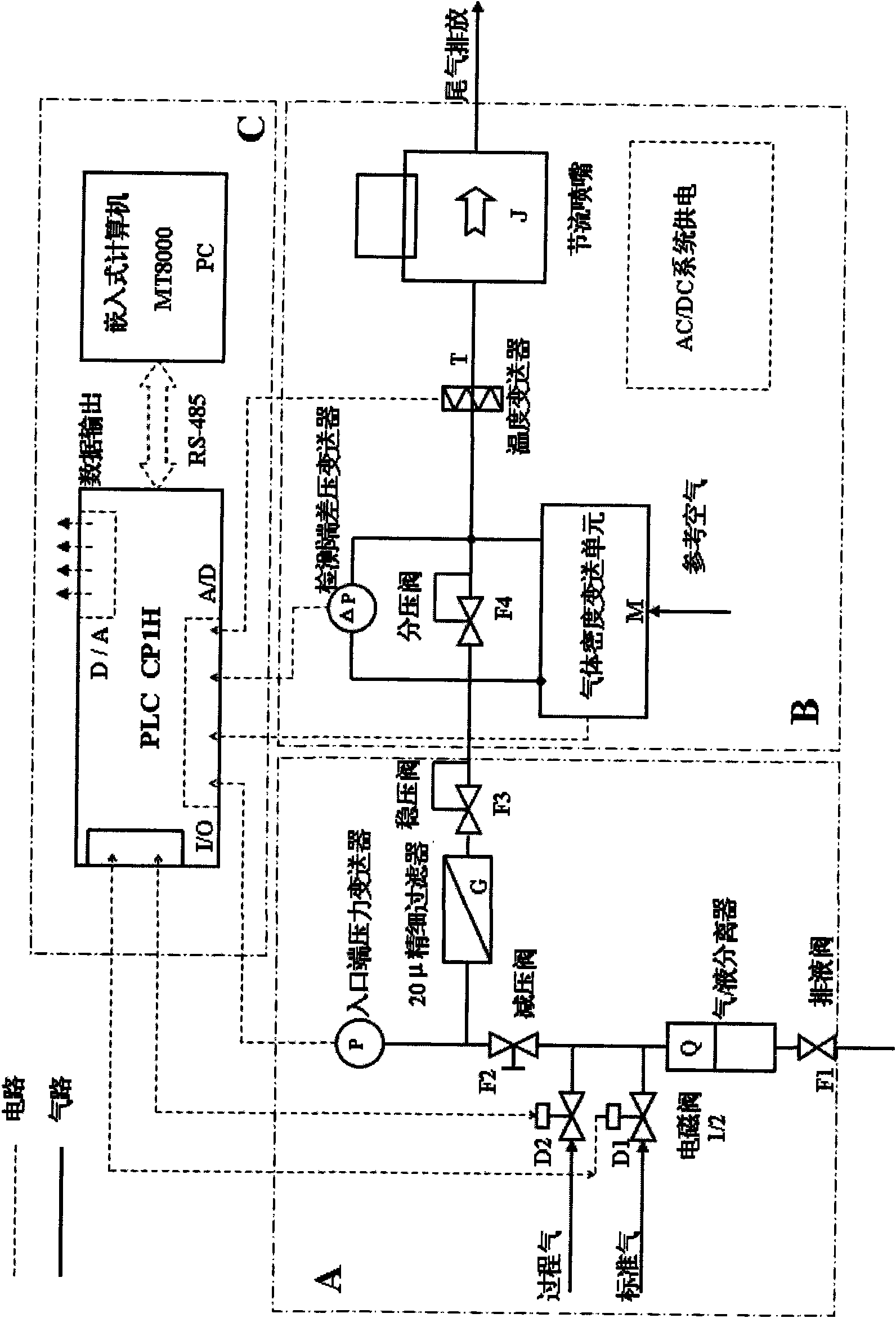

Method and device for light hydrocarbon gas calorific-value on-line analysis

InactiveCN101571500AGuaranteed accuracyHigh measurement accuracyMaterial thermal analysisSpecial data processing applicationsMathematical modelAutomated control system

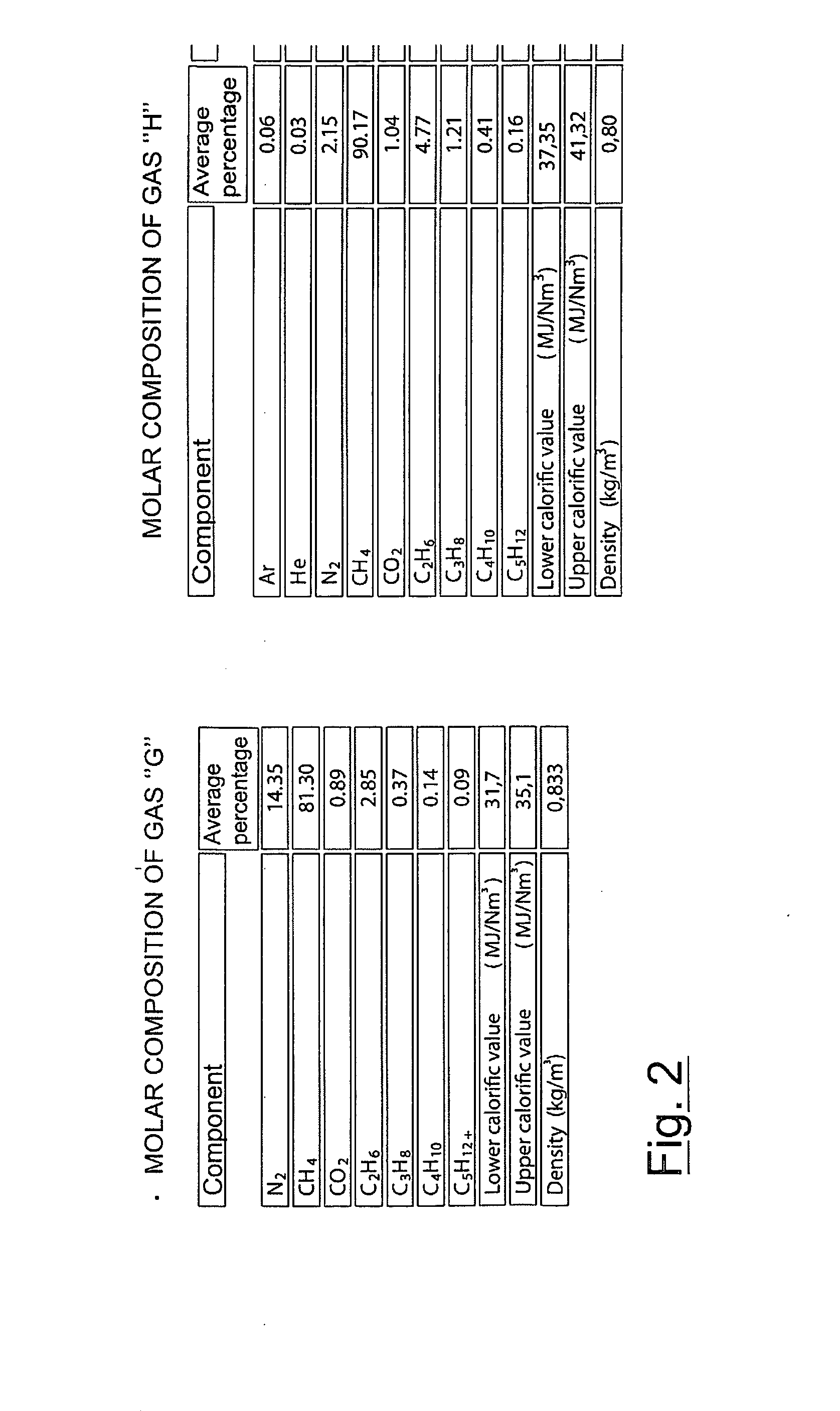

The invention relates to a method and a device for light hydrocarbon gas calorific-value on-line analysis. The method is based on a mathematical model that the density of a mixed gas is equal to the sum of the densities of all gas components in the mixed gas and the percent content of the all gas components in the mixed gas, on the premise that the density of the mixed gas is measured, the mixing ratio between the measured gas components and other gas components in the mixed gas is calculated according to the known gas density, then the light hydrocarbon gas calorific value, the Wobbe-index, the specific weight, the density, the oxygen content and the mixing ratio value are deduced according to the mixing ratio, and the gas density can be accurately measured through a gas density transducing unit; the device has the advantages of stable running, accurate measurement, easy and convenient operation, good security and intelligent measurement; and the method can be applied to an automatic light hydrocarbon gas control system and a portable light hydrocarbon gas calorific-value off-line analysis device and also can perform on-line analysis to the related parameters of the mixed gas of which one component parameter is taken as the variable and other component parameters are taken as the constant.

Owner:刘庆杰

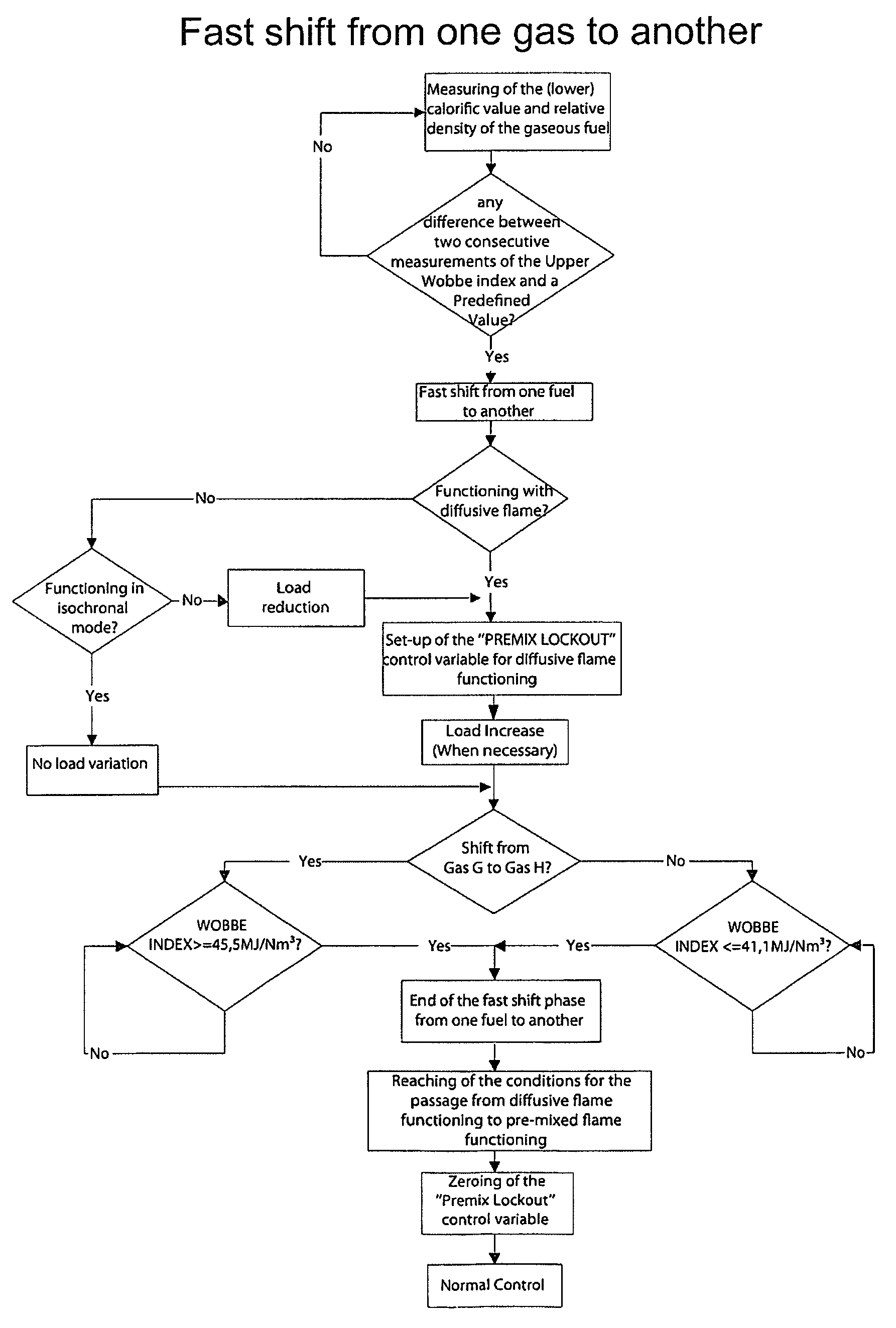

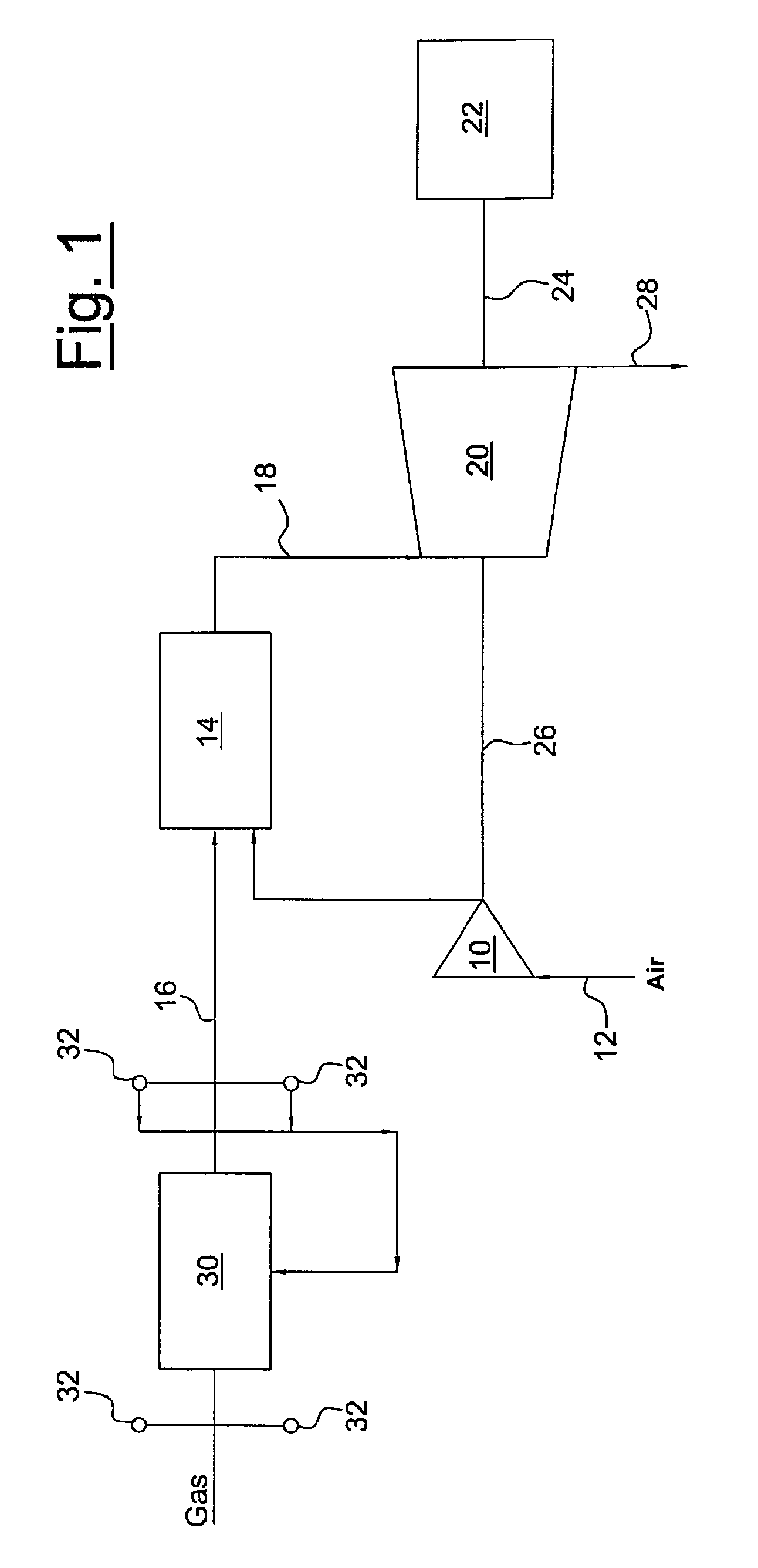

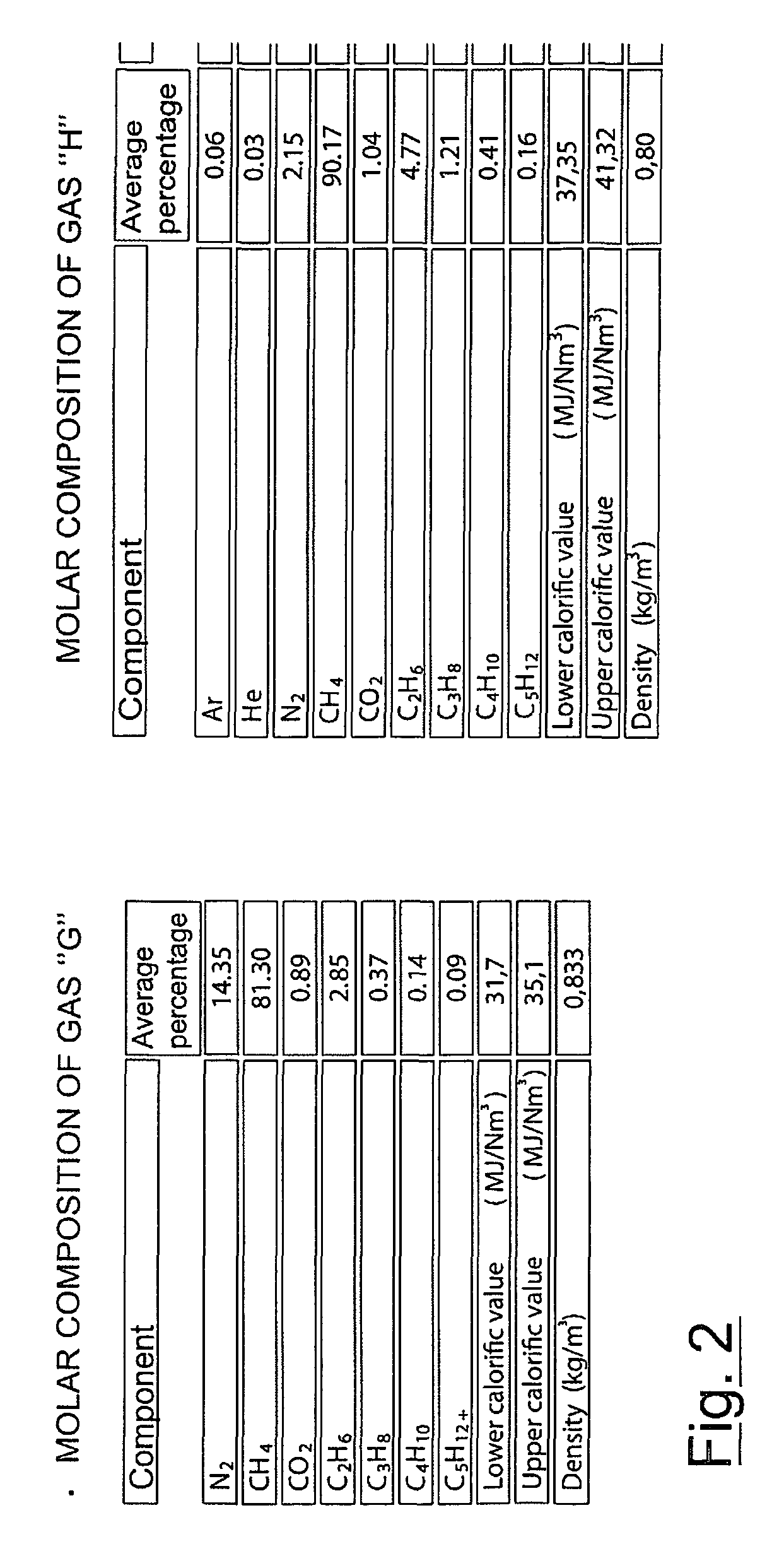

Method and apparatus for controlling the combustion in a gas turbine

InactiveUS20080289339A1Efficient solutionPrecise functionFuel supply regulationGaseous fuel pretreatmentCombustionProcess engineering

A method and apparatus are described for controlling the combustion in a gas turbine. The method includes measuring, by means of one or two calorimeters, the temperature, calorific value and relative density of a gaseous fuel in order to determine the Wobbe index, comparing the Wobbe index value measured with a predefined Wobbe index value for the gaseous fuel and regulating the temperature of the gaseous fuel by means of at least one heat exchanger in order to reach the predefined Wobbe index value. The method may also include using a second gaseous fuel, having a different Wobbe index from the gaseous fuel, or a fuel obtained by mixing the gaseous fuel and the second gaseous fuel, according to arbitrary proportions and variable with time.

Owner:NUOVO PIGNONE SPA

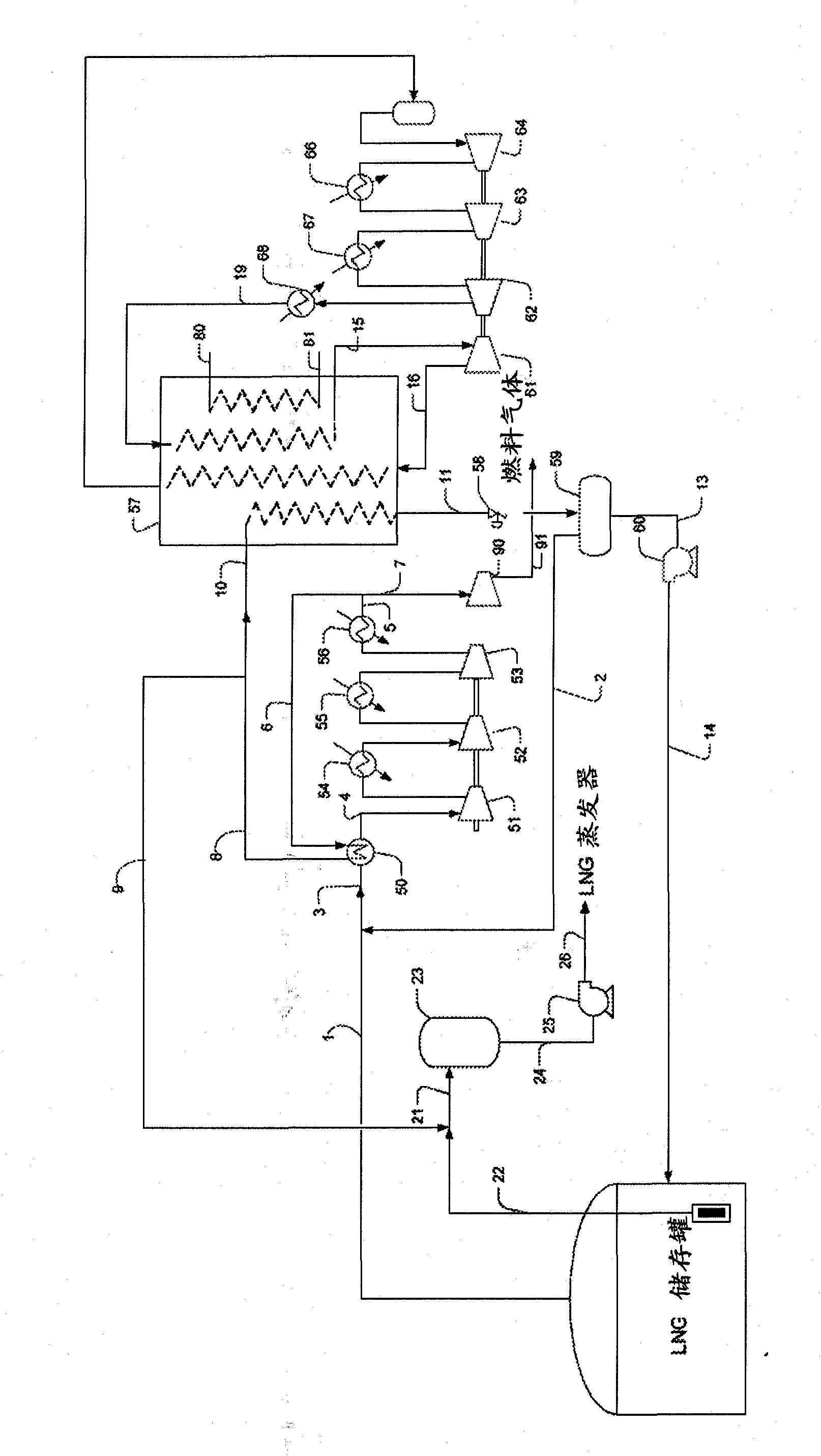

Methods and configurations of boil-off gas handling in LNG regasification terminals

A LNG storage and regasification plant includes a reliquefaction unit in which boil-off vapors from the storage tanks are re liquefied and recycled back to the LNG storage tanks for tank pressure and Wobbe index control. Preferably, LNG cold is used for reliquefaction and operational flexibility is achieved by feeding a portion of the pressurized boil-off gas to a fuel gas header and / or to be recondensed by the sendout LNG.

Owner:FLUOR TECH CORP

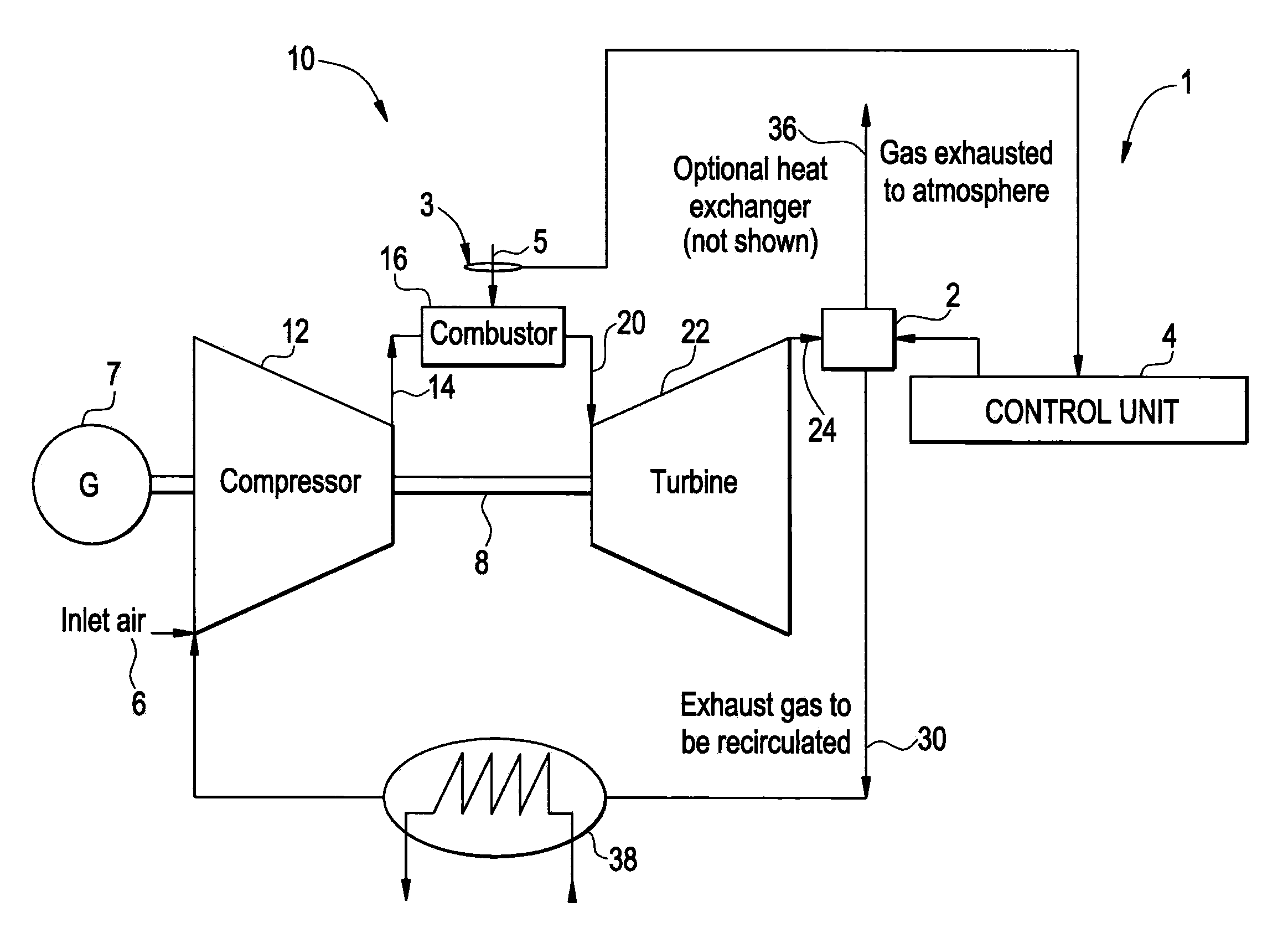

Gas turbine combustion system with rich premixed fuel reforming and methods of use thereof

InactiveUS20110296844A1Turbine/propulsion fuel supply systemsGas turbine plantsCombustion systemControl system

A gas turbine engine system, comprising a compressor, a combustor, and a turbine; a fuel system comprising one or more fuel circuits configured to provide fuel to the combustor; a non-catalytic fuel reformer in fluid communication with the one or more fuel circuits, wherein the non-catalytic fuel reformer is configured to receive an oxidant and a fraction of the fuel in the one or more fuel circuits in a fuel-rich ratio and reform the fraction of the fuel to produce a reformate; and a control system configured to regulate at least one of fuel flow and oxidizer flow to the non-catalytic fuel reformer to control a Modified Wobbe Index of the fuel entering the combustor.

Owner:GENERAL ELECTRIC CO

Method and apparatus for controlling the combustion in a gas turbine

InactiveUS7730726B2Efficient solutionPrecise functionFuel supply regulationGaseous fuel pretreatmentCombustionEngineering

Owner:NUOVO PIGNONE SPA

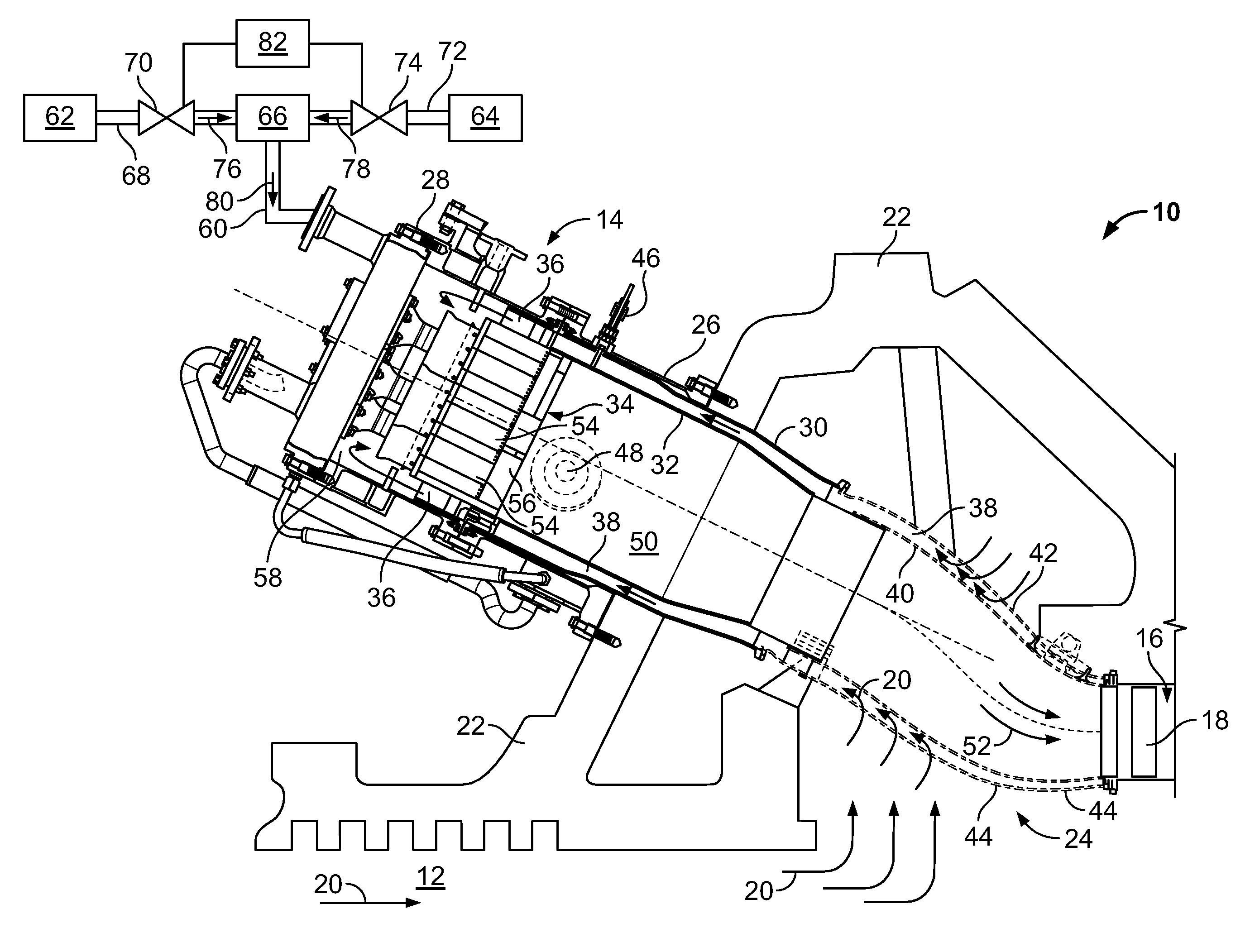

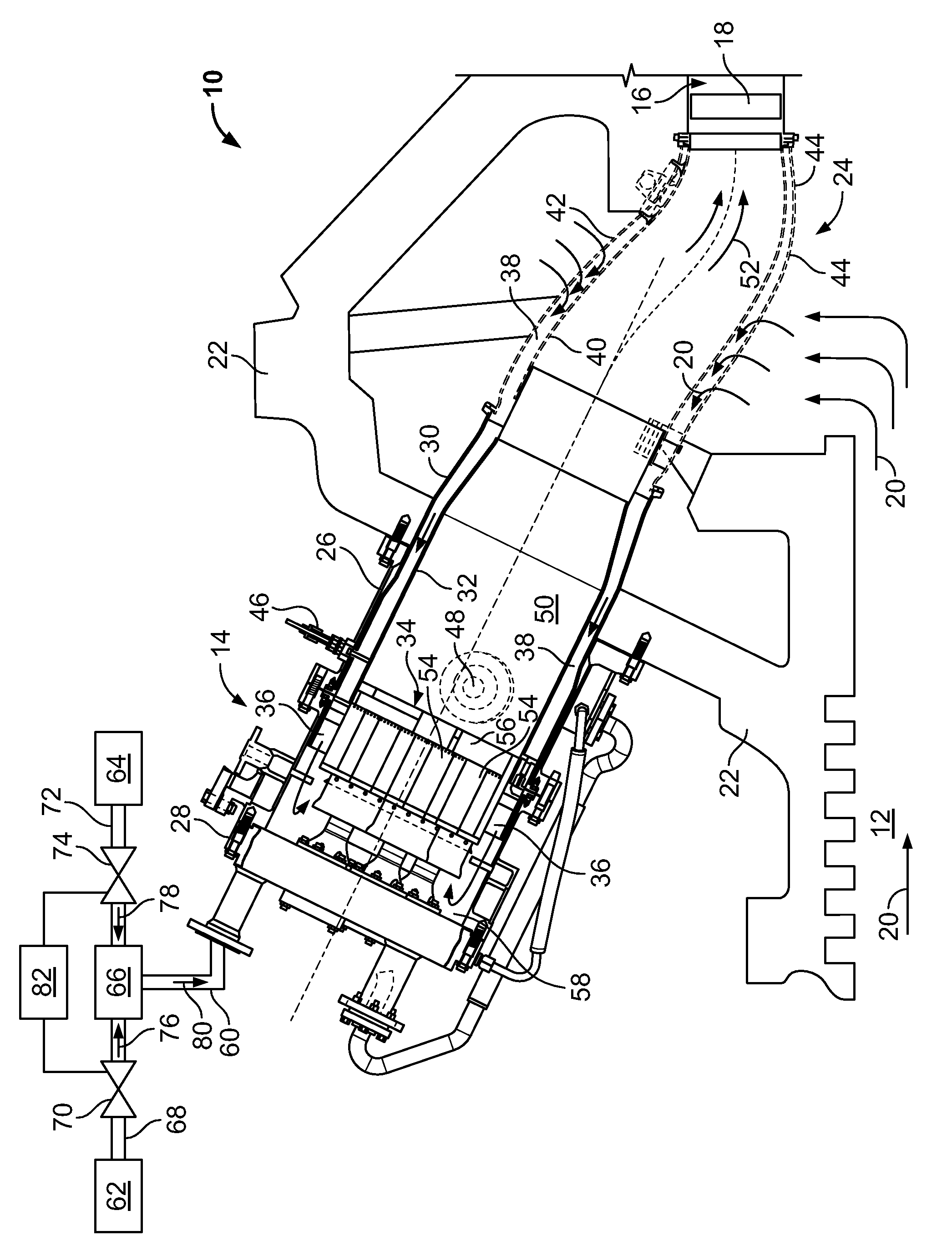

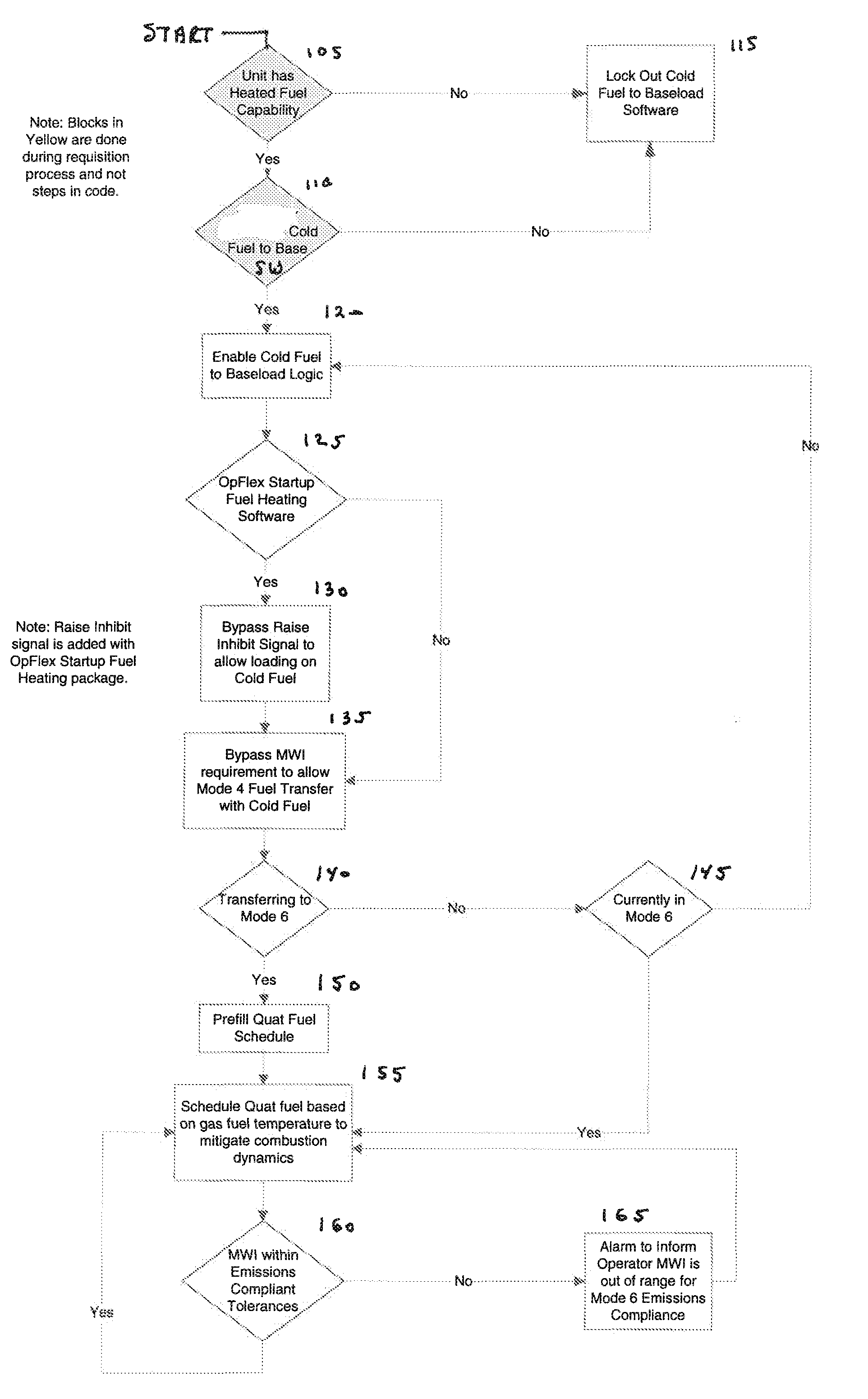

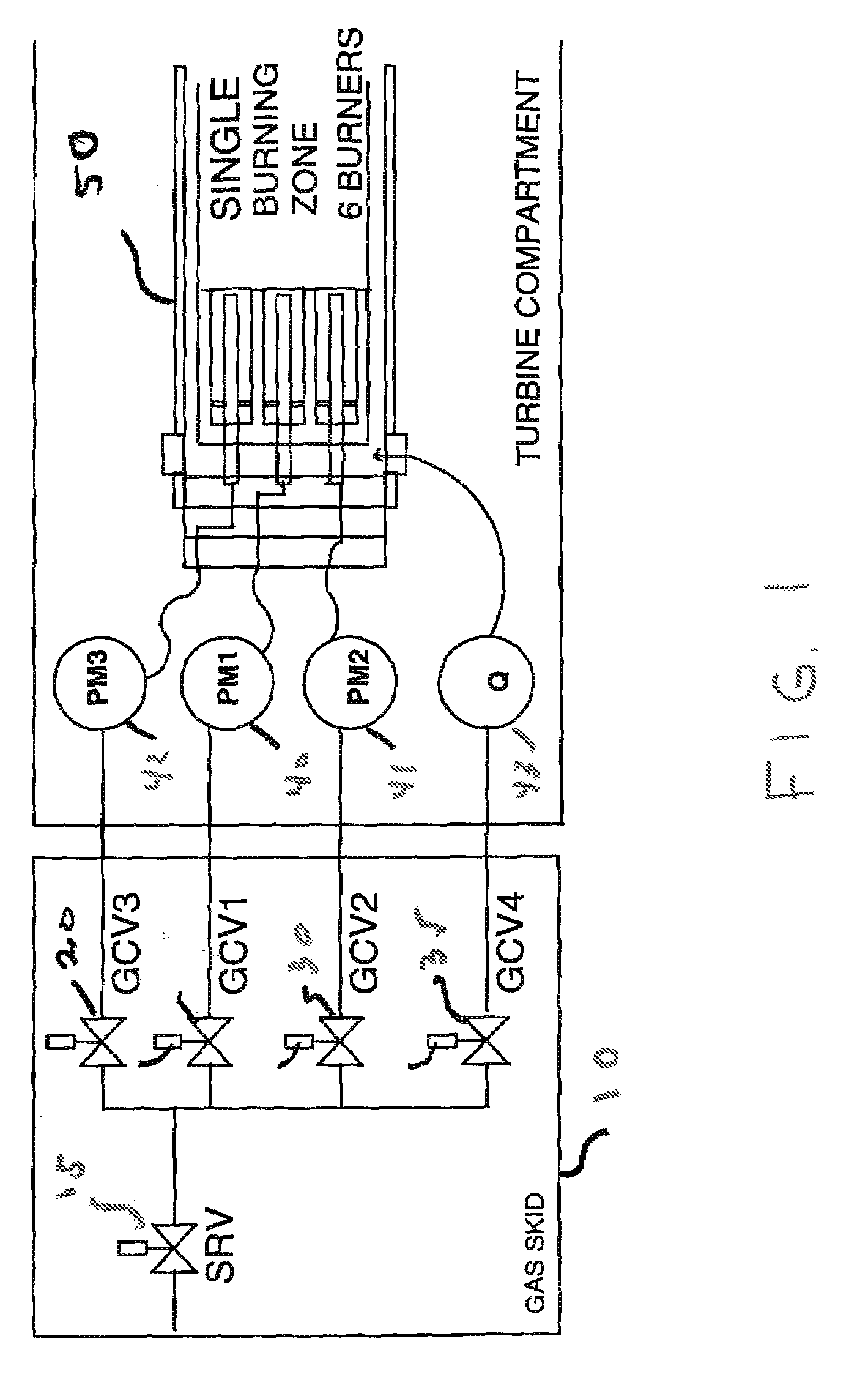

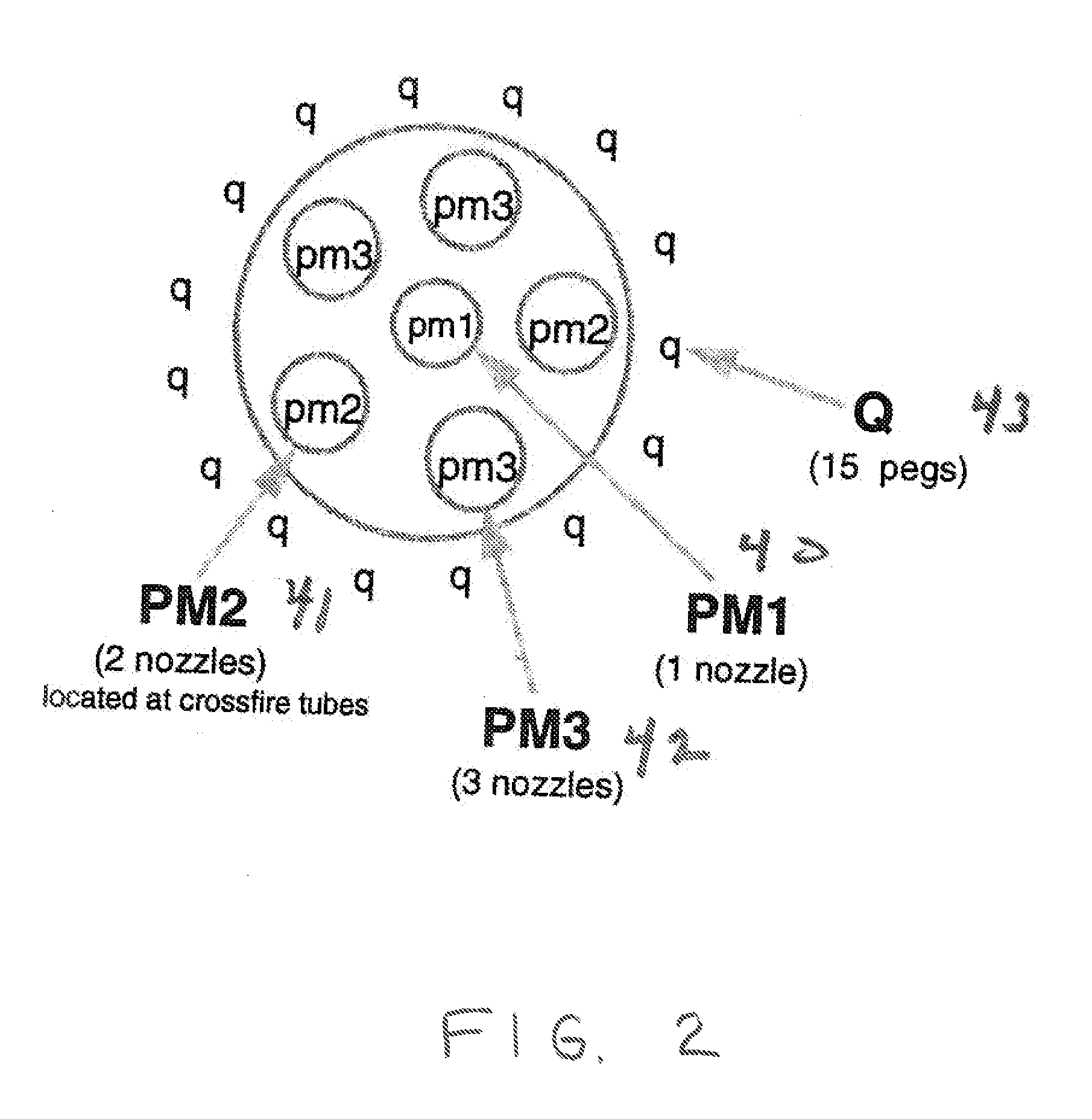

Operating a turbine at baseload on cold fuel with hot fuel combustion hardware

ActiveUS8145403B2Analogue computers for vehiclesContinuous combustion chamberCombustionEmission standard

Owner:GE INFRASTRUCTURE TECH INT LLC

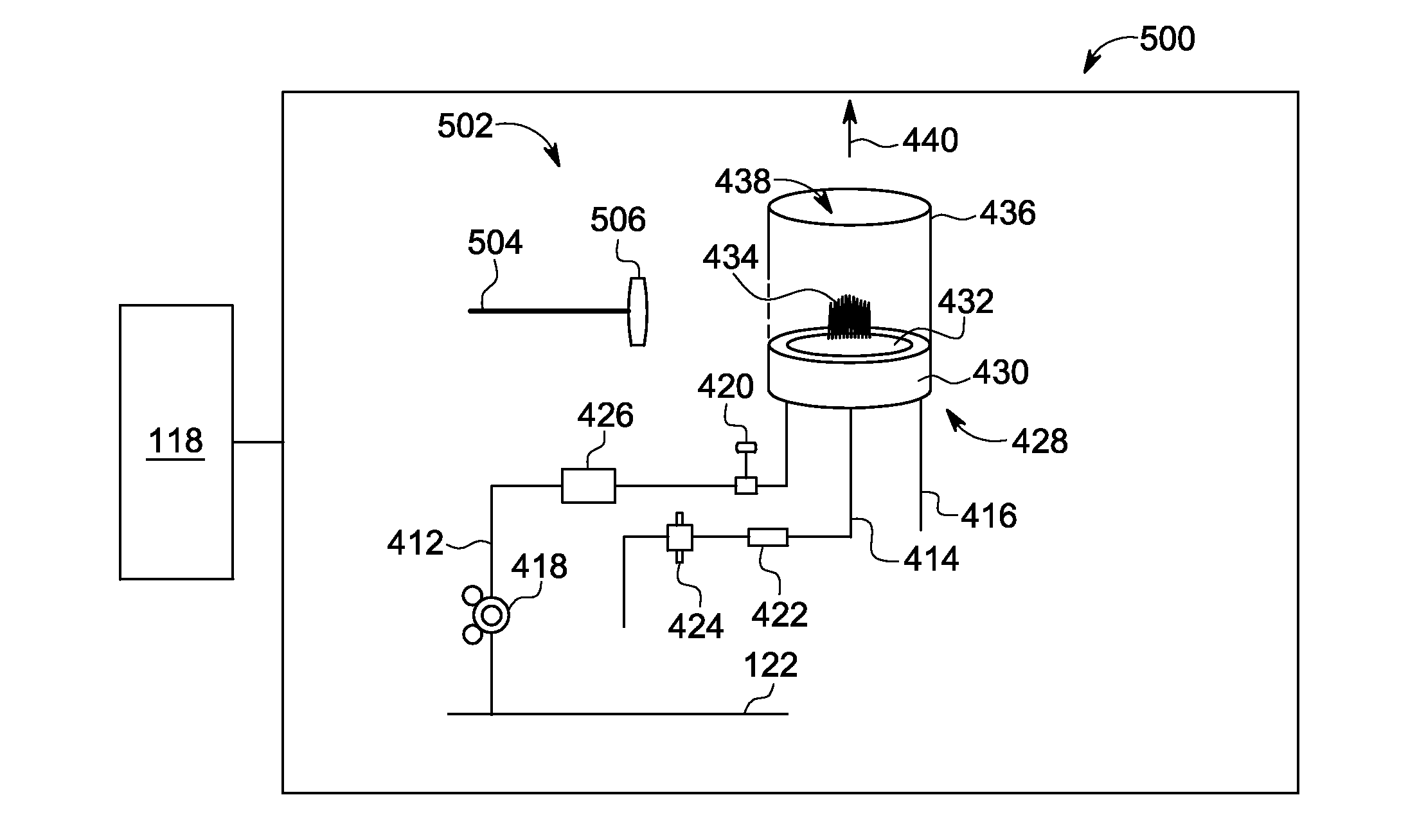

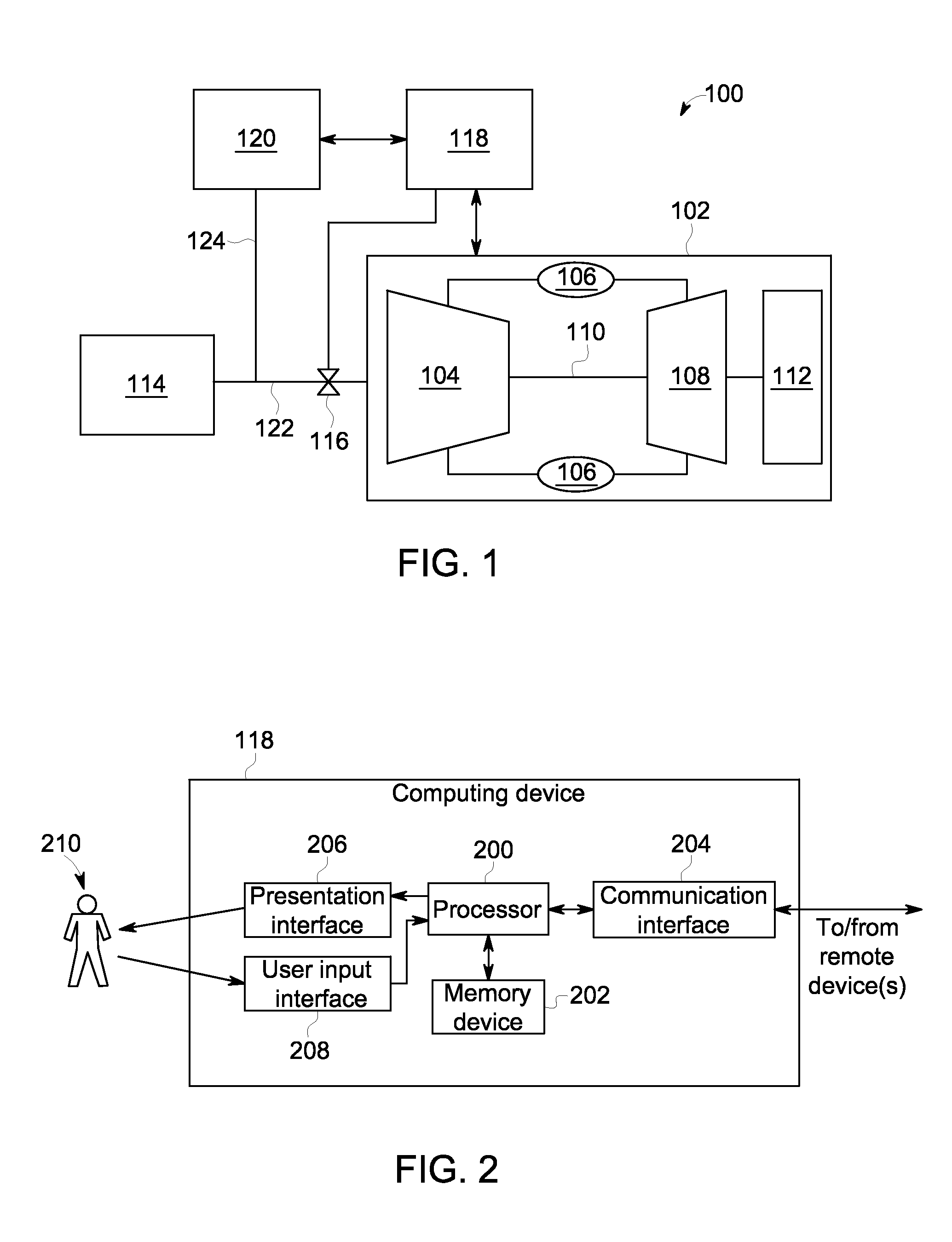

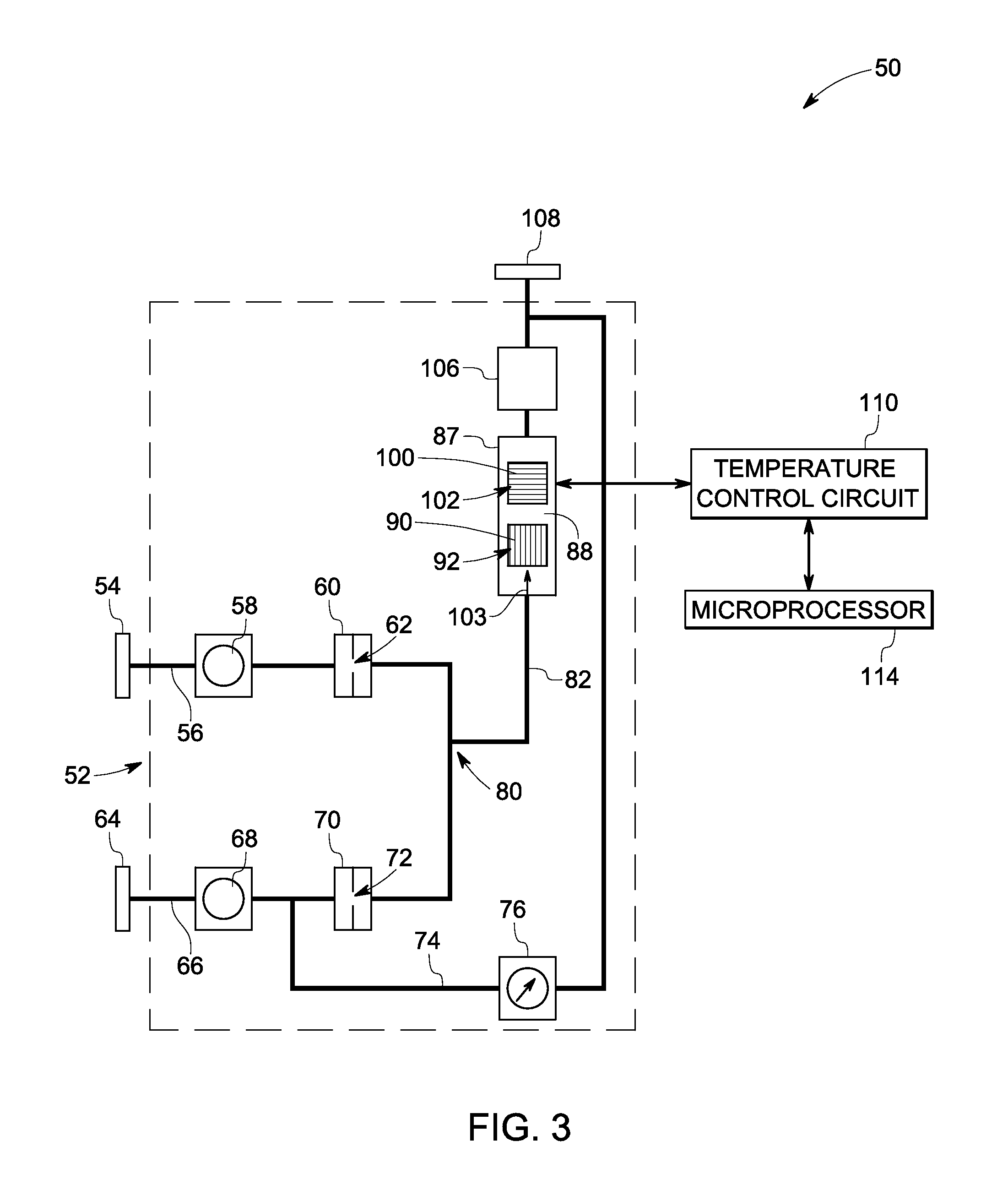

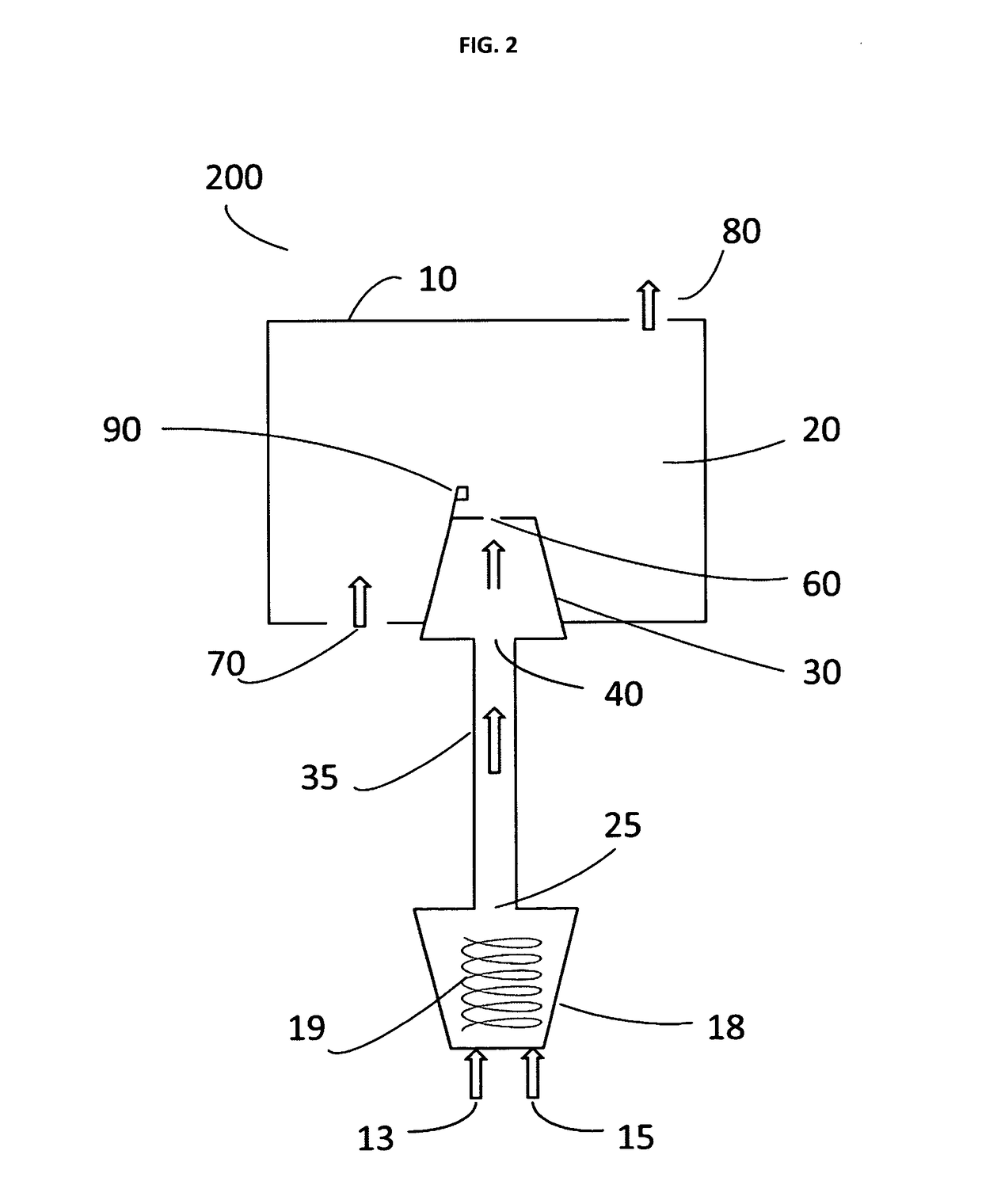

Methods and apparatus for rapid sensing of fuel wobbe index

A sensor apparatus and methods for facilitating combustion of a gaseous fuel are provided. The sensor apparatus comprises a combustion apparatus defining a combustion chamber therein. The combustion apparatus is configured to combust a fuel-air mixture within the combustion chamber to produce at least one combustion product. At least one optical diagnostic apparatus is coupled to the combustion apparatus for measuring at least one property of the at least one combustion product within the combustion chamber. A controller is coupled to the at least one optical diagnostic apparatus, and is configured to determine the Wobbe index of the fuel in real-time based on the measured at least one property of the at least one combustion product and pre-determined combustion state data stored within the controller.

Owner:GENERAL ELECTRIC CO

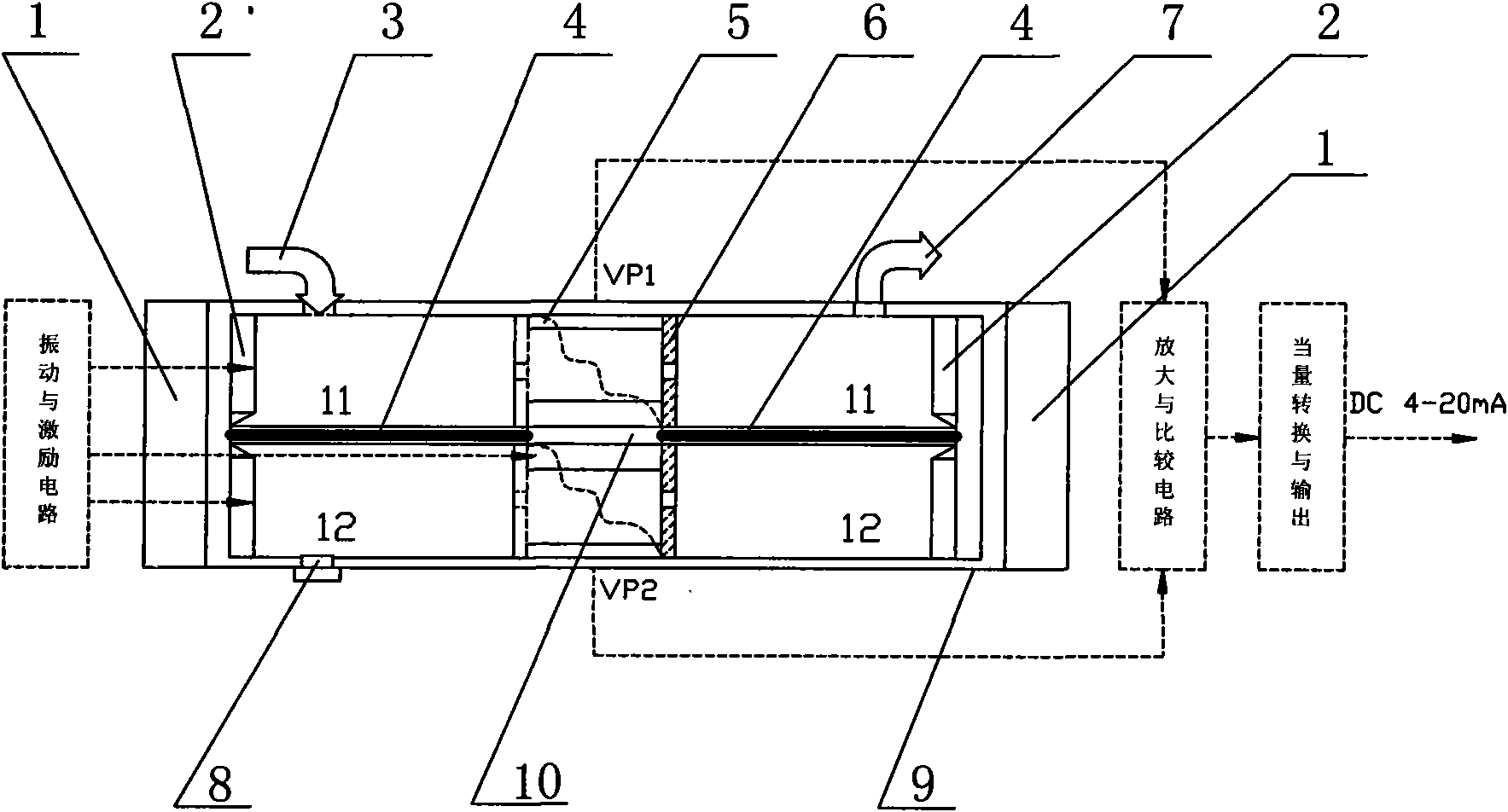

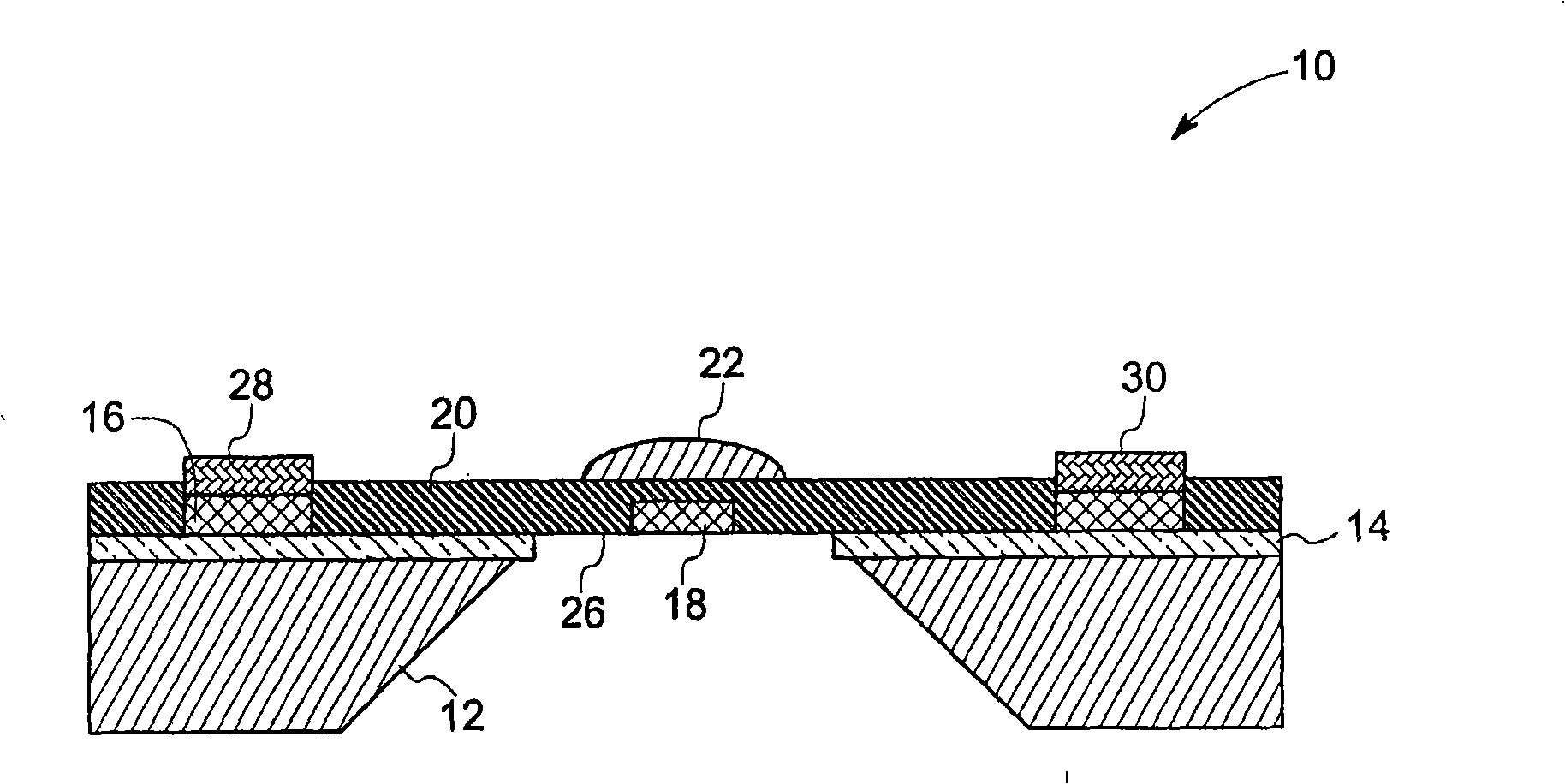

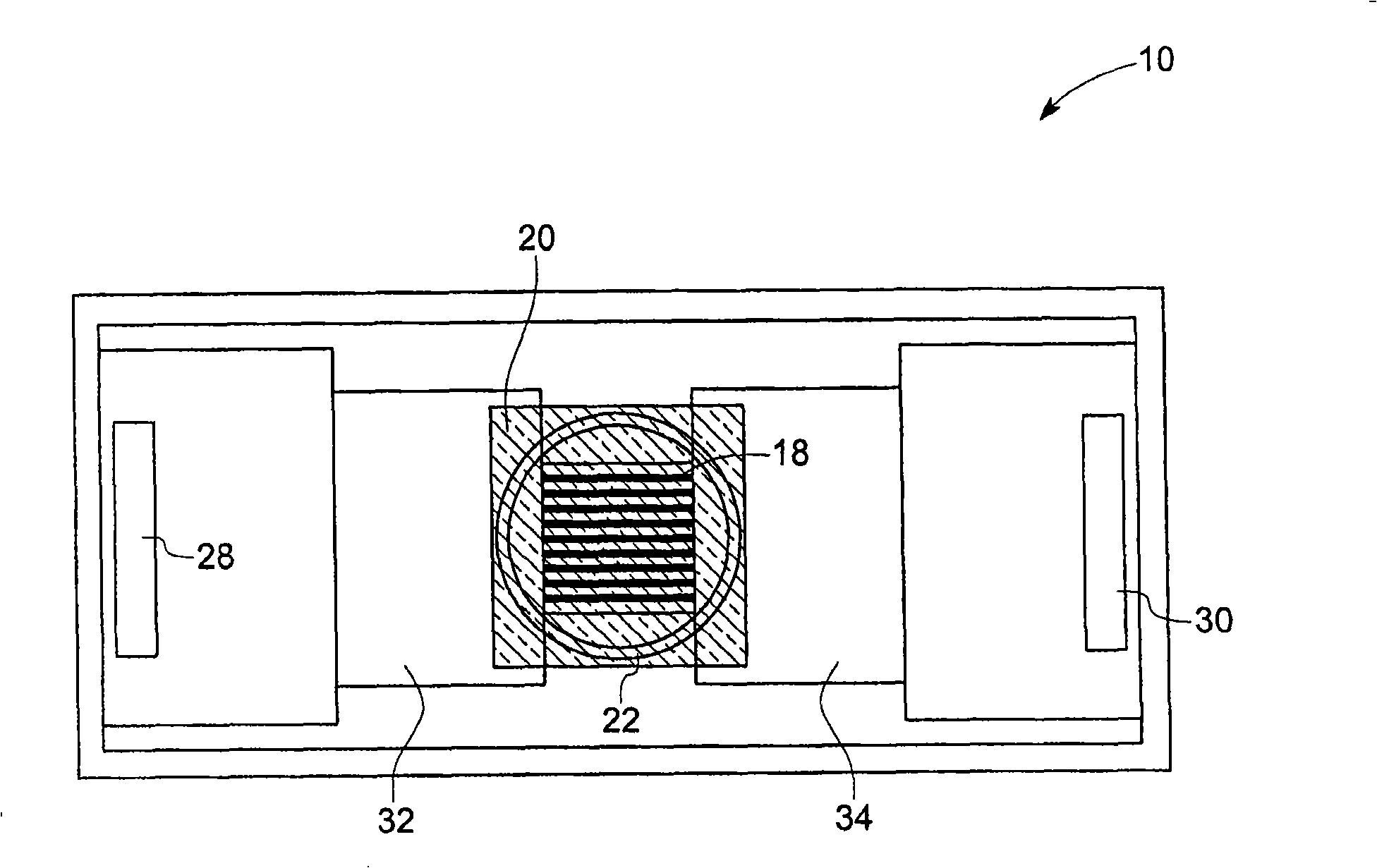

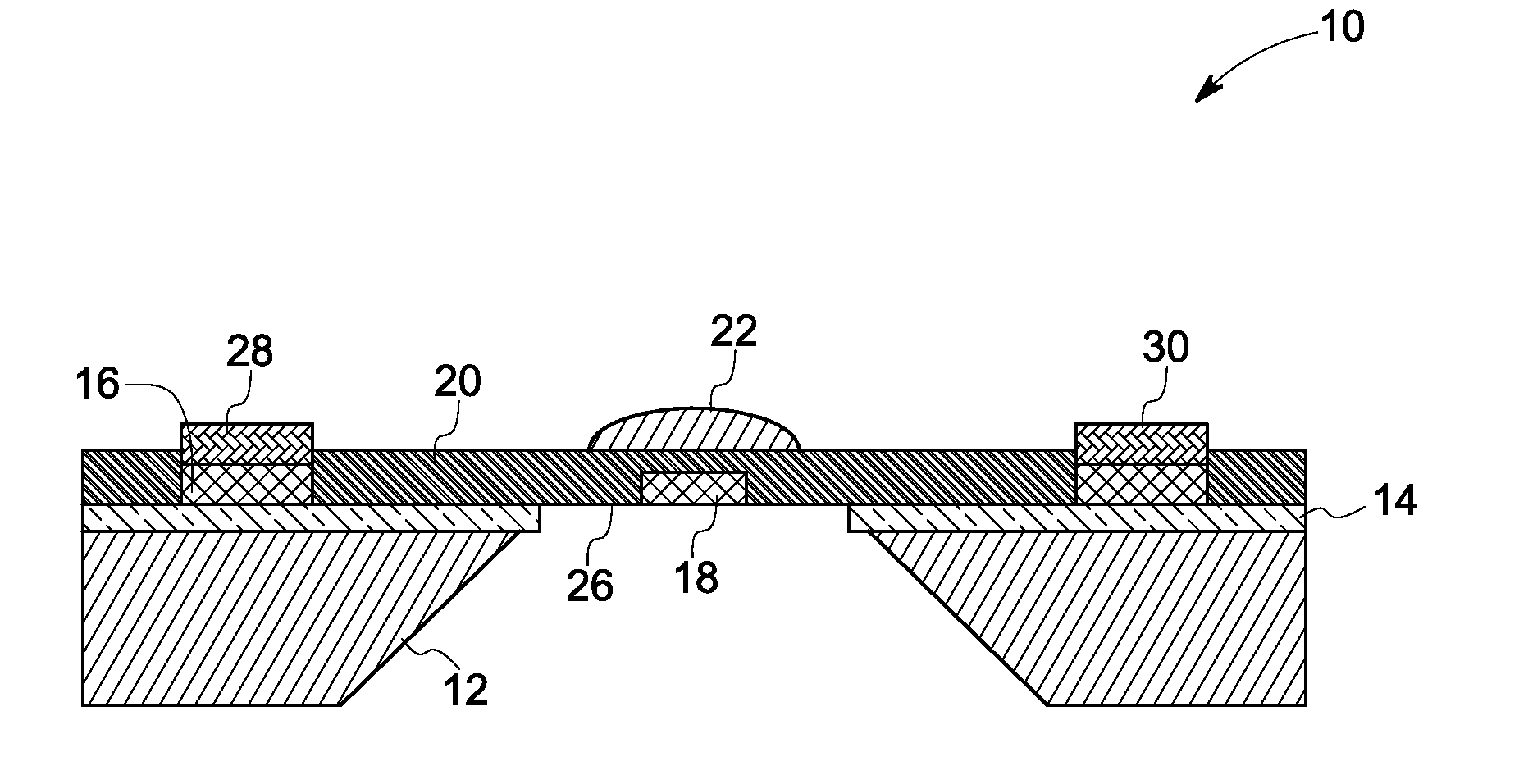

Wobbe index sensor system

InactiveCN101344510APrevent oxidationMeasurable volumetric flow rateChemical analysis using combustionMaterial thermal conductivityThermal isolationEngineering

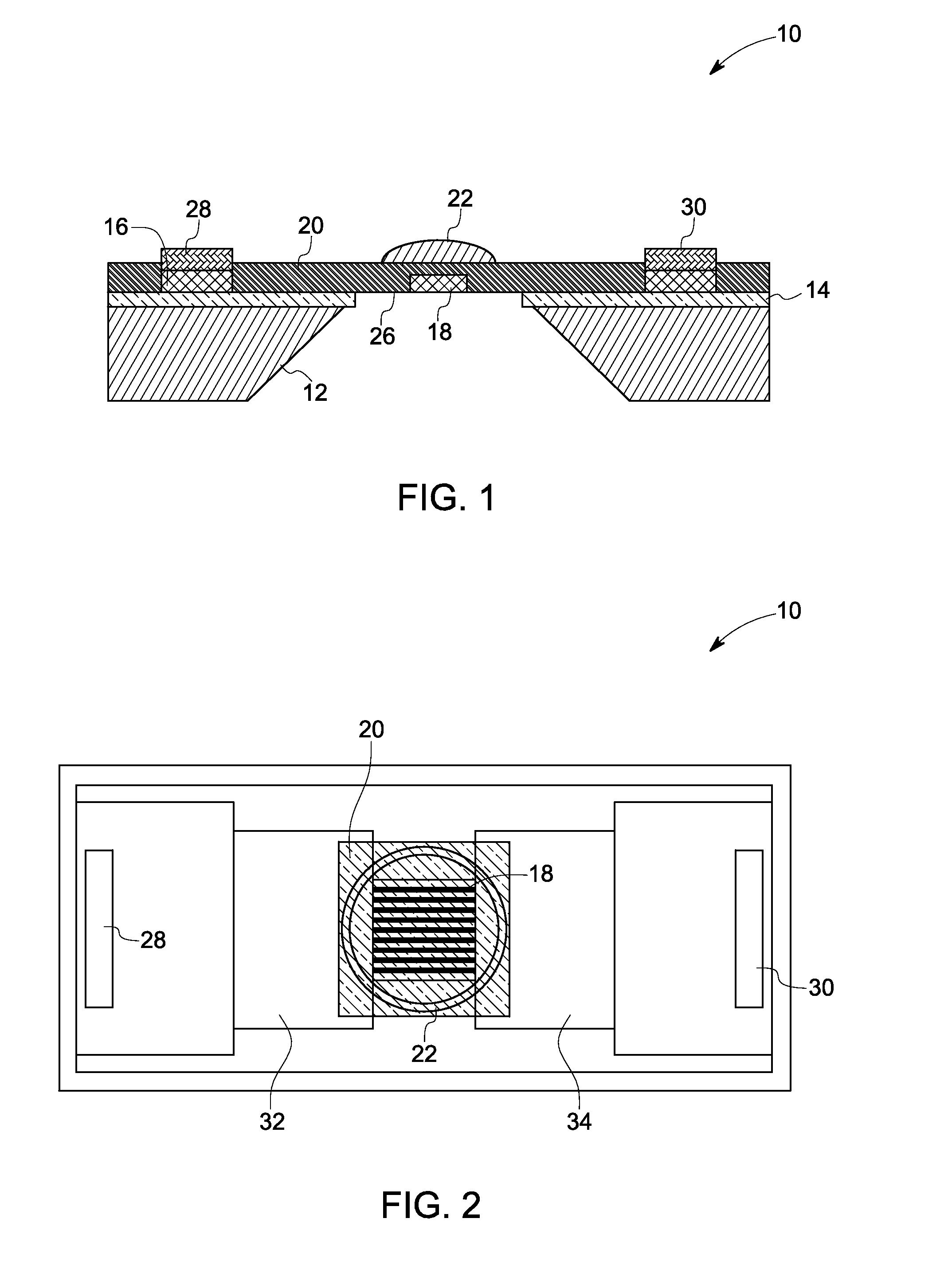

The present invention relates to a Wobbe index sensor system and a sensor (10) for measuring Wobbe index of a fuel. The sensor (10) includes a substrate (12) and a diaphragm layer (16). The diaphragm layer (16) includes a first layer (18) having at least one heating element configured to sense energy content in a fuel, wherein the heating element includes a doped poly-silicon carbide that is disposed on the substrate (12). The diaphragm layer (16) also includes a second layer (22) including an undoped poly-silicon carbide layer configured to prevent oxidation of the first layer (18). The sensor (10) further includes a sensing layer (22) having a catalyst suspended in a support structure. The sensor (10) also includes a cavity formed under the diaphragm layer (16) and is configured to provide thermal isolation of the heating element.

Owner:GENERAL ELECTRIC CO

Method and system for modulating the modified wobbe index of a fuel

A method and system for modulating the Modified Wobbe Index (MWI) of a fuel is provided. A variety of industrial components, which may require a gas fuel, such as but not limiting of, a heavy-duty gas turbine; an aero-derivative gas turbine; or a boiler may utilize the method and system. The method and system may provide an industrial component comprising at least one steam injection system, wherein the at least one steam injection system injects steam into at least one fuel supply line upstream of a combustion system to modulate the MWI of at least one fuel. The method and system may also determine whether the MWI of the at least one fuel is outside of a predetermined range; and utilize the at least one steam injection system to automatically inject the steam at a flowrate for adjusting the MWI of the at least one fuel.

Owner:GENERAL ELECTRIC CO

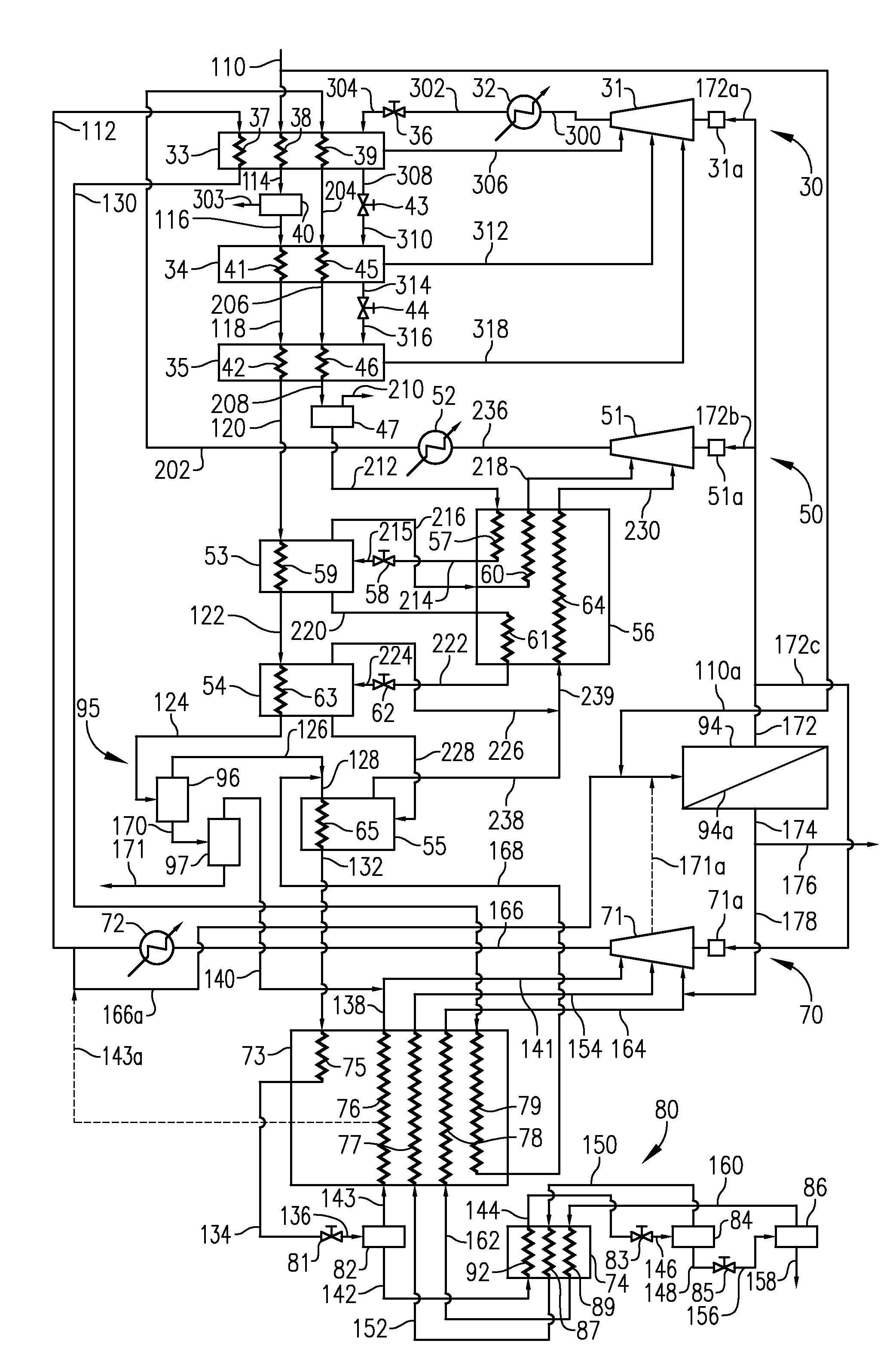

Methods and configuration of boil-off gas handling in LNG regasification terminals

InactiveCN102084171AThe goal is obviousDistinctive featuresSolidificationLiquefactionProcess engineeringWobbe index

A LNG storage and regasification plant includes a reliquefaction unit in which boil-off vapors from the storage tanks are re liquefied and recycled back to the LNG storage tanks for tank pressure and Wobbe index control. Preferably, LNG cold is used for reliquefaction and operational flexibility is achieved by feeding a portion of the pressurized boil-off gas to a fuel gas header and / or to be recondensed by the sendout LNG.

Owner:FLUOR TECH CORP

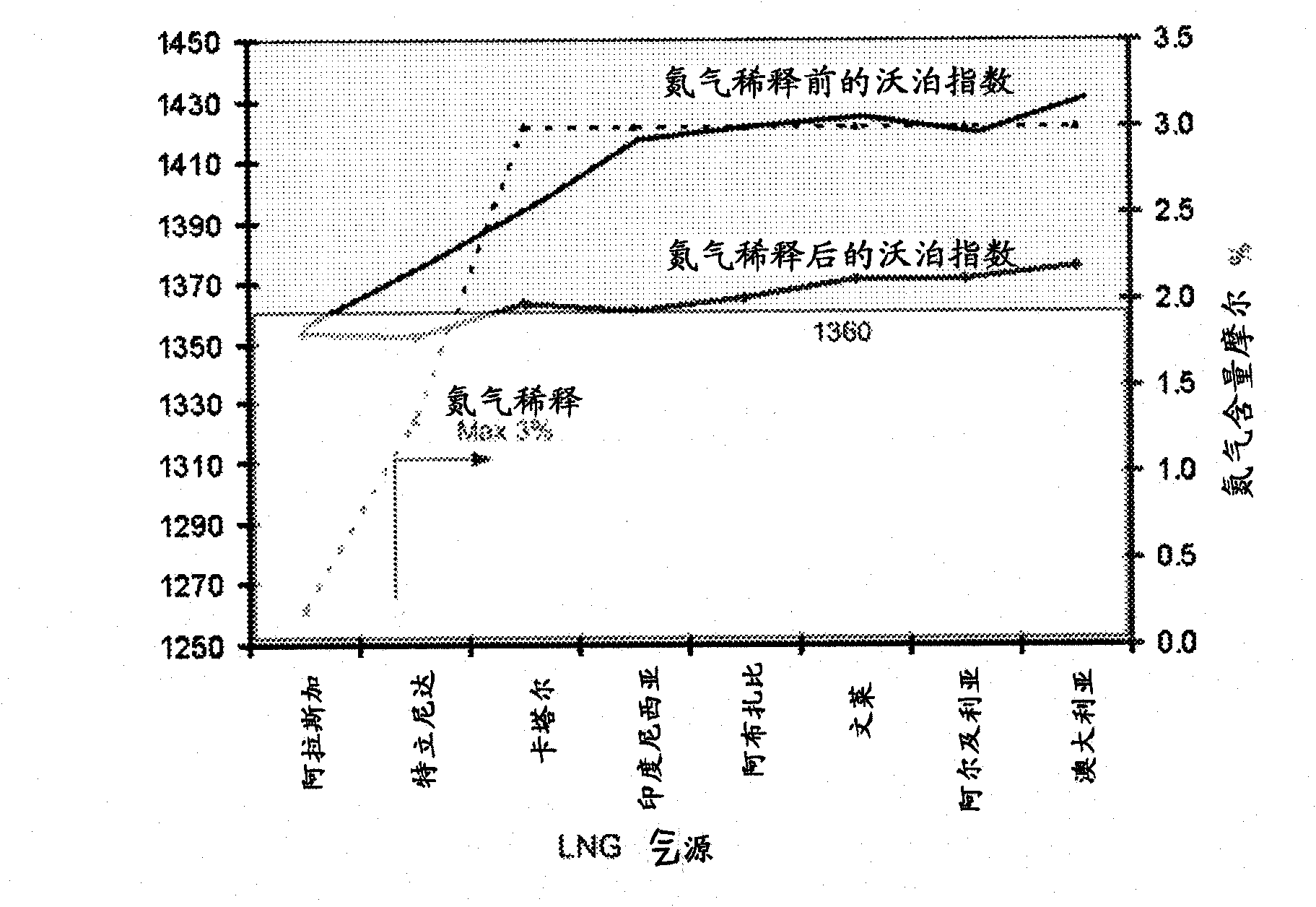

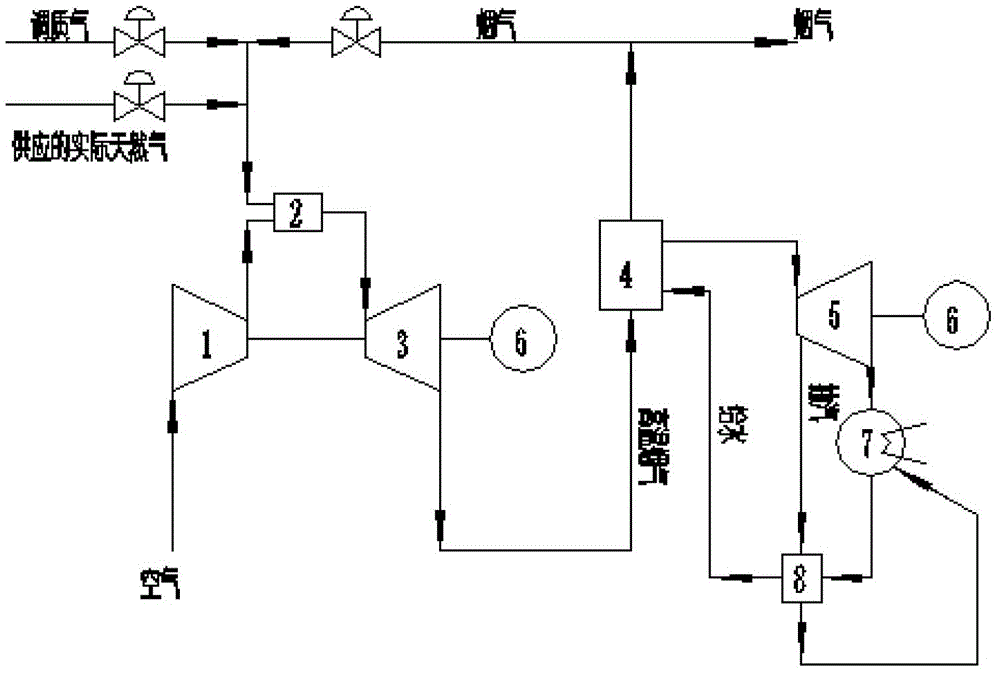

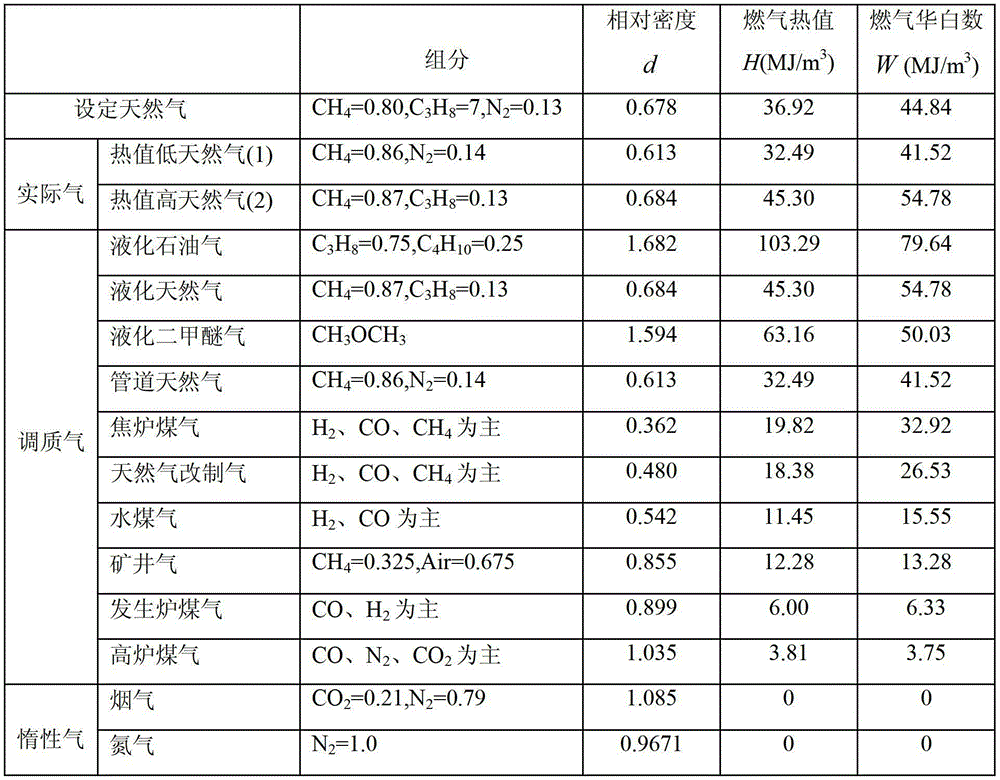

Method for quality conditioning of industrial combustion natural gas

The invention relates to a method for quality conditioning of industrial natural gas. When the actual wobbe index of natural gas is lower than a set wobbe index, conditioning gas and / or inert gas with a wobbe index higher than the set wobbe index of natural gas can be selected for blending; and when the actual wobbe index of natural gas is higher than a set wobbe index, conditioning gas and / or inert gas with a wobbe index lower than the set wobbe index of natural gas can be selected for blending. By controlling the wobbe index of natural gas and theoretical air requirement, the method can control the heat load capacity of natural gas combustion and the air-fuel ratio, thus being conducive to optimization and conditioning of a natural gas combustion utilization system, and enhancing the utilization efficiency of natural gas. With the characteristics of strong practicability, wide control range, flexibility and controllability, the method can make full use of the existing medium and low calorific value fuel gas, saves natural gas resources, mitigates the quality requirements for actual natural gas supplied to the upstream, also can solve air source quality adjustment during conventional combustible gas industrial application, and at the same time lowers the natural gas conditioning cost.

Owner:PETROCHINA CO LTD +1

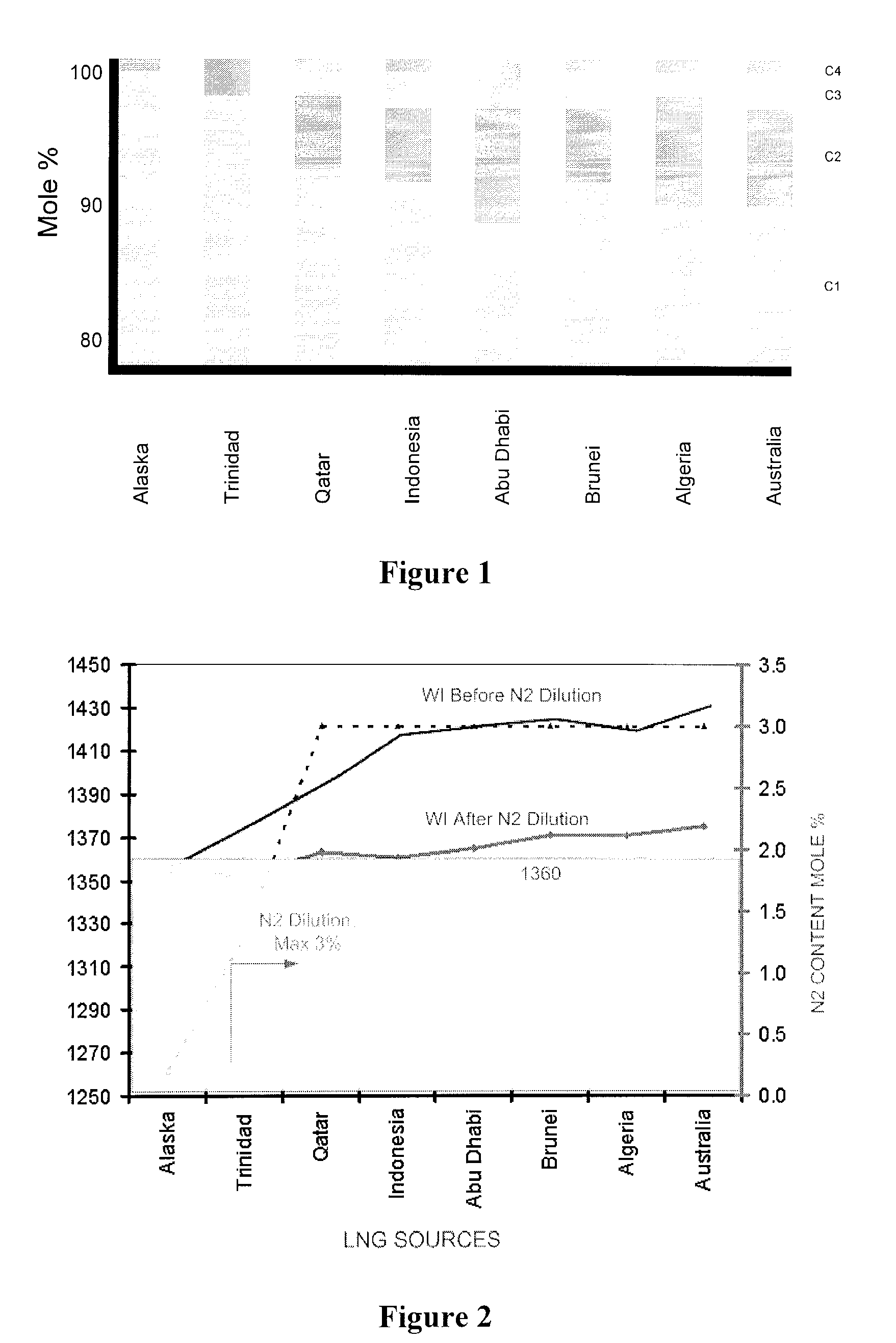

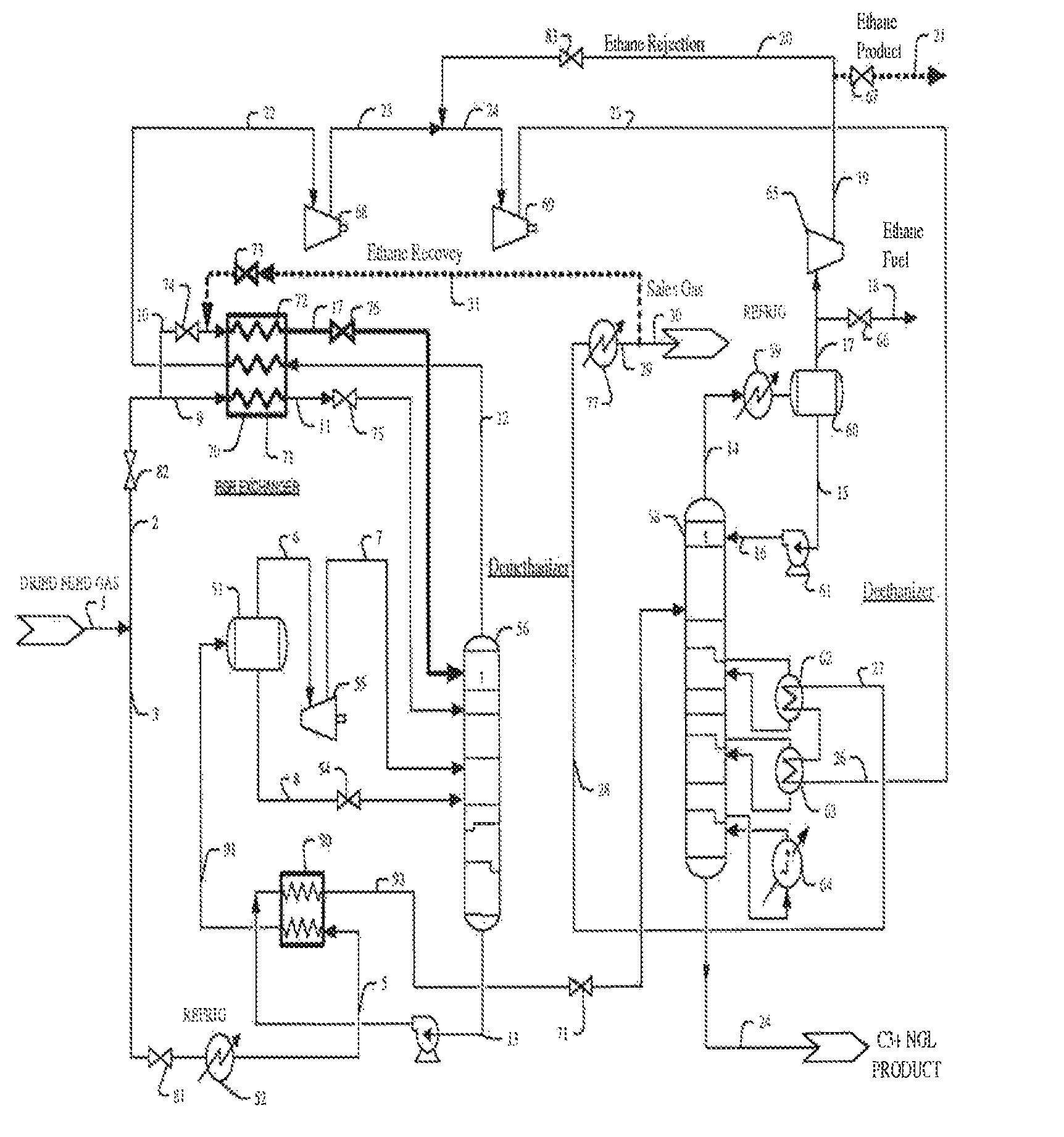

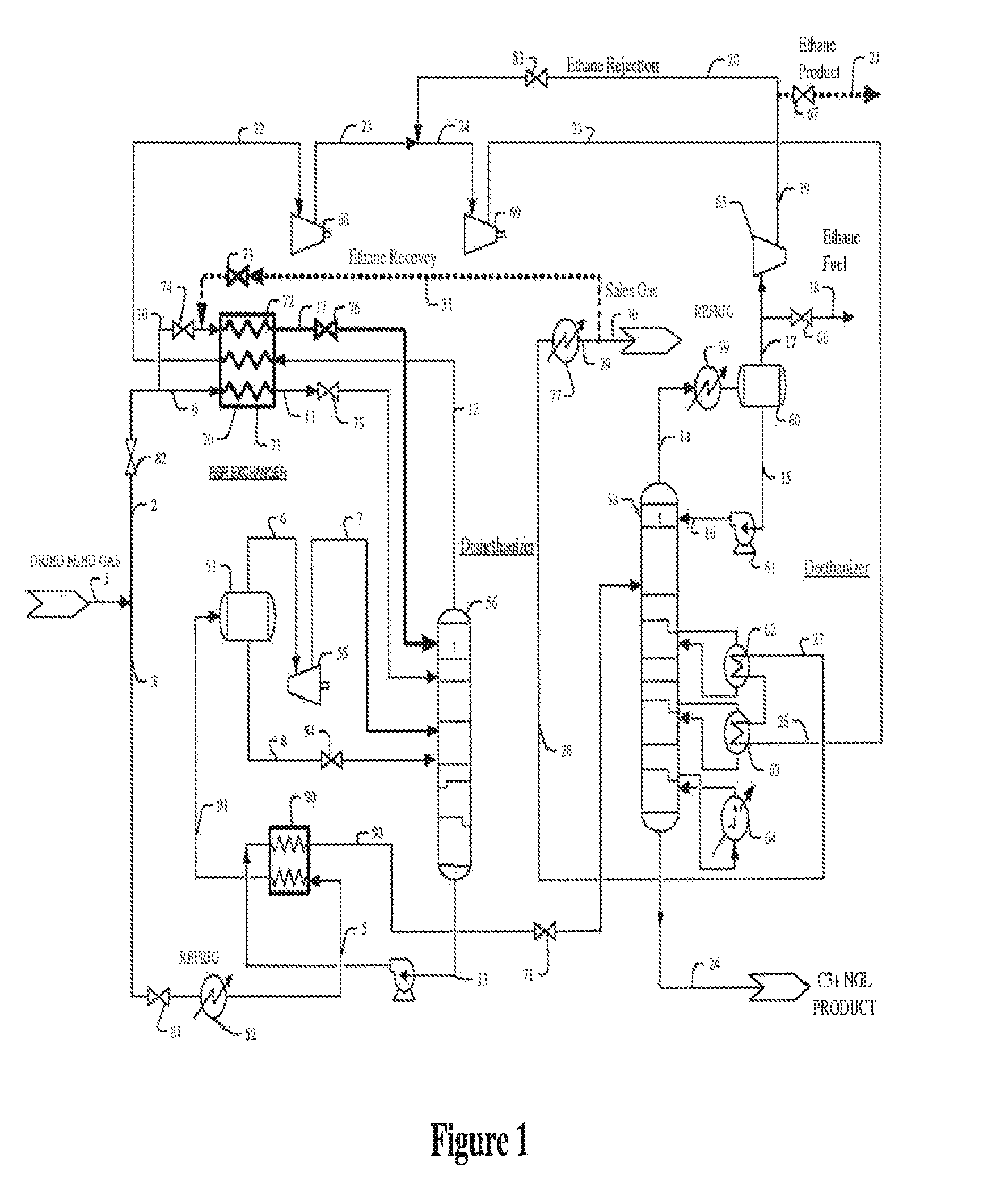

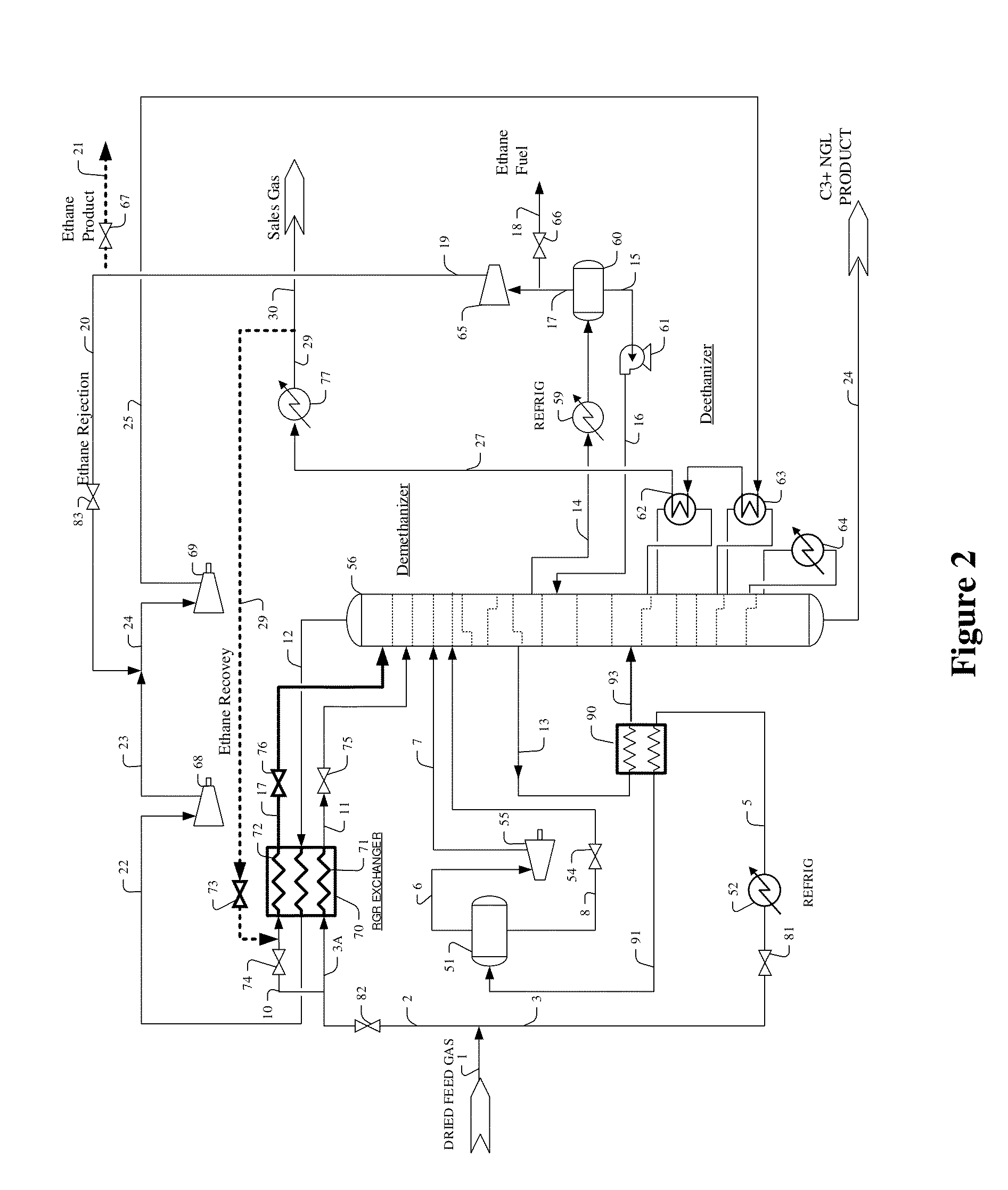

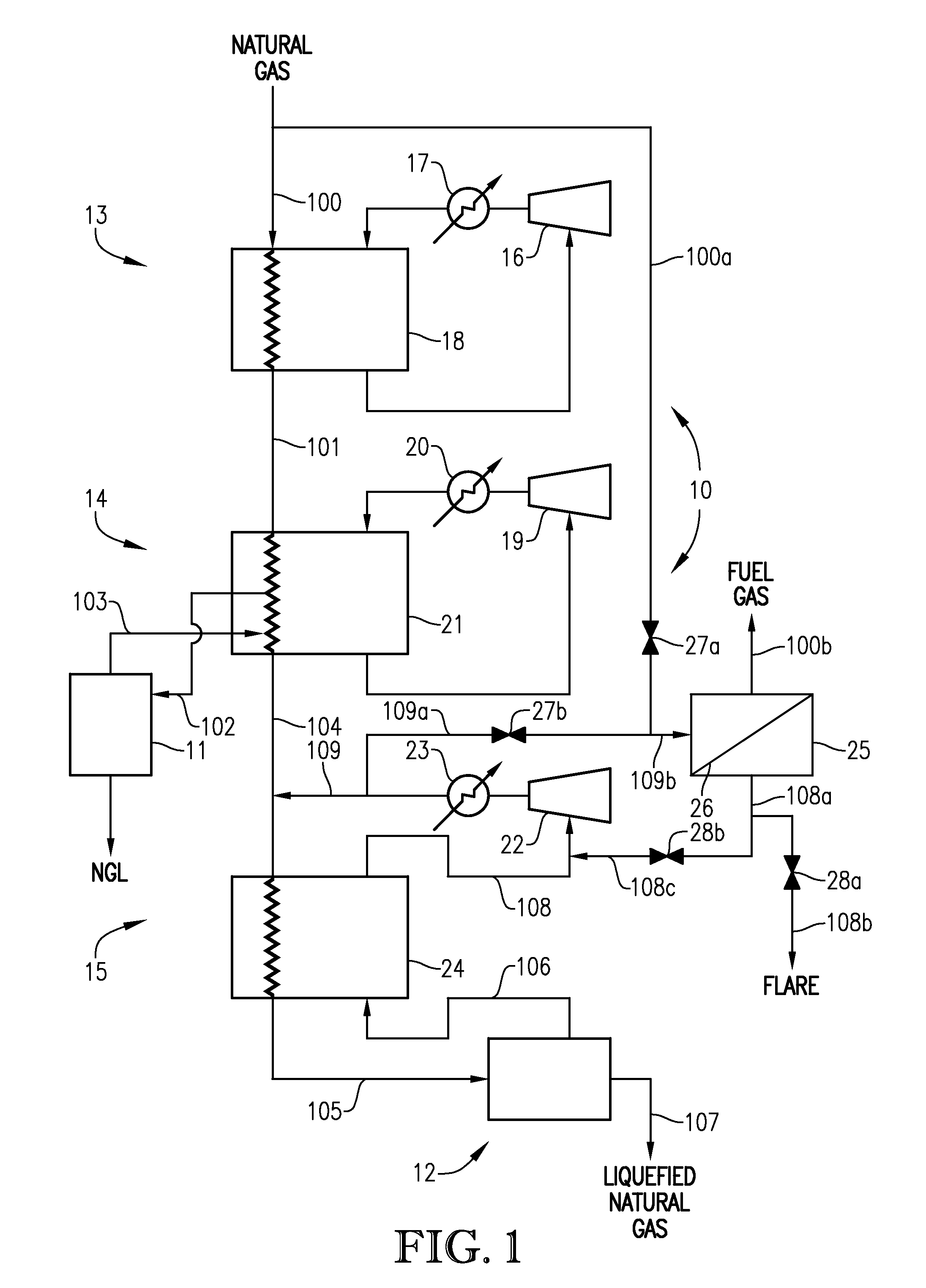

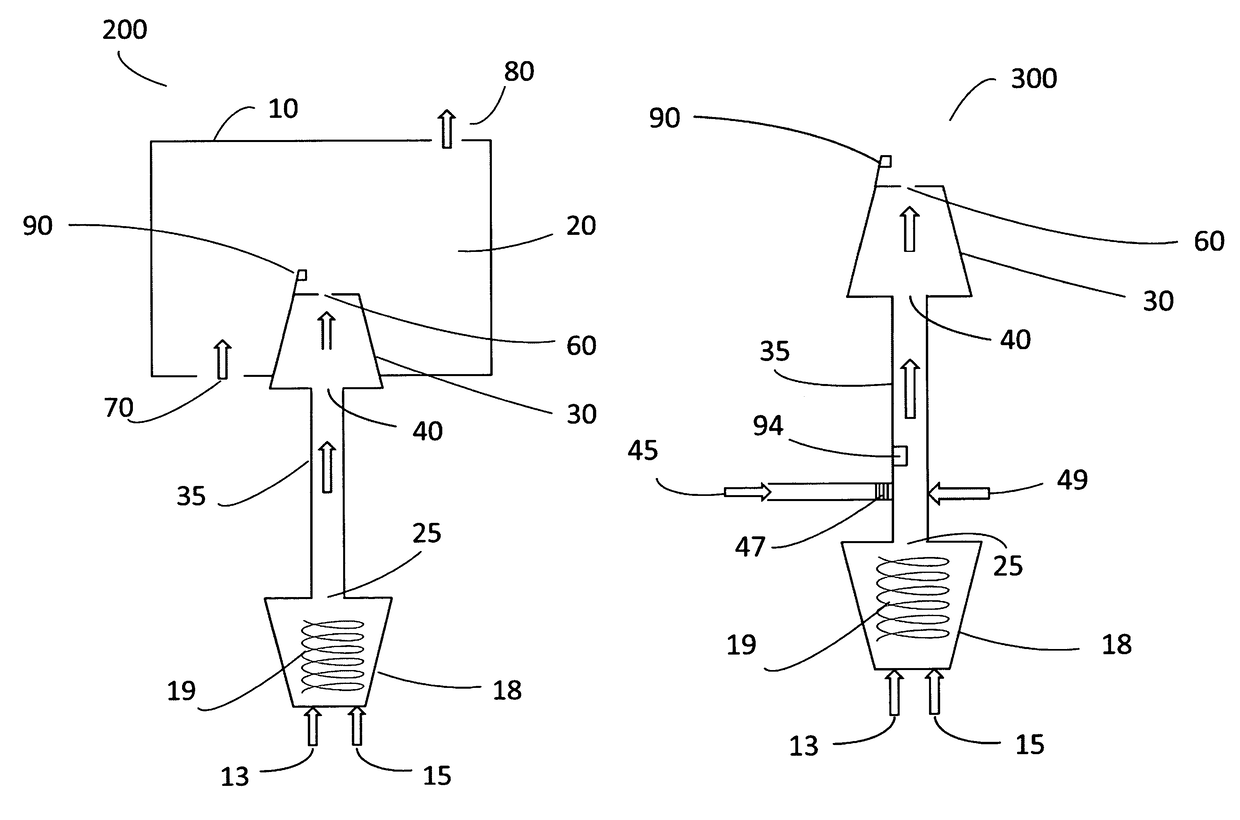

Flexible NGL recovery methods and configurations

A natural gas liquids plant uses a demethanizer and a deethanizer in a two-column or single column configuration that can be used for ethane recovery and ethane rejection. During ethane recovery, 95% ethane recovery and 99% propane recovery are achieved, while during ethane rejection the sales gas Wobbe Index requirement is maintained while maintaining 95% propane recovery. A residue gas recycle exchanger is most preferably configured to use the demethanizer overhead product to either cool a portion of the residue gas and a portion of the feed gas during ethane recovery, or to cool a portion of the feed gas using two distinct heat transfer areas to produce a feed gas reflux at significantly lower temperature.

Owner:FLUOR TECH CORP

Fuel heater system including hot and warm water sources

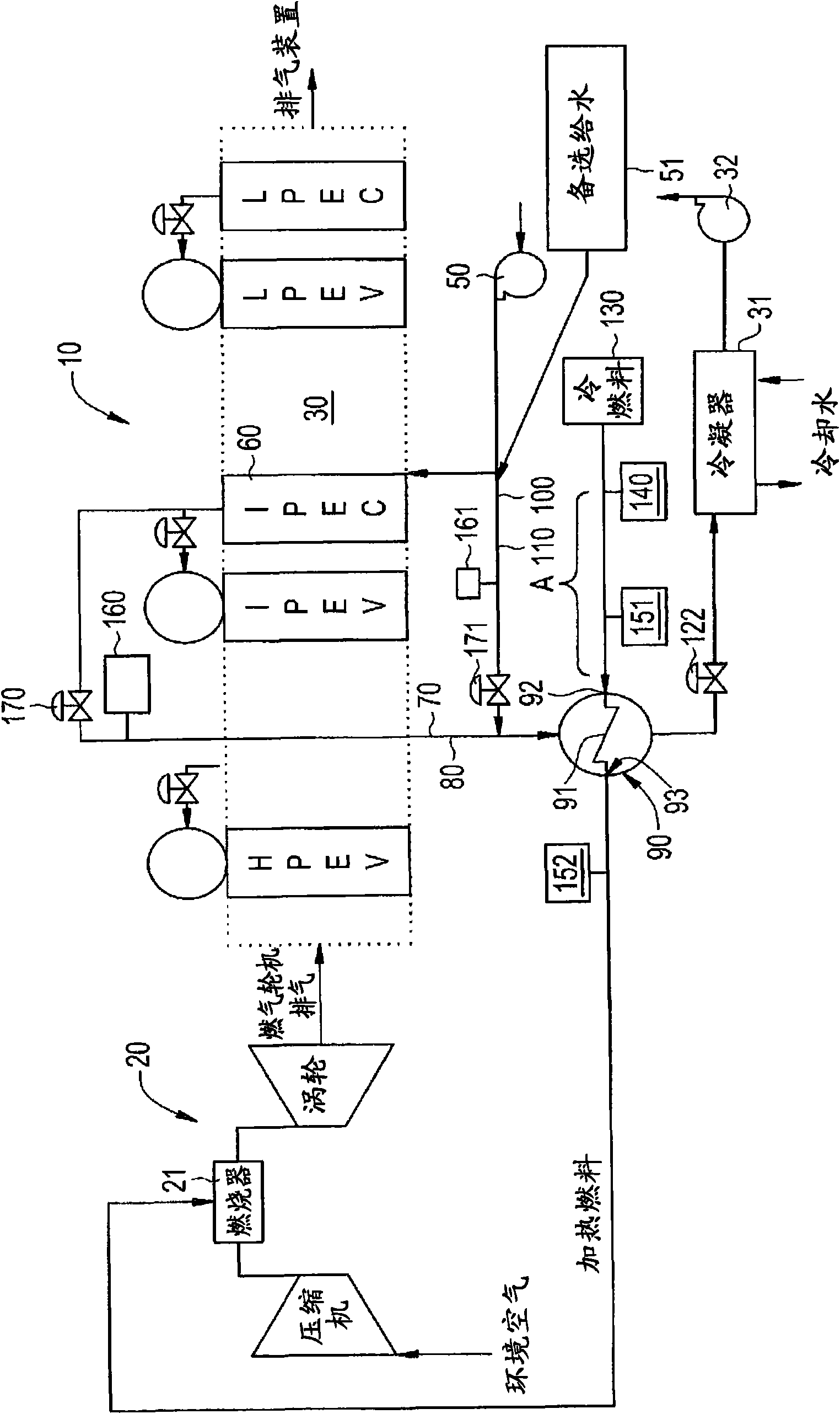

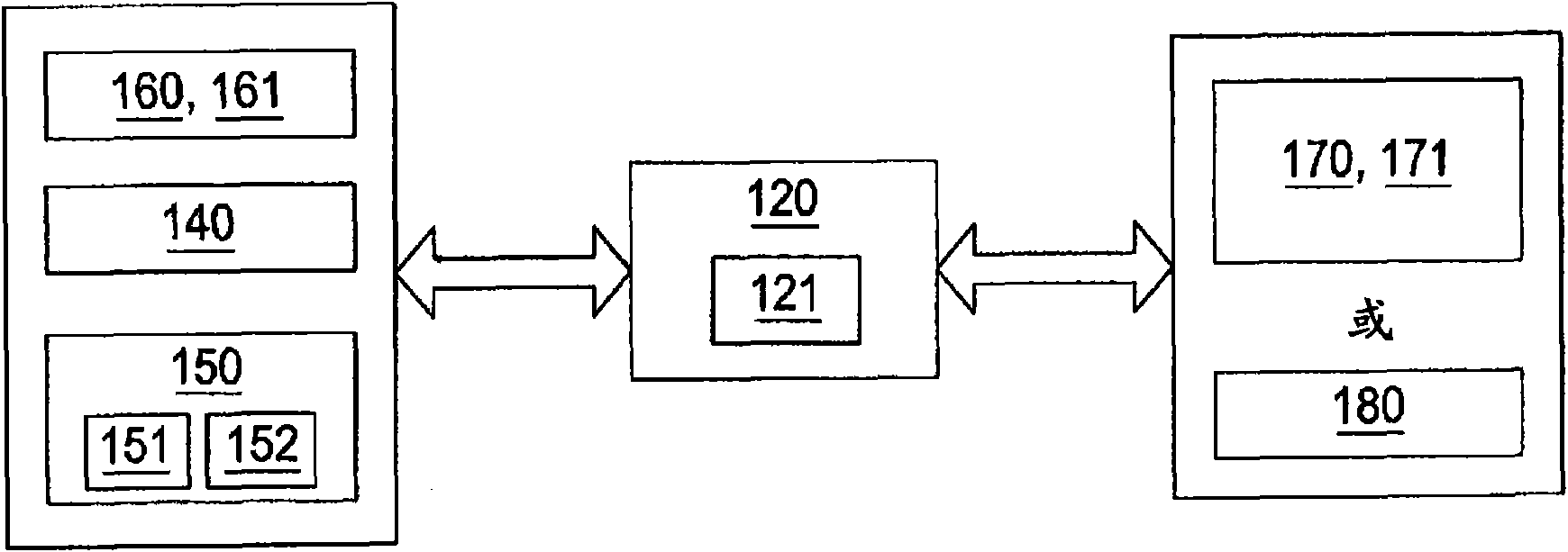

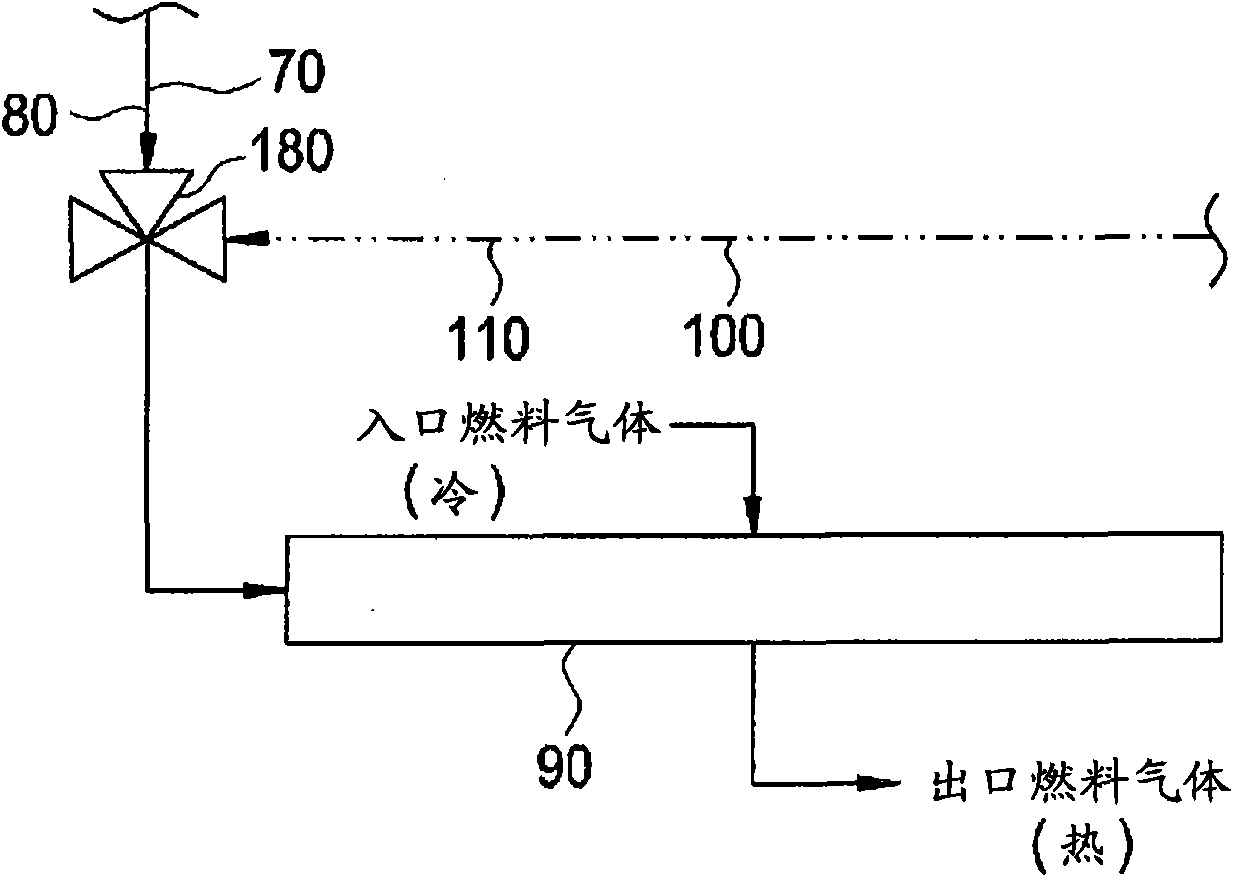

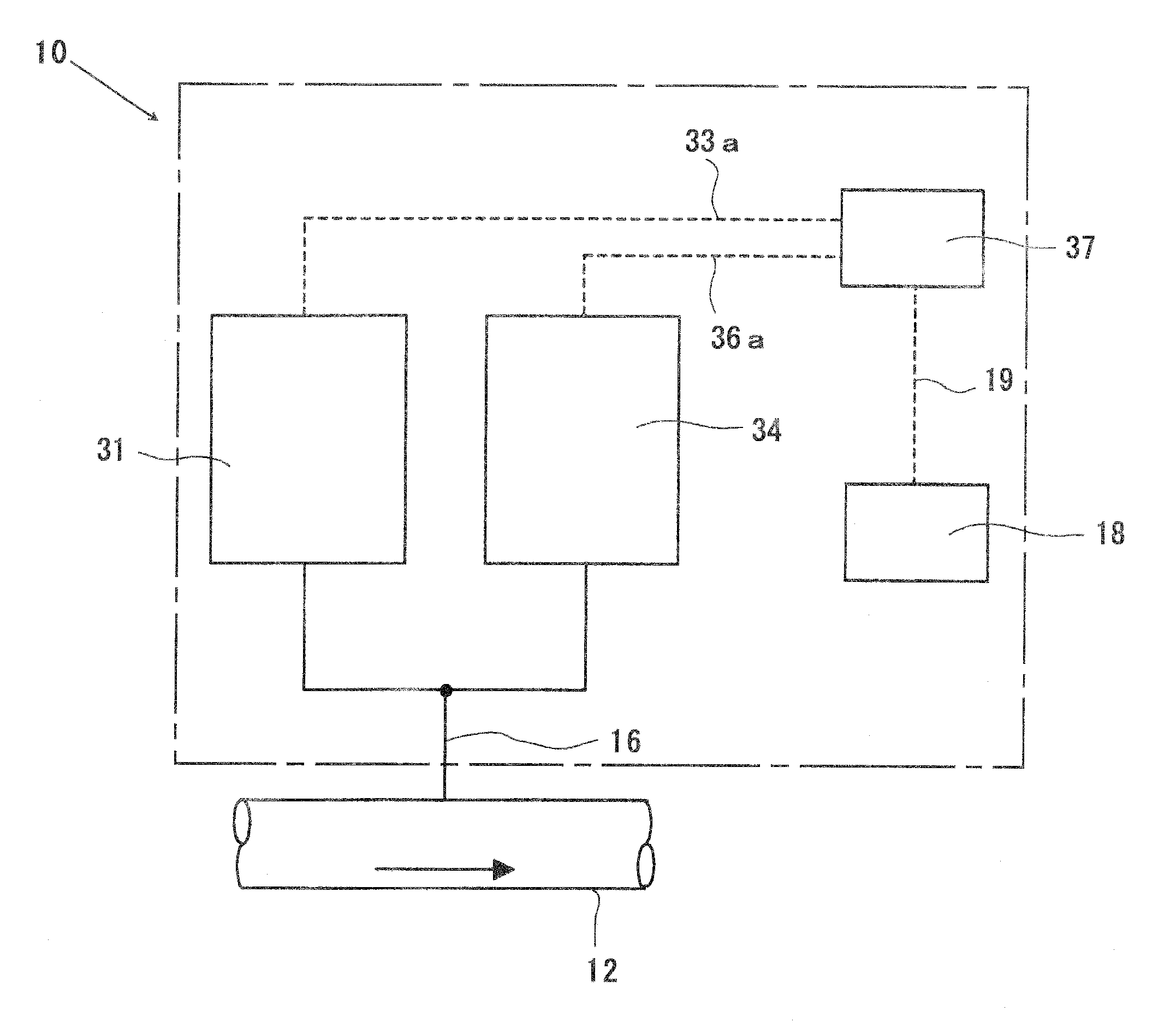

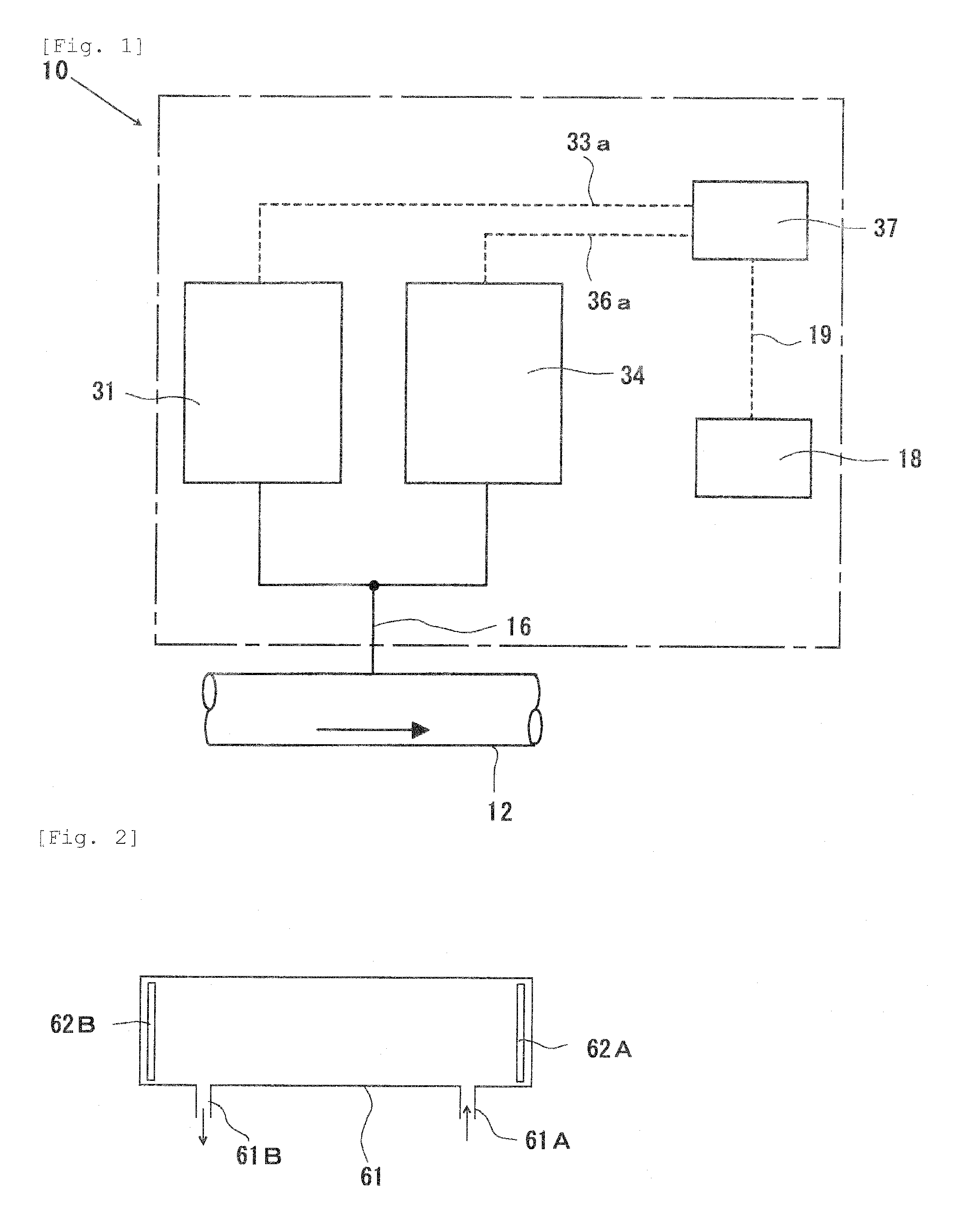

The present invention relates to a fuel heater system including hot and warm water sources. Concretely, a system is provided and includes first and second water supplies (70, 100) at first and second relatively high and low temperatures, respectively; a heat exchanger (90), coupled to the water supplies (70, 100), through which fuel and relative amounts of the water supplies at the first and second temperatures flow for fuel heating; and a controller (120), operably interposed between the water supplies (70, 100) and the heat exchanger (90), to select and / or modulate the relative amounts of the water supplies (70, 100) permitted to flow through the heat exchanger (90) to heat the fuel to a temperature based on a heating requirement to meet a modified wobbe index (MWI) rating.

Owner:GENERAL ELECTRIC TECH GMBH

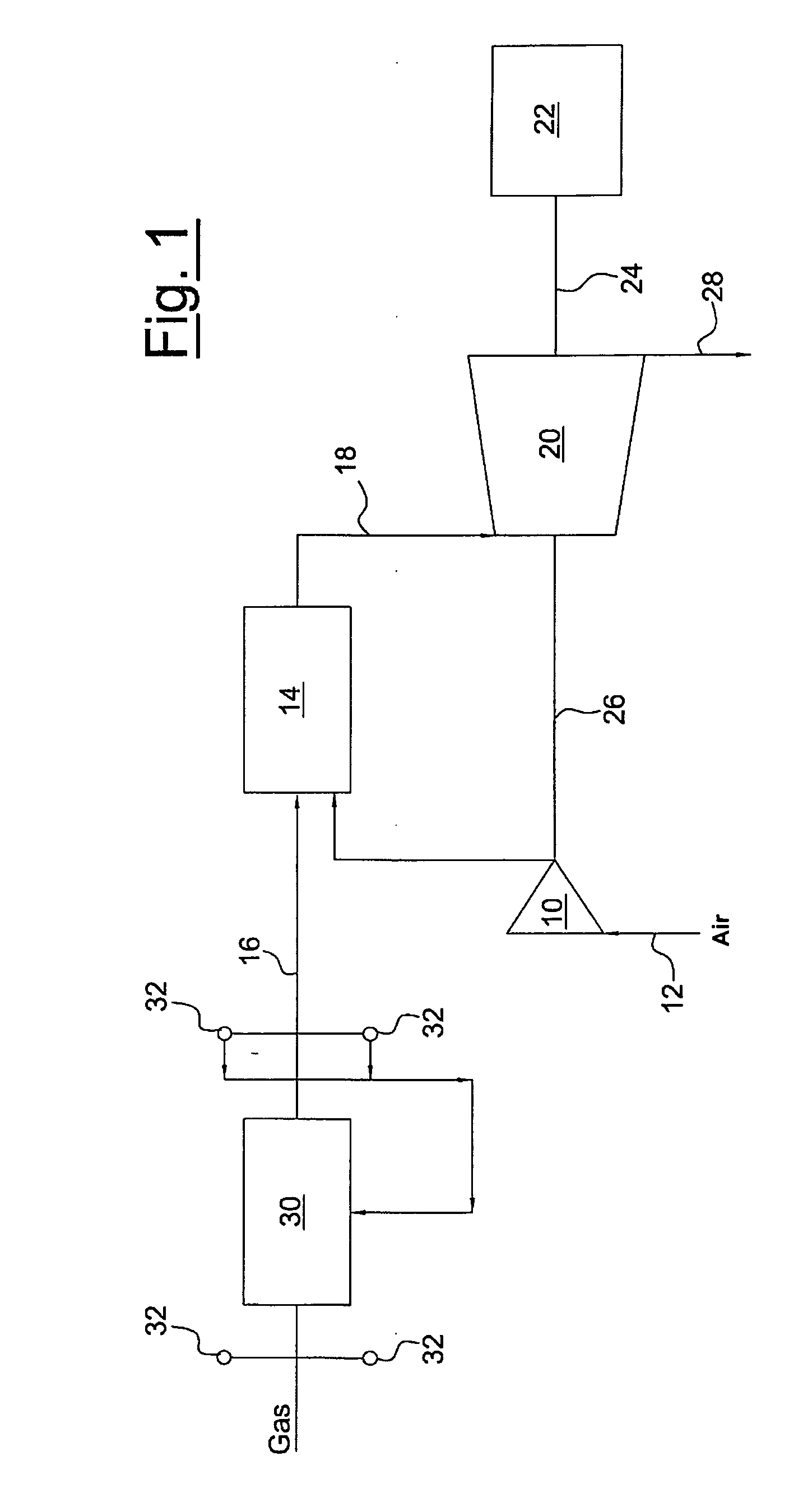

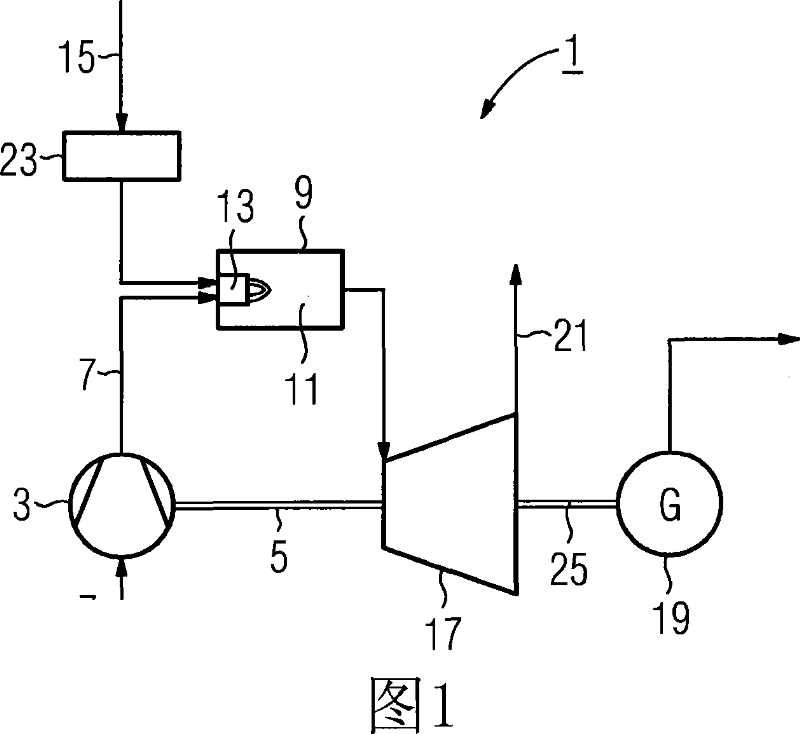

Method for operation of a burner in particular a burner for a gas turbine and device for carrying out said method

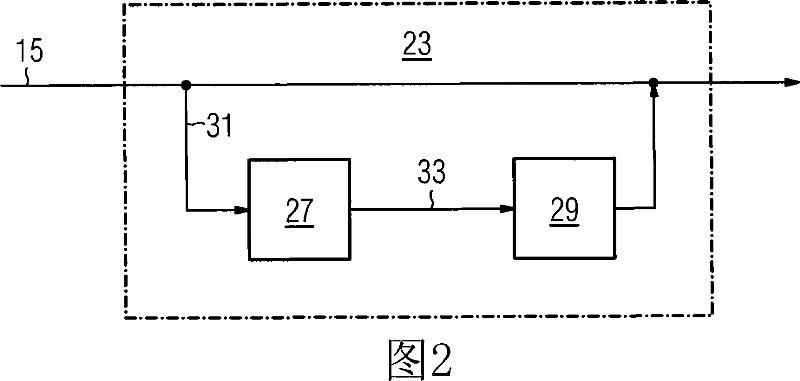

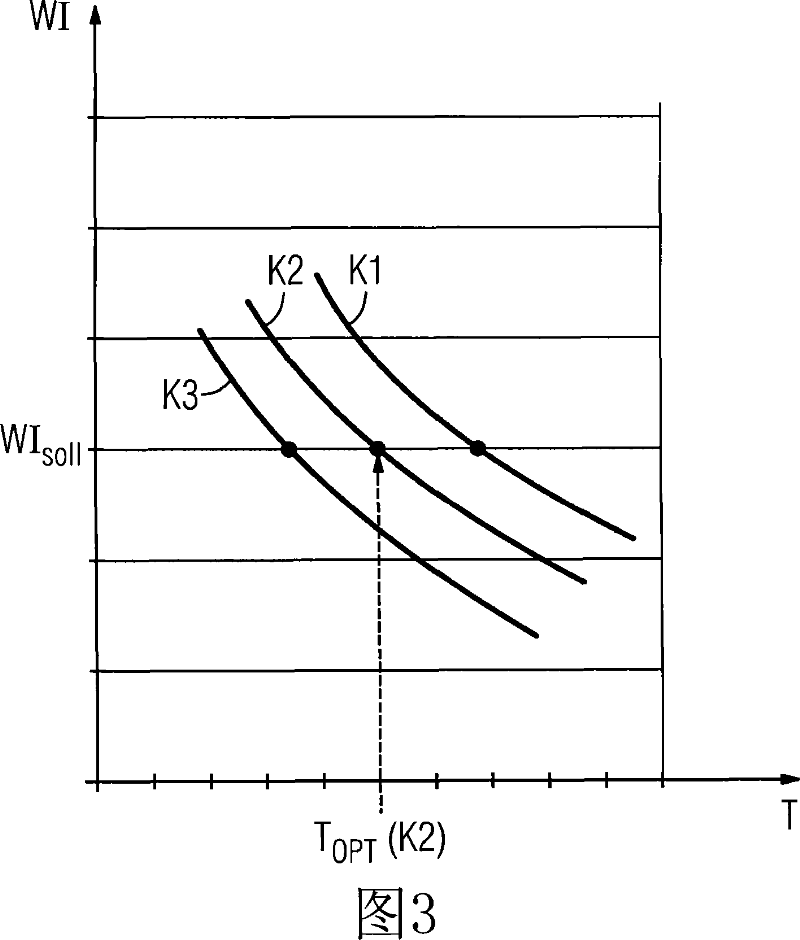

The invention relates to a method for operation of a burner (13), whereby a fuel (15) is supplied to the burner (13), sprayed into the combustion air (7), mixed with the combustion air (7) to give a fuel / air mixture and burnt in a combustion chamber (11). With regard to a combustion particularly low in pollutants and, in order to reduce the nitrogen oxide emissions with relation to achieving a given nitrogen oxide emission level, a change in parameters characterising the fuel (15) is determined. Such a parameter may, for example, be the Wobbe index (WI). The invention further relates to a device for carrying out said method, comprising a fuel treatment device (23), with an analytical device (27) for the analysis of the current fuel composition and a monitoring and control system (29).

Owner:SIEMENS ENERGY GLOBAL GMBH CO & KG

Method for measuring specific gravity of combustible gases, device for measuring specific gravity, and device for measuring wobbe index

InactiveUS20130233056A1Improve reliabilityAvoid it happening againMaterial analysis using sonic/ultrasonic/infrasonic wavesPhase-affecting property measurementsHydrogenPhysical chemistry

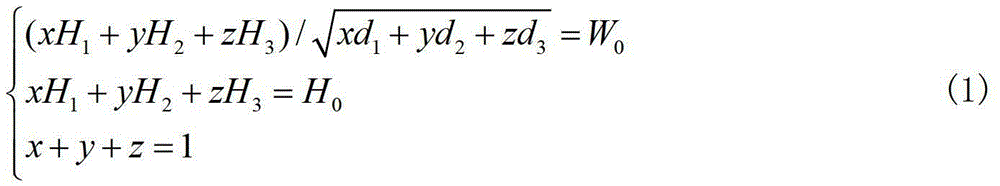

A method for measuring specific gravity of a combustible gas includes measuring the refractive index and sound speed of a gas of interest which contains at least one type of gas selected from a hydrocarbon gas, hydrogen gas, and carbon monoxide gas, and computing the value of the specific gravity Da of the gas of interest from Equation (1) below using a value selected as a correction factor x from within a range of 2.4 to 9.3 on the basis of a refractive index converted specific gravity Dn determined from the refractive index and a sound speed converted specific gravity Ds determined from the sound speed:Da=Ds−[(Ds−Dn) / (1−x)] Equation (1).

Owner:RIKEN KEIKI KK

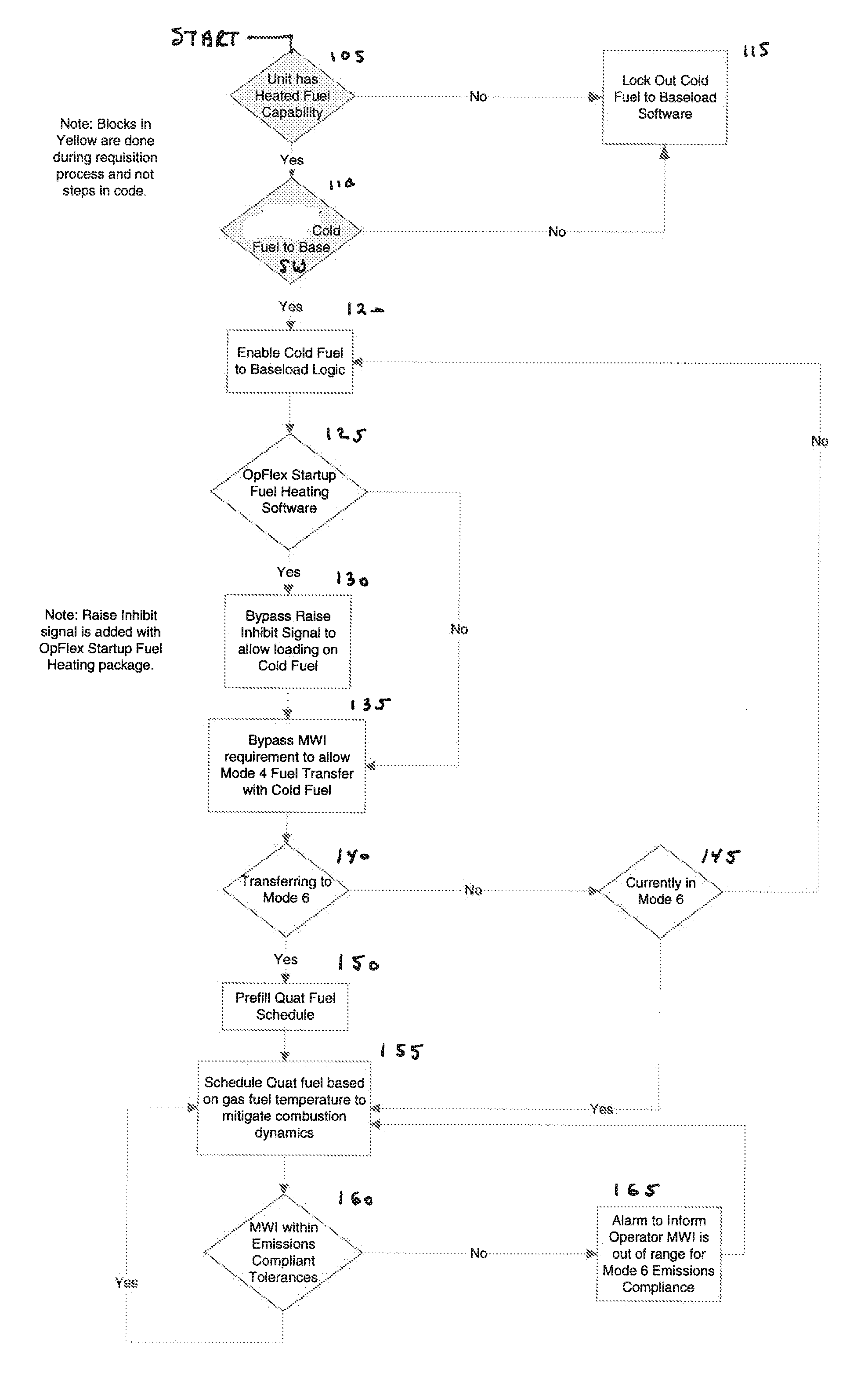

Operating a turbine at baseload on cold fuel with hot fuel combustion hardware

ActiveUS20100168980A1Reduce combustion dynamicAnalogue computers for vehiclesContinuous combustion chamberCombustionEmission standard

A method and algorithm are provided to operate a gas turbine at baseload in an emission compliant capable mode to avoid combustion dynamics while operating with cold fuel and hot fuel combustion hardware. The method includes performing a gas turbine operational sequence such as a startup to an emission compliant capable mode. A gas fuel temperature is measured. The gas turbine is operated in the emissions compliant capable mode according to a designated fuel split for avoiding combustion dynamics when a temperature for a gas fuel is below a designated value. A determination is made whether a modified wobbe index for the gas fuel is below an emissions compliant value. An alarm is activated if the modified wobbe index is below the emissions compliant value to notify the operator of a potential emissions shift.

Owner:GENERAL ELECTRIC CO

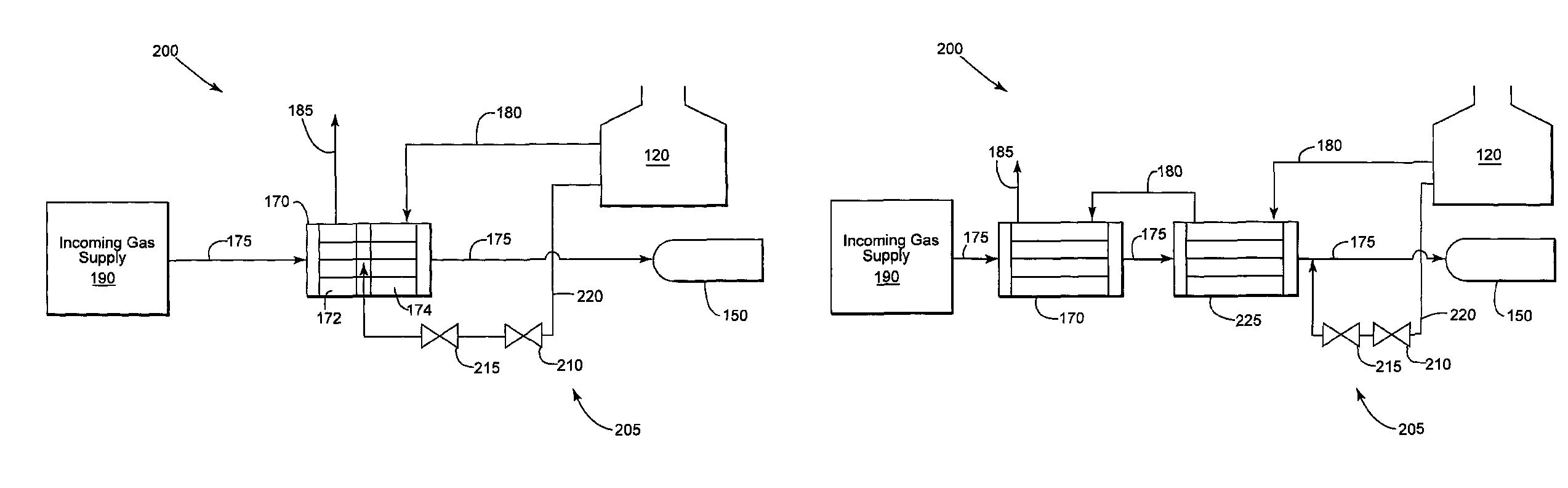

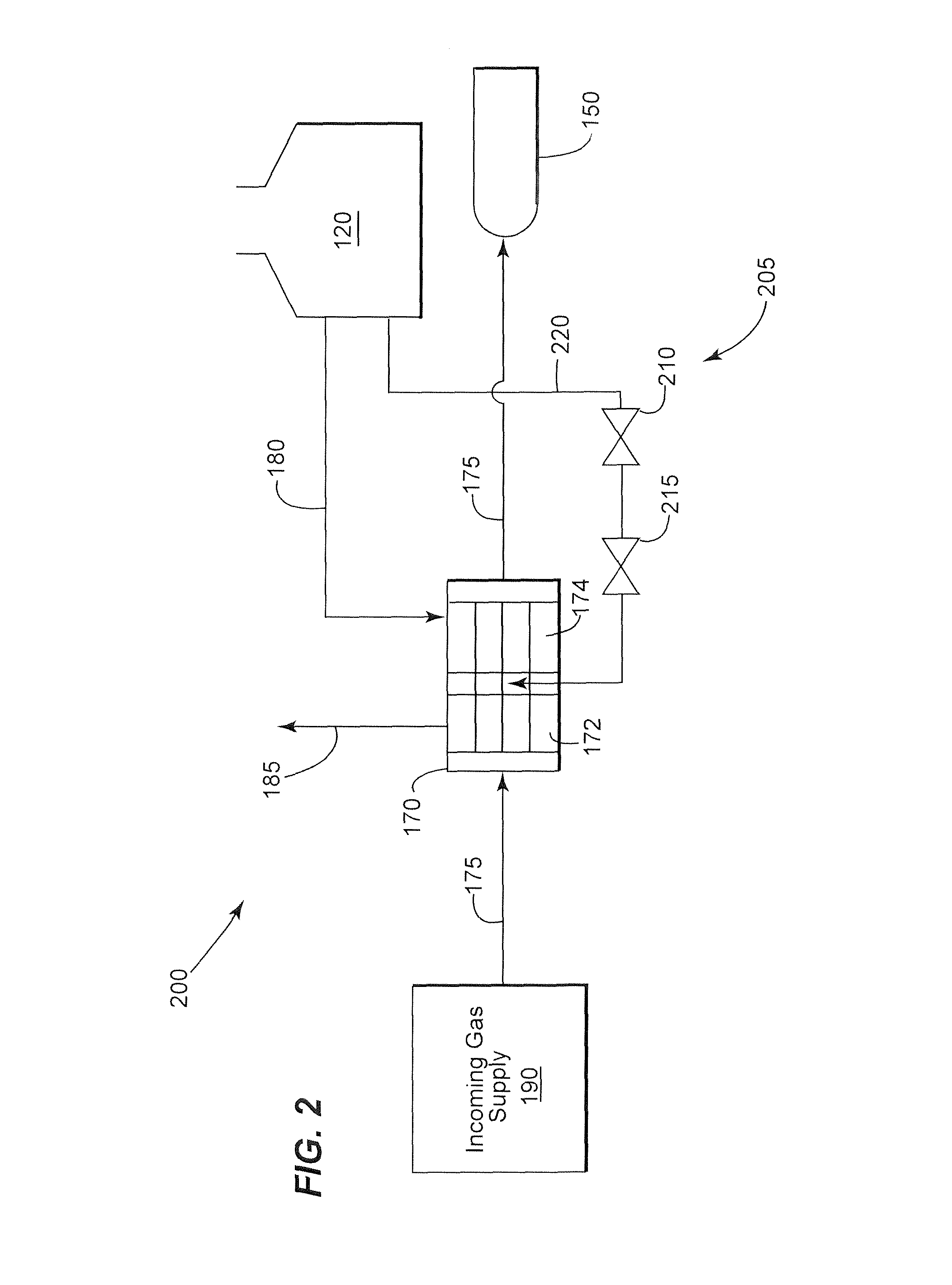

System for enhanced fuel gas composition control in an LNG facility

An LNG facility employing an enhanced fuel gas control system. The enhanced fuel gas control system is operable to produce fuel gas having a substantially constant Modified Wobbe Index (MWI) during start-up and steady-state operation of the LNG facility by processing one or more intermediate process streams in a fuel gas separator. In one embodiment, the fuel gas separator employs a hydrocarbon-separating membrane, which can remove heavy hydrocarbons and / or concentrate nitrogen from the incoming process streams.

Owner:CONOCOPHILLIPS CO

Wobbe index sensor system

InactiveUS20090013759A1Prevent oxidationMaterial thermal conductivityMaterial heat developmentThermal isolationEngineering

A sensor for measuring Wobbe index of a fuel is provided. The sensor includes a substrate and a diaphragm layer. The diaphragm layer includes a first layer having at least one heating element configured to sense energy content in a fuel, wherein the heating element includes a doped poly-silicon carbide that is disposed on the substrate. The diaphragm layer also includes a second layer including an undoped poly-silicon carbide layer configured to prevent oxidation of the first layer. The sensor further includes a sensing layer having a catalyst suspended in a support structure. The sensor also includes a cavity formed under the diaphragm layer and is configured to provide thermal isolation of the heating element.

Owner:GENERAL ELECTRIC CO

Apparatus and method for operating a gas-fired burner on liquid fuels

ActiveUS10001278B1Increased flame speedIncreased fuel energy densityLiquid fuel feeder/distributionFuel supply regulationDiffusion flameLiquid fuel

An apparatus and method for operating a gas-fired burner on a liquid fuel. The apparatus integrates a catalytic liquid fuel reformer with a flame burner designed for operation on a gaseous fuel of high Wobbe Index, e.g., natural gas. The method involves reacting a mixture of a liquid fuel and oxidant in a catalytic reformer to obtain a gaseous reformate having a low Wobbe Index; and thereafter combusting the gaseous reformate, optionally augmented with liquid co-fuel and oxidant, in the gas-fired burner under diffusion flame conditions. The invention allows commercial gas-fired appliances, such as stoves, ovens, ranges, grills, griddles, stock pot burners, clothes dryers, hot water heaters, and boilers to be operated on a liquid fuel, which offers advantages in logistics and camp operations.

Owner:PRECISION COMBUSTION

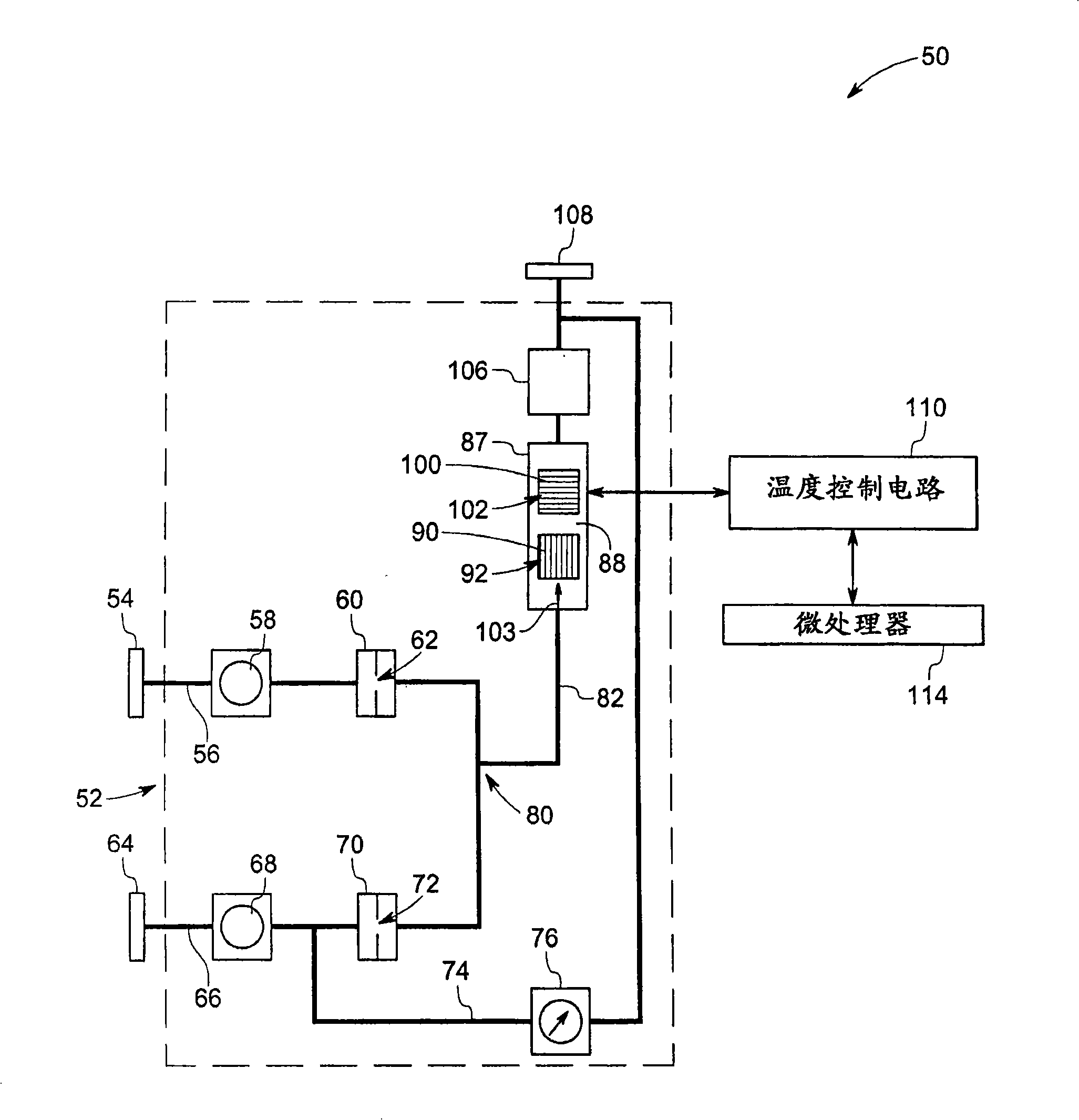

Method, sensor and system for measuring a lower heating value and a wobbe index of a gaseous fuel

A method for measuring a lower heating value of a gaseous fuel. The method includes mixing a gaseous fuel with air to provide a combustible air-fuel mixture. The air-fuel mixture is directed to flow across a flow surface of a first micro-hotplate maintained at a constant temperature. A change in power required to maintain a constant temperature of the first micro-hotplate flow surface due to a convective and conductive heat transfer from the first micro-hotplate flow surface to the air-fuel mixture is measured. The air-fuel mixture is directed to flow across a flow surface of a second micro-hotplate maintained at a constant temperature. The air-fuel mixture is combusted as the air-fuel mixture flows across the second micro-hotplate flow surface. A change in power required to maintain a constant temperature of the second micro-hotplate flow surface due to the combustion of the air-fuel mixture is measured.

Owner:SANDIA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com